Super-strong high-phosphorus boron cast iron

A high-phosphorus-boron, cast iron technology, applied in the field of cast iron, can solve the problems of affecting the service life of the whole machine, being too soft and not wear-resistant, and the cast iron is easy to be damaged, so as to achieve the effects of long life, good wear resistance and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The formula seasoning is (percentage by weight):

[0012] C: 3.1%; S: 0.05%; Si: 1.7%; P: 0.3%; Cr: 0.3%; Mn: 0.8%; B: 0.15%, and the rest is molten iron.

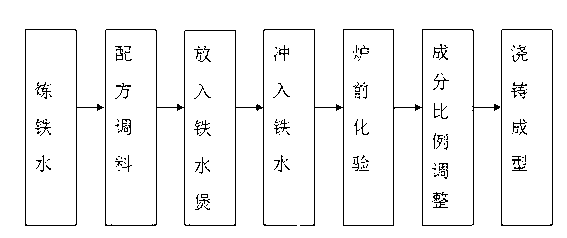

[0013] according to figure 1 The process shown was carried out.

Embodiment 2

[0015] The formula seasoning is (percentage by weight):

[0016] C: 3.2%; S: 0.08%; Si: 1.8%; P: 0.23%; Cr: 0.3%; Mn: 0.7%; B: 0.1%, and the rest is molten iron.

[0017] according to figure 1 The process shown was carried out.

Embodiment 3

[0019] The formula seasoning is (percentage by weight):

[0020] C: 3.3%; S: 0.1%; Si: 2%; P: 0.22%; Cr: 0.1%; Mn: 0.6%; B: 0.08%, and the rest is molten iron.

[0021] according to figure 1 The process shown was carried out.

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com