Patents

Literature

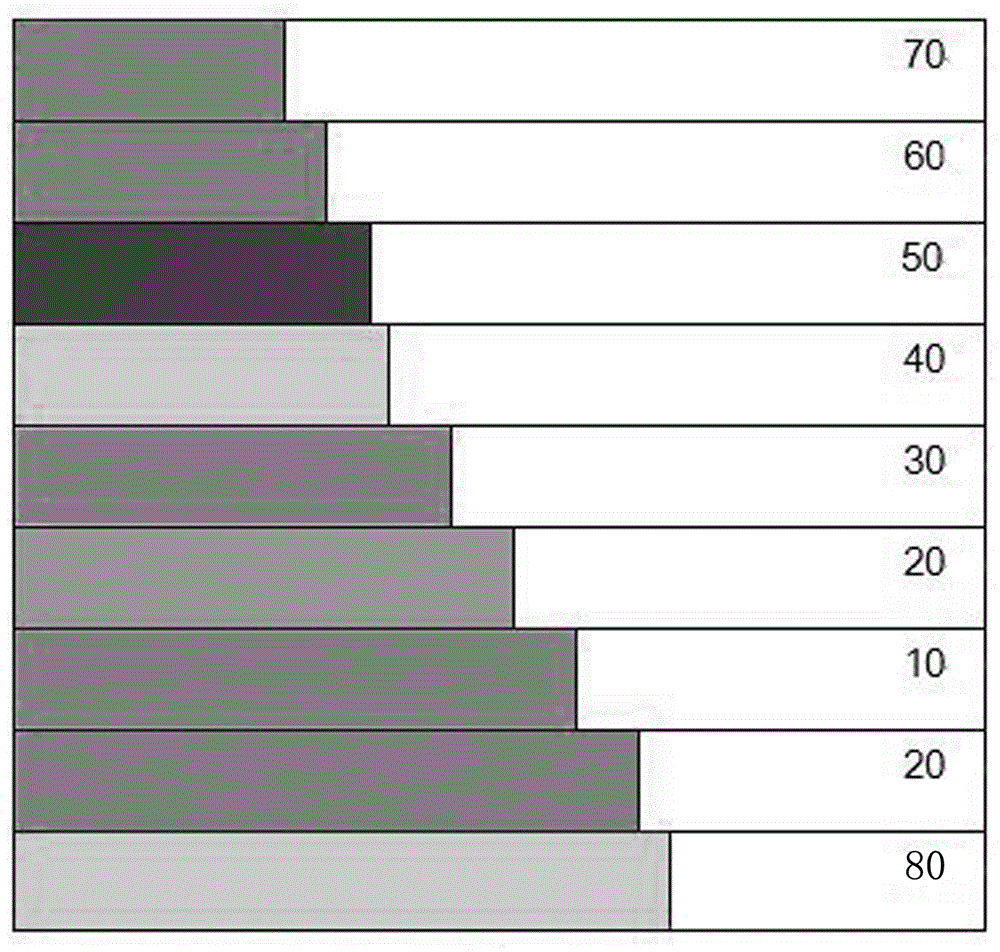

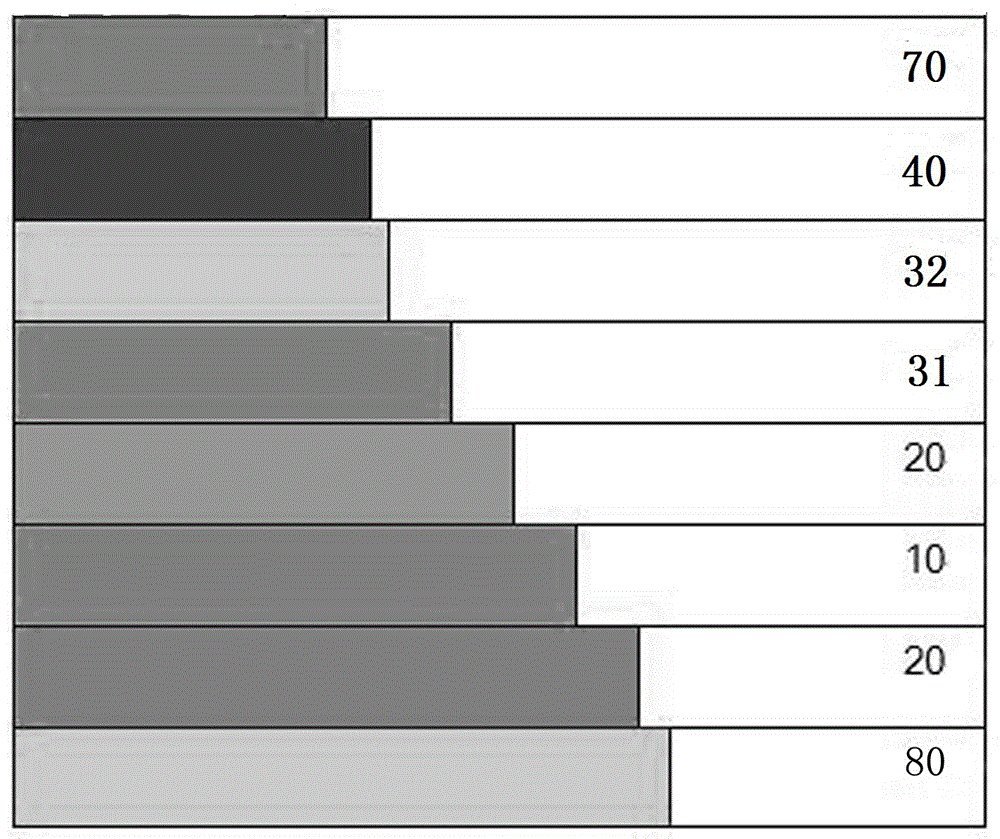

32results about How to "Suitable for cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal cutting solution of green semi-synthesis double-base oil and preparation method thereof

InactiveCN101531946ASuitable for cuttingSuitable for grindingBase-materialsFoaming agentActive agent

The invention relates to a metal cutting solution of green semi-synthesis double-base oil, which comprises the following components in percentage by weight: 0 to 30 percent of mineral oil, 0 to 30 percent of synthetic ester, 5 to 10 percent of anionic surfactant, 5 to 10 percent of non-ionic surfactant, 5 to 15 percent of anti-rust agent, 0 to 15 percent of extreme pressure agent, 1 to 3 percent of de-foaming agent and 0 to 2 percent of bactericide, and the balance being water. A preparation method for the metal cutting solution comprises the following steps: firstly, heating the mineral oil to about 50 DEG C, adding the synthetic ester into the mineral oil, and stirring the mixture evenly to form a double-base oil system; and then adding the anti-rust agent, the extreme pressure agent, the de-foaming agent and the bactericide into the water respectively, and using the anionic surfactant and the non-ionic surfactant to regulate the system to balance so as to form the metal cutting solution of the green semi-synthesis double-base oil. Because the synthetic ester is added in the preparation process to form the double-base oil system, the biodegradability, oxidative stability and flash point are improved; and the method meets the requirement of environmental protection, and is applicable to cutting, grinding and processing various mechanical parts.

Owner:SHANGHAI INST OF TECH

Method for preparing jade type microcrystalline glass with high-temperature furnace slag

The invention discloses a method for preparing jade type microcrystalline glass with high-temperature furnace slag, which comprises the steps of: taking molten furnace slag as main materials; adding auxiliary materials such as fluxing clarifying agent and additive, and the like; further melting and clarifying in a high-temperature furnace to form glass liquid; pouring or calendaring the glass liquid to form basic glass; heat processing the basic glass by means of crystallization to obtain the rough product of the jade type microcrystalline glass; and finish machining to obtain the finished product of the jade type microcrystalline glass. The method not only effectively utilizes the molten high-temperature furnace slag, but also sufficiently utilizes heat energy stored in the high-temperature furnace slag, and prevents the high-temperature furnace slag from generating huge amounts of corrosive hot steam in the process of discharging. The jade type microcrystalline glass prepared by the method is in the status of semitransparent wax, exactly looks like natural jade, has good cutting performance, high intensity and good tenacity, can be used for replacing natural stones in construction industry, and can be used for replacing natural rare jades in machining artware.

Owner:TSINGHUA UNIV

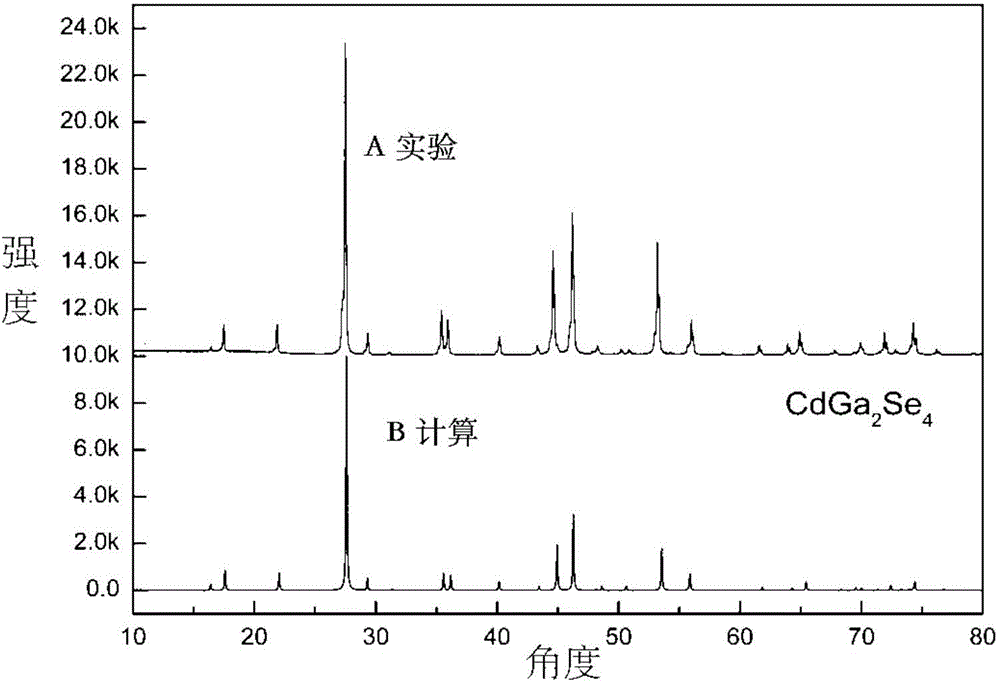

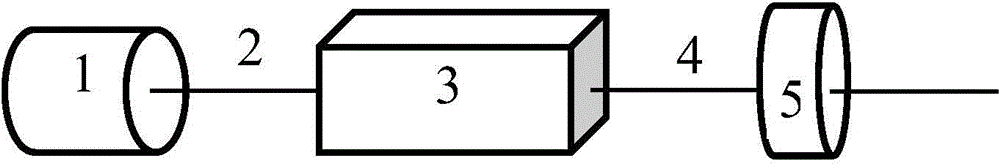

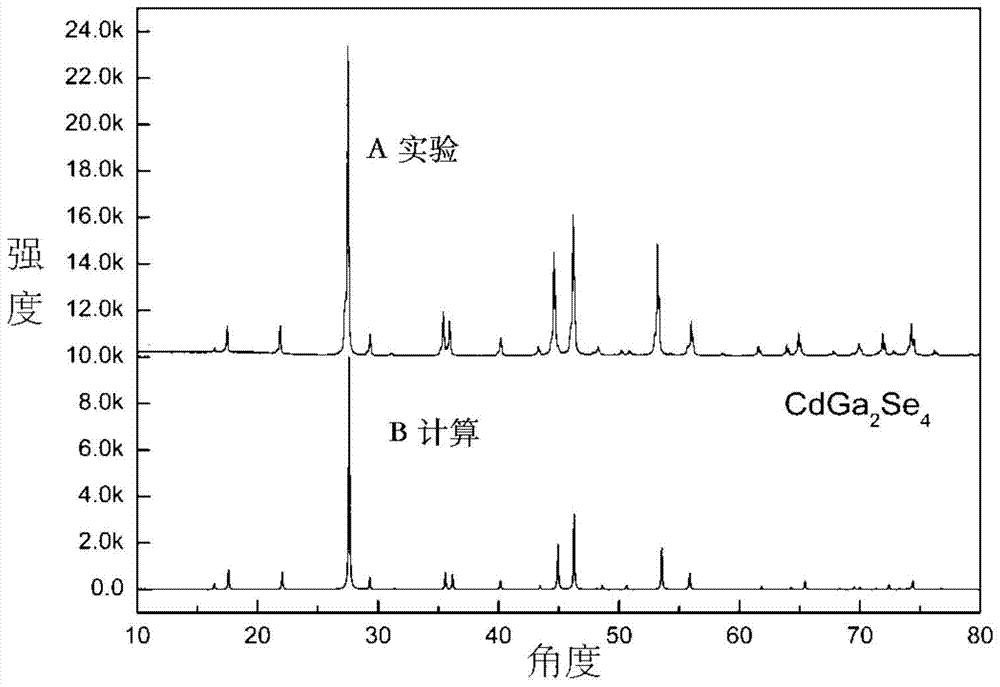

Long wave infrared nonlinear CdGa2Se4 crystal as well as growth method and use of crystal

ActiveCN104695022AImprove mechanical propertiesStable chemical propertiesPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationLong wave infrared

The invention relates to a long wave infrared nonlinear CdGa2Se4 crystal as well as a growth method and the use of the crystal. The CdGa2Se4 polycrystal material is synthesized by virtue of a high-temperature solid-phase reaction; the long wave infrared nonlinear CdGa2Se4 crystal is grown by use of a spontaneous nucleation Bridgman-Stockbarger method or an oriented seed crystal assisted Bridgman-Stockbarger method; the frequency doubling effect of the obtained nonlinear optical CdGa2Se4 crystal powder is about three times of that of AgGaS2, and the transparent waveband of the infrared region of the CdGa2Se4 crystal powder is capable of reaching long wave infrared 21 microns; besides, the CdGa2Se4 crystal powder is good in mechanical properties, stable in chemical properties, not prone to deliquescence, and suitable for orientation, cutting and polishing. The long wave infrared nonlinear CdGa2Se4 crystal is applicable to manufacturing infrared nonlinear optical devices.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

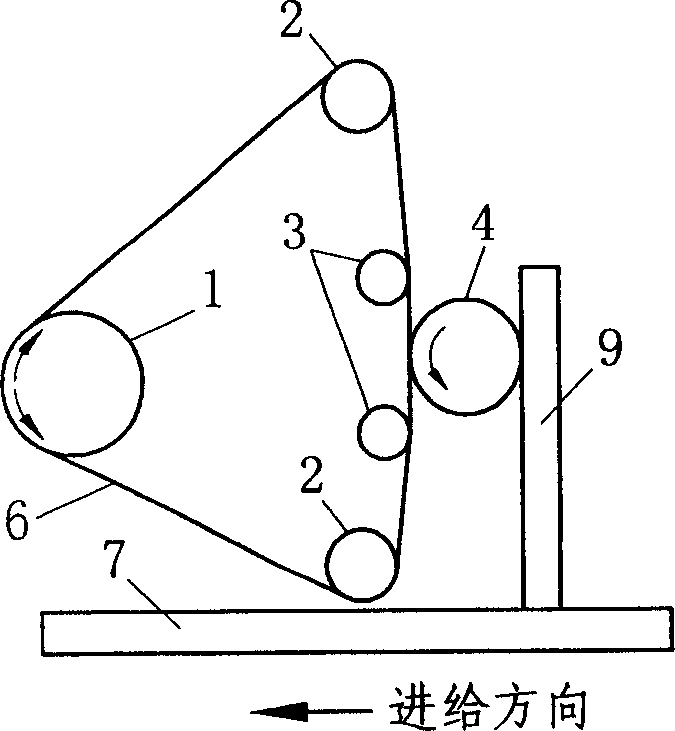

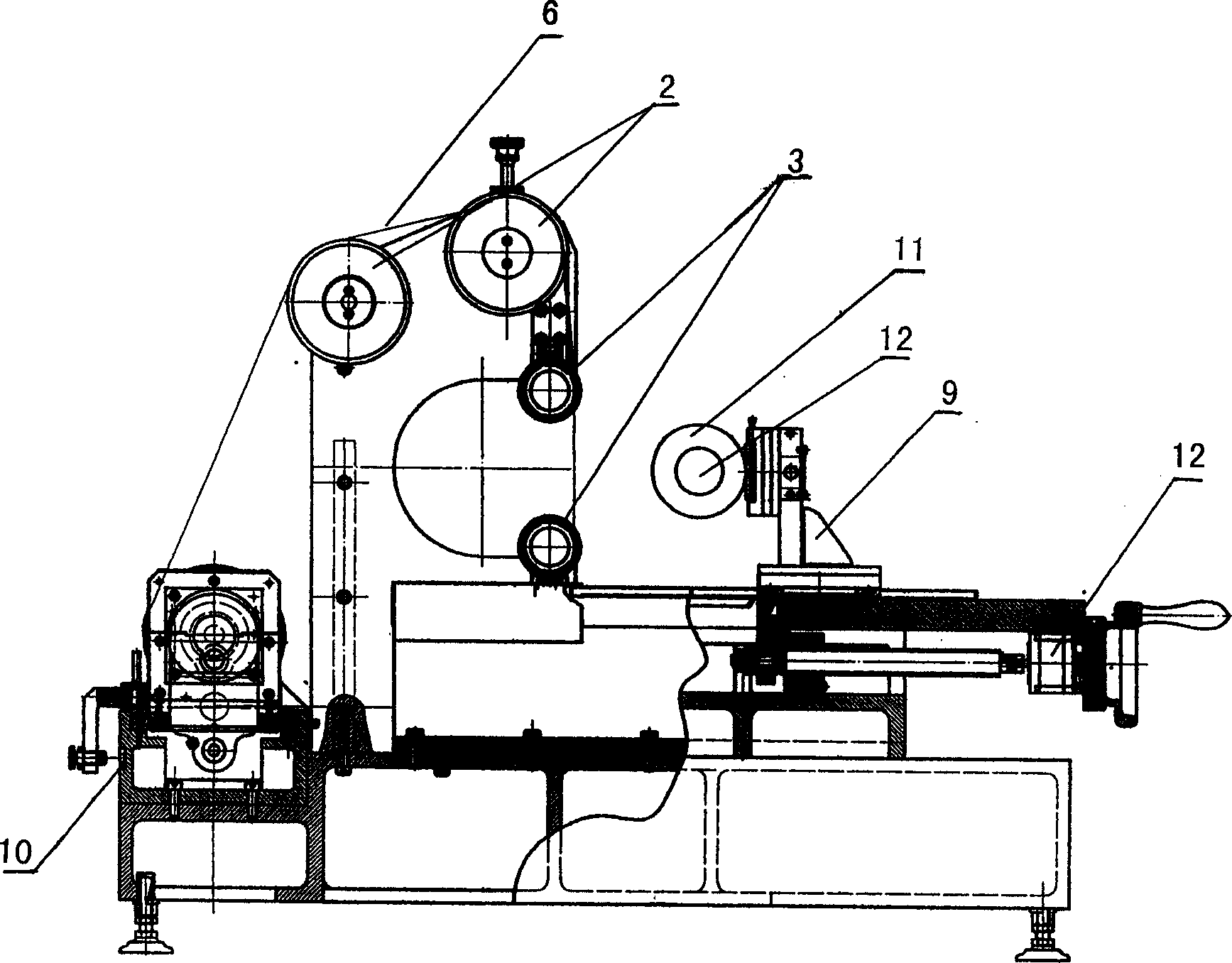

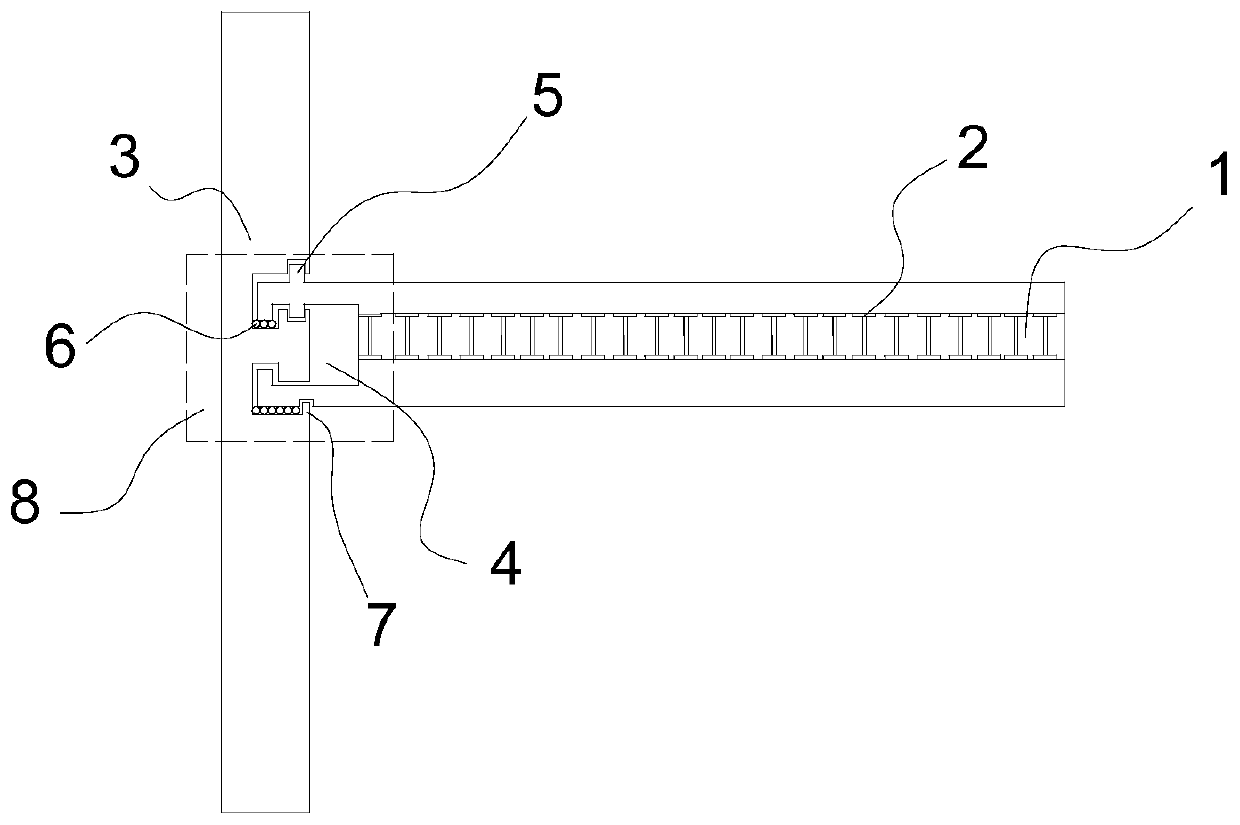

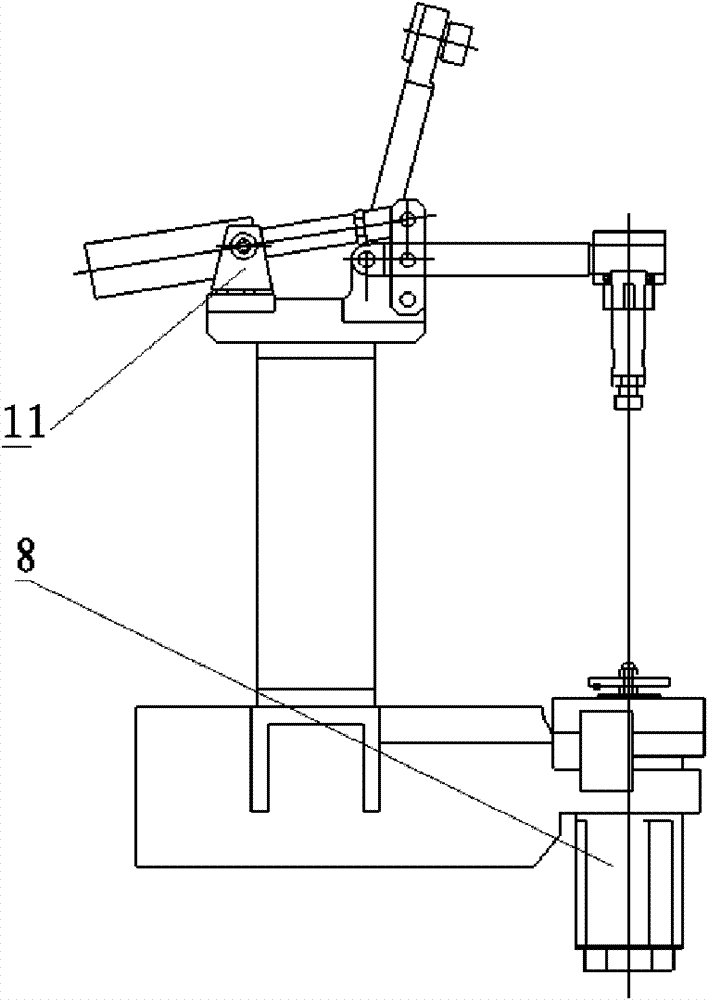

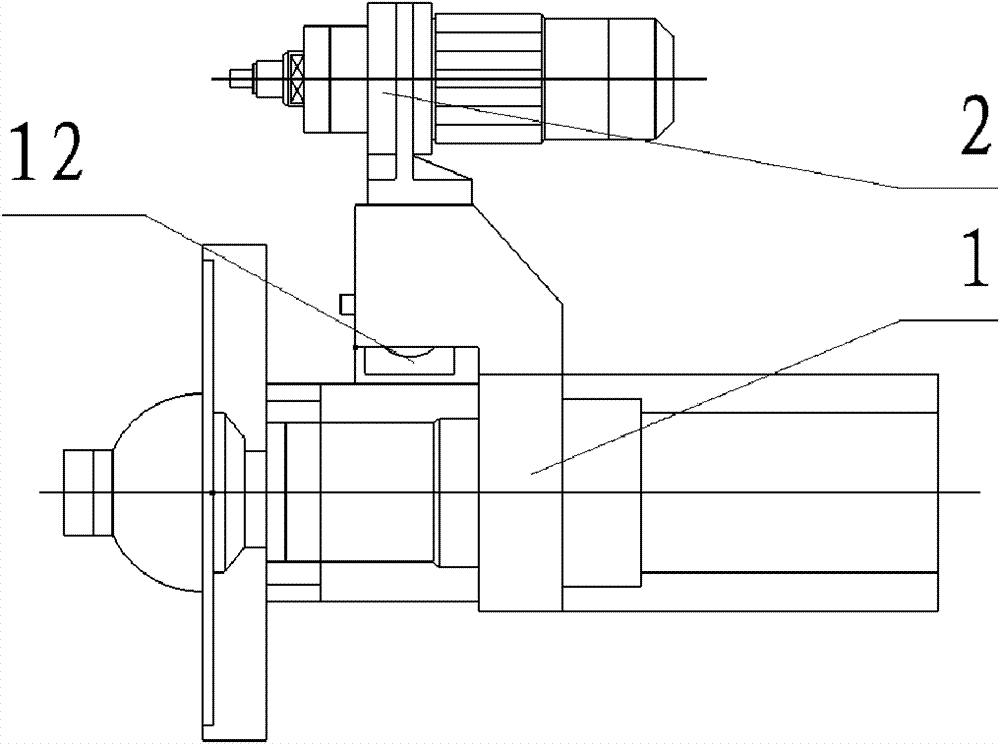

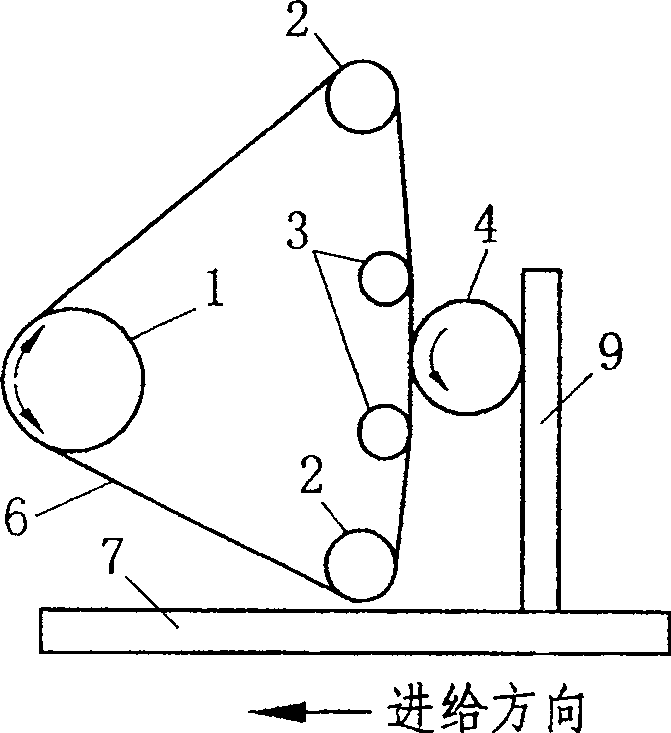

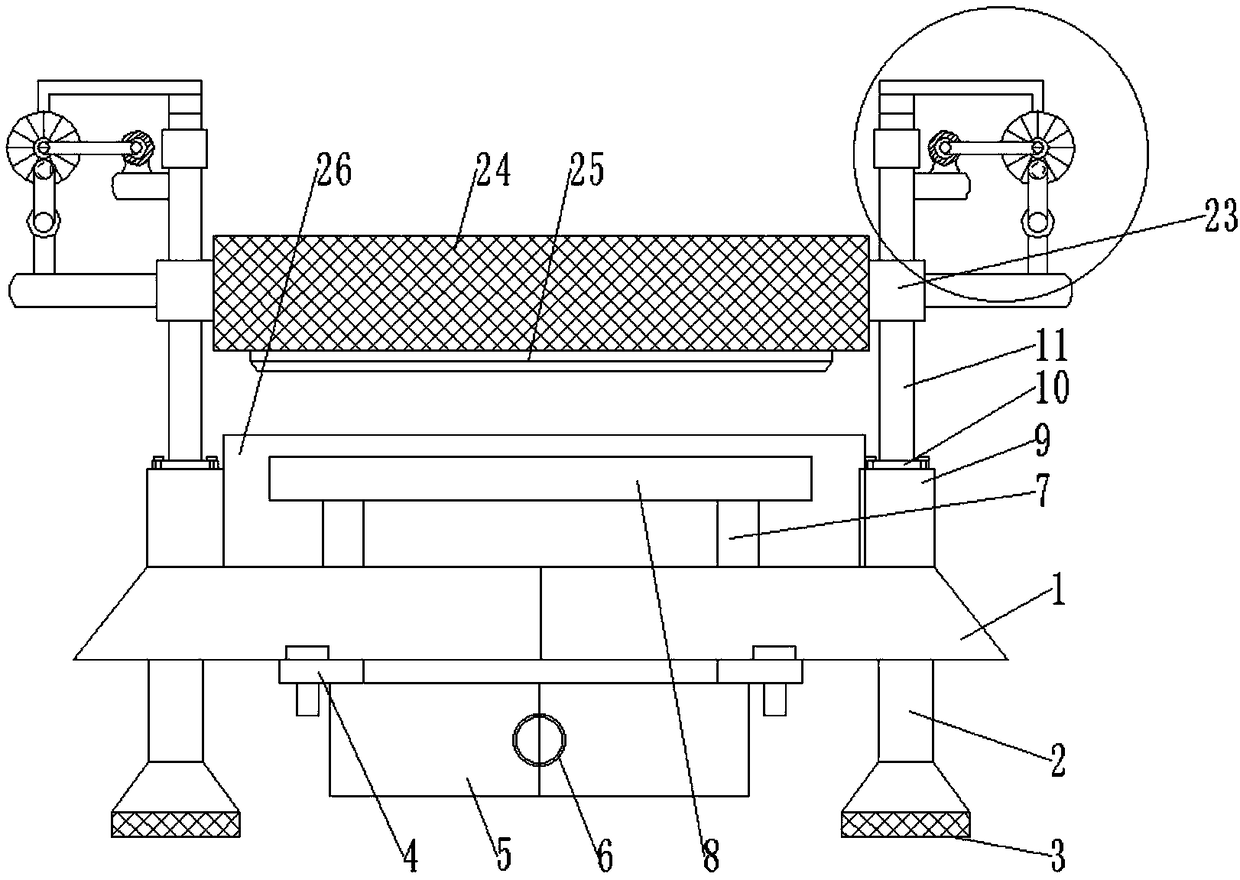

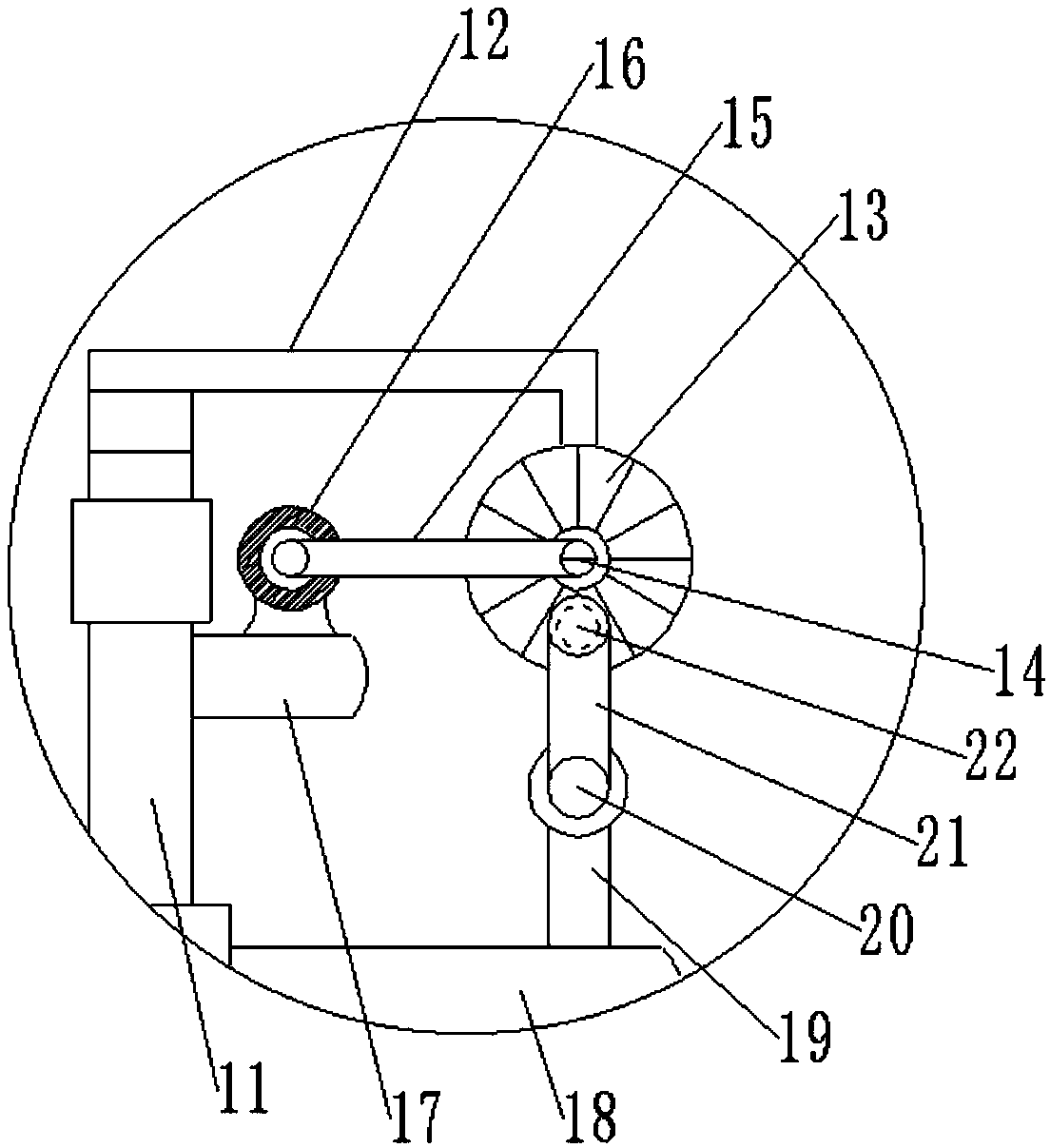

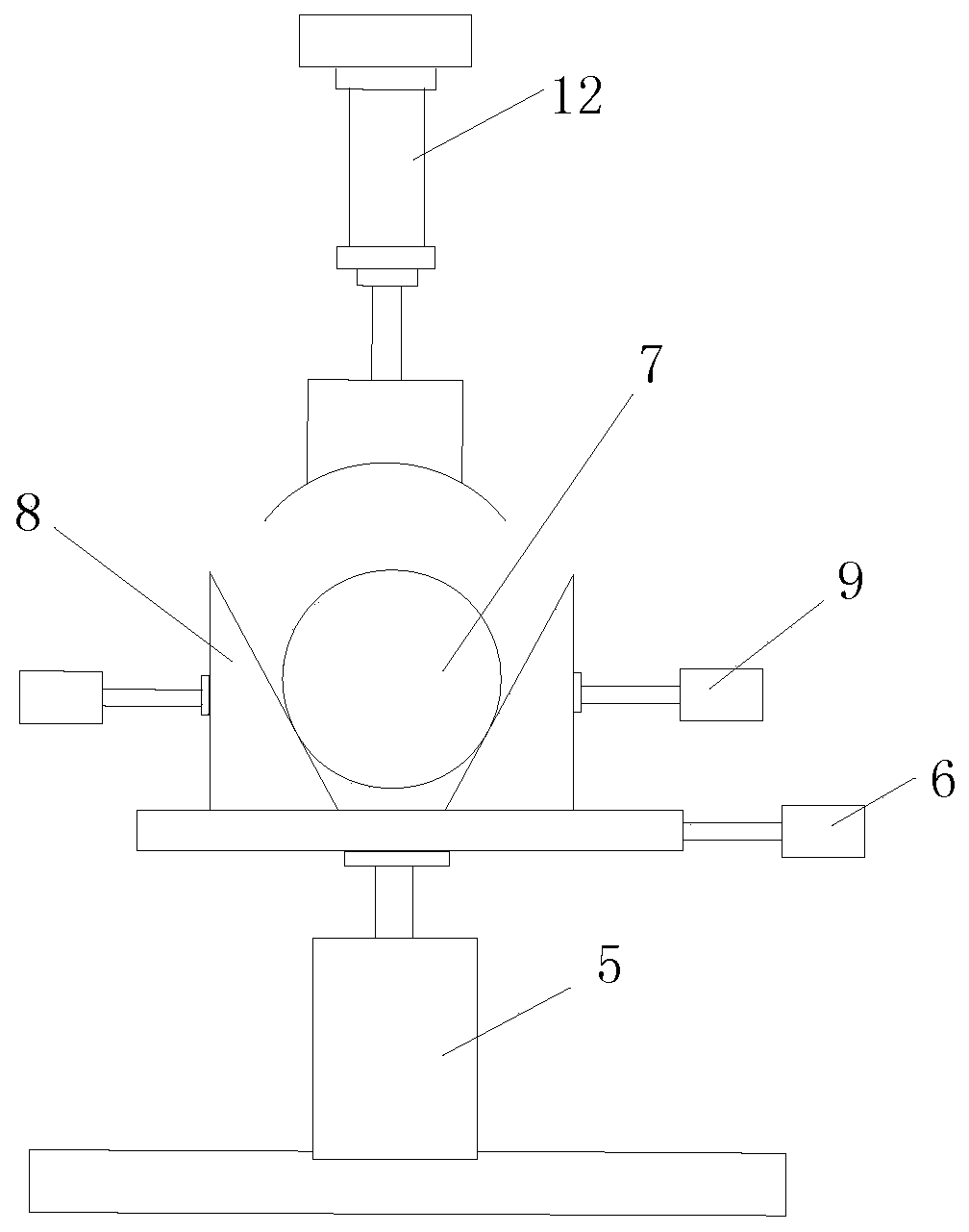

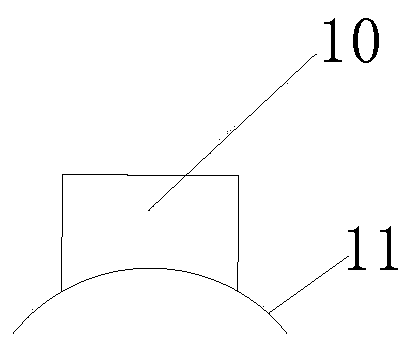

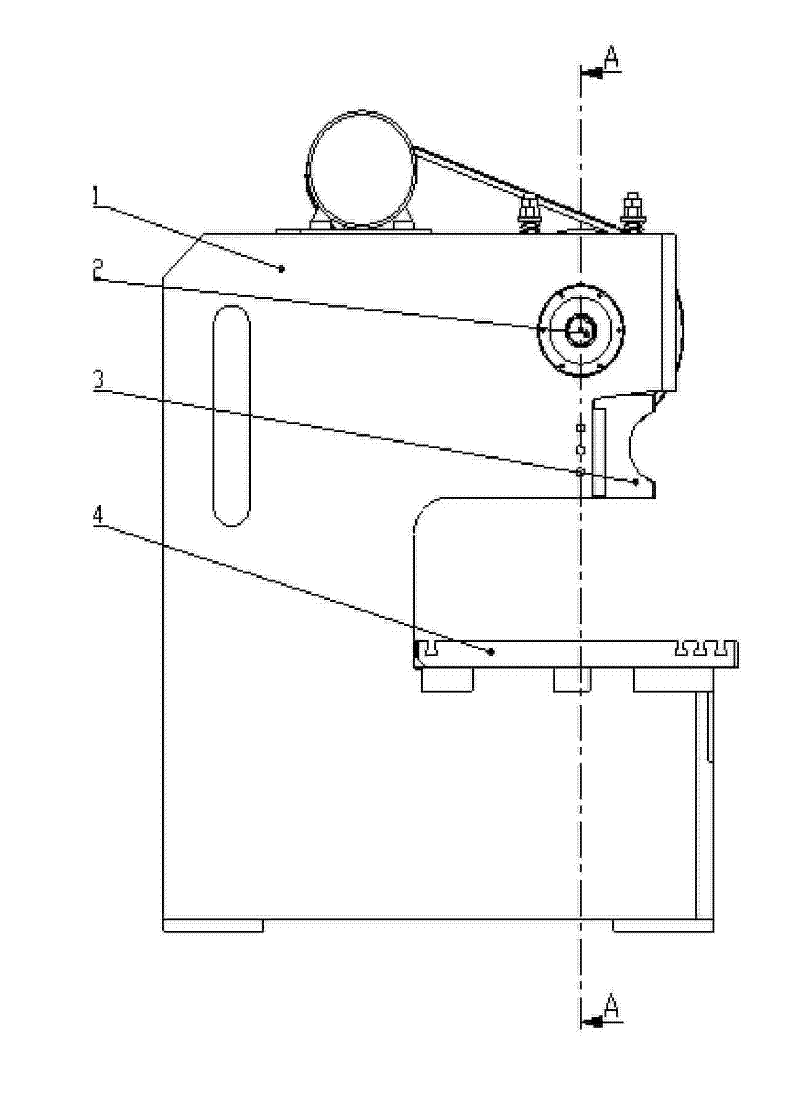

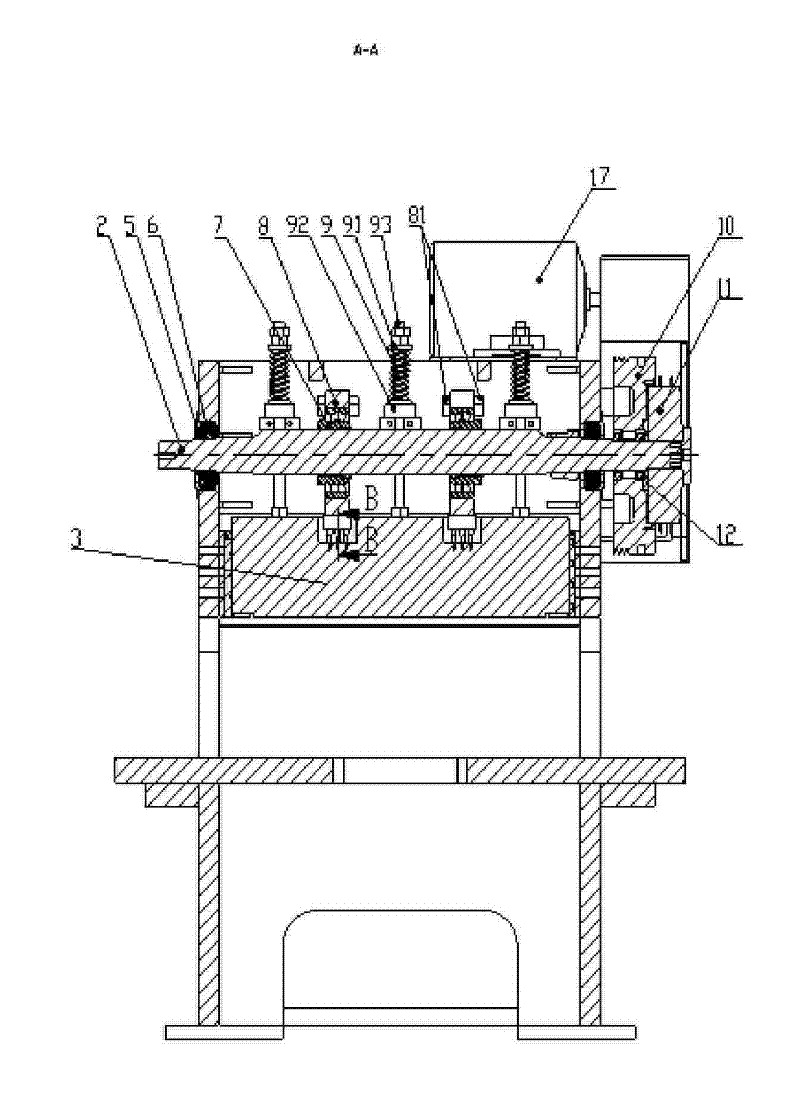

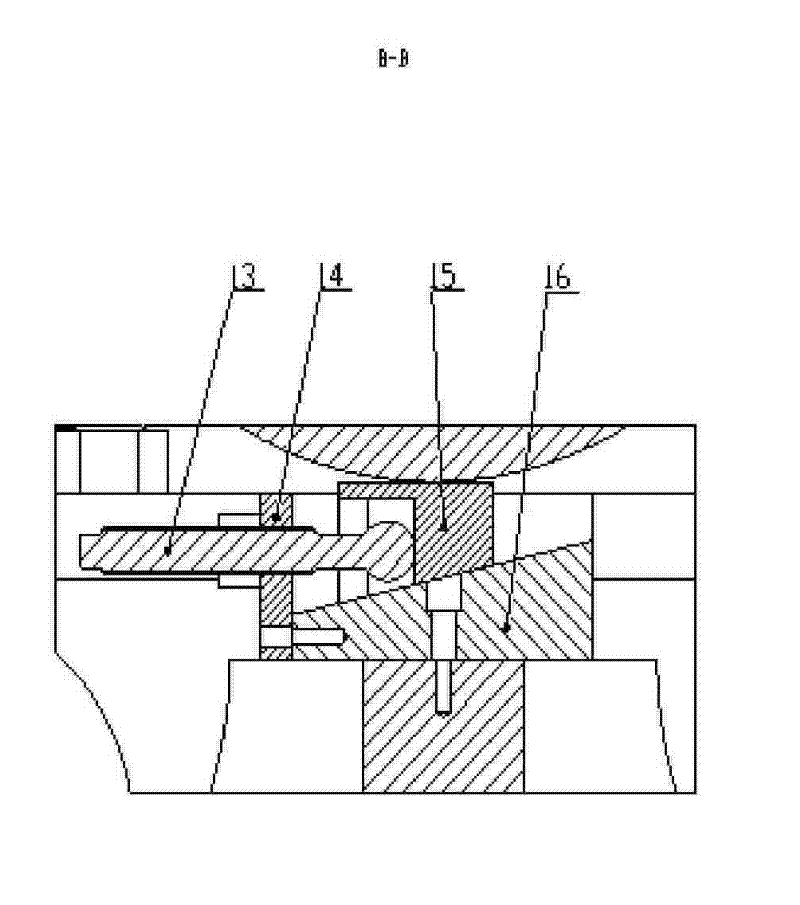

Apparatus for rotating point cutting large size silicon-carbide crystal

InactiveCN1724234AGuaranteed not to shakeIncrease cutting spaceFine working devicesStone-like material working toolsMaterials processingManipulator

An apparatus for cutting large-size SiC crystal by the moving dots is composed of base, sensor, sawing diamond string, pneumatic tension roller, working rollers, DC servo motor and 2D fixture mechanism consisting of rotary manipulator and step motor. A horizontal angle regulating turn-table is linked on a Y-axis moving platform. A vertical angle regulating turn-table is linked on said horizontal angle regulating one. Said step motor is fixed to an adjustable supporting plate.

Owner:张革 +1

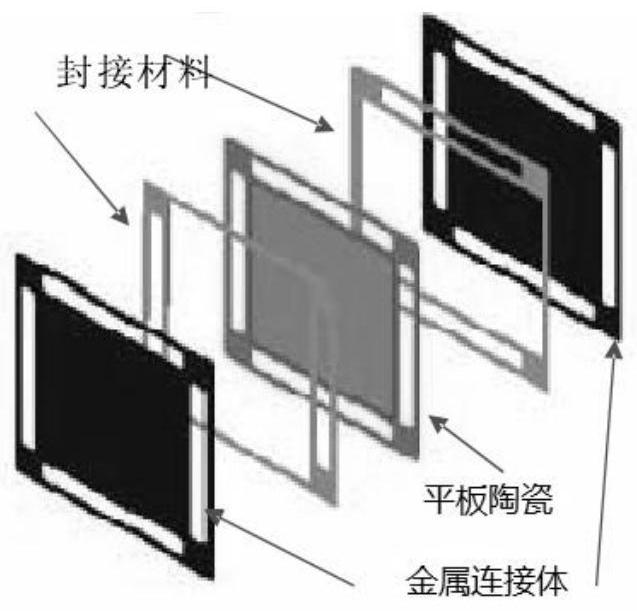

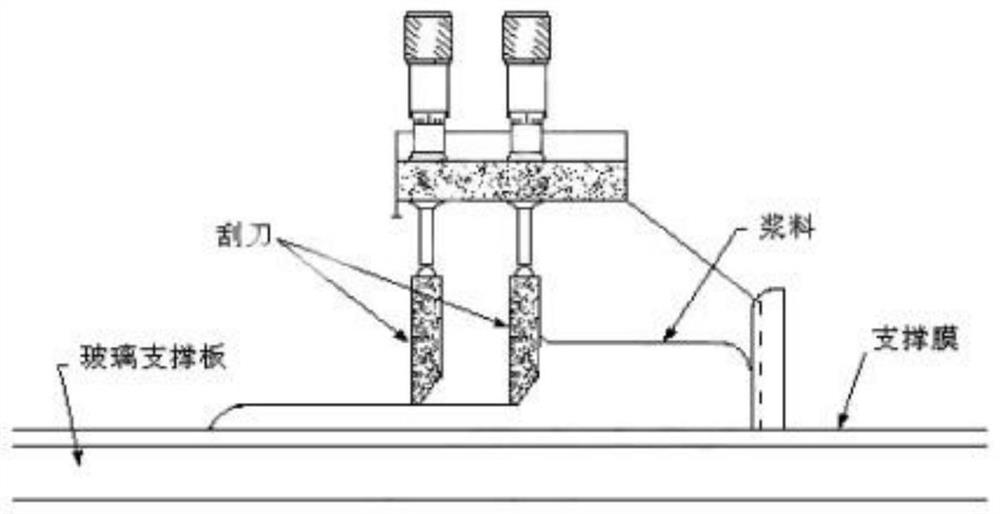

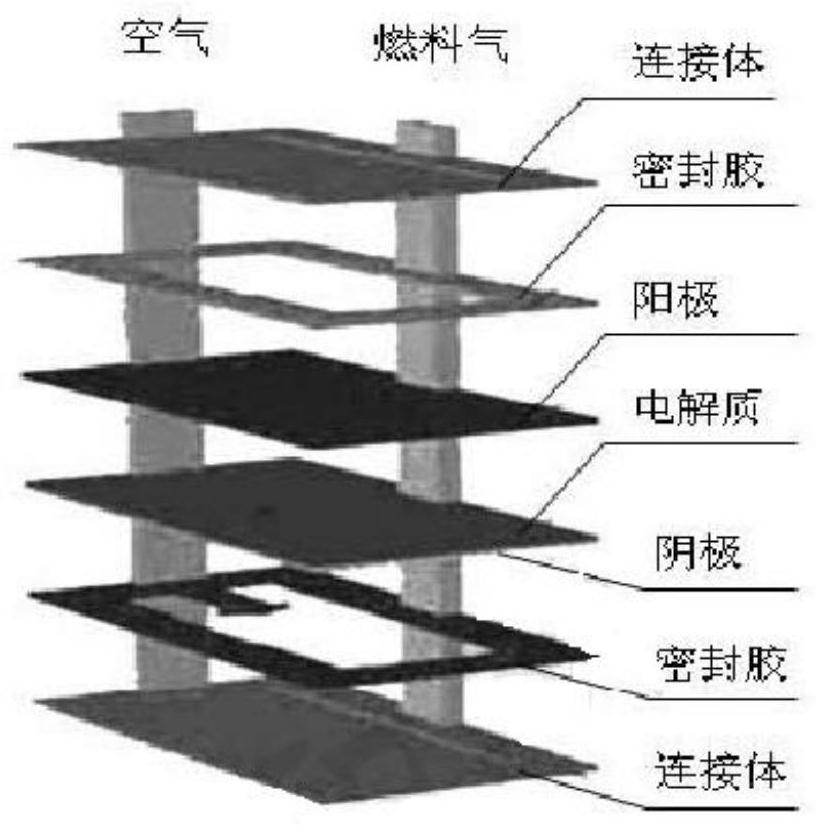

Ceramic-metal sealing ceramic chip prepared by tape casting method

The invention discloses a ceramic metal sealing ceramic chip prepared by a tape casting method. A sealing butt joint process flow comprises the following steps: (1) drying inorganic powder at 110 DEGC for 4 hours; (2) using a ball mill, weighing the powder as required, and performing crushing to obtain glass powder to be sealed; and (3) adding the prepared glass powder into a ball milling tank according to a pulping formula to prepare glass pulp. According to the ceramic metal sealing ceramic chip prepared by the tape casting method, different from the prior art, the ceramic metal sealing ceramic chip prepared by the tape casting method is suitable for high-temperature use, uniform in density, suitable for cutting and processing, good in fit plating with a plane, good in sealing propertyafter sintering and high in chemical stability in an oxidizing gas environment; and the thermal expansion amount is uniformly matched with each part of a solid oxide fuel cell, and the failure causedby local thermal expansion amount difference is avoided, so that the air tightness, the insulativity, the thermal stability and the chemical stability of the solid oxide fuel cell are greatly improved.

Owner:娄底市精细陶瓷工业技术检测中心

Straw board for floor and manufacturing method and application of straw board

PendingCN111483032AHigh strengthImprove water resistanceRadiation/waves wood treatmentNon-macromolecular adhesive additivesFiberAdhesive cement

The invention discloses a straw board for a floor and a manufacturing method and application of the straw board. The manufacturing method comprises the following steps that rice straws are cleaned upwith water, dried and crushed to obtain a straw crushed material; the straw crushed material is taken to be stir and wash in water, extruding, dehydrating and drying are conducted on the washed straws, the straw crushed material is added into sodium hydroxide solution, ultrasonic soaking at room temperature is conducted, the straw crushed material is neutral after water washing, soaking at room temperature with sulfuric acid solution is conducted after drying, and the straw crushed material is neutral after water washing; the straw crushed material is soaked into sodium silicate solution to obtain straw fibers after drying finally, a hydrophobic material and a modifier are added into the straw fibers, the obtained straw fibers are sent into a stirring-type glue sprayer, a spray gun is arranged in the stirring-type glue sprayer for glue spraying, and the straw fibers are uniformly mixed with an adhesive by stirring; and the straw fibers mixed with the adhesive are transferred into a mould press, and pre pressing and hot pressing in the mould press after paving are conducted to obtain the straw board. By means of the method, the mechanical properties of the board are improved while the application amount of the adhesive is reduced, meanwhile, the product has hydrophobicity and fireproof performance, and secondary processing molding is facilitated.

Owner:江苏禾吉新材料科技有限公司

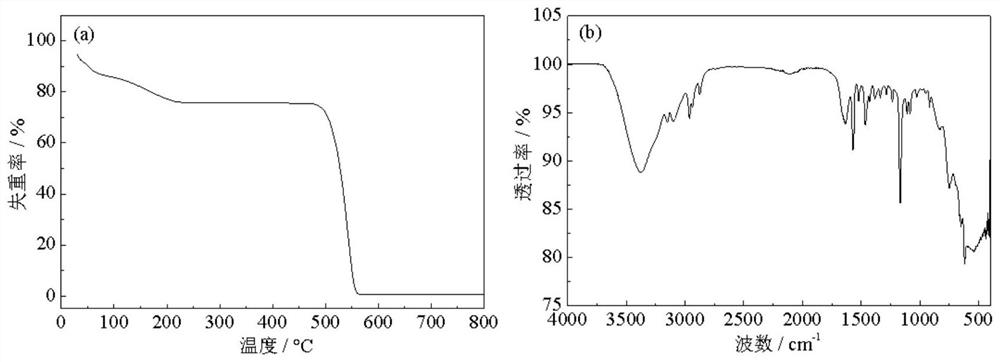

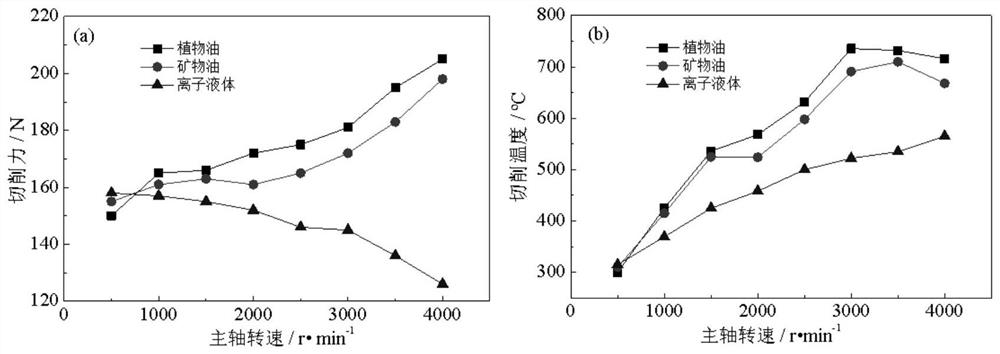

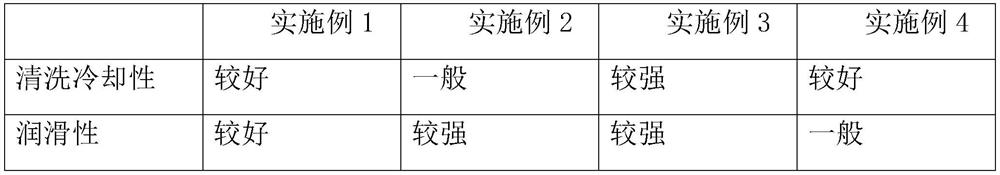

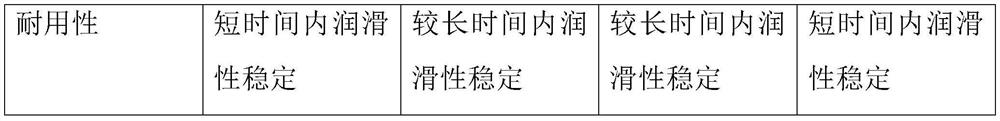

High-temperature-resistant ionic liquid cutting fluid with lubrication self-enhancement function

PendingCN114657003AImprove thermal stabilitySuitable for cuttingOrganic chemistryAdditivesVegetable oilIonic liquid

The invention belongs to the technical field of metal cutting processing, and discloses a high-temperature-resistant ionic liquid cutting fluid with a lubrication self-enhancement function in a cutting processing area, the ionic liquid cutting fluid is composed of imidazole cations and boron fluoride anions, the preparation method comprises the following steps: carrying out quaternization reaction on proper amine and alkyl halide to prepare halogenated salt containing target cations, and carrying out replacement reaction on the halogenated salt, silver of the target anions, alkali metal and ammonium salt to prepare the ionic liquid. Compared with common vegetable oil and mineral oil cutting fluid, the cutting fluid can resist the high temperature of 500 DEG C or above, the anion and cation structures of the cutting fluid have electrical conductivity, and efficient and rapid infiltration and adsorption of the cutting fluid can be promoted through friction electron emission and a self-generated electric field in a cutting area. The cutting fluid has a lubrication self-enhancement function, lubrication of the cutting fluid can be promoted under harsh processing conditions, and the higher the cutting speed is within a certain range, the more sufficient and stable the formed lubricating film is. The lubricating grease can be used for minimum quantity lubrication (MQL) during high-speed cutting machining.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

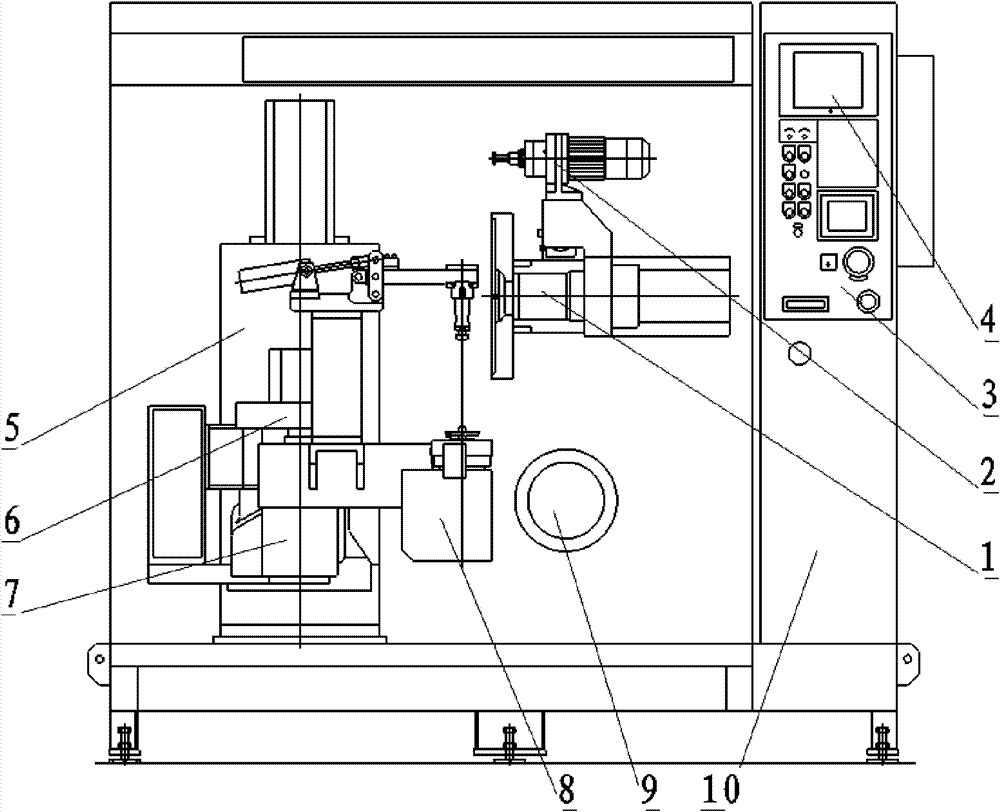

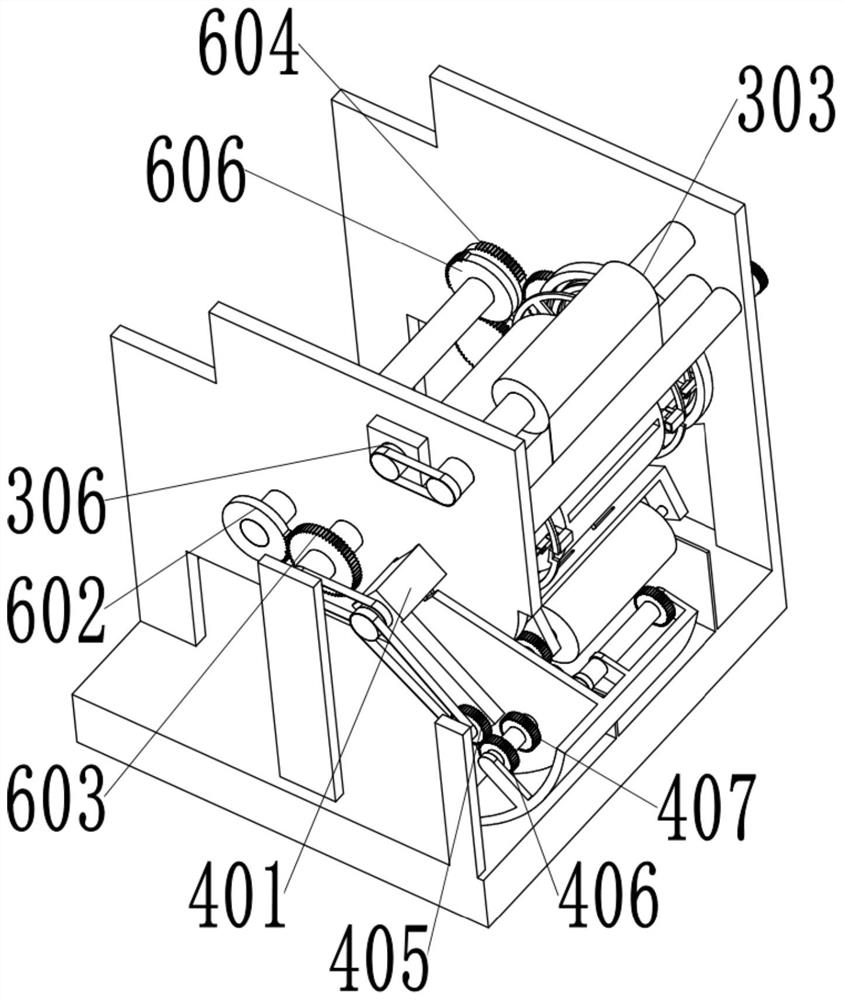

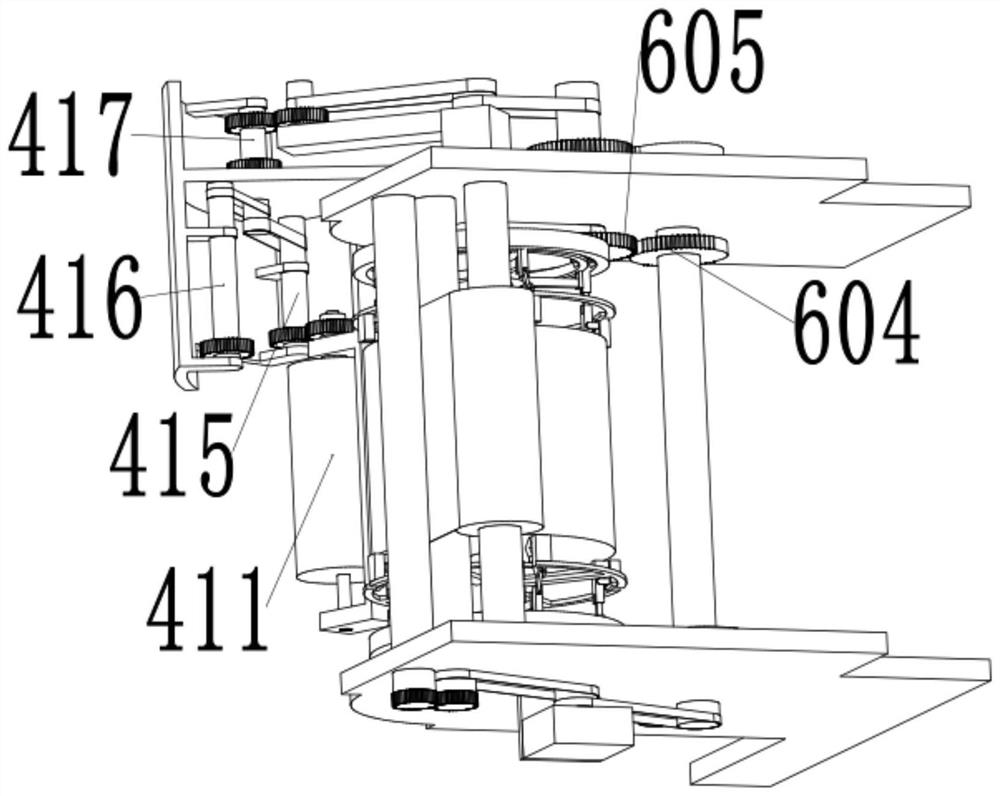

Multi-axis linkage numerical-control burr and flashing cutting machine tool

ActiveCN102172860BFreedom of movementWide range of processingEdge grinding machinesGrinding drivesEngineeringMulti axis

The invention relates to a multi-axis linkage numerical-control burr and flashing cutting machine tool, comprising a numerical-control system, multi-axis transmission mechanisms mutually connected and a grinding tool, wherein the tail end of each the multi-axis transmission mechanism is provided with a pneumatic fixture for fixing workpieces; under the control of the multi-axis transmission mechanisms by the numerical-control system, the workpiece and the grinding tool flexibly and freely move in respective space; during grinding, the workpiece and the grinding tool relatively move to cut andclean the burr and the flashing; and dust generated in the grinding process falls in a sealed machine tool body and is collected manually or by a dust collection device. The multi-axis linkage numerical-control burr and flashing cutting machine tool has the advantages of high machining efficiency, convenience in operation, small installation area, simpleness in programming, good safety and the like, is simple to replace tools and is convenient to operate.

Owner:WUHAN UNIV OF TECH

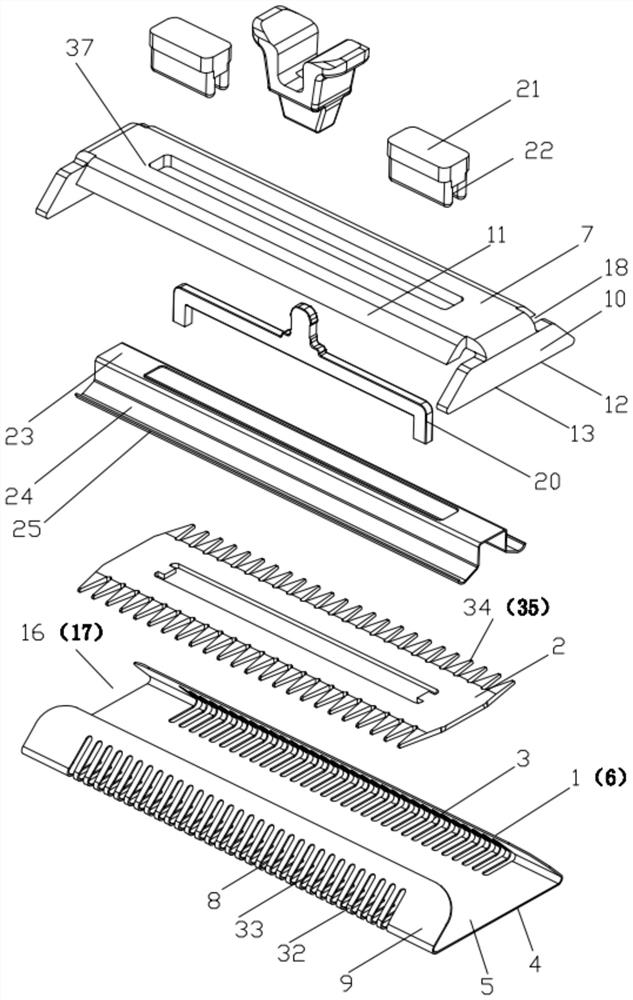

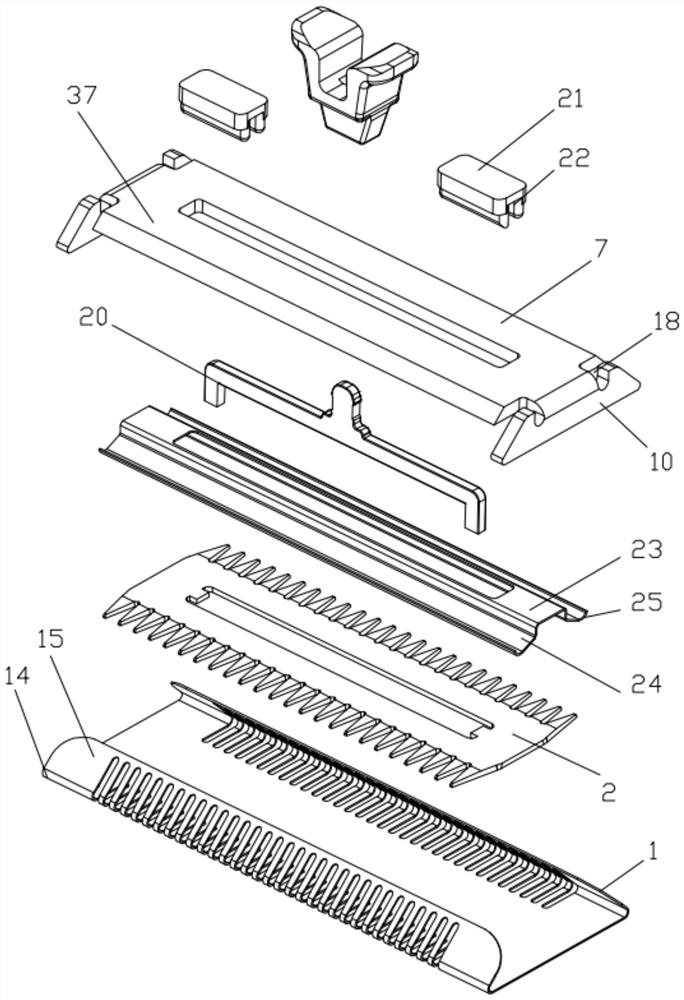

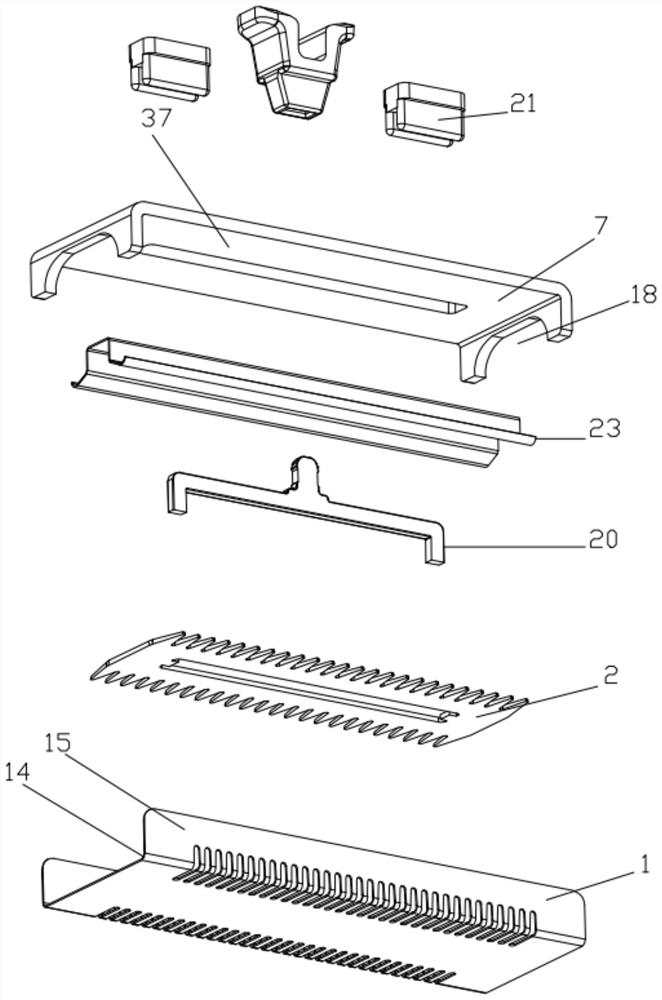

Static cutter and shaver with same

The invention discloses a static cutter and a shaver with the same. The static knife is matched with a dynamic knife to shear hair, the static knife comprises a static knife blade and a static knife fixing base, the static knife blade is provided with a static knife shearing part, the static knife shearing part forms static knife teeth, the static knife blade comprises a static knife blade body and wall parts extending out of the two sides of the static knife blade body. The static knife blade fixing base comprises a base body and supporting walls, the supporting walls are arranged at the two ends of the base body in the moving direction of the dynamic knife, and the ends of the supporting walls support the static knife blade body. According to the arrangement mode of the static knife, the overall stability of the static knife is made high, the requirement for high-precision matching of all the parts needed by the shaver in the working process can be better met, the abrasion, caused by microscopic deformation, between the dynamic knife and the static knife is avoided, and temperature rise is effectively reduced. And meanwhile, the shape of the static knife is kept, so that the shearing force formed between the static knife teeth and dynamic knife teeth during shearing is ensured, the galling problem is avoided, and the use comfort is further improved.

Owner:元海医疗科技有限公司

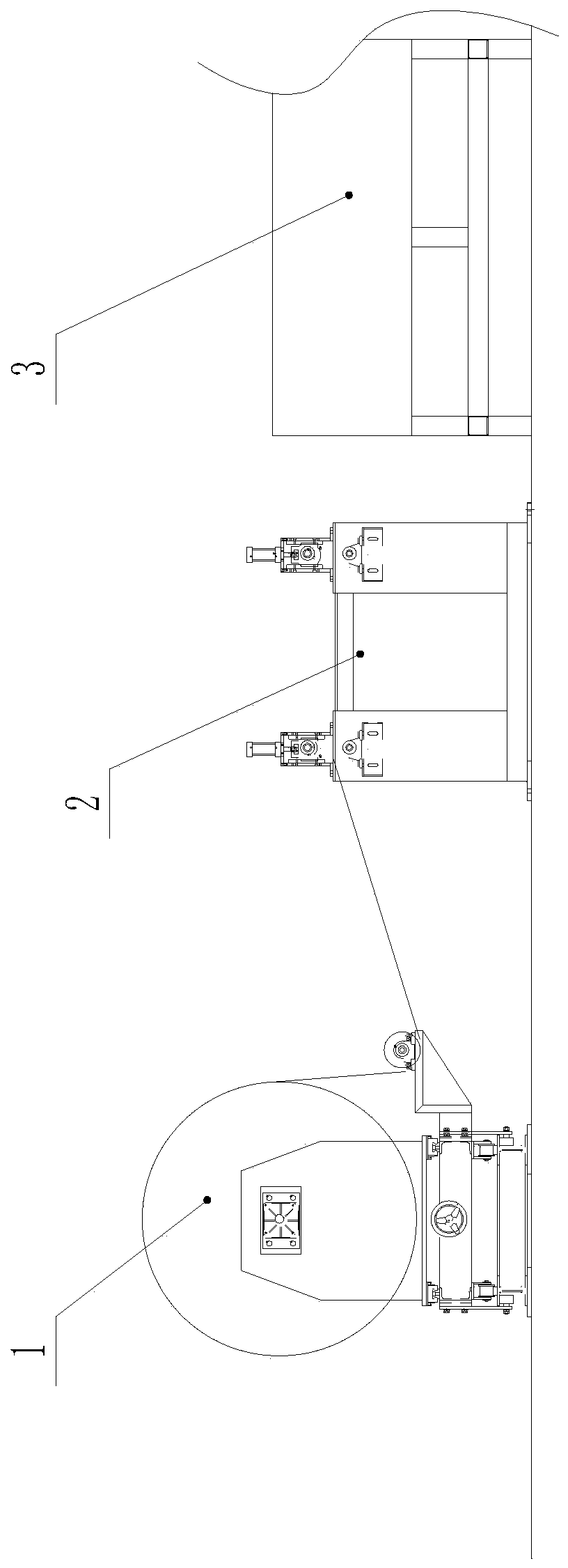

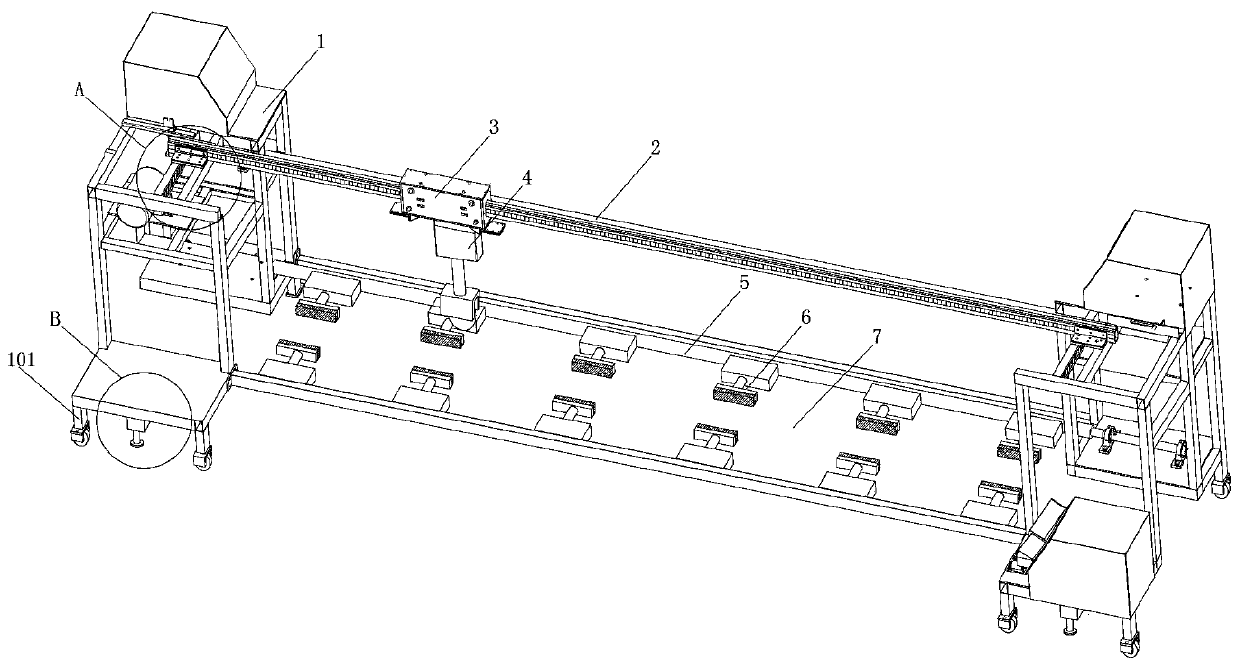

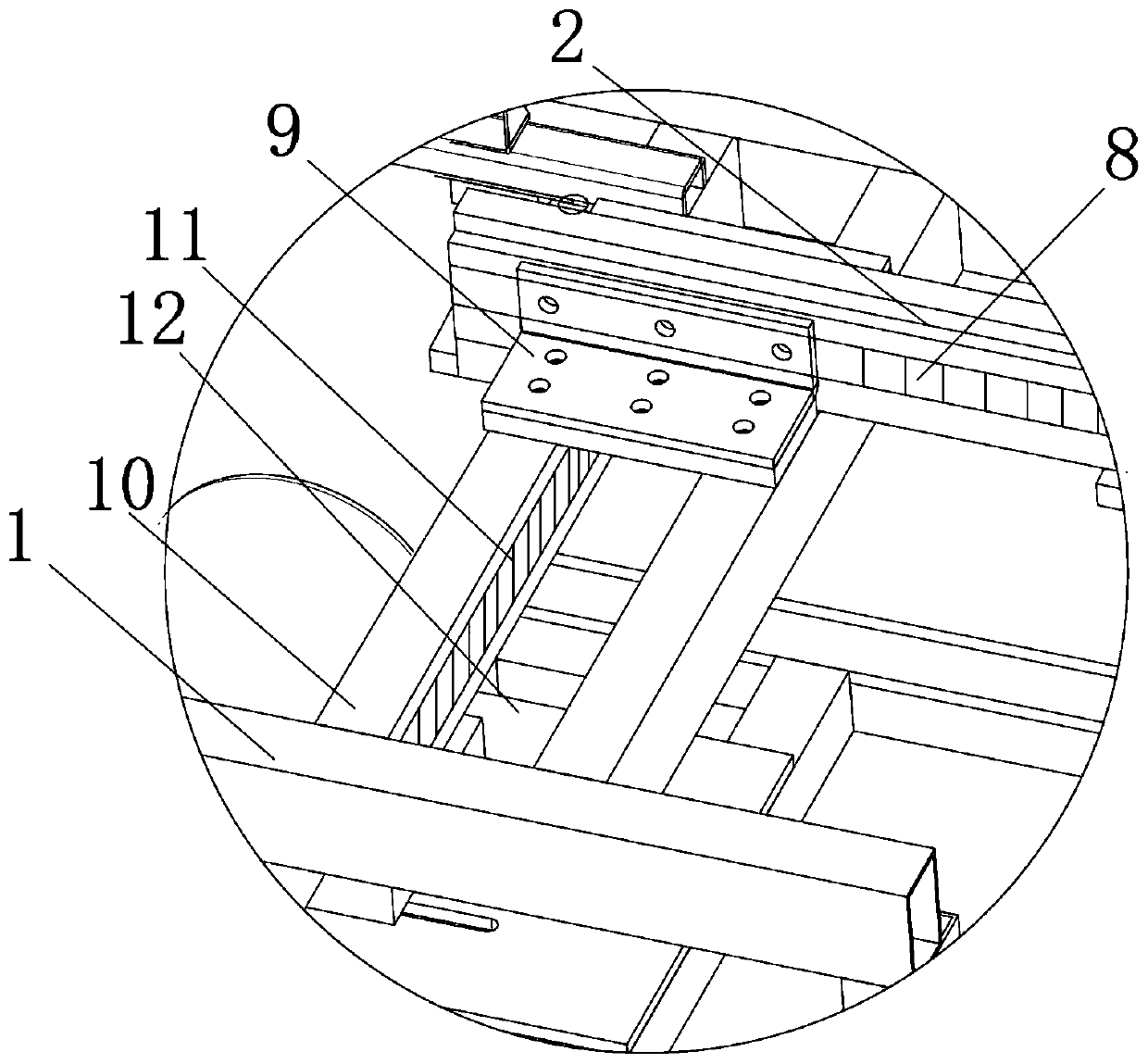

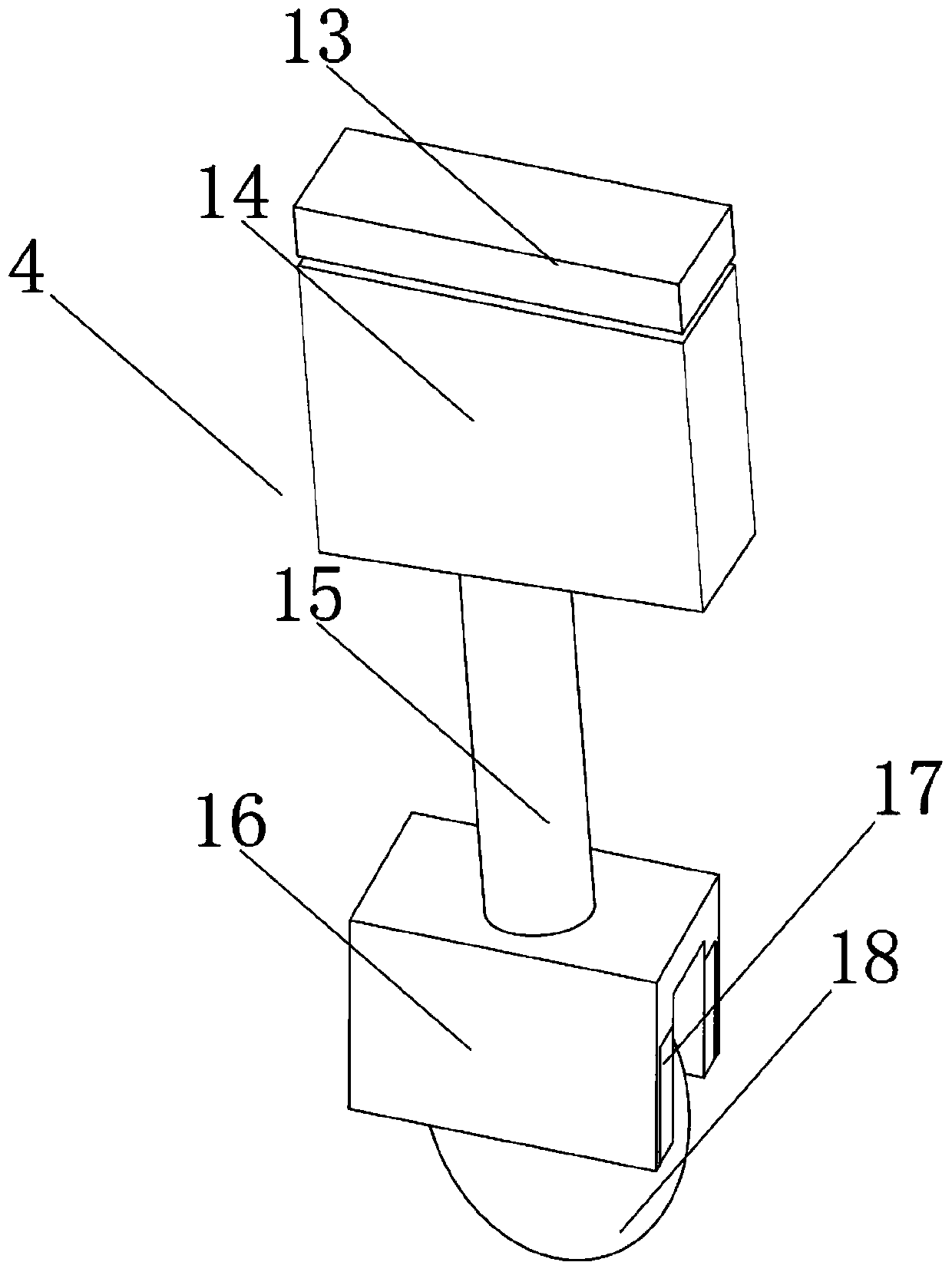

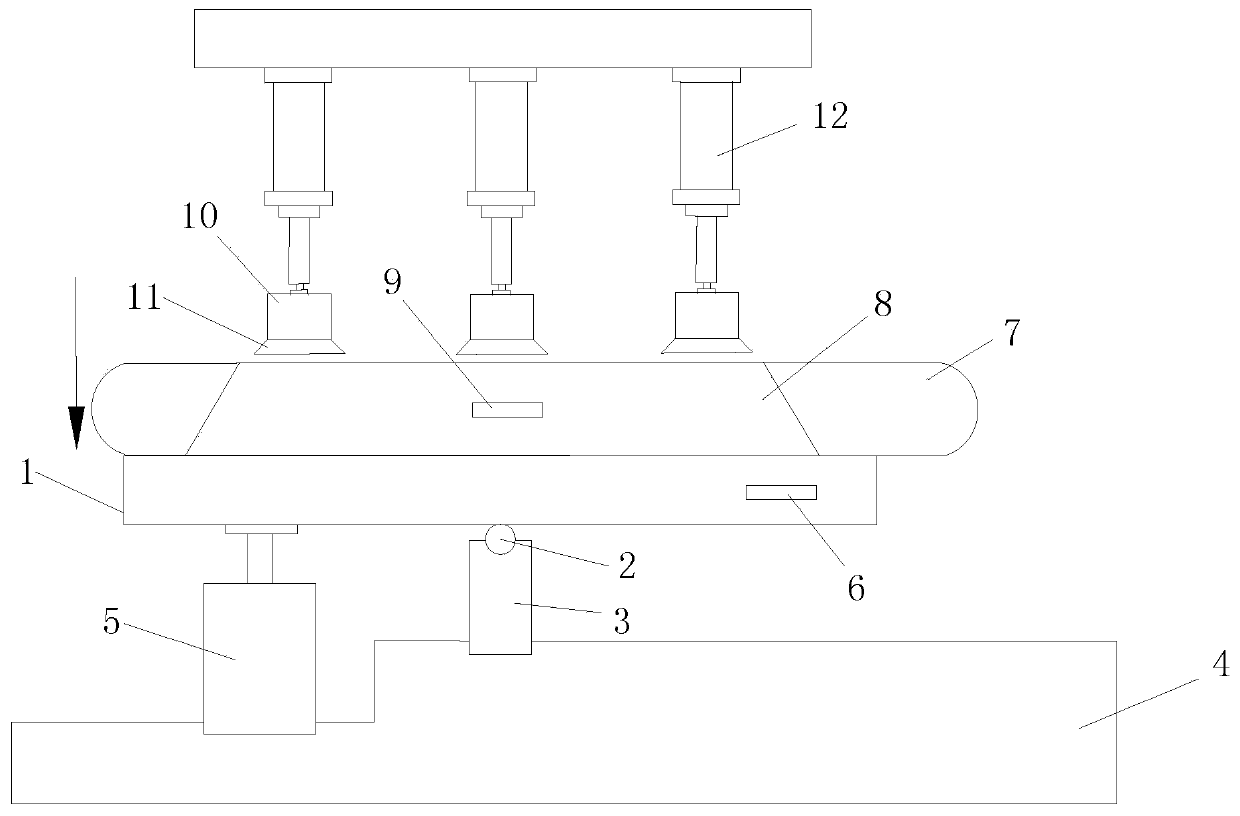

Multifunctional production line and production method for level A2, level B1 and three-dimensional core layer composite boards

PendingCN110315833AOptimize layoutReduce investmentLamination ancillary operationsLaminationProduction lineMethods of production

The invention discloses a multifunctional production line for level A2, level B1 and three-dimensional core layer composite boards. According to the production line, production equipment of the threekinds of composite boards is combined, a movable slide base is utilized for changing the positions of the equipment, and then by optimizing the positions of the equipment and the working states of different sets of equipment, the purpose that the same line is suitable for production of the three kinds of different composite boards is achieved. In this way, the arrangement of production workshops is greatly simplified, the investment of the equipment is lowered, and the occupied area is also reduced.

Owner:张家港市弘扬机械设备有限公司

Method for preparing jade type microcrystalline glass with high-temperature furnace slag

Owner:TSINGHUA UNIV

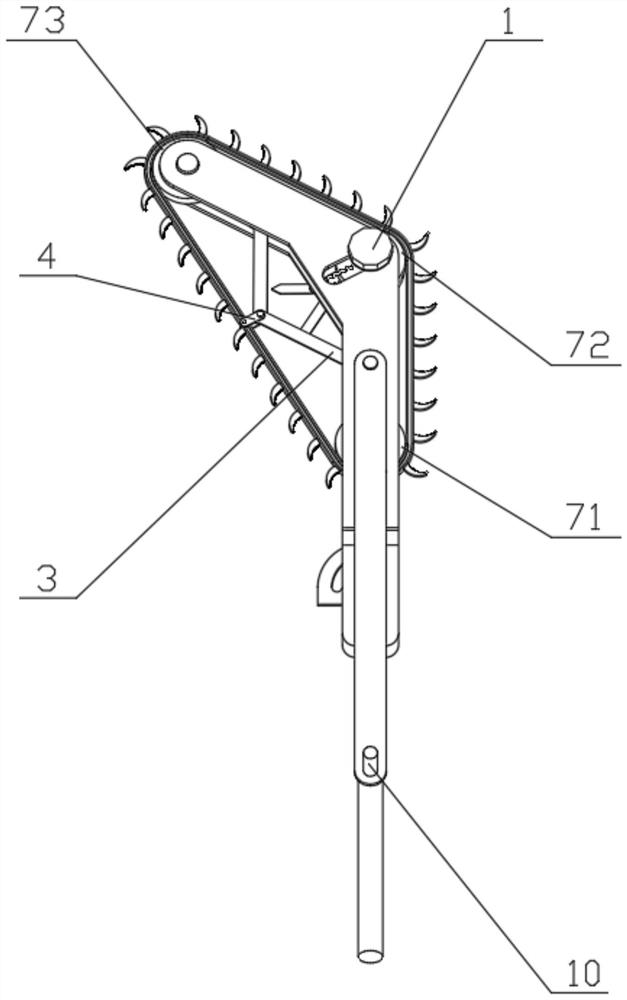

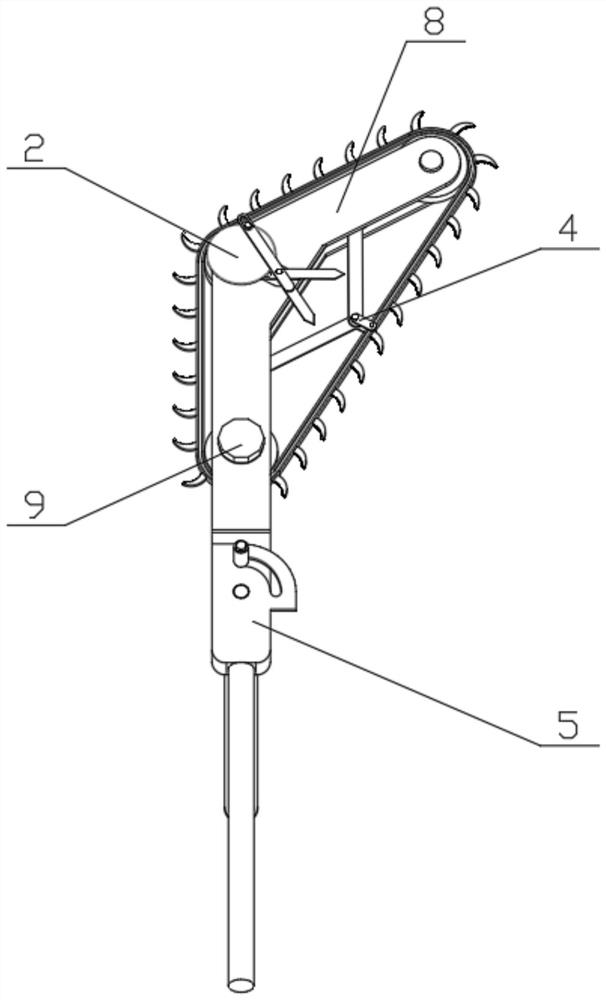

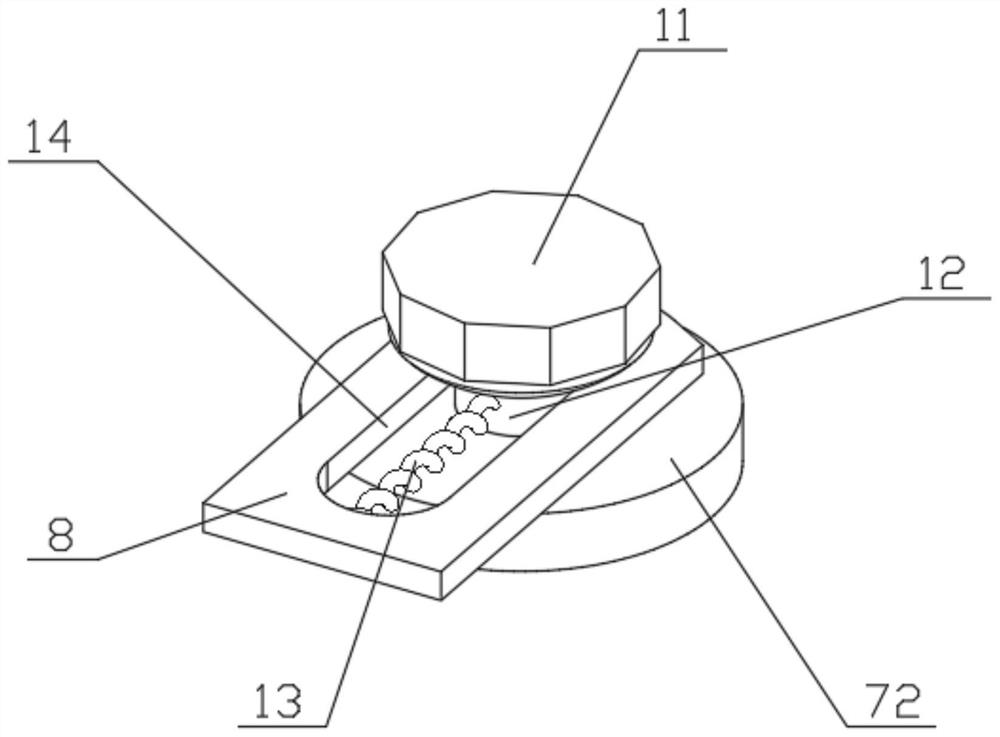

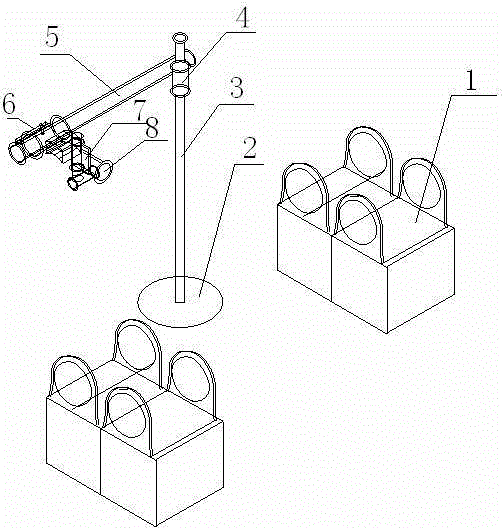

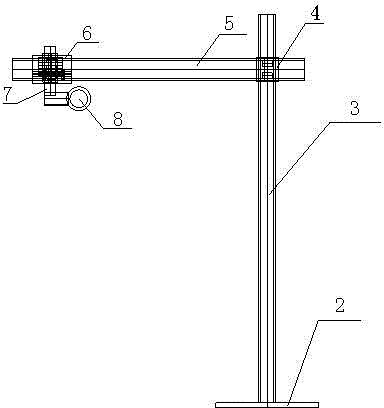

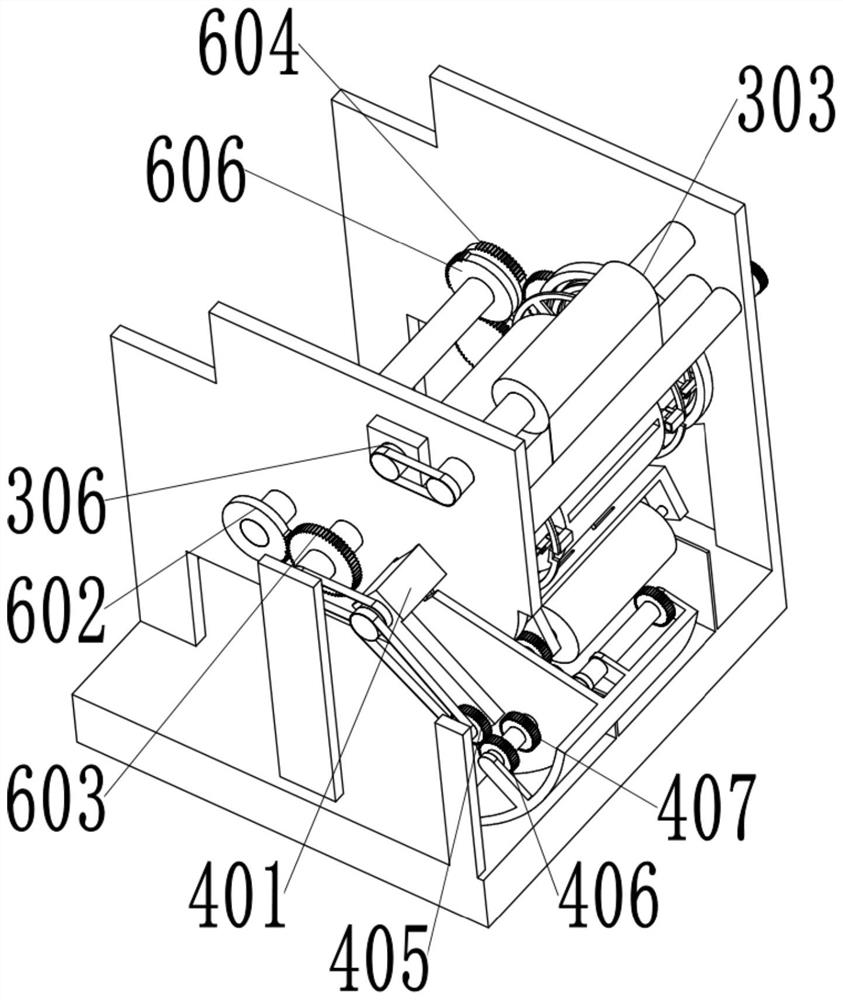

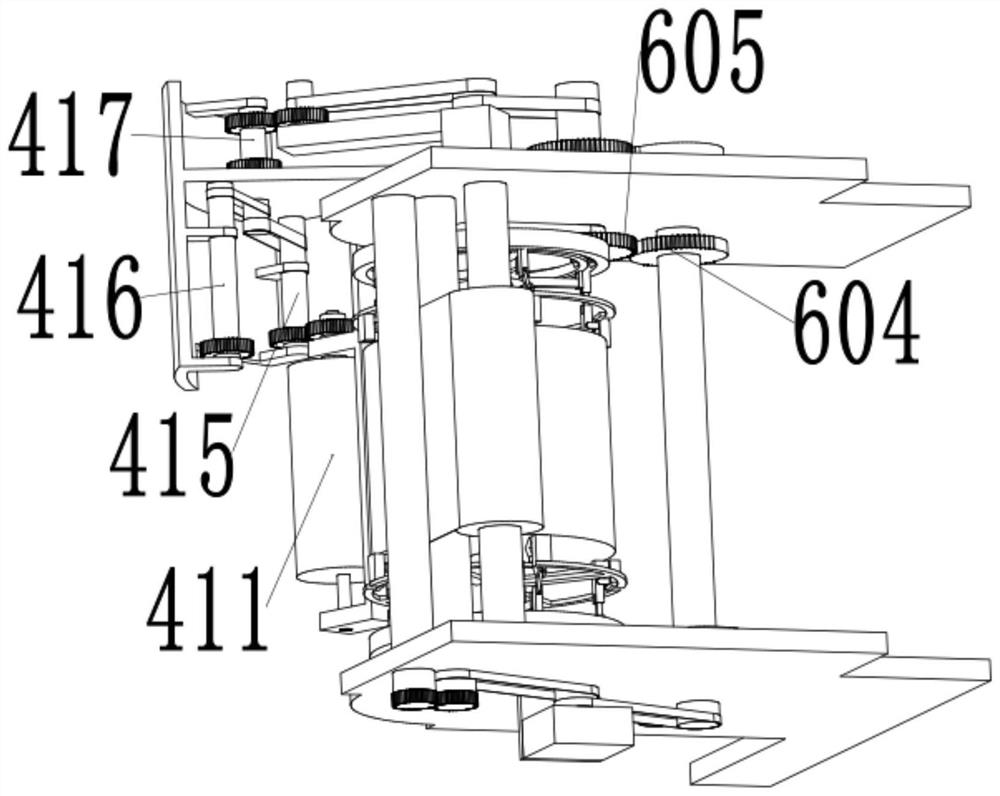

Walnut tree pruning device and method

ActiveCN113475258AImprove stabilityImprove functionalityCuttersCutting implementsAlgorithmStructural engineering

The invention discloses a walnut tree pruning device and method. The walnut tree pruning device comprises a shell and a tightening wheel mechanism, wherein the upper end and the lower end of the shell are of hollow structures, the tightening wheel mechanism is installed on the shell in a sliding mode, the lower end of the shell is connected with a steering structure used for adjusting the use angle of the shell, and rolling wheel assemblies are installed at the end corners of the shell. The tightening wheel mechanism can be arranged to push a connecting rod mechanism after making contact with a supporting rod or a rotating hook claw mechanism pulls the supporting rod, so that a shear mechanism can achieve feed shearing conveniently, different pruning devices and pruning methods can be used according to different branches, the stability of the walnut tree in the pruning process is improved, the functionality of the pruning tool is improved, the walnut tree pruning device is suitable for shearing operation of branches with different hardness, the angle of the device shell can be adjusted according to the height of the branches and the branch and trunk angles, the cutting position of the shear mechanism can be matched with the specific positions of the branches and trunks, accordingly, shearing operation can be rapidly carried out, the shearing efficiency can be improved, and meanwhile, various shearing requirements can be met.

Owner:濮阳市林业科学院

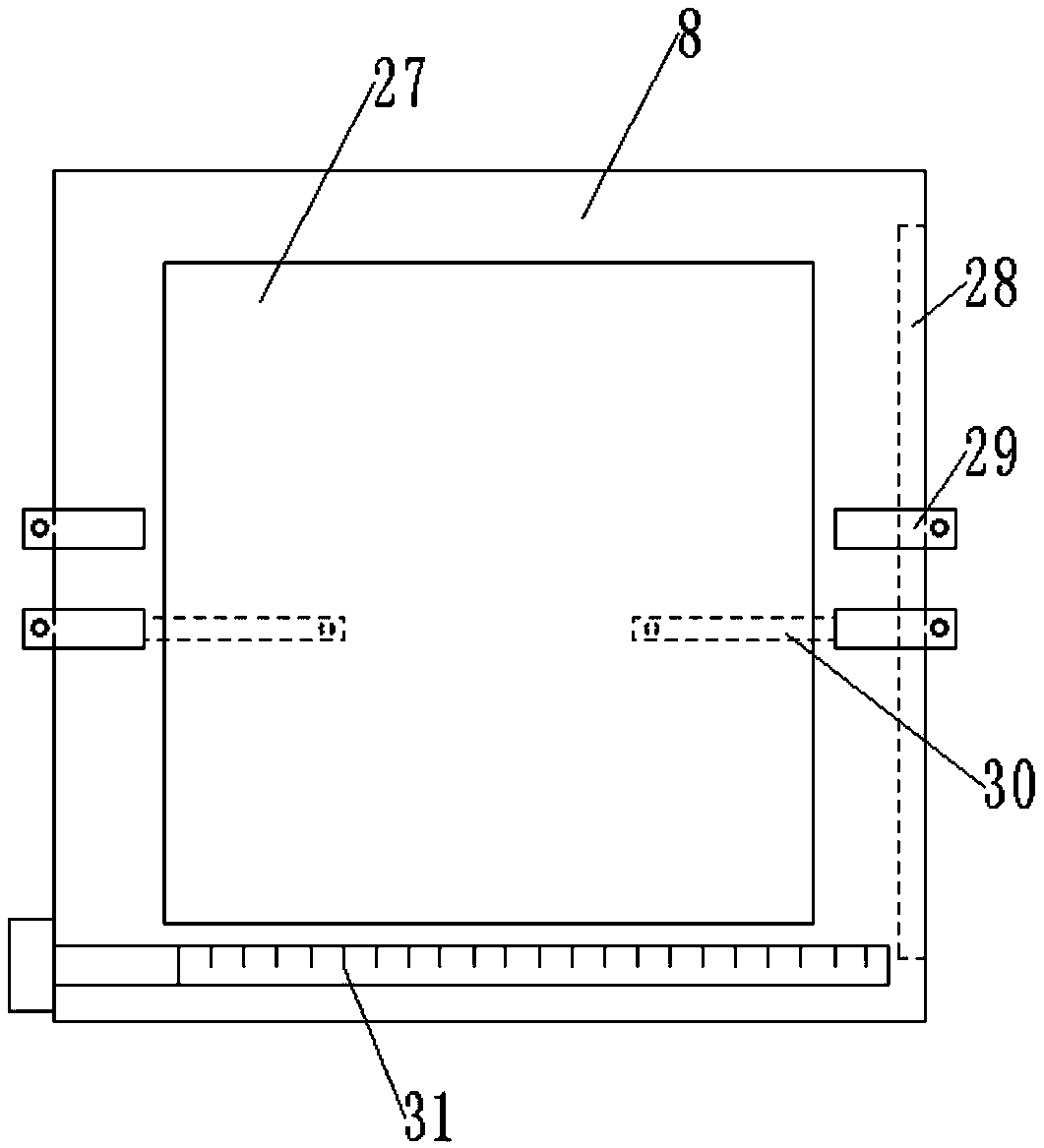

Fabric cutting device

ActiveCN112501900ASimple structureEasy to operateSevering textilesIndustrial engineeringSupport plane

The invention discloses a fabric cutting device which comprises a supporting frame, a servo motor, a conveying part, a cutting part, a clamping part and a transmission part. The supporting frame is amounting platform for the servo motor, the conveying part, the cutting part, the clamping part and the transmission part, and fabric is conveyed through the conveying part and the clamping part. The fabric is cut by the cutting part.

Owner:湖北美春服装有限公司

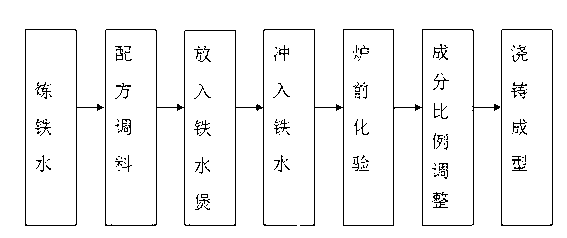

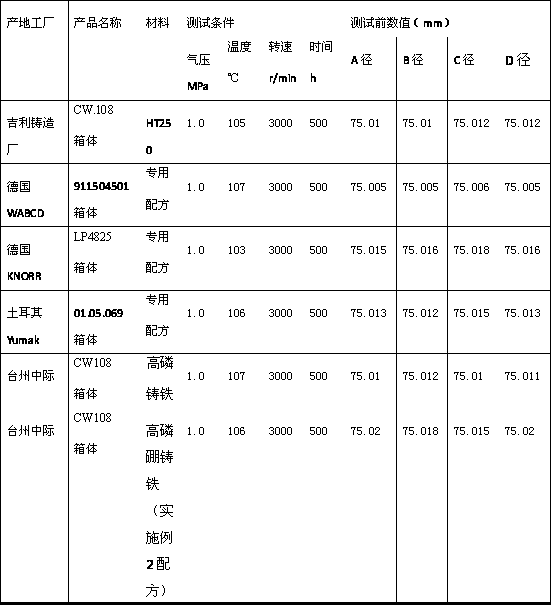

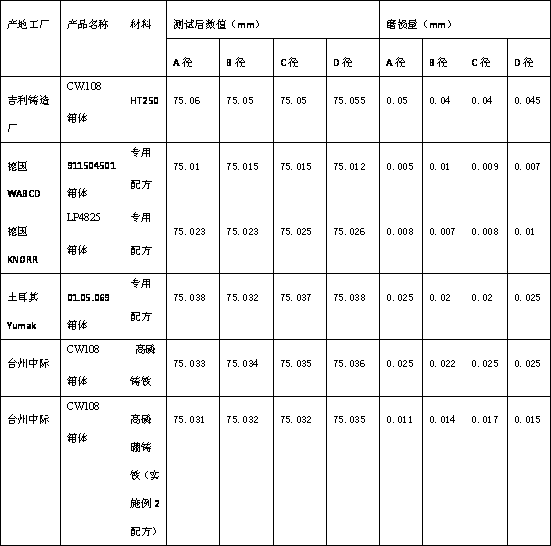

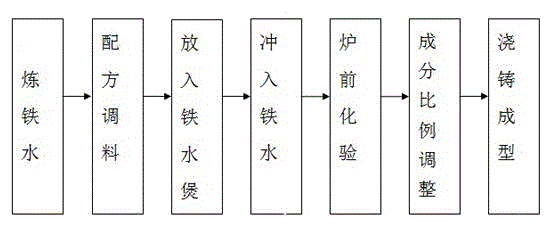

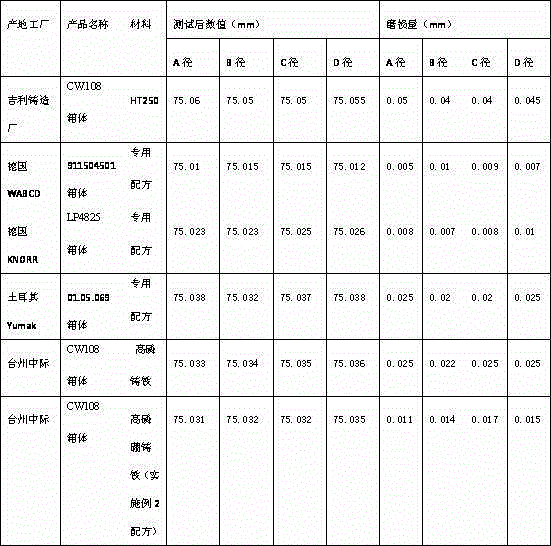

Super-strong high-phosphorus boron cast iron

The invention provides super-strong high-phosphorus boron cast iron. The super-strong high-phosphorus boron cast iron is made from molten iron and ingredients and is characterized in that the ingredients comprise the following raw materials in percentage by weight: 2.5-4% of C, 0-0.1% of S, 1.5-2.5% of Si, 0.2-0.4% of P, 0.05-0.5% of Cr, 0.5-1% of Mn and 0.05-0.2% of B. The super-strong high-phosphorus boron cast iron has the advantages that the abrasive resistance is good; the complete machine is durable in use and long in life; the economic benefit is increased; in the meantime, the energy consumption is low and the stability is good; virtuous circle is formed among components; the energy is saved and the emission is reduced; the boron cast iron is suitable for cutting machining; the machining indexes achieve the design standard; and the best adaptation performance is shown between the boron cast iron and a piston ring.

Owner:威佰昇科技(台州)有限公司

Apparatus for rotating point cutting large size silicon-carbide crystal

InactiveCN100480015CGuaranteed not to shakeIncrease cutting spaceFine working devicesMetal working apparatusMaterials processingControl theory

An apparatus for cutting large-size SiC crystal by the moving dots is composed of base, sensor, sawing diamond string, pneumatic tension roller, working rollers, DC servo motor and 2D fixture mechanism consisting of rotary manipulator and step motor. A horizontal angle regulating turn-table is linked on a Y-axis moving platform. A vertical angle regulating turn-table is linked on said horizontal angle regulating one. Said step motor is fixed to an adjustable supporting plate.

Owner:张革 +1

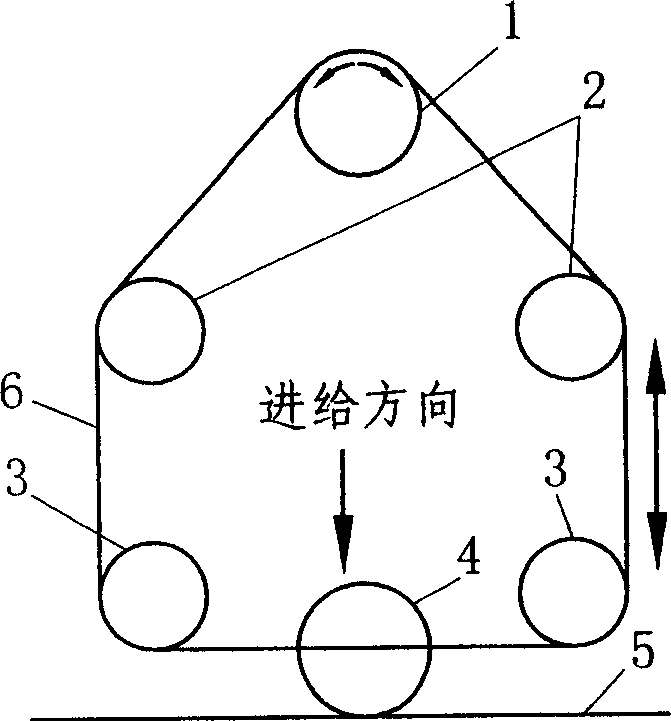

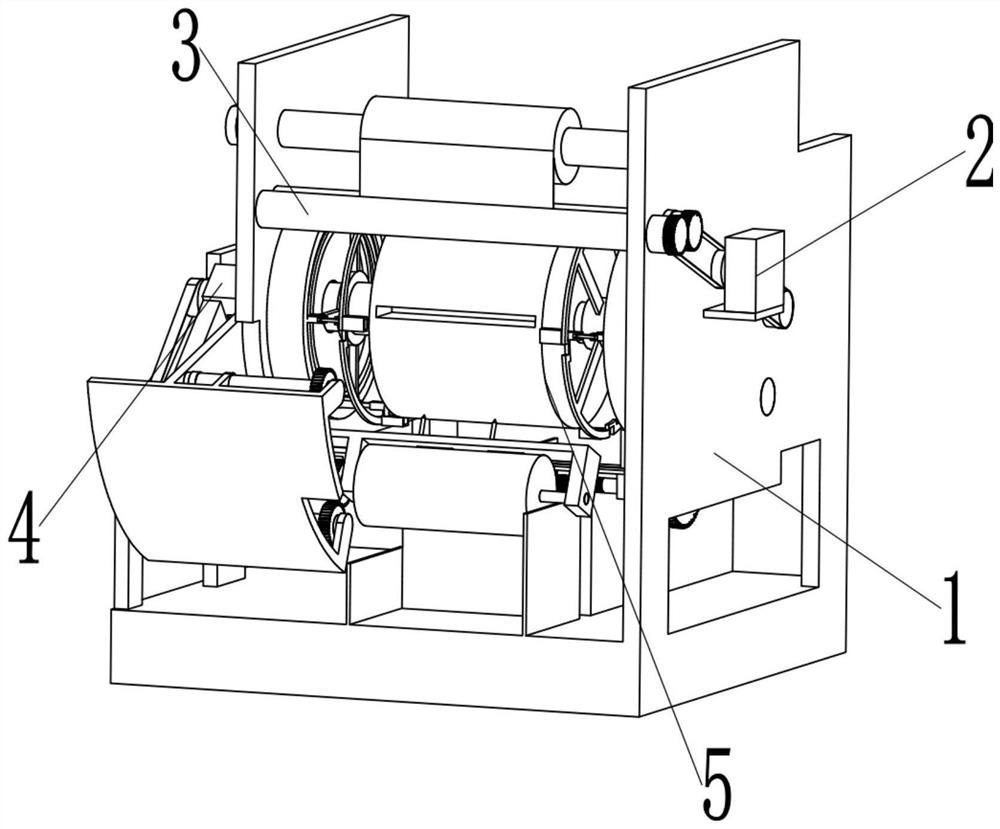

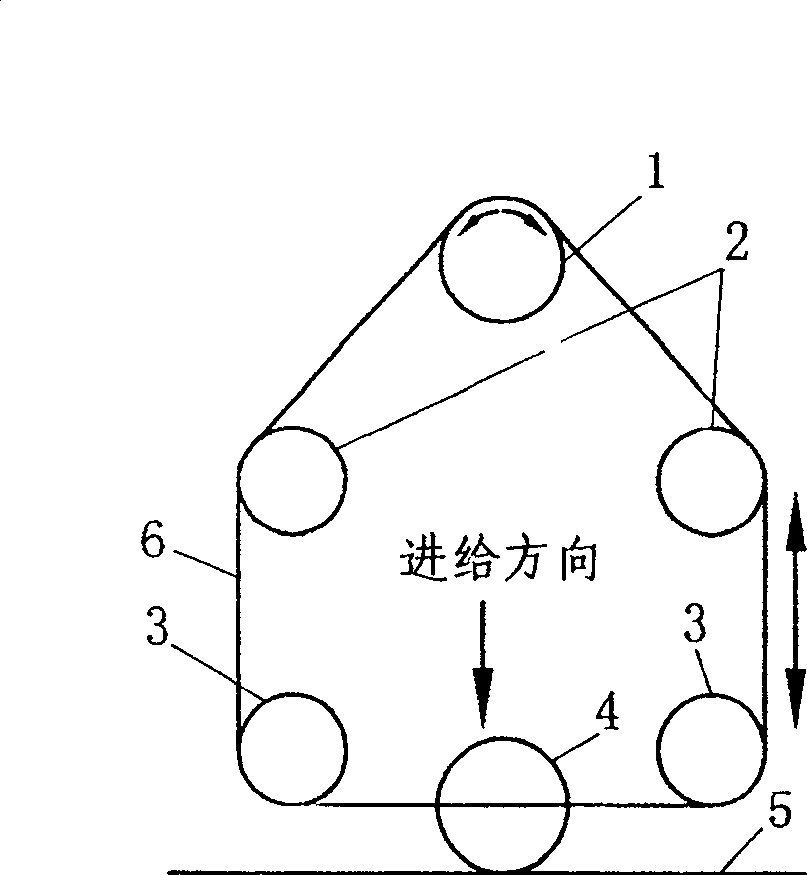

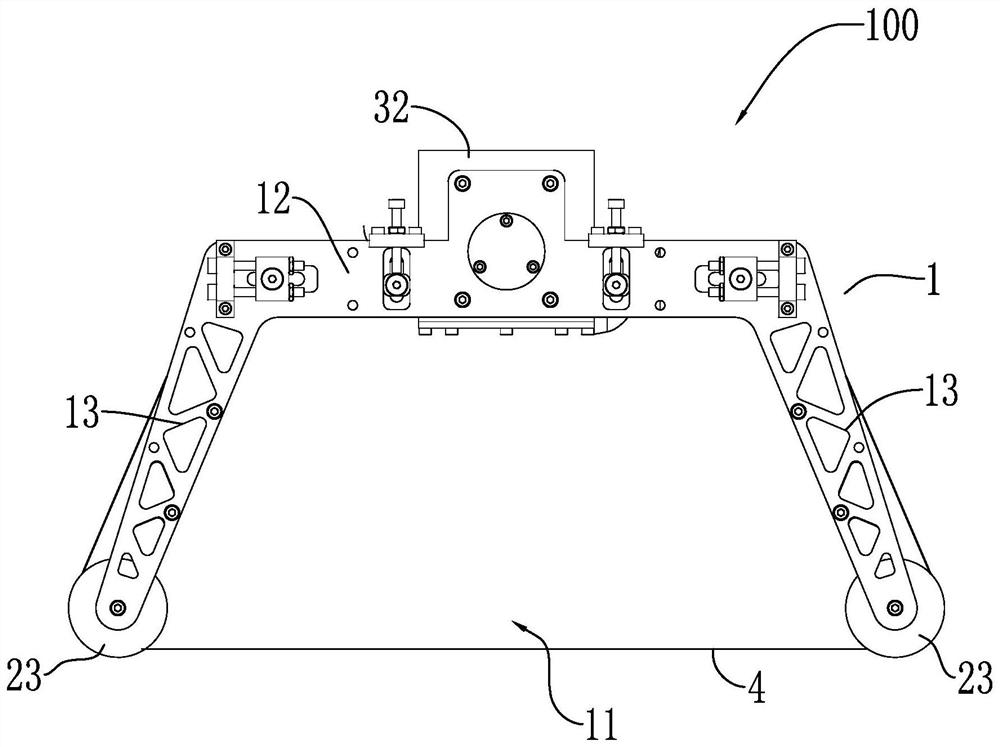

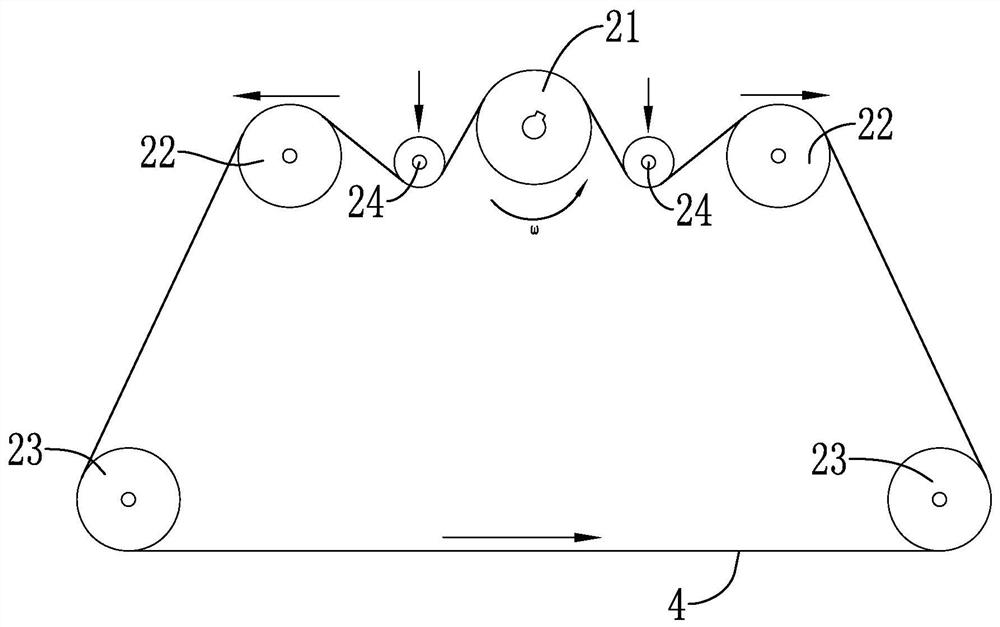

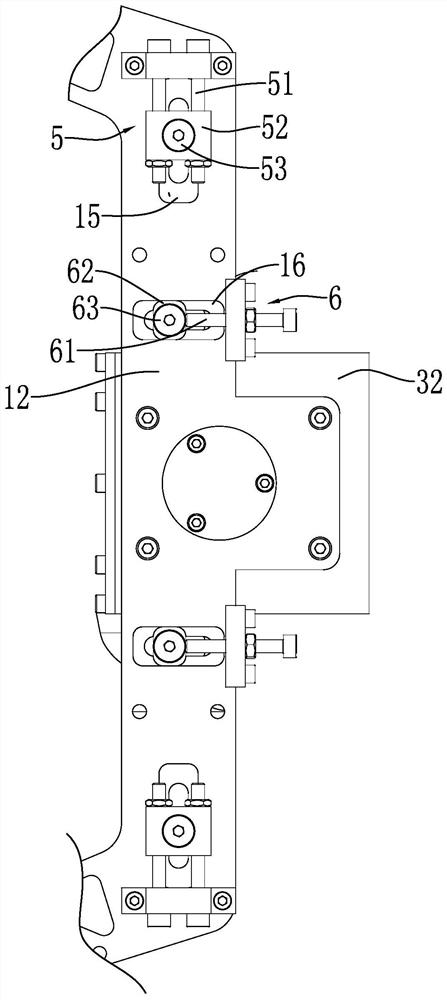

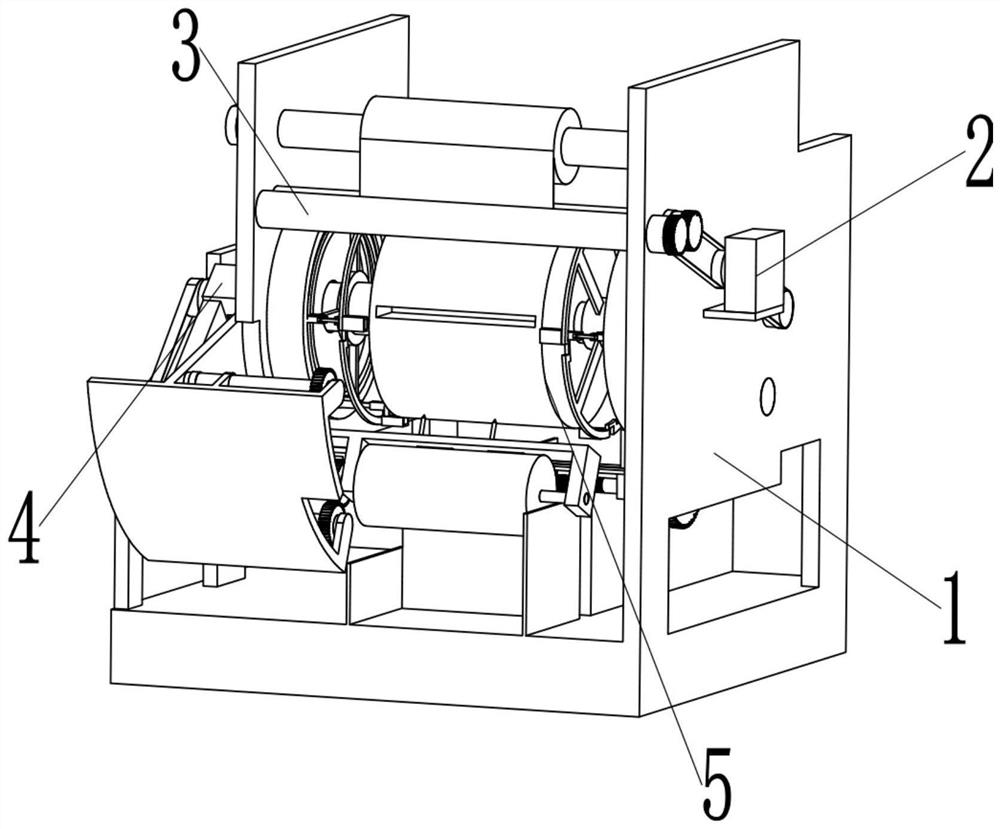

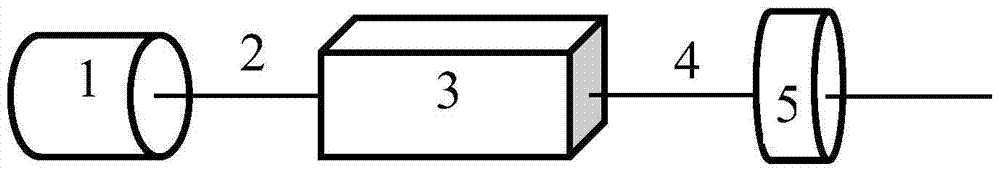

Wire saw mechanism and wire saw cutting device based on small-load robot

PendingCN112976347AChange the tensionIncrease wrap angleWorking accessoriesBand sawsDrive wheelStructural engineering

The invention provides a wire saw mechanism and a wire saw cutting device based on a small-load robot. The wire saw mechanism comprises a rack, a diamond string bead wire, a driving device, a driving wheel, two tensioning wheels, two guide wheels and two auxiliary wheels. The tensioning wheels are arranged on the two sides of the driving wheel and adjustably get away from or get close to the driving wheel so as to change the tensioning force of the diamond string bead wire; the auxiliary wheels are arranged between the driving wheel and the tensioning wheels and push the diamond string bead wire to abut against the driving wheel and the tensioning wheels; and the auxiliary wheels adjustably move so as to change the tensioning force of the diamond string bead wire. According to the technical scheme, the wire saw mechanism with a large tension adjusting range can be provided.

Owner:HUAQIAO UNIVERSITY

Precoated metal plate and manufacturing method thereof

InactiveCN106626613AVariety of colorsGood lookingSynthetic resin layered productsFurniture partsSurface cleaningUltraviolet lights

The invention discloses a precoated metal plate and a manufacturing method thereof. The precoated metal plate sequentially comprises a metal substrate, a solvent type coating and a second UV (Ultraviolet) coating from bottom to top, or sequentially comprises the metal substrate, the solvent type coating, a first UV coating, a transfer printing pattern and the second UV coating from bottom to top. The manufacturing method comprises the following steps: enabling a metal coiled tape with the solvent type coating to sequentially enter an uncoiling procedure I, a surface cleaning procedure II, a first UV glue coating procedure III, a transfer printing membrane laminating procedure IV, a first ultraviolet light curing procedure V and a transfer printing membrane tearing procedure VI, wherein the transfer printing membrane laminating procedure IV adopts an unpatterned transparent transfer printing membrane or a plastic transfer printing membrane with a pattern; sequentially entering a second UV glue coating procedure VII, a second ultraviolet light curing procedure VIII, a protective film pasting and covering procedure IX and a coiling procedure X, thus obtaining the precoated metal plate. The invention provides the precoated metal plate with abundant colors, processability and high distinctness; the precoated metal plate has excellent brightness, transparency and mirror surface effect.

Owner:青岛河钢复合新材料科技有限公司 +1

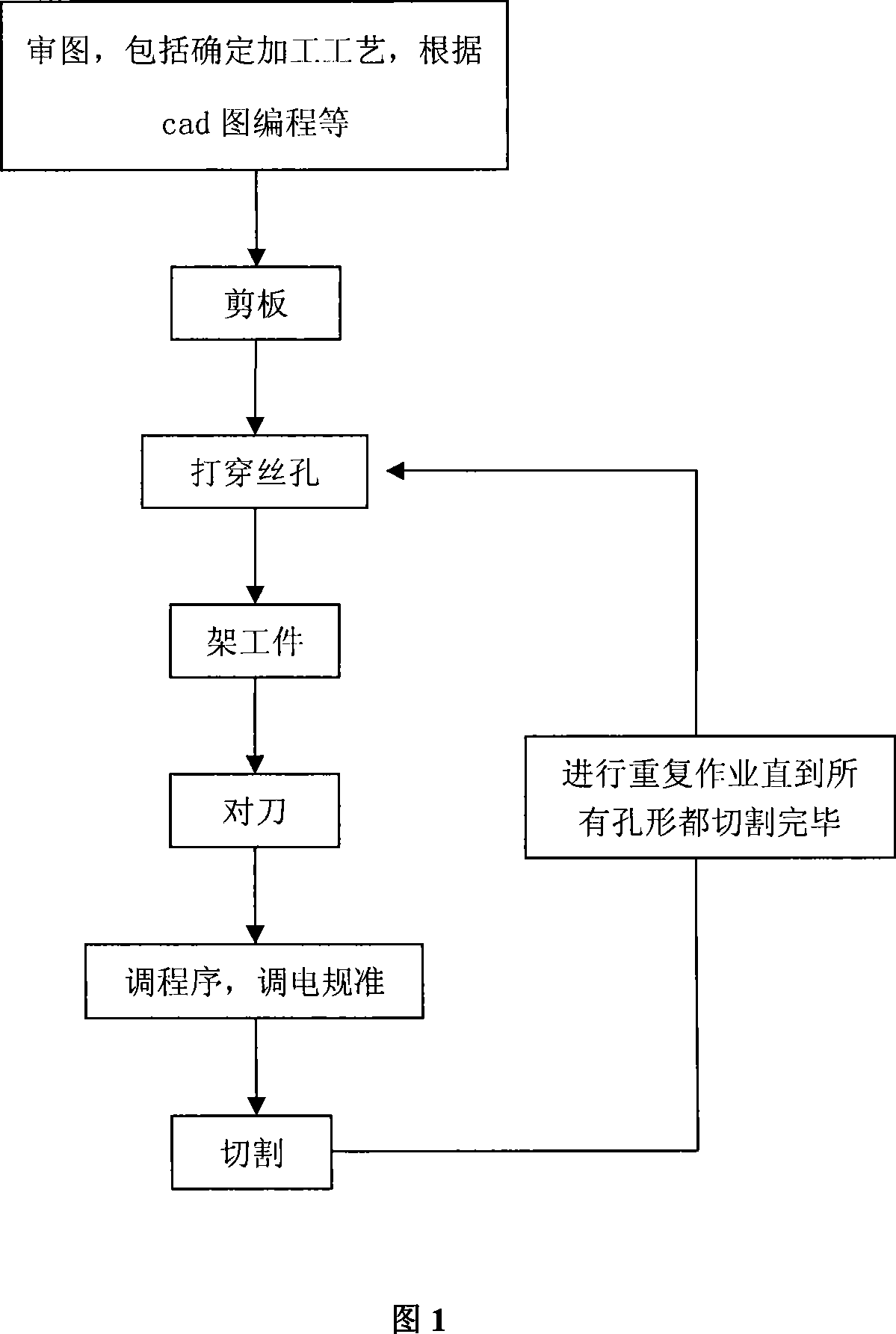

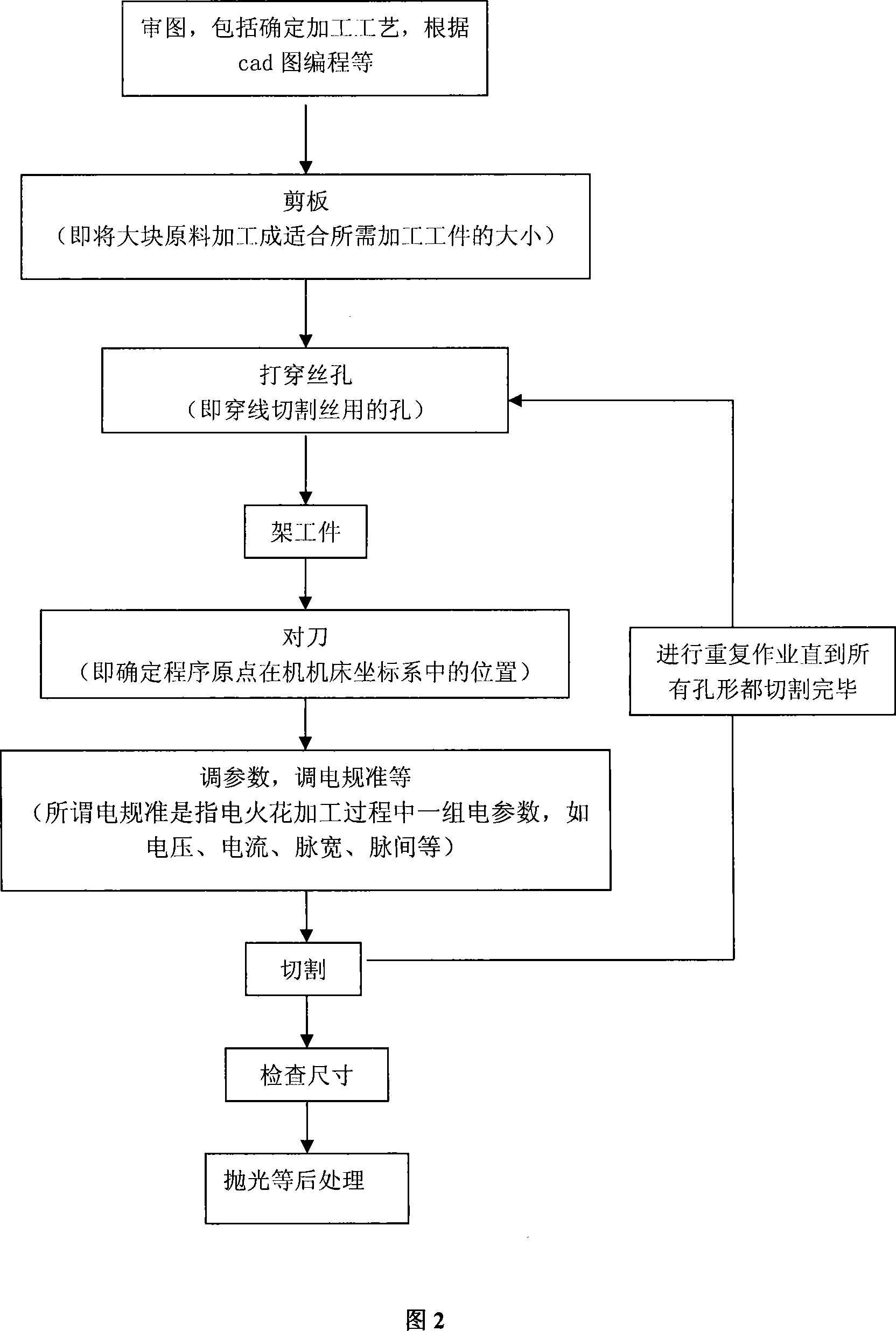

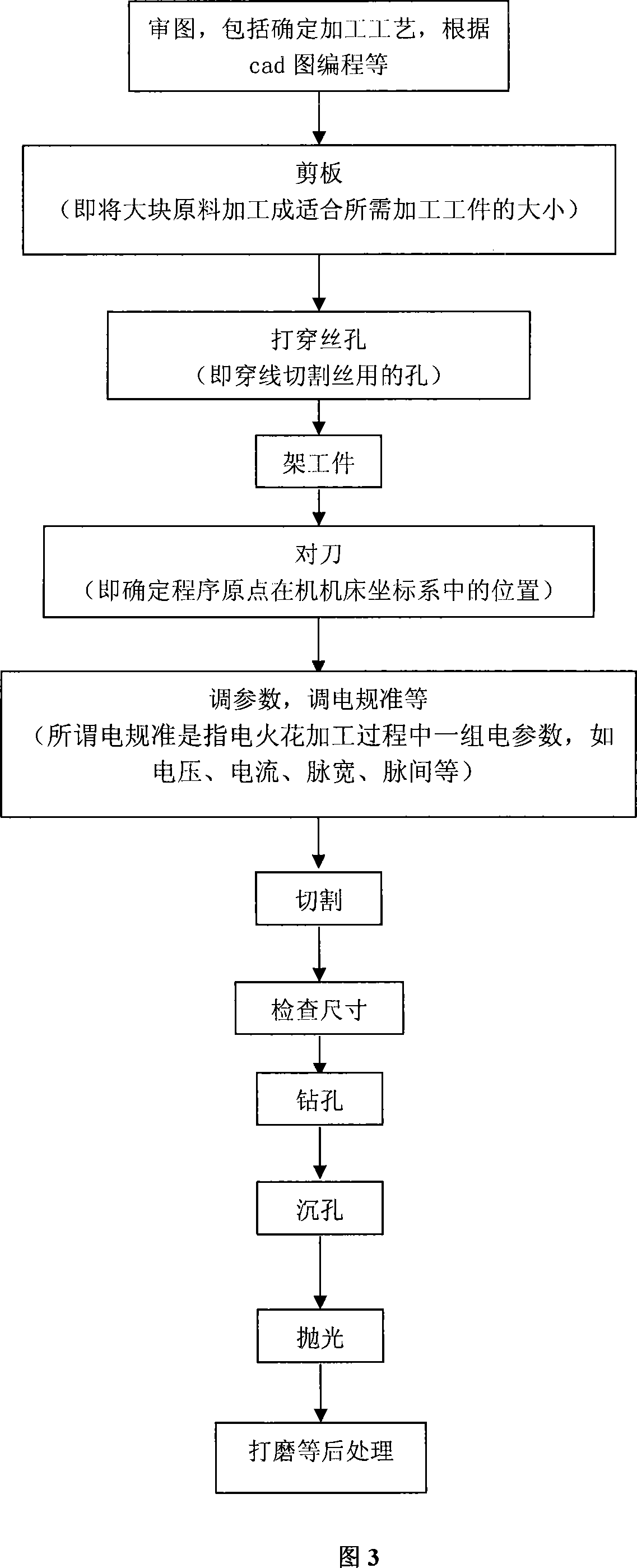

Method of preparing bone injury repair member made of titanium

The invention provides a method for manufacturing a titanium bone injury repairing element which is characterized in that the invention utilizes a numerical control linear cutting machine to carry through linear cutting processing on a plate body material of titanium metal or titanium alloy; thereby acquiring the titanium bone injury repairing element. Adopting the manufacturing method can meet the manufacture requirements of small manufacture batch and diversity products for each bone injury repairing element.

Owner:北京吉马飞科技发展有限公司

Steel pipe cutting and blanking device

InactiveCN105728919AEasy to unloadEasy to storePlasma welding apparatusEngineeringMechanical engineering

The invention discloses a steel pipe machining device, in particular to a steel pipe cutting and blanking device. The steel pipe cutting and blanking device comprises a bottom plate and a blanking bracket arranged on the bottom plate. The steel pipe cutting and blanking device is characterized in that the blanking bracket is provided with a toroidal bracket body, an axial adjusting control ring is arranged at the tail end of the toroidal bracket body and provided with a local height adjusting ring, and a cutting spray gun fixing opening used for fixing a spray gun is arranged at the tail end of the local height adjusting ring. The steel pipe cutting and blanking device has the beneficial effects that the blanking pipe diameter size of a steel pipe is unrestricted, and the device is suitable for blanking machining in a machining workshop; blanking and cutting can be conducted in any position of the steel pipe, and actual machining and using are facilitated; and moving is convenient, and blanking and cutting can be conducted in any places.

Owner:中电装备青岛豪迈钢结构有限公司

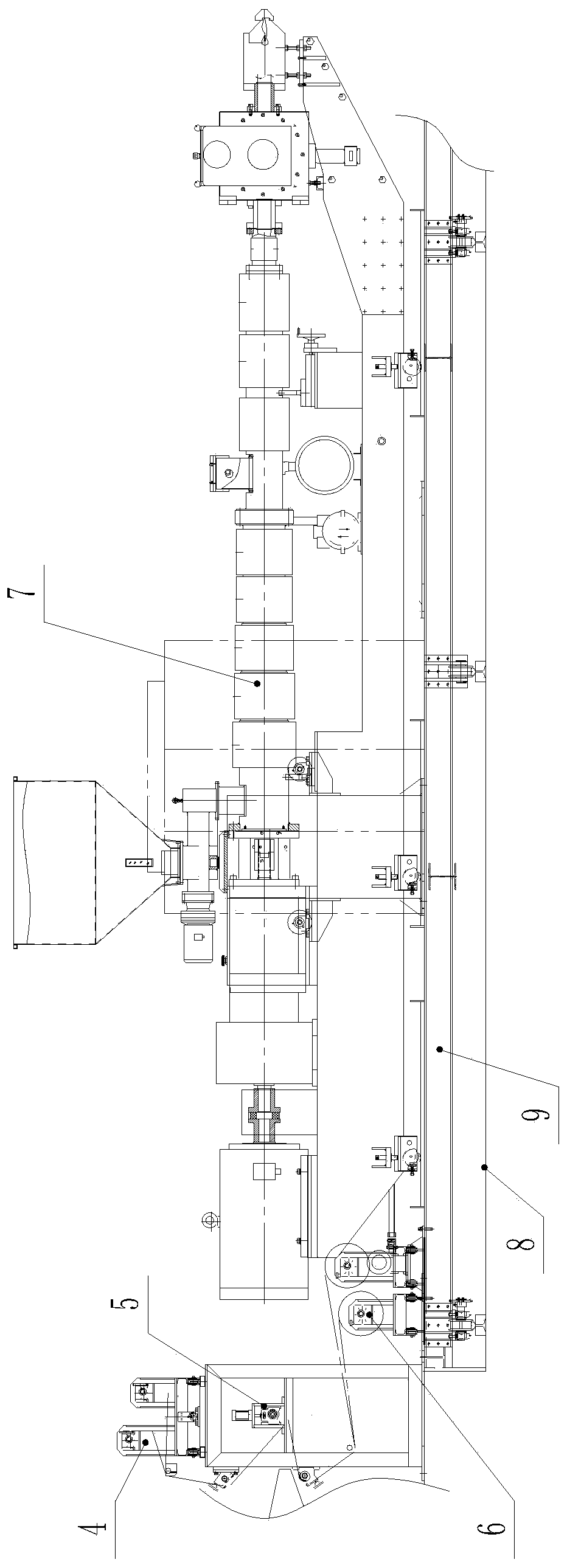

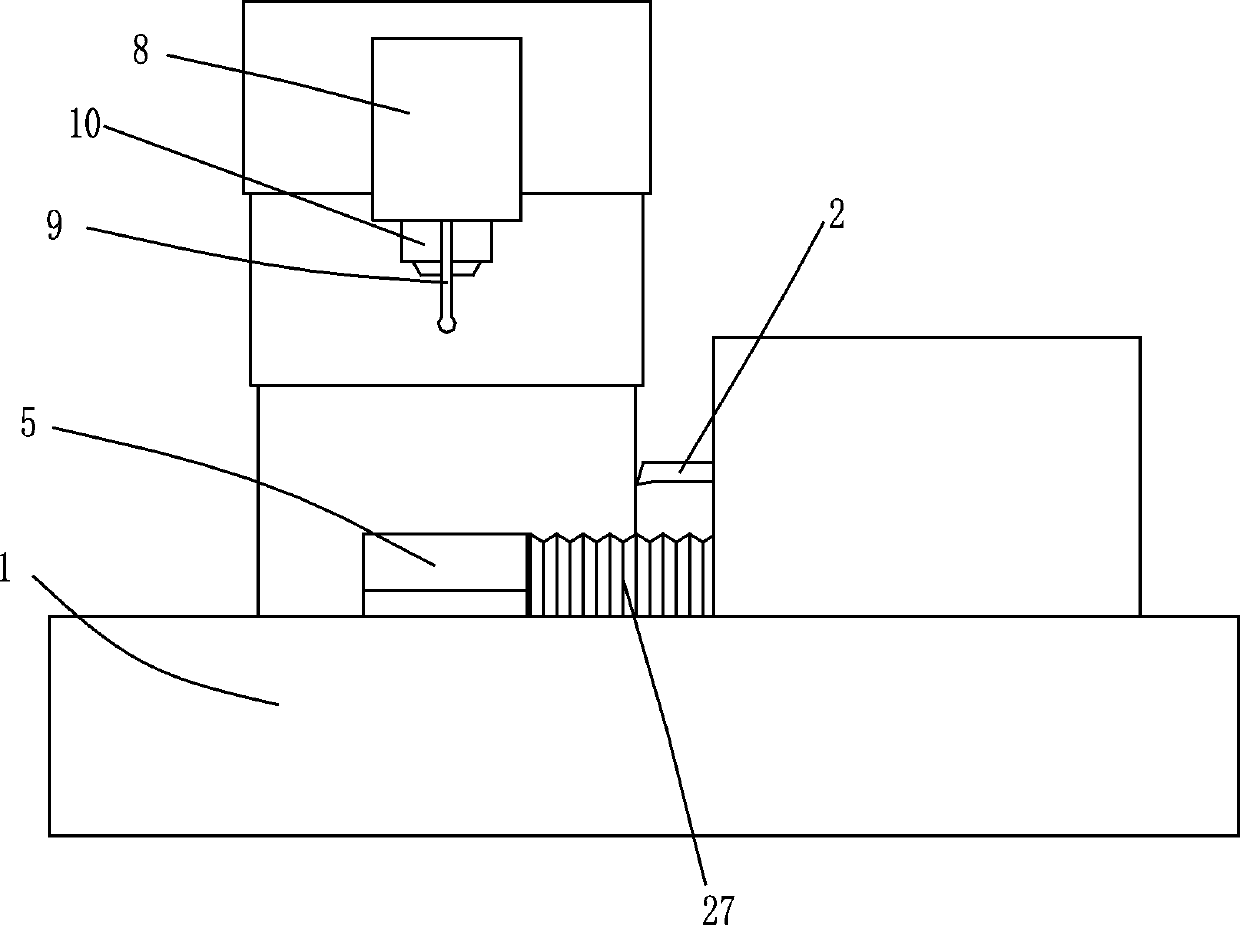

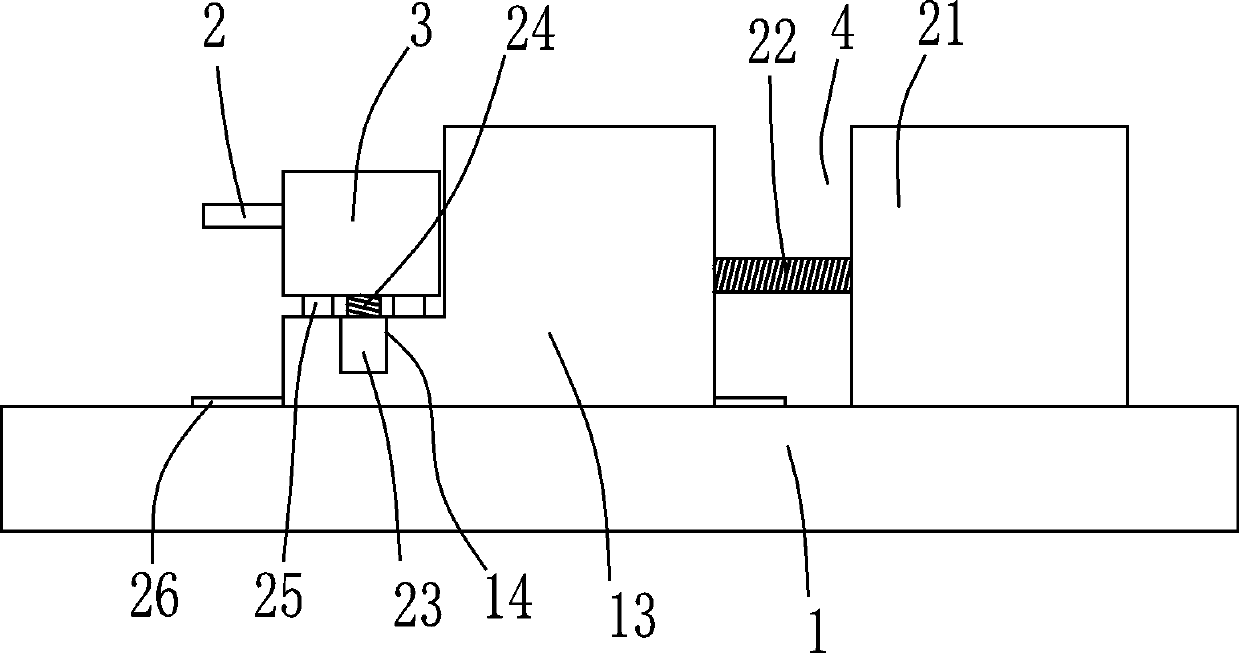

Hub unit finished product turning lathe

PendingCN110076353ASuitable for cuttingSmooth glidingAuxillary equipmentMeasurement/indication equipmentsMeasuring instrumentEngineering

The invention discloses a hub unit finished product turning lathe. The lathe comprises a base, a cutting edge, a cutter holder and a first feeding device, wherein positioning profiling is arranged onthe base, a lifting base is arranged on one side of the base through a first lifting structure, a top base is arranged on the lifting base, a height measuring instrument is arranged on the top base, atop column is rotationally arranged on the top base, the top column is driven by a first motor, a second feeding device for driving the top base to move is arranged on the lifting base, the cutting edge is fixed on the cutter holder, a sliding base is arranged on the base, the sliding base is driven by the first feeding device, the sliding base is connected with the cutter holder through a secondlifting structure, and the first feeding device, the height measuring instrument, the first motor, the first lifting structure and the second lifting structure are all connected with a control device. The lathe can adjust the height of the cutting edge according to the height of the end faces of hub units, so that the flange end faces of the hub units with different tolerance ranges can be turned, and the lathe can be applied to the different types of hub units.

Owner:浙江凯久汽车部件有限公司

Method for preparing microcrystalline jade plate by phosphorus slag

The invention provides a method for preparing a microcrystalline jade plate by phosphorus slag, comprising the following steps: blending materials: mixing an addictive with a clarifying agent to form a uniform auxiliary mixed material; melting: adding the auxiliary mixed material to the molten phosphorus slag to obtain molten glass by melting, performing heat preservation, homogenizing and clarifying the molten glass to obtain molten high-temperature glass melt; molding: molding the high-temperature glass melt to obtain a formed base glass plate; crystallizing: transferring the formed glass plate to a crystallizing and annealing kiln for crystallizing and annealing; and finish machining: after the microcrystalline jade plate is delivered from the kiln, machining the glass plate to obtain a finished product of the microcrystalline jade plate. The microcrystalline jade plate obtained by the method has the advantages of wear resistance, corrosion resistance, high temperature resistance, no radiation, high utilization rate of the phosphorus slag, higher social benefit and higher economic benefit.

Owner:TSINGHUA UNIV

A fabric cutting device

The invention discloses a material cutting device, which comprises a support frame, a servo motor, a conveying part, a cutting part, a clamping part and a transmission part. The support frame is the installation platform of the servo motor, the conveying part, the cutting part, the clamping part and the transmission part, and the fabric is conveyed by using the conveying part and the tightening part. Use the cutting section to cut the fabric.

Owner:湖北美春服装有限公司

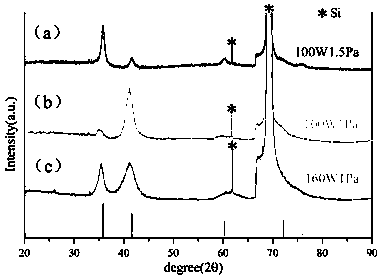

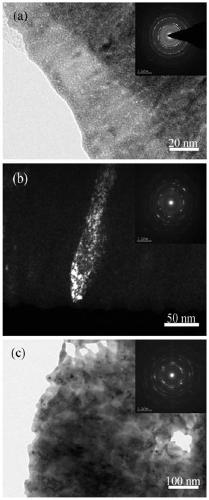

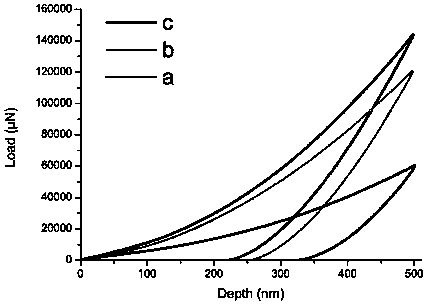

A kind of wear-resistant delta-tan thin film and its preparation method and application

ActiveCN108977767BReduce control difficultyIncrease profitVacuum evaporation coatingSputtering coatingNitrogen gasRadio frequency

The invention relates to a wear-resistant delta-TaN film, and a preparation method and application thereof, and belongs to the technical field of wear-resistant material design and preparation. A texture coefficient I(200) / [I(200) + I(111)] of the delta-TaN film is 0.2 to 0.8; the crystal structure of the film is delta-TaN of an NaCl crystal form. In the film, an atomic ratio of Ta / N is about 0.72 to 1.33. The preparation method comprises the following steps: using radio frequency reactive magnetron sputtering, using nitrogen and argon as working gases, using a tantalum target as a tantalumsource, and fixing a flow ratio of nitrogen and argon; adjusting a grain texture coefficient of the film by changing working pressure and / or tantalum target power. The application of the resulting filmincludes use as a cutting device, a diffusion impervious layer for electronic packaging, and the like. The invention opens up a new method for controlling the grain texture coefficient of the film; an obtained product is excellent in performance and is convenient for high-precision and large-scale generation and application.

Owner:HUNAN UNIV

Efficient cutting device which has good safety performance and is used for buildings

InactiveCN108890707AMeet cuttingGuaranteed cleanlinessMetal working apparatusWorking environmentCivil engineering

The invention belongs to the technical field of building plate processing and particularly relates to an efficient cutting device which has good safety performance and is used for buildings. In orderto solve the problems that large building decoration plates or small building decoration plates cannot be cut separately, a debris collection device does not exist, the cleanness of the working environment cannot be guaranteed, motion of cutters is unreliable, cuts of the building decoration plates are not flat, and the cutting precision is influenced, the following scheme is put forward. The device comprises a fixing base, and supporting columns are welded to the outer walls of the two sides of the top of the fixing base respectively. According to the efficient cutting device, cutting of various building decoration plates can be achieved, debris generated when the building decoration plates are cut can be collected, the cleanness of the environment of a processing workshop is guaranteed,the coinciding degree of the movable cutters and the fixed cutters is guaranteed, the cutting precision of the building decoration plates is improved, the building decoration plates can be stably positioned, and the device is suitable for cutting processing of the building decoration plates different in thickness.

Owner:王智光

long wave infrared nonlinear cdga 2 the se 4 Crystals and their growth methods and uses

ActiveCN104695022BImprove mechanical propertiesStable chemical propertiesPolycrystalline material growthFrom frozen solutionsNonlinear optical crystalSpontaneous nucleation

The invention relates to a long wave infrared nonlinear CdGa2Se4 crystal as well as a growth method and the use of the crystal. The CdGa2Se4 polycrystal material is synthesized by virtue of a high-temperature solid-phase reaction; the long wave infrared nonlinear CdGa2Se4 crystal is grown by use of a spontaneous nucleation Bridgman-Stockbarger method or an oriented seed crystal assisted Bridgman-Stockbarger method; the frequency doubling effect of the obtained nonlinear optical CdGa2Se4 crystal powder is about three times of that of AgGaS2, and the transparent waveband of the infrared region of the CdGa2Se4 crystal powder is capable of reaching long wave infrared 21 microns; besides, the CdGa2Se4 crystal powder is good in mechanical properties, stable in chemical properties, not prone to deliquescence, and suitable for orientation, cutting and polishing. The long wave infrared nonlinear CdGa2Se4 crystal is applicable to manufacturing infrared nonlinear optical devices.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

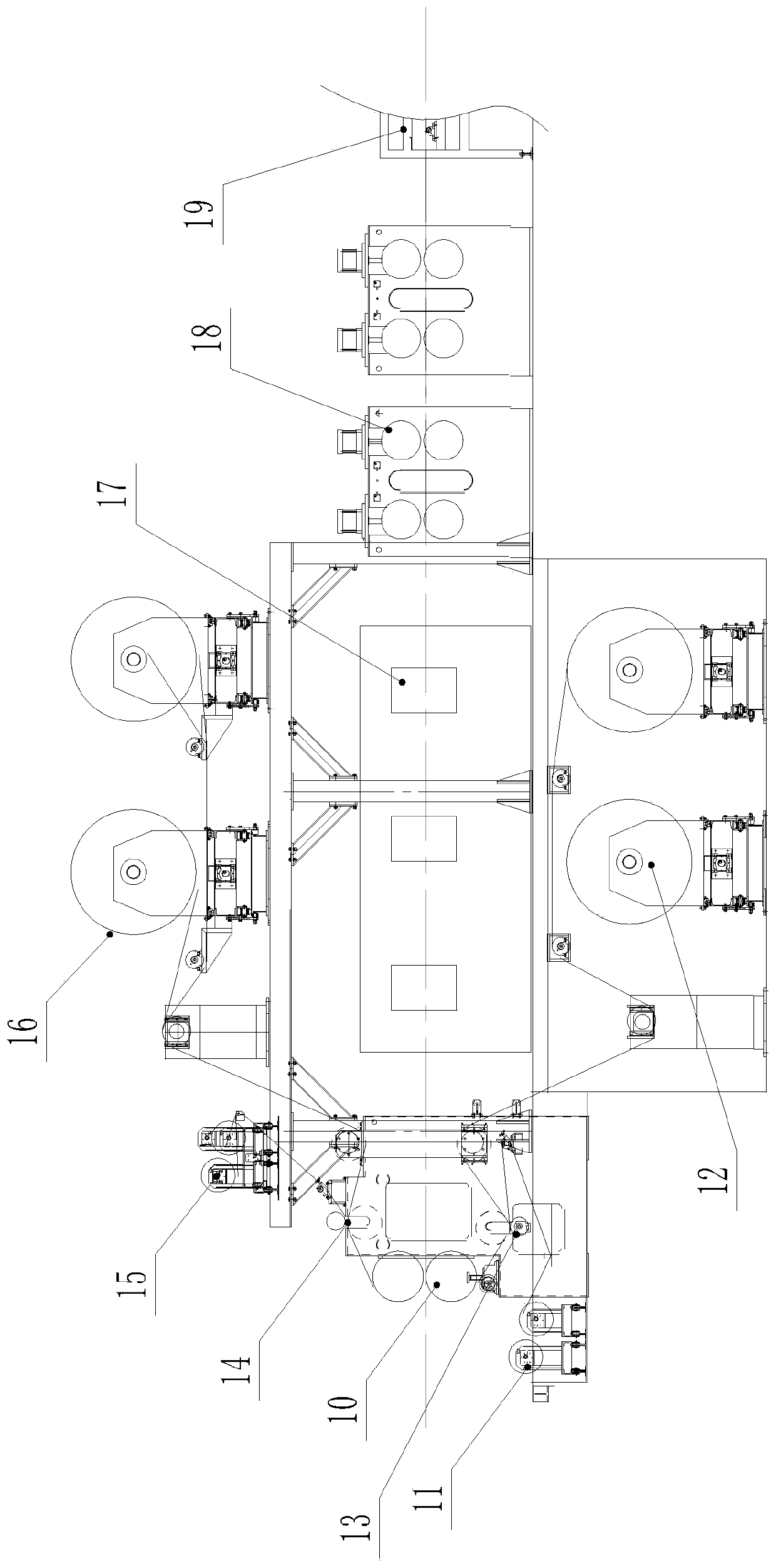

Grooving equipment for solar panel embedding support machining

InactiveCN111318752ASmooth and reliable adjustmentImprove stabilityShearing machinesFeeding apparatusEngineeringStructural engineering

The invention discloses grooving equipment for solar panel embedding support machining. The grooving equipment comprises two end supporting tables, a horizontally-arranged upper hanging rod, two lowerconnecting plates and a vertically-arranged hanging cutting mechanism, wherein the two end supporting tables are arranged at two ends of the equipment correspondingly. The grooving equipment for thesolar panel embedding support machining has the beneficial effects that push plates are attached and clamped to the side walls of the two sides of an embedding support through rubber push pads, it isguaranteed that the embedding support is stabler and firmer when being cut and grooved, and the working accuracy of the equipment is greatly improved; pushing and clamping bases on the two lower connecting plates clamp and fix the embedding support on the two sides of the embedding support correspondingly, and the plurality of pushing and clamping bases are distributed at equal intervals and tightly attached to the embedding support through the rubber pushing pads, so that the clamping and fixing firmness of the equipment on the embedding support is greatly improved; and the pushing and clamping bases push the pushing plates to move through second hydraulic rods, the embedding support is driven to move front and back to be adjusted, it is guaranteed that the hanging cutting mechanism is more accurate and appropriate in cutting and grooving positions of the embedding support, and the use flexibility is guaranteed.

Owner:刘凡

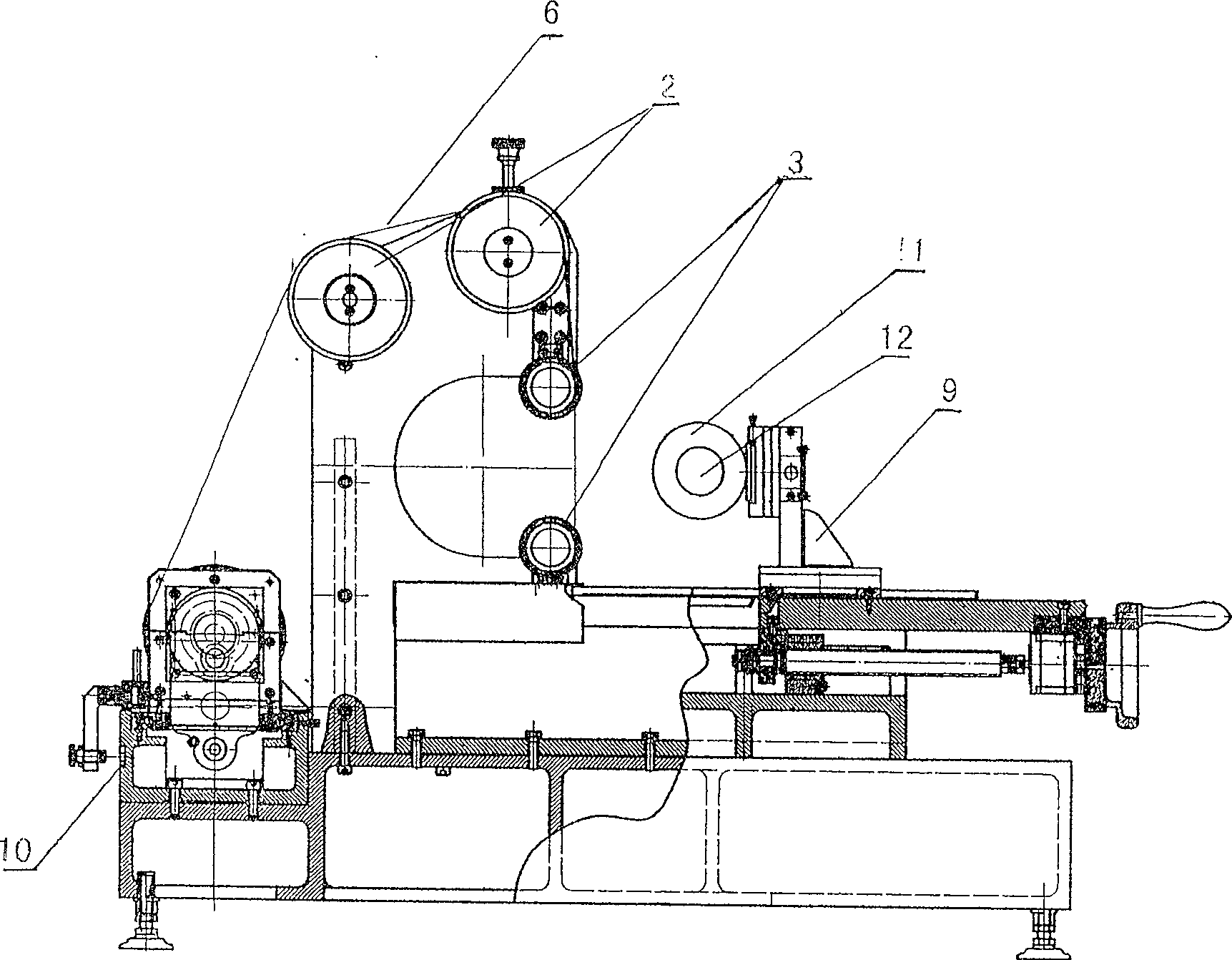

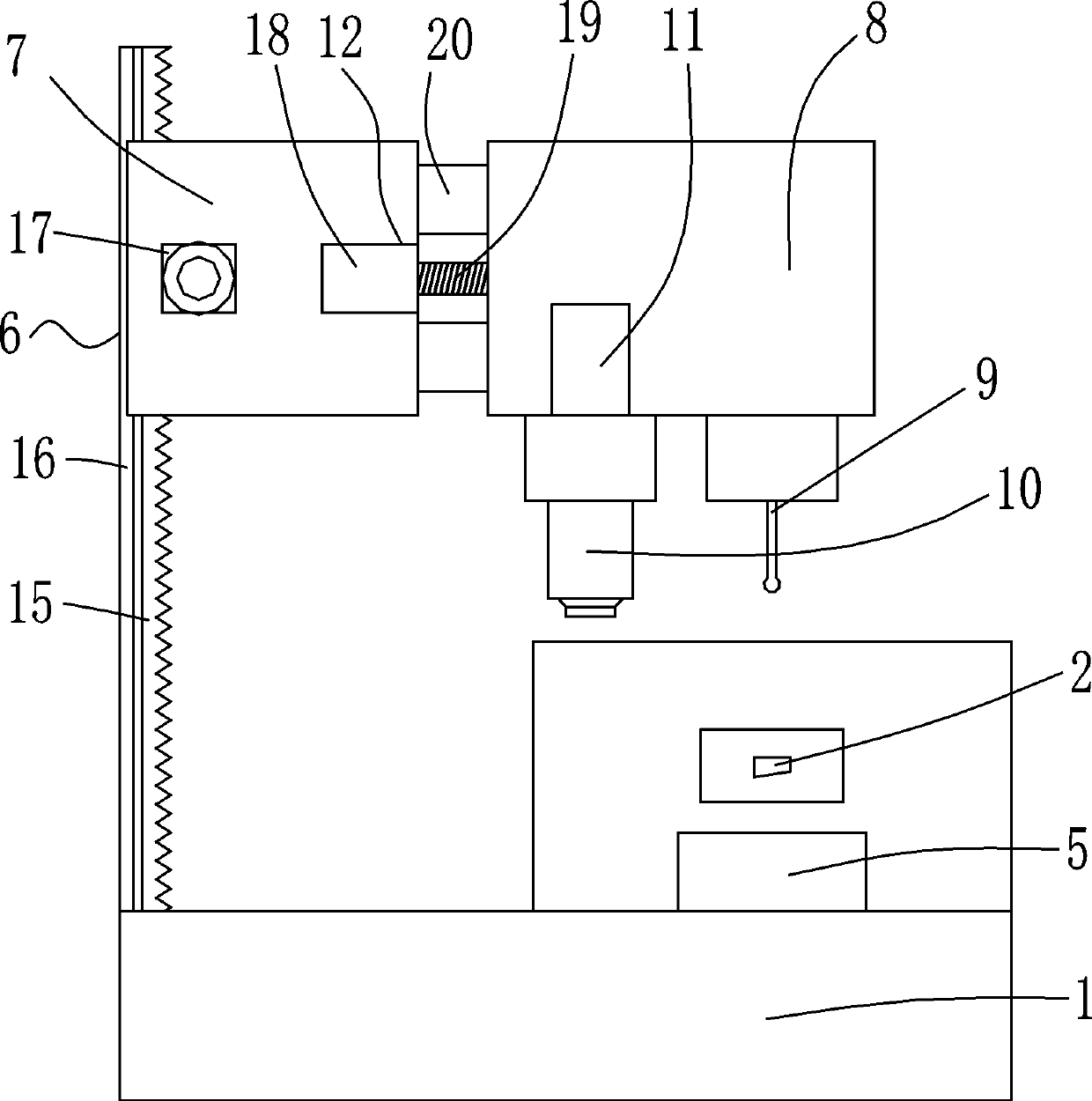

A single crystal silicon rod cutting machine

ActiveCN108673767BGuaranteed cutting qualityAutomate operationFine working devicesControl cellEngineering

This invention discloses a monocrystalline silicon rod guillotine, and belongs to the technical field of monocrystalline silicon rod processing. The monocrystalline silicon rod guillotine includes a worktable, a clamping unit, an adjusting unit and a controlling unit, wherein the worktable is used for supporting monocrystalline silicon rods; the clamping unit is used for clamping and positioning the monocrystalline silicon rods; the adjusting unit is used for adjusing the horizontal position and the height position of the worktable to allow the axial direction of the monocrystalline silicon rods located on the worktable to be perpendicular to the cutting direction of the saw blade of the guillotine; and the controlling unit is used for controlling the clamping unit and the adjusting unit.The monocrystalline silicon rod guillotine is particularly suitable for cutting and processing of the monocrystalline silicon rods with different size and front-and-back inconsistent thickness.

Owner:SHANDONG DAHAI NEW ENERGY DEV

High-lubrication universal total synthesis cutting fluid

PendingCN113897239ASuitable for cuttingTo achieve the effect of grindingLubricant compositionLubricationMaterials science

The invention belongs to the technical field of total synthesis cutting fluid, and particularly relates to high-lubrication universal total synthesis cutting fluid, which comprises an antirust agent, an alkali storage agent, a metal ion chelating agent, an aluminum corrosion inhibitor, a copper corrosion inhibitor, a special lubricant, a wetting agent, a hard water resistant agent, a bactericidal bacteriostatic agent, a settling agent, a defoaming agent and a diluent. According to the invention, by adding the special lubricant SA1801, most lubrication requirements can be met, and the special lubricant SA1801 is matched with the aluminum alloy corrosion inhibitor and the copper alloy corrosion inhibitor, so that the cutting fluid can be suitable for cutting grinding processing of ferrous metals, aluminum alloys and copper alloys so as to further improve the lubricating property of the high-lubrication universal total synthesis cutting fluid, and the high-lubrication universal total synthesis cutting fluid can be suitable for cutting grinding processing of ferrous metals, aluminum alloys and copper alloys.

Owner:深圳市油博士润滑科技有限公司

Eccentric crankshaft punching machine

The invention relates to an eccentric crankshaft punch. A crankshaft is an eccentric shaft, an eccentric part is sleeved with a rolling element, and a sliding block arranged below the crankshaft and provided with a die at the bottom is provided with a spring which forms an upward acting force to the sliding block; and the sliding block forms vertically moving punching motion under the combined actions of the upward acting force formed by compressing the spring and a downward acting force formed by rotation of the crankshaft. By adopting the structure, the crankshaft is easy to process with low cost; a punching stroke is short and suitable for cutting thick plates; the punching force is smaller so as to cause low noise during punching; and particularly the die with larger working area can be mounted in the structure, so that the structure is suitable for cutting of the plates with large area.

Owner:宁波澳玛特高精冲压机床股份有限公司

Super strong high phosphorus boron cast iron

The invention provides super-strong high-phosphorus boron cast iron. The super-strong high-phosphorus boron cast iron is made from molten iron and ingredients and is characterized in that the ingredients comprise the following raw materials in percentage by weight: 2.5-4% of C, 0-0.1% of S, 1.5-2.5% of Si, 0.2-0.4% of P, 0.05-0.5% of Cr, 0.5-1% of Mn and 0.05-0.2% of B. The super-strong high-phosphorus boron cast iron has the advantages that the abrasive resistance is good; the complete machine is durable in use and long in life; the economic benefit is increased; in the meantime, the energy consumption is low and the stability is good; virtuous circle is formed among components; the energy is saved and the emission is reduced; the boron cast iron is suitable for cutting machining; the machining indexes achieve the design standard; and the best adaptation performance is shown between the boron cast iron and a piston ring.

Owner:威佰昇科技(台州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com