Graphene/titanium carbide water body purifying composite membrane material

A water purification and titanium carbide technology, which is used in adsorption water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., to improve performance, improve hydrophilic performance, and remove heavy metal ions. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

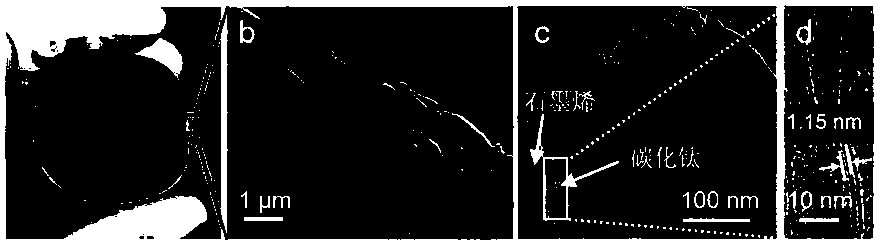

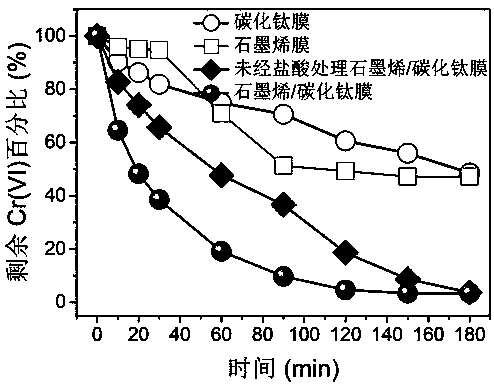

[0033] 1 g Ti 3 AlC 2 The raw material was added to 10 mL of hydrochloric acid solution (9 mol / L) dissolved with 1 g LiF, and the temperature of the solution was kept at 35 ° C. After 24 hours of reaction, it was washed with deionized water by centrifugation until the pH of the supernatant was 5-6, and the product was redispersed In 200 mL of deionized water, ultrasonically in a water bath for 1 hour, then centrifuge at 3500 rpm for 1 hour, and take the upper liquid to obtain titanium carbide nanosheet colloids. Dendritic polyethylenimine solution (86 mg / mL, 2 mL) was added dropwise to graphene oxide aqueous solution (0.5 mg / mL, 34.5 mL), refluxed at 90 °C for 2 hours and washed by centrifugation, and the obtained graphene was re- Disperse in deionized water to obtain a graphene dispersion. The prepared graphene dispersion (0.5 mg / mL, 1.2 mL) was added dropwise into titanium carbide nanosheet colloid (0.5 mg / mL, 22.8 mL), stirred at room temperature for 1 hour, and filtered ...

Embodiment 2

[0035] 1 g Ti 3 AlC 2The raw material was added to 10 mL of hydrochloric acid solution (9 mol / L) dissolved with 1 g LiF, and the temperature of the solution was kept at 35 ° C. After 24 hours of reaction, it was washed with deionized water by centrifugation until the pH of the supernatant was 5-6, and the product was redispersed In 200 mL of deionized water, ultrasonically in a water bath for 1 hour, then centrifuge at 3500 rpm for 1 hour, and take the upper liquid to obtain titanium carbide nanosheet colloids. Dendritic polyethylenimine solution (86 mg / mL, 2 mL) was added dropwise to graphene oxide aqueous solution (0.5 mg / mL, 34.5 mL), refluxed at 90 °C for 2 hours and washed by centrifugation, and the obtained graphene was re- Disperse in deionized water to obtain a graphene dispersion. The prepared graphene dispersion (0.5 mg / mL, 2.4 mL) was added dropwise into the titanium carbide nanosheet colloid (0.5 mg / mL, 21.6 mL), stirred at room temperature for 1 hour, and filter...

Embodiment 3

[0037] 1 g Ti 3 AlC 2 The raw material was added to 10 mL of hydrochloric acid solution (9 mol / L) dissolved with 1 g LiF, and the temperature of the solution was kept at 35 ° C. After 24 hours of reaction, it was washed with deionized water by centrifugation until the pH of the supernatant was 5-6, and the product was redispersed In 200 mL of deionized water, ultrasonically in a water bath for 1 hour, then centrifuge at 3500 rpm for 1 hour, and take the upper liquid to obtain titanium carbide nanosheet colloids. Dendritic polyethylenimine solution (86 mg / mL, 2 mL) was added dropwise to graphene oxide aqueous solution (0.5 mg / mL, 34.5 mL), refluxed at 90 °C for 2 hours and washed by centrifugation, and the obtained graphene was re- Disperse in deionized water to obtain a graphene dispersion. The prepared graphene dispersion (0.5 mg / mL, 4.8 mL) was added dropwise to the titanium carbide nanosheet colloid (0.5 mg / mL, 19.2 mL), stirred at room temperature for 1 hour, and filtere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com