Combined stirred tank reactor

A stirring reactor and agitator technology, applied in mixers, chemical/physical/physicochemical stationary reactors, dissolution, etc., can solve the problem of insufficient heterogeneous reaction of raw materials, easy deposition of mixed raw materials, large difference in specific gravity, etc. problems, to achieve the effect of smooth discharge, not easy to stick to the wall, and not easy to deposit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

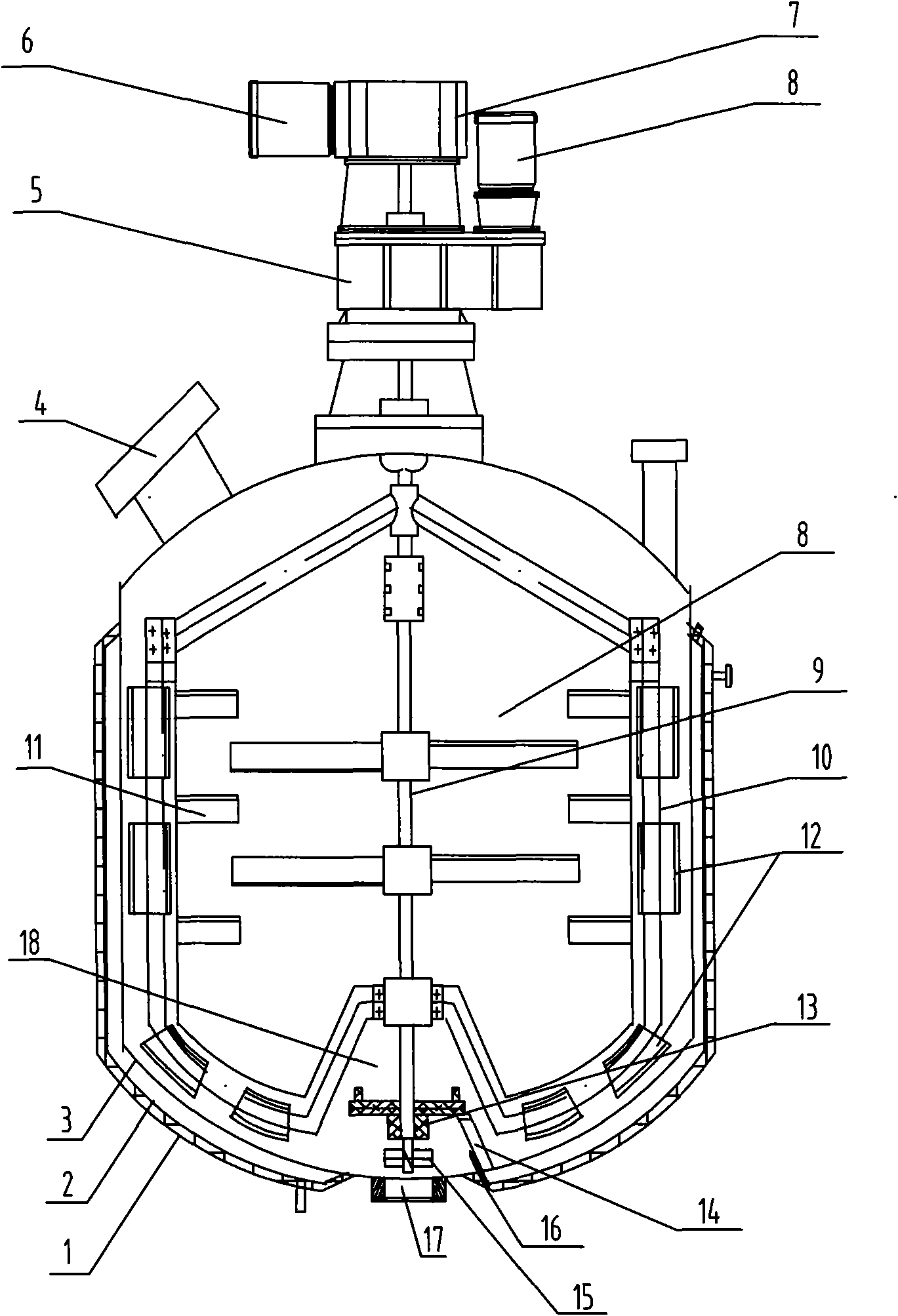

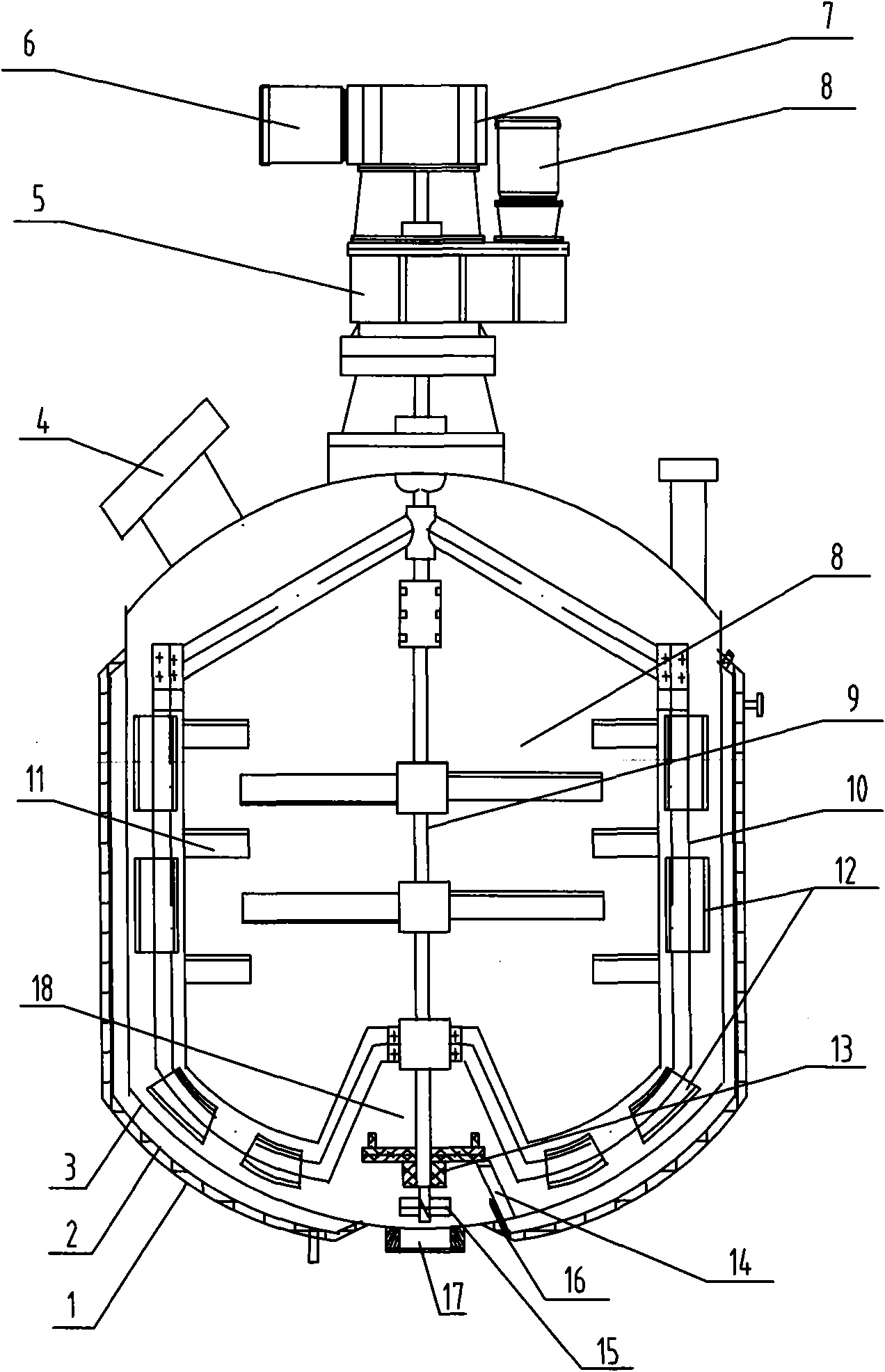

[0017] This embodiment is a combined stirring reactor, which consists of an outer cylinder 1, a cylinder jacket 2, an inner cylinder 3, a hand hole 4, a transmission device 5, a motor 6, a reducer 7, a paddle type stirring blade 8, a center Rotary shaft 9, frame agitator 10, inner stirring blade 11, outer scraper 12, bottom bearing 13, triangular support frame 14, small paddle 15, thermometer 16 and discharge port 17. The agitating device of the present invention is composed of a central paddle agitator coaxially arranged in the inner cylinder 1 and a frame agitator positioned around; the paddle agitator is composed of a central rotating shaft 9 and a central rotating shaft 9 At least one paddle-type stirring blade 8 is composed of; the frame-type stirrer 10 is composed of a frame arranged along the inner wall of the inner cylinder 1, an outer scraper 12 arranged on the outer peripheral wall of the frame and an inner stirring blade 11 arranged on the inner peripheral wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com