Aluminum alloy surface B4C particle reinforced Al base composite cladding layer and preparation method

A technology of aluminum alloy surface and particle reinforcement, applied in metal processing equipment, metal material coating technology, coating, etc., can solve the problem of light weight, poor wetting of powdered aluminum alloy melt, and difficulty in breaking dense oxide film, etc. problem, to achieve the effect of reduced dosage, good combination and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

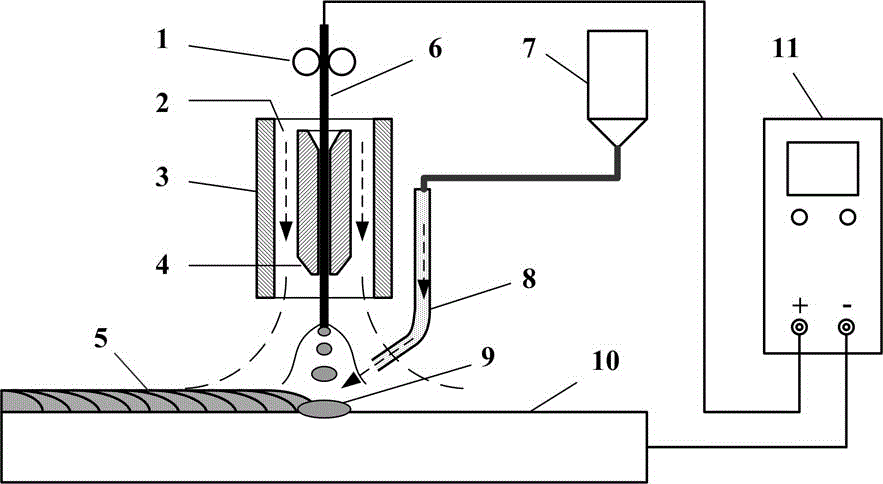

[0036] The invention as Figure 1-5 shown.

[0037] Aluminum alloy surface B 4 C Particle reinforced Al-based composite cladding layer, combined with powder-silk composite cladding technical scheme, where B 4 C particle reinforced Al-based composite cladding layer 5 is composed of aluminum alloy matrix and B 4 Composition of C particles, using molten inert gas shielded welding-MIG welding, while transitioning aluminum alloy welding wire to the aluminum alloy surface, assisting side injection of B 4 C particles are integrated into the Al-based cladding layer, which is to prepare B on the surface of the aluminum alloy. 4 C particles reinforce the Al-based composite cladding layer 5 .

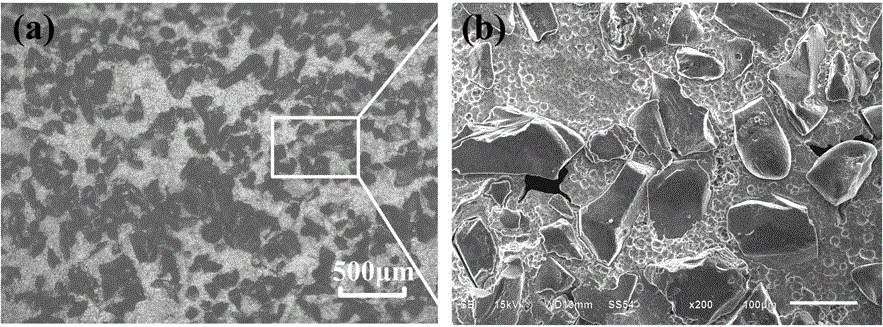

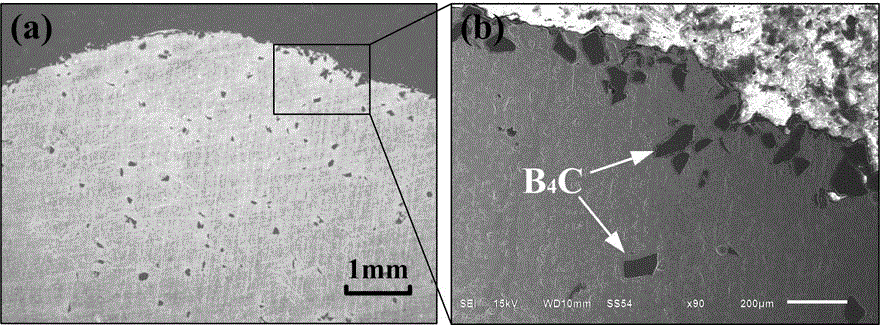

[0038] Among them, B in the cladding layer 4 C particles are unevenly distributed; B on the surface 4 The coverage rate of C particles is 30% to 40%, and the content gradually decreases from the surface along the depth direction.

[0039] The aluminum alloy surface B 4 The thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com