Method for treating cellulose

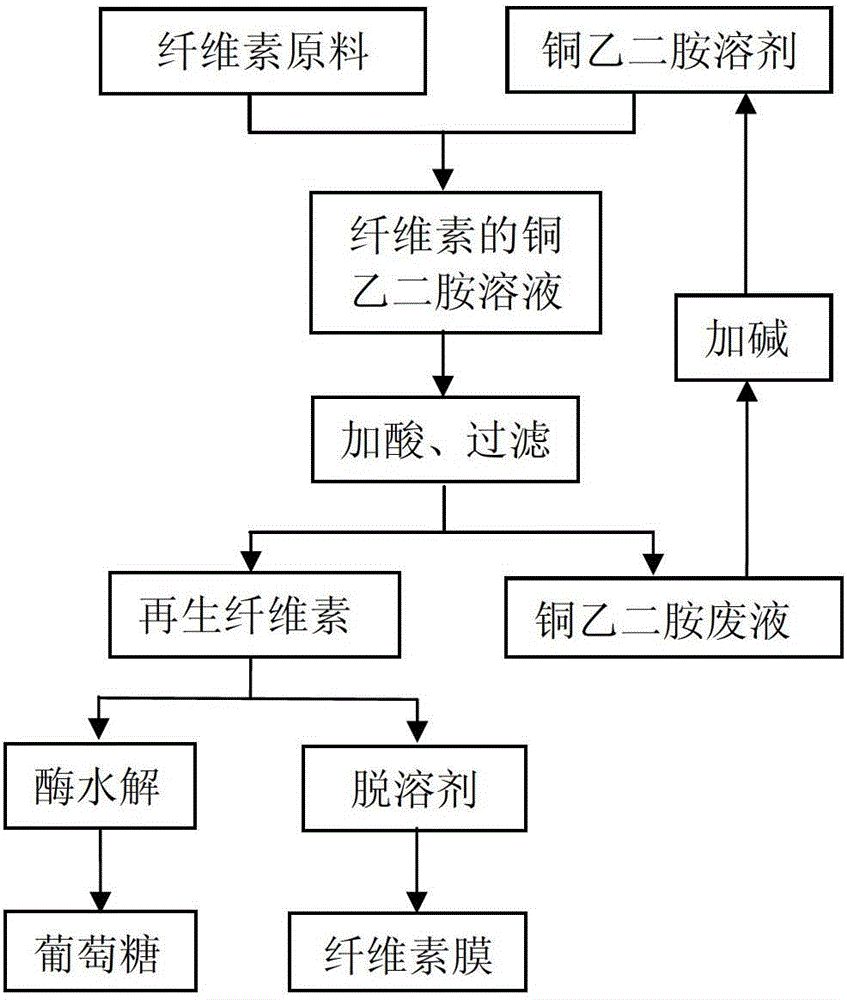

A treatment method and cellulose technology, applied in the field of cellulose, can solve problems such as the complexity of the film-forming process, and achieve the effects of simplifying the film-forming process, high utilization efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 1g of microcrystalline cellulose and 50mL of water into a 250mL beaker, add 50mL of copper ethylenediamine solution with a concentration of 1mol / L after fully moistening, stir vigorously to fully dissolve the cellulose, and obtain copper ethylenediamine dissolved in cellulose Amine solution.

[0023] Put the above beaker in an ice-water bath. After the temperature is constant, slowly add concentrated sulfuric acid dropwise to it, and keep stirring. value up to 6. After filtering, the filter residue is washed three times with a dilute sulfuric acid solution with a mass percentage below 30%, and finally washed with water until neutral to obtain regenerated cellulose.

[0024] In a 100mL plastic bottle, add 0.8g of the above-mentioned regenerated cellulose, adjust the pH value to 4.8 with 40mL of citric acid-sodium citrate buffer solution, the amount of cellulase used is 15FPU / g regenerated cellulose, and the enzymatic hydrolysis temperature is 50°C. The stirring spe...

Embodiment 2

[0028] Grind moso bamboo into bamboo powder, take 10g of bamboo powder and add it to a beaker, then add 70mL of sodium chlorite (2% by mass fraction) / acetic acid (4% by mass fraction) solution, place the beaker in a water bath at 75°C, After 2 hours, filter, wash, and add 70 mL of fresh sodium chlorite / acetic acid solution to the filter residue, repeat several times until the filter residue turns white, indicating that the lignin has been completely removed and bamboo cellulose is obtained.

[0029] Add 1g of the above-mentioned bamboo cellulose and 50mL of water into a 250mL beaker, add 50mL of copper ethylenediamine solution with a concentration of 1.5mol / L after fully moistening, stir vigorously to fully dissolve the bamboo cellulose, filter to obtain dissolved cellulose copper ethylenediamine solution.

[0030] Put the above beaker in an ice-water bath. After the temperature is constant, slowly add concentrated sulfuric acid dropwise to it, and keep stirring. value up to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com