Refrigerator oil composition

A refrigeration oil and composition technology, applied in lubricating compositions, petroleum industry, additives, etc., to achieve the effect of prolonging the oxidation induction period and excellent oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

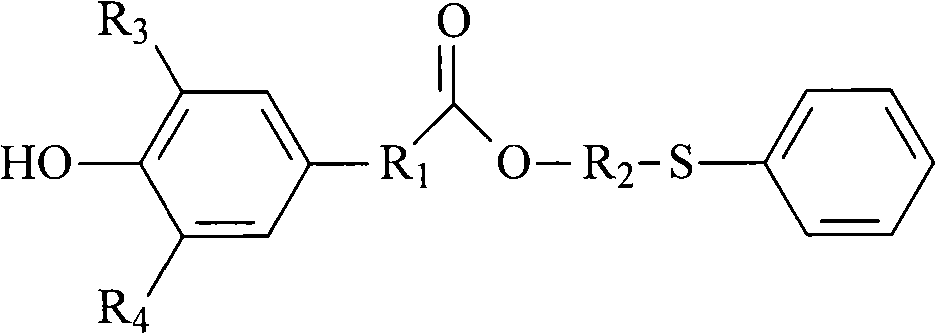

AI Technical Summary

Problems solved by technology

Method used

Image

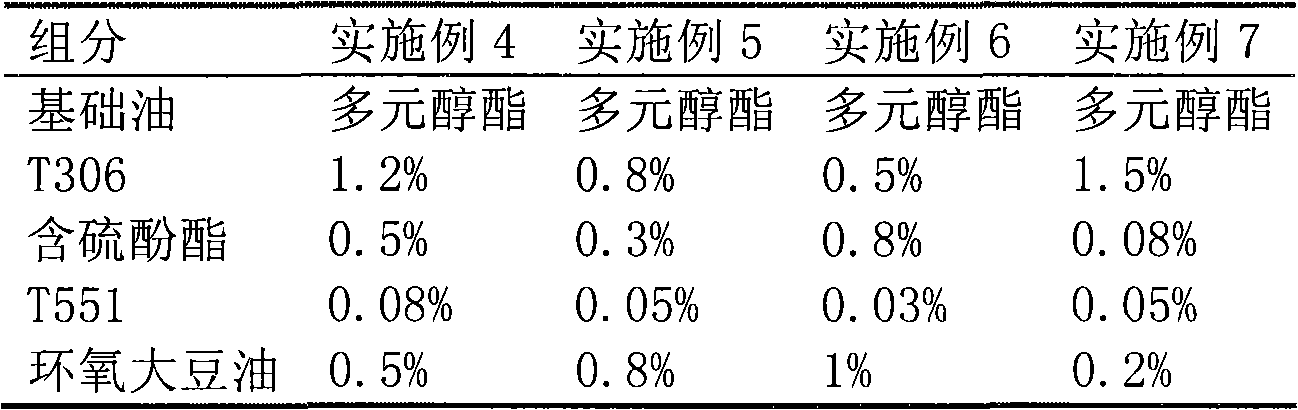

Examples

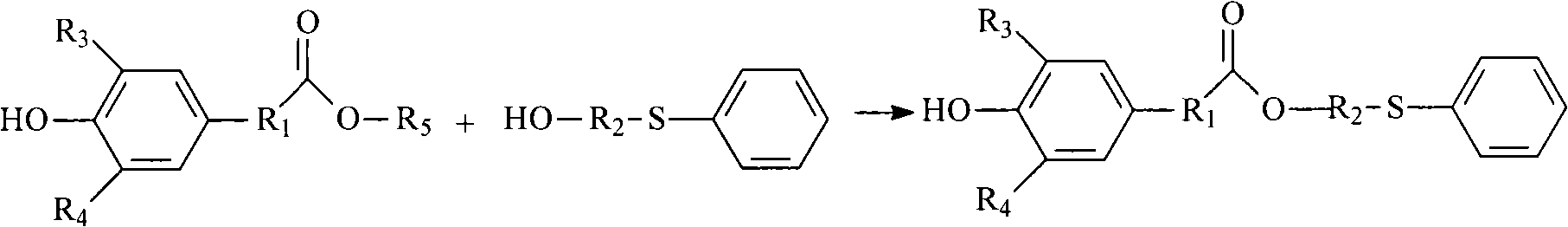

Embodiment 1

[0034] Put 0.2mol (30.8g) of phenylthioethanol and 0.24mol (70.08g) of (3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate into a 250ml three-necked reaction flask, add 0.4gLiOH Catalyst, stirring, heating. The pressure was reduced to 0.02Mpa, the temperature was 120°C, and the reaction was carried out for 3 hours. A viscous substance was obtained, light brown in color. The temperature was raised to 260°C, and unreacted raw materials were removed by distillation under reduced pressure. A brown-red transparent viscous liquid was obtained. The product conversion was 83.6%.

Embodiment 2

[0036] Put 0.2mol (30.8g) of phenylthioethanol and 0.24mol (70.08g) of (3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate into a 250ml three-necked reaction flask, add 0.8gLiOH Catalyst, stirring, heating. The pressure was reduced to 0.085Mpa, the temperature was 180°C, and the reaction was carried out for 5 hours. A viscous substance was obtained, light brown in color. The temperature was raised to 260°C, and unreacted raw materials were removed by distillation under reduced pressure. A brown-red transparent viscous liquid was obtained. Product conversion was 95.1%.

Embodiment 3

[0038] Put 0.2mol (30.8g) of phenylthioethanol and 0.24mol (70.08g) of (3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate into a 250ml three-necked reaction flask, and add 1g of LiOH catalyst , stir and heat. The pressure was reduced to 0.005Mpa, the temperature was 160°C, and the reaction was carried out for 8 hours. A viscous substance was obtained, light brown in color. The temperature was raised to 260°C, and unreacted raw materials were removed by distillation under reduced pressure. A brown-red transparent viscous liquid was obtained. Product conversion was 95.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com