Patents

Literature

996 results about "Plastic recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic recycling is the process of recovering scrap or waste plastic and reprocessing the material into useful products. Since the vast majority of plastic is non-biodegradable, recycling is a part of global efforts to reduce plastic in the waste stream, especially the approximately 8 million metric tonnes of waste plastic that enters the Earth's ocean every year.

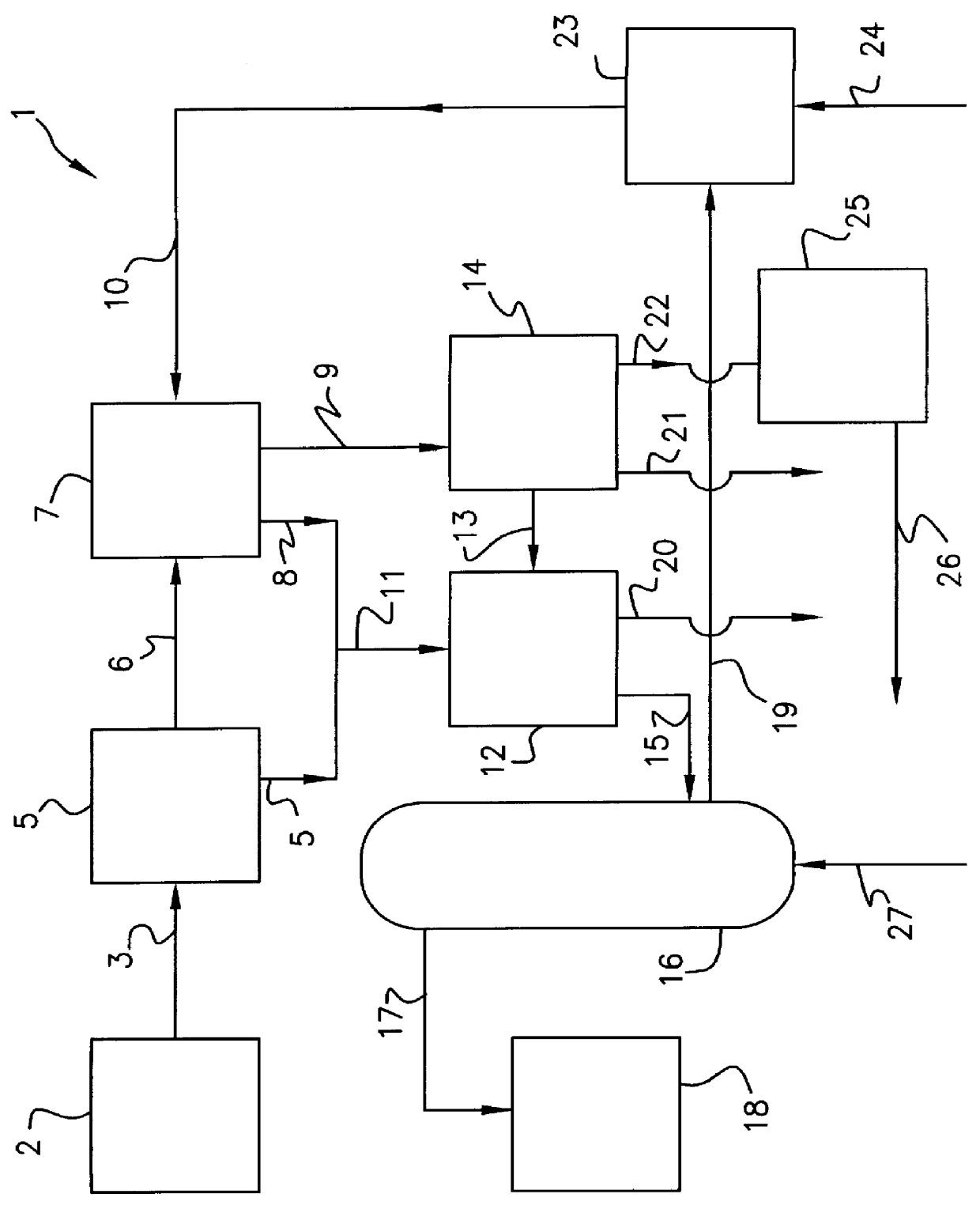

Plastic reclamation process

A plastic article or plastic container reclamation process if provided in which plastic containers are divided into relatively large pieces, then washed, agitated and separated using an aqueous solvent to remove residual materials. The residual materials such as motor oil are reclaimed for reuse and the aqueous solvent is regenerated for reuse in the process. Residual materials such as dirt, labels and adhesives from the plastic containers is recovered for recycling or passed to waste for disposal or reuse.

Owner:DOONAN BILLIE ODELL

Process for waste plastic recycling

InactiveUS6861568B1Reduce demandReduce dependenceLiquid hydrocarbon mixture productionHydrocarbonsPolyvinyl chlorideDiluent

A process for recycling or decomposing waste plastic where such wasteplastic is decomposed in a diluent such as hot oil through actions involvingfree radical precursor, such as polyvinyl chloride or polyurethane, is achievedat low temperature. The thermal decomposition (or pyrolysis) reaction is forabout 1 hour at 375° C., and useable products, such as distillate, coke, and oilare recovered. Additionally the diluent may be recycled within the process.

Owner:UNIV OF WYOMING RES

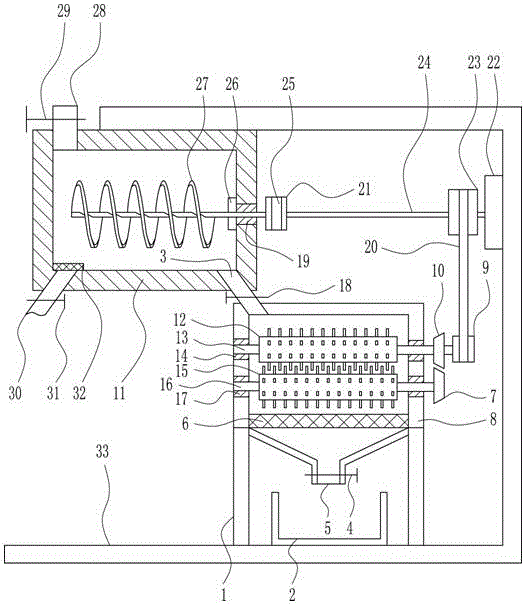

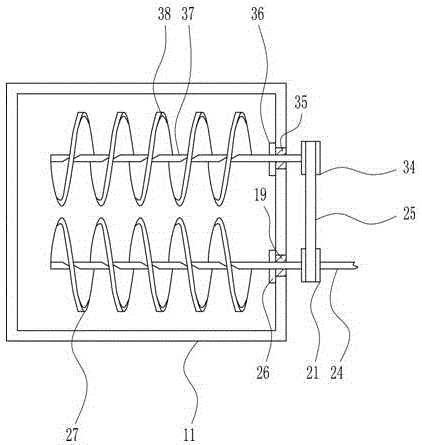

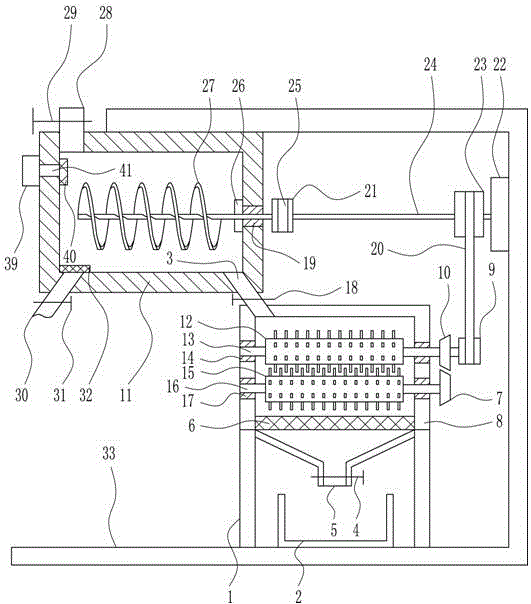

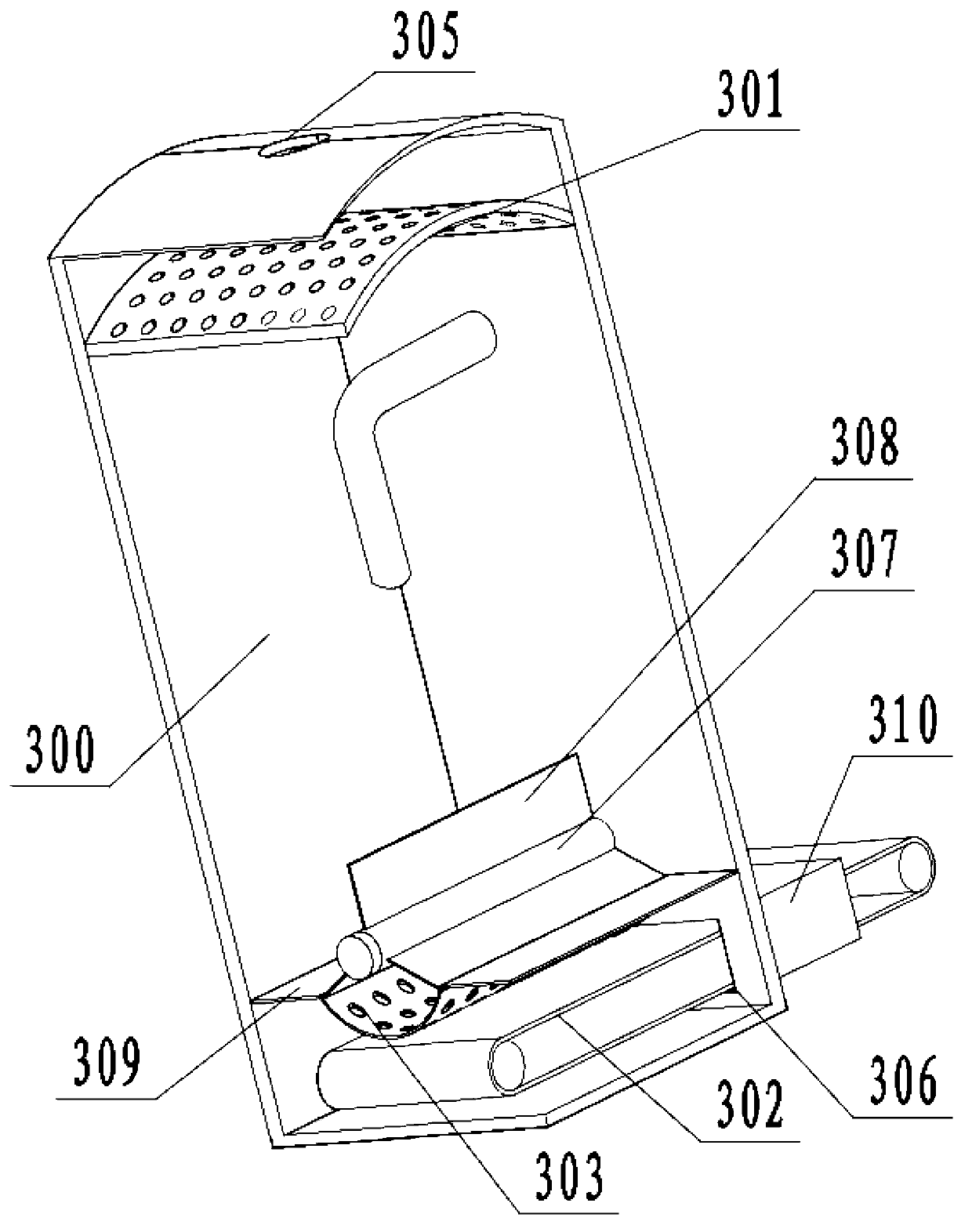

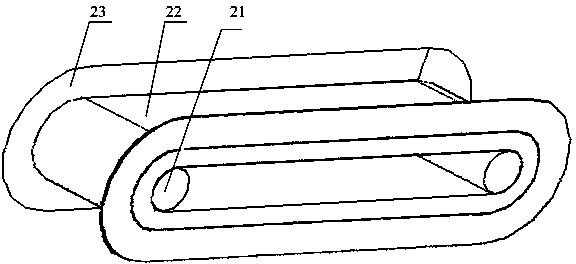

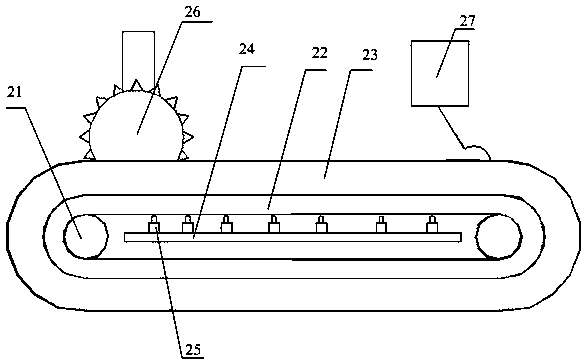

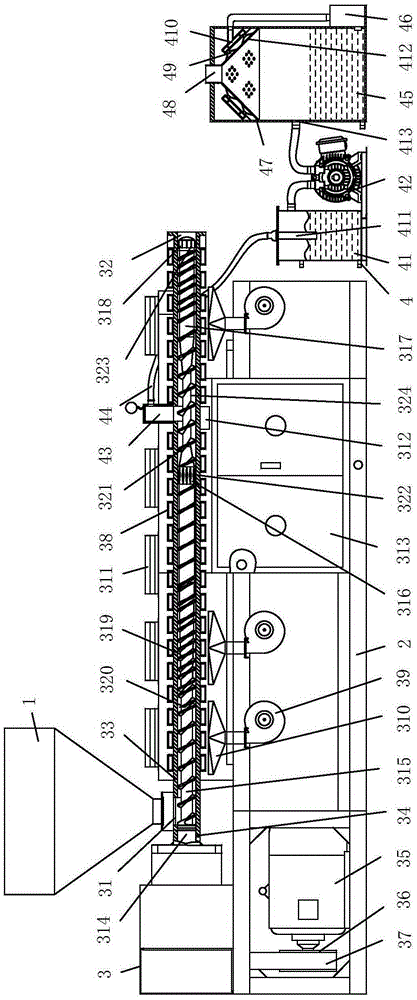

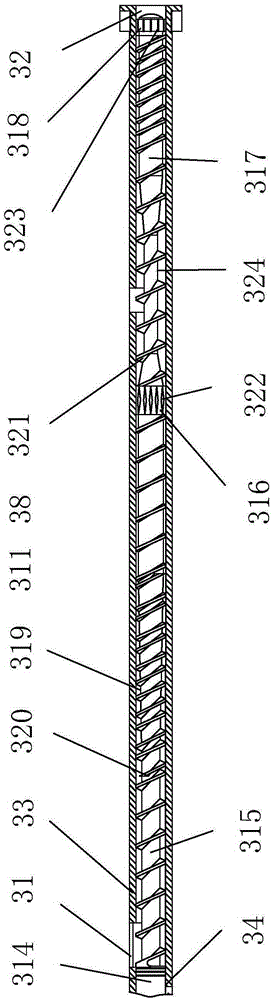

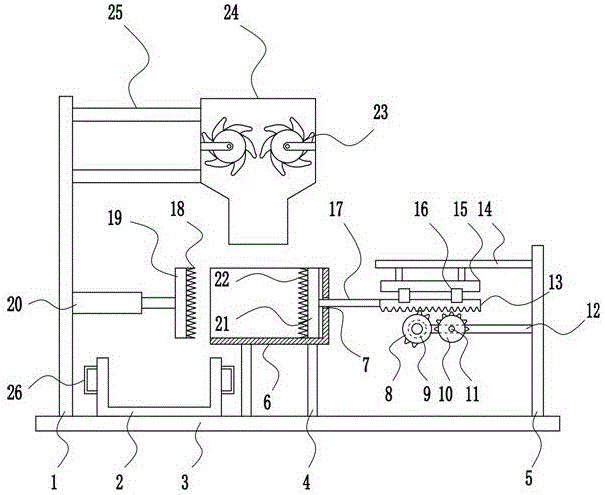

Foamed plastic recycling granulation pretreatment device

ActiveCN106476163ANot easy to corrodeExtended service lifePlastic recyclingCleaning using liquidsHelical bladePlastic recycling

The invention relates to a foamed plastic treatment device, in particular to a foamed plastic recycling granulation pretreatment device. The technical purpose is to provide the foamed plastic recycling granulation pretreatment device which carries out cleaning and smashing simultaneously and achieves ideal treatment. To realize the technical purpose, the foamed plastic recycling granulation pretreatment device comprises supporting rods, a collecting frame, a discharging pipe, a first valve, a discharging hopper, a filter screen, a first bevel gear, a first box body, a first belt pulley, a second bevel gear and the like. The supporting rods are welded symmetrically on the right side of the bottom inside a mounting bracket; the first box body is welded on the tops of the supporting rods; the filter screen is welded on the bottom inside the first box body; and the discharging hopper is arranged on the bottom of the first box body. According to the foamed plastic recycling granulation pretreatment device, a first helical blade and a second helical blade are arranged to agitate and wash foamed plastic and push the foamed plastic leftwards and rightwards at the same time, so that cleaning efficiency is significantly improved, and a motor is used for transmission in the whole process.

Owner:江苏沛思福板材有限公司

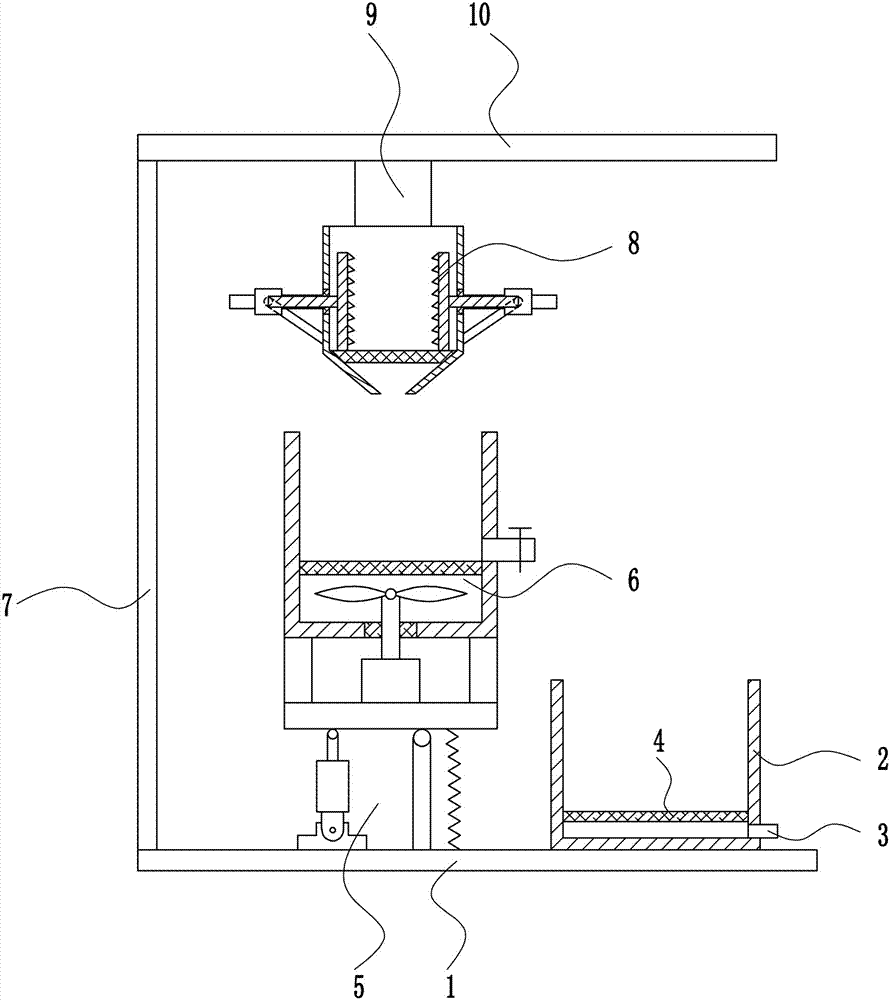

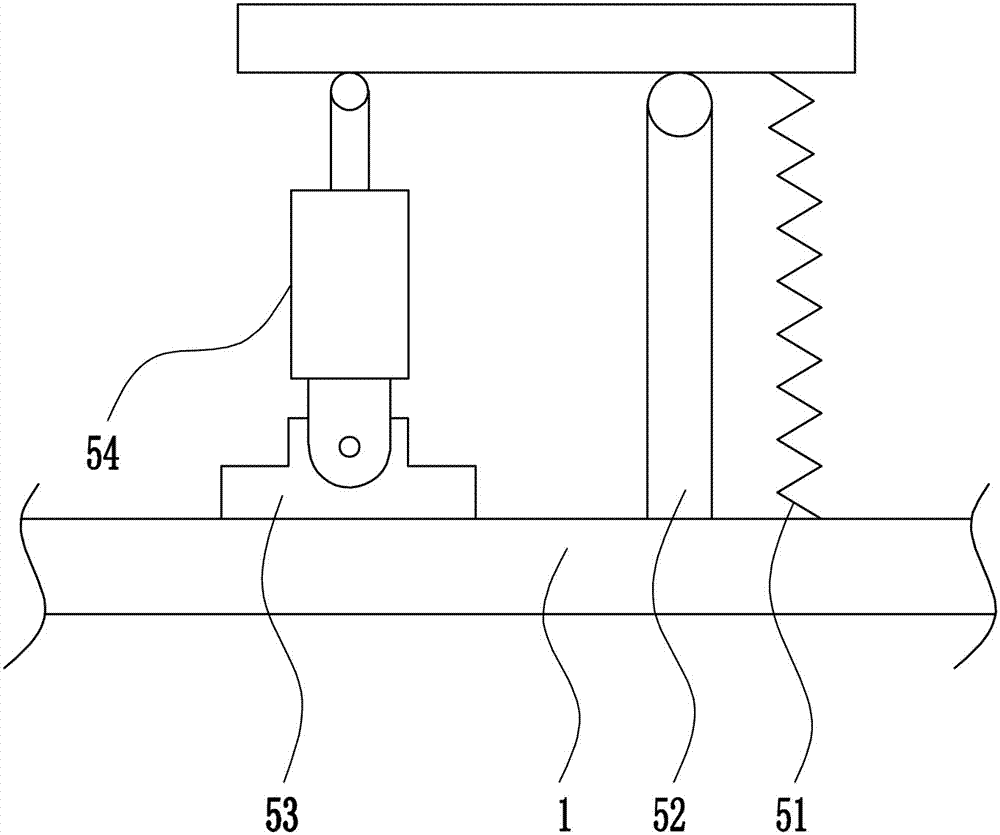

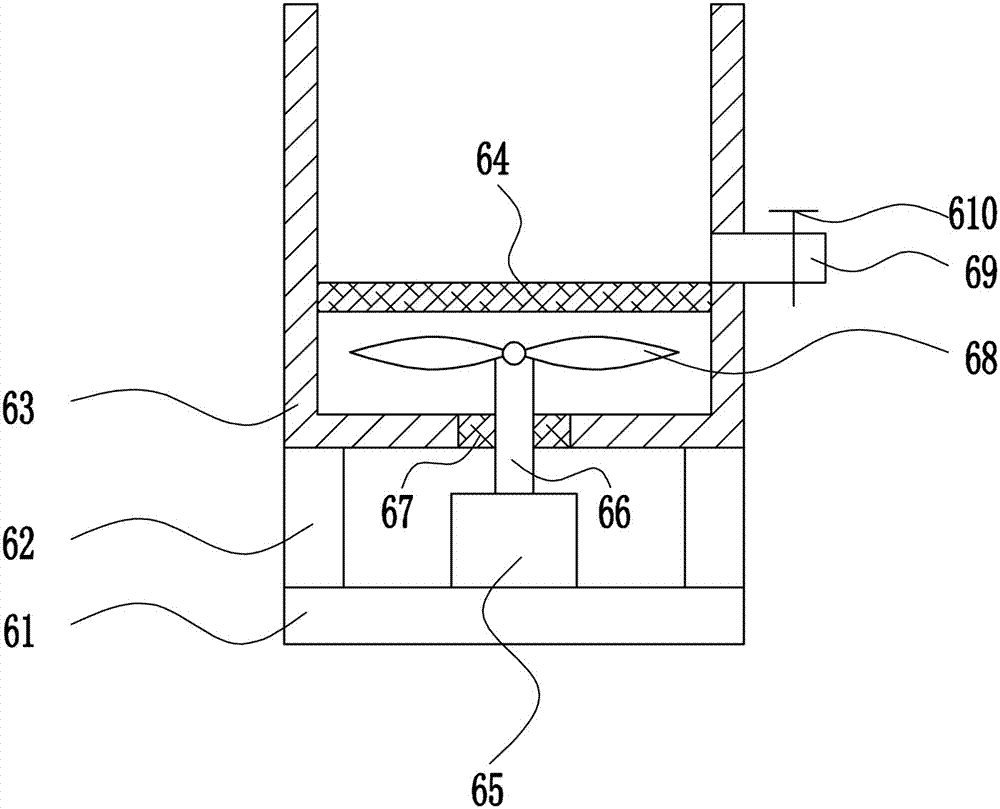

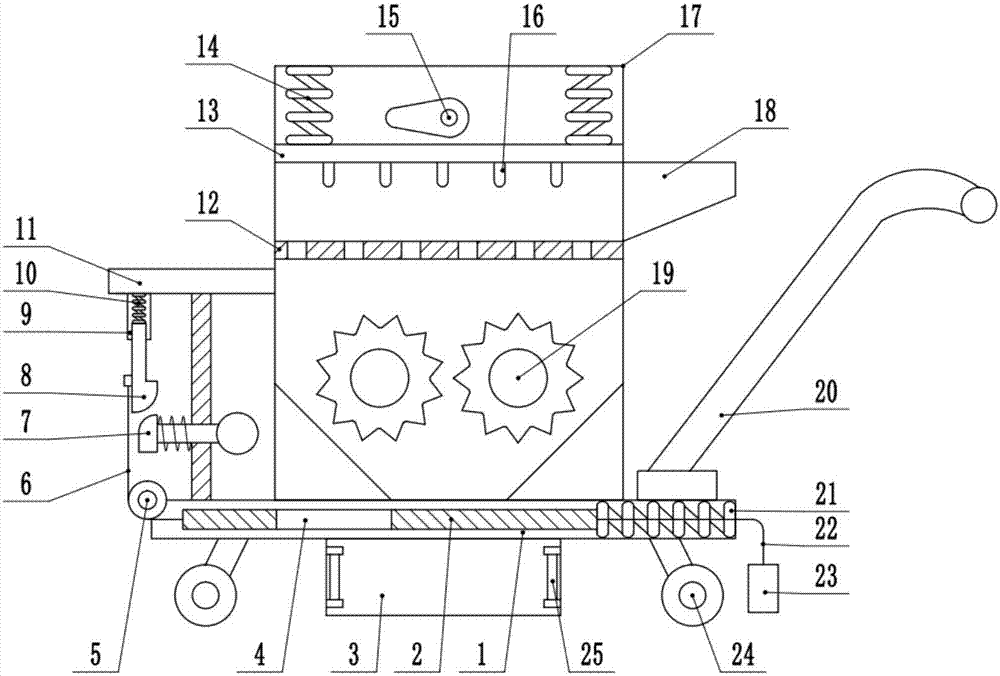

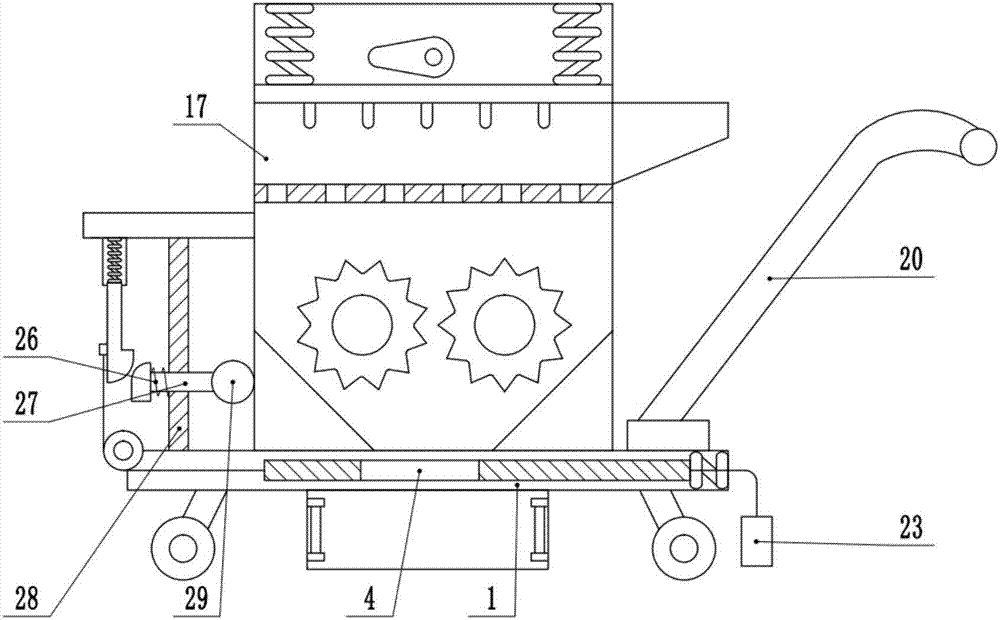

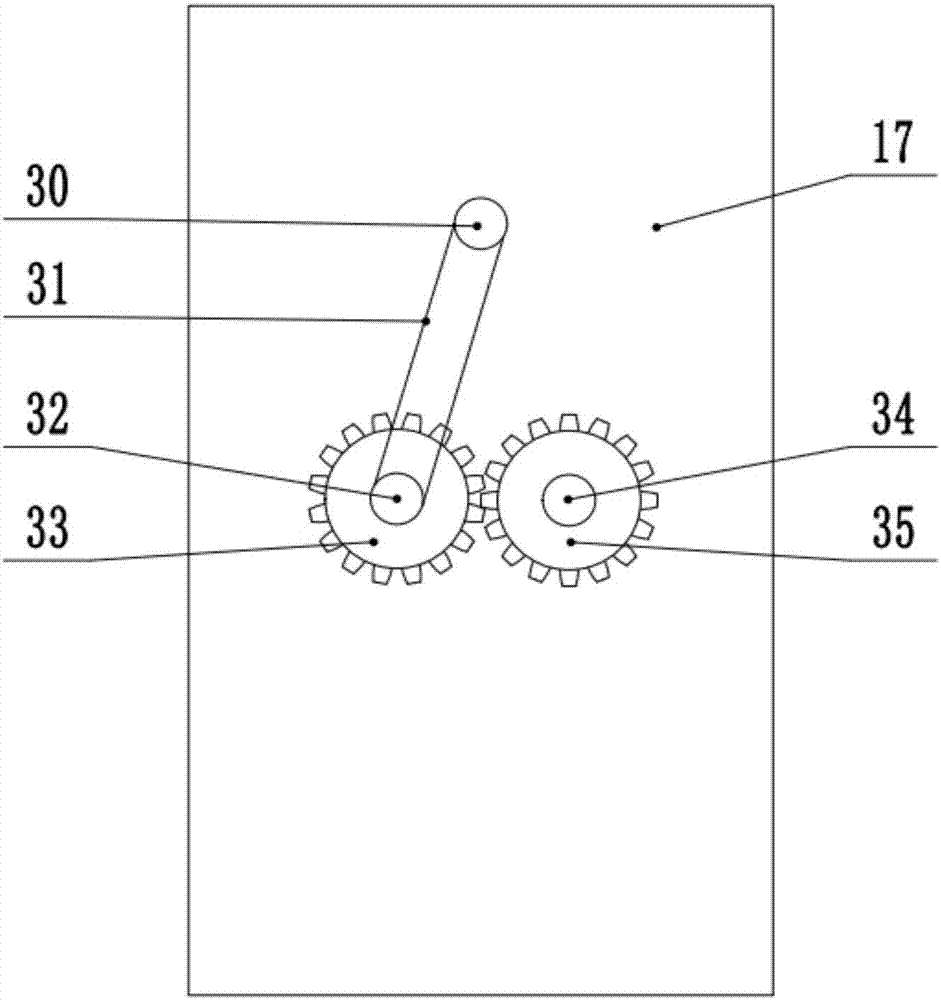

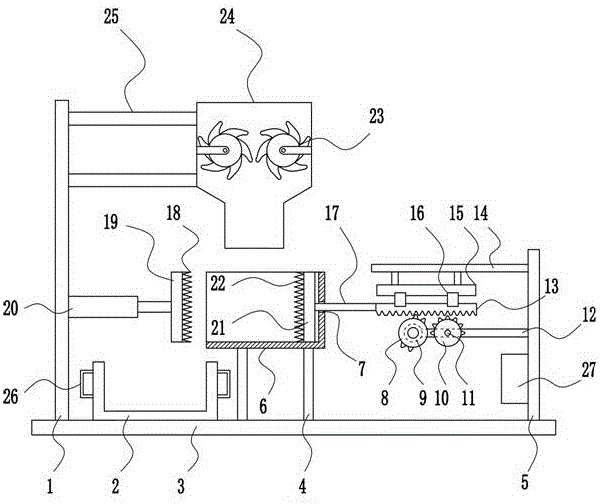

Crushing and cleaning integrated machine used for recycling waste plastics

PendingCN107097367APlay a stabilizing rolePlay a protective effectPlastic recyclingCleaning using liquidsPlastic recycling

The invention belongs to the field of recycling of waste plastics, and particularly relates to a crushing and cleaning integrated machine used for recycling waste plastics. The technical problem needing to be solved by the invention is to provide the crushing and cleaning integrated machine used for recycling waste plastics, and the crushing and cleaning integrated machine used for recycling waste plastics can crush and clean simultaneously, and is simple in recycling process and high in efficiency. In order to solve the technical problem, the invention provides the crushing and cleaning integrated machine used for recycling waste plastics. The crushing and cleaning integrated machine used for recycling waste plastics comprises a base plate, a collecting frame, a liquid discharge pipe, a first screen plate, a turning mechanism and a cleaning mechanism; the collecting frame is arranged on the right side of the top of the base plate, the liquid discharge pipe is arranged at the bottom of the right wall of the collecting frame, the first screen plate is installed at the bottom of the interior of the collecting frame, the turning mechanism is installed in the middle of the top of the base plate, and the cleaning mechanism is connected onto the turning mechanism. The crushing and cleaning integrated machine used for recycling waste plastics achieves the effects that the crushing and cleaning integrated machine crushes and cleans simultaneously, is simple in recycling process, and is high in efficiency.

Owner:JIANGSU COLLEGE OF INFORMATION TECH

Medical plastic garbage recycling and granulating device

InactiveCN107442223AEasy to handleEffective crushing and granulationPlastic recyclingGrain treatmentsEngineeringPlastic recycling

The invention discloses a medical plastic garbage recycling and granulating device. The medical plastic garbage recycling and granulating device comprises a base, a disinfection box and a crushing box; a feeding hopper is arranged on the upper right side of the crushing box; a chopping plate is arranged in the crushing box in a sliding mode; a plurality of cutters are uniformly arranged on the lower side of the chopping plate; two crushing rollers are further arranged in the crushing box in a rotating mode; a funnel-shaped discharge port is formed in the bottom of the crushing box; trundles are arranged at four corners of the base; and a push rod is further fixedly arranged on the right side of the base. According to the medical plastic garbage recycling and granulating device, a medical plastic recycling device is arranged to be of a trolley structure so that the device can move conveniently, and therefore plastic garbage can be treated at any time; the chopping plate and the crushing rollers are further arranged so that the plastic garbage can be effectively crushed and granulated; and a beating ball is further arranged so that the plastic garbage can be prevented from being attached to a sieve plate, and in addition, the phenomenon that the discharge port is blocked can be avoided.

Owner:王冠伟

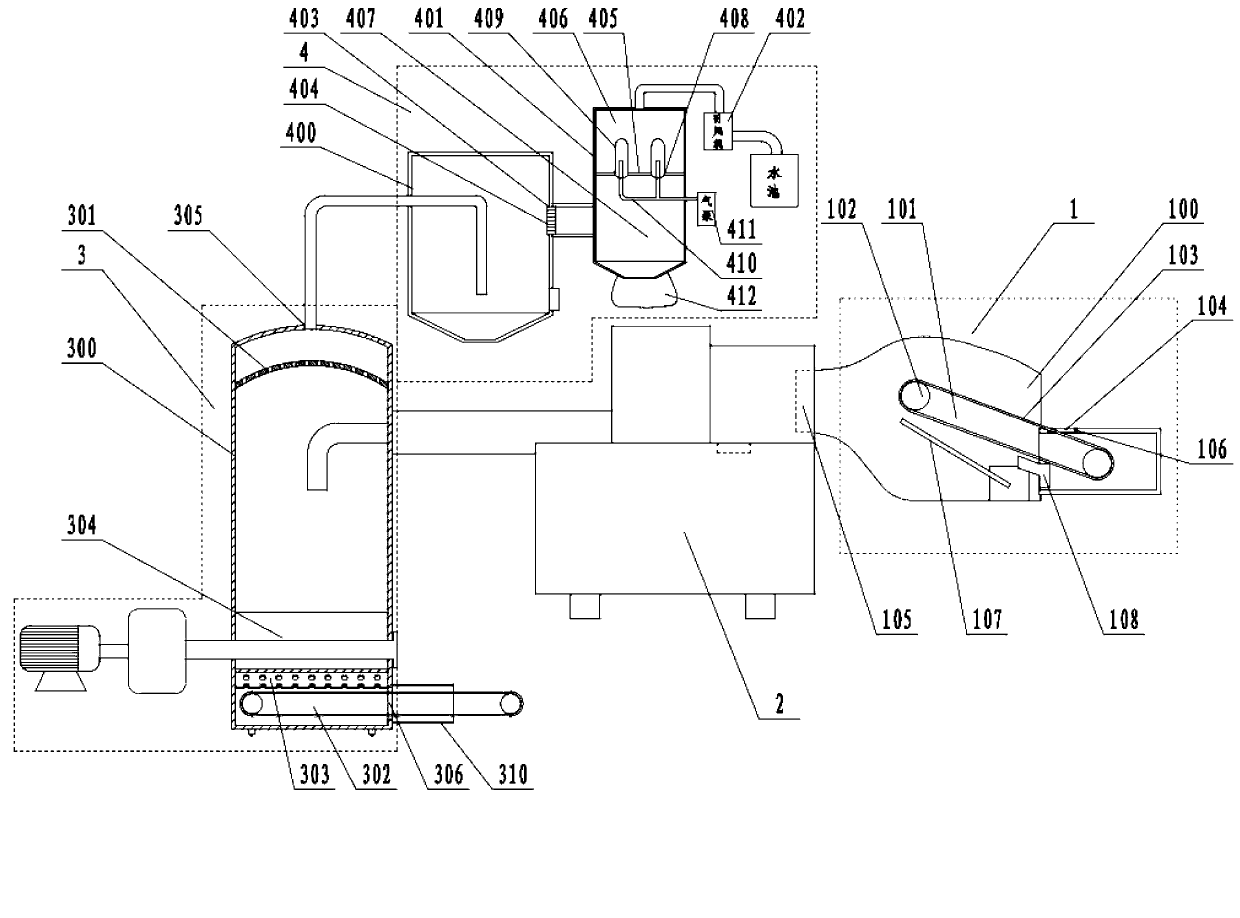

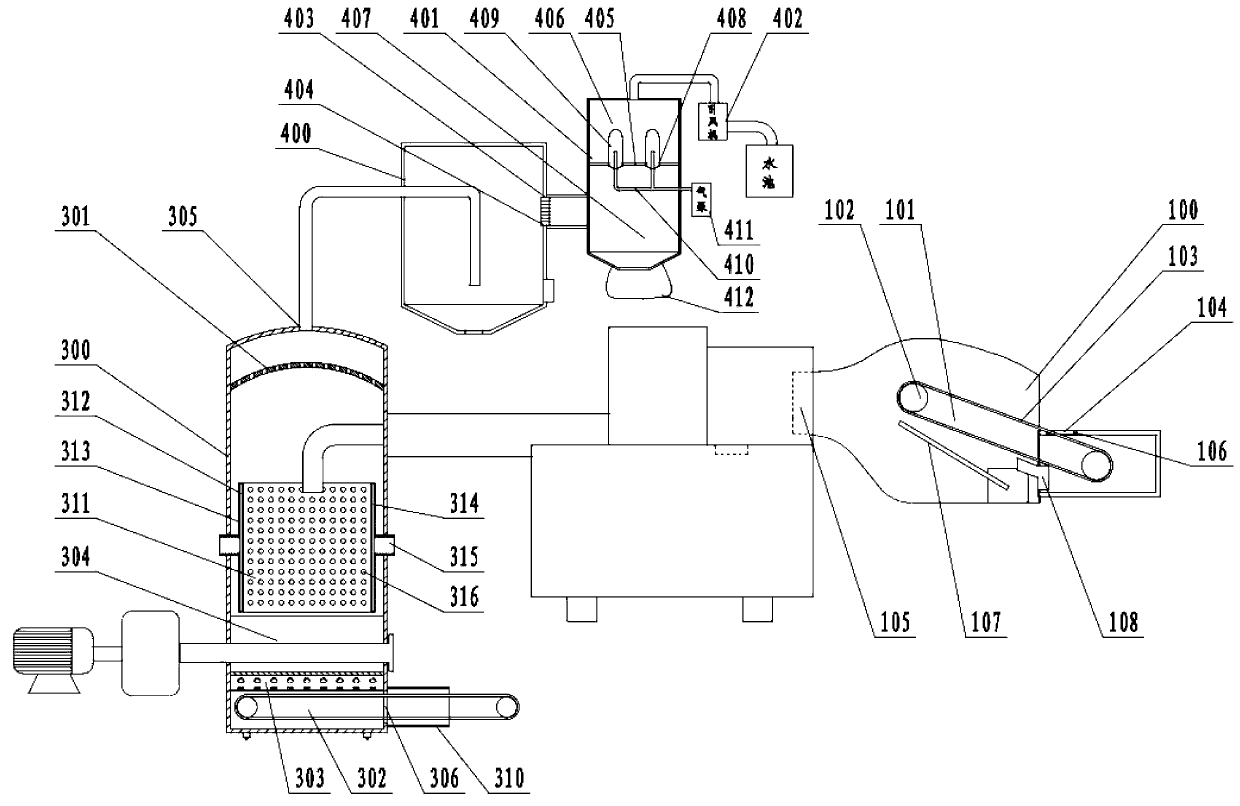

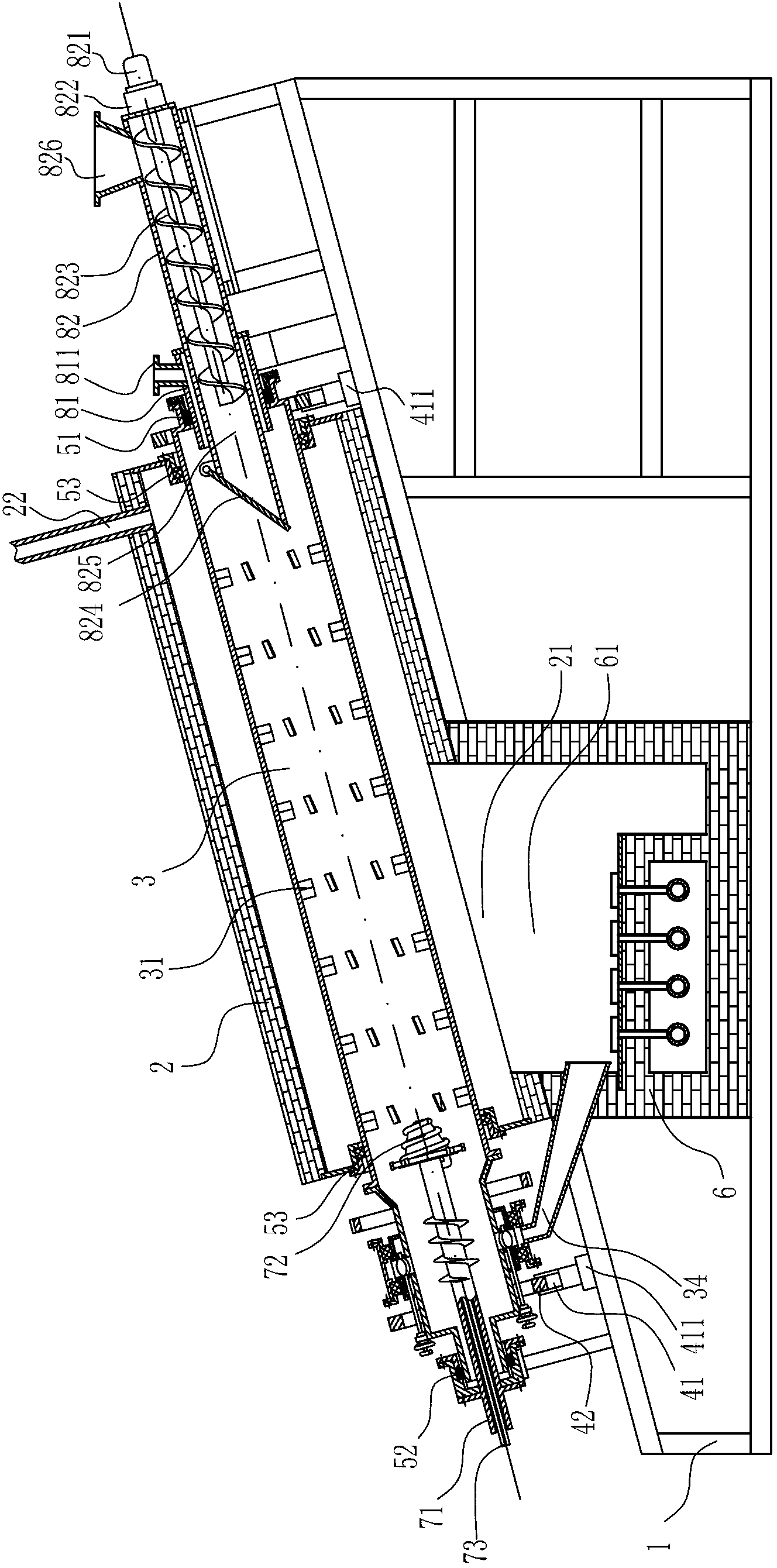

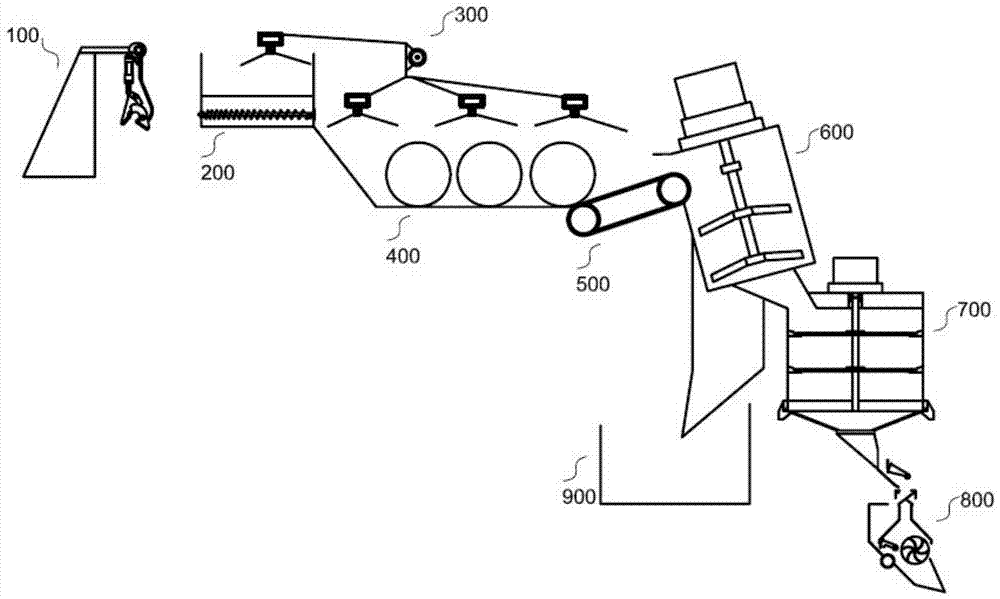

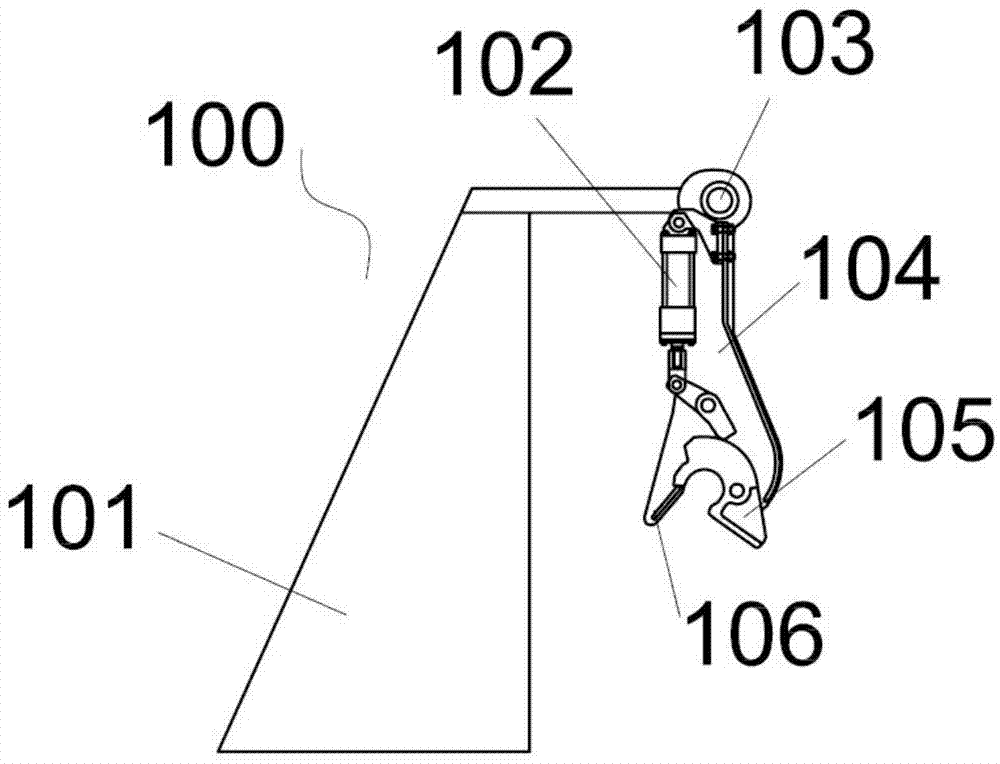

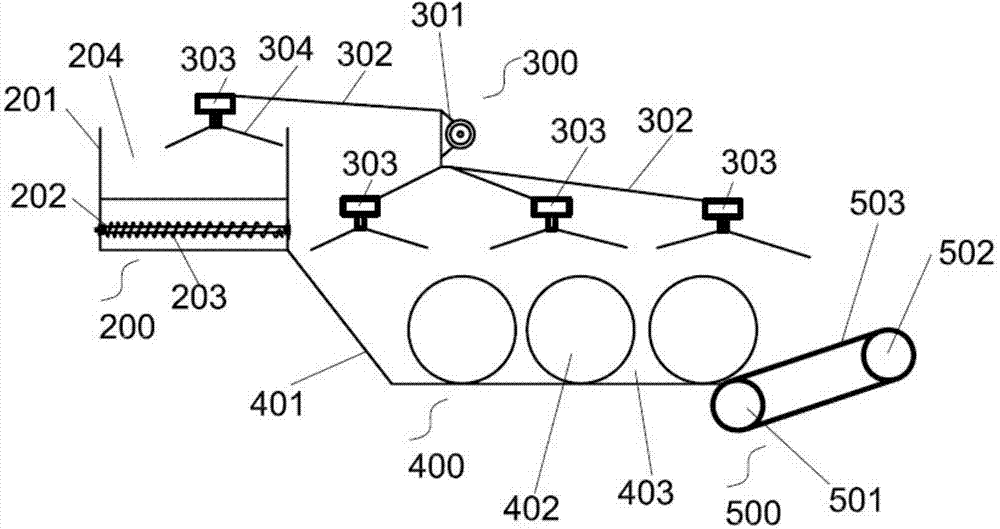

Waste plastic recycling system

ActiveCN103128869ASimple structureReduce utilizationDirt cleaningMagnetic separationFlue gasEngineering

The invention discloses a waste plastic recycling system, and aims to overcome the defects that in an existing waste plastic recycling system, structure is complex, process is cumbersome, washing of waste plastic raw materials is needed, recycling cost of waste plastics is high, a utilization rate of the plastic raw materials is low, and harmful gas produced in the recycling process of the waste plastics can pollute environment. The waste plastic recycling system comprises a feeding device, an extrusion device, a discharging device and a dust suction device which are connected in sequence. The feeding device enables the waste plastic raw materials to be delivered to the extrusion device without washing, investment of washing devices is eliminated, recycling cost of the waste plastics is reduced, and the utilization rate of the waste plastic raw materials is increased. Due to the fact that the discharging device is designed in a closed mode, the waste gas is led into the dust suction device, and the environment is not polluted. Besides, flue-gas temperature is low in the recycling process of the waste plastics, no harmful gas such as dioxin is produced, and the waste plastic recycling system is environment-friendly.

Owner:广州凌富机电有限公司

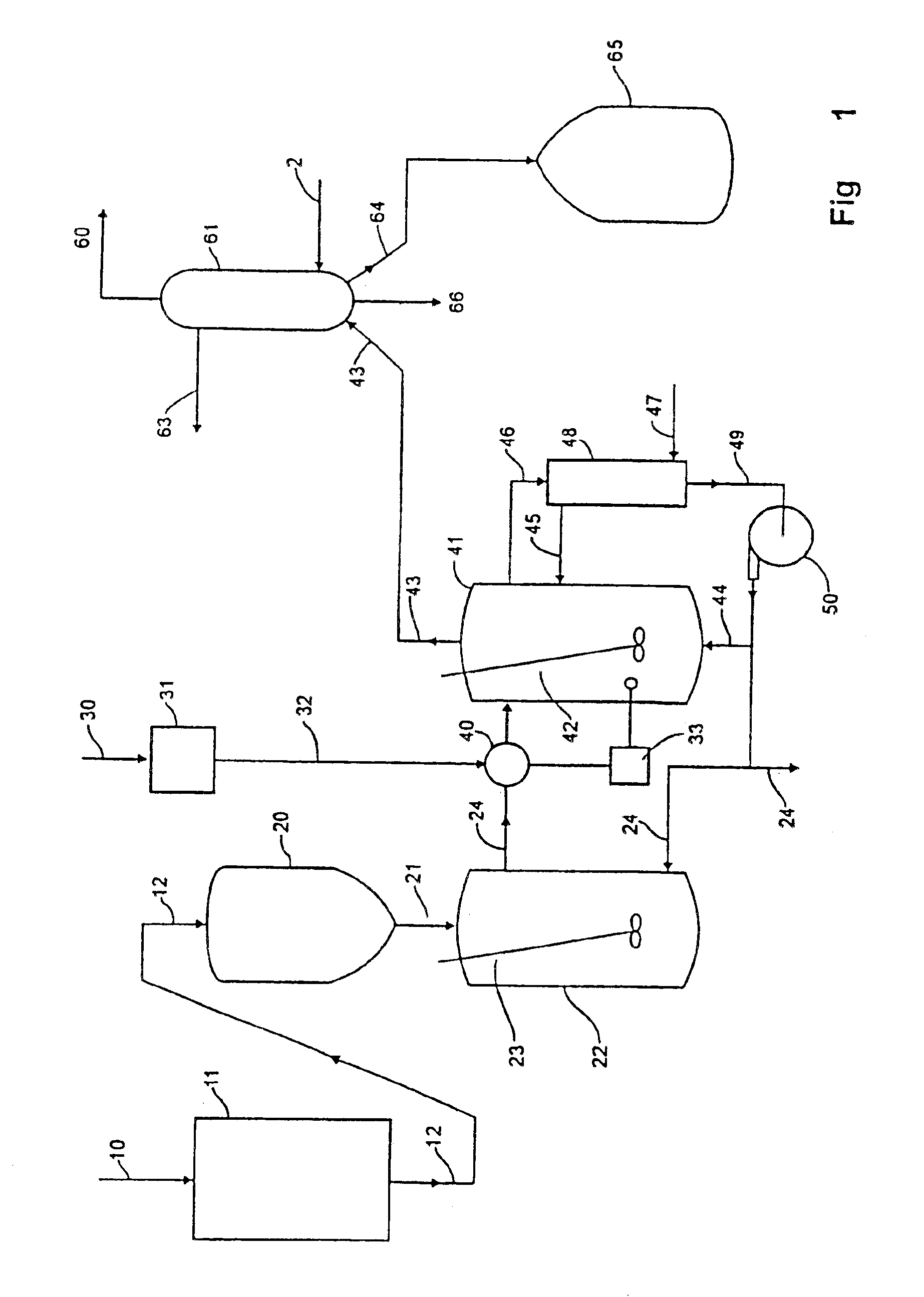

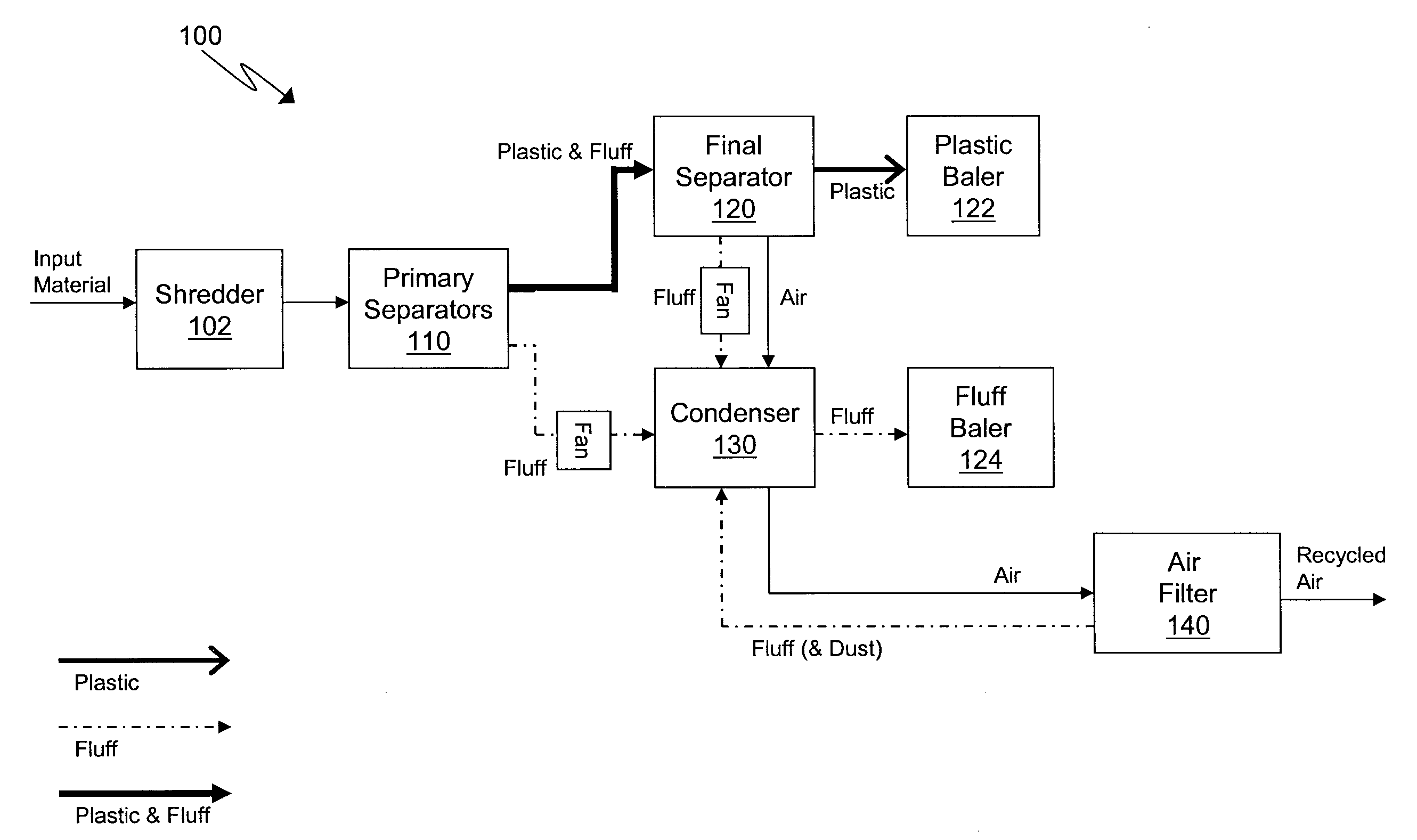

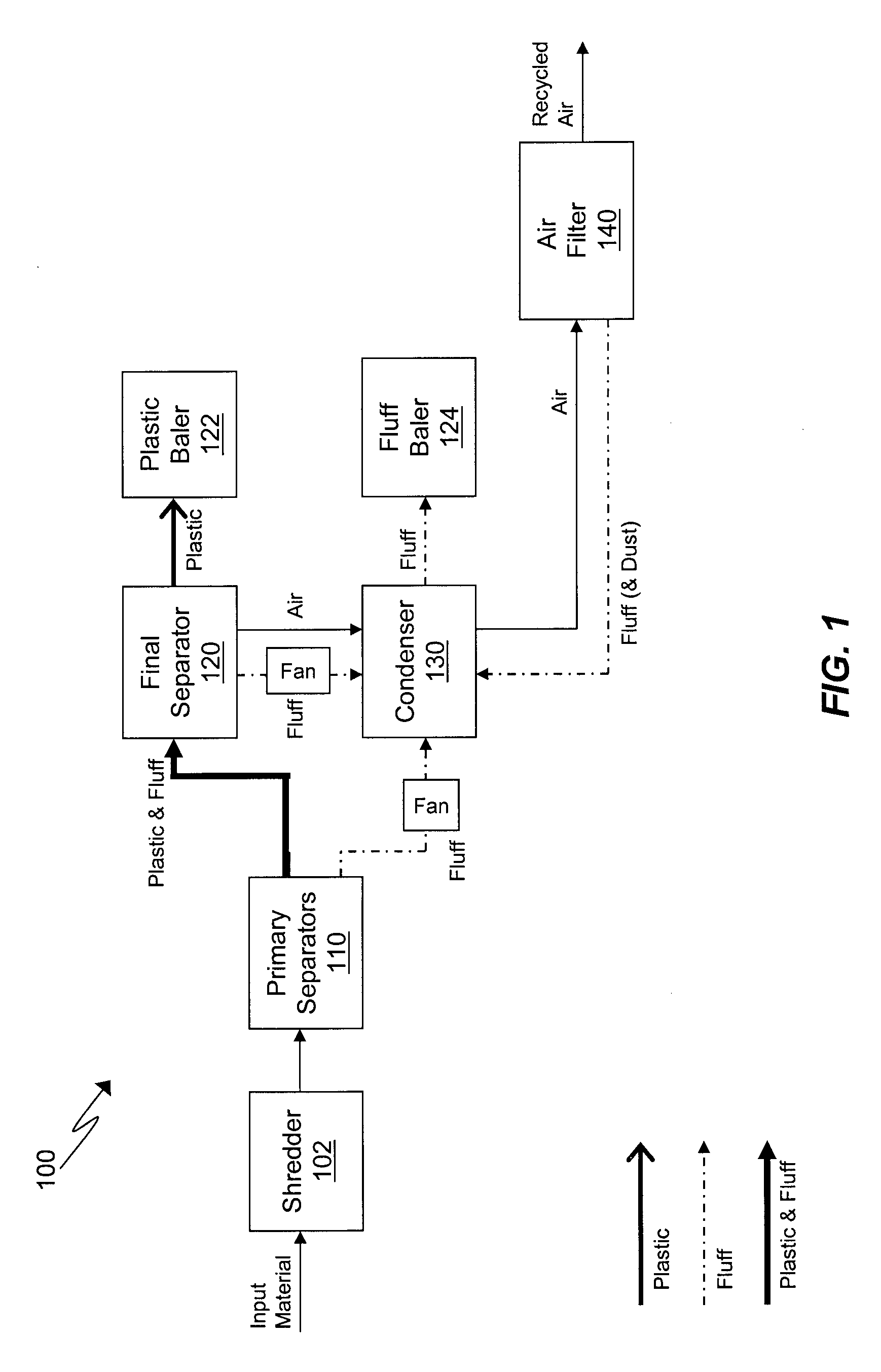

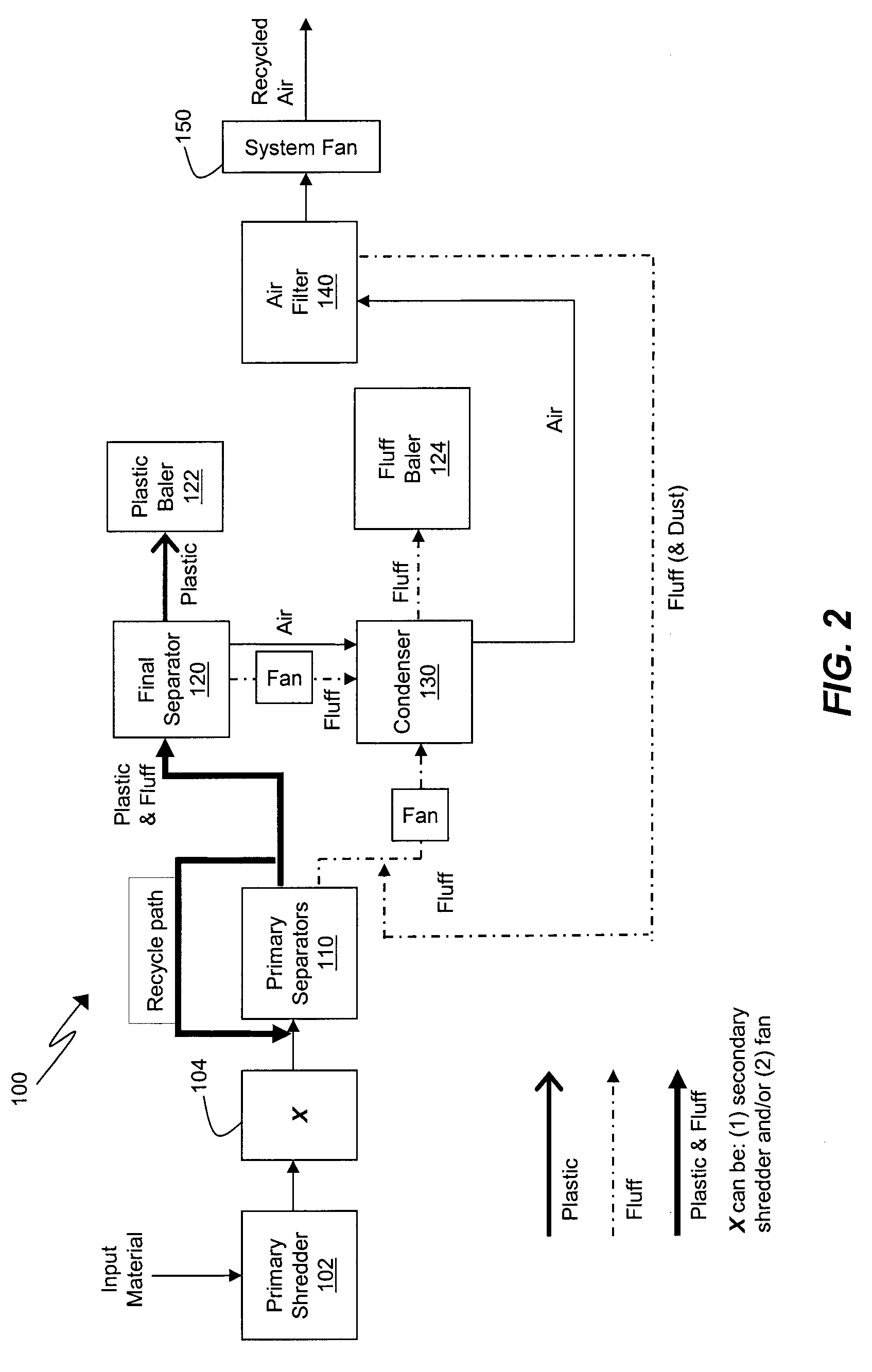

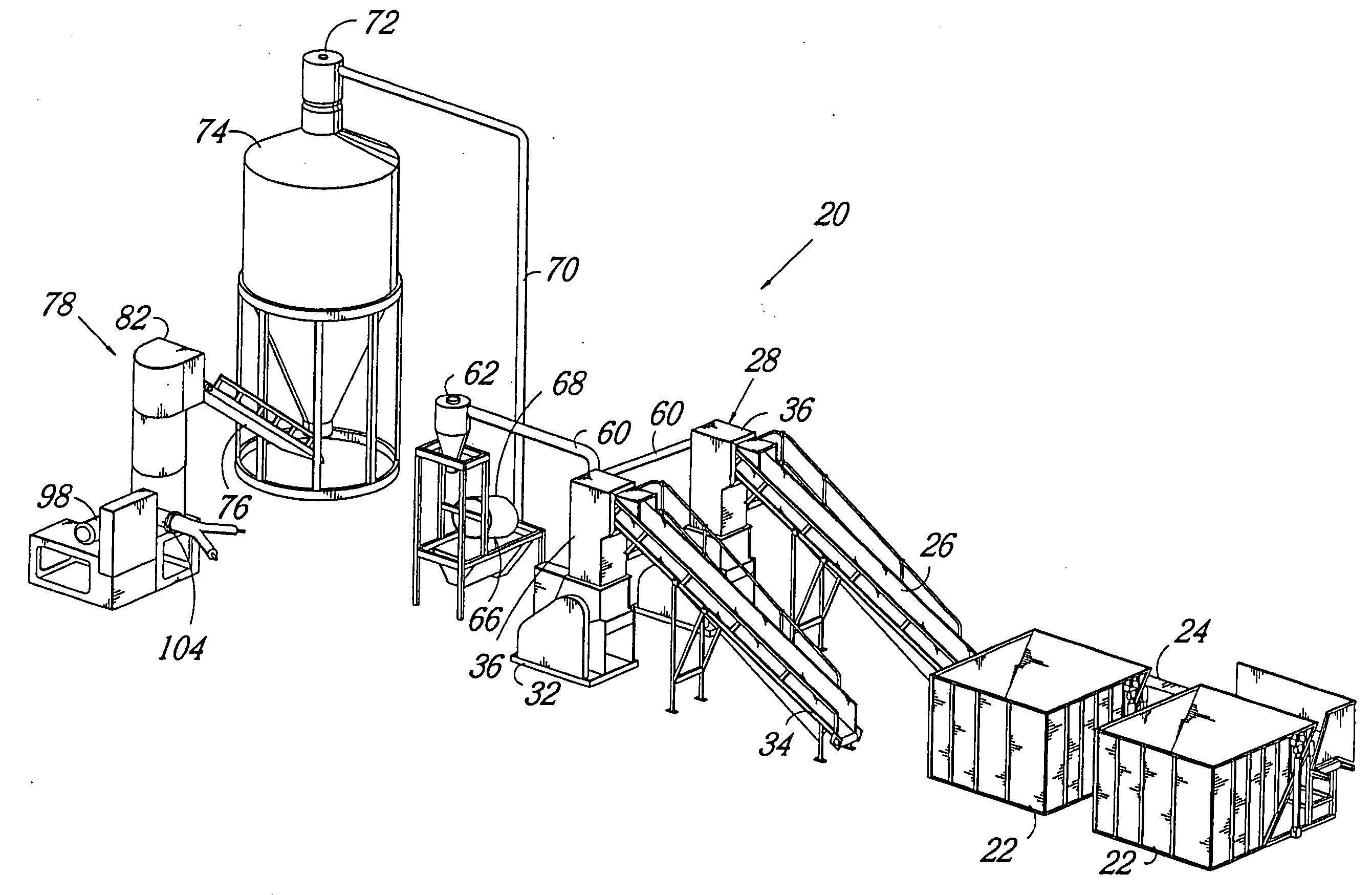

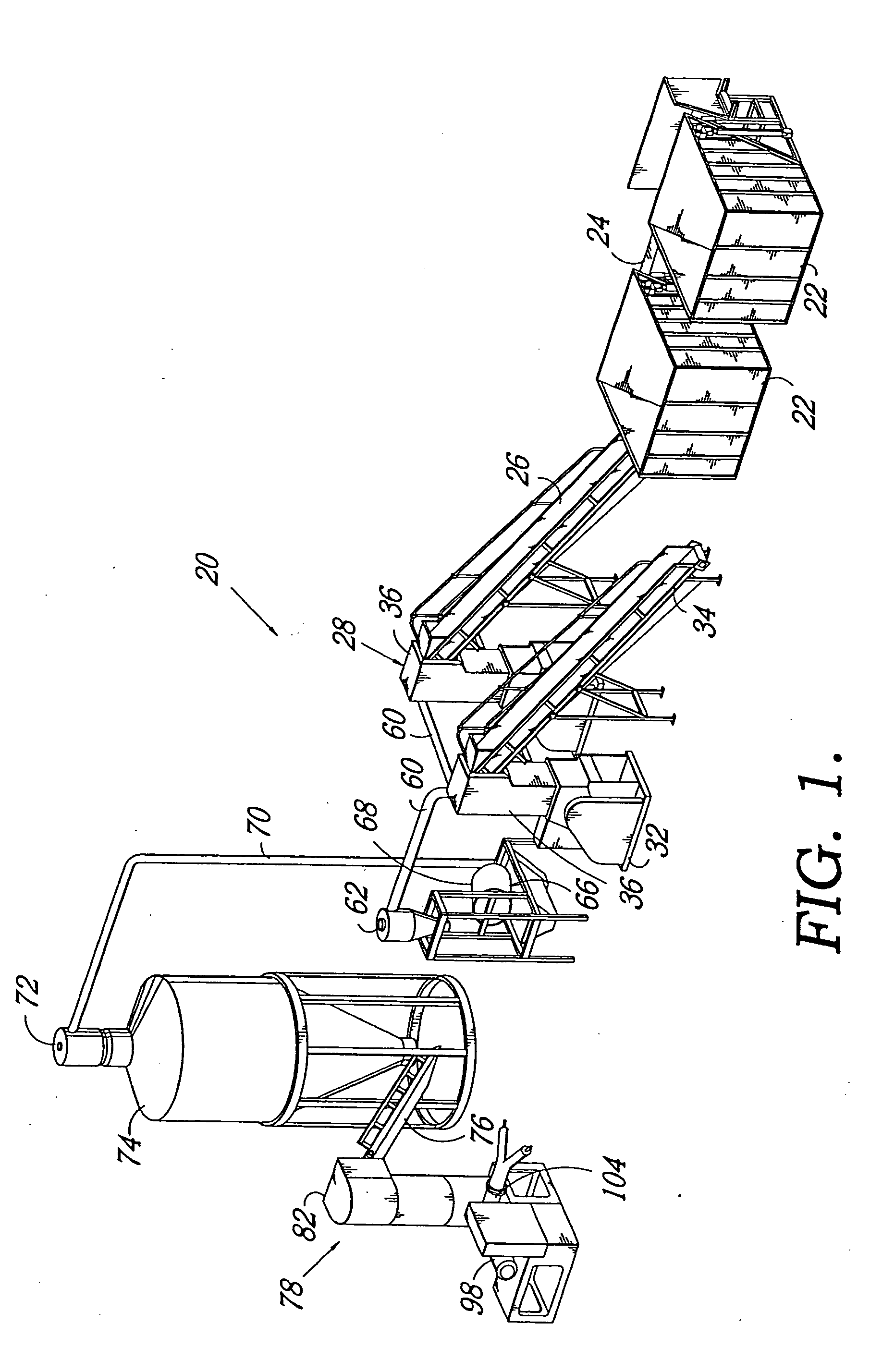

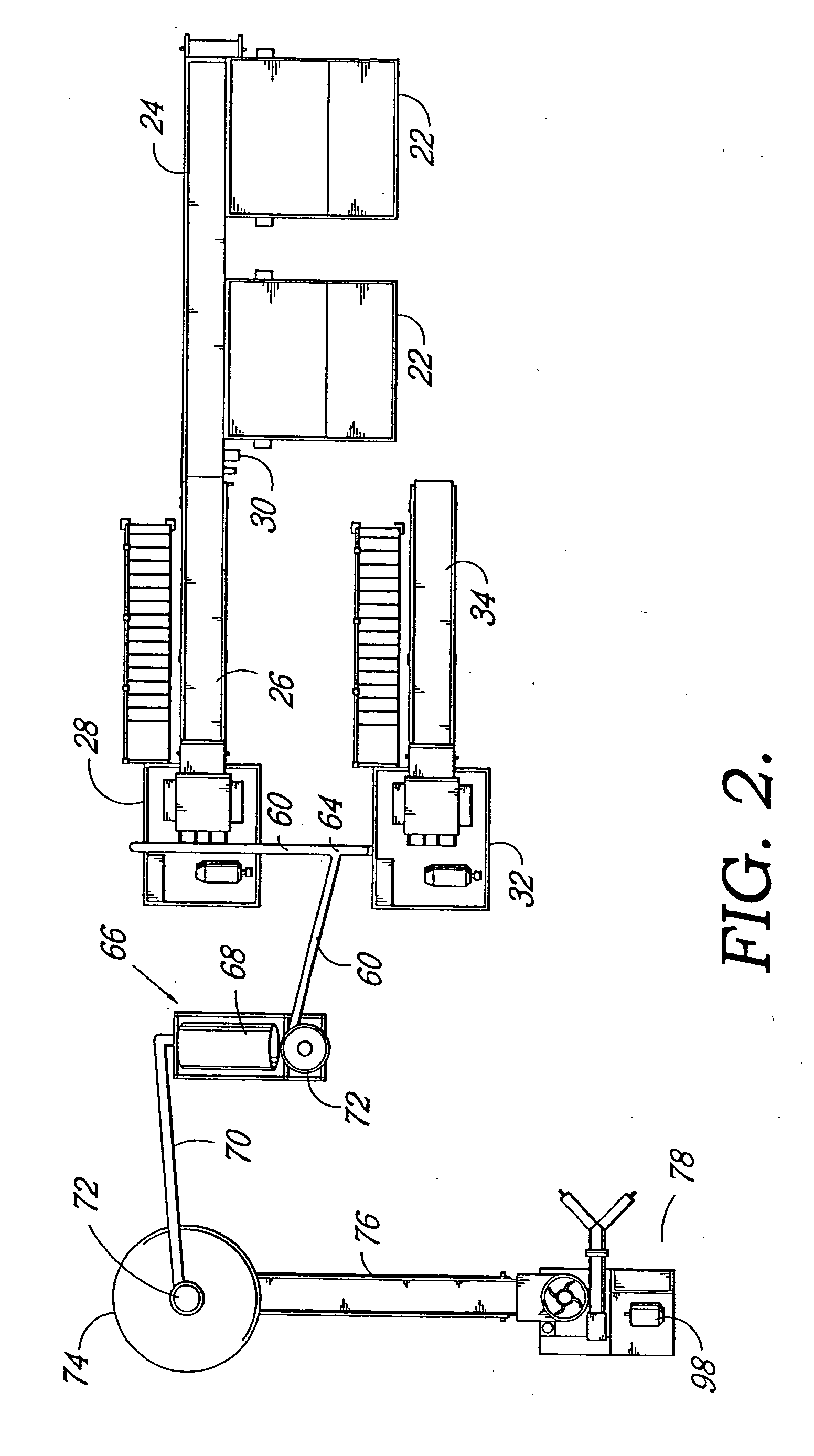

Plastic reclaim system

InactiveUS20090032626A1Mechanical working/deformationGas current separationEngineeringPlastic recycling

Systems and methods are provided for separating materials, such as fluff and plastic found in disposable diapers. A separator unit is provided having an inlet for receiving the materials, means for separating the materials, and multiple outlets for each of the respective materials. In one aspect, the system is substantially pneumatic, and air is used to separate the materials. In some aspects, a shredder is provided for shredding the materials prior to separating, and balers are provided for baling each of the respective materials.

Owner:ARMSTRONG STEVEN L +3

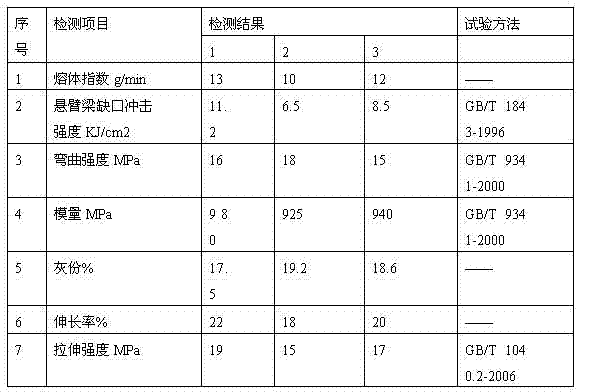

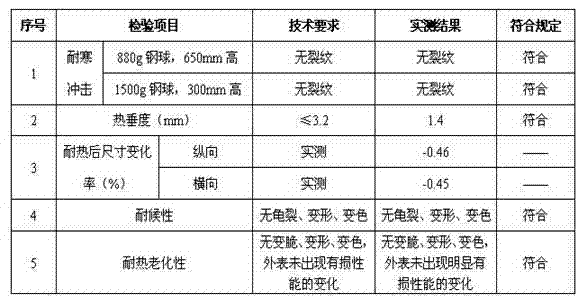

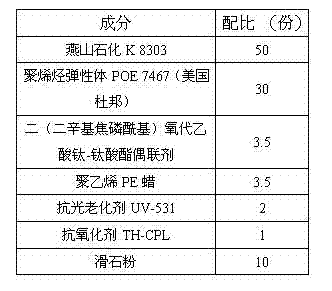

Method for recycling thermoplastic polypropylene plastic parts of scraped automobile

InactiveCN102173007AAvoid problems that are difficult to recycleSolve the problem of strong bonds that are difficult to removePlastic recyclingThermoplasticEngineering

The invention belongs to the field of recycling of waste plastics of scraped automobiles, and relates to a method for recycling thermoplastic polypropylene plastic parts of a scraped automobile. The method comprises the following steps of: manually disassembling nonmetallic inner and outer ornaments and structural parts of the scraped automobile, manually sorting thermosetting plastic parts and thermoplastic plastic parts, further manually sorting the thermoplastic polypropylene plastic parts, manually disassembling and separating metallic linkage parts, circuits and the like of the sorted thermoplastic polypropylene plastic parts, performing two-stage crushing on the polypropylene plastic parts, performing ferromagnetic sorting on two crushed materials respectively to separate out metallic scraps, separating out fine metallic scraps and metallic paint by using a roller direct-current high-voltage corona and electrostatic composite electric field sorter, performing sampling performance detection on the cleaned and dried materials, adding a modifier according to the detection results and the using requirements, granulating, and manufacturing automobile plastic members by using the materials. By using the method, the plastic recycling problem of the scraped automobile is solved, broken plastic resources of the scraped automobile are recycled, environmental pollution is avoided, the energy consumption is low, and the additional value is high.

Owner:路洪洲 +3

High-toughness halogen-free flame-retardanting reclaimed polycarbonate compound and preparation method thereof

InactiveCN101709142AIn line with the development trend of non-halogenated flame retardantImprove flame retardant performanceAntioxidantUltraviolet

The invention relates to a high-toughness halogen-free flame-retardanting reclaimed polycarbonate compound and a preparation method thereof, belonging to the field of reclaimed plastic flame-retardanting and toughening-modified products. The invention aims to provide a high-toughness halogen-free flame-retardanting reclaimed polycarbonate compound which uses reclaimed polycarbonate as a matrix. The invention is characterized in that the compound comprises the following components by weight percent: 81.0-93.4% of reclaimed polycarbonate, 3.0-10.0% of latex particles of core-shell silicon rubber, 1.0-7.0% of bulking agent, 0.1-0.5% of antioxidant, 0.1-0.5% of light stabilizer, 0.1-0.5% of ultra-violet absorber, 0.8-1.2% of heat barrier and 0.3-0.5% of anti-dripping agent. The preparation method of the compound comprises the following steps: evenly mixing the components, melting the components on a double-screw extruder, blending, extruding, cooling and pelleting the melted components to prepare the reclaimed polycarbonate compound. The compound has the advantages of good anti-impact properties, retardanting level of UL94 V-0 and low cost, thereby meeting the requirements of industries such as electronic and electric products and the like on the high-property polycarbonate engineering plastics.

Owner:BEIJING UNIV OF CHEM TECH

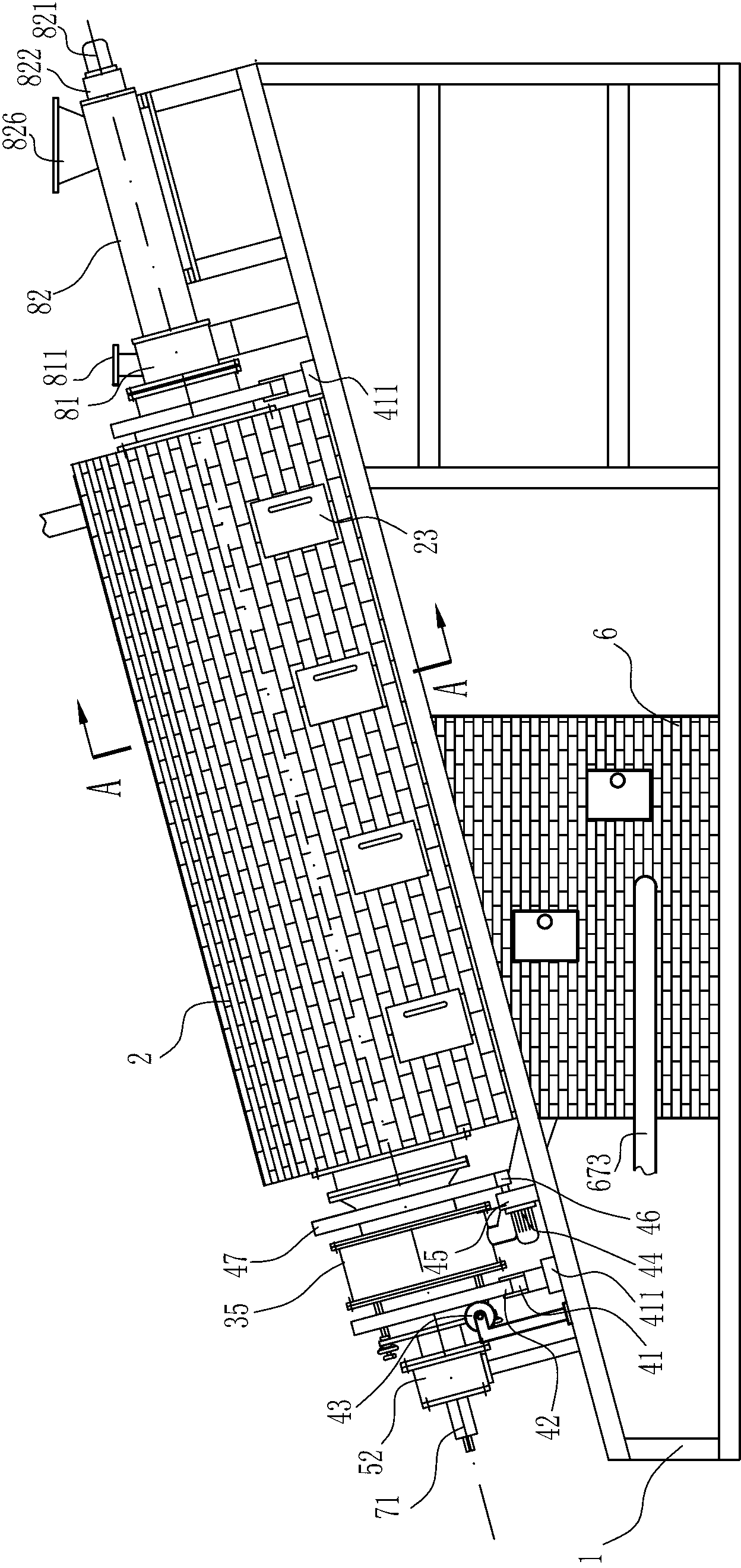

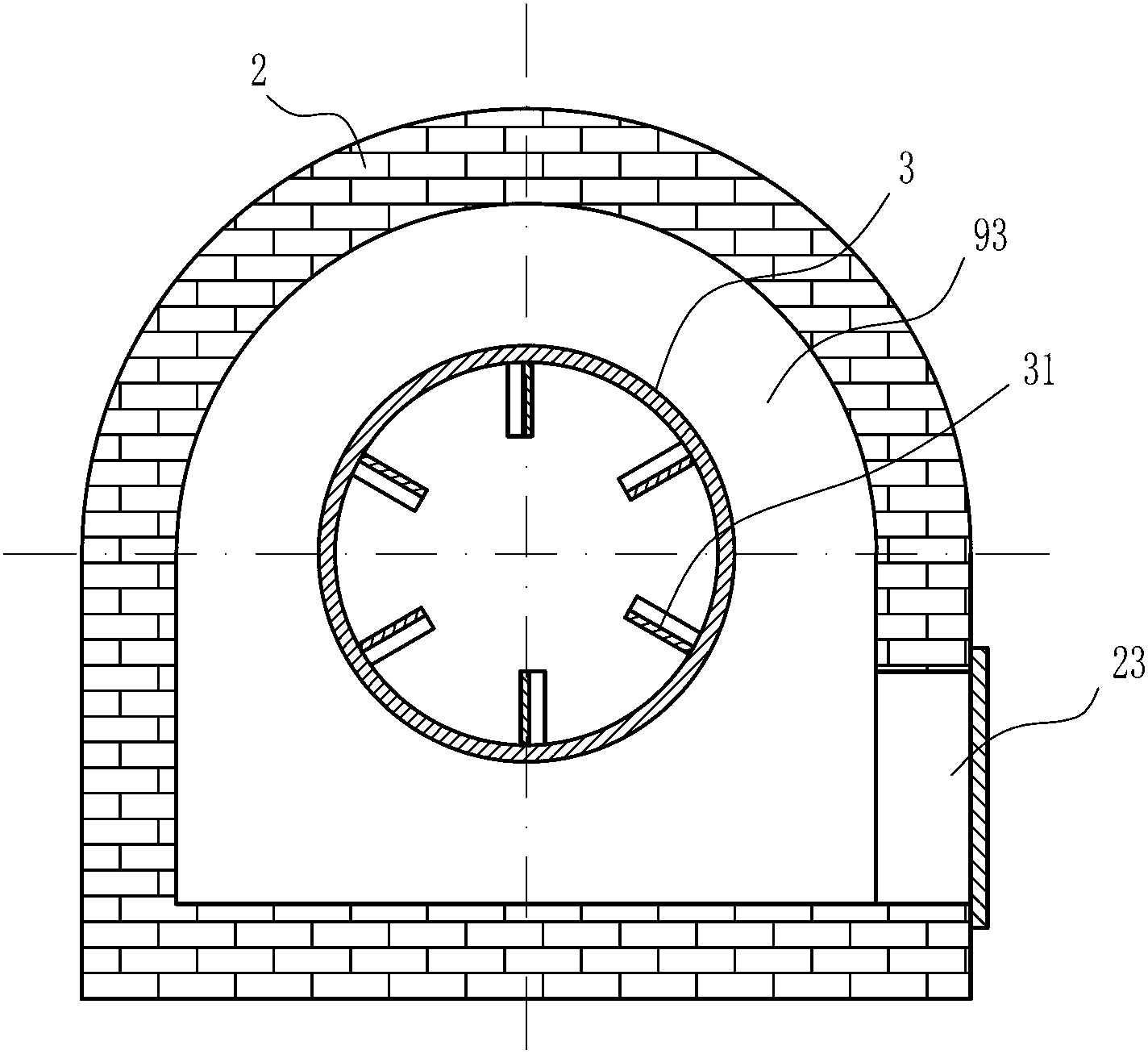

Continuous gasifying and cracking multi-effect furnace for plastic recycling

InactiveCN103060013AImprove breathabilitySmooth responseLiquid hydrocarbon mixture productionCombustible gas productionThermal energySlag

The invention discloses a continuous gasifying and cracking multi-effect furnace for plastic recycling, which comprises a base, a kiln cylinder, a tailings burner and a rotationally arranged cylindrical furnace body. The furnace makes the best of energy of plastics to gasify and crack plastics. The cracking and gasifying process comprises the following steps of: firstly, cracking the plastics at the upper part of the cylindrical furnace body, and cracking to generate gas-state crude oil; secondly, gasifying highly carbonic slag generated by cracking at the lower part of the cylindrical furnace body, and further extracting the energy in the plastics; and finally, feeding the slag generated by gasifying into the tailings burner for completely burning, and using heat energy generated by the tailings burning to provide the needed energy for the plastic cracking. According to the invention, through cracking, gasifying and burning, the needed energy for the plastic processing is automatically performed through internal circulation, the plastics are changed into products such as crude oil and combustible gas and the processed final residues are changed into ash. The continuous gasifying and cracking multi-effect furnace processes the plastics thoroughly, so that the damage to the environment caused by the wasted plastics is solved completely.

Owner:潍坊金丝达环境工程股份有限公司

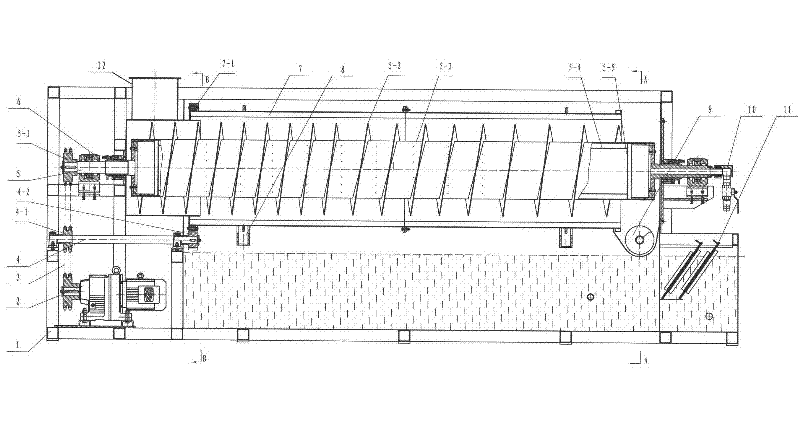

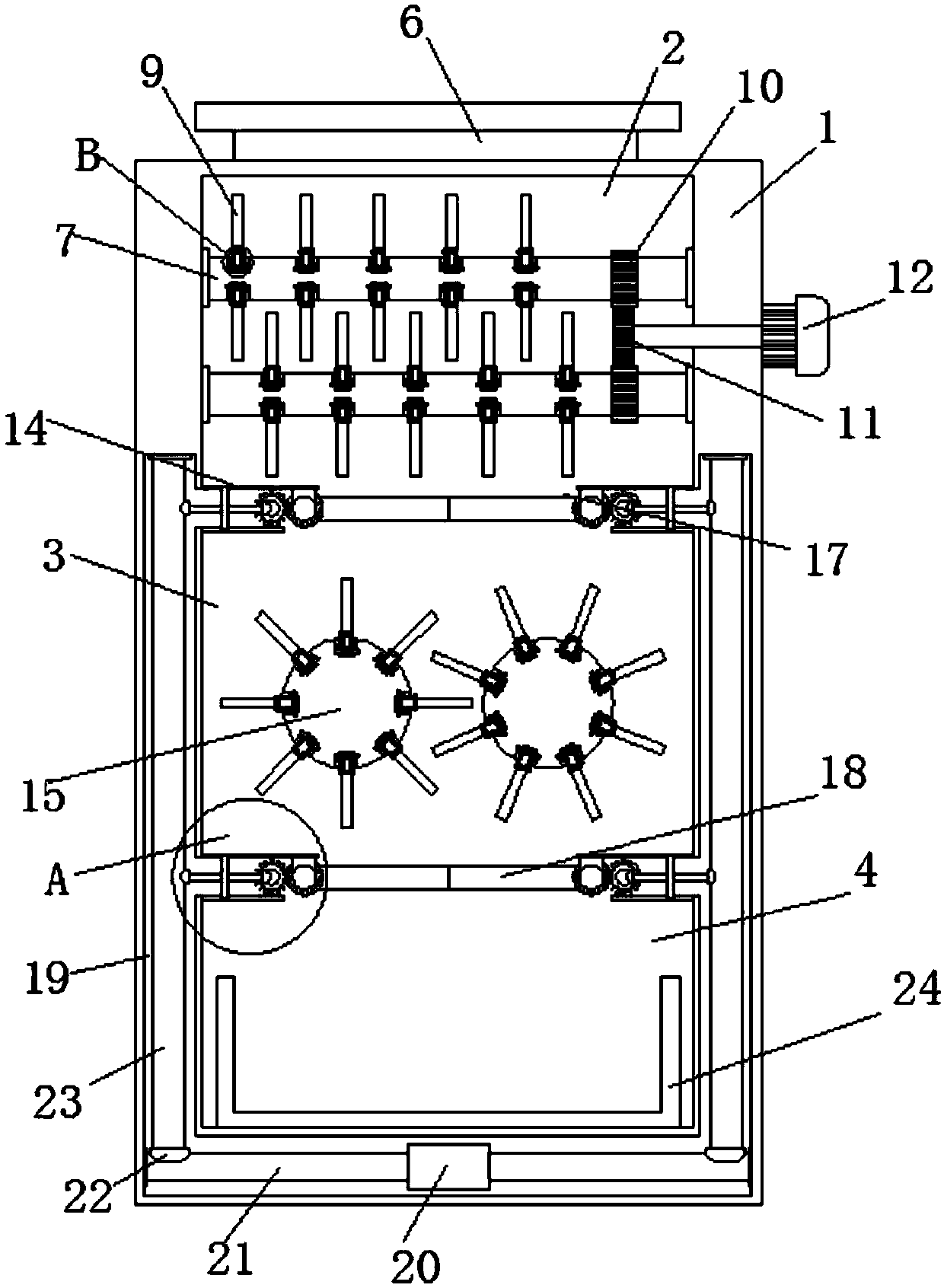

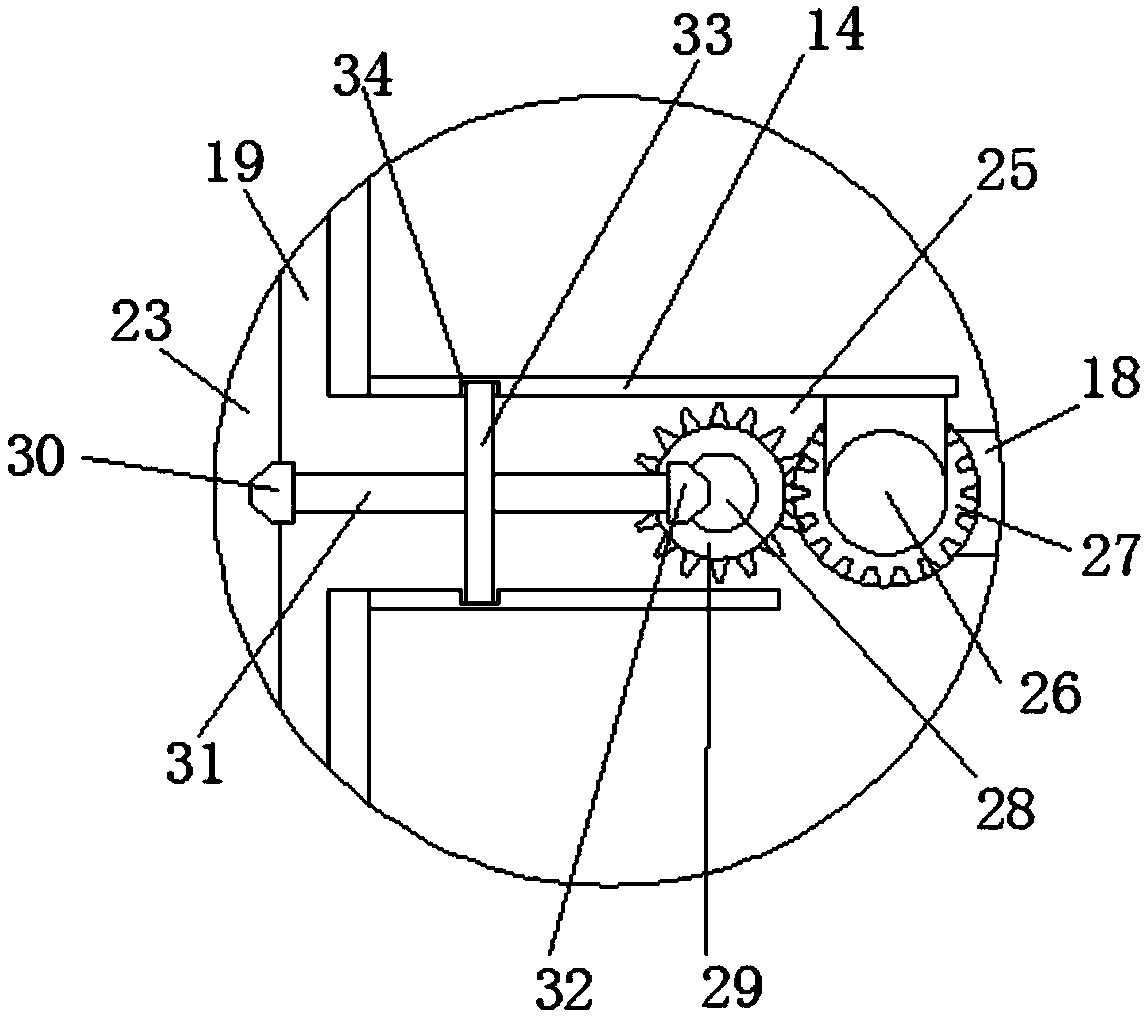

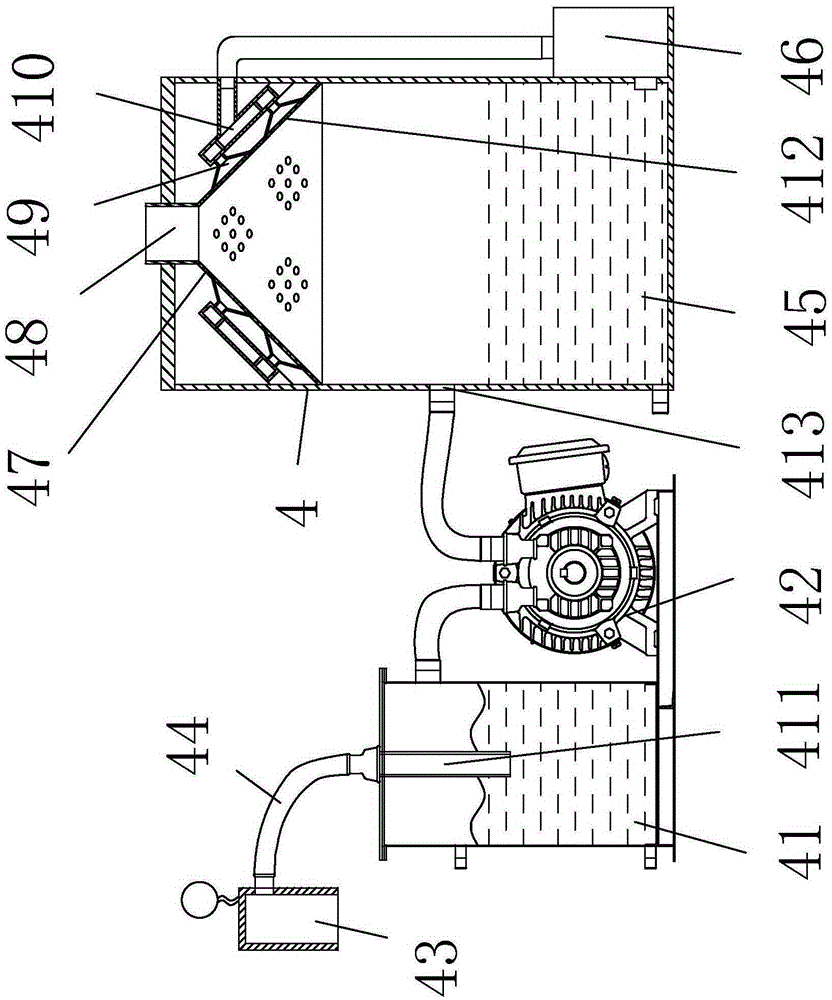

Cleaning machine

InactiveCN102380487AContinuous and stable dischargeIncrease productivityCleaning using liquidsGear wheelReducer

A cleaning machine is used for a granulation production line by recovery of waste plastics and capable of realizing continuous discharging and being adaptable to materials in different specific gravity. A water tank is arranged in a framework, a speed reducer and a transition wheel component are mounted on the left side of the framework, bearing components are respectively mounted at the left end and the right end of the upper portion of the framework, the left end and the right end of a screw shaft penetrates through the bearing components respectively, an outer sleeve is sleeved on the screw shaft to be positioned by a supporting component, and a discharging screw conveyor which is disposed horizontally and perpendicular to the axis of the screw shaft is mounted on the framework and at the rightmost end of the outer sleeve. Further, a gear is fixed at the left end of the outer sleeve and meshes with a pinion at the right end of the transition wheel component, a plurality of elongated triangular stirring ribs distributed uniformly are welded to the inner wall of the outer sleeve, and a feed cylinder coaxial with the screw shaft is mounted at the leftmost end of the screw shaft. The speed reducer drives the screw shaft to rotate relative to the outer sleeve reversely through a chain.

Owner:江苏美星大地环保科技有限公司

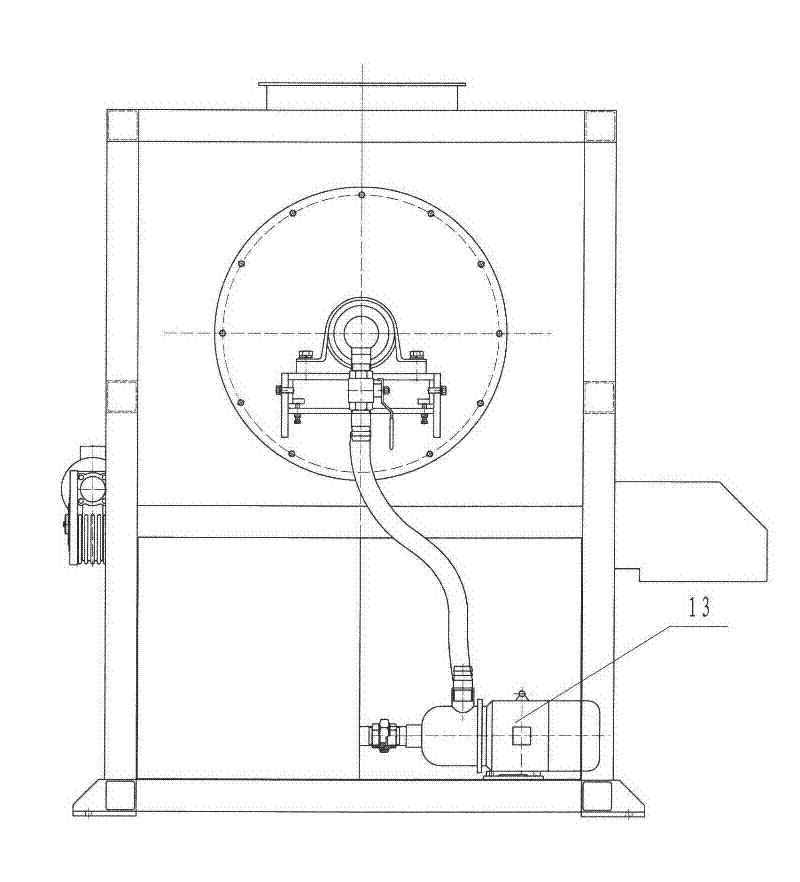

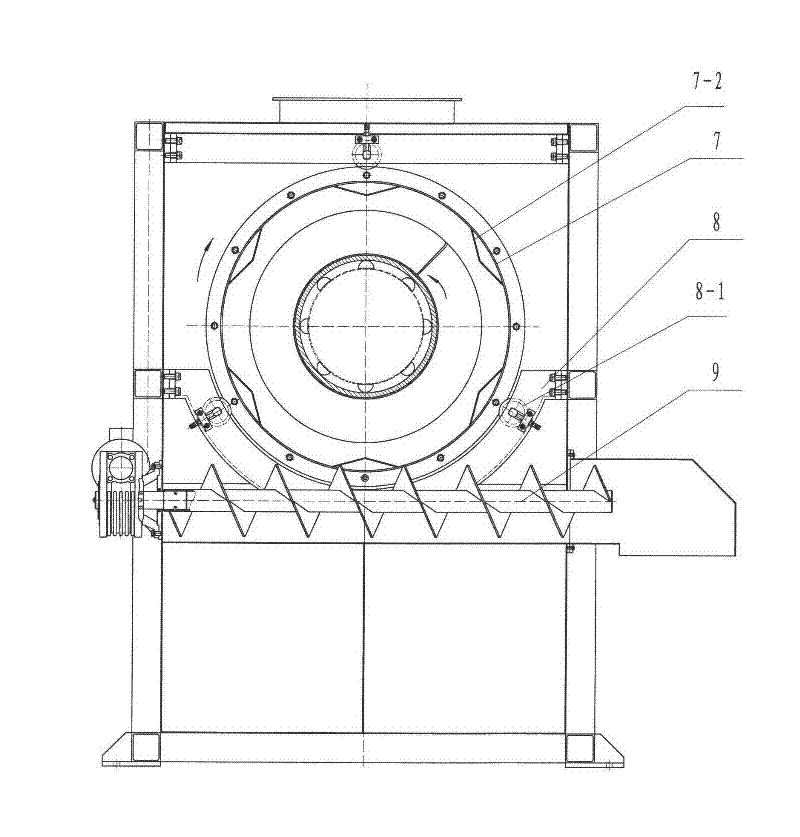

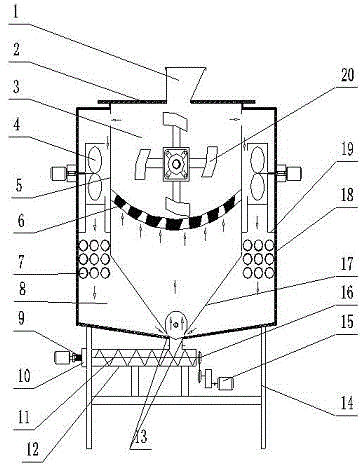

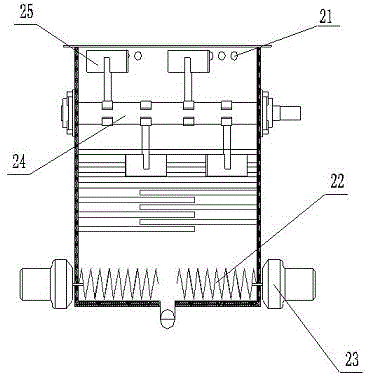

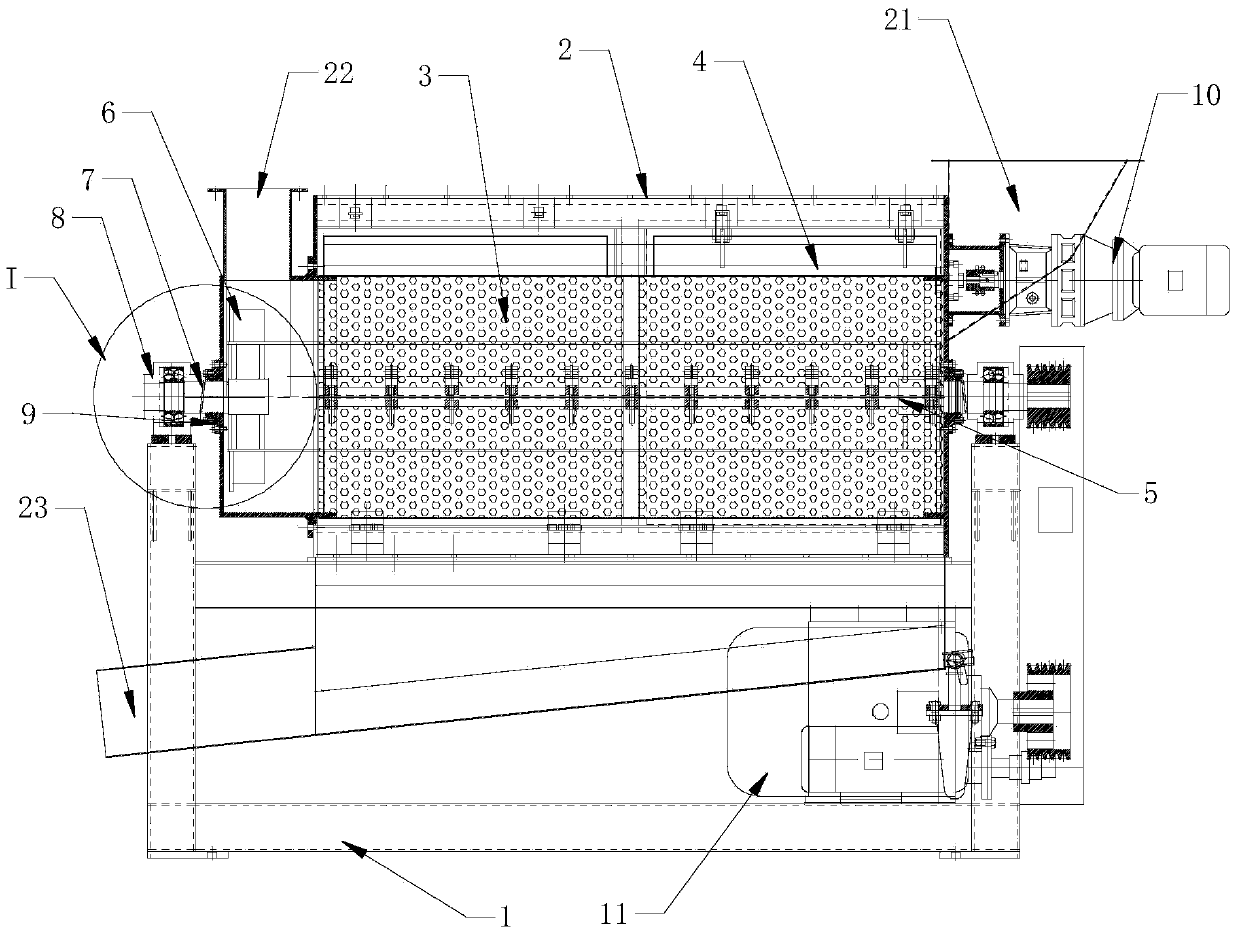

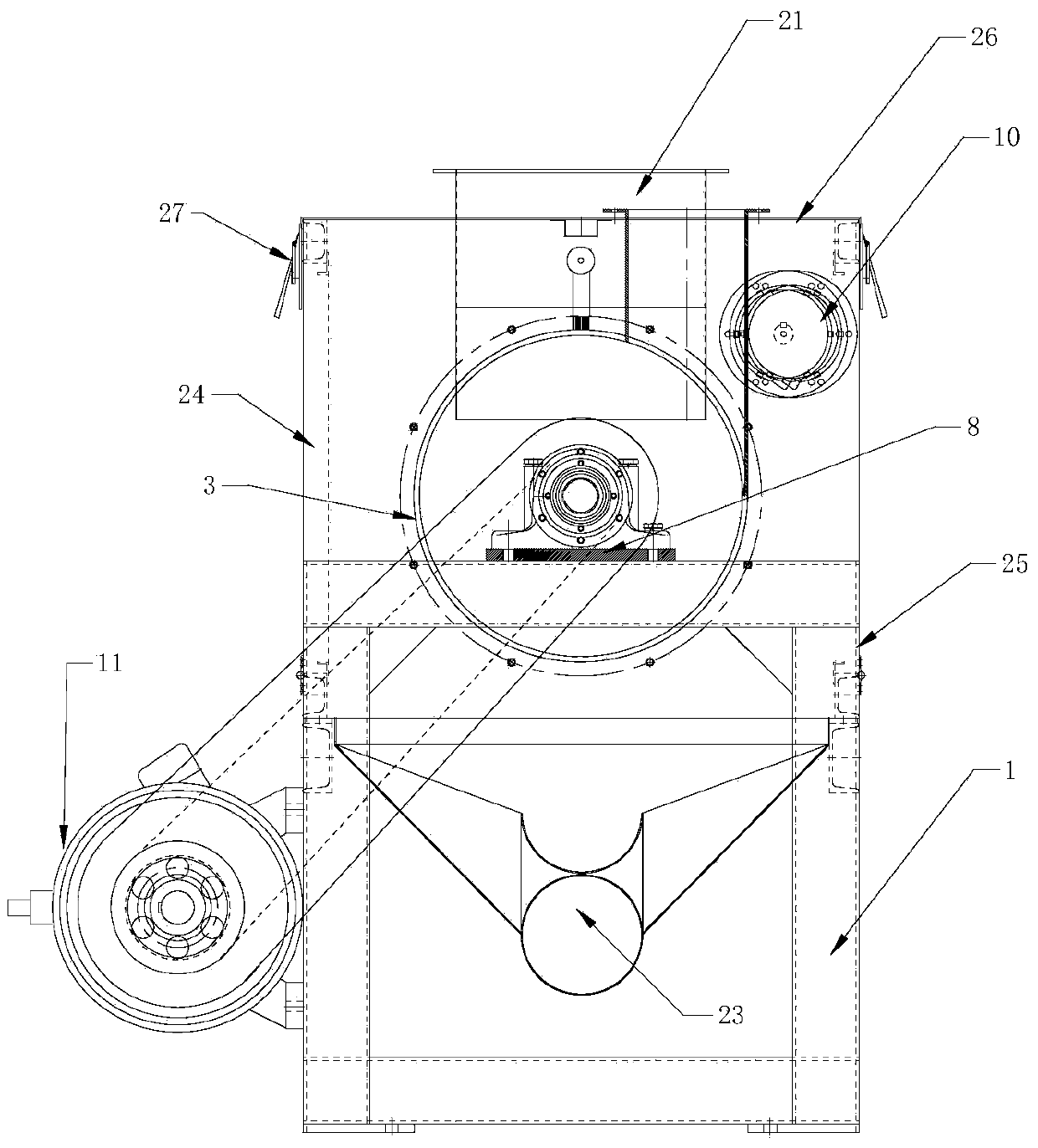

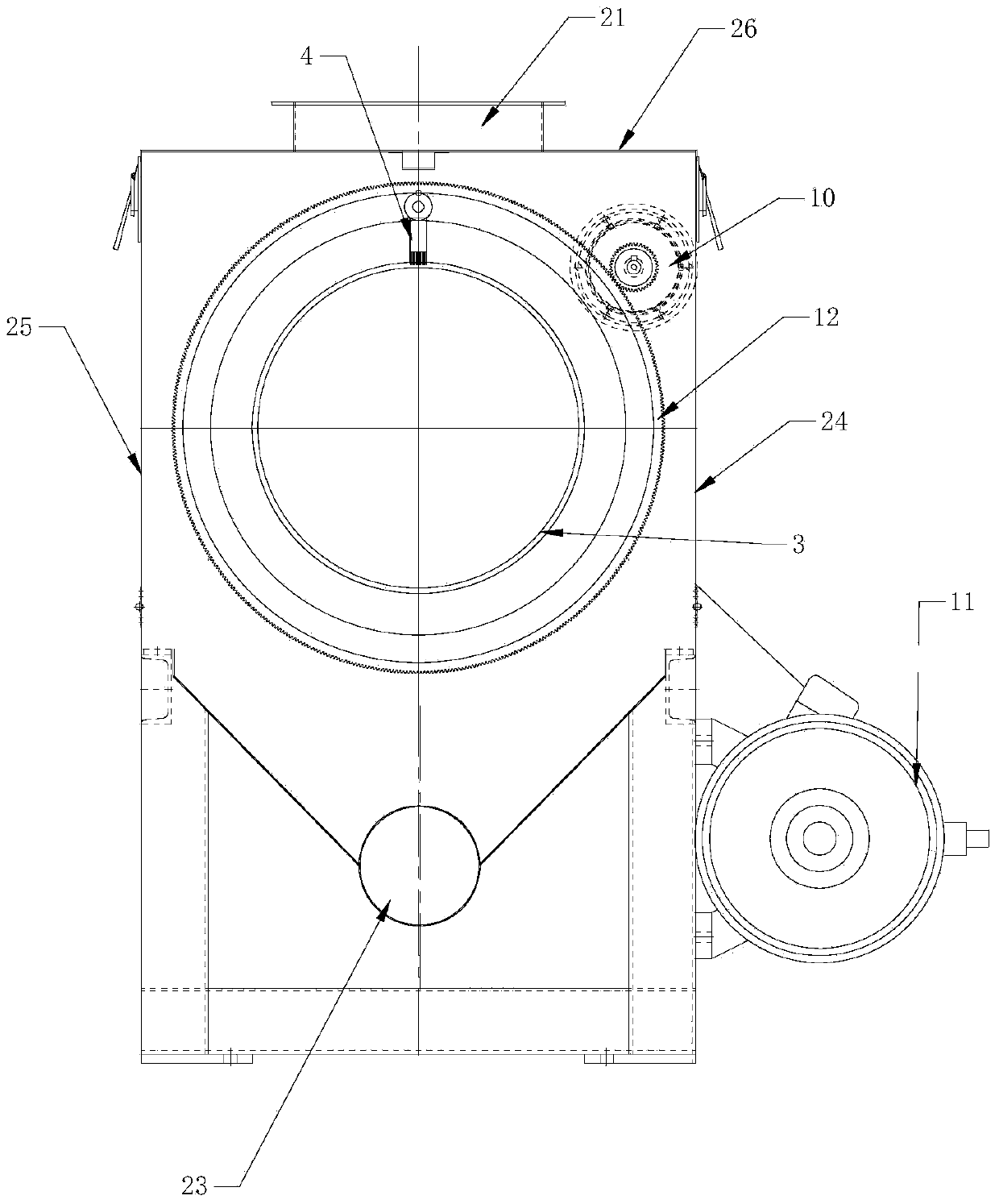

Horizontal plastic waste recovering granulator

InactiveCN104859067AAvoid it happening againImprove working environmentPlastic recyclingThermodynamicsPlastic waste

A horizontal plastic waste recovering granulator is composed of a hopper, a box cover, a melting chamber, a fan, an arc-shaped screen, a heating tube, a mouth mold, a pelletizing mechanism, an extrusion screw, a machine cylinder, a frame, a driving mechanism, a transmission mechanism, a V-shaped receiving hopper, a hot air circulating box body, a separator plate and a stirring mechanism. The granulator adopts hot air to directly melt plastic wastes, so the crushing and cleaning processes of traditional technologies are omitted, the working environment is improved, and secondary pollution is avoided; and the temperature of the hot air is controllable, so the overheating decomposition of plastics is avoided, cycle use of the hot air is realized, and the heat efficiency is high.

Owner:NANCHANG UNIV

Method for preparing activated carbons by using plastics of recycled waste circuit boards as raw material

InactiveCN101948110AImprove heat utilizationReduce heat lossSolid waste disposalElectronic waste recyclingRecovery methodActivated carbon

The invention discloses a method for recycling the plastics of waste circuit boards, which comprises the following steps: preparing activated carbons by using the plastics of screened waste circuit boards as a raw material through the methods of chemical activation and microwave heating; then soaking the obtained activated carbons in drug with certain concentration for twenty-four hours, wherein the volume ratio of the plastic powder of the waste circuit boards to the drug is 1:3; activating by putting the activated carbons in a micro-wave oven for radioactivation; carrying out acid-washing on the activated carbons subjected to radioactivation by hydrochloric acid solution with 1:9 in volume ratio so as to remove ashes; rinsing the activated carbons subjected to acid-washing by water so as to regulate the pH value of the activated carbon to be 7; finally, putting the activated carbons in a drying oven, and then crushing the dried activated carbons so as to obtain the finished activated carbon product. The iodine sorption value of the prepared activated carbon product is 404.8 mg / g, the methylene blue sorption value thereof is 47.2 mg / g, and the yield is 38.1 percent. By using the method of the invention, the plastics of waste circuit boards are prepared into activated carbons by using the methods of chemical activation and microwave heating, and the adsorption property of the prepared activated carbon is similar to that of general industrial activated carbons, therefore, the method of the invention is also a new better way for recycling the plastics of waste circuit boards.

Owner:KUNMING UNIV OF SCI & TECH

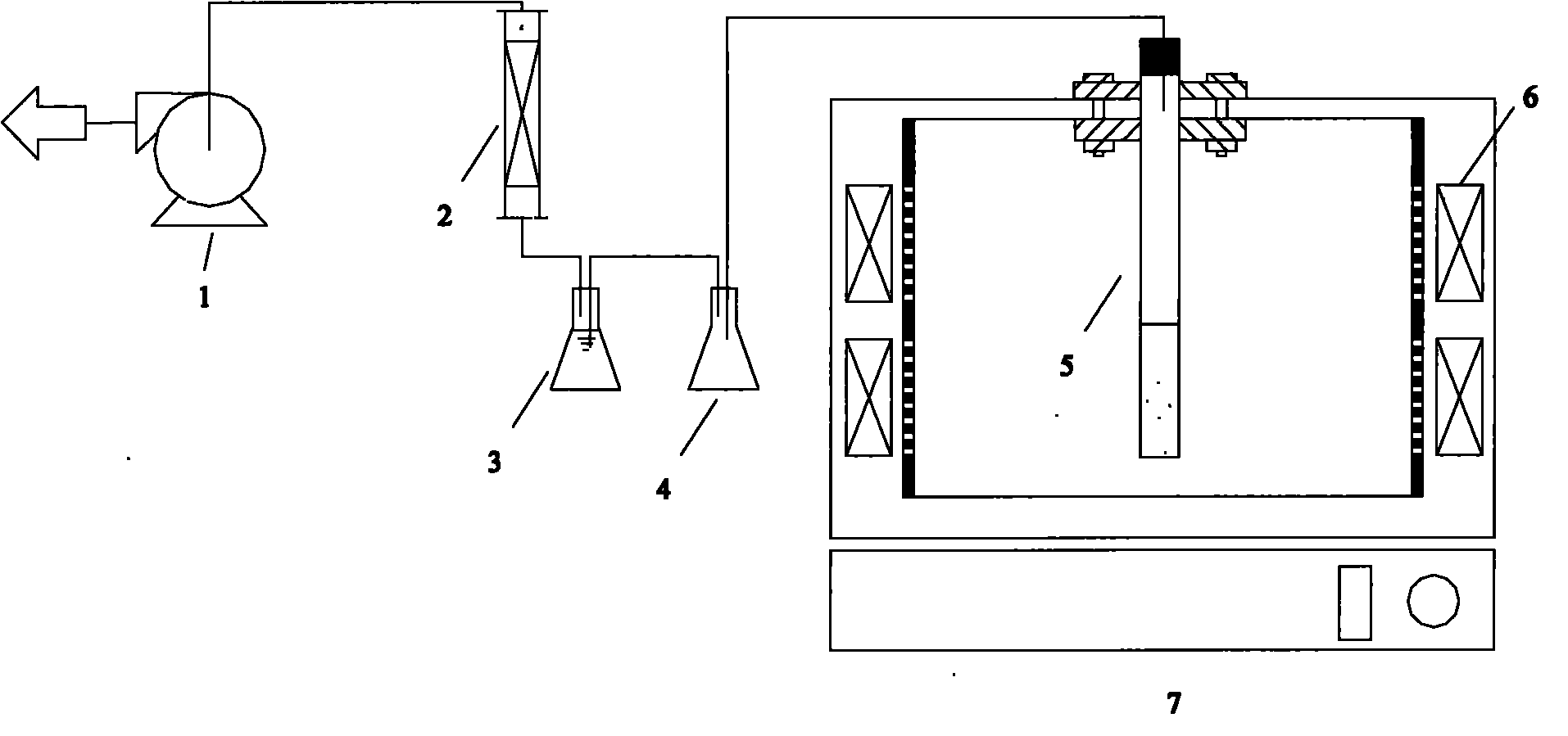

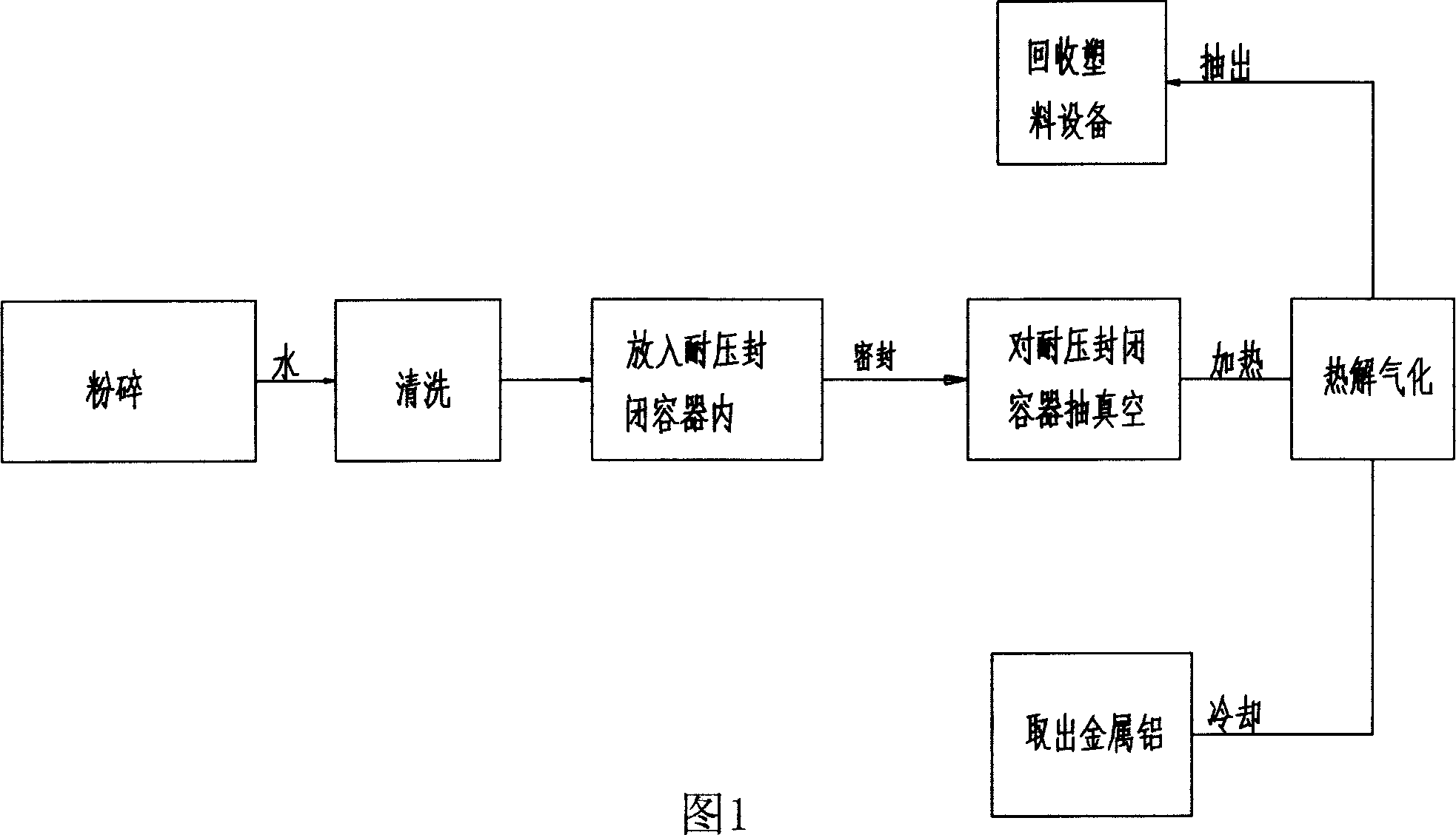

Recovery method of separating waste composite material of aluminum and plastic

InactiveCN1915635AReduce and eliminate oxidationAvoid Separation of WorkProductsReagentsRecovery methodPlastic recycling

A method for separating and recovering the rejected aluminum-plastics composition includes such steps as breaking, loading the broken composition in a pressure container, sealing, vacuumizing, heating for thermally decomposing the plastic to become gas state, and pumping the gas into recovering apparatus while obtaining Al metal in said container.

Owner:徐考伸

Plastic product recycling machine

InactiveCN108015927ACompletely brokenReduce recycling efficiencyPlastic recyclingGrain treatmentsEngineeringPlastic recycling

The invention discloses a plastic product recycling machine. The plastic product recycling machine comprises a shell, wherein the shell is of a hollow structure; the interior of the shell is divided into a first crushing cavity, a second crushing cavity and a collecting cavity through two partition plates which are arranged in parallel; discharge ports are formed in the partition plates; the firstcrushing cavity, the second crushing cavity and the collecting cavity communicate with one another through the discharge ports; two first rotating rollers which are arranged in parallel are connectedin the first crushing cavity in a rotating mode; and a plurality of cutting blades are arranged on the two first rotating rollers and are arranged in a staggered mode. According to the plastic product recycling machine, waste plastic can be fully crushed so that the plastic can be crushed more thoroughly, the space, occupied by the plastic, of a collecting box can be decreased, and the phenomenonthat the collecting box is frequently replaced can be avoided; and meanwhile, the cutting blades on the rotating rollers can be conveniently replaced, and the phenomenon that the plastic recycling efficiency is reduced due to the fact that the crushing efficiency is influenced by blade passivation can be avoided.

Owner:YINGSHANG LONGYUYANG IND & TRADE

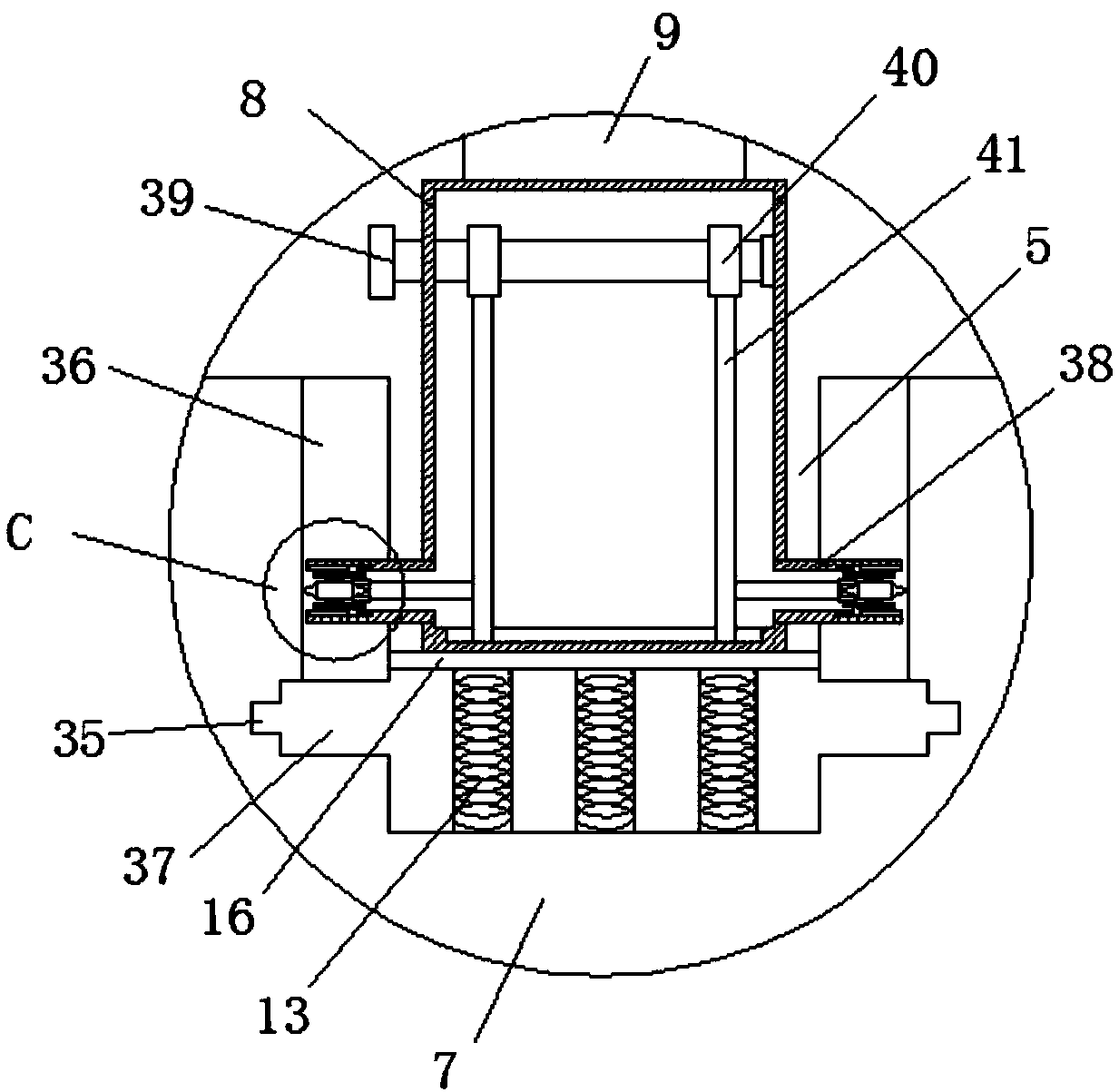

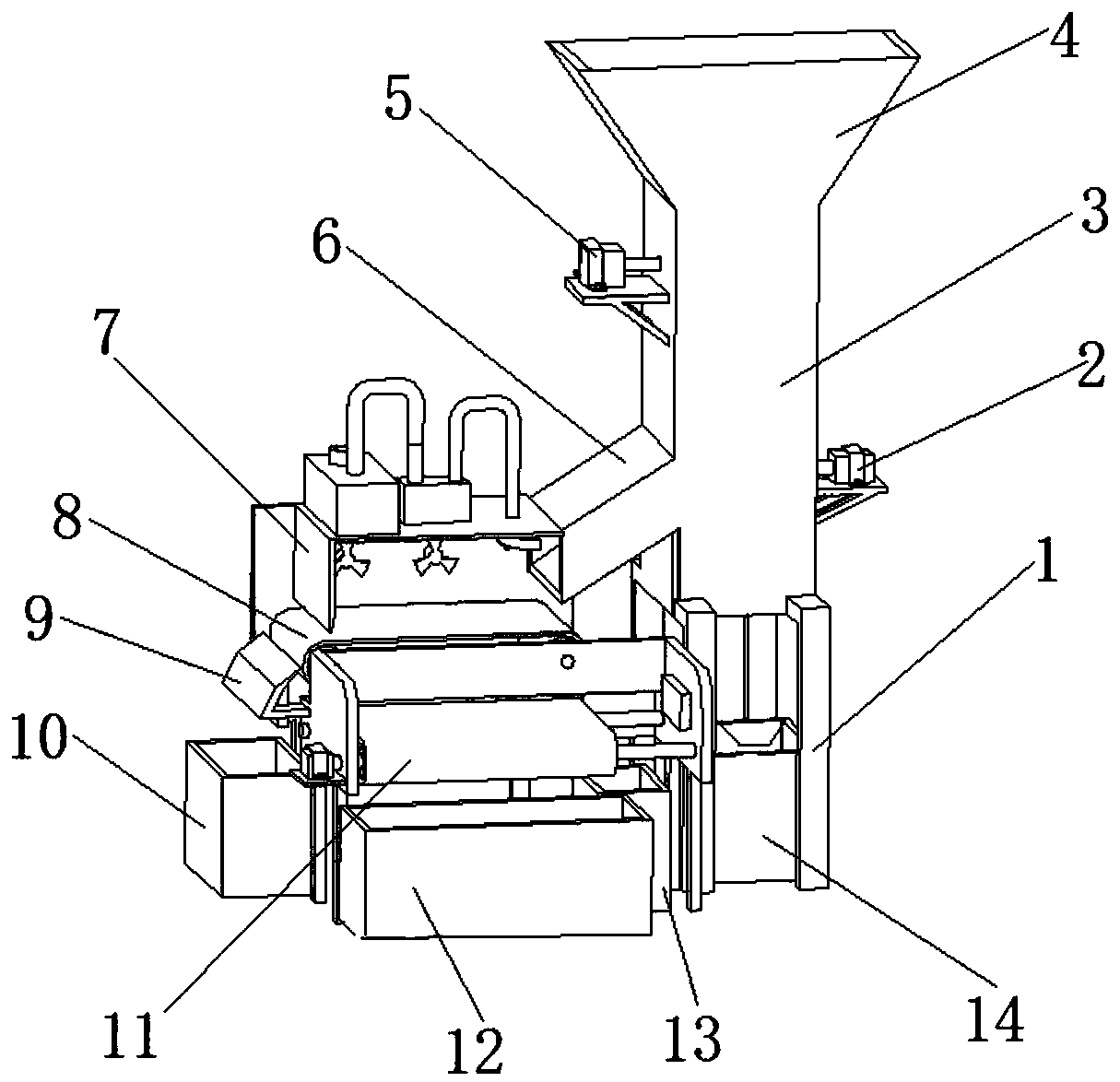

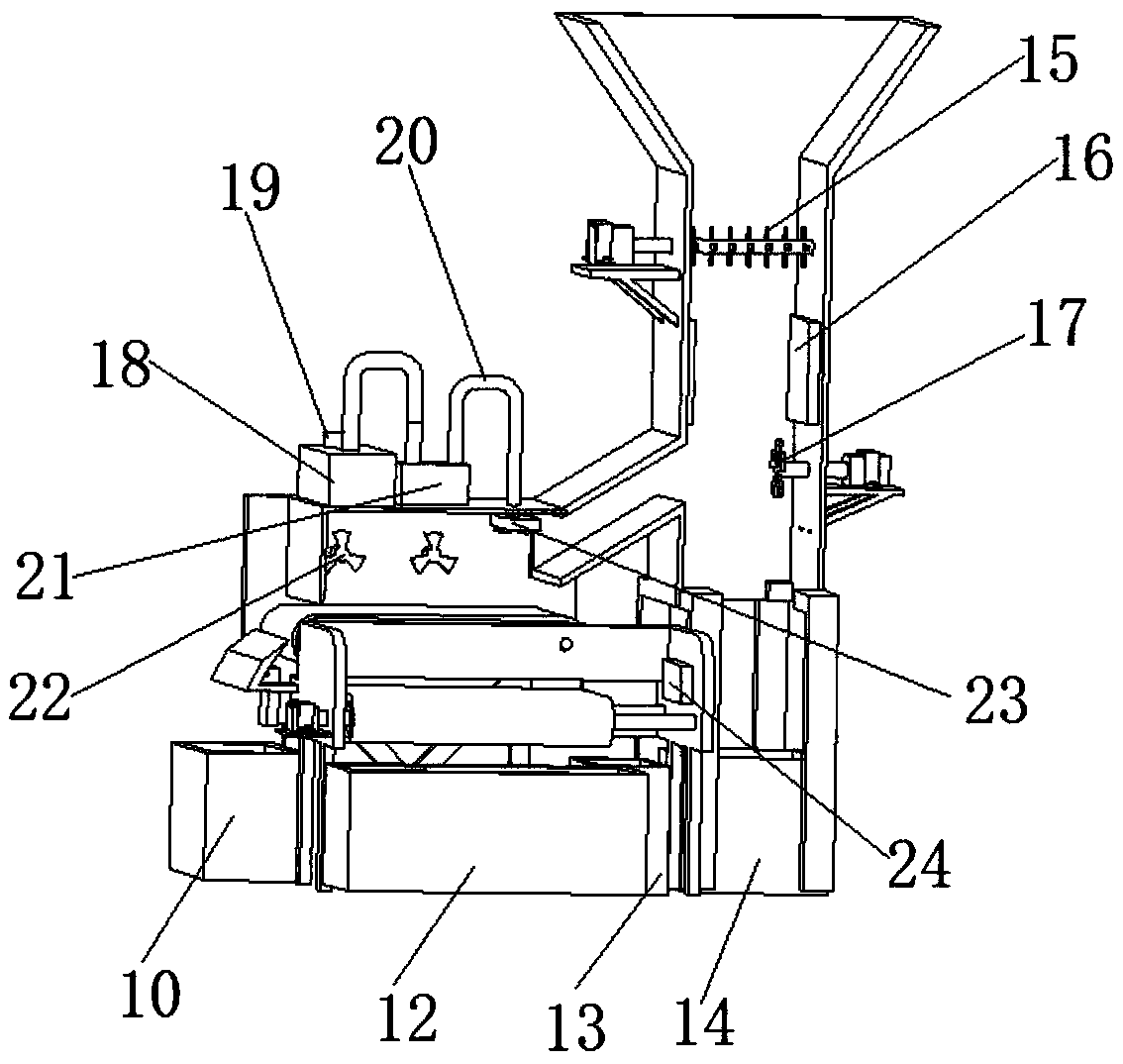

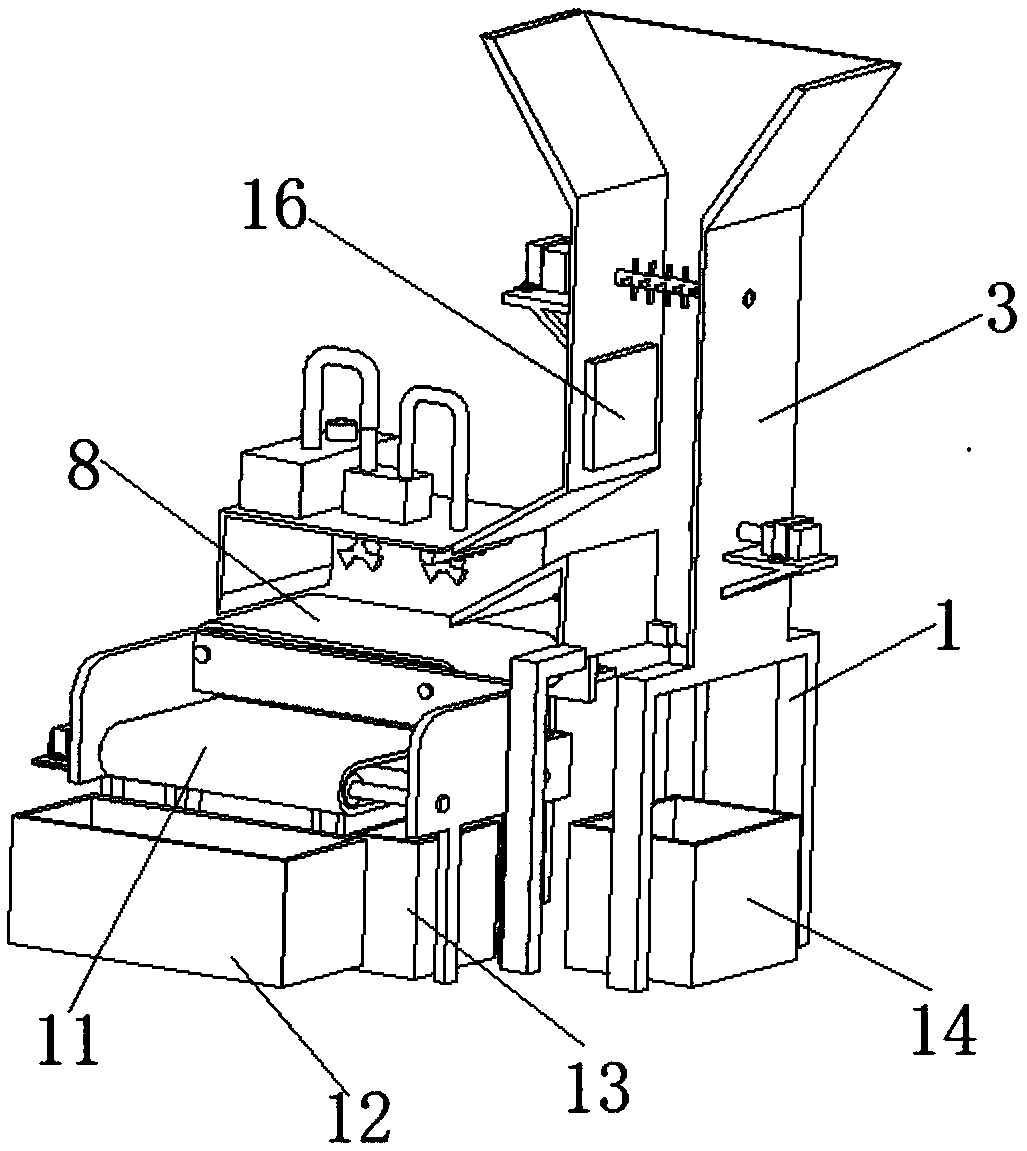

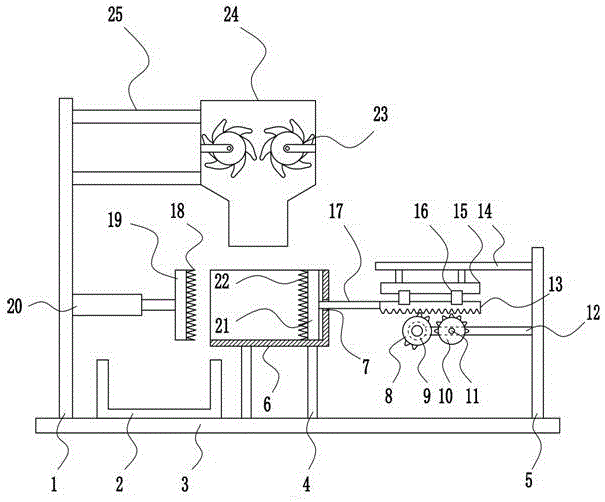

Cap and label removal device for plastic bottles

The invention relates to the technical field of waste plastic recycling and processing, in particular to a cap and label removal device for plastic bottles. The device comprises a rack, a cap removalmechanism and a label removal mechanism, wherein the cap removal mechanism is used for conveying the recovered plastic bottles and separating caps from bottle bodies, and the label removal mechanism scrapes labels of the plastic bottle bodies so as to remove the labels. The recovered plastic bottles are transported by a flexible conveying mechanism, and the flexible conveying mechanism can move freely when conveying the bottles with different sizes because internal support components of the flexible transport mechanism are springs; the caps are clamped by cams, the caps and the bottle bodies are separated by a rotating belt after clamping, accordingly, integrity of the bottle bodies is guaranteed, the labels are removed by scrapers moving in two directions and a label removal roller, ,complete separation of the labels is realized, and the influence on subsequent recovery due to partial label adhesion is avoided.

Owner:合肥岭启信息科技有限公司

Plastic recycling system and process

InactiveUS20050051646A1Increase frictionIncrease wastePlastic recyclingGrain millingPlastic wasteEngineering

The present invention provides a plastic recycling system, including a first granulator for reducing plastic waste to a first particle size. The system also includes a second granulator for reducing plastic waste to a second particle size. A frictional melting stricture is provided which melts the first particles and the second particles via use of a rotating plate.

Owner:COLLEX

Method for recycling waste hard foam polyurethane plastic

The invention discloses a recycling using method of waste hard polyurethane foam plastic, which comprises the following steps: putting the waste hard polyurethane foam plastic into breaker to form powder foam particle; separating to remove impurity from powder foam particle; blending the foam particle and combined polyether polyol (material A)and isocyanate (material B)to foam; obtaining the product.

Owner:林永飞

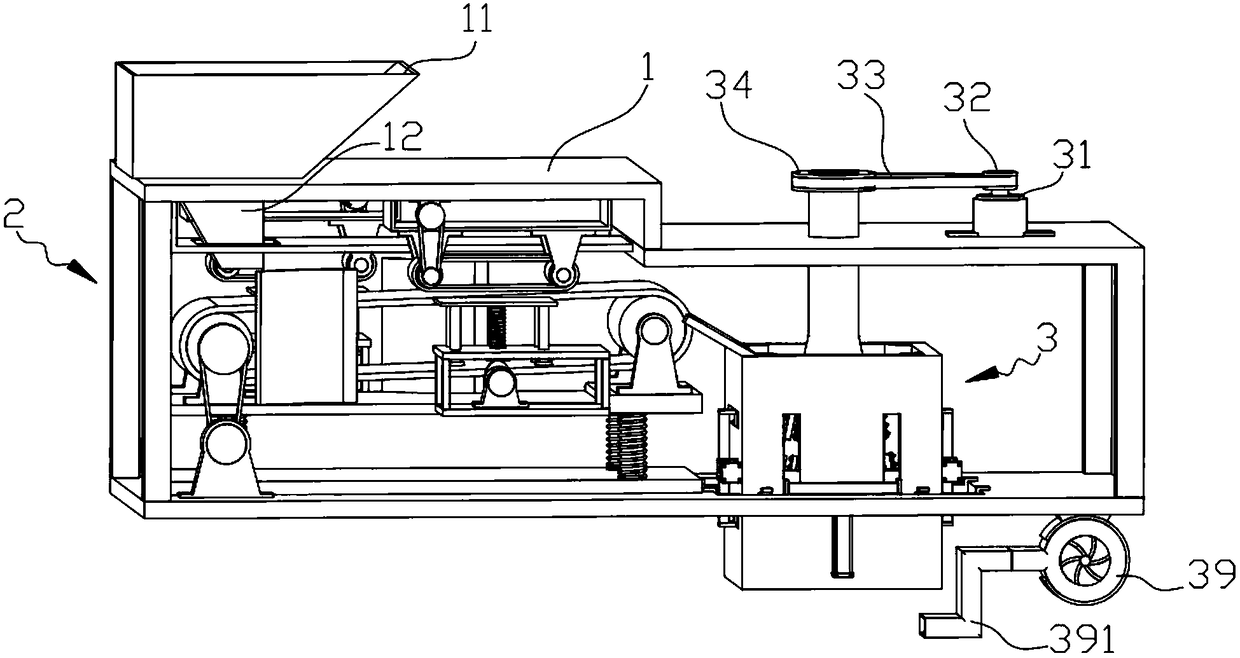

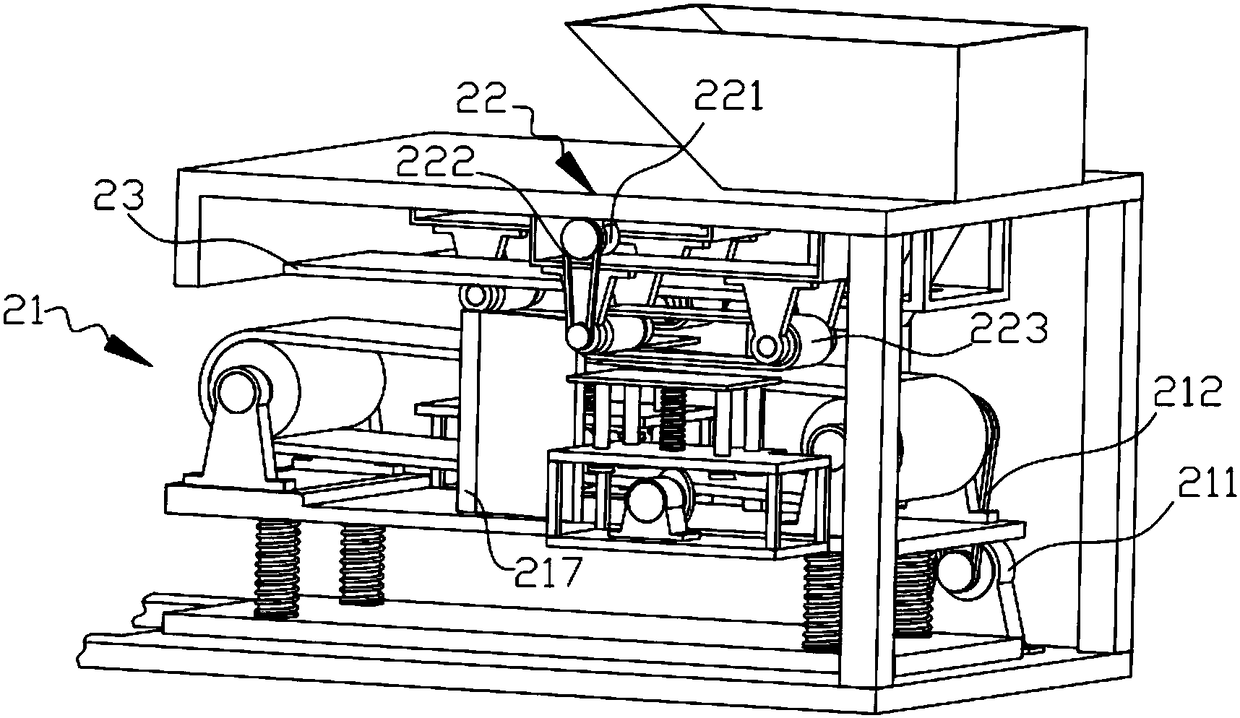

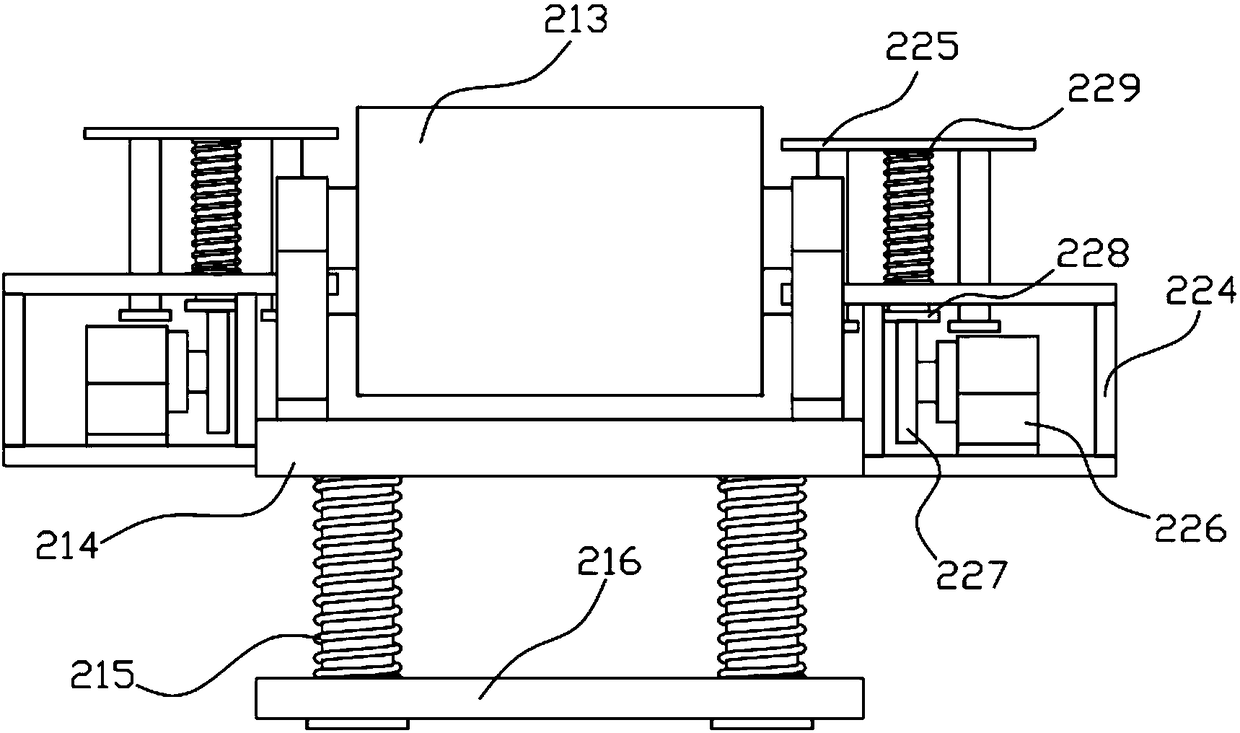

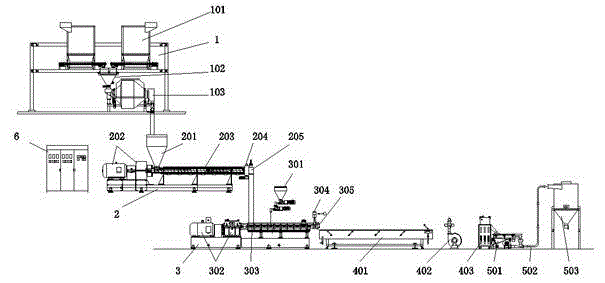

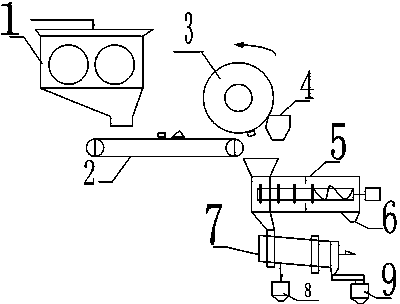

Efficient and energy-saving waste plastic recycling and granulating complete device

InactiveCN104162941AImprove the mixing effectLower energy consumption ratioCoatingsUnit deviceMaterial resources

The invention discloses an efficient and energy-saving waste plastic recycling and granulating complete device, which is characterized by comprising a main control device and a raw material supply device, an extrusion machine unit device, a granulating auxiliary device and a product conveying device, which are connected in sequence, wherein the extrusion machine unit device comprises a single-screw extrusion machine unit and a double-screw extrusion machine unit which are connected in sequence; the single-screw extrusion machine unit is connected with the raw material supply device; the product conveying device comprises a layering vibration screen, a conveying device and a drying and homogenizing material bin which is provided with a matched stirring screw rod; the drying and homogenizing material bin is used for drying by hot air. The efficient and energy-saving waste plastic recycling and granulating complete device has the beneficial effect that the comprehensive requirements of automation, efficiency, energy saving and environment friendliness are met; the production mode and economical benefit of the waste plastic recycling industry can be improved from every aspects and great manpower and material resources are saved.

Owner:江苏诚盟装备股份有限公司

Waste plastic recycling system

The invention discloses a waste plastic recycling system. The waste plastic recycling system comprises a feeding unit, a rough washing unit, a fine washing unit, a dehydrating unit, a crushing unit, and a drying unit, wherein the dehydrating unit comprises a dehydrating barrel, a dehydrating shaft and a plurality of dehydrating wheels; the dehydrating shaft is rotationally arranged on the dehydrating barrel, and the dehydrating wheels are fixedly arranged on the dehydrating shaft; the crushing unit comprises a crushing barrel, a crushing rotating shaft, a plurality of stationary knives and a plurality of rotating knives; the drying unit comprises a flow control device and a drying device, wherein the drying device comprises a drying oven and a fan. The waste plastic recycling system is high in automation degree, low in manufacture cost and simple in structure and can be maintained conveniently, the production takts of all units are consistent, energy is saved, the production yield in unit time is high, the human invention is reduced and the labor investment is saved.

Owner:ZHEJIANG EXPO NEW MATERIALS CO LTD

Household garbage refined classifying system and treatment method

ActiveCN104384008ATo achieve the purpose of class separationEasy to separateSievingScreeningMaterial typePlastic materials

The invention discloses a household garbage refined classifying system and a treatment method. The household garbage refined classifying system comprises a conveyer, wherein a garbage crusher and a magnetic separator are arranged above the conveyer; an outlet of the garbage crusher is opposite to the upper surface of the conveyer; a plastic recycler is arranged below a material outlet of the conveyer; a rotary screen is arranged below a material outlet of the plastic recycler; a compost raw material bin and a combustion raw material bin are arranged below the rotary screen. Separation on four major types of materials, including separation of metallic objects, separation of plastic materials, separation of compost raw materials and separation of combustion raw materials, is realized; the separation effect is good; the cost is low; the single mode of separating according weight is solved; the aim of separation according to the material types is achieved.

Owner:成都首创环境工程有限公司

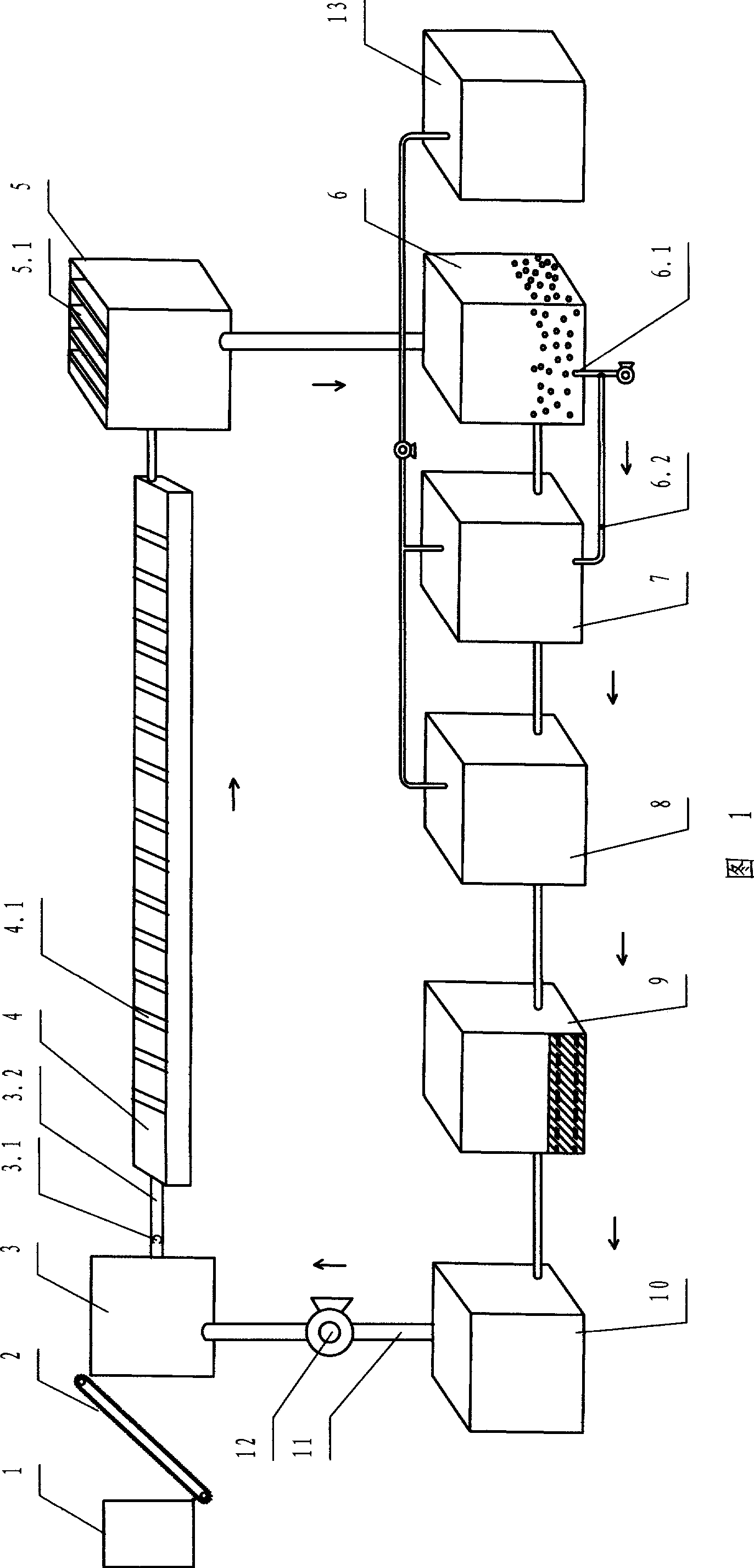

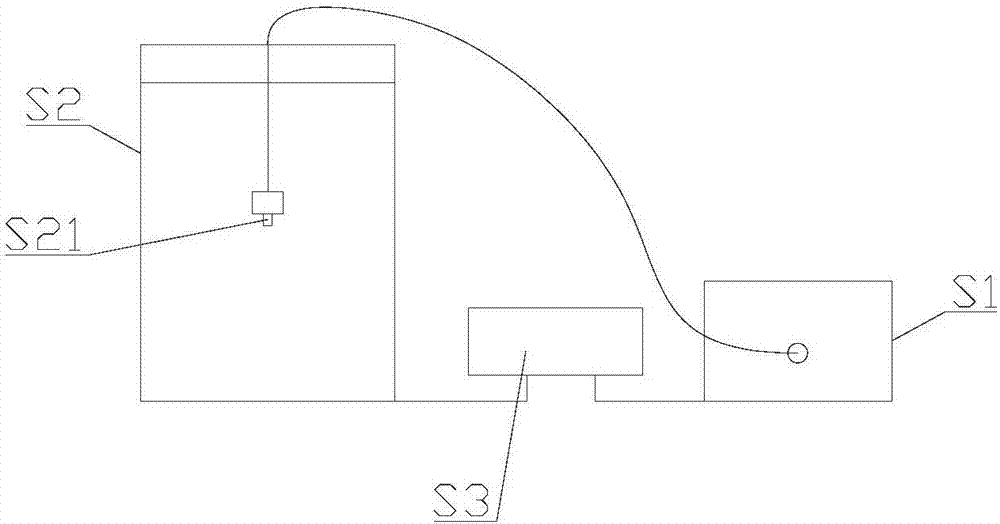

Method for recycling sewage for cleaning waste plastic and device thereof

InactiveCN101445303AGood removal effectStir wellPlastic recyclingMultistage water/sewage treatmentRefluxAfter treatment

The invention relates to a method for recycling sewage cleaning waste plastic and a device thereof. The method comprises the steps that the waste plastic is sorted, crushed, cleaned and dried and can be sold; and washing sewage is filtered, electrolyzed, aerated, flocculated and deposited and can be recycled after filtering. The device is characterized in that a conveyer belt is arranged between a crushing mill and a cleaning machine; a sewage outlet pipe of the cleaning machine is communicated with a water collecting and filtering tank, an electrolyzing tank, an aerating tank, a dosing tank, a sedimentation tank, a filter tank and a reservoir sequentially; the bottoms of the aerating tank and the dosing tank are provided with an aerating head which is communicated with a turbine aeration machine; the bottoms of the dosing tank and the sedimentation tank are communicated with a sludge pool by a sludge pipe and a reflux pump; and the reservoir is communicated with the cleaning machine by a pipeline and a back water pump. The method and the device not only can recycle the waste plastic and reduce the pollution to the environment caused by white garbage, but the sewage can also be recycled and utilized after treatment and is discharged in compliance with standard finally. The dirt produced during the sewage treatment process can be reused after condensing.

Owner:王静丽

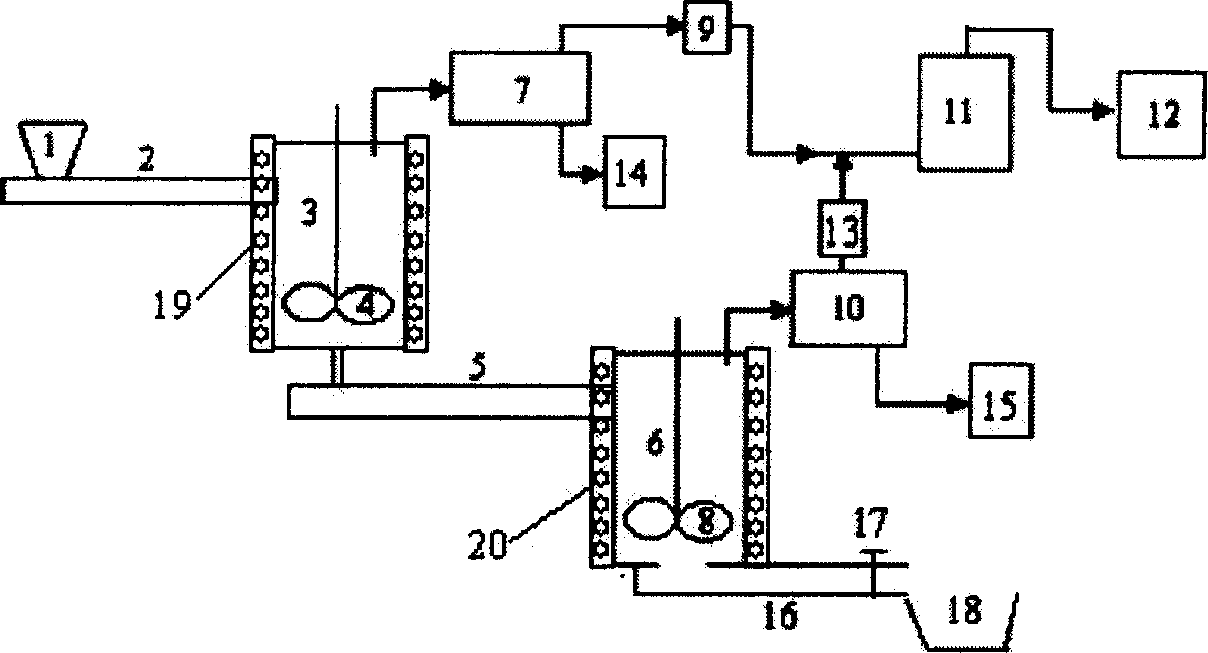

Two-stage vacuum hot chemical treating and recovering process and apparatus for halogen-containing waste plastic

The present invention discloses two-stage vacuum heat chemical treating and recovering process and apparatus for halogen containing waste plastic. The process includes melting the waste plastic, separating fire retardant, condensing fire retardant gas, treating un-condensed gas, pyrolysis of waste plastic melt, condensing pyrolysis gas, treating pyrolysis residue and other steps. The apparatus for the treatment includes feeding bin, vacuum melting and separating tank with feeding screw, stirrer, vacuum pyrolysis reactor with feeding screw, fire retardant gas condenser, pyrolyzed oil condenser, gas washing tower, un-condensed gas treating system, vacuum pump, halogen containing fire retardant collecting tank, low halogen pyrolyzed oil collecting tank, pyrolysis residue discharging screw, vacuum sealing valve, pyrolysis residue storage and electric heating system.

Owner:SOUTH CHINA UNIV OF TECH

Polyolefin burning process of synthesizing carbon nanotube

The present invention is polyolefin burning process of synthesizing carbon nanotube. Polyolefin, expander, organic matter modified montmorillonite and nickel-loading catalyst in certain proportion are mixed in n. banbury mixer or double-screw extruder, and mixture is set inside crucible and heated in gas flame to prepare carbon nanotube through combustion at 660-850 deg.c. The present invention uses cheap polyolefin as carbon source material and common equipment and has the advantages of low cost.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Waste rubber plastic toughening device

The invention relates to the field of waste rubber plastic recycling, and aims at providing a waste rubber plastic toughening device. The waste rubber plastic toughening device comprises a rack with a hopper and further comprises a toughness strengthening device with a feeding opening connected with an outlet of the hopper and a vacuum air removing device with an inlet connected with the toughness strengthening device. According to the waste rubber plastic toughening device, toughness of a rubber plastic finished product can be improved, and the cost is lower.

Owner:NINGBO LVHUA RUBBER & PLASTIC MACHINERY IND & TRADE

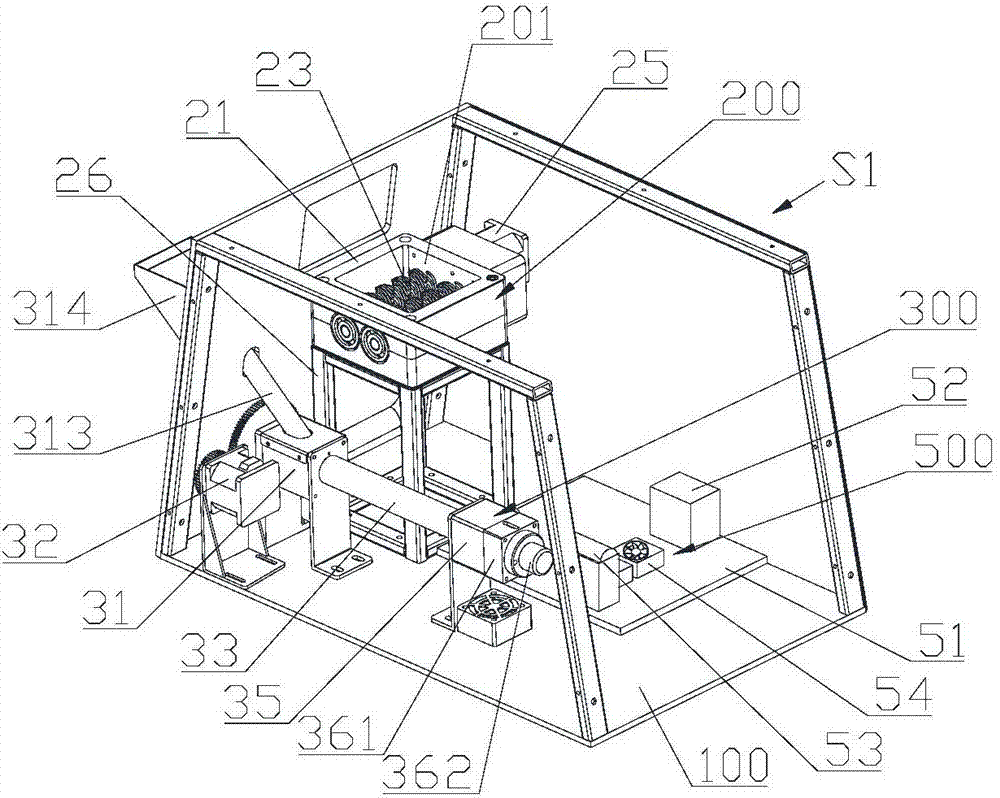

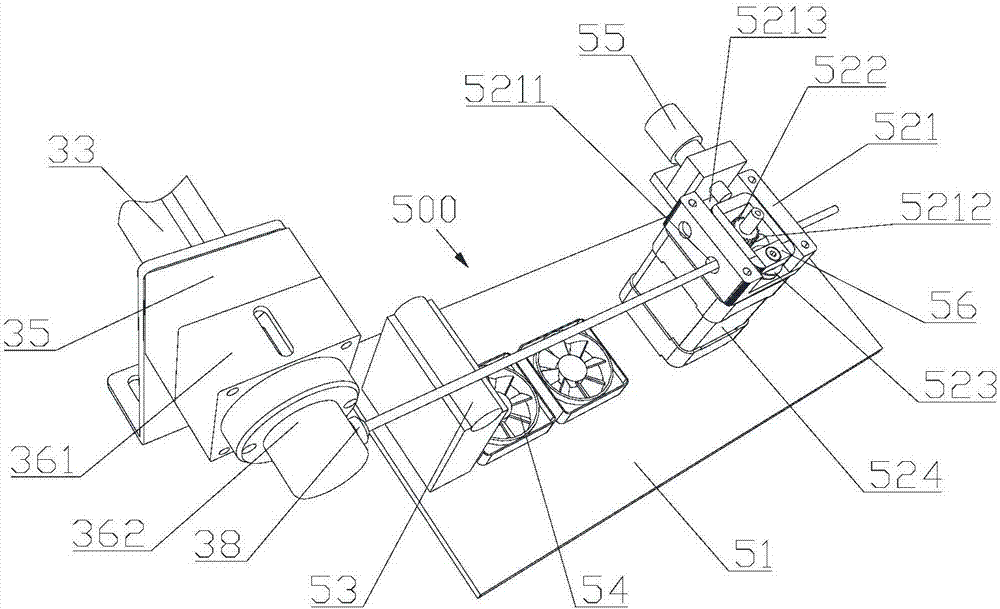

3D printing machine for recycling 3D printing plastic and printing method of 3D printing machine

ActiveCN106945265ATimely processingReduce flow rateAdditive manufacturing apparatusManufacturing recyclingSpray nozzleEngineering

The invention discloses a 3D printing machine for recycling 3D printing plastic and belongs to the field of 3D printing. The 3D printing machine solves the problem that in the prior art, recycled 3D printing plastic cannot be directly printed. According to the technical scheme for solving the problem, the 3D printing machine mainly comprises a recycling device and a printing device. The recycling device comprises a main rack, a material smashing assembly and a melting extrusion assembly, wherein the material smashing assembly and the melting extrusion assembly are located on the main rack. The material smashing assembly is used for smashing recycled plastic into plastic particles and conveying the plastic particles into the melting extrusion assembly. The melting extrusion assembly is used for melting the plastic particles and extruding the plastic particles to form a plastic line. The recycling device further comprises a cooling traction assembly. The cooling traction assembly is used for cooling the plastic line and conveying the plastic line to the printing device. The melting extrusion assembly comprises a melting cavity and an extrusion nozzle. The cooling traction assembly is located on the transverse side of the melting cavity, and the extrusion nozzle faces the cooling traction assembly. The 3D printing machine is mainly used for improving the printing quality of direct printing of the recycled 3D printing plastic. The invention further provides a printing method of the above 3D printing machine.

Owner:MOXIN (HUZHOU) TECH CO LTD

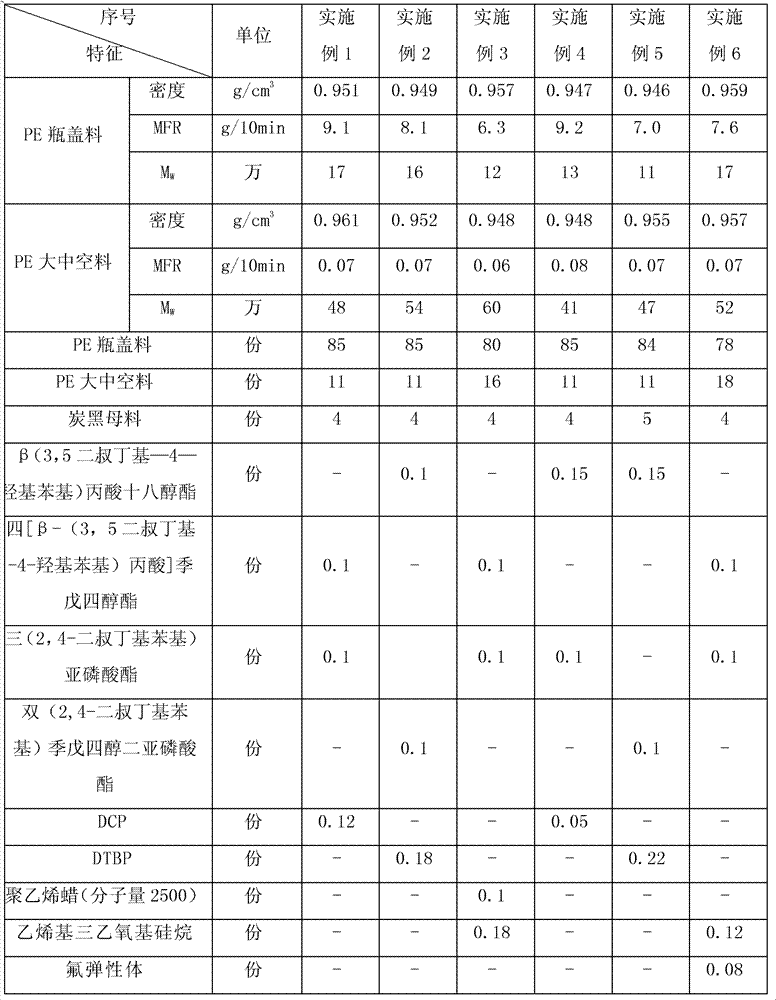

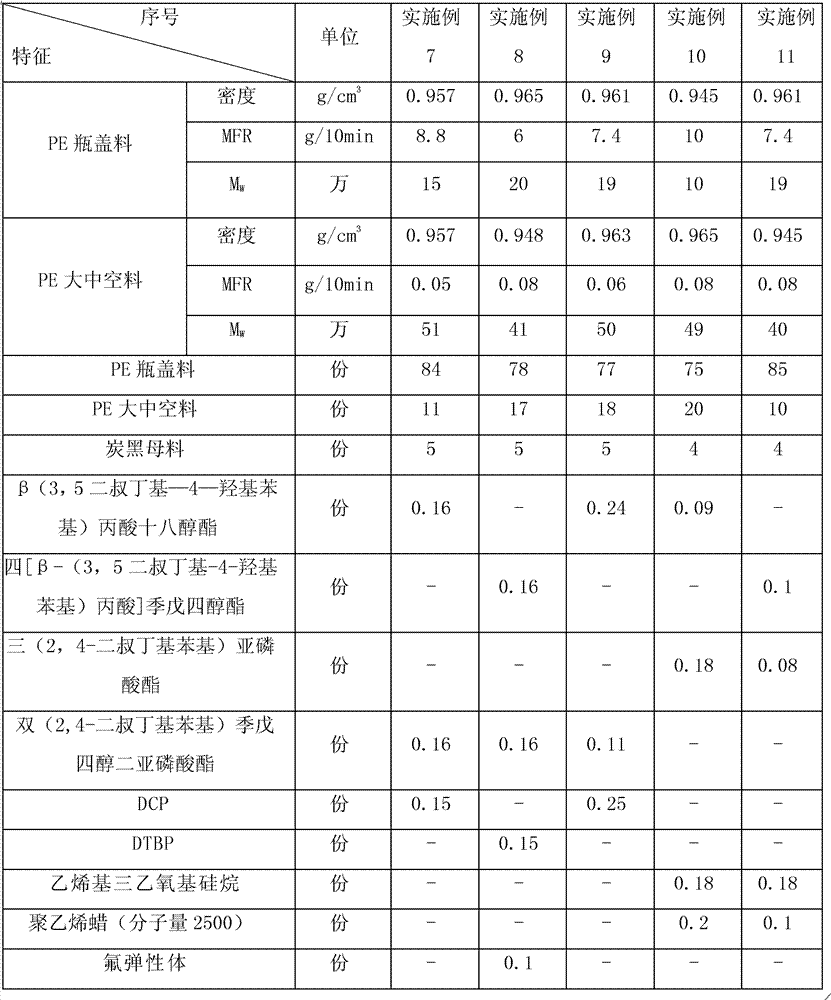

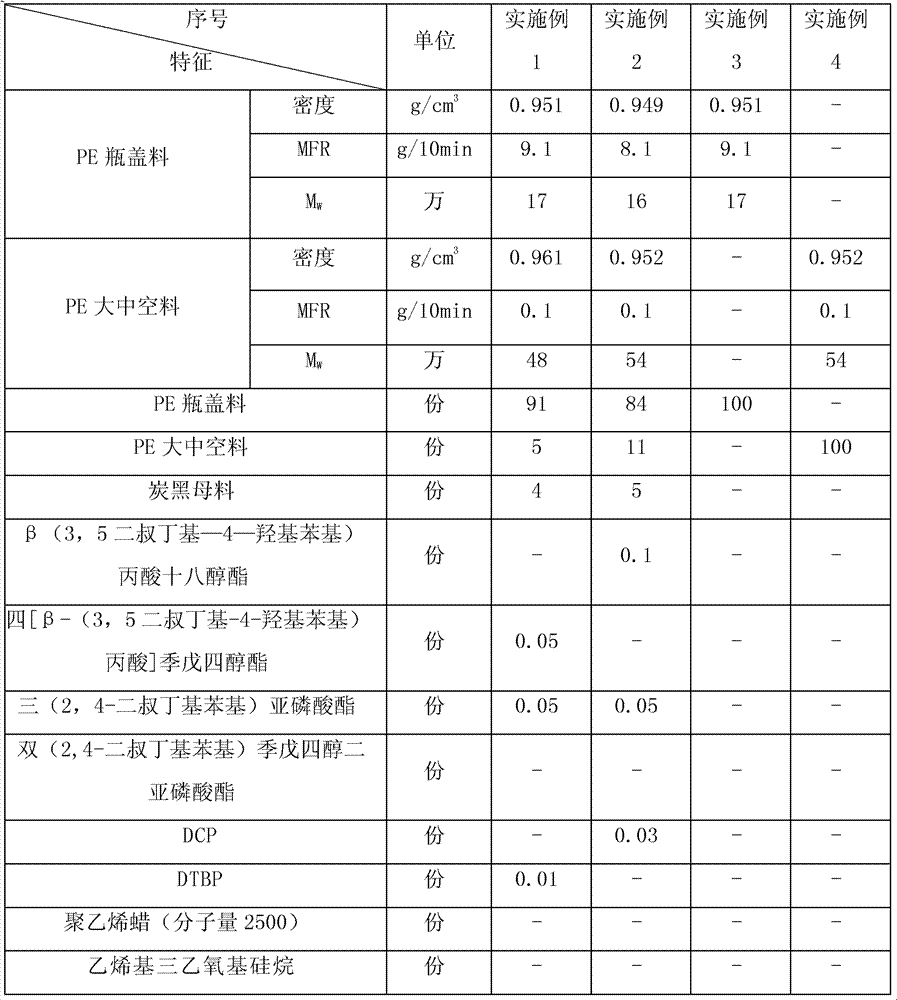

Regenerated polyethylene composition and preparation method thereof

The invention provides a regenerated polyethylene composition and a preparation method thereof, and belongs to the technical field of recovery processing of waste plastics. The regenerated polyethylene composition comprises the following components in parts by weight: 75 to 85 parts of PE (Poly Ethylene) bottle cap material, 10 to 20 parts of PE large blow molding grade, 4 to 5 parts of carbon black masterbatch, 0 to 0.2 part of processing agent, 0.05 to 0.25 part of crosslinking agent, and 0.18 to 0.35 part of antioxidant. The composition has relatively high flexural modulus and elongation at break as well as high processing performance; the melt strength of the composition is 10 times that of the recovered bottle cap material; the tensile strength ranges from 25.4 to 29.4MPa; the oxidative induction time (200 DEG C) is 38 to 71 minutes, and therefore, a tubing composition is ensured to have high thermal stability and long service life. The composition can be directly used for manufacturing a pipe, and also can be used as a raw material to be added to a special material for a marketed double-wall corrugated pipe to produce large-aperture double-wall corrugated pipes, winding pipes or the like with different specifications and apertures and capable of draining water and sewage, and more than 10% of the production cost can be decreased.

Owner:CHINA PETROLEUM & CHEM CORP

Solid domestic waste crushing and sorting device

InactiveCN108906263AImprove classification efficiencyImprove protectionGas current separationPlastic recyclingElectrometerEngineering

The invention discloses a solid domestic waste crushing and sorting device. The device comprises an underframe, the underframe is vertically fixedly provided with a feeding pipeline, the bottom of thefeeding pipeline is provided with a discharging opening, a glass recovery box is arranged below the discharging opening, a discharging tube is arranged at one side of the feeding pipeline below a crusher, the inner wall of the feeding pipeline is provided with a sheet magnet, a powder collecting box is arranged at the injection opening of the discharging tube, one side of the powder collecting box is opened, fans are arranged at one side opposite to the opening, a first conveyor belt is arranged at the bottom of the powder collecting box, a waste paper recovery box is arranged below the outlet of the first conveyor belt, a second conveyor belt is arranged just below the open side of the powder collecting box, the side surface of the second conveyor belt is provided with an electrometer, aplastic recovery box is arranged below the electrometer, and a nonmagnetic metal recovery box is arranged below the outlet of the second conveyor belt. A problem of difficult sorting and recovery ofsolid domestic wastes in the prior art is solved.

Owner:SHAANXI UNIV OF SCI & TECH

Waste plastic recycling dewatering machine

InactiveCN103438674AGood effectImprove dehydration efficiencySievingScreeningPulp and paper industryEngineering

The invention discloses a waste plastic recycling dehydrater which comprises a base, a machine shell, a screen drum and a main shaft with mixing blades. The bottom of the machine shell is fixed on the base, the screen drum is fixed in the machine shell, and the main shaft is horizontally installed in the center of the screen drum and penetrates through the screen drum and the machine shell. The two ends of the main shaft are fixed on the base through bearing pedestals, sealing devices are arranged at the connecting positions of the two ends of the main shaft and the machine shell respectively, and the main shaft is driven by a main shaft rotation power device to rotate. One end of the machine shell is provided with a feed port communicated with the interior of the screen drum, the other end of the machine shell is provided with a discharge port communicated with the interior of the screen drum, and a water outlet is formed in the bottom of the machine shell. The dewatering machine is reasonable in stress, and the sealing effect between the main shaft and the machine shell is good. In comparison with an existing structure, the main shaft of the dewatering machine is higher in speed, so that the dewatering effect is better.

Owner:ZHANGJIAGANG LIANDA MACHINERY

Foamed plastic recycling equipment

InactiveCN106393496AHigh hardnessAvoid deformationPlastic recyclingGrain treatmentsEngineeringElectric drive

The invention relates to recycling equipment, in particular to foamed plastic recycling equipment. The foamed plastic recycling equipment is convenient to operate, high in smashing efficiency and capable of achieving thorough smashing. In order to solve the technical problems, the foamed plastic recycling equipment comprises a left frame, a collecting frame, a bottom plate, a supporting rod, a right frame, a smashing frame, a first missing gear, a rotating motor, a second missing gear, a rotating shaft, a first fixing plate and the like. The left frame is welded to the left side of the top of the bottom plate. The middle part of the right side of the left frame is connected with an electric drive pusher in a bolted connection mode. The right end of the electric drive pusher is connected with a first push block in a bolted connection mode. By means of the foamed plastic recycling equipment, foamed plastic can achieve primary smashing through rotation of an electric smashing wheel at first, and then a rack can be driven to move left and right through the matching of the first missing gear and the second missing gear.

Owner:WUXI TONGXIN PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com