Patents

Literature

72results about How to "Increase swirl intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

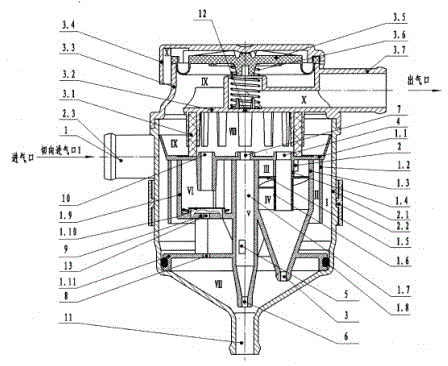

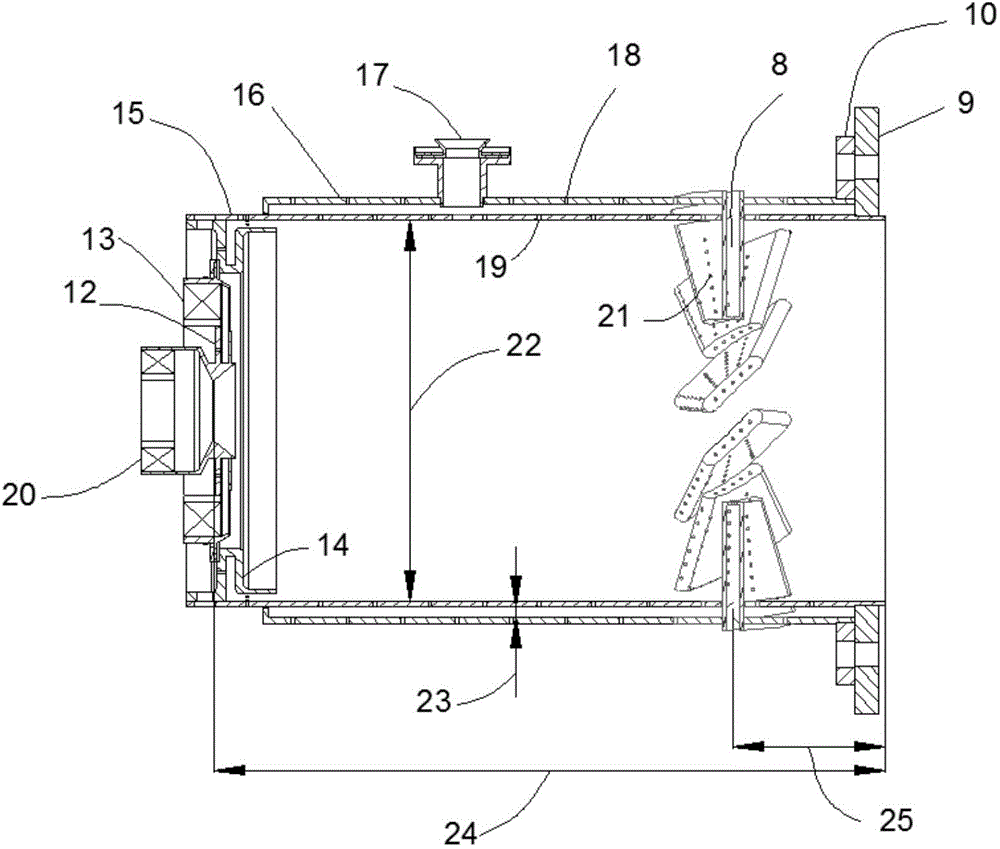

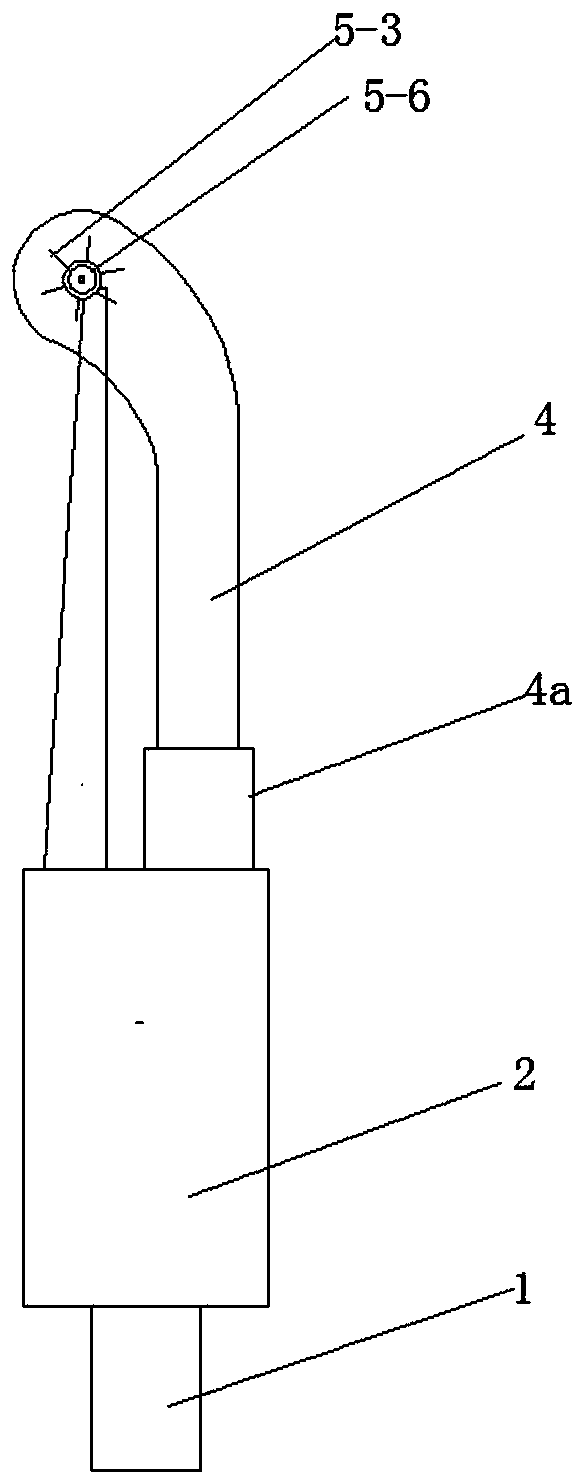

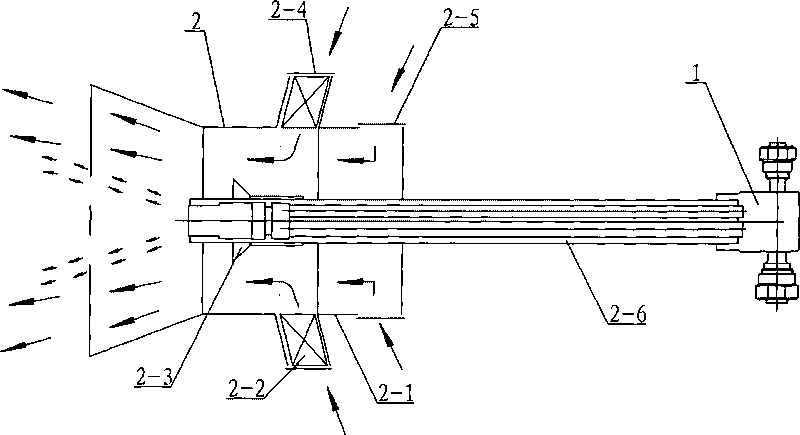

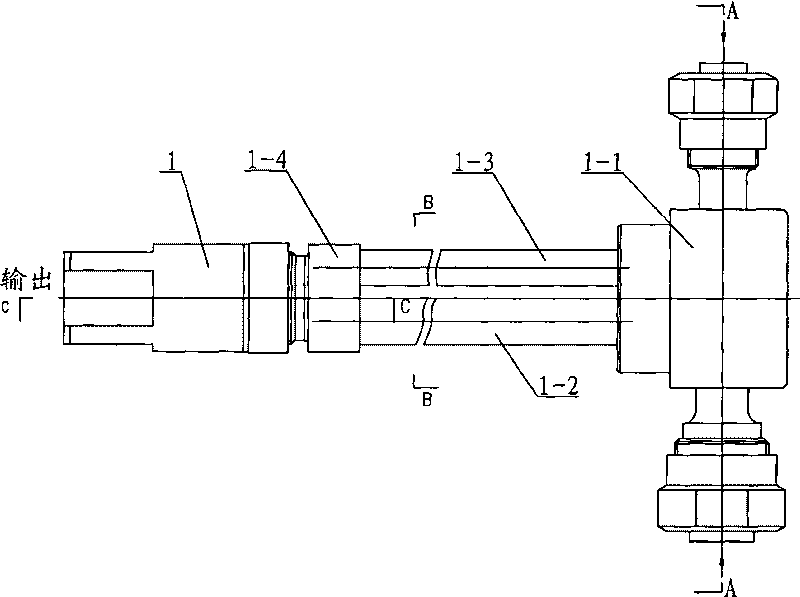

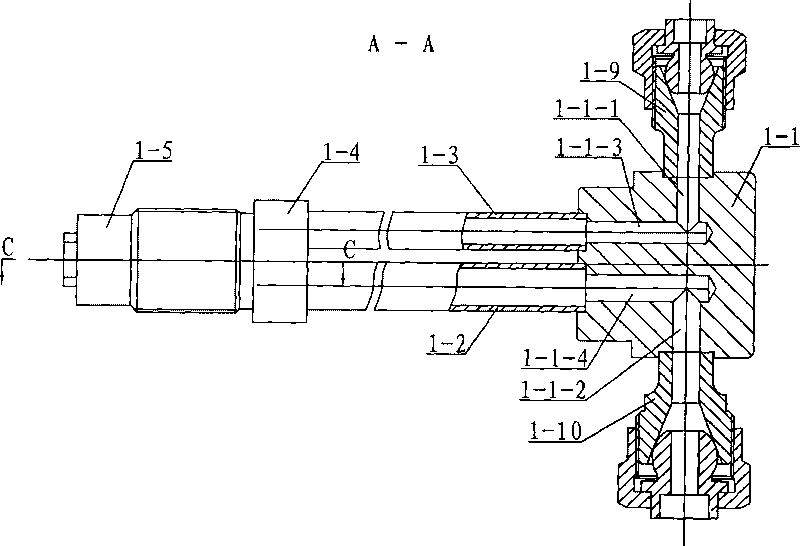

Independent external-mounting maintenance-free multi-stage oil and gas separator assembly

InactiveCN102705040BIncrease swirl intensityIncrease flow rateMachines/enginesCrankcase ventillationCyclonic separationRespirator

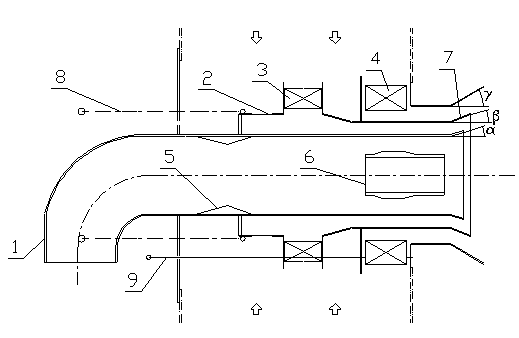

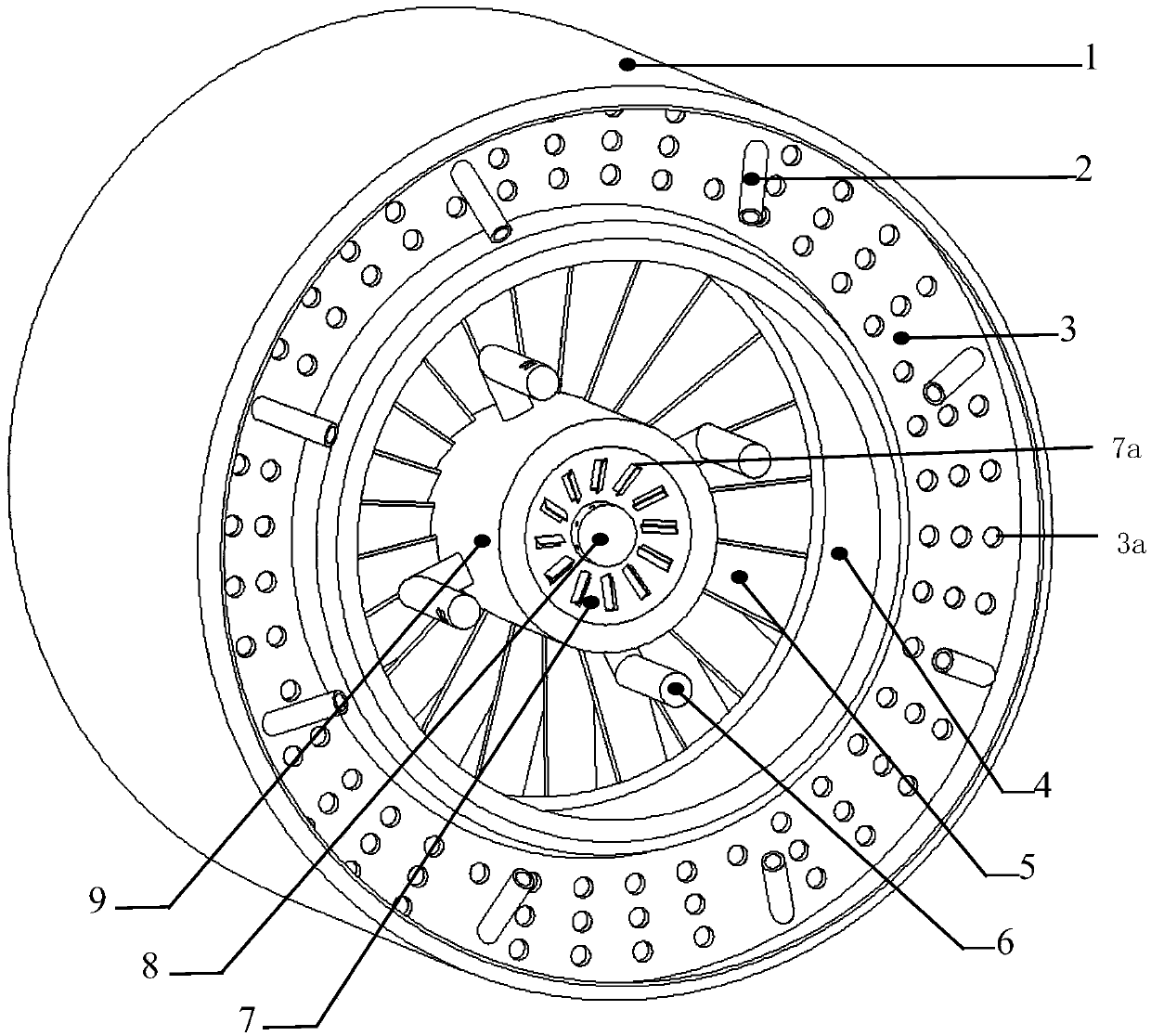

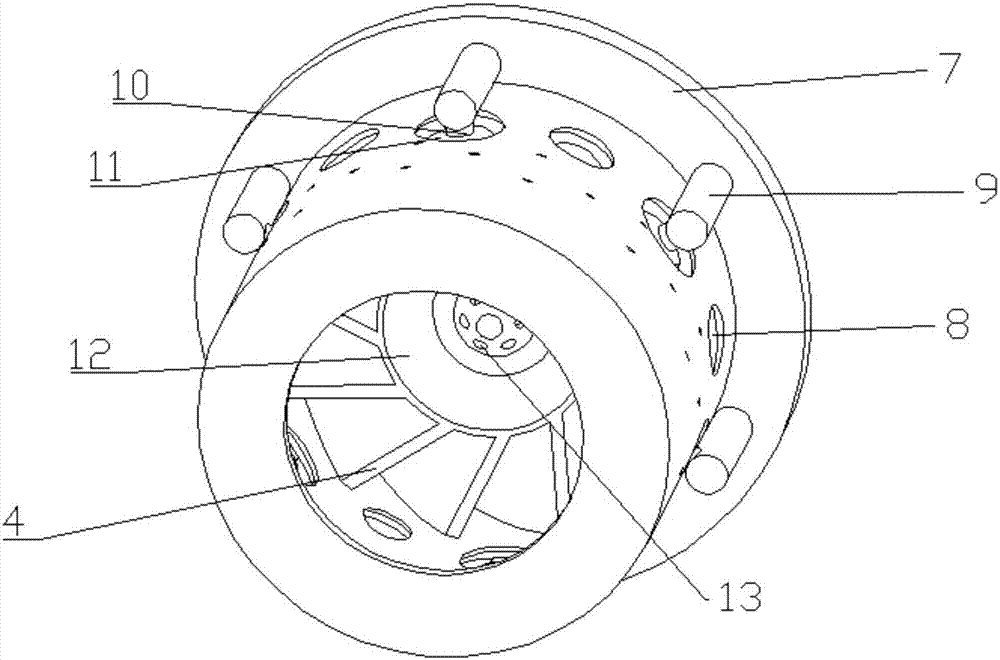

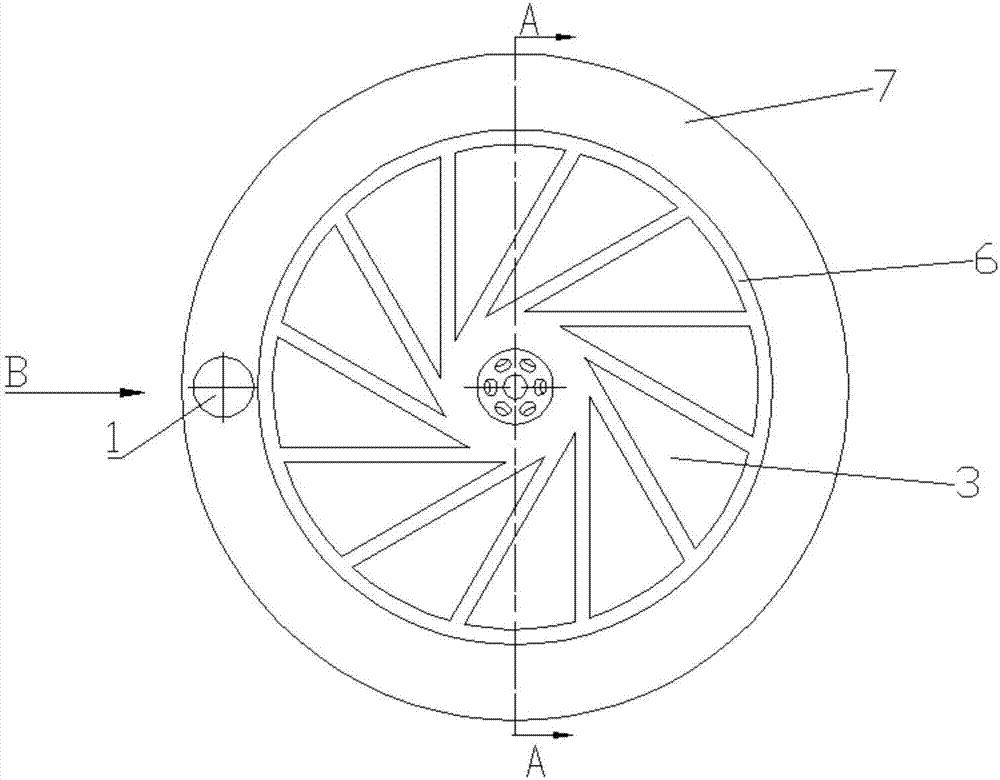

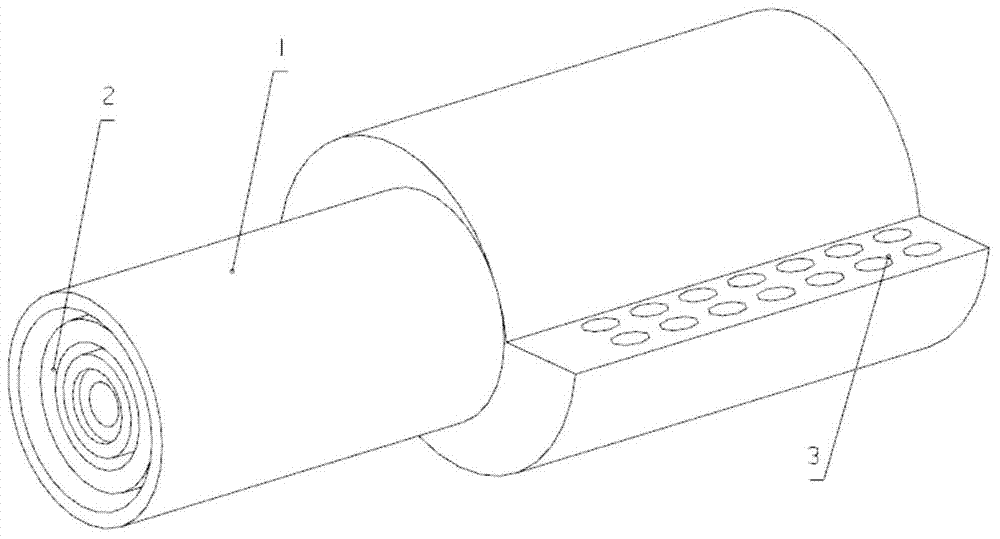

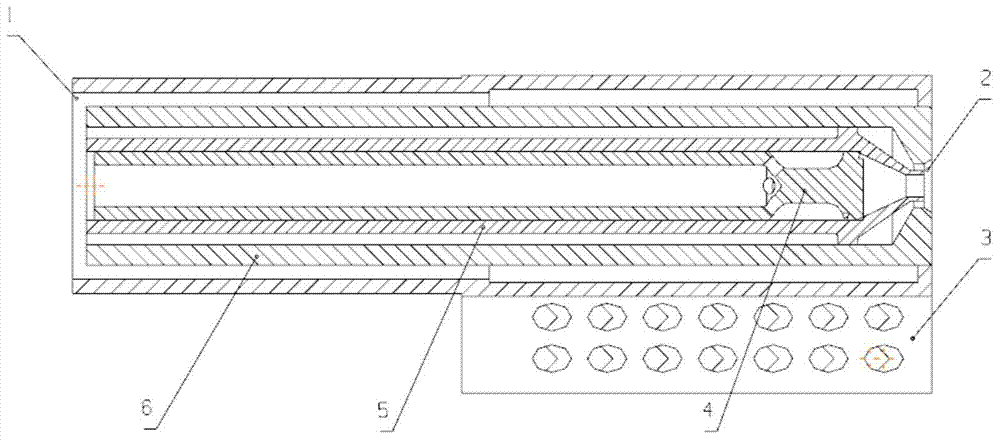

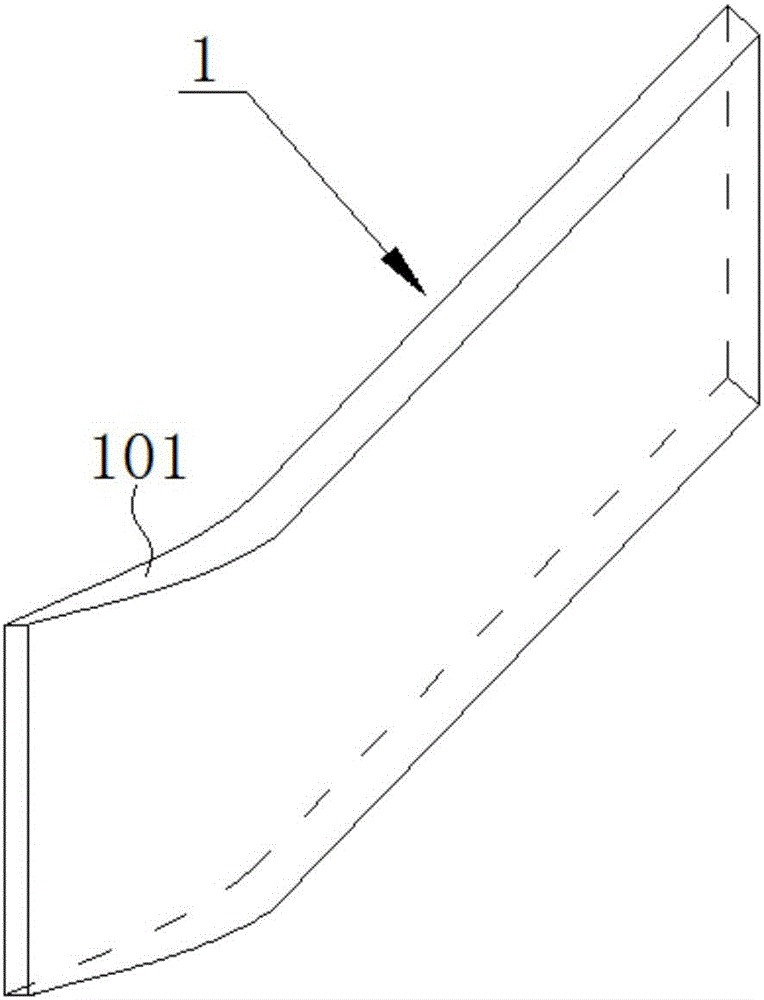

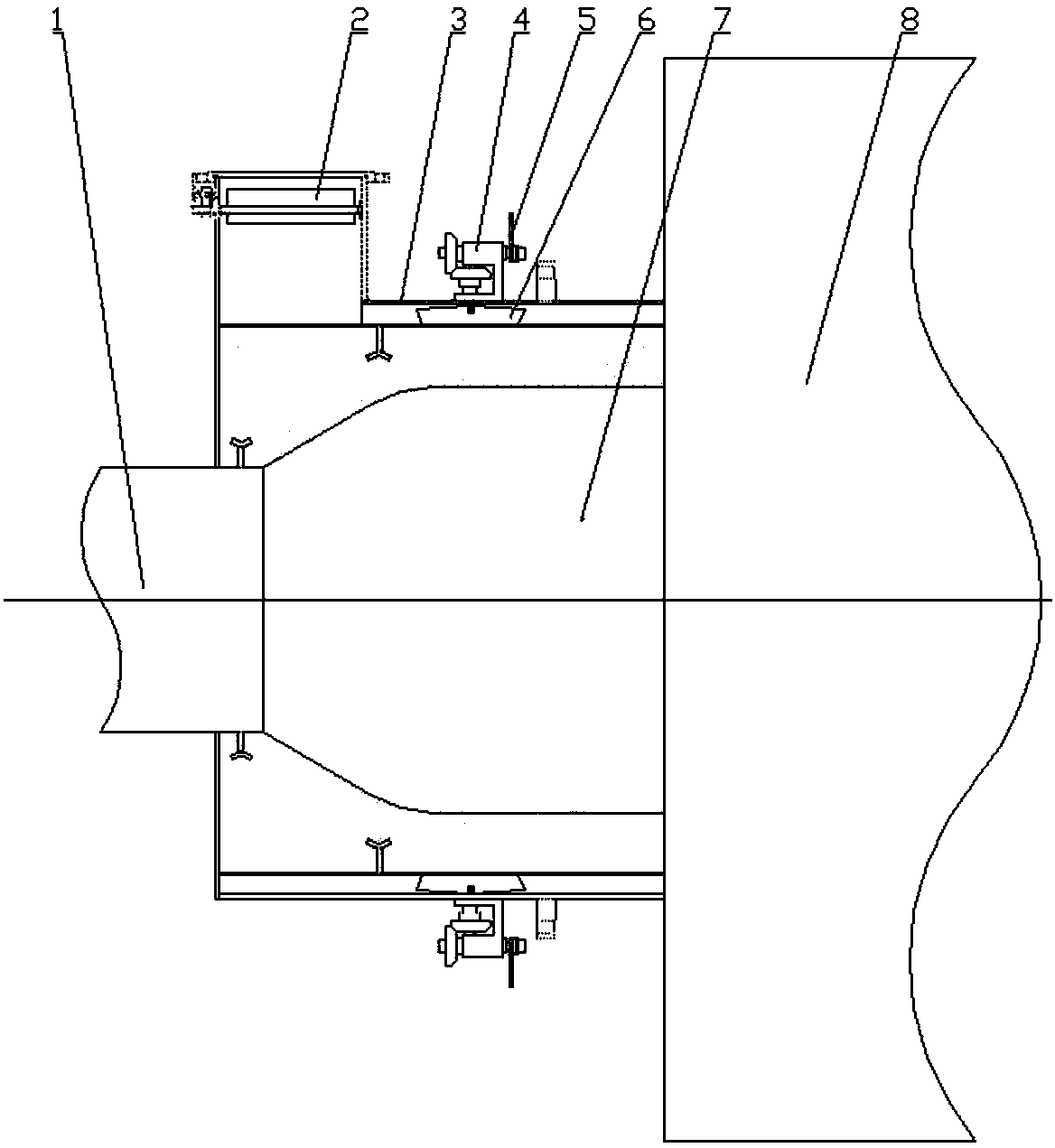

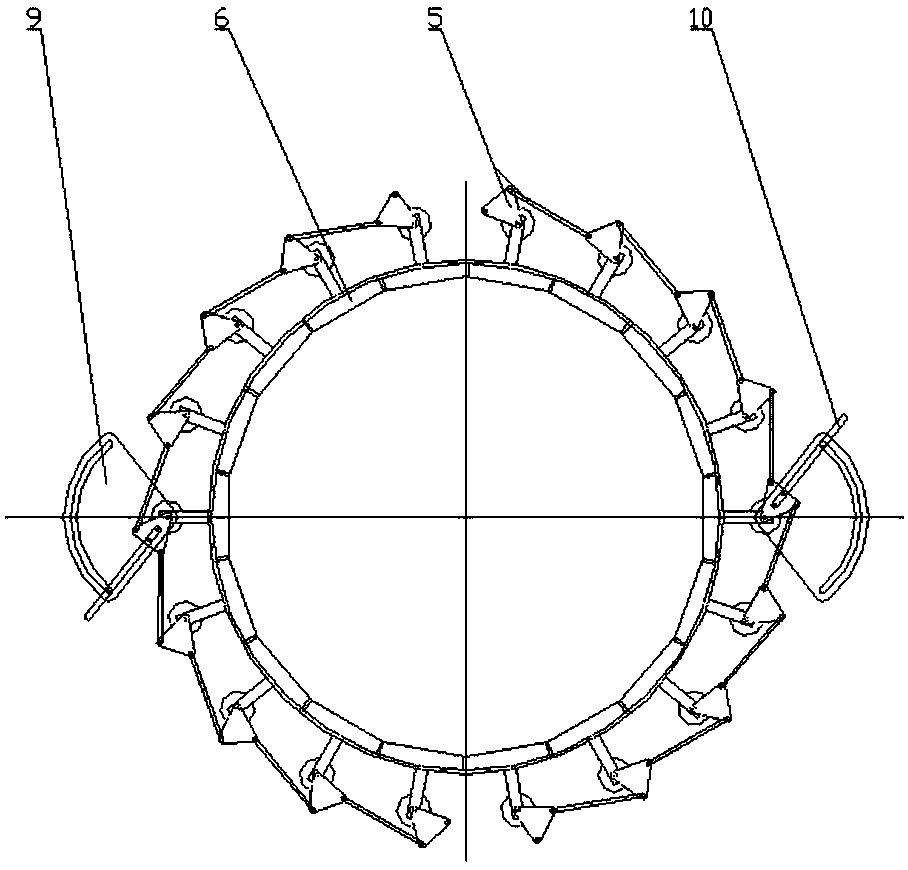

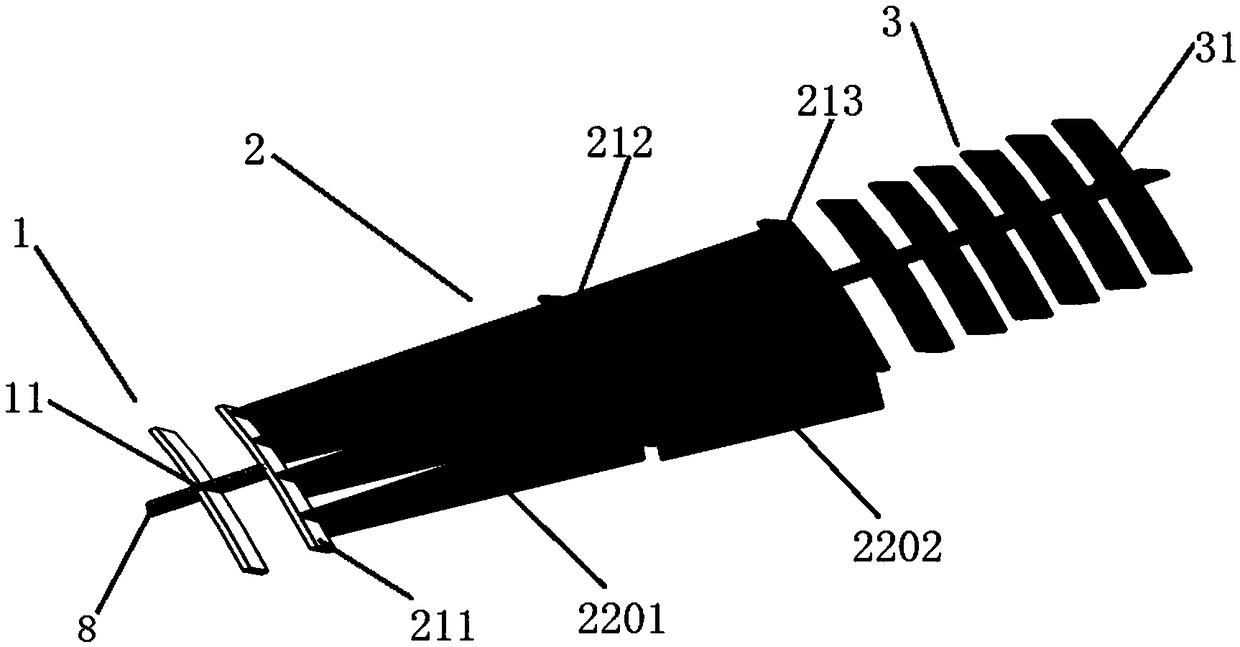

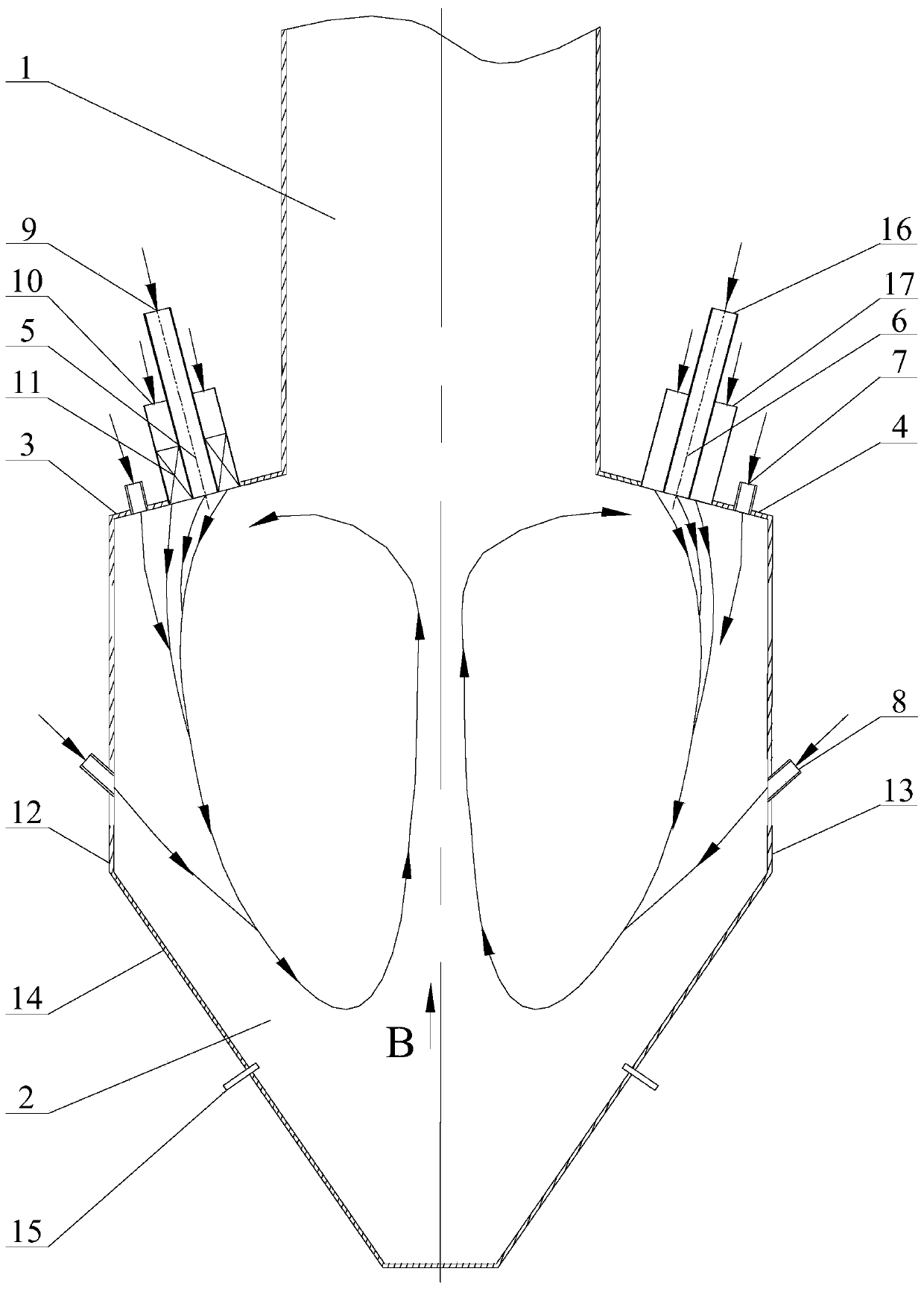

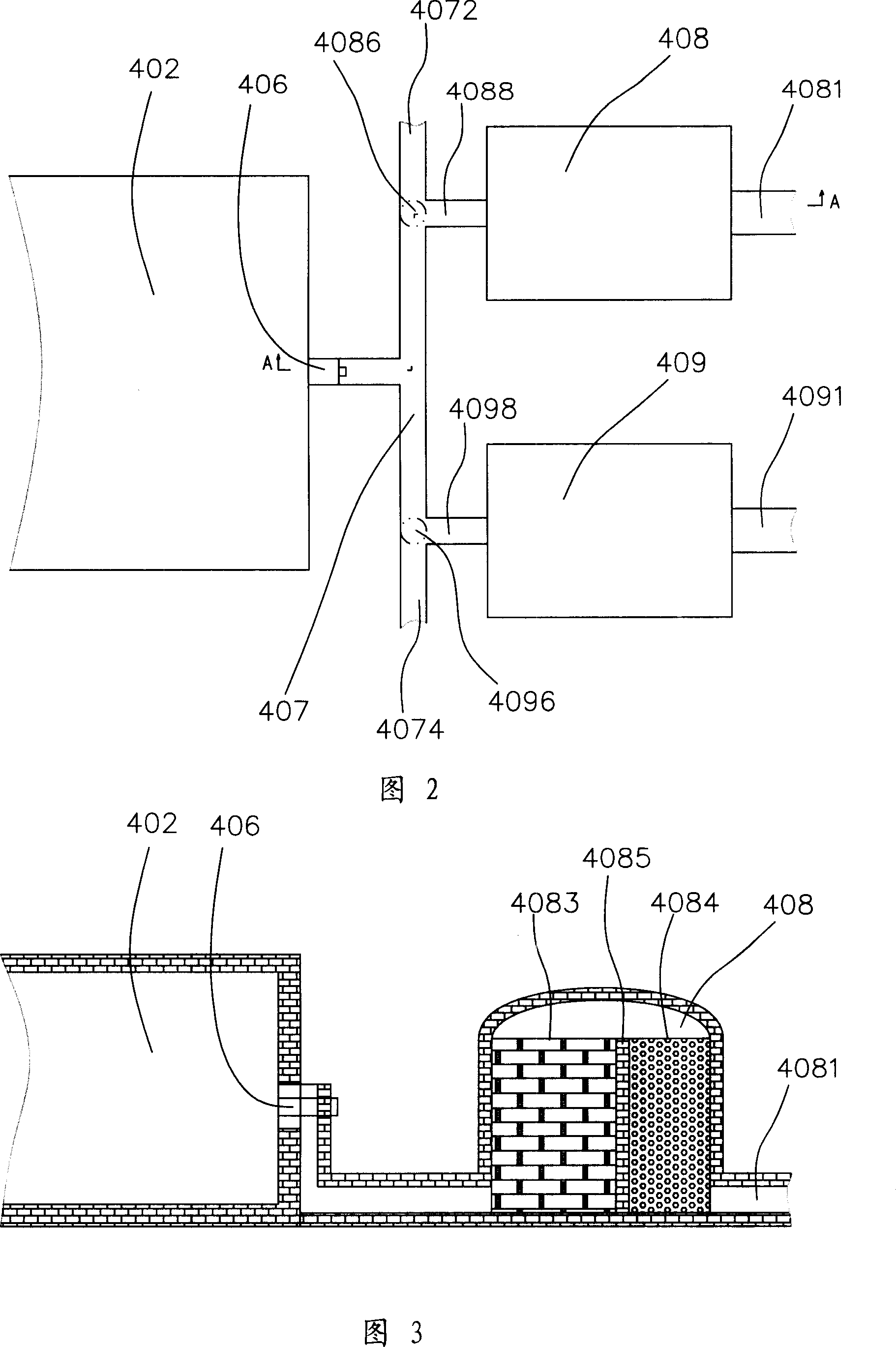

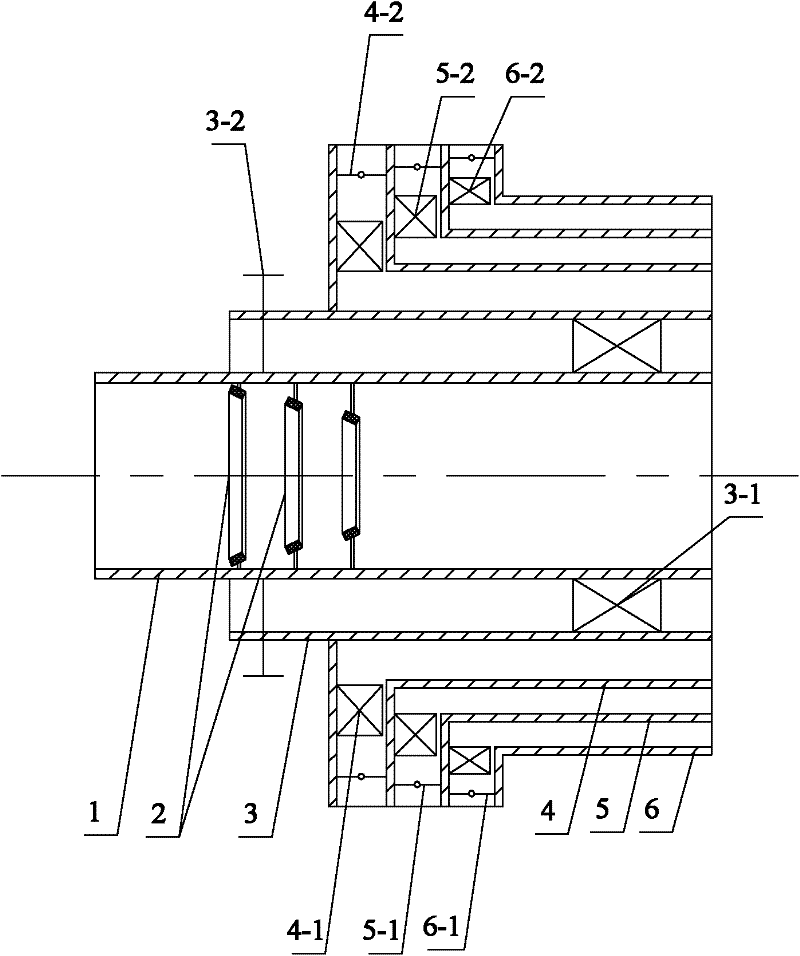

The invention discloses an independent external-mounting maintenance-free multi-stage oil and gas separator assembly. The oil and gas separator assembly is characterized in that a first cyclone separation cavity consists of an oil and gas separator outer shell and an oil and gas separator body shell; a second dispersing separation cavity consists of the oil and gas separator body shell, an oil and gas separator cover and the outer walls of three refine separation conical pipes which are distributed on the circumference at 90 degrees; a third refine cyclone separation cavity consists of the three refine separation conical pipes which are distributed on the circumference at 90 degrees and a central pipe; a fourth reinforcement cyclone separation cavity consists of the three refine separation conical pipes which are distributed on the circumference at 90 degrees, a central pipe, and a cyclone blade; a fifth refine cyclone separation cavity consists of a small refine separation conical pipe arranged in the center of the circumference; a sixth compact and dispersing safety separation cavity consists of a safety valve cavity and a safety valve; an eighth separation cavity consists of a respirator compact plate and a safety damping net; a flow pressure adjusting valve consists of a flow pressure adjusting diaphragm in a respirator and a flow pressure adjusting spring; any installation mechanism consists of an installation support and variable air inlet and outlet pipe included angles; and an oil return cavity consists of a separation conical pipe bottom and an independent separator shell.

Owner:NANCHONG LINGYUN GAOJU MFG

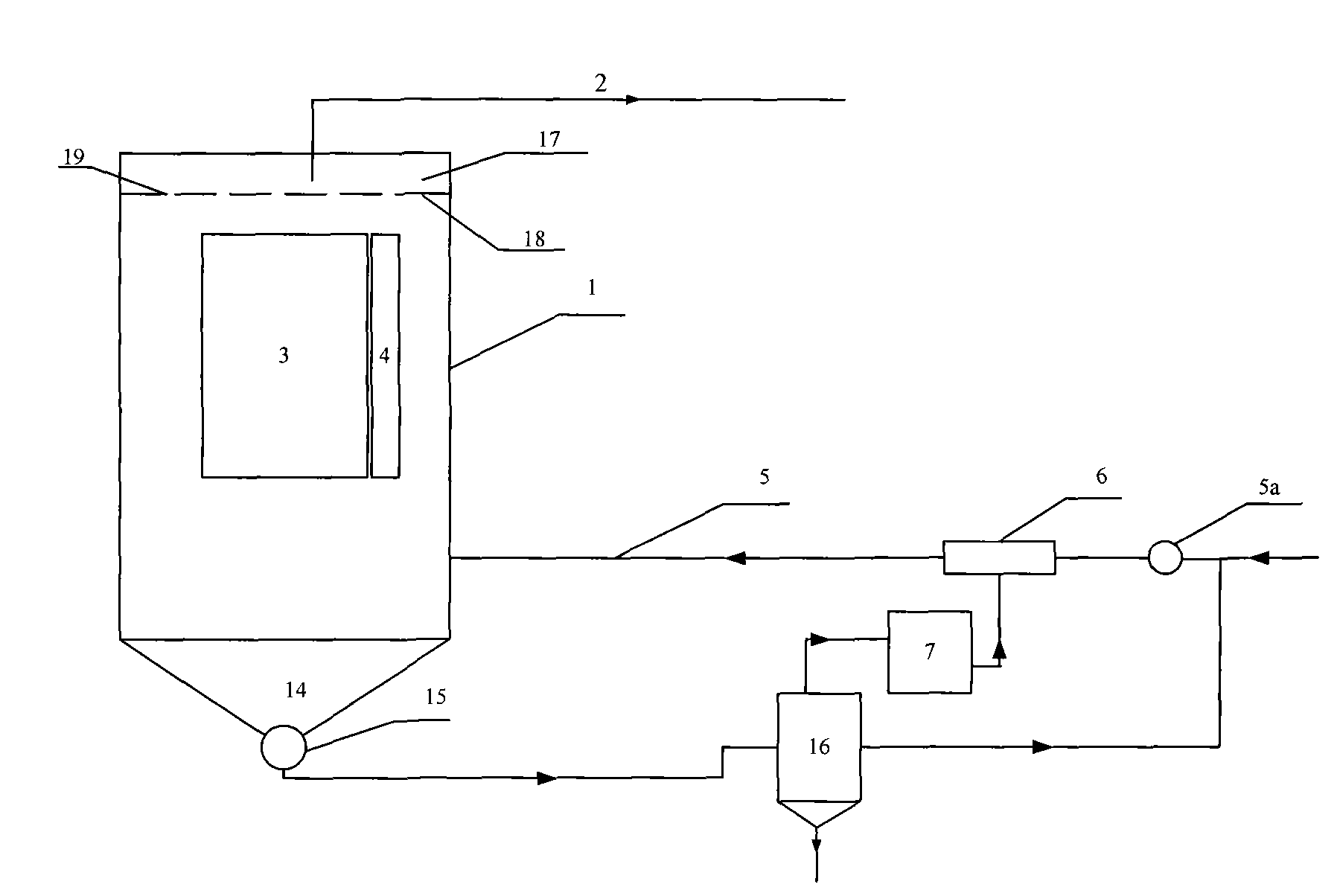

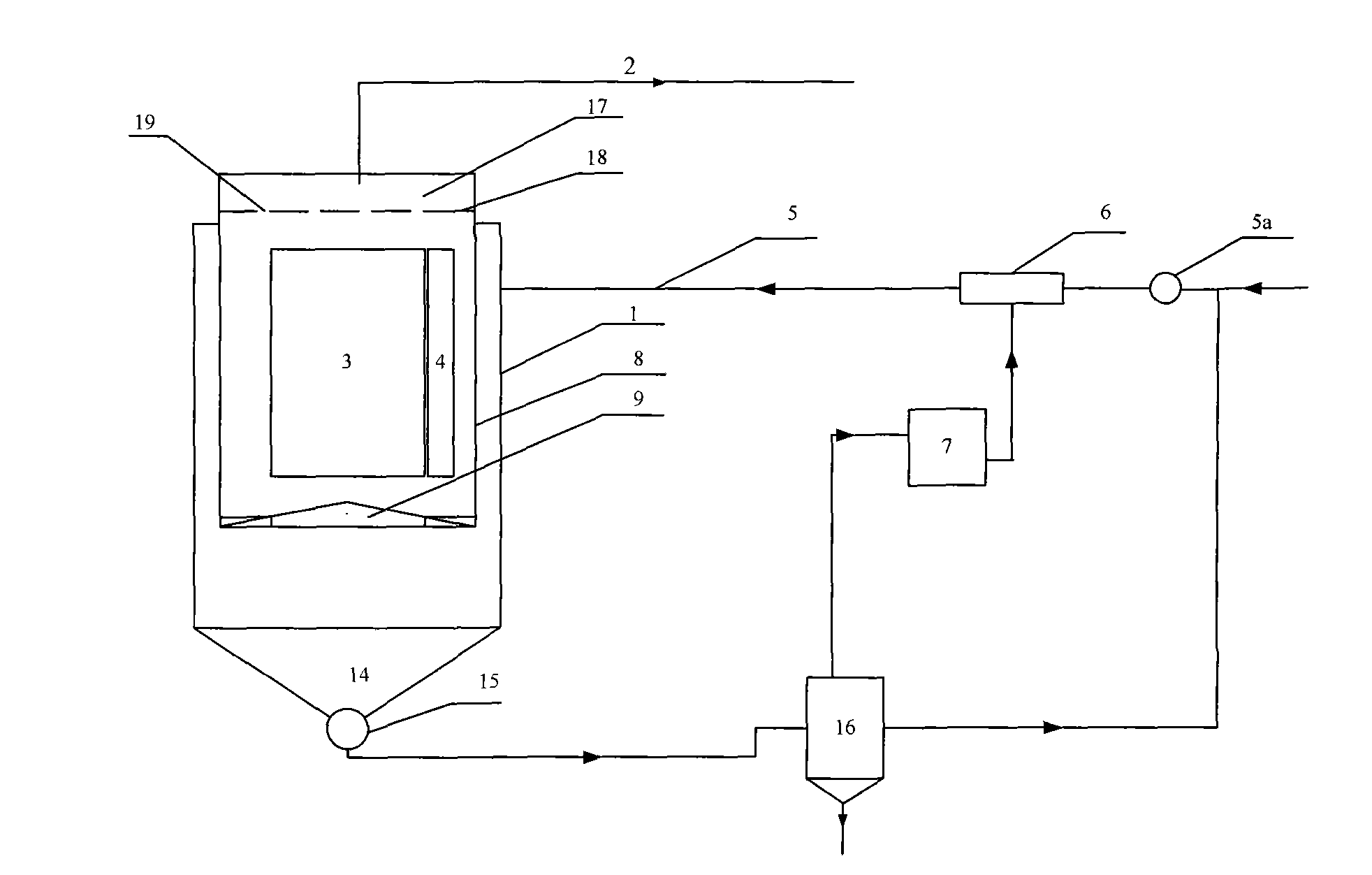

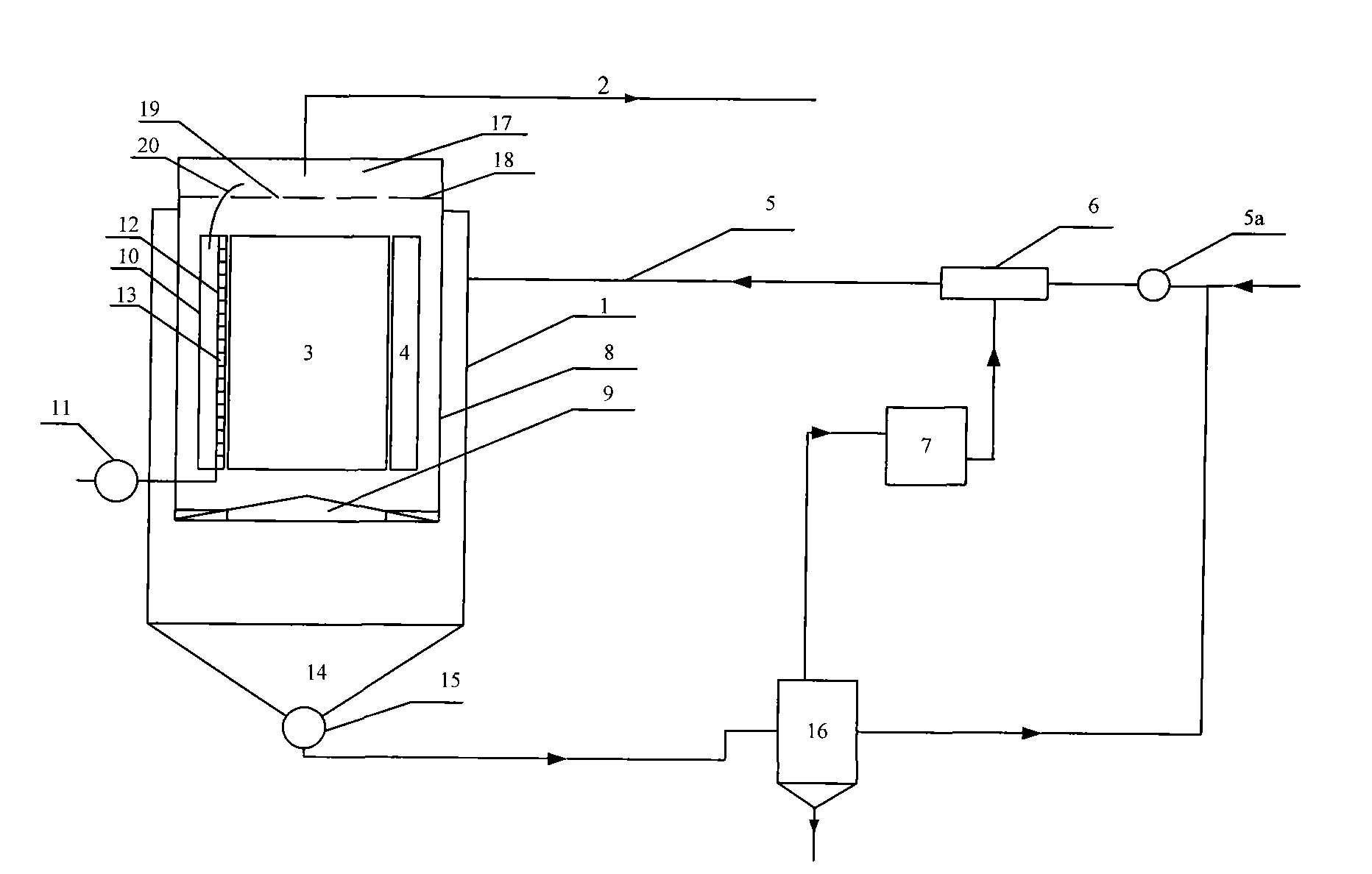

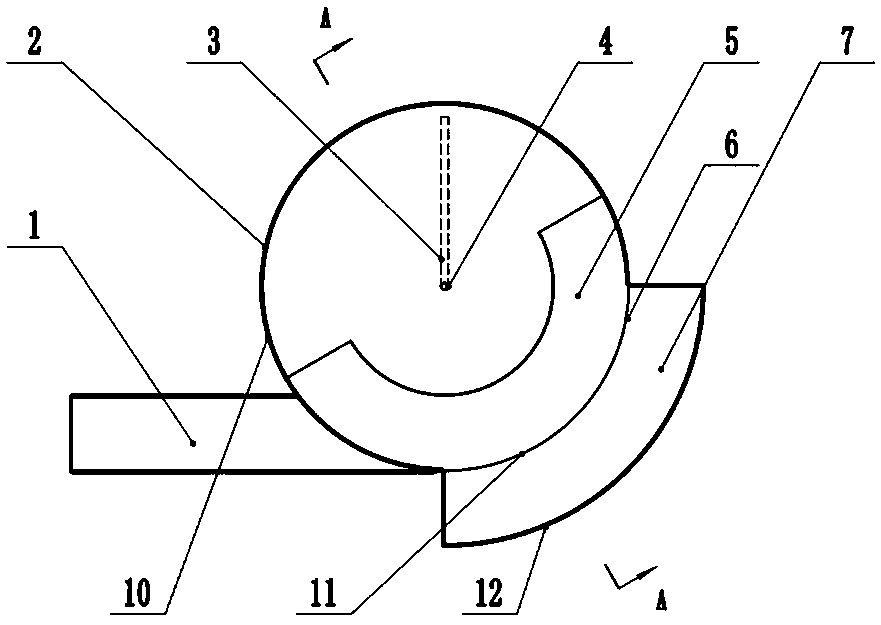

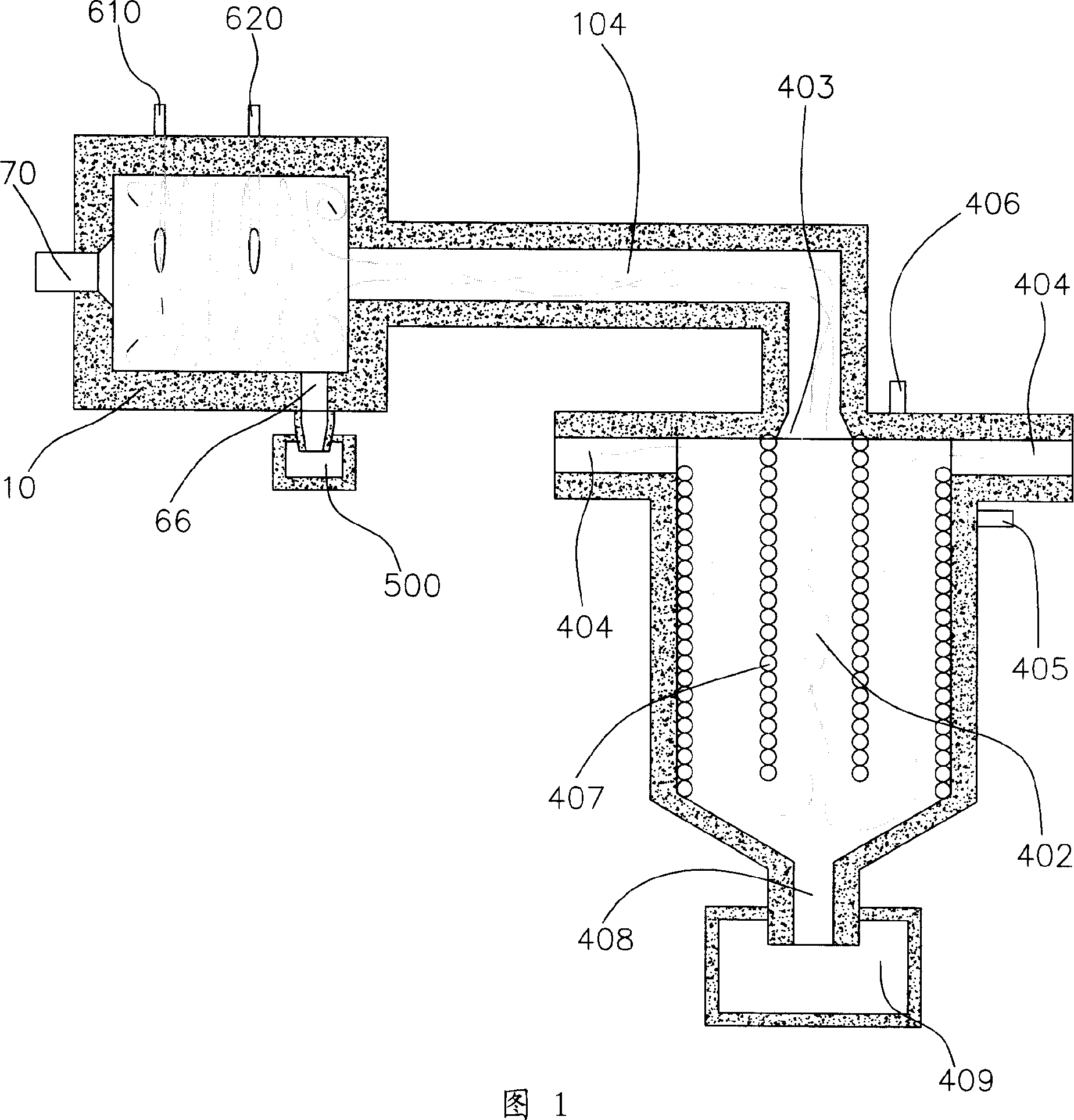

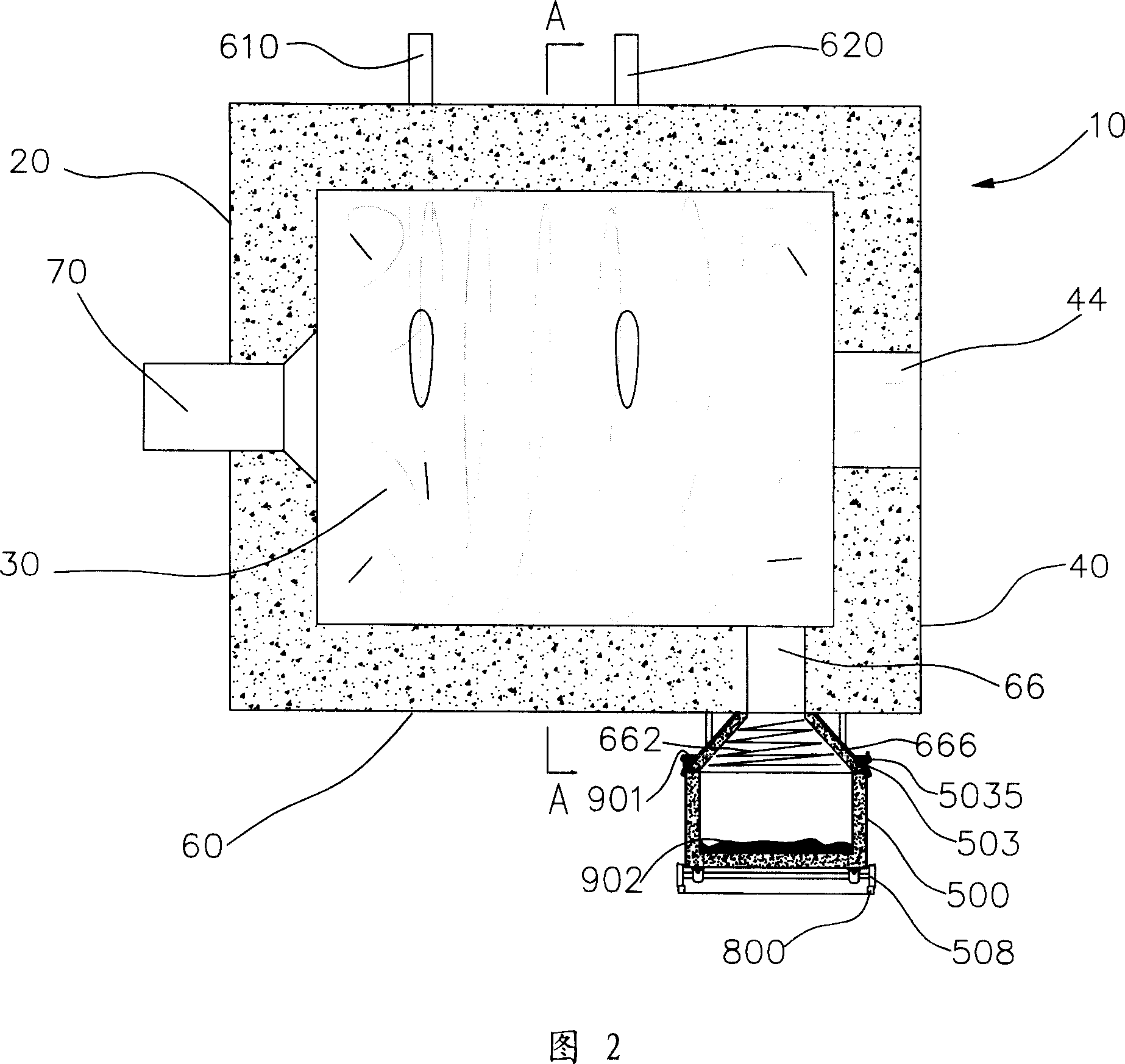

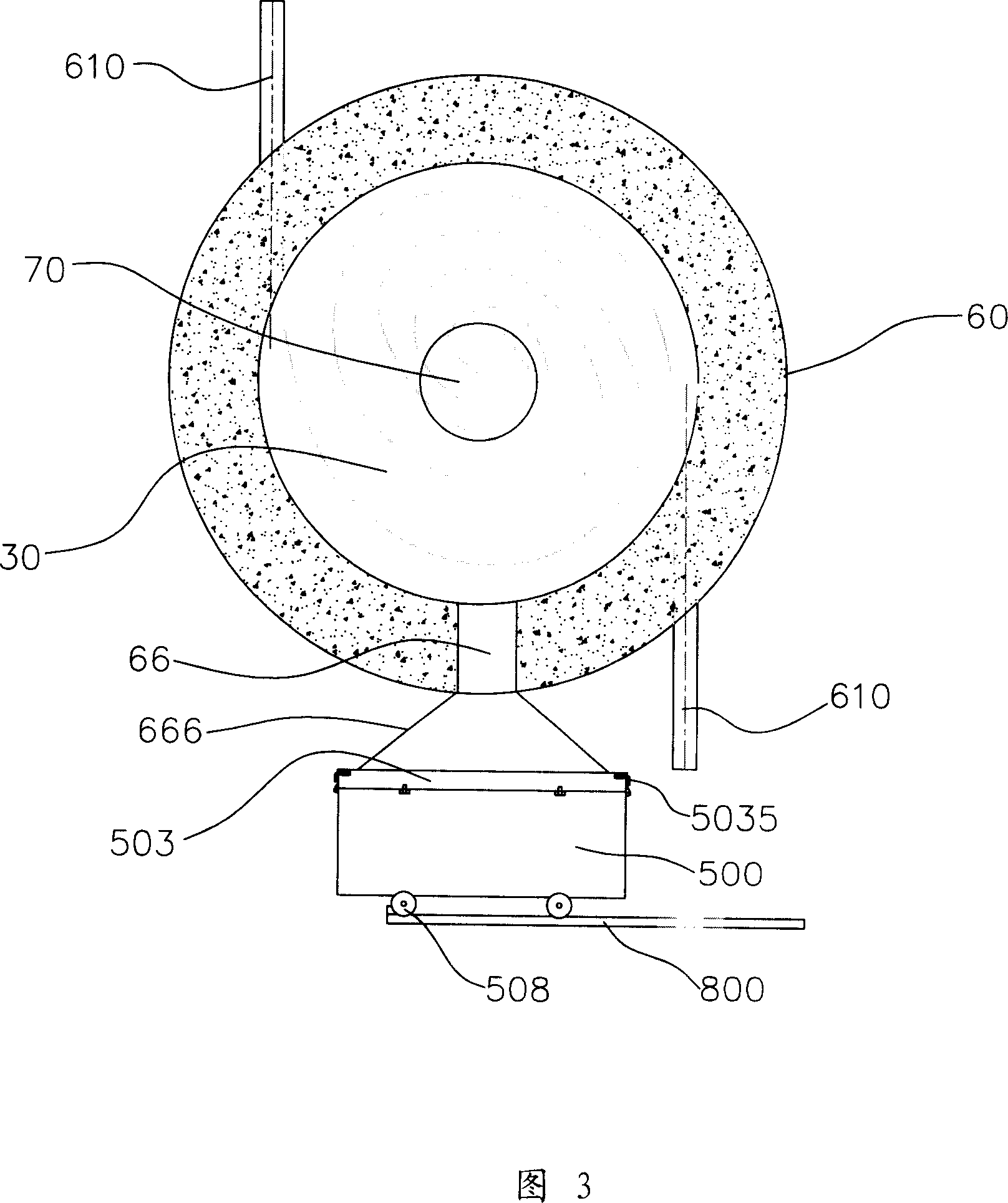

Sewage processing method and sewage processing device

InactiveCN101580322AEfficient removalImprove separation efficiencyWater/sewage treatment by centrifugal separationWater/sewage treatment by magnetic/electric fieldsCycloneSludge

The invention provides a sewage processing method, solving the problems of unsatisfactory effect of the sewage processing and the existing dead end of the sewage processing in a prior technology. The method comprises the following steps: adding medications into the sewage; flowing the mixed liquor into a cyclone reactor tangentially to perform cyclone separate; performing magnetic separation process on the mixed liquor after being cyclone separated through a magnetic roller. Meanwhile, the invention also provides a sewage processing device adopting the method; the device consists of a sewage inlet pipe, a clear water outlet pipe, a medication-adding system, a cyclone reactor, a magnetic roller and a scraper. The medication-adding system is connected with the sewage inlet pipe; an outlet end nozzle of the sewage inlet pipe is connected tangentially into the cyclone reactor, the cyclone reactor is a revolving body, the magnetic roller and the scraper are positioned in the cyclone reactor, the magnetic roller and the cyclone reactor are arranged on a same axial-line, and the scraper is used to scrape ferromagnetism mud cluster which is absorbed magnetically on the magnetic roller. In the invention, sewage purification has a good effect, the yielding water is clear, sewage processing method and sewage processing device of the invention are applicable to processing the sewage and the sewage containing grease and mud.

Owner:郑州紫盈节能环保科技有限公司

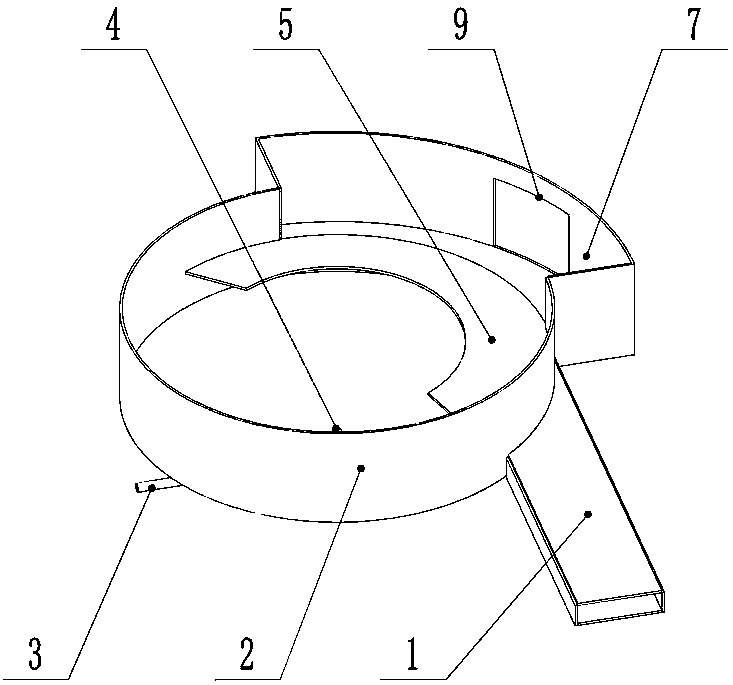

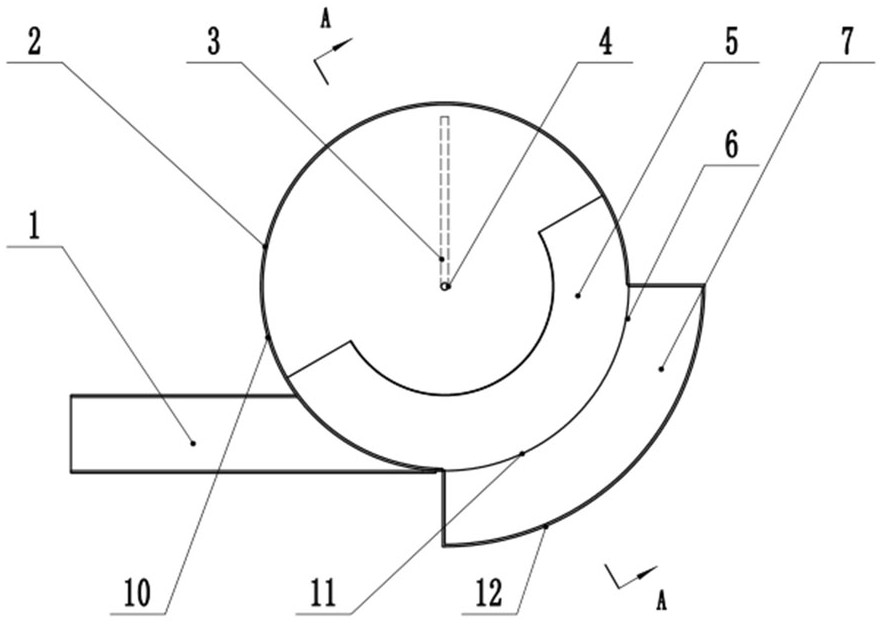

Cyclone dust removal device

InactiveCN108480066AAvoid enteringAvoid the problem of secondary backmixing and dischargeReversed direction vortexCycloneDust particles

The invention provides a cyclone dust removal device which comprises a cyclone cylinder, wherein an air inlet is formed in a top side face of the cyclone cylinder; an exhaust pipe stretching into thecyclone cylinder is arranged at the top of the cyclone cylinder; an ash bucket is arranged at the lower part of the cyclone cylinder; an inverted cone is arranged at the bottom in the cyclone cylinder; a gap is reserved between the periphery of the inverted cone and a conical cylinder part of the cyclone cylinder. According to the cyclone dust removal device disclosed by the invention, the separation efficiency of dust particles can be improved, and secondary back-mixing discharge of the dust is avoided.

Owner:重庆福锦塑胶有限责任公司

Liquefied gas combustion chamber with outlet equipped with swirling vanes

ActiveCN104807044AReduce thermal shockSimple structureContinuous combustion chamberCombustion chamberCoupling

The invention discloses a liquefied gas combustion chamber with an outlet equipped with swirling vanes. The liquefied gas combustion chamber adopts a single-tube cylindrical combustion chamber structure and mainly comprises a liquefied gas spray nozzle, a combustion chamber case, a flame tube and the swirling vanes, wherein the swirling vanes are welded to strip-shaped grooves of the flame tube, form certain angles with the axial direction and are uniformly distributed circumferentially; the flame tube and the case are connected by a bolt; liquefied gas enters the head of the combustion chamber from an oblique hole of the spray nozzle, and the combustion of the liquefied gas is completed by using an electrospark lighter; a combustion organization generates strong-swirl stable flame by adopting internal-external two-stage swirlers, and a cooling manner is an impact wall-divergence wall coupled vane gas film hole manner; the swirling direction of an external swirler is the same as that of the swirling vanes of the outlet of the combustion chamber, due to the coupling of swirling, the strength of swirling in the flame tube is strengthened, and the length of flame is shortened; high-temperature combustion gas generated from combustion generates relatively-strong swirling flow when the high-temperature combustion gas passes through the swirling vanes, the high-temperature combustion gas is exhausted from the outlet of the combustion chamber and forms expanding gas flow, and thus, the radial distribution of outlet combustion gas in space is enlarged.

Owner:BEIHANG UNIV

Cavity trapped vortex and rectifying support plate combined type integrated afterburner

InactiveCN109539309AStable reflux strengthShorten the lengthContinuous combustion chamberCombustion chamberEngineering

The invention provides a cavity trapped vortex and rectifying support plate combined type integrated afterburner. The ignition stability can be improved effectively, and the swirling intensity of a backflow area and the fuel atomization effect are improved, so that the combustion efficiency and stability are improved. A rectifying support plate flame stabilizer is combined with cavity trapped vortex; on one hand, air flow of inner and outer ducts enters a cavity from different positions, and a trapped vortex area is formed; duty-level flame is generated, so that mixed gas of a main flow area is ignited; on the other hand, a stable main backflow area with a certain gas backflow amount and in an appropriate size is formed downstream; and ignited high-temperature air and air in the outer ductare promoted to mix, and play a role in rectification and stabilization of combustion. The integrated afterburner has the advantages that the structural design of a cavity duty stabilizer is added atthe rear edge of the rectifying support plate flame stabilizer on the original basis of the integrated afterburner, and the ignition ability under the rich oil and high altitude conditions can be improved effectively; and the high combustion stability and efficiency are ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Intensive-classification low-NOx pulverized coal burner

ActiveCN103759259AIncrease swirl intensityIncrease combustionPulverulent fuel combustion burnersCombustion apparatusSlagNitric oxide

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

Multistage gas reverse swirl burner

PendingCN109611835AEfficient mixingStable combustion characteristicsPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationPollutant emissionsEngineering

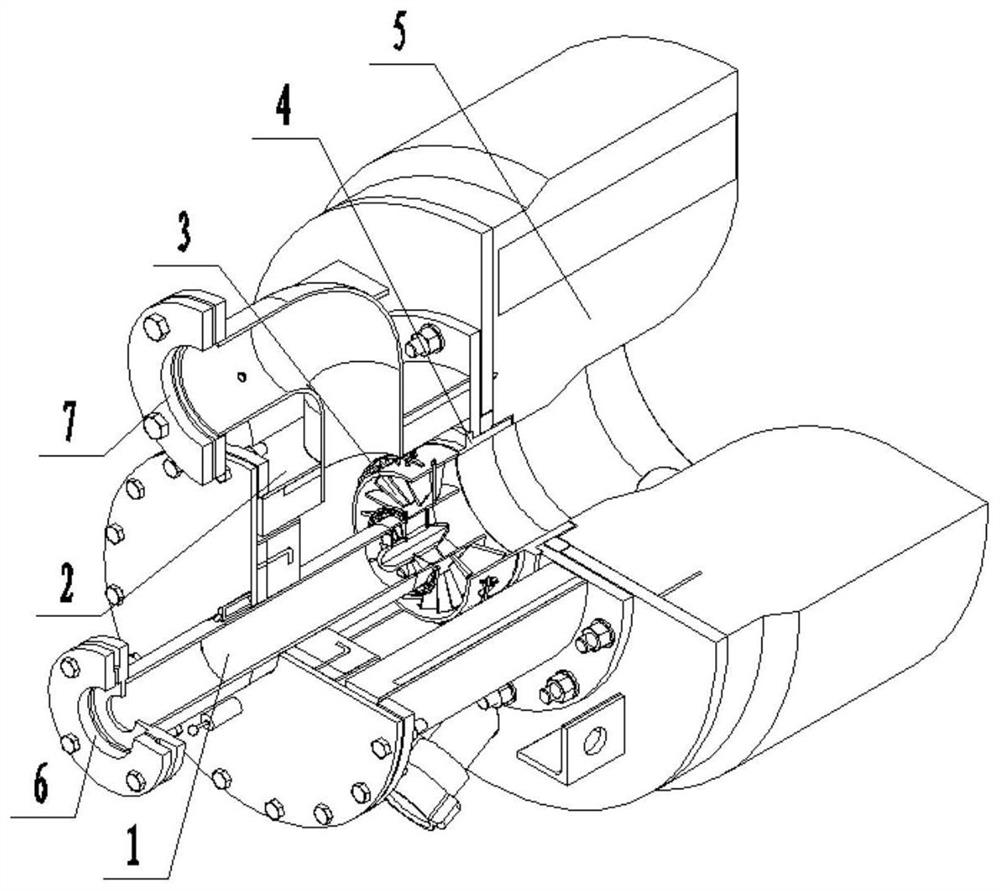

The invention discloses a multistage gas reverse swirl burner. The multistage gas reverse swirl burner comprises a fuel spraying pipe and an air guide barrel set; the air guide barrel set comprises afirst-stage air guide barrel, a second-stage air guide barrel and a third-stage air guide barrel, the air outlet end of the first-stage air guide barrel is provided with a flame stabilizing disc to output first-stage swirl gas, the first-stage air guide barrel is sleeved with the second-stage air guide barrel, the second-stage air guide barrel is provided with multiple second blades to output second-stage swirl gas, the first-stage swirl gas and the second-stage swirl gas are opposite in swirl direction, the second-stage air guide barrel is sleeved with the third-stage air guide barrel, the third-stage air guide barrel is provided with a porous plate to output high-speed straight-through flow gas, the fuel spraying pipe set comprises a first-stage fuel spraying pipe, a second-stage fuel spraying pipe and a third-stage fuel spraying pipe, the first-stage fuel spraying pipe is located on the first-stage air guide barrel to spray fuel to the first-stage swirl gas, the second-stage fuel spraying pipe is located on the second-stage air guide barrel to spray fuel to the second-stage swirl gas, and the third-stage fuel spraying pipe is located on the third-stage air guide barrel. The airand gas mixing degree can be greatly improved, gas mixing is more uniform, combustion is more sufficient, and pollutant emission is lower.

Owner:HUAQIAO UNIVERSITY

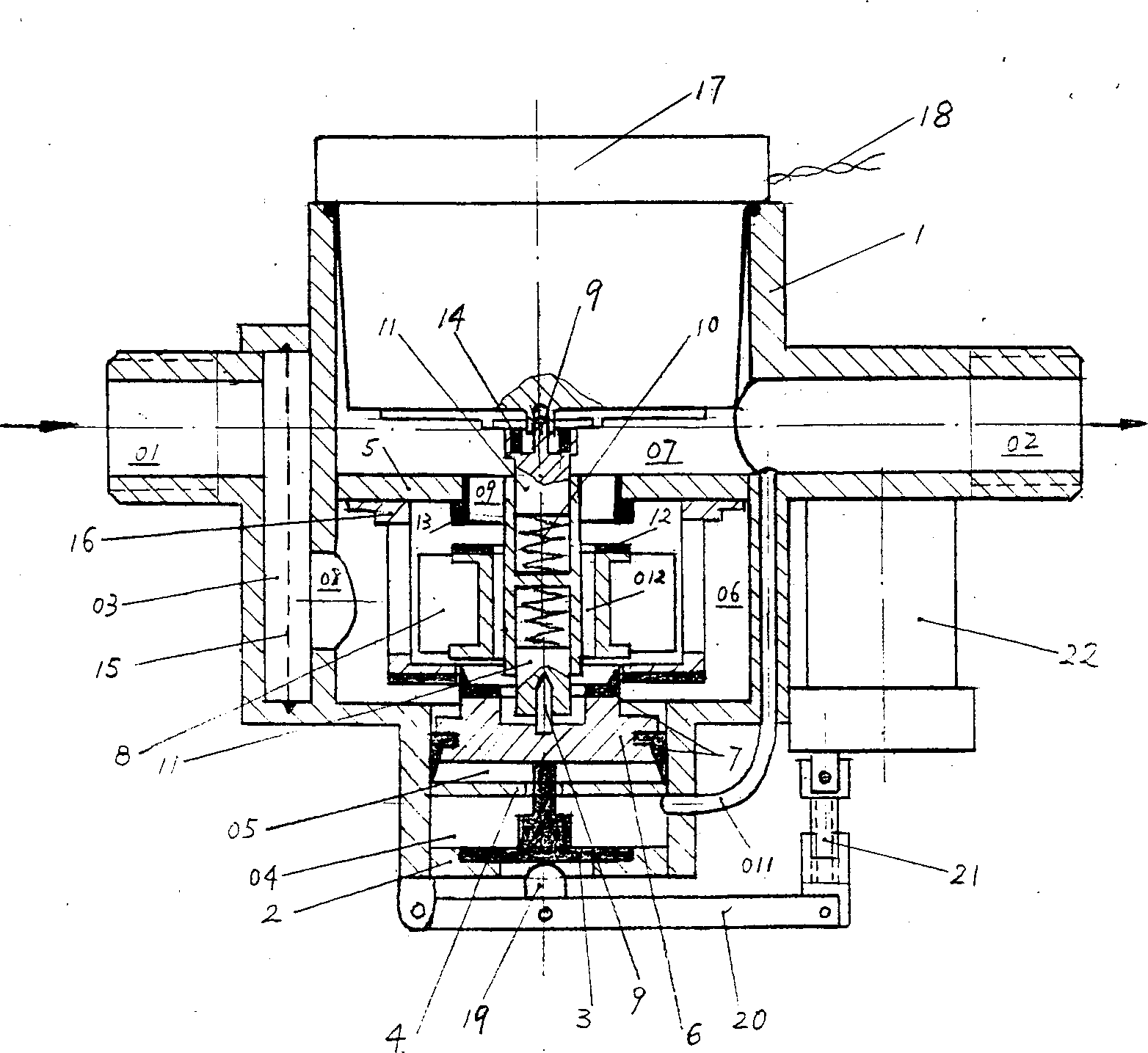

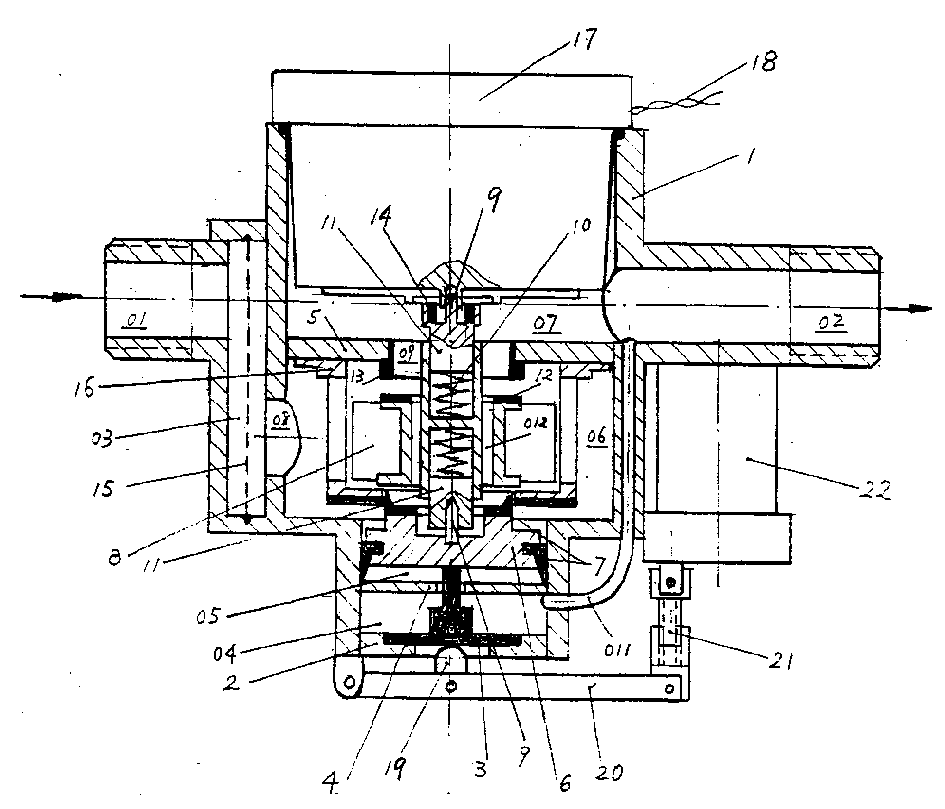

Pilot differential valve with metering function

InactiveCN1356485AReduce volumeReduce weightOperating means/releasing devices for valvesVolume/mass flow measurementImpellerPre-charge

A pilot-type differential valve with metering function for the water meter system with IC card pre-charge function features that the meter, blade wheel, permanent-magnetic ring and guide cover of traditional water meter and the partition, piston, valve plug and valve seat of pilot-type differential valve are assembled in a single casing, and a specia blade wheel structure is used, which features that the blade wheel is separated from its axle for moving up and down under the action of spring. Its advantages include light weight low cost small size.

Owner:HARBIN ENG UNIV

Gas turbine low-pollution combustion chamber single-vortex head structure

ActiveCN107543202AImprove mixing uniformityAvoid hot spotsContinuous combustion chamberNuclear engineeringGas turbines

The invention relates to a gas turbine low-pollution combustion chamber single-vortex head structure. Firstly, central vortex air and central natural gas are mixed, and outer wall non-vortex air and outer wall natural gas are mixed. After that, the vortex air, the non-vortex air, the central natural gas and the outer wall natural gas are further mixed in a natural gas-air mixing cavity, the mixinguniformity of the natural gas and air can be improved, generation of hot spots can be avoided, and generation of nitric oxide is effectively lowered. By means of the gas supply mode of combination ofcentral vortex and outer wall non-vortex, the vortex intensity of head outlet airflow can be lowered, and the risk of occurrence of oscillation combustion is also lowered. By means of the combinationof the central natural gas and outer wall natural gas, the NOx-CO proportion can be improved, and flame stability is facilitated. A head outlet convergence section can improve the speed of natural gas-air mixed airflow, and tempering is effectively prevented. A tangential gas inlet small hole in the outer wall of a whirlcone can lower the risk of spontaneous combustion occurring inside the head structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

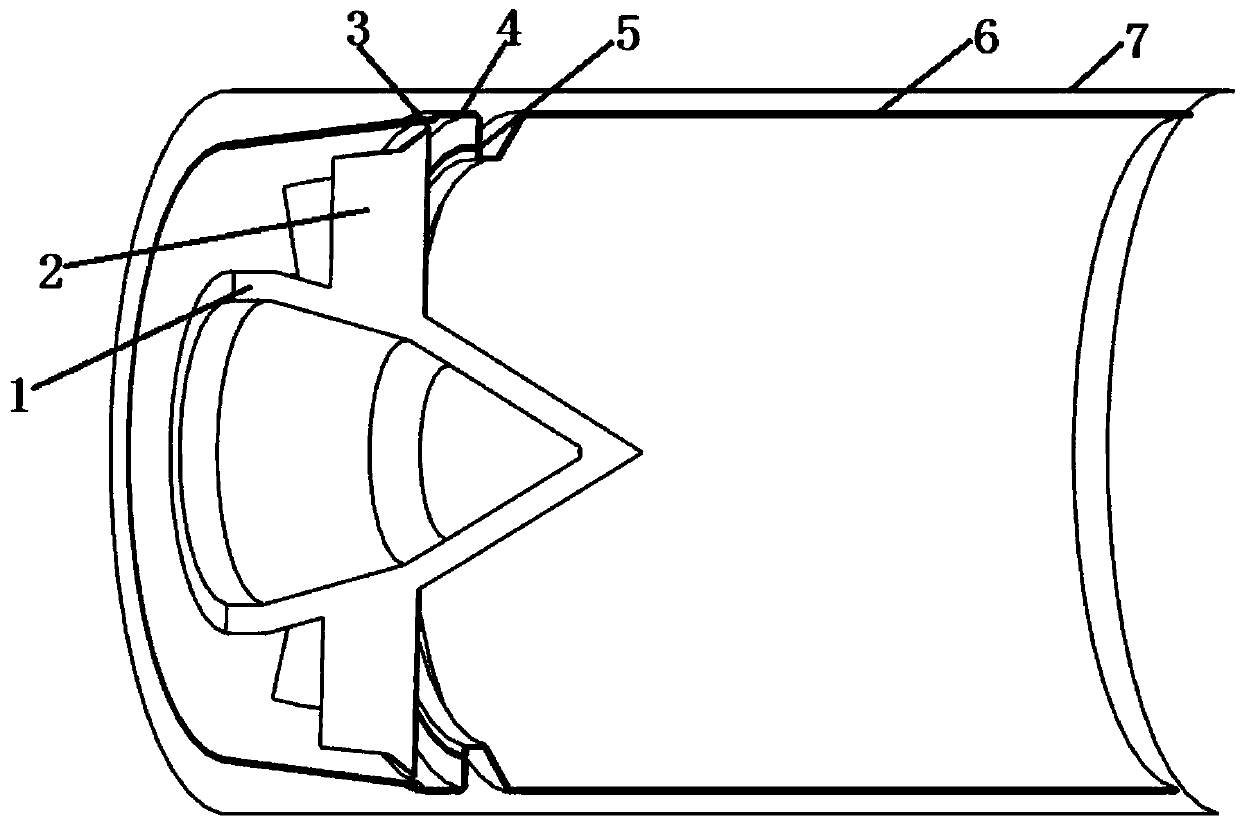

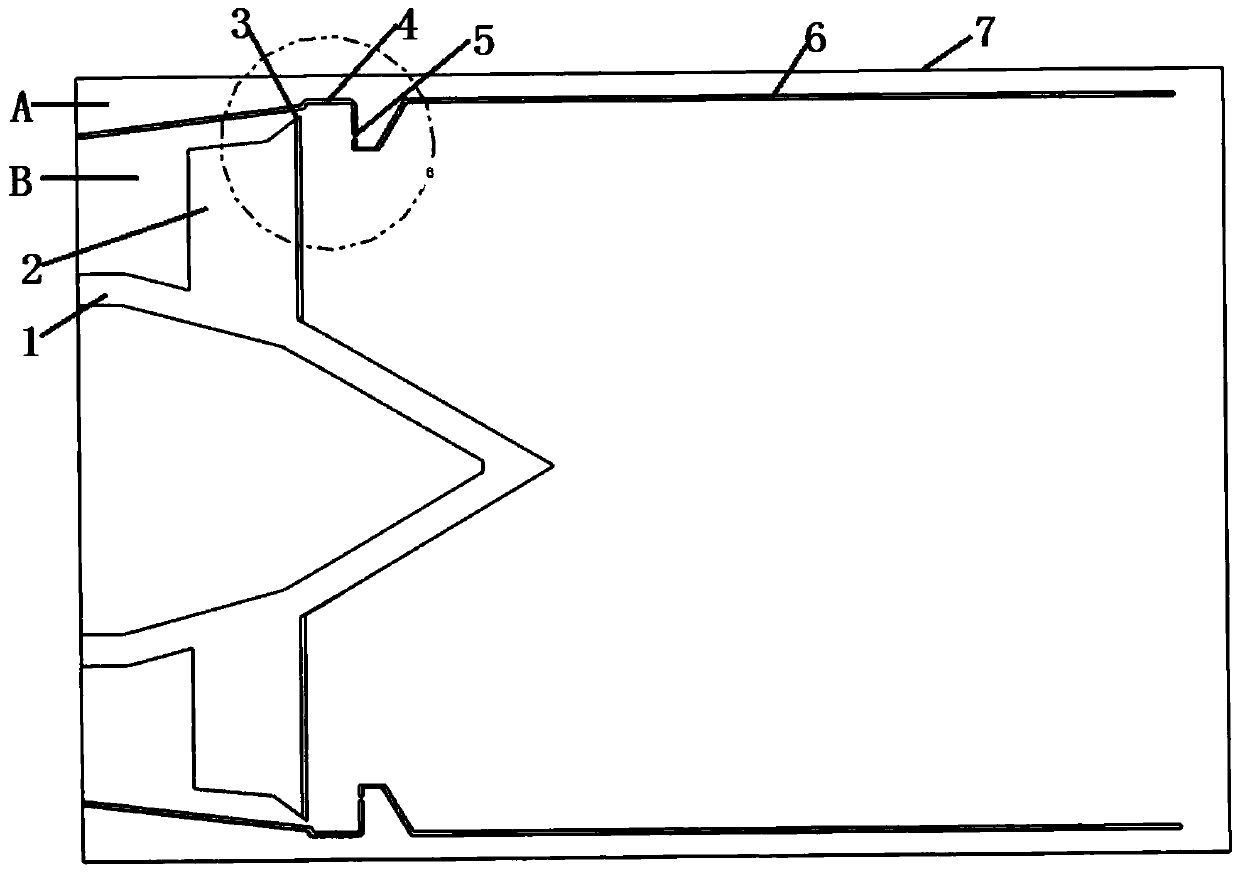

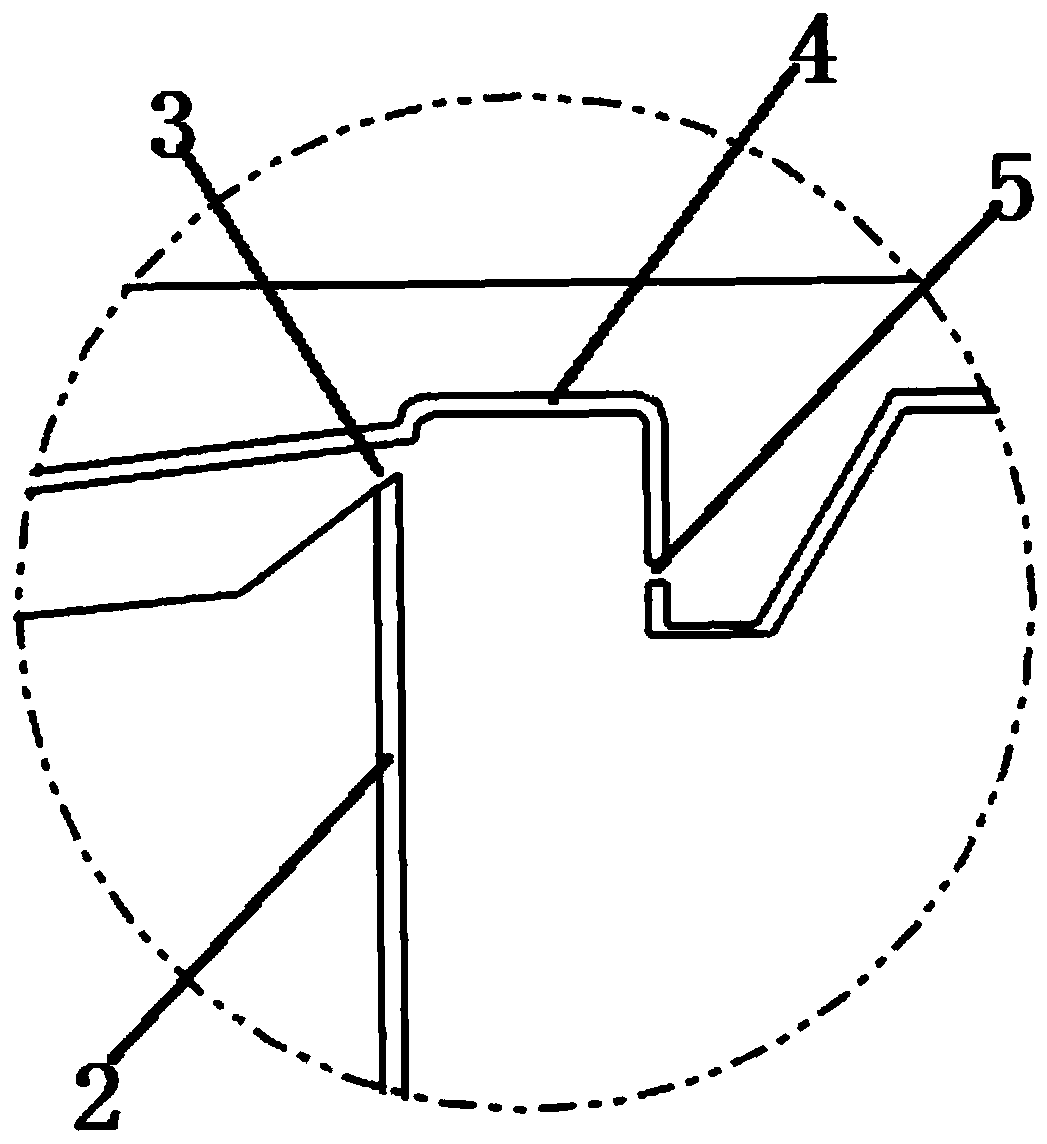

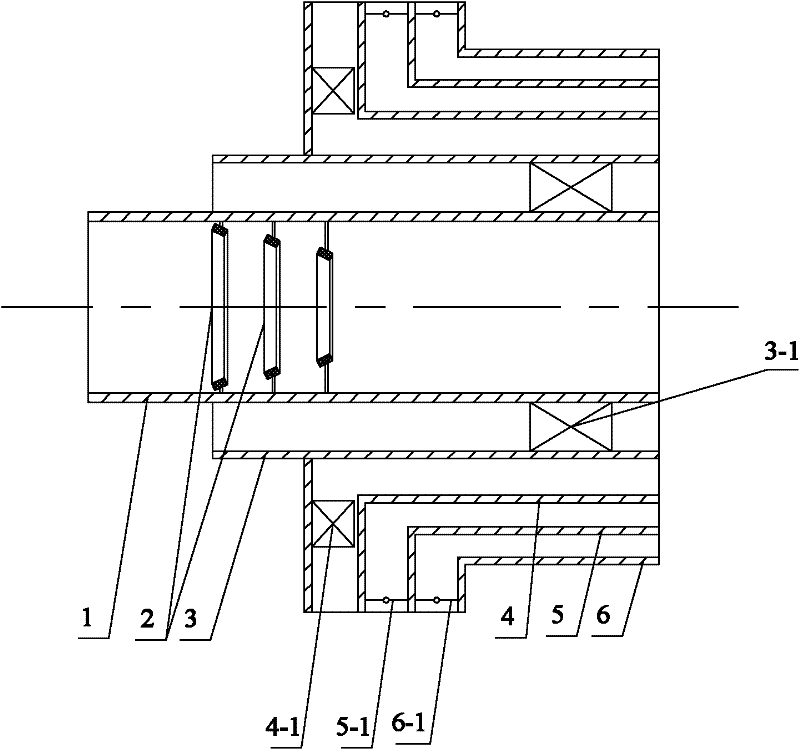

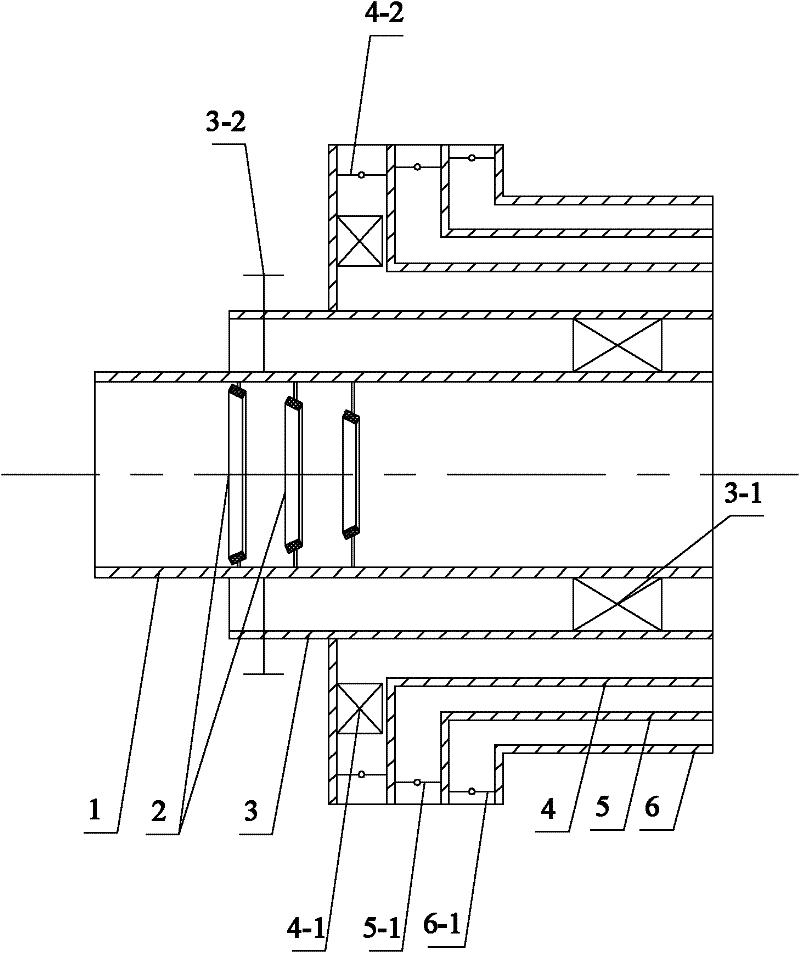

Double-flap swirl-type dual-fuel nozzle used for chemical regenerative cycle

InactiveCN103939944AReduce flow rateReduce axial speedContinuous combustion chamberWater vaporSpray nozzle

The invention aims to provide a double-flap swirl-type dual-fuel nozzle used for a chemical regenerative cycle. The double-flap swirl-type dual-fuel nozzle comprises an auxiliary oil-path channel wall, a main oil-path channel wall, a gas-path outer wall and an oil-path spout. An auxiliary oil-path channel is formed inside the auxiliary oil-path channel wall, and an auxiliary oil-path swirler is arranged at the end of the auxiliary oil-path channel wall and communicated with the oil-path spout. The main oil-path channel wall is arranged outside the auxiliary oil-path channel wall, and a main oil-path channel is formed between the main oil-path channel wall and the auxiliary oil-path channel wall and communicated with the oil-path spout. The gas-path outer wall is arranged outside the main oil-path channel wall, and a gas-path channel is formed between the gas-path outer wall and the main oil-path channel wall. Flap type swirl cavities are formed in the end, located on the oil-path spout, of the gas-path outer wall, and gas injection holes are formed in the end faces of the flap type swirl cavities and communicated with the gas-path channel. According to the double-flap swirl-type dual-fuel nozzle, the flow speed is decreased, the swirl speed is pre-increased, and mixing of gas fuel and air is enhanced. When liquid fuel is combusted independently, water vapor reinjection can also be conducted through a gas path, and NOx emission is reduced.

Owner:三亚哈尔滨工程大学南海创新发展基地

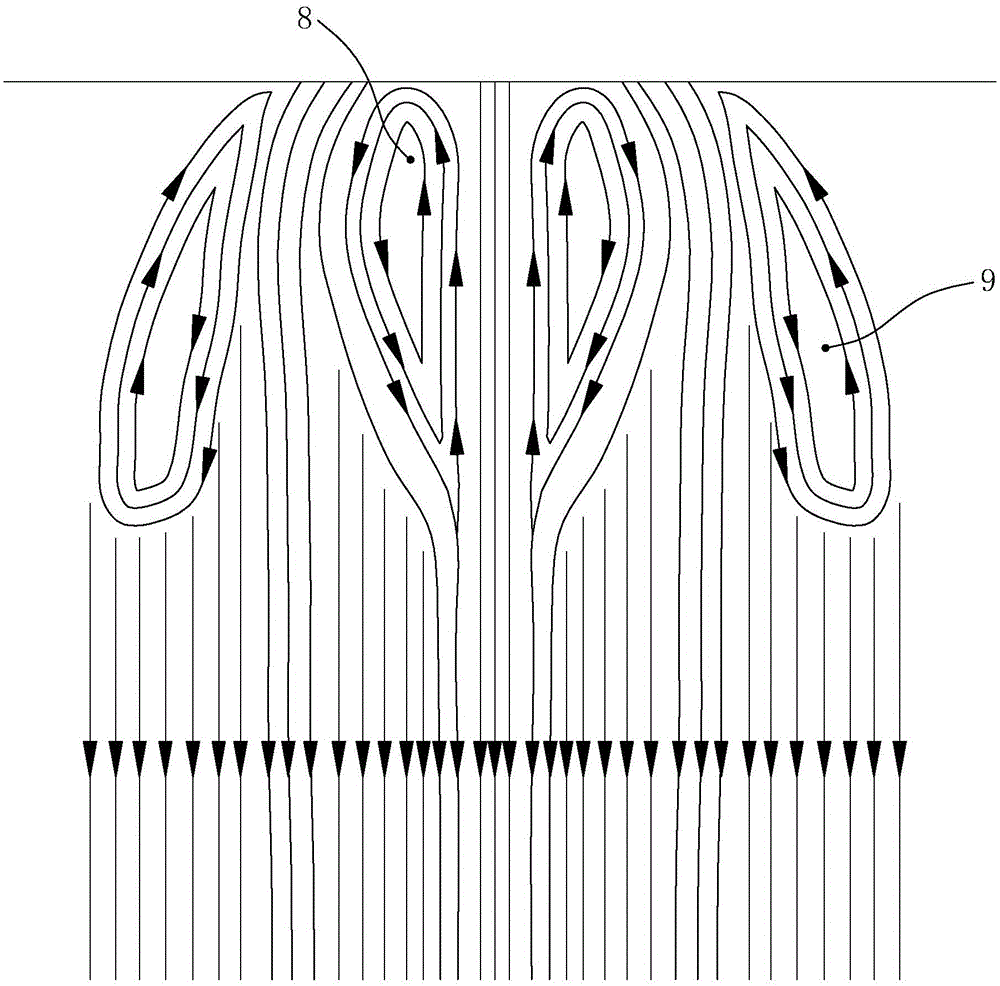

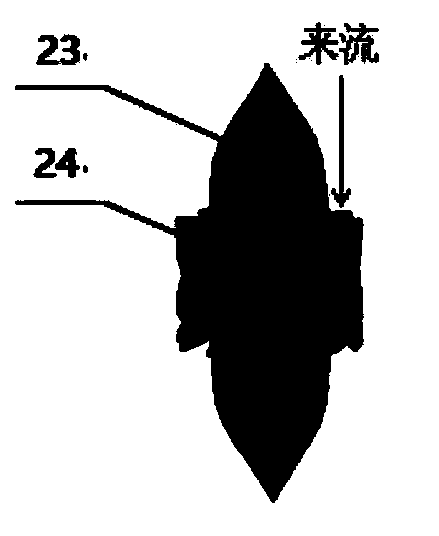

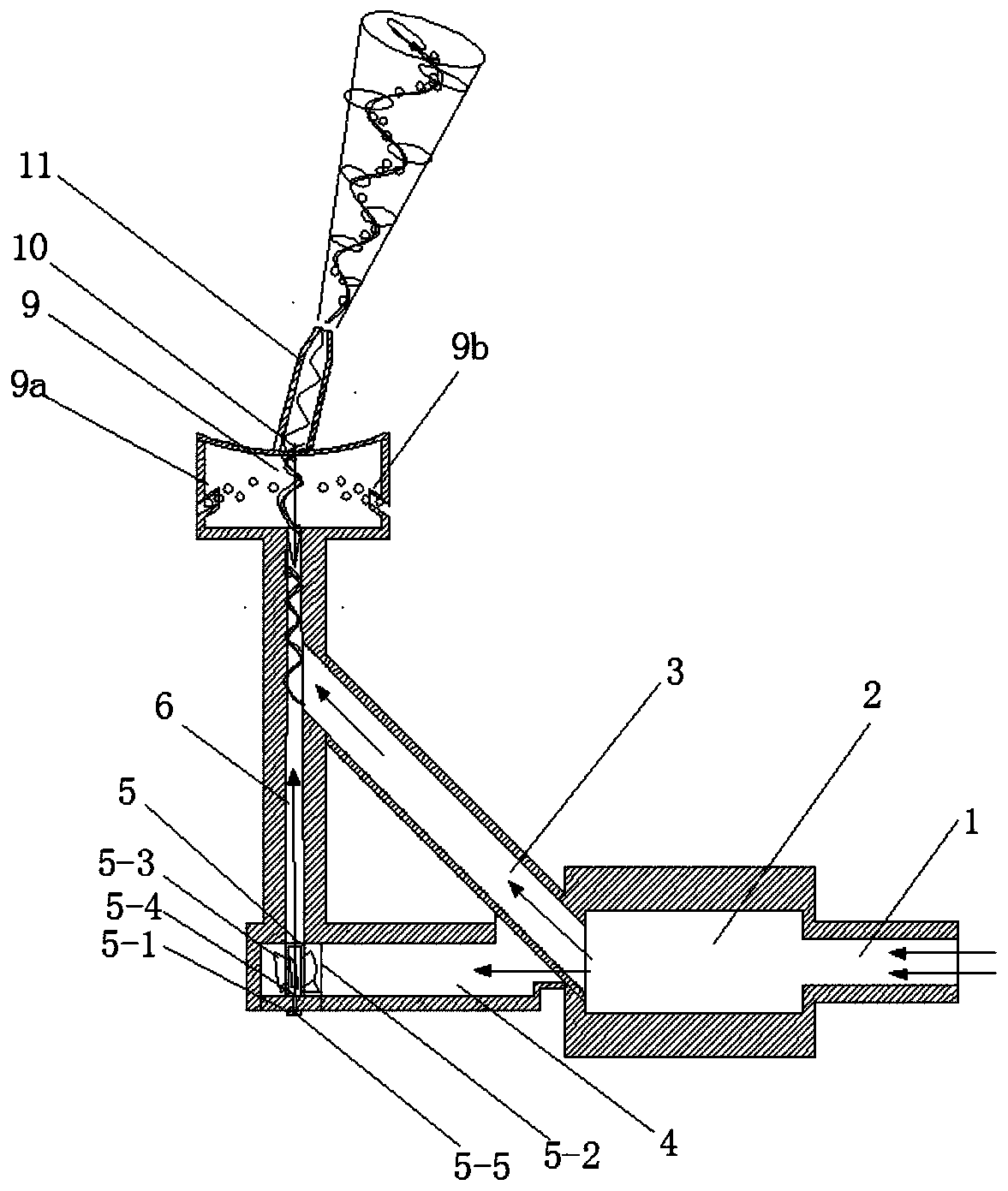

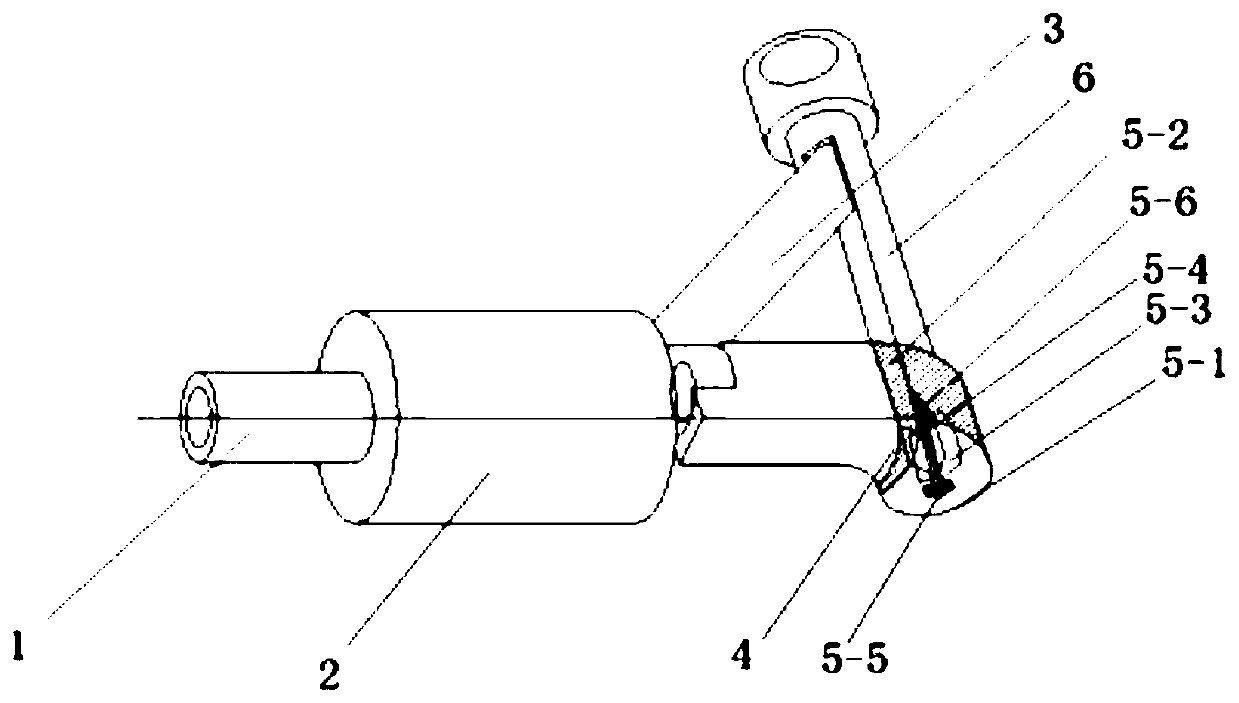

Suspension smelting method and suspension smelting nozzle

ActiveCN105112683APromote fireImprove responseRotary drum furnacesCrucible furnacesReaction speedTower

The invention provides a suspension smelting method. According to the method, the heating speed and the reaction speed of materials are increased by a central backflow area and / or an external backflow area as well as grading reaction; by the aid of higher cyclone intensity, mixing uniformity of the materials and oxygen-enriched air is improved, and the suspension time of the materials in a reaction tower is increased; metallurgy reaction proceeding and sufficient reaction are promoted remarkably, the productivity of a flash furnace is improved, and suspension smelting of concentrate containing high impurities is realized better. The invention further provides a suspension smelting nozzle for implementing the suspension smelting method.

Owner:YANGGU XIANGGUANG COPPER

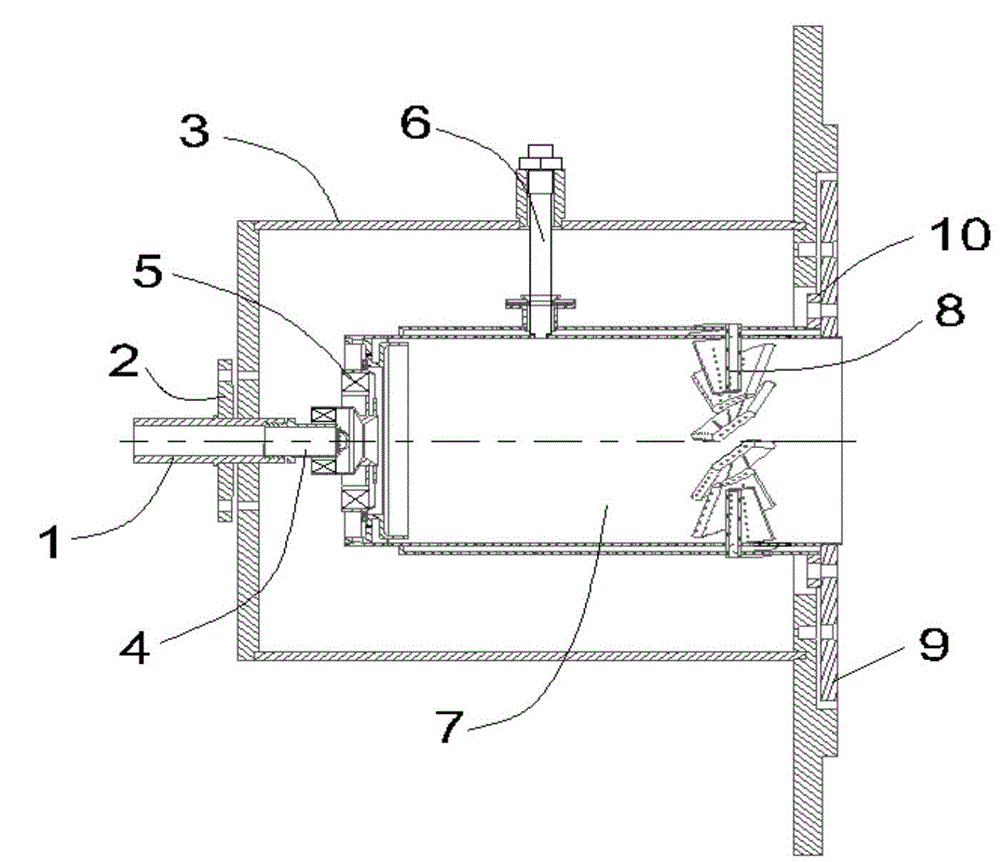

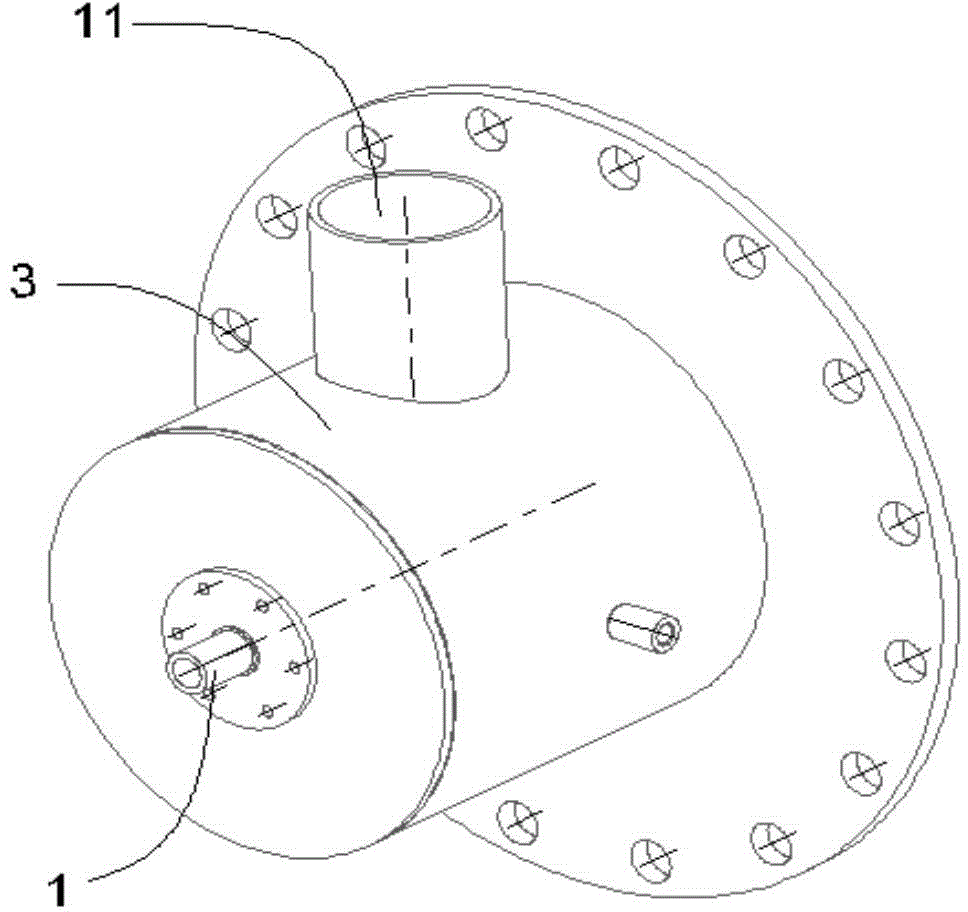

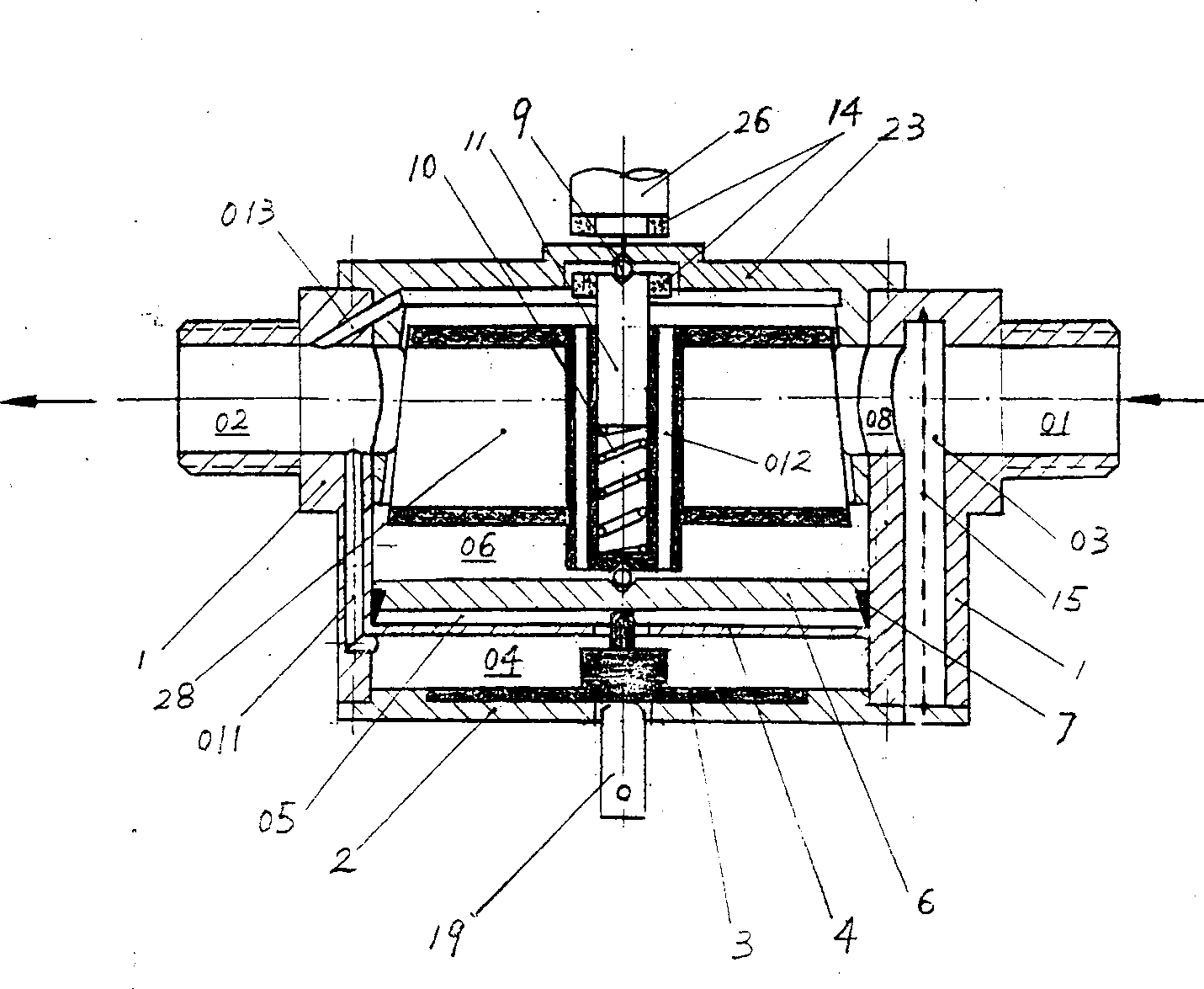

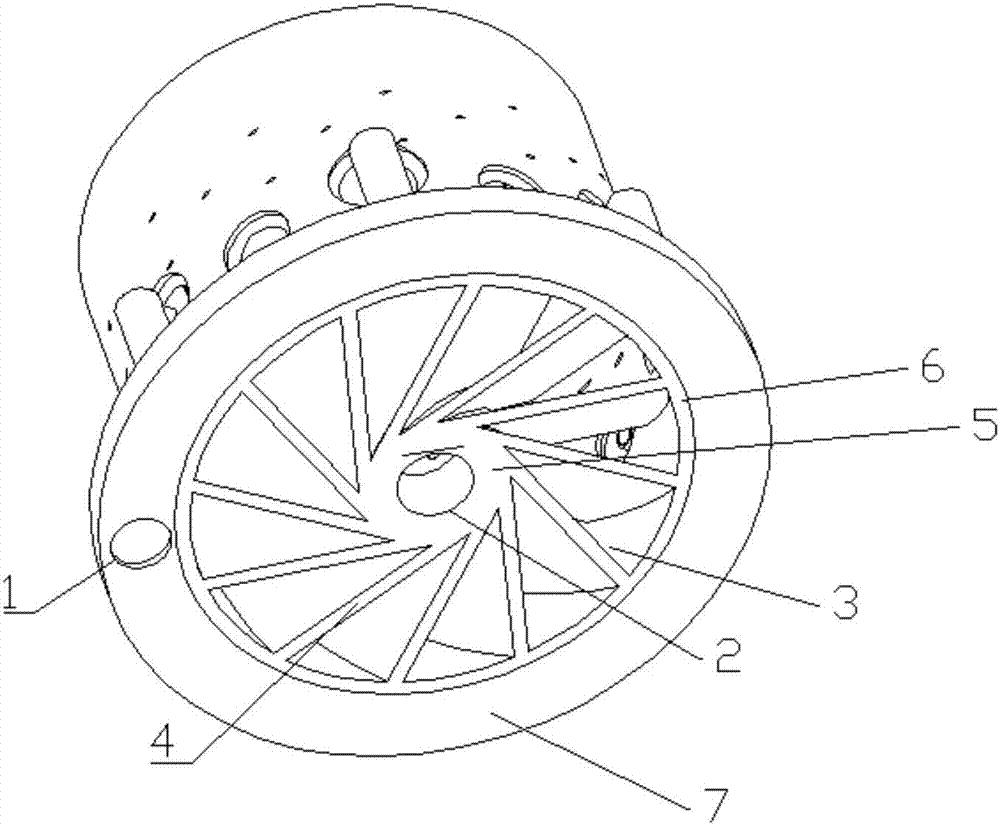

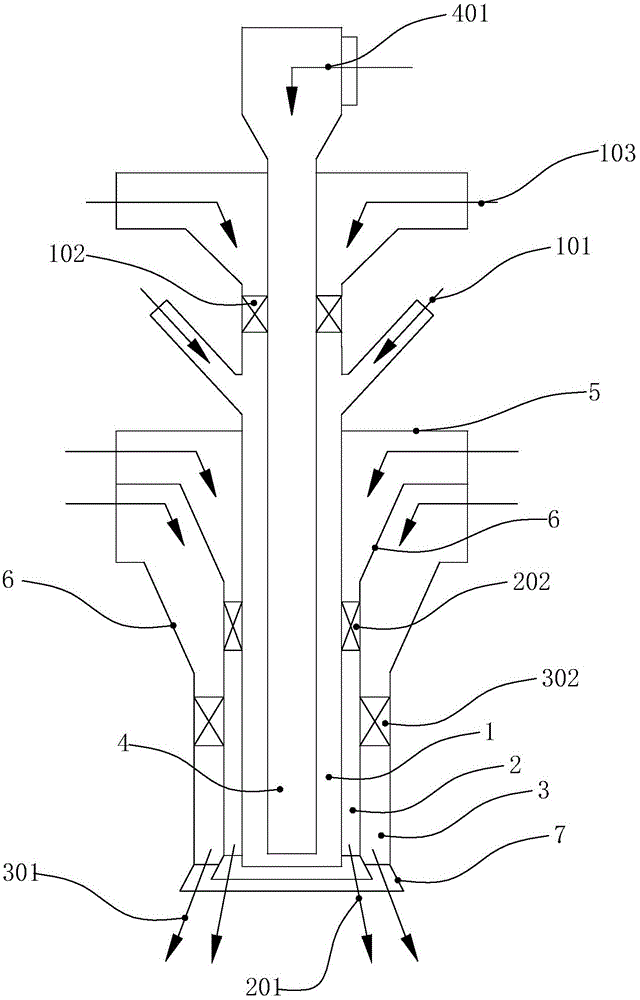

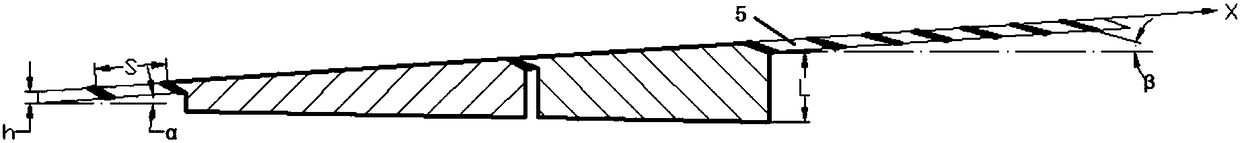

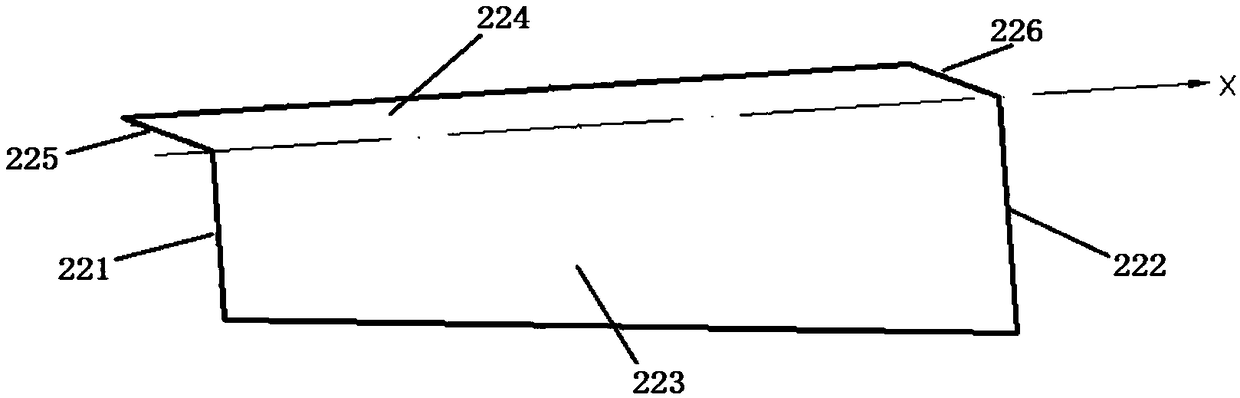

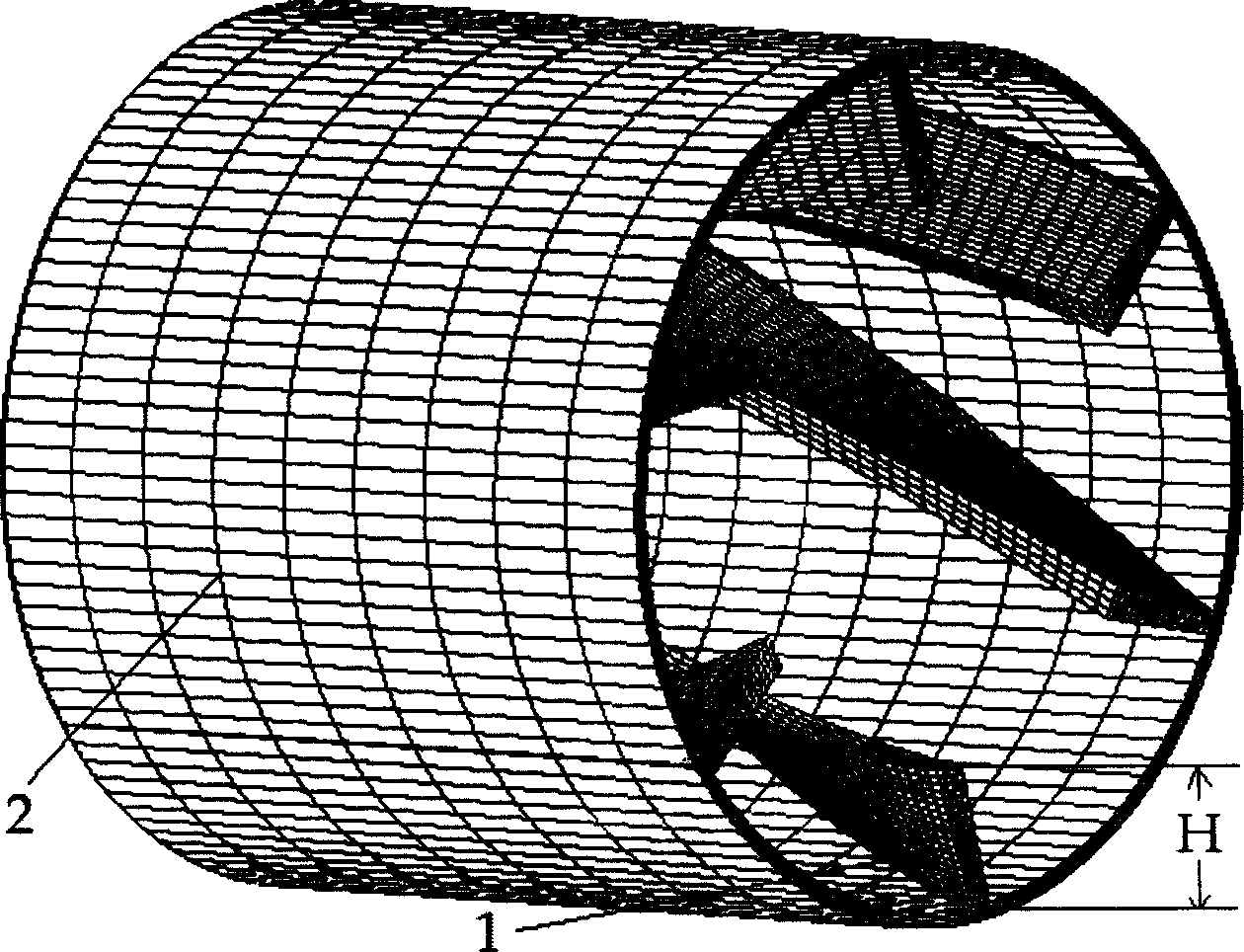

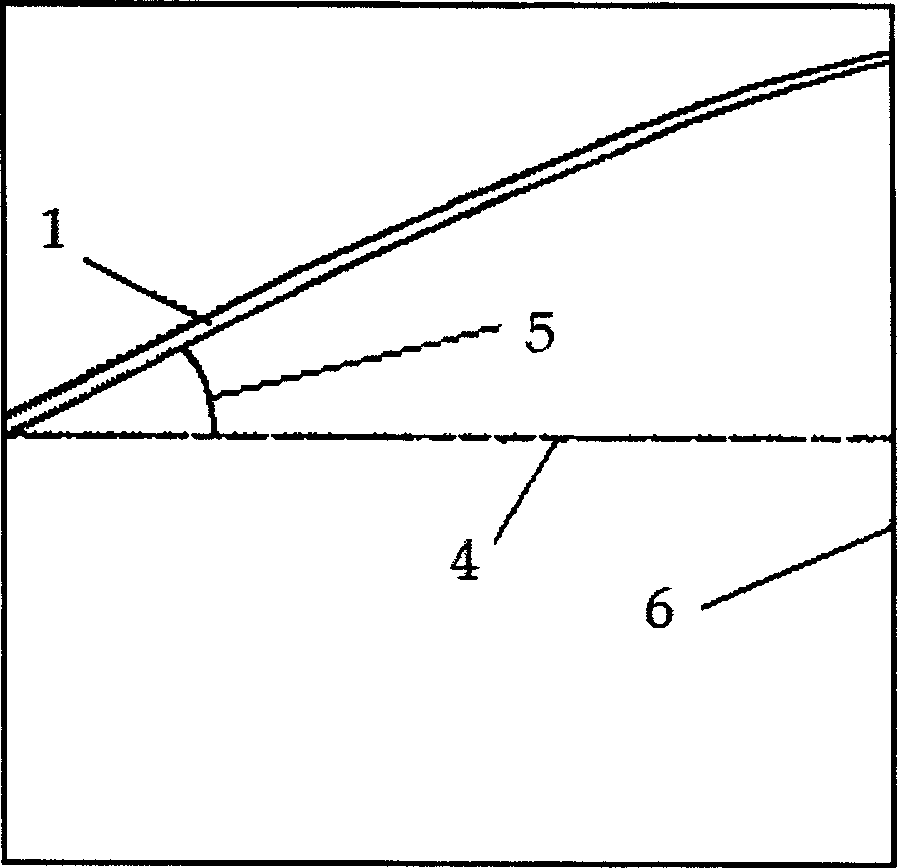

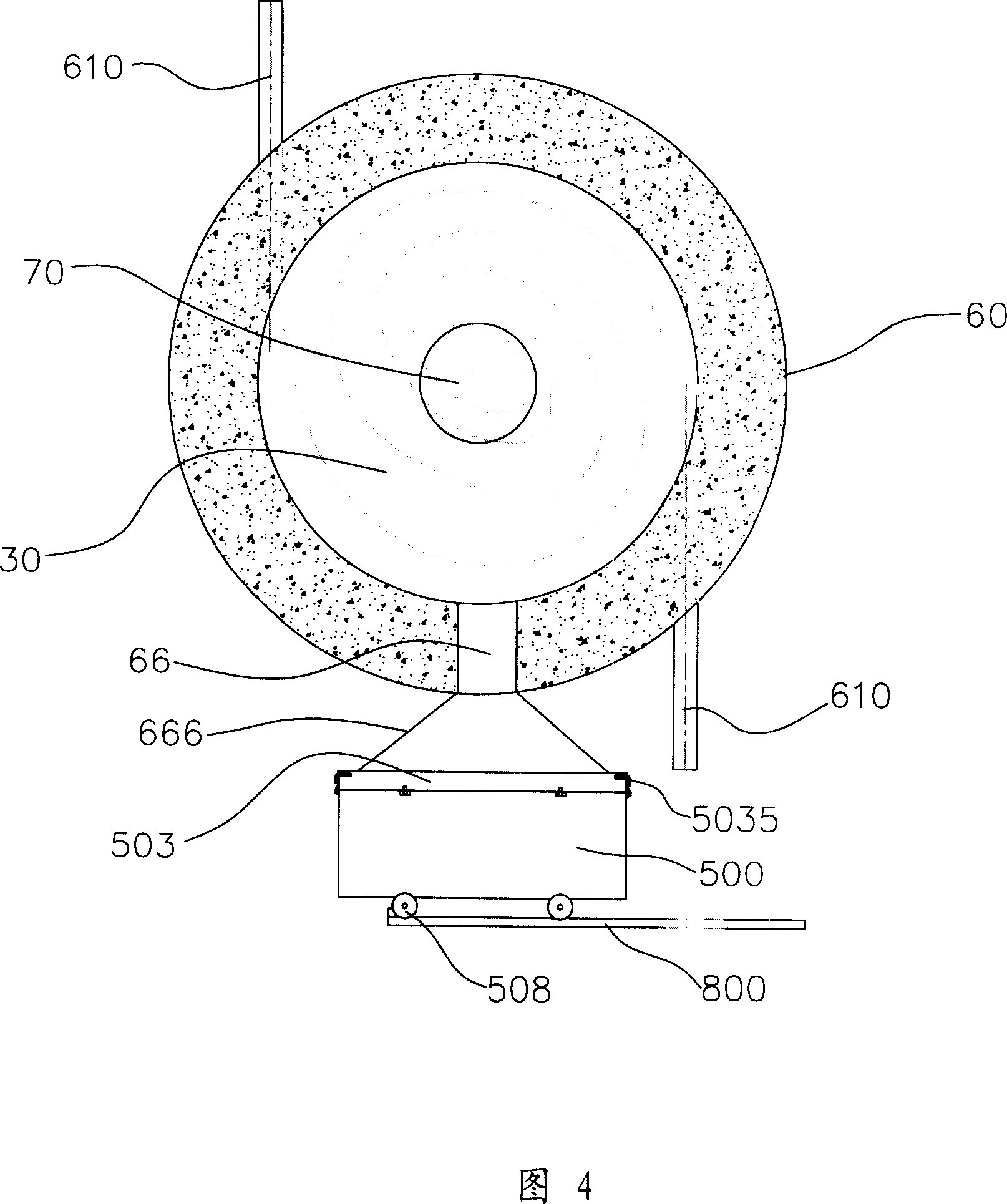

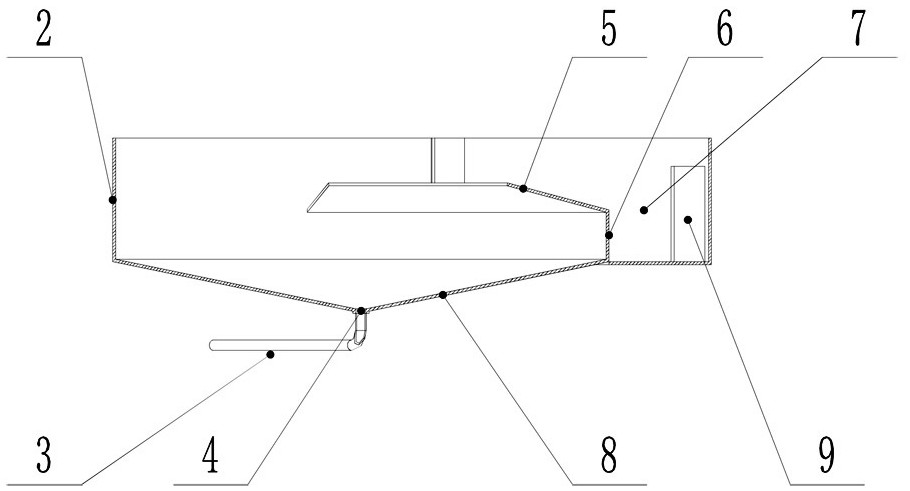

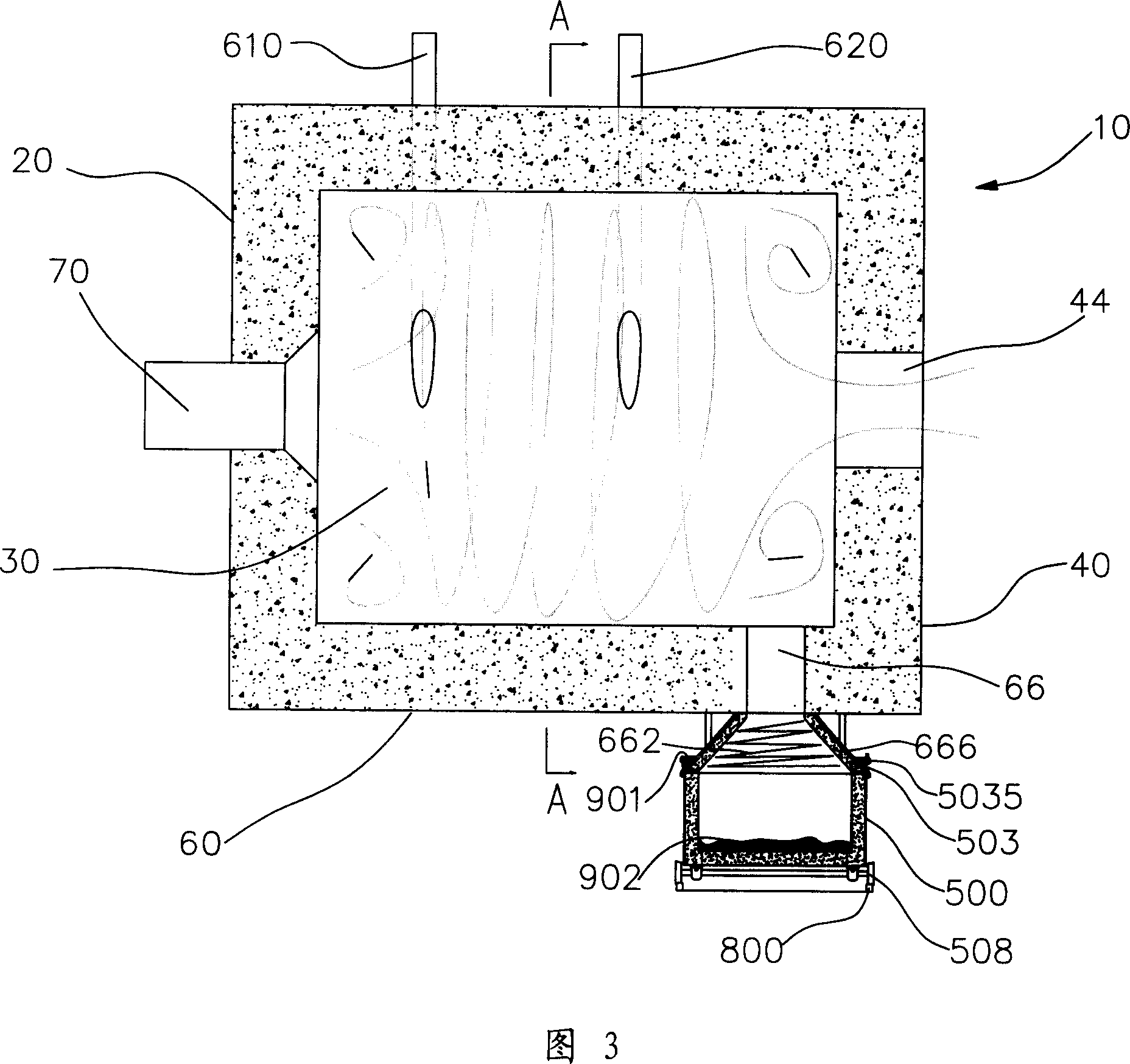

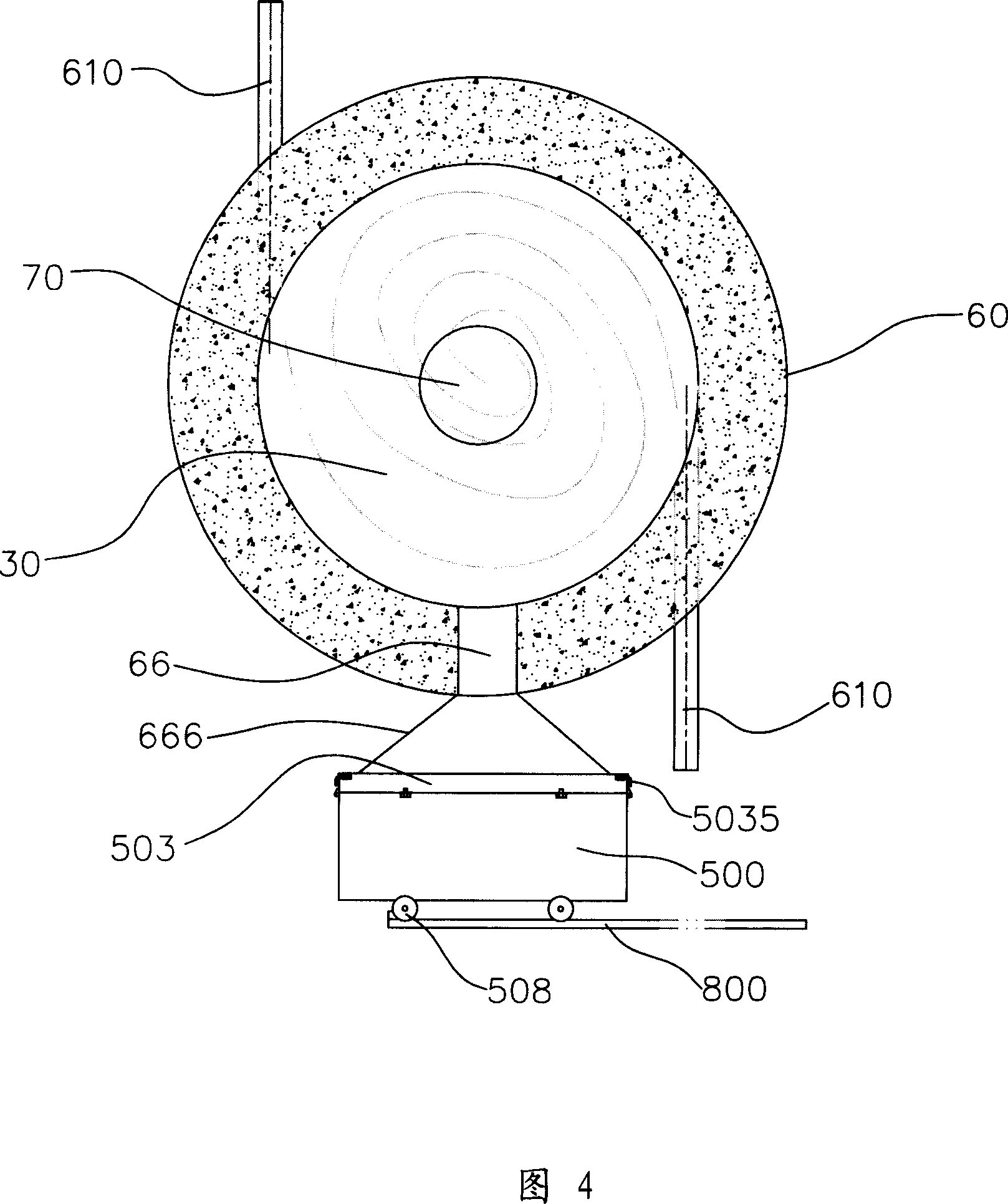

Pipeline type multistage oil-water separator utilizing angular momentum conservation

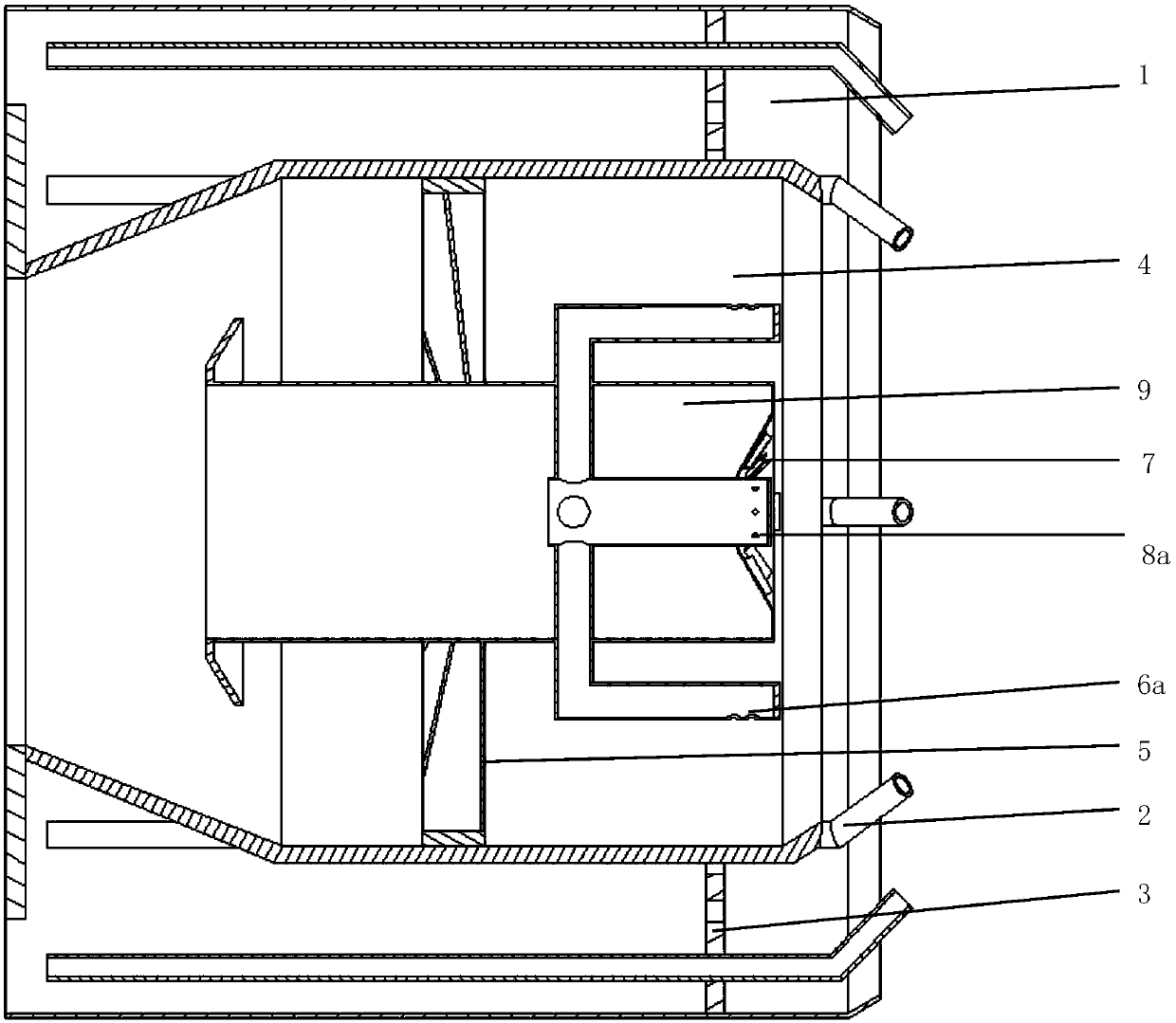

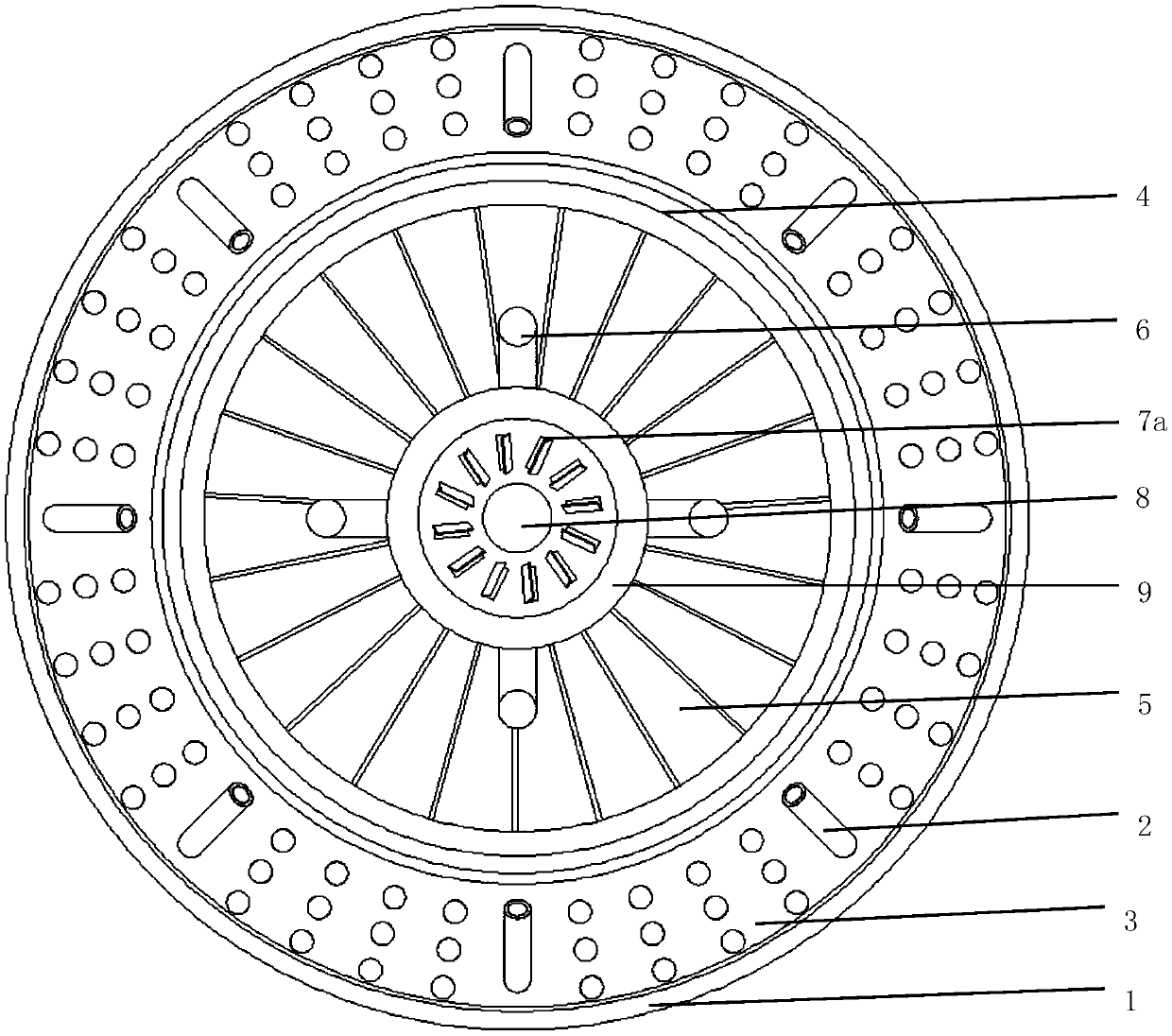

The invention aims to provide a pipeline type multistage oil-water separator utilizing angular momentum conservation. The separator comprises a separator cylinder, the separator cylinder sequentiallycomprises a separator inlet section, a first-stage reducing section, a first-stage separation section, a second-stage reducing section and a second-stage separation section from front to back, a first-stage impeller is arranged at the separator inlet section, a second-stage impeller is arranged at the first-stage separation section, a first-stage oil guide port is formed in the separator inlet section, and a second-stage oil guide port and a third-stage oil guide port are formed in the first-stage separation section. According to the invention, by utilizing the angular momentum conservation principle, a tapered pipeline structure is adopted, the cyclone strength of the separator is enhanced, the separation efficiency is improved, the turbulence intensity in the separator is reduced throughthe unique multi-stage oil guide opening structure of the separator, excessive breaking of oil drops is avoided, and efficient separation under the wide oil content condition can be met.

Owner:HARBIN ENG UNIV

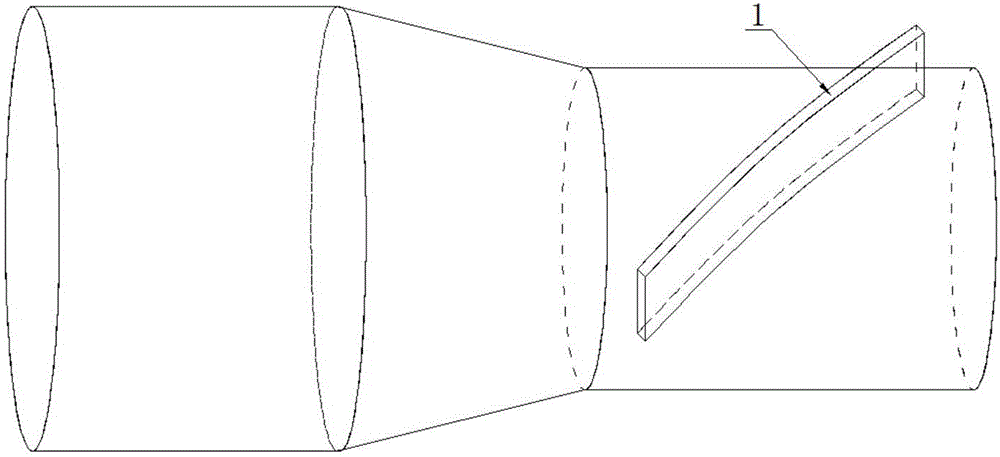

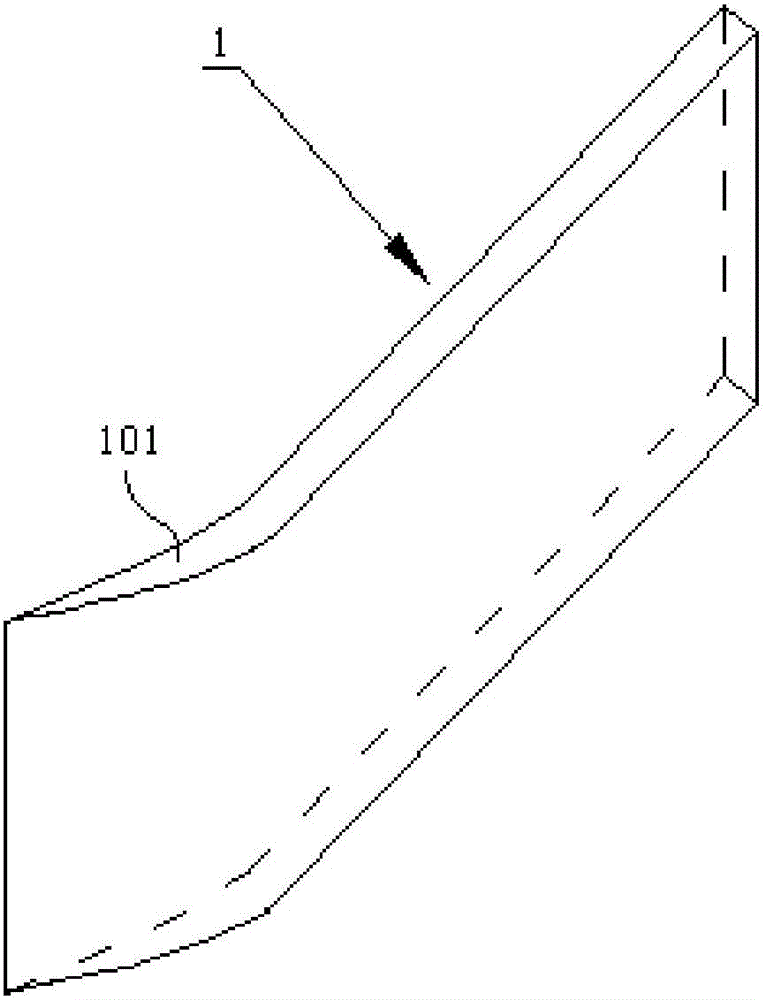

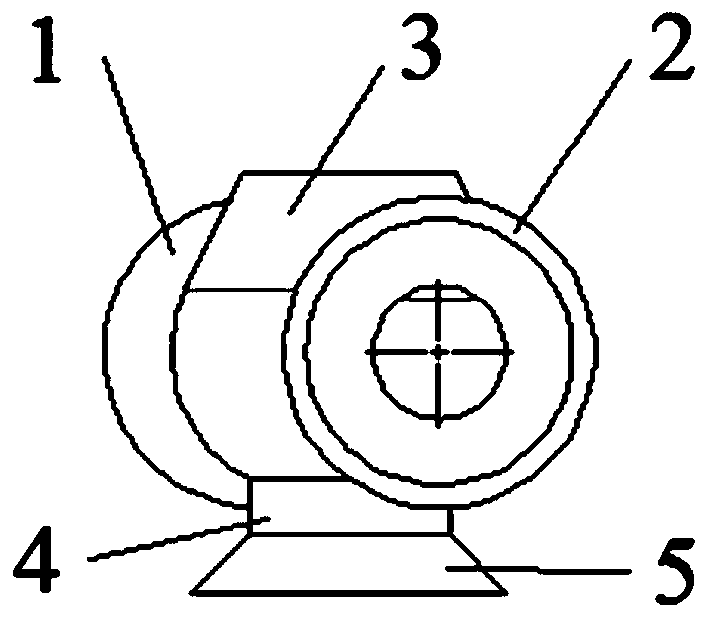

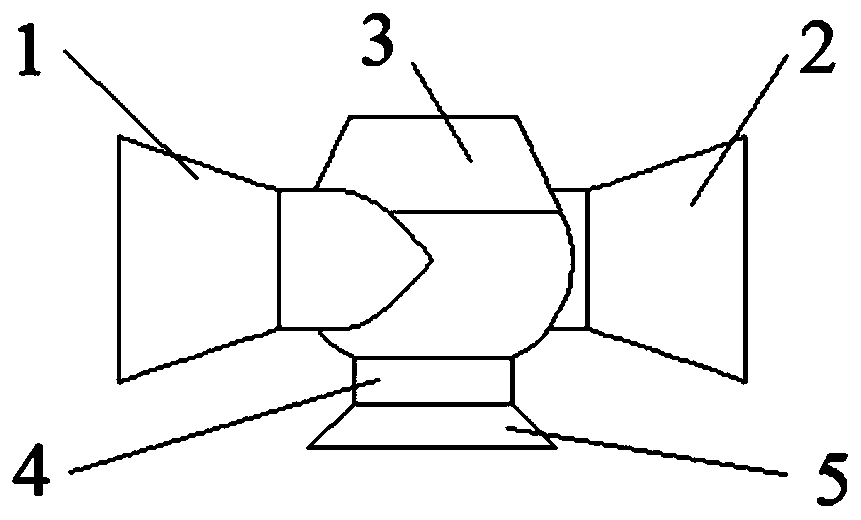

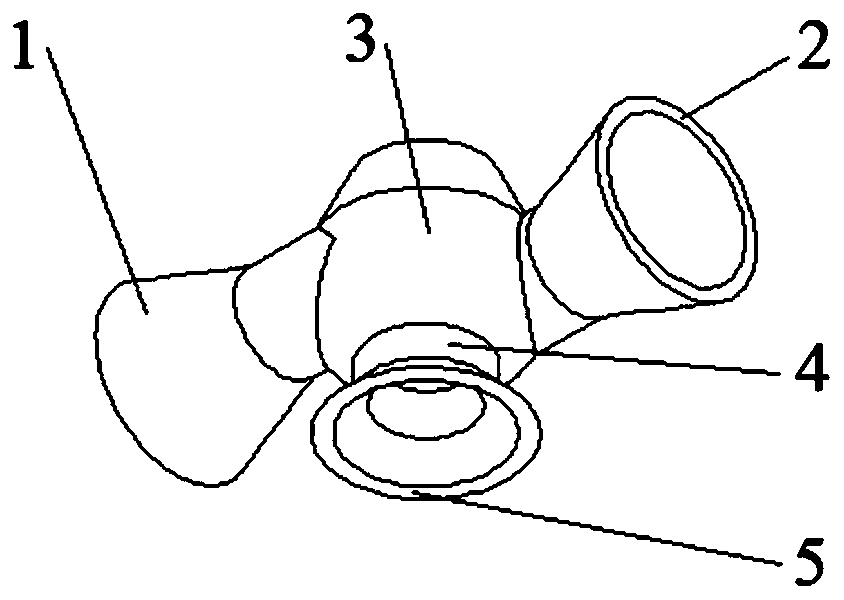

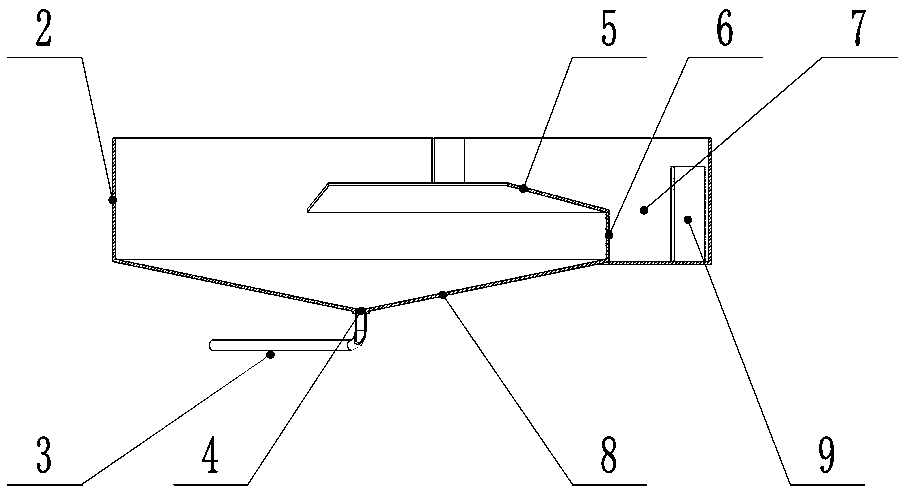

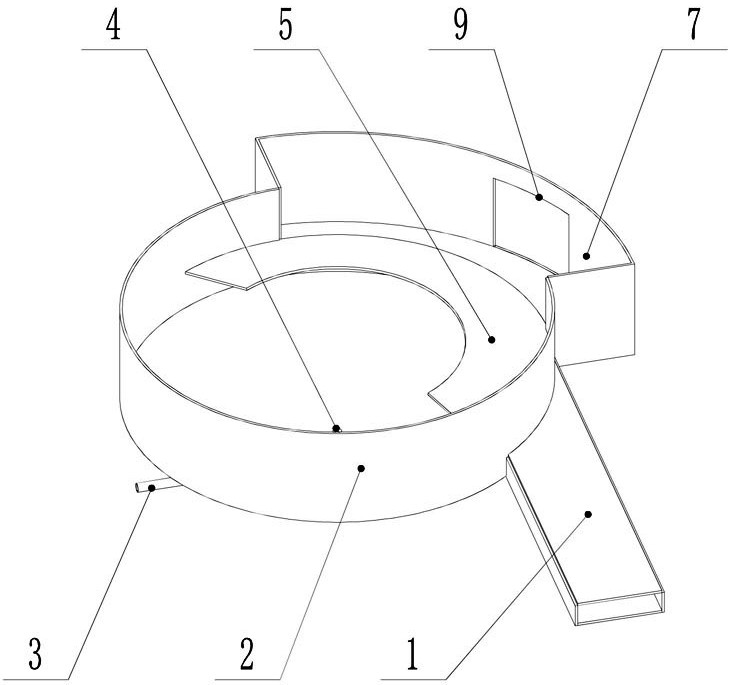

Swirling piece, swirling burner and manufacturing method of swirling burner

The invention discloses a swirling piece, a swirling burner and a manufacturing method of the swirling burner and relates to the field of swirling combustion equipment adopting the swirling piece. The swirling piece comprises a swirling piece body. An against-wind section is arranged at one end of the swirling piece body, and a wind outlet section is arranged at the other end of the swirling piece body. Fluid flows towards the wind outlet section from the against-wind section. The thickness of the against-wind section is gradually increased in the flowing direction of the fluid till being the same as that of the swirling piece body. The swirling burner comprises an inner pipeline, an outer pipeline, one swirling piece arranged on the inner wall of the inner pipeline, one swirling piece arranged on the outer wall of the inner pipeline and / or one swirling piece arranged on the inner wall of the outer pipeline, wherein, the inner pipeline is sleeved with the outer pipeline. According to the swirling piece, the swirling burner and the manufacturing method of the swirling burner, pressure loss after the high speed fluid passes through the swirling piece can be reduced by the swirling piece and the swirling burner at low cost, and the mounting procedure of the swirling piece can be greatly simplified through the manufacturing method of the swirling burner.

Owner:ANHUI CHENGMING HEAT ENERGY TECH

Device for preventing burner nozzle from bonding slag, with axial adjustable blades

PendingCN108167823ADecreased swirl intensityIncrease swirl intensityCombustion apparatusIndirect carbon-dioxide mitigationCombustorBoiler furnace

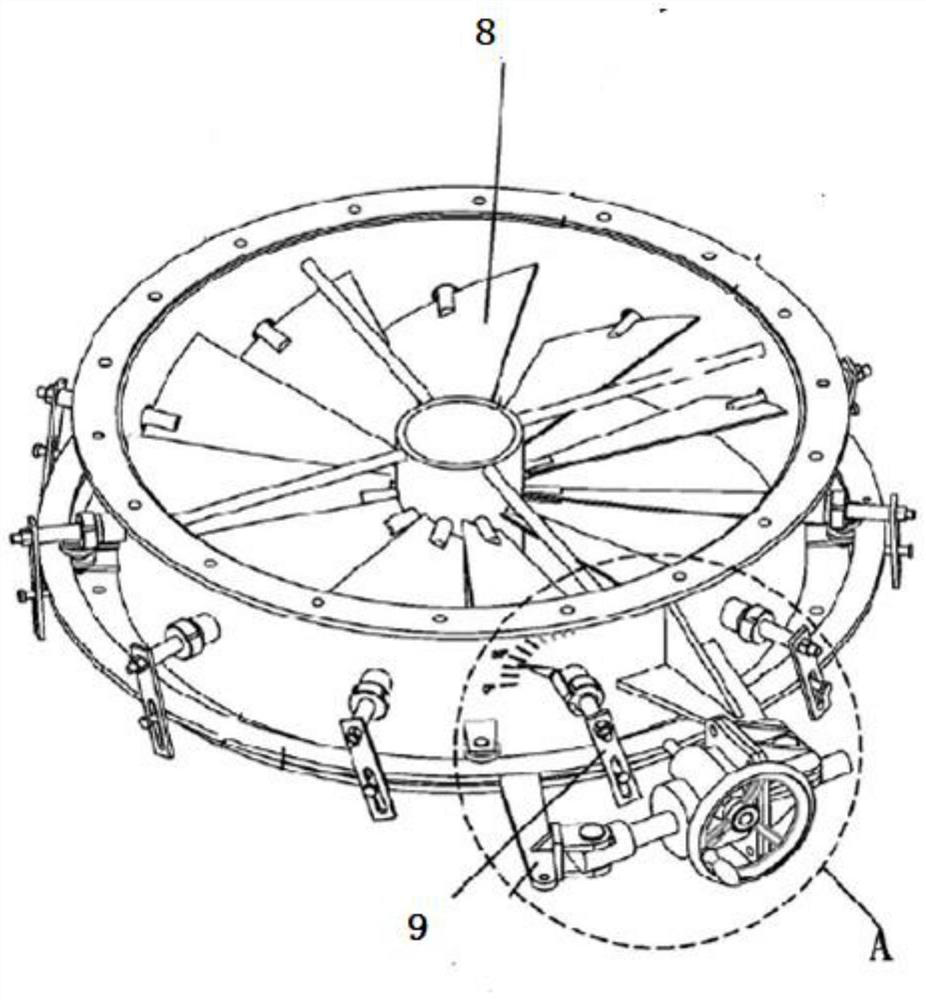

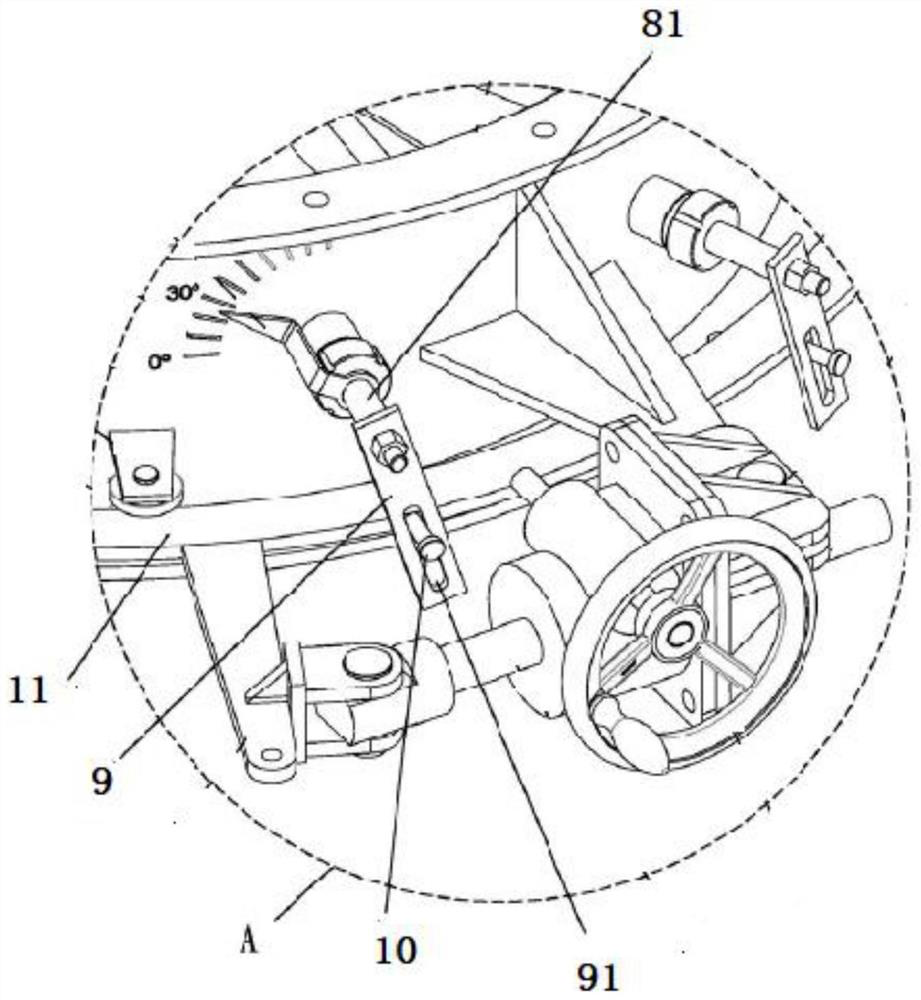

The invention discloses a device for preventing a burner nozzle from bonding slag, with axial adjustable blades. The device comprises a precombustion chamber, a burner body and a furnace, wherein theouter wall of the precombustion chamber is provided with remote over-fire air ducts distributed annually, and the burner body communicates with an inlet of the precombustion chamber; a nozzle of the precombustion chamber and outlets of the remote over-fire air ducts communicate with a boiler furnace; and the remote over-fire air ducts are internally provided with a plurality of axial blades used for regulating the swirling intensity of remote over-fire air, and the outer wall of each remote over-fire air duct is provided with a linkage regulating device which is composed of an angle regulatinghandle, a dial, a linkage device and a transmission device and used for regulating the angle of the axial blades. The device can be used for preventing the burner nozzle from bonding the slag, and the safe, efficient and stable combustion in the furnace is ensured.

Owner:XI AN JIAOTONG UNIV

Flow guiding and flow whirling integrated blade grid type device and combustion chamber

ActiveCN108361735AReduce weightShorten the lengthContinuous combustion chamberFlame propagationCombustion chamber

The invention provides a flow guiding and flow whirling integrated blade grid type device and a combustion chamber. The blade grid type device comprises a front blade grid section, a flow whirling section and a rear blade grid section, wherein the flow whirling section is connected with the front blade grid section and is used for making air flow generate partial tangent flowing; the rear blade grid section is connected with the other end of the flow whirling section; the front blade grid section comprises at least one first circular platform-shaped flow guide plate; and the rear blade grid section comprises at least one second circular platform-shaped flow guide plate. The blade grid type device provided by the invention implements distribution of inlet flow of the combustion chamber by utilizing the flow guide plates of the front and rear blade grid sections and forms reasonable and uniform centrifugal force distribution of the combustion chamber by utilizing rotational flow generated by the flow whirling section so as to enhance oil and gas mixing and promote flame propagation. The combustion chamber which utilizes the blade grid type device is simplified in structure and is reduced in weight, so the thrust-weight ratio of an engine is increased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

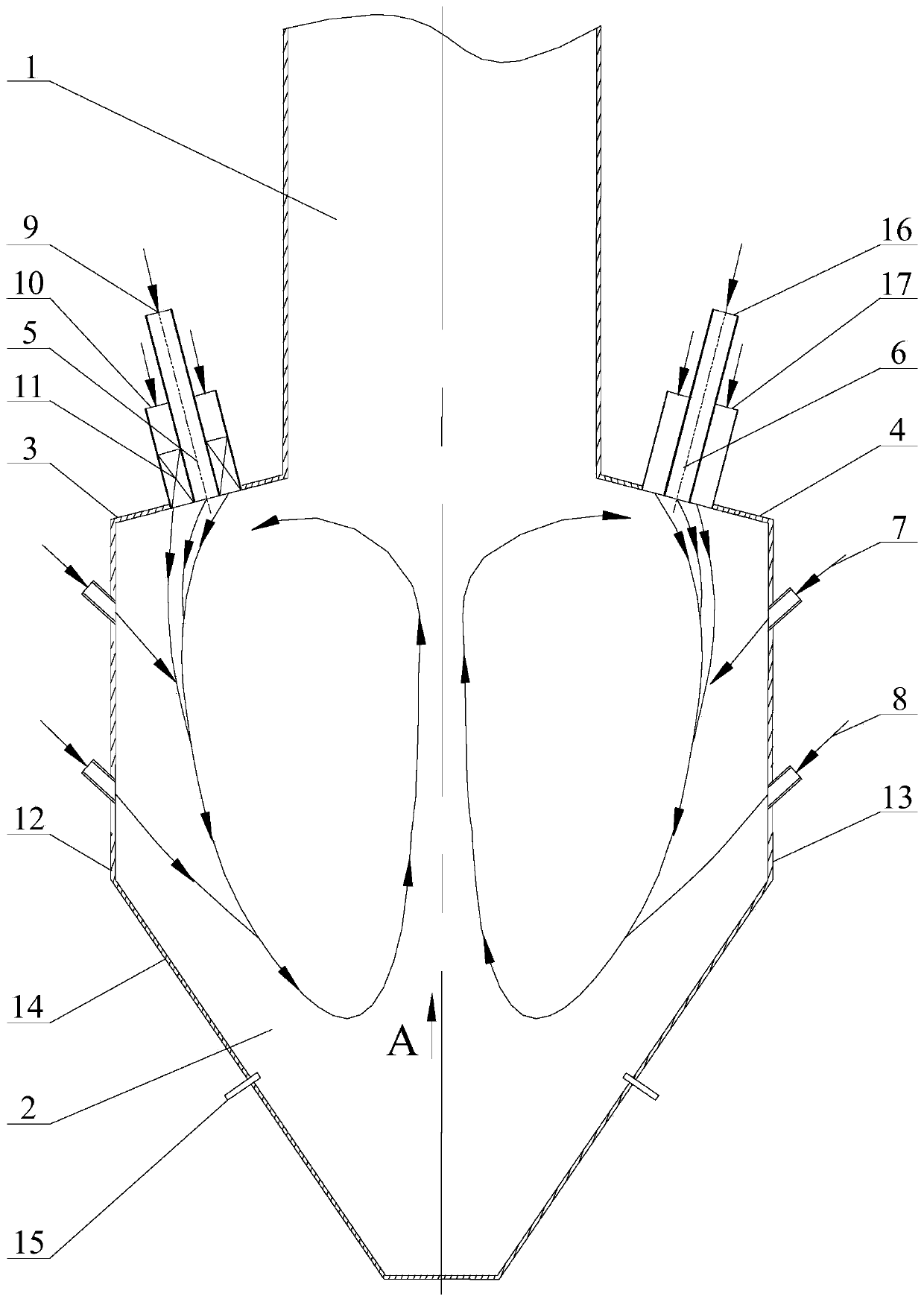

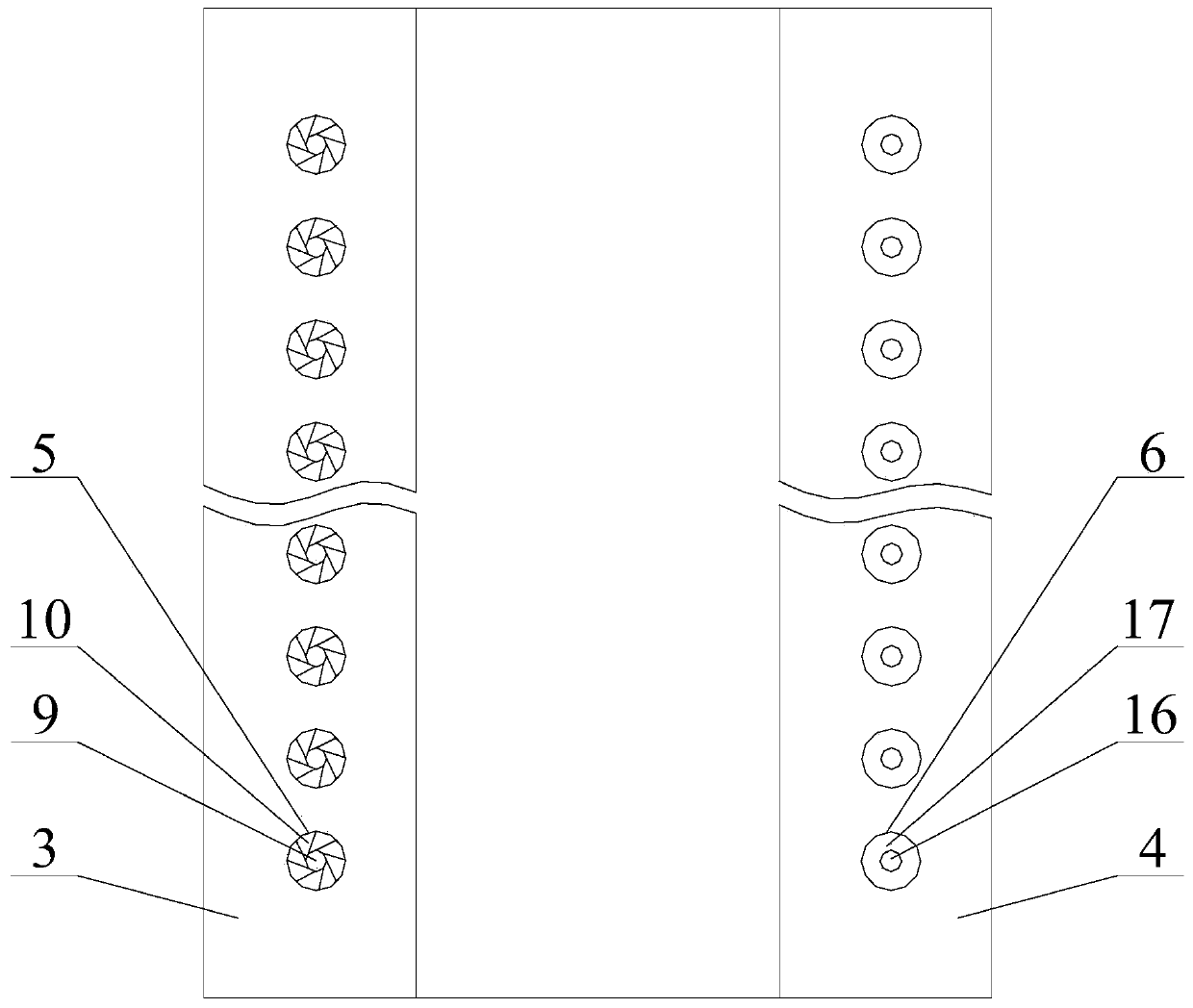

W flame boiler provided with turbulent burners and direct flow burners

ActiveCN109931598AReduce extrusionLow shot depthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBoiler furnacePrimary channel

The invention discloses a W flame boiler provided with turbulent burners and direct flow burners and relates to a pulverized coal boiler, and belongs to the technical field of boiler combustion. The Wflame boiler provided with the turbulent burners and the direct flow burners aims to solve the problem the flow field in the W flame boiler deflects. The W flame boiler provided with the turbulent burners and the direct flow burners comprises an upper hearth, a lower hearth, a front furnace arch, a rear furnace arch and a plurality of graded air spray ports, and further comprises the plurality ofturbulent burners and the plurality of direct flow burners; each turbulent burner comprises a primary air channel I, a secondary air channel I and blades; the secondary air channels are arranged outside the primary channels in a sleeving manner; the blades are arranged in the secondary air channels I; each direct flow burner comprises a primary air channel II and a secondary air channel II; the upper hearth is arranged above the lower hearth; the front furnace arch is provided with one row of the turbulent burners in the hearth width direction; the rear furnace arch is provided with one row of the direct flow burners in the hearth width direction; and a plurality of the graded air spray ports are formed in a front wall in the hearth width direction, and a plurality of the graded air sprayports are formed in a rear wall in the hearth width direction.

Owner:HARBIN INST OF TECH

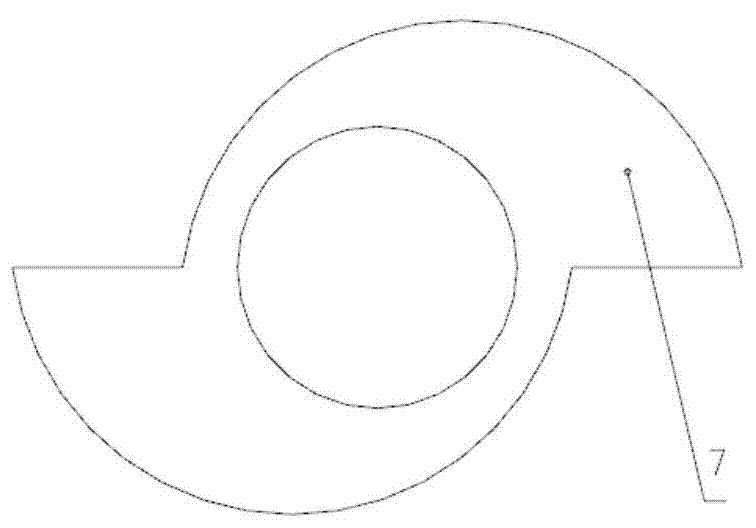

Efficient double-inlet channel rotational flow atomization desulfurization nozzle

PendingCN111330432AIncrease initial kinetic energySymmetrical outflow pathGas treatmentDispersed particle separationFlue gasStraight tube

The invention discloses an efficient double-inlet channel rotational flow atomization desulfurization nozzle. A first inlet channel is communicated with a left side inlet of a rotational flow cavity,a second inlet channel is communicated with a right side inlet of the rotational flow cavity, the upper end of an outlet straight pipe section is communicated with a bottom outlet of the rotational flow cavity, and the lower end of the outlet straight pipe section is communicated with an outlet flaring section; the inner wall of a front side surface of the first inlet channel is tangent to the inner wall of a front side surface of the rotational flow cavity; the inner wall of a rear side surface of the second inlet channel is tangent to the inner wall of the rear side surface of the rotationalflow cavity; the axial line of the outlet straight pipe section, the axial line of the outlet flaring section and the axial line of the rotational flow cavity are located on the same straight line. The nozzle can effectively improve the phenomenon that the space flow of a single-inlet channel atomization desulfurization nozzle is not uniform, reduce the atomization particle size, improve the probability that flue gas reacts with liquid drops and improve the desulfurization efficiency of the flue gas.

Owner:HUANENG POWER INT INC +2

Sand discharge funnel

ActiveCN111270657ASmall wet areaIncrease flow rateBarrages/weirsMechanical engineeringDrainage ditch

The invention provides a sand discharge funnel. The sand discharge funnel comprises a water inlet culvert, an edge wall, a funnel chamber, a flow adjusting suspension plate, an overflow weir and a side groove; the water inlet culvert is connected to the upper portion of the funnel chamber, and is tangential to the outer periphery of the funnel chamber; and a sand discharge bottom hole is formed inthe bottom of the funnel chamber, and is connected to a sand discharge gallery. The edge wall is connected to the upper portion of the funnel chamber to form a first arc section envelope structure. The overflow weir is connected to the upper portion of the funnel chamber to form a second arc section envelope structure. The flow adjusting suspension plate is provided with a center-near end and a center-far end; the center-far end is connected to the upper end of the overflow weir; and the center-near end is near the center of the funnel chamber and higher than the center-far end. The side groove is connected to one side of the overflow weir to form a third arc section envelope structure with the edge wall; and a drainage ditch port is formed in the side groove. Through structural improvement, the problems of bad sediment accumulation at the bottom of the funnel chamber and on the suspension plate and high sand discharge water consumption rate are solved, and the sand discharge efficiency of the sand discharge funnel is improved.

Owner:XINJIANG AGRI UNIV

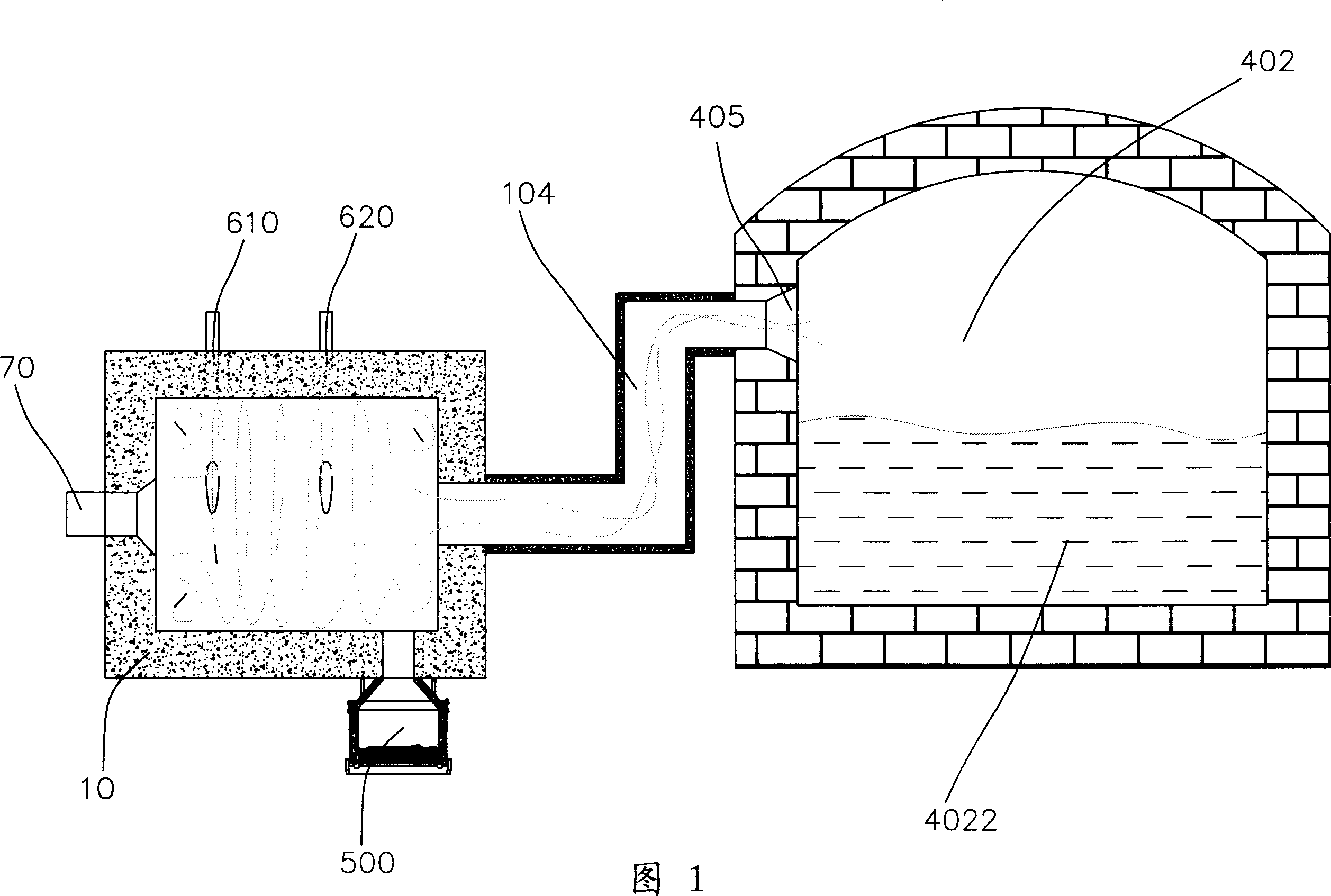

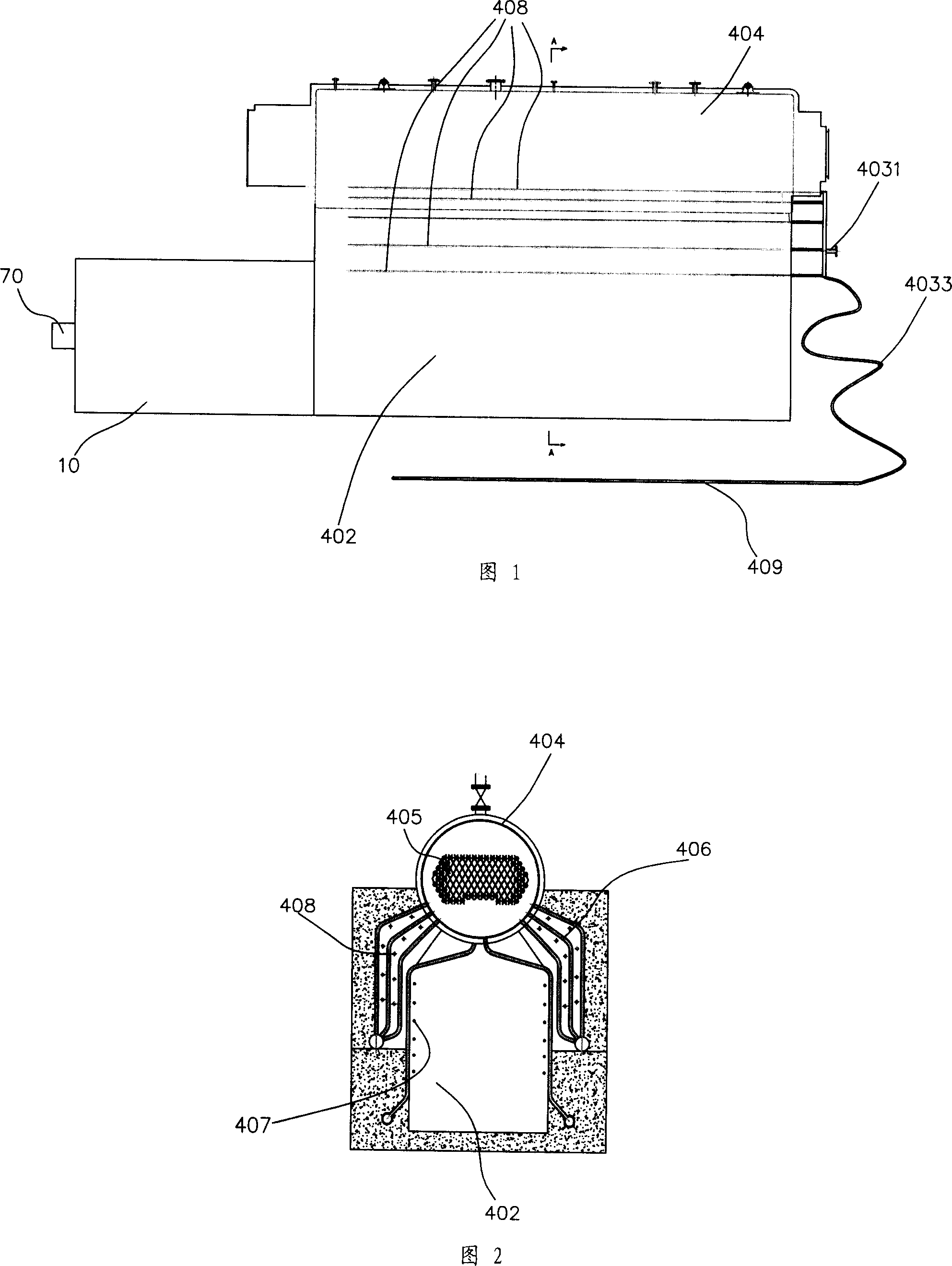

Glass kiln with emulsified coke slurry burner

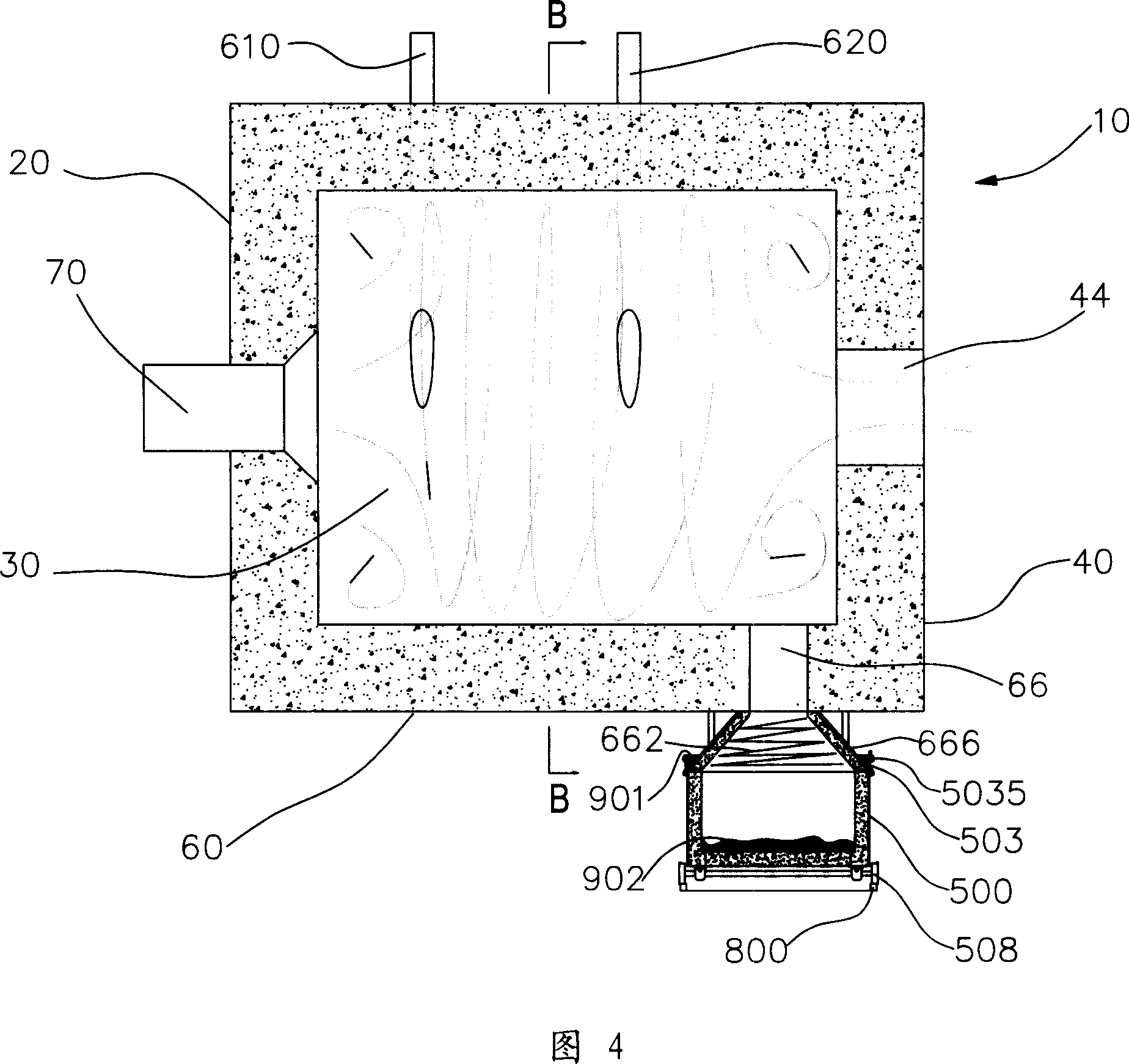

InactiveCN101020596AEfficient and stable combustionMake up for the shortcomings of low calorific valueGlass furnace apparatusGlass productionBurn unitsBrick

The glass kiln with emulsified coke slurry burner includes one kiln body and one emulsified coke slurry burner. The kiln body includes one hearth, one flame inlet and one fume outlet. The emulsified coke slurry burner includes one casing forming one inside cylindrical burning space, at least one emulsified coke slurry burning unit, at least one oil / gas burner, one outlet communicated via hot blast pipe to the flame inlet of the hearth. The glass kiln includes also two or more switchable heat accumulating chambers connected via pipeline with the fume outlet of the kiln body. The present invention has double heat accumulation with lattice brick and ceramic ball reaching a heat accumulating temperature as high as 1200 deg.c to make up the low heat value emulsified coke slurry.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Multichannel rotational flow coal burner

InactiveCN102269404AReduce adverse effectsReduce the impactPulverulent fuel combustion burnersCombustionRotational flow

The invention discloses to a multichannel rotational flow coal burner and relates to a rotational flow coal burner, and the multichannel rotational flow coal burner is used for solving the problems that the coal dust flame of the existing rotational flow coal burner has bad stability, and the burning is insufficiency and the perfect diffusion airflow exists. The burner provided by the invention is characterized in that one end of a primary air pipeline is arranged in a secondary air first pipeline, and the secondary air first pipeline is arranged in a secondary air second pipeline; the secondary air second pipeline is arranged in a secondary air third pipeline, and the secondary air third pipeline is arranged in a secondary air regulating pipeline; a first swirler is arranged in the secondary air first pipeline, and a second swirler is arranged in the secondary air second pipeline; and the ventilation door of the secondary air third pipeline is arranged in the secondary air third pipeline, and the ventilation door of the secondary air regulating pipeline is arranged in the secondary air regulating pipeline. The rotational flow coal burner provided by the invention is used for boiler combustion.

Owner:HARBIN INST OF TECH

Adjustable swirl blade assembly and flat flame burner comprising same

ActiveCN113932220AEasy to adjustLarge adjustment ratioIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorCoaxial line

The invention relates to an adjustable swirl blade assembly and a flat flame burner comprising the same, and belongs to the technical field of combustion equipment. The adjustable swirl blade assembly comprises an adjustable swirl blade assembly body and a blade transmission device, and the body comprises a central rectification body, an outer cylinder, an inner cylinder and a plurality of rotatable blades which are coaxially arranged; the blade transmission device comprises a plurality of blade rotating shafts which are fixedly connected with the blades and are used for controlling the blades to rotate, transmission connecting rods which are fixedly connected with one ends of the blade rotating shafts in a one-to-one correspondence manner, a total connecting ring which is connected with the transmission connecting rods and surrounds the adjustable swirl blade assembly body, and an operating rod which is connected with the total connecting ring and is used for controlling the total connecting ring to move; and each transmission connecting rod is formed by rotationally connecting three rigid connecting rods, and two rotating pairs with non-coaxial lines and non-parallel rotating shafts are formed at the joint. The technical problem that in a traditional device, control over blades is not accurate is solved, a combustor can operate under the small-load working condition, the large air-fuel ratio working condition and the condition that the fuel heat value fluctuates violently, and stable flat flames are formed.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

Plasma nozzle

ActiveCN107484321AEliminate dissipationIncrease swirl intensityContinuous combustion chamberPlasma techniqueVoltageEngineering

The invention provides a plasma nozzle, the plasma nozzle comprises an outer cylinder, a middle cylinder, an axial suspending plate, at least one power supply and at least one plasma actuator, wherein the axial suspending plate is arranged between the outer cylinder and the middle cylinder; the power supply is used for providing excitation voltage for the plasma actuator; and the plasma actuator is arranged on the axial suspending plate and is used for generating plasma under the function of the excitation voltage. According to the invention, the flowing induced by the plasma can form free jet on the edge of the axial suspending plate, so that the dissipation for flowing momentum induced by the plasma from a wall boundary layer is eliminated, the swirling intensity can be effectively enhanced, and the burning is stable.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Main burner equipment with outer rotational flow and inner direct flow

ActiveCN1687640AIncrease entrainmentIncreased turbulence intensityPulverulent fuel combustion burnersCoalAirflow

The invention is the outer cyclone inner direct flow main combustor device and belongs to the combustor device of boiler. The purpose of the invention is to produce the backflow area and the stable combustion. One device of the invention is to evenly arrange the delivery blades between the primary air diverting tube and the delivery tube, and the inside diameter of the delivery tube is as 0.5-0.7 times as the diameter of the primary air diverting tube. The other device is to evenly arrange the delivery blades in the inner chamber of the primary air diverting tube, and the axial height of the delivery blades is as 0.1-0.5 time as the semi-diameter of the primary air diverting tube. The invention through changing the opposite angles, the number, the length and the height of the delivery blades and the lengths and the section of the delivery tube to change the intensity and the size of the cyclone amount to adapt the characteristics of different fuels and ensure the stability and economy of the boiler combustion. The invention has simple structure and convenient equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

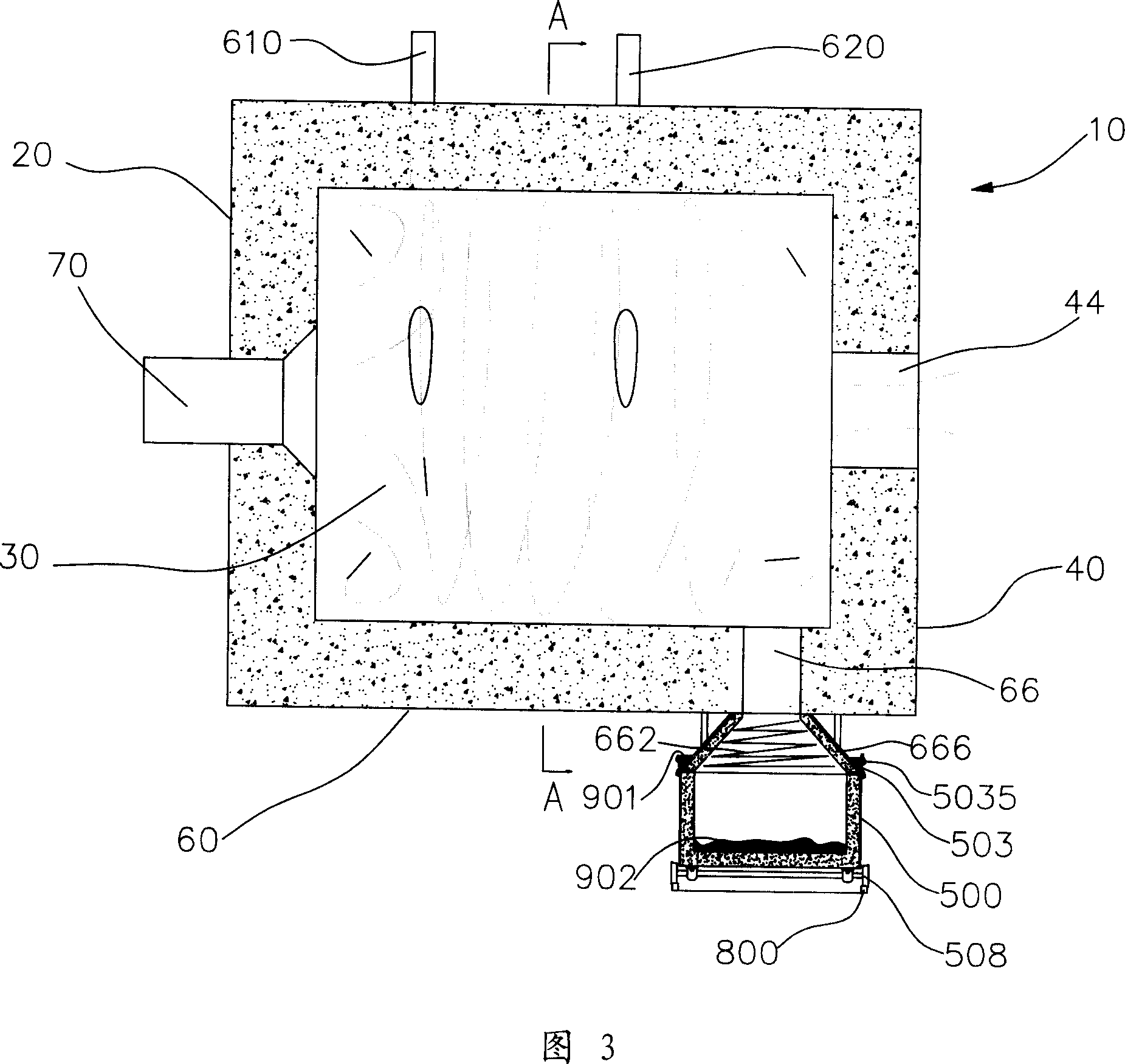

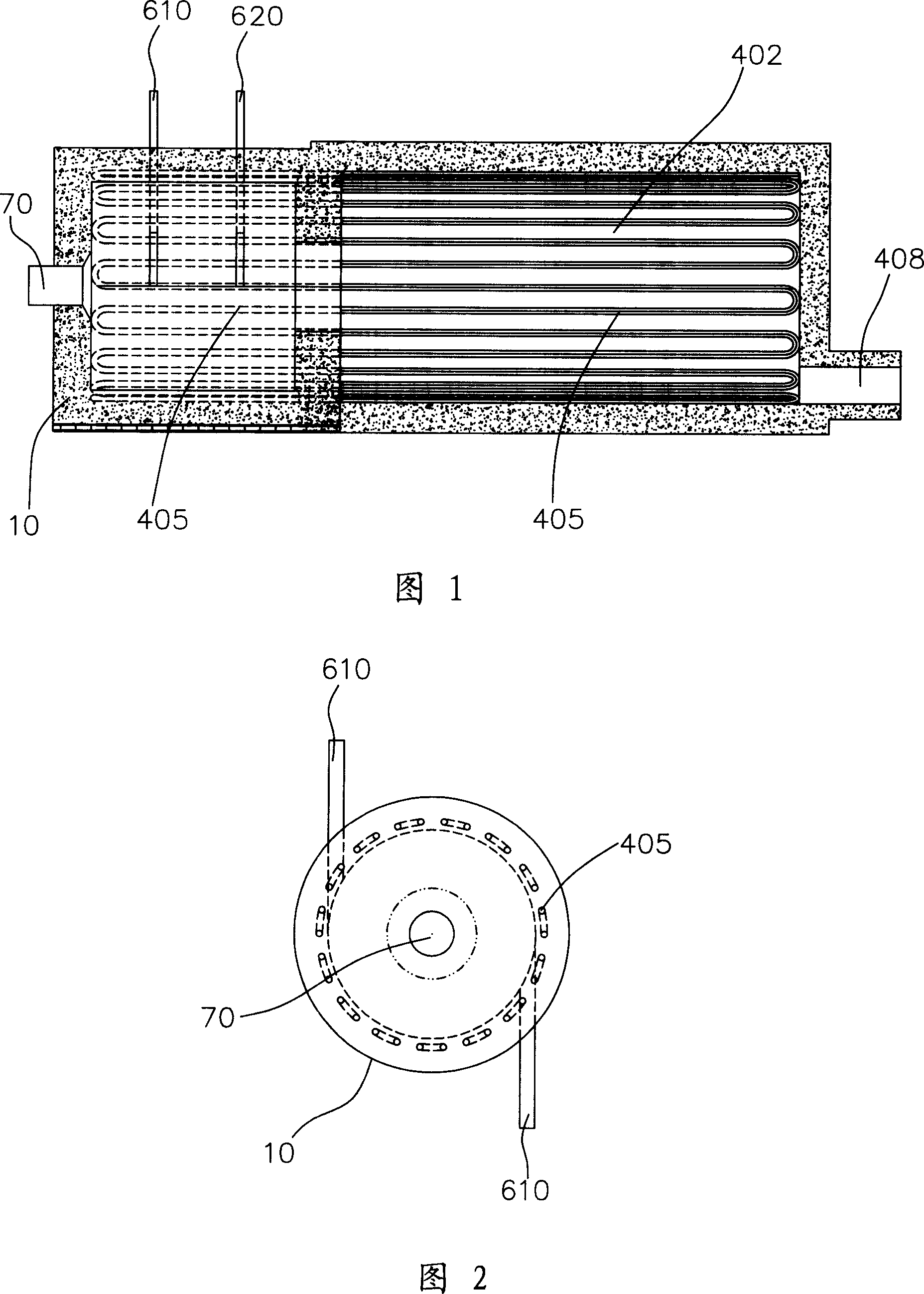

Industrial boiler using emulsifying coke mortar burning device

InactiveCN101021326AEfficient and stable combustionContinuous effective liquid slag removalCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlurryEngineering

The present invention discloses an industrial boiler adopting emulsified coke slurry combustion equipment. It includes boiler self-body and emulsified coke slurry combustion equipment. The boiler self-body includes furnace cavity, boiler barrel set over the furnace cavity, water pipe which is set in the upper portion of said furnace cavity and is adjacent to the side wall of furnace cavity and fire pipe which is set in the central zone of boiler barrel and is soaked in the water of boiler barrel interior. Said emulsified coke slurry combustion equipment includes a shell body formed from front end wall, rear end wall and side wall, in said shell body interior a cylindrical combustion space is formed, on the front end wall are set at least one emulsified coke slurry combustor, at least one oil combustor and / or at least one gas combustor and on the rear end wall an outlet is cut, said outlet is communicated with the furnace cavity. Said invention also provides the working principle of said industrial boiler and its concrete operation method.

Owner:广州迪森热能设备有限公司

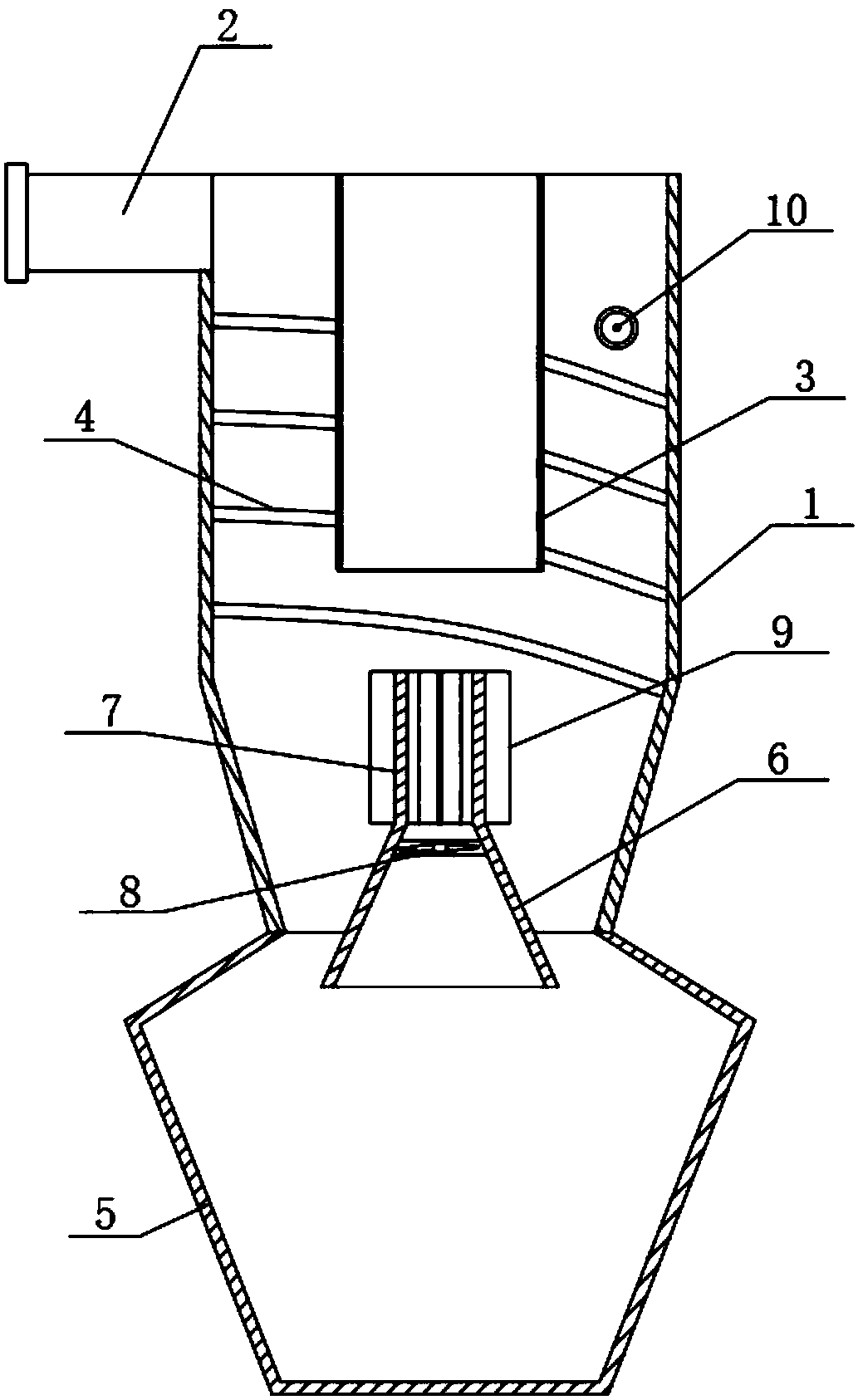

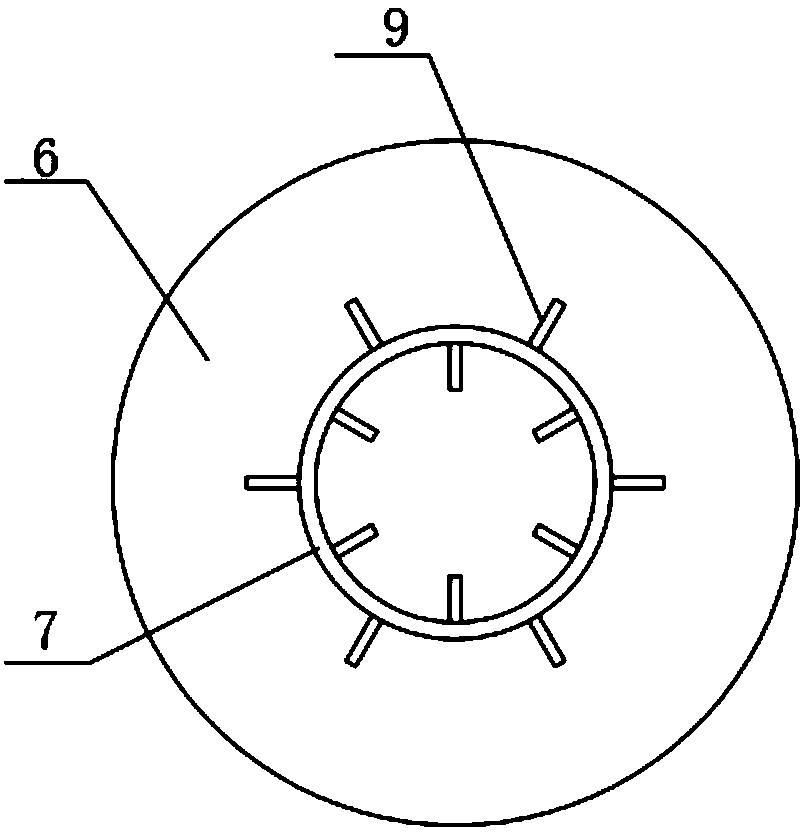

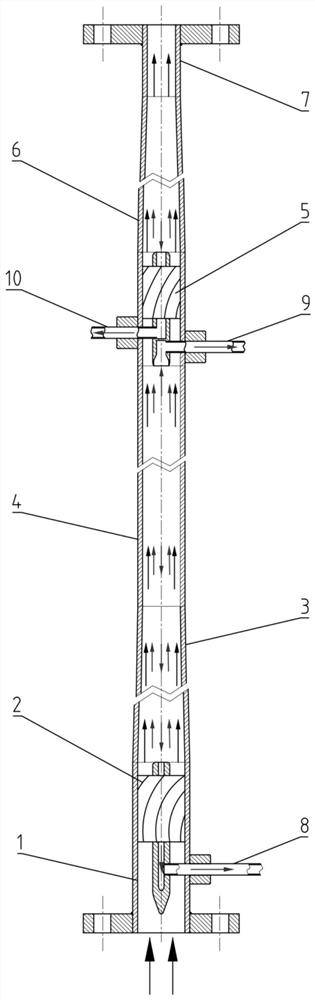

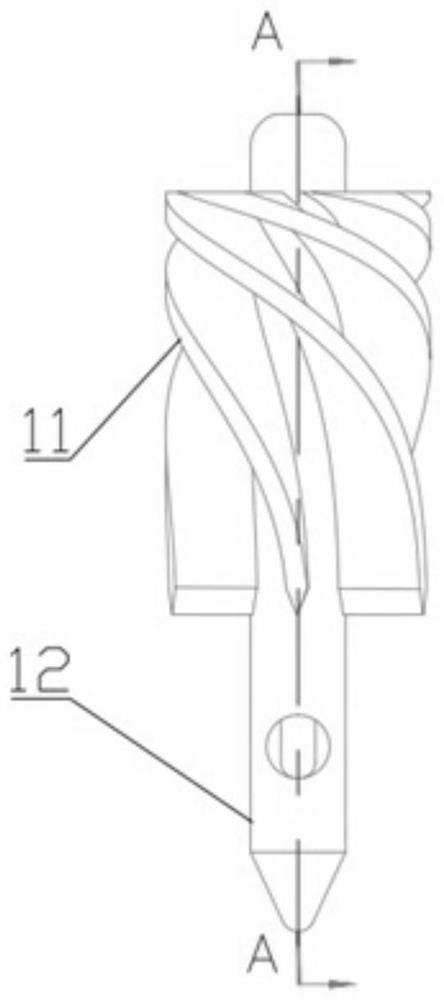

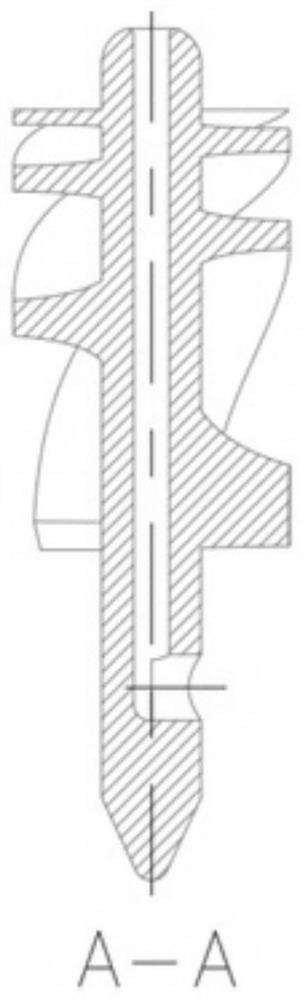

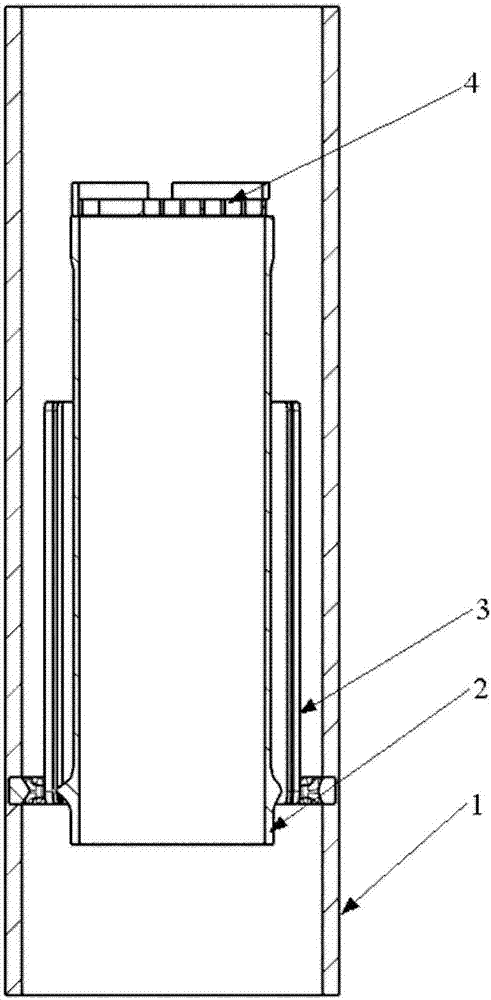

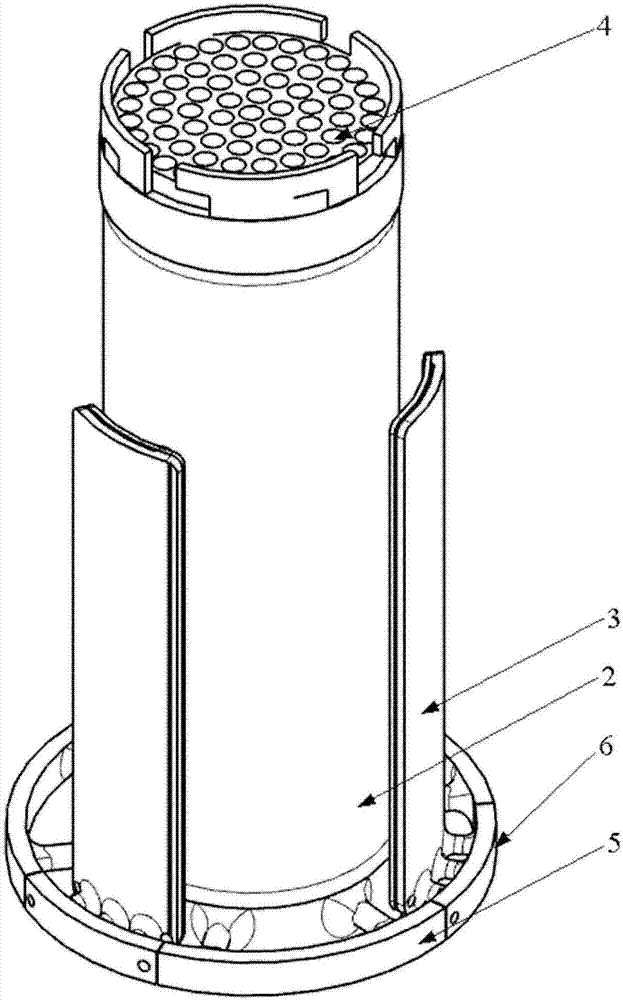

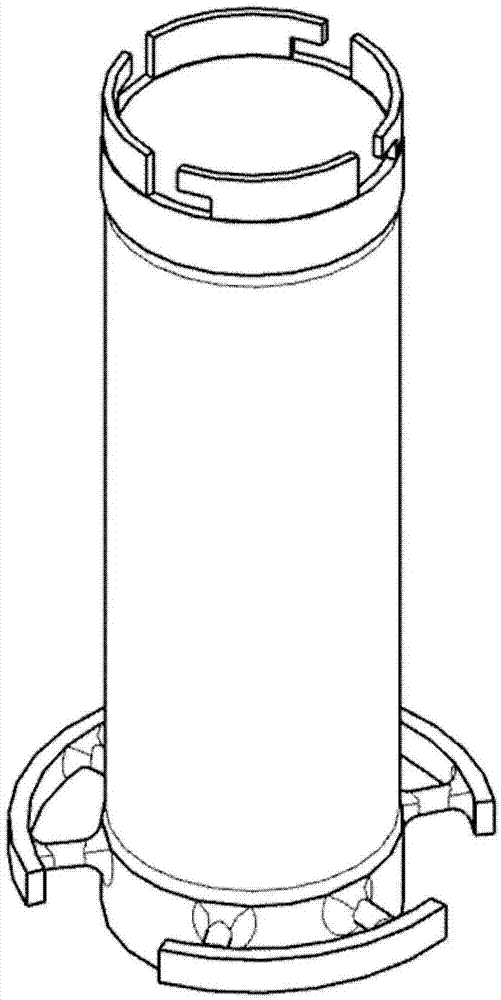

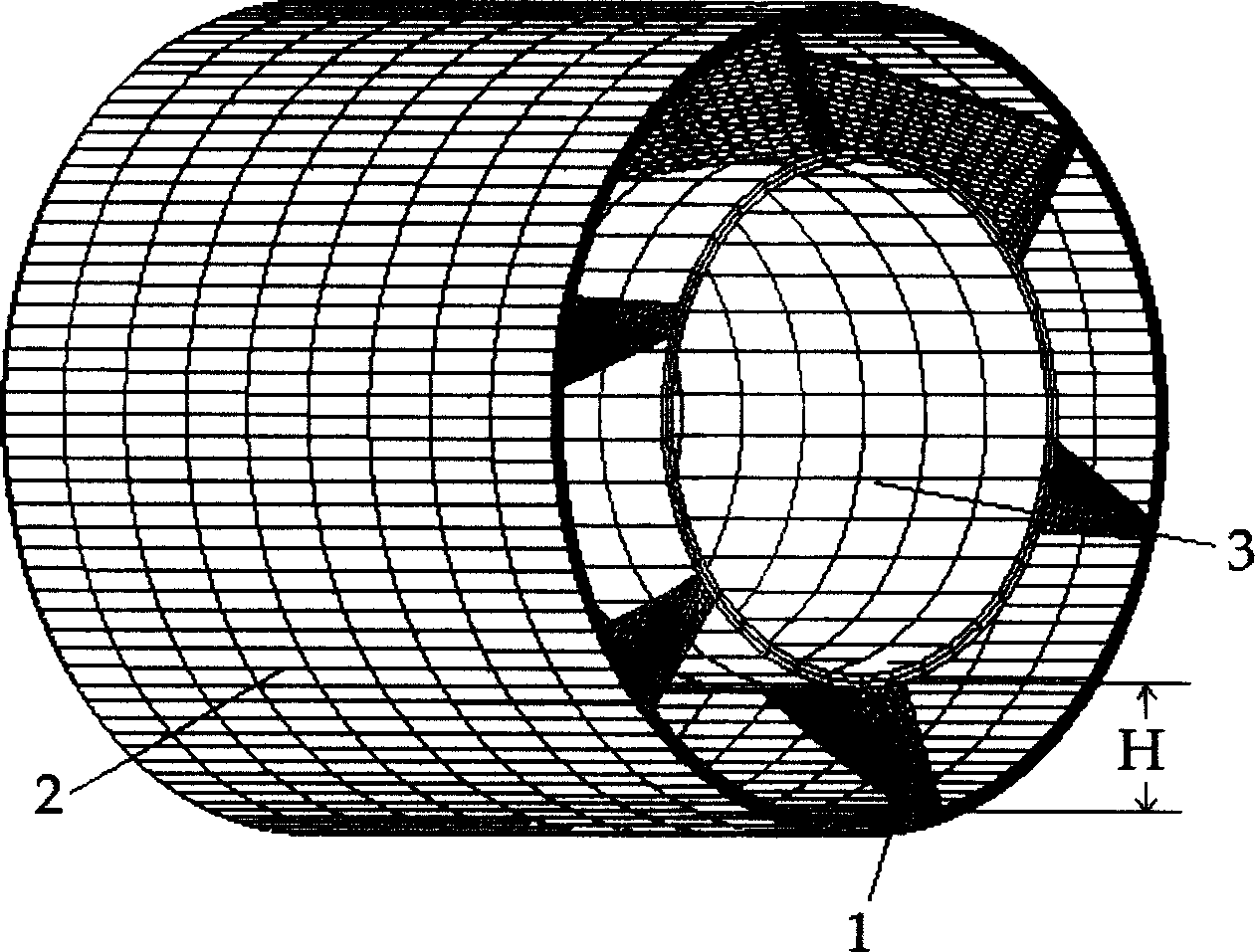

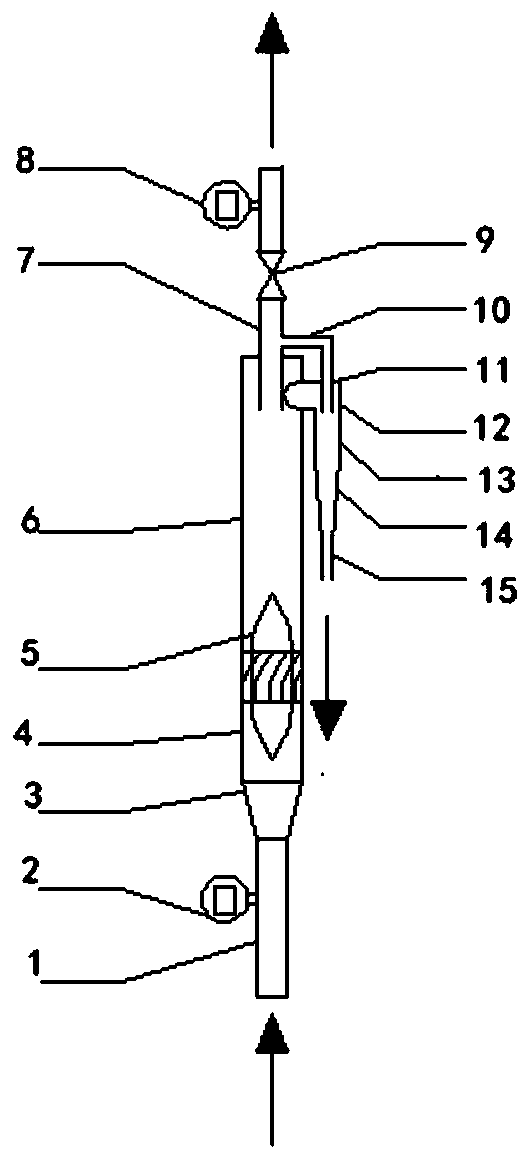

Under-well double-vortex type rotational flow oil and water separator

The embodiment of the invention relates to an under-well double-vortex type rotational flow oil and water separator. The separator is an under-well rotational flow oil and water separation plant usinga high-speed rotational flow principle, and compared with a traditional hydrocyclone, the separator comprehensively uses double same-direction rotational flows for pre-separating oil and water and double opposite-direction rotational flows for conducting under-well refining oil-contained waste water treatment. In the pre-separation process of the oil and the water, two phases of the oil and the water move in the same axial direction in a rotational flow field, so that the two phases of the oil and the water are barely mixed compared with those conducting rotational flow motion in the oppositeaxial directions, a separation effect is better, and accuracy is higher; and in the oil-contained waste water treatment process, a long and thin cone is used for increasing the rotational flow intensity, so that the oil content of the separated water phase is lower. Compared with a traditional gravity sedimentation plant, the separator is better in treatment effect and smaller in occupied space and is a physical separation plant with application prospects.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

a sand funnel

ActiveCN111270657BHighlight substantive featuresSignificant progressBarrages/weirsCentrifugal force sediment separationWater diversionMechanical engineering

The invention provides a sand discharge funnel, which includes a water inlet culvert, a side wall, a funnel chamber, a flow regulating suspension plate, an overflow weir and a side groove. Cut, the bottom of the funnel chamber is provided with a sand-discharging bottom hole, and the sand-discharging bottom hole is connected with a sand-discharging corridor. The side wall is connected to the upper part of the funnel chamber to form a surrounding structure of the first arc segment. The overflow weir is connected to the upper part of the funnel chamber to form the surrounding structure of the second arc segment. The flow-regulating suspension plate has a proximal end and a distal end, the distal end is connected to the upper end of the overflow weir, the proximal end is close to the center of the funnel chamber, and the proximal end is higher than the distal end. The side trough is connected to one side of the overflow weir and the side wall to form a third circular arc segment surrounding structure, and the side trough is provided with a diversion channel opening. By improving the structure, the invention solves the problems of serious sediment deposition on the bottom of the funnel chamber and the suspension plate and high sand discharge water consumption rate, and improves the sand discharge efficiency of the sand discharge funnel.

Owner:XINJIANG AGRI UNIV

Low-pressure rotational flow bubble type nozzle

The invention provides a low-pressure rotational flow bubble type nozzle. The low-pressure rotational flow bubble type nozzle comprises a flow distribution chamber, a tangential water inlet pipeline,an axial water inlet pipeline, a mixed flow pipe and a gas-liquid mixing cavity; an outlet of the flow distribution chamber is communicated with each the tangential water inlet pipeline and the axialwater inlet pipeline, the outlet of the axial water inlet pipeline is communicated with the mixed flow pipe, and a rotational flow device is arranged in the axial water inlet pipeline and used for generating rotational flow to enter the mixed flow pipe; the outlet of the tangential water inlet pipeline is in tangent connection with the mixed flow pipe and is used for generating tangential flow; the mixed flow pipe is used for converging the rotational flow and the tangential flow; the gas-liquid mixing cavity is communicated with the mixed flow pipe, and the outlet of the gas-liquid mixing cavity is connected with the nozzle. The low-pressure rotational flow bubble type nozzle provided by the invention can generate rotary bubble type water drops, not only increases the cleaning area and enhances the cleaning effect, but also has the massage and striking effect, the blood circulation of the human body is promoted, and the human body has more comfortable skin feeling.

Owner:JIANGSU UNIV

Heat conductive oil furnace using emulsifying coke mortar vortex burning device

InactiveCN101021357AEfficient and stable combustionContinuous effective liquid slag removalCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHeat conductingLiquid slag

The invention discloses a heat-conducting oil stove used the emulsifying burnt plasma vortex burning device. It includes the oil stove body and the emulsifying burnt plasma vortex burner which includes the shell composed by the front wall, the back wall and the side wall. The burning room is formed in the shell. At least one emulsifying burnt plasma vortex burner and at least one oil burner or at least one gas burner is set in the front wall; an outlet is set in the back wall which is connected with the flame inlet of furnace chamber by the warm-air pipe. The two or above groups of tangential wind inlets are set on the shell side wall alternately; the outlet of the liquid slag is on the side wall of the burning room bottom which is near to the back wall. The invention uses the emulsifying burnt plasma as the fuel, so it can save the cost.

Owner:广州迪森热能设备有限公司

Oil burner with high viscosity

The invention provides an oil burner with high viscosity, relating to a burner, aiming at solving the problem that the fuel injector on the current burner generally adopts mechanical atomization type and spinning cup type and steam jet type, the flame size of the burner is great and can not be used in the offshore platform steam injection boiler. Fuel oil enters a steam through hole through a second fuel hole, a fuel chamber, a first through hole, a second circular groove, a third circular groove, a first tangential groove, a center hole via a fuel pipe, and simultaneously, the atomizing medium enters the inner cavity of the compression nut through a second atomizing medium hole and the steam cavity via the atomizing medium pipe, then enters the steam through hole via a second tangential groove and a fifth circular groove; the atomizing medium and the fuel mix in the steam through hole and enter the conical hole to obtain primary atomization under the action of the rotational centrifugal force; and the mixed oil is impacted violently by the wind from the tangential air door and the axial air door to obtain the secondary atomization. The invention is applied to the offshore platform steam injection boiler.

Owner:HARBIN GUANGHAN POWER TECH DEV CO LTD

Gas injection boiler using the emulsifying coke mortar combustion device

InactiveCN101021313AEfficient and stable combustionReasonable useCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlurryEngineering

The present invention discloses a steam-injecting boiler adopting emulsified coke slurry combustion equipment. It includes boiler self-body and emulsified coke slurry combustion equipment. Said boiler self-body includes furnace cavity, at least one steam pipe set in the furnace cavity interior and smoke outlet cut on one end wall far-separated from the emulsified coke slurry combustion equipment. Said emulsified coke slurry combustion equipment includes a shell body formed from front end wall, rear end wall and side wall, a cylindrical combustion space is formed in the shell body, on the front end wall at least one emulsified coke slurry combustor, at least one oil combustor and / or at least one gas combustor are set, its rear end wall is equipped with an outlet, said outlet is communicated with furnace cavity.

Owner:广州迪森热能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com