Novel high-heat-conductivity graphene or graphite film/carbon fiber composite material preparation method

A technology of high thermal conductivity graphite and composite materials, which is applied in the field of preparation of new high thermal conductivity graphene or graphite film/carbon fiber resin matrix composite material laminates, and can solve problems such as difficult engineering applications, limited applications, and shortages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

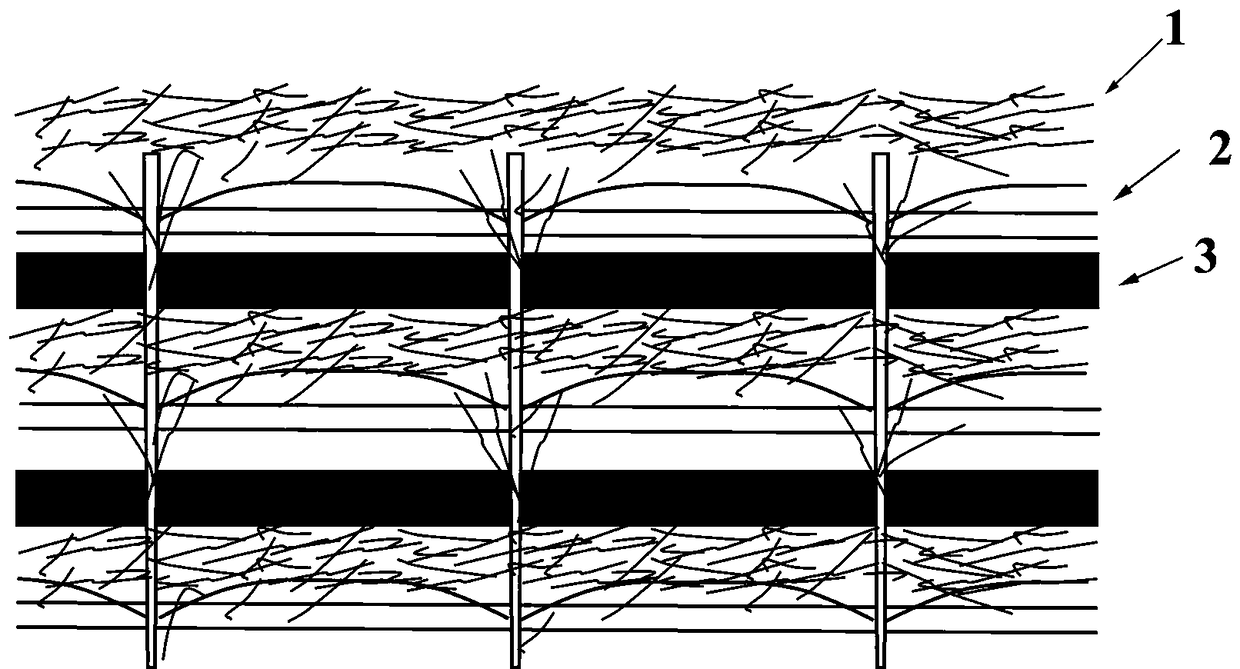

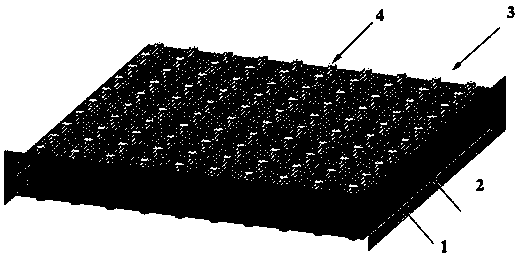

[0024] (1) Cut the 25μm thick graphene film into a size of 35mm×35mm, and use an industrial punch to punch the high thermal conductivity graphene film in advance to obtain a network graphene film, and obtain a 0.1-1mm diameter on the graphene film. Uniform voids. Here, 0.5 mm array punches are used to obtain uniformly distributed holes with a diameter of 0.5 mm on the graphene film. After the end, it is dried in a vacuum oven at 60 ° C for 60 min;

[0025] (2) Prepare the epoxy resin main agent, curing agent and diluent according to the ratio of 10:25:15 into a solution, stir on a magnetic stirrer for 5 minutes, and then evenly coat the resin solution on the network graphene film surface, to obtain a prepreg with a thickness of 0.03-0.1;

[0026] (3) Cut the carbon fiber resin prepreg (resin content is 30-40wt%, single-layer thickness is about 0.02mm) into 100mm×100mm size by using a paper knife and ruler, and put the cut prepreg Sealed in a ziplock bag;

[0027] (4) Spread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com