Patents

Literature

100results about How to "With self-cleaning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

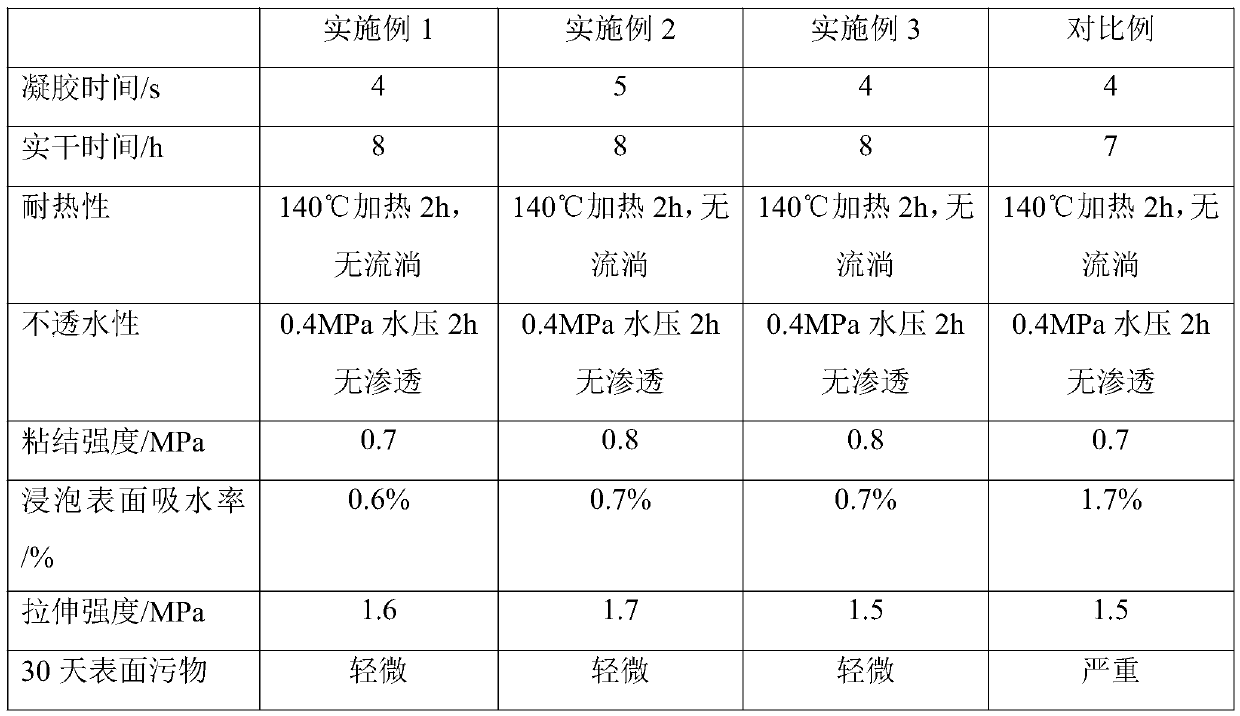

Preparation method of self-cleaning ceramic nanometer glass antireflective coating material and preparation method of reflection deducting coating

InactiveCN102061111AWith self-cleaning effectHas surface antistatic propertiesCoatingsWater basedTin dioxide

The invention discloses a preparation method of a self-cleaning ceramic nanometer glass antireflective coating material and a coating preparing technique thereof. The reflection deducting coating is formed by coating a composite of amorphous porous silicon dioxide and one or a plurality of titanium dioxide, zirconium dioxide, tin dioxide, ceria, yttria, and the like on the surface of photovaltic glass or common float glass, the reflection deducting coating coated on the surface of the glass has the characteristics of self-cleaning effect, high ceramic hardness and wear resistance. surface antistatic property of dust protection, aging resistance and zero-decrement, can be used for 25 years; and within 250nm-2500nm, the degree of transparency of the photovoltaic glass coated with the reflection deducting coating can be improved by 2.5%-3.5%, and the degree of transparency of the common glass coated with the reflection deducting coating can be improved by 2.8%-3.8%. The nanometer antireflective coating material provided by the invention is a water-based paint, the three wastes are not generated in the preparing course, the preparation method is simple, and the cost is low; and the coating preparing technical process is low in requirement and simple and easy to operate, the energy is saved, thereby being suitable for industrial production in large scale.

Owner:中山市旌旗纳米材料科技有限公司

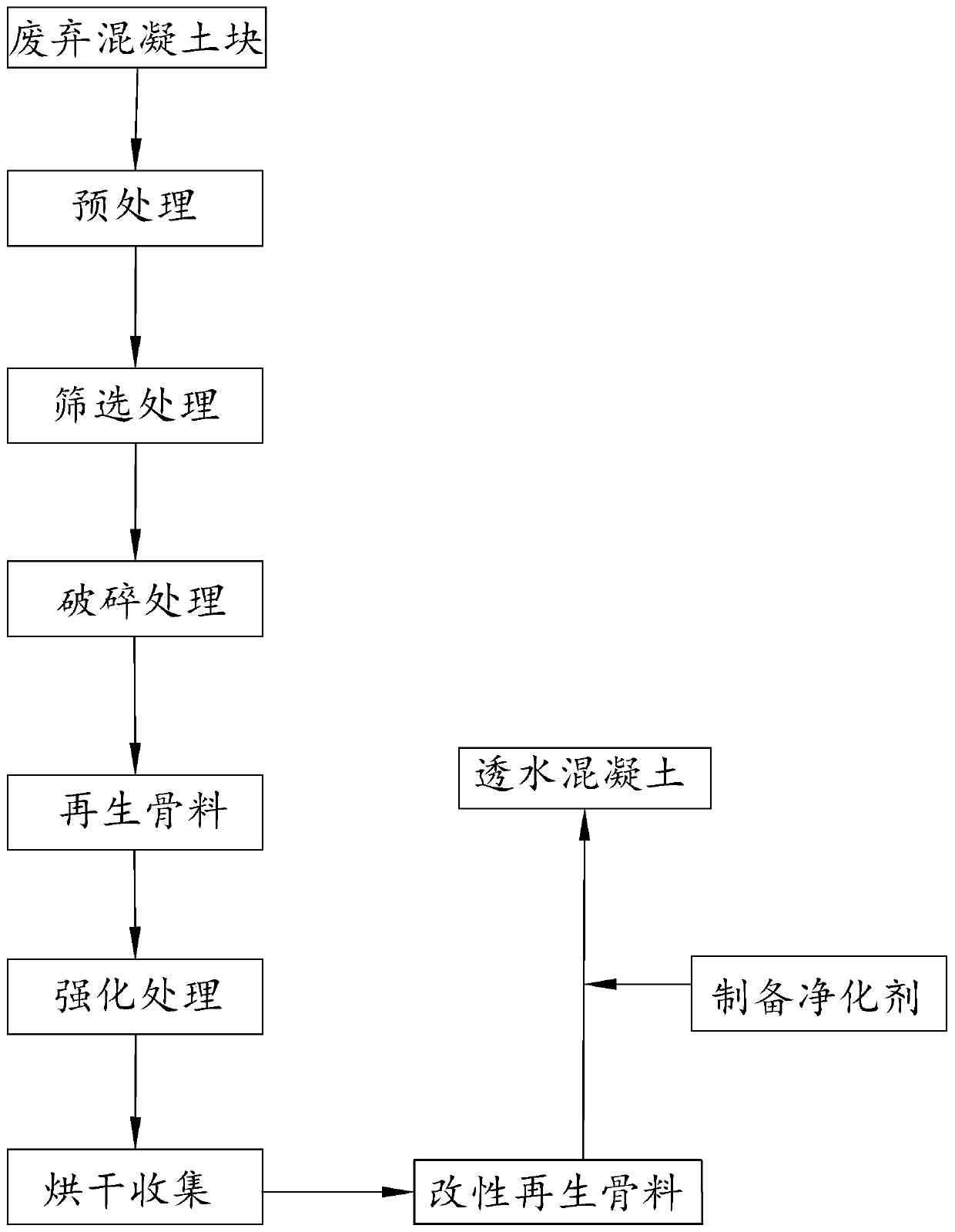

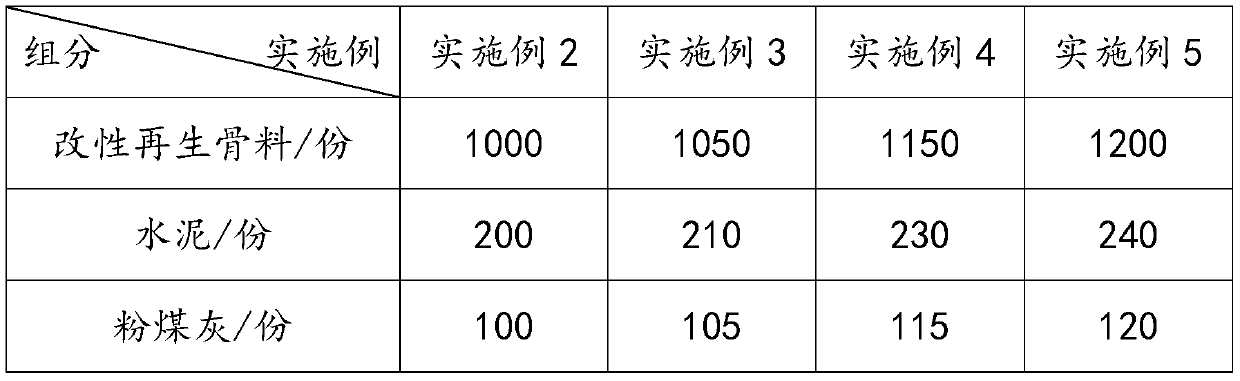

Pervious concrete prepared from recycled aggregate and preparation process of pervious concrete

InactiveCN110482936AHigh strengthWith self-cleaning effectSolid waste managementUltimate tensile strengthFly ash

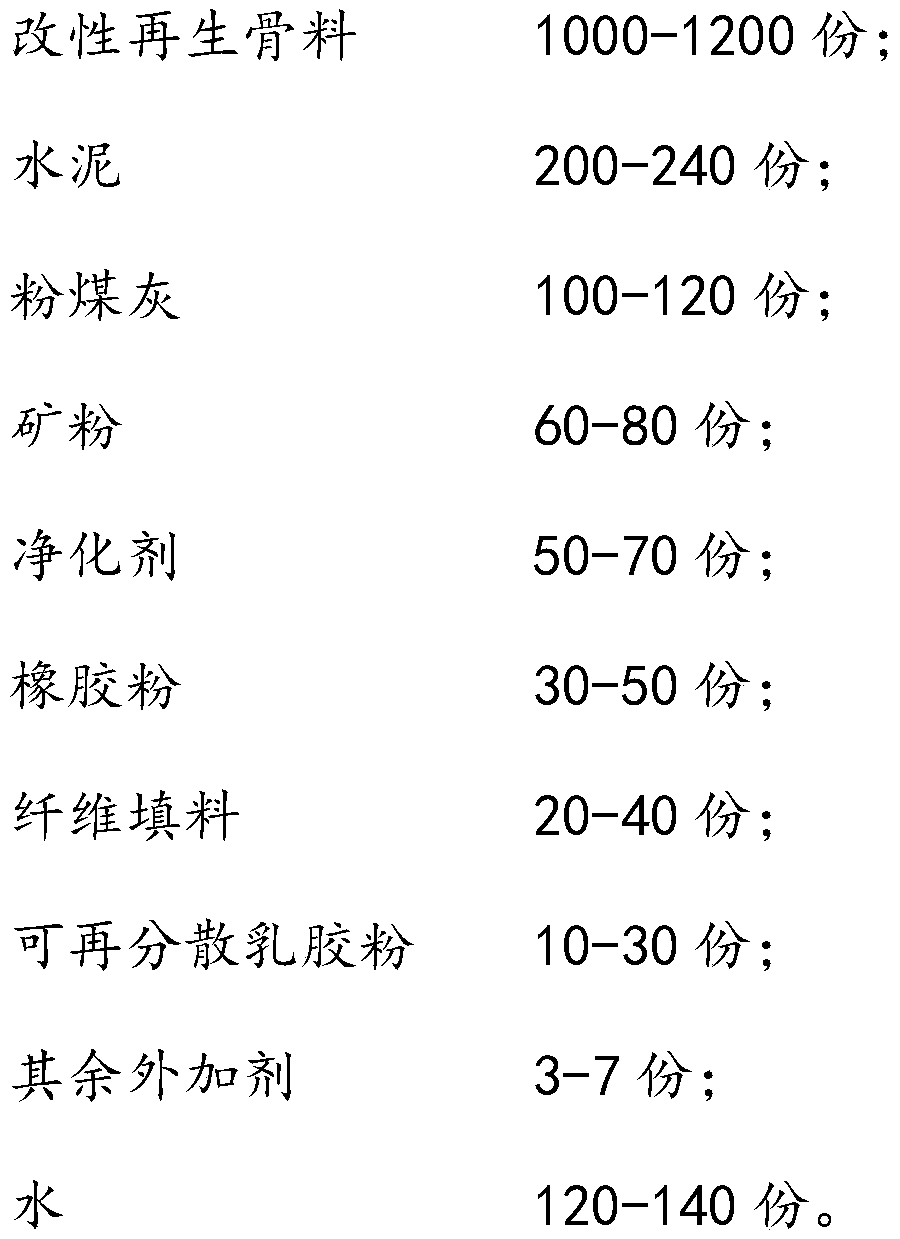

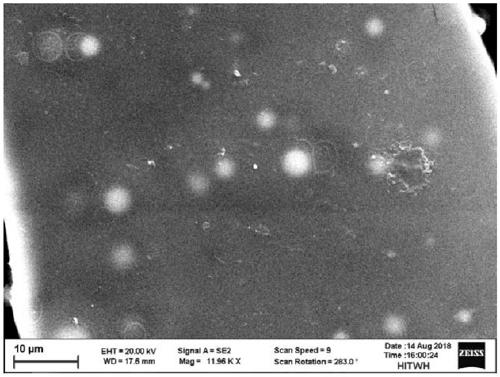

The invention discloses pervious concrete prepared from recycled aggregate and a preparation process thereof, and relates to the technical field of concrete preparation, the pervious concrete is prepared from the following raw materials in parts by weight: 1000 to 1200 parts of modified recycled aggregate; 200 to 240 parts of cement; 100 to 120 parts of fly ash; 60 to 80 parts of mineral powder; 50 to 70 parts of a purifying agent; 30 to 50 parts of rubber powder; 20-40 parts of a fiber filler; 10 to 30 parts of redispersible latex powder; 3-7 parts of other additives; and 120-140 parts of water. The pervious concrete is prepared by modifying the recycled aggregate, so that the strength of the recycled aggregate is improved, and the application range of the pervious concrete is widened.

Owner:ZHEJIANG YUEDA TRAFFIC ENG CO LTD

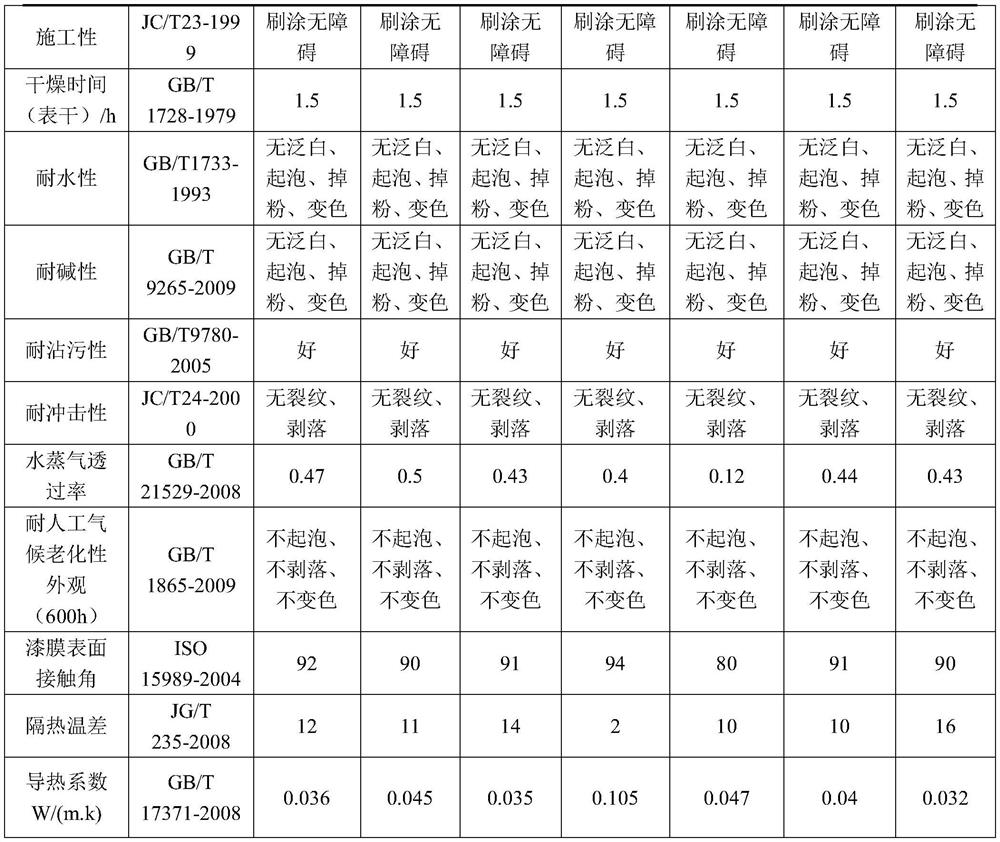

Radiation cooling coating with self-cleaning function and preparation method thereof

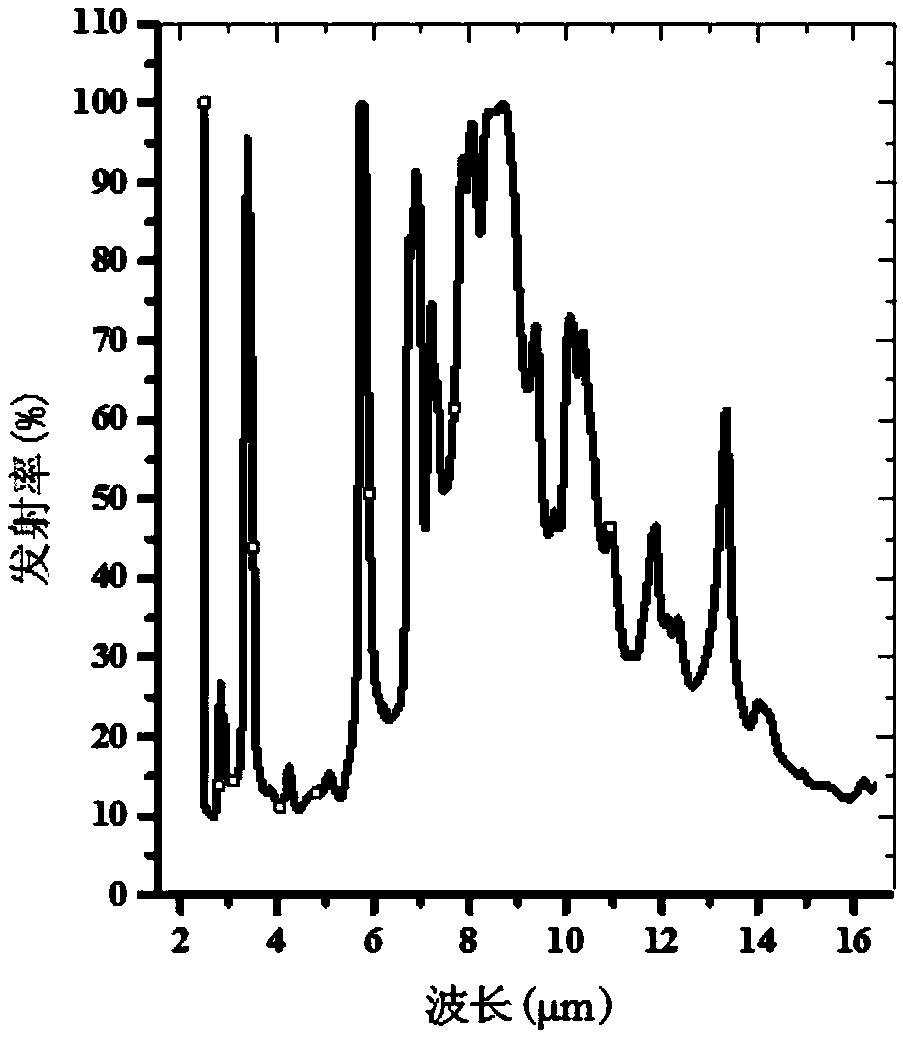

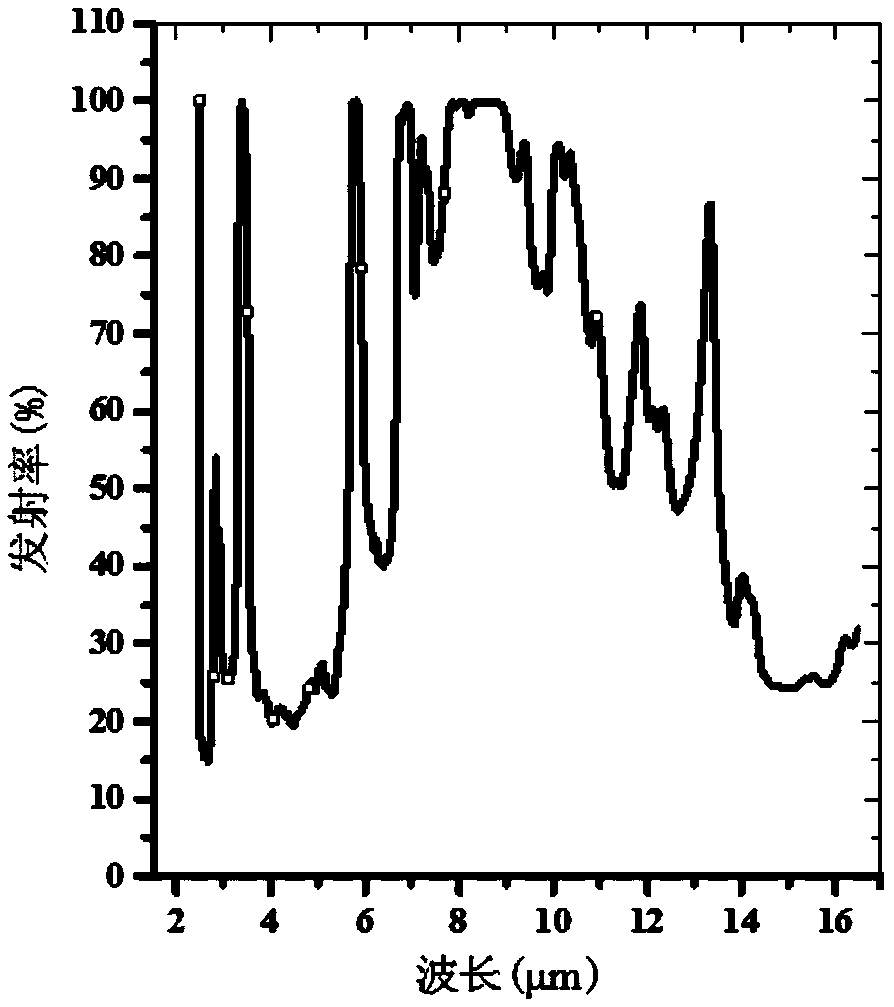

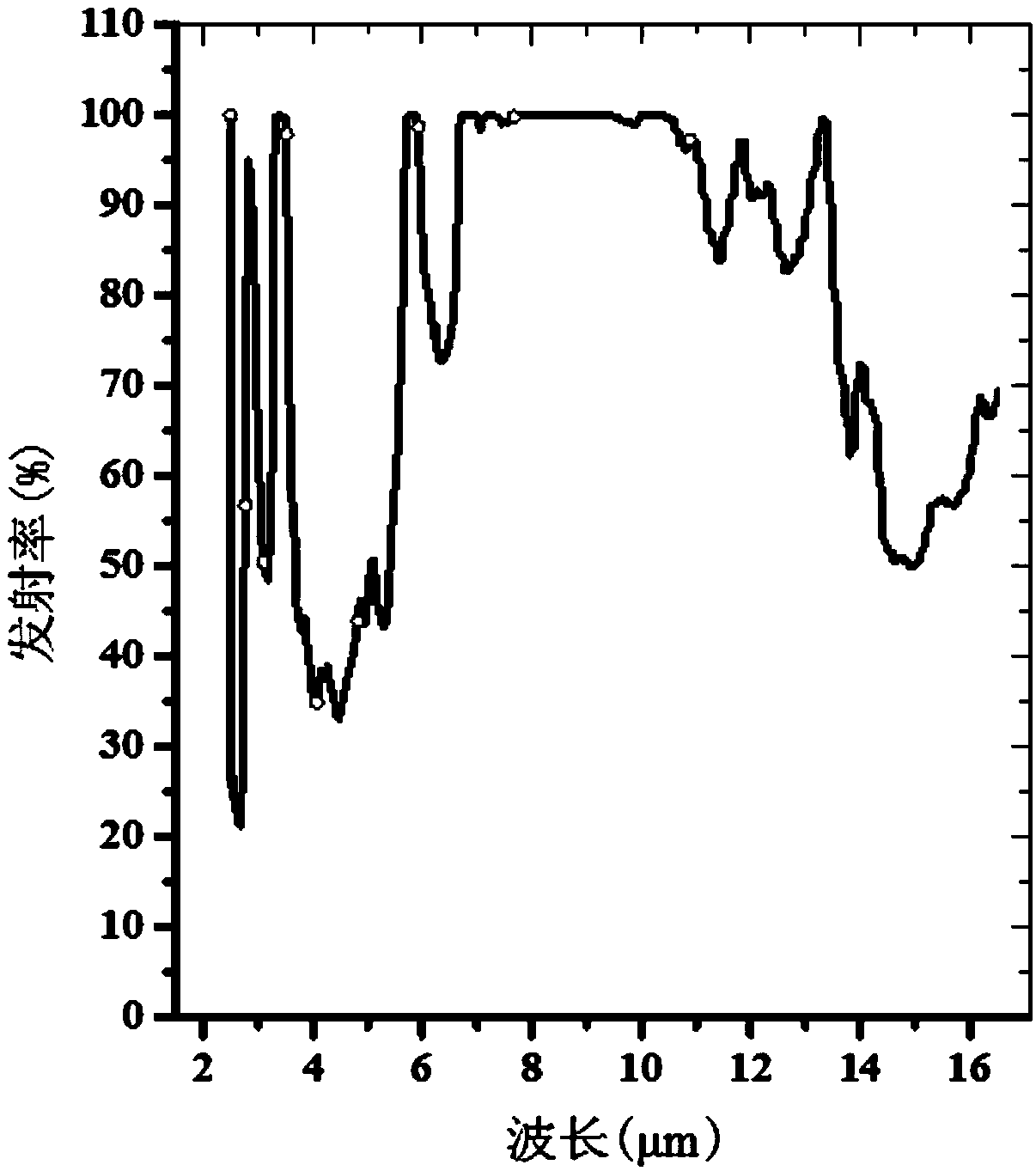

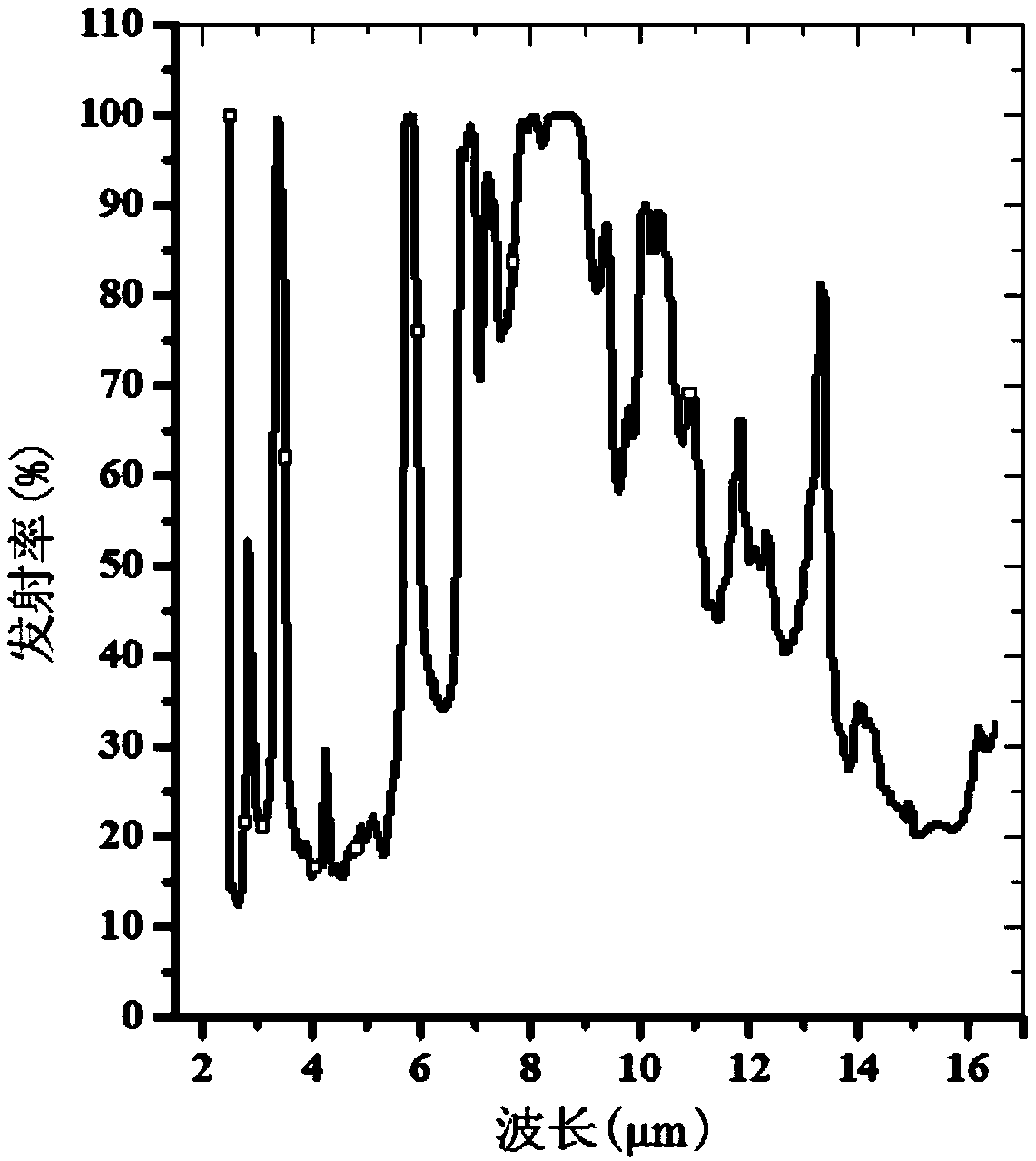

ActiveCN109161241AWith self-cleaning functionWith self-cleaning effectAntifouling/underwater paintsPaints with biocidesEmissivityTransmittance

The invention belongs to the technical field of radiation cooling, and particularly relates to a radiation cooling coating with a self-cleaning function and a preparation method thereof. The radiationcooling coating comprises a bottom layer binder, and a radiator and hydrophobic nano particles, which are covered on the bottom layer binder; and an infrared emission peak of the radiator is positioned within an infrared radiation waveband range of 8 to 13 mum and at least covers one wave band interval in the range of 8 to 13 mum. According to the invention, by utilizing high hydrophobicity of the nano hydrophobic particles, the radiation cooling coating has a self-cleaning effect and a phenomenon of reducing the cooling effect due to dust accumulation is avoided. The radiation cooling coating disclosed by the invention has high emissivity on the wave band of 8 to 13 mum, is large in transmittance on a visible light wave band, is excellent in lighting performance, can also reduce absorption on energy on the rest of wave bands and ensures the cooling effect. The radiation cooling coating further adopts two different particle sizes of radiators, so that the radiation range is widened, ground heat is radiated to the outer space to the greatest degree, and the cooling effect is improved.

Owner:HARBIN INST OF TECH AT WEIHAI

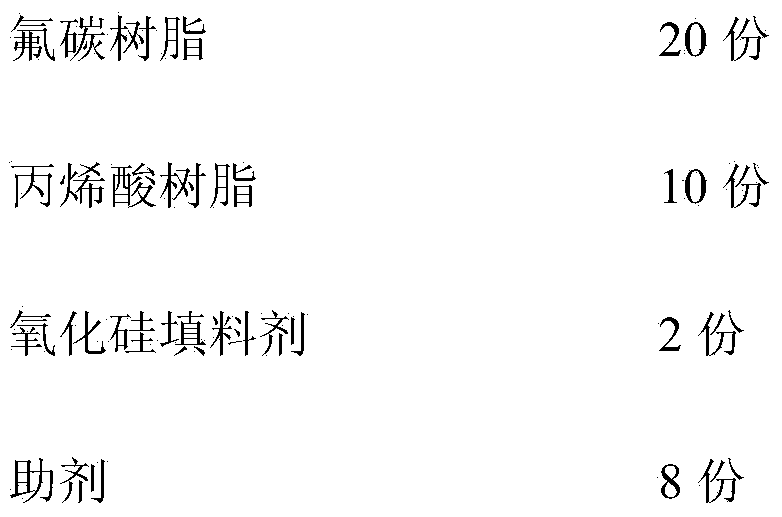

Preparation method of water-repellent hybrid fluorine-containing resin coating

The invention discloses a preparation method of a water-repellent hybrid fluorine-containing resin coating. The preparation method comprises the following steps: first, under the action of an initiator, carrying out solution copolymerization on perfluoroalkyl acrylate, other acrylates, styrene and a reactive styrene epoxy compound to synthesize an epoxy fluorostyrene-acrylic resin intermediate; second, carrying out hydrolytic polycondensation on aminoalkyl trialkoxy silane in an alcohol solution to prepare an aminoalkyl silsesquioxane oligomer in a topological structure; and third, hybridizing and cross-linking the epoxy fluorostyrene-acrylic resin by the aminoalkyl silsesquioxane oligomer, co-mixing with a nano-paint to prepare a coating; and leveling, surface-drying, roasting and curing to obtain the resin coating with a good water-repellent effect.

Owner:德施普(辽宁)新材料技术有限公司

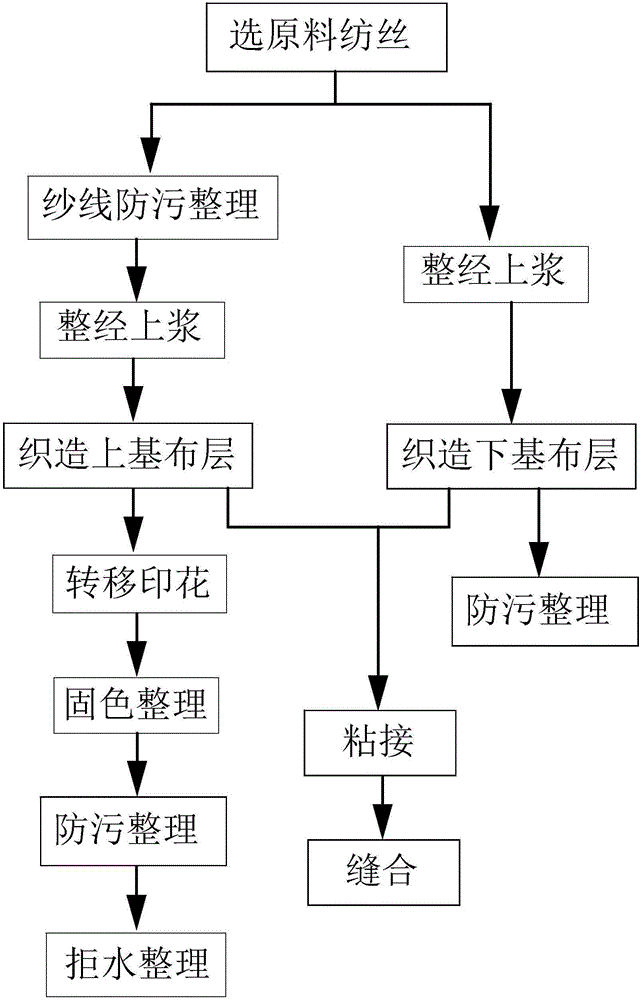

Production method of antifouling sofa fabric

ActiveCN106283340AIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnAdhesive

The invention provides a production method of an antifouling sofa fabric, belonging to the technical field of home textiles. The production method comprises the following steps: (1) selecting raw materials and spinning; (2) performing anti-pollution finishing of yarns; (3) warping and sizing; (4) weaving: weaving an upper base cloth layer and a lower base cloth layer; (5) transferring and printing; (6) fixing color and finishing; (7) performing anti-pollution finishing; (8) conducting water repellent finishing; (9) adhering: coating adhesives on the upper side and the lower side of a sponge respectively, applying pressure to the upper base cloth layer, the sponge and the lower base cloth layer which are superposed vertically, so as to enable the three to be adhered as a whole; and (10) sewing. The yarns treated by a warping and sizing machine are high in sizing rate, and fewer in feathers, so that static electricity generated due to friction among yarns can be reduced, the static electricity of the fabric can be effectively reduced, and the woven fabric is difficult to generate static electricity, thus being relatively difficult to adsorb dust; and the sofa fabric produced by utilizing the method has multiple antifouling capabilities, and has obvious antifouling effect.

Owner:海宁宝祥布业有限公司

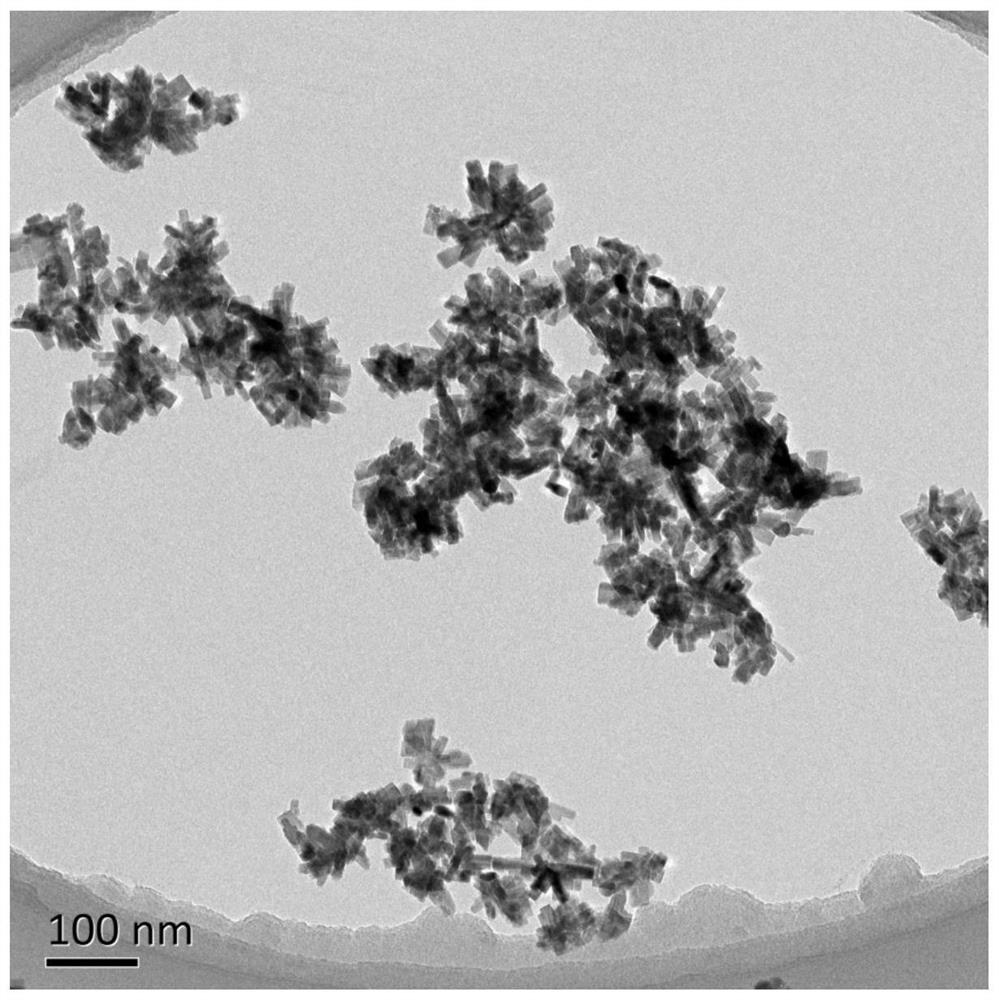

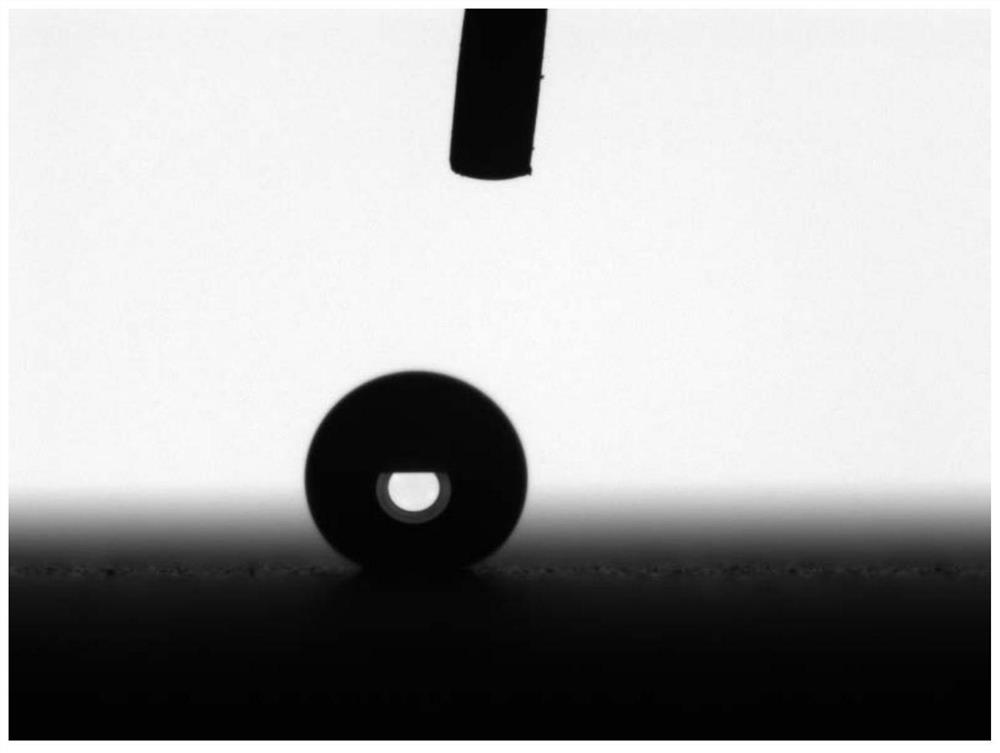

Tungsten bronze-based super-hydrophobic transparent thermal insulation coating and preparation method thereof

InactiveCN113185871AWith self-cleaning effectGood dispersionNanotechnologyCoatingsSodium tungsten bronzeOrganic solvent

The invention discloses a tungsten bronze-based super-hydrophobic transparent heat-insulating coating and a preparation method thereof. The tungsten bronze-based super-hydrophobic transparent heat-insulating coating is obtained by adding hydrophobically modified nano tungsten bronze and hydrophobically modified powder into a resin solution for dissolving an organic solvent to form a film, synthesizing nanometer cesium-tungsten bronze and nanometer sodium-tungsten bronze through a solvothermal method, then respectively modifying the nanometer cesium-tungsten bronze, the nanometer sodium-tungsten bronze and nanometer silicon dioxide to serve as inorganic components, combining organic resin to prepare the super-hydrophobic coating, and coating the surface of a substrate with the tungsten bronze-based super-hydrophobic transparent heat-insulating super-hydrophobic coating by adopting a film forming process, wherein the static contact angle of the obtained tungsten bronze-based super-hydrophobic transparent heat-insulating coating is larger than 155 degrees, and the rolling angle is smaller than 10 degrees. The nano tungsten bronze-based super-hydrophobic transparent heat-insulating super-hydrophobic coating is good in dispersity, and a prepared coating is good in binding force with a matrix and good in transparent heat-insulating effect.

Owner:SOUTH CHINA UNIV OF TECH

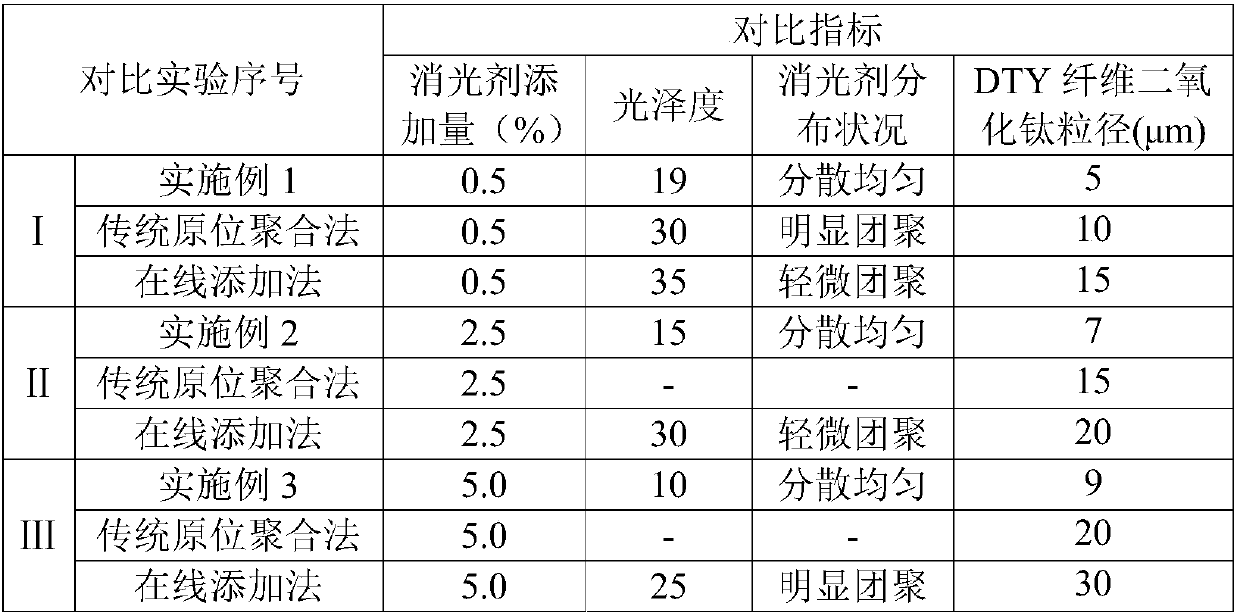

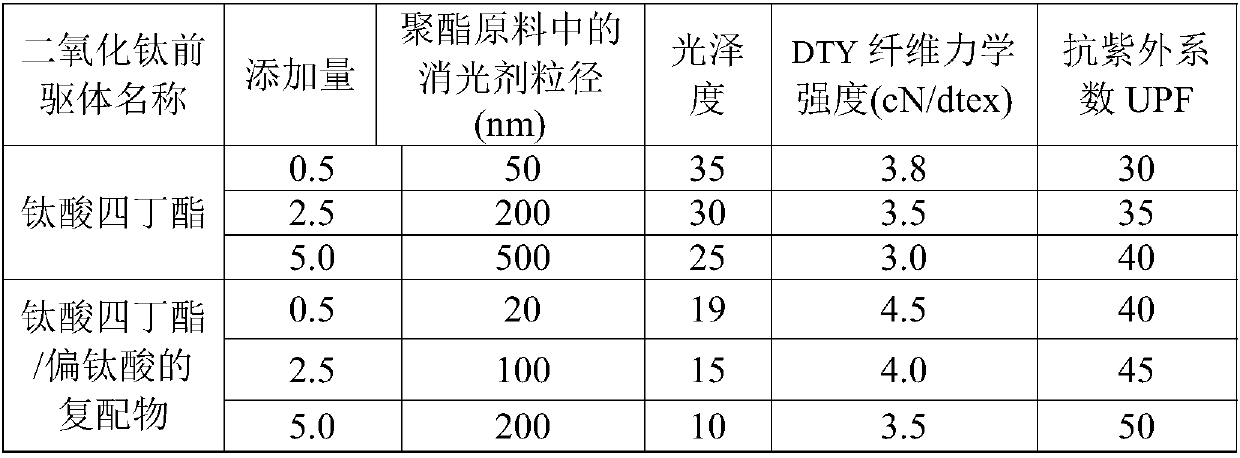

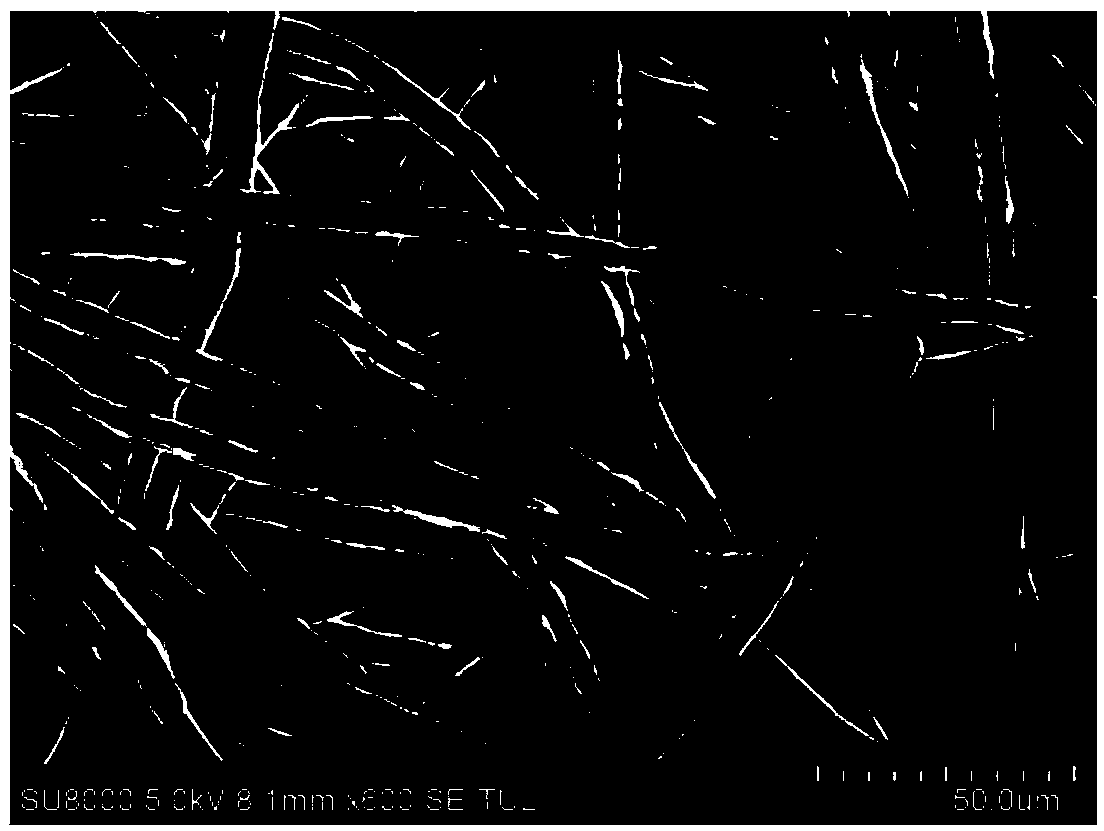

Light extinction polyester and low-gloss elastic composite fiber

ActiveCN107641196AEvenly dispersedGood mattingConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolyesterFiber

The invention provides light extinction polyester and a low-gloss elastic composite fiber. The light extinction polyester comprises the following component in percentage by mass: 0.5-5.0% of titaniumdioxide nano granules, wherein the particle size of the titanium dioxide nano granules is 20-200 nm; detection with incident rays of 45 degrees shows that the gloss of the light extinction polyester is less than 20. The titanium dioxide nano granules are uniformly dispersed in the light extinction polyester and are not agglomerated. The mass ratio of a PET component to a PTT component in the low-gloss PET / PTT elastic composite fiber is (40:60)-(60:40), the composite fiber is formed through a composite melting spinning component, titanium dioxide is uniformly dispersed in the composite fiber, no agglomeration phenomenon is caused, the particle size of the titanium dioxide dispersed in the fiber is less than 10 [mu]m, the strength of the composite elastic fiber is greater than 3.0 cN / dtex, the gloss on the surface of the fiber is less than 20, and the elastic recovery rate is greater than or equal to 90%.

Owner:ZHANGJIAGANG GLORY CHEM IND CO LTD +1

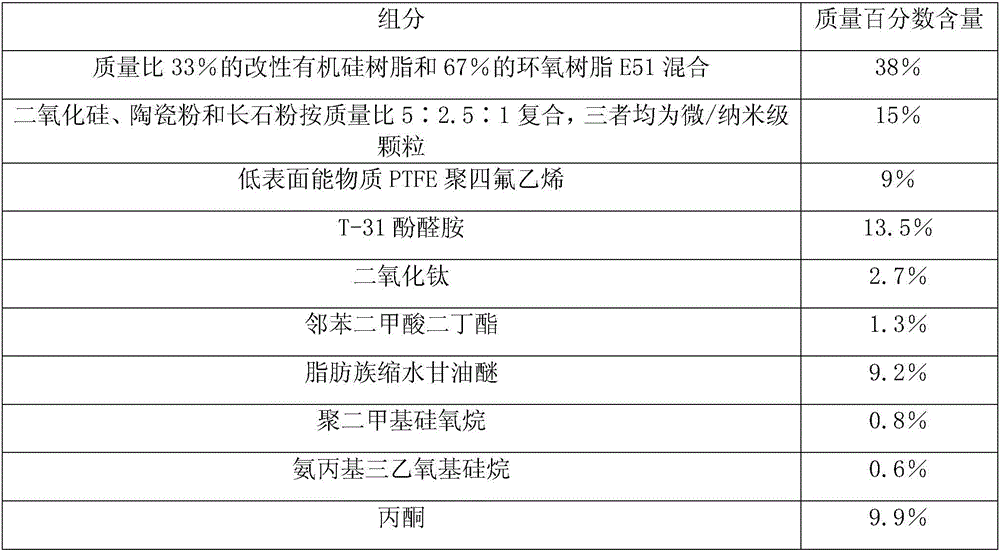

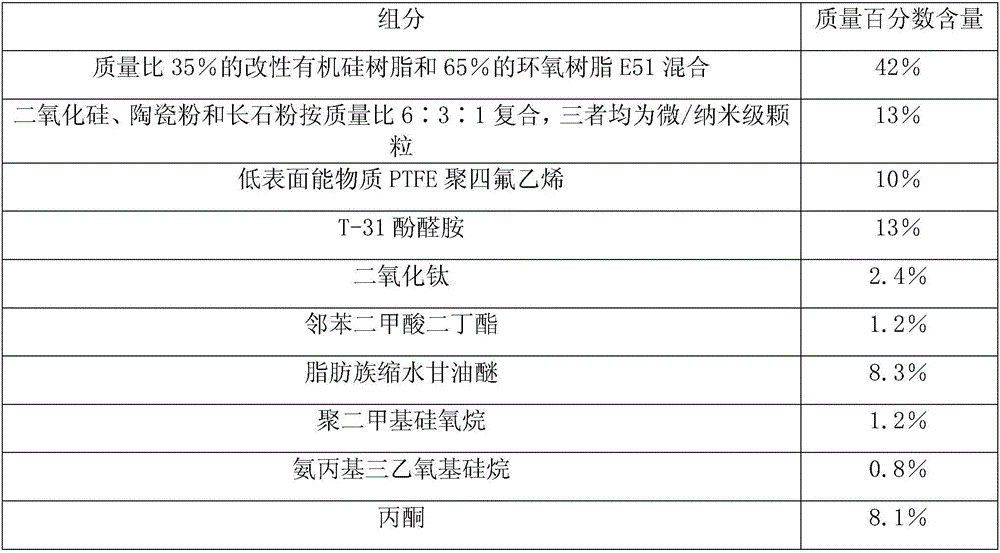

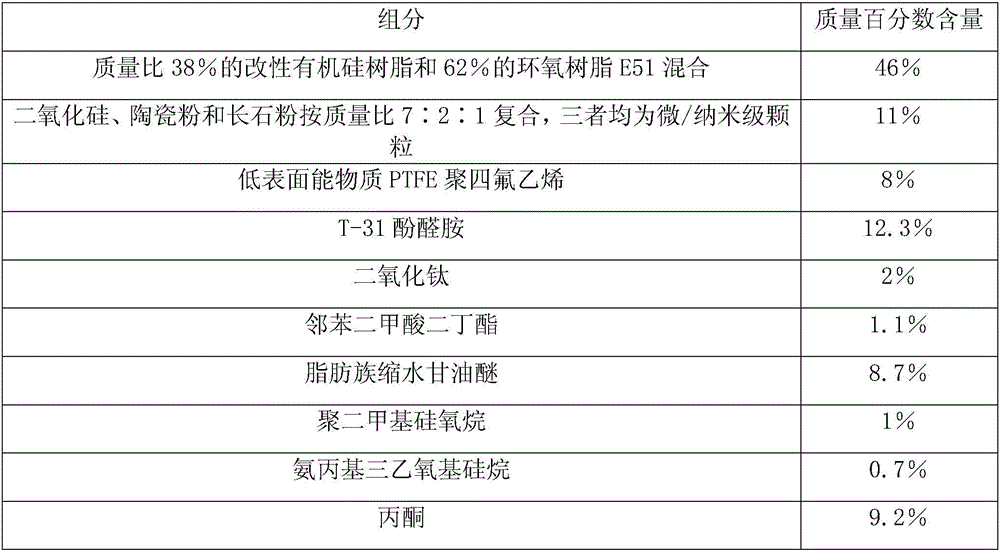

Hydrophobic corrosion-resistant ceramic paint and preparing method thereof

InactiveCN106010122AImprove performanceStrong adhesionAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceEpoxy

The invention discloses a hydrophobic anti-corrosion ceramic coating, which uses epoxy resin and modified silicone resin as a film-forming material, and adds various fillers, auxiliary agents and solvents, including body fillers, pigments and fillers, curing agents, coloring Agent, toughener, diluent, leveling agent, epoxy coupling agent and solvent. The hydrophobic anti-corrosion ceramic coating of the present invention has stable performance, strong adhesion, excellent salt water resistance, strong acid and alkali corrosion resistance, good weather resistance, high hardness, and excellent wear resistance; and it is environmentally friendly and non-toxic (low VOC), and has Good protection, decoration and functional effects, low price of raw materials, simple preparation method, suitable for the surface of metal substrates that need to be protected under harsh corrosion environments.

Owner:GUANGXI UNIV

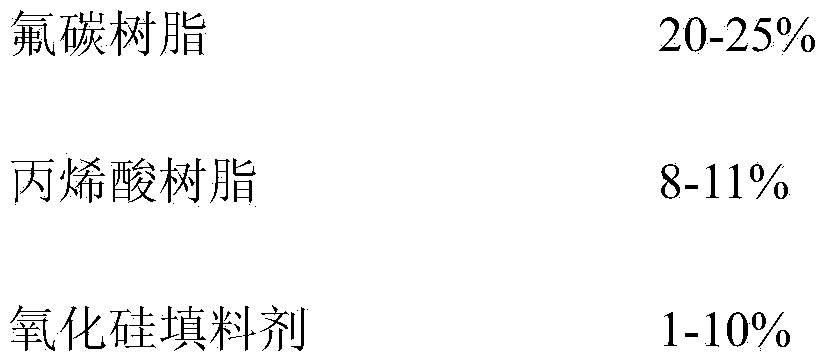

Water dispersible fluorocarbon finish coating and preparation method thereof

InactiveCN103709854AImprove stain resistanceImprove appearance performanceAntifouling/underwater paintsPaints with biocidesWater dispersibleAcrylic resin

The invention discloses a water dispersible fluorocarbon finish coating. The finish coating consists of the following components in percentage by weight: 20-25% of fluorocarbon resin, 8-11% of acrylic resin, 1-10% of silicon oxide filler, 5-10% of auxiliaries and 50-60% of a solvent. The water dispersible fluorocarbon finish coating disclosed by the invention has a self-cleaning effect and is excellent in stain resistance; meanwhile, the coating improves apparent property through addition of the inorganic filler silicon oxide; the finish coating, through regulating proportion of the silicon oxide filler, can achieve coating effects of high light, semi matte and lusterless, and can improve wear-resisting property of the coating.

Owner:SHANGHAI JIAO TONG UNIV

Radiative cooling film with self-cleaning function, and preparation method thereof

The invention especially relates to a radiative cooling film with a self-cleaning function and a preparation method thereof, belonging to the technical field of radiative cooling. The radiative cooling film comprises a base film and further comprises radiators and hydrophobic nanoparticles dispersed in the base film, wherein the infrared emission peaks of the radiators are in the infrared radiation band range of 8 to 13 [mu]m and covers at least one band interval in the range of 8 to 13 [mu]m. According to the invention, the high hydrophobicity of the hydrophobic nanoparticles is utilized so as to allow the radiative cooling film to have self-cleaning effect, so the phenomenon of reduction in cooling effect due to dust accumulation is avoided. The radiative cooling film of the invention has high emissivity in the band of 8 to 13 [mu]m, high transmittance in a visible light band and good lighting performance, and can reduce the absorption of energy in other bands by the object to ensurecooling effect. Furthermore, the radiators with two different particle sizes are adopted in the invention, so a radiation range is broadened, and ground heat is maximally radiated to the outer space,thereby improving cooling effect.

Owner:天佑(山东)新能源科技有限公司

Anti-condensation coating and preparation method thereof

The invention discloses an anti-condensation coating. The anti-condensation coating comprises a mixed emulsion formed by a pure acrylic emulsion and a silicon resin emulsion and a heat insulation material formed by combining microbeads and aerogel slurry, wherein the mixed emulsion accounts for 20-40% of the total mass of the anti-condensation coating; and the heat insulation material accounts for 15-20% of the total mass of the anti-condensation coating. According to the anti-condensation coating disclosed by the invention, the heat insulation material containing the microbeads and the aerogel is added, so a temperature difference between a wall surface and air is reduced, the wall surface is prevented from condensation, and the problems of moisture absorption saturation, moisture absorption expansion and adhesive force reduction of a traditional anti-condensation coating due to moisture absorption of water vapor in air are also solved; and meanwhile, the pure acrylic emulsion and the silicon resin emulsion are used, and the water resistance and excellent physical performance of the pure acrylic waterproof emulsion and the air permeability and hydrophobicity of the silicon resin emulsion are effectively combined, so the coating has better physical performance, is not prone to damage, and has waterproof and lotus leaf self-cleaning effects to prevent external water from invading.

Owner:SUZHOU GUARDEX NEW MATERIAL TECH CO LTD

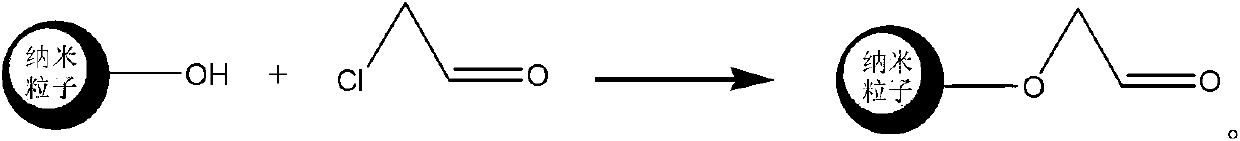

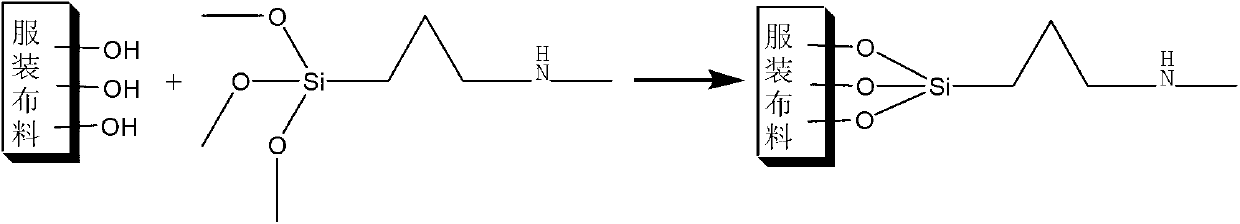

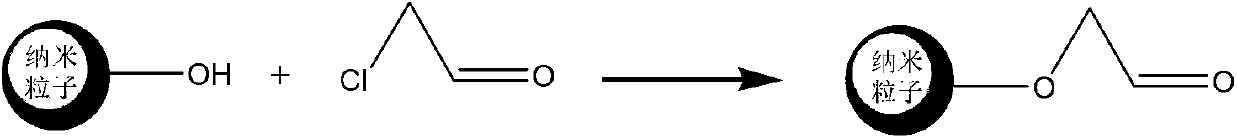

Multifunctional finishing agent for costume, as well as preparation and using method of multifunctional finishing agent

The invention relates to a multifunctional finishing agent for costume, as well as a preparation and a using method of the multifunctional finishing agent, and aims at providing an active nanometer titanium dioxide particle with surface a decoration function, and an active garment material with the decoration function. The nanometer titanium dioxide particle is stably and firmly linked to the garment material in a form of a chemical bond through the reaction of the active nanometer titanium dioxide particle and the active garment material. The multifunctional finishing agent has the advantages that the active nanometer titanium dioxide particle is linked to the garment material, so that a nano-scale coarse structure is formed on the cloth surface, and large specific surface area is achieved, and the apparent contact angle of liquid on the material surface is large, so as to achieve a self-cleaning effect; the titanium dioxide particle has antifungal and antibacterial functions, and the functions of resisting virus and removing peculiar smell; and the multifunctional finishing agent can react with hydroxyl on the fabric surface to form a stable and firm chemical bond, so that an air pore of the fabric is not blocked, and the air permeability of the fabric is not affected.

Owner:QUANZHOU YALIN NEW MATERIAL TECH

Dehydration-prevention gecko hydrogel application and preparation method thereof

The invention belongs to the field of medical high-molecular materials, and discloses a dehydration-prevention gecko hydrogel application and a preparation method thereof. The hydrogel application is prepared from the following raw materials in parts by weight: 0.25-1.55 parts of polyvinyl alcohol, 0.04-0.27 part of polyglutamic acid, 0.03-0.35 part of tannic acid, 0.05-0.12 part of glutaraldehyde having a mass concentration of 2-10 percent, 10-23 parts of water, and the balance of an acidity regulating agent. The gecko hydrogel application can adsorb and closely attach the surface of human skin since the application surface has tissues similar to the nano-sucker structure of gecko feet so as to effectively prevent falling off and effectively prevent hydrogel from being dehydrated. The hydrogel application can be well attached to skin to achieve a self-cleaning effect, and is applicable to wound protection and treatment of physical therapy, burning, scalds and traumatic wounds by cold application.

Owner:NANJING SHINEKING BIOTECH CO LTD

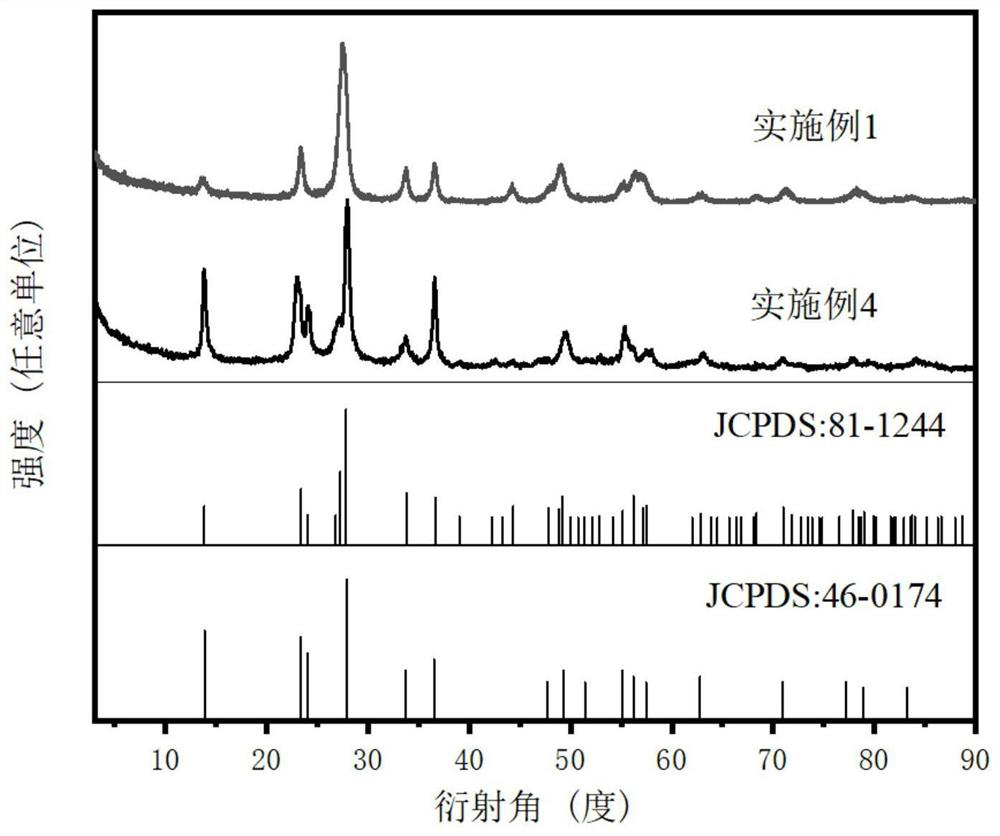

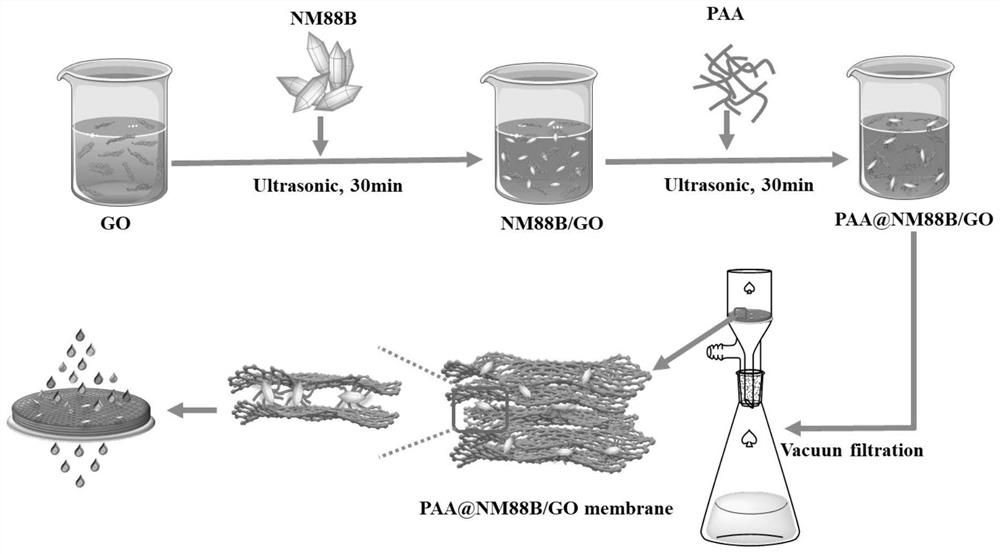

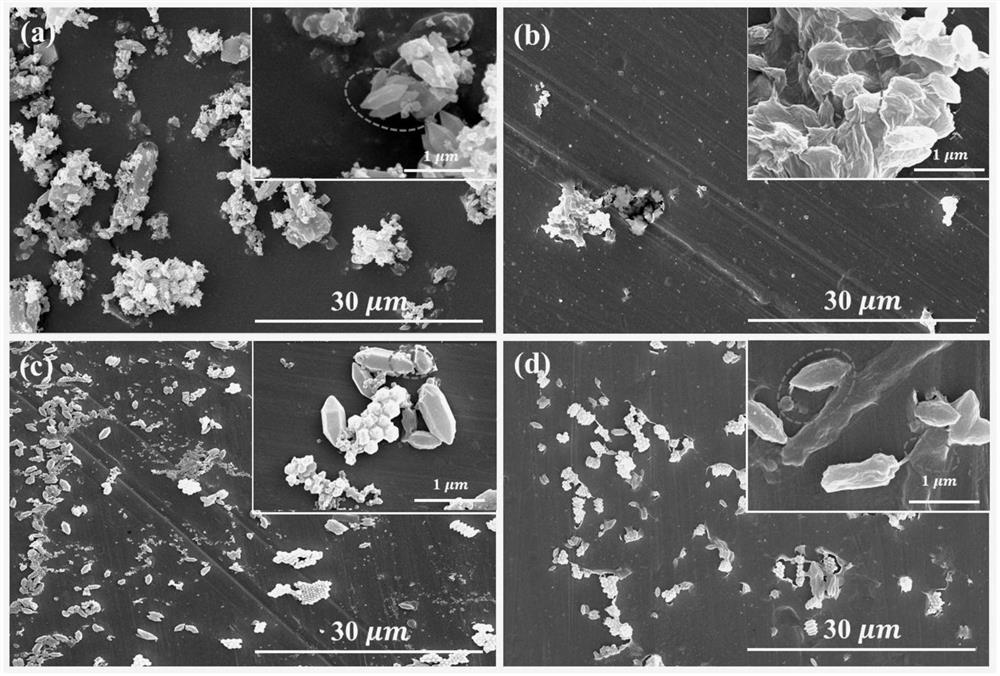

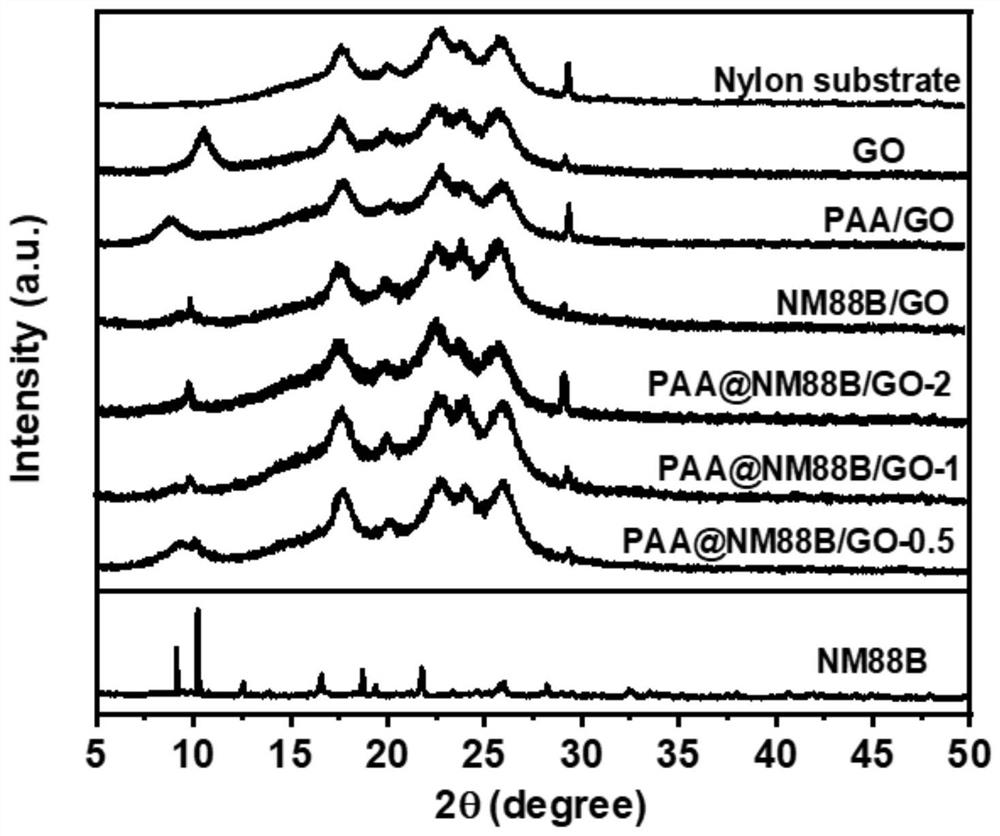

Composite membrane based on synergistic separation and photo-Fenton self-cleaning

ActiveCN112791601AImprove stabilityIncrease interlayer spacing and hydrophilicitySemi-permeable membranesChemistryGraphite oxide

The invention discloses a composite membrane based on synergistic separation and photo-Fenton self-cleaning. The composite membrane is formed by compounding graphene oxide, polyacrylic acid and NH2-MIL-88B (Fe). The preparation method of the composite membrane comprises the following steps of: ultrasonically dispersing graphene oxide powder into water to prepare a uniform dispersion liquid with the concentration of 0.05 mg / mL; adding NH2-MIL-88B (Fe) into the dispersion liquid, and carrying out ultrasonic dispersion to obtain a uniform mixed suspension; adding polyacrylic acid into the suspension, and carrying out ultrasonic dispersion to form a uniform PAA@NM88B / GO suspension; and pouring the PAA@NM88B / GO suspension into a vacuum filter filled with a nylon membrane substrate, and preparing the composite membrane by using a vacuum filtration method. The composite membrane prepared by the invention effectively retains the retention rate of dye while improving the water flux, has a self-cleaning effect, and provides a new thought for commercial popularization of the graphene oxide membrane.

Owner:成都恒固新材料科技有限公司

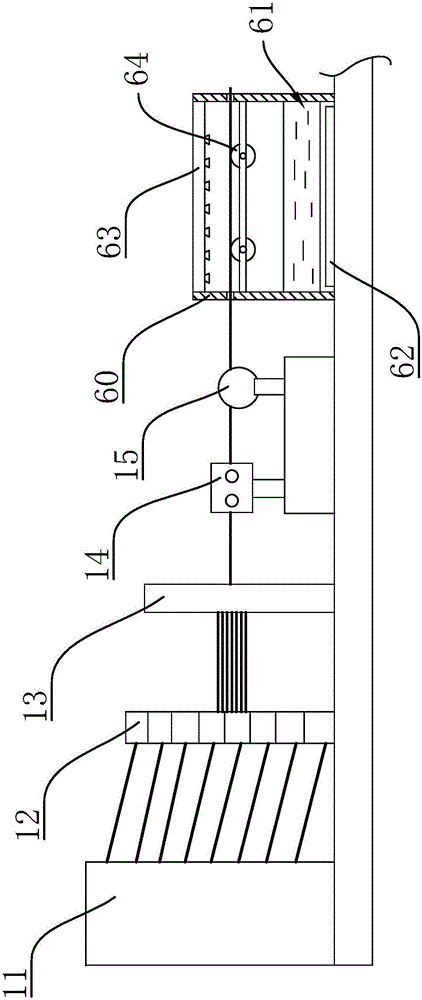

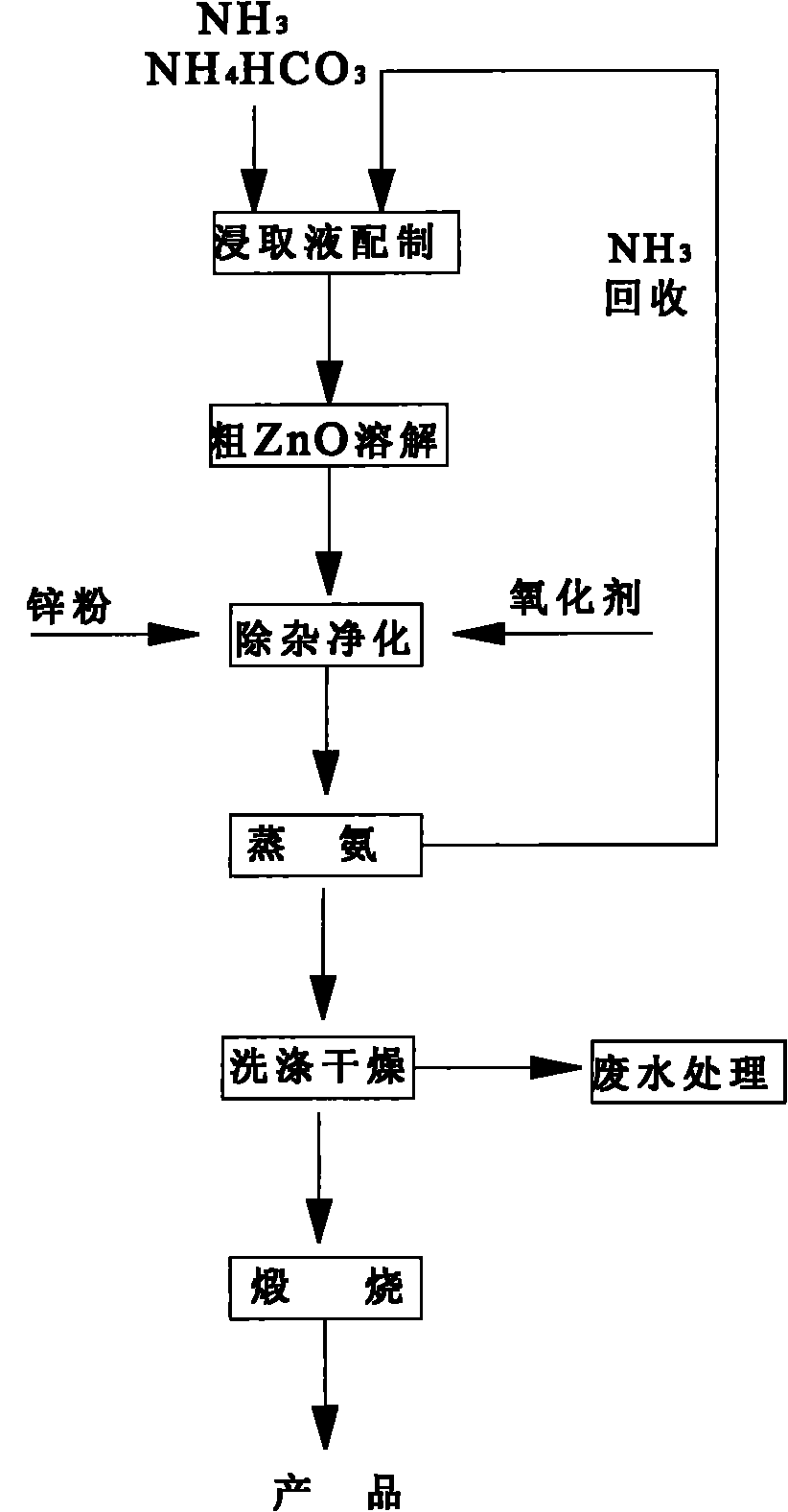

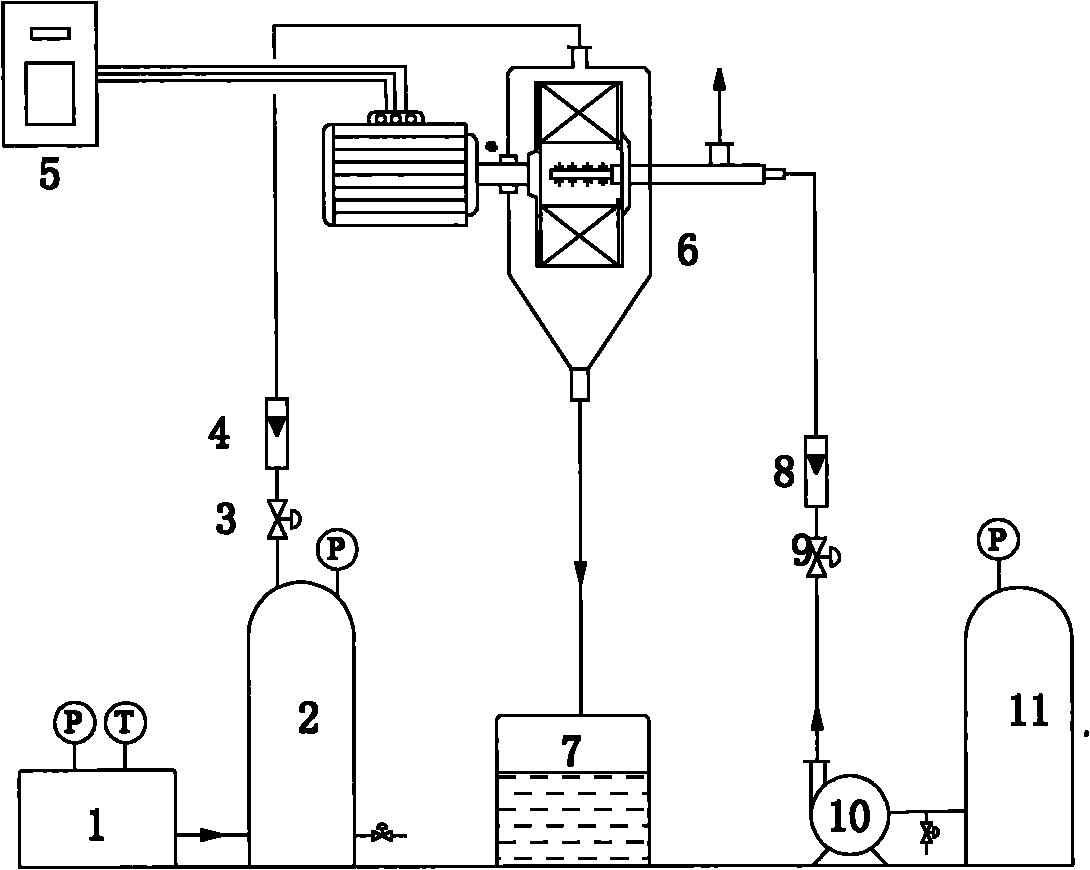

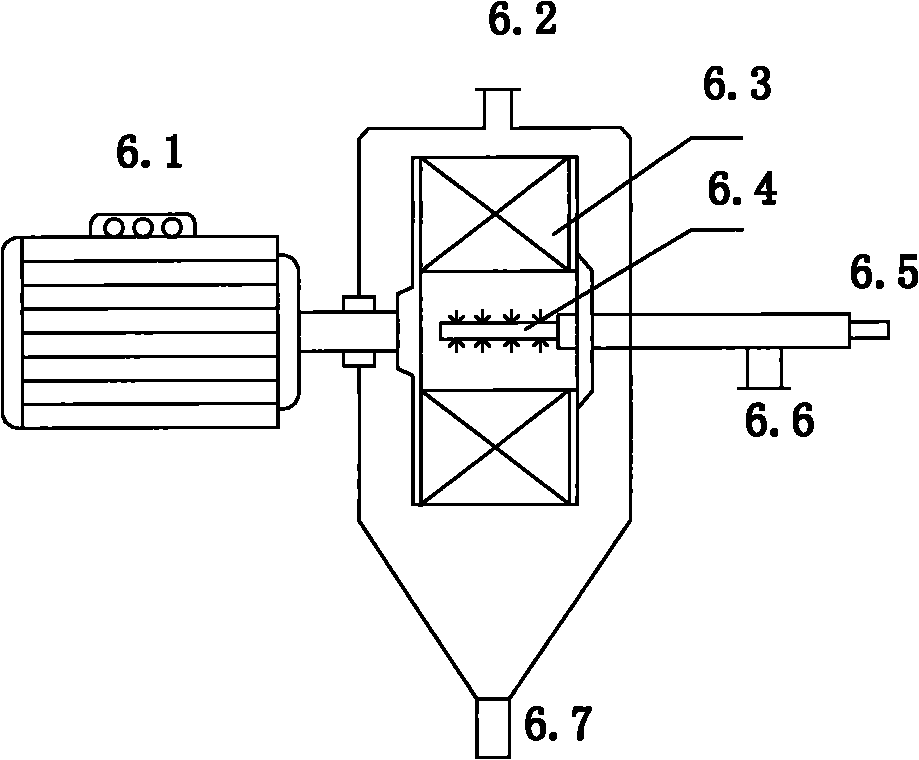

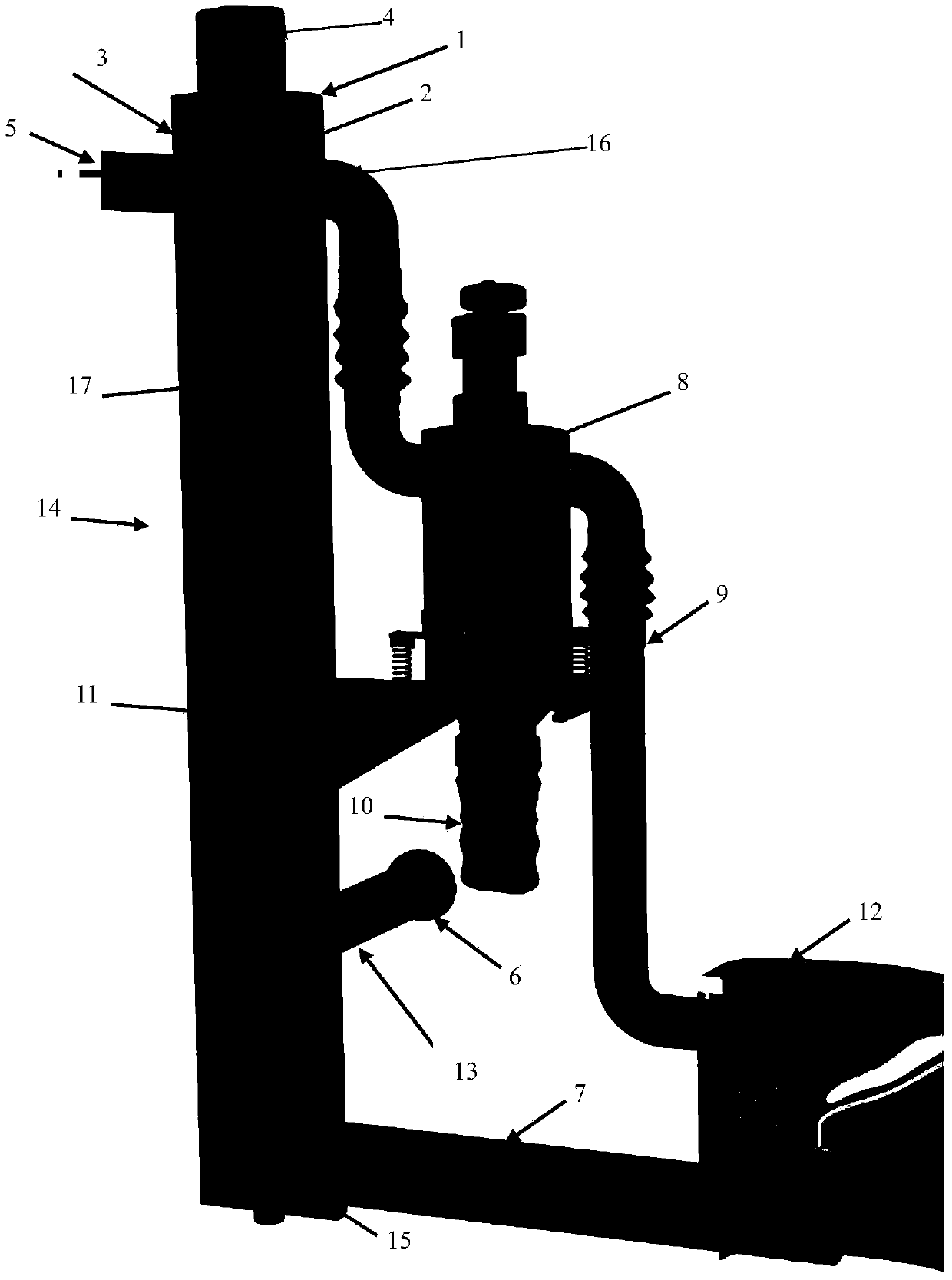

Method and device for preparing nano zinc oxide

The invention belongs to the technical field of zinc oxide preparation, in particular to a method and a device for preparing nano zinc oxide so as to realize a continuous process which has the advantages of higher deamination and zinc deposition rate under low energy consumption and preparation of higher quality nano zinc oxide. The preparation method comprises the following steps of: performing reaction on a zinc-ammonia complex and hot steam in a rotary packed bed to generate a zinc oxide precursor; and baking to prepare the nano zinc oxide. The device comprises a steam kettle, a zinc-ammonia complex solution storage tank, the rotary packed bed and a product storage tank, wherein the zinc-ammonia complex solution storage tank is connected with the liquid inlet of the rotary packed bed; the steam kettle is connected with a buffer tank; the gas outlet of the buffer tank is connected with the gas inlet of the rotary packed bed; and the liquid outlet of the rotary packed bed is connected with the product storage tank. The method has the advantages of simple process operation, low cost, high efficiency, and continuity; and the device has the advantages of obvious transmission effect, low power consumption, small equipment volume, self-cleaning function, and low possibility of scale formation and blockage.

Owner:ZHONGBEI UNIV

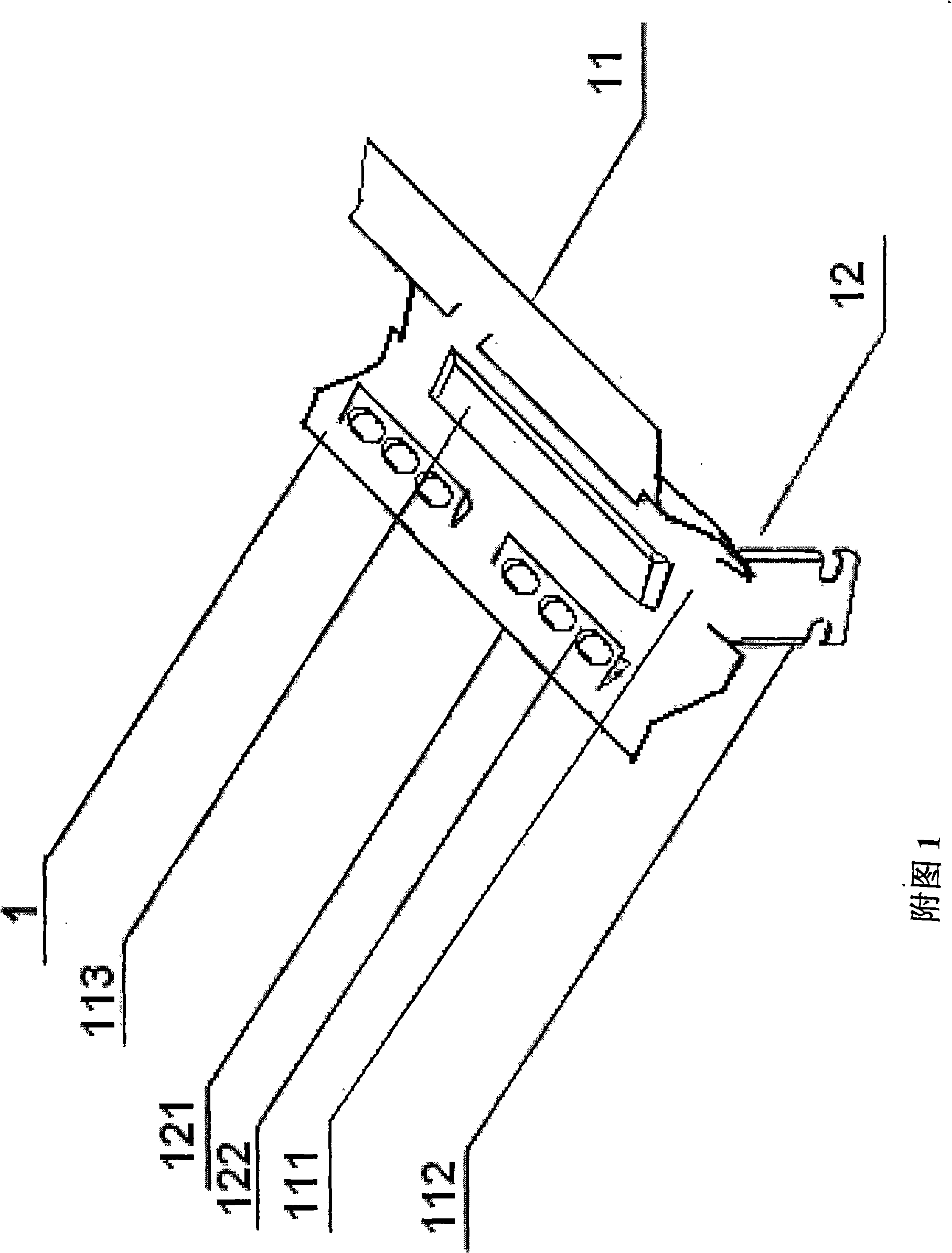

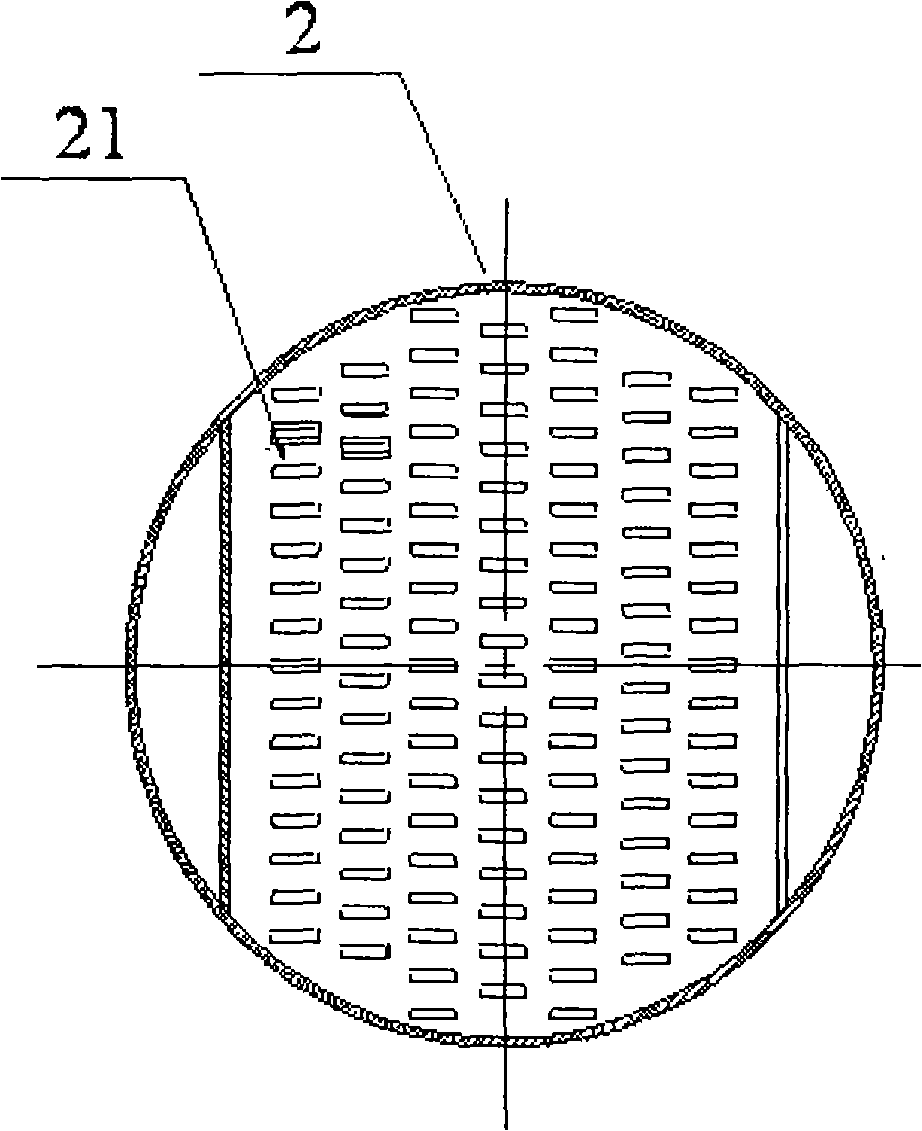

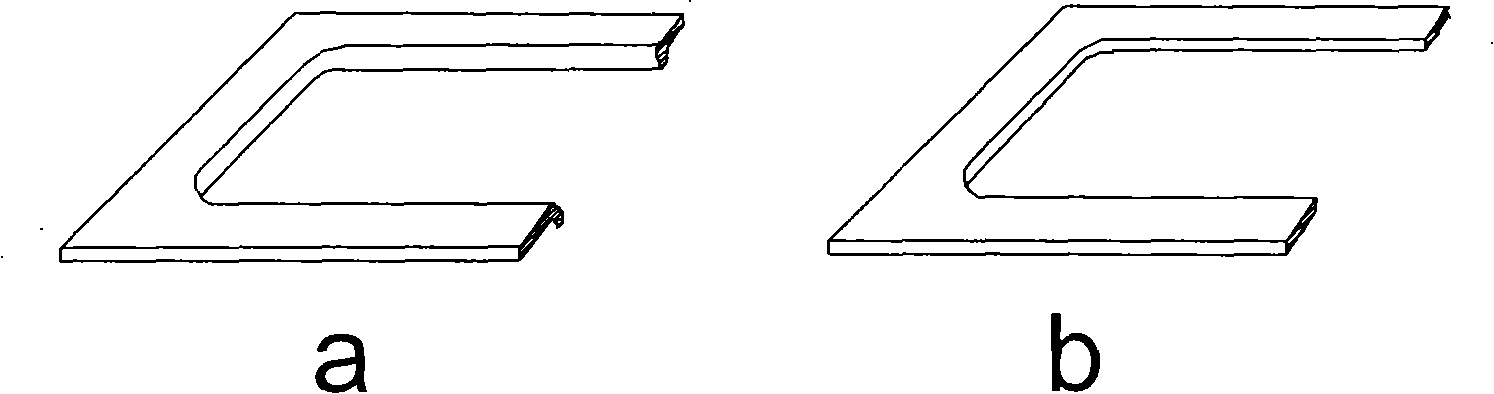

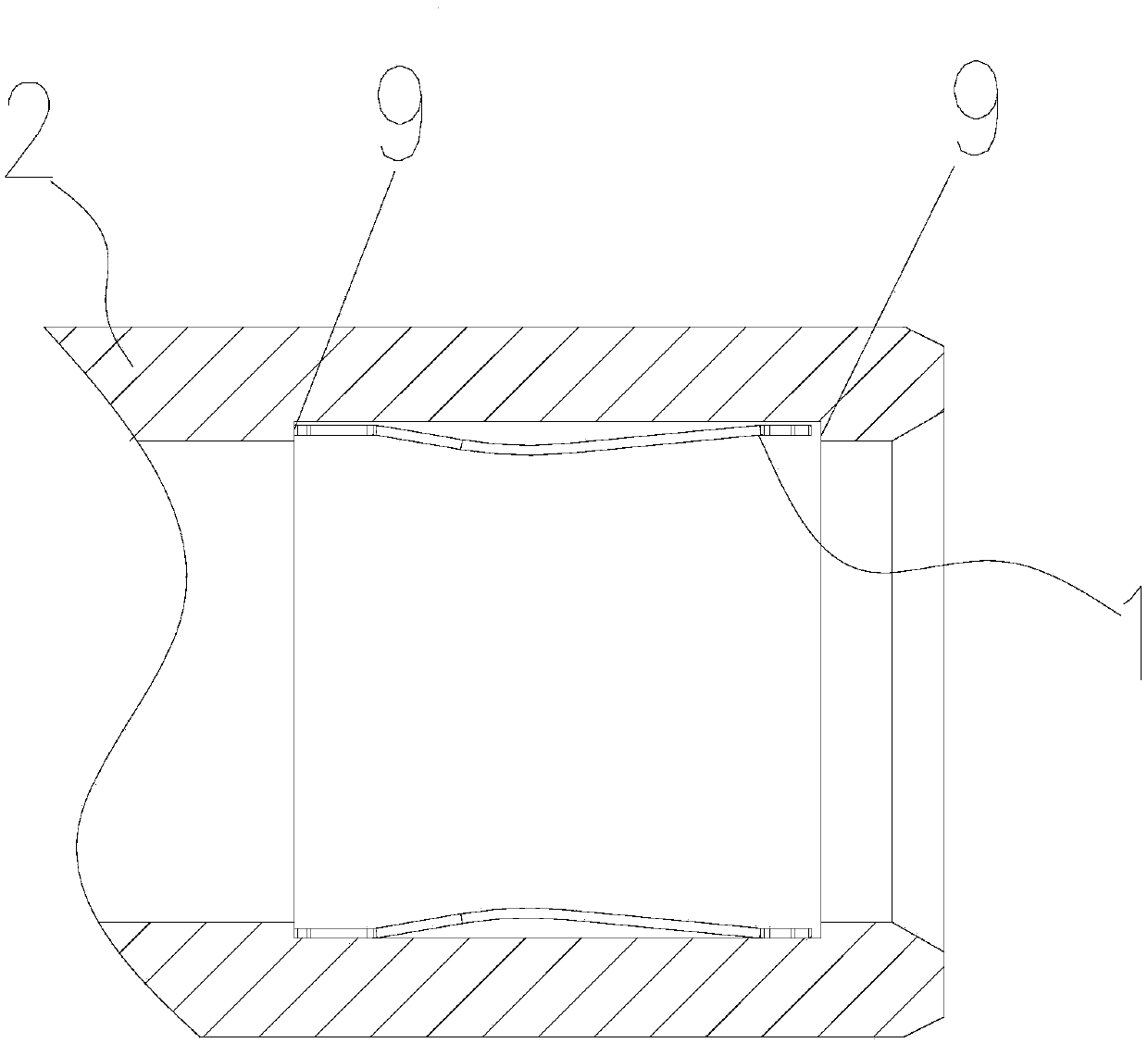

A packing float valve plate

InactiveCN101279143AReduce leak rateIncrease contact areaFractional distillationPressure systemLow voltage

The invention relates to a stuffing floating valve tray which consists of a floating valve (1) and a tray (2). The floating valve (1) is installed in a valve opening (21) and is hung at the tray (2). The stuffing floating valve tray is characterized in that the floating valve (1) has a rectangle structure formed by a valve body (11) and a stuffing part (12); the valve body (11) consists of a valve plate (111) and a valve leg (112); the stuffing part (12) is positioned at the upper part of the valve body (11), and is connected with the valve body (11). Compared with the prior art, the stuffing floating valve tray integrates the characteristics of the floating valve tray and that of the stuffing, thus not only having the advantages of large stuffing interface contact area, comparatively low voltage drop and comparatively high tray efficiency, but also being characterized in that the floating valve tray has large operation flexibility and high processing ability. The stuffing floating tray is applicable to regular type gas-liquid tower devices and ultra-large type gas-liquid tray devices with normal pressure system and pressurized system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

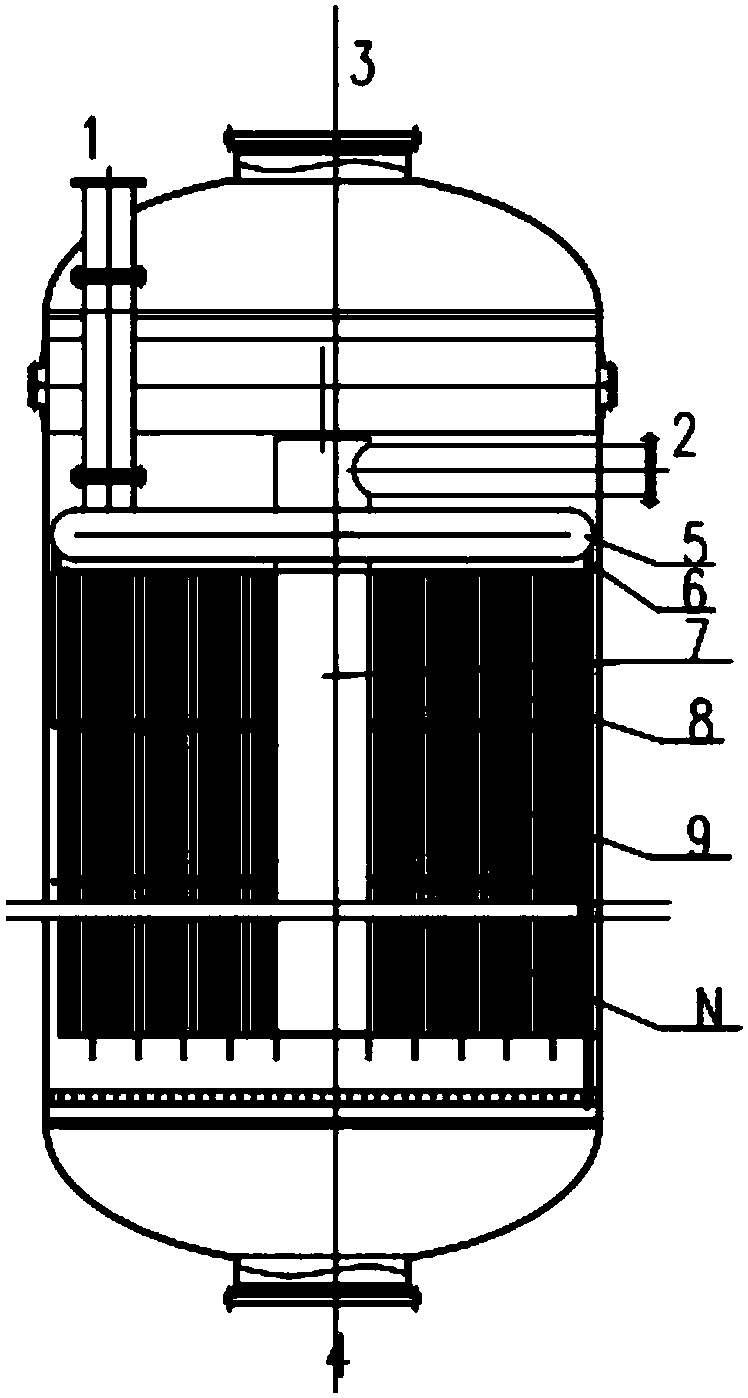

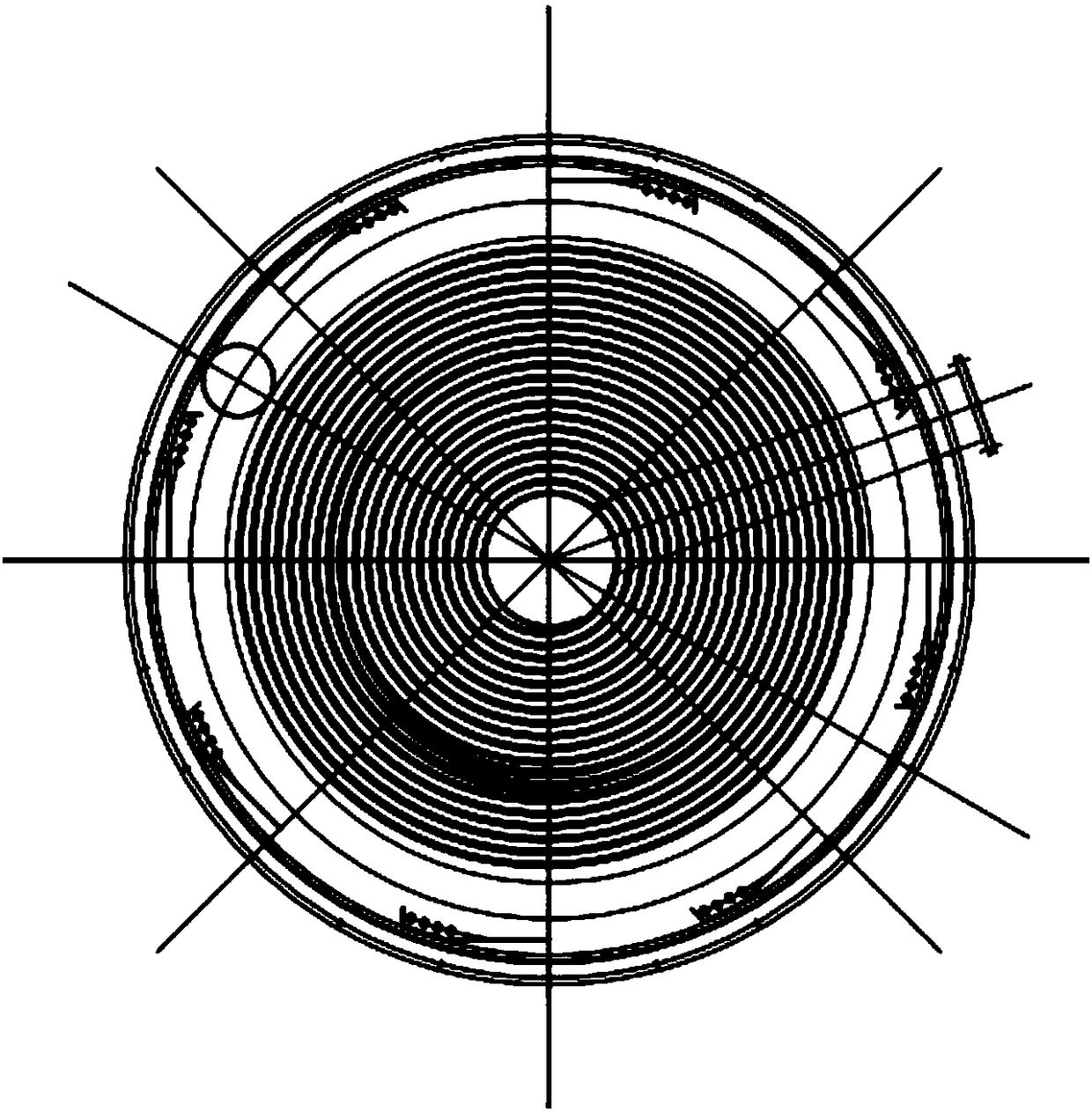

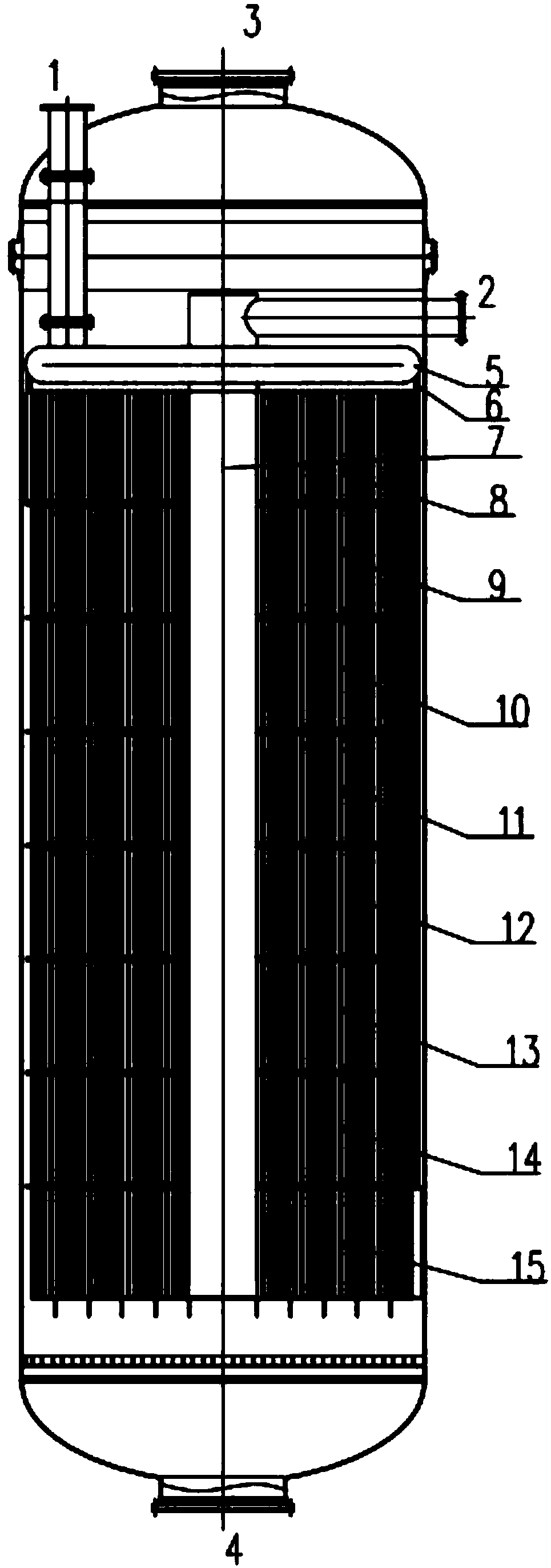

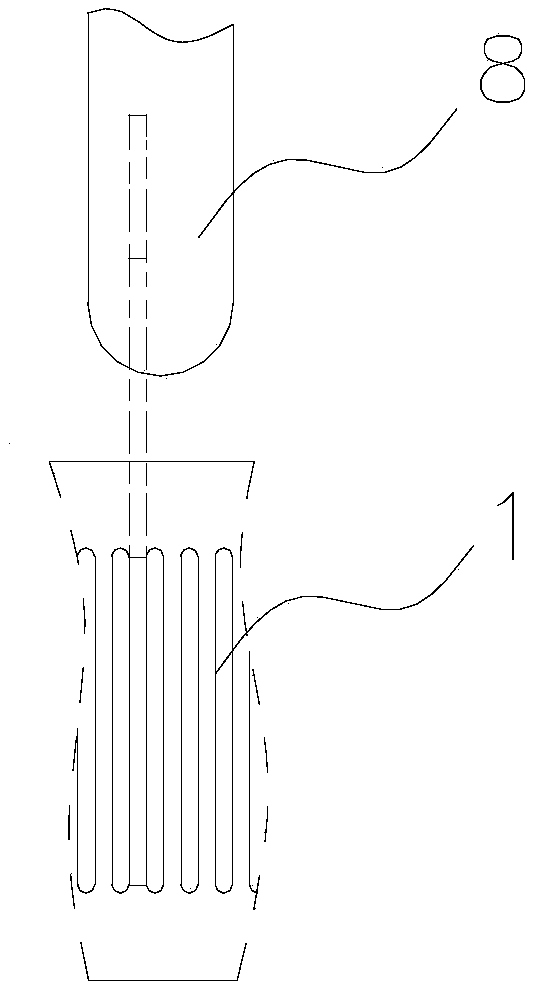

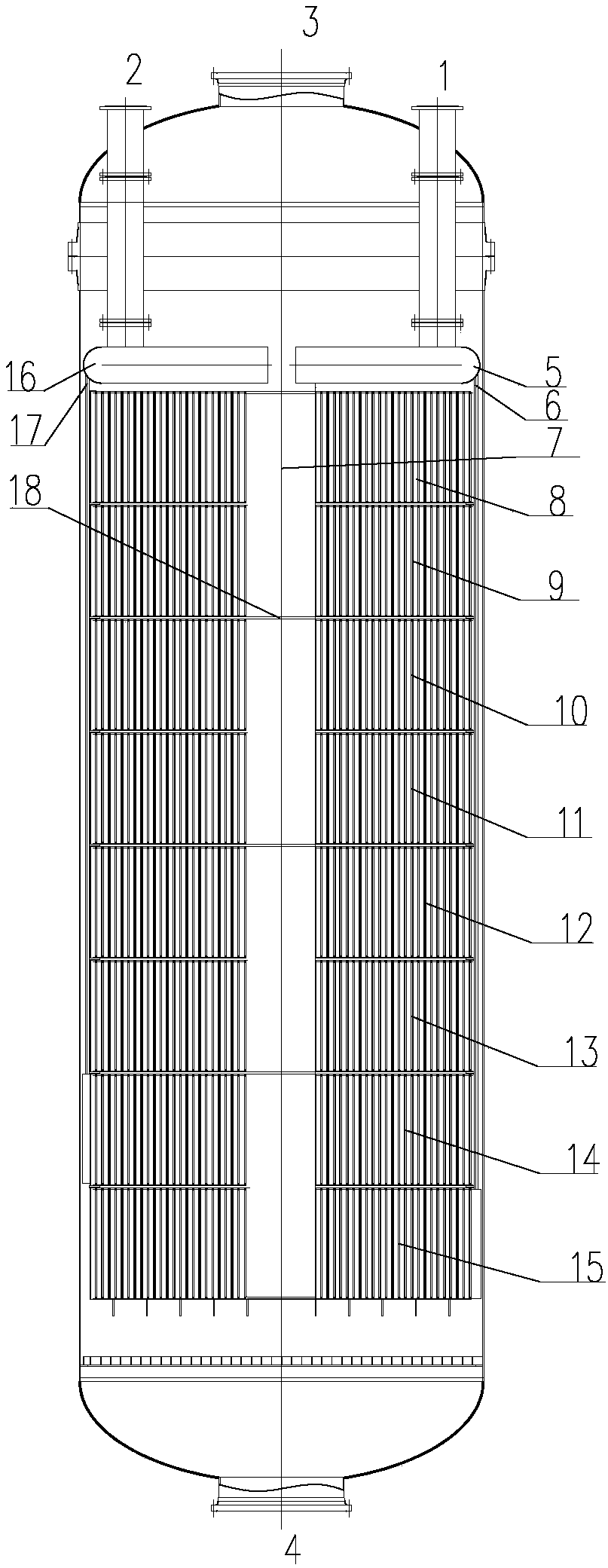

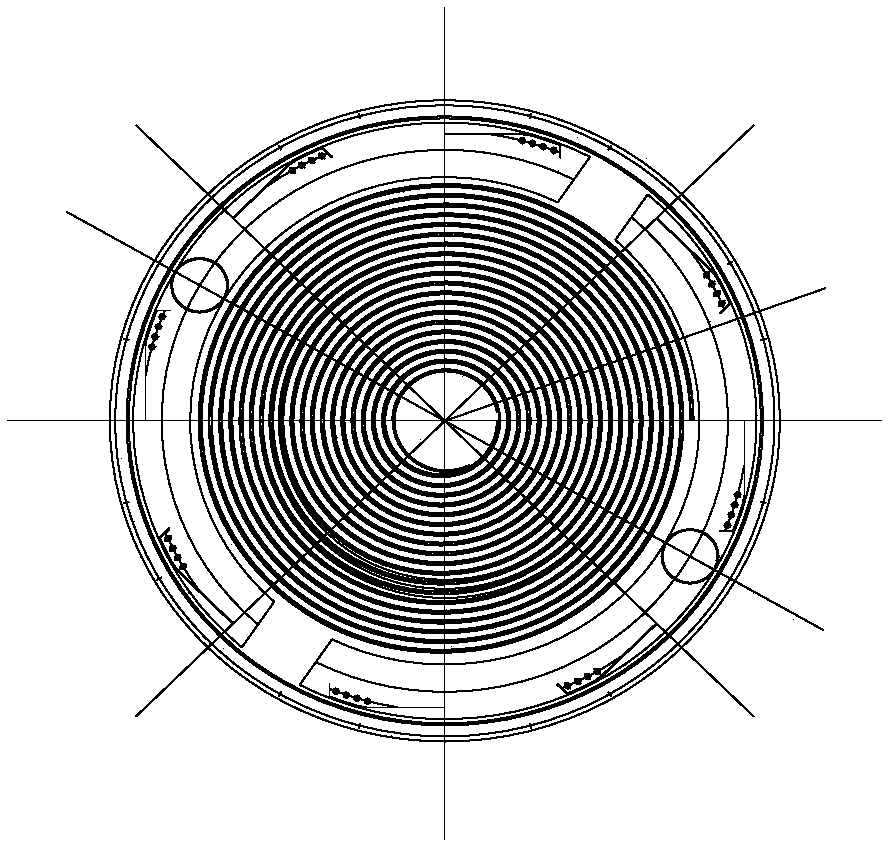

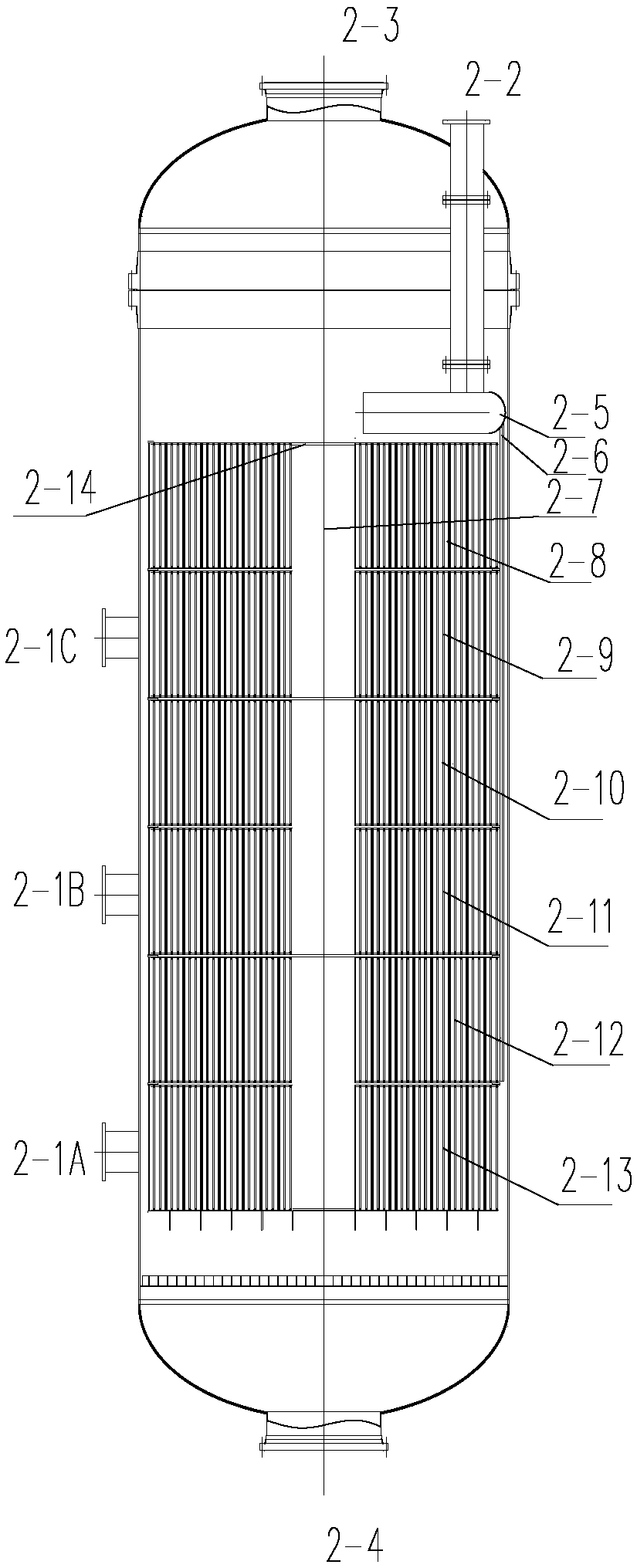

Soaking type screw plate fixed-bed reactor for gas-solid catalytic reaction

ActiveCN108114672ATemperature uniformity and controlFlexible control distanceChemical/physical processesGas solidGas phase

The invention relates to a soaking type screw plate fixed-bed reactor for a gas-solid catalytic reaction. The soaking type screw plate fixed-bed reactor comprises a gaseous phase and an inlet / outlet of a heat exchange medium; one or more screw plate fixed-bed reaction sections are arranged in the reactor. The soaking type screw plate fixed-bed reactor disclosed by the invention has the advantagesthat firstly, a shell pass heat exchange coefficient is remarkably increased, a total heat transfer coefficient is enabled to be increased, a heat transfer effect is intensified and heat transfer temperature difference is reduced; secondly, heat transfer distance and heat transfer area can be flexibly controlled and uniformity and control of the temperature of a reaction bed layer are facilitated;thirdly, the volume utilization rate is high (the maximum can reach 70 percent or higher, and the maximum of a shell and tube reactor is about 40 percent), the capacity of single equipment is high, and the occupied area and the investment are obviously reduced; fourthly, a heat exchange medium channel has a self-cleaning effect, so that dirt and block are not easily generated.

Owner:QINGDAO UNIV OF SCI & TECH

Coalescence material for emulsified water as well as preparation method and application of coalescence material

InactiveCN110743202AGood for coalescence and separationImprove separation efficiencyNon-miscible liquid separationPolymer scienceOil emulsion

The invention relates to a coalescence material for emulsified water as well as a preparation method and application of the coalescence material. The coalescence material for the emulsified water includes a substrate and a fluorine-containing polyurethane coating layer coating the surface of the substrate. The fluorine-containing polyurethane coating layer of the coalescence material contains a hydrophobic fluorine-containing chain segment and a hydrophilic chain segment, thereby having hydrophobic and lipophilic characteristics in the air; the contact angle between the fluorine-containing polyurethane coating layerandwater drops is 100-120 degrees, the contact angle between the fluorine-containing polyurethane coating layerandoil drops is 50-80 degrees, the contact angle of water under oil changes dynamically and decreases from 120-150 degrees to 50-80 degrees within 2 min, so that favorable conditions are provided for demulsification mixingof liquid drops in a water-oil emulsion, andcompared with other fluorocarbon materials in the prior art, the coalescence material provided by the invention has a significantly better coalescence and separation effect on the emulsified water; and the coalescence material is suitable for the separation of the water-oil emulsion containing different types and different concentrations of surfactants, and the water-oil separation efficiency isas high as 91-98%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Electrophoresis cell with conductive diamond film as electrode

InactiveCN102288668AGood chemical stabilityCorrosion resistantMaterial analysis by electric/magnetic meansDiamond electrodesGas phase

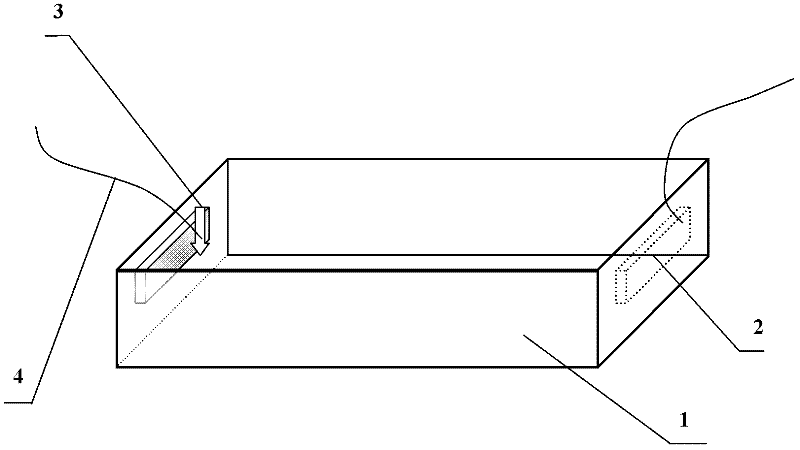

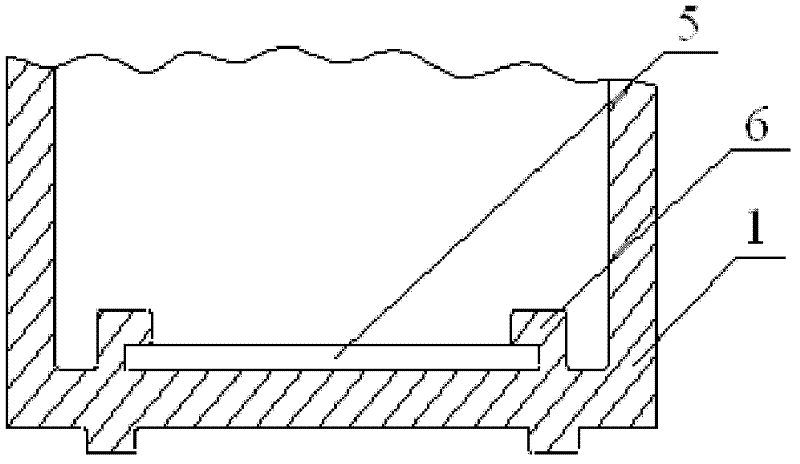

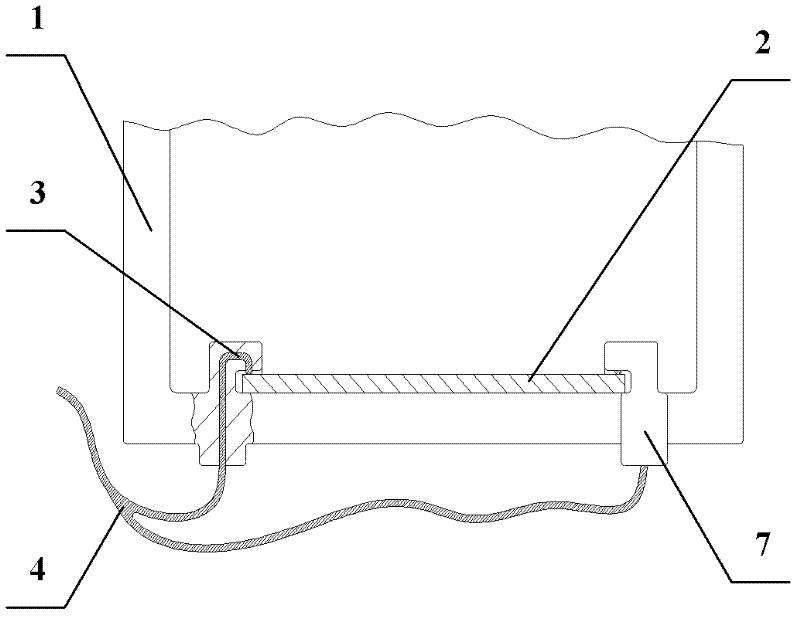

The electrophoresis tank in which the conductive diamond film is used as an electrode of the invention belongs to the technical field of biological equipment. The structure has an electrophoresis tank (1), electrodes, wires (4) connecting the electrodes and a power supply, and an electrode fixing device (3); the electrode is a conductive diamond film electrode (2), which is formed by chemical vapor deposition. The boron or nitrogen doped diamond film grown on the substrate or the self-supporting boron or nitrogen doped diamond film has a resistivity in the order of 10-4 to 10-2 Ω·cm. The electrode fixing device (3) is a fixed slot type. The electrophoresis nucleic acid and protein molecular results of the conductive diamond film electrode of the present invention are similar to the platinum wire electrode, even better than the platinum wire electrode, and can be easily removed and cleaned repeatedly without damage. After repeated experiments and cleaning electrophoresis The result has no significant change; it has the characteristics of long service life, low maintenance cost, simple preparation method, no pollution, strong corrosion resistance and the like.

Owner:JILIN UNIV

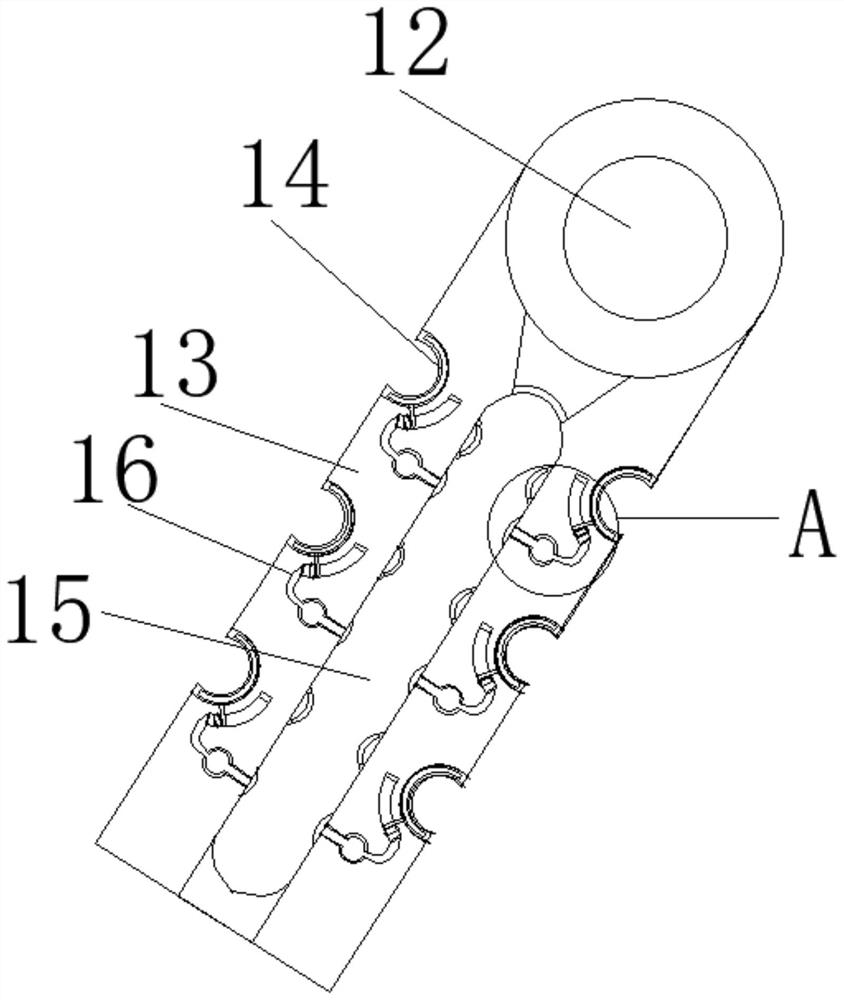

Crown spring mounting structure with good restriction and convenient disassembly

InactiveCN109638511AEasy charging connectionAvoid axial displacement and circumferential displacementSecuring/insulating coupling contact membersCoupling contact membersEngineeringAxial displacement

The invention belongs to the technical field of electric connectors and particularly relates to a crown spring mounting structure with good restriction and convenient disassembly. The crown spring mounting structure includes a crown spring and a sleeve. Elastic folding plates are uniformly distributed on the outer circumferential surfaces of the two ends of the crown spring. A plurality of throughholes are uniformly arranged on the cylinder surfaces of the two ends of the sleeve. The elastic folding plates are disposed in the through holes and have opposite folding directions. The free ends of the elastic folding plates are abutted against the walls of the through holes. The crown spring mounting structure has the beneficial effects that the axial displacement and the circumferential displacement of the crown spring in the sleeve can be avoided, the connection structure of the crown spring and the sleeve is firmly installed, which is convenient for charging connection; regardless of the diameter of the crown spring, the crown spring is convenient to disassemble and convenient to be taken out of the sleeve, thereby contributing to the maintenance of the crown spring; when the crownspring is maintained, the replacement of the connection structure of the sleeve and the crown spring can be avoided and the maintenance cost is saved.

Owner:JIANGSU WANBANG DEHE NEW ENERGY TECH CO LTD

Production process of loop tweed

InactiveCN108486735AStrong sense of three-dimensional and colorFeel plumpLiquid repellent fibresWoven fabricsPolyesterWeft yarn

The invention discloses a production process of loop tweed. The production process comprises the following steps of preparing raw materials of the loop tweed, wherein the raw materials comprise, by weight, 25% of polyester fibers, 25% of 64S Australian short fibers, 30% of 64S Australian wool fibers and 20% viscose fibers; finely spinning the polyester fibers into 38 / 2-Nm fine spun yarn; finely spinning the 64S Australian short fibers and the 64S Australian wool fibers into 38 / 2-Nm fine spun yarn; finely spinning the viscose fibers into 4 / 1-Nm fine spun yarn; conducting beam-warping and blending on the yarn to prepare the 38 / 2-Nm fine spun yarn and the 4 / 1-Nm fine spun yarn, wherein the 38 / 2-Nm fine spun yarn and the 4 / 1-Nm fine spun yarn are interwoven to serve as weft yarn, and the 38 / 2-Nm fine spun yarn serves as warp yarn; weaving the spun yarn on a rapier loom through a single-warp single-weft mode; preparing the finished product by conducting the processes of edge sewing, fulling, washing, dewatering, drying, fuzzing, ironing cutting and steaming on woven cloth in sequence. The loop tweed is soft in hand feel, novel in style and easy to take care of.

Owner:江阴市长泾花园毛纺织有限公司

Turning lathe

InactiveCN113458850APlay a buffer roleAvoid safety hazardsGrain treatmentsMaintainance and safety accessoriesElectric machineCoupling

The invention provides a turning lathe, and relates to the field of machining. The turning lathe comprises a machining head, a mounting plate, a fixed plate, a pressing plate, a movable table and a bottom plate, one end of the machining head is connected with a rotating motor in the mounting plate through a coupler, a mounting groove is reserved inside the mounting plate, a cooling lubricating liquid box is arranged on the inner wall of the mounting groove, the movable table is fixedly connected with the outer wall of the top end of the bottom plate, a sliding rail is arranged on the movable table, a sliding plate is arranged at the bottom of the mounting plate, the sliding plate is matched with the sliding rail, the fixed plate is movably connected with the outer wall of one end of the mounting plate, and the pressing plate is arranged below the fixed plate. The turning lathe can play a role in buffering high-speed splashing chippings and prevent the chippings from splashing to the outside to cause potential safety hazards, the movable plate can continuously press the chippings under the impact force and the elastic force of an air bag, large chippings are crushed, and the situation that the large chippings are accumulated on the pressing plate to generate adverse effects on machining is prevented.

Owner:周云娟

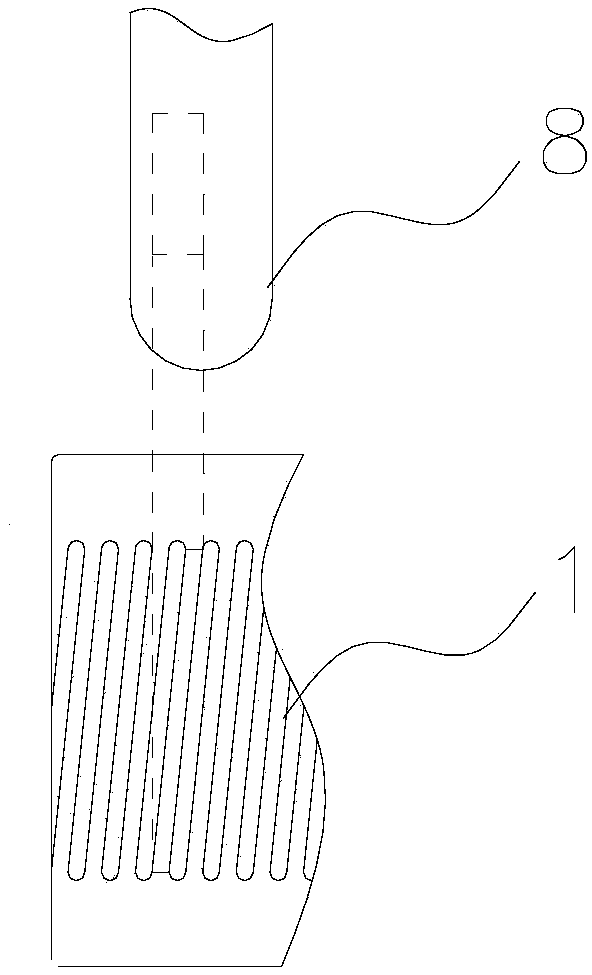

A spiral plate fixed bed reactor for gas-solid phase contact catalytic reaction

InactiveCN109382045AImprove heat transfer coefficientImprove overall heat transfer coefficientOrganic compound preparationCarboxylic acid esters preparationGas solidGas phase

Owner:QINGDAO KEDA LONGTENG TECH DEV +2

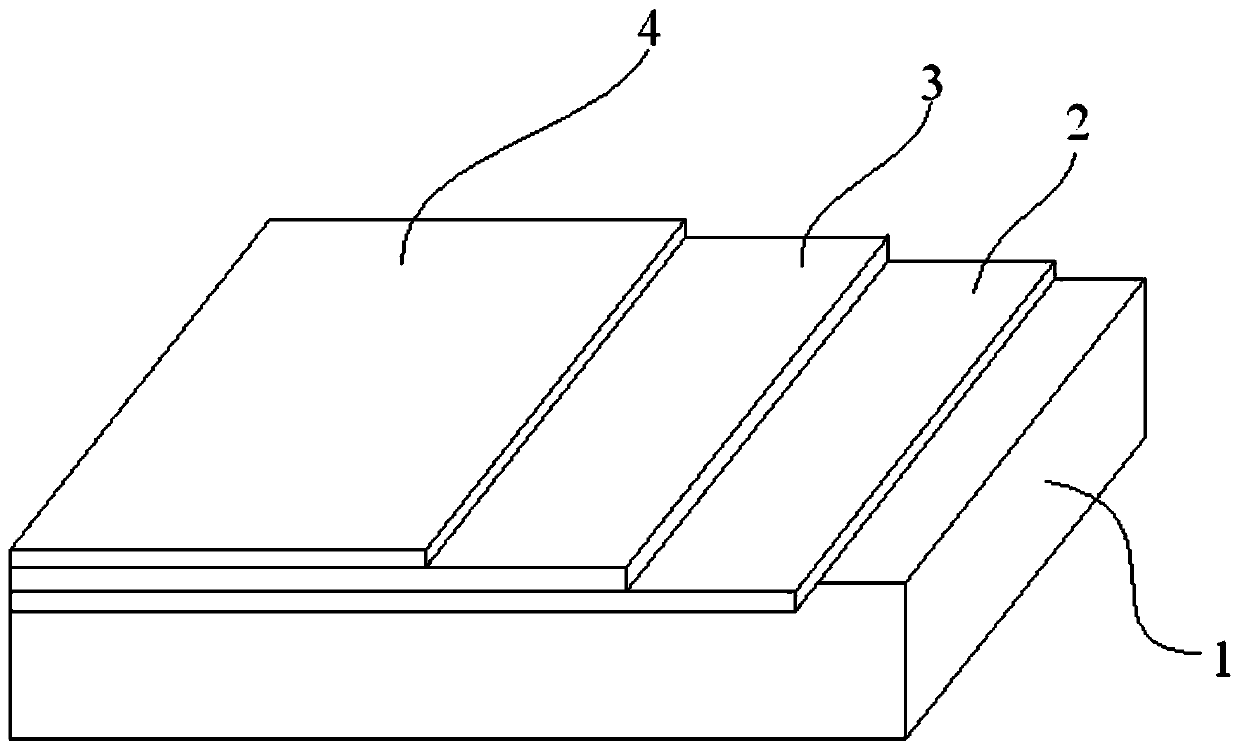

Self-cleaning spraying rubber asphalt waterproof system and preparation method thereof

ActiveCN111534228AWith self-cleaning effectLow water absorptionAntifouling/underwater paintsConjugated diene hydrocarbon coatingsBituminous waterproofingMoisture permeation

The invention discloses a self-cleaning spraying rubber asphalt waterproof system and a preparation method. The waterproof system comprises a sealing paint layer, a spraying rubber asphalt coating layer and a super-hydrophobic self-cleaning polyurethane coating layer which are sequentially arranged on a base material from bottom to top. The preparation method comprises the following steps: preparing a spraying rubber asphalt composite material, preparing a super-hydrophobic polyurethane coating solution, brushing sealing paint on the surface of the base material, spraying a rubber asphalt waterproof film on the surface of the sealing paint, and spraying a super-hydrophobic polyurethane coating on the surface of dried rubber asphalt. The problems that the surface of the rubber asphalt absorbs water, the water absorption rate of a coating film is high, water permeates into the rubber asphalt coating film to cause swelling of the coating film, and the rubber asphalt coating film cannot resist frost cracking are solved, and the self-cleaning performance of the spraying rubber asphalt coating film is improved.

Owner:铁科腾跃科技有限公司

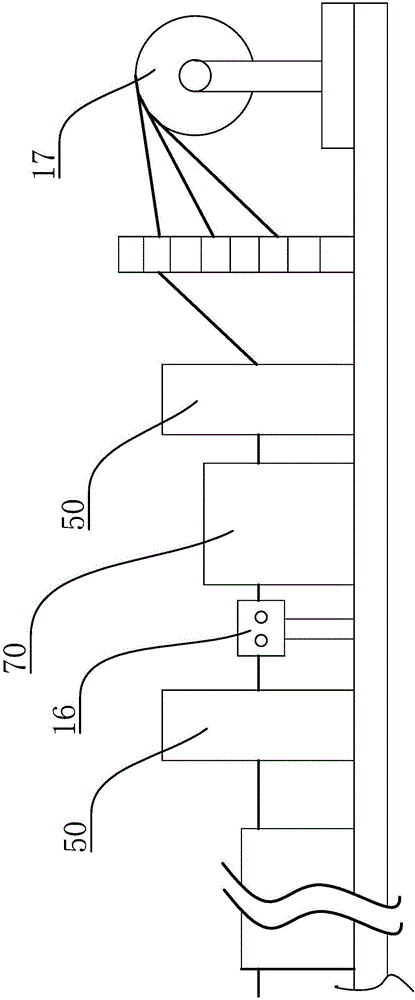

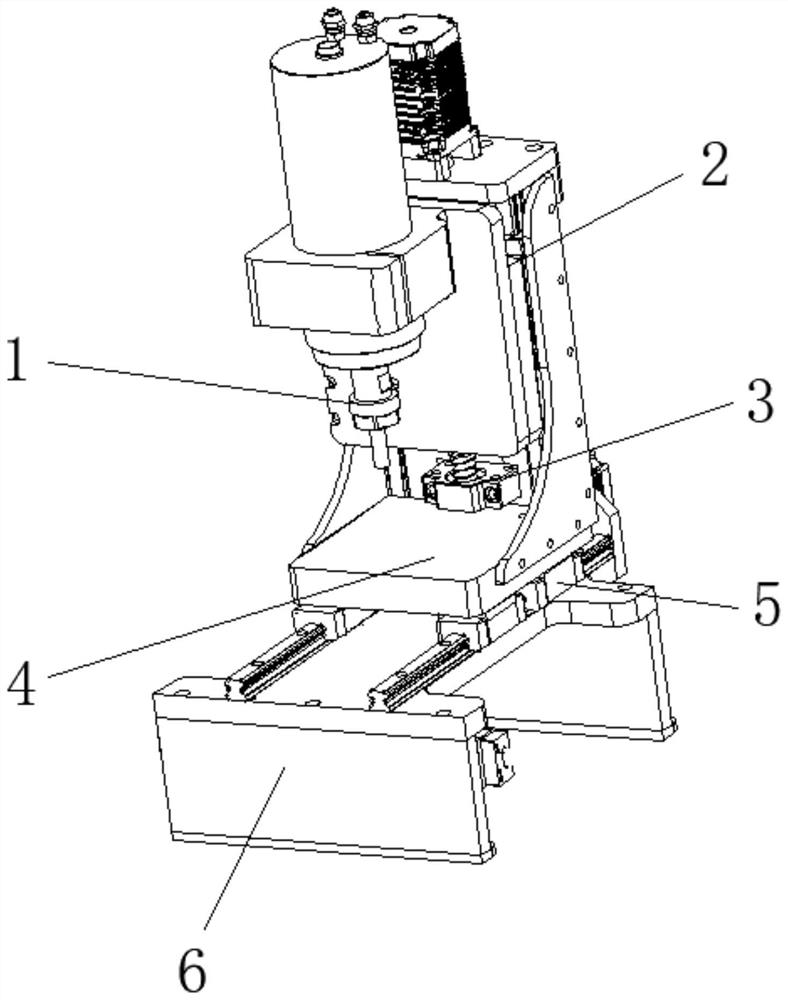

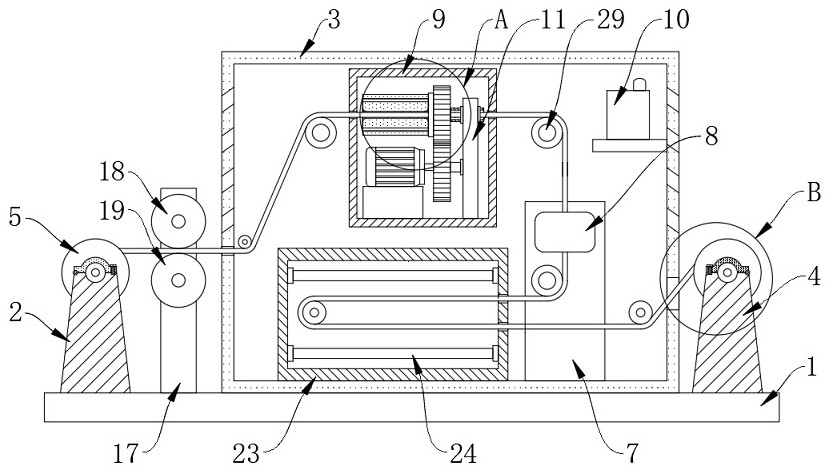

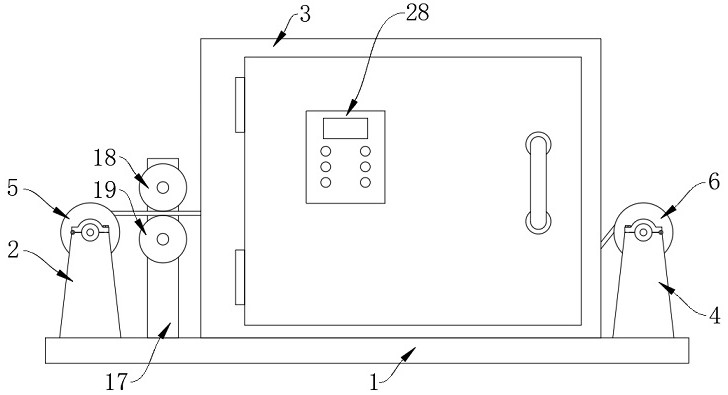

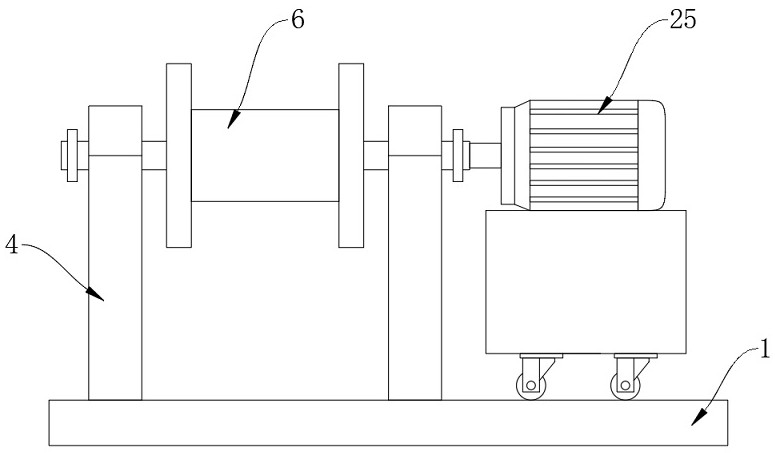

Coating system for stainless steel welding wire finish machining

InactiveCN111889919AWith self-cleaning effectEasy to rewindCleaning using toolsWelding/cutting media/materialsDrive wheelCoating system

The invention discloses a coating system for stainless steel welding wire finish machining. The coating system comprises a bottom plate; an uncoiling base, a conveying structure, a main body box and acoiling base are fixedly connected with the upper surface of the bottom plate, an uncoiling groove is formed in the upper surface of the uncoiling base, and an uncoiling shaft is in lap joint with the inner wall of the uncoiling groove; and an uncoiling wheel is fixedly connected with the surface of the uncoiling shaft, a coiling groove is formed in the upper surface of the coiling base, and a coiling shaft is in lap joint with the inner wall of the coiling groove. According to the coating system for stainless steel welding wire finish machining, the conveying direction of stainless steel welding wire can be adjusted by arranging a guide wheel, the cleaning structure can be driven to rotate by arranging a cleaning motor, a cleaning driving wheel and a cleaning driven wheel, dust on the surface of the stainless steel welding wire can be cleaned and sucked by arranging a cleaning sponge, and the stainless steel welding wire can be coated by arranging a coating main body machine and a coating nozzle, so that the coating system for stainless steel welding wire finish machining has an automatic cleaning effect.

Owner:颜培吉

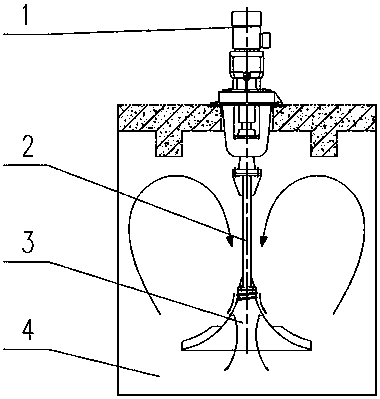

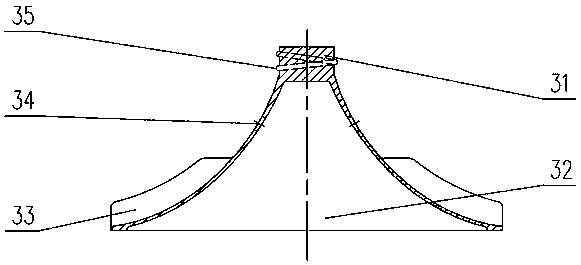

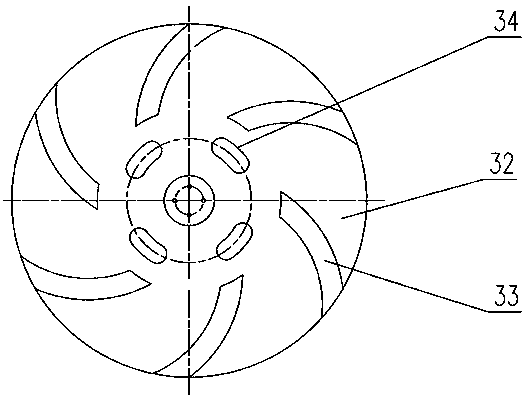

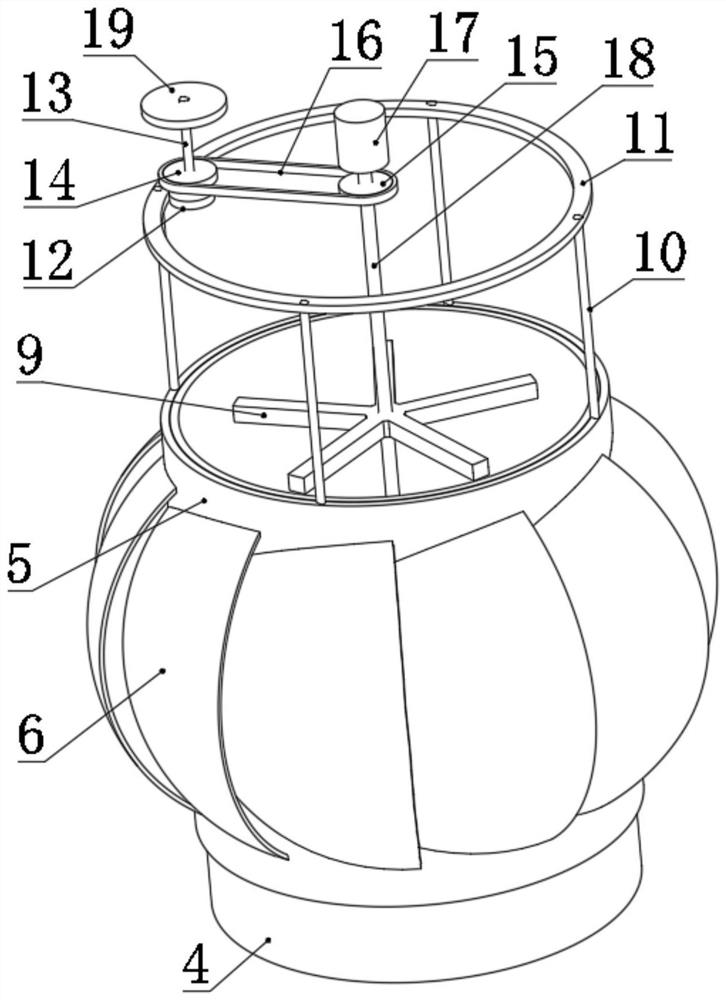

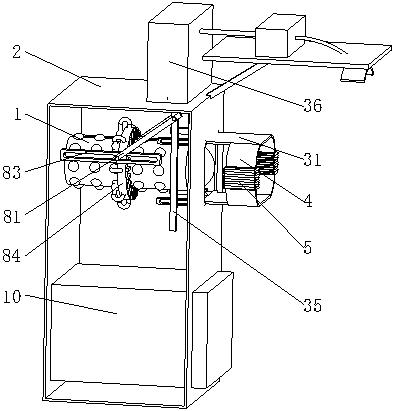

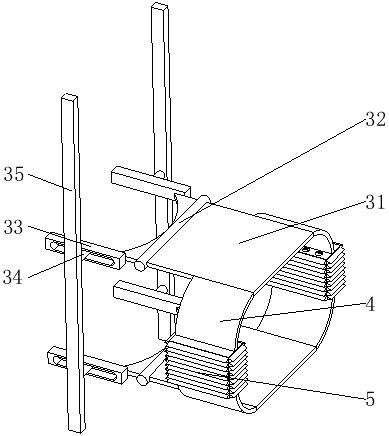

Self-cleaning vertical stirring machine

PendingCN108236860AWith self-cleaning effectNo stirring dead angleRotary stirring mixersTransportation and packagingImpellerDrive shaft

The invention discloses a self-cleaning vertical stirring machine. The self-cleaning vertical stirring machine comprises a driving device, a transmission shaft, a self-cleaning impeller and a tank body, wherein the self-cleaning impeller comprises a cylindrical hub, a curved surface hub, main blades and reflux tanks; and the driving device is assembled to the tank body, the upper end of the transmission shaft is connected with the lower end of the driving device, and the self-cleaning impeller is assembled to the lower end of the transmission shaft. The self-cleaning vertical stirring machinehas the beneficial effects that the self-cleaning of the impeller is realized, materials are adequately mixed and stirred at the bottom of the tank, no stirring dead corner exists, and the good operation of the process is effectively guaranteed.

Owner:JIANGSU OPEN UNIV

Method for preparing nanometer titanium dioxide (TiO2) self-cleaning film

InactiveCN102560325ASuperhydrophilicHas superhydrophilic propertiesMolten spray coatingMolten statePorosity

The invention relates to a method for preparing a nanometer titanium dioxide (TiO2) self-cleaning film. The method comprises the following steps of: (1) preparing granular powder from a titanium-containing compound, wherein the titanium-containing compound is oxide or inorganic salt of titanium, and the granularity of the granular powder prepared from the titanium-containing compound is 80 to 350 meshes; (2) performing cleaning pretreatment on a substrate to be sprayed; and (3) conveying the granular powder which is prepared from the titanium-containing compound and taken as a spraying raw material to a plasma arc by using a spray gun, quickly heating the spraying raw material until the spraying raw material is melted or semi-melted, allowing the spraying raw material to impact the surface of the pretreated substrate along with plasma jet, and reacting to form a TiO2-based film on the surface of the substrate. The TiO2-based film prepared by the method has small thickness, slightly influences the transmittance of the substrate, is compactly combined with the substrate, and has low porosity, high timeliness, corrosion resistance and high-temperature oxidation resistance.

Owner:TRINA SOLAR CO LTD

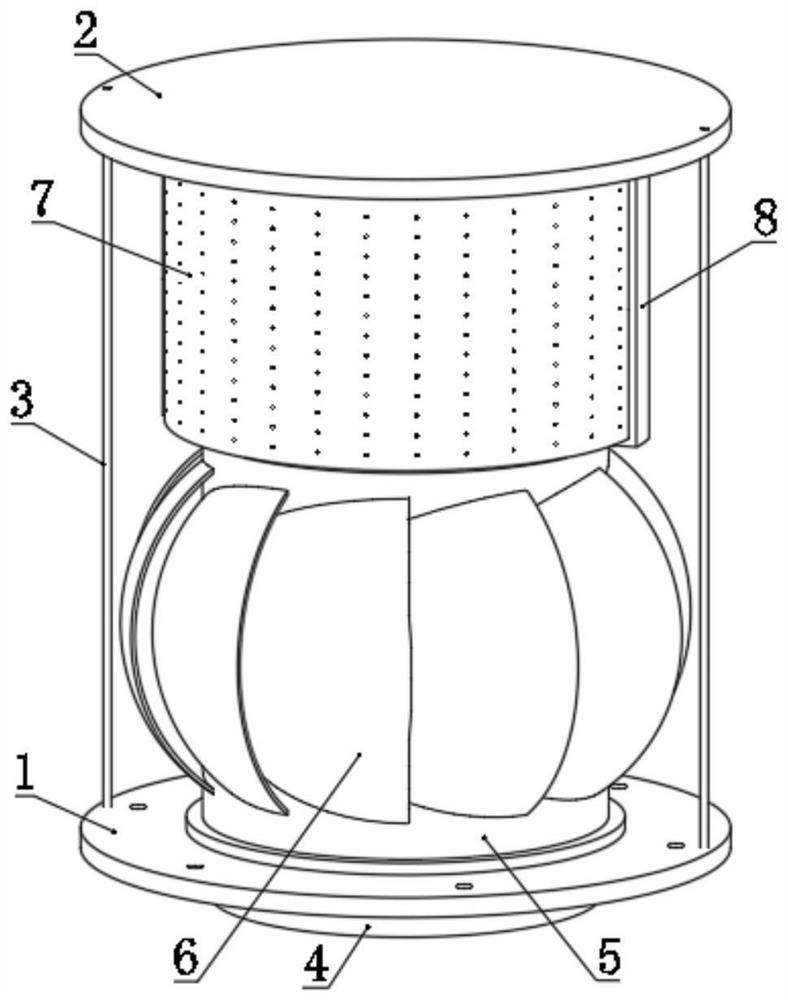

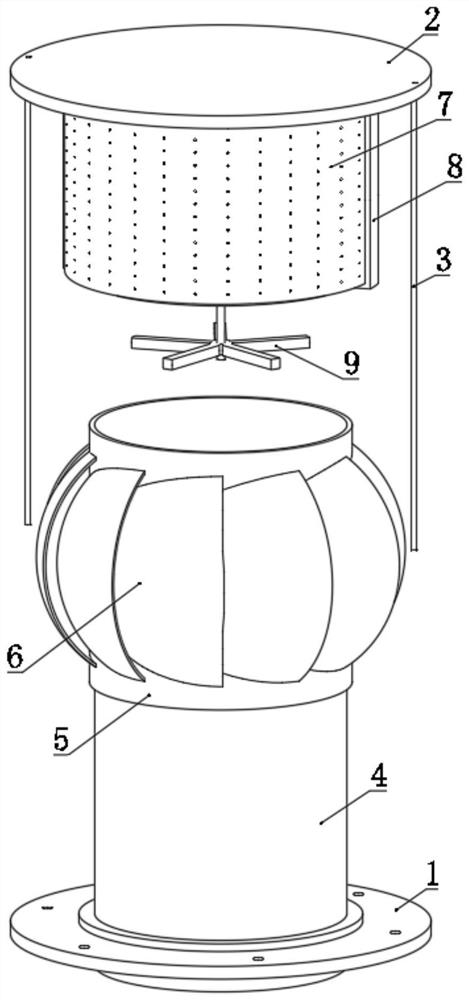

Ventilation energy-saving equipment for green building

PendingCN114234324AConvenient drummingImprove comfortMechanical apparatusLighting and heating apparatusFresh airElectric machinery

The invention discloses ventilation energy-saving equipment for a green building, and belongs to the field of building ventilation, the ventilation energy-saving equipment comprises a rotating pipe, a plurality of fan blades are mounted on the outer surface of the rotating pipe, the rotating pipe rotatably sleeves the outer side of a fixed pipe, a bottom ring is mounted on the outer wall of the top end of the fixed pipe, and a top plate is mounted on the bottom ring through a supporting rod; the top plate is located above the fixed pipe and the rotating pipe, a net cover is installed on the bottom wall of the top plate, a cleaning brush is slidably arranged on the outer side wall of the net cover, a fan is arranged in the fixed pipe, and the fan is installed at the bottom of the main shaft; natural wind and the motor are matched to drive the fan to rotate, outdoor fresh air is quickly blown into a room, the comfort degree of the indoor environment is improved, meanwhile, dust in the air is filtered, the quality of the blown air is improved, the device has a self-cleaning effect, and the manual cleaning cost is saved.

Owner:XIHUA UNIV

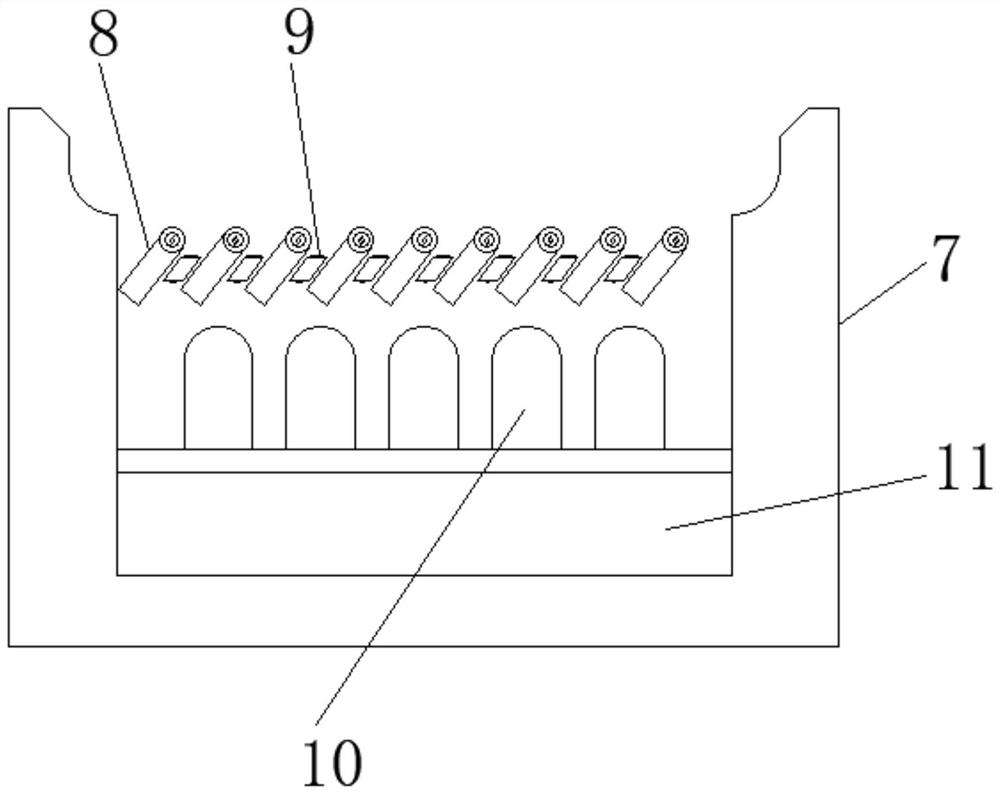

Flush-free toilet and excrement in-service treatment method

InactiveCN103735212AGet rid of dependenceImprove sanitationBathroom accessoriesAgainst vector-borne diseasesEngineeringMechanical engineering

The invention relates to a flush-free toilet which comprises a pedestal pan or a squatting pan 12, a stirring mixer 7 and a spiral conveying dryer 14. A plurality of carrying balls 11 for carrying excrement are contained in the pedestal pan or the squatting pan 12. Excrement is discharged out of the pedestal pan or the squatting pan 12 by discharging the carrying balls. The stirring mixer 7 is used for receiving the excrement and the carrying balls from the pedestal pan or the squatting pan 12 and mixing the two. The spiral conveying dryer 14 comprises a sealed shell 1 and spiral conveying blades 2. The spiral conveying blades 2 can e driven by a spindle 3 to rotate. A spiral passage is formed between the spiral conveying blades and the sealed shell. A dry air inlet 5, a moist air outlet 6, an excrement inlet 15 and a dry excrement residue outlet 16 are respectively disposed at two ends of the spiral passage. The excrement inlet 15 is connected with the outlet of the stirring mixer 7. The invention further relates a flush-free excrement treatment method.

Owner:北京林峰源投资顾问有限公司

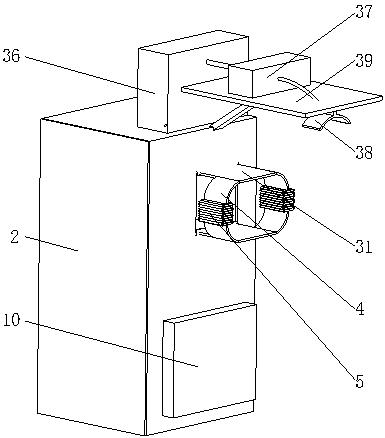

Face image capturing device

ActiveCN113610063AImprove work efficiencyPlay a compression effectTelevision system detailsCharacter and pattern recognitionLight guidePlane mirror

The invention discloses a face image capturing device, and relates to the technical field of machinery. The device comprises a face capturing camera, the face capturing camera is fixedly installed on the inner wall of a working box, a light guide device is arranged outside the face capturing camera, the light guide device comprises a plane mirror, and the plane mirror penetrates through and is installed on a rotating column in a sliding mode. According to the human face image capturing equipment, through the arrangement of the light guide device, when people with different heights carry out human face capturing, people with different heights stand below the radar range finder, when the height is high, the radar range finder can detect a height signal and transmit the height signal to the control module, and the control module can control the lifting machine to drive the sliding rod to move downwards; and on the contrary, the elevator receives a signal to drive the sliding rod to move upwards, and finally, the people and the face capturing camera can carry out shooting operation without adjusting the positions, so that the working efficiency is improved.

Owner:SUZHOU SIYUAN KEAN INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com