Patents

Literature

329results about How to "Reduce stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic compound, electronic element comprising same, and electronic device

ActiveCN111018797AIncrease space volumeHigh glass transition temperatureOrganic chemistrySolid-state devicesArylSimple Organic Compounds

The invention relates to the technical field of organic photoelectric materials, and in particular, relates to an organic compound, an electronic element containing the same and an electronic device.The compound has a structure represented by a chemical formula 1', wherein one of R1, R2, R3 and R4 is a group defined in the specification, and the other three are selected from substituents such asalkyl, halogen and cyano; one of R5, R6, R7 and R8 is a group defined in the specification, the other three are selected from substituents such as alkyl, halogen and cyano, Y and Y1 are respectively and independently a group defined in the specification, and L and L1 are single bonds, aryl, heteroaryl and the like. By using the organic compound in an electronic component, the driving voltage, luminous efficiency, and life of the electronic component are improved.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

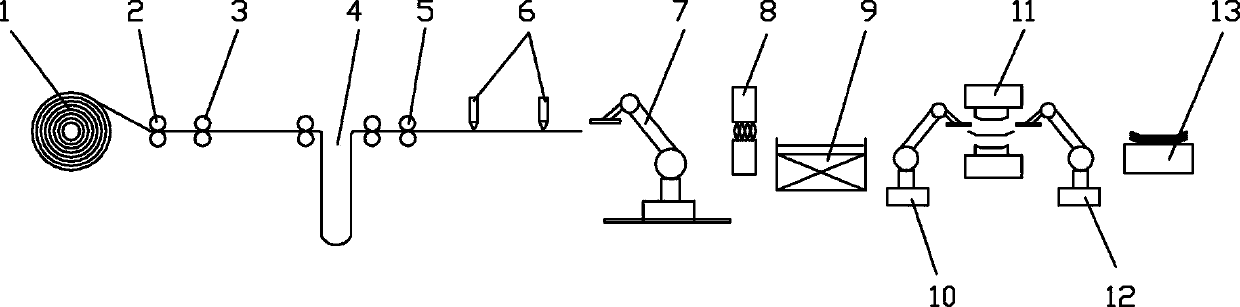

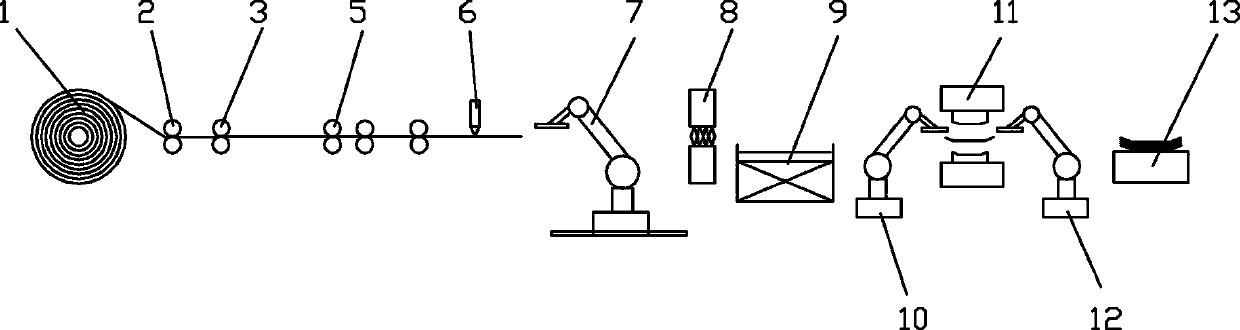

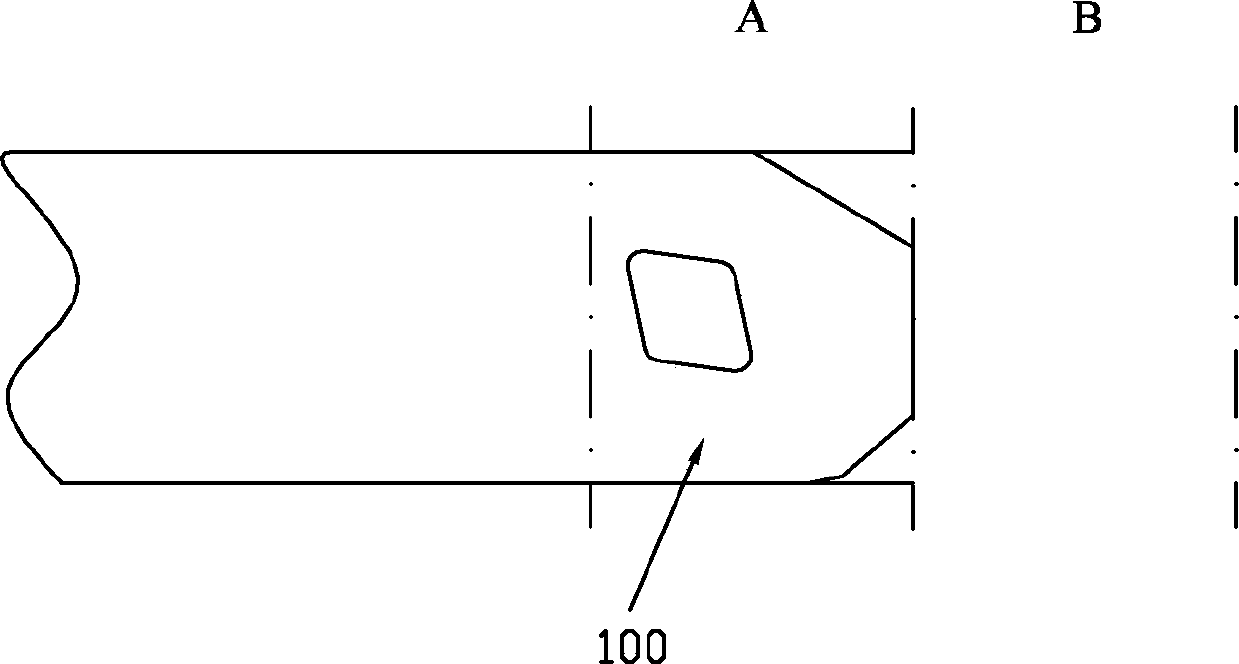

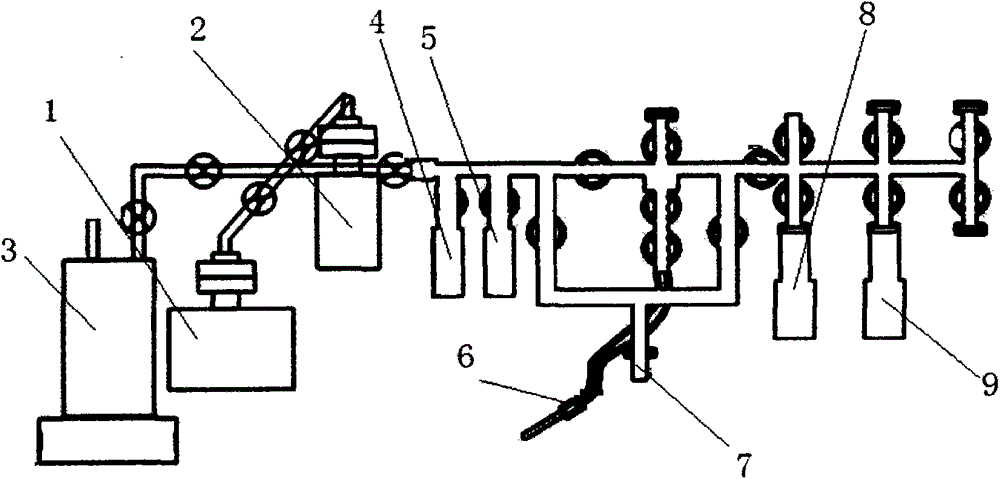

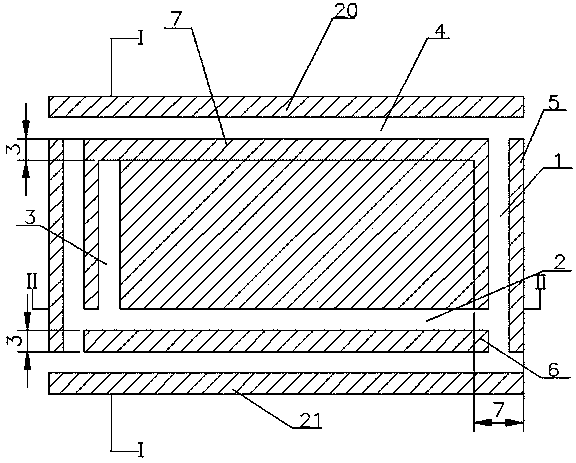

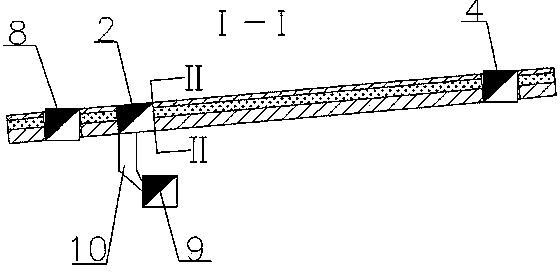

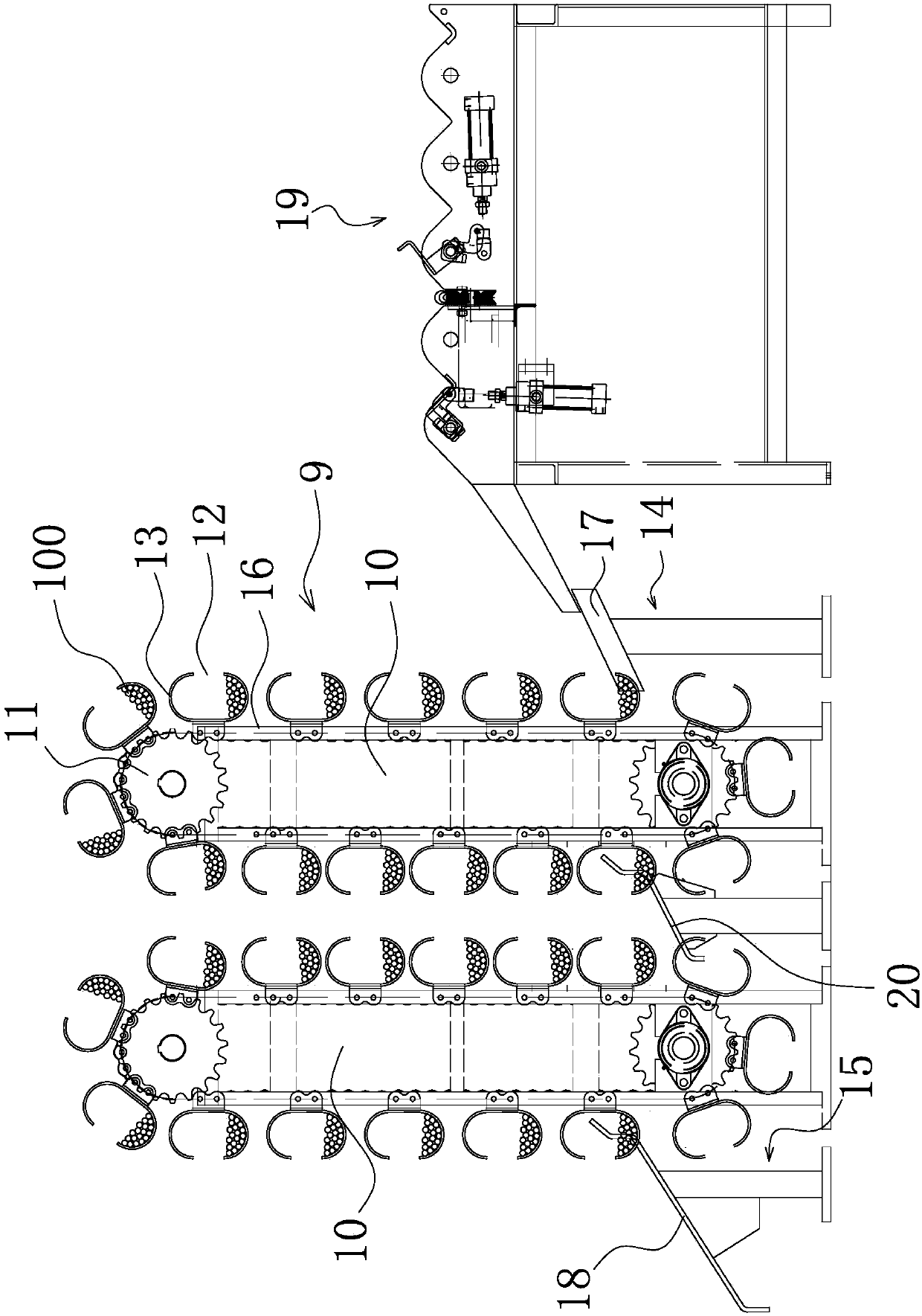

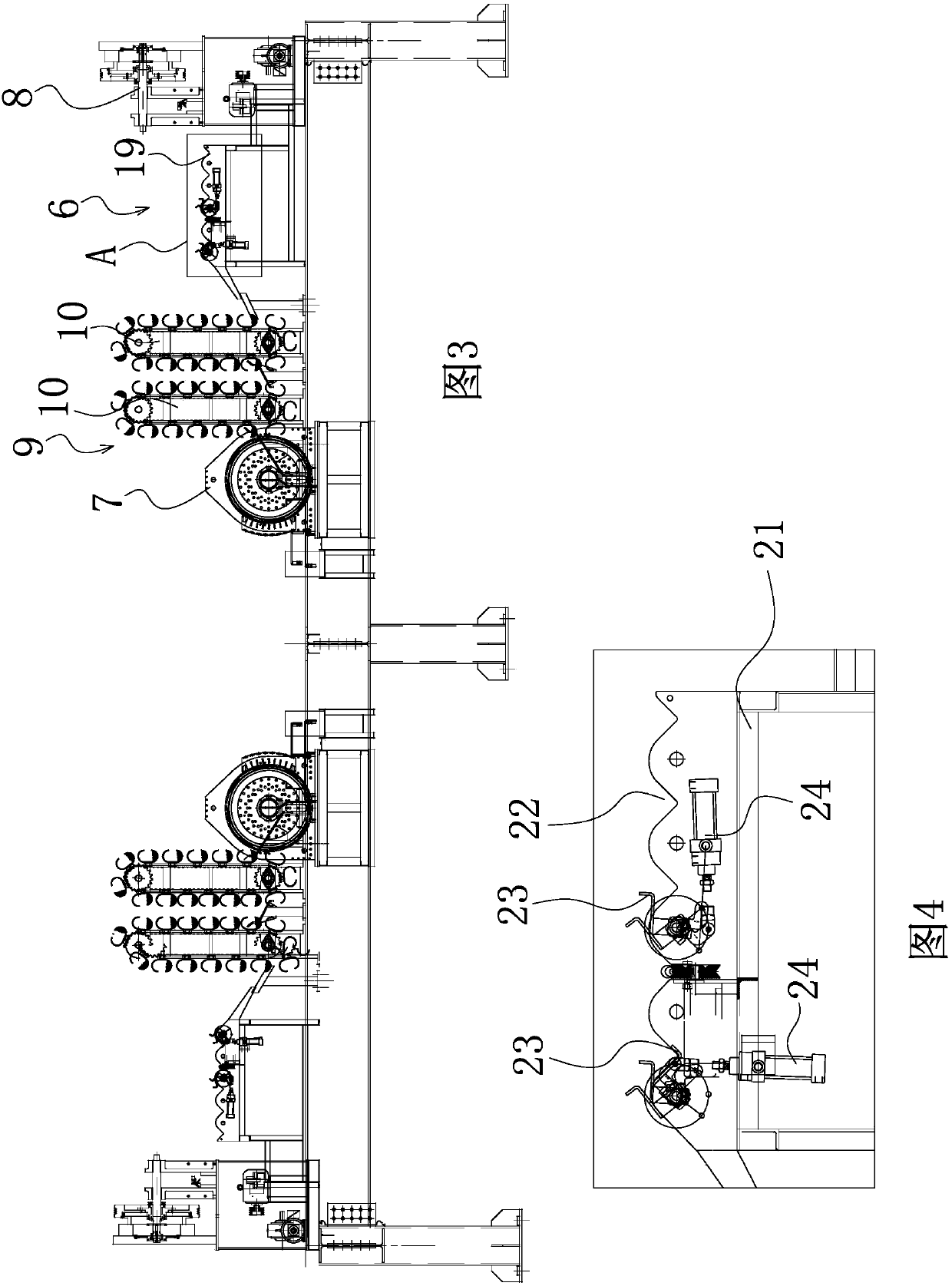

Uncoiling blanking forming method

InactiveCN103624487AReduce stackingSimple processMetal-working feeding devicesPositioning devicesManipulatorSteel belt

An uncoiling blanking forming method comprises the following steps that 1) steel coil uncoiling is carried out, namely a steel belt after steel coil uncoiling is subjected to washing and straightening and enters a blanking zone through a clamping conveying roller; 2) laser blanking is carried out, namely a steel coil enters the blanking zone, a laser blanking mode is used, a material piece with the needed shape is formed by cutting of a laser cutting head, and waste materials fall down and are output; 3) material piece output is carried out, namely the material piece is conveyed through a magnetism stretching conveying belt machine and then is carried to a stamping procedure through a mechanical arm or a robot; 4) stamping forming is carried out, namely the material piece is subjected to stamping and is machined into a workpiece; and 5) checking is carried out, namely the workpiece is checked and put in storage. The method can achieve series connecting of a blanking line and a stamping forming line, matching can be achieved, the middle links such as stacking, packing, conveying, locating, unpacking, conveying and position centering of piece materials and stamping forming workpieces and transferring sites are reduced, the technology processes are simplified and connected in series, and by laser blanking, coiling materials are directly machined into forming pieces.

Owner:BAOSHAN IRON & STEEL CO LTD +1

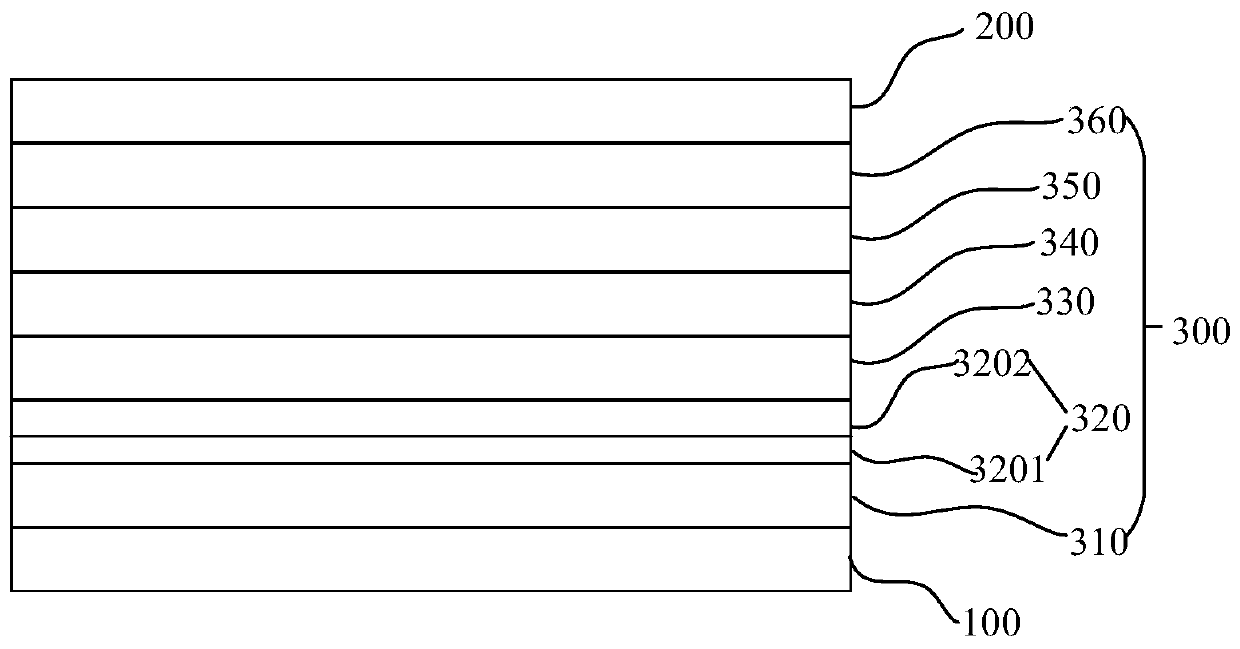

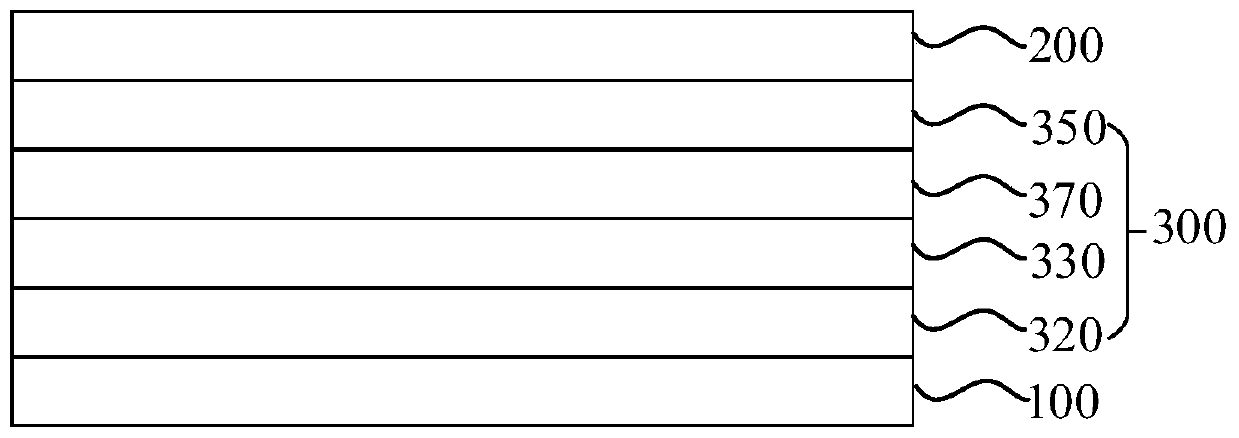

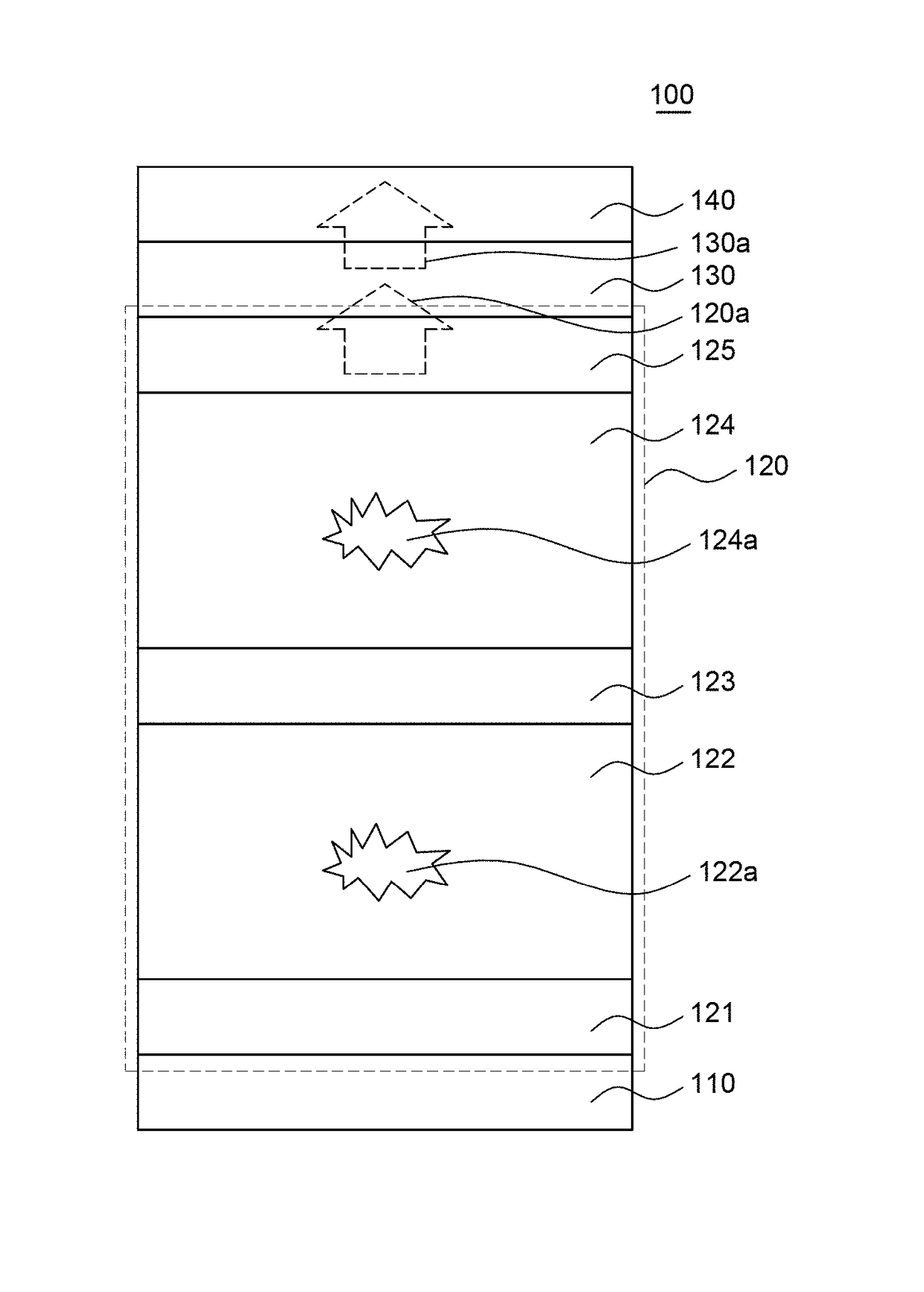

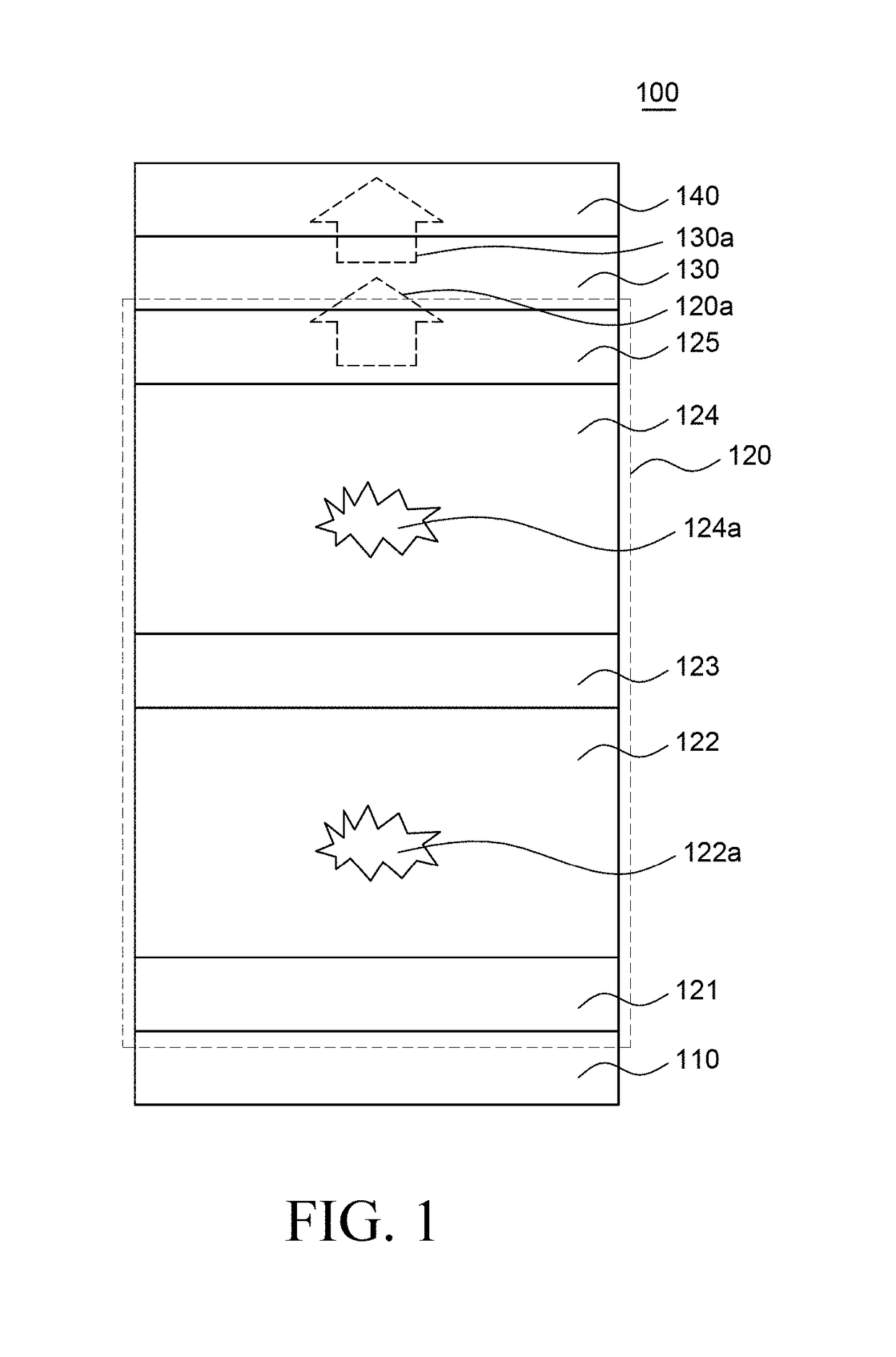

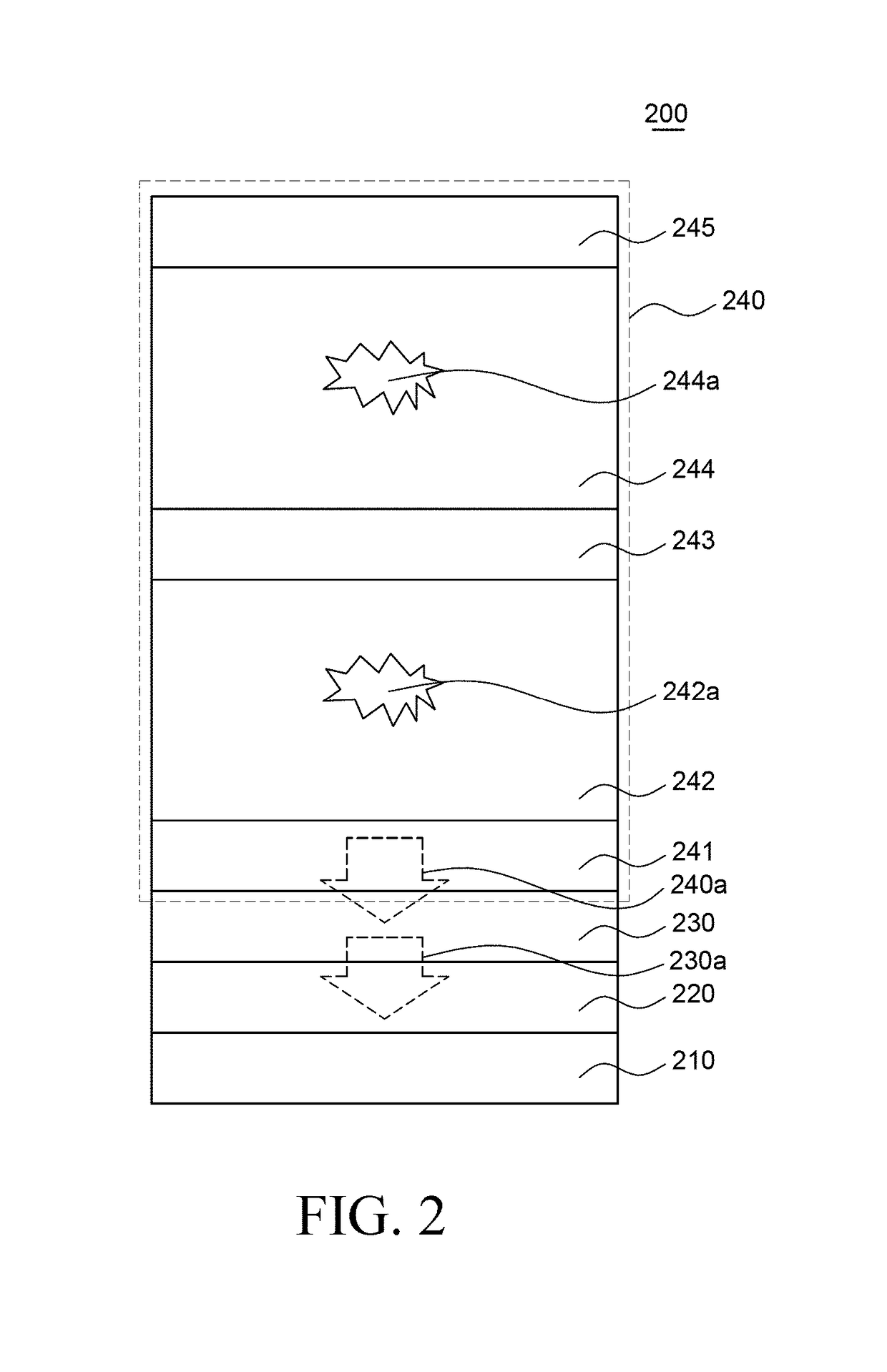

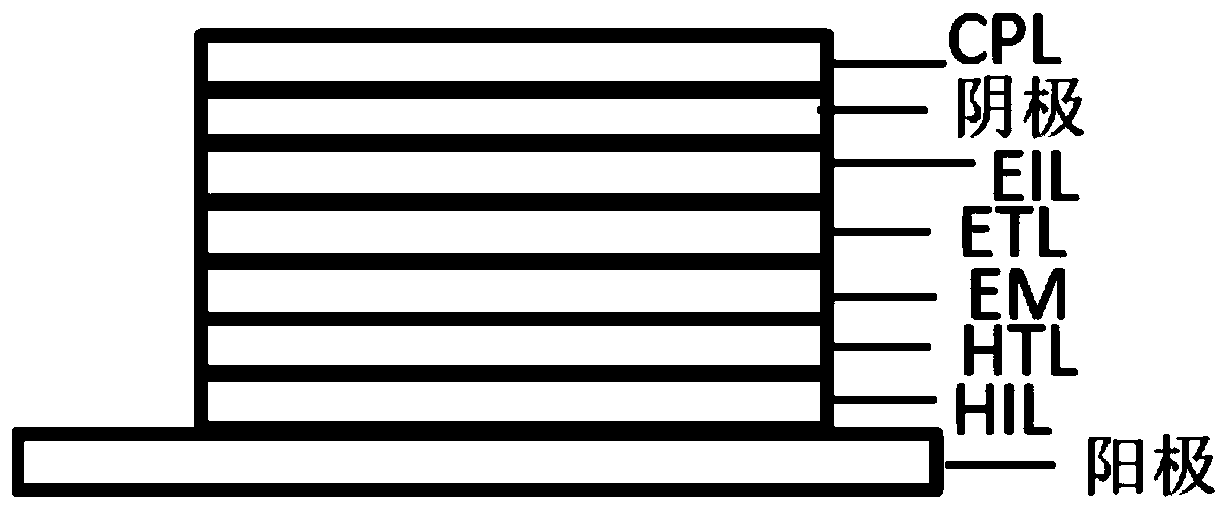

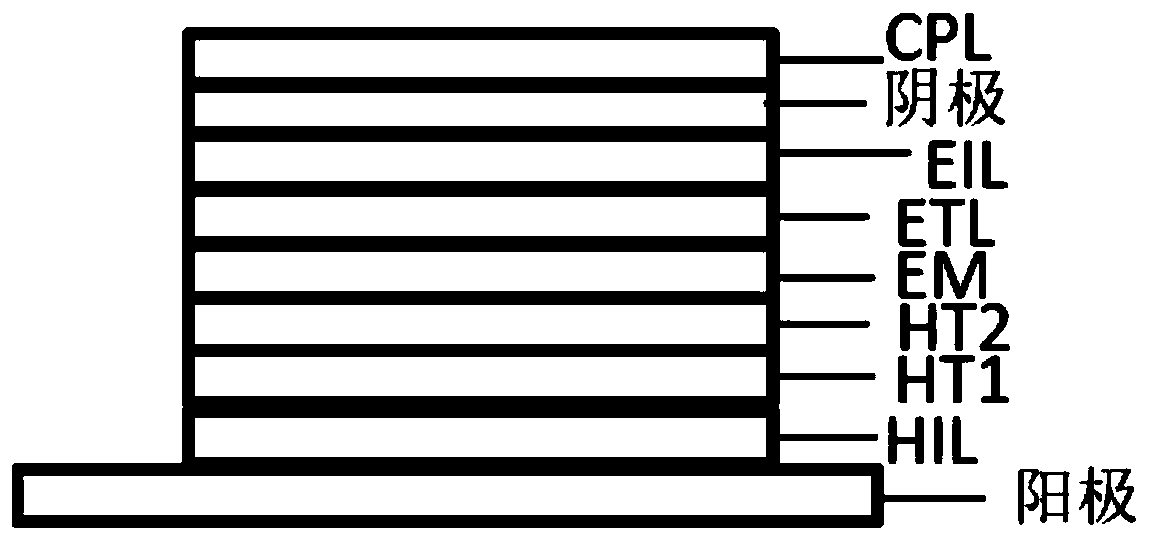

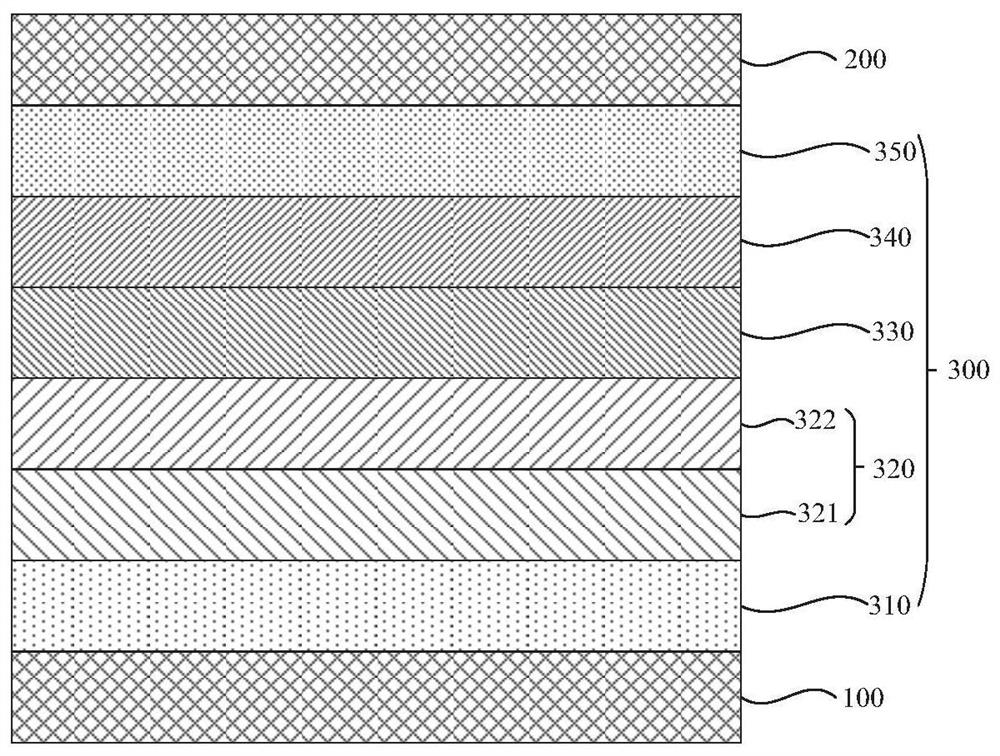

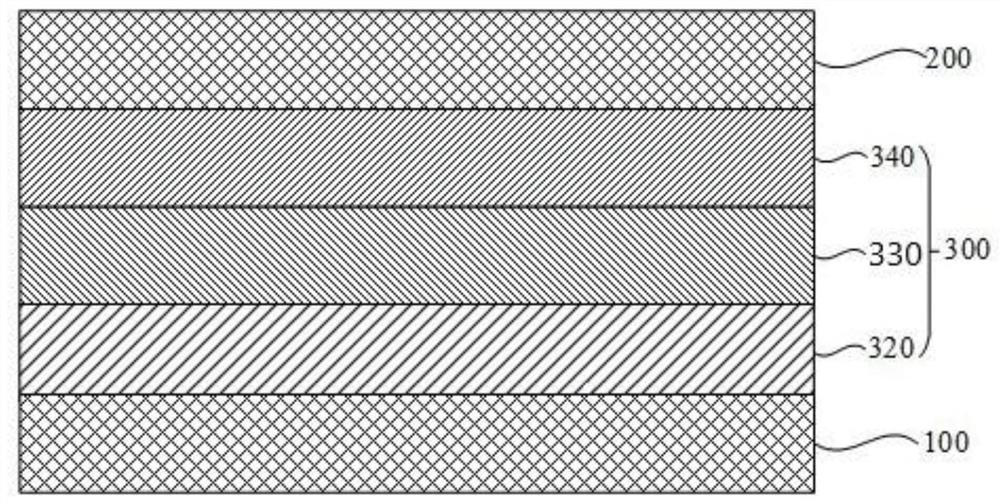

Organic light emitting diode display panel

ActiveUS9960212B2High voltageReduce stackingSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeOLED

An organic light-emitting diode (OLED) display panel includes: an OLED layer; a color filter layer; and a color coordinate tuning layer disposed between the OLED layer and the color filter layer, wherein the OLED layer includes a first light-emitting portion comprising a first light-emitting layer configured to emit a first light and a second light-emitting portion comprising a second light-emitting layer configured to emit a second light. The OLED layer is configured to emit a third light produced by mixing the first light and the second light. The color coordinate tuning layer is configured to output a fourth light different from the third light. The number of all of peaks and shoulders that an EL spectrum of the fourth light has is higher than the number of all of peaks and shoulders that an EL spectrum of the third light has throughout an entire range of a visible wavelength band.

Owner:LG DISPLAY CO LTD

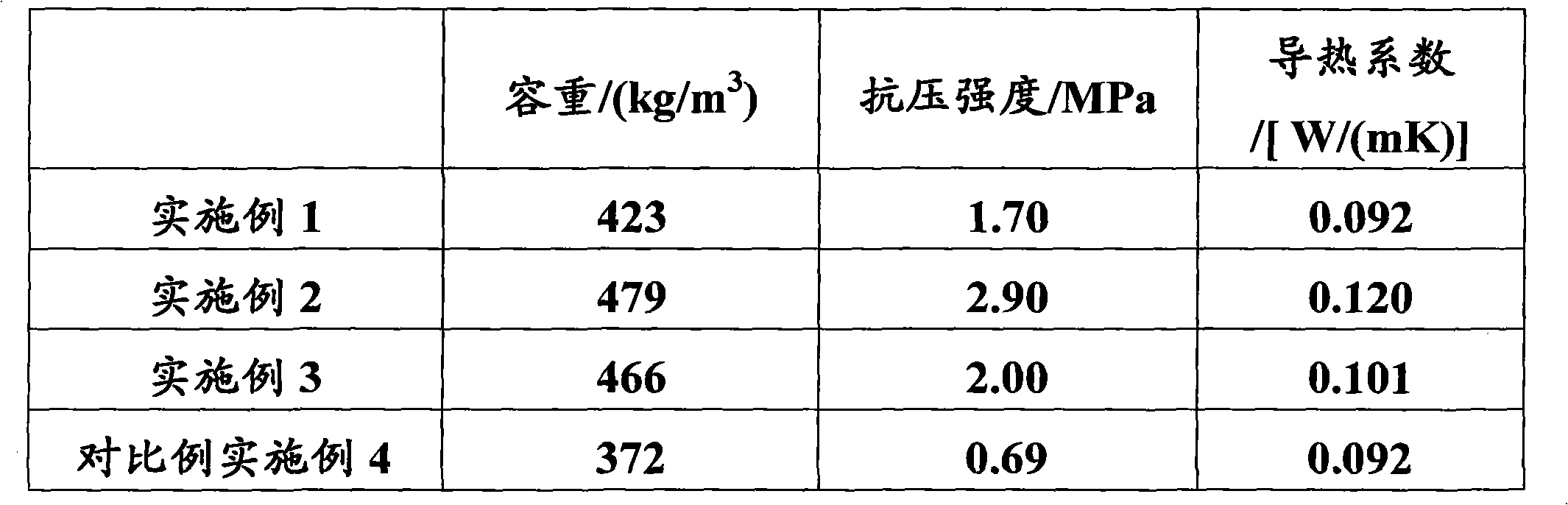

Phosphogypsum-based light-weight insulation board and preparation method thereof

InactiveCN105777039ALow densityImprove fire performanceLaminationLamination apparatusSurface layerSlurry

The invention relates to a phosphogypsum-based light-weight insulation board and a preparation method thereof. The phosphogypsum-based light-weight insulation board is prepared from the following raw material components in parts by weight: 100 parts of phosphorus building gypsum, 10-30 parts of high-strength gypsum, 3-12 parts of lightweight aggregates, 0.1-0.3 part of a dispersing agent, 0.3-0.5 part of a retarder, 0.2-0.4 part of a water-retaining agent and 0.1-0.3 part of an air entraining agent. The preparation method comprises the following steps: adding water into a stirring machine in a water-cement ratio of (0.70-0.80):1, adding the air entraining agent, the retarder, the dispersing agent and the water-retaining agent, stirring, then adding a dry material, obtained by uniformly mixing the phosphorus building gypsum, high-strength gypsum and lightweight aggregates, into the stirring machine, continuously stirring to obtain slurry, paving basalt fiber mesh cloth in a bottom die of a gypsum board forming die, pouring into the slurry, vibrating for 1 minute, then paving a layer of basalt fiber mesh cloth on the surface layer, closing a cover die of the gypsum board forming die, carrying out roller forming, taking apart the die after solidification, and drying, so that the phosphogypsum-based light-weight insulation board is obtained.

Owner:WUHAN UNIV OF TECH

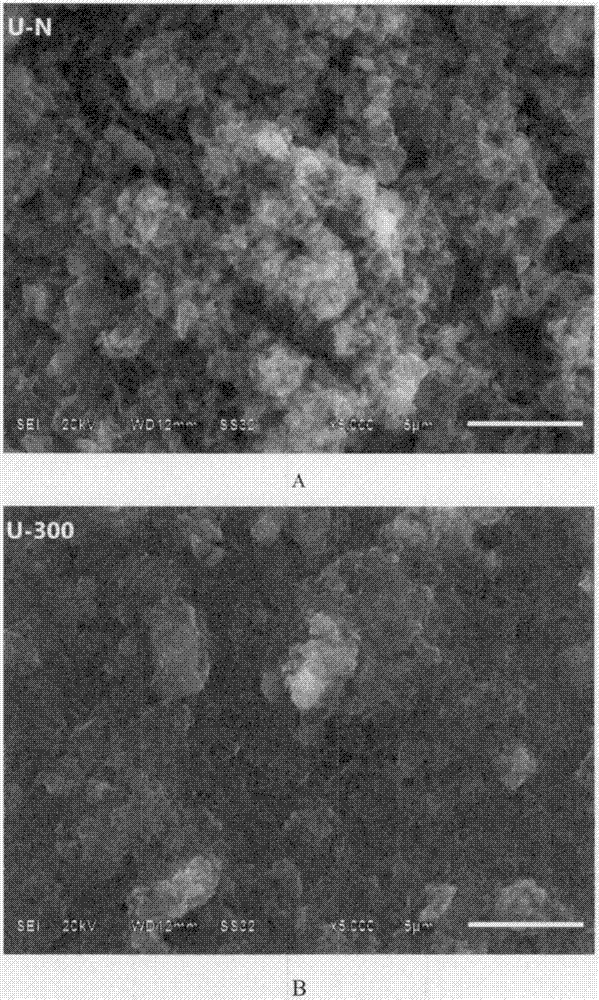

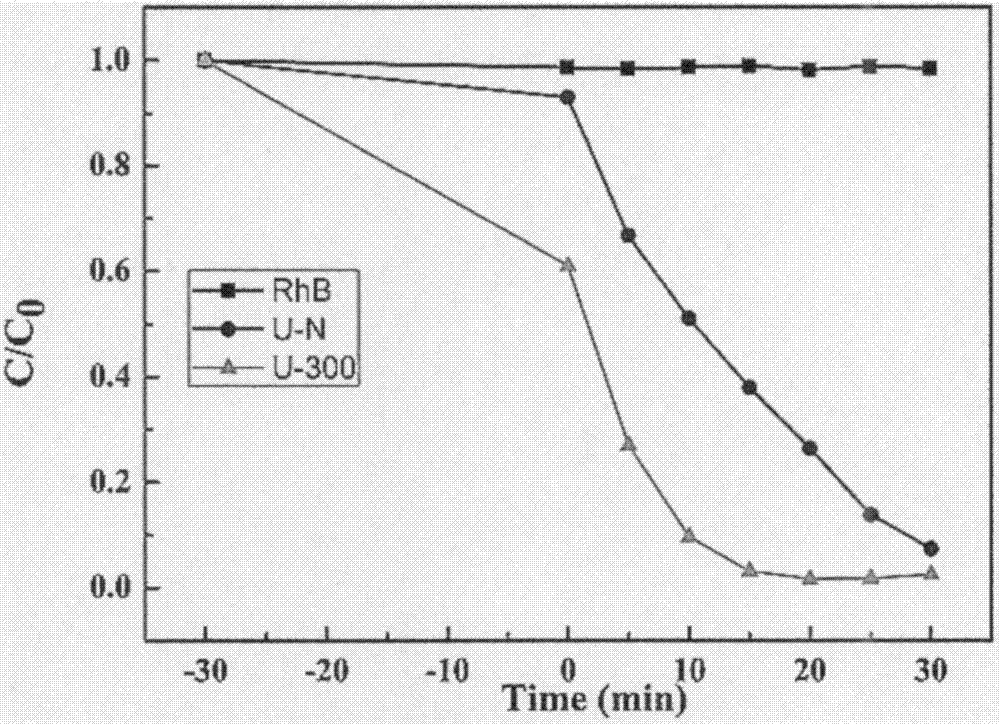

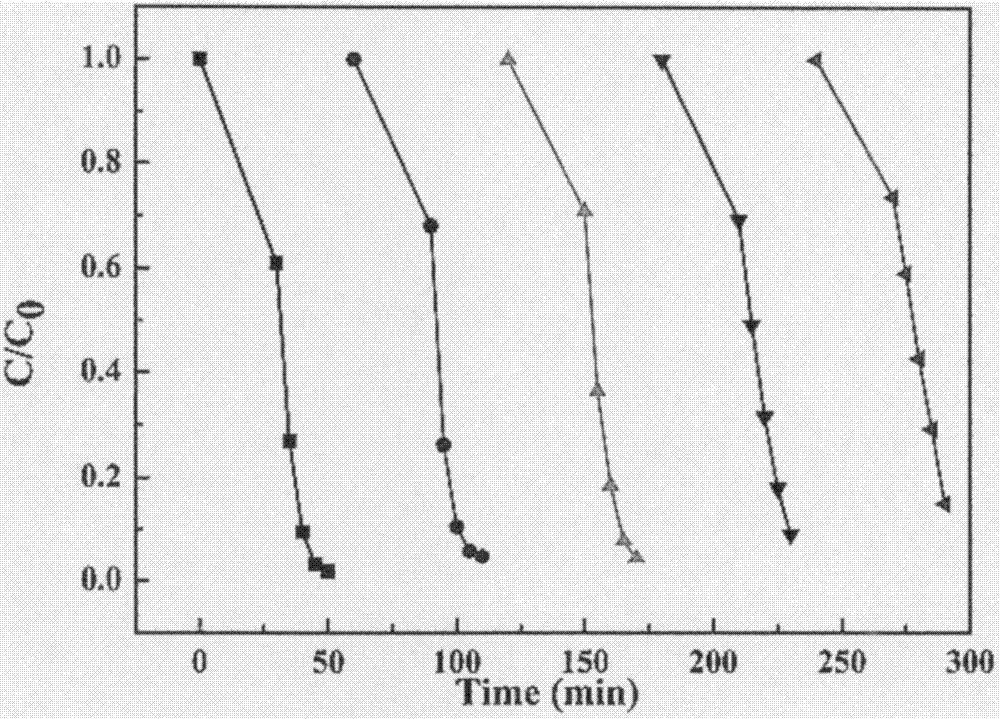

High-activity graphite-phase carbon nitride material and preparation method thereof

InactiveCN107252701AReduce compoundingImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationMaterials preparationReactive site

The invention belongs to the technical field of material preparation and photocatalysis, and discloses a high-activity graphite-phase carbon nitride material and a preparation method thereof. The preparation method comprises the following steps: forming a self-generated gas atmosphere a gas generated from a precursor by pyrolysis in the high-temperature calcining process under the control on an inert gas, and guiding synthesis of a carbon nitride material, thereby obtaining a flaky porous graphite-phase carbon nitride material. According to the preparation method, after the inert gas is not introduced any longer, a self-generated gas generated from the precursor is relatively uniform at different parts, and the carbon nitride material prepared with the preparation method is uniform in morphology and relatively good in crystal form; due to the escape of the self-generated gas, the material is effectively pored, and thus the specific surface area and the active sites of the material are increased; due to the self-generated gas atmosphere, the polymerization degree of the precursor is reduced, and the obtained carbon nitride material has a relatively large amount of unpolymerized amino or imino groups. The preparation method disclosed by the invention is simple, efficient and low in cost, and the carbon nitride material prepared with the preparation method is excellent in photocatalysis activity and very good in practicability.

Owner:CHINA WEST NORMAL UNIVERSITY

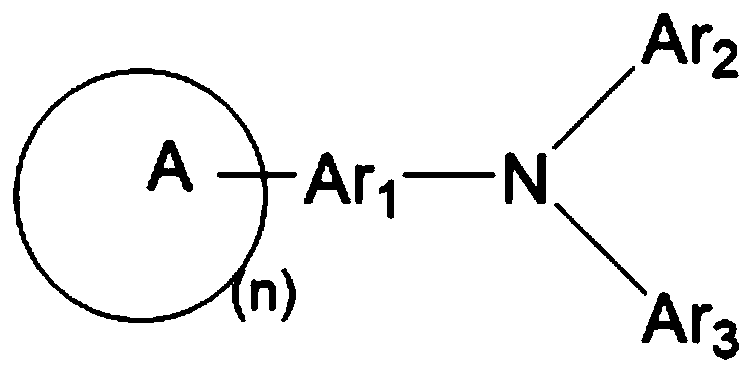

Aromatic derivative with polycyoalkane and organic electroluminescence device with derivative

ActiveCN110183332AImprove stabilityImprove heat resistanceOrganic chemistrySolid-state devicesHeat resistanceOrganic layer

The invention relates to an aromatic derivative with polycyoalkane and an organic electroluminescence device with the derivative. The aromatic derivative structurally has a chemical formula I as shownin the specification. The compound provided by the invention is the aromatic derivative with polycyoalkane as a framework, has excellent stability and high thermal resistance, energy loss can be greatly reduced, and a stable condensed ring can be formed. By adopting the aromatic derivative with the polycyoalkane, the stability of an organic layer in the organic electroluminescence device can be improved.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

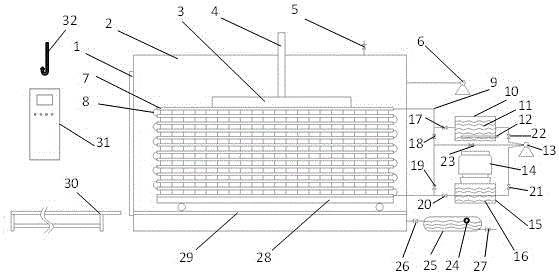

Method and equipment for drying and carbonizing wood integrally on vacuum condition

InactiveCN106426473AShorten carbonization timeImprove processing efficiencyDrying solid materials without heatWood treatment detailsWood dryingHeating cooling

The invention provides equipment for drying and carbonizing wood integrally. The equipment comprises a pressure adjusting system, a heating and cooling system, a material loading, transporting and pressurizing system and a water drainage system; an exo-box heat conduction oil pipe of the heating and cooling system penetrates through a treatment box and is welded to a wall of the treatment box for being sealed; a water inlet valve of the water drainage system is connected to the treatment box and a water drainage box through connection pipelines; and an outer wall of a hydraulic cylinder of the material loading, transporting and pressurizing system is welded to the treatment box in a sealed mode. The equipment has the advantages that the repeated loading, stacking, heating and cooling steps of the drying and heat treating steps of wood are reduced, so that the processing efficiency is improved, and the energy consumption is lowered; a processing method is flexible and multipurpose and the equipment is multifunctional; the whole drying and carbonizing treatment is carried out on the vacuum and negative pressure conditions, the content of air in the treatment box is small, and the oxygen content is low; carbonized wood making contact with a hot plate can be fast cooled; and the wood can be prevented from being deformed, warped and cracked in the vacuum drying and vacuum carbonizing stages.

Owner:GUANGDONG YIHUA TIMBER IND

Lightweight gypsum plaster mortar

The invention belongs to building mortar, and particularly relates to lightweight gypsum plaster mortar which is the secondary development of gypsum plastered product technology. The lightweight gypsum plaster mortar is used for leveling inner sides of outer walls, inner partition walls and ceilings of buildings, and the heat-insulated effect is good. Because the flue gas desulphurized building gypsum of power plants is used, the problem of disposing and using the desulphurized gypsum is solved, and the circulating economy is developed. The method for preparing the plaster mortar comprises the following steps of: accurately weighing up the following materials in part by weight: 70 to 80 parts of flue gas desulphurized gypsum of power plants, 15 to 25 parts of vitreous hollow microsphere, 0.2 to 0.4 part of cellulose ether, 0.3 to 0.6 part of air entraining agent and 0.2 to 0.5 part of retarding agent; and putting the materials into a container, adding 60 to 120 parts of water into the container, and uniformly stirring the mixture at the normal temperature to obtain the lightweight gypsum plaster mortar. The lightweight gypsum plaster mortar has the advantages of moderate strength, unnecessary additional making of protective covering, direct leveling after plastering, high performance cost, high workability, short construction period, functions of preventing fire, absorbing sound, and adjusting air humidity and no emission of CO2 in the production process.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Method for disposing industrial waste sulfuric acid by utilizing carbide slag

InactiveCN105645453AEasy to produceSimple processCalcium/strontium/barium sulfatesSlagPhysical chemistry

The invention relates to a method for disposing industrial waste sulfuric acid by utilizing carbide slag. The method comprises the following steps: evenly mixing the carbide slag with water in an airtight mixing tank to obtain a carbide slag suspension of which the solid content is 15 wt% (weight percentage) to 35 wt%; then, delivering the carbide slag suspension into a neutralizing tank; adding the waste sulfuric acid into the neutralizing tank under stirring until the pH (Potential Of Hydrogen) of a system in the neutralizing tank is 7 to 9; then, delivering a mixture to a filter press for solid-liquid separation; returning filtrate to the airtight mixing tank for recycling, wherein a filter cake is water-contained calcium sulfate. The method disclosed by the invention is greatly simplified in production flow, very simple in process, easy to operate and low in energy consumption; meanwhile, after two kinds of industrial waste are disposed, the filtrate returns to the system for reuse; the water-contained calcium sulfate filter cake can be directly used as a raw material for producing cement and gypsum, and can also be used directly used for paving and the like, and no secondary pollutants are generated.

Owner:河南开祥精细化工有限公司

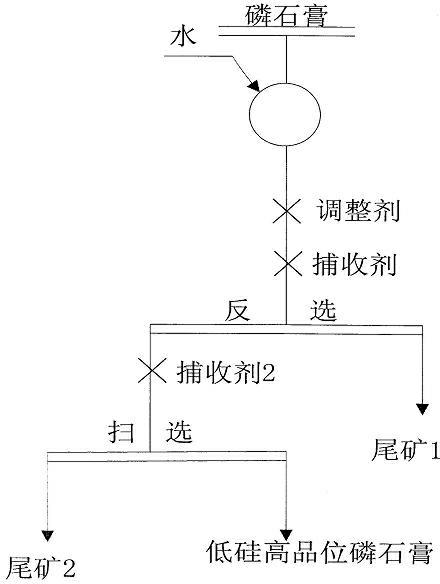

Phosphogypsum reverse flotation, desilication and impurity removal process

InactiveCN102500469AQuality improvementIncrease volume fractionFlotationPhosphogypsumReverse flotation

The invention relates to a phosphogypsum reverse flotation, desilication and impurity removal process; and targeting at the characteristic that the content of SiO2, phosphorus, F, acid insoluble substances and other impurities in phosphogypsum solid waste is high, a process of carrying out single or double reverse flotation by adding in regulator and collector is adopted; the regulator used in the reverse flotation is NaOH, Na2CO3, water glass, CaO, hydrochloric acid, sulfuric acid and other conventional regulator, and the used amount of the regulator is 1kg / t to 15kg / t. The collector used in the reverse flotation is fatty acid collector, negative ion collector, amine collector and other conventional desilicated collector, and the used amount of the collector is 1kg / t to 10kg / t. The process reduces the SiO2, phosphorus, F, acid insoluble substances and other impurities in the phosphogypsum, can prepare low-silicon and high-grade gypsum products, improve the grade and quality of gypsum, improve the mineral characteristics of the gypsum, and lay technical foundation for the industrialization of the phosphogypsum.

Owner:QUJING NORMAL UNIV

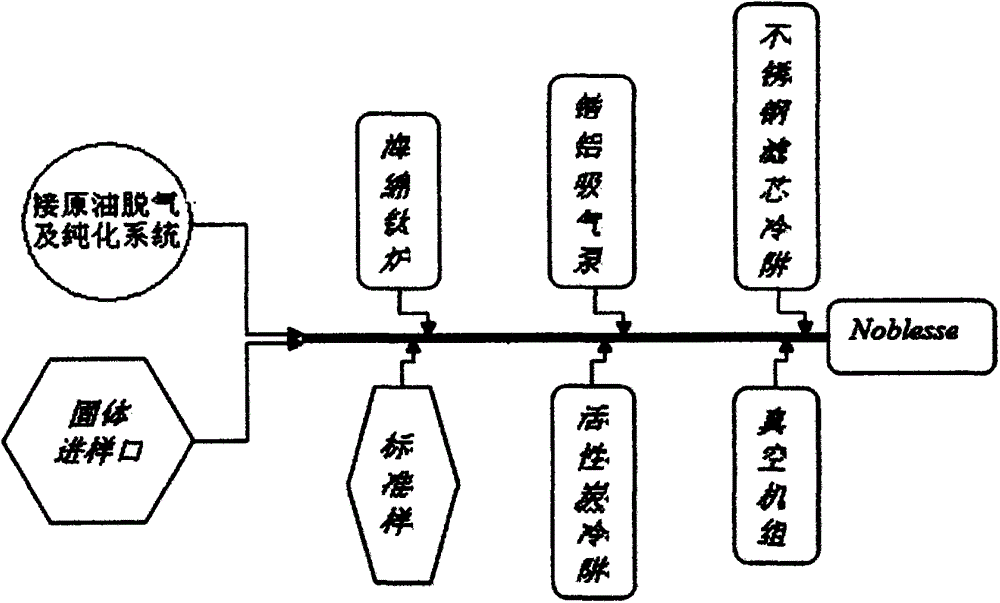

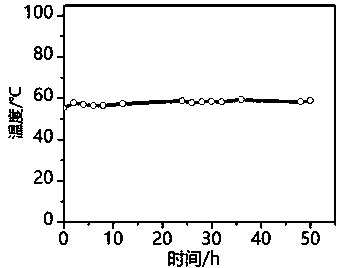

Determination method and apparatus for noble gas isotope in crude oil

ActiveCN103604860AIncrease profitNo pollutionPreparing sample for investigationMaterial analysis by electric/magnetic meansVacuum pumpingCooking & baking

The invention relates to the field of oil gas, especially to a determination method and a determination apparatus for noble gas isotope in crude oil. According to the invention, a crude oil sample is pre-purified, and the pre-purified sample mainly comprises a noble gas component and does not pollute an instrument, thereby avoiding baking and vacuum-pumping of a system after sample determination each time and substantially increasing the utilization rate of the instrument. The pre-purified sample almost does not contain any organic component, so a background is reduced, influence of organic fragment ions on measurement results is eliminated, and accuracy of test data is improved; organic ingredients in released gas of crude oil are effectively prevented from polluting a high vacuum noble gas isotope mass spectrometer, the superposition effect of organic fragment ion peaks on a target ion peak is reduced, so isotope detection precision is effectively improved. The technological difficulty that noble gas isotope in a crude oil sample is difficult to detect is overcome. Gas-oil-source ternary noble gas isotope data comparison is realized. Accurate and reliable noble gas isotope data are provided for oil gas tracing, oil source comparison and gas source comparison.

Owner:LANZHOU CENT FOR OIL & GAS RESOURCES INST OF GEOLOGY & GEOPHYSICS CAS

Graphene-based water-based conductive ink prepared by one-step method and preparation method thereof

The invention relates to graphene-based water-based conductive ink prepared by a one-step method and a preparation method thereof. The preparation method comprises the steps: jointly adding 1 to 8 parts of expanded graphite, 10 to 30 parts of conductive filler, 10 to 50 parts of water-soluble resin, 20 to 80 parts of solvent and 1 to 10 parts of aid into a high-pressure homogenizer to perform high-pressure shear; grinding until the particle size of slurry is smaller than 80mu m to obtain the graphene-based conductive ink with excellent conductivity and good stability. By means of the method, expanded graphite peeling and intercalation of conductive particles among graphite flakes can be finished at the same time in a shearing and grinding process; thus, an integrated good conductive network is established. The method has the advantages of simpleness in operation, short consumed time, ability in avoiding stack among the graphene flake layers and avoiding a grinding medium, simpleness infollow-up processing and suitability for production. The prepared graphene-based water-based conductive ink has the advantages of good dispersion and high stability.

Owner:北京航科航天科技有限公司

Coal composite sulfur fixing agent

The invention relates to a coal composite sulfur fixing agent, belonging to the technical field of boiler combustion desulphurization. The composite sulfur fixing agent is made of the following raw materials in parts by weight: 40-70 parts of CaO, 5-10 parts of SiO2, 5-15 parts of Al2O3, 3-5 parts of Fe2O3, 0.5-1 parts of BaS, 0.5-1 parts of BaCO3, 0.1-1.5 parts of Zn, 0.02-0.05 parts of Cu, 0.05-0.1 parts of As, 0.01-0.05 parts of Pb, 1-5 parts of CaF2, 0.05-0.2 parts of MgO, 0.5-1.0 parts of TiO2, 0.5-1.0 parts of K2O, 0.1-1.0 parts of Na2O and 0.04-0.06 parts of Ag. The coal composite sulfur fixing agent of the invention can reduce the emission of SO2, the atmospheric pollution and the formation conditions for acid rain. Since pulverized fuel ash and coal cinder are converted to modified ash and can be used in cement production technology, the clinker production of common cement can be reduced generally, the mine resources and the energy consumed during cement production are reduced, and the emission of CO2 is reduced.

Owner:河南中上环保科技有限公司

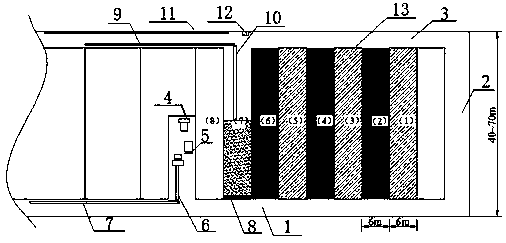

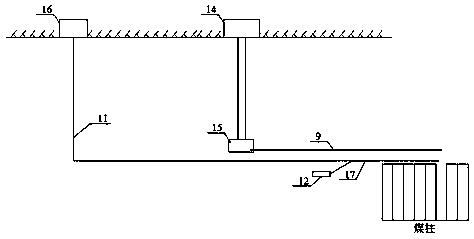

Method for achieving coal pillar mining replacement through gangue strip filling

The invention belongs to the field of waste disposal and mine coal extraction methods, and relates to a method for achieving coal pillar mining replacement through gangue strip filling, in particularto a waste comprehensive utilization method for coal-electricity integrated enterprises. Down-hole coal pillars are replaced through power plant flyash, heavy salt water and mine waste gangue, and theresource recovery rate and the economical benefits are increased.

Owner:CHINA UNIV OF MINING & TECH +1

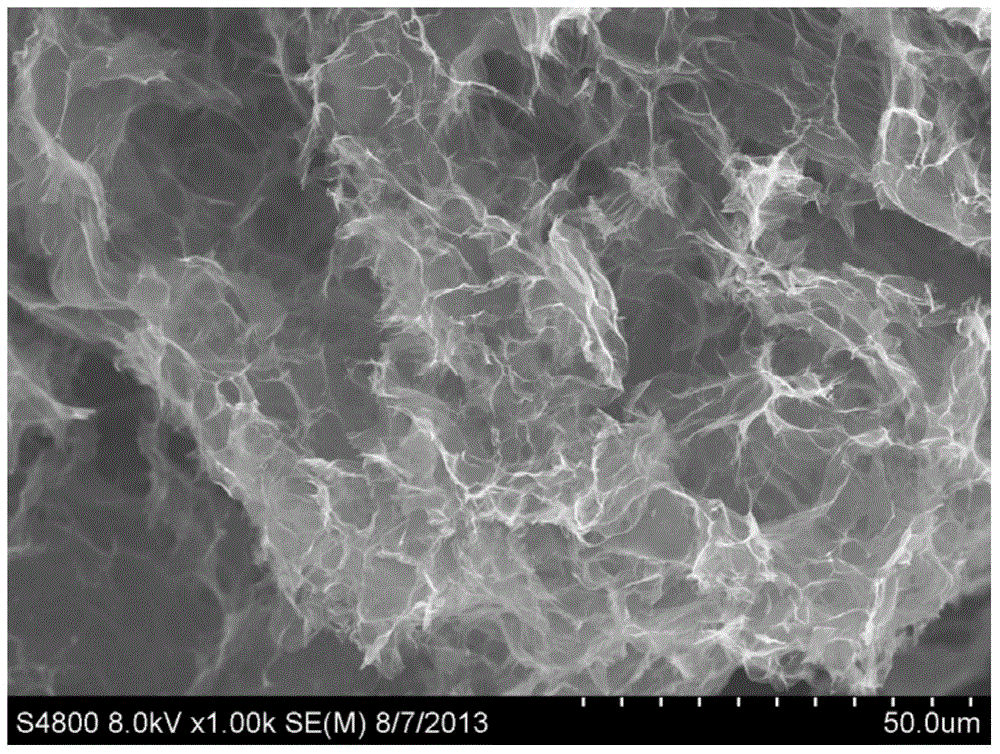

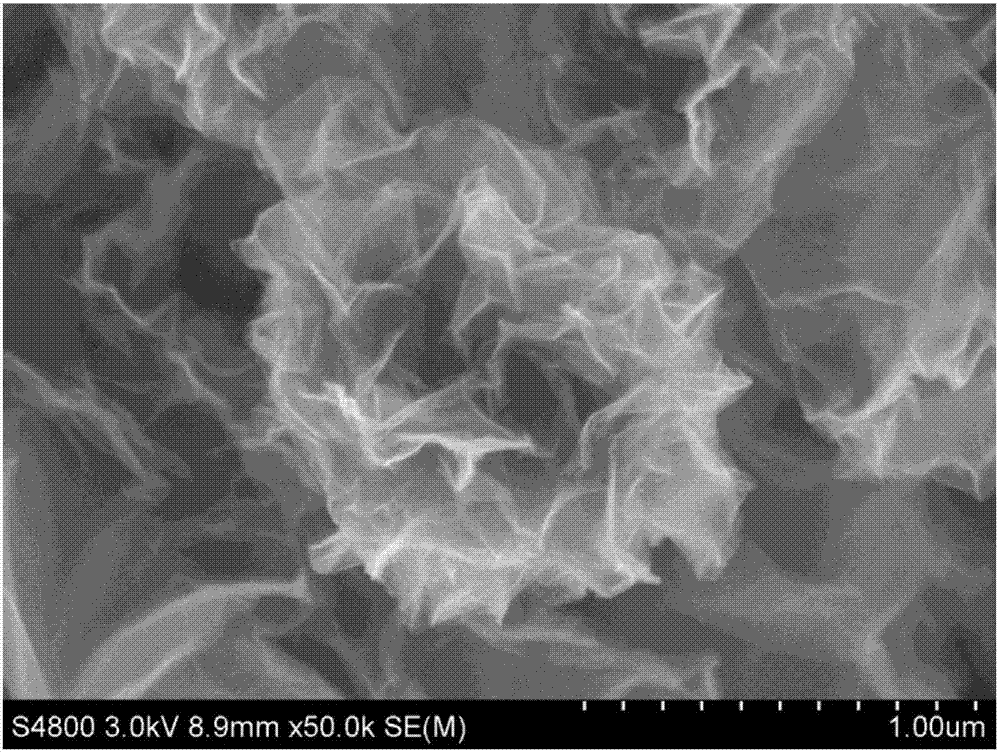

Graphene-based carbon nanofiber preparation method

InactiveCN106521719AImprove hydrophilicityReduce stackingGrapheneFibre chemical featuresElectrospinningPolypropylene

The invention provides a graphene-based carbon nanofiber preparation method, characterized in that polyacrylonitrile is taken as a carbon source, oxidized graphene prepared by an improved method provided by the invention is added, then an electrospinning technique is used for preparing and obtaining oxidized graphene / polypropylene nanofiber, then pre-oxidation and carbonization steps are adopted to prepare and obtain graphene-based carbon nanofiber. The graphene-based carbon nano material prepared by the method provided by the invention is very easily dispersed, the overlapping of sheets is reduced, and the removal of a functional group at high temperature is facilitated, so that the conductivity and specific surface area of nanofiber are improved. Under the condition that the current density is 1A / g, the specific capacitance is 468F / g.

Owner:过冬

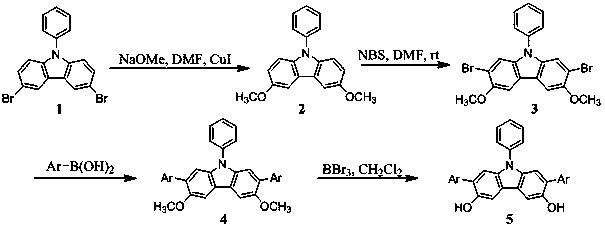

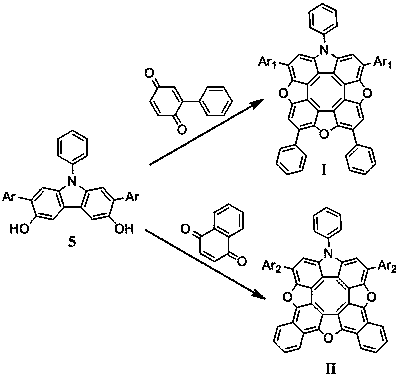

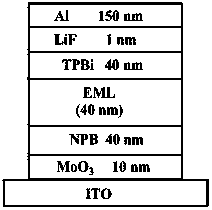

Rotaviral tetraene fluorescent compound, preparation method and application thereof, and electroluminescent device

ActiveCN103524518AReduce π-π stackingImprove conductivityOrganic chemistrySolid-state devicesQuantum efficiencyLuminophore

The invention discloses a rotaviral tetraene fluorescent compound, a preparation method and application thereof, and an electroluminescent device. The structural general formula of the rotaviral tetraene fluorescent compound is as follows, wherein Ar1 is phenyl, 1-naphthyl or 2-naphthyl, and Ar2 is phenyl, 1-naphthyl or 2-naphthyl. A special rotaviral tetraene conjugate rigid structure containing heteroatoms is utilized and connected with a blue luminophore with high quantum efficiency, so as to obtain the rotaviral tetraene fluorescent compound. Thus, a more distorted molecular structure is achieved; pi-pi accumulation between molecules is reduced; meanwhile, the conductivity of the fluorescent compound is improved. By adopting the rotaviral tetraene fluorescent compound, stabilization of an apparatus is facilitated; excellent electroluminescent properties are obtained; development of an efficient full-color display is facilitated; the rotaviral tetraene fluorescent compound can be widely applied to OLED (organic light-emitting diode) large-screen display and OLED white-light illumination with high brightness demands.

Owner:TCL CORPORATION

Desulfurized gypsum thermal-insulation material

The invention relates to a desulfurized gypsum thermal-insulation material belonging to thermal-insulation materials. The waste pollutant desulfurized gypsum in the existing heat power plants is piled and filled in land, thereby polluting the ecological environment and influencing the safe operation of the power plants. The desulfurized gypsum thermal-insulation material provided by the invention comprises the following components in parts by weight: 80-85 parts of desulfurized building gypsum, 15-20 parts of vitrified microbead, 0.1-0.25 part of cellulose ether, 0.2-0.4 part of air entraining agent, 0.01-0.015 part of retarder and 70-100 parts of water. The components are added into water and evenly mixed to obtain the desulfurized gypsum thermal-insulation material. The desulfurized gypsum thermal-insulation material has the advantages of low coefficient of heat conductivity, thermal insulation and heat-shielding performance, energy saving, moderate strength, favorable workability and short construction cycle, has the functions of fire resistance, sound absorption, air humidity conditioning and the like, and reduces the piling and landfilling of the desulfurized waste residues as well as environmental pollution; and no CO2 is emitted in the production process.

Owner:上海城建置业发展有限公司 +1

Mining method for multilayer fragile gently-inclined extra-narrow ore vein

The invention discloses a mining method for a multilayer fragile gently-inclined extra-narrow ore vein. According to the method, mining areas are divided along the ore body trend; mining area columns (5) are reserved among the mining areas; a mine slope (1) is arranged in each mining area column (5); one vein following combined roadway is arranged in the inclination direction every 20m to 40m; vein following cutting roadways (2) and cutting mine slopes (3) are excavated at the end part of a chamber in the trend direction and the inclination direction; and a first layered ore vein, a rock sandwich layer and a second layered ore vein are totally excavated in one step along the vein following cutting roadways (2) and the cutting mine slopes (3). In the backstopping process, different drilling and blasting parameters are adopted at the first layered ore vein, the rock sandwich layer and the second layered ore vein, rocks among the ore veins can be removed; the problem of ore mixing into the rocks is solved; and the ore dilution is reduced. The method provided by the invention is particularly applicable to the mining of the underground metal mine multilayer fragile gently-inclined extra-narrow ore vein and the ore vein easy to crush due to blasting disturbance; the simultaneous recovery of the multilayer ore vein is realized; and the problem of personnel operation and equipment operation space limitation is solved through full thickness mining.

Owner:河南发恩德矿业有限公司

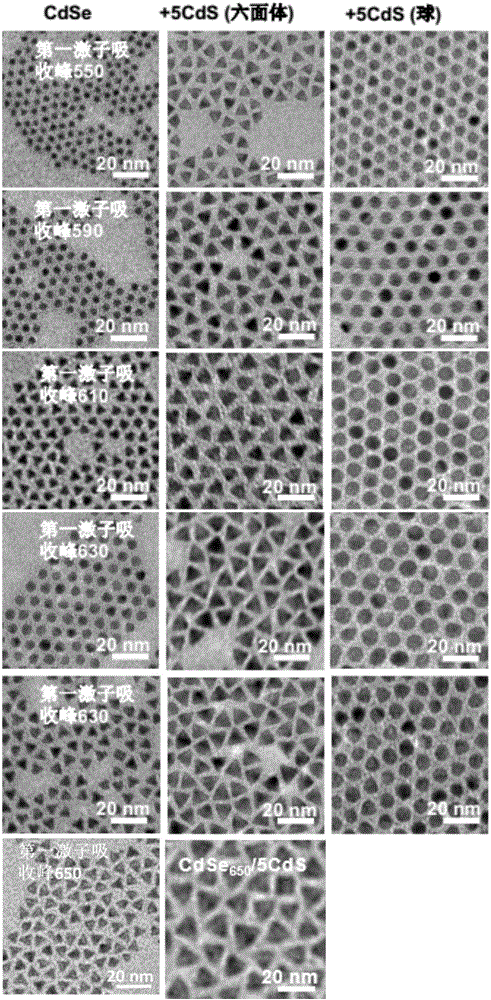

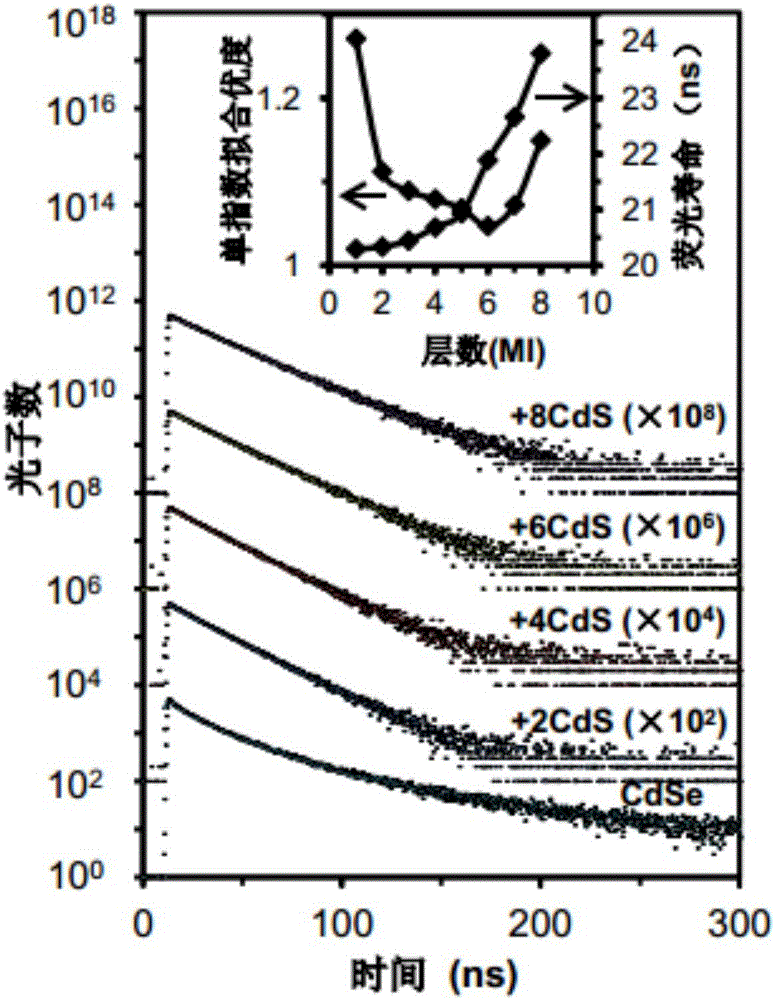

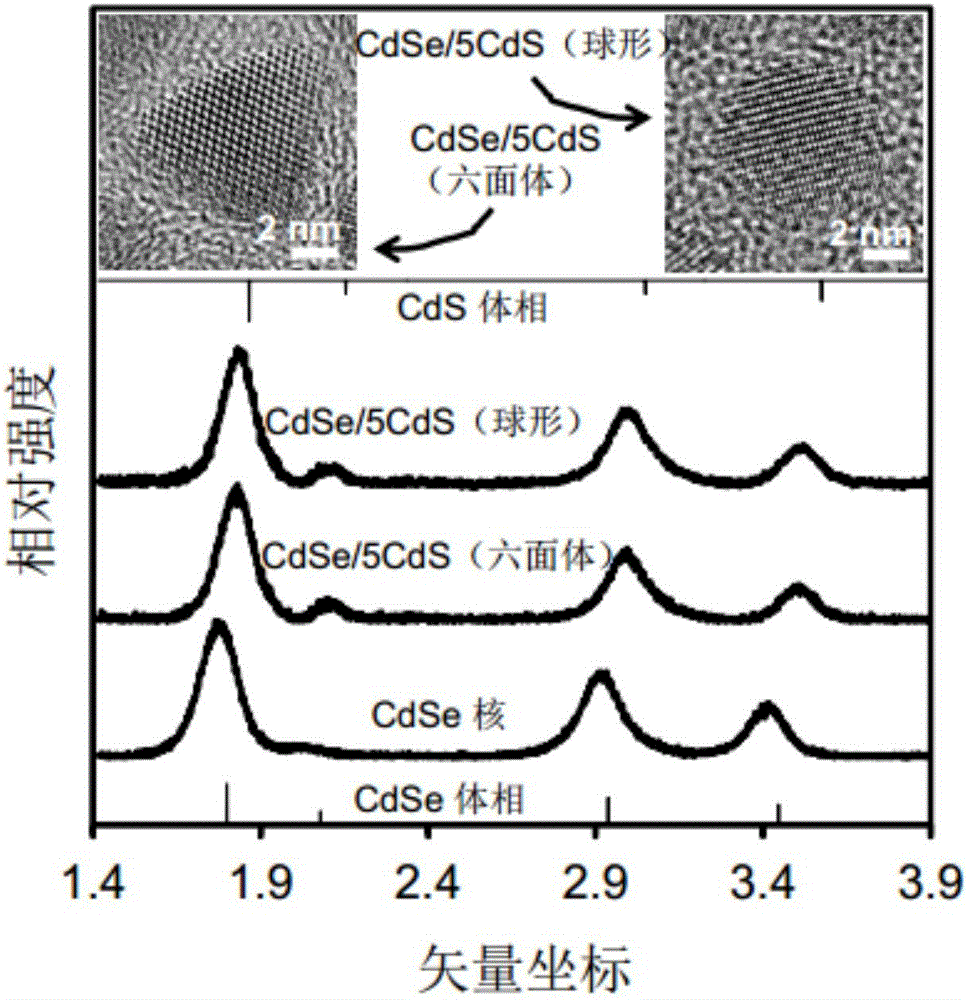

Nanocrystal-ligand complex, preparation method and application thereof

ActiveCN107522723AImprove solubilityLow quantum efficiencyMaterial nanotechnologySolid-state devicesQuantum efficiencySolubility

The invention provides a nanocrystal-ligand complex, a preparation method and application thereof. The nanocrystal-ligand complex comprises nanocrystals and at least two ligand forming surface coordination with nanocrystals, the ligand is unitary or polygonal carboxylic acid ligand, and C-chain skeletons of at least two ligand are different in chain length. The nanocrystal surface has at least two ligand, the interaction between different ligand is reduced, i.e., alternation of the molecular chains and packing of crystalloid can be reduced, a rotation entropy / bending entropy is increased, a C-Csigma conformation freedom degree between different ligand is sufficiently released, a vast dissolution entropy is generated, and the solubility of the nanocrystal can be increased; moreover, since the unitary or polygonal carboxylic acid ligand is lower than the cost of the branch-chain carboxylic acid ligand, a purpose of improving the solubility of the nanocrystal with low cost can be realized; and meanwhile, based on the chemical stability and good solubility of the unitary carboxylic acid, the nanocrystal-ligand complex has high quantum efficiency.

Owner:ZHEJIANG UNIV +1

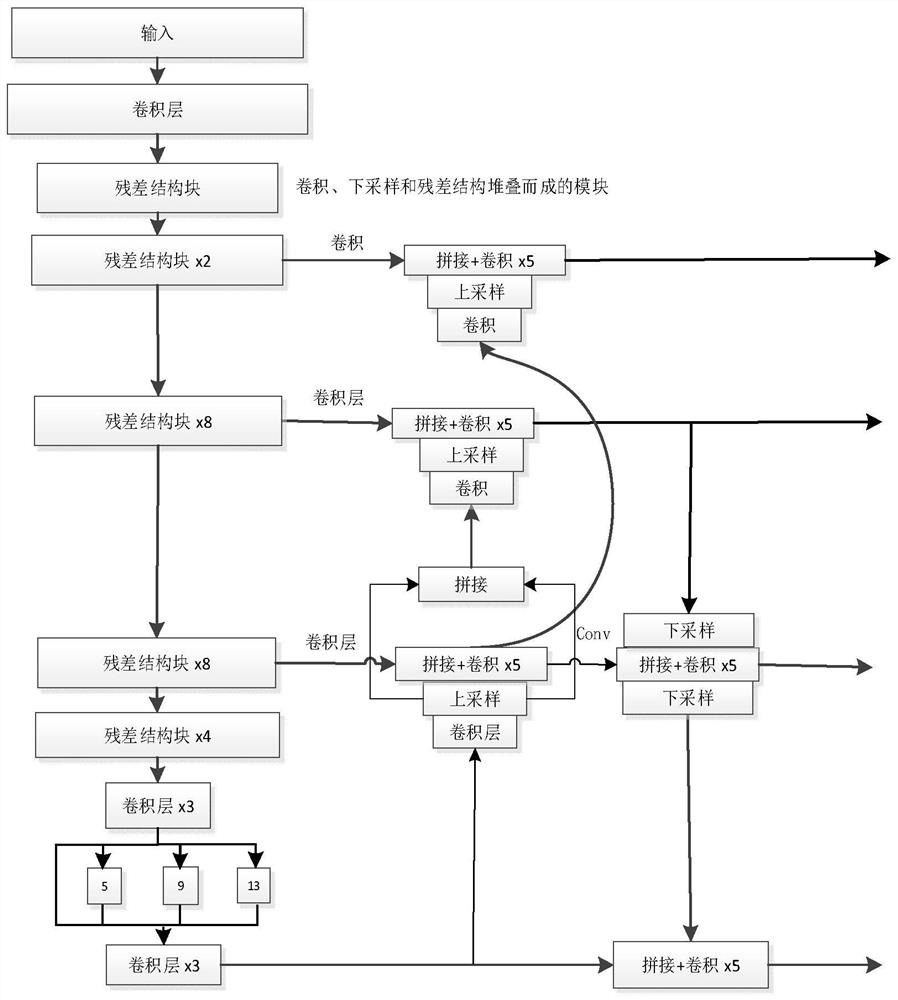

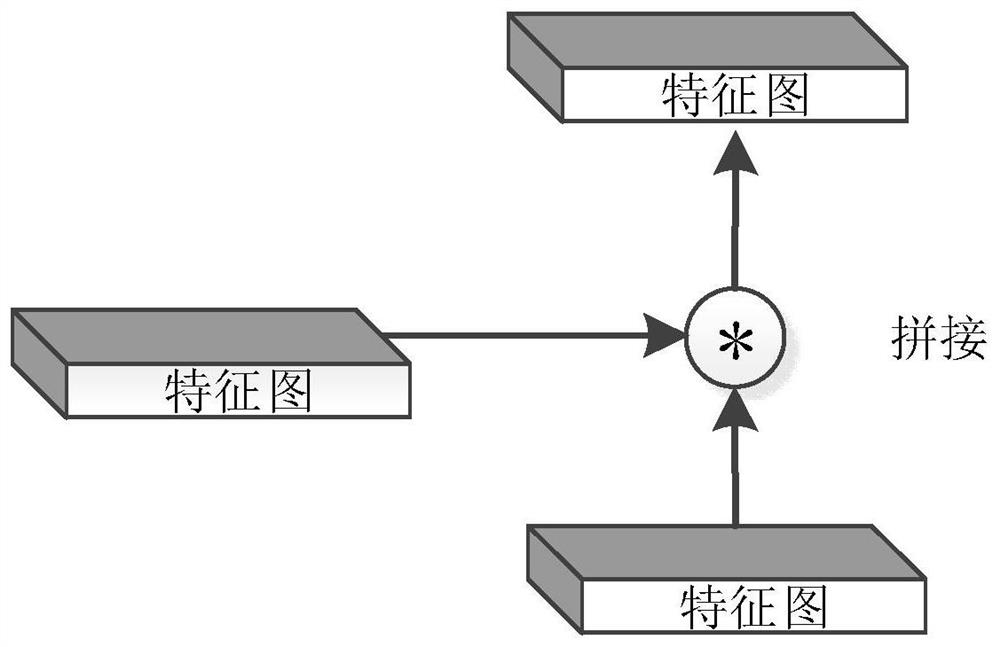

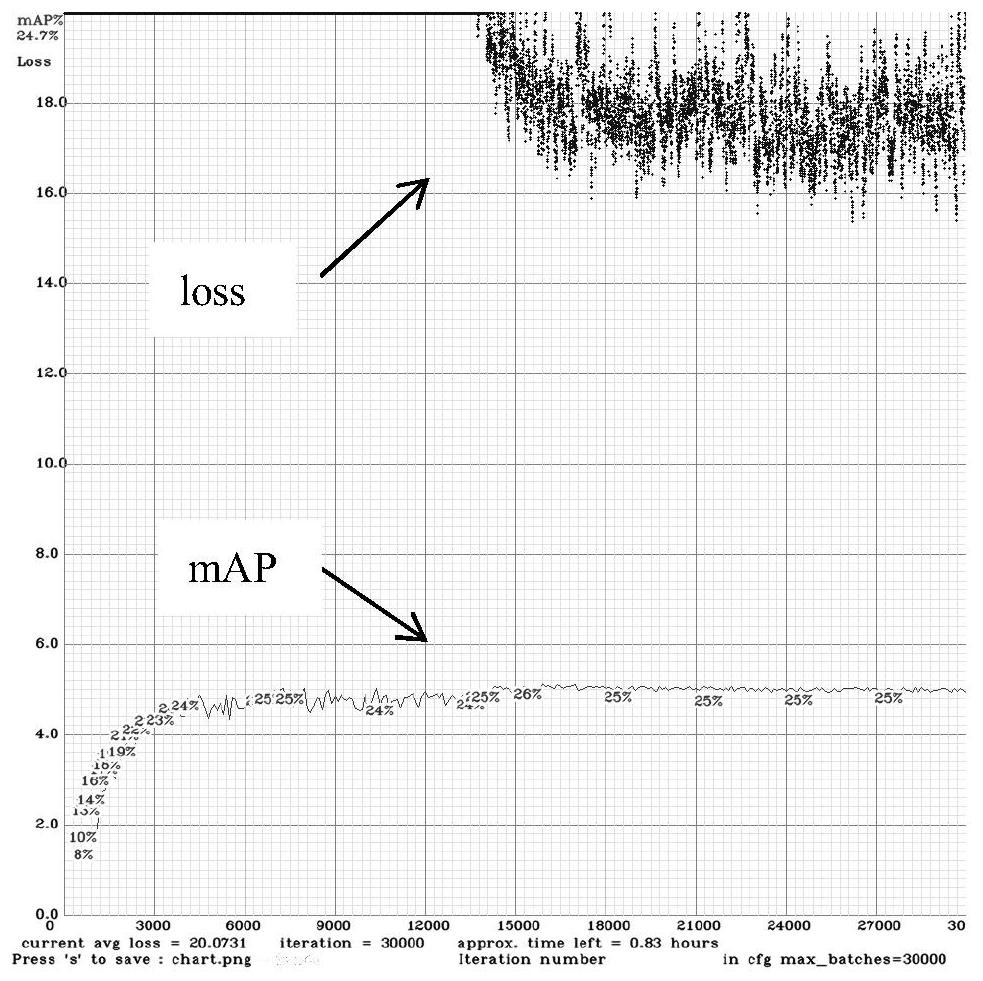

Unmanned aerial vehicle multi-scale target detection and identification method

PendingCN113420607AShorten the information pathEnhance feature hierarchyCharacter and pattern recognitionNeural architecturesIdentification rateNetwork model

The invention discloses an unmanned aerial vehicle multi-scale target detection and recognition method, which is high in recognition rate, small in calculation amount and high in robustness. The method is realized through the following technical scheme: forming a real-time target detection and identification network model by adopting three parts, namely a trunk structure for extracting different scale features, a network neck (Neck) and a network detection head for predicting target information, performing feature extraction on an input image by adopting a CSPDarknet53 trunk network in a target detection and identification network-YOLOv4, and expanding the original three-scale feature output into four-scale feature output; using an improved two-branch PANet to reduce the number of convolution layers through which features pass; predicting a conditional probability value for each category by each detection output, directly obtaining a prediction result from the picture, and obtaining target information; and transmitting the four feature maps with different sizes to a detection head for joint training, and performing category judgment and position regression on the unmanned aerial vehicle target to obtain a detection and recognition result.

Owner:10TH RES INST OF CETC

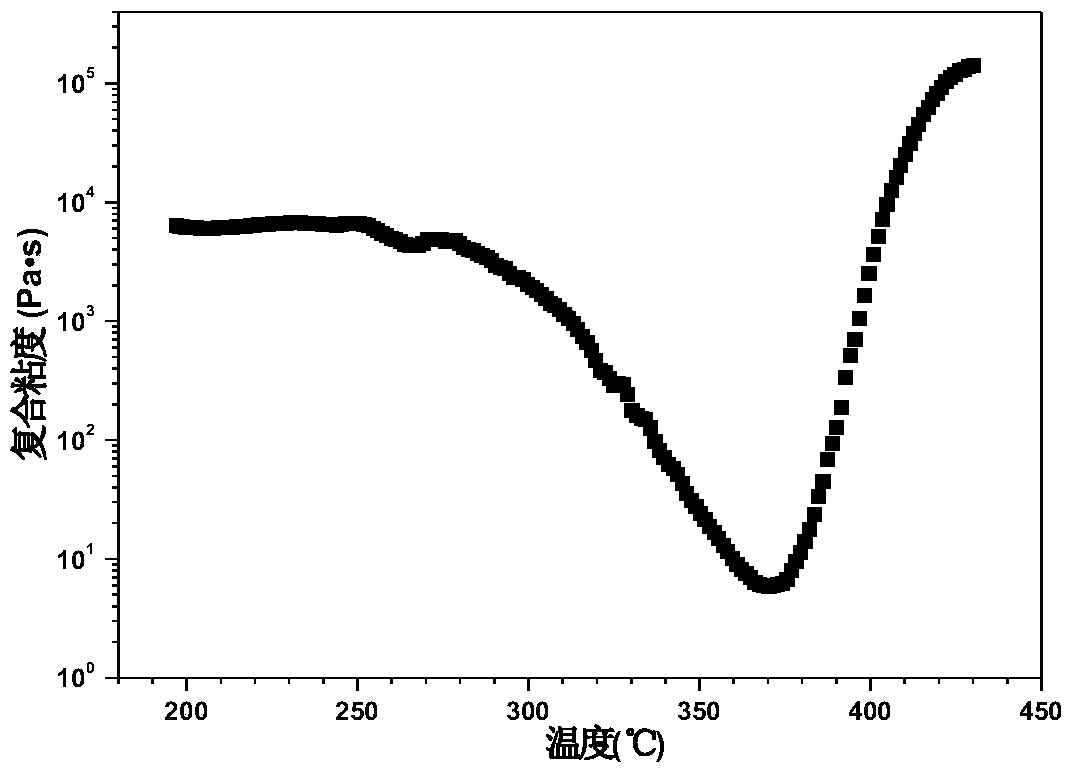

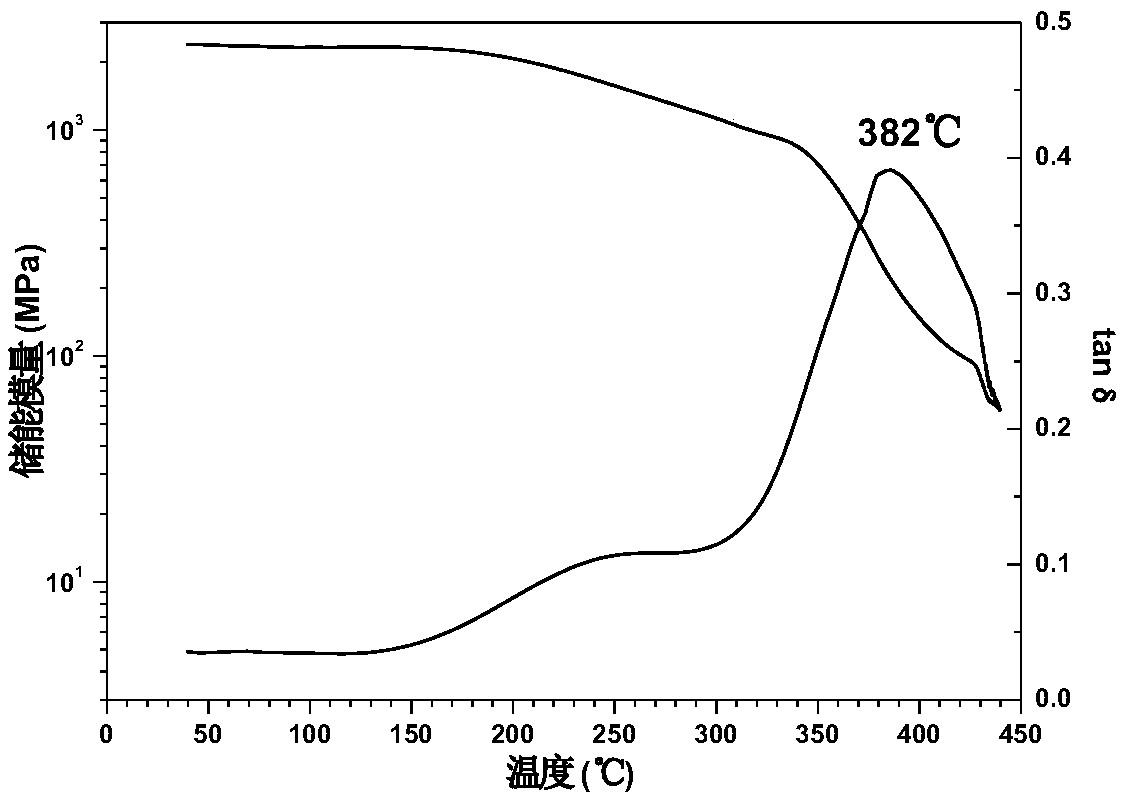

Polyimide adhesive and preparation method thereof

The invention relates to a polyimide adhesive and a preparation method thereof and belongs to the technical field of adhesives. The polyimide adhesive solves the problem that the polyimide adhesive ata temperature of greater than 350 DEG C has poor thermal instability and low adhesive properties. The polyimide adhesive is prepared from a polyimide adhesive prepolymer through curing. The preparation raw materials of the polyimide adhesive prepolymer comprise aromatic diamine containing a biphenyl structure, aromatic diamine containing a siloxane structure, aromatic dianhydride and a blocking agent. The preparation method comprises dissolving the polyimide adhesive prepolymer in an organic solvent to obtain a homogeneous solution, coating the surface of the adherend with the homogeneous solution, removing the organic solvent, carrying out curing to obtain the polyimide adhesive and bonding the adherend The polyimide adhesive can be used for the bonding of high temperature resistant parts in the fields of aviation, aerospace, precision machinery and petrochemical industry.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Graphene powder and preparation method thereof

ActiveCN104787751ALower decomposition temperatureConducive to the degree of oxidationState of artCvd graphene

The present invention provides a graphene powder preparation method, which comprises: a, carrying out a reaction of graphite oxide and a dispersant to obtain an intermediate product, wherein the dispersant comprises an ammonium salt; and b, carrying out a heat treatment on the intermediate product to obtain the graphene powder. According to the present invention, the close contact degree of the graphite oxide sheet layers can be weakened through the dispersant, such that the obtained graphene powder of the present invention has characteristics of low agglomeration degree and good dispersion property; the dispersant is subjected to thermal decomposition to produces gas during the heat treatment process and the gas makes the graphite oxide be peeled, such that the agglomeration degree of the obtained graphene powder of the present invention is further weakened so as to obtain the graphene powder having the good dispersion property; and the graphene powder having the good dispersion property can be obtained without the spray drying compared with the method in the prior art, such that the graphene powder preparation method of the present invention has characteristics of high efficiency and low energy consumption, and can be used for large-scale production of the graphene powder.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Sludge building material and preparation method thereof

InactiveCN101381212ASimple methodReduce manufacturing costSolid waste managementBrickMunicipal sewage

The invention provides a sludge building material and a method for preparing the same, which particularly relates to a fresh sludge building material and a method for preparing the same. The building material consists of sludge, shale and fly ash. In the method, a gravity thickening pond of the prior municipal sewage plant is utilized, the prior gravity thickening process is adopted, the shale and the fly ash are added in the fresh sludge in the pond, and the discharged enriched mixture are directly used as the building material or the discharged enriched mixture is further dewatered to obtain the finished product. The building material has the advantages of few components and large sludge consumption. The method has the advantages of simple method, mature technique and low cost, and provides a new approach for the treatment and the utilization of sludge resources and solves the problems of large land occupation, difficult investment and environmental pollution in the municipal sewage plant. The technical proposal of the invention can be wide applied to the municipal sewage plant adopting the continuous current gravity thickening process. The product prepared by the technical proposal of the invention can be widely applied to the preparation of building bricks, porcelain granules and the like.

Owner:CHONGQING UNIV

Graphene-based waterborne acrylic paint and preparation method thereof

ActiveCN106987188ASimple structureCompact structureAntifouling/underwater paintsPaints with biocidesEmulsionAcrylic resin

The invention discloses a graphene-based waterborne acrylic paint and a preparation method thereof. The paint is prepared by mixing the following raw materials in parts by weight: 100 parts of an acrylic resin emulsion, 0.1-1 part of spitball graphene microspheres, 30-60 parts of an inorganic filler, 9-12 parts of an assistant and 10-20 parts of water. The spitball graphene microspheres with good mechanical property and elasticity can be obtained through spray drying and two-step method reduction. The spitball graphene microspheres are capable of effectively absorbing shock after being added to the paint, so that the abrasive resistance of a coating is improved and the chemical corrosion resistance can be improved. The spitball graphene microspheres have a unique microstructure, so that graphene can be effectively prevented from being stacked, the phenomena of aggregation and precipitation of the graphene in the paint are avoided and the overall stability of the paint is greatly improved.

Owner:HANGZHOU GAOXI TECH CO LTD

Gel material for filling worked out section by vanadium-titanium-containing slags

The invention discloses a gel material for filling a worked out section by vanadium-titanium-containing slags. The gel material comprises the following components in percentage by weight: 8-11% of an alkaline excitant, 14-16% of desulfurized gypsum and 71-77% of vanadium-titanium slags. The gel material further can comprise 1-2% of mirabilite as an early strength agent. The invention discloses filling slurry prepared from the gel material, full mill-tailing filler and tap water at the same, wherein the weight ratio of the gel material to the full mill-tailing filler is (1:15)-(1:4), and the percentage by weight of the tap water is 22-32%. The gel material disclosed by the invention realizes resource utilization of vanadium-titanium-containing slags and reduction of stacking of solid residues on the surface, and the filling cost of the worked out section of a mine is greatly reduced. Meanwhile, the filling body prepared has high strength.

Owner:JINCHUAN GROUP LIMITED +1

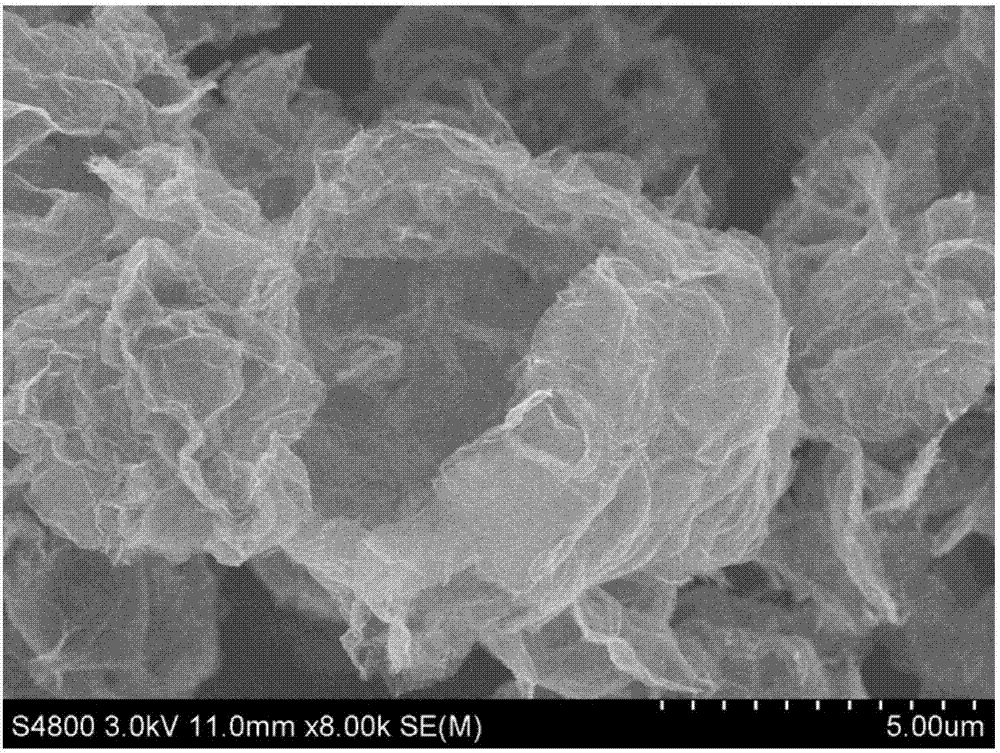

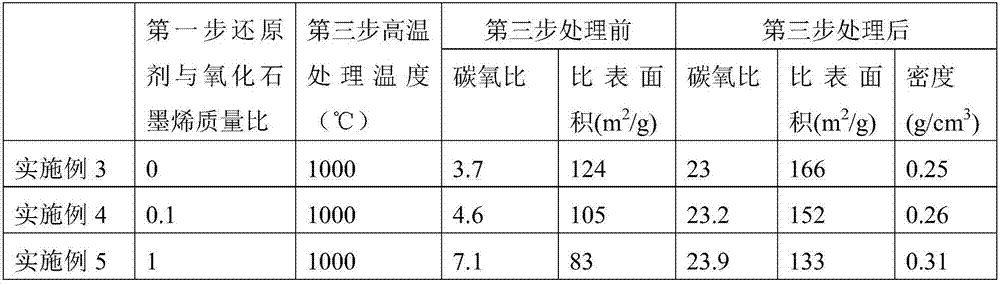

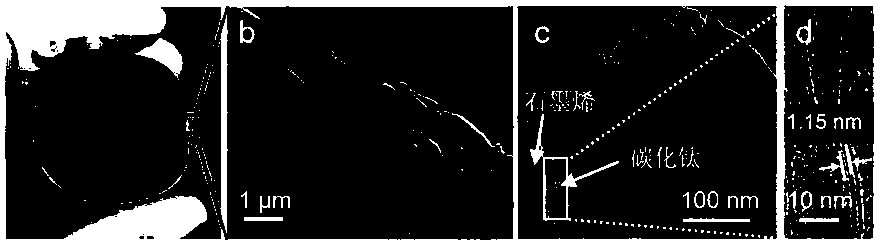

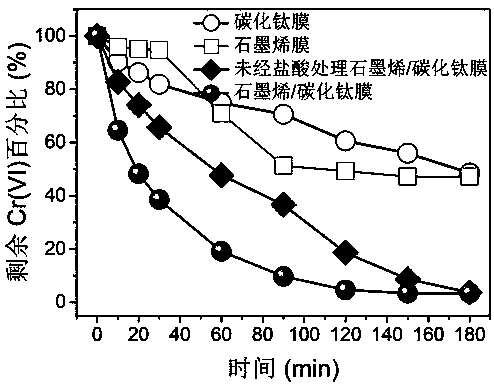

Graphene/titanium carbide water body purifying composite membrane material

InactiveCN107551829AImprove hydrophilicityReduce stackingSemi-permeable membranesOther chemical processesFiltrationTitanium carbide

The invention discloses a graphene / titanium carbide water body purifying composite membrane material. According to the graphene / titanium carbide water body purifying composite membrane material, a titanium carbide nano-sheet colloid is firstly prepared by adopting Ti3AlC2 as a raw material; afterwards, a graphene nano sheet is prepared through a method for reducing graphene oxide by (dendritic) polyethyleneimine; the prepared graphene dispersion liquid is dropwise added into a titanium carbide nano-sheet colloid solution, the vacuum suction filtration is carried out, and then an obtained composite membrane material is soaked in a hydrochloric acid solution, so as to prepare for obtaining the graphene / titanium carbide water body purifying composite membrane material. The graphene / titanium carbide water body purifying composite membrane material prepared by the invention, compared with a graphene membrane, a titanium carbide membrane and a composite membrane which is not subjected to thetreatment with hydrochloric acid, has the higher performance of removing a heavy metal ion in a water body. A method is simple in preparation process and mild in reaction condition and the membrane material can be realized in effective recovery and separation and has the important practical application value to the removal of the heavy metal ion in the water body.

Owner:FUZHOU UNIV

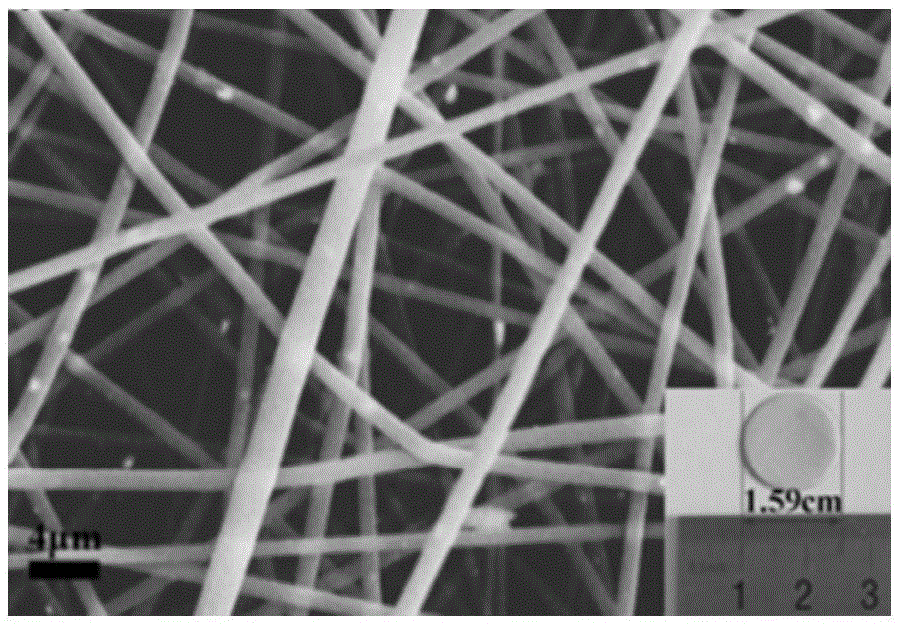

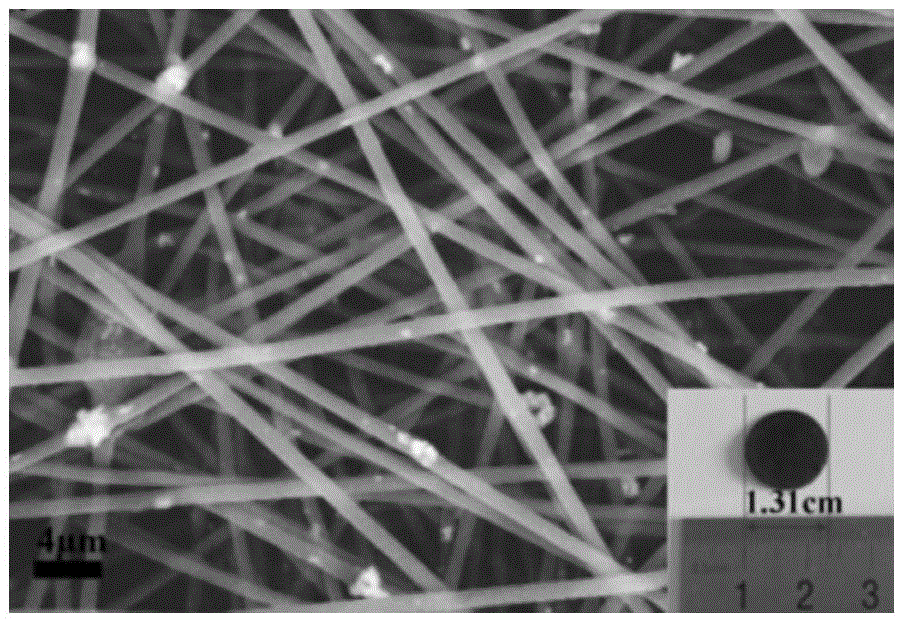

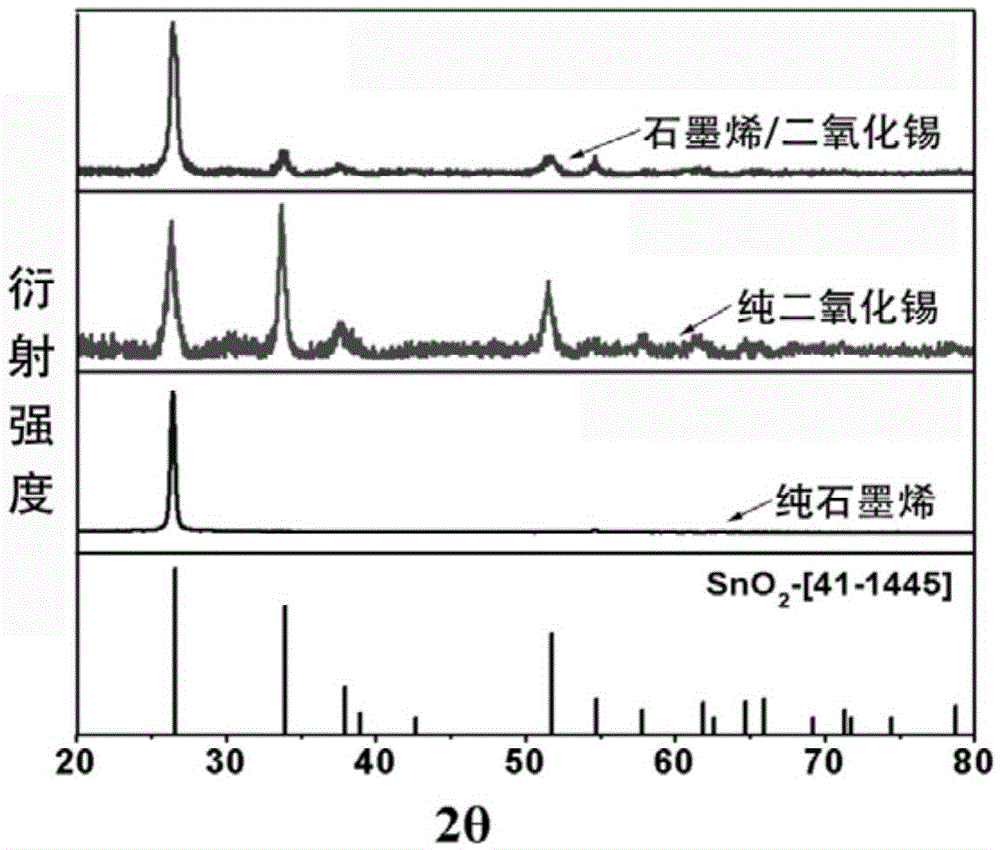

Preparation method of graphene/stannic oxide composite nanofiber membrane and application

InactiveCN105470484AEvenly distributedHigh porosityMaterial nanotechnologyCell electrodesFiberPorous graphene

The invention discloses a preparation method of a graphene / stannic oxide composite nanofiber membrane and an application, and relates to anode materials for lithium-ion batteries. The preparation method comprises the following steps: adding graphene to deionized water and carrying out ultrasonic treatment; adding NaOH and stannic chloride under a stirring condition, and mixing the deionized water evenly to obtain a mixed solution; transferring the mixed solution to a reaction kettle for reaction, and filtering, cleaning and drying the mixed solution to obtain graphene / stannic oxide composite nano-particles; ultrasonically dispersing the graphene / stannic oxide composite nano-particles into a mixed solvent of methanol and water, and adding PVAc to obtain a spinning precursor solution; carrying out high-pressure electrospinning on the spinning precursor solution to obtain a PVAc / graphene / stannic oxide composite nanofiber membrane; and carrying out drying and thermal treatment to obtain the porous graphene / stannic oxide composite nanofiber membrane, wherein the diameters of fibers in the composite nanofiber membrane are 800-1200nm and the lengths are greater than 0.5mm. A conductive agent and a binder do not need to add, and the graphene / stannic oxide composite nanofiber membrane can be directly applied to preparation of the lithium-ion battery as an electrode material.

Owner:XIAMEN UNIV

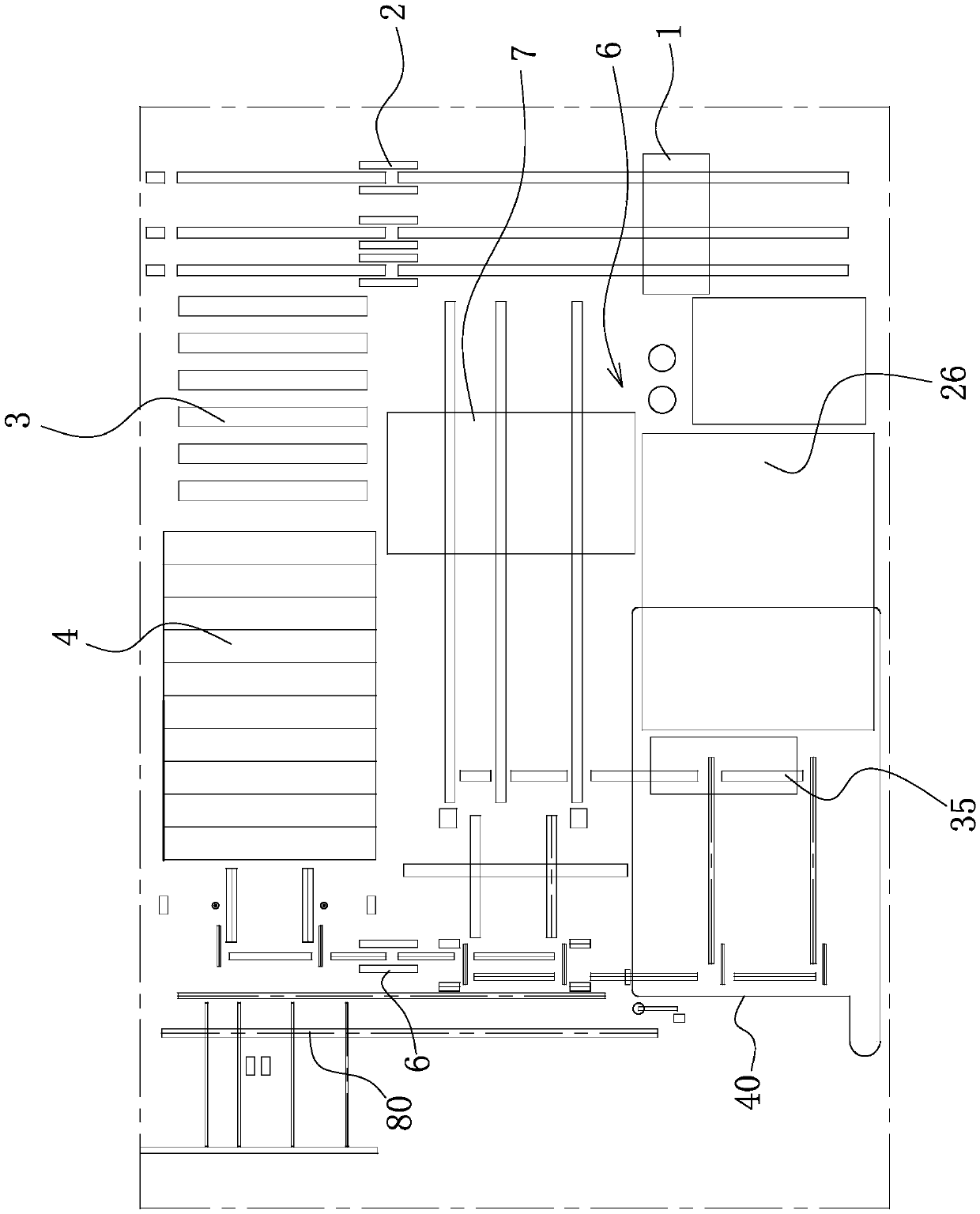

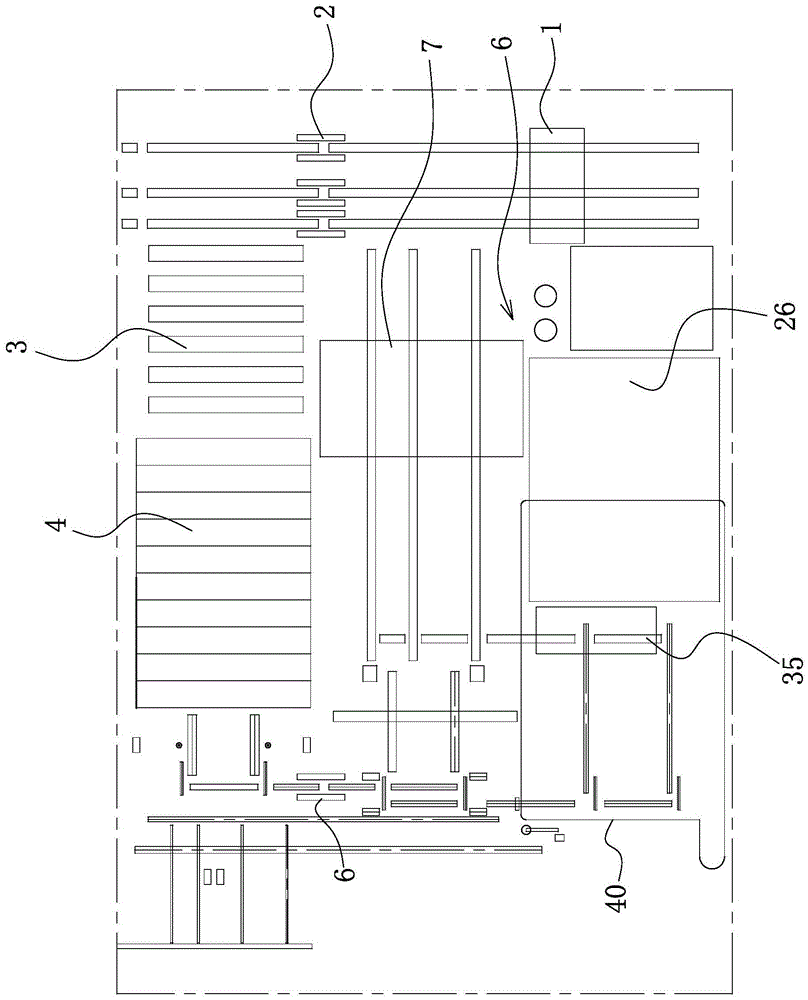

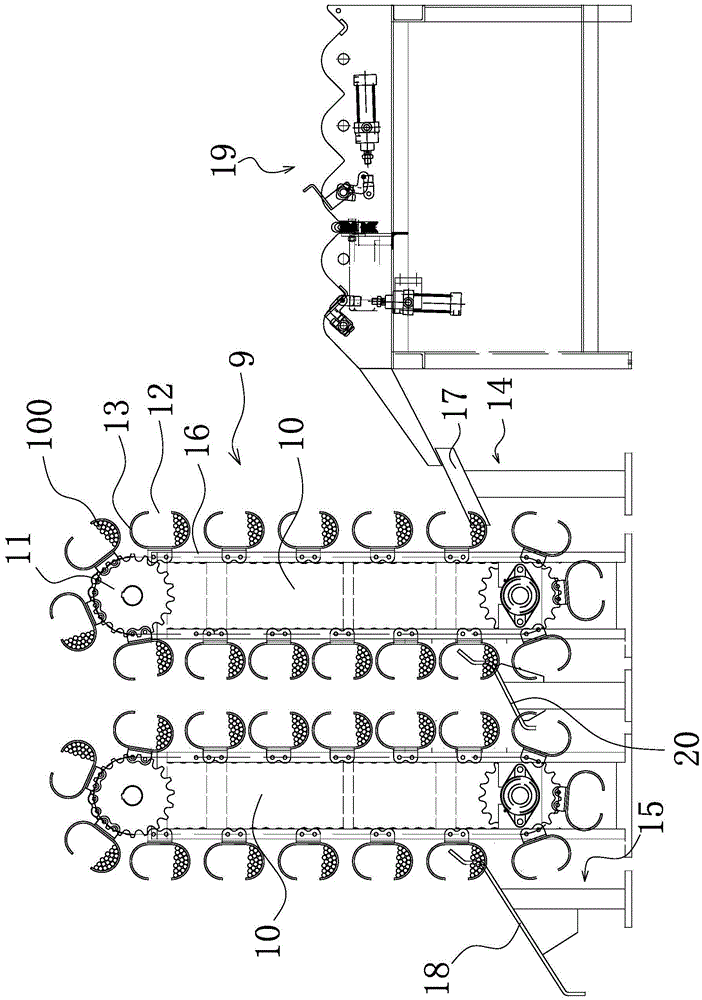

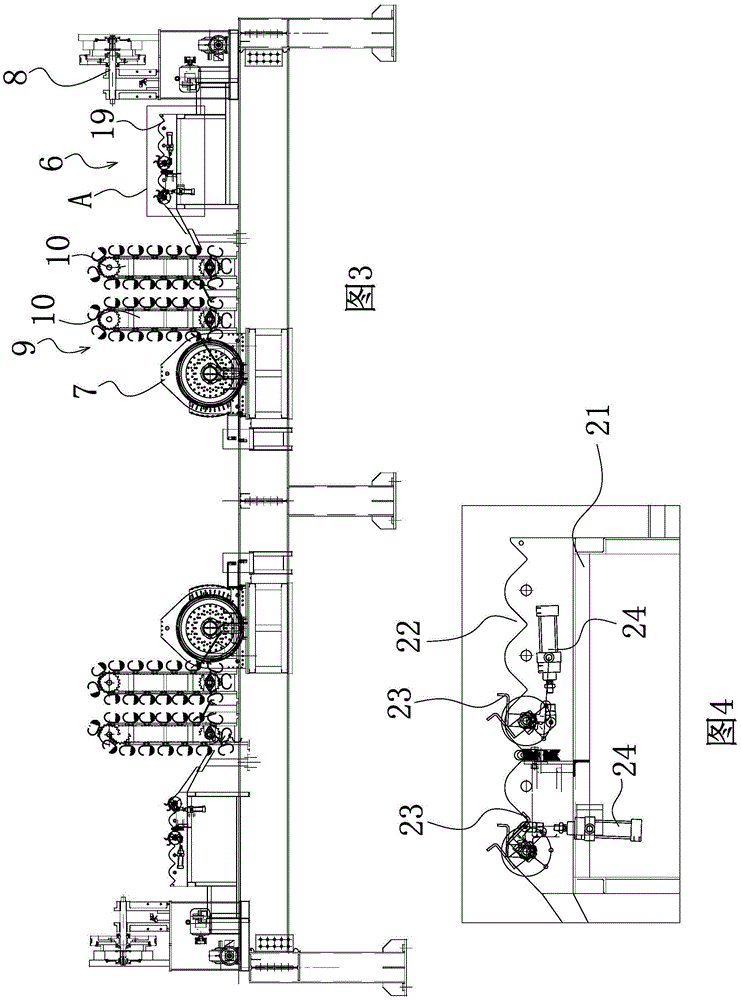

Fully automatic pipe pile production line

ActiveCN105599128BReliable disengagementSafe escapeCeramic shaping plantsShaping reinforcementsProduction lineDrive shaft

The invention belongs to the technical field of construction and relates to a fully-automatic tubular pile production line. The fully-automatic tubular pile production line comprises a material distribution device, die assembly devices, centrifugal devices, steaming-curing and maintaining devices, a die disassembly device and a cage making device and further comprises an automatic pile outputting device; the automatic pile outputting device comprises pile outputting and overturning arms and a pile outputting maintaining frame, the pile outputting overturning arms are connected with pile outputting and overturning arm drivers, the pile outputting and overturning arm drivers are provided with drive shafts capable of rotating in the peripheral direction, the pile outputting maintaining frame is connected with a maintaining frame driver, and the maintaining frame driver is provided with a drive shaft capable of rotating in the peripheral direction; when the pile outputting and overturning arms drive a pipe die to rotate, the pile outputting maintaining frame is pressed into a tubular pile of the pipe die and can conduct synchronous rotation with the pile outputting and overturning arms. By means of the fully-automatic tubular pile production line, continuous demoulding can be achieved, and thus production efficiency is improved.

Owner:浙江兆弟技术有限公司

Organic compound, and electronic element and electronic device using same

ActiveCN111848588AImprove rigidityHigh hole mobilitySilicon organic compoundsSolid-state devicesSimple Organic CompoundsOrganic electroluminescence

The present invention relates to an organic compound, the structure of the organic compound comprises a formula I and a formula II, the structure represented by the formula I is fused with the structure represented by the formula II, and * represents a connection point capable of being fused with the formula II in the formula I. When the organic compound provided by the invention is used for a light-emitting layer of an organic light-emitting device, the device efficiency of the device can be effectively improved, and the service life of the organic light-emitting device is prolonged.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

Continuous cage weaving type tubular pile production line

ActiveCN105583947ARealize automated continuous storageRealize automatic dischargeCeramic shaping plantsShaping reinforcementsComing outProduction line

The invention belongs to the technical field of construction, and relates to a continuous cage weaving type tubular pile production line. The continuous cage weaving type tubular pile production line comprises a material distribution device, a die assembly device, a centrifugation device, a steam-curing device, a die disassembly device and a cage weaving device. The cage weaving device comprises a cage weaving machine and a steel bar end upsetting machine. A steel bar storage mechanism is arranged between the steel bar end upsetting machine and the cage weaving machine. One side of the steel bar storage mechanism is connected with the steel bar end upsetting machine, and the other side of the steel bar storage mechanism is connected with the cage weaving machine. The steel bar storage mechanism comprises steel bar storage racks. Steel bar storage rack chain assemblies capable of rotating around the steel bar storage racks in the circumferential direction are connected to the steel bar storage racks in a rotating manner. A plurality of steel bar brackets with opening parts are fixed to the steel bar storage rack chain assemblies. When the steel bar storage rack chain assemblies rotate, the steel bar brackets and the steel bar storage rack chain assemblies synchronously rotate. Steel bars coming out of the end upsetting machine can be automatically stored and conveyed to the cage weaving machine, and therefore the links of conveying and stacking the steel bars are omitted, and the work efficiency is further improved.

Owner:浙江兆弟技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com