Patents

Literature

30results about How to "Fast exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

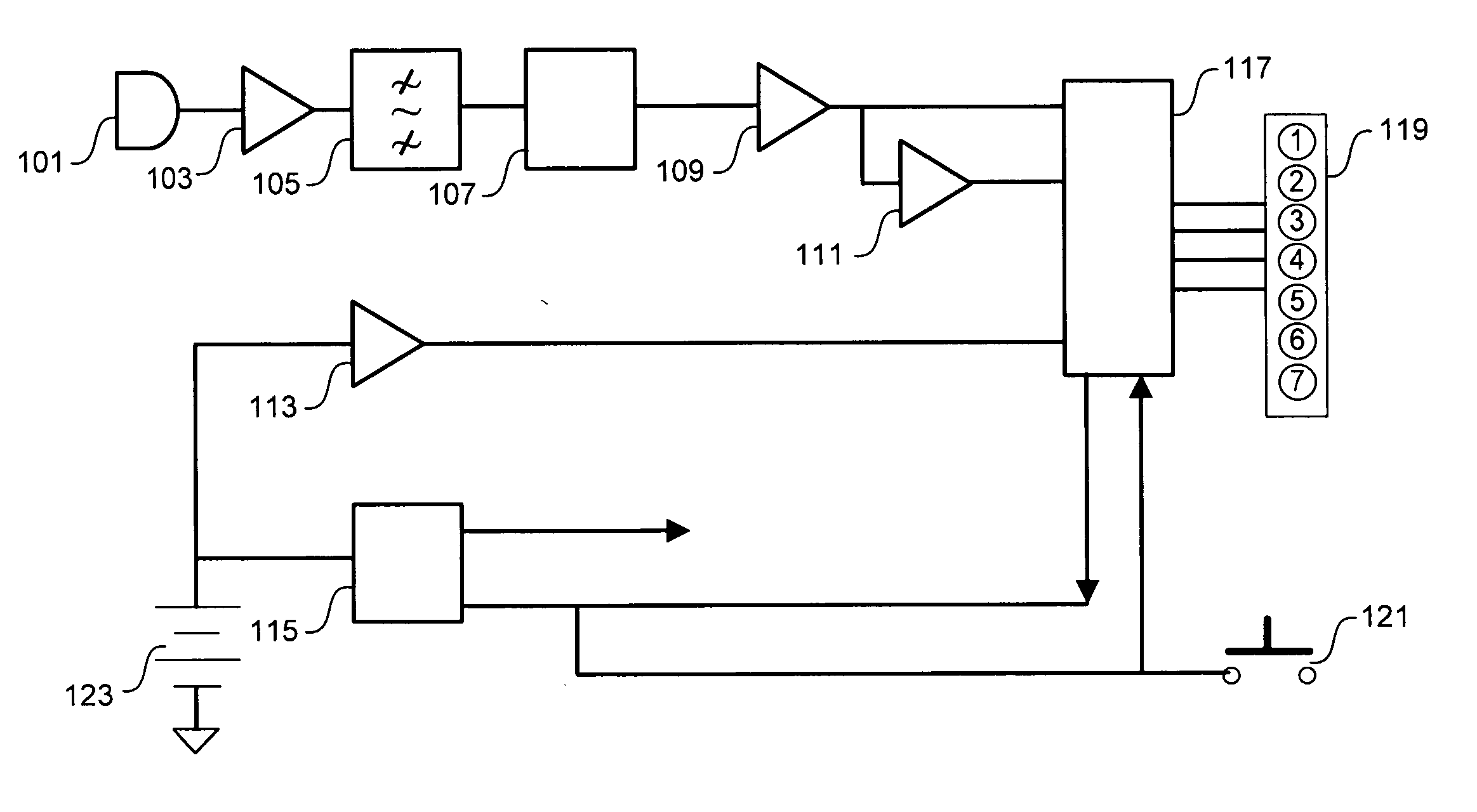

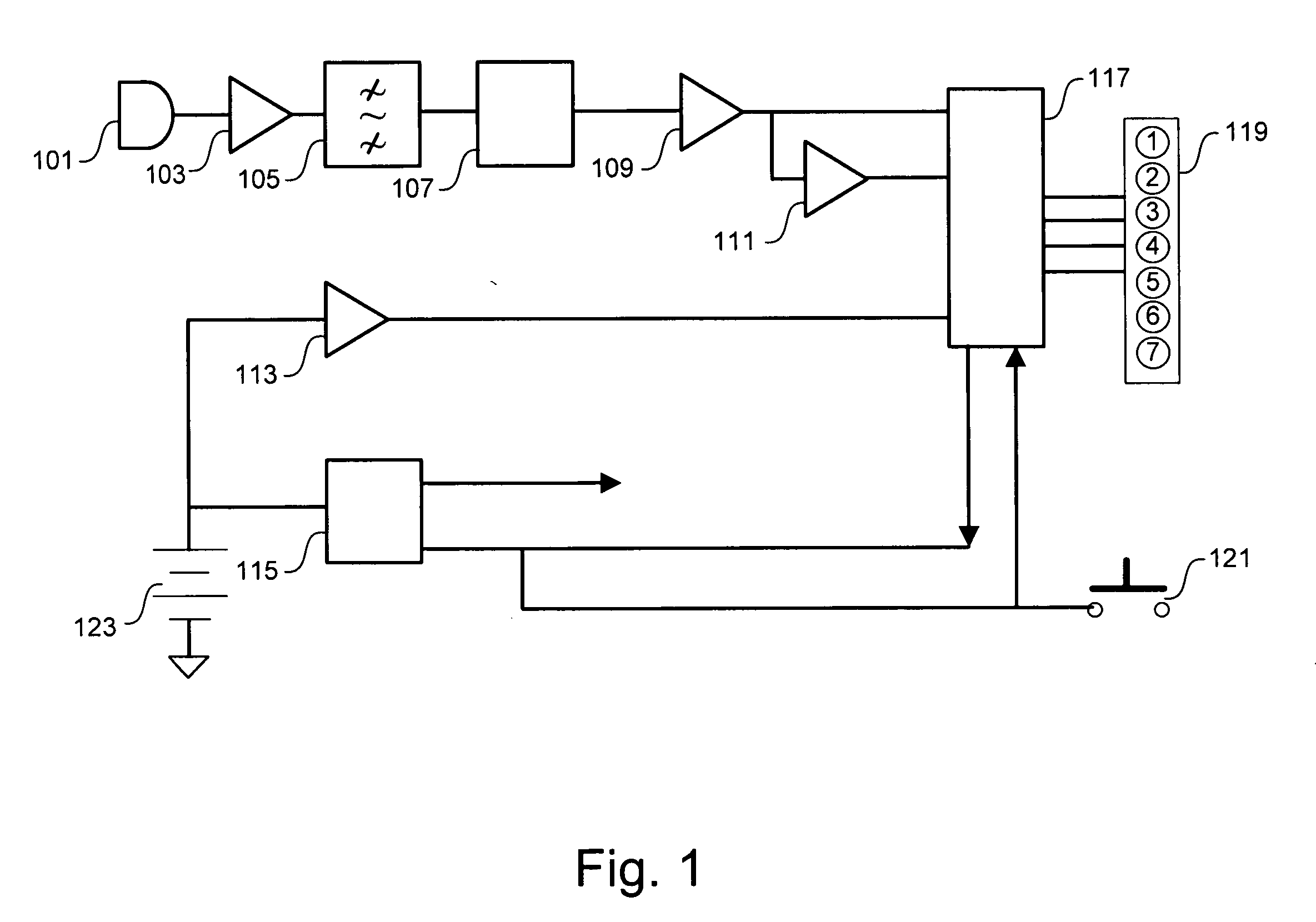

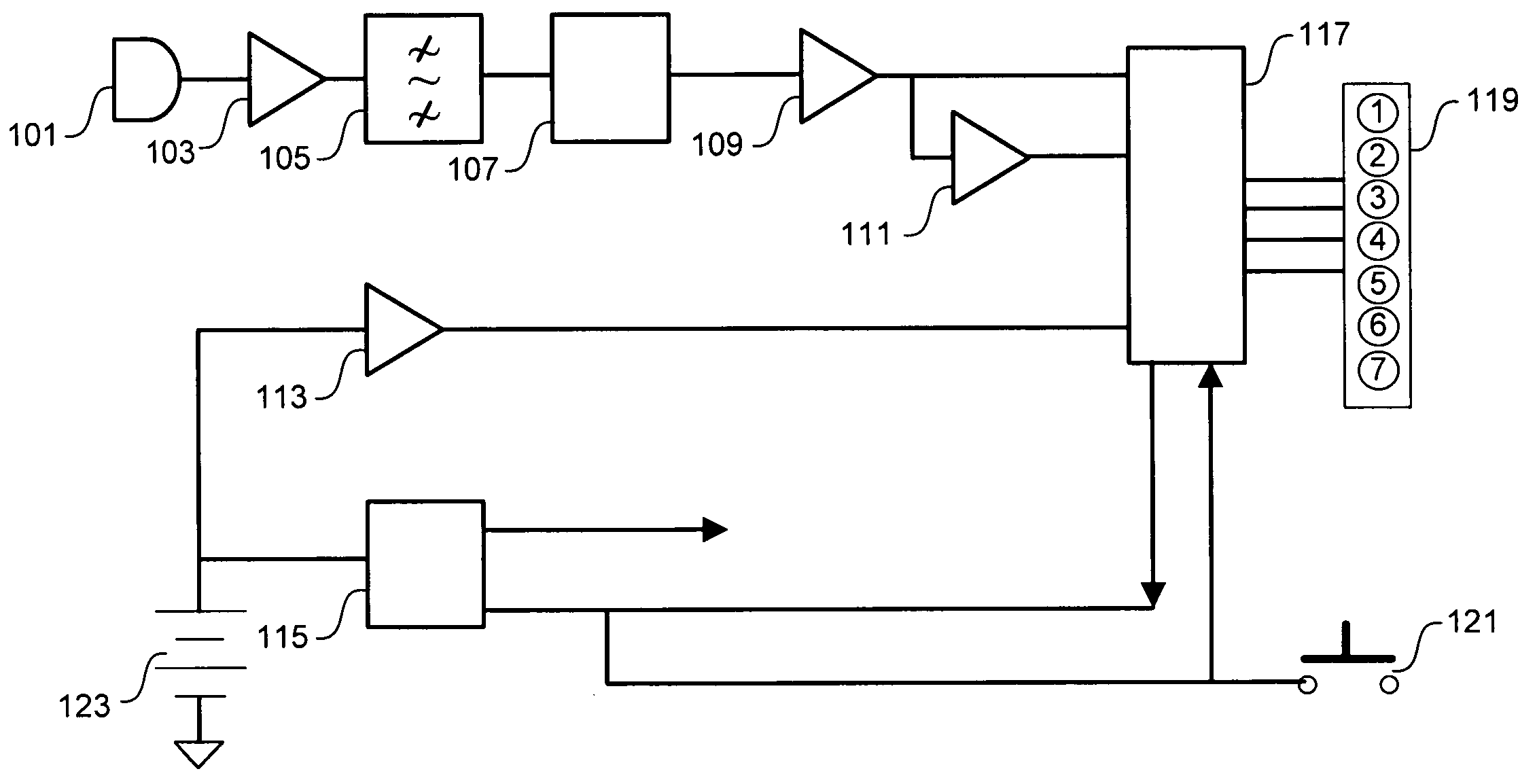

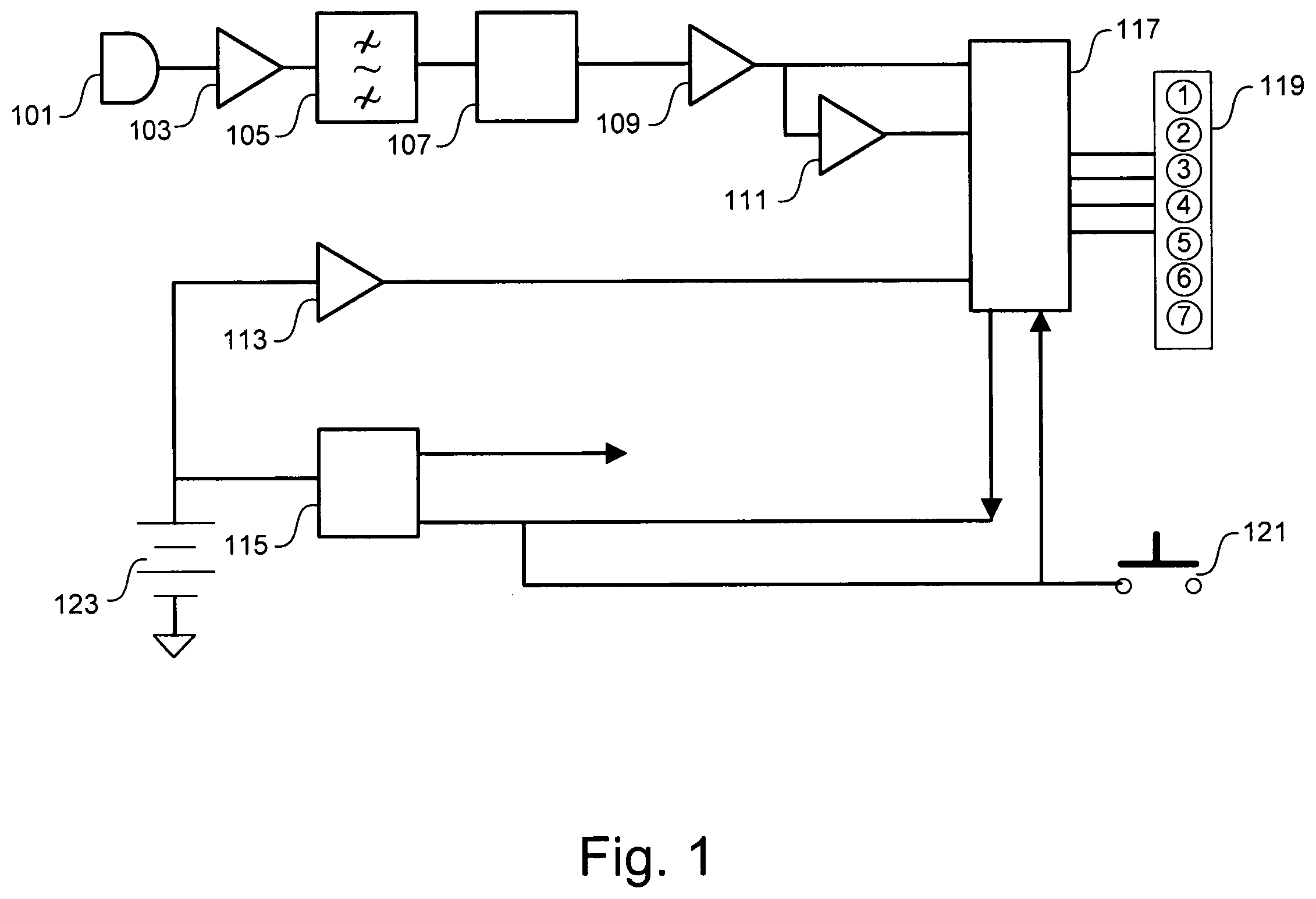

Method and system for noise dosimeter with quick-check mode and earphone adapter

ActiveUS20070186656A1Rapidly predict noise exposureLow signalVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSound sourcesDisplay device

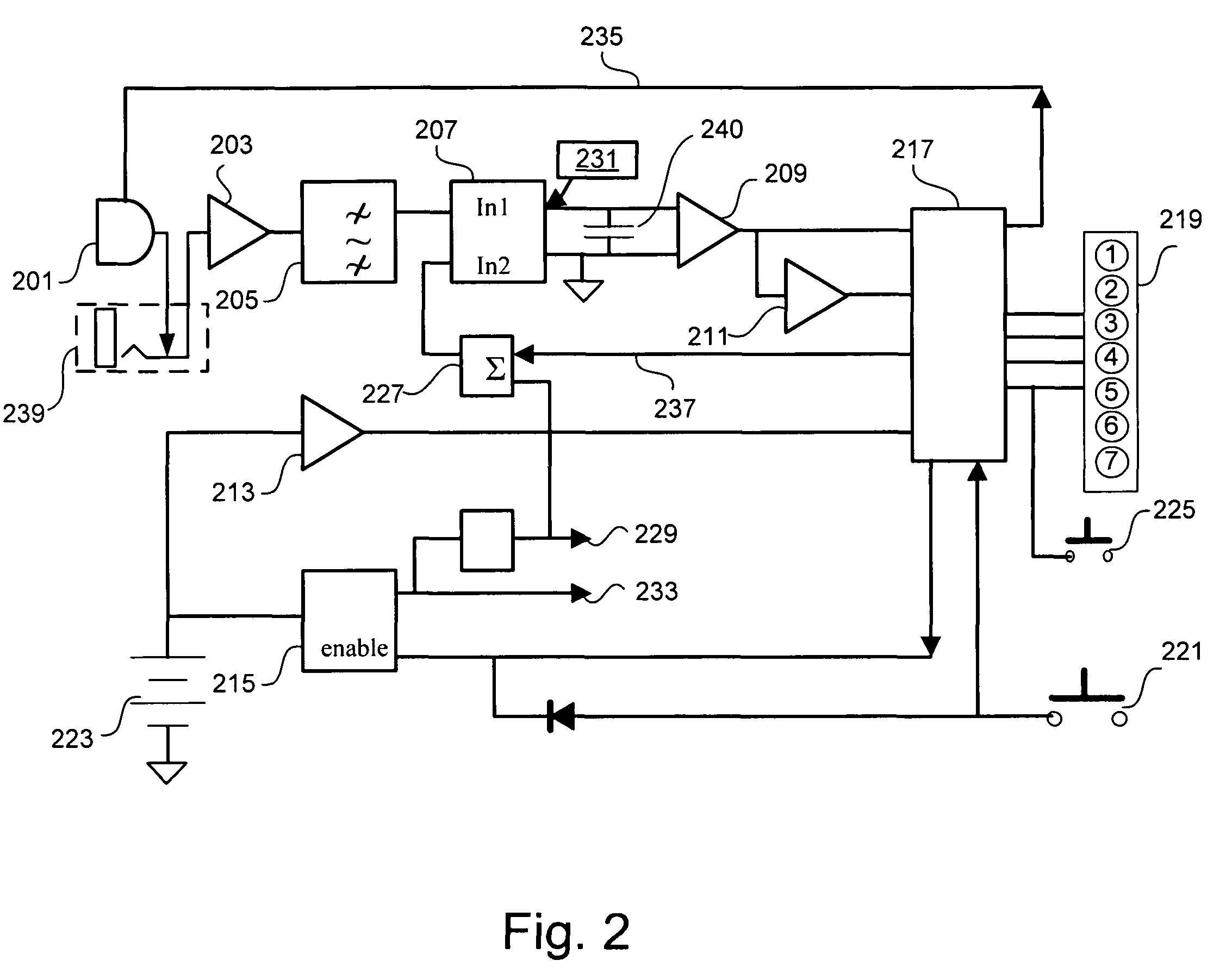

A noise dosimeter with capability to rapidly predict noise exposure over an extended time period based on a measurement of short duration. Either an acoustic or an electrical earphone adapter provides a convenient means to connect the noise dosimeter to an external sound source. A direct input jack operable to receive at least one audio signal provides a signal to an RMS detector, which provides a DC signal to a two-stage amplifier circuit. The outputs of the amplifiers are provided to a processor having multiple A / D channels. The processor calculates accumulated noise doses and drives a display, which in one embodiment includes a panel of light-emitting diodes. In one embodiment, the dosimeter includes functionality for control of external devices such as sound boards.

Owner:ETYMOTIC RES

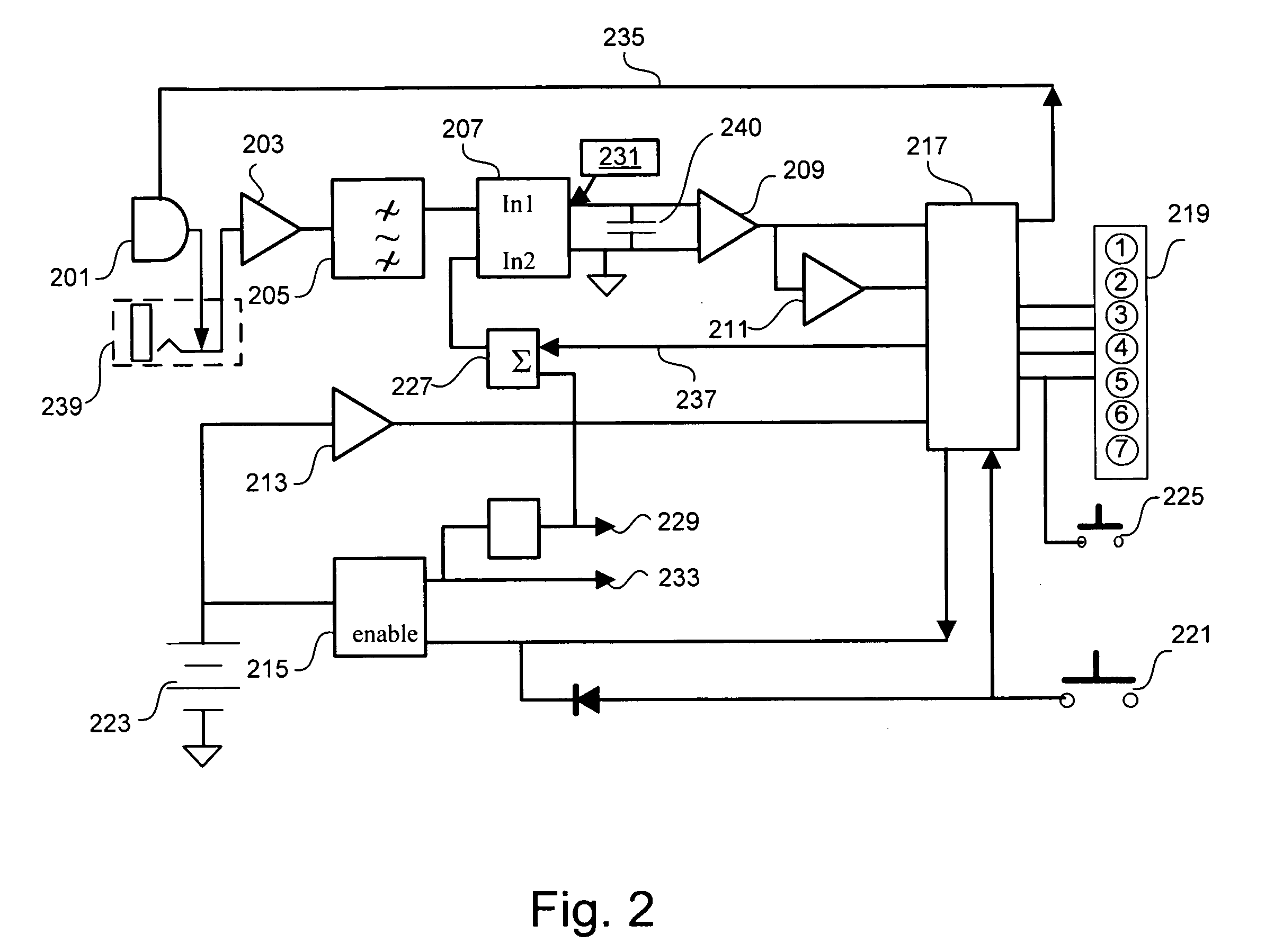

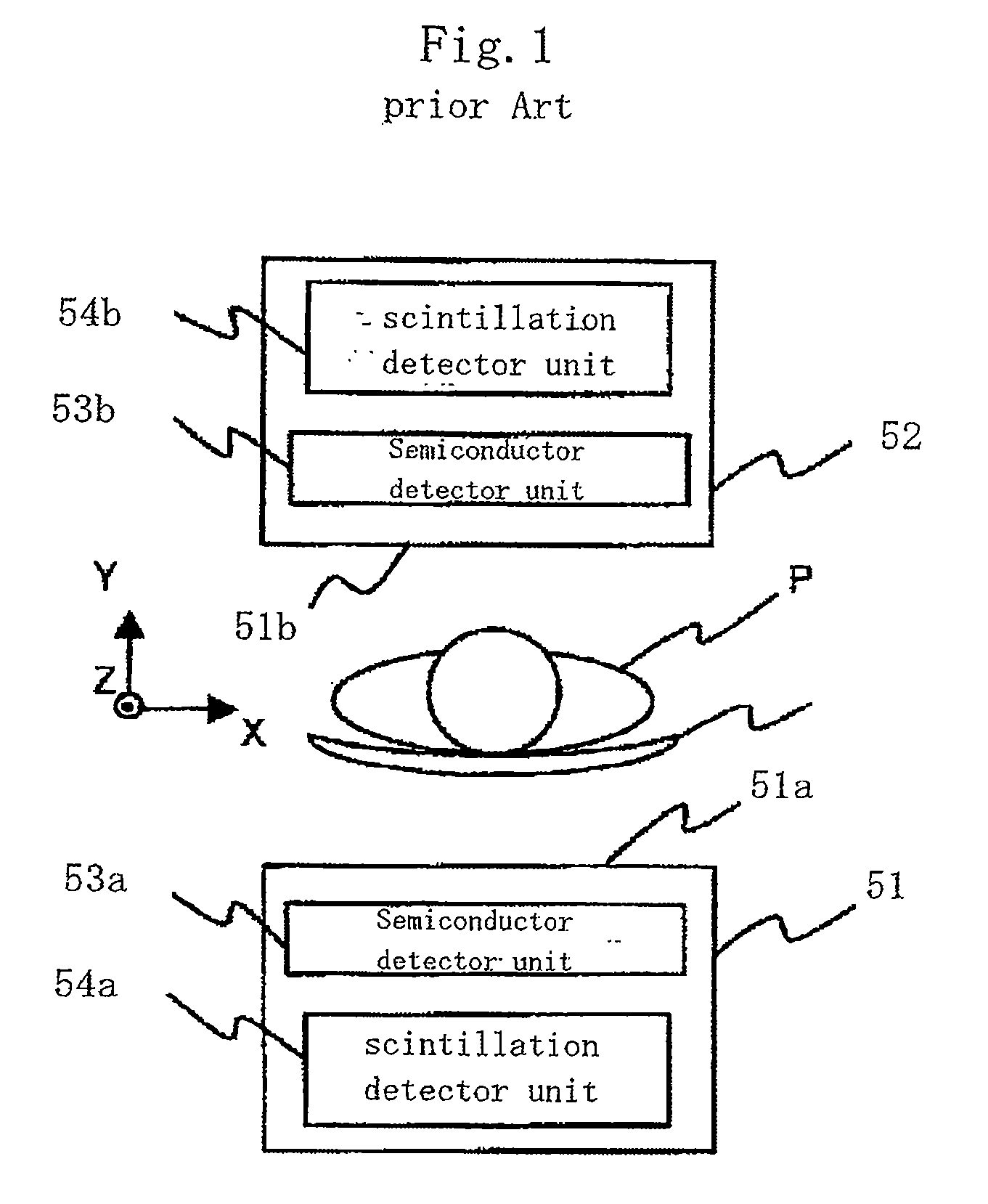

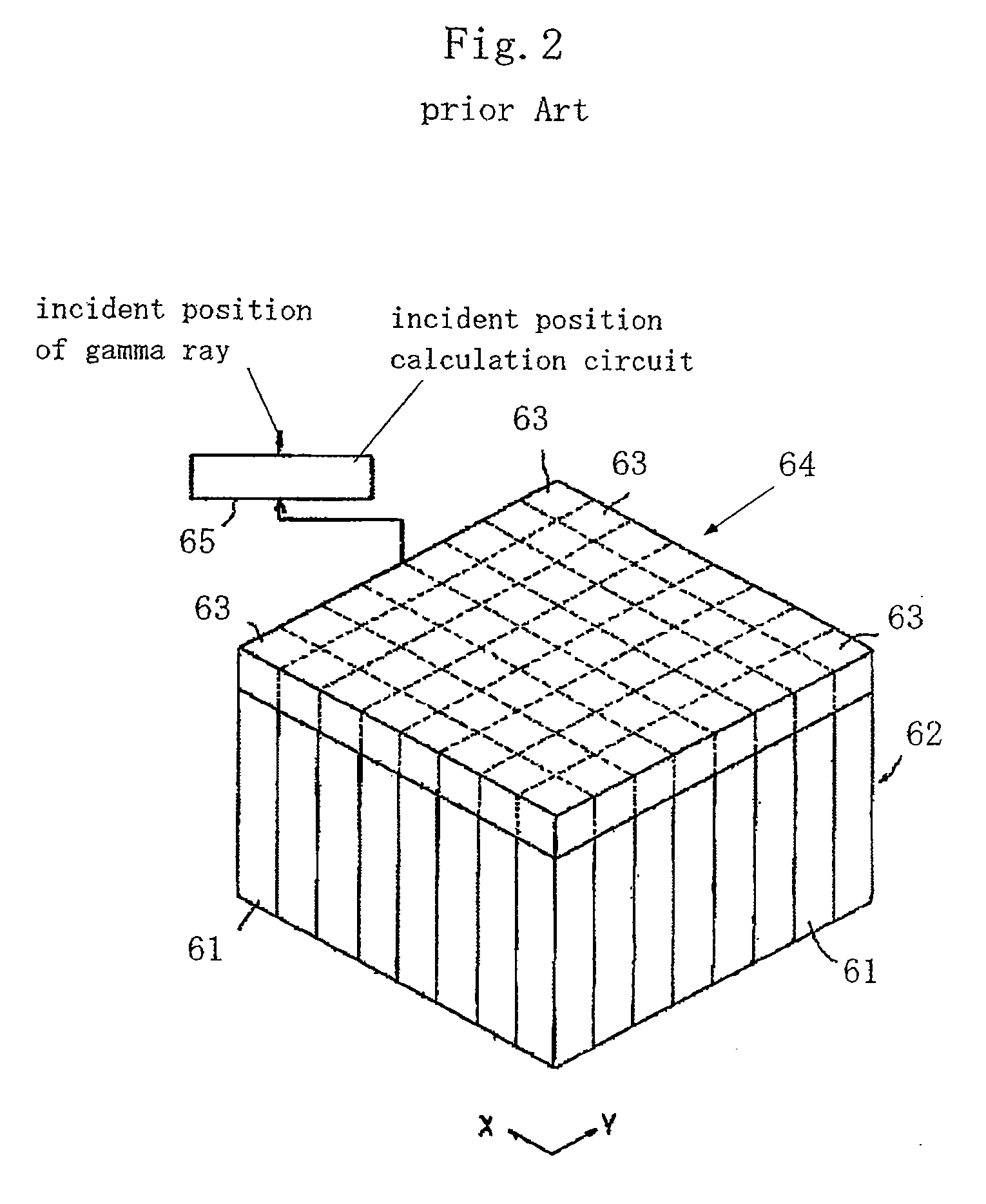

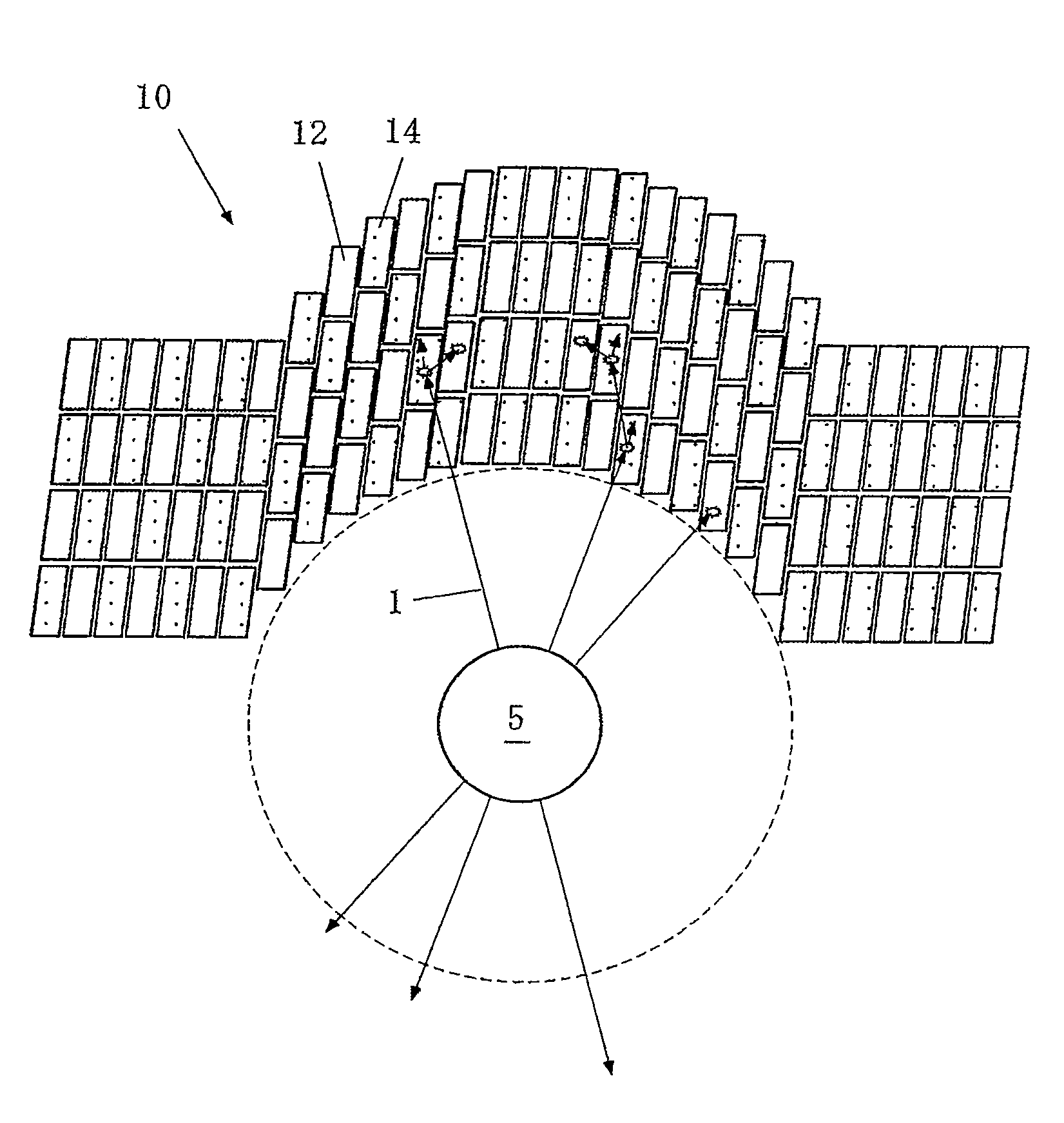

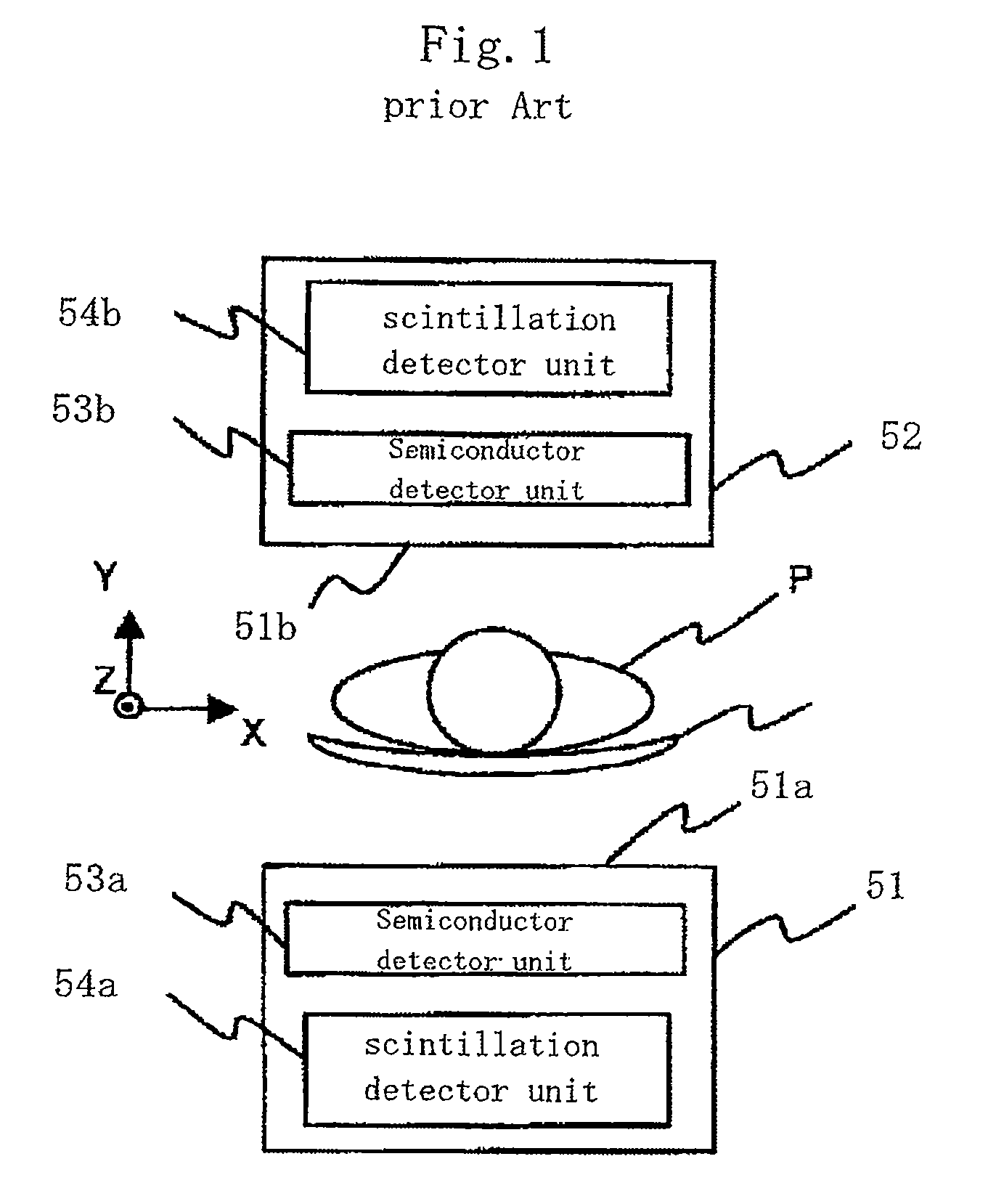

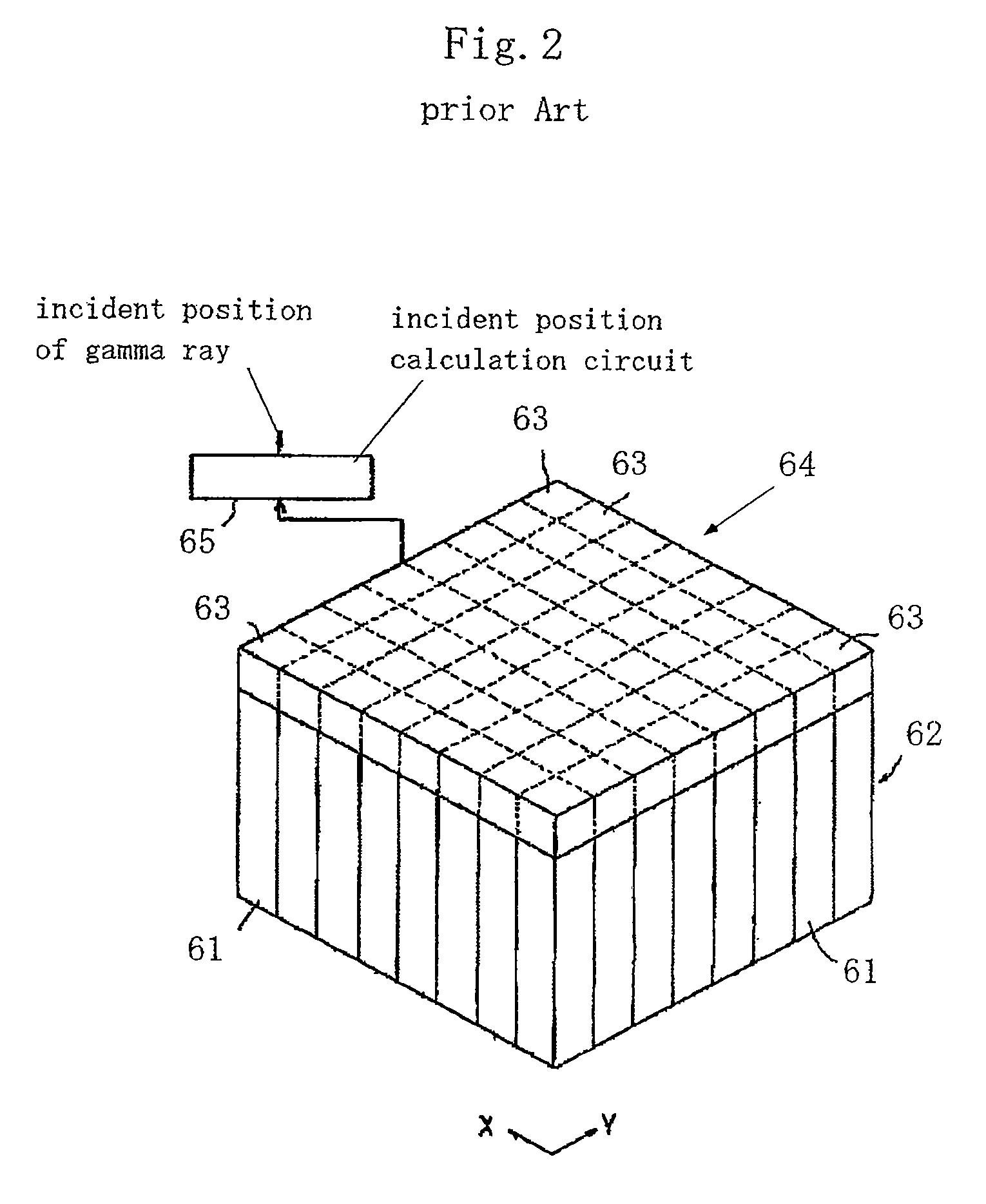

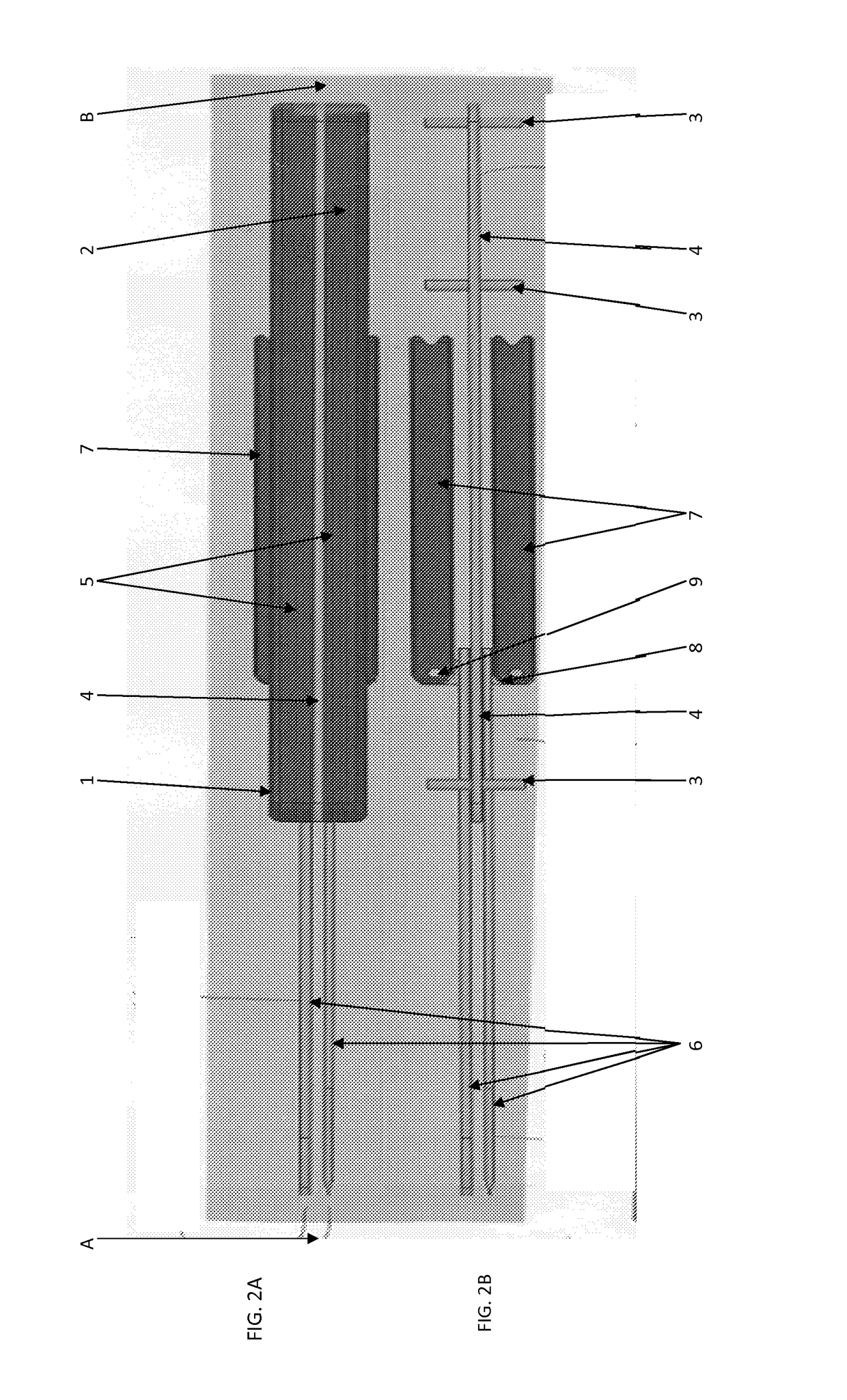

Gamma ray detector and gamma ray reconstruction method

InactiveUS20100301221A1Increasing gamma ray detection sensitivityDecreasing amountMaterial analysis by optical meansTomographyHigh rateEnergy absorption

Provided are a gamma ray detector and a gamma ray reconstruction method which can be used in SPECT and PET and which combine and reconstruct the information on “Compton-scattered” gamma rays, thereby remarkably increasing gamma ray detection sensitivity, decreasing the amount of a radioactive substance given to a subject, and remarkably reducing the concern about the amount of radiation exposure. The gamma ray detector comprises an absorber scintillator 12 made from an absorptive substance exhibiting a high rate of absorption with respect to gamma rays 1 in an energy region, emitted from a subject, a Compton scattering scintillator 14 made from a Compton scattering substance exhibiting a high probability of Compton scattering, and an energy detector 16 which combines the amounts of gamma ray energy absorption simultaneously measured by the two types of scintillators to reconstruct the gamma rays emitted from the subject. The two types of scintillators 12 and 14 are arranged in multiple layers so as to absorb or Compton-scatter the whole energy of the gamma rays 1.

Owner:NAT INST OF RADIOLOGICAL SCI

Method and system for noise dosimeter with quick-check mode and earphone adapter

ActiveUS7836770B2Fast exposureQuick forecastVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSound sourcesDisplay device

A noise dosimeter with capability to rapidly predict noise exposure over an extended time period based on a measurement of short duration. Either an acoustic or an electrical earphone adapter provides a convenient means to connect the noise dosimeter to an external sound source. A direct input jack operable to receive at least one audio signal provides a signal to an RMS detector, which provides a DC signal to a two-stage amplifier circuit. The outputs of the amplifiers are provided to a processor having multiple A / D channels. The processor calculates accumulated noise doses and drives a display, which in one embodiment includes a panel of light-emitting diodes. In one embodiment, the dosimeter includes functionality for control of external devices such as sound boards.

Owner:ETYMOTIC RES

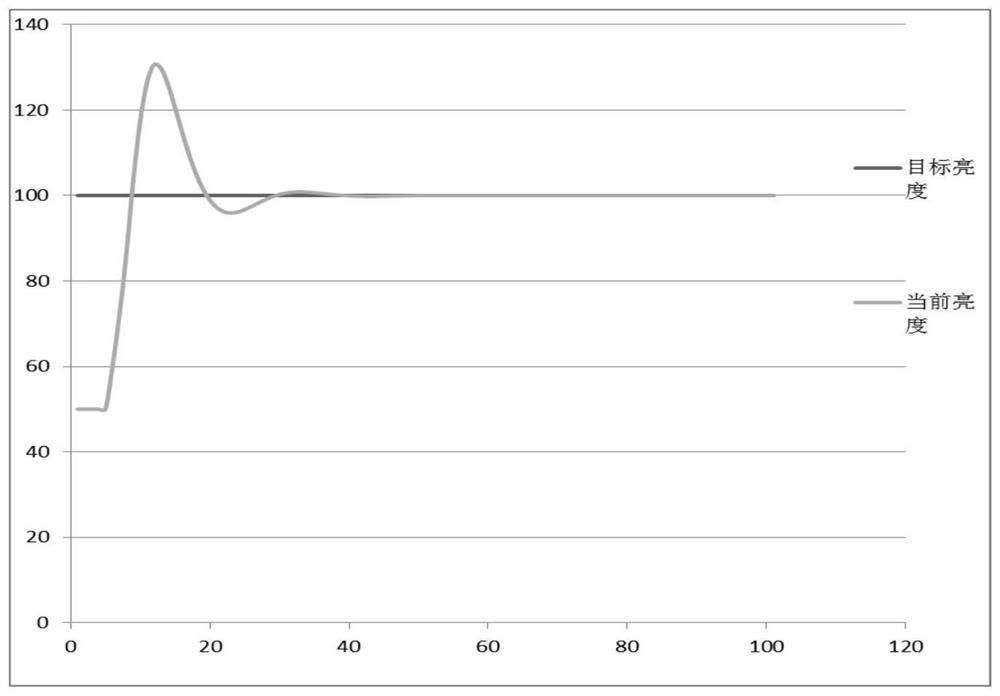

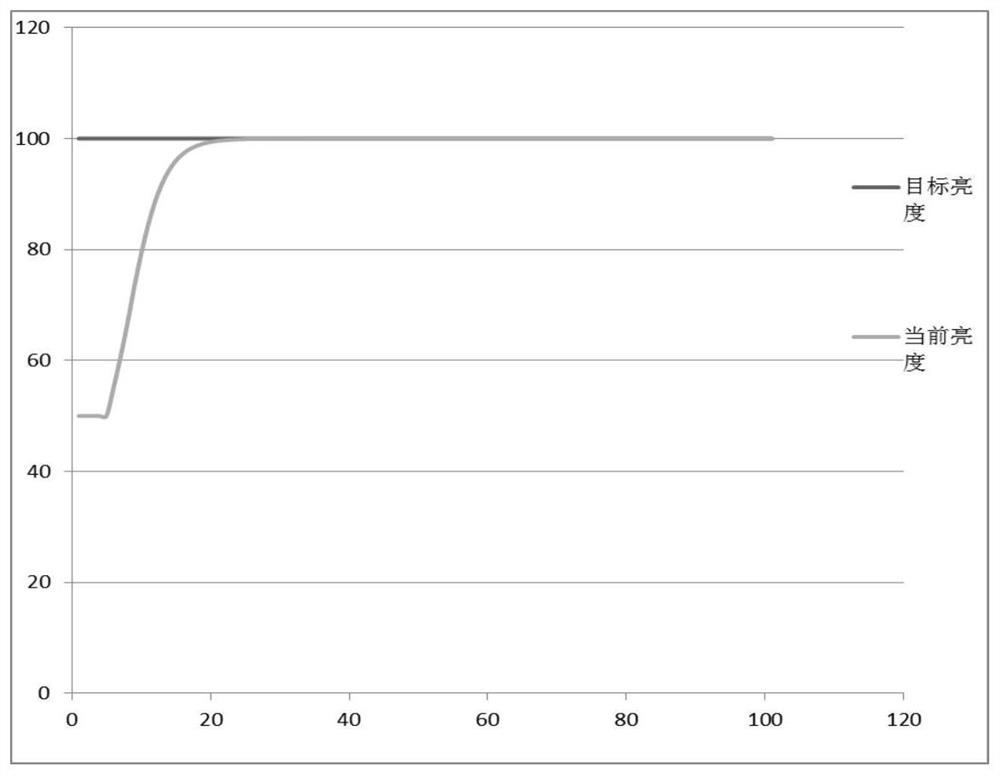

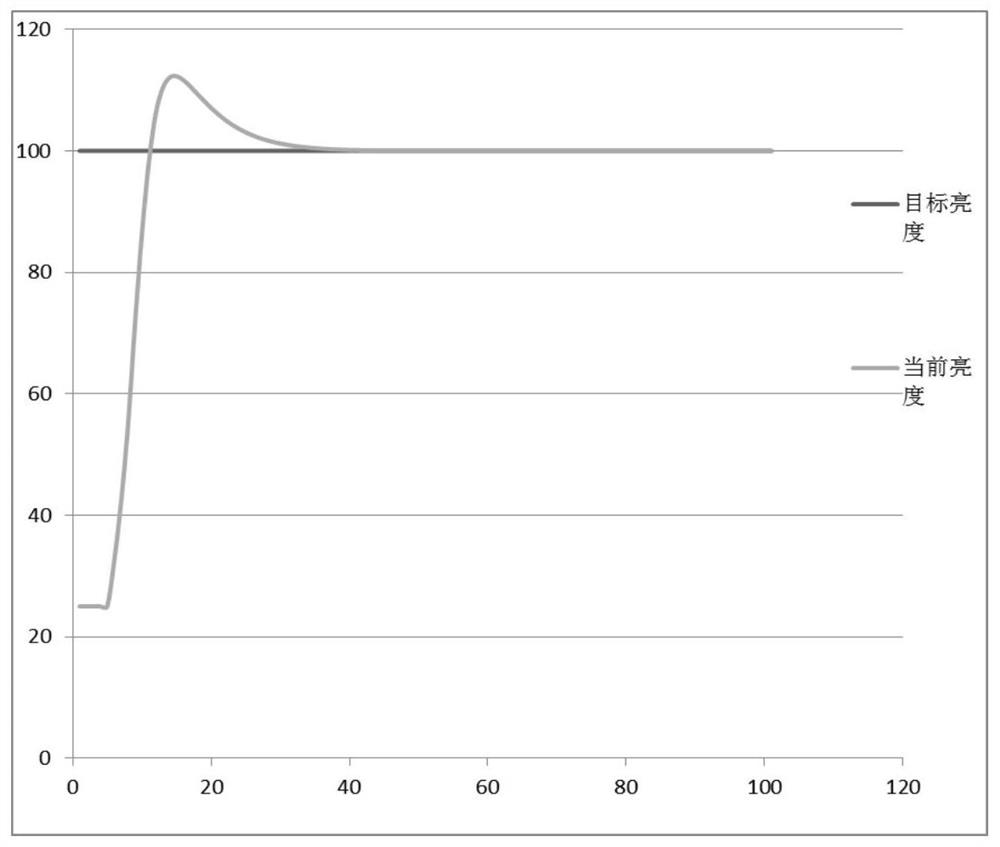

Exposure adjustment method and device, camera and computer storage medium

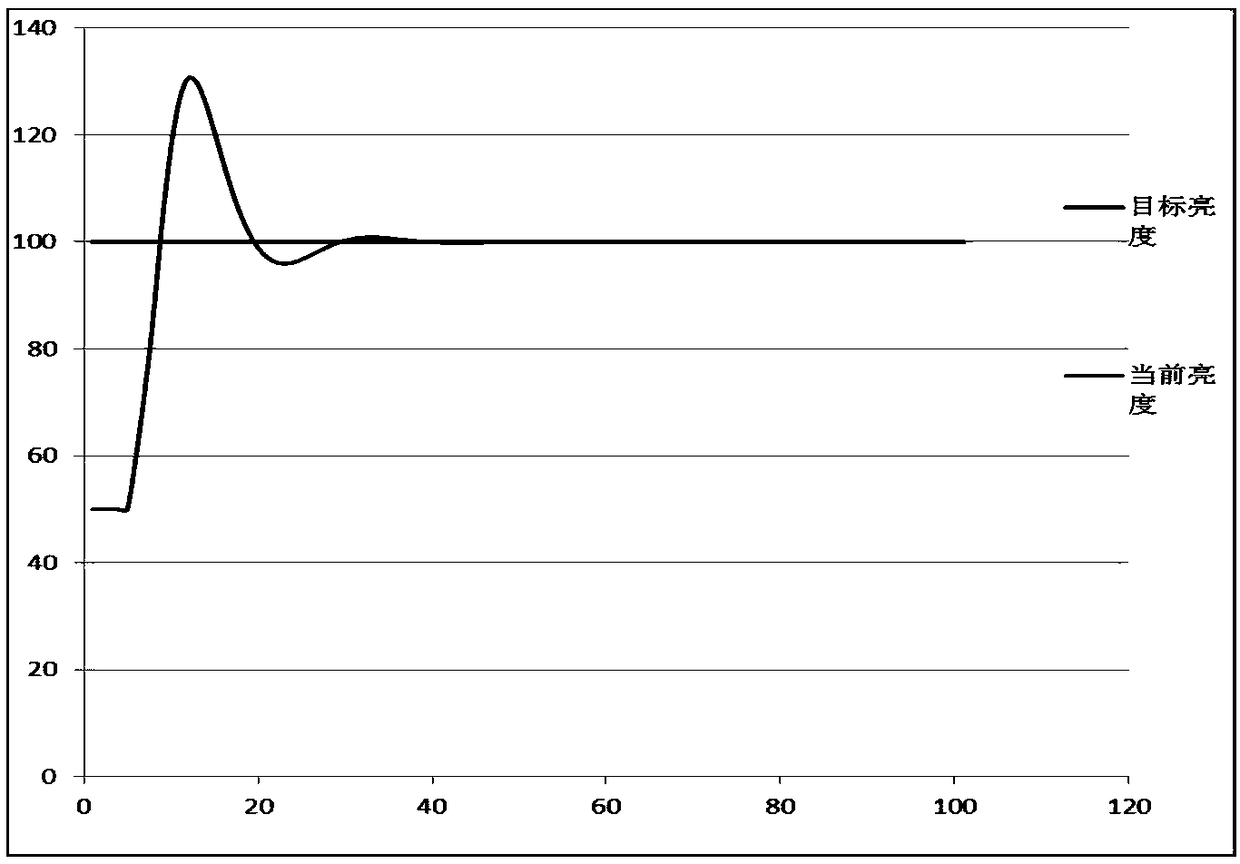

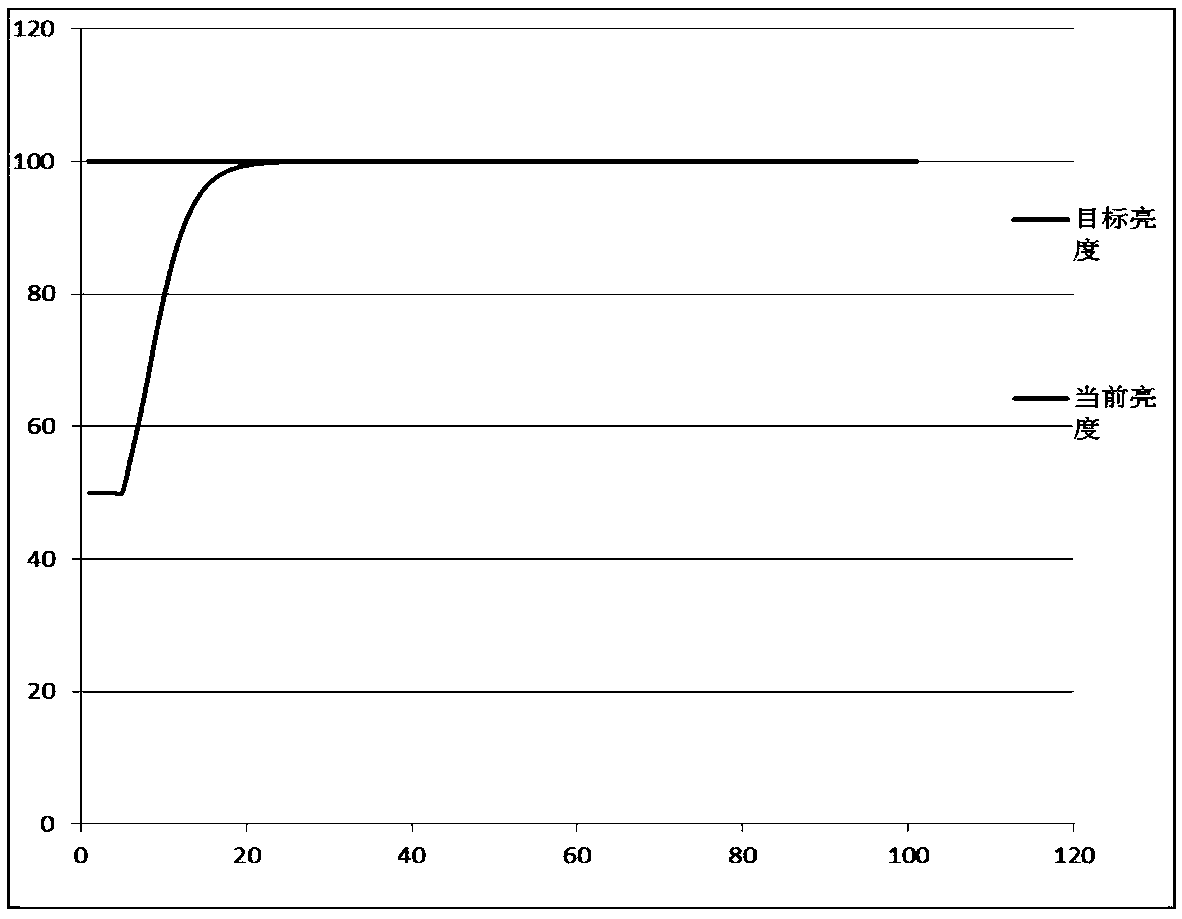

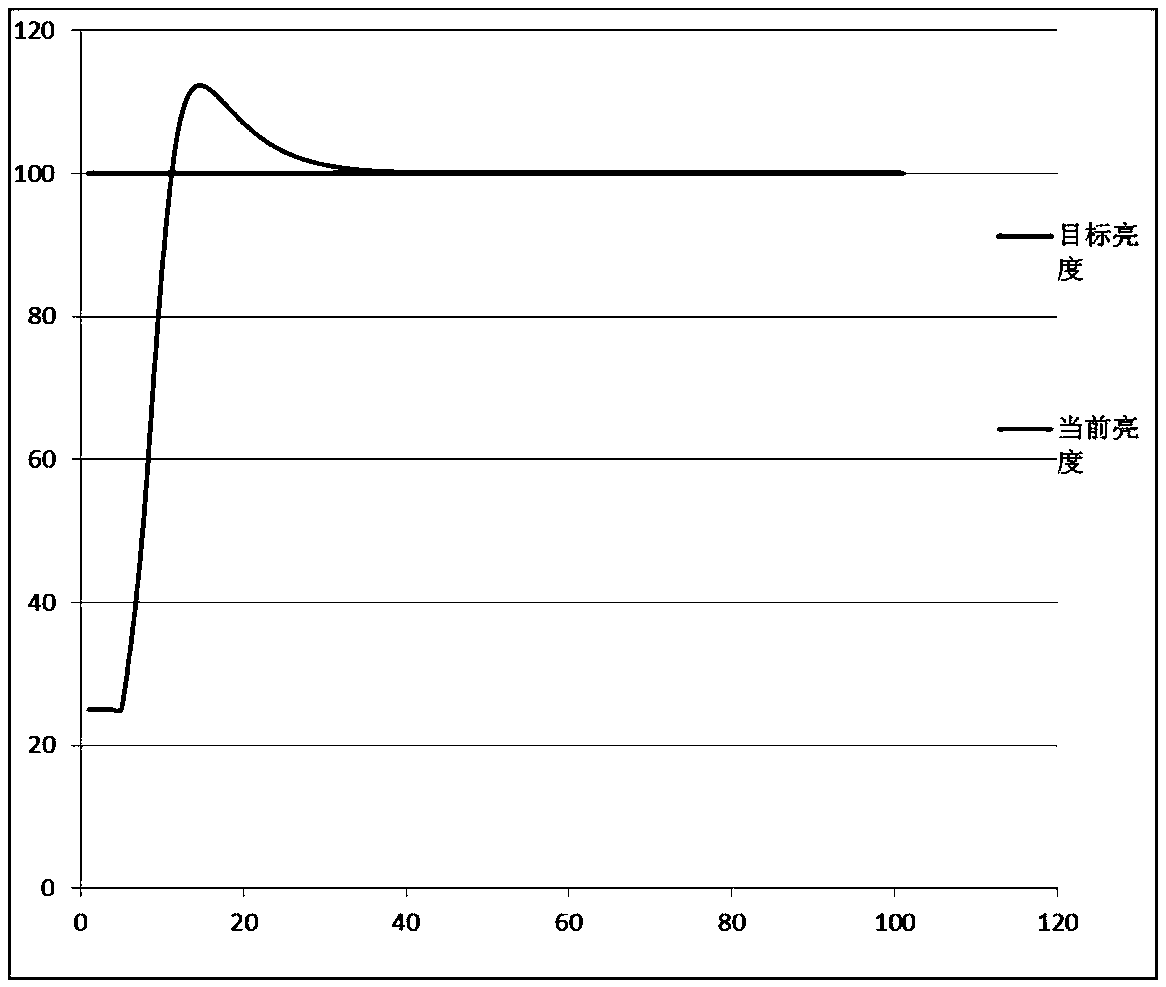

ActiveCN109474790AExposure adjustments are accurateAvoid repeated exposure adjustmentsTelevision system detailsColor television detailsComputer scienceVideo camera

The invention discloses an exposure adjustment method and device, a camera and a computer storage medium, and belongs to the technical field of cameras. The method, the device, the camera and the medium are used for using an explore value, which is after taking effect by prediction adjustment, as a basis of exposure adjustment, and thus alleviating the overshooting problem occurring in the prior art. The method includes: obtaining an estimated explore value, which is after taking effect by setting of lastly output exposure parameter values, according to an explore value of a shot current picture and historical exposure parameter values corresponding to the explore value of the current picture, wherein exposure parameters include a gain, a shutter or an aperture; determining whether a ratioof a target explore value (TEV) to the estimated explore value is in a preset range; and when it is determined that the ratio of the target explore value to the estimated explore value is not in thepreset range, determining a new exposure parameter value according to on the ratio of the target explore value to the estimated explore value, and carrying out exposure adjustment according to the newexposure parameter value.

Owner:ZHEJIANG DAHUA TECH CO LTD

Exposure device and exposure method for electronic endoscope

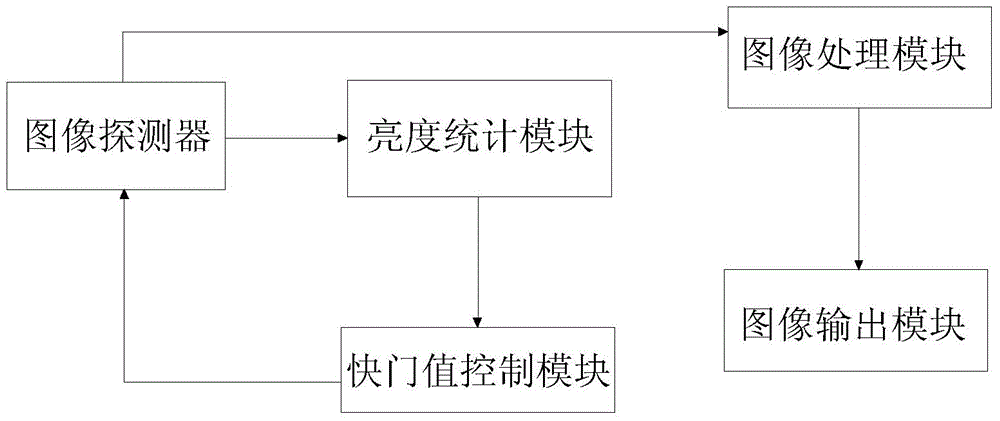

InactiveCN104580923ASolve glareSolve flickeringTelevision system detailsColor television detailsImaging processingImage detection

The invention discloses an exposure device and an exposure method for an electronic endoscope. The exposure device comprises an image detection module, an image processing module and an image output module, wherein the image detection module comprises an image detector, a brightness statistics module and a shutter value control module. The exposure method comprises the following steps: transmitting a video signal of a detection region to the brightness statistics module by the image detector, obtaining a current brightness value Yc and a target brightness value Ya through the brightness statistics module, and transmitting the current brightness value Yc and the target brightness value Ya to the shutter value control module; calculating a target shutter value Sa and controlling a shutter to reach proper exposure quantity by the shutter value control module; sending the video signal of the detection region under the proper exposure quantity to the image processing module by the image detector; performing image processing on the received video signal by the image processing module, and transmitting the processed video signal to the image output module for outputting. According to the exposure device and the exposure method, a detection image is relatively clear, a situation of overexposure or over-darkness is avoided, the exposure speed is increased, and the problems of dazzling and flickering of the image are solved.

Owner:CHONGQING JINSHAN SCI & TECH GRP

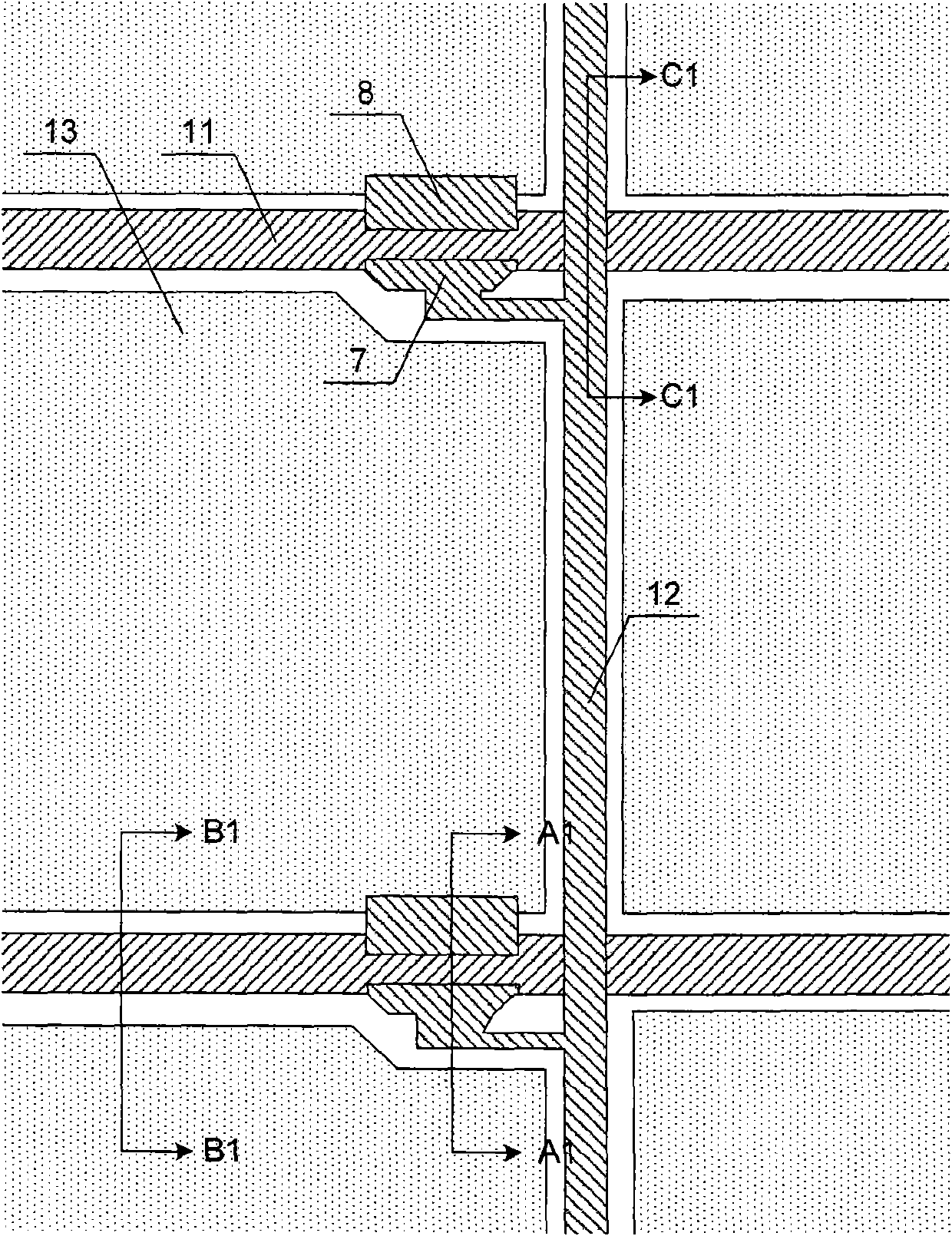

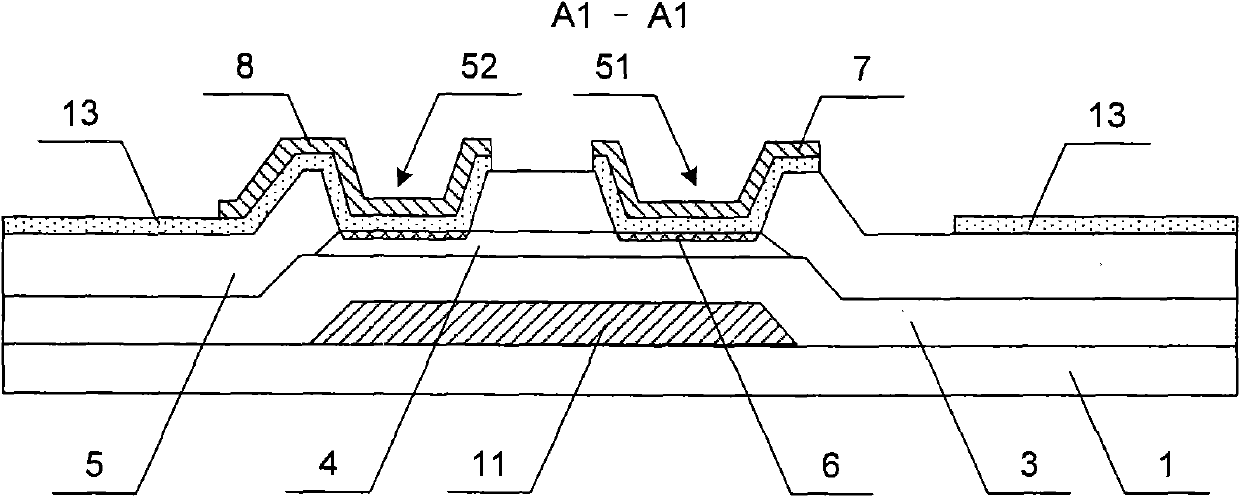

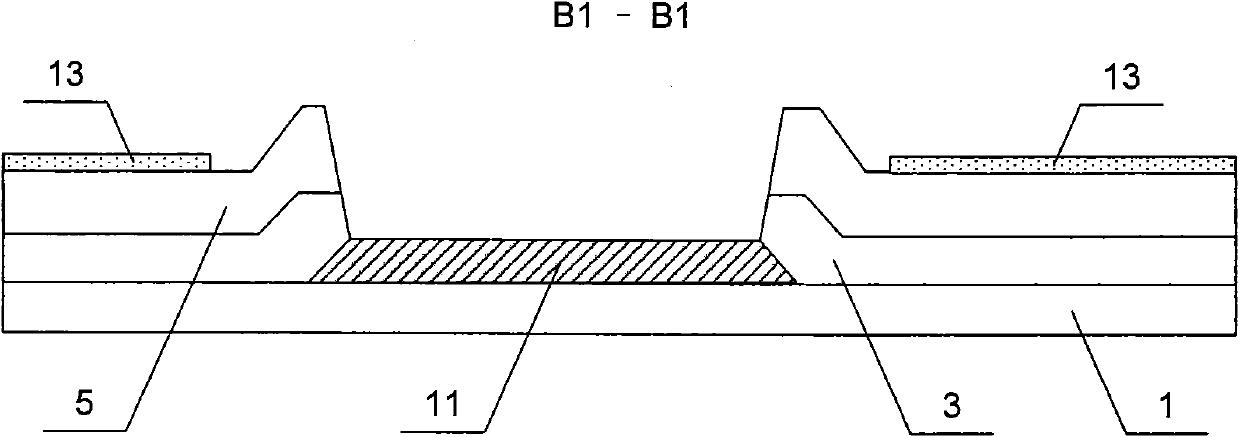

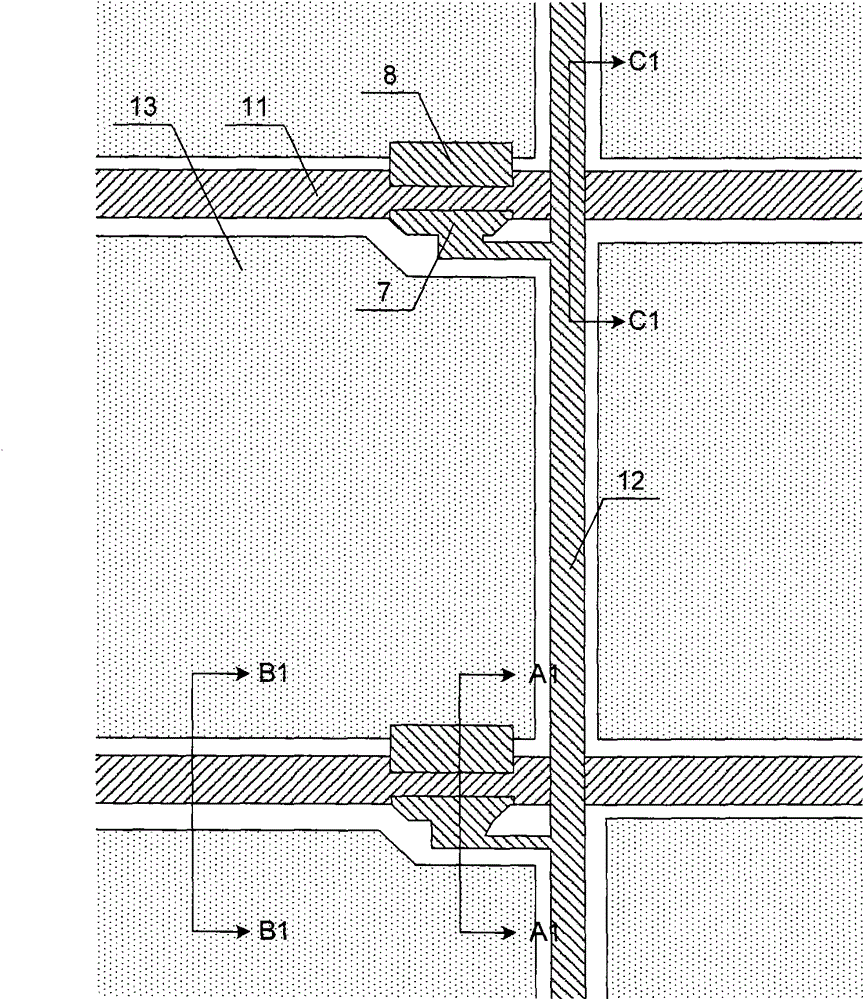

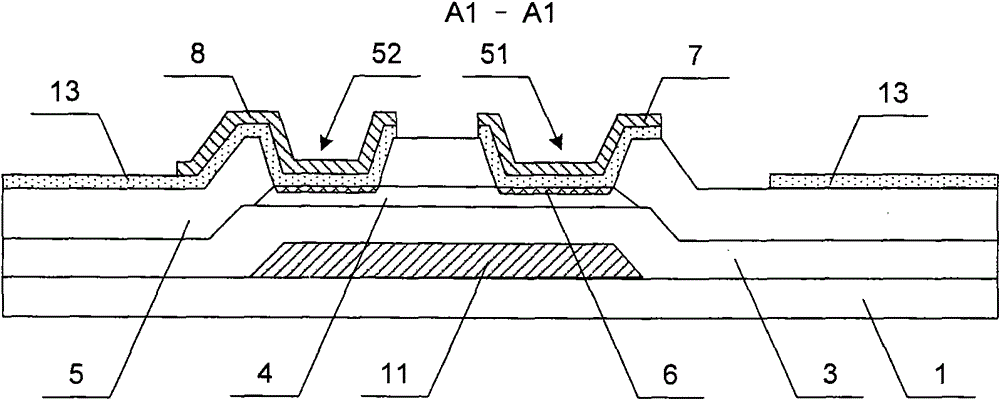

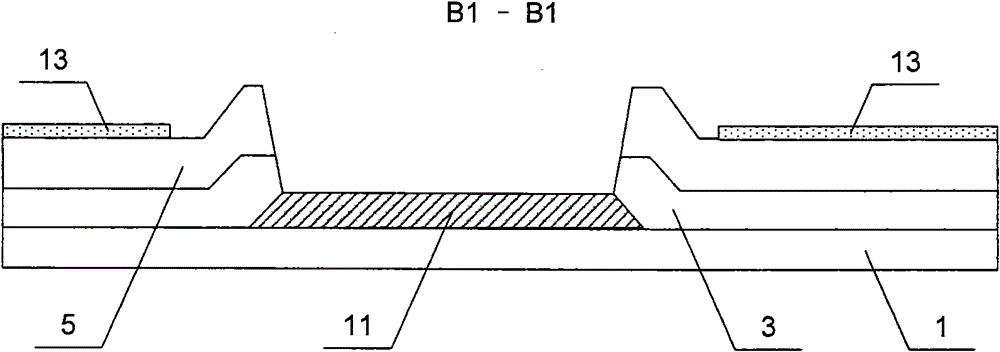

Thin film transistor liquid crystal display (TFT-LCD) array substrate and manufacturing method thereof

InactiveCN102023431AImprove performanceFast exposureSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringThin-film-transistor liquid-crystal display

The invention relates to a thin film transistor liquid crystal display (TFT-LCD) array substrate and a manufacturing method thereof. The manufacturing method comprises the following steps of: depositing a grid metal film, a grid insulation layer and a semiconductor film to form a figure comprising a grid line and a quasi semiconductor layer; depositing a passivation layer to form a semiconductor layer figure, a figure comprising a source electrode via hole and a drain electrode via hole on the semiconductor layer, and a doped semiconductor layer on the surface of the semiconductor layer in the source electrode via hole and the drain electrode via hole; and depositing a transparent conductive film and a source and drain metal film to form a figure comprising a pixel electrode, a data line,a source electrode and a drain electrode, wherein the source electrode is connected with the semiconductor layer through the doped semiconductor layer in the source electrode via hole and the drain electrode is connected with semiconductor layer through the doped semiconductor layer in the drain electrode via hole. The TFT-LCD array substrate can be manufactured through three times of processes, so the process is relatively simple, the process time can be shortened to the maximum extent, the production efficiency is improved, and the production cost is reduced.

Owner:BOE TECH GRP CO LTD +1

Method and system for image processing

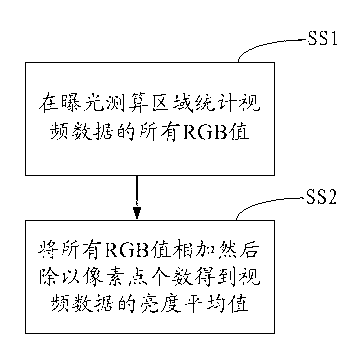

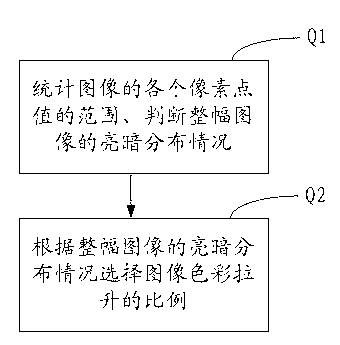

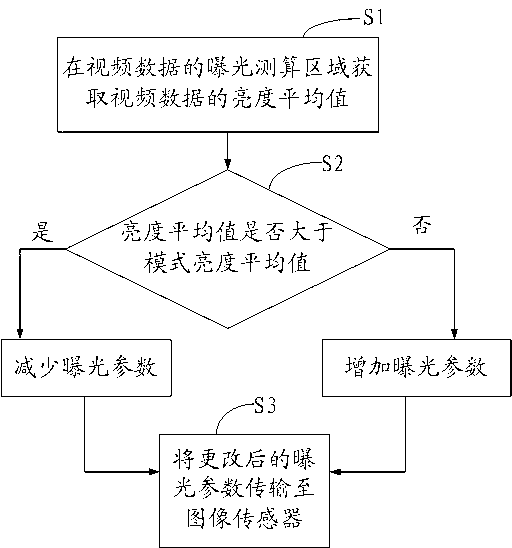

InactiveCN102984463AAccelerateFast exposureTelevision system detailsPicture signal generatorsImage sensorExposure measurement

The invention provides a method for image processing. The method for the image processing comprises an image exposure adjusting processing method. The image exposure adjusting processing method includes the following steps: A. Acquiring a brightness average value of video data in an exposure measurement area of the video data. B. Comparing the brightness average value with a mode brightness average value, increasing exposure parameters and carrying out step C if the brightness average value is smaller than the mode brightness average value; decreasing the exposure parameters and carrying out the step C if the brightness average value is bigger than the mode brightness average value; maintaining the exposure parameters if the brightness average value is equal to the mode brightness average value. C. Transmitting the changed exposure parameters to an image sensor. The method and the system for the image processing have the advantages that the method for the image processing is capable of significantly increasing exposure response speed and improving camera exposure speed.

Owner:QIHAN TECH

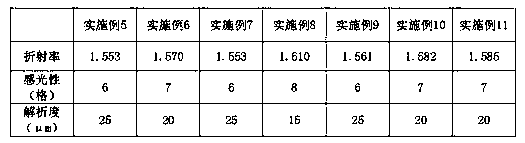

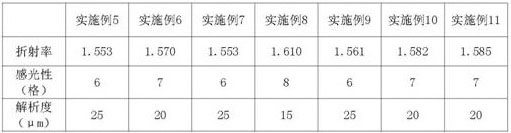

High-refractive-index alkaline water soluble resin and preparation method thereof, and high-refractive-index photoresist

ActiveCN111100237AHigh refractive indexHigh light transmittancePhotosensitive materials for photomechanical apparatusAlkaline waterPolymer science

The invention relates to high-refractive-index alkaline water soluble resin. The alkaline water soluble resin is characterized by being obtained by copolymerization of a monofunctional monomer with high refractive index and acrylic acid or methacrylic acid or / and an acrylate monomer, the weight-average molecular weight of the alkaline water soluble resin with the high refractive index is 20,000-150,000, the acid value is 500mgKOH / g-100mgKOH / g, and the refractive index is greater than or equal to 1.50. The invention also relates to a preparation method of the high-refractive-index alkaline water soluble resin and a high-refractive-index photoresist containing the high-refractive-index alkaline water soluble resin. The high-refractive-index alkaline water soluble resin and the preparation method thereof, and the high-refractive-index photoresist have the advantages that the alkaline water soluble resin with high refractive index and the photoresist with high refractive index have higherrefractive index and light transmittance.

Owner:WUXI DERBELL PHTO ELECTRONICS MATERIAL

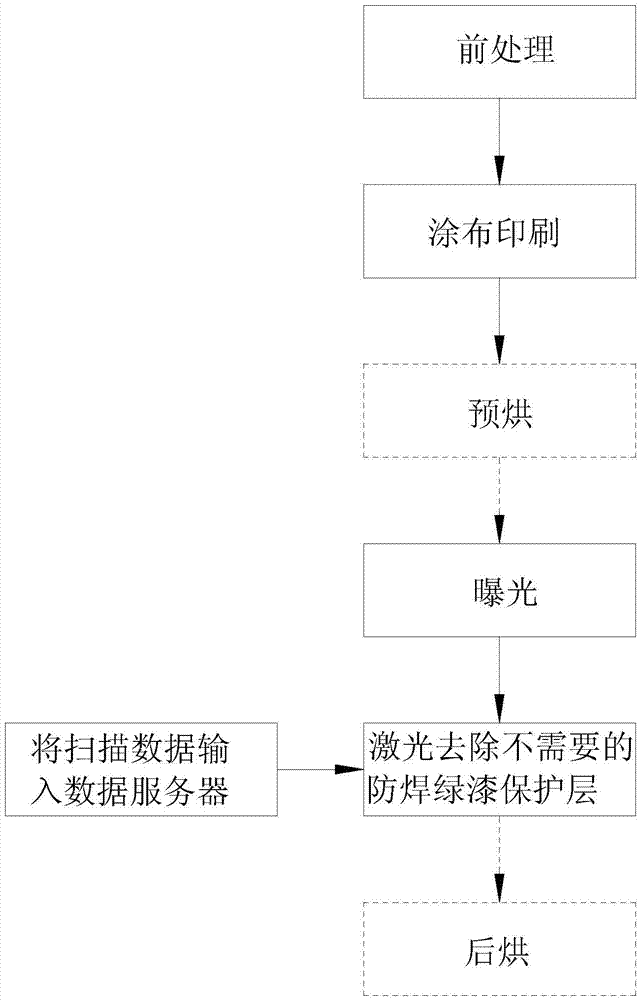

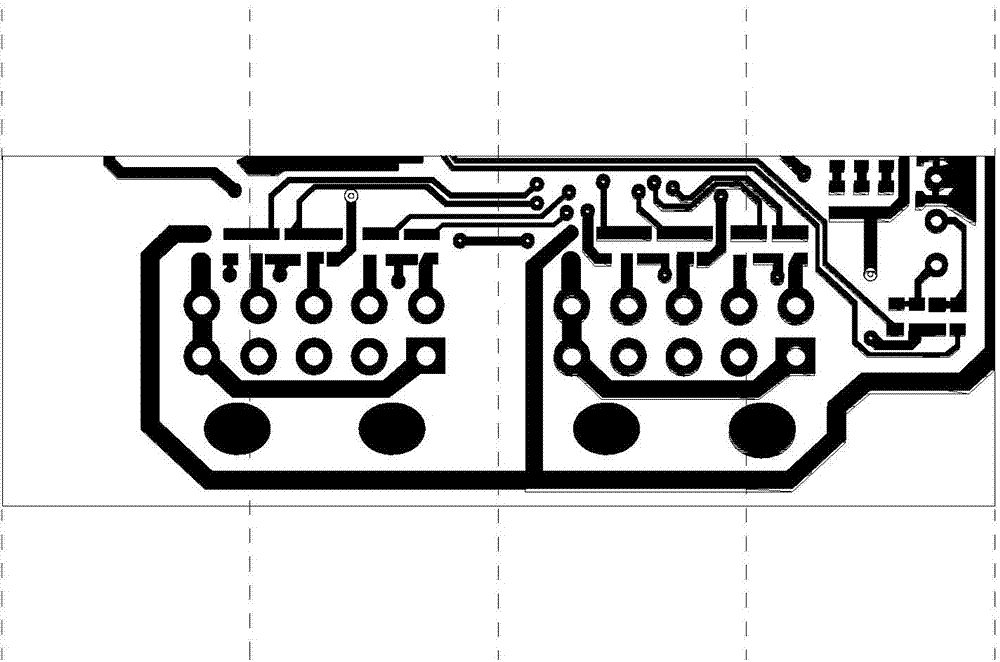

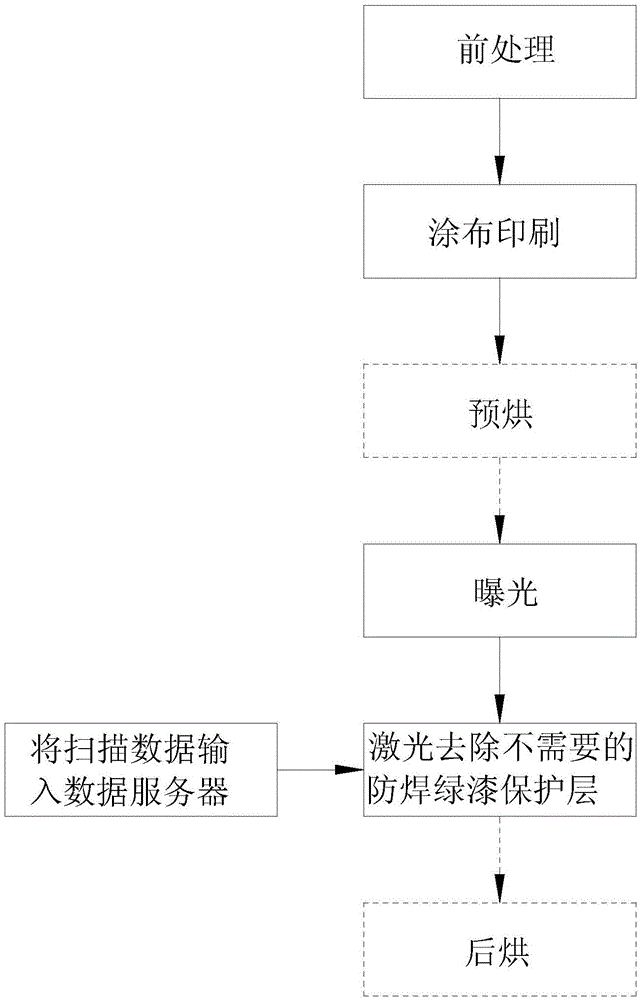

Method for machining solder mask of circuit board through laser

ActiveCN104117778ASimple production processFast exposurePrinted circuitsMetal working apparatusSolder maskLight painting

The invention discloses a method for machining a solder mask of a circuit board through a laser. The method comprises the step of performing preprocessing, coating printing and exposure and removing an unnecessary soldering preventing green paint protection layer through the laser. The development technology is replaced by the technology of removing the protection layer through the laser, waste water is not produced, environmental friendliness is achieved, energy is saved, and production cost of enterprises can be reduced. In the exposure step, the soldering preventing green paint protection layer can be directly exposed through a high-energy UV light source, the exposure speed is high, the whole face of the circuit board is directly irradiated in the exposure process, a light painting film shade does not need to be adopted, the pre-drying and post-drying steps can be omitted, the production technology is simplified, and the production cycle of products can be shortened. In the step of removing the unnecessary soldering preventing green paint protection layer through the laser, laser dynamic scanning is adopted, an image scanned by the laser can be dynamically adjusted according to deformation of the circuit board, and the quality of the products is improved.

Owner:ZHONGSHAN AISCENT TECH

Gamma ray detector and gamma ray reconstruction method

InactiveUS8299437B2Decreasing amountLess attentionMaterial analysis by optical meansTomographyHigh rateEnergy absorption

Provided are a gamma ray detector and a gamma ray reconstruction method which can be used in SPECT and PET and which combine and reconstruct the information on “Compton-scattered” gamma rays, thereby remarkably increasing gamma ray detection sensitivity, decreasing the amount of a radioactive substance given to a subject, and remarkably reducing the concern about the amount of radiation exposure. The gamma ray detector comprises an absorber scintillator 12 made from an absorptive substance exhibiting a high rate of absorption with respect to gamma rays 1 in an energy region, emitted from a subject, a Compton scattering scintillator 14 made from a Compton scattering substance exhibiting a high probability of Compton scattering, and an energy detector 16 which combines the amounts of gamma ray energy absorption simultaneously measured by the two types of scintillators to reconstruct the gamma rays emitted from the subject. The two types of scintillators 12 and 14 are arranged in multiple layers so as to absorb or Compton-scatter the whole energy of the gamma rays 1.

Owner:NAT INST OF RADIOLOGICAL SCI

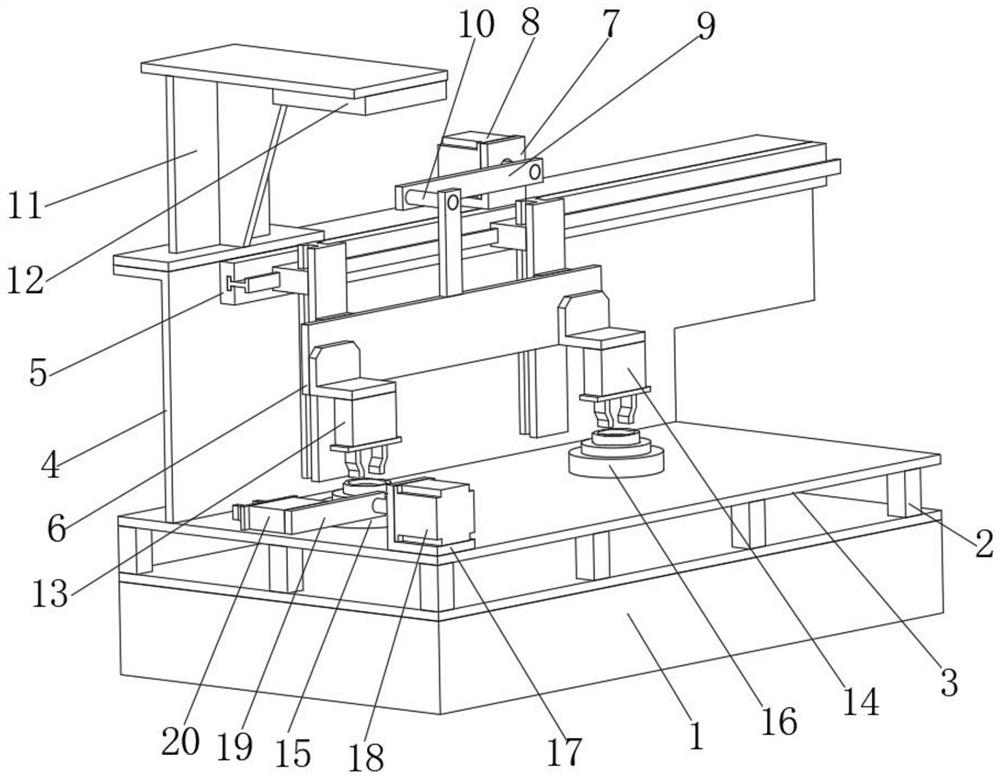

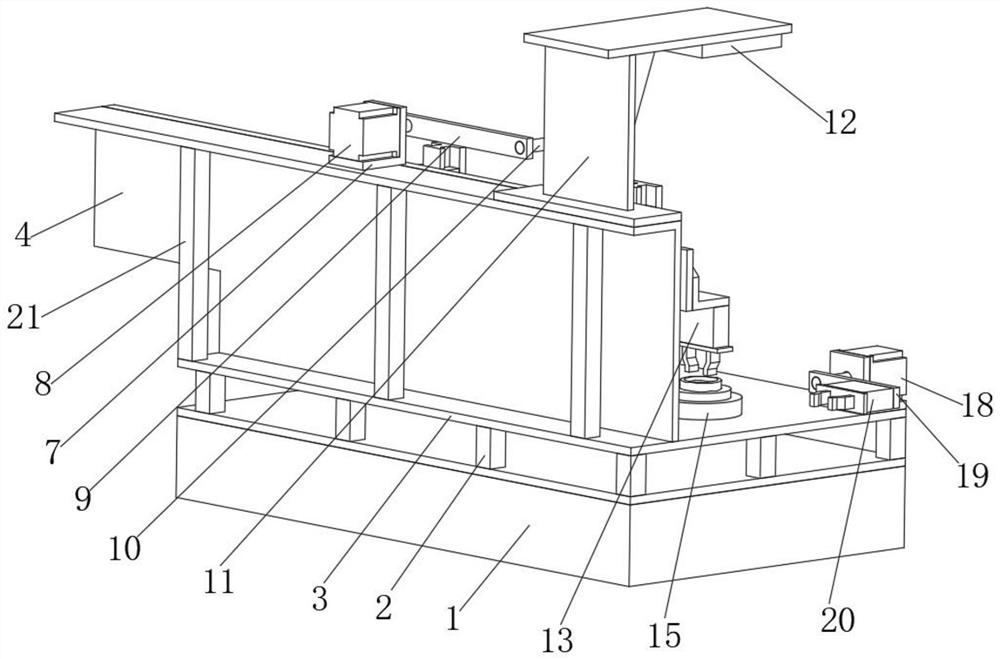

High-speed continuous automatic exposure machine

PendingCN111913366AReduce consumptionFast exposurePhotomechanical exposure apparatusMicrolithography exposure apparatusElectric machineControl engineering

The invention discloses a high-speed continuous automatic exposure machine, and the exposure machine comprises a supporting table; a plurality of supporting columns are fixedly connected to the upperend of the supporting table, a working table plate is connected to the upper ends of the supporting columns in a solitary manner, a connecting frame is fixedly connected to the rear portion of the upper end of the working table plate, and a transverse moving mechanism is fixedly connected to the upper portion of the front end of the connecting frame. A lifting mechanism is movably connected to thefront portion of the transverse moving mechanism, a first machine base is fixedly connected to the middle of the upper end of the connecting frame, a first motor is fixedly connected to the upper endof the first machine base, a supporting frame is fixedly connected to the left portion of the upper end of the connecting frame, and an exposure device is fixedly connected to the front portion of the lower end of the supporting frame. According to the high-speed continuous automatic exposure machine, the feeding, exposure, feeding and other operation processes are fully automatic, the exposure speed is high, an operator does not need to carry out frame placing preparation, unnecessary waiting time is saved, production efficiency is improved, productivity is improved, and electric energy consumption can be reduced.

Owner:嘉善福广电子科技股份有限公司

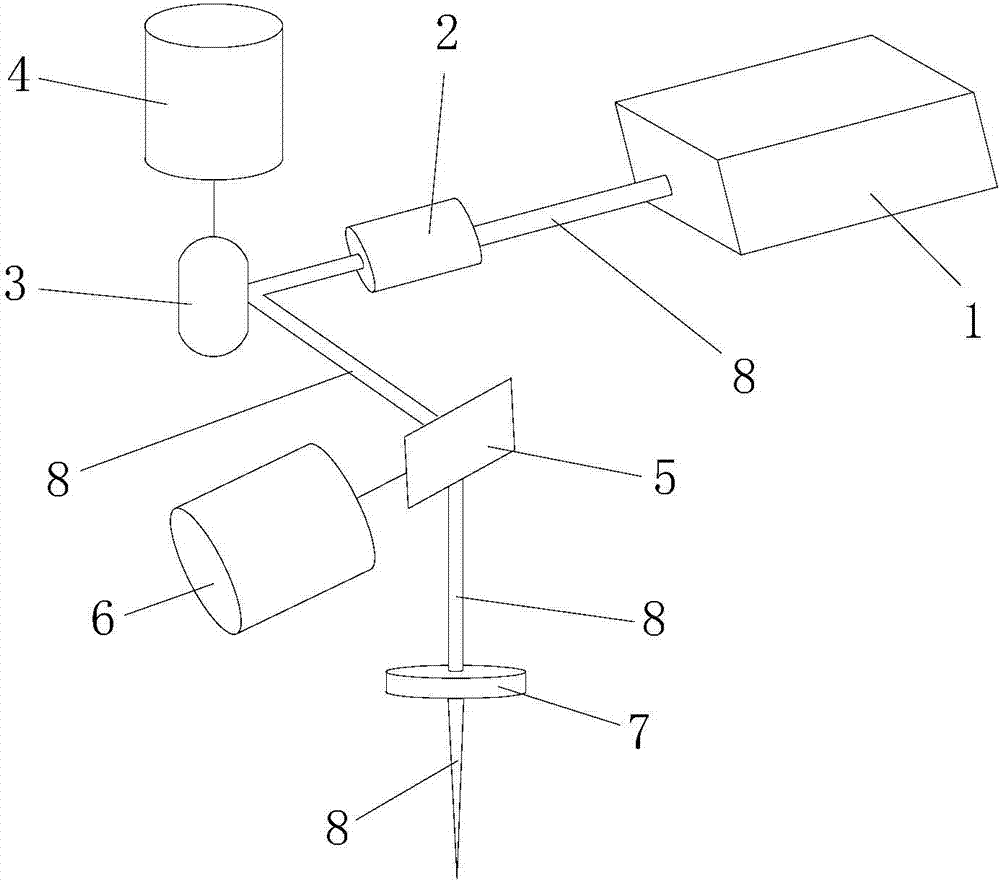

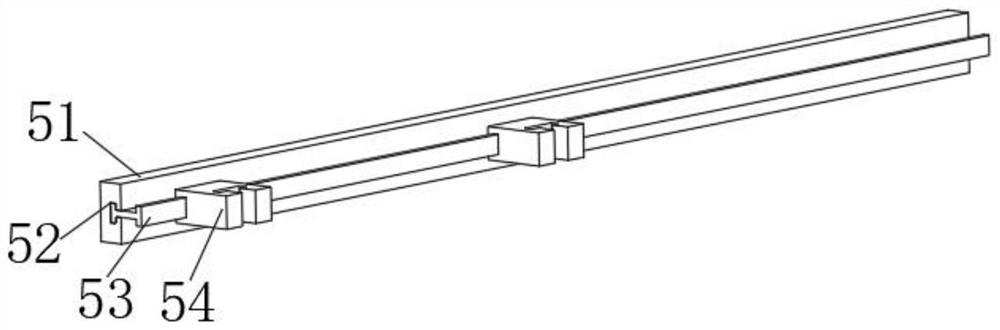

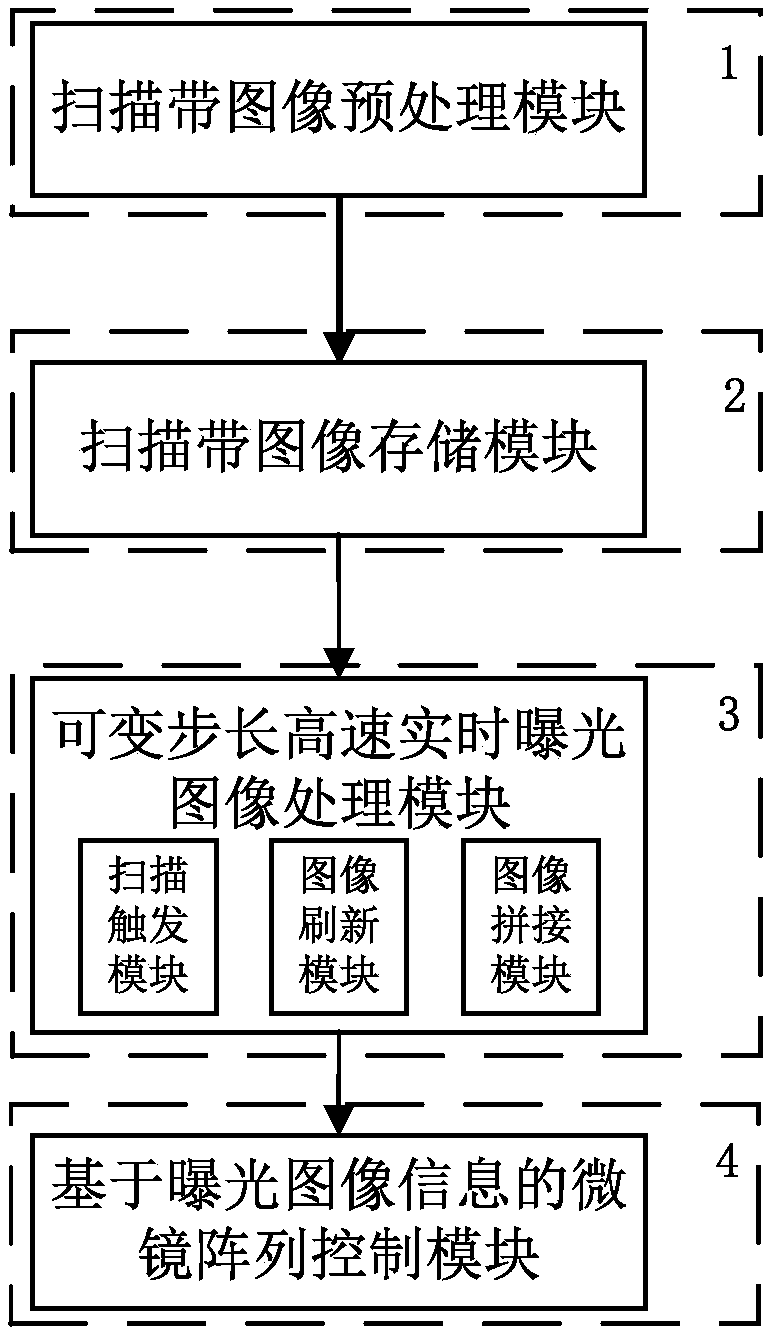

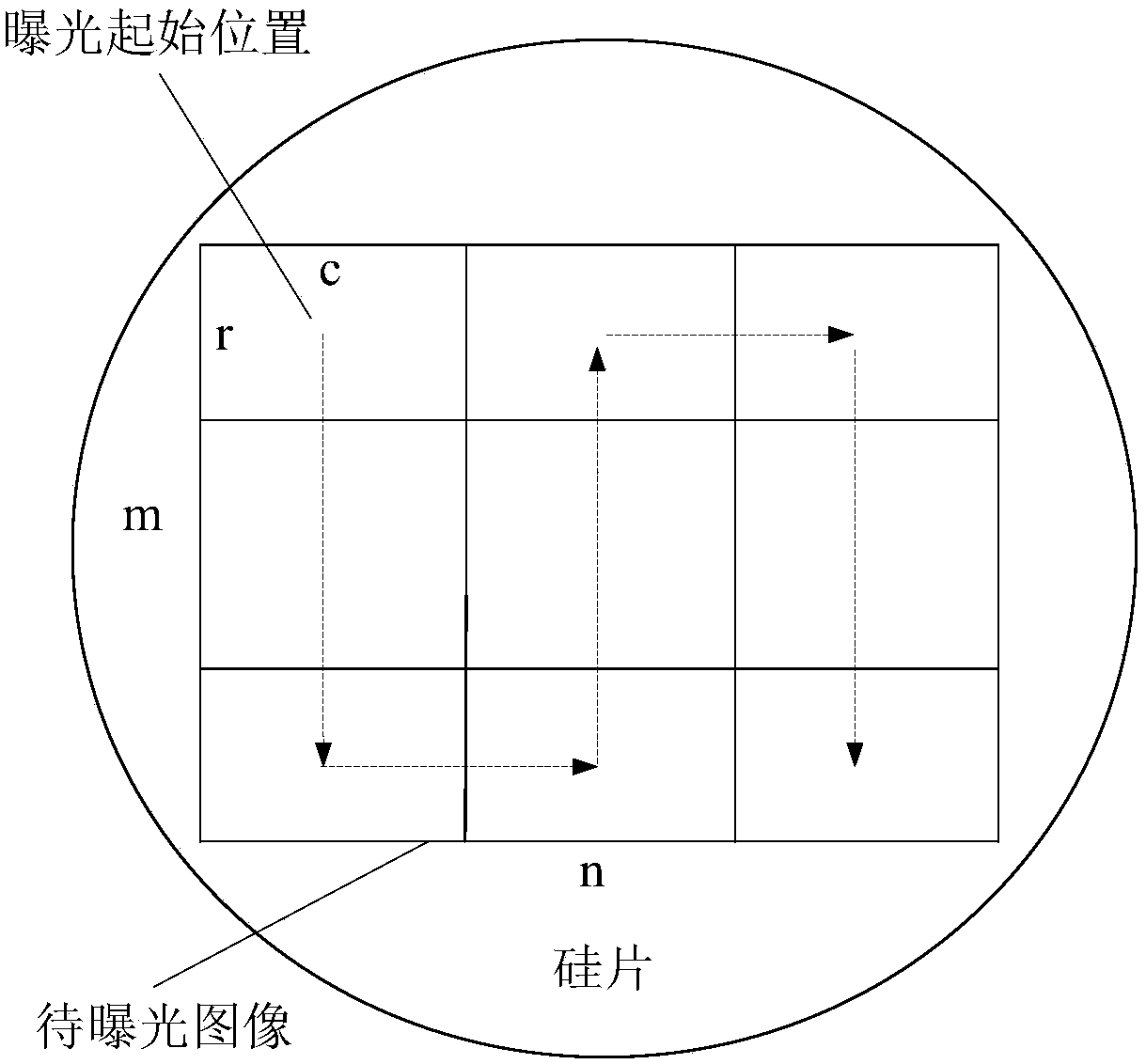

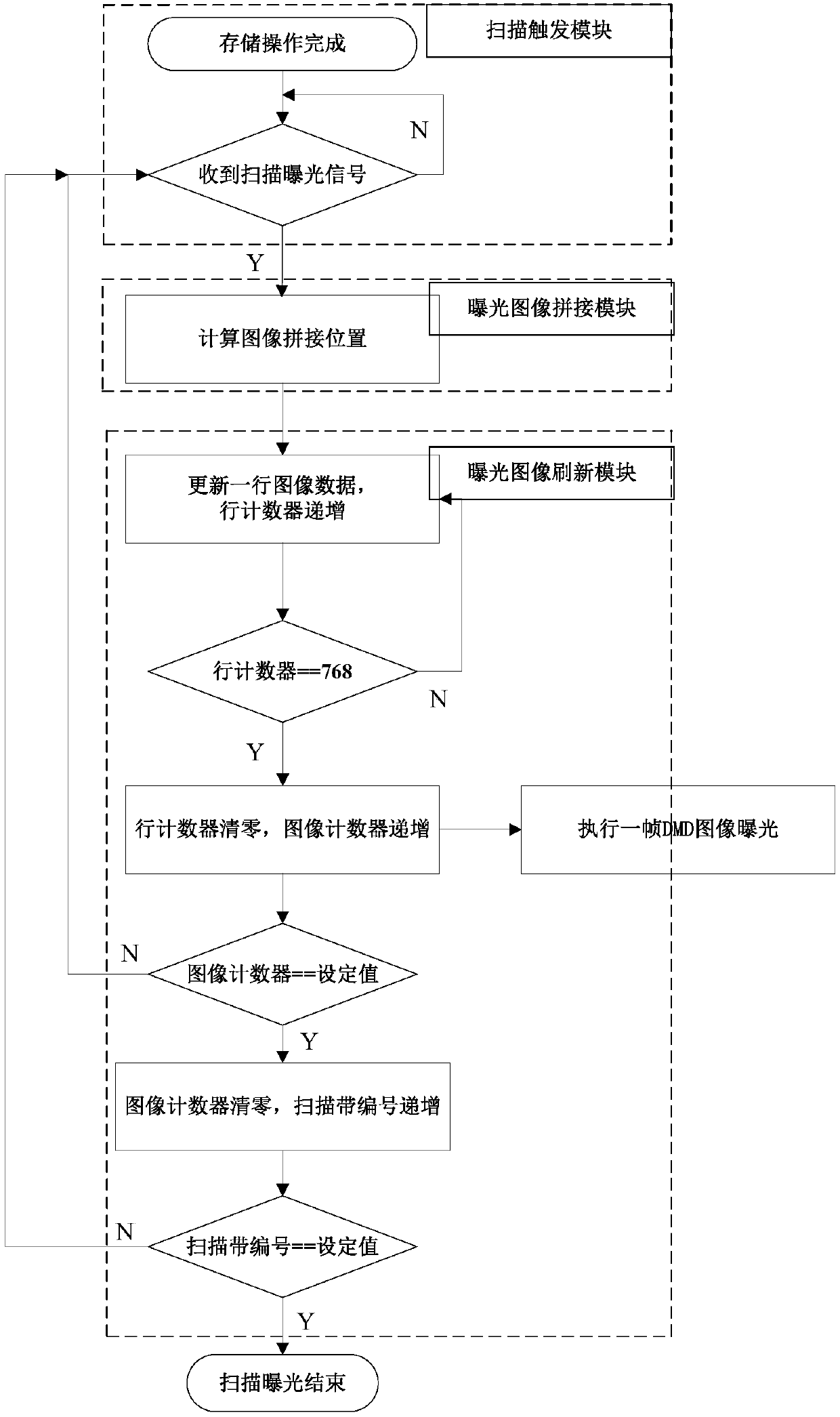

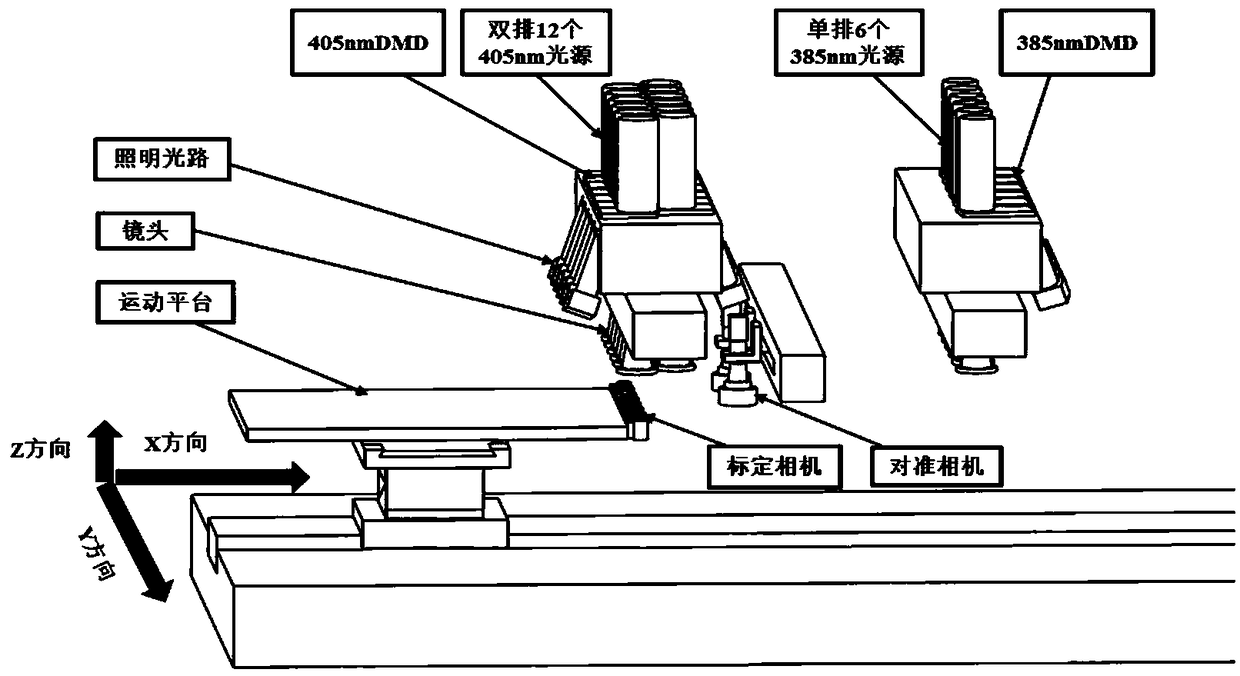

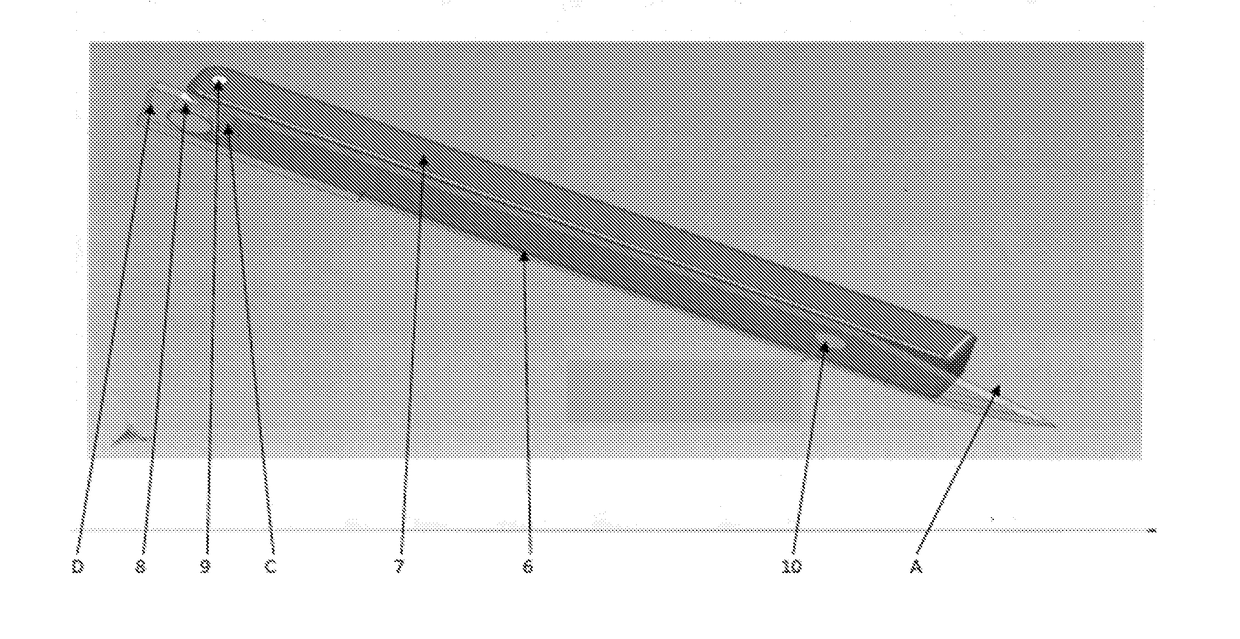

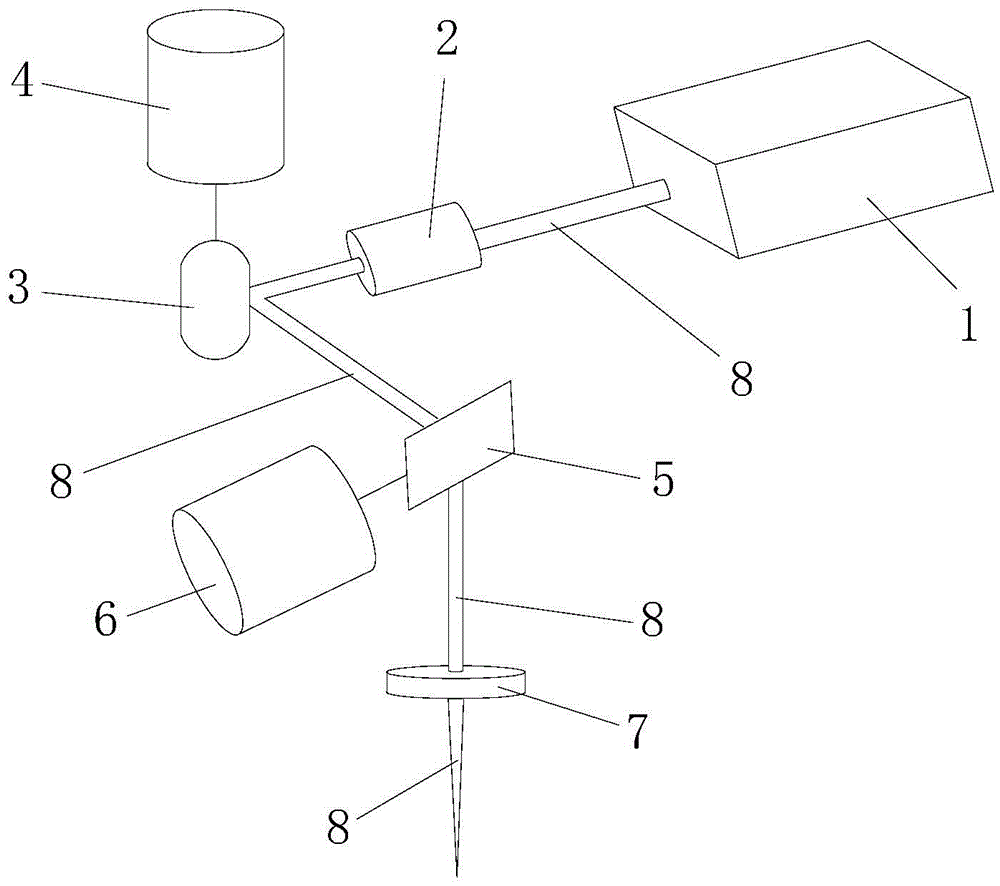

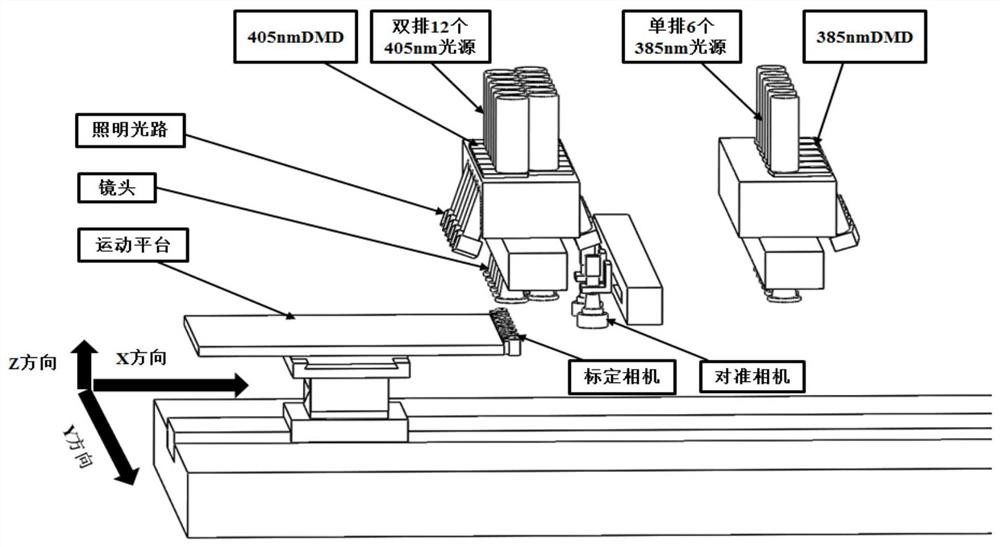

A high-speed image exposure method for dmd maskless lithography machine

InactiveCN106647181BImprove work efficiencyFast exposurePhotomechanical exposure apparatusMicrolithography exposure apparatusFully developedData transmission time

The invention discloses a high-speed image exposure method for a DMD maskless lithography machine, optimizes the DMD lithography exposure control process, avoids directly sending real-time exposure images to the DMD for exposure by the host computer software, and uses a storage device instead The image to be processed is cached, and the high-speed real-time exposure image processing is completed through the DMD control board instead of the host computer software, without the need for a communication interface transmission for each frame of the DMD real-time exposure image, reducing the amount of transmitted data and effectively reducing the transmission of the communication interface The speed limits the lithography efficiency. In the actual exposure stage, the exposure image information is directly obtained from the external storage device, and based on the exposure image information, the DMD micromirror array is automatically controlled to complete the rapid flip, giving full play to the high-speed data transmission and the hardware control board. The advantage of powerful timing control ability greatly shortens the data transmission time, improves the DMD image exposure speed, and improves the working efficiency of the DMD maskless lithography machine.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

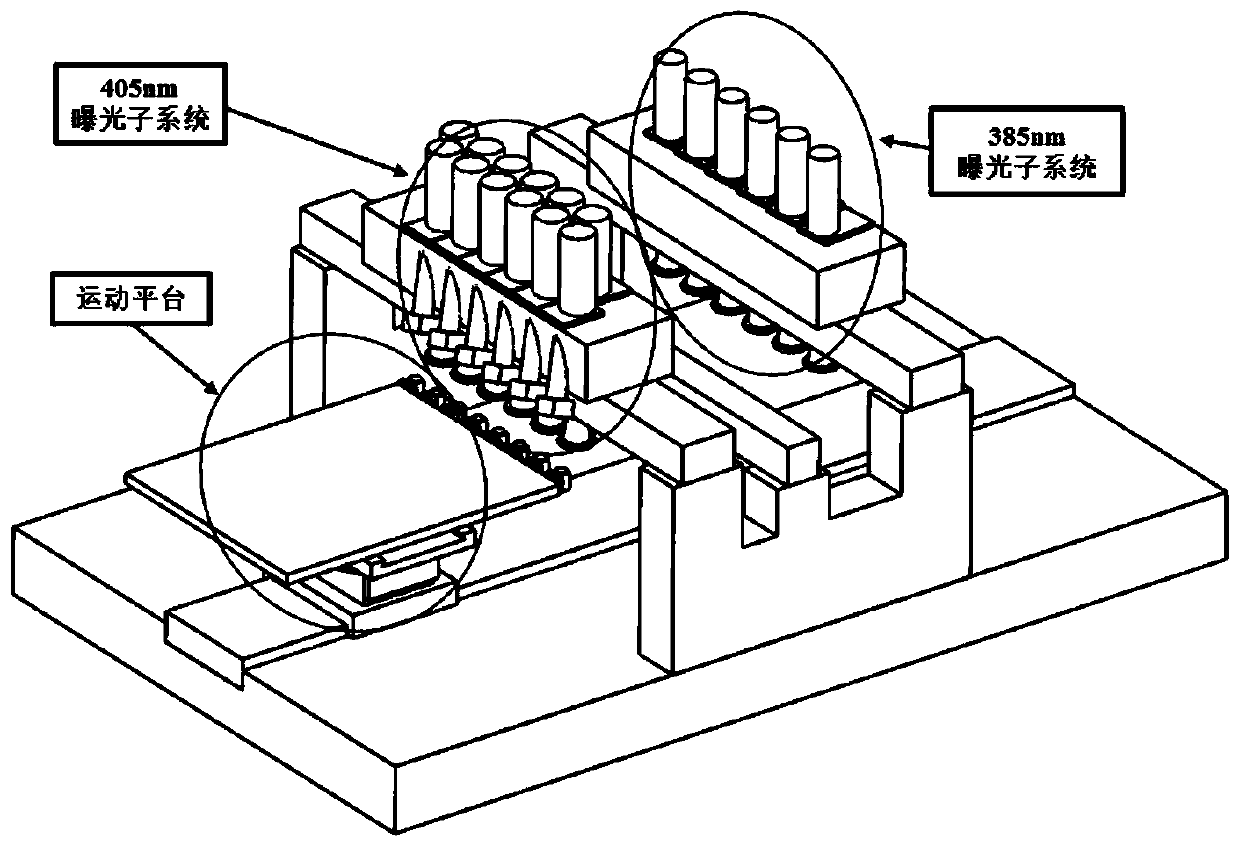

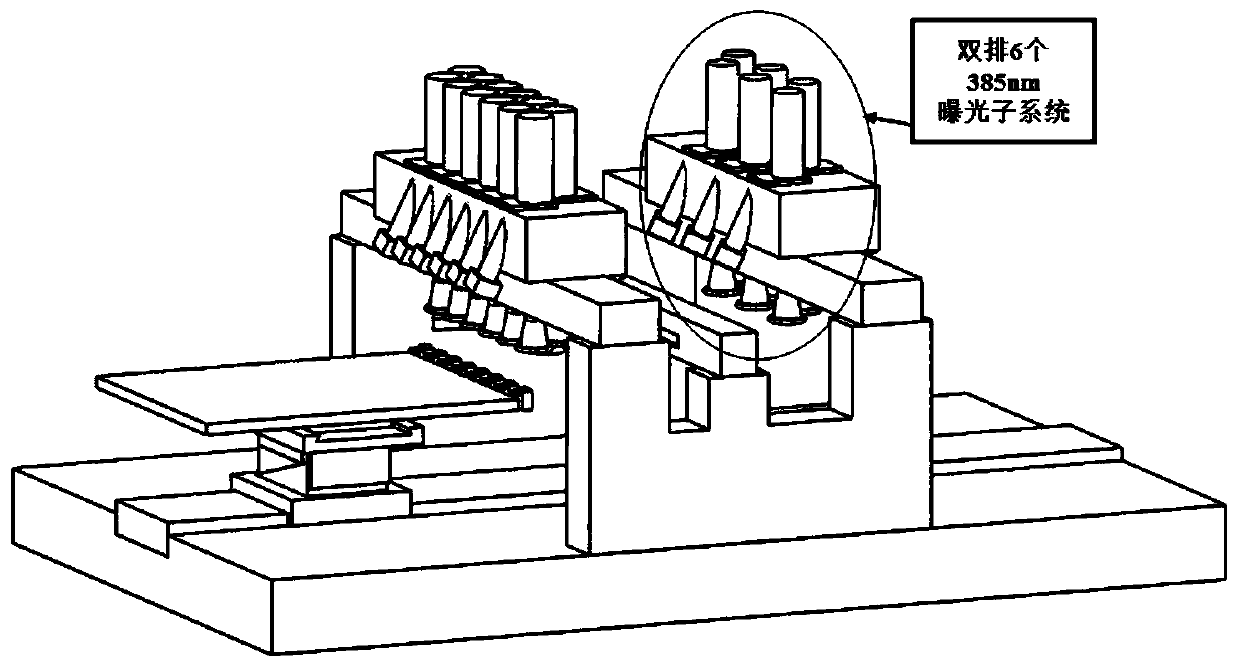

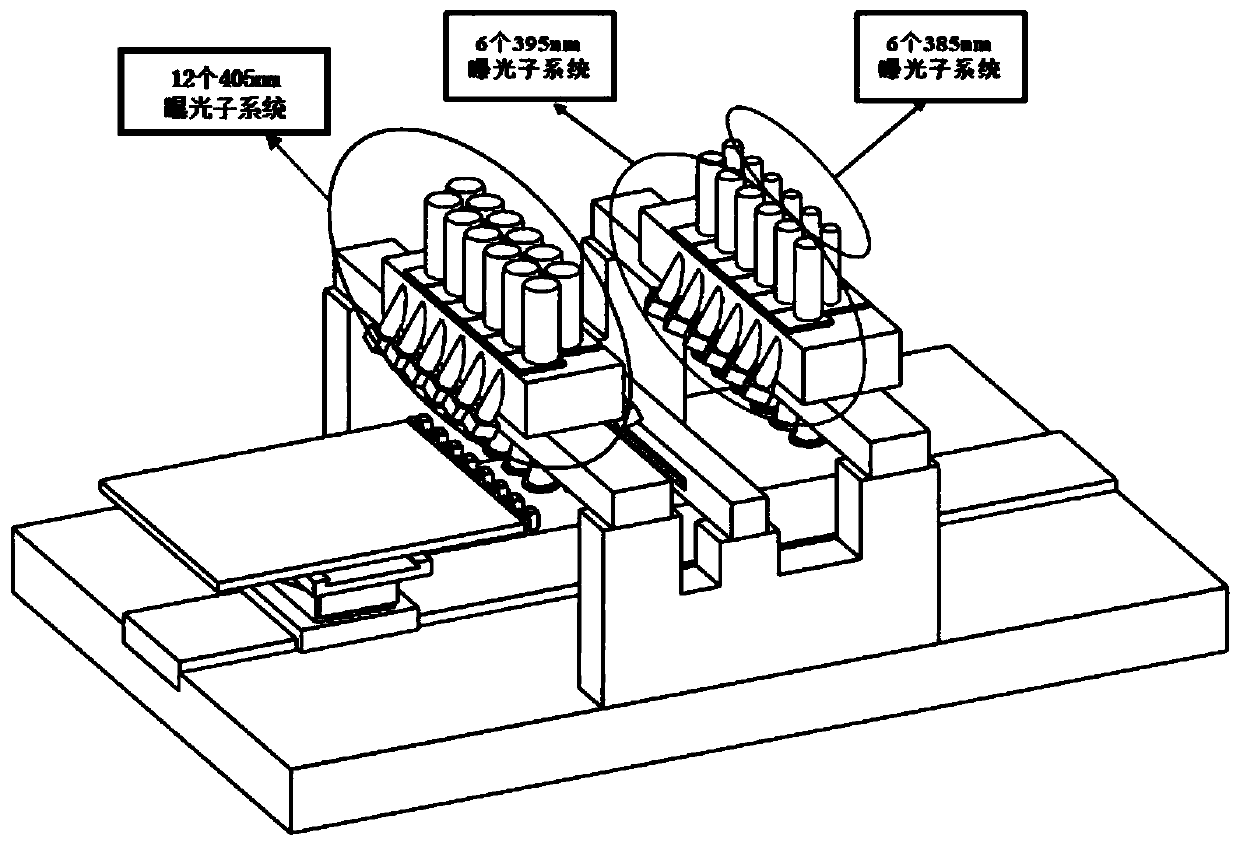

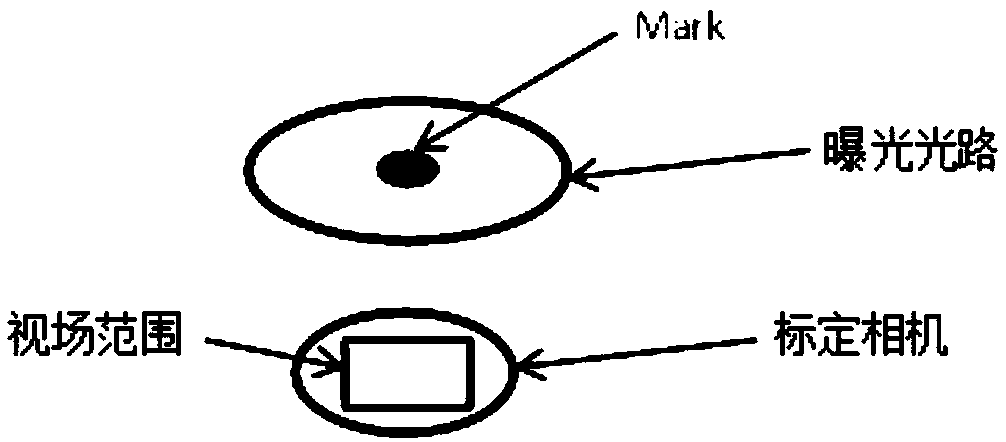

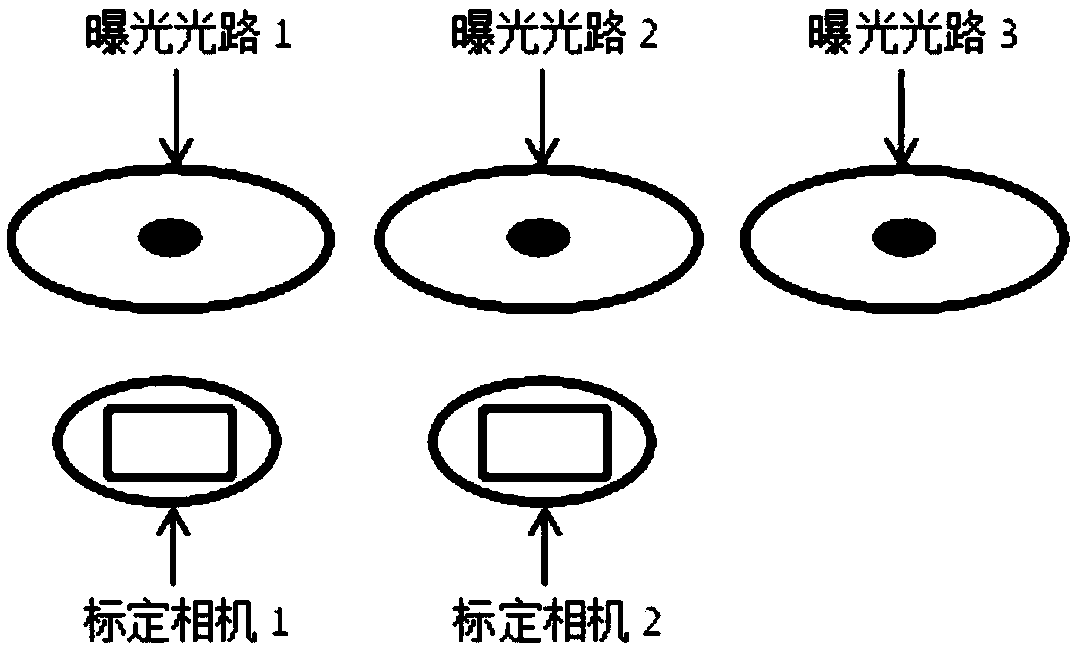

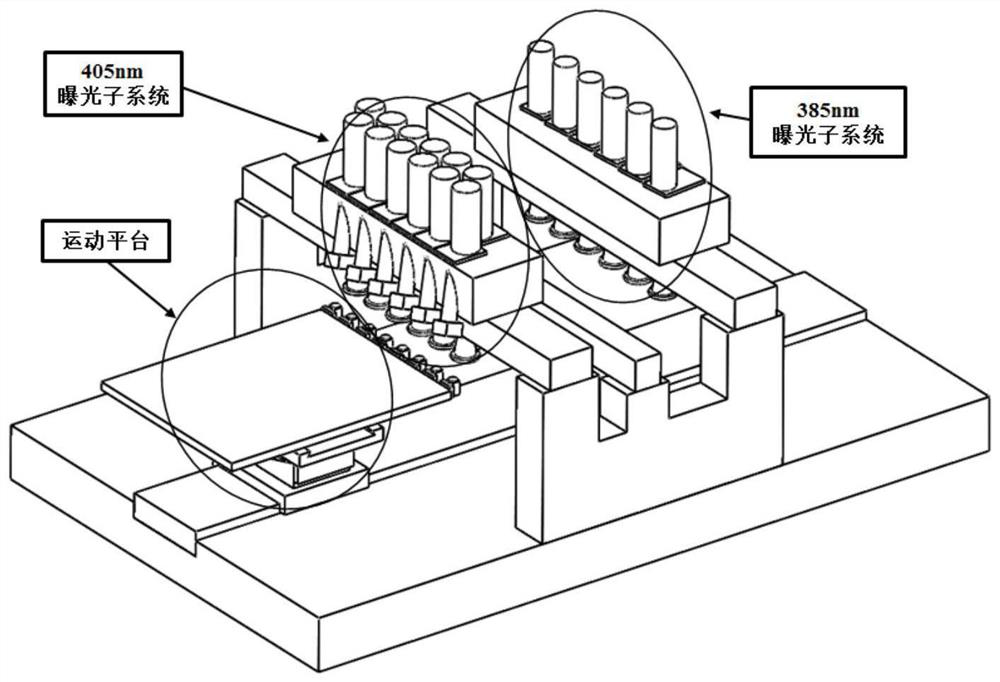

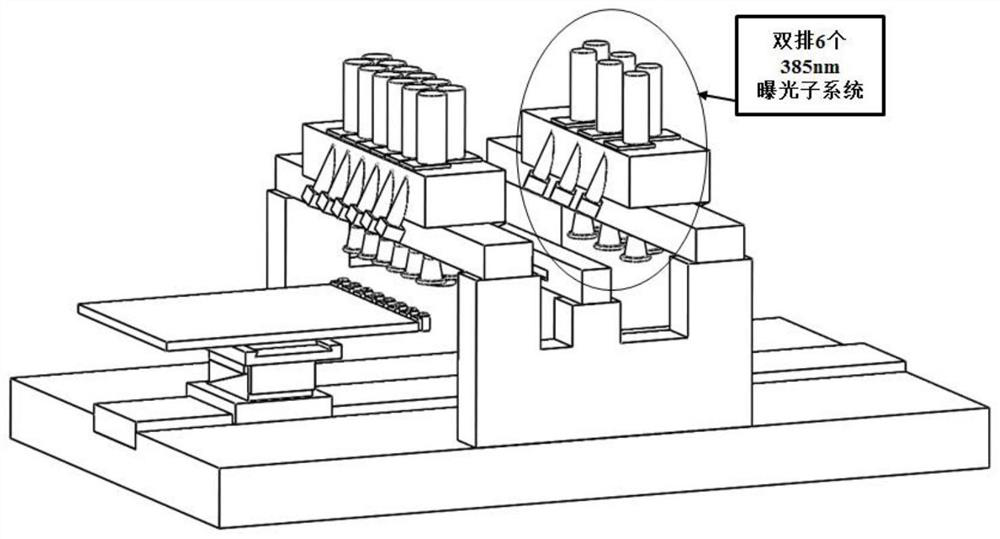

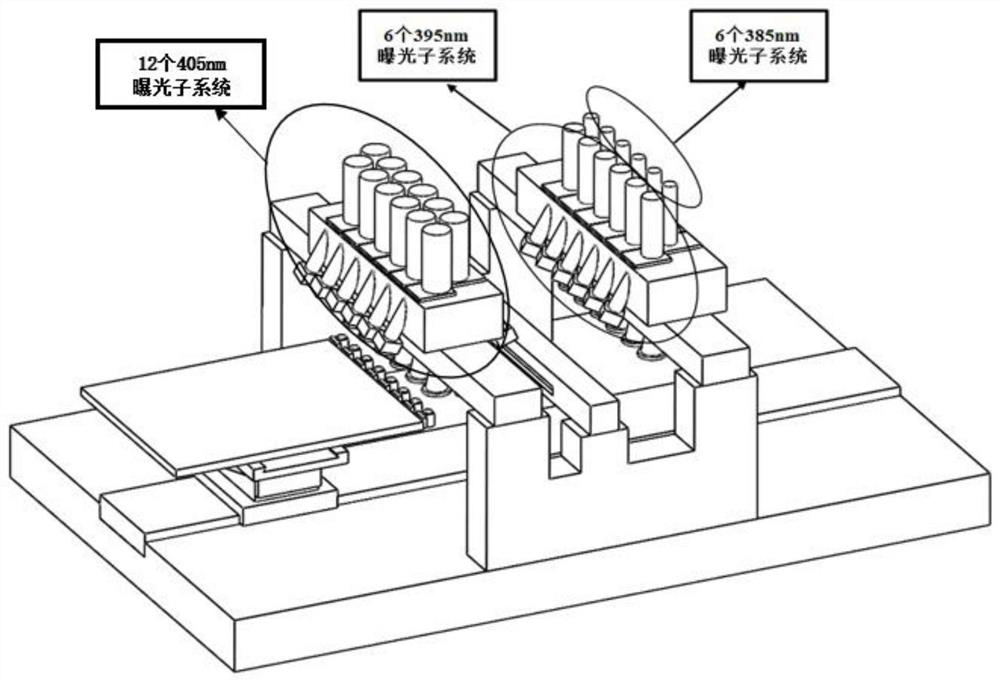

Multi-band time-dividing optical exposure device and method

ActiveCN109725503AGraphic gloss is goodImprove clarityPhotomechanical exposure apparatusMicrolithography exposure apparatusMulti bandGraphics

The invention discloses a multi-band time-dividing optical exposure device and method, and belongs to the technical field of printed circuit boards. According to the method, light sources with different wavelengths are separated, on a set of photoelectric exposure device, a plurality exposure sub systems are adaptive, each exposure sub system is matched with the light sources with different wavelengths and spatial light modulators corresponding to different wavelength ranges to perform multi-time sequencing exposure for a substrate to be exposed, the exposure sub systems are arranged at intervals at different positions in the multi-band optical exposure device scanning direction according to the time required when exposure of the substrate to be exposed is performed by employing the lightsources with the matching wavelengths to allow different exposure sub systems to allow different exposure sub systems to have a certain time interval in the photochemical reaction at different depthsof the material or with different photoinitiators to allow the photochemical reaction to be more full and allow the exposed images to be better in glossiness and clearer.

Owner:JIANGSU YSPHOTECH INTERGRATED CIRCUIT EQUIP CO LTD

Multi-band optical exposure system, device and method

ActiveCN109407473AImprove work efficiencyExtended service lifePhotomechanical exposure apparatusMicrolithography exposure apparatusMulti bandChemical reaction

The invention discloses a multi-band optical exposure system, device and method, and belongs to the technical field of printed circuit boards. The multi-band optical exposure system, device and methodseparate light sources of different wavelengths, the light sources of the different wavelengths are matched with corresponding optical devices, and the service life of the optical devices is prolonged. Exposure subsystems matched with the light sources of the different wavelengths are arranged at different positions of the multi-band optical exposure system in the scanning direction, so that thedifferent exposure subsystems can achieve the effect that photochemical reactions at different depths of a material or photochemical reactions with different photoinitiators have certain time intervals, the photochemical reactions are more sufficient, and a composite photosensitive material has better graphic gloss and higher definition. At the same time, the overall capacity and the working efficiency of the exposure device are improved.

Owner:JIANGSU YSPHOTECH INTERGRATED CIRCUIT EQUIP CO LTD

A multi-band and time-division optical exposure device and method

ActiveCN109725503BGraphic gloss is goodImprove clarityPhotomechanical exposure apparatusMicrolithography exposure apparatusSpatial light modulatorExposure

The invention discloses a multi-band time-dividing optical exposure device and method, and belongs to the technical field of printed circuit boards. According to the method, light sources with different wavelengths are separated, on a set of photoelectric exposure device, a plurality exposure sub systems are adaptive, each exposure sub system is matched with the light sources with different wavelengths and spatial light modulators corresponding to different wavelength ranges to perform multi-time sequencing exposure for a substrate to be exposed, the exposure sub systems are arranged at intervals at different positions in the multi-band optical exposure device scanning direction according to the time required when exposure of the substrate to be exposed is performed by employing the lightsources with the matching wavelengths to allow different exposure sub systems to allow different exposure sub systems to have a certain time interval in the photochemical reaction at different depthsof the material or with different photoinitiators to allow the photochemical reaction to be more full and allow the exposed images to be better in glossiness and clearer.

Owner:JIANGSU YSPHOTECH INTERGRATED CIRCUIT EQUIP CO LTD

Alkaline water-soluble resin with high refractive index and preparation method and high refractive index photoresist

ActiveCN111100237BHigh refractive indexHigh light transmittancePhotosensitive materials for photomechanical apparatusAlkaline waterPolymer science

Owner:WUXI DERBELL PHTO ELECTRONICS MATERIAL

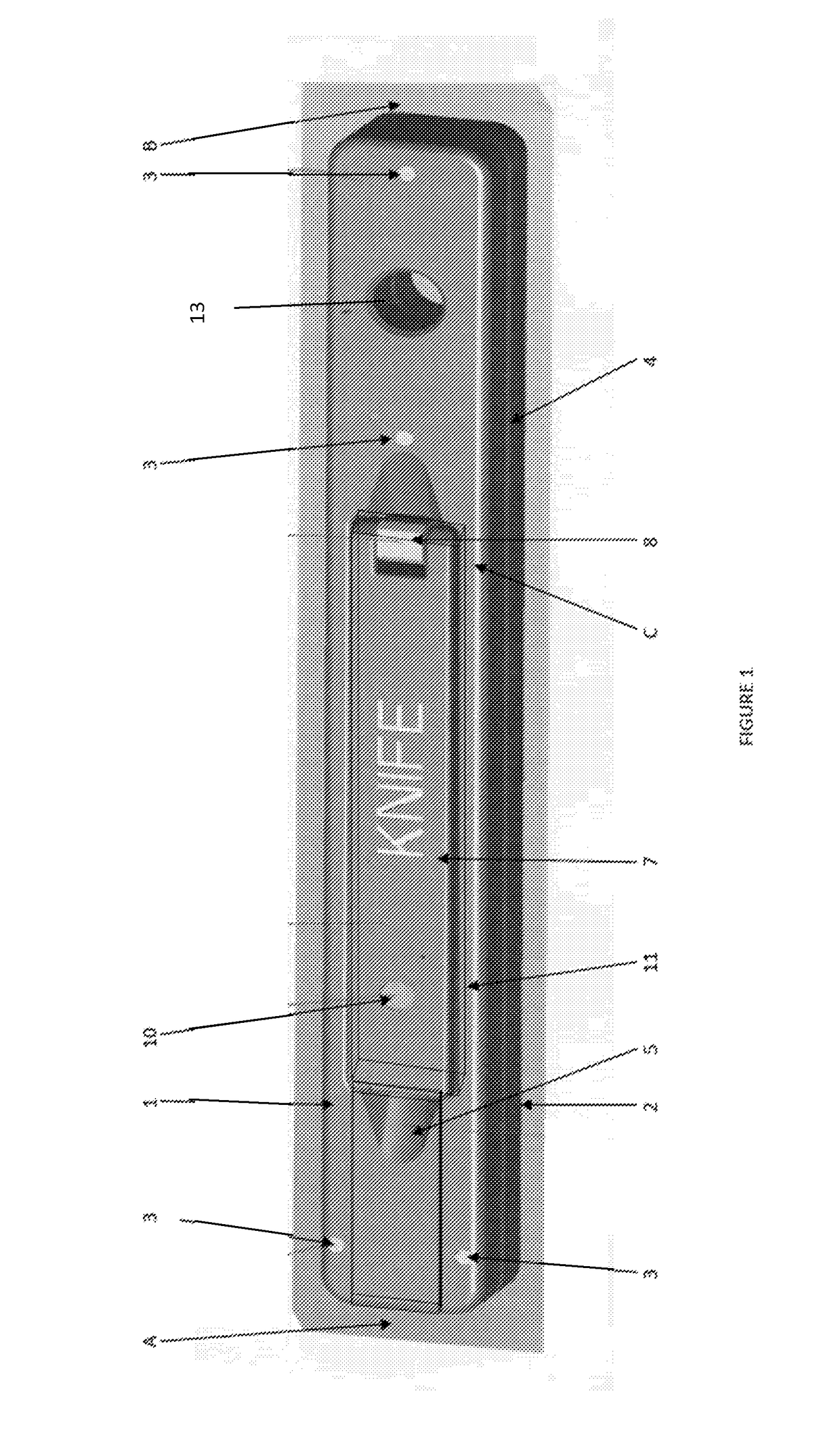

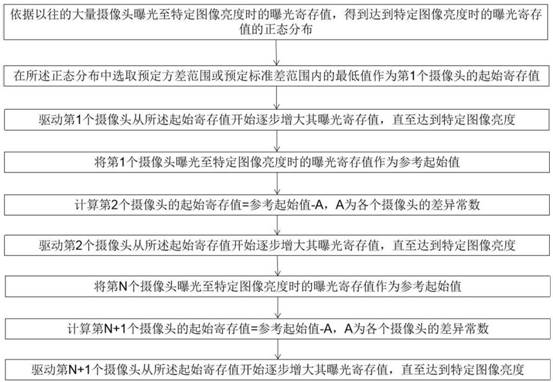

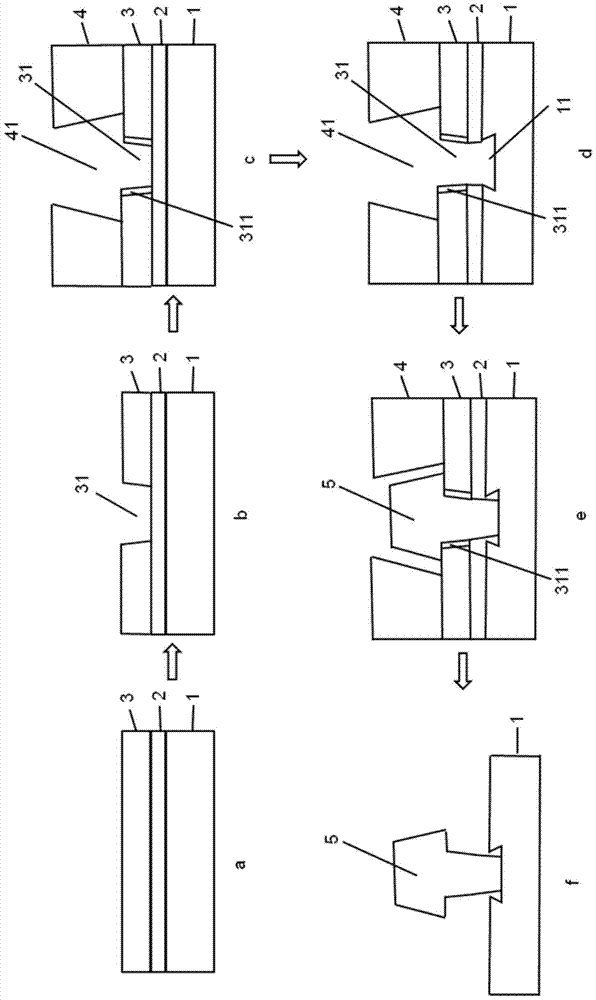

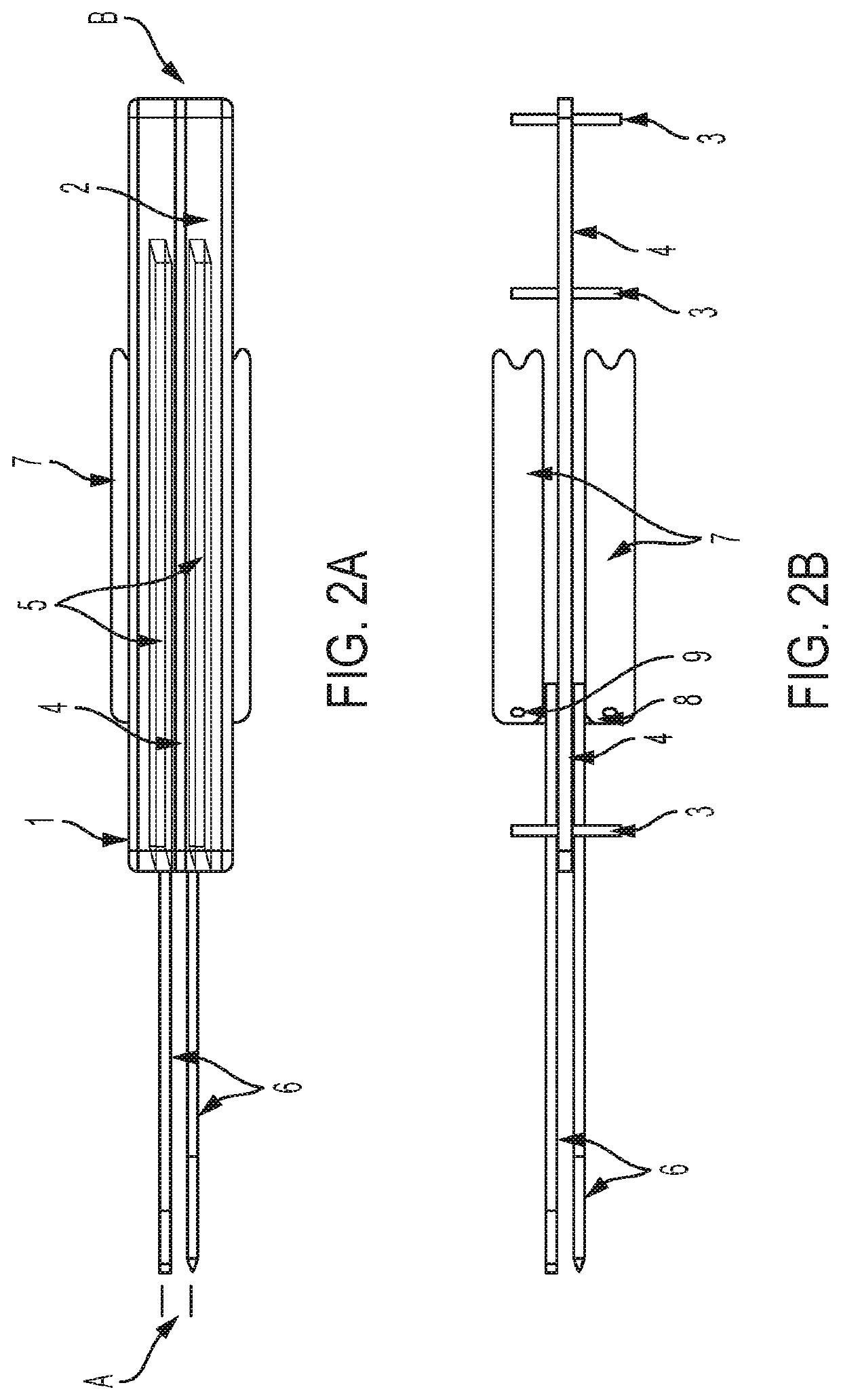

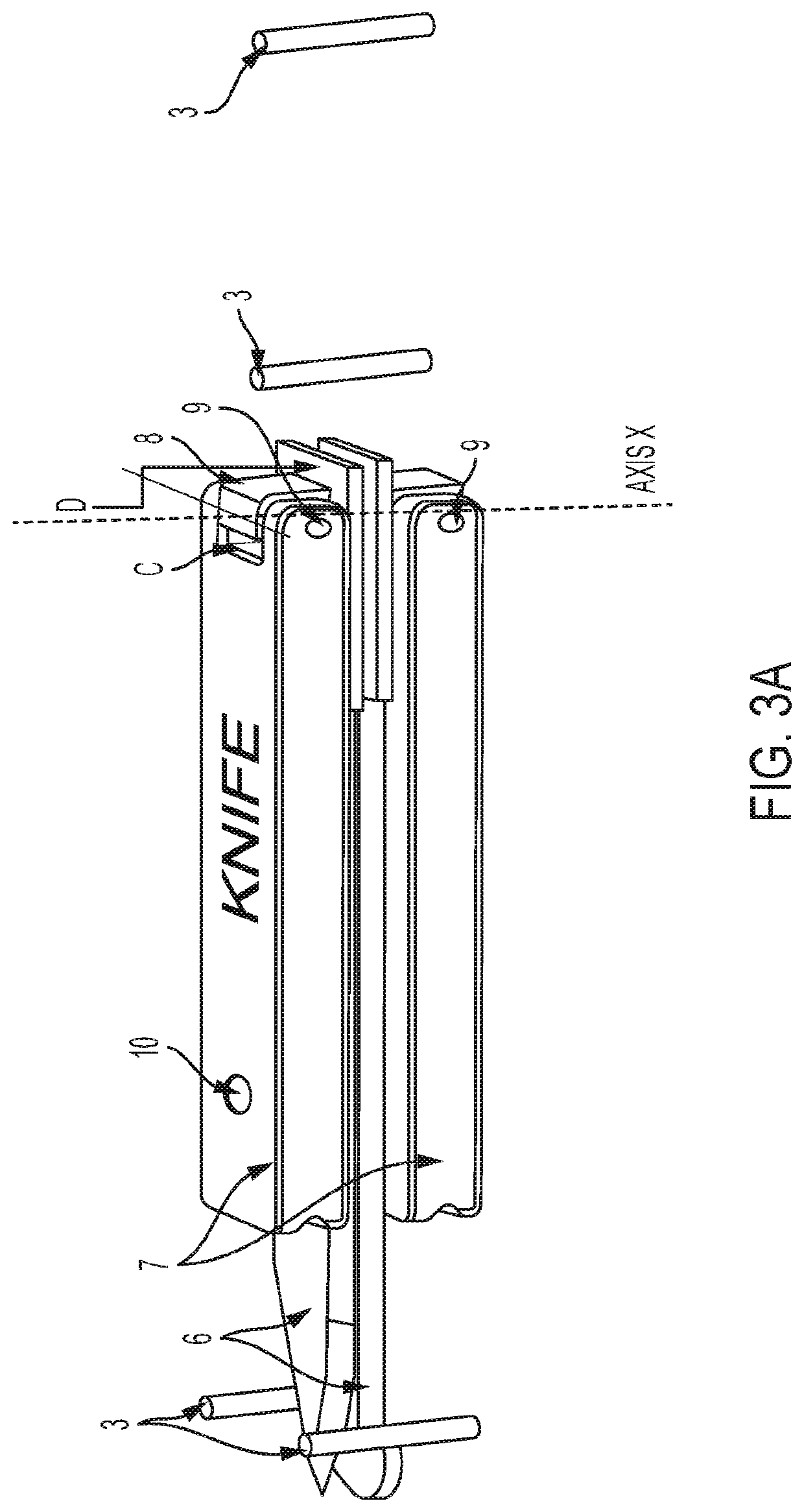

Magnetic locking utility knife

InactiveUS20170355085A1Quick and safe exposureFast exposureIncision instrumentsDiagnosticsEngineeringMagnet

A utility tool device including a handle with a tool recess and a lever arm recess; a rotatable lever arm with a magnet that is configured to fit in the lever arm recess; and a rotatable lever hinge attached to the lever arm and configured to attach to a tool; wherein the tool recess is configured to have a tool fit in the tool recess; and wherein the magnet is configured to lock a tool in place when the lever arm is in the lever arm recess.

Owner:TRIMARCHE ROBERT +2

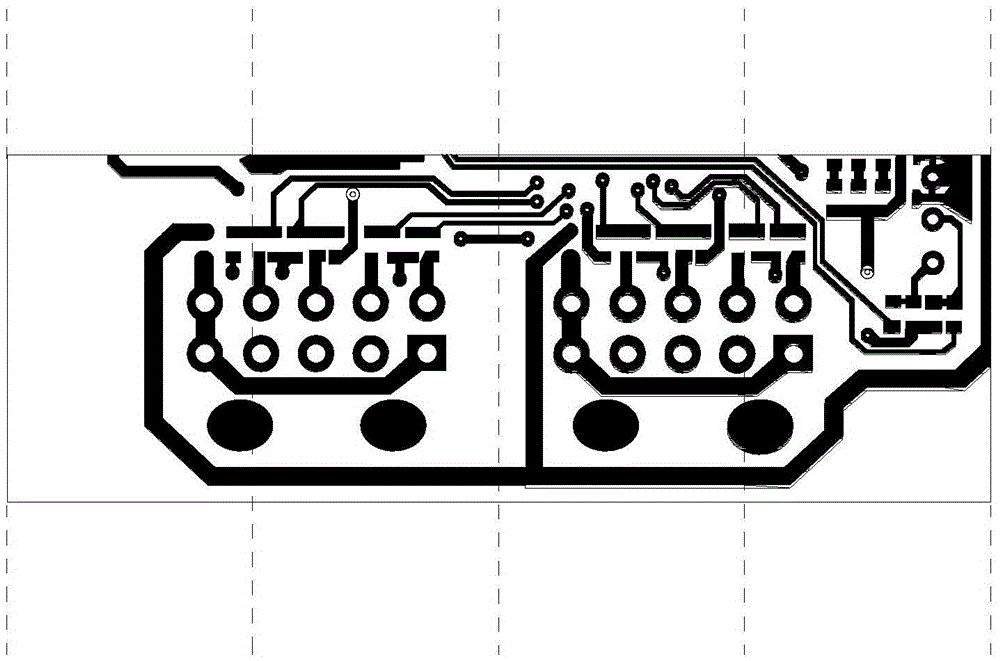

PCB production process based on laser direct writing exposure

ActiveCN114126244AImprove qualityImprove efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusAcid etchingCopper plating

The invention provides a PCB production process based on laser direct writing exposure. The PCB production process comprises the steps of S1, vacuum pressing; s2, horizontal copper deposition; s3, VCP electroplating is carried out; s4, automatically pasting a dry film; s5, performing laser direct writing exposure; s6, developing the dry film; s7, carrying out acid etching; and S8, solder resist printing. According to the method, the PCB is produced in a mode of combining VCP electroplating and laser direct writing exposure, through pulse current VCP electroplating, the copper plating depth capacity reaches 100%, the thickness ratio of hole copper to surface copper of a plating layer is 1: 1, the product quality is remarkably improved, and the production cost is reduced. A circuit film does not need to be manufactured through laser direct writing exposure, the problem of circuit exposure deviation caused by expansion and shrinkage of a circuit negative film is solved, the problem of insufficient exposure or overexposure caused by insufficient energy is solved, the exposure speed is high, the efficiency is high, the quality of a final PCB product is remarkably improved through VCP electroplating, the production cost is reduced, and the economic benefit is improved; the method has market application prospects and market popularization values.

Owner:广德东风电子有限公司

A kind of laser processing method of solder mask layer of circuit board

ActiveCN104117778BSimple production processFast exposurePrinted circuitsMetal working apparatusLaser processingSolder mask

The invention discloses a method for machining a solder mask of a circuit board through a laser. The method comprises the step of performing preprocessing, coating printing and exposure and removing an unnecessary soldering preventing green paint protection layer through the laser. The development technology is replaced by the technology of removing the protection layer through the laser, waste water is not produced, environmental friendliness is achieved, energy is saved, and production cost of enterprises can be reduced. In the exposure step, the soldering preventing green paint protection layer can be directly exposed through a high-energy UV light source, the exposure speed is high, the whole face of the circuit board is directly irradiated in the exposure process, a light painting film shade does not need to be adopted, the pre-drying and post-drying steps can be omitted, the production technology is simplified, and the production cycle of products can be shortened. In the step of removing the unnecessary soldering preventing green paint protection layer through the laser, laser dynamic scanning is adopted, an image scanned by the laser can be dynamically adjusted according to deformation of the circuit board, and the quality of the products is improved.

Owner:ZHONGSHAN AISCENT TECH

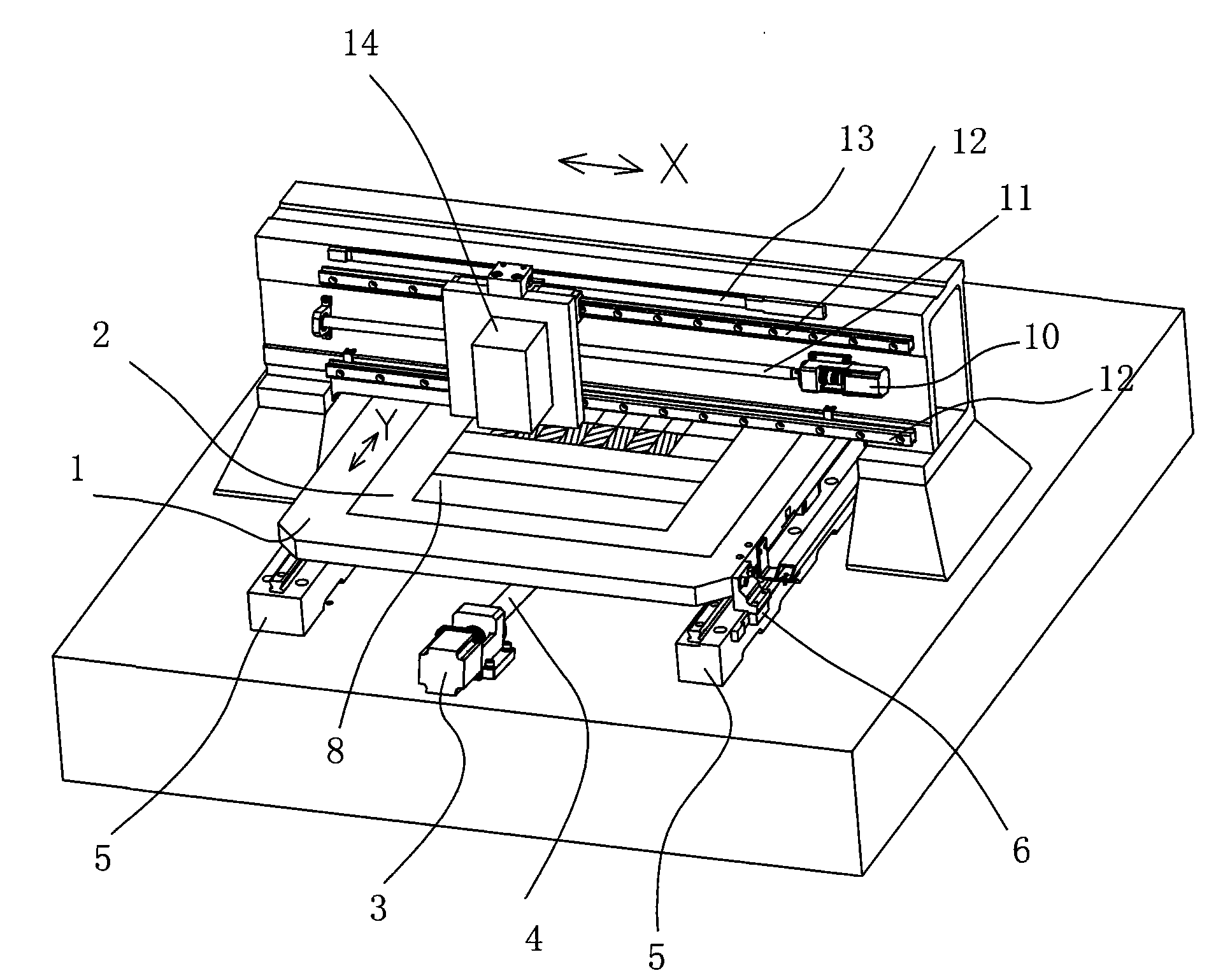

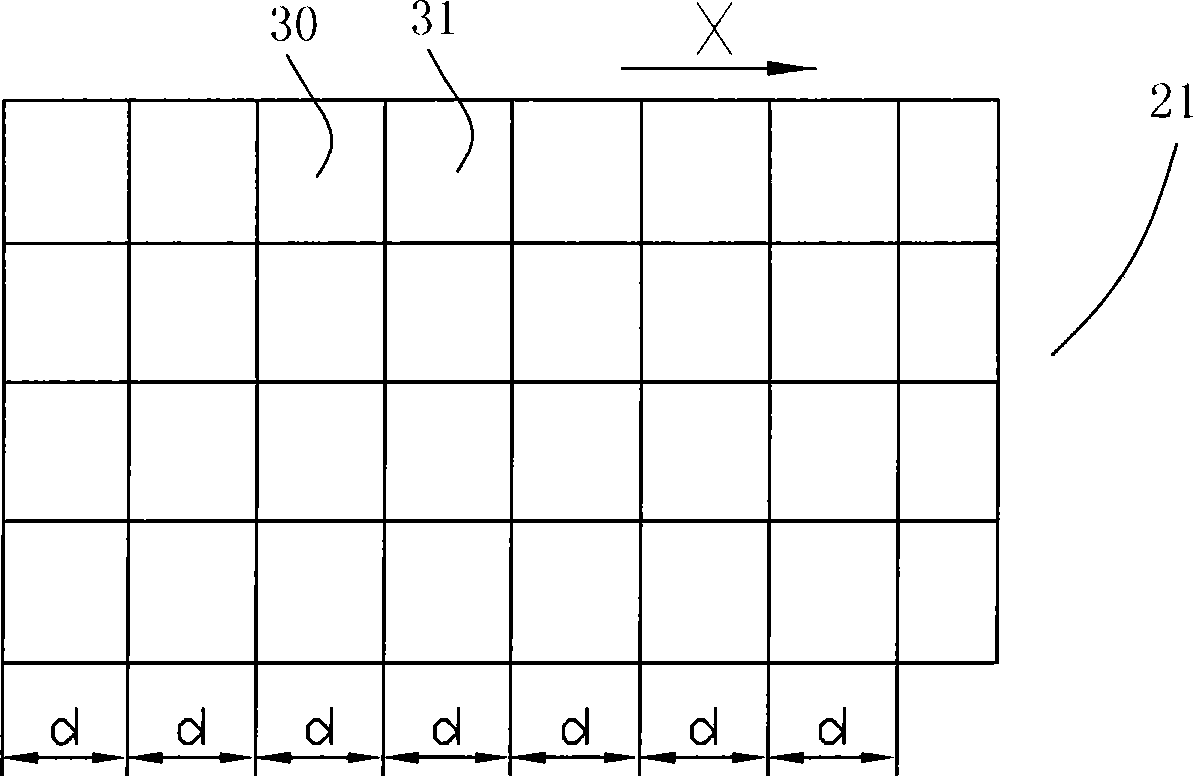

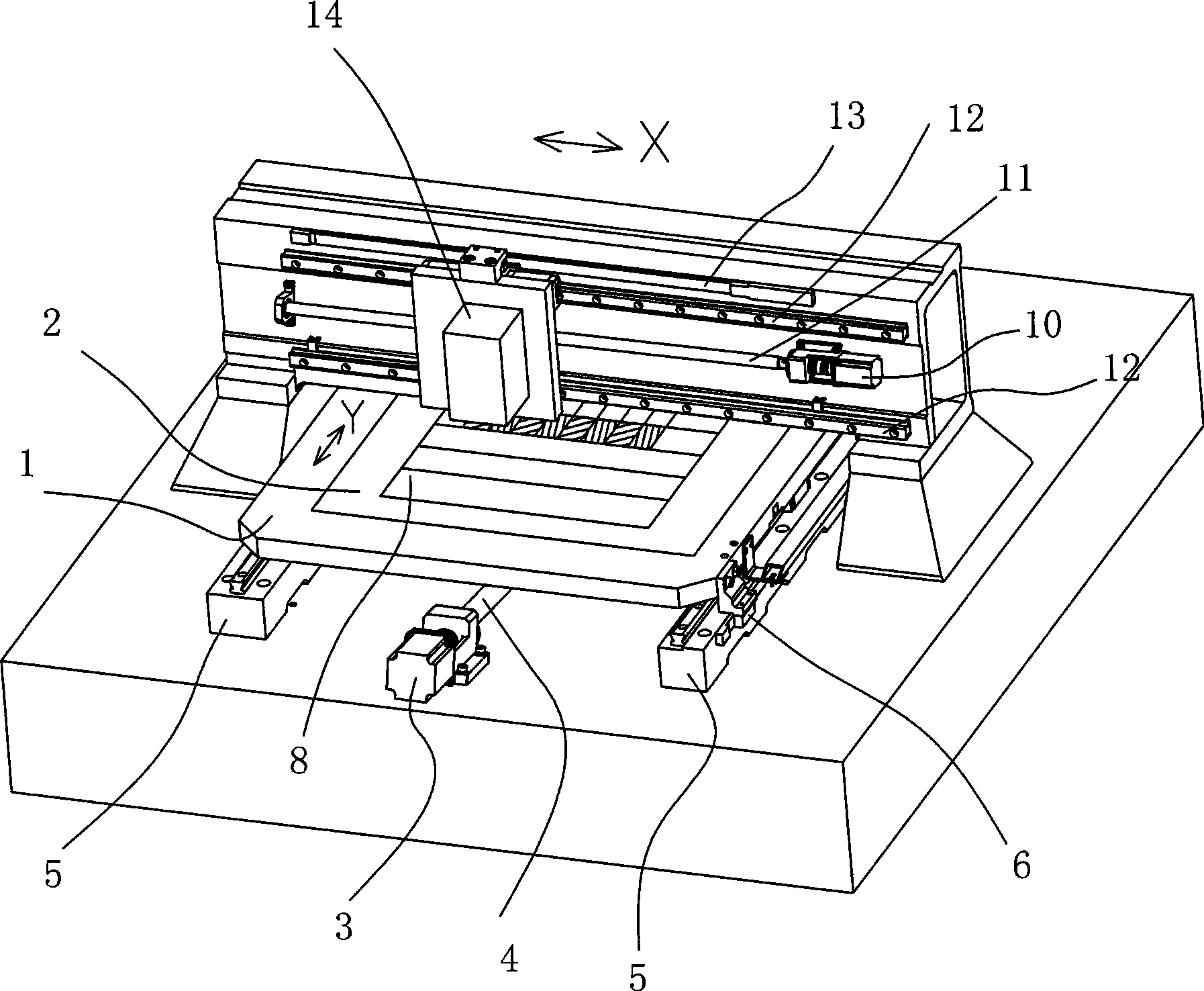

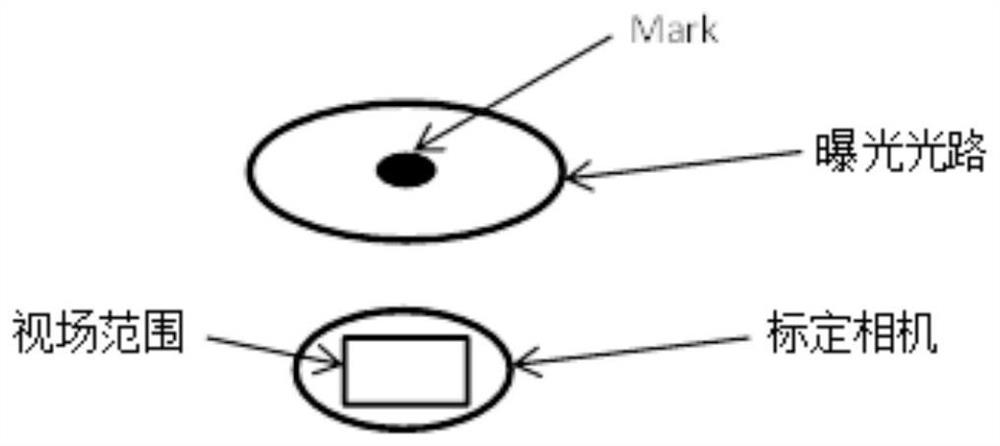

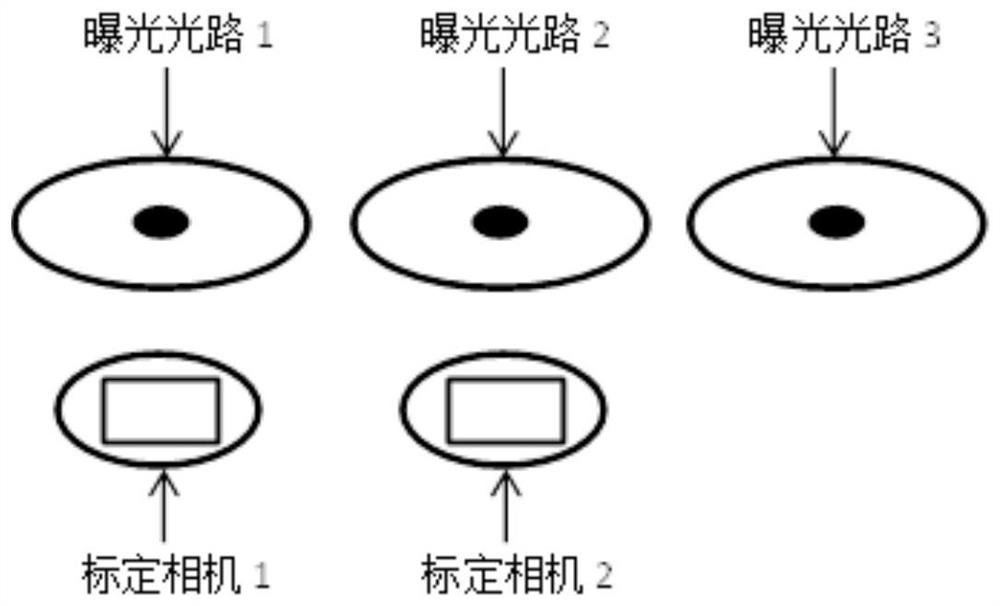

Planar array exposure device and exposure method thereof

InactiveCN101419390BEliminate Oscillation AdjustmentShorten positioning timePhotographic printingComputer visionExposure Location

The invention discloses an area array exposure device and an exposure method. The method comprises the following steps: a moving step in which an optical head of the area array exposure device moves to a position near an adjacent N+1st preset exposure position after exposing an Nth image block at an Nth exposure position, wherein N is a positive integer; a detection and adjustment step in which aposition at which the optical head stops is detected to judge whether complete pixel splicing can be realized among adjacent image blocks, if yes, an exposure step is carried out, if no, the positionof the optical head is adjusted finely to realize the complete pixel splicing of the adjacent image blocks and then turn to the exposure step; an exposure step in which the N+1st image block is exposed at the N+1st actual exposure position, and a starting point of the N+1st image block is connected with an end point of the Nth image block; and the steps are repeated until the image to be exposed is completely exposed. In the method, the position adjustment range of the optical head is controlled within the width of the pixels, thus largely reducing the positioning time and improving the exposure efficiency.

Owner:HANS LASER TECH IND GRP CO LTD +1

A multi-band optical exposure system, equipment and method

ActiveCN109407473BImprove work efficiencyExtended service lifePhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsEngineering

The present invention disclosed a multi -band optical exposure system, equipment and methods, which belong to the field of printing line board technology.The multi -wave segment optical exposure system, equipment and methods provided by the present invention can increase the service life of optical devices by separating different wavelength light sources.The system is set in different positions in the direction of the optical exposure system of multi -band optical exposure system, so that different exposure subsystems can be realized in different depths of the material, or a certain time interval between photochemical reactions with different optical reactions, making the optical chemical reaction more more more than a more chemical reaction.Fully allows the graphic gloss of composite light -sensitive materials to better gloss and higher definition, and at the same time, the overall production capacity and work efficiency of the exposure equipment have been improved.

Owner:JIANGSU YSPHOTECH INTERGRATED CIRCUIT EQUIP CO LTD

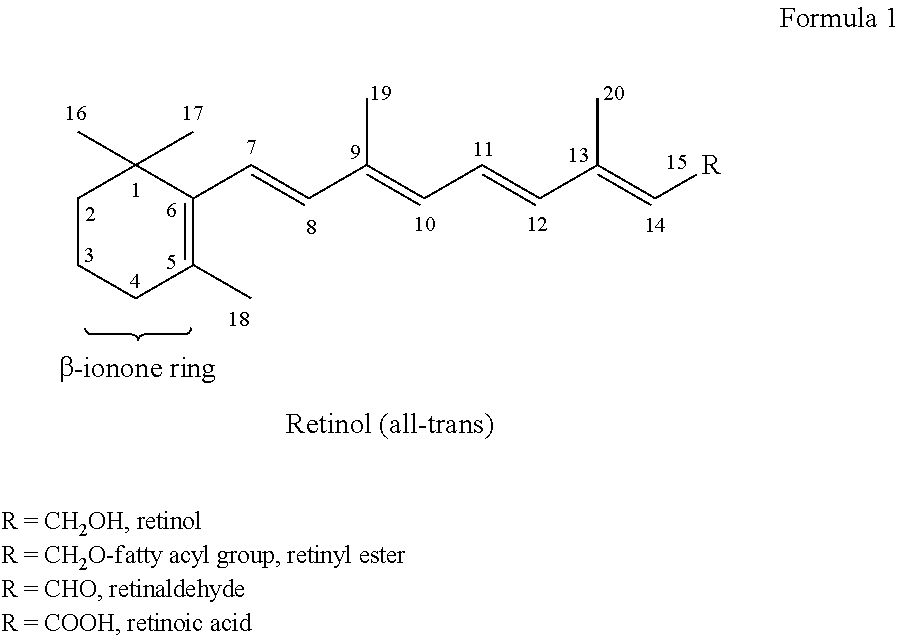

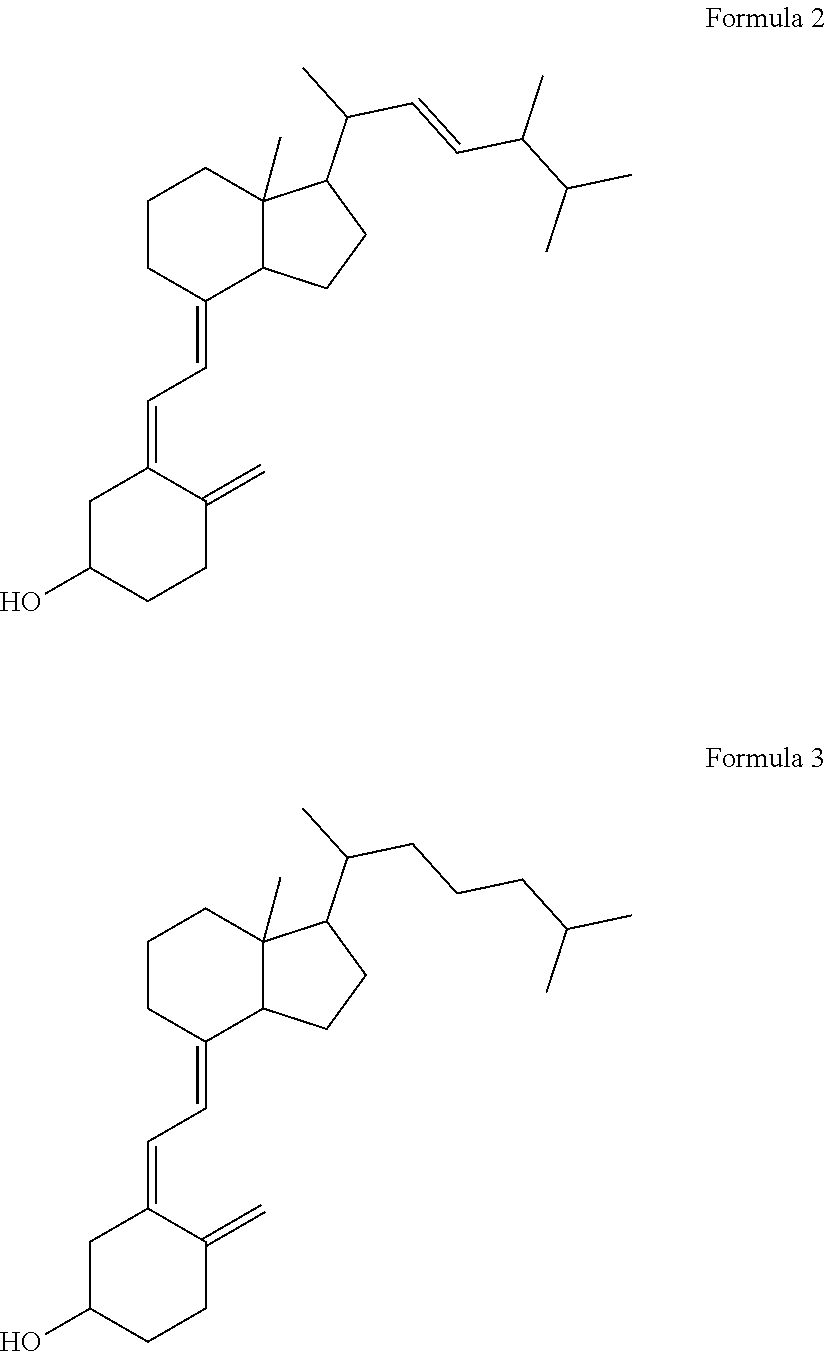

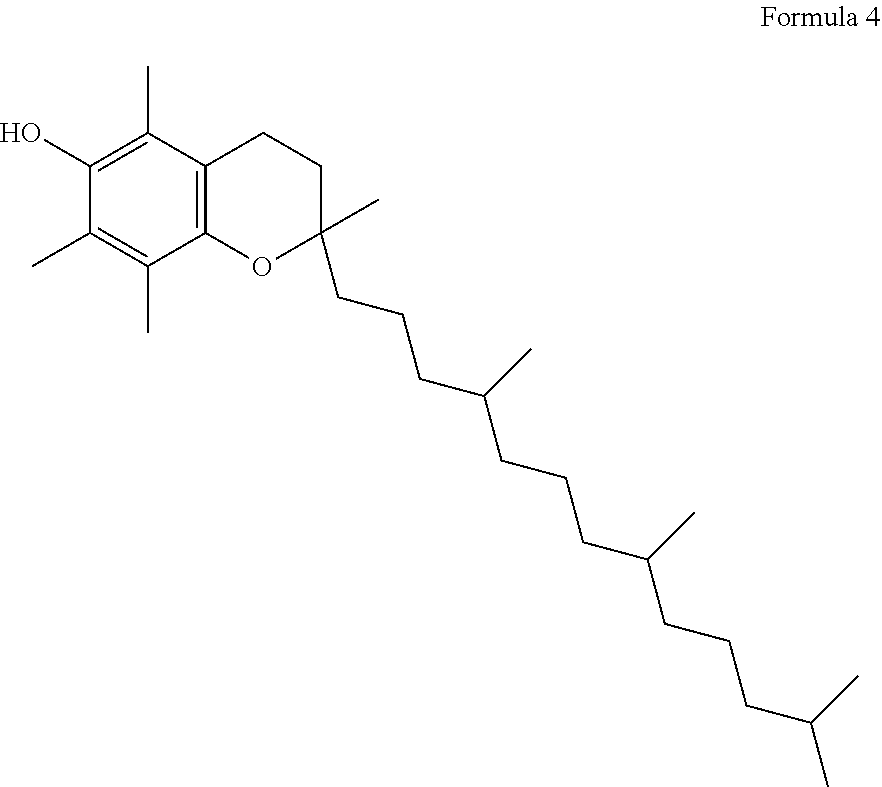

Capsule, Tablet or Pill

InactiveUS20220047611A1Fast exposureQuick exposureHydroxy compound active ingredientsPharmaceutical non-active ingredientsFat-Soluble VitaminVitamin a1

Disclosed is a capsule, tablet or pill comprising a formulation at least two of the fat-soluble vitamins vitamin A, vitamin D, vitamin E and vitamin K; and one or more kinds of medium-chain triglyceride; also disclosed are foods, drinks and pharmaceutical compositions comprising the capsule, tablet or pill; and methods of treatment of a patient comprising administration of an effective amount of the capsule, tablet or pill. The capsule, tablet or pill is particularly, but not exclusively, suitable for use in treating cystic fibrosis patients.

Owner:PARAPHARM DEV LTD

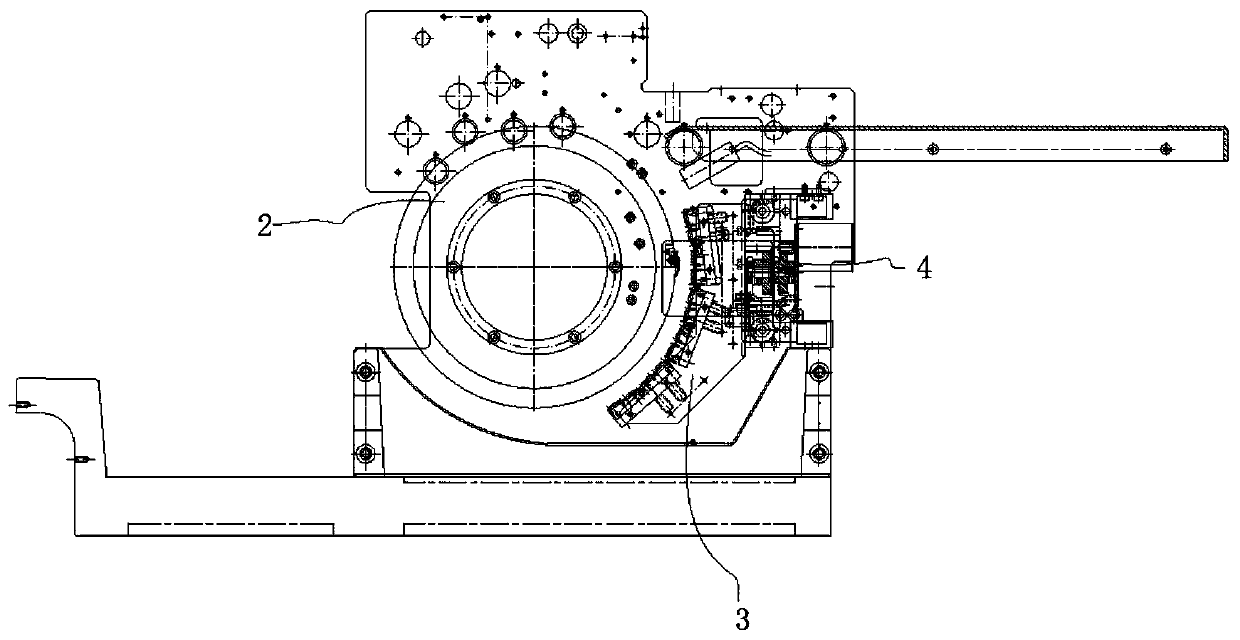

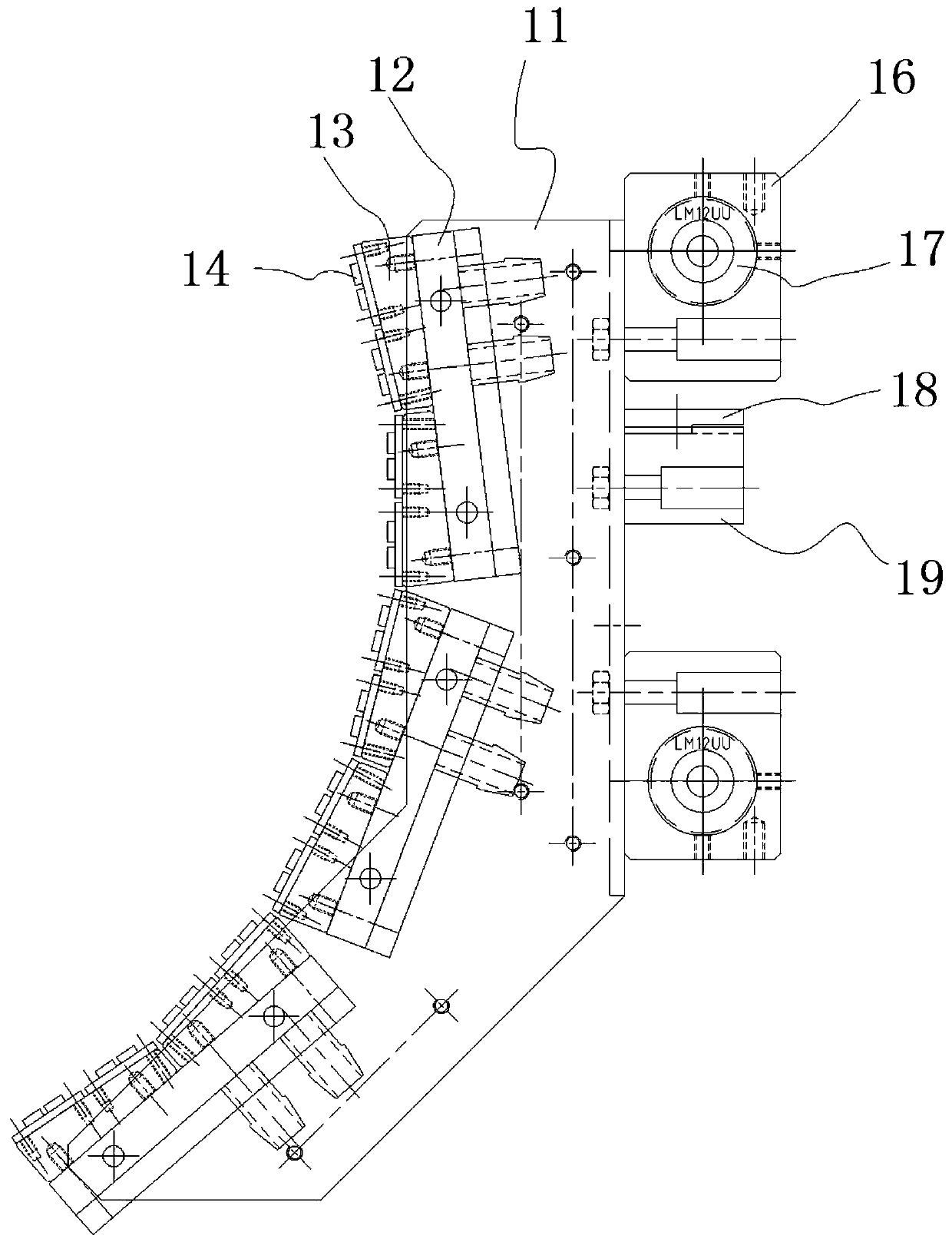

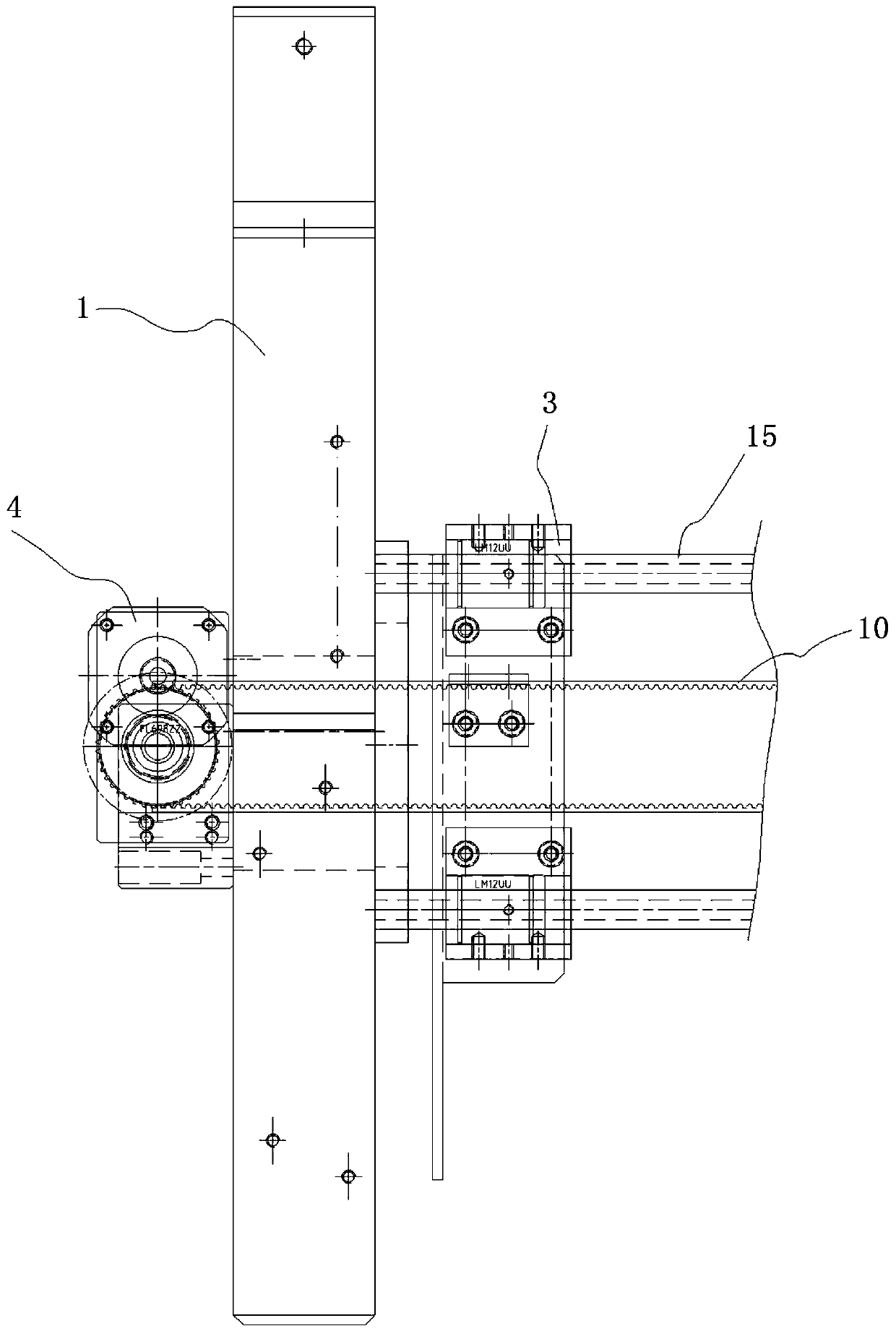

Exposure mechanism of platemaking machine

The invention relates to an exposure mechanism, in particular to an exposure mechanism of a plate making machine. The mechanism comprises a wall plate and a light drum, a displaceable execution assembly is arranged in the wall plate, transmission assemblies are arranged at the two side ends of the wall plate respectively, the transmission assemblies drive the execution assembly to displace, and the execution assembly is in movable contact with the light drum. The exposure speed of the plate is greatly increased, and the production efficiency is improved.

Owner:HANGZHOU CRON MACHINERY & ELECTRONICS CO LTD

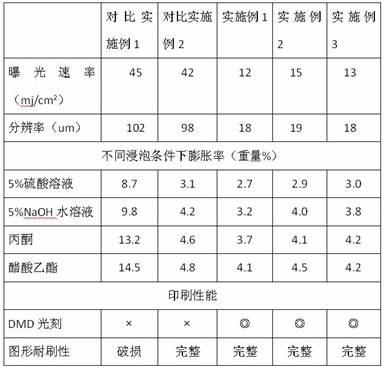

A kind of high-sensitivity environment-friendly one-component rotary mesh photoresist and its preparation method and application

ActiveCN110083011BImprove physical and chemical propertiesImprove heat resistancePhotosensitive materials for photomechanical apparatusPolymer scienceImage resolution

The invention relates to a new environment-friendly photosensitive polymer material, in particular to a high-sensitivity environment-friendly single-component rotary mesh photosensitive adhesive and a preparation method and application thereof. The high-sensitivity and environment-friendly one-component rotary network photosensitive adhesive of the present invention is mainly composed of a thermosetting resin, a latent curing agent, a toughening resin, a photocurable resin, a photopolymerization initiator, a sensitizer, a free radical scavenger and an additive. The self-emulsifying process is used to make high-sensitivity and environmental-friendly one-component rotary screen photosensitive adhesive. Due to the efficient sensitization reaction of the photosensitive system, a high-sensitivity photosensitive speed and an ultra-high resolution of 20um are obtained; the environmentally friendly one-component rotary screen photosensitive adhesive made from this can be stored stably for a long time, not only can replace the traditional Bichromate / PVA and other two-component photosensitive systems solve the problem of hexavalent chromium heavy metal pollution in the prior art, and its exposure speed is extremely fast, which can be quickly exposed and cured under low ultraviolet energy under DMD lithography rays to complete fine The requirements for rapid mesh making of the pattern are suitable for the rapid mesh making of DMD lithography technology.

Owner:浙江易能感光材料有限公司

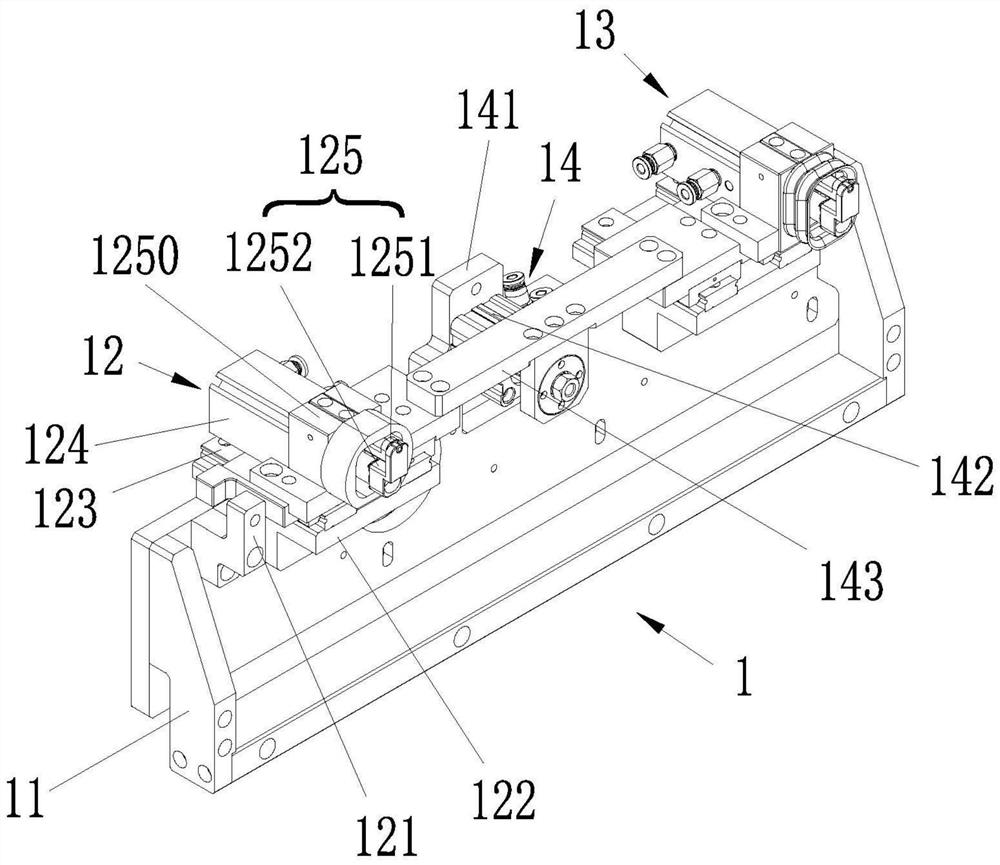

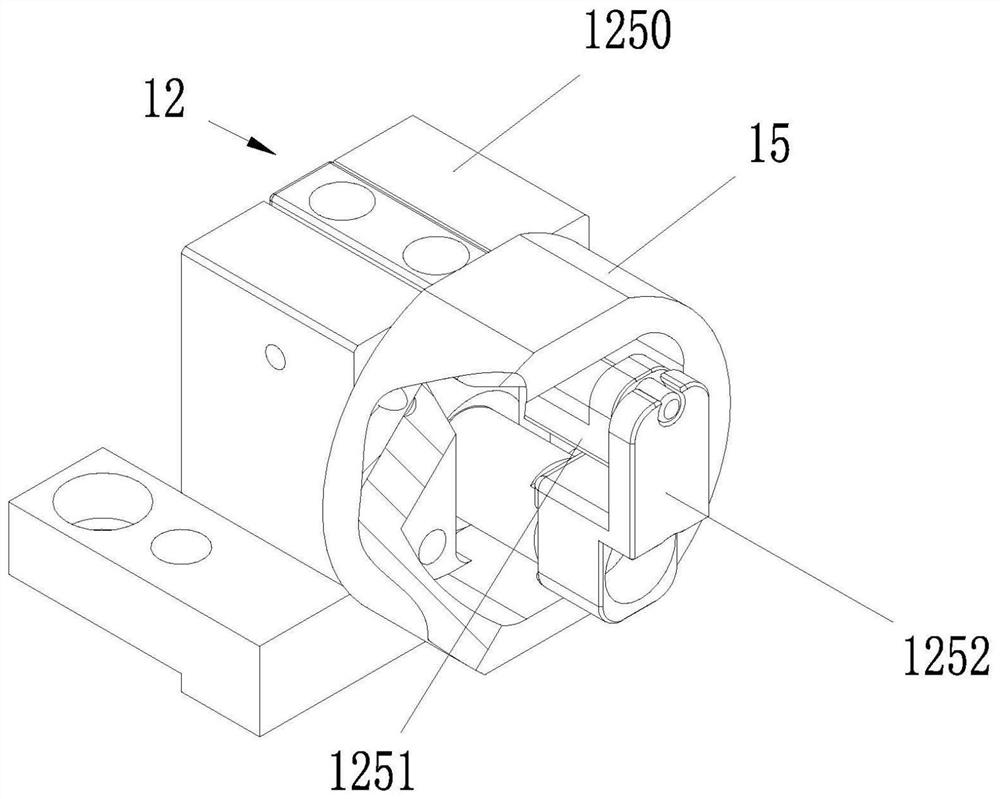

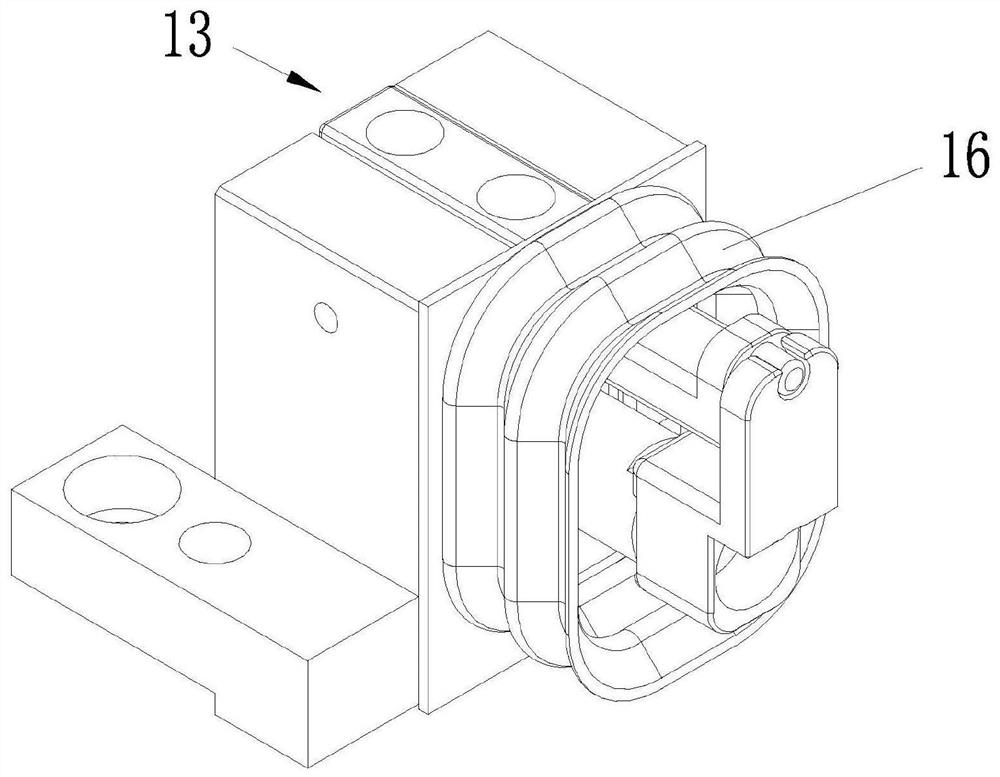

A clamping and lifting device

ActiveCN113207231BExquisite designReasonable control principleCircuit board tools positioningPhotomechanical exposure apparatusElectronic control systemControl engineering

The invention discloses a clamping and lifting device, which includes a positioning component for connecting and clamping a plate, a lifting device for driving the positioning component to move to lift the plate, and controlling the positioning component and the lifting device to realize connection, clamping and clamping. Electric control system for lifting process. The positioning component is used for fast and accurate positioning of the semi-finished PCB board, clamping and fixing and releasing; the lifting device drives the positioning component to lift the semi-finished PCB board to separate the attached film for subsequent position adjustment operations without manual adjustment Positioning, the whole process is realized by the driving parts and actuators under the control of the electronic control system. It has the advantages of rapid action, high efficiency, accurate alignment, and easy operation. It replaces the previous manual alignment operation and manual repetition with automation. Heavy work, significantly improving production efficiency.

Owner:东莞市多普光电设备有限公司

Exposure adjustment method, device, camera and computer storage medium

ActiveCN109474790BExposure adjustments are accurateAvoid repeated exposure adjustmentsTelevision system detailsColor television detailsShutterExposure

The invention discloses an exposure adjustment method and device, a camera and a computer storage medium, which belong to the technical field of cameras, and are used to use the brightness value after the adjustment takes effect as the basis for exposure adjustment, so as to alleviate the overshoot problem in the prior art . The method includes: according to the captured brightness value of the current picture and the historical exposure parameter value corresponding to the brightness value of the current picture, obtaining an estimated brightness value after the last output exposure parameter value setting takes effect, wherein the exposure parameter includes Gain, shutter or aperture; determine whether the ratio of the target brightness value to the estimated brightness value is within a preset range; when it is determined that the ratio of the target brightness value to the estimated brightness value is not within a preset range, according to the Determine a new exposure parameter value based on the ratio of the target brightness value to the estimated brightness value, and perform exposure adjustment according to the new exposure parameter value.

Owner:ZHEJIANG DAHUA TECH CO LTD

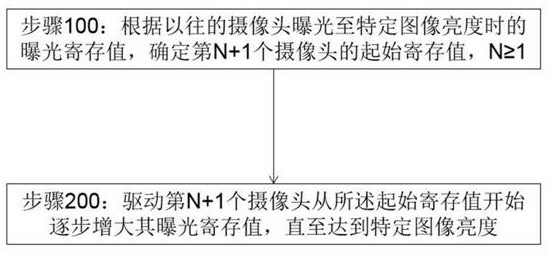

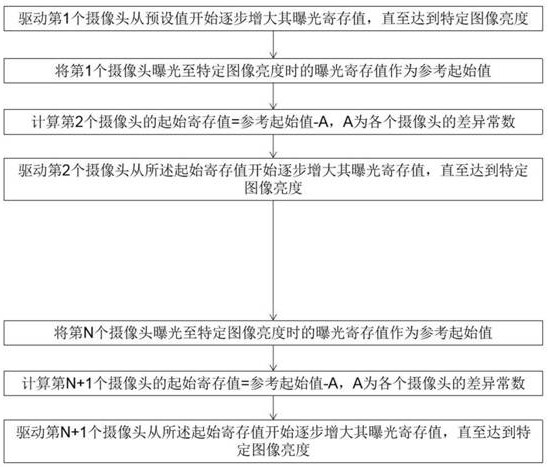

Camera test exposure method

PendingCN114040190AFast exposureReduce distanceTelevision system detailsColor television detailsMedicineComputer graphics (images)

The invention discloses a camera test exposure method, which comprises the following steps: step 100, determining an initial register value of an (N+1)th camera according to an exposure register value when a previous camera is exposed to specific image brightness, N being greater than or equal to 1; and step 200, driving the (N+1)th camera to gradually increase the exposure register value of the (N+1)th camera from the initial register value until the specific image brightness is reached. The camera test exposure method can improve the camera test exposure speed.

Owner:TRULY OPTO ELECTRONICS

A method for fabricating a T-gate of a high ion mobility transistor

ActiveCN104900503BLow costFast exposureSemiconductor/solid-state device manufacturingSemiconductor devicesGallium arsenidePhotoresist

The invention discloses a fabrication method of the T type gate of a high-ion mobility transistor. The method includes the following steps that: an anti-reflection layer and first photoresist are sequentially formed on a gallium arsenide (GaAs) substrate; the first photoresist is subjected to exposure and development, so that a display area of which the width ranges from 0.16 to 0.19 microns can be formed, and the display area is further subjected to a chemical shrinkage process, so that the width of the display area can be decreased to a range from 0.11 to 0.13 microns; and the display area of the first photoresist is coated with second photoresist, and the second photoresist is subjected to exposure and development, so that the exposed and developed second photoresist and the display area of the first photoresist can jointly form an etching window of the T type gate, and the T type gate of which the width ranges from 0.11 to 0.13 microns can be formed through metal deposition. The fabrication method of the invention has the advantages of low equipment input and high production capacity, and can effectively reduce production cost and is suitable for practical production application.

Owner:XIAMEN SANAN INTEGRATED CIRCUIT

Magnetic locking utility knife

PendingUS20220001553A1Quick and safe exposureFast exposureIncision instrumentsMetal working apparatusEngineeringMechanical engineering

A utility tool device including a handle with a tool recess and a lever arm recess; a rotatable lever arm with a magnet that is configured to fit in the lever arm recess; and a rotatable lever hinge attached to the lever arm and configured to attach to a tool; wherein the tool recess is configured to have a tool fit in the tool recess; and wherein the magnet is configured to lock a tool in place when the lever arm is in the lever arm recess.

Owner:ELLEGALA DILANTHA B +2

Thin film transistor liquid crystal display (TFT-LCD) array substrate and manufacturing method thereof

InactiveCN102023431BImprove performanceFast exposureSolid-state devicesSemiconductor/solid-state device manufacturingThin-film-transistor liquid-crystal displayEngineering

The invention relates to a thin film transistor liquid crystal display (TFT-LCD) array substrate and a manufacturing method thereof. The manufacturing method comprises the following steps of: depositing a grid metal film, a grid insulation layer and a semiconductor film to form a figure comprising a grid line and a quasi semiconductor layer; depositing a passivation layer to form a semiconductor layer figure, a figure comprising a source electrode via hole and a drain electrode via hole on the semiconductor layer, and a doped semiconductor layer on the surface of the semiconductor layer in the source electrode via hole and the drain electrode via hole; and depositing a transparent conductive film and a source and drain metal film to form a figure comprising a pixel electrode, a data line,a source electrode and a drain electrode, wherein the source electrode is connected with the semiconductor layer through the doped semiconductor layer in the source electrode via hole and the drain electrode is connected with semiconductor layer through the doped semiconductor layer in the drain electrode via hole. The TFT-LCD array substrate can be manufactured through three times of processes, so the process is relatively simple, the process time can be shortened to the maximum extent, the production efficiency is improved, and the production cost is reduced.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com