Patents

Literature

769 results about "Graphene membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

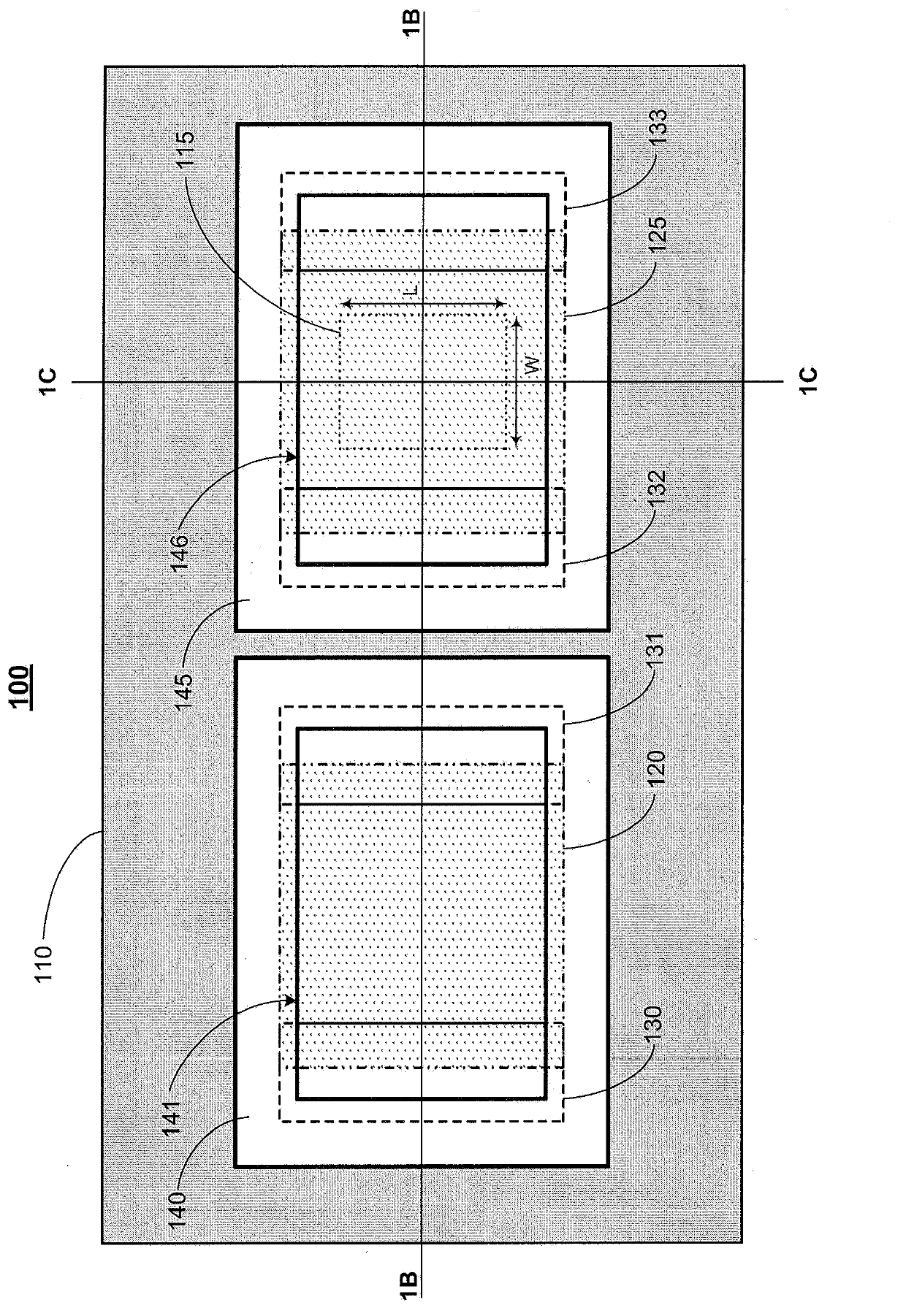

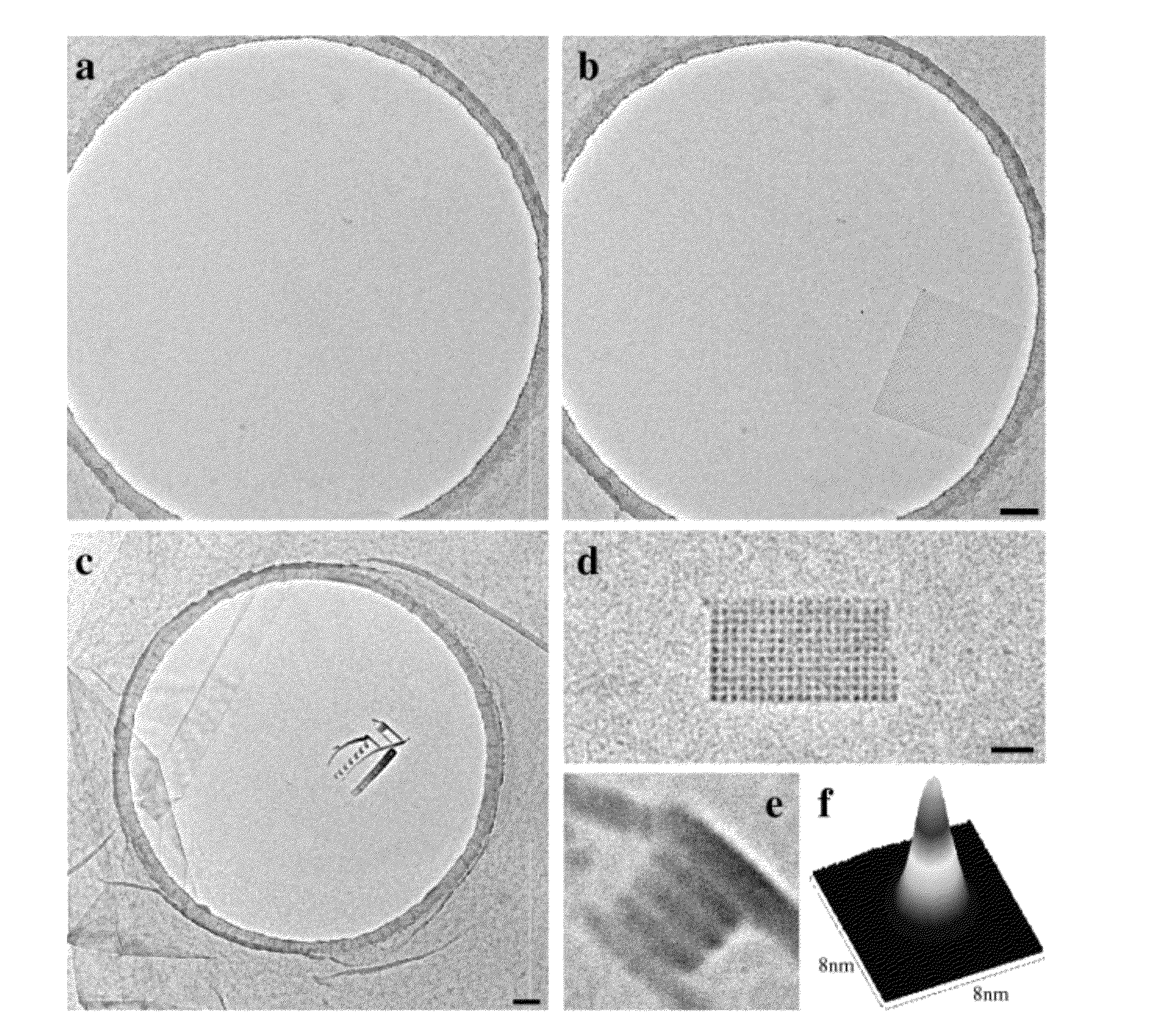

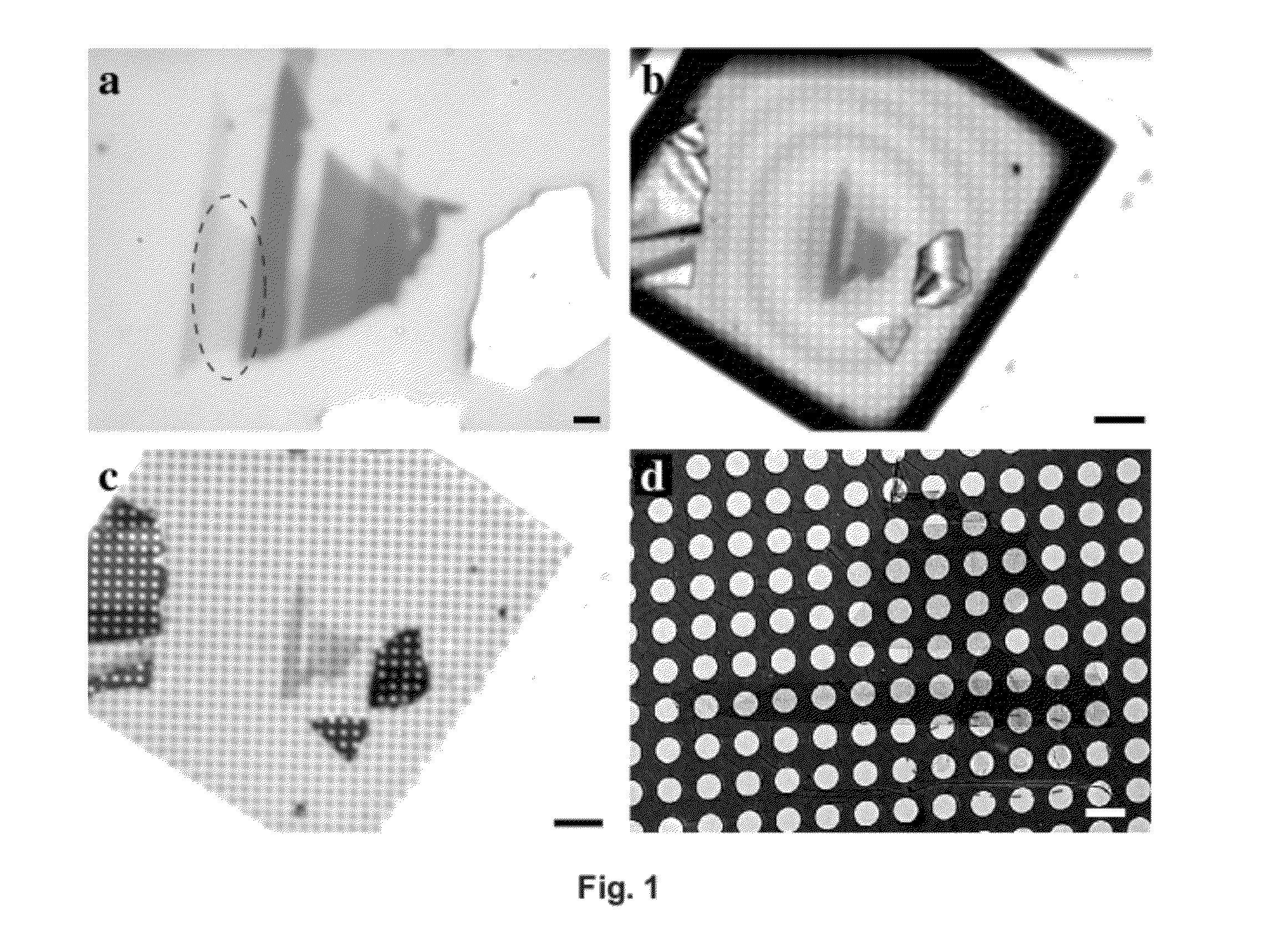

Graphene-based structure, method of suspending graphene membrane, and method of depositing material onto graphene membrane

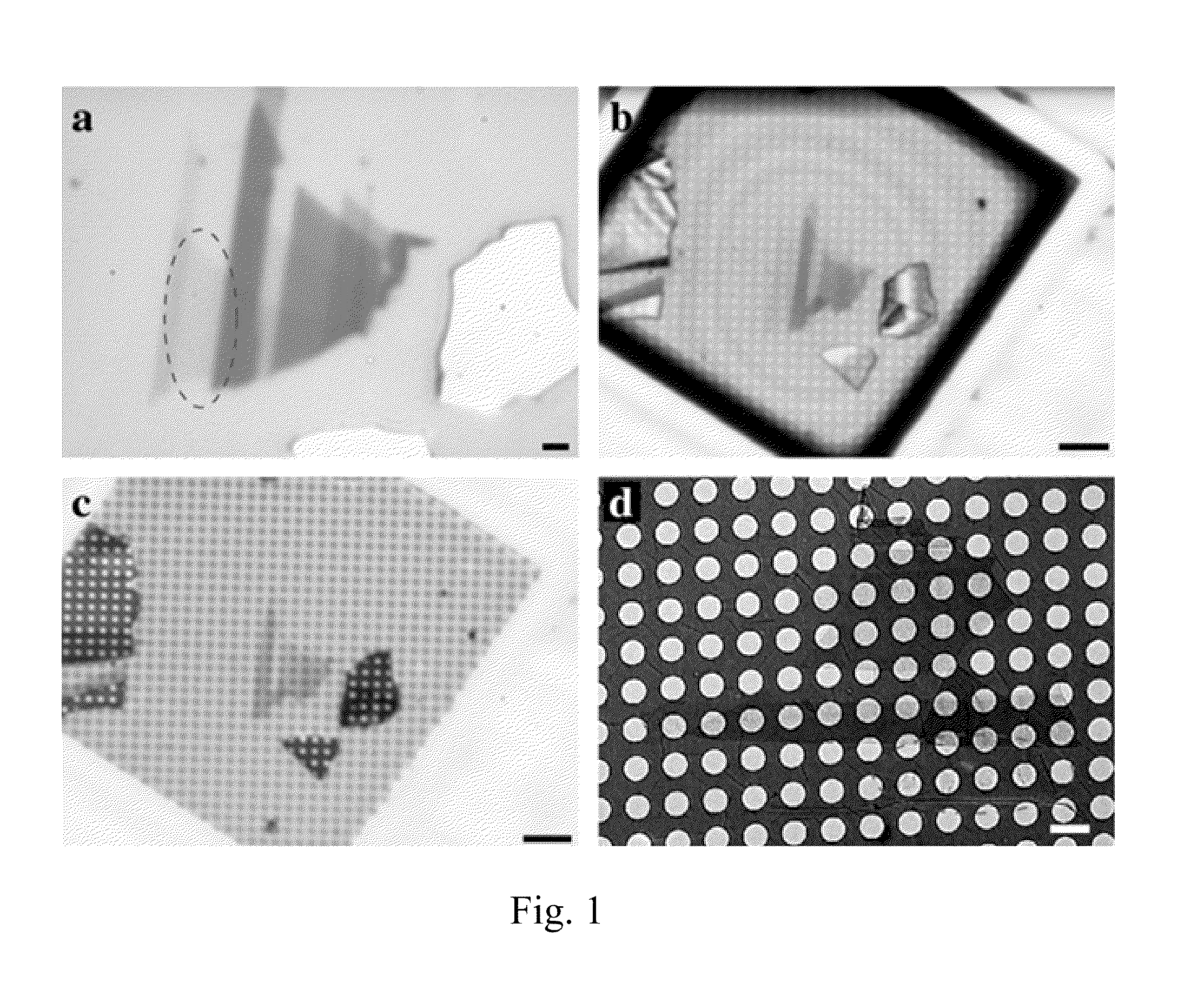

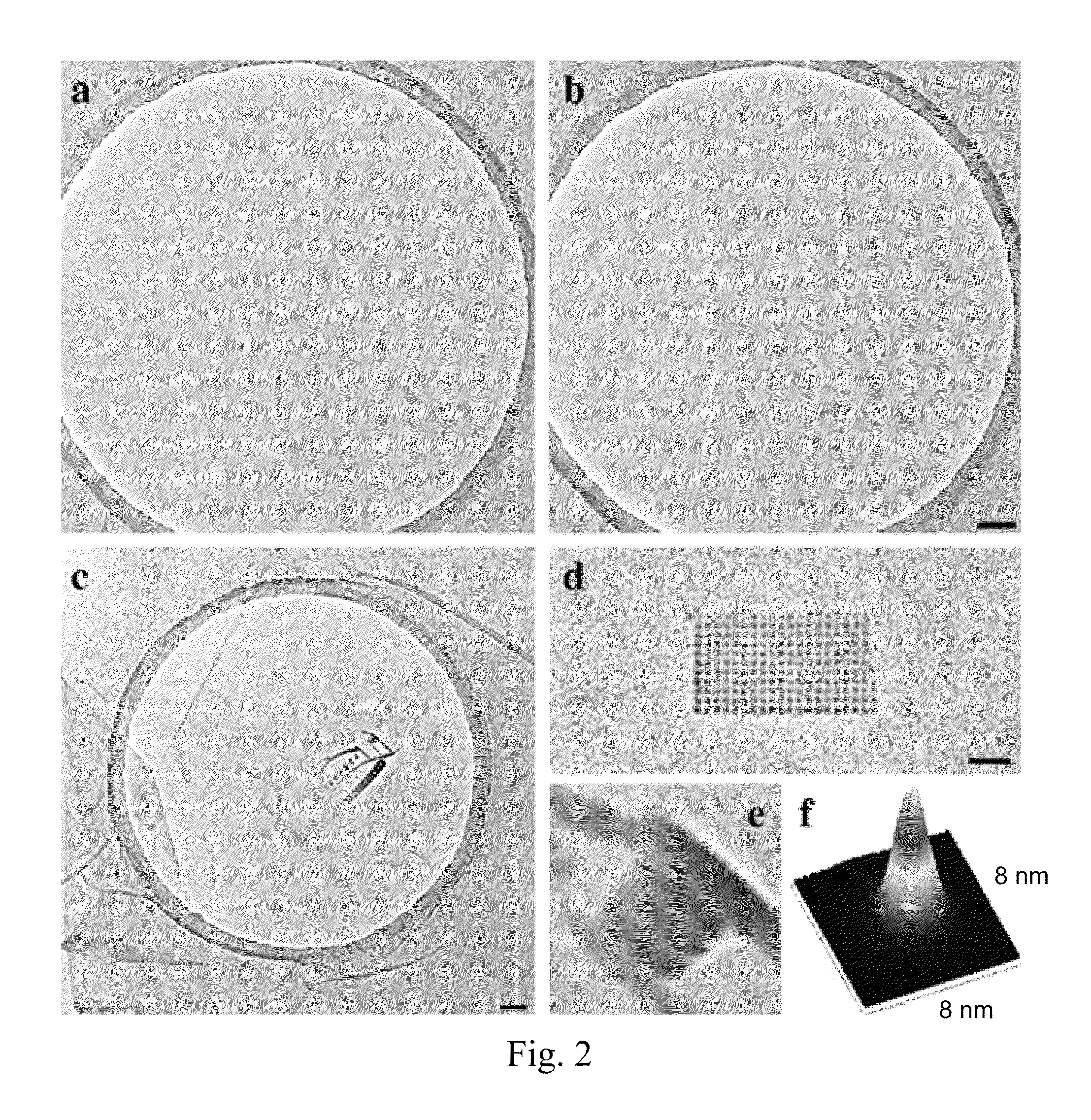

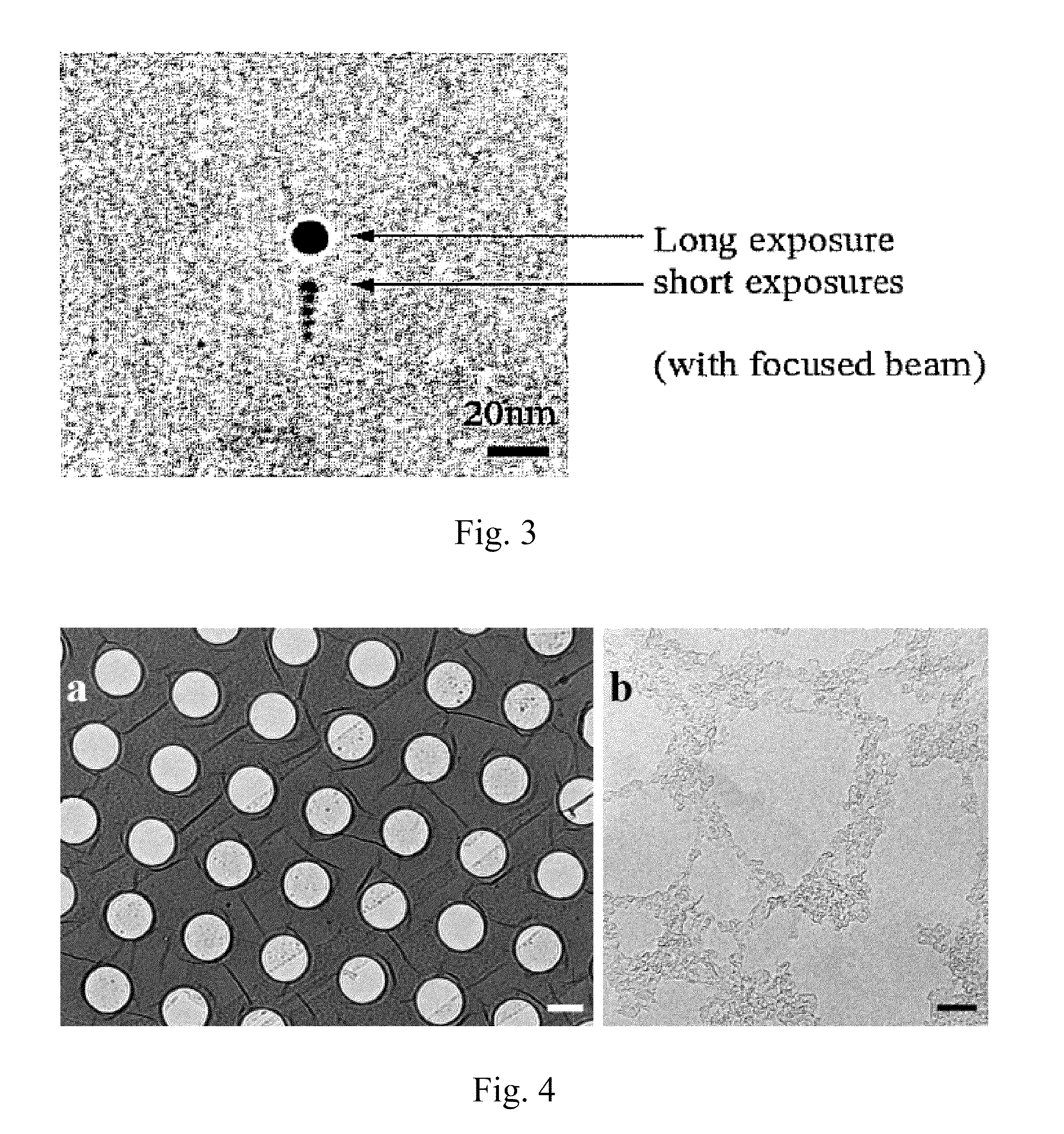

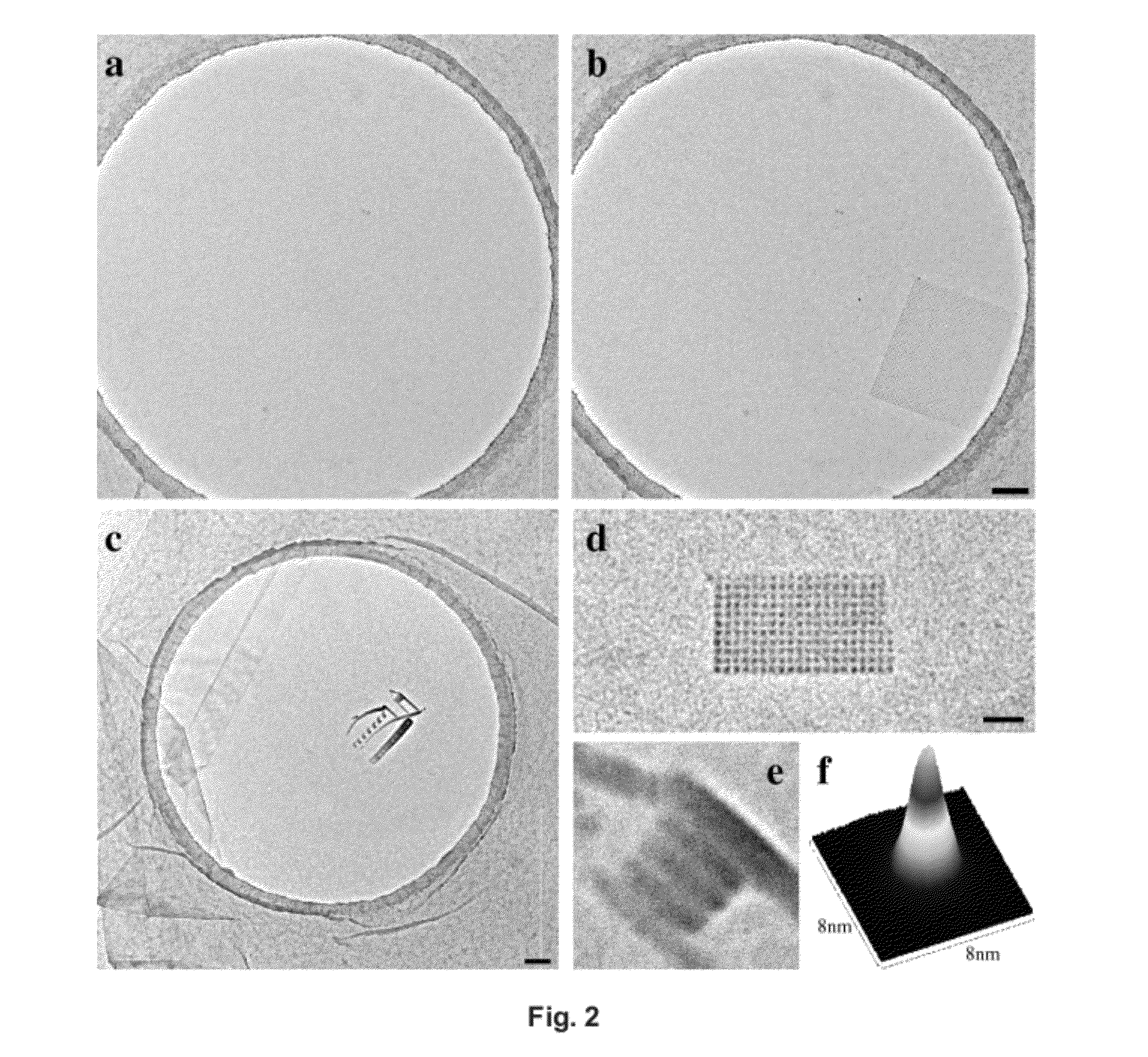

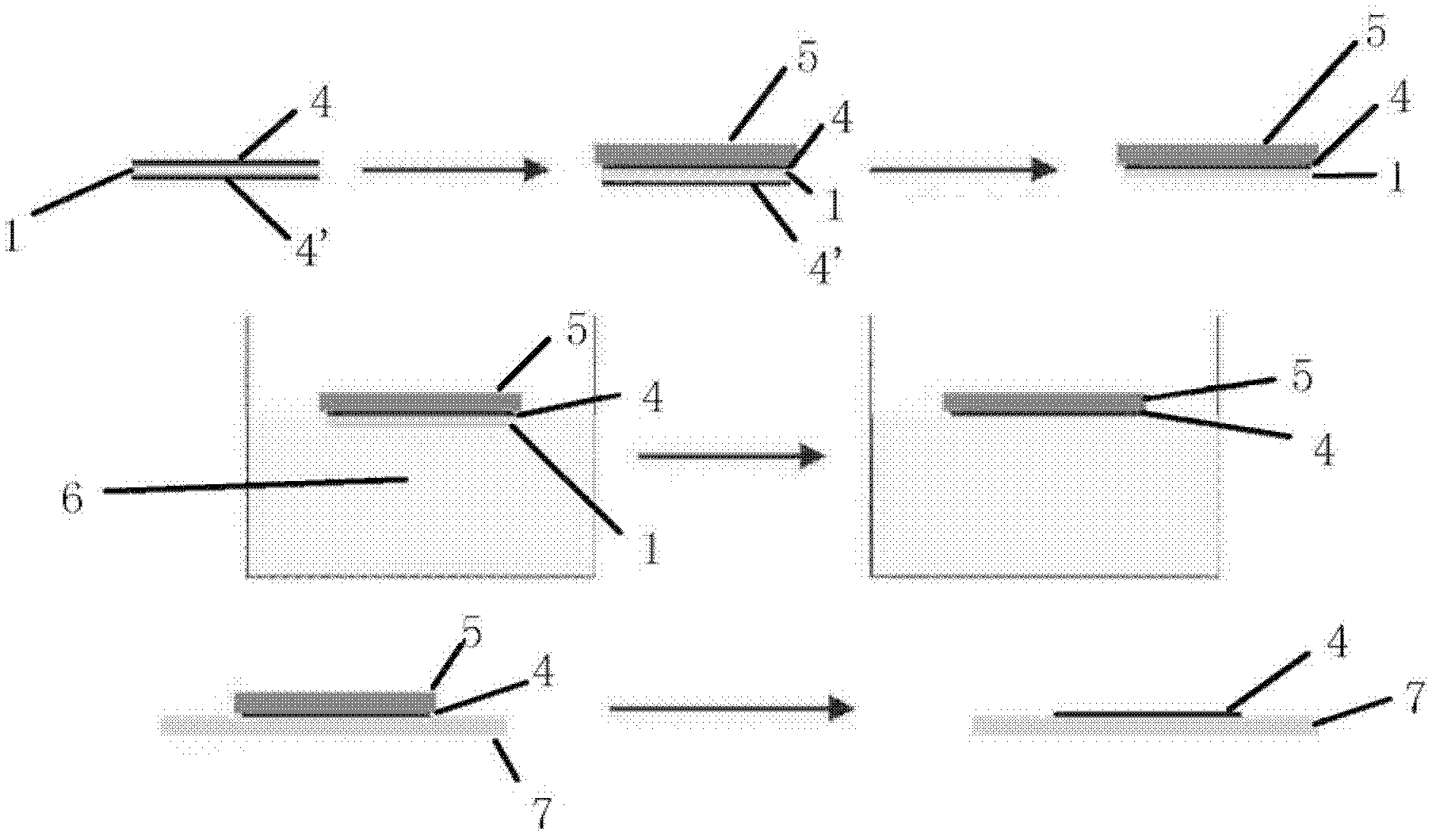

An embodiment of a method of suspending a graphene membrane across a gap in a support structure includes attaching graphene to a substrate. A pre-fabricated support structure having the gap is attached to the graphene. The graphene and the pre-fabricated support structure are then separated from the substrate which leaves the graphene membrane suspended across the gap in the pre-fabricated support structure. An embodiment of a method of depositing material includes placing a support structure having a graphene membrane suspended across a gap under vacuum. A precursor is adsorbed to a surface of the graphene membrane. A portion of the graphene membrane is exposed to a focused electron beam which deposits a material from the precursor onto the graphene membrane. An embodiment of a graphene-based structure includes a support structure having a gap, a graphene membrane suspended across the gap, and a material deposited in a pattern on the graphene membrane.

Owner:RGT UNIV OF CALIFORNIA

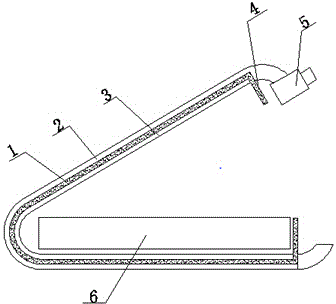

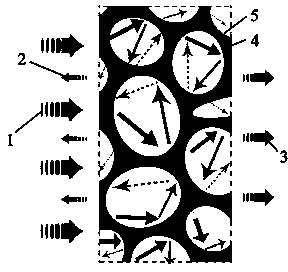

Mobile phone case with signal shielding function

InactiveCN104683519AEffective shieldingTelephone set constructionsMobile phoneElectrical and Electronics engineering

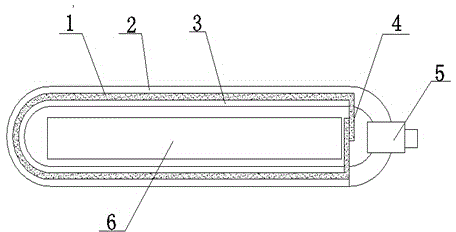

The invention relates to a mobile phone case with a signal shielding function. The mobile phone case consists of a leather housing (1), a graphene film layer (2), a cotton liner (3), a zipper (4), and a graphene film overlapped edge (5), and is characterized in that the graphene film layer (2) is sewn in an interlayer formed by the leather housing (1) and the cotton liner (3); both ends of the leather housing (1) are sewn together by the zipper (4) and then are sewn inside the zipper (4) by the graphene film overlapped edge (5). According to the mobile phone case, all mobile phone signals from the outsides can be effectively shielded, so that a user cannot be entangled due to shutdown when using a mobile phone.

Owner:ZHENJIANG BROWAH TECH

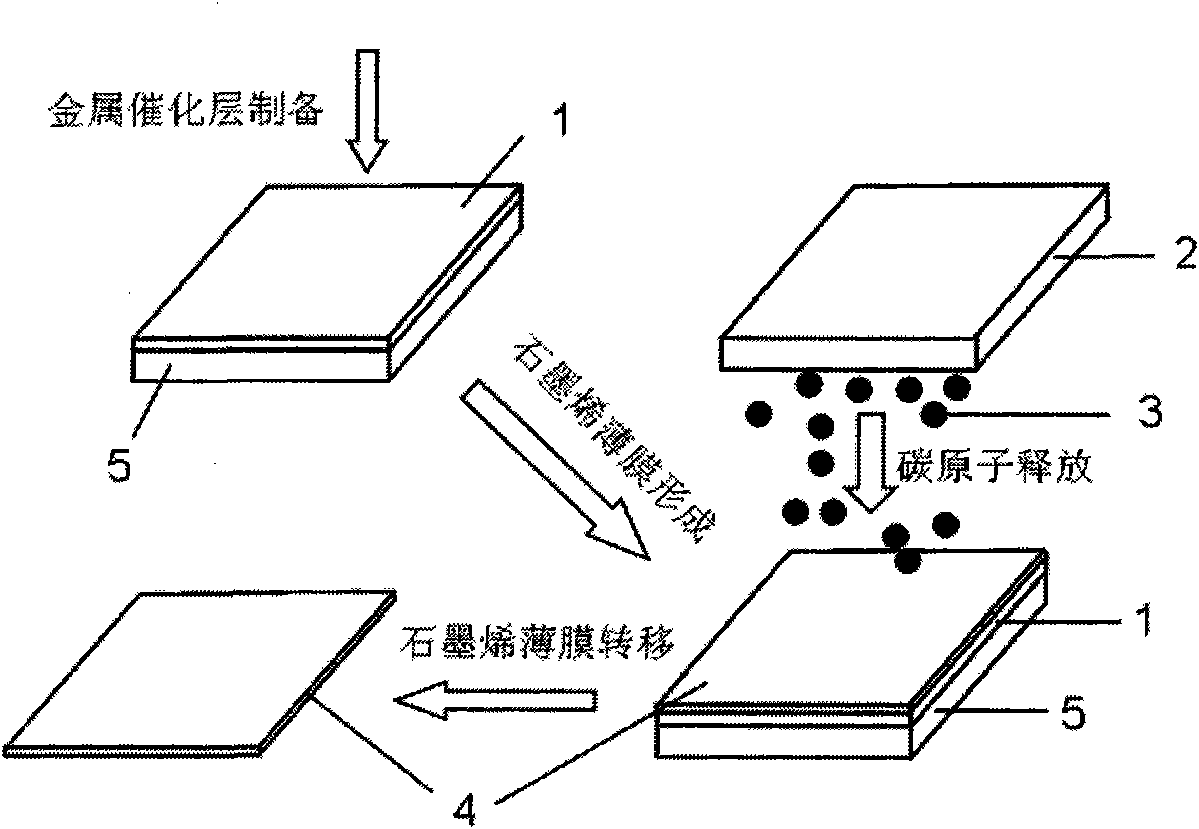

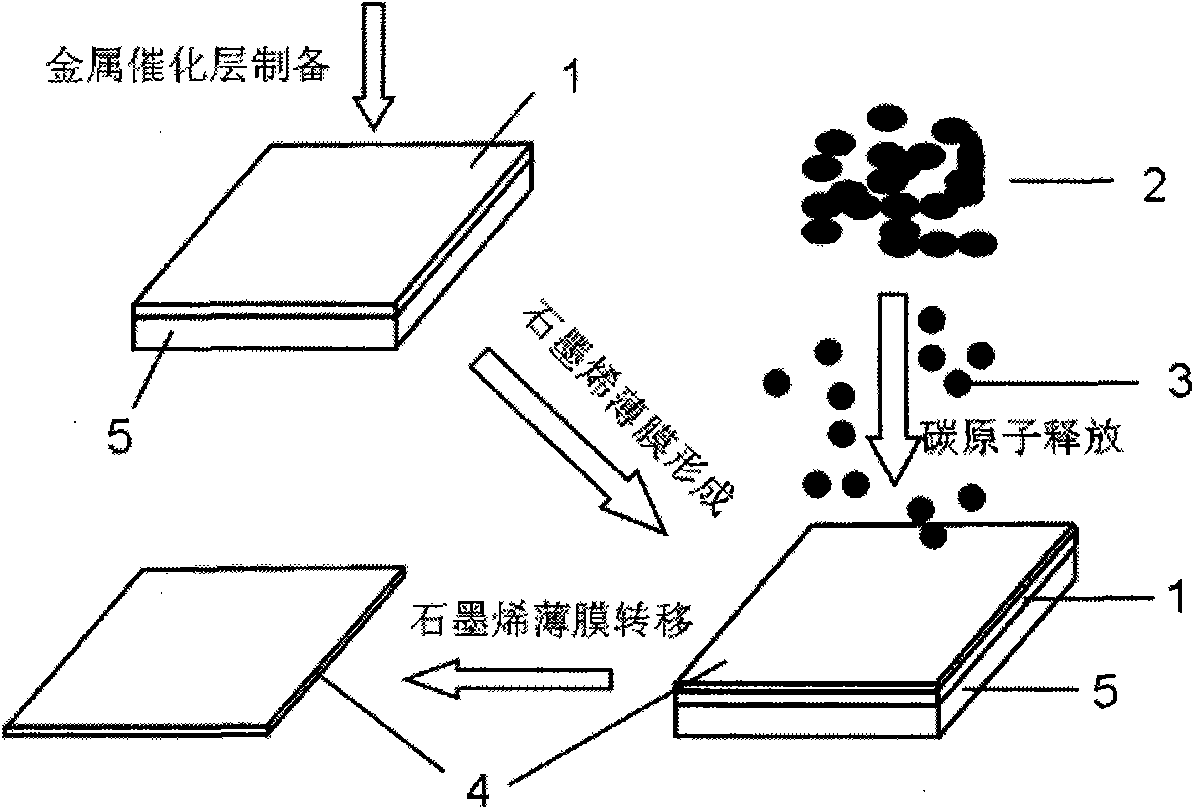

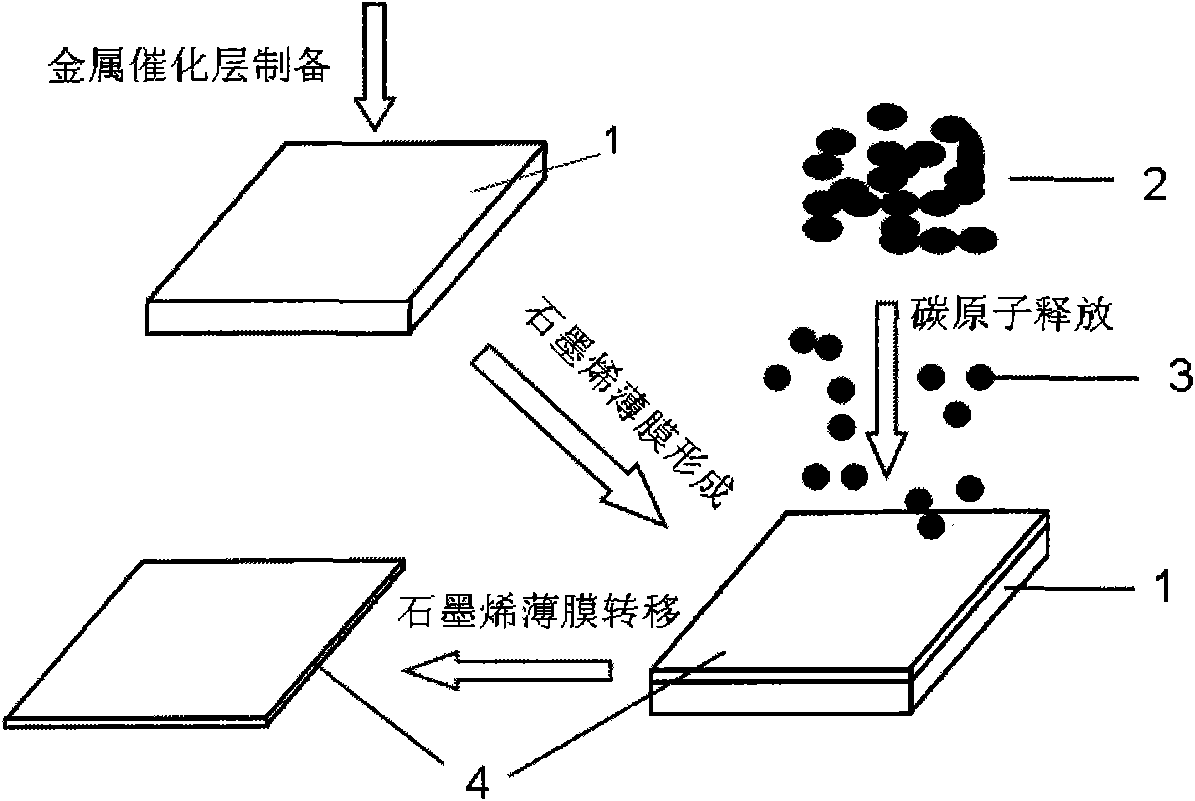

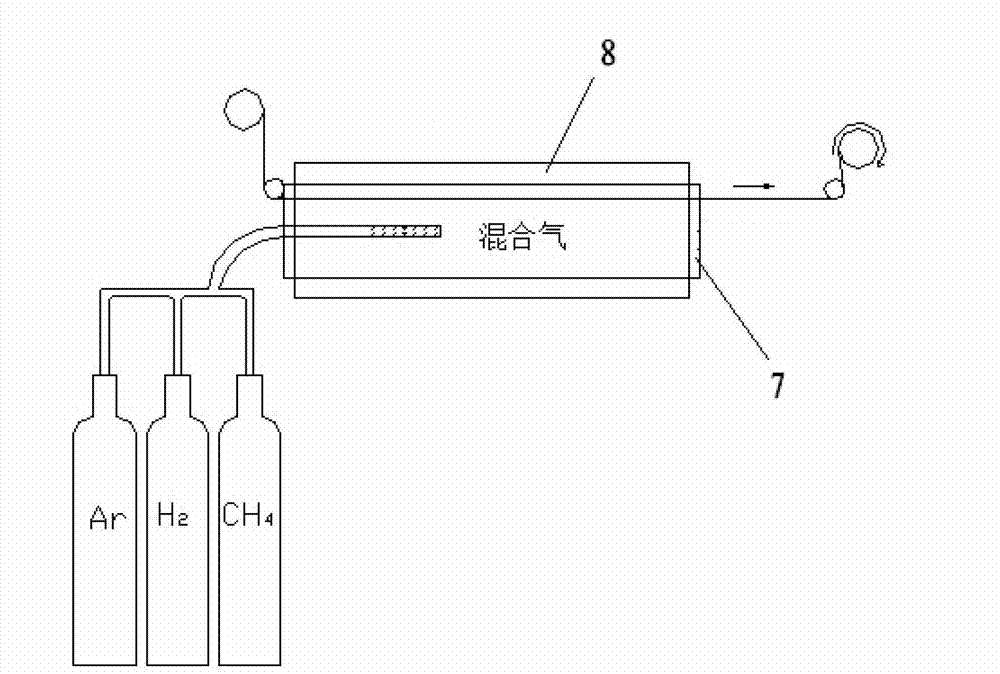

Method for preparing graphene membrane

The invention discloses a method for preparing a graphene membrane. Carbon atoms are released from a solid carbon source by a method such as heat treatment, heat evaporation, sputtering, electron beam deposition, laser deposition or plasma deposition to form the graphene membrane on a catalytic layer or a substrate, wherein the solid carbon source is graphite, amorphous carbon, diamond, fullerene or carbon nano tubes. In the method for preparing the graphene membrane, the solid carbon source is used, the method is simple; and the prepared graphene membrane is easy to control in terms of thickness, structure and size, has excellent photoelectric characteristics and is suitable for preparing high-performance photoelectronic devices on a large scale.

Owner:ZHEJIANG UNIV

Nanometric Material Having a Nanopore Enabling High-Sensitivity Molecular Detection and Analysis

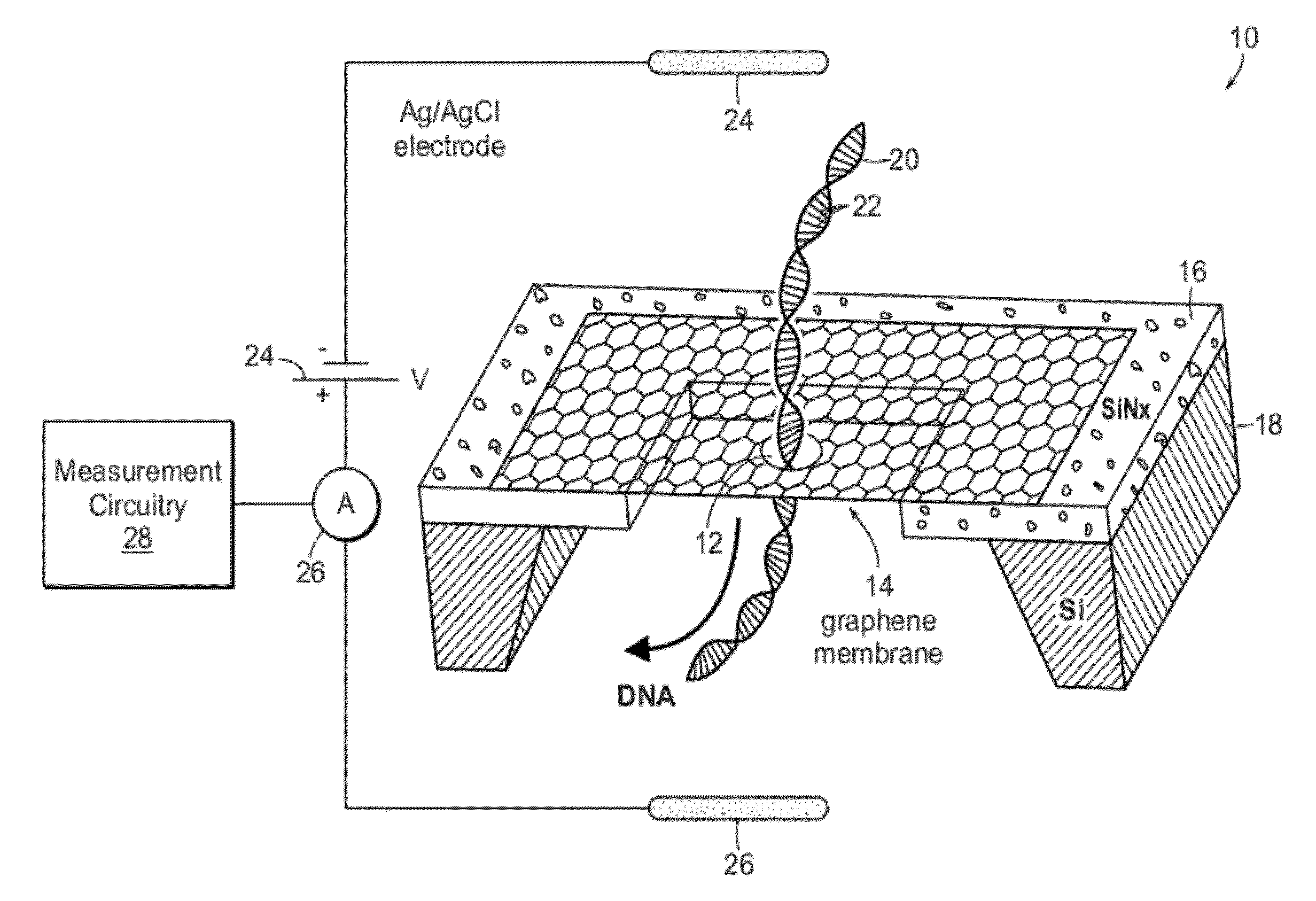

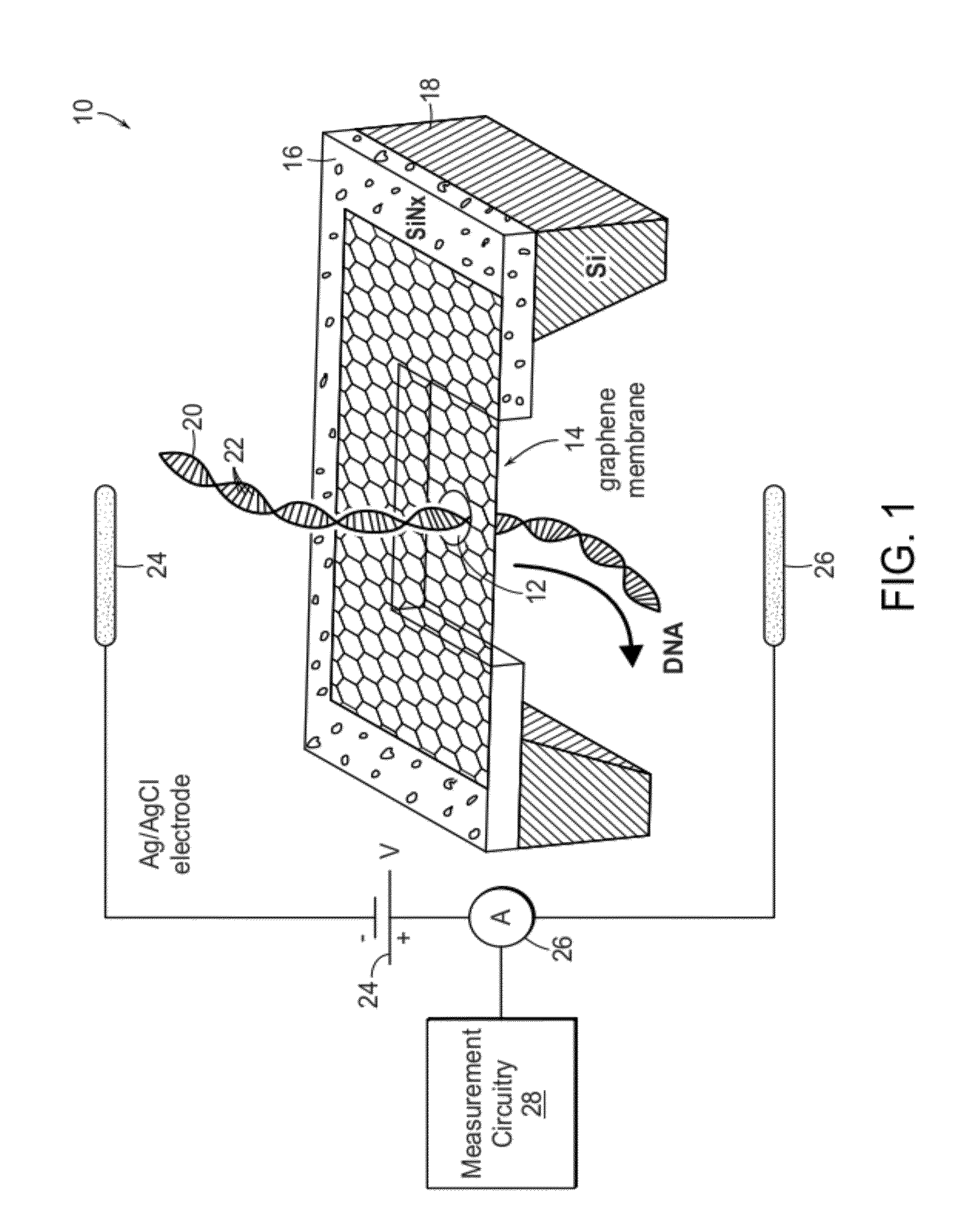

ActiveUS20120234679A1Sludge treatmentVolume/mass flow measurementSingle layer grapheneProtein translocation

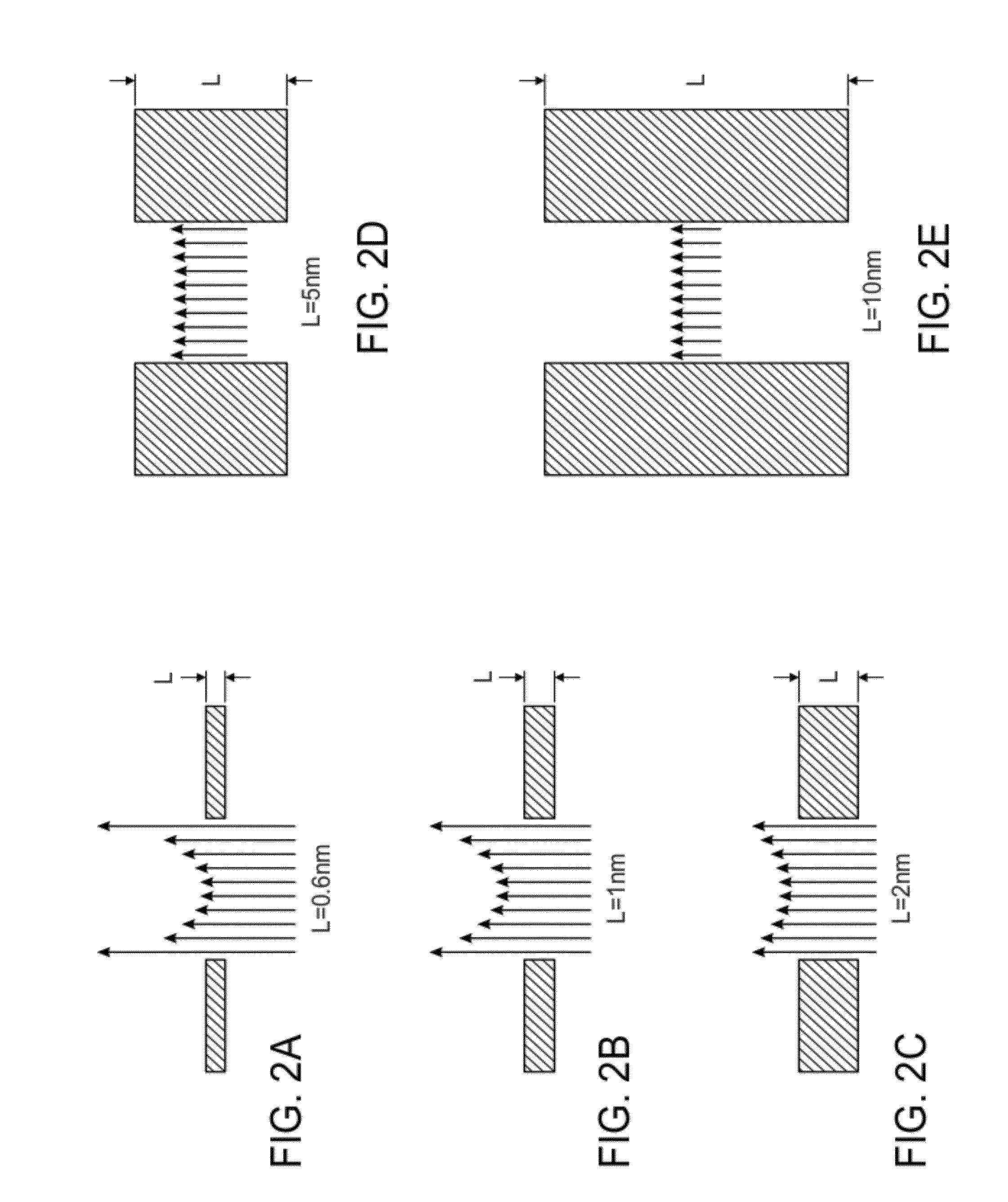

There is provided a substantially bare, self-supported single-layer graphene membrane including a nanopore extending through a thickness of the graphene membrane from a first to a second membrane surface opposite the first graphene membrane surface. A connection from the first graphene membrane surface to a first reservoir provides, at the first graphene membrane surface, a species in an ionic solution to the nanopore, and a connection from the second graphene membrane surface to a second reservoir is provided to collect the species and ionic solution after translocation of the species and ionic solution through the nanopore from the first graphene membrane surface to the second graphene membrane surface. An electrical circuit is connected on opposite sides of the nanopore to measure flow of ionic current through the nanopore in the graphene membrane.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

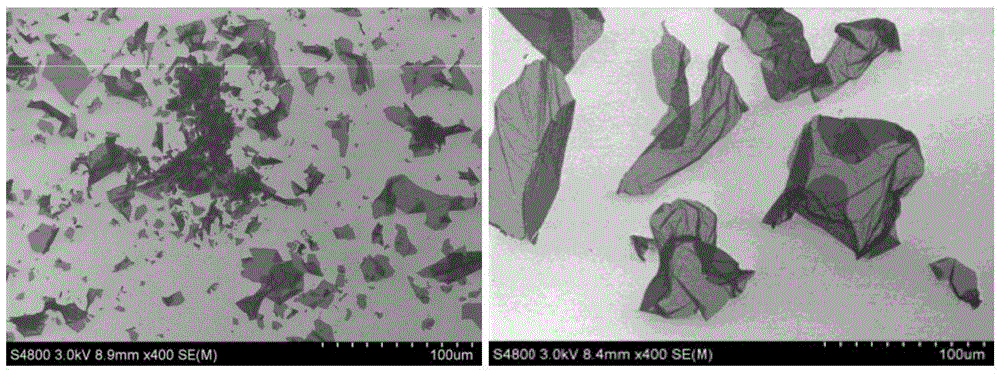

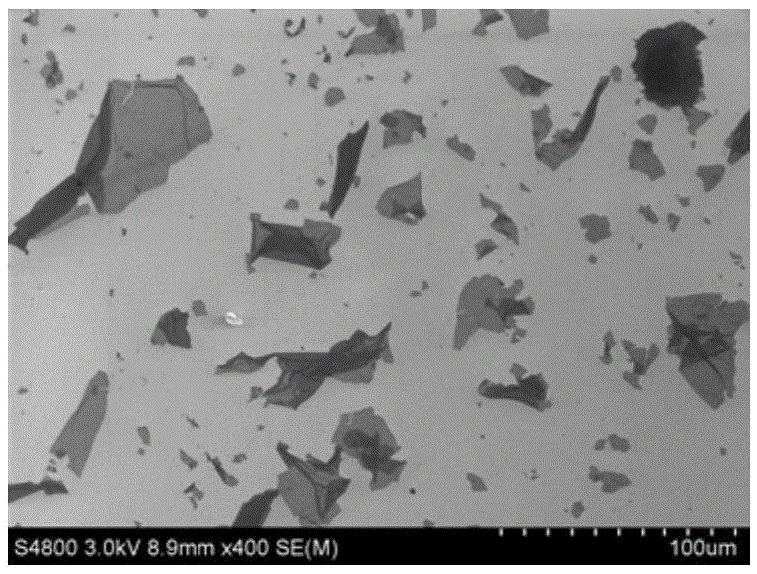

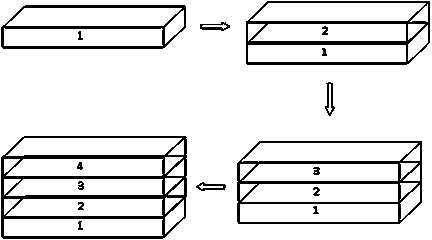

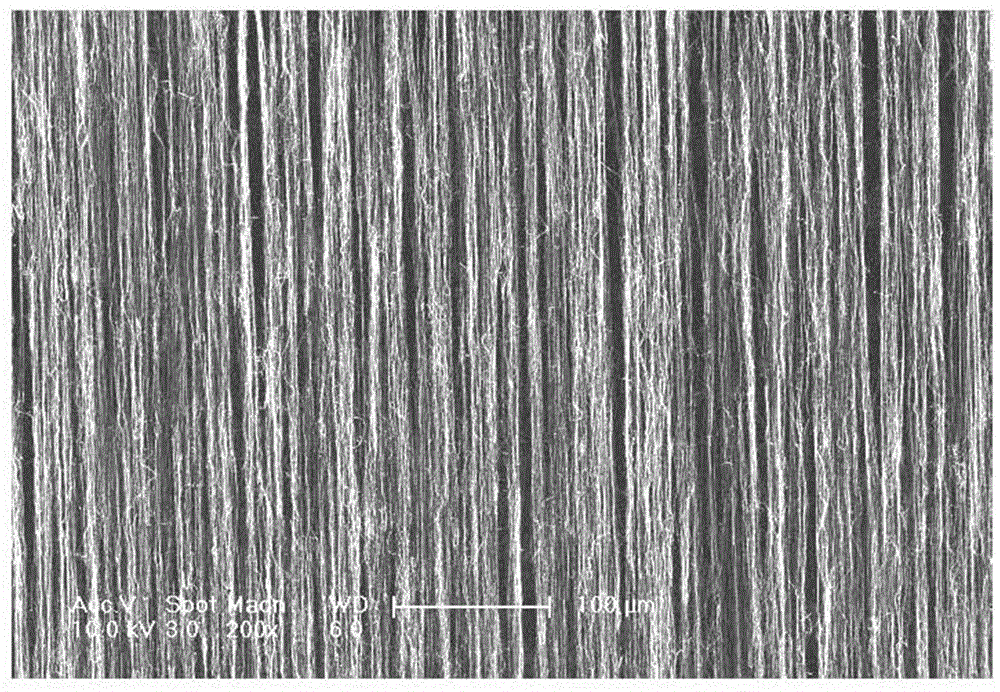

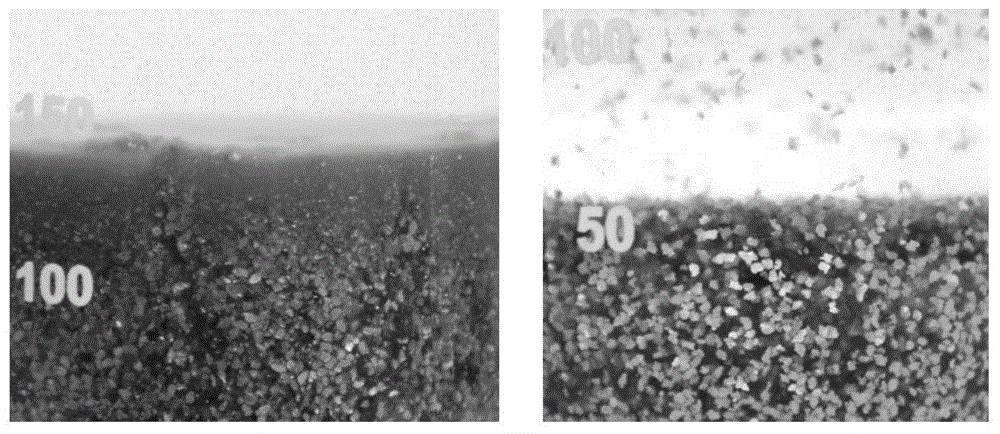

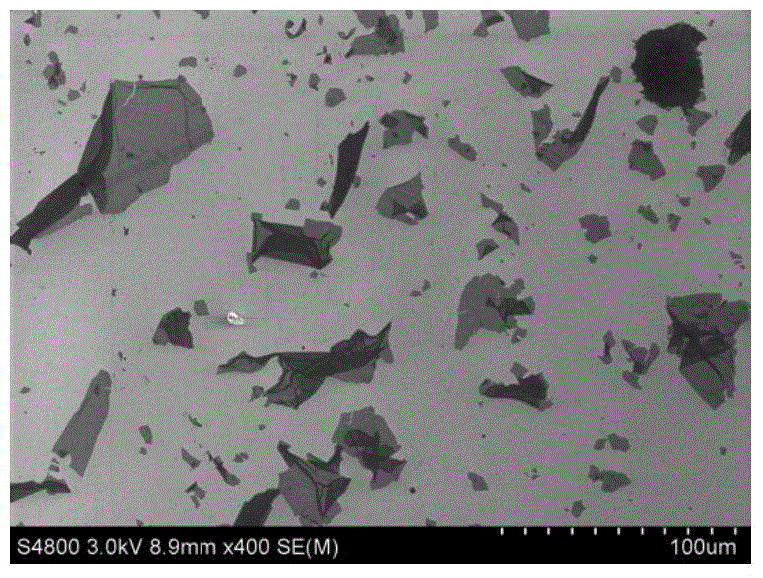

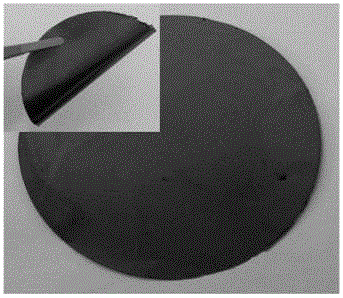

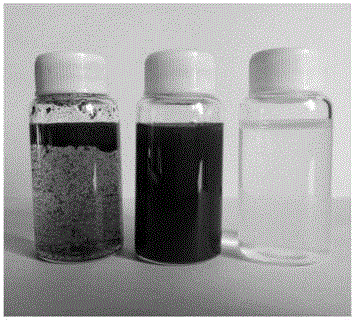

Graphene film with ultrahigh flexibility and high thermal conductivity and preparation method of graphene film

ActiveCN105523547AGuarantee unimpededGood electrical and thermal conductivityGrapheneHigh pressureCvd graphene

The invention discloses a graphene film with ultrahigh flexibility and high thermal conductivity and a preparation method of the graphene film. The graphene film is prepared from an ultralarge uniform graphene oxide sheet through steps of solution film-formation, chemical reduction, high-temperature reduction, high-pressure compression and the like. The graphene film is formed through physical crosslinking of macroscopic multi-layer folded graphene with microscale folds, and inter-lamella slippage can be realized, so that the graphene film has ultrahigh flexibility. The graphene lamellar structure of the graphene film is perfect, the lamellas have ultralarge crystalline areas which are about 100 mu m and contain few defects, the structure is compact after high-pressure compression, and the graphene film has ultrahigh electrical conductivity and thermal conductivity. The graphene film with ultrahigh flexibility and high thermal conductivity can be bent repeatedly more than 1,200 times, the elongation at break is 12%-18%, the electrical conductivity is 8,000-10,600 S / cm, the thermal conductivity is 1,800-2,600 W / mK, and the graphene film can be used as a high-flexibility, thermal-conducting and electric-conducting device.

Owner:杭州德烯科技集团有限公司

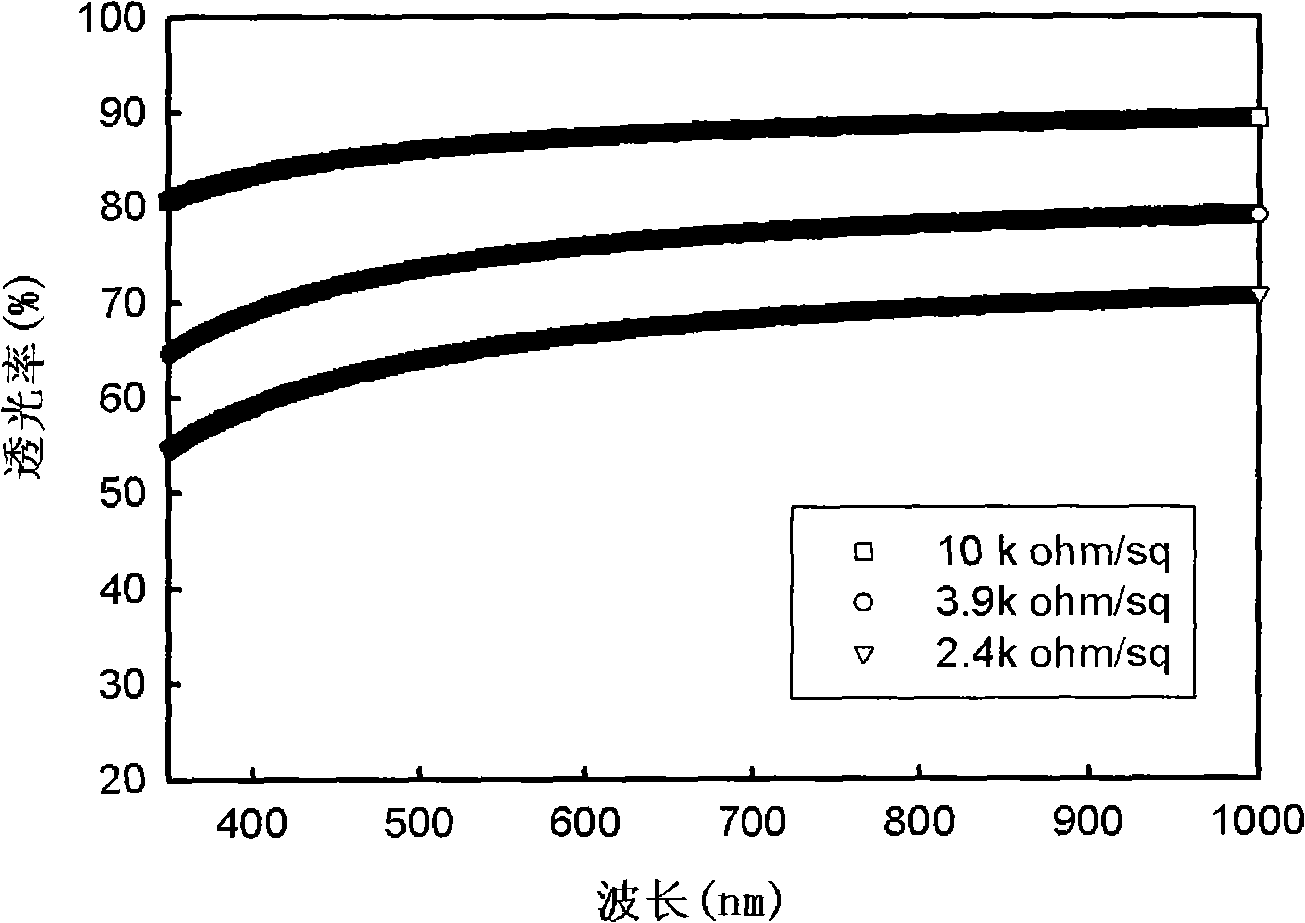

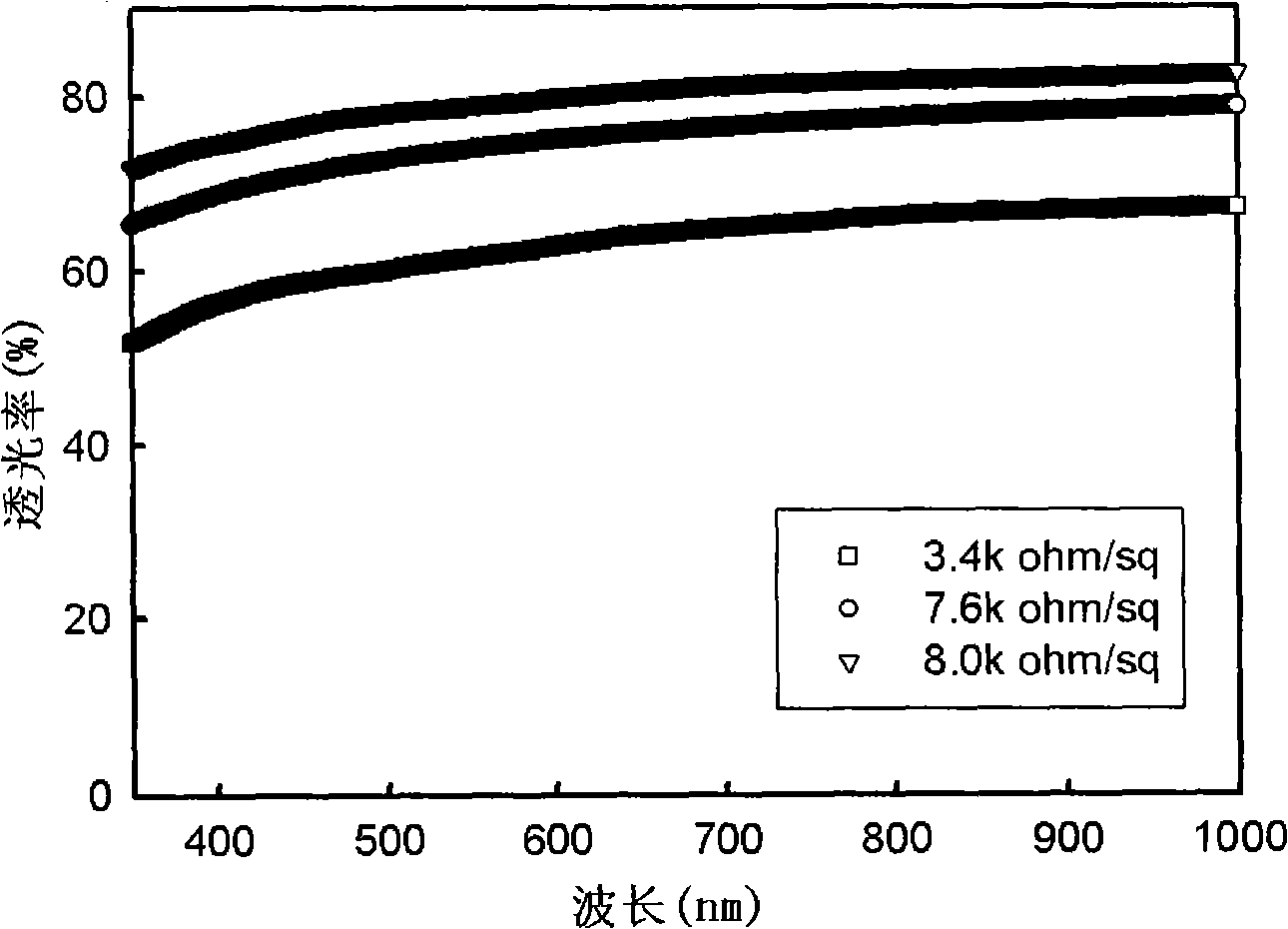

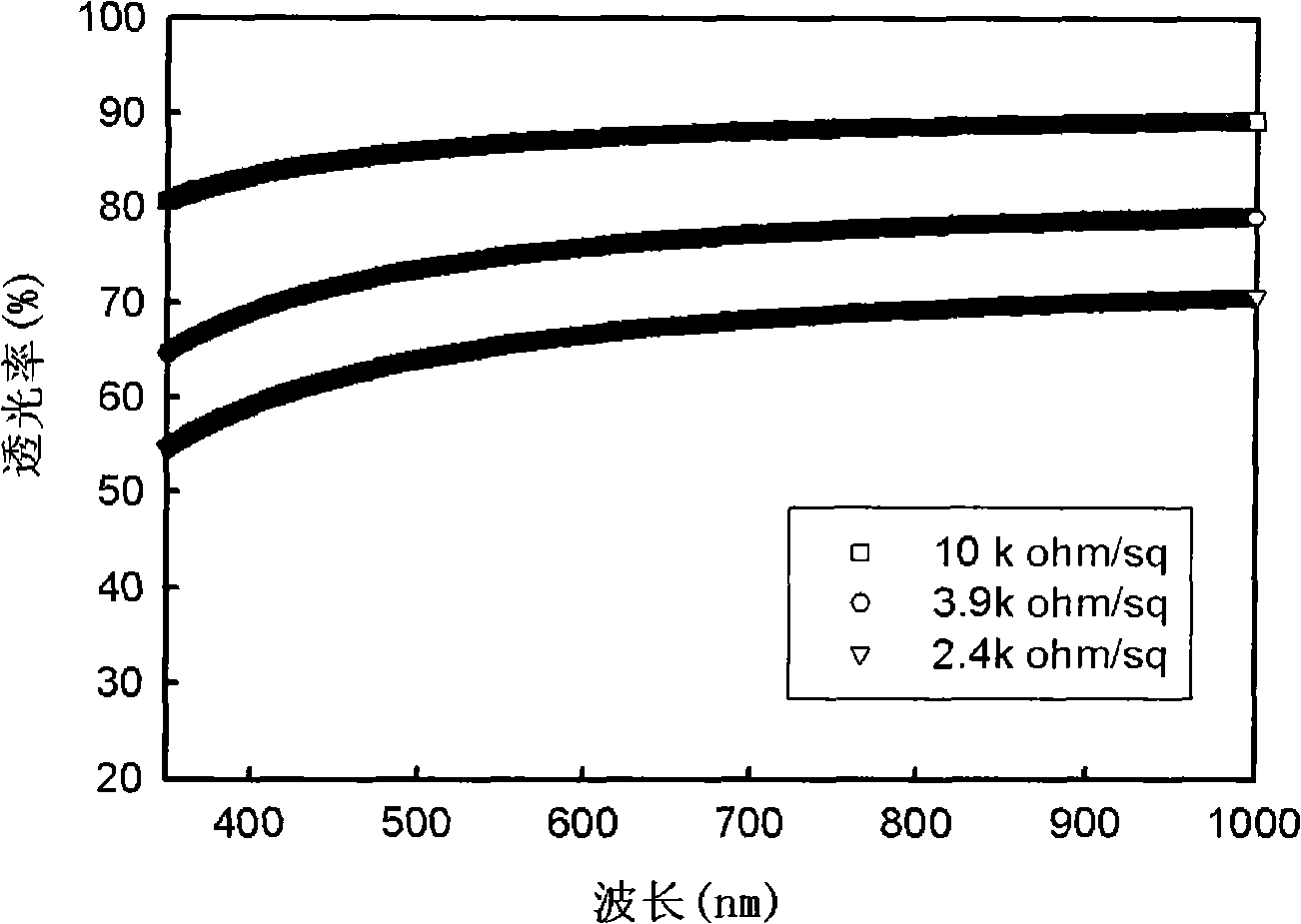

Method for preparing flexible and transparent conductive graphene membrane

InactiveCN101901640AImprove conductivityGood light transmissionConductive layers on insulating-supportsCable/conductor manufactureOrganic solar cellConductive polymer

The invention relates to a method for preparing a flexible and transparent conductive graphene membrane, belongs to the field of the science and technology of nanometer photoelectric materials and particularly relates to the preparation of a thermal reduction and oxidation graphene membrane at the temperature of 1,000 DEG C and technology for transferring the membrane onto a flexible substrate. The flexible and transparent conductive graphene membrane provided by the invention has the advantages of high electrical conductivity, high transmission of light, large-area preparation, rich raw materials, high material utilization ratio, simple preparation method, environmental protection and the like. The technology overcomes the defects of easy brittleness of the conventional indium tin oxide (ITO) and poor electrical conductivity of the conventional flexible conductive polymer membrane, is hopeful to prepare a novel flexible and transparent conductive membrane, is potentially applied to photoelectric functional apparatuses such as organic electroluminescent displays, organic electrical storages, organic solar cells and the like and is particularly applied to flexible photoelectric apparatuses.

Owner:NANJING UNIV OF POSTS & TELECOMM

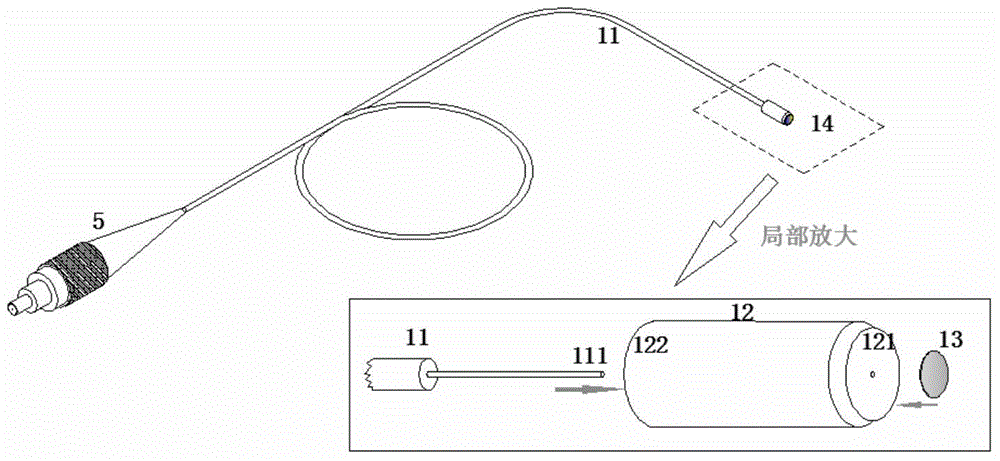

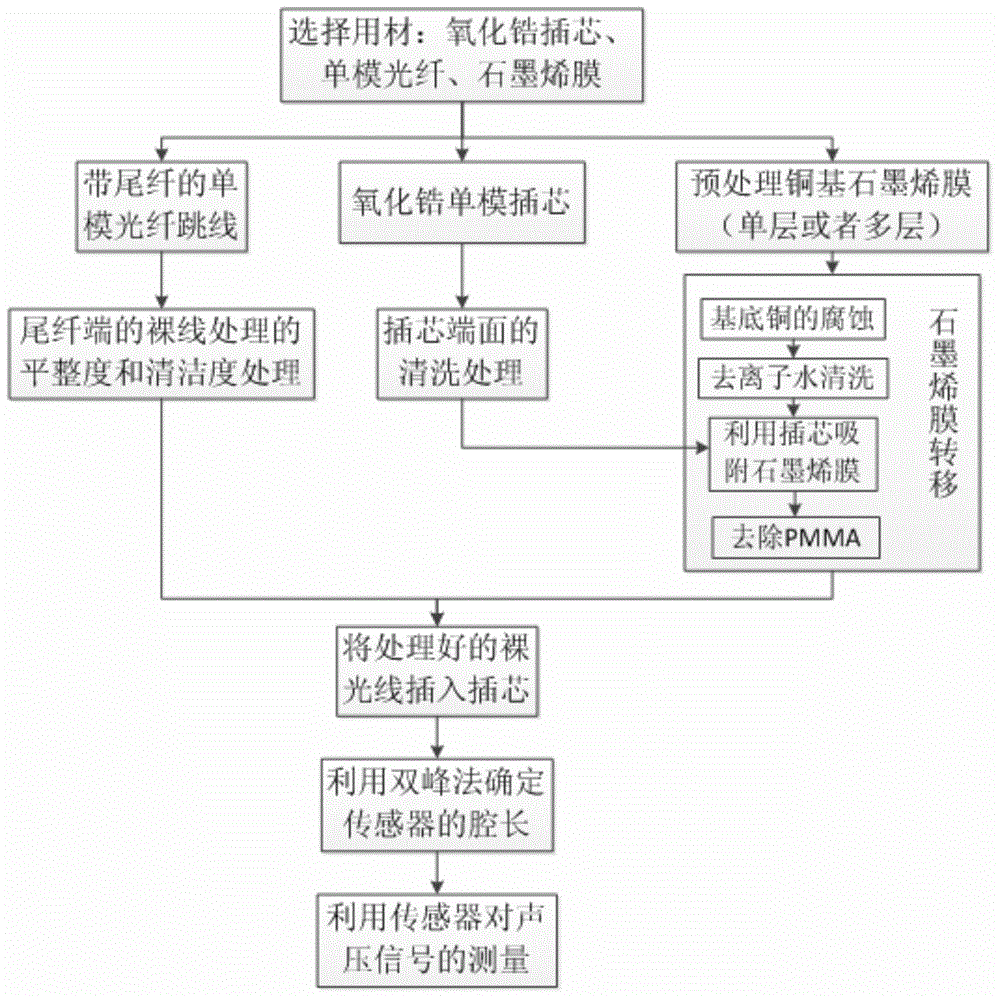

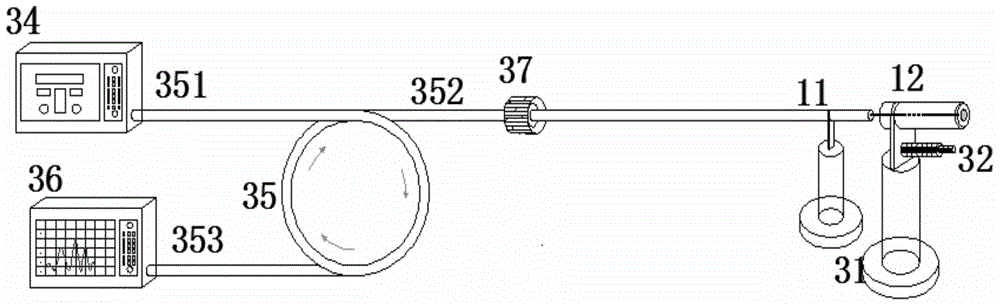

Optical fiber Fabry-Perot sound pressure sensor manufacturing method based on graphene membrane and measuring method and device thereof

ActiveCN103557929AThe overall thickness is thinExpand the measurement rangeSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectromagnetic interferenceSound pressure

The invention discloses an optical fiber Fabry-Perot sound pressure sensor manufacturing method based on a graphene membrane and a measuring method and device thereof. A sensor is manufactured based on the graphene membrane and the optical fiber Fabry-Perot interference optical principle. Firstly, a single mode fiber is rinsed and processed, the graphene membrane is transferred, and the graphene membrane is adsorbed to a zirconium oxide single mode inserting core; then, the zirconium oxide single mode inserting core is inserted into the processed single mode fiber from the other end. Therefore, two reflecting surfaces of Fabry-Perot interference are formed by the end face of the single mode fiber and the graphene membrane, an optical fiber-air-graphene membrane interference cavity is formed, an interference cavity length detecting device is set up, interference spectrum signals are demodulated by using a two-peak method, and the high sensitivity detection of weak sound pressure signals is achieved. The sensor has the advantages of being simple in manufacturing, high in sensitivity, small in size, resistant to electromagnetic interference and the like, the problem that a sensor is low in sensitivity due to the limitation of the reduction of the thickness of a membrane in the prior art is solved, the sensitivity of the membrane type sound pressure sensor is improved, and the sensor can be expected to be applied to the underwater sound field, the electroacoustic field, medical field, biomedical engineering filed and the like.

Owner:BEIHANG UNIV

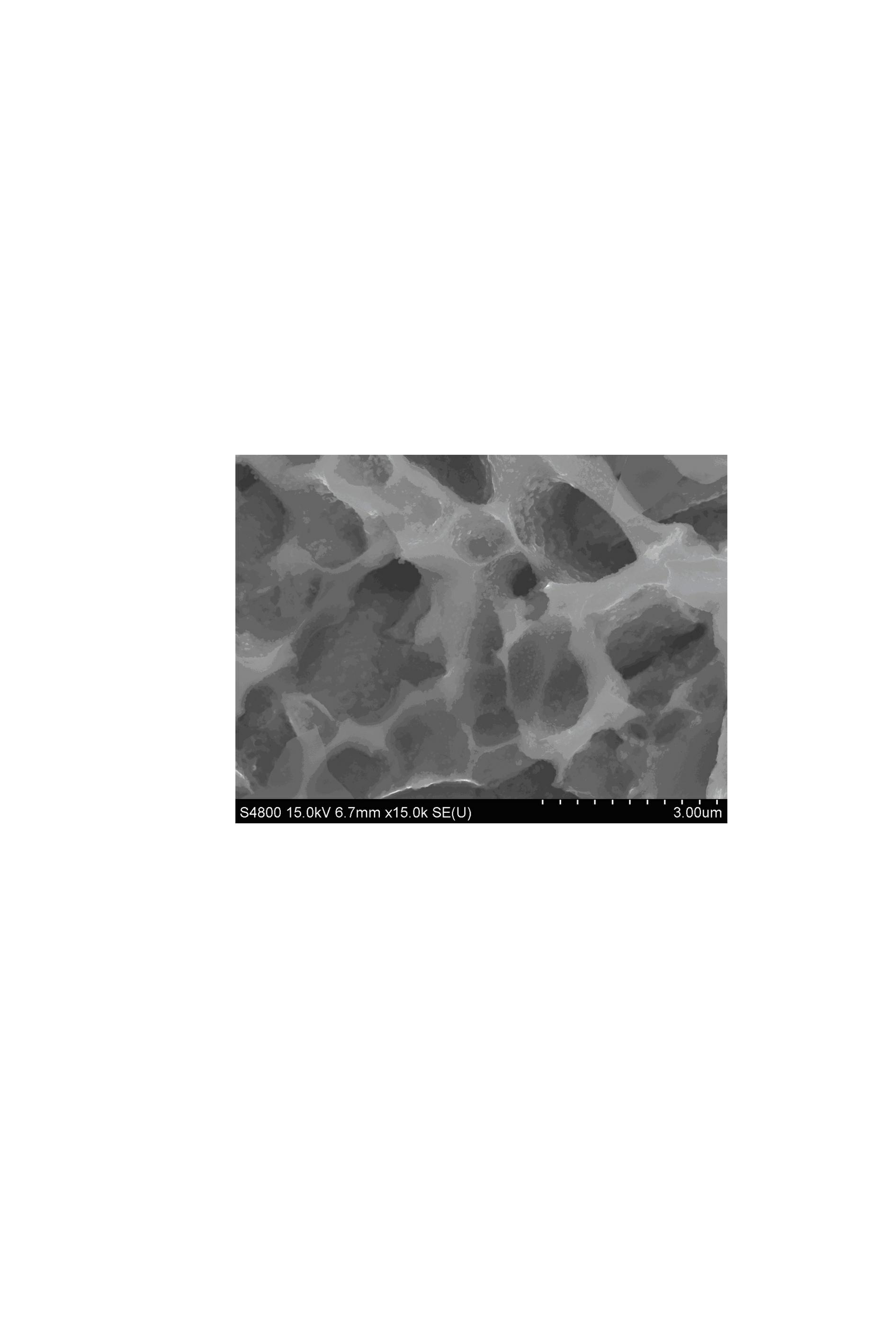

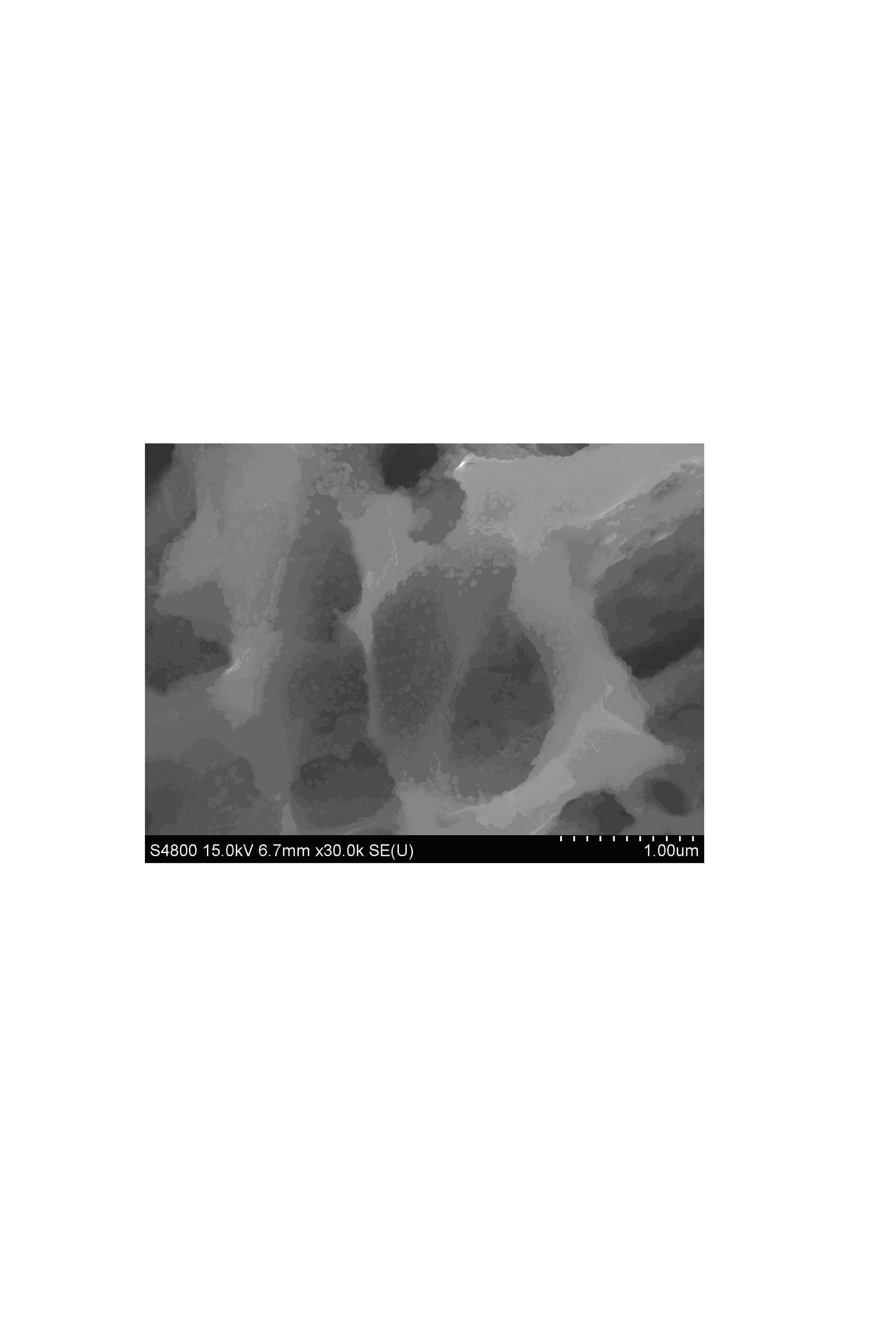

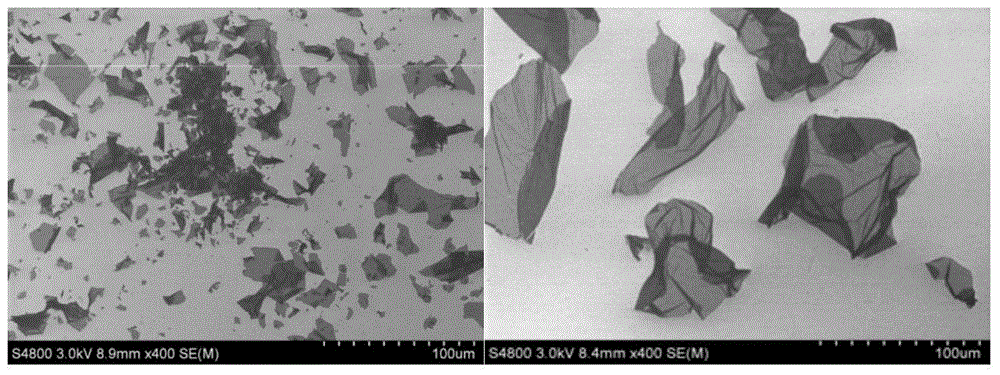

Nanometer perovskite/graphene composite material and preparation method thereof

The invention relates to a nanometer perovskite / graphene composite material. The nanometer perovskite / graphene composite material is of a porous structure, the aperture of the nanometer perovskite / graphene composite material is about 0.5-1.5 microns, nanometer perovskite particles are distributed uniformly on a graphene film, and the average crystallite dimension of the composite material is about 10-20nm. A preparation method of the nanometer perovskite / graphene composite material comprises the following steps of: with graphite paper as an anode, a carbon rod as a cathode and concentrated sulfuric acid as an electrolyte, carrying out oxidation peeling to prepare a thin-layer graphene material, and then preparing graphene suspension from the thin-layer graphene material; adding nitrate and citric acid to the graphene suspension to enable the metal nitrate to be hydrolyzed to form sol, polymerizing the sol to form gel, finally drying and baking the gel to obtain the nanometer perovskite / graphene composite material. The preparation method disclosed by the invention has the advantages of simple process and low cost; and the nanometer perovskite / graphene composite material disclosed by the invention has good chemical uniformity; in addition, a reaction process is easy to control, and nanometer perovskite particles are more uniformly distributed on the graphene film and have smaller particle sizes, thus the nanometer perovskite / graphene composite material prepared by the method disclosed by the invention has excellent electro-catalysis performances and is suitable for being taken as an electro-catalysis material of a fuel cell.

Owner:YANSHAN UNIV

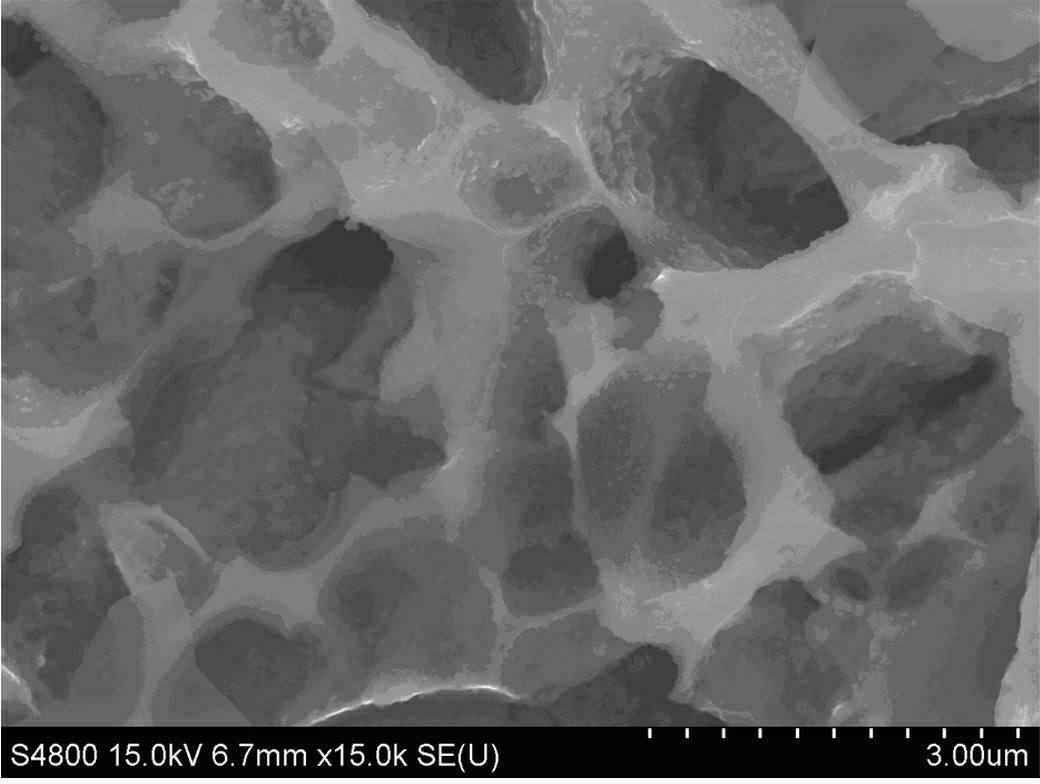

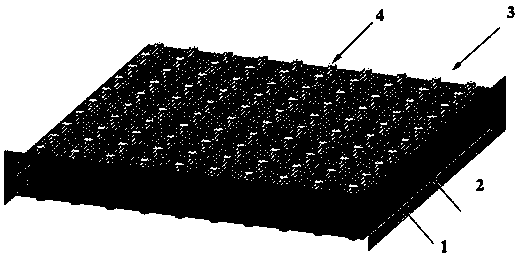

Foam metal-graphene composite material and preparation method thereof

ActiveCN103436939ALarge specific surface areaImprove conductivityElectrophoretic coatingsDielectricElectrophoreses

The invention discloses a foam metal-graphene composite material and a preparation method thereof. The composite material comprises a foam metal substrate and a graphene film layer positioned on the substrate. The foam metal-graphene composite material is prepared by means of electrophoresis. Specifically, the preparation method comprises the following steps: removing greasy dirt and oxides from the surface of a foam metal substrate, preparing graphene by the oxidation-reduction method, modifying graphene, and performing electrophoretic deposition on the graphene on the surface of the foam metal substrate. Within a certain of electromagnetic waveband, on one hand, the foam metal-graphene composite material has the structural advantages of light weight and porosity, large specific surface area and good conductivity of a foam metal, and on the other hand, the composite material integrates excellent electrical conductivity and high dielectric constant, a capacity of being more conducive to absorbing electromagnetic waves due to a large amount of defects and functional group residues of the self-made graphene, and other properties of self-made graphene. The composite material has a higher electromagnetic shielding performance and can serve as an excellent electromagnetic shielding material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

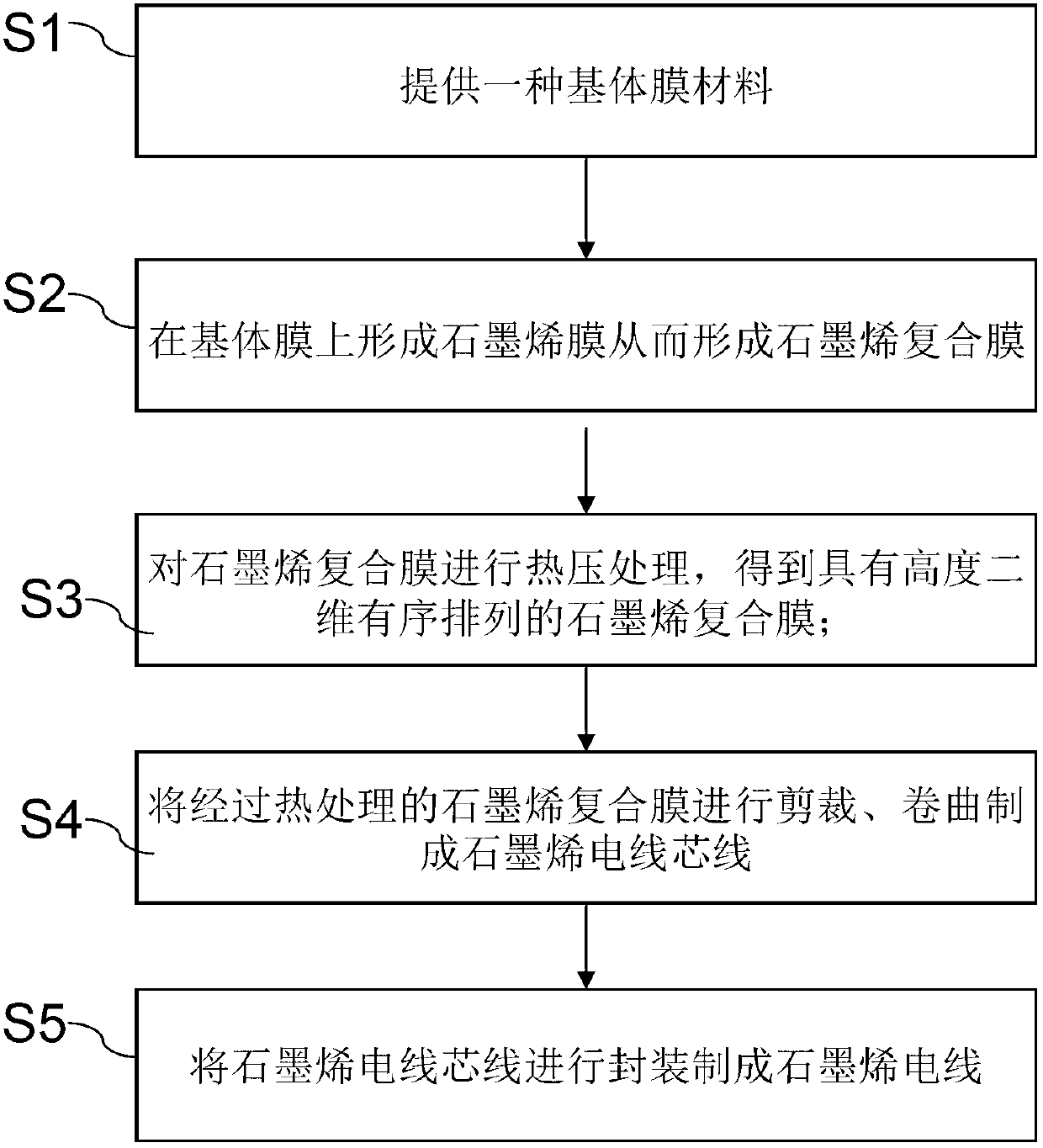

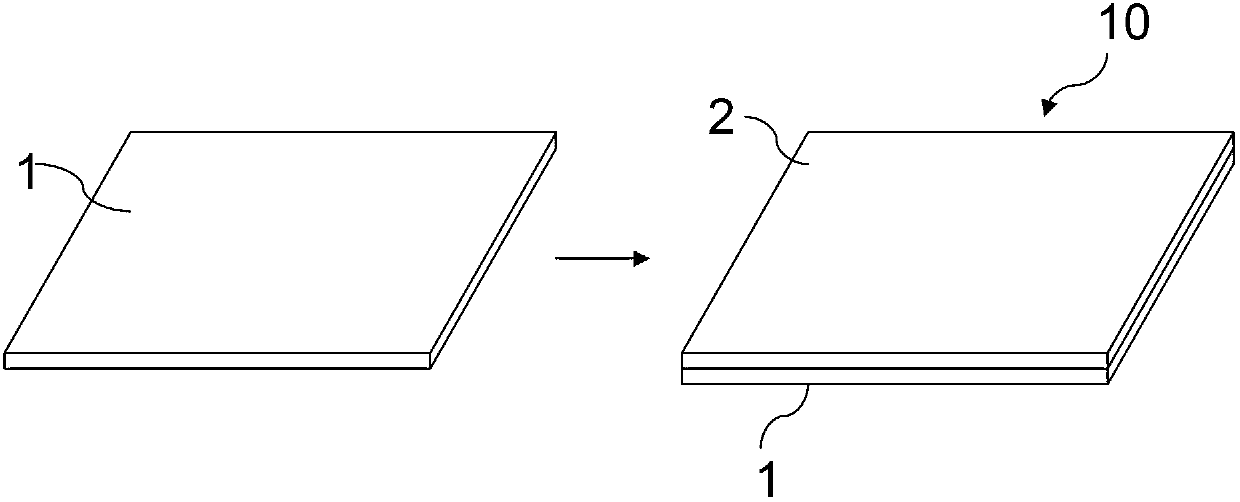

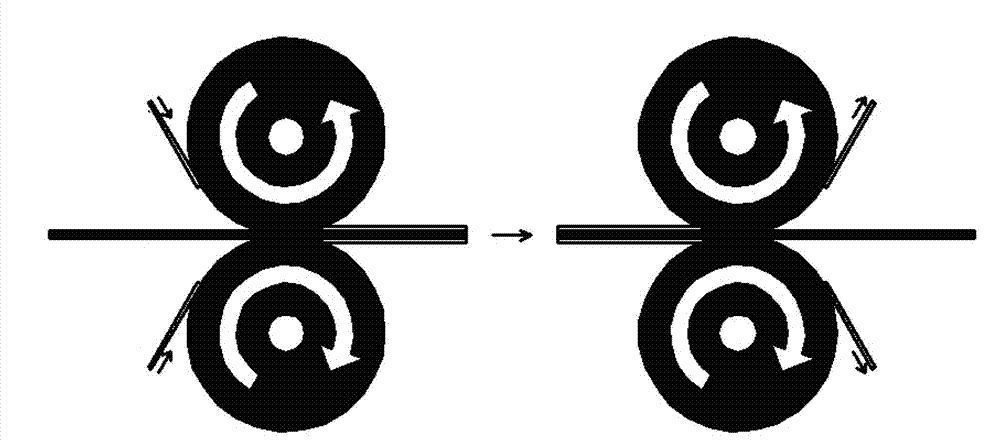

Method for preparing graphene wire and cable

InactiveCN103123830AExcellent two-dimensional conductive propertiesHigh conductivity densityCable/conductor manufactureElectrical conductorTemperature resistance

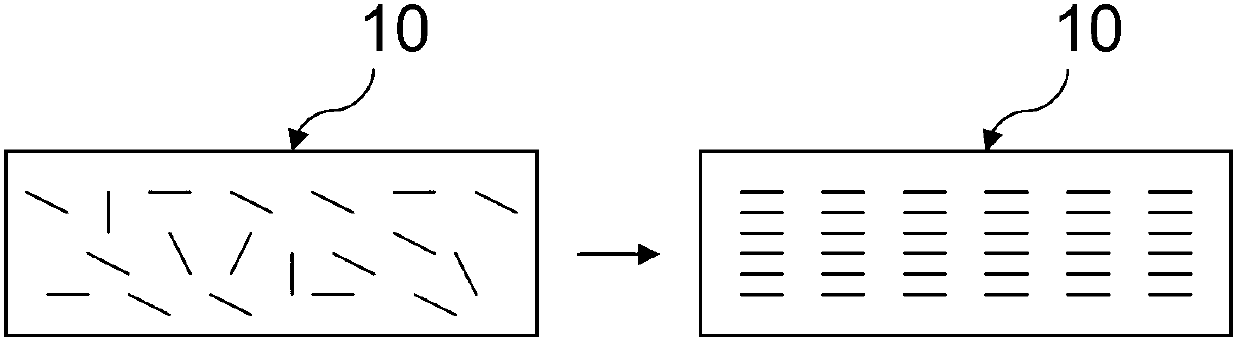

The invention provides a method for preparing a graphene wire and cable. The method comprises the following steps of: spraying or growing a graphene functional material with superior two-dimensional conduction characteristic on a substrate membrane material, and converting disordered graphene nanosheets into highly ordered two-dimensional graphene membranes through treatment of a hot pressing technology so as to prepare the graphene membrane material with the superior two-dimensional conduction characteristic; and then winding the two-dimensional graphene membrane material into the graphene wire with superior one-dimensional conduction characteristic through a winding technology. The graphene wire has the advantages of low resistance, high conduction density, superior conduction characteristic to that of metal conductors such as copper and silver, light weight, high temperature resistance and good chemical stability; and the graphene wires can be assembled and packaged to prepare a high-current graphene cable.

Owner:青岛科孚纳米技术有限公司

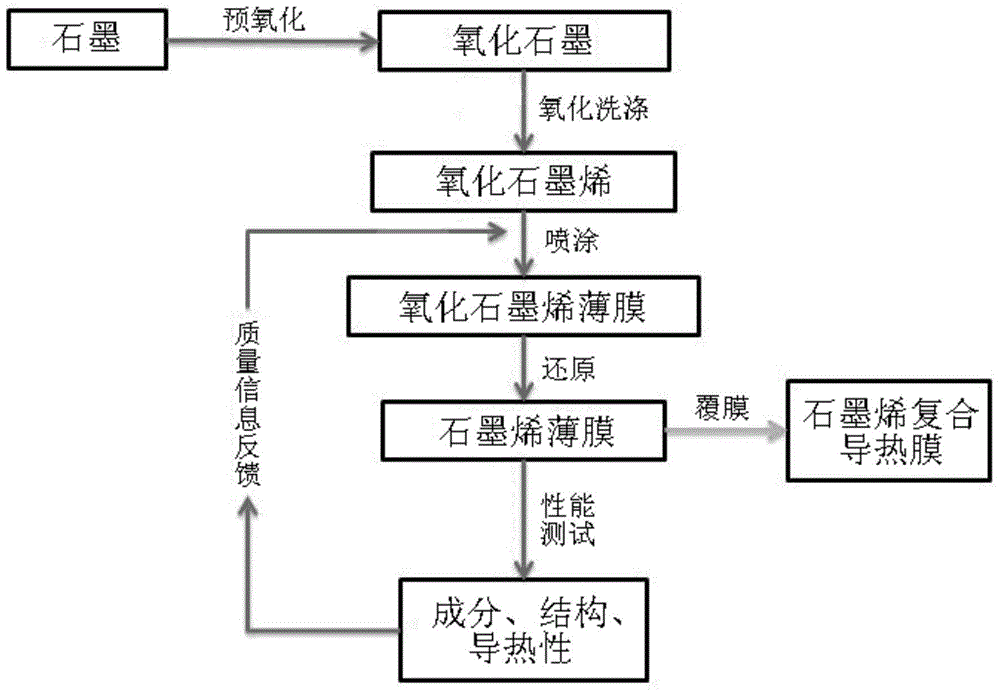

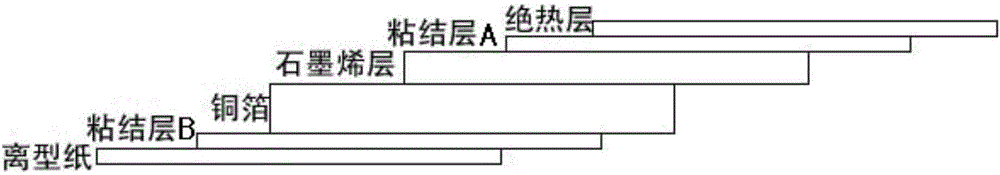

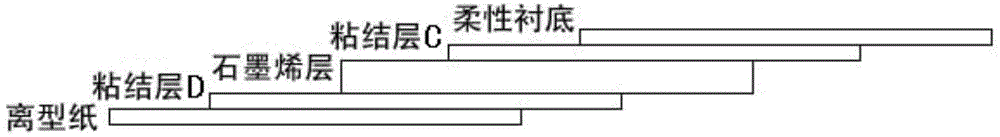

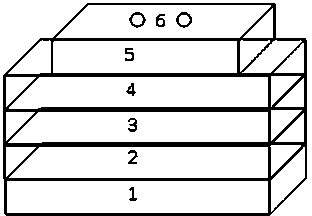

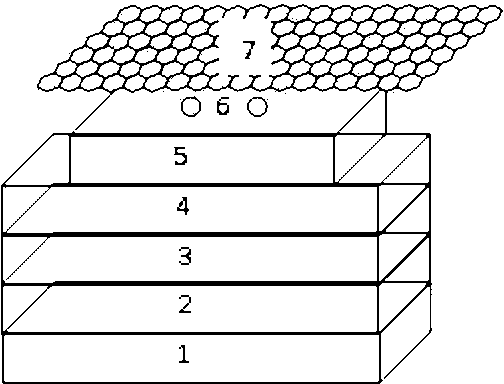

Preparation method of composite heat conduction graphene film and composite heat conduction graphene film

ActiveCN104085143AIncrease layer spacingThoroughly oxidizedMetal layered productsPotassium persulfateFiltration

The invention discloses a preparation method of a composite heat conduction graphene membrane and the composite heat conduction graphene film. The preparation method comprises the following steps: S1, putting crystalline flake graphite or graphite powder into a mixed solution of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide, soaking for a day and a night, then carrying out suction filtration, drying, and carrying out pre-oxidizing; S2, oxidizing pre-oxidized graphite further by adopting a Hummers method, that is, oxidizing fully in concentrated sulfuric acid and potassium permanganate, then adding deionized water for diluting, and carrying out repeated washing and suction filtration, so as to obtain an oxidized graphene aqueous solution; S3, spraying the oxidized graphene aqueous solution on a substrate by adopting a thermal spray method, and depositing, so as to obtain an oxidized graphene film; S4, reducing the oxidized graphene film, so as to obtain the graphene film; and S5, laminating the graphene film, so as to obtain the composite heat conduction graphene film. Compared with the prior art, the preparation method is simple, the cost is low, and the prepared composite heat conduction graphene film has a favorable heat conduction performance.

Owner:成都科愿慧希科技有限公司

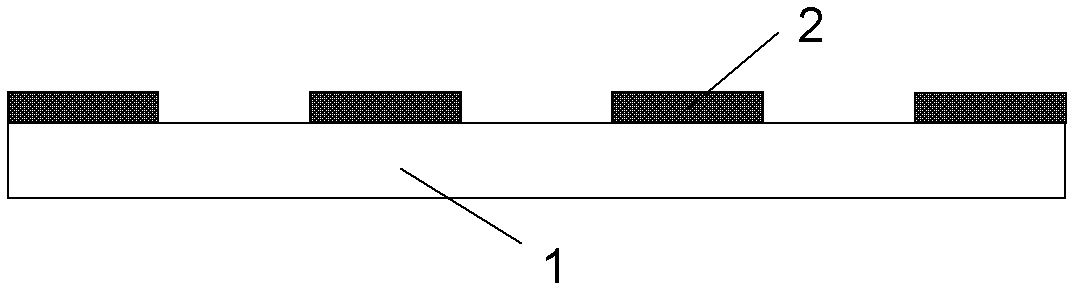

Integrated hydrogen sensor made from mixed graphene film, noble metal particles and metallic oxide materials and preparation method thereof

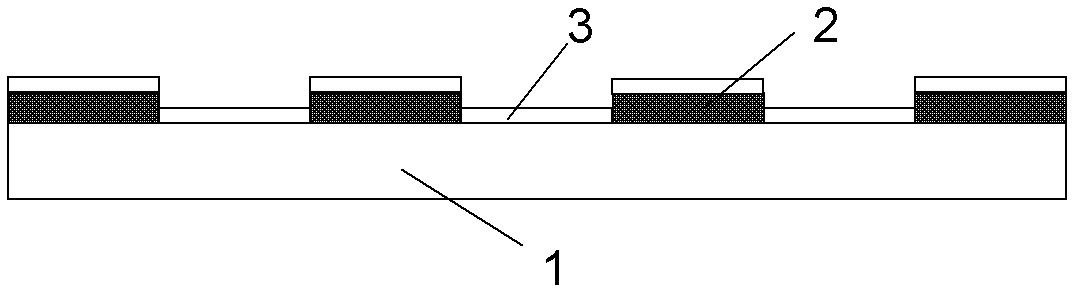

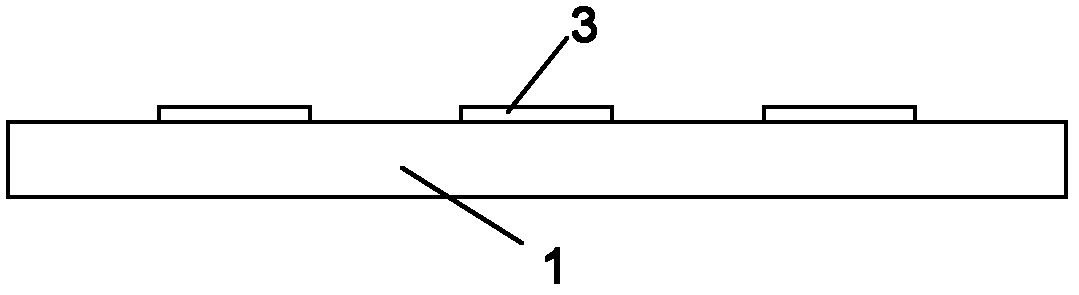

InactiveCN104034758AHigh sensitivityHigh selectivityMaterial resistanceInsulation layerThin membrane

The invention discloses an integrated hydrogen sensor made from mixed graphene film, noble metal particles and metallic oxide materials and a preparation method of the integrated hydrogen sensor. The sensor comprises a substrate, a heating electrode, a heat-conducting insulation layer and a detection electrode; the heating electrode is placed on the substrate; the heat-conducting insulation layer is placed between the heating electrode and the detection electrode and further the sensor further comprises a metallic oxide film deposited on the detection electrode, the noble metal particles deposited on the metallic oxide film, and the graphene film covers the metallic oxide film on which the noble metal particles are deposited. The noble metal particles covering the metallic oxide film are single atoms, wherein the covering rate is 0.05-100 percent, the particle size is 0.2-0.4 nanometers, and the noble metal particles are randomly and uniformly arranged. The metallic oxide film is 10 nanometers to 2 micrometers in thickness. The graphene film is 0.5-1.2 nanometers in thickness. By adopting the integrated hydrogen sensor provided by the invention, high-sensitivity and high-selectivity detection and monitoring for hydrogen can be simultaneously achieved.

Owner:NANJING YIDEGUAN ELECTRONICS TECH +1

Preparation method for patterned graphene membrane

InactiveCN102653454ANo damageEasy to operateMaterial nanotechnologyGraphenePolymethyl methacrylateCvd graphene

The invention provides a preparation method for a patterned graphene membrane. The preparation method comprises the following steps of: firstly coating photoresist or PMMA (polymethyl methacrylate) on a substrate; carrying out patterning process on the substrate; removing the photoresist or PMMA of the area required to form a grapheme pattern; then coating graphene oxide solution on the substrate to form a membrane; carrying out reduction on the obtained substrate in hydrazine steam; processing the graphene oxide into graphene to obtain the graphene membrane; finally immersing the obtained substrate in acetone or photoresist stripping solution; and removing the photoresist or PMMA and the graphene membrane on the photoresist or PMMA to obtain the patterned graphene membrane. With the preparation method disclosed by the invention, the patterned photoresist or PMMA is simply formed on the substrate so as to prepare the patterned graphene membrane. The method is simple to operate and low in cost, can be used on a large scale, does not damage the substrates and is suitable for various substrates, and the application of the solution method in preparing the graphene is expanded.

Owner:BOE TECH GRP CO LTD

Graphene based transparent electric heating film and production method thereof

ActiveCN102883486AGood defogging and defrosting functionsGuaranteed defogging and defrosting functionsTransparent/reflecting heating arrangementsElectricityHigh volume manufacturing

The invention relates to a graphene based transparent electric heating film and a production method thereof. The graphene based transparent electric heating film comprises a transparent flexible substrate, a graphene film is arranged on the transparent flexible substrate, a conductive connection mesh film is arranged on the graphene film and provided with electrodes which are electrically connected with the conductive connection mesh film and the graphene film. The electrodes are provided with protective layers covering the electrodes as well as covering the graphene film and the conductive connection mesh film. The graphene transparent electric heating film is suitable for large-scale production, labor cost is greatly reduced, and meanwhile, product stability is improved and the graphene based transparent electric heating film has the advantages of uniformity in heating, high transparency, good flexibility, low cost and good stability. Besides, heating power of the transparent electric heating film can be designed according to practical needs, heating curves can be designed according to service needs, and the heating film is guaranteed to have demisting and defrosting functions. Simultaneously, brittle cracking of glass due to sudden change of temperature is avoided. The graphene based transparent electric heating film is wide in application range, stable and reliable.

Owner:中科芯未来微电子科技成都有限公司

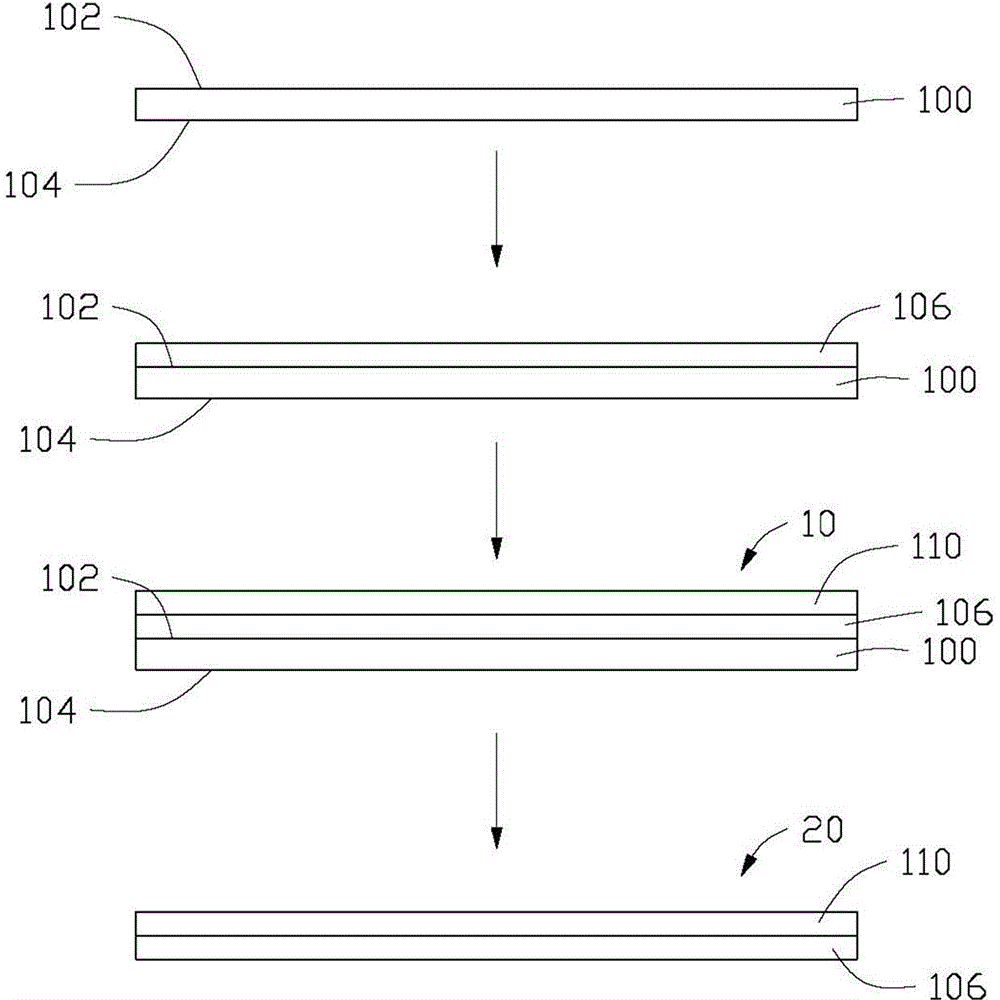

Preparation method of graphene-carbon nano tube composite structure

ActiveCN102795613AImprove conductivityImprove toughnessMaterial nanotechnologySingle layer grapheneCarbon nanotubeCvd graphene

The invention provides a preparation method of a graphene-carbon nano tube composite structure, comprising the following steps of: providing a substrate, wherein the substrate is provided with a first surface and a second surface which is opposite to the first surface; providing at least one graphene membrane, wherein the graphene membrane is formed or arranged on the first surface of the substrate; providing at least one carbon nano tube layer; compounding the substrate and the graphene membrane with the carbon nano tube layer; contacting the graphene membrane with the carbon nano tube layer to obtain a substrate-graphene-carbon nano tube composite structure; and removing the substrate to obtain the graphene-carbon nano tube composite structure.

Owner:TSINGHUA UNIV +1

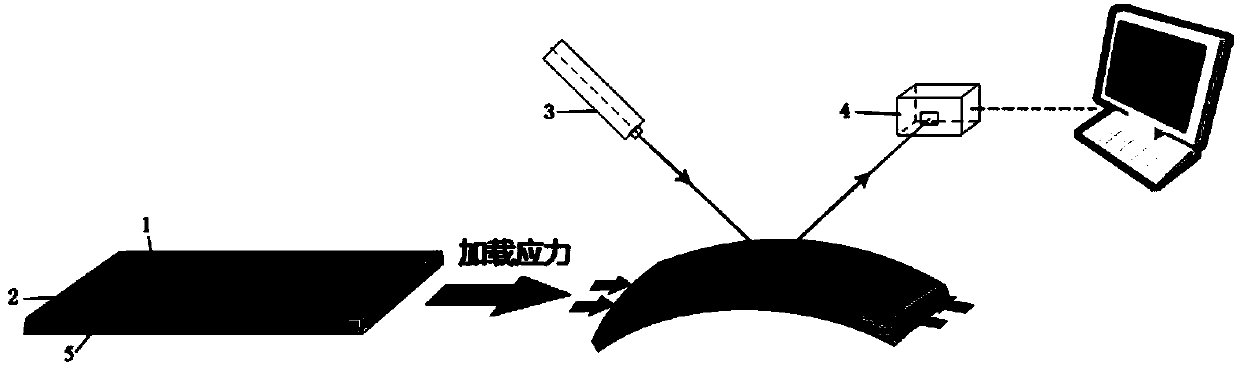

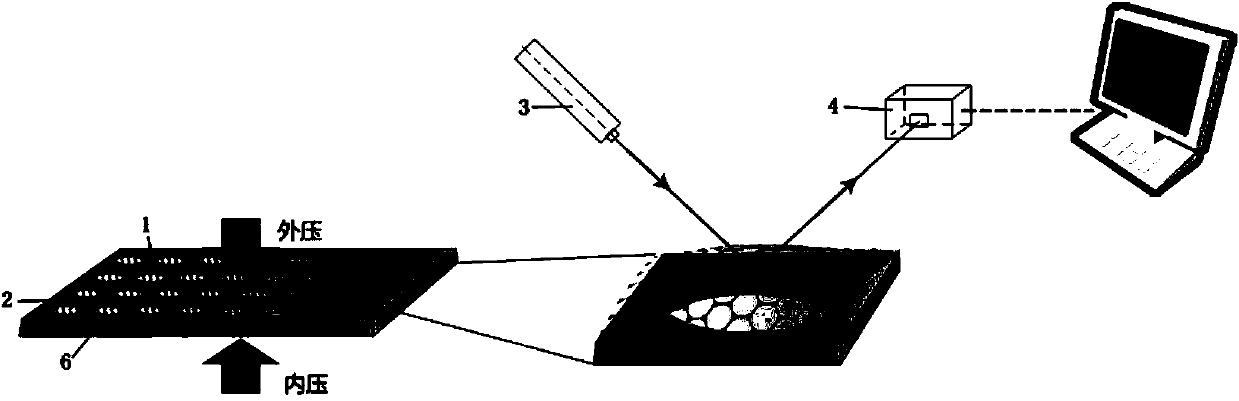

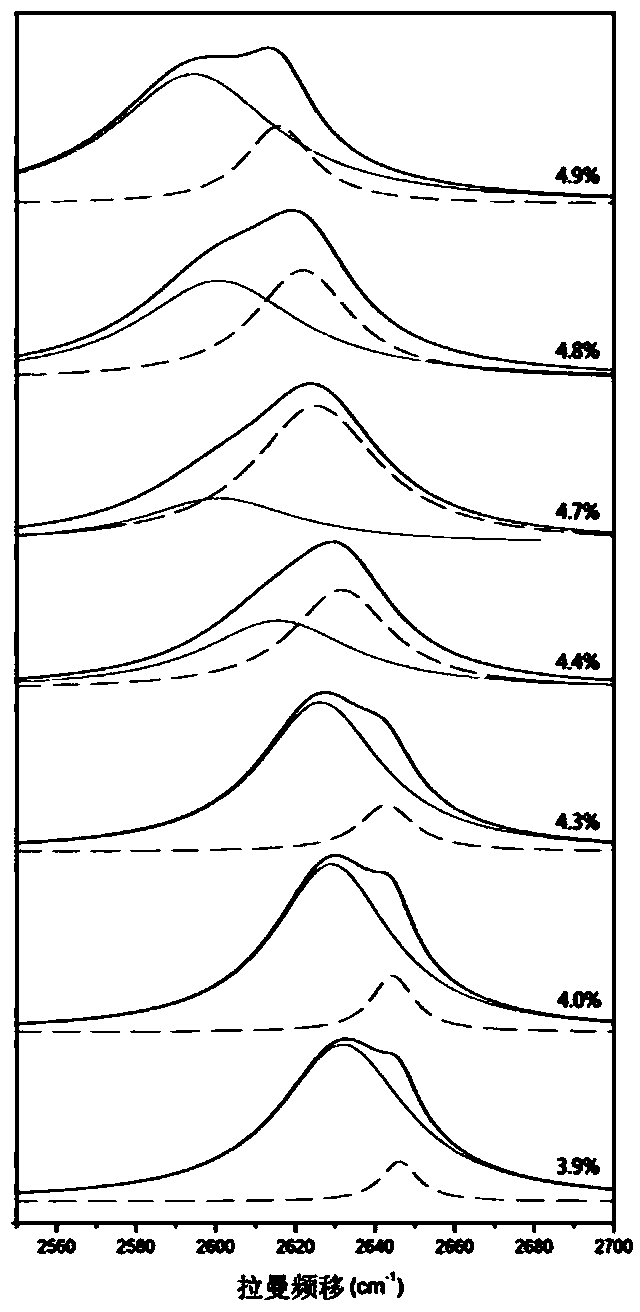

Device for measuring object stress by utilizing graphene membrane, and preparation method and testing method of device

ActiveCN103630272ASimple structureEasy to operateUsing optical meansChemical vapor deposition coatingStress measurementTechnical design

The invention discloses a device for measuring object stress by utilizing a graphene membrane, and a preparation method and a testing method of the device. The testing method is characterized in that graphene is arranged on a flexible stretchable substrate by utilizing a growth and transfer technology of the graphene and is tightly adhered to the surface of a to-be-measured object or a single crystal silicon substrate which is provided with a through hole, a characteristic peak of a Raman spectrum of the graphene can be subjected to shifting and splitting when the to-be-measured object is subjected to deformation or gas pressure difference exists between the internal part and the external part of the through hole, and sensing on strain or gas pressure can be realized basing on shifting and splitting amount of the characteristic peak. According to the device, the preparation method and the testing method, disclosed by the invention, the technical design is simple, the performance is stable, non-contact with the to-be-measured object is realized, and the complexity of an electrical measurement method which is in need of arranging leading wires can be avoided; the strain loading range is large, and the stress measurement accuracy degree is high.

Owner:西安超宇微晶新材料技术有限公司

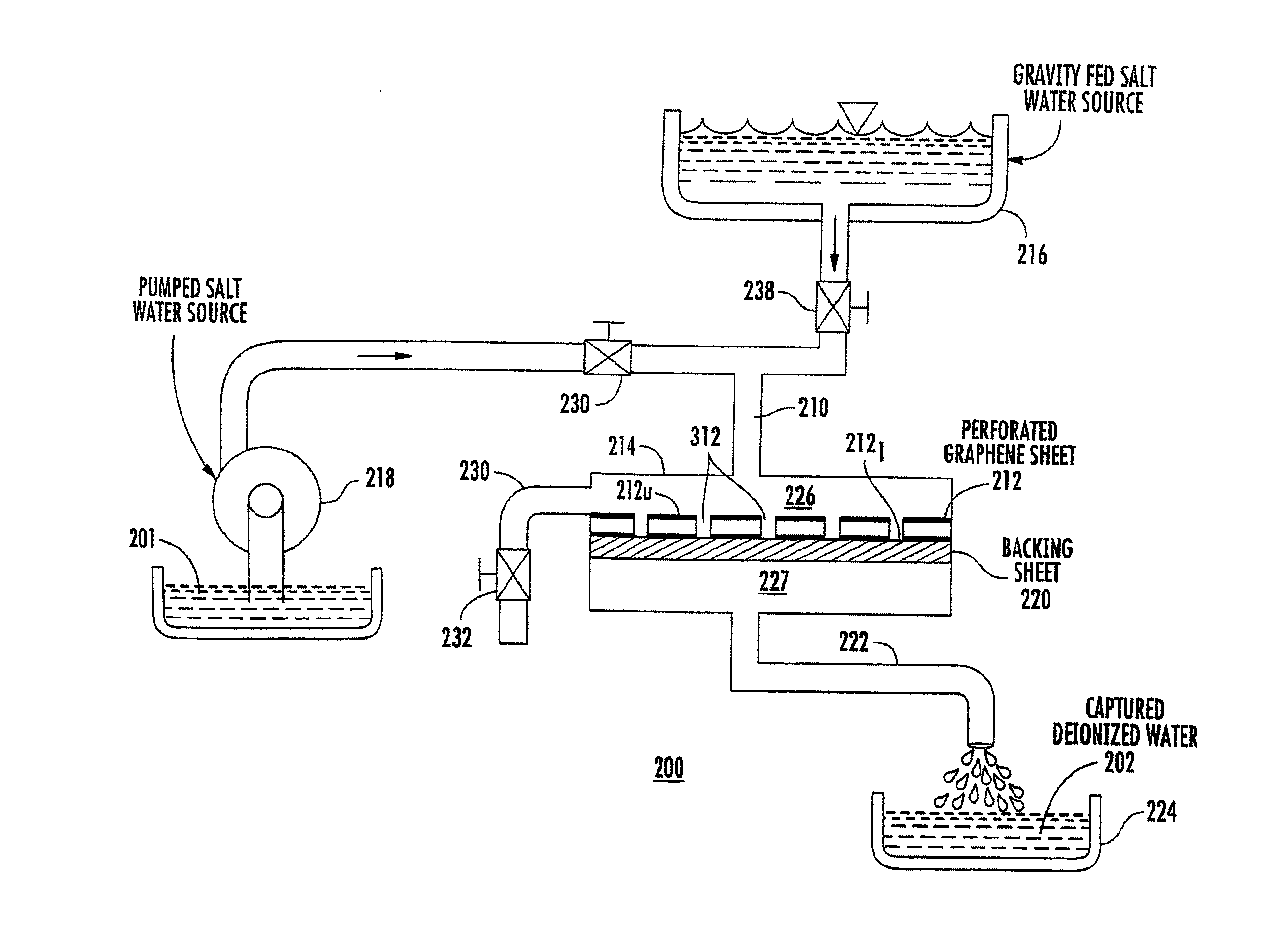

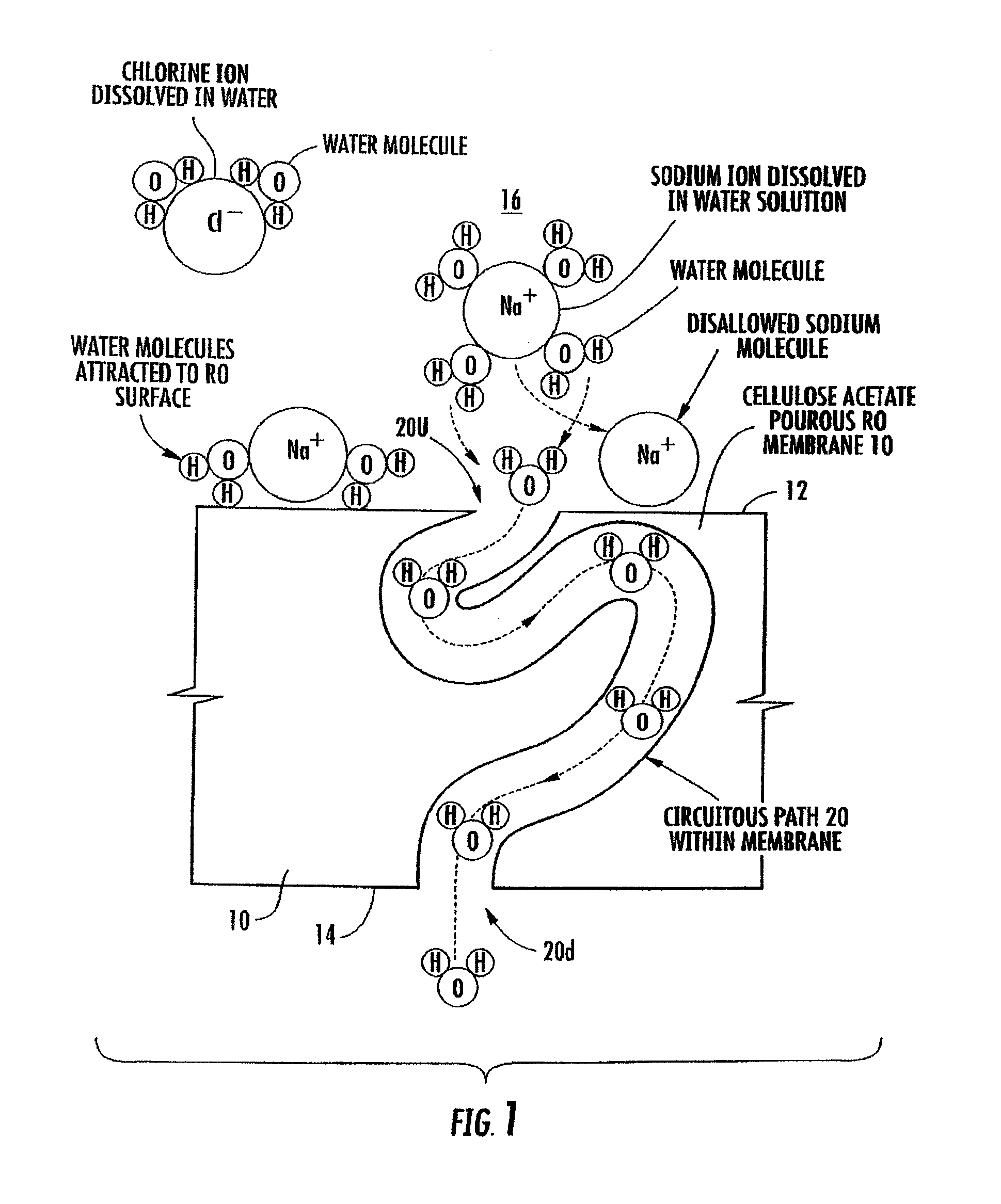

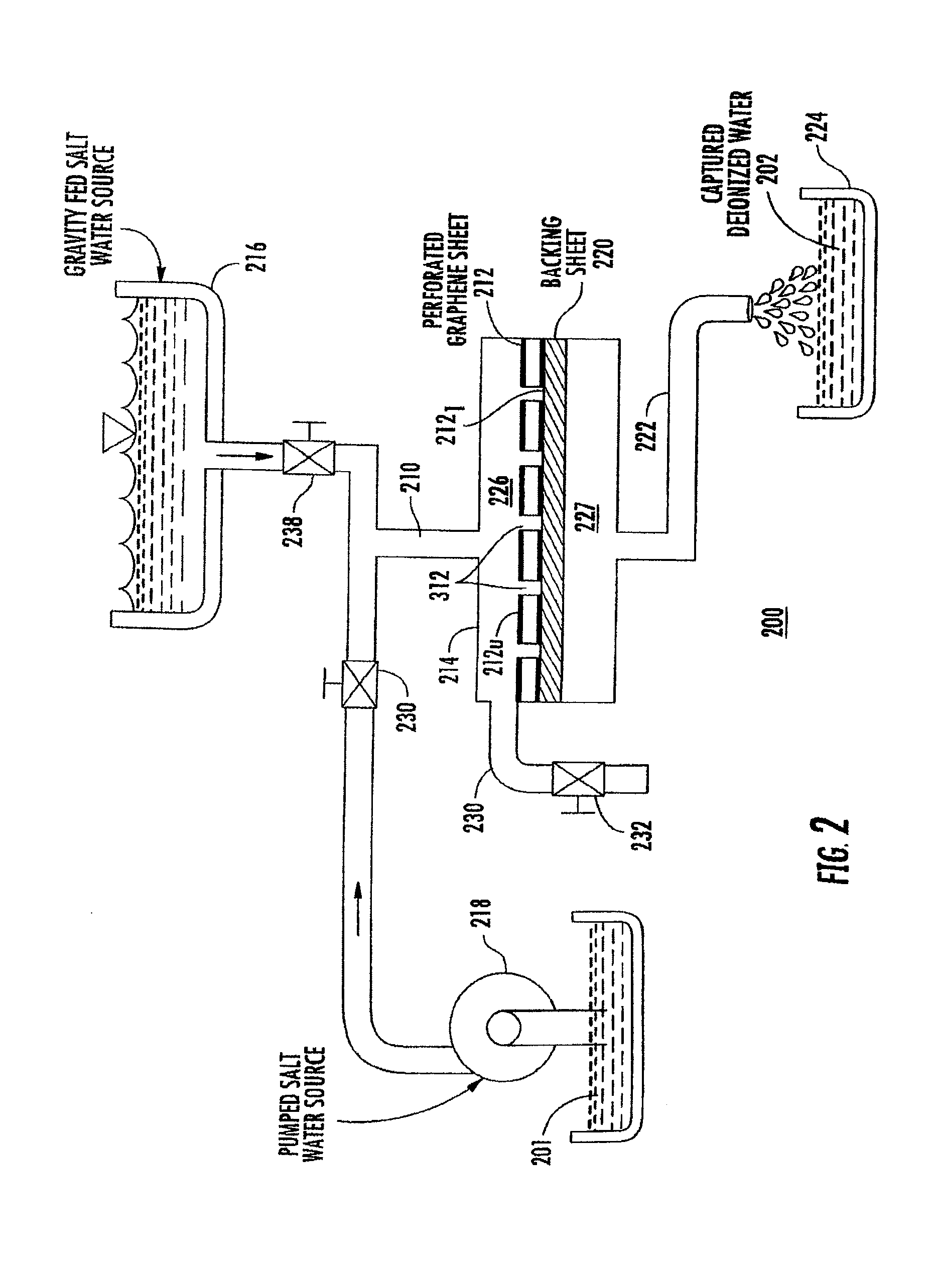

Selectively perforated graphene membranes for compound harvest, capture and retention

Devices and related methods for arresting and retaining molecules from solution upon the surface of a perforated graphene membrane with plural apertures selected to allow passage of the solutions' solvent while simultaneously arresting desired molecules upon the surface of the membrane. The method continues with arranging the perforated graphene membranes in a sequence of successively smaller plural aperture diameters to arrest and retain successively smaller molecules in series. The dislodging devices include electromagnetic, electromechanical and electrostatic configurations.

Owner:LOCKHEED MARTIN CORP

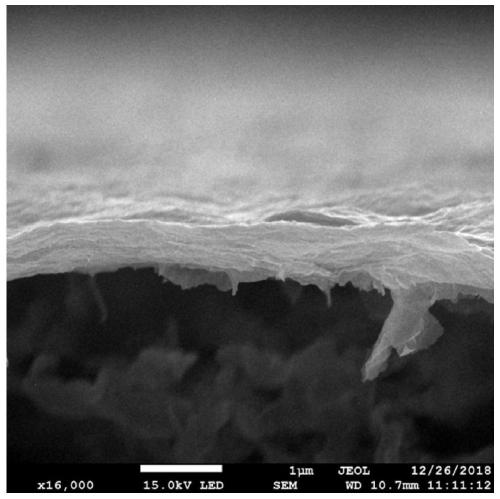

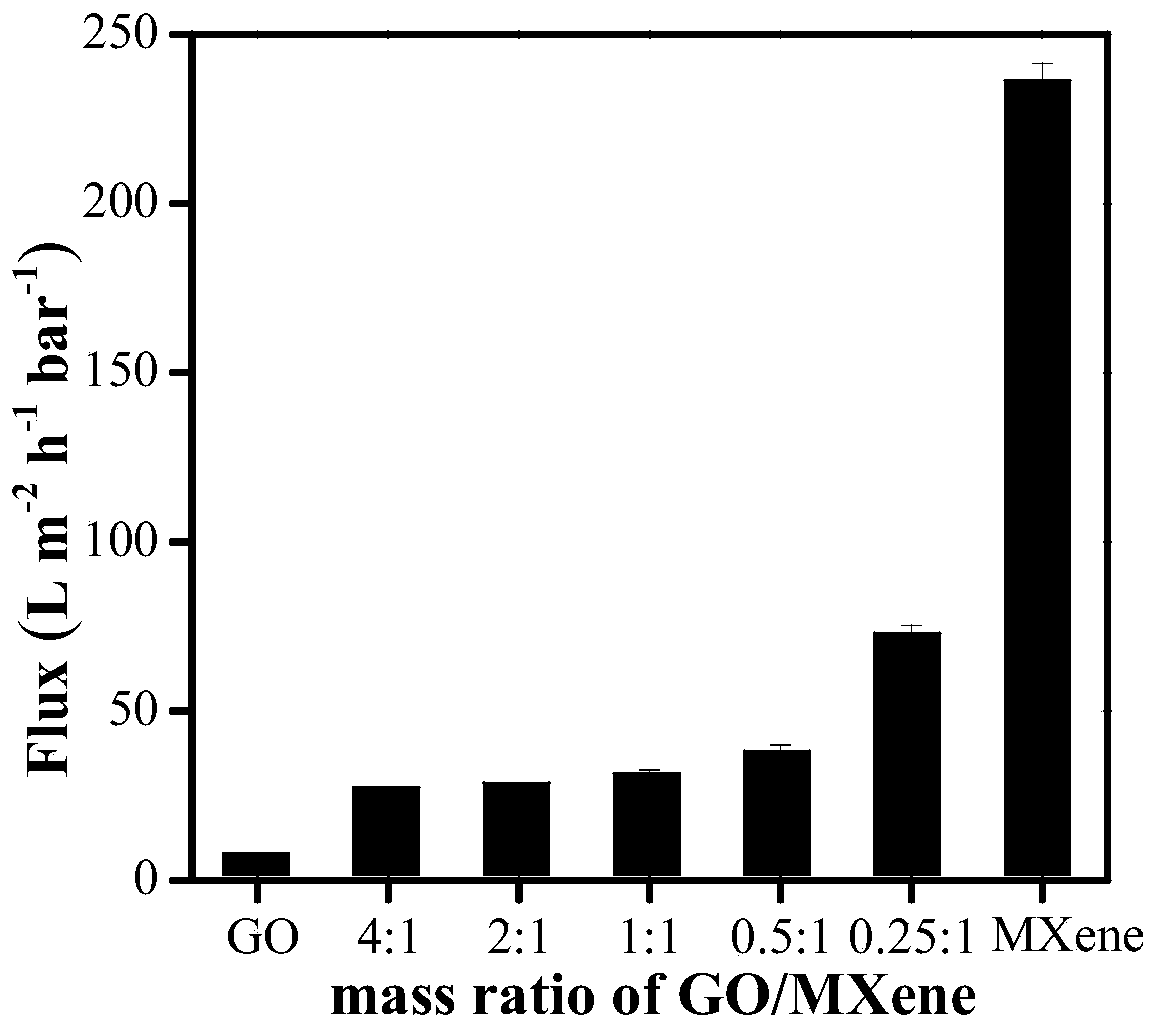

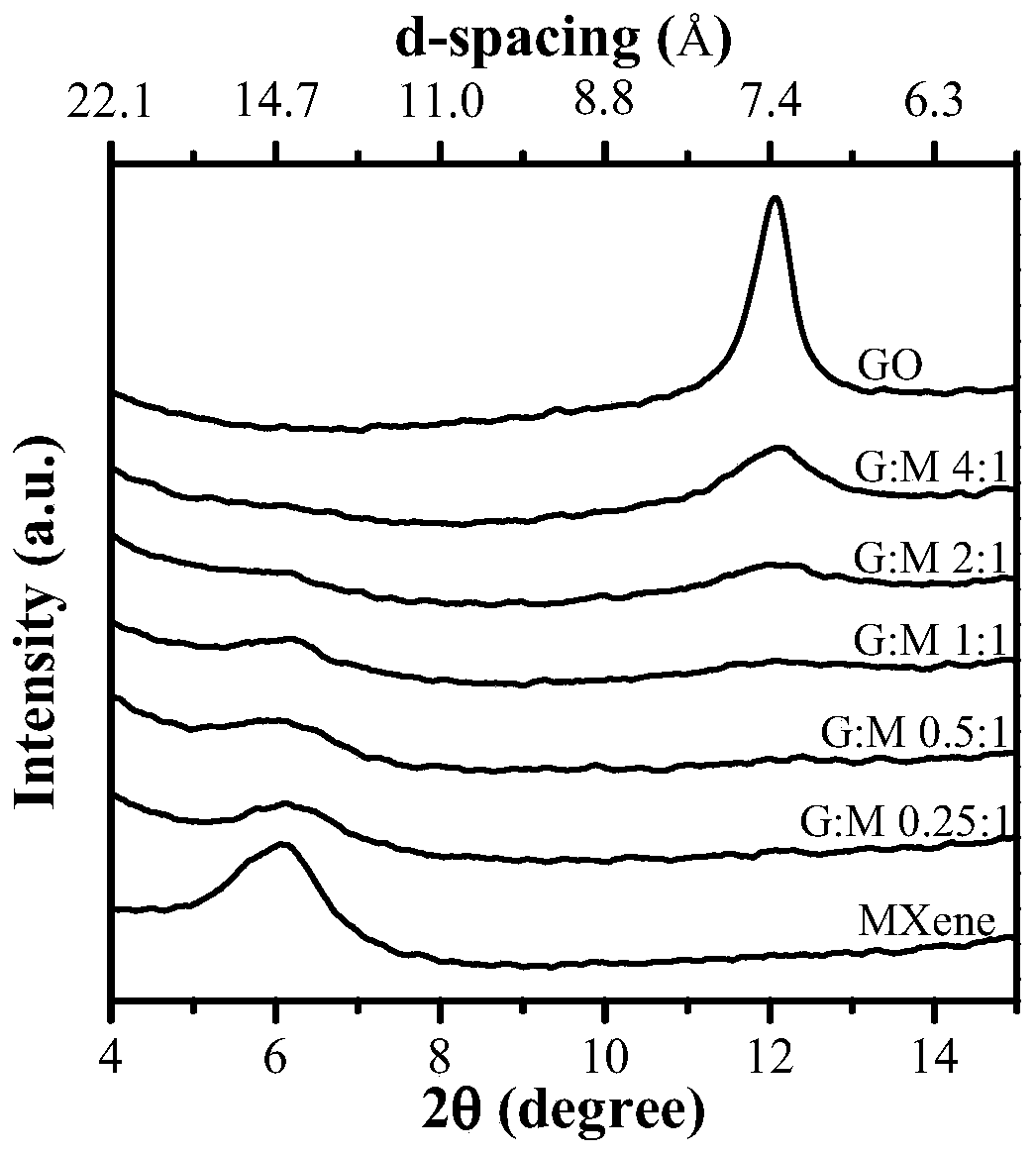

Preparation method and application of graphene oxide/MXene composite film

InactiveCN110124529AIncreased pure water fluxHigh removal rateSemi-permeable membranesOther chemical processesComposite filmMicrofiltration membrane

The invention provides a preparation method and application of a graphene oxide / MXene composite film. The method comprises the following steps: mixing a graphene oxide solution and an MXene solution in proportion to obtain a mixed solution, carrying out ultrasonic treatment on the mixed solution, pouring the solution into a suction filtration bottle with a microfiltration membrane, and carrying out vacuum filtration treatment for compounding and supporting the two two-dimensional materials on the surface of the microfiltration membrane to obtain the composite membrane. The pure water flux of the graphene oxide (GO) / MXene composite membrane is far greater than that of a pure graphene oxide membrane; with the increase of the MXene doping proportion, the flux is in an increasing trend; the removal rate of the composite membrane to small molecular dyes in water is up to 99.5% or above; the method is simple, easy to operate, easy to use on a large scale and beneficial to popularization.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Graphene/graphene oxide composite membrane and preparation method thereof

InactiveCN102166844AImprove mechanical propertiesStrong response characteristicsLayered productsOxide compositeGraphite oxide

The invention provides a graphene / graphene oxide composite membrane which is composed of a graphene layer and a graphene oxide layer, wherein the thickness of each layer is 50 nanometers-1 millimeter. The preparation method of the graphene / graphene oxide composite membrane comprises the following steps of: putting a graphene oxide solution into a container for filtering or evaporating to obtain agraphene oxide membrane; and putting a graphene solution into the container containing the graphene oxide membrane for filtering or evaporating to obtain the graphene / graphene oxide composite membrane. The membrane has excellent mechanical properties and has a very strong response characteristic to temperature or humidity; and by the characteristic, the graphene / / graphene oxide composite membranecan be applied on a micro-actuator or sensor.

Owner:SOUTHEAST UNIV

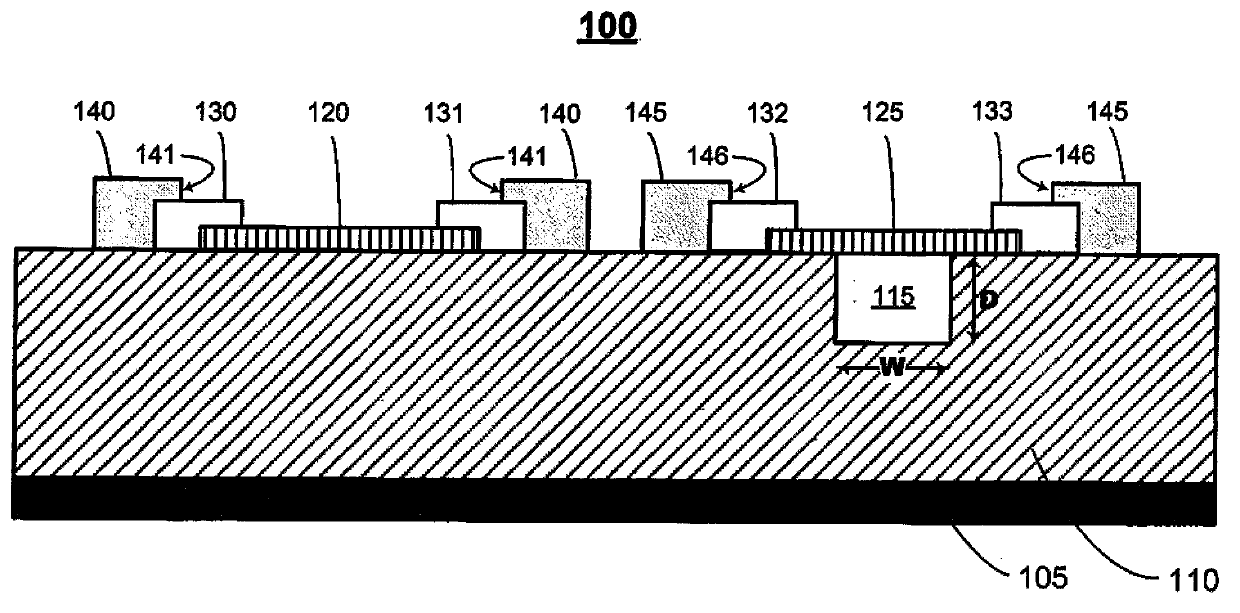

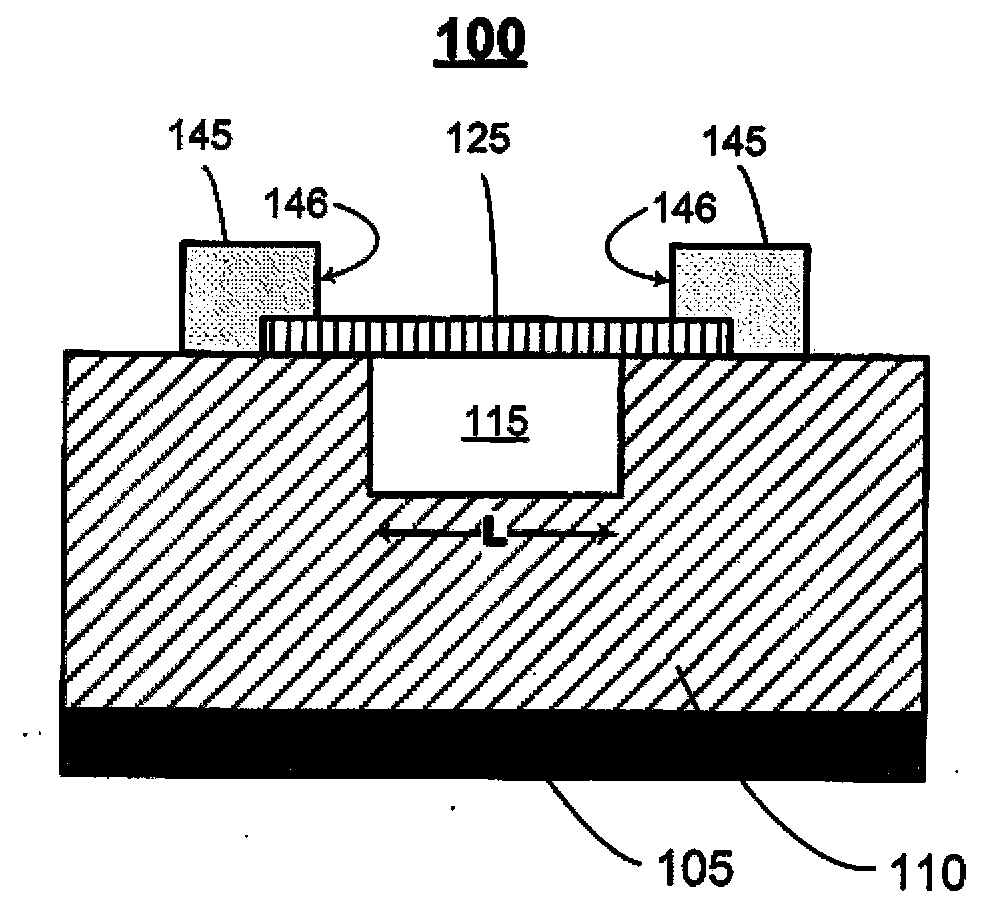

Graphene pressure sensors

InactiveCN103378082AFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsCvd grapheneForce sensor

Semiconductor nano pressure sensor devices having graphene membrane suspended over open cavities formed in a semiconductor substrate. A suspended graphene membrane serves as an active electro-mechanical membrane for sensing pressure, which can be made very thin, from about one atomic layer to about 10 atomic layers in thickness, to improve the sensitivity and reliability of a semiconductor pressure sensor device.

Owner:IBM CORP

Graphene-based structure, method of suspending graphene membrane, and method of depositing material onto graphene membrane

An embodiment of a method of suspending a graphene membrane on a support structure includes attaching graphene to a substrate. A pre-fabricated support structure having the gap is attached to the graphene. The graphene and the pre-fabricated support structure are then separated from the substrate which leaves the graphene membrane suspended on the pre-fabricated support structure. An embodiment of a method of depositing material includes placing a support structure having a suspended graphene membrane under vacuum. A precursor is adsorbed to a surface of the graphene membrane. A portion of the graphene membrane is exposed to a focused electron beam which deposits a material from the precursor onto the graphene membrane. An embodiment of a graphene-based structure includes a support structure having a gap, a graphene membrane suspended across the gap, and a material deposited in a pattern on the graphene membrane.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Preparation method of porous-ceramic-supported graphene film

ActiveCN103611431AHigh strengthSimple and economical processSemi-permeable membranesOrganic solventComposite film

The invention relates to a preparation method of a porous-ceramic-supported graphene film. An inorganic ceramic material serves as a support body, and one side of a silane-modified inorganic ceramic support body is coated with a graphene film-forming material. The preparation method can be applied to removal of water in an organic solvent through a pervaporation method and separation of organic systems in other fields of industrial production. A composite film has the unique properties of a graphene material and the own advantages of a ceramic material. The inherent limitations of common organic and inorganic materials are overcome. The preparation method is simple and economic in process, and wide in application range.

Owner:NANJING UNIV OF TECH

High-strength flexible graphene composite heat conduction film and preparation method thereof

The invention discloses a high-strength flexible graphene composite heat conduction film and a preparation method thereof. The film is formed by physically cross-linking macroscopic multi-layer folded graphene with micro-scale folds, wherein slice layers can slip, so that the film has extremely high flexibility. The graphene slice layers are perfect in structure, and slice-layer crystalline areas of the graphene slice layers are extremely great and have less defects, so that the graphene slice layers are compact in structure after being pressed under high pressure, and have extremely high conductivity and heat conduction. Meanwhile, in the presence of polymer based composites, the graphene slice layers can be cross-linked, so that the strength of the graphene film is strengthened. The high-strength flexible graphene composite heat conduction film has strength which can be up to 100-300MP, can be resistant to repeated bending by more than 1000 times, has elongation at break of 6-16%, has electric conductivity of 6000-8600S / cm, has thermal conductivity of 1400-1800W / mk, and can be widely used for high-strength designable heat-conduction and conductive apparatuses.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

Nanocellulose-assisted preparation method of high-content graphene flexible conductive composite membrane

The invention aims to provide a nanocellulose-assisted preparation method of a high-content graphene flexible conductive composite membrane. The preparation method is characterized in that a low-content nanocellulose waterborne suspension is used to help disperse a graphene powder so as to obtain a uniform stable graphene / nanocellulose dispersion, and a flexible graphene composite membrane with graphene content up to 98 wt% and controllable mechanical property and conductivity can be prepared by a solvent evaporation method. The method is simple and low-cost, requires no complex equipment and is environmentally friendly. By the method, problems such as poor film-forming property of graphene, low strength, environmental pollution and the like existing in the prior art can be solved. In comparison with the prior art, the graphene membrane obtained by the method has advantages of good strength, controllable size and high conductivity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

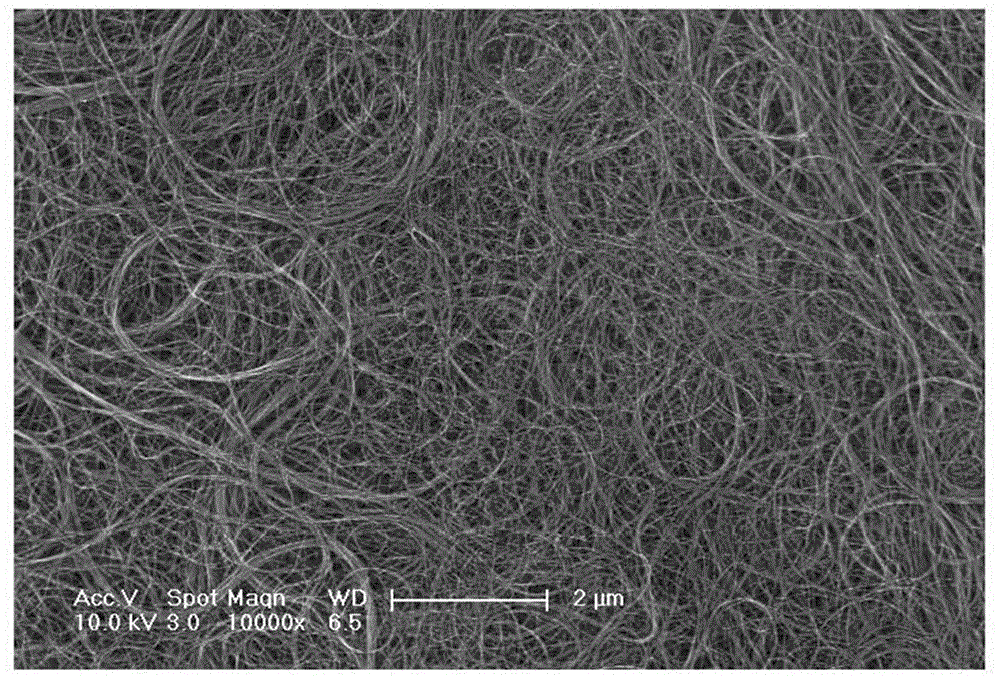

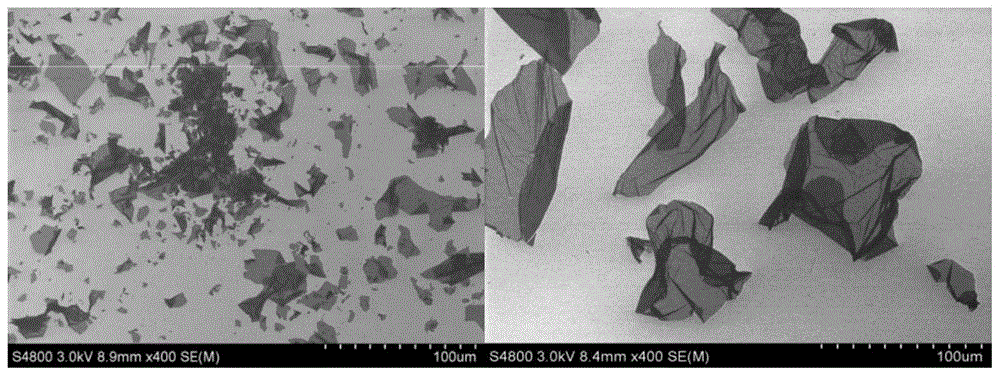

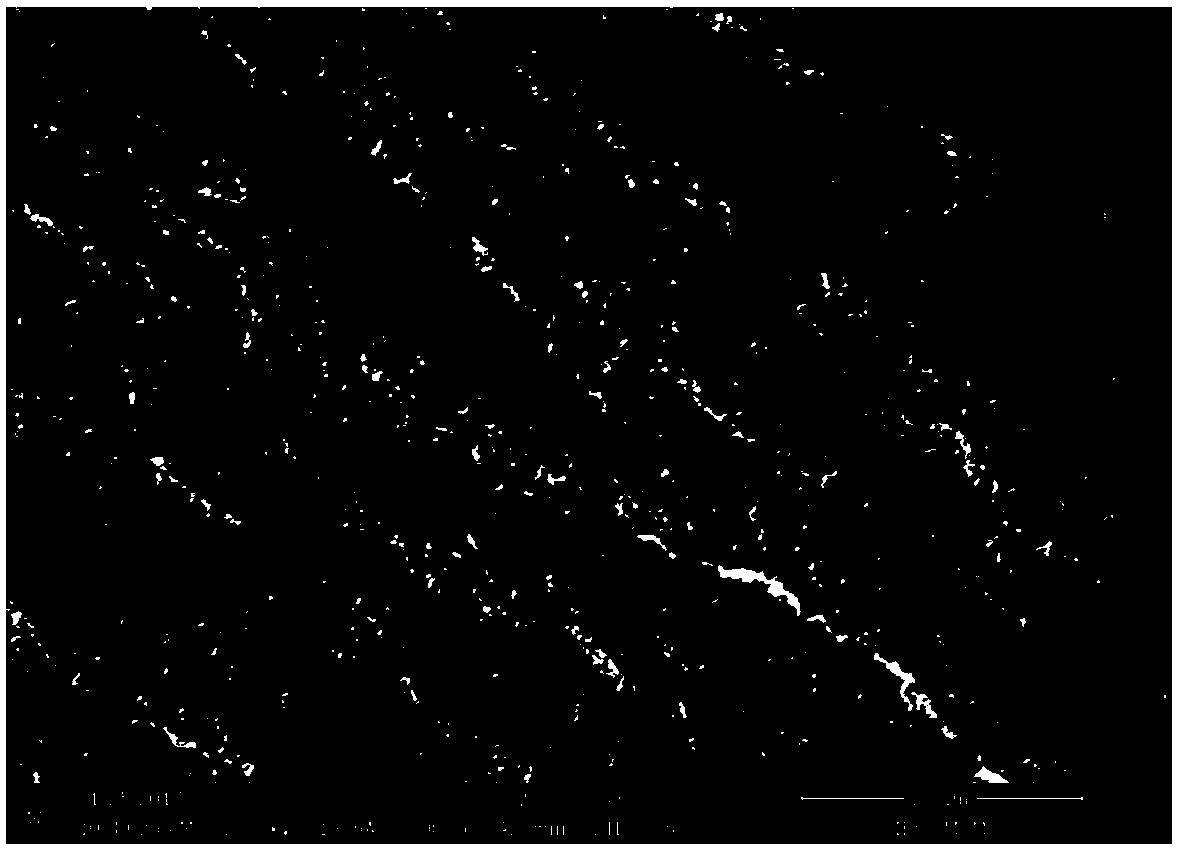

Independent self-support wrinkled graphene film in nano thickness and preparation method thereof

The invention discloses an independent self-support wrinkled graphene film in nano thickness and a preparation method thereof. The independent self-support wrinkled graphene film in nano thickness isobtained through film formation by suction filtration of oxidized graphene prior to chemical reduction and high-temperature treatment. The independent self-support wrinkled graphene film in nano thickness is formed by single-layer graphene through physical crosslinking, wherein the graphene is complete in base structure without obvious defects and rich in wrinkles, and the content of turbostraticstructures among lamellas exceed 30%. Since the independent self-support wrinkled graphene film in nano thickness is extremely thin in thickness (16-130 nm) with a great quantity of superficial wrinkles, thereby being highly flexible.

Owner:杭州德烯科技集团有限公司

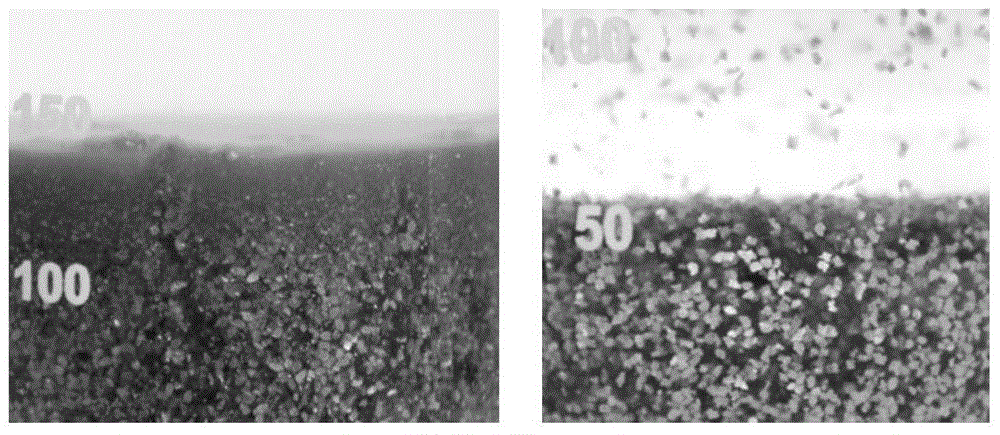

Graphene film for light efficient electromagnetic shielding and preparation method thereof

ActiveCN105731434ASimple processGood electromagnetic shielding performanceGrapheneDefective grapheneCvd graphene

The invention discloses a graphene film for light efficient electromagnetic shielding and a preparation method thereof. An oversized graphene oxide sheet is used for forming the film and by virtue of an annealing mode under high temperature, the graphene defect is perfectly repaired, the edge defect is reduced to the lowest to form a perfect large conjugate structure, and the smoothness of a head conducting path of the graphene is guaranteed; furthermore, through three steps of independent warming processes, a functional group is separated from the surface of the graphene step by step, a pore-foaming agent included between the graphene sheets is slowly decomposed, and the functional group and the pore-forming agent are released step by step in a gas mode; and meanwhile, the graphitization process is gradually developed to form a graphene micro airbag; in the forming process of the micro gasbag, the most stable functional group on the surface of the graphene falls off, thereby producing the graphene structure formed by 1-4 layers of graphene sheets with the gas expansion under high temperature; the successful introduction of the graphene few-layer structure greatly promotes the conductivity performance of the material. The micro gasbag structure is assisted by good conductivity performance so that the graphene of the invention has strong electromagnetic shielding performance.

Owner:HANGZHOU GAOXI TECH CO LTD

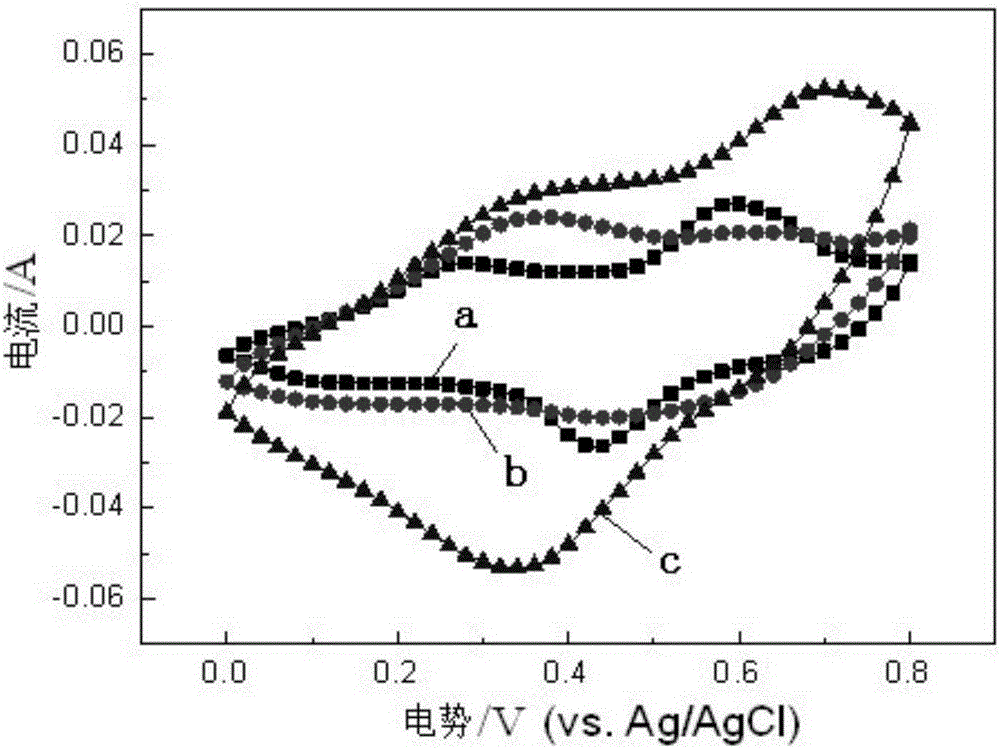

Preparation method of bacterial cellulose/polyaniline/graphene film material and application thereof

InactiveCN105175761AImprove stabilityImprove mechanical propertiesMaterial nanotechnologyHybrid capacitor electrodesFiltrationFilm material

The invention discloses a preparation method of a bacterial cellulose / polyaniline / graphene film material and application thereof and relates to the preparation method of the film material and application thereof. The invention aims at solving the problems of complex preparation process, high cost and poor stability and mechanical property of an existing flexible electrode material. The preparation method disclosed by the invention comprises the following steps: preparing bacterial cellulose pulp; preparing a polyaniline-graphene compound material solution, carrying out vacuum filtration on the bacterial cellulose to form a film, then adding the polyaniline-graphene compound material solution, continuously carrying out filtration and drying, and preparing the bacterial cellulose / polyaniline / graphene film material for the application in a supercapacitor. The bacterial cellulose / polyaniline / graphene film material has the advantages that large-scale production can be achieved; the preparation process is simple; the cost is low; the stability and the mechanical property of the conducting film material are good, and the prepared supercapacitor has good capacitive character. The invention belongs to the technical field of nano materials.

Owner:HARBIN INST OF TECH

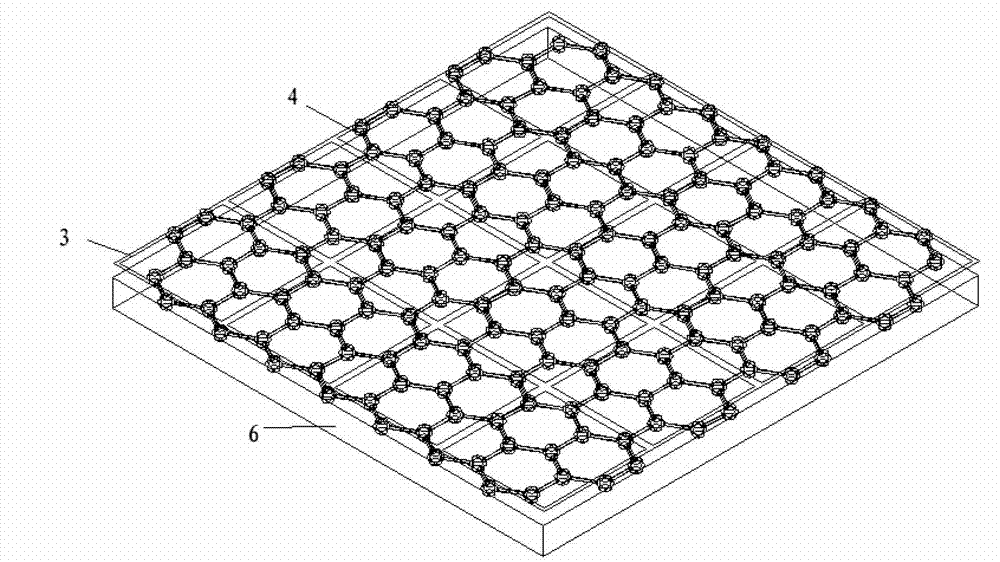

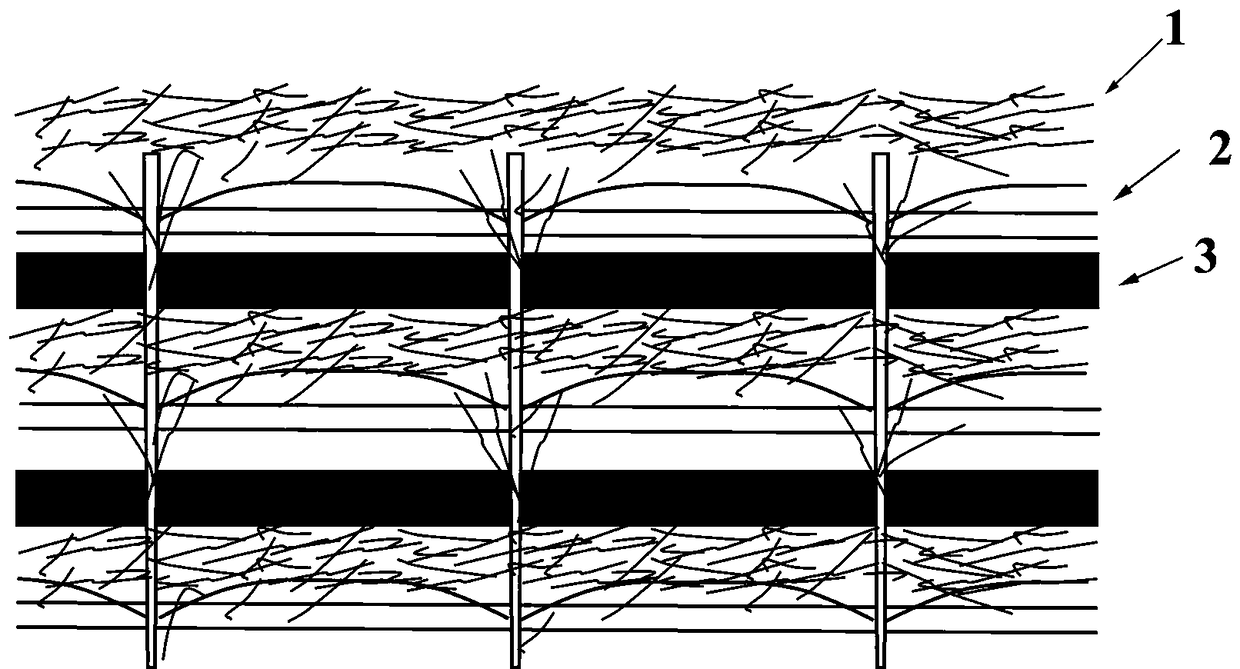

Novel high-heat-conductivity graphene or graphite film/carbon fiber composite material preparation method

The invention belongs to the field of heat-conducting materials, and particularly relates to a preparation method of a novel high-heat-conductivity graphene film / carbon fiber heat-radiating plate. A graphene-carbon fiber resin matrix composite material is prepared from a graphene layer, a carbon fiber woven mesh layer and a vertical alignment carbon fiber reinforced layer. The graphene film is punched in advance through a stamping technology so as to obtain a meshy graphene film, and is then pre-impregnated with epoxy so as to obtain a prepreg. The graphene film and the carbon fiber sheet prepreg are sequentially laminated and paved, and then an ultrasonic impacting gun is used for driving a carbon fiber needling preform into a composite plate, or a needling method is used for vertically aligning part of carbon fiber, so that a shearing performance is improved. According to the preparation method provided by the invention, graphene powder and the carbon fiber sheet are compounded, so that the composite material has excellent heat conductivity and better machinability. The composite material plate can be used for heat radiation of a large-scale component, has a heat radiation performance similar to pure metal and other heat-radiating materials, and has cuttability and better flexibility. The material is simple in production process, energy-saving, environmental-friendly, high inapplicability, and capable of being produced in a large scale.

Owner:PEKING UNIV +1

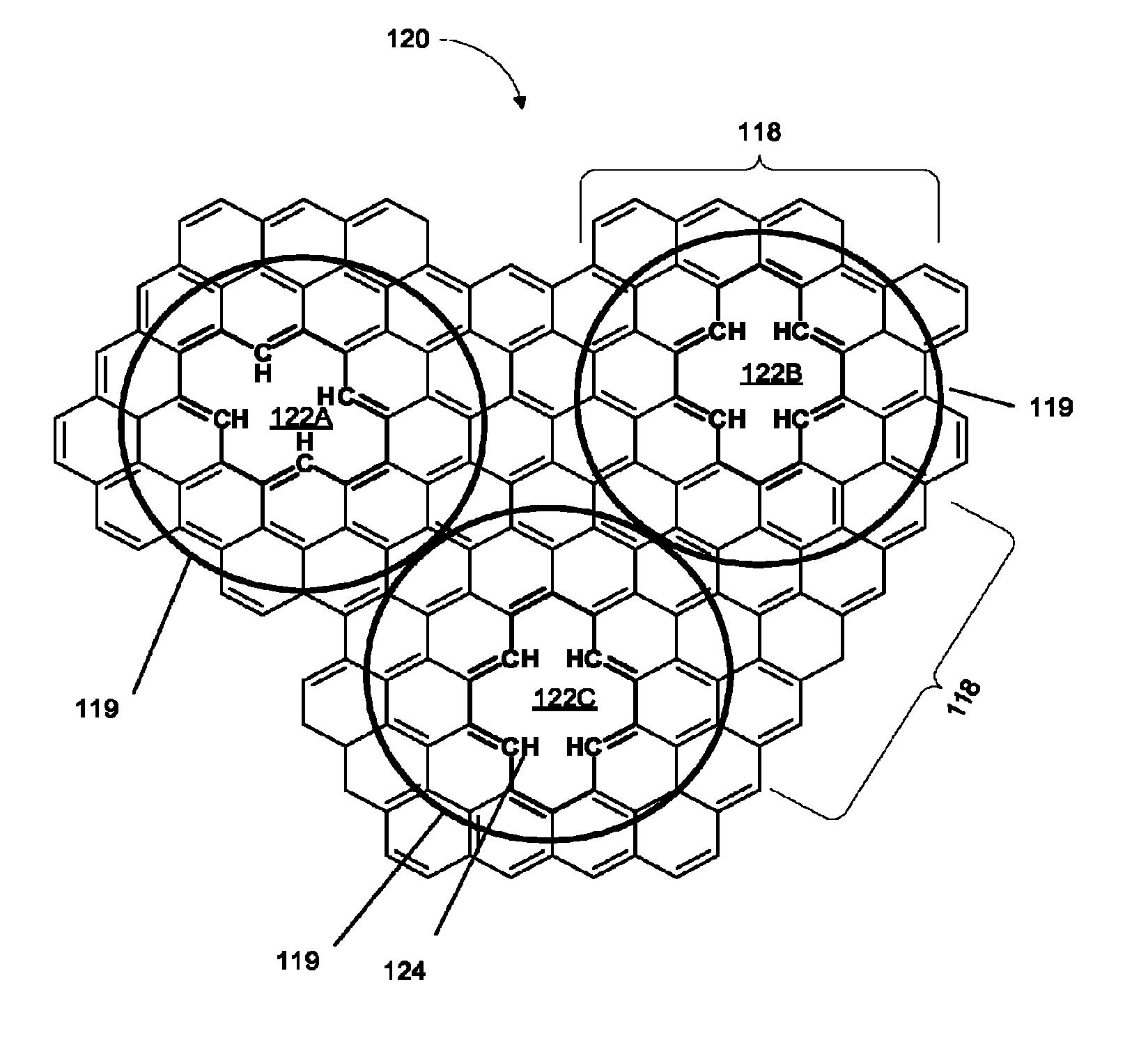

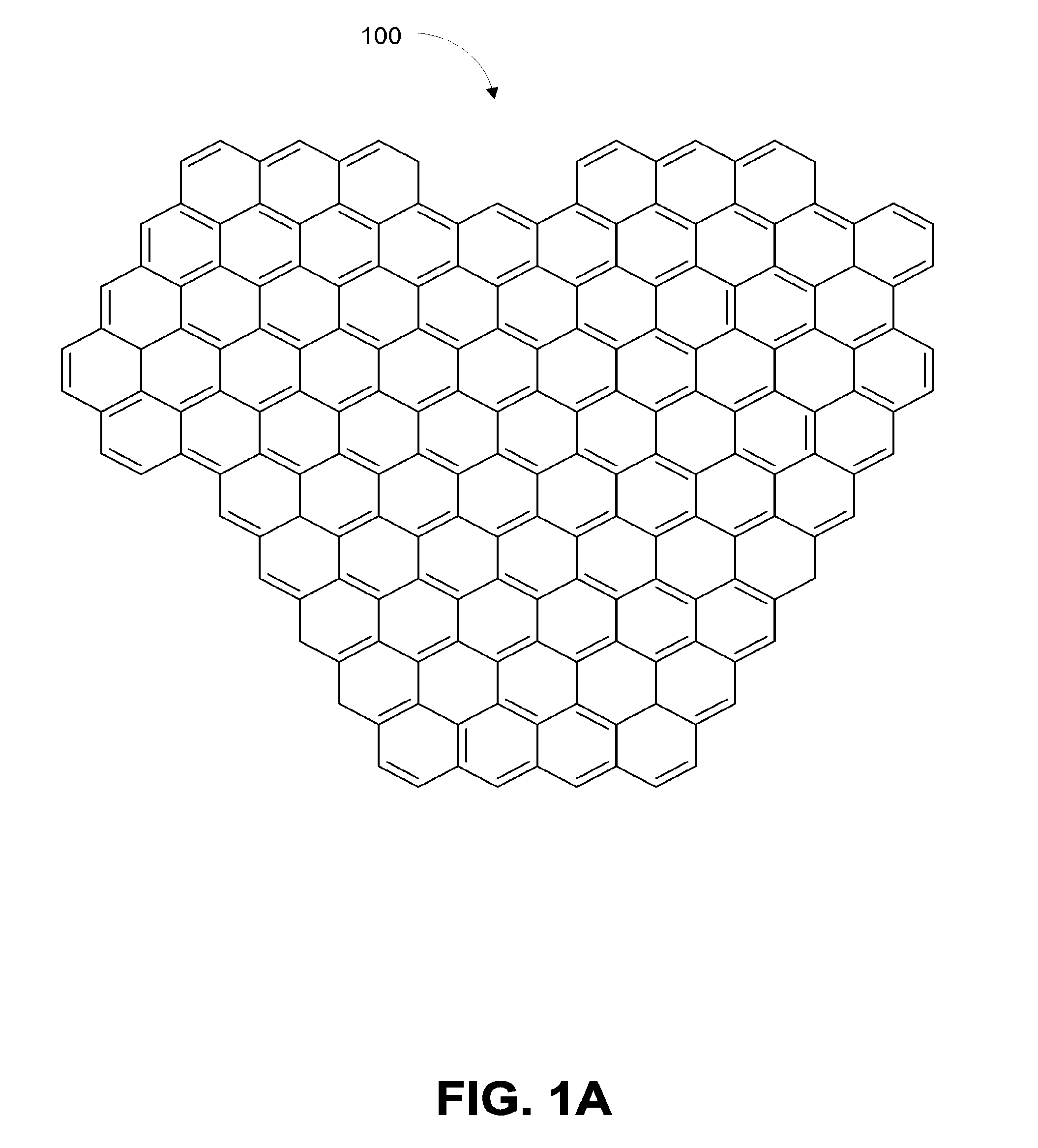

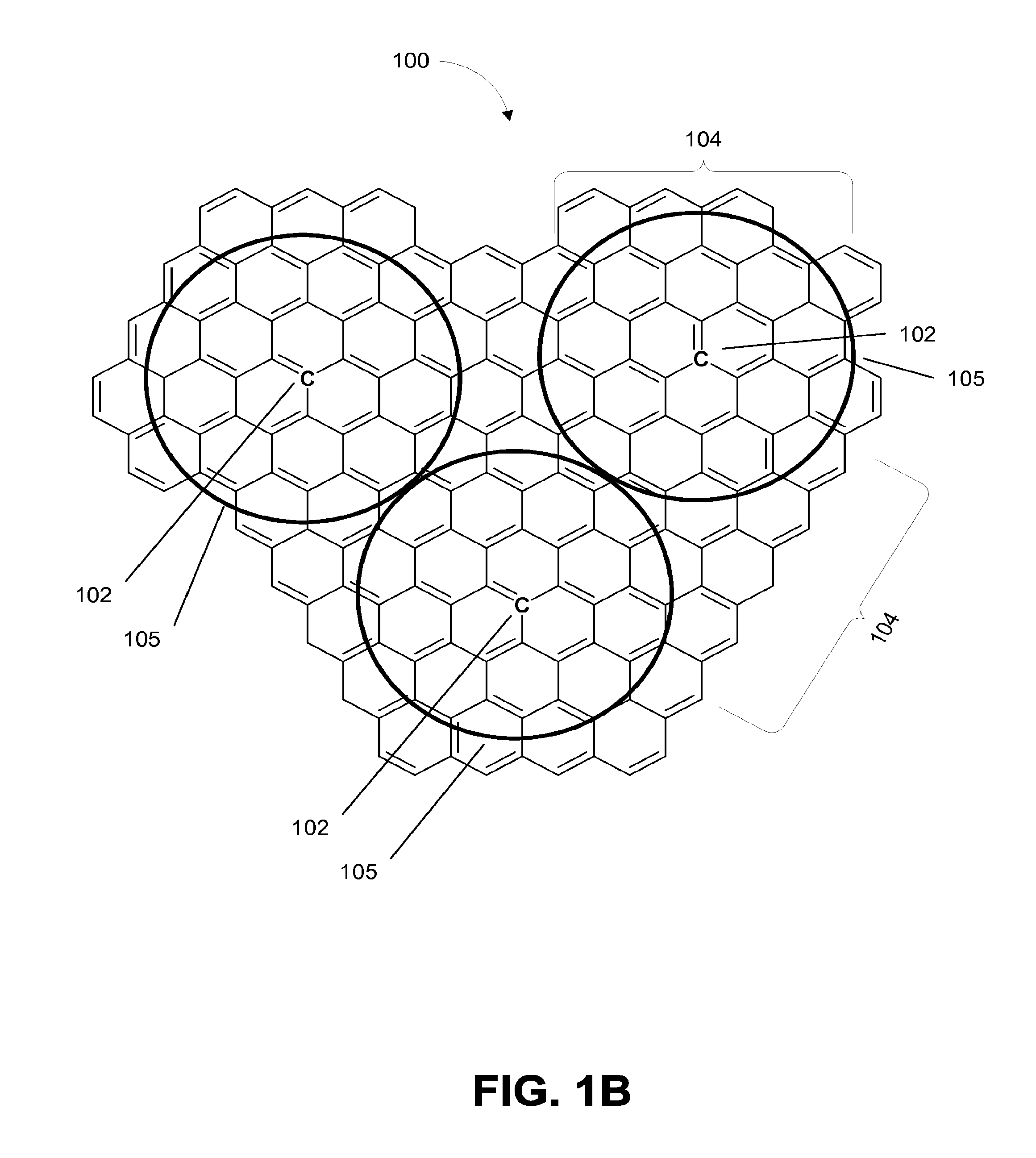

Graphene membrane with regular angstrom-scale pores

InactiveUS8979978B2Uniform pore sizeMaterial nanotechnologySemi-permeable membranesVacancy defectPore diameter

Technologies are generally described for perforated graphene monolayers and membranes containing perforated graphene monolayers. An example membrane may include a graphene monolayer having a plurality of discrete pores that may be chemically perforated into the graphene monolayer. The discrete pores may be of substantially uniform pore size. The pore size may be characterized by one or more carbon vacancy defects in the graphene monolayer. The graphene monolayer may have substantially uniform pore sizes throughout. In some examples, the membrane may include a permeable substrate that contacts the graphene monolayer and which may support the graphene monolayer. Such perforated graphene monolayers, and membranes comprising such perforated graphene monolayers may exhibit improved properties compared to conventional polymeric membranes for gas separations, e.g., greater selectivity, greater gas permeation rates, or the like.

Owner:EMPIRE TECH DEV LLC

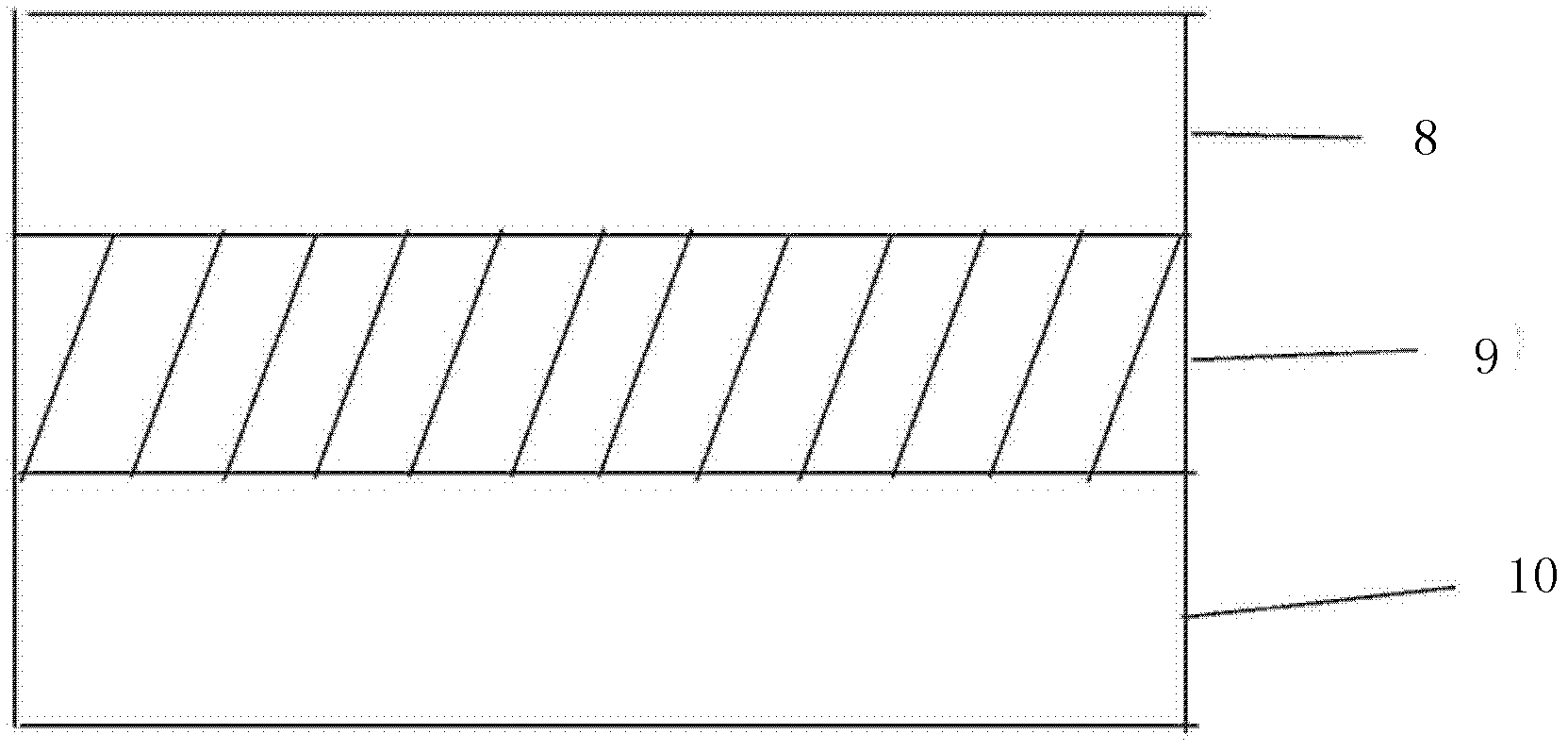

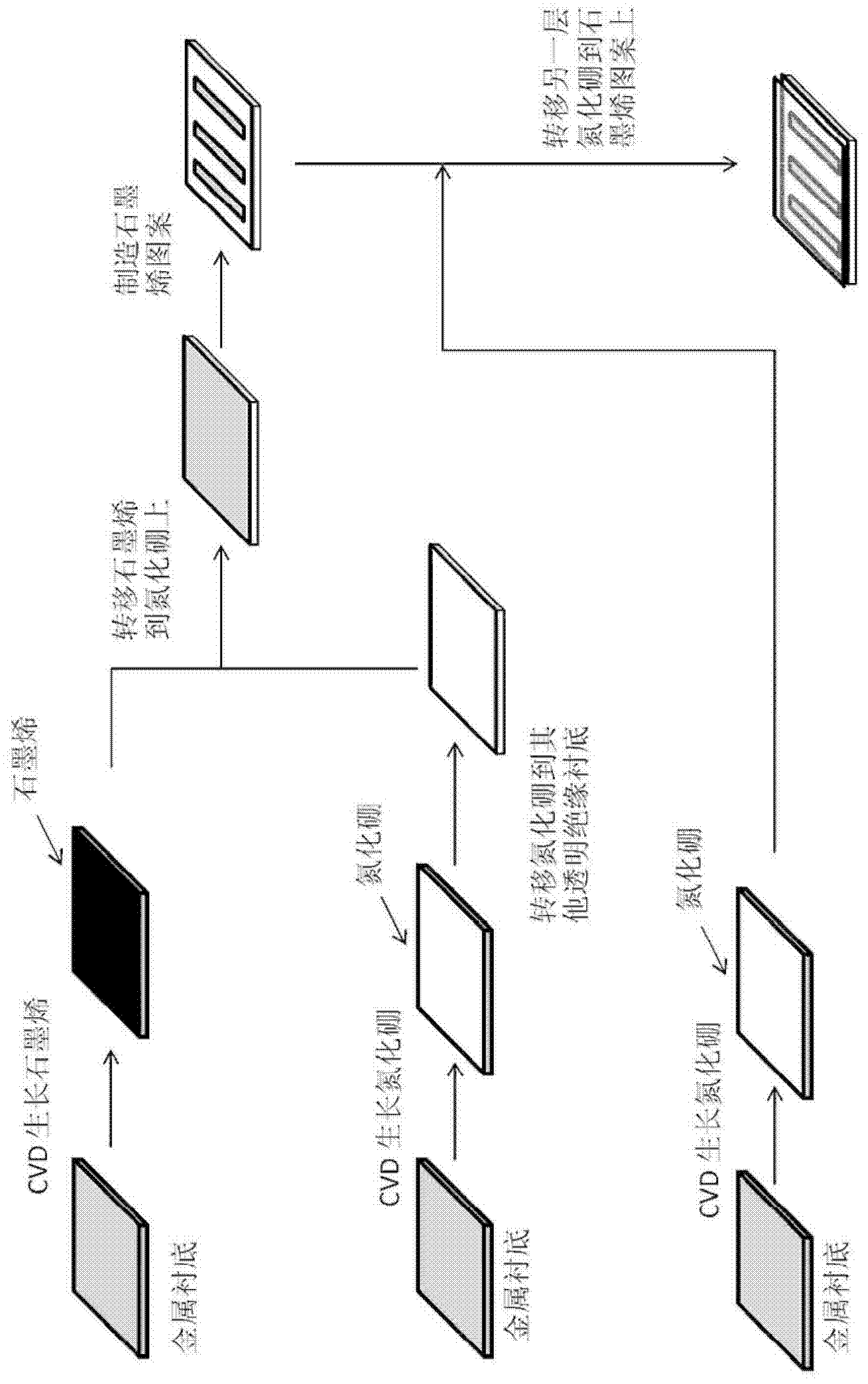

Boron nitride-graphene composite material, preparation method and purpose thereof

InactiveCN102496668AImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingCharge carrierBoron nitride

The invention relates to a boron nitride-graphene composite material which sequentially comprises a boron nitride film (8), a graphene film (9) and the boron nitride film (10). By using the composite material, under the condition that a carrier density is not increased, conductivity of the grapheme can be substantially increased. In addition, the invention also relates to a preparation method of the composite material and a purpose of preparing a transparent electrode.

Owner:金虎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com