Composite membrane based on synergistic separation and photo-Fenton self-cleaning

A composite membrane and self-cleaning technology, applied in the field of membrane separation, can solve the problems of reduced service life and easy pollution of the membrane, and achieve the effects of enhanced stability, enhanced absorption, and enhanced photo-Fenton activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

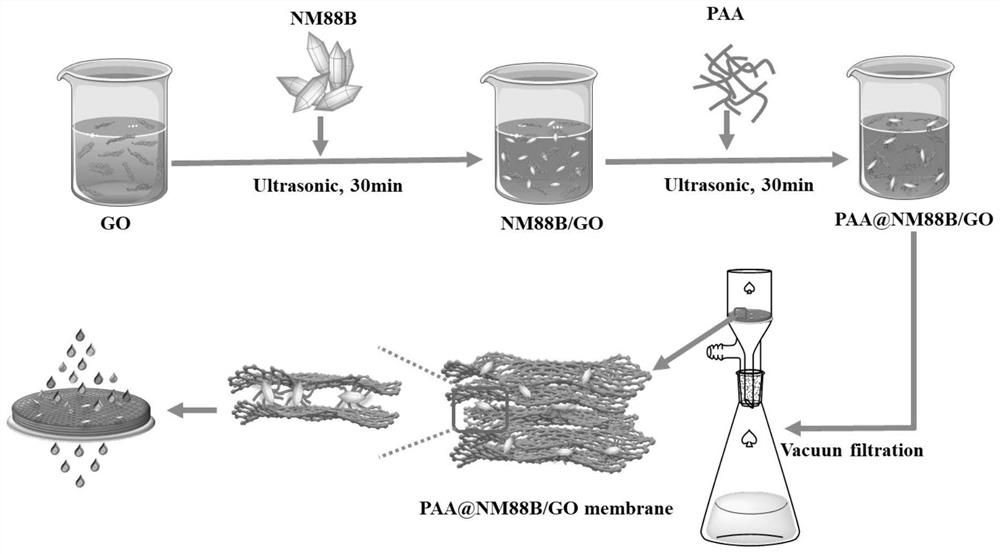

[0039] A preparation method of PAA@NM88B / GO composite membrane is as follows:

[0040] (1) NH 2 - Preparation of MIL-88B(Fe)

[0041] Take 0.54g of FeCl 3 ·6H 2 O and 0.362g of 2-aminoterephthalic acid were dissolved in 30mL of DMF and ultrasonically dispersed for 10min to form a homogeneous solution. Then the solution was transferred to a 100mL autoclave and reacted at 110°C for 12h. After natural cooling, it was washed and centrifuged 3 times with DMF and absolute ethanol to obtain NH 2 -MIL-88B (NM88B for short). Finally, the synthesized brown NM88B was dried in a vacuum oven at 70°C for 12h.

[0042] (2) Preparation of PAA@NM88B / GO membrane

[0043] Add 0.25 mg of GO powder into a beaker filled with pure water, disperse under ultrasonic for 30 min, and prepare a uniform dispersion with a concentration of 0.05 mg / mL. Then 0.13 mg of NM88B was added to the dispersion liquid and ultrasonically dispersed for 30 minutes to obtain a uniform mixed suspension. Subsequently...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com