Crushing device for plastic recovery processing

A crushing device and plastic recycling technology, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of complex structure, non-recyclable plastic cleaning, and plastic cleaning, etc., to achieve convenient use, simple structure, Smash thoroughly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

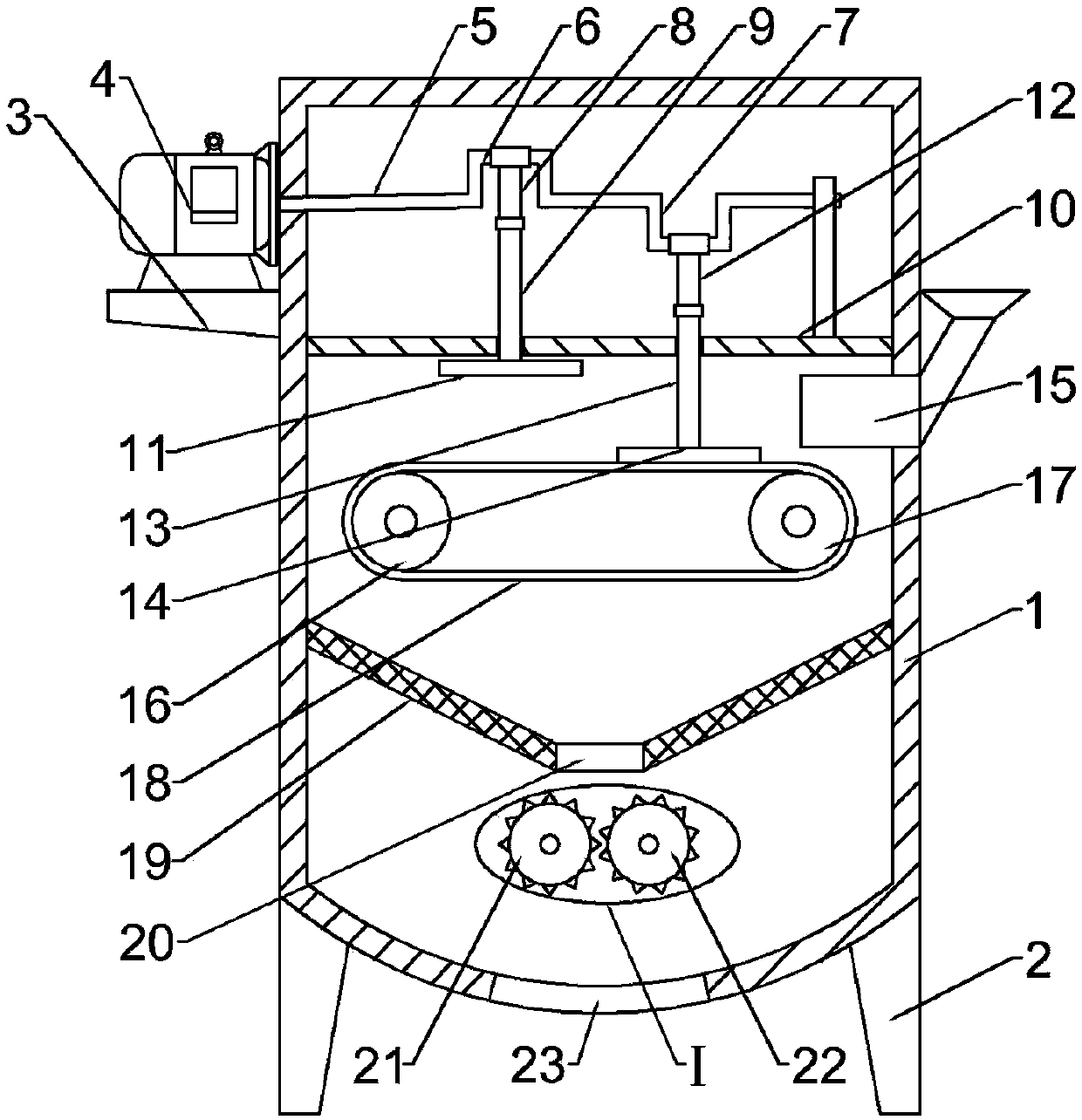

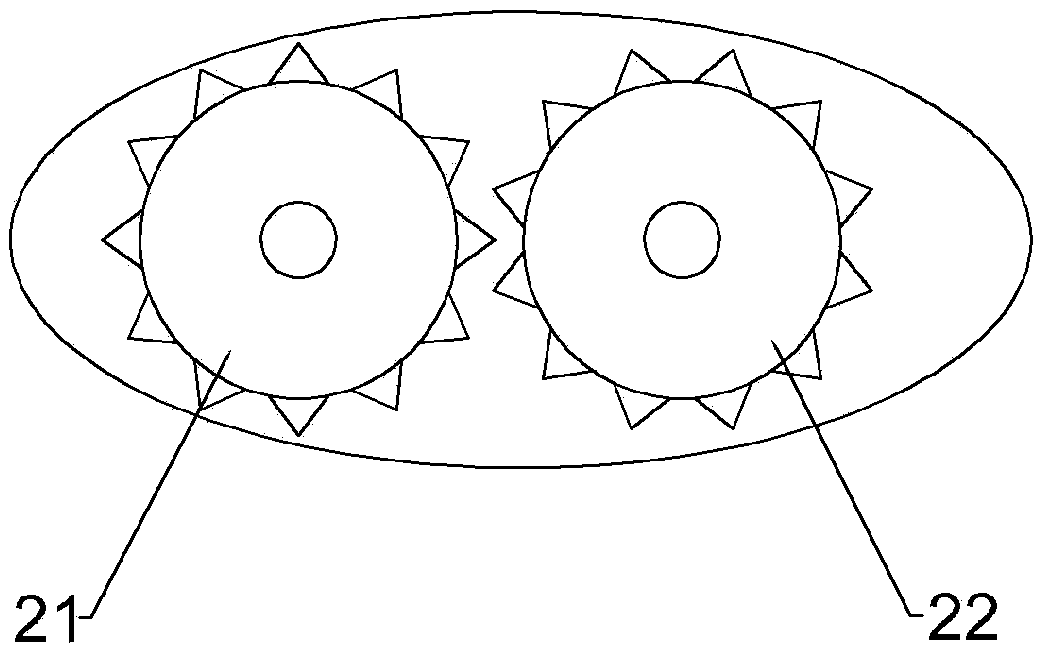

[0018] see Figure 1-2 , a crushing device for plastic recycling and processing, comprising a housing 1, a motor base 3 is fixedly connected to the upper left of the housing 1, a motor 4 is fixedly connected to the top of the motor base 3, and the output end of the motor 4 is fixedly connected to The rotating shaft 5 passes through the right side wall of the housing 1 and is rotationally connected with the housing 1. The left side of the rotating shaft 5 is fixedly connected with the first bell crank 6, and the lower right side of the first bell crank 6 is fixedly connected with the second bell crank 6. Two crank throws 7, the first connecting rod 8 is rotatably connected below the first crank throw 6, the second connecting rod 9 is rotatably connected below the first connecting rod 8, and a horizontal guide plate is fixedly connected above the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com