Greening matrix containing quarry mucks, animal manures, straws and charcoal powder and preparation method thereof

A technology for greening substrates and quarries, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve problems such as quarry dregs that have not yet been seen, solve the problem of dregs consumption, and relieve land pressure. , the effect of reducing the amount of stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

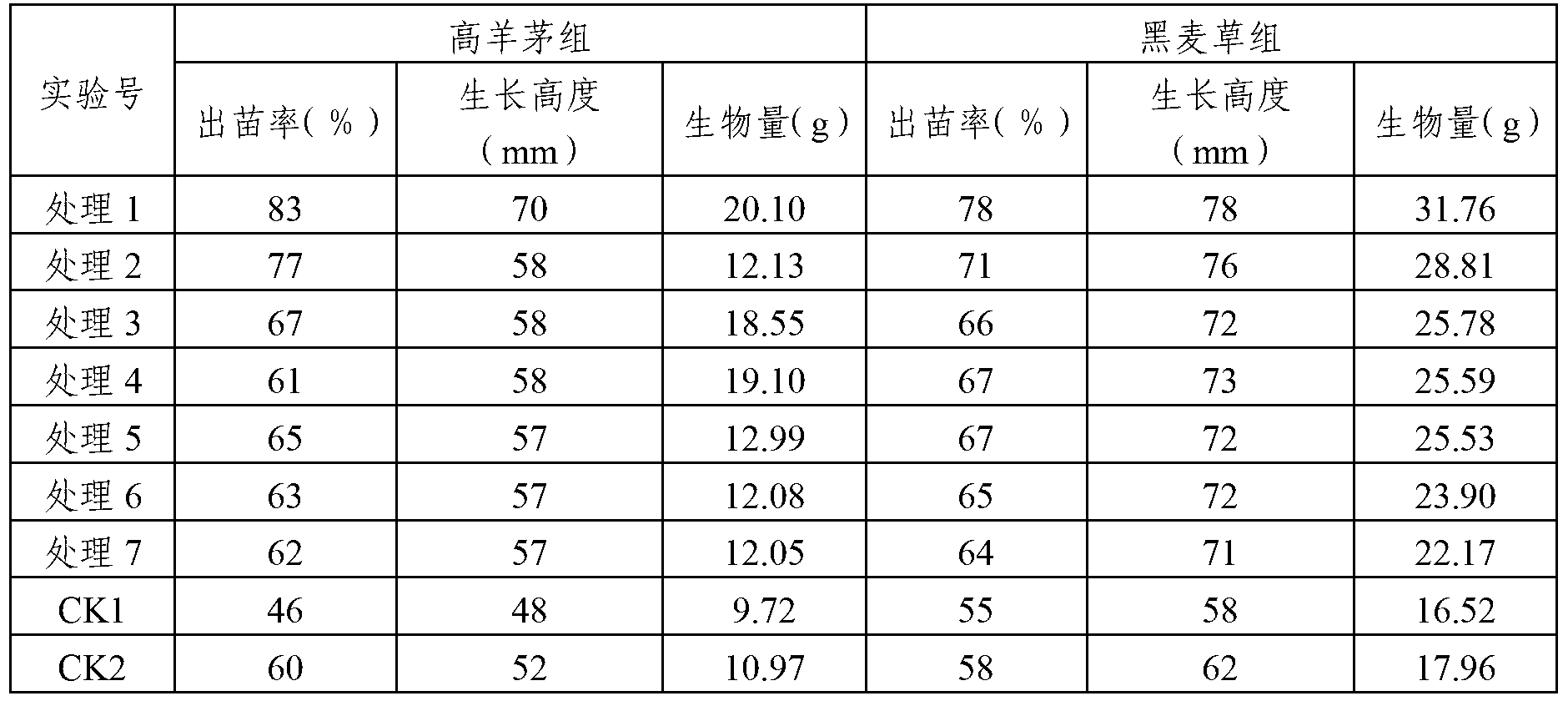

Examples

Embodiment 1

[0069] Example 1: A greening substrate containing quarry waste, livestock manure, straw and charcoal powder

[0070] 1. Composition: 18g of quarry residue (a 10mm sieve), 9.0g of sheep dung, 220g of corn stalks and 6g of charcoal powder.

[0071] 2. Preparation method:

[0072] 1) Straw decomposing agent dilution: mix the straw decomposing agent and water at a weight ratio of 11:50 to obtain the straw decomposing agent diluent for use;

[0073] 2) Crush the corn stalks and sheep dung separately through a 5mm sieve, and weigh the quarry residue, sheep dung, corn stalks and charcoal powder according to the ratio, and set aside;

[0074] 3) Pre-soak the corn stalks in water. It is advisable to hold the dripping water tightly with your hands. Then mix them with the sheep dung and stack them neatly in a woven bamboo basket. Spread a mixture of corn stalks and sheep dung with a thickness of 15 cm on each layer. Pour the straw decomposing agent diluent in layers. The amount of straw decomposi...

Embodiment 2

[0076] Example 2: A greening substrate containing quarry residue, livestock manure, straw and charcoal powder

[0077] 1. Composition: 18g of quarry residue (a 10mm sieve), 13.5g of sheep dung, 330g of corn stalks and 12g of charcoal powder.

[0078] 2. Preparation method:

[0079] 1) Straw decomposing agent dilution: Mix the straw decomposing agent and water at a weight ratio of 11:52 to obtain the straw decomposing agent dilution solution for use;

[0080] 2) Crush the corn stalks and sheep dung separately through a 5mm sieve, and weigh the quarry residue, sheep dung, corn stalks and charcoal powder according to the ratio, and set aside;

[0081] 3) Pre-soak the corn stalks in water. It is advisable to hold the dripping water tightly with your hands. Then mix them with the sheep dung and stack them neatly in a woven bamboo basket. Spread a mixture of corn stalks and sheep dung with a thickness of 20 cm on each layer, and then one by one. Pour the straw decomposing agent diluent in la...

Embodiment 3

[0083] Example 3: A greening substrate containing quarry waste, livestock manure, straw and charcoal powder

[0084] 1. Composition: 18g of quarry residue (a 10mm sieve), 9.0g of cow dung, 220g of corn stalks and 6g of charcoal powder.

[0085] 2. Preparation method:

[0086] 1) Straw decomposing agent dilution: mix the straw decomposing agent and water at a weight ratio of 11:60 to obtain the straw decomposing agent diluent for use;

[0087] 2) Crush the corn stalks and cow dung through a 5mm sieve respectively, and weigh the quarry slag, cow dung, corn stalks and charcoal powder according to the ratio for use;

[0088] 3) Pre-soak the corn stalks in water. It is advisable to hold the dripping water tightly with your hands. Then mix them with the cow dung and stack them neatly in a woven bamboo basket. Spread a mixture of corn stalks and cow dung with a thickness of 15 cm on each layer, and then pour layer by layer. Add the straw decomposing agent diluent, the amount of straw decompos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain weight | aaaaa | aaaaa |

| Seeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com