Patents

Literature

725results about How to "Smash thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for separating water from sludge

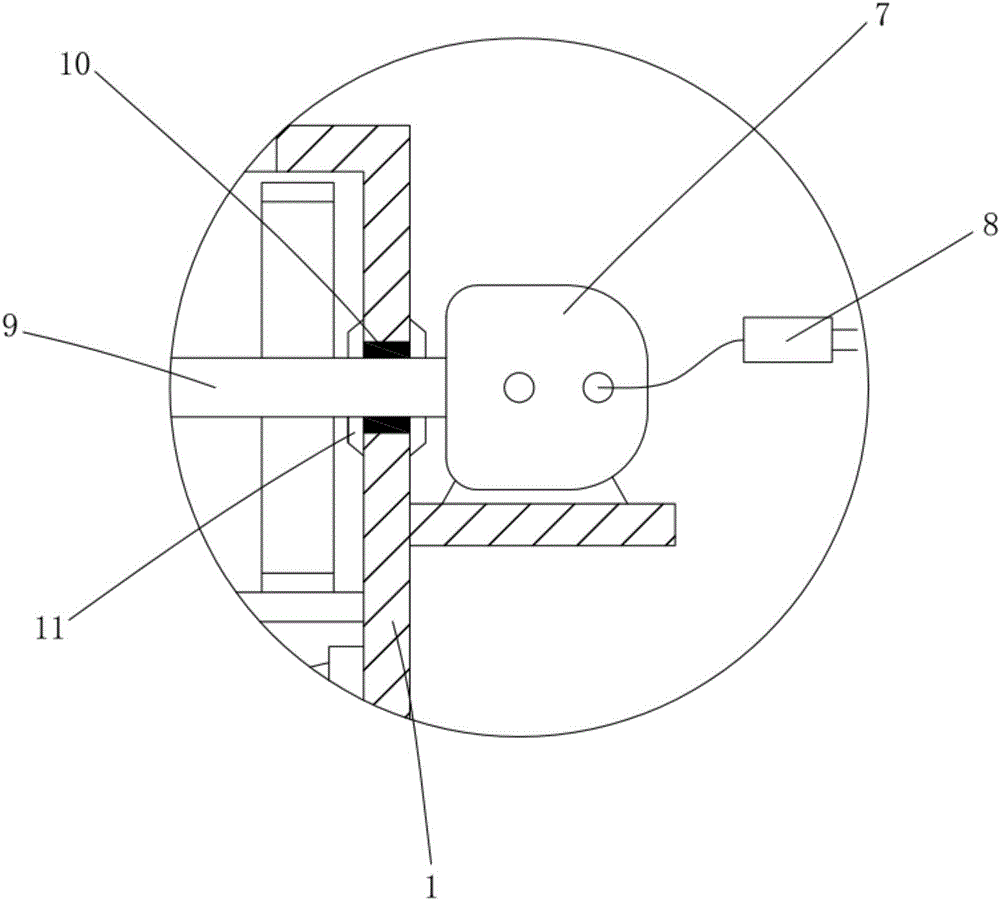

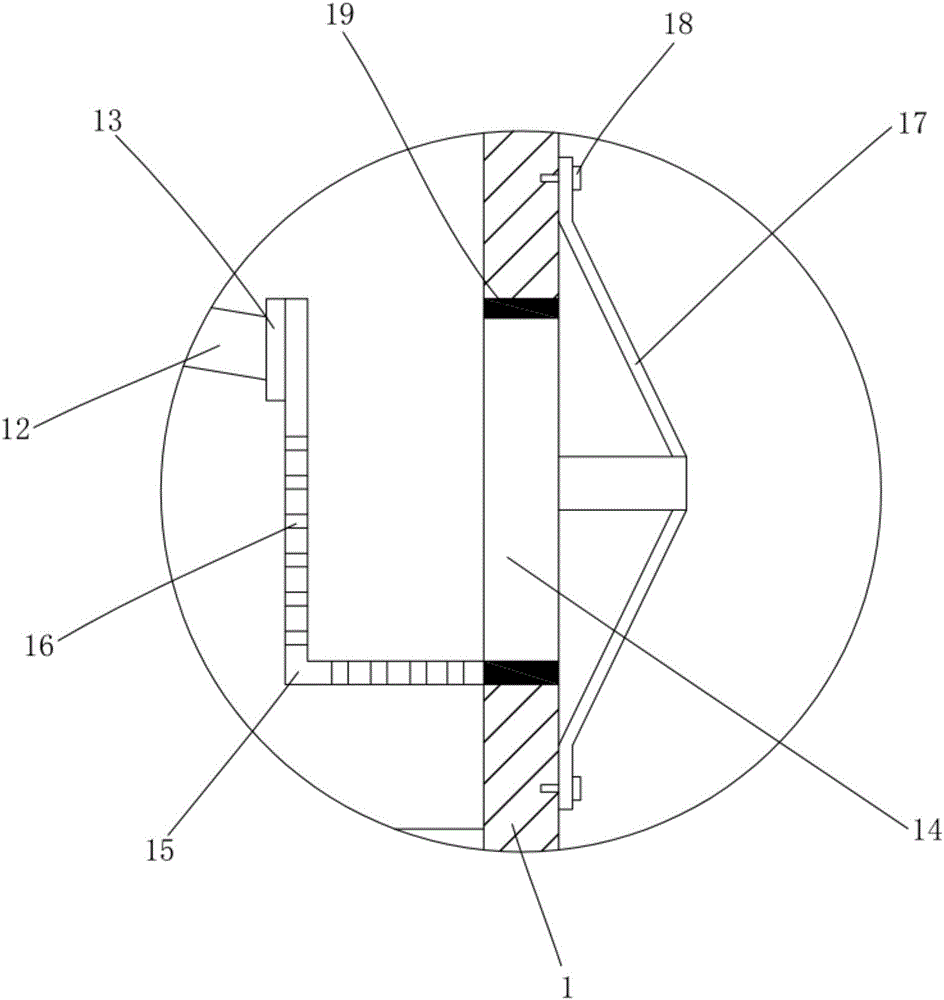

InactiveUS10053385B1Convenient guidanceEfficient and cheapSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSpiral bladeSludge

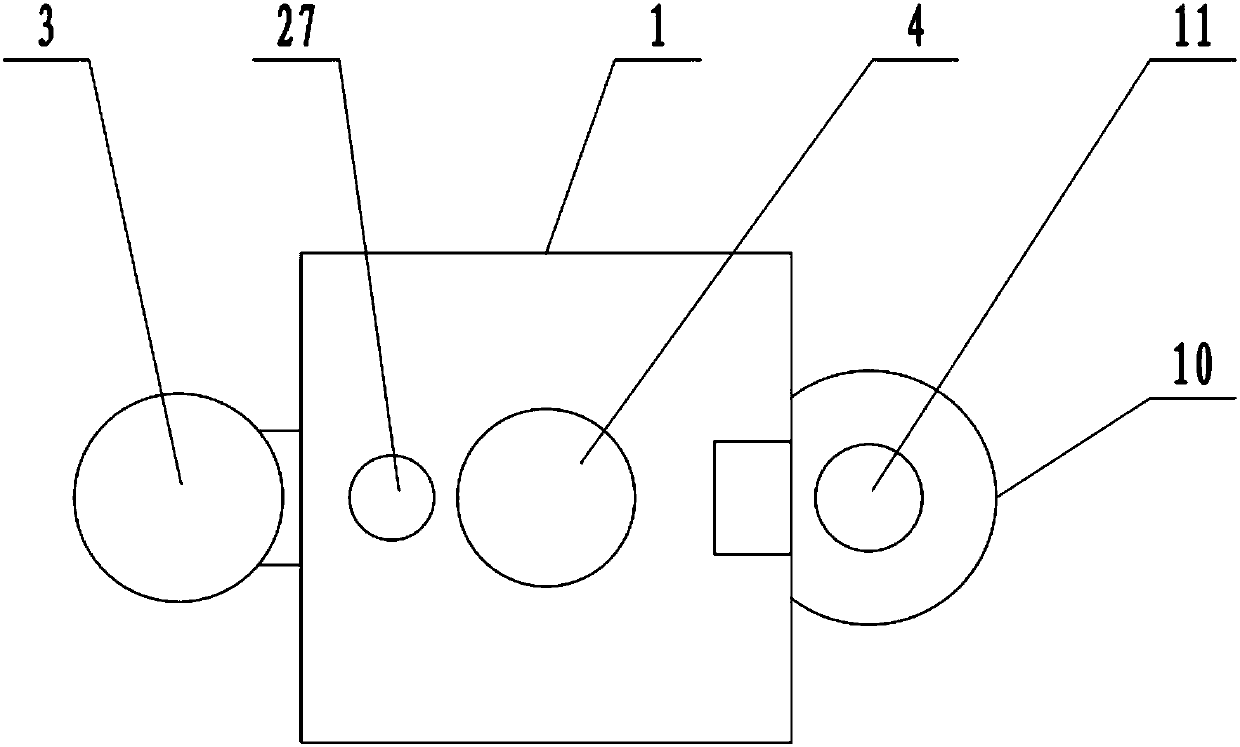

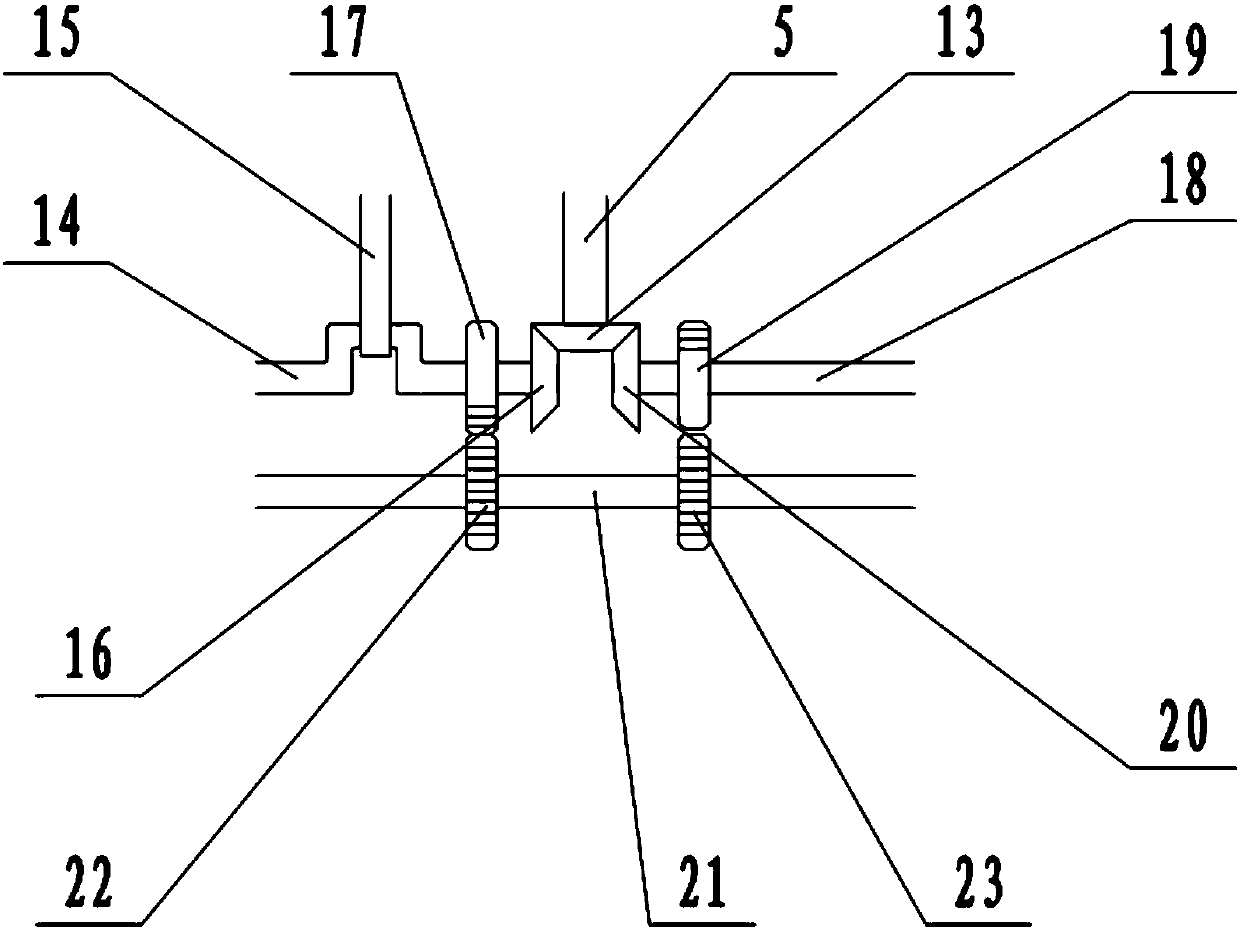

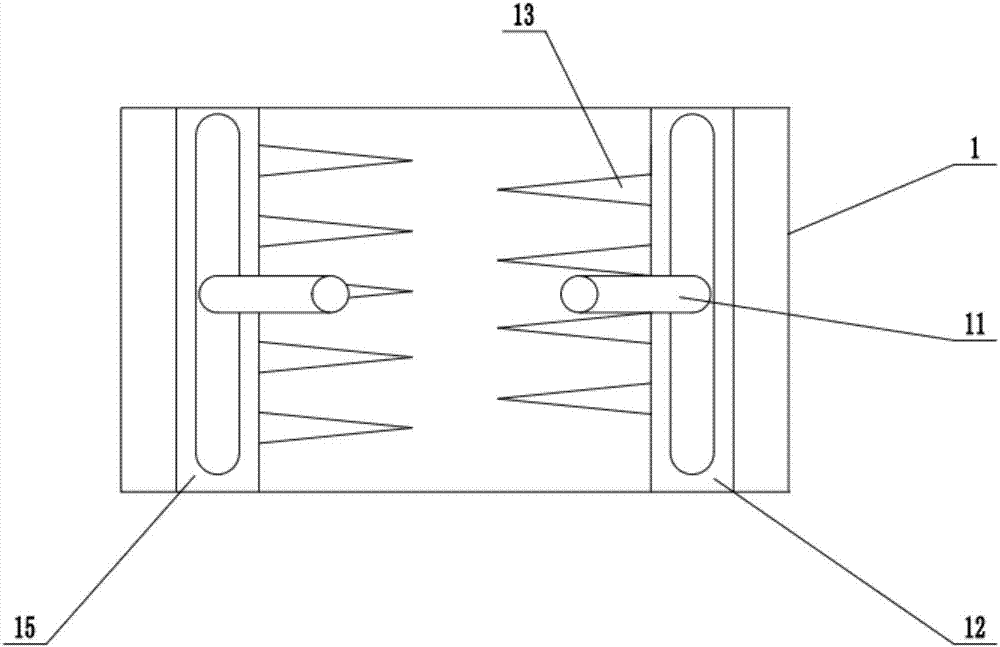

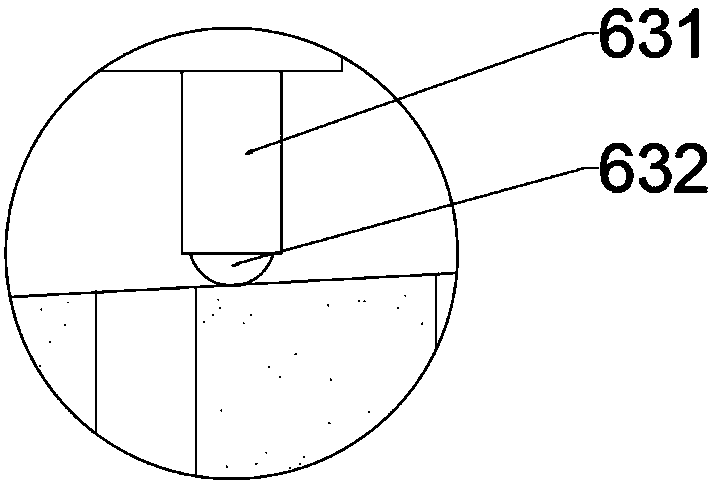

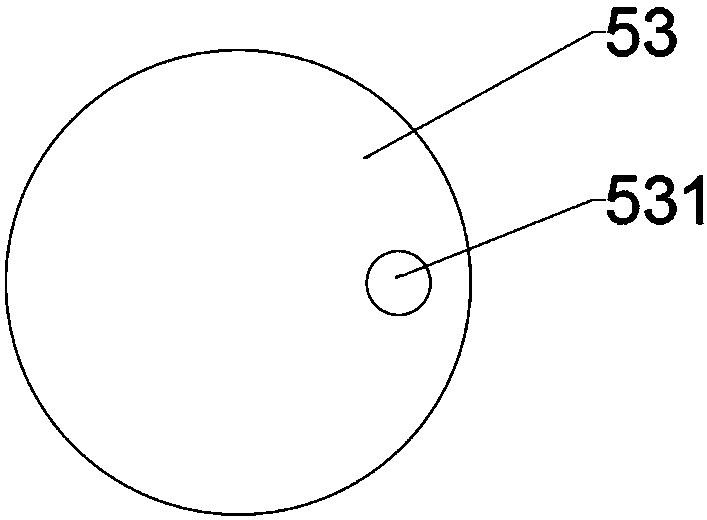

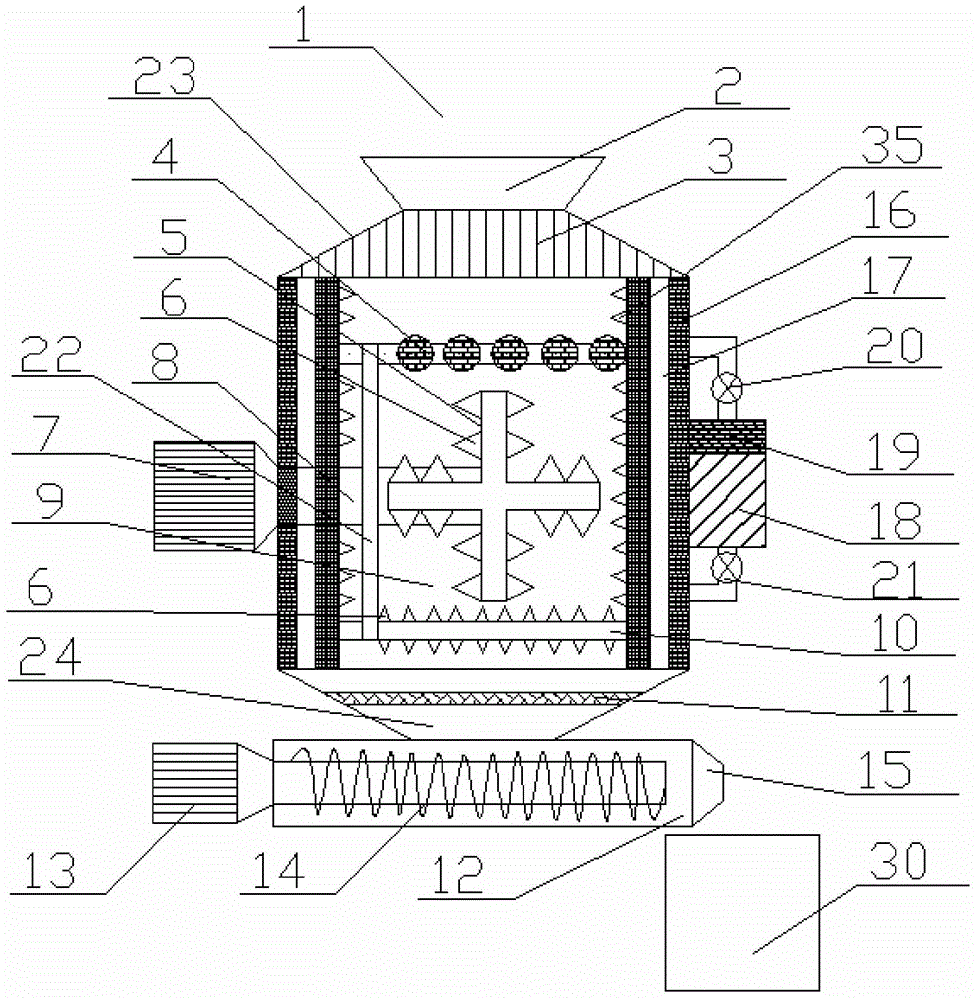

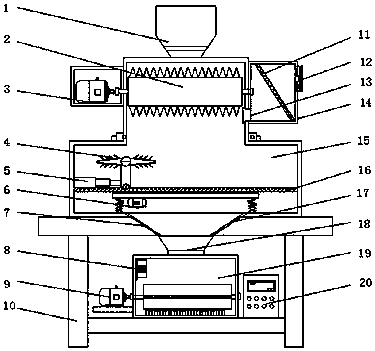

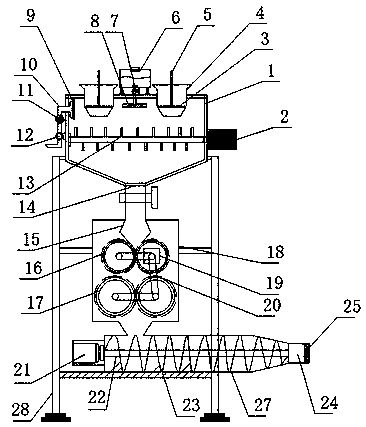

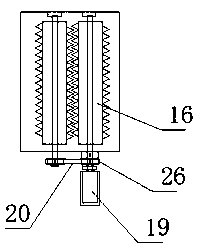

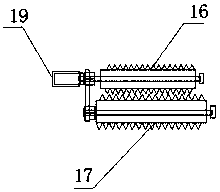

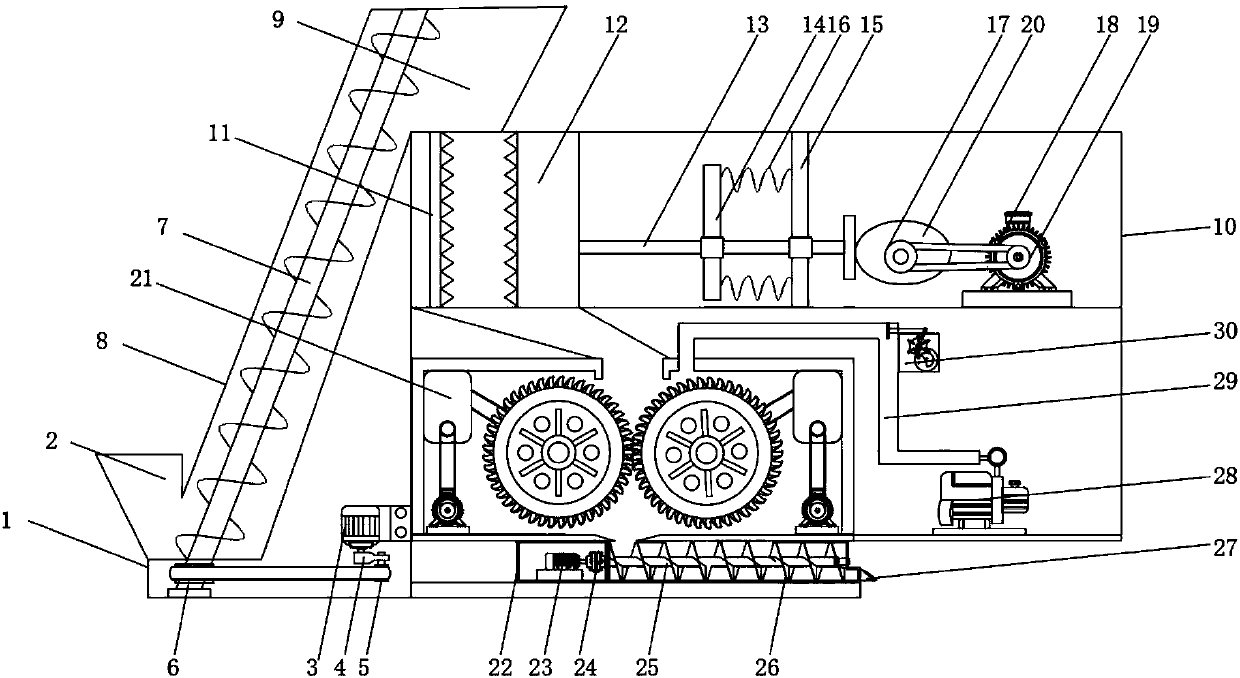

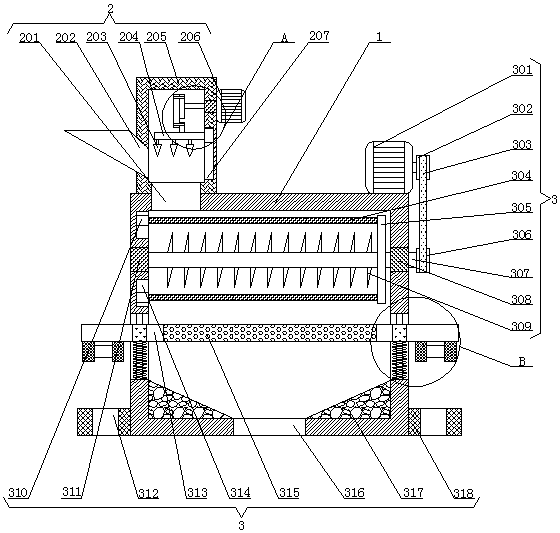

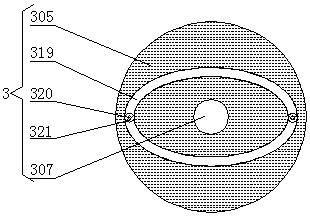

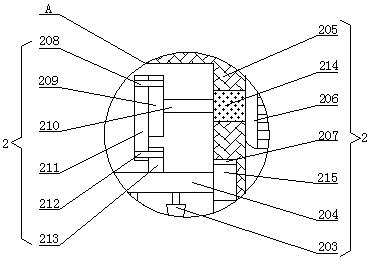

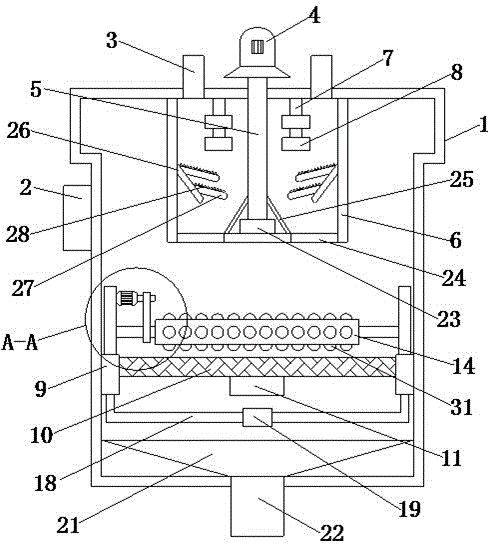

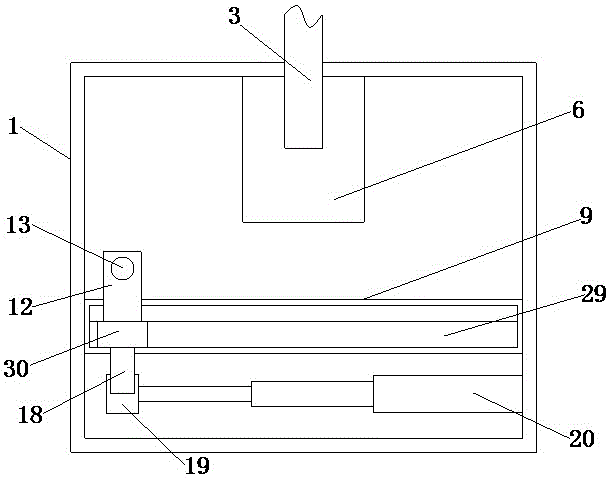

A device for separating water from sludge comprising a processing box, wherein a feeding cylinder is disposed above the processing box, and the feeding cylinder is fixedly connected to the processing box through a plurality of connecting rods; a rotating rod is rotationally connected into the feeding cylinder; a first rotating motor is fixedly connected to one side of the feeding cylinder; the output end of the first rotating motor penetrates through the side wall of the feeding cylinder, and is fixedly connected to the rotating rod; a spiral blade is fixedly sleeved with the rotating rod, and the outer side of the spiral blade is matched with the inner side wall of the feeding cylinder.

Owner:ZHU ZIYU

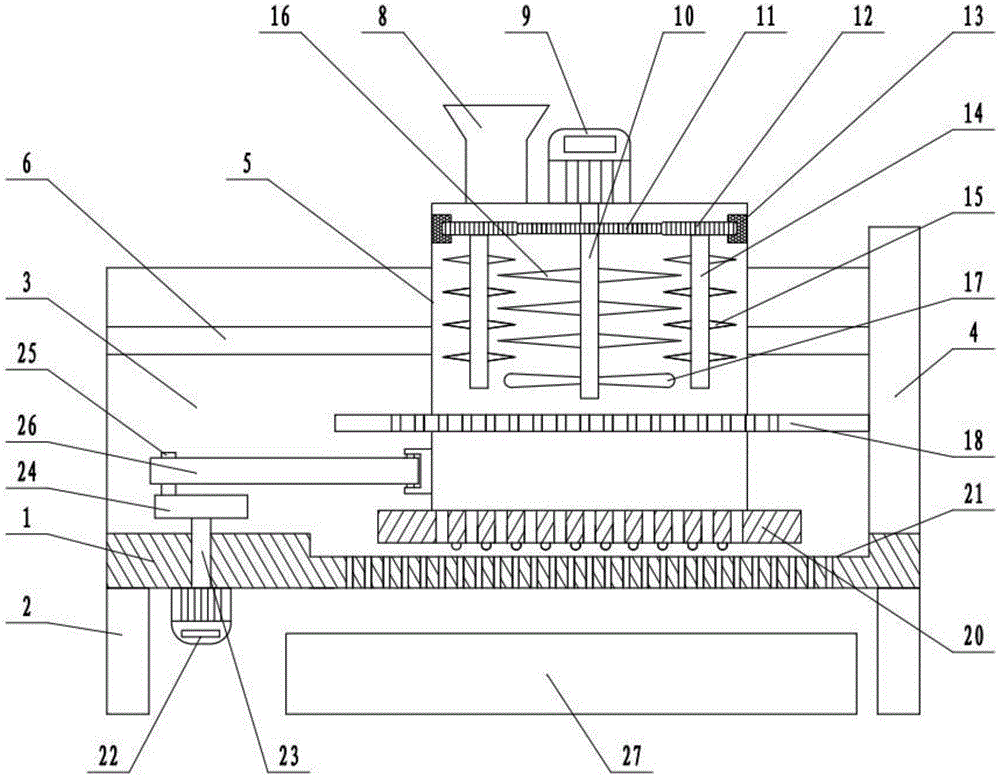

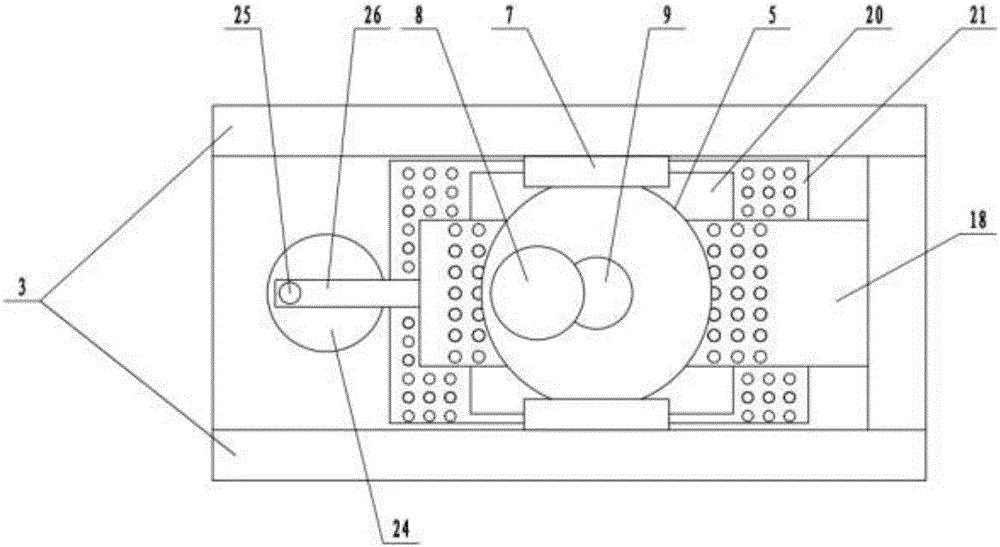

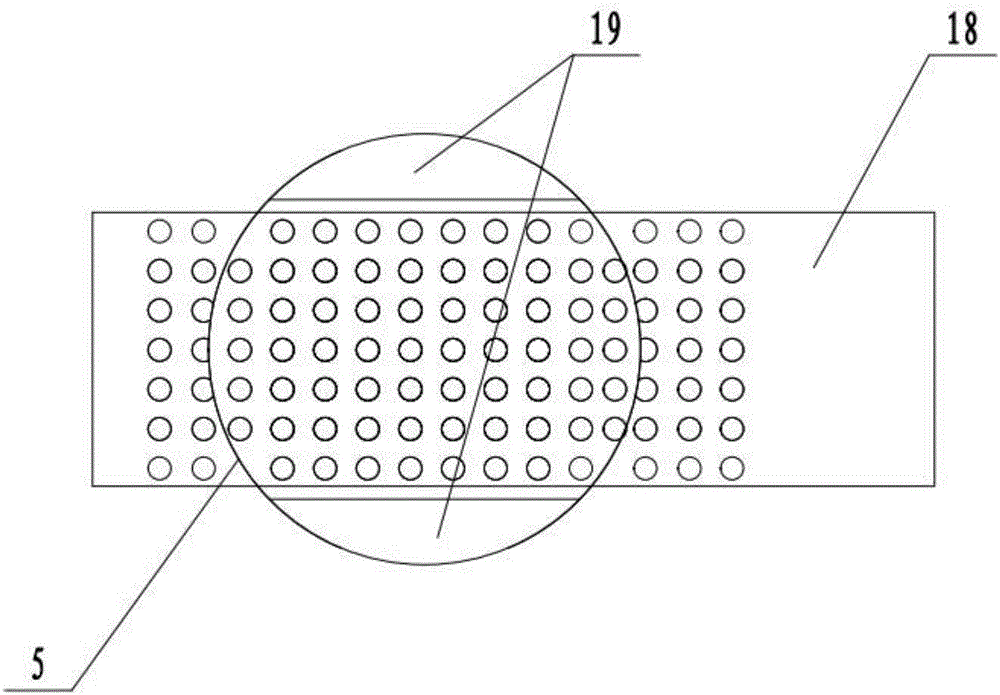

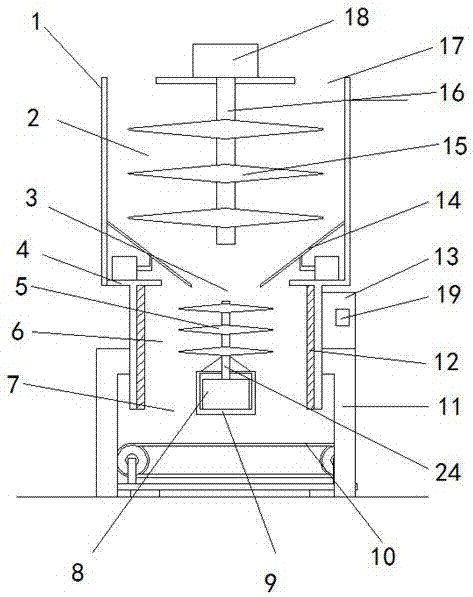

Swing type coffee bean crushing and grinding equipment

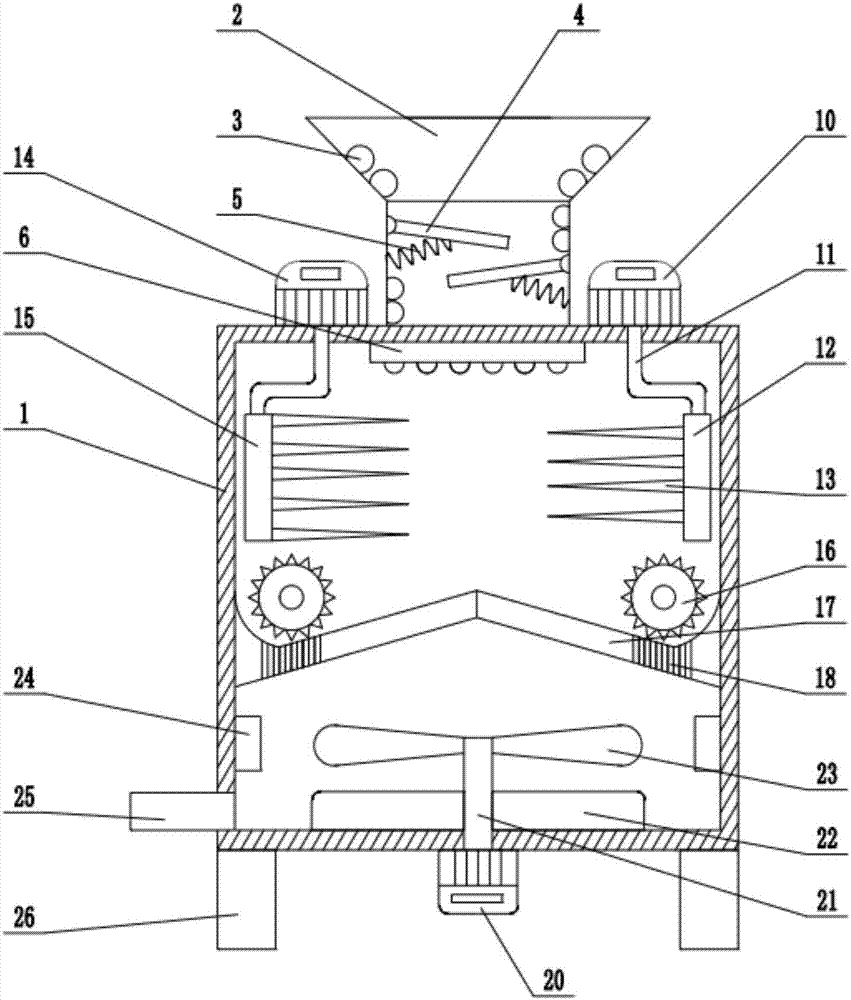

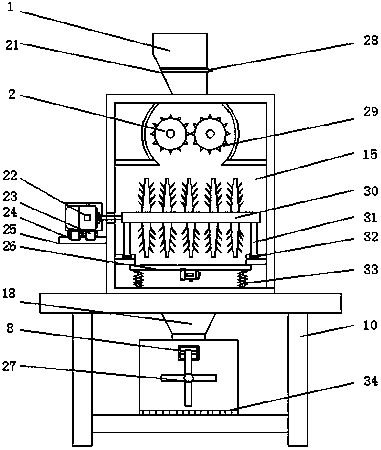

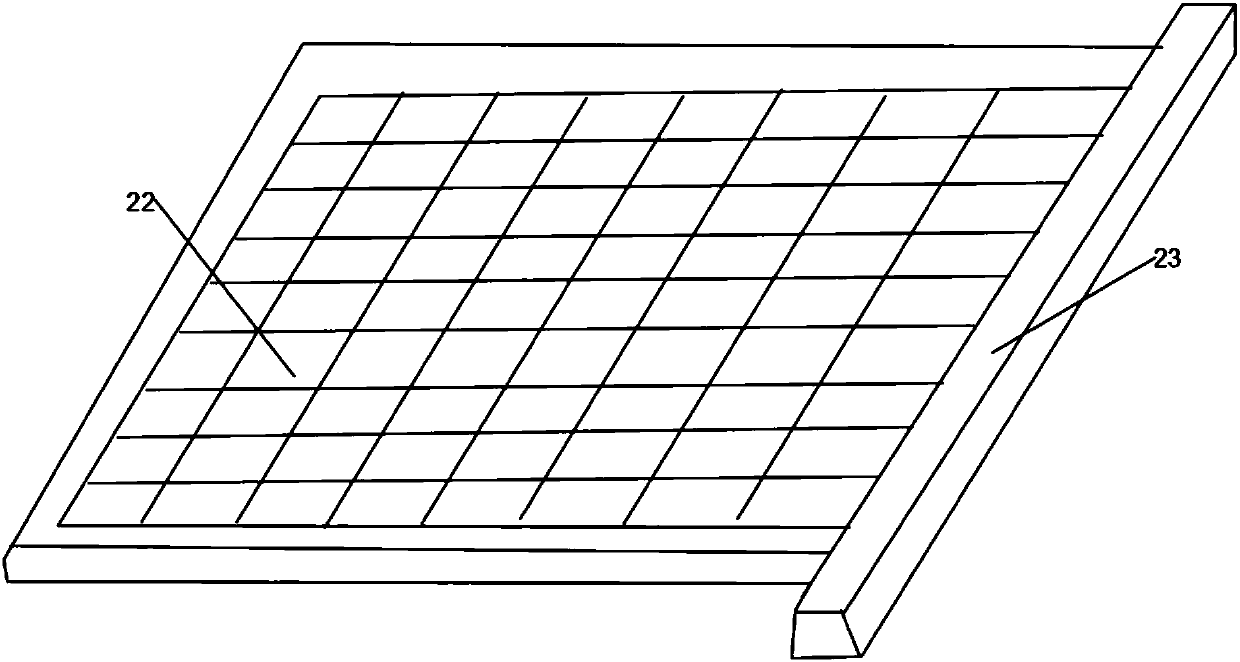

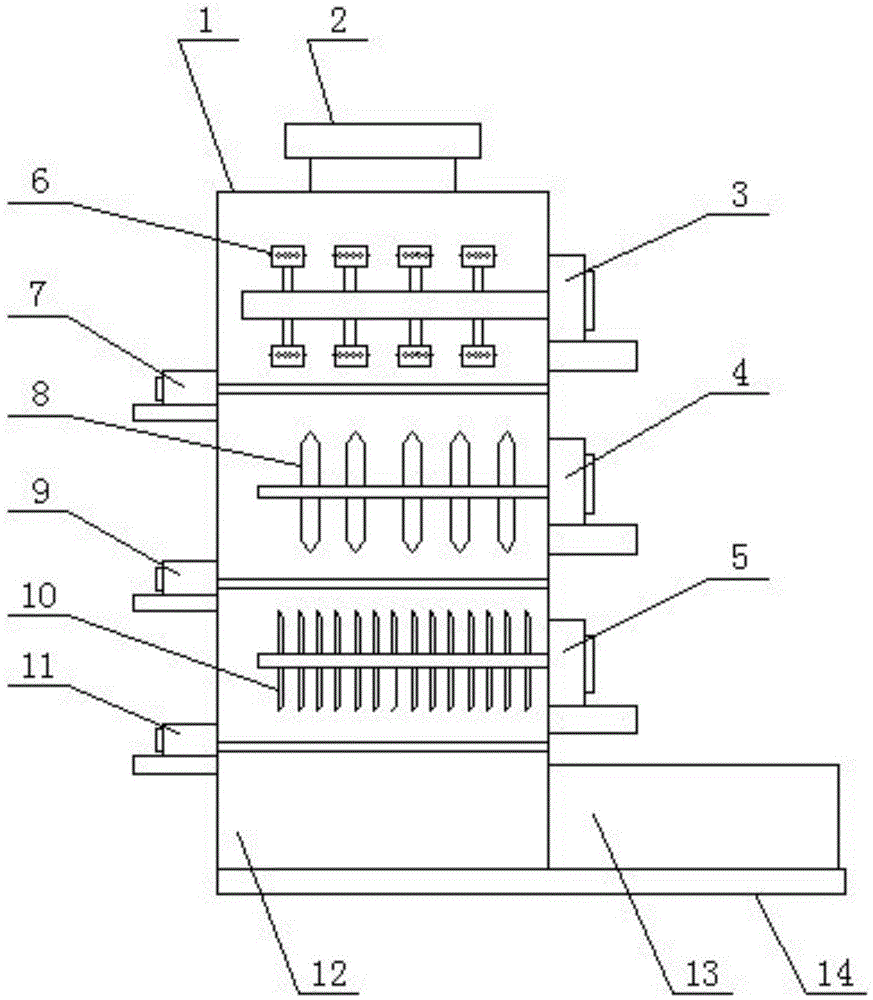

The invention discloses swing type coffee bean crushing and grinding equipment. The equipment comprises a base, supporting feet, a left fixing frame, a right fixing frame and a crushing tank; the leftfixing frame is fixedly connected at the left end of the base; the right fixing frame is fixedly connected at the right end of the base; the crushing tank is arranged between the left fixing frame and the right fixing frame; a motor is fixedly connected on the upper surface of the crushing tank; a crankshaft is arranged inside the crushing tank; a sliding block is arranged below a feeding port; the right end of a connecting rod is hinged to the side wall of the sliding block; a plurality of main crushing blades are distributed on the crankshaft; a plurality of auxiliary crushing blades are fixedly connected on the inner walls of the left side and the right side of the crushing tank; a fixing rod is arranged below the main crushing blades; a sieve plate is arranged below the fixing rod; and a grinding hammer head is fixedly connected at the lower end of the crankshaft. Coffee beans are intermittently placed into the crushing tank, so that the coffee beans are crushed more thoroughly, and the crushing efficiency is improved; the coffee beans are crushed through cooperation of the main crushing blades with the auxiliary crushing blades; and the sieve plate is vibrated up and down, sothat the crushed coffee beans fall to the bottom of the crushing tank favorably.

Owner:张先吉

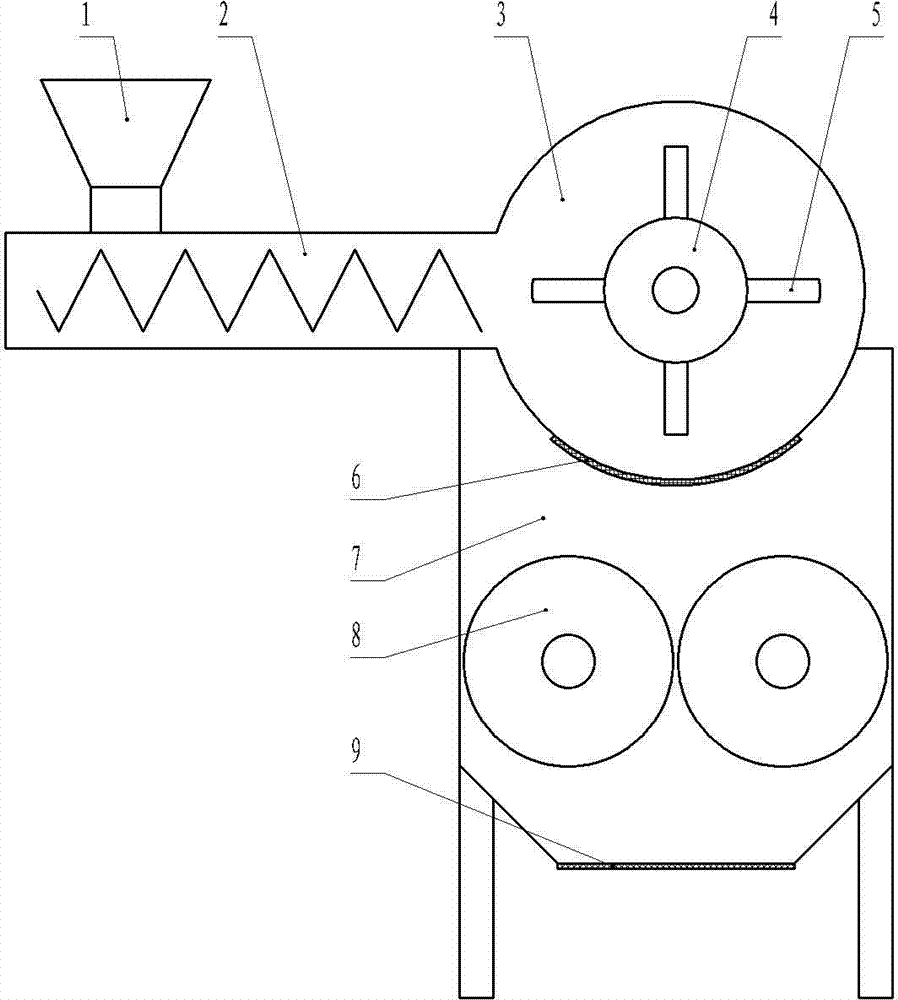

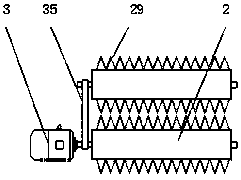

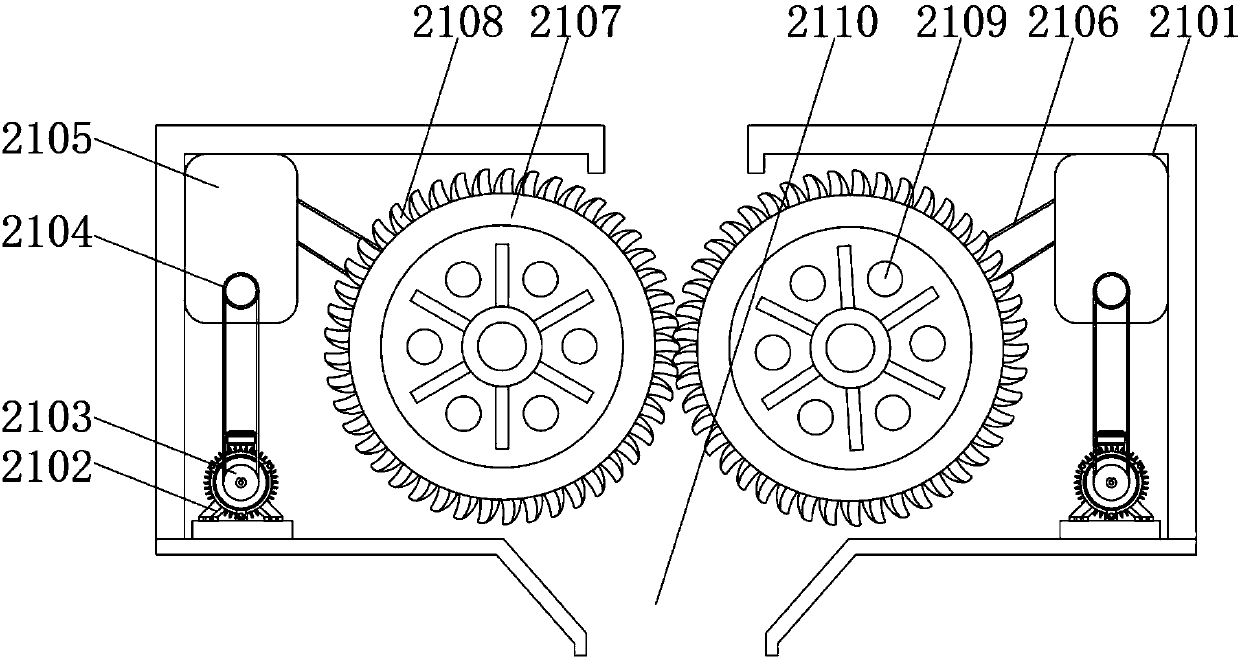

Paint pulverizer

The invention discloses a paint pulverizer, and relates to the technical field of paint production equipment manufacture. The paint pulverizer comprises a pulverizing cylinder, whose bottom is provided with a first filtering screen, the pulverizing cylinder is connected to a feed hopper, a rotation shaft and a plurality of pulverizing blades are arranged in the pulverizing cylinder, the plurality of pulverizing blades are fixed on the rotation shaft, one end of the rotation shaft is connected to a first motor through mechanical transmission; a powder pressing box is arranged under the pulverizing cylinder, the powder pressing box is provided with a discharge opening provided with a second filtering screen, two press rollers, which rotate in the opposite directions, are arranged in the powder pressing box and connected through gear transmission, and one of the press rollers is connected to a second motor. The paint fed into the pulverizing cylinder is pulverized by the pulverizing blades, then screened by the first filtering screen, transported to the powder press box, rolled by two press rollers that rotate in the reverse directions, and finally screened by the second filtering screen, the paint is more radically pulverized, the powder is finer, and the paint luster is brighter, compared to the prior art.

Owner:WUZHOU WANGJIE MACHINERY MFR

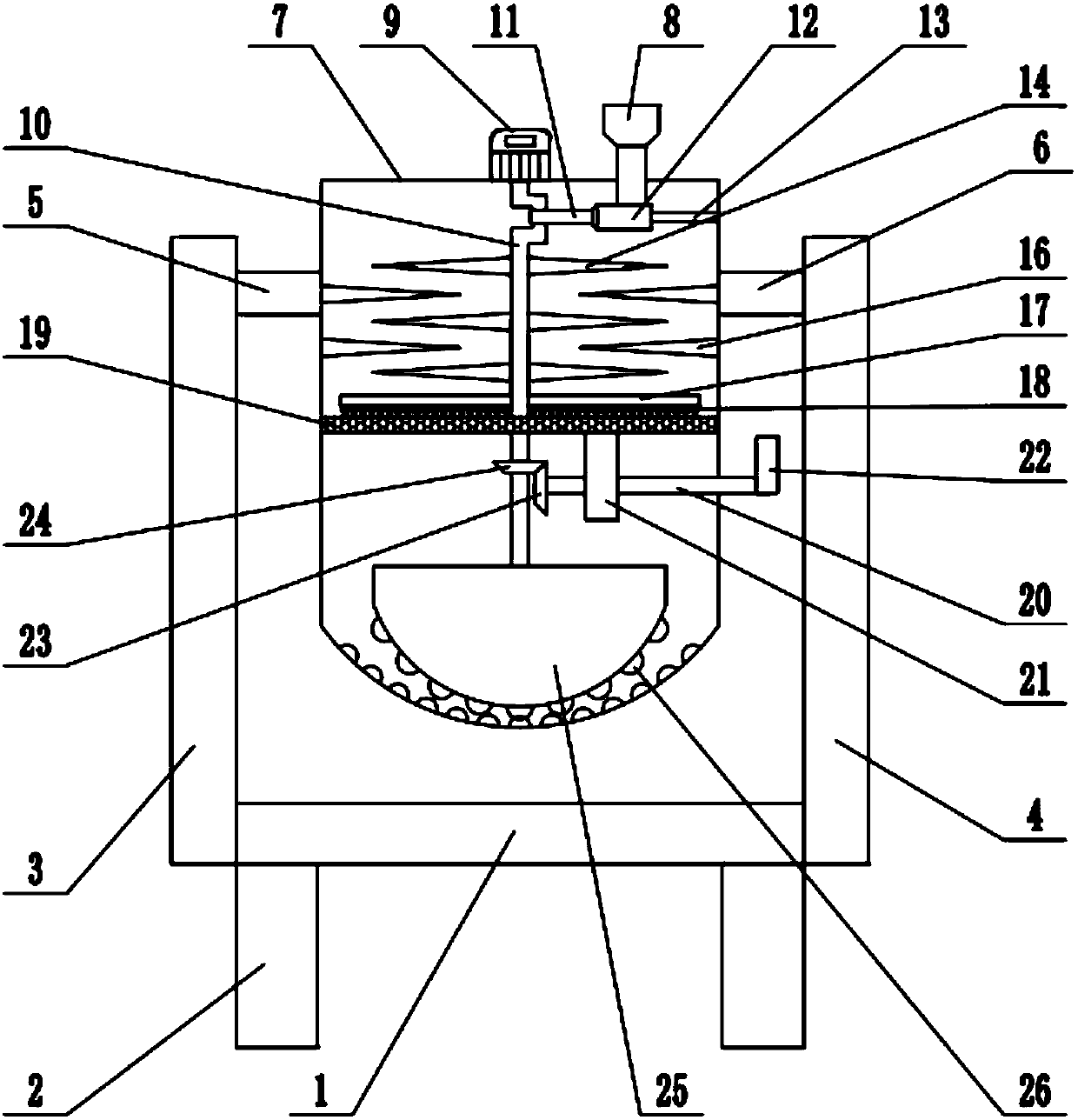

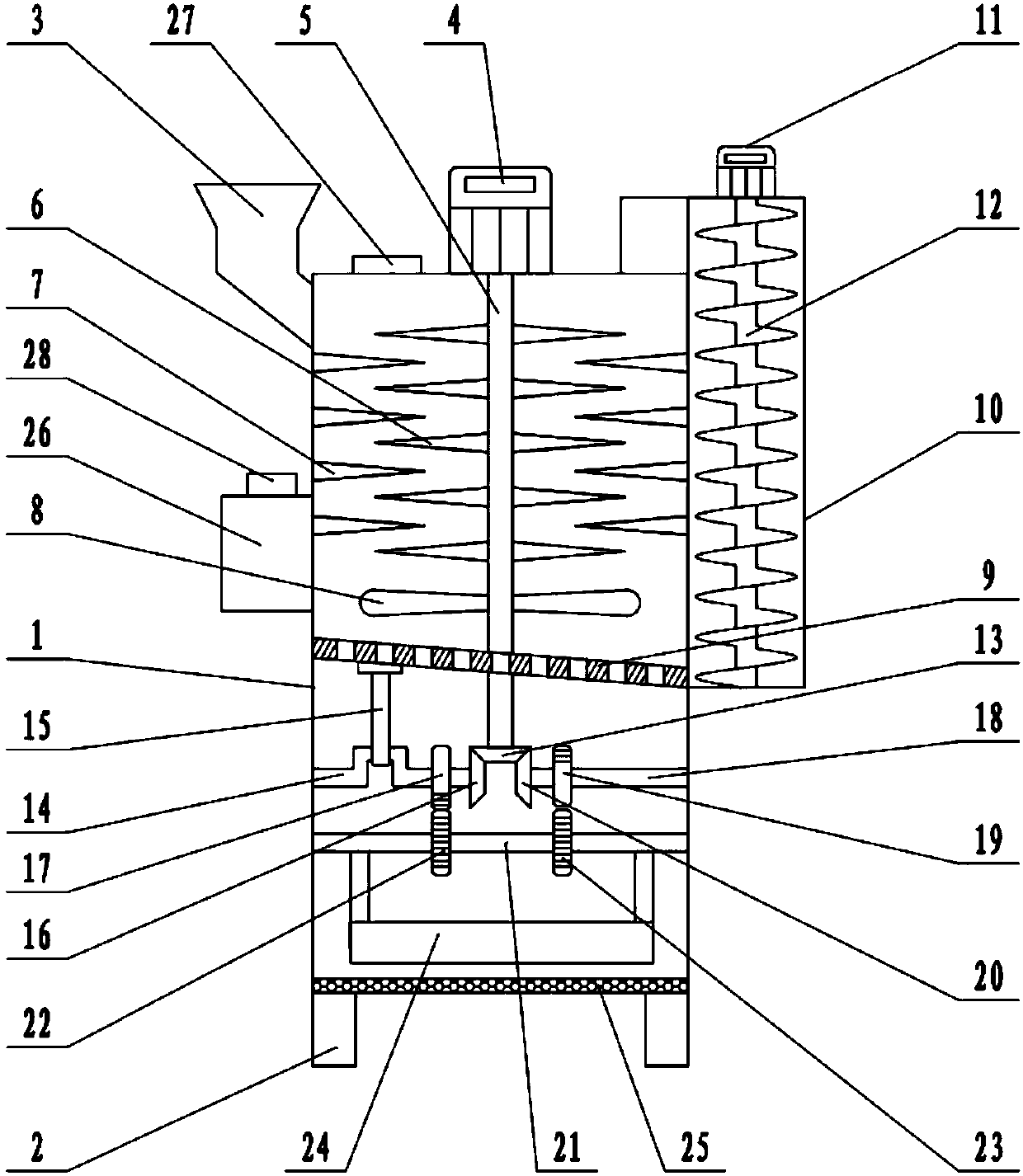

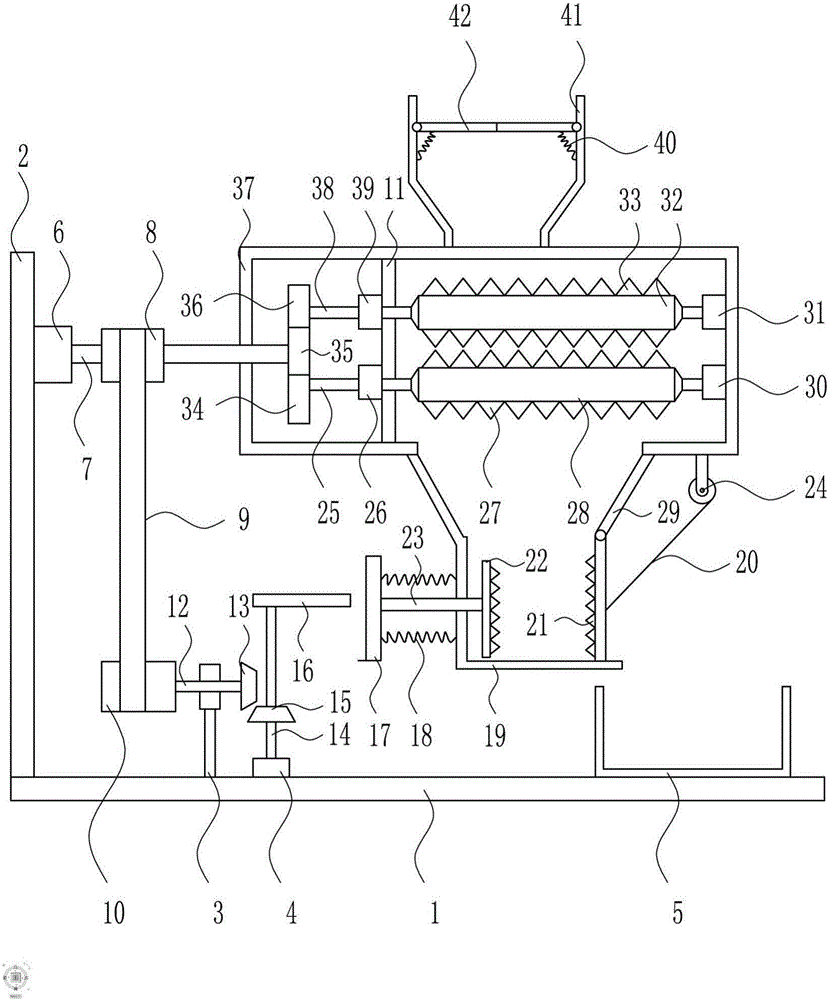

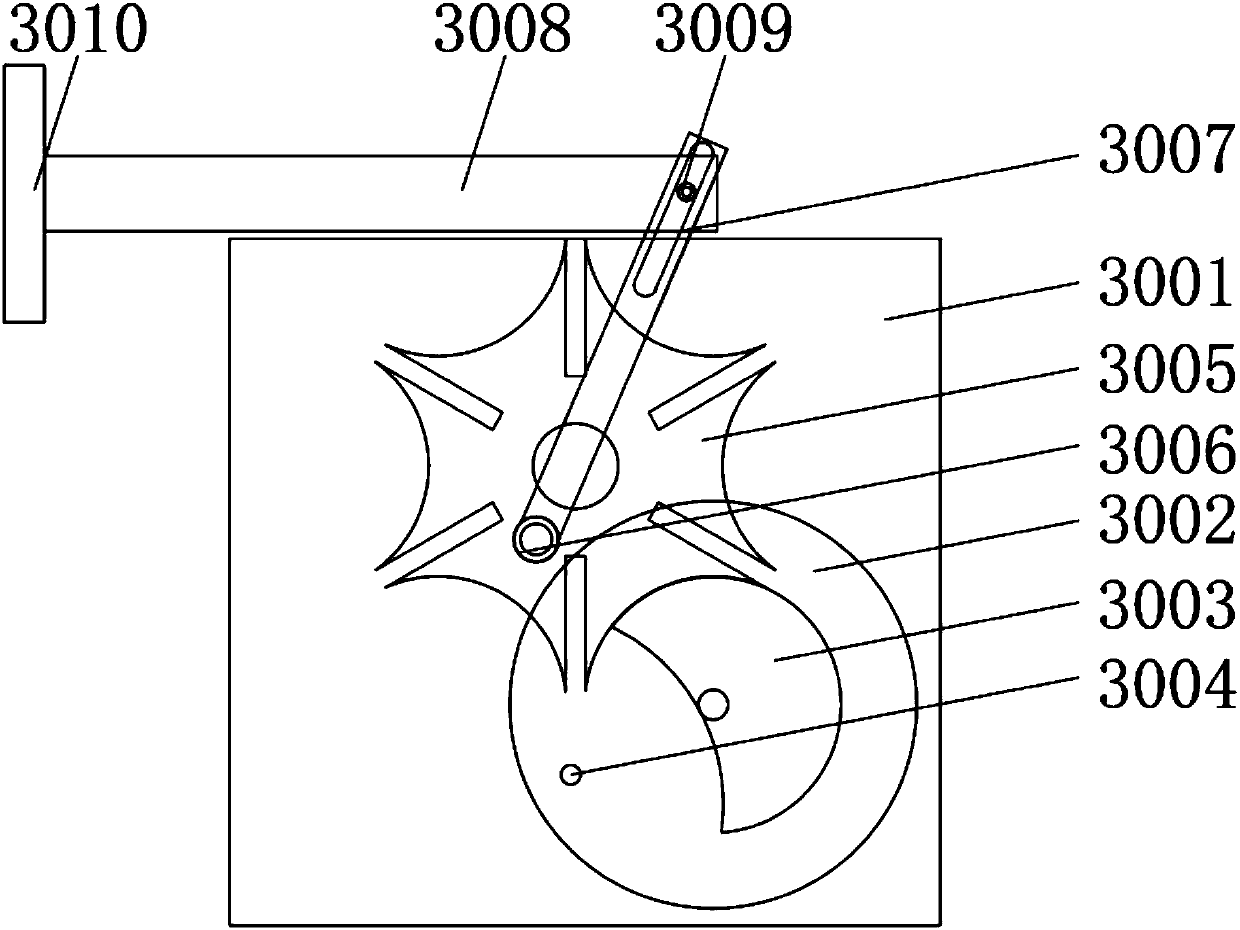

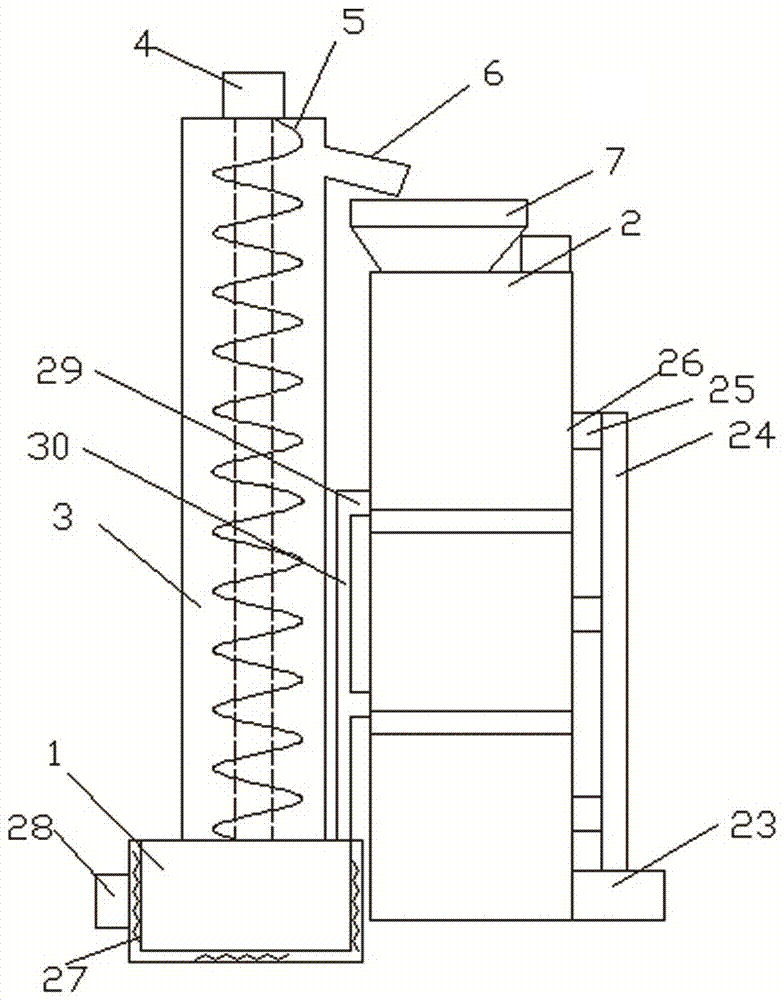

Self-circulation type coffee bean grinding and drying integrated machine

InactiveCN107597329AEvenly heatedImprove drying efficiencyGrain treatmentsFood treatmentDrive shaftPulp and paper industry

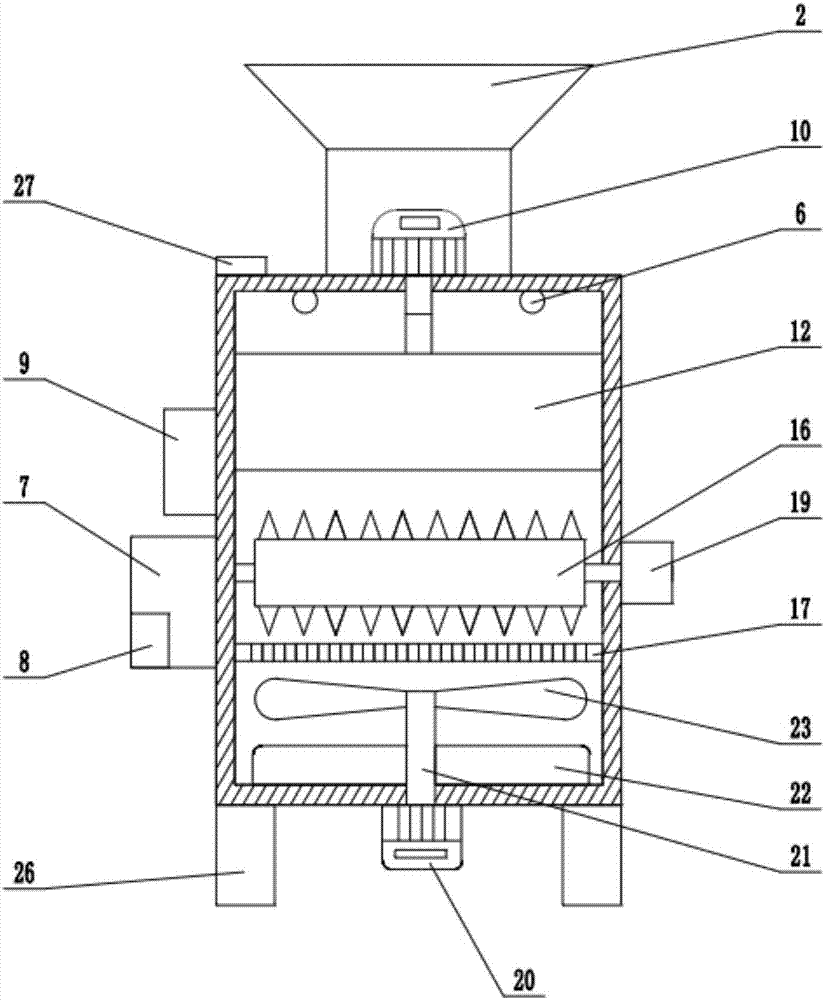

The invention discloses a self-circulation type coffee bean grinding and drying integrated machine. The machine comprises a shell, support legs, a feed port, a smashing motor, a smashing shaft, main smashing blades and a heating plate. The upper surface of the shell is fixedly connected with the smashing motor. The shaft extension end of the smashing motor is fixedly connected with the smashing shaft. The main smashing blades are distributed on the sidewall of the smashing shaft. A screen plate is arranged below the main smashing blades. A crankshaft is arranged below the screen plate. The journal of the crankshaft is sleeved with a connecting rod. The upper end of the connecting rod is hinged to the lower surface of the screen plate. A transmission shaft is further arranged below the screen plate. The middle portion of the crankshaft and the middle portion of the transmission shaft are sleeved with a first semi-gear and a second semi-gear correspondingly. A rotary shaft is arranged below the transmission shaft. A scraping plate is arranged below the rotary shaft. The machine conducts cyclic smashing on coffee beans in the smashing process to make smashing more thorough. The smashed coffee beans fall onto the bottom of the shell. The screen plate vibrates up and down to make the smashed coffee beans to pass through the screen plate. The coffee beans are turned over repeatedly through the scraping plate. Accordingly, the coffee beans are heated more uniformly.

Owner:杨鹏

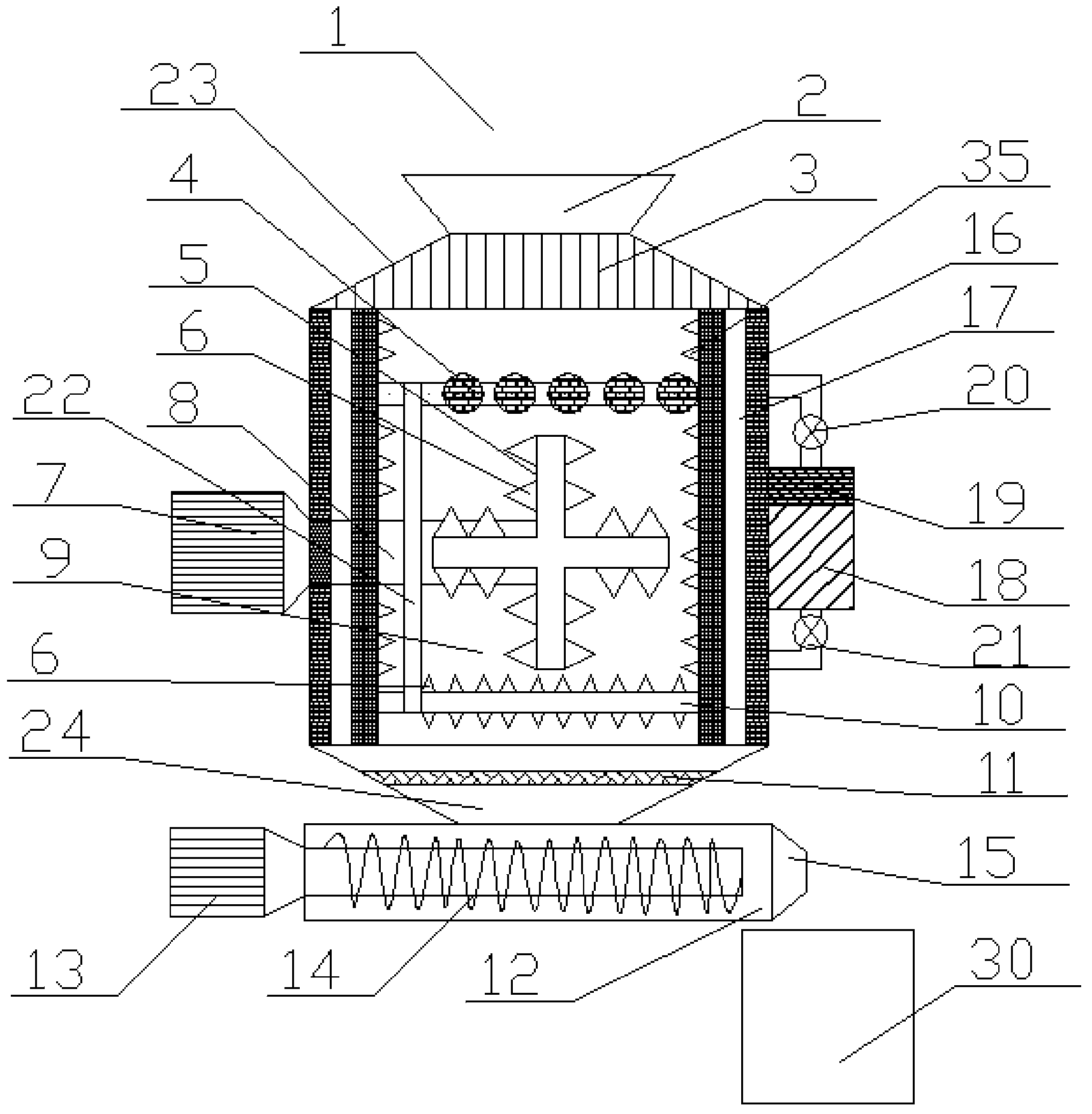

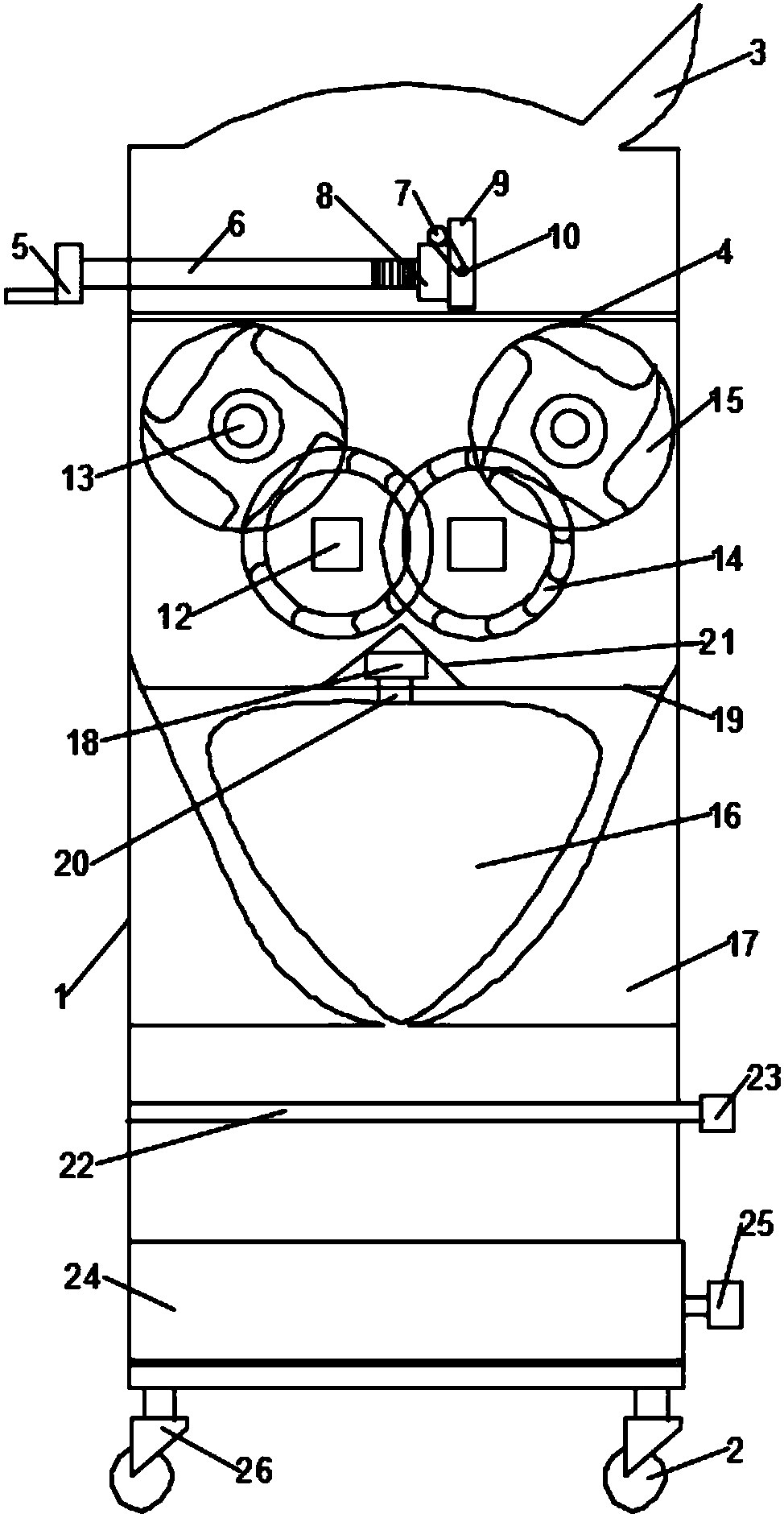

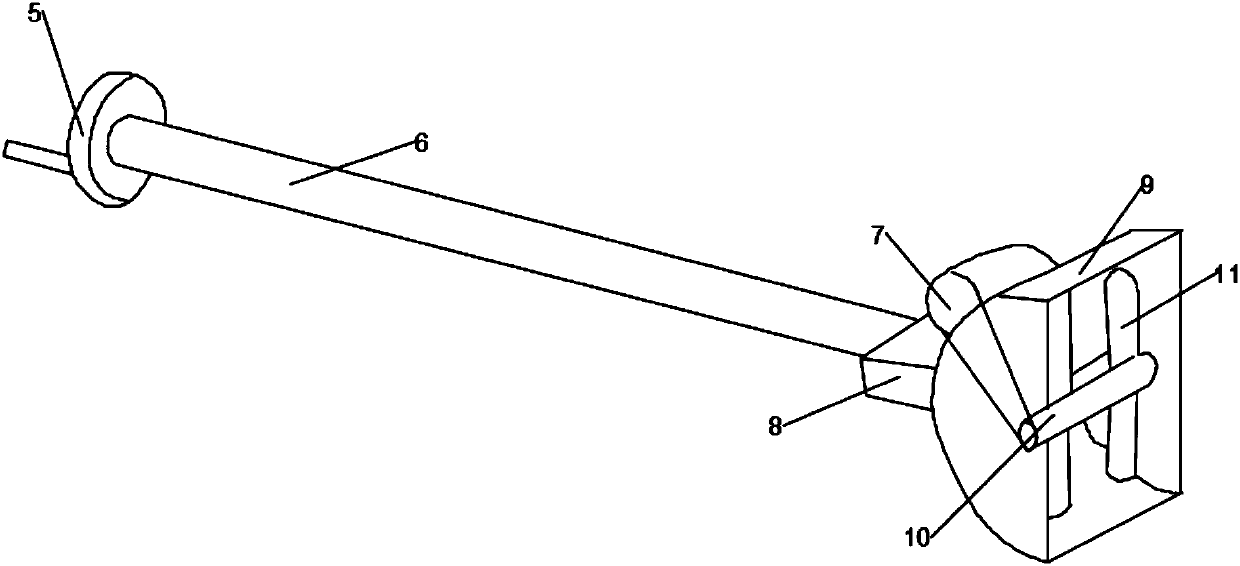

Glass smashing machine used for building industry

InactiveCN107096617AExtended stayImprove the heating effectDrying solid materialsDrying machines with non-progressive movementsPulverizerElectric heating

The invention discloses a glass smashing machine used for the building industry. The glass smashing machine comprises an outer shell, a feed inlet, a smashing roller, a guide plate, a smashing motor, a discharge outlet and supporting legs. The inner wall of the feed inlet is fixedly connected with an electric heating pipe. The top of the outer shell is fixedly connected with a water spray pipe. The upper surface of the outer shell is fixedly connected with a first crushing motor and a second crushing motor. The shaft extension ends of the first crushing motor and the second crushing motor are fixedly connected with crankshafts correspondingly. The outer shell is internally provided with a first crushing plate and a second crushing plate. Glass garbage is heated through the electric heating pipe, meanwhile, buffering plates and springs are matched, the retention time of the glass garbage in the feed inlet is prolonged, and the heating effect is improved; high-temperature glass is rapidly cooled through cold water, so that the glass becomes fragile and can be easily crushed, and the smashing effect is improved; the glass garbage between the first crushing plate and the second crushing plate can be crushed through crushing blades; and the glass garbage is further smashed through the smashing roller, so that the glass garbage is more thoroughly smashed.

Owner:ANHUI YIQI SOFTWARE TECH

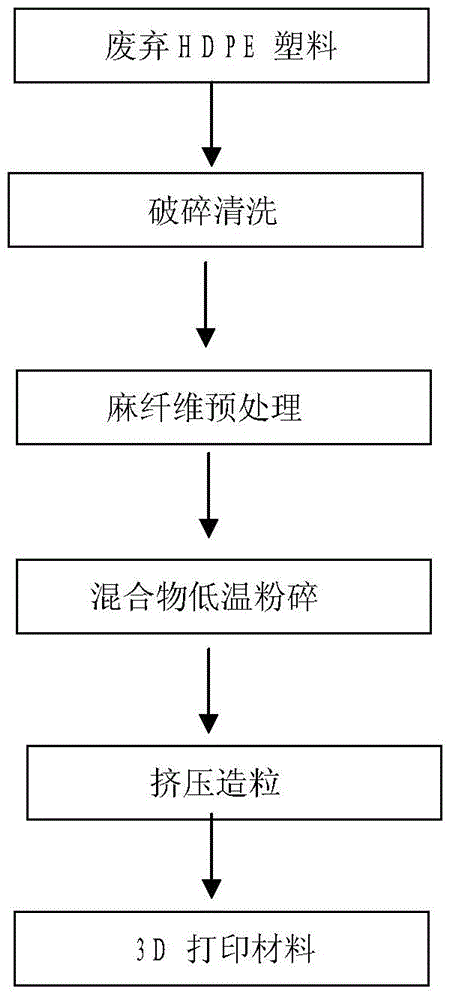

Method for preparing 3D printing material by use of recycled waste high-density polyethylene plastics

ActiveCN104629152AReduce performance lossSmall granularityAdditive manufacturing apparatusPlastic recyclingFiberCalcium silicate

The invention discloses a method for preparing a 3D printing material by use of recycled waste high-density polyethylene plastics. The raw material adopted by method is the waste high-density polyethylene plastics which are prepared from the following components in parts by weight: 100 parts of high-density polyethylene, 10-40 parts of jute fibers, 10-30 parts of calcium lignosulfonate, 10-30 parts of calciumsilicate, 0.8-1.4 parts of a coupling agent, 10 parts of a compatilizer and 20-30 parts of a plasticizer. The method comprises the following steps: 1, breaking and cleaning the waste plastics; 2, preprocessing the jute fibers; 3, adding additives, and grinding at low temperature; 4, extruding and pelletizing. According to the method, the waste high-density polyethylene plastics are recycled, and the additives are added to modify the recycled plastics and enhance the toughness, tensile strength and impact strength of the plastics, so that the plastics can be accepted as a material meeting 3D printing requirements, and the cost of the 3D printing material is greatly reduced.

Owner:康硕(河南)智能制造有限公司

Preparation method of dragon fruit juice

InactiveCN104248014AAnti-agingHave weight lossFood ingredient functionsFruit juiceAdditive ingredient

The invention relates to the field of food processing, in particular to a preparation method of dragon fruit juice. The preparation method comprises the steps of sorting and slicing; preparing dragon fruit peel juice; preparing diced dragon fruit; preparing lychee juice; blending the dragon fruit juice; sterilizing; filling, and the like. The dragon fruit juice prepared by the preparation method is sweet and tasty, is not added with any synthetic materials such as pigments, essences and preservatives and sufficiently utilizes peel, fruit pulp and fruit seeds of dragon fruit in the preparing process; no raw materials are wasted; and the obtained juice comprises all nutrition ingredients of dragon fruit. Lychee and dragon fruit are ingenuously matched, so that the prepared juice is mild and is suitable for people with different constitutions to drink; and meanwhile, lychee is sweet in taste and also improves taste of the juice by being matched with dragon fruit.

Owner:南宁振企农业科技有限公司 +1

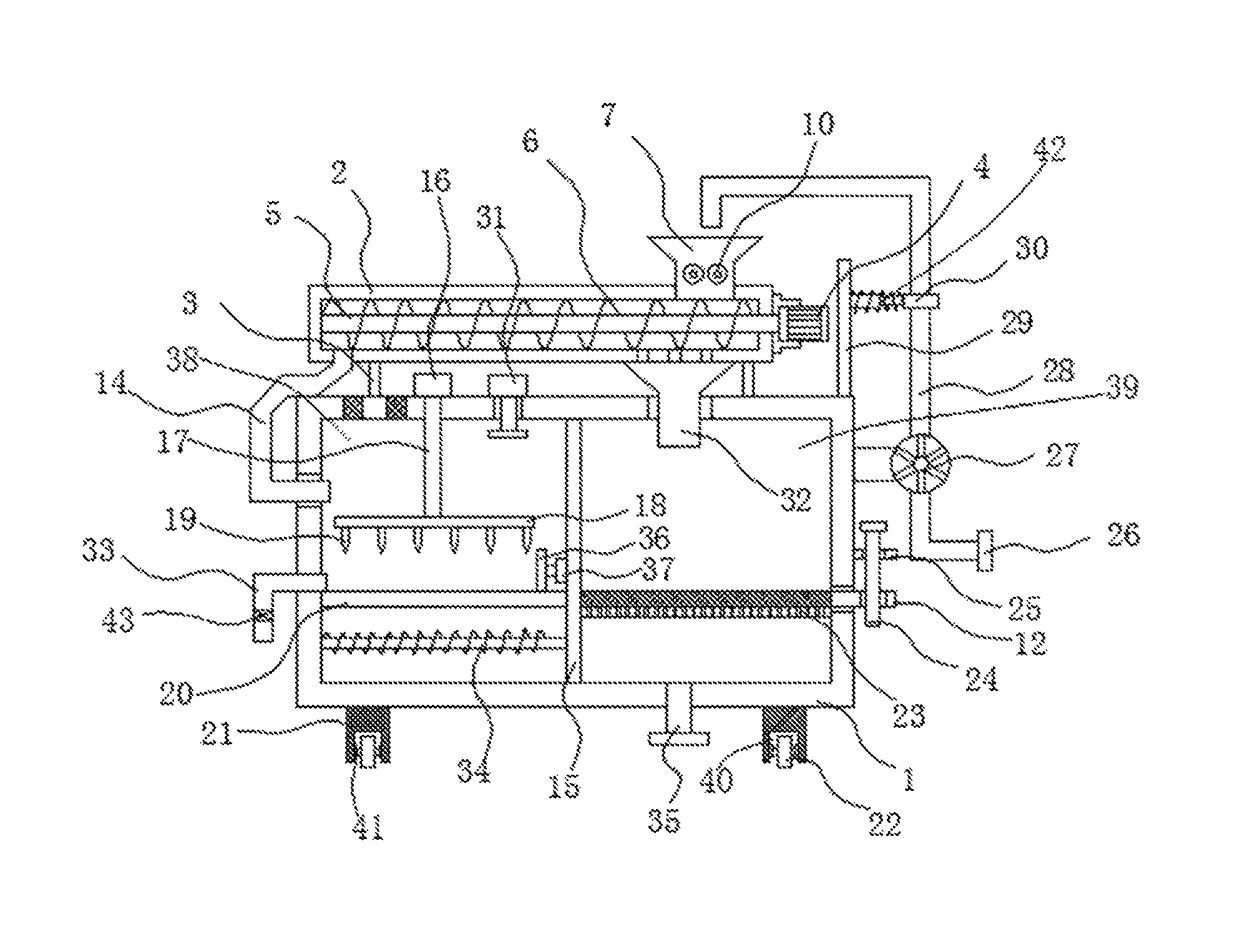

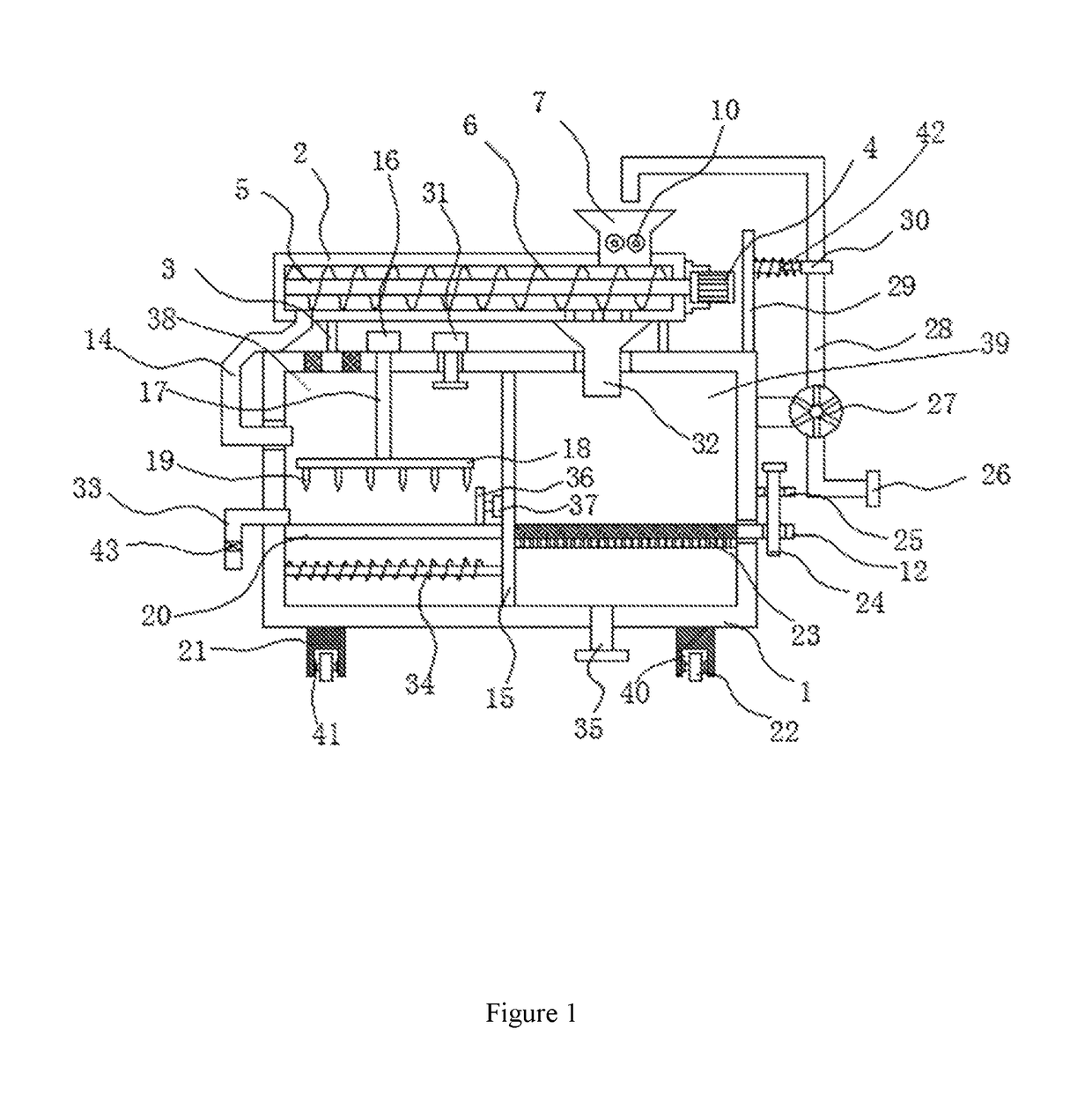

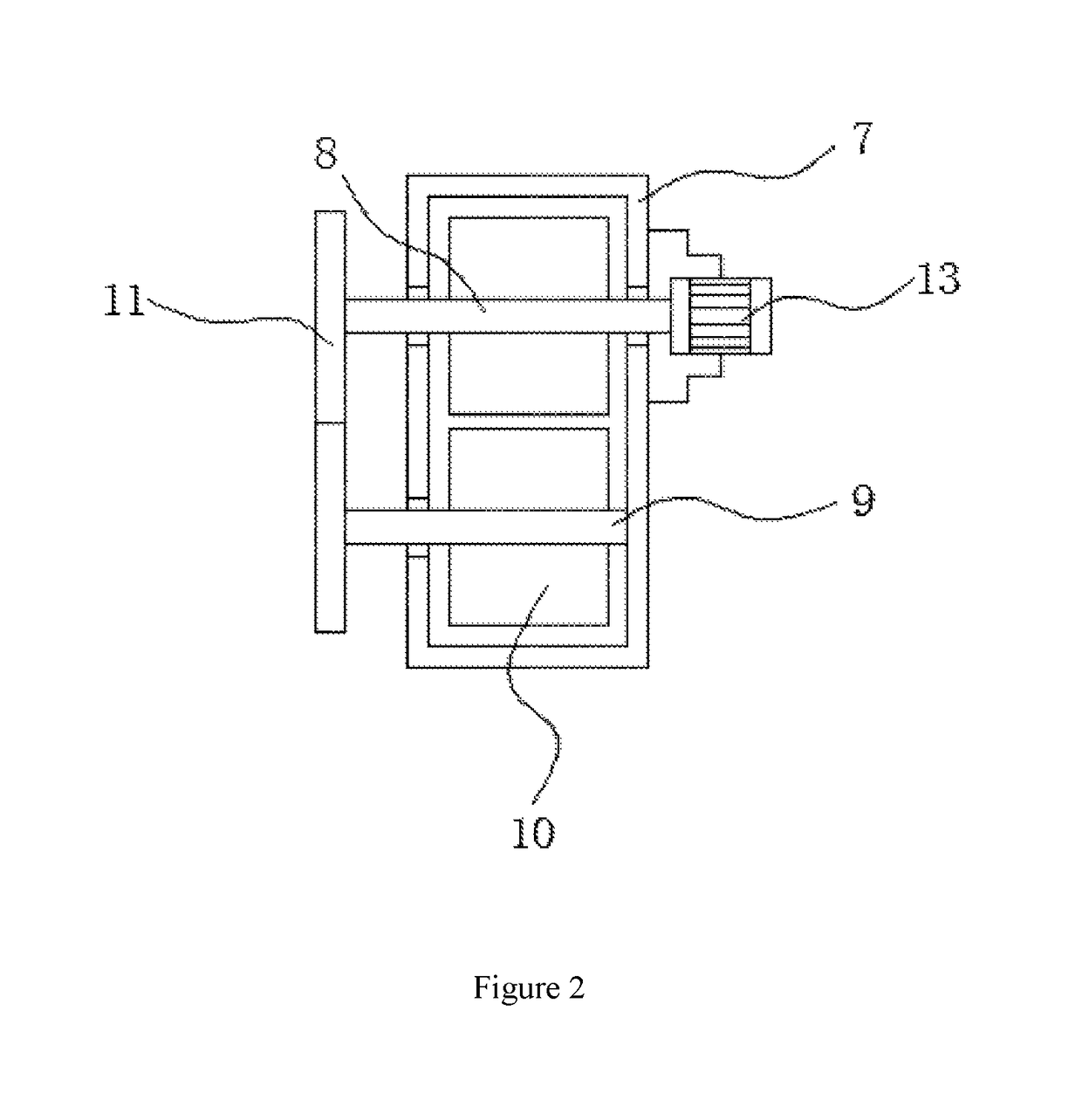

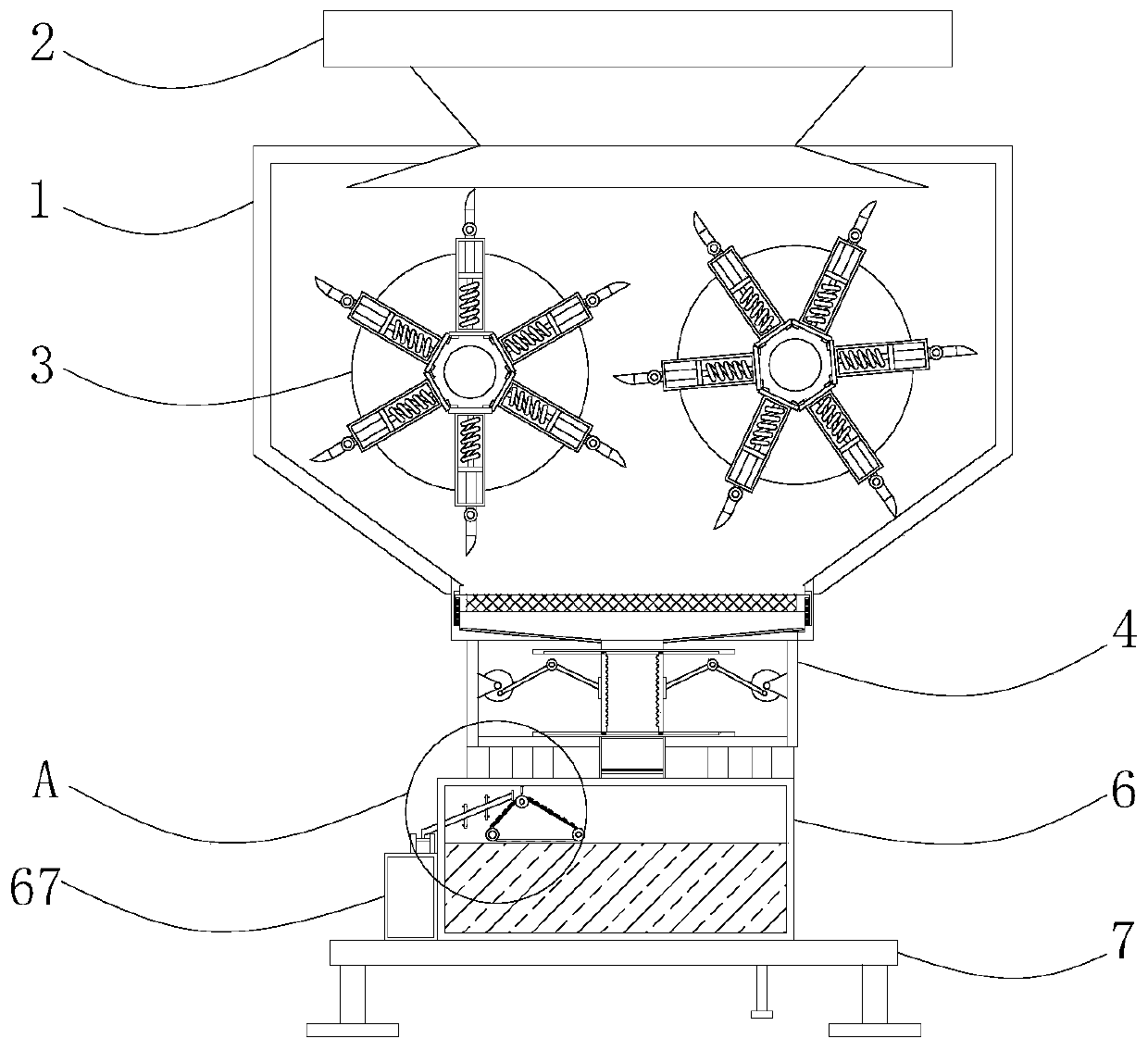

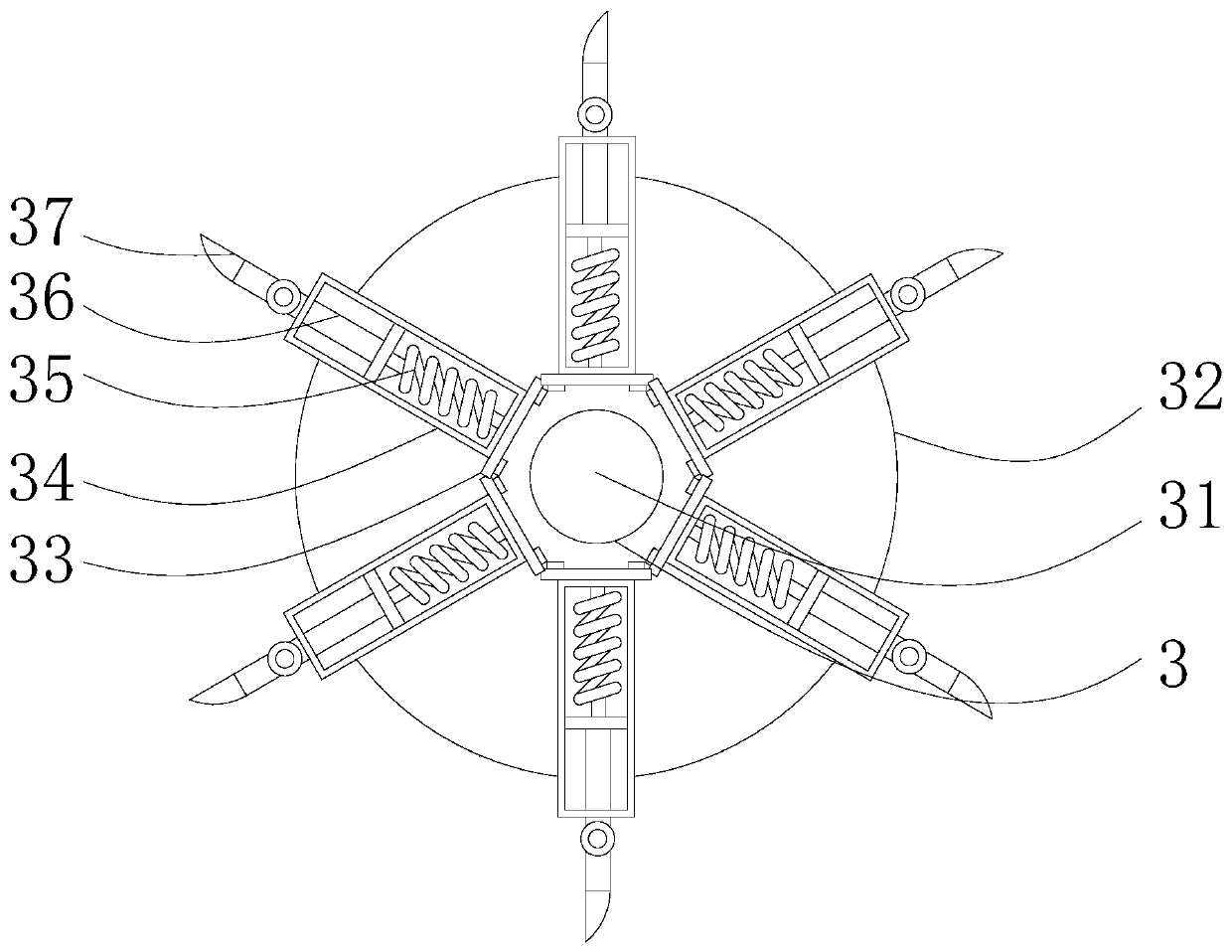

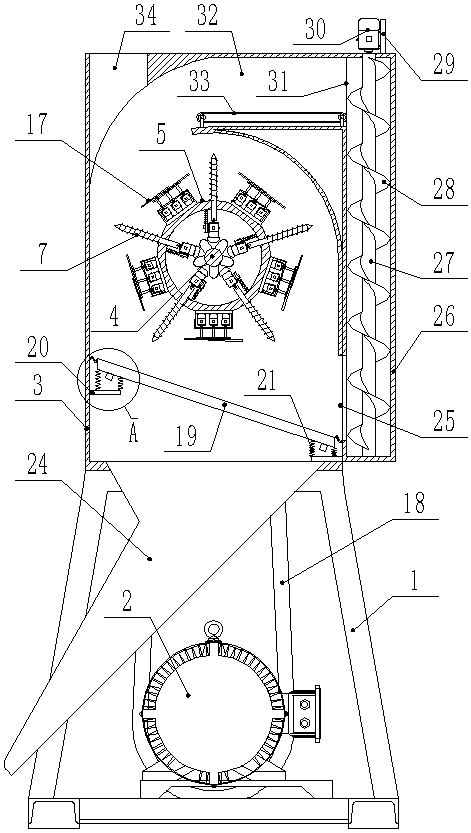

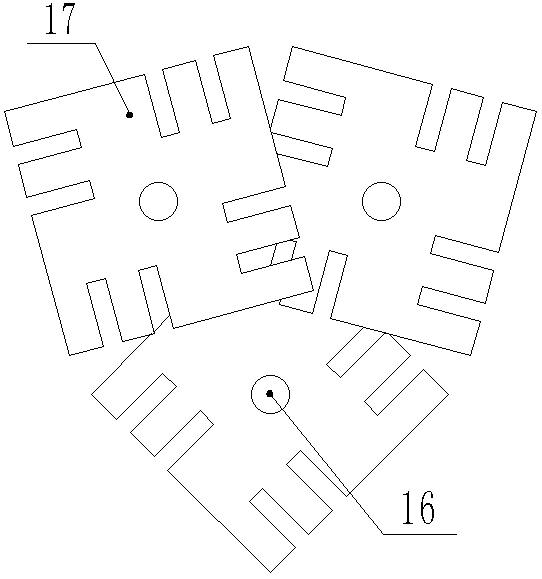

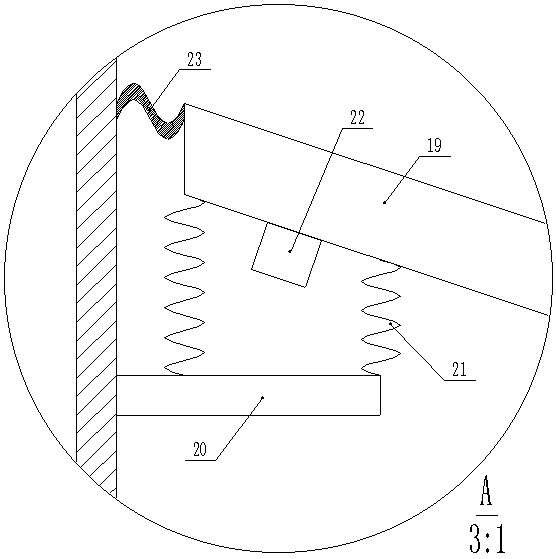

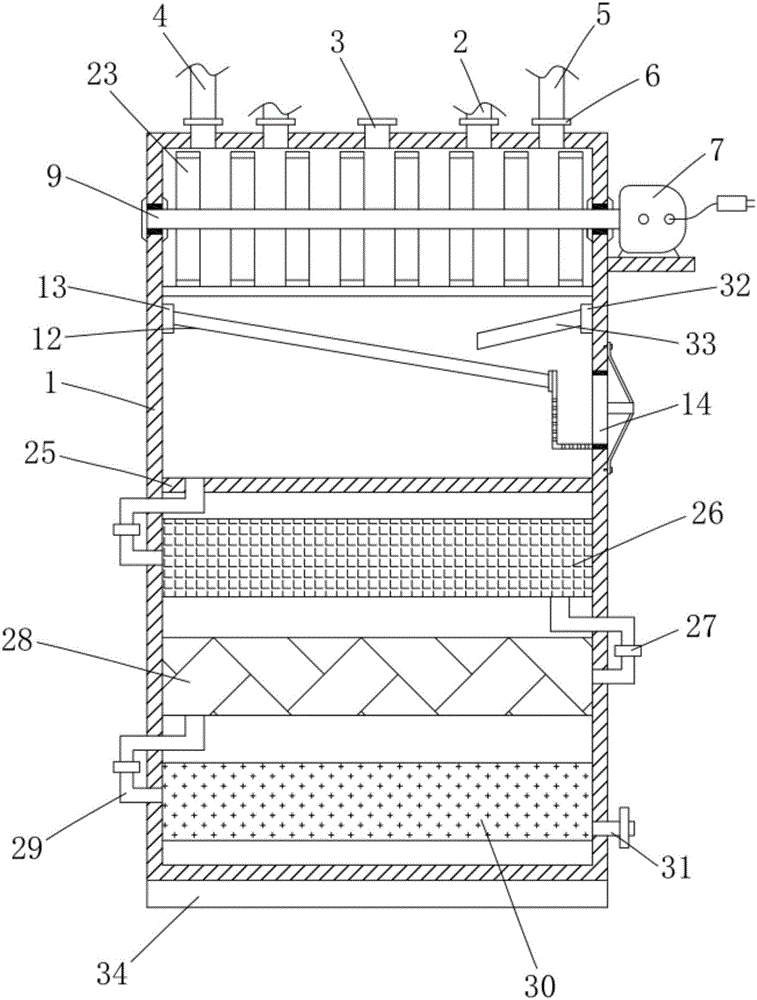

Anaerobic fermentation equipment for organic garbage

InactiveCN110004034ACut finely and thoroughlyCut thoroughlyBiological substance pretreatmentsGas production bioreactorsPhysical healthLitter

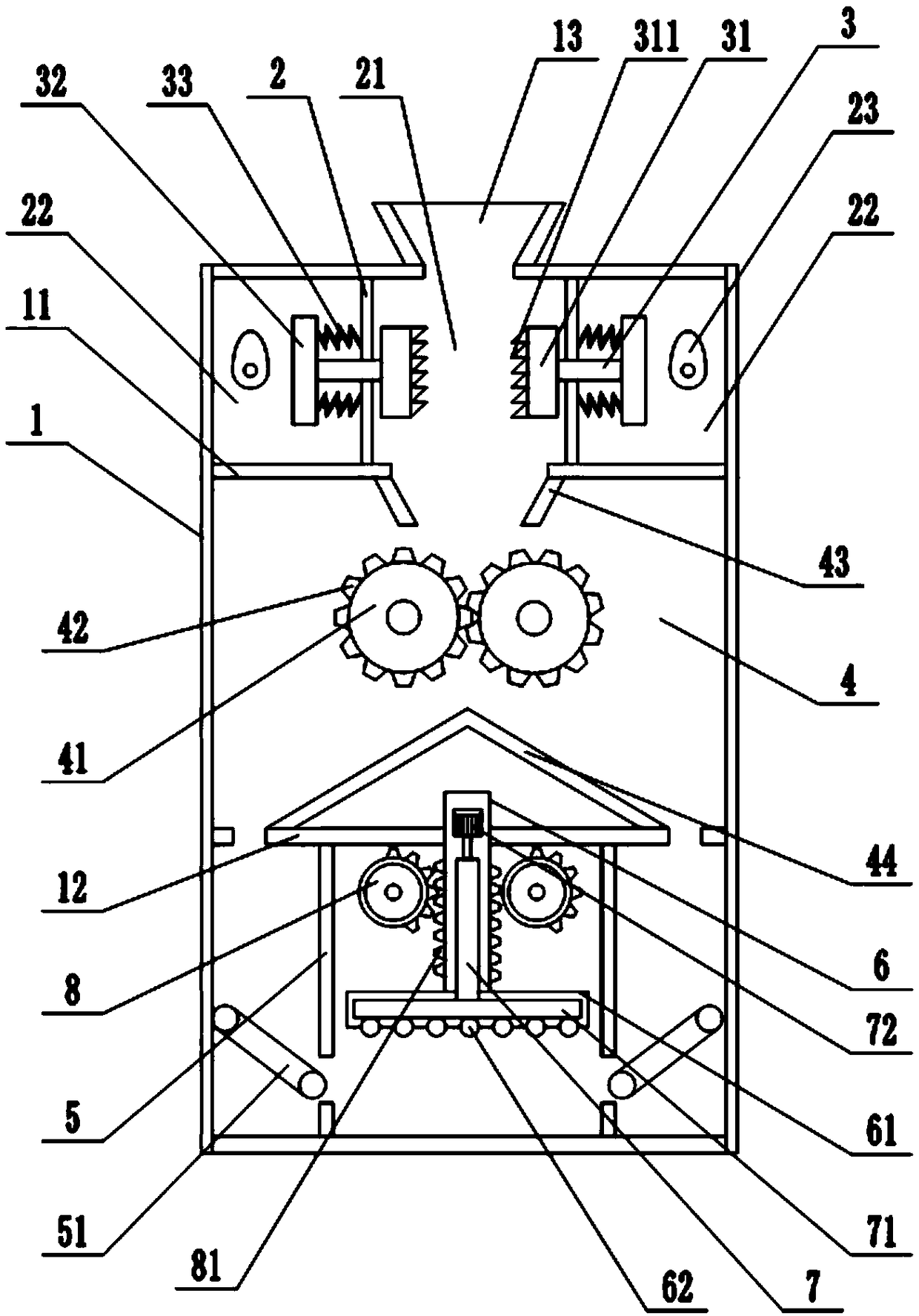

The invention discloses anaerobic fermentation equipment for organic garbage. The equipment comprises a shell, a cutting device, an extrusion device, a solid waste treatment device and a waste liquidtreatment device, the cutting device is installed in the shell, and the extrusion device is installed at the lower end of the shell; the solid waste treatment device is installed at the lower end of the extrusion device, the waste liquid treatment device is installed at the lower end of the solid waste treatment device, the cutting device comprises a motor, and a turntable is fixedly installed atthe front end of the motor. By arranging the cutting device, the phenomenon that the garbage adheres to blades, so that the smashing and cutting effects are influenced is avoided, it is guaranteed that the surfaces of the blades are kept clean, the organic garbage is cut more completely, and smashing is more complete; by arranging the extrusion device, the solid waste treatment device and the waste liquid treatment device, the organic garbage is treated more completely, the environment is protected, and the physical health of people is also ensured.

Owner:南通富海环保设备有限公司

Brick tea crushing device

ActiveCN108311220ASmash thoroughlyCrush fitPre-extraction tea treatmentGrain treatmentsBrickEngineering

The invention discloses a brick tea crushing device which comprises a fixing support. A motor A is fixed to the middle of the fixing support, a box is fixed to the upper end of the fixing support, a central shaft is horizontally fixed to the middle portion of the interior of the box, the central shaft is sleeved with a roller rotationally connected with the side wall of the box, a cavity is formedbetween the outer wall of the central shaft and the inner wall of the roller, the axis of the central shaft is the same as the axis of the roller, a plurality of drill bits in sliding connection withthe roller are annularly inserted into the roller in the direction perpendicular to the tangent line, the tails of the drill bits point to the axis, the tails of the drill bits are provided with motors B with output shafts fixed to the drill bits, sleeves are fixed to the motors B, positioning rods fixedly connected with the inner wall of the roller are inserted into the sleeves, and springs A are fixed between the inner wall of the roller and the sleeves. The brick tea crushing device is high in crushing speed and good in thorough crushing effect, the brick tea crushing efficiency is greatlyimproved, brick tea chippings can be automatically screened, unqualified crushed products can be automatically circulated to be crushed, manpower consumption is reduced, operation is simple, and thebrick tea crushing device is suitable for crushing all brick tea on the market.

Owner:YIYANG SHENGXI MACHINERY EQUIP MFG

Traditional Chinese medicine powder grinding and crushing integrated machine

The invention discloses a traditional Chinese medicine crushing and grinding machine, which comprises a workbench, supporting feet, a crushing tank, a feeding port, a crushing motor, a crushing shaft, crushing blades and a collection box; the upper surface of the workbench is fixedly connected with side plates, side plates The right end of the shaft is fixedly connected with a fixed plate, a crushing tank is arranged between the two side plates, the top of the crushing tank is fixedly connected with a crushing motor, the side wall of the crushing shaft is fixedly connected with a main crushing blade, and the lower surface of the driven gear is fixedly connected with a The driven shaft is equipped with a sieve plate under the crushing blade, and the lower end of the crushing tank is fixedly connected with a grinding plate. The traditional Chinese medicine is crushed by the cooperation of the main crushing blade and the auxiliary crushing blade to improve the crushing effect. It is more thorough and improves the crushing efficiency; during the crushing process, the crushing tank shakes left and right to make the crushing more thorough, and the grinding tank moves left and right to drive the grinding plate to move left and right to grind the traditional Chinese medicine. .

Owner:王冠伟

Pasture smashing device for animal husbandry

The invention relates to an animal husbandry smashing device, in particular to a pasture smashing device for animal husbandry. The pasture smashing device for animal husbandry is complete and uniform in smashing and simple in structure. In order to achieve the technical aim, the pasture smashing device for animal husbandry comprises a bottom plate, a left frame, a guide sleeve, a first bearing seat, a collecting frame, a motor, a first rotary shaft, a small belt wheel, a flat belt, a large belt wheel, an installing plate, a second rotary shaft, a first bevel gear, a third rotary shaft, a second bevel gear and the like. A smashing box is arranged over the bottom plate. The effects of being complete and uniform in smashing and simple in structure are achieved, the manufacturing cost is low, the structure is reasonable, and maintenance and repair are easy; use is convenient, investment of manpower and material resources is reduced, and cost is reduced.

Owner:邵鹏程

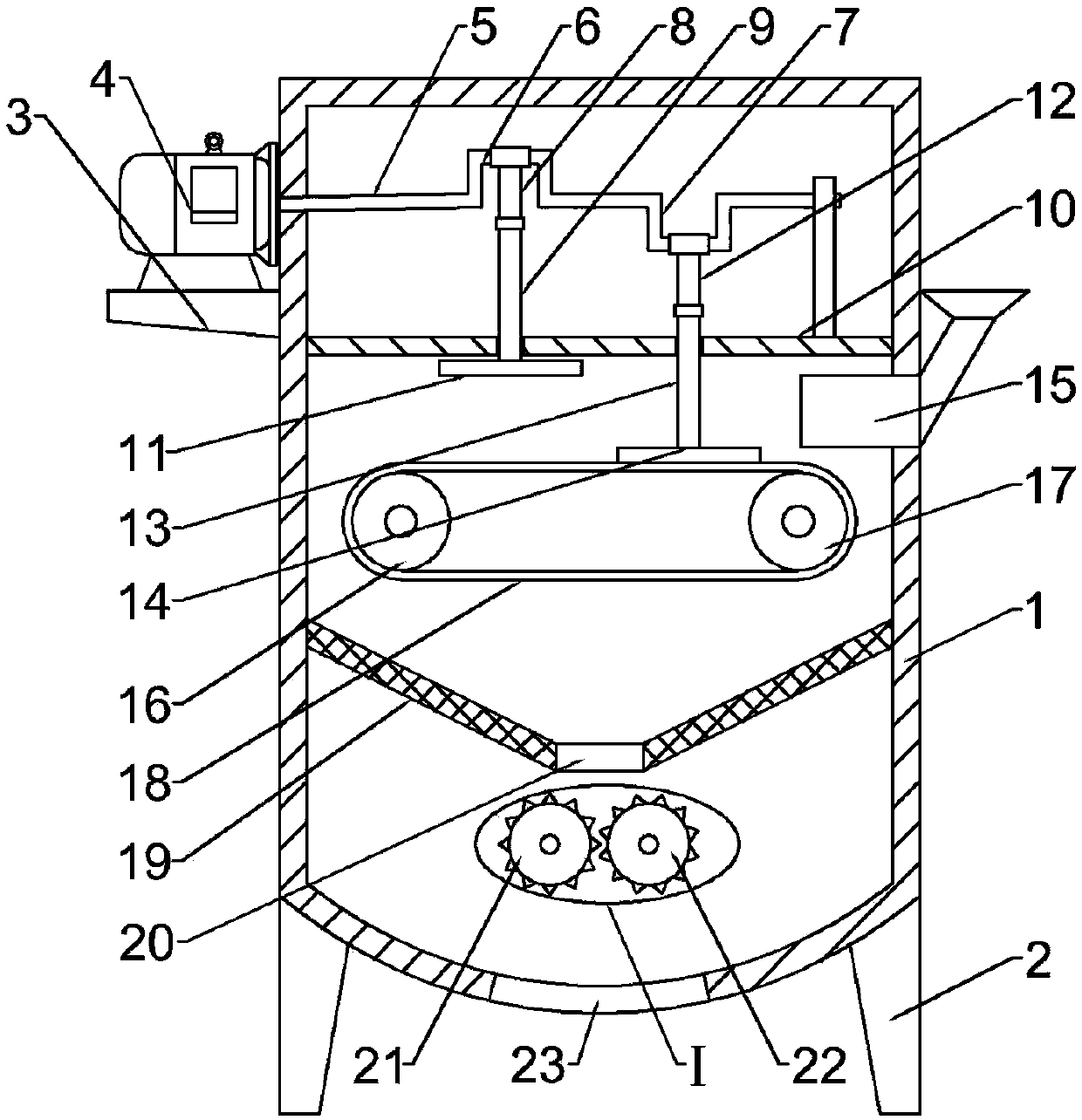

Building waste crushing apparatus

ActiveCN106622473ASimple enoughSimple and fast operationMagnetic separationGrain treatmentsBulky wasteMetal

The invention discloses a building waste crushing apparatus, comprising a bottom plate; four supports are arranged on the upper surface of the bottom plate; a primary crushing unit is arranged among the upper ends of the four supports, the upper end of the primary crushing unit is provided with a feed port, the upper end of the feed port is provided with a feed trough, a first motor is arranged on one side of the primary crushing unit, and the lower end of the primary crushing unit is provided with a discharge port; it is possible to crush bulky waste through the primary crushing unit so that crushing is more convenient; a secondary crushing unit is arranged below the primary crushing unit; it is possible to crush the waste thoroughly through the secondary crushing unit so that crushing is more thorough; it is possible to attract metals in the crushed waste through an electromagnetic plate so that the metals can be recycled; the building waste crushing apparatus is simple in structure and simple to operate, and is capable of crushing waste thoroughly and sorting the metals in the waste in order to collect and reuse the metals.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

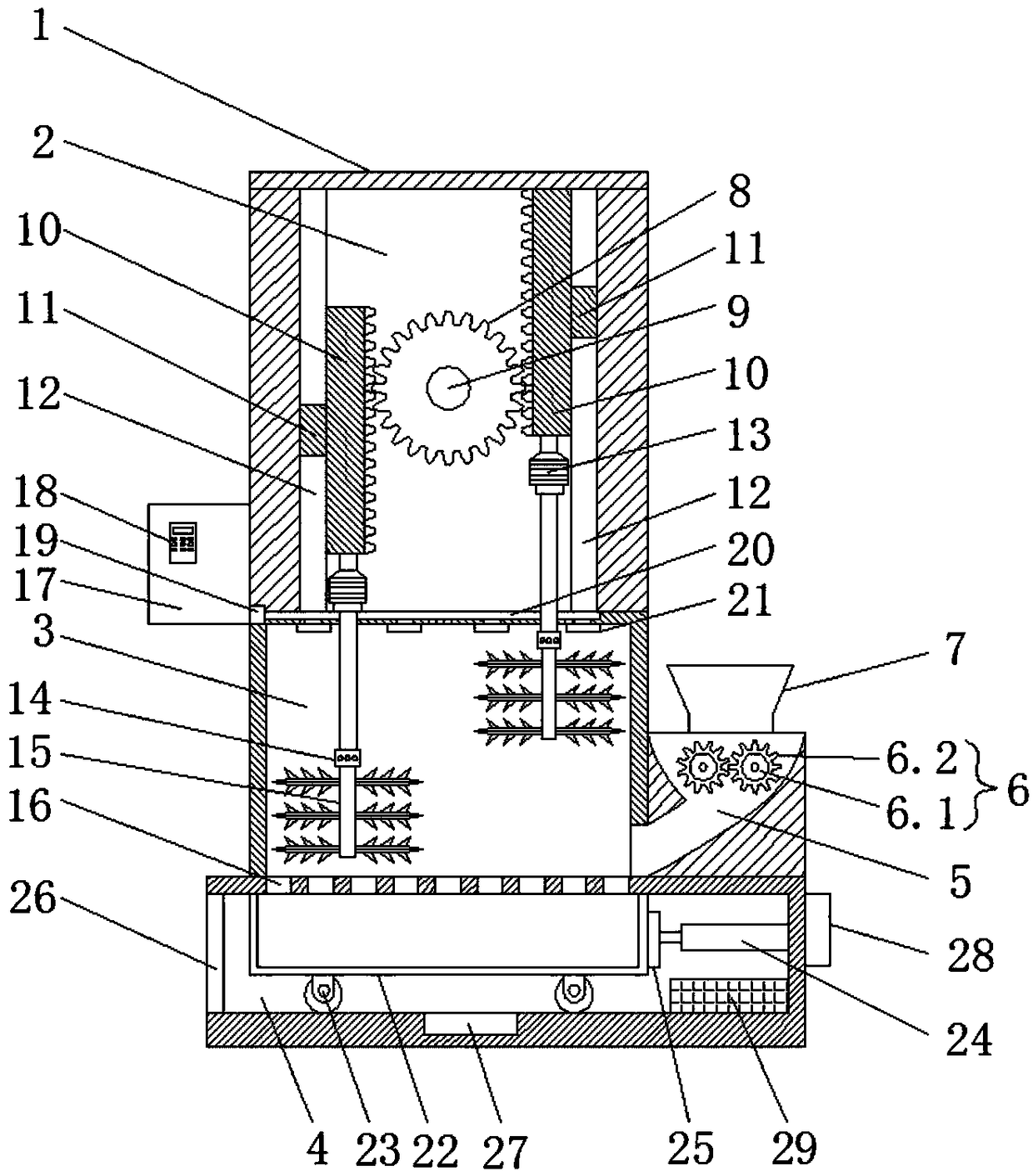

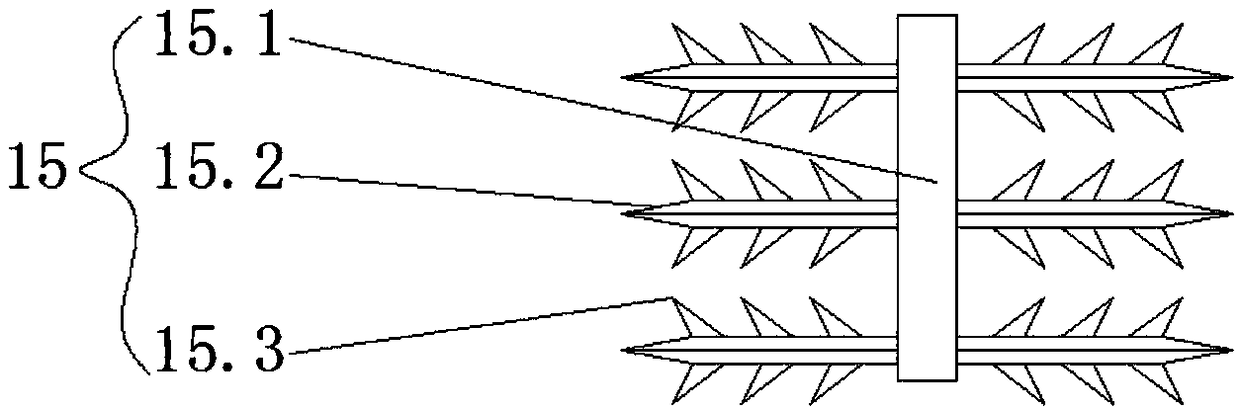

Intelligent crushing treatment equipment

InactiveCN108176452ABroken fastImprove crushing efficiencyGrain treatmentsChemicalsCouplingMedical waste

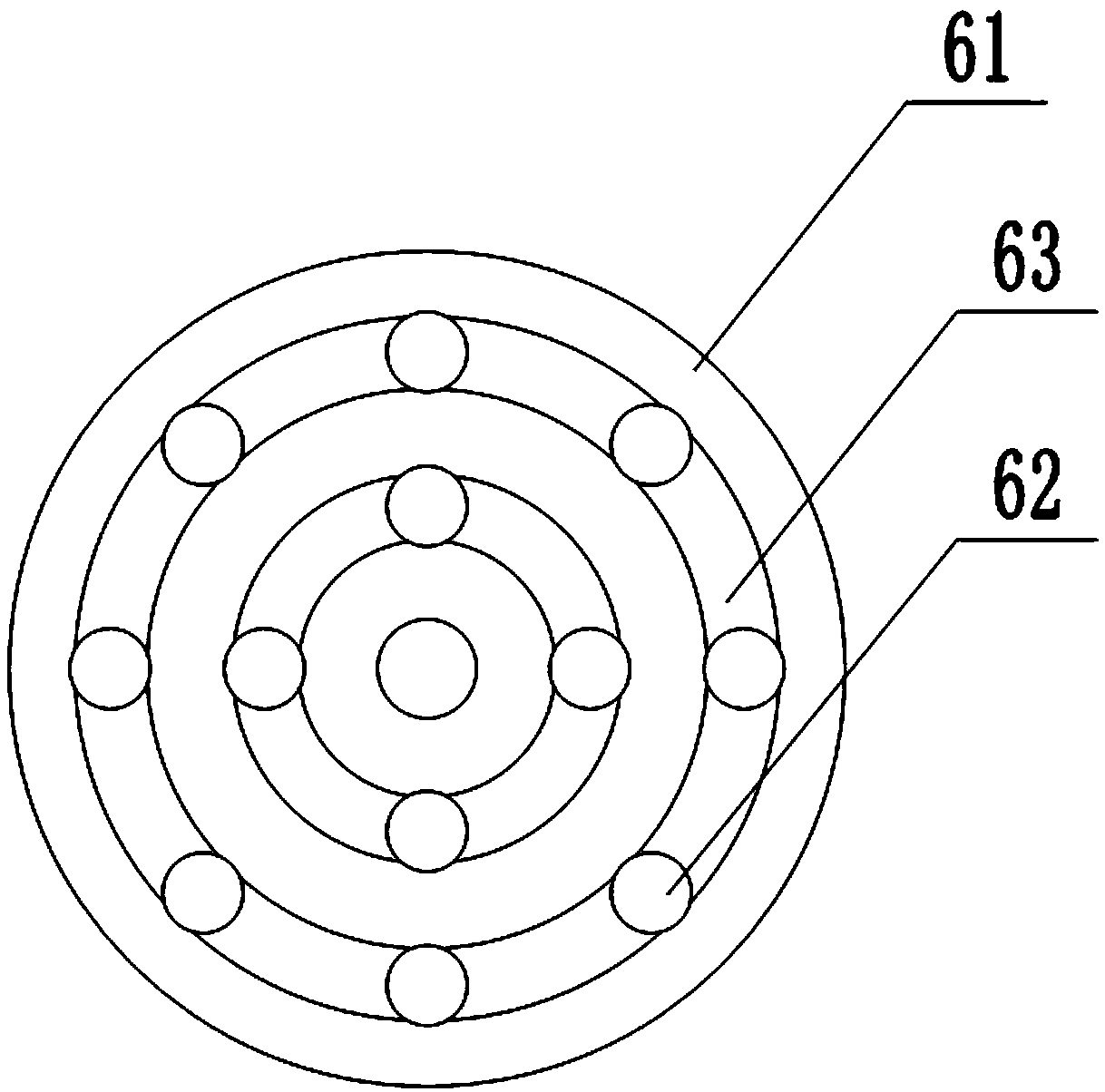

The invention discloses intelligent crushing treatment equipment, and relates to the technical field of medical waste treatment equipment. The intelligent crushing treatment equipment comprises an enclosure, wherein a driving cavity, a secondary crushing cavity and a collecting cavity are sequentially formed in the enclosure from top to bottom; a primary crushing cavity communicated with the secondary crushing cavity is formed in the outer wall of the secondary crushing cavity; a grinding mechanism is arranged in the primary crushing cavity; a driving gear is arranged in the driving cavity; the driving gear is connected with a forward and reverse rotation motor; two sides of the driving gear are engaged and connected with vertical racks; guide sliding blocks are arranged on the back surfaces of the racks; guide sliding grooves matched with the guide sliding blocks are formed in the inner side wall of the driving cavity; the bottom parts of the two racks are both connected with rotatingmotors; output shafts of the rotating motors stretch into the secondary crushing cavity and are connected with smashing mechanisms through couplers; a plurality of discharging holes communicated withthe collecting cavity are formed in the bottom part of the secondary crushing cavity. The intelligent crushing treatment equipment disclosed by the invention has the advantages of simple operation, high waste smashing efficiency and high automation degree.

Owner:郑州神盾智能科技有限公司

Method for inoculating stock spawn of edible fungi

The invention relates to a method for inoculating stock spawn of edible fungi. The method comprises the steps: stock culture compost manufacturing; inoculating; culturing; compounding; loading; sterilizing; inoculating; culturing; sterile water manufacturing; conducting sterilization for 30 min at 121 DEG C by a pulverizer, after asepsis is guaranteed and the temperature is lowered to indoor temperature, taking out the compost from a stock spawn bacteria culturing bottle, wherein the stock spawn overgrows the compost, mixing the compost with the sterile water, grinding the mixture in the pulverizer, and mixing the sterile water with the compost overgrown by hyphae, wherein the proportion of the sterile water and the compost is one L sterile water is mixed with 50-100 g compost; filtrating the ground bacteria culture, taking a filtered bacterium solution, and diluting the bacterium solution by 80-100 times for production inoculation. By grinding the compost containing the stock spawn, the hyphae are segmented, the growing points of the edible fungi are greatly enlarged, the propagation expansion multiple is increased greatly, and the production cost is reduced. The sterile water is added in the grinding process, so that the grinding is more sufficient, the growing points of the edible fungi are further increased; the sterile water can serve as a great carrier of the stock spawn of the edible fungi, the physiological activity of the stock spawn of the edible fungi is guaranteed before culturing, and the fruiting rate of cultivated species is improved.

Owner:青岛联合菌业科技发展有限公司

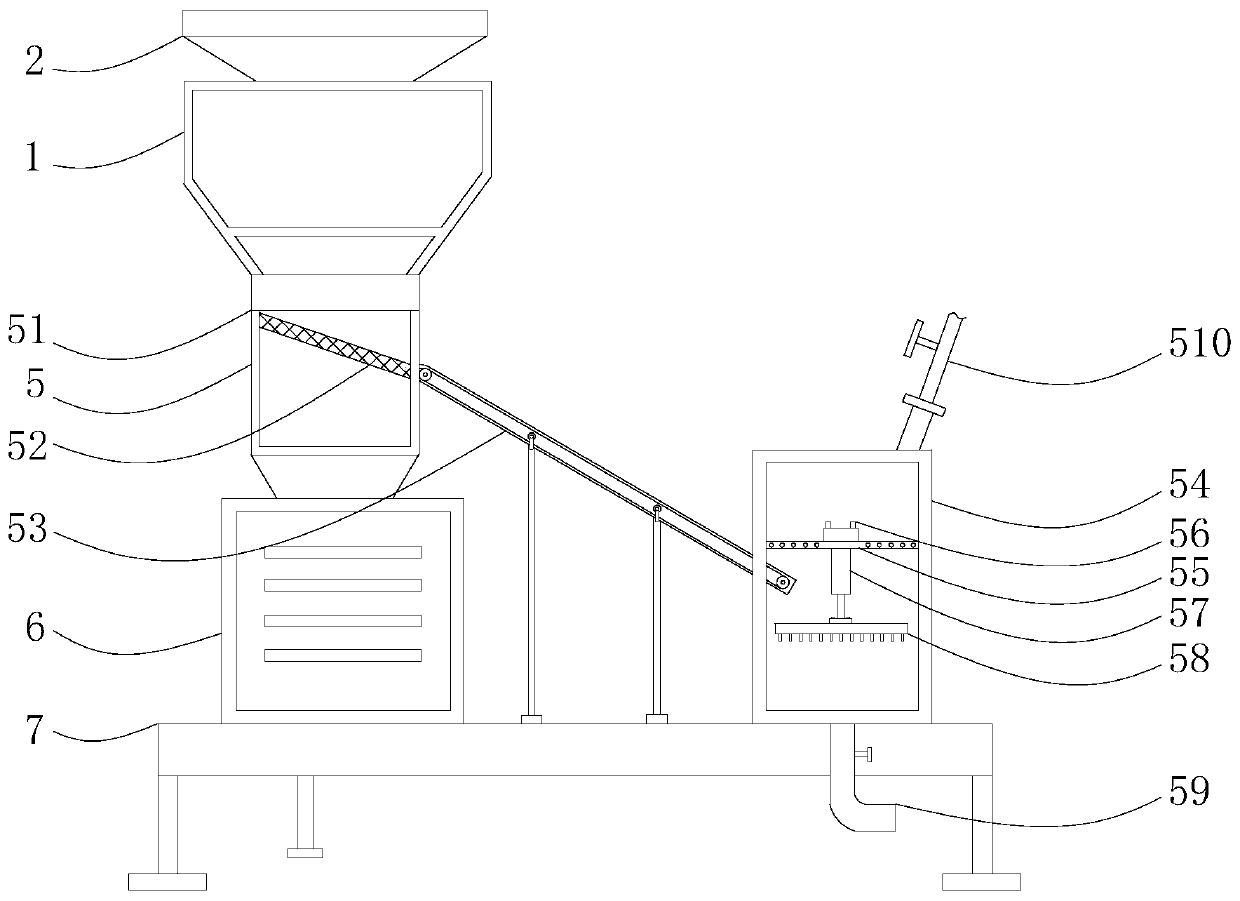

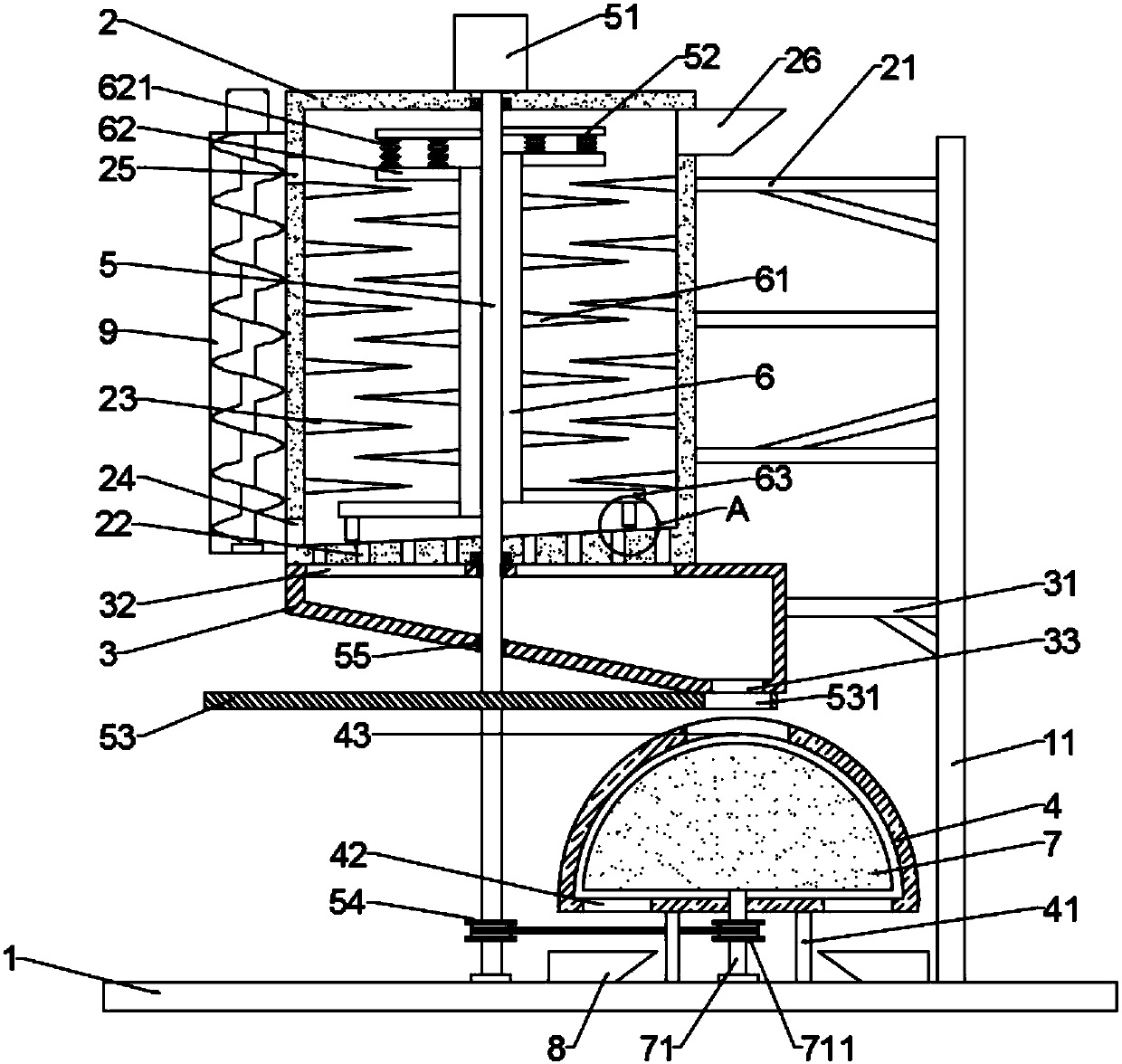

Pulverizing and grinding all-in-one machine for preparing Chinese herbs

ActiveCN107755050ARealize circular crushingGuaranteed uniformityGrain treatmentsDrive shaftMaterial transfer

The invention discloses a pulverizing and grinding all-in-one machine for preparing Chinese herbs. The pulverizing and grinding all-in-one machine comprises a pulverizing box, a material transfer boxand a grinding shell which are arranged on a base from top to bottom as well as a transmission shaft connected with the base in a rotating manner; the transmission shaft is disposed on the center of the pulverizing box, the transmission shaft is connected with a plurality of tool posts in a sliding manner, and the tool posts are provided with movable cutter blades; the material transfer box is fixed on the bottom of the pulverizing box, and the periphery of a shaft body, disposed below the material transfer box, of the transmission shaft is fixedly provided with a rotating baffle plate; the grinding shell is disposed below the right of the material transfer box; a grinding block is arranged in the grinding shell. By integrating a pulverizing step and a grinding step of the Chinese herbs, the working efficiency is increased; moreover, the Chinese herbs can be efficiently and thoroughly pulverized; the ground Chinese herb particles are high in uniformity.

Owner:武汉钧安制药有限公司

Industrial grinder suitable for chemical engineering, pharmacy and food material processing

The invention discloses an industrial grinder suitable for chemical engineering, pharmacy and food material processing. The industrial grinder comprises a grinder body and a storage bin, wherein the grinder body comprises a feed port, a variable frequency motor, a grinding bin, a stirring wheel and a discharge port; the feed port is arranged above the grinding bin, and a flow guiding plate is arranged in a feed channel between the feed port and the grinding bin, an extrusion roller is arranged below the flow guiding plate, the stirring wheel and a rotating shaft are arranged in the grinding bin, and the surfaces of the stirring wheel and the rotating shaft are respectively provided with teeth; the variable frequency motor is arranged on the grinding body, and the variable frequency motor is capable of respectively driving the stirring wheel, the rotating shaft and the extrusion roller to rotate through a connecting piece and / or a transmission tape; the bottom of the grinding bin is provided with an inverted trapezoidal discharge funnel, a filter net is arranged in the discharge funnel, a material conveying cavity is arranged below the grinder body, and the discharge port is formed at one side of the material conveying cavity. The material can be completely ground, the grinding effect is good, and the grinding efficiency is high.

Owner:YANCHENG XINANZHOU PHARMA +1

Crusher for preparation of agricultural fertilizer

InactiveCN107876140AStir quicklyFast crushingRotary stirring mixersTransportation and packagingAgricultural scienceReciprocating motion

The invention discloses a crusher for preparation of agricultural fertilizer. The crusher comprises a frame body and a crushing box arranged on the frame body, wherein a feeding hopper is arranged onthe top of the crushing box; a material storage cavity is formed in the bottom of the crushing box; the bottom of the material storage cavity is connected with a discharging hopper; a material storagebox is arranged under the discharging hopper; a second motor is fixed to one side of the material storage box, and a control box is arranged on the other side of the material storage box; a dust collecting box is arranged on the side, far away from a first motor, of the top end of the crushing box; and a fan is arranged on the outer side of the dust collecting box. Stirring blades are arranged inthe material storage box of the crusher and can be used for rapidly stirring the fertilizer, a heating wire is arranged inside the material storage box and can be used for heating the fertilizer, thus the wet caking fertilizer can be rapidly stirred into particles, and the stirring process is accelerated. A sliding rod, a hydraulic telescopic rod and a third motor are arranged, so that crushing fan blades can do reciprocating motion back and forth while rotating and crushing is more thorough.

Owner:CHANGSHU HAOYU ELECTRONICS INFORMATION TECH

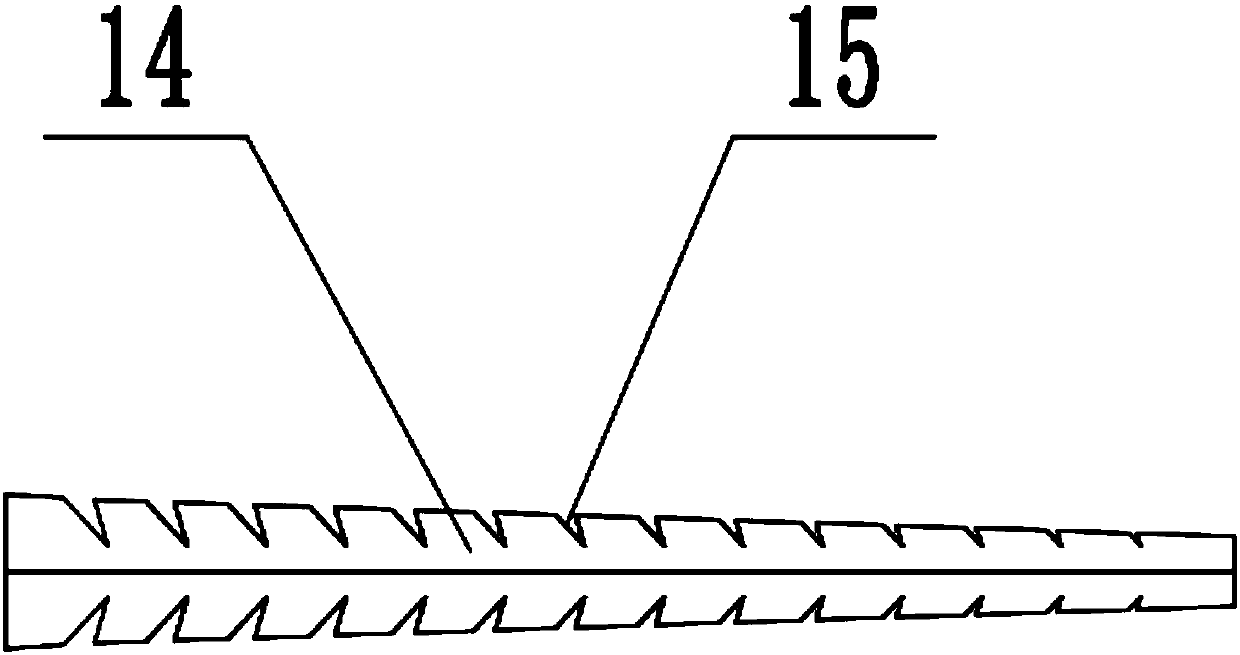

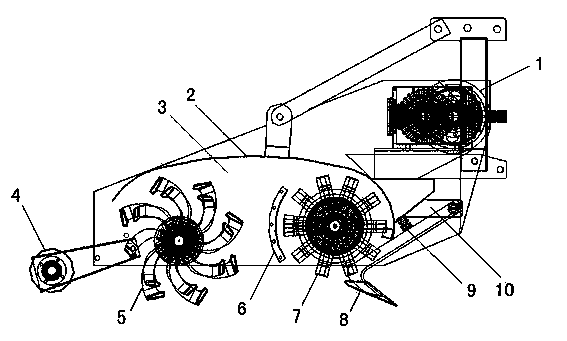

Straw smashing and stubble breaking rotary tillage all-in-one machine

InactiveCN103650676ASmash thoroughlyPrevent moisture from evaporatingSpadesCrop conditionersAgricultural engineeringEnergy consumption

The invention discloses a straw smashing and stubble breaking rotary tillage all-in-one machine, and relates to the technical fields of straw returning machines and rotary tillage. The straw smashing and stubble breaking rotary tillage all-in-one machine comprises a machine frame, a machine case, a power transmission mechanism and a straw smashing device. The machine case is fixed onto the machine frame, the straw smashing device is arranged on the front portion inside the machine case, the straw smashing device rotates counterclockwise, a baffle is arranged behind the straw smashing device, the two ends of the baffle are fixed onto side plates of the machine case, a gap exists between the upper portion of the baffle and the machine case, a stubble breaking rotary tillage device is arranged on the rear portion of the baffle, and the machine case extends to the rear portion of the stubble breaking rotary tillage device. Straw is guided to the position behind the stubble breaking rotary tillage device under the action of the baffle and the machine case. Furthermore, the front side of the machine case is further provided with a straw combing plough. Press wheels are arranged on the rear portion of the machine case. The straw smashing and stubble breaking rotary tillage all-in-one machine has the advantages that straw smashing field returning and stubble breaking rotary tillage are completed at a time, residual straw which is not smashed does not exist under tracks, the efficiency is high, the energy consumption is low and soil moisture conservation is achieved. The development of the straw smashing and stubble breaking rotary tillage all-in-one machine is a breakthrough of agricultural machines.

Owner:董志军

Bio-organic fertilizer raw material crushing equipment with good crushing effect

InactiveCN108704707AEvenly crushedSmash thoroughlyRotary stirring mixersTransportation and packagingCouplingEngineering

The invention discloses a bio-organic fertilizer raw material crushing equipment with a good crushing effect. The bio-organic fertilizer raw material crushing equipment is characterized in that a first motor is fixedly arranged on one side of a stirring cavity through a motor assembly base; the output end of the motor is connected with a stirring shaft I through a coupling; the stirring shaft I islocated in the stirring cavity; stirring blades are fixedly arranged on the stirring shaft I; the other side of the stirring cavity is fixedly provided with a ventilation fan; a ventilation pipelineis connected to the ventilation fan; the ventilation pipeline at the input end of the ventilation fan is located in the stirring cavity; the part, which is located in the stirring cavity, of the ventilation pipeline is fixedly provided with a sponge block; the ventilation pipeline at the output end of the ventilation fan is located out of the stirring cavity; a material outlet of a primary crushing cavity faces right to a material inlet of a secondary crushing cavity; a third motor is fixedly arranged on the outer part of the secondary crushing cavity; the output end of the third motor is connected with a stirring shaft II through a coupling; the stirring coupling II is located in the secondary crushing cavity; and a thread reamer is arranged on the stirring shaft.

Owner:王玉玲

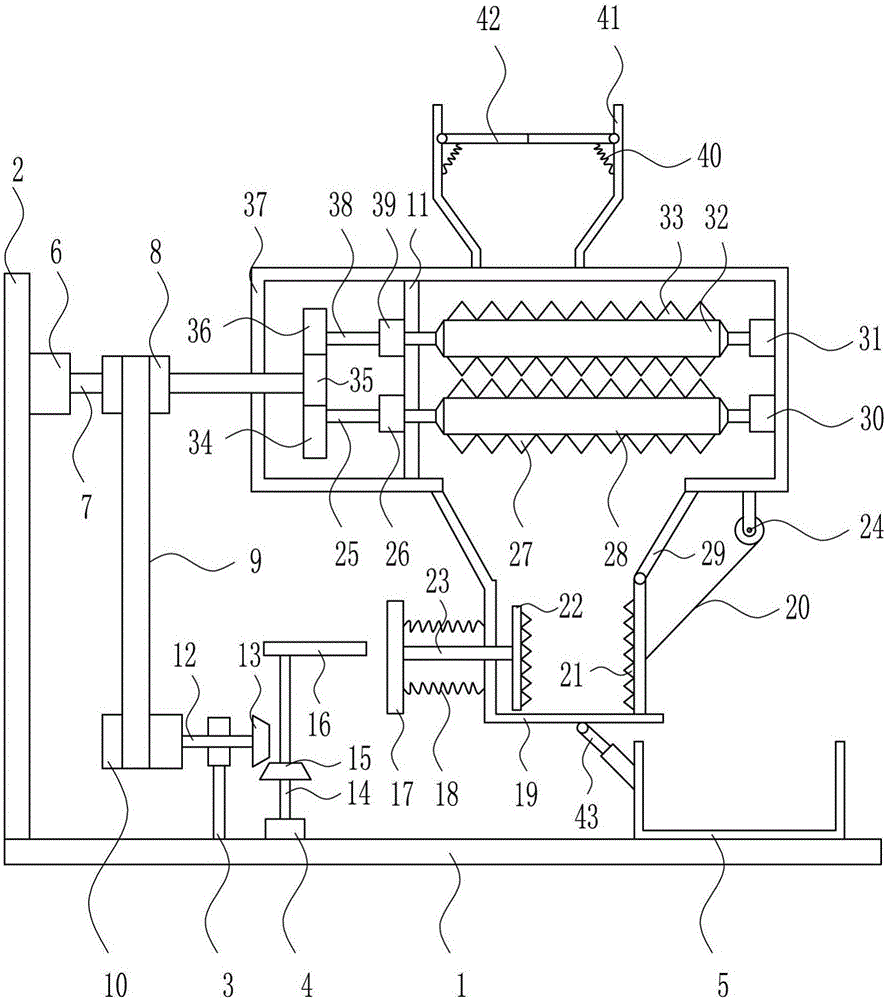

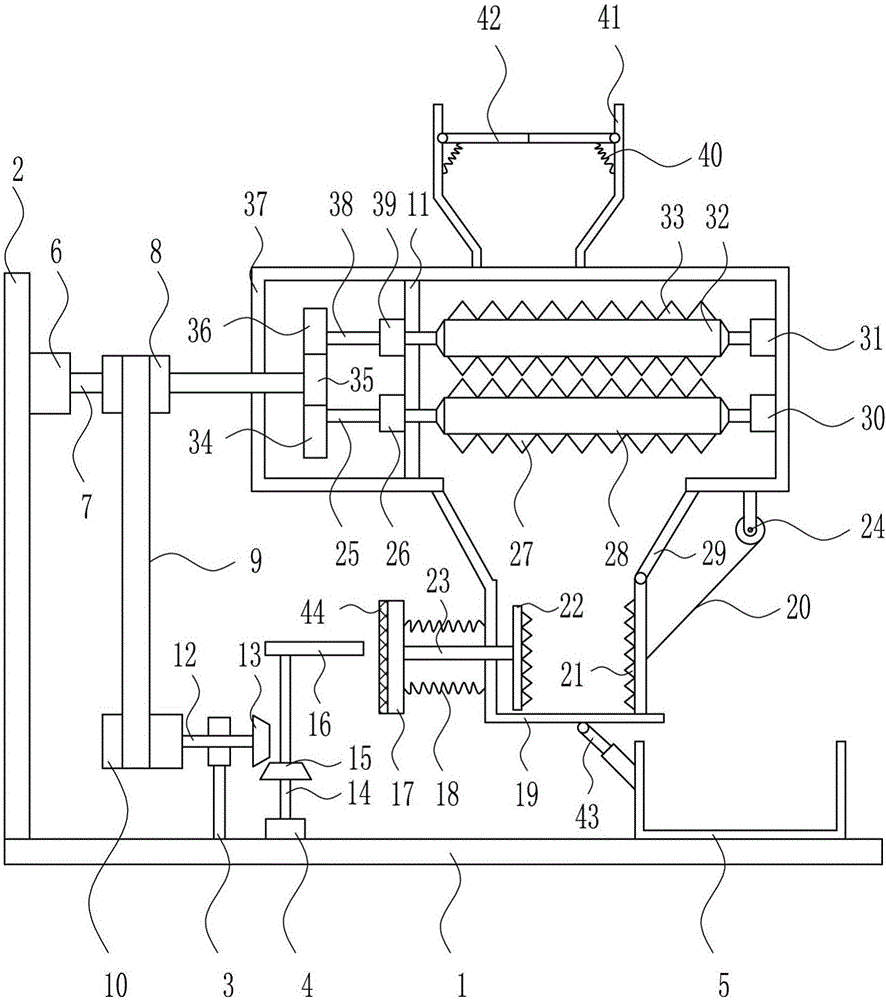

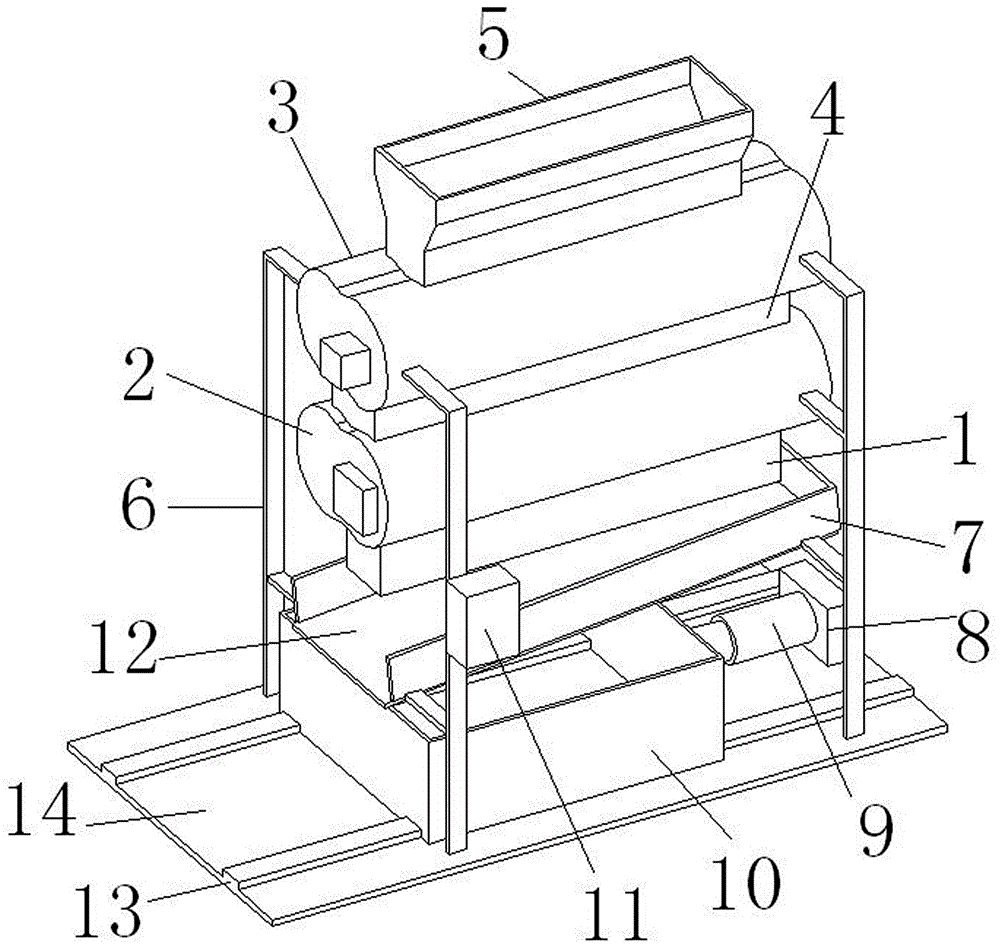

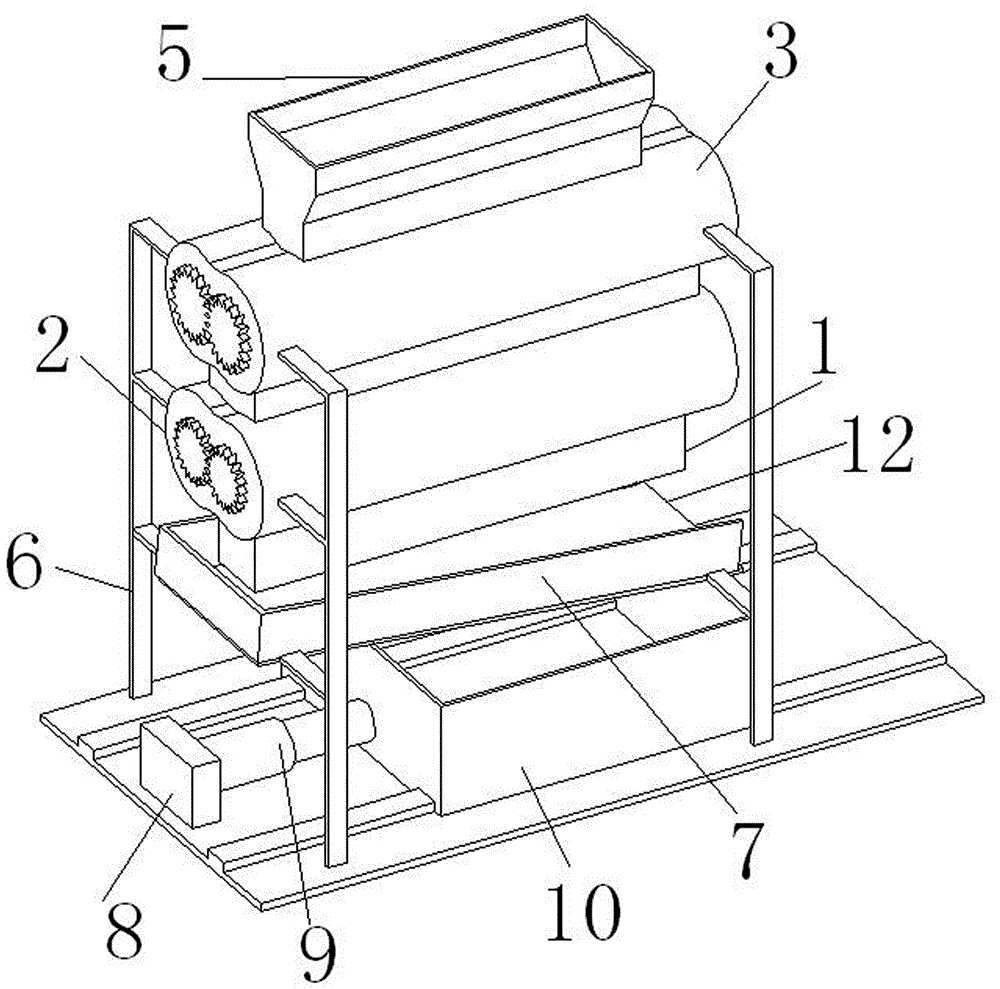

Smashing and drying device for chemical engineering materials

InactiveCN107774425AGuaranteed power outputIncrease profitDrying gas arrangementsGrain treatmentsFixed frameElectric machinery

The invention discloses a smashing and drying device for chemical engineering materials, and relates to the technical field of chemical engineering processing. The smashing and drying device comprisesa feeding cabinet. A feed inlet is fixedly connected to the top of the feeding cabinet. A power motor is fixedly connected to one side of the inner wall of the feeding cabinet through a fixing frame.A speed-reducing connector is connected with the power motor through an output shaft rotationally. A first belt pulley is connected with the speed-reducing connector through an output shaft rotationally. A second belt pulley is connected with the first belt pulley through belt rotation. A conveyor is fixedly connected with the second belt pulley through a flat key. A material conveying tube is arranged on the outer wall of the conveyor, and a material conveying inlet is arranged at the top of the material conveying tube. The smashing and drying device has the advantages that conveying and classified smashing of the chemical engineering materials, conveying of smashed chemical engineering materials and drying of the chemical engineering materials are achieved, thorough smashing is realized, production quality is guaranteed, and output and overall quality of chemical engineering products and stability of the chemical engineering materials are guaranteed.

Owner:湖州城区天顺化工厂

Industrial grinder with noise reduction and temperature reduction functions

The invention discloses an industrial grinder with noise reduction and temperature reduction functions. The industrial grinder comprises a grinder body and a storage bin, wherein the grinder body comprises a feed port, a variable frequency motor, a grinding bin, a stirring wheel and a discharge port; the feed port is formed above the grinding bin, guide plates are arranged in a feed channel between the feed port and the smashing bin, extrusion rolls are arranged below the guide plates, the stirring wheel and a rotating shaft are arranged in the grinding bin, teeth are arranged on the surfaces of the stirring wheel and the rotating shaft, an inverted trapezoidal discharge hopper is arranged at the bottom of the smashing bin, a filter net is arranged in the discharge hopper, a cooling liquid pipe cavity is further formed and surrounds the outer wall of the grinding bin, and a noise reduction layer is arranged on the outer side of the cooling liquid pipe cavity; a cooling water tank is arranged on the grinder body and communicated with the cooling liquid pipe cavity, and water is circularly supplied by the cooling water tank, so that the grinding bin is cooled. The industrial grinder can thoroughly grind a material, has a good grinding effect and is low in heat productivity and small in noise.

Owner:中国检验认证集团珠海有限公司

Sewage purification treatment device of municipal sewage pipe network

InactiveCN106517666AAvoid cloggingSmash thoroughlyTreatment involving filtrationMultistage water/sewage treatmentEngineeringMunicipal sewage

The invention discloses a sewage purification treatment device of a municipal sewage pipe network. The sewage purification treatment device comprises a tank body, wherein a medicament adding hole is formed in the central position of the top of the tank body; a sewage branch pipe is mounted on an outer side of the medicament adding hole; an exhausting hole and a washing pipe are mounted on left and right sides of the sewage branch pipe; stop valves are mounted on outer walls of the sewage branch pipe, the medicament adding hole, the exhausting hole and the washing pipe; a motor is mounted at the top of the outer wall on the right side of the tank body; an external power supply is mounted on the right side of the motor; the motor is electrically connected with the external power supply through a connecting wire; a rotary shaft is mounted at the left end of the motor; the rotary shaft penetrates through the tank body; a crushing paddle is mounted on the outer wall of the rotary shaft; and a rotary shaft ring is mounted at a connecting part of the rotary shaft. According to the sewage purification treatment device of the municipal sewage pipe network, crushing and filtering are more complete under the matching of a coarse filter screen, a fine filter screen, the crushing paddle and a hairbrush, and thus the requirements of people are greatly met.

Owner:施阿丹

Bamboo smashing device with drying function

InactiveCN107570304ASmash thoroughlyImprove product qualityDrying solid materials with heatWood working apparatusEngineeringVibration motor

The invention discloses a bamboo smashing device with a drying function. The bamboo smashing device comprises a shell. A first smashing bin and a second smashing bin are arranged inside the shell. Thefirst smashing bin is arranged on the upper side of the second smashing bin. The joint between the first smashing bin and the second smashing bin is provided with a discharge outlet. Guide plates arearranged on the two sides of the discharge outlet. The lower surfaces of the guide plates are connected with vibration motors. The surfaces of the left side and the right side of the second smashingbin are provided with microwave heating devices correspondingly. A first smashing knife and a second smashing knife are arranged inside the first smashing bin and the second smashing bin correspondingly. Since the first smashing bin and the second smashing bin are arranged, bamboo can be smashed twice after being put into the shell so as to be smashed more thoroughly, bamboo powder is dried through the microwave heating devices, the drying speed can be increased, and product quality can be improved.

Owner:练淑荣

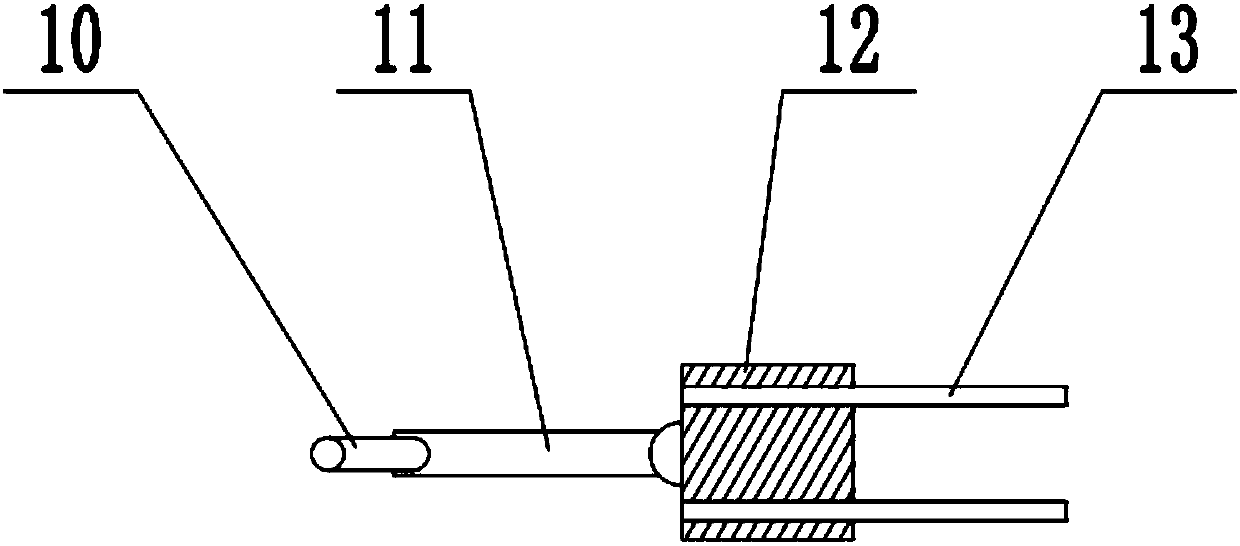

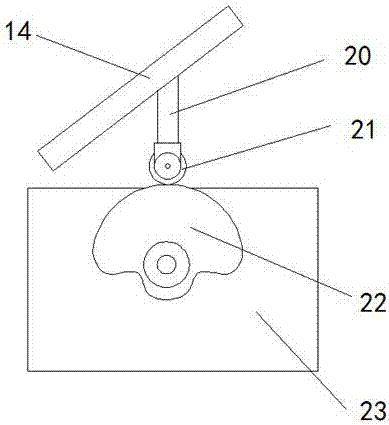

Equipment for preparing feed from straw and preparation method of feed

The invention discloses equipment for preparing feed from straw and a preparation method of the feed, and relates to the technical field of feed preparation. The equipment comprises a box body, and afeeding mechanism is fixedly connected to the left side of the upper surface of the box body; a crushing mechanism is arranged in the box body; the feeding mechanism comprises a connecting pipe, a feeding hopper, a cutter, a transverse plate, a feeding box body, a first motor, a first sliding groove, a first pin shaft, a round plate, a rotating rod, a first connecting rod and a second pin shaft. According to the equipment for preparing the feed from the straw and the preparation method of the feed, the feeding mechanism is fixedly arranged on the upper surface of the box body, the straw entering a feeding cylinder can be cut off and cut into sections, and the cut straw can easily enter the box body; the transverse plate moves up and down in a reciprocating mode so that the straw can be pushed into the box body, then feeding is more convenient, the straw can be prevented from being accumulated in the feeding box body, and the problem that the straw cannot conveniently enter the equipment is solved.

Owner:山东纪华家禽育种股份有限公司

Smashing device used for pesticide production

InactiveCN106694179ATo achieve the initial unbroken effectAchieve unbroken effectGrain treatmentsEconomic benefitsEngineering

The invention provides a smashing device used for pesticide production, and relates to the field of pesticide production. The smashing device used for pesticide production comprises a box body. A controller is fixedly installed at one side of the box body. Two feeding pipes are symmetrically arranged at the top of the box body. One end of each feeding pipe penetrates through the box body and stretches into the box body, and a centrifugal motor is arranged between the two feeding pipes. The output end of the centrifugal motor is fixedly connected with a rotating shaft. One end, far away from the centrifugal motor, of the rotating shaft sequentially penetrates through the box body and an inner barrel and stretches into the inner barrel. The top of the inner barrel is movably connected with the top of the inner wall of the box body. According to the smashing device used for pesticide production, raw materials can be smashed more thoroughly, normal production of pesticide products is guaranteed, production efficiency of the products is improved, the production cost of pesticide is reduced, and economic benefits of enterprises are increased; and moreover, the structure is simple, operation is convenient, time and labor are saved, and application and popularization are facilitated.

Owner:WUXI JIABAO PESTICIDE & PHARMA

Ore crushing device

The invention discloses an ore crushing device. The ore crushing device comprises a body. A feeding hopper is arranged at the top end of the body. A hammering device, a smashing device and a grindingdevice are installed in the body, and a first screen net is arranged at the lower end of the hammering device. The hammering device comprises a hand-rocked handle, an anti-explosion motor, a hammer protective cover, a rotary shaft and a hammer. The smashing device is located below the first screen net and comprises two driving shafts and two auxiliary transmission shafts. A plurality of smashing blades are evenly distributed on the driving shafts. A plurality of auxiliary blades are evenly distributed on the auxiliary transmission shafts. The grinding device is located below the smashing device and comprises a grinding head, a grinding body and a grinding motor. A second screen net is arranged under the grinding body and inserted into the body. A collecting box is arranged at the bottom end inside the body. The ore crushing device is reasonable in design, large ore is smashed through the hammering device, the smashing device and the grinding device, the smashing effect is good, smashing is thorough, and use requirements of people are met.

Owner:徐继传

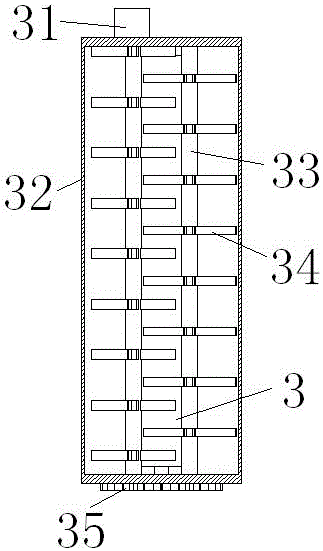

Waste slag classifying and crushing equipment provided with vibratory screening device

The invention relates to the technical field of waste slag crushing equipment and particularly relates to waste slag classifying and crushing equipment provided with a vibratory screening device. The waste slag classifying and crushing equipment comprises a crushing tank; a feeding hole is formed in the top of the crushing tank; a first vibrating screen, a second vibrating screen and a third vibrating screen are sequentially arranged from top to bottom inside the crushing tank; a first crushing chamber, a second crushing chamber, a third crushing chamber and a storage chamber are formed inside the crushing tank; a first vibrating motor, a second vibrating motor and a third vibrating motor are sequentially arranged from top to bottom at the left side surface of the crushing tank and are respectively connected with the first vibrating screen, the second vibrating screen and the third vibrating screen. By adopting multi-layer classified crushing, the waste slag classifying and crushing equipment can be used for simultaneously crushing waste slag different in diameter, so the crushing speed is greatly increased and the crushing quality is guaranteed; the waste slag classifying and crushing equipment has the advantages of high speed, complete crushing, high work efficiency and the like.

Owner:CHONGQING LONGJIAN METAL MFG

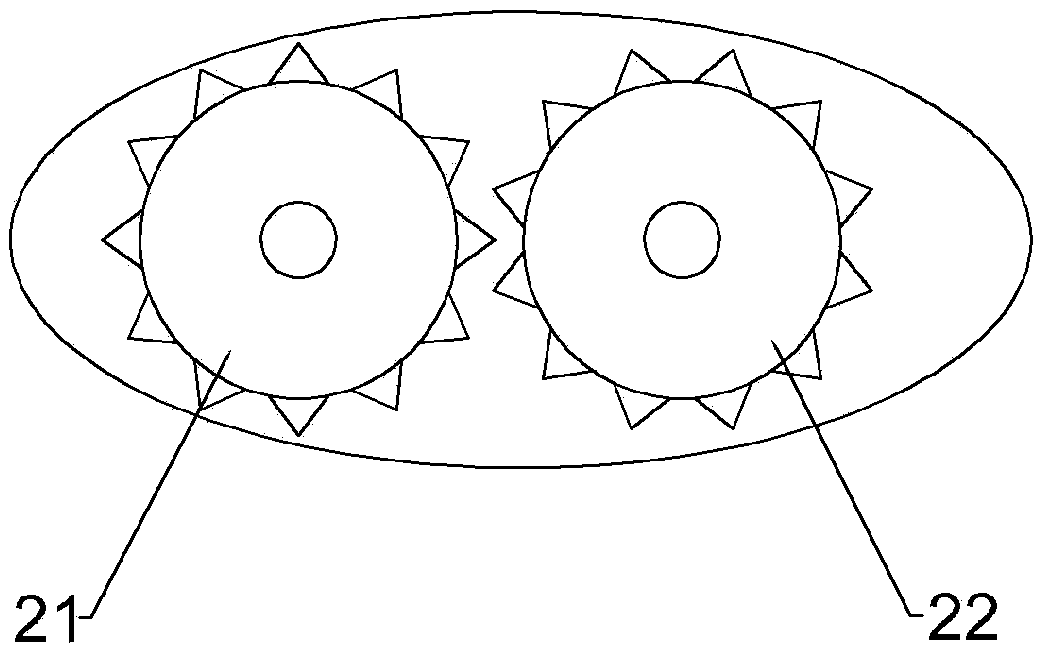

Automotive trim plastic part smashing device

InactiveCN109016252ANo accidental injurySmash thoroughlyPlastic recyclingMechanical material recoveryEngineeringState of art

The invention relates to the technical field of mechanical equipment, and discloses an automotive trim plastic part smashing device. The automotive trim plastic part smashing device comprises a box body, an extrusion chamber, a rolling chamber and a grinding chamber are sequentially arranged in the box body from top to bottom, a feeding hopper is connected to the top of the extrusion chamber, twomatched rotating rollers are arranged in the rolling chamber, breaking teeth are arranged on the rotating rollers densely, the grinding chamber is divided into one grinding area and two symmetric guide areas, the grinding area is provided with a grinding device, waste plastic parts are sequentially extruded, rolled and ground through the extrusion chamber, the rolling chamber and the grinding chamber, and finally the parts are thoroughly ground. The device is novel in structure, and the problems that in the prior art, a cart plastic part breaking device is not thorough in breaking, low in workefficiency, and complex in operation, and plastic is prone to splashing everywhere are solved.

Owner:宁波高新区意川汽车零部件有限公司

Crushing device for plastic recovery processing

InactiveCN109648741ASimple structureEasy to usePlastic recyclingGrain treatmentsEngineeringMechanical engineering

The invention discloses a crushing device for plastic recovery processing. The crushing device comprises a shell, wherein a motor base is fixedly connected with the upper left part of the shell; a motor is fixedly connected onto the motor base; the output end of the motor is fixedly connected with a rotary shaft; the rotary shaft penetrates through the right side wall of the shell to be rotatablyconnected with the shell; a first crank is fixedly connected with the left side of the rotary shaft; a second crank is fixedly connected with the lower right part of the first crank; a first connecting rod is rotatably connected below the first crank; a second connecting rod is rotatably connected below the first connecting rod; and a horizontal guide plate is fixedly connected with the upper partof the interior of the shell. Compared with the prior art, the crushing device has the benefits of being simple in structure and convenient to use and used for smashing a plastic product, and enabling smashing to be more thorough through dual smashing during the smashing process; and in addition, the crushing device can avoid the problem that large to-be-crushed plastic has difficulty in enteringbetween smaller smashing teeth and deserves popularization.

Owner:TIANJIN XINLIN PLASTIC PRODS

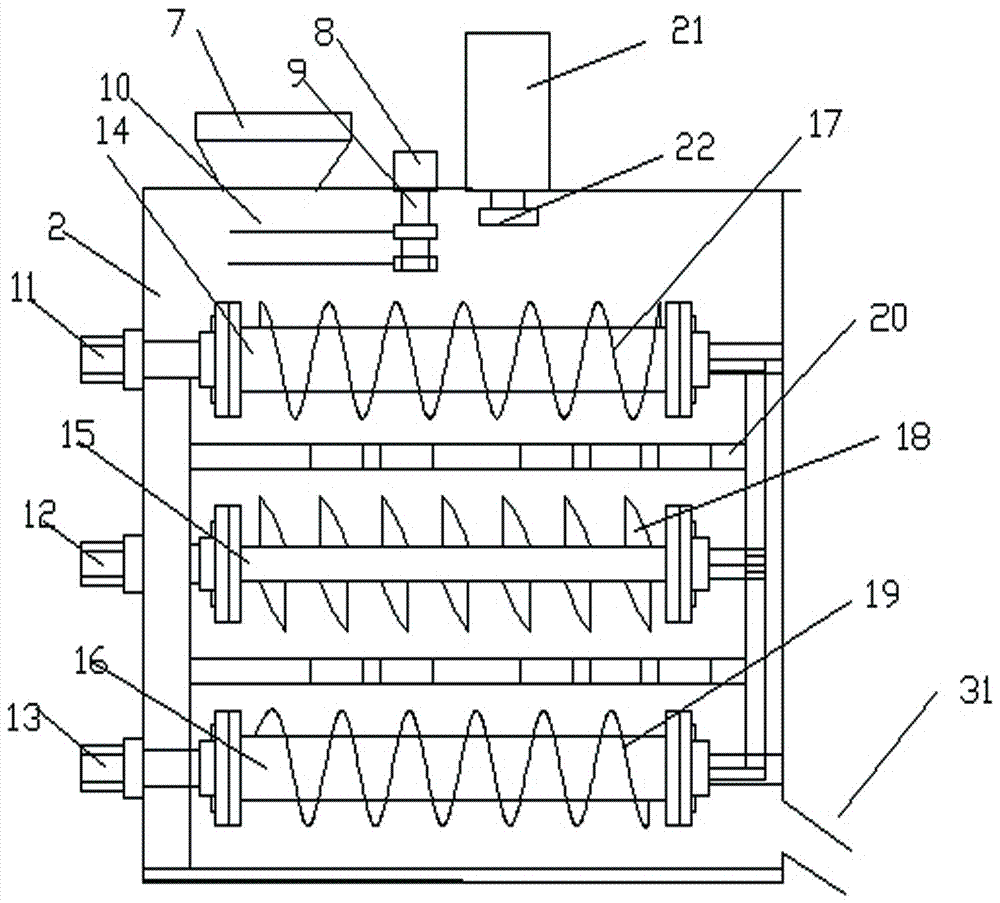

Straw pulverizer

InactiveCN107318399ASmash thoroughlyEasy to cleanHollow article cleaningCuttersHelical bladeMotor shaft

The invention discloses a straw pulverizer, which comprises a feeding box and a crushing box, a lifting cylinder and a driving auger are connected above the feeding box, a cutting motor is installed on the upper surface of the pulverizing box, and the cutting motor is connected with a cutting shaft, and the left side of the pulverizing box is The side outer wall is equidistantly equipped with rotating shaft motor 1, rotating shaft motor 2 and rotating shaft motor 3, the right end of rotating shaft motor 1 is connected with rotating shaft 1, the right end of rotating shaft motor 2 is connected with rotating shaft 2, the right end of rotating shaft motor 3 is connected with rotating shaft 3, rotating shaft The first outer surface is equipped with a spiral blade, the second outer surface of the rotating shaft is equipped with a bidirectional cutting knife, the third outer surface of the rotating shaft is equipped with a discharge spiral blade, the left end of the feeding box is equipped with a heating power supply; the lower right corner of the crushing box is equipped with a discharge port. The invention can crush the stalks more thoroughly; and dry the stalks with moisture; the top of the crushing box is equipped with a spray head, which is convenient for cleaning.

Owner:何天行

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com