Manufacturing resource intelligent matching system based on cloud platform

A technology of manufacturing resources and cloud platform, applied in manufacturing computing systems, resources, instruments, etc., can solve the problem of affecting the efficiency and accuracy of matching manufacturing resources and services, unable to meet the individual needs of users, and unable to achieve quantitative calculation of resource service matching, etc. problem, to achieve the effect of strong optimization ability and robustness, improved operation efficiency, and reasonable task allocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

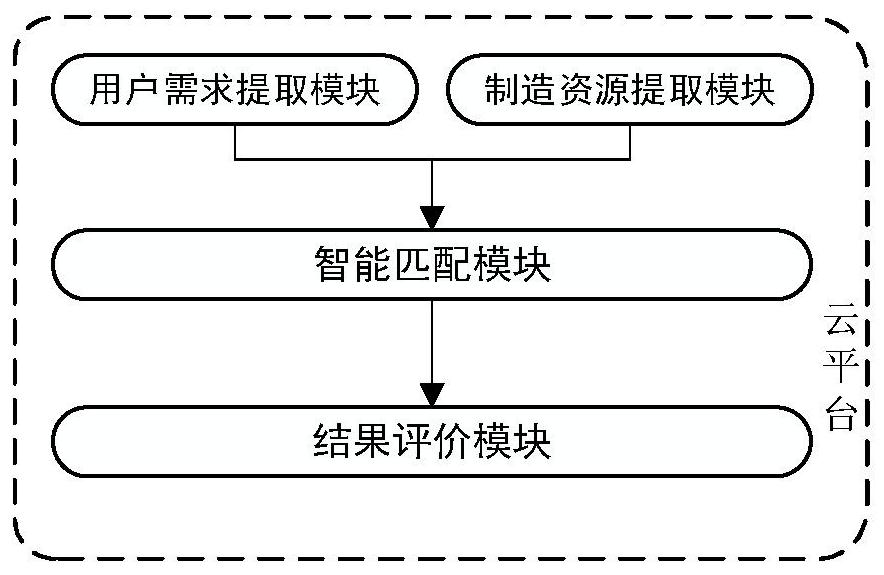

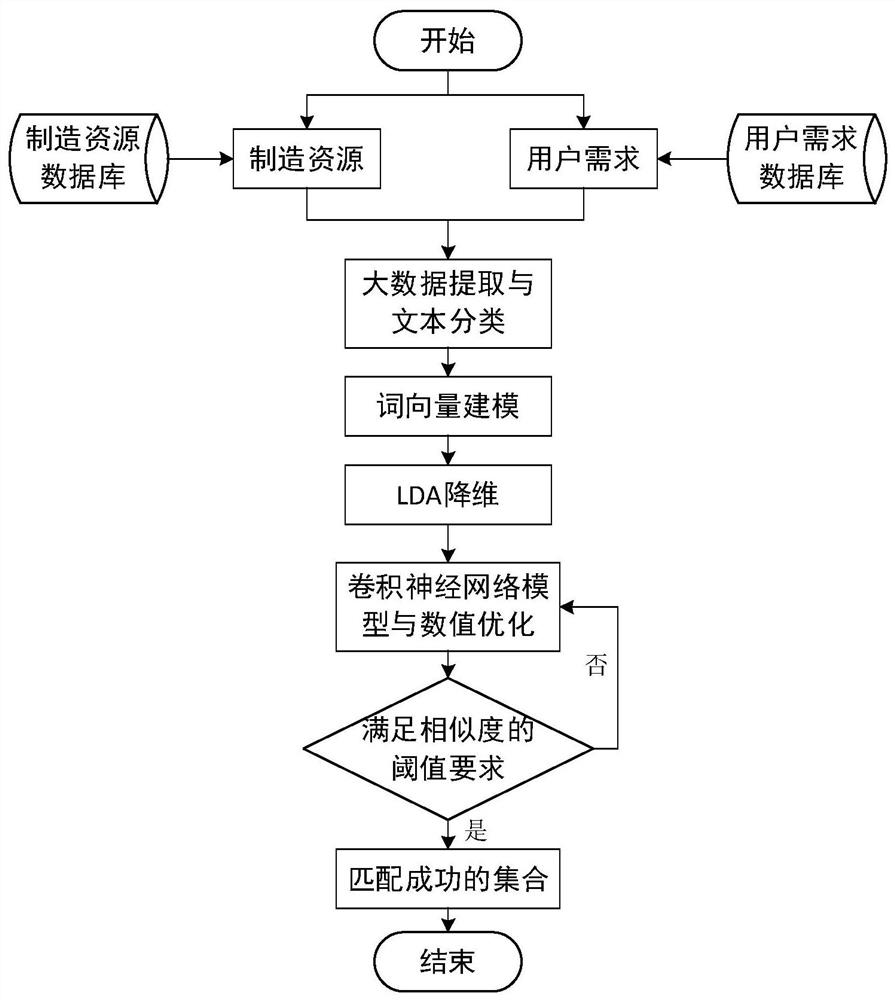

[0049] This embodiment discloses a cloud platform-based intelligent manufacturing resource matching system, see figure 1 and figure 2 , including user requirement database, manufacturing resource database, user requirement extraction module, manufacturing resource extraction module, intelligent matching module and result evaluation module.

[0050] The user demand database stores information data of various demand items of the user.

[0051] The manufacturing resource database stores information data of various resource items of production equipment.

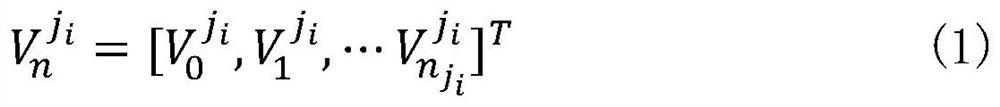

[0052] The user demand extraction module extracts various demand item information data from the user demand database through the material information extraction method for classification and induction, establishes a complete user demand information tree, and uploads it to the cloud platform. The user demand extraction module extracts various demand item information data from the user demand database and classifies and summari...

Embodiment 2

[0111] This embodiment provides a relatively basic implementation method. This embodiment discloses a cloud platform-based intelligent manufacturing resource matching system. See figure 1 and figure 2 , including user requirement database, manufacturing resource database, user requirement extraction module, manufacturing resource extraction module, intelligent matching module and result evaluation module.

[0112] The user demand database stores information data of various demand items of the user.

[0113] The manufacturing resource database stores information data of various resource items of production equipment.

[0114] The user demand extraction module extracts various demand item information data from the user demand database through the material information extraction method. For example, a customer in Chongqing needs a batch of shaft parts made of aluminum alloy, and the processing accuracy is at least IT8. The total number is X pieces, and the delivery is expected...

Embodiment 3

[0145] The main structure of this embodiment is the same as that of Embodiment 2. Further, the user demand extraction module extracts various demand item information data from the user demand database and classifies and summarizes the following steps:

[0146] 1) Establish a corpus for the extracted information data of various demand items, and carry out label classification.

[0147] 2) Natural language processing and text classification through deep learning framework.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com