Sintered alpha-alumina/polyviny lidene fluoride blended hollow fiber membrane preparing method and its product

A technology of polyvinylidene fluoride and aluminum oxide, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of low strength, complicated process, high production cost, etc. The effect of simple process and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

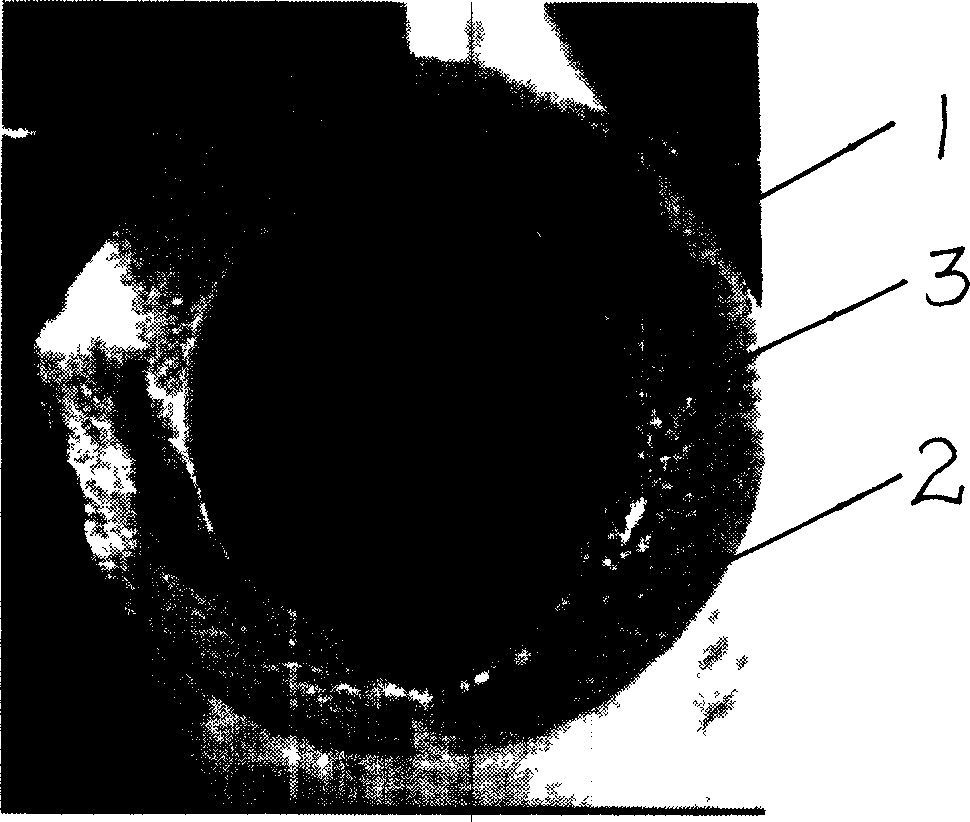

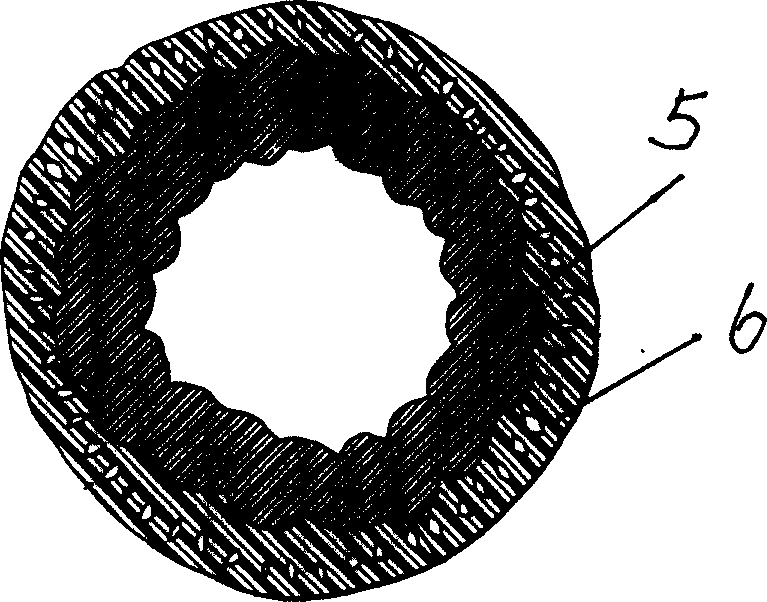

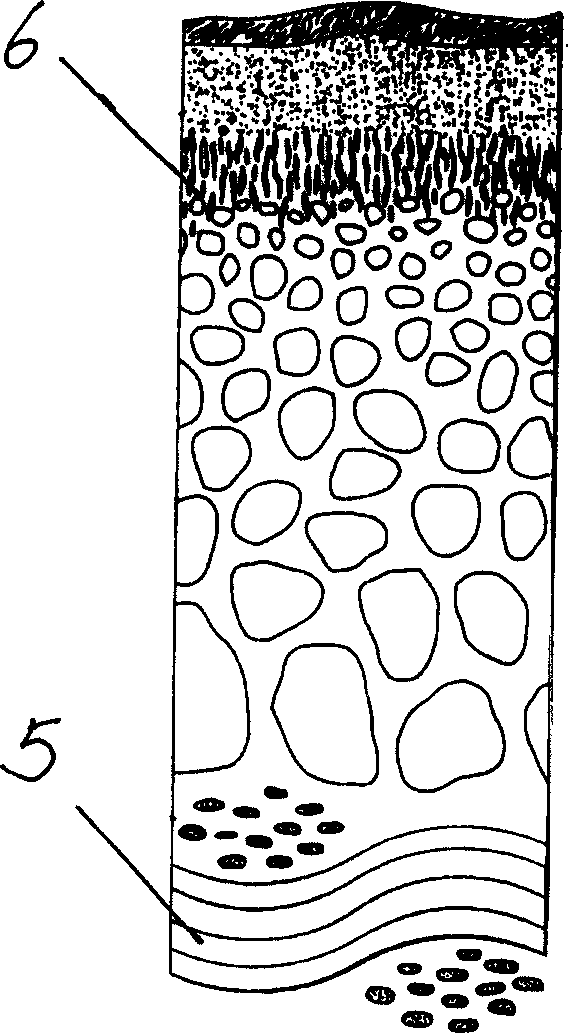

Image

Examples

Embodiment 1

[0025] Step 1, 70g of sintered α-alumina with an average particle size of 0.4 μm is added to a flask containing 2787g of N-methyl-2-pyrrolidone (hereinafter abbreviated as NMP), placed in Sonicator.RTM. Disperse in the container for at least 1.5 hours to disperse the agglomerates, and the color is milky white at this time.

[0026] Step 2: Slowly add 525 g of polyvinylidene fluoride (hereinafter abbreviated as PVDF) with a molecular weight of about 100,000 Daltons to the milky white solution under vigorous stirring. During this addition, the color of the solution first changed from milky white to pink, then to tan, and finally to gray or brown.

[0027] Step 3, after the above-mentioned gray or brown mixed solution is stable (the color does not change in 4-24 hours), add 118g of NMP solution containing 30% polyvinyl alcohol and 1.6-1.7% sulfuric acid, and the degree of hydrolysis of polyvinyl alcohol is 50 % After stirring vigorously for 4-24 hours, let stand or centrifuge to...

Embodiment 2

[0030] The hollow fiber membrane was prepared by the same method and steps as in Example 1. The difference is that N,N'-dimethylacetamide (DMAC) is used as a good solvent, the sintered α-alumina added is 60g with an average particle size of 0.4μm, and the polyvinylidene fluoride (PVDF) used is a molecule 400g of approximately 400,000 Daltons, 100g of NMP solution containing 30% polyvinyl alcohol and 1.6-1.7% sulfuric acid was added to the stable mixture. The prepared hollow fiber membrane has a porosity of 50%, an average pore diameter of 0.02 μm, and a pure water flux of 400 L / m at room temperature and 34.45 kPa (5 psi). 2 h.

Embodiment 3

[0032] The hollow fiber membrane was prepared by the same method and steps as in Example 1. The difference is that the concentration of polyvinylidene fluoride (PVDF) accounts for 10% of the total weight of the membrane-forming liquid, and the molecular weight of PVDF is 1,000,000 Daltons. The concentration of sintered α-alumina is 30% of the total weight of the membrane-forming solution, and the average particle size is 5 μm. The concentration of the hydrophilic additive polyvinylpyrrolidone is 5% of the total weight of the membrane-forming solution. The prepared hollow fiber membrane has a porosity of 70%, an average pore diameter of 0.3 μm, and a pure water flux of 800 L / m at room temperature and 34.45 kPa (5 psi). 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com