Sand discharge funnel

A funnel and flow regulating technology, which is applied in the field of sand discharge funnel and sediment secondary treatment facilities, can solve the problems of sedimentation at the bottom of the funnel chamber, sedimentation of hanging plate sedimentation and water consumption rate, etc. The effect of small circumference and large flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

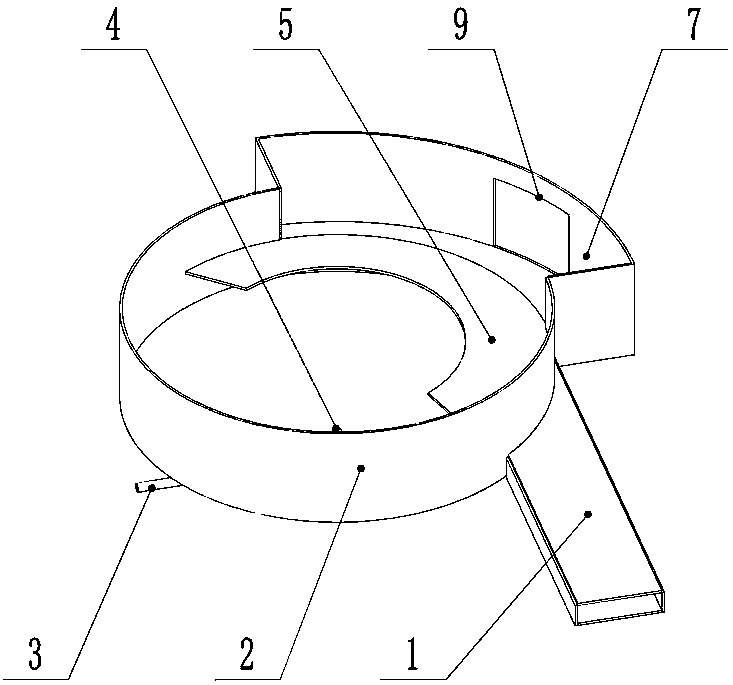

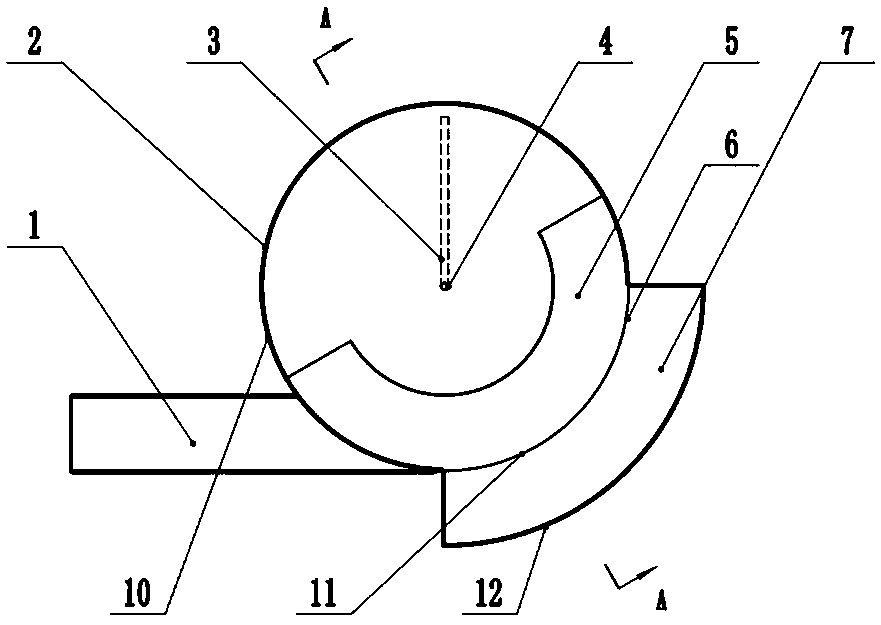

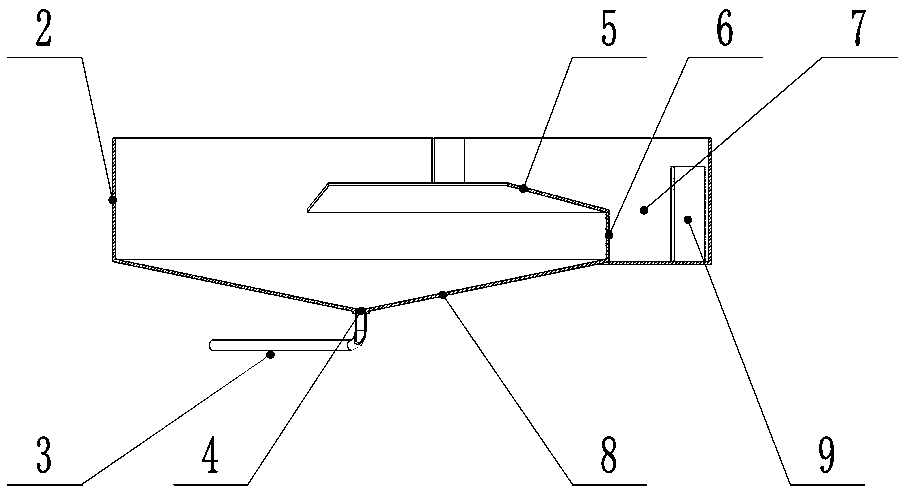

[0022] The sand discharge funnel of present embodiment is as figure 1 , figure 2 with image 3 As shown, the water inlet culvert 1, the side wall 2, the funnel chamber 8, the flow regulating suspension plate 5, the overflow weir 6 and the side groove 7 are included, and the water inlet culvert 1 is connected to the upper part of the funnel chamber 8, and is connected to the top of the funnel chamber 8. The outer circumference is tangent, the bottom of the funnel chamber 8 is provided with a sand discharge bottom hole 4, the sand discharge bottom hole 4 is connected with a sand discharge corridor 3, and the side wall 2 is connected to the upper part of the funnel chamber 8 to form a first circular arc section surrounding structure 10, The overflow weir 6 is connected to the upper part of the funnel chamber 8 to form a second circular arc segment surrounding structure 11. The height of the overflow weir 6 is lower than that of the side wall 2. The flow-regulating suspension pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com