Noise elimination structure of vacuum cleaner

A technology for vacuum cleaners and exhaust outlets, which is applied to vacuum cleaners, cleaning equipment, household appliances, etc. It can solve problems such as high-frequency noise and large noise volume, and achieve the effects of improving work performance, smooth exhaust, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

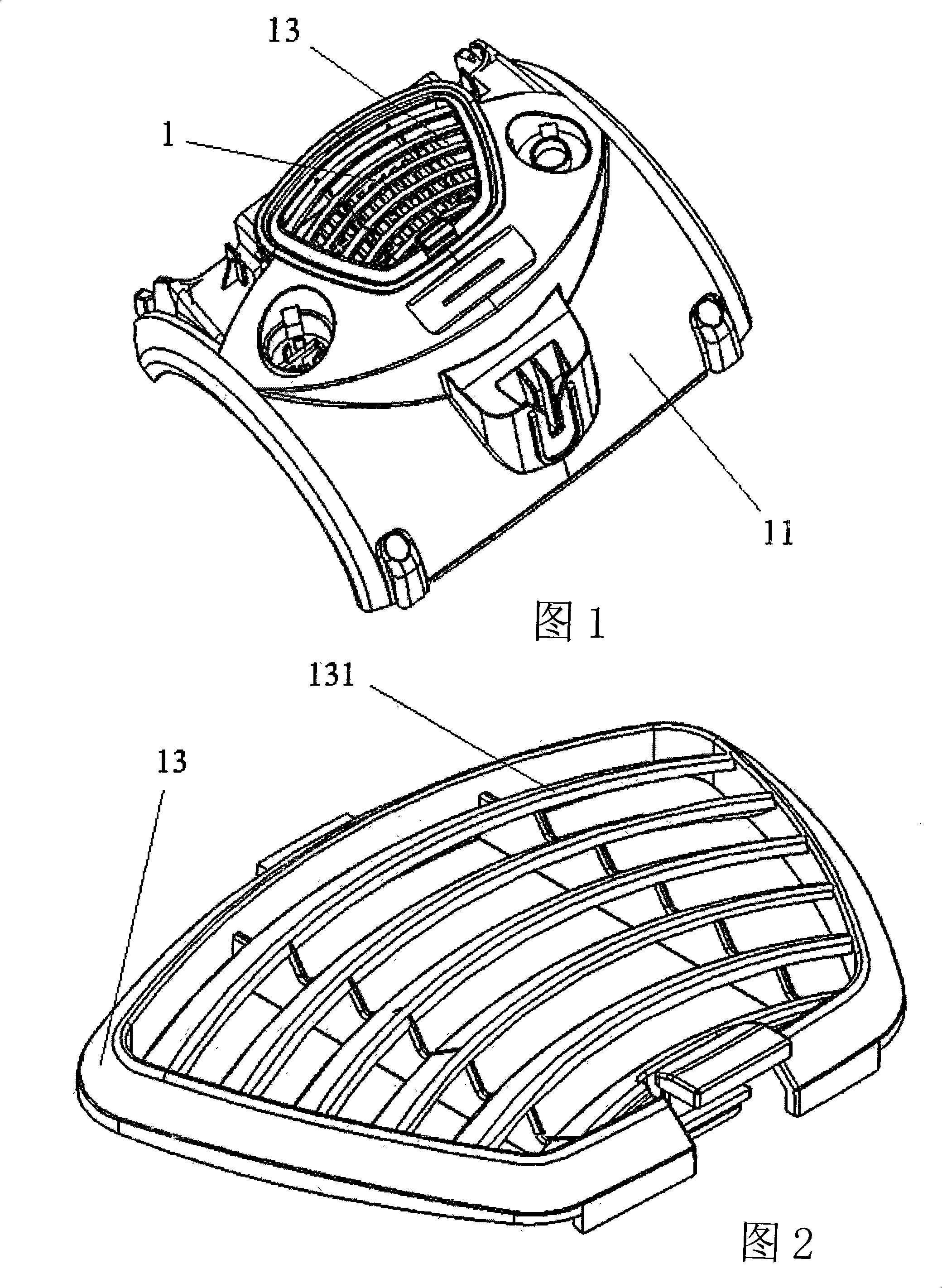

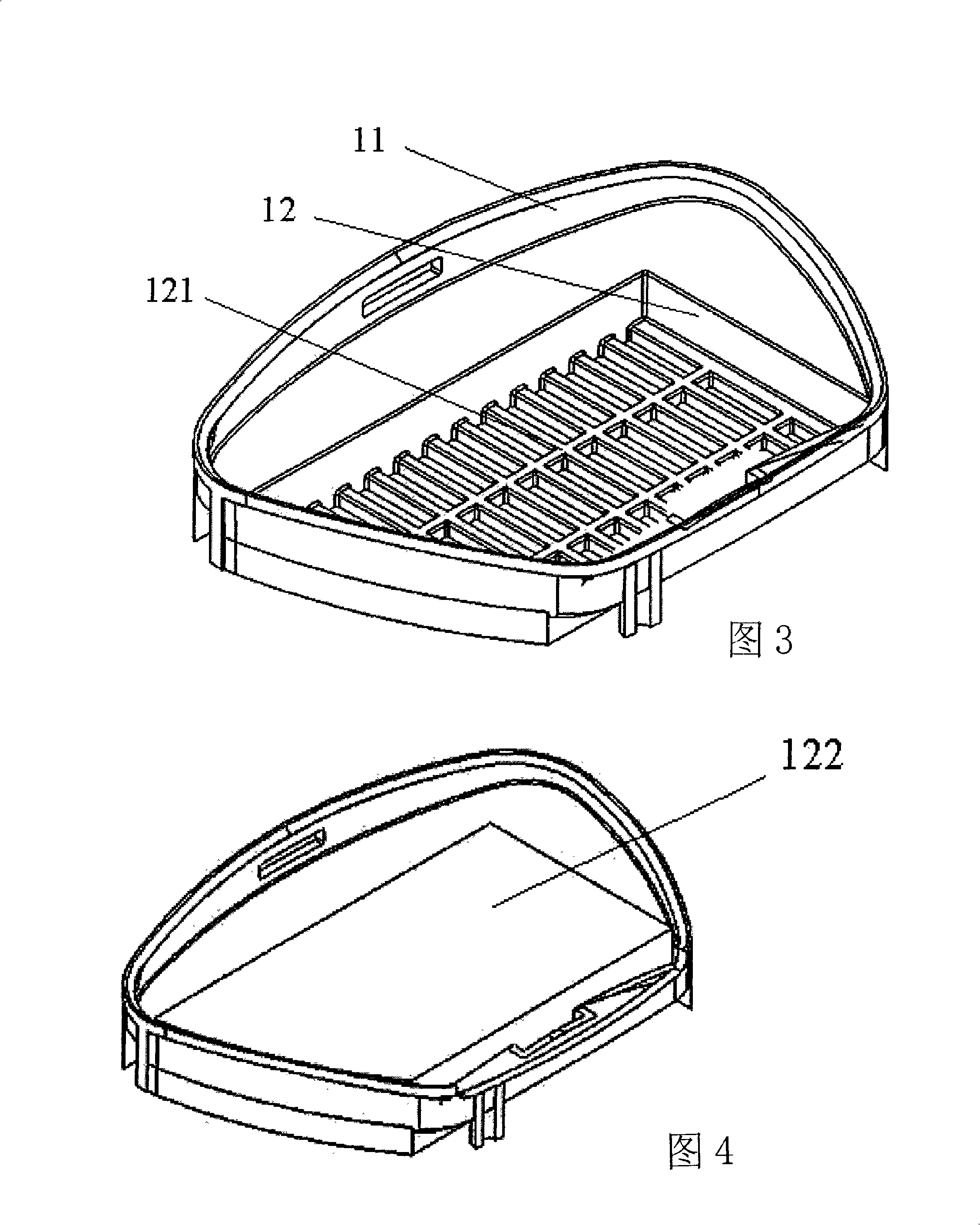

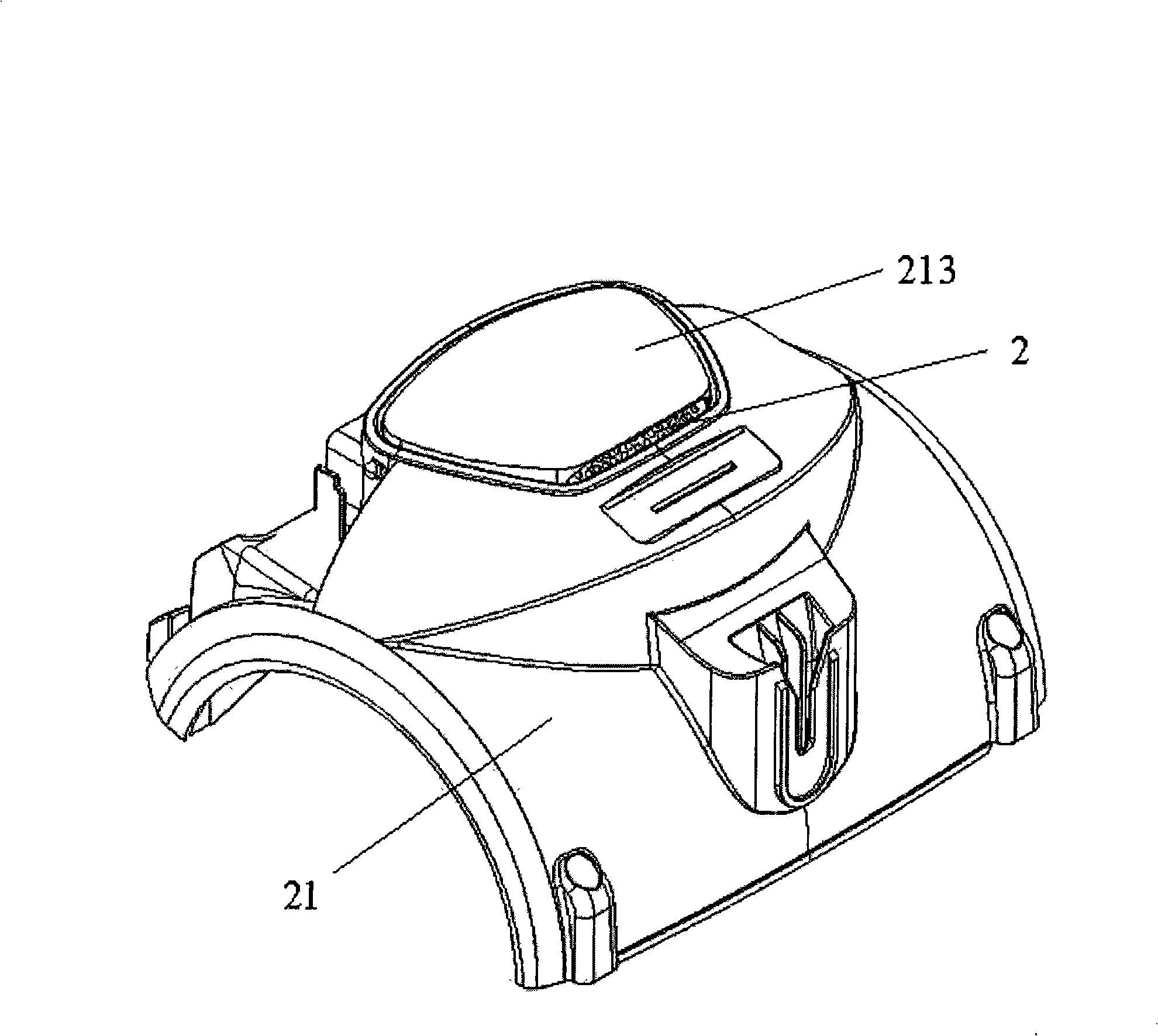

[0033] refer to Figure 5 , as shown in Fig. 6 and Fig. 7, the noise reduction structure of the vacuum cleaner of the present invention includes an upper casing 21, a groove 211 is integrally formed on the upper casing 21, a cover body 213 is arranged on the groove 211, and a cover body 213 is arranged on the groove 211. The pad body 215 is placed; the improvement is that several air outlets 212 are provided at the bottom of the groove 211; several air outlets 214 are provided on the side of the rear end of the cover 213.

[0034] The noise reduction structure of the vacuum cleaner of the present invention, wherein, several exhaust ports 212 provided at the bottom of the groove 211 are integrally formed on the bottom of the groove 211, and the opening area of each exhaust port 212 is less than or equal to the vibration frequency of the motor or fan. A quarter of the wavelength; several exhaust ports 214 provided on the rear end side of the cover body 213 are integrally formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com