Patents

Literature

39 results about "Distributed manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distributed manufacturing also known as distributed production, cloud producing and local manufacturing is a form of decentralized manufacturing practiced by enterprises using a network of geographically dispersed manufacturing facilities that are coordinated using information technology. It can also refer to local manufacture via the historic cottage industry model, or manufacturing that takes place in the homes of consumers.

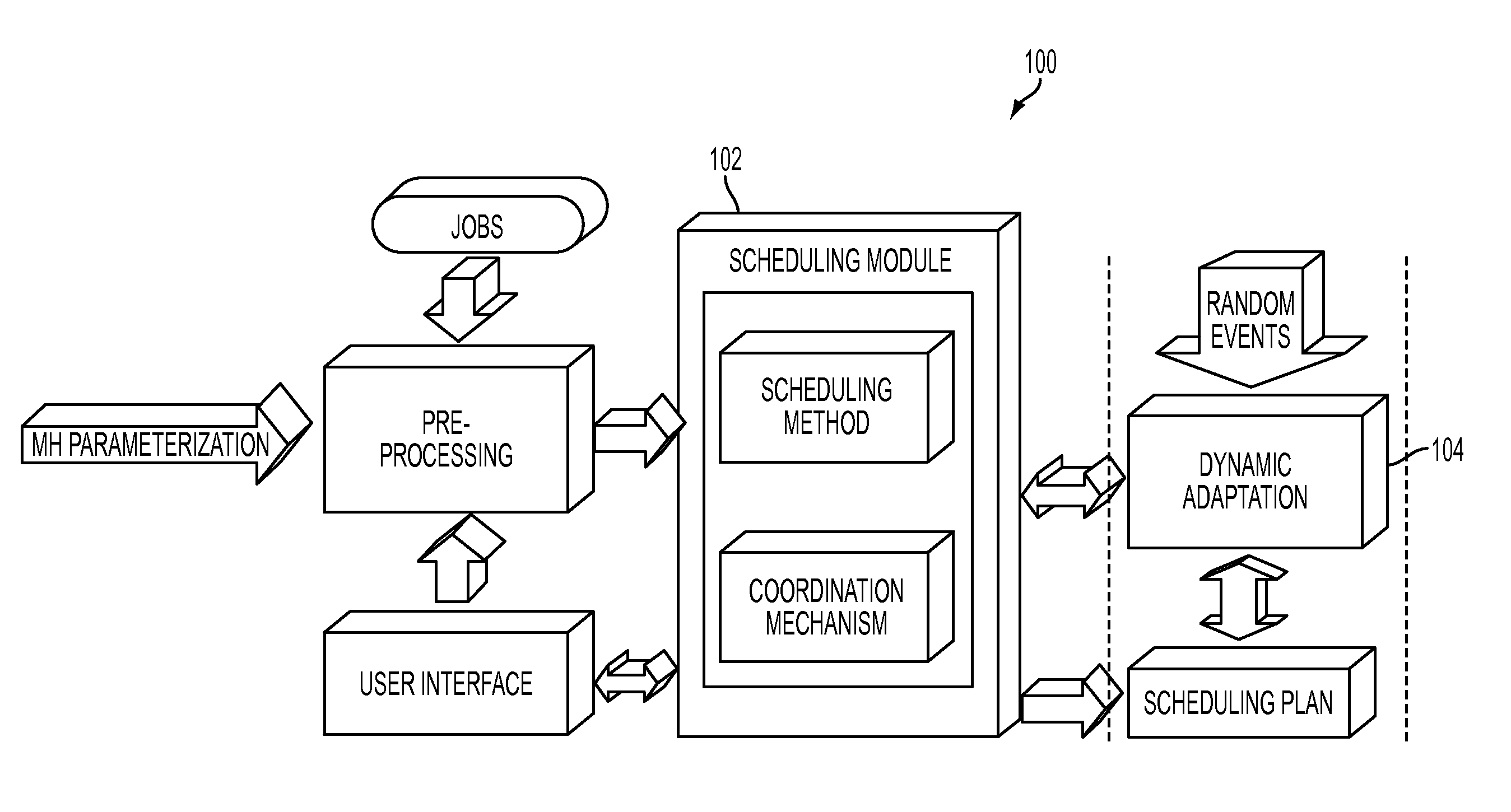

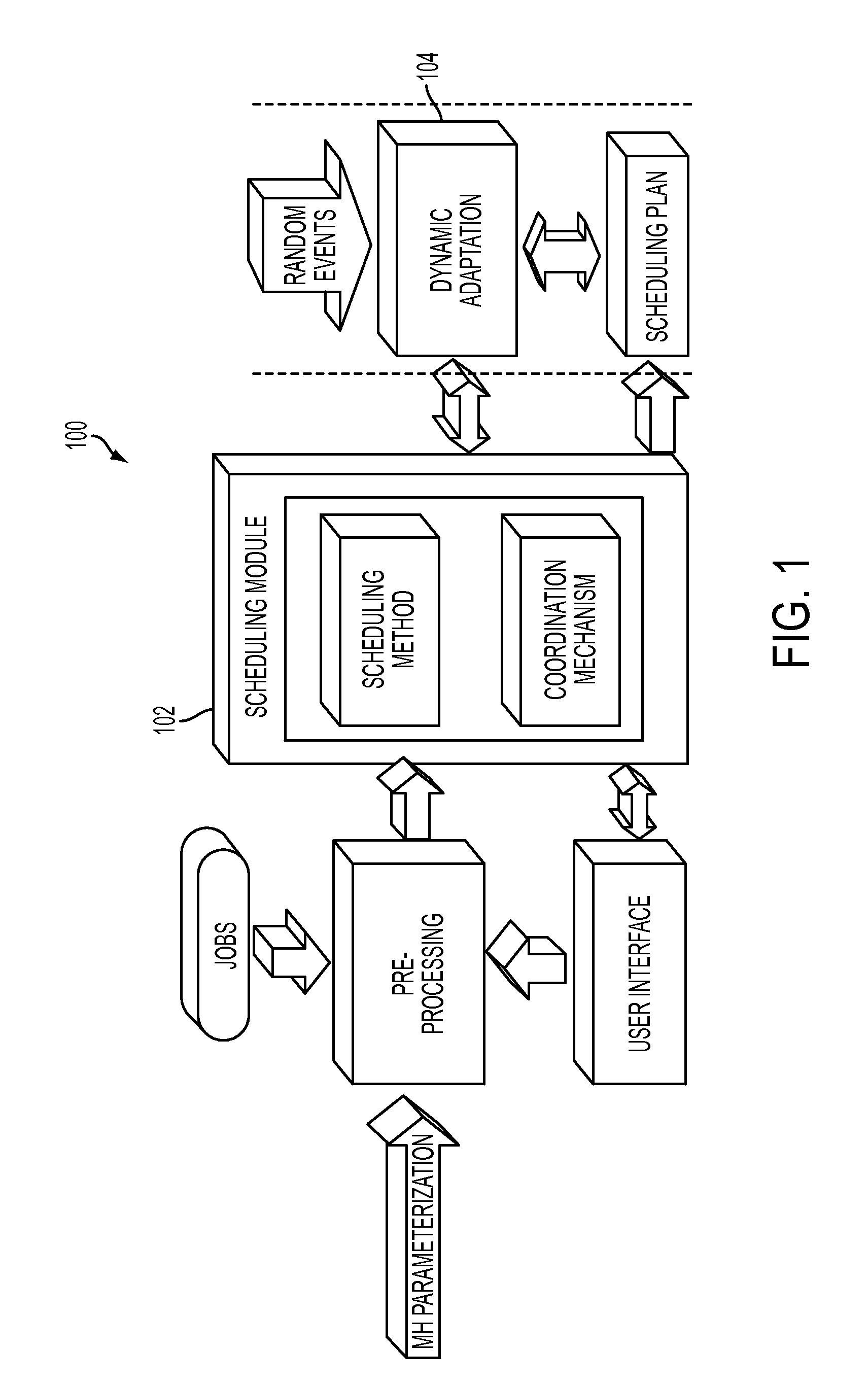

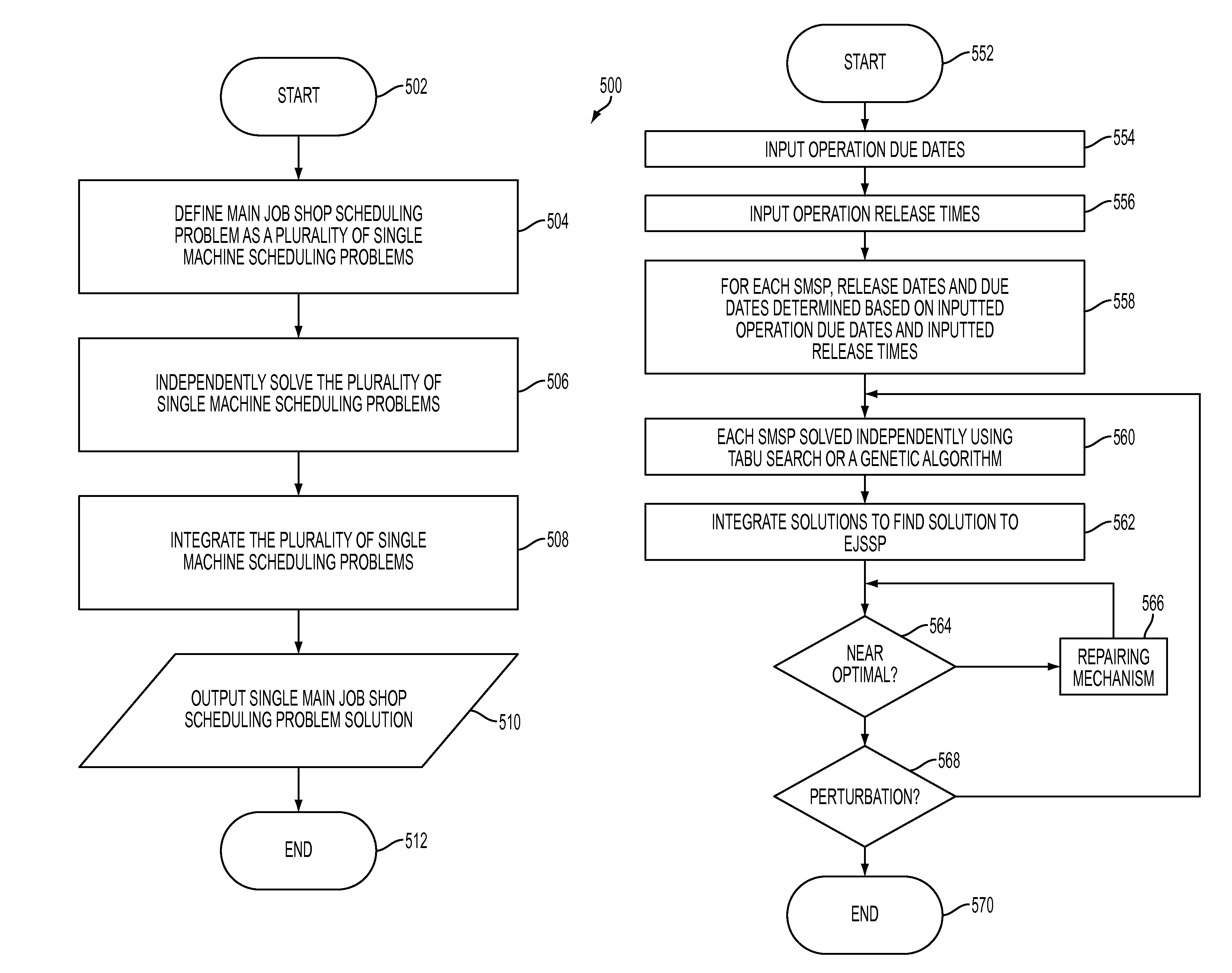

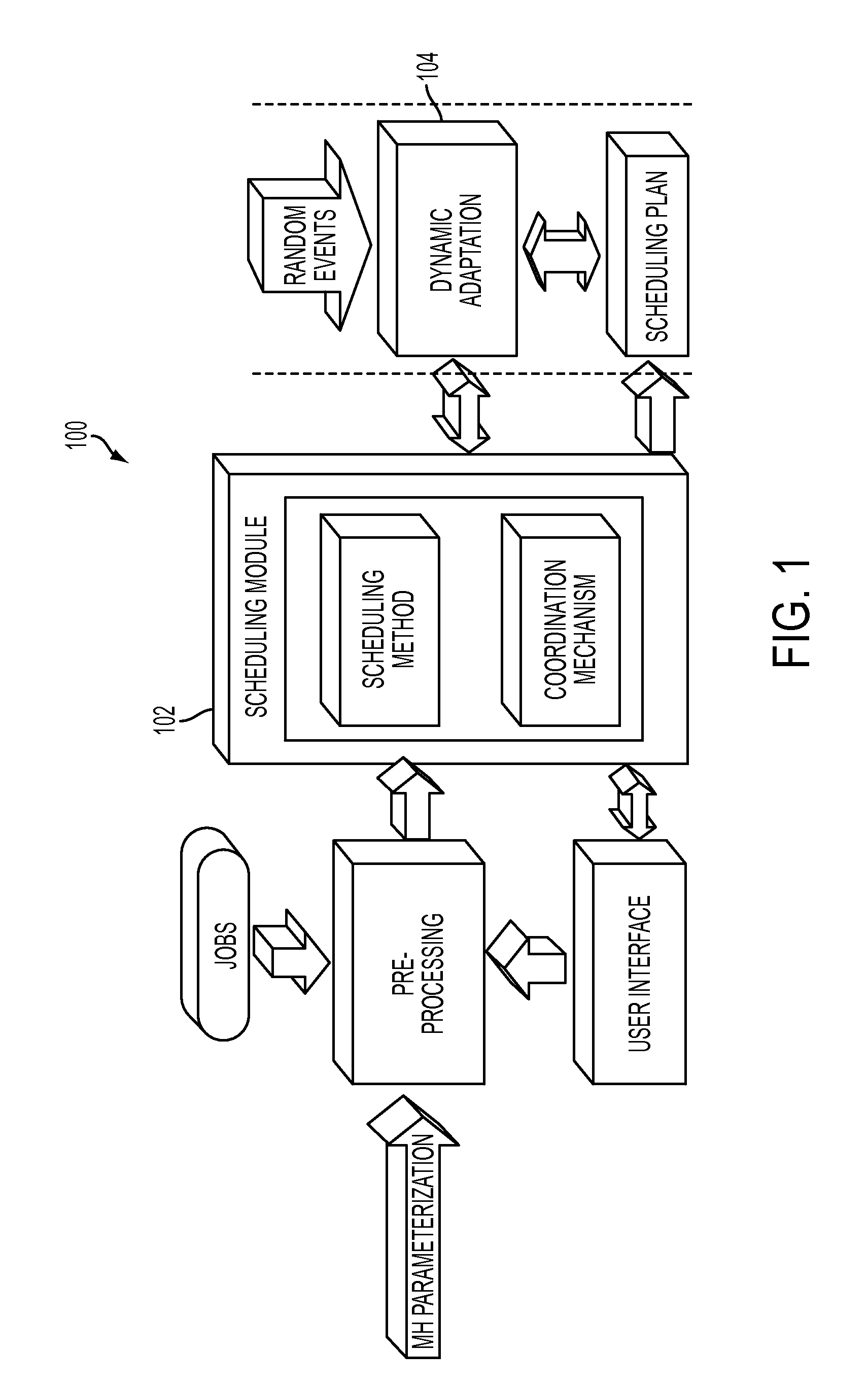

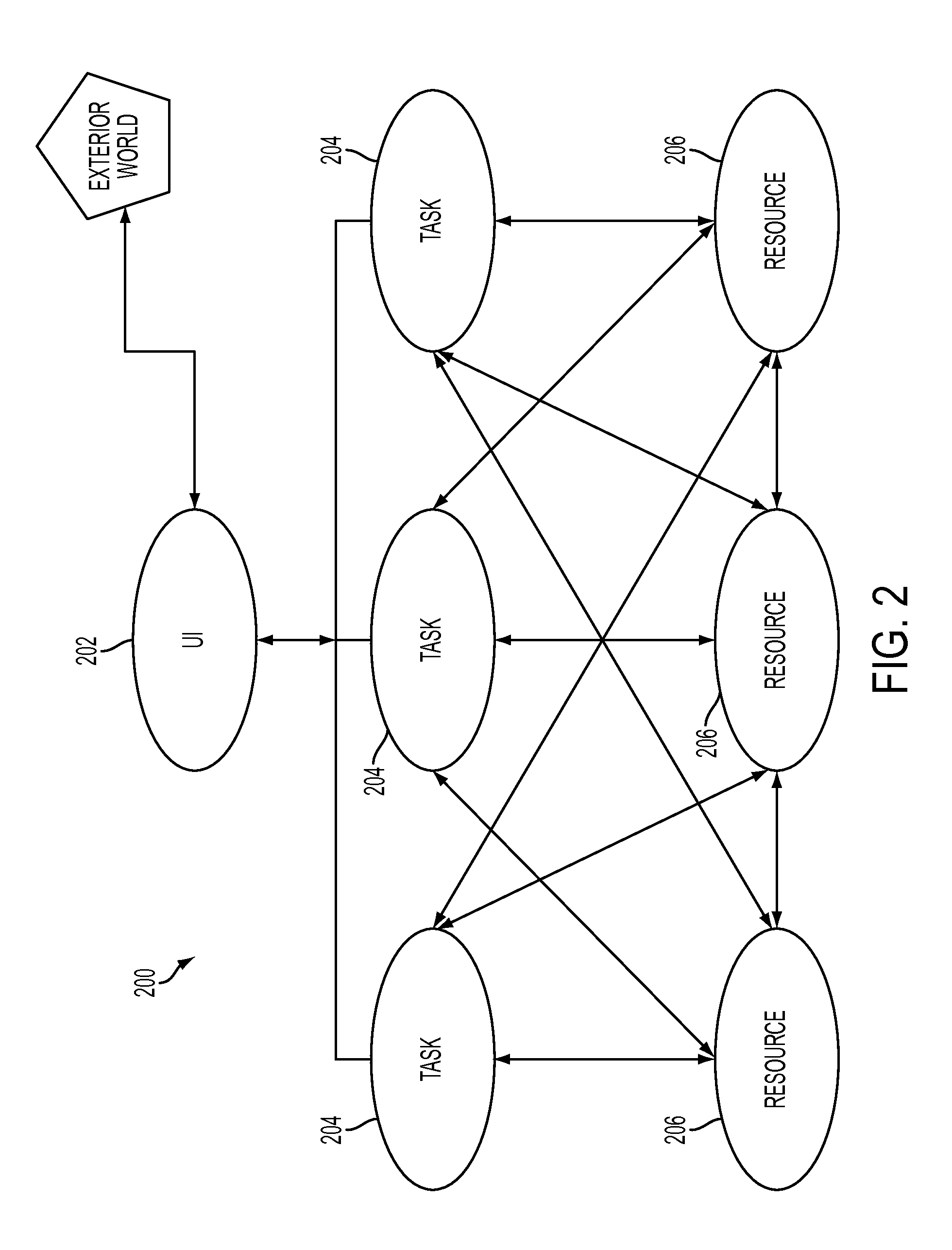

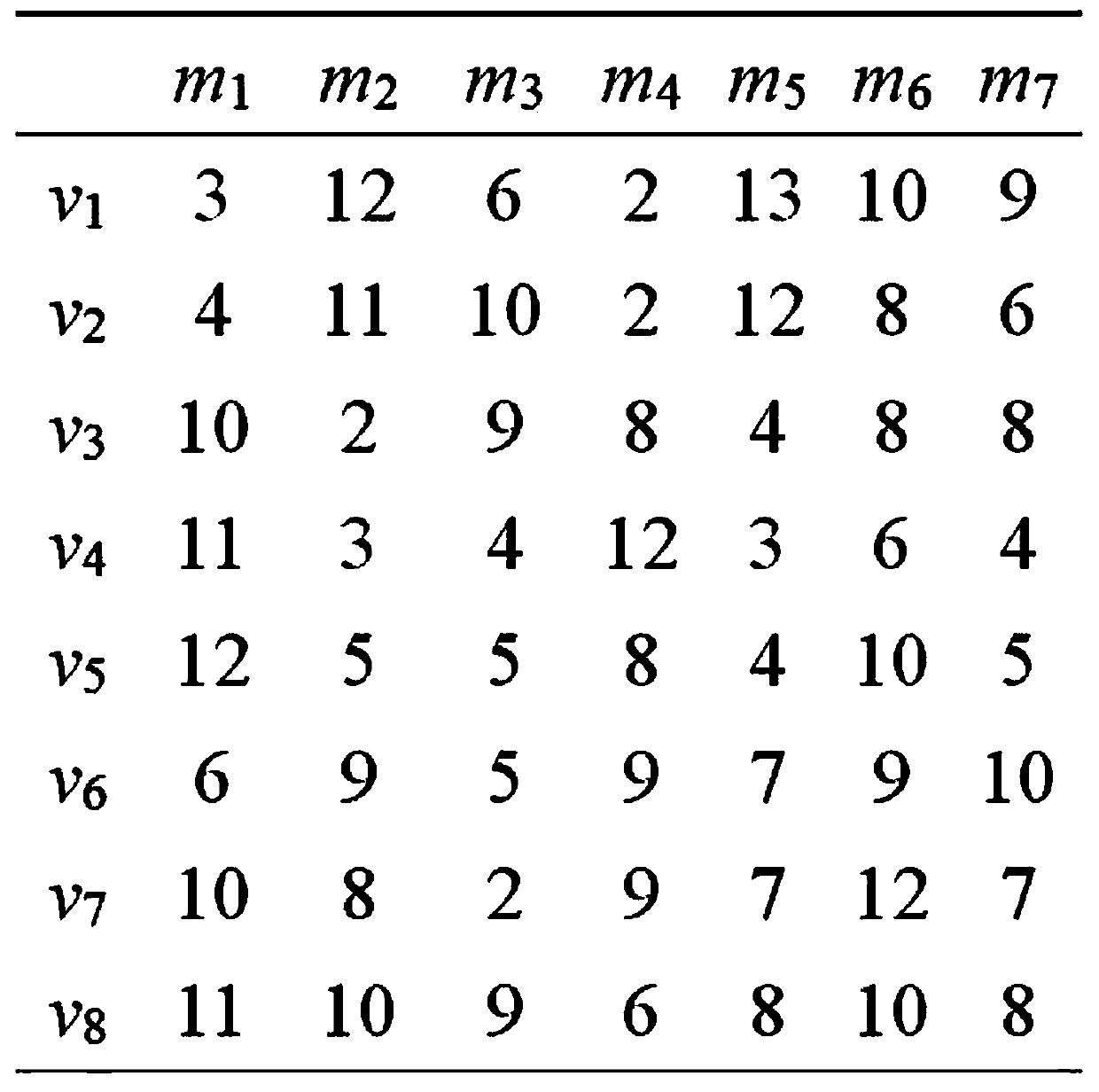

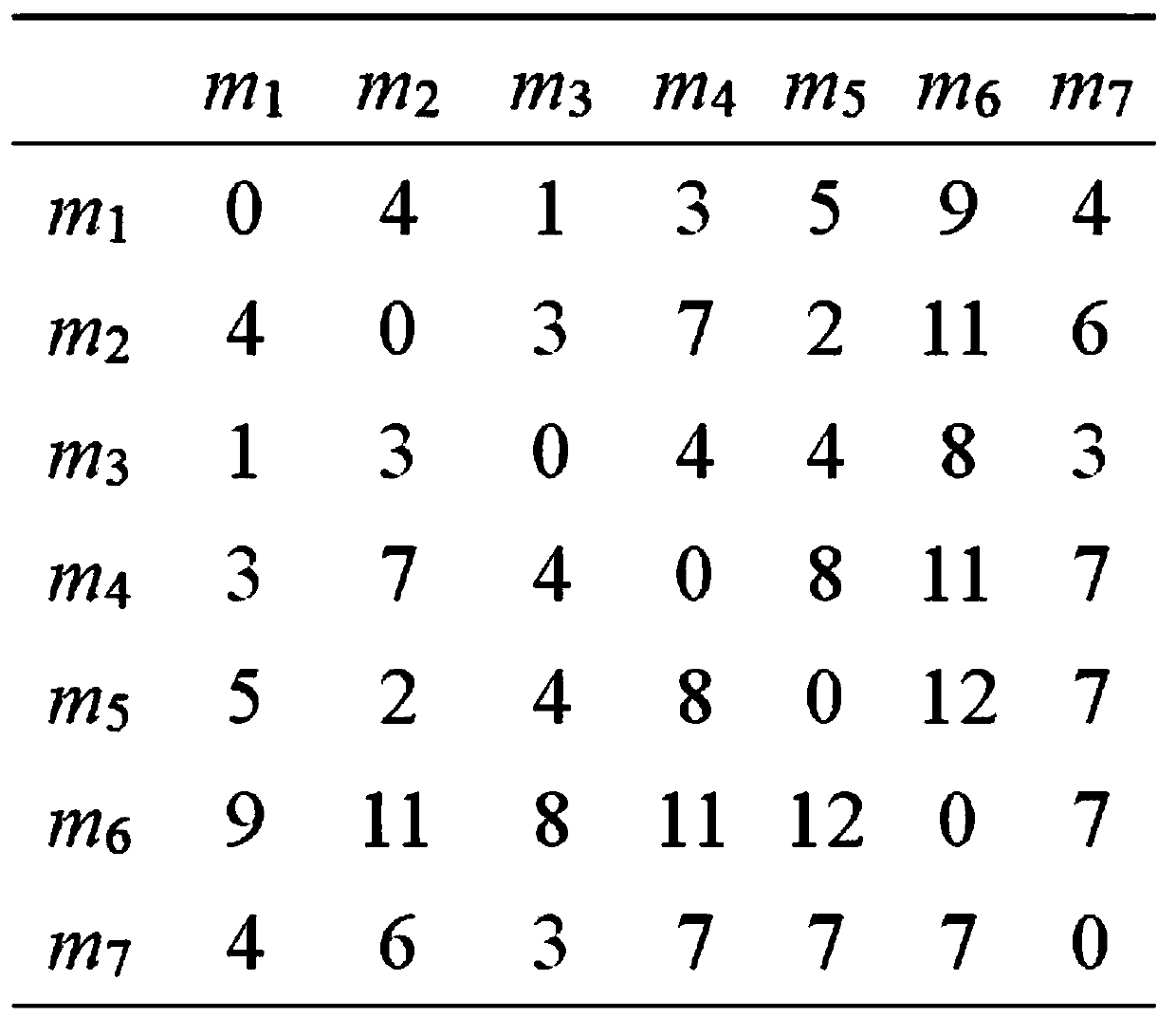

Multi-agent system for distributed manufacturing scheduling with genetic algorithms and tabu search

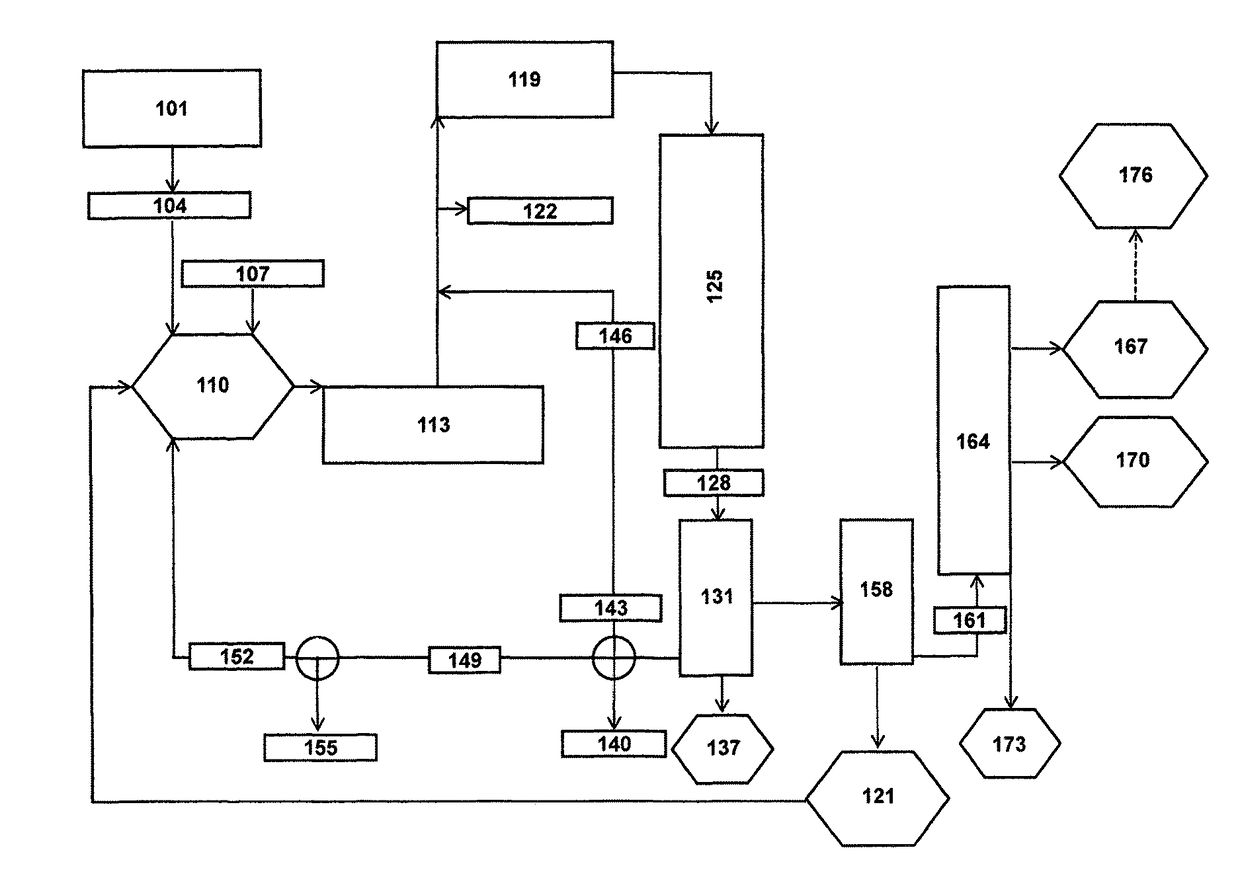

Computerized scheduling methods and computerized scheduling systems according to exemplary embodiments. A computerized scheduling method may be stored in a memory and executed on one or more processors. The method may include defining a main multi-machine scheduling problem as a plurality of single machine scheduling problems; independently solving the plurality of single machine scheduling problems thereby calculating a plurality of near optimal single machine scheduling problem solutions; integrating the plurality of near optimal single machine scheduling problem solutions into a main multi-machine scheduling problem solution; and outputting the main multi-machine scheduling problem solution.

Owner:PEREIRA ANA MARIA DIAS MEDUREIRA

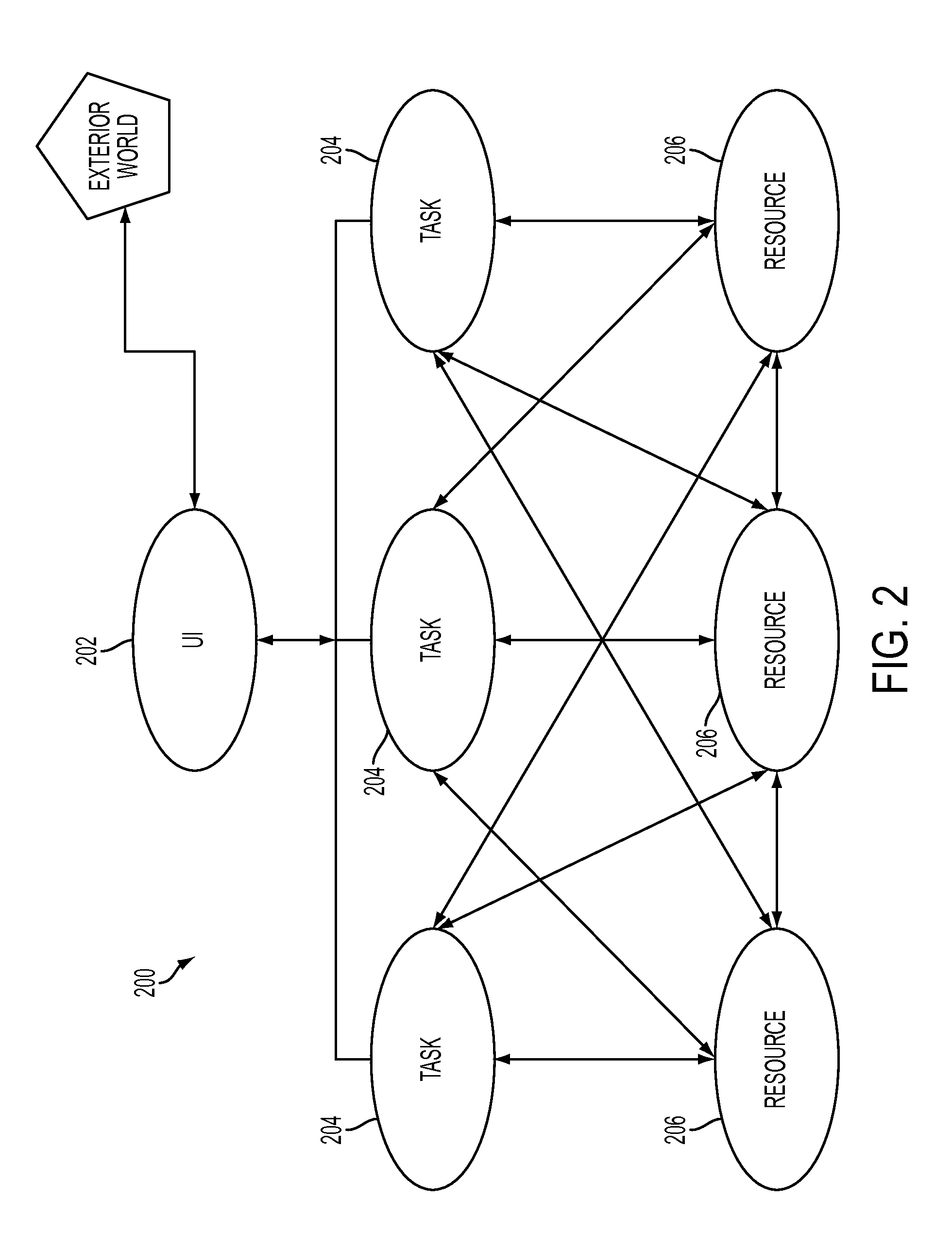

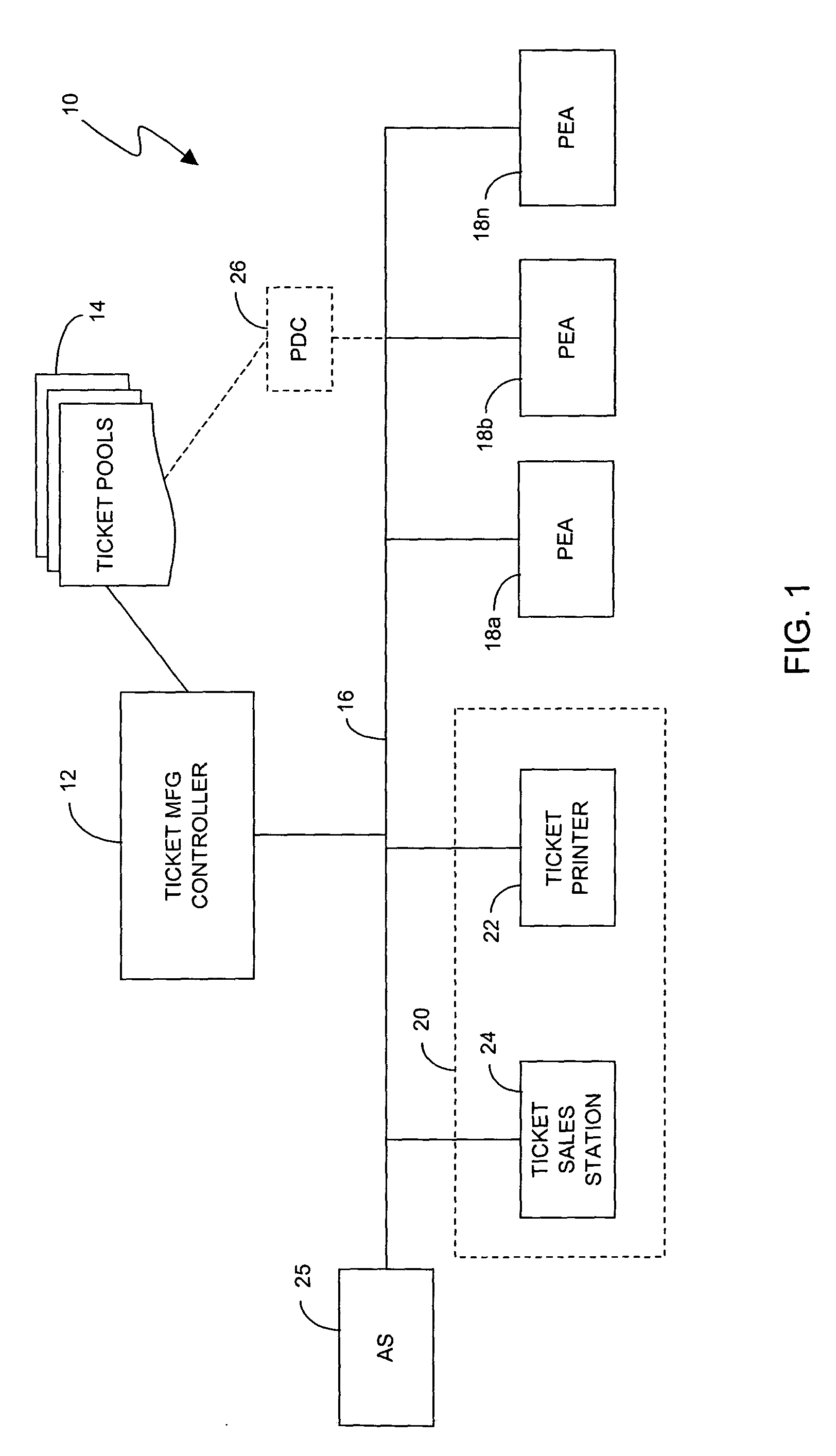

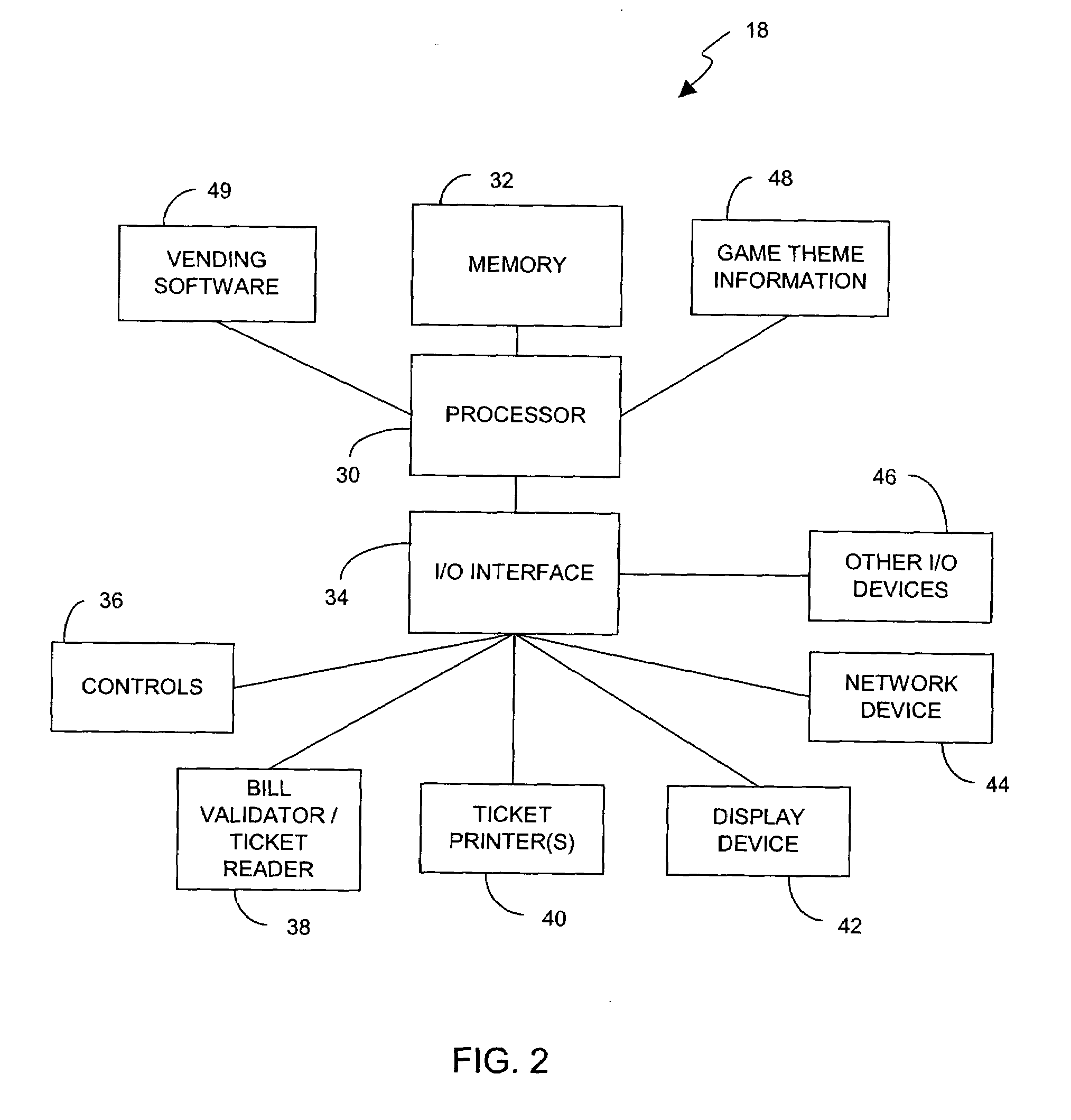

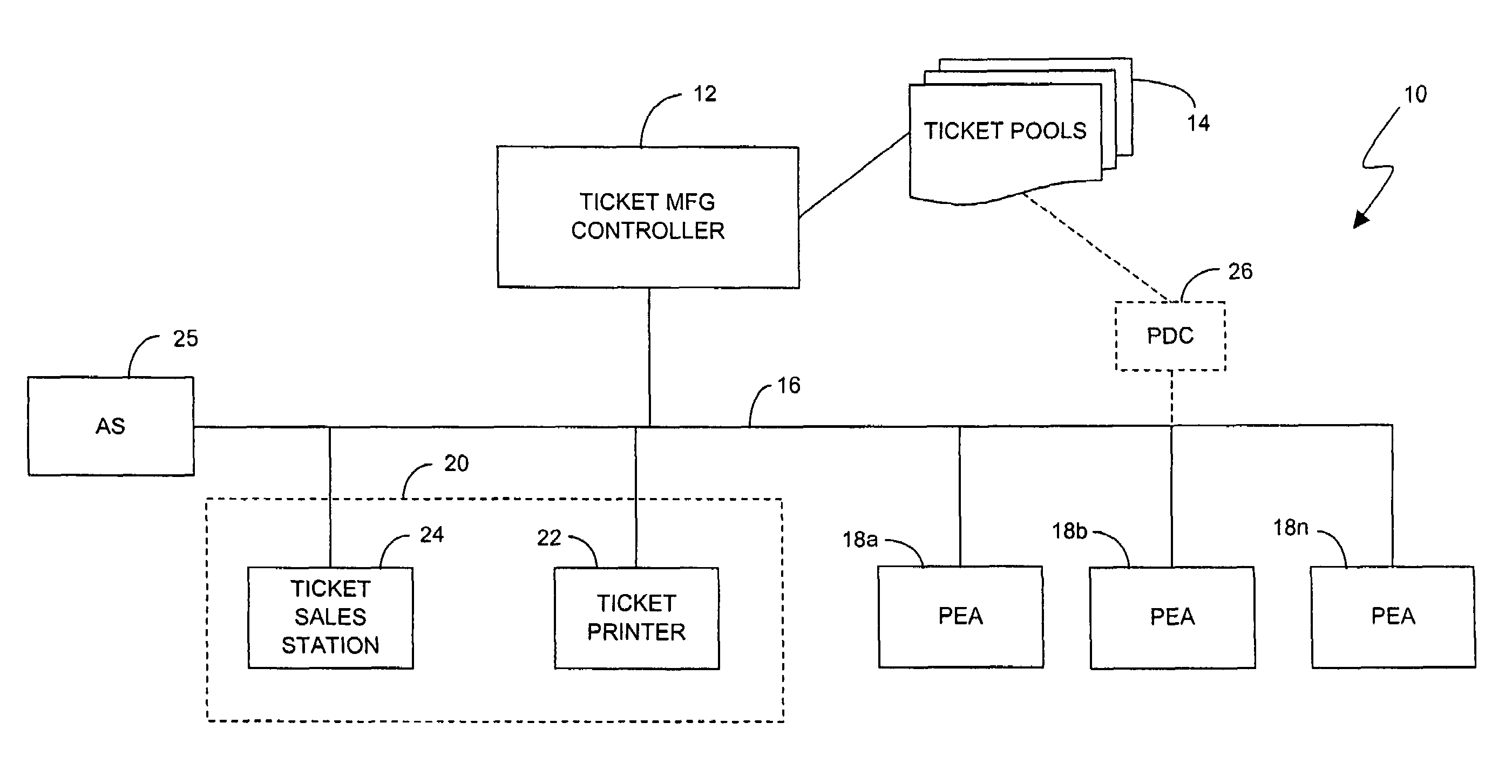

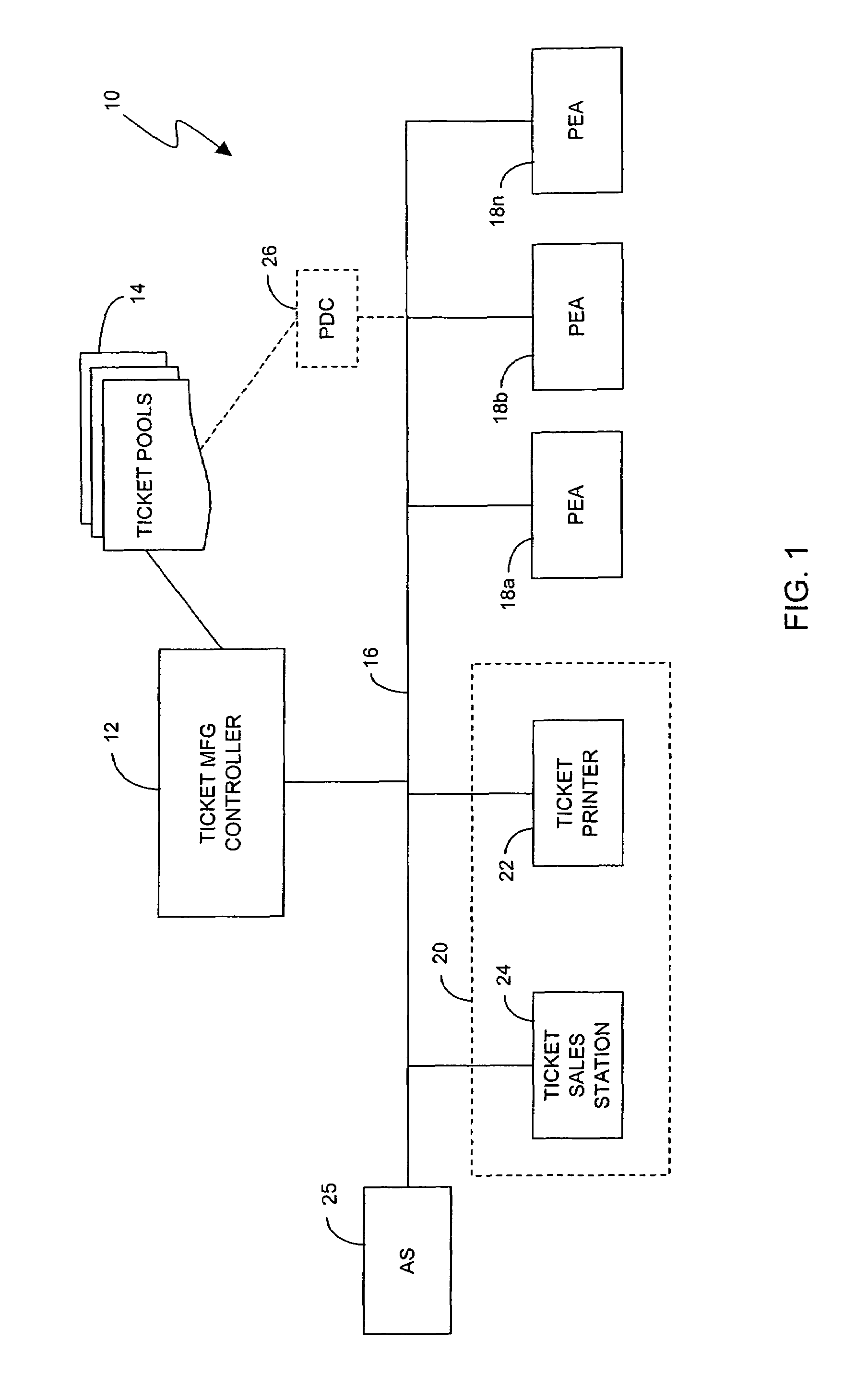

Lottery-style on-demand ticket system and method

InactiveUS6958014B1Other printing matterApparatus for meter-controlled dispensingNetwork connectionDistributed manufacturing

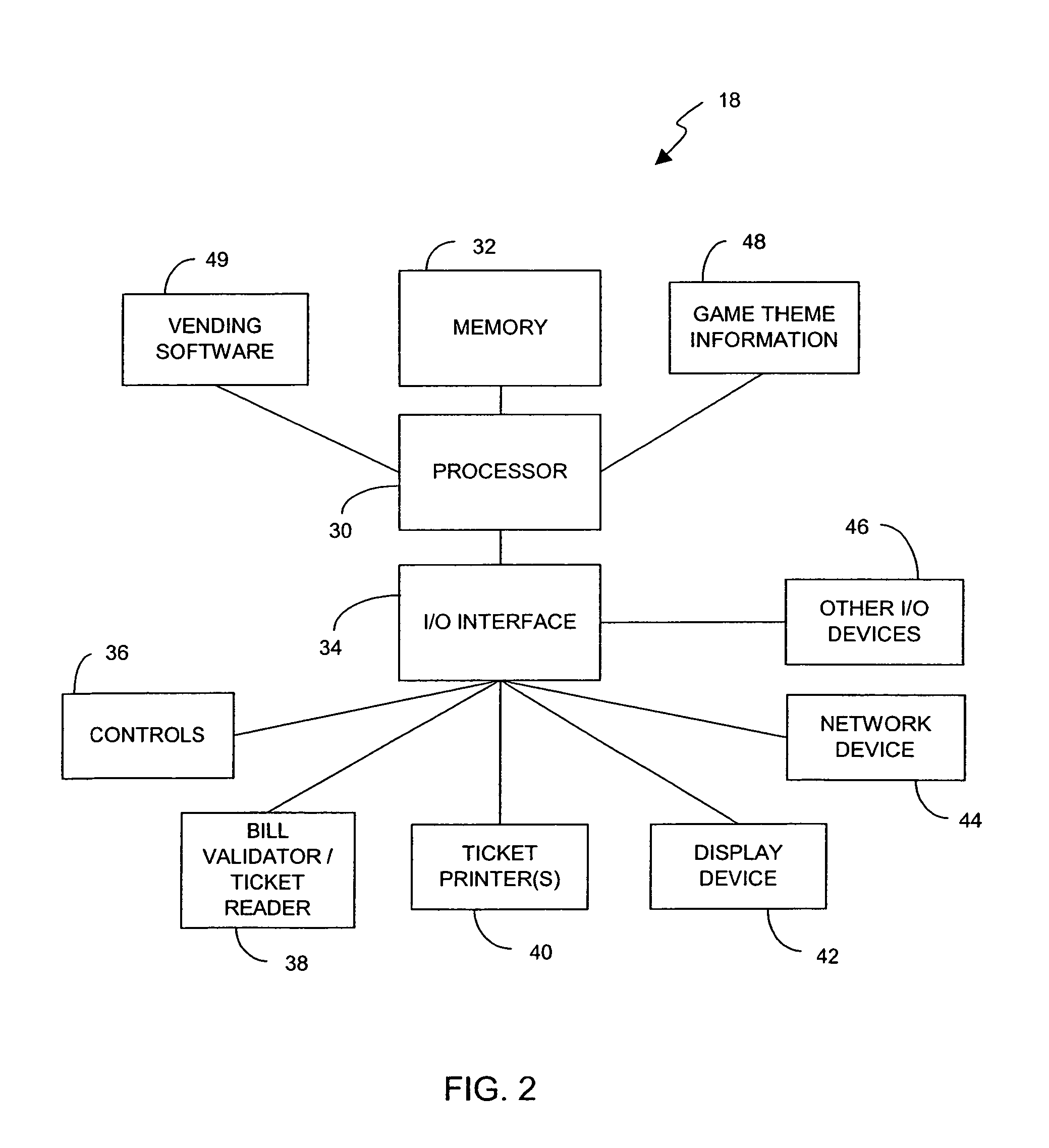

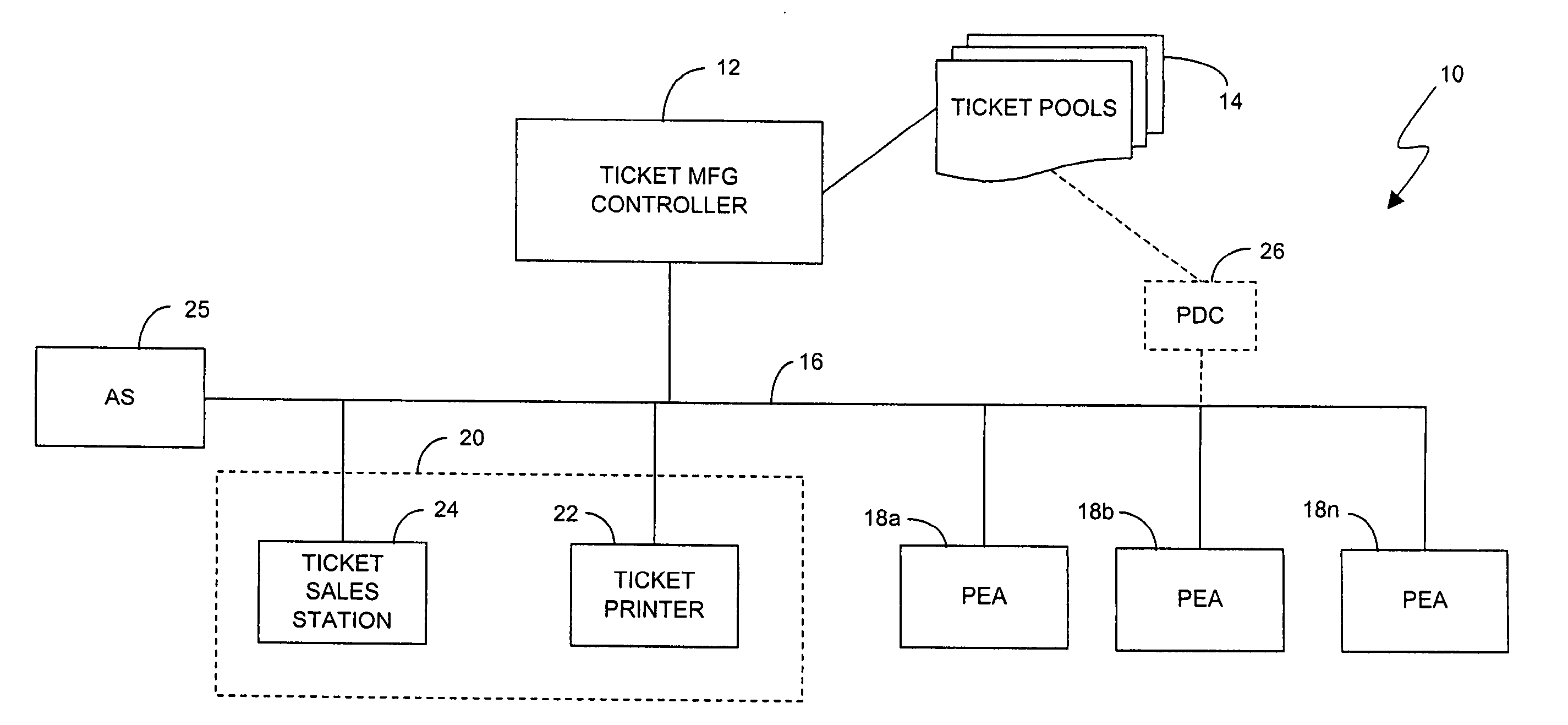

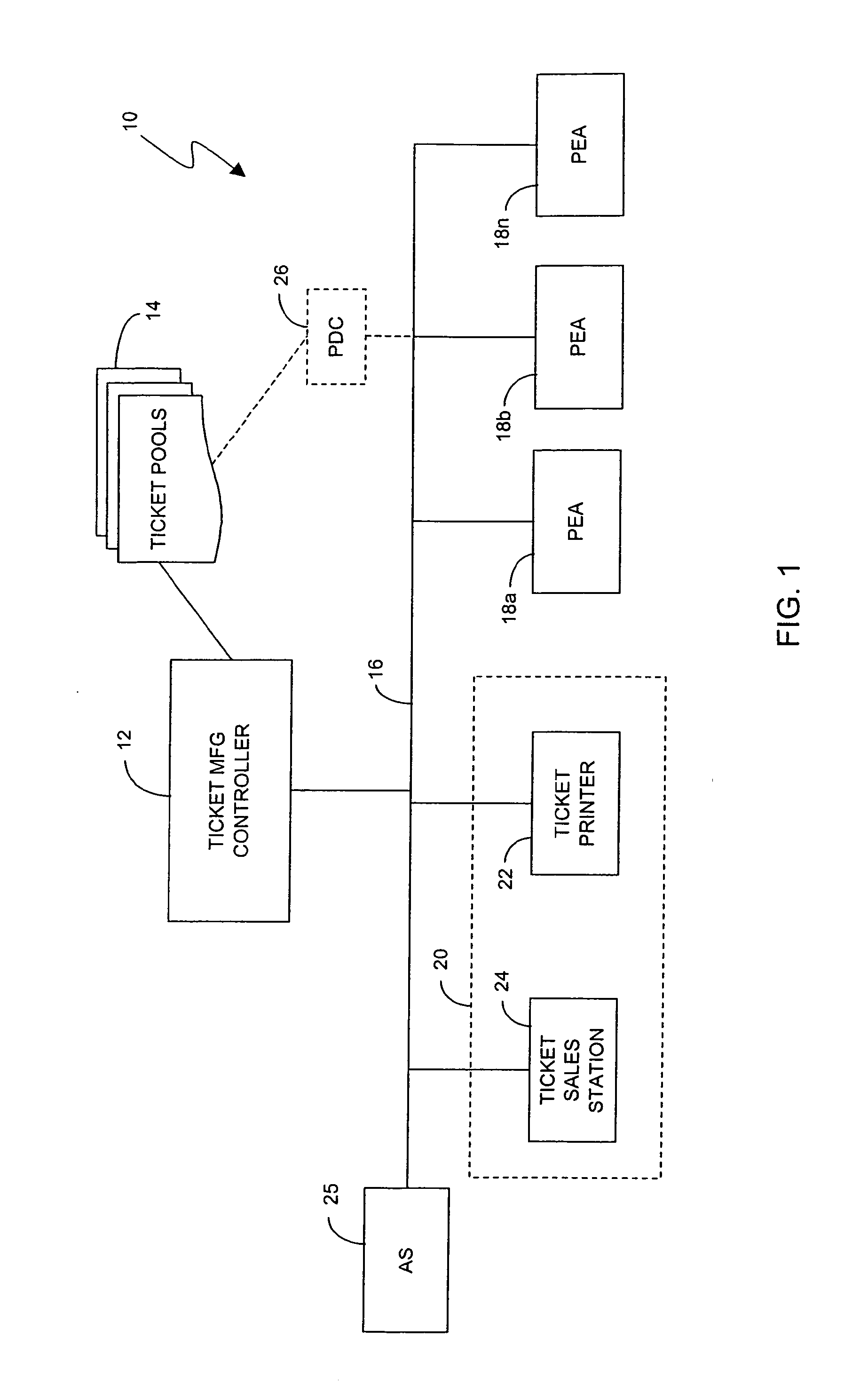

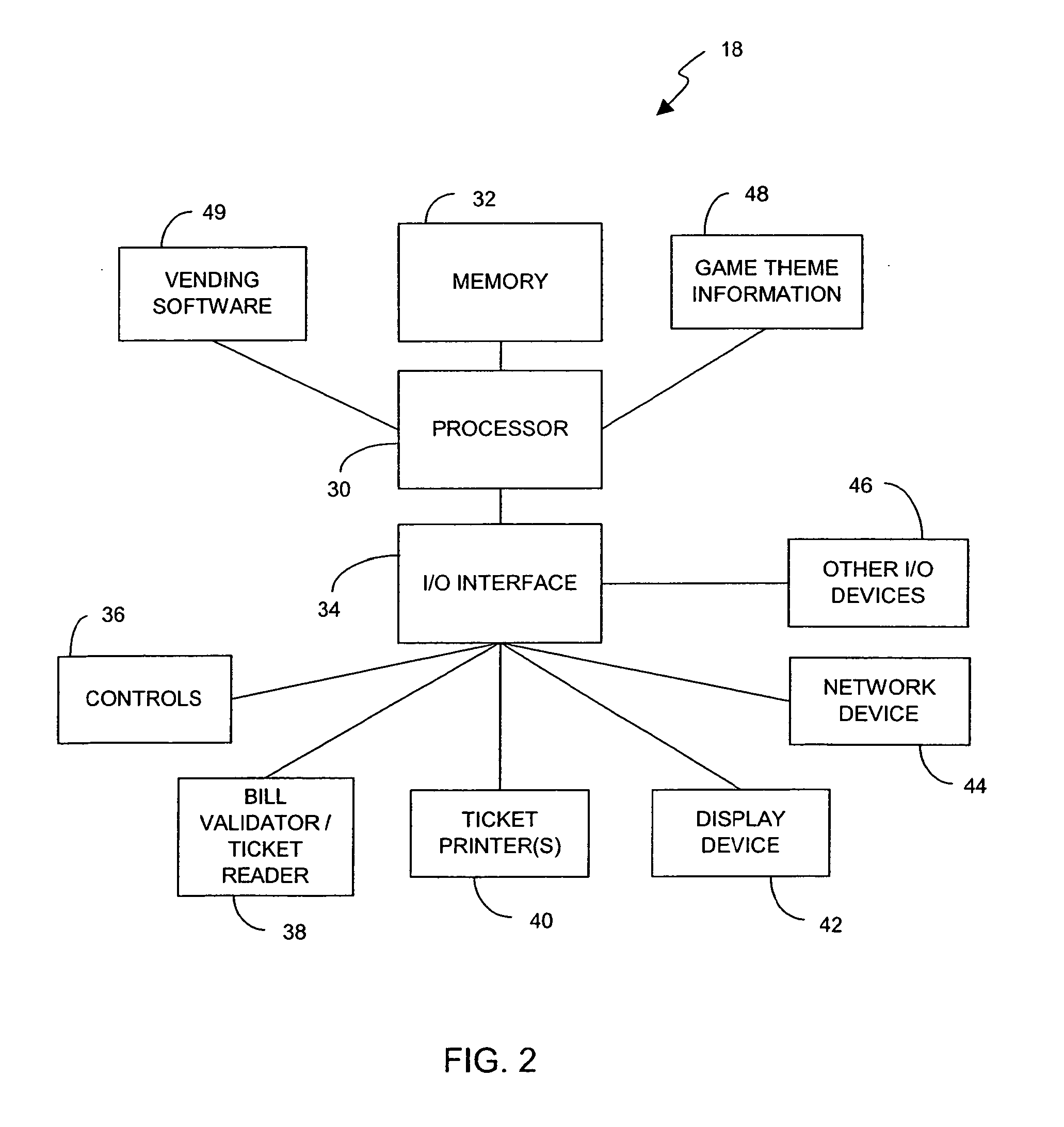

A distributed manufacturing and distribution process for lottery tickets is disclosed. The manufacturing / vending system comprises a centralized ticket manufacturing controller located at a centralized location and one or more vending devices located at remote sites. Each vending device is operatively coupled for communication with the centralized ticket manufacturing controller, normally via a network connection. Each vending devices is further equipped with a printer and ticket media, so that a customer is able to purchase on-demand tickets from vending device in communication with the centralized ticket manufacturing controller. Additionally, the vending devices may be configured as electronic aid to display the results of the purchased lottery tickets in entertaining ways to the customer.

Owner:BALLY GAMING INC

On-demand ticket system

A distributed manufacturing and distribution process for lottery tickets is disclosed. The manufacturing / vending system comprises a ticket manufacturing server and one or more vending devices located at remote sites. Each vending device is operatively coupled for communication with the server, normally via a network connection. Each vending devices is further equipped with blank media and printing means, so that a customer is able to purchase on-demand tickets from a vending device in communication with the server. Additionally, the vending devices may be configured as electronic aid to display the results of the purchased lottery tickets in entertaining ways to the customer.

Owner:BALLY GAMING INC

Method for Manufacturing On-Demand Lottery Tickets

A distributed manufacturing and distribution process for lottery tickets is disclosed. The manufacturing / vending system comprises a ticket manufacturing server and one or more vending devices located at remote sites. Each vending device is operatively coupled for communication with the server, normally via a network connection. Each vending devices is further equipped with blank media and printing means, so that a customer is able to purchase on-demand tickets from a vending device in communication with the server. Additionally, the vending devices may be configured as electronic aid to display the results of the purchased lottery tickets in entertaining ways to the customer.

Owner:BALLY GAMING INC

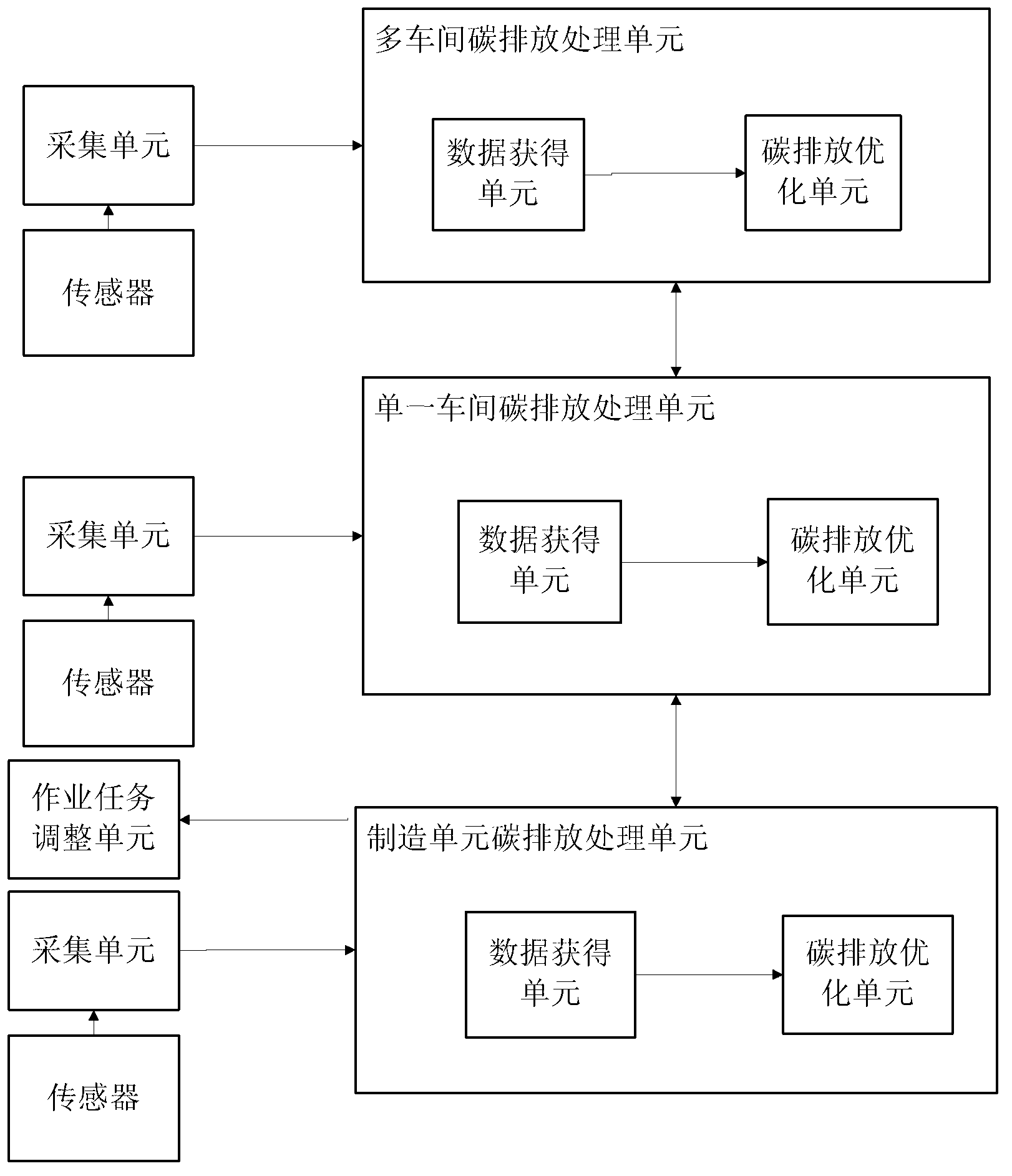

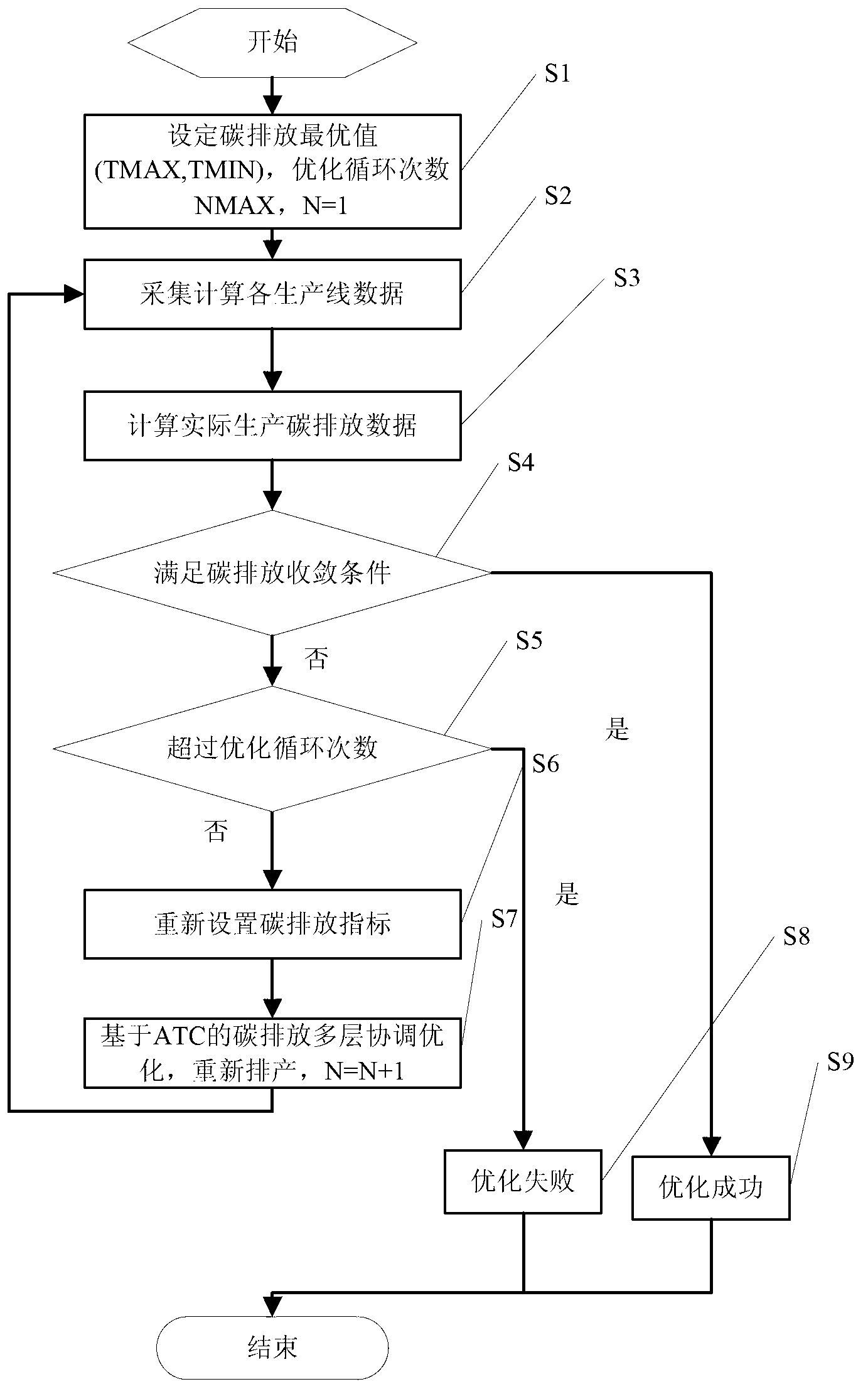

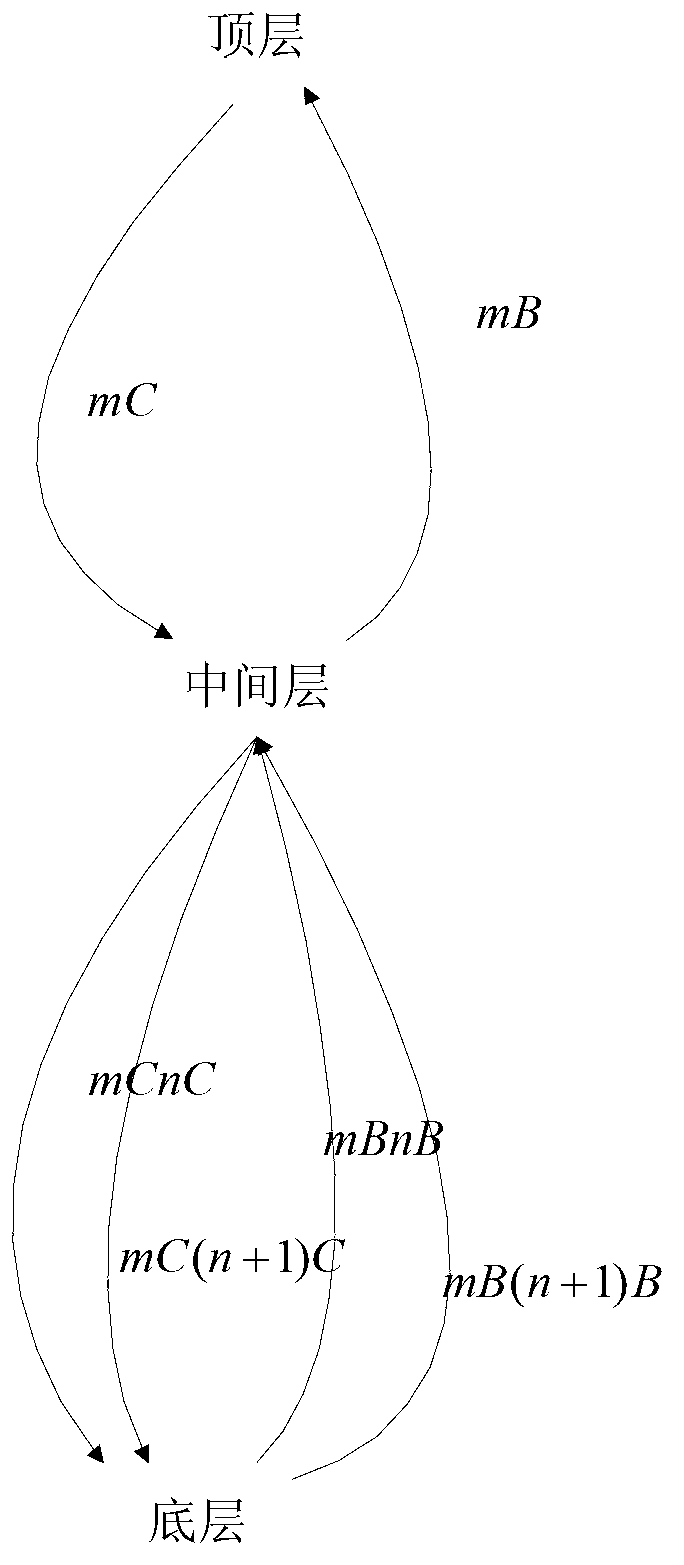

Carbon emission optimization method based on target cascading analytical method

InactiveCN103258247AImprove utilization efficiencyReduce use costEnergy industryForecastingManufacturing cellManufacturing enterprises

According to a carbon emission optimization method based on a target cascading analytical method, a production process is divided into a top multiple-workshop scheduling layer, a middle single-workshop scheduling layer and bottom manufacturing unit planning layers, wherein an optimal production scheme of a manufacturing unit of each manufacturing unit planning layer is respectively designed, the carbon emission of each producing activity is calculated, multiple layers of coordination and optimization of carbon emission based on the target cascading analytical method are carried out, the production scheme of each manufacturing unit planning layer is optimized and designed again, and one more cycle time is optimized. The carbon emission optimization method based on the target cascading analytical method tightly combines an optimization process and an energy collecting and monitoring device, improves energy comprehensive utilization efficiency of large-scale distributed manufacturing enterprises, and lowers energy use cost. By mean of the carbon emission optimization method based on the target cascading analytical method, the requirement for individual energy conservation and emission reduction of different types of workshops of the distributed manufacturing enterprises can be met, the carbon emission optimization method can be provided in the manufacturing process of the distributed products, and positive effects of promoting the energy-saving technology to be rapidly popularized and applied in the manufacturing enterprises are achieved.

Owner:GUANGDONG UNIV OF TECH

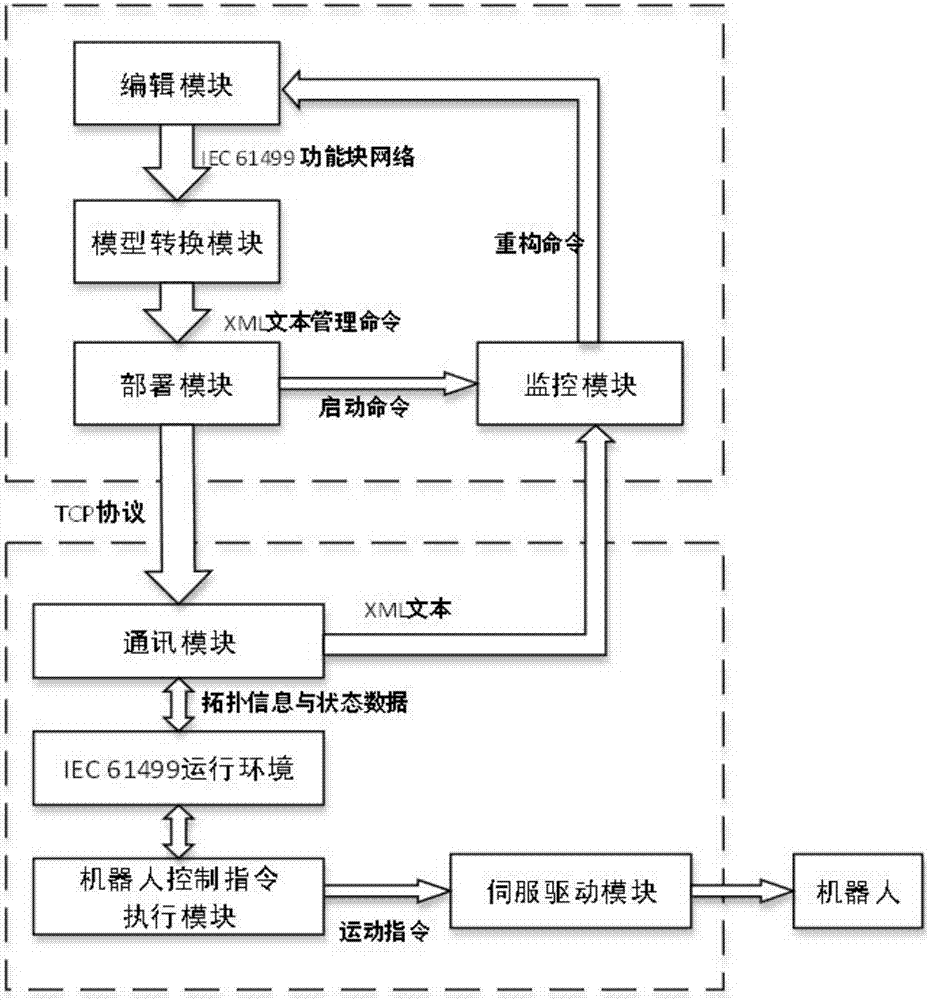

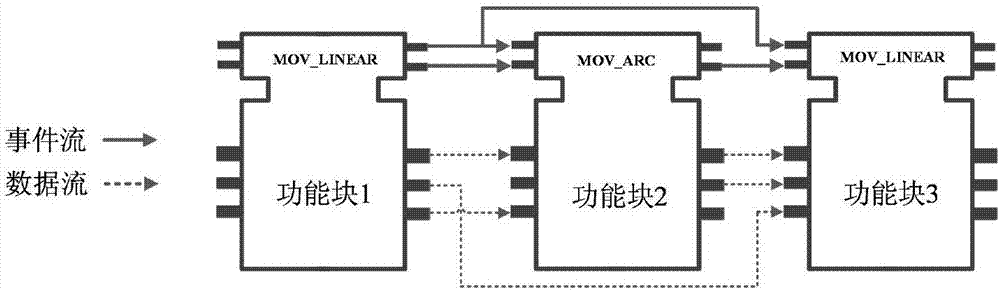

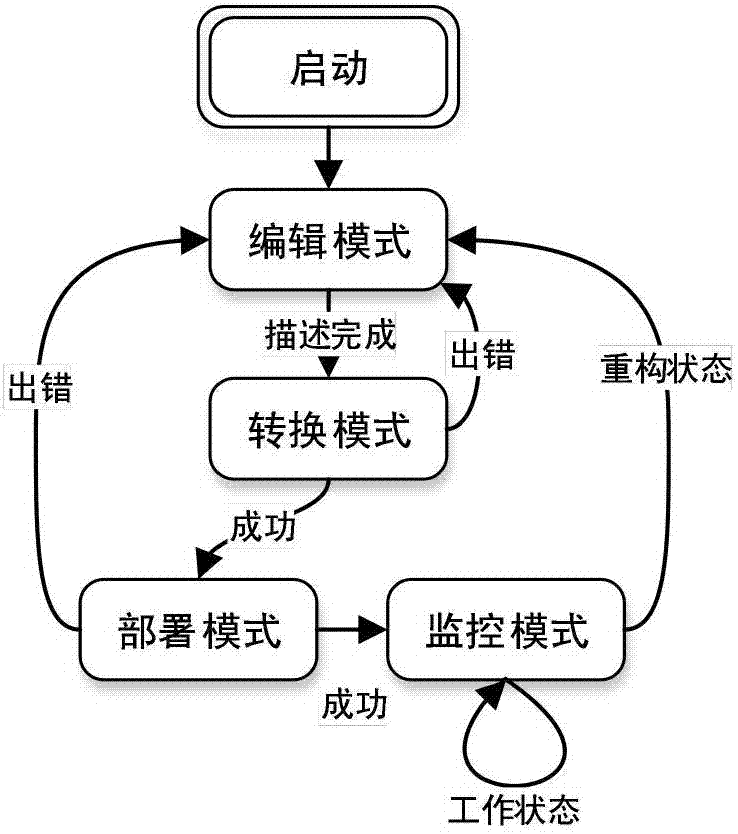

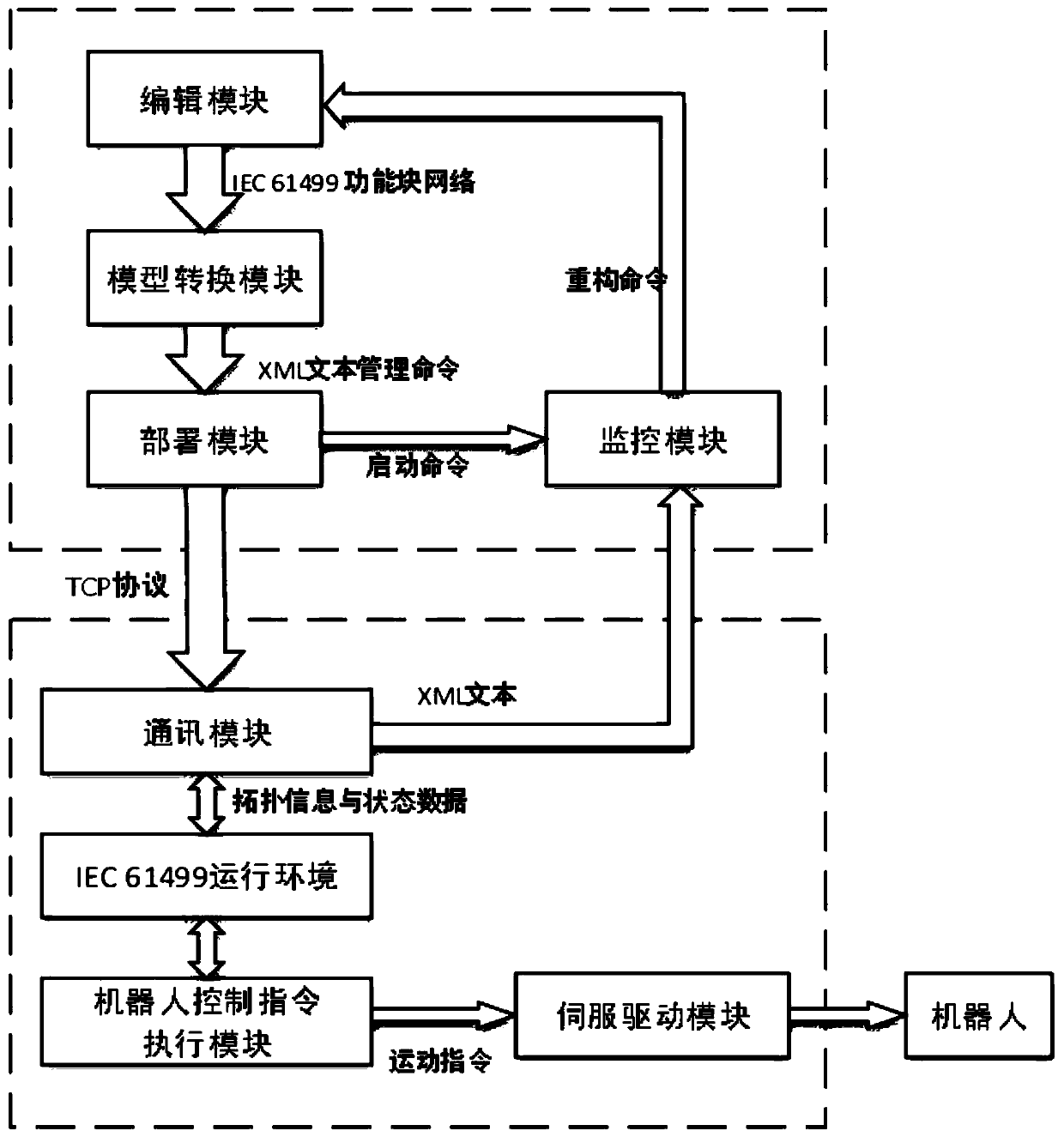

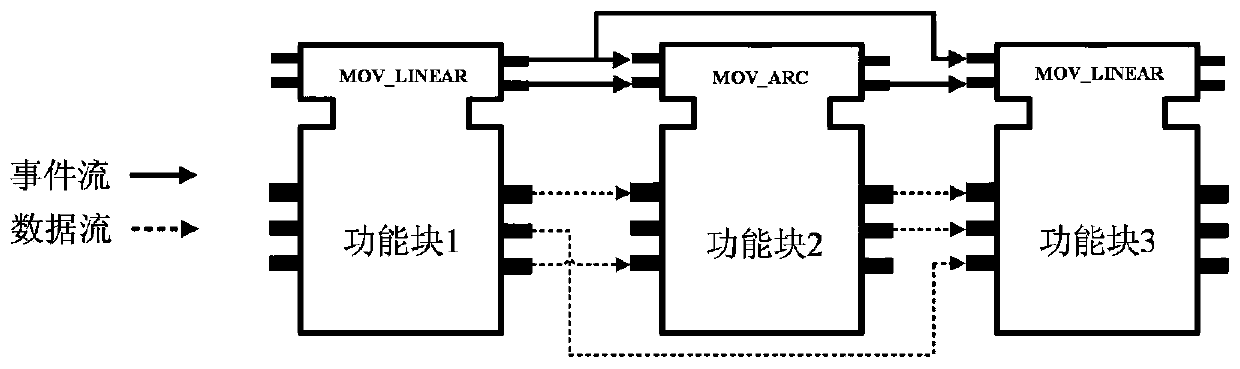

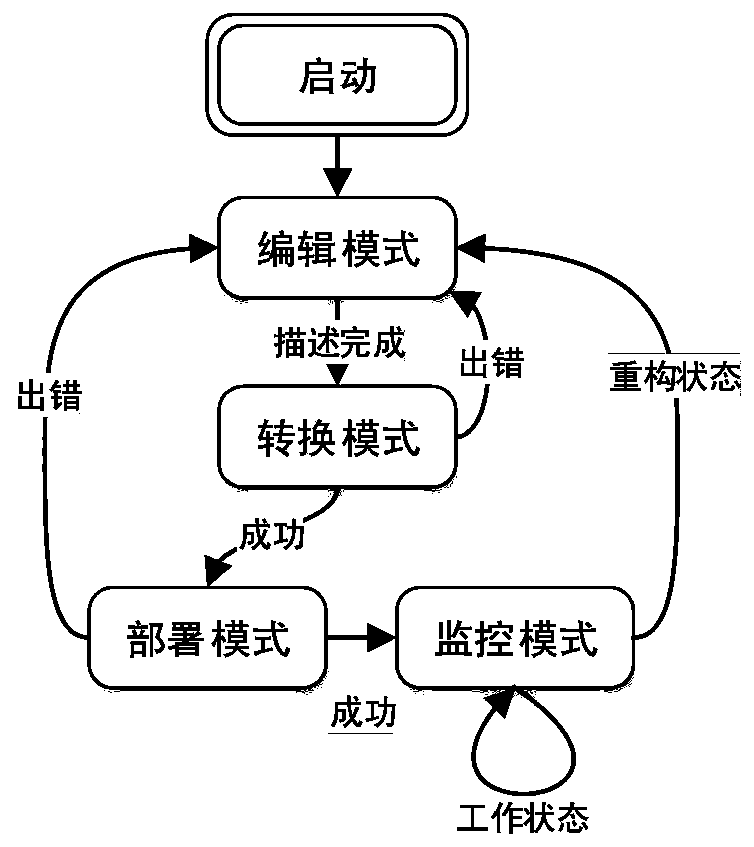

Programmable control method of reconfigurable industrial robot in distributed manufacturing environment

ActiveCN106933212AImprove flexibilityRealize online dynamic refactoringTotal factory controlProgramme total factory controlInternational standardComputer module

The invention discloses a programmable control method of a reconfigurable industrial robot in a distributed manufacturing environment. An editing module, a model conversion module, a deployment module, a communication module, an IEC 61499 operating environment, a robot control instruction execution module, a servo drive module and a robot are in successive telecommunication connection. The deployment module is in telecommunication connection with a monitoring module which is connected with the editing module. The communication module is in telecommunication connection with the monitoring module. According to the invention, a graphical programming language conforming to the international standard is adopted to replace a dedicated robot controller programming language based on text; the efficiency of a development process and the portability of a control program are improved; based on a modular operating environment and a standardized management command, the on-line dynamic reconstruction of the industrial robot control program can be realized; and the flexibility of a robot controller is improved.

Owner:SOUTH CHINA UNIV OF TECH

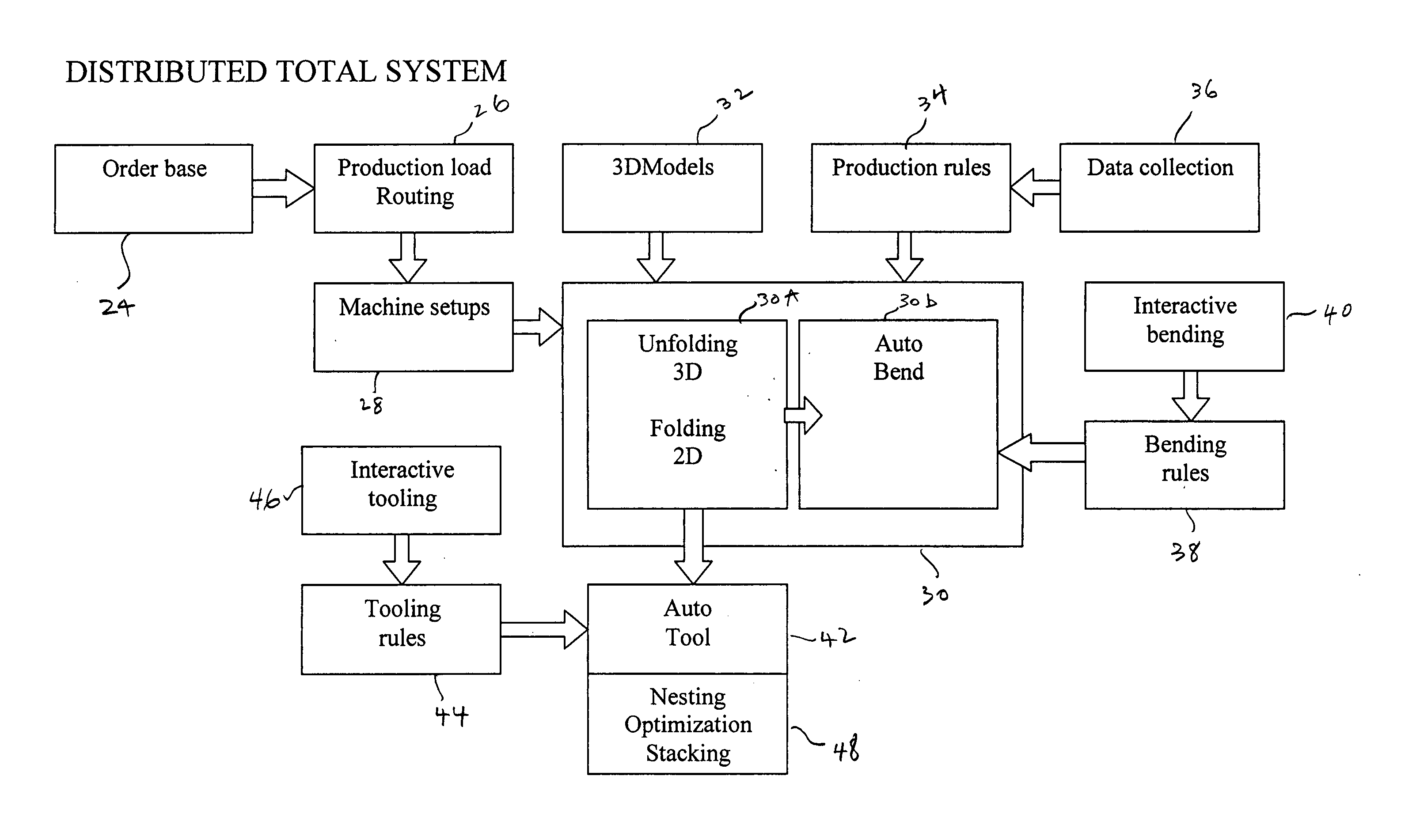

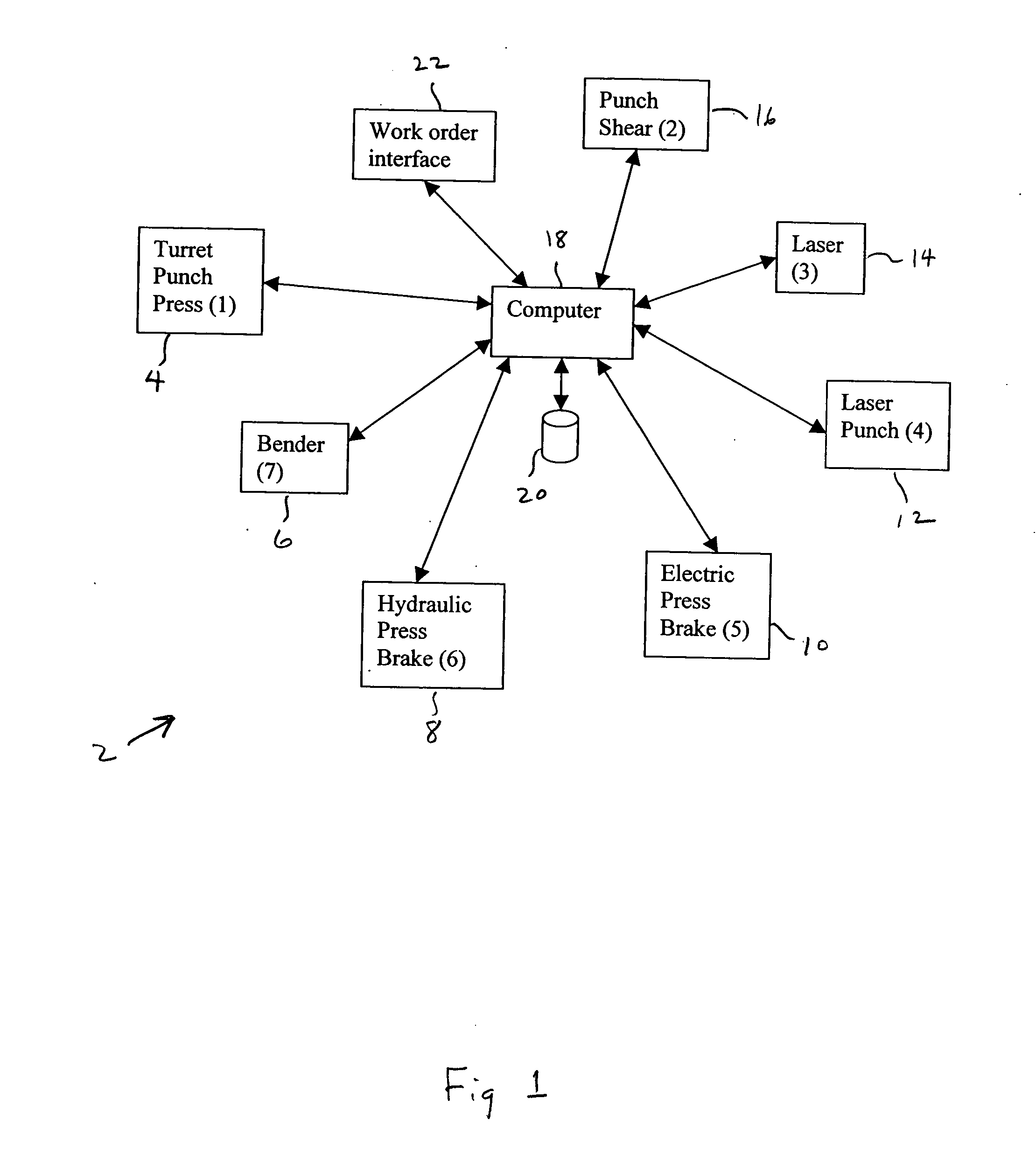

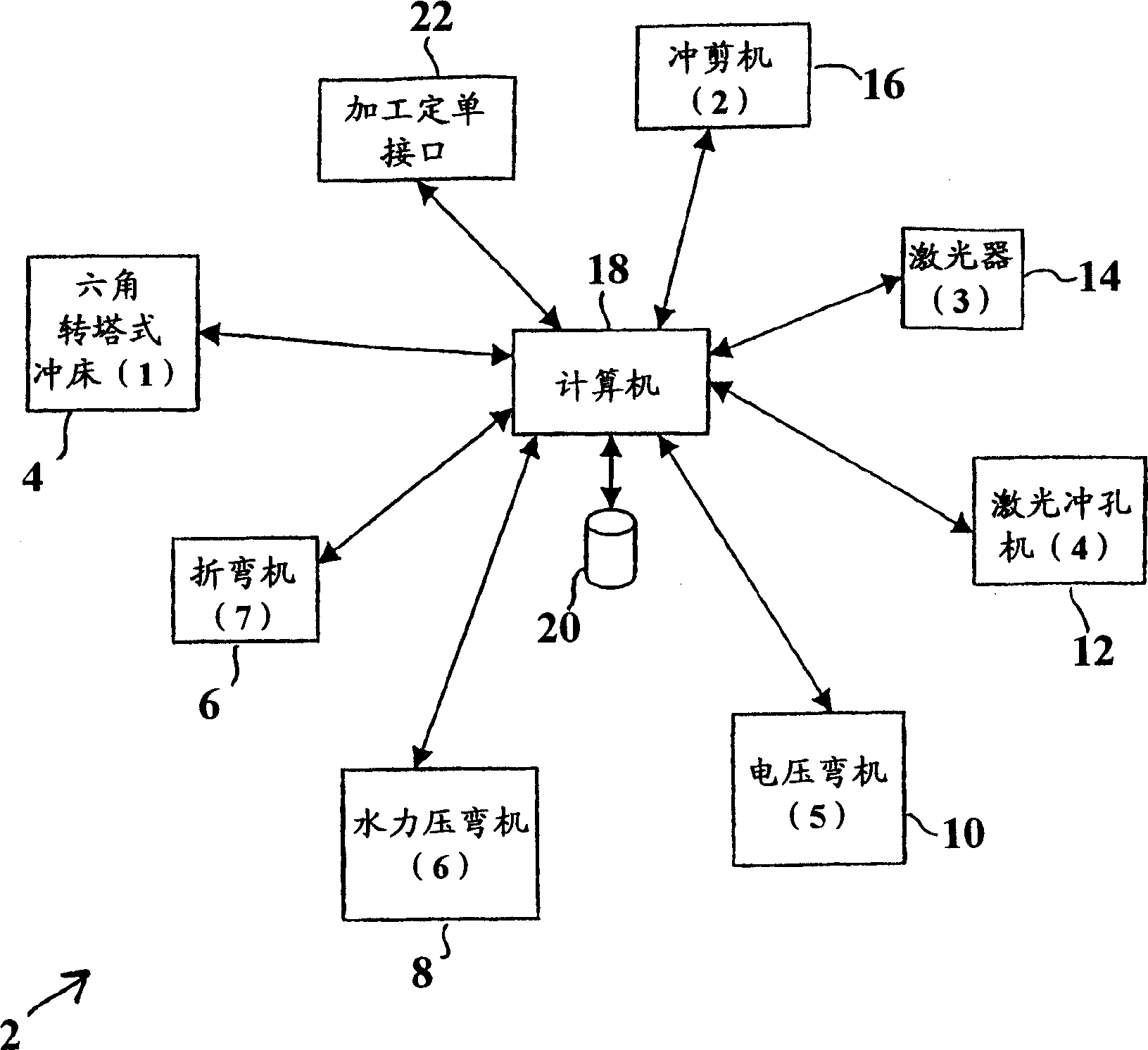

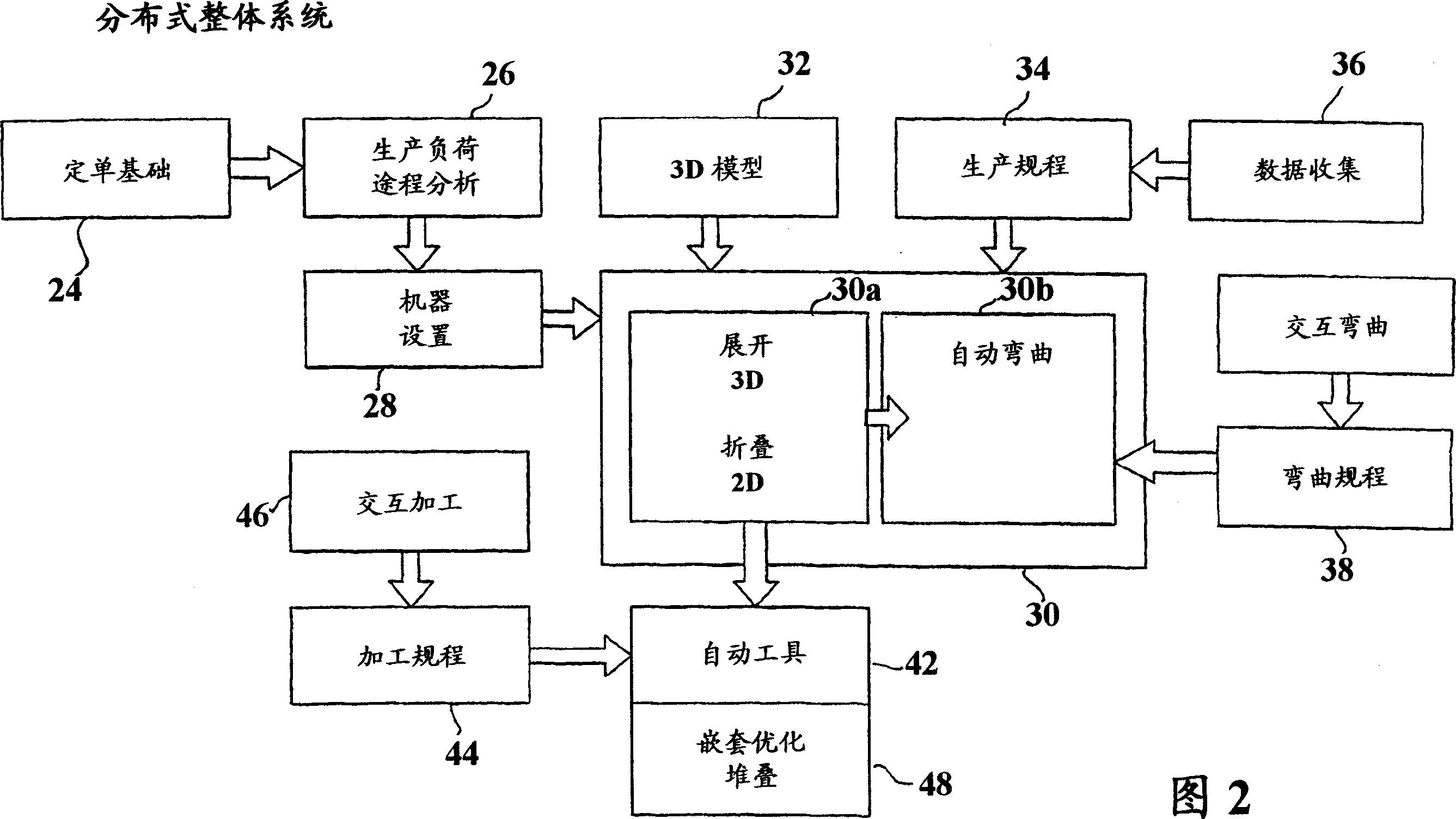

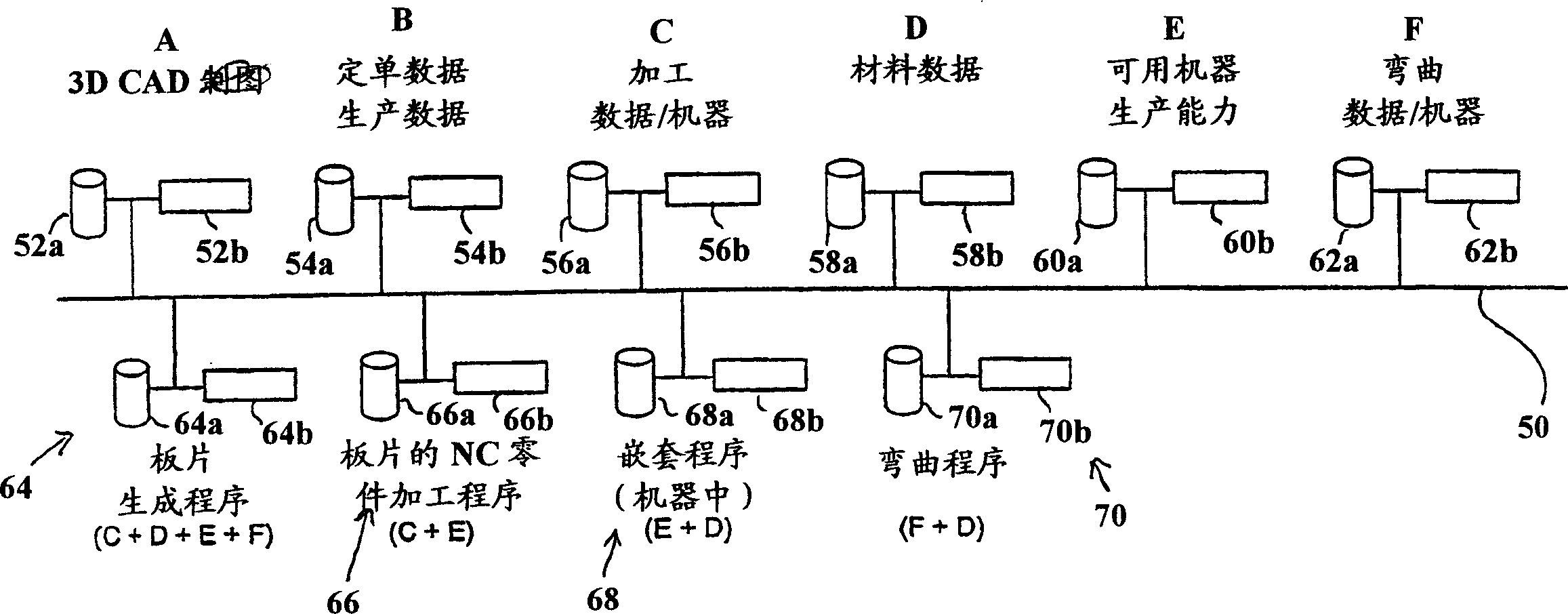

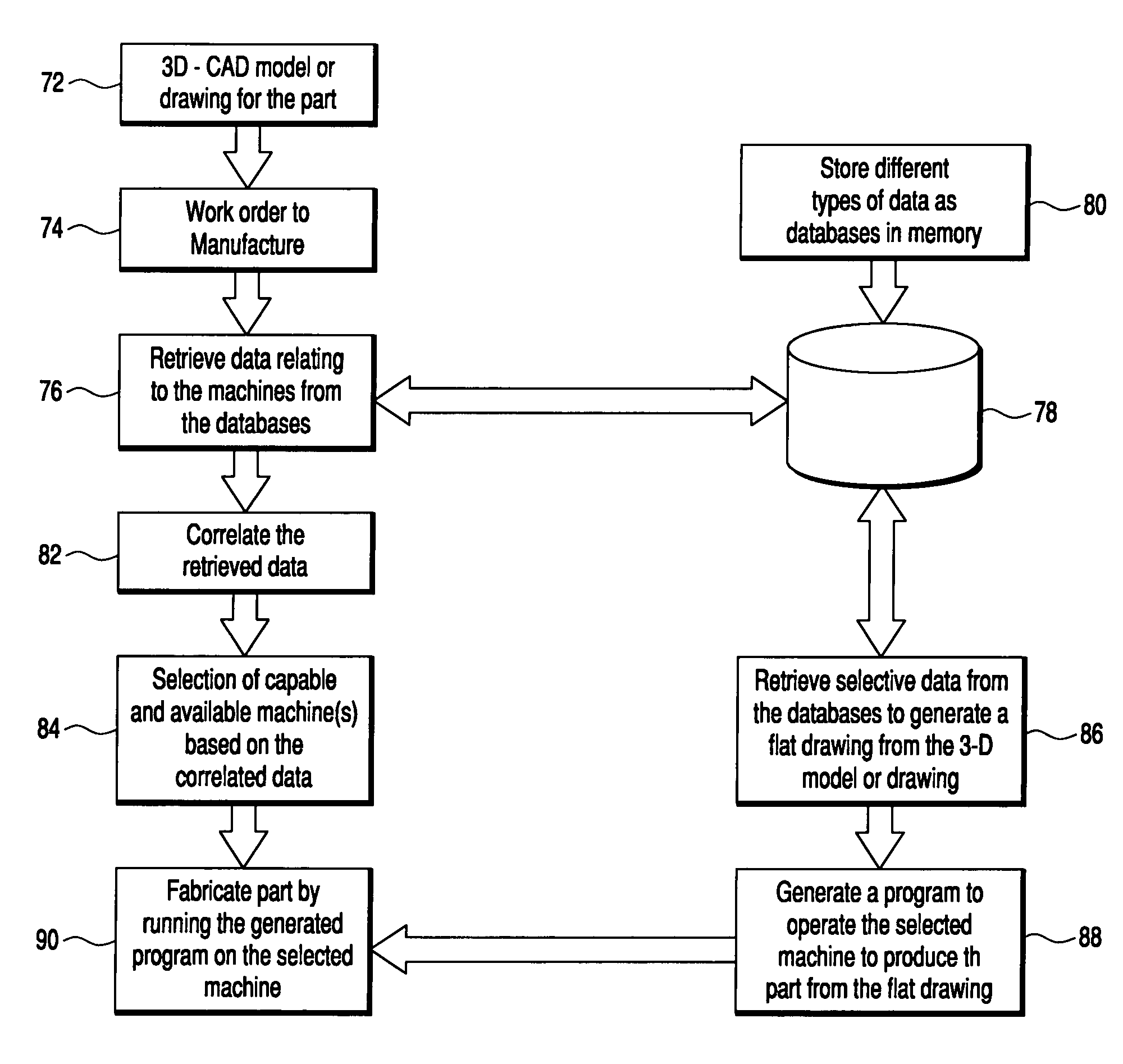

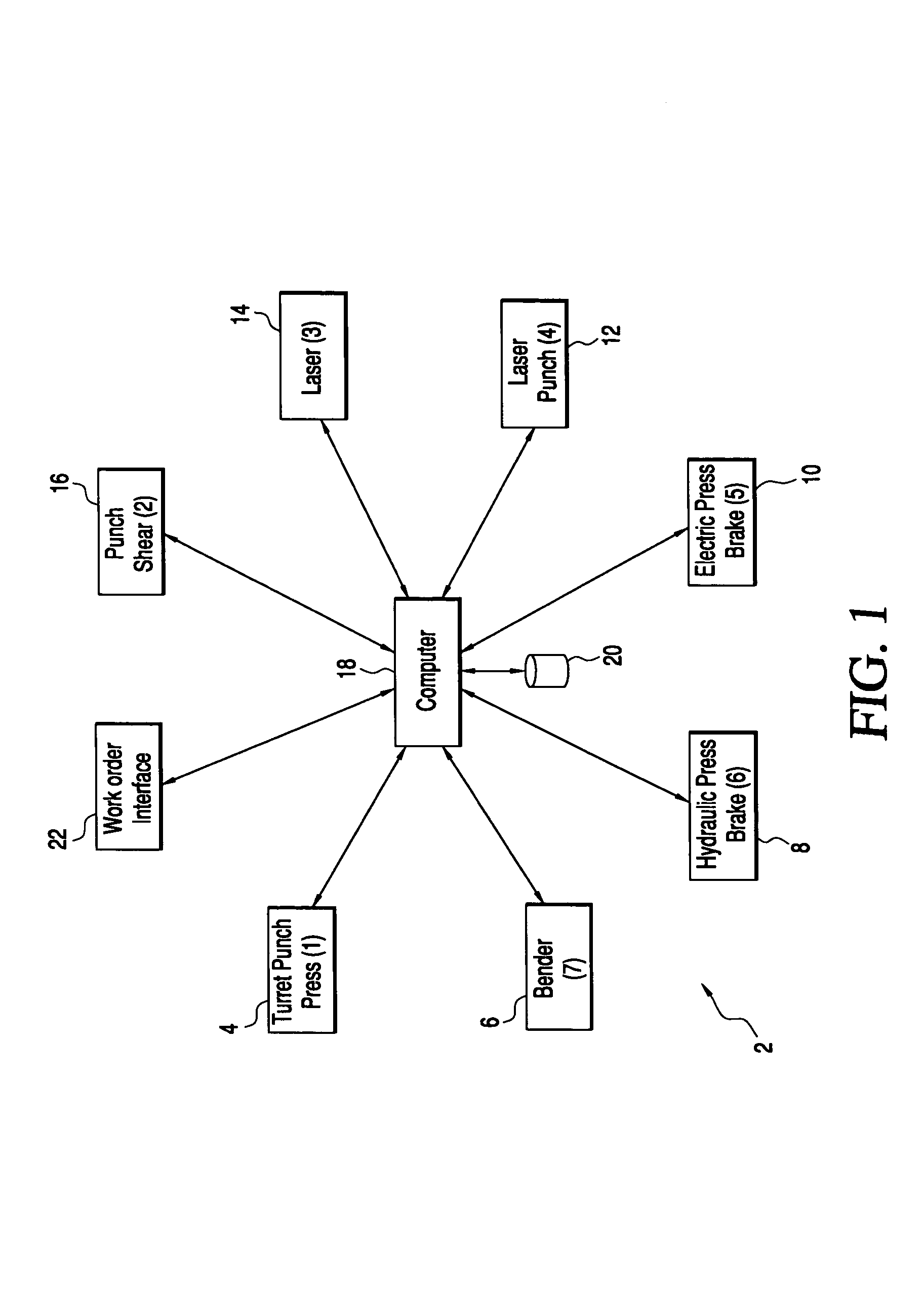

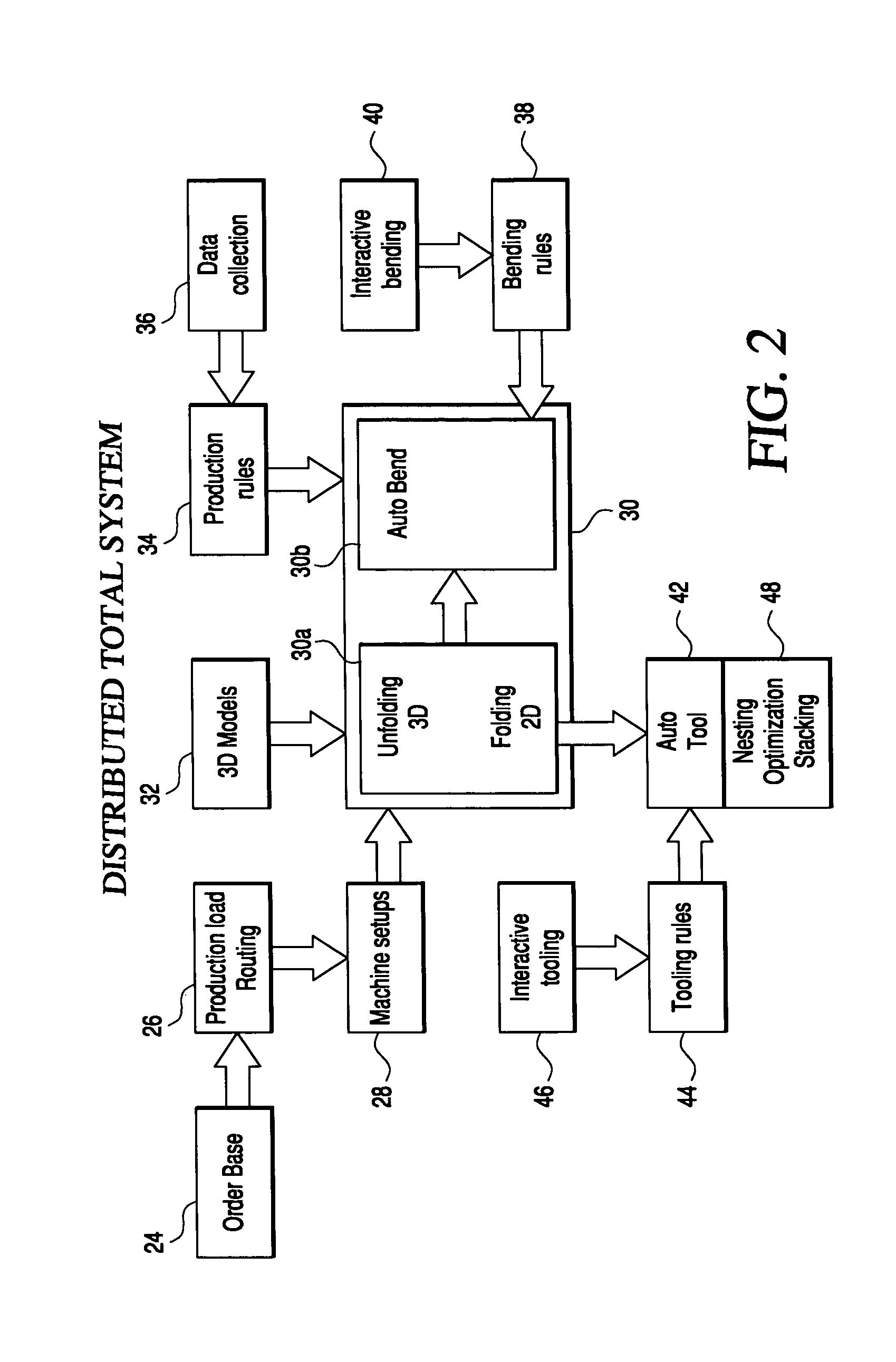

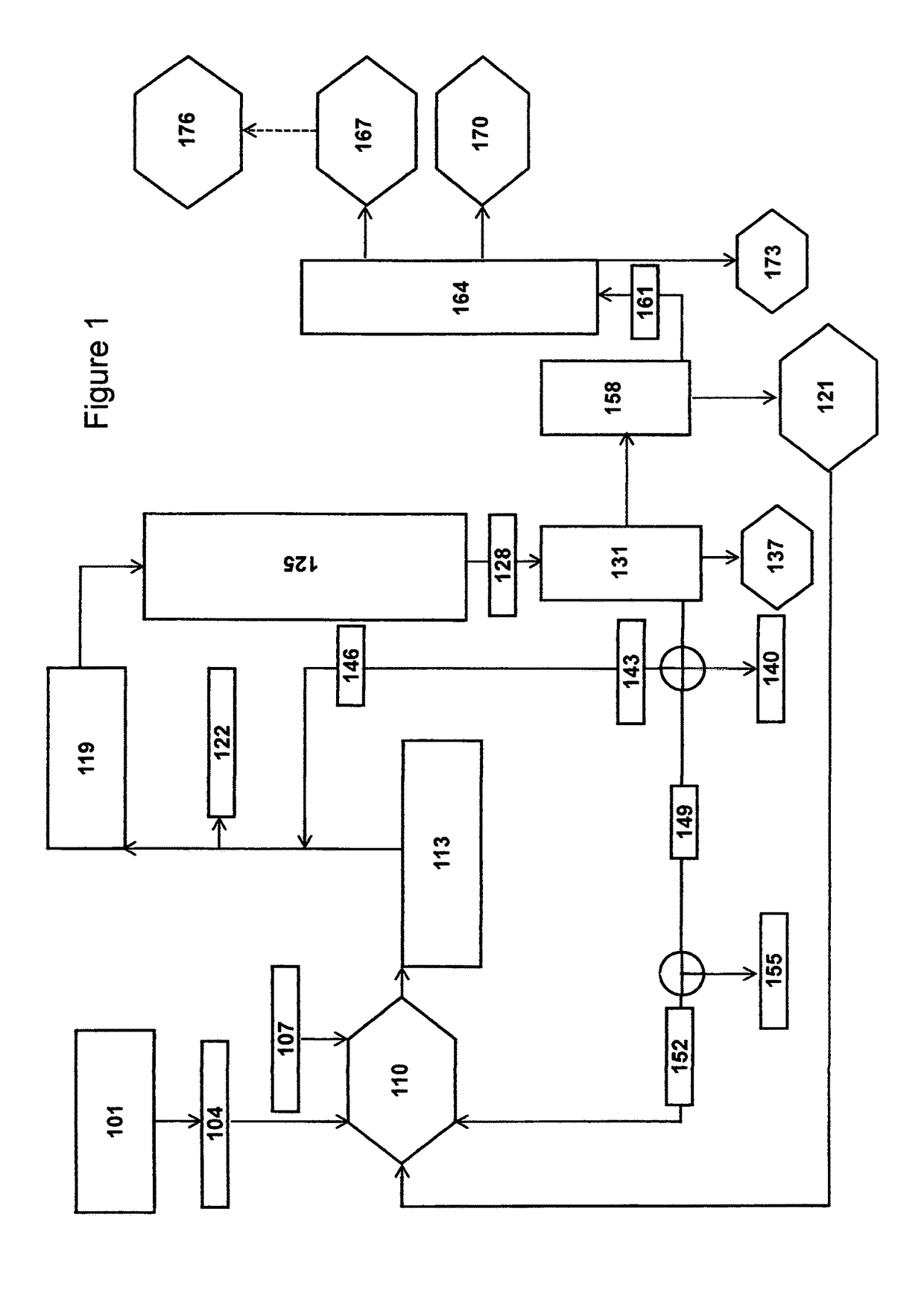

Flexible distributed manufacturing method and system therefor

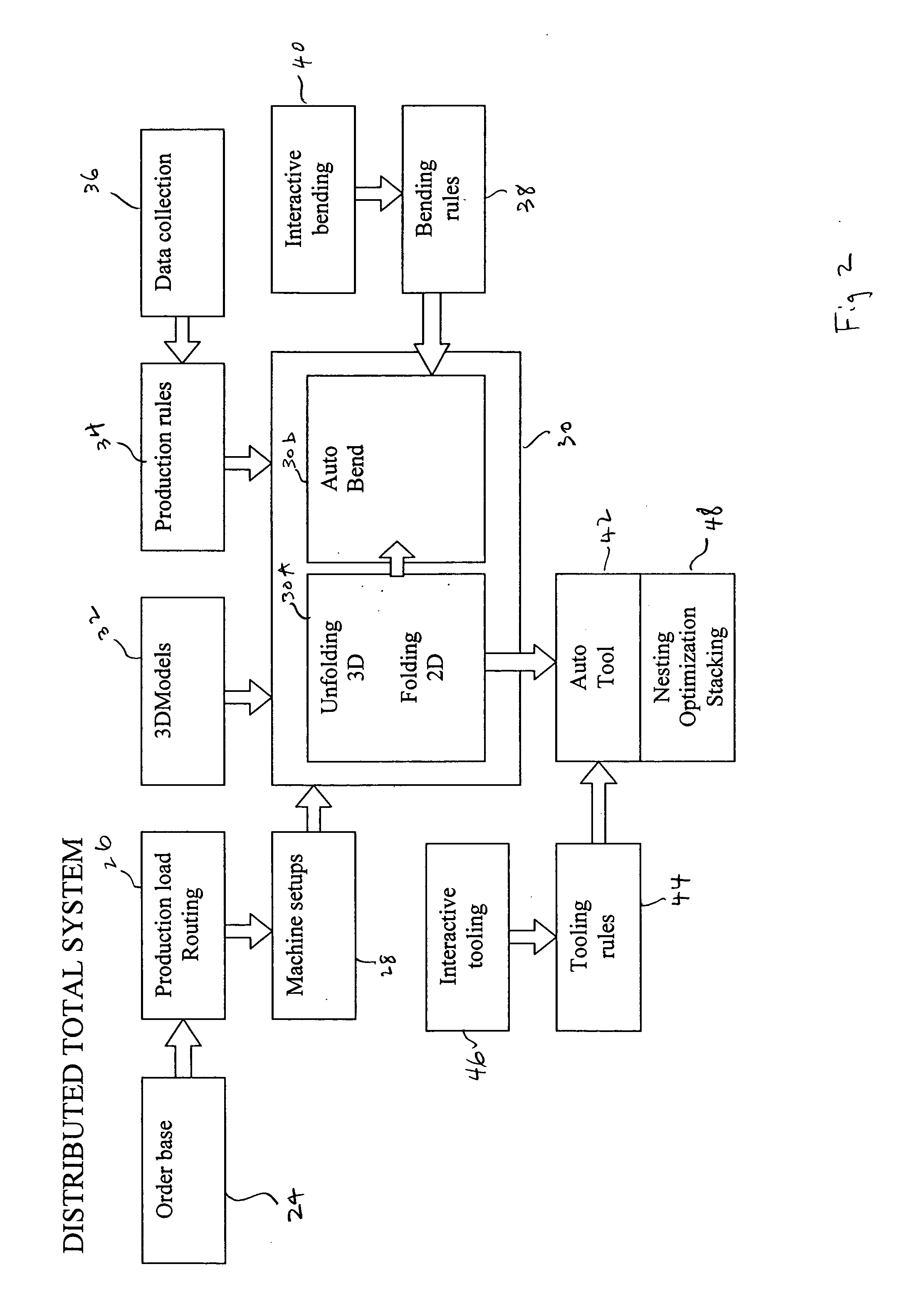

ActiveUS20050137740A1Data processing applicationsTotal factory controlSelection systemMulti dimensional

In a manufacturing system that has a plurality of sheet fabrication machines, to enhance the efficiency of the system, there are provided a plurality of databases each for storing particular data relating to the machines, the types of materials to be used, the tooling of the machines, etc. of the system. When a multi-dimensional model of a component part to be produced by the system is input to the system, selective data is retrieved from the various databases so that at least one machine of the plurality of machines of the system is selected to produce the part from a worksheet of a chosen material. Concurrently, or shortly thereafter, a NC part program for programming the selected machine to execute the necessary operations in accordance with a flat drawing generated from the multi-dimensional model to fabricate the component part is generated based on selective data retrieved from the databases. With the NC part program, the selected machine performs the operations necessary for producing the component part from the sheet stock material chosen for the component part. If there are multiple component parts to be produced in the same production run, the system would sort the different parts and arrange for the ordered fabrication of the different parts by respective selected machines equipped with corresponding appropriate NC programs to eliminate any potential bottleneck or conflicts that may arise due to the fabrication of multiple parts by multiple machines during the same production run.

Owner:FINN POWER INT

Multi-agent system for distributed manufacturing scheduling with Genetic Algorithms and Tabu Search

Computerized scheduling methods and computerized scheduling systems according to exemplary embodiments. A computerized scheduling method may be stored in a memory and executed on one or more processors. The method may include defining a main multi-machine scheduling problem as a plurality of single machine scheduling problems; independently solving the plurality of single machine scheduling problems thereby calculating a plurality of near optimal single machine scheduling problem solutions; integrating the plurality of near optimal single machine scheduling problem solutions into a main multi-machine scheduling problem solution; and outputting the main multi-machine scheduling problem solution.

Owner:PEREIRA ANA MARIA DIAS MEDUREIRA

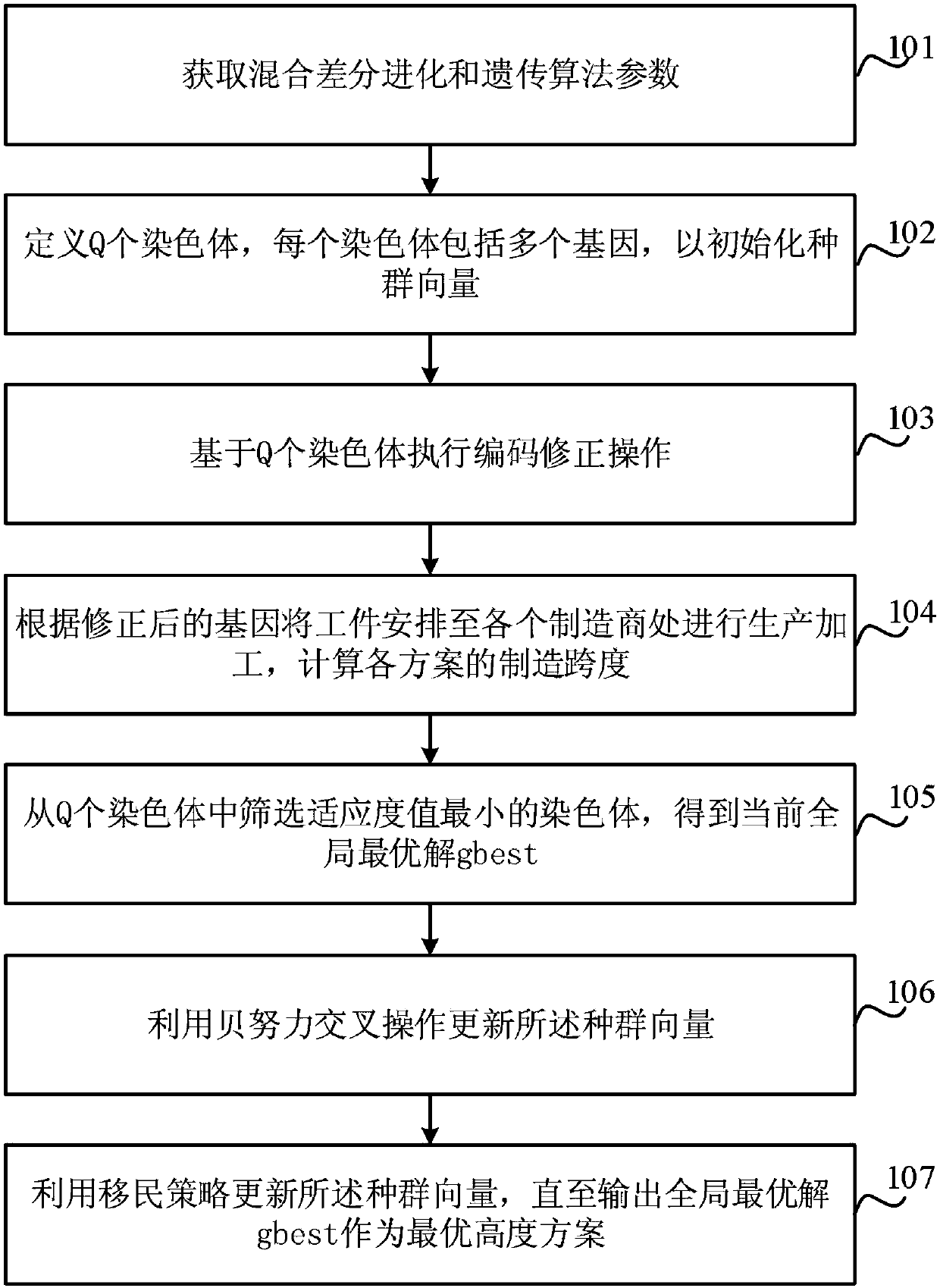

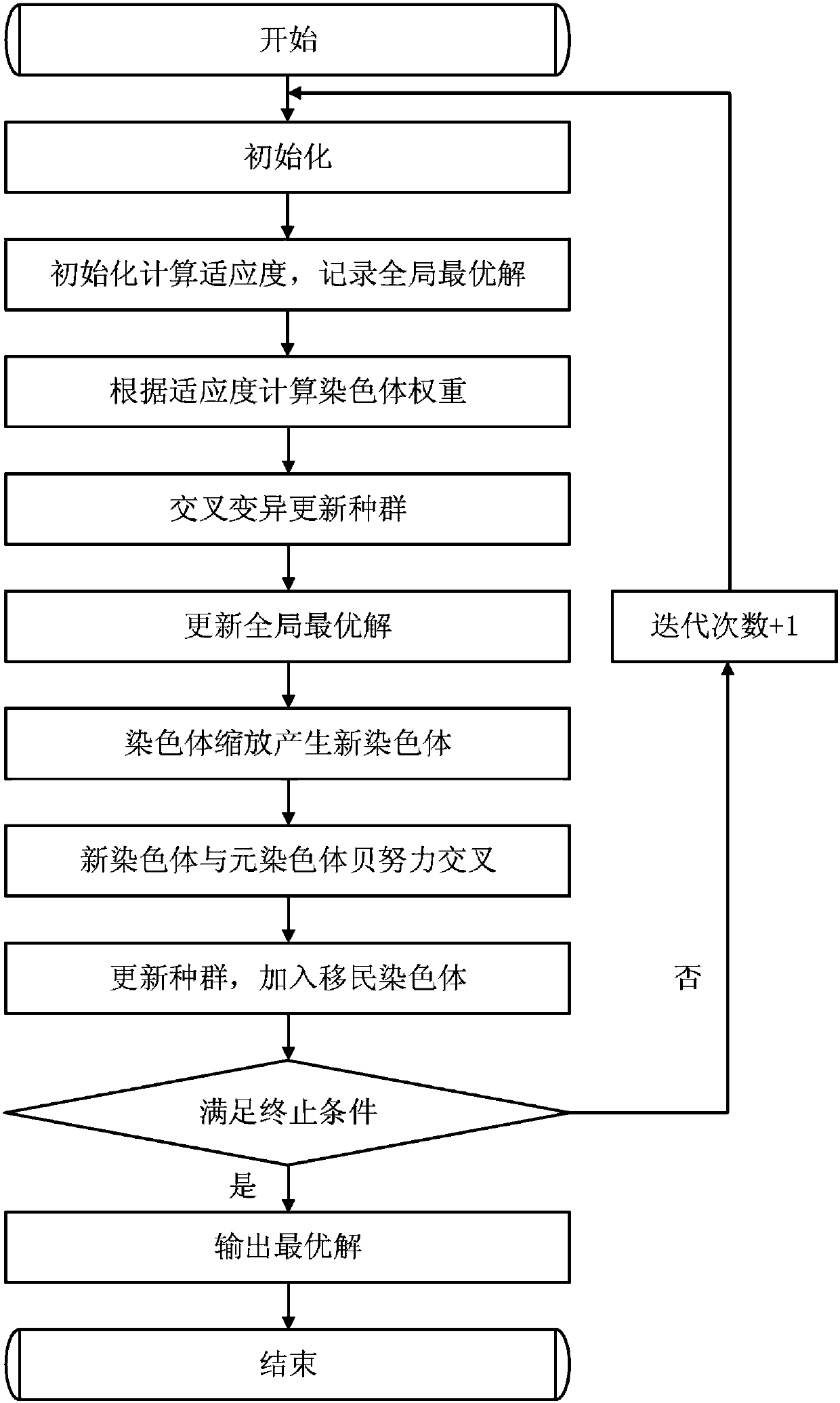

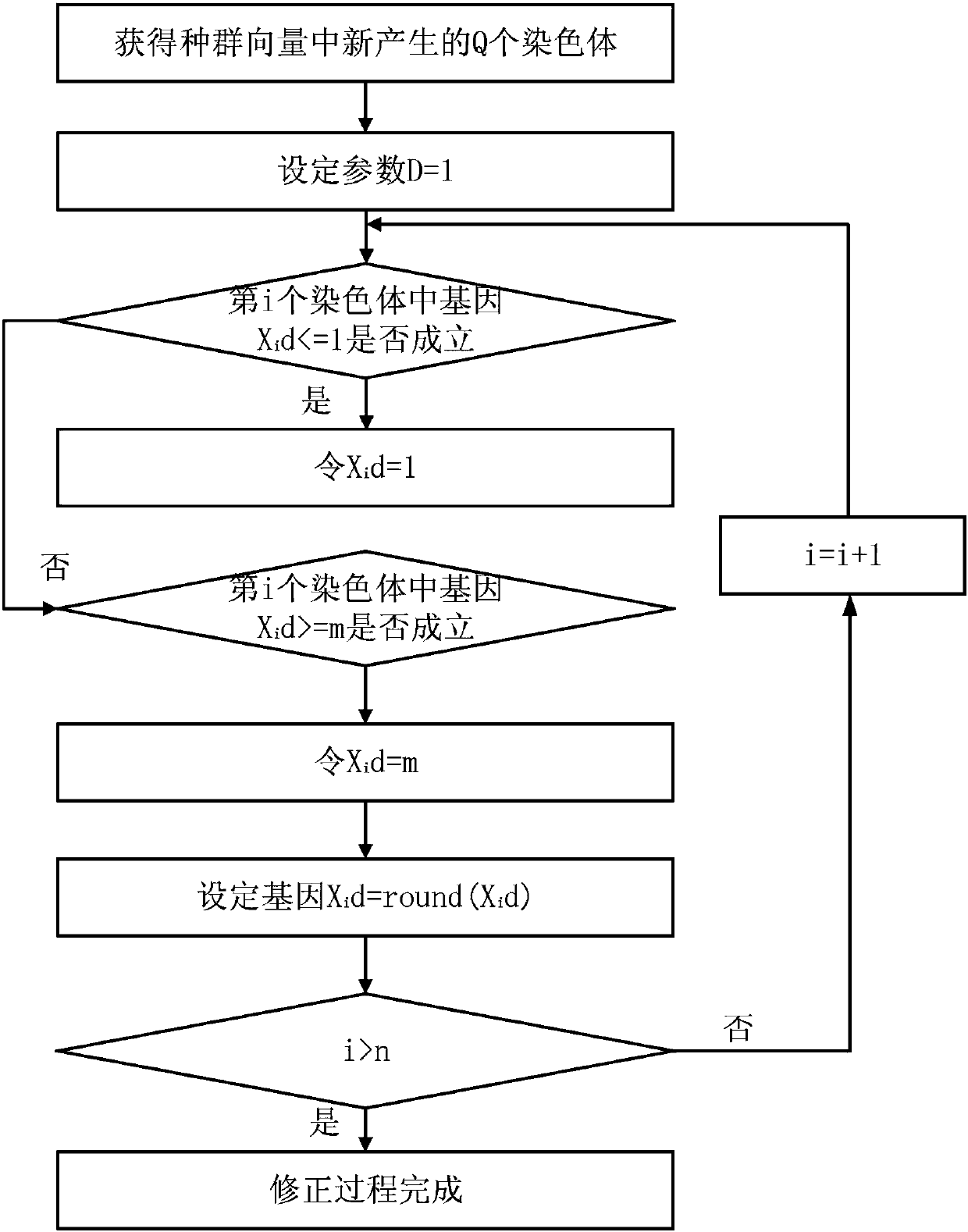

Collaborative scheduling method of high-end equipment manufacturing process, based on hybrid differential genetic algorithm

InactiveCN108492025AReduce collaboration costsSolve the collaborative scheduling problemResourcesManufacturing computing systemsGenetic algorithmComputer science

The invention provides a collaborative scheduling method of high-end equipment manufacturing process, based on a hybrid differential genetic algorithm. The collaborative scheduling method includes thesteps: obtaining hybrid differential evolution and genetic algorithm parameters; defining Q chromosomes, wherein each chromosome includes a plurality of genes to initialize a population vector; performing code correction operation based on the Q chromosomes; according to the corrected gene, arranging workpieces to each manufacturer for production processing, and calculating the manufacturing spanof each scheme; screening the chromosome with the smallest fitness value from the Q chromosomes, and obtaining the current global optimal solution gbest; updating the population vector by using Bernoulli crossover operation; and updating the population vector by means of an immigration strategy until the global optimal solution gbest is output as the optimal height scheme. The collaborative scheduling method of high-end equipment manufacturing process, based on a hybrid differential genetic algorithm can successfully solve the collaborative scheduling problem of production and transportationin the distributed manufacturing process, and is beneficial to improving the overall efficiency and service level of the production system.

Owner:HEFEI UNIV OF TECH

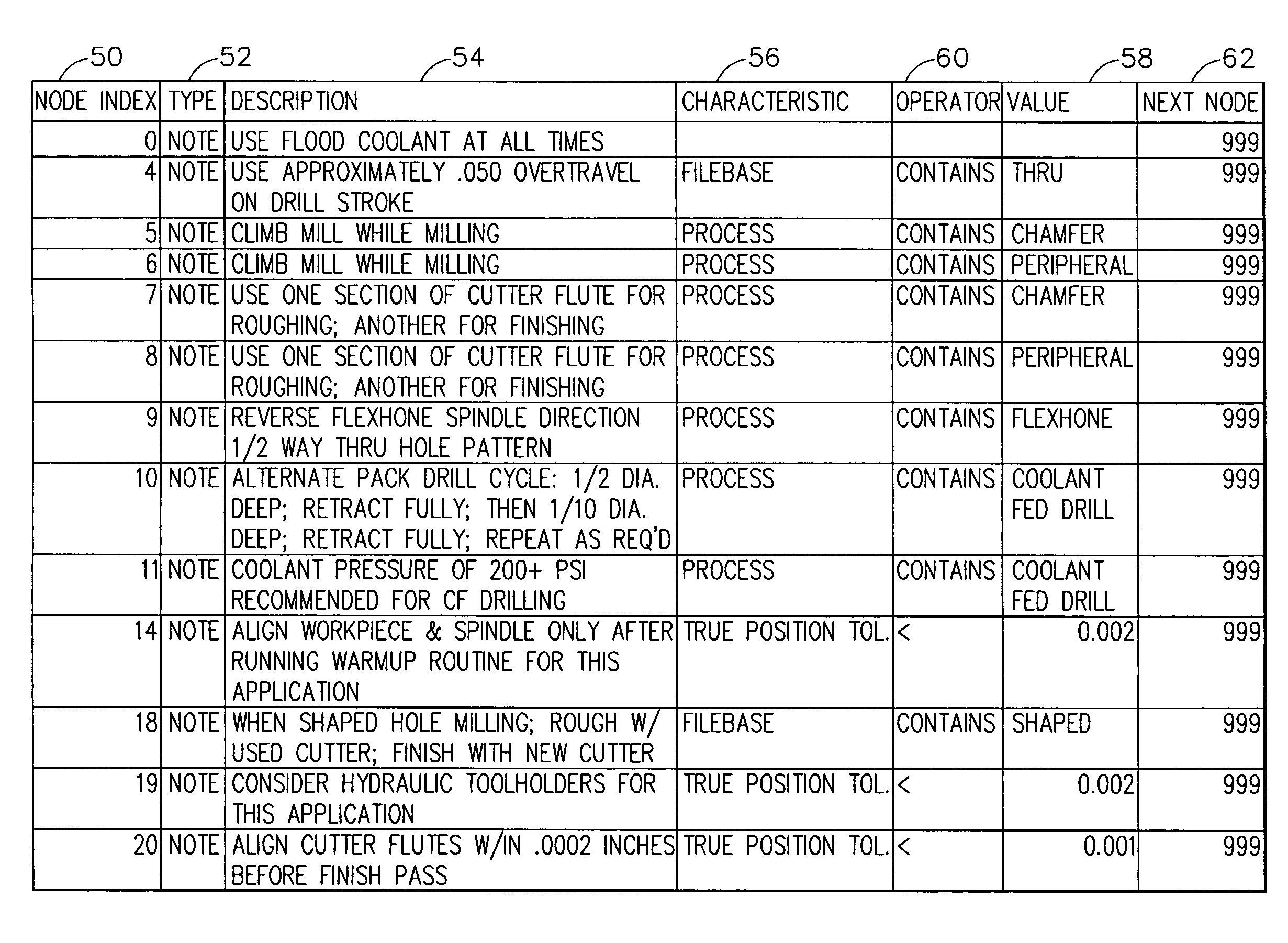

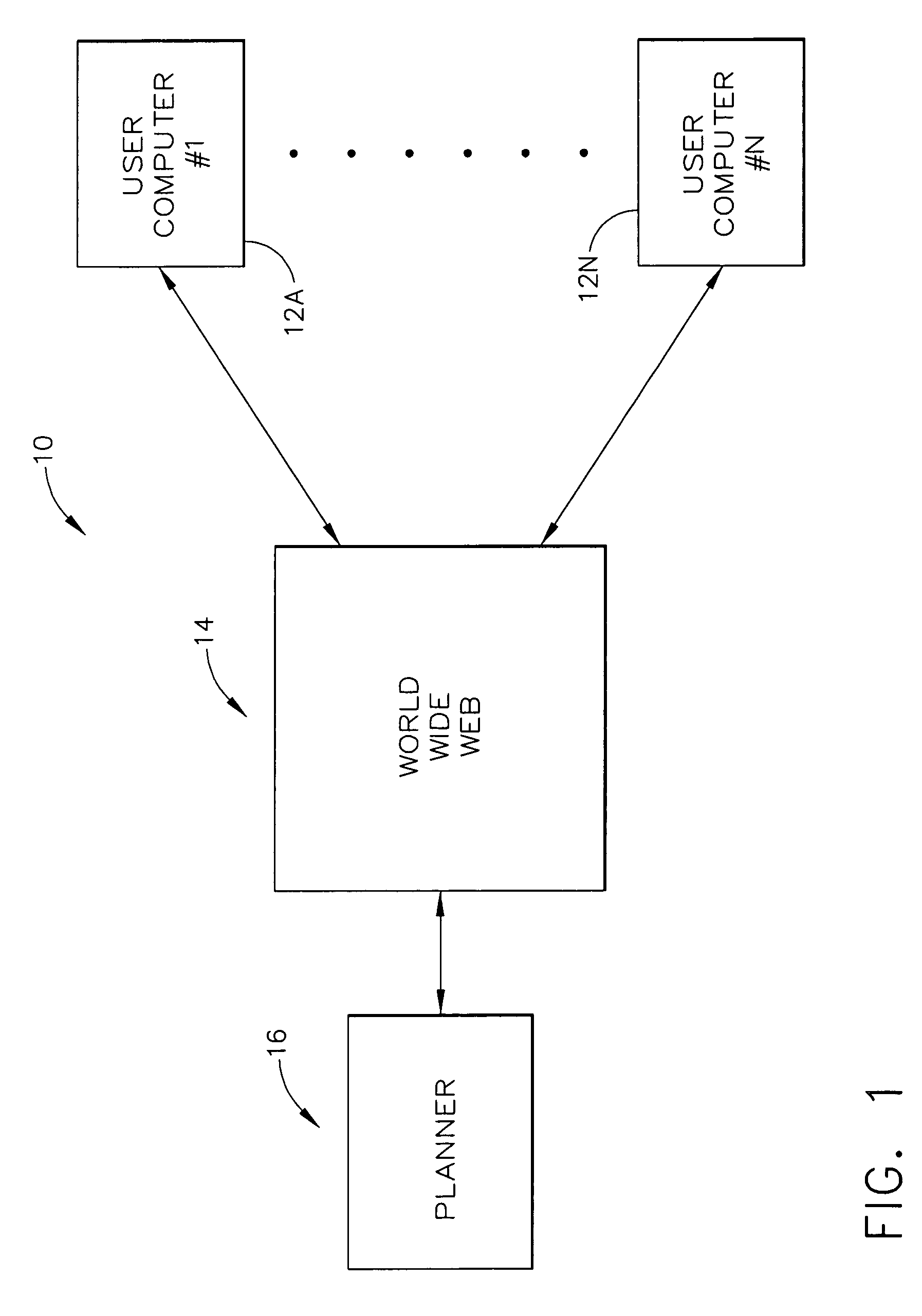

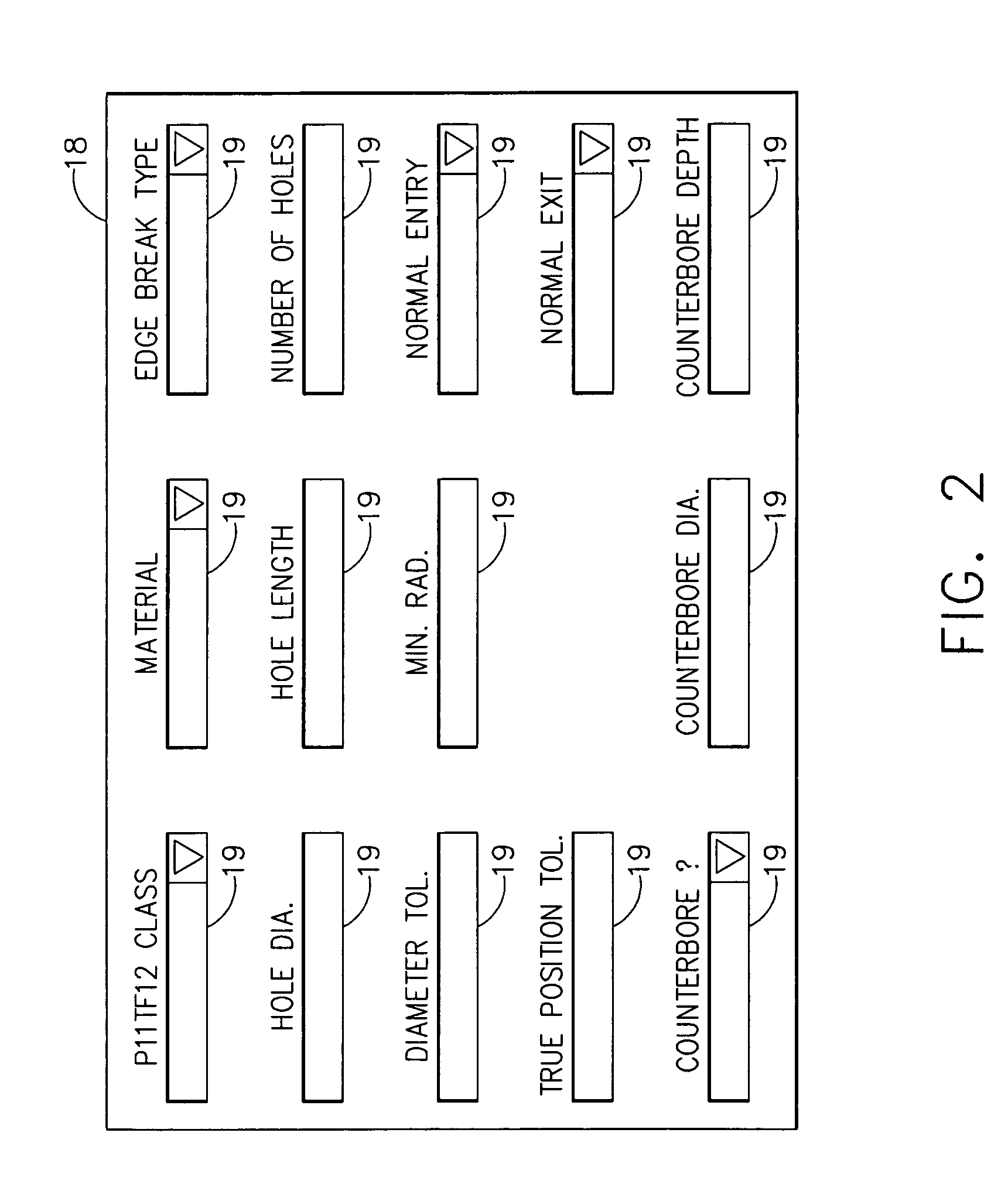

Process planning for distributed manufacturing and repair

InactiveUS6973361B1Efficient implementationEvenly distributedTechnology managementResourcesComputer scienceDistributed manufacturing

The present invention relates to a method for optimizing the performance of a process, especially where the process is performed at several different locations. In one embodiment, one or more experts produce a decision tree for use in determining a recommended sequence of steps for the process. A computer network, such as the World Wide Web, is used to convey a request to a computer that has access to the decision tree for a recommended sequence of steps. The request includes any information that is needed by the decision tree to determine the recommended sequence of steps. In response to the request, the computer uses the information in the request and the decision tree to produce the recommended sequence of steps. The recommended sequence of steps is then directed over the network to the user.

Owner:GENERAL ELECTRIC CO

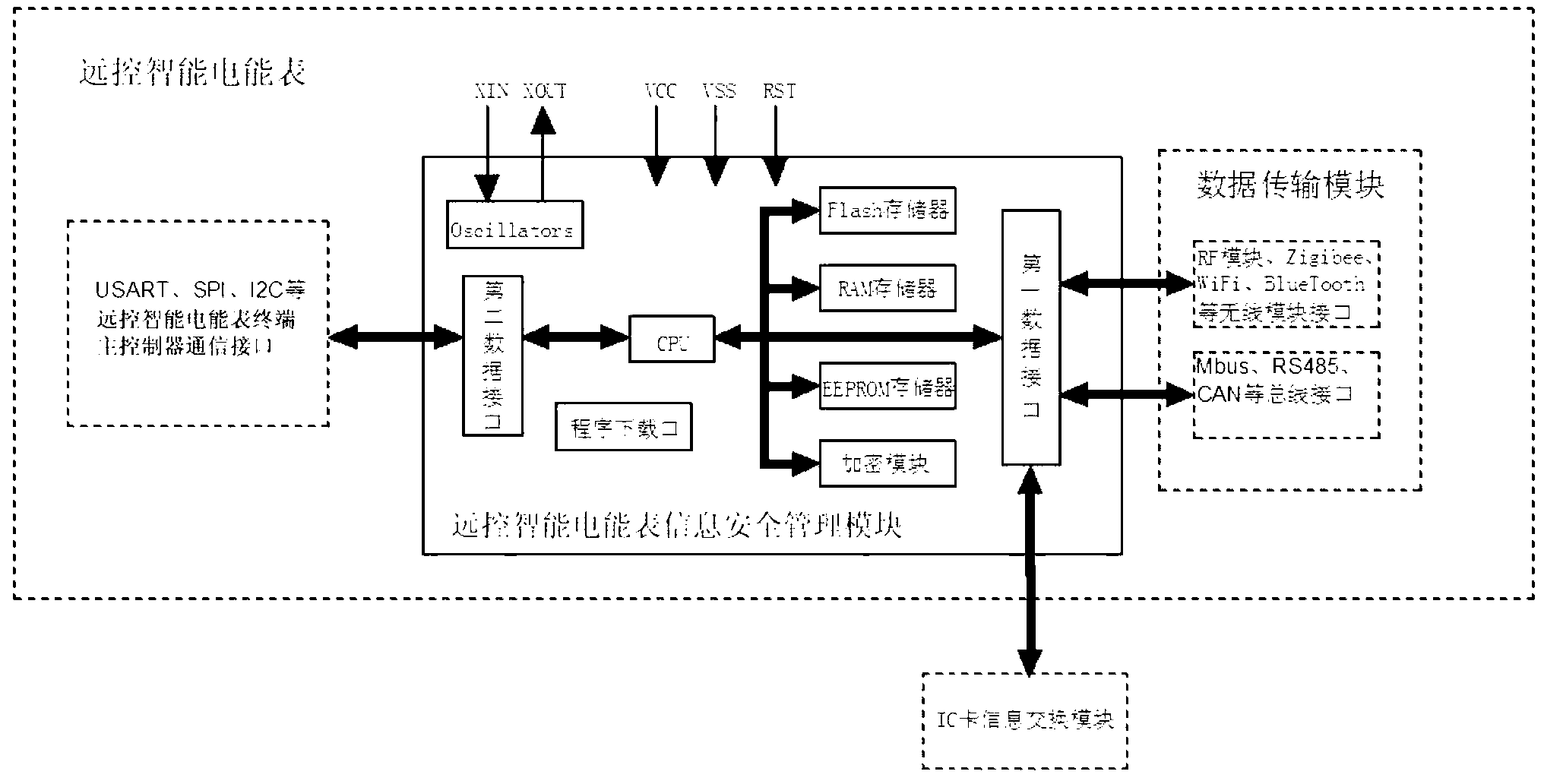

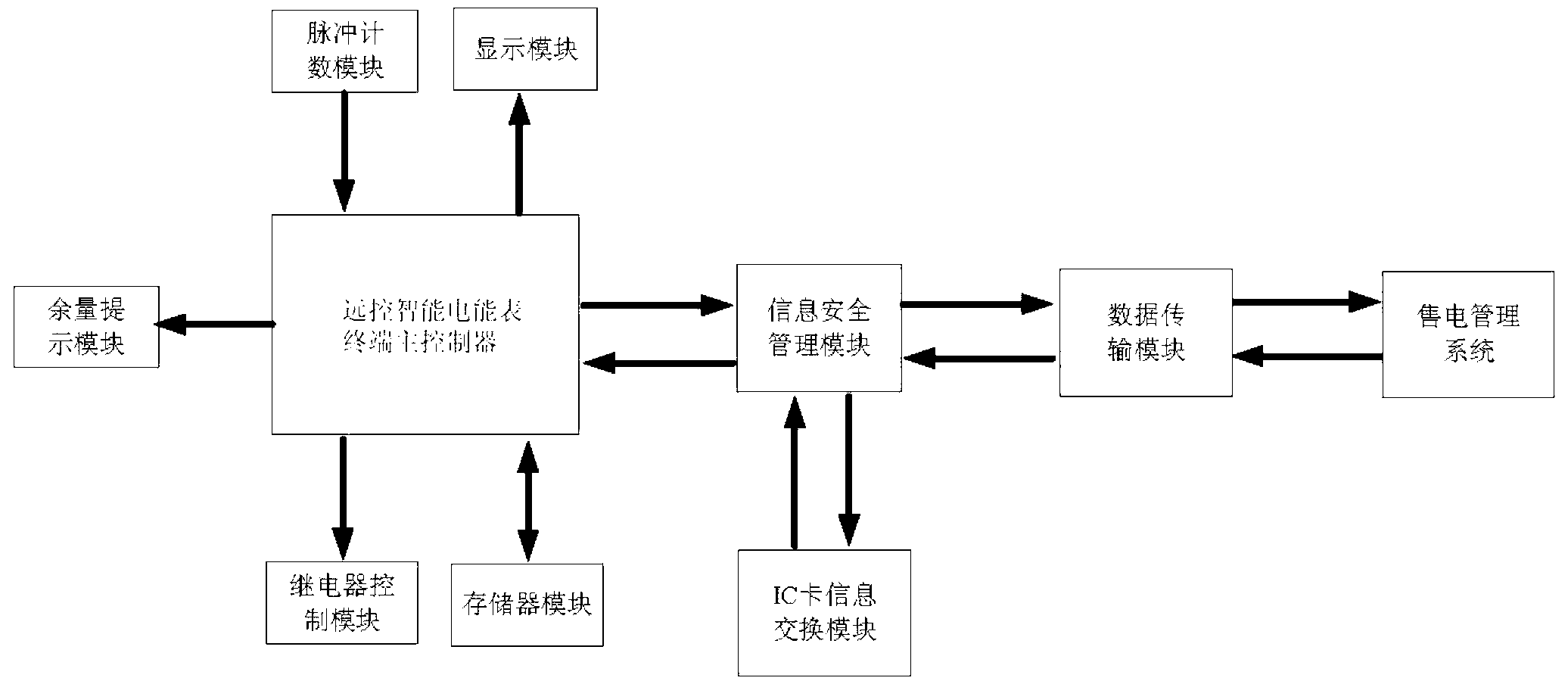

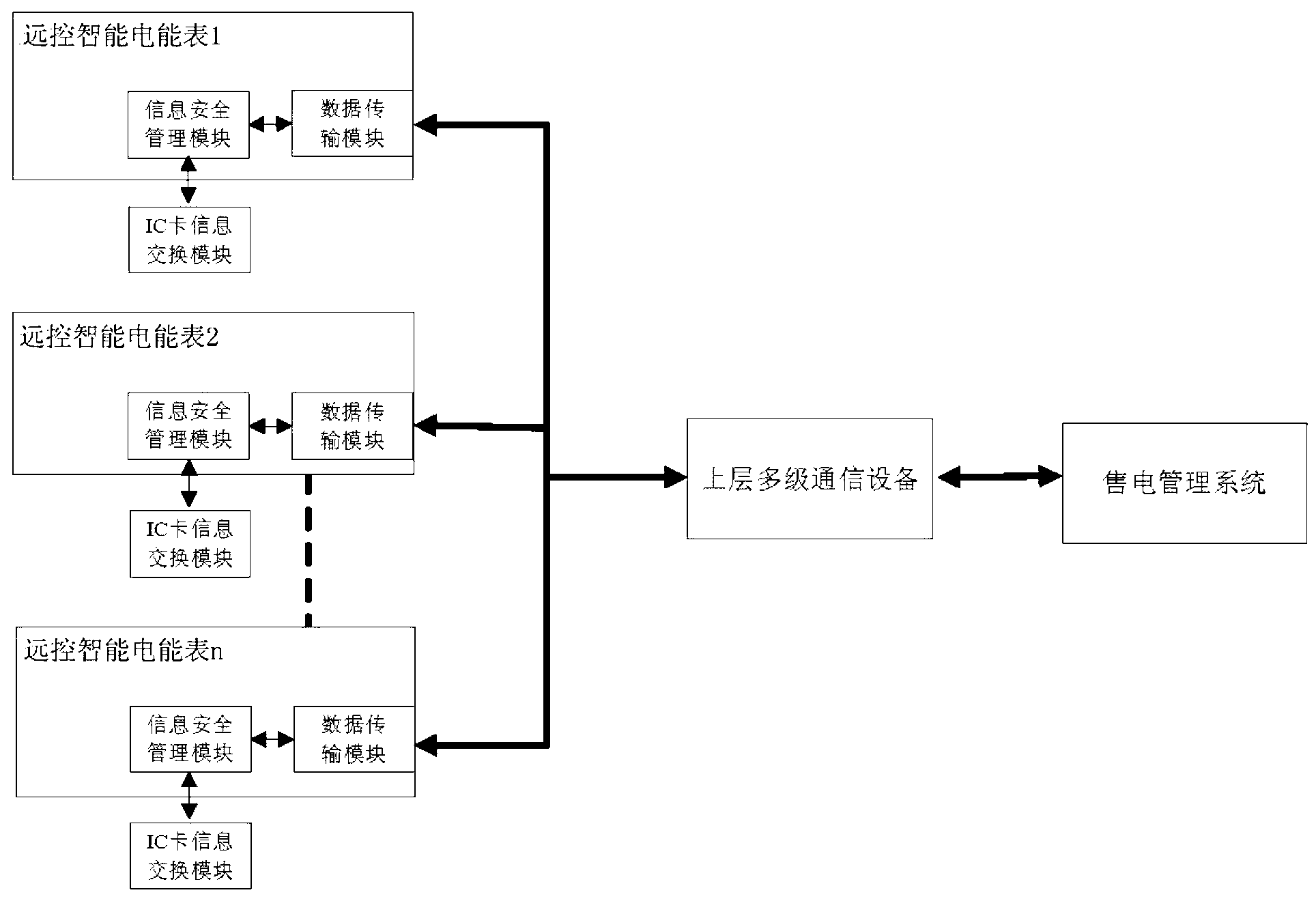

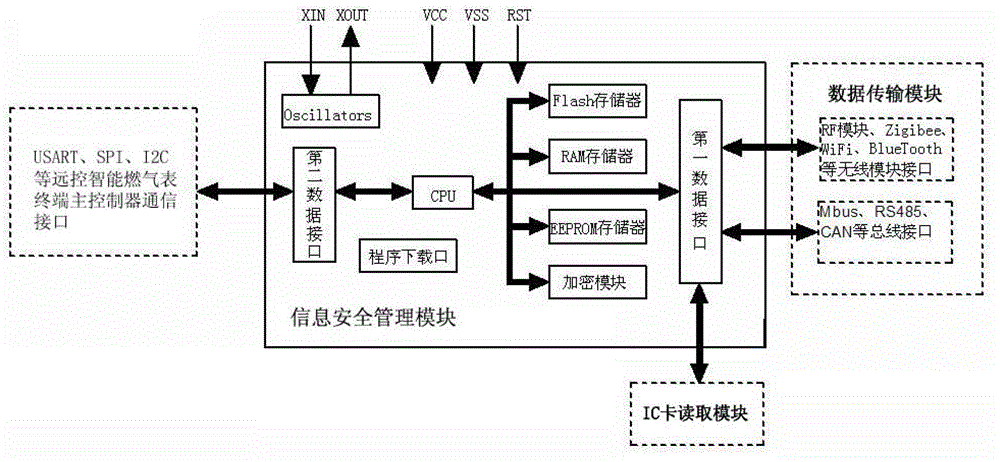

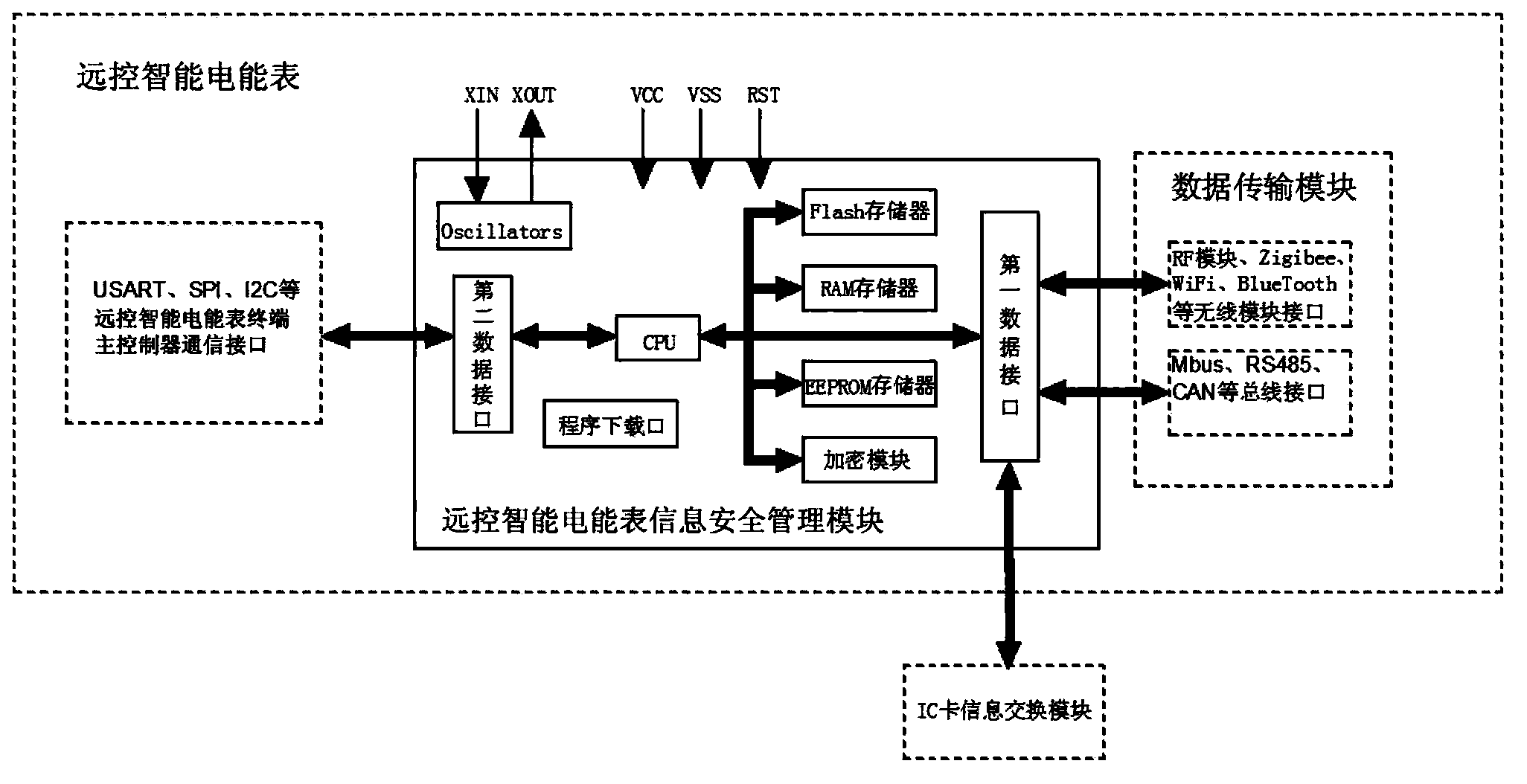

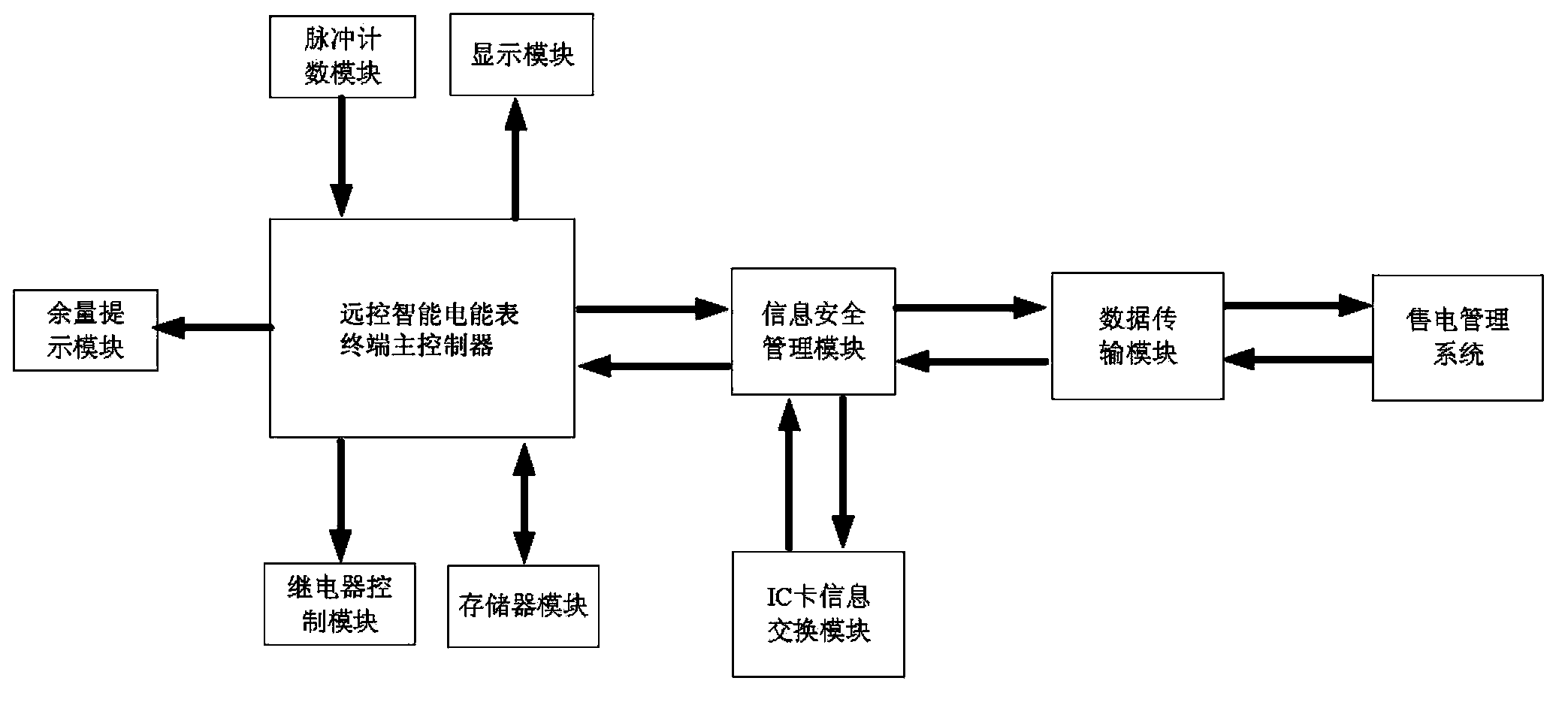

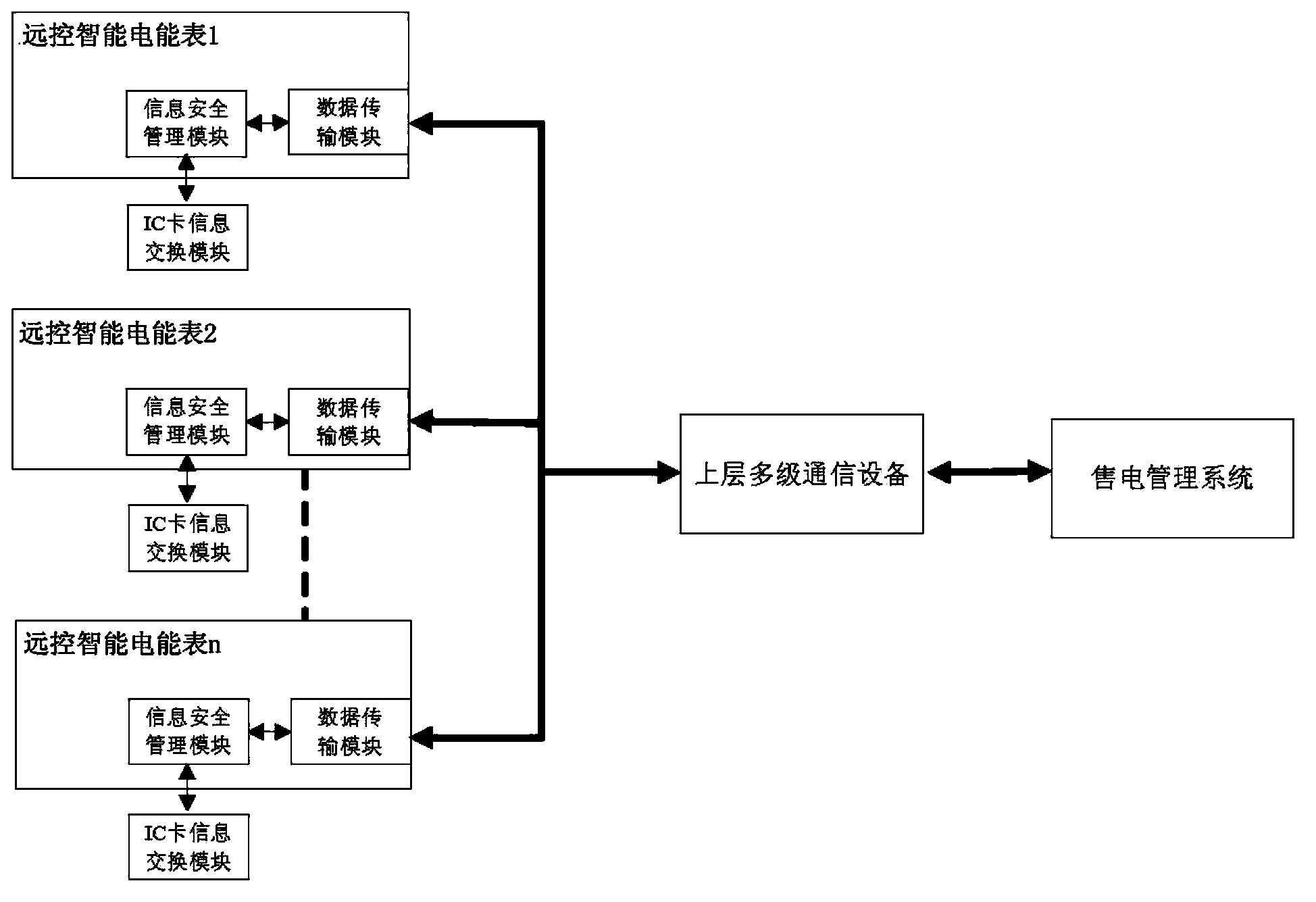

Information security management module of remote control intelligent electric energy meter

ActiveCN103218876AGuaranteed independenceSimple structureApparatus for hiring articlesTransmission technologyInformation security management

The invention discloses an information security management module of a remote control intelligent electric energy meter, which belongs to a management assistance device of the remote control intelligent electric energy meter. The information security management module comprises a processor, a first data interface, a second data interface and a FLASH memorizer, wherein the processor is respectively accessed to the first data interface, the second data interface and the FLASH memorizer. The information security management module disclosed by the invention is subjected to identity authentication while being subjected to data exchange with an electricity selling management system through a data transmission module, the legality of communication between the information security management module and the electricity selling management system can be ensured, and a terminal main controller of the remote control intelligent electric energy meter can be in communication with the outside just by means of the information security management module; and meanwhile, the information security management module disclosed by the invention has a simple structure, can be embedded in remote control intelligent electric energy meters of various types, can be compatible with the terminal main controller of the remote control intelligent electric energy meter through various communication transmission technologies and bus interfaces and can be seamlessly accessed to a power supply management system, distributed manufacturing and unified management of the remote control intelligent electric energy meter can be realized, and the application range is wide.

Owner:眉山秦川智能传感器有限公司

Flexible distributed manufacturing method and system therefor

InactiveCN1918573AData processing applicationsTotal factory controlMachine buildingMulti dimensional

In a manufacturing system that has a plurality of sheet fabrication machines, to enhance the efficiency of the system, there are provided a plurality of databases each for storing particular data relating to the machines, the types of materials to be used, the tooling of the machines, etc. of the system. When a multi-dimensional model of a component part to be produced by the system is input to the system, selective data is retrieved from the various databases so that at least one machine of the plurality of machines of the system is selected to produce the part from a worksheet of a chosen material. Concurrently, or shortly thereafter, a NC part program for programming the selected machine to execute the necessary operations in accordance with a flat drawing generated from the multi-dimensional model to fabricate the component part is generated based on selective data retrieved from the databases. With the NC part program, the selected machine performs the operations necessary for producing the component part from the sheet stock material chosen for the component part. If there are multiple component parts to be produced in the same production run, the system would sort the different parts and arrange for the ordered fabrication of the different parts by respective selected machines equipped with corresponding appropriate NC programs to eliminate any potential bottleneck or conflicts that may arise due to the fabrication of multiple parts by multiple machines during the same production run.

Owner:FINN POWER INT

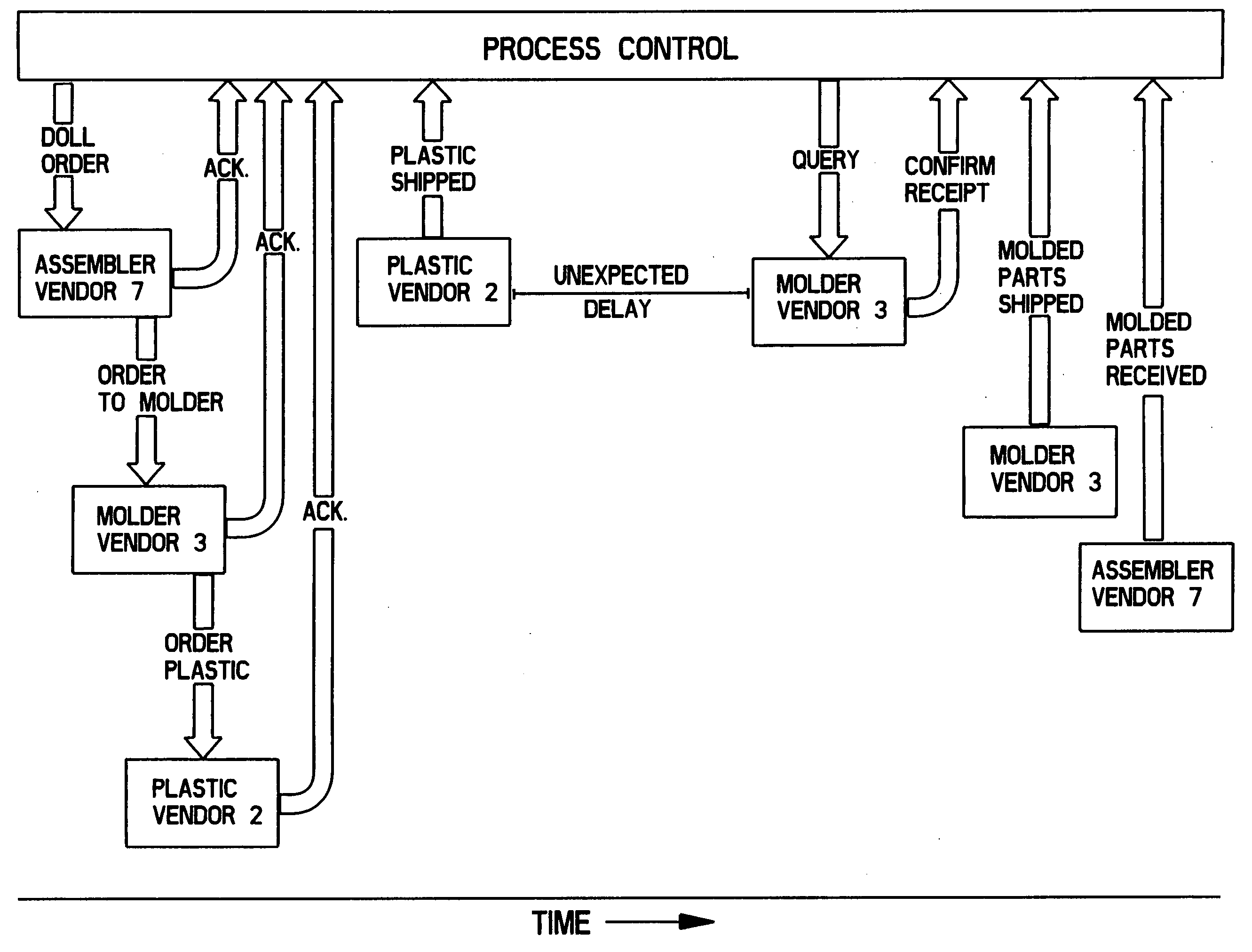

Method of process control for widely distributed manufacturing processes

An integrated process management system particularly suited for an environment in which multiple vendors must interact to cooperatively deliver products. The invention uses a preferably centralized process controller running on a computer. Discrete items or steps in the product manufacturing and delivery processes are given unique identifiers. The unique identifiers may assume many forms. For physical components, such as containers of raw materials, the identifier can be a tamper-resistant label containing a unique alphanumeric sequence. The identifiers are used to track the performance of each defined step in the process.

Owner:CHESTER JAMES S

Flexible distributed manufacturing method and system therefor

Owner:FINN POWER INT

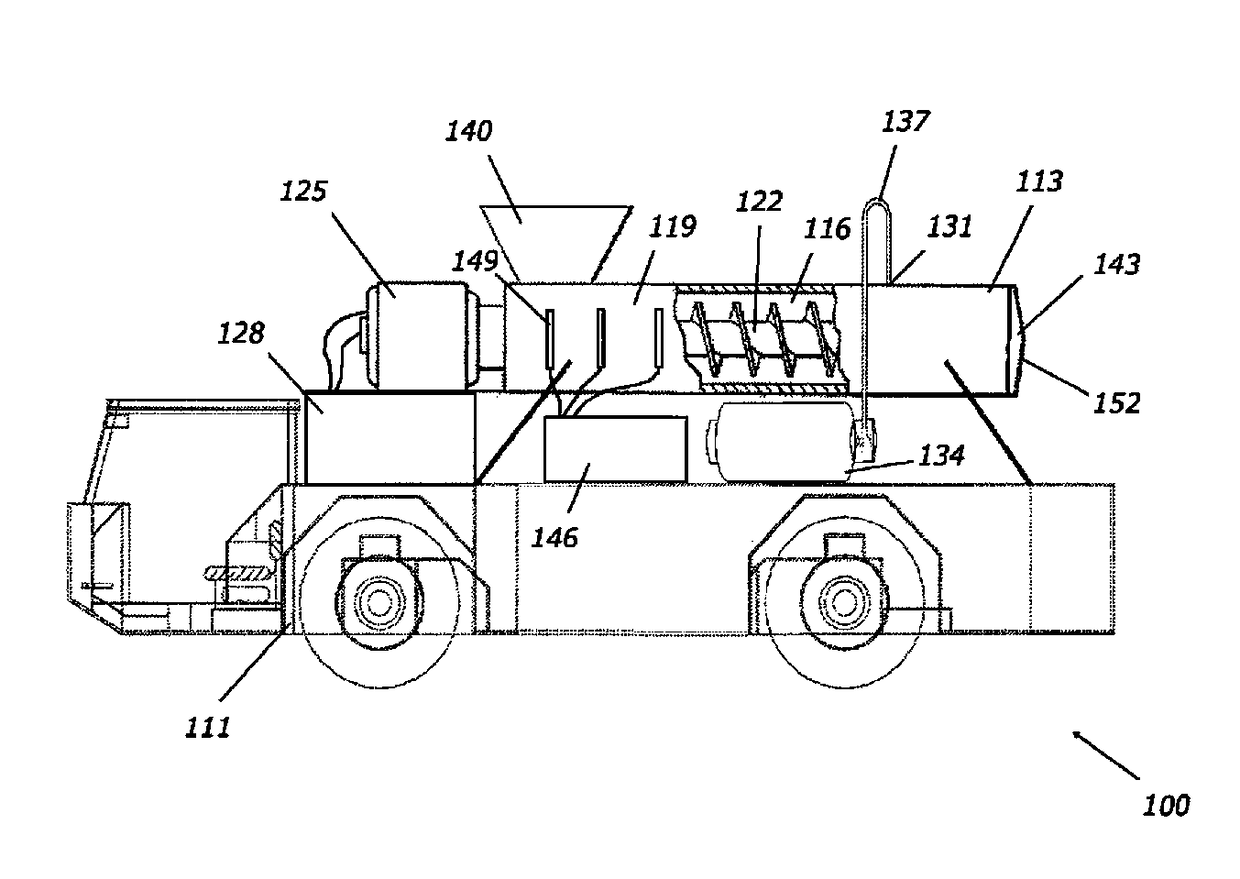

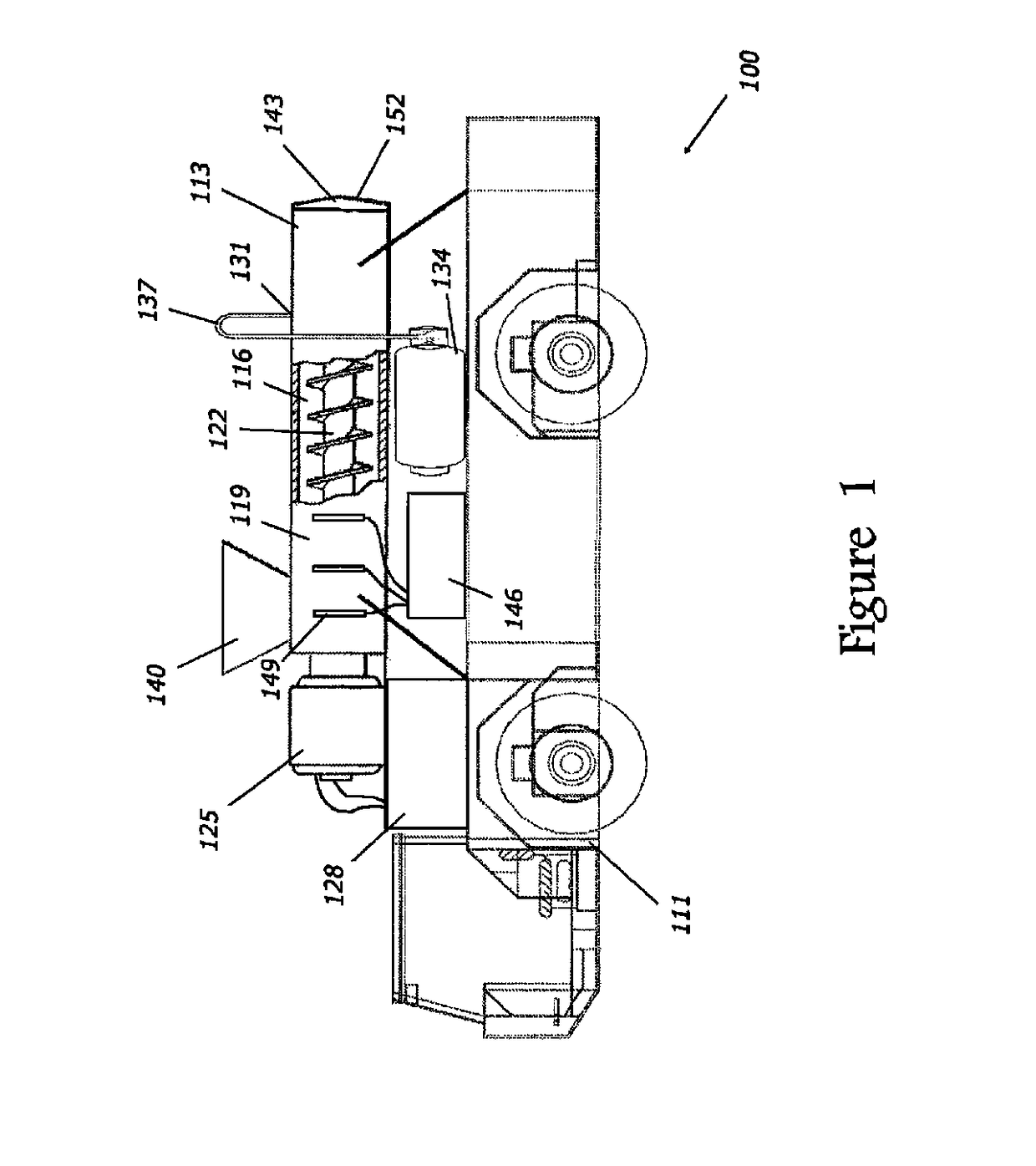

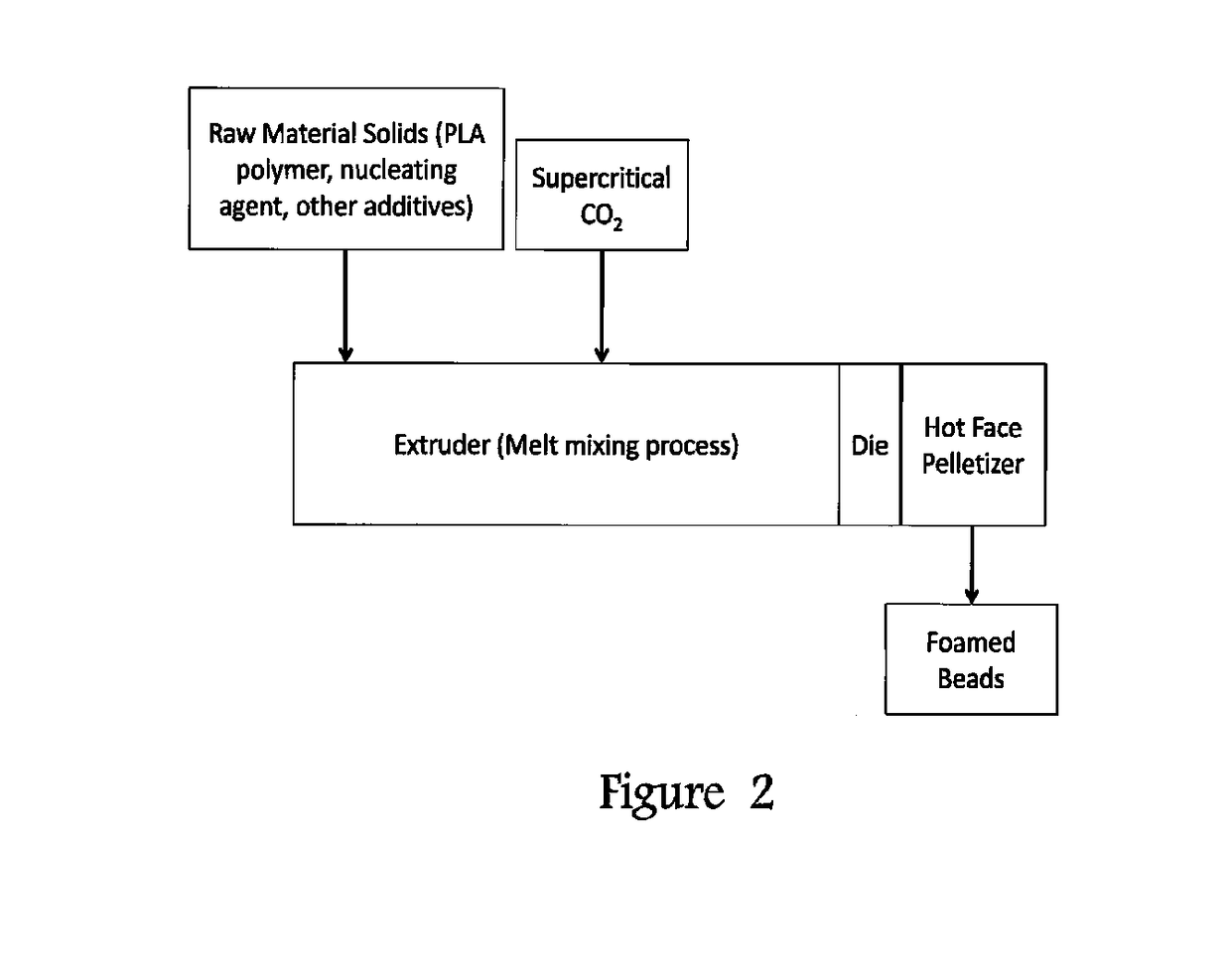

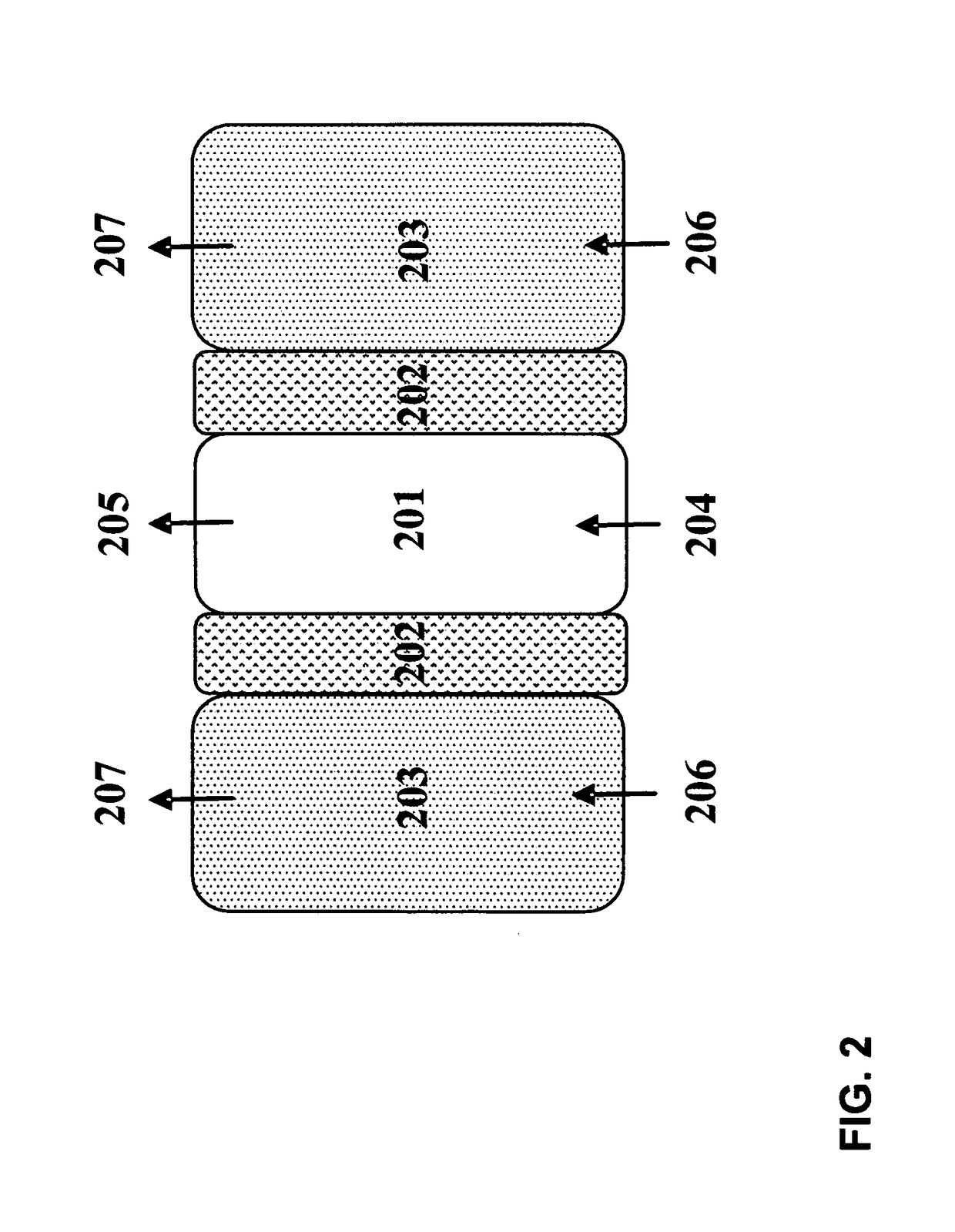

Particle foam distributed manufacturing apparatus and method and particle foam articles

A mobile platform including an extruder for melting and extruding materials for producing lightweight, compostable or biobased foams for various expandable materials. A mobile platform is described including a screw extruder for processing poly meric material, a housing with a longitudinal bore in which an extruder screw is coaxially fitted for rotation around an axis of the screw to advance the polymeric material through the bore by threads on the screw. A feed hopper, PLA hoist / feeder, standard EPS machine equipped with electric heating and related equipment are also provided on the mobile platform. Distributed manufacturing of low density protective packaging, insulation panels and thermal insulators is also described.

Owner:LIFOAM IND

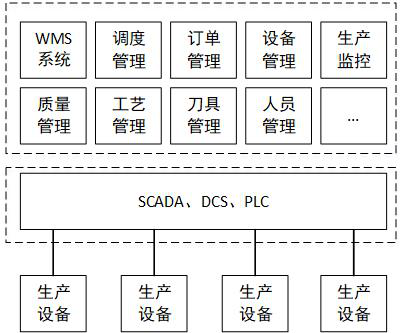

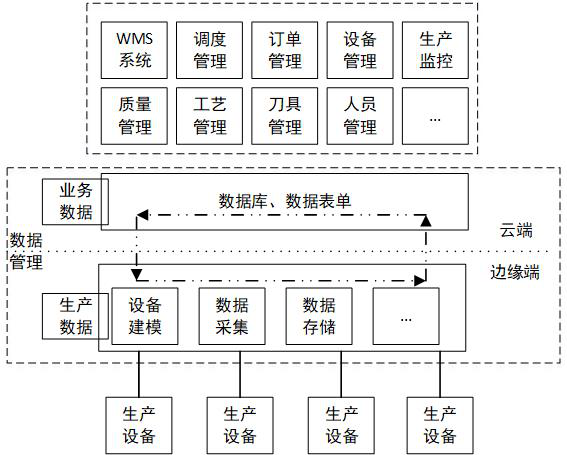

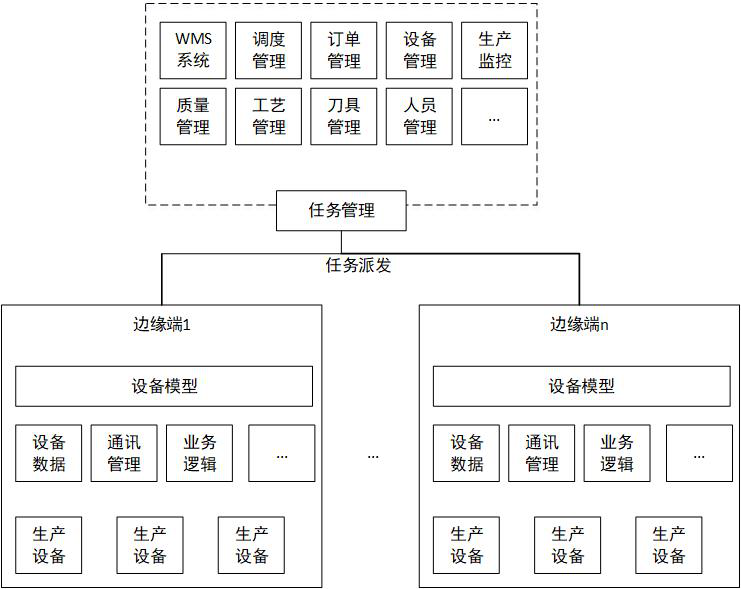

Cloud-edge collaborative and flexible distributed manufacturing management and control method and software system thereof

ActiveCN113256162ARealize flexible control scheduling productionShorten the debugging cycleResourcesTotal factory controlSoftware systemTask management

The invention provides a cloud-side collaborative and flexible distributed manufacturing management and control method and a software system thereof. The method comprises the following steps: a cloud service subsystem provides software service required by business for a user; one distributed edge end service subsystem corresponds to one equipment unit; the distributed edge end service subsystem maps data model construction of the corresponding equipment unit, and the data model construction comprises equipment data mapping and equipment business function logic mapping; the software service of the cloud service subsystem sends business requirements to task management in a task form, the business requirements are stored in a task pool of the task management, the task management is combined with a production scheduling algorithm to screen tasks in the task pool, and the tasks are split and sent to the corresponding distributed edge end service subsystems according to needs; and the distributed edge end service subsystem controls the corresponding equipment units based on the received tasks. According to the invention, production control is realized by scheduling and monitoring the edge end at the cloud end, and flexible production control with stronger adaptability and better universality is realized.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

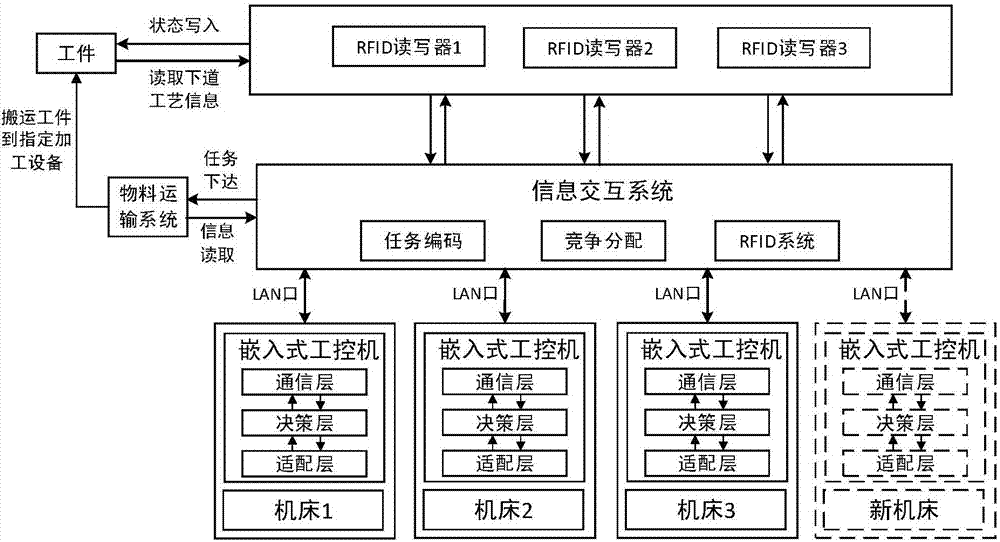

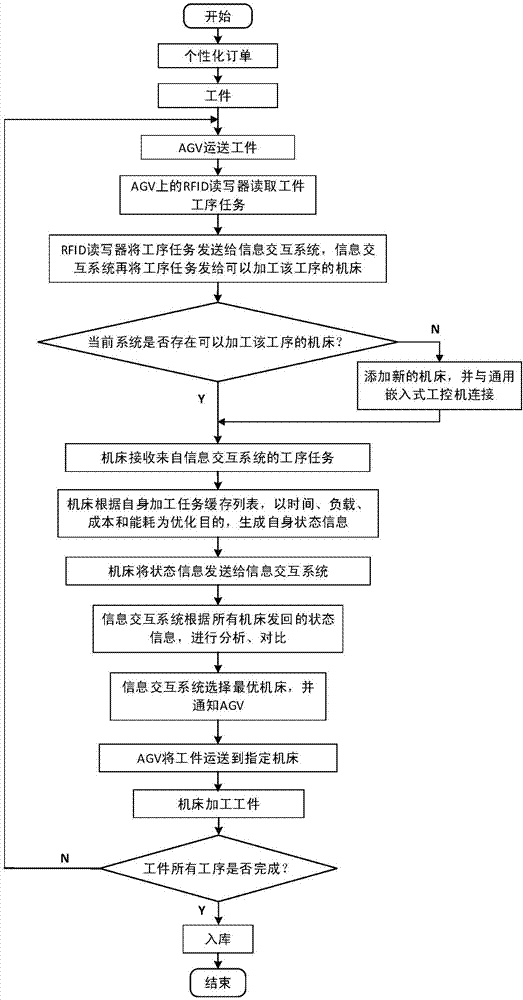

Distributed manufacturing system based on universal embedded industrial control computer, and implementation method for distributed manufacturing system

InactiveCN107103427ASolve the problem that is relatively fixed and difficult to expand after completionSolve the problem that is not easy to expandCo-operative working arrangementsResourcesInteraction systemsProduction model

The invention discloses a distributed manufacturing system based on a universal embedded industrial control computer, and an implementation method for the distributed manufacturing system. The system comprises the universal embedded industrial control computer, a material processing system, a material conveying system and an information interaction system. The system solves problems that a conventional flexible manufacturing system is relatively fixed in production line and is not liable to be extended after building, and can add any equipment conveniently in a production process. Moreover, the material processing system and the material conveying system have the decision making function, and can communicate with each other, thereby changing the current situation that an upper management machine of the conventional flexible manufacturing system always controls processing equipment and conveying equipment. The system is enabled to be suitable for small-batch and multi-variety mixed production model.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

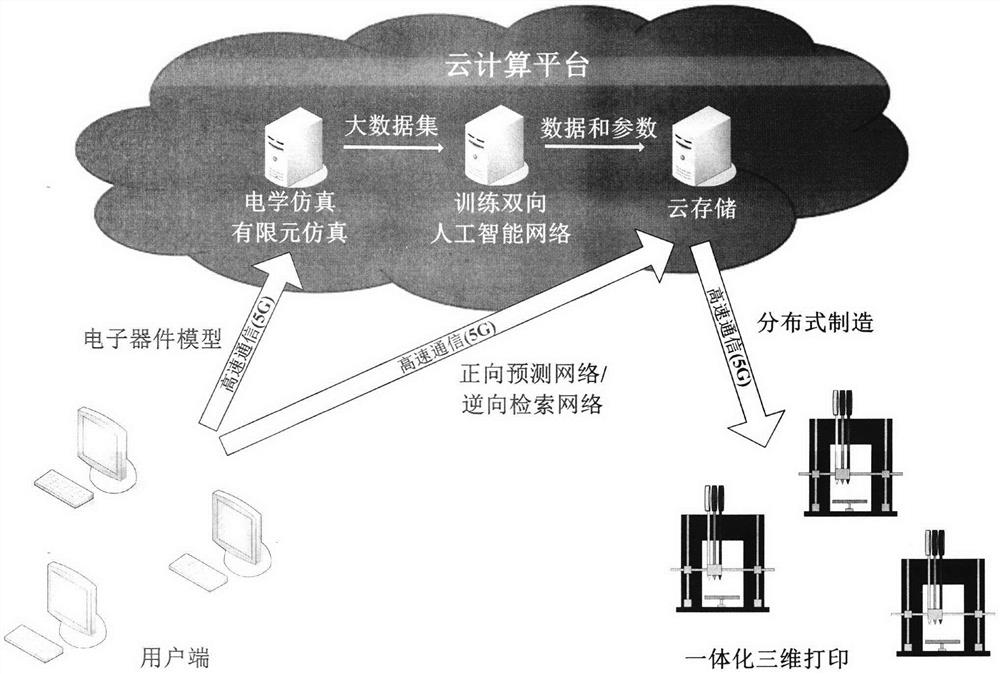

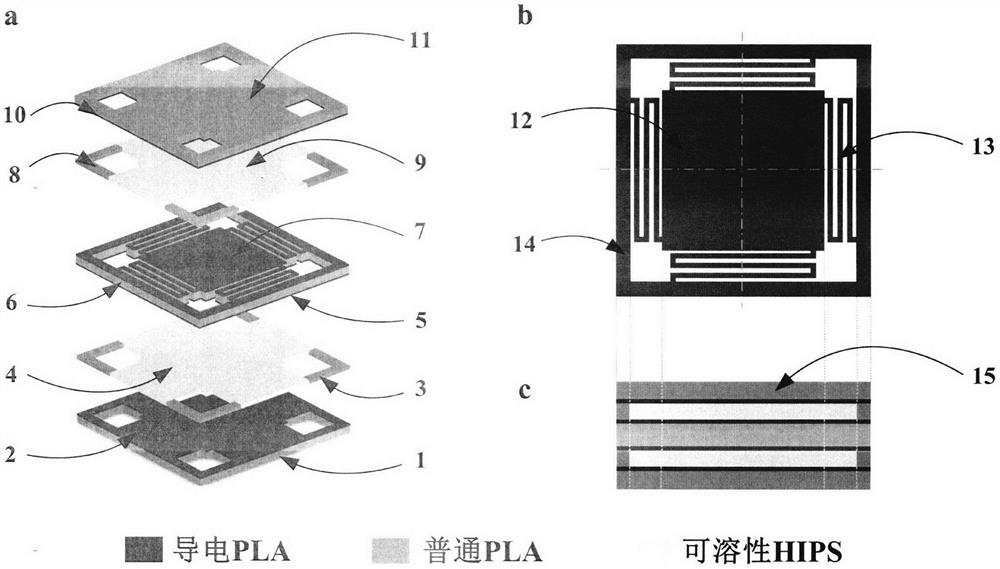

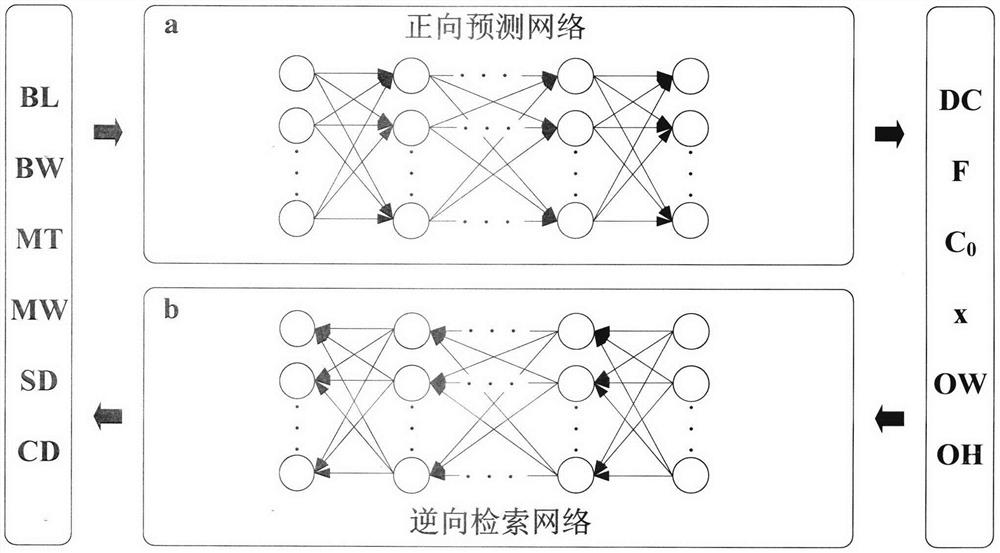

Accelerometer based on artificial intelligence design and distributed manufacturing

PendingCN112001036AQuick forecastImprove fullyGeometric CADDesign optimisation/simulationPersonalizationAccelerometer

The invention discloses an accelerometer based on artificial intelligence design and distributed manufacturing. Big data sets in one-to-one correspondence between geometric parameters and response results of a device by using a simulation method; the big data sets are respectively fed into a bidirectional artificial intelligence network for training; a three-dimensional model is constructed according to the geometrical parameters obtained by the reverse retrieval; a three-dimensional printer which is controlled and managed by a cloud computing platform is used for manufacturing, and the cloudcomputing platform can provide various materials at the same time; a mechanical structure of the device is made of an insulating material; electrodes and leads of the device are manufactured by conductive materials to be interconnected, a temporary supporting structure of a three-dimensional structure is manufactured by sacrificial materials capable of being selectively removed, the supporting structure is selectively removed after integrated manufacturing is completed to obtain the complete device, the design and manufacturing difficulty is lowered, the design and manufacturing period is shortened, and the personalized and intelligent manufacturing is achieved.

Owner:NAT INST OF METROLOGY CHINA +1

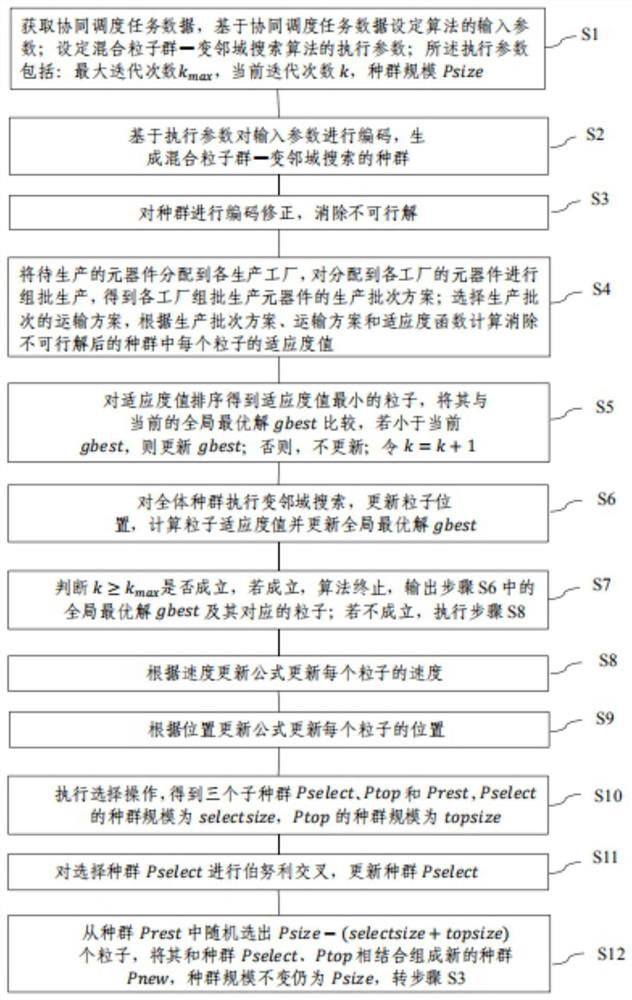

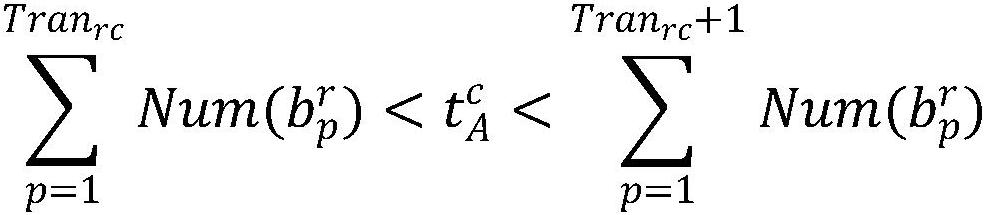

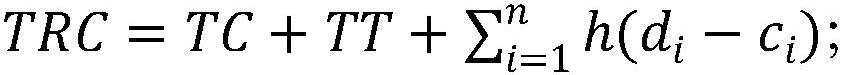

Cooperative scheduling method for distributed manufacturing and multi-mode transportation of high-end equipment

ActiveCN113128839AImprove adaptabilityShorten the manufacturing cycleArtificial lifeOffice automationMode of transportCoscheduling

The invention provides a cooperative scheduling method for distributed manufacturing and multi-mode transportation of high-end equipment, and relates to the technical field of task scheduling. According to the invention, distributed manufacturing, learning effects, multiple transportation modes and production and transportation collaboration are combined together, and learning effects of factories distributed at different positions in the production process and multiple transportation modes of the transportation process are considered in the classical production and transportation collaboration problem, so the research content is closer to the actual production environment, and the adaptability of the obtained scheduling scheme is improved.

Owner:HEFEI UNIV OF TECH

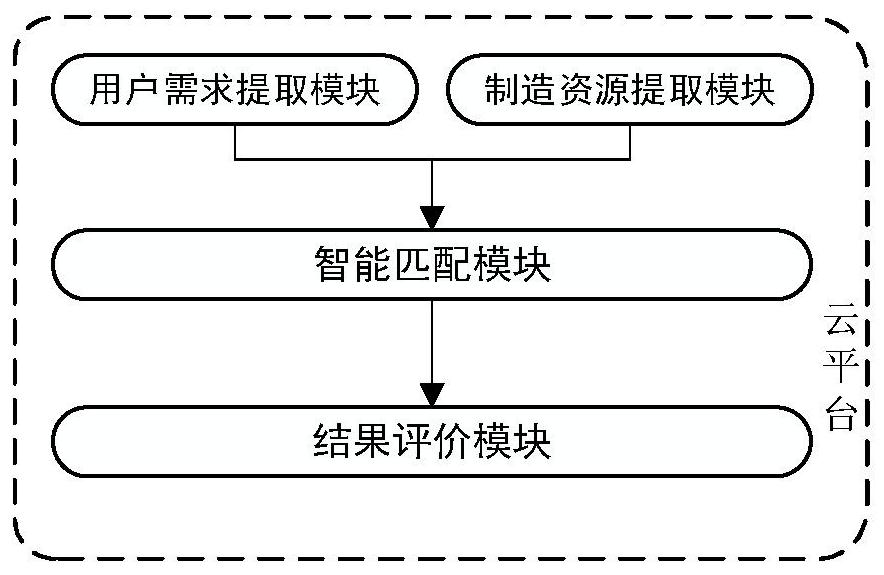

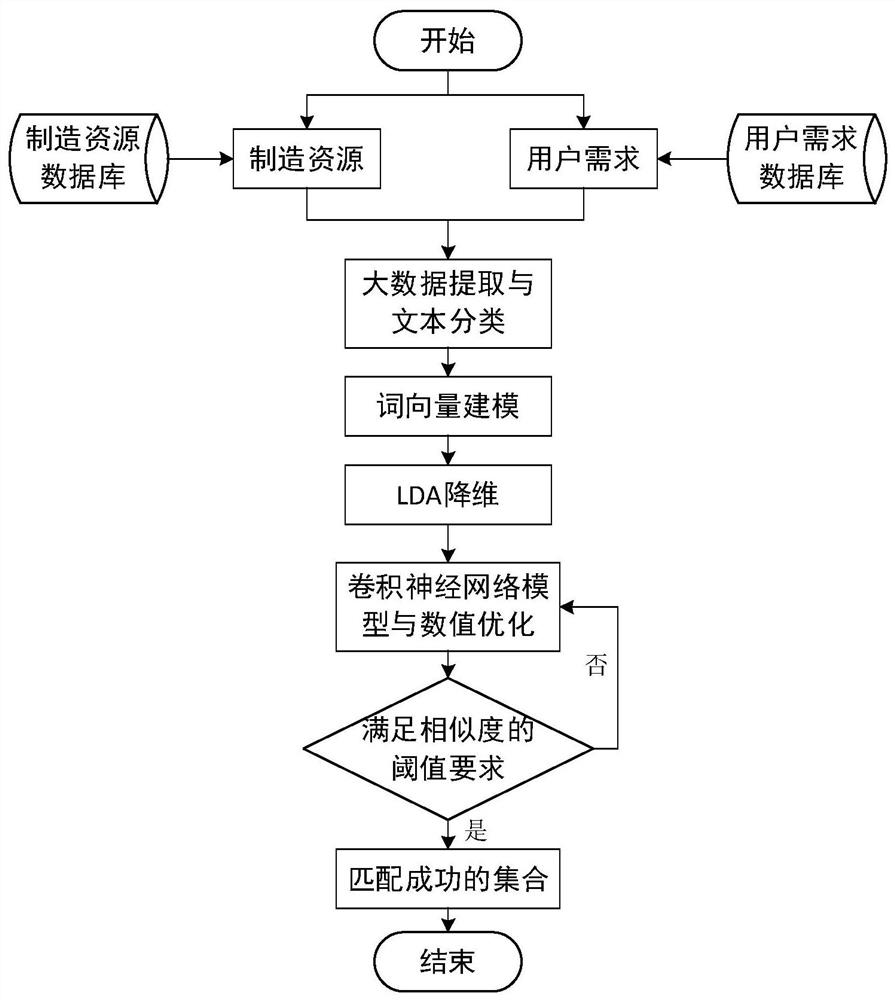

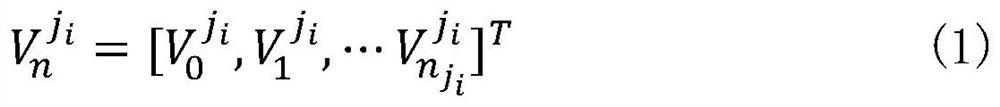

Manufacturing resource intelligent matching system based on cloud platform

PendingCN112364889AImprove operational efficiencyQuality improvementSemantic analysisCharacter and pattern recognitionCosine similarityUser needs

The invention discloses a manufacturing resource intelligent matching system based on a cloud platform. The manufacturing resource intelligent matching system comprises a user demand database, a manufacturing resource database, a user demand extraction module, a manufacturing resource extraction module, an intelligent matching module and a result evaluation module. The user demand extraction module extracts various types of demand item information data from a user demand database for classification and induction, establishes a complete user demand information tree, and performs word vector modeling; the manufacturing resource extraction module extracts various resource item information data from a manufacturing resource database for classification and induction, establishes a complete manufacturing resource information tree, and performs word vector modeling; the intelligent matching module takes the user demand word vector and the manufacturing resource word vector as input of a convolutional neural network to perform convolution training; the result evaluation module judges the cosine similarity of the user demand item and the manufacturing resource item; the invention is suitable for intelligent matching of a large number of discretely distributed manufacturing resources, and an optimal production process scheme is allocated to users.

Owner:CHONGQING UNIV +1

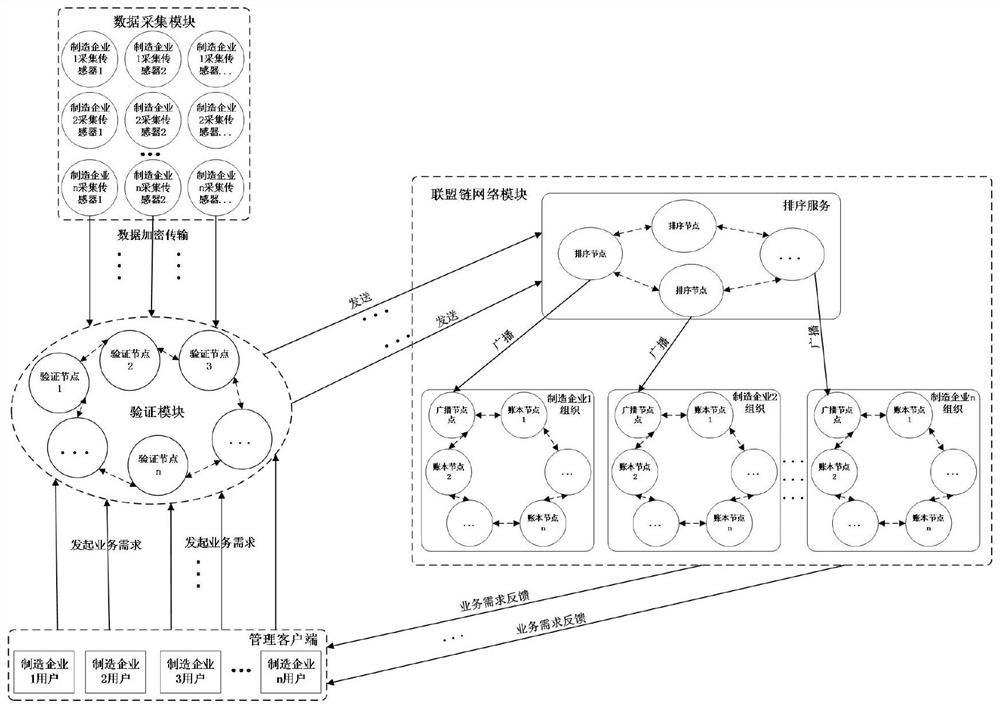

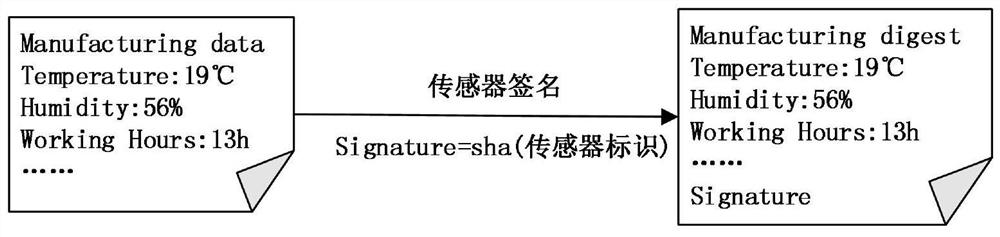

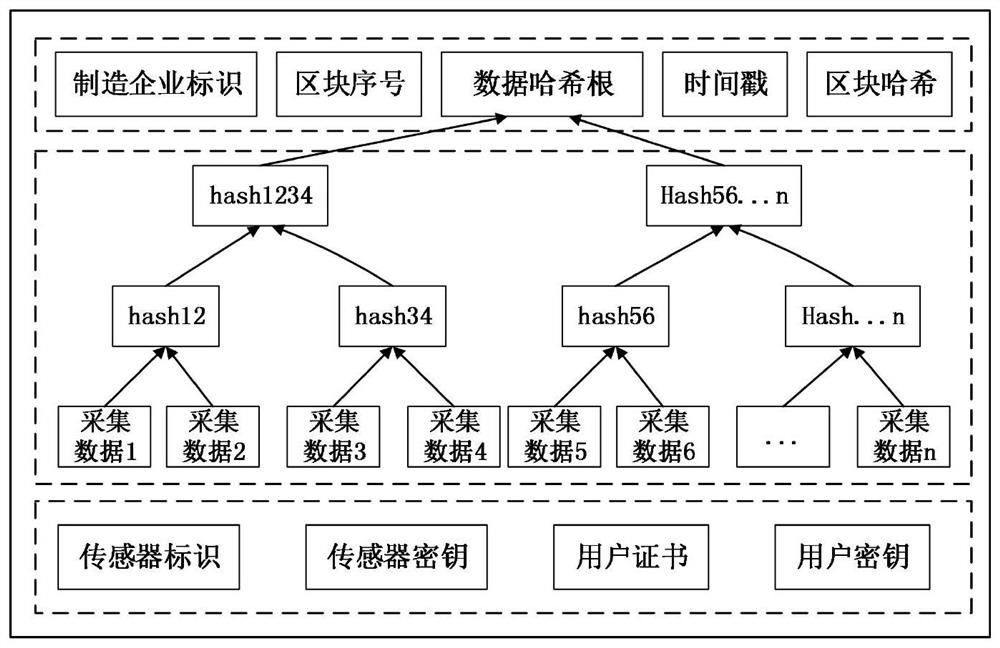

Data acquisition and storage method for distributed manufacturing industry based on alliance chain

PendingCN112241539APrevent tamperingAvoid lossDatabase distribution/replicationDigital data protectionData acquisitionEngineering

The invention relates to a data acquisition and storage method for distributed manufacturing industry based on alliance chain. The method comprises a management client, a data acquisition module, a verification module and an alliance chain network module. A plurality of sensors in the distributed data acquisition module is used for respectively acquiring data in the manufacturing process, the verification module is used for verifying acquired data identifiers, and sorting service is used for classifying and packaging the data passing the verification and distributing the data to correspondingmanufacturing enterprise organizations for data chaining; a manufacturing enterprise user logs in through a management user client and carries out management operations such as query and modificationon manufacturing data; a block chain technology is integrated into distributed data management, so that the safety of data is guaranteed, users of different manufacturing enterprises can manage and maintain the data conveniently, and the effective supervision strength and utilization rate of the data are improved.

Owner:KUNMING UNIV OF SCI & TECH

Method of real-time scheduling of processes at distributed manufacturing sites

In a method of scheduling of processes at distributed and interacting manufacturing sites, a potential availability of predictive pairings of materials and work machines processing the materials over a predetermined period of time is determined for a plurality of manufacturing sites. The potential availability data of the predictive pairings is recorded. The method senses what materials and work machines are available in real-time, and records the real-time availability data of sensed materials and work machines. The real-time availability data is compared with the potential availability data of predictive pairings. In case of a discrepancy, the method determines for each manufacturing site local pairings of materials and work machines processing the materials, and processes the local pairings.

Owner:SIEMENS AG

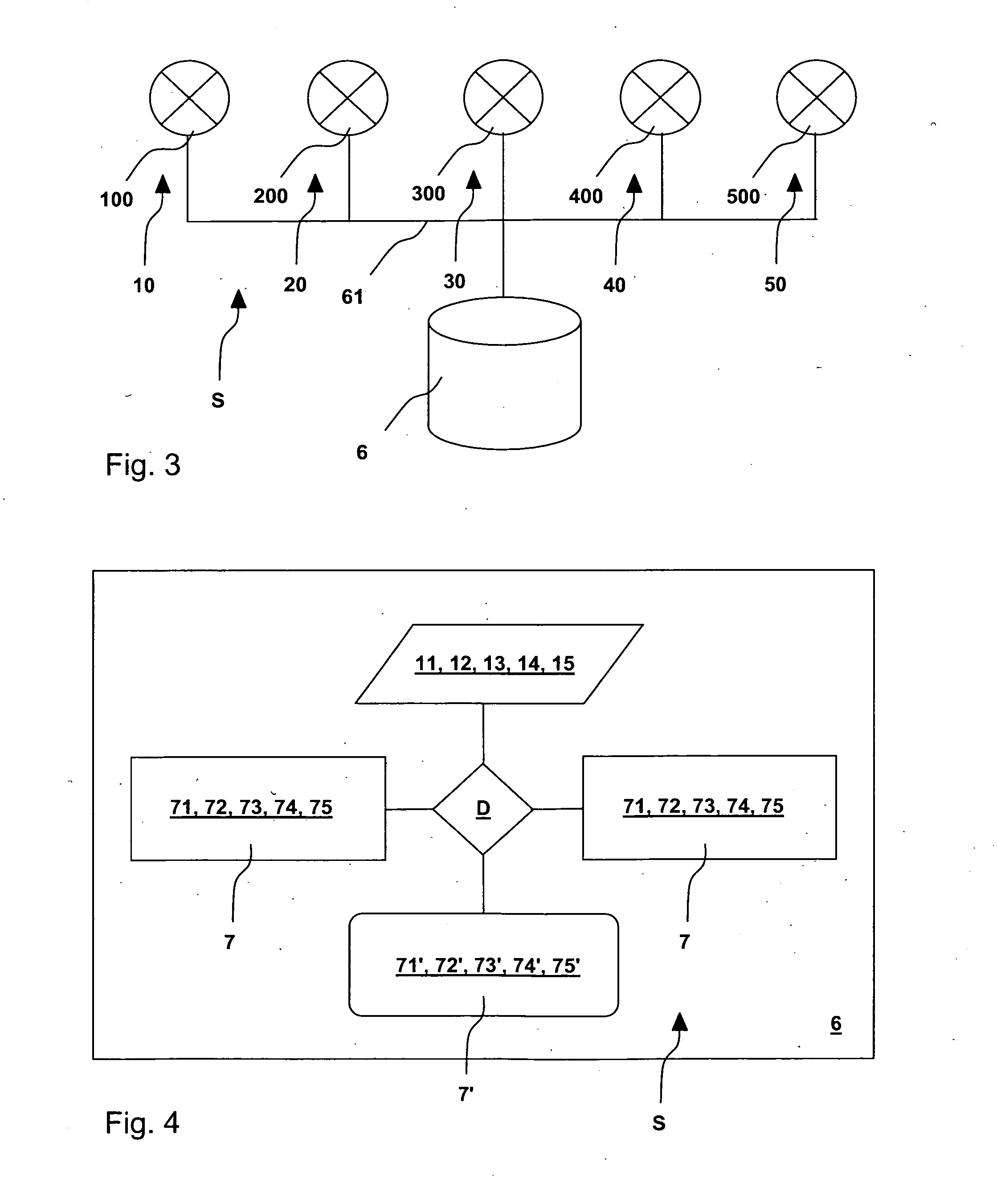

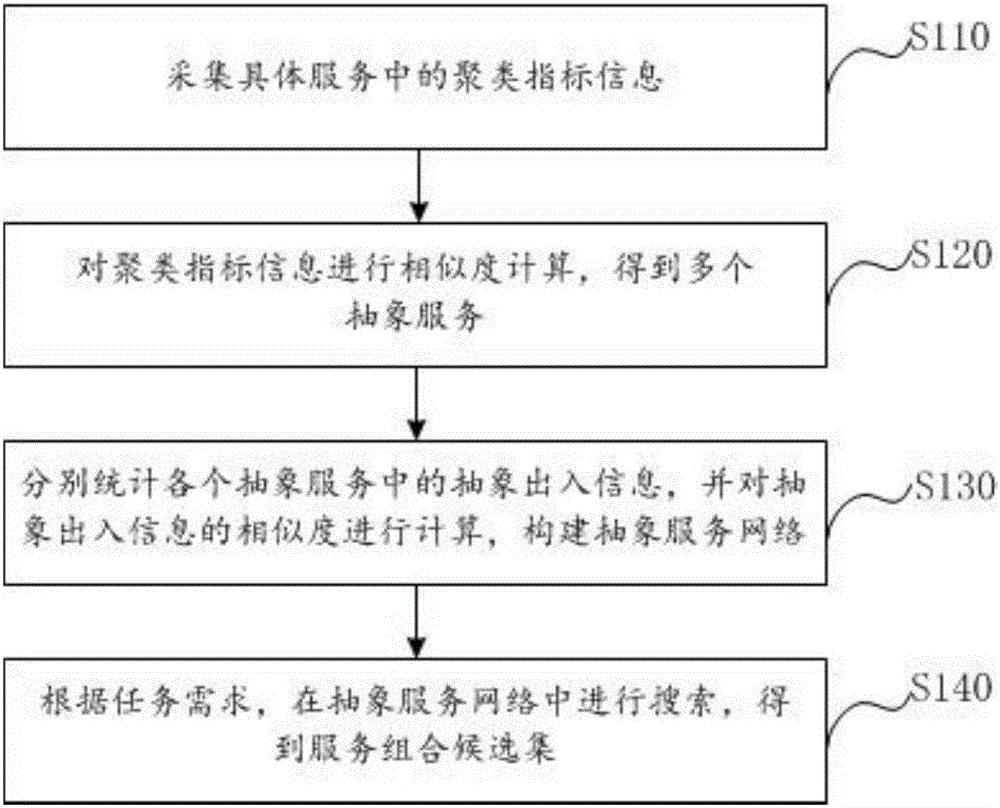

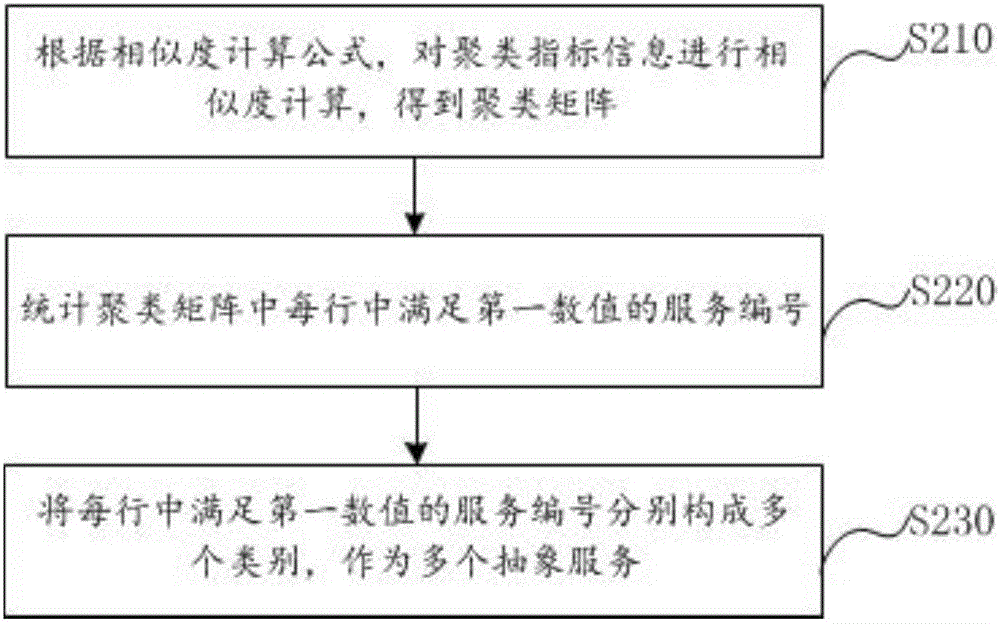

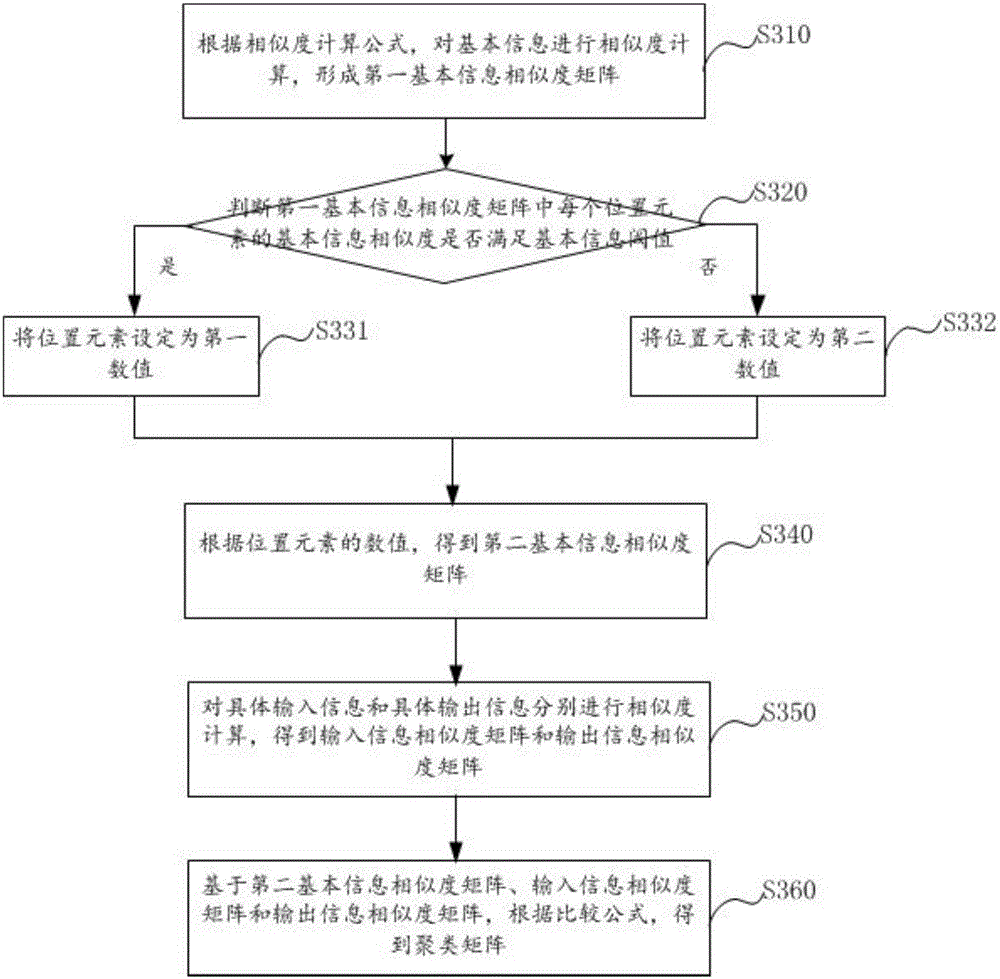

Service composition candidate set construction method and system

ActiveCN106529801AImprove efficiencyImprove adaptabilityWeb data indexingResourcesService compositionOperability

The invention provides a service composition candidate set construction method and system, and relates to the technical field of distributed manufacturing system information integration. The method comprises the steps that clustering index information in a specific service is collected; similarity degree calculating is carried out on the clustering index information to acquire a number of abstract services; abstract access information in each abstract service is calculated, and the similarity degree of the abstract access information is calculated; an abstract service network is constructed; and searching is carried out in the abstract service network according to task requirements to acquire a service composition candidate set. According to the invention, the efficiency, the adaptability, the operability and the convenience of service composition candidate set construction can be improved.

Owner:BEIHANG UNIV

Apparatus and process for efficient production of liquid fuels from gaseous hydrocarbons

An apparatus for a distributed manufacturing plant that allows direct, economical production of transportation fuels and / or chemicals at remote sites is described. The production plant employs two primary integrated systems consisting of a syngas generator and a catalytic process that are used to directly produce fuels and chemicals. The syngas generator utilizes oxygen anions, produced from a ceramic membrane system, to generate high quality syngas directly at pressures of about 100-600 psia. The tail gas and water containing hydroxyl-alkanes from the catalytic process are recycled into the syngas generator, in automatically controlled proportions, to regulate the hydrogen to carbon monoxide within the preferred H2 / CO stoichiometric range of about 1.8-2.4. The primary products produced directly from the plant include reformulated gasoline blendstocks, #1 diesel fuels, and #2 diesel fuels.

Owner:GREYROCK TECH LLC

A Reconfigurable Industrial Robot Programming Control Method in Distributed Manufacturing Environment

ActiveCN106933212BImprove flexibilityRealize online dynamic refactoringTotal factory controlProgramme total factory controlInternational standardModularity

The invention discloses a programmable control method of a reconfigurable industrial robot in a distributed manufacturing environment. An editing module, a model conversion module, a deployment module, a communication module, an IEC 61499 operating environment, a robot control instruction execution module, a servo drive module and a robot are in successive telecommunication connection. The deployment module is in telecommunication connection with a monitoring module which is connected with the editing module. The communication module is in telecommunication connection with the monitoring module. According to the invention, a graphical programming language conforming to the international standard is adopted to replace a dedicated robot controller programming language based on text; the efficiency of a development process and the portability of a control program are improved; based on a modular operating environment and a standardized management command, the on-line dynamic reconstruction of the industrial robot control program can be realized; and the flexibility of a robot controller is improved.

Owner:SOUTH CHINA UNIV OF TECH

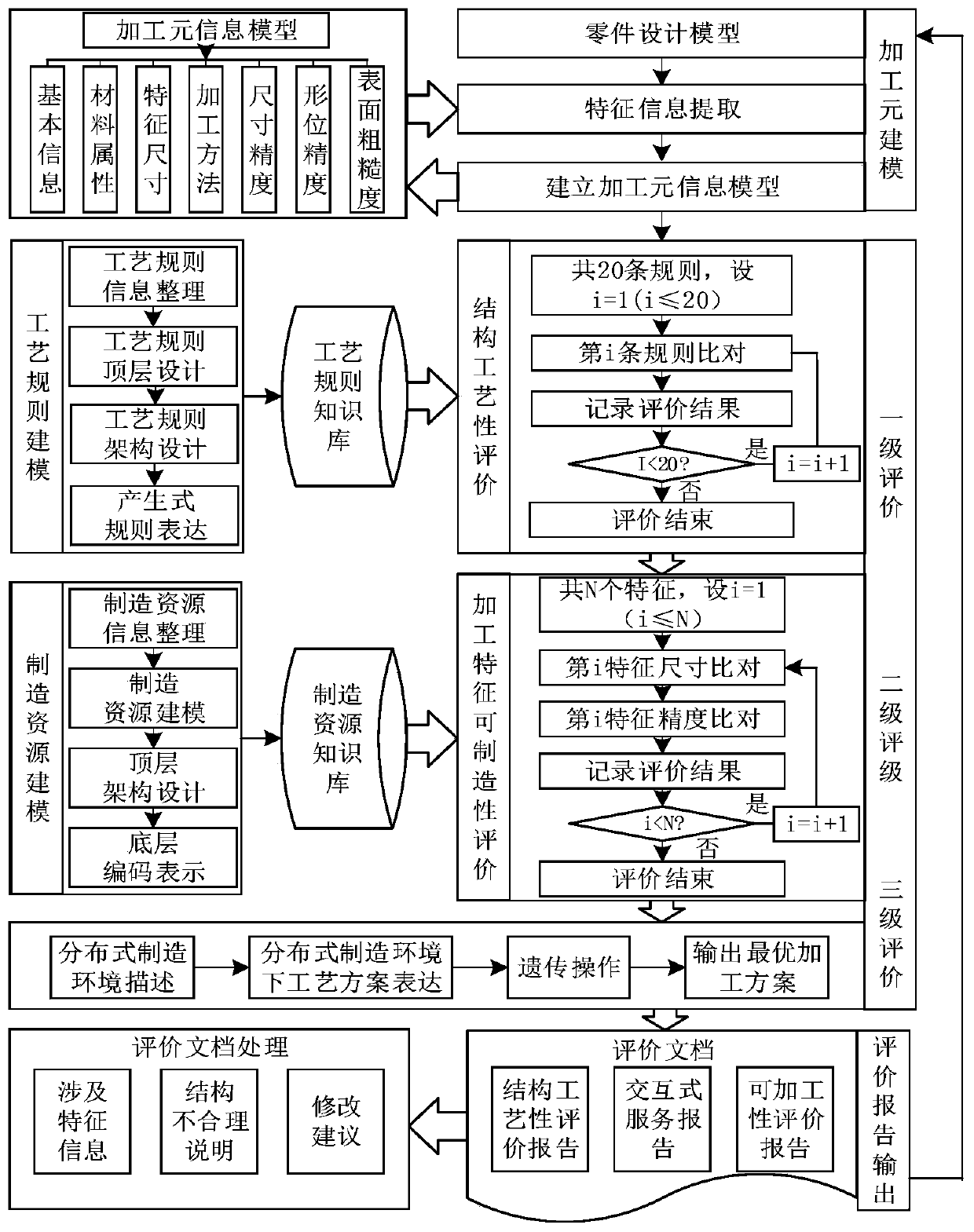

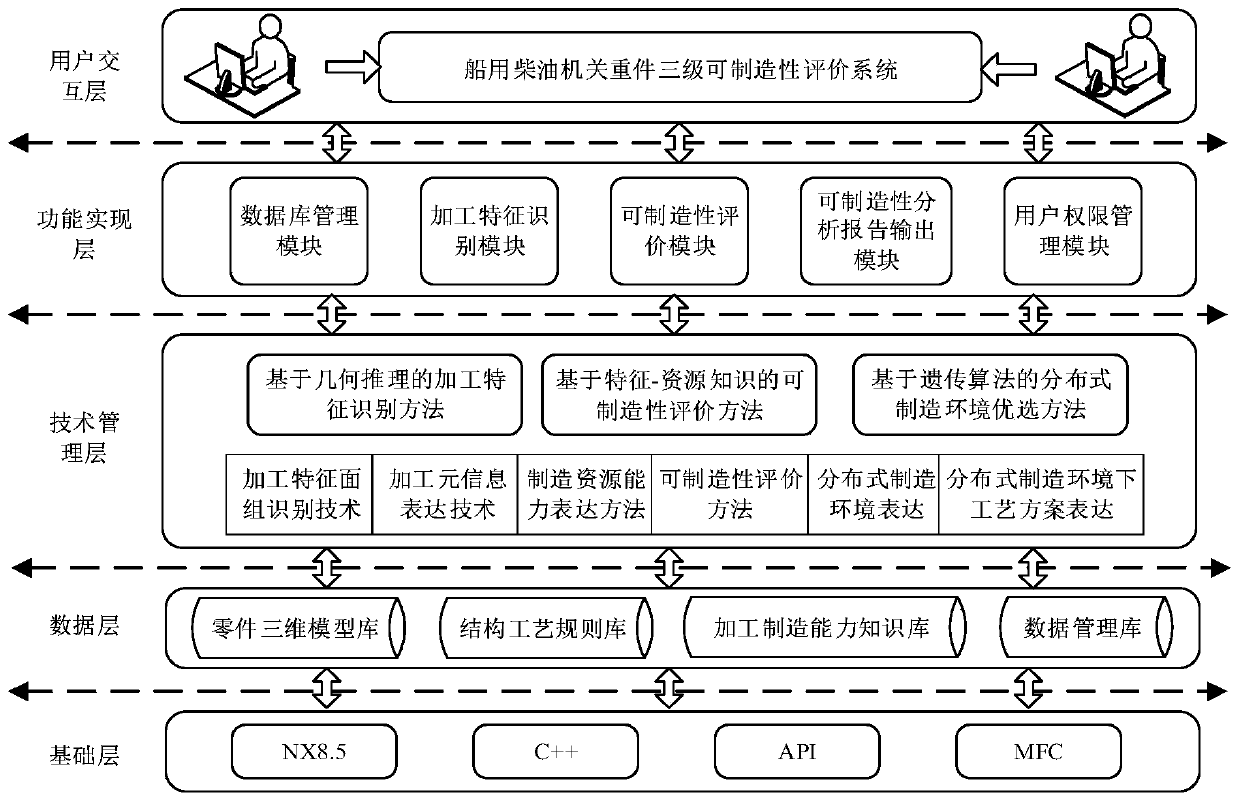

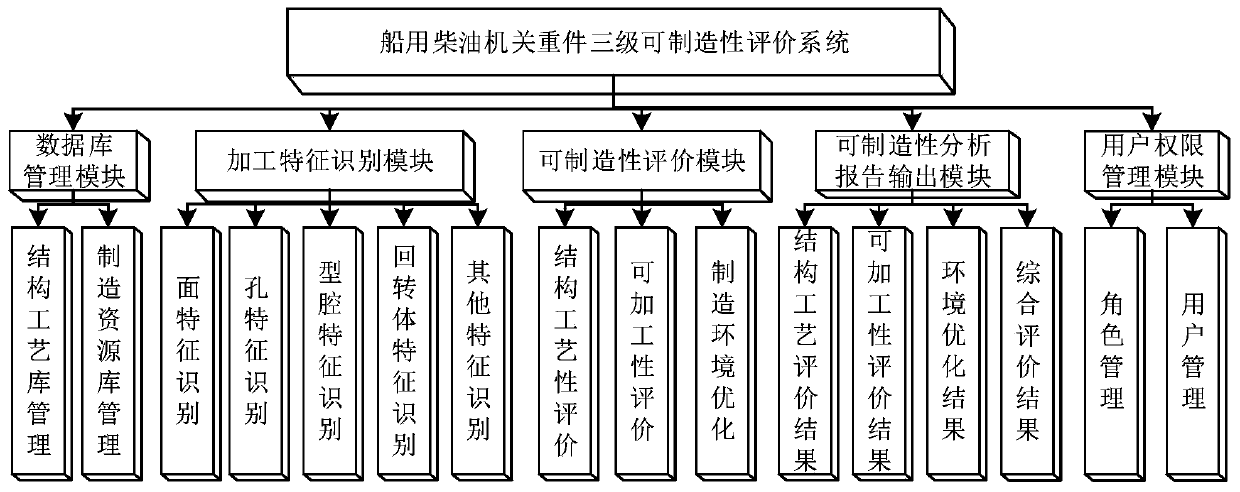

Marine diesel engine heavy part manufacturability three-level optimization method based on feature-resource knowledge

PendingCN110990907ASolve process problemsSolve processabilityGeometric CADDesign optimisation/simulationDiesel engineDistributed manufacturing

The invention discloses a marine diesel engine heavy part manufacturability three-level optimization method based on feature-resource knowledge. The method comprises the following steps that 1, machining features of marine diesel engine heavy parts are classified; 2, completing feature recognition based on a surface and rule processing feature recognition algorithm; 3, obtaining size and precisioninformation from the part three-dimensional model, and establishing a machining meta-information model; 4, creating a structural manufacturability rule knowledge base; 5, establishing a processing and manufacturing capability model and a knowledge base; 6, proposing a distributed manufacturing environment optimization method based on a genetic algorithm; and 7, establishing a verification platform, and outputting a three-level manufacturability optimization scheme and an evaluation report. The manufacturability three-level optimization method provided by the invention is progressive layer bylayer, fully considers difficulties in actual processing of marine diesel engine heavy parts, has good practicability and expansibility, and can effectively discover defects existing in design, so that the product development period is shortened, and the cost is saved.

Owner:JIANGSU UNIV OF SCI & TECH

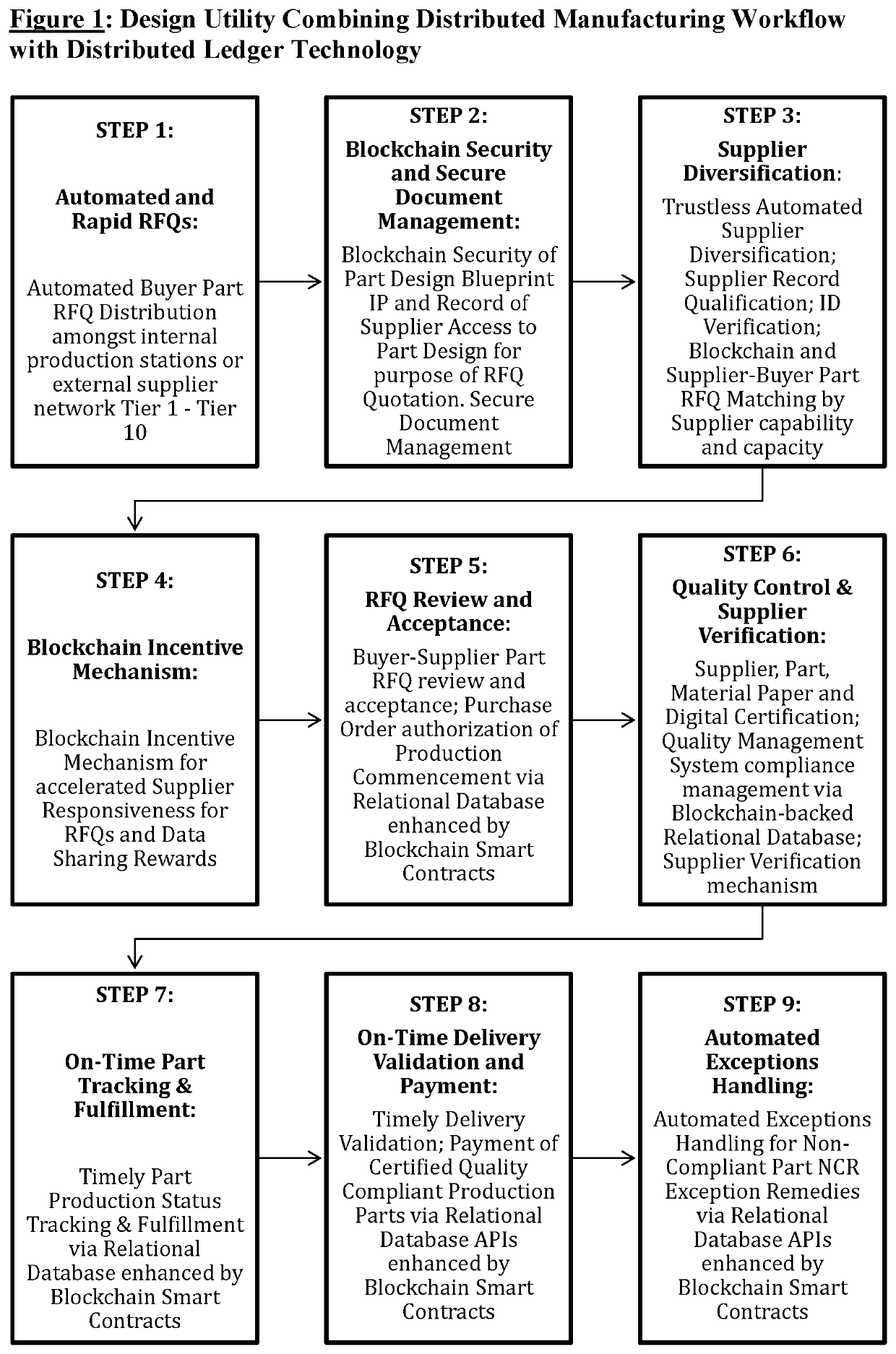

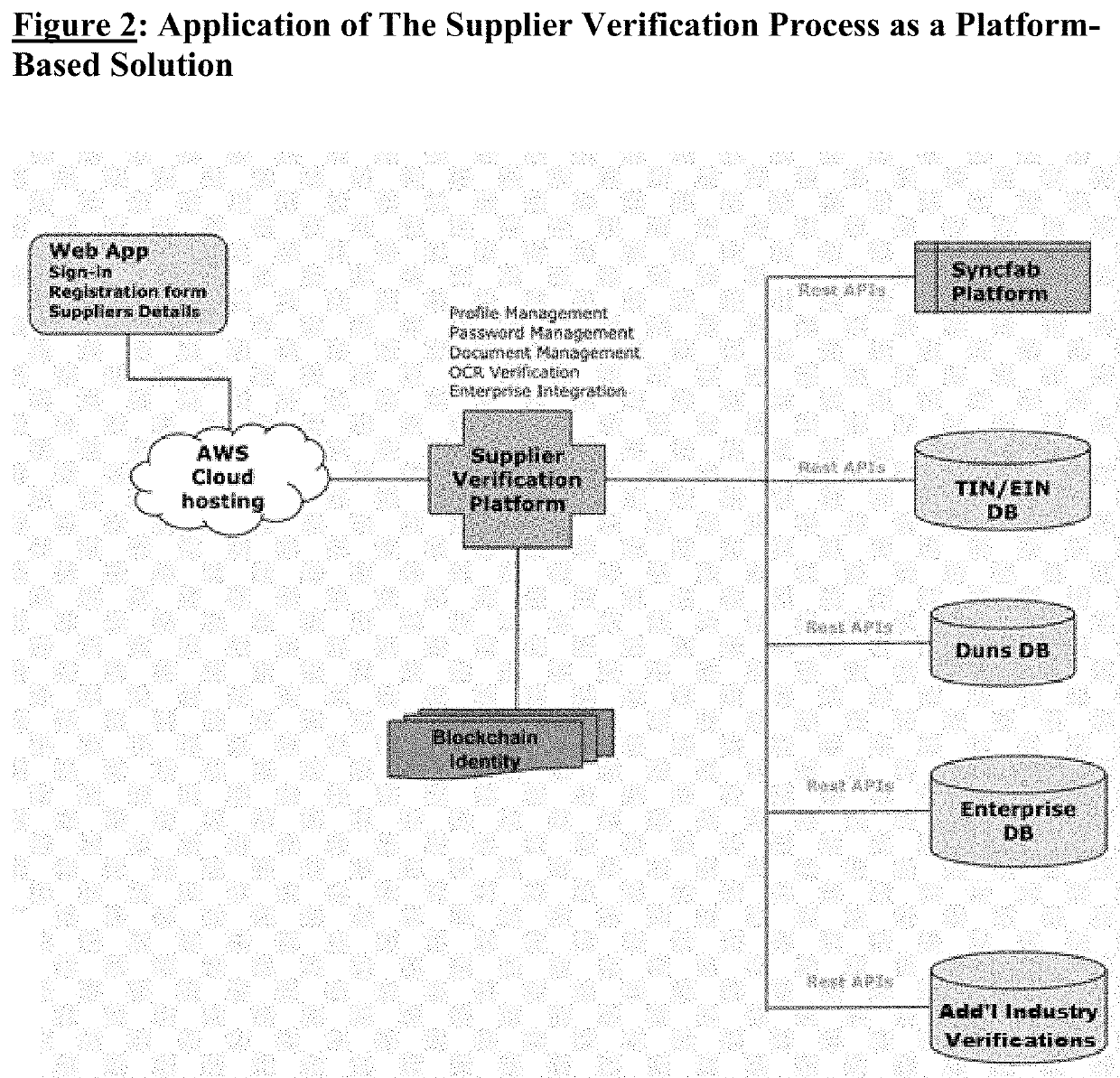

Industry workflow of distributed manufacturing, incorporating OEM part manufacturing outsourcing, web workflow coupled with real-world workflow integrations and distributed ledger technology functionality.

InactiveUS20220004984A1Eliminate inefficienciesImprove supply efficiencyDigital data information retrievalResourcesDistributed manufacturingAuthentication

The supply chain process described herein offers a business-ready original equipment manufacturer (OEM) blockchain supply chain and part procurement platform, with modular ERP value added solutions. This process is designed to resolve a multitude of longstanding inefficiencies for procurement and IT departments in the manufacturing and supply chain process, allowing procurement departments get precision parts faster and cheaper, suppliers to stay busy and profitable, and OEM IT teams to gain a powerful new tool to assist with digital transformation in the part supply chain lifecycle from procurement to recall while procuring from Tier-agnostic suppliers. This process merges the industrial manufacturing industry best practices workflow, to deliver the functionality and benefits of commercialized blockchain technology to large manufacturers and OEMs. The use of a distributed manufacturing workflow with the integration of distributed ledger technology in this process fosters convenience, cost-control, and flexibility for distributed OEM parts manufacturing networks as well as optimized security, supplier verification, supplier smart contract, part authentication and part traceability.

Owner:SYNCFAB CO

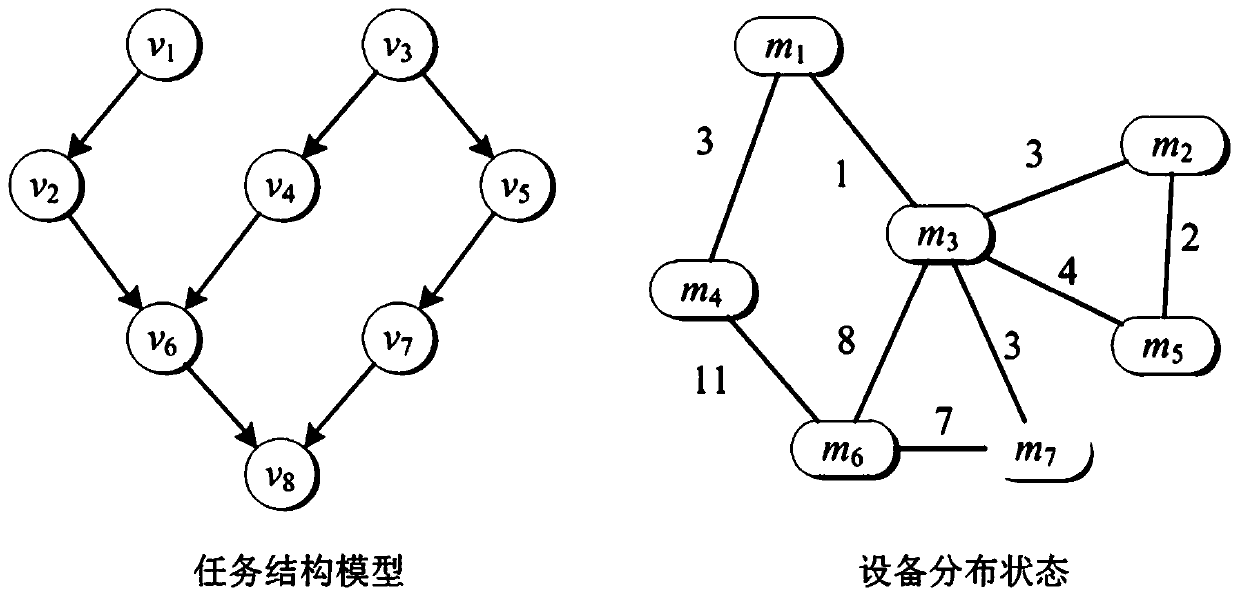

A Distributed Manufacturing Scheduling Method Oriented to Fixed-Point Output

ActiveCN109598450BGuaranteed Scheduling OptimizationEmbody dependencyResourcesManufacturing computing systemsData fieldStructure of Management Information

The invention provides a distributed manufacturing scheduling method for fixed-point output. The data field model is adopted to measure a task structure and an equipment distribution state, the task structure measurement reflects the influence of a subsequent process on an alternative process, and the equipment distribution state measurement reflects the local influence of equipment in an equipment network; By adopting a reverse scheduling method, starting from termination equipment and termination working procedures, equipment is reversely distributed for the working procedures, so that fixed-point output constraint of the task is guaranteed; Quantitative measurement of the established alternative processes and alternative devices can provide a basis for task scheduling, the scheduling process is simplified, and optimization of two aspects of tasks and device structures is considered.

Owner:SHENZHEN LOTUT INNOVATION DESIGN CO LTD

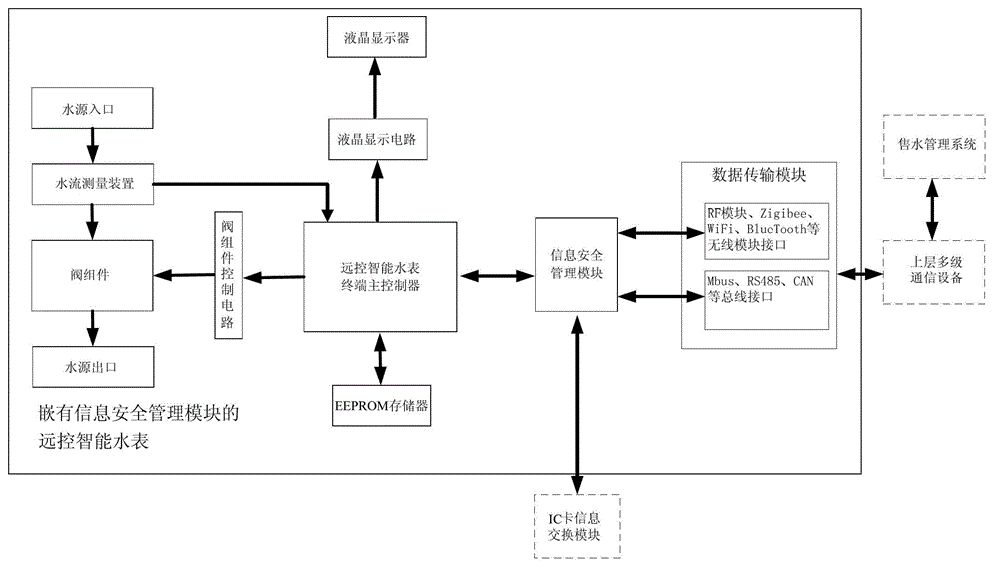

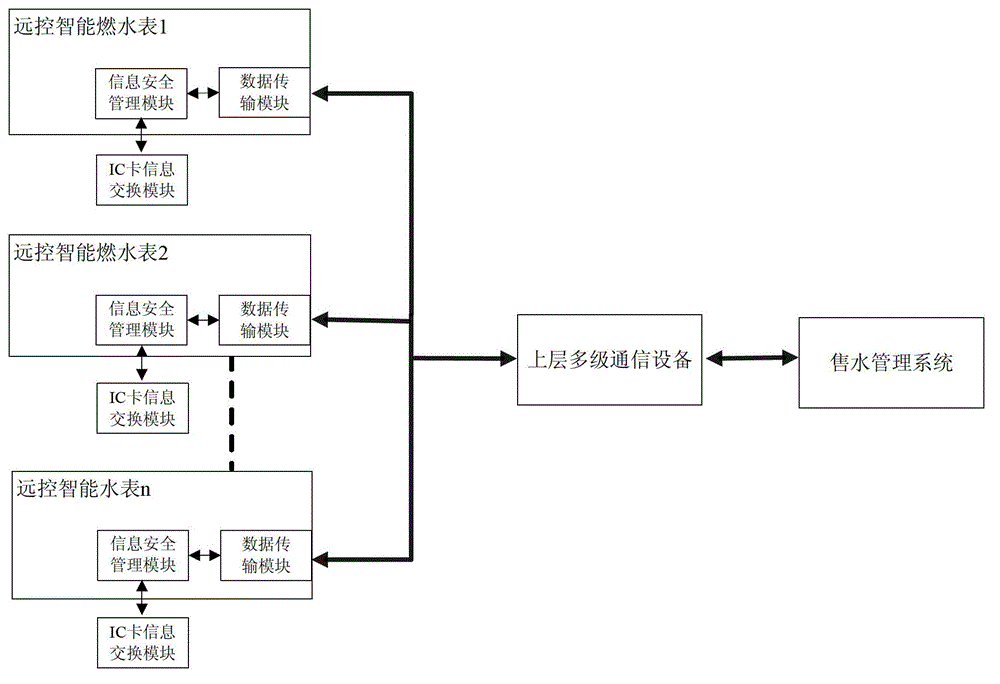

Remote control smart water meter embedded with information security management module

ActiveCN103198574BSimple structureGuaranteed independenceApparatus for hiring articlesTransmission technologyInformation security management

The invention discloses a remote control intelligent water meter embedded with an information safety management module, which belongs to a remote control intelligent water meter management auxiliary device. The remote control intelligent water meter comprises an information safety management module; the information safety management module includes a processor, a first data interface, a second data interface and a FLASH memory; the processor is respectively accessed to the first data interface, the second data interface and the FLASH memory; the information safety management module carries out identity authentication when a data transmission module exchanges data with a water sale manangement system, the communication legality of the data transmission module and the water sale management system is ensured, and a remote control intelligent water meter terminal main controller is communicated with an external device only via the information safety manangement module; and in addition, after embedding the information safety management module, the remote control intelligent water meter and a bus interface are compatible with the remote control intelligent water meter terminal main controller via multiple communication transmission technologies, and a water supply management system is seamlessly accessed, so that distributed manufacturing and unified management of the intelligent water meter are achieved.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

Information security management module of remote control intelligent electric energy meter

ActiveCN103218876BGuaranteed independenceSimple structureApparatus for hiring articlesStructure of Management InformationTransmission technology

The invention discloses an information security management module of a remote control intelligent electric energy meter, which belongs to a management assistance device of the remote control intelligent electric energy meter. The information security management module comprises a processor, a first data interface, a second data interface and a FLASH memorizer, wherein the processor is respectively accessed to the first data interface, the second data interface and the FLASH memorizer. The information security management module disclosed by the invention is subjected to identity authentication while being subjected to data exchange with an electricity selling management system through a data transmission module, the legality of communication between the information security management module and the electricity selling management system can be ensured, and a terminal main controller of the remote control intelligent electric energy meter can be in communication with the outside just by means of the information security management module; and meanwhile, the information security management module disclosed by the invention has a simple structure, can be embedded in remote control intelligent electric energy meters of various types, can be compatible with the terminal main controller of the remote control intelligent electric energy meter through various communication transmission technologies and bus interfaces and can be seamlessly accessed to a power supply management system, distributed manufacturing and unified management of the remote control intelligent electric energy meter can be realized, and the application range is wide.

Owner:眉山秦川智能传感器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com