Patents

Literature

346results about How to "Guaranteed flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

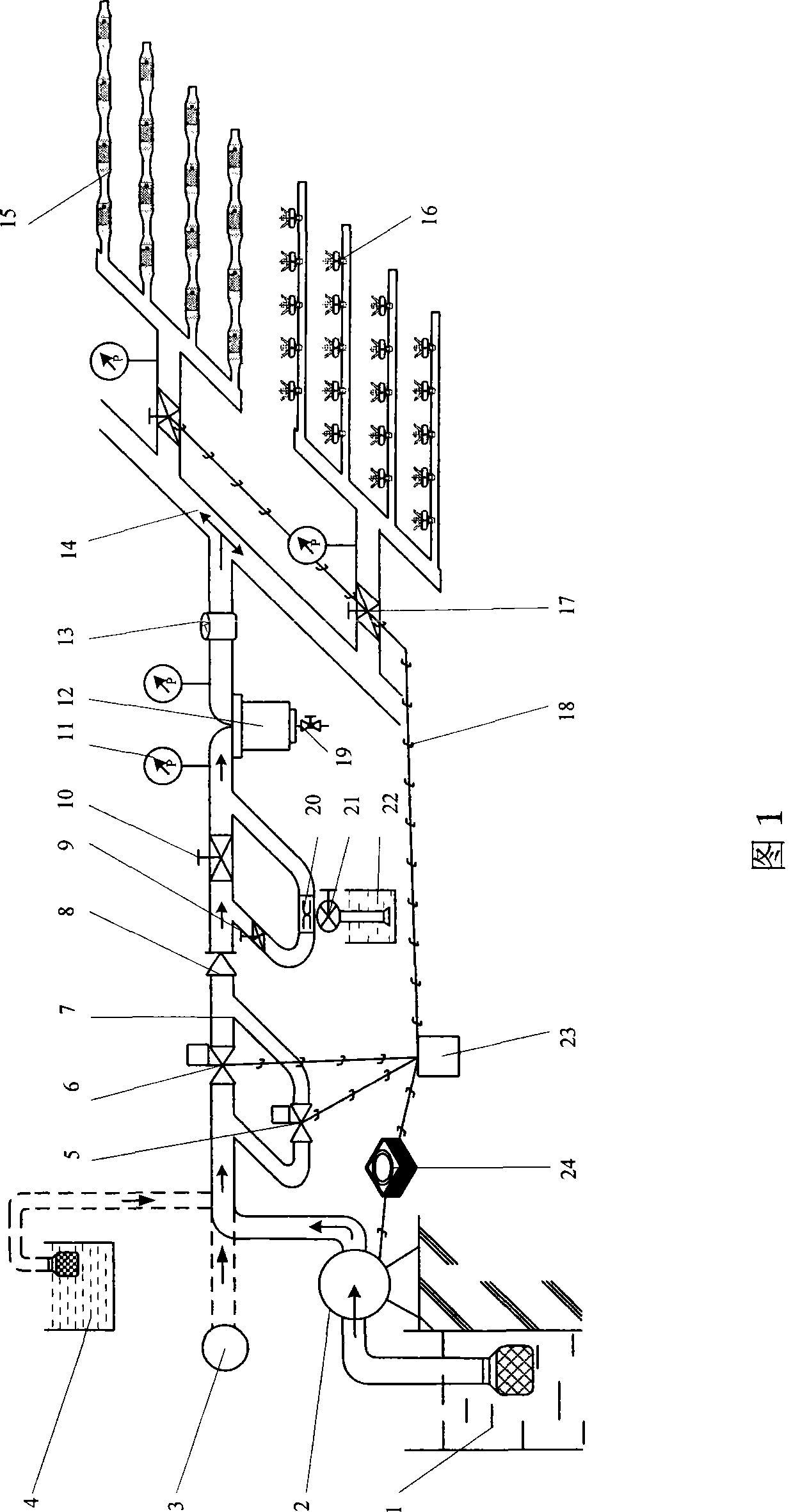

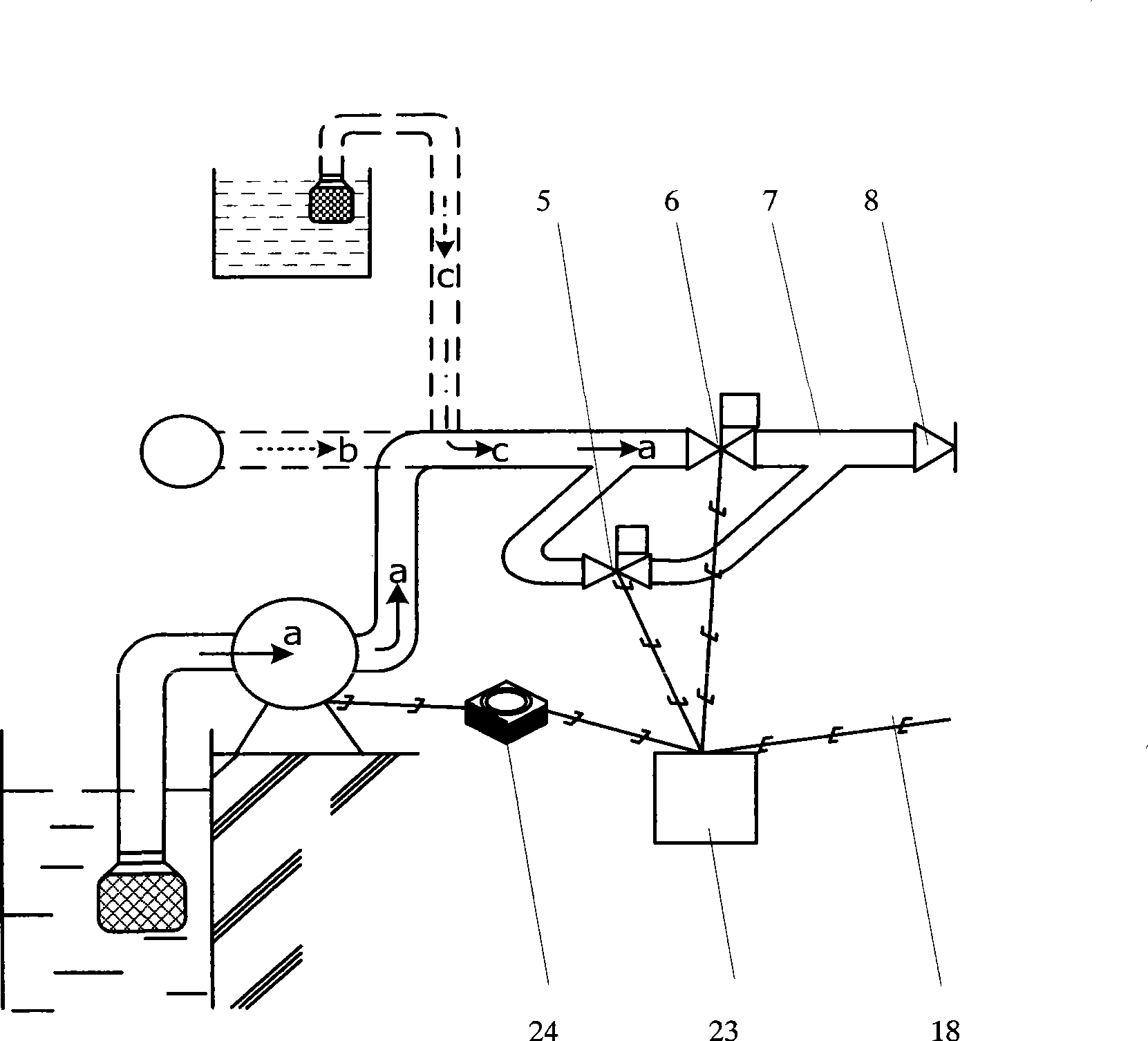

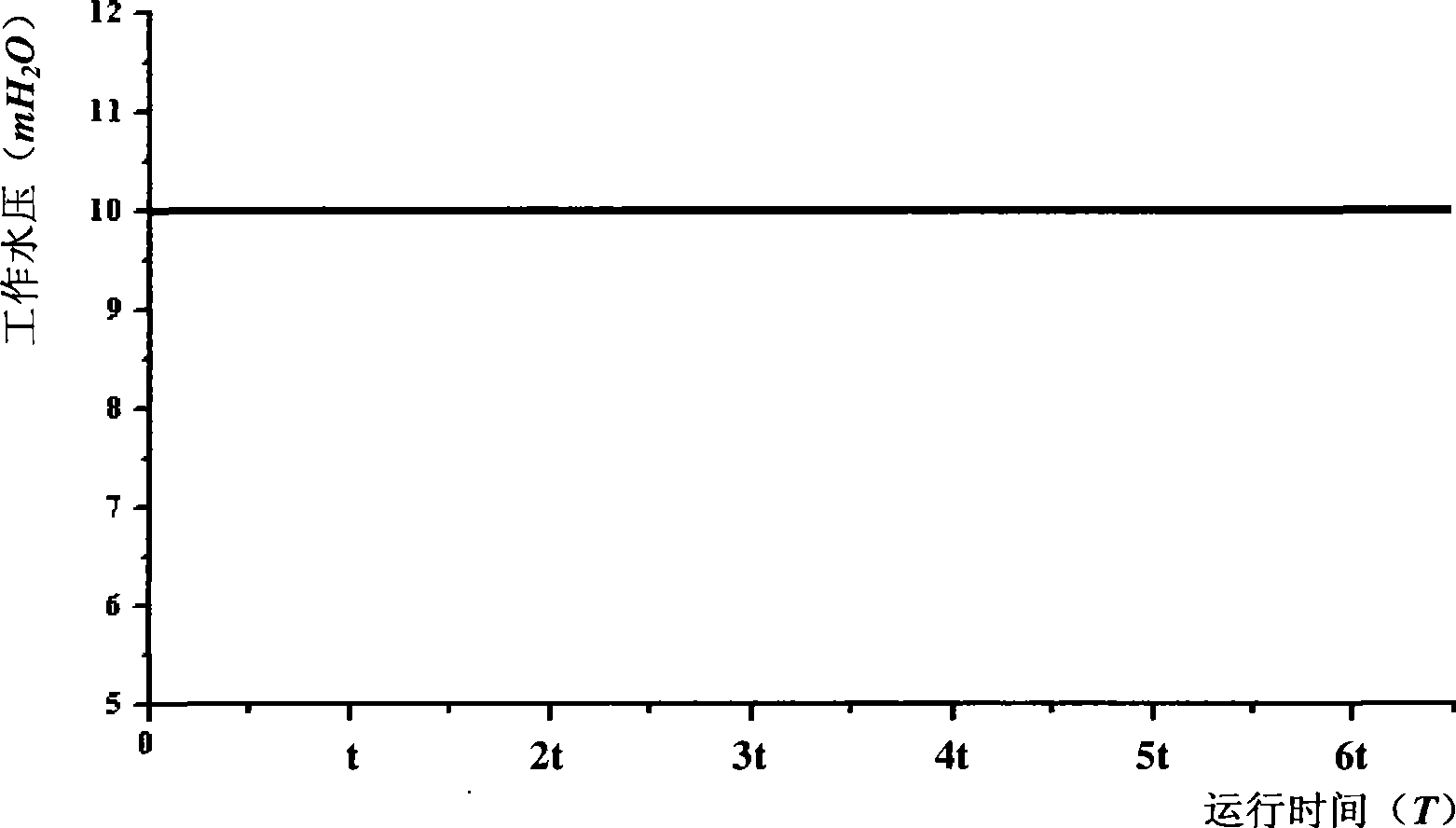

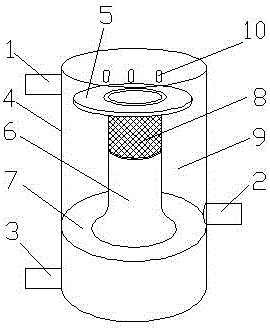

Dynamic water-pressure drip-irrigation system

ActiveCN101449654AAvoid cloggingLow running costClimate change adaptationWatering devicesSolenoid valveWater source

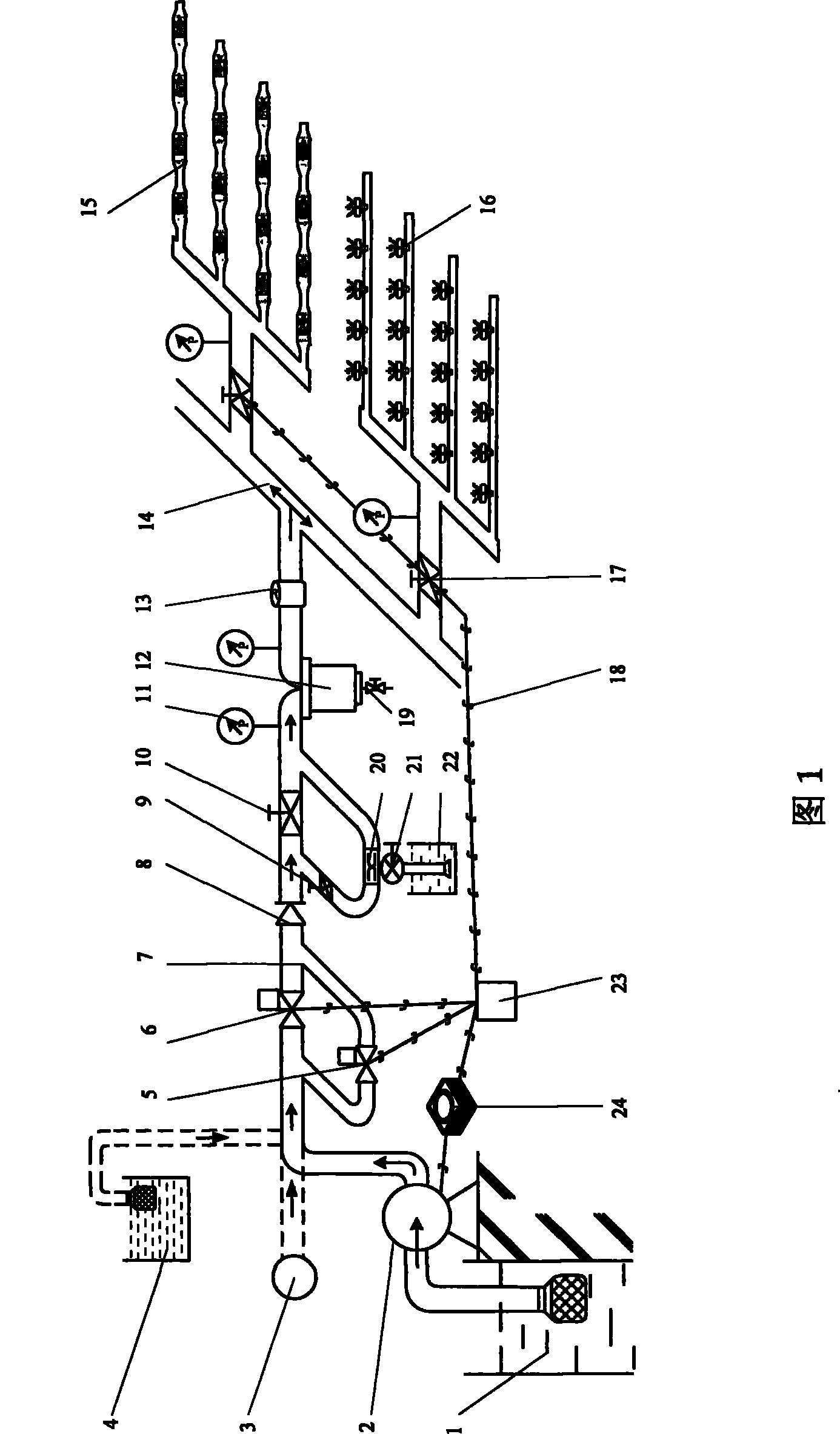

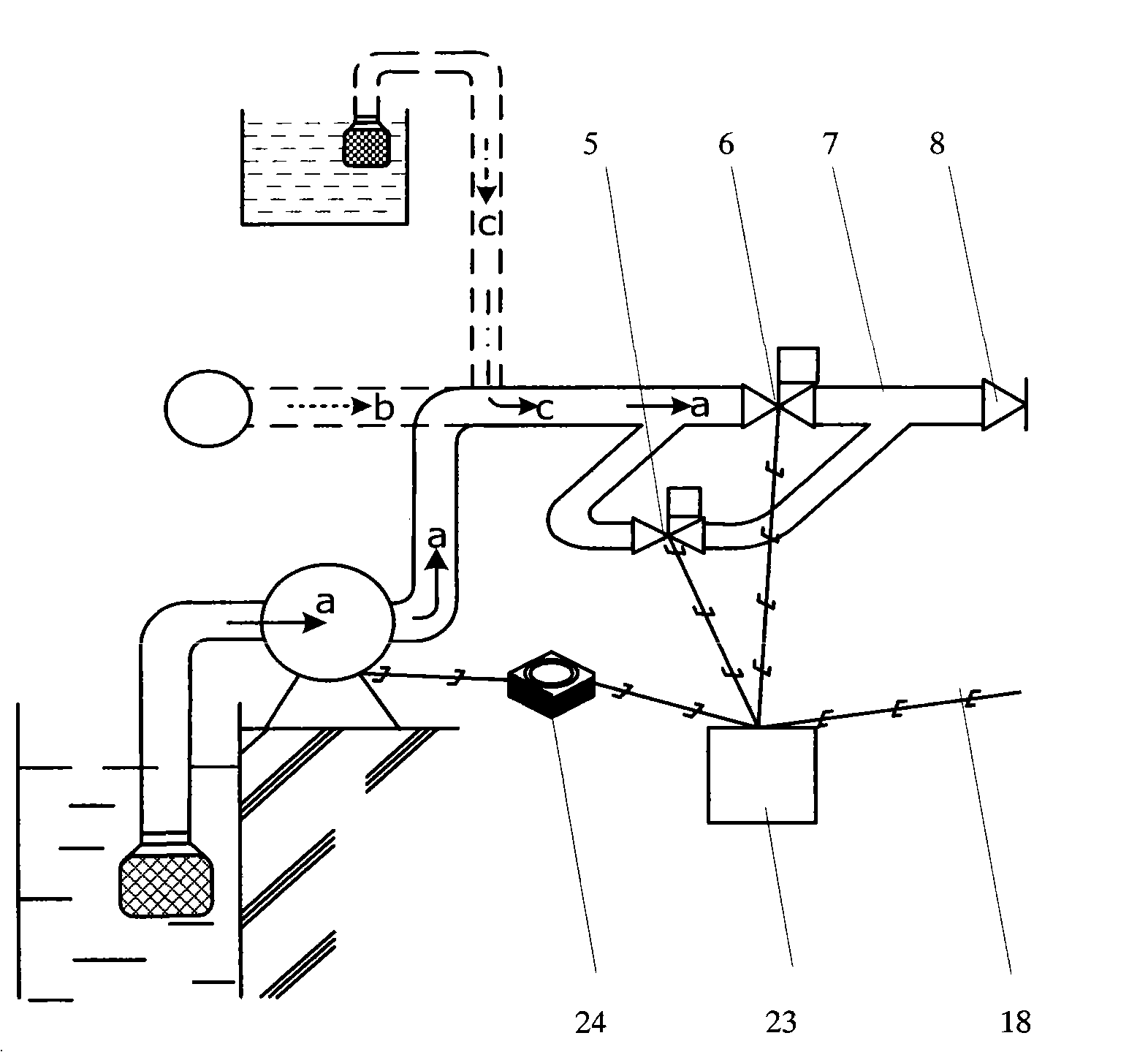

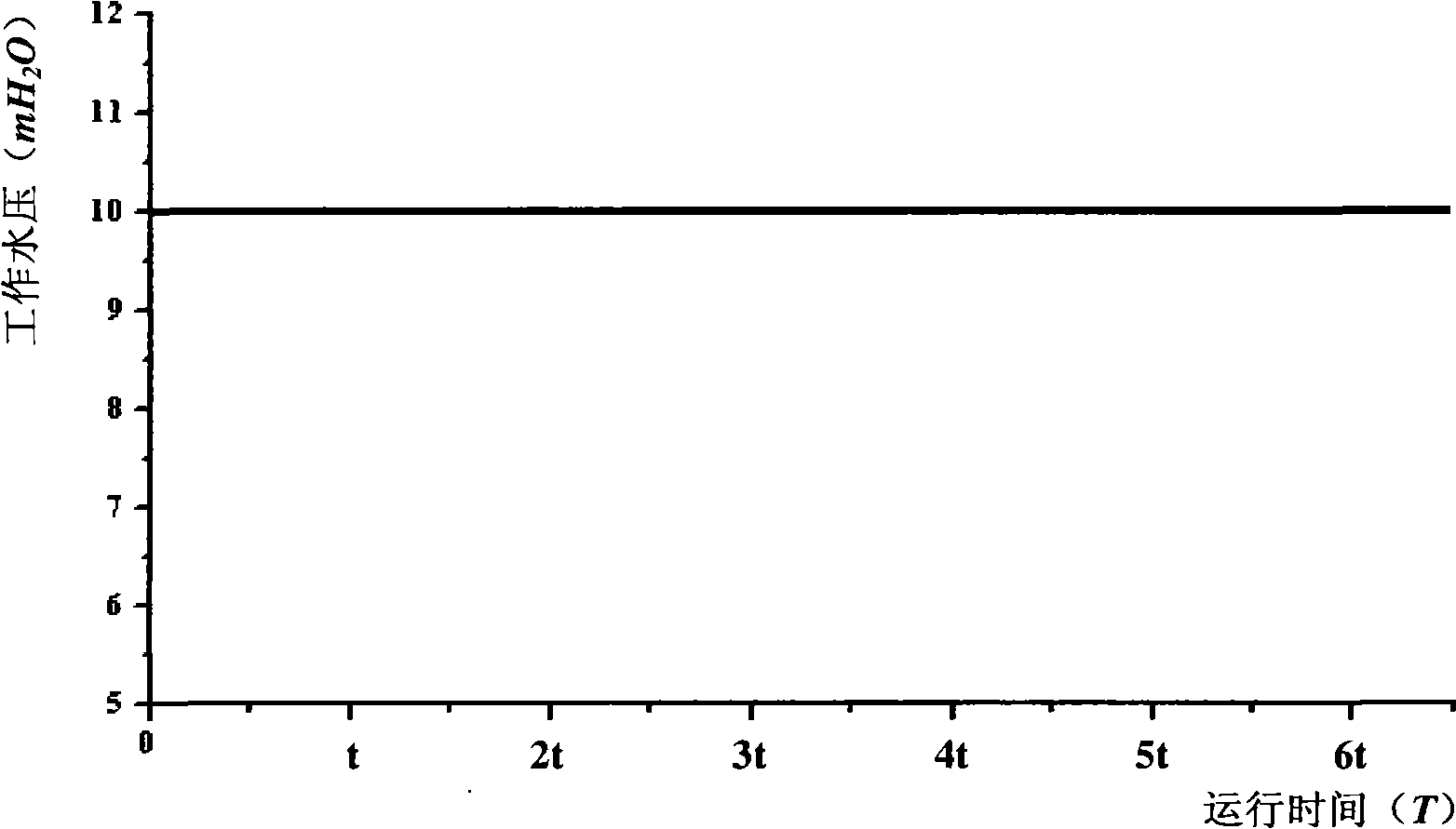

The invention discloses a dynamic hydraulic pressure drip irrigation system, characterized in that, an inlet of a water pump is connected with a caml water source through a pipe, a pressure water source and a reservoir enter a trunk after being connected with an outlet of the water pump; a switch solenoid valve, a check valve, an irrigation main switch and a main filter are arranged in turn on the trunk, a solenoid valve is connected in parallel with the switch solenoid valve through a branch pipe, a fertilization switch and a fertilizer placer are connected with the irrigation main switch in parallel through the branch pipe, a fertilizer controlling valve and a fertilizer pot are connected in turn under the fertilizer placer; a pressure gauge, main filter, a filter flushing valve and a water gauge are arranged on the trunk; a douche is arranged on bottoms of different branches of the branch pipe; each valve is connected with a controller through control lines, a frequency converter is connected between the water pump and the controller. The system causes operation water pressure to change antomatically and dynamically, keeps a larger working water pressure, meanwhile, reduces practical working pressure of the drip irrigation system, also reduces operation cost of the micro irrigation system.

Owner:HUAZHONG UNIV OF SCI & TECH

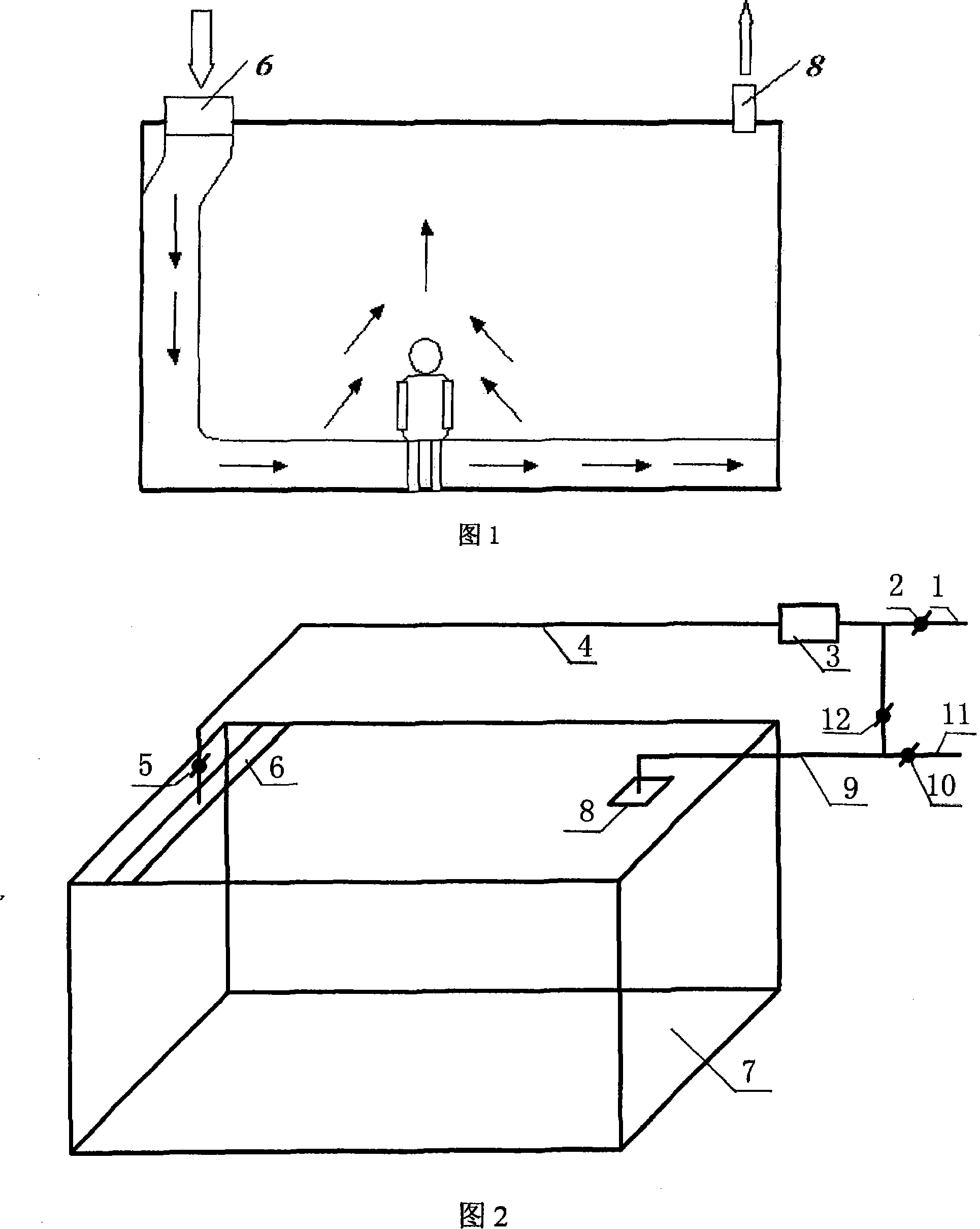

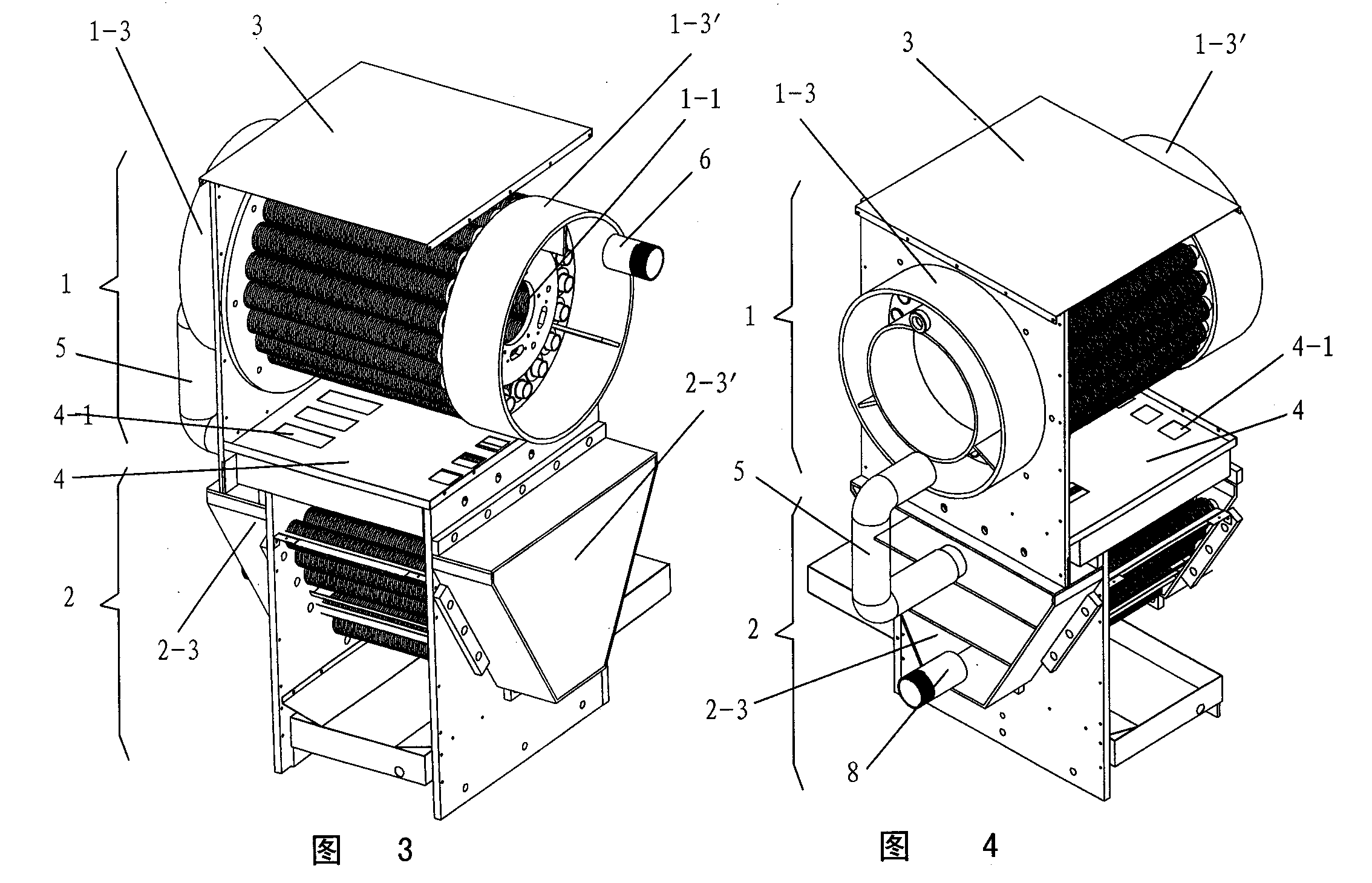

Ventilating system of vertical wall attaching jet air lake mode

ActiveCN101225988AGuaranteed air temperatureGuaranteed flow rateLighting and heating apparatusVentilation systemsEngineeringStructural engineering

The invention discloses a vertical wall attaching jet air lake mode ventilation system, which comprises a blast pipe (4) and an exhaust duct (11); wherein, an air supply port (6) is arranged close to side wall at the top part of a room; the distance of the air supply port (6) from the side wall is designed into: the ratio between vertical distance of the center of the air supply port (6) from the side wall and the width of the air supply port (6) is 0 to 15. The vertical wall attaching jet air lake mode ventilation system has the advantages of facilitating body health due to being close to the air supply environment, easily arranging the ventilation system in the building space and not occupying building space at the lower part (working area).

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

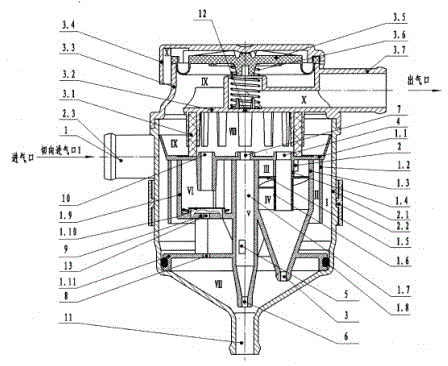

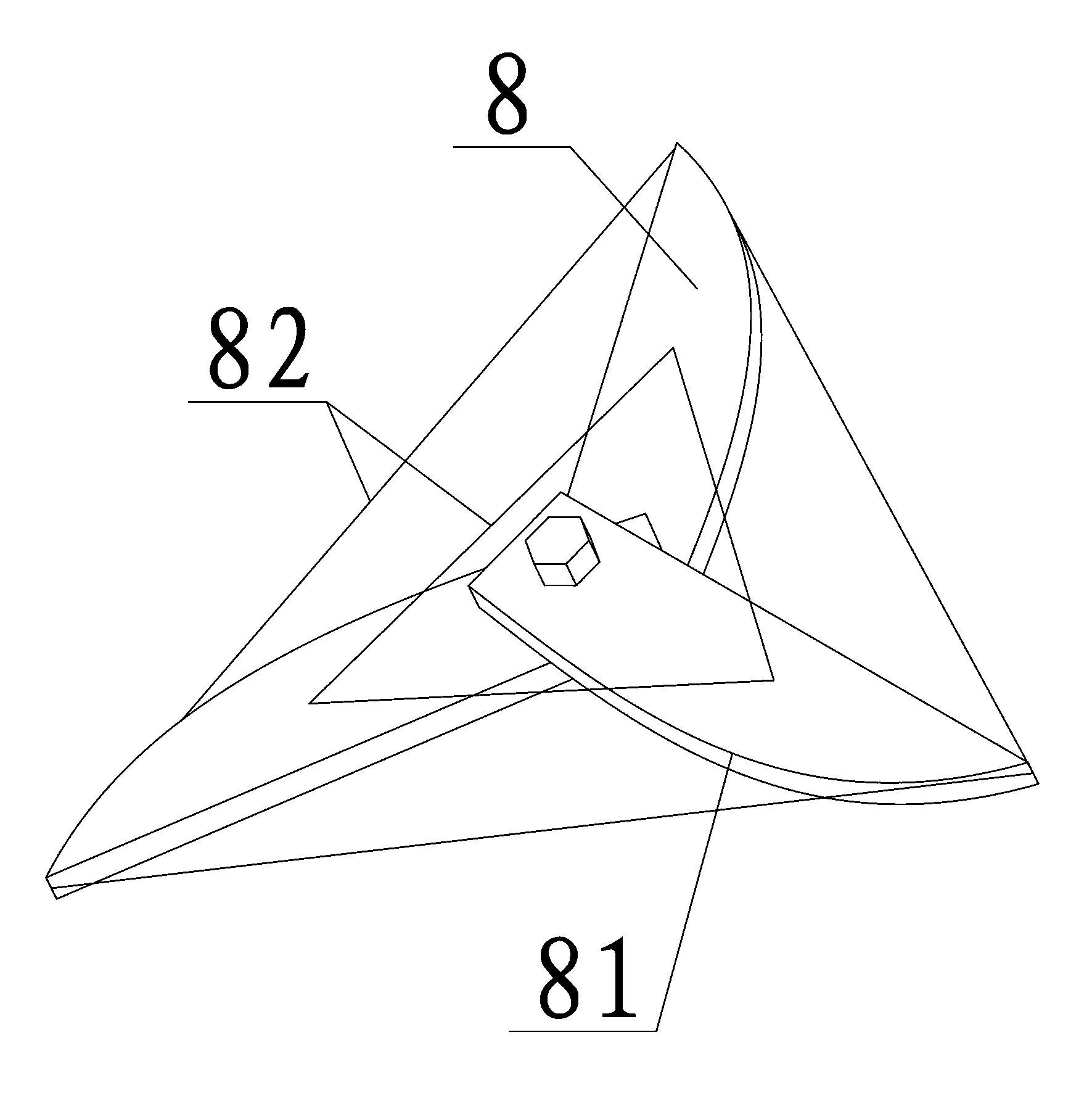

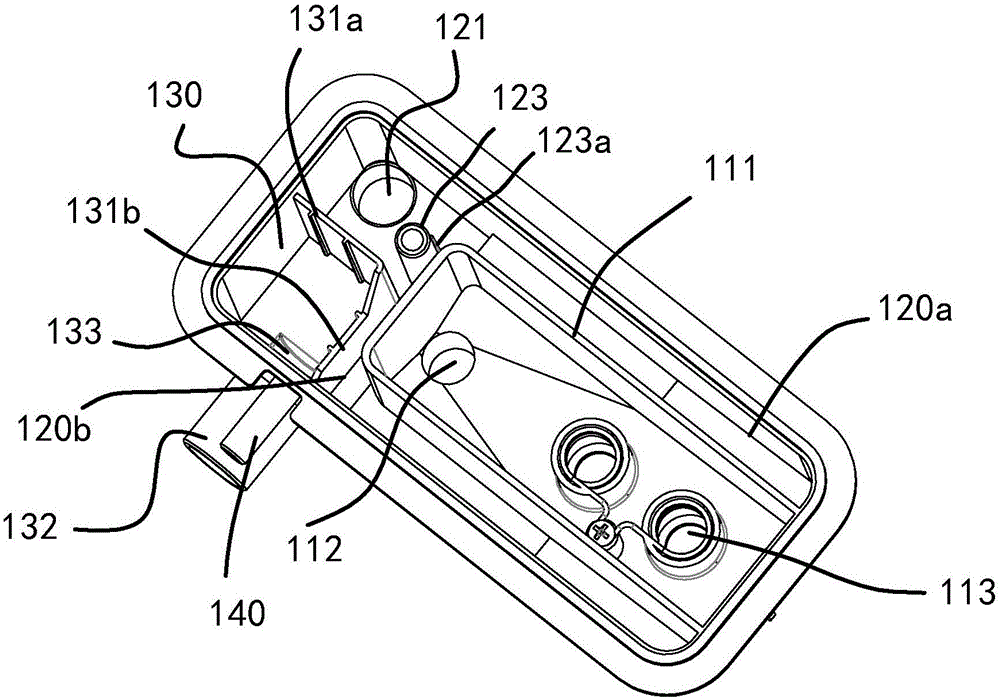

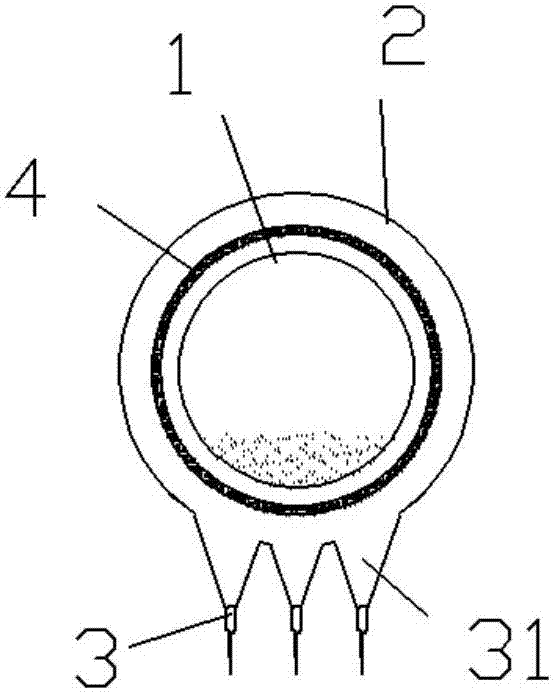

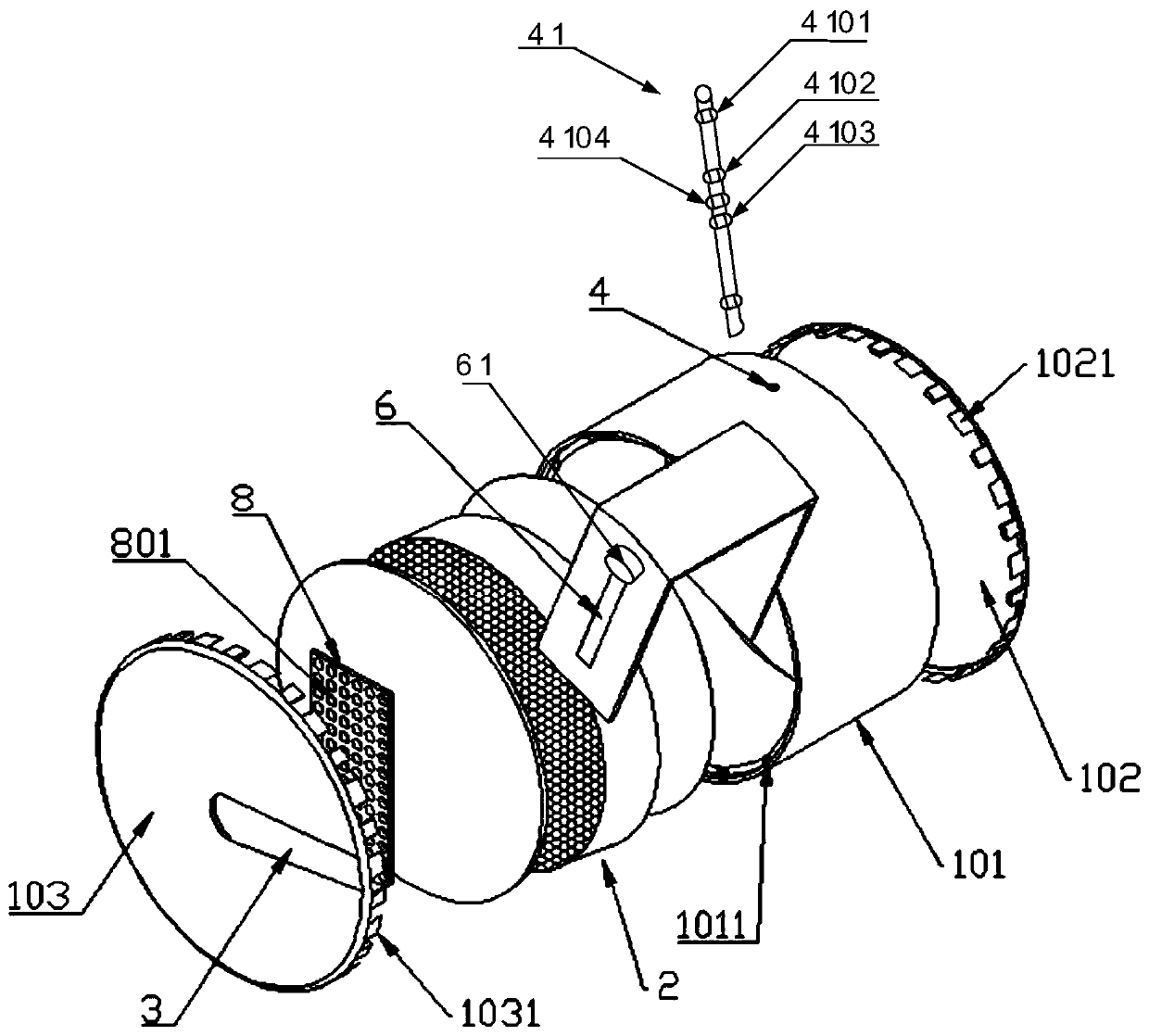

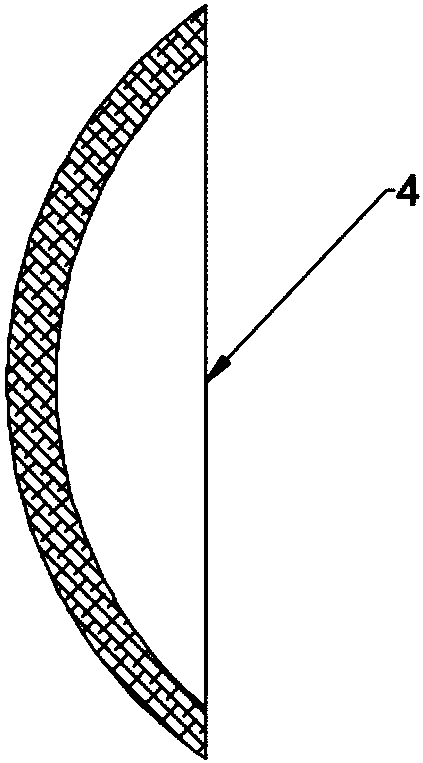

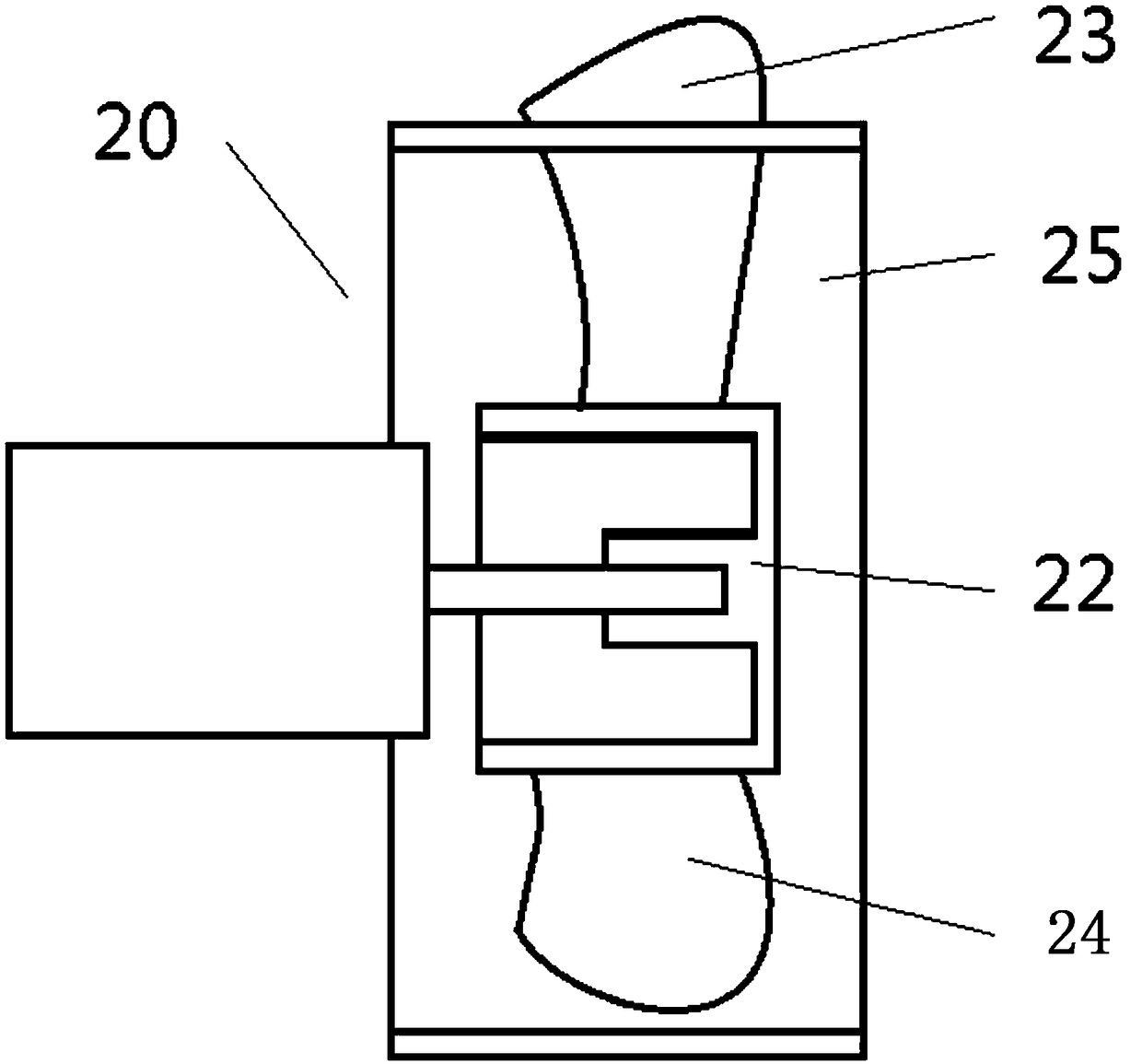

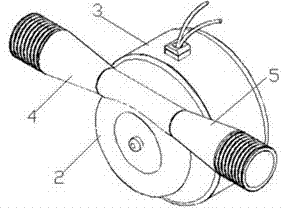

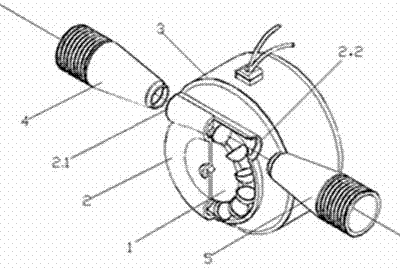

Independent external-mounting maintenance-free multi-stage oil and gas separator assembly

InactiveCN102705040BIncrease swirl intensityIncrease flow rateMachines/enginesCrankcase ventillationCyclonic separationRespirator

The invention discloses an independent external-mounting maintenance-free multi-stage oil and gas separator assembly. The oil and gas separator assembly is characterized in that a first cyclone separation cavity consists of an oil and gas separator outer shell and an oil and gas separator body shell; a second dispersing separation cavity consists of the oil and gas separator body shell, an oil and gas separator cover and the outer walls of three refine separation conical pipes which are distributed on the circumference at 90 degrees; a third refine cyclone separation cavity consists of the three refine separation conical pipes which are distributed on the circumference at 90 degrees and a central pipe; a fourth reinforcement cyclone separation cavity consists of the three refine separation conical pipes which are distributed on the circumference at 90 degrees, a central pipe, and a cyclone blade; a fifth refine cyclone separation cavity consists of a small refine separation conical pipe arranged in the center of the circumference; a sixth compact and dispersing safety separation cavity consists of a safety valve cavity and a safety valve; an eighth separation cavity consists of a respirator compact plate and a safety damping net; a flow pressure adjusting valve consists of a flow pressure adjusting diaphragm in a respirator and a flow pressure adjusting spring; any installation mechanism consists of an installation support and variable air inlet and outlet pipe included angles; and an oil return cavity consists of a separation conical pipe bottom and an independent separator shell.

Owner:NANCHONG LINGYUN GAOJU MFG

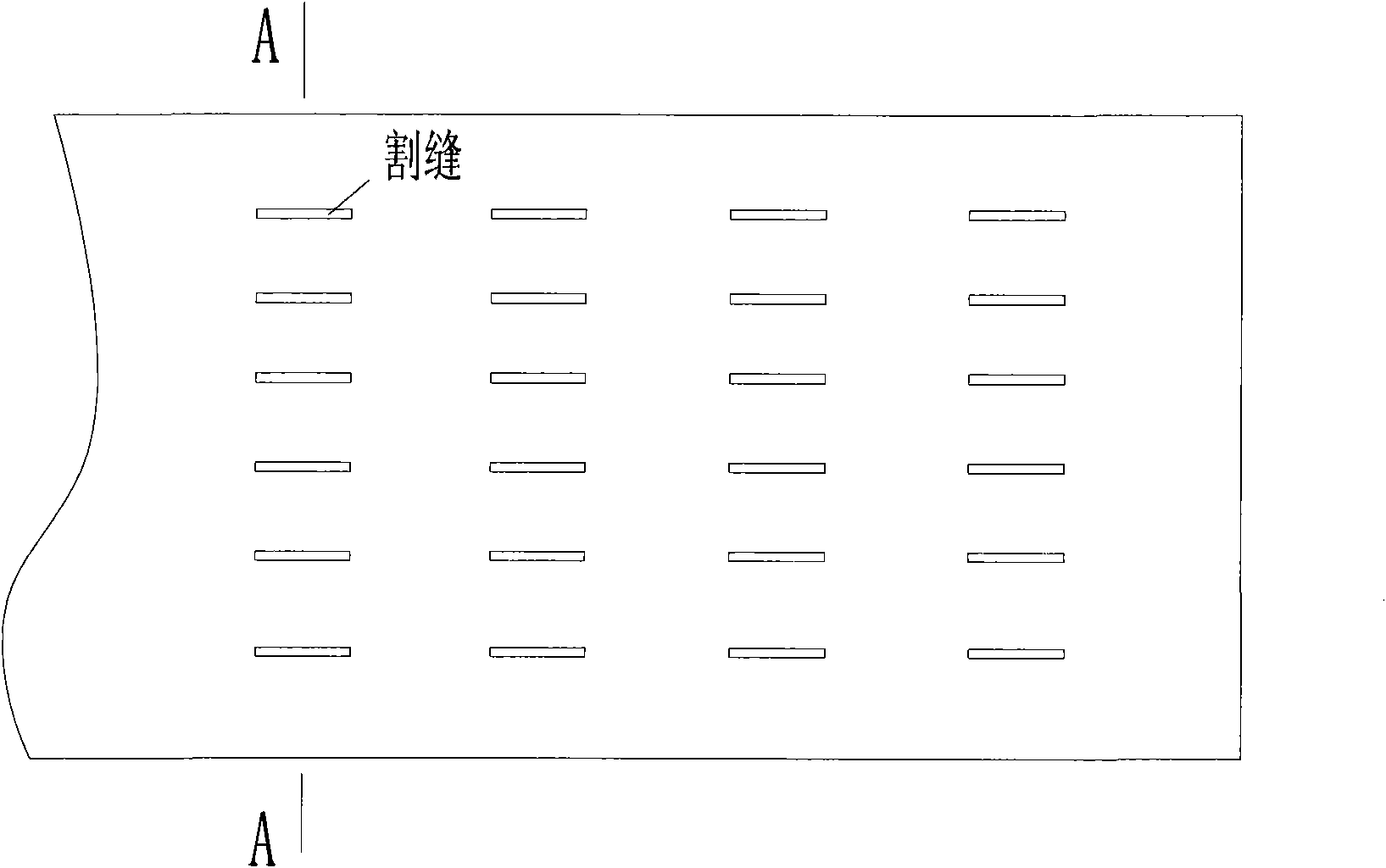

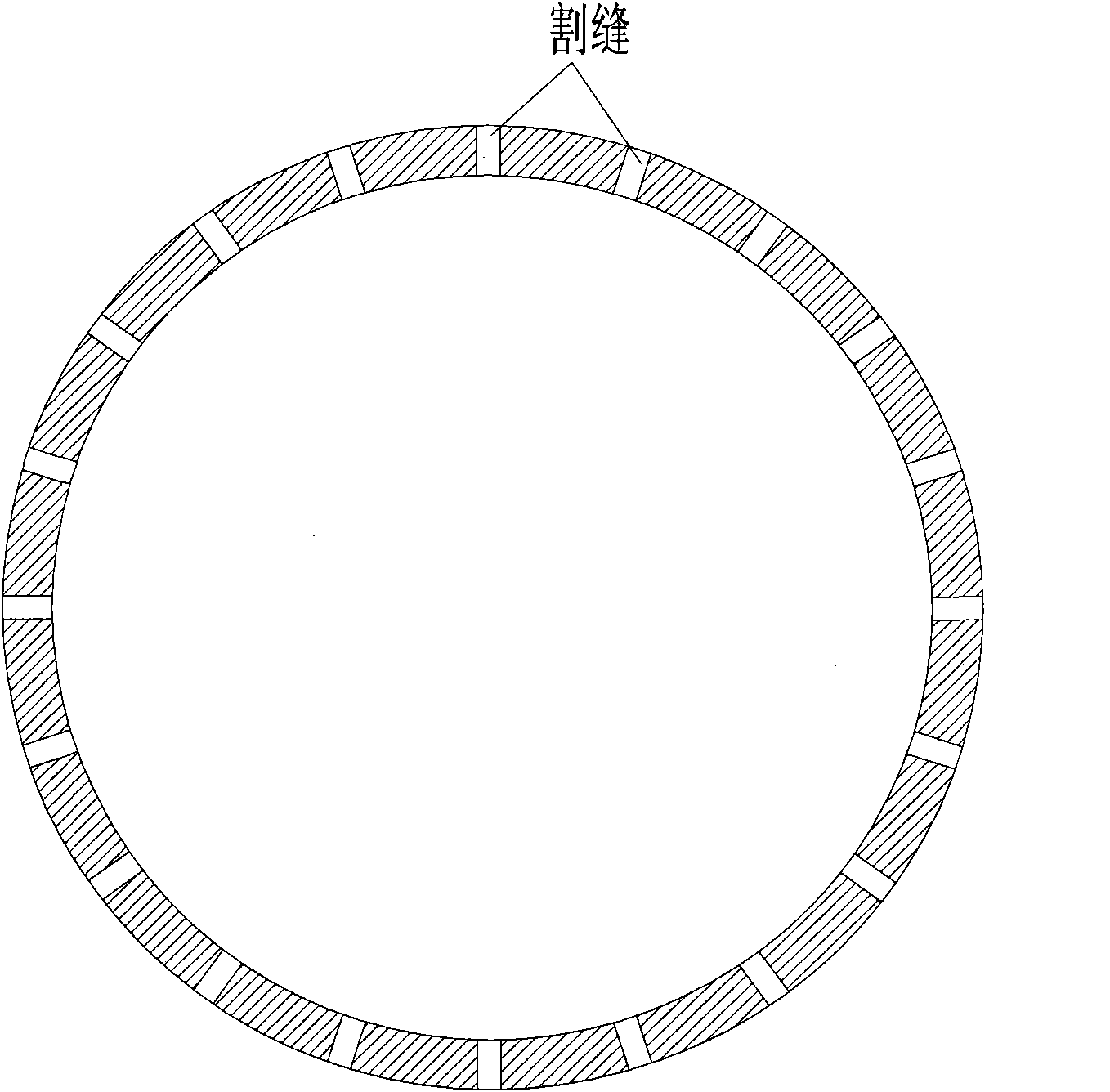

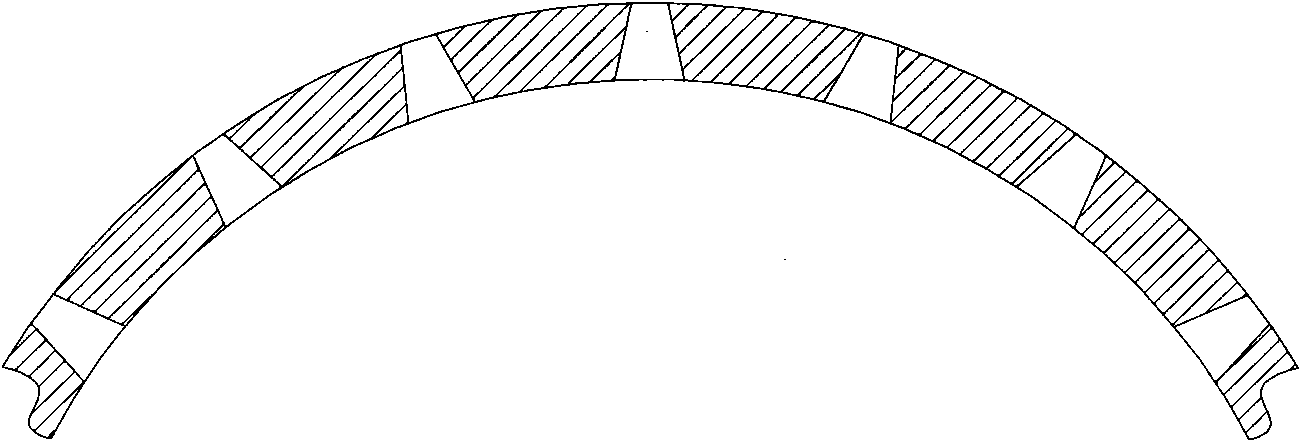

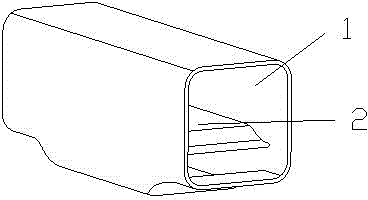

Laser processing method for steel sieve tube slit

InactiveCN101890582AGuaranteed trafficGuaranteed flow rateLaser beam welding apparatusLaser processingChemical reaction

The invention discloses a laser processing method for a steel sieve tube slit. One end point of one long edge of the slit is used an initial point. The method comprises the following steps of: perforating a hole at the initial point of a cut by using pulse laser, and then finishing the cutting of the whole slit from the initial point by using continuous laser. During cutting, oxygen is used as an auxiliary gas, the metal at a cutting point is further heated by using reaction heat released by the reaction of the oxygen and the molten iron at the cutting point, meanwhile the molten iron is changed into ferroferric oxide with good liquidity by using chemical reaction, and the ferroferric oxide is blown away the cutting point by using airflow so as to ensure continuous cutting. The processing method solves the problems of irregular slit shape, slag adhesion at the cut and oblique blowing trace in the conventional laser cut sieve tube slit.

Owner:北京宏诚拓业科技发展有限公司 +1

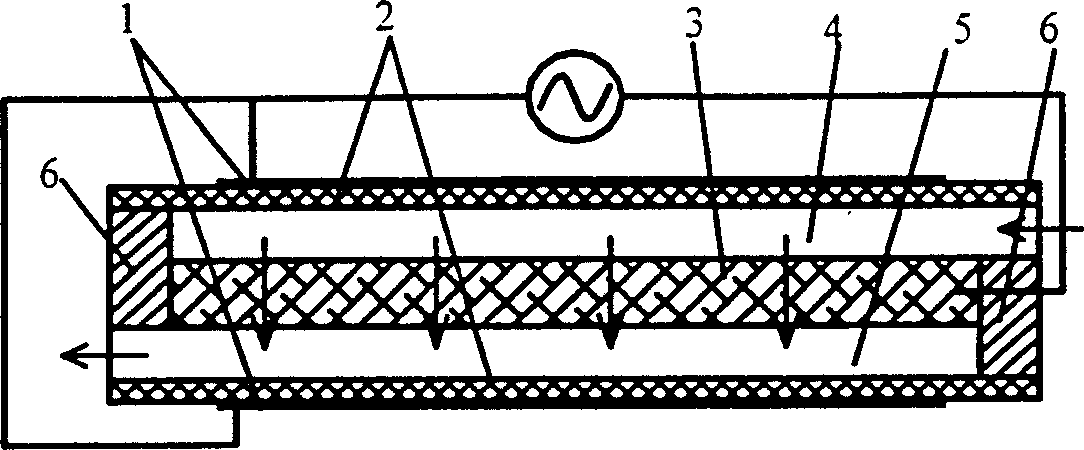

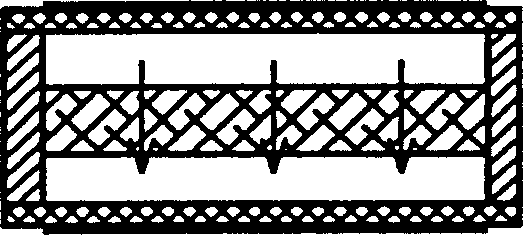

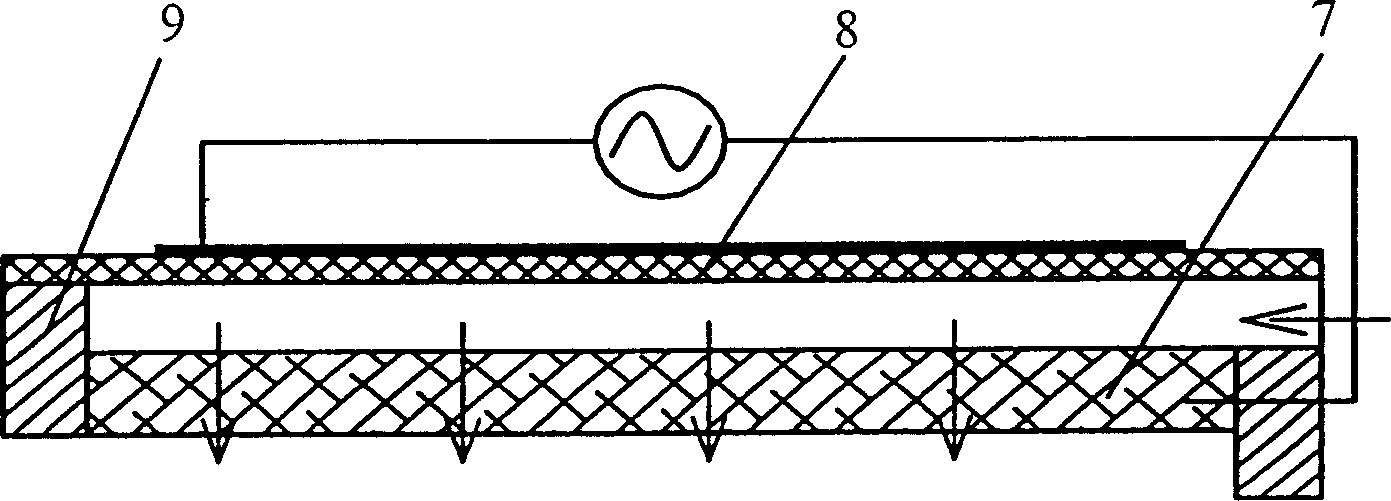

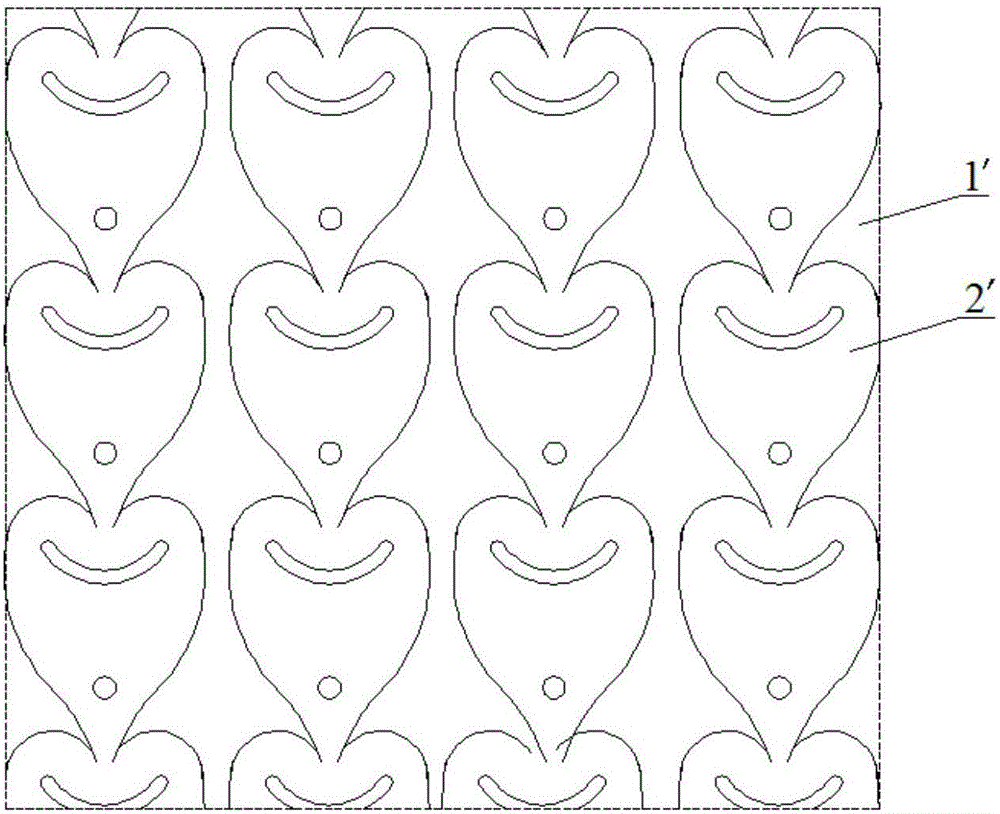

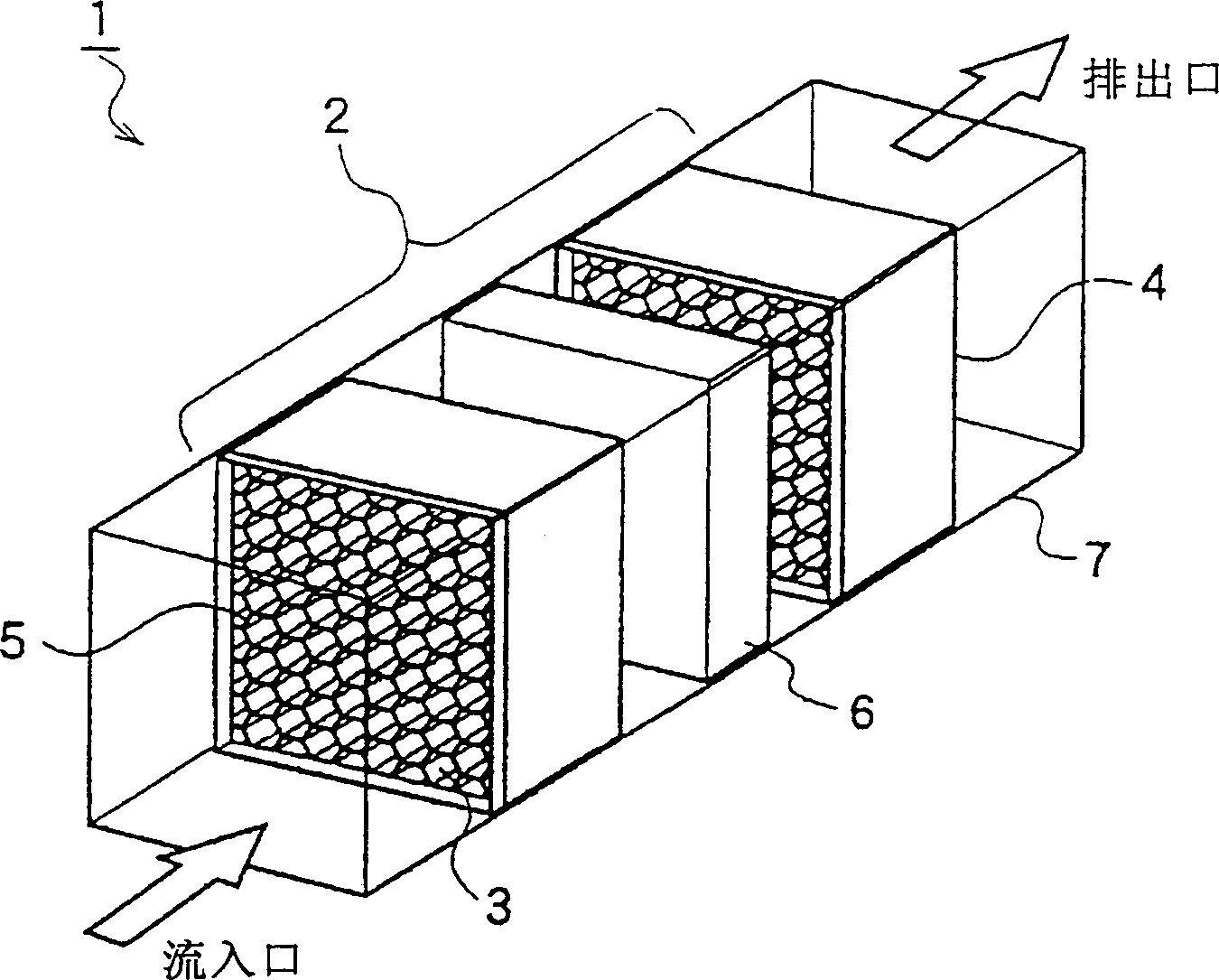

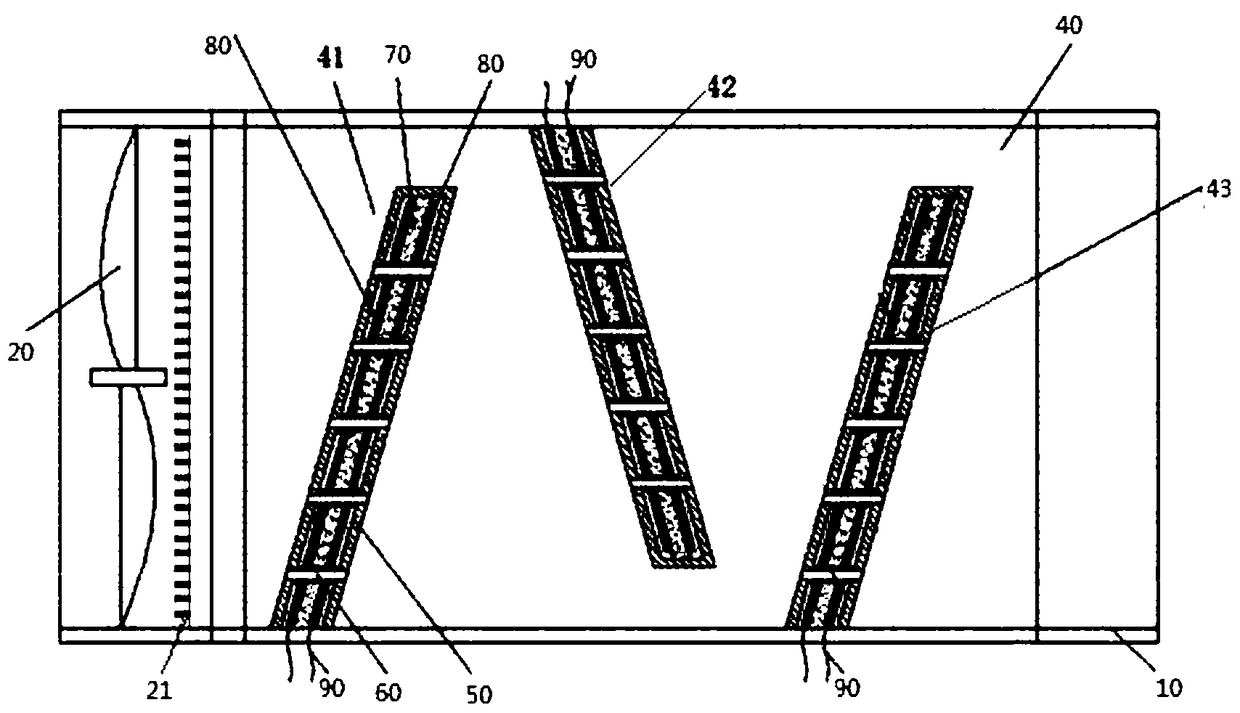

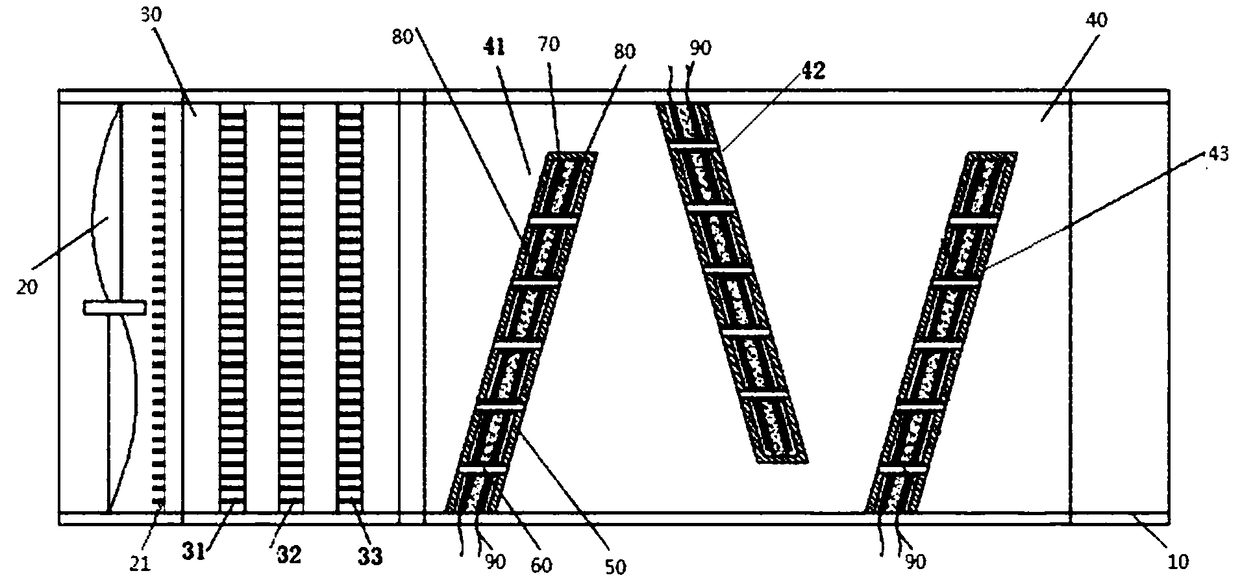

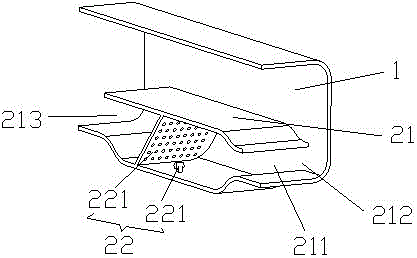

Plasma coupling light catalytic unit assembly and gas purifier therewith

InactiveCN1614321AEasy to handleEasy to cleanLighting and heating apparatusAir conditioning systemsMolecular physicsAirflow

A plasma coupled photocatalyzing module used for gas purifier is composed of the plate electrodes with rigid dielectric barrier layer on its inner surface, the porous photocatalytizing body arranged between two dielectric barrier layers, and the sealing apron arranged to the peripheries of two dielectric barrier layers to form two spaces (one having gas inlet and another having gas outlet). Said gas purifier is composed of at least one said module.

Owner:UNIV OF SCI & TECH OF CHINA

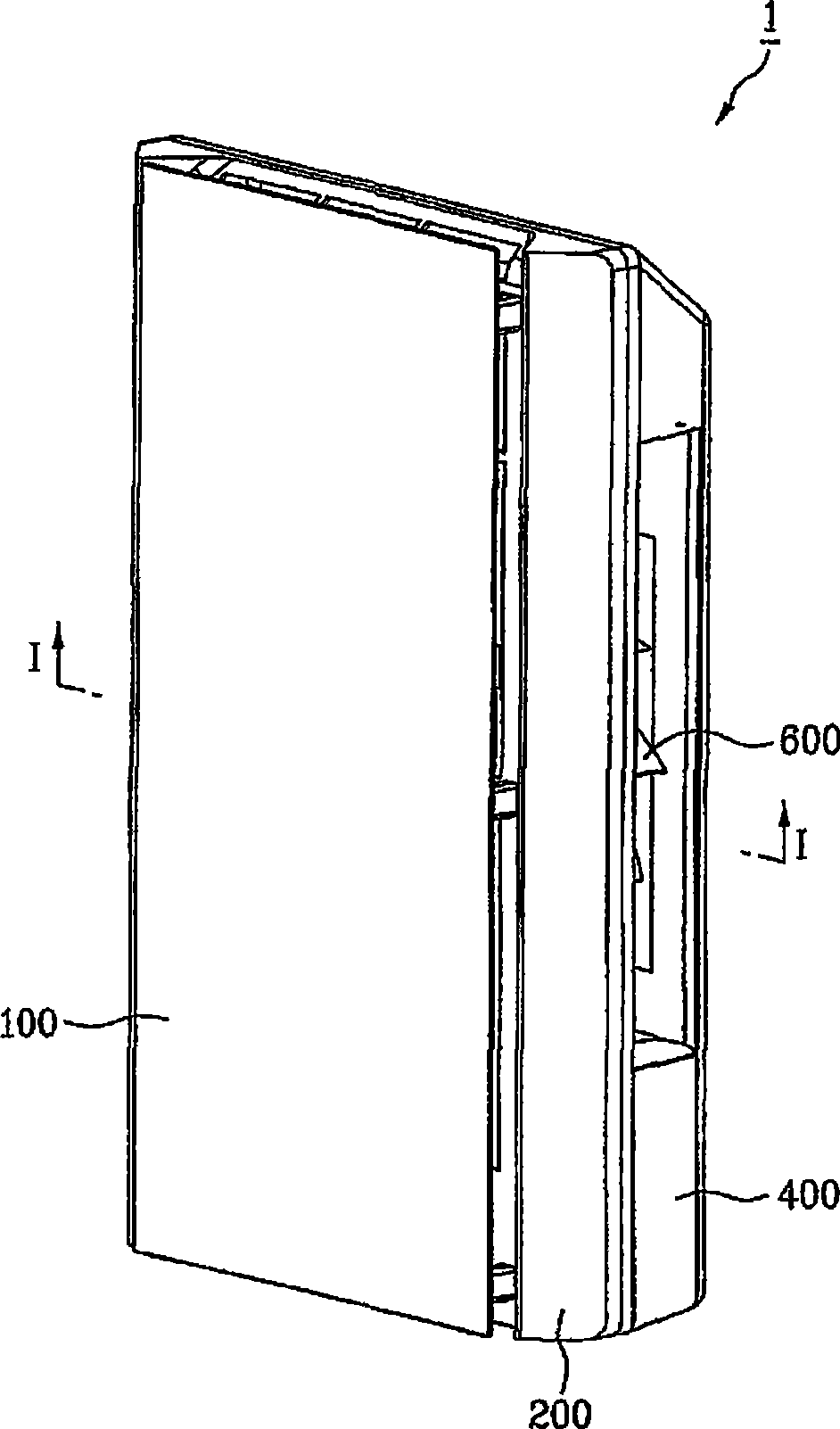

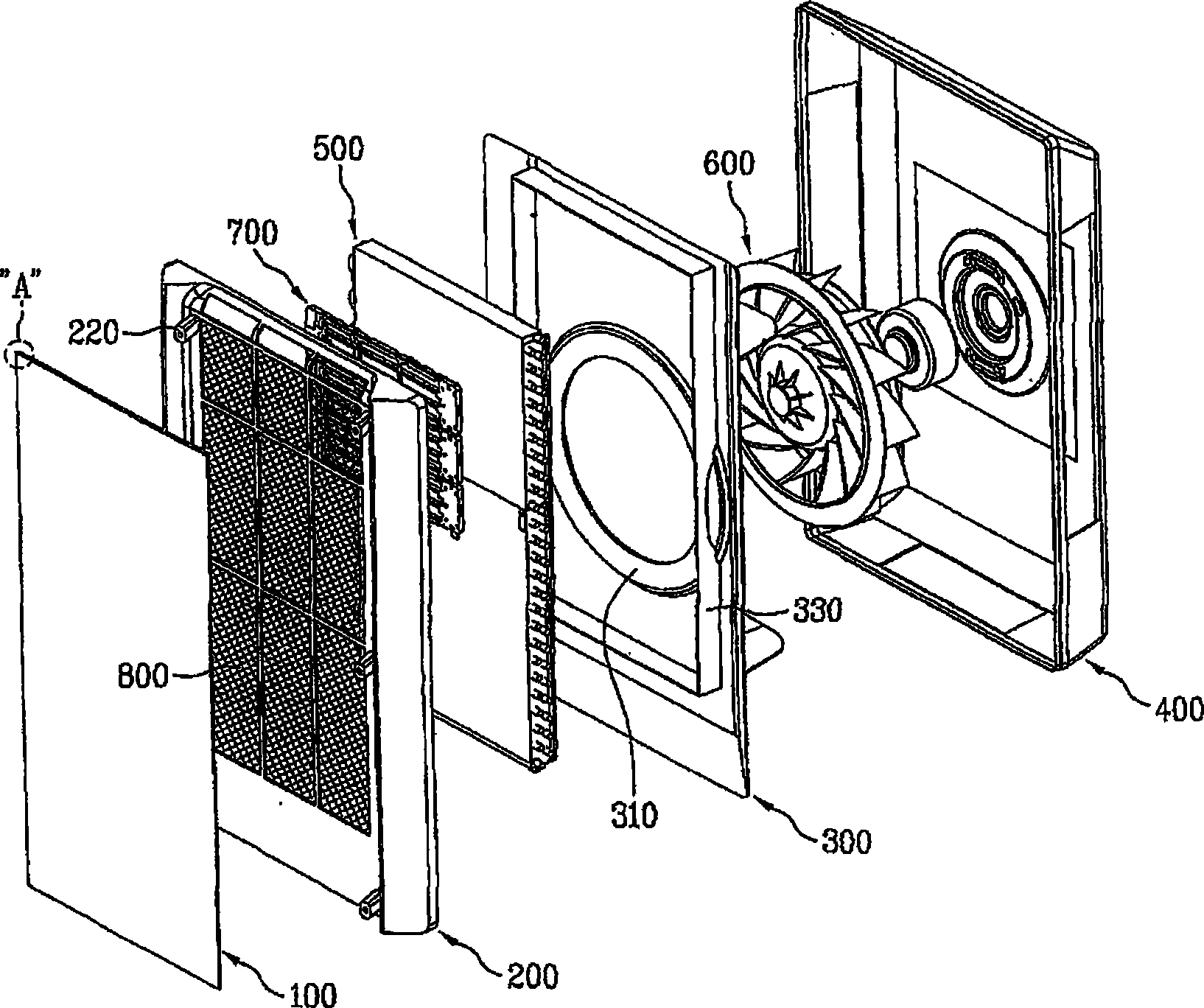

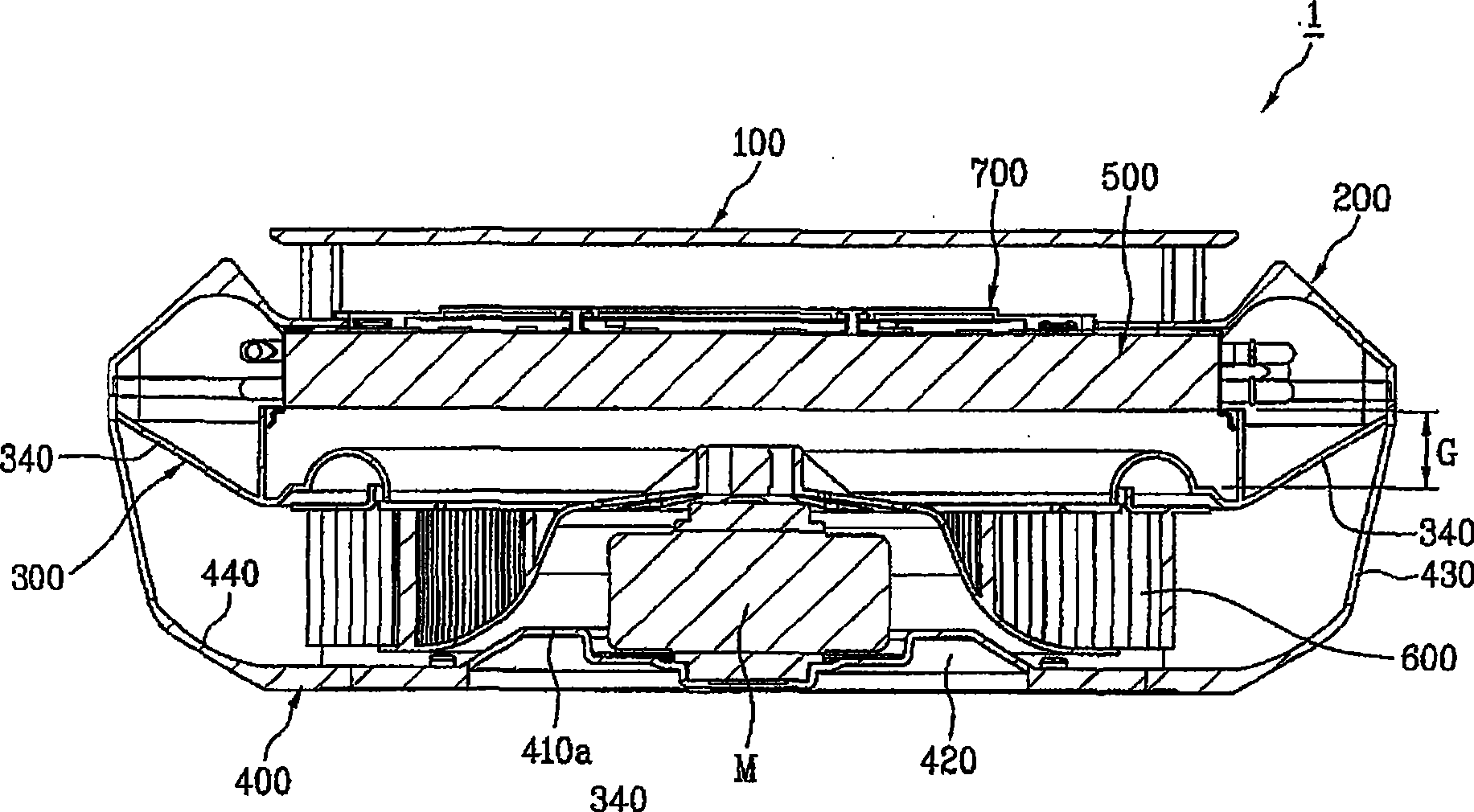

Indoor unit of air conditioner

InactiveCN101512237AReduce noiseIncrease inhalationLighting and heating apparatusHeating and ventilation casings/coversLow noiseDrive motor

Indoor unit which draws air through a front, and discharges air heat exchanged therein in a front direction through sides, having an optimized stricture with increased suction and discharge rates and low noise. For this, the indoor unit includes a front frame made to enable air suction through a front thereof, a base frame joined with the front frame, having outlets in sides and a bottom, and a motor seat for mounting a fan driving motor thereon, a guide frame between the front frame and the base frame for guiding an airflow, a heat exchanger between the front frame and the guide frame, a fan for discharging heat exchanged air to an outside of the indoor unit, and a front panel mounted in front of the front frame with a space thereto.

Owner:LG ELECTRONICS INC

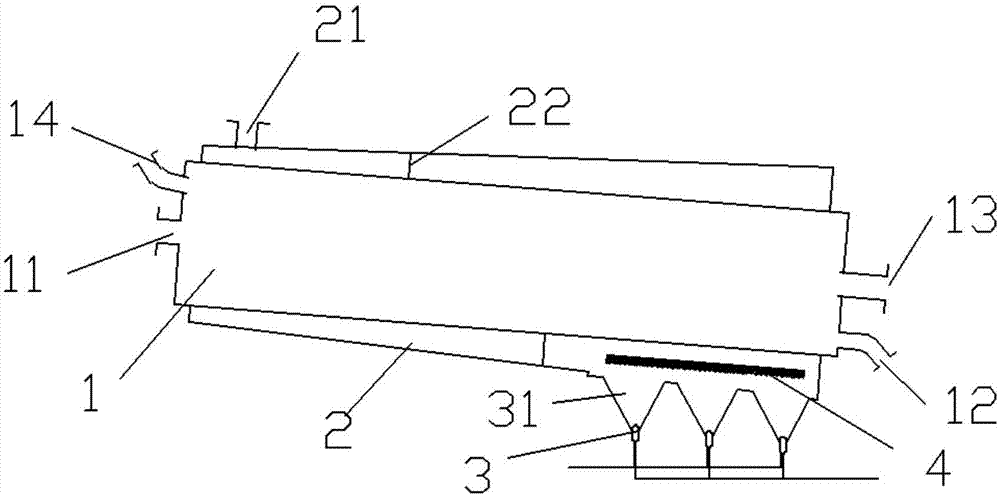

Condensing gas boiler

InactiveCN101782270AGuaranteed flow rateSufficient heat exchangeCorrosion preventionWater heatersCombustorCombustion chamber

The invention relates to a condensing gas boiler, which belongs to the technical field of heat exchange facilities. The condensing gas boiler mainly comprises a burner and a heat exchange device with smoke and water passages, wherein the heat exchange device comprises a horizontal heat exchanger and a V-shaped heat exchanger which are mutually connected in series; a first group of water pipes forming a roundabout flow passage are distributed at the circumference of the horizontal heat exchanger, and the middle part of the horizontal heat exchanger is provided with a cylindrical combustion chamber; the burner is arranged at one end of the cylindrical combustion chamber, and the smoke passes through the horizontal heat exchanger and enters the V-shaped smoke passage of the V-shaped heat exchanger through a downward through hole; a second group of water pipes forming a roundabout flow passage are distributed in the V-shaped smoke passage at intervals; and reverse heat exchange is formed between the water first flowing through the second group of water pipes and then the first group of water pipes and the smoke coming from the combustion chamber and flowing through the V-shaped smoke passage. The heat exchange is sufficient, the flow rate of the cooled smoke can be kept to ensure the heat exchange efficiency, and the condensing gas boiler has a reasonable structure and occupies small area.

Owner:A O SMITH CHINA WATER HEATER CO LTD

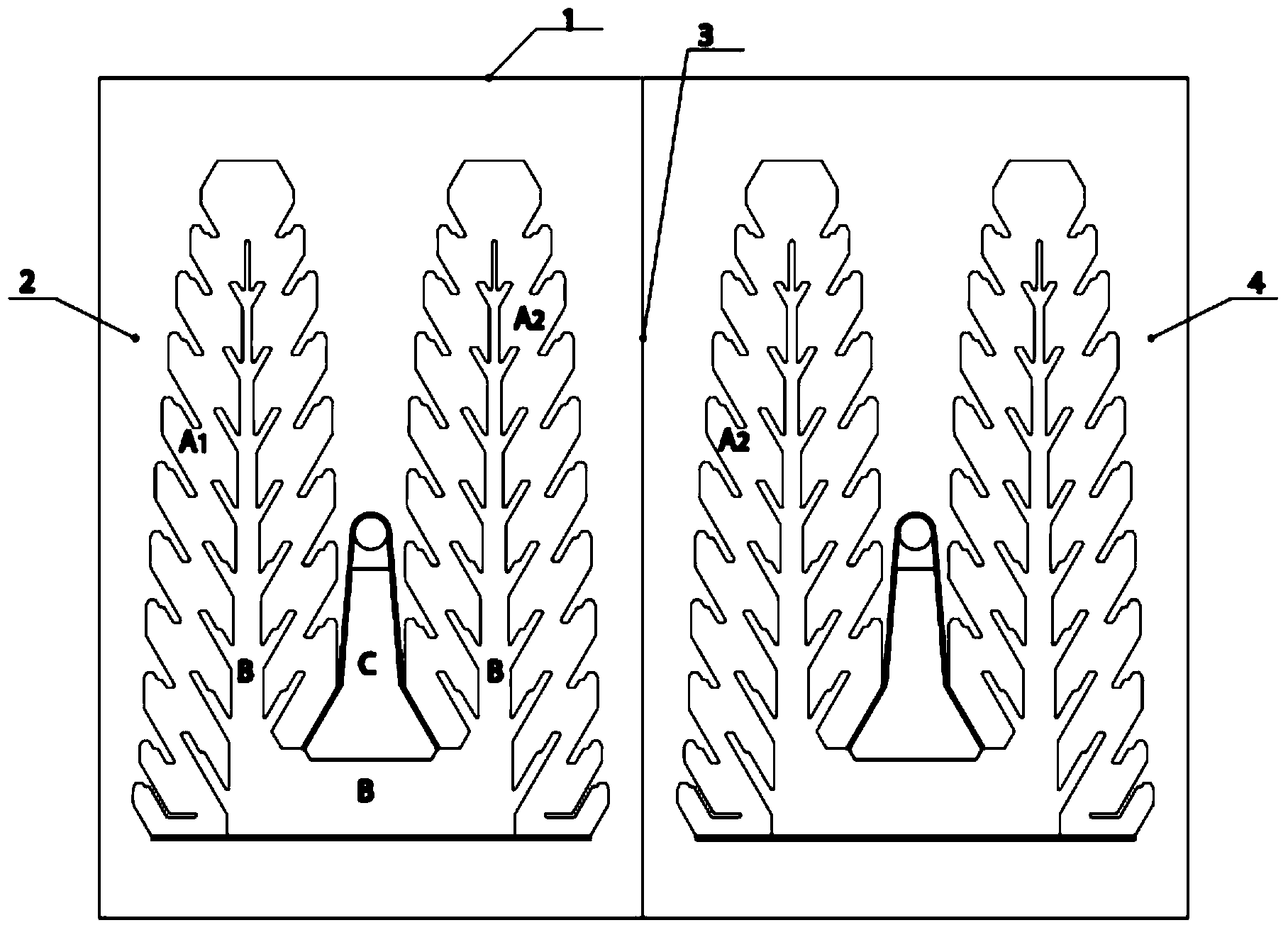

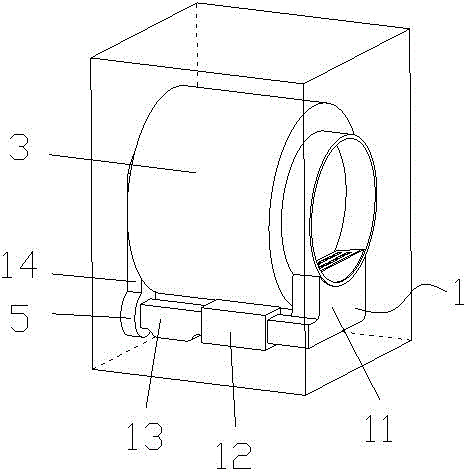

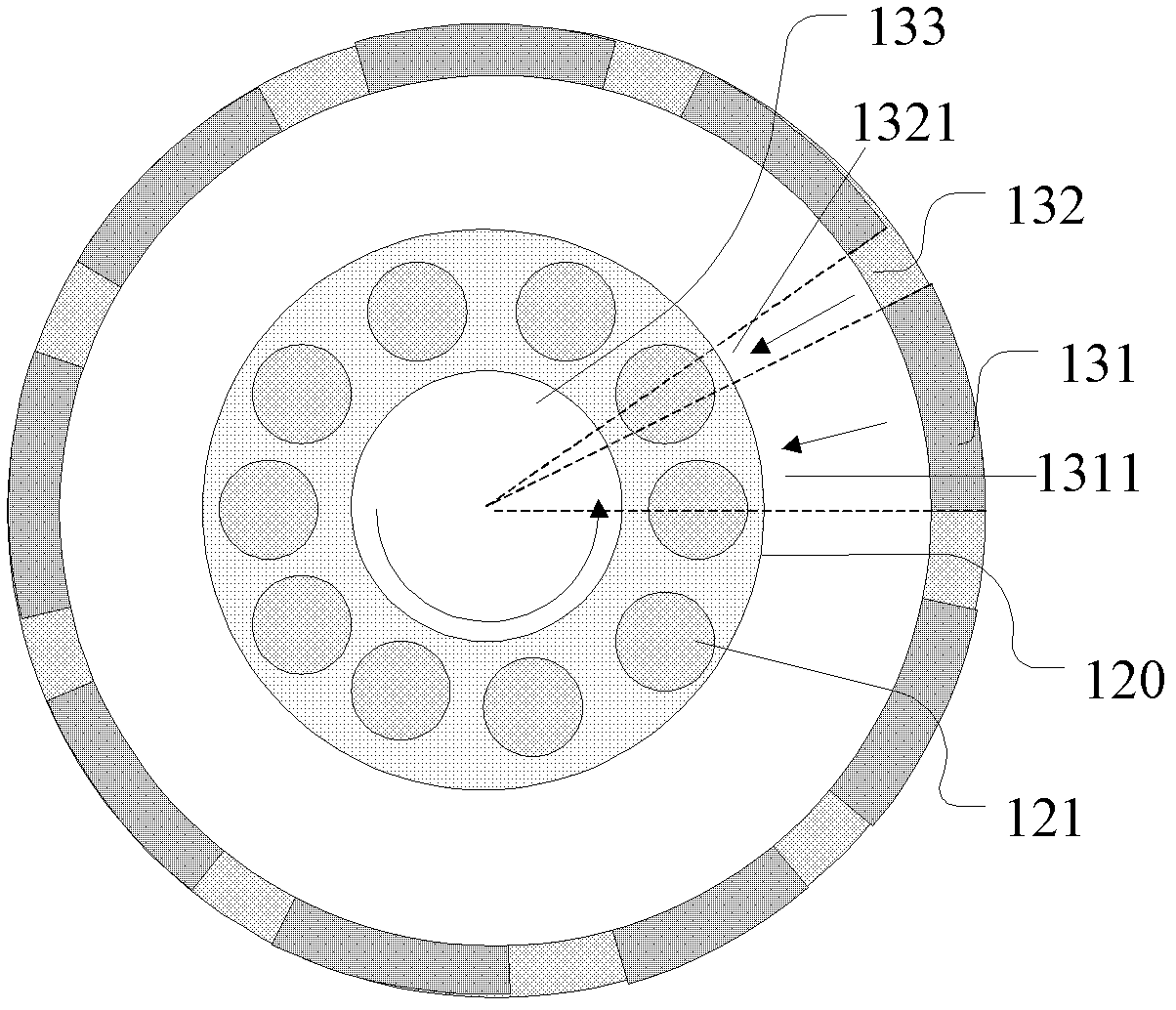

Micro-reactor

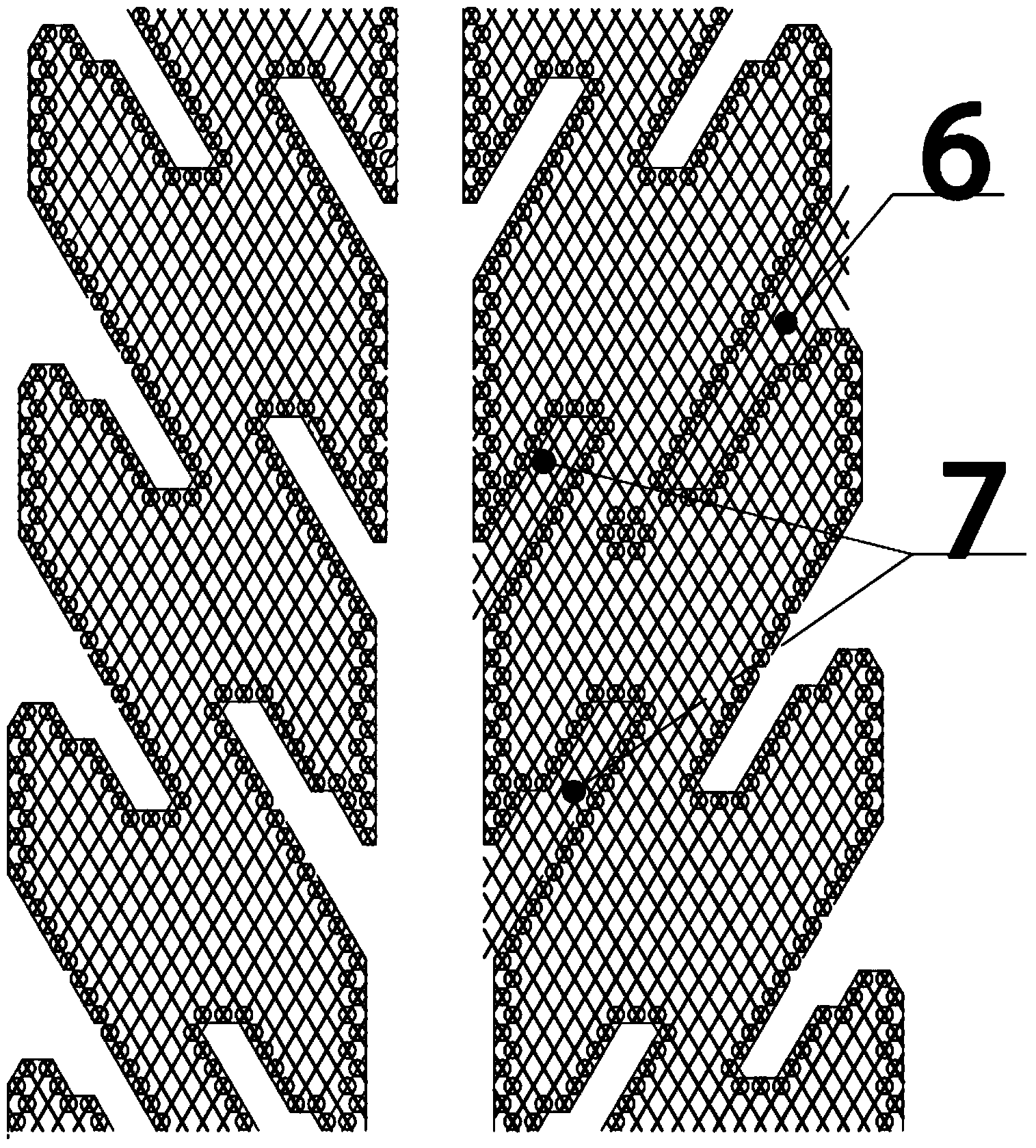

ActiveCN106423033AReduce areaKeep for a long timeChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical stationary reactorsMicroreactorEnergy consumption

The invention discloses a micro-reactor. The micro-reactor is provided with a reaction channel; the reaction channel is provided with a plurality of reaction cavities (12), and each reaction cavity (12) is internally provided with a diversion body (15) and a spoiler body (16); all the reaction cavities (12) are respectively in a rectangle; an outlet of each reaction cavity (12) comprises a V-shaped channel (17) and a linear channel (18), wherein the widths of the V-shaped channels (17) are reduced gradually, and the widths of the linear channels (18) are the same as one another; the widths a of the linear channels (18) are 0.002-6mm, and the ratios of distances b between the spoiler bodies (16) and two sides of the V-shaped channels (17) to the widths a of the linear channels (18) are equal to 0.93-2.2. The micro-reactor has a high specific surface area so as to augment and strengthen a reaction process, thus further increasing liquid holdup and handling capacity, effectively improving the conversion rate and yield of products and remarkably improving coefficient of heat conduction and heat exchange effect; furthermore, when a medium passes through a channel, the pressure drop is greatly reduced, so that the micro-reactor is beneficial to accurate control of reaction conditions and reduction of energy consumption.

Owner:SHANDONG HIMILE CHEM TECH

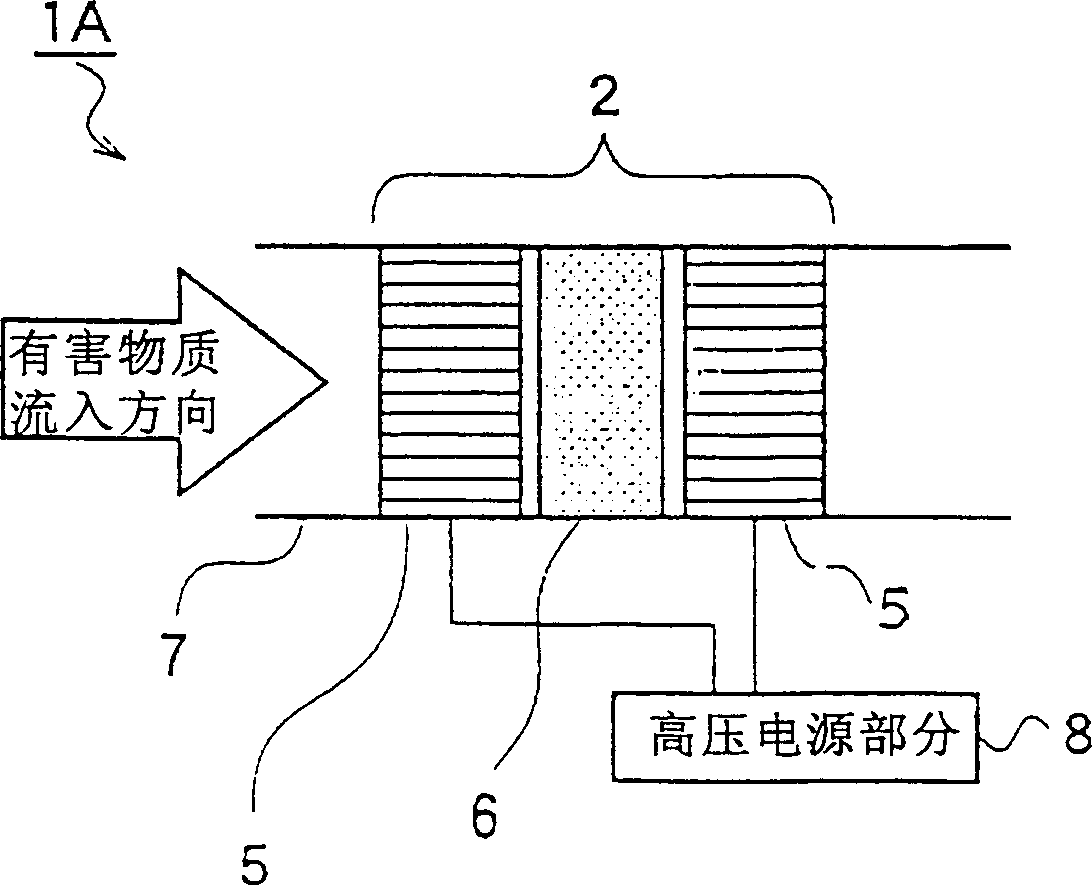

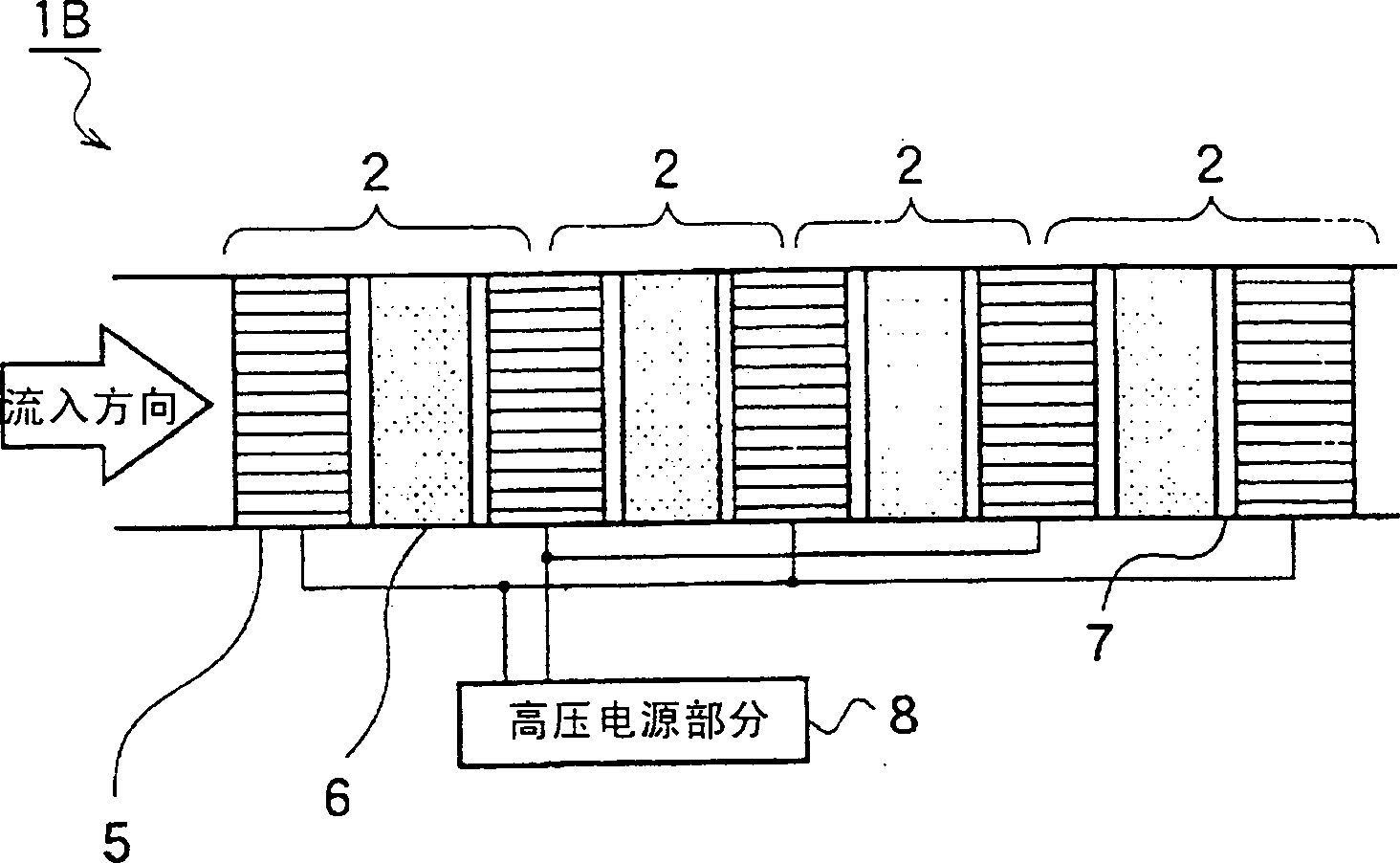

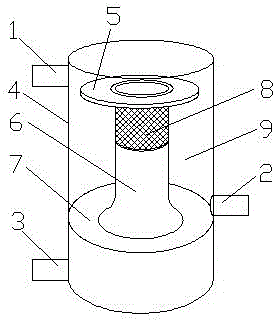

Discharging electrode and light catalyst reactor

InactiveCN1386574AImprove corrosion resistanceStable and uniform discharge lightNitrous oxide captureGas treatmentHazardous substanceThin membrane

The present invention provides a discharge electrode and a photocatalyst reaction device, which utilizes a three-dimensional discharge electrode that discharges effectively and stably, the relationship between the discharge light emitted from the discharge electrode and the photocatalyst, and can effectively, long-term, and stably remove harmful substances. The discharge electrode is a three-dimensional electrode. The main body (3) of the honeycomb electrode is formed of a conductive film. The shape is honeycomb when viewed from the front and back. Gases containing harmful substances can pass from the front to the back. The sides of the electrode are conductive. The casing (4) covers the electrode and has a specified thickness in the direction from the front to the back of the electrode. In addition, the photocatalyst reaction device includes at least one group of unit structures (2). The unit structure (2) has: at least one photocatalyst component (6) and a honeycomb electrode (5), wherein the photocatalyst component (6) ) holds a photocatalyst on its ceramic substrate with a three-dimensional network structure; among a pair of electrodes sandwiching the photocatalyst component 6 between the honeycomb electrode (5), at least one electrode is composed of a conductive shell (4) and It is composed of honeycomb electrode body 3.

Owner:KK TOSHIBA

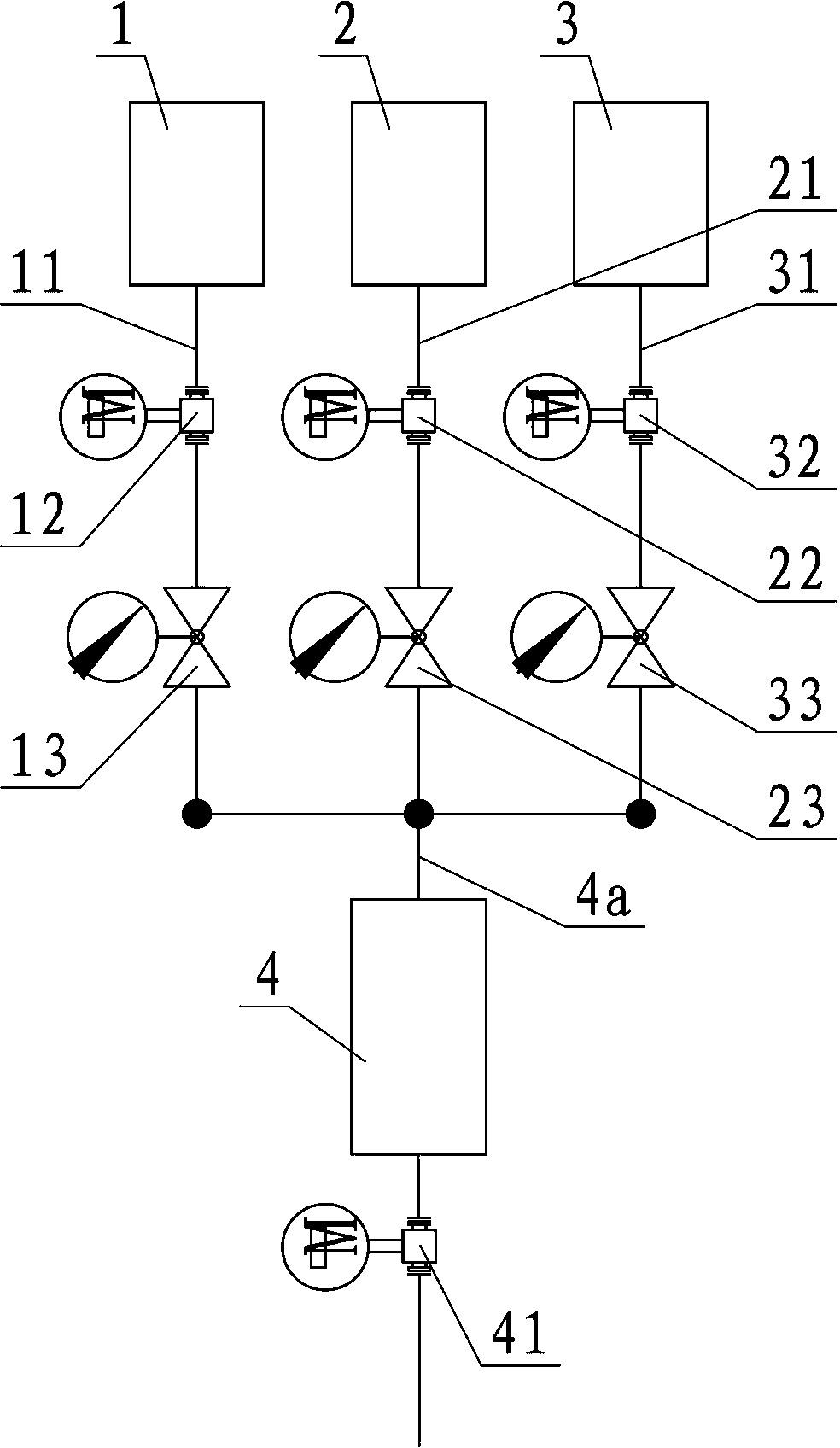

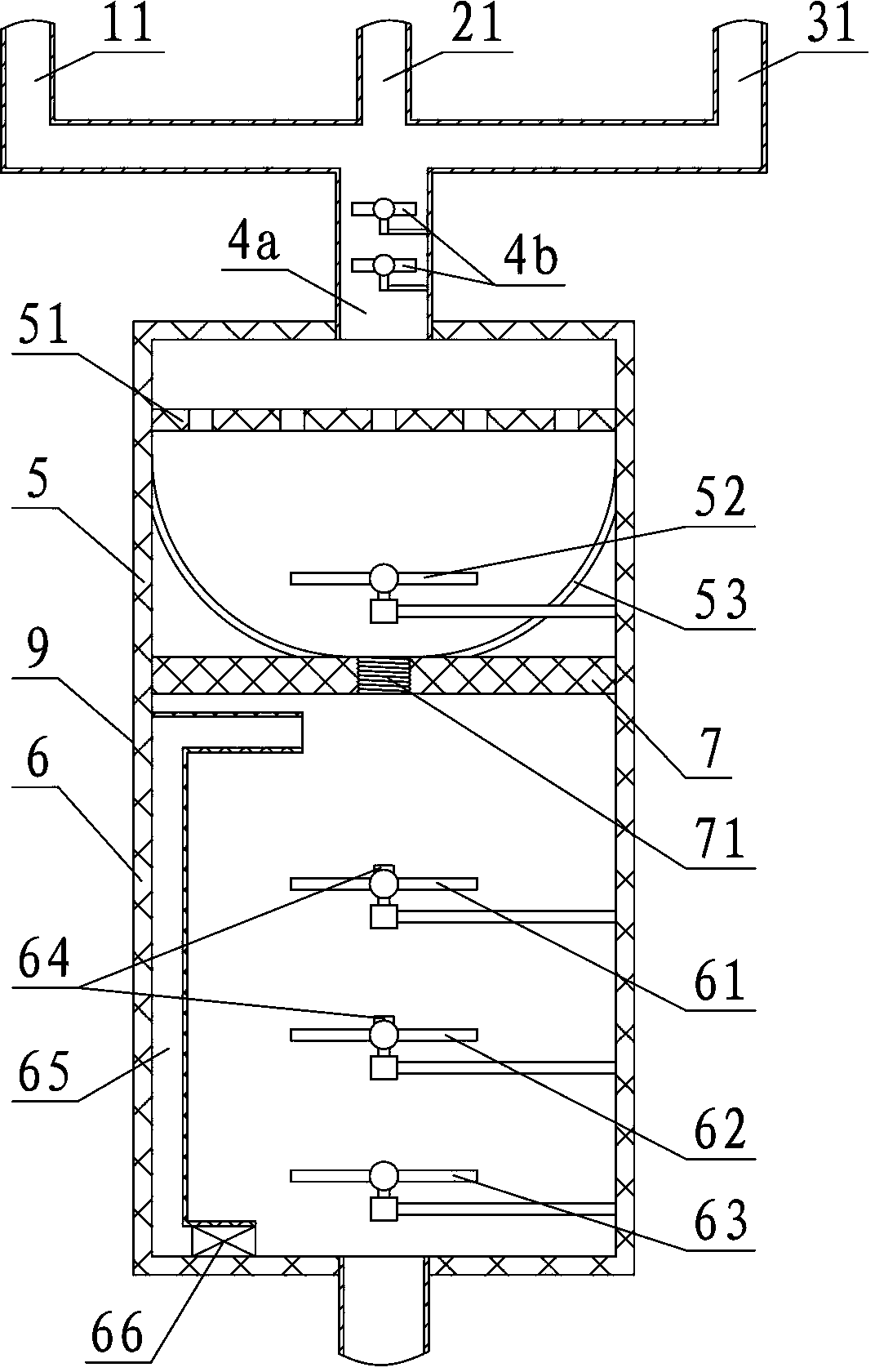

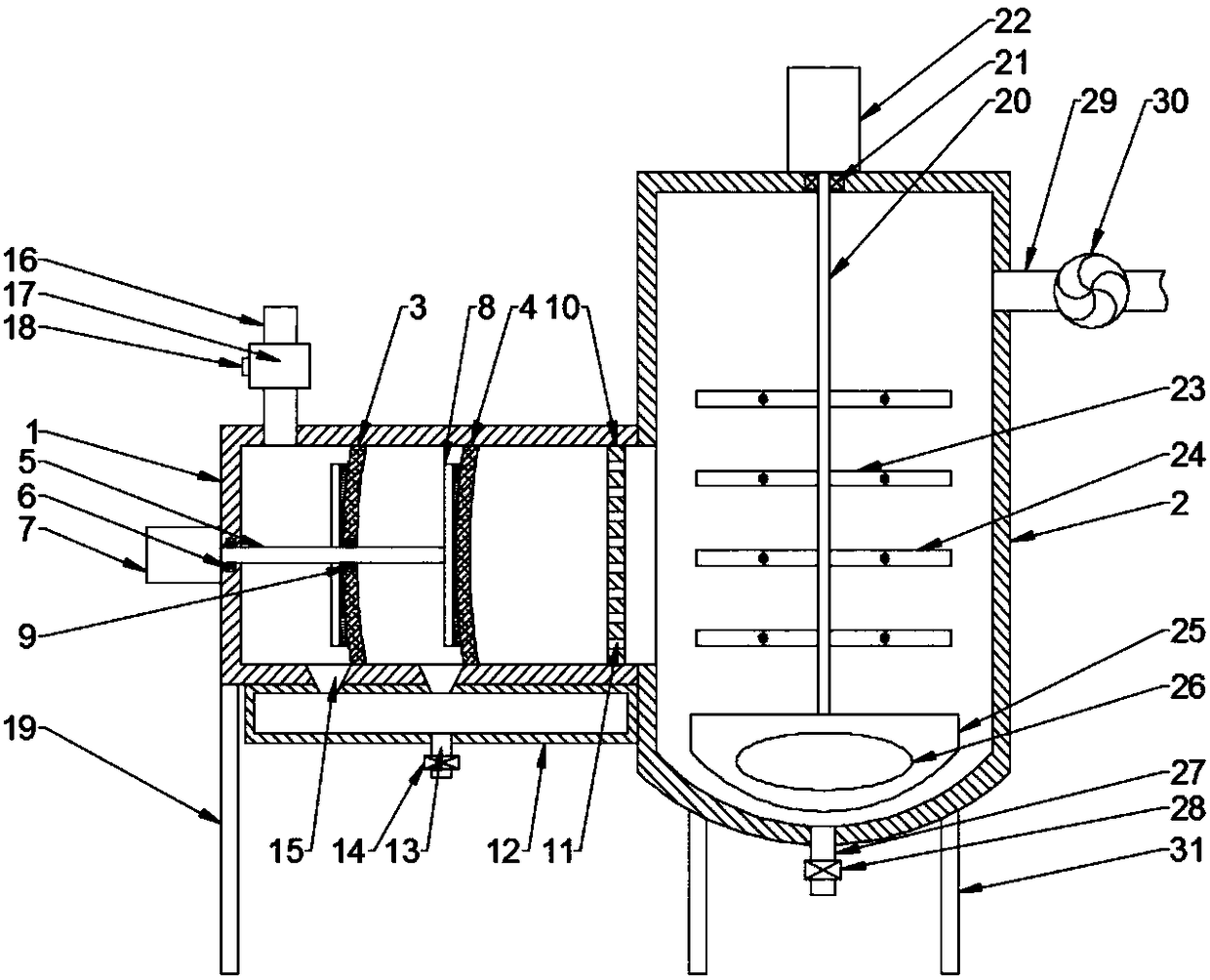

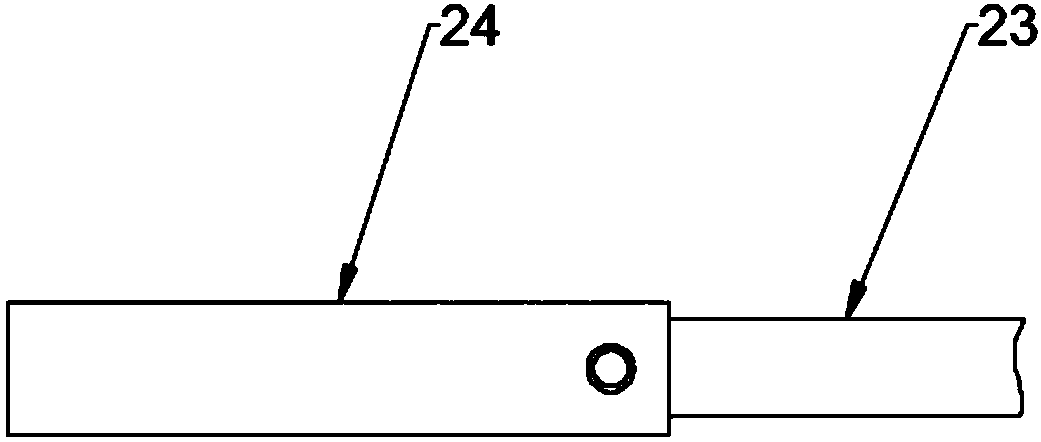

Concentration preparation device for mixed solution

InactiveCN104258780AGuaranteed ratioGuaranteed flow rateMixing methodsMixer accessoriesProcess engineeringProduction quality

The invention discloses a concentration preparation device for a mixed solution. The device comprises three solution storage devices and a solution mixing device, wherein the three solution storage devices are communicated with an input opening of the solution mixing device through respective pipelines; a flow meter and a proportion regulating valve are arranged on each pipeline; a flow meter is arranged on an output opening pipeline of the solution mixing device; the openness of the three proportion regulating valves is changed, so that the proportion of different solutions, entering the solution mixing device, in the three pipelines is further regulated. According to the invention, the proportioning is stable, and the mixed solution can be used for a long time after the proportion of the mixed solution is regulated; the production efficiency can be improved to the greatest extent, and meanwhile, the production quality is guaranteed; the production automation is realized, and the labor intensity of workers is alleviated; the device is convenient to operate and reliable to run.

Owner:HANGZHOU FANTENG TECH

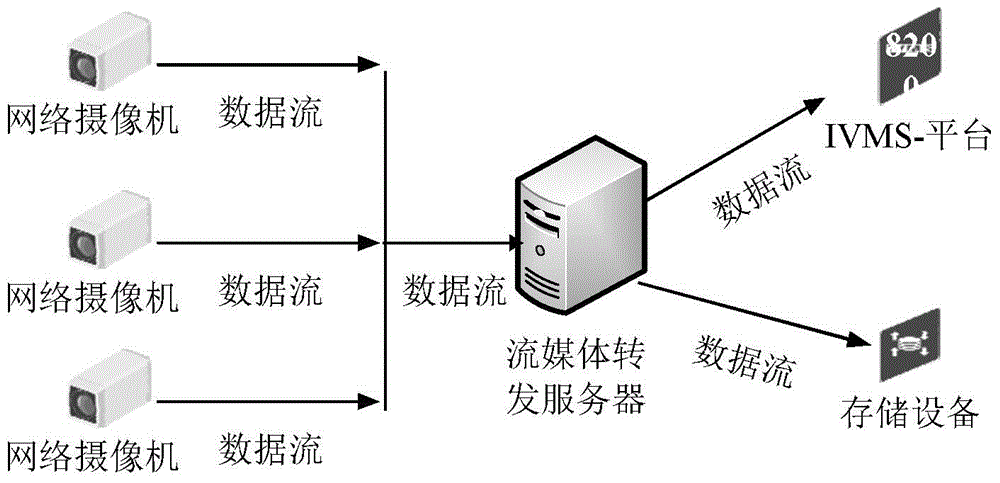

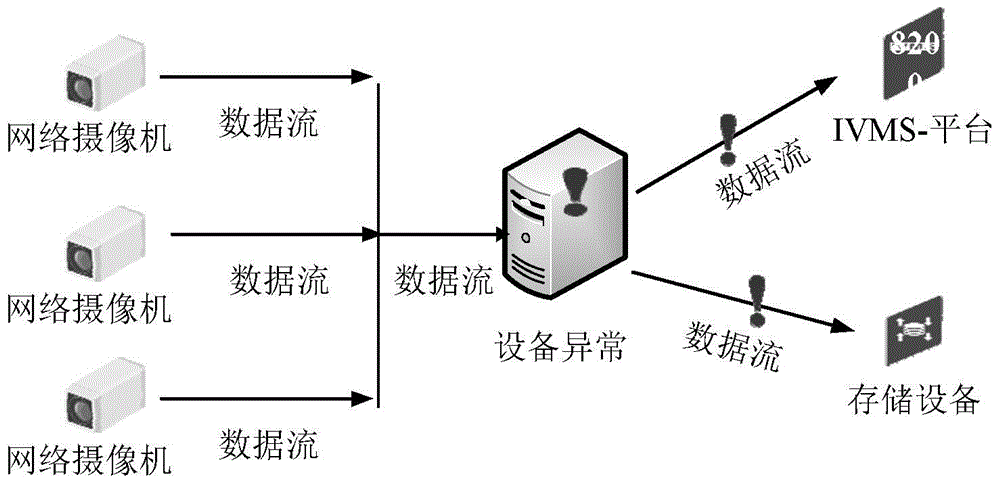

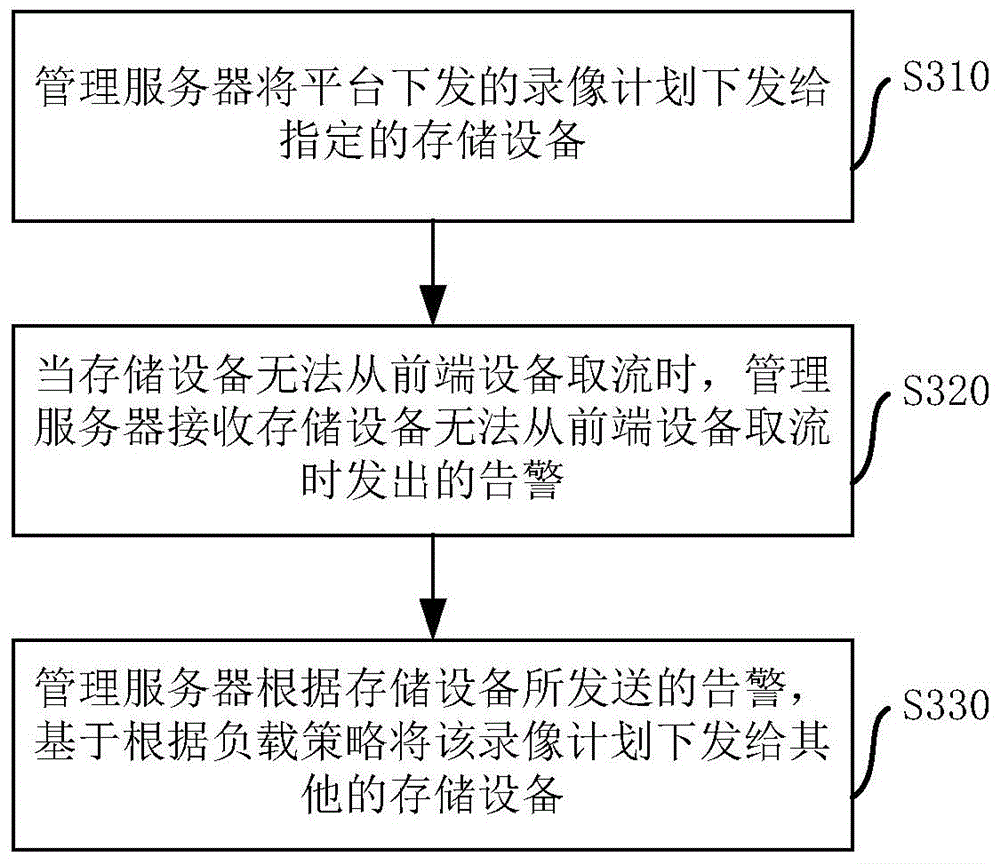

Video cloud storage method and system as well as method and system for previewing cloud storage video

ActiveCN106162219AGuaranteed flow rateEnsure safety and effectivenessClosed circuit television systemsTransmissionProgram planningCloud storage system

Owner:HANGZHOU HIKVISION SYST TECH

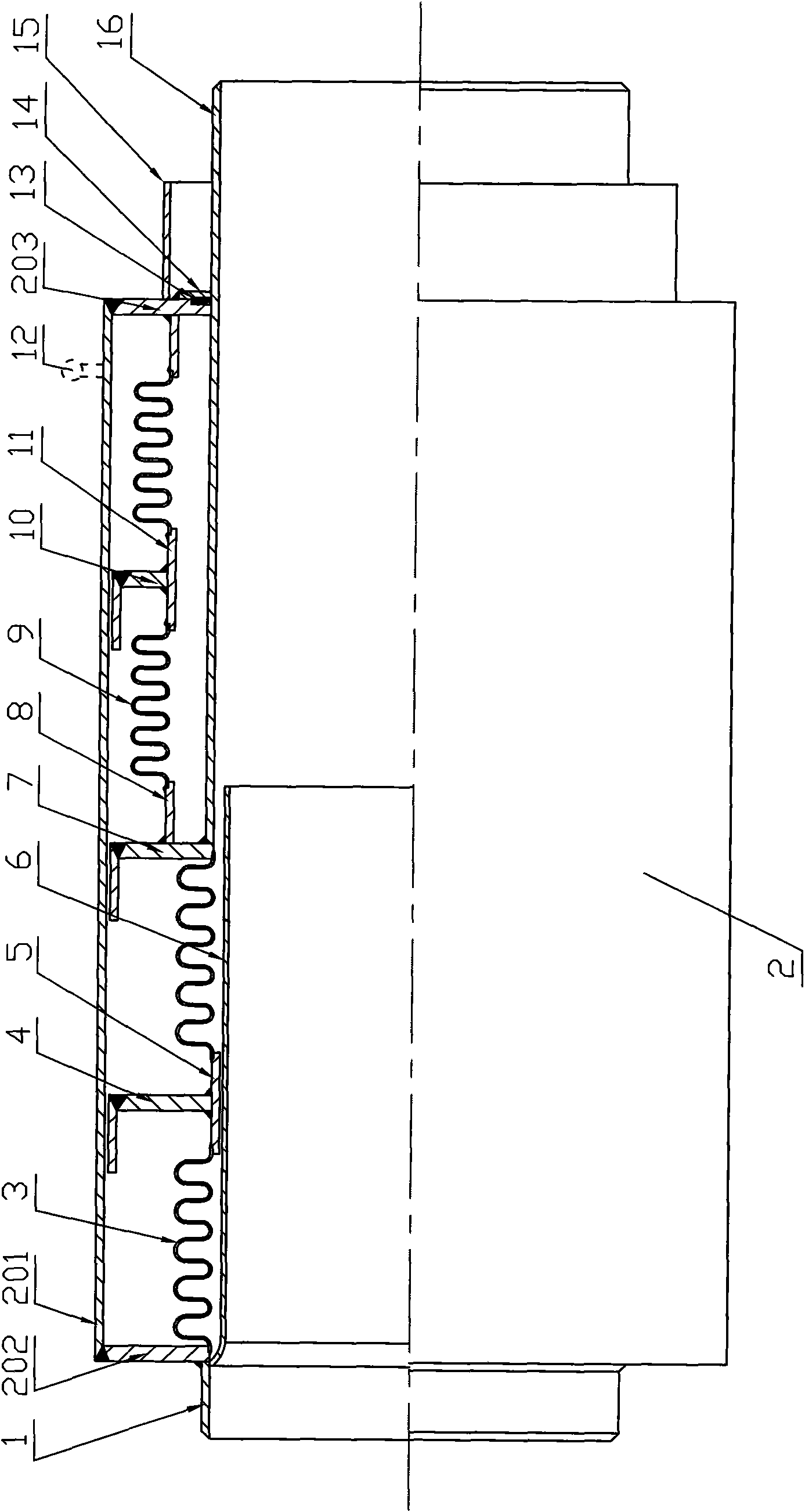

Corrugation self-check double-protection compensator

InactiveCN101672406AExtended service lifeAvoid harmPipeline expansion-compensationCorrosionSelf checking

The invention discloses a corrugation self-check double-protection compensator. The compensator comprises an operating corrugated pipe, both ends of the operating corrugated pipe are provided with aninlet end pipe and an outlet end pipe respectively, a draft tube and an external protection tube are provided in and outside the corrugated pipe respectively. The compensator is characterized in that:a connection flange is welded between the operating corrugated pipe and the outlet end pipe, a protective corrugated pipe is connected between the connection flange and the external protection tube,and the protective corrugated pipe is sheathed on the outlet end pipe, and the external protection tube is fixedly provided with a leak detection device. The compensator has the advantages of being capable of ensuring flow quantity and flow rate of media, the protective corrugated pipe act sealing effect to protect the operating corrugated pipe from corrosion by external sewage and impurities, thus prolonging service life of the compensator; the compensate can continue work even the operating corrugated pipe present leakage, thus providing double protection; the protective corrugated pipe hasprotection and compensation effect, thus being capable of avoiding environment hazards caused by media leakage, so the compensator is especially applicable to pipes for conveying toxic and harmful dangerous media.

Owner:锦州中德波纹管件制造有限公司

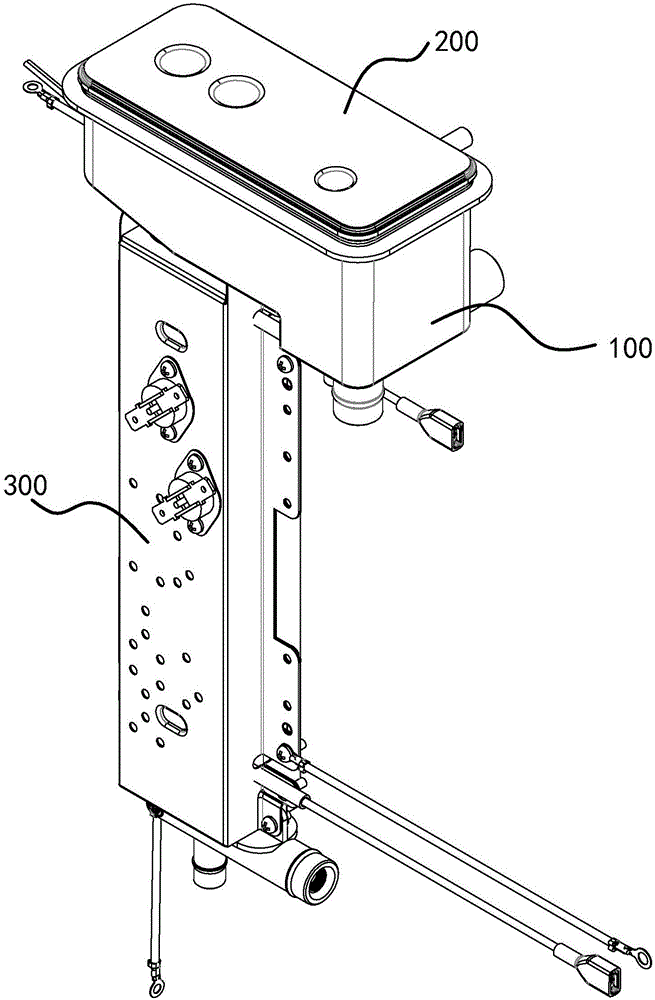

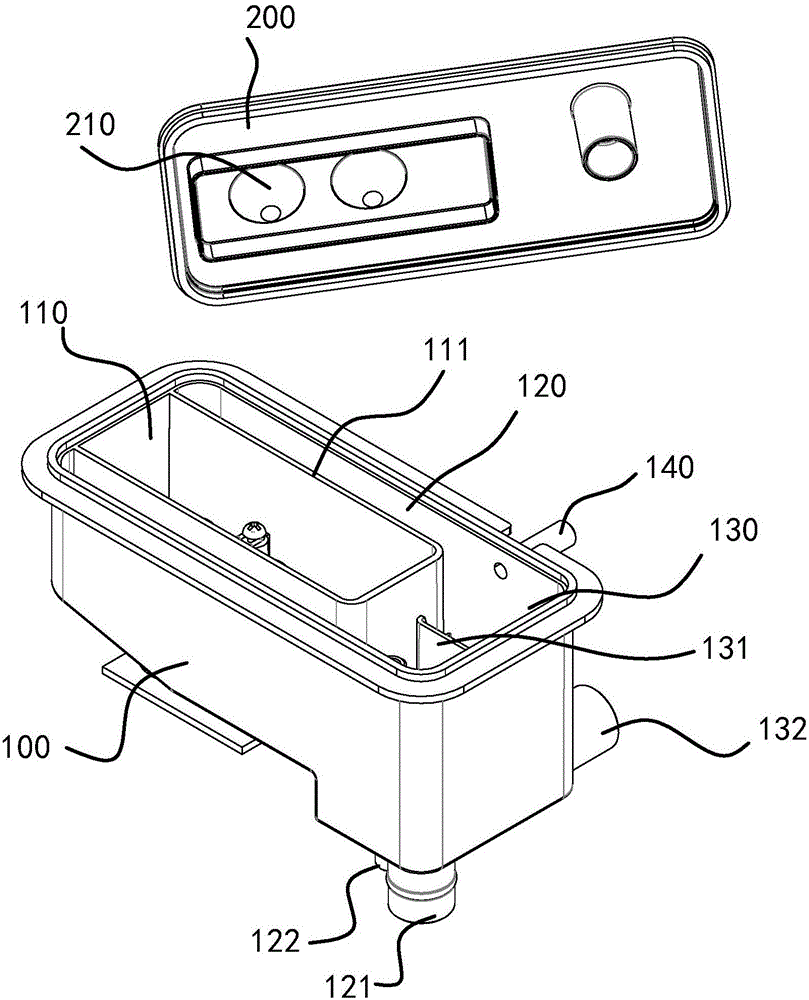

Water tank structure of instant heating water dispenser

The invention provides a water tank structure of an instant heating water dispenser, and aims to solve the technical problem that an existing water tank structure of an instant heating water dispenser is simple and poor in steam-water separating effect. The water tank structure comprises a water tank body and an end cover, the water tank body comprises a water level chamber, a steam and water separating chamber, a water return chamber and a steam outlet, the water level chamber is positioned in the middle of the water tank body, a cold water inlet and a cold water outlet are formed in the water level chamber, the steam and water separating chamber and the water level chamber are separated by a first partition, the water level chamber encircles the steam and water separating chamber, a hot water inlet and a hot water outlet are formed in the steam and water separating chamber, the first partition is lower than the water level chamber, the water return chamber and the water level chamber are separated by a second partition, the second partition is lower than the first partition, and a reflow opening is formed in the water return chamber. The water tank structure has the advantages of good steam-water separating effect and water level control effect.

Owner:宁波云川环保科技有限公司

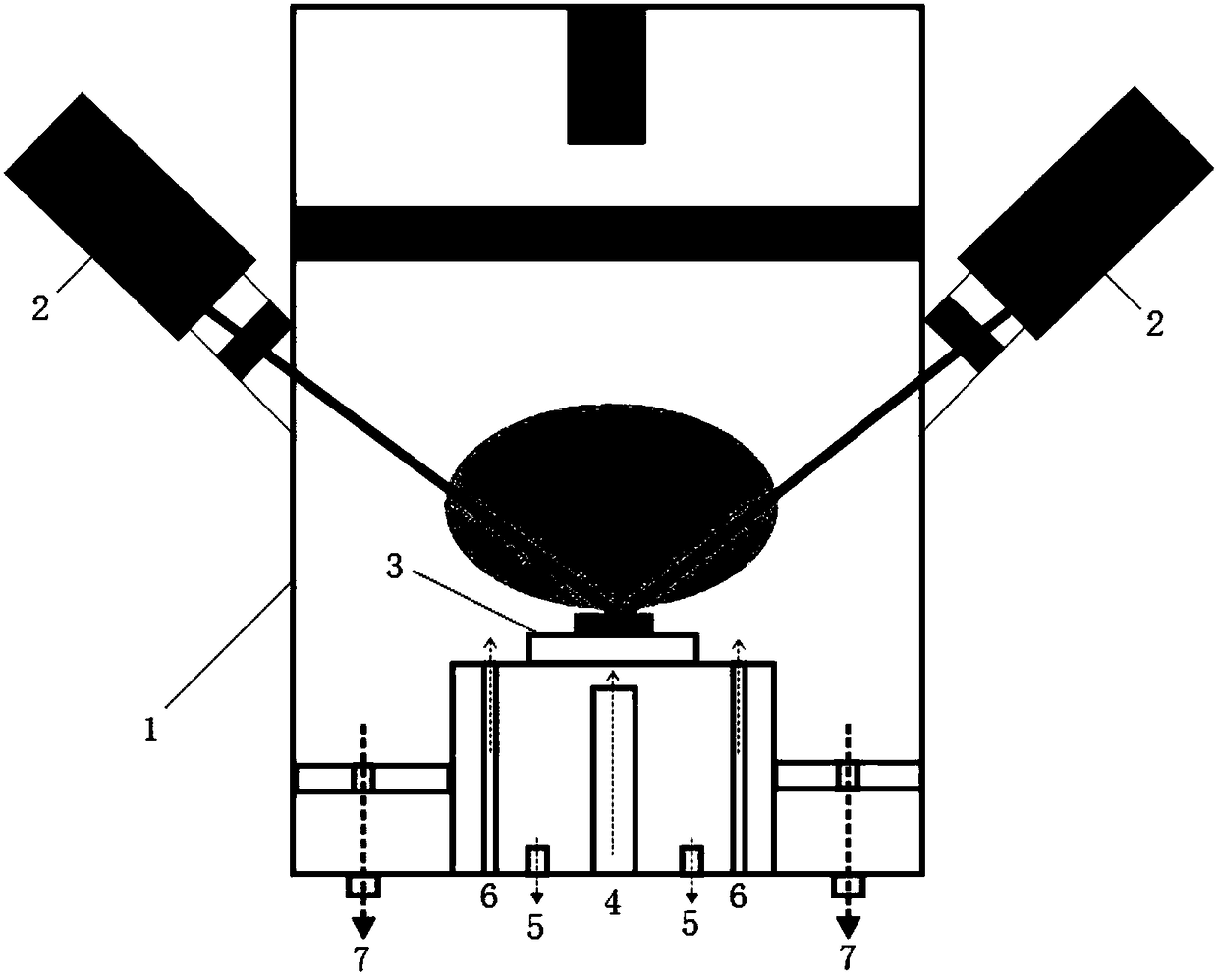

Device and method for preparing single crystal diamonds by laser enhanced plasma CVD

ActiveCN108251892AHigh densityIncrease dissociation ratePolycrystalline material growthFrom chemically reactive gasesMicrowaveSingle crystal

The invention discloses a device and method for preparing single crystal diamonds by laser enhanced plasma CVD. The device comprises plasma CVD equipment and laser equipment, wherein more than 1 set of laser equipment is respectively positioned on the outside of a cylindrical cavity of the plasma CVD equipment, laser emitted by the laser equipment can irradiate onto a substrate table positioned inthe cavity of the plasma CVD equipment; the substrate table is positioned in the middle of the cavity of the plasma CVD equipment, a cooling water circulation system is arranged at the lower part ofthe substrate table and comprises a cooling water inlet and a cooling water outlet; and a raw material gas inlet and an extraction opening are formed in the bottom of the cavity of the plasma CVD equipment. The method combines microwave energy (or electric energy) with laser energy and improves the energy of plasma and the gas dissociation rate in a diamond synthesizing process by using low-cost high-energy laser, thereby improving the synthetic rate of the diamonds and effectively solving the problem of high-speed mass preparation of diamonds.

Owner:湖北碳六科技有限公司

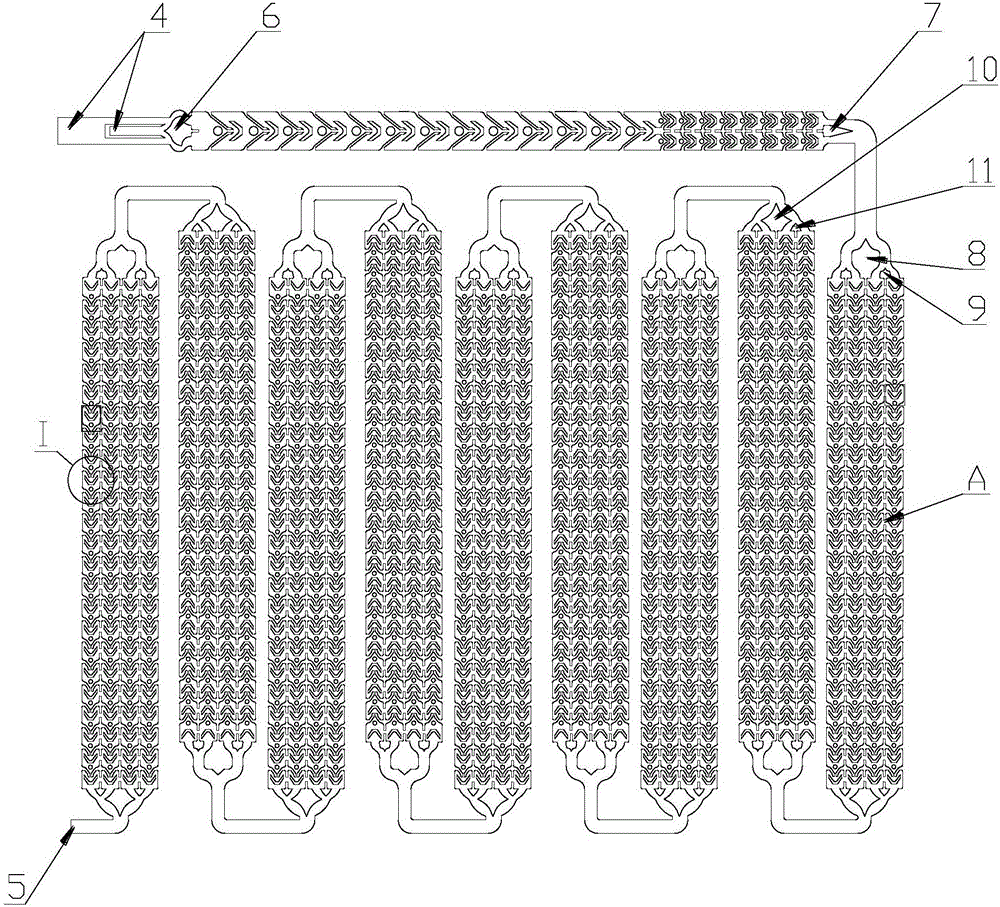

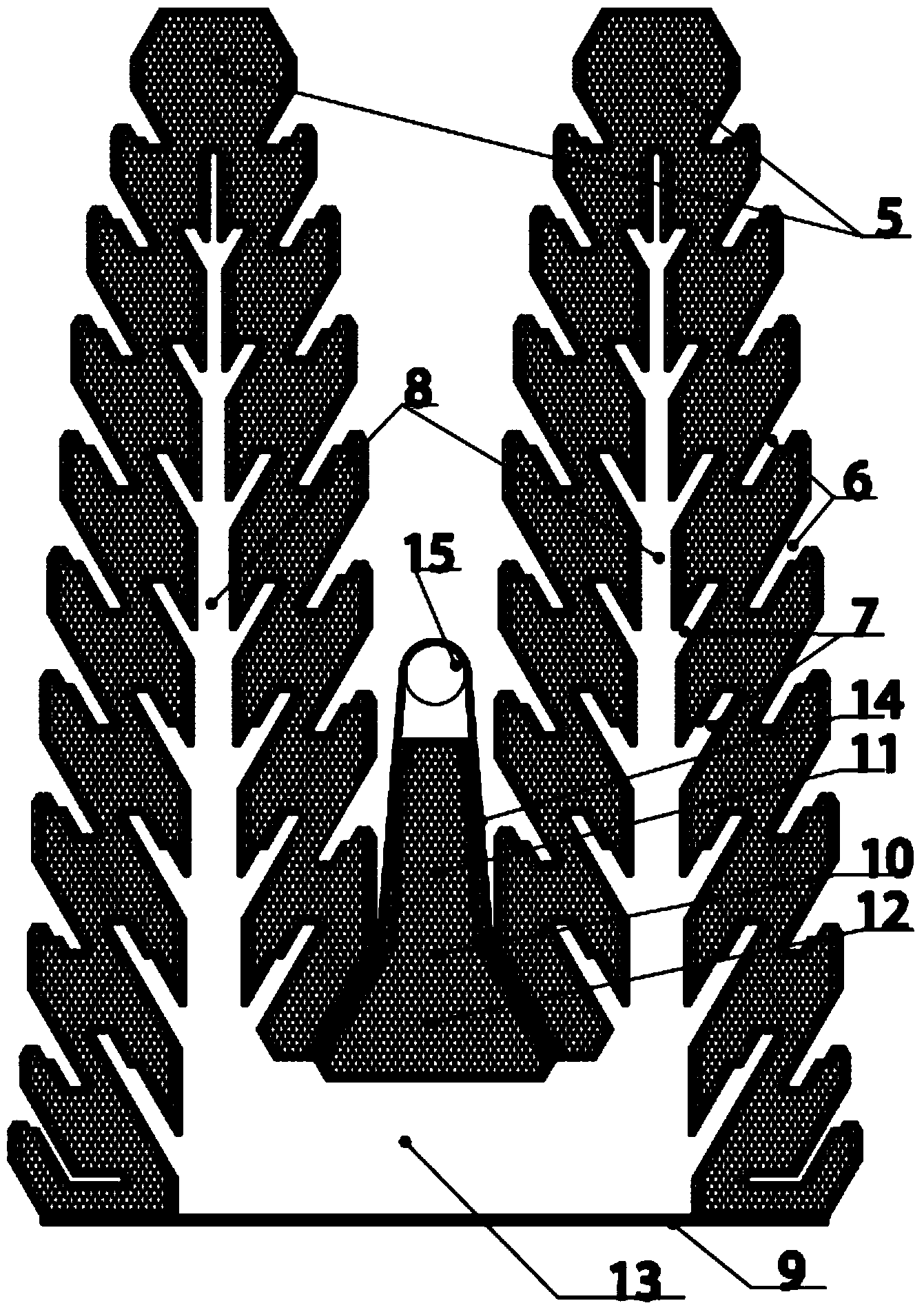

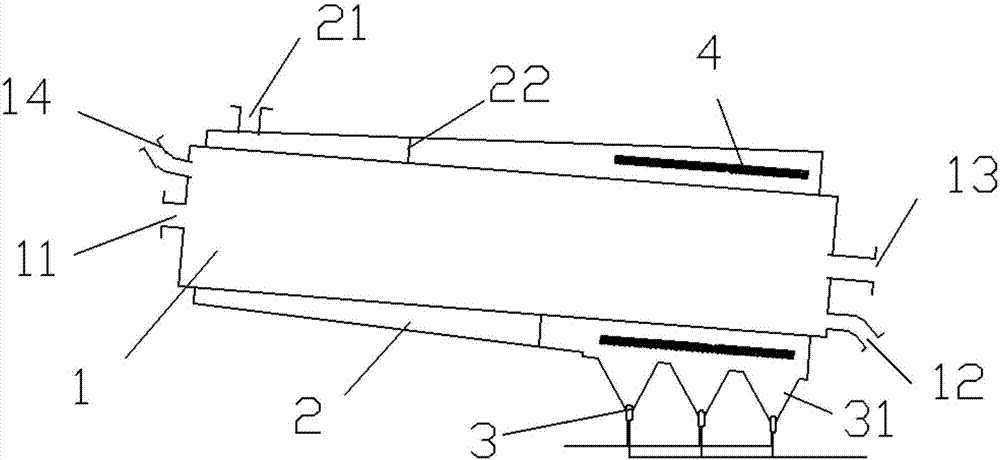

Narrow-band concurrent steam condenser tube bundle with dual-trapezoid air cooling region

ActiveCN104266501ASmall vapor resistanceSpeed up the flowSteam/vapor condensersEngineeringNarrow band

The invention relates to a narrow-band concurrent steam condenser tube bundle with a dual-trapezoid air cooling region. The tube bundle comprises two main condensing regions and the air cooling region between the two narrow-band concurrent main condensing regions, wherein all the main condensing regions and the air cooling region are formed by arranging cooling water tubes in a staggering manner; the outer edges of the main condensing regions are provided with a plurality of reducing steam guide passages which tilt upwards, and the inner edges of the main condensing regions are provided with a plurality of uncondensed gas collection passages which tilt downwards; the steam guide passages and the uncondensed gas collection passages are arranged in the staggering manner to partition the main condensing regions into turned narrow-band ribbons; the air cooling region is integrally elongated and consists of an upper trapezoid and a lower trapezoid; steam uniformly and concurrently flows into the main condensing regions for condensation through the guide passages, and the remaining uncondensed gas flows into the elongated air cooling region for further cooling through the uncondensed gas collection passages. Compared with the prior art, the tube bundle has the advantages of small steam resistance, full condensation, high air concentration at an outlet and capability of exhausting uncondensed gas by using exhaust equipment under low exhaust pressure without increasing the pressure of a steam condenser.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

Control method of dynamic water-pressure drip-irrigation system

ActiveCN101449654BAvoid cloggingLow running costLiquid fertiliser distributionClimate change adaptationWater sourceSolenoid valve

Owner:HUAZHONG UNIV OF SCI & TECH

Method for extracting orientin from bamboo leaf

The invention provides a method for providing active compound orientin with myocardium nourishing function from bamboo leaf. The method is characterized in that bamboo leaf raw material is smashed, the smashed bamboo leaf is added into 8-12 times alkaline water containing borax, heating extraction is carried out for 2-3 times, extracting solution is acidized and then is added into a polyamide chromatographic column, ethanol-water mixed solvent is used for elution, eluent is concentrated, butyl alcohol is used for extraction for 2-3 times, an ODS silicagel column is used for separation, methyl alcohol-water-acetic acid mixed solvent is used for pressurization and elution, thin-layer chromatography monitoring is carried out, orientin fraction is collected, and vacuum drying is carried out, thus obtaining the product. The method has simple operation, high product content and good repeatability.

Owner:NANJING ZELANG MEDICAL TECH

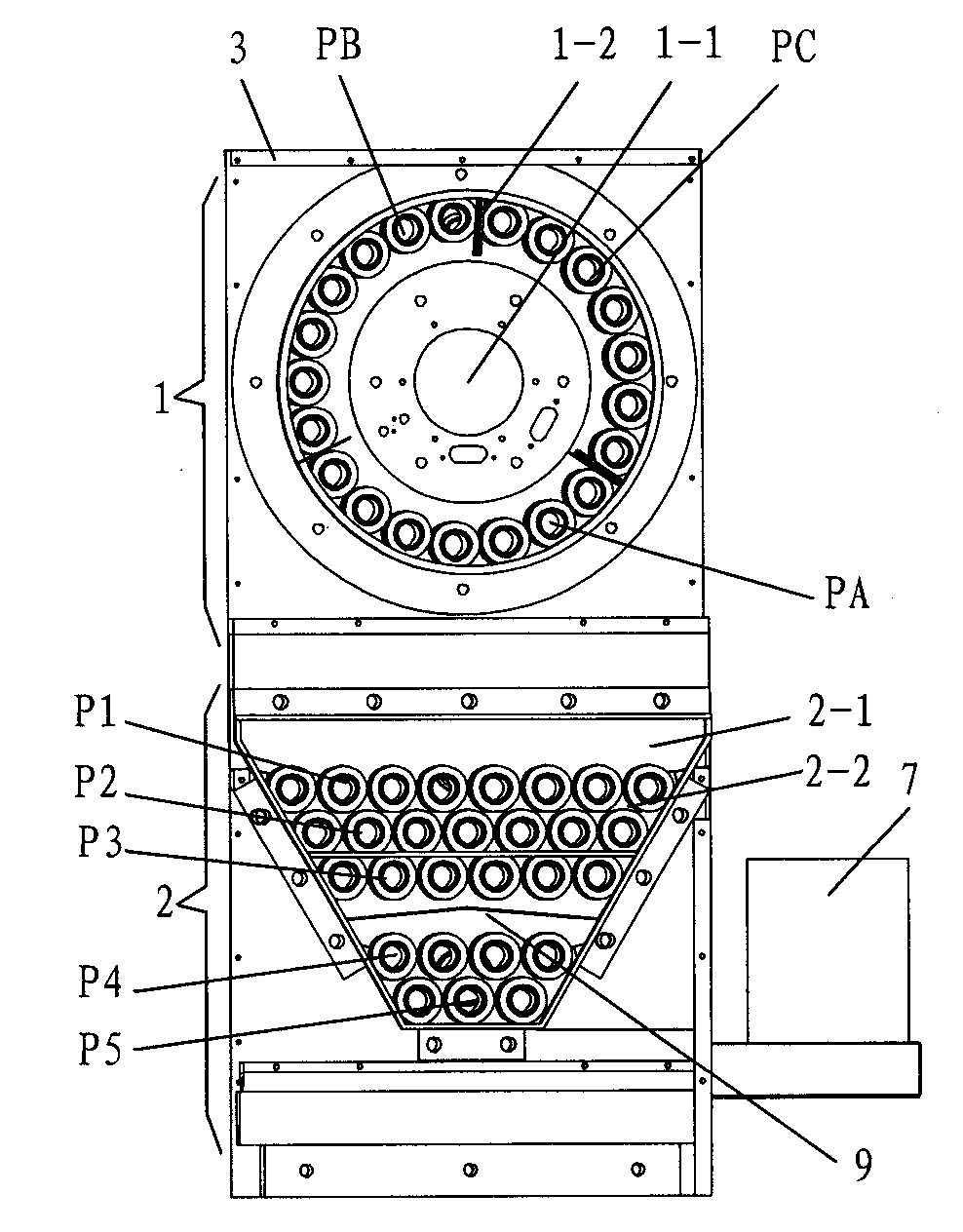

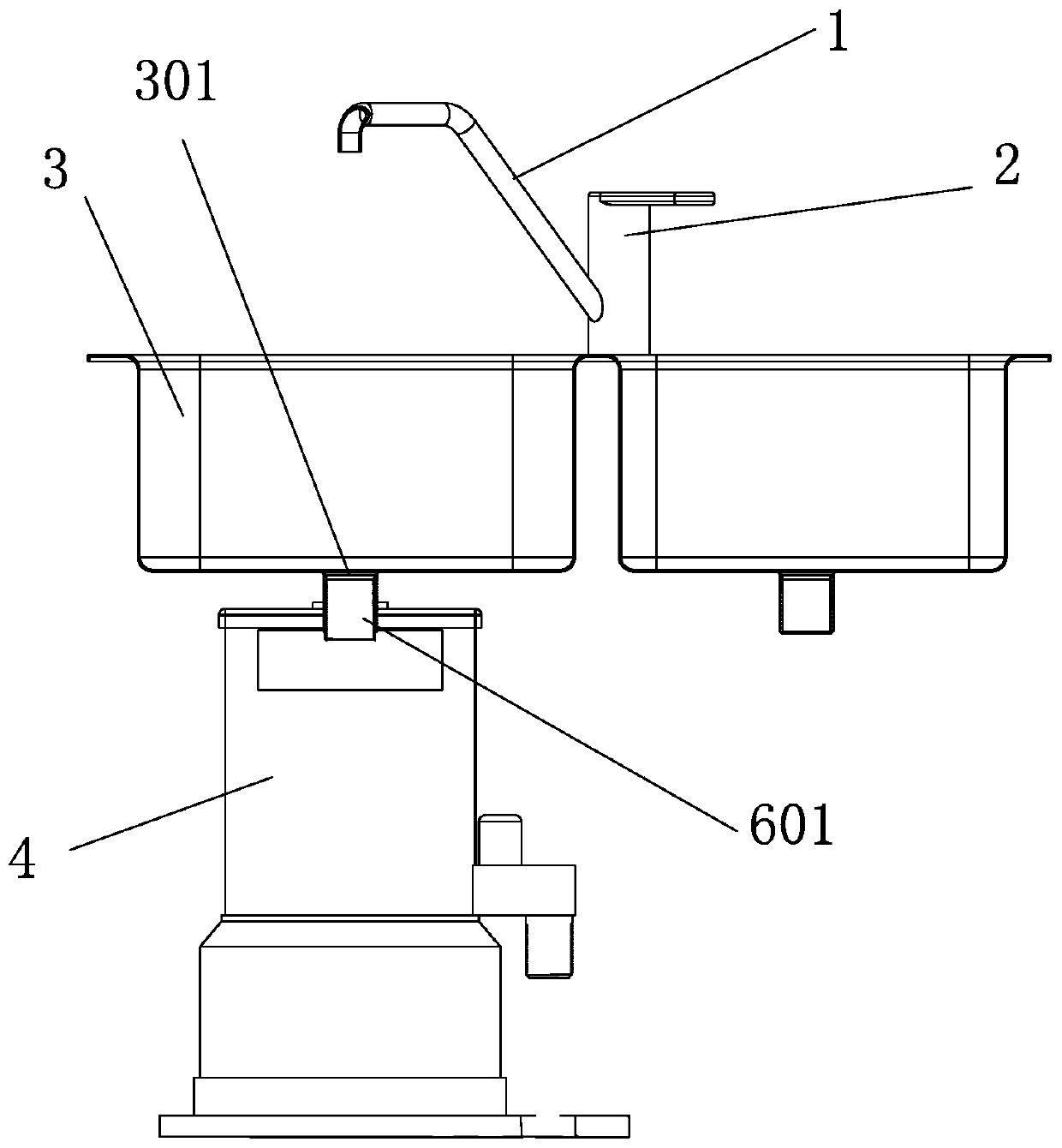

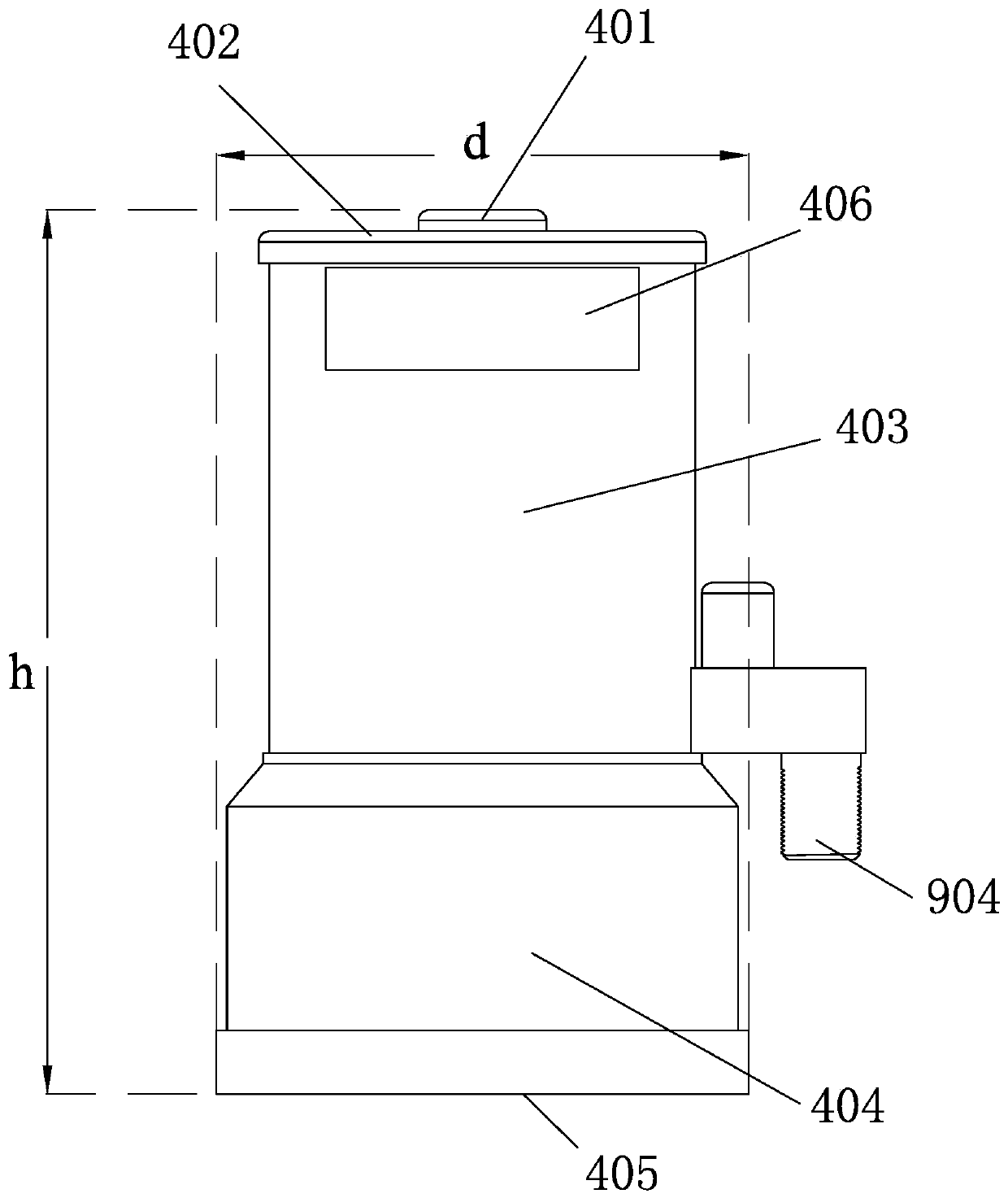

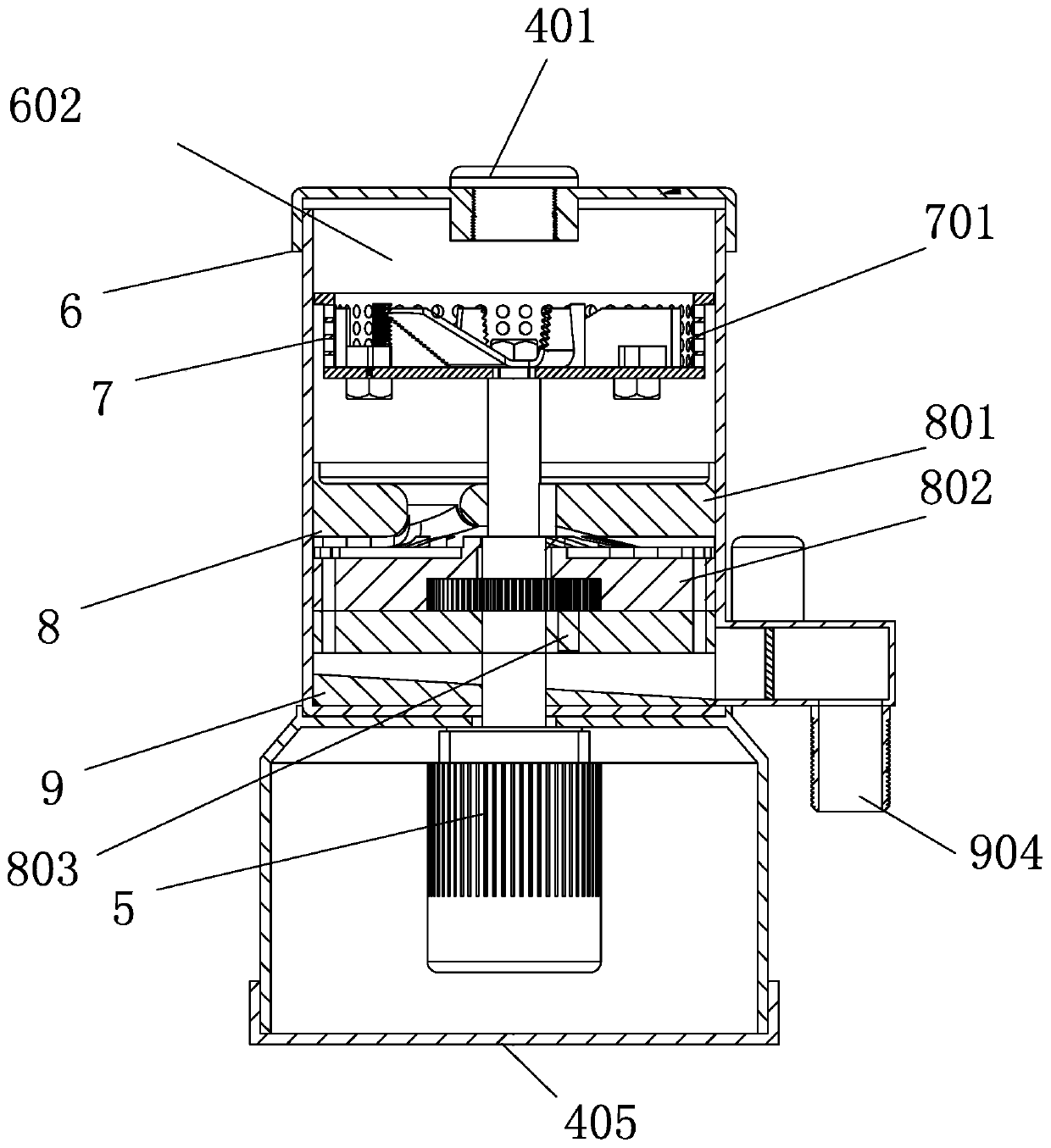

Crushing-grinding-disc-type kitchen waste processor and treatment method thereof

The invention discloses a crushing-grinding-disc-type kitchen waste processor and a treatment method thereof, and belongs to the technical field of waste treatment. The crushing-grinding-disc-type kitchen waste processor comprises a feeding device, a sealing plug, an upper cover, a cylinder, a base, a bottom disc, a maintenance cover, a motor, a driving shaft, a crushing basket, four toothed crushing knives, three collision blocks, five ring cutting collision knives, an upper grinding disc, a lower grinding disc, a gear fixing disc, a slurry discharging inclined disc, a slurry discharging solenoid valve and a slurry discharging opening. The treatment method comprises a feeding layer, a crushing layer, a grinding disc layer and a waste discharging layer. According to the crushing-grinding-disc-type kitchen waste processor, collision crushing is conducted on the kitchen waste, and grinding disc grinding crushing is conducted on the kitchen waste into a slurry dilution flow to be discharged; and the crushing-grinding-disc-type kitchen waste processor has the beneficial effects that the kitchen waste develops towards the direction of reduction, recycling and harmlessness, collision crushing and grinding disc grinding crushing are conducted on the kitchen waste into a slurry dilution flow so as to be suitable for being discharged to a municipal sewage system in China for treatment.

Owner:NINGBO DONGDA AIR CONDITIONING EQUIP

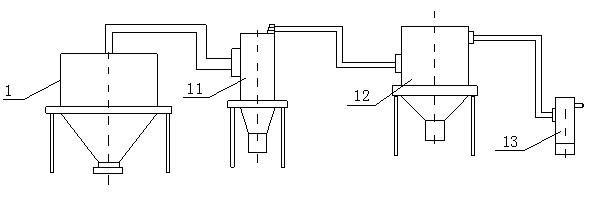

Radiation type rotary drying device for waste salt treatment

PendingCN107062836AEvenly heatedStable temperatureDrying machines with non-progressive movementsDrying solid materialsCombustorFlue gas

The invention discloses a radiation type rotary drying device for waste salt treatment. The radiation type rotary drying device comprises a rotary material cylinder. A heating jacket is arranged on the outer side of the rotary material cylinder. The heating jacket and the rotary material cylinder are the same in inclination direction and inclination angle. A burner is arranged below the lower end of the heating jacket. A flame spray opening of the burner is connected with an inner cavity of the heating jacket. A heat radiation plate is arranged in the heating jacket. A heat jet opening of the burner directly faces the heat radiation plate. Compared with the prior art, the radiation type rotary drying device has the following beneficial effects that the energy of flames is absorbed by the heat radiation plate, and then the heat is transmitted to the rotary material cylinder in a heat radiation manner, so that the rotary material cylinder is uniformly heated, and the temperature is quite constant; the heating jacket is fixedly arranged, and a rotary cylinder body rotates in the heating jacket, so that the heating of the whole rotary cylinder body is consistent in the radial direction; and the flue gas flow speed can be guaranteed due to the special design of the shape of the heating jacket, the thickness of a stagnant layer is reduced, and the heat transfer efficiency is improved.

Owner:安徽今朝环保科技有限公司

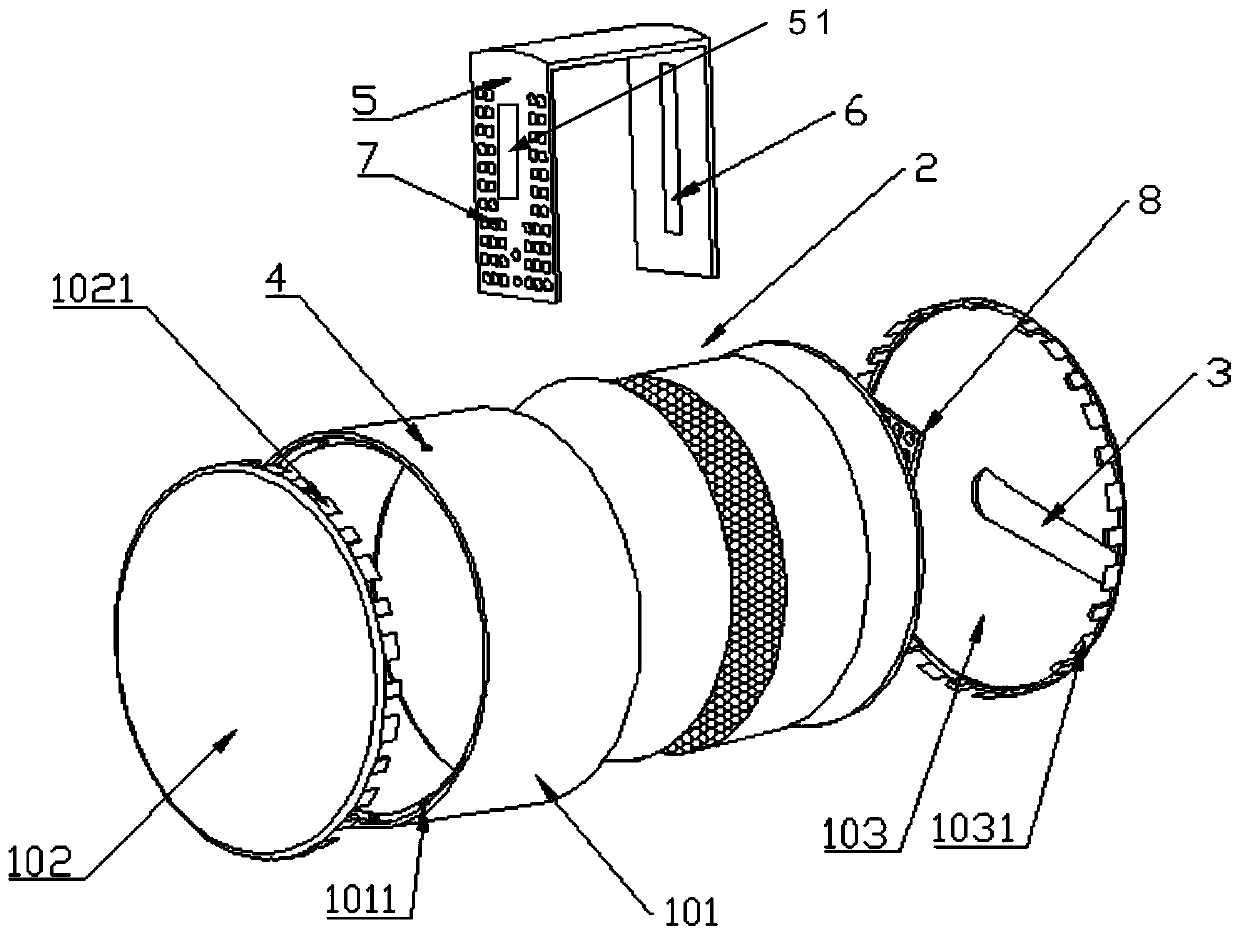

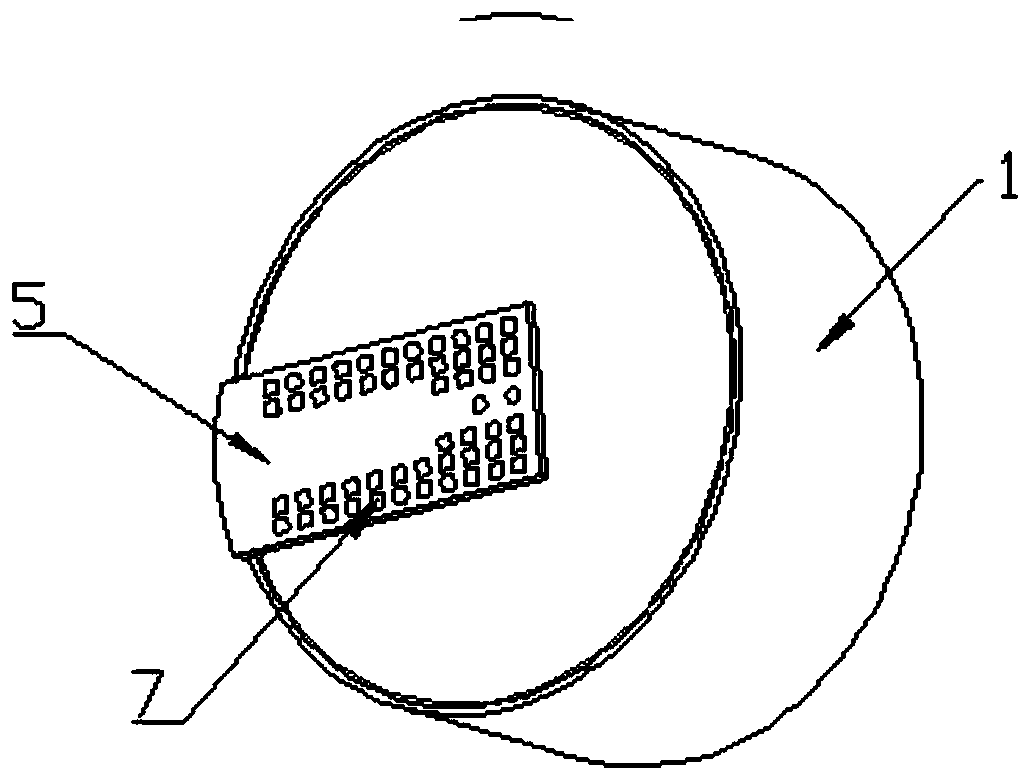

Special rotating printing integral ink box for seal printing

The invention discloses a special rotating printing integral ink box for seal printing. The special rotating printing integral ink box for seal printing comprises an ink box body with a cylindrical orcylindroid outer contour; a spray head with a circuit board is arranged outside the ink box body, and the circuit board is integrated with contacts; and the rotating fixed surface of the ink box bodyis parallel to the rotating injection surface of the spray head. According to the special rotating printing integral ink box for seal printing, the ink box body is designed into a regular shape, thewhole printing equipment can be adaptive with the design of the ink box to be of the regular shape, and the whole printing equipment is more miniaturized and portable through the design of the ink boxin such form; the effective length of an ink outlet and the spray head is equal to the vertical distance between the edge of the cross section of the ink box body and the center of the cross sectionof the ink body or twice of the vertical distance, and graphic printing can be completed just by rotating the ink box by 180 degrees or 360 degrees, so that the printing speed and printing efficiencyare improved.

Owner:HAIMING UNITED ENERGY GRP MATRIXNETS TECH CO LTD

High-efficiency step-by-step tea oil filtering device

InactiveCN108587779AGuaranteed qualityEnsure complete removalFatty-oils/fats refiningFiltration circuitsSolid particleImpurity

The present invention discloses a high-efficiency step-by-step tea oil filtering device, comprising a filter tank and a settling tank. A first filter screen, a second filter screen and an isolation plate are sequentially arranged in the inner cavity of the filter tank from left to right. A rotating shaft is arranged in the filter tank, and one end of the rotating shaft extends through the first filter screen and is fixedly connected to a cleaning brush which is matched with the second filter screen. Two discharge holes which are matched with the first filter screen and the second filter screenrespectively are formed in the bottom wall of the filter tank. The bottom end of the filter tank is fixedly connected to an oil residue tank. The top left side of the filter tank communicates with anoil inlet pipe. A stirring rod is arranged in the settling tank, and a plurality of connecting rods are uniformly arranged on the stirring rod, with the other end of each connecting rod hinged to a first stirring blade. According to the present invention, the first filter screen and the second filter screen are arranged to filter raw oil, thereby removing impurities and other solid particles in tea oil. The settling tank is arranged to allow the filtered oil to further settle, thereby guaranteeing complete removal of impurities from tea oil and ensuring the quality of the tea oil.

Owner:余慧文

Air flue type PTC heater

InactiveCN109458737AEasy to useExtended service lifeDispersed particle filtrationAir heatersMoistureFlue

The invention discloses an air flue type PTC heater. The air flue type PTC heater comprises a square air pipe. A fan and at least one set of heating areas are arranged in the square air pipe. A filtering net used for filtering out dust and moisture is arranged on an air outlet of the fan. Each heating area comprises a plurality of PTC heating plates arranged obliquely, wherein a ventilation interval for passing of airflow is arranged between every two adjacent PTC heating plates. The filtering net is arranged on the air outlet of the fan of the air flue type PTC heater, dust, particles, moistand the like in the air can be removed, dust accumulation and dirt formation on the PTC porous heating plates in the heating areas and the inner wall of the square air pipe are prevented, the influence of dust accumulation on heating efficiency is reduced, the dust removing frequency and maintenance cost are reduced, the quality of heated air is improved, and meanwhile the heating efficiency is improved.

Owner:JIANGSU JIUZHOU ELECTRIC APPLIANCE CO LTD

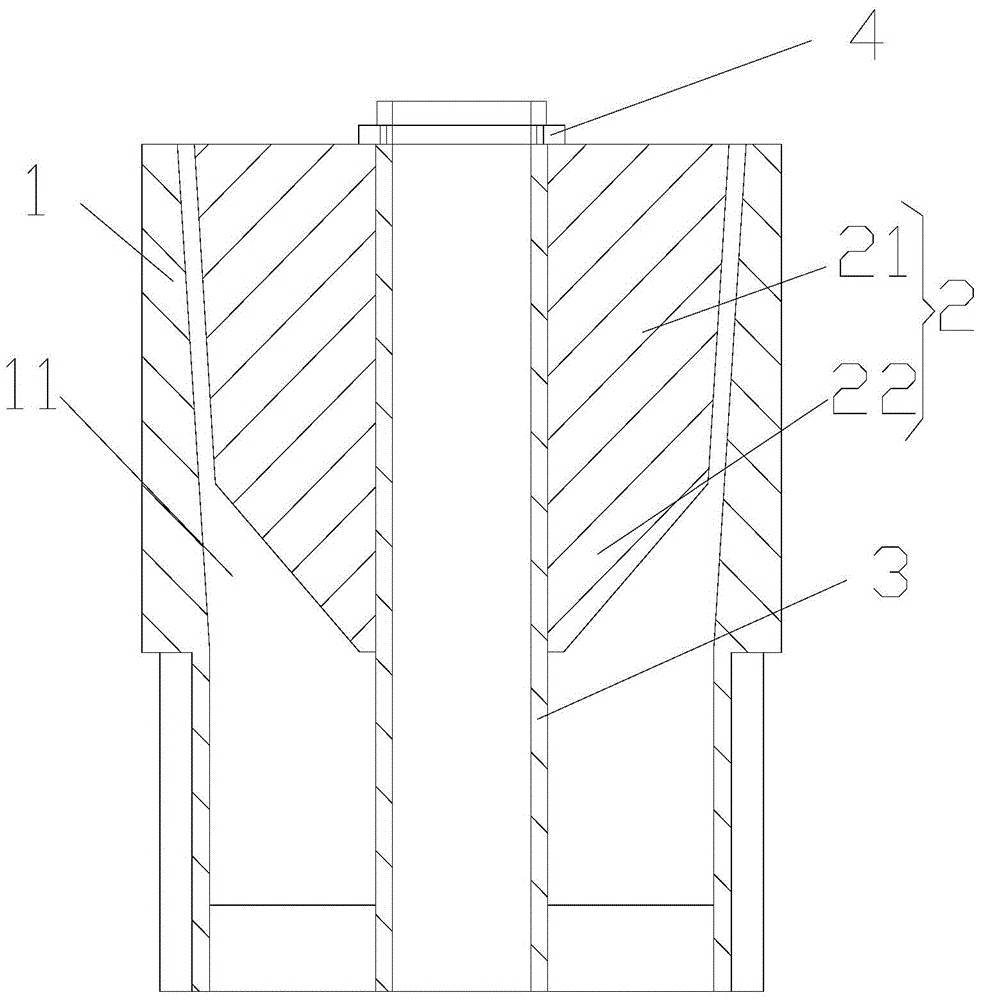

Nozzle

ActiveCN104401998ARealize the function of self-adjusting flow rateReduce flow rateSilicon compoundsEngineeringNozzle

The invention provides a nozzle. The nozzle comprises a nozzle body and a floater, wherein a conical cavity which allows fluid circulation is formed inside the nozzle body; the floater comprises a floater body; a circulation gap from which the fluid flows out is formed by the outer circumferential surface of the float body and the inner circumferential surface of the cavity; the floater is movably arranged relative to the nozzle body in the direction of a connecting line of the inlet end of the cavity and the outlet end of the cavity and tends to move to the inlet end of the cavity; when the floater moves in the direction from the inlet end to the outlet end, the circulation gap is gradually enlarged. When the flow of the fluid entering the inlet end of the cavity is higher, the floater moves in the direction from the inlet end to the outlet end under the action of the impact force of the fluid, and the circulation gap is gradually enlarged, so that the flow speed is effectively decreased; when the flow of the fluid is lower, the circulation gap is smaller, so that the flow speed of the fluid flowing out of the circulation gap is guaranteed favorably, and the function of automatically regulating the flow speed by the nozzle according to the flow magnitude of the fluid is achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

Hydraulic turbine generator

InactiveCN104775970AIncrease specific speedIncrease loading capacityHydro energy generationEngine componentsWater flowEngineering

The invention discloses a hydraulic turbine generator. The hydraulic turbine generator comprises a hydraulic turbine room and a power generation room; the hydraulic turbine room is provided with a water inlet and a water outlet that have equal calibers and overlapped axes, and are opposite in the directions; a rotating wheel is arranged in the hydraulic turbine room; the rotating wheel is composed of a wheel disc and a water bucket or blades; the hydraulic turbine generator further comprises a reducing pipe connected with the water inlet and an increasing pipe connected with the water outlet; between the inner wall of the hydraulic turbine room and a rotatable sweeping space of the rotating wheel, a design of uniform small clearances is adopted; the power generation room is arranged at the outer side of the hydraulic turbine room; preferably, a contraction angle of the reducing pipe is 15-30 degrees; preferably, the axial length of the reducing pipe is greater than the inside diameter of the large opening; the clearance between the inner wall of the hydraulic turbine room and the rotatable sweeping space of the rotating wheel is less than or equal to 1mm, and less than or equal to 0.5mm preferably. Compared with the prior art, the hydraulic turbine generator disclosed by the invention has the beneficial effects of greatly increasing the velocity of water flow which impacts the blades of the rotating wheel, raising a specific rotary speed and loading ability of the rotating wheel, and further improving power generation efficiency; and meanwhile, the hydraulic turbine generator further has the beneficial effects of keeping the velocity of tail water, and being convenient in mounting and the like.

Owner:卢润侨

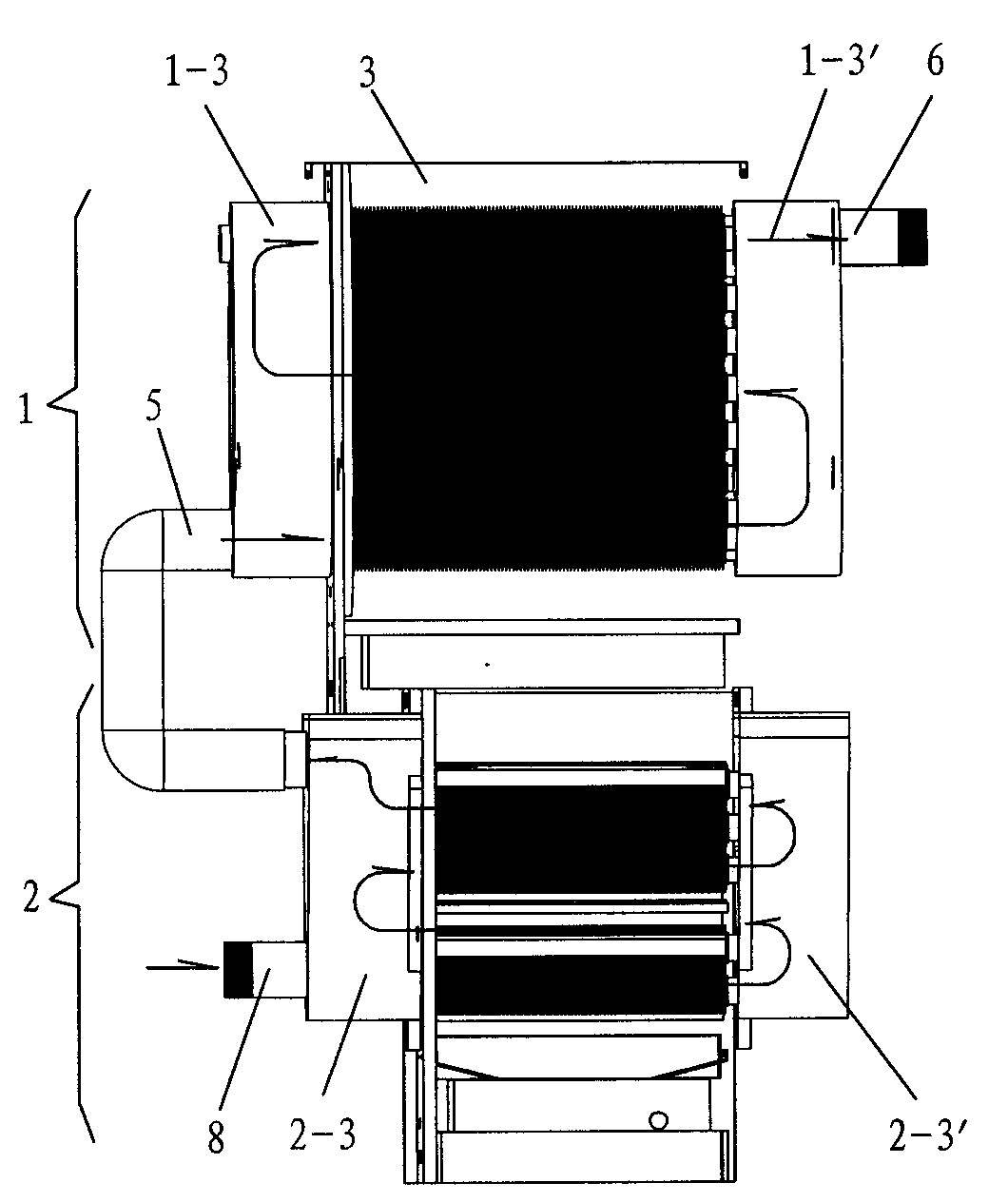

Clothes dryer with air purifying device

ActiveCN104674530AGuaranteed flow rateGuaranteed drying effectDispersed particle separationTextiles and paperComputer moduleProduct gas

The invention provides a clothes dryer with an air purifying device. The clothes dryer with the air purifying device comprises an air channel in which the air purifying device is arranged; the air purifying device comprises a housing, and a filtering module fixed in the housing; a reduced section is arranged one end of the housing; an air inlet is formed in the end part of the reduced section; an air outlet is formed in the other end of the housing. According to the clothes dryer with the air purifying device, the air purifying device is arranged in the air channel to purify air entering the air purifying device, so as to remove small and bacteria in the air; the reduced section is arranged to slow down the air entering the housing, thus the time of contacting with the filtering module is increased, and as a result, the air can be fully purified, and the purifying effect is good; meanwhile, an air purifying path extending into the housing and a straight air path directly passing through the air channel are arranged in the air channel of the housing, and therefore, part of the air in the air channel enters the purifying device, and air circulates in the air channel to remove the smell and bacteria in the clothes; meanwhile, the flowing speed of air in the whole air channel can be ensured.

Owner:HAIER GRP CORP +1

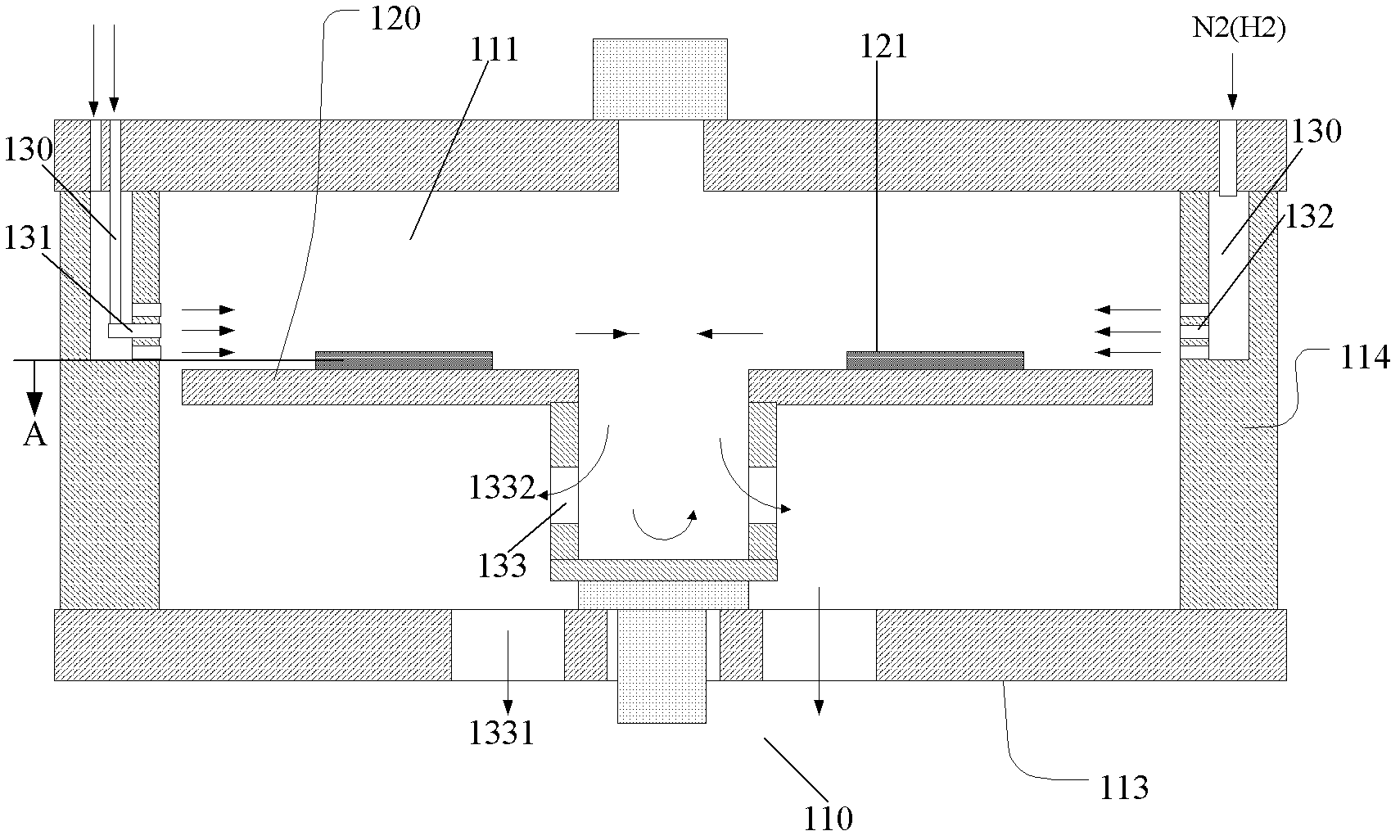

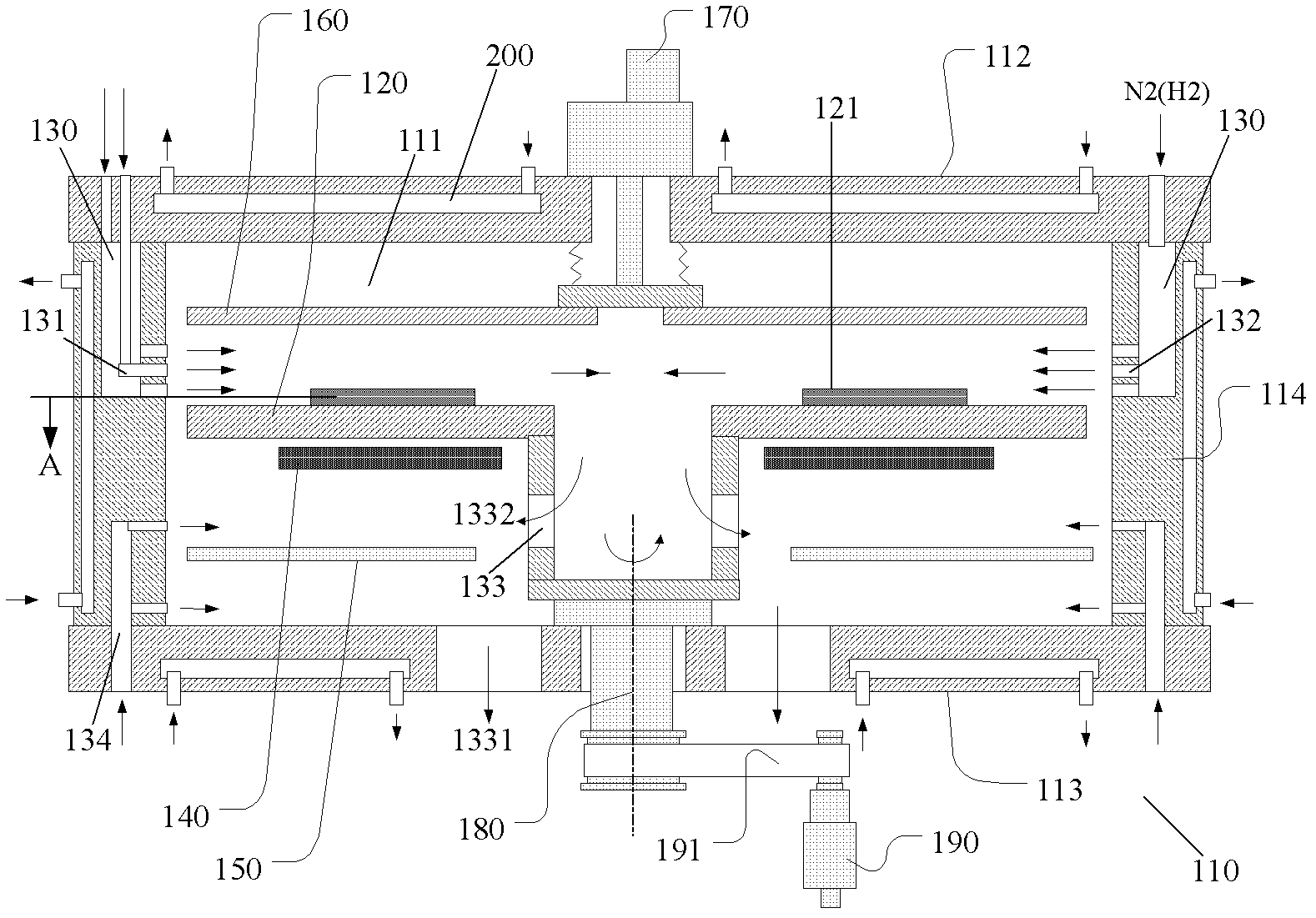

Reaction cavity device and substrate processing equipment with same

ActiveCN103031540AReduce flow rateIncrease profitSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

The invention provides a reaction cavity device. The reaction cavity device comprises a cavity body, a tray and a gas inlet device, wherein a reaction cavity is restricted in the cavity body, the tray is arranged in the reaction cavity and can rotate, and the gas inlet device is used for forming a first gas region and a second gas region which are mutually alternate in the cavity body; a process gas is fed into the first gas region, an isolation gas is fed into the second gas region, and a substrate on the tray alternatively passes the first gas region and the second gas region along with the rotation of the tray. The invention also provides substrate processing equipment. According to the reaction cavity device provided by the invention, the impact of byproducts generated after a reactant gas reacts on the film formation of the substrate can be effectively prevented. According to the substrate processing equipment provided by the invention, the impact of the byproducts of the reactant gas on the film formation of the substrate is reduced, process indexes for the film formation of the substrate are promoted, the utilization rate of the reaction gas can also be increased, and the utilization efficiency of the substrate processing equipment is increased.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

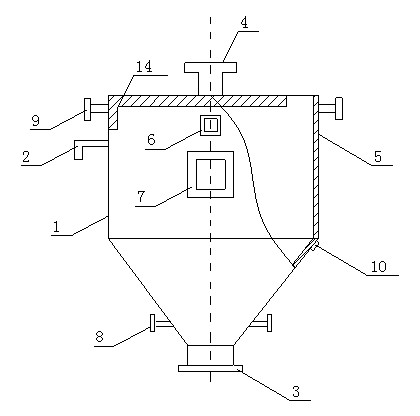

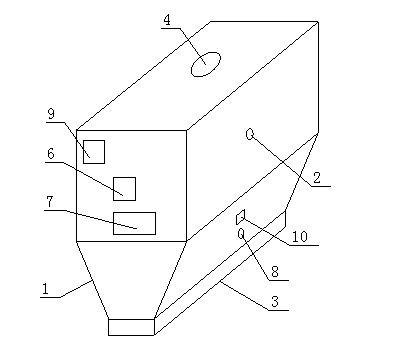

Glass microballoon manufacturing device and preparation method thereof

InactiveCN102417291APrevent molten buildupReduce devitrificationGlass shaping apparatusGlass productionDevitrificationCombustor

The invention discloses a glass microballoon manufacturing device comprising a furnace body (1) and a waste gas treatment device, wherein the furnace body (1) is formed by air-tight connection of an upper part and a lower part, the upper part of the furnace body is of a cubic shape, a waste gas emission port (4) is arranged at the top of the upper part, one or more injection-type burners (2) are horizontally installed on the side of the upper part, a preheating air pipe (14) is arranged in the upper part, the lower part of the furnace body is of a square conical shape, and one or more microballoon collectors (3) are arranged at the bottom of the lower part. According to the glass microballoon manufacturing device and the preparation method thereof provided by the invention, the furnace body which adopts the cubic structure enlarges the cooling space; the horizontally installed injection-type burners and the preheating air pipe arranged in the furnace body can give full play to the heat value of fuel, thus reducing energy source waste, saving energy and reducing emission; TiO2 and Al2O3 with relatively lower costs are adopted, the refractive index of the product is greater than or equal to 1.93; and the glass microballoon manufacturing device and the preparation method thereof have the advantages of reducing devitrification, improving the cooling velocity, having good product quality, improving the utilization ratio of raw material, being capable of large-scale production, and the like.

Owner:SICHUAN ZHONGKE BETTER TECH

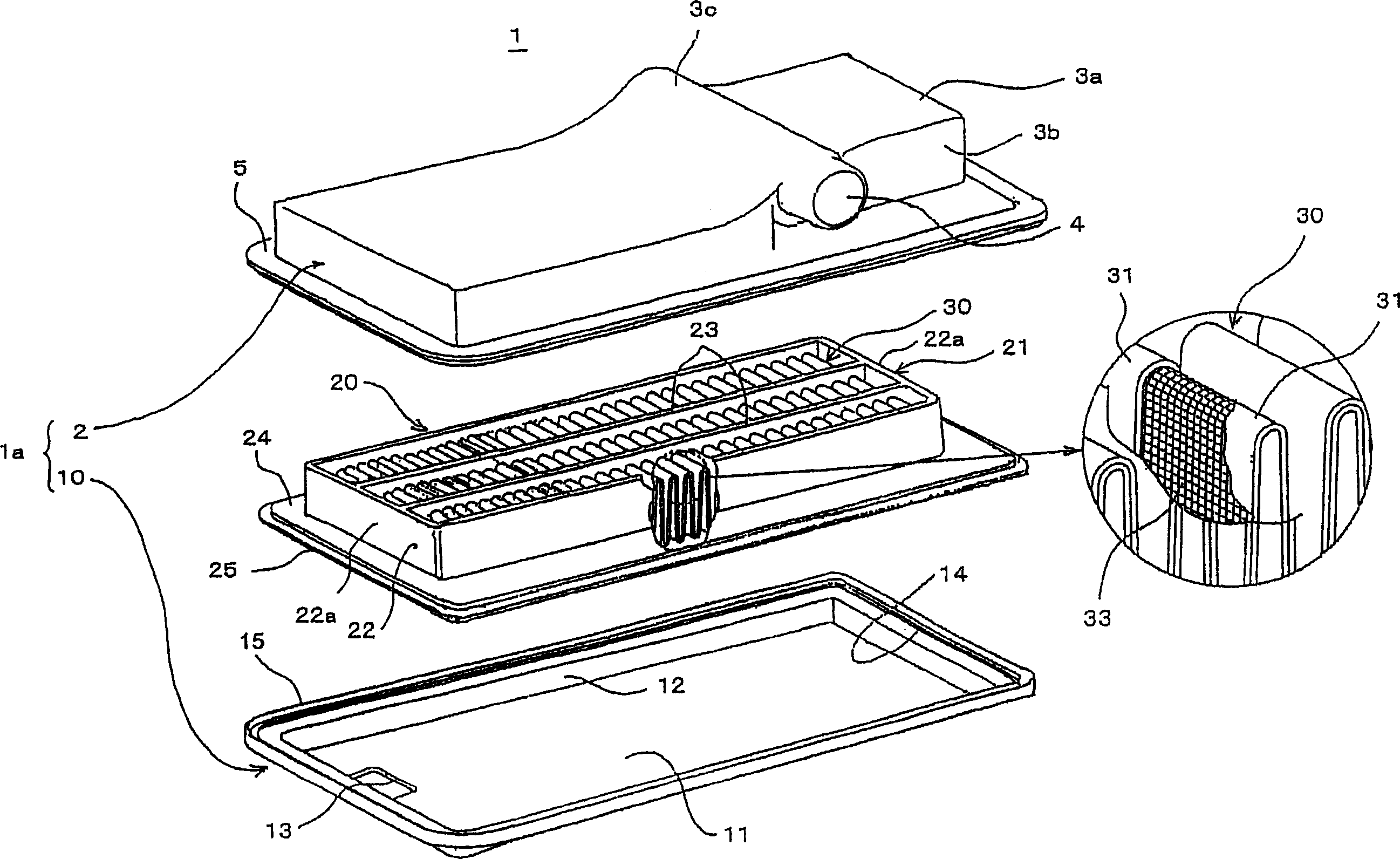

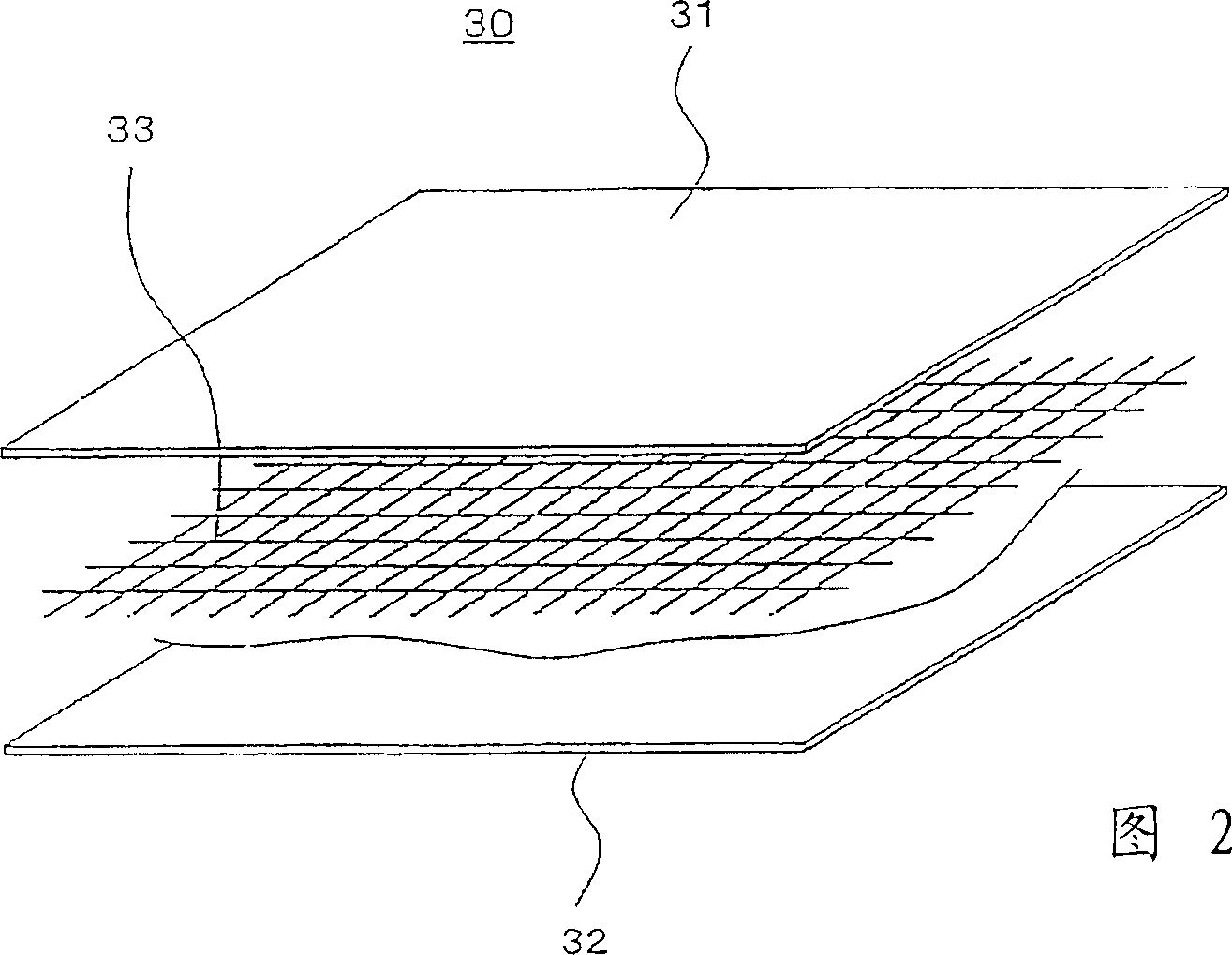

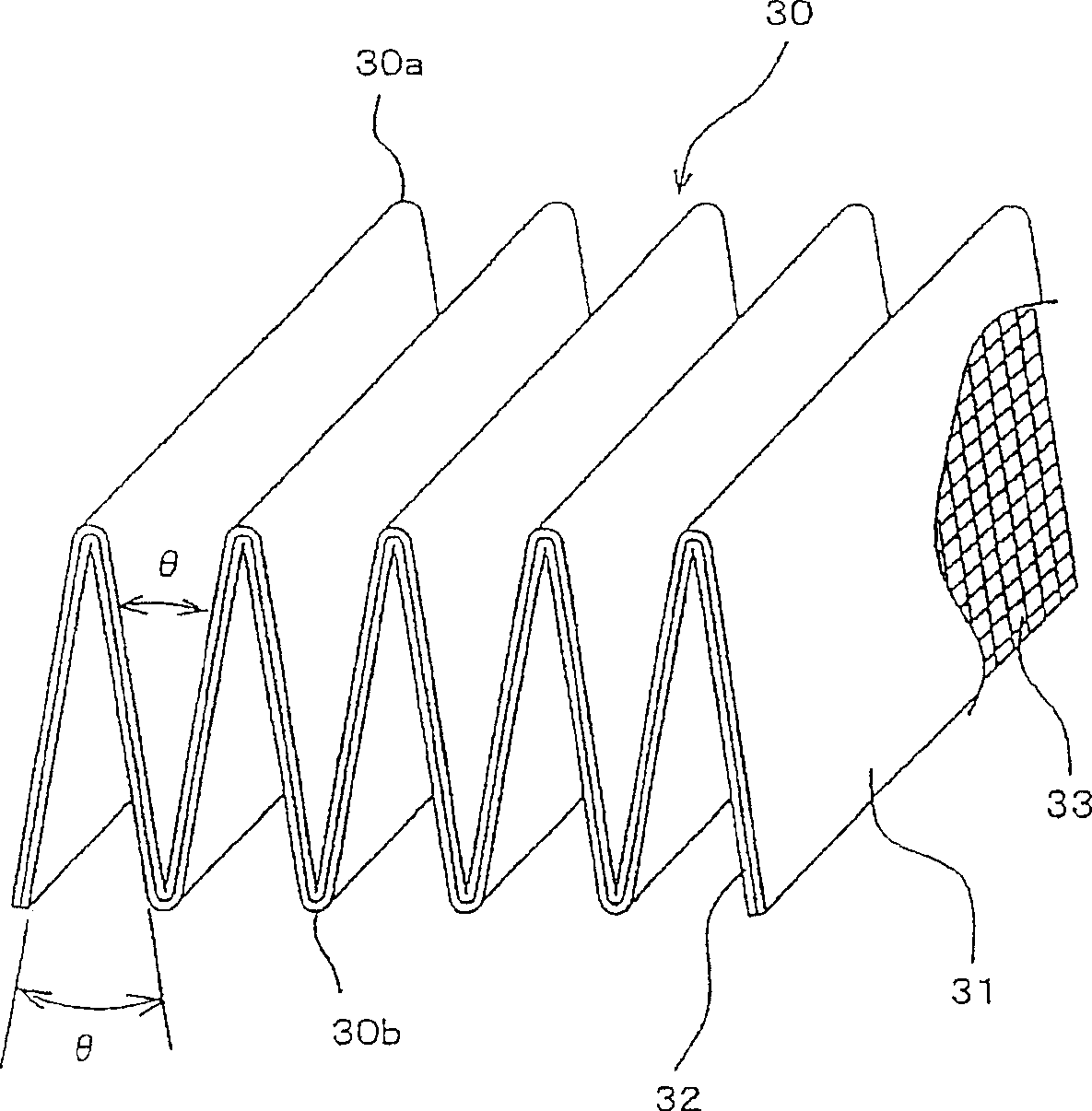

Filter element

InactiveCN1831381AInhibition of stickingAvoid normal workGear lubrication/coolingMembrane filtersFilter mediaEngineering

Owner:TOYO ROKI MFG CO LTD

Mud-and-water auto-separating pipeline apparatus

InactiveCN106039804ARealize automatic separationSuitable water for irrigationStationary filtering element filtersAgricultural irrigationWater flow

The invention discloses a mud-and-water auto-separating pipeline apparatus and belongs to the technical field of water conservancy transportation pipelines. The pipeline apparatus includes a water inlet pipe, a water outlet pipe and a drainage pipe and also includes a mud-and-water auto-separating part. The mud-and-water auto-separating part includes a cylindrical pipe body, wherein annular steps are formed on an inner side wall of the cylindrical pipe body. An inner fixing base is arranged under the annular steps. An annular groove is formed by the inner fixing base and the inner side wall of the cylindrical pipe body. An annular filter screen is disposed on the annular steps, wherein the top end of the annular filter screen is connected to the annular steps and the bottom end of the annular filter screen is connected to the inner fixing base. A clear water chamber is formed by the inner side wall of the cylindrical pipe body and an outer side wall of the annular filter screen. The water outlet pipe is communicated with the clear water chamber. The water inlet pipe is arranged on the side wall of the cylindrical pipe body and is arranged above the annular steps. The pipeline apparatus can automatically separate mud from water, wherein clear water flows out through the water outlet pipe while a mud and sand mixture is discharged through the drainage pipe. The pipeline apparatus is free of extra kinetic energy, is low in energy consumption and is suitable for agricultural irrigation.

Owner:张铁耀

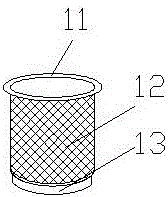

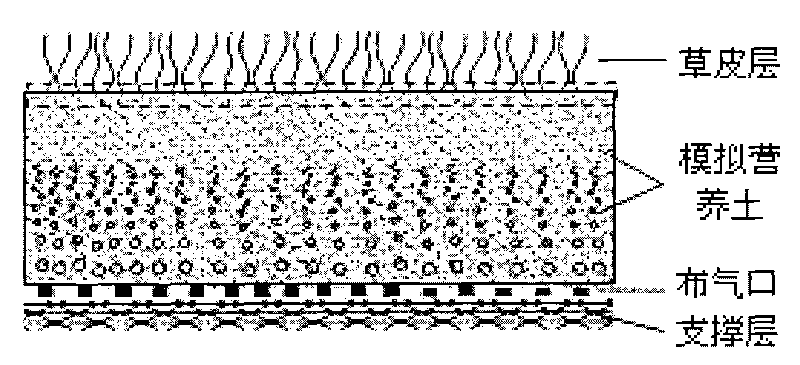

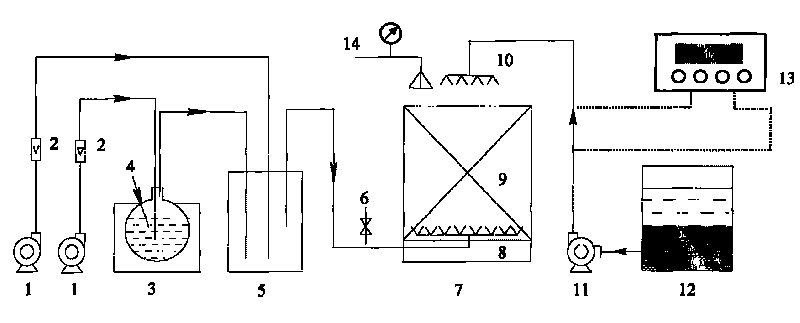

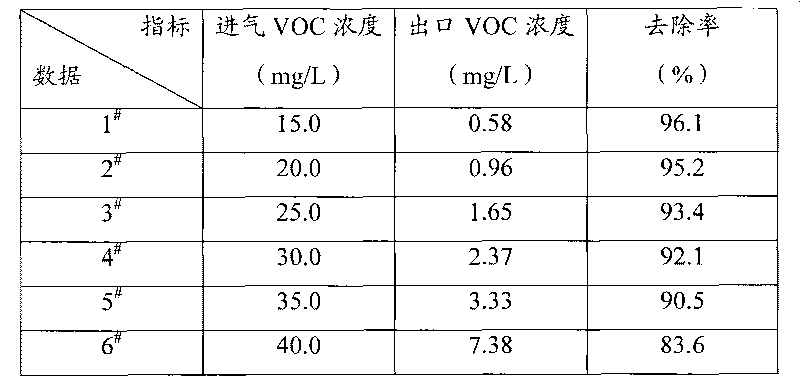

Method for biofiltration processing of soot exhaust gas on basis of roofing greening nutritive soil

InactiveCN101708425AGuaranteed flow rateBlock growthDispersed particle separationAir quality improvementBio filtrationNutrient solution

The invention provides a method for biofiltration processing of soot exhaust gas on basis of roofing greening nutritive soil, comprising the following steps: taking roofing greening vegetation and the nutritive soil thereof as biological filler; arranging a supporting layer and a gas distribution device below the biological filler; spraying nutrient solution onto the biological filler; and when liquid phase pH is 6.0-7.5 and temperature is 20-35 DEG C, processing soot exhaust gas. The method of the invention has the advantages of large biomass, high mass transfer efficiency, small possibility of blocking, easy operation and control and the like; the invention expands the application of the roofing greening engineering, combines roofing greening with the processing of soot exhaust gas with a biological method and saves operation cost and floor space.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com