Straw smashing and stubble breaking rotary tillage all-in-one machine

A technology of straw crushing and integrated machine, which is applied in the field of agricultural machinery, can solve the problems of wear of blades and various rotating parts, high power consumption of tractors, and increase of comprehensive cost, etc., and achieves significant economic and social benefits, reduced rotary cutting resistance, Overall energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

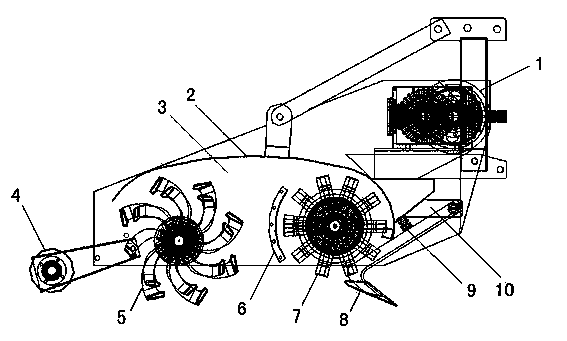

[0018] Such as figure 1 As shown, the straw crushing and stubble breaking rotary tiller includes a frame 10, a casing 2, a power transmission mechanism 1, a stubble breaking rotary tiller 5, the casing 2 is fixed on the frame 10, and the front part of the casing 2 is set Straw pulverizer 7, the direction of rotation of straw pulverizer 7 is counterclockwise, a baffle 6 is arranged behind the straw pulverizer 7, the two ends of the baffle 6 are fixed on the side plate 3 of the casing 2, the upper part of the baffle 6 is connected with the casing 2 has a gap, the stubble-breaking rotary tiller 5 is arranged at the baffle plate 6 rear portion, and the casing 2 extends to the rear of the stubble-breaking rotary tiller 5.

[0019] When necessary, a supporting plate is connected at the rear of the baffle plate 6, and the supporting plate and the casing form a straw channel, which is convenient for the straw to guide to the rear of the stubble breaking rotary tiller 5.

[0020] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com