A kind of high-sensitivity environment-friendly one-component rotary mesh photoresist and its preparation method and application

A high-sensitivity, single-component technology, applied in the direction of optomechanical equipment, photosensitive materials for optomechanical equipment, optics, etc., can solve the problems of unseen high-sensitivity photosensitive adhesive patent disclosure, photosensitive adhesive pollution, resolution accuracy and Exposure speed can not be achieved and other problems, to achieve the effect of fast exposure speed, improved physical and chemical properties, water resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 30wt% bisphenol A epoxy resin, 5wt% acrylic resin, 5wt% liquid nitrile rubber and 20wt% modified acid anhydride as thermosetting resin composition and 10wt% polyvinyl alcohol cinnamate, 5wt% organic styrylpyridine Onium salt, 5wt% tetramethylbenzoquinone, 5wt% benzophenone are in a water bath at a constant temperature of 80 degrees Celsius, slowly add 3wt% phenethylphenol polyoxypropylene polyoxyethylene ether aqueous solution for modification while stirring, and stir After one hour, a stable aqueous mixture was obtained, and the reaction was kept for 2 hours. After cooling to room temperature, 10% polyvinyl acetate acrylic copolymer, defoamer, surfactant, dyeing agent, and acrylic acid copolymer were added to the prepared emulsion while stirring. Add water appropriately to adjust the viscosity to obtain photosensitive colloid. Then, according to the method of Comparative Example 1, a rotary screen printing screen was prepared.

Embodiment 2

[0038] 30wt% bisphenol A epoxy resin, 5wt% acrylic resin, 5wt% liquid nitrile rubber and 20wt% modified acid anhydride were used as thermosetting resin composition and 10wt% 1,6 hexanediol diacrylate, 5wt% organic benzene Vinyl pyridinium salt, 5wt% tetramethylbenzoquinone, 5wt% benzophenone are slowly added in 3wt% phenethyl cumyl phenol polyoxyethylene ether aqueous solution while stirring at a constant temperature of 80 degrees Celsius in a water bath. Modified, stirred for one hour to obtain a stable aqueous mixture, incubated for 2 hours, cooled to room temperature, and added 10% polyvinyl acetate acrylic copolymer and defoamer, surface Activating agent, dyeing agent, and appropriately adding water to adjust the viscosity to obtain photosensitive colloid. Then, according to the method of Comparative Example 1, a rotary screen printing screen was prepared.

Embodiment 3

[0040] 20wt% bisphenol A epoxy resin, 5wt% acrylic resin, 5wt% liquid nitrile rubber and 10wt% modified acid anhydride as thermosetting resin composition and 40wt% 1,6 hexanediol diacrylate, 15wt% organic benzene Vinylpyridinium salt, 15wt% tetramethyl benzoquinone, 15wt% benzophenone are slowly added 10wt% phenethyl cumyl phenol polyoxyethylene ether aqueous solution under the condition of constant temperature of 80 degrees Celsius in a water bath. Modified, stirred for one hour to obtain a stable aqueous mixture, incubated for 2 hours, cooled to room temperature, and added 50% polyvinyl acetate acrylic copolymer and defoamer, surface Activating agent, dyeing agent, and appropriately adding water to adjust the viscosity to obtain photosensitive colloid. Then, according to the method of Comparative Example 1, a rotary screen printing screen was prepared.

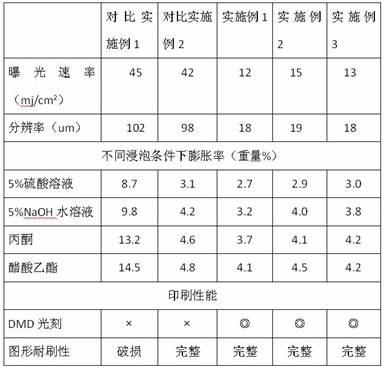

[0041] Table 1: Experimental Results

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com