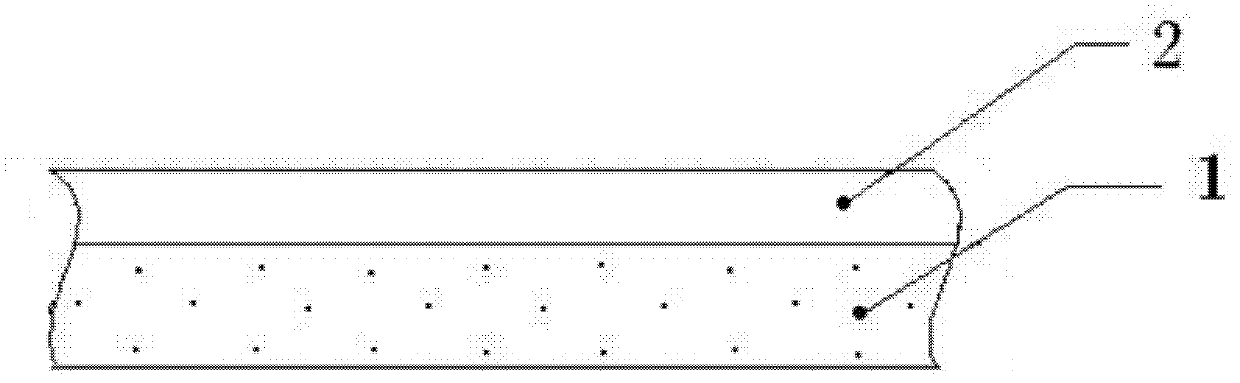

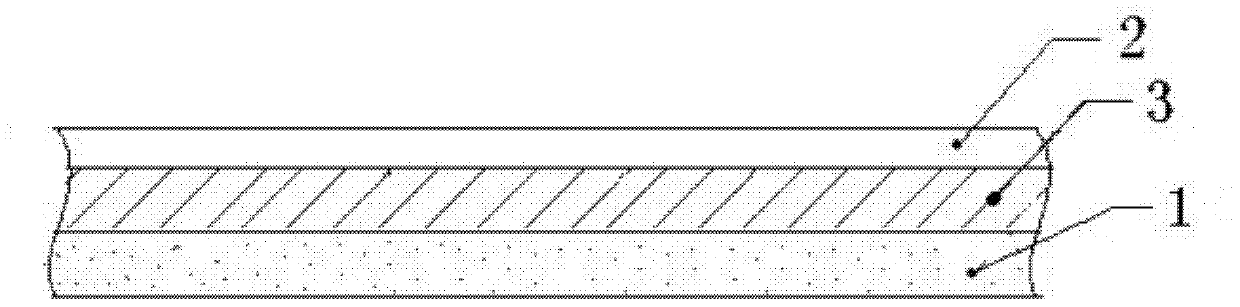

Polyurea waterproof coiled material

A waterproofing membrane, polyurea technology, applied in water conservancy projects, building insulation materials, roofing using flexible materials, etc. Application and other problems, to achieve the effect of simple structure, strong adhesion and stable construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

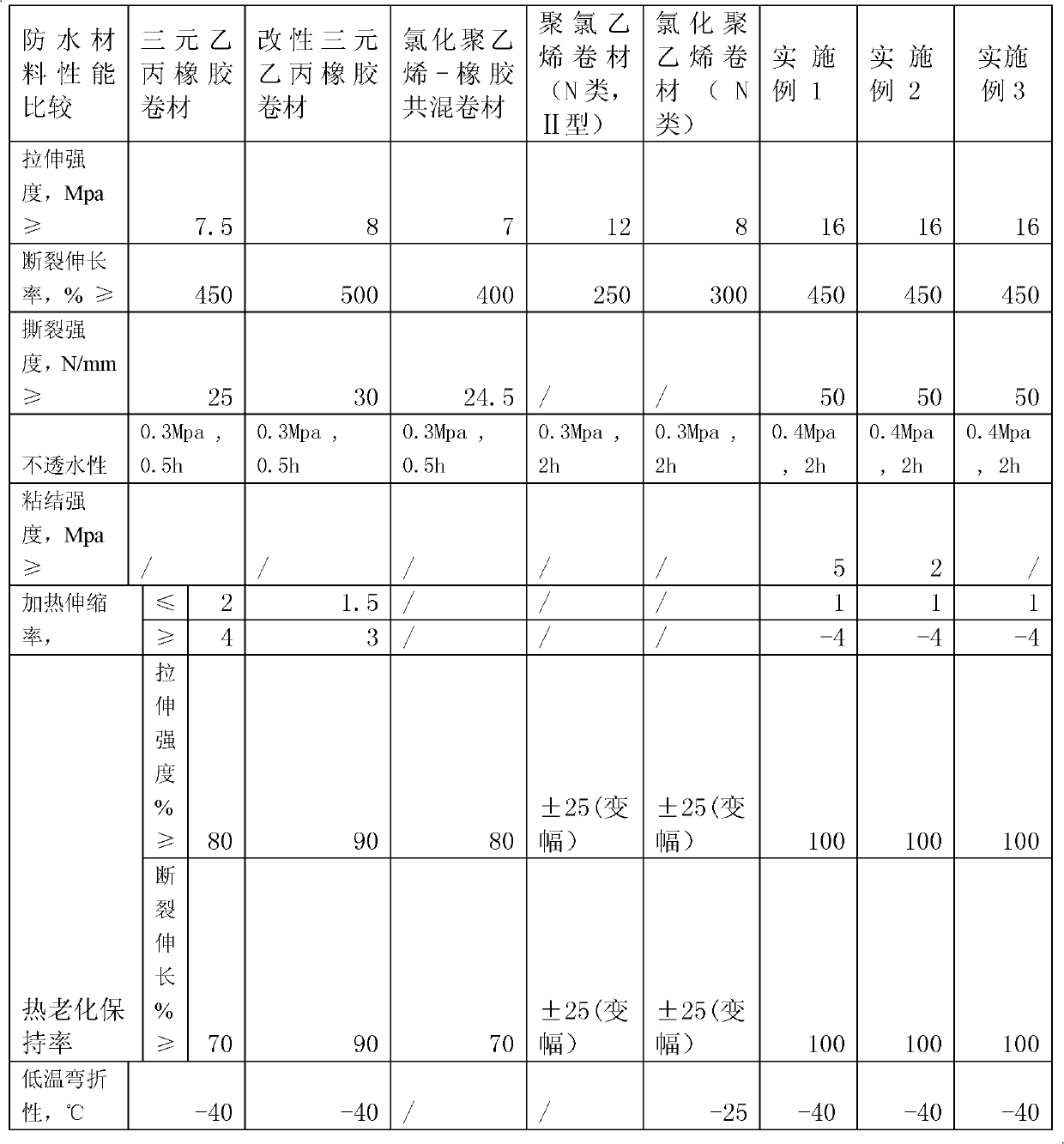

Embodiment 1

[0022] The liquid material for preparing the polyurea elastic layer includes component A and component R with a volume ratio of 1:1.

[0023] Wherein, component A includes: 42% (weight) of PPG2000 polyether polyol and 58% (weight) of liquefied diphenylmethane diisocyanate (MDI).

[0024] Preparation process of component A: Dehydrate PPG2000 polyether polyol at 100-105°C and vacuum degree of -0.07--0.10Mpa for 3 hours, then lower the temperature to 78-82°C, add liquefied diphenylmethane Diisocyanate (MDI), stirred, and kept warm for 2 hours; the temperature was lowered to below 70°C, filtered with a 200-mesh filter, and discharged.

[0025] The R component comprises the liquid material of following percentage by weight: polyether diamine (4000 molecular weight) 38%, polyether diamine (2000 molecular weight) 19.5%, polyether triamine (3000 molecular weight) 13%, diethyltoluenediamine (DETDA) 10%, di-tert-butylethylenediamine 16%, titanium dioxide 3%, black paste 0.5%.

[0026]...

Embodiment 2

[0033] The liquid material for preparing the polyurea elastic layer includes component A and component R with a volume ratio of 1:1.

[0034] Wherein, component A includes: 44.2% (weight) of PPG2000 polyether polyol, 50.8% (weight) of liquefied diphenylmethane diisocyanate (MDI) and 5.0% (weight) of toluene diisocyanate (TDI).

[0035] Preparation process of component A: dehydrate PPG2000 polyether polyol at 100-105°C, vacuum degree -0.07-0.10Mpa for 3 hours, then lower the temperature to 78-82°C, add toluene diisocyanate (TDI ), stirred evenly, and reacted for 2 hours; then added diphenylmethane diisocyanate (MDI), stirred, and reacted for 2 hours; then lowered the temperature below 70°C, filtered and discharged with a 200-mesh filter.

[0036] The R component comprises the liquid material of following percentage by weight: PPG2000 polyether polyol 54.8%, polyether diamine (4000 molecular weight) 17.7%, polyether diamine (2000 molecular weight) 8.5%, polyether triamine (3000 ...

Embodiment 3

[0044] The liquid material for preparing the polyurea elastic layer includes component A and component R with a volume ratio of 1:1.

[0045] Wherein, component A includes: 44% (weight) of PPG2000 polyether polyol and 56% (weight) of hydrogenated diphenylmethane diisocyanate (hydrogenated MDI).

[0046] Preparation process of component A: Dehydrate PPG2000 polyether polyol at 100-105°C and vacuum degree of -0.07--0.10Mpa for 3 hours, then lower the temperature to 80-85°C, add hydrogenated diphenylmethane Diisocyanate (hydrogenated MDI), stirred, and kept warm for 3.5 hours; the temperature was lowered to below 60°C, filtered with a 200-mesh filter, and discharged.

[0047] The R component comprises the liquid material of following percentage by weight: polyether diamine (4000 molecular weight) 35%, polyether diamine (2000 molecular weight) 19.5%, polyether triamine (3000 molecular weight) 13%, diethyltoluenediamine (DETDA) 16%, di-tert-butylethylenediamine 13%, titanium dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com