Patents

Literature

853results about How to "Quick forecast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

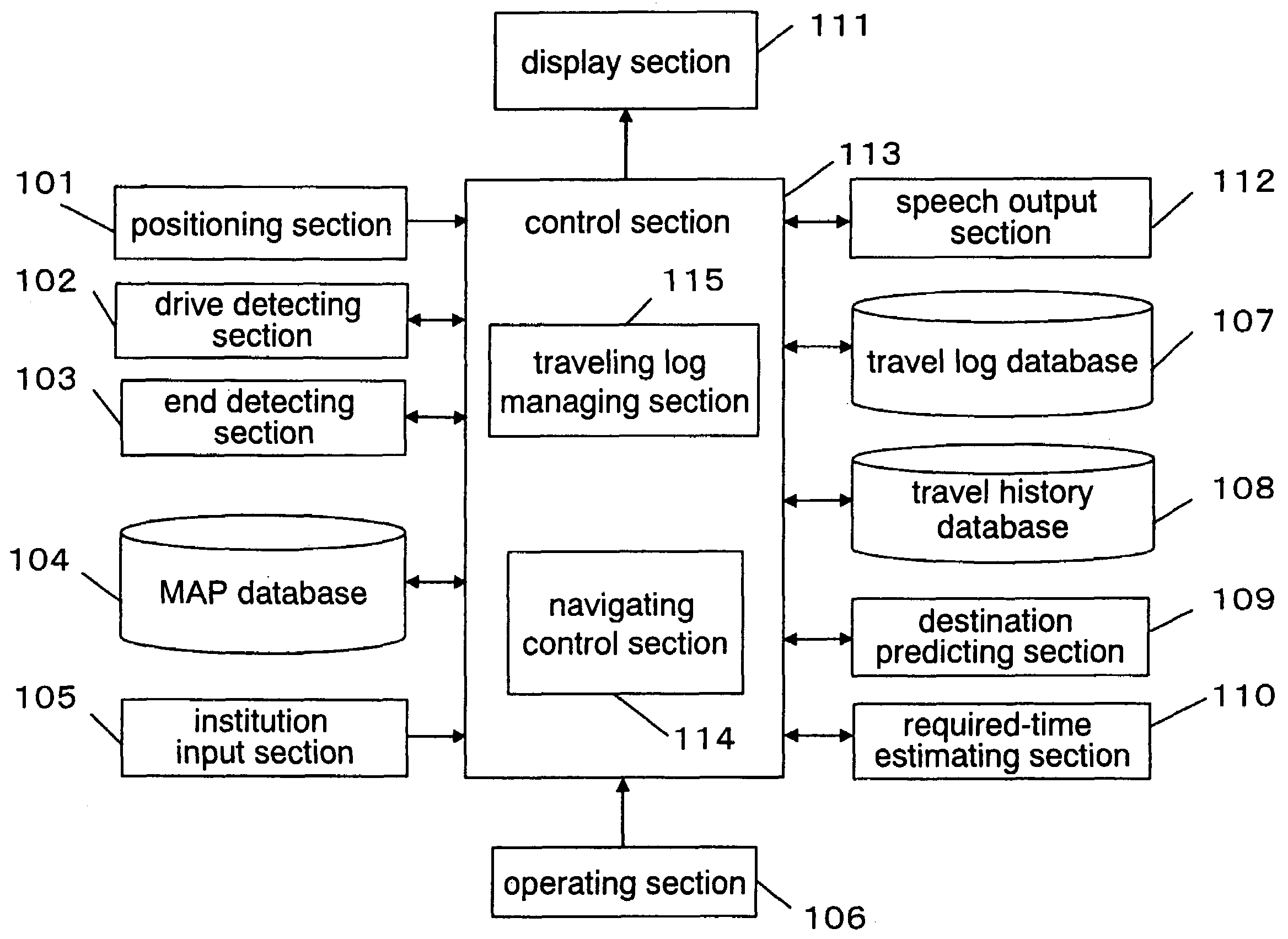

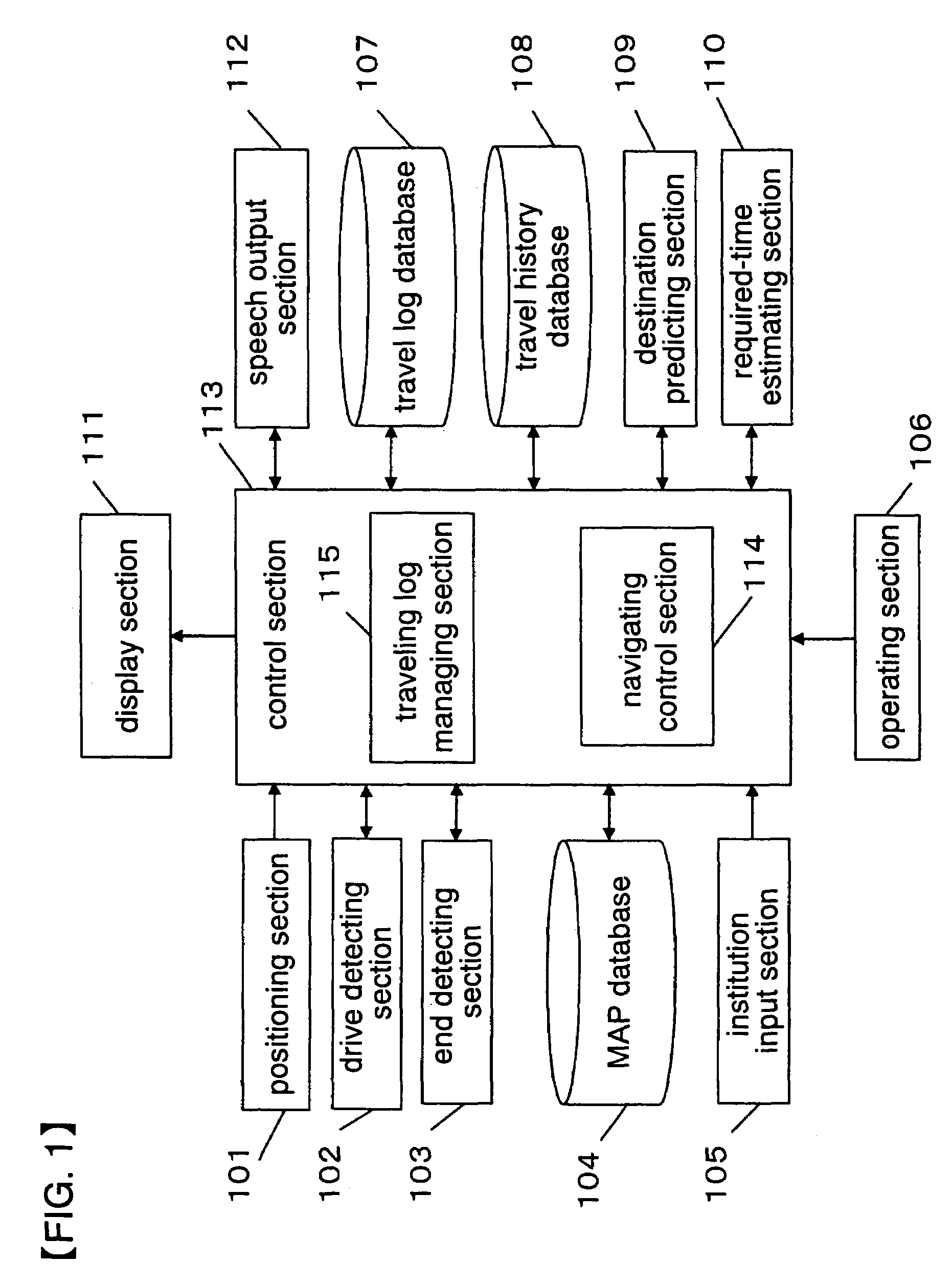

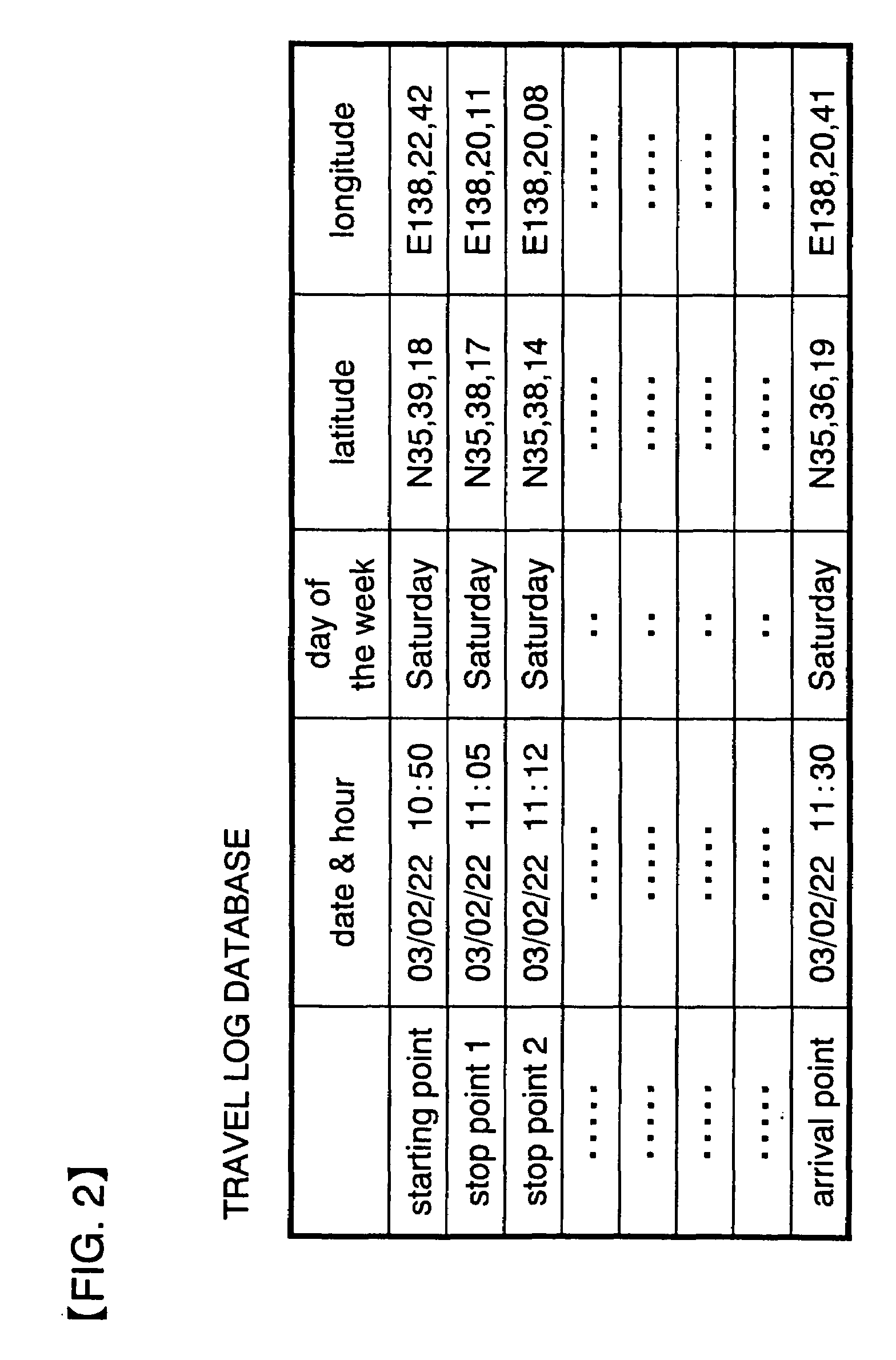

Place guidance system

InactiveUS7058506B2Prediction is simpleQuick forecastInstruments for road network navigationControl with pedestrian guidance indicatorGuidance systemEngineering

There are provided a positioning section for locating a current position, a travel history database for storing a history of a current position located by the positioning section and a history of a travel to an institution or the like actually visited by walking or so from at least one geographic point in the history, and a destination predicting section for predicting a destination on the basis of a history of using an institution actually visited by walking or so stored in the travel history database. This makes it possible to practically predict as a destination an institution actually visited by walking or so.

Owner:PANASONIC CORP

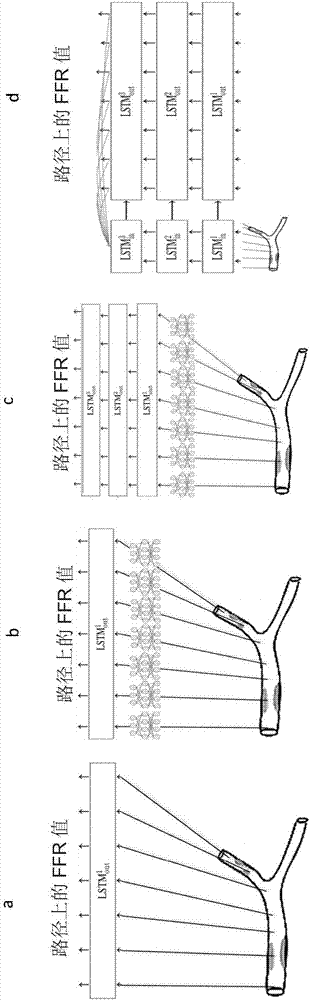

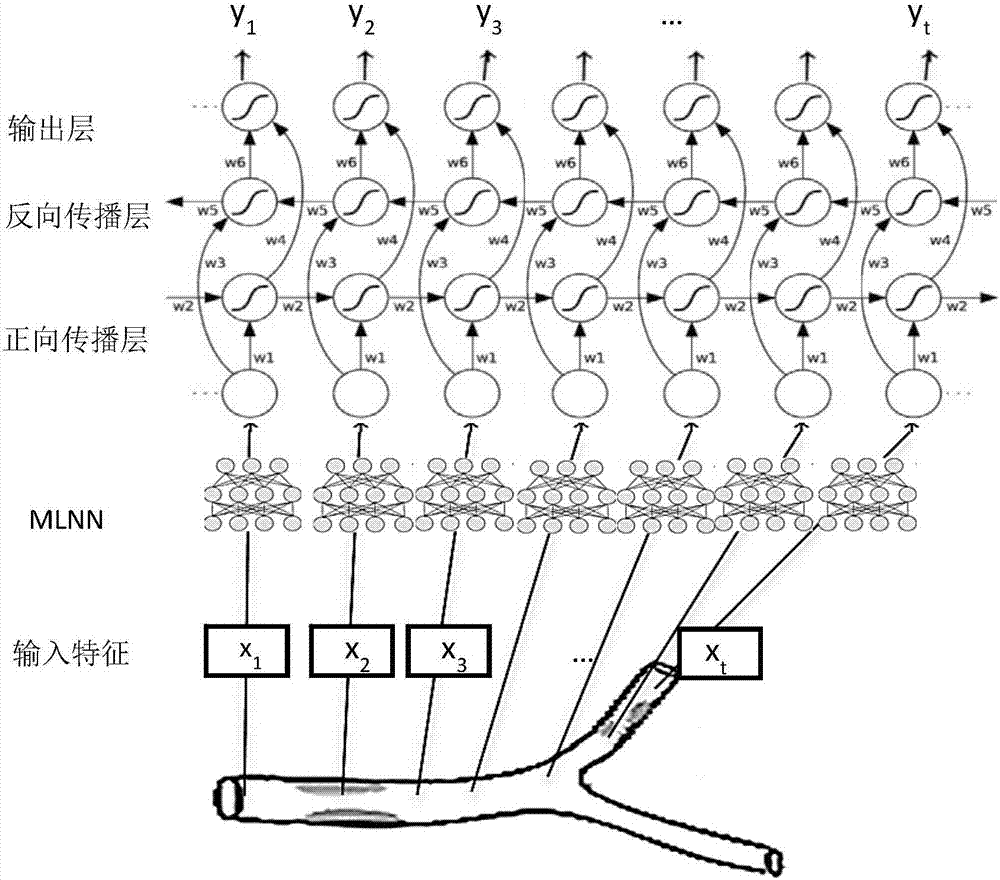

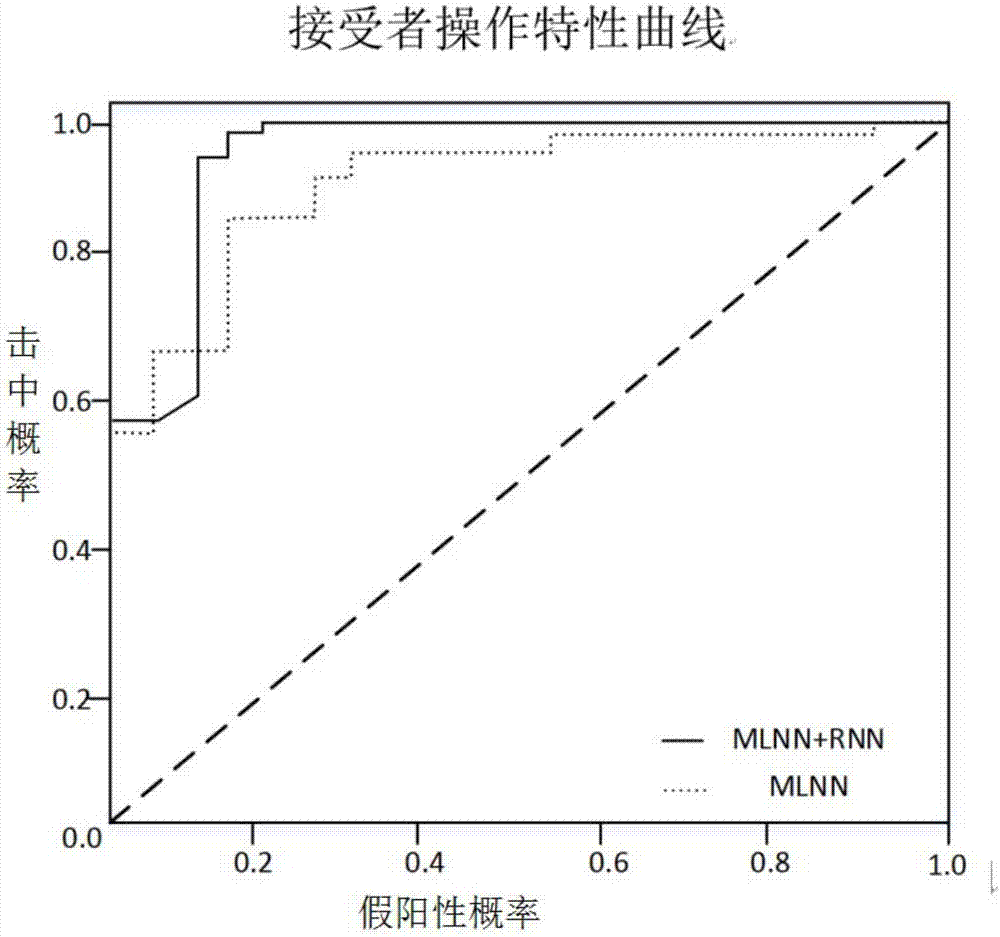

Deep learning model and system predicting blood flow characteristic in blood vessel path of blood vessel tree

ActiveCN106980899AAccurate predictionQuick forecastNeural learning methodsPattern recognitionAlgorithm

The invention discloses a deep learning model and system predicting a blood flow characteristic in a blood vessel path of a blood vessel tree. The deep learning model comprises a neural network arranged for different points in the blood vessel path, receives at least one, as input, selected from image, structure and function characteristics of the points in the blood vessel path, and predicts the blood flow characteristic, as output, of the points of a point sequence in the blood vessel path,; and the deep learning model is established via a recursive neural network or by combining a multilayer neural network with a recursive neural network sequentially. The deep learning model can predict the blood flow characteristic (as a blood flow reservation fraction) in the whole blood vessel path, and the computing efficiency is improved greatly.

Owner:BEIJING CURACLOUD TECH CO LTD

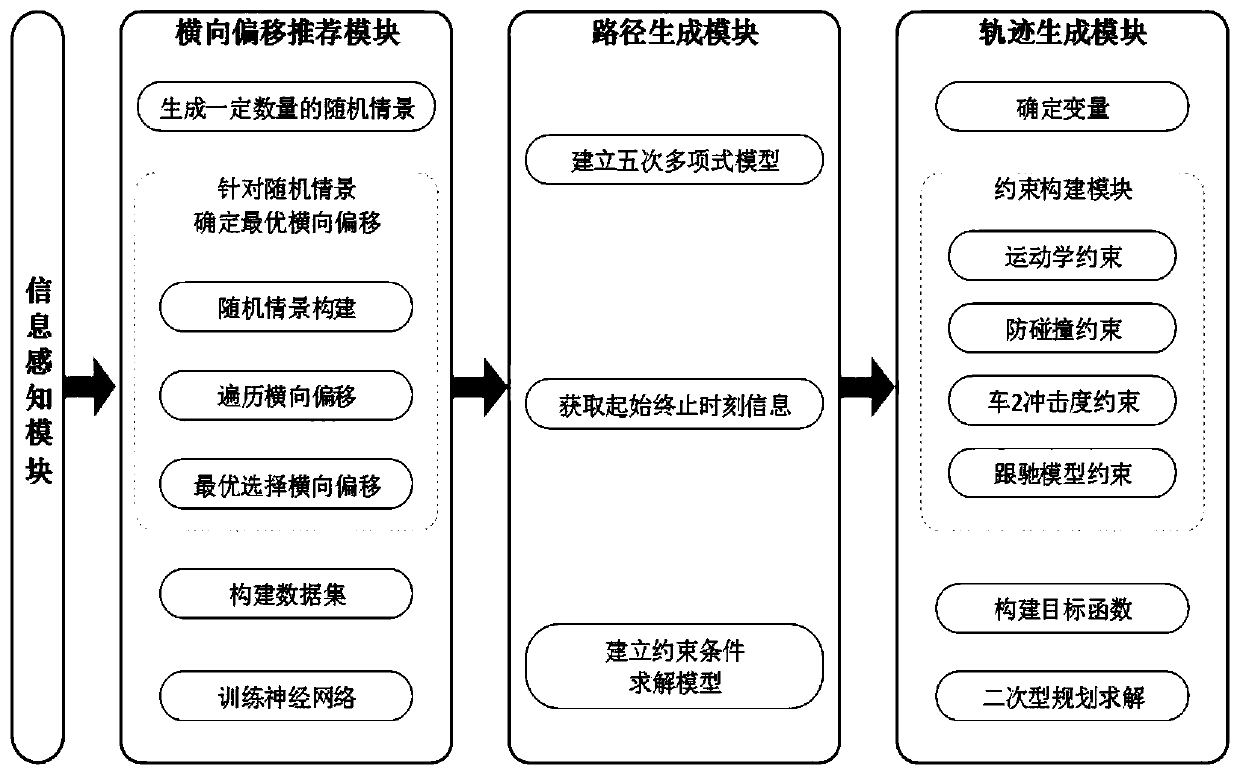

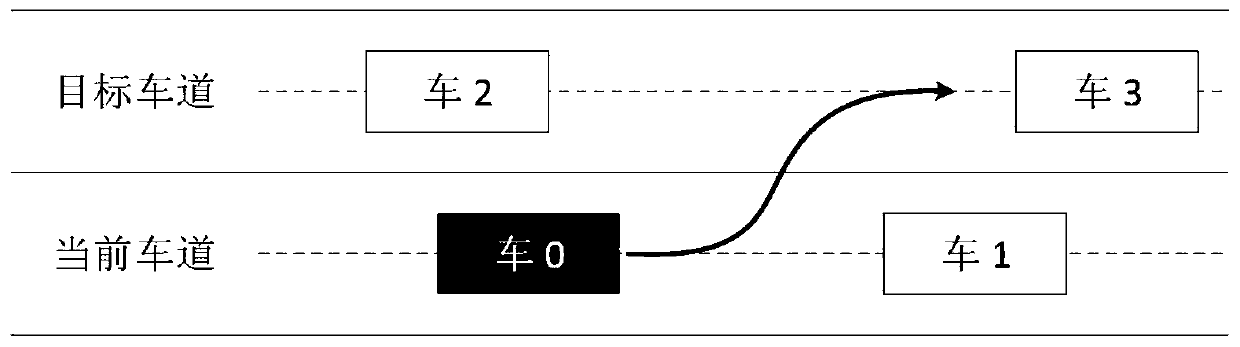

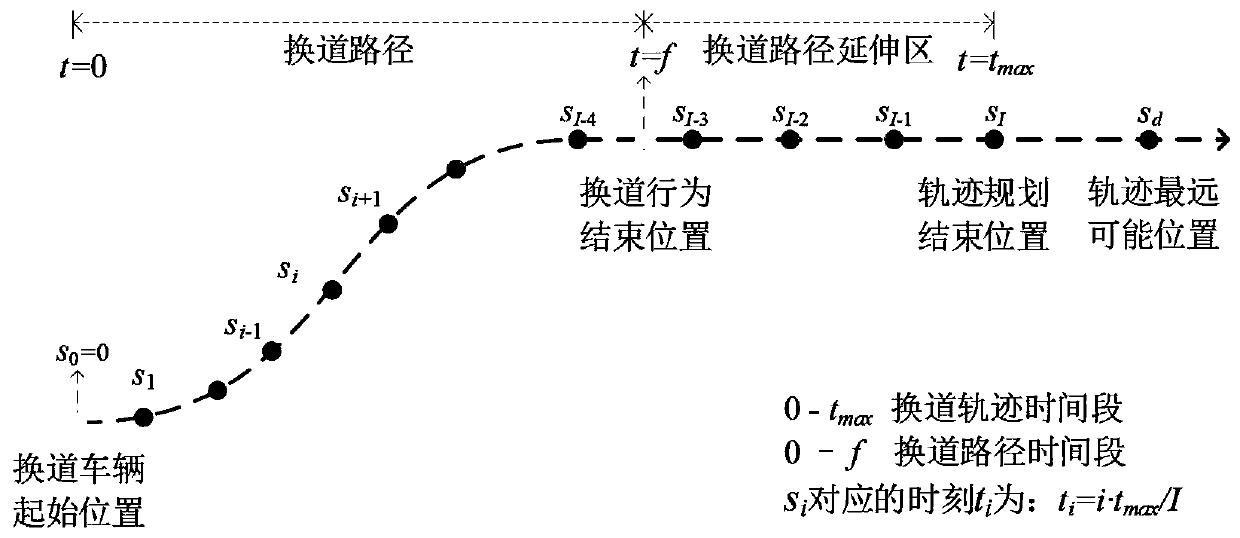

Automatic driving lane change trajectory planning method based on quadratic form planning and neural network

ActiveCN110597245ARapid lateral displacement targetEnsure safetyPosition/course control in two dimensionsEngineeringTrajectory planning

The invention belongs to the field of intelligent transportation, and provides an automatic driving lane change trajectory planning method based on quadratic form planning and a neural network. The method provided by the invention comprises the steps of: obtaining driving information of a lane change vehicle and surrounding vehicles by using an information sensing module; providing, by a lateral deviation recommendation module, a lateral deviation value based on the vehicle driving information so as to determine starting point and ending point position information of the lane change vehicle; calculating, by a path planning module, a static lane change path in a plane coordinate system of the lane change vehicle by using the vehicle driving information and the lateral deviation as input; and finally, providing, by a trajectory planning module, a time varying change law of the lane change vehicle and the surrounding vehicles to complete the target of lane change process planning. By adopting the automatic driving lane change trajectory planning method provided by the invention, under the premise of ensuring the safety of the lane change vehicle, the movement trajectories of the lanechange vehicle and the surrounding vehicles are comprehensively considered, and fast solution is achieved by using the quadratic form planning to improve the speed and comfort of the lane change process, thereby satisfying the requirements of automatic driving for the lane change sub-task optimization solution fastness.

Owner:BEIJING JIAOTONG UNIV

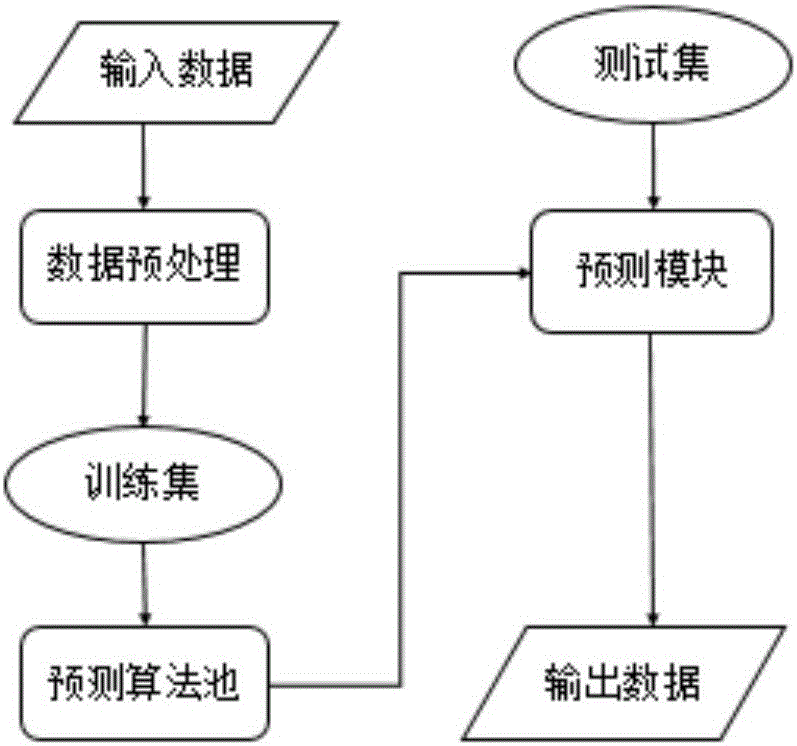

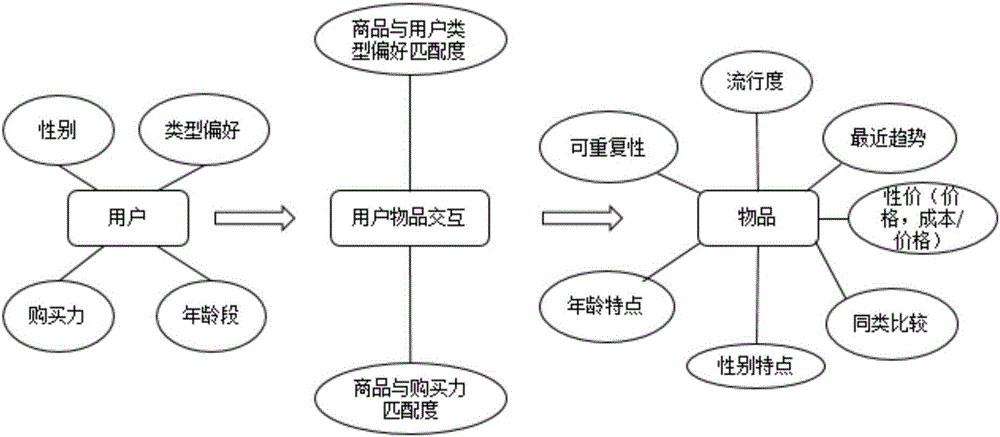

TV shopping commodity recommendation method based on classification algorithm

InactiveCN106127525AQuick calculationQuick forecastSelective content distributionMarketingPrediction scoreLinear regression

The invention discloses a TV shopping commodity recommendation method based on a classification algorithm. The TV shopping commodity recommendation method comprises the steps of: converting a prediction problem into a classification problem by utilizing logistic regression and a random forest, namely, predicting that purchasing behaviors of a user about a commodity can be divided into two categories: purchasing and not purchasing; extracting features from commodity information, user information and a user behavior record as input, and taking a prediction score of the user as output, thereby forming a function; and training a model by adopting a linear regression method, and converting the problem into a training classifier problem. The TV shopping commodity recommendation method does not carry out prediction and calculation on the basis of a heuristic rule, but carries out prediction on the basis of data analysis and statistics as well as machine learning for training model; and new users and new commodities can be calculated and predicted quickly as long as the model is trained.

Owner:ZHEJIANG UNIV

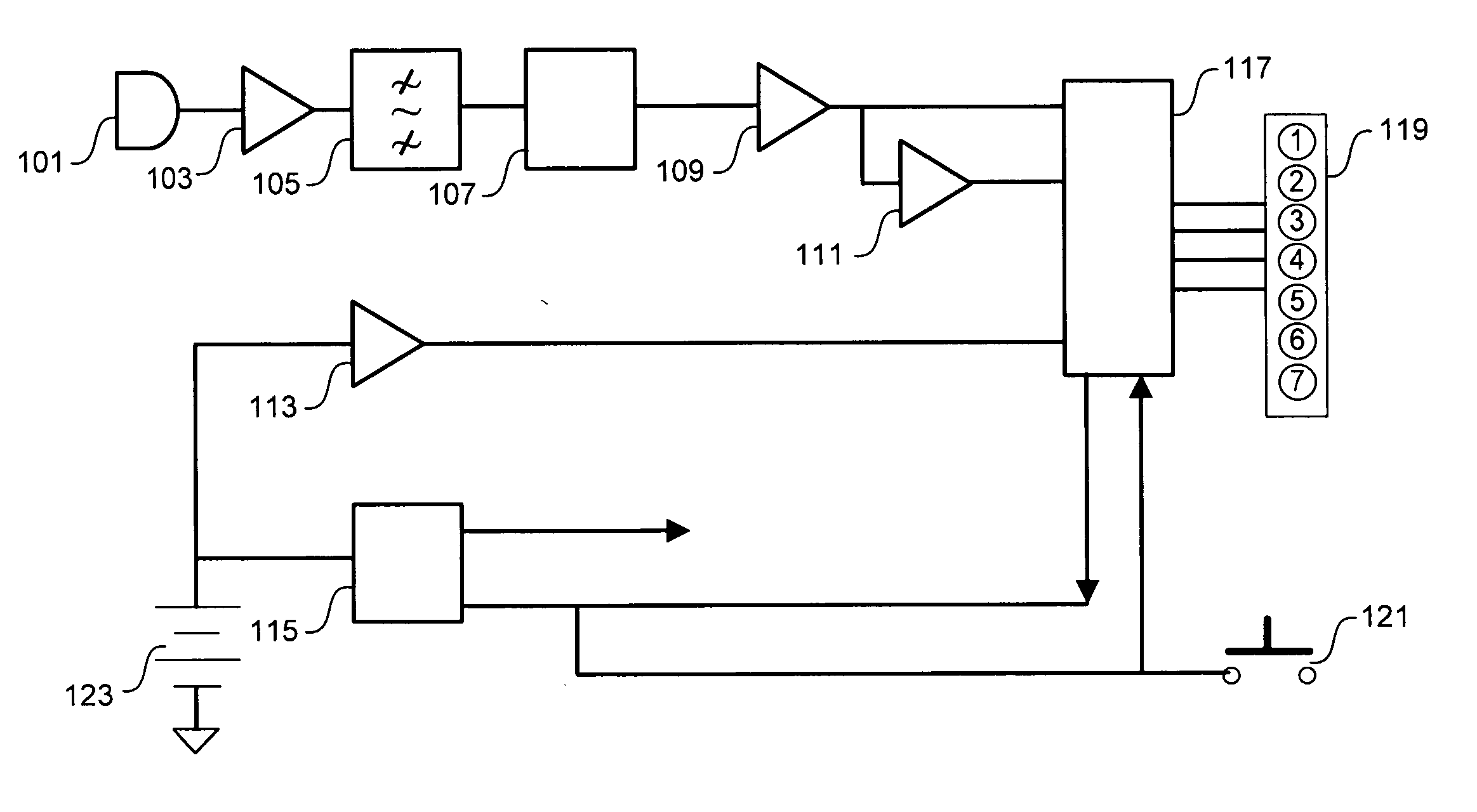

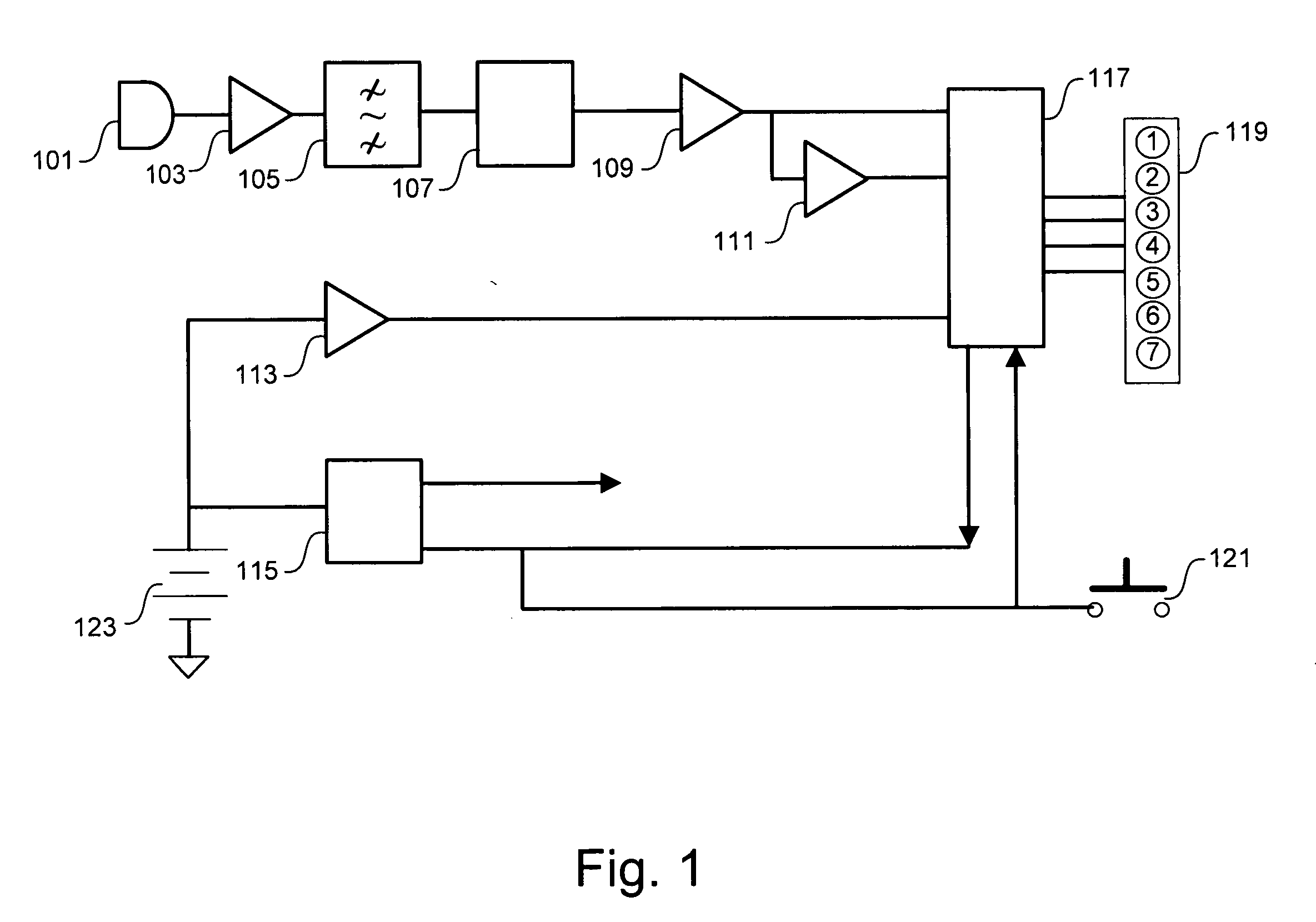

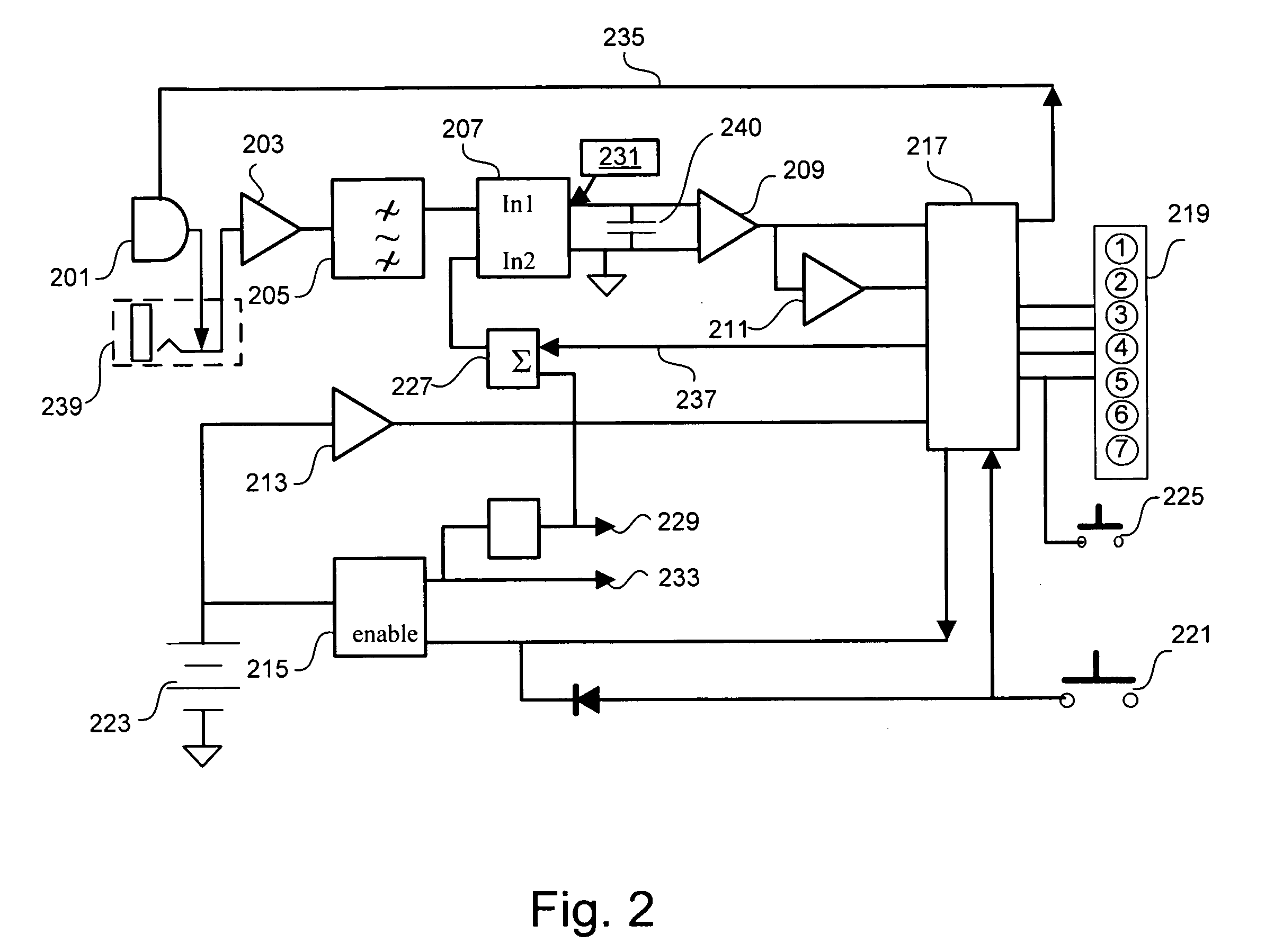

Method and system for noise dosimeter with quick-check mode and earphone adapter

ActiveUS20070186656A1Rapidly predict noise exposureLow signalVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSound sourcesDisplay device

A noise dosimeter with capability to rapidly predict noise exposure over an extended time period based on a measurement of short duration. Either an acoustic or an electrical earphone adapter provides a convenient means to connect the noise dosimeter to an external sound source. A direct input jack operable to receive at least one audio signal provides a signal to an RMS detector, which provides a DC signal to a two-stage amplifier circuit. The outputs of the amplifiers are provided to a processor having multiple A / D channels. The processor calculates accumulated noise doses and drives a display, which in one embodiment includes a panel of light-emitting diodes. In one embodiment, the dosimeter includes functionality for control of external devices such as sound boards.

Owner:ETYMOTIC RES

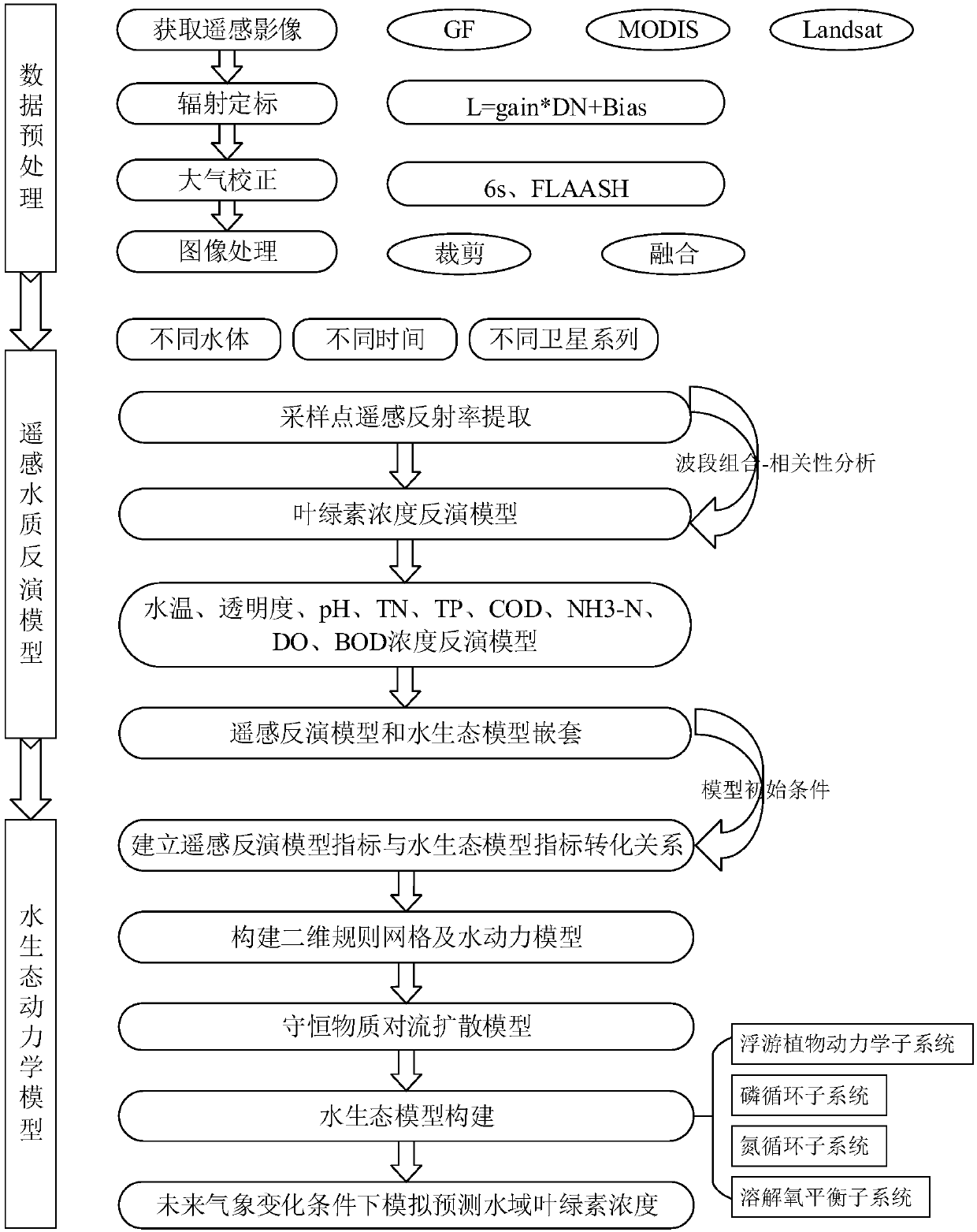

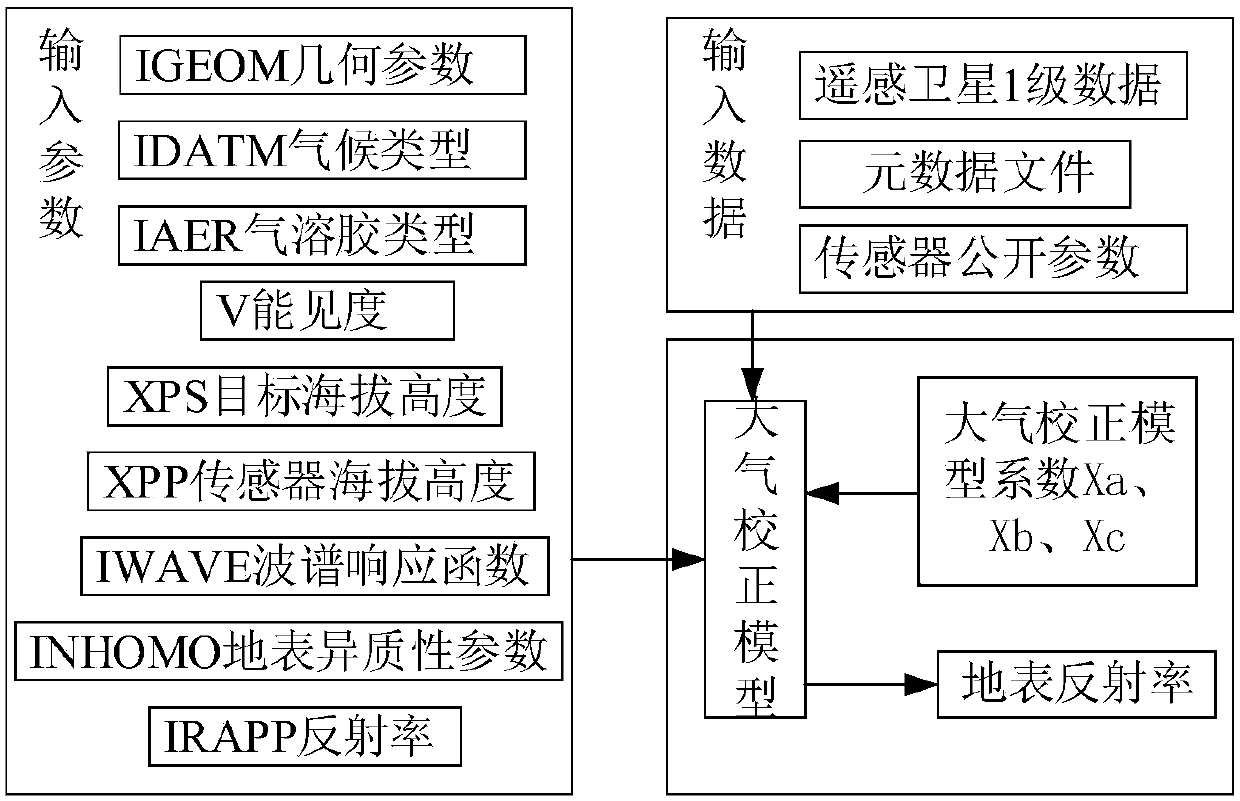

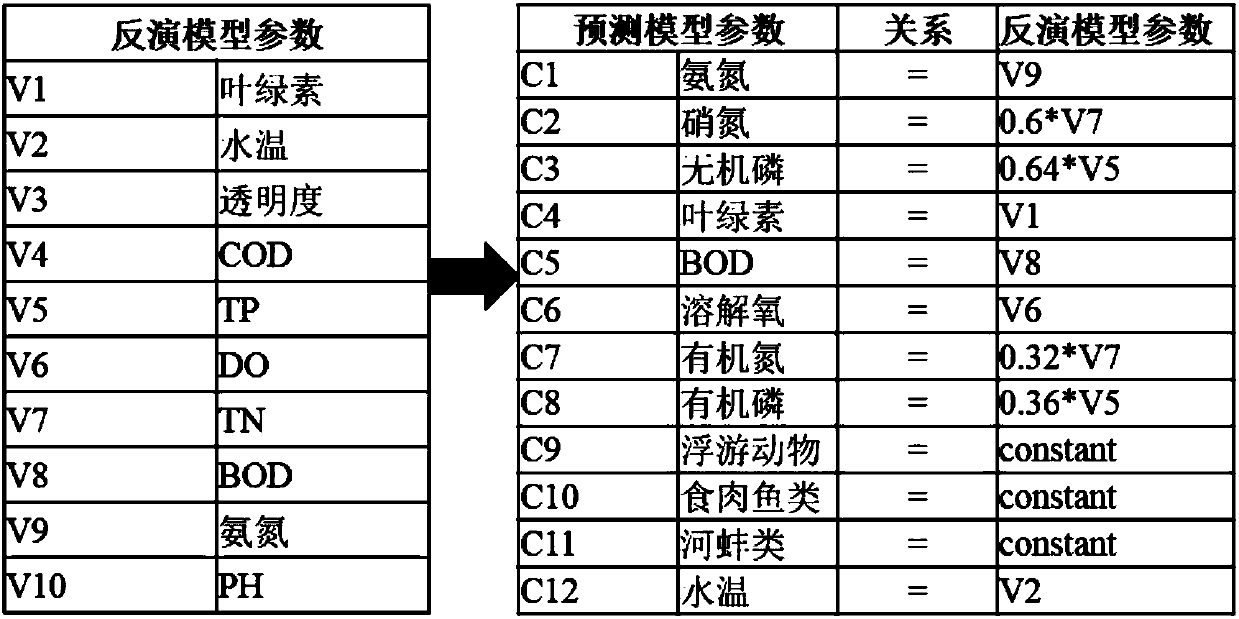

Chlorophyll calculating method based on remote-sensing images and water ecological model

ActiveCN108038351AComprehensiveImprove applicabilityCharacter and pattern recognitionSystems biologyWater qualityAtmospheric correction

The invention discloses a chlorophyll calculating method based on remote-sensing images and a water ecological model. The method comprises the steps of 1, based on remote-sensing image data, data preprocessing like radiometric calibration, atmospheric correction and image cropping and fusing is conducted; 2, a remote-sensing water quality inversion model is constructed, and respective inversion ofindexes like water temperature and chlorophyll concentration is achieved; 3, various index concentrations and future weather change which are obtained through inversion of the remote-sensing images are regarded as input conditions of the water ecological model, and the chlorophyll concentration dynamic change process of a water area environment is simulated within a future duration caused by change like nutritive substance conversion and algae growth and death under a future weather change condition. The chlorophyll calculating method is applicable to water environment monitoring and predicting, and has popularity and high calculation precision, chlorophyll concentration prediction and simulation of a large area of a drainage basin are achieved in real time under the condition of the limited monitoring site, and an integrated chlorophyll concentration predicting system integrating the remote-sensing images and the water ecological model can be formed.

Owner:WUHAN UNIV

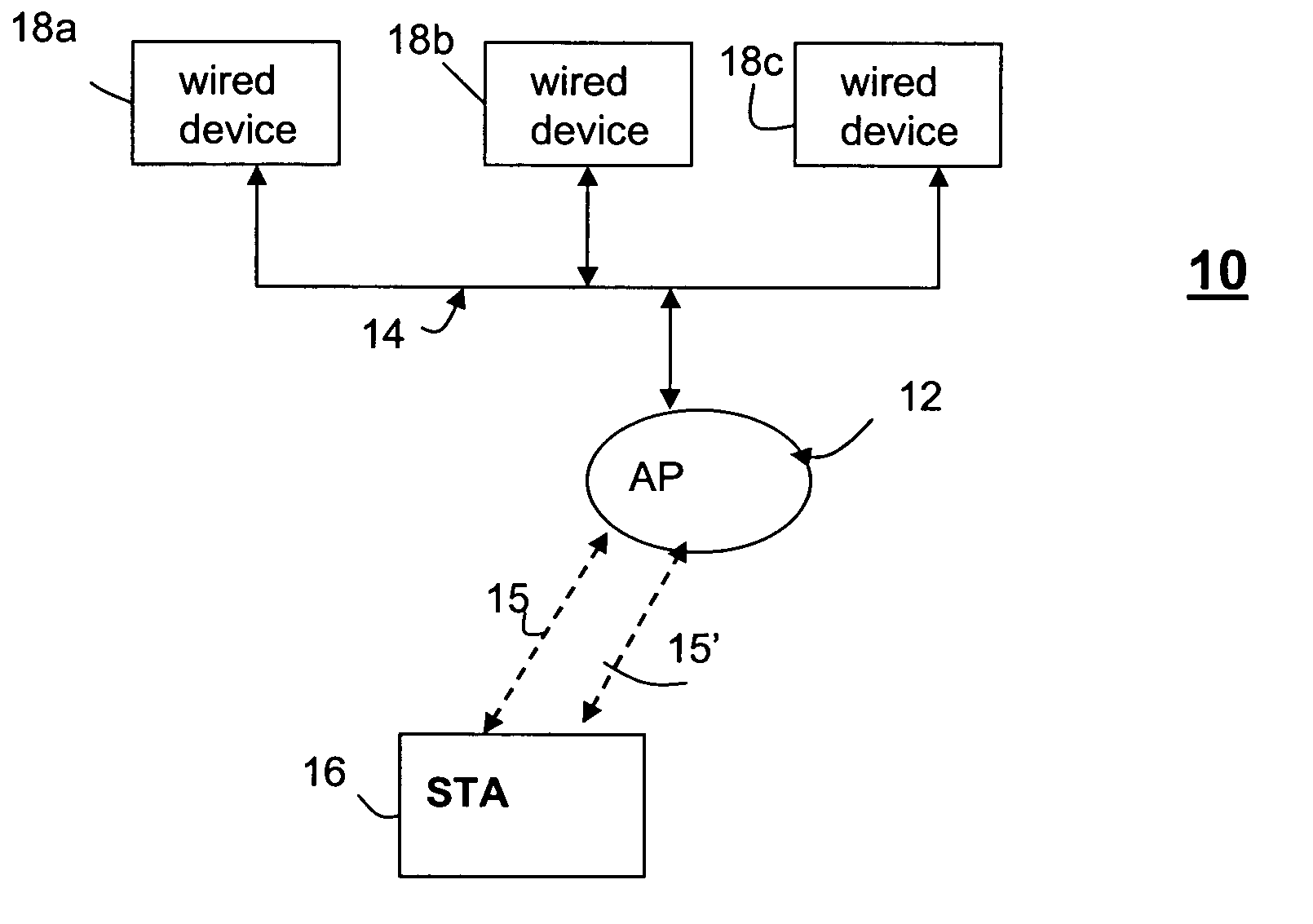

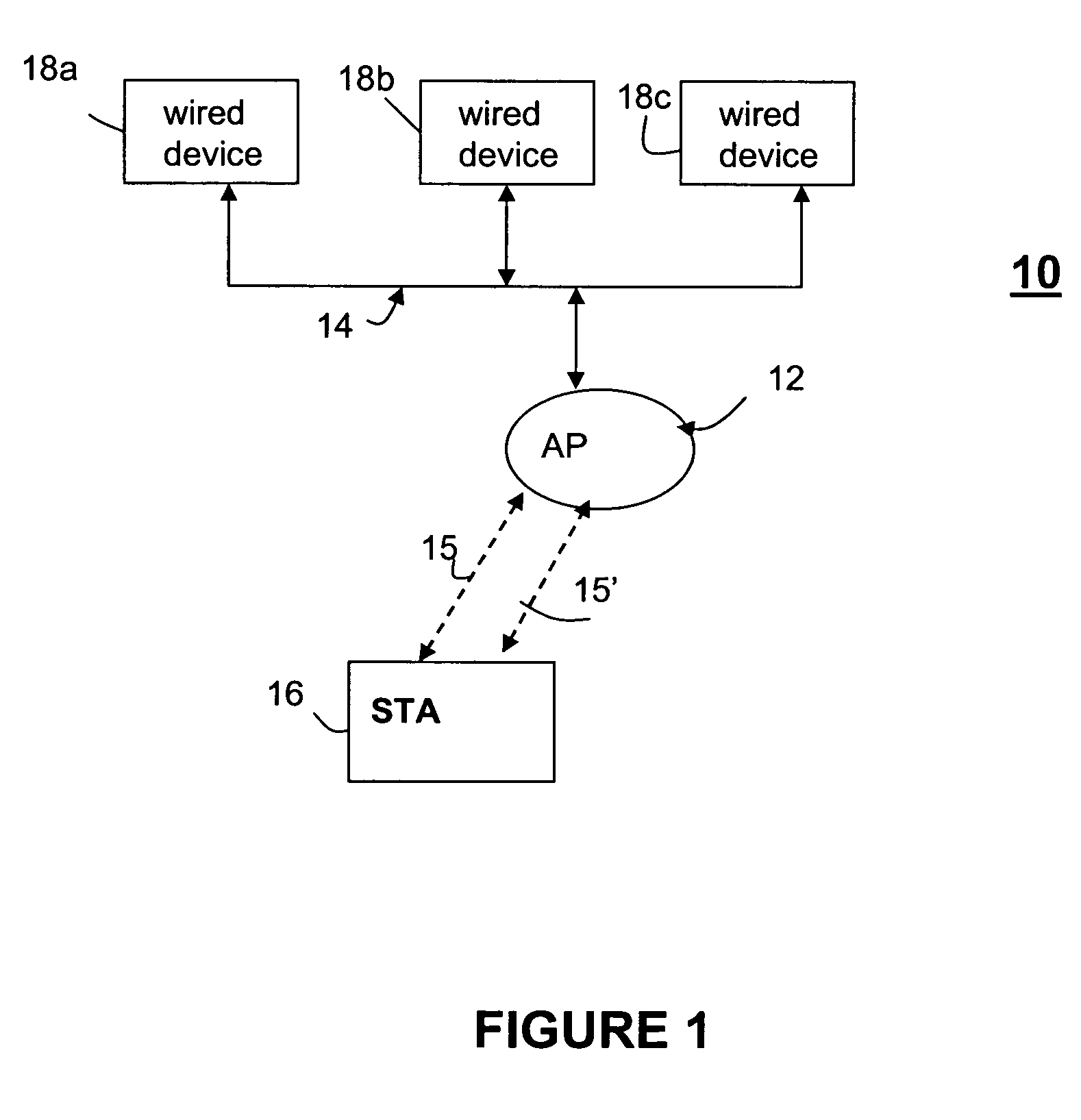

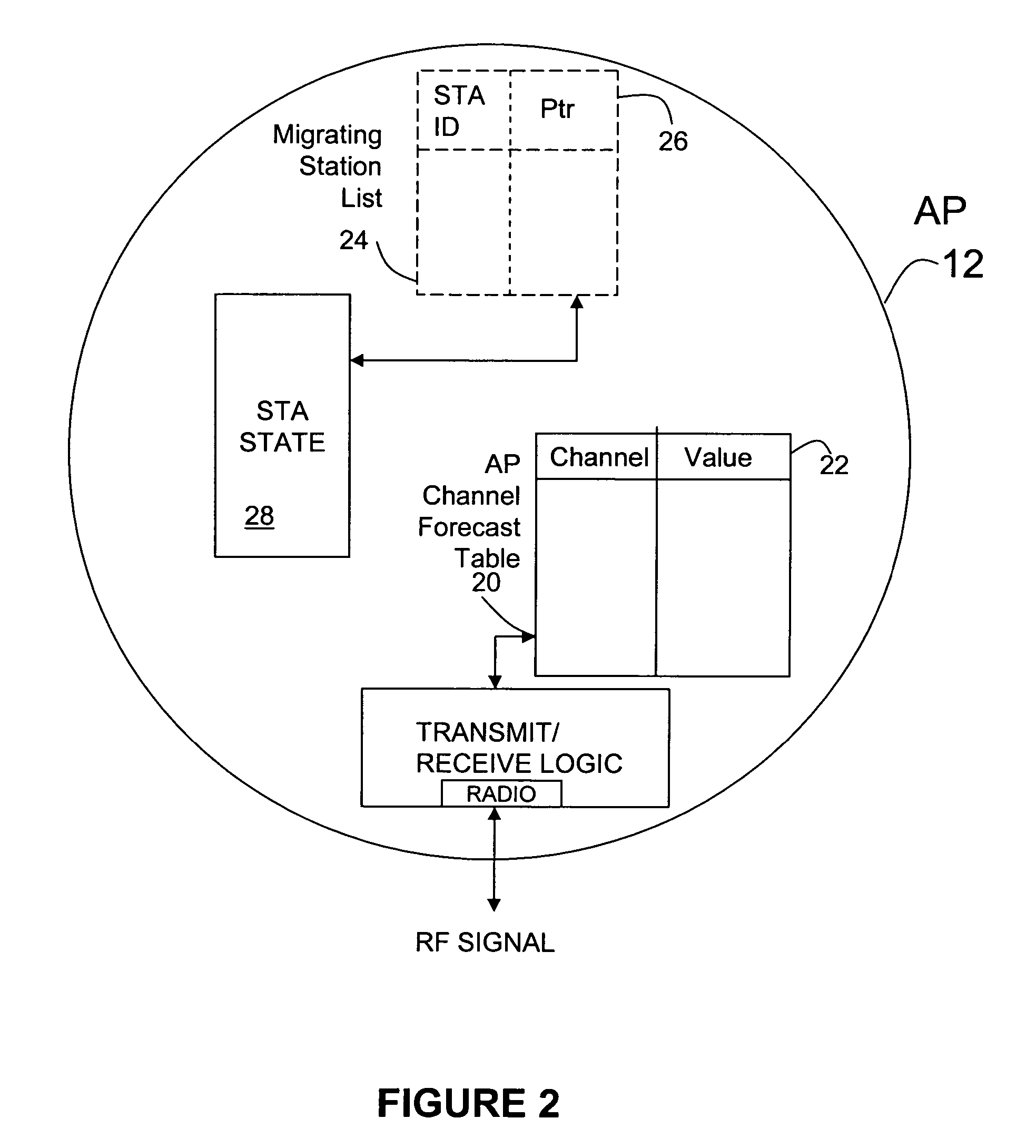

Access point channel forecasting for seamless station association transition

InactiveUS20060171305A1Quick forecastError preventionFrequency-division multiplex detailsTelecommunicationsBusiness forecasting

Seamless migration of an AP / STA link across channels to compensate for a changing RF environment is achieved by forecasting alternate AP communication channels to an STA prior to loss of connectivity on the link. The AP, when identifying a preferred communication channel, also identifies an alternate communication channel, and communicates this alternate channel to a coupled STA. In the event that communication between the AP and the STA is lost, the STA can quickly predict the new location of the AP, and migrate to the new channel without loss of communication state. The AP is not required to communicate to any STA that it has switched stations. Rather, the fact that the AP has switched is inferred at the STA by the inability of the STA to communicate with the AP. Thus the present invention may be used to preserve link state when a communication channel used by the AP / STA link is blocked.

Owner:PICCATA FUND LIABILITY

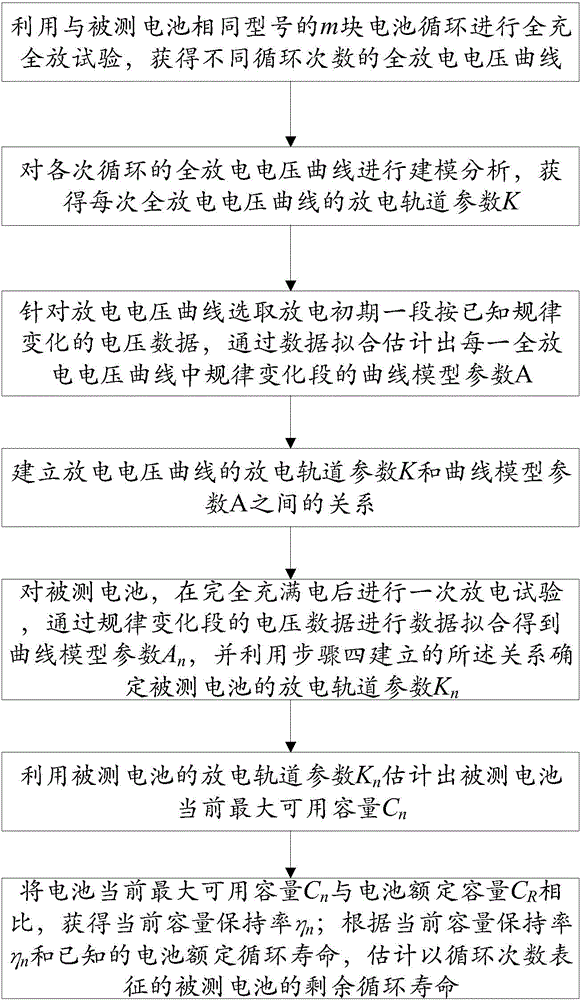

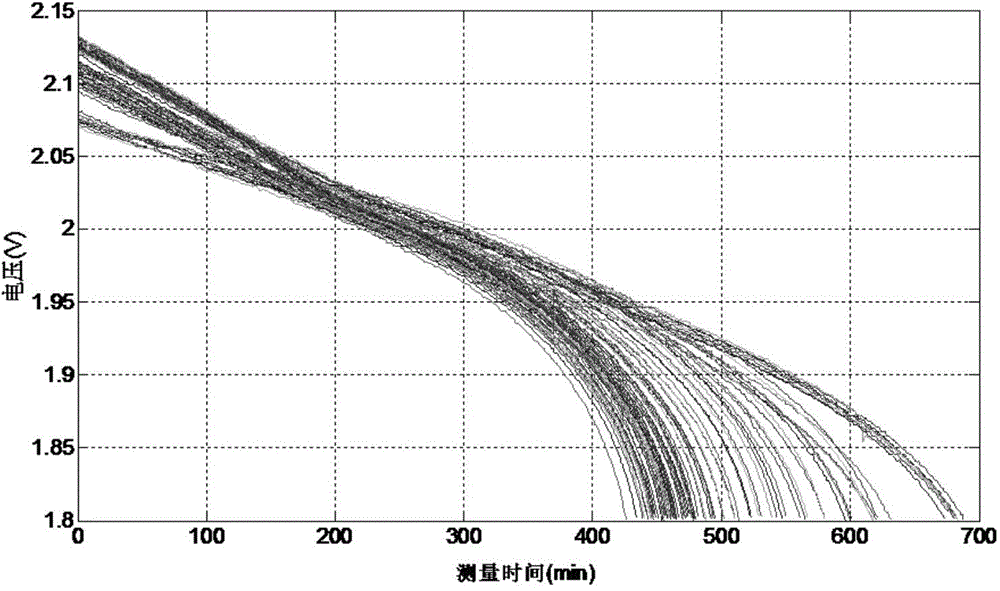

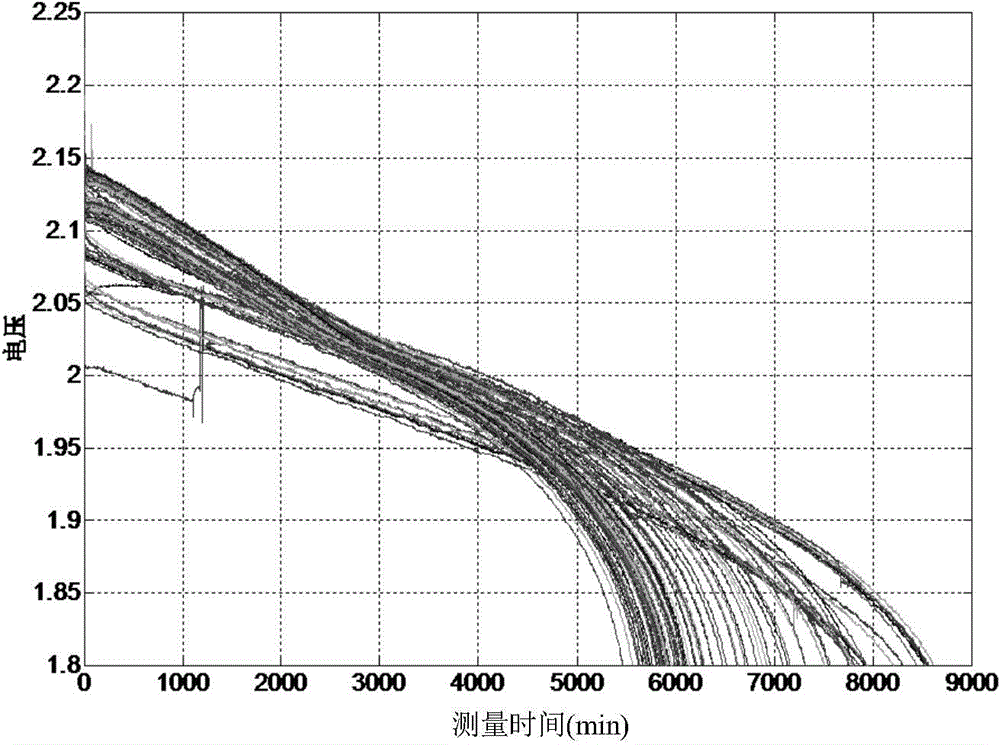

Rapid detection method for battery life

The invention discloses a rapid detection method for the battery life. The rapid detection method for the battery life comprises the steps that firstly, the maximum available capacity of a battery is rapidly estimated on the basis of a partial discharge method; secondly, the capacity retention rate is acquired through the maximum available capacity; finally, the residual cycle life, represented in a cycle index mode, of the battery is estimated according to the current capacity retention rate and the known rated cycle life of the battery. It is clear that the maximum available capacity is selected as a key performance parameter, degradation track modeling is conducted on the maximum available capacity of the battery on the basis of a performance degradation method, and then prediction of the residual cycle life of the lead-acid battery is achieved. In addition, the maximum available capacity of the battery is estimated on the basis of the partial discharge method, so that rapid prediction of the residual cycle life of the battery is achieved. Due to the fact that whole-process discharge operation does not need to be conducted, the test time is greatly shortened, the accuracy can be satisfactory on the premise that the discharge rule of the battery is grasped, and the rapid detection method for the battery life has the high application value in the fields of military, energy sources and traffic.

Owner:中国人民解放军92537部队

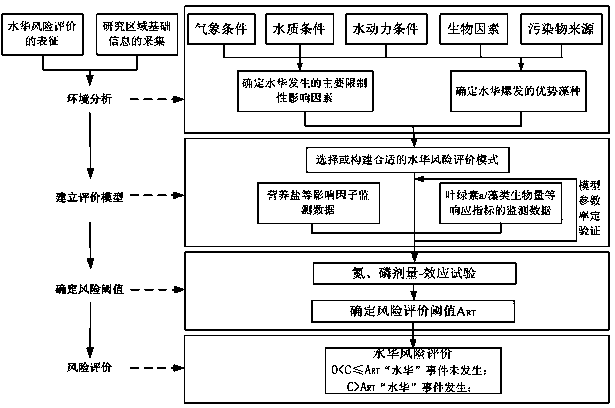

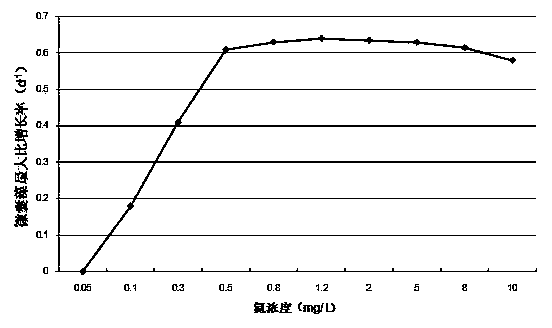

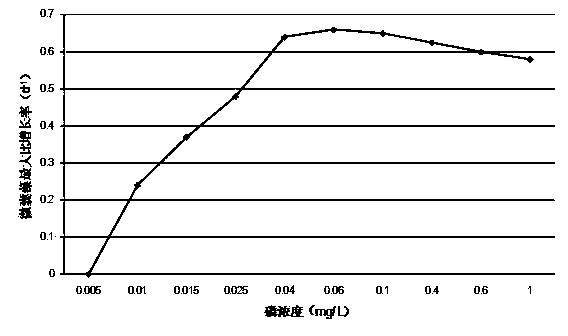

Method for fast early warning against water body water bloom risk

ActiveCN104112080ASimple structureFew parametersSpecial data processing applicationsEnvironmental qualityCvd risk

The invention discloses a method for fast early warning against a water body water bloom risk. The method comprises a first step of constructing an alga biomass prediction model based on environment analysis results; a second step of adopting the alga biomass prediction model to obtain an alga biomass prediction value; a third step of determining an alga biomass water bloom risk threshold of advantageous algae; and a fourth step of comparing the alga biomass prediction value with the alga biomass water bloom risk threshold and judging whether water bloom early warning is sent out. The method is suitable for water environmental quality monitoring, is simple, convenient and rapid, can achieve fast early warning of the water bloom risk and can provide timely and effective technical support for water environment emergency management.

Owner:珞珈浩景数字科技(湖北)有限公司

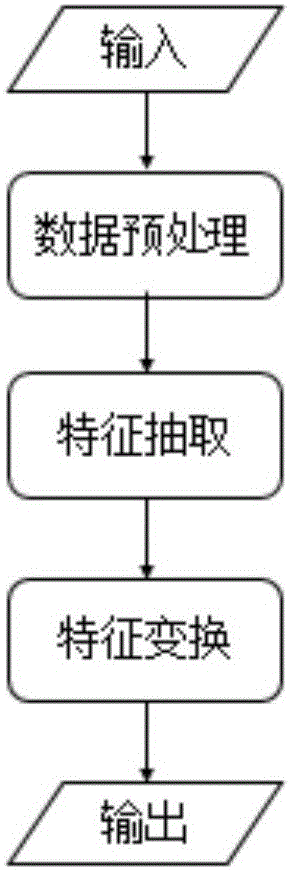

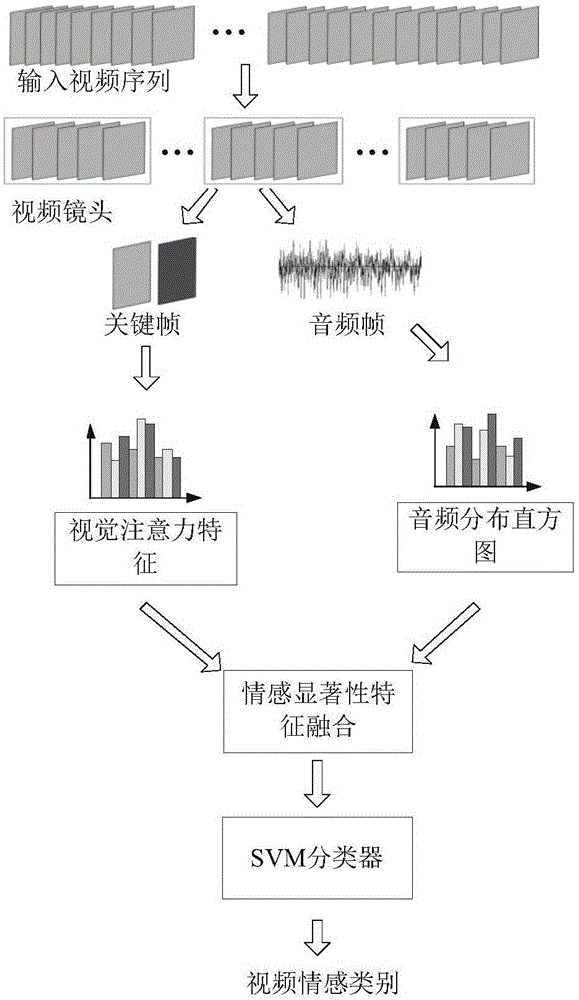

Video emotion identification method based on emotion significant feature integration

ActiveCN105138991ADiscriminatingEasy to implementCharacter and pattern recognitionIntegration algorithmVision based

The invention discloses a video emotion identification method based on emotion significant feature integration. A training video set is acquired, and video cameras are extracted from a video. An emotion key frame is selected for each video camera. The audio feature and the visual emotion feature of each video camera in the training video set are extracted. The audio feature is based on a word package model and forms an emotion distribution histogram feature. The visual emotion feature is based on a visual dictionary and forms an emotion attention feature. The emotion attention feature and the emotion distribution histogram feature are integrated from top to bottom to form a video feature with emotion significance. The video feature with emotion significance is sent into an SVM classifier for training, wherein the video feature is formed in the training video set. Parameters of a training model are acquired. The training model is used for predicting the emotion category of a tested video. An integration algorithm provided by the invention has the advantages of simple realization, mature and reliable trainer and quick prediction, and can efficiently complete a video emotion identification process.

Owner:SHANDONG INST OF BUSINESS & TECH

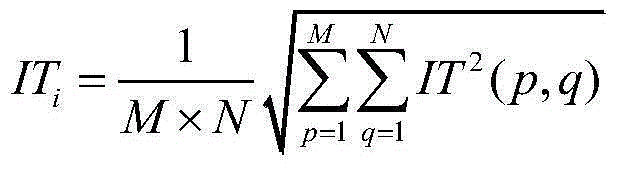

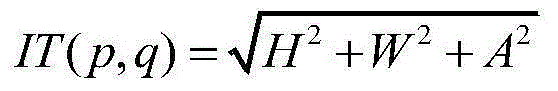

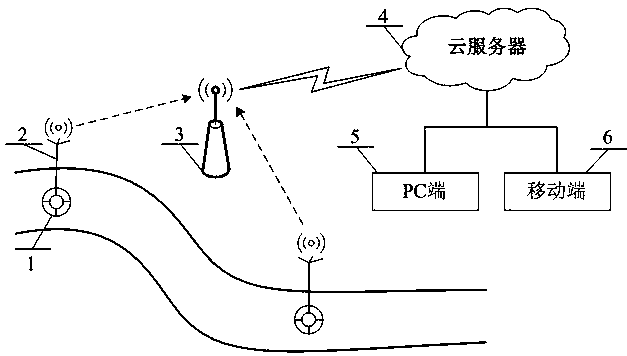

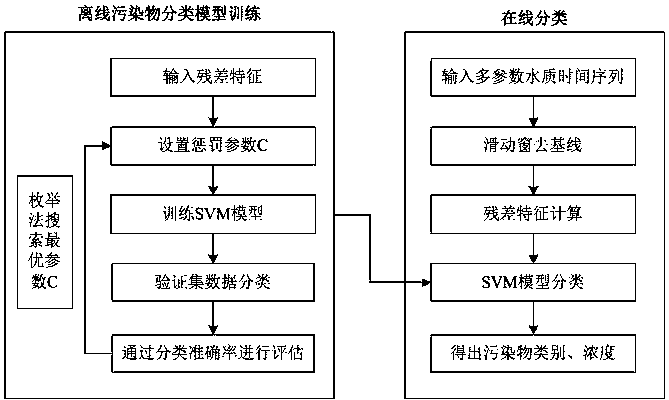

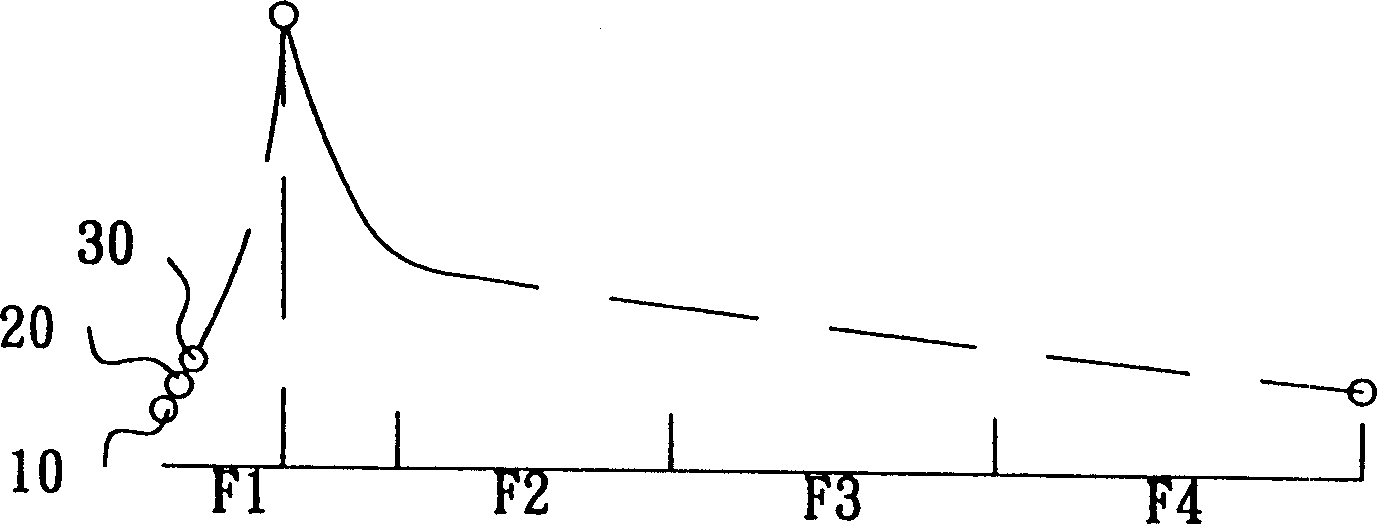

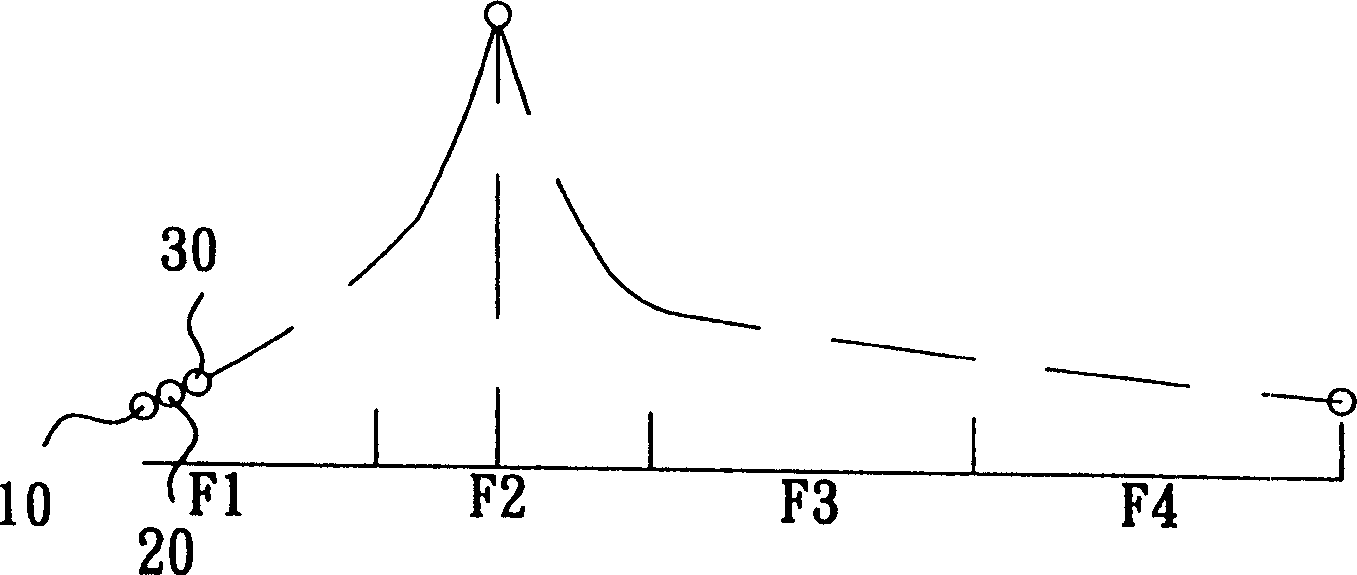

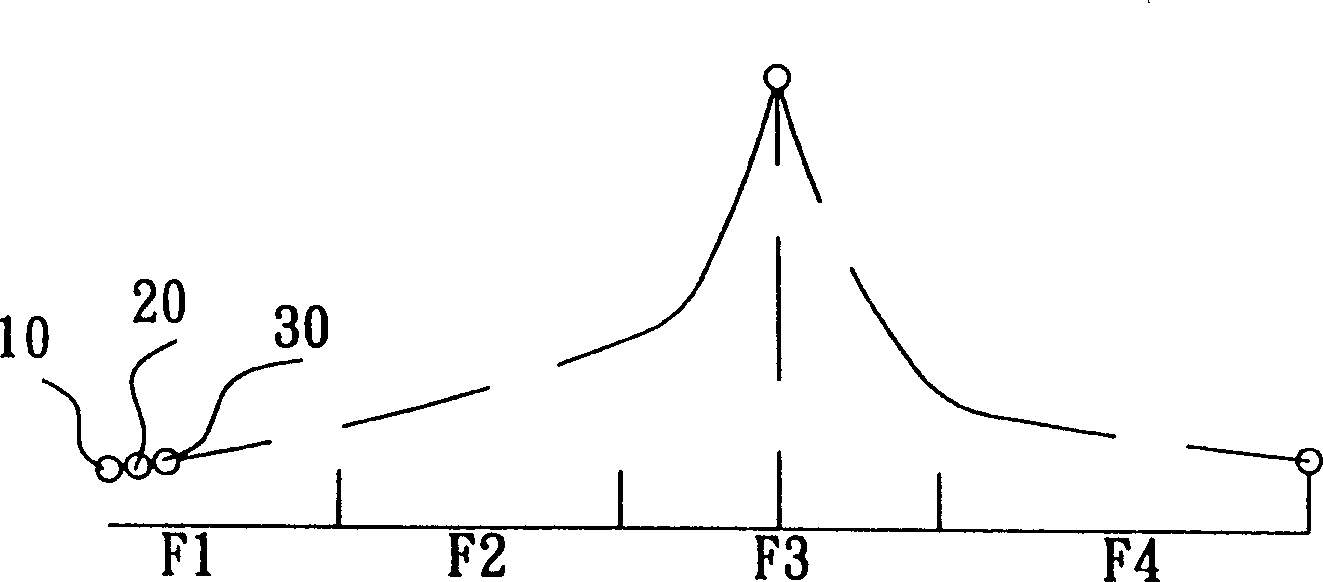

River way multi-sensor fusion upstream and downstream pollution early warning system and method

InactiveCN108132340AEffective early warningImprove detection abilityProgramme controlComputer controlWater qualityBuoy

The invention discloses a river way multi-sensor fusion upstream and downstream pollution early warning system and method. A river way part includes a water quality on-line monitoring buoy nodes deployed on multiple parts of the upstream and the downstream of a river way, and a shore part includes a wireless gateway and a cloud server. The water quality on-line monitoring buoy nodes are used for real-time collection, storage and transmission of water quality data; the system includes a water quality multi-sensor system, a water flow sensor, a real-time clock module, a microprocessor, a wireless communication module, an antenna, a storage module and a power source module. A river way multi-sensor data fusion analysis model is established by the cloud server, the multi-sensor data fusion method is used for analyzing whether the pollution exists in the river way, classifying pollutants and estimating the location of a pollution source, the upstream and downstream relations are combined for on-line monitoring and classified early warning on the river way water quality, whether the river way is invaded by the pollutants is judged, and the location of the pollution source is estimated. The system and the method perform on-line monitoring by multiple water quality parameters, and have the advantages of low energy consumption, high detection rate of the pollutants and wide applicationrange.

Owner:ZHEJIANG UNIV

Automatic focusing method of camera

Owner:KINPO ELECTRONICS

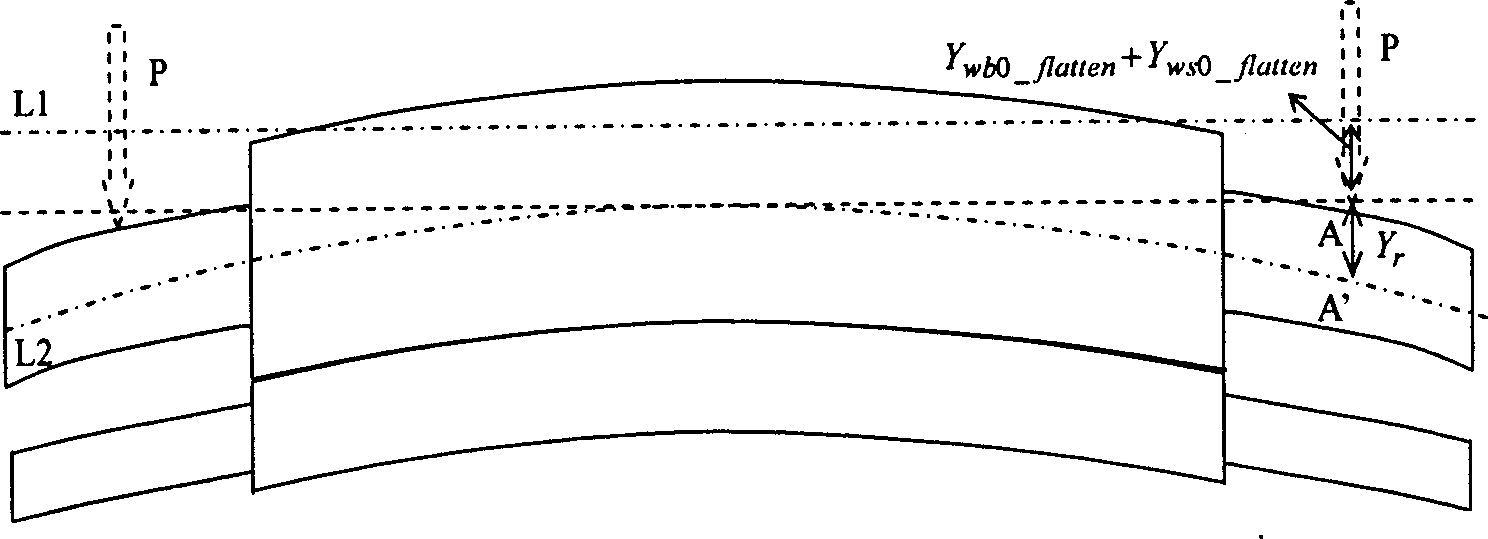

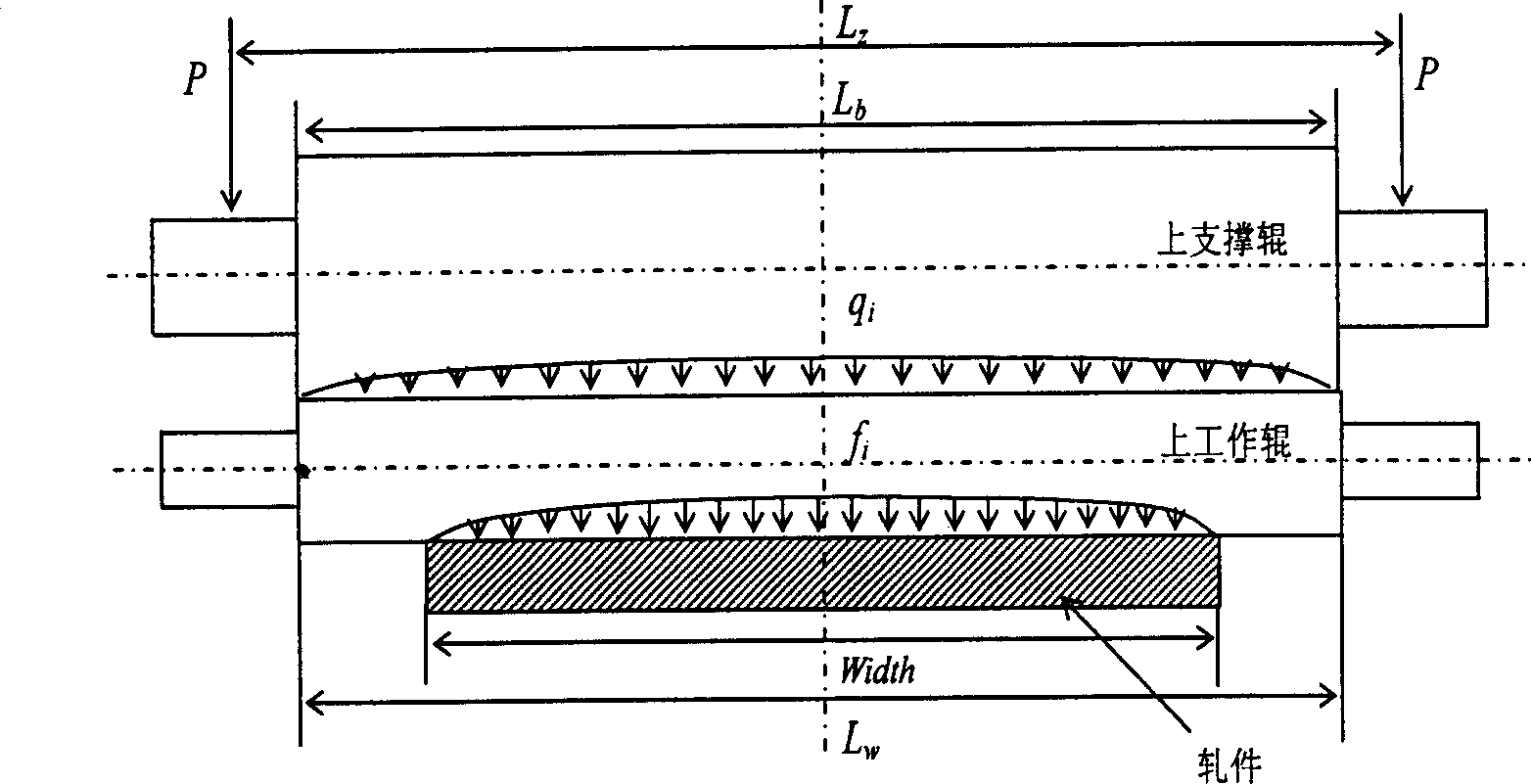

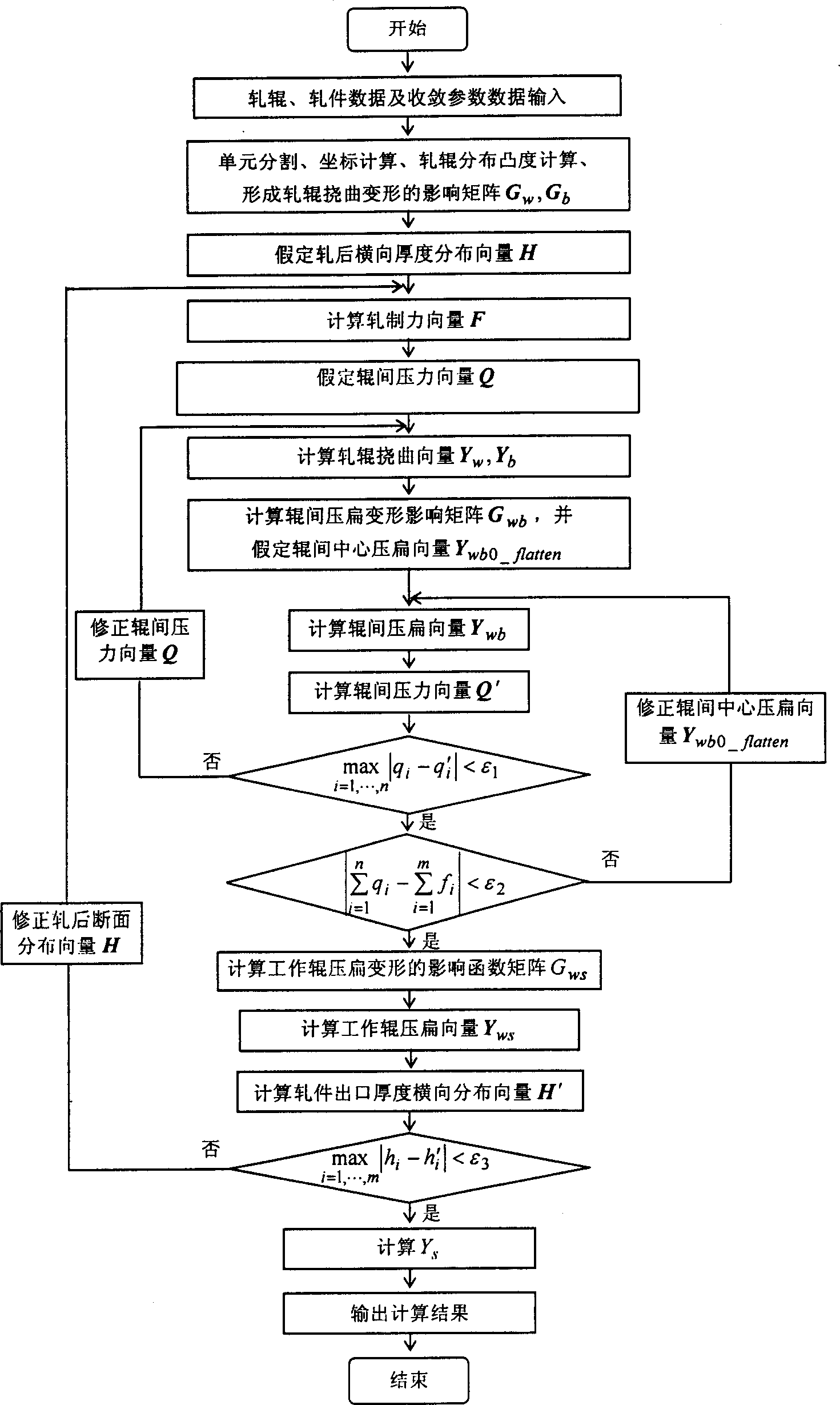

Method for predicting steel plate thickness during rolling process

InactiveCN1546947AQuick forecastAvoid double measurementMeasurement devicesSheet steelAutomatic control

Owner:NORTHEASTERN UNIV

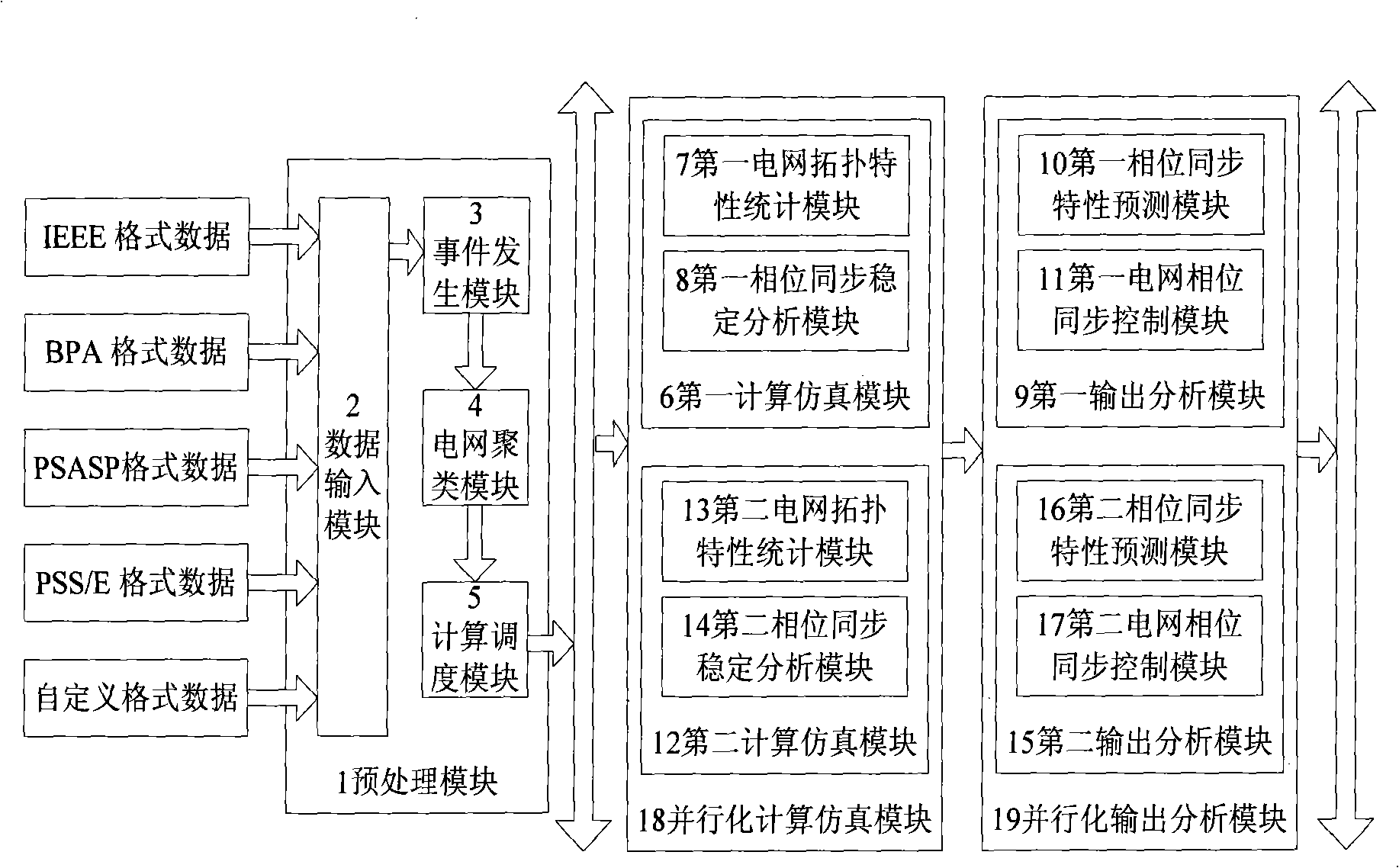

Parallelization estimation system for complex electric network phase synchronization

InactiveCN101256550ARealize simulationTake advantage ofData processing applicationsData acquisition and loggingElectric power systemPower grid

The invention relates to a complicated power network Phase synchronization parallelization evaluation system in electric system number value emulation field. In the invention, a pretreatment mould reads static spirit and dynamic component data needed by electric system stable analysis, transfers format of a data-in and generates a parallelization calculation task scheduling result, outputs the transferred data and the parallelization calculation task scheduling result to a parallelization calculation emulation mould via computer net; the parallelization calculation emulation mould carries out a electric net topology feature statistics and a Phase synchronization stability analysis according to the task scheduling result of the pretreatment mould, and transfers the result to a parallelization output analysis mould; the parallelization output analysis mould carries out a phase synchronization feature prediction and generates a Phase synchronization control strategy for user long-distance monitoring and maintenance via computer net. The invention improves use efficiency of each software and hardware source by utilizing the topology analysis features of entire electric net.

Owner:SHANGHAI JIAO TONG UNIV

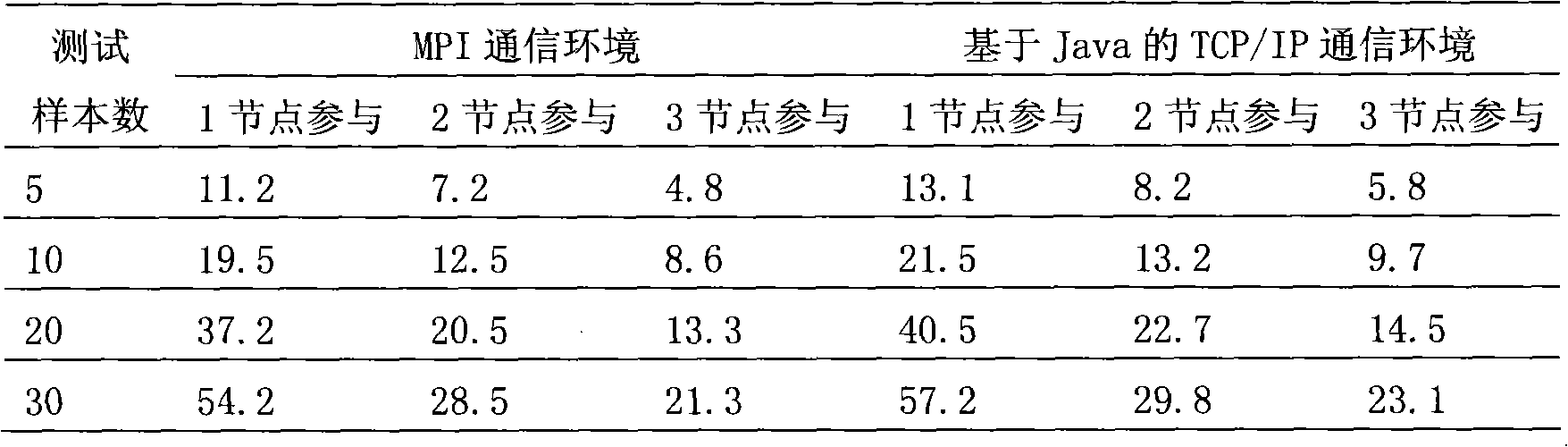

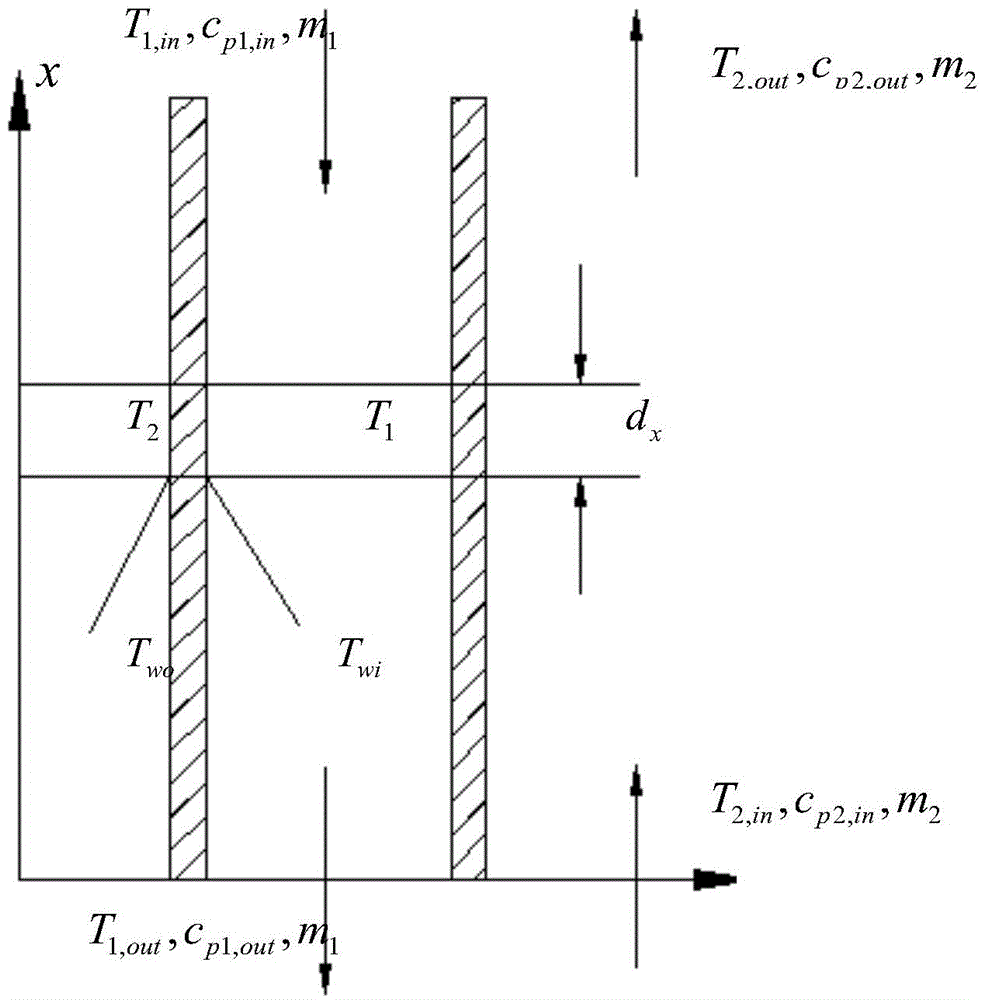

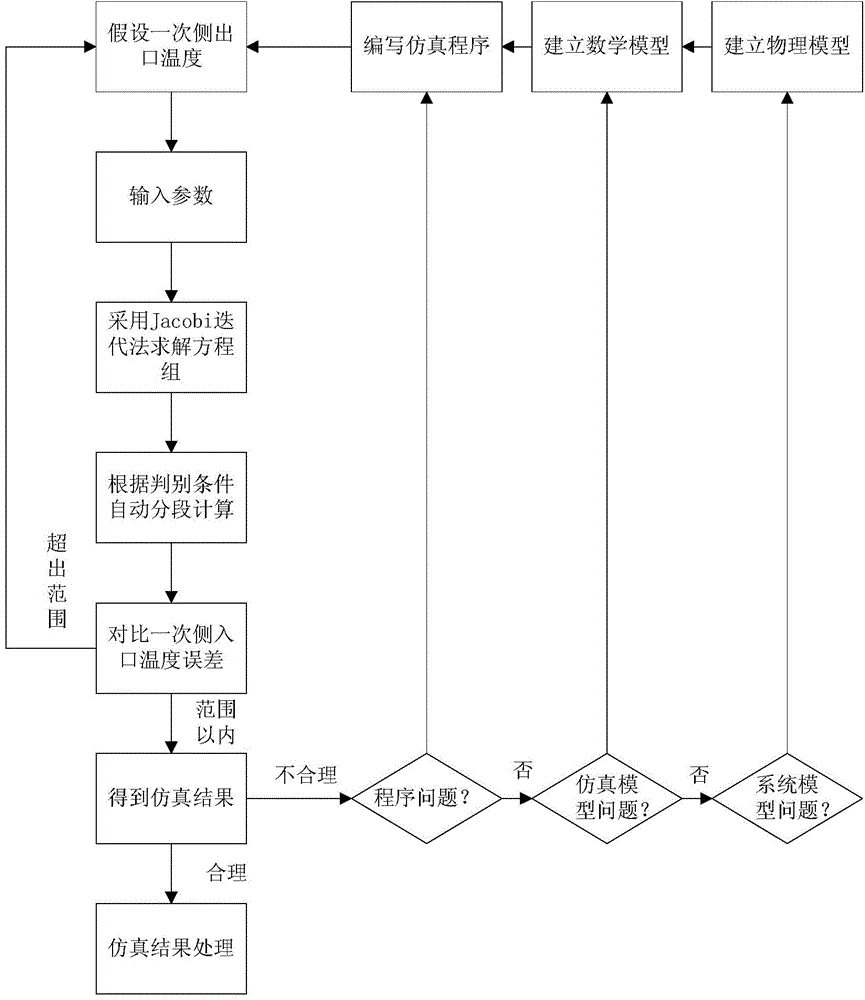

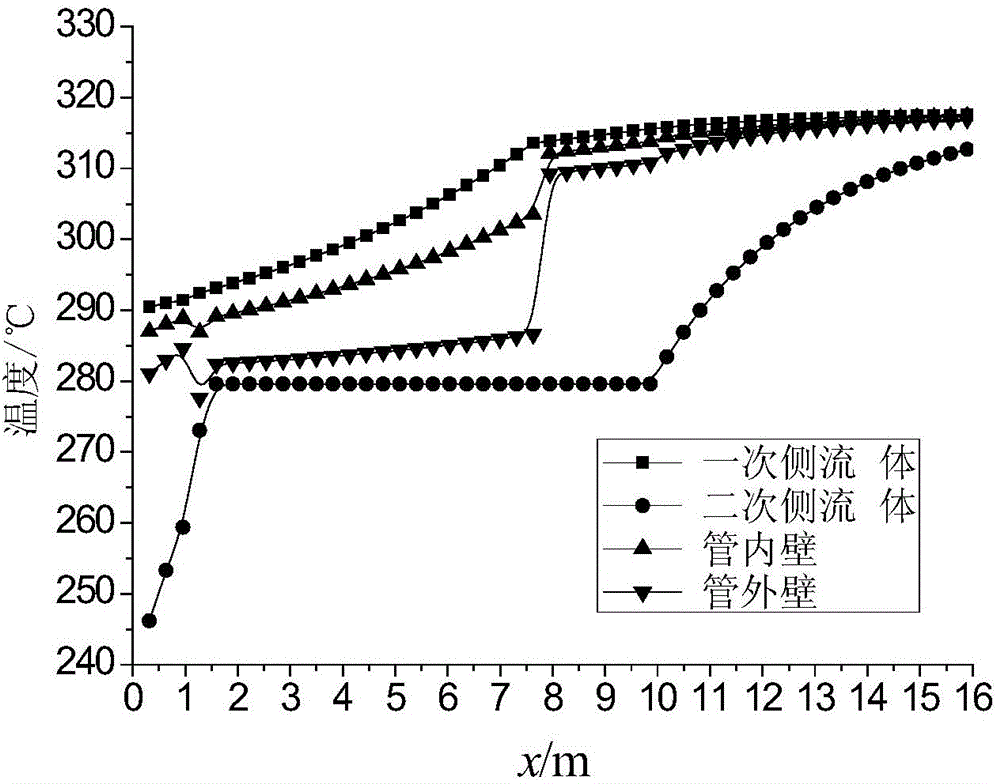

Simulation method for heat exchange performance of straight tube type once-through steam generator

ActiveCN104834773AQuick forecastAccurate predictionSpecial data processing applicationsStraight tubeEngineering

The invention discloses a simulation calculation model for the heat exchange performance of a straight tube type once-through steam generator and an algorithm thereof. According to the simulation calculation model, a one-dimensional homogeneous flow mathematic model of the once-through steam generator based on heat transfer partition is established, a secondary side heat exchange process is divided by adopting appropriate distinguishing conditions, a once-through steam generator heat exchange simulation program based on MATLAB (matrix laboratory) software is developed independently on the basis of the simulation calculation model, and the simulation for the steady state heat exchange performance of the once-through steam generator under different working conditions is carried out. The programming difficulty is simplified and reduced, automatic judgment and piecewise calculation can be realized, the range and position of wall temperature uprise and the lengths of heat exchange tubes in all heat transfer areas under different working conditions are accurately predicted, and thus a serious working area of the once-through steam generator is obtained. Theoretical support can be provided for preventing the accidents, such as overtemperature tube burst, of the once-through steam generator.

Owner:HARBIN ENG UNIV

BP neutral network-based method for predicting dissolved oxygen saturation in water body

InactiveCN102662039AGreat flexibility and adaptabilitySimplified calculation procedureTesting waterNeural learning methodsPhysicsMonitoring data

The invention relates to a method for predicting dissolved oxygen saturation in a downstream water body of a high dam, in particular to a BP (back propagation) neutral network-based method for predicting the dissolved oxygen saturation in a water body. The method is characterized in that a three-layer BP neural network model is built to predict the dissolved oxygen saturation in a downstream designated area of the high dam. The method comprises the main steps as follows: (1) determining the main influencing factors of downstream dissolved oxygen of the high dam, and taking the main influencing factors as input variables of the BP model; (2) sample data acquisition: using monitoring data of the downstream designated area of the high dam as a learning sample; (3) BP neural network training: inputting the sample data obtained in step (2) in the three-layer BP network for training, comparing the output value of the network with the actual monitoring value until the mean square deviation of the network training meets the requirement, and determining the weight and the threshold value of the network; and (4) using the BP neural network, which passes the test, to predict the dissolved oxygen saturation of the downstream designated area. The method provided by the invention applies the neural network technology to prediction of dissolved oxygen saturation of the water body of the downstream designated area of the high dam, and solves the problem of quickly predicting the dissolved oxygen of the downstream designated area of the high dam.

Owner:戴会超

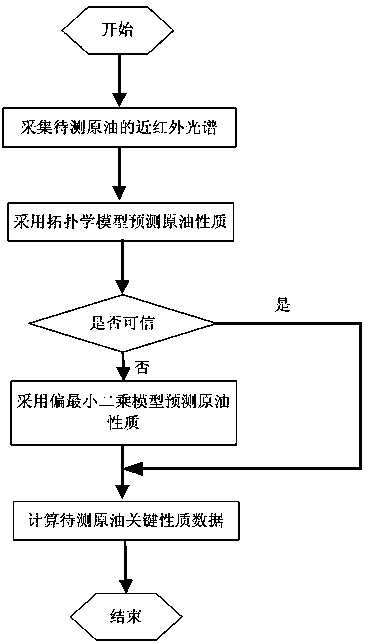

Crude oil property rapid detection method based on recombination prediction technology

ActiveCN103364364AEconomical and real-timeQuick checkColor/spectral properties measurementsLeast squaresRefinery

The invention discloses a crude oil property rapid detection method based on a recombination prediction technology. The method is used for refinery enterprises, and adopts a near infrared spectrum database and the corresponding crude oil property database as a foundation. The crude oil property rapid detection method comprises the following steps of: firstly adopting a topology modelling technology to distinguish whether the topology modeling technology forecast is credible, if so, adopting the topology modeling technology to carry out crude oil key property data forecast, if not, adopting a partial least squares to carry out the crude oil key property data forecast, and guaranteeing the forecast accuracy of the crude oil key property data. The method provided by the invention can accurately forecast the crude oil property in ten minutes, so that the in-time accurate crude oil key property data is provided for the operation guidance of vacuum distillation units of the refinery enterprises, the blindness of a crude oil in a machining process is avoided, and the production efficiency and economic benefits of the refinery enterprises are improved.

Owner:南京富岛信息工程有限公司

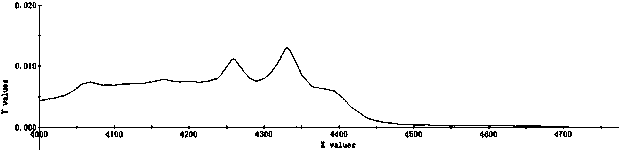

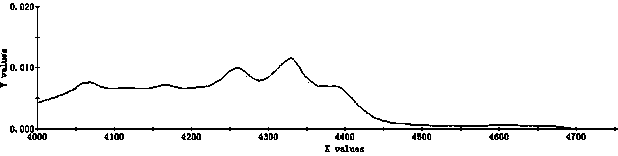

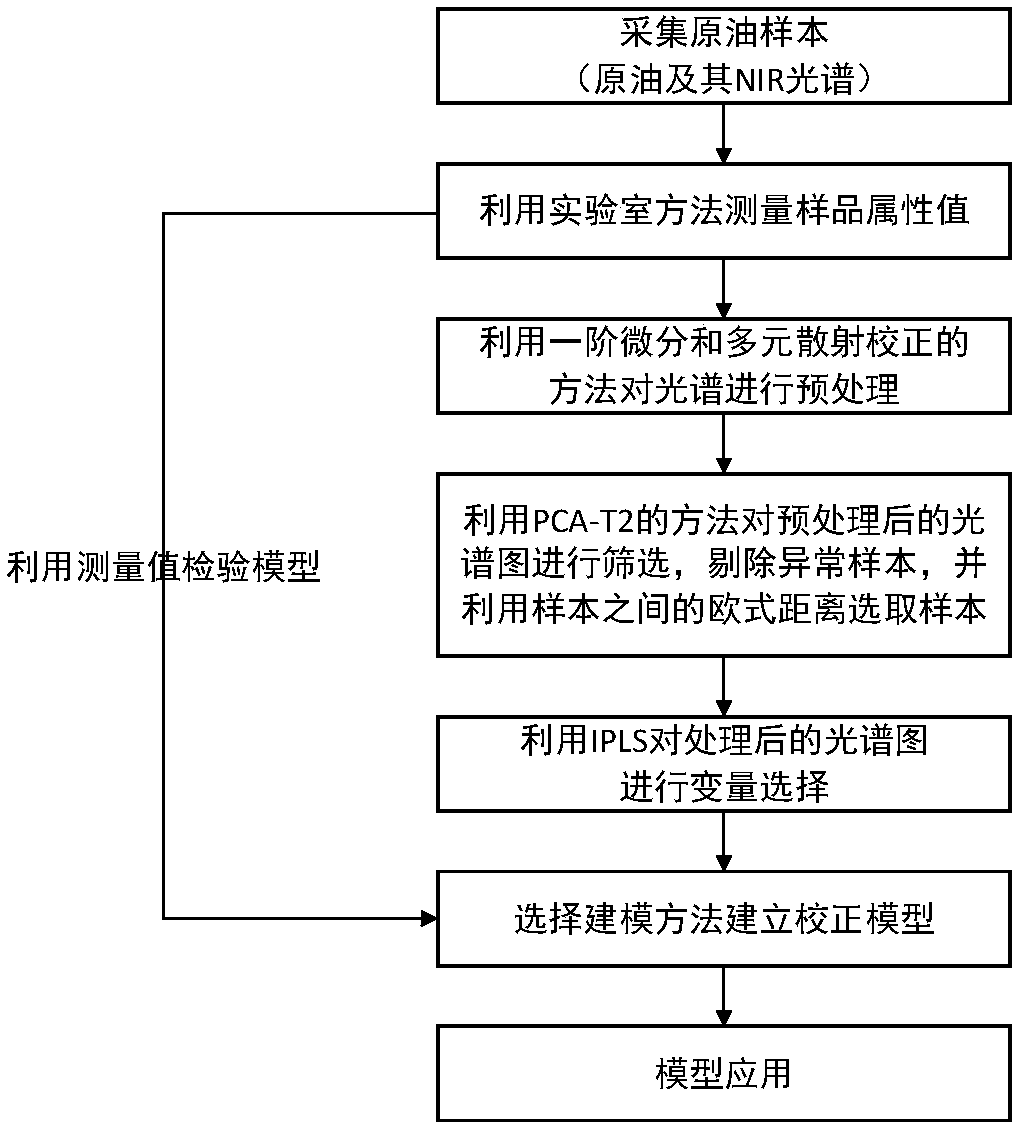

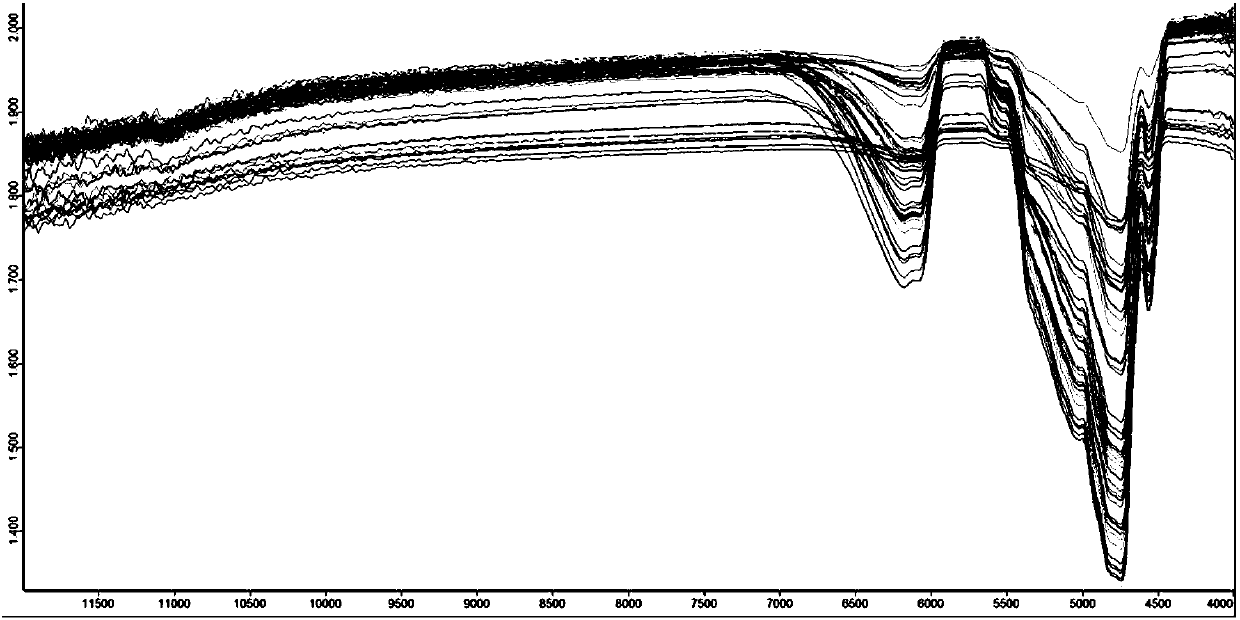

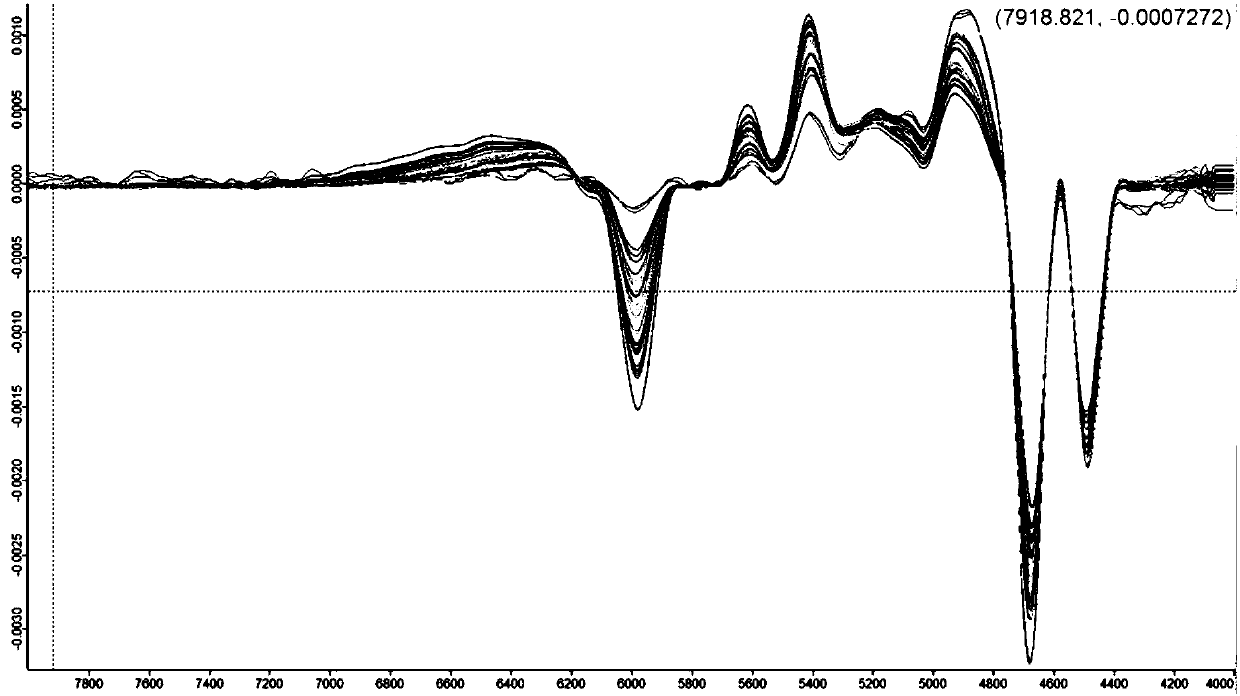

Method for rapidly predicting attribute of crude oil based on near-infrared spectroscopy

InactiveCN107748146AImprove signal-to-noise ratioQuick forecastColor/spectral properties measurementsPrincipal component analysisPredictive methods

The invention relates to a method for constructing a near-infrared model for predicating the attribute of crude oil, and a method for rapidly predicting the attribute of the crude oil based on near-infrared spectroscopy. The model construction method includes the following steps: detecting the attributes of different types of crude oil samples; determining the near-infrared spectrograms of the crude oil samples; and carrying out first-order differential processing and multiplicative scatter correction on the absorbance of the 12500-4000 cm<-1> spectral region in the near-infrared spectrograms;carrying out main component analysis on preprocessed spectra, calculating the T2 value of every crude oil sample, rejecting the values being greater than a threshold, and establishing an initial training set; selecting samples by using the Euclidean distance between the samples with the obtained main component score in the initial training set as a characteristic variable to determine a final training set; selecting one or more wave-number segments by using a moving window partial least squares technology; and establishing the near-infrared model between the attribute and the near-infrared spectrum of the crude oil by using a regression technology. The methods are especially suitable for the online fast prediction analysis of the crude oil.

Owner:EAST CHINA UNIV OF SCI & TECH

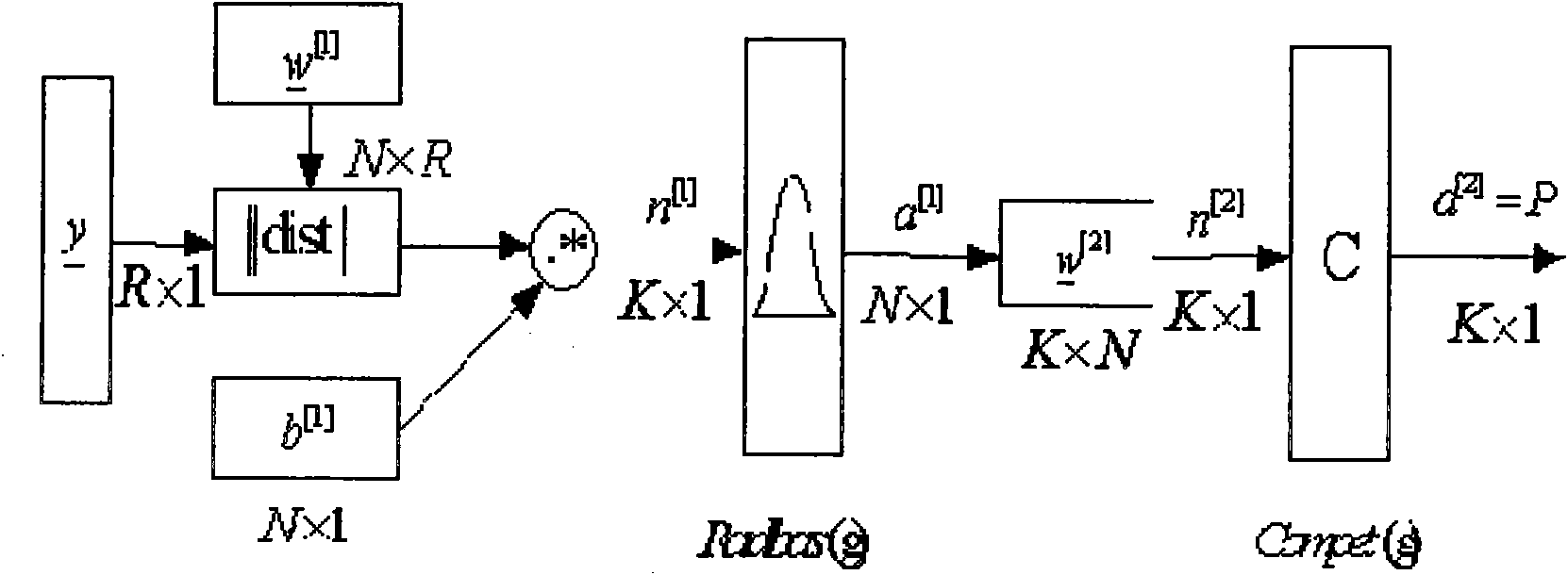

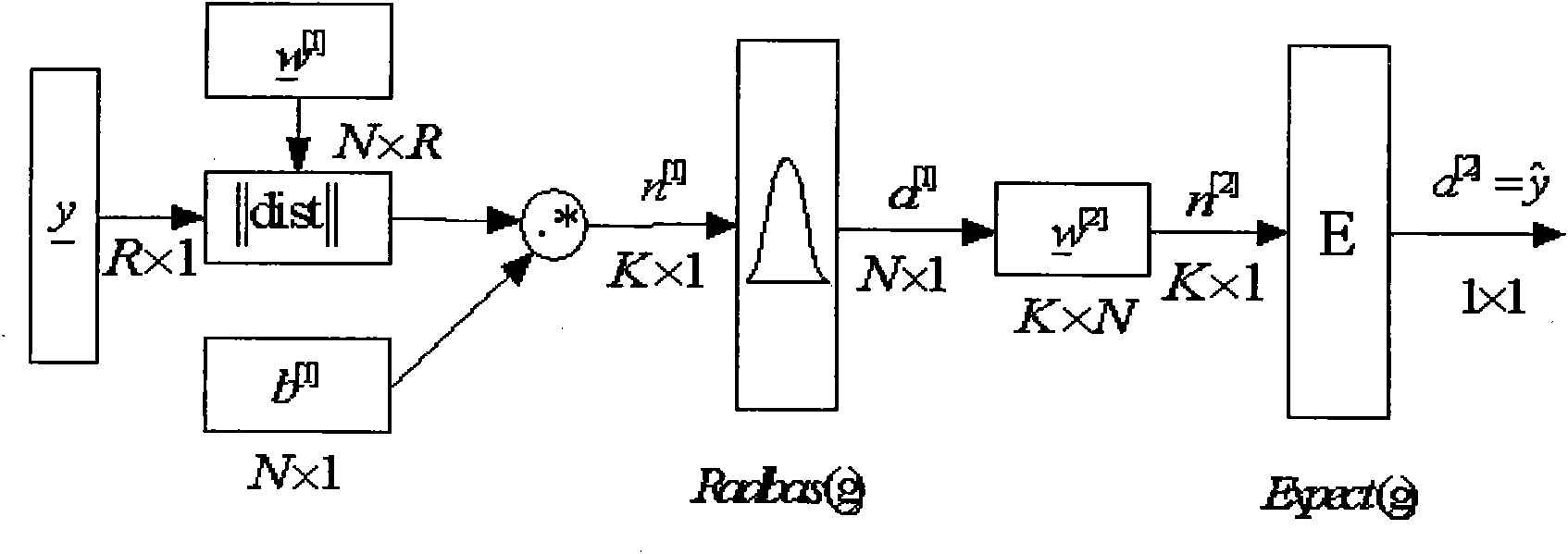

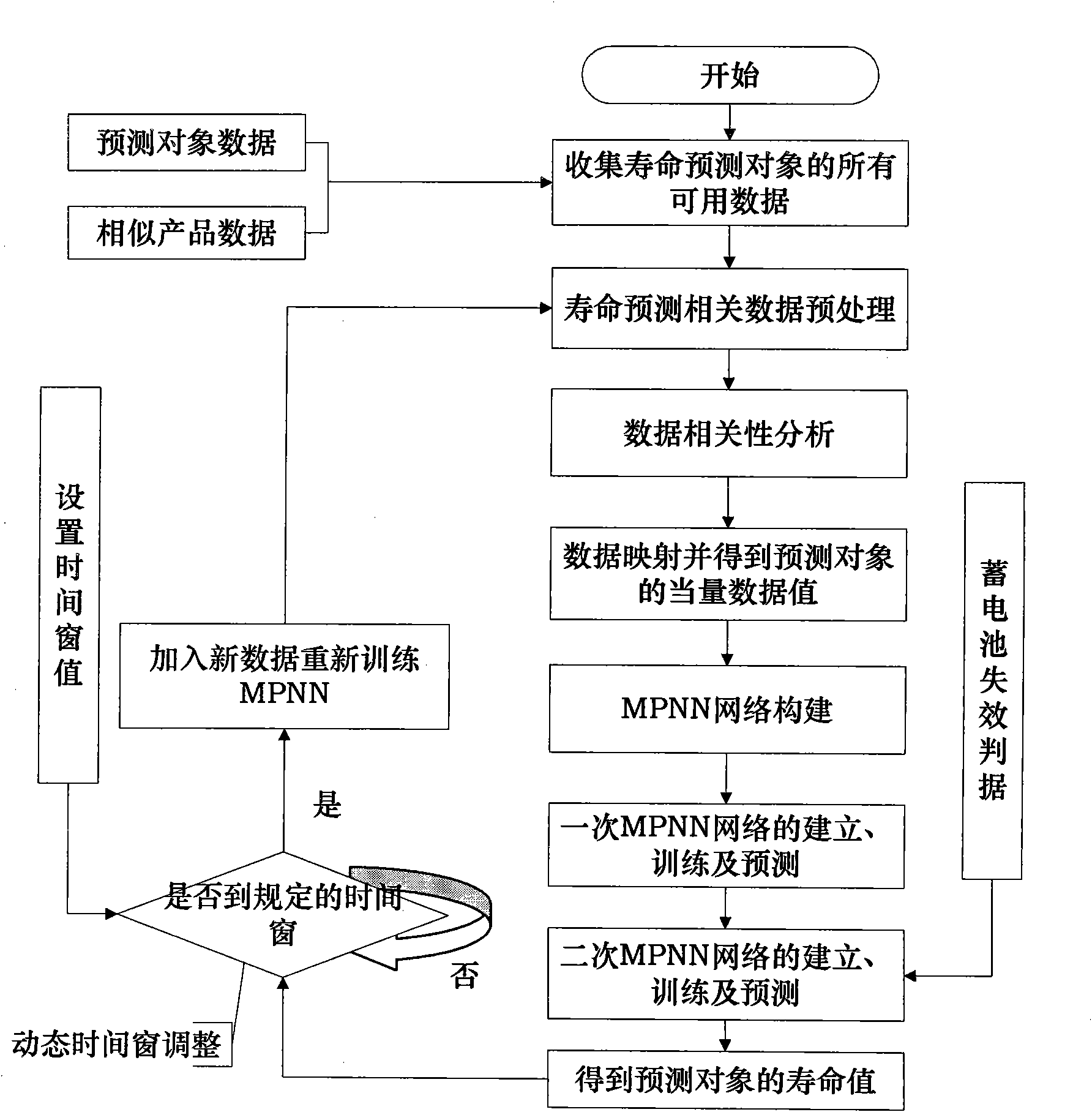

Method for predicting life of small sample data object based on dynamic bipolar modified probabilistic neural network (MPNN)

InactiveCN101894185AVersatileFast Training and PredictionBiological neural network modelsSpecial data processing applicationsData valueLife value

The invention discloses a method for predicting the life of a small sample data object based on a dynamic bipolar modified probabilistic neural network (MPNN) and belongs to the technical field of the life prediction of small samples. The method comprises the following steps of: obtaining a function relation between life influencing factors and life characteristic parameters of a prediction object by collecting all available data of a life prediction object and preprocessing life prediction related data and analyzing data dependency for the life prediction object; then mapping data and obtaining equivalent data values of the prediction object; performing a primary MPNN training and prediction and a secondary MPNN training and prediction by using the improved MPNN; and finally, determining life values of the prediction object according to a life termination criterion of the life characteristic parameters of the prediction object. The method can realize the life prediction of the small sample data object by fully using the life influencing factor data of the prediction object under an adverse condition of a little practical available data of the prediction object and has a strong universality; and moreover, a life prediction model can dynamically regulate a neural network and can constantly improve the precision of the life prediction.

Owner:BEIHANG UNIV +2

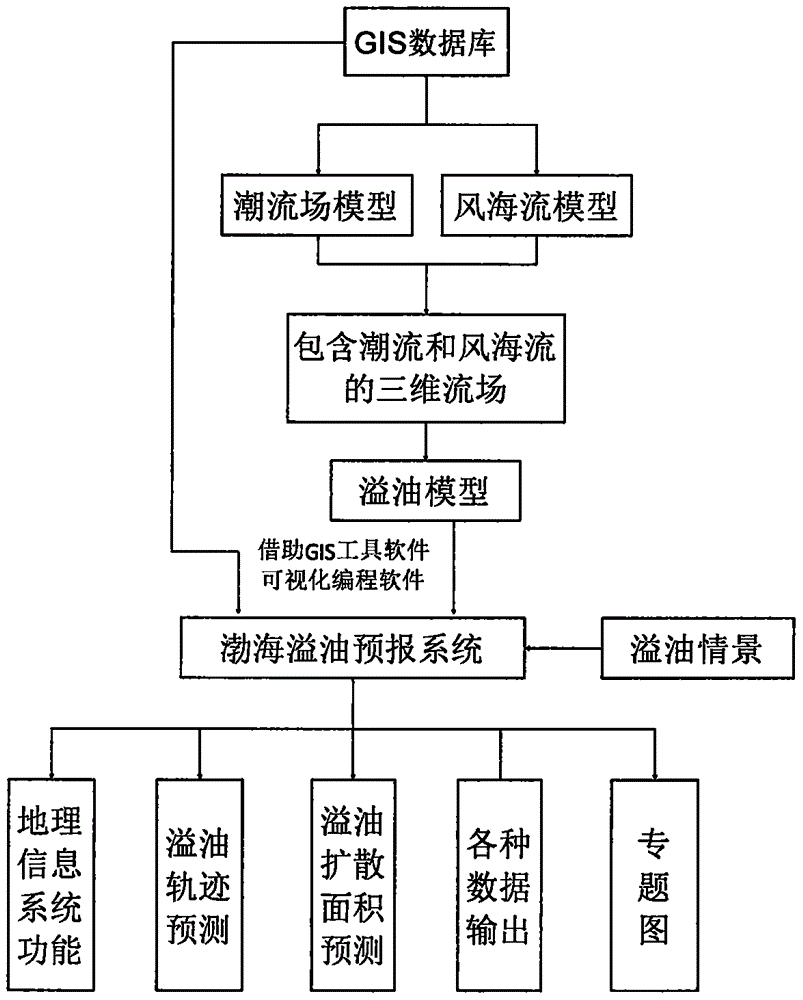

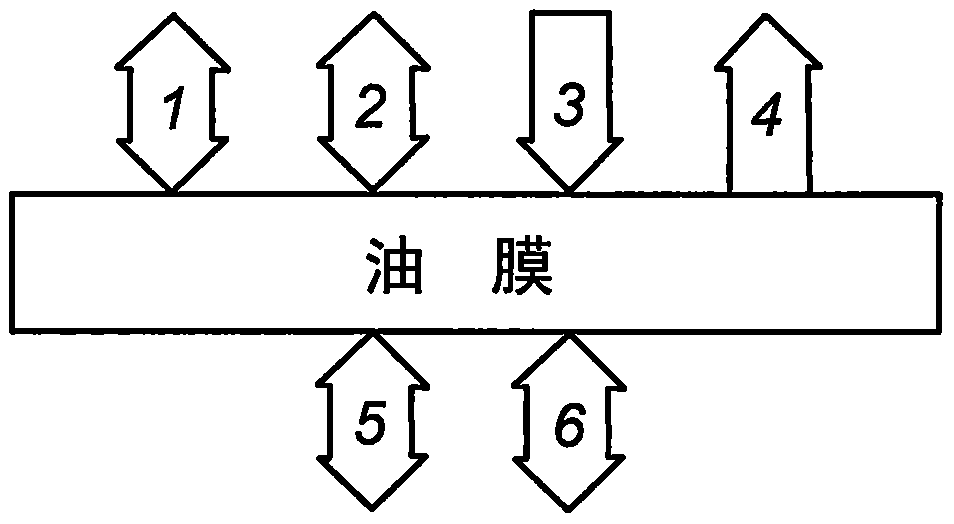

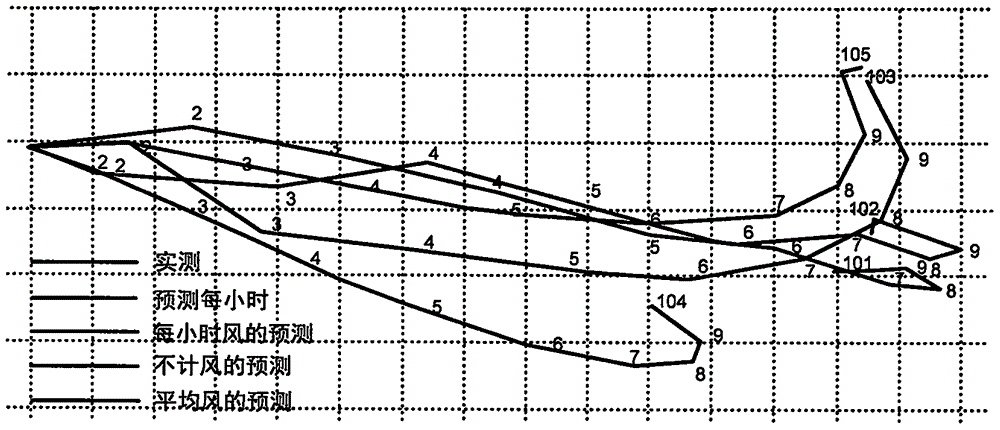

Building method of Bohai sea spilled-oil transporting and extension value forecasting system

InactiveCN105760575AAccurate forecastQuick forecastSpecial data processing applicationsMarine engineeringBusiness forecasting

The invention discloses a Bohai sea spilled-oil transporting and extension value forecasting system.The system can conduct forecasting on a transporting trajectory of an oil film, an extended range, the oil film thickness, the oil-passing-through area, the time for spilled-oil for reaching a shore or a sensitive area and the like after oil spilling occurs on a point source and a continuous source in Bohai sea area, and a forecasting result can be displayed on a computer screen visually and dynamically.Oil spill emergency action modes, types and number of vessels and situations of laying oil fences or using oil dispersant or the like are selected according to the forecasting result, oil spill damage is relieved or eliminated, and disaster prevention and reduction are achieved.Back tracking is conducted on the source of spilled oil in the Bohai sea area by combining with finger prints and satellite remote sensing, the source of the spilled oil on the sea is found out, and therefore a troublemaker is determined.

Owner:OCEAN UNIV OF CHINA

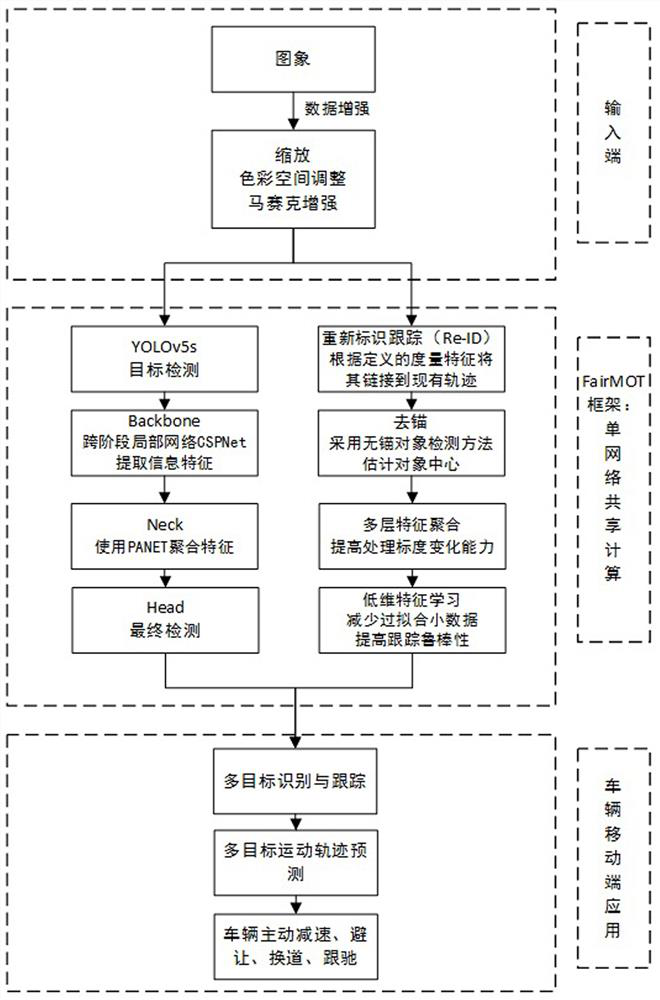

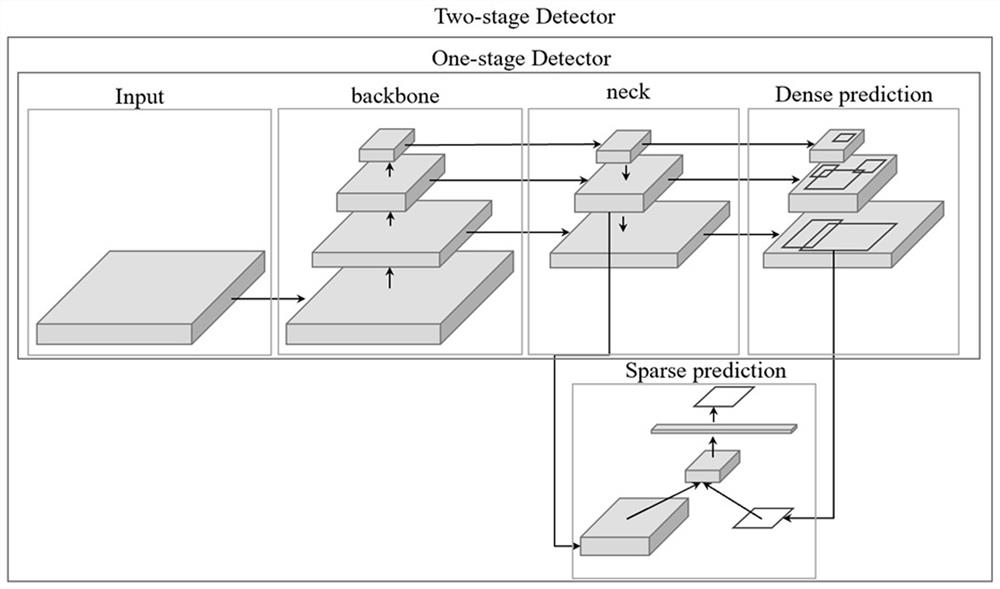

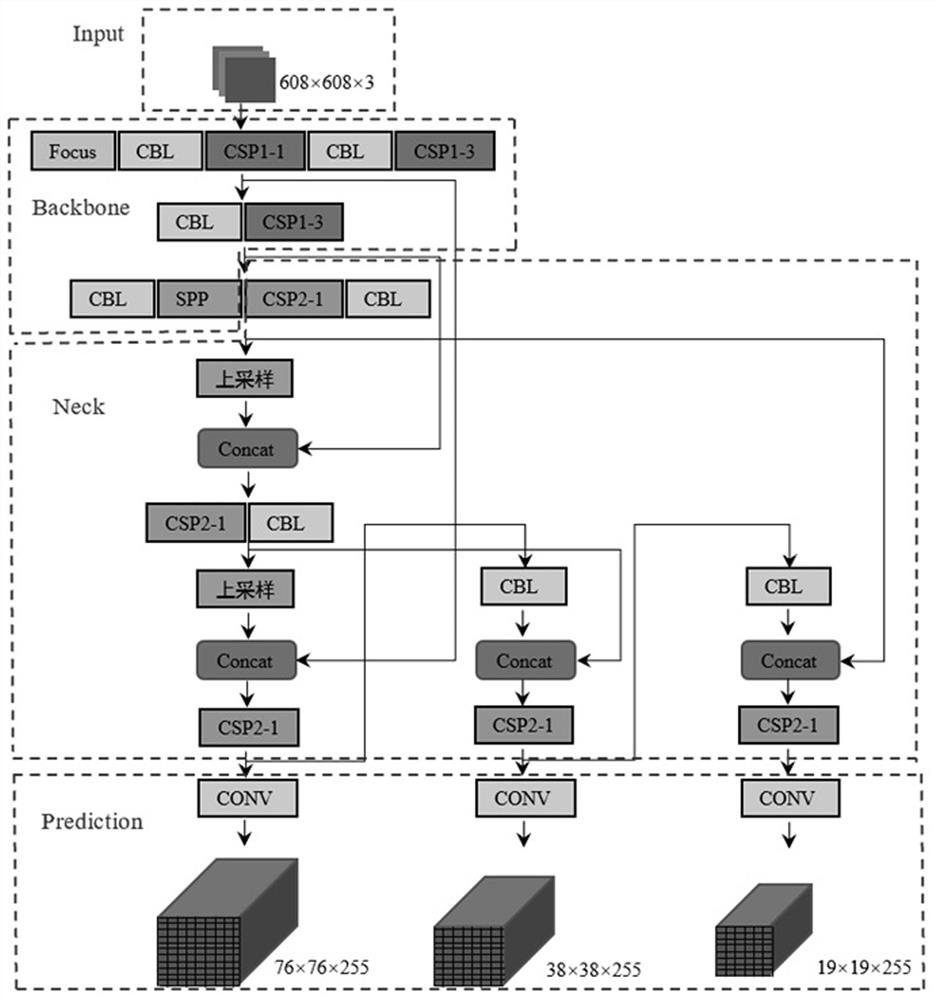

Vehicle-mounted terminal multi-target identification tracking prediction method

The invention discloses a vehicle-mounted terminal multi-target recognition tracking prediction method, which is a vehicle-mounted terminal multi-target recognition tracking prediction method based onYOLOv5s (You Only Look Once v5s) and FairMOT (FairMOT) fusion, and detects vehicles in front of a road quickly and accurately in real time by using a YOLOv5s deep learning object detection technology. The YOLOv5s model is fused into the FairMOT architecture detection module to perform target detection and re-identification tracking in a single network so as to realize position detection, type identification and multi-target motion trajectory tracking of the traffic target in front of the vehicle on the road, thereby achieving prediction of driving behaviors of lane change, following, deceleration and the like of the traffic target in front of the vehicle.

Owner:GUILIN UNIV OF ELECTRONIC TECH +1

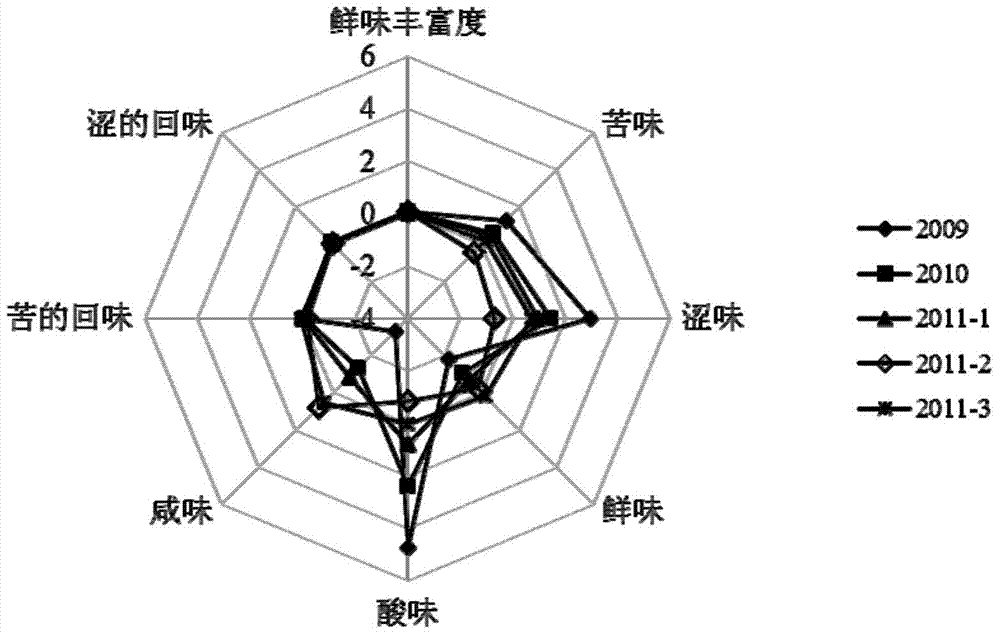

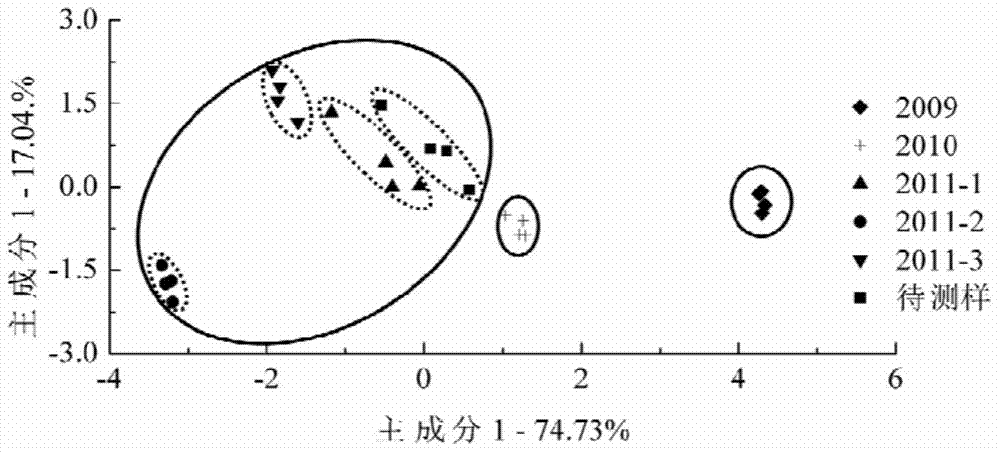

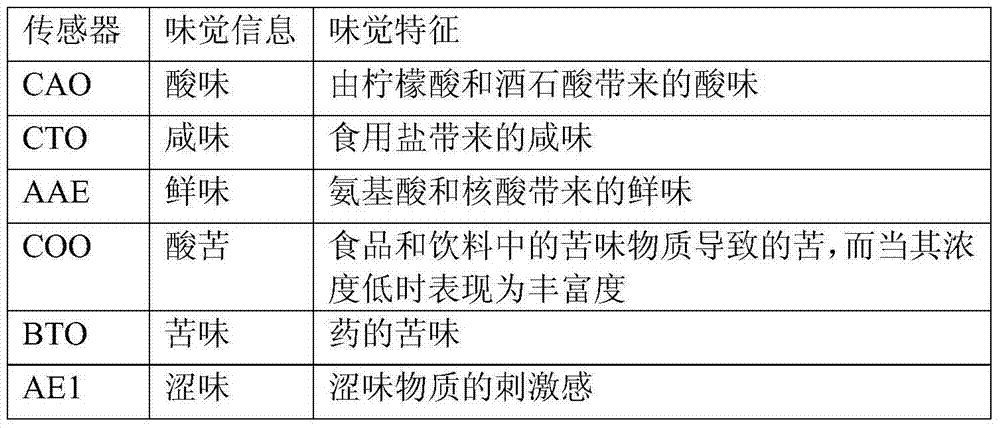

Method for rapidly identifying years of production of lycium barbarum by gustation finger-prints

ActiveCN103674638ABroaden the approach to quality assessmentFill in research gapsPreparing sample for investigationMaterial electrochemical variablesSensor arrayLiquid ratio

The invention discloses a method for rapidly identifying the years of production of lycium barbarum by gustation finger-prints. The method comprises the following steps: selecting samples of lycium barbarum produced in different years, adding cooled boiled water at temperature of 60-80 DEG C into the lycium barbarum samples at a set solid-to-liquid ratio of 1:15 to 1:25, extracting for 5-15 minutes, filtering to obtain leach liquor of gustation matters, contacting an electronic tongue sensor array with the sample leach liquor so as to obtain sensor responding signals, extracting characteristic data from the gustation finger-prints, establishing correlation between the gustation finger-prints and the years of production by virtue of multiple linear regression analysis, and establishing a module for predicating the years of production, thus realizing the purpose of rapidly identifying the years of production of the lycium barbarum by the gustation finger-prints. With the adoption of the method, the detection difficulty caused by the fact that external characters of lycium barbarum are similar, and the detection on internal bioactive constituents is complicated and wastes time is solved, the lycium barbarum produced in different years can be conveniently, rapidly and objectively evaluated, and therefore, the basis is provided for accurately, rapidly and reliably detecting medicinal values of lycium barbarum.

Owner:ZHEJIANG UNIV

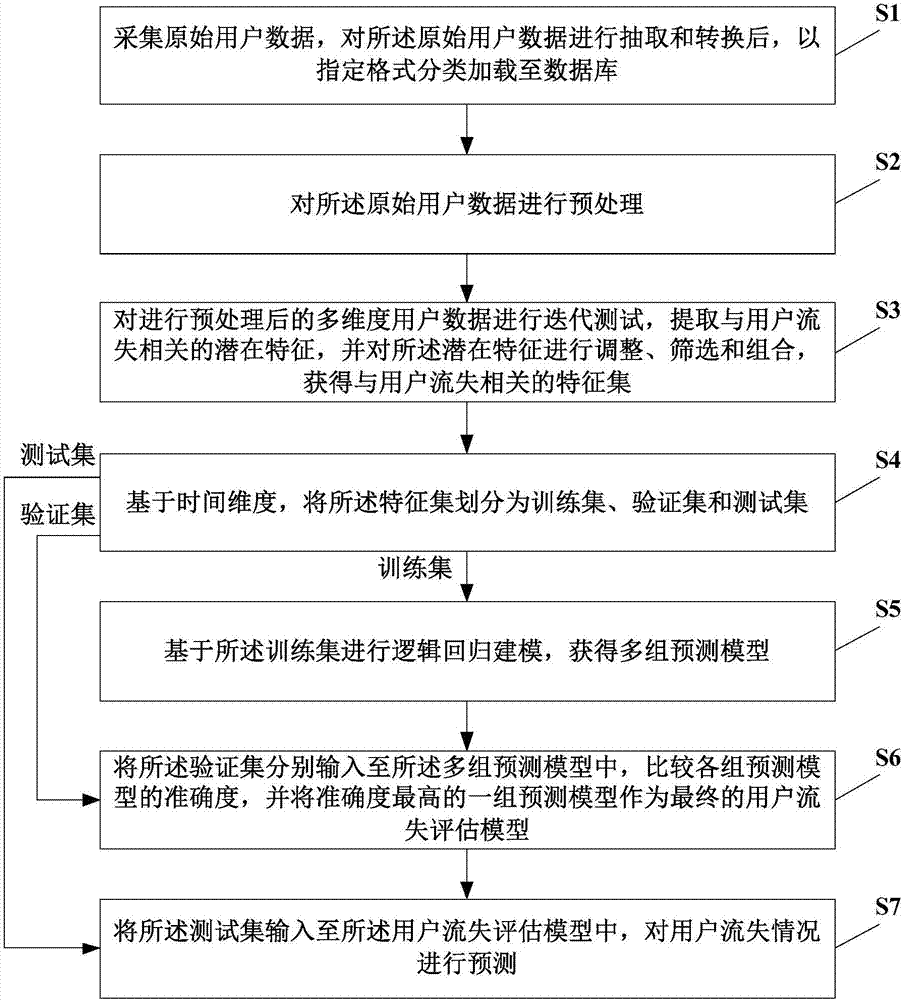

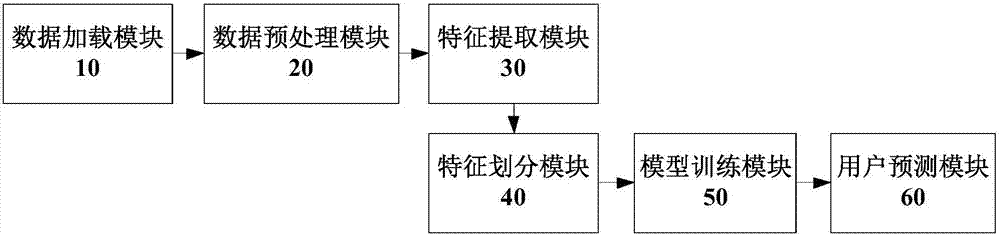

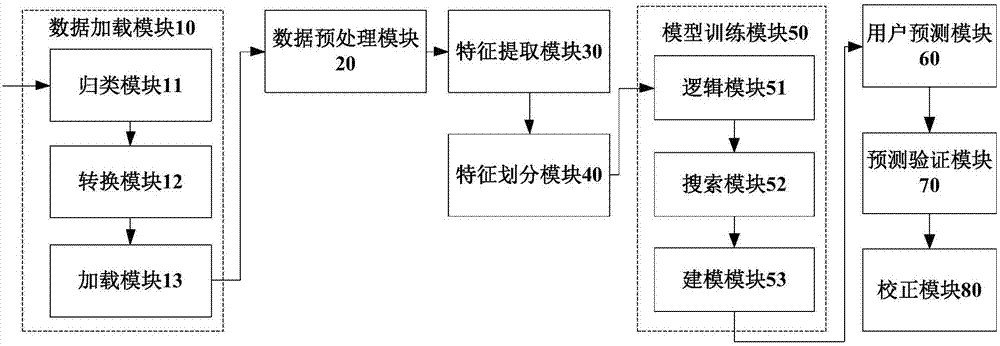

Lottery user churn prediction method based on multi-dimensional data and system thereof

InactiveCN106997493AImprove performanceImprove accuracyForecastingSpecial data processing applicationsFeature setMulti dimensional data

The invention provides a lottery user churn prediction method based on multi-dimensional data. The method comprises the steps that original user data are collected; the original user data are extracted and converted, and are classified and loaded to a database in a specified format; preprocessed multi-dimensional user data are iteratively tested to extract potential features related to user churn to acquire a feature set; the feature set is divided into training set, a verification set and a test set based on time dimension; logistic regression modeling is carried out based on the training set to acquire multiple sets of prediction models; the verification set is input into the prediction models; the prediction model with the highest accuracy is used as the final user churn evaluation model; and the test set is input into the user churn evaluation model to predict the user churn situation. The invention further provides a lottery user churn prediction system based on multi-dimensional data. According to the technical scheme provided by the invention, the prediction difficulty can be reduced, and the prediction accuracy is improved.

Owner:云数信息科技(深圳)有限公司

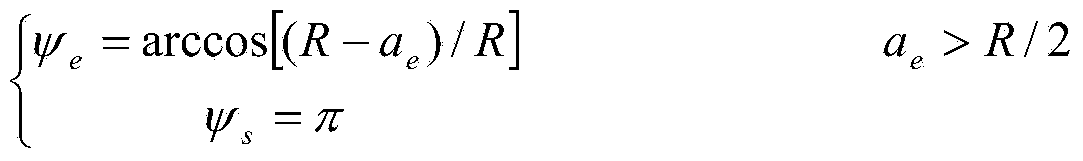

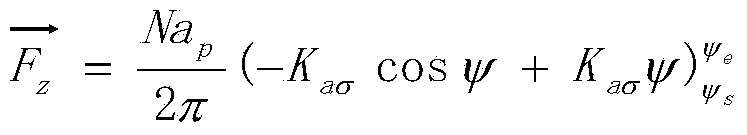

Cutting force prediction method based on features

InactiveCN103439917ASave process modification timeMaximize processing efficiencyProgramme controlComputer controlEngineeringCutting force

A cutting force prediction method based on features is characterized in that feature recognition is carried out on a part based on a CAD three-dimensional model, and drive geometry recognizing the features is extracted according to a feature recognition result and is dispersed into some points. A primary process decision is carried out to obtain rotating speed, feeding, cutting depth, cutting width and other process parameters, a shearing force action coefficient and a cutting edge force coefficient are measured through experiments, a cut-in angle and a cut-out angle are calculated according to cutting parameters, and finally cutting force is calculated. According to cutting force prediction based on the features, the cutting force can be calculated according to the cutting parameter with different features in the part process decision process, and warning and process modification are carried out on the relatively large feature of the cutting force. Before post-processing, the cutting force can be predicted earlier. The predicted cutting force aims at each feature, that is, the modification is for a single feature, the processing efficiency of each feature of a plane structural component can be maximized, overall efficiency is accordingly maximized, and the number of simulation times is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method and system for judging crowd density in image

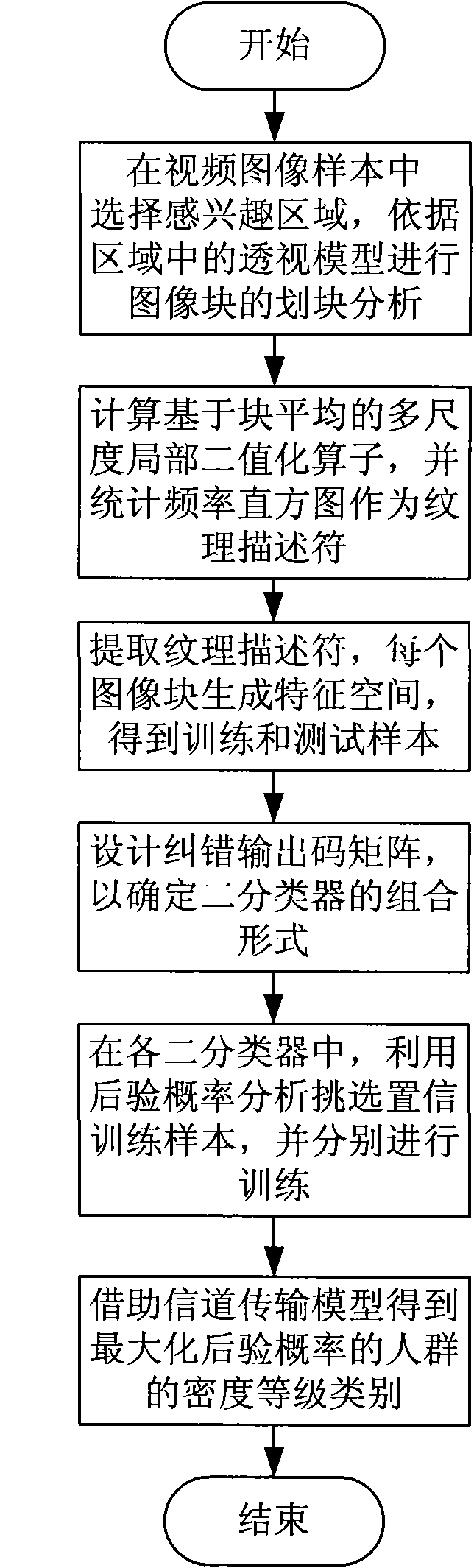

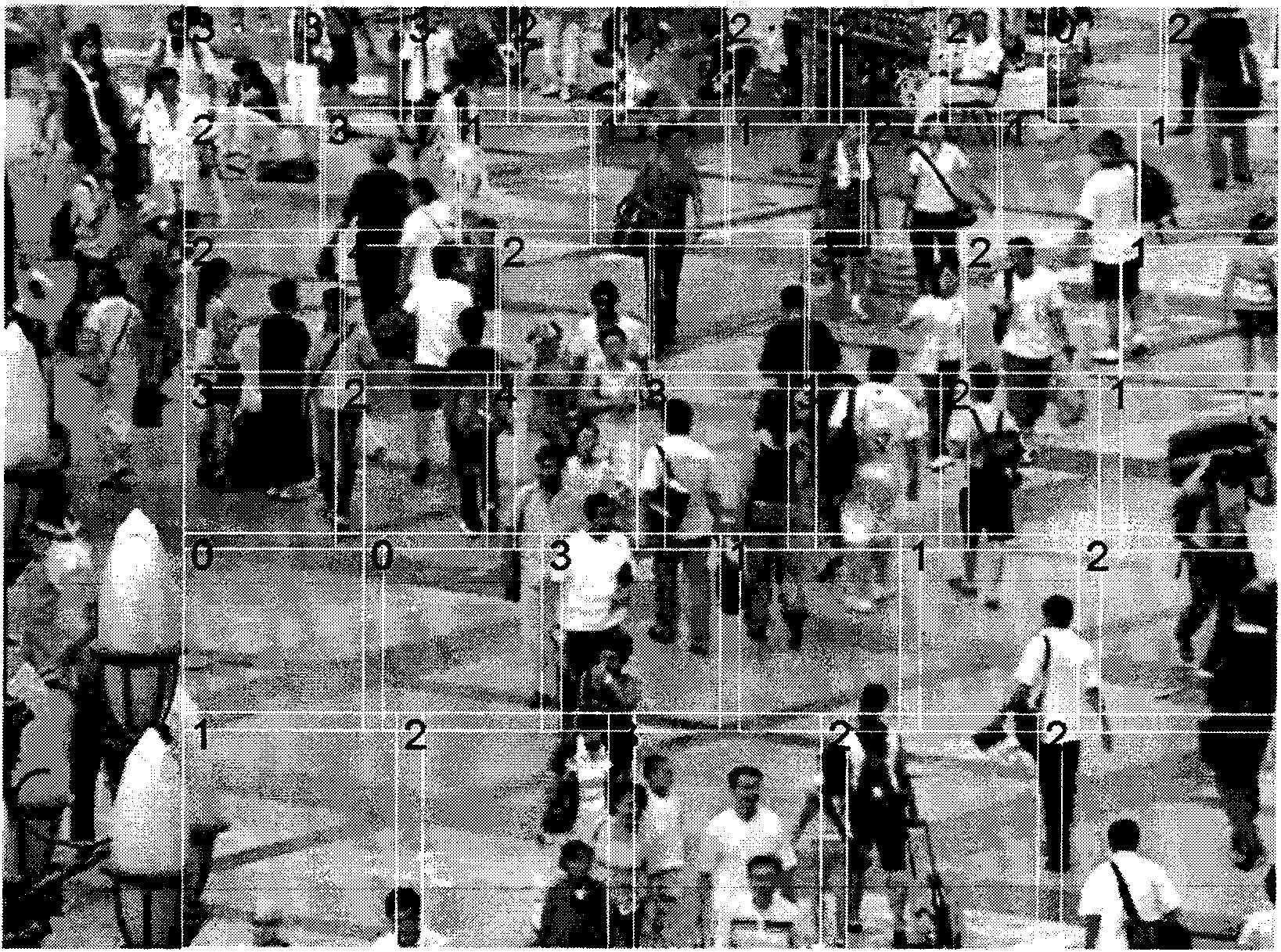

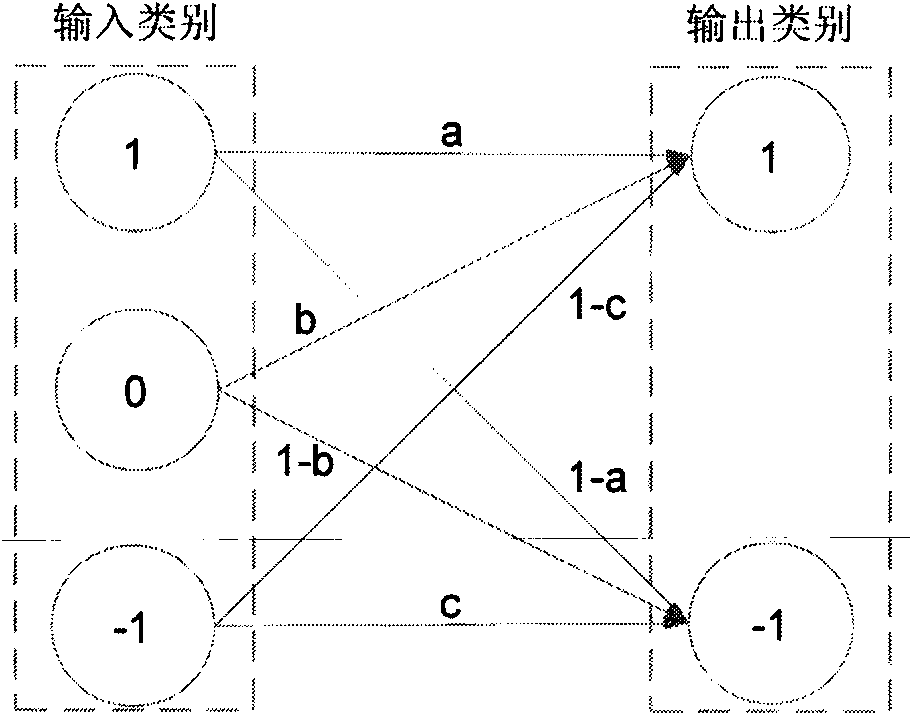

ActiveCN102044073AConfidence Density Class EstimationQuick forecastImage analysisCharacter and pattern recognitionCrowd monitoringPosteriori probability

The invention provides a method and system for judging the crowd density in an image. The method comprises the following steps: 1. selecting a target region from a video image sample acquired in an image acquisition device by utilizing a block analysis unit, and carrying out block analysis of image blocks in the target region; 2. determining the composite form of two-classifiers by a coding unit;3. selecting a confidence training sample by a training unit, and respectively training each two-classifier; and 4. obtaining the crowd density grade category of the maximum posteriori probability through a decoding unit by means of a channel transmission model. The method can be suitable for obtaining the credible crowd density grade in different scenes and can provide the basis for crowd monitoring and safety guarantee of important regions.

Owner:北京汉王智远科技有限公司

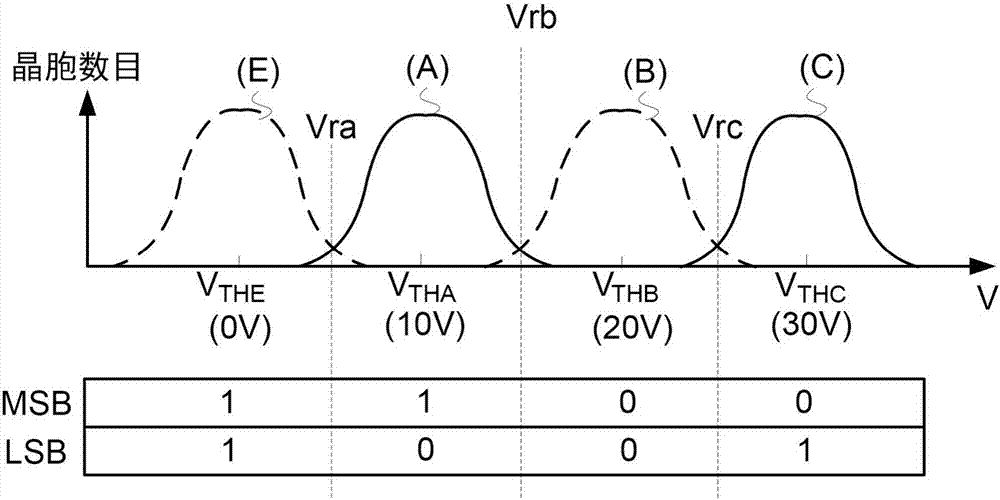

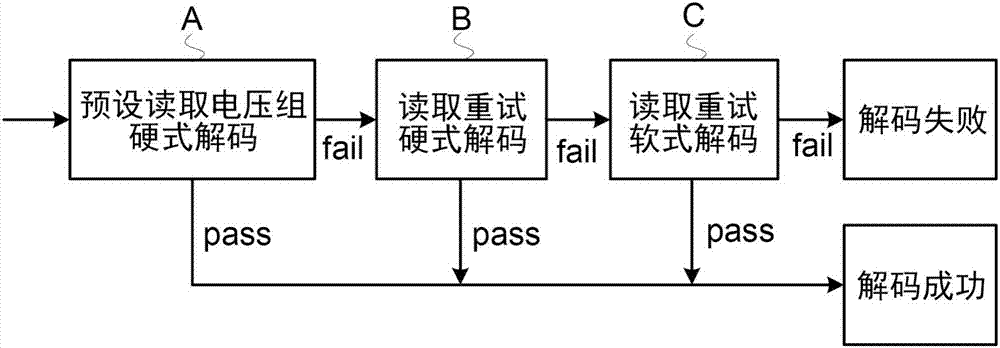

Solid-state storage device and state prediction method thereof

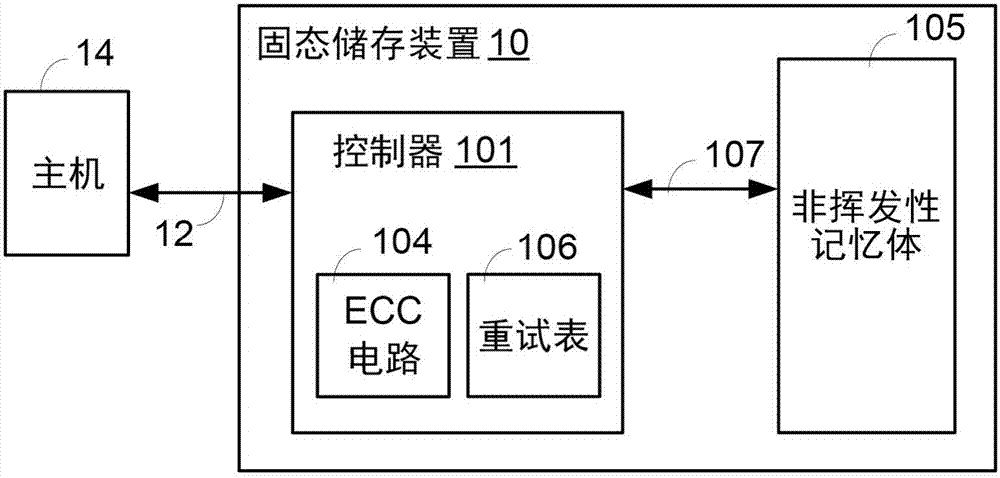

ActiveCN107452421AQuick forecastSuitable for decoding processError detection/correctionRead-only memoriesSolid-state storageState prediction

The invention discloses a solid-state storage device and a state prediction method thereof. The solid-state storage device comprises a nonvolatile memory and a controller, wherein the nonvolatile memory comprises a first block; the controller is connected to the nonvolatile memory and comprises an equation storage circuit; multiple prediction equations are stored in the equation storage circuit; and the controller performs matching on a first prediction equation among the prediction equations according to multiple state parameters corresponding to the first block, and the first prediction equation is used for predicting a reading voltage deviation of the first block.

Owner:SOLID STATE STORAGE TECH CORP

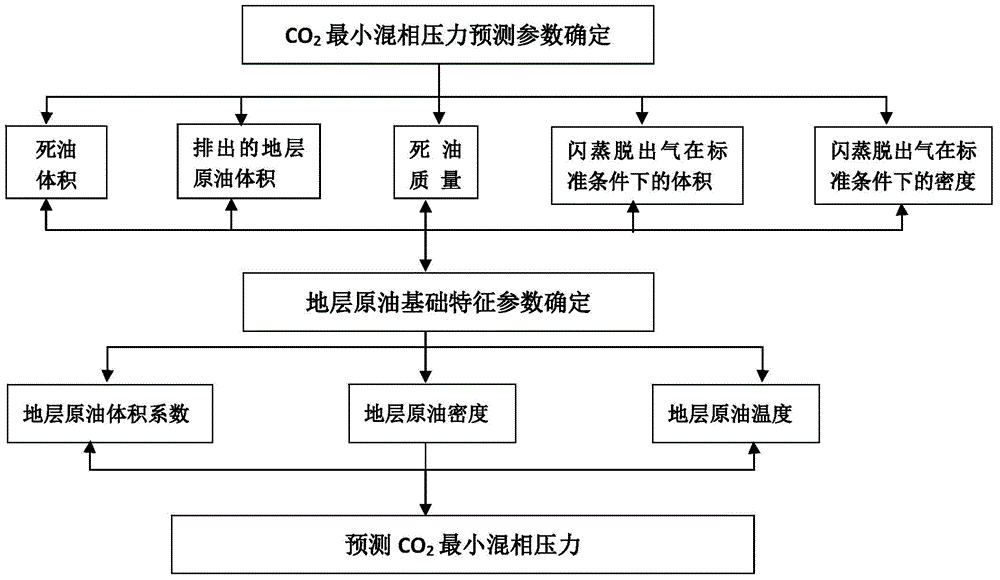

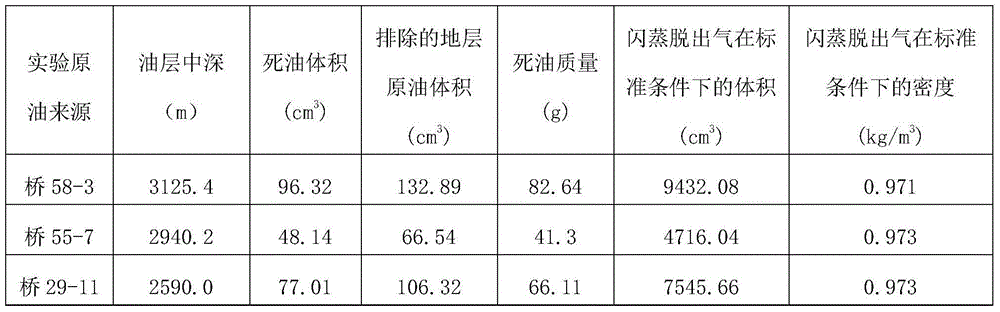

CO2 flooding minimum miscrible pressure prediction method

ActiveCN104462753AQuick forecastForecasting economyFluid removalSpecial data processing applicationsCo2 floodingProcess engineering

The invention relates to a CO2 flooding minimum miscrible pressure prediction method, and belongs to the technical field of increasing the recovery ratio through CO2 flooding. The method includes the steps of firstly, determining basic characteristic parameters of in-place oil, wherein the basic characteristic parameters include the size of dead oil, the size of discharged in-place oil, the mass of the dead oil, the size of gas discharged through flashing under the standard condition and the density of the gas discharged through flashing under the standard condition; predicting parameters by determining the CO2 minimum miscrible pressure, wherein the parameters include the size coefficient of the in-place oil, the density of the in-place oil and the temperature of the in-place oil; predicting the CO2 flooding minimum miscrible pressure through the combination with the CO2 minimum miscrible pressure empirical constant. According to the method, the CO2 flooding minimum miscrible pressure is predicted only through the size coefficient and the density of the in-place oil and the temperature parameter of the in-place oil, the number of required experimental data is small, calculation is easy, and the CO2 flooding minimum miscrible pressure of a target oil deposit can be rapidly, economically and accurately predicted.

Owner:CHINA PETROLEUM & CHEM CORP +1

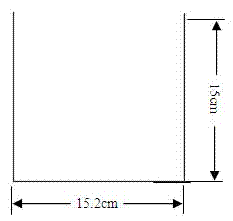

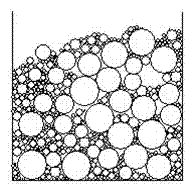

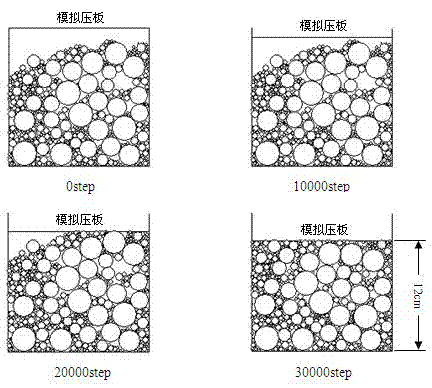

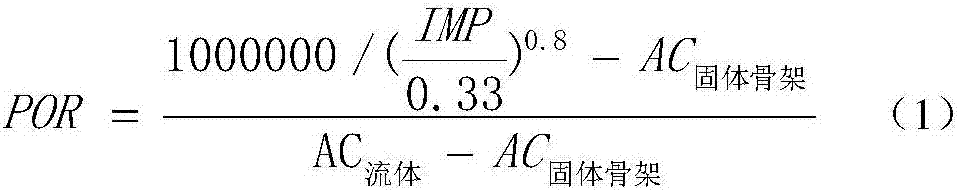

Method for testing grading broken stone CBR numerical value

InactiveCN102230870AQuick forecastAccurate predictionInvestigating material hardnessPenetration forceMechanical models

The invention discloses a method for testing grading broken stone CBR numerical value. According to the invention, a physical model and a mechanical model are established for simulating the grading broken stone CBR test, the method comprises the following steps: testing basic parameters, simulating of a CBR testing model, test pieces, a load plate, a CBR pressure head and the like, endowing the physical model with micro mechanics parameters, simulating a loading process of CBR test, finishing an arrangement of the simulation result to obtain the relational curve of the pressure head penetration rate and the penetration force, and obtaining the penetration force corresponding to a penetration rate of 2.5 mm according to the relational curve of the penetration rate and the penetration force. According to the invention, the grading broken stone CBR value can be rapidly and accurately predicted by the method, and a change rule of grading broken stone stress-strain can be represented.

Owner:CHANGAN UNIV

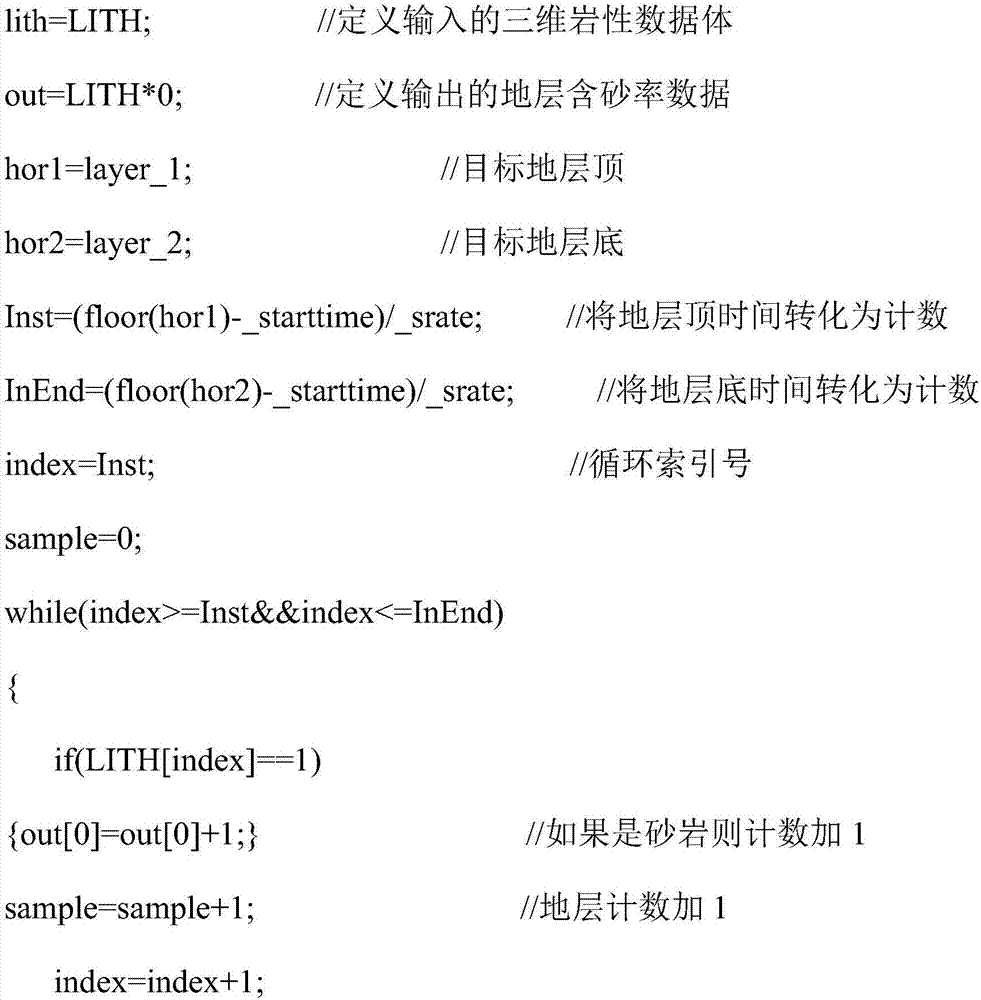

Method for comprehensively predicting earthquake in sandstone uranium ore

The invention belongs to the technical field of comprehensive prediction methods of earthquake in uranium ore, in particular to a method for comprehensively predicting earthquake in sandstone uraniumore. A seismic wave impedance inversion method is used to reversely calculate distribution of sand to obtain sand content information of a target formation directly related to uranium ore formation; wave impedance information of the target formation is converted into porosity information related to ore forming action via the conversion relation or experiential conversion relation of drilling datastatistics; a three-dimensional seismic data body is finally used to extract sensitive seismic attribute information related to a uranium ore forming environment; by comprehensively analyzing and studying and predicating the uranium ore forming potential of a work area via the three types of information, it is possible to quickly and effectively predict the development range of a sandstone uraniumore target reservoir.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

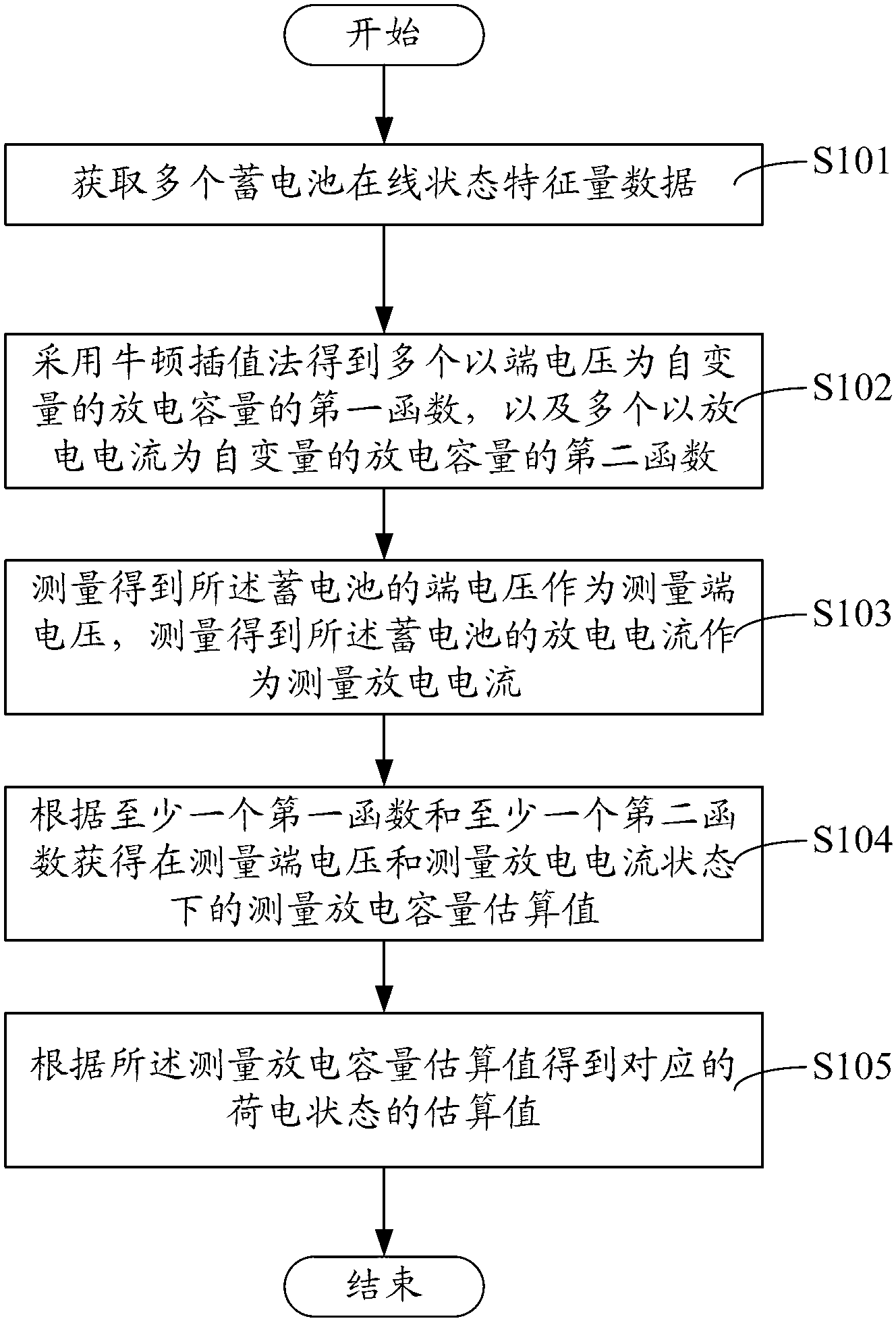

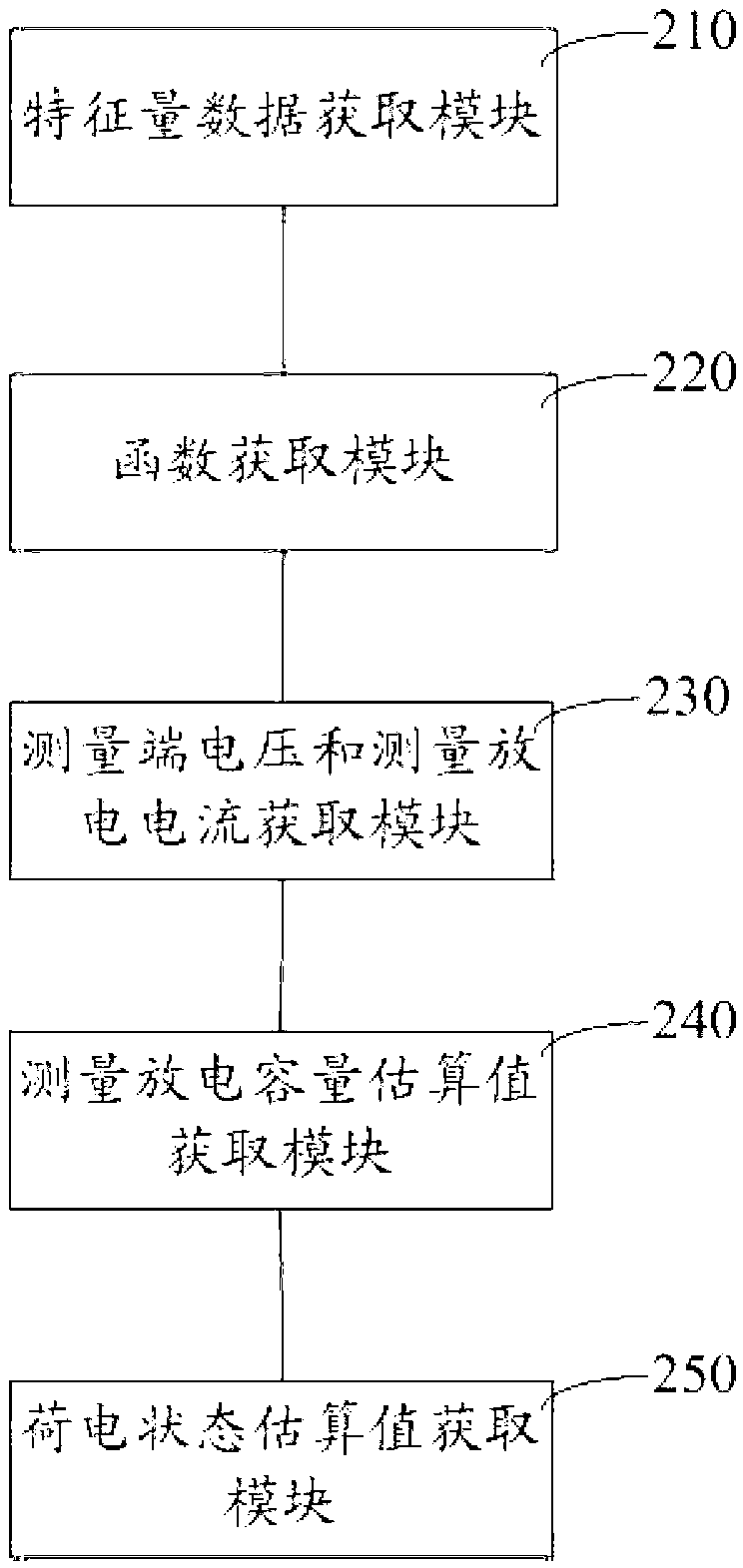

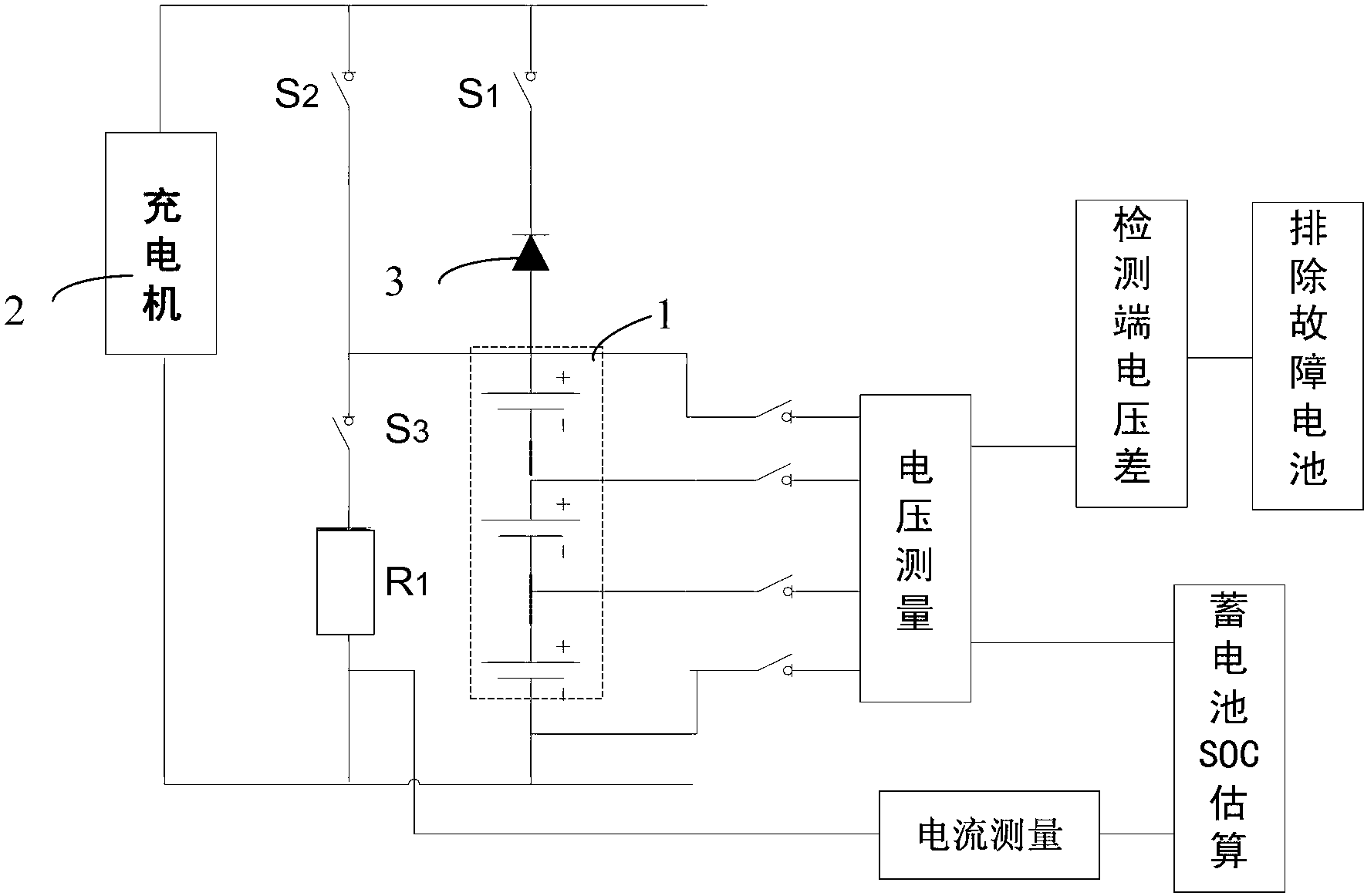

Method and system for estimating charge state of storage battery

The invention relates to the technical field of parameter estimation of a storage battery, in particular to a method and a system for estimating a charge state of the storage battery. The method comprises the steps of obtaining data of on-line state characteristic quantity of the storage battery; utilizing the Newton interpolation method to obtain a plurality of first functions of discharging capacity with terminal voltage serving as an independent variable and a plurality of second functions of discharging capacity with discharging current serving as an independent variable; obtaining an evaluation value of measurement discharging capacity in a state of measuring the terminal voltage and the discharging current according to at least one first function and at least one second function; and obtaining a corresponding evaluation value of the charge state according to the evaluation value of measurement discharging capacity. The method and the system for estimating the charge state of the storage battery utilizes the Newton interpolation method to carry out evaluation of an SOC value of the storage battery, can accurately derive the remaining capacity variation trend so as to intuitively analyze problems and fast predict a phenomenon, and can achieve on-line measurement and high accuracy.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com