Polystyrene microsphere/carbon nanotube co-modified hybrid polyether sulfone nanofiltration membrane as well as preparation method and application thereof

A composite technology of polystyrene microspheres and carbon nanotubes is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., and can solve the problems of easy pollution, high preparation cost, and low flux of nanofiltration membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

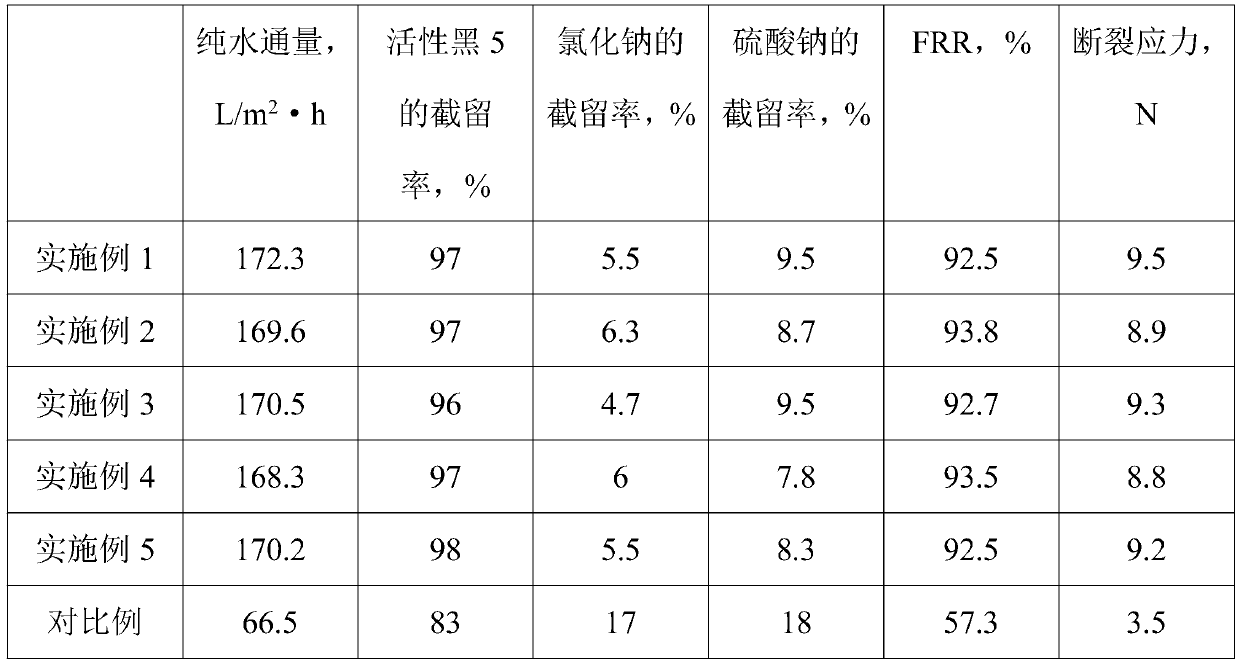

Embodiment 1

[0030] (1) Dissolve 1ml of tetraethoxysilane in absolute ethanol, add 1ml of deionized water, stir and hydrolyze for 20min, then slowly add 5ml of 10wt% ammonia solution dropwise, and stir for 30min to obtain silica sol, and let it stand at room temperature Aging treatment for 10 hours to obtain silica gel, the gel powder obtained after drying the silica gel was calcined in a muffle furnace at 200-300°C for 20 minutes to obtain nano-silica;

[0031] (2) Chitosan is dissolved in the acetic acid solution that mass concentration is 3%, makes mixed solution; Nano silicon dioxide, silane coupling agent and water are mixed and stirred to make nano silicon dioxide dispersion liquid, mixed solution Mix with silica dispersion, then add 13wt% glutaraldehyde aqueous solution, stir and react at 40-50°C for 30min, cool to room temperature, filter, wash the filter residue with deionized water and dry at 80°C for 3h to prepare Get chitosan cross-linked coated silica powder; wherein, the mass...

Embodiment 2

[0035] (1) Dissolve 1ml of tetraethoxysilane in absolute ethanol, add 1ml of deionized water, stir and hydrolyze for 60min, then slowly add 5ml of 10wt% ammonia solution dropwise, and stir for 30min to obtain silica sol, and let it stand at room temperature Aging treatment for 20 hours to obtain silica gel, and the gel powder obtained after drying the silica gel was calcined in a muffle furnace at 200-300°C for 40 minutes to obtain nano-silica;

[0036] (2) Chitosan is dissolved in the acetic acid solution that mass concentration is 3%, makes mixed solution; Nano silicon dioxide, silane coupling agent and water are mixed and stirred to make nano silicon dioxide dispersion liquid, mixed solution Mix with silica dispersion, then add 13wt% glutaraldehyde aqueous solution, stir and react at 40-50°C for 90min, cool to room temperature, filter, wash the filter residue with deionized water and dry at 80°C for 3h to prepare To obtain chitosan cross-linked coated silica powder; wherein...

Embodiment 3

[0040] (1) Dissolve 1ml of tetraethoxysilane in absolute ethanol, add 1ml of deionized water, stir and hydrolyze for 30min, then slowly add 5ml of 10wt% ammonia solution dropwise, stir for 30min to obtain silica sol, and let stand at room temperature Aging treatment for 12 hours to obtain silica gel, the gel powder obtained after drying the silica gel was calcined in a muffle furnace at 200-300°C for 20-40 minutes to obtain nano-silica;

[0041] (2) Chitosan is dissolved in the acetic acid solution that mass concentration is 3%, makes mixed solution; Nano silicon dioxide, silane coupling agent and water are mixed and stirred to make nano silicon dioxide dispersion liquid, mixed solution Mix with silica dispersion, then add 13wt% glutaraldehyde aqueous solution, stir and react at 40-50°C for 40min, cool to room temperature, filter, wash the filter residue with deionized water and dry at 80°C for 3h to prepare To obtain chitosan cross-linked coated silica powder; wherein, the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com