Method for preparing flexible and transparent conductive graphene membrane

A graphene film, transparent and conductive technology, which is applied in the manufacture of cables/conductors, conductive layers on insulating carriers, circuits, etc., can solve problems such as limiting the preparation of graphite films, and achieve a simple and environmentally friendly preparation process. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

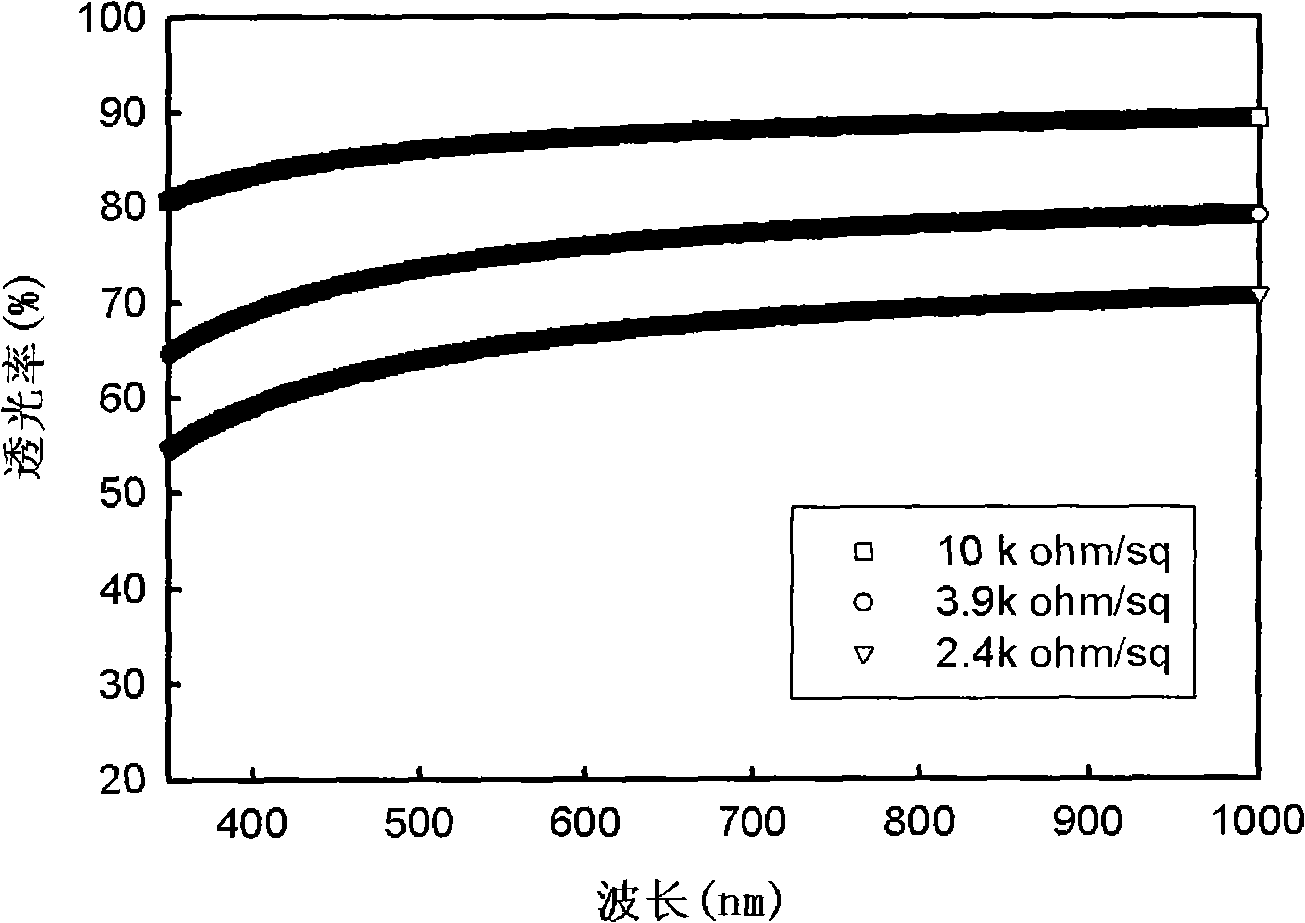

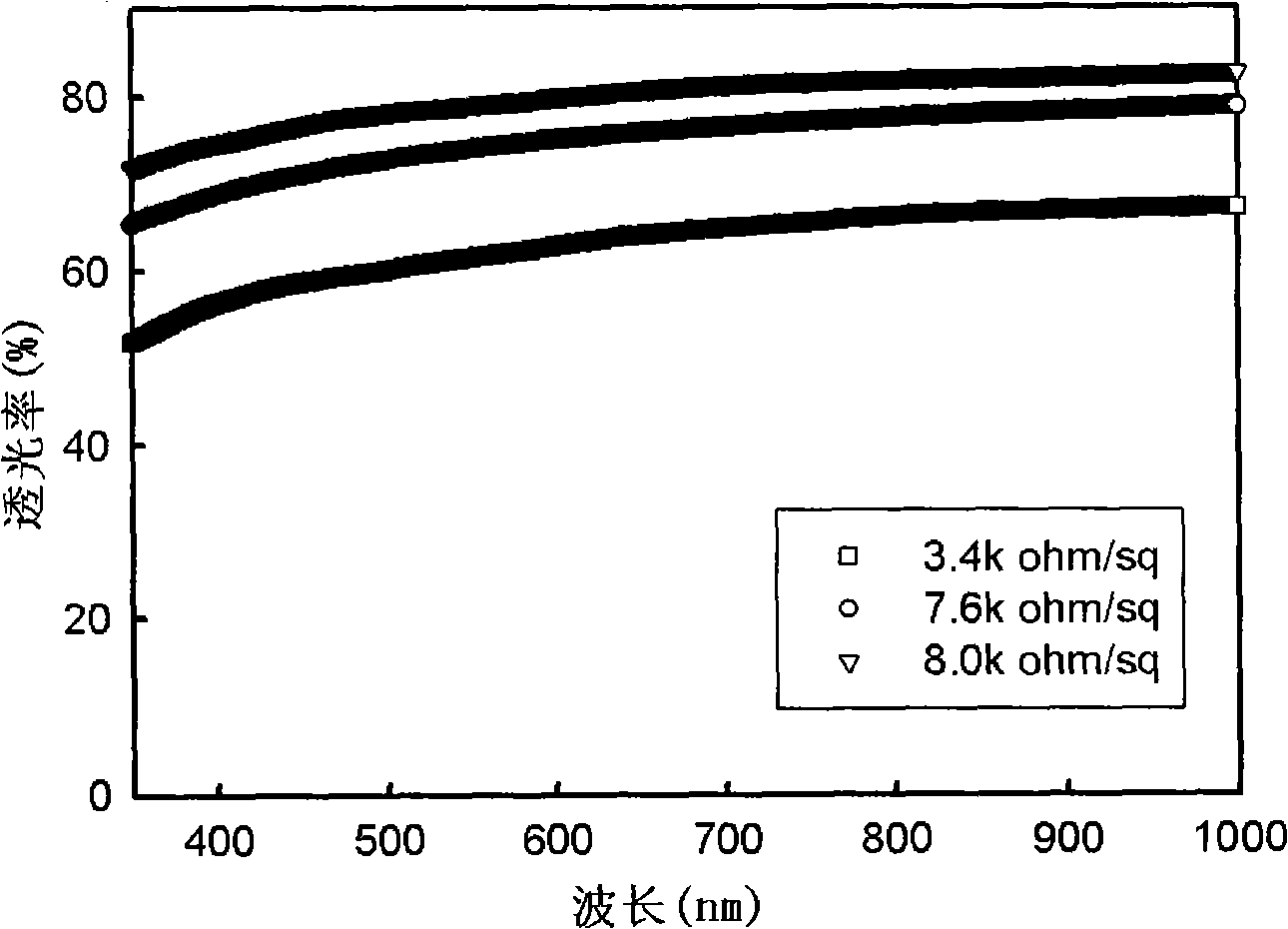

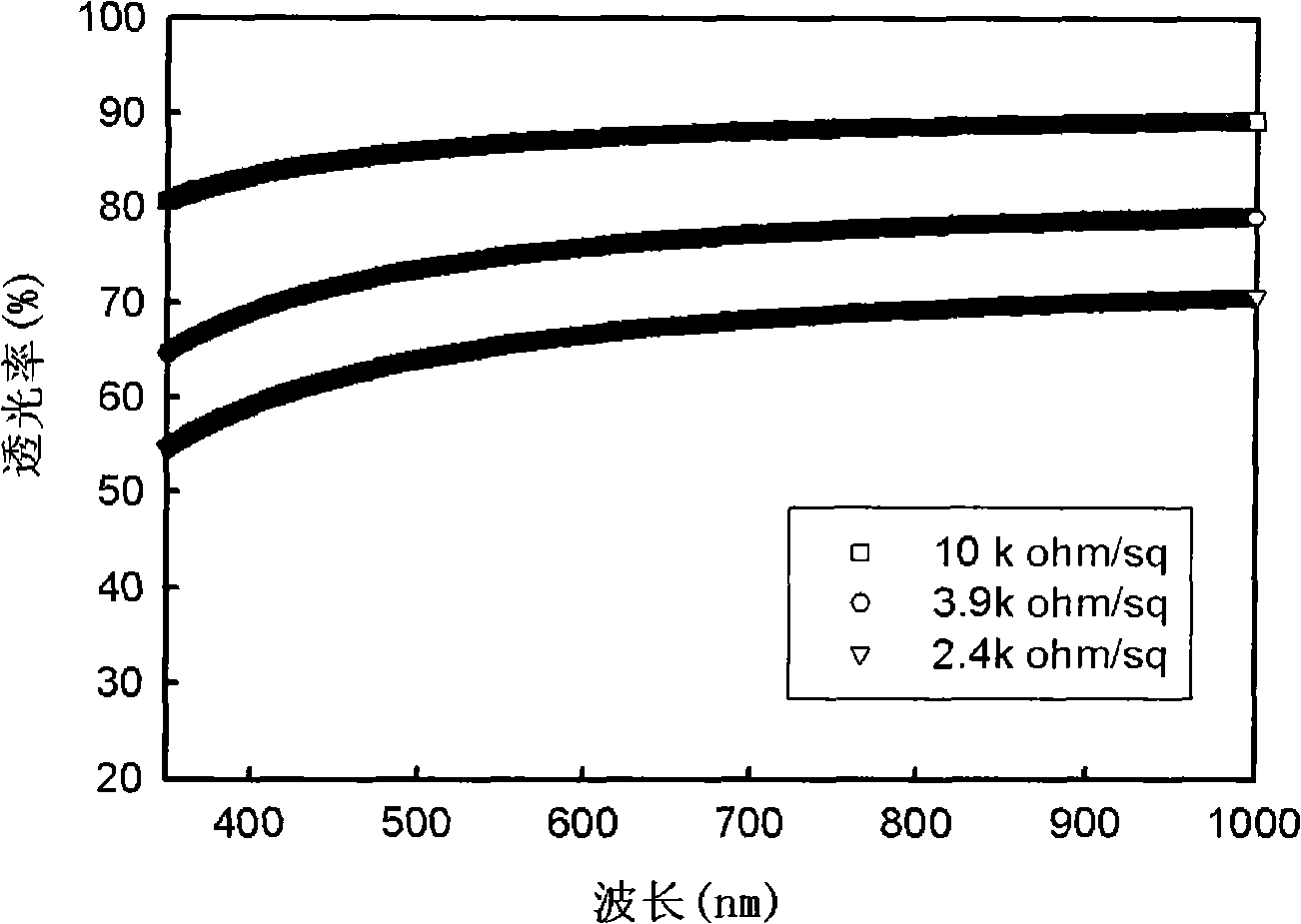

[0027] The preparation method of the flexible transparent conductive graphene film of the present invention includes the preparation of the high-temperature reduced graphene oxide film and the technology of transferring it to a flexible substrate.

[0028] The film material that prepares graphene oxide film among the present invention is large sheet of graphene oxide, and film substrate is SiO 2 / Si, the methods for preparing graphene oxide films include spin coating and LB self-assembly, etc. The area of the film depends on the size of the substrate, and the thickness of the film can be regulated by film forming technology.

[0029] The reduction method of the prepared graphene oxide film is high-temperature thermal annealing, and the condition is to use a mixed gas of argon and hydrogen as a protective gas at a temperature of 800 ° C to 1100 ° C, and heat treatment for 2 hours to obtain a conductive graphene film.

[0030] Before the prepared reduced graphene oxide film is...

Embodiment 1

[0040] Embodiment 1: the preparation method of flexible transparent conductive graphene film.

[0041] Graphene oxide preparation: 2.5g graphite, 1.9g NaNO 3 , 11.5g KMnO 4 and 85ml concentrated H 2 SO 4 After mixing, stir in an ice bath for 1 hour, then stir at room temperature for 2 days, and finally add 250ml of 5wt% concentrated sulfuric acid and 20ml of 30wt% H 2 o 2 Continue to stir for 2 days, centrifuge, and wash with deionized water, repeating this 8 times to obtain graphene oxide.

[0042] Preparation and reduction of graphene oxide film: First, the prepared graphene oxide is ultrasonically obtained to obtain a dispersed graphene oxide solution, and a very small amount of unexfoliated particles is removed by centrifugation at 3000rpm, and the centrifugation time is 30min. Secondly, the centrifuged upper layer solution was centrifuged again at a speed of 4000 rpm for 30 minutes to obtain a sediment containing a large sheet of graphene oxide, which was dispersed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com