A spiral plate fixed bed reactor for gas-solid phase contact catalytic reaction

A fixed-bed reactor and fixed-bed reaction technology, which are applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of low utilization rate of catalyst bed space, reduction of heat exchange medium circulation, and difficulty in large-scale installations. To solve problems such as chemical change, it can achieve the effect of high production capacity, reduced circulation consumption, and less fouling and clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 75,000 tons / year ethylene glycol hydroxylation synthesis reactor

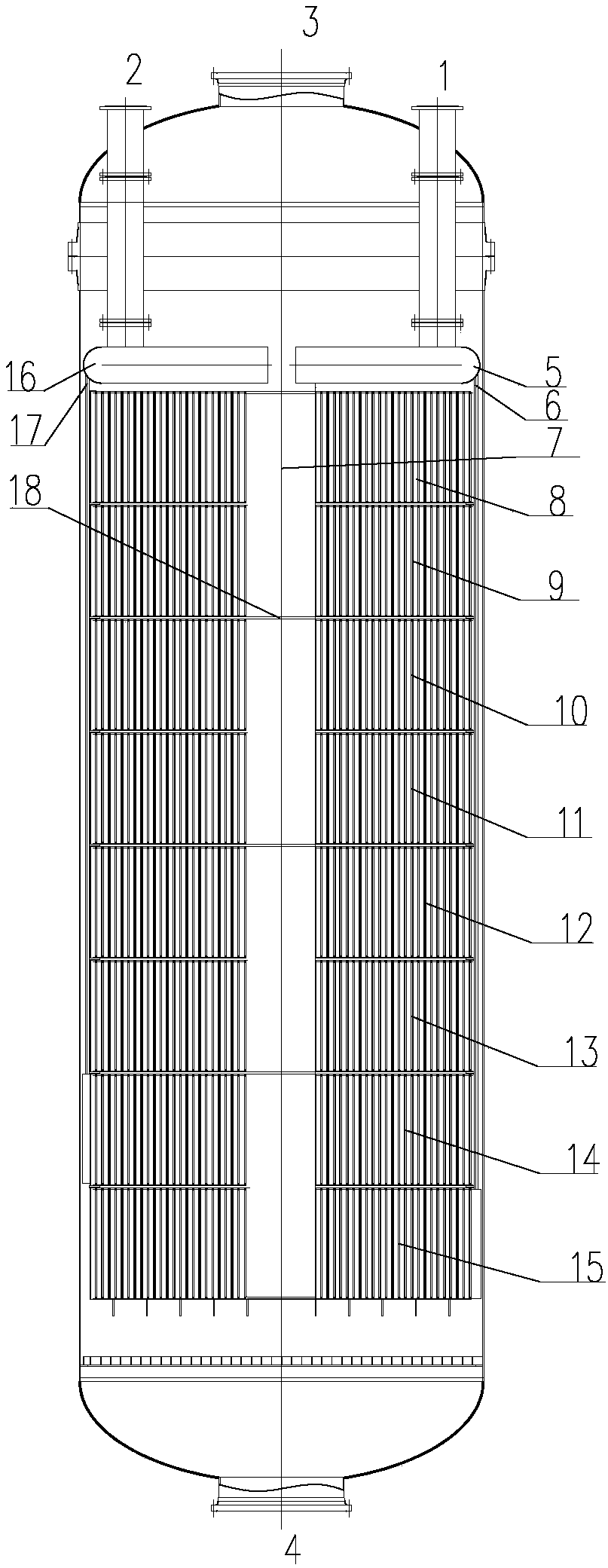

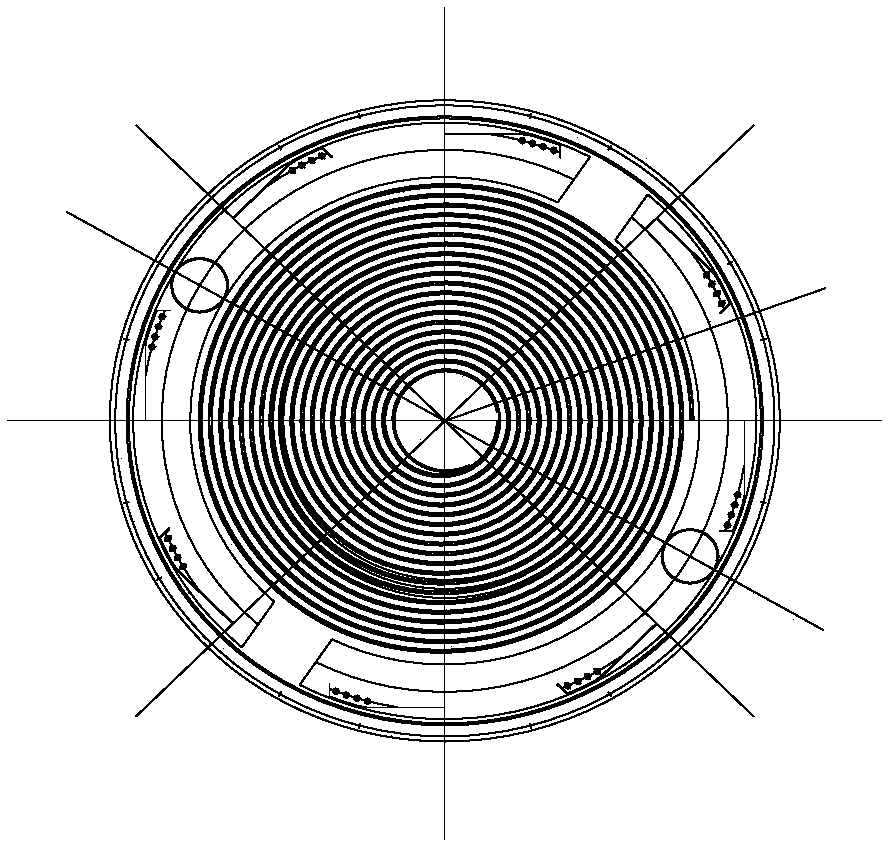

[0032] When the reactor of the present invention is used as a 75,000-ton / year ethylene glycol hydroxylation synthesis reactor, 8 stages of spiral plate type fixed bed reaction sections are required through comprehensive calculation, and the heat exchange medium circulation is calculated: the heat exchange medium channel adopts two stages in series The method has a relatively ideal heat exchange effect, and its structure is shown in figure 1 with figure 2 .

[0033] The gas enters the reactor through the top air inlet 3, passes through the catalyst fixed bed (8-15) and reacts, and leaves the reactor together with the product through the bottom gas outlet 4.

[0034]The heat exchange medium inlet is arranged on one side of the upper part of the reactor, and the outlet is arranged on the other side of the upper part of the reactor. After the heat exchange medium enters the reactor through the inlet pipe...

Embodiment 2

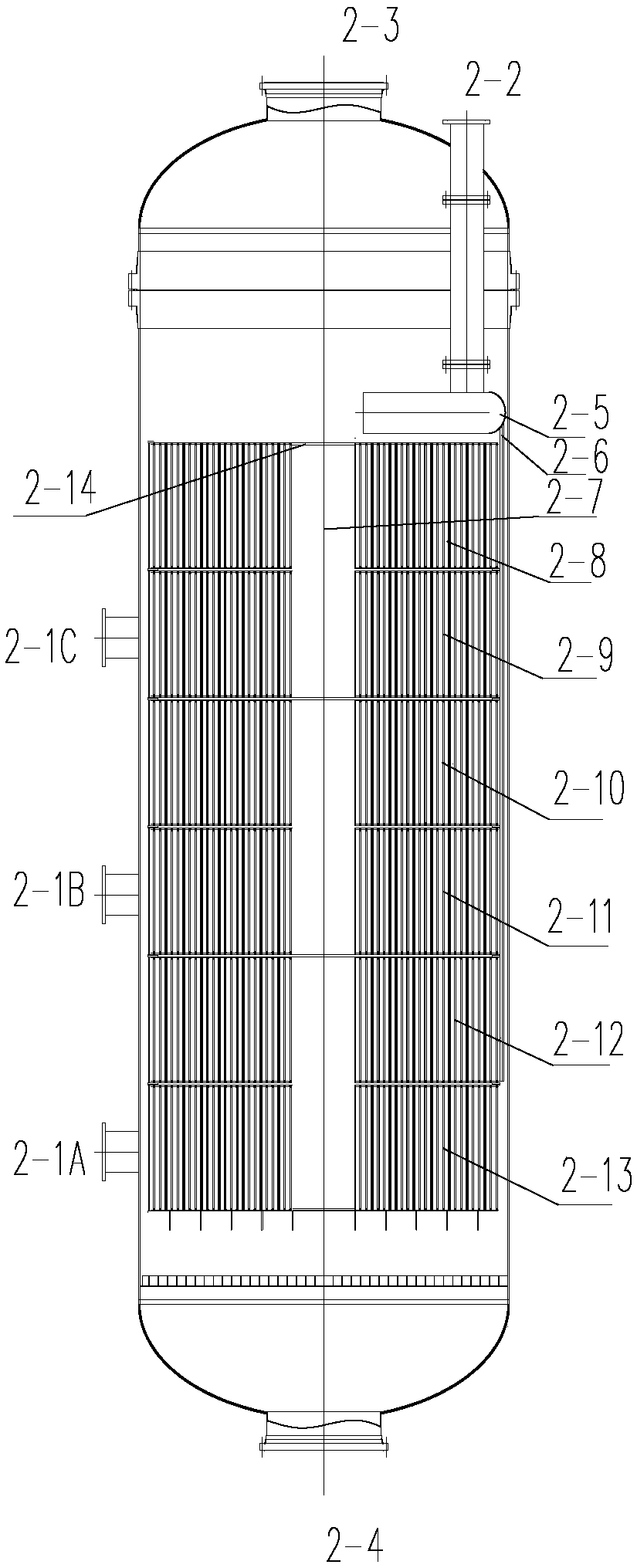

[0039] 20,000 tons / year vinyl acetate synthesis reactor

[0040] When the reactor of the present invention was used as a 20,000 ton / year vinyl acetate synthesis reactor, 6 sections of spiral-plate type fixed-bed reaction sections were needed through comprehensive accounting, and its structure is shown in image 3 . In order to enhance the heat exchange effect and reduce the circulation consumption of heat exchange medium, a heat exchange medium is installed in each spiral plate reaction group to realize segmental temperature control. Specifically: the heat exchange medium inlets 2-1A, 2-1B, and 2-1C (medium temperatures can be the same or different) are set in three spiral plate fixed bed reaction sections 2-13, 2-11, and 2-9. It is connected to the outer side of the heat exchange medium channel inside the reaction section, through the heat exchange medium channel, it spirals into the center tube from the outside of the reaction section, and then enters the three spiral plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com