Patents

Literature

525results about How to "Not easy to deposit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

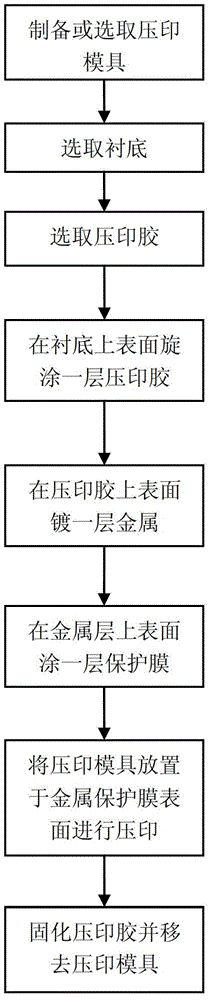

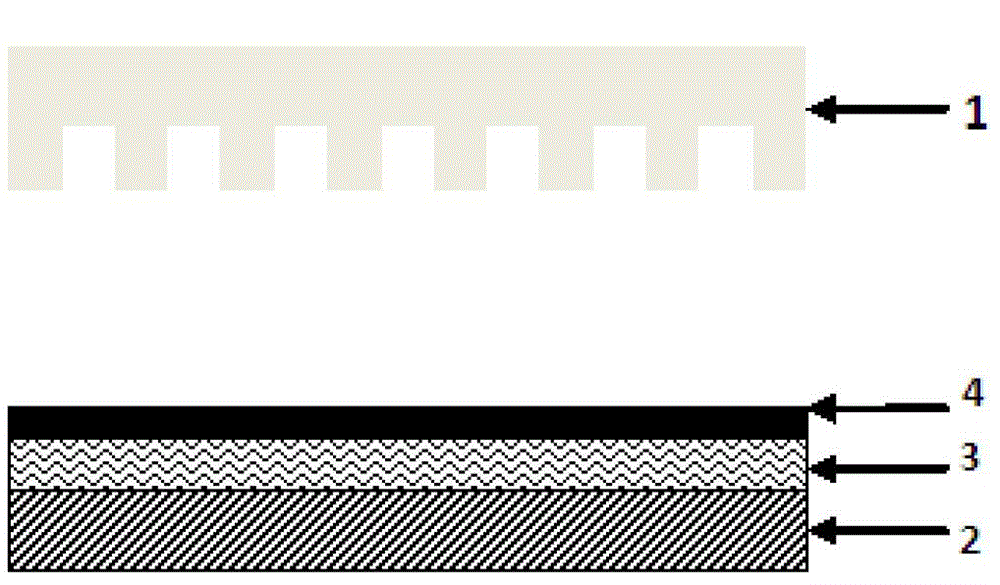

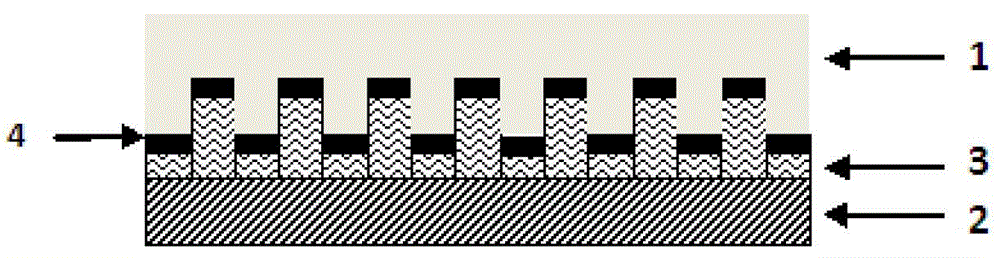

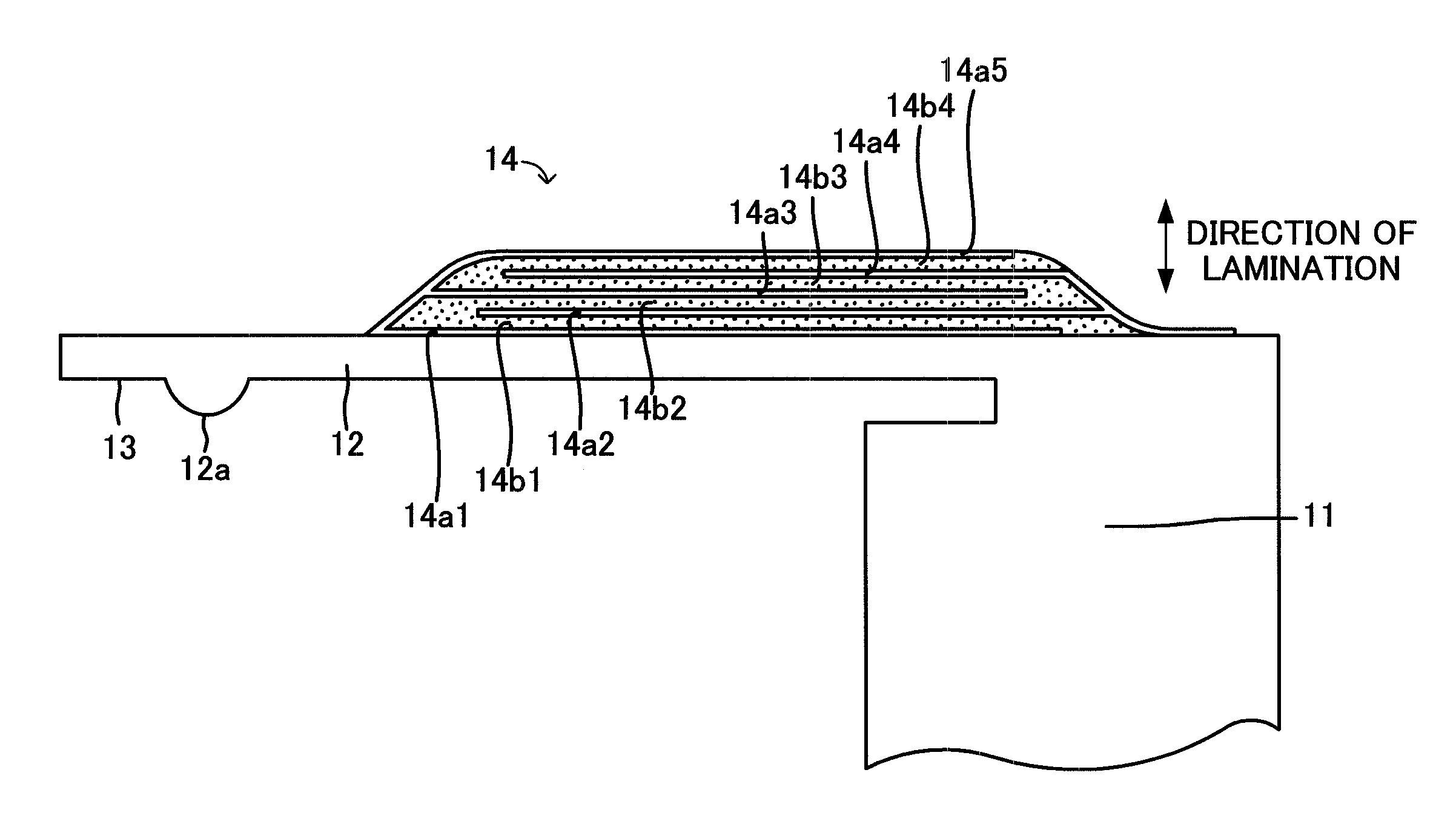

Preparation method of multilayer metal grating

InactiveCN103149615ANot easy to depositImprove fidelityPhotomechanical apparatusDiffraction gratingsTectorial membraneMetal

The invention relates to a preparation method of a multilayer metal grating. The preparation method comprises the following steps of: preparing or selecting an imprinting template; spin coating a layer of imprinting glue on an upper surface of a substrate; plating a metal layer on a surface of the imprinting glue; coating a layer of protection film on an upper surface of a metal layer; placing the imprinting template on an upper surface of the protection film, and carrying out nano-imprinting; and after curing the imprinting glue, removing the imprinting template to obtain a double-layer metal grating or the multilayer metal grating. According to the preparation method of the multilayer metal grating, a step of pattern transfer is omitted, the process is simpler, the cost is lower, a metal film obtained through the method cannot be coated on a side wall of a pattern to affect the transmission efficiency, the shape of a cross section of the metal film is strictly matched with the shape of a cross section of the imprinting template, and compared with adoption of a traditional method, the fidelity of the pattern and the TM transmission rate and the polarization rejection ratio of the grating are higher.

Owner:SHANGHAI JIAO TONG UNIV

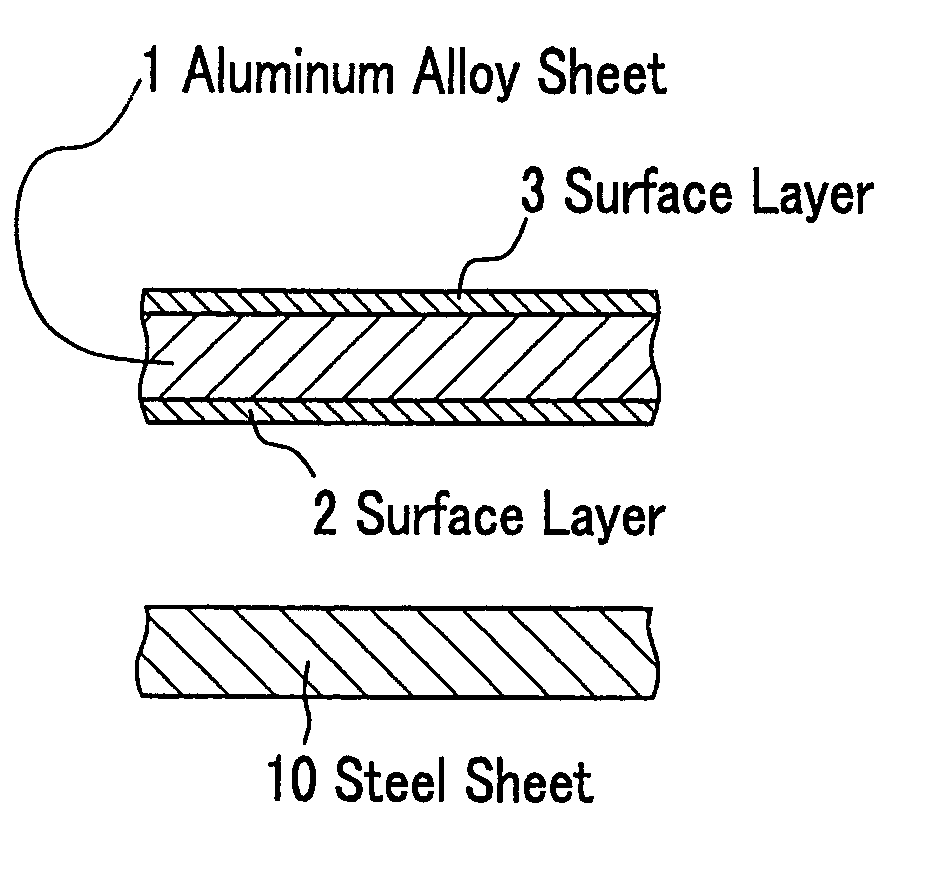

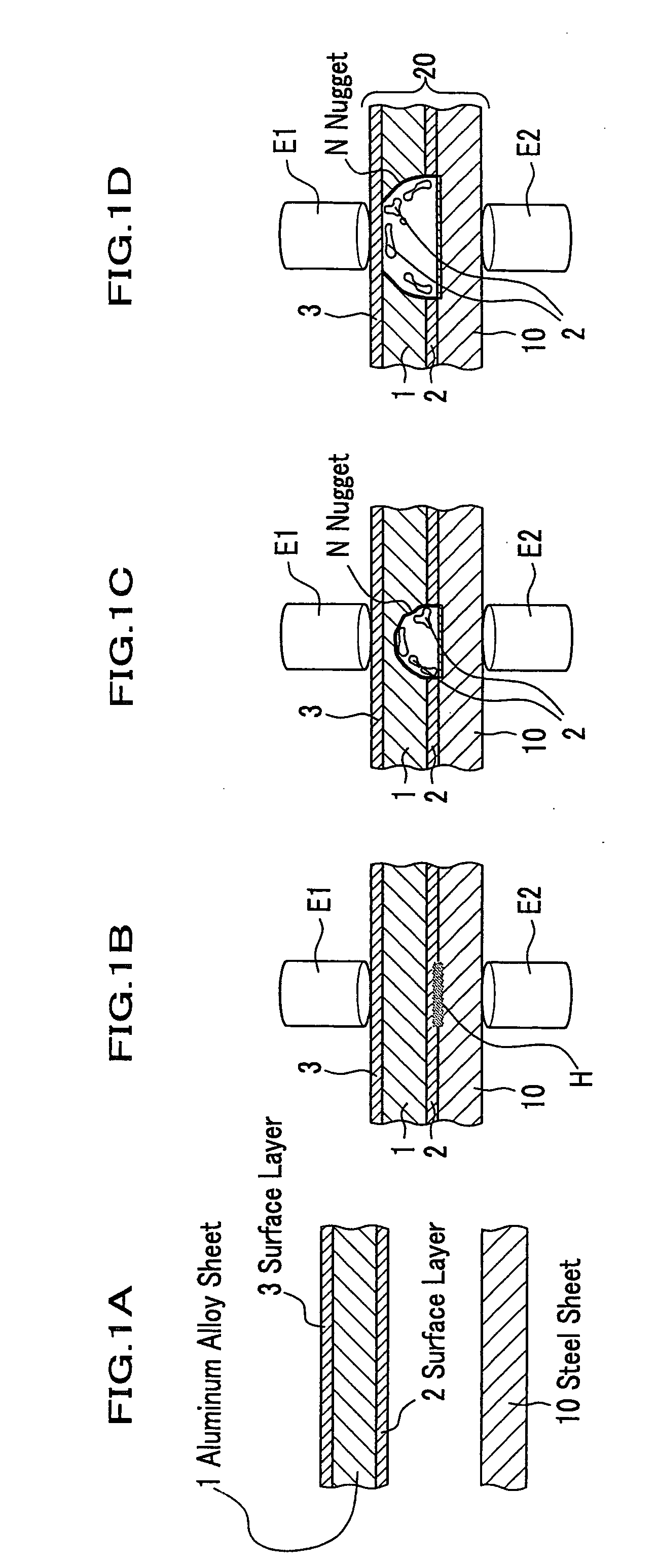

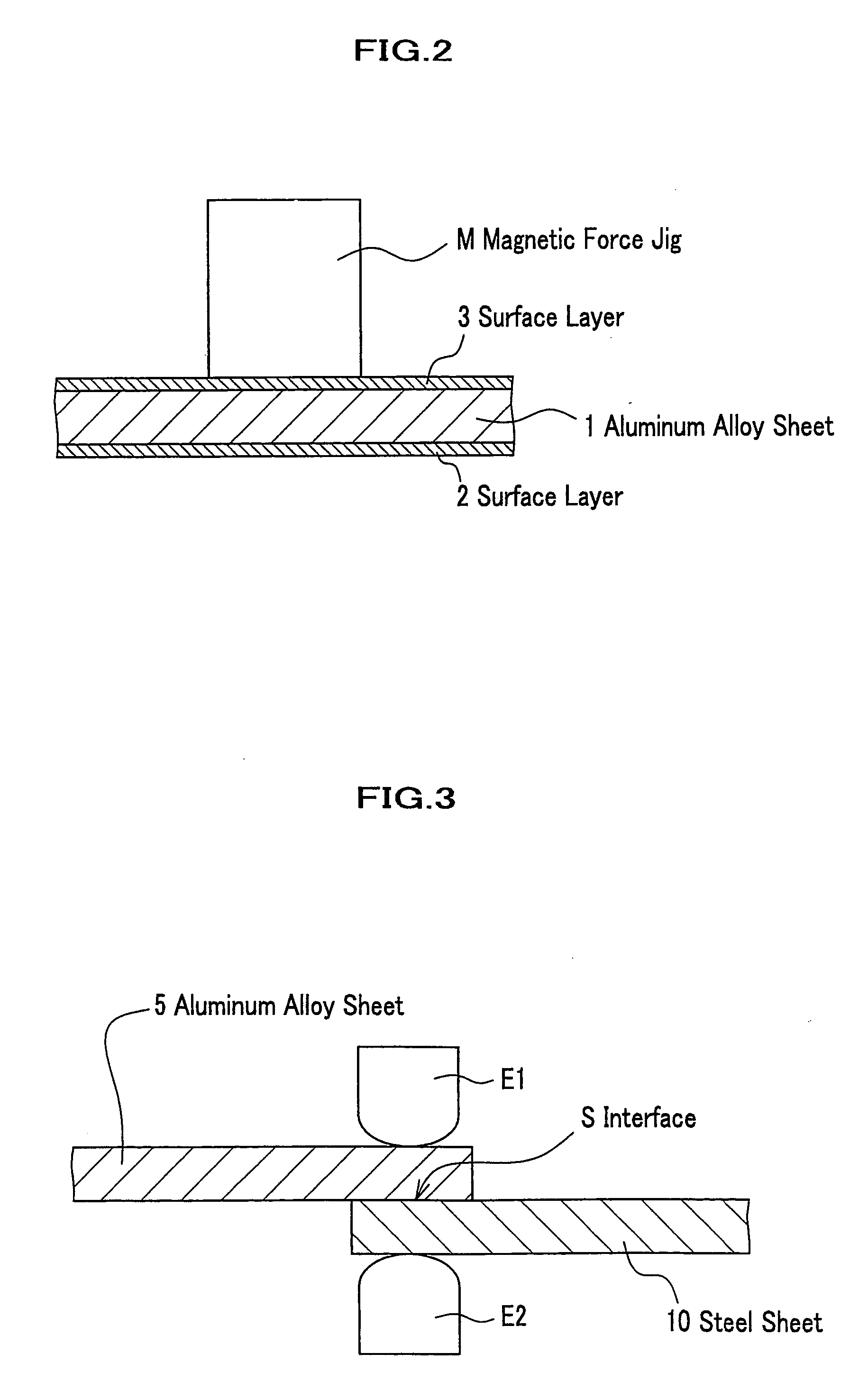

Resistance welding method of different kinds of materials, and resistance welding member of aluminum alloy material and different kind of material

InactiveUS20050218121A1Improve solderabilityEfficiency of manufacturing can not be realizedHot-dipping/immersion processesArc welding apparatusSurface layerSpot welding

The resistance welding method of different kinds of materials is the method for welding an iron material and an aluminum alloy material, and comprises the steps of: performing in advance a coating treatment at least to a portion of the aluminum alloy material, where resistance welding is performed, with any of iron and iron-base alloy and forming a surface layer; and performing resistance welding of the iron material and the aluminum alloy material through the surface layer, and the resistance welding may be any of spot welding and projection welding.

Owner:HONDA MOTOR CO LTD +1

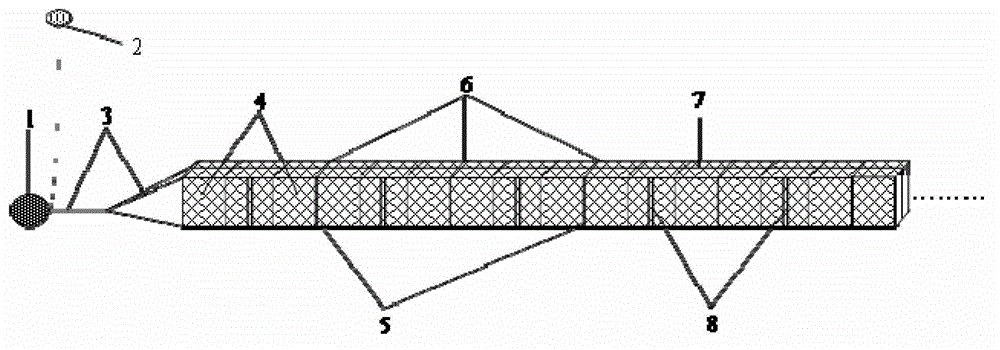

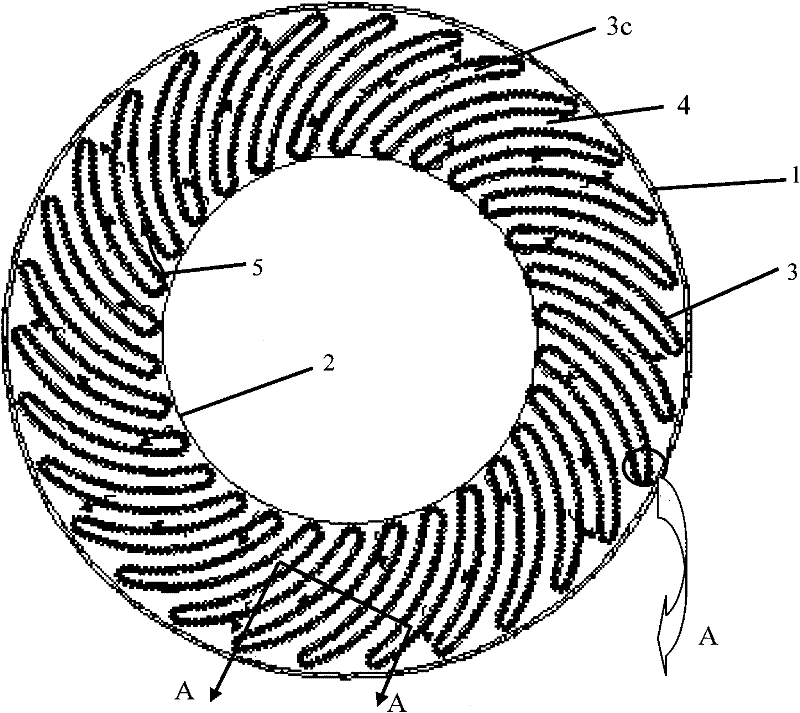

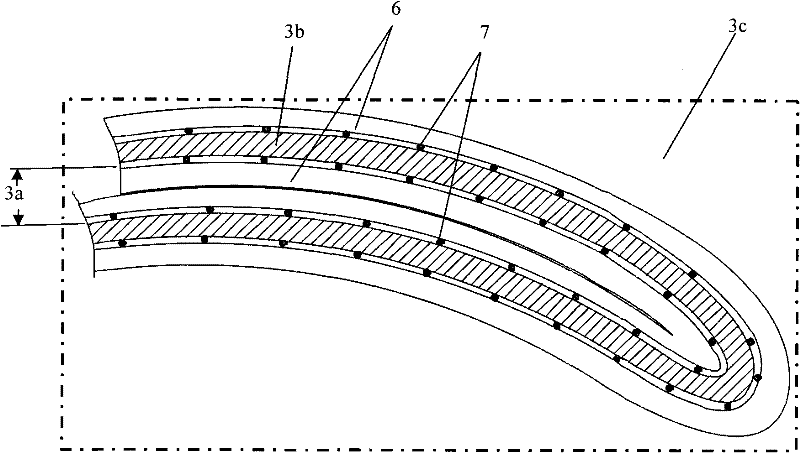

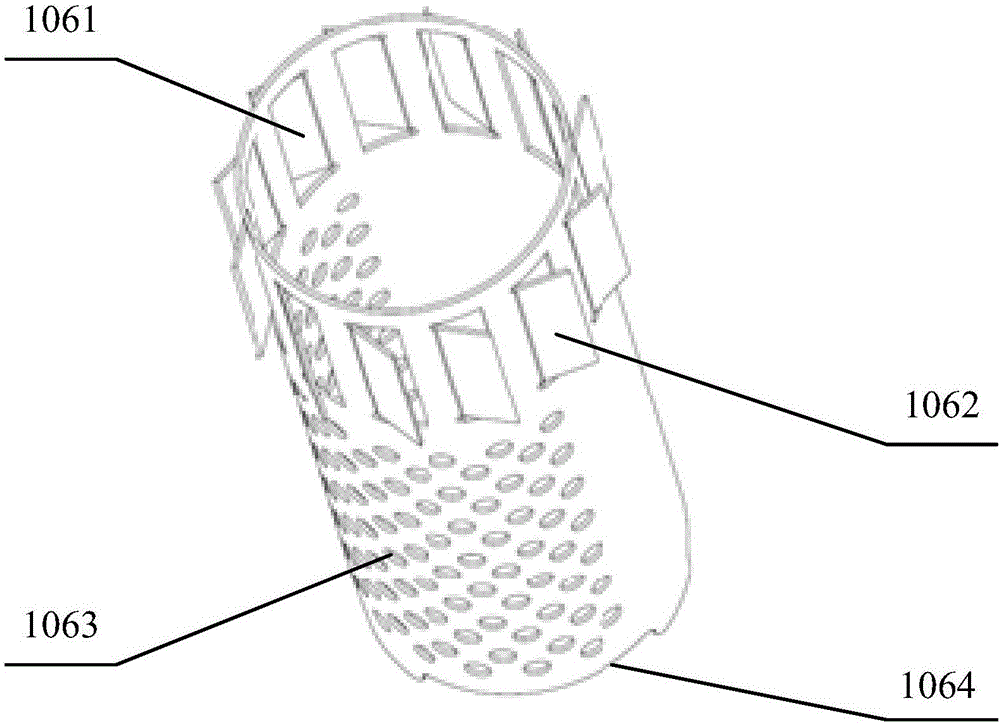

Sea cucumber bottom-sowing culture facility suitable for soft seabed

ActiveCN102972318AEfficient retentionIncrease the attachment areaClimate change adaptationPisciculture and aquariaNatural disasterSurvival ratio

The invention provides a sea cucumber bottom-sowing culture facility suitable for a soft seabed. The facility comprises frameworks, built-in separation nets, built-in dense nets, cuffs, a traction rope, an anchoring object and a marking floater. The frameworks are arranged in parallel and are covered with outer-wrapping netlike clothing, the frameworks are mutually connected to be of a telescopic mesh cage shape, the built-in separation nets for separating each framework into a plurality of culture units are arranged on each framework, the built-in dense net for catching and gathering sea cucumber baits is arranged in each culture unit, cuffs for taking and placing a sea cucumber is arranged on the outer-wrapping netlike clothing of each culture unit, the frameworks on two ends are respectively and sequentially connected with the traction rope and the anchoring object to be fixedly arranged in a seabed, and the marking floater is connected onto one end of the culture facility. Compared with the traditional culture facility, the culture facility provided by the invention is light and convenient, can be compressed, and is convenient for transportation, throwing and management, and the affect from a natural disaster of typhoon and the like is avoided; and by the adoption of the culture facility, the problems of easiness in entrapping by silt, poor culture effect and the like of the traditional culture facility can be solved, particle-like suspended matters in seabed water can be effectively held back as sea cucumber baits, and the survival ratio and the growth rate of the sea cucumber are improved.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

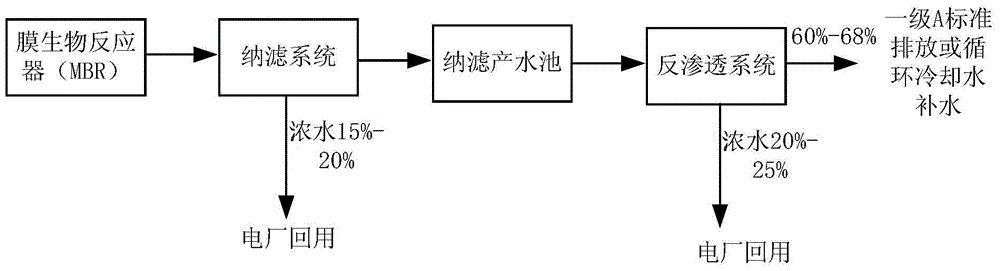

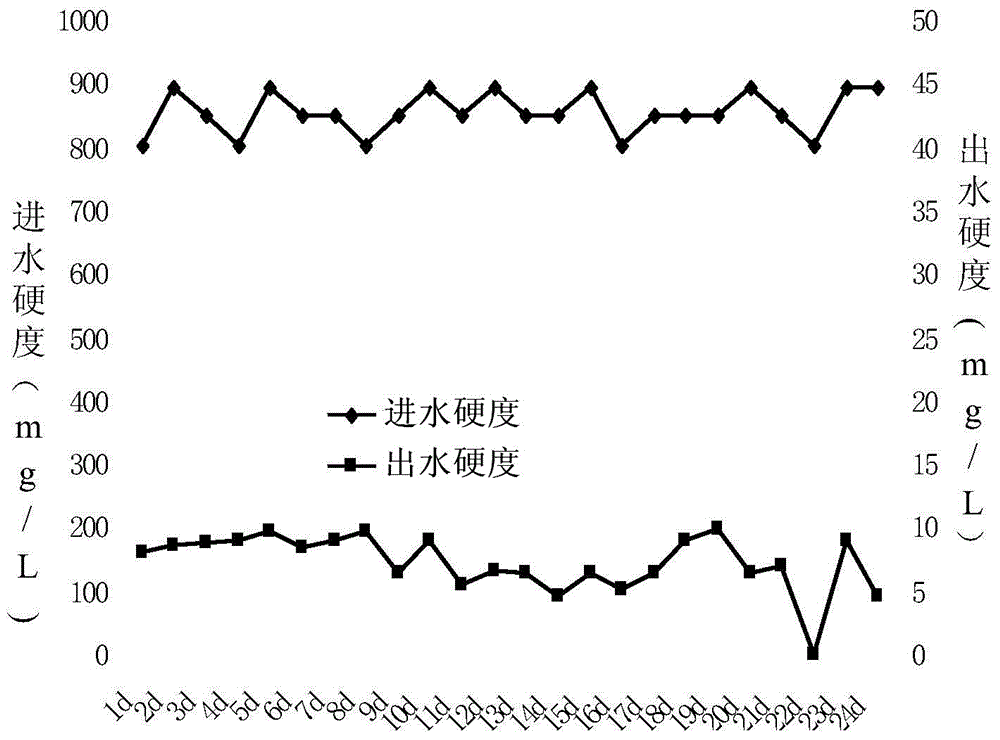

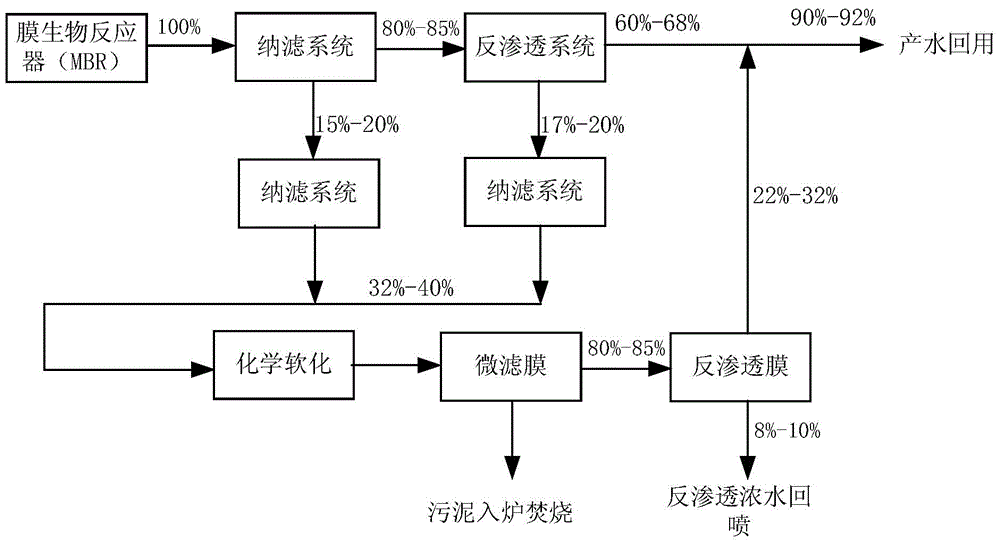

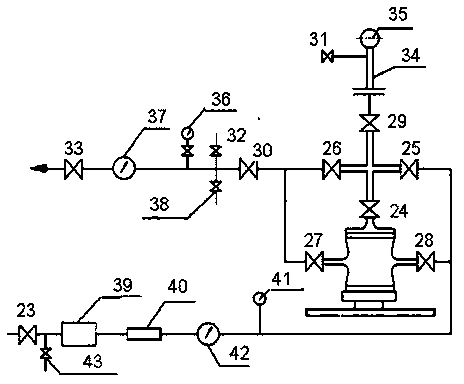

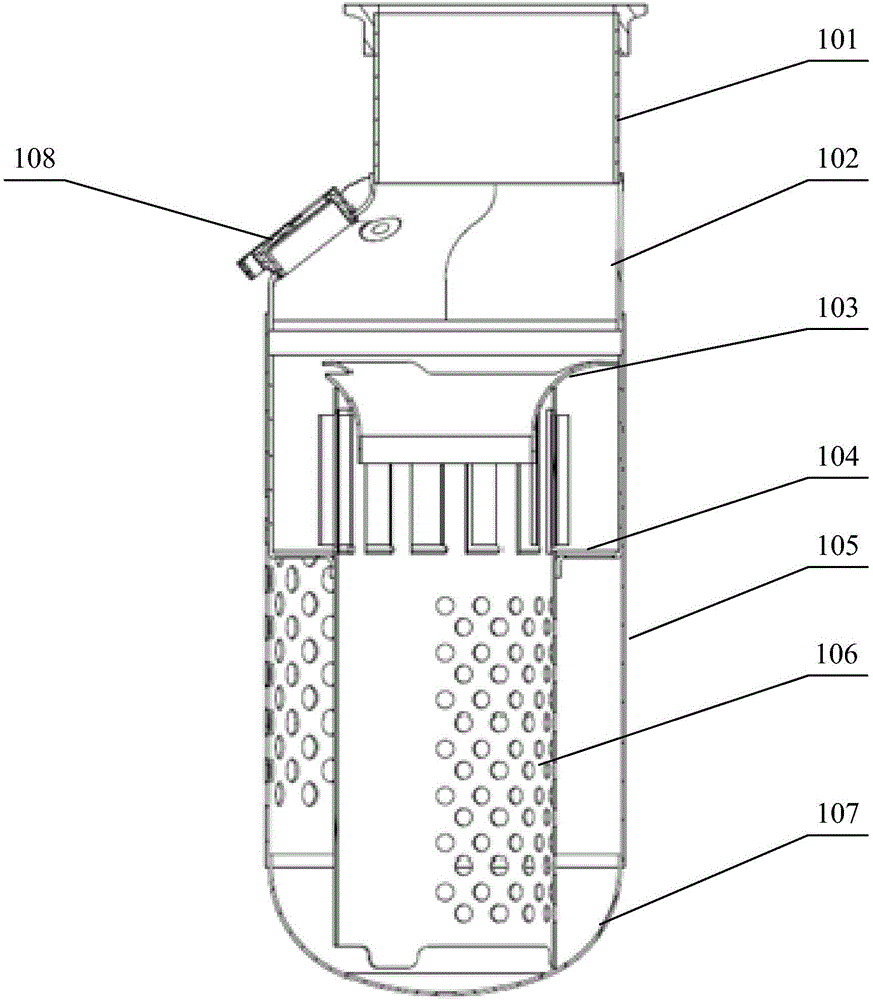

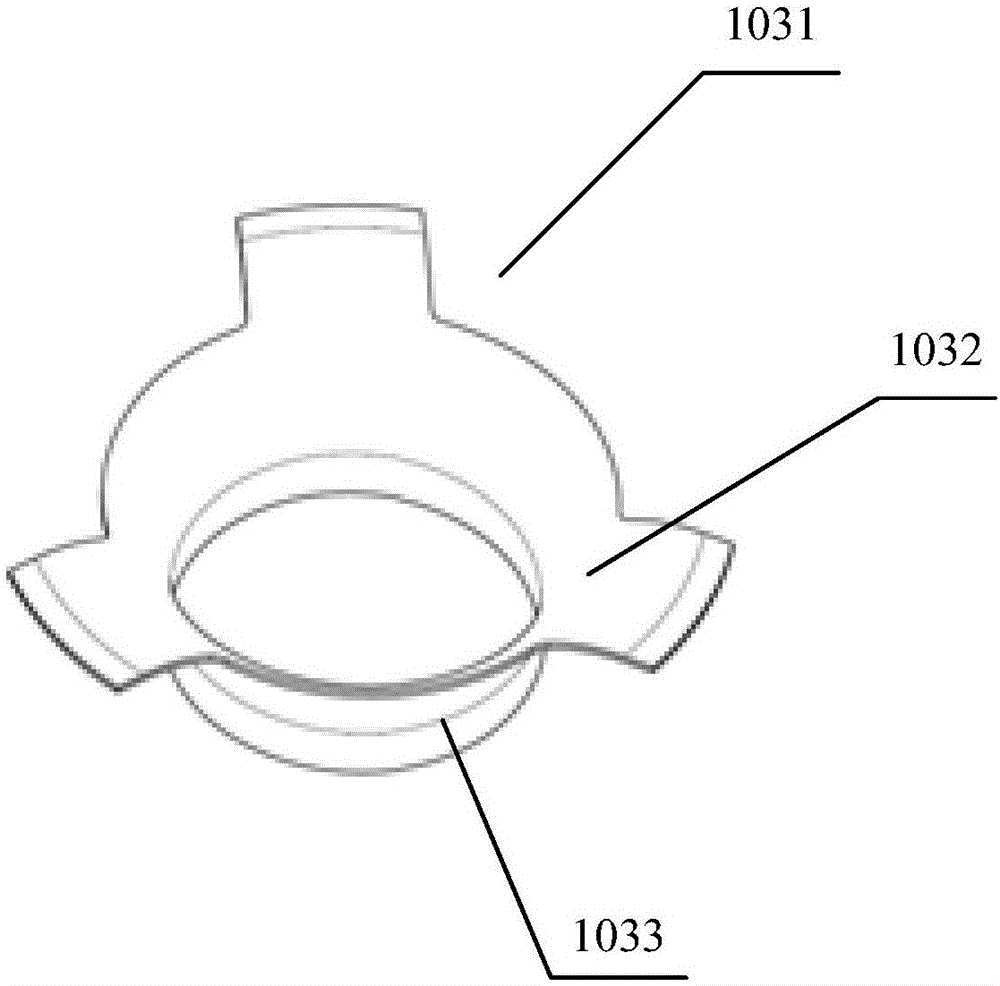

Treatment method and device of landfill leachate concentrate

InactiveCN104787929AIncrease productionAchieve recyclingUltrafiltrationMultistage water/sewage treatmentReverse osmosisWater resources

The invention relates to a treatment method and a device of landfill leachate concentrate. The method comprises the following steps: Step S1: carrying out chemical softening treatment on the concentrate to reduce hardness of the concentrate, Step S2: filtering effluent of Step S1 with a microfiltration membrane to remove suspended solids from the concentrate, and Step S3: carrying out reverse osmosis treatment on effluent of Step S2 with a disc tubular reverse osmosis membrane to form recycled effluent. The method and the device have the following advantages: 1, a 'chemical softening, microfiltration membrane and DTRO (Disk Tubular Reverse Osmosis)' technology is employed for treating the nanofiltration and reverse osmosis concentrate, the fresh water yield of a whole system is increased, the recycling of water resources is achieved, and operating cost of a power plant is saved; and 2, the 'chemical softening, microfiltration membrane and DTRO' technology is employed for treating the nanofiltration and reverse osmosis concentrate, so that the concentrate is reduced, and the predicament that the yield of the concentrate is high, and the power plant cannot eliminate the concentrate is solved.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD

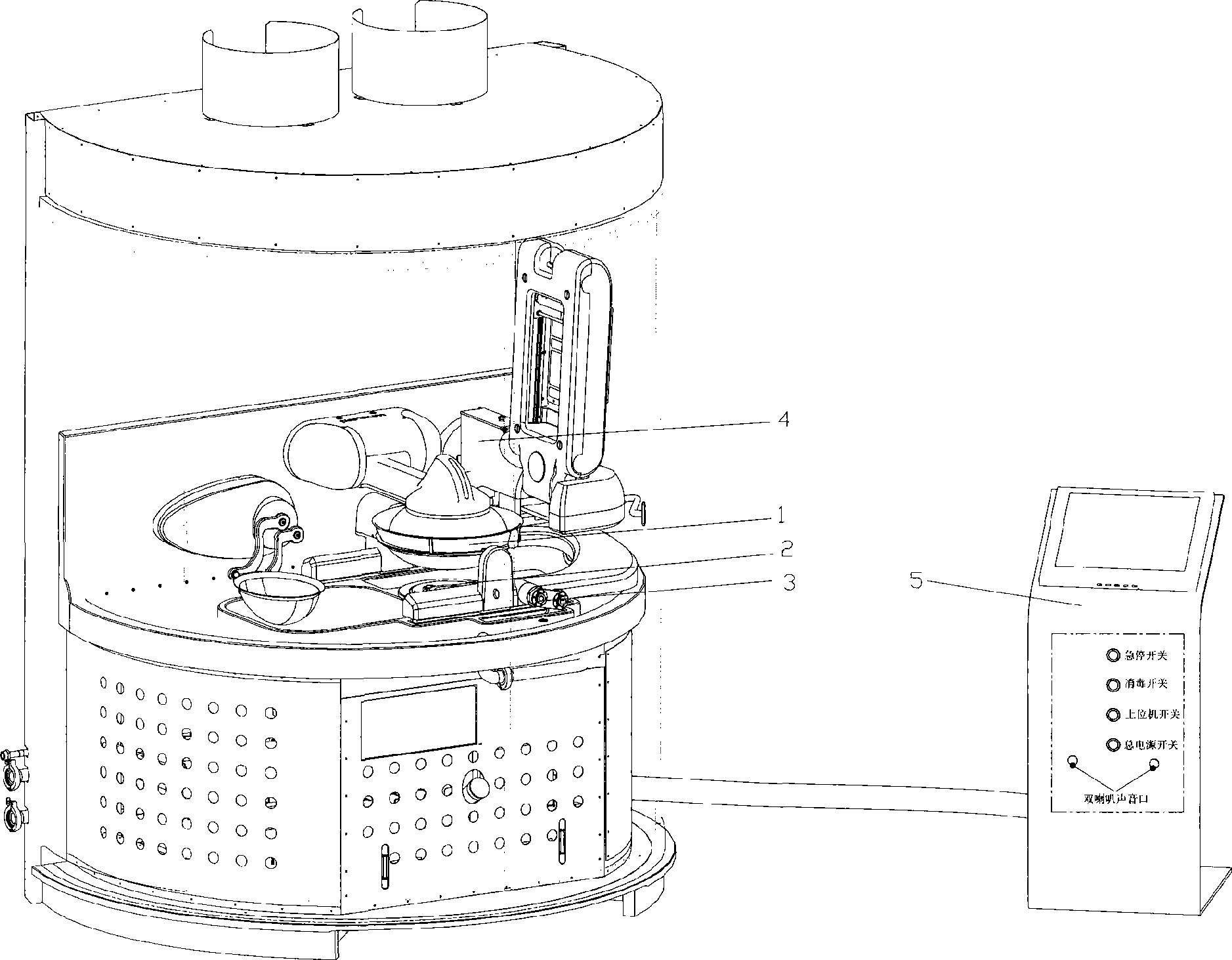

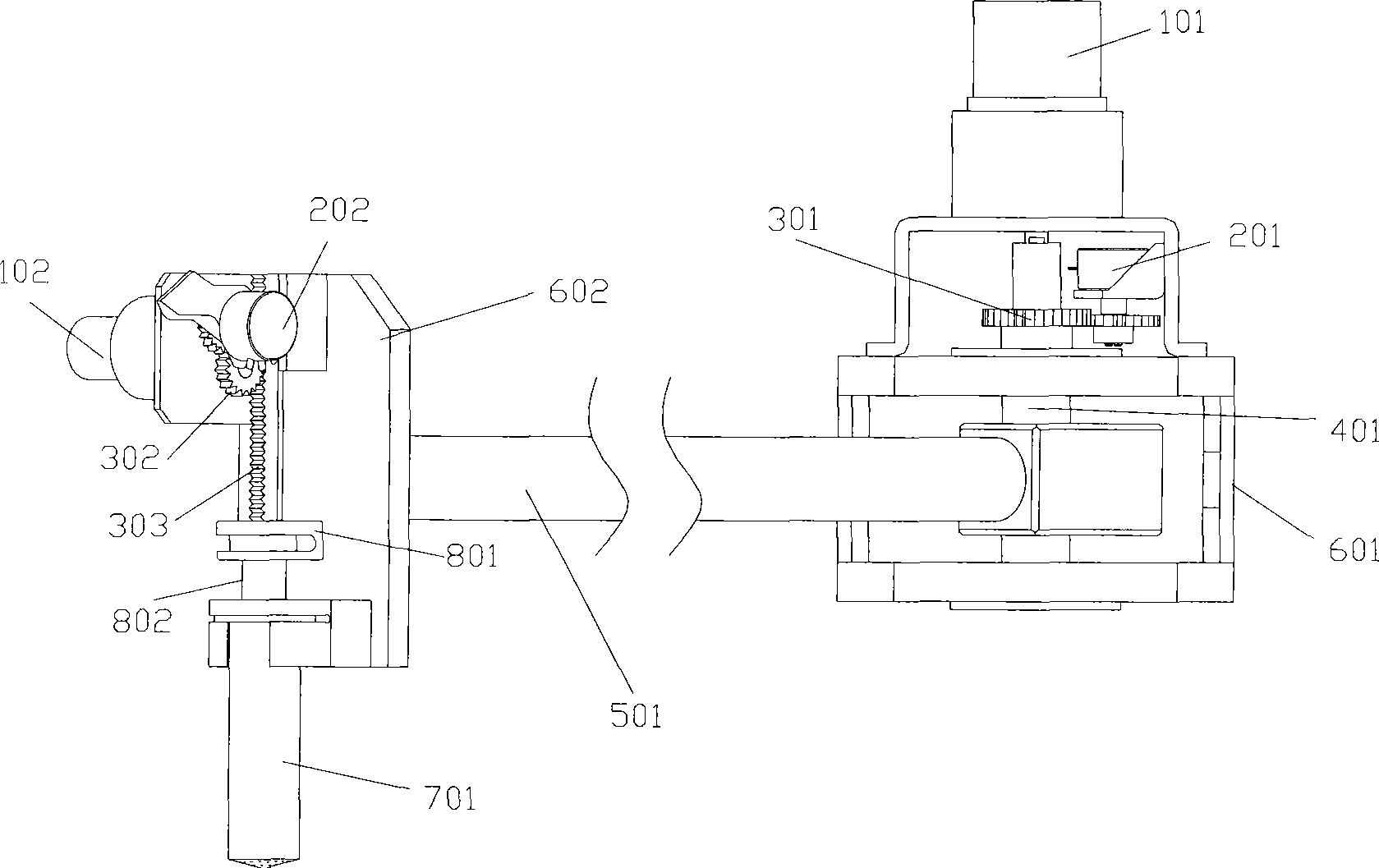

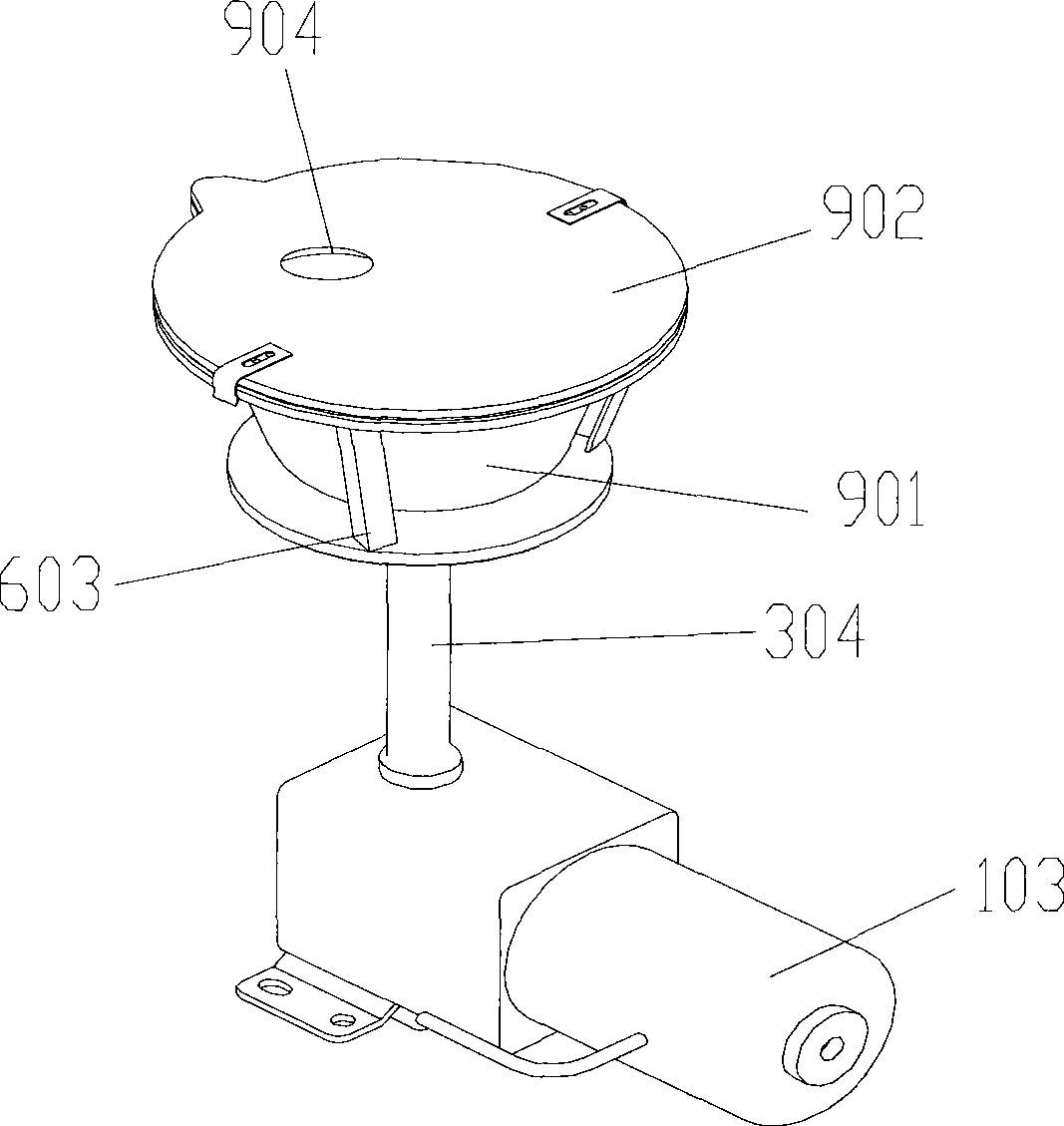

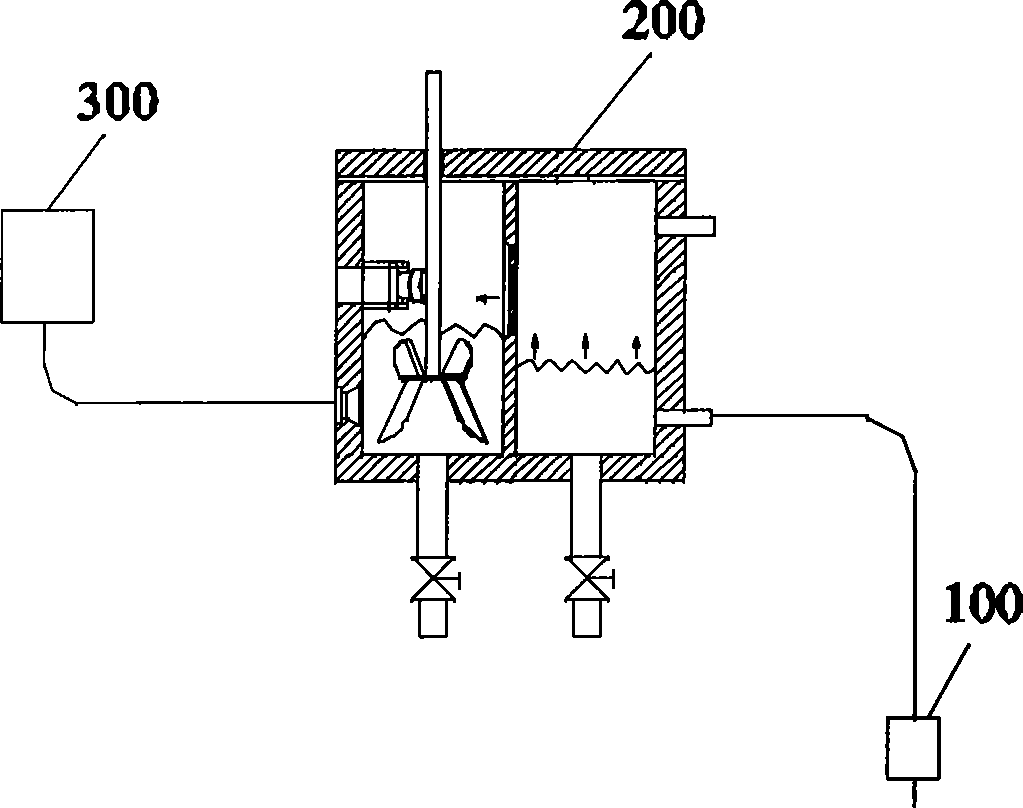

Device for automatically delivering fluid material and automatic/semiautomatic cooking device

InactiveCN101461652ARealize automatic deliveryImprove efficiencyCooking vesselsElectric controllersSolid componentSolid mass

The invention discloses a fluid material automatic delivering device for automatic / semi-automatic cooking equipment including a cooking container, a heating device, a material turning device and an overhead control system, wherein, the fluid material automatic delivering device includes a controller, implementation components, a material distribution mechanism for distributing the fluid material in the cooking container and a material storage device for storing the fluid material for delivery. The invention also discloses an automatic / semi-automatic cooking equipment provided with the fluid material automatic delivering device. The inventive fluid material automatic delivering device may realize the automatic delivery of the fluid material; and the fluid material can not only be equably distributed in the required scope, but also the solid component in the solid-liquid mixture is not easy to deposit on the material output position.

Owner:AIC ROBOTICS TECH

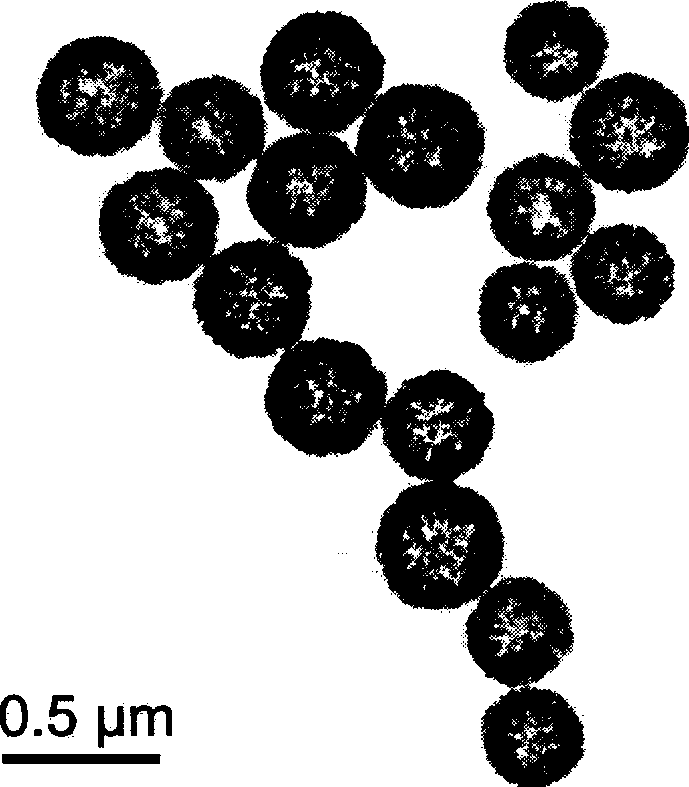

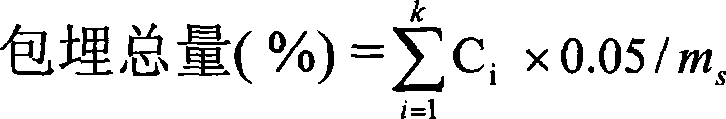

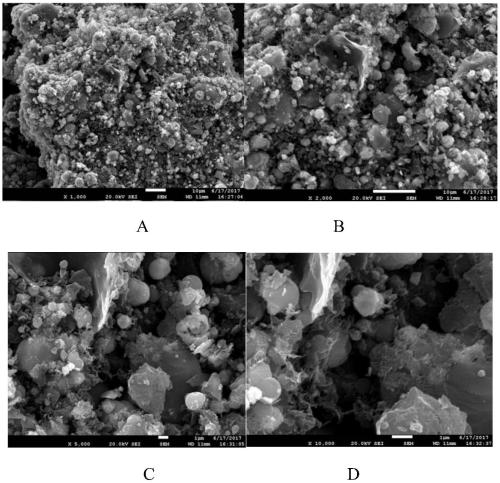

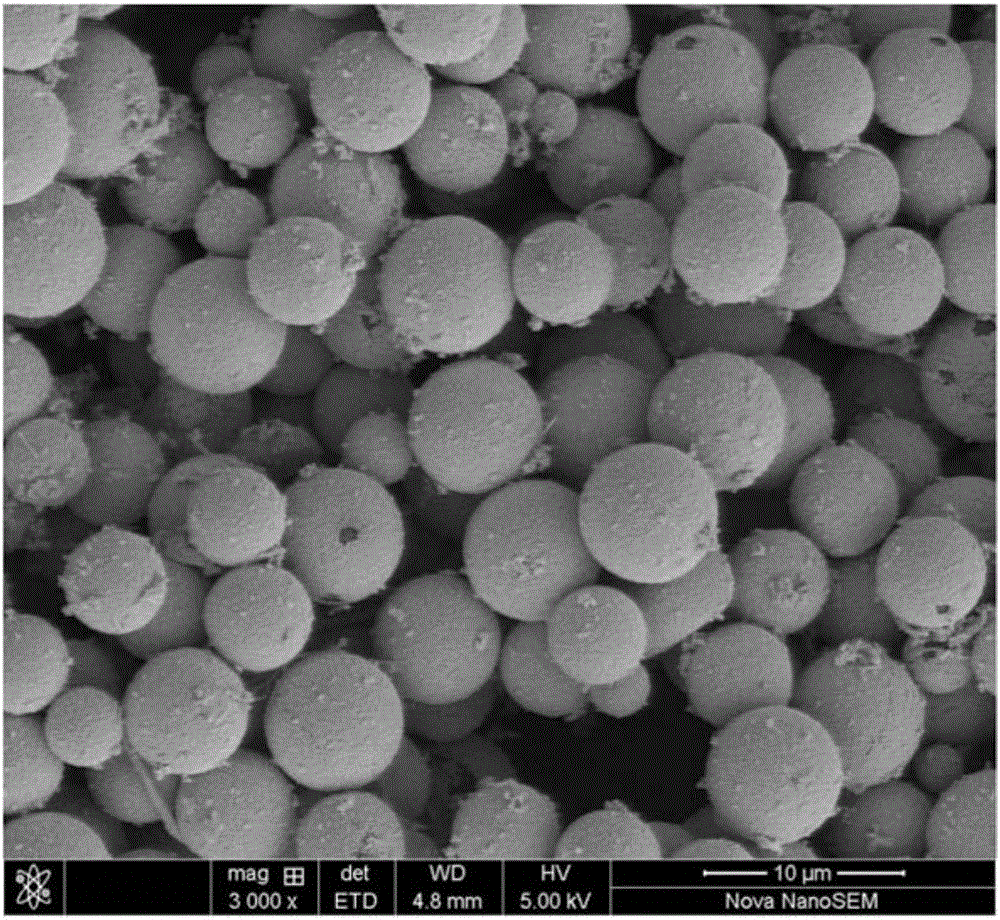

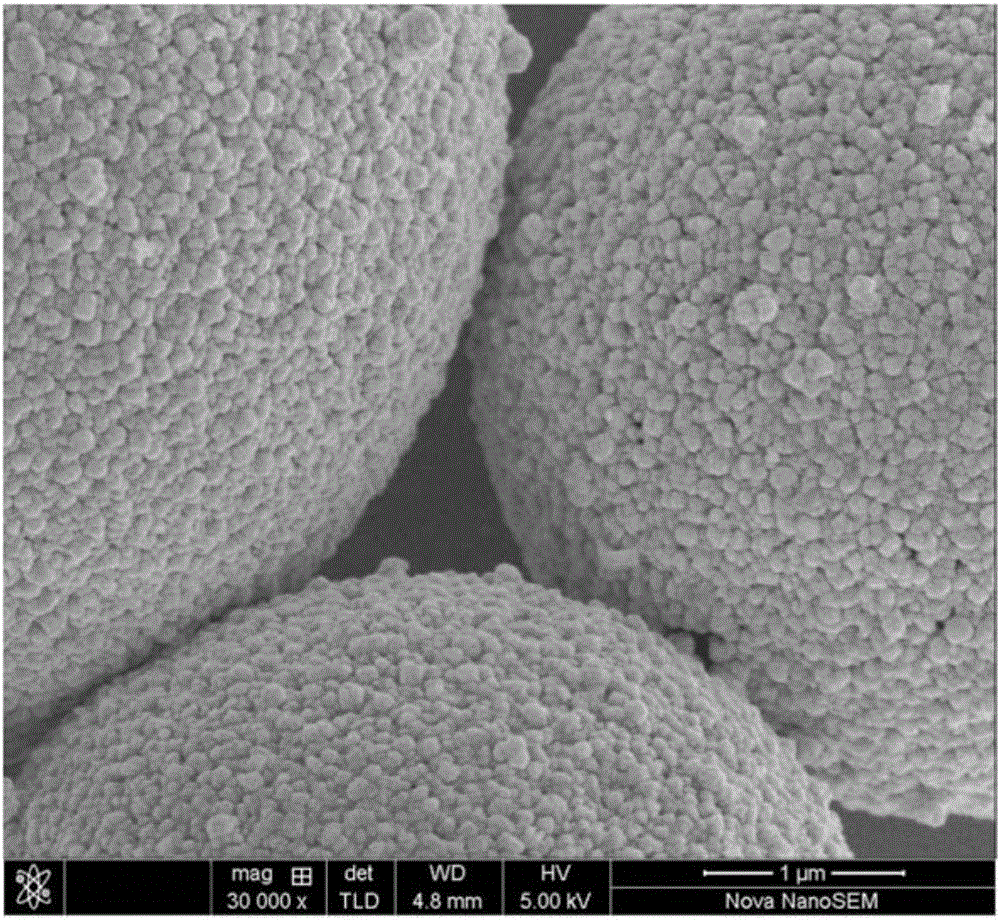

Method for preparing low-toxicity marine antifouling paint by applying Cu2O submicrospheres

InactiveCN101531841ALow densityEvenly dispersedRubber derivative coatingsAntifouling/underwater paintsMicrosphereSolvent

The invention discloses a method for preparing a low-toxicity marine antifouling paint by applying Cu2O hollow submicrospheres, and belongs to the fields of preparation and application of inorganic functional materials and marine antifouling paints. The method applies the Cu2O hollow submicrospheres singly or the Cu2O hollow submicrospheres embedded with a nontoxic organic antifouling composition as an antifouling composition to prepare the low-toxicity marine antifouling paint; and the antifouling composition, resin base stock, pigment (filler), and solvent are added to a ball mill for grinding to prepare the marine antifouling paint, wherein the antifouling composition consists of the Cu2O hollow submicrospheres with adjustable grain diameter (150-500nm), hollow structures and porous surfaces or the Cu2O hollow submicrospheres embedded with other antifouling compositions. The method has the characteristics that the Cu2O grain diameter reaches nano / micron grade, and grains in the paint are distributed uniformly; and the special appearance of the hollow structures and the porous surfaces can be used for embedding and slowly releasing other nontoxic organic antifouling compositions, reduces Cu2O dosage and has the function of cooperative antifouling so as to prolong the antifouling term, strengthen the antifouling effect and reduce the emission pollution.

Owner:JIANGNAN UNIV

Water quality on-line detection method and system

ActiveCN101430312ANot easy to blockImprove reliabilityPreparing sample for investigationTesting waterOnline analysisWater velocity

The invention discloses a method for on-line detecting water quality, which comprises the following steps: a. sample collecting, wherein, water sample in the test environment is collected and delivered to pretreatment device; b, pretreatment, wherein, water sample flows out from an inlet tube into a water container after flowing through a filter screen, wherein, the angle formed between the water velocity attitude and the filter screen is an acute or a right angle; and c. measuring, wherein, the water sample to be tested is collected from the water container, and the water parameter is obtained by analyzing the test water sample to be tested. The invention also discloses a system for on-line detecting water quality. The invention has the advantages of continuous working, uneasy blockage, low cost, and the like, and the invention can be applied in various water sample on-line analysis.

Owner:FOCUSED PHOTONICS +1

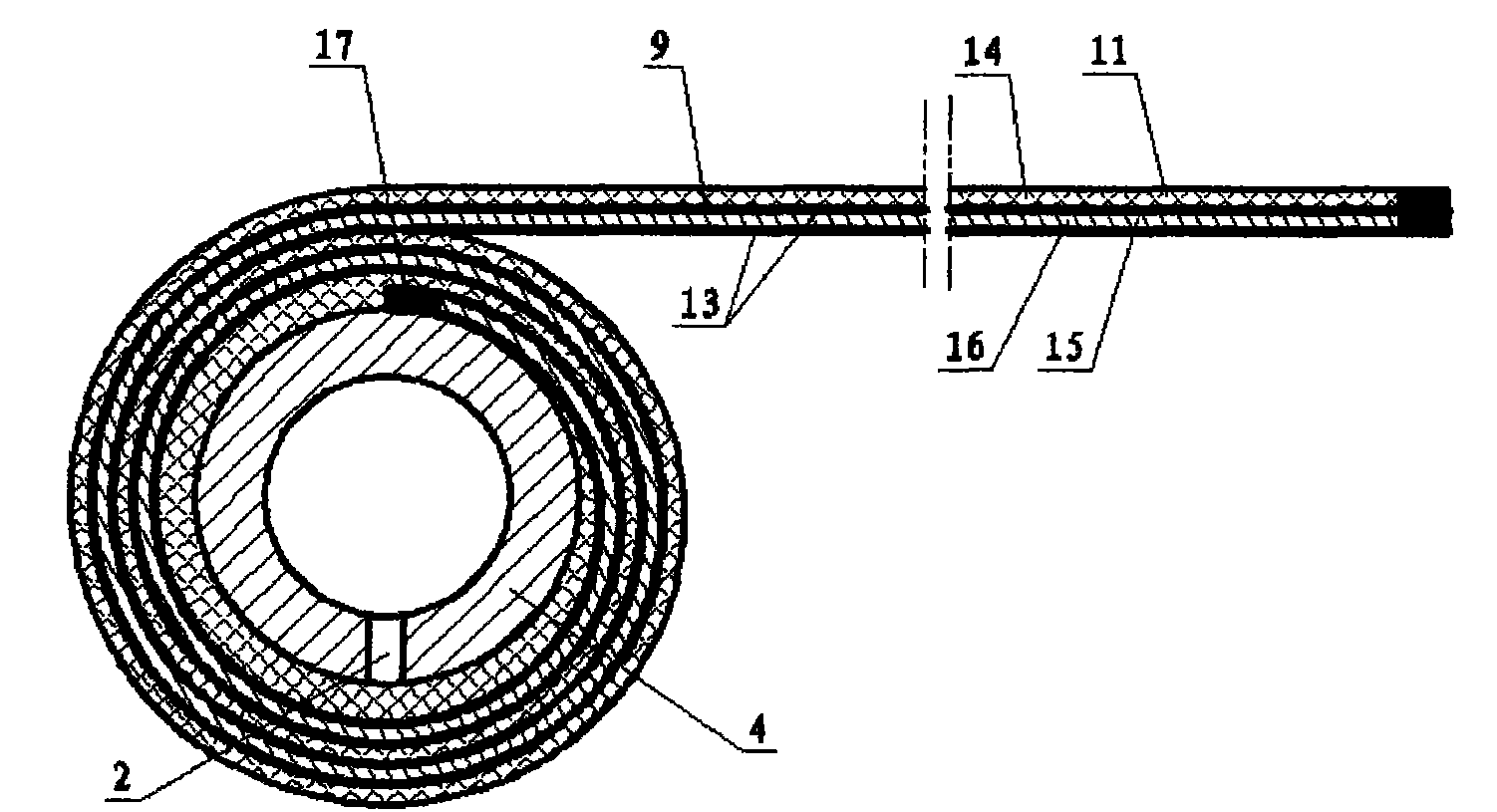

Roll-type membrane element

InactiveCN103521076AExtended service lifeSpeed up the flowSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWind directionWaste management

The invention discloses a roll-type membrane element comprising a central tube, a water purification diaphragm group and a guide bar, wherein the water purification diaphragm group is wound on the central tube, and comprises a raw water guide net, a flake high-precision filter membrane and a product water guide net; one side surface of the flake high-precision filter membrane is adjacent to a raw water runner or adjacent to the raw water guide net; the other side surface of the flake high-precision filter membrane is adjacent to a water-yielding runner or adjacent to the product water guide net; a space for arranging the raw water guide net is the raw water runner; a space for arranging the product water guide net is the water-yielding runner; at least one guide bar is arranged inside the raw water runner; the length of the guide bar is close to that of the raw water guide net in a winding direction after being unfolded; the internal part of the central tube is communicated with the raw water runner; the entire outer side surface is wound and sealed by an adhesive tape after the water purification diaphragm group is wound on the central tube. The roll-type membrane element disclosed by the invention is not easily blocked, long in service life and high in recovery rate.

Owner:黄瑞中

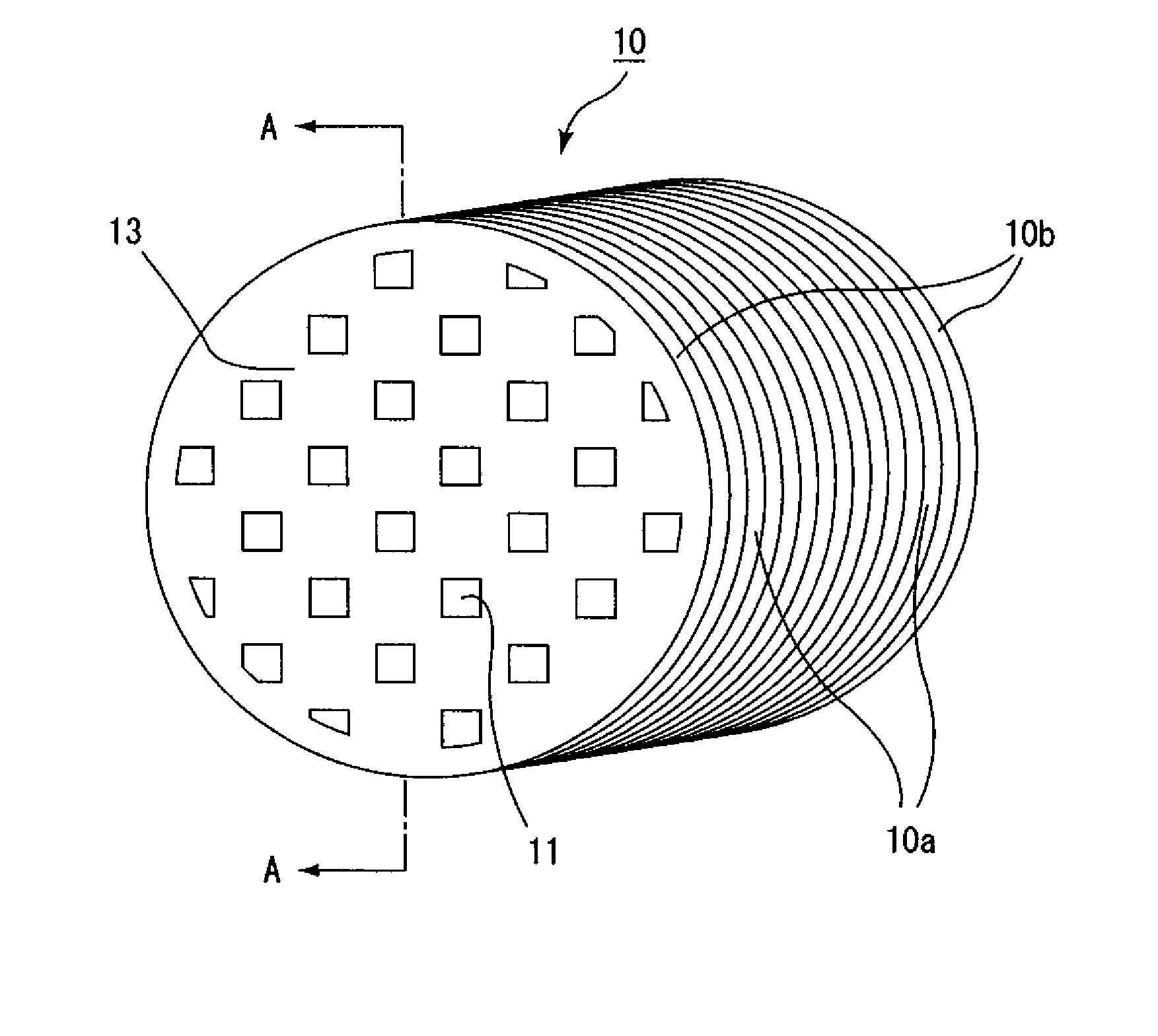

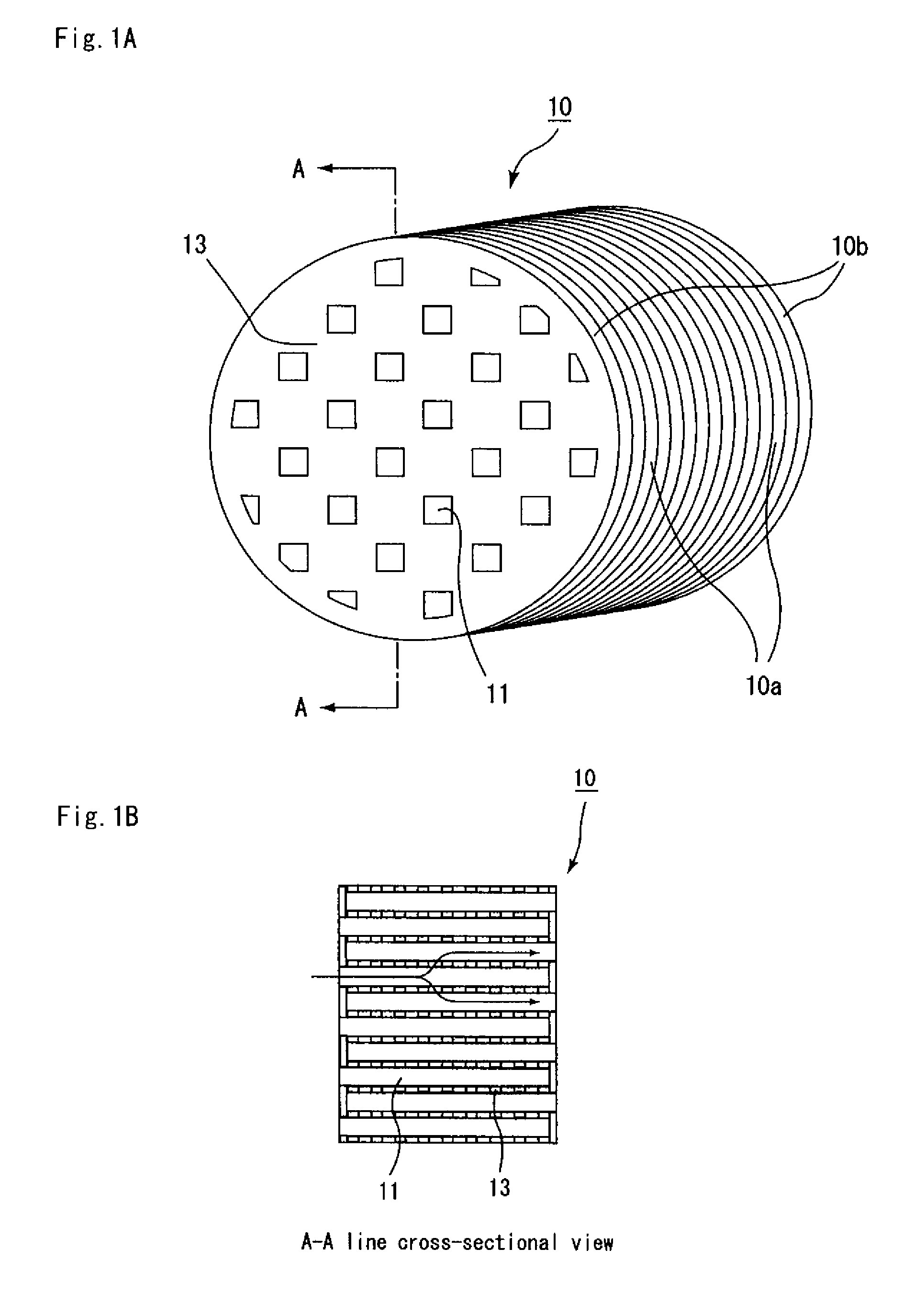

Honeycomb structured body

ActiveUS20070148402A1Increase pressureImprove capture efficiencyInternal combustion piston enginesDispersed particle filtrationPorosityEngineering

A honeycomb structured body of the present invention is a honeycomb structured body in which a plurality of cells are placed in parallel with one another in the longitudinal direction with a cell wall therebetween, either one of the end portions of the cells being sealed, wherein a porosity is at least about 70% and at most about 95%, and a ratio of a diameter of a cross-section perpendicular to the longitudinal direction of the honeycomb structured body to a length of the honeycomb structured body in the longitudinal direction is at least about 0.2 and at most about 0.9.

Owner:IBIDEN CO LTD

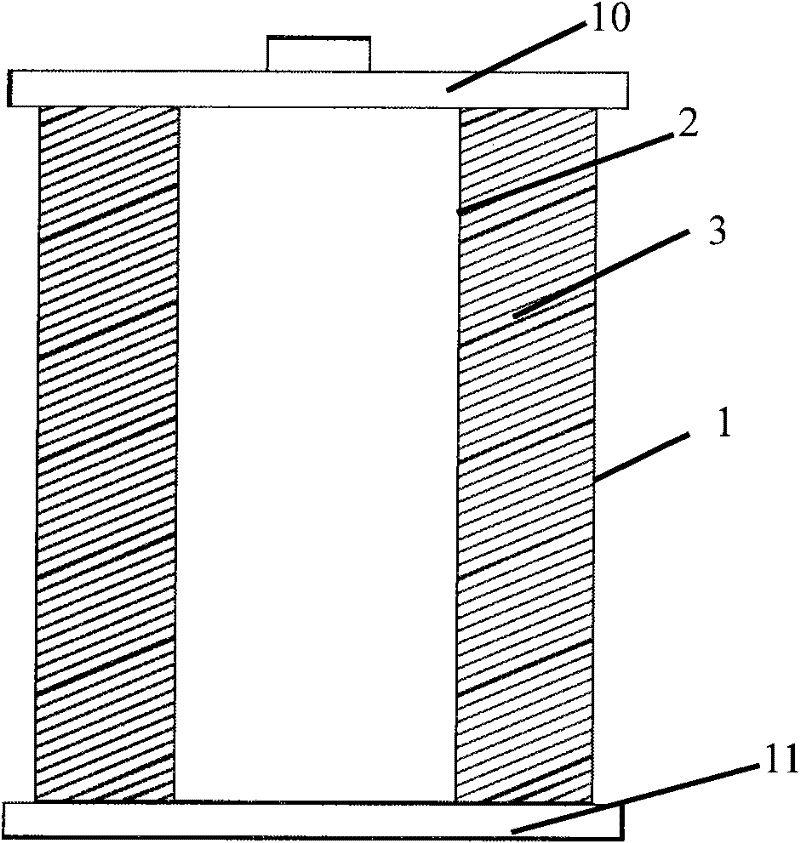

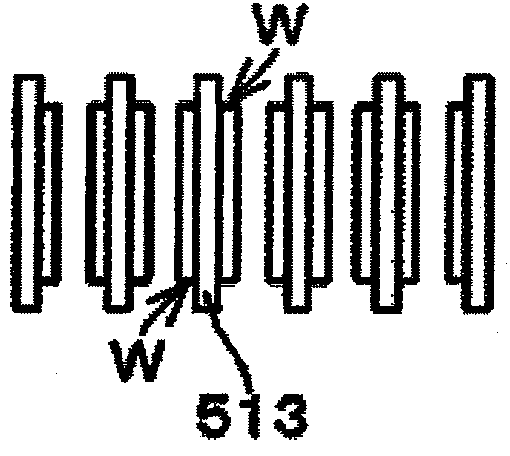

High-flux high-dirt-holding-capacity filtering element and preparation method thereof

InactiveCN102188848AExtended service lifeEven distribution of water flowStationary filtering element filtersCENBOLFiltration membrane

The invention discloses a high-flux high-dirt-holding-capacity filtering element, which comprises a filtering medium layer (3), a central tube (2), a shell (1) and upper and lower end covers (10, 11), wherein the filtering medium layer (3) is folded into an arc-shaped fold and then encloses the central tube (2), and the whole is cylindrical; the shell (1) is sleeved outside a cylindrical filtering medium; the filtering medium layer comprises a filtering layer (3b) and plastic net layers (8) which are positioned on two sides of the filtering layer; the filtering layer consists of at least two layers of filtering materials (3d); and the upper and lower ends of the central tube (2) and the shell (1) are fixedly connected with the upper and lower end covers. A high-flux folding filtering element is wide in runner, relatively low in fluid resistance, and more uniform in flow distribution of water inlet and outlet ends of the filtering element. Compared with the conventional W-shaped linear fold designing filtration membrane, the high-flux folding filtering element is improved by over 30 percent in terms of filling density, large in filtering area, high in total dirt-holding capacity and long in service life of the filtering element.

Owner:浙江瑞普环境技术有限公司

Corrosion-inhibition type water-based metal cleaner

The invention discloses a corrosion-inhibition type water-based metal cleaner. The corrosion-inhibition type water-based metal cleaner comprises the following raw materials in parts by weight: 15-30 parts of coconut diethanolamide, 5-12 parts of octyl phenol polyoxyethylene ether, 3-10 parts of alkyl benzene sodium sulfonate, 7-15 parts of sodium xylene sulfonate, 5-10 parts of citric acid, 4-12 parts of sodium citrate, 1-4 parts of polyvinyl chloride latex, 0.5-3 parts of non-ionic polyacrylamide, 4-10 parts of sodium carbonate, 15-30 parts of hydrophilic alcohol, 3-6 parts of instant modified sodium disilicate, 15-30 parts of dodecanedioic triethanolamine, 2-5 parts of N-lauroyl sarcosine triethanolamine, 3-8 parts of mercaptobenzothiazole sodium, 1-5 parts of a defoaming agent, 1-5 parts of a fungicide, 30-40 parts of soft water and 100-150 parts of water. The corrosion-inhibition type water-based metal cleaner disclosed by the invention is strong in detergency, good in anti-rusting property, less in environment-friendly pollution, high in cleaning speed, less in residues after cleaning, good in stability and capable of being used in hard water.

Owner:CHAOHU GUANGFENG METAL PROD

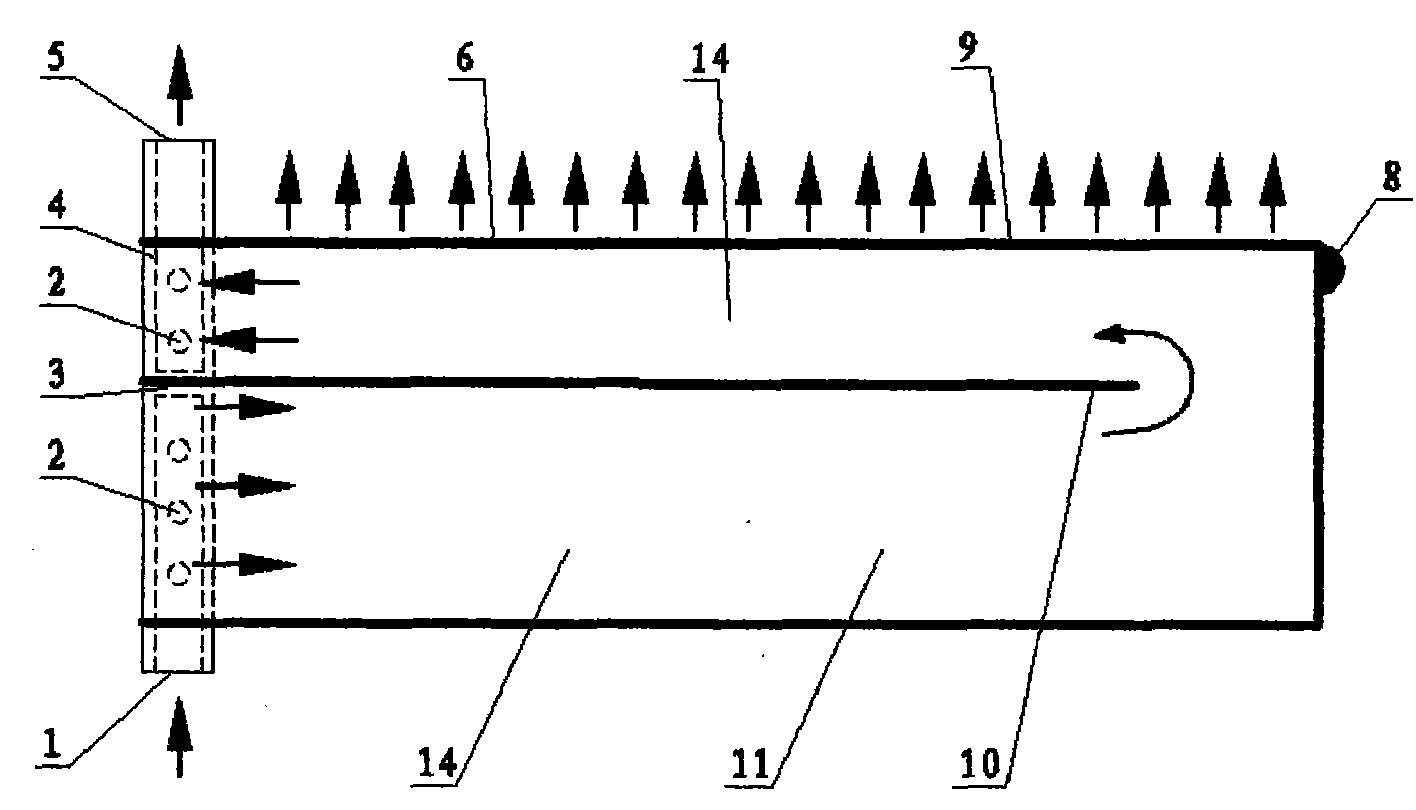

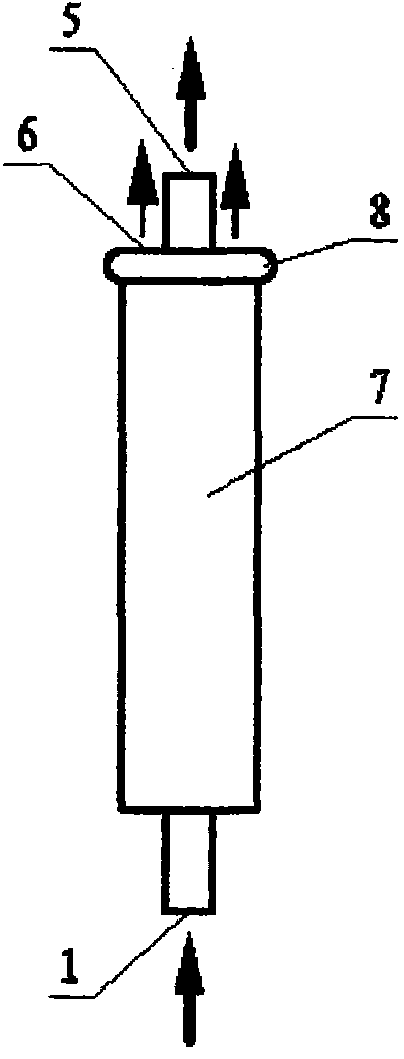

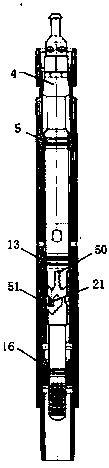

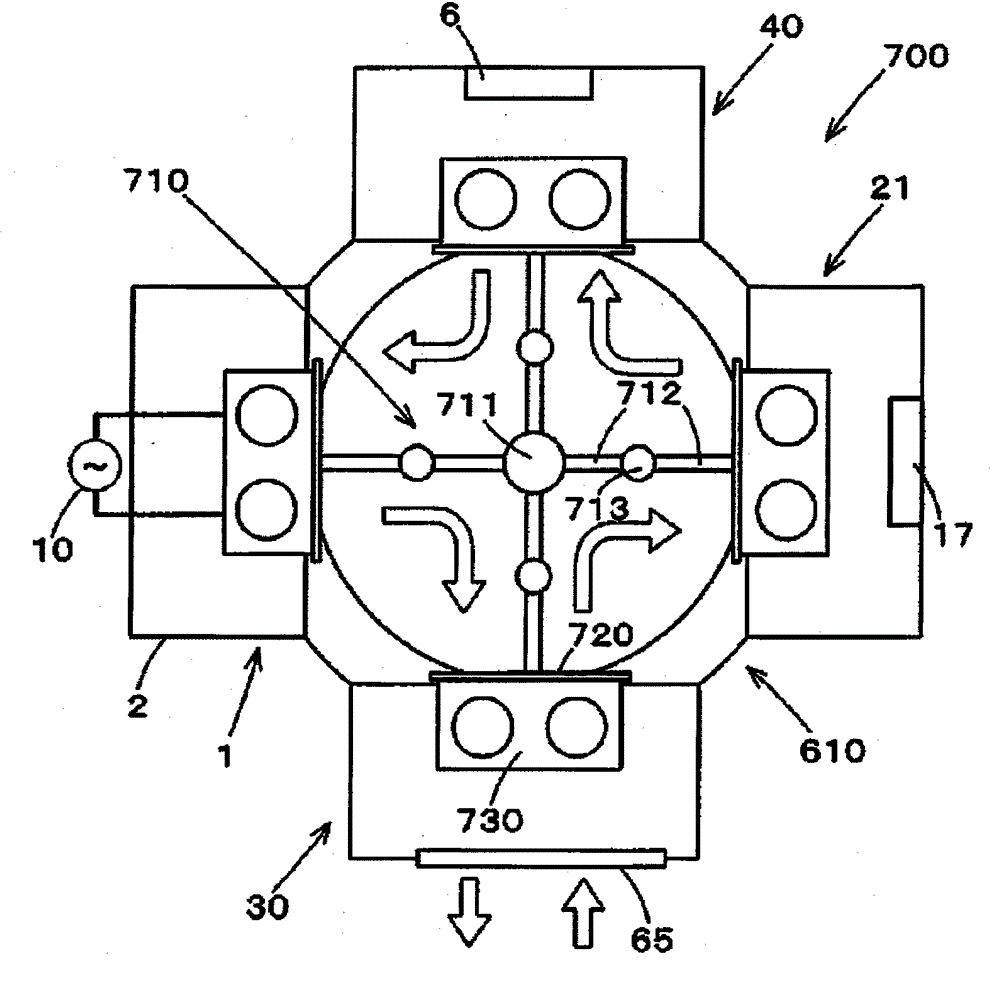

Method and device for reversely cyclically producing and lifting pump core of hydraulic jet pump

ActiveCN103899581ATroubleshoot overhaul operationsReduce riskDrilling rodsJet pumpsHorizontal wellsHydraulic pump

The invention discloses a method and a device for reversely cyclically producing and lifting a pump core of a hydraulic jet pump and belongs to the technical field of oil recovery in the oil field. The method is characterized by adopting reverse circulation, that is, pumping into hydraulic liquid from a casing pipe and returning to be output on the ground from an oil pipe together with stratum liquid; adopting a ground water injection net as power liquid, enabling the power liquid to flow through a nozzle and form high-speed jet flow together with the stratum liquid, and enabling the high-speed jet flow to pass a venturi pipe diffusion zone and enter an on-pump oil pipe. The method for reversely cyclically producing and lifting the pump core of the hydraulic jet pump effectively solves the problems that sand flow forms on the stratum, annular spaces of the oil pipes and the casing pipes are large, flow velocity is slow to cause sand deposition, jamming of a packer by wax precipitation and oil pipe blockage of highly-deviated wells and horizontal wells and finally cause overhauling of the wells, risk in overhauling and abandonment of the wells is reduced, and application range of the hydraulic jet pump is enlarged. The method has no demand for any extra tools to lift and lay down the pump core, only needs to repeat procedures above, and the pump core can be backwashed out immediately by vertically moving in a working barrel.

Owner:PETROCHINA CO LTD

Slightly alkaline sapphire polishing solution and preparation method thereof

ActiveCN101870853AStrong dilutable ratioImprove stabilityPolishing compositions with abrasivesSURFACTANT BLENDSapphire

The invention provides a slightly alkaline sapphire polishing solution and a preparation method thereof, which relates to the field of sapphire polishing technology. The method comprises the following steps: firstly, suspending nano-silica sol particles of which the particle diameters are 3-300nm in water; adding a complexing agent into the suspension; then, adding a surfactant; and finally, regulating the pH value of the suspension to 7-9.5. The method of the invention is simple and reasonable, easy production and good product stability. The product has high dilution rate, high polishing efficiency, good and strong stability and easy production and can not deposit on the surfaces of polishing machines and polishing materials easily; and because of unique fluid property, the product can not be air-dried on the surface of sapphire easily after being polished, thereby greatly reducing the burden of the subsequent cleaning processes. Different from the traditional sapphire polishing solution, the product of the invention has the advantage that under the condition of regulation of a reasonable formula, the polishing and cutting rate of sapphire increases when the pH (10.5) decreases.

Owner:江苏集萃中以科技产业发展有限公司

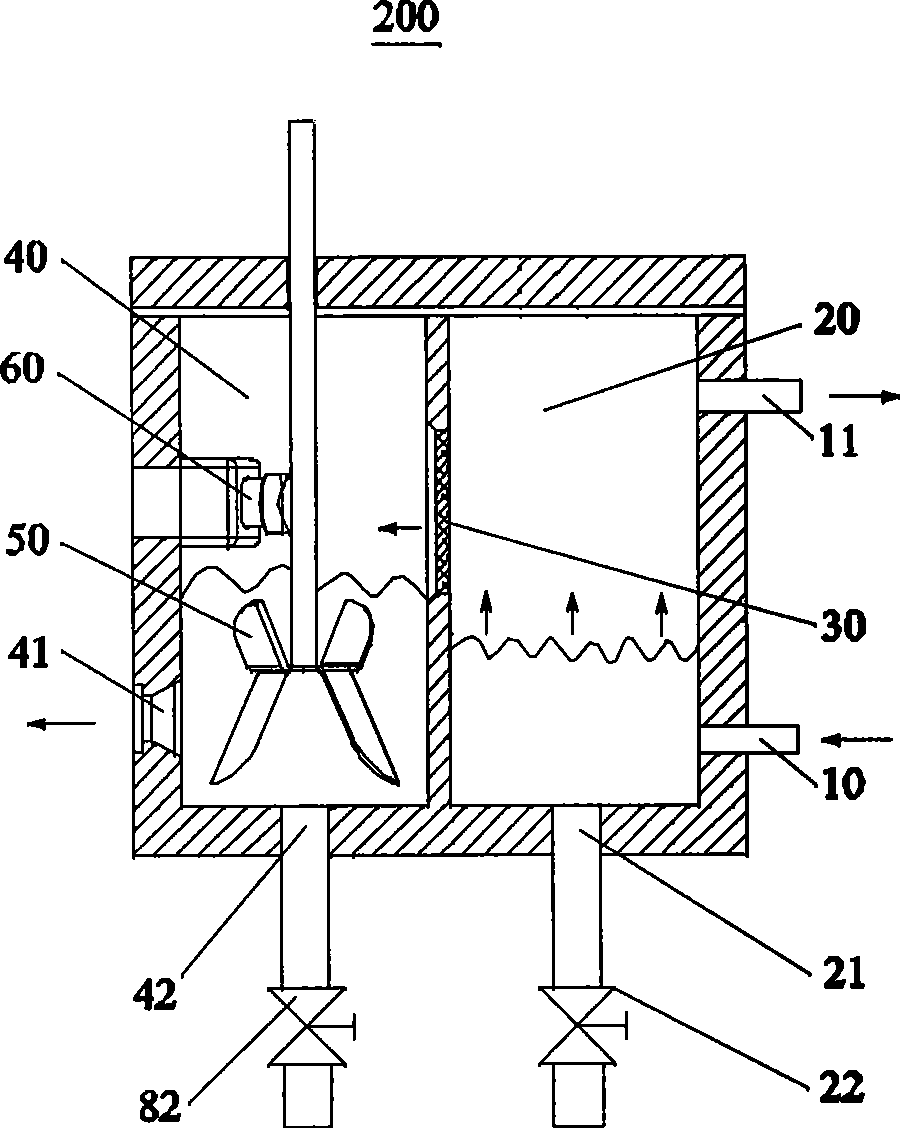

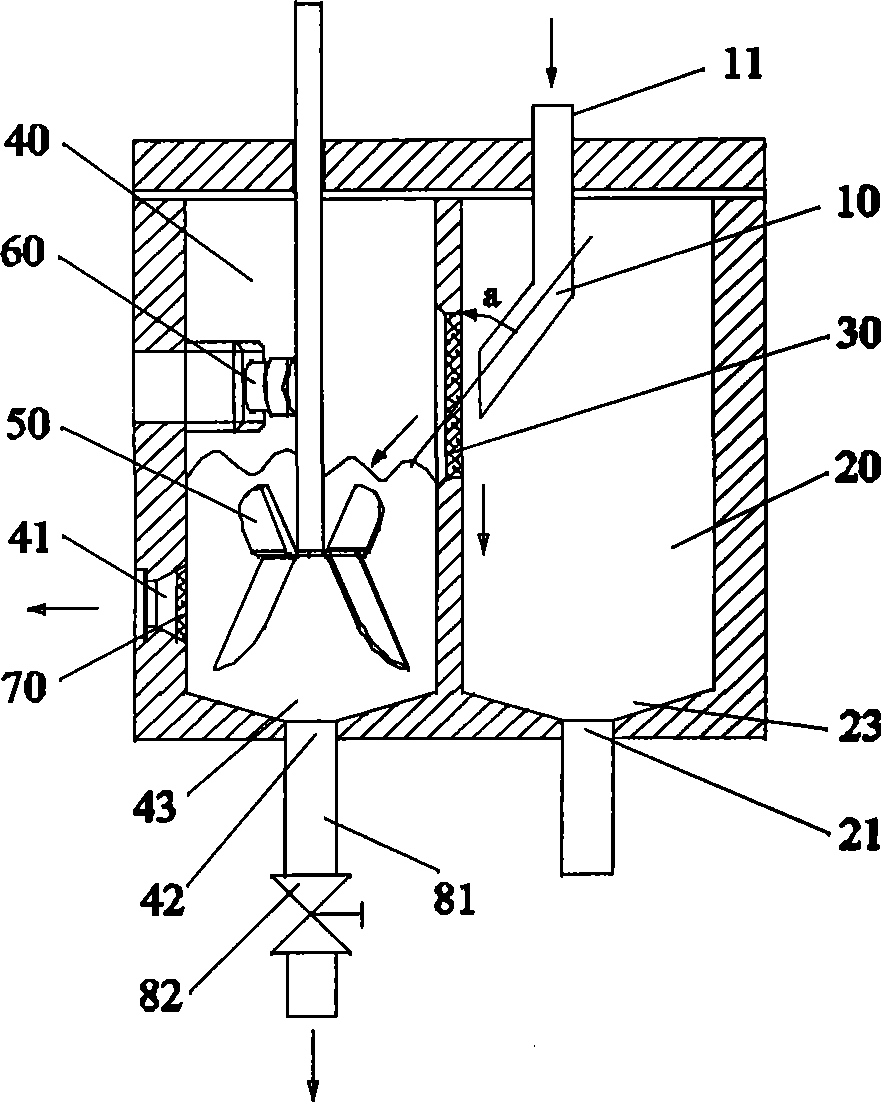

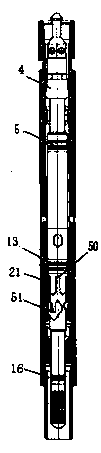

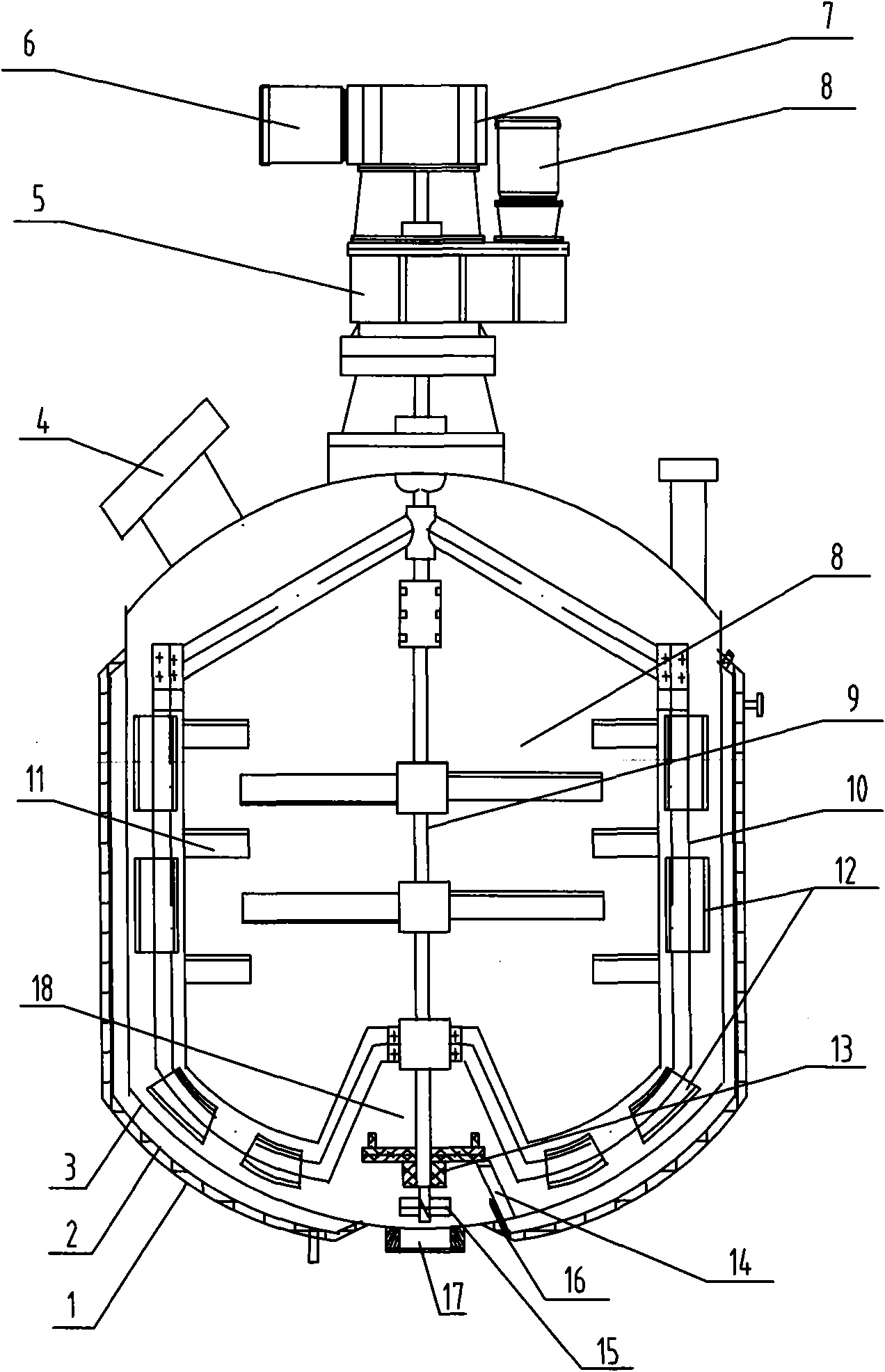

Combined stirred tank reactor

InactiveCN101972624AStir wellSmooth rotationMixersChemical/physical/physico-chemical stationary reactorsEngineeringCavity wall

The invention relates to a reactor, in particular to a combined stirred tank reactor used for producing a composite stabilizer and a modifier, which comprises a barrel, a stirring device and a material outlet, wherein the stirring device consists of a blade stirrer and a frame stirrer; the blade stirrer consists of a central rotating shaft and at least one blade stirring paddle arranged on the central rotating shaft; the frame stirrer consists of a frame body arranged along the cavity wall of the barrel, outer scraping plates arranged on the outer circumferential wall of the frame body and inner stirring paddles arranged on the inner circumferential wall of the frame body; an upwards-sunken groove is reserved above the material outlet at the bottom of the frame body; a bottom bearing is arranged on the central rotating shaft in the groove; a triangular support frame is arranged below the bottom bearing; the upper end of the triangular support frame is fixed with the bottom of the bottom bearing, while a lower end is fixed with the inner bottom of the barrel; and a small paddle is arranged below the bottom bearing on the central rotating shaft, and is in contact with the periphery of the material outlet at the bottom in the barrel. The combined stirred tank reactor can solve the problems that mixed raw materials are easy to deposit, easily adhered to the wall and unsmooth to discharge, and that reaction is incomplete, and is more environmentally-friendly and energy-saving.

Owner:NANJING CONCORD FERTILIZER CHEM

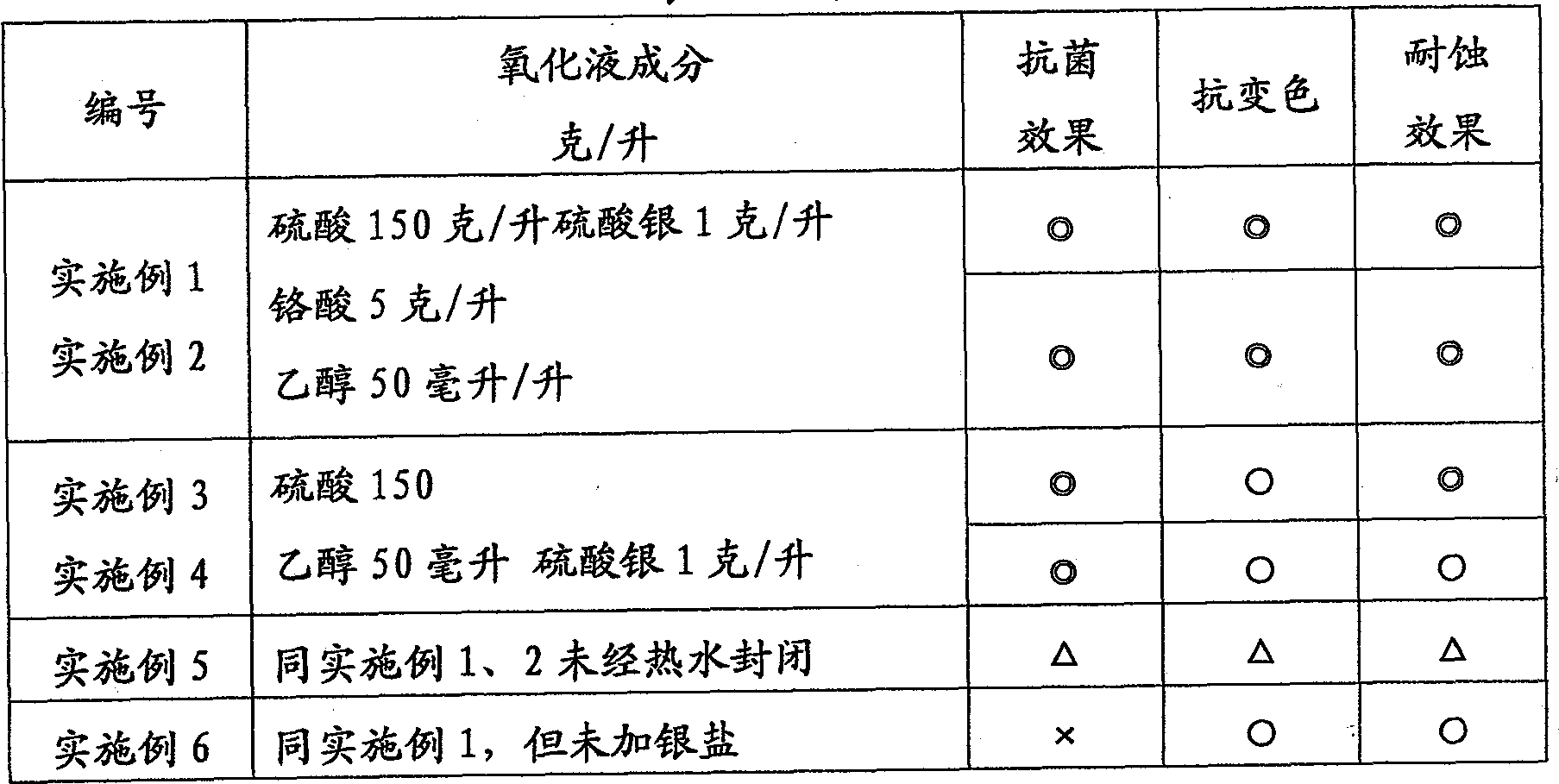

Surface processing technique for bacterium resistance, erosion resistance and tarnish resistance of aluminum or aluminum alloy material

ActiveCN101629316AImprove corrosion resistanceSlow down the rate of formationAnodisationLiquid temperatureSilver chromate

The invention relates to a surface processing technique for the bacterium resistance, the erosion resistance and the tarnish resistance of aluminum or aluminum alloy material, comprising the following steps: firstly, degreasing processing is carried out on an aluminum material used as a workpiece, the aluminum material after being degreased is put into an acid solution, the workpiece is used as one pole, an aluminum plate or a lead plate is used as the other pole and is electrified with alternating current, the liquid temperature is kept between 0 DEG C and 30 DEG C, an oxidation film with bacterium resistance, erosion resistance and tarnish resistance is formed on the surface of the aluminum material after oxidation for 10-30 minutes, and finally, the workpiece is taken out and placed in purified water of 90-100 DEG C and closed for 15-20 minutes. The acid solution has the components and the content that each liter of acid solution contains 80-150 grams of industrial grade sulfuric acid, 2-10 grams of chromic anhydride and 0.1-1.5 grams of water soluble silver salt. The surface of the aluminum material after being processed by the invention is provided with a layer of oxidation film, silver compounds with bacterium resistance and tarnish resistance, such as silver chromate, silver dichromate and the like, are formed in the film, then the film is closed by hot water, and the erosion resistant performance is more excellent.

Owner:CHANGZHOU GARDENSUN ANTI BACTERIAL MATERIALS TECH

SCR deNOx catalyst added with attapulgite and preparation method thereof

InactiveCN101862648AReduce poisonNot easy to depositDispersed particle separationCatalyst activation/preparationChemistryTitanium dioxide

The invention relates to a method for preparing an SCR deNOx catalyst added with attapulgite, which comprises the following steps of: (1) purifying the attapulgite by adopting a dry or wet method to make the purity of the attapulgite reach over 60 percent, and dispersing attapulgite crystal fibers; (2) adding water to the purified attapulgite, titanium dioxide, active ingredients and a forming aid in a certain ratio, performing high-speed stirring, homogenizing, filtering, and fully mixing the raw materials by using a mixing mill; (3) forming the mixed slurry by using an extruder according to engineering requirement; and (4) drying at certain humidity and temperature to obtain a catalyst blank, and sintering the blank in a sintering furnace to obtain the finished product. The invention also relates to the SCR deNOx catalyst prepared by the method. The attapulgite is added to form a pore structure in the SCR deNOx catalyst, so that the catalyst has elasticity and thermal stress resistance, and can be used for removing NOx from flue gas of heat-engine plants and industrial stoves.

Owner:石磊

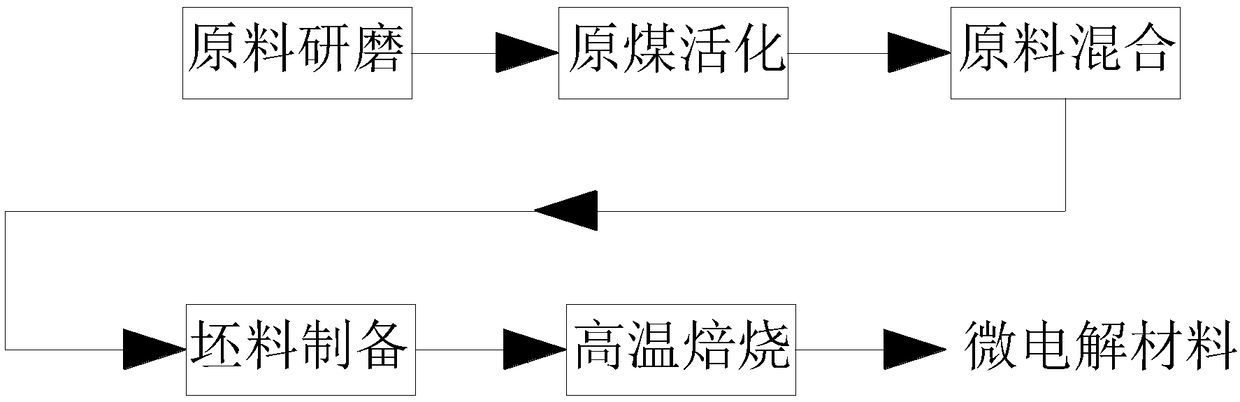

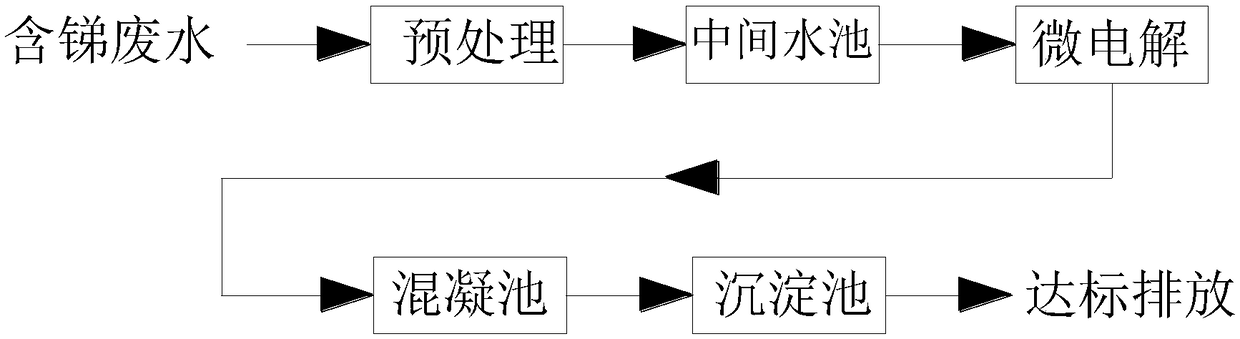

Preparation for composite carbon based nano zero-valent iron micro electrolysis material and method for treating antimony-contained wastewater

ActiveCN109110883AReduce lossesSolve churnWater contaminantsWater/sewage treatmentElectrolysisEnvironment water

The invention provides a preparation method for a composite carbon based nano zero-valent iron micro electrolysis material and a method for treating antimony-contained wastewater. The composite carbonbased nano zero-valent iron micro electrolysis material provided by the invention is a micro electrolysis material which takes an element carbon as a carrier, is loaded with nano zero-valent iron, and is doped with an element copper as auxiliaries, wherein the metal element is covered by the element carbon. The material has relatively high redox potential difference of the micro electrolysis material, an over-sized specific surface area of a mesoporous material, excellent redox activity and excellent performances of the nano material. The composite carbon based nano zero-valent iron micro electrolysis material provided by the invention is low in preparation cost, is high in efficiency of treating antimony-contained wastewater, is simple in operation method and is very suitable for adsorbing pollutants in an environment water sample.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Heat conductive silicone grease containing liquid metal heat conductive filler

ActiveCN107501953ANot suitable for short circuitImprove thermal efficiencyHeat-exchange elementsHydrogenLiquid metal

The invention creatively provides heat conductive silicone grease containing liquid metal heat conductive filler. The silicone grease includes, by weight, 40-60 parts of organic silicon basic resin, 40-100 parts of the liquid metal heat conductive filler, and 0-10 parts of other additives. The organic silicon basic resin is composed of, by mass, 30-70% of vinyl-terminated dimethyl polysiloxane, of which the dynamic viscosity is lower than 2000 cst at 25 DEG C, 25-40% of vinyl-terminated dimethyl polysiloxane, of which the dynamic viscosity is higher than 10000 cst at 25 DEG C, 5-10% of vinyl cyclopolysiloxane, 2-10% of hydrogen-containing silicone oil, of which the dynamic viscosity is 50-2000 cst at 25 DEG C, and 5-20% of polyether-modified polysiloxane. The heat conductive silicone grease has high heat conductivity and matrix stability.

Owner:深圳沃尔提莫电子材料有限公司

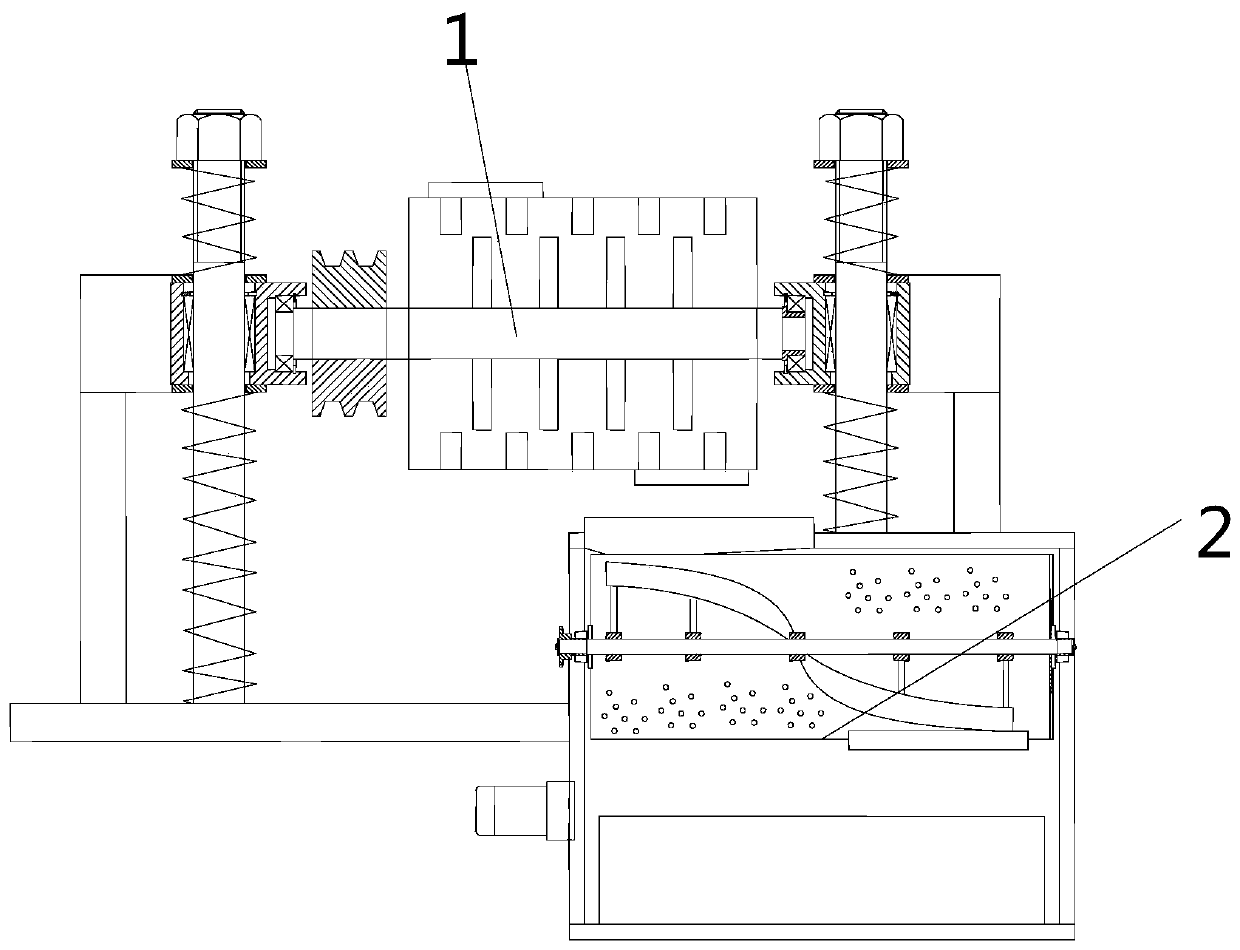

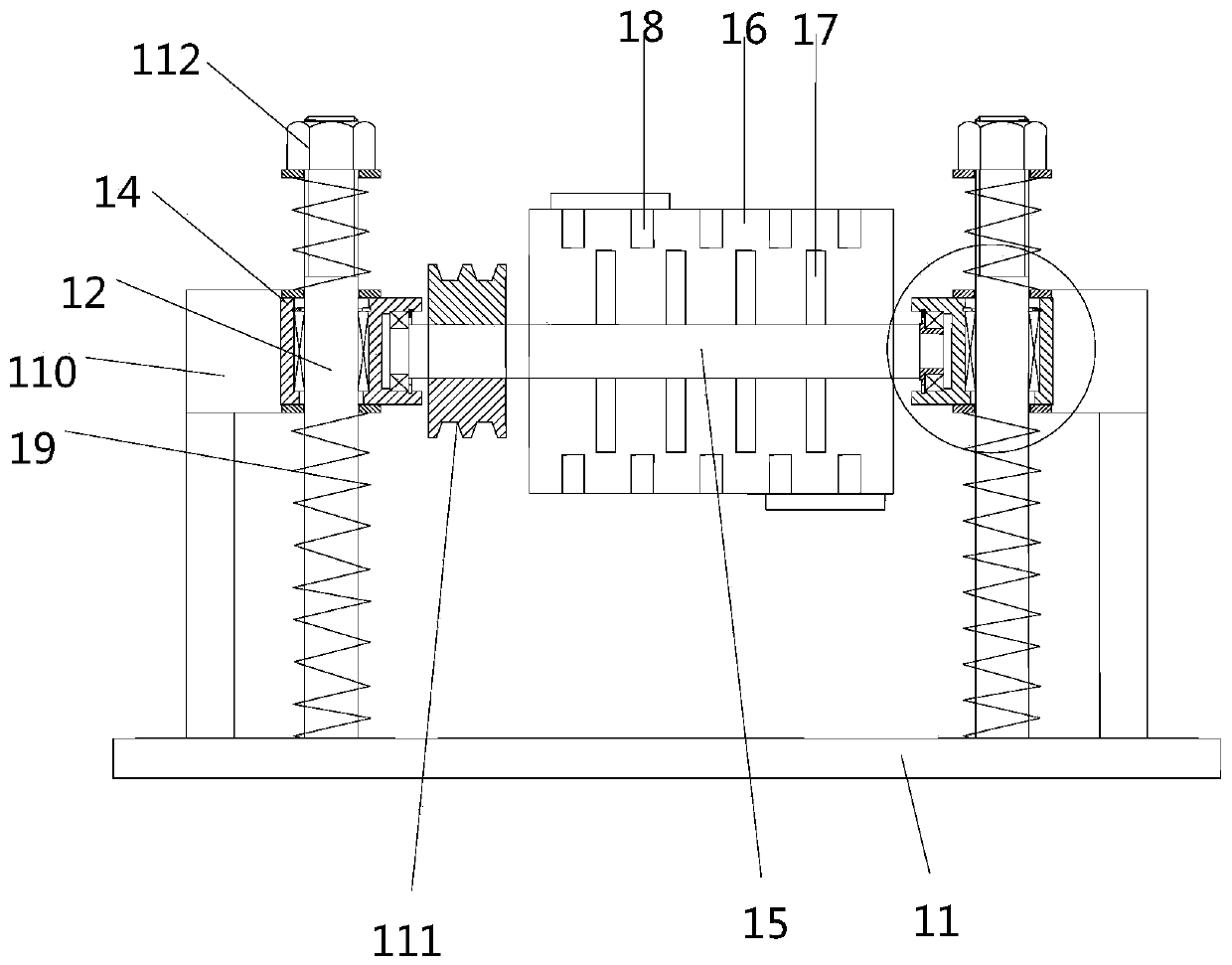

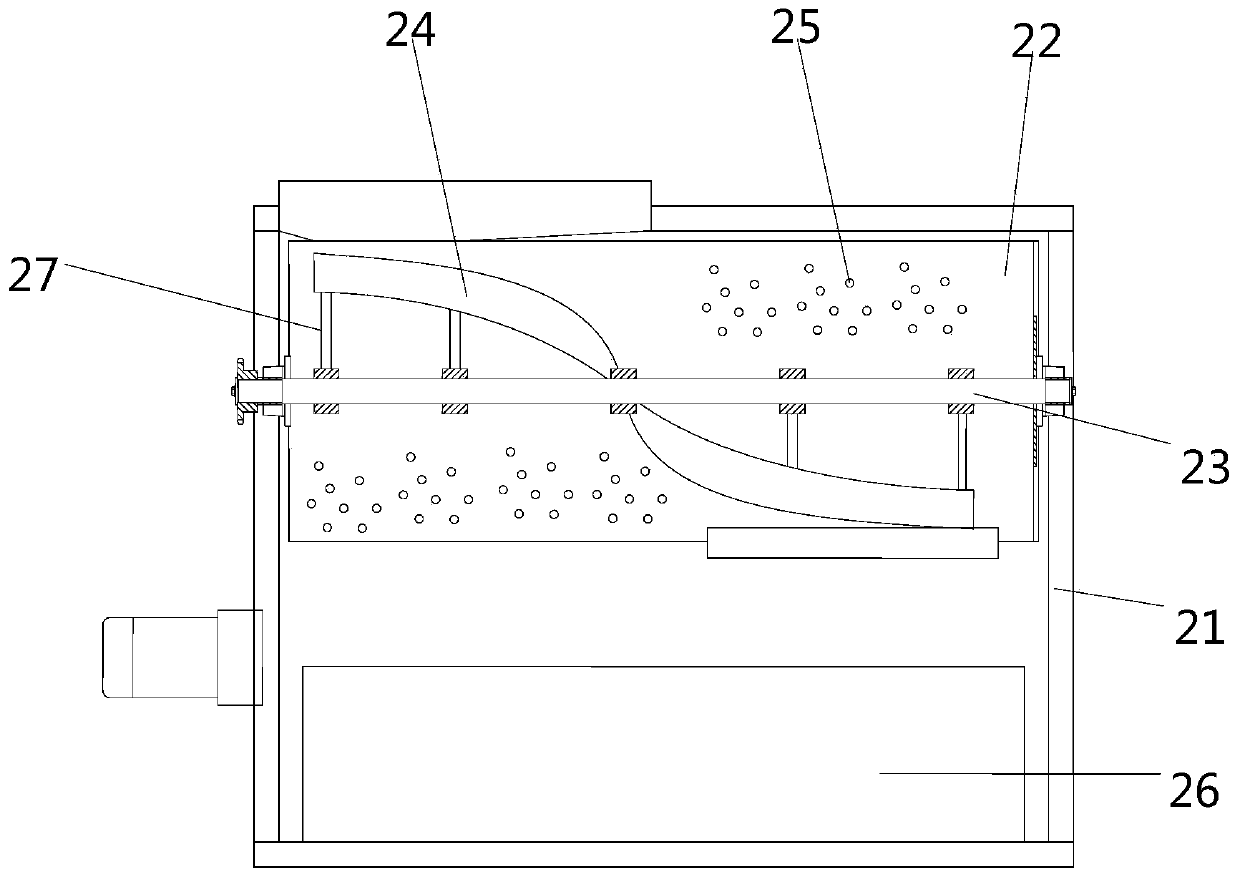

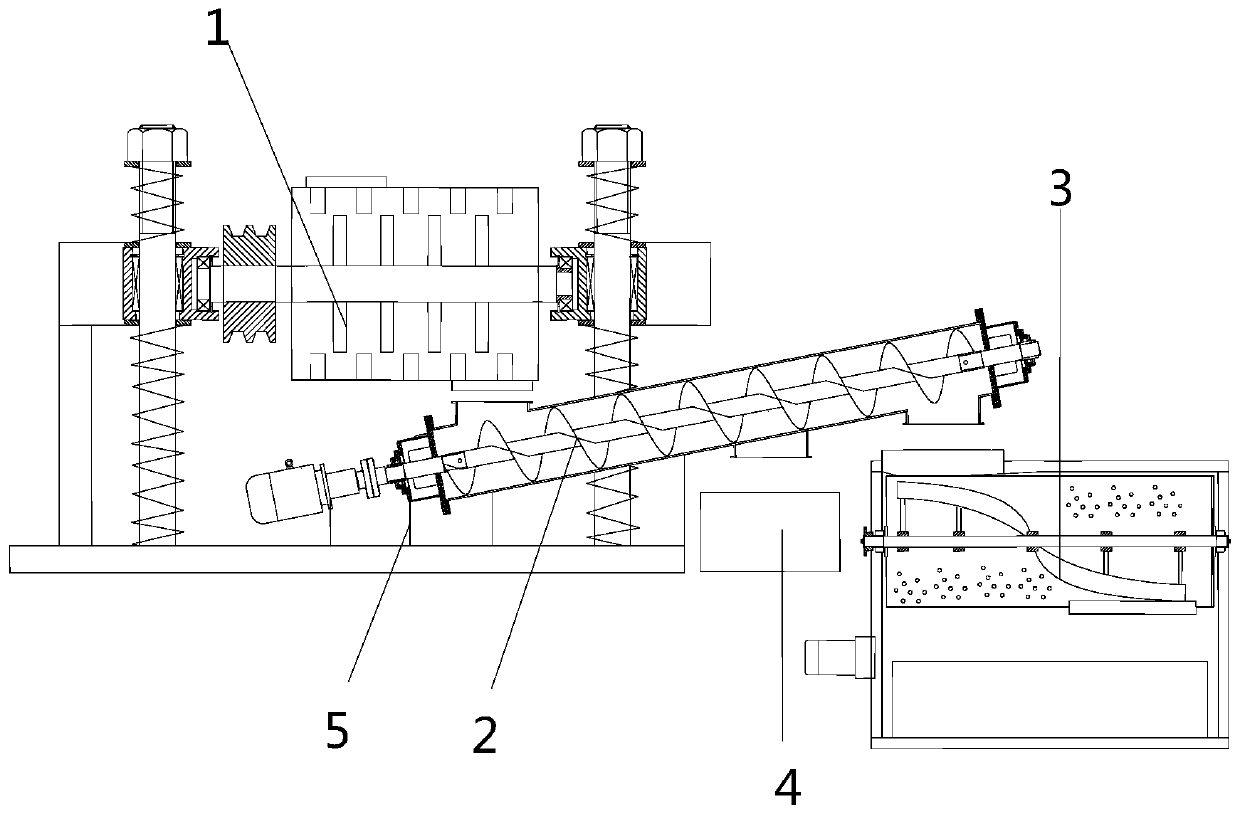

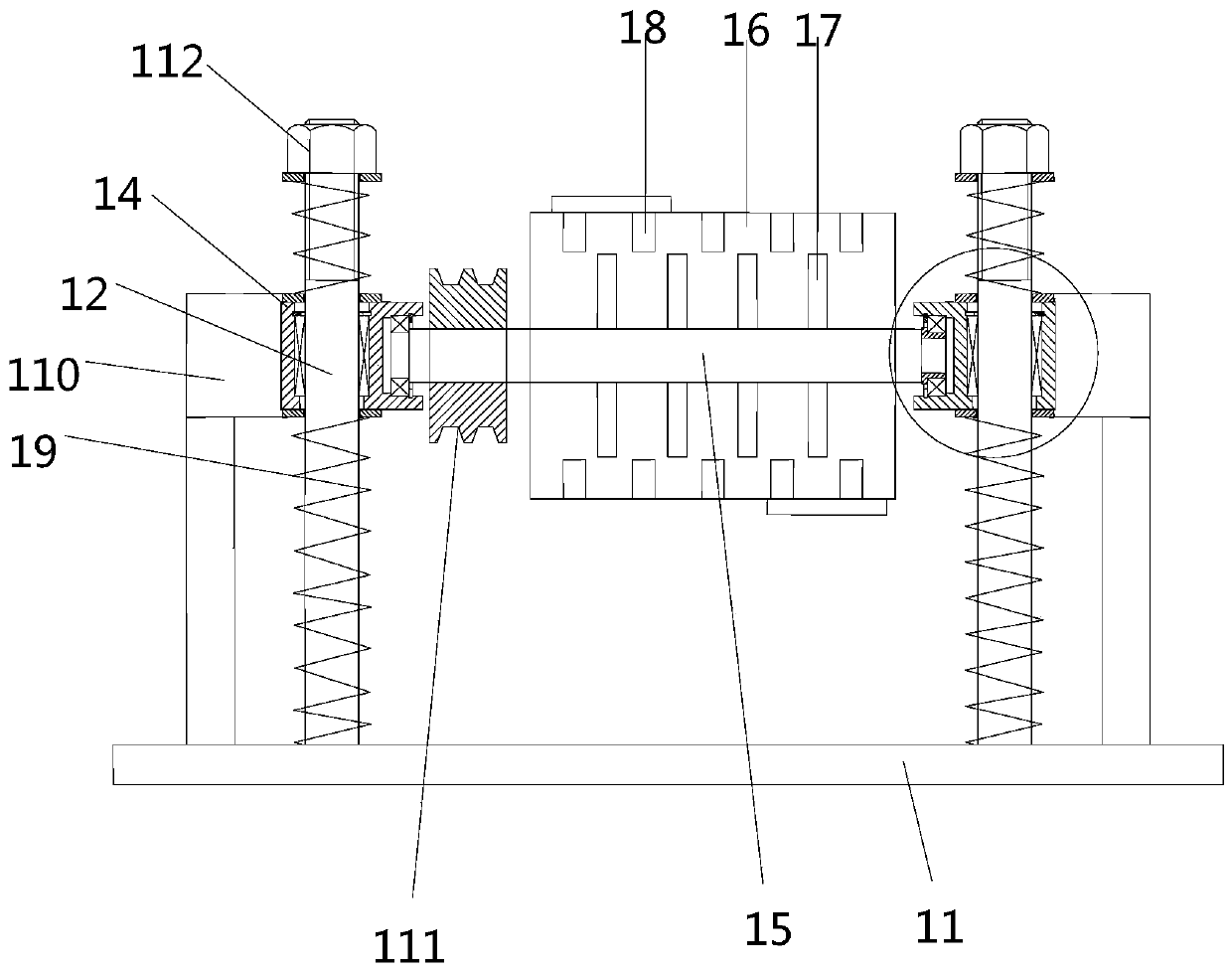

Drum-type deburring device for small part

InactiveCN110860994ANot easy to depositComplete structureEdge grinding machinesPolishing machinesStructural engineeringMechanical engineering

The invention discloses a drum-type deburring device for a small part. The drum-type deburring device comprises a drum deburring mechanism, wherein a discharge port of the drum deburring mechanism isconnected with an abrasive separating mechanism; the drum deburring mechanism comprises a base, a pair of upright posts are arranged on the base, sliding blocks with built-in sliding sleeves are respectively arranged on the pair of upright posts, bearing blocks are arranged on the sliding blocks, a rotating shaft is arranged through the bearing blocks, a drum fixed with the rotating shaft is arranged on the rotating shaft, a first stirring blade is arranged on the rotating shaft positioned in the drum, a second stirring blade is arranged on the inner wall of the drum, compression springs sleeved on the upright posts are arranged on the upper parts and the lower parts of the sliding blocks, reciprocating vibrators are also connected with the sliding blocks, and a transmission device is arranged on the rotating shaft at one side of the drum. The drum-type deburring device for the small part has the advantages of good deburring effect and high working efficiency.

Owner:湖州市漾西电化有限公司

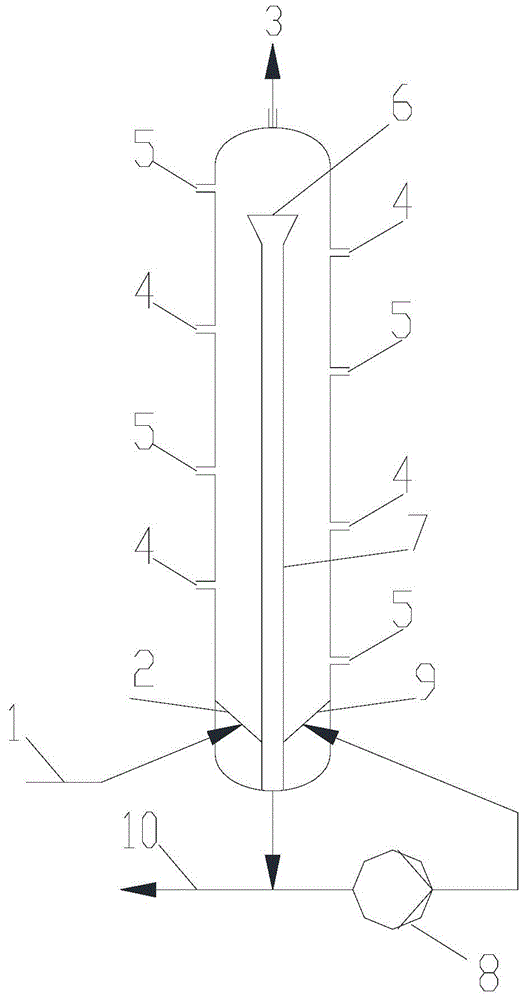

Multi-optimized slurry bed hydrogenation reactor, application and design method thereof

InactiveCN104818050AEnhance heat and mass transferImprove conversion rateHydrocarbon oil crackingHydrocarbon oils refiningBiochemical engineeringSlurry

The invention discloses a multi-optimized slurry bed hydrogenation reactor, an application and a design method thereof, wherein the multi-optimized slurry bed hydrogenation reactor includes an internal circulating structure and a feed distributor. A material inlet is arranged on a lower part of a column body of the reactor while a material outlet is arranged on the top of the column body. The internal circulating structure includes a circulating bubble cap, a circulating tube and a circulating pump. The circulating bubble cap is arranged in the upper part in the column body and is in the structure of an inverted circular truncated-conical hollow cup. The lower end of the circulating bubble cap is connected to the circulating tube, is communicated with the bottom of the column body and is communicated with the circulating pump outside the column body. The feed distributor includes an inlet feed distributor and a circulating feed distributor and is arranged between the inner wall in the lower part of the column body and the circulating tube. The material inlet includes an entrance inlet and a circulating inlet. Reaction materials are fed into the column body through the entrance inlet and then through the inlet feed distributor, wherein circulated material recycled by the internal circulating structure is fed into the circulating inlet through the circulating pump and then is fed into the column body through the circulating feed distributor. The multi-optimized slurry bed hydrogenation reactor is improved in backmixing degree of reactants and is improved in conversion rate of raw materials and yield of light oil.

Owner:CATECH TECH

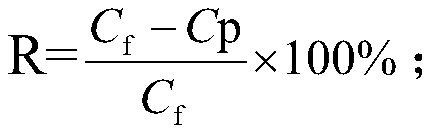

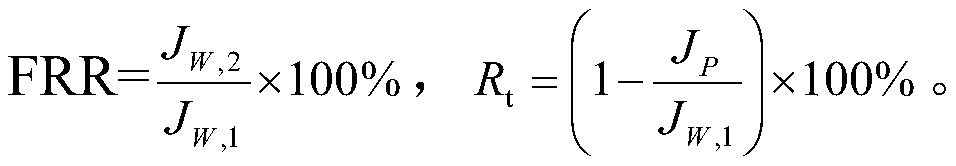

Polystyrene microsphere/carbon nanotube co-modified hybrid polyether sulfone nanofiltration membrane as well as preparation method and application thereof

ActiveCN110339726AHigh temperature resistantWith mechanical propertiesGeneral water supply conservationReverse osmosisNano siliconMicrosphere

The invention provides a polystyrene microsphere / carbon nanotube co-modified hybrid polyether sulfone nanofiltration membrane. The nanofiltration membrane uses polyether sulfone as a substrate membrane, the substrate membrane is doped with nano silicon oxide, the surface of the nano silicon oxide is coated with chitosan, carbon nanotubes are deposited at the surface of the substrate membrane, wherein the thickness of the carbon nanotubes is 80-100 nm, the surfaces of the carbon nanotubes are coated with polydopamine, and polystyrene microspheres are deposited between the polydopamine and the carbon nanotubes. The hybrid polyether sulfone nanofiltration membrane prepared by the invention can be used for salt removing treatment in the preparation process of dye and effectively improve purityof the dye; and the nanofiltration membrane has good mechanical properties and strong anti-pollution ability.

Owner:浙江海印数码科技有限公司

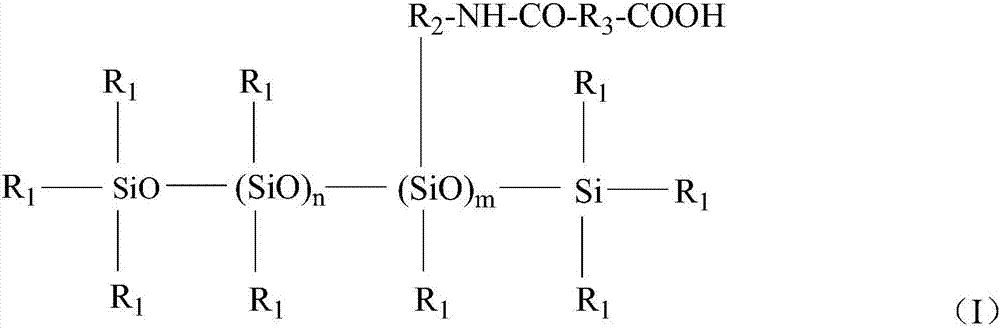

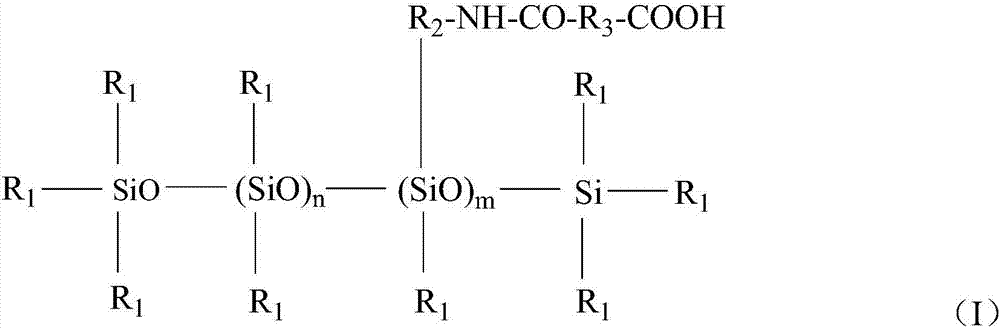

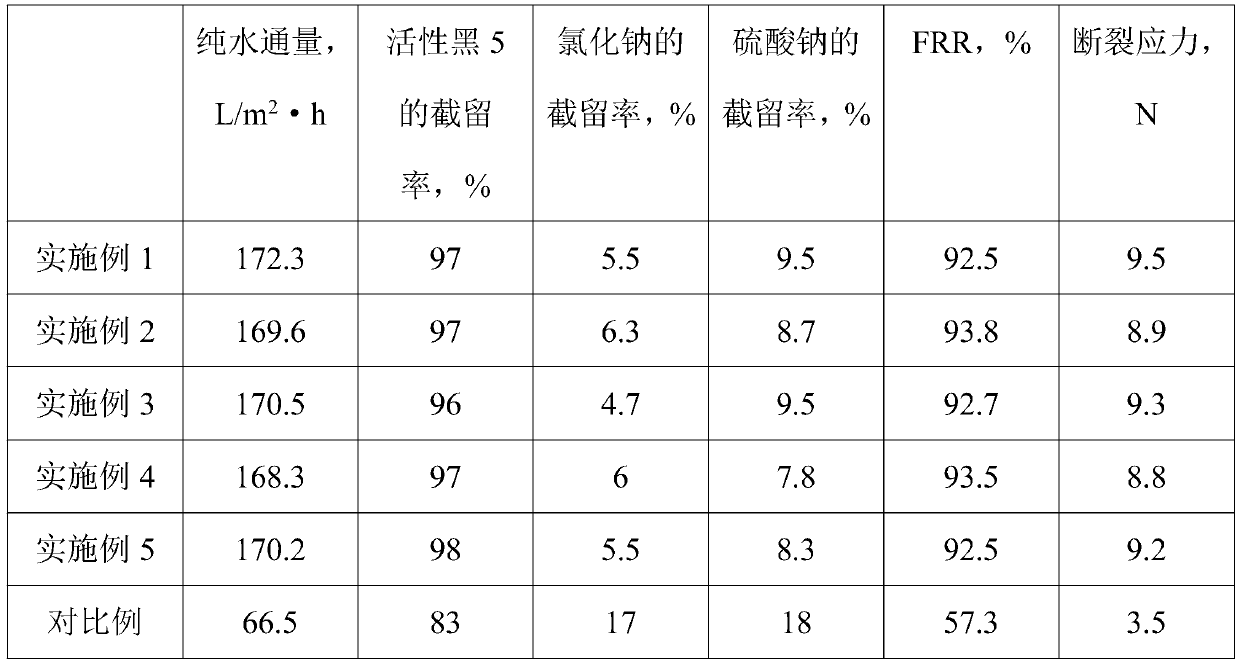

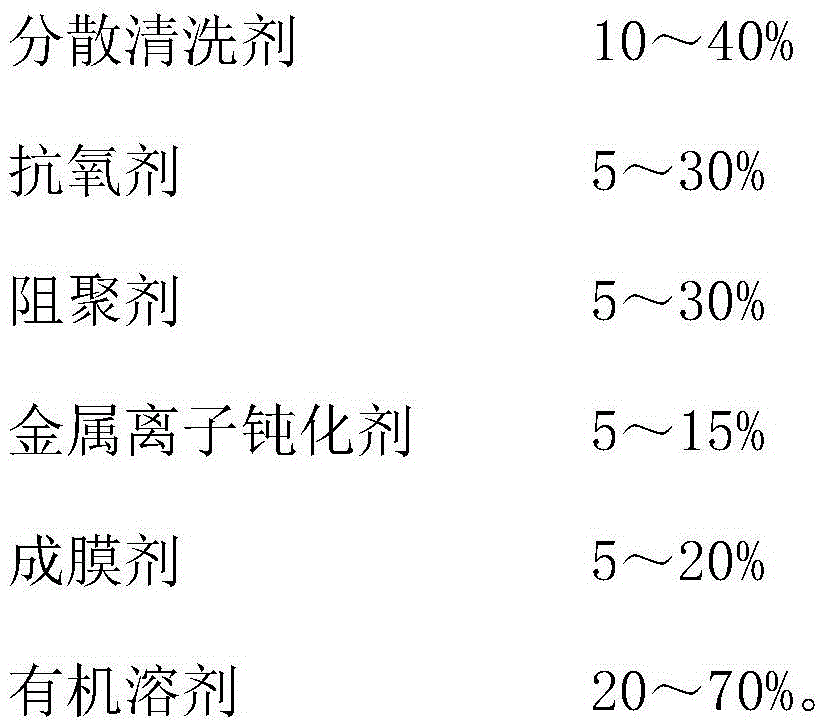

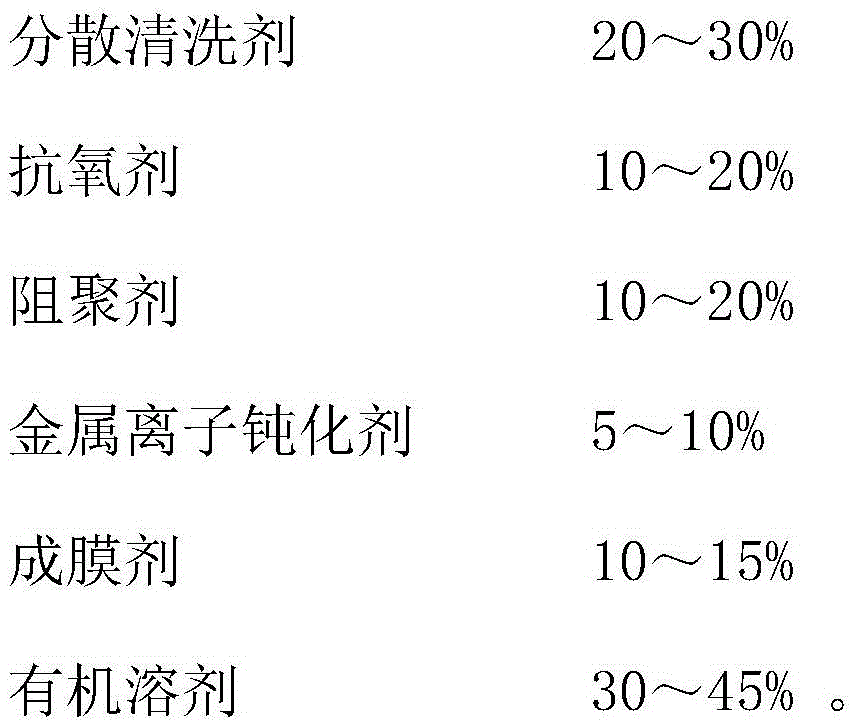

Scale inhibitor for oil refining technology process and preparation method thereof

ActiveCN105482851AInhibition of polymeric foulingStrong scale resistanceTreatment apparatus corrosion/fouling inhibitionOrganic solventFuel oil

The invention relates to a scale inhibitor for the oil refining technology process. In order to provide an efficient environment-friendly scale inhibitor which is suitable for various oil refining technologies, the invention provides the scale inhibitor for the oil refining technology process. The scale inhibitor is characterized by being prepared from, by mass, 10%-40% of scattered detergent, 5%-30% of antioxygen, 5%-30% of polymerization inhibitor, 5%-15% of metal-ion passivator, 5%-20% of film-forming agent and 20%-70% of organic solvent, and the scale inhibitor is obtained by compounding all the substances. The scale inhibitor for the oil refining technology process has the advantages that the effect and the adaptability are strong, wherein the scattered detergent can scatter the scale inhibitor in the material, and the scale inhibitor is not prone to stick to and deposit on the surface of equipment; the stability is good, the scale inhibitor can still play a role under the high-temperature conditions such as heavy oil hydrogenation, therefore, polymerization and scaling of a hydrogenation system can be effectively inhibited, and long period operation of a device is guaranteed; elements of sulphur, phosphorus and the like are not contained, toxicity and undesirable odor do not exist, and pollution does not exist in the preparation and use process.

Owner:SHENZHEN GCD PETROLEUM ADDITIVE CO +1

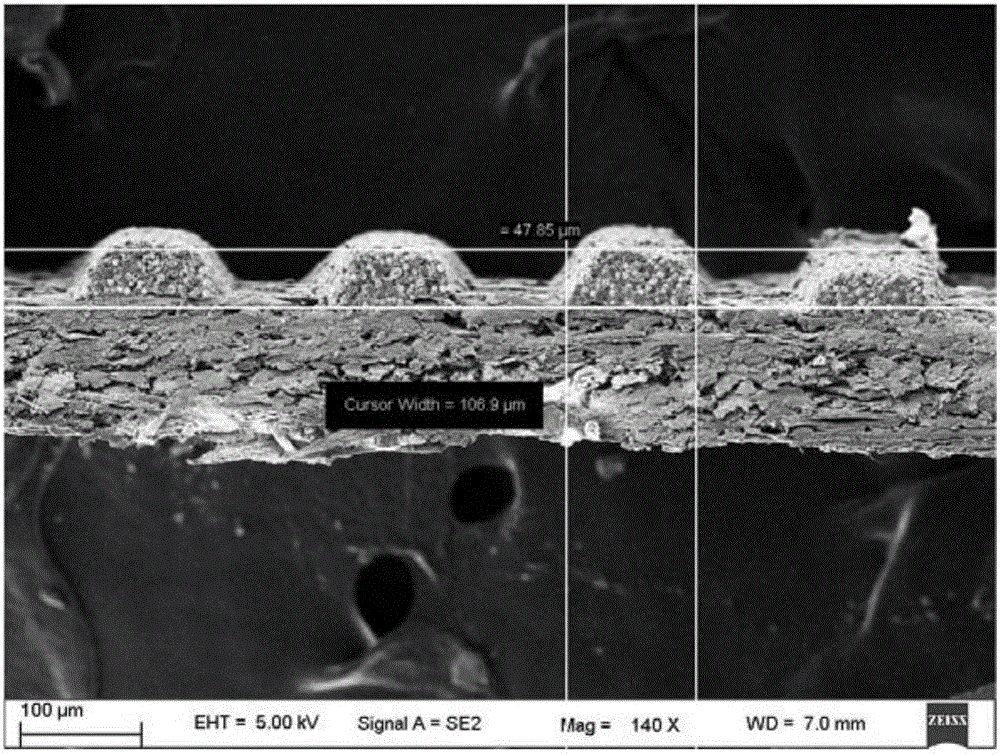

Printable flexible conductive paste as well as conductive line and preparation method thereof

ActiveCN106782757ALow densityNot easy to depositConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialSilver platePolymer

The invention discloses printable flexible conductive paste as well as a conductive line and a preparation method thereof. Particularly, the printable flexible conductive paste is prepared from composite conductive particles and polysiloxane, wherein the mass percent of the composite conductive particles is 40 to 85 percent; the composite conductive particles are particles of which the nonmetallic kernel surface is plated with a metal surface layer and the diameter is not greater than 20mu m. Silver-plated conductive particles are used to replace traditional pure metal conductive particles or carbon series conductive filler, have the characteristics of high electrical conductivity, low density and low cost, are not easy to settle in a polysiloxane flexible polymer and can be used for preparing flexible conductive paste with high conductivity; in addition, simple production of the flexible conductive line can be realized by traditional printing modes such as silk-screen printing. The printable flexible conductive paste disclosed by the invention has the advantages of low cost, simple structure, simplicity and feasibility in production and suitability for the emerging fields such as flexible printed circuits, flexible display screens, flexible wearable electronics, electronic skin and the like.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

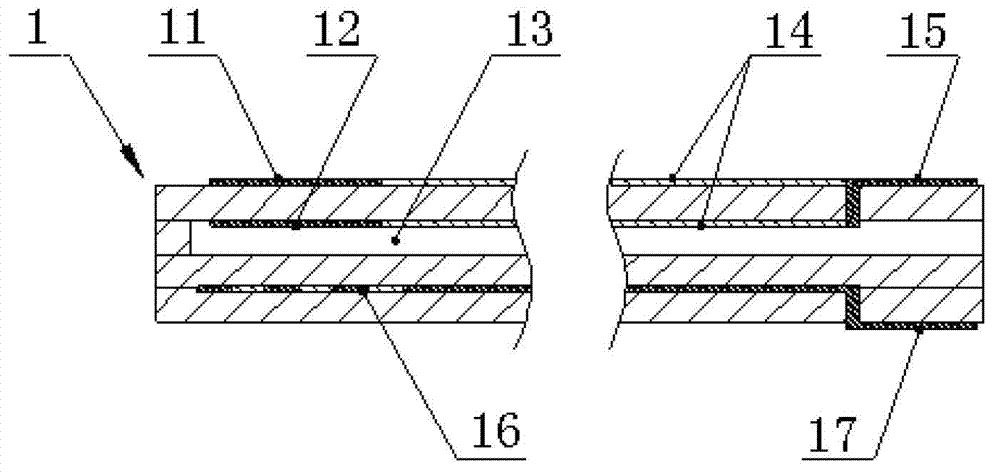

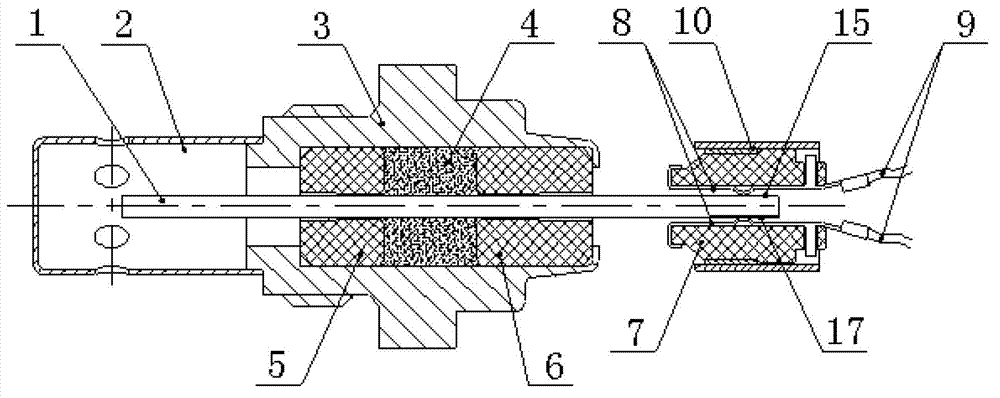

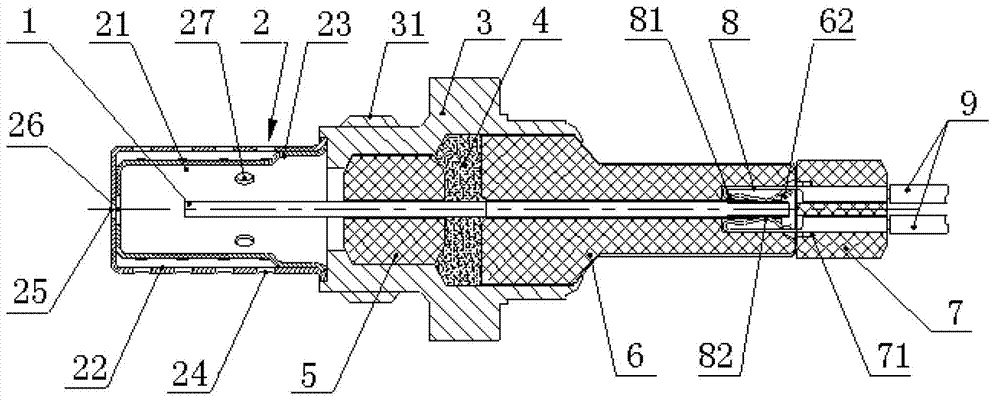

Packaging structure of flat plate type oxygen sensor

InactiveCN103196953AHigh precisionEfficient conductionMaterial analysis by electric/magnetic meansOxygen sensorElectrical and Electronics engineering

The invention discloses a packaging structure of a flat plate type oxygen sensor. The packaging structure is mainly characterized in that a socket and the structure of an upper positioning ceramic piece are structurally improved, wherein the socket is used for positioning and sealing an oxygen sensor chip, the conduction structure of chip electrode pins and wire terminals is improved, and a probe cover for protecting the head of the chip is improved, so that the oxygen sensor chip is simple in assembly process and easy to assemble, a signal of a packaged chip can be effectively conducted, the leakage of gas can be effectively prevented on the basis of effectively detecting the gas, and the detection accuracy of the oxygen sensor is greatly improved.

Owner:WUXI LONGSHENG TECH

Strengthened heat exchange tube

ActiveCN101799252AIncrease the heat exchange areaEnhanced heat transferCorrosion preventionTubular elementsHeat transfer tubeMicro nano

The invention provides a strengthened heat exchange tube comprising a heat exchange tube and a strap-type metal slice, wherein one surface of the strap-type metal slice is a smooth plane, and the other surface of the strap-type metal slice obtains a super hydrophobic surface by advanced manufacturing methods, such as precise rolling, chemical, electrochemical methods and the like; the super hydrophobic surface is burr bulge with a micro-nano structure; the strap-type metal slice is tightly and spirally coiled on the outer surface of the heat exchange tube; the smooth surface of the strap-type metal slice and the outer surface of the heat exchange tube are tightly laminated, and the coiled strap-type metal slice is fixed on the heat exchange tube; before the strap-type metal slice is coiled, the outer surface of the heat exchange tube is covered with heat conduction filler, and the strap-type metal slice is coiled and fixed on the heat exchange tube covered with heat conduction filler. The heat transfer tube of the invention has simple production, convenient installation, favorable adaptability and small possibility of scaling and has the effect on strengthening heat transfer.

Owner:BEIJING UNIV OF CHEM TECH

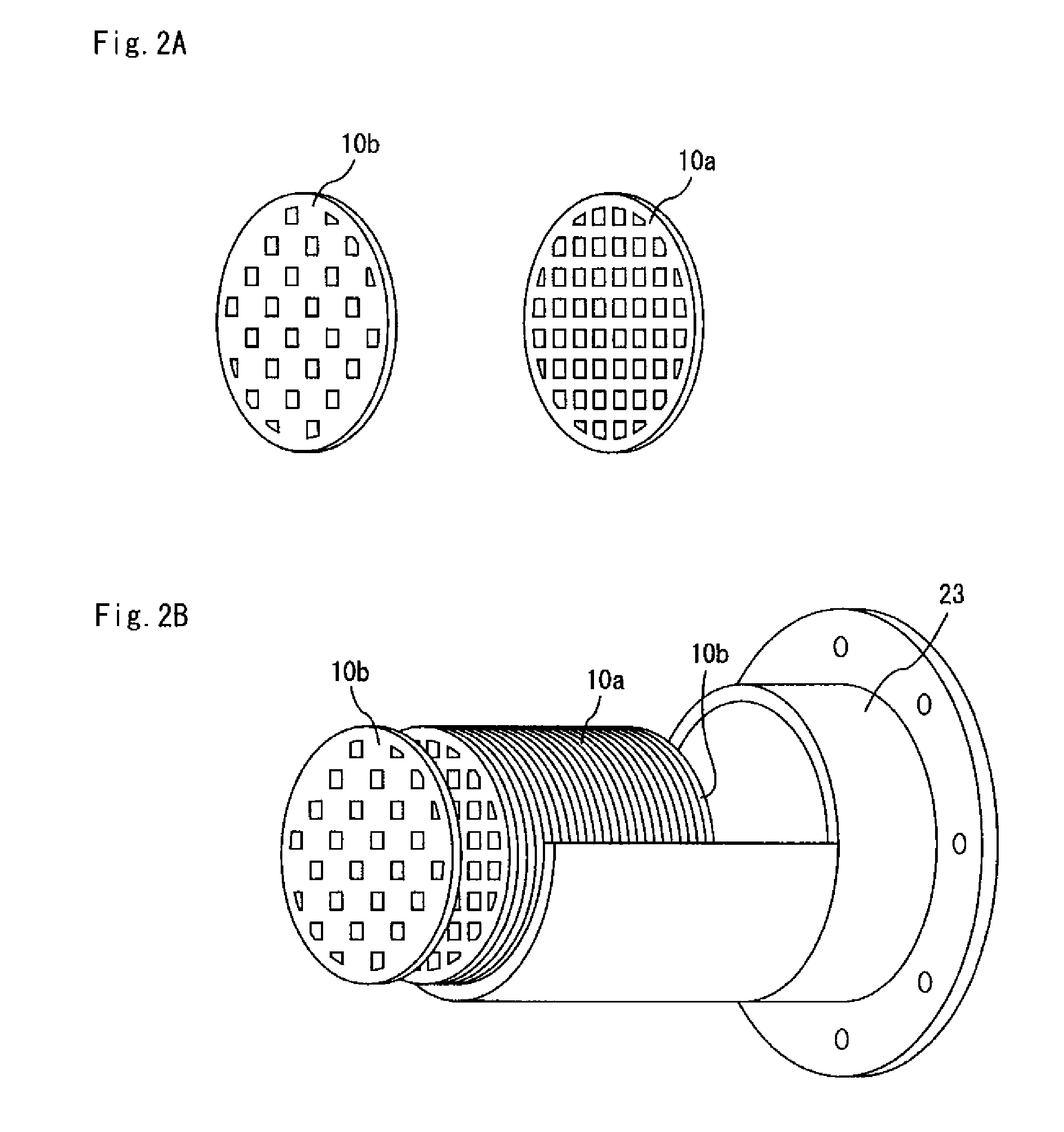

In-line plasma CVD device

InactiveCN104903491ANot easy to depositIncrease productivityElectric discharge tubesSemiconductor/solid-state device manufacturingGas phaseElectrical polarity

Owner:KOBE STEEL LTD

SCR (Selective Catalytic Reduction) urea solution mixer

InactiveCN106110980AComplicated air flowImprove mixing uniformityInternal combustion piston enginesExhaust apparatusUreaAirflow

The embodiment of the invention discloses an SCR (Selective Catalytic Reduction) urea solution mixer which comprises an outer-layer tube and an inner-layer tube, wherein the inner-layer tube is arranged inside the outer-layer tube; side wall air outlet holes through which air flows out are formed in the side wall of the inner-layer tube; outer-layer tube air outlet holes through which air flows out are formed in the side wall of the outer-layer tube; the side wall air outlet holes and the outer-layer tube air outlet holes are formed in a staggered manner. According to the SCR urea solution mixer which is disclosed by the invention, as the side wall air outlet holes in the inner-layer tube and the outer-layer tube air outlet holes in the outer-layer tube are formed in the staggered manner, and air needs to flow to another side of the inner-layer tube to flow into SCR through outer-layer tube air outlet holes in the outer-layer tube after flowing outside the side wall air outlet holes in the inner-layer tube, the air flowing situation between the inner-layer tube and the outer-layer tube is relatively complex, the mixing uniformity of a urea solution is further improved, sufficient utilization of the urea solution is promoted, and the purpose of preventing urea from excessive precipitation is finally achieved.

Owner:WEICHAI POWER CO LTD

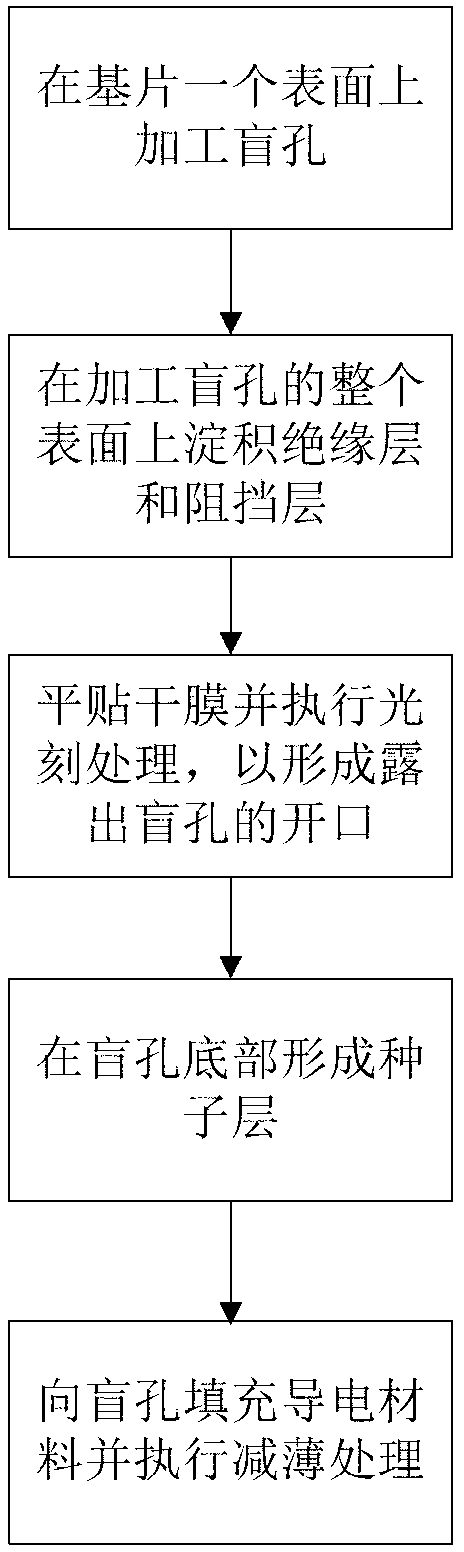

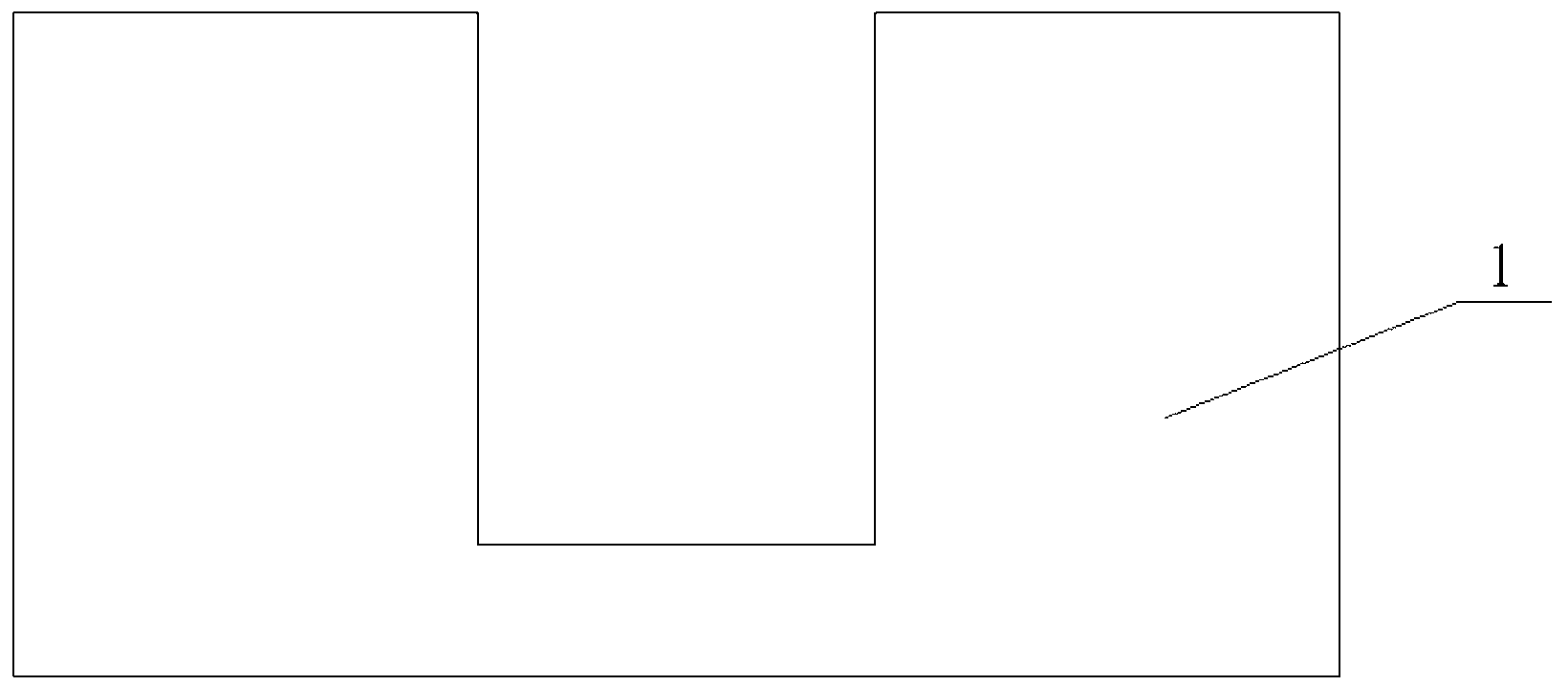

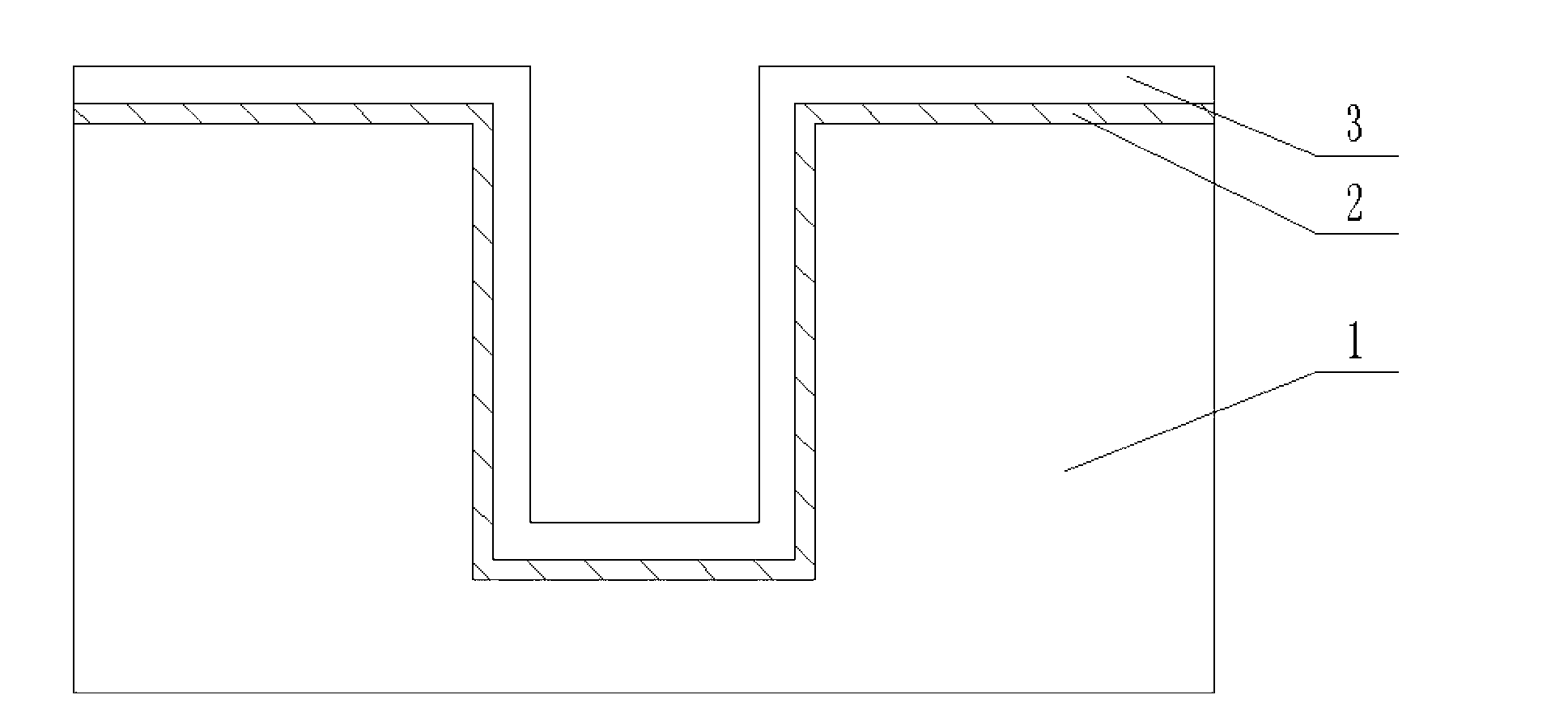

Manufacturing method of through hole interconnection structure and product of through hole interconnection structure

InactiveCN103258789AQuality improvementFilling high speedSemiconductor/solid-state device manufacturingInterconnectionEngineering

The invention discloses a manufacturing method of a through hole interconnection structure. The manufacturing method of the through hole interconnection structure comprises the following steps: (a) a blind hole is machined in one surface of a substrate; (b) an insulating layer and a barrier layer are deposited on the whole surface in sequence, where the blind hole is machined, of the substrate; (c) a light-sensitive dry film is paved on and attached to the surface, containing the barrier layer, of the substrate, and exposure imaging treatment is carried out on the surface, so that an opening exposed out of the blind hole is formed; (d) the dry film is used as a covering film, a seed layer is formed on the barrier layer on the bottom of the blind hole, and the seed layer is prevented from covering the barrier layer deposited on the lateral wall of the blind hole; (e) growth from bottom to top is achieved with the seed layer on the bottom of a through hole as guiding media, and the thickness of another surface of the substrate is reduced until the blind hole is machined to be the through hole. The invention further discloses a product of the through hole interconnection structure. According to the manufacturing method of the through hole interconnection structure and the product of the through hole interconnection structure, through hole electroplating which is convenient to control, low in cost, and high in efficiency can be achieved, and the product of the through hole interconnection structure and with better filling effect can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

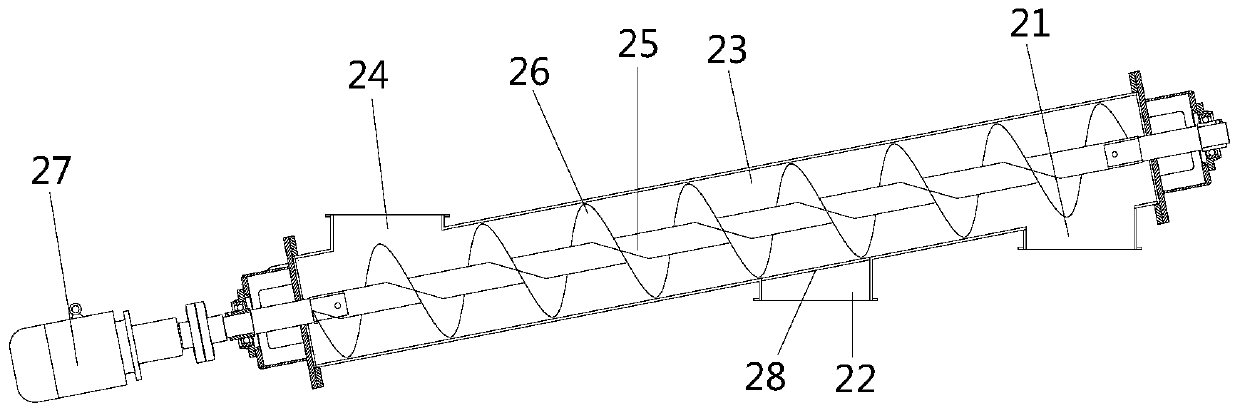

Surface deburring device for small revolving body part

InactiveCN110871393ANot easy to depositComplete structureEdge grinding machinesPolishing machinesScrew conveyorStructural engineering

The invention discloses a surface deburring device for a small revolving body part. The surface deburring device comprises a roller deburring mechanism, wherein a discharging port of the roller deburring mechanism is connected with a spiral conveying mechanism, a first discharging port and a second discharging port are arranged on the lower side of the tail segment of the spiral conveying mechanism, the first discharging port is connected with an abrasive separating mechanism, and a first abrasive recovery box is arranged below the second discharging port; and the roller deburring mechanism comprises a base, a pair of stand columns are arranged on the base, sliding blocks with built-in sliding sleeves are arranged on the pair of stand columns, bearing seats are arranged on the sliding blocks, a rotating shaft is arranged through the bearing seats, the rotating shaft is provided with a roller fixed on the rotating shaft, a first stirring blade is arranged on the position, located in theroller, of the rotating shaft, the inner wall of the roller is provided with a second stirring blade, the upper and lower portions of the sliding blocks are provided with compression springs sleevingon the stand columns, the sliding blocks are also connected with reciprocating vibrators, and the position, on one side of the roller, of the rotating shaft is provided with a transmission device. The device has the advantages of good deburring effect and high working efficiency.

Owner:湖州市漾西电化有限公司

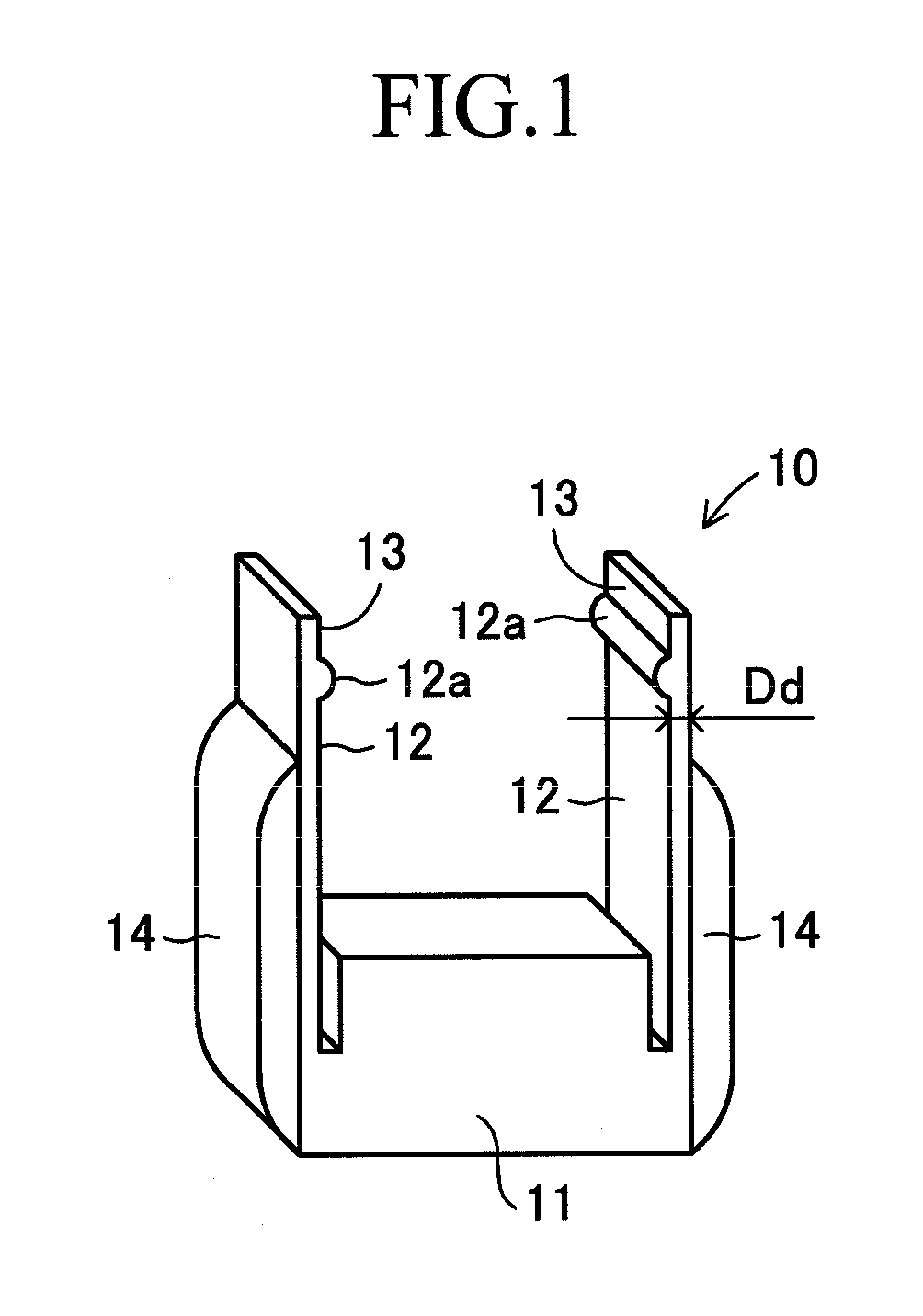

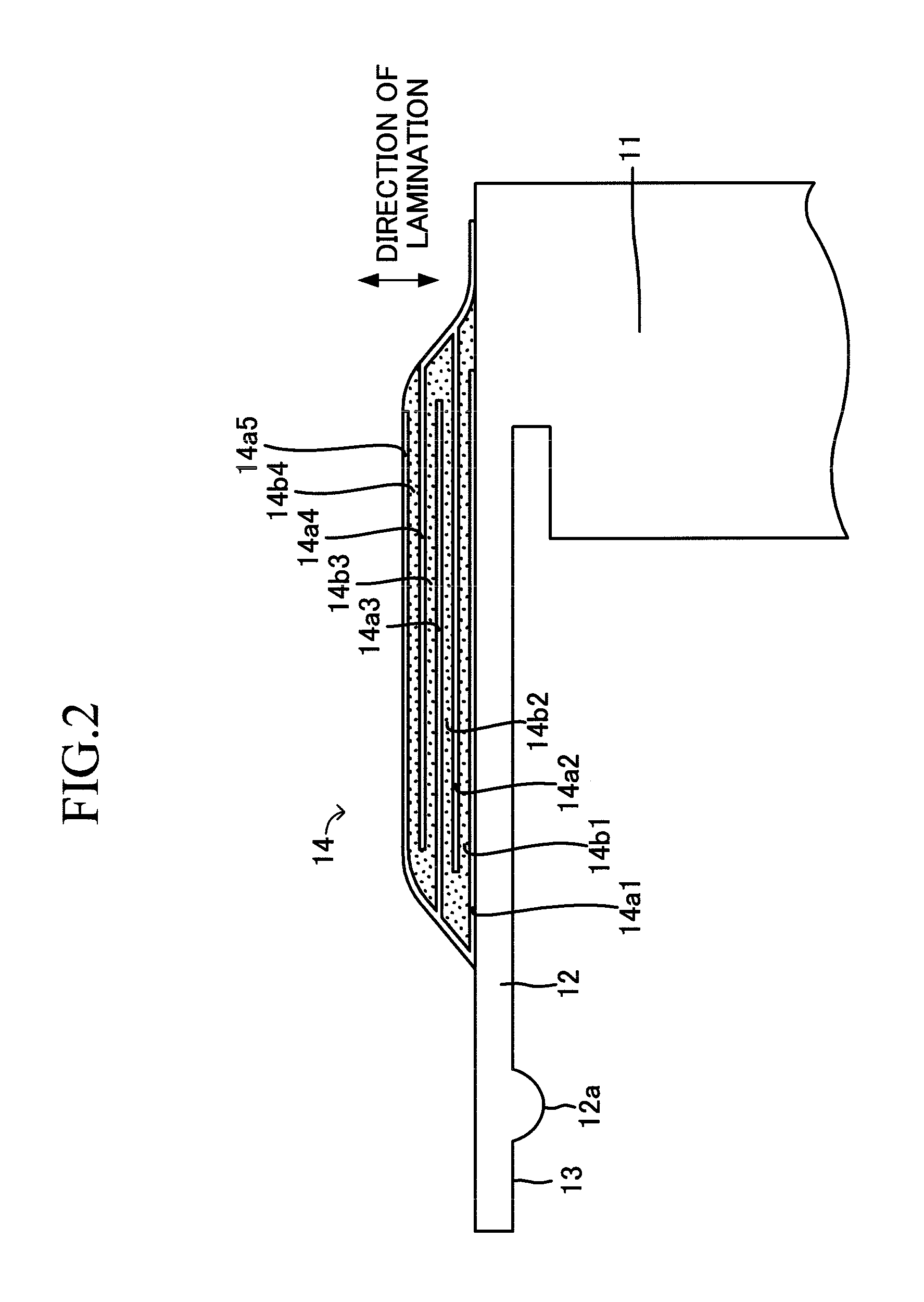

Piezoelectric/electrostrictive device

InactiveUS20070188052A1Avoid depositionNot easy to depositPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringMoisture

A piezoelectric / electrostrictive device is provided with a stationary portion, a thin-plate portion supported by the stationary portion, and piezoelectric / electrostrictive element formed by alternately laminating a plurality of electrodes and a plurality of piezoelectric / electrostrictive layers. The piezoelectric / electrostrictive device is produced by cutting a thin-plate body that composes the thin-plate portion afterward and a laminated body comprising the piezoelectric / electrostrictive layers and thereafter applying prescribed specific processing (for example, heat treatment) to the cut plane (the lateral end surfaces). By so doing, the ratio of the actual surface area of the lateral end surface of the piezoelectric / electrostrictive element to the area of the lateral end surface of the piezoelectric / electrostrictive element in the orthographic projection is four or less, and the deposition of moisture on the lateral end surfaces is suppressed to the extent of not substantially generating electric leakage or ion migration. As a result, a highly durable piezoelectric / electrostrictive device can be provided.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com