Patents

Literature

109results about How to "Unobstructed discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

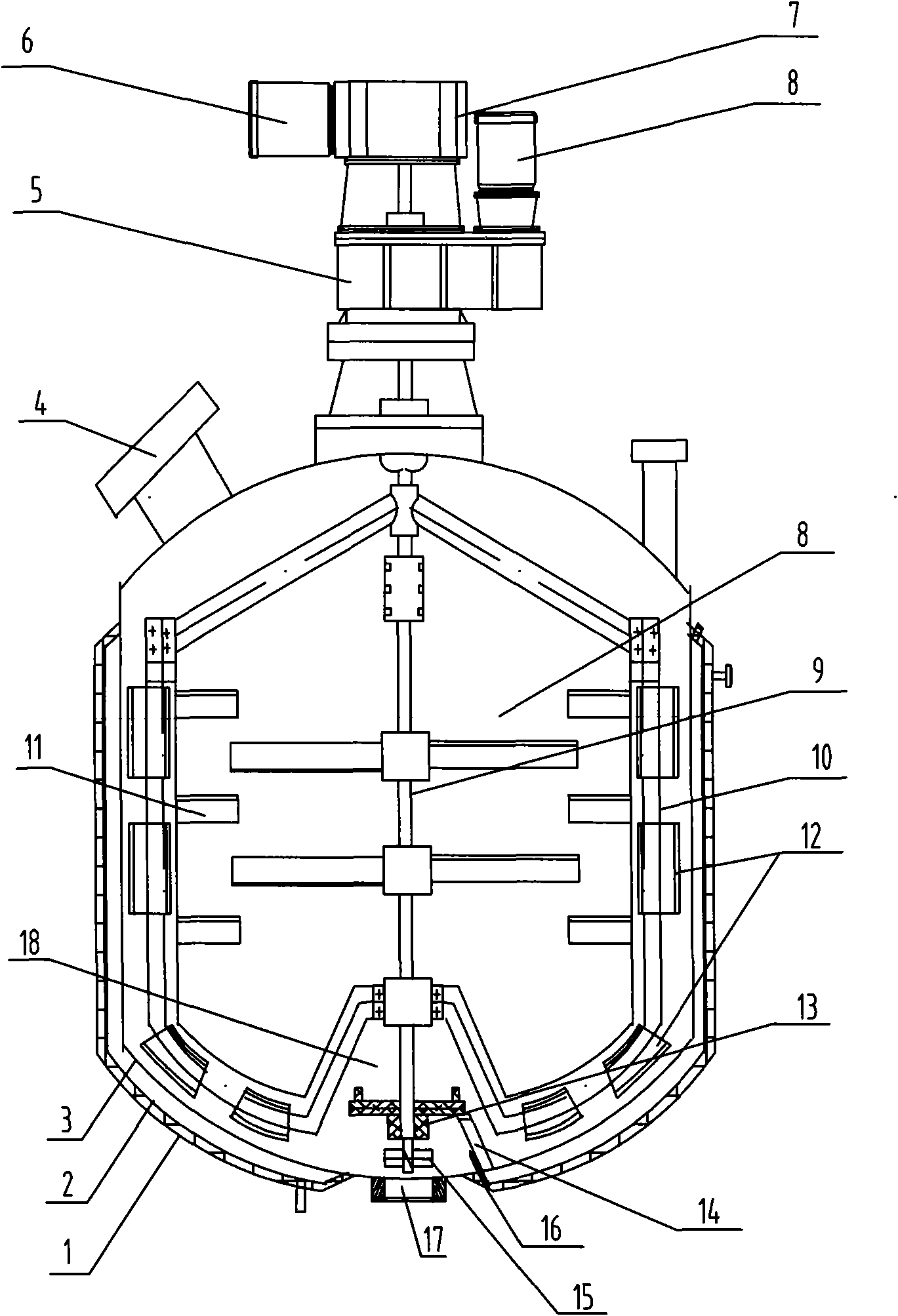

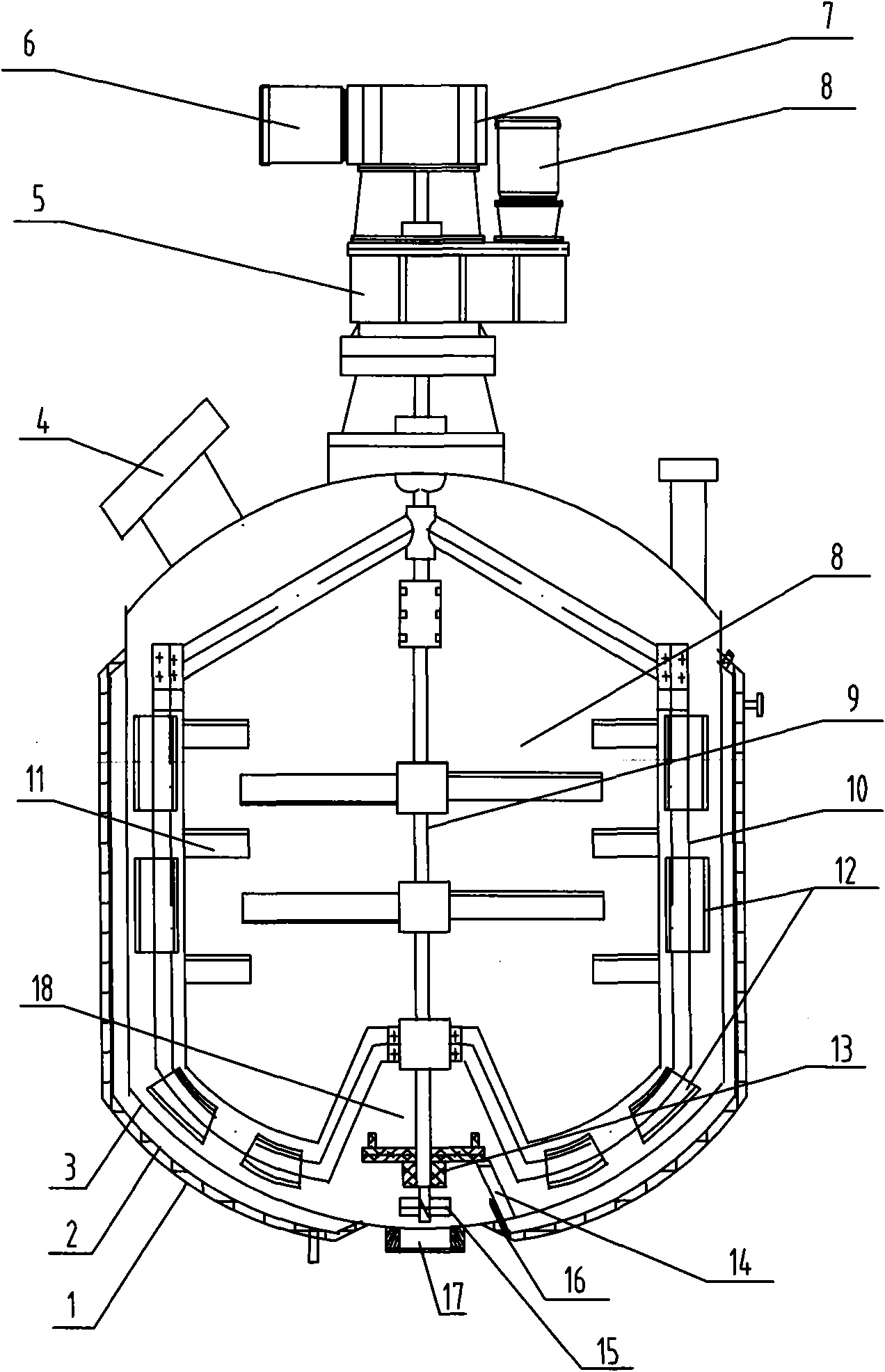

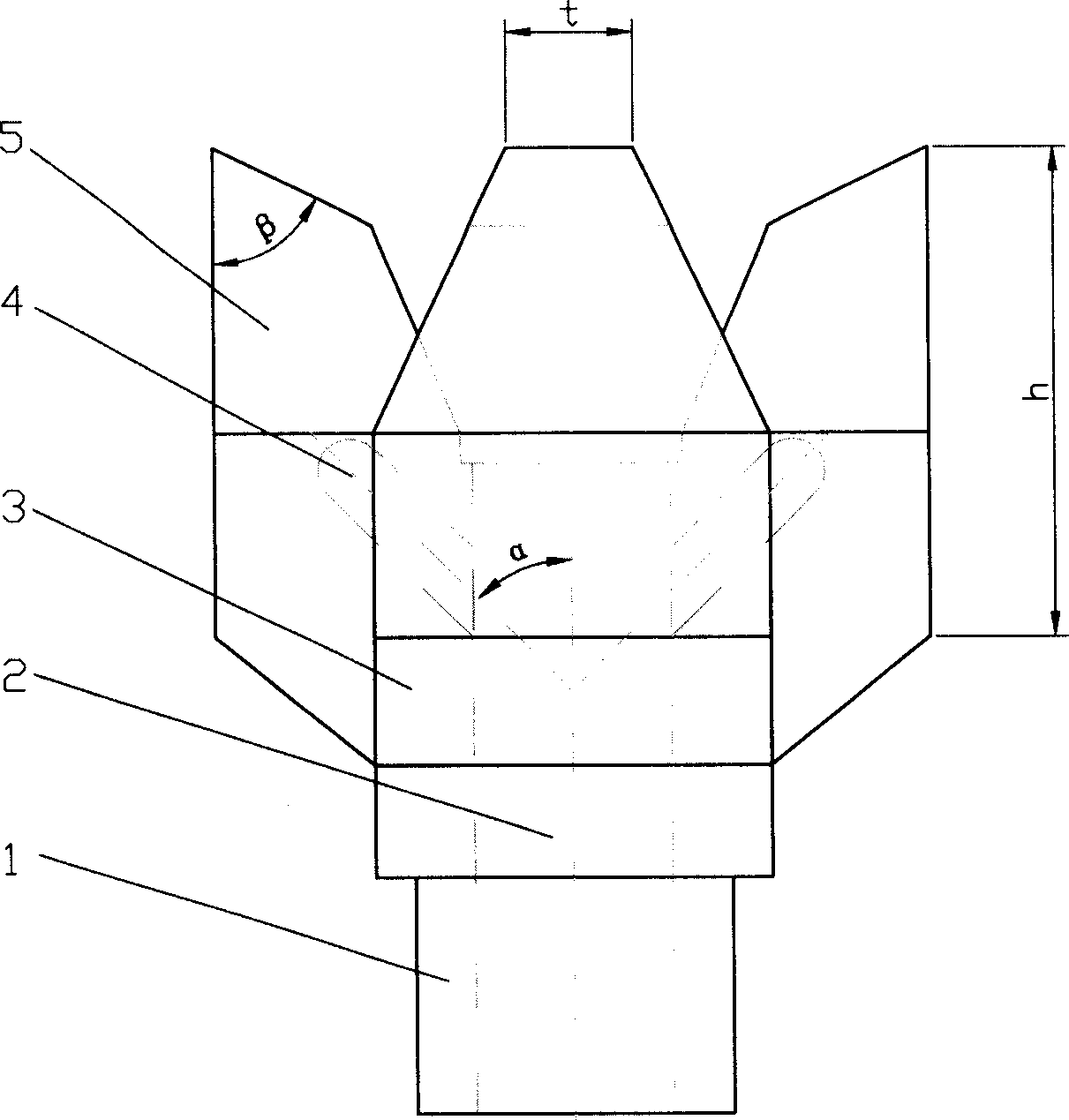

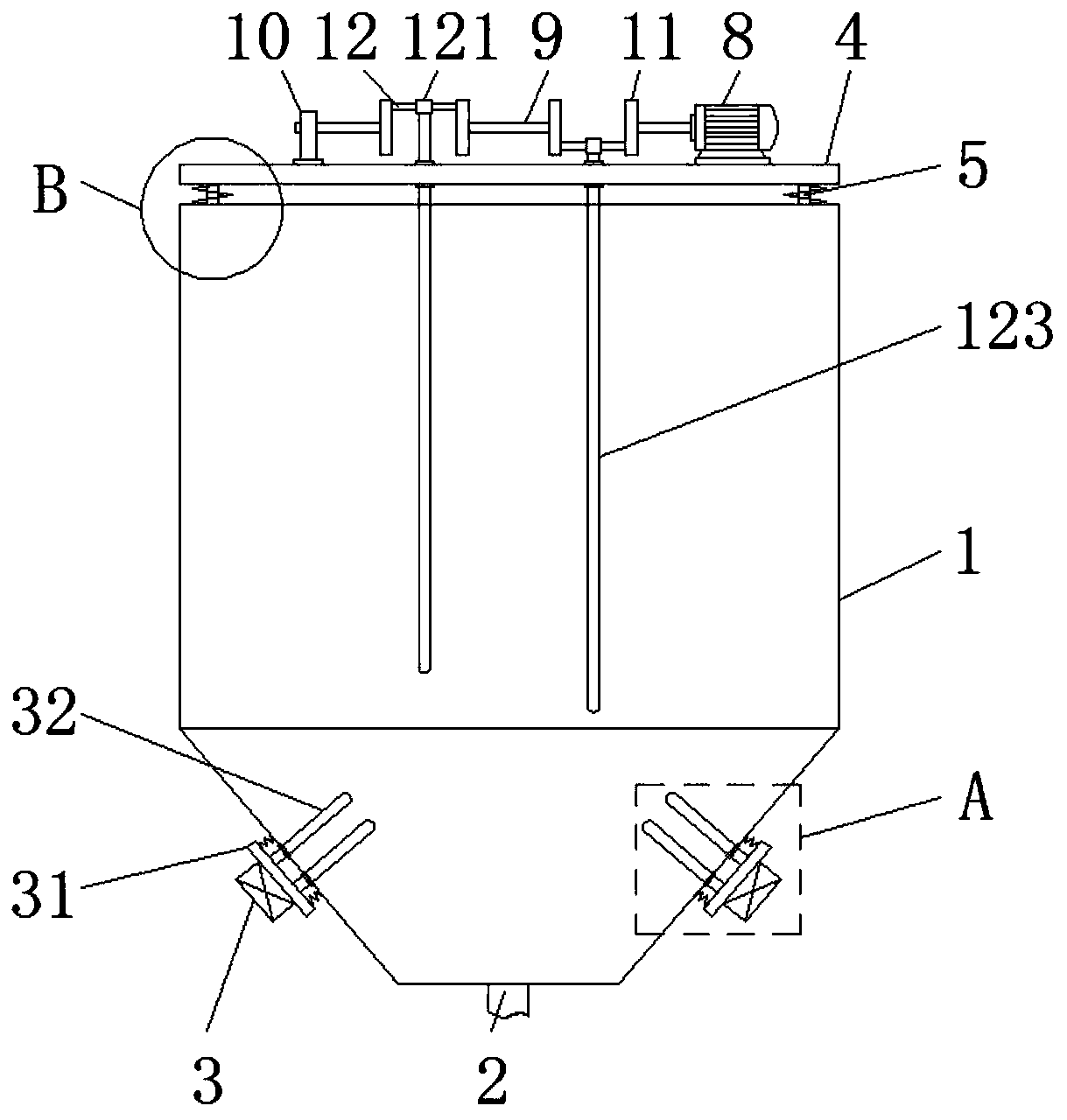

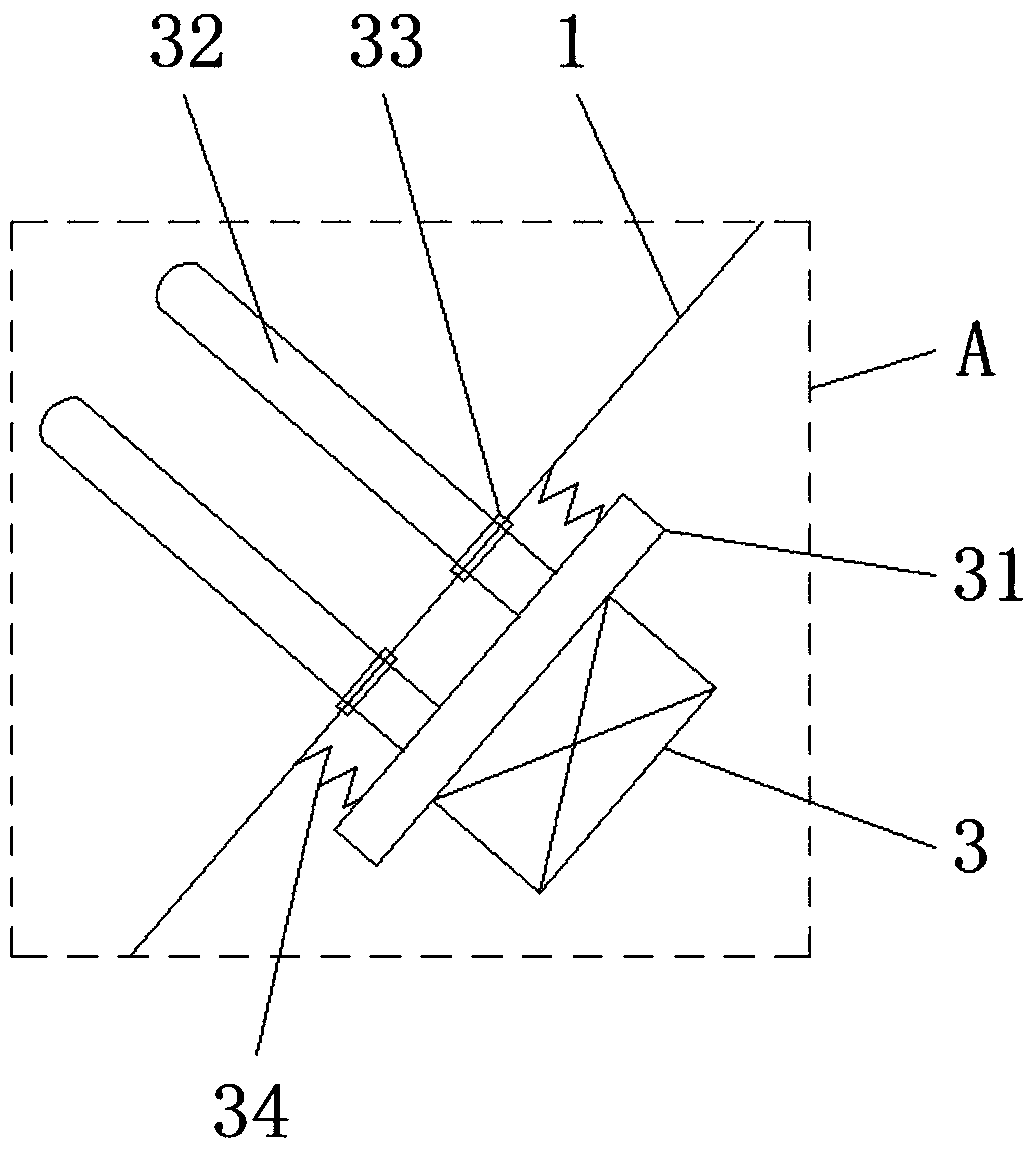

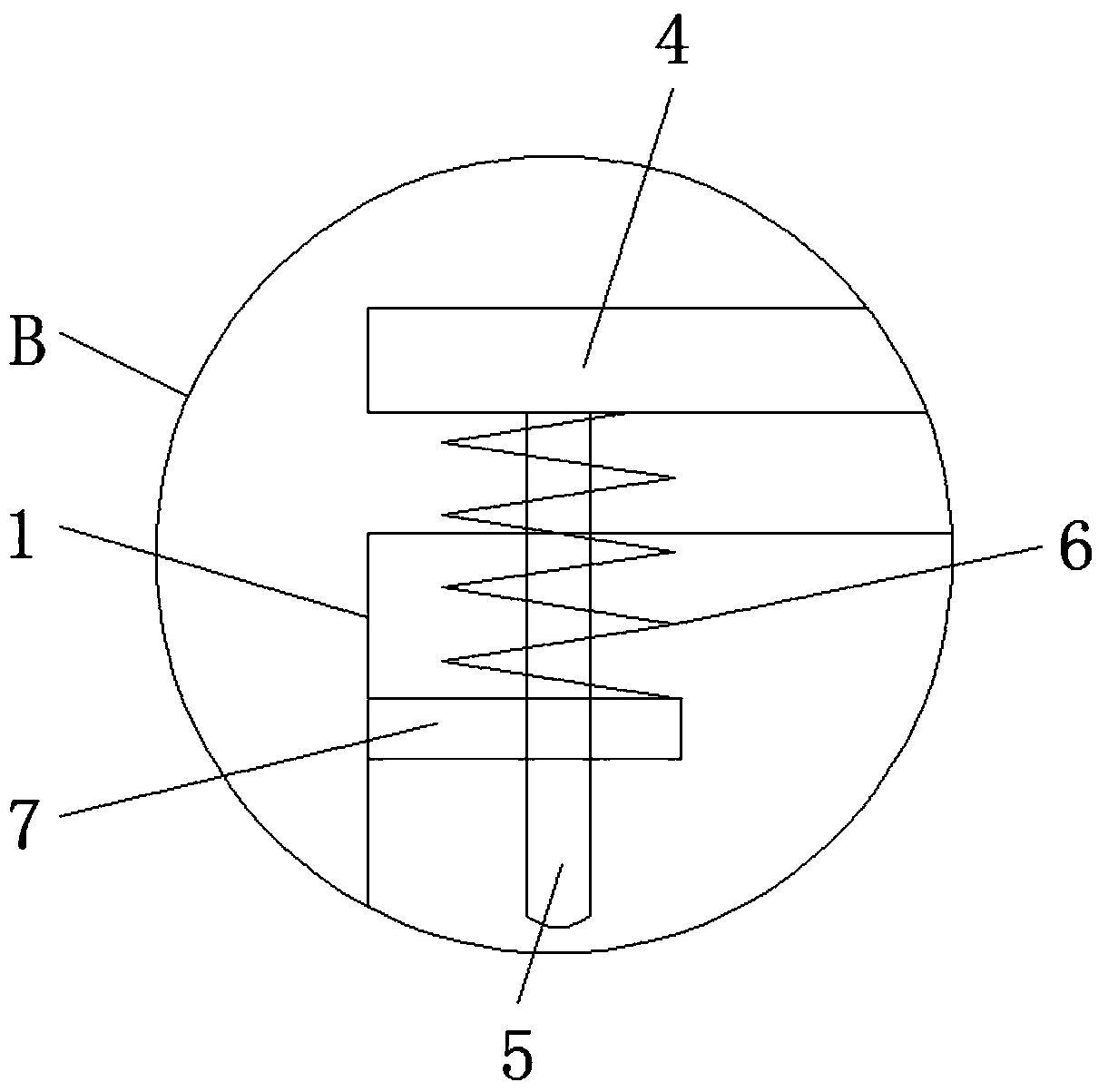

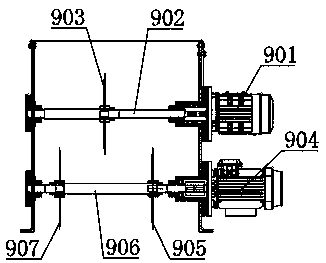

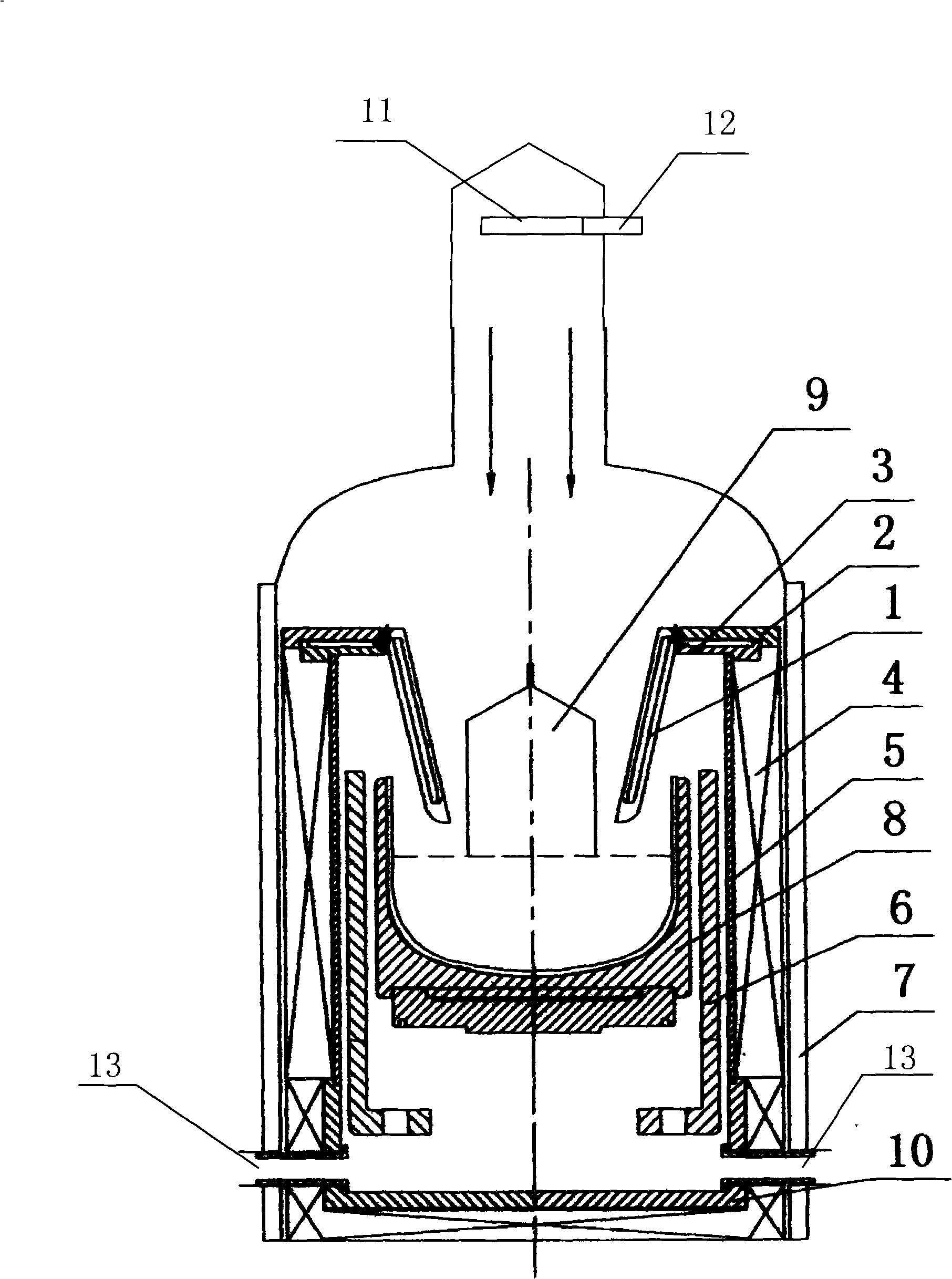

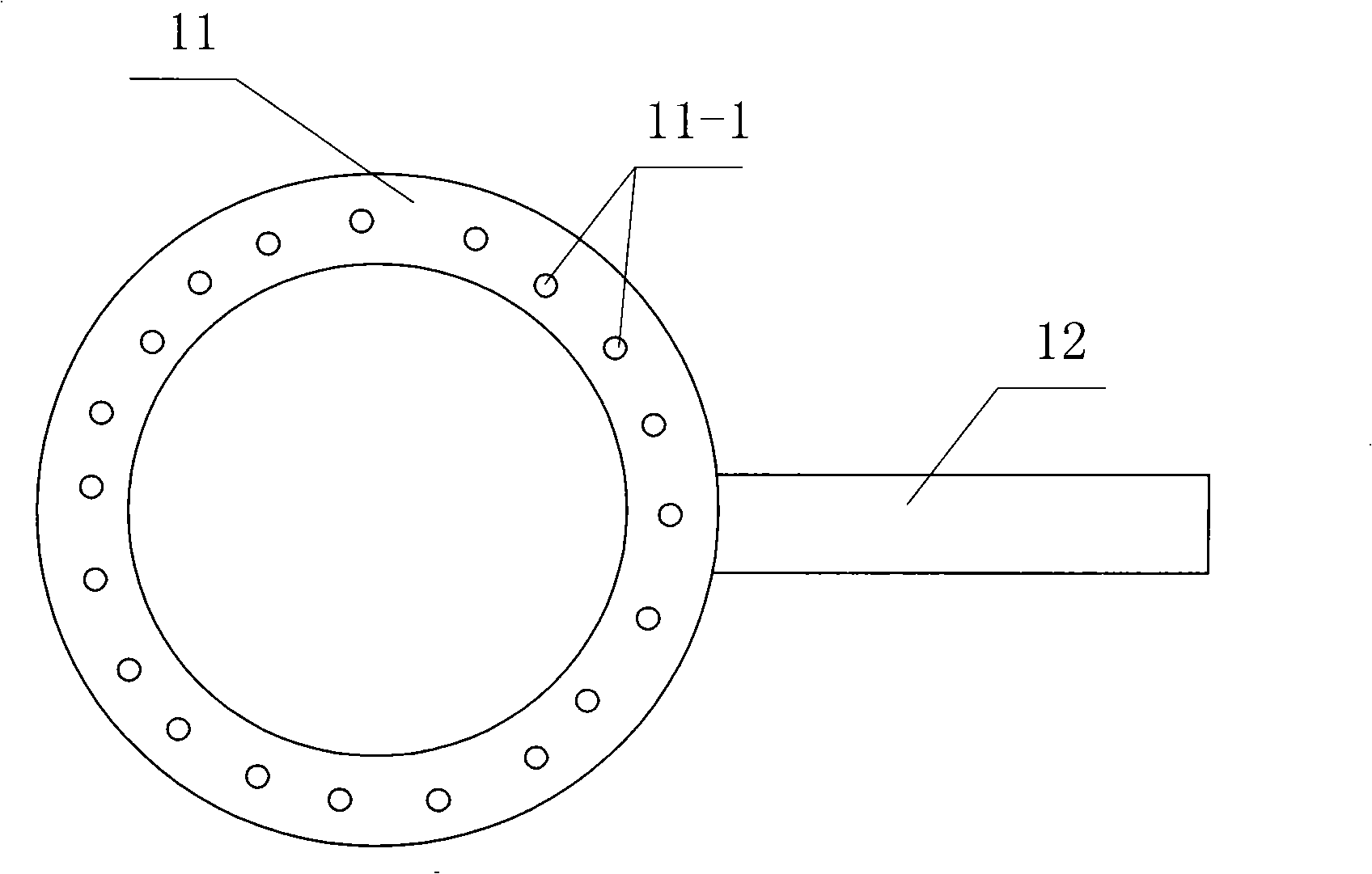

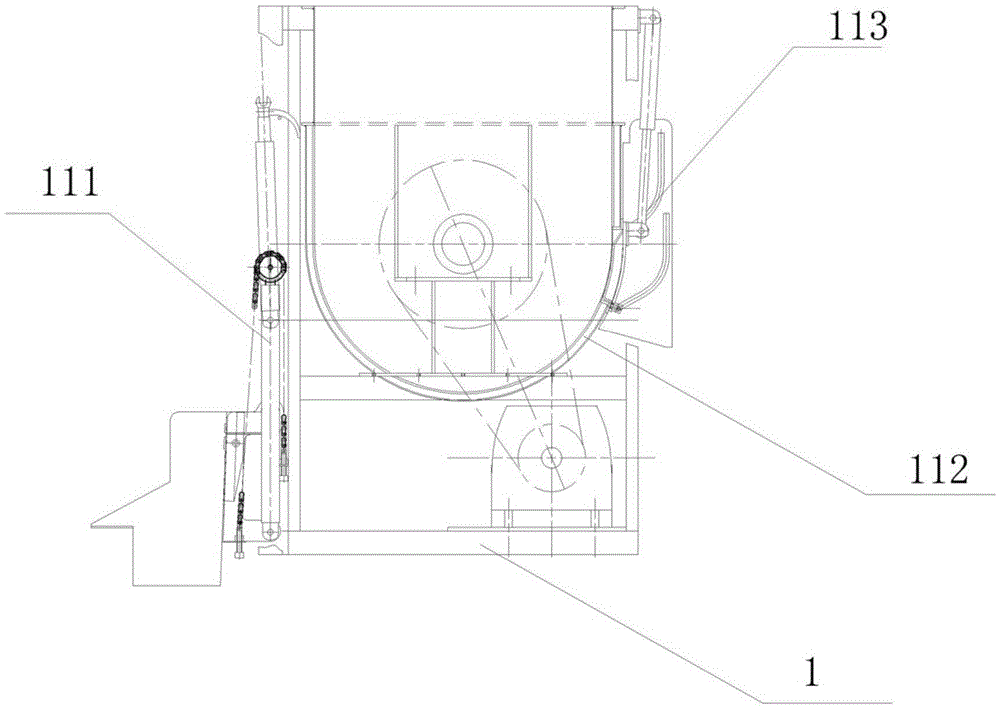

Combined stirred tank reactor

InactiveCN101972624AStir wellSmooth rotationMixersChemical/physical/physico-chemical stationary reactorsEngineeringCavity wall

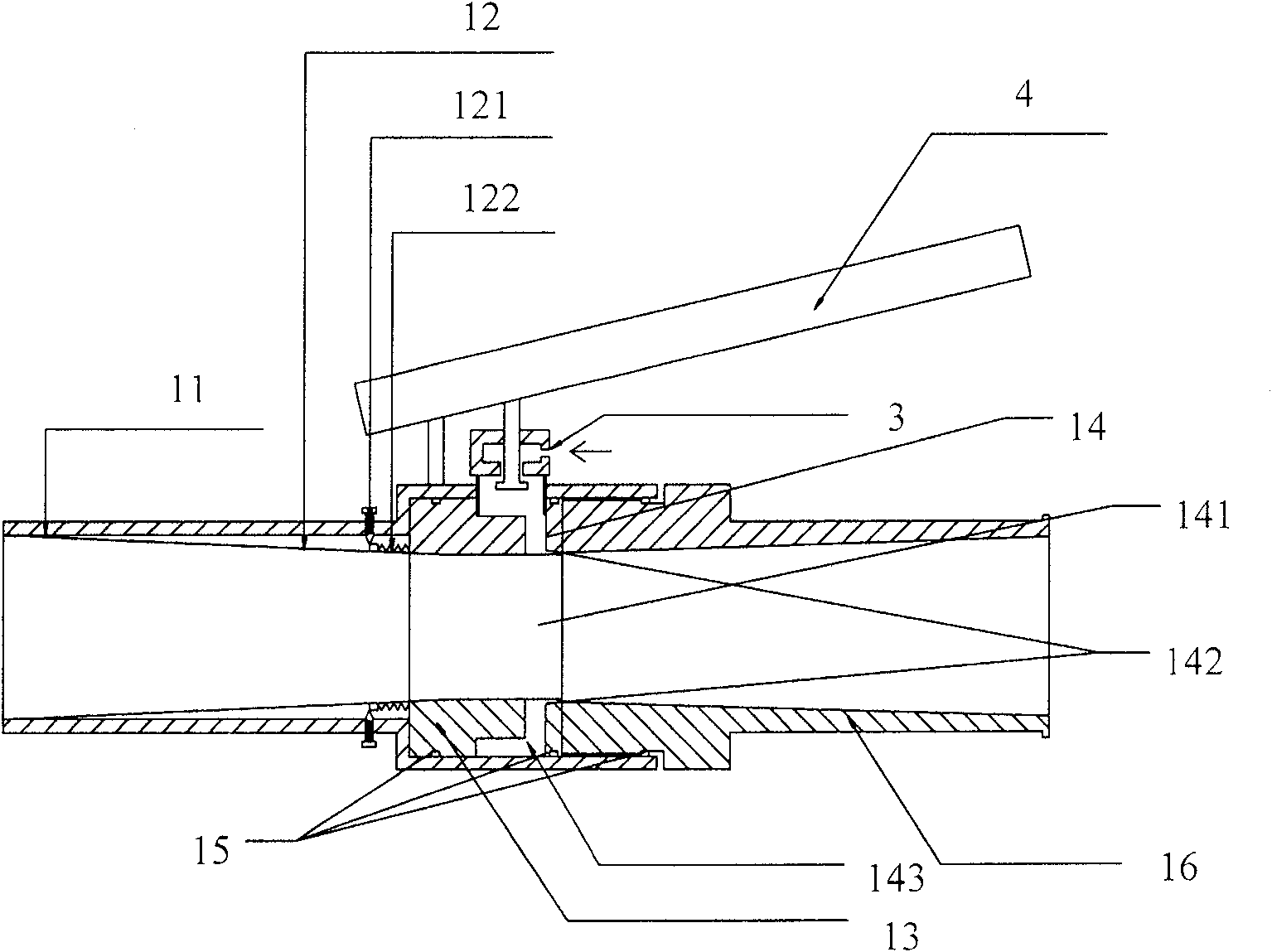

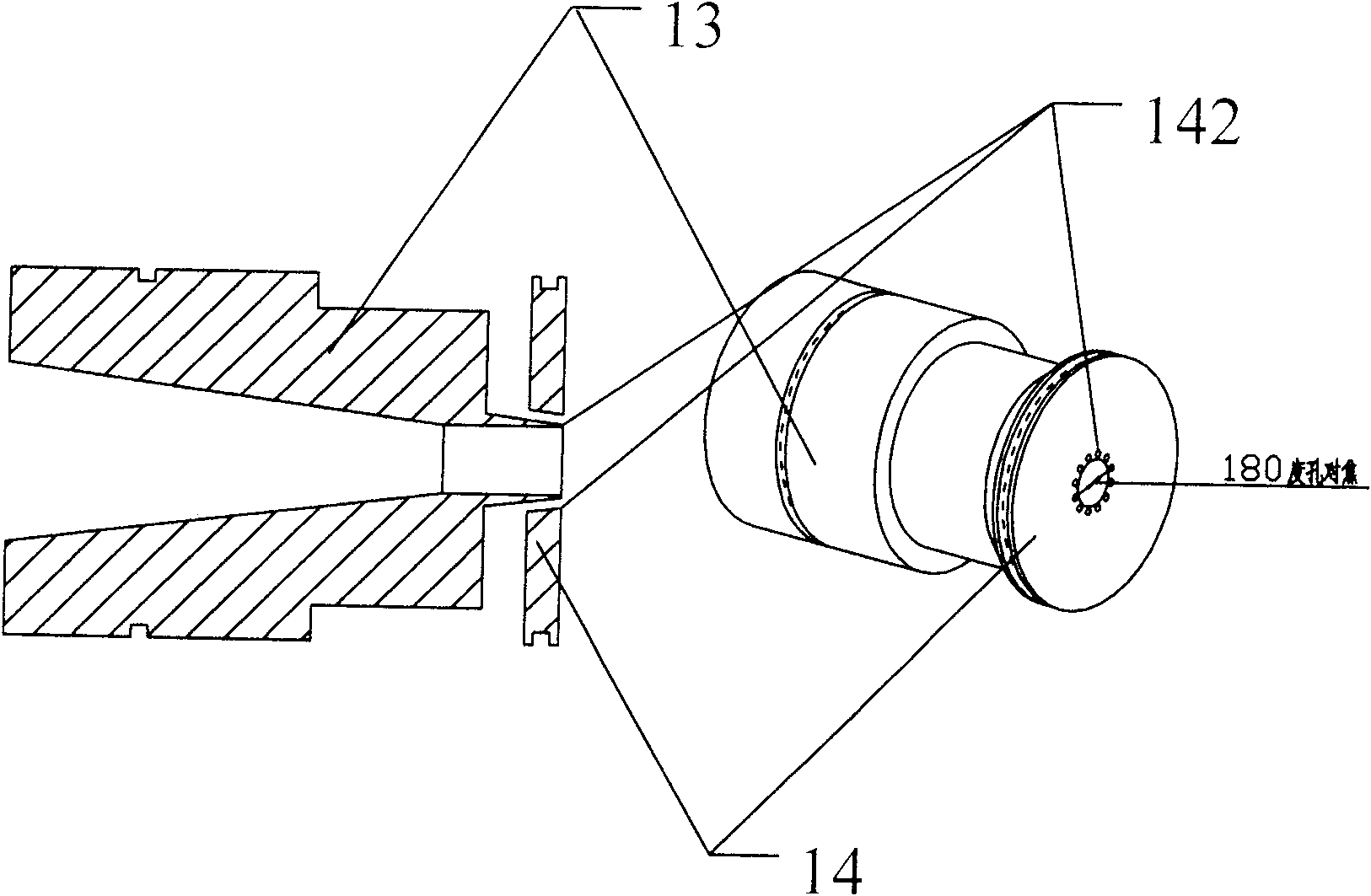

The invention relates to a reactor, in particular to a combined stirred tank reactor used for producing a composite stabilizer and a modifier, which comprises a barrel, a stirring device and a material outlet, wherein the stirring device consists of a blade stirrer and a frame stirrer; the blade stirrer consists of a central rotating shaft and at least one blade stirring paddle arranged on the central rotating shaft; the frame stirrer consists of a frame body arranged along the cavity wall of the barrel, outer scraping plates arranged on the outer circumferential wall of the frame body and inner stirring paddles arranged on the inner circumferential wall of the frame body; an upwards-sunken groove is reserved above the material outlet at the bottom of the frame body; a bottom bearing is arranged on the central rotating shaft in the groove; a triangular support frame is arranged below the bottom bearing; the upper end of the triangular support frame is fixed with the bottom of the bottom bearing, while a lower end is fixed with the inner bottom of the barrel; and a small paddle is arranged below the bottom bearing on the central rotating shaft, and is in contact with the periphery of the material outlet at the bottom in the barrel. The combined stirred tank reactor can solve the problems that mixed raw materials are easy to deposit, easily adhered to the wall and unsmooth to discharge, and that reaction is incomplete, and is more environmentally-friendly and energy-saving.

Owner:NANJING CONCORD FERTILIZER CHEM

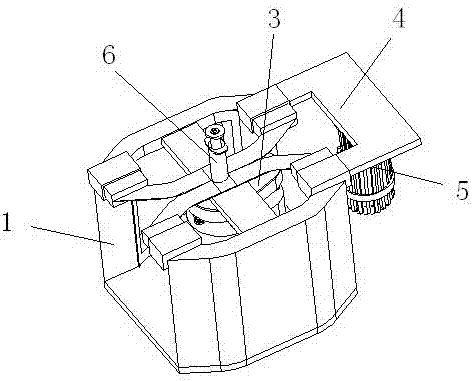

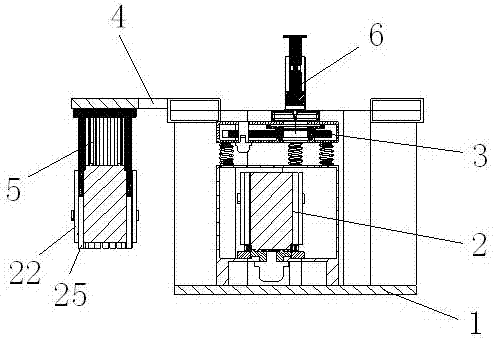

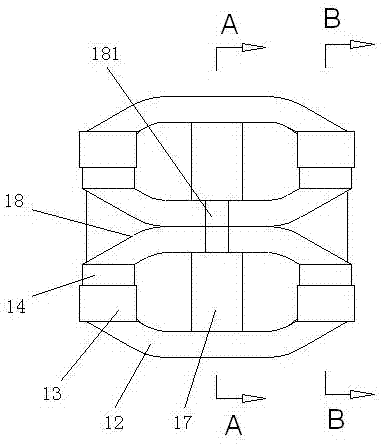

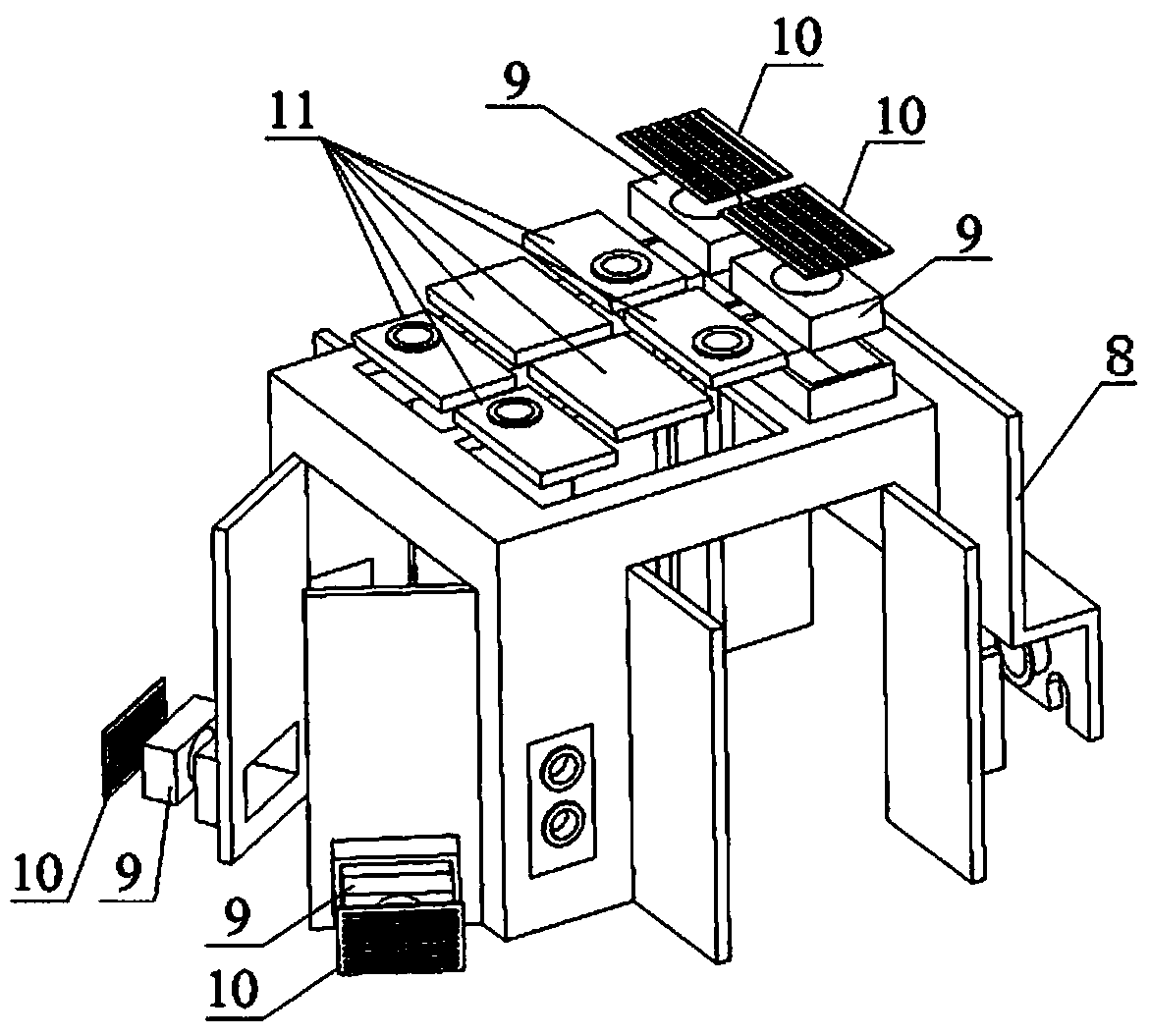

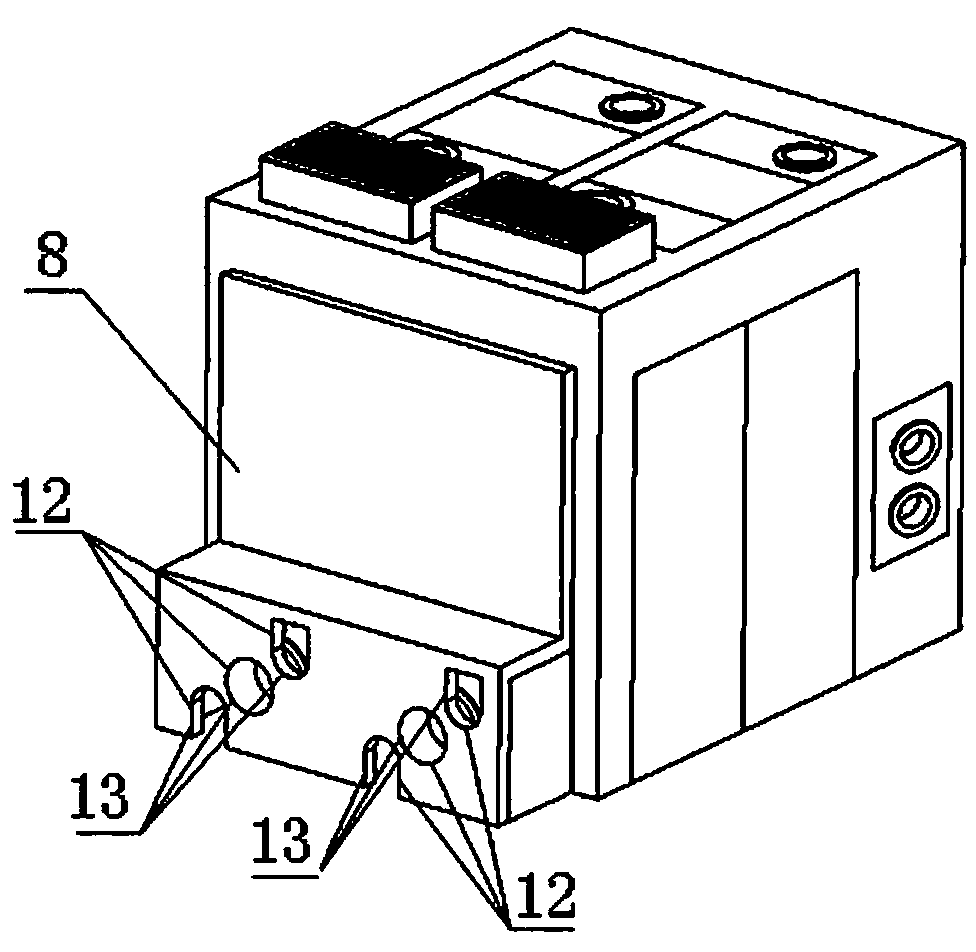

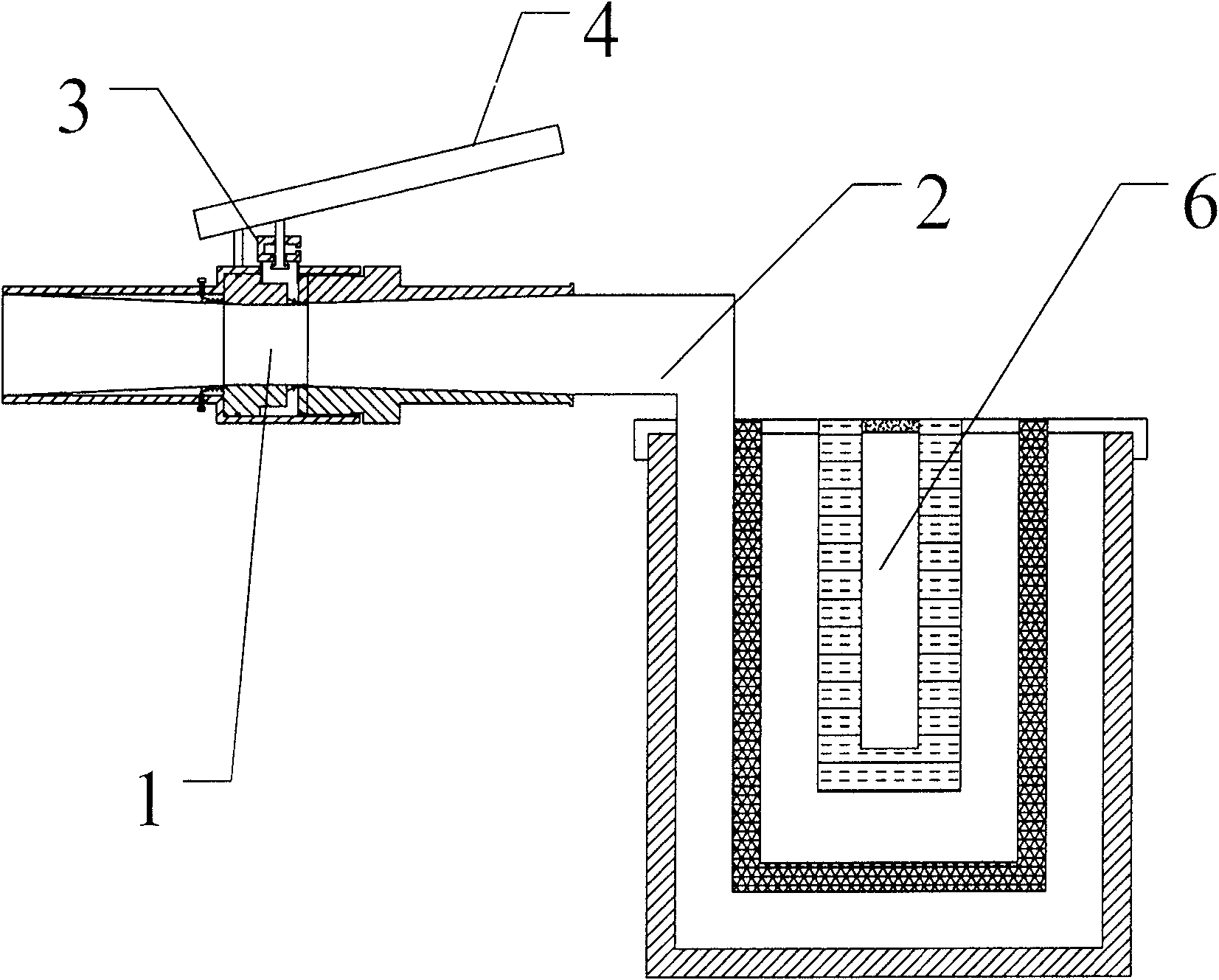

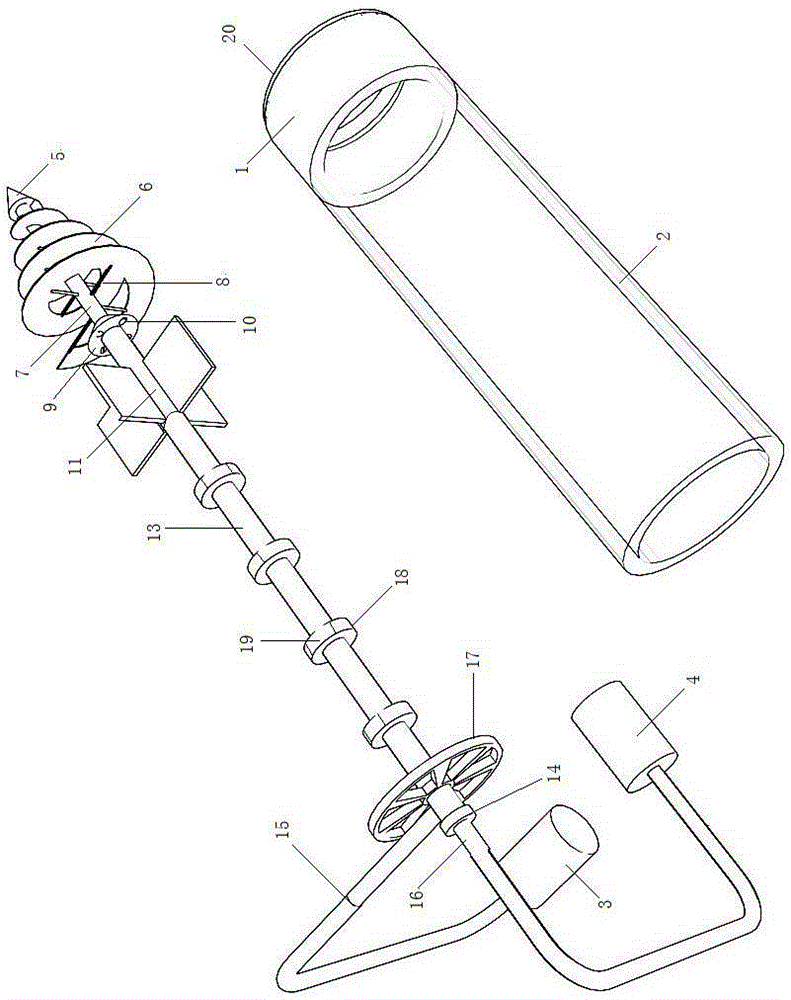

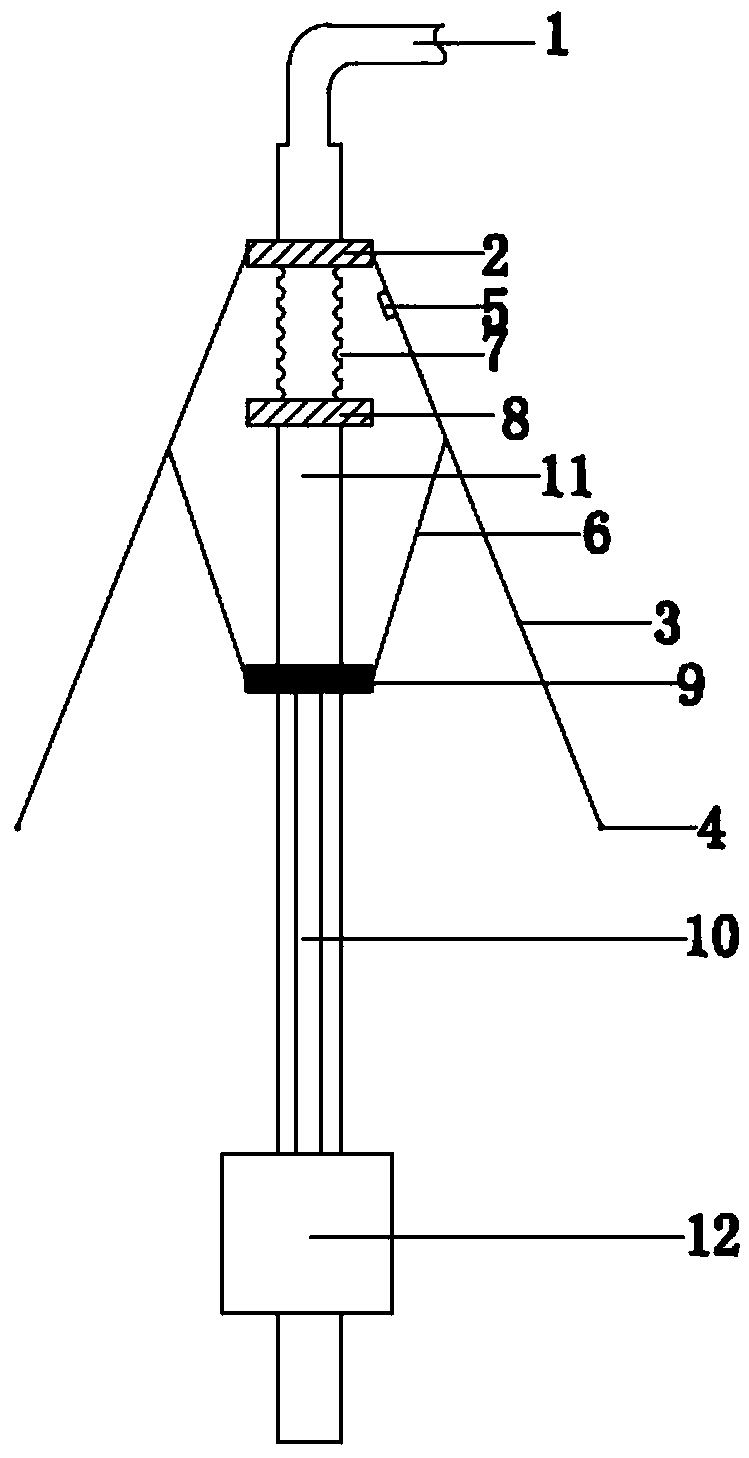

Medical portable syringe needle recoverer for clinical usage

ActiveCN107485765AEasy to useHigh degree of automationInfusion needlesSyringe needleBiomedical engineering

The invention discloses a medical portable syringe needle recoverer for clinical usage. The recoverer includes a splint device, a syringe needle pulling device and a syringe needle collecting device, wherein the splint device includes a rack base, two support plates symmetrically arranged above the rack base and two splint fixing mechanisms which are symmetrically and fixedly arranged on the inner sides of the upper portions of the two support plates respectively and used for fixing and clamping a needle cap in a syringe needle assembly; the rack base is successively provided with the syringe needle pulling device and the syringe needle collecting device which are positioned under the two splint fixing mechanisms from top to bottom, the syringe needle pulling device is used for clamping and pulling out a metal syringe needle fixedly inserted in the bottom of the needle cap, and the syringe needle collecting device is used for collecting the metal syringe needles pulled out by the syringe needle pulling device. The medical portable syringe needle recoverer for the clinical usage has the advantages of being small in overall occupied space, convenient to carry, high in automation degree, convenient to operate and use, environment-friendly and capable of well recovering the medical syringe needles alone.

Owner:李奇元

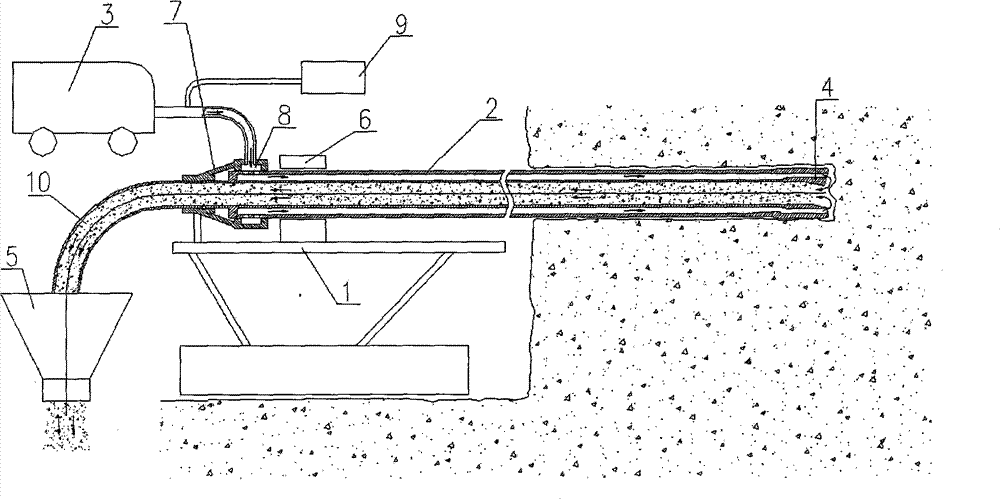

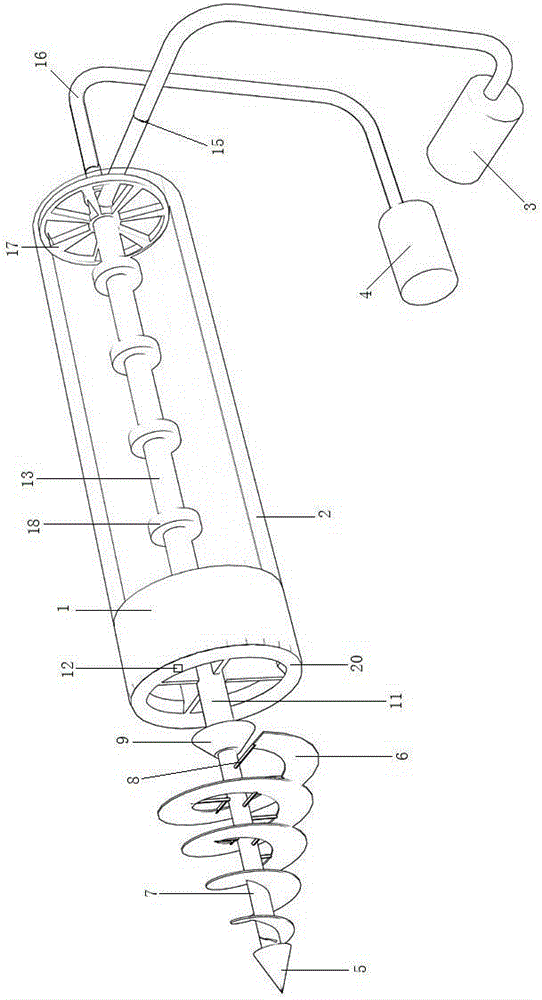

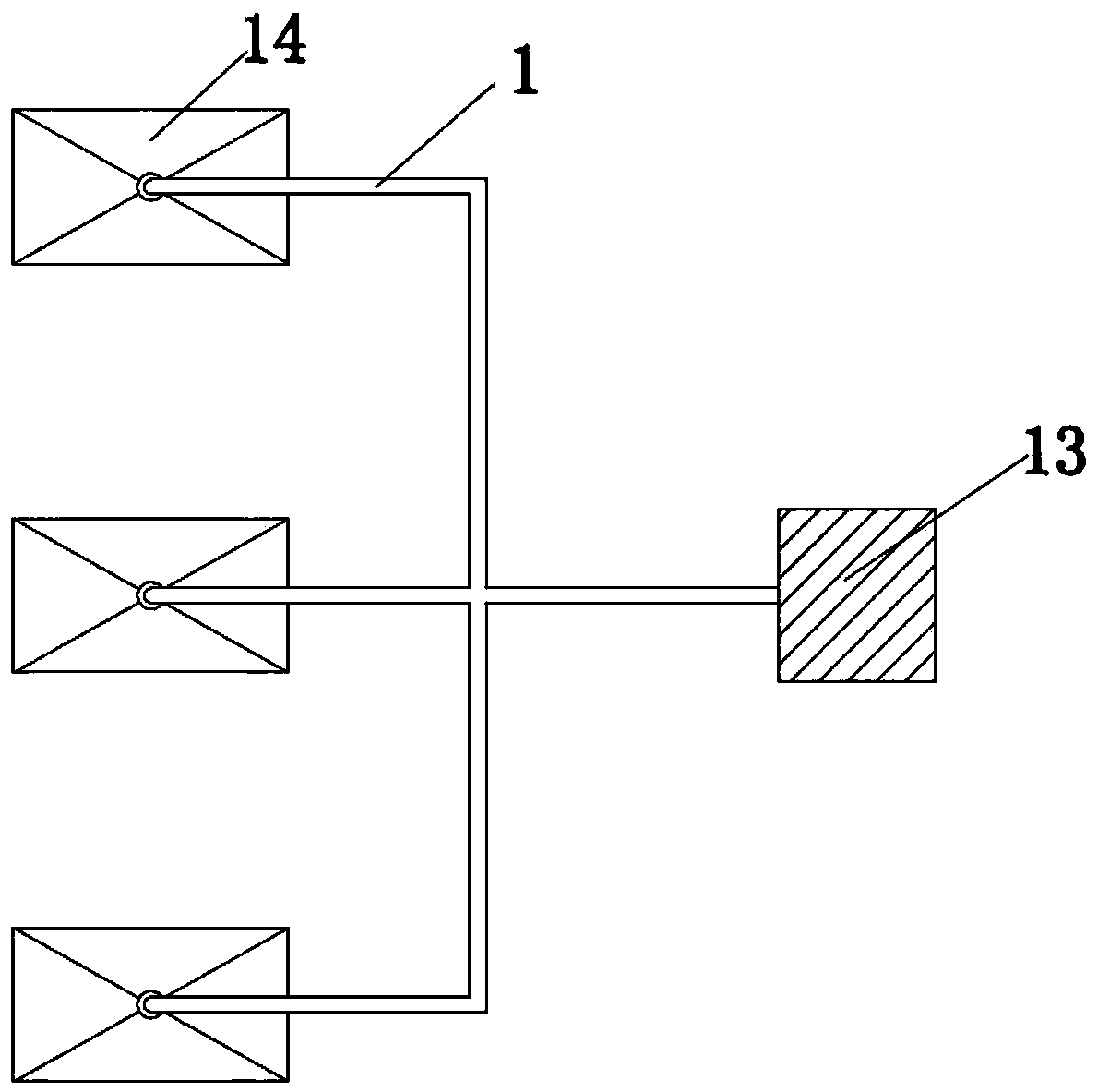

Reverse circulation drilling device and process for soft projecting coal seam

InactiveCN104514487AImprove drilling efficiencyImprove porosityFlushingDrilling machines and methodsCoalDrill bit

The invention provides a reverse circulation drilling device for a soft projecting coal seam. The device comprises a drilling machine, an active double-wall drilling rod, a double-channel pneumatic faucet; a power head is arranged on the drilling machine; the active double-wall drilling rod passes through the power head to be mounted; an inner pipe at one end of the active double-wall drilling rod is connected with a rubber pipe through the double-channel pneumatic faucet; a pulverized coal receiving device is connected to the tail end of the rubber pipe; an air box which communicates with internal and external pipe annular channels of the active double-wall drilling rod is arranged on the double-channel pneumatic faucet; the air box is connected with an air compressor through an air pipe; a drill bit is connected to the other end of the active double-wall drilling rod. With the adoption of the device, the disturbance to the coal seam can be minimized, so that the collapse in holes can be effectively prevented, and that the frequent drilling blocking accidents can be avoided; the circumstance that gas is concentrated is prevented, and therefore, the phenomenon of blowout through the holes can be effectively avoided; the production cost is low; in addition, the working environment at the construction field can be effectively improved; the purpose of drilling in collapse and reducing stratums synchronously by one drilling rod can be achieved.

Owner:周升风

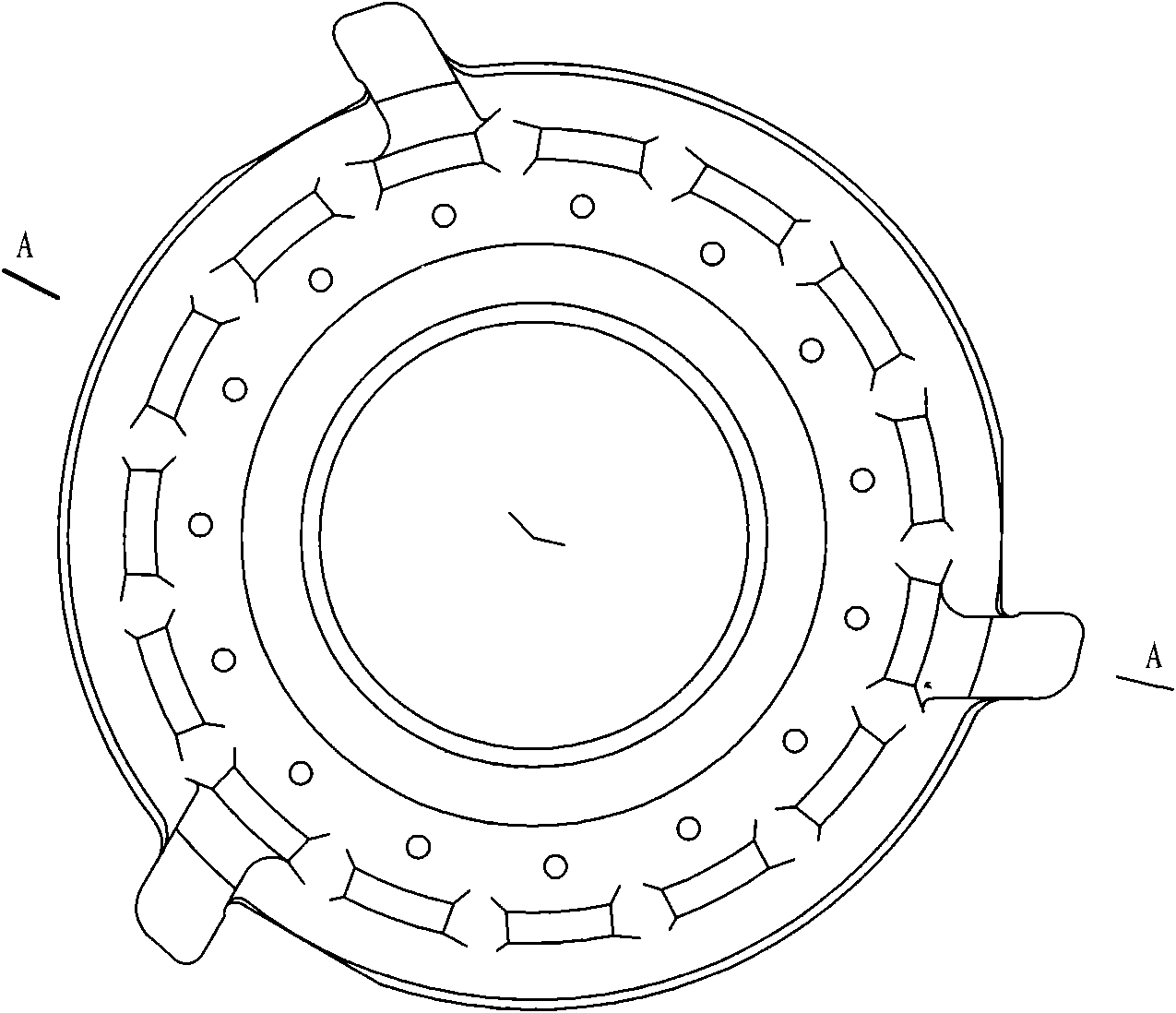

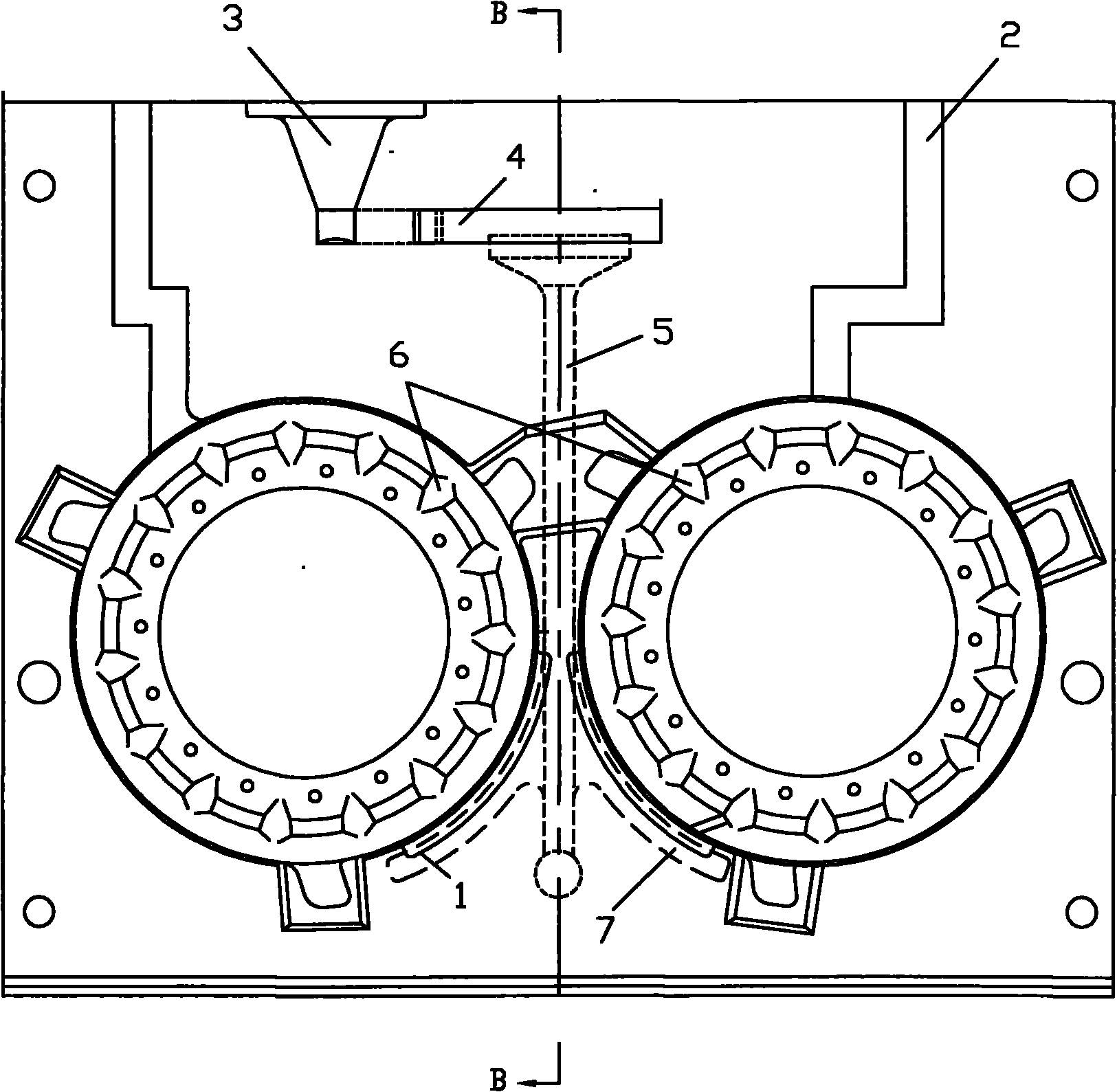

Process for manufacturing saloon car clutch pressure plate casting

The invention provides an optimized process for manufacturing a saloon car clutch pressure plate casting on a vertical modeling production line. The process comprises the following steps of mulling sand, modeling, melting burden, inoculating iron, pouring, cooling, opening case and clearing casting, wherein in the modeling step, two and more raw castings are horizontally and asymmetrically arranged; a pouring iron liquid enters into a straight pouring channel through a pouring cup and an upper cross channel; and the straight pouring channel enters into a lower cross channel by passing through the middle of a casting cavity and then asymmetrically enters into the cavity from the lower side of the cavity. The pressure plate casting produced by using the process of the invention has a single-cast coupon tensile strength equal to or more than 250 MPa, a casting body tensile strength equal to or more than 200 MPa and the casting body hardness from 170 to 241HBS. The product metallographic structure mainly uses the A type graphite; the length of the graphite is 4 to 6 level; the matrix contains more than 95% of small pearlites and less ferrites; and all the parts of the casting have no casting flaw and meet the technical requirements of the saloon car clutch pressure plate casting.

Owner:上海华新合金有限公司

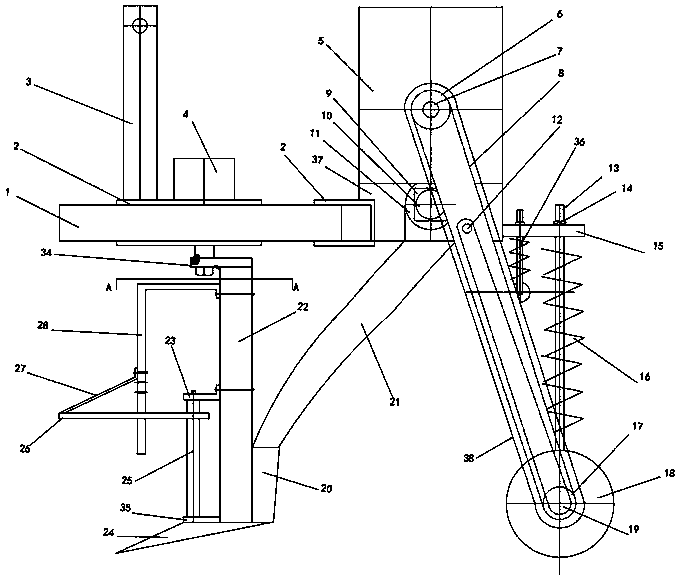

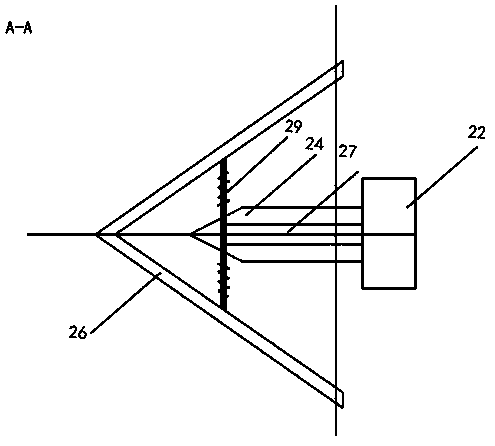

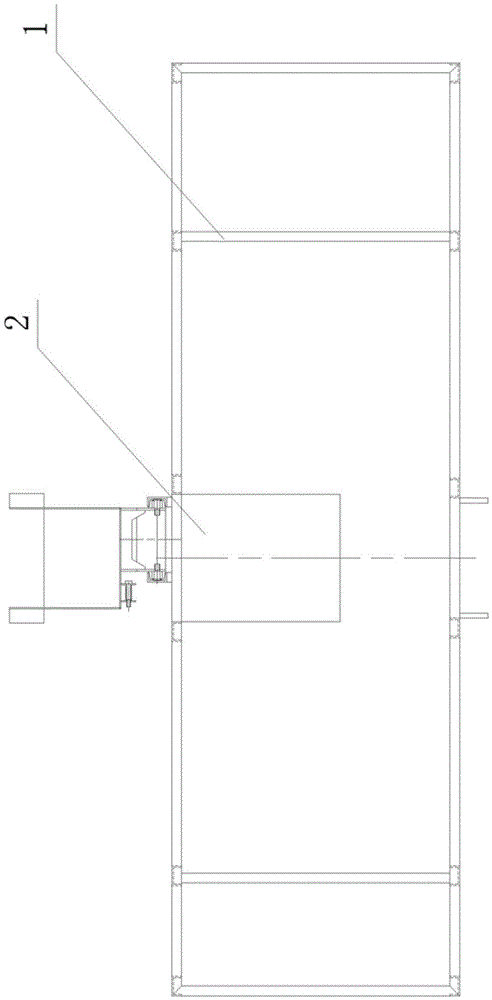

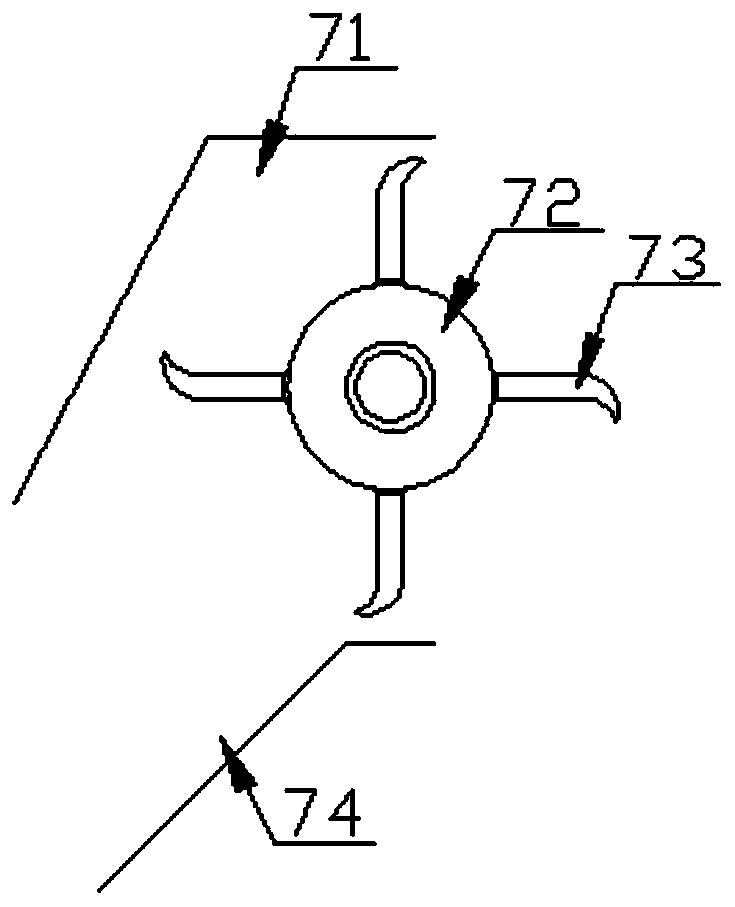

Plant avoidance type appropriate fertilizer applicator

InactiveCN103392434AImprove versatilityIncrease profitPlantingFertiliser distributersHydraulic motorAgricultural science

The invention designs a plant avoidance type appropriate fertilizer applicator, which relates to the field of agriculture. The plant avoidance type appropriate fertilizer applicator is mainly characterized by comprising a hooking part for hooking the applicator with a tractor, a plant avoidance part and an appropriate fertilizer application part. The fertilizer applicator is hooked behind the tractor in a three-point suspension manner; when a rightwards transverse V-shaped induction bar of the plant avoidance part touches a plant, two telescopic springs deform, an avoidance hydraulic motor is controlled to start and a furrowing blade is driven to turn so as to realize plant avoidance; a stirring shaft and stirring rods are driven by a land wheel of the appropriate fertilizer application part through a chain wheel and a chain, so that fertilizer is stirred to prevent caking; the rotation speed of a fertilizer feeding hydraulic motor is adjusted to realize appropriate fertilizer application according to soil fertility and crop requirements; the machine space and the operation lines can be adjusted according to the tractor and parcels; the furrowing blade is changed into a sub-soiling shovel, so that sub-soiling fertilizer application can be performed, and the universality and the utilization rate of the applicator are improved.

Owner:CHINA AGRI UNIV

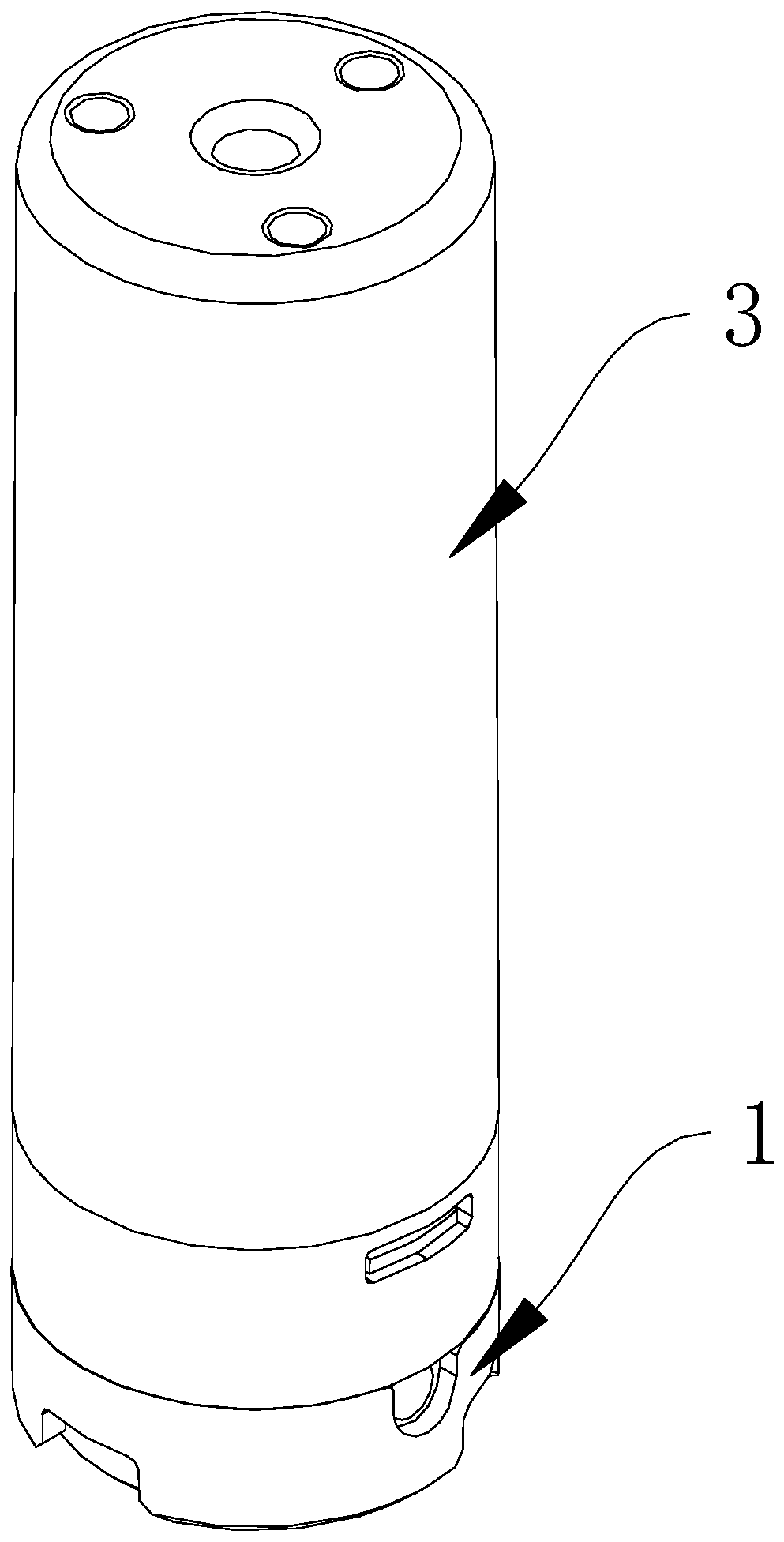

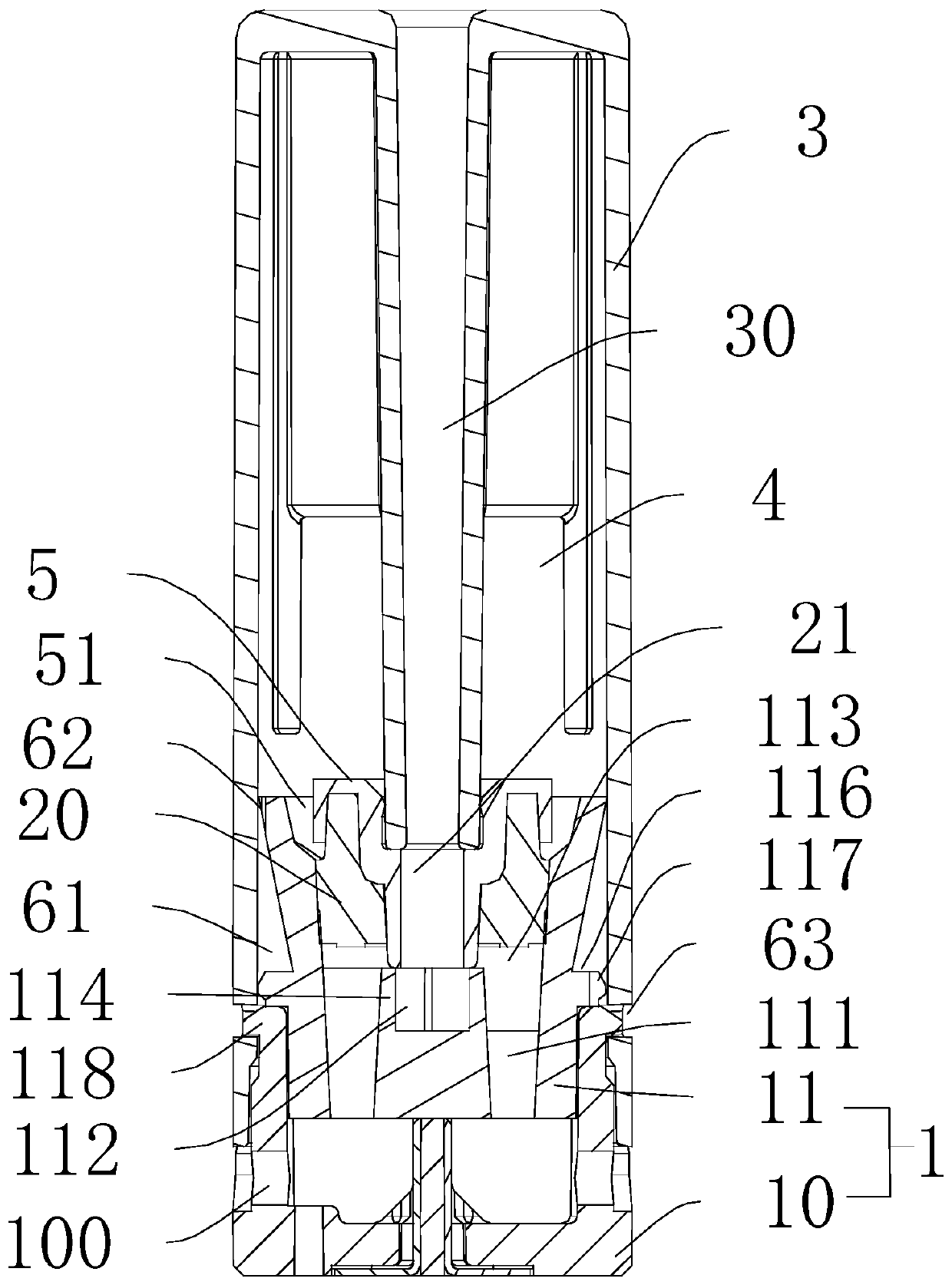

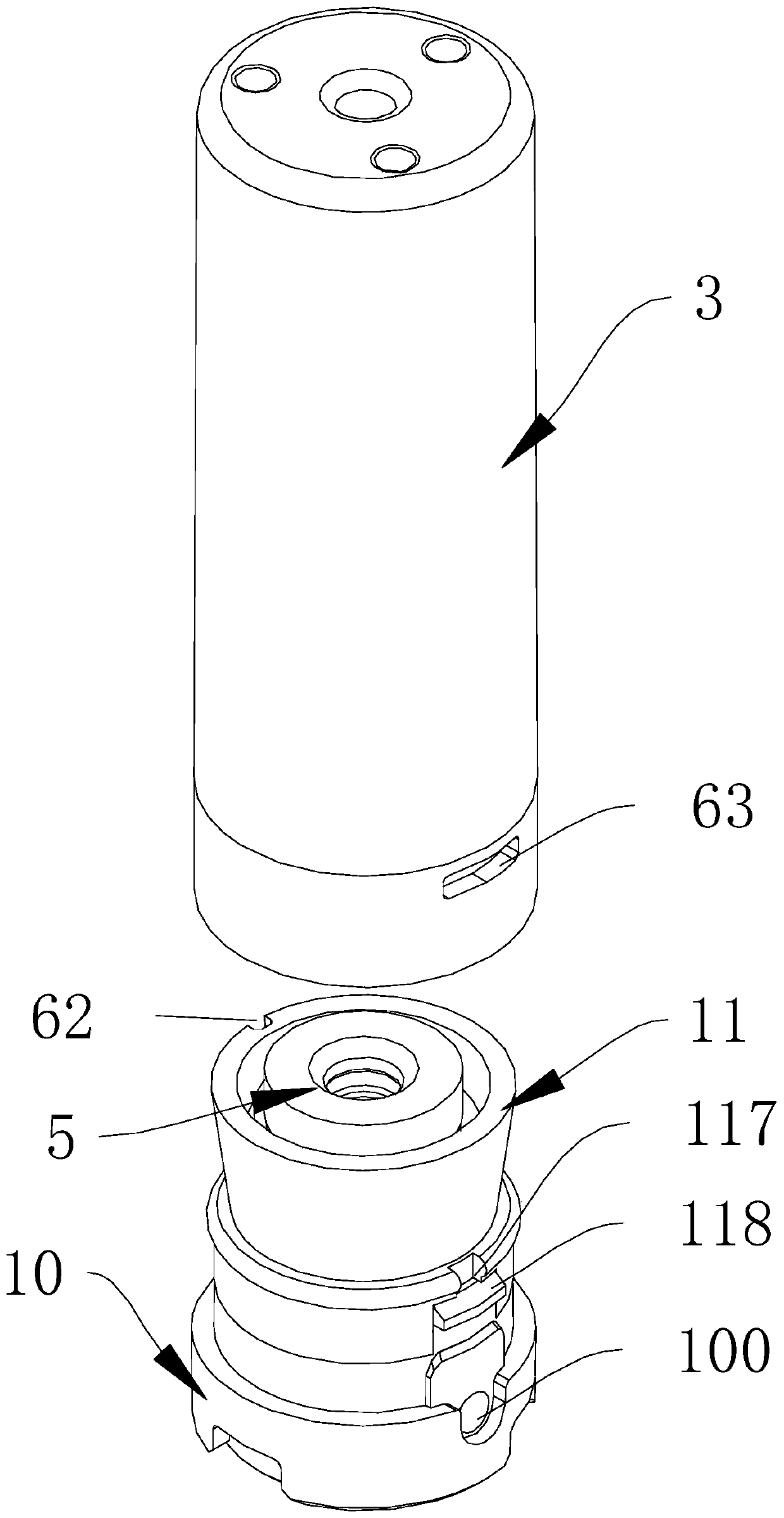

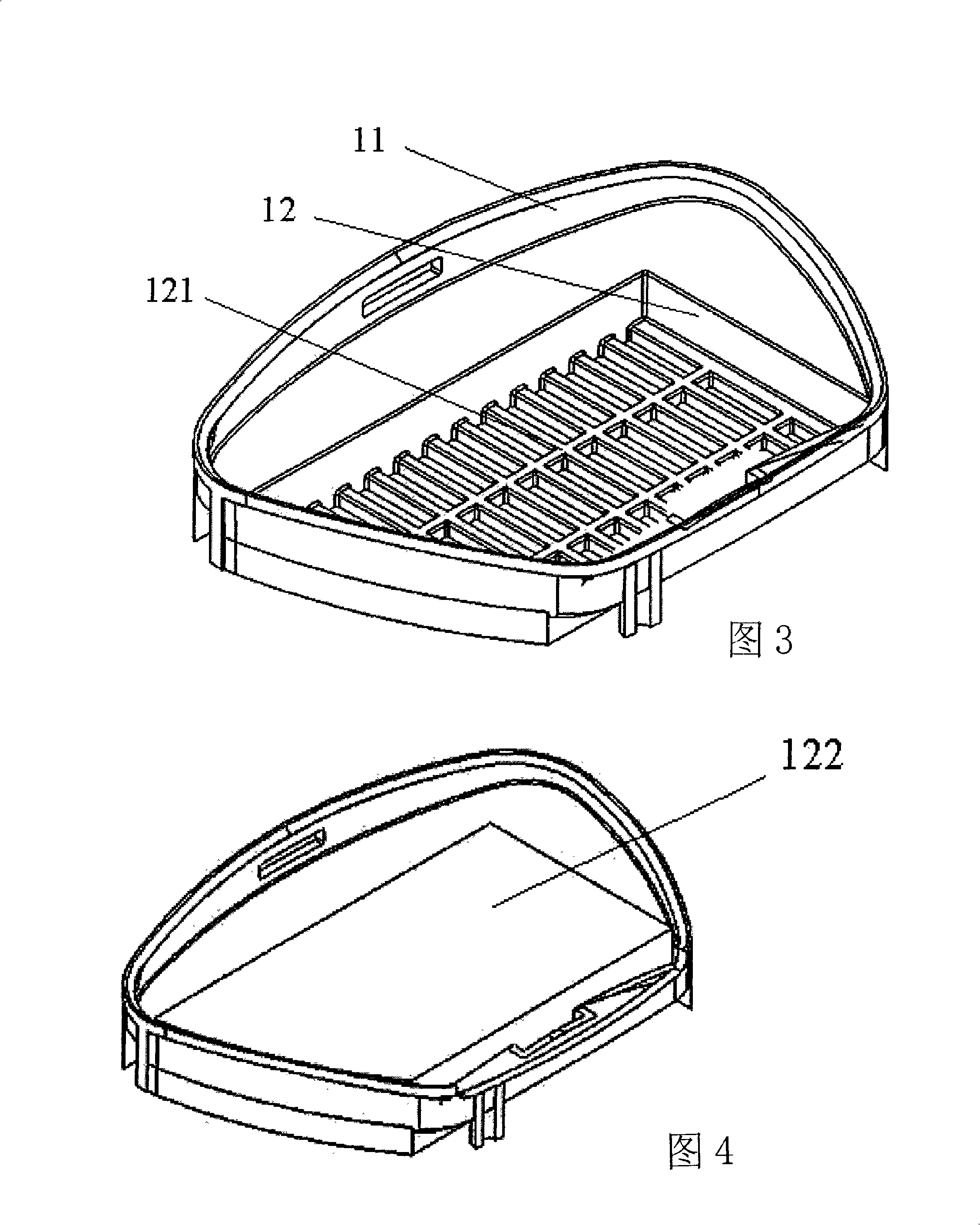

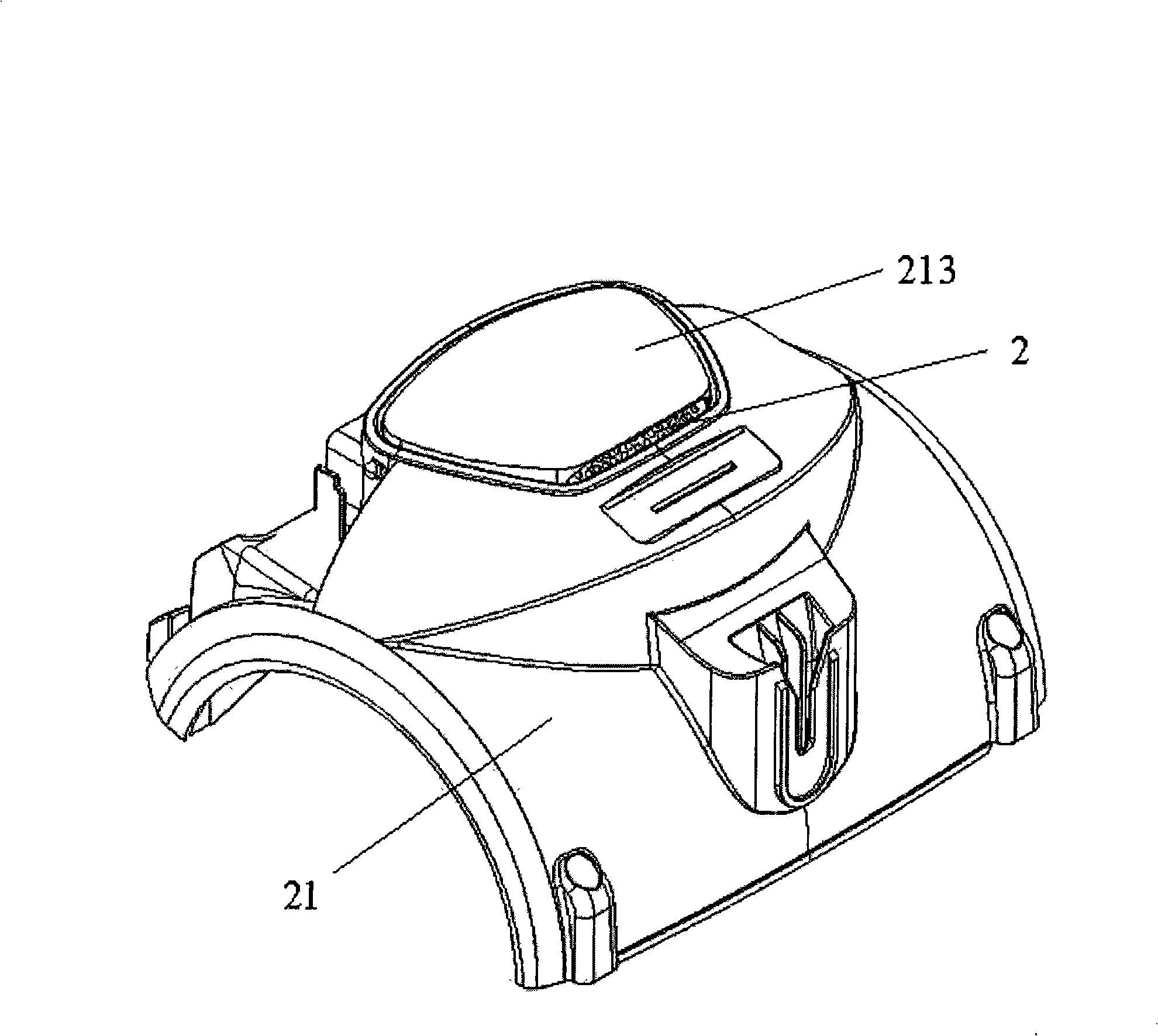

Electronic atomization device and atomizer thereof

PendingCN111011933AAchieve gas-liquid balanceUnobstructed dischargeMedical atomisersTobaccoPhysicsEngineering

The invention discloses an electronic atomization device and an atomizer thereof. The atomizer comprises a liquid storage cavity used for storing liquid; and an air exchange channel communicating theliquid storage cavity with the outside. The air exchange channel comprises an air inlet communicated with the outside; a cavity communicated with the air inlet; an air exchange groove communicated with the cavity and the liquid storage cavity, wherein the cavity is annular or a part of the annular shape, and the end, close to the air exchange groove, of the cavity has capillary acting force. By means of the air exchange channel, the liquid storage cavity is communicated with the outside, air is supplemented to the liquid storage cavity, air-liquid balance is achieved, and liquid in the liquidstorage cavity can flow more smoothly. Liquid locking in a shelving state and leaked liquid recovery in a suction state are realized.

Owner:SHENZHEN SMOORE TECH LTD

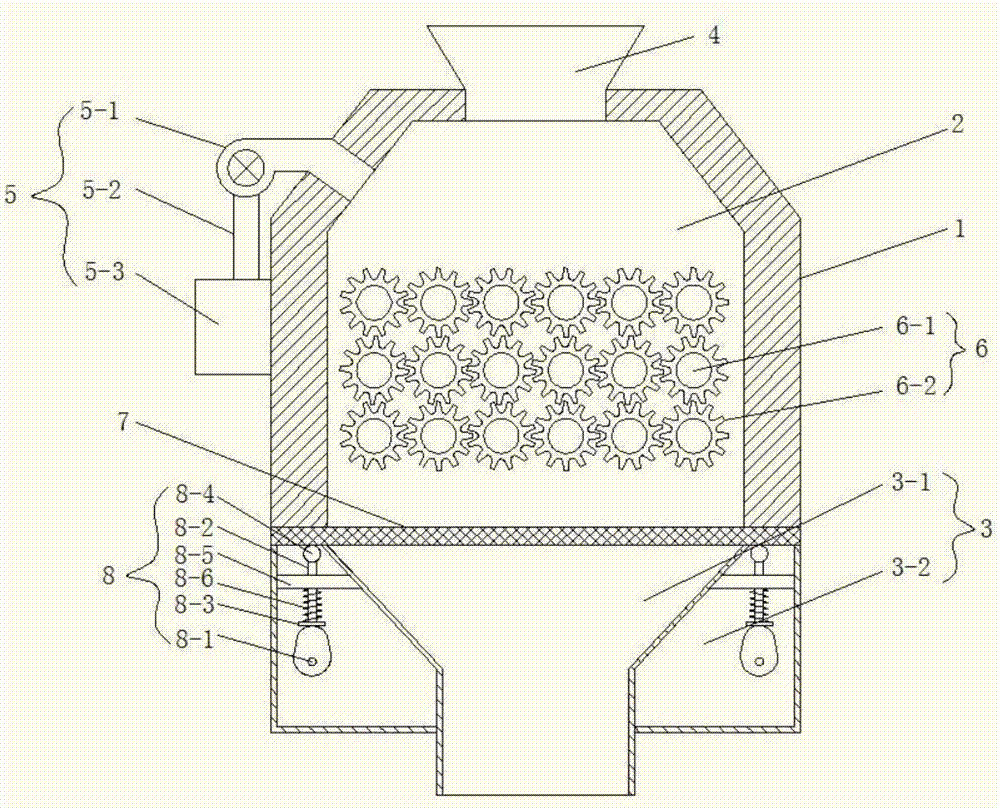

Anti-blocking molybdenum powder processing pulverizer

The invention discloses an anti-blocking molybdenum powder processing pulverizer, and relates to the technical field of pulverizers. The anti-blocking molybdenum powder processing pulverizer comprisesa machine shell; the machine shell is internally provided with a pulverizing chamber and a discharging chamber from top to bottom, a filter plate is arranged between the pulverizing chamber and the discharging chamber, and the pulverizing chamber is internally provided with a pulverizing mechanism; the discharging chamber comprises a funnel-shaped discharging cavity and vibrating cavities uniformly distributed on the two sides of the discharging cavity, and the two vibrating cavities are internally provided with same vibrating mechanisms; each vibrating mechanism comprises a cam and a cylindrical pushing rod arranged above the cam; the bottoms of the pushing rods are connected with stop blocks making contact with the cams, the tops of the pushing rods are connected with hammering balls used for striking the filter plate, and the diameter of each hammering ball is greater than that of each pushing rod; fixing plates are arranged on the pushing rods in a penetrating mode, and the fixingplates are located between the hammering balls and stop blocks and fixed in the vibrating cavities; and buffering springs which are wound around the pushing rods are arranged between the fixing plates and the stop blocks. The anti-blocking molybdenum powder processing pulverizer has the advantages of being simple in structure, convenient to operate and smooth in discharging of molybdenum powder.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

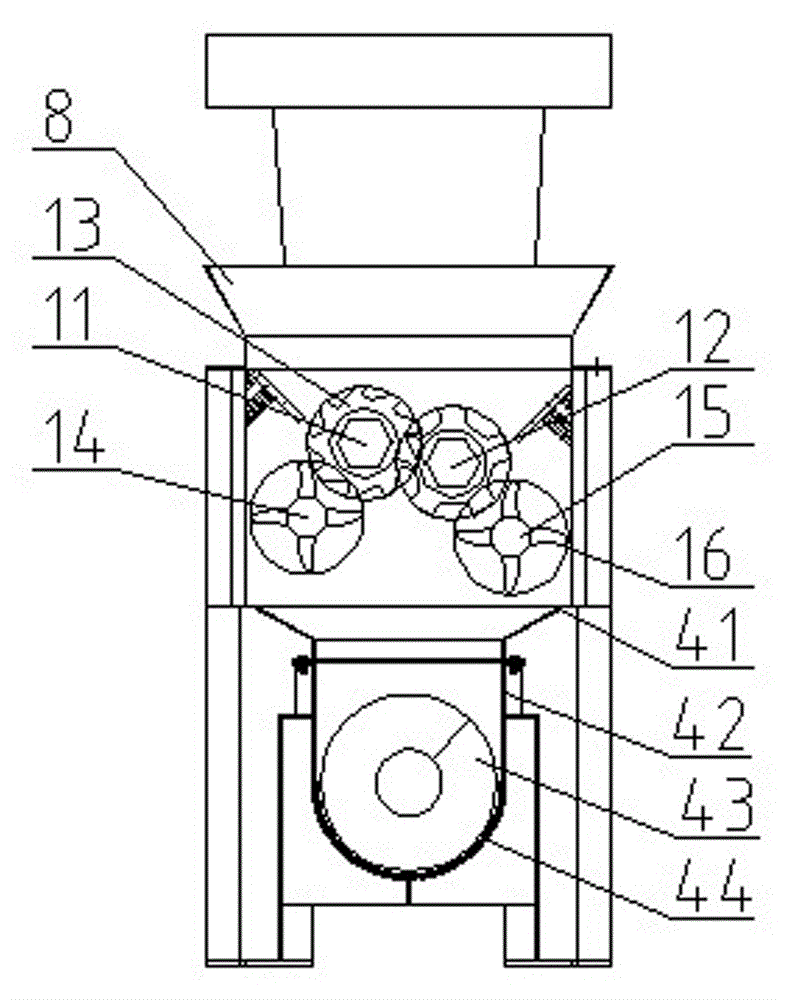

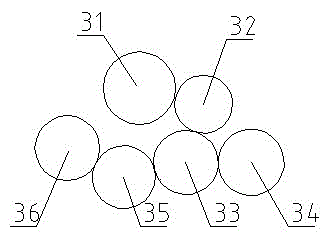

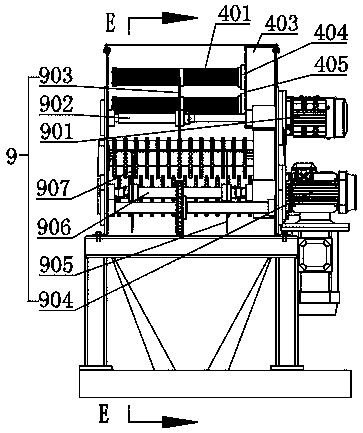

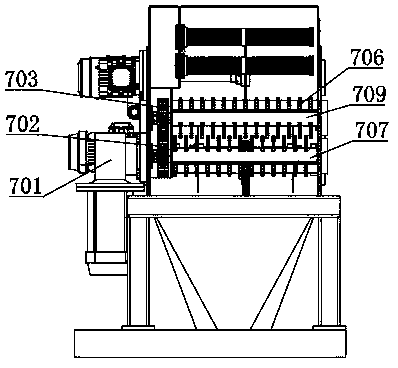

Solid rubbish smashing all-in-one machine

InactiveCN105032905AGood crushing effectSmash thoroughlySolid waste disposalGrain treatmentsPulverizerFunnel shape

The invention relates to a solid rubbish smashing all-in-one machine. The solid rubbish smashing all-in-one machine comprises a smashing machine and a pressing machine. A funnel-shaped feeding opening is formed in the top of the smashing machine. A discharging opening is formed in the bottom of the smashing machine. A double-shaft smashing blade set is arranged in the smashing machine. A shaving tooth assembly matched with the double-shaft smashing blade set is arranged slantly below the double-shaft smashing blade set. A speed reducer and a reduction gearbox are arranged at the left side of the smashing machine. The output end of the speed reducer is connected with the double-shaft smashing blade set. The double-shaft smashing blade set drives the shaving tooth assembly through the reduction gearbox to jointly move. The pressing machine comprises a horizontal cylindrical trough. The trough is installed on an installation support. A conical opening is formed in the top of the trough. A spiral conveying shaft is arranged in the trough. A liner plate is arranged on the inner wall of the trough. A motor is installed at the left side of the trough and connected with the spiral conveying shaft. A compressing pipe is communicated to the right side of the trough. Water draining holes are formed in the bottom of the compressing pipe. The smashing machine is installed on the top face of the trough, and the discharging opening of the smashing machine corresponds to the conical opening in the top of the trough.

Owner:JIANGSU HEHAI WATER SUPPLY & DRAINAGE EQUIP CO LTD

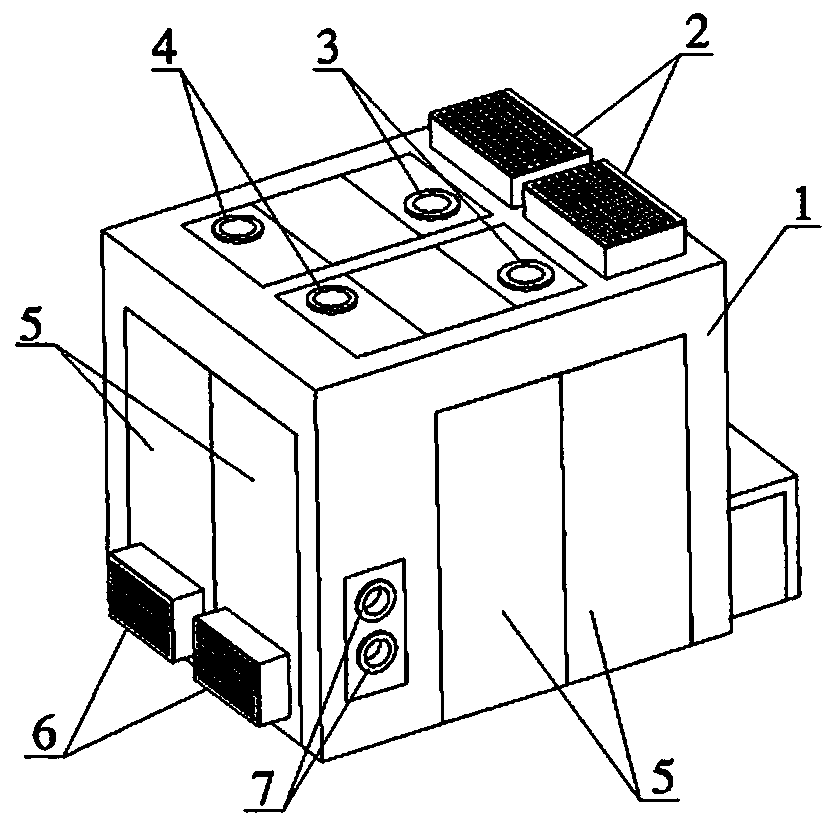

Noise insulating cover of power system

ActiveCN104033247AGuaranteed uptimeInsulate the influenceMachines/enginesEngine componentsElectrical and Electronics engineering

A noise insulating cover of a power system comprises a body used for sealing the power system, and side-opening doors arranged on the side face of the body. The noise insulating cover is characterized in that a ventilating system and an air renewal system are arranged on the body, a movable noise insulating device matched with the side face of the body is arranged, and power ports are arranged on the movable noise insulating device. The noise insulating cover has the advantages that the noise insulating cover is good in noise reducing effect, simple in structure, convenient to mount and good in heat radiating effect.

Owner:四机赛瓦石油钻采设备有限公司

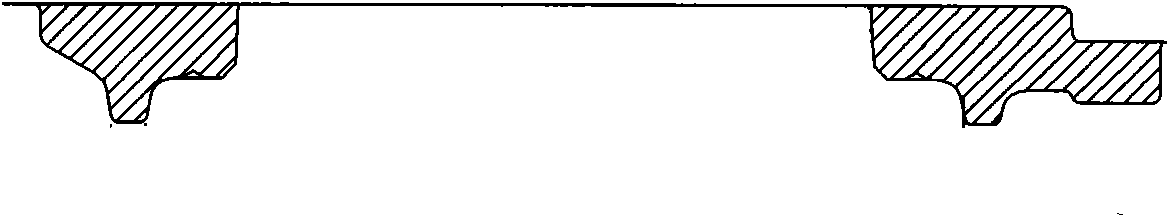

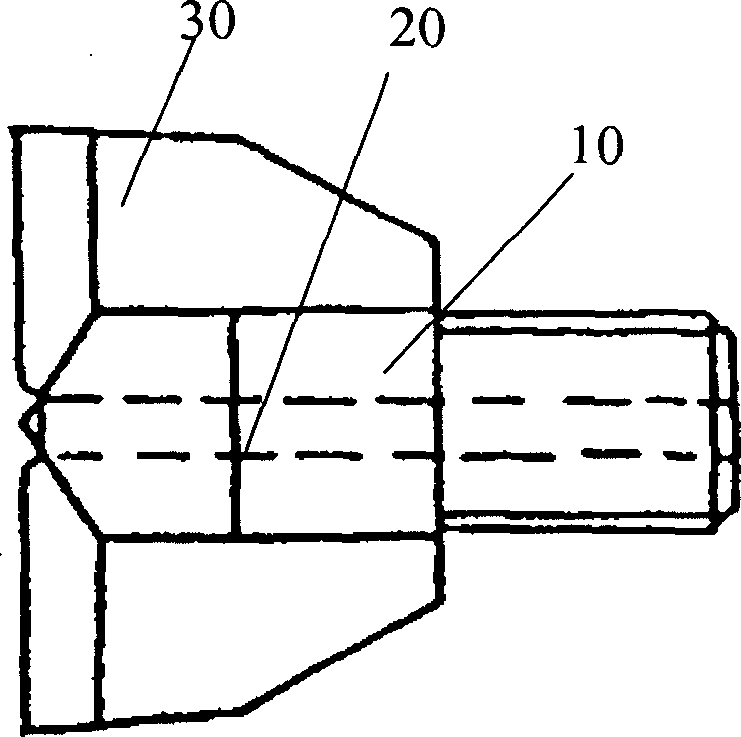

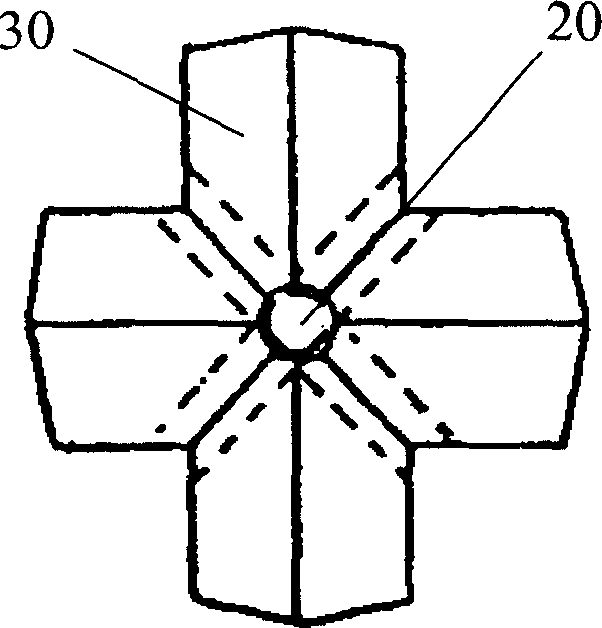

Drill bit for taphole of blast furnace and method for producing same

ActiveCN1704481AMaterial selection is easy and easy to obtainReduce procurement costsBlast furnace componentsBlast furnace detailsAlloyEngineering

Disclosed is a drill bit for taphole of blast furnace, which comprises a base and three blades, the base is provided with a venting hole in the center, and side air passages in communication with the central venting hole, the blades are in uniform distribution on the base, the head of the blades are of trapezoidal structure inclining toward the central venting hole, the exterior height of the drilling bit is 13-16 mm. The invention also discloses the process for making the dill bit.

Owner:BAOSHAN IRON & STEEL CO LTD +1

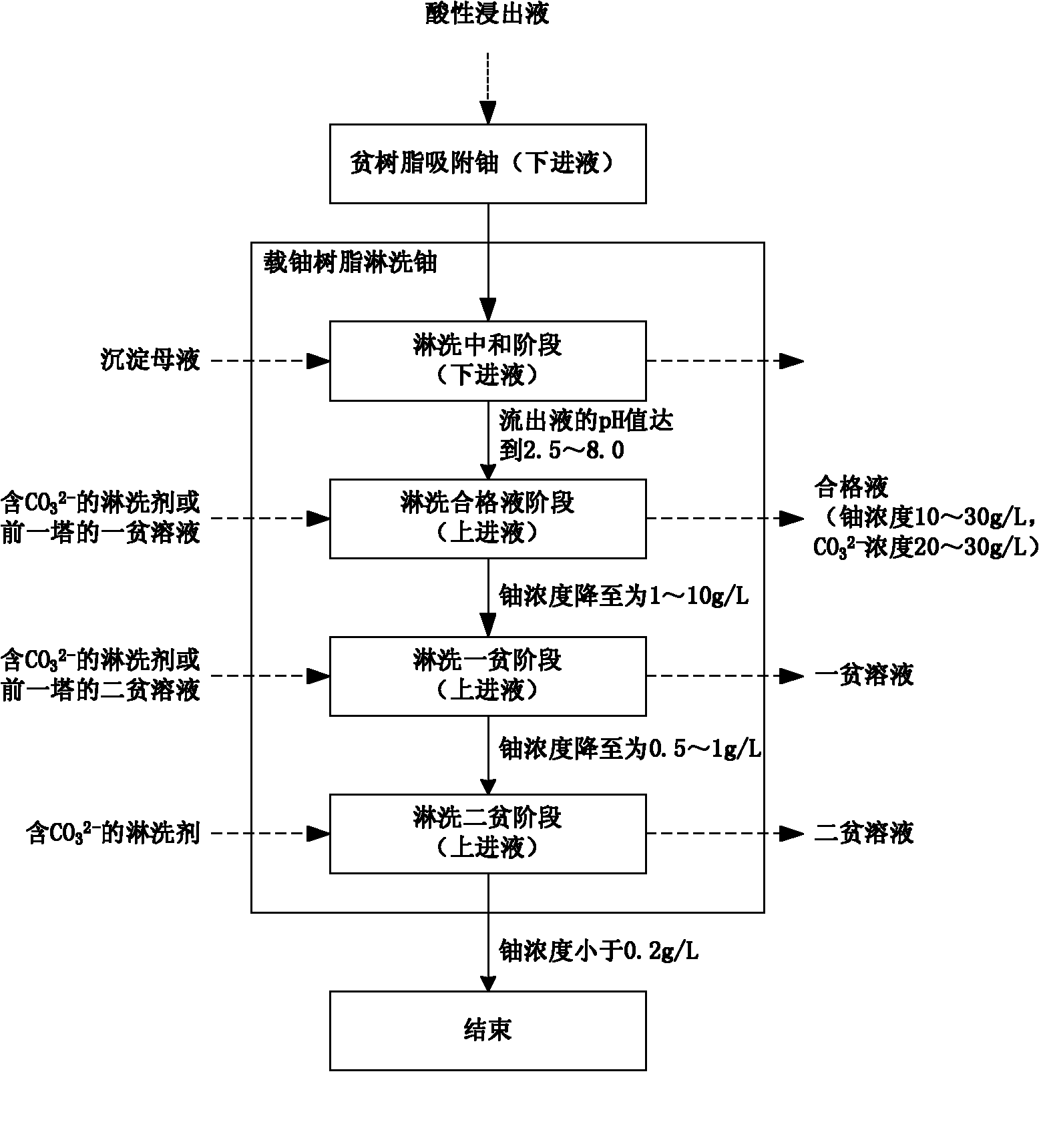

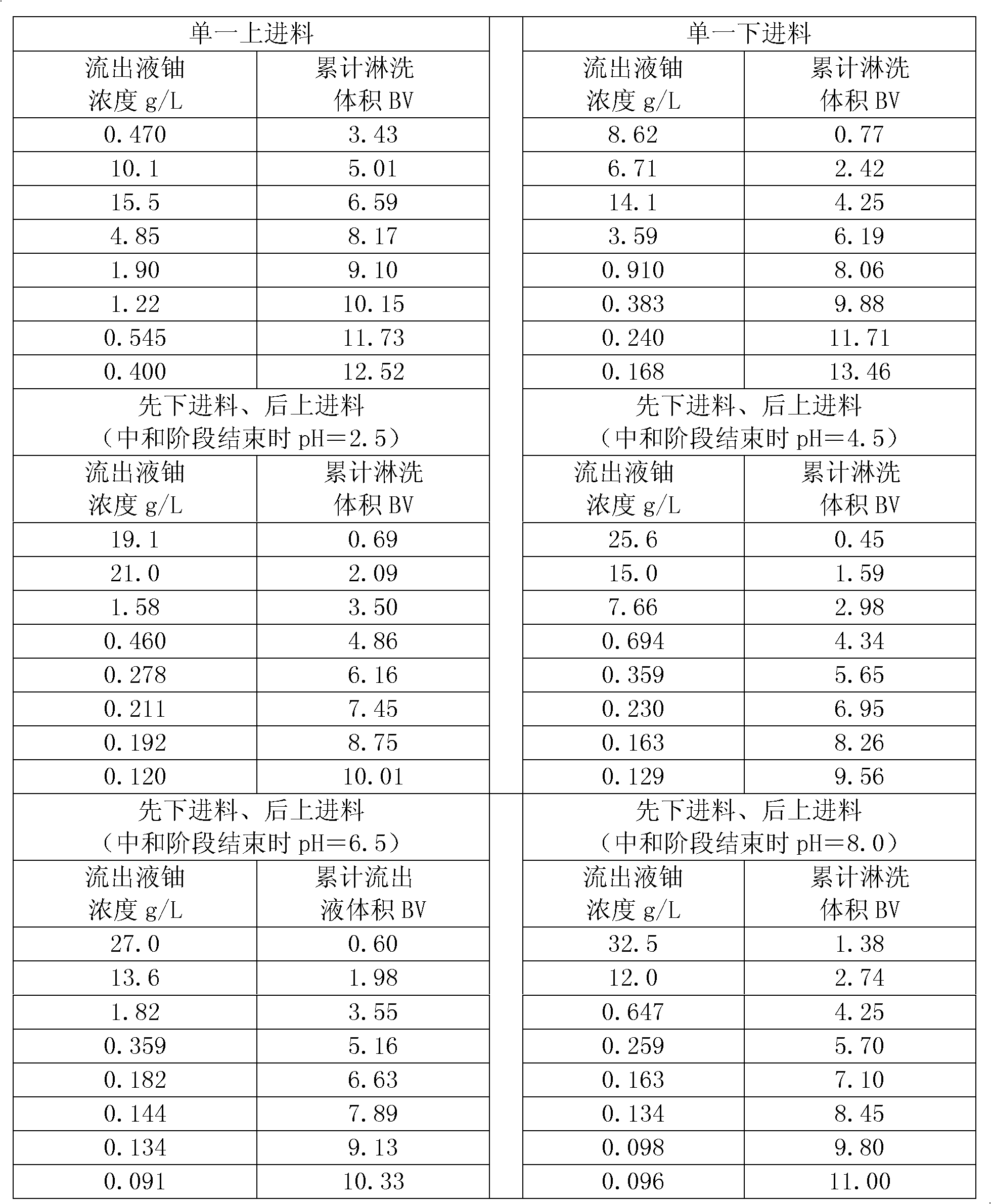

Method for extracting uranium by using ion exchange fixed tower under alternate Ph condition

InactiveCN102031369AUnobstructed dischargeAvoid "dead spots"Process efficiency improvementIon exchangeElution

The invention relates to a method for extracting uranium by using an ion exchange fixed tower, in particular to a method for extracting uranium by using an ion exchange fixed tower under the alternate Ph condition. The method comprises the steps of absorbing uranium by barren resin and eluting the uranium-carried resin to obtain uranium, wherein the step of eluting the uranium-carried resin to obtain uranium also comprises the following stages of elution neutralization, qualified liquid elution, first barren elution and second barren elution. In the stage of elution neutralization, an alkali eluent is used to neutralize residual acid in the uranium-carried resin, and the feeding mode is lower liquid feeding; in the stage of qualified liquid elution, the feeding mode is upper liquid feeding; in the stage of first barren elution, the feeding mode is upper liquid feeding, and the effluent liquid is a first barren solution; and in the stage of second barren elution, the feeding mode is upper liquid feeding, and the effluent liquid is a second barren solution. The invention increases elution efficiency and shortens elution volume by dividing the step of eluting the uranium-carried resin to obtain uranium into the stages of elution neutralization and qualified liquid elution and by respectively using the upper liquid feeding mode and the lower liquid feeding mode.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

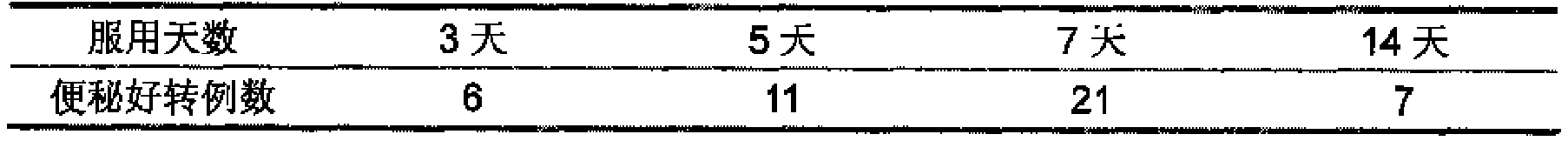

Function food capable of moisturizing the intestine and expelling toxin using apple pectin as main component and preparation method thereof

ActiveCN101416723AImprove adaptabilityPromote proliferationDigestive systemAntinoxious agentsIntestinal structureApple pectin

The present invention relates to a functional food using apple pectin as main component to moisten the intestines and expel toxin and preparation method thereof, prepared by the combination of the main component of apple pectin and other functional factors, The invention is characterized by being composed of the following components: apple pectin of 25-50%, glutamine of 26-67%, xylo-oligosaccharide of 7-14% and hydroxypropyl methylcellulose of 1-10% by weight; and is prepared by combination, granulating, drying, sizing, and packaging and the like as a granule functional food with good effect to moisten the intestines and expel toxin, The functional food provided by the invention has the advantages of simple preparation method and convenient for eating.

Owner:YANTAI ANDRE PECTIN

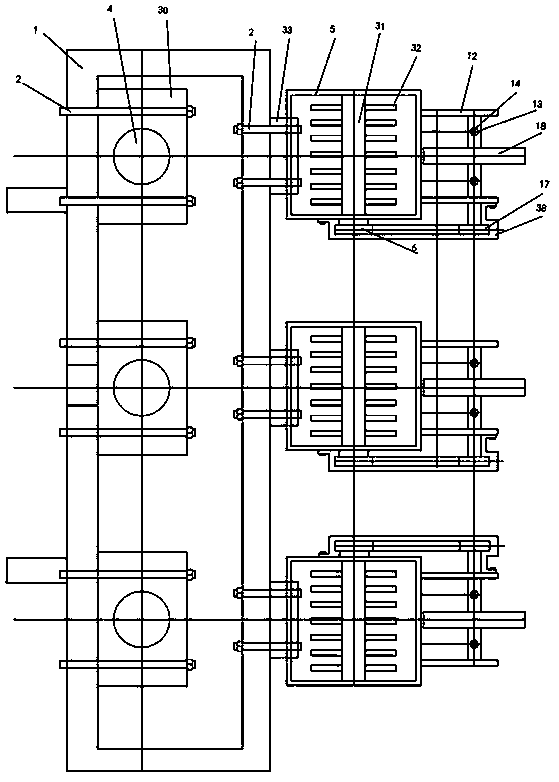

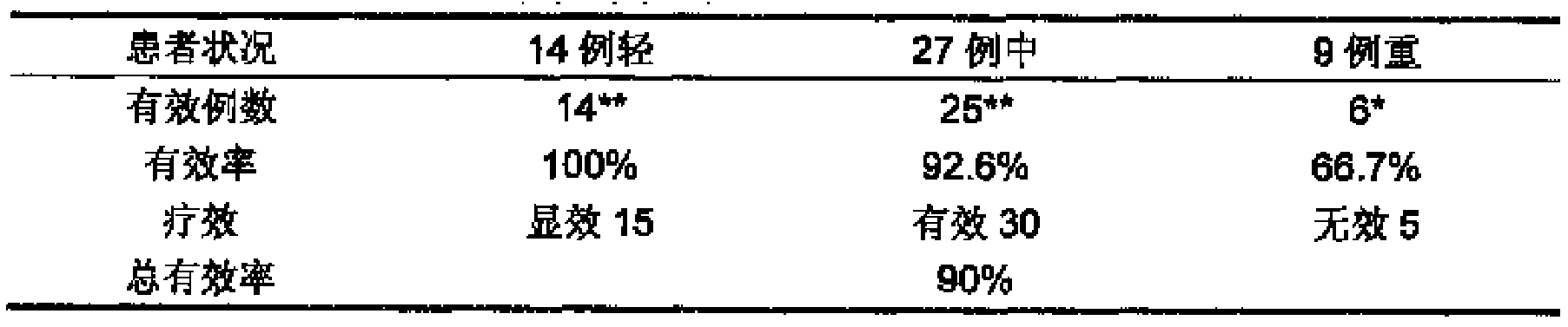

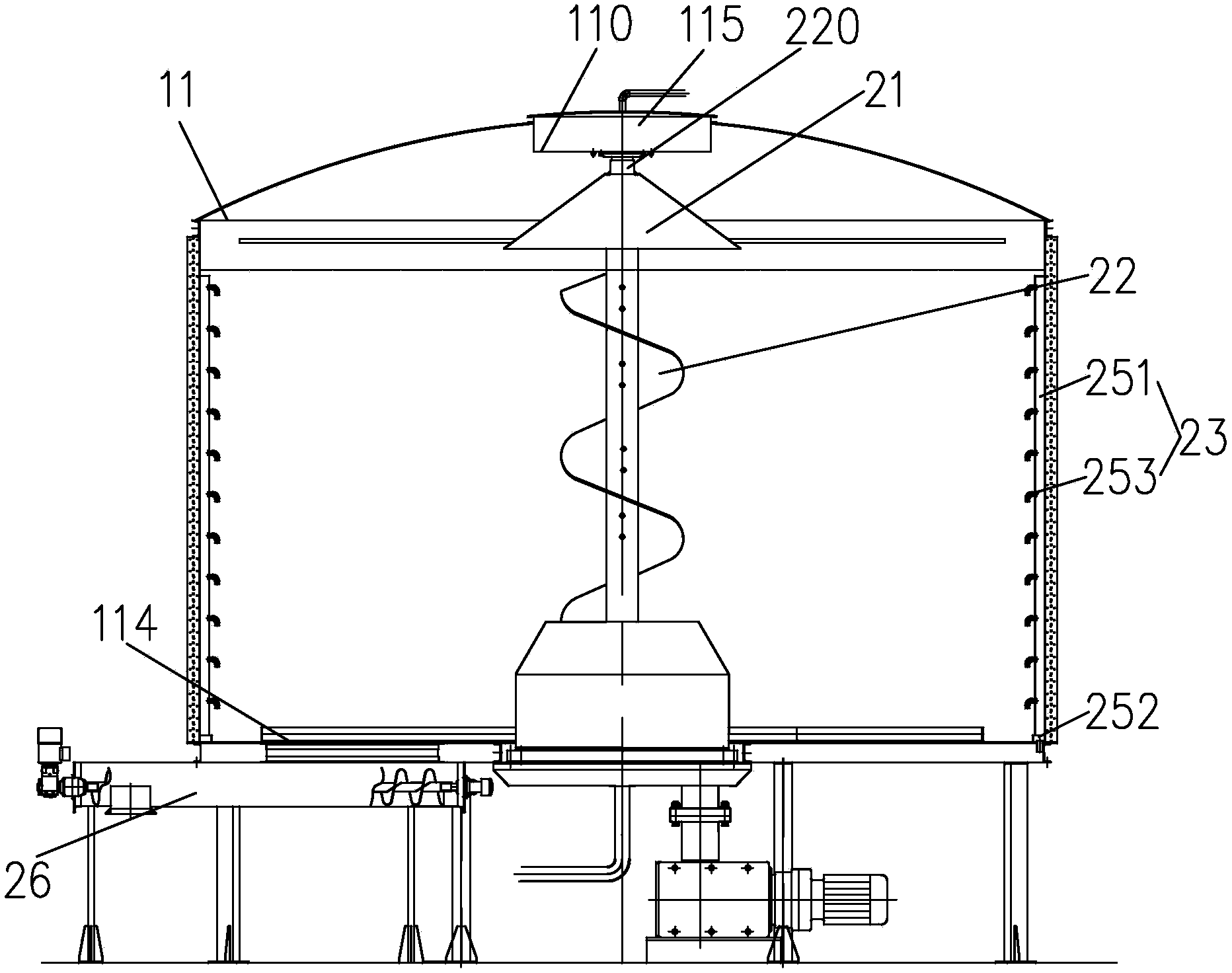

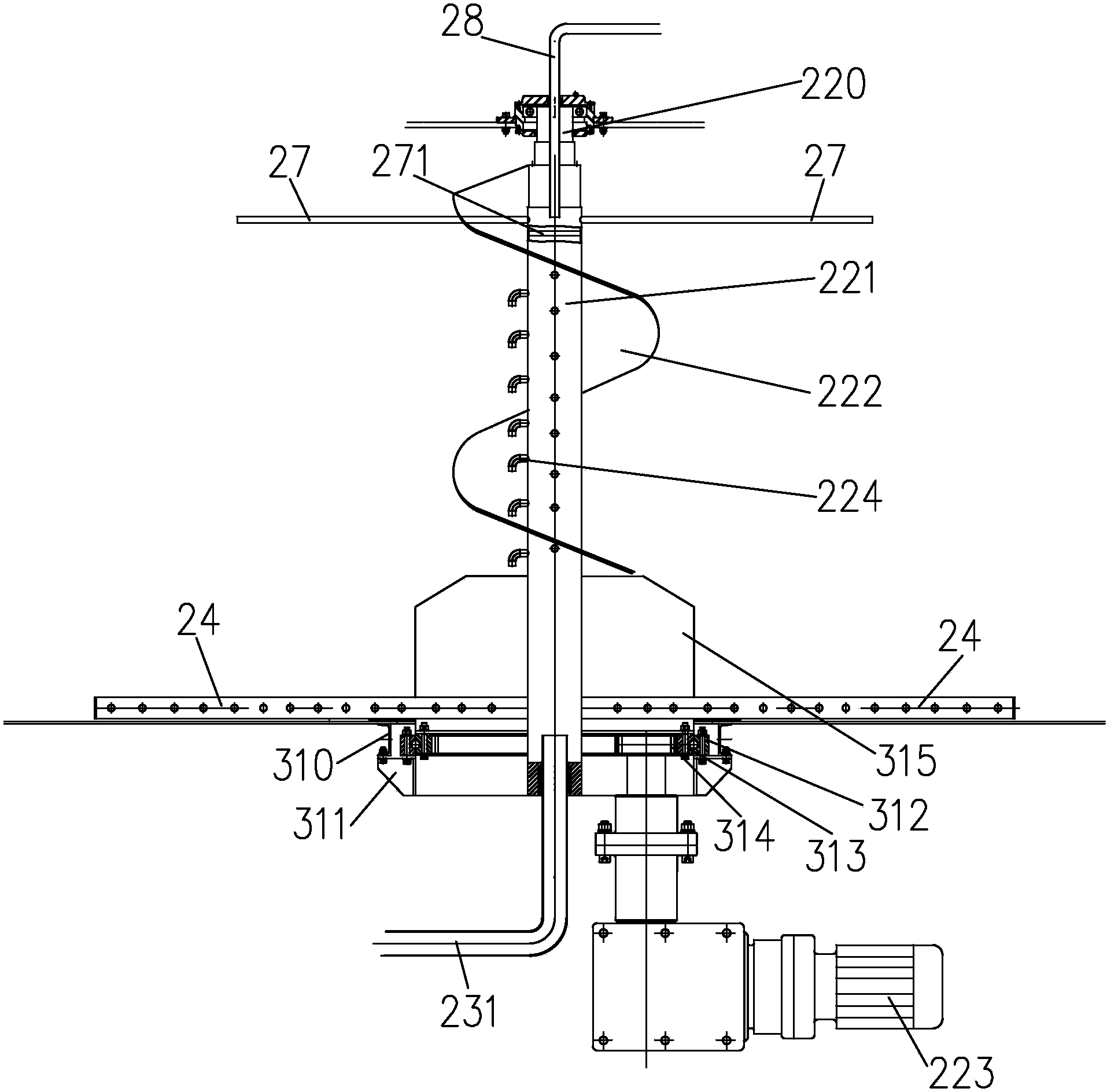

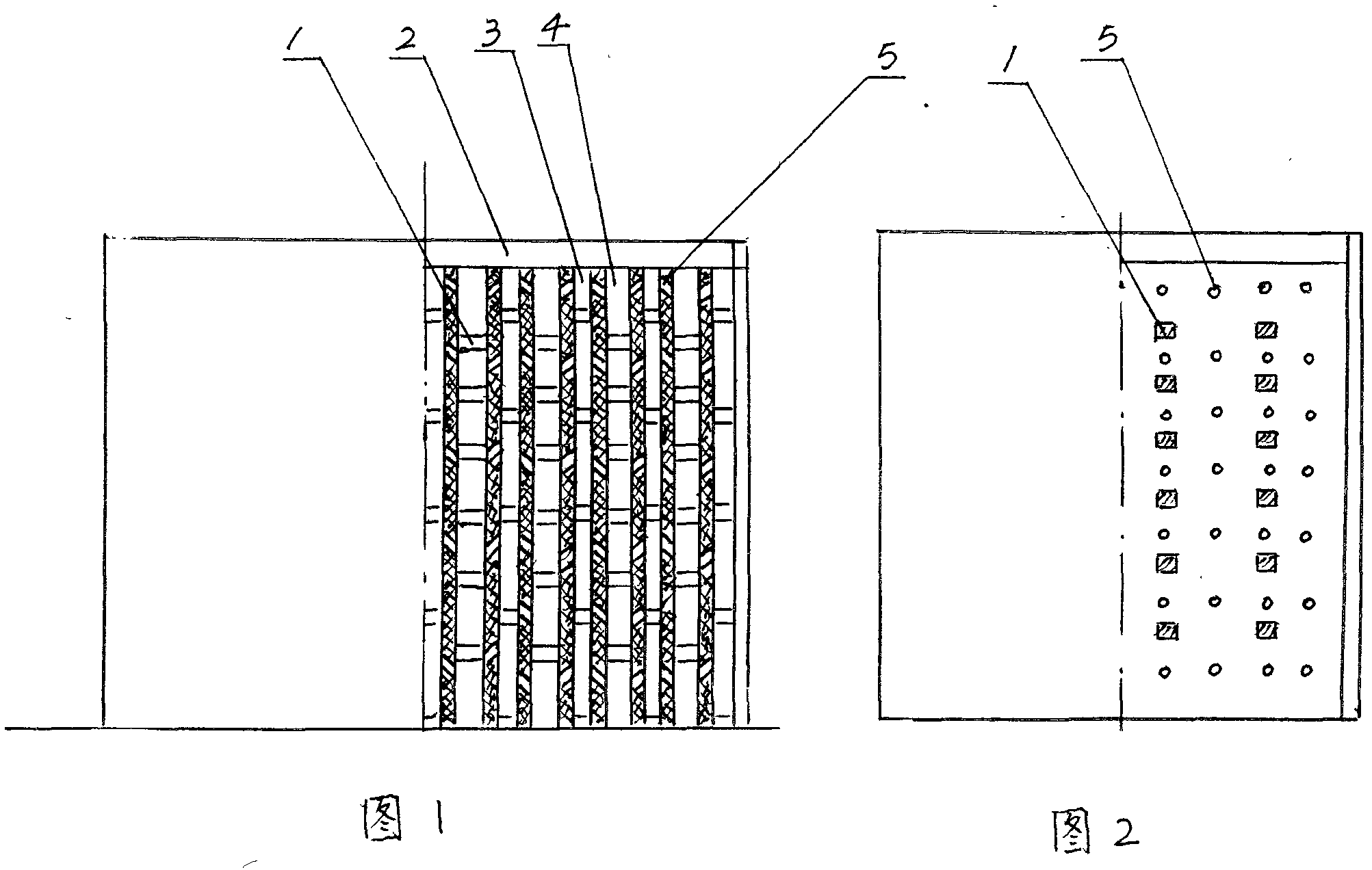

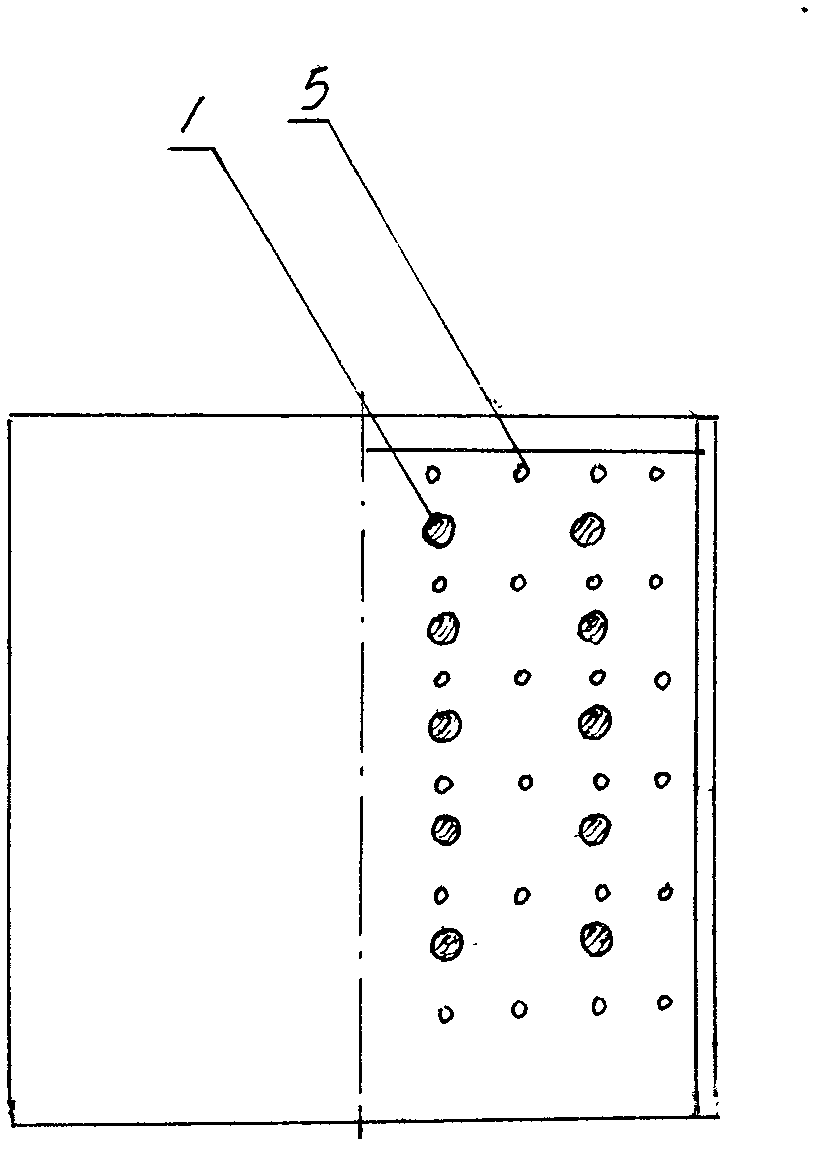

Vertical aerobic fermentation bin

ActiveCN104072213APrevent compactionSolve the problem of uneven clothClimate change adaptationOrganic fertilisersLitterDrive motor

The invention discloses a vertical aerobic fermentation bin belonging to a garbage treatment device and comprising a tank body, wherein a distributor and a ventilation device are arranged in the tank body; the tank body comprises a tank top, a tank bottom and side walls; a discharge port is formed in the tank bottom, a feeding port is formed in the tank top, and a stirring and turning device is also arranged in the tank body; the stirring and turning device comprises a central shaft, a helix fixed on the central shaft, a driving motor and a transmission device. The vertical aerobic fermentation bin disclosed by the invention can be used for loosening materials to prevent hardening, so as to enhance the aerobic fermentation effect.

Owner:北京舞鹤环境工程设计有限公司

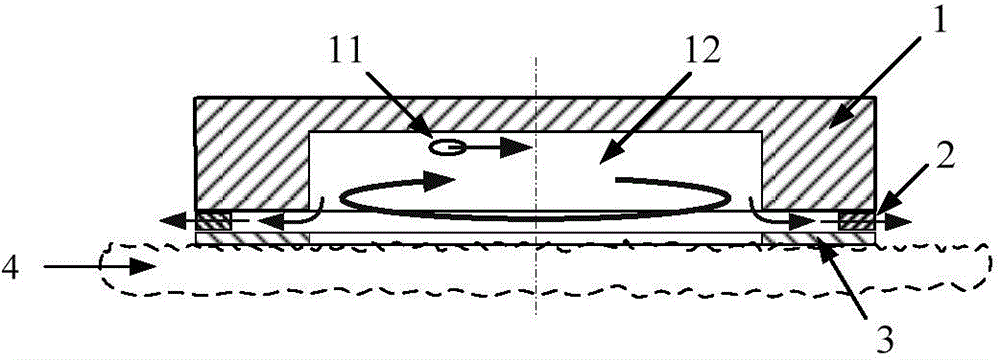

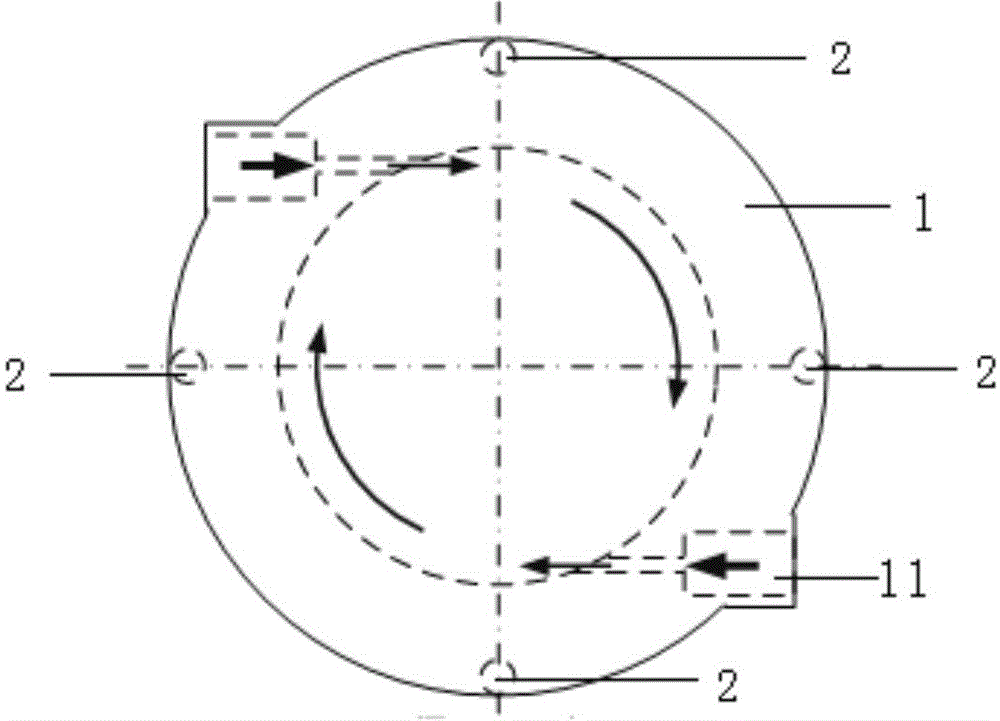

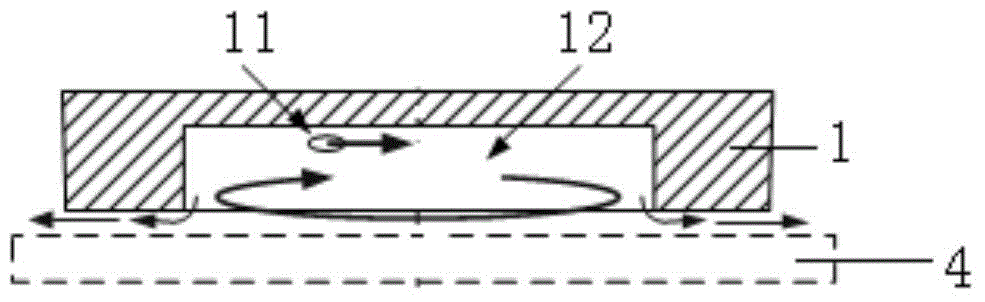

Suction cup

ActiveCN104626174AGood friction effectFully contactedGripping headsConveyor partsCushionRough surface

A sucking disc comprises a sucking disc body (1), an annular separation plate (3), and cushion blocks (2). The sucking disc body (1) is internally provided with a chamber body (12) of which a transverse cross section is circular. A tangential nozzle (11) is disposed on a wall surface of the chamber body (12). An upper surface of the annular separation plate (3) is fixedly connected to the edge of a bottom surface of the sucking disc body (1) by mans of the cushion blocks (2). The cushion blocks (2) are disposed on the edge of the bottom surface of the sucking disc body (1) in a spaced manner. The number of the cushion blocks (2) is four, and the four cushion blocks (2) cover part of the area of the annular separation plate (3). Space between the cushion blocks (2) forms a fixed flow channel between the edge of the bottom surface of the sucking disc body (1) and the annular separation plate (3), and the fixed flow channel is in communication with the chamber body (12) and the peripheral environment. The sucking disc can suck a soft object with a rough surface, and consumes a little gas.

Owner:ZHEJIANG UNIV

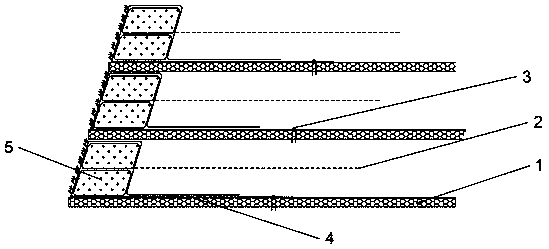

Geocell composite reinforcing rib ecological retaining wall and construction method thereof

InactiveCN108035378AImprove integrityImprove continuityArtificial islandsUnderwater structuresGeocellsStructural stability

The invention discloses a geocell composite reinforcing rib ecological retaining wall and a construction method thereof. The ecological retaining wall comprises retaining wall units sequentially constructed from bottom to top, and each retaining wall unit comprises a bottom geocell layer, a unidirectional geogrid, at least one inverse filter inclusion layer, a bidirectional geogrid and a filling layer. The construction method includes: S1, performing earth excavation and pouring retaining wall rigid strip foundation; S2, laying geocells, and filling filler in the geocells; S3, carrying out unidirectional geogrid return construction; S4, arranging the bidirectional geogrid; S5, repeating the steps until a retaining wall design height is achieved. By adoption of the geocells with a stereo reinforcing rib structure as a bottom layer structure, the geocells are filled with the filler, the unidirectional geogrid is laid at the top of the leveled filler in the geocells, and the inverse filter inclusion layers are arranged while the bidirectional geogrid is arranged between every two composite reinforcing rib layers, structural stability of the ecological retaining wall is guaranteed by layer-by-layer construction, and simplicity in construction is realized.

Owner:SHIJIAZHUANG TIEDAO UNIV

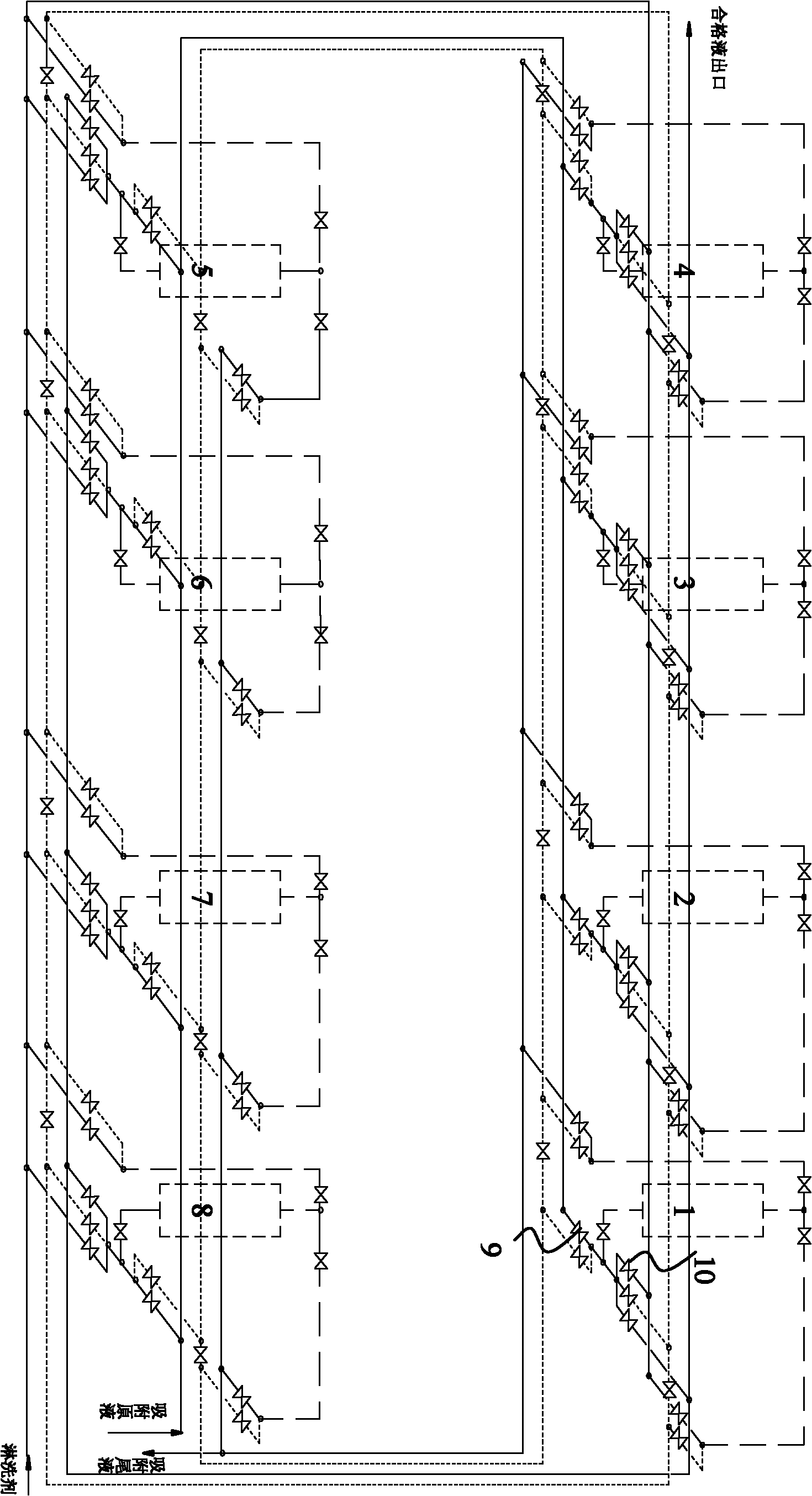

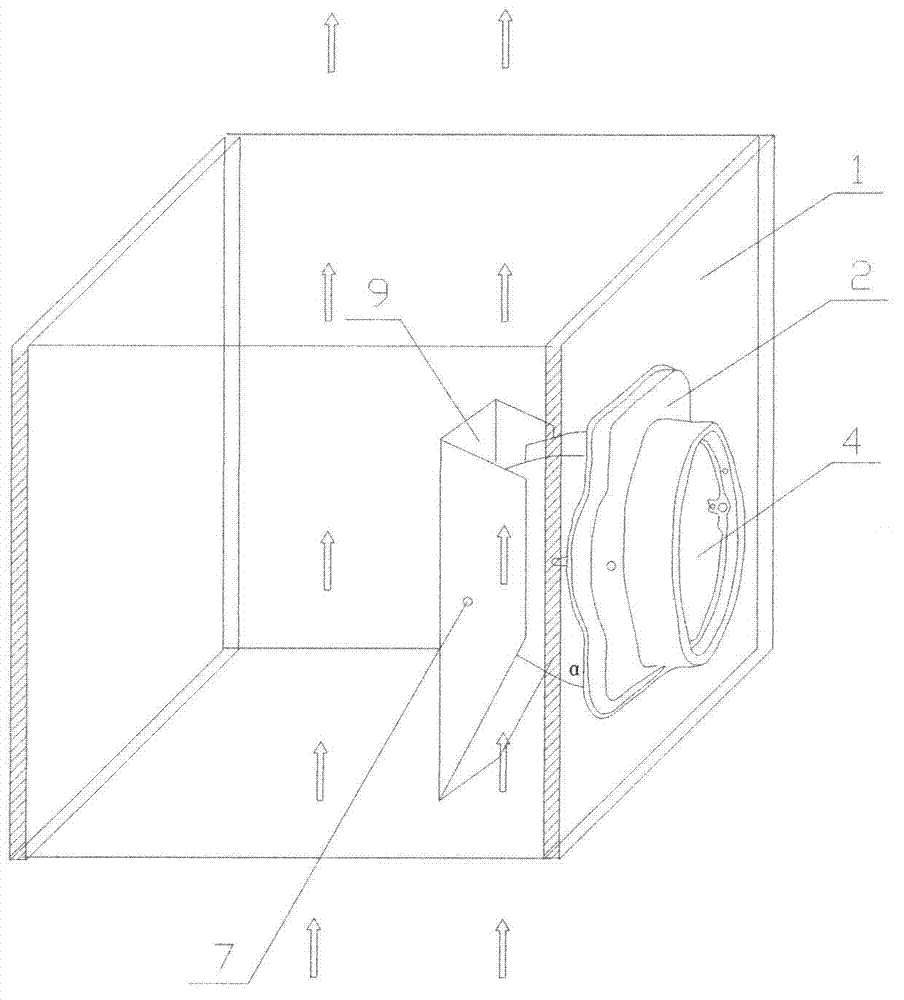

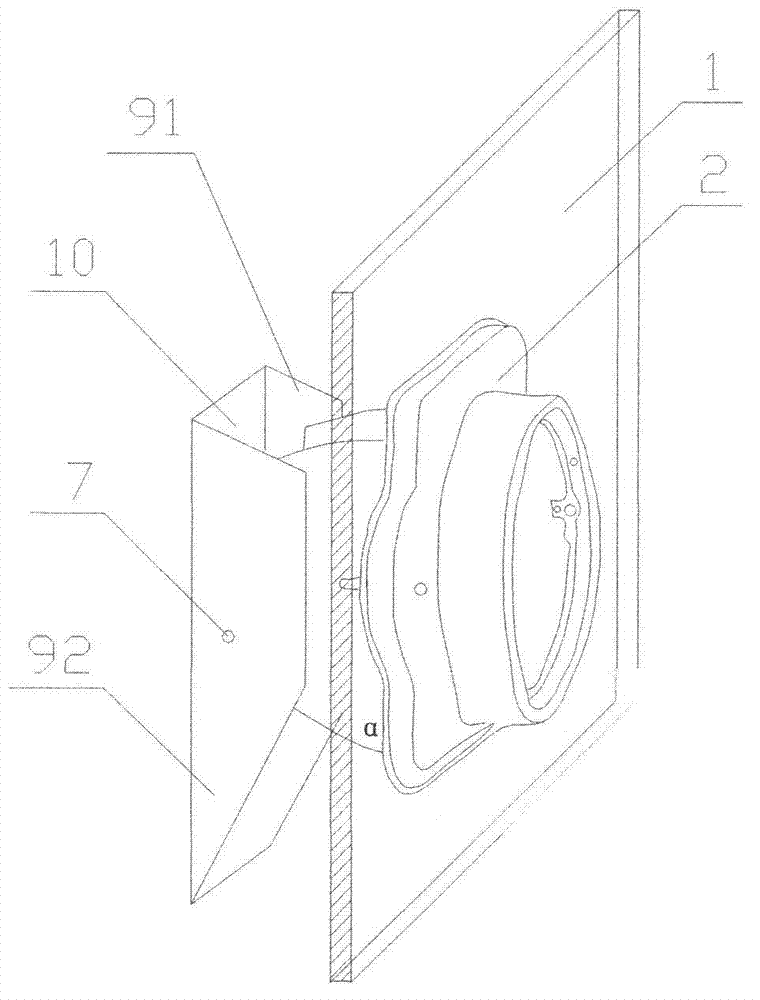

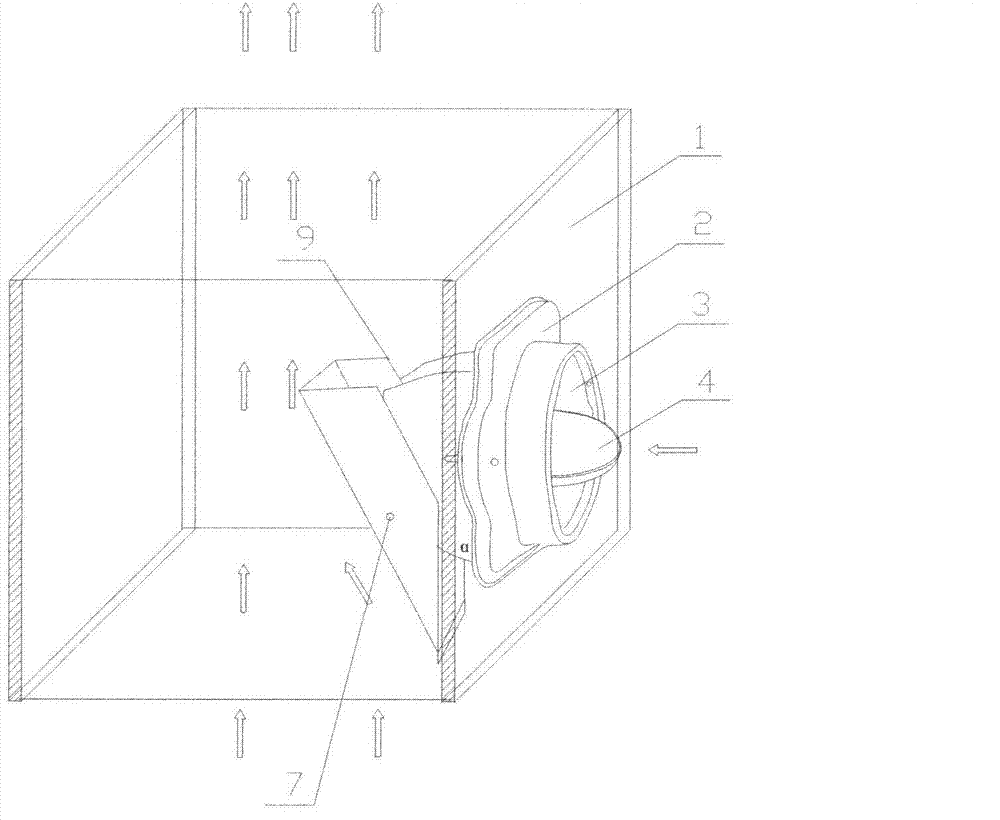

Fireproof air exhaust duct inlet voltage transformation flow guide device

The invention relates to an air exhaust duct inlet flow guide device, and discloses a fireproof air exhaust duct inlet voltage transformation flow guide device which comprises a fireproof stop valve (2) arranged on an air exhaust duct, a flow guide plate device (9) as well as a right wing plate (51) and a left wing plate (52); the fireproof stop valve (2) is connected with an outer wall of the air exhaust duct (1) through a connecting panel; the flow guide plate device (9), an inner wall of the air exhaust duct (1), the right wing plate (51) and the left wing plate (52) form a ventilating pipeline which is sealed in periphery and runs through from top to bottom. According to the invention, when a range hood is opened, a valve sheet of the fireproof stop valve and the flow guide plate device are pushed away through wind force and pressure, thus the flow guide plate rotates into a flow guide form, which is beneficial to flue gas discharge; and after the range hood is closed, the valve sheet is closed, a back flow guide plate of the flow guide device is parallel to the air exhaust duct, the internal air exhaust space of the air exhaust duct is not occupied, the air exhaust duct space utilization ratio is improved greatly, and the flue gas discharge is more smooth.

Owner:HANGZHOU XIAOMI ENVIRONMENTAL SCI & TECH

Device for solving powder material coking arch

InactiveCN109353704AImprove arch breaking effectGood for arch breakingLarge containersDevice PlateEngineering

The invention discloses a device for solving powder material coking arch. The device comprises a material bin, shaking devices and a driving motor, wherein the bottom end of the material bin is provided with a material outlet, the shaking devices are arranged on the edge sides of the material bin, the top of the material bin is provided with device plates horizontally distributed, the inner wall of the top end of the material bin is provided with horizontal plates horizontally distributed in a welded manner, the driving motor is installed on the upper end faces of the device plates and connected with a rotating shaft, round plates connected with the rotating shaft are arranged above the device plates, and every two adjacent round plates are connected through horizontal rods. According to the device for solving the powder material coking arch, by means of redesign on the top structure of an existing material bin, arch breaking operations on middle-lower portion materials inside the material bin are facilitated, by means of use of the shaking devices and related structures, the use of a traditional fluidization device is replaced, the bottom arch breaking effect of the material bin can be made to be better, and meanwhile, the material unloading process is made to be more unobstructed.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

Electroless energy-conservation water and dust collector

The invention provides an efficient electroless energy-conservation water and dust collector which has simple and stable structure, easy maintenance, favorable energy conservation and low maintenancecost and is environmentally friendly and safe. The technical scheme of the water and dust collector comprises an integrated electroless water and dust collecting main body, a dust discharge connectingpipe, an air inlet switch, an air inlet switch handle and a dust collecting chamber. The integrated electroless water and dust collecting main body comprises a front-end Venturi dust collecting tubeshell, a variable front-end Venturi tube body, a front-end Venturi dust collecting tube connector, a honeycomb-style integrated Venturi air exhaust device, a sealing ring and a rear-end Venturi dust discharging tube. The dust collecting chamber is in three-level dust filtration structure, and comprises a dust collecting chamber shell, an upper cover, a first-stage filter net, a second-stage filternet and a third-stage filtration exhaust outlet. In the invention, the structure adopting rapid high pressure air exhausting as driving is used; in the whole operation process, no sport-type drivingdevice is not needed, thus greatly improving stability and reducing failure rate.

Owner:王鹏

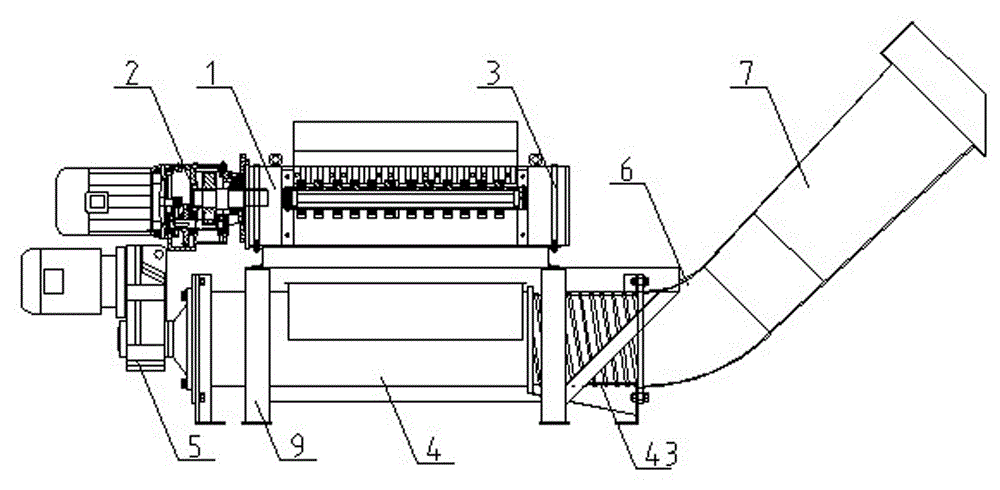

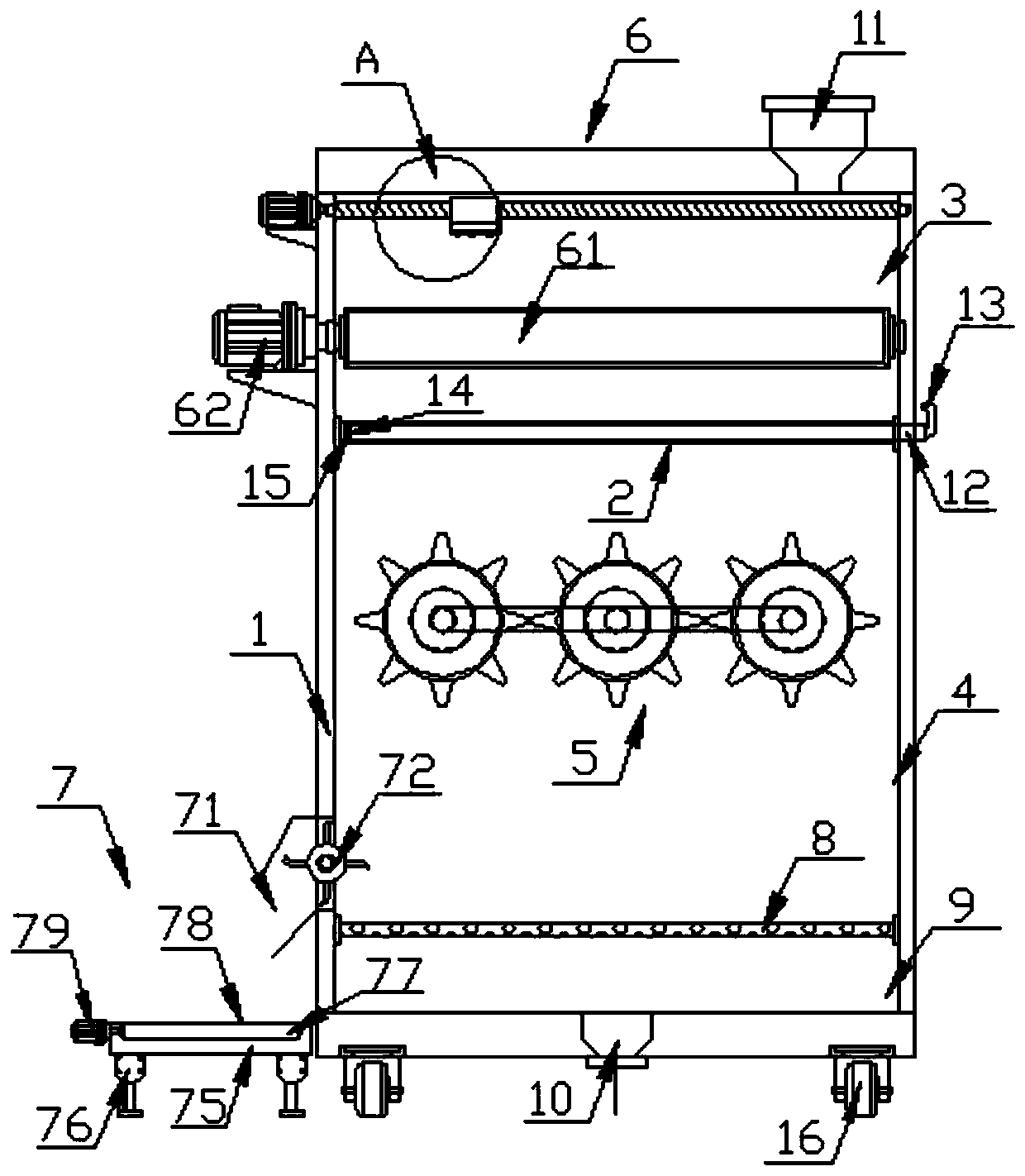

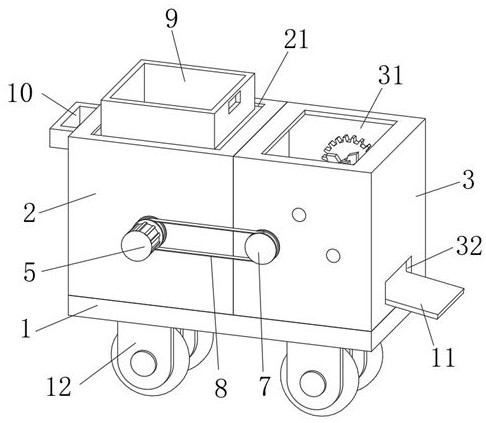

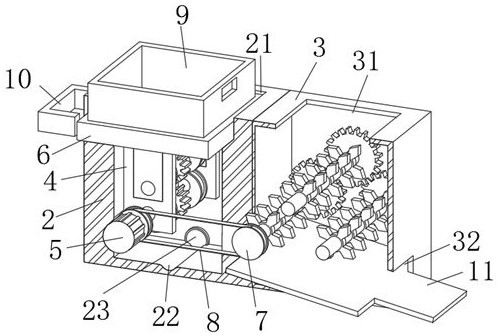

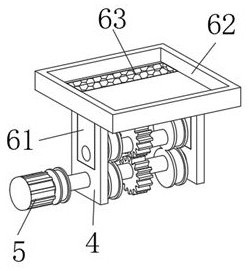

Ratchet chain type automatic bag breaking equipment

ActiveCN111332570AAvoid cloggingUnobstructed dischargeLoading/unloadingUnpacking by cuttingRatchetProcess engineering

The invention relates to the technical field of material unpacking equipment, and particularly discloses ratchet chain type automatic bag breaking equipment which comprises a base and a bag breaking bin. The bag breaking bin comprises a feeding opening and a waste bag discharging opening, the bag breaking bin is internally provided with a bag breaking mechanism close to the feeding opening, a waste bag extruding mechanism close to the waste bag discharging opening and a chain wheel mechanism penetrating through the feeding opening and the waste bag discharging opening, and the chain wheel mechanism is used for receiving material bags input from the feeding opening and conveying the material bags to the waste bag discharging opening; the bag breaking mechanism is used for cutting the material bags conveyed by the chain wheel mechanism, so that the material bags are unloaded; the waste bag extruding mechanism is used for smoothly discharging and recovering the empty material bags after unloading, rapid bag breaking of the material bags is achieved, the material bags are prevented from being blocked in the bag breaking bin, materials are smoothly discharged, blocking of the discharging opening due to winding of the waste material bags is effectively avoided, the outer side of the discharging opening can be sleeved with a waste bag collecting bag, and the waste bags are recycled ina centralized mode.

Owner:SHANDONG WANBANG PETROLEUM TECH CO LTD

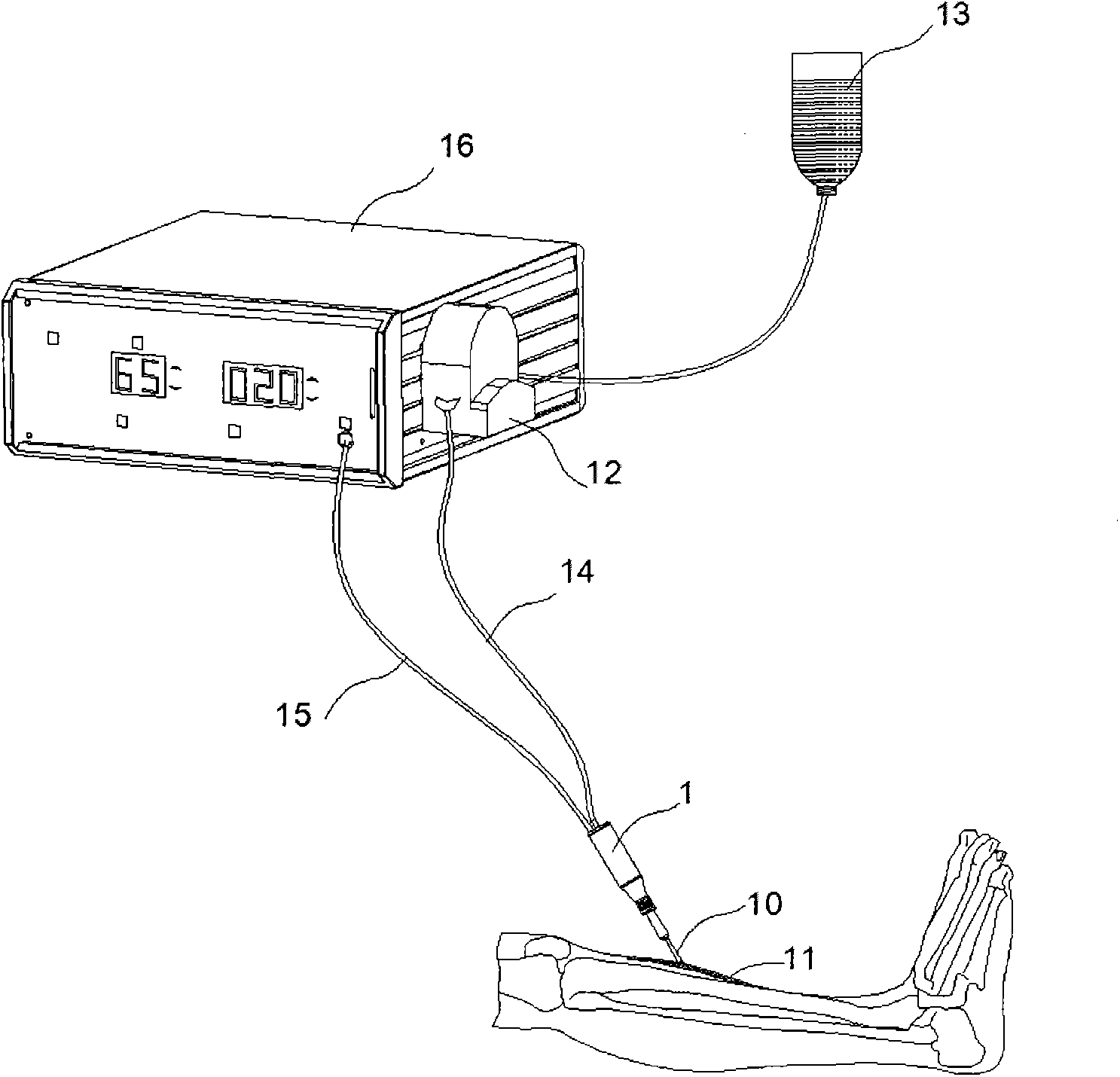

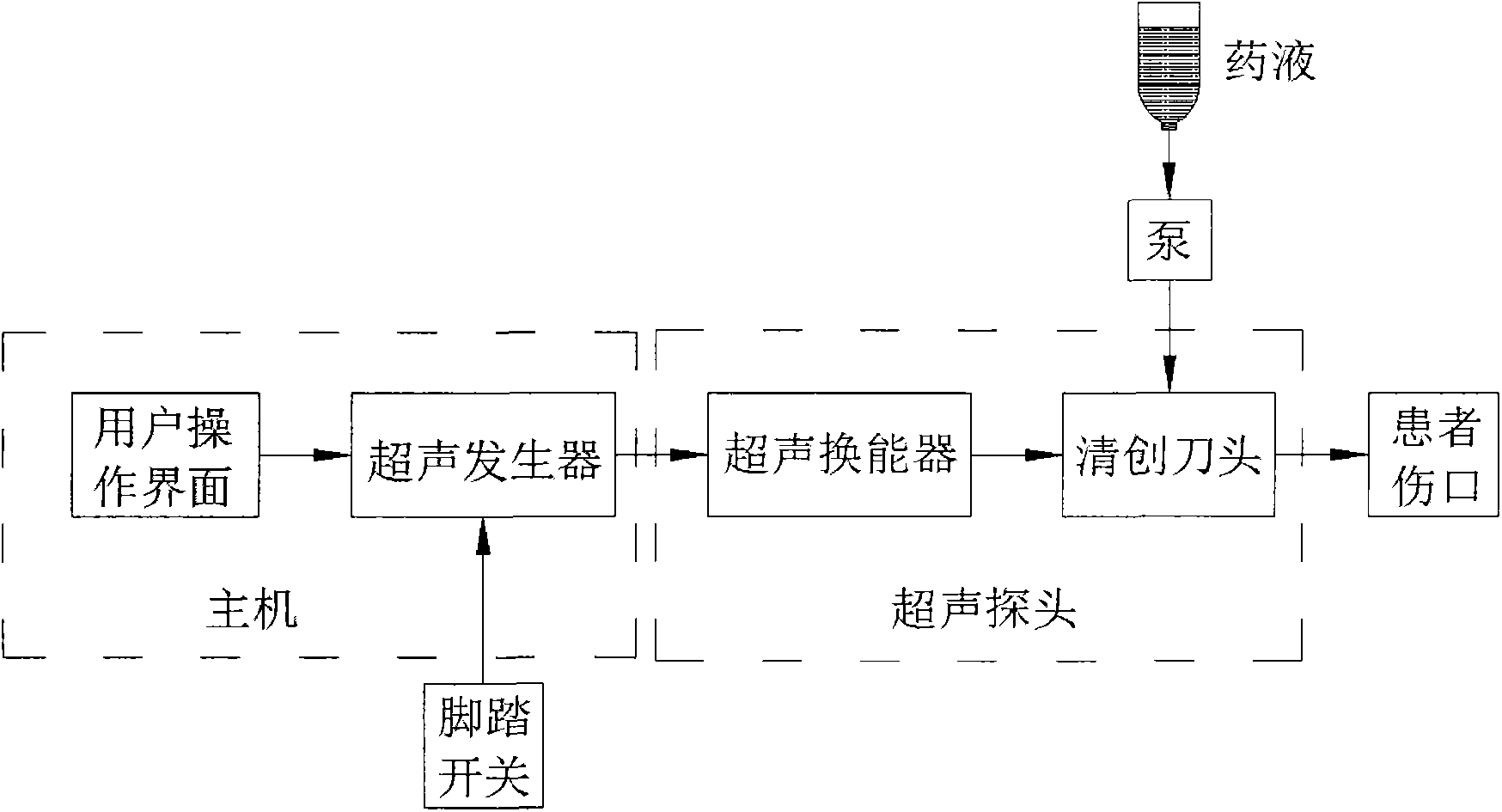

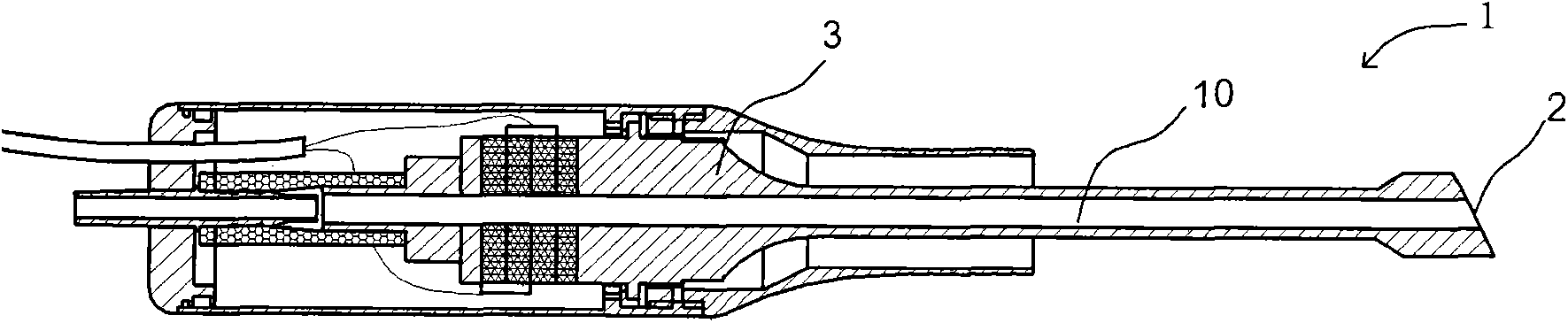

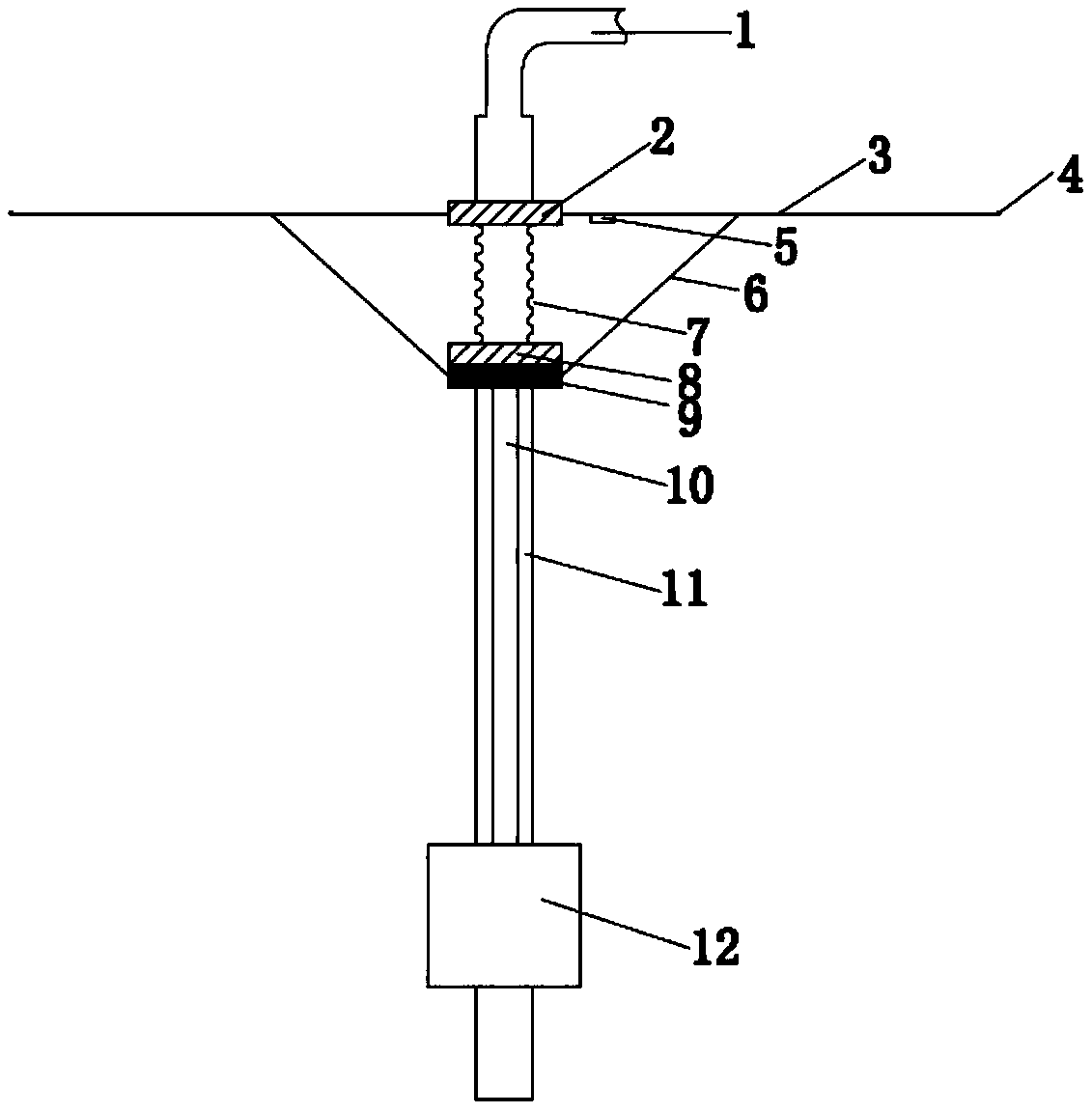

Supersonic wave device used for improving acute wound debridement efficiency

InactiveCN104338246AAvoid the defects of reduced service lifeEffective penetrationUltrasound therapySurgeryAcute woundSupersonic waves

The invention relates to a supersonic wave device used for improving acute wound debridement efficiency. The supersonic wave device comprises a host computer (16), a pump (12), a supersonic wave probe (1), a probe front end face (2), a probe front end face side face (3) and an inner probe through hole (4). The supersonic wave device is characterized in that the probe front end face side face (3) is provided with multiple tooth type cones (5), and front side faces of the tooth type cones are processed to be front inclination angles. Compared with the prior art, the mechanical fragmentation effect of a debridement cutter is fully performed, and wound debridement efficiency is greatly improved.

Owner:HOCER BEIJING MEDICAL TECH

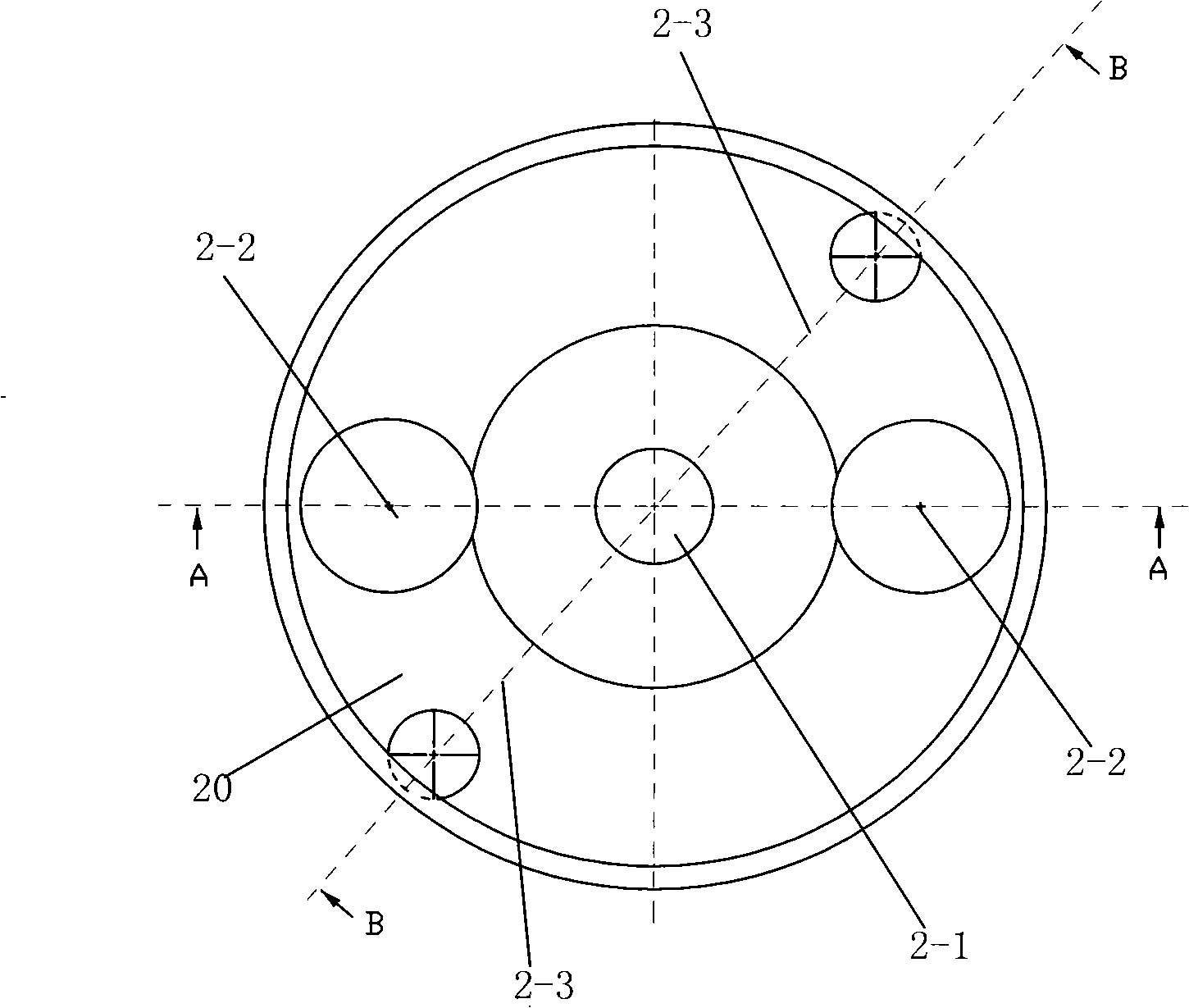

Vertical pulling type single crystal growth furnace

InactiveCN101319352AGrowth does not affectGood neatnessBy pulling from meltUnder a protective fluidGraphiteSingle crystal

The invention provides a Czochralski single-crystal growth furnace in order to solve the technical problem of reducing the argon gas consumption of the Czochralski single-crystal growth furnace. The Czochralski single-crystal growth furnace comprises an argon gas input pipe and an annular gas distributor which is communicated with the argon gas input pipe, and is characterized in that: the pressure of argon gas inputted through the argon gas input pipe is between 0.8x10 < 3 > and 0.9x10 < 3 >Pa, and the flow rate of the argon gas is 30 liters per minute. The Czochralski single-crystal growth furnace also comprises a bowl-shaped air flow guide device which is arranged between the lower part of a crucible supporter and an air outlet, wherein, the bowl-shaped air flow guide device comprises a center shaft hole, a pair of electrode holes, and a ventholes which are opposite to the air outlet; a graphite center shaft passes through the center shaft hole of the air flow guide device; electrode poles respectively pass through the electrode holes; the air outlet is communicated with the ventholes of the air flow guide device; and the upper end part of the air flow guide device is arranged between an insulated cylinder and a heating element.

Owner:常州中弘光伏有限公司

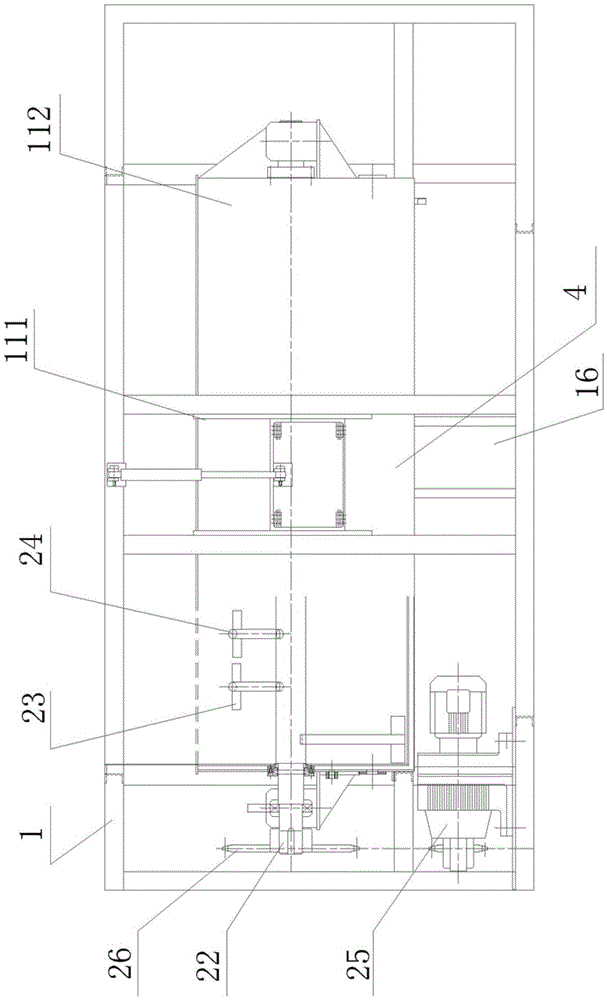

Full-automatic garbage disposer

InactiveCN105642151AImprove processing efficiencyAvoid residueTransportation and packagingSolid waste disposalEngineeringGarbage disposal

The invention discloses a full-automatic garbage disposer. The full-automatic garbage disposer comprises a frame, a feeding mechanism, a stirring mechanism and a discharging mechanism. The feeding mechanism comprises a feeding door, a tipping bucket, a lifting trolley, a lifting oil cylinder and a tipping oil cylinder, the feeding door is arranged on the frame, the lifting oil cylinder is used for controlling lifting of the tipping bucket, and the tipping oil cylinder is used for controlling tipping of the tipping bucket. The stirring mechanism comprises a stirring vessel, a stirring spindle, two groups of stirring scrapers and a speed reduction motor, the stirring spindle is arranged in the stirring vessel which is arranged on the frame, the stirring scrapers are fixed to the stirring spindle, and the speed reduction motor is fixed to the frame and drives the stirring spindle to rotate. The discharging mechanism comprises a discharging door and a discharging door control oil cylinder, and the position of the discharging door is in correspondence to the middle position of the stirring spindle. The full-automatic garbage disposer has the advantages that garbage in a garbage bin on the tipping bucket can be automatically poured into the feeding door, convenience in operation, stability and reliability in operation, time saving and labor saving are realized, and garbage disposal efficiency is improved; uniformity and thoroughness in stirring, high stirring efficiency and quickness and cleanness in discharging are realized; garbage residues on the spindle and the stirring scrapers are avoided.

Owner:HANGZHOU HUAGUAN IND CO LTD

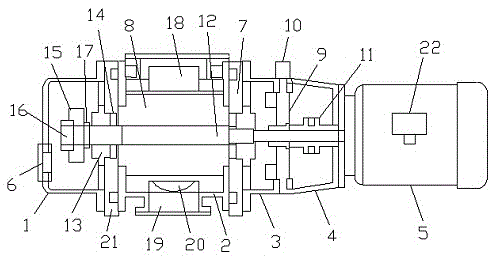

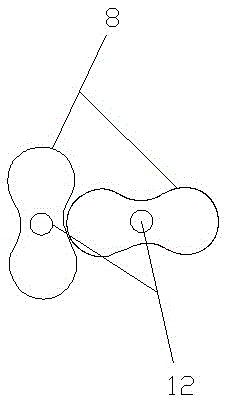

Low-noise vacuum pump

InactiveCN105626535AImprove structural strengthImprove stabilityRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsLow noiseCoupling

The invention discloses a low-noise vacuum pump. The low-noise vacuum pump comprises a rear cover, a pump body, a front cover, a support and a motor, wherein the rear cover, the pump body, the front cover, the support and the motor are sequentially and fixedly connected; a sight glass is arranged at the front end of the rear cover and is connected to the rear cover in a sealed mode; middle walls are arranged at the two ends of the pump body and are welded to the pump body, and two rotors are arranged in the pump body and are double-blade rotors; a shaft seal is arranged between the front cover and the support and is provided with an oil cup; a coupling is installed at the front end of the motor and is provided with two main shafts, shaft sleeves are arranged at the two ends of each main shaft and are connected to the middle walls in a clamped mode, and the main shafts are connected to the shaft sleeves in a rotating mode. The low-noise vacuum pump is compact in structure, stable in operation, low in noise, convenient to operate and good in sealing effect.

Owner:WUHU HUANQIU AUTO PARTS

Hydraulic pressure-type cable tunnel cleaning device

InactiveCN105275032AWill not cause collapseKeep dryMechanical machines/dredgersDrive shaftButt joint

The invention discloses a hydraulic pressure-type cable tunnel cleaning device, and relates to the technical field of cable casting construction tools. The hydraulic pressure-type cable tunnel cleaning device comprises a conveying device, a water spraying device, a hard flared tube, a soft mud tube, a water pump and a driving motor; the conveying device consists of a conical cover, a conical spiral conveying sheet and a transmission shaft; the conical cover is fixedly arranged on the left end of the transmission shaft; the conical spiral conveying sheet is located behind the conical cover and is fixedly connected with the transmission shaft through support rods; the right part of the transmission shaft penetrates through the water spraying device and is in rotary hermetic match with the water spraying device; the left end of the water spraying device is a truncated cone-shaped water sprinkling cover; a cavity is arranged in the truncated cone-shaped water sprinkling cover; a soft shaft is coaxially arranged in a soft water inlet sleeve pipe; the output end on the left side of the soft shaft is connected with the right end of the transmission shaft; and the right end of the hard flared tube is in butt joint communication with the soft mud tube. The hydraulic pressure-type cable tunnel cleaning device is high in mud cleaning efficiency, small in work resistance and small in water consumption amount and can clean cleanly.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER +2

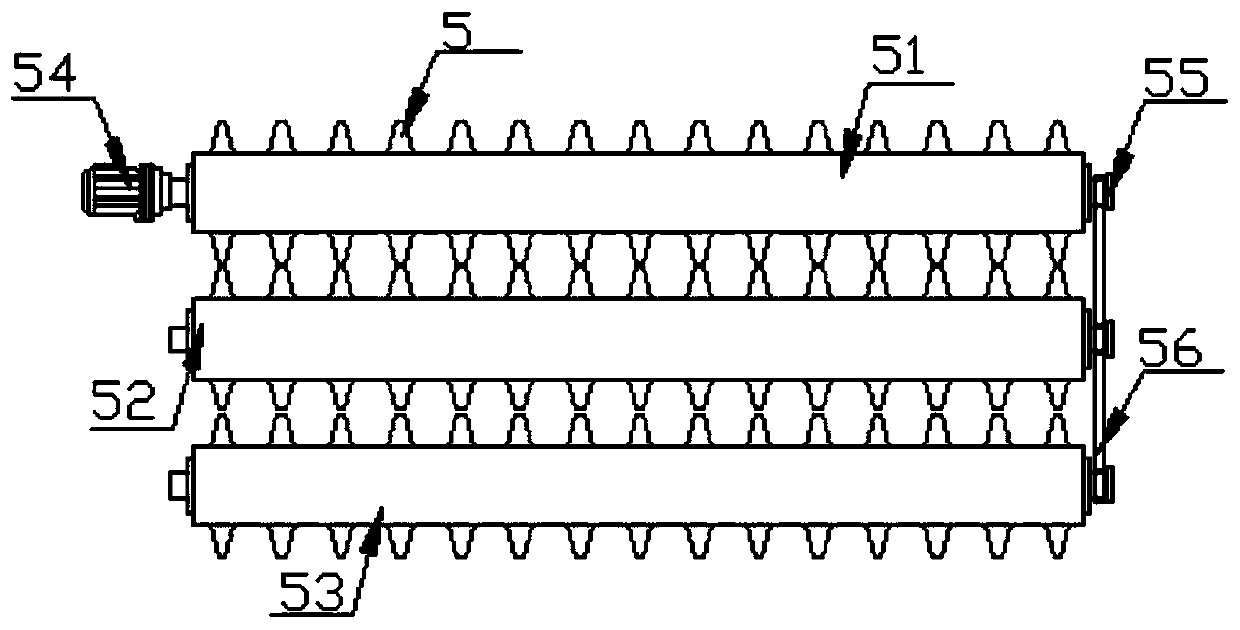

Scutching device for textile production

ActiveCN109989135AIncrease the output speedSimple structureFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersEngineeringTextile production

The invention discloses a scutching device for textile production, comprising a box, a cleaning scutching mechanism, a hybrid scutching mechanism, a discharging mechanism and a cleaning screening screen. A bearer is welded inside the box and divides the same into an upper box and a lower box; the cleaning scutching mechanism is arranged inside the lower box; the hybrid scutching mechanism is arranged inside the upper box; the discharging mechanism is arranged on one side of the lower box; the cleaning scutching screen is welded in the lower box at the bottom of the cleaning scutching mechanism; a collection box is arranged in the lower box on the side, far away from the cleaning scutching mechanism of the cleaning screening screen. The scutching device for textile production is simple andreasonable in structure and convenient to use, can provide higher scutching efficiency and better scutching quality, allows scutching discharging speed to be increased effectively, has good discharging stability, has no need for manual discharging and carrying, has lower scutching intensity and reduced manpower cost, and is more practical.

Owner:应辉辉

Low-power-consumption miniaturized kitchen waste intelligent treatment device

InactiveCN112588002AAccelerate sinkingSave waterMoving filtering element filtersEnvironmentally friendlyStructural engineering

The invention discloses a low-power-consumption miniaturized kitchen waste intelligent treatment device. The device comprises a base, a filter box and a crushing box are fixedly installed on the leftportion and the right portion of the upper end of the base correspondingly, fixing plates are fixedly welded to the upper portions of the front box wall and the rear box wall in the filter box correspondingly, a driving mechanism is movably connected to the lower portions of the two fixing plates, the upper portions of the fixing plates are jointly connected with a lifting mechanism in a sliding mode, the lifting mechanism is in transmission connection with a driving mechanism, a crushing mechanism is connected into the crushing box in a penetrating mode, the crushing mechanism and the drivingmechanism are jointly connected with a conveying belt in a transmission mode,a guide plate is inserted into the crushing box in a connection mode, a garbage containing box is arranged at the upper end of the lifting mechanism, a filtering groove is formed in the upper end of the filtering box, an arc groove is formed in the middle of the lower box wall in the filtering box, and a drainage pipe isconnected to the rear end of the filtering box in a penetrating mode. The low-power-consumption miniaturized kitchen waste intelligent treatment device is low in energy consumption, environmentally friendly, capable of achieving solid-liquid separation and sufficient in crushing.

Owner:胡增永

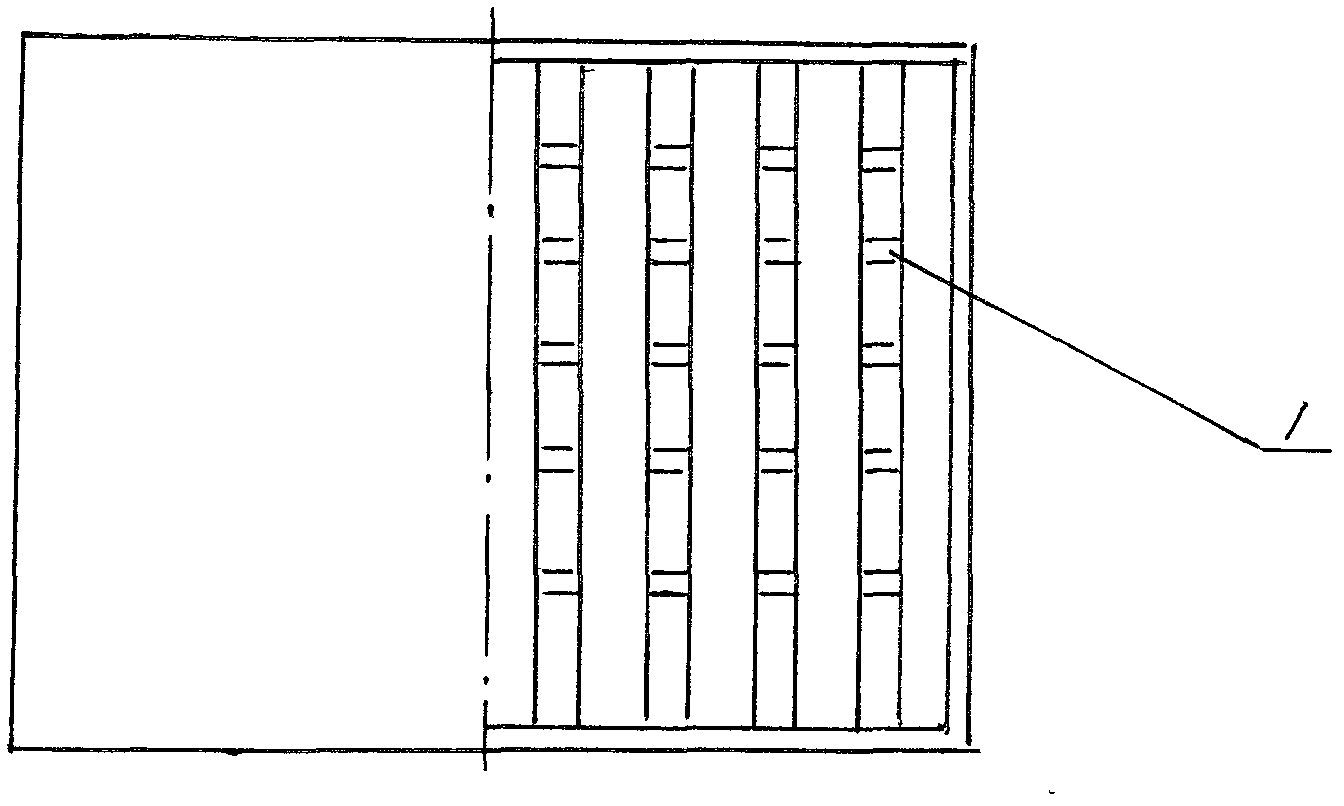

Improved shell charcoal activation furnace

InactiveCN102515159AImprove the activation effectQuality improvementCarbon compoundsCarbonizationEngineering

The invention discloses an improved shell charcoal activation furnace, which comprises a feeding channel, flues and a steam supply system, wherein the feeding channel and the flues are arranged in a staggering way, the feeding channel comprises a feeding port, a carbonization section, an activation section and a discharge port which are arranged from top to bottom, the flues are arranged into a plurality of layers, all the layers are communicated with one another end to end to form a circulation flue, and smoke vents are arranged between the feeding channel and the flues. The improved shell charcoal activation furnace is characterized in that: reinforcing ribs are laterally and horizontally arranged in the feeding channel uniformly, are laterally and horizontally arranged equidistantly, and are aligned from top to bottom to form a latticed feeding channel, the smoke vents between the feeding channel and the flues are inclined holes, and a smoke inlet which is communicated with the feeding channel is positioned at a lower position. Because the reinforcing ribs are arranged in the feeding channel, the strength of the feeding channel is increased, the feeding channel is ensured to not deform, meanwhile, the reinforcing ribs have the function of naturally turning the charcoal, the charcoal activation effect is further improved, the product quality is more stable, the smoke vents between the feeding channel and the flues are the inclined holes, so smoke is more smoothly discharged.

Owner:承德绿世界活性炭有限公司

Deodorization device for gutter inlet

ActiveCN109440894AEasy to collect and processEfficient collectionSewerage structuresSewage drainingEngineeringMoisture sensor

The invention discloses a deodorization device for a gutter inlet, and relates to the technical field of drainage systems. The deodorization device comprises an umbrella-shaped deodorization stoppingcloth, an umbrella handle, a connecting device and a control device used for shrinking and opening the deodorization stopping cloth, and the control device comprises an air cylinder and a humidity sensor; when it rains and the humidity sensor senses that the humidity of the deodorization stopping cloth is equal to or higher than a rated value, a signal is sent to the air cylinder, the air cylinderis started, so that a piston rod drives a lower disc to move downwards along the umbrella handle, and thus the purpose of shrinking the deodorization stopping cloth for drainage is achieved; when itstops raining and the humidity sensor senses that the humidity of the deodorization stopping cloth is lower than the rated value, a signal is transmitted to the air cylinder, the air cylinder is started, so that the piston rod drives the lower disc to move upwards along the umbrella handle, and thus the purpose of opening the deodorization stopping cloth for stopping odor is achieved. By means ofthe deodorization device for the gutter inlet, on the condition that smooth drainage of rainwater is guaranteed, the diffusion of peculiar smell is stopped, and the living environment of cities is improved.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

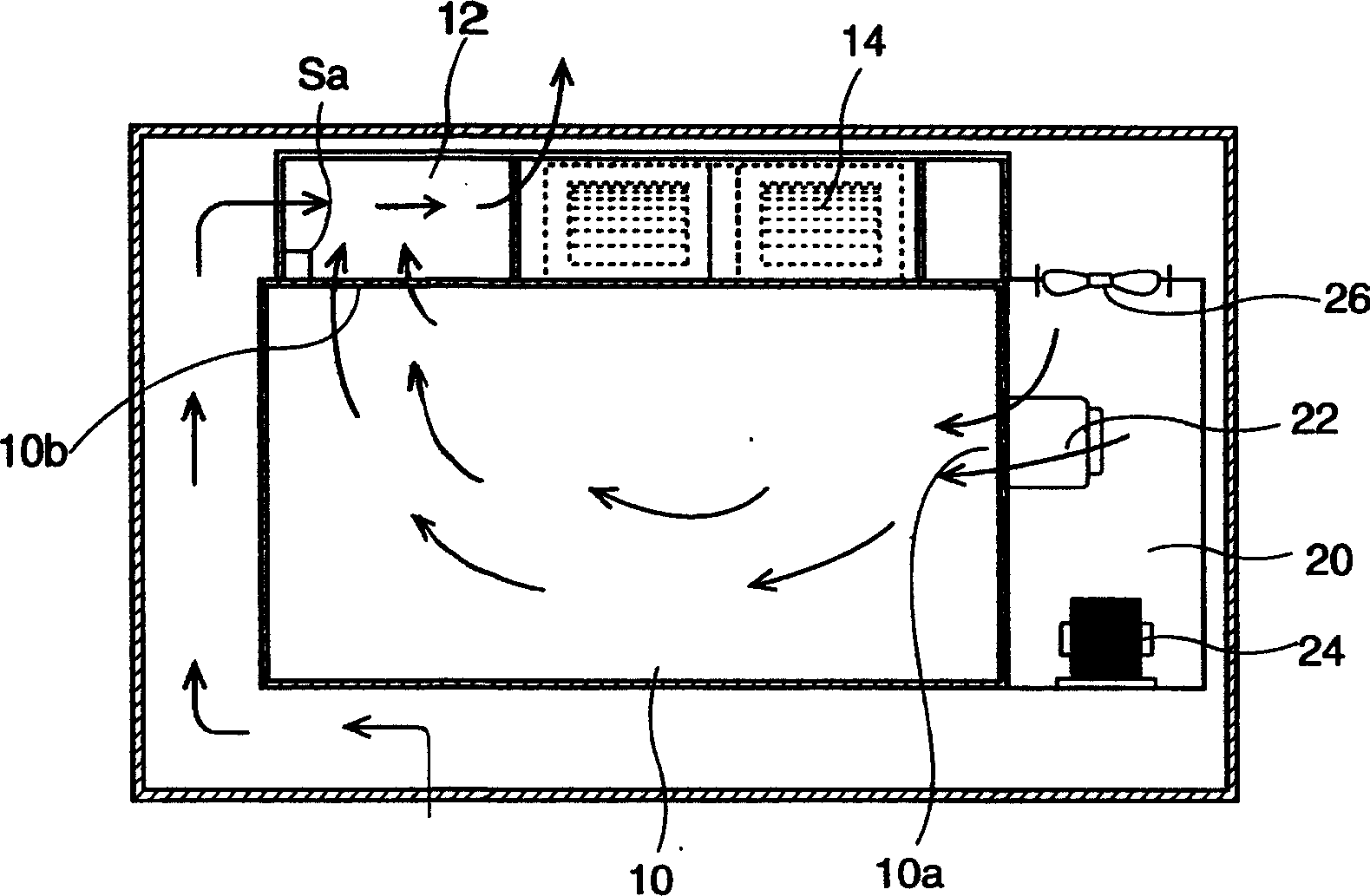

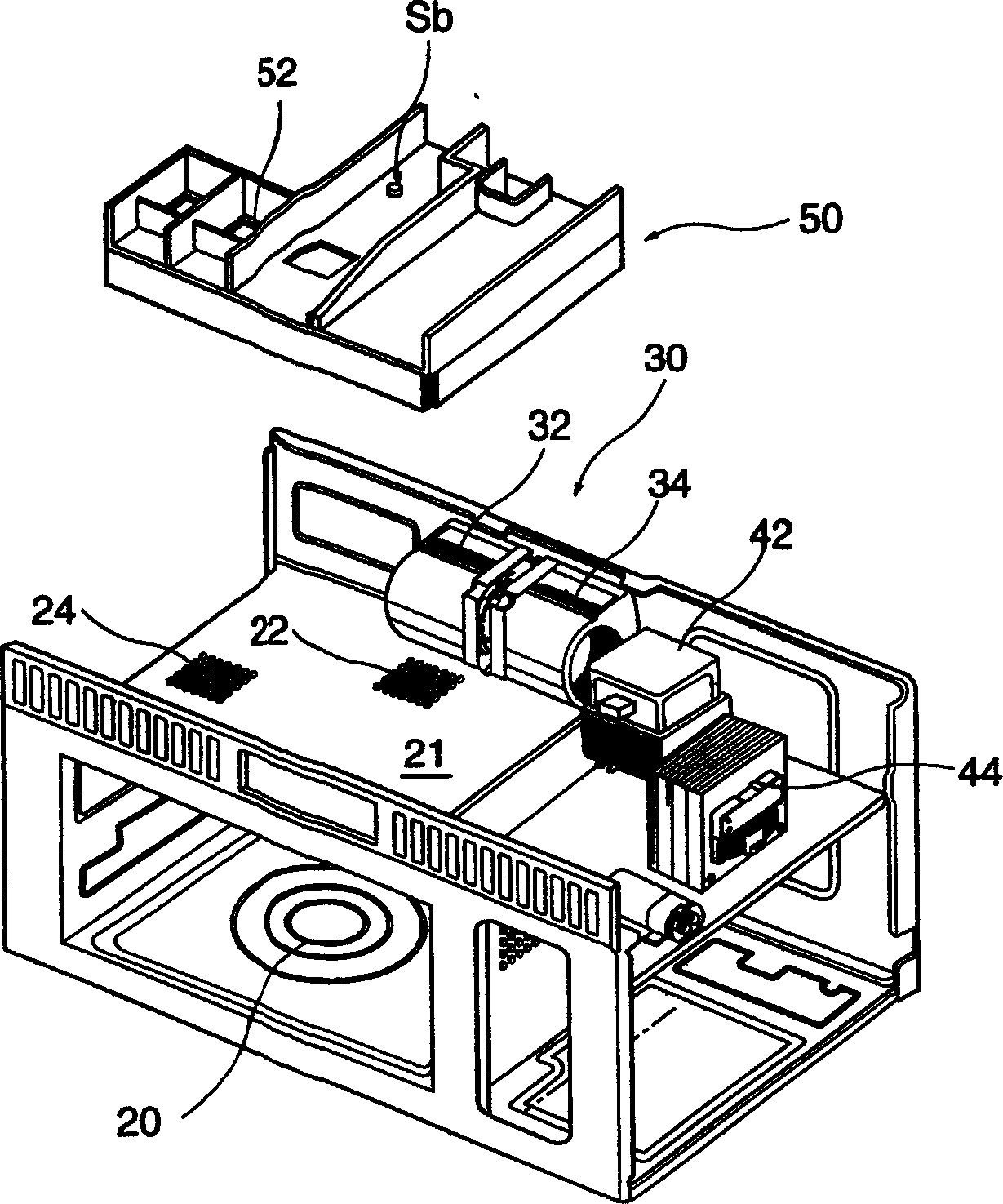

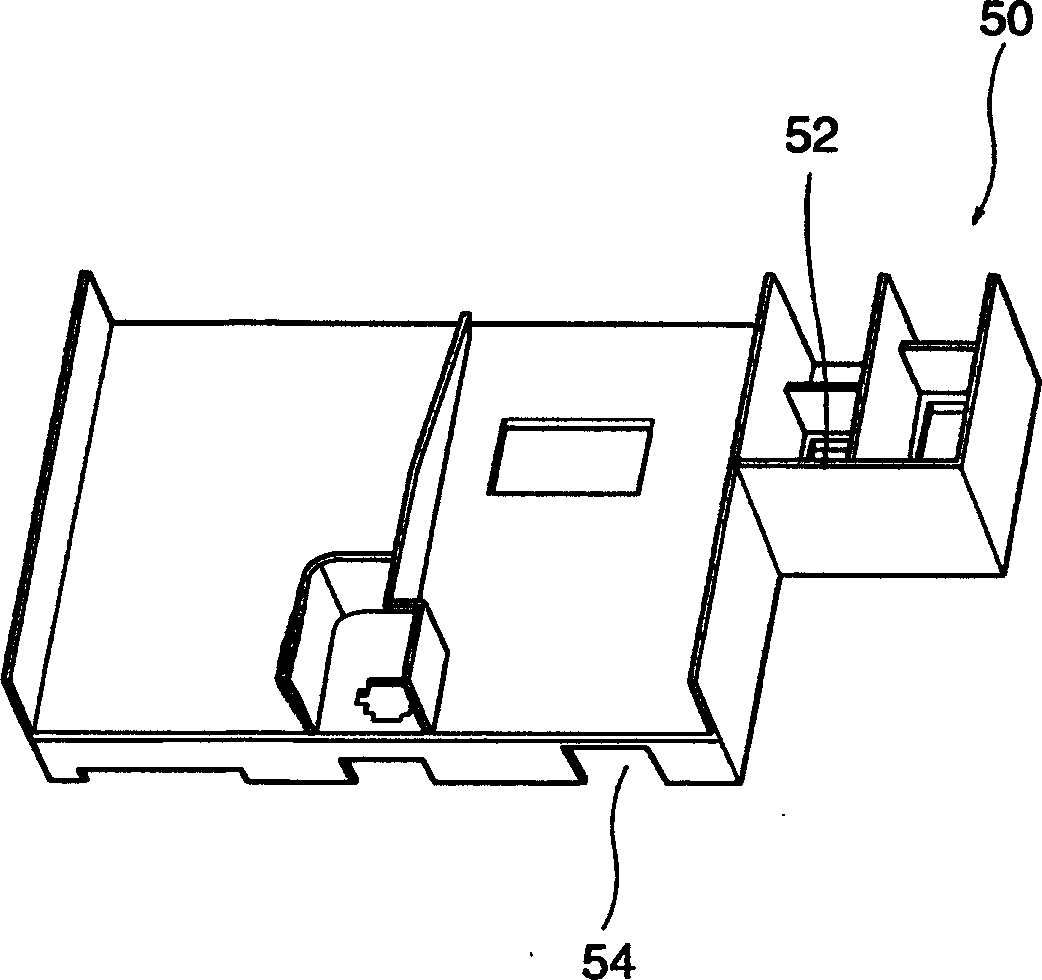

Humidity sensing arrangement for microwave oven with vented fume hood

InactiveCN1523284AUnobstructed dischargeReduce in quantityDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The present invention discloses a humidity preception device of microwaven oven with a ventilation cover. Said invention includes: upper cavity of heating chamber, exhaust motor component placed in the rear portion of upper cavity of heating chamber, exhaust hole palced near by exhaust motor component and communicated with the heating chamber, air inlet placed in the front of upper cavity of heating chamber and communicated with heating chamber and humidity sensor placed near by exhaust hole and used for determining humidity of exhausted air. In the described upper cavity of heating chamber an air channel for guiding air flow is set, and the humidity sensor Sb is placed on the air channel correspondent to upper portion of exhaust hole.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

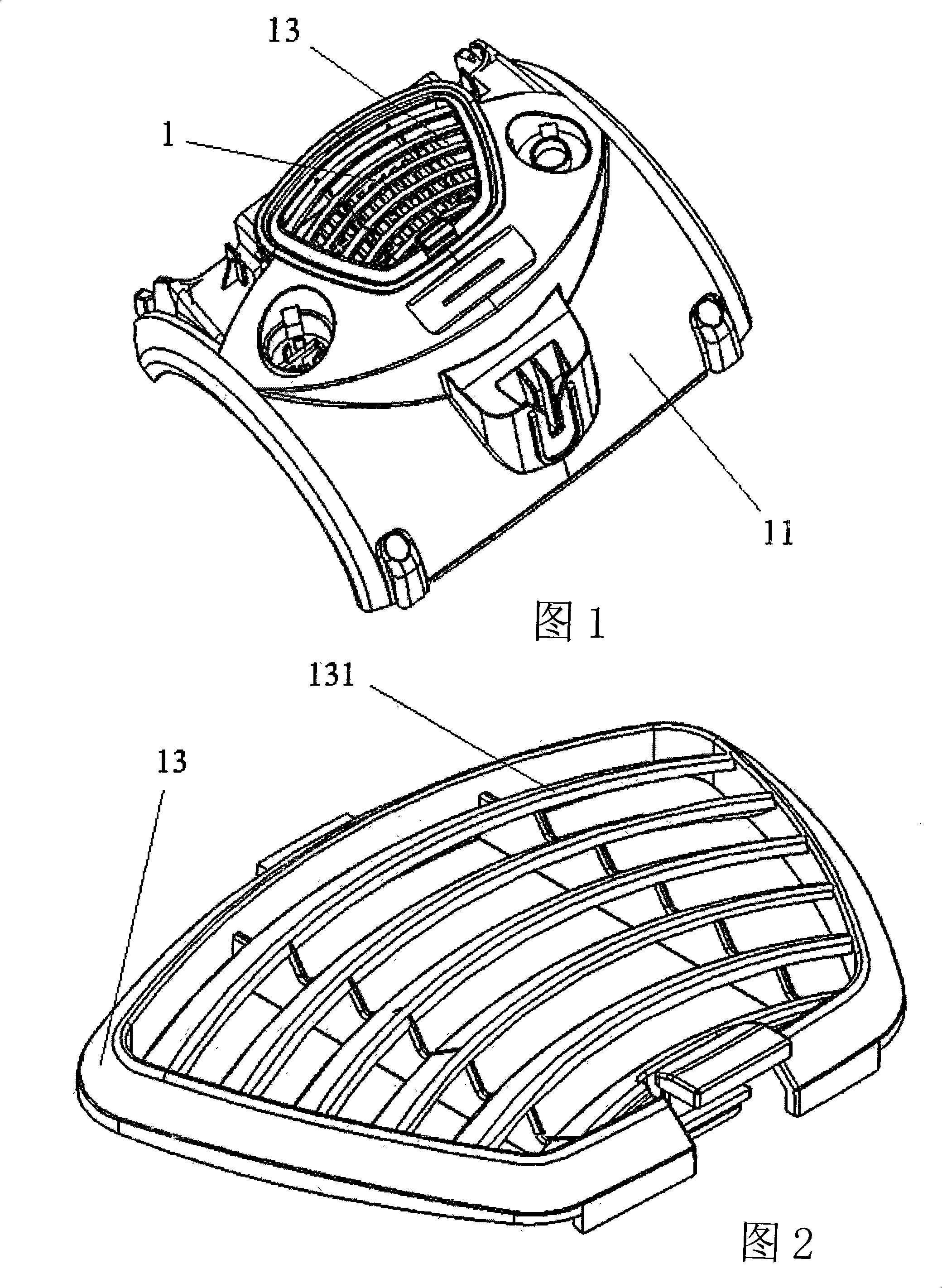

Noise elimination structure of vacuum cleaner

InactiveCN101301180AGood coolingUnobstructed ventilationSuction cleanersElectric machineryEngineering

The invention provides a muffler structure of a vacuum dust cleaner, comprising an upper casing having an integrally-molded groove with a cover for receiving a liner, wherein the bottom of the groove is provided with a plurality of air outlets, and the opening area of each air outlet is less than or equal to one quarter of the wavelength corresponding to the vibration frequency of the motor or the fan; the side surface on the rear end of the casing is provided with a plurality of air outlets, and the opening area of each air outlet is less than or equal to one quarter of the wavelength corresponding to the vibration frequency of the motor or the fan; the liner in the groove is arranged movably, and can efficiently absorb the high-frequency noise caused by vibration of the motor and the fan, improve the sound quality of the vacuum dust cleaner in operation, and reduce the total noise of the vacuum dust cleaner, so that the noise of the vacuum dust cleaner in operation can be controlled within about 70dB at standard measuring point.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com