Patents

Literature

61 results about "Oxidative-induction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidation induction time or OIT is a standardized test performed in a DSC which measures the level of thermal stabilization of the material tested. The time between melting and the onset of decomposition in isothermal conditions is measured. The atmosphere is nitrogen up to melting and then oxygen. The typical temperature is 190-220 °C.

Regenerated polyethylene composition and preparation method thereof

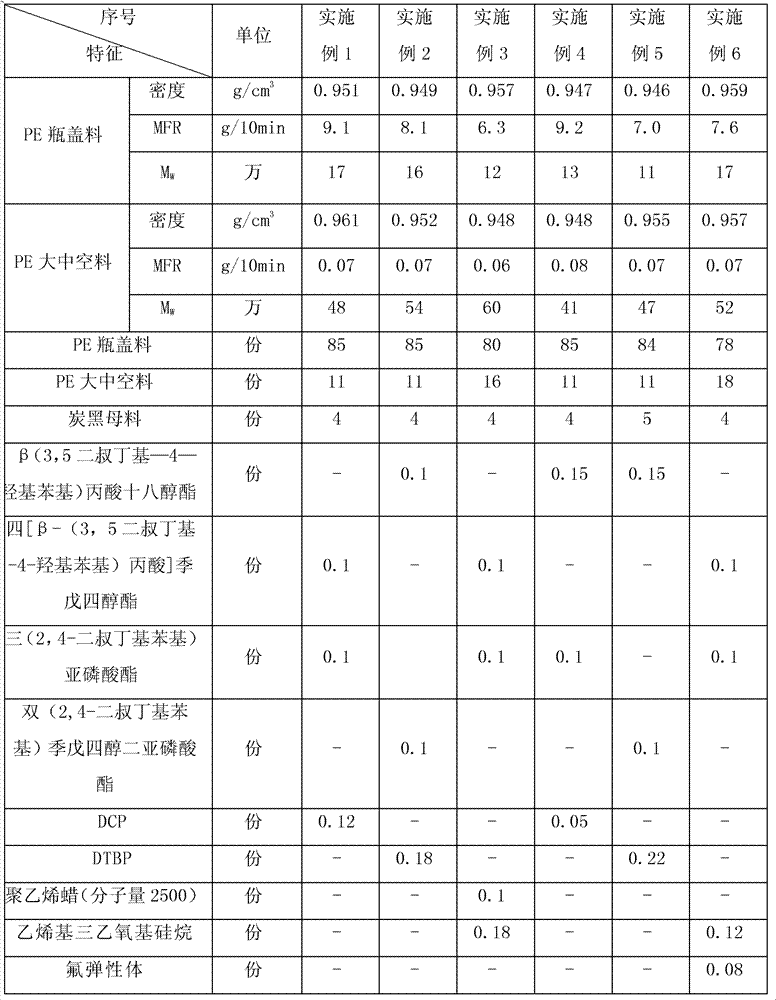

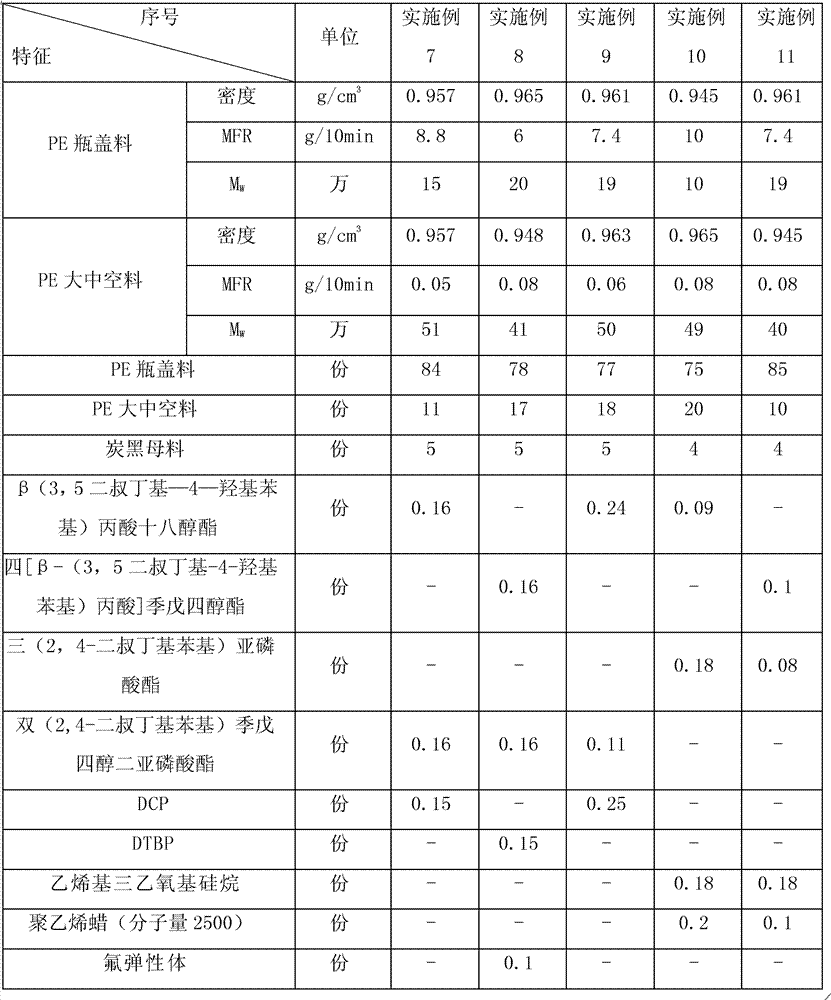

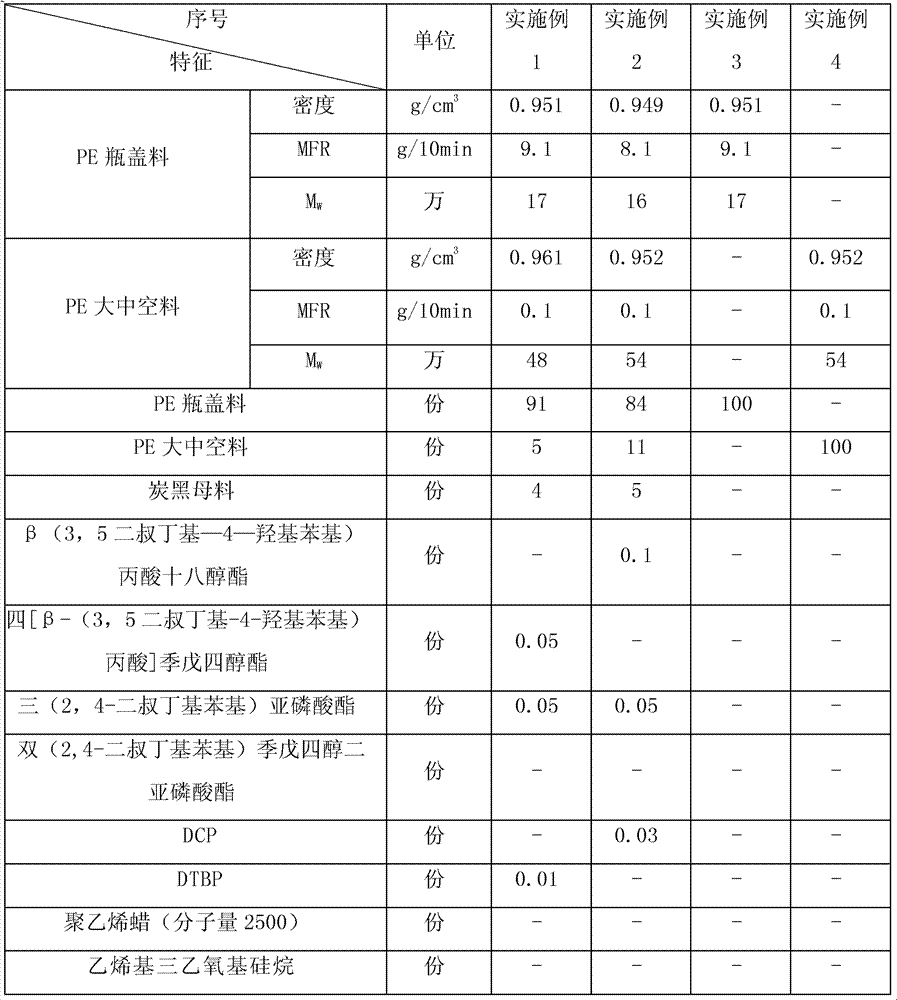

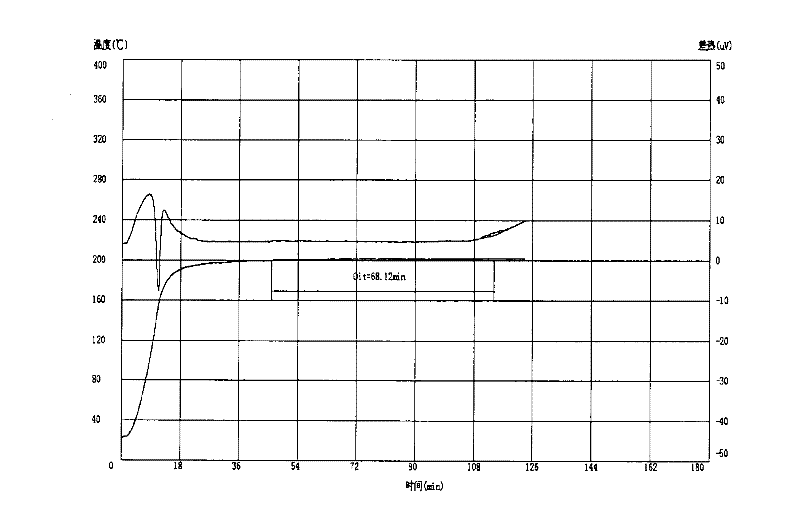

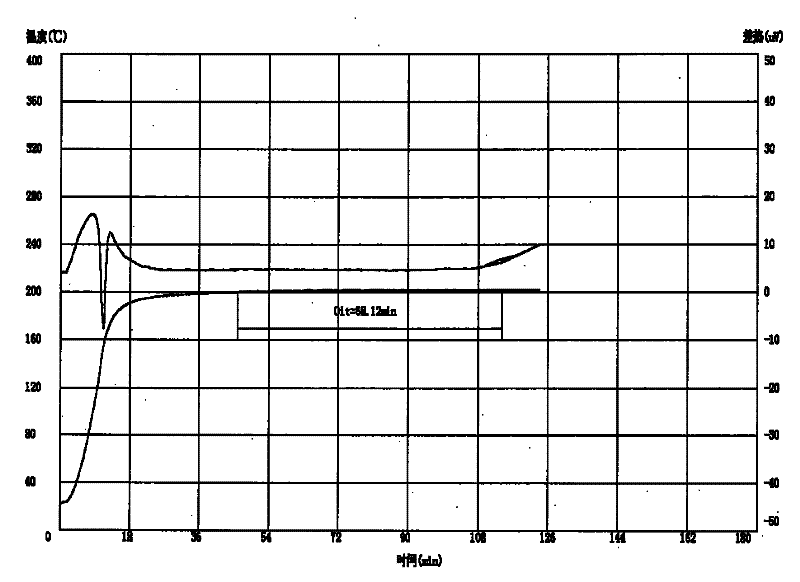

The invention provides a regenerated polyethylene composition and a preparation method thereof, and belongs to the technical field of recovery processing of waste plastics. The regenerated polyethylene composition comprises the following components in parts by weight: 75 to 85 parts of PE (Poly Ethylene) bottle cap material, 10 to 20 parts of PE large blow molding grade, 4 to 5 parts of carbon black masterbatch, 0 to 0.2 part of processing agent, 0.05 to 0.25 part of crosslinking agent, and 0.18 to 0.35 part of antioxidant. The composition has relatively high flexural modulus and elongation at break as well as high processing performance; the melt strength of the composition is 10 times that of the recovered bottle cap material; the tensile strength ranges from 25.4 to 29.4MPa; the oxidative induction time (200 DEG C) is 38 to 71 minutes, and therefore, a tubing composition is ensured to have high thermal stability and long service life. The composition can be directly used for manufacturing a pipe, and also can be used as a raw material to be added to a special material for a marketed double-wall corrugated pipe to produce large-aperture double-wall corrugated pipes, winding pipes or the like with different specifications and apertures and capable of draining water and sewage, and more than 10% of the production cost can be decreased.

Owner:CHINA PETROLEUM & CHEM CORP

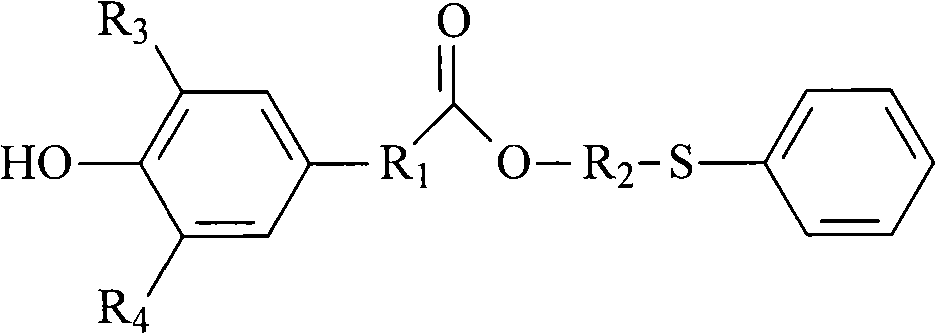

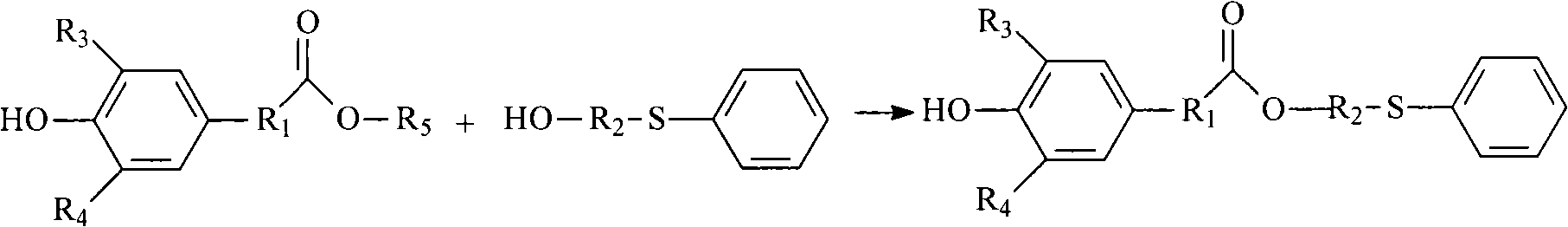

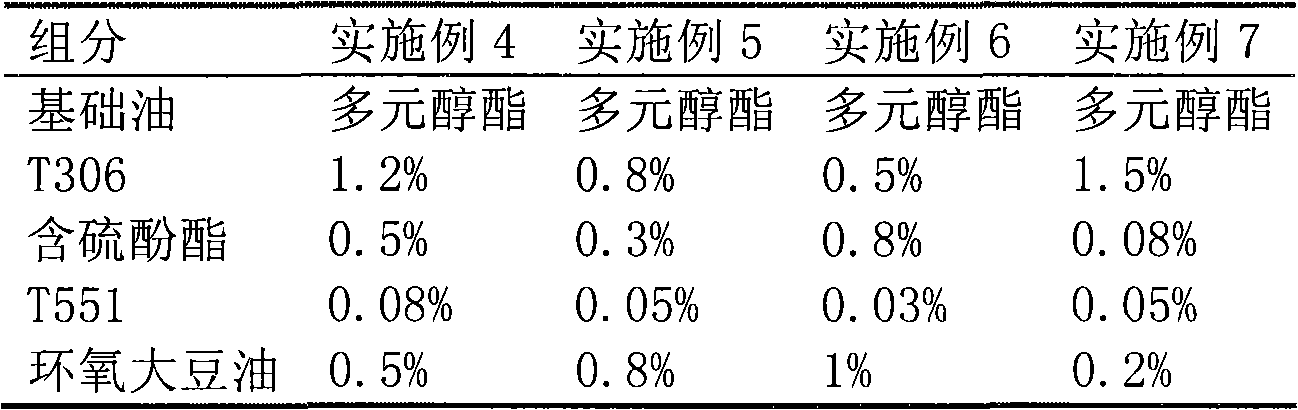

Refrigerator oil composition

InactiveCN101851545AImprove Oxidation StabilityProlonged oxidation induction periodAdditivesPolyolesterPentaerythritol

The invention relates to a refrigerator oil composition, which comprises polyol ester, (3,5-dialkyl-4-hydroxyphenyl) carboxylic thiophenyl alkyl ester, an antiwear agent, a metal passivator and an acid catching agent, wherein the polyol ester is pentaerythritol tetranitrate generated by reacting pentaerythritol with a mixture of isononanoic acid and diethyl caproic acid. The refrigerator oil composition provided by the invention has excellent oxidation stability. Compared with that of the refrigerator oil using the conventional antioxidant, the oxidative induction time of the refrigerator oil composition is obviously prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of wires and cables

InactiveUS20090176093A1Higher oxidative induction timeCladded optical fibreSynthetic resin layered productsPolyolefinAntioxidant

A coated or jacketed wire or cable, and components thereof are disclosed. The coating, jacket, and components, which comprise a polyolefin and a phenolic polymeric antioxidant, exhibit outstanding oxidative thermal stability (as indicated by the increase in the oxidative inductive time (OIT)), when compared to polyolefins containing traditional non-polymeric antioxidants. A greater improvement in the thermal oxidative stability is observed after the polyolefin mixtures have been aged in water-blocking filler(s).

Owner:EQUSR CHEM LP

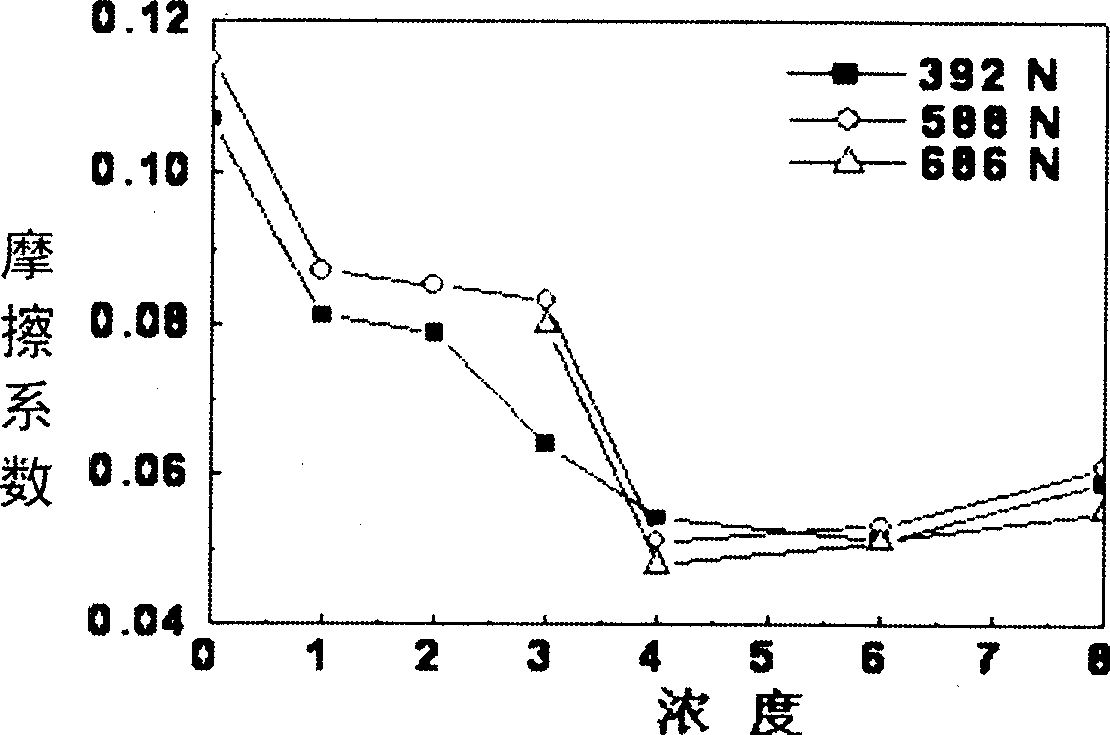

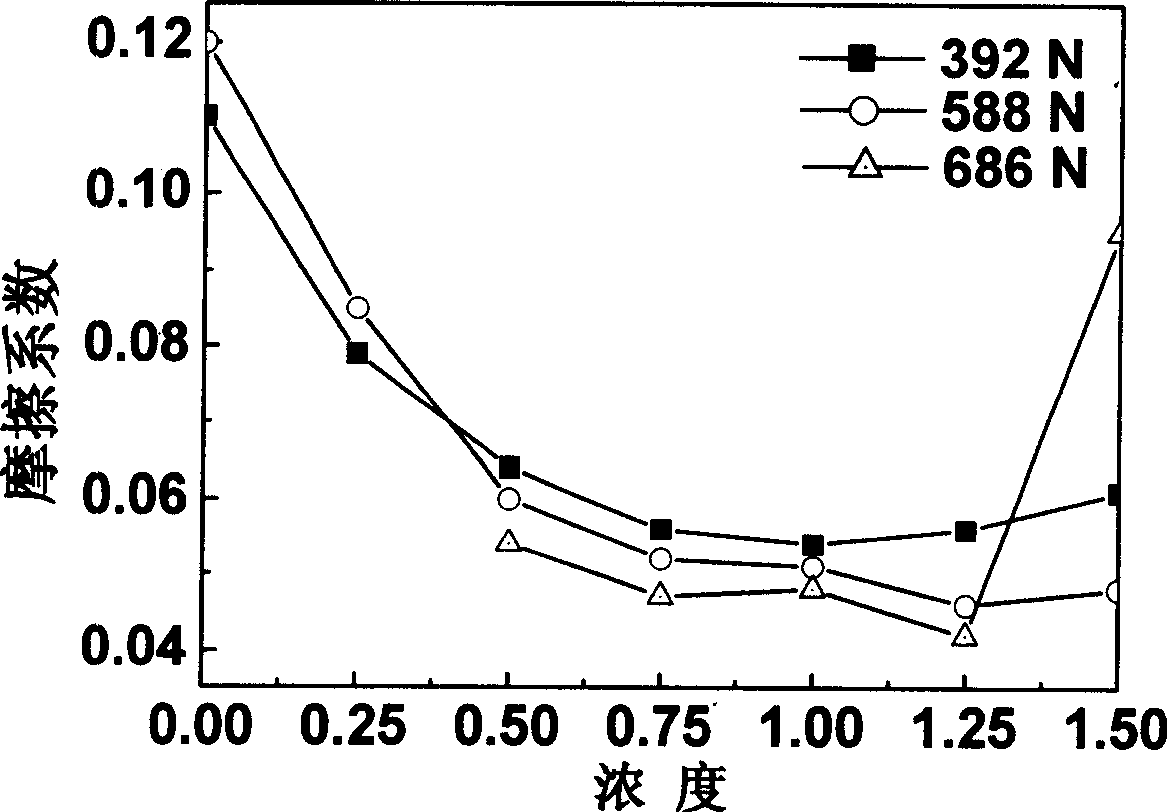

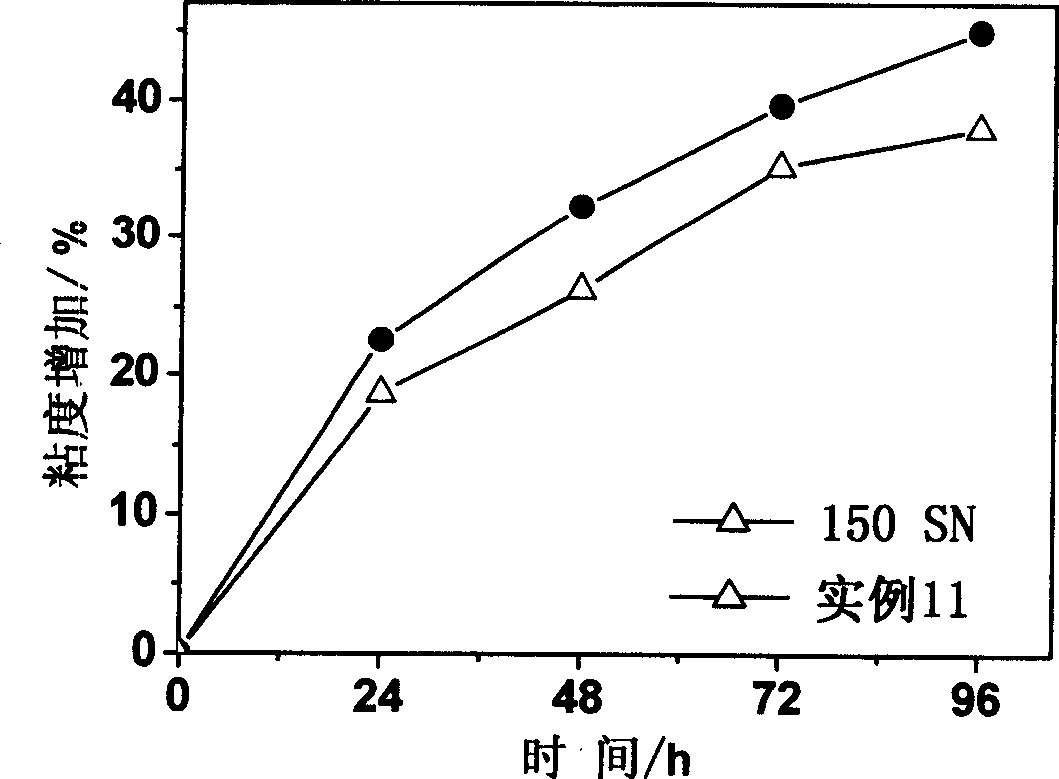

Non-sulphur and phosphorus antiwear and friction reducing multifunctional additive agent and preparation method

InactiveCN101381649ARaise the initial oxidation temperatureProlonged oxidation induction timeAdditivesAntioxidantInternal combustion engine

The invention belongs to the technical field of lubricating oil and discloses a non-sulfur non-phosphorus anti-wear and antifrictional multifunctional additive and a preparation method thereof. The compositions of the additive comprise a friction modifier, an antiwear agent, an antioxidant, a detergent dispersant, and an antirusting agent. Firstly, the friction modifier is synthesized, then the friction modifier, the antiwear agent, the detergent dispersant, the antioxidant, and the antirusting agent with the needed amount are orderly mixed according to the proportion, and the mixture is heated to between 50 and 70 DEG C under the stirring and then is stirred evenly. The additive can be widely applied to various lubricating oil products including lubricant base oil or lubricant oil finished products, such as internal combustion engine oil, gear oil and so on, and is added into lubricating oil of an internal combustion engine with 3 to 20 weight percentage during the use. The additive can greatly improve the abrasion resistance and the antifriction performance of oil products, can also apparently improve the initial oxidation temperature and the oxidation induction time of the oil products, effectively suppress the viscosity of the oil products from increasing, and ensure that the high-temperature antioxidation performance of the internal combustion engine oil is greatly improved.

Owner:天津市东宝润滑油脂有限公司

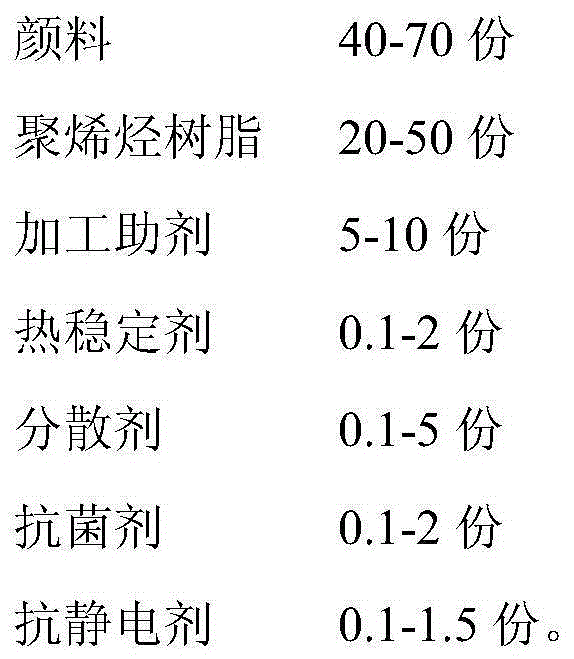

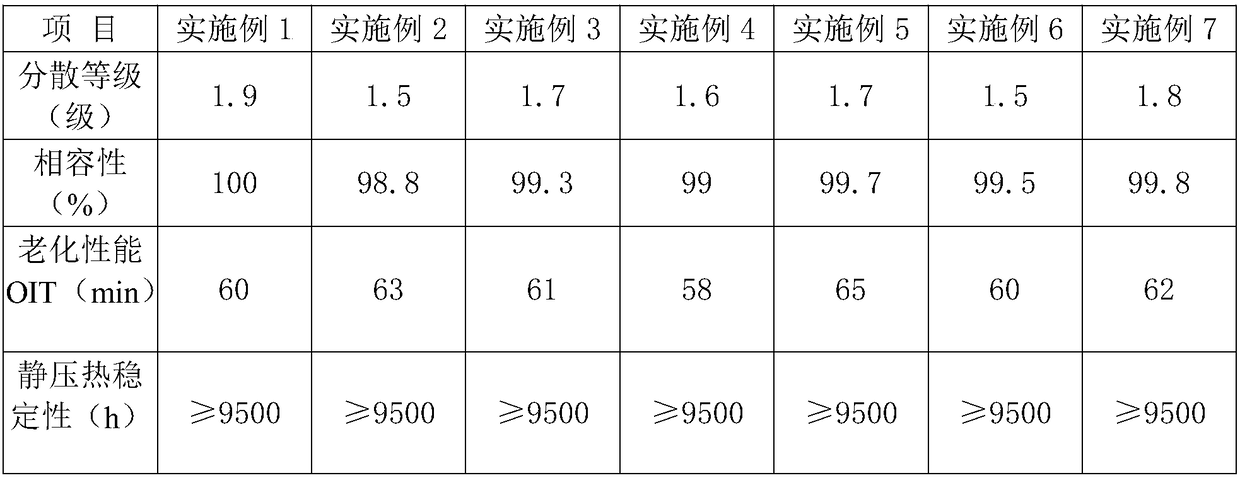

Color masterbatch for polyolefin pipes, pipe fittings and inspection wells

InactiveCN105086145AEvenly dispersedImprove weather and pressure resistanceProcedure AgentsPolymer science

The invention provides a color masterbatch for polyolefin pipes, pipe fittings and inspection wells. The color masterbatch comprises, by weight, 40-70 parts of pigment, 20-50 parts of polyolefin resin, 5-10 parts of processing agent, 0.1-2 parts of heat stabilizer, 0.1-5 parts of dispersing agent, 0.1-2 parts of antibacterial agent and 0.1-1.5 parts of antistatic agent. The color masterbatch is high in dispersibility, and accordingly, weather and pressure resistance properties of the pipes are improved. According to the color masterbatch for the polyolefin pipes, the pipe fittings and the inspection wells, color intensity reaches 95-105; mobility resistance is larger than 4; heat resistance is larger than 4, and each of three grades is smaller than or equal to 3; melt flow rate is 30-50g / 10min; OIT (oxidative induction time) is more than 20 minutes; and if the masterbatch is black, the content of carbon black is 38-41 parts.

Owner:ANHUI YONGGAO PLASTIC IND DEV CO LTD

Preparation of wires and cables

A coated or jacketed wire or cable, and components thereof are disclosed. The coating, jacket, and components, which comprise a polyolefin and a phenolic polymeric antioxidant, exhibit outstanding oxidative thermal stability (as indicated by the increase in the oxidative inductive time (OIT)), when compared to polyolefins containing traditional non-polymeric antioxidants. A greater improvement in the thermal oxidative stability is observed after the polyolefin mixtures have been aged in water-blocking filler(s).

Owner:EQUSR CHEM LP

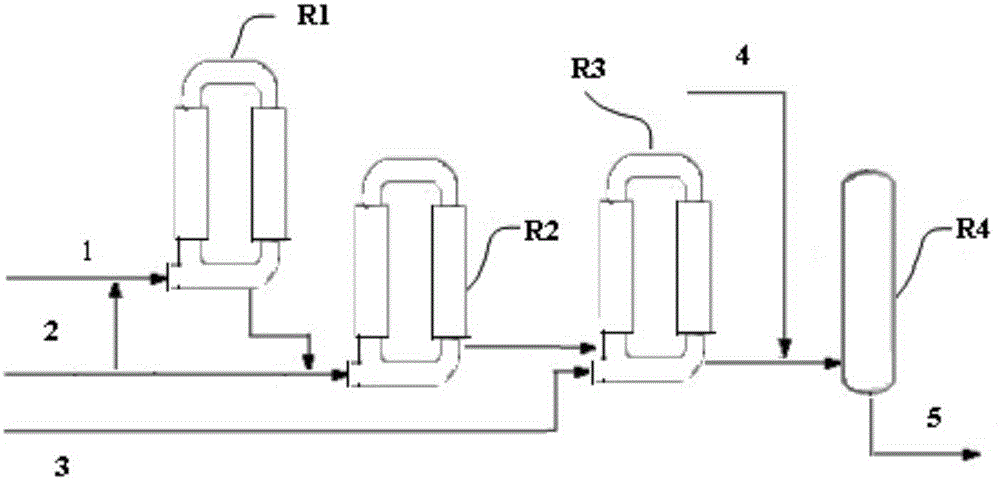

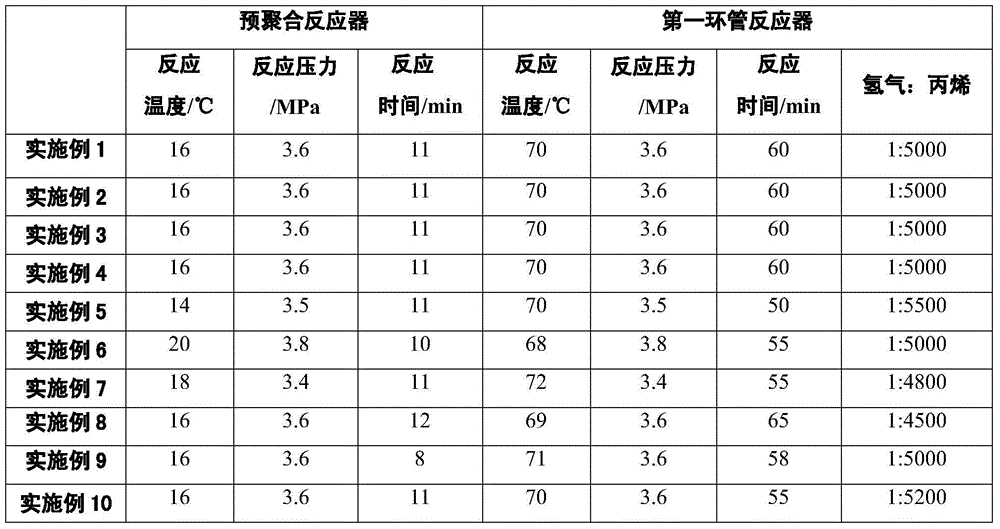

A preparing method of an anti-shock polypropylene special-purpose material with a high melt index

A preparing method of an anti-shock polypropylene special-purpose material with a high melt index is disclosed. A multi-section loop process is adopted. A new external electron donor is added during polymerization. The polymerization molecular weight is controlled by adjusting the ethylene adding amount. The mass ratio of a catalyst to propylene is 1:170000-190000. The mass ratio of a cocatalyst to the propylene is 1:5700-6700. The mass ratio of the cocatalyst to the external electron donor is 1.5-3:1. Compared with present products, a product of the polypropylene special-purpose material is long in stabilization period, almost free of odor, more in high molecular weight part, wide in molecular weight distribution, long in oxidation induction time and good in antishock performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

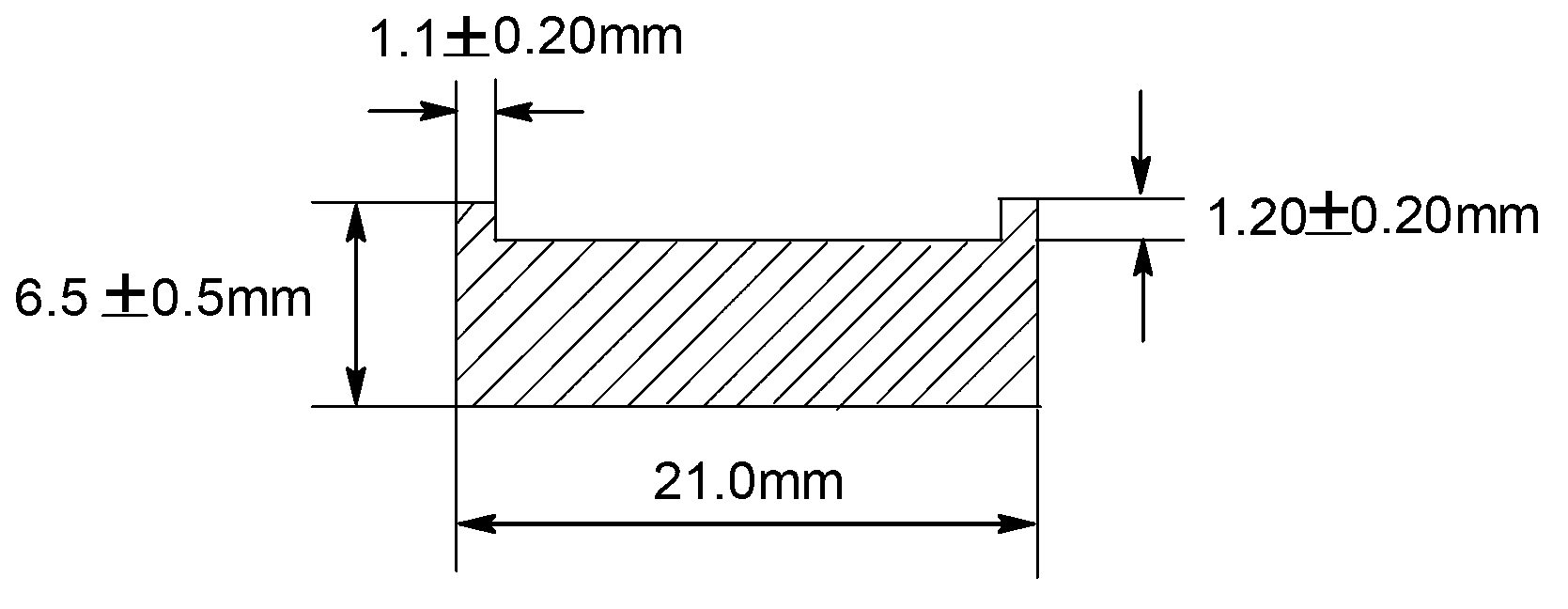

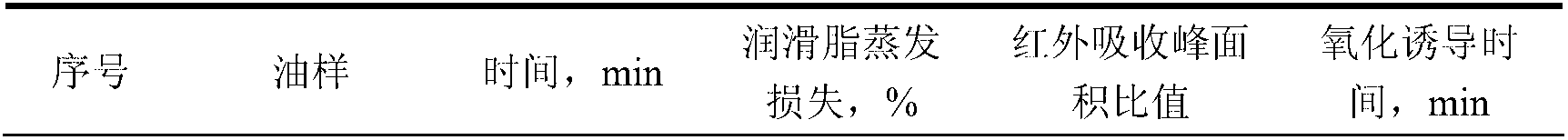

Method for rapid assessing high-temperature oxidation resistance of lubricating grease

InactiveCN102937581AReal-time analysis of antioxidant processesQuickly monitor service lifeWeighing by removing componentColor/spectral properties measurementsEvaporationEngineering

The invention discloses a method for rapid assessing high-temperature oxidation resistance of lubricating grease and belongs to the technical field of the lubricating grease. The method comprises the steps of weighing a small quantity of lubricating grease sample into a testing grease cup, placing the grease cup contained with the sample into an oxidimetry instrument heating groove with constant temperature, leading a certain flow of air into the groove, taking out the grease cup oxidized in different time, weighing the mass of the grease cup before and after the sample is oxidized, calculating an evaporation loss value of the sample in different testing time, using a solvent to wash the lubricating grease sample in the grease cup and performing infrared spectroscopic analysis to confirm the oxidation induction time of the lubricating grease sample. The oxidation resistance of lubricating grease can be rapidly assessed according to the evaporation loss value and the oxidation induction time. The method for rapid assessing the high-temperature oxidation resistance of the lubricating grease has the advantages of being simple in test device and operation process, short in detection time, accurate in detection result and good in repeatability.

Owner:中国人民解放军空军勤务学院

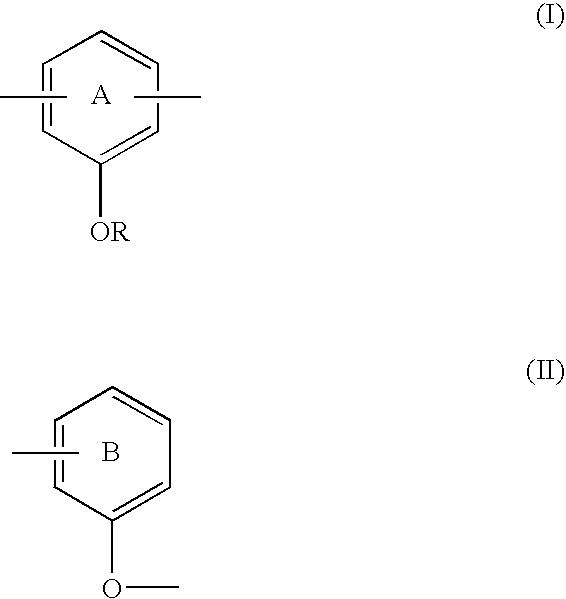

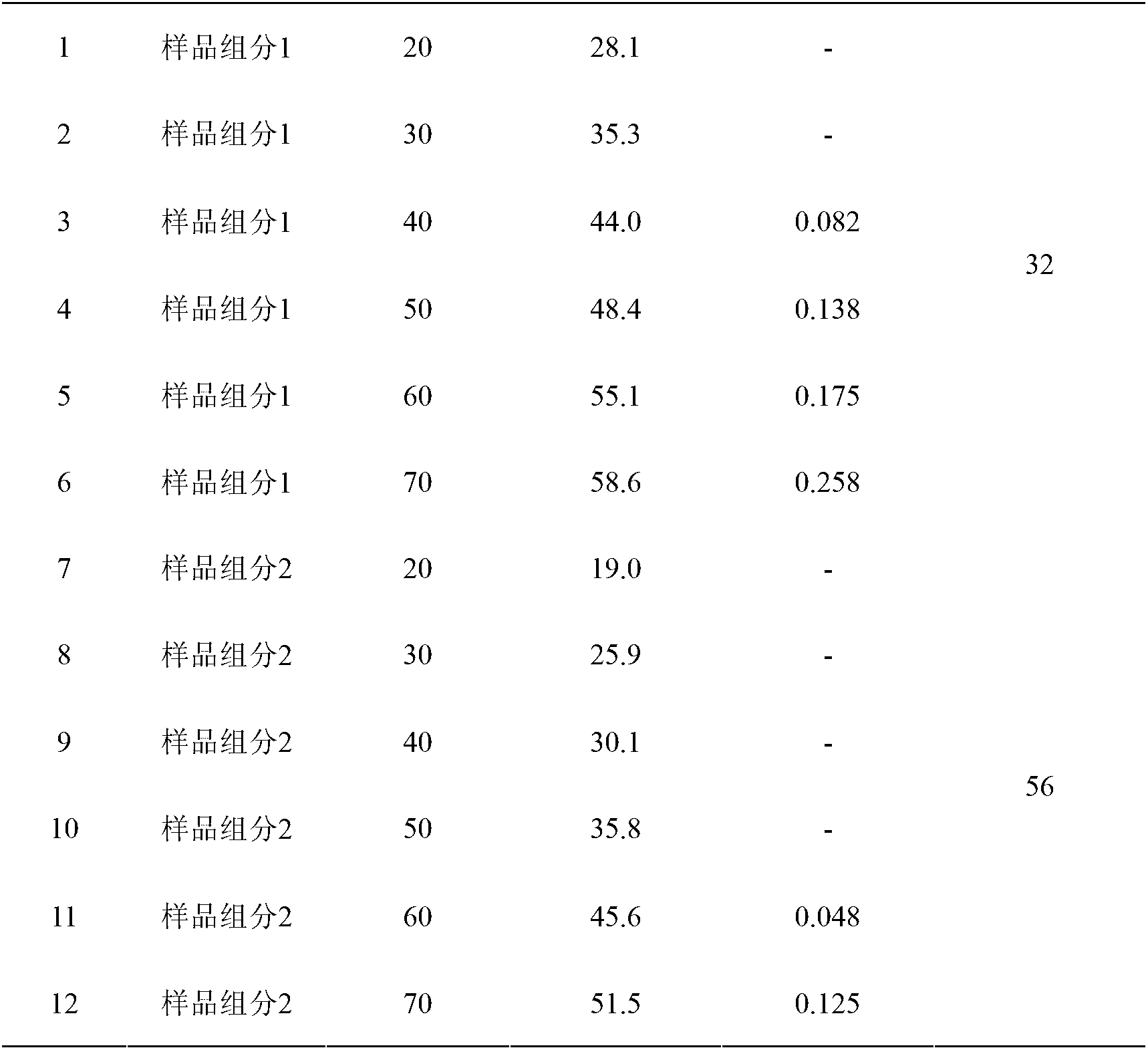

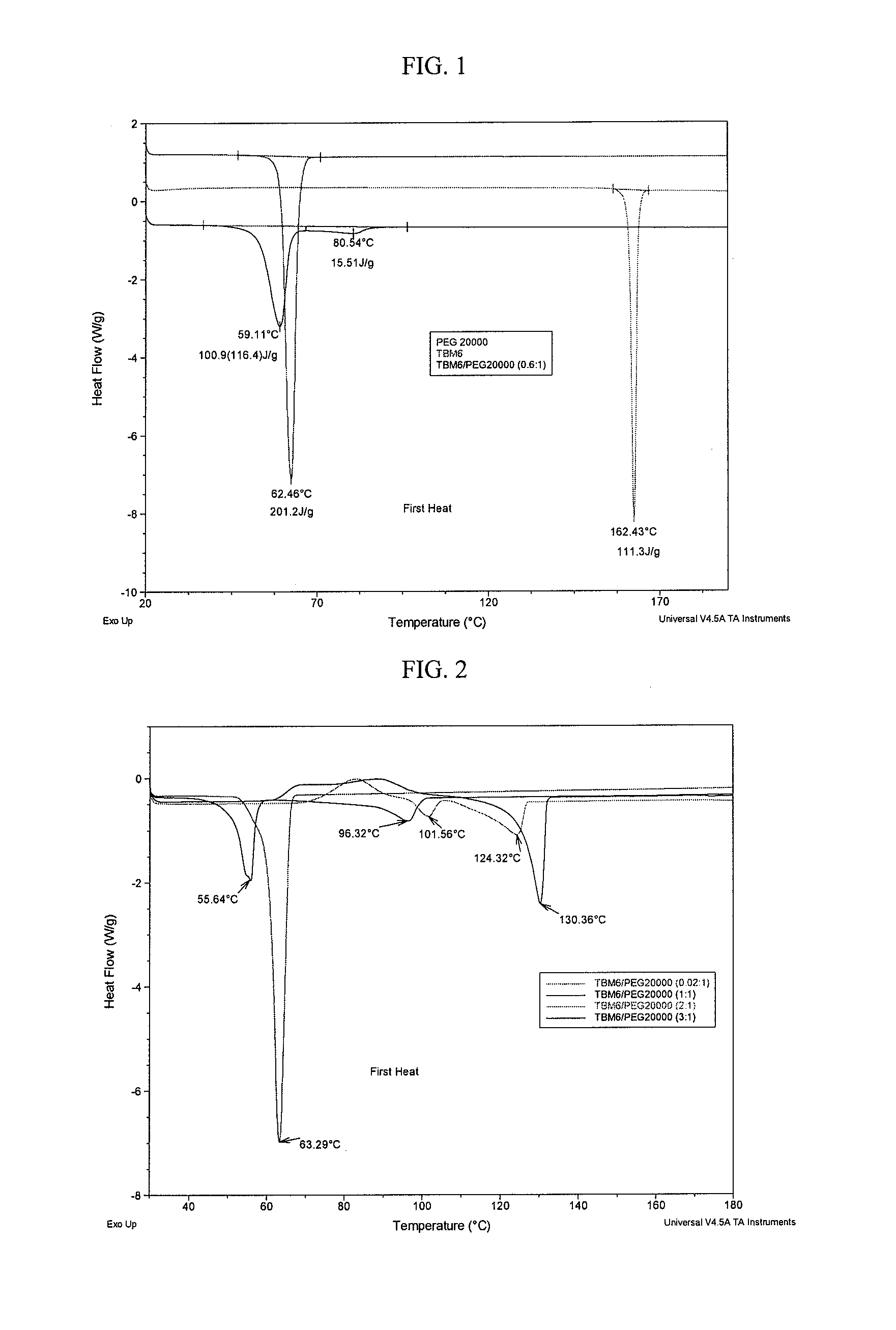

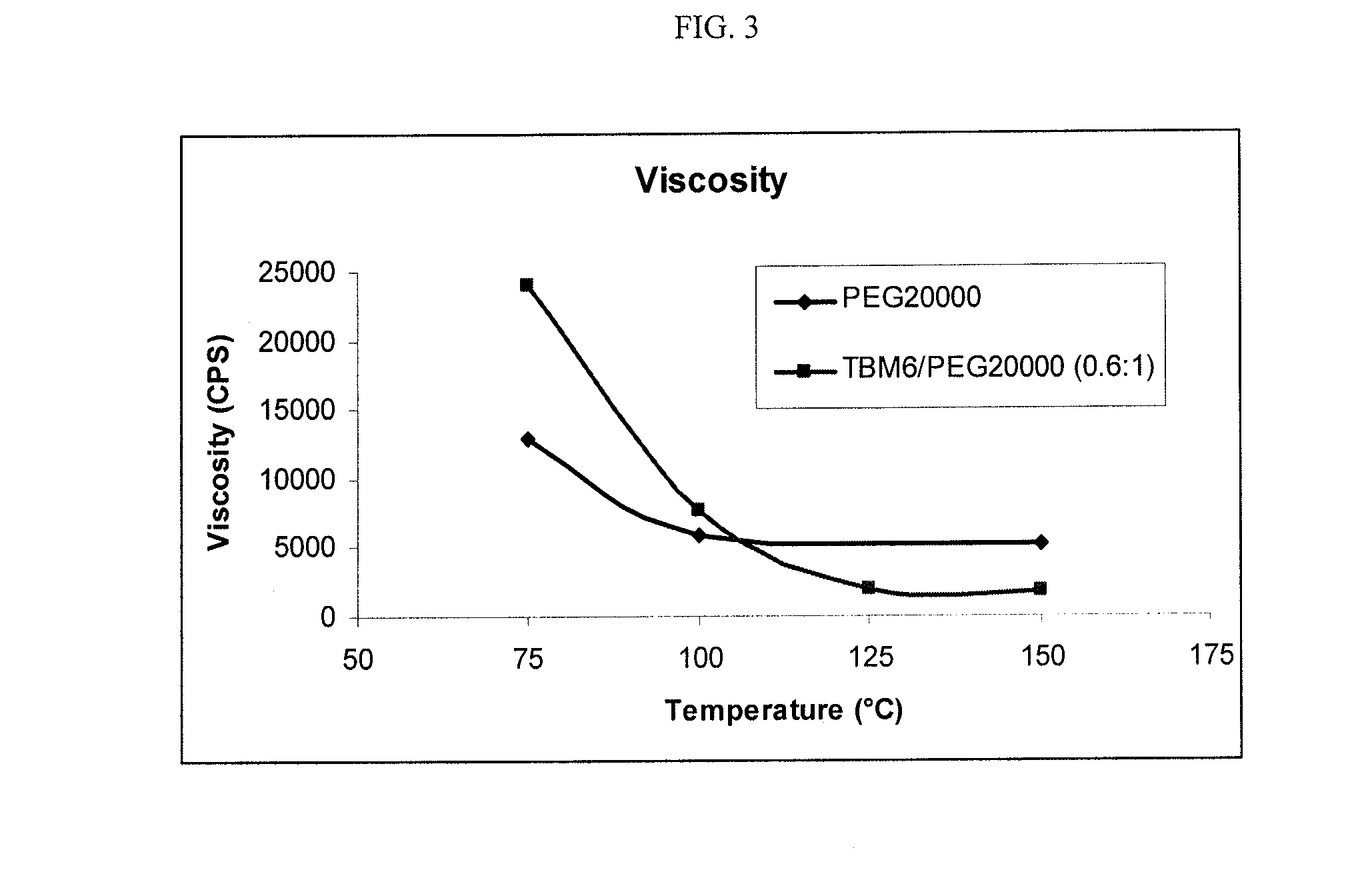

Thiobis Phenolic Antioxidant/Polyethylene Glycol Blends

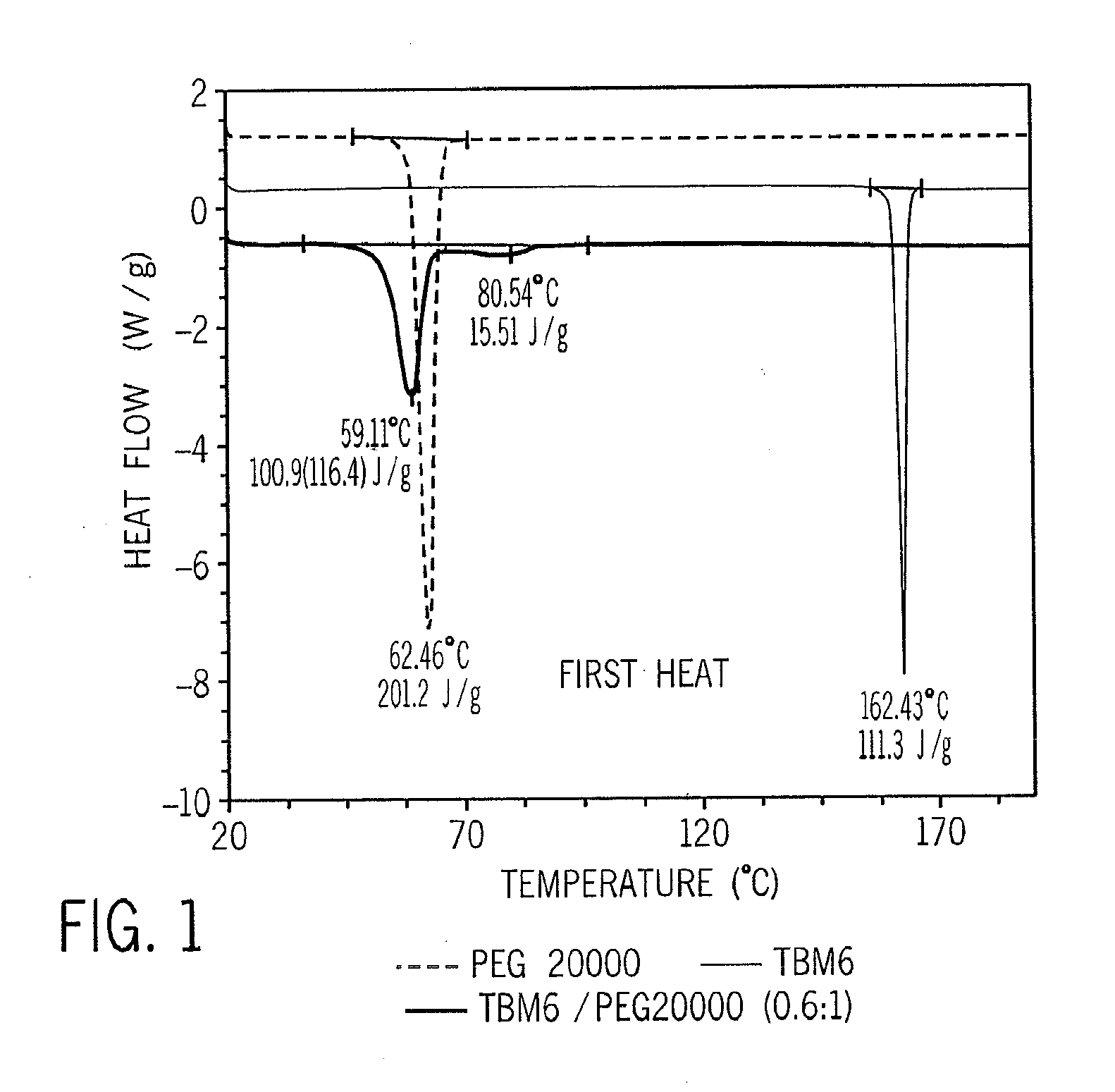

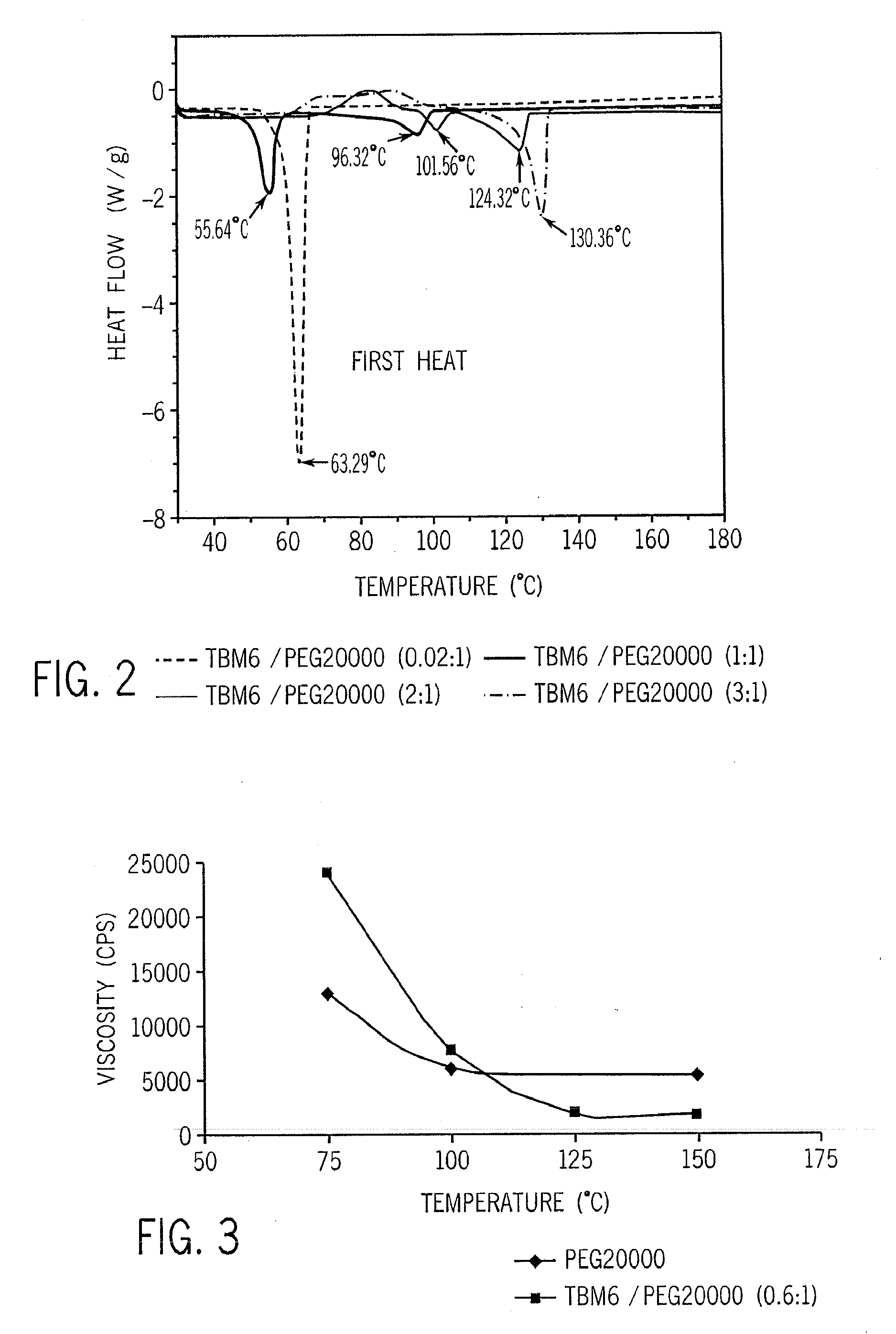

InactiveUS20140182882A1Higher oxidative induction timeMeasurement stabilityPlastic/resin/waxes insulatorsInsulated cablesPhenolic antioxidantPolyethylene glycol

Thiobis phenolic antioxidants are efficiently dry or melt blended with a tree-resistant, crosslinkable polyethylene by first forming a blend, preferably a dry blend, of the antioxidant with a polyalkylene glycol (PAG), and then mixing the blend with the polyethylene. The incorporation of thiobis phenolic antioxidant and PAG blend into polyethylene provides the PE with high oxidative induction time (OIT) which is a measure of the oxidative stability of the PE.

Owner:ADAMCZYK ANTONI +4

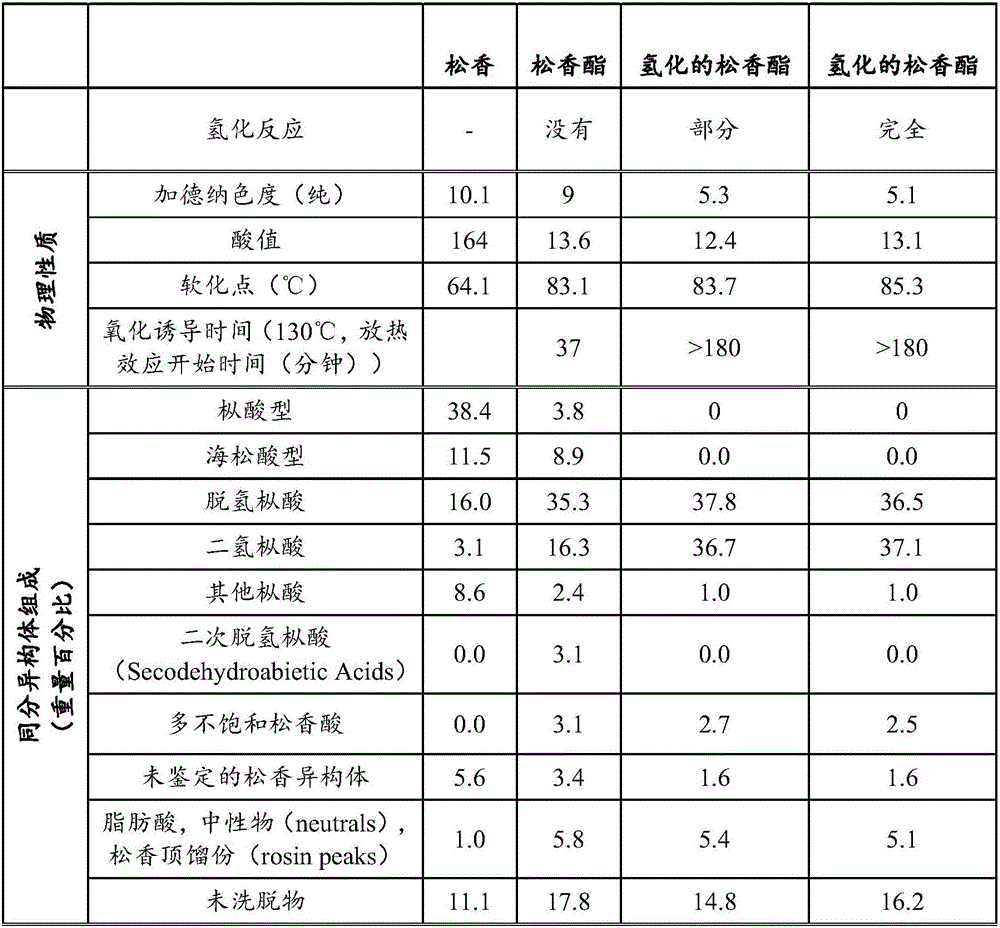

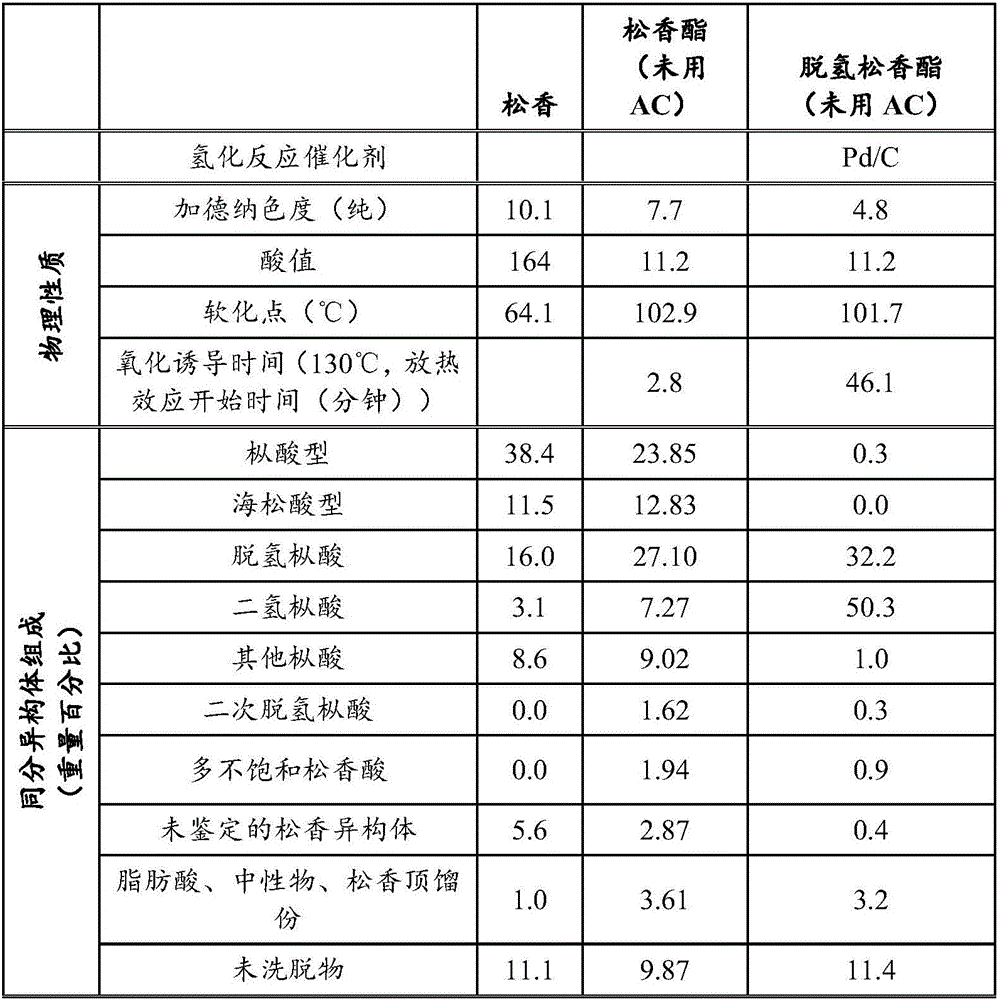

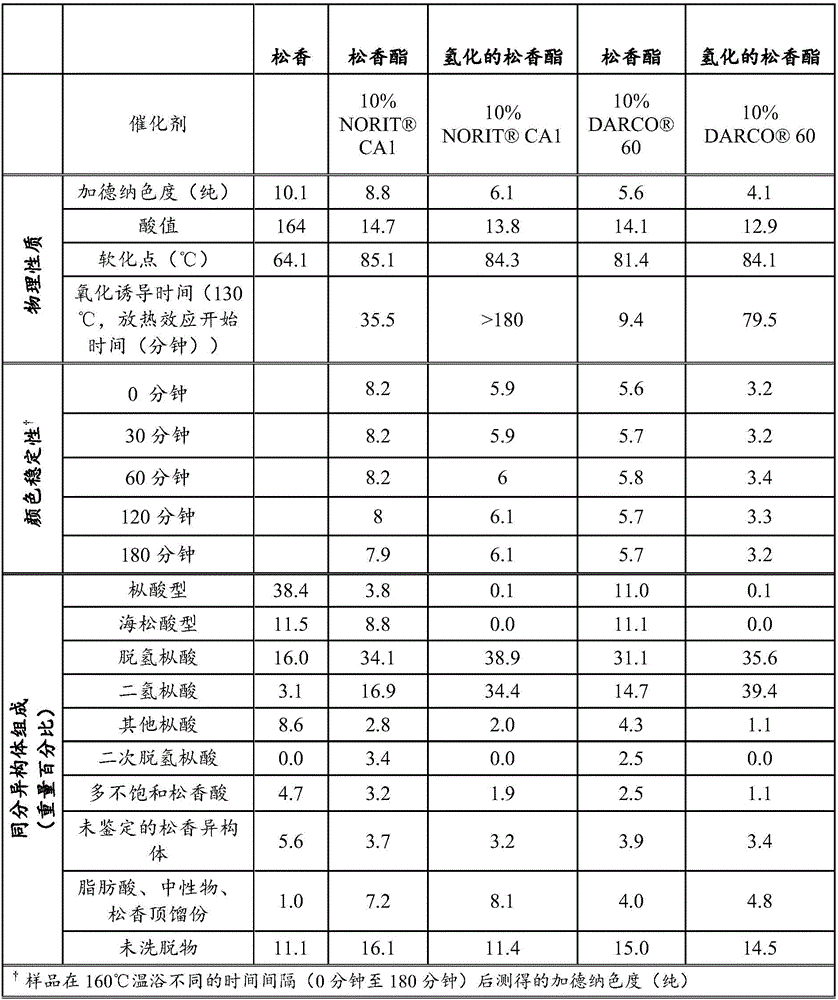

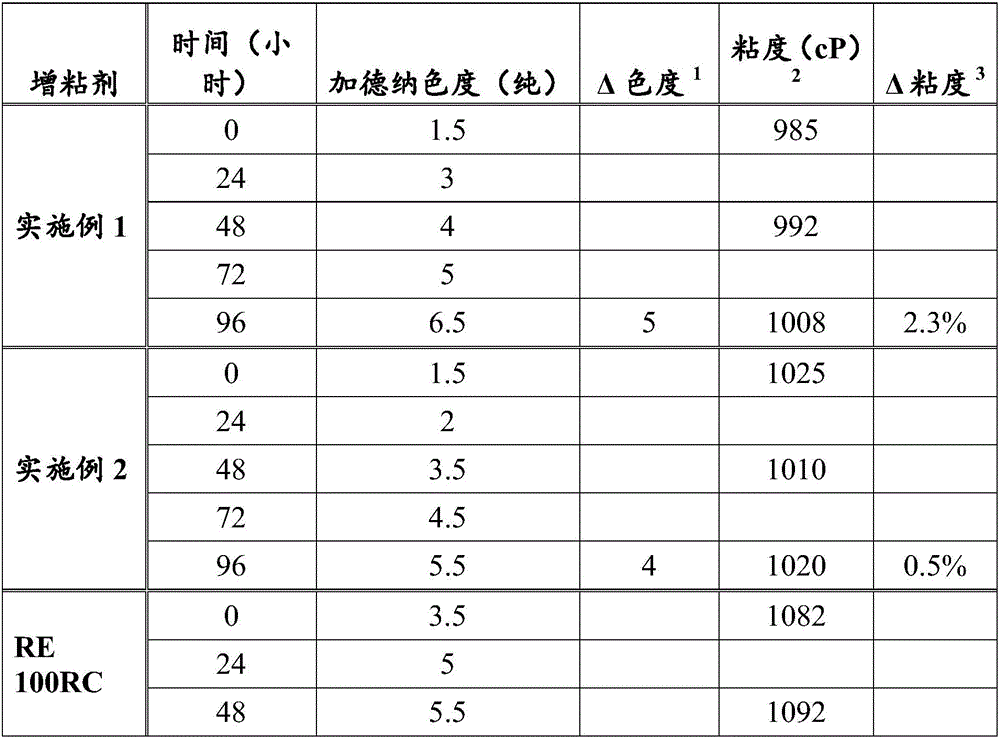

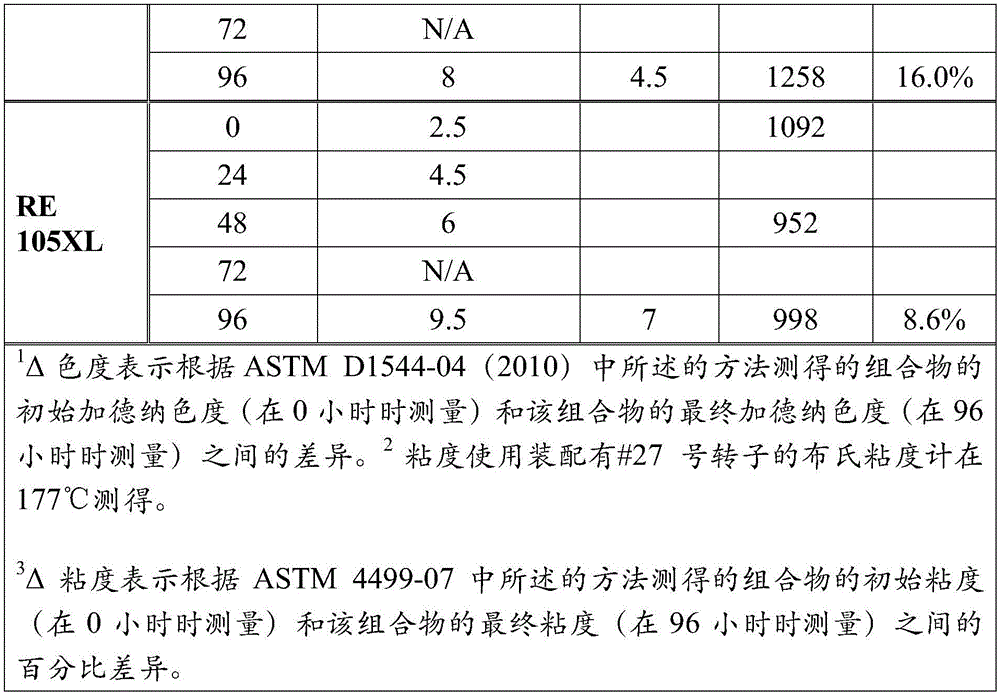

Rosin esters and compositions thereof

InactiveCN105916950AImprove thermal stabilityGood viscosity stabilityNatural resin chemical modificationShow cardsGardner color scaleAntioxidant

Rosin esters are provided. The rosin esters can exhibit improved color (e.g., the rosin ester can have a neat Gardner color of 8.5 or less), improved oxidative stability (e.g., when 1000 ppm or less of an antioxidant is present in combination with the rosin ester, the rosin ester can exhibit an oxidative-induction time at 130 DEG C of at least 75 minutes), improved color stability (e.g., the rosin ester can exhibit less than a 10% change in neat Gardner color when heated to a temperature of 160 DEG C for a period of three hours), or combinations thereof. Also provided polymeric compositions comprising the rosin esters, as well as methods of making the rosin esters.

Owner:ARIZONA CHEM CO

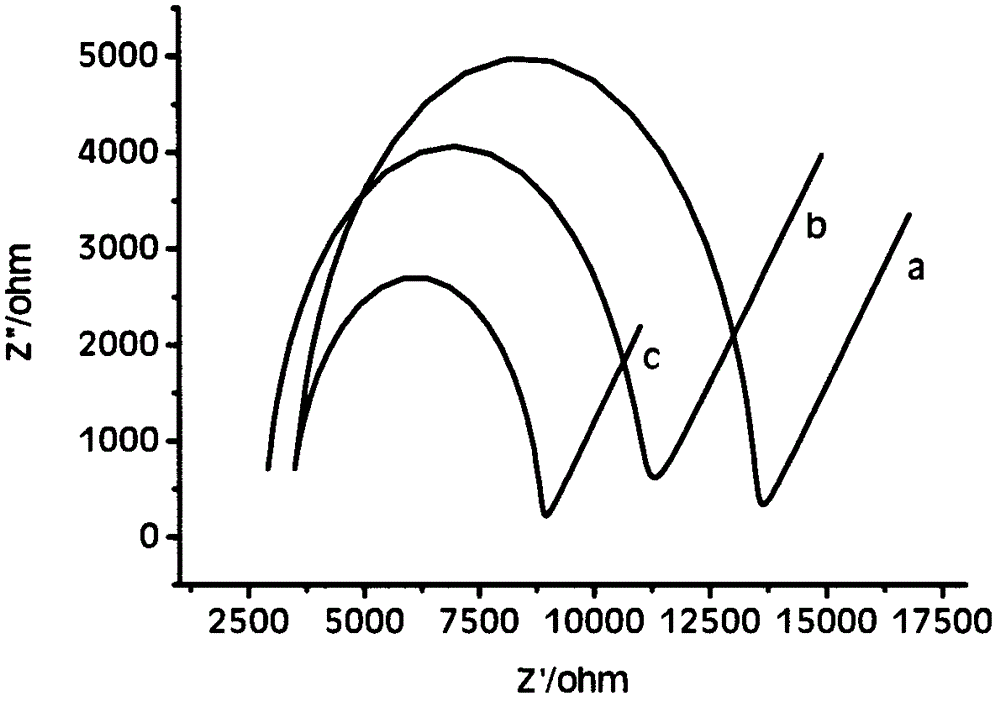

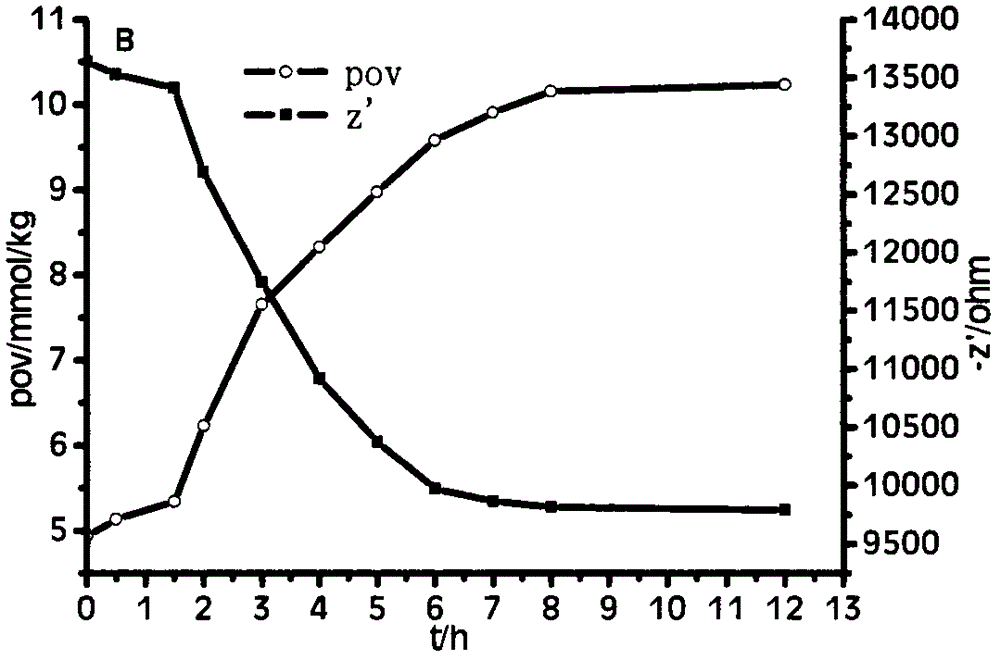

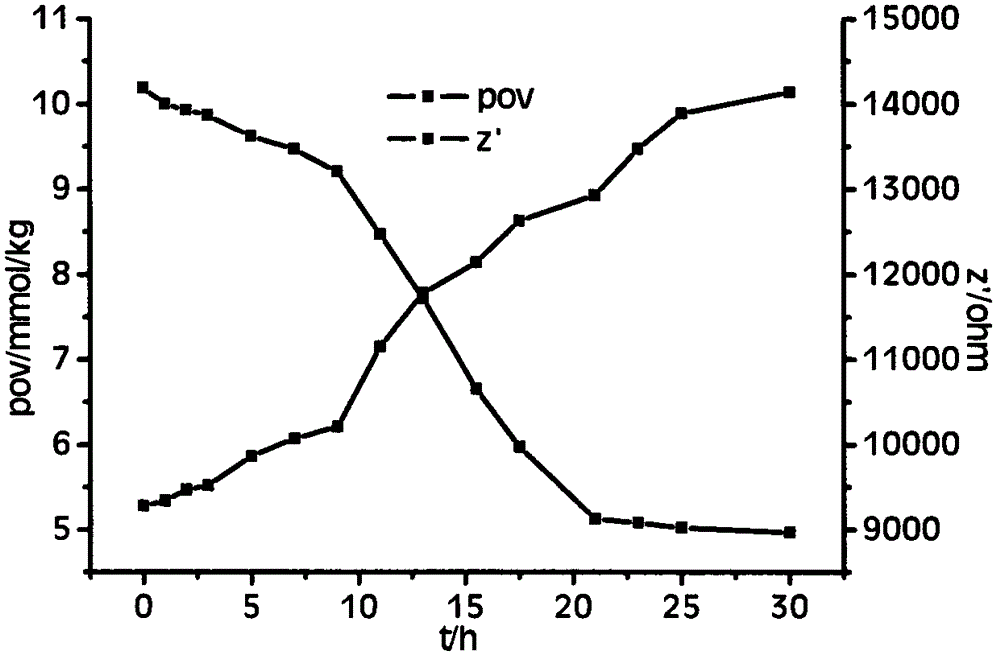

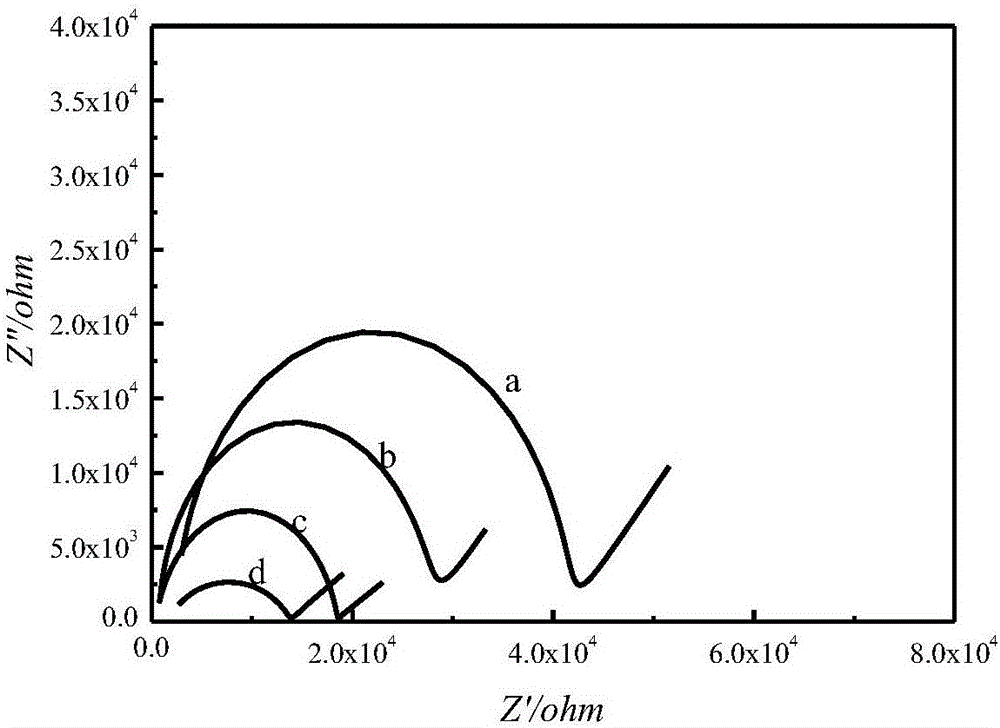

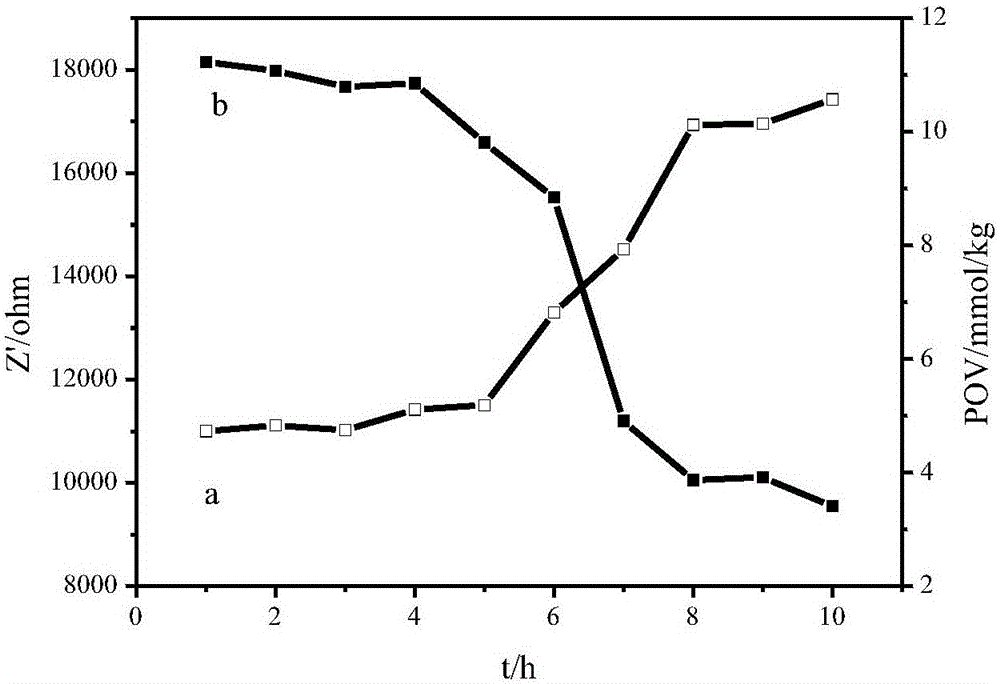

Electrochemical method for measuring oxidation inducing time of grease

ActiveCN105891289ASimple methodAccurate measurementMaterial electrochemical variablesSupporting electrolyteDisturbance voltage

The invention discloses an electrochemical method for measuring the oxidation inducing time of grease. The electrochemical method comprises the steps of to reducing graphene suspension by using electrodeposition to prepare a graphene-modified electrode; diluting supporting electrolyte solution for the grease to be measured, adding diluent into an electrolytic tank to form a three-electrode system (the working electrode is the graphene-modified electrode, the counter electrode is a platinum sheet and the reference electrode is a calomel electrode), adjusting disturbance voltage and frequency, measuring and recording an alternating-current impedance spectrum; solving an impedance value of solution by an equivalent circuit of the impedance spectrum; and solving the oxidation inducing time of the grease accurately by a double-tangent method. The electrochemical method disclosed by the invention has the advantages that the change of the impedance value in the process of grease oxidation can be quickly and accurately measured by the graphene-modified glass-carbon electrode, so that an electrochemical method for measuring the oxidation inducing time of the grease in a simple-sensitive-accurate manner is established.

Owner:JIANGNAN UNIV

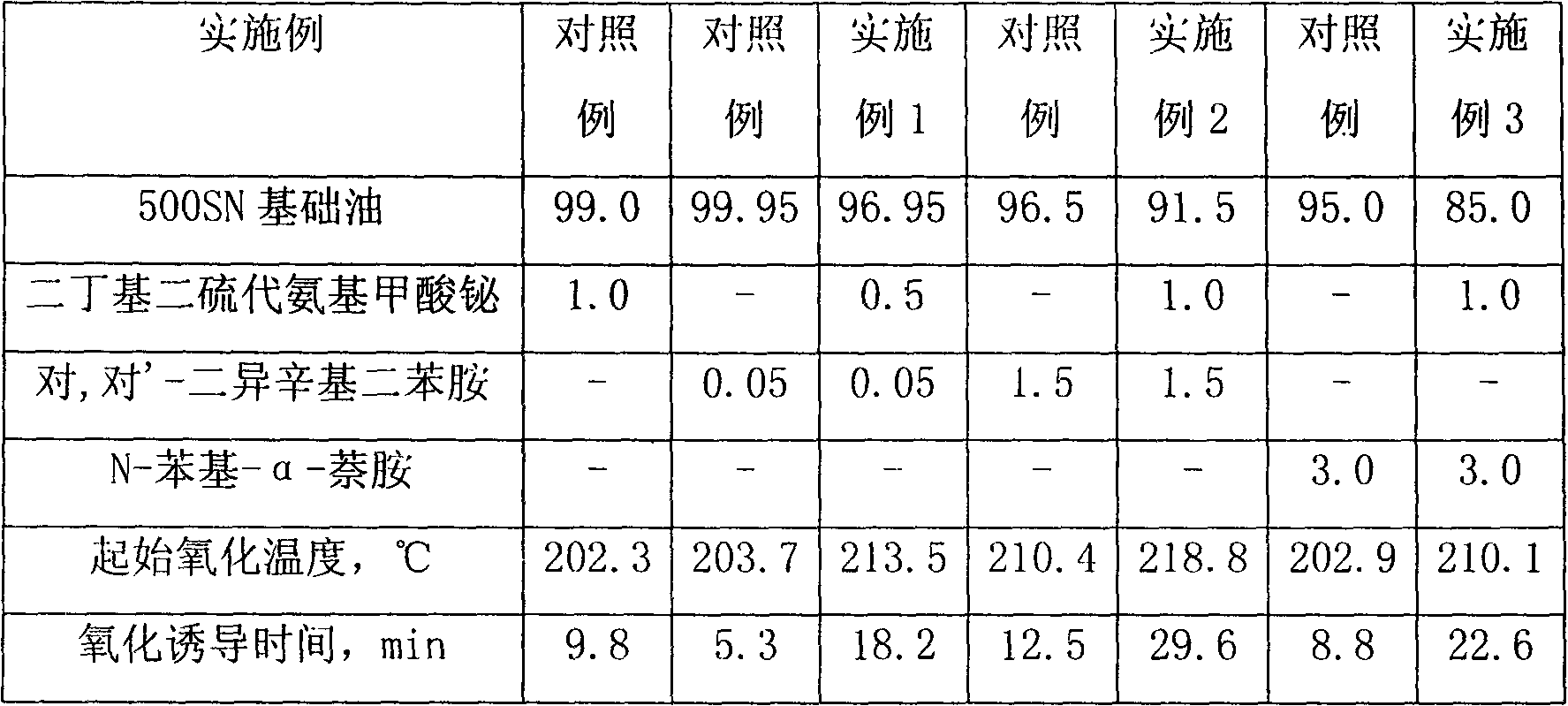

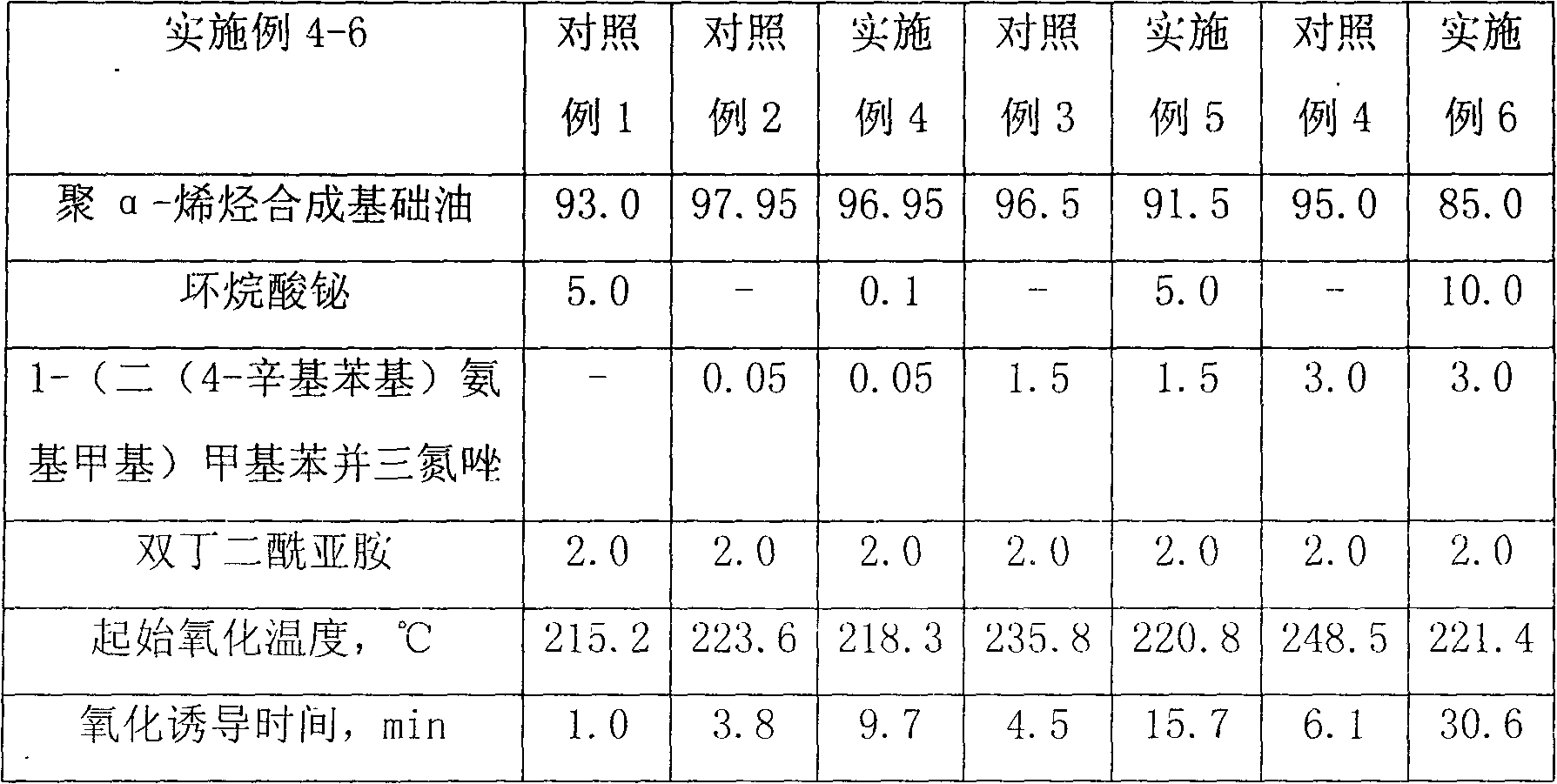

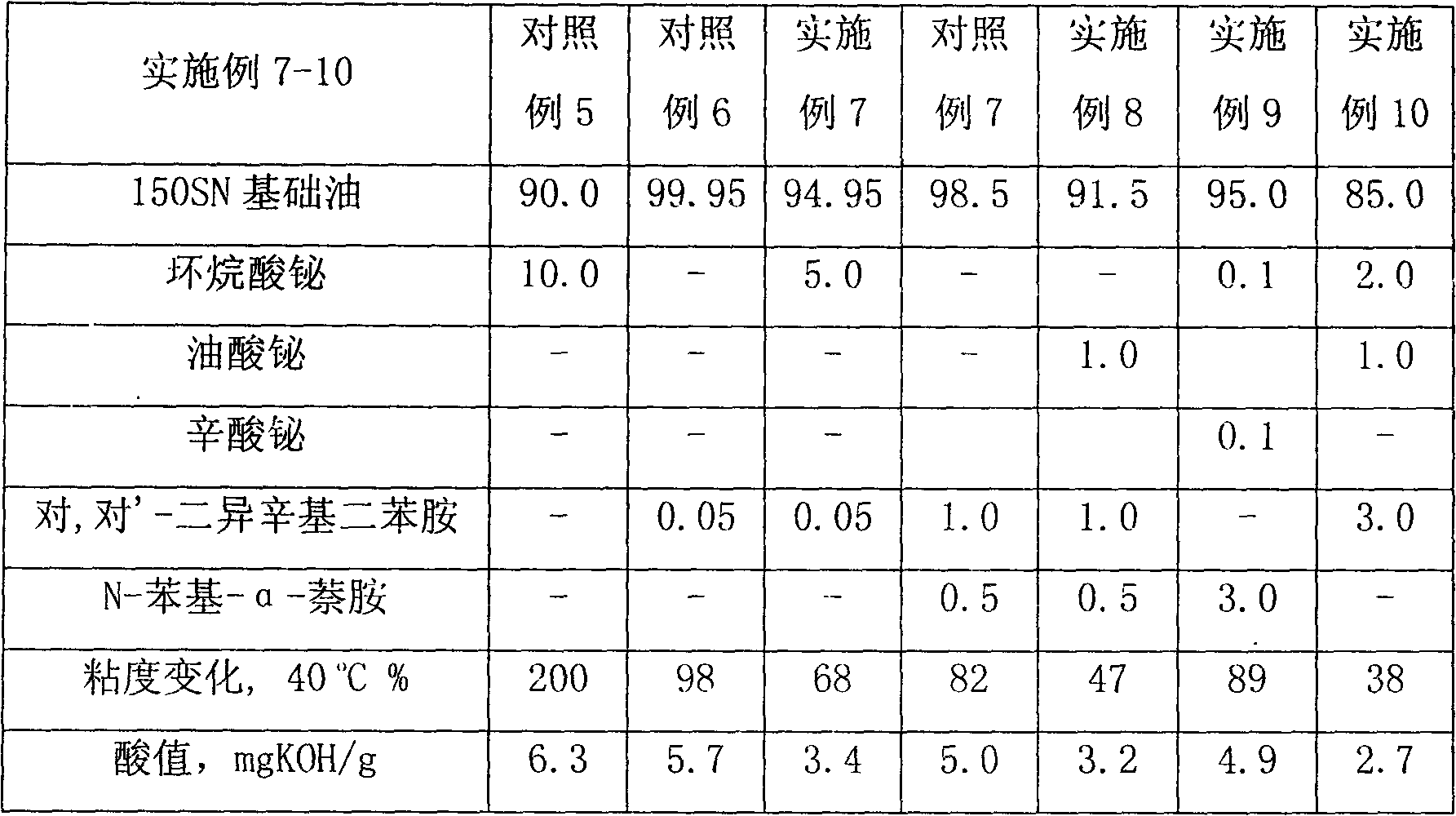

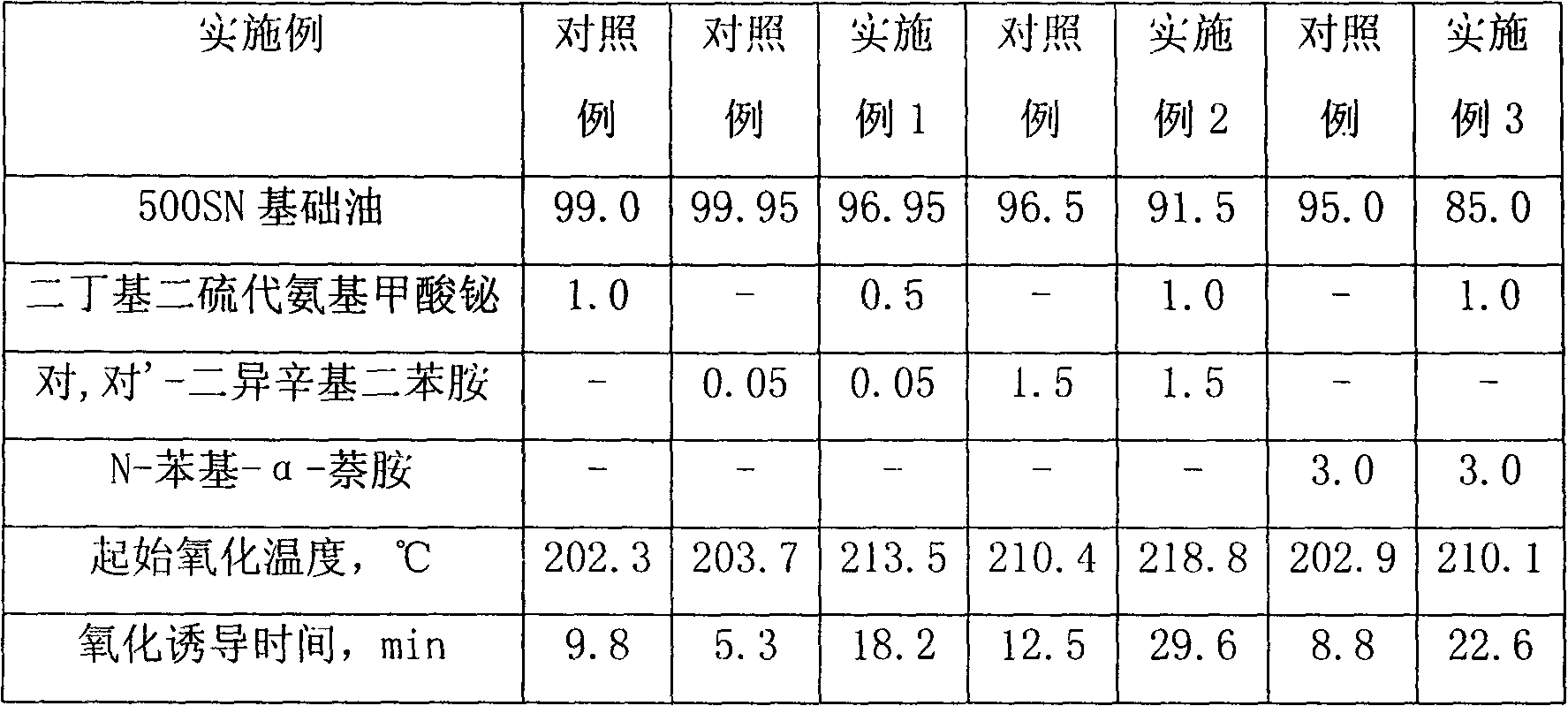

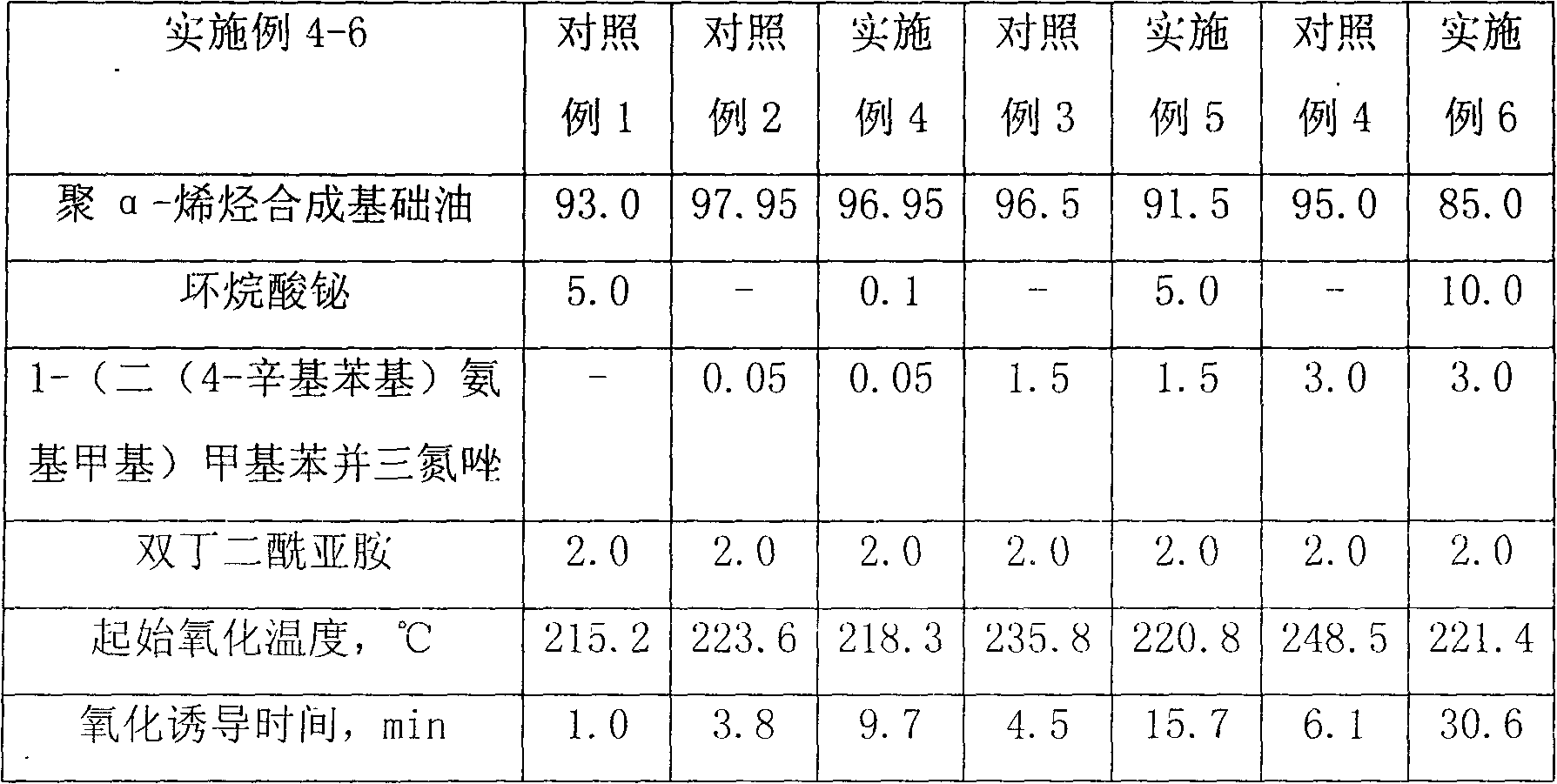

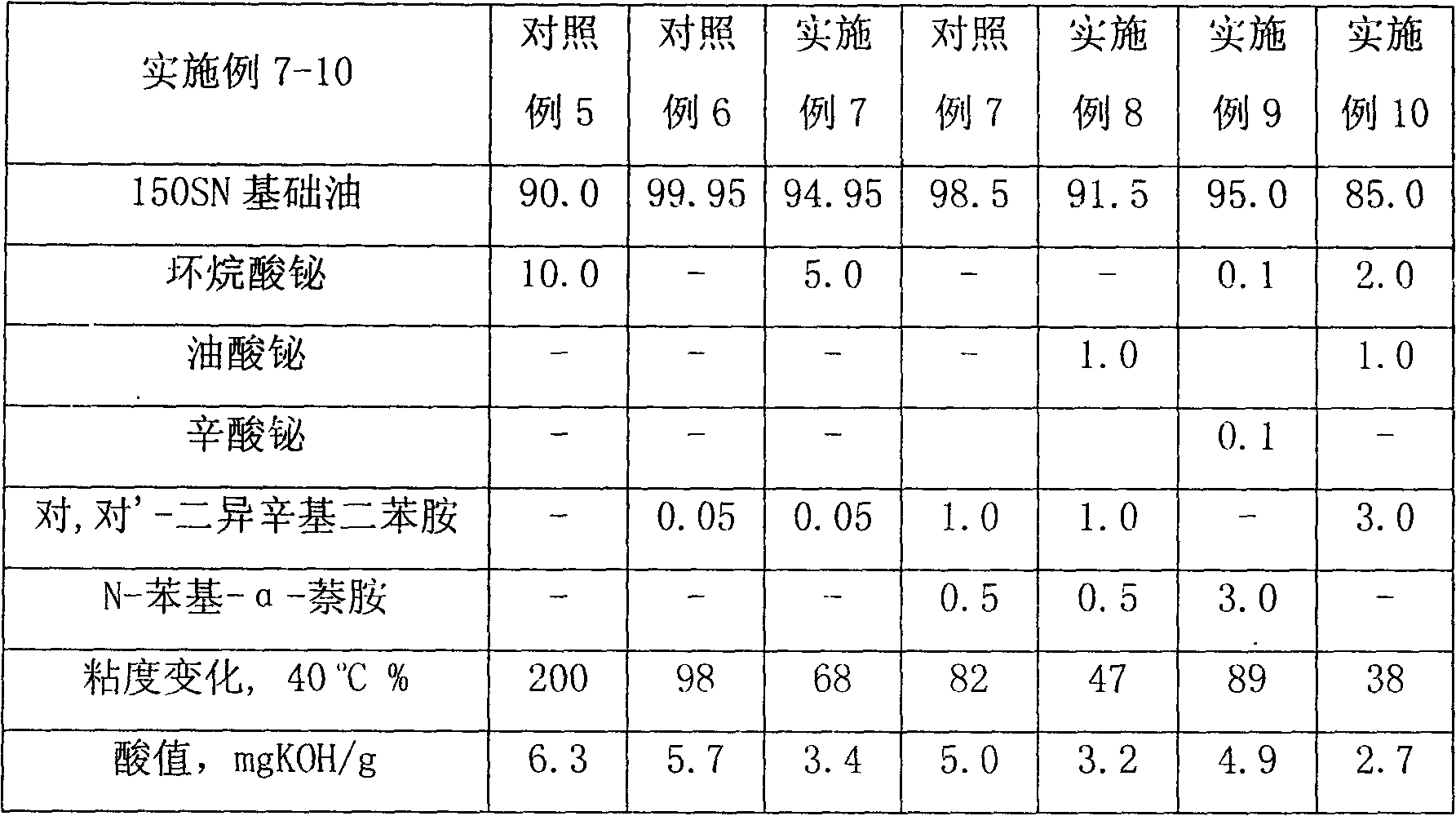

Antioxidant additive composite

InactiveCN102206532AGood high temperature oxidation resistanceRaise the initial oxidation temperatureAdditivesBismuth compoundInternal combustion engine

The invention discloses an antioxidant additive composite, belonging to the technical field of lubricating oil. The antioxidant additive composite consists of the following compounds in parts by weight: 0.1-1 part of bismuth compound and 0.05-3 parts of arylamine compound. After the antioxidant additive composite is added into lubricating oil, the initial oxidation temperature and oxidation induction time of the lubricating oil can be greatly increased, and the high-temperature antioxidant property of the lubricating oil can be greatly improved. The antioxidant additive composite can be widely applied to various lubricating oil products including basic lubricating oil or finished lubricating oil, such as internal combustion engine oil, gear oil and the like.

Owner:中国人民解放军徐州空军学院

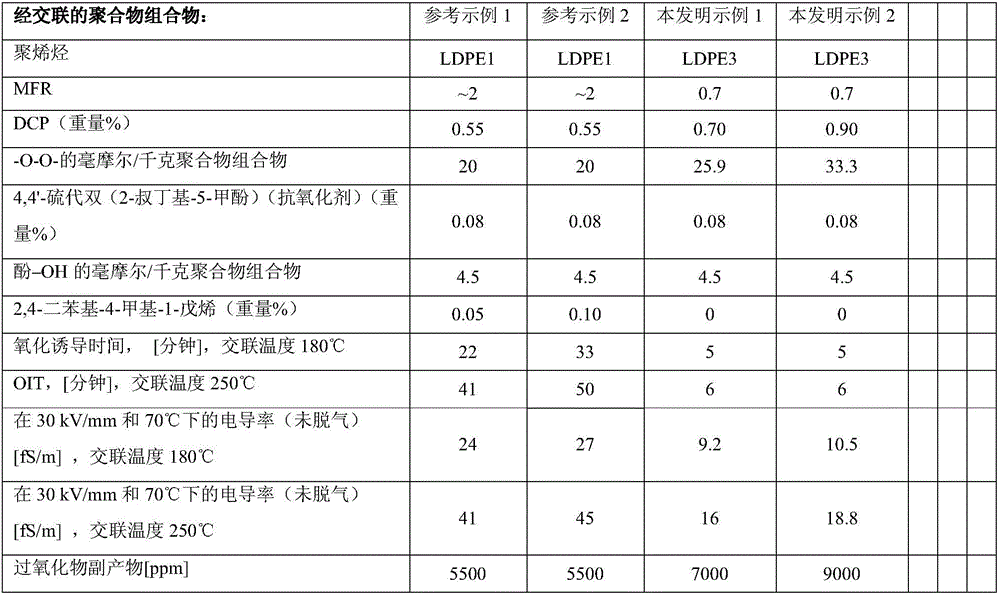

A new crosslinked low mfr polymer composition, power cable insulation and power cable

InactiveUS20160314869A1Maintain good propertiesPlastic/resin/waxes insulatorsPolymer sciencePolyolefin

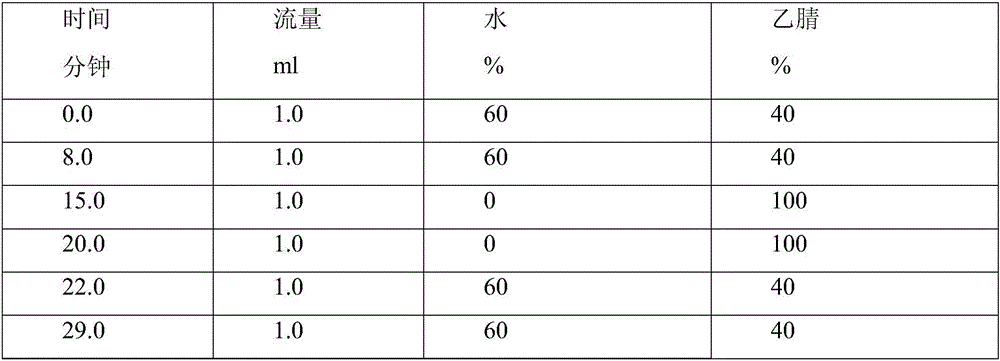

The present invention relates to a crosslinked polymer composition, which is obtained by crosslinking a polymer composition, which polymer composition has a melt flow rate (MFR) of less than 1.7 and comprises a polyolefm, peroxide and sulphur containing antioxidant, characterised by that the crosslinked polymer composition has an Oxidation Induction Time, determined according to ASTM-D3895, ISO / CD 11357 and EN 728 using a Differential Scanning Calorimeter (DSC), which Oxidation Induction Time corresponds to Z minutes, and comprises an amount of peroxide by-products which corresponds to W ppm determined according to BTM2222 using HPLC, wherein Z1≦Z≦Z2, W1≦W≦W2, and W≦p−270*Z, wherein Z1 is 0, Z2 is 60, W1 is 0 and W2 is 9500, and p is 18500; and use thereof, a power cable insulation and a power cable, useful in high voltage (HV) and extra high voltage (EHV) cable applications direct current (DC) applications.

Owner:BOREALIS AG

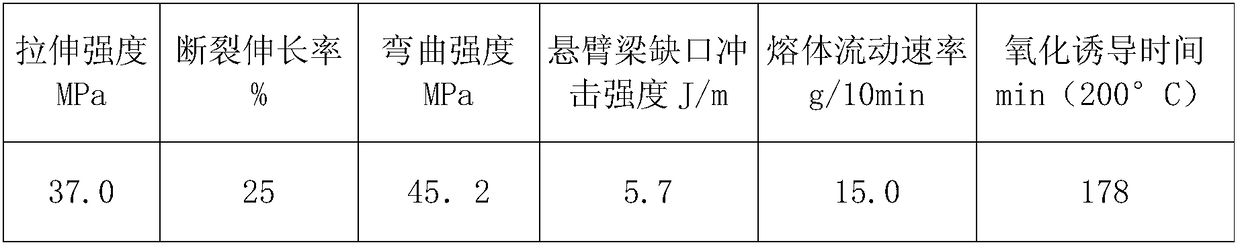

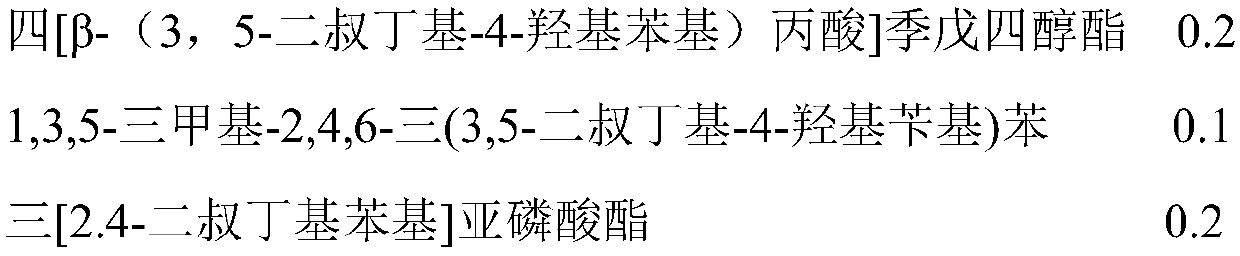

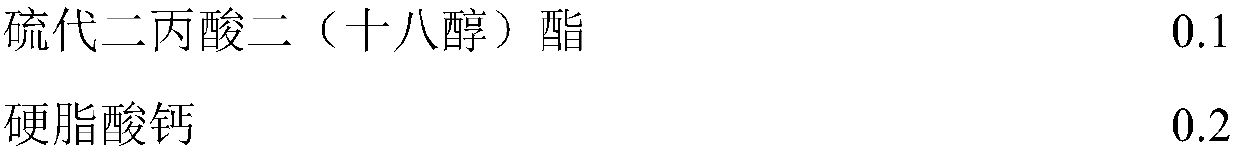

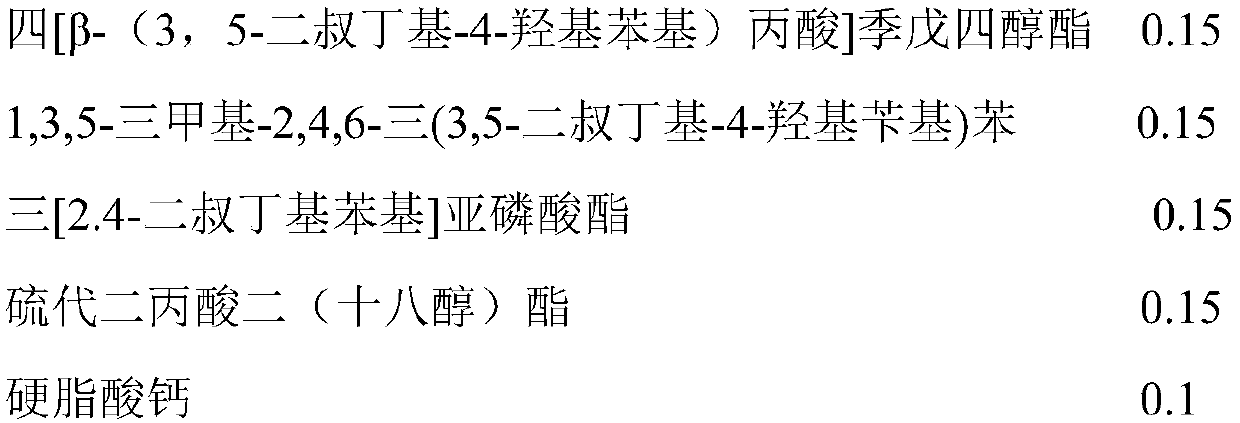

Heatproof oxidized polypropylene composite material with long oxidative induction time and preparation method of heatproof oxidized polypropylene composite material

The invention discloses a heatproof oxidized polypropylene composite material with long oxidative induction time. The heatproof oxidized polypropylene composite material is characterized by being prepared from, by mass, 58-62% of polypropylene, 28-32% of inorganic filler, 2-5% of a reinforcing agent, 0.1-0.5% of a silane coupling agent, 2-3% of a toughening agent, 0.4-0.8% of a main anti-oxidationadditive, 0.15-0.9% of an auxiliary anti-oxidation additive, 0.1-0.4% of a synergist and 0.8-1.5% of a hyperdispersant, wherein epoxy resin serves as the hyperdispersant. The preparation method includes: well mixing the inorganic filler, the silane coupling agent and the hyperdispersant into a mixture; well mixing other components in a mixer, adding the mixture, well mixing, adding into a double-screw extruder, and subjecting to melt mixing, extrusion and granulation to obtain the composite material. The composite material is long in oxidative induction time and applicable to plastic fittingswith thin wall characteristics.

Owner:MIANYANG HONGQI NEW MATERIAL SCI & TECH

Rosin esters and compositions thereof

InactiveCN105916949AImprove thermal stabilityGood viscosity stabilityRosin coatingsNatural resin chemical modificationGardner color scaleAntioxidant

Rosin esters are provided. The rosin esters can exhibit improved color (e.g., the rosin ester can have a neat Gardner color of 4 or less), improved oxidative stability (e.g., when 1000 ppm or less of an antioxidant is present in combination with the rosin ester, the rosin ester can exhibit an oxidative-induction time at 130 DEG C of at least 30 minutes), improved color stability (e.g., the rosin ester can retain a neat Gardner color of 5 or less when heated to a temperature of 160 DEG C for a period of three hours), or combinations thereof. The invention also provides polymeric compositions comprising the rosin esters, as well as methods of making the rosin esters.

Owner:ARIZONA CHEM CO

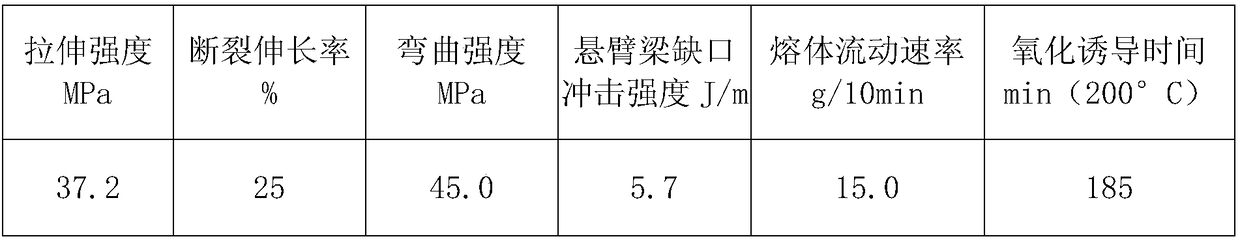

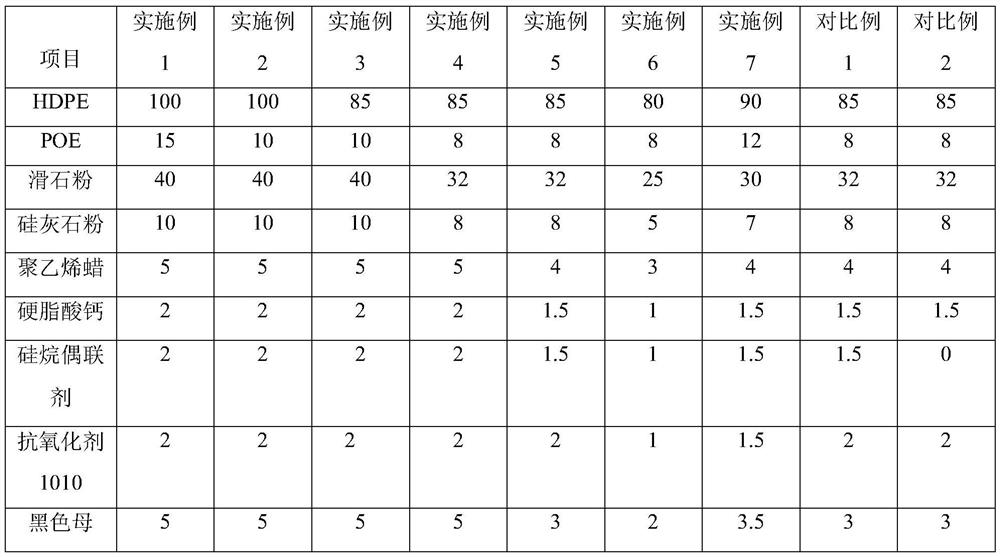

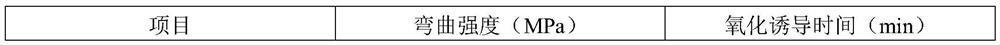

Special polyethylene double-wall corrugated pipe outer wall material with high bending modulus and high oxidation induction time and preparation method of special material

The invention provides a special polyethylene double-wall corrugated pipe outer wall material with high bending modulus and high oxidation induction time and a preparation method thereof, and the special polyethylene double-wall corrugated pipe outer wall material comprises the following components in parts by weight: 80-100 parts of HDPE, 8-15 parts of POE, 25-40 parts of talcum powder, 5-10 parts of wollastonite powder, 3-5 parts of polyethylene wax, 1-2 parts of calcium stearate, 1-2 parts of a silane coupling agent, 1-2 parts of an antioxidant and 2-5 parts of black masterbatch. The HDPE, the POE, the polyethylene wax and the calcium stearate in the components are all powder materials. According to the special polyethylene double-wall corrugated pipe outer wall material, chemical bonding is generated between polyethylene resin and the inorganic powder by adding the coupling agent, so that the polyethylene resin and the inorganic powder are combined more stably and dispersed more uniformly, and the prepared special material has higher flexural modulus and oxidation induction time; and the oxidation resistance of each part is uniform and consistent while the oxidation resistance is improved.

Owner:TIANJIN YONGGAO PLASTIC IND DEV CO LTD

Special anti-aging modified master batch for polyethylene tubes

InactiveCN102161792ASolve the difficulties that are difficult to addNo pollution in the processRigid pipesMasterbatchPolymer science

The invention relates to a special anti-aging modified master batch for polyethylene tubes, which comprises the following raw materials in percentage by weight: 15-30% of HDPE (high-density polyethylene), 30-70% of LLDPE (linear low-density polyethylene), 15-30% of antioxidant, 0.5-3% of polyethylene wax and 1-5% of white oil. The master batch can be produced by carrying out granulation with a double screw extruder. The oxidation induction time of the polyethylene tube produced by adding 2% of the special anti-aging modified master batch for polyethylene tubes can reach more than 60 minutes, and the estimated service life can reach more than 60 years. The invention can solve the problem of difficulty in addition in the tube production process, does not produce any environmental pollution, and enhances the interior processability and the like.

Owner:山东东宏集团有限公司

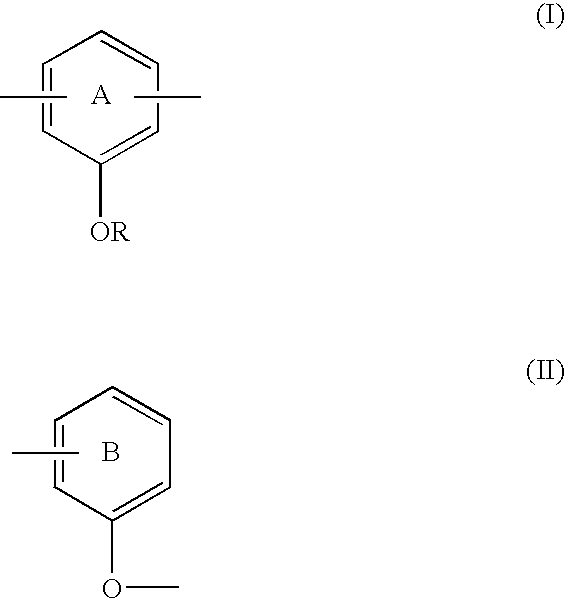

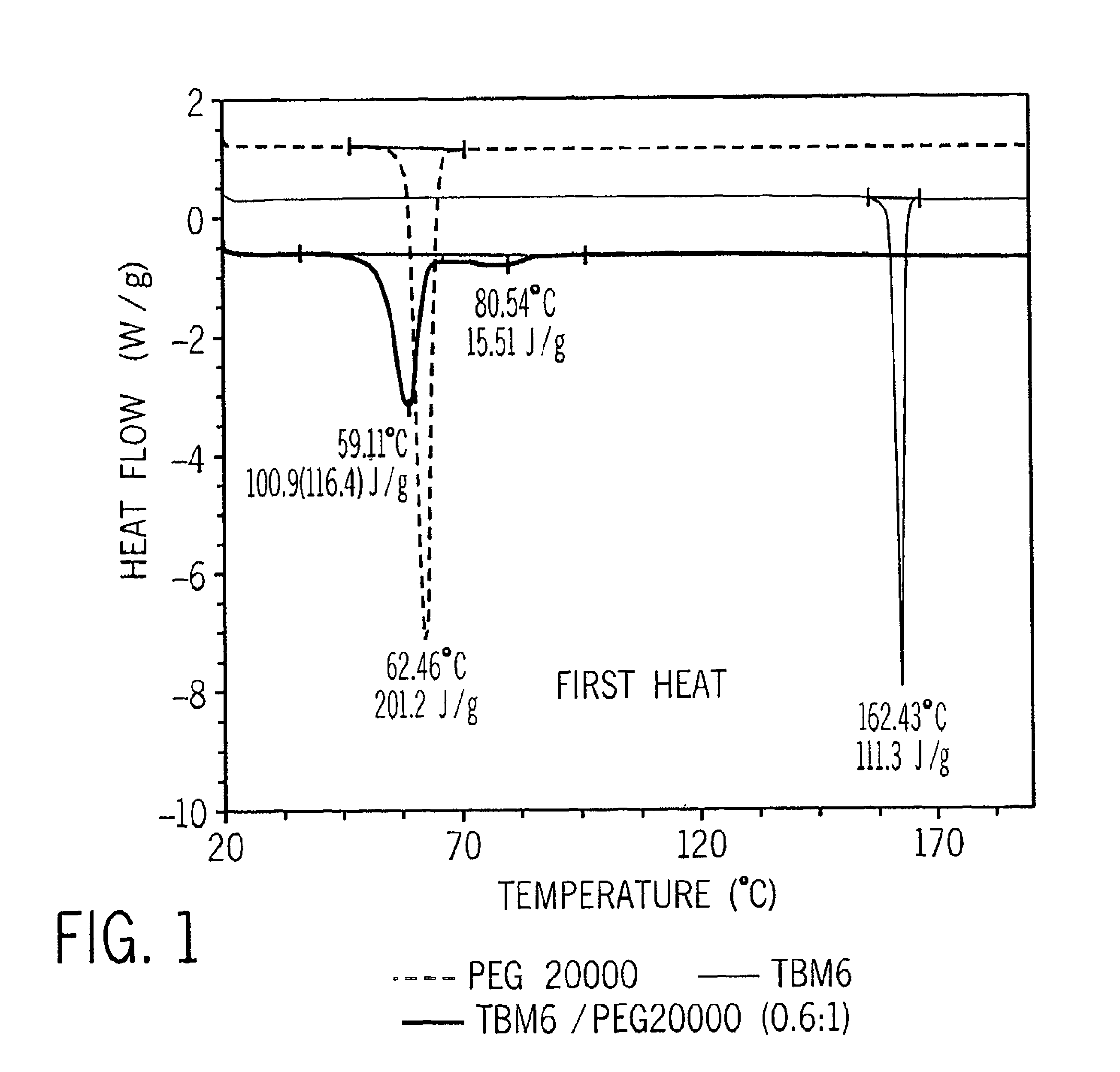

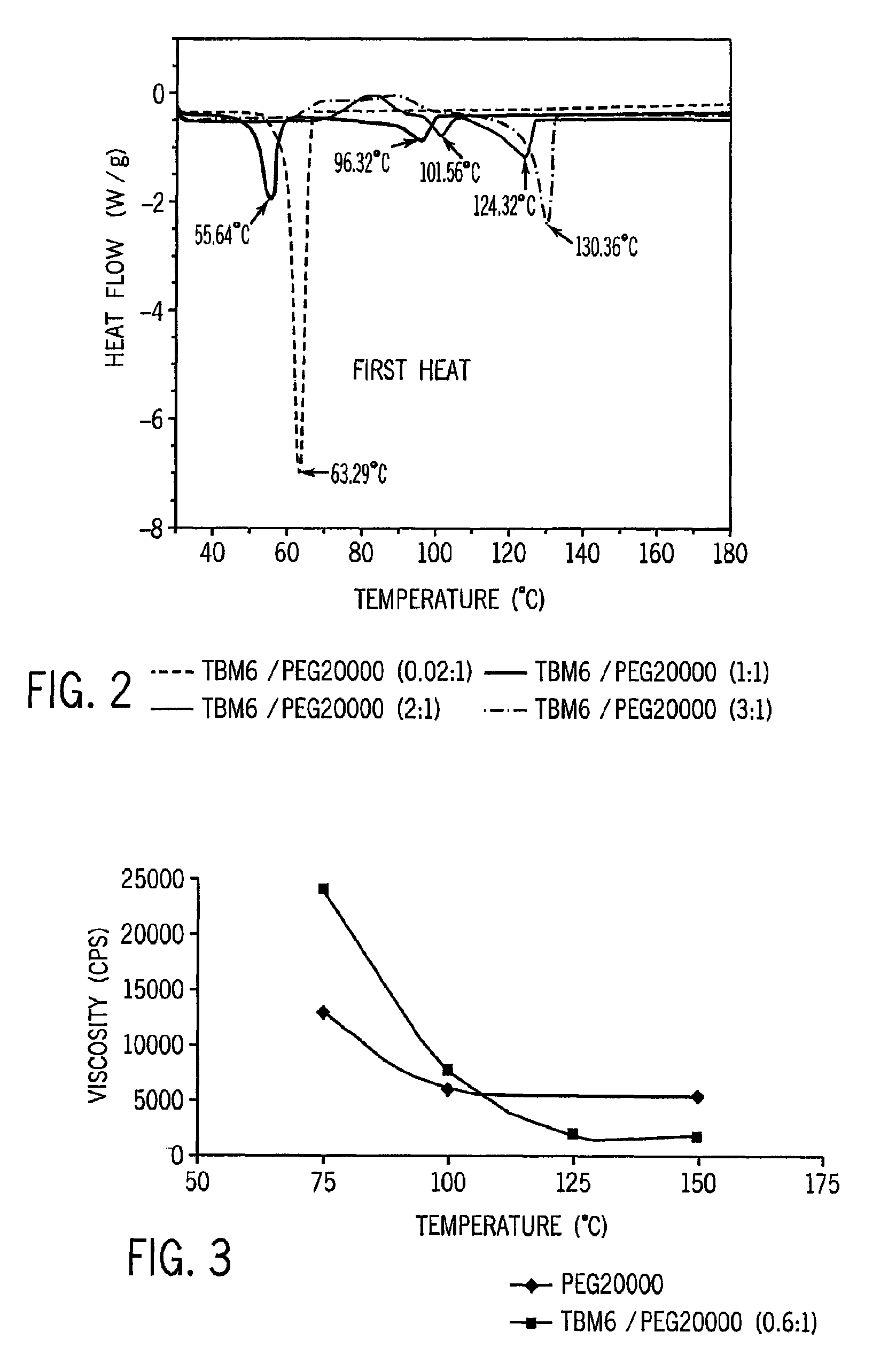

Thiobis Phenolic Antioxidant/Polyethylene Glycol Blends

InactiveUS20130068498A1Higher oxidative induction timeMeasurement stabilityPlastic/resin/waxes insulatorsThin material handlingPolymer scienceThio-

Thiobis phenolic antioxidants are efficiently dry or melt blended with a tree-resistant, crosslinkable polyethylene by first forming a blend, preferably a dry blend, of the antioxidant with a polyalkylene glycol (PAG), and then mixing the blend with the polyethylene. The incorporation of thiobis phenolic antioxidant and PAG blend into polyethylene provides the PE with high oxidative induction time (OIT) which is a measure of the oxidative stability of the PE.

Owner:UNION CARBIDE CORP

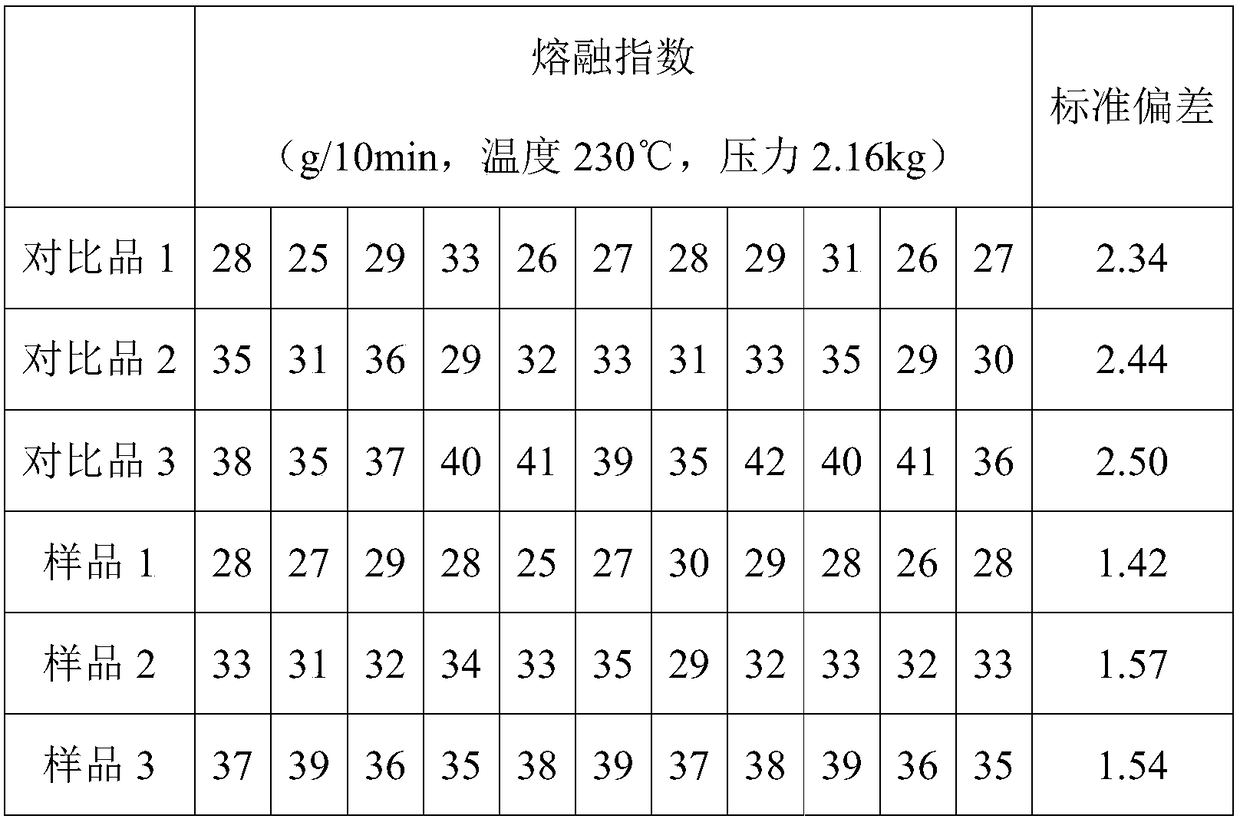

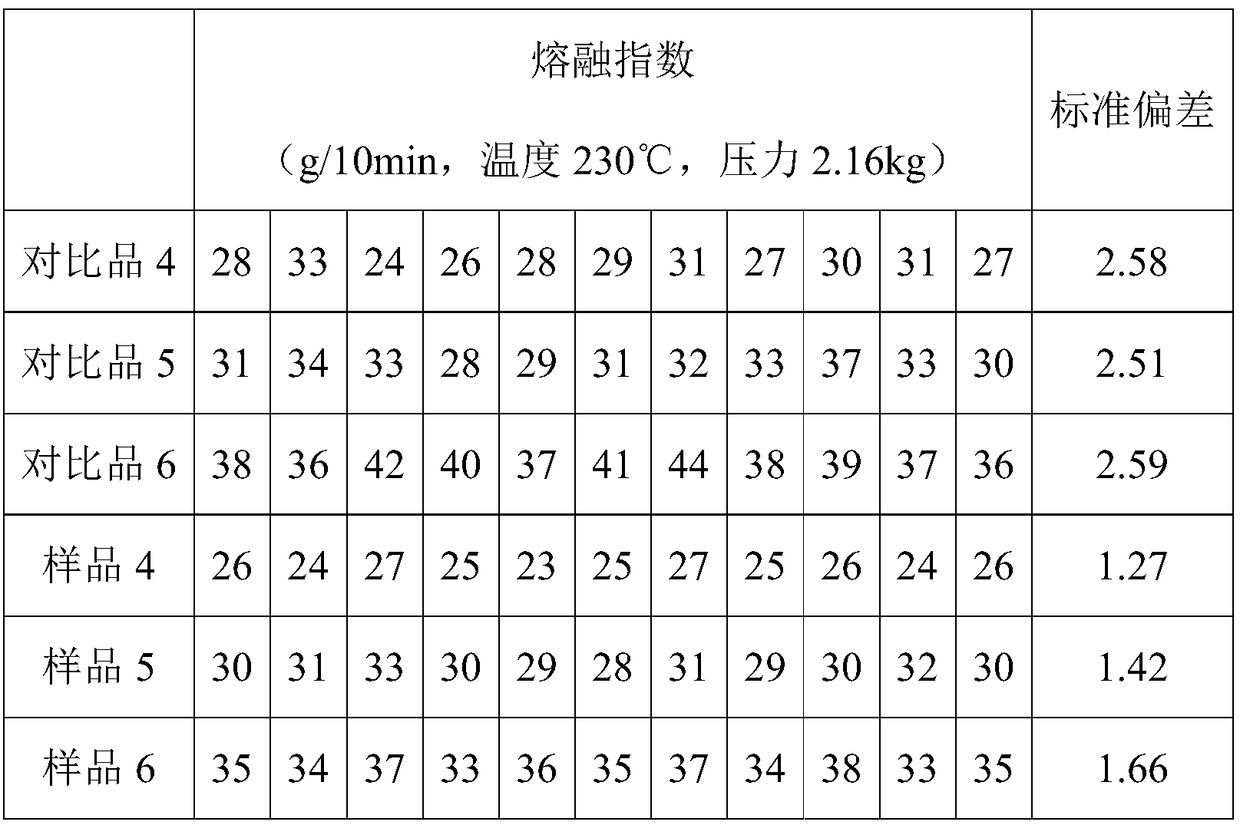

Functional polyolefin solid degradation agent

The invention relates to a functional polyolefin solid degradation agent and belongs to the technical field of degradation agents. The functional polyolefin solid degradation agent is prepared from the following components in parts by weight: 30 to 70 parts of polypropylene, 5 to 20 parts of peroxide, 10 to 30 parts of an antioxidant, 5 to 15 parts of a smoothening agent / antistatic agent and 5 to15 parts of an acid cleaning agent, wherein peroxide is at least one of di-tert-pentyl peroxide, 2,5-dimethyl-2,5bis(tert-butylperoxyl)hexane and dicumyl peroxide. A high-melting-index polypropylene product produced by the functional polyolefin solid degradation agent has narrow molecular weight distribution and also has excellent anti-oxidization performance; the oxidative induction time of a product is greater than 8min when the temperature is 200 DEG C.

Owner:DALIAN XINGHUI CHEM

Method for measuring grease oxidation induction time based on screen printing modified electrode

ActiveCN106596670AEasy to makeLow costMaterial electrochemical variablesDisturbance voltageSupporting electrolyte

The invention relates to a method for measuring grease oxidation induction time based on a screen printing modified electrode. The method comprises the following steps: carbon paste, silver paste, graphene, pyridine ionic liquid and carbonitride construct a screen printing modified electrode three-electrode measurement system; a support electrolyte solution is used for diluting to-be-measured grease, disturbance voltage and frequency are adjusted, AC impedance spectroscopy is measured and recorded; impedance value of the solution is obtained through an equivalent circuit of impedance spectroscopy; and through a bitangent method, the grease oxidation induction time can be obtained in a rapid, convenient and accurate mode. Compared with the current measurement method and the measurement system, the method has the advantages of simple process, convenient usage and low cost, enables on-site instant and accurate measurement of the grease oxidation induction time, and provides good base for automation and miniaturization for grease detection.

Owner:JIANGNAN UNIV

Antioxidant additive composite

InactiveCN102206532BGood high temperature oxidation resistanceRaise the initial oxidation temperatureAdditivesBismuth compoundInternal combustion engine

The invention discloses an antioxidant additive composite, belonging to the technical field of lubricating oil. The antioxidant additive composite consists of the following compounds in parts by weight: 0.1-1 part of bismuth compound and 0.05-3 parts of arylamine compound. After the antioxidant additive composite is added into lubricating oil, the initial oxidation temperature and oxidation induction time of the lubricating oil can be greatly increased, and the high-temperature antioxidant property of the lubricating oil can be greatly improved. The antioxidant additive composite can be widely applied to various lubricating oil products including basic lubricating oil or finished lubricating oil, such as internal combustion engine oil, gear oil and the like.

Owner:中国人民解放军徐州空军学院

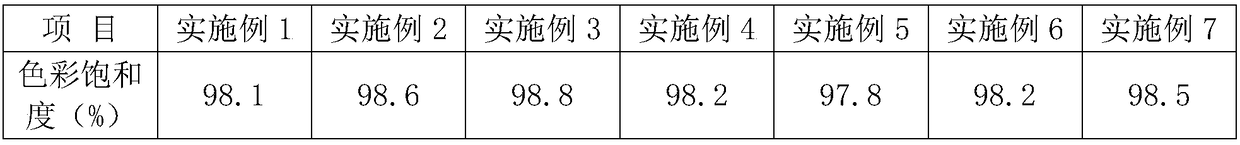

Special compounded level marking line color master batch for PP-RCT cold water pipe, and preparation method thereof

The invention discloses a special compounded level marking line color master batch for a PP-RCT cold water pipe, and a preparation method thereof. Raw materials of the color master batch comprise, byweight, 75-90 parts of Yanshan Petrochemical PP-RCT3120, 6-16 parts of phthalocyanine blue 7090, 8-18 parts of an antioxidant, 9-20 parts of a processing aid and 6-15 parts of a surfactant. Compared with color master batches in the prior art, the color master batch in the invention has the characteristics of high dispersibility, high color saturation, strong coating property and good heat resistance, and makes a line have a color saturation reaching 91.5% or above; and the oxidation induction time of the line in the production process is prolonged, and reaches about 60min, so the aging resistance of the color master batch is improved, thereby the produced pipe has a long service life.

Owner:CHONGQING AOCAI NEW MATERIAL CORP LTD

New crosslinked polymer composition, power cable insulation and power cable

The present invention relates to a crosslinked polymer composition, which is obtained by crosslinking a polymer composition, which polymer composition has a melt flow rate (MFR) of at least 1.7 and comprises a polyolefin, peroxide and sulphur containing antioxidant, characterised by that the crosslinked polymer composition has an Oxidation Induction Time, determined according to ASTM-D3895, ISO / CD 11357 and EN 728 using a Differential Scanning Calorimeter (DSC), which Oxidation Induction Time corresponds to Z minutes, and comprises an amount of peroxide by-products which corresponds to W ppm determined according to BTM2222 using HPLC, wherein Z1≦Z≦Z2, W1≦W≦W2, and W≦p−270*Z, wherein Z1 is 0 , Z2 is 60, W1 is 0 and W2 is 9500, and p is 18500; and use thereof, a power cable insulation and a power cable, useful in high voltage (HV) and extra high voltage (EHV) cable applications direct current (DC) applications.

Owner:BOREALIS AG

Production method of HDPE regenerated modified material

Owner:陕西榆林协创资源再生有限公司

PPR water supply pipe tubular product

The invention provides a PPR water supply pipe tubular product which comprises the following raw materials: polypropylene resin powder, a polypropylene random copolymer, color master batch, a clay nano composite material, color masterbatch ash and an adjuvant, wherein the adjuvant comprises an antioxidant and crosslinked high density propylene; the color masterbatch ash comprises calcium carbonate and a talcum powder filler; the melt flow rate of the raw materials is 0.2-0.22 g / 10 minutes, the melt density is 0.8-0.96 g / cm3, the oxidation induction time is 110-130 minutes, the tensile strength is 35MPa, and the fracture depth rate is 600%. The PPR water supply pipe tubular product provided by the invention has good anti-pressure ability, flexibility, low-temperature resistance, high-temperature resistance and strong rapid crack propagation breaking tenacity, and the PPR water supply pipe tubular product is better in pressure resistance as a result of the added color masterbatch ash and the clay nano composite material.

Owner:GUANGXI JINTAN PIPE IND TECH CO LTD

Polyethylene composition used for geomembrane

InactiveCN109575408AIncrease stressImprove aging resistanceLinear low-density polyethylenePolymer science

The invention discloses a polyethylene composition used for a geomembrane. The composition includes, by mass, the following components: 70-90 parts of high-density polyethylene resin, 10-30 parts of linear low-density polyethylene resin, 0.1-0.4 part of a main antioxidant, 0.1-0.4 part of an auxiliary antioxidant, and 0.1-0.2 part of a lubricant. The polyethylene composition used for the geomembrane of the invention has excellent performance of stress cracking resistance and aging resistance, stress cracking under tensile load (NCTL) time is more than 2000 h, the oxidation induction time is more than 100 minutes, and production and use requirements of downstream users can be satisfied well.

Owner:SINOPEC YANGZI PETROCHEM +1

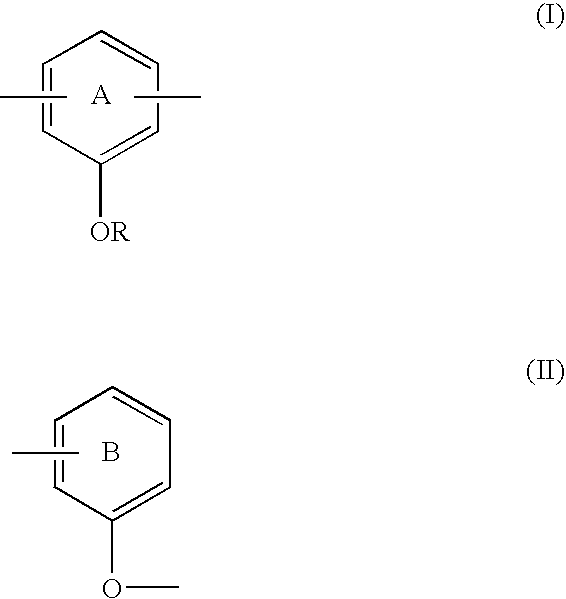

Thiobis phenolic antioxidant/polyethylene glycol blends

InactiveUS8691904B2Higher oxidative induction timeMeasurement stabilityPlastic/resin/waxes insulatorsThin material handlingPolyethylene glycolPhenolic antioxidant

Thiobis phenolic antioxidants are efficiently dry or melt blended with a tree-resistant, crosslinkable polyethylene by first forming a blend, preferably a dry blend, of the antioxidant with a polyalkylene glycol (PAG), and then mixing the blend with the polyethylene. The incorporation of thiobis phenolic antioxidant and PAG blend into polyethylene provides the PE with high oxidative induction time (OIT) which is a measure of the oxidative stability of the PE.

Owner:UNION CARBIDE CORP

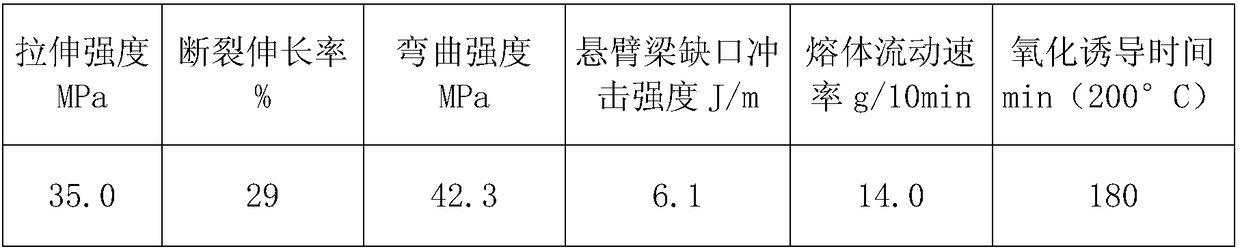

Anti-aging geocell material and preparation method thereof

The invention discloses an anti-aging geocell material. The high-density polyethylene material is prepared from the following raw materials in parts by weight: 70 to 85 parts of high-density polyethylene, 7 to 16 parts of ethylene-vinyl acetate copolymer, 2 to 6 parts of basalt fiber, 3 to 8 parts of nano zinc oxide, 0.2 to 1 part of ultraviolet absorbent, 0.3 to 1 part of antioxidant, 2 to 6 parts of interfacial compatibilizer and 0.3 to 1 part of processing aid. The ultraviolet absorbent is at least one of a hindered amine ultraviolet absorbent, benzotriazole UVP and dihydroxy benzophenone UV531; the antioxidant is a mixture of a hindered phenol main antioxidant and a phosphite ester auxiliary antioxidant, and the mass ratio of the hindered phenol main antioxidant to the phosphite esterauxiliary antioxidant is 1:(0.2-0.4). The aging-resistant geocell material disclosed by the invention is long in oxidation induction time and excellent in aging resistance; the tensile strength is high and the mechanical property is good. The geocell material is high in cantilever beam notch impact strength and good in impact resistance, is high in the bending modulus and has good comprehensive mechanical property.

Owner:哈尔滨金蜂巢工程材料开发有限公司

A new crosslinked low MFR polymer composition, power cable insulation and power cable

Owner:BOREALIS AG

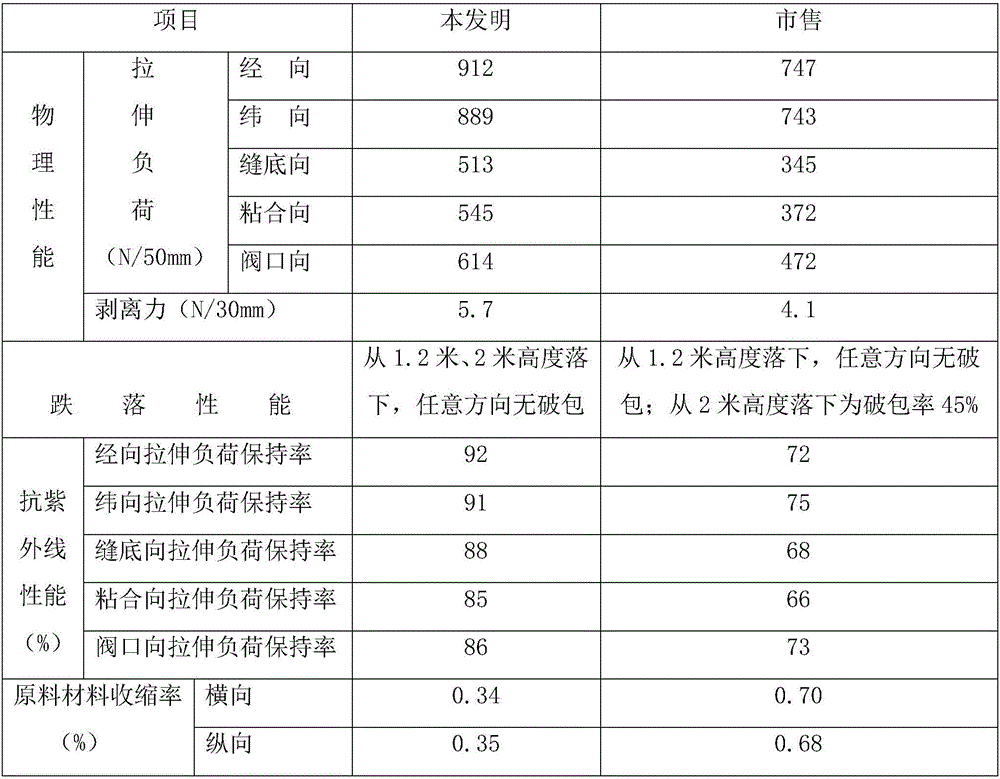

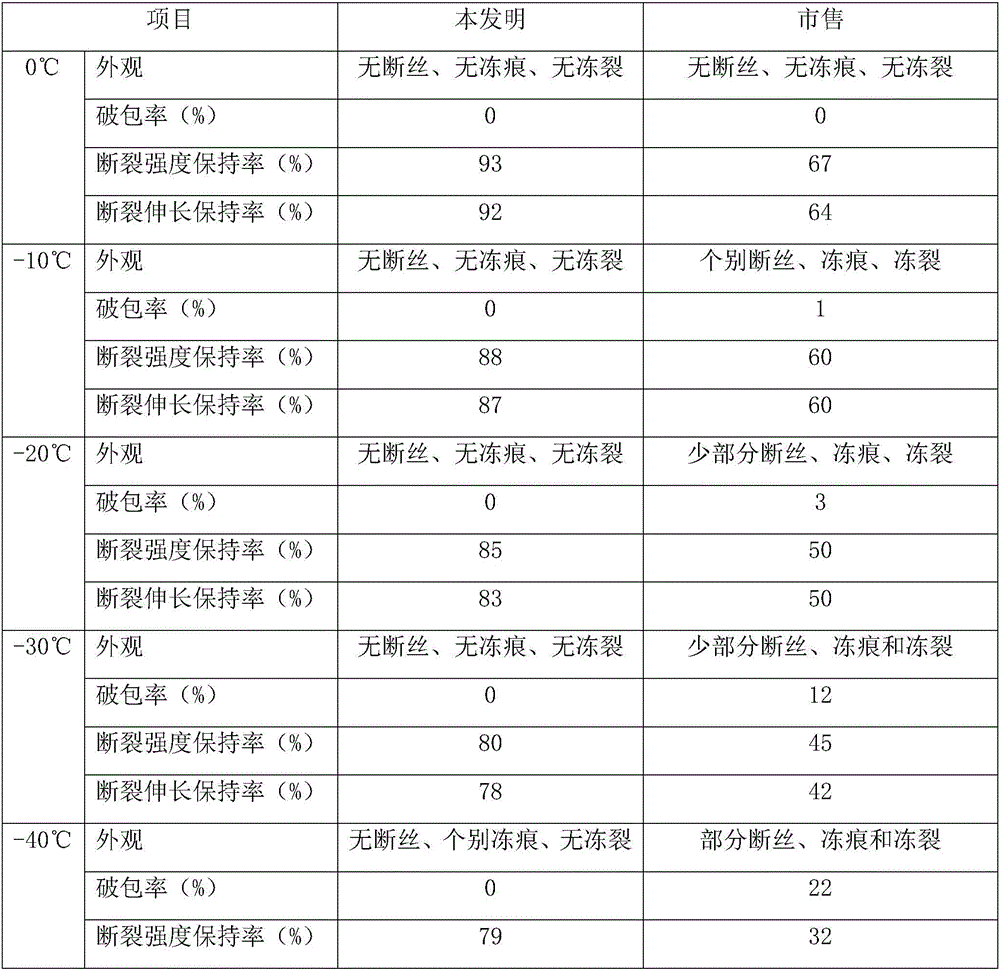

Antioxidative plastic woven bag and preparation method thereof

InactiveCN106496767ANot volatileImprove antioxidant capacityFatty-oils/fats refiningFatty-oils/fats productionFiberShock resistance

The invention discloses an antioxidative plastic woven bag. According to the invention, polypropylene is used as a base material, the varieties and formula of master batch raw materials are optimized, production technology is improved, and a composite anti-oxidant containing bitter apricot kernel oil (rich in vitamin E) is scientifically compounded; the antioxidative plastic woven bag employs modified nano-carbon capable of substantially improving the high-temperature resistance, contraction resistance, relative tensile load, strength, toughness and elastic modulus of the plastic woven bag; the antioxidative plastic woven bag also employs Cerasus humilis fiber capable of substantially improving the shock resistance of the plastic woven bag and reducing production cost and easy to biodegrade, a polyethylene / winter rye peptide compound capable of greatly improving the low-temperature resistance of the plastic woven bag, and the bitter apricot kernel oil capable of effectively enhancing the lubricity and inoxidizability of the plastic woven bag; and preparation raw materials for the antioxidative plastic woven bag have a long oxidation induction period, and the oxidation induction time is decreased by 58.33% compared with a commercially-available antioxidative modified polypropylene material. The prepared antioxidative plastic woven bag has substantial antioxidation performance and anti-aging performance, good weatherability, good environmental suitability and long service life.

Owner:吴忠市富林塑料包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com