Preparation method and application of graphene oxide/MXene composite film

A graphene and composite membrane technology, applied in the field of composite membranes, can solve problems such as small flux, and achieve the effect of promoting promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

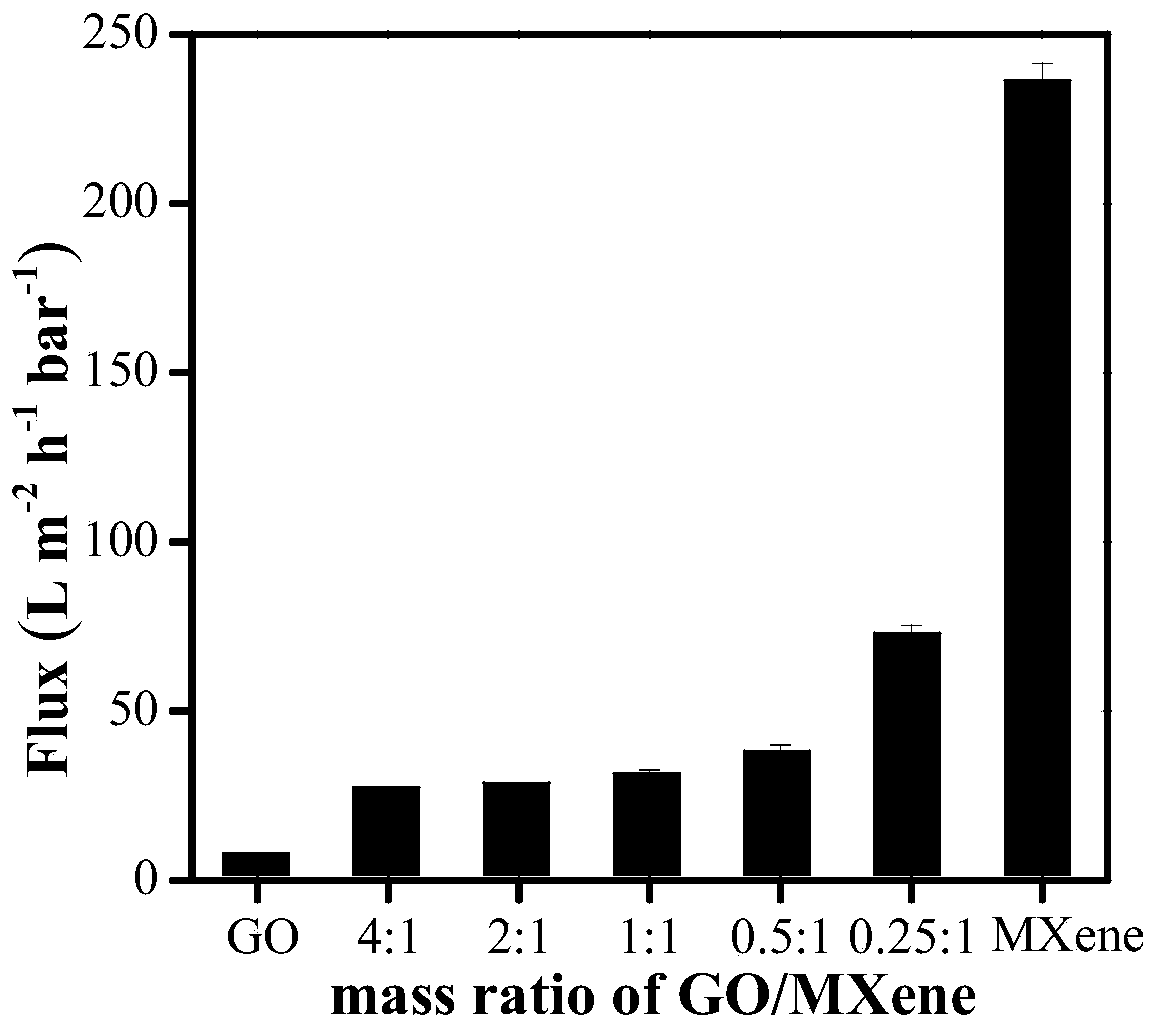

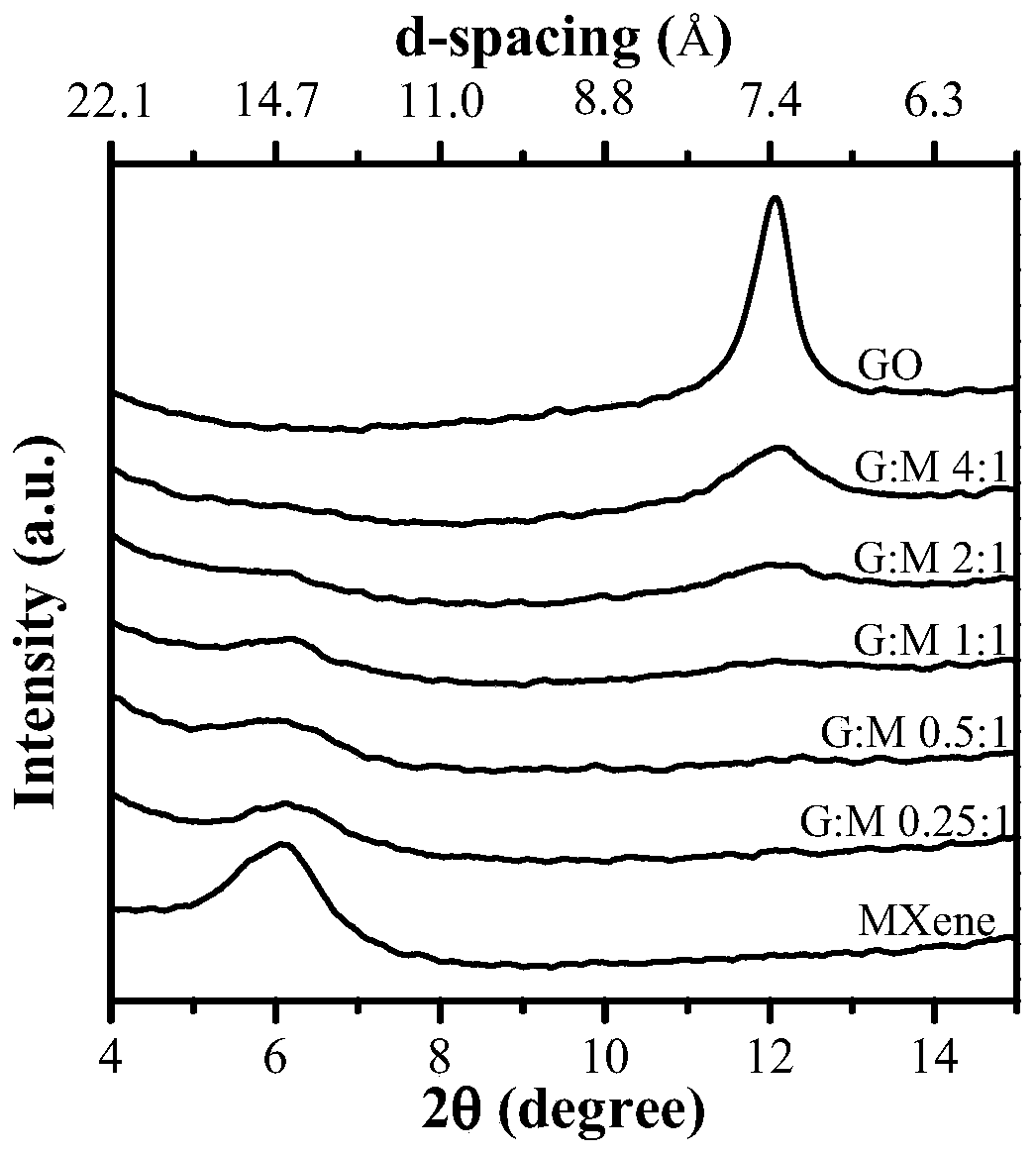

[0037] Preparation of Graphene Oxide (GO) / MXene Membranes with a Composite Ratio of 1:1

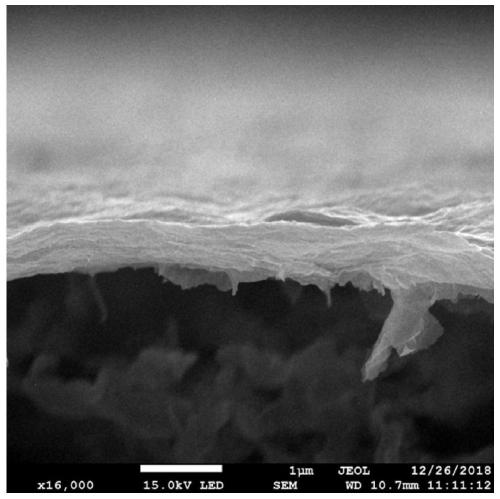

[0038] Take 1g NaNO 3 Add to the beaker, pour 46mL concentrated H 2 SO 4 , placed in a water bath and stirred, then added 2g flake graphite with a mesh number of 325, cooled to 5°C and stirred for 1h; slowly added 6g KMnO 4 , add in batches for 1 hour; then raise the temperature to 35°C and react for 2 hours, slowly add 92mL deionized water, react at 98°C for 15 minutes, and finally add an appropriate amount of hydrogen peroxide to react for 30 minutes, centrifuge the obtained product, first use 5% HCl Solution cleaning, centrifuging at 4000rpm for 8min three times, pouring off the supernatant, and then washing with deionized water, centrifuging at 8000rpm for 8min three times until the pH is neutral, pouring off the supernatant, and finally centrifuging at 12000rpm for 10min to take The upper layer solution was sonicated for 1 h, freeze-dried to a solid, and 100 mg of graphene oxide s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com