Patents

Literature

177results about How to "Increased pure water flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinylidene fluoride hollow fiber film and preparation method thereof

ActiveCN101590374AProper temperature regulationExtraction is easy and fastMembranesSemi-permeable membranesFiberPolyvinylidene difluoride

The invention discloses a polyvinylidene fluoride hollow fiber film and a preparation method thereof. The polyvinylidene fluoride hollow fiber film comprises the following components by weight percent: 20-60% of polyvinylidene fluoride resin, 10-50% of organic pore-forming agent, 1-30% of inorganic pore-forming agent and 5-30% of solvent. The preparation method comprises the following steps: mixing, squeezing, cooling, stretching, extracting the organic pore-forming agent and the inorganic pore-forming agent, and thermally shaping. The obtained polyvinylidene fluoride hollow fiber film has the advantages of high strength, good performance, better hydrophilicity, simple preparation process and energy saving.

Owner:江苏美能膜材料科技有限公司

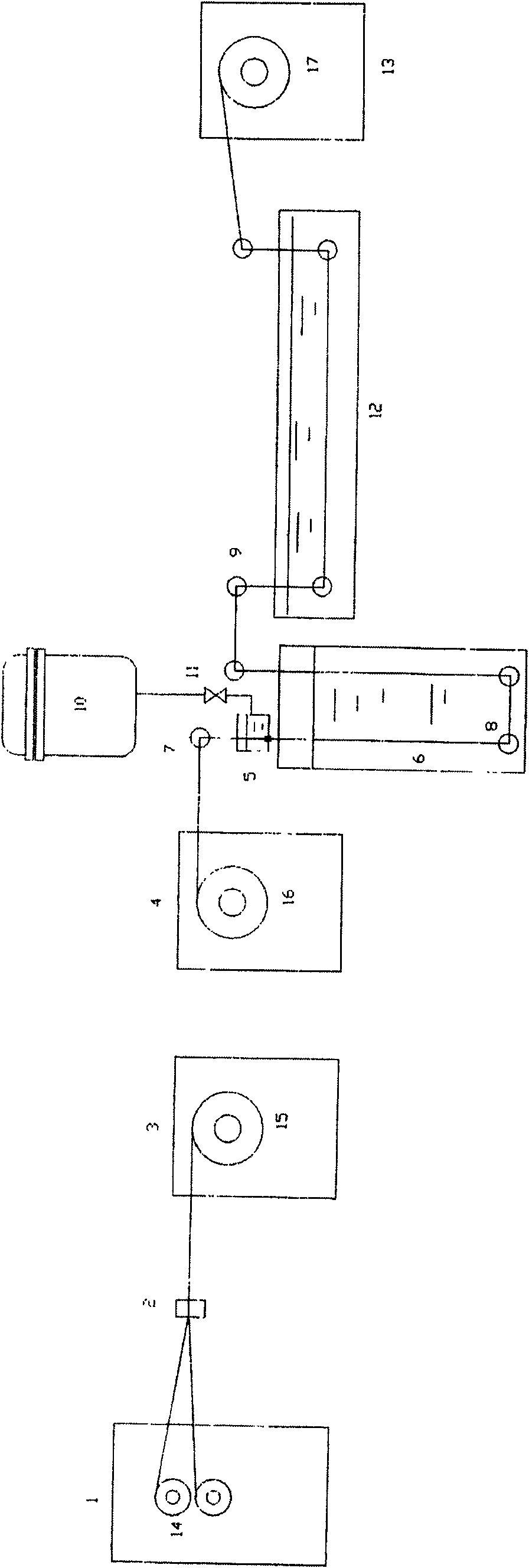

Preparation method of layer-by-layer self-assembled hollow fiber forward osmosis membrane

ActiveCN108325400ALess materialSimple production processSemi-permeable membranesGeneral water supply conservationHollow fibreFiber

The invention discloses a preparation method of a layer-by-layer self-assembled hollow fiber forward osmosis membrane. The preparation method comprises the steps of: preparing hollow fiber forward osmosis base film, modifying hollow fiber ultrafiltration base film, repeating layer-by-layer assembly of polycation and polyanion layers, performing interface cross-linking polymerization for preparinga selective functional layer, conducting moisturizing, and carrying out treatment and storage so as to prepare the layer-by-layer self-assembled hollow fiber forward osmosis membrane. The surface of the hollow fiber self-support base film which is prepared by using a phase conversion method is activated firstly, layer-by-layer assembly of polycation and polyanion is repeated on the surface of thefilm so as to form an functional polarization layer for an electrolyte solution, and the polyamide selective layer is prepared through interfacial chemical cross-linking polymerization. The prepared hollow fiber forward osmosis membrane has a controllable thickness and an internal polarization layer with a high charge capacity, and the internal concentration polarization phenomenon can be alleviated effectively during the forward osmosis process; therefore, the hollow fiber forward osmosis membrane can simultaneously obtain high flux and low reverse salt flux, has high filtration separation efficiency, easy cleaning and a long service life, and can be widely applied to seawater desalination and concentration and desalination of brine.

Owner:西安金藏膜环保科技有限公司

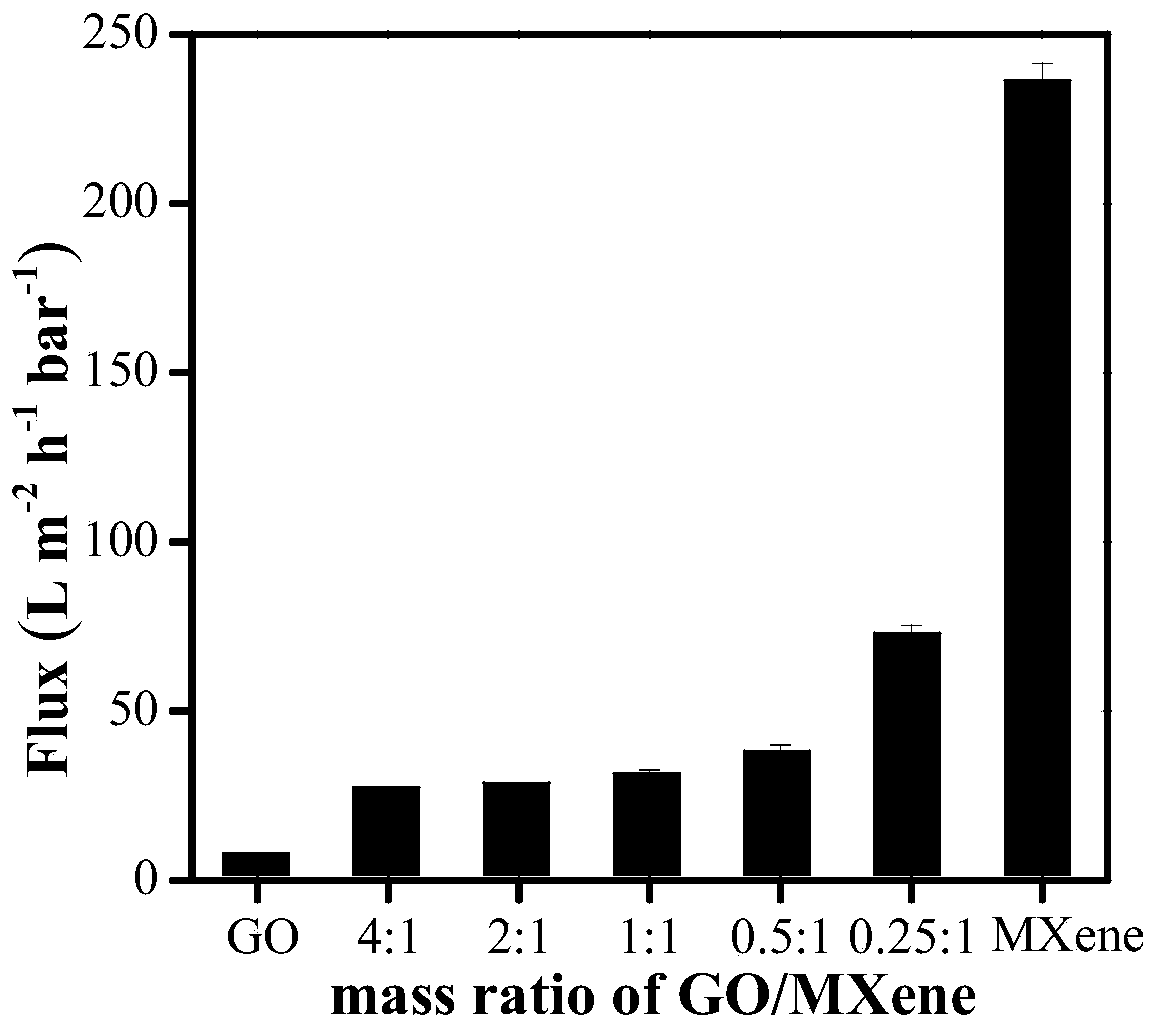

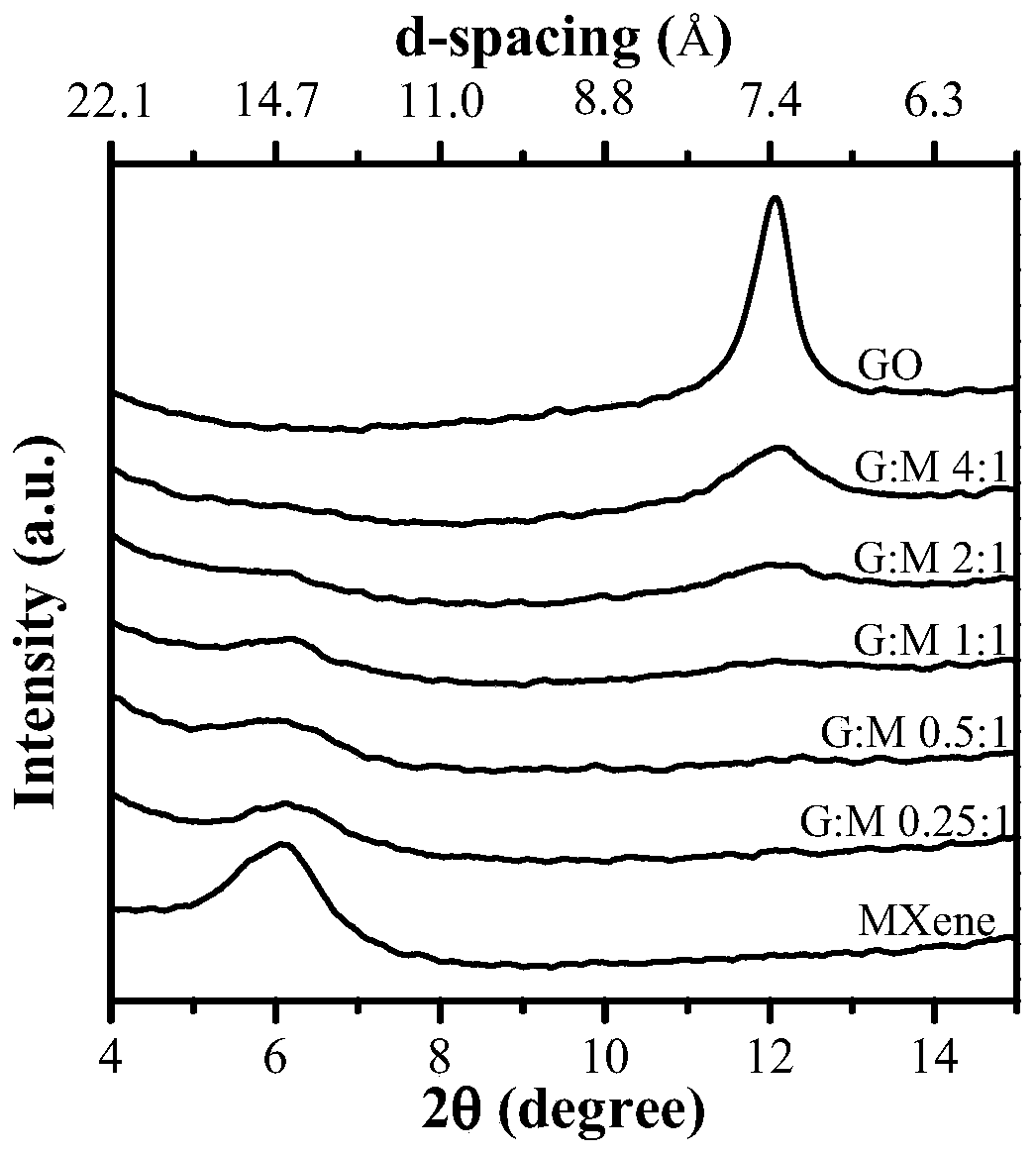

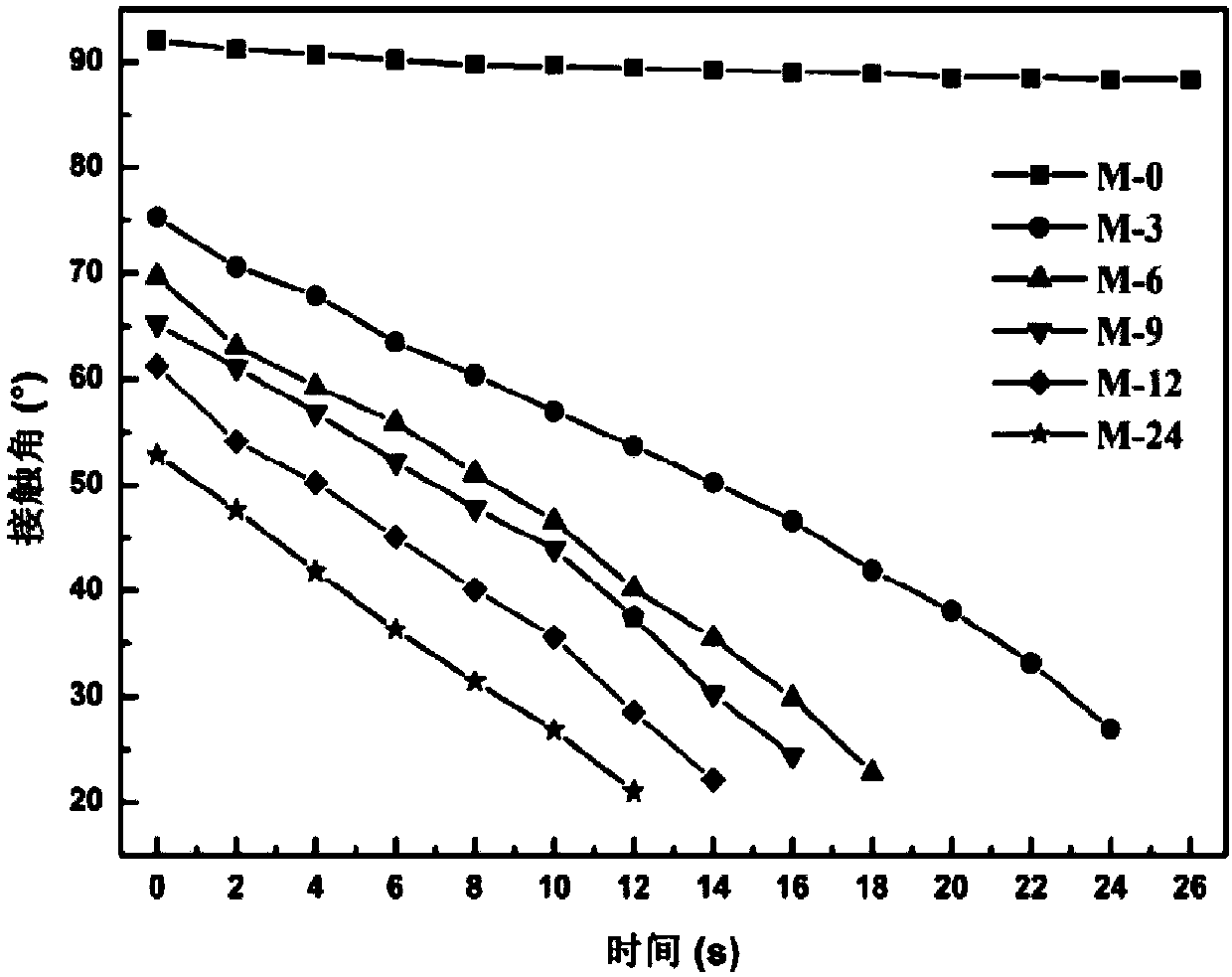

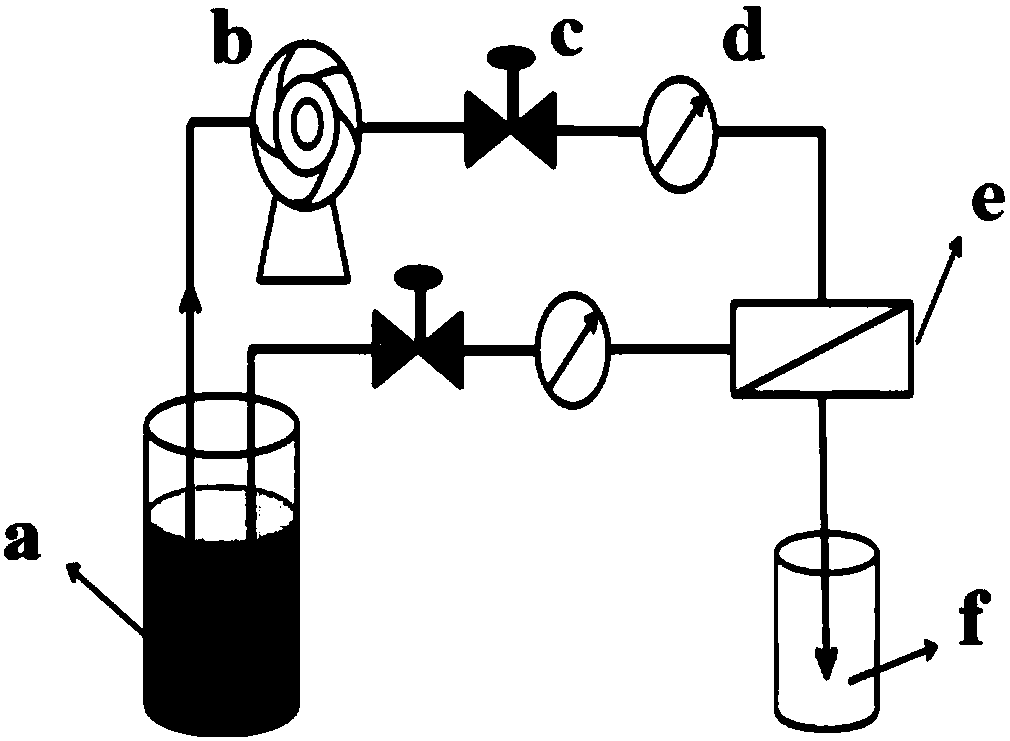

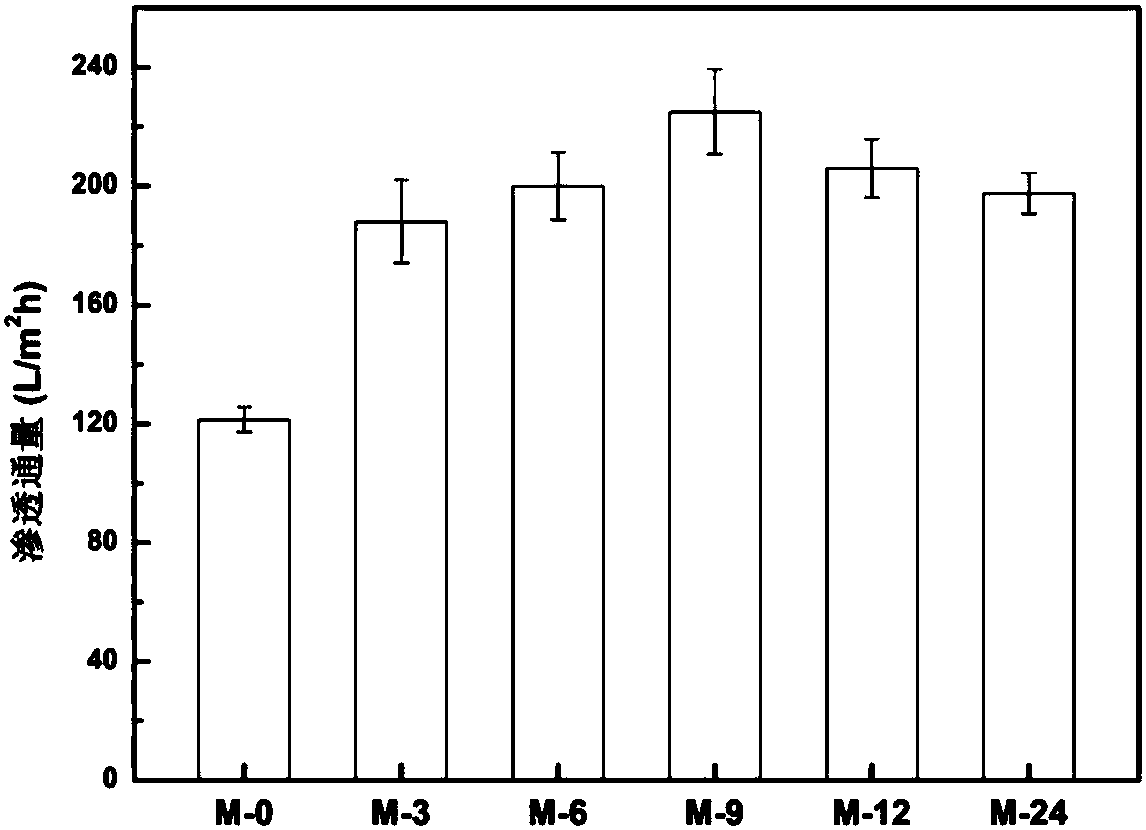

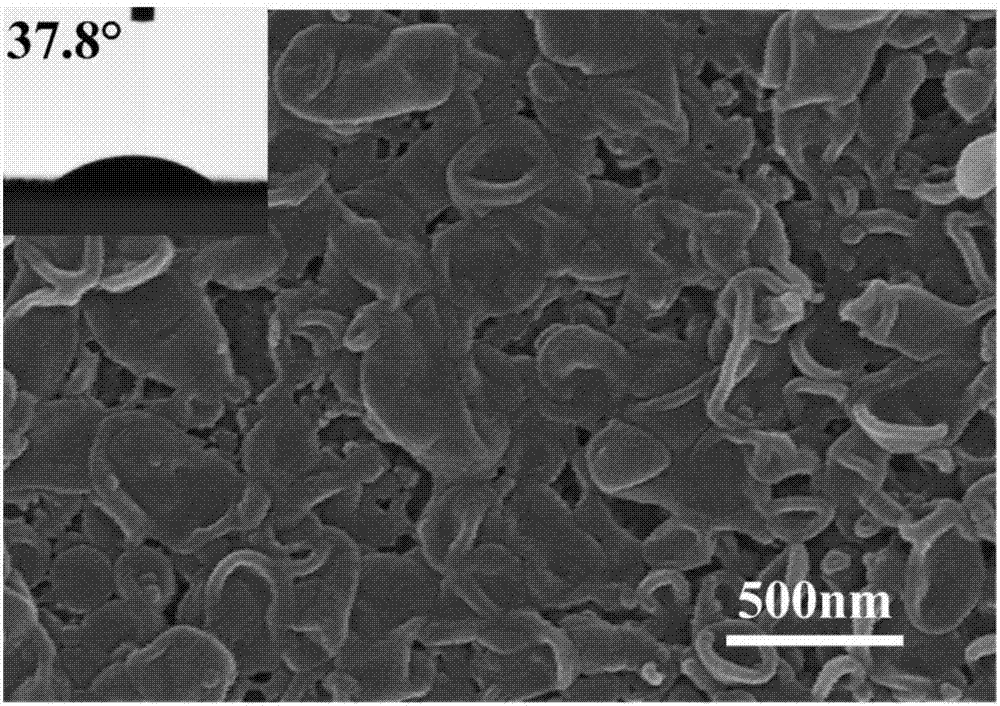

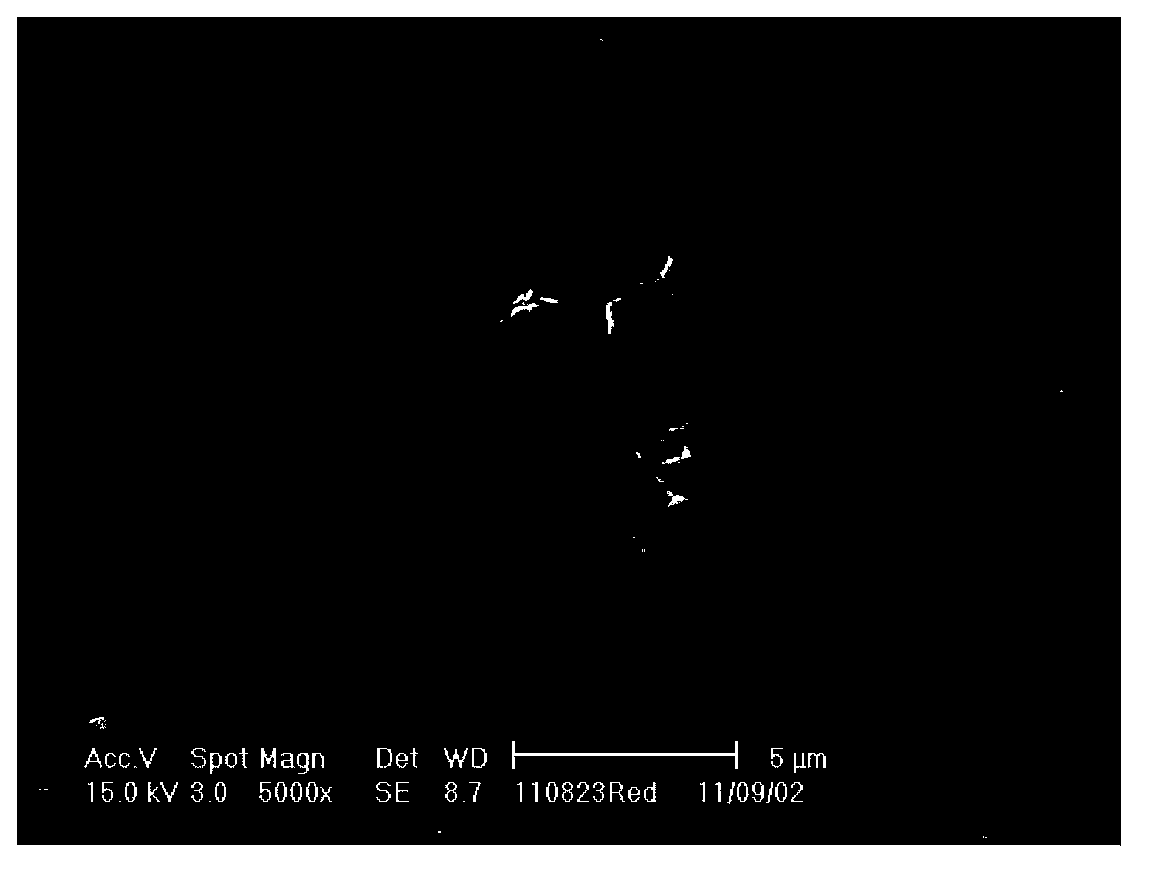

Preparation method and application of graphene oxide/MXene composite film

InactiveCN110124529AIncreased pure water fluxHigh removal rateSemi-permeable membranesOther chemical processesComposite filmMicrofiltration membrane

The invention provides a preparation method and application of a graphene oxide / MXene composite film. The method comprises the following steps: mixing a graphene oxide solution and an MXene solution in proportion to obtain a mixed solution, carrying out ultrasonic treatment on the mixed solution, pouring the solution into a suction filtration bottle with a microfiltration membrane, and carrying out vacuum filtration treatment for compounding and supporting the two two-dimensional materials on the surface of the microfiltration membrane to obtain the composite membrane. The pure water flux of the graphene oxide (GO) / MXene composite membrane is far greater than that of a pure graphene oxide membrane; with the increase of the MXene doping proportion, the flux is in an increasing trend; the removal rate of the composite membrane to small molecular dyes in water is up to 99.5% or above; the method is simple, easy to operate, easy to use on a large scale and beneficial to popularization.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

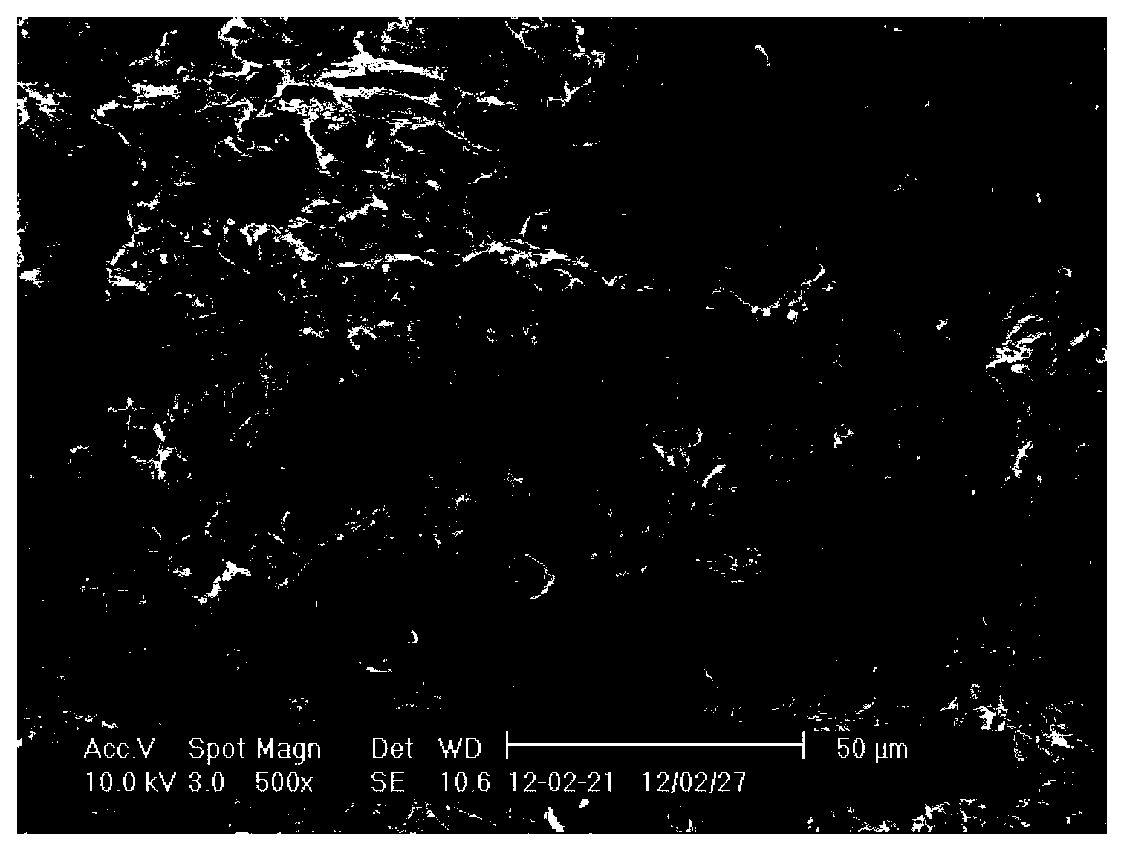

Modification film of polyvinylidene fluoride and preparation method thereof

The present invention relates to a polyvinylidene flouride modified film and its prparation method. Said invention is prepared by using (by wt%) 14-20% of high-molecular material dissolved in organic solvent and adding 1-6% of organic additive, 0.01-4% of inorganic additive and 0.01-0.9% of titanuim dioxide, whose average grain size is 1-20 nm. Said invention improves the hydrophilic property of polyvinylidene flouride, and the pure water flux of said polyvinylidene flouride film can be raised.

Owner:HARBIN INST OF TECH

Plant polyphenol modified polymer membrane as well as preparation method and application thereof

ActiveCN107670513AAvoid performance damageAvoid pollutionMembranesSemi-permeable membranesHydrophilic coatingPolymer science

The present invention discloses a plant polyphenol modified polymer membrane as well as a preparation method and application thereof, in particular relates to the field of modified polymer membranes with anti-fouling properties. In the prior art, due to low surface energy of the polymer membrane, the polymer membrane is susceptible to contamination with proteins, oils and the like and causes a series of temporary or permanent pollution problems. The polymer membrane provided by the invention utilizes the super-strong adhesive ability of plant polyphenols and the coordination of polyphenols andmetal ions to build a hydrophilic coating on the surface of a hydrophobic polymer membrane. The polymer membrane provided by the invention has the advantages of simplicity, high efficiency, mild reaction condition and strong practicability. The controllable hydrophilic modification of a hydrophobic polymer can be realized by changing the conditions of the dip-coating time, the concentration of aplant polyphenol mixed solution, the pH, the temperature and the like, and a high permeation flux can be maintained in the course of cross-flow continuous work, so that the polymer membrane has a verygood application prospect in the field of water treatment. The invention also opens up an effective way, which is simple and easy to operate and has strong universality, for modification of polymer membranes under mild conditions.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of gradient silicon carbide ceramic membrane for water purification

ActiveCN104174298AHigh connected porosityHigh strengthSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisBreaking strengthPore distribution

The invention belongs to the fields of material science and engineering, and particularly relates to a preparation method of a gradient silicon carbide ceramic membrane for water purification. The method comprises the following steps: (1) preparing a silicon carbide ceramic support body; (2) preparing a silicon carbide intermediate layer; and (3) preparing a silicon carbide film, and finally preparing the gradient silicon carbide ceramic membrane for the water purification. The method has the beneficial effects that the prepared silicon carbide ceramic membrane material is high in communicating porosity, high in strength, high in pure water flux, and high in strong acid and alkali resistance; the pore distribution is in a gradient shape, different levels of connection surface are high in bonding strength, the method is simple and convenient to operate, and the gradient silicon carbide ceramic membrane is high in yield. According to the prepared gradient silicon carbide ceramic membrane material for water purification, the breaking strength is greater than 30MPa, the pure water flux is greater than 5m<3> / (m<2>h), and the range tolerance of the pH value is 0-14.

Owner:湖北迪洁膜科技有限责任公司

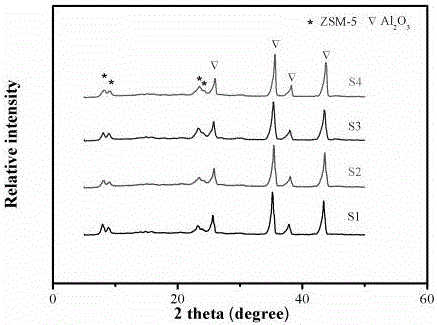

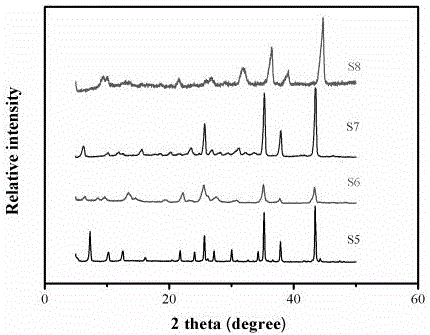

Preparation method and application of hierarchical porous molecular sieve membrane

ActiveCN106378013AIncreased pure water fluxImprove interception effectSemi-permeable membranesMembranesMolecular sieveSynthesis methods

The invention relates to a preparation method and application of a hierarchical porous molecular sieve membrane. A mesoporous structure guiding agent is added to limit the growth of a molecular sieve crystal, and is subjected to self-assembly in a crystallization process of the molecular sieve crystal, so as to generate a mesoporous structure. The hierarchical porous molecular sieve membrane is synthesized by using a seed crystal inducing secondary nucleation mechanism and a hydrothermal one-step synthesis method; synthesis conditions are mild and controllable, the simplicity in preparation and good repeatability are realized, energy consumption is reduced, and the cost is reduced. The hierarchical porous molecular sieve membrane prepared by adopting the method shows good retention performance, and the retention molecular weight is controllable between 200 and 500000 Da. The method for preparing the hierarchical porous molecular sieve membrane, provided by the invention, can be used for synthesizing the hierarchical porous molecular sieve membrane with other micropore skeleton structures, and has high cost performance and a broad industrial production prospect; the application of the preparation method also can be popularized to the field of catalysis.

Owner:NANJING TECH UNIV

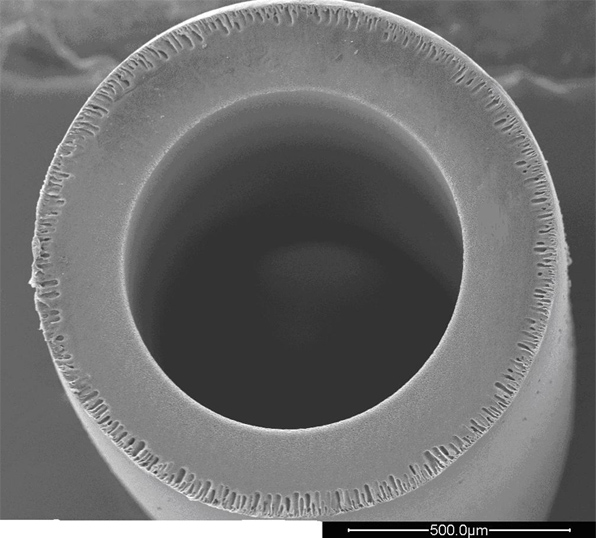

Polyvinylidene-fluoride hollow fibre membrane and preparation method thereof

InactiveCN102836645AEasy extractionPrevent shrinkage deformationSemi-permeable membranesHollow filament manufactureFiberHollow fibre membrane

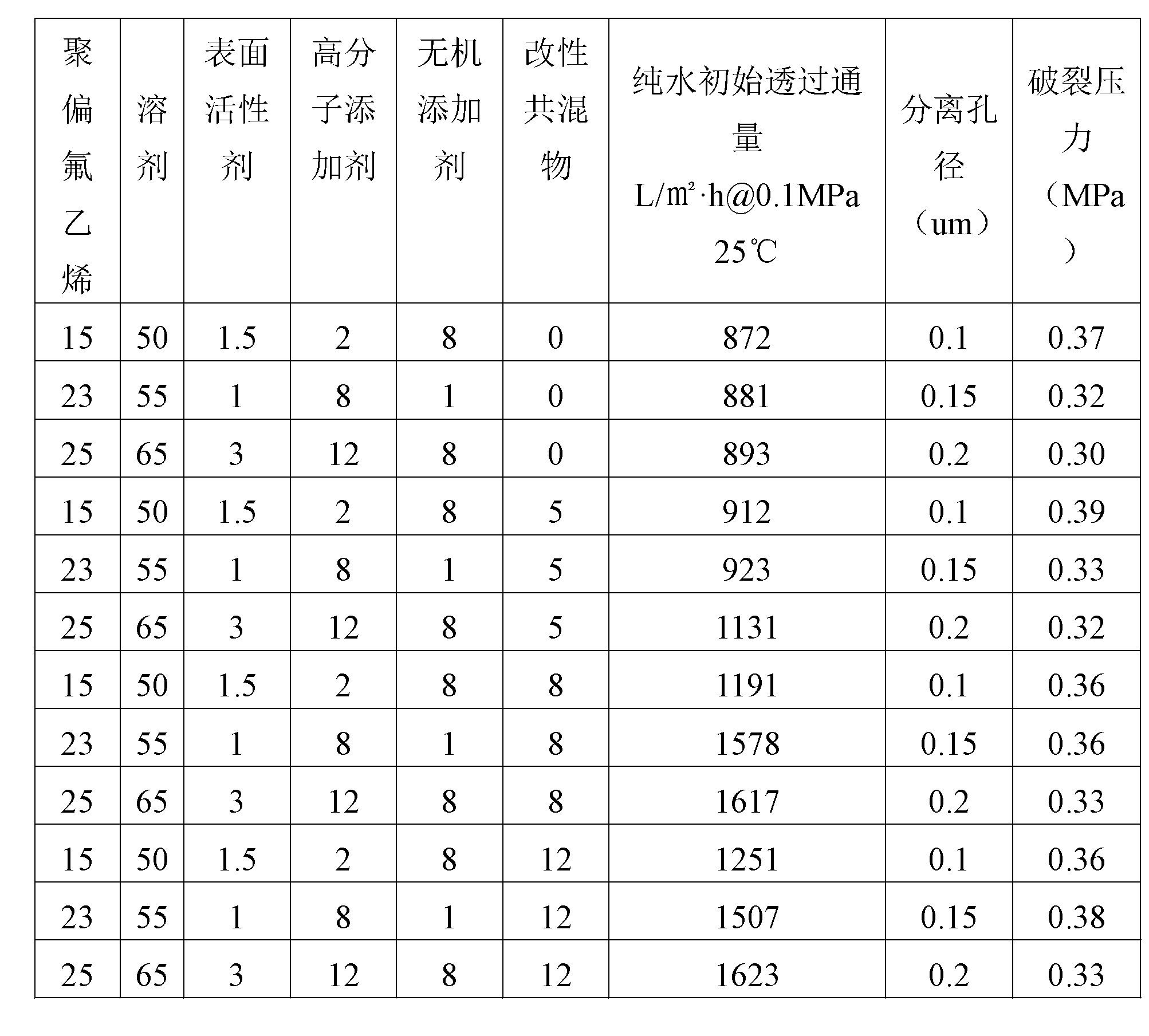

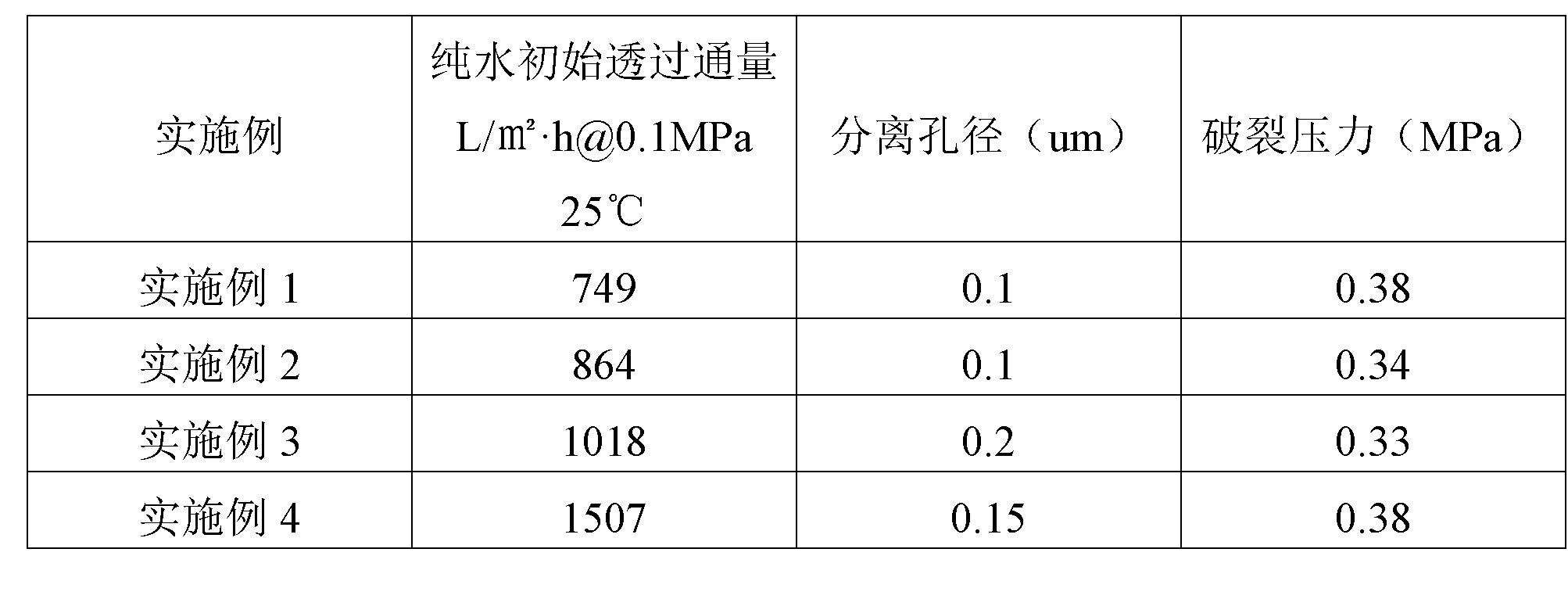

The invention discloses a polyvinylidene-fluoride hollow fibre membrane and a preparation method thereof. Calculated according to parts by weight, the polyvinylidene-fluoride hollow fibre membrane is mainly prepared by the following components: 15 to 25 parts of polyvinylidene fluoride, 50 to 80 parts of solvent, 1 to 3 parts of surfactant, 2 to 12 parts of polymeric additive, 1 to 8 parts of inorganic additive and 1 to 12 parts of modified blend. By utilizing the simultaneous action of two modes of organic blending and inorganic adding according to the polyvinylidene-fluoride hollow fibre membrane and the preparation method thereof, the hydrophilcity of the polyvinylidene-fluoride hollow fibre membrane is obviously improved, and the pollution resistance can be obviously reinforced; and the pure water flux of the polyvinylidene-fluoride hollow fibre membrane is further enhanced by selecting and regulating the raw materials and the mixture ratio of the modified blend and the inorganic additive so as to obtain the permanently hydrophilic modified polyvinylidene-fluoride hollow fibre membrane.

Owner:CHINA HUADIAN ENG

Metal ion-carried nerchinskite nano tube/polyether sulfone hybridized antibacterial membrane and preparation method thereof

ActiveCN102049204AIncreased pure water fluxGood antibacterial effectSemi-permeable membranesAnti bacterialSulfone

The invention discloses a preparation method of a metal ion-carried nerchinskite nano tube / polyether sulfone hybridized antibacterial membrane, and belongs to the technical field of membranes. The invention is characterized in that: the antibacterial property and the contamination resistance of the membrane are improved by using the antibacterial property of a metal ion-carried nerchinskite nano tube and the hydrophilic property of the nerchinskite nano tube under the condition that the water flux and the interception rate of the polyether sulfone ultra-filtration membrane are not reduced. Meanwhile, the preparation method and preparation equipment are simple. The membrane serving as a novel ultra-filtration membrane is expected to be applied in wastewater treatment more widely.

Owner:ZHENGZHOU UNIV

Polymetafluoroethylene/organic clay nanometer composite ultra-low pressure ultrafiltering membrane and its preparation method

InactiveCN101053784AIncreased pure water fluxSolve pollutionSemi-permeable membranesFiberUltrafiltration

The invention relates to a polyvinylidene fluoride / organic clay nano composite ultralow pressure ultrafiltration membrane and a preparation method thereof, and to a nano composite membrane and a preparation method thereof. The invention resolves the problem that the existing membrane material has a bad hydrophilicity and a low surface energy and is easily be polluted, and the existing modified method has the disadvantage that it can not run under ultralow pressure and the running cost is high. It is composed of 20-50 shares by weight of PVDF, 0.1-20 shares by weight of organic clay, 10-1000 shares by weight of disperse medium, 10-50 shares by weight of organic addition agent and 0.1-30 shares by weight of inorganic additive. The invention adds the organic clay, inorganic additive, organic addition agent and PVDF in turns into the disperse medium to get the casting film liquor after 3-48 hours dissolution and 5-24 hours stewing deaeration; plate membrane, tubular type membrane, hollow fibre membrane, and comparable membrane module can be prepared. The invention can change the hydrophilicity of the composite membrane, resolve the pollution of exiting membrane effectively, increase the water flux and retain ratio, extend the washing period, raise the treating capacity, and realize the large scale use and run in ultralow pressure.

Owner:HARBIN INST OF TECH

Heavy metal ion adsorption type polyvinylidene fluoride (PVDF) hollow fiber membrane

ActiveCN102527261AReduce dosageLow priceSemi-permeable membranesOther chemical processesFiberMass ratio

The invention discloses a heavy metal ion adsorption type polyvinylidene fluoride (PVDF) hollow fiber membrane. The invention belongs to the technical field of membranes and in particular relates to a preparation technology for an organic-inorganic hybrid hollow fiber membrane. The heavy metal ion adsorption type PVDF hollow fiber membrane comprises modified attapulgite, wherein the mass ratio of the PVDF to the modified attapulgite is (1:0.01)-(1:0.1). The heavy metal ion adsorption type PVDF hollow fiber membrane has the advantages that high pressure resistance is achieved, a supporting body is not required, a membrane component has any sizes and shapes and large filling density, and unit volume membrane area and flux are large. In addition, the hybrid membrane is high in spinning performance, the spinning membrane-forming process is simple in process, and cost is low.

Owner:TIANJIN POLYTECHNIC UNIV

Polyvinylidene fluoride membrane and preparation method thereof

ActiveCN104226124AEasy to prepareLow costSemi-permeable membranesPolyvinylidene difluoridePolyvinylidene fluoride

The invention relates to a polyvinylidene fluoride membrane. The membrane casting liquid comprises the following components in percentage by weight: 10-25% of polyvinylidene fluoride resin, 1-4% of diatomite, 1-5% of amphiphilic copolymer, 4-12% of organic pore-forming agent, 0.2-3% of inorganic pore-forming agent, 0.1-3% of surfactant and the balance of solvent. According to the polyvinylidene fluoride membrane, the diatomite and the amphiphilic copolymer are added; by virtue of the diatomite, the mechanical strength and pure water flux of the membrane are improved; the amphiphilic copolymer and polyvinylidene fluoride have good compatibility; the combination force is strong; the copolymer is unlikely to run off and the continuous hydrophily of the membrane is guaranteed. The invention further relates to a preparation method of the polyvinylidene fluoride membrane. The preparation method comprises the following steps: (1) uniformly stirring the membrane casting liquid, standing and defoaming; (2) enabling the membrane casting liquid to vertically flow in the air by virtue of a spinning spinneret, so that the membrane casting liquid enters the coagulating bath and is cured and formed; (3) soaking the spun and formed polyvinylidene fluoride membrane in pure water and a glycerol water solution in sequence and drying so as to obtain the polyvinylidene fluoride membrane.

Owner:安徽指南针科创园发展有限公司

High-flux polyvinylidene fluoride hollow fiber membrane

ActiveCN103111189AIncrease water productionReduce manufacturing costSemi-permeable membranesFiltrationHigh flux

The invention relates to a high-flux polyvinylidene fluoride hollow fiber membrane which is in an asymmetrical structure. From outside membrane fibers to the hollow inside, the high-flux polyvinylidene fluoride hollow fiber sequentially comprises a compact outer skin layer, a first structural layer with finger-like pores, a spongy layer with abundant pores, a second structural layer with finger-like pores and an inner skin layer, wherein the finger-like pores in the first structural layer are larger than those in the second structural layer. The high-flux polyvinylidene fluoride hollow fiber membrane is prepared through a dry-wet spinning process. According to the invention, the polyvinylidene fluoride hollow fiber membrane is in a five-layer structure; above all, the loose spongy layer structure ensures that the polyvinylidene fluoride hollow fiber membrane has high pure water flux and high filtration accuracy; and meanwhile, the polyvinylidene fluoride hollow fiber membrane also has the advantages of satisfactory flexibility and chemical resistance of a polyvinylidene fluoride material. Thus, the water yield in unit membrane area can be effectively increased, and the manufacturing and use cost of a membrane component can be lowered.

Owner:JIANGSU SUJING GROUP +1

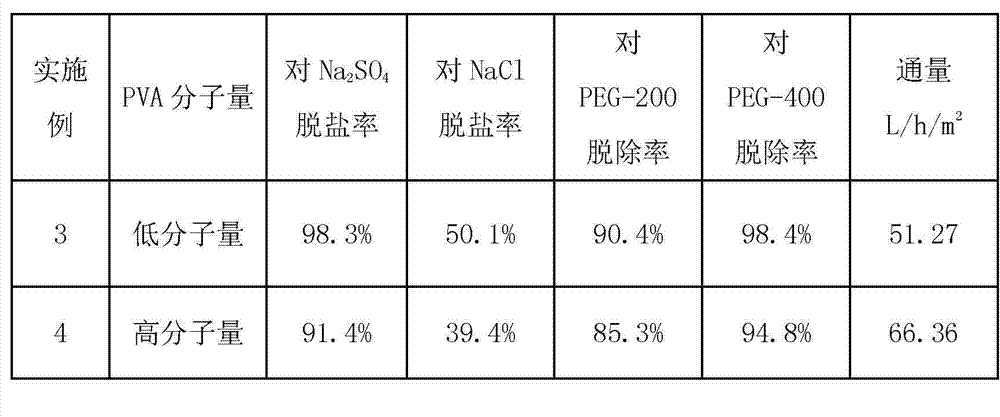

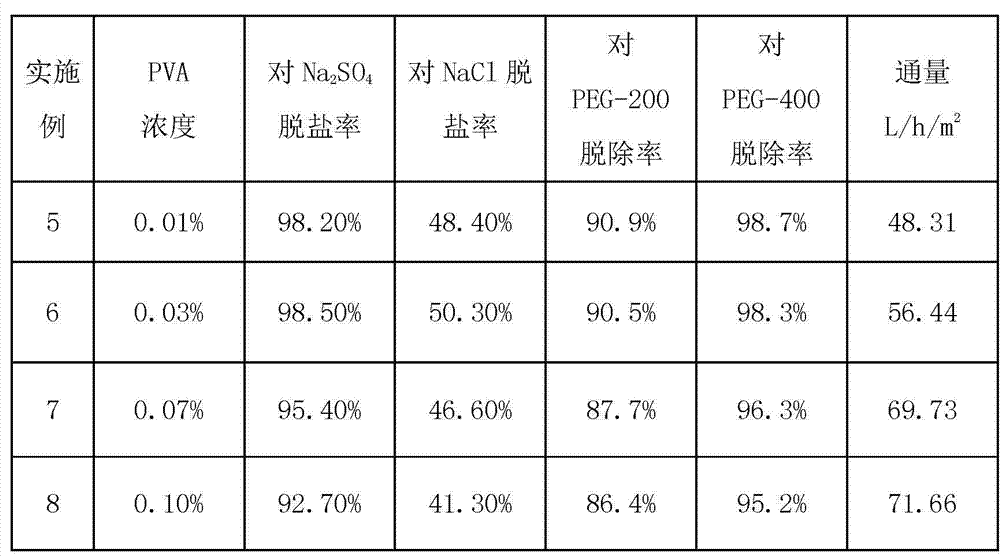

Preparation method of nanofiltration membrane

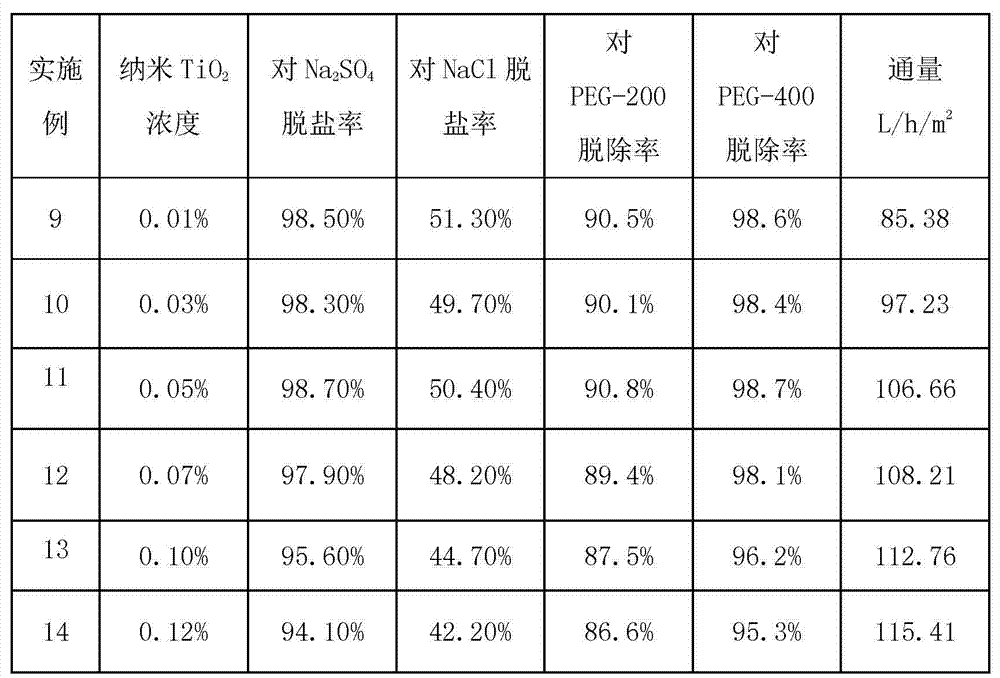

InactiveCN103111196AHigh mechanical strengthIncreased pure water fluxSemi-permeable membranesSodium sulfateDivalent

The invention discloses a preparation method of a nanofiltration membrane, and particularly relates to a preparation method of a PVA (Polyvinyl Acetate)-Polypiperazine-amide nanofiltration membrane doped with acyl-chloride-modified nano-TiO2 particles. The preparation method of the nanofiltration membrane comprises the steps of adding organically-modificed nano-TiO2 particles with benzoyl chloride groups into an organic trimesoyl chloride (TMC) solution to be dispersed into a solution, and then, enabling the solution to contact with an aqueous solution containing piperazine (PIP) and polyving alcohol (PVA) to be subjected to interfacial polymerization reaction to obtain an organic nano-modification composite nanofiltration membrane. The preparation method has the advantages that under the 1MPa operating pressure on the prepared membrane, water flux is obviously enhanced, meanwhile, high salt rejection to sodium sulfate is displayed, the rejection ratio of the sodium chloride is 50.4%, and different separation capabilities to univalent salt and divalent salt are represented; and the acyl-chloride-modified nano-TiO2 particles can favorably disperse in an organic phase, and assists an aqueous phase in forming a uniform membrane structure in the interfacial polymerization reaction.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

MXene-based bismuth-based photocatalytic composite membrane and preparation method thereof

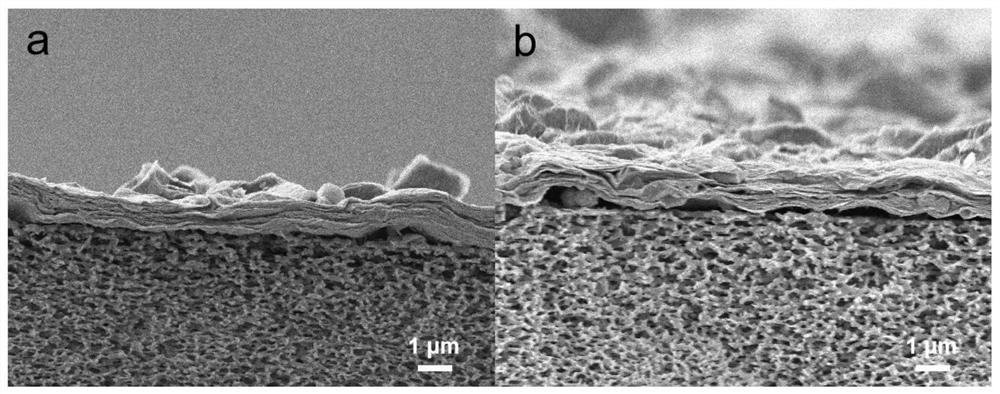

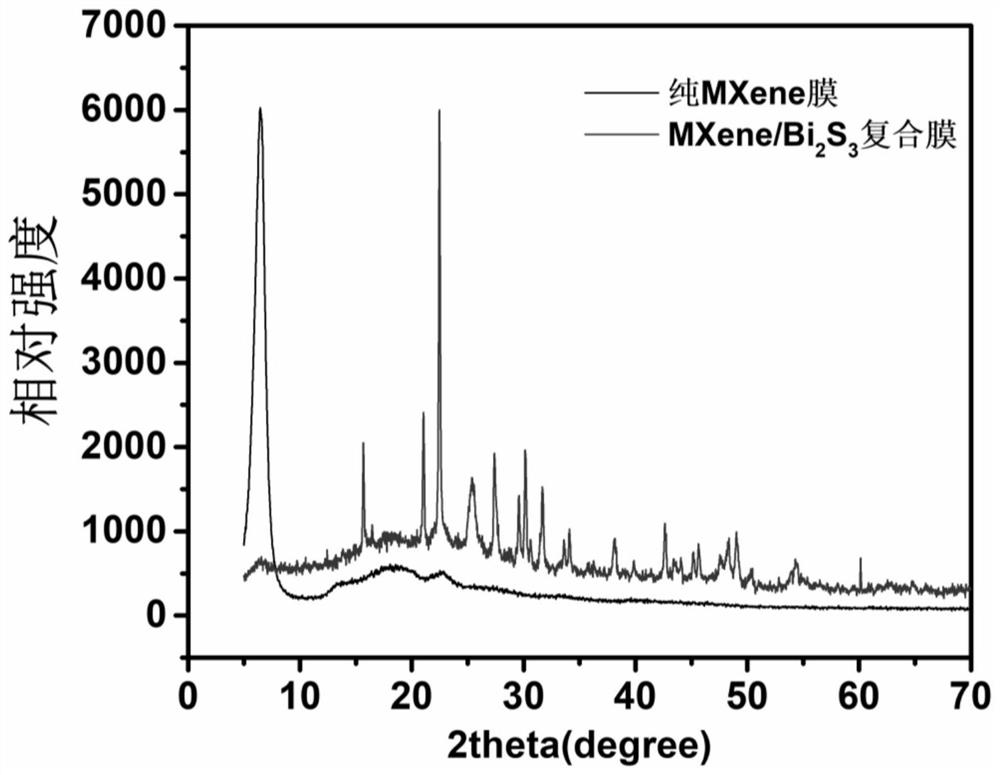

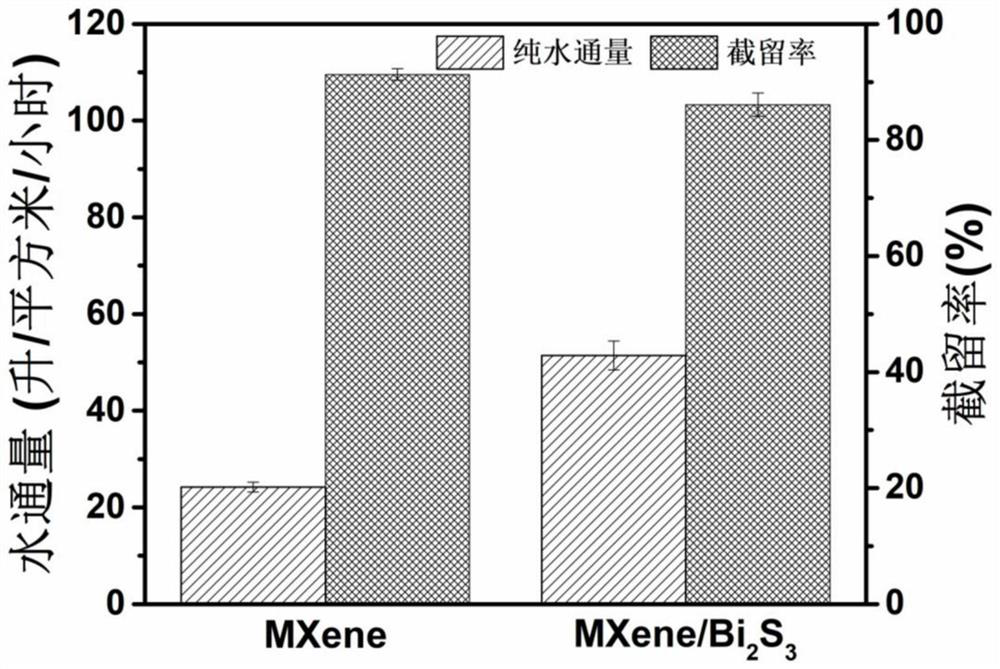

ActiveCN111822028AEasy to separateGood self-cleaning and anti-pollution propertiesMembranesSemi-permeable membranesNanoparticlePhysical chemistry

The invention belongs to the technical field of membrane preparation, and particularly provides a MXene-based bismuth-based photocatalytic composite membrane which comprises an MXene nanosheet, bismuth-based photocatalytic nanoparticles and a porous support layer, wherein the bismuth-based photocatalytic nanoparticles grow on a single-layer MXene nanosheet in situ to form an MXene / bismuth-based photocatalytic nanoparticle composite material, and the MXene / bismuth-based photocatalytic nanoparticle composite material is prepared on the porous support layer; the membrane has good separation performance, and the pure water flux is increased by 2-23 times compared with that of a traditional polymer membrane on the premise that the rejection rate is kept; the membrane has excellent self-cleaningand anti-pollution performance, after the membrane performs a filtering experiment on dye molecules rhodamine B for 12 hours, the dye adsorbed on the membrane is degraded for 20 minutes by using simulated sunlight, and the water flux recovery rate of the membrane is as high as 97.6%; the preparation method of the MXene-based bismuth-based photocatalytic composite membrane is relatively simple, low in cost, time-saving and suitable for industrial expanded production.

Owner:XIAN TECHNOLOGICAL UNIV

Polyvinylidene fluoride (PVDF) hollow-fiber membrane with base material and production method thereof

ActiveCN101632904AMeet the exchange timeIncrease productivitySemi-permeable membranesFiberHollow fibre membrane

The invention relates to a polyvinylidene fluoride (PVDF) hollow-fiber membrane with a base material, which has an average aperture of 0.03-0.5 micrometer, an inner diameter of 0.4-1.8 millimeters, an outer diameter of 1.1-4.5 millimeters, a strength of 200-500N and a pure water flux of 500-10,000L / m<2> / h at 25 DEG C under atmospheric pressure. The invention also relates to a production method of the hollow-fiber membrane with a base material, which can solve the essential problem of low gel efficiency of the PVDF hollow-fiber membrane with a base material (hollow-fiber rope) so as to solve the problems of poor membrane homogeneity, wide aperture distribution, low spinning speed, high production cost, and the like.

Owner:BEIJING ORIGIN WATER FILM TECH

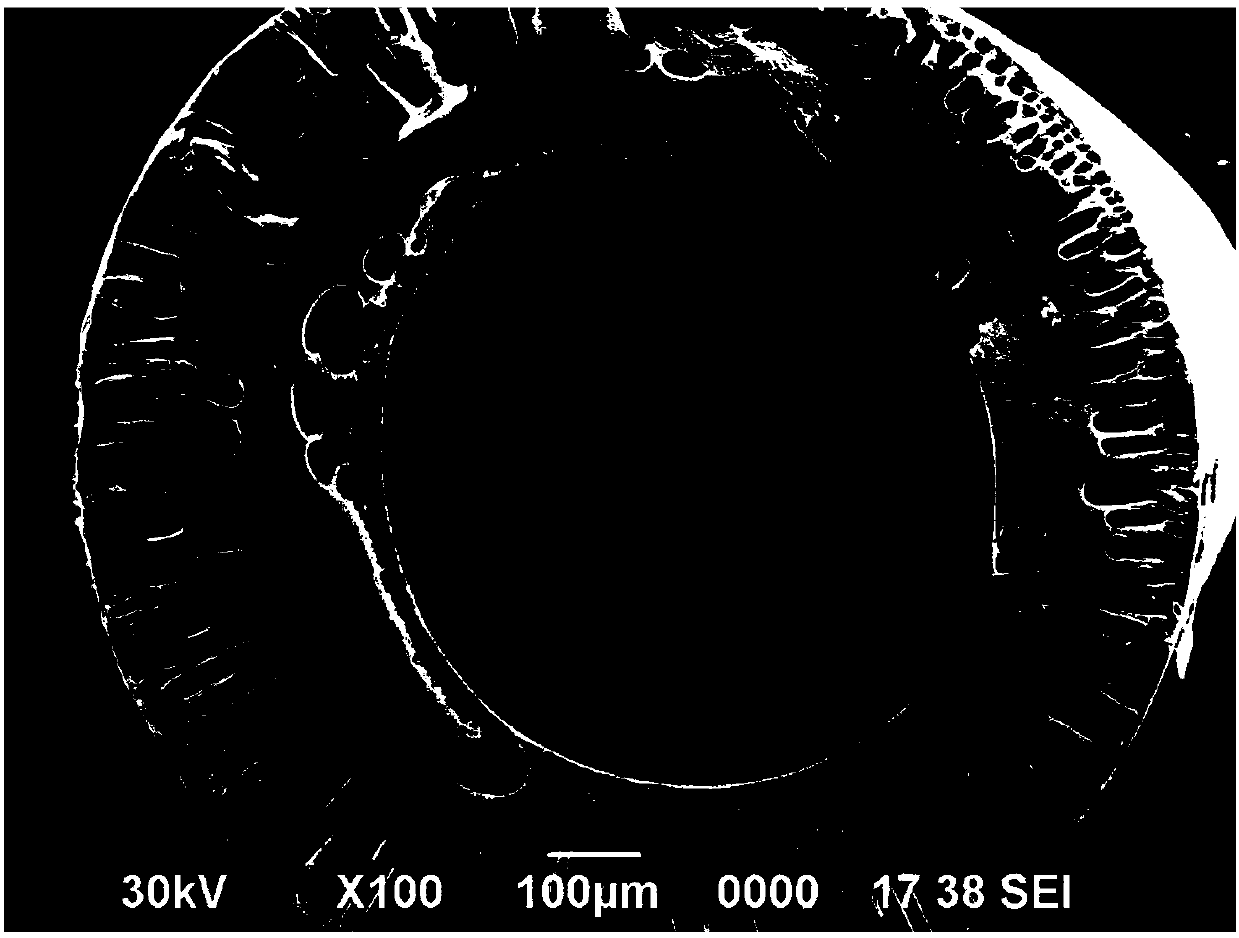

High-strength high-flux hollow fiber membrane and preparation method thereof

The invention discloses a high-strength and high-flux hollow fiber membrane and a preparation method thereof. The method is characterized by comprising the following main steps: taking ultrahigh molecular weight polyvinylidene fluoride as a raw material and adding nano-size inorganic additives, PVP (polyvinyl pyrrolidone) and a solvent to the raw material for mixing; using a single screw to transmit a feed liquid at the condition of even dissolving and high-speed stirring in a stirred tank; carrying out vacuum defoaming on one section of the single screw; using a metering pump and a spinning nozzle to extrude; and adopting acid or alkali to wash after the gel is coagulated in a gel groove, thus obtaining the high-strength and high-flux polyvinylidene fluoride hollow fiber membrane. The external diameter, the internal diameter and the bore diameter of a membrane wire of the high-strength and high-flux hollow fiber membrane are 1200 micrometer, 600 micrometer and 0.06-0.2 micrometer respectively, thus solving the problems that a hollow fiber membrane prepared by a traditional non-solvent phase separation method is low in strength and small in water flux.

Owner:北京伟思德克科技有限责任公司

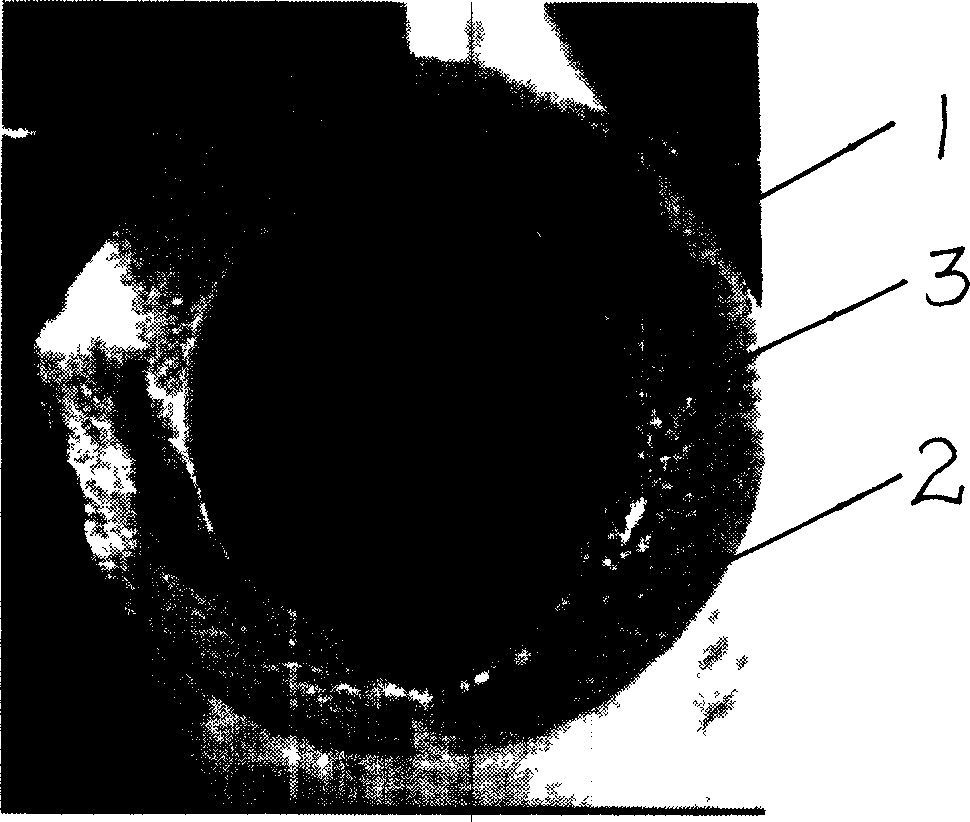

Sintered alpha-alumina/polyviny lidene fluoride blended hollow fiber membrane preparing method and its product

InactiveCN1579602AReasonable ingredientsLarge apertureSemi-permeable membranesPolymer sciencePolyvinylidene difluoride

The invention relates to an approach of producing asymmetry sintering alpha-alumina / polyvinylidene fluoride crossblend hollow fibre membrane. It also relates prescription of private membrane-forming liquor and its production. Use polyvinylidene fluoride as materials; disperse sinteringalpha-alumina in its good solvent to make them react to form mixing liquor; Add hydrophilicity compound which react with the mixing liquor to get membrane-forming liquor with some viscosity; using phase transmitting method to produce hollow fibre membrane. So the invention has merits of rational proportion, simple technics, low requirements to equipment and components complementation. It can manufacture bigger aperture, high permeation flux and asymmetry membranes.

Owner:ZHEJIANG OMEX ENVIRONMENTAL ENG CO LTD

Crossblend separation membrane for polyvinyl chloride in high pass quantity and preparation method

InactiveCN1562451AImprove solubilityImprove insulation performanceSemi-permeable membranesOrganic solventPolyvinyl alcohol

A high-throughness separating PVC mixture membrane with high hydrophilicity is prepared through proportionally dissolving the polyvinyl alcohol, alkoholyzed halogene-fatty-acid-ene and PVC in organic solvent, adding additive, dissolving, ageing, doctor blading to form membrane, evaporating, and automatic stripping in gel bath.

Owner:BEIJING UNIV OF TECH

Polyvinylidene fluoride hollow fiber membrane with base material and production method thereof

The invention relates to a polyvinylidene fluoride (PVDF) hollow fiber membrane with a base material and a production method thereof. The average pore size of the membrane is 0.04-0.4mu m, the inner diameter and the outer diameter of the hollow fiber of the membrane are respectively 0.5-1.6mm and 1.0-4.0mm, the strength of the membrane is 100-300N, the wetting angle of the membrane is less than 60 degrees and the pure water flux under 25 DEG C and an atmospheric pressure is 100-400L / m2.h. The invention also relates to the production method of the hollow fiber membrane with the base material. The radical problems of poor hydrophilicity and low flux of the PVDF hollow fiber membrane with the base material (the hollow fiber rope) can be solved by the production method.

Owner:BEIJING ORIGIN WATER FILM TECH

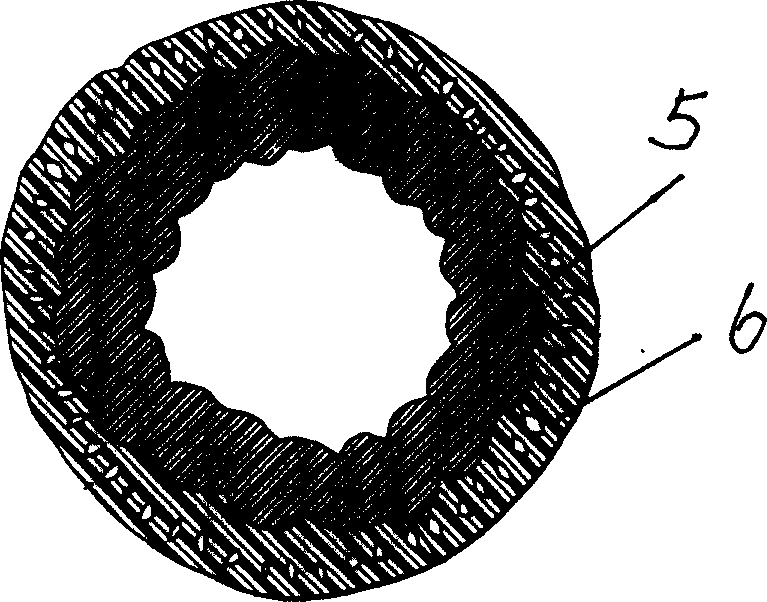

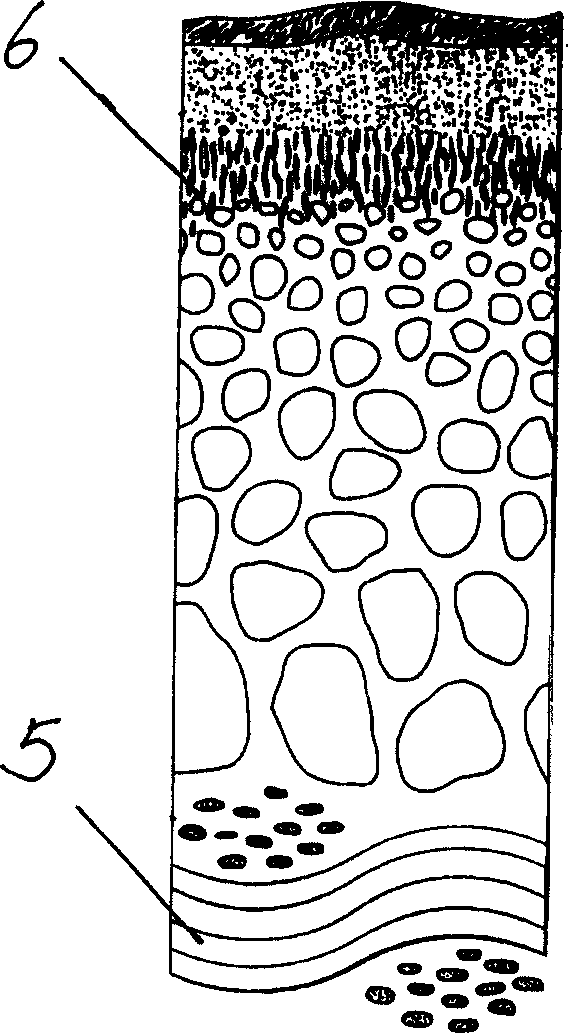

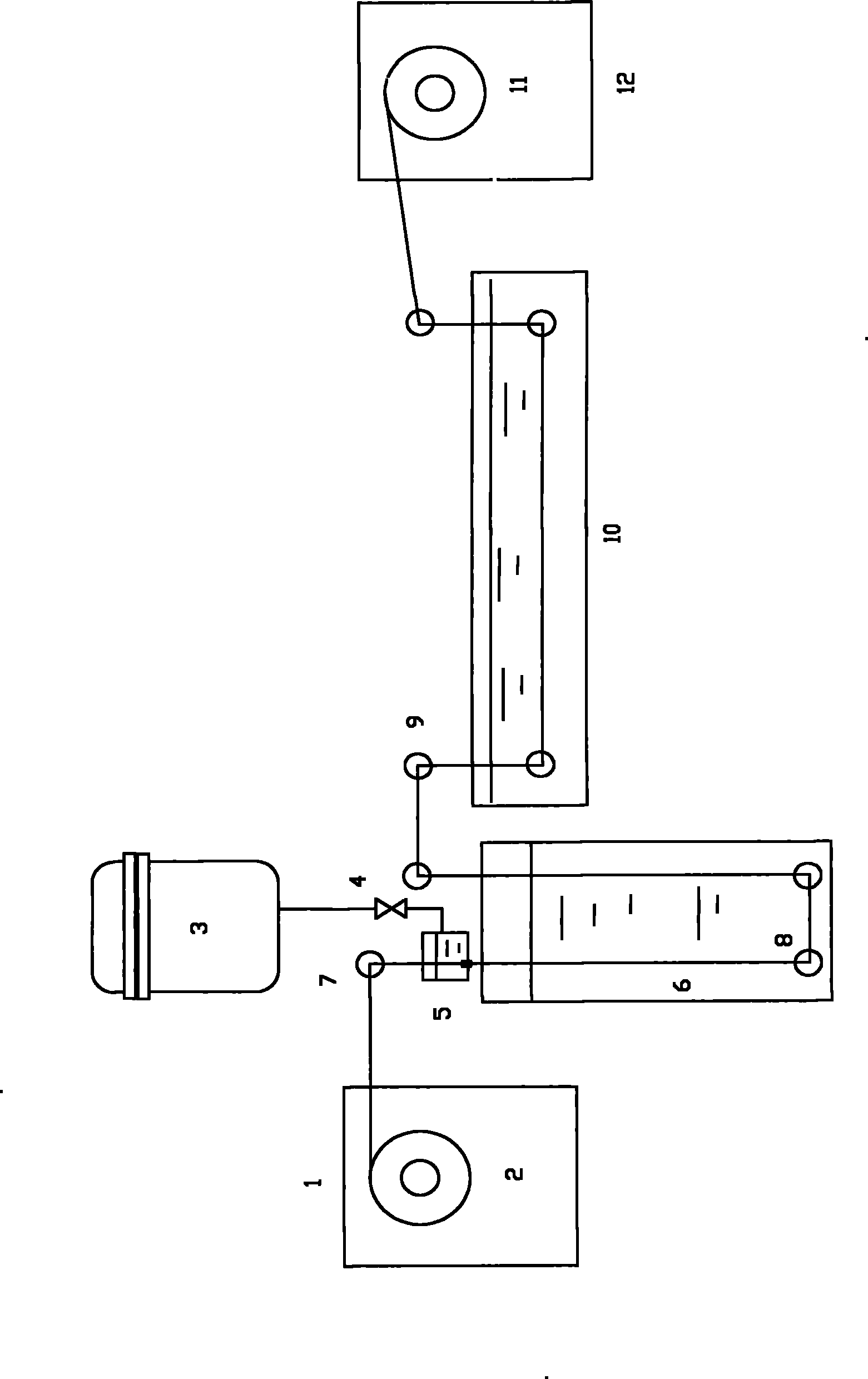

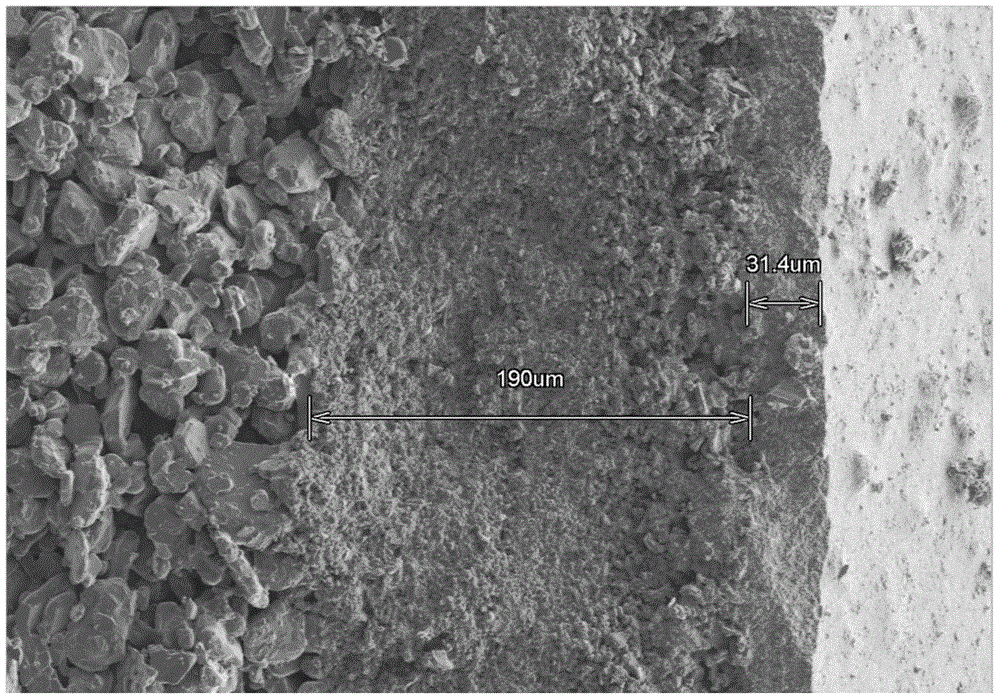

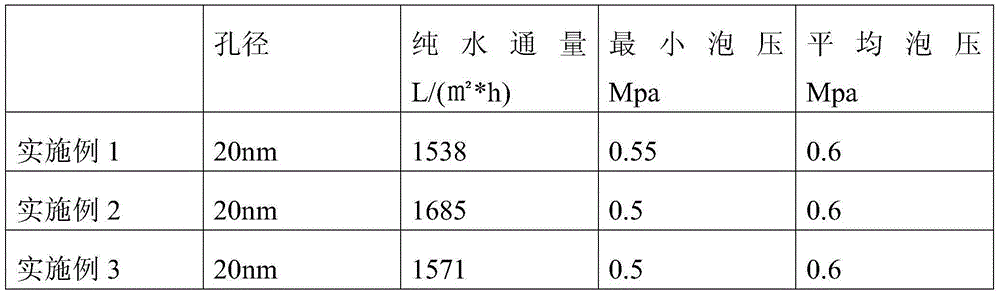

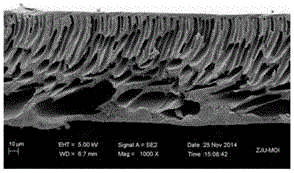

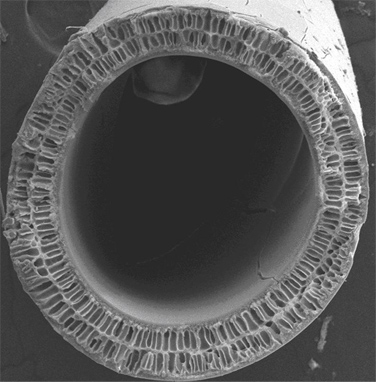

Tubular type ceramic filter element and preparation method thereof

ActiveCN104785119AIncreased pure water fluxImprove operational efficiencyUltrafiltrationFiltration separationSupport matrixMetallurgy

The invention provides a tubular type ceramic filter element which comprises a tubular type support matrix and a membrane transition layer and a membrane separation layer which respectively cover the tubular type support matrix and a method for preparing the ceramic filter element. Pure water flux of the tubular type ceramic filter element reaches up to 1000-2000L / m<2>.h and is 3-5 times higher than that of like products in the current market. According to the invention, operation efficiency is greatly raised, and application range of the tubular type ceramic filter element is broadened.

Owner:江苏赛启分离科技有限公司

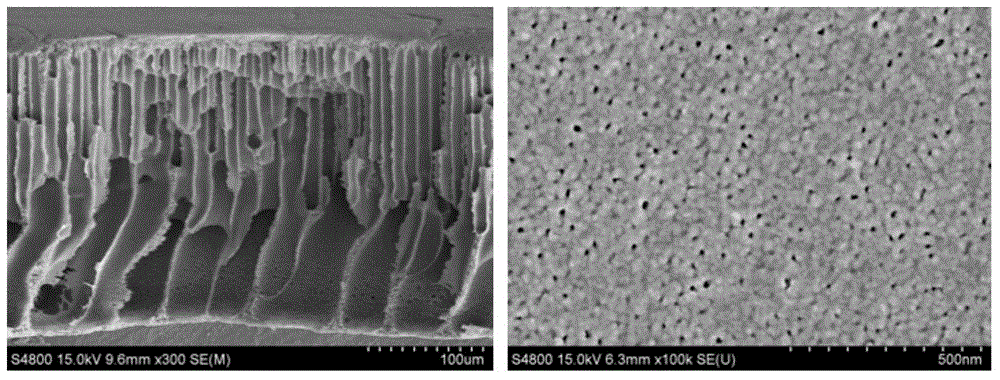

Amphiphilic fluorine-containing gradient copolymer, and preparation method and application thereof

ActiveCN104927011AEasy to prepareSimple processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisNon solventUltrafiltration

The invention discloses a preparation method of an amphiphilic fluorine-containing gradient copolymer, and the method is used in oil-water separation ultrafiltration membrane antifouling modification. First, with a reversible addition fragmentation chain transfer (RAFT) controlled free radical polymerization method, with a semi-continuous feeding manner, an amphiphilic fluorine-containing gradient copolymer is prepared; the prepared amphiphilic fluorine-containing gradient copolymer is adopted as a modifying agent, and is used for modifying the ultrafiltration membrane with a blending modification method, wherein the membrane is prepared with a classic non-solvent induced phase transformation method. The surface of the membrane modified with the amphiphilic fluorine-containing gradient copolymer has an amphiphilic hierarchical structure with the coexistence of hydrophilic and hydrophobic regions. The amphiphilic fluorine-containing gradient copolymer preparation method is simple; and the modified membrane preparation process has the advantages of easy operation and mild conditions. The modified membrane has good oil-water separation performance and excellent antifouling effect, and can be used in water treatment and especially the separation purification of oil-containing wastewater.

Owner:ZHEJIANG UNIV

Preparation method of nanometer composite forward osmosis membrane with organic silane grafted multi-wall carbon nanometer tubes embedded into polyamide separation layer

InactiveCN107398188AImprove compatibilityImprove hydrophilicitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFilling materialsPolyamide

The invention discloses a preparation method of a nanometer composite forward osmosis membrane with organic silane grafted multi-wall carbon nanometer tubes embedded into a polyamide separation layer. The carbon nanometer tube is added into concentrated acid to obtain the carbon nanometer tubes with carboxyls on the surface; thionyl chloride is used for acyl chlorization on the carbon nanometer tubes; further, reaction is performed with organic silane containing amino groups or sulfydryls; the organic silane is grafted onto the carbon nanometer tubes; macromolecular membrane materials are prepared into a porous organic filtering membrane; a thin separation layer is polymerized on the surface interface of a support layer of the porous organic filtering membrane; the organic silane grafted carbon nanometer tubes are used as nanometer filling materials to be added into an oil phase; the organic silane grafted carbon nanometer tubes are embedded into a separation layer to obtain a target product. The method provided by the invention has the advantages that the water flux of the product is greatly improved; the reverse diffusion quantity of a draw solution solute is reduced; in addition, good anti-pollution capability is shown; the membrane belongs to a novel forward osmosis membrane with a wide application potential.

Owner:ZHEJIANG UNIV OF TECH

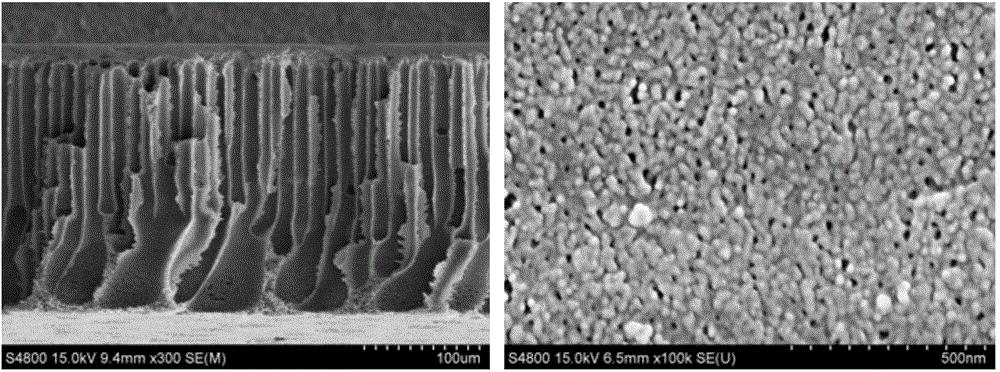

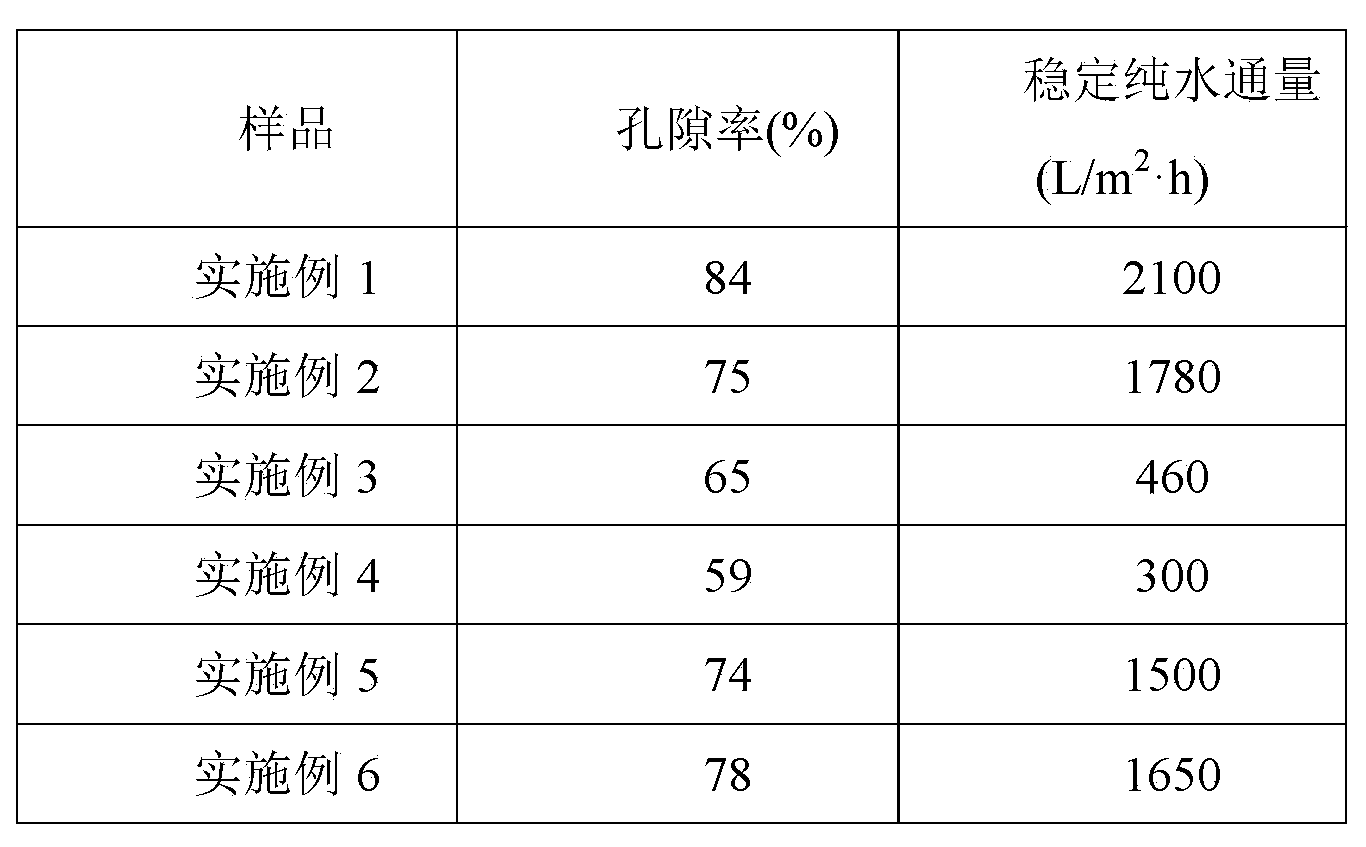

Polyether sulfone ultrafiltration membrane preparation method capable of improving permeability and selectivity simultaneously

ActiveCN104056557AHigh porosityIncreasing the thicknessSemi-permeable membranesPolyetherimideUltrafiltration

The invention discloses a polyether sulfone ultrafiltration membrane preparation method capable of improving permeability and selectivity simultaneously. An ultrafiltration membrane is prepared by adopting a phase inversion method, and PEI (polyetherimide) is used as an additive, and is added to change the phase inversion process and regulate the structure of the PES ultrafiltration membrane to achieve high permeability and high selectivity. The preparation method comprises the following steps of (1) dissolving the PEI in a solvent (DMF) (dimethyl formamide), adding polyether sulfone and PVP (polyvinylpyrrolidone), and performing heating to dissolve the polyether sulfone and the PVP to form a homogeneous membrane coating solution; and (2) controlling membrane forming conditions, and preparing the flat membrane. According to the method, the structure of the PES ultrafiltration membrane is effectively regulated, and the aperture ratio of the PES ultrafiltration membrane and the thickness of a selective layer are increased to greatly improve the permeability and the selectivity; the preparation method is simple and suitable for being used in the industrial production and the preparation of a basic membrane of a nanofiltration membrane.

Owner:NANJING UNIV OF SCI & TECH

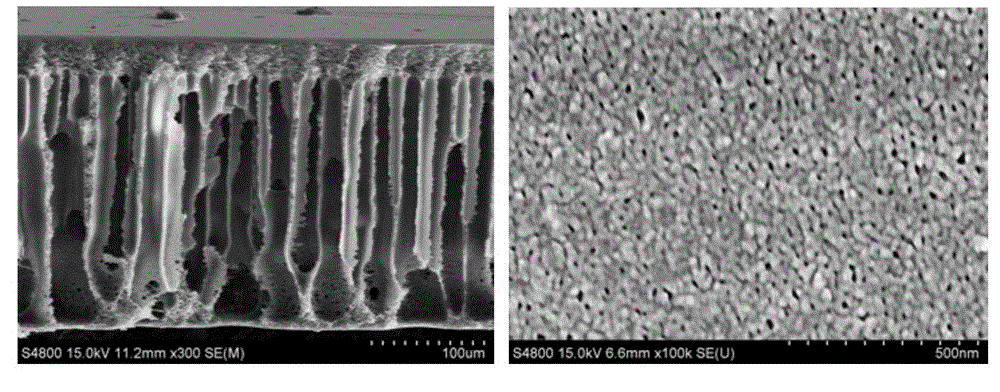

Polypropylene hollow fiber separating membrane and preparation method thereof

The invention discloses a polypropylene hollow fiber separating membrane and a preparation method thereof. The polypropylene hollow fiber separating membrane disclosed by the invention comprises the components of 10-40 percent of polypropylene resin and 60-90 percent of diluting agent, the melt index of the polypropylene resin used in the invention is 0.1-4g / 10min, and the weight-average molecular weight of the polypropylene resin is 3*10<5>-1.2*10<6>. According to the polypropylene hollow fiber separating membrane, by using the polypropylene resin with high weight-average molecular weight, the concentration of a casting film solution can be reduced; the preparation method is convenient and simple to operate and easy to realize. The polypropylene hollow fiber separating membrane disclosed by the invention has the advantages of large micropores in the surface, large flux and higher porosity, and can be widely applied to the fields such as water treatment, membrane distillation, biology, medicines and energy sources, and is better in application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

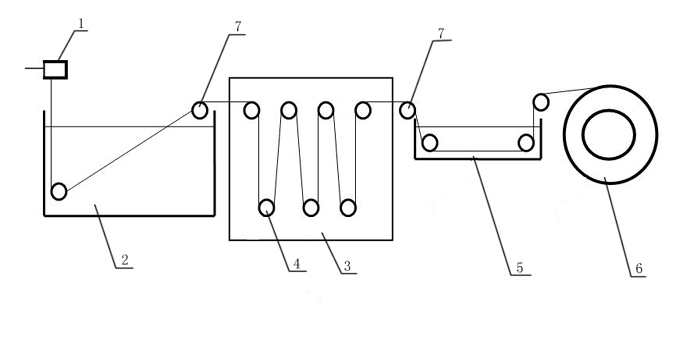

Method for preparing polyvinylidene fluoride hollow fiber membrane

The invention relates to a method for preparing a polyvinylidene fluoride hollow fiber membrane. The method comprises the steps of the preparation of a membrane liquid and the preparation of hollow fiber membrane silks, and specifically comprises the following steps of: injecting the membrane liquid and an internal gel medium into a latent solvent, namely external gel medium No. 1 of polyvinylidene fluoride by using an annular spinneret plate, drawing by using a group of traction wheels, and then making the obtained product enter gel medium No. 2, namely desalted water which is a non-solvent of the membrane liquid to ensure that the membrane silks are subjected to phase exchange formation quickly. The elasticity and flexibility of the hollow fiber membrane obtained by the method are greatly improved on the premise of ensuring higher pure water flux and strength to ensure that the membrane is more suitable for high-turbidity water quality treatment in which frequent gas washing and brushing are required, and only the stretch deformation of local membrane silk networks is caused during the gas washing and shaking of the membrane silks and the filter capacity of structural holes of other networks of the membrane is not damaged, so that the filter capacity of a membrane module cannot be influenced.

Owner:河北诺恩水净化设备有限公司

Positively charged composite nano filtration membrane and preparation method

ActiveCN109794166AImprove chlorine resistanceIncreased pure water fluxReverse osmosisFiltration membranePolyamide

The invention discloses a positively charged composite nano filtration membrane. The nano filtration membrane is characterized in that a modified meta-aramid hollow fiber membrane is taken as a base membrane, an ultra-thin polyamide layer is formed by positively charged polyelectrolyte, polyamine and polyacyl chloride through interfacial polymerization, and a method for preparing the composite nano filtration membrane is prepared. According to the composite nano filtration membrane, pure water throughput under 0.3 MPa is greater than or equal to 24 L (m2 h), the desalting rate of 2g / L divalentcation salt solution is greater than or equal to 90%, the needed cost is lower, and industrialization is easy. The preparation method is simple, operation is easy, reaction conditions are mild, the performance is stable, and the market application prospects are wider.

Owner:OCHEMATE MATERIAL TECH CO LTD

Preparation method for polyisophthaloyl metaphenylene diamine nanofiltration membrane

InactiveCN105413500AAvoid the disadvantage of uneven dispersionIncreased pure water fluxReverse osmosisSilica gelGraphene

The invention provides a preparation method for a polyisophthaloyl metaphenylene diamine nanofiltration membrane and belongs to the field of membrane pollution resistance. The method includes the steps that a fully-dried polyisophthaloyl metaphenylene diamine nanofiltration membrane is flatly laid on a glass plate, the glass plate is placed in a plate frame to be tightened, a prepared solution containing an acid binding agent is poured to the surface of the membrane for impregnation, the remaining solution is poured out, and the membrane is placed in a fume cupboard to be dried in shade; then a prepared crosslinking solution is poured to the surface of the membrane for impregnation, and the surplus solution is removed through a silica gel wheel; then an oxidized graphene solution is poured to the surface of the membrane for impregnation, the remaining solution is poured out, and the membrane is dried in shade; finally the treated membrane is placed within the temperature interval of 40-80 DEG C for heat treatment for 60-180 s, and the modified nanofiltration membrane is obtained. The technological operation is easy, the original excellent characteristics of the polyisophthaloyl metaphenylene diamine nanofiltration membrane are kept, the hydrophilia of the surface of the membrane is also well enhanced, the pollution resistance of the membrane is improved, and wide application prospects are achieved.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Composite nano-filtration membrane and preparation method thereof

ActiveCN109663511AImprove chlorine resistanceImprove throughputSemi-permeable membranesFiltration membraneDesalination

The invention discloses a composite nano-filtration membrane, wherein a modified meta-aramid hollow fiber membrane is used as a base membrane, and polyamine, a diaminobenzene fluoride and polyacyl chloride are subjected to an interface polymerization reaction on the base membrane to form an ultra-thin polyamide layer. The invention further provides a preparation method of the composite nano-filtration membrane. With the technical scheme of the present invention, the pure water flux of the prepared composite nano-filtration membrane is more than or equal to 50 L / (m<2>.h) at 0.5 MPa, the desalination rate of the prepared composite nano-filtration membrane to the 2 g / L divalent cation salt solution is more than or equal to 80%, the required cost is low, and the method is suitable for industrial production; and the preparation method has characteristics of simpleness, mild reaction condition, stable product performance and wide market application prospect.

Owner:OCHEMATE MATERIAL TECH CO LTD

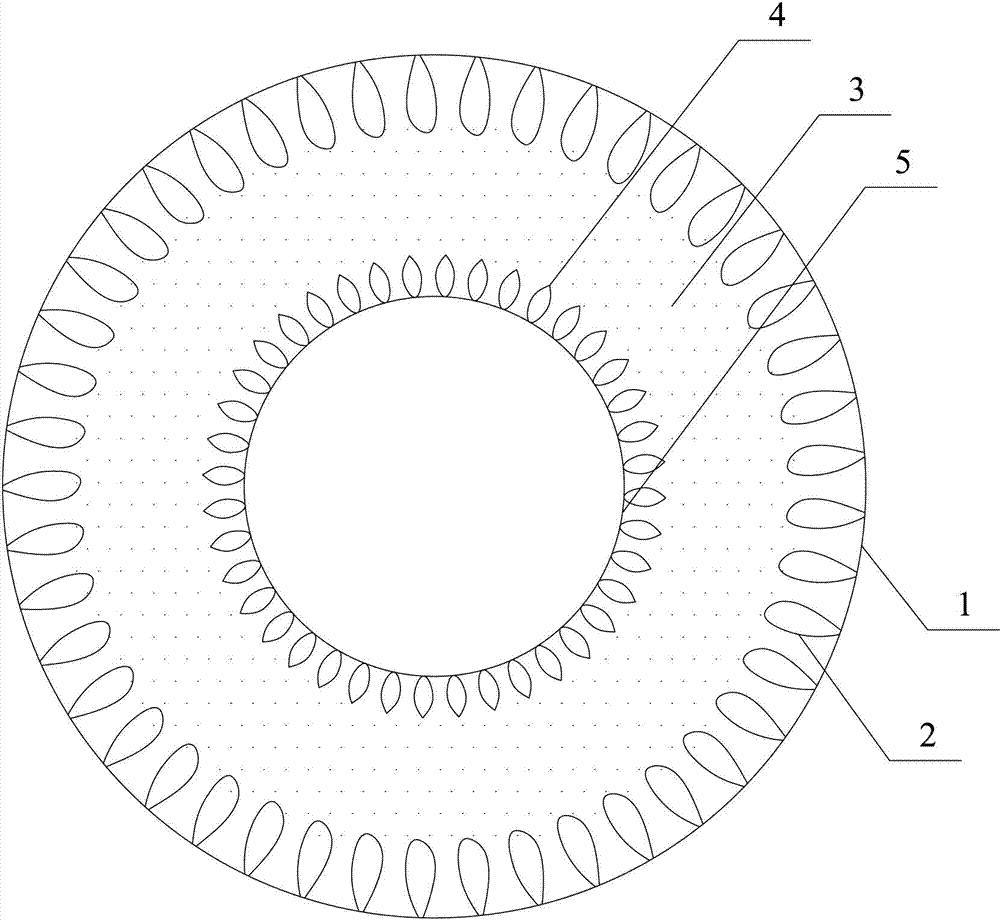

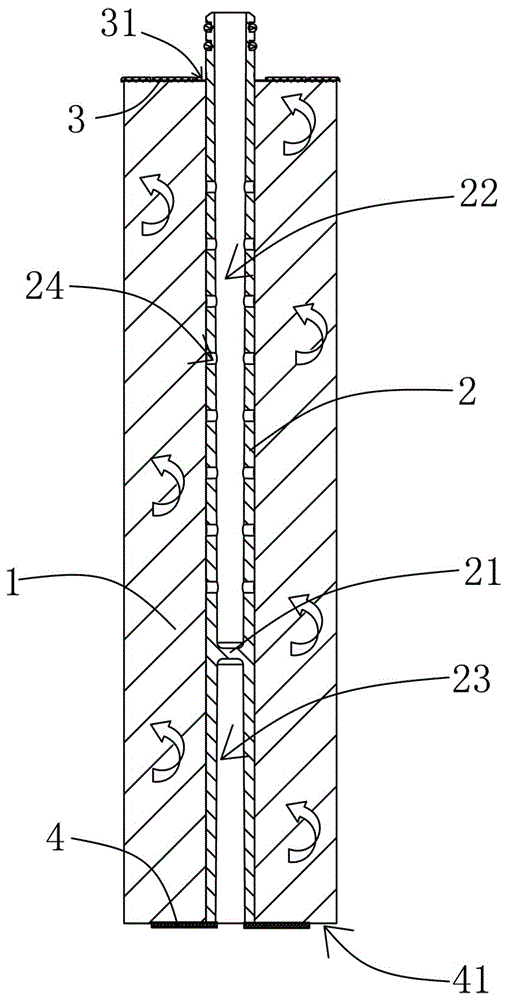

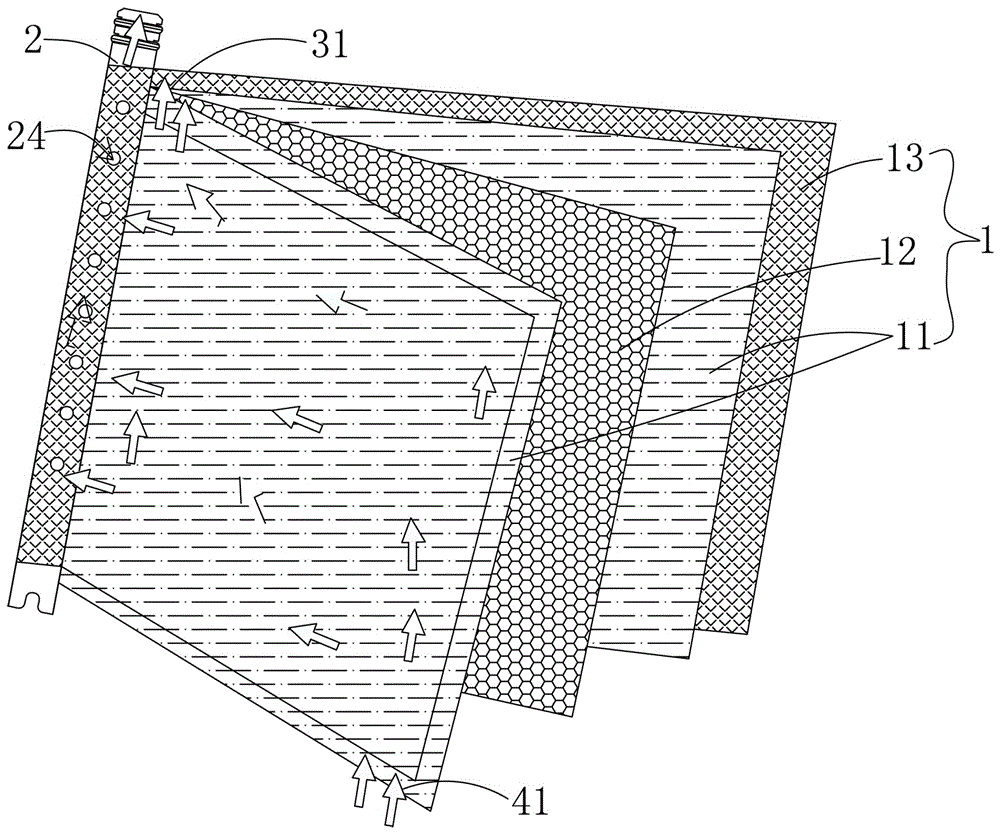

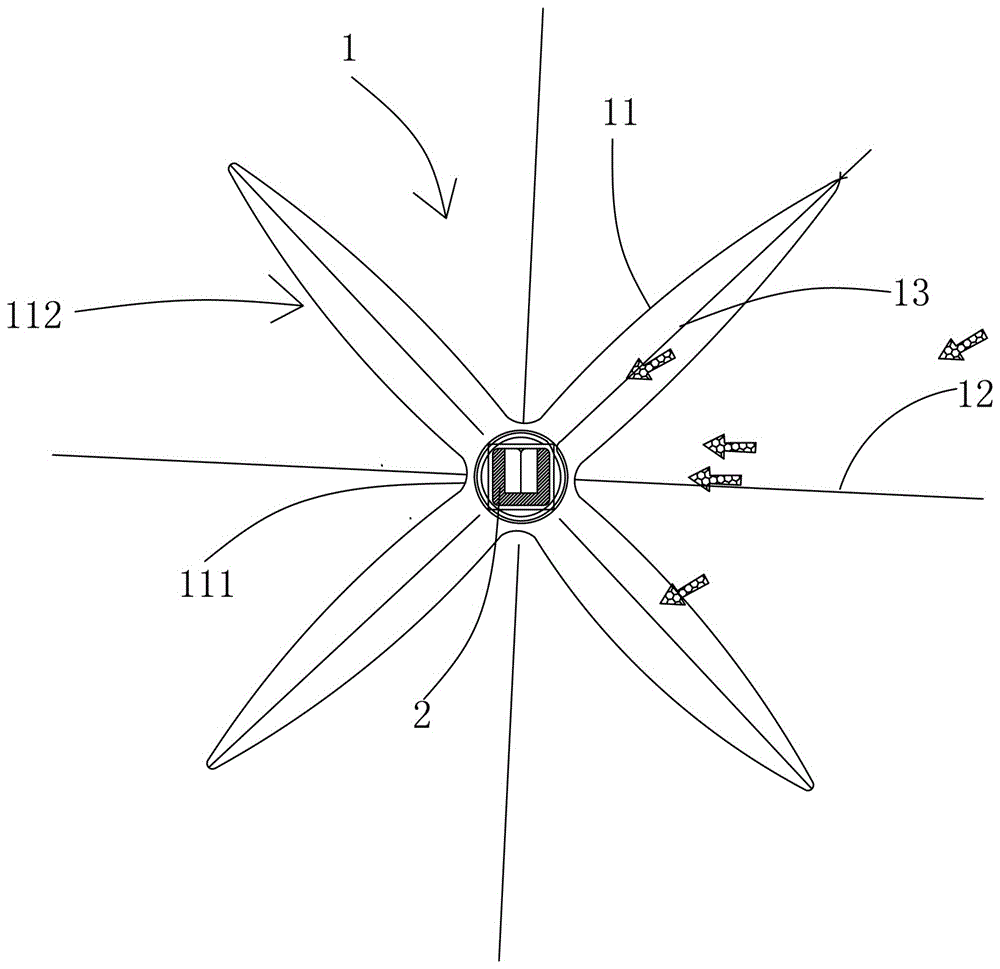

Water-saving membrane component and filter structure thereof

ActiveCN106110893ATake advantage ofReduce lossSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater savingFiltration

The invention discloses a water-saving membrane component and a filter structure thereof. The water-saving membrane component comprises a center tube, a filter membrane component, an upper seal part and a lower seal part, and the filter membrane component is rolled centering on the center tube. The upper seal part seals the outer periphery of the upper end face of the filter membrane component to make the inner periphery, close to the center tube, of the upper end face, serve as a wastewater outlet. The lower seal part seals the inner periphery, close to the center tube, of the lower end face of the filter membrane component to make the outer periphery of the lower end face serve as a water inlet. Due to adoption of the water-saving membrane component, during filtering, raw water enters the outermost layer of the water-saving membrane component from the water inlet of the outer periphery of the lower end face and then spirally flows into the innermost layer of the water-saving membrane component from the outermost layer of the water-saving membrane component, pure water flows into the center tube, and waste water flows out from the wastewater outlet. The water-saving membrane component and the filter structure thereof have advantages of complete utilization of the filter membrane component, low loss, high pure water flux, less wastewater, uniformity in water feeding, long filter flow passage, effectiveness in filtration and the like.

Owner:FOSHAN MICRO MIDEA FILTER MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com