Patents

Literature

101results about How to "Simple film forming process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controlled release fertilizer coated by vegetable oil based polyurethane and preparation method thereof

InactiveCN103304772AWide variety of sourcesSimple film forming processFertilizer mixturesFertilizerIsocyanate

The invention discloses a controlled release fertilizer coated by vegetable oil based polyurethane and a preparation method thereof. The preparation method of the controlled release fertilizer coated by vegetable oil based polyurethane comprises the following steps of: 1) preheating the granular fertilizer; 2) heating plant oil polyhydric alcohol containing 2-6 hydroxys and isocyanate containing at least two isocyanate groups, and uniformly mixing the ingredients to form a vegetable oil based polyurethane coating liquid; 3) spray coating the vegetable oil based polyurethane coating liquid on the surfaces of the preheated fertilizer granules, repeatedly spray coating the vegetable oil based polyurethane coating liquid for 2-10 times after the vegetable oil based polyurethane coating liquid solid is solidified to obtain the controlled release fertilizer coated by vegetable oil based polyurethane. According to the controlled release fertilizer coated by vegetable oil based polyurethane and the preparation method thereof provided by the invention, the adopted coating material is extensive in resource, cheap and liable to obtain, non-toxic, harmless, simple in production process and good in controlled release effect of fertilizer.

Owner:上海永通生态工程股份有限公司

Silicone modified acrylic ester emulsion and preparation method thereof

The invention discloses a silicone modified acrylic ester emulsion and a preparation method thereof. The emulsion is prepared from the following raw materials in parts by weight: 6.5-9 parts of acrylic ester mixed monomers, 1-3.5 parts of an organosilicone monomer, 0.4-0.6 part of an emulsifier, 0.2-0.3 part of an initiating agent, 0.01-0.03 part of a pH conditioning agent, 28-32 parts of deionized water, wherein the acrylic ester mixed monomers are methyl methacrylate and butyl acrylate with the mass ratio of (5.5-6.5):(3.5-4.5); the organosilicone monomer is gamma- 3-[Tris(trimethylsiloxy)silyl]propyl methacrylate. According to the emulsion, the reactive emulsifier is adopted for polymerization reaction, the prepared emulsion is stable, and the latex film of the emulsion has lower surface energy and better water resistance, and can be used as the main film forming matter of a metal anti-corrosion coating.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

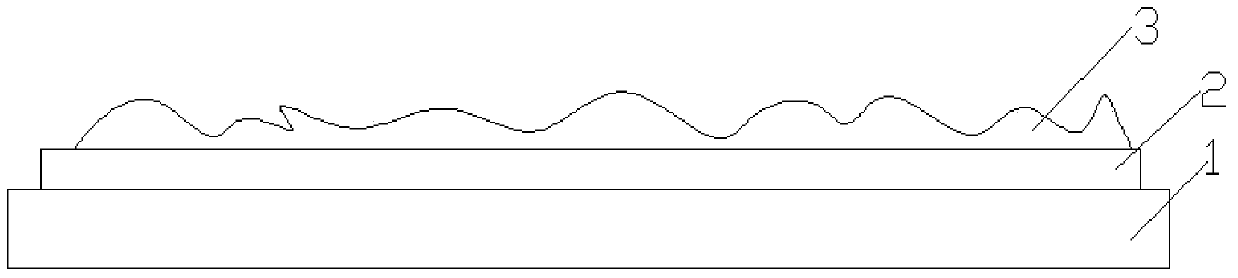

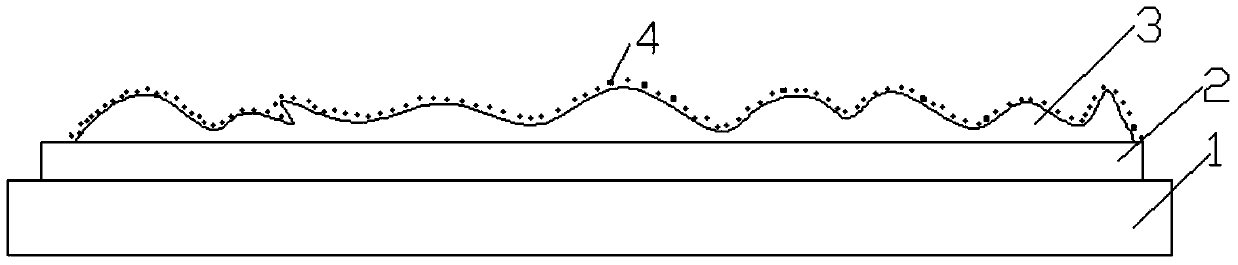

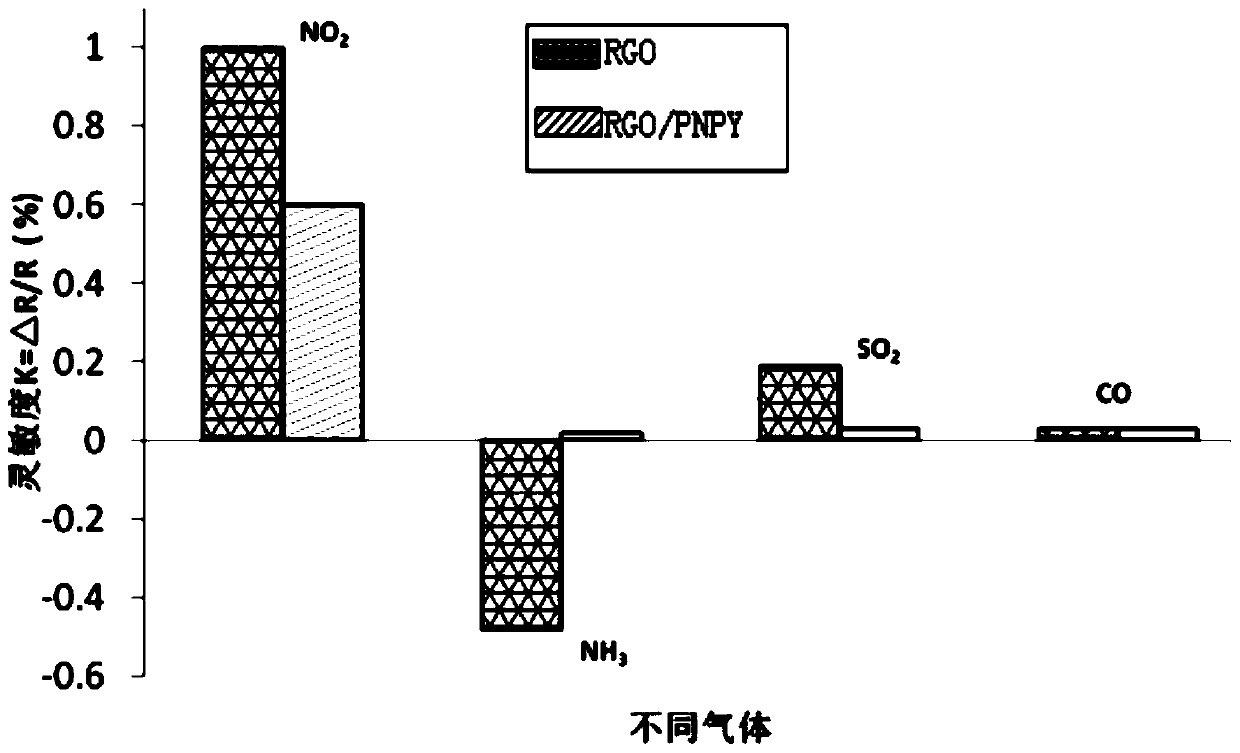

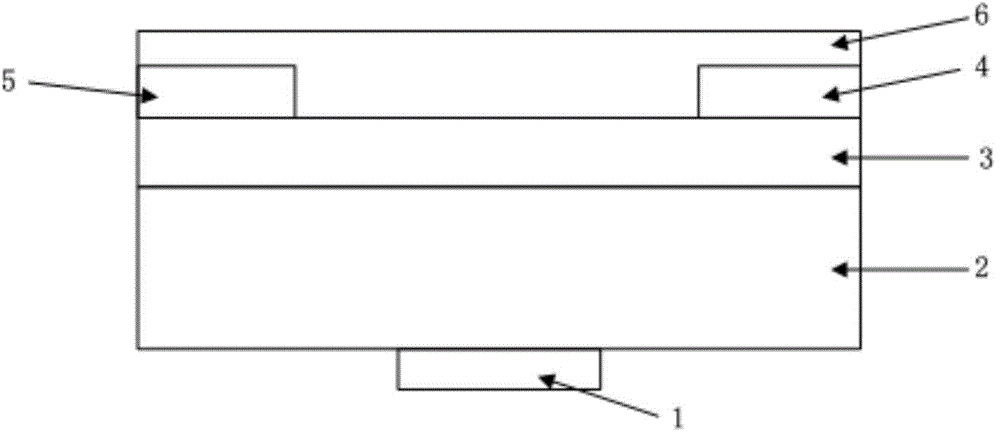

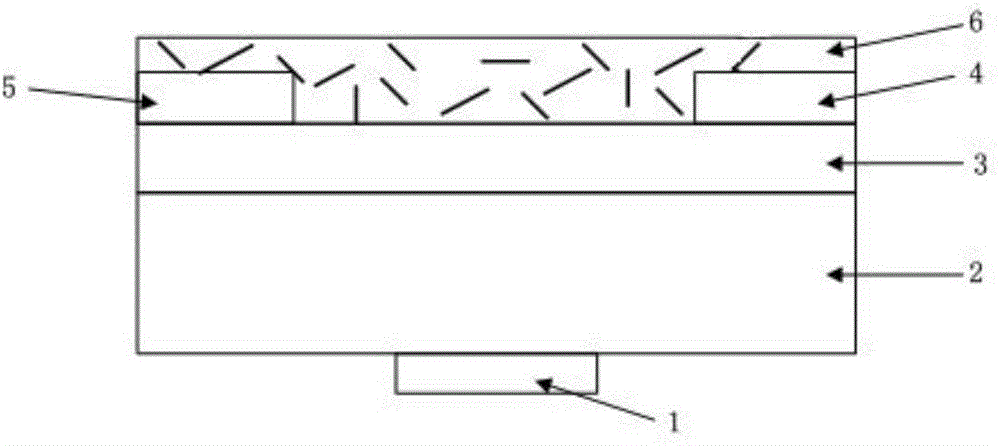

Nitrogen dioxide gas sensor and preparation method thereof

The invention discloses a nitrogen dioxide gas sensor and a preparation method thereof, and relates to the technical field of sensors. The nitrogen dioxide gas sensor comprises a substrate; an interdigital electrode is arranged on the upper surface of the substrate; a reduced graphene oxide thin film is deposited on the surface of the interdigital electrode to form a film-covered interdigital electrode structure; a poly-N-methylpyrrole thin film is deposited on the surface of the film-covered interdigital electrode structure; a few of poly-N-methylpyrrole materials in the poly-N-methylpyrrole thin film pass through slits of the reduced graphene oxide thin film and then are in contact with the interdigital electrode, and most poly-N-methylpyrrole materials are deposited on the surface of the reduced graphene oxide thin film. With poly-N-methylpyrrole serving as a gas adsorption selection layer and with reduced graphene oxide serving as a gas sensitive material to test nitrogen dioxide gas molecules, the selectivity on nitrogen dioxide gas is improved, and nitrogen dioxide in mixed gas can be detected. The nitrogen dioxide gas sensor is simple in structure, easy to prepare, low in production cost, convenient for experiment operation and suitable for nitrogen dioxide gas detection.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

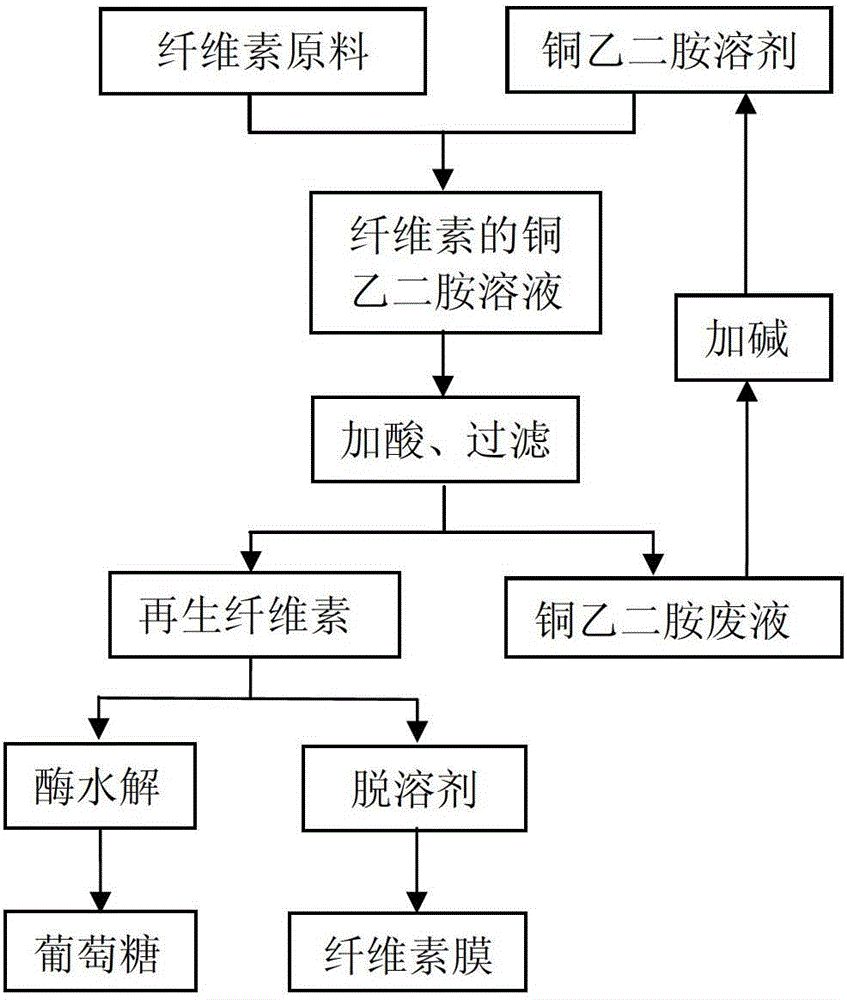

Method for treating cellulose

InactiveCN103397061BImproved hydrolysis and saccharification efficiencyImprove utilization efficiencyFermentationEthylene diamineEnzymatic hydrolysis

The invention relates to a method for treating cellulose. The method comprises the following steps of: dissolving the cellulose into a copper ethylene diamine solution, adding an inorganic acid to separate out regenerated cellulose, separating the obtained regenerated cellulose, performing enzymatic hydrolysis and saccharification or preparing a regenerated cellulose film. By adopting the treatment method provided by the invention, the hydrolysis and saccharification efficiency of the cellulose is greatly improved, and the utilization efficiency of the cellulose is improved; by adopting the treatment method, the film forming process of the cellulose is simplified, and the manufacturing cost is reduced; the copper ethylene diamine solution used in the treatment method can be recycled, so the treatment method is environment-friendly, and the cost is further reduced. In conclusion, the treatment method is simple, convenient, low in cost and high in utilization efficiency of the cellulose, and is wide in application prospect.

Owner:INT CENT FOR BAMBOO & RATTAN

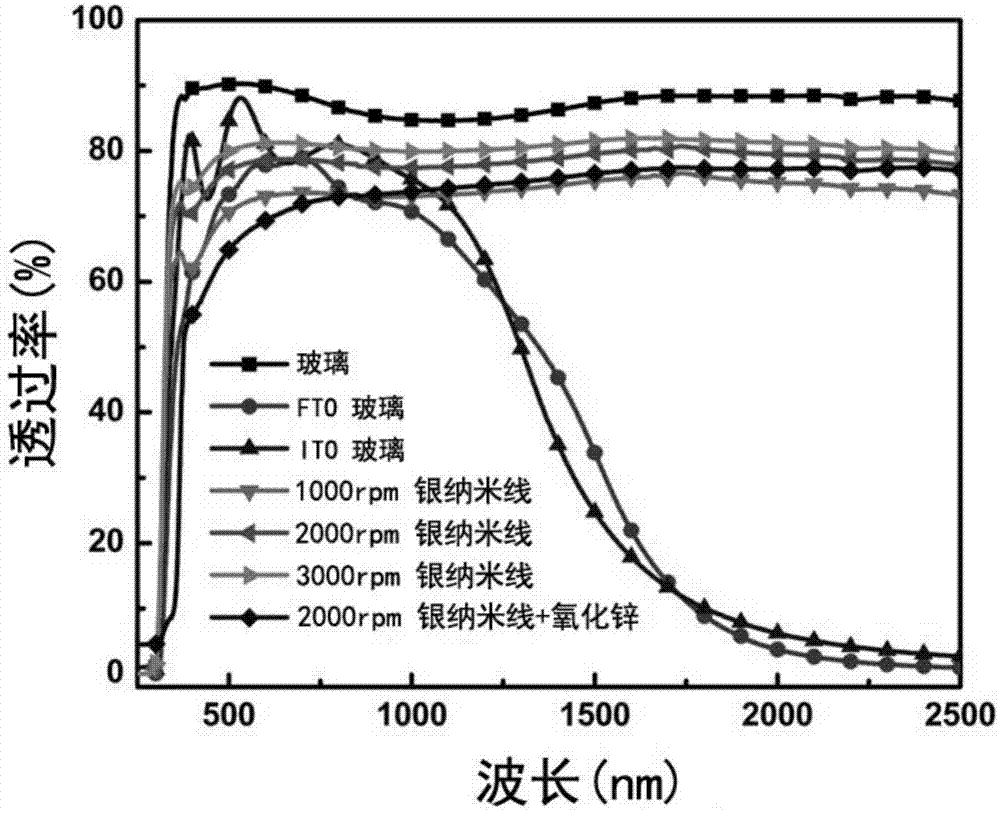

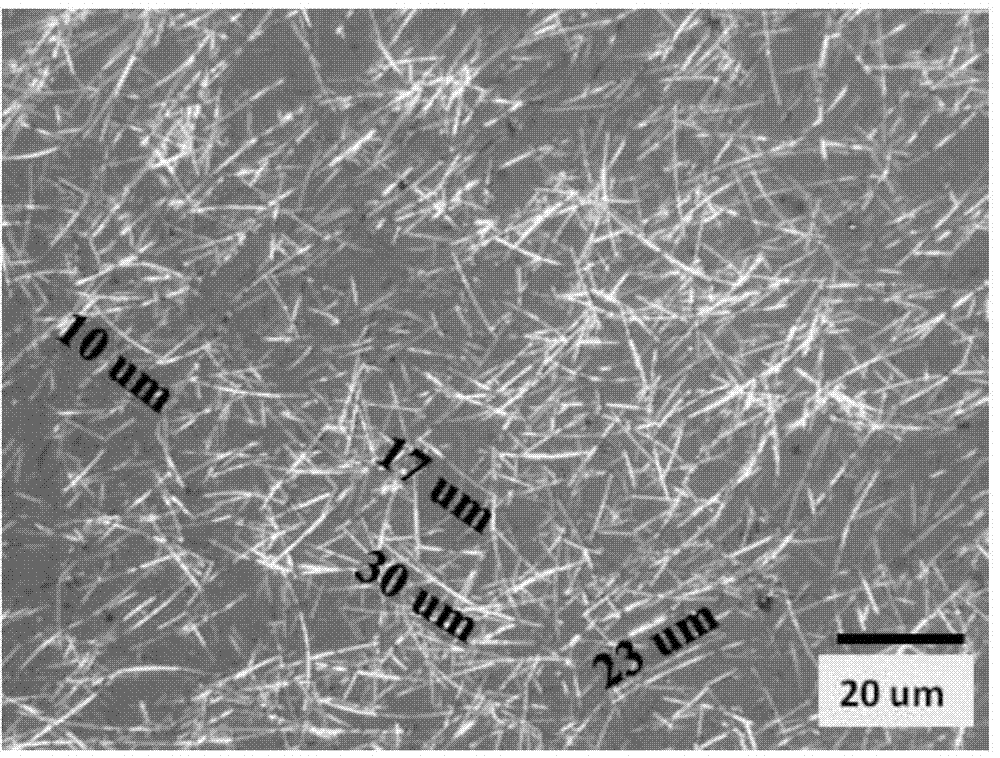

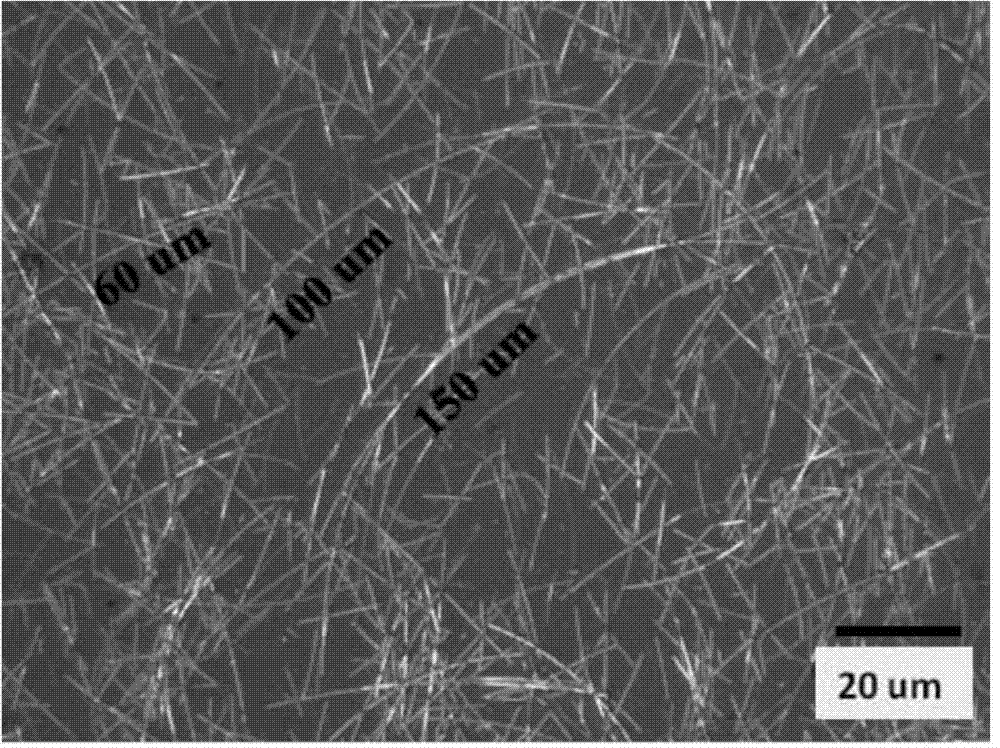

Preparation method of silver nanowire-zinc oxide composite transparent electrode

InactiveCN103700446AAvoid clustersHigh viscosityCable/conductor manufactureOxide compositeZinc nanoparticles

The invention belongs to the field of application of a nano material, particularly relates to a preparation method of a silver nanowire-zinc oxide composite transparent electrode and aims to simplify process, reduce cost and obtain the silver nanowire-zinc oxide composite transparent electrode with excellent light transmission and electrical conductivity, high wear resistance and environmental stability. The invention adopts the following technical scheme: 1, an ultra long silver nanowire is prepared by an improved polyol reduction method; 2, the silver nanowire is processed by a post-processing process; 3, a silver nanowire transparent conductive film is prepared; 4, zinc oxide nano particles are filled. The preparation method has various advantages of simple process, high repeatability, easiness for operation and control and the like.

Owner:XI AN JIAOTONG UNIV

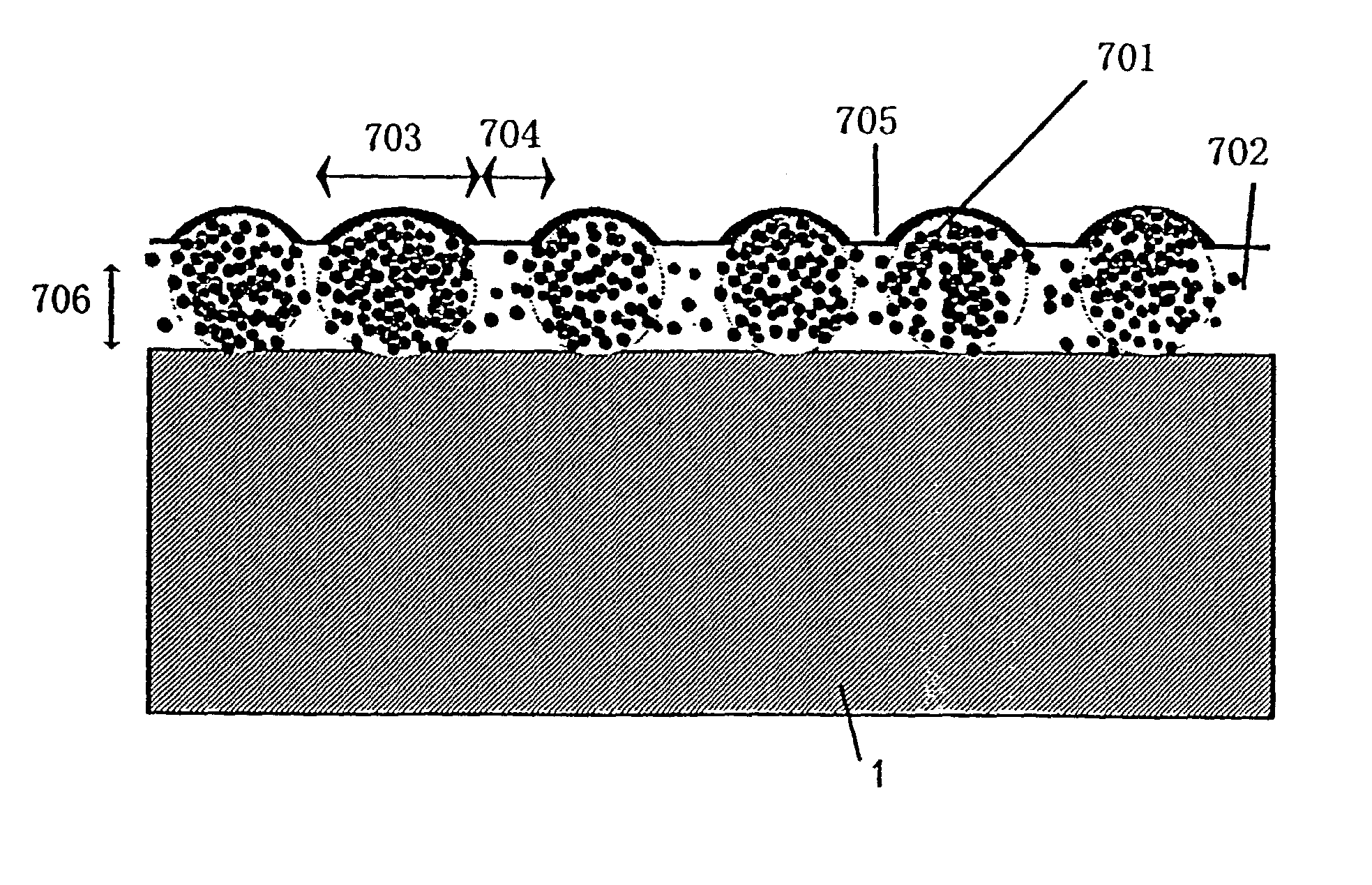

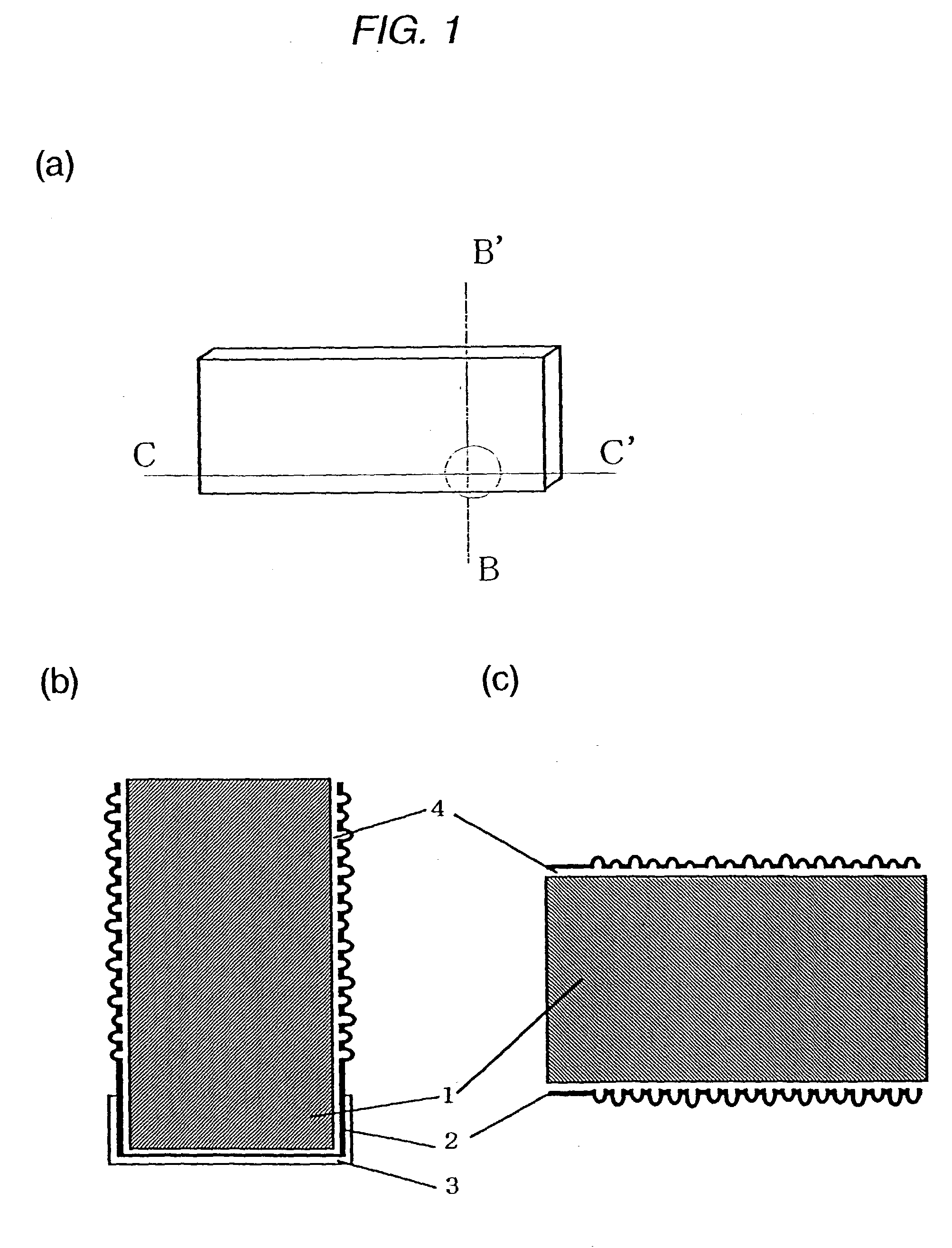

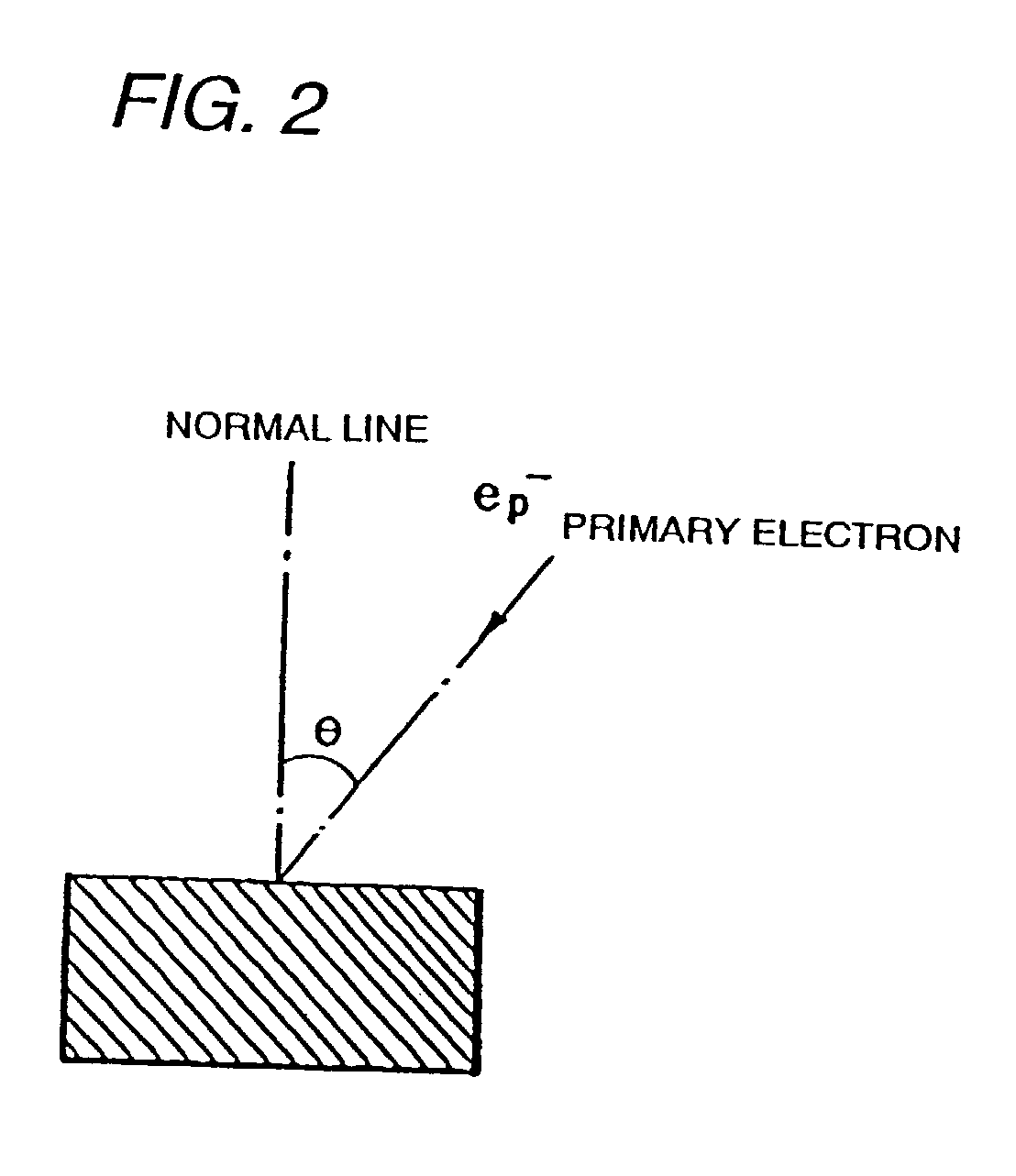

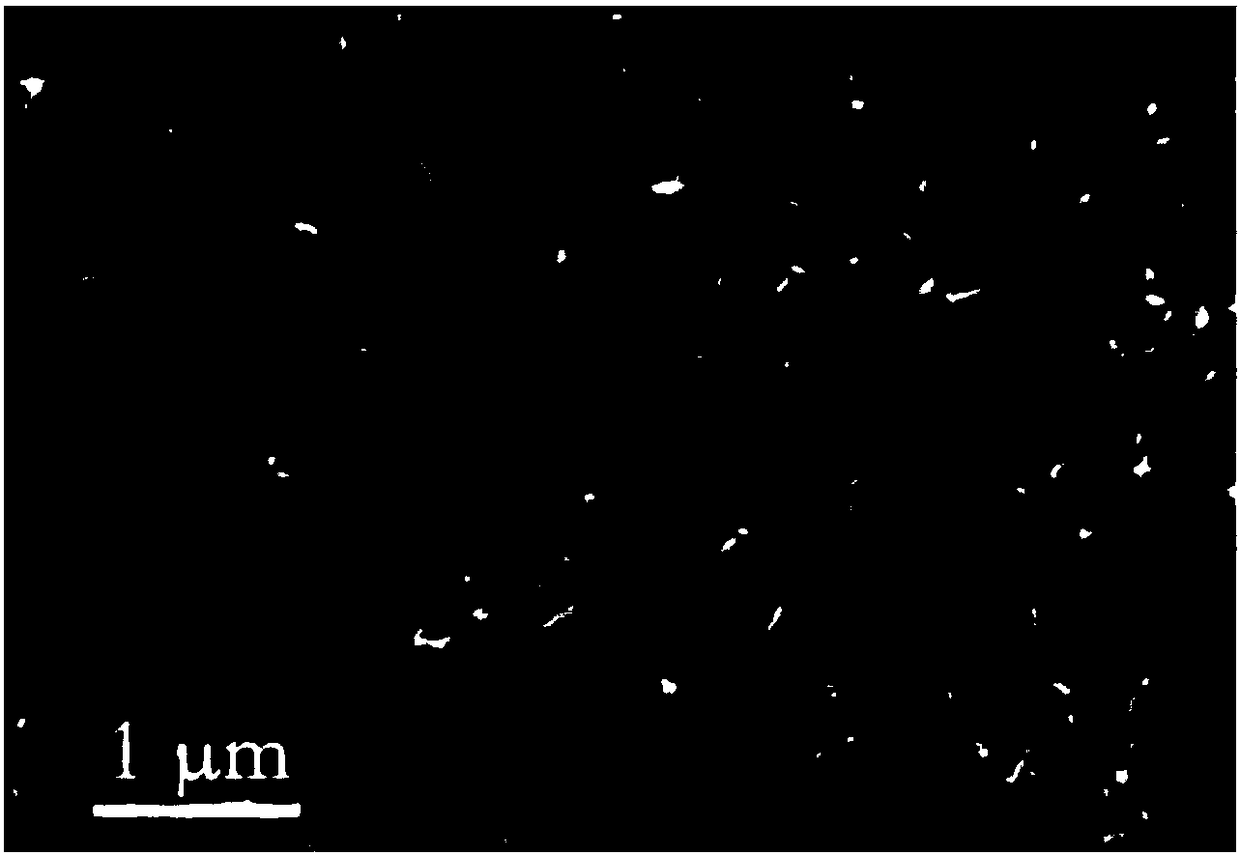

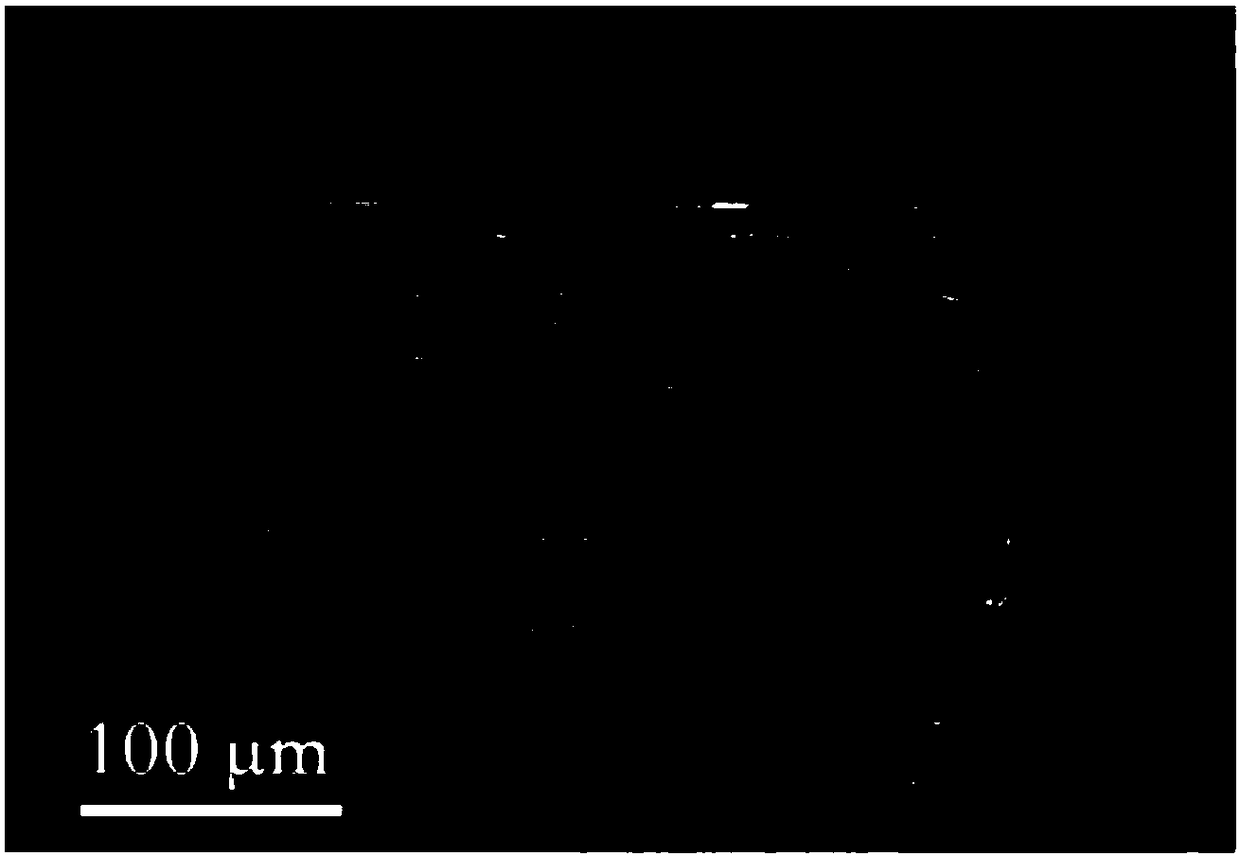

Electron beam apparatus and image forming apparatus

InactiveUS20040041507A1Prevent deterioration of display contrastAvoid chargingElectrode assembly support/mounting/spacing/insulationIncadescent body mountings/supportElectron sourceLight emission

The present invention is concerned with an electron beam apparatus comprising: a hermetic container; an electron source disposed within the hermetic container; and a spacer; wherein the spacer includes at least a region where a layer containing fine particles exists, a sheet resistance measured at the surface of the region of the spacer is 10<7 >Omega / □ or more, and the fine particles are 1000 Å or less in the average diameter of the particles and includes at least metal elements. The electron beam apparatus exhibits the excellent display quality which suppresses the displacement of the light emission point with the charge and the creeping discharge, and the long-period reliability.

Owner:CANON KK

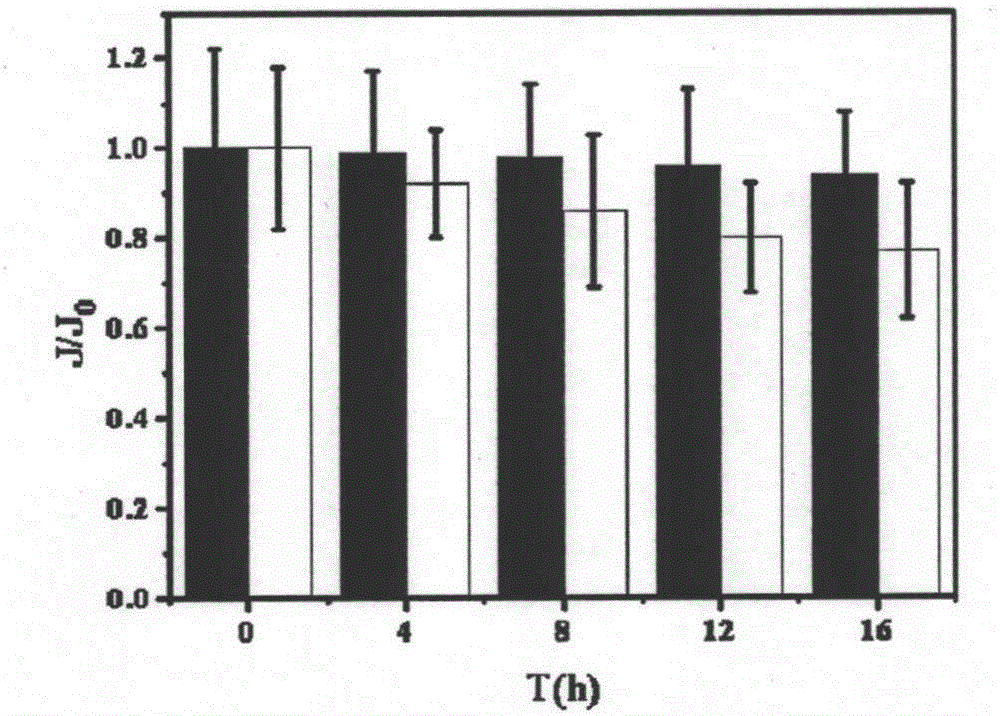

TiO2 / PVDF cross blend cation exchange membrane and preparation method

InactiveCN101091882AImprove hydrophilicityHigh mechanical strengthSemi-permeable membranesPolypropyleneGlass sheet

The invention publishes a method for producing the TiO2 / PVDF blending positive ion exchange membrane, which involves a method for producing high polymer organic membrane. This invention enhances the water affinity of PVDF positive ion exchange membrane, the mechanical strength and anti-pollution capacity. The positive ion exchange membrane includes FI ethane, polypropylene, crosslinking agent, titanium dioxide grain and organic solvent with activity groups. This invention is as follows: a. dissolving the FI ethane and polypropylene in the organic solvent; B. joining crosslinking agent; C. filtering insoluble substance; D. joining titanium dioxide grain; E, mixing the solution well-proportioned and deaeration; F, creating membrane on the glass plate; G, drying, and solidifying. The TiO2 / PVDF blending positive ion exchange membrane does not only retains the fine characteristic of FI ethane exchange membrane, but also improves the membrane surface energy,and enhances the water affinity, and increases the ability to repel outside pollutant.

Owner:HARBIN INST OF TECH

Gel polymer electrolyte, polymer lithium ion battery and making method of polymer lithium ion battery

ActiveCN103633367AImprove electrochemical performanceLyophilicSolid electrolytesFinal product manufacturePolymer scienceLithium-ion battery

The invention provides a gel polymer electrolyte. A polymer membrane absorbs an electrolyte and swells to form the gel polymer electrolyte, and the polymer membrane is formed through thermocuring self-crosslinking of a liquid polymer mixture; and the liquid polymer mixture contains a pure acrylic emulsion, water and ammonia water, and the glass transition temperature of the pure acrylic emulsion is -30 - 50 DEG C. The invention also provides a polymer lithium ion battery adopting the gel polymer electrolyte, and a making method of the polymer lithium ion battery. The gel polymer electrolyte has the advantages of substantial improvement of the security, stable electrochemical performances and high voltage resistance, can realize the inhibition of the generation of lithium dendrites, no liquid leakage, substantial improvement of the security and good cycle stability when the gel polymer electrolyte is used in the polymer lithium ion battery, and is more suitable for lithium ion power batteries.

Owner:BYD CO LTD

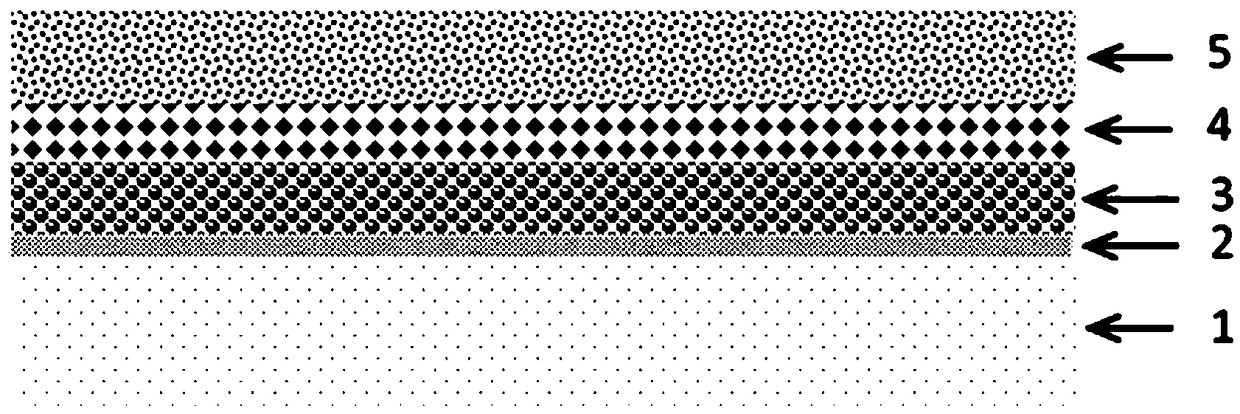

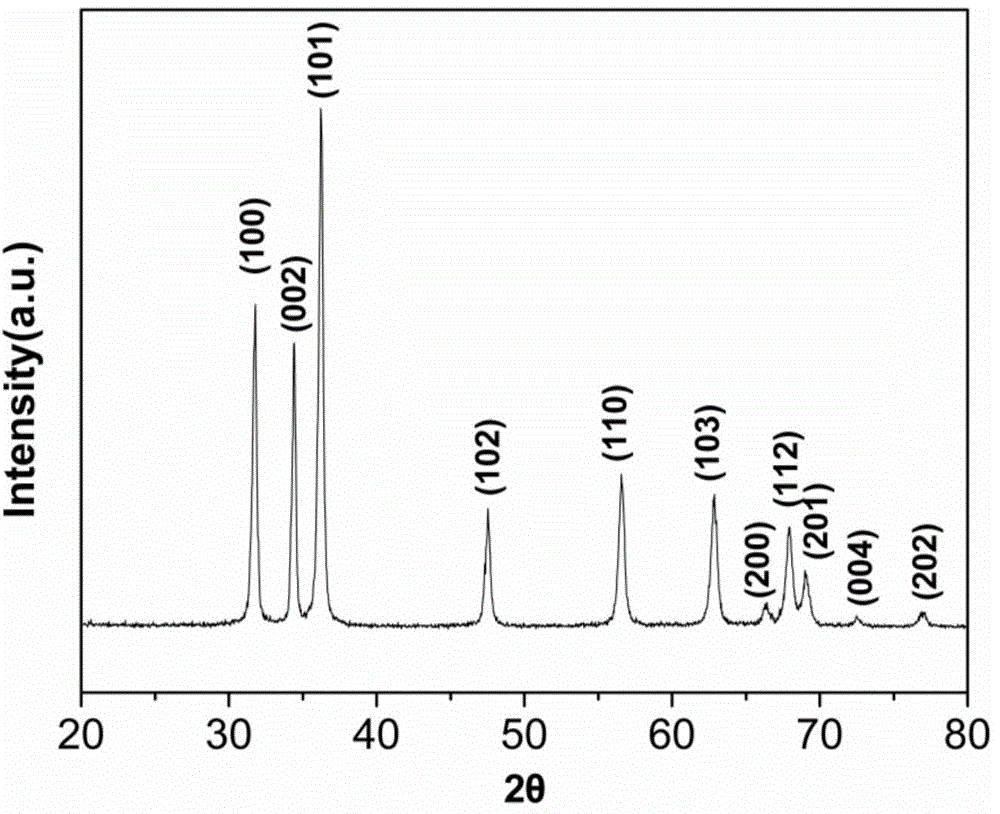

Porous perovskite film, carbon slurry and carbon electrode based solar cell

ActiveCN108269918AIncrease profitReduce dosageSolid-state devicesSemiconductor/solid-state device manufacturingSlurrySolar cell

The invention relates to a porous perovskite film, carbon slurry and a carbon electrode based solar cell. The chemical formula of the perovskite film is ABX3, wherein A is at least one monovalent cation, and is preferably at least one or a mixed ion of CH3NH3<+>, NH2-CH=NH2<+>, Cs<+>, Li<+>, C4H9NH3<+>, CH6N3<+>, Na<+> and K<+>, B is at least one of PB<2+>, Sn<2+>, Ge<2+>, Co<2+>, Fe<2+>, Mn<2+>,Cu<2+> and Ni<2+>, and X is at least one of Cl<->, Br<->, I<->, SCN<-> and BF4<->. The perovskite film is of a porous structure.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Biodegradable algae liquid plastic film and preparation method thereof

ActiveCN102212214AImprove wet strengthImprove water retentionClimate change adaptationPlant protective coveringsCarboxymethyl cellulosePlastic film

The invention provides a biodegradable algae liquid plastic film, which is characterized by comprising the following components in parts by weight: 100 parts of algae extract, 2-10 parts of polyacrylate alginate jelly resin, 50-70 parts of lignosulfonate, 10-20 parts of humic acid, 20-30 parts of molasses or biochemical fulvate or a mixture of molasses and biochemical fulvate at a weight ratio of 1: 2, 10-20 parts of carboxymethyl cellulose and 300-500 parts of water. In addition, the invention also provides a preparation method of the algae liquid plastic film.

Owner:BEIJING LEILI MARINE BIOINDUSTRY INC

Preparation method of temperature response type polyvinylidene fluoride flat separation film

InactiveCN101721923ASimple processLow costSemi-permeable membranesTemperature responsePolyvinylidene difluoride

The invention discloses a preparation method of a temperature response type polyvinylidene fluoride flat separation film, in particular to an intelligent type macromolecular flat separation film technology, belonging to the technical field of films. The intelligent type macromolecular flat separation film technology comprises the following steps of: 1, conducting the alkali treatment of PVDF powder; 2, preparing a temperature-sensitive copolymer, i.e. copolymerizing the PVDF powder subjected to the alkali treatment with a temperature-sensitive monomer NIPAAm, and synthetizing a PVDF-g-PNIPAAm copolymer; and 3, preparing the temperature response type PVDF flat separation film by using a phase inversion method. The preparation method of a film-forming copolymer has simple process, low cost, no need of special equipment, easy industrialized construction, and the like. The intelligent film product is a novel temperature response type PVDF intelligent film which can sensitively respond to the change of environmental temperature.

Owner:TIANJIN POLYTECHNIC UNIV

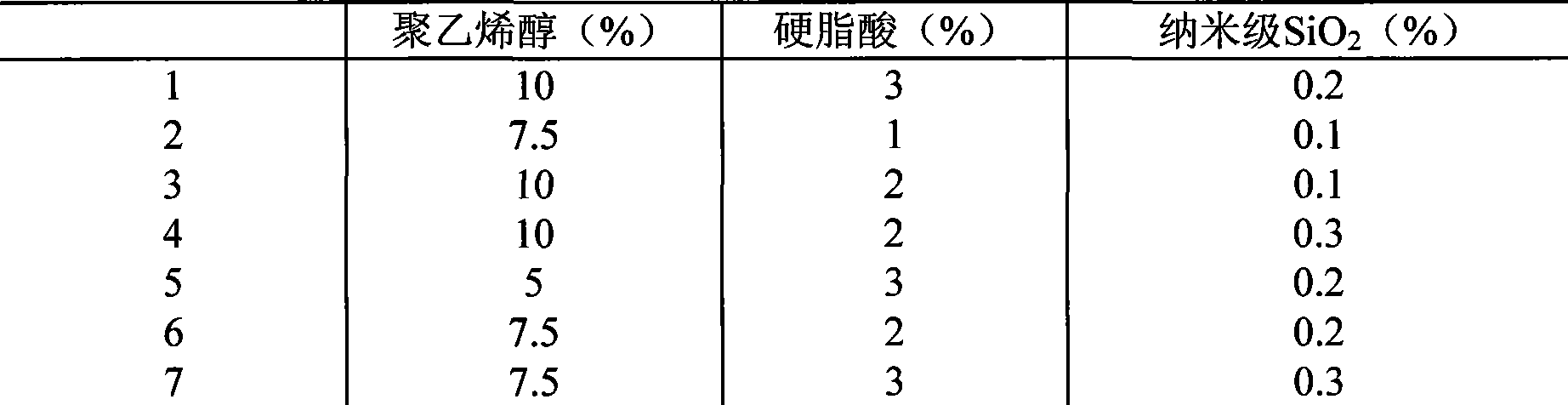

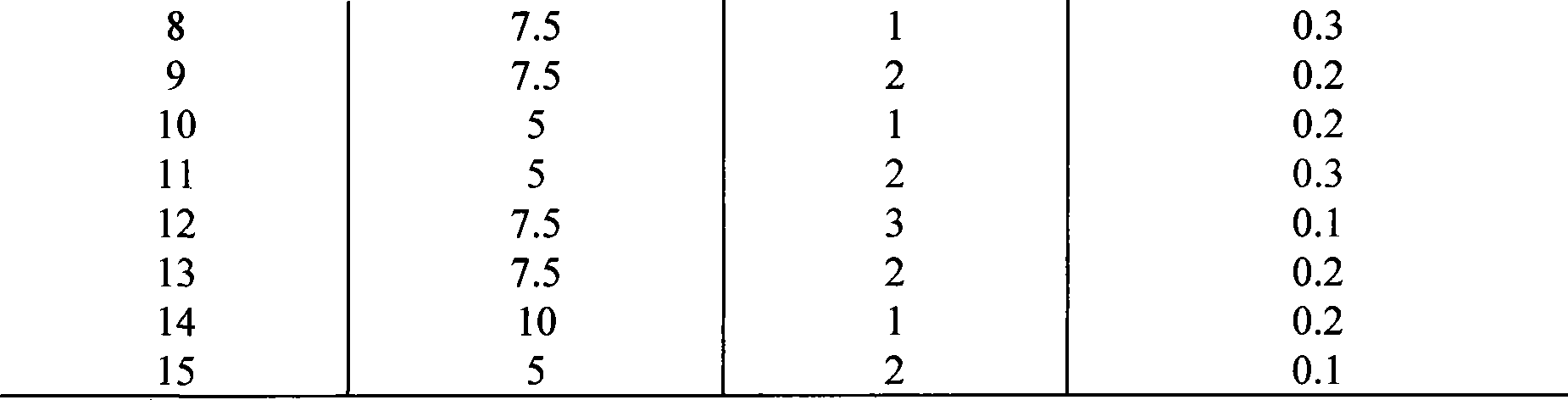

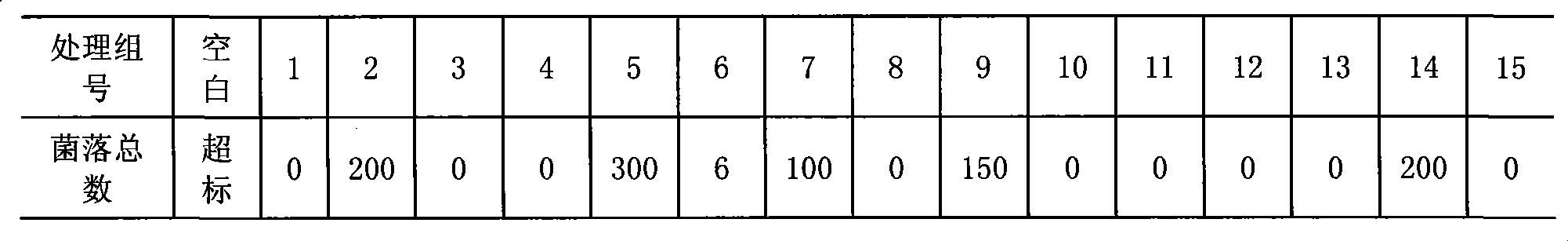

Traditional poultry eggs compound nano material coating-film fresh-keeping method

InactiveCN101390531ASimple film forming processUniform film thicknessEggs preservation by coatingComposite filmPolyvinyl alcohol

The invention relates to a traditional poultry egg product composite nano-material coating preservation method, belonging to the poultry egg fresh-keep packaging technical field. The method comprises the following steps: 5%-10% polyvinyl alcohol and 0.1%-0.5% nano-SiO2 are dissolved in water and heated; 1% -5% stearic acid is dissolved in (w / v is equal to 1:15-20) ethanol and heated; when the temperature of the polyvinyl alcohol solution and that of the stearic acid solution reach 80-85 DEG C at the same time, the two solutions are mixed, heated and stirred evenly to prepare the composite film coating agent; and the composite coating agent is hot-coated on the surface of the poultry egg and then dried with hot air and filmed. Compared with the cooked egg vacuum-packaging, the poultry egg coating preservation method can significantly reduce the using amount of packaging materials and simplify the packaging sterilization technique of the cooked eggs; besides, the poultry egg coating preservation method can achieve mechanized operation, effectively reduce the damage rate of eggs and significantly improve the economic benefits; moreover, the composite coating material is safe and degradable, which improves the marketability of products after being filmed on the egg surface and can also extend the shelf-life of the cooked egg products.

Owner:CHANGSHU YIHAO FOOD PACKAGING MATERIAL TECH +2

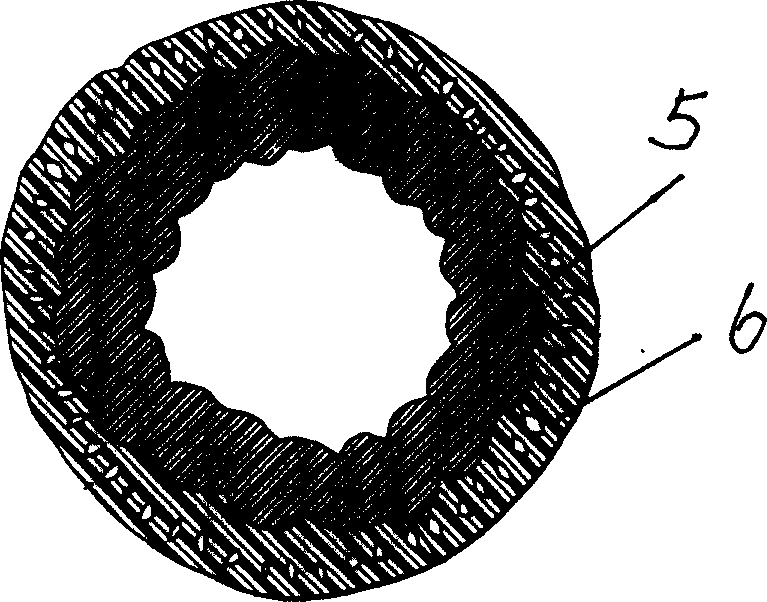

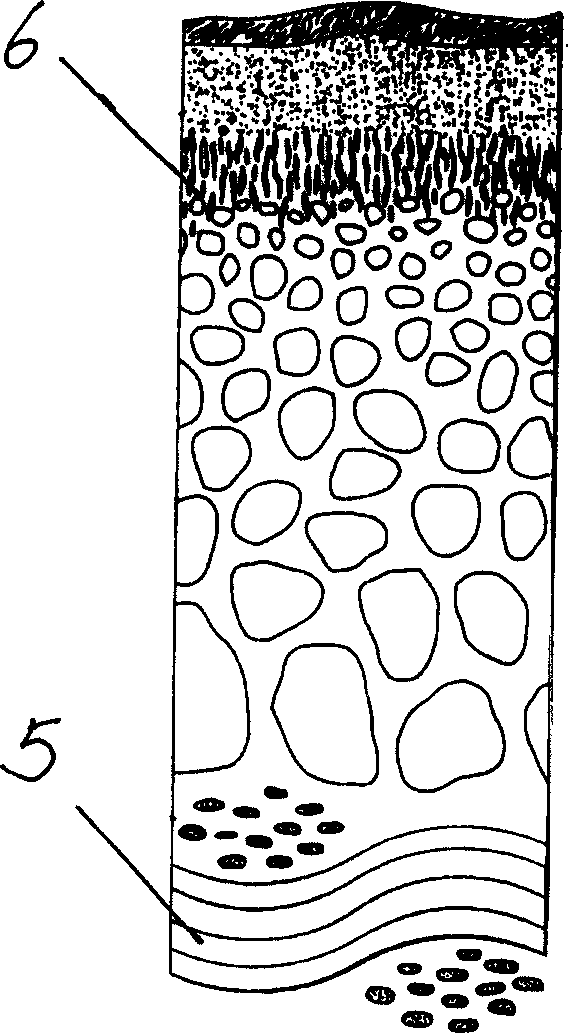

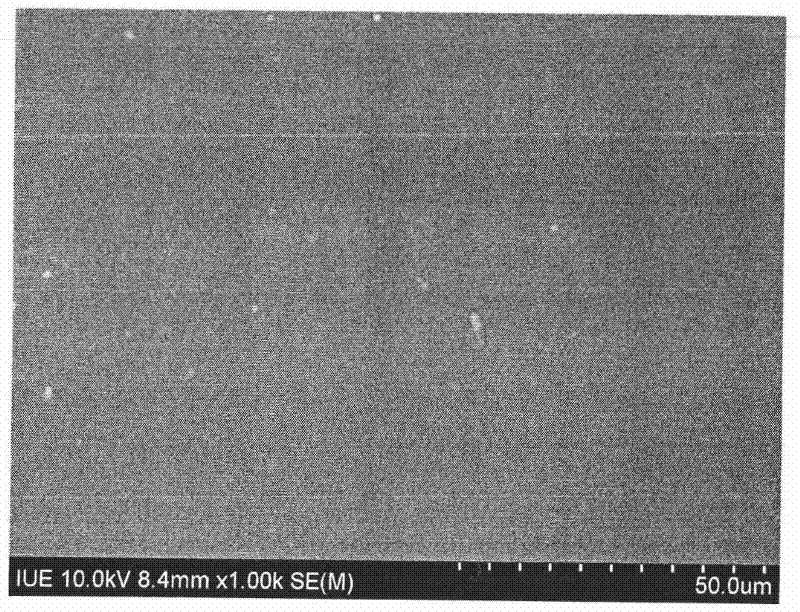

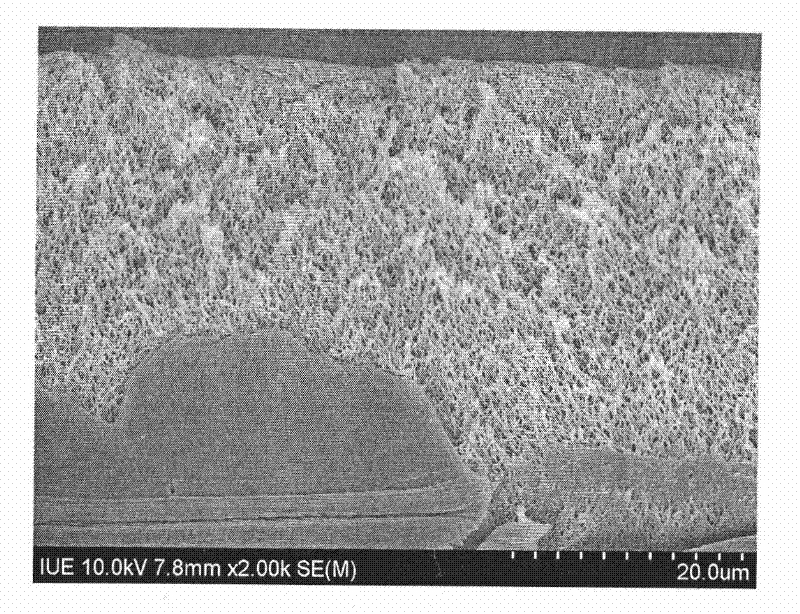

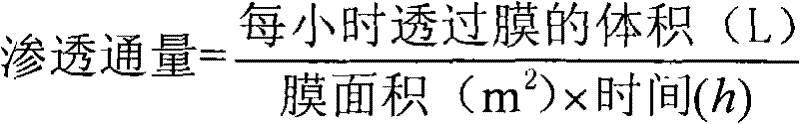

Sintered alpha-alumina/polyviny lidene fluoride blended hollow fiber membrane preparing method and its product

InactiveCN1579602AReasonable ingredientsLarge apertureSemi-permeable membranesPolymer sciencePolyvinylidene difluoride

The invention relates to an approach of producing asymmetry sintering alpha-alumina / polyvinylidene fluoride crossblend hollow fibre membrane. It also relates prescription of private membrane-forming liquor and its production. Use polyvinylidene fluoride as materials; disperse sinteringalpha-alumina in its good solvent to make them react to form mixing liquor; Add hydrophilicity compound which react with the mixing liquor to get membrane-forming liquor with some viscosity; using phase transmitting method to produce hollow fibre membrane. So the invention has merits of rational proportion, simple technics, low requirements to equipment and components complementation. It can manufacture bigger aperture, high permeation flux and asymmetry membranes.

Owner:ZHEJIANG OMEX ENVIRONMENTAL ENG CO LTD

Method for preparing bacterial cellulose/polyvinyl alcohol composite membrane by wet process

The invention relates to a method for preparing a bacterial cellulose / polyvinyl alcohol composite membrane by a wet process, which comprises the following steps: mechanically crushing bacterial celluloses to obtain a bacterial cellulose homogenate, and then determining the water content; preparing polyvinyl alcohol into a solution with a mass concentration of 5-15%; and uniformly mixing the bacterial cellulose homogenate and the polyvinyl alcohol solution, spreading in a mold, deaerating, standing at room temperature for 12-36 hours, and crosslinking with an aldehyde solution in a supersaturated salt solution to obtain the bacterial cellulose / polyvinyl alcohol composite membrane. By preparing the bacterial cellulose and water-soluble high molecular composite membrane by chemical crosslink in a coagulation bath, the preparation method has the characteristics of simple film-forming process, low cost, environmental friendliness and the like, and has favorable application prospects in industrial production.

Owner:DONGHUA UNIV +1

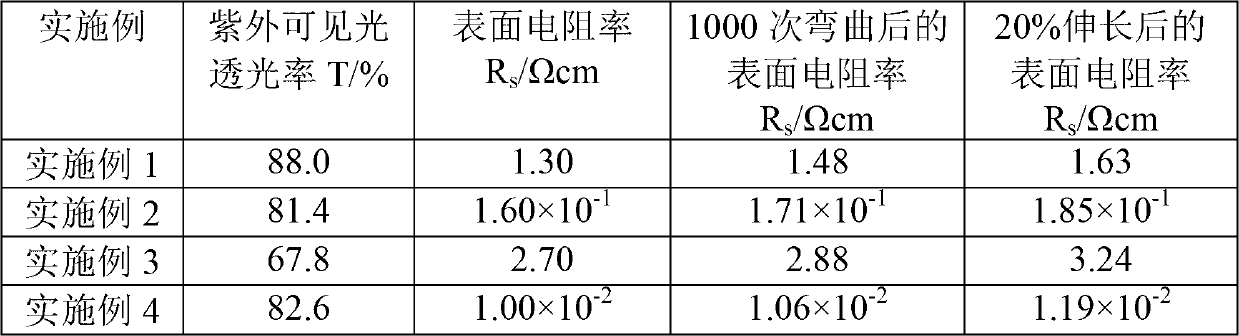

Preparation method of transparent conductive film

InactiveCN102993995ALower surface resistivityHigh visible light transmittanceFilm/foil adhesivesLaminationPolyethylene terephthalate glycolPolyethylene terephthalate

The invention relates to a preparation method of a transparent conductive film, wherein the method comprises the following steps of: uniformly dispersing an ethanol solution of a silver nano-wire on the surface of a transparent polyethylene terephthalate (PET) thin film; drying for 10minutes at 60 DEG C until the ethanol is completely volatilized; coating a layer of oil-face paper on the surface of the PET thin film; transferring the thin film onto a flat hot press; and heating, pressurizing, forming a film and cooling to obtain the transparent conductive film. The preparation method of the transparent conductive film disclosed by the invention is simple in process, low in cost of the adopted equipment, and high in light transmittance and excellent in bending resistance of the prepared film.

Owner:海泰纳鑫科技(成都)有限公司

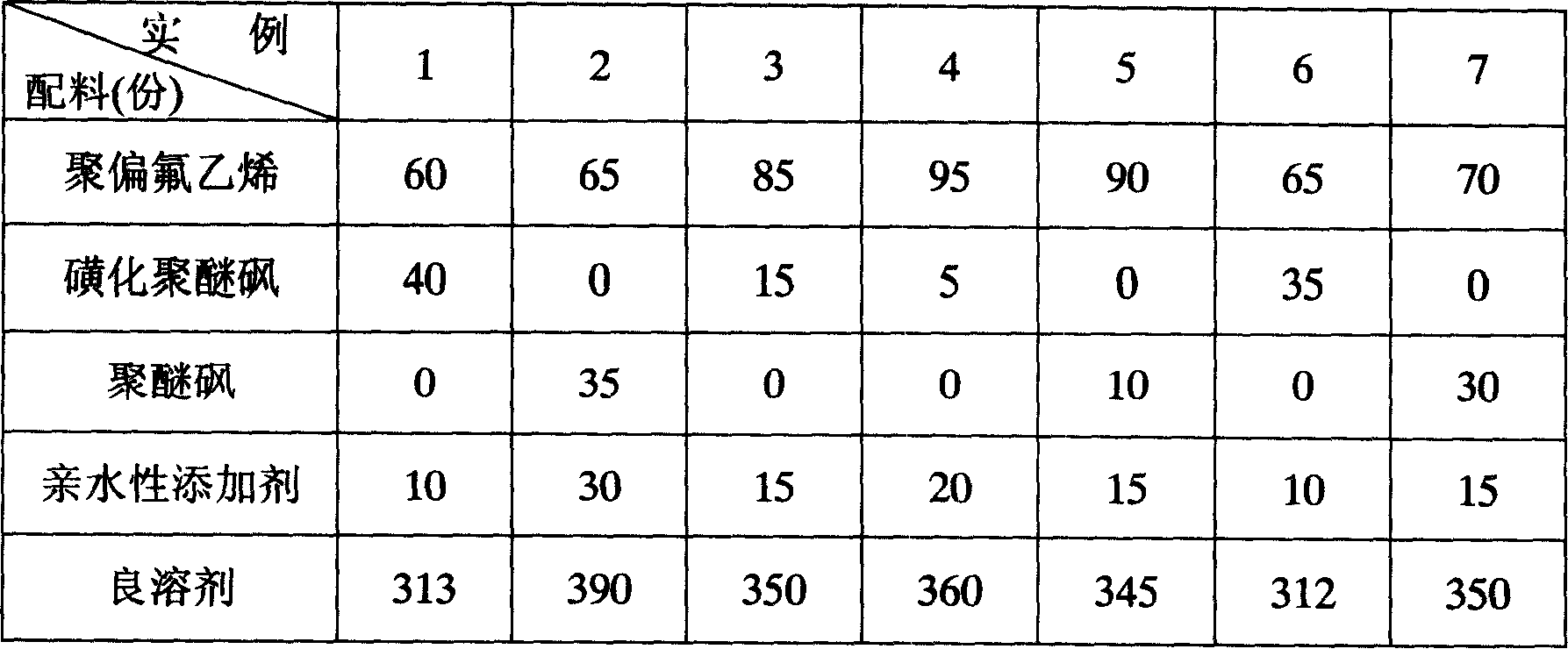

Formula of preparation liquid for hollow-fibre membrane and products thereof

InactiveCN1593734AMaintain stabilityReasonable ingredientsSemi-permeable membranesPolymer sciencePolyvinyl alcohol

The invention relates to a kind of hollow fiber membrane, especially a hollow fiber membrane formula with mixing hydrophilic poly-biasfluorine ethylene and its products. Raw material of this membrane is the mixture of poly-biasfluorine ethylene and sulfonated poly-ethersulphone or the mixture of bias fluorine polyethylene and poly-ethersulphone. Then the mixture reacts with hydrophilic additive that is polyethylene pyrrolidone or polyvinyl alcohol, then forms the hydrophilic hollow fiber membrane by the way of chemical grafting. Poly-biasfluorine ethylene has nice flexibility and poly-ethersulphone or sulfonated poly-ethersulphone has high intensity, so mixing them can make advantages for them of their abilities. In the result, it can make the resulting hollow fiber membrane have the high water flux and the temperate intensity, can improve hydrophilicity and stability of it, and can make it have longer service life. This membrane can be used extensively in the fields such as Medicine, Sanitation, Foodstuff, Industry and so on.

Owner:ZHEJIANG OMEX ENVIRONMENTAL ENG CO LTD

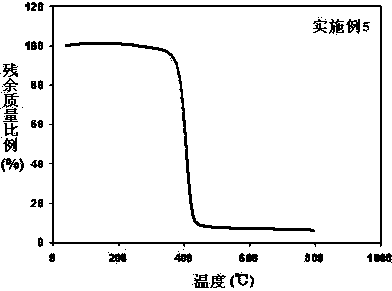

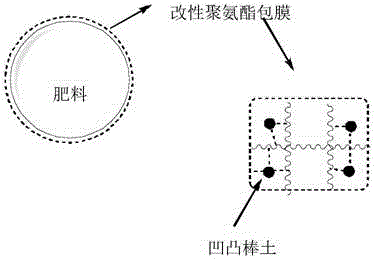

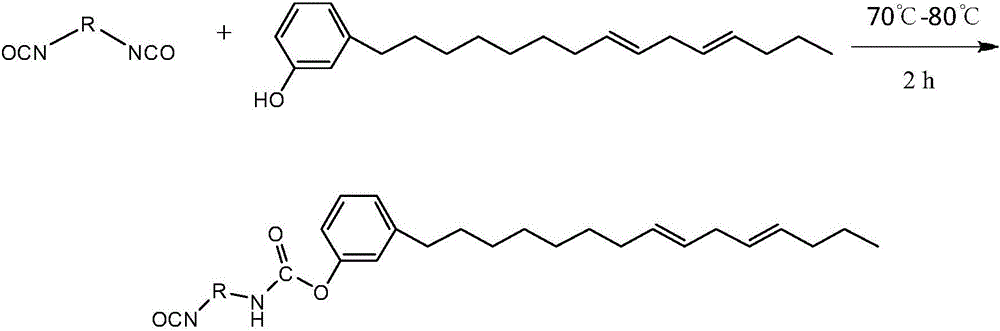

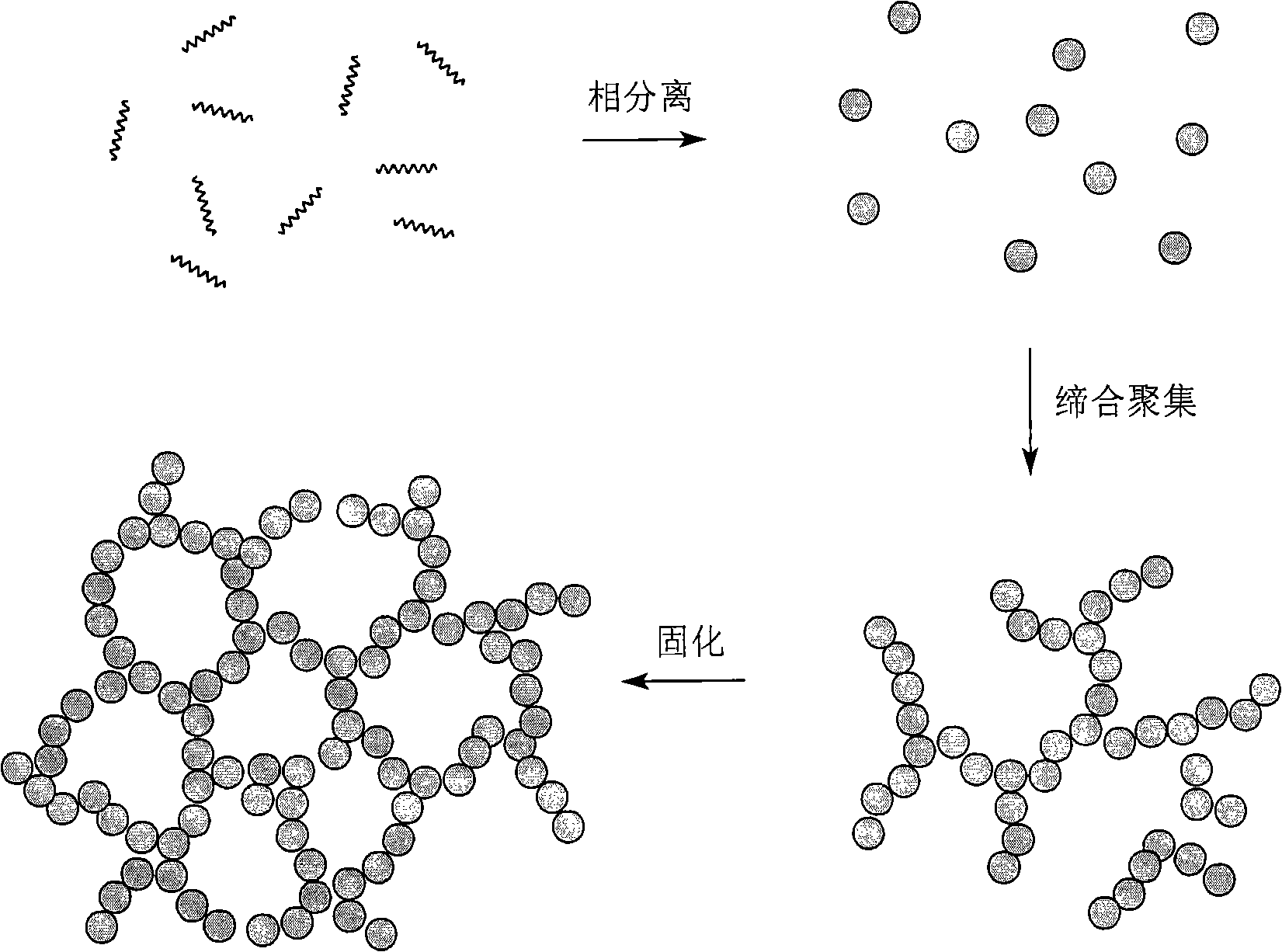

Composite modified polyurethane coating slurry, controlled release fertilizer and preparation method of controlled release fertilizer

ActiveCN106800472AWide variety of sourcesGood adhesionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersControlled releaseAlcohol

The invention discloses composite modified polyurethane coating slurry, a controlled release fertilizer and a preparation method of the controlled release fertilizer. The preparation method of the polyurethane coating controlled release fertilizer comprises the following steps: (1) vegetable oil polyhydric alcohol and attapulgite are uniformly mixed at a preset ratio to obtain an A component; (2) polymethylene polyphenyl isocyanate and cardanol with a mole ratio of 10-15% react for 1-3h at 70-80 DEG C to obtain a B component; (3) the A component and the B component are uniformly mixed in proportion to obtain vegetable oil based attapulgite hybridized composite modified polyurethane coating slurry; (4) a to-be-coated granular fertilizer is preheated; (5) the composite modified polyurethane coating slurry is sprayed on the surface of the preheated granular fertilizer; (6) the vegetable oil based polyurethane coating slurry is repeatedly sprayed for 3-6 times after the vegetable oil based polyurethane coating slurry is solidified to obtain the vegetable oil based attapulgite hybridized composite modified polyurethane coating controlled release fertilizer.

Owner:上海永通生态工程股份有限公司

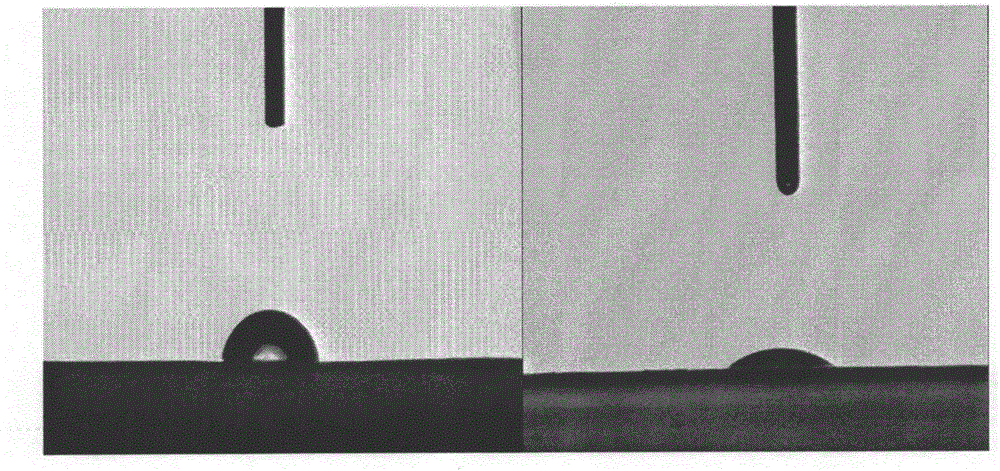

Tungsten bronze-based super-hydrophobic transparent thermal insulation coating and preparation method thereof

InactiveCN113185871AWith self-cleaning effectGood dispersionNanotechnologyCoatingsSodium tungsten bronzeOrganic solvent

The invention discloses a tungsten bronze-based super-hydrophobic transparent heat-insulating coating and a preparation method thereof. The tungsten bronze-based super-hydrophobic transparent heat-insulating coating is obtained by adding hydrophobically modified nano tungsten bronze and hydrophobically modified powder into a resin solution for dissolving an organic solvent to form a film, synthesizing nanometer cesium-tungsten bronze and nanometer sodium-tungsten bronze through a solvothermal method, then respectively modifying the nanometer cesium-tungsten bronze, the nanometer sodium-tungsten bronze and nanometer silicon dioxide to serve as inorganic components, combining organic resin to prepare the super-hydrophobic coating, and coating the surface of a substrate with the tungsten bronze-based super-hydrophobic transparent heat-insulating super-hydrophobic coating by adopting a film forming process, wherein the static contact angle of the obtained tungsten bronze-based super-hydrophobic transparent heat-insulating coating is larger than 155 degrees, and the rolling angle is smaller than 10 degrees. The nano tungsten bronze-based super-hydrophobic transparent heat-insulating super-hydrophobic coating is good in dispersity, and a prepared coating is good in binding force with a matrix and good in transparent heat-insulating effect.

Owner:SOUTH CHINA UNIV OF TECH

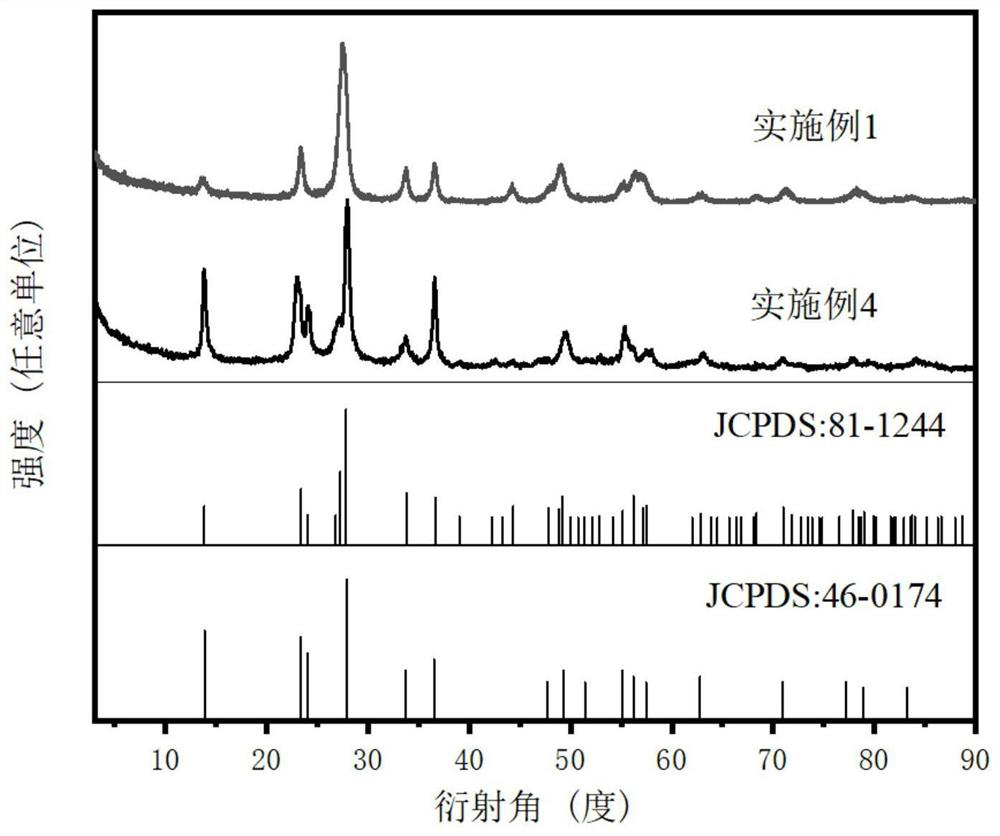

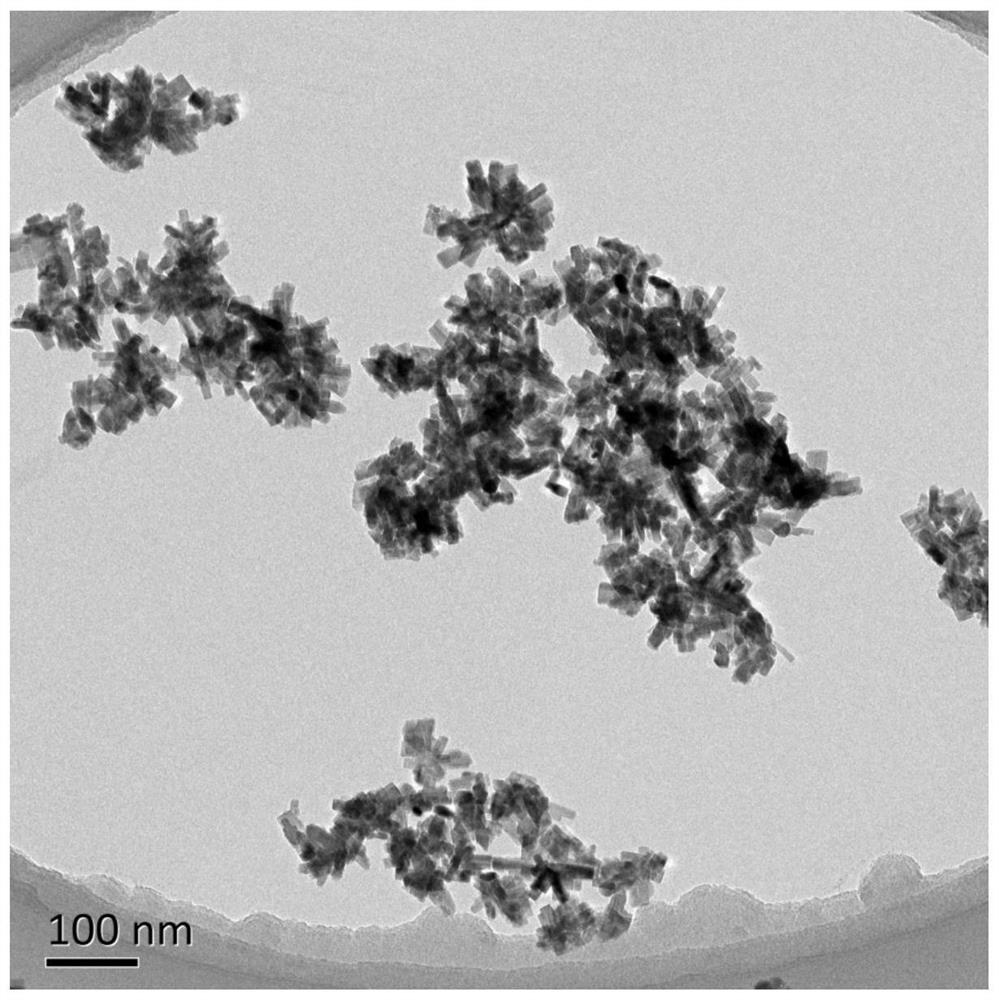

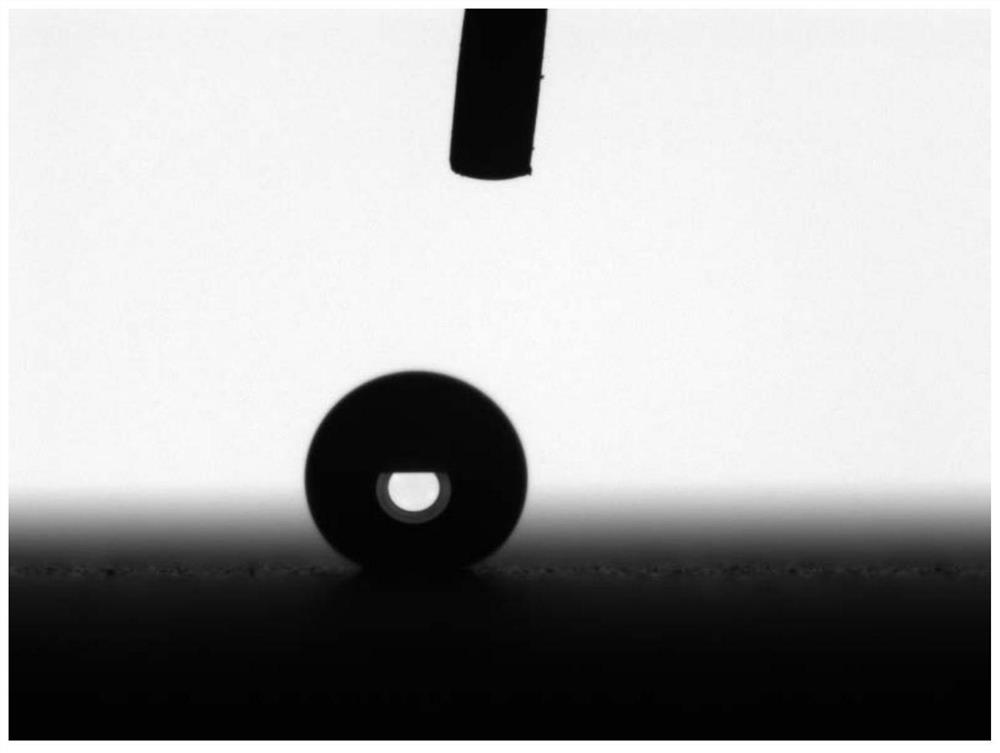

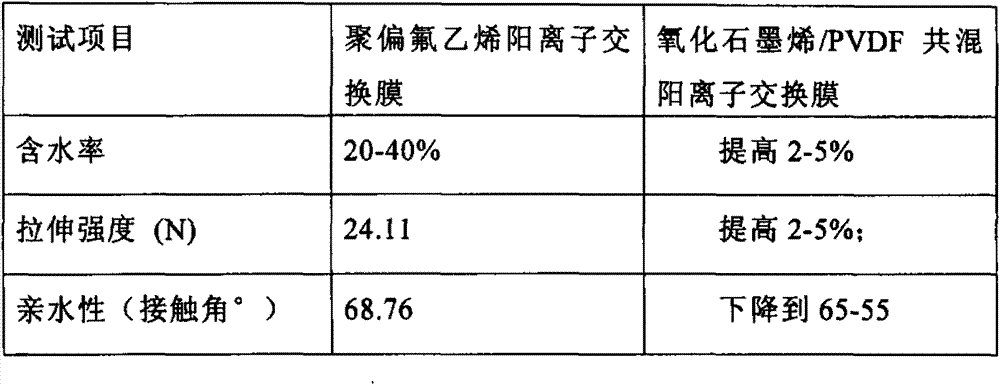

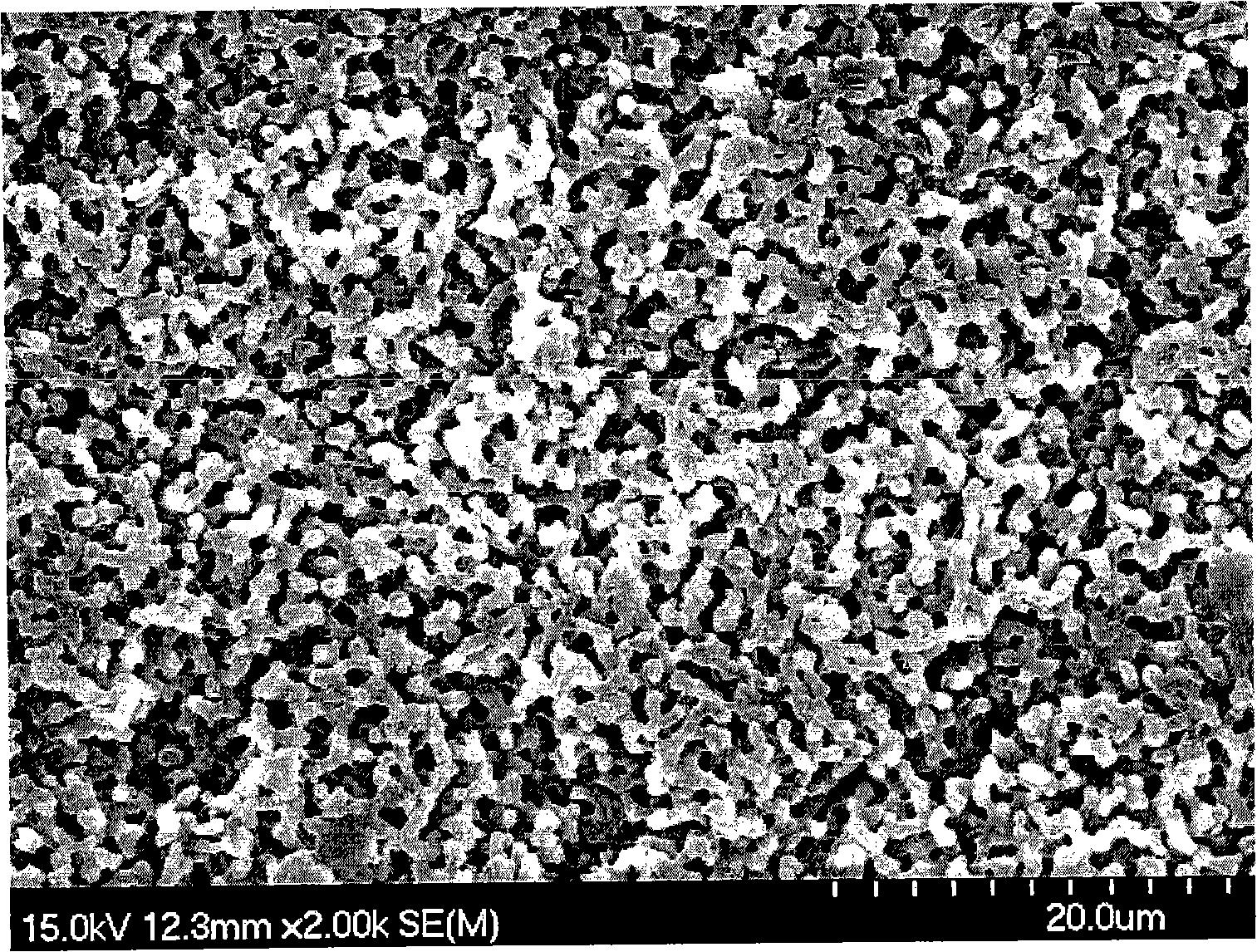

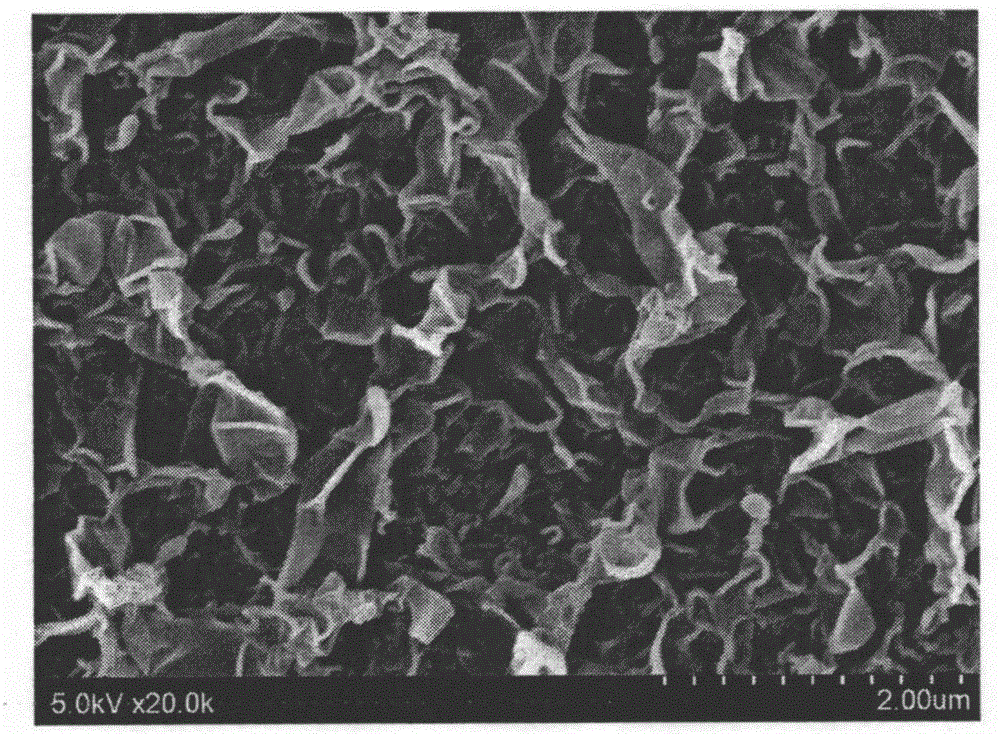

Graphene oxide/PVDF (polyvinylidene fluoride) blended cation exchange membrane and preparation method thereof

InactiveCN103087342AImprove hydrophilicityHigh mechanical strengthSemi-permeable membranesGlycidyl methacrylateBenzoyl peroxide

The invention relates to a graphene oxide / PVDF (polyvinylidene fluoride) blended cation exchange membrane and a preparation method thereof. The cation exchange membrane is prepared from the following components and raw materials in percentage by weight: 5-20% of polyvinylidene fluoride, 0.1-5% of graphene oxide, 50-70% of an organic solvent, 10-20% of divinyl benzene, 6-20% of glycidyl methacrylate, and 0.5-5% of benzoyl peroxide. The preparation method comprises the following steps: preparing membrane casting liquid firstly, preparing the membrane casting liquid into a base membrane by utilizing a tape casting method, cleaning the base membrane, and modifying the base membrane so as to obtain the cation exchange membrane. Compared with the prior art, the graphene oxide / PVDF blended cation exchange membrane prepared by using the method disclosed by the invention has the advantages that not only can the original excellent characteristics of PVDF cation exchange membranes be retained, but also the surface properties of PVDF cation exchange membranes are improved, the hydrophilicity, mechanical strength and acid and alkali resistances of membranes are enhanced, and the anti-pollution capacity of membranes is improved.

Owner:TONGJI UNIV

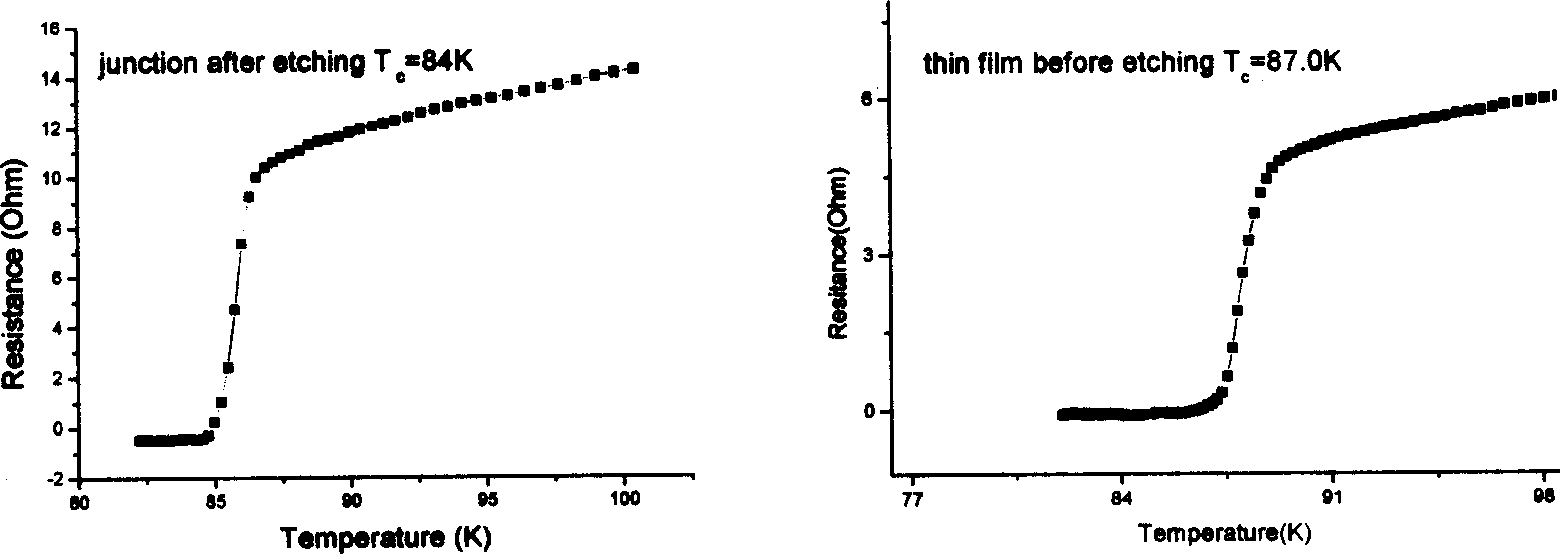

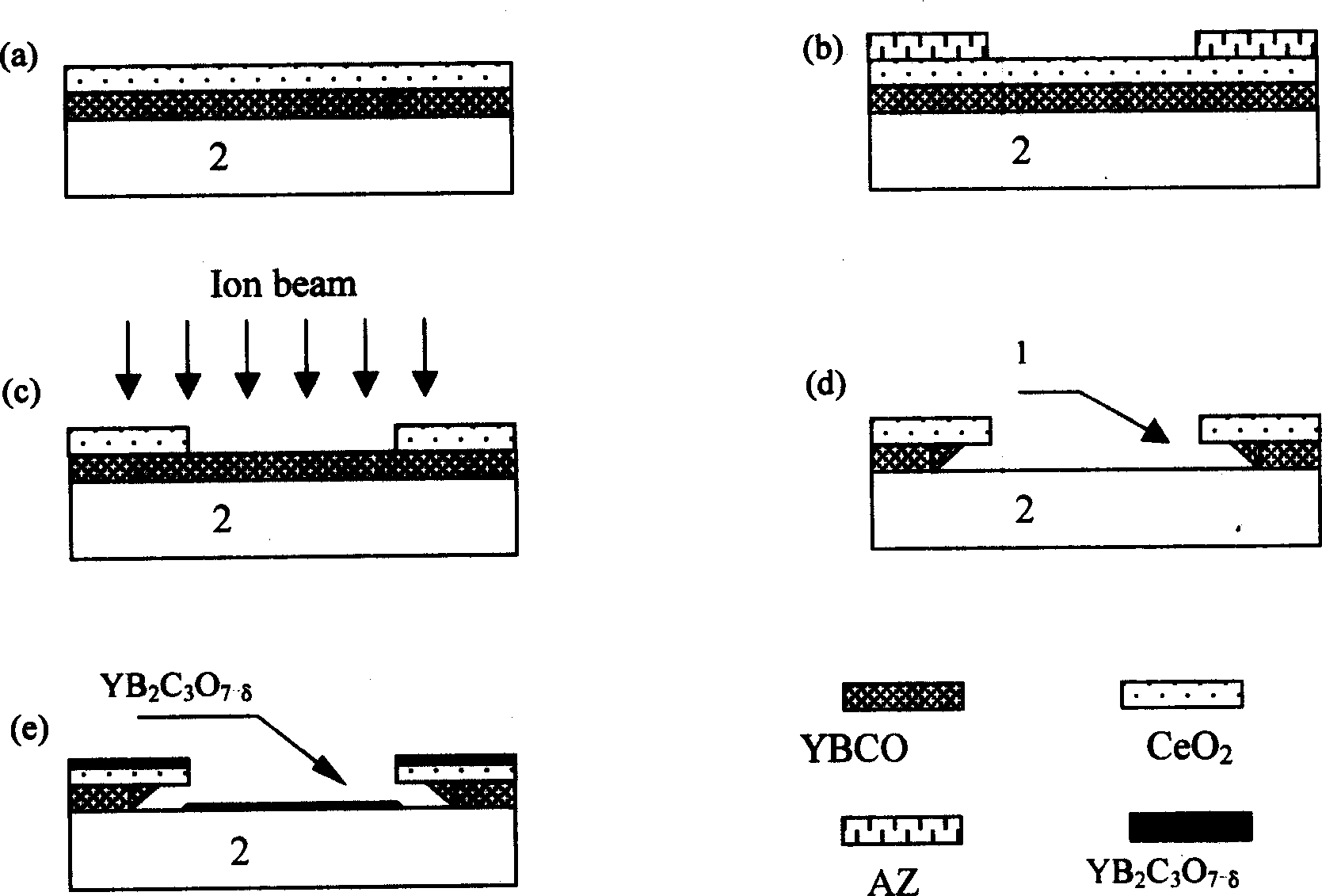

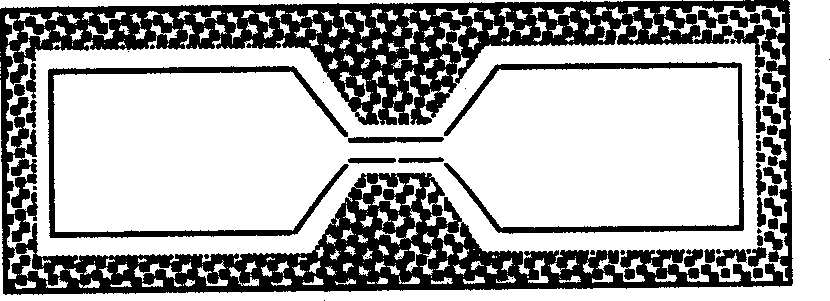

Method for preparing high-temp. superconductive Josephson junction by using refractory micromask process

InactiveCN1461063AImprove characteristic parameters such as transition temperatureImprove consistencyDissimilar materials junction devicesSuperconductor device manufacture/treatmentHigh-temperature superconductivityPhosphoric acid

The preparation of high-temp. superconductive Josephson junction includes the following steps: using conventional or double-crystal or step substrate, preparing CeO2 / YBCO double-layer film on the substrate by using in-site preparation process, preparing photoresist mask on the double-layer film, exposing and developing to obtain microbridge pattern, using plasma etching process to remove CeO2 film from microbridge zone to prepare CeO2 mask, using dilute phosphoric acid to corrode YBCO film of microbridge portion so as to completely remove YBCO of substrate, placing the above-mentioned material into film-forming system to grow out high-temp. superconductive film with required pattern so as to directly form Josephson junction.

Owner:NANJING UNIV

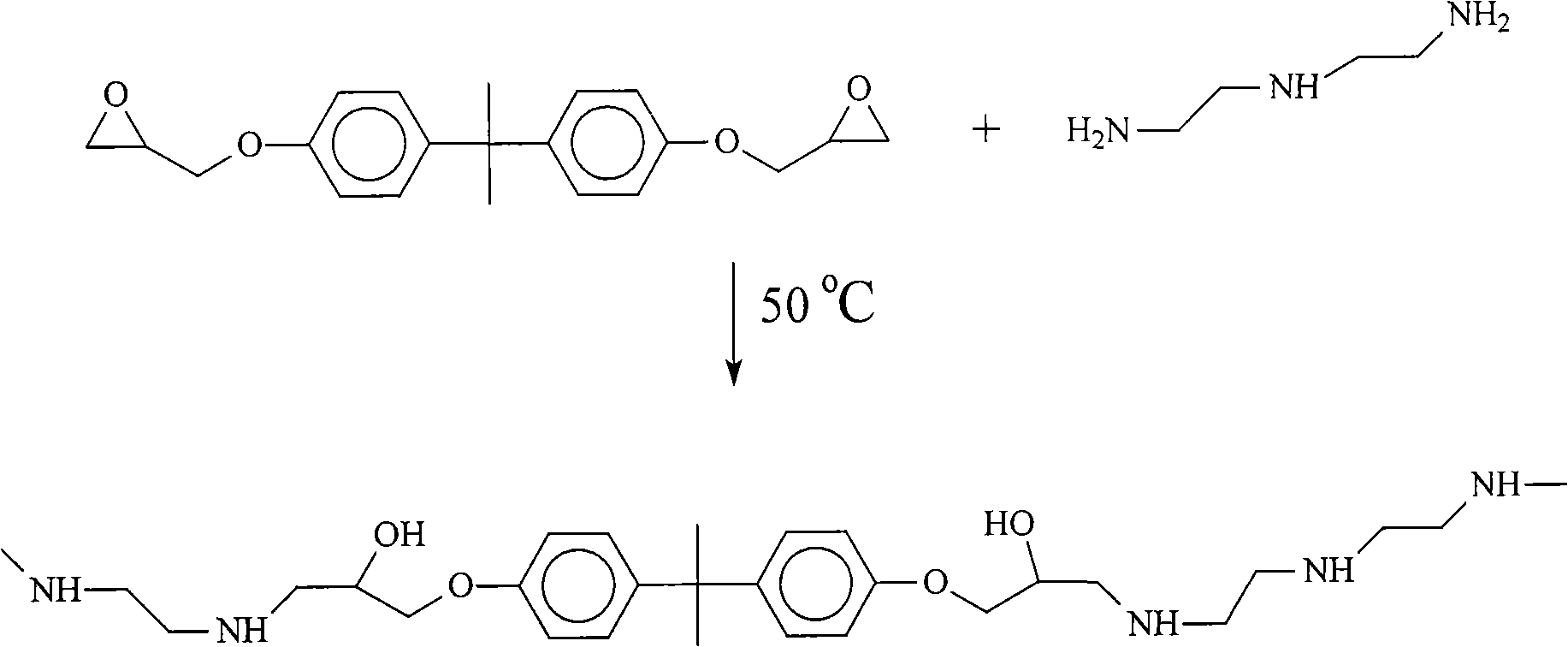

Method for preparing polymer micro-filter membrane

The invention relates to a preparation method of an epoxy resin-based micro-filtration film. Firstly, under a certain temperature, the epoxy resin and amines such as diethylene triamine or triethylenetetramine is completely dissolved in polyethyleneglycol medium by a certain weight ratio, and the air bubble is then removed; the solution is cast or flow-cast on supporting material such as metal or plastic tape, and suitable temperature is kept. After a certain time, monomer solution generates polymerization and phase separation at the same time; gel is solidified as white epoxy resin-based nascent state film; the nascent state film is finally dipped in water, and the medium polyethyleneglycol is removed to obtain the micro-filtration film. Other organic solvents are not required to be added in the preparation process, with green environmental protection. The prepared micro-filtration film has good mechanical strength, uniform distribution of aperture, adjustable size, strong hydrophilicity, acid resistance, alkali resistance and solvent resistance; furthermore, the structure of the film is not damaged by high-temperature germicidal treatment under the temperature of 120 DEG C; the film has excellent performance and the method of the invention can be widely applied to the separation and filtration in the industries such as instrument analysis, water disposal and biological medicine, etc.

Owner:NINGBO UNIV

Preparation method for anti-pollution hydrophilic positive permeable membrane

InactiveCN106345323AEasy to manufactureHigh reactivityMembranesSemi-permeable membranesReverse osmosisPolyamide

The invention provides a preparation method for an anti-pollution hydrophilic positive permeable membrane. The method is characterized by comprising the following steps: preparing amino-terminated zwitterion according to a one-pot method; utilizing a phase inversion method to prepare a polyether sulfone support layer; utilizing interfacial polymerization to prepare a polyamide compound membrane on the surface of the polyether sulfone support layer; utilizing unreacted acyl chloride group on the surface of the compound membrane to react with the amino-terminated group of zwitterion, thereby obtaining the anti-pollution hydrophilic positive permeable membrane. The modified positive permeable membrane prepared according to the method provided by the invention has the advantages of higher hydrophilia and water flux, strong anti-pollution capacity, lowered cleaning cost of the membrane and greatly prolonged service life of the membrane. The method for preparing the anti-pollution hydrophilic separating membrane is strong in universality and is suitable for a nanofiltration membrane or a reverse osmosis membrane with a polyamide coating on the surface.

Owner:DONGHUA UNIV

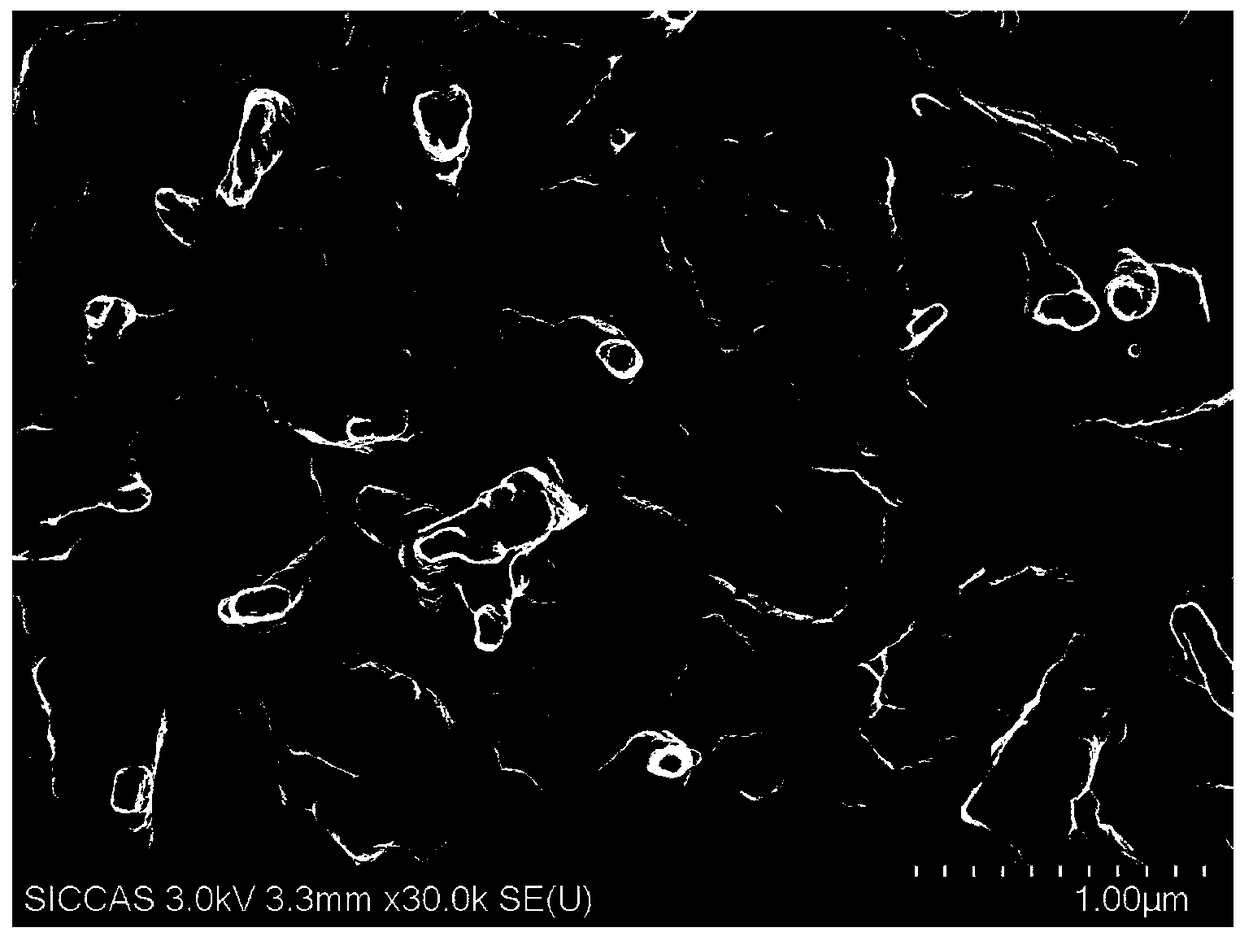

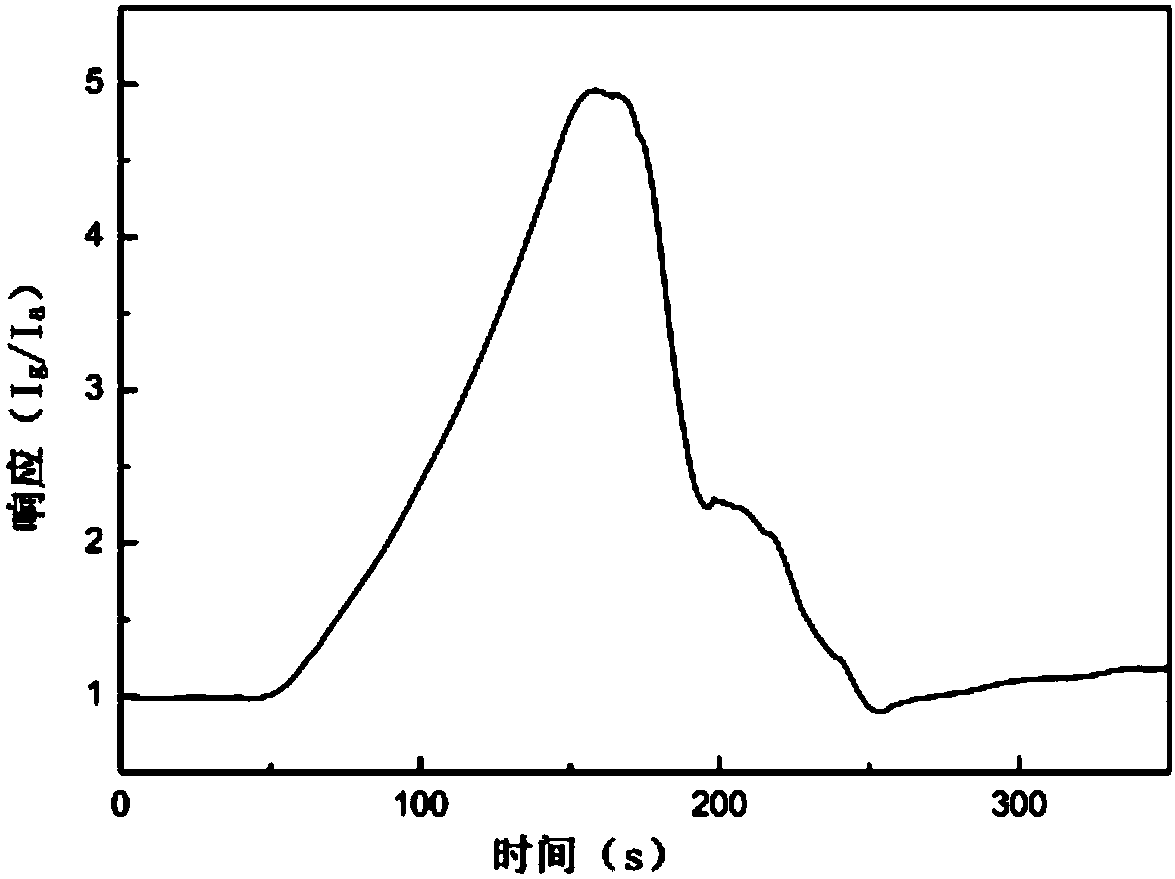

Nitrogen dioxide gas sensor and preparation and testing methods of nitrogen dioxide gas sensor

InactiveCN104677966AImprove mobilityImprove electrical performanceMaterial analysis by electric/magnetic meansHeterojunctionComposite film

The invention provides a nitrogen dioxide gas sensor and preparation and testing methods of the nitrogen dioxide gas sensor. The sensor structure is an organic thin-film field effect transistor, and comprises a gate electrode, a substrate, a gate oxide layer, a source electrode and a drain electrode, as well as an active layer; the active layer is a composite thin film formed by compounding ZnO nanorods and a P3HT polymer; the preparation method comprises the following steps: (1) preparing the ZnO nanorods by use of a low-temperature hydrothermal method; (2) depositing a P3HT-ZnO composite material on the source electrode and the drain electrode by use of a spraying film-forming method, wherein the ZnO nanorods are in contact with the P3HT polymer to form a heterojunction structure; the sensor is capable of effectively increasing the migration rate of the OTFT device and the response of the gas sensor to a gas to be tested; the film forming process is simple, the production cost is low, the electrical properties of the FET device can be improved favorably, and the response of the gas sensor can be effectively improved according to the change of the potential barrier of the interface after the molecules of the gas to be tested are adsorbed on the interface of the formed heterojunction structure.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Polysulfone amide separating membrane and its modifying method utilizing nanotitanium dioxide

ActiveCN1935340AExcellent photocatalytic oxidation performanceImprove surface propertiesSemi-permeable membranesOrganic solventMacromolecule

The present invention relates to a polyphenylene sulfonamide separation membrane and its modification method by using nano titanium dioxide. Said polyphenylene sulfonamide separation membrane is made up by using (by wt%) 5%-20% of polyphenylene sulfonamide, 78%-94% of organic solvent and 1%-5% of pore-forming agent through a certain preparation process. Its modification method includes the following steps: a), soaking the polyphenylene sulfonamide separation membrane in concentrated sulfuric acid for 1-3hr, then cleaning said polyphenylene sulfonamide separation membrane by using deionized water; and b) soaking the polyphenylene sulfonamide separation membrane in the nano titanium dioxide sol for 5-15min, finally using deionized water to wash said polyphenylene sulfonamide separation membrane so as to obtain the invented nano titaminum dioxide modified polyphenyl sulfonamide separation membrane.

Owner:HARBIN INST OF TECH

Preparation method of nanofiltration membrane for dye concentration and desalination

InactiveCN102451622AGood concentration and desalination abilityLow running costSemi-permeable membranesOrganic dyesOrganic solventDesalination

The invention discloses a preparation method of an aromatic polyamide nanofiltration membrane. The method is mainly characterized by comprising the following steps of: on the basis of utilizing aromatic polyamide as a major polymer membrane preparation material, completely defoaming a membrane casting liquid containing aromatic polyamide, organic solvent and additives; then flatly paving the product on a non-woven fabric by use of a membrane casting machine; evaporating in an oven for certain time; and curing in a gel tank to obtain the membrane. By adopting the preparation method, the nanofiltration membrane has relatively high rejection rate against small-molecular organisms, especially the dye with molecular weight of about 400, and has a penetration rate of greater than 80% for sodium sulfate and sodium chloride, thus being suitable for the concentration and desalination of dye.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

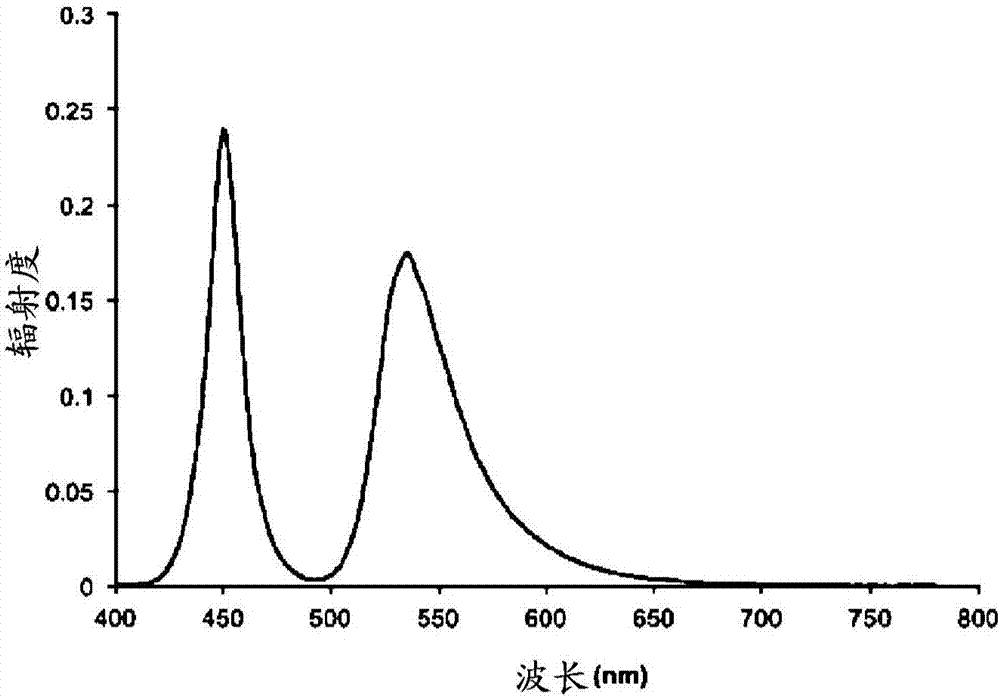

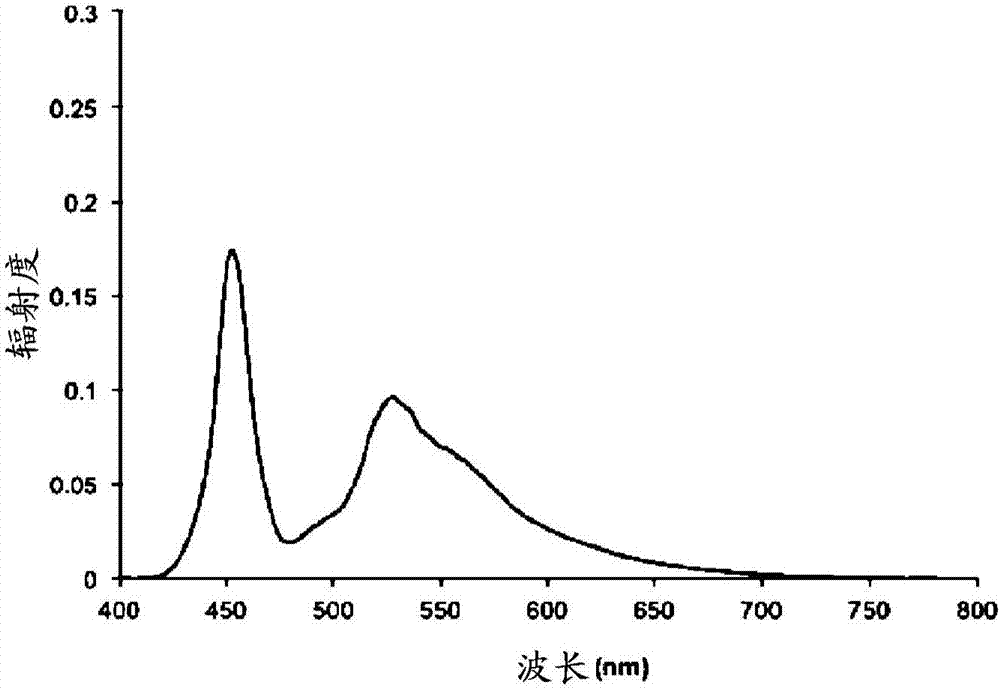

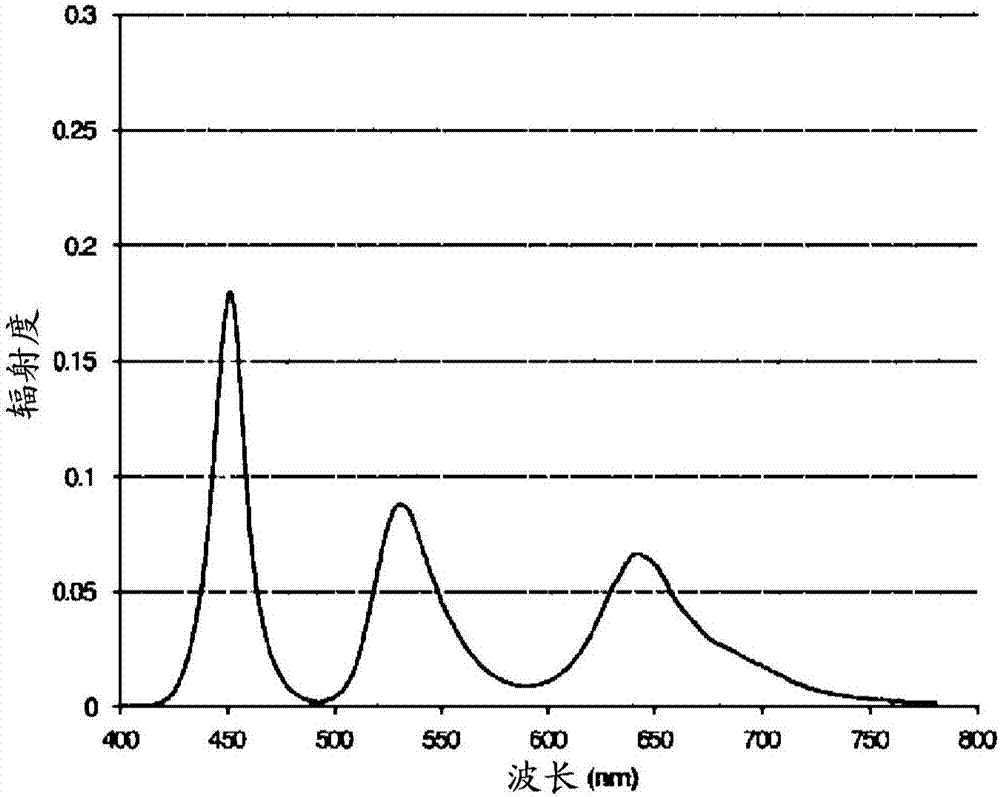

Color conversion film, method for producing same, back-light unit and display apparatus

ActiveCN107109021AGood environmental stabilityImprove quantum efficiencyOptical filtersLuminescent compositionsQuantum efficiencyLuminous intensity

The present invention relates to a color-conversion film, a method for producing same, and a back-light unit comprising the color-conversion film, the color-conversion film comprising: a resin matrix; and an organic fluorescent substance dispersed within the resin matrix and absorbing blue or green light to emit light of a different wavelength from the absorbed light, wherein the resin matrix comprises a thermoplastic resin, and the color-conversion film has: a light-emission peak at 450 nm; a half-width of 40 nm; a half-width of 60 nm or less at the light emission peak when irradiated with light having a mono-modal distribution of luminous intensity; a quantum efficiency of 80% or greater; and an absorption coefficient of 30,000 M-1cm-1 or greater at the maximum absorption wavelength.

Owner:LG CHEM LTD

Bipolar membrane with aluminum hydroxide as intermittent interface layer catalyst and preparation method of bipolar membrane

InactiveCN107737614AModerate thicknessThickness is easy to controlCellsPhysical/chemical process catalystsInterface layerIon-exchange membranes

The invention relates to a bipolar membrane with aluminum hydroxide as an intermittent interface layer catalyst and a preparation method of the bipolar membrane. The bipolar membrane comprises an anion exchange membrane layer, an intermittent interface layer and a cation exchange membrane layer, wherein the intermittent interface layer is positioned between the anion exchange membrane layer and the cation exchange membrane layer; the intermittent interface layer is prepared from nano aluminum hydroxide powder of which the particle size is 10-30nm. As Al(OH)3 is adopted as the catalyst of the intermittent interface layer of the bipolar membrane, the bipolar membrane is relatively solidly combined with the ion exchange membrane layer, the loss of reaction activity sites is greatly retarded,and the obtained bipolar membrane is high in hydrolysis efficiency, good in membrane layer compatibility, low in transmembrane voltage and stable in use performance.

Owner:WUHAN UNIV OF TECH

Preparation method of gas sensor based on metal phthalocyanine and use method of gas sensor

ActiveCN108362741AEasy to filmSimple film forming processMaterial resistanceN dimethylformamidePhthalocyanine

The invention provides a preparation method of a gas sensor based on metal phthalocyanine and a use method of the gas sensor. The preparation method comprises the following steps: dissolving the metalphthalocyanine into a mixed solution of N,N-dimethylformamide and water and dropping the mixed solution on an electrode; drying to form a metal phthalocyanine thin film covering the electrode, wherein the electrode is an interdigital electrode. The invention also provides the use method of the gas sensor based on the metal phthalocyanine. The use method comprises the following steps: putting thesensor into a sealed cavity, filling the sealed cavity with detect gas with preset concentration and maintaining preset concentration gas atmosphere; filling the closed cavity with dry air or nitrogenduring recovering; in addition, enabling the detection gas to be desorbed by using a laser irradiation sensor. According to the method, the problems of slow response, low recovery speed and no possibility of carrying out normal temperature detection of the metal phthalocyanine gas sensor in the prior art can be effectively solved.

Owner:SHANGHAI JIAO TONG UNIV

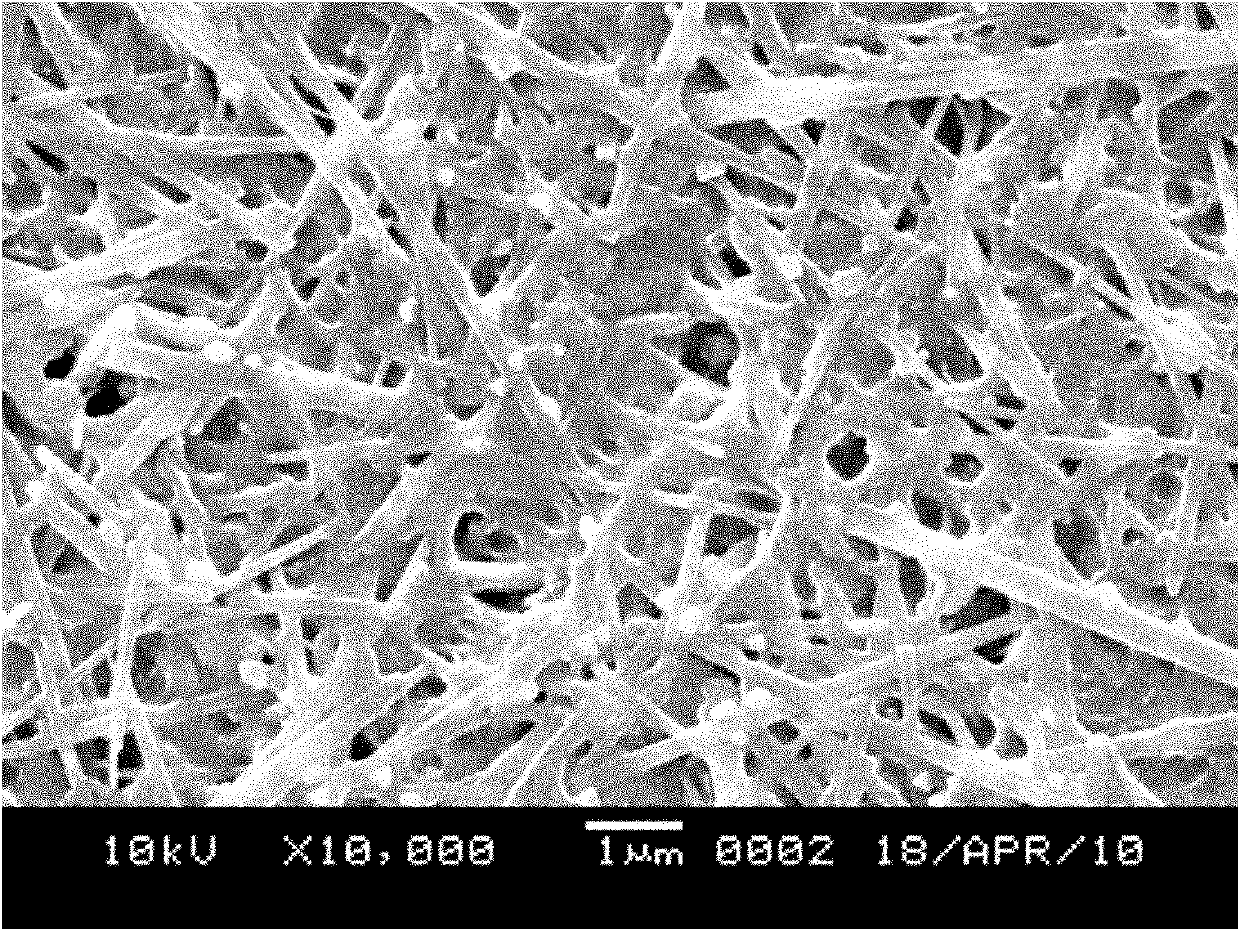

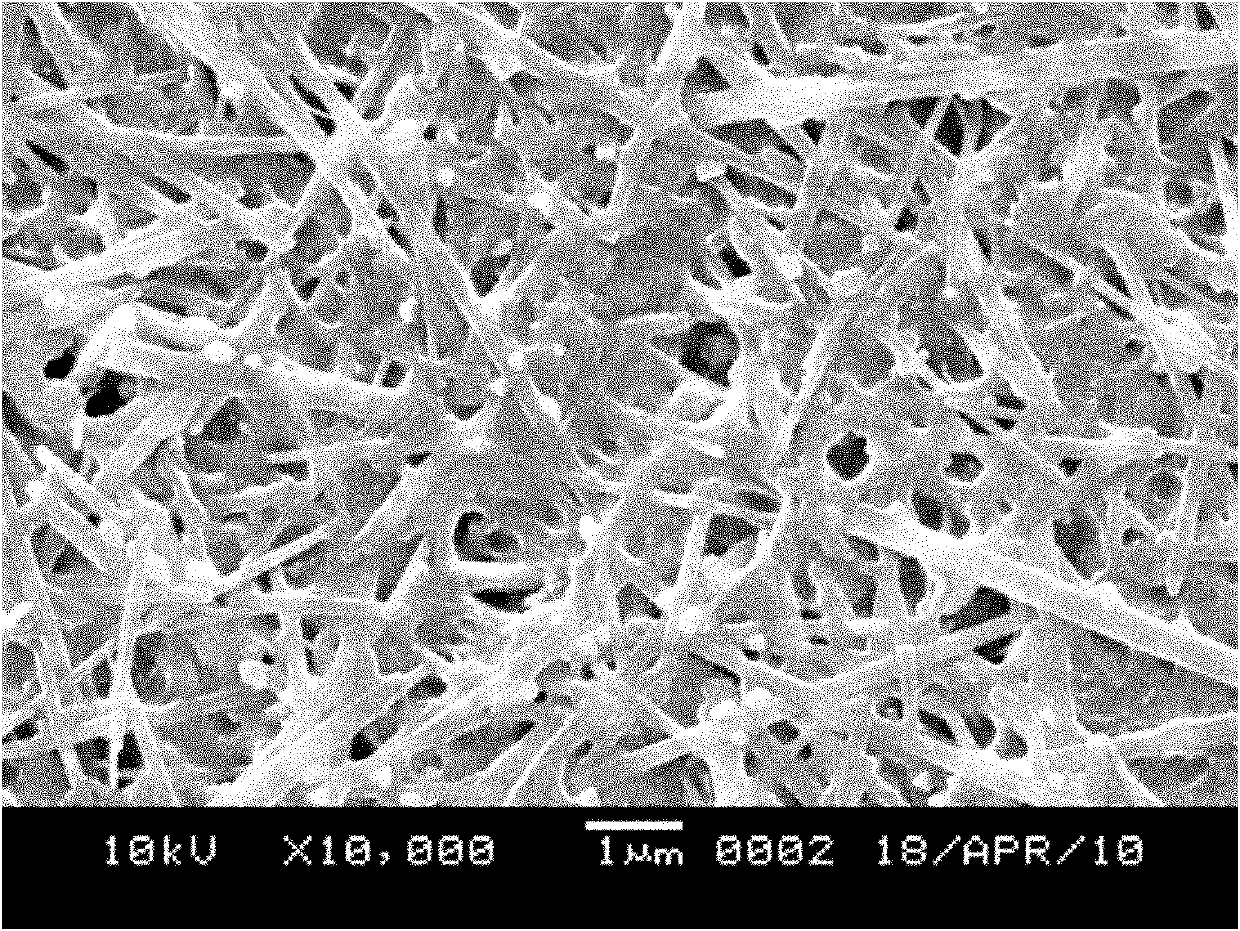

Hollow hydrophobic fiber membrane and preparation method thereof

ActiveCN103495350ASimple film forming processEasy to operateSemi-permeable membranesPolyvinylidene fluorideOrganic fluid

The invention discloses a hollow hydrophobic fiber membrane and a preparation method thereof, and provides a hollow hydrophobic fiber membrane with good hydrophobic performance and a preparation method thereof. The hydrophobic membrane comprises, by mass, 13-17% of polymers, 5-15% of inorganic nanoparticle nucleating agents, 1-5% of organic liquid nucleating agents, 60-66% of organic solvent and 5-15% of pore-forming additives. The preparation method includes evenly mixing the dried inorganic nanoparticle nucleating agents and the dried polymers at a high speed, evenly dispersing in the organic solvent while stirring, adding the pore-forming additives and organic liquid nucleating agents, mixing evenly and removing bubbles to obtain required membrane casting liquor, extruding the membrane casting liquor by a spinning jet, subjecting the membrane casting liquor to a coagulating bath at the temperature of 40-60 DEG C, fully rinsing in ethyl alcohol at the temperature of 10-60 DEG C after freezing, and drying at the temperature of 30-70 DEG C to obtain the hollow hydrophobic fiber membrane. During membrane forming, polyvinylidene fluoride forms crystalline structures in different sizes, so that high hydrophobization of the hollow hydrophobic fiber membrane is realized.

Owner:TIANJIN MOTIMO MEMBRANE TECH

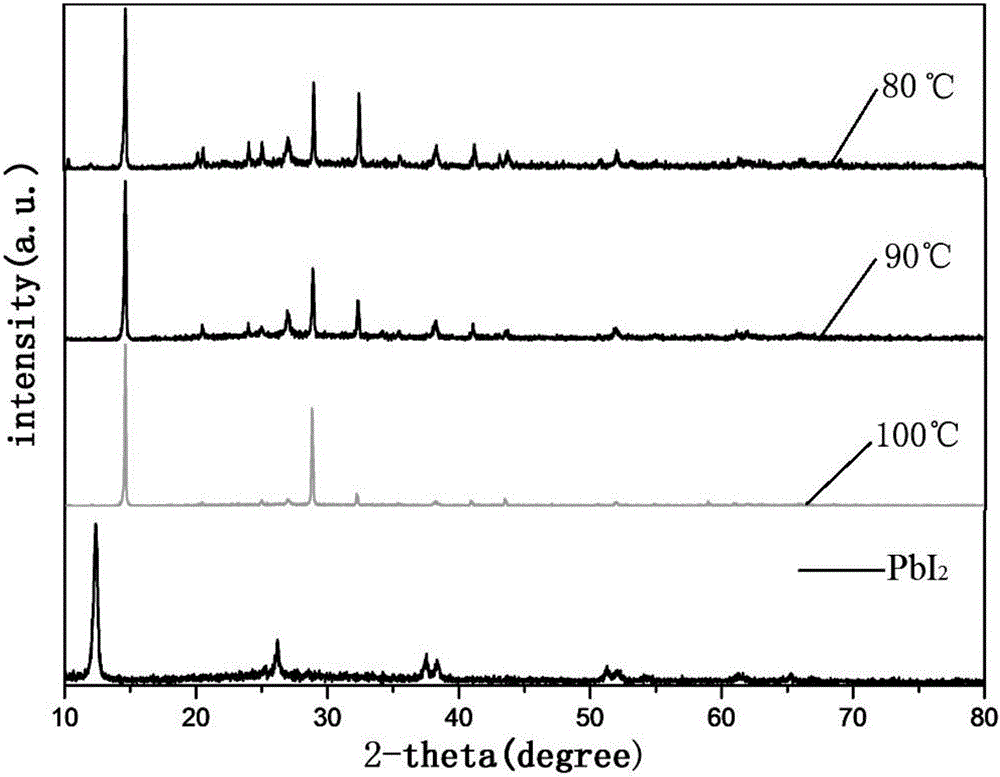

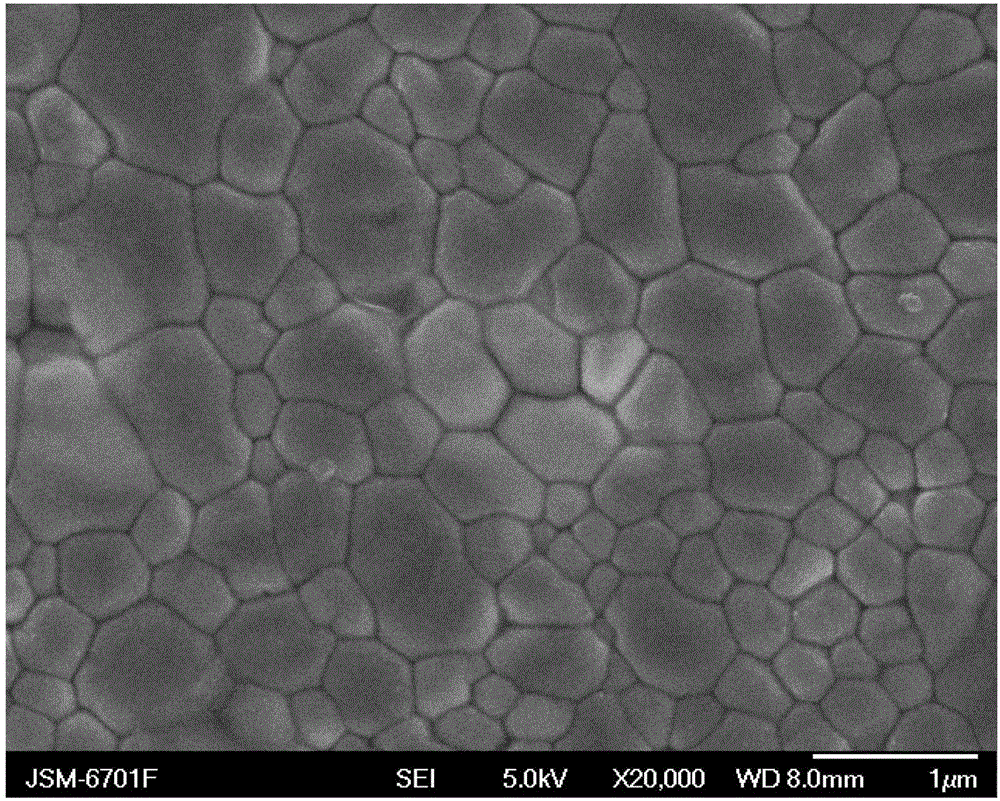

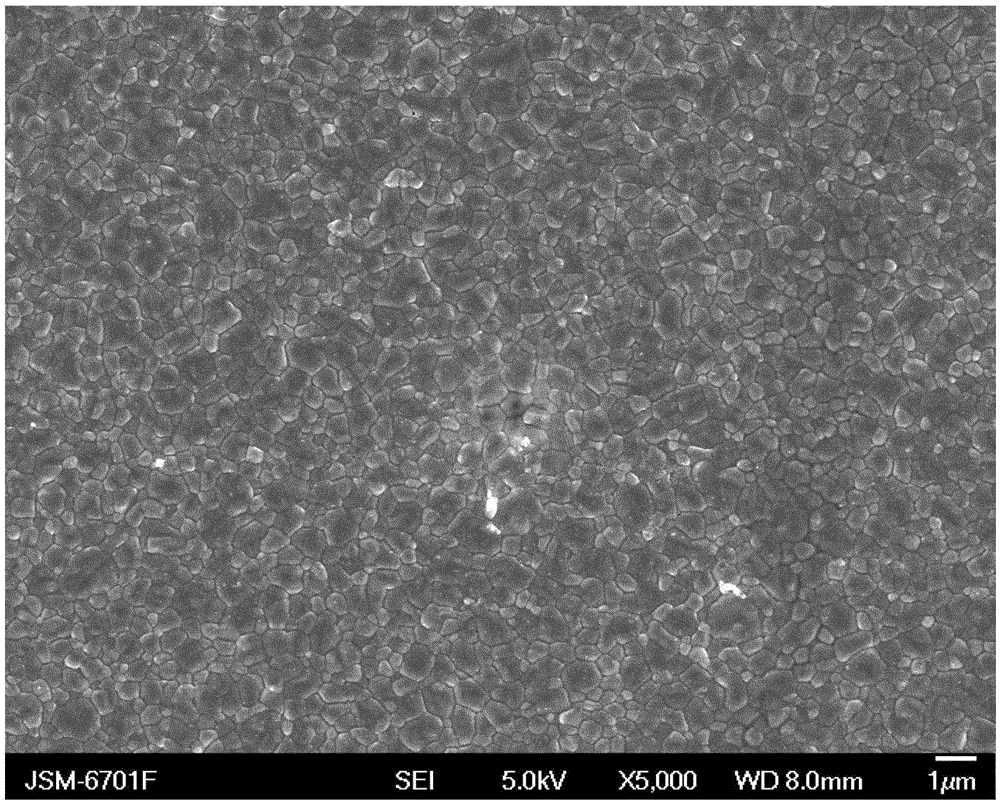

Powder covering substrate heating CH3NH3PbI3 perovskite film preparation method

ActiveCN106340591ASimple film forming processGood absorptionSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellMicrometer

The invention provides a powder covering substrate heating CH3NH3PbI3 perovskite film preparation method, belonging to the technical field of perovskite solar cell films. The process steps of the prior art are complex, and the requirement of process conditions is high. According to the method, a PbI2 film is prepared on a substrate firstly, and a CH3NH3PbI3 perovskite film is generated by the solid phase reaction of CH3NH3I and PbI2 in the PbI2 film. The method is characterized in that CH3NH3I crystal powders with the particle diameter of 10 to 50 micrometers are evenly spread at the surface of the PbI2 film, the heating is carried out from the substrate and 80 to 100 DEG C solid phase reaction temperature is provided for the CH3NH3I and the PbI2, and the solid phase reaction is completed through 8 to 10 minutes. The preparation method is simple, the process condition is loose, the product film is in a multi-crystalline state, the structure is compact, the crystallinity is high, the grain size reaches a micrometer level, the absorption is good in a visible light band, and the method can be used as a light absorbing material in the field of photovoltaic.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com