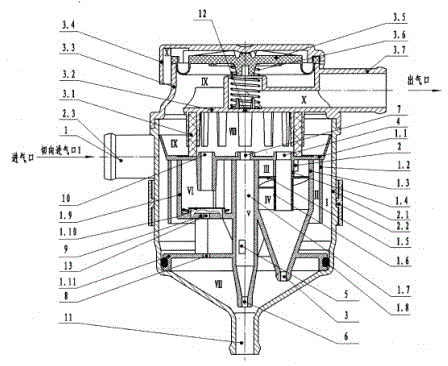

Independent external-mounting maintenance-free multi-stage oil and gas separator assembly

An oil-gas separator and plug-in technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve problems such as poor safety, high maintenance costs, and increased crankcase pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the first cyclone separation chamber is composed of the oil-gas separator shell and the oil-gas separator body shell, which is composed of the oil-gas separator body shell, the oil-gas separator cover and the outer wall of three fine separation conical tubes distributed at 90° on the circumference The second diffusion separation chamber is composed of three fine separation conical tubes distributed at 90° on the circumference and the center tube of the oil-gas separator cover. The third fine cyclone separation chamber is composed of three fine separation conical tubes distributed at 90° on the circumference and The swirling blades and the central tube of swirling blades form the fourth enhanced cyclone separation chamber, the fifth fine cyclone separation chamber is formed by the small fine separation cone tube set in the center of the circumference, and the sixth impact and diffusion chamber is composed of the safety valve cavity and safety valve. The safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com