Oil burner with high viscosity

An oil burner, high-viscosity technology, applied in the direction of burner, combustion type, combustion method, etc., can solve the problems of unusable steam injection boiler, large burner flame size, etc., achieve good energy saving effect, complete combustion, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

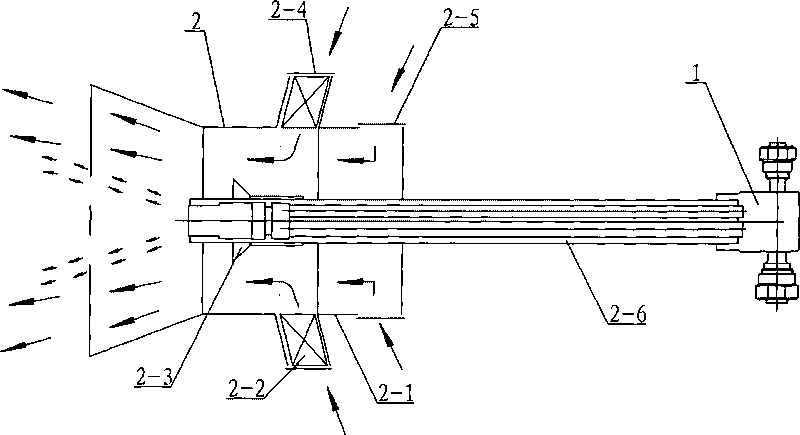

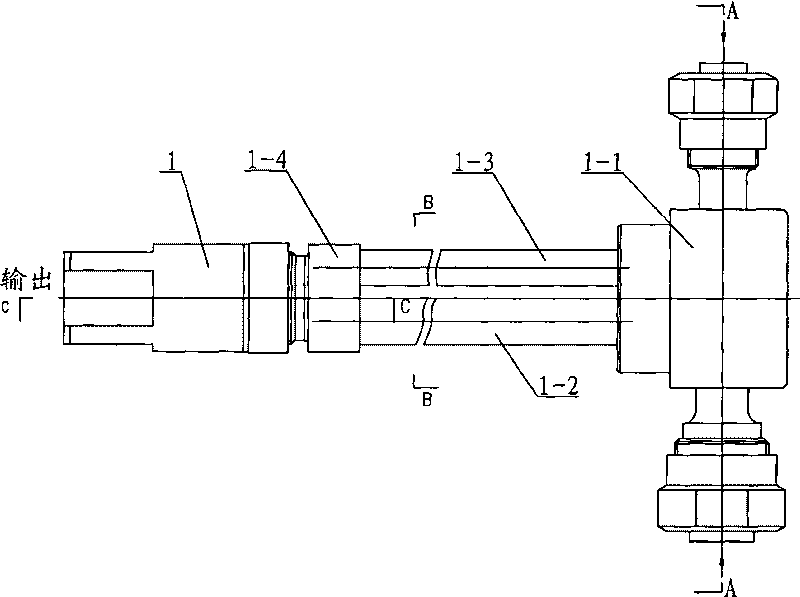

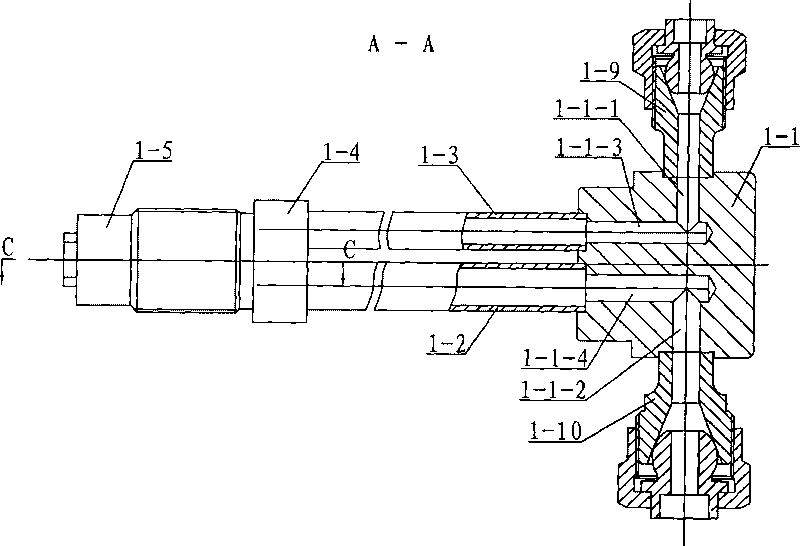

[0008] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this embodiment, the burner of this embodiment is composed of fuel injector 1 and air regulator 2, and air regulator 2 is composed of air regulator body 2-1, swirler 2-2, stabilizing burner 2-3, cutting Composed of directional damper 2-4, axial damper 2-5 and central pipe 2-6, the output end of central pipe 2-6 is set in the inner cavity of air regulator body 2-1, and cyclone 2-2 is set in On the outer wall of the air regulator body 2-1, and the swirler 2-2 communicates with the inner cavity of the air regulator body 2-1, and the steady burner 2-3 is fixed on the output end of the central tube 2-6, The tangential damper 2-4 is set on the outer ring of the swirler 2-2, the axial damper 2-5 is set on the outer ring of the input end of the air regulator body 2-1, and the output end of the injector 1 is set on In the central tube 2-6, the fuel injector 1 is composed of a fuel injection seat 1-1, a fu...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 7 To describe this embodiment, the inner diameter of the steam through hole 1-8-1 on the steam pan 1-8 in this embodiment is 3-5 mm larger than the outer diameter of the flange 1-7-7 on the atomizing sheet 1-7. It is designed to enter the burner 2-3 smoothly after the atomizing medium is mixed with the fuel oil. Other components and connections are the same as those in the first embodiment.

[0010] Working principle: Connect the atomizing medium pipe to the atomizing medium connecting pipe 1-10, connect the fuel pipe to the fuel connecting pipe 1-9, and the fuel passes through the fuel pipe through the second fuel hole 1-1-3, and the fuel pipe 1-2 The inner cavity of the fuel chamber 1-4-2, the first through hole 1-6-2, the second annular groove 1-6-1, the third annular groove 1-7-1, the first tangential groove 1-7 -3. The center hole 1-7-2 enters the steam through hole 1-8-1, and at the same time, the atomizing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com