Patents

Literature

58results about How to "Well combined" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

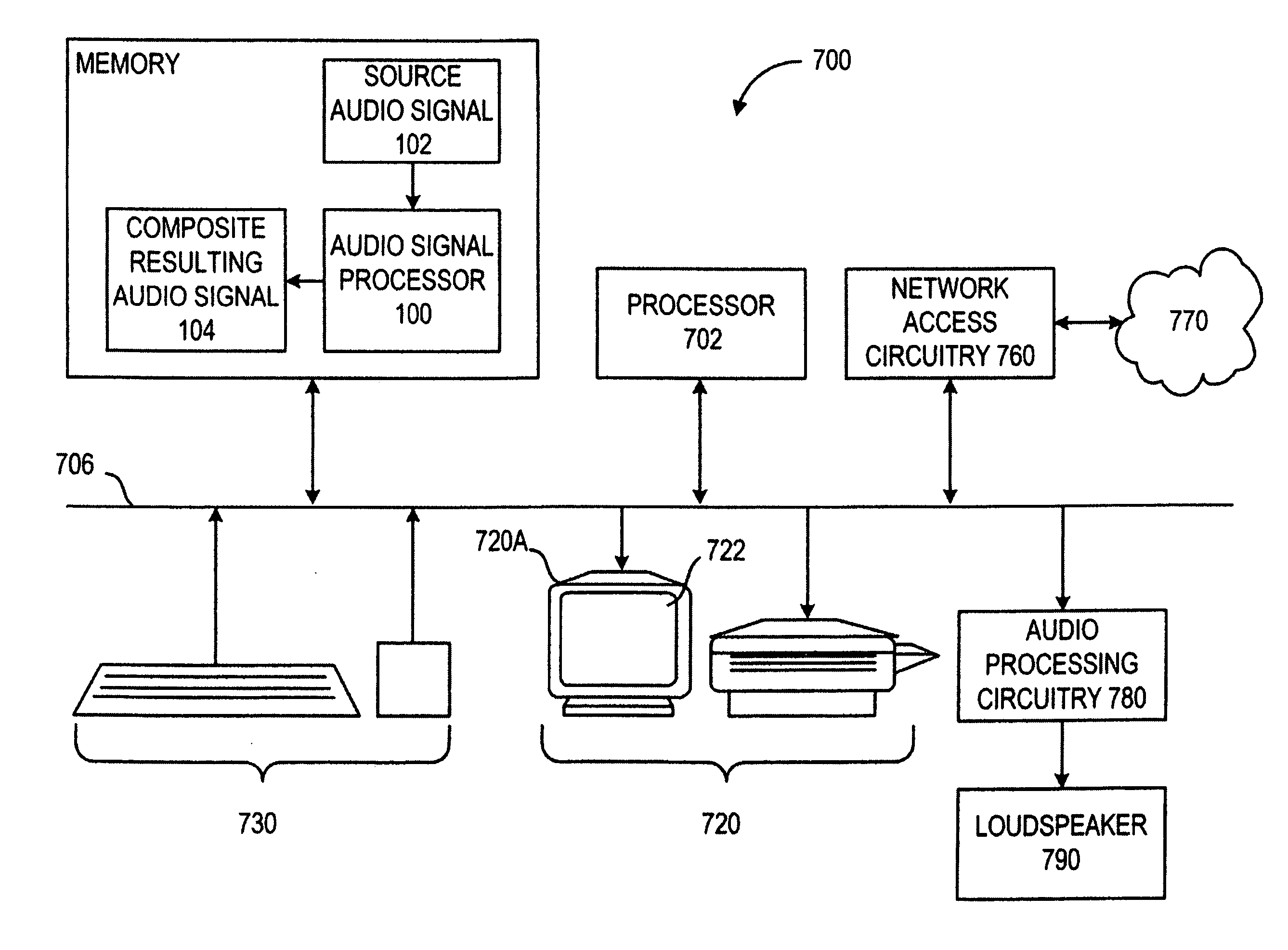

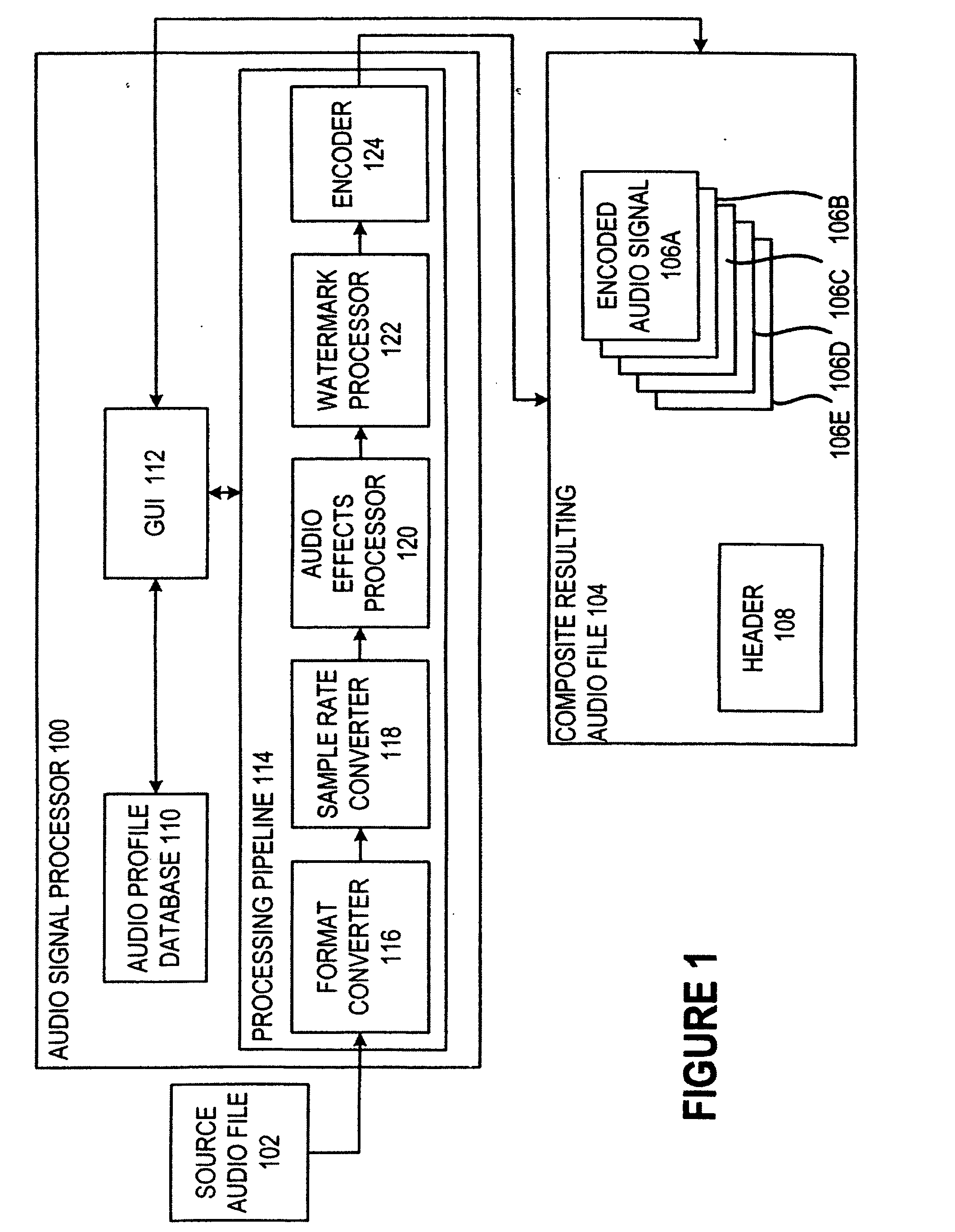

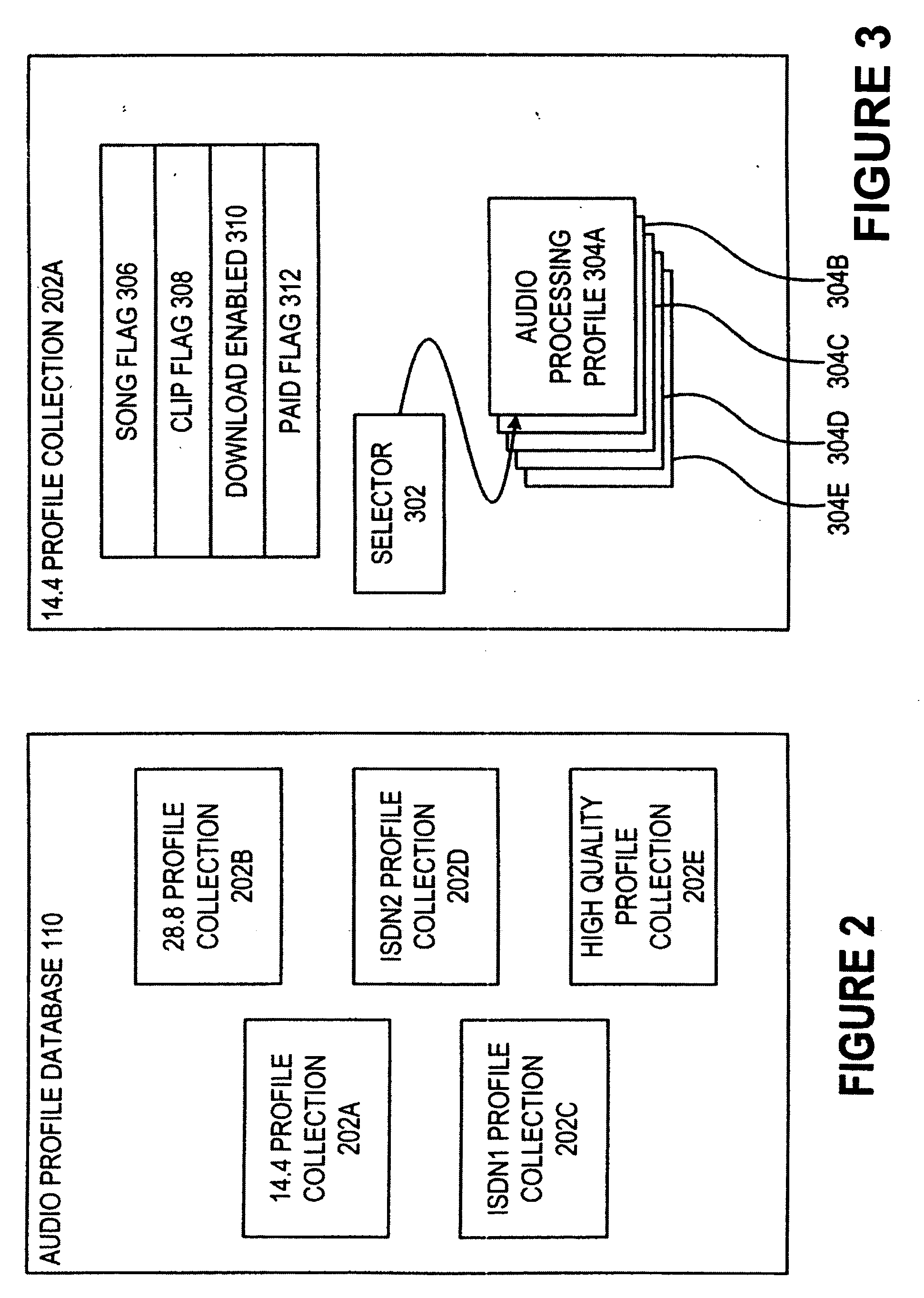

Digital audio signal filtering mechanism and method

InactiveUS20050065780A1Good resultWell combinedTelevision system detailsSpeech analysisDigital audio signalsTransmission bandwidth

Essentially all of the processing parameters which control processing of a source audio signal to produce an encoded audio signal are stored in an audio processing profile. Multiple audio processing profiles are stored in a processing profile database such that specific combinations of processing parameters can be retrieved and used at a later time. Audio processing profiles are organized according to specific delivery bandwidths such that a sound engineer can quickly and efficiently encode audio signals for each of a number of distinct delivery media. Synchronized A / B switching during playback of various encoded audio signals allows the sound engineer to detect nuances in the sound characteristics of the various encoded audio signals.

Owner:MICROSOFT TECH LICENSING LLC

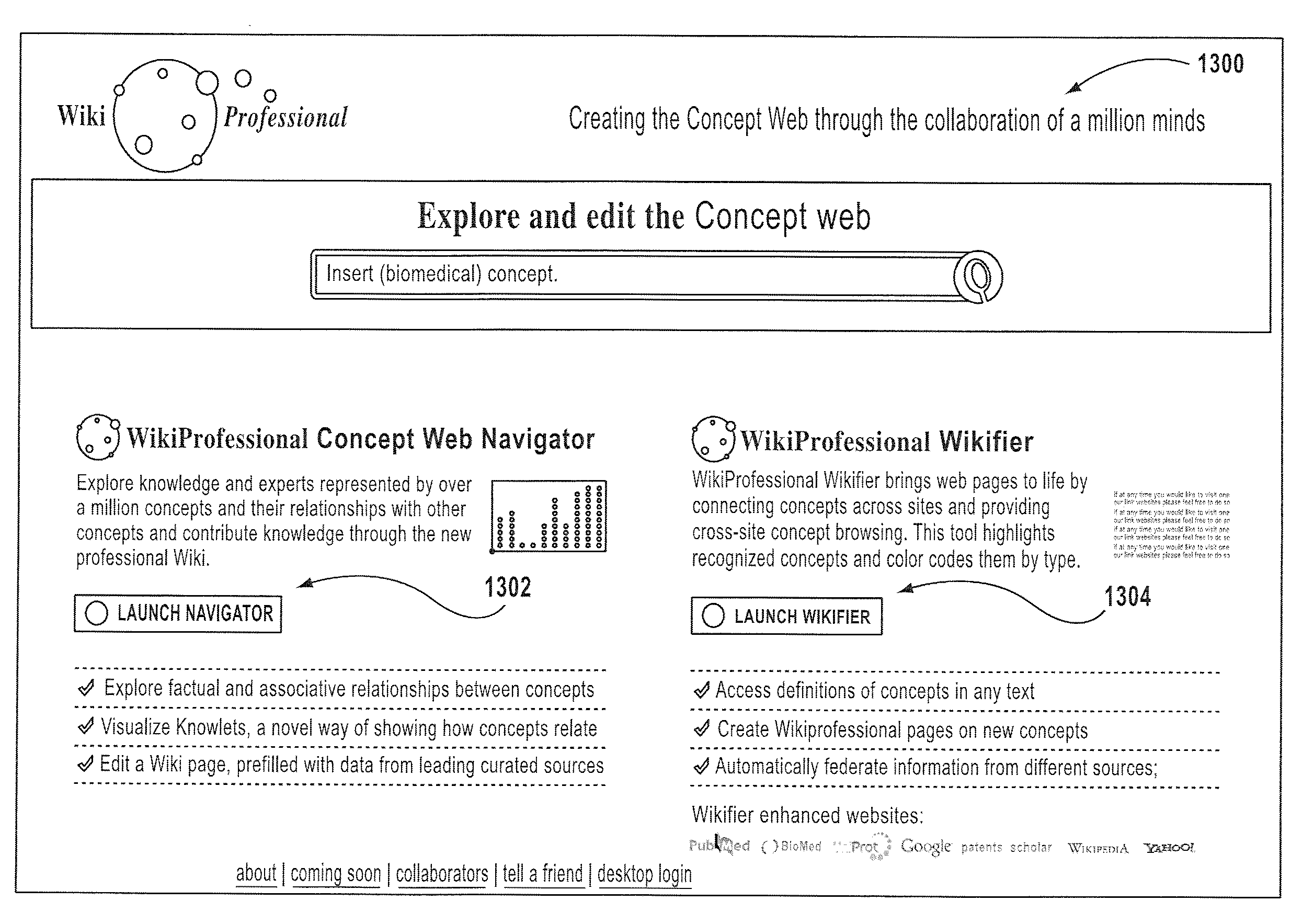

System and method for knowledge navigation and discovery utilizing a graphical user interface

InactiveUS20090217179A1Well combinedFacilitate relational and associative and other typeWebsite content managementWeb data navigationConcept mapGraphical user interface

Methods and computer program products utilizing a graphical user interface for navigating concepts found in data produced by intellectuals in a knowledge discovery process are disclosed. The present invention utilizes a graphical user interface and related facilities for enabling community-based contributions in identifying associations between concepts disclosed by intellectuals. The present invention's approach results in having concepts mapped to authors and tools for linking related concepts with groups of intellectuals and / or contributors.

Owner:KNEWCO INC WIKI PROFESSIONAL

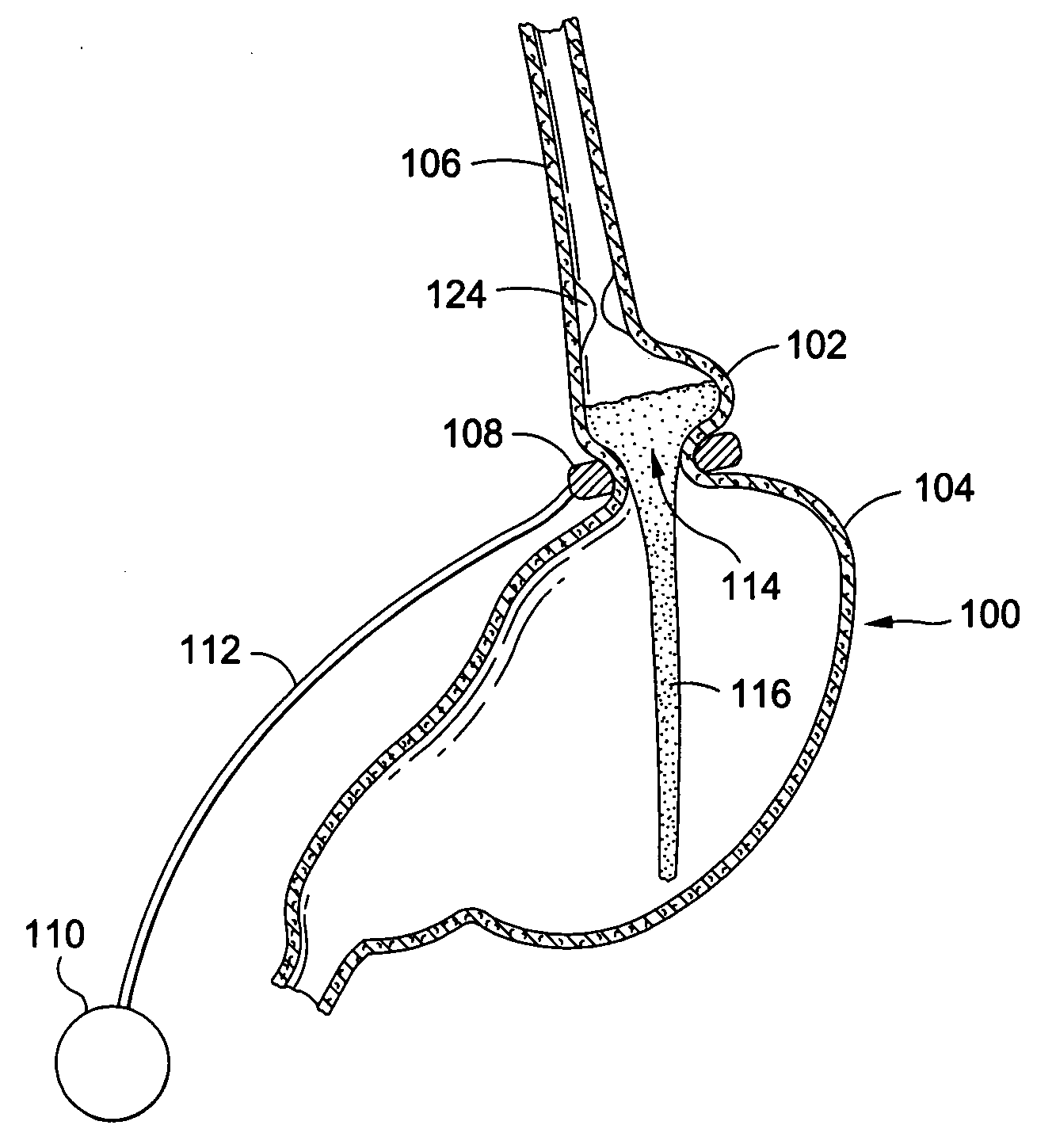

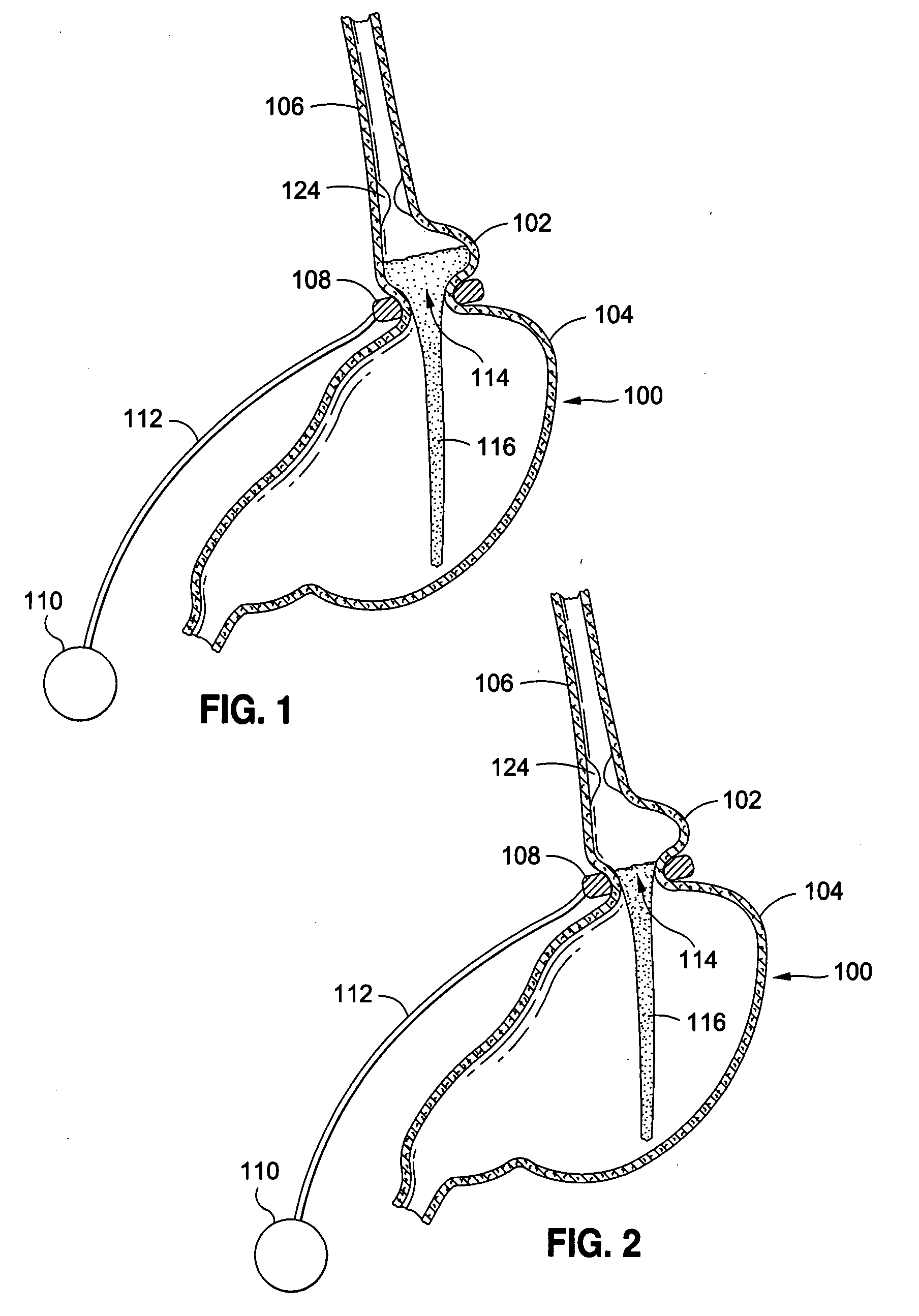

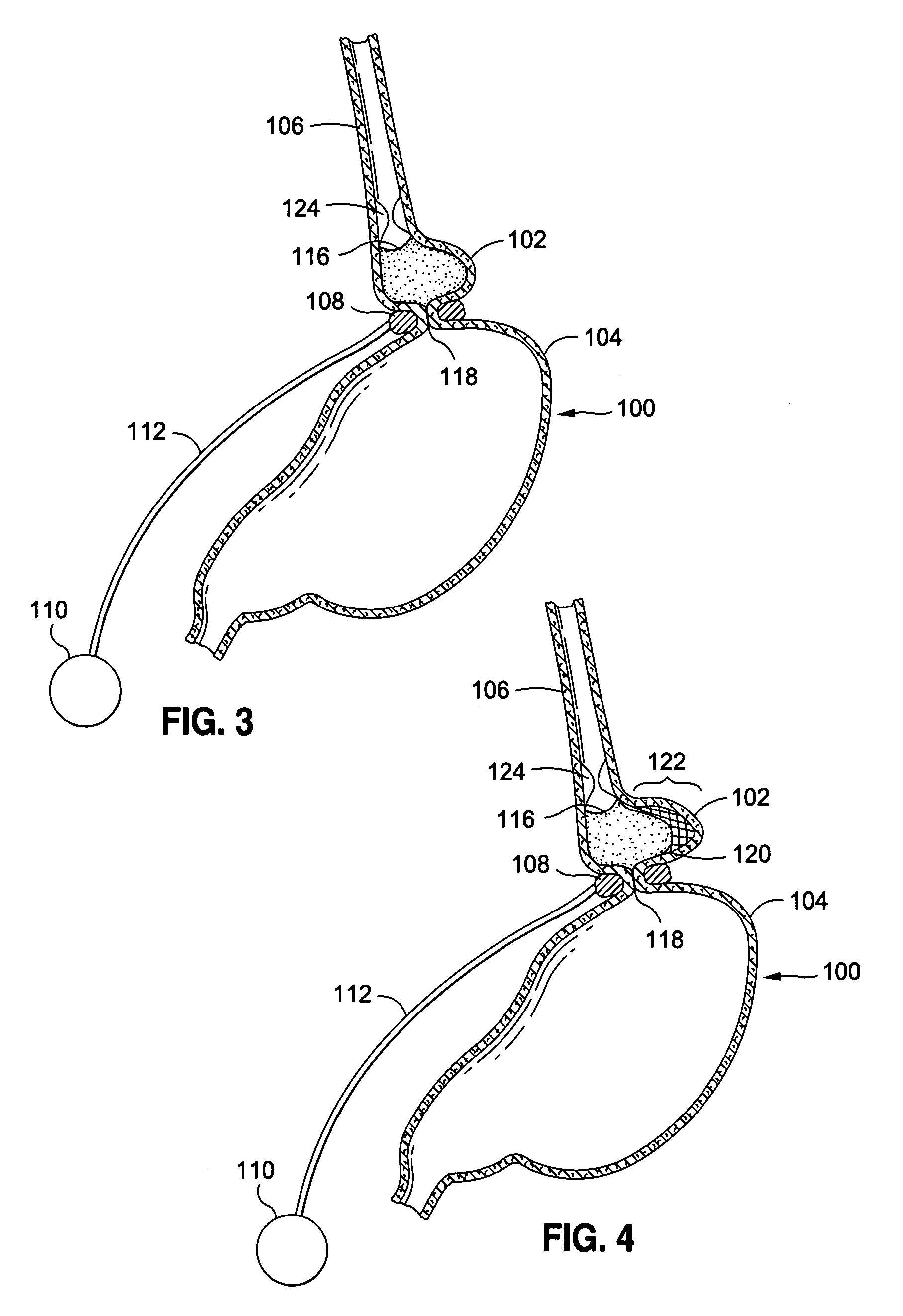

External sensing system for gastric restriction devices

InactiveUS20080097249A1Reduce costs and risksWell combinedPerson identificationAuscultation instrumentsUrologyStethoscope

Methods and apparatus useful for monitoring fluid flow past a gastric restriction device using noninvasive means are described. Some methods involve the use of acoustic energy, e.g., Doppler ultrasound, to monitor the passage of fluid past the restriction device, and apparatus to detect the acoustic energy. In some embodiments the method detects a sound-producing fluid using a microphone, stethoscope, or ultrasound probe and detector combination. In some embodiments, there are described methods of using Doppler ultrasound to monitor the flow of a fluid through a stomal opening, allowing a flow condition, e.g., a flow rate, to be determined, so that a physician can accurately adjust the gastric restriction device.

Owner:ELLIPSE TECH

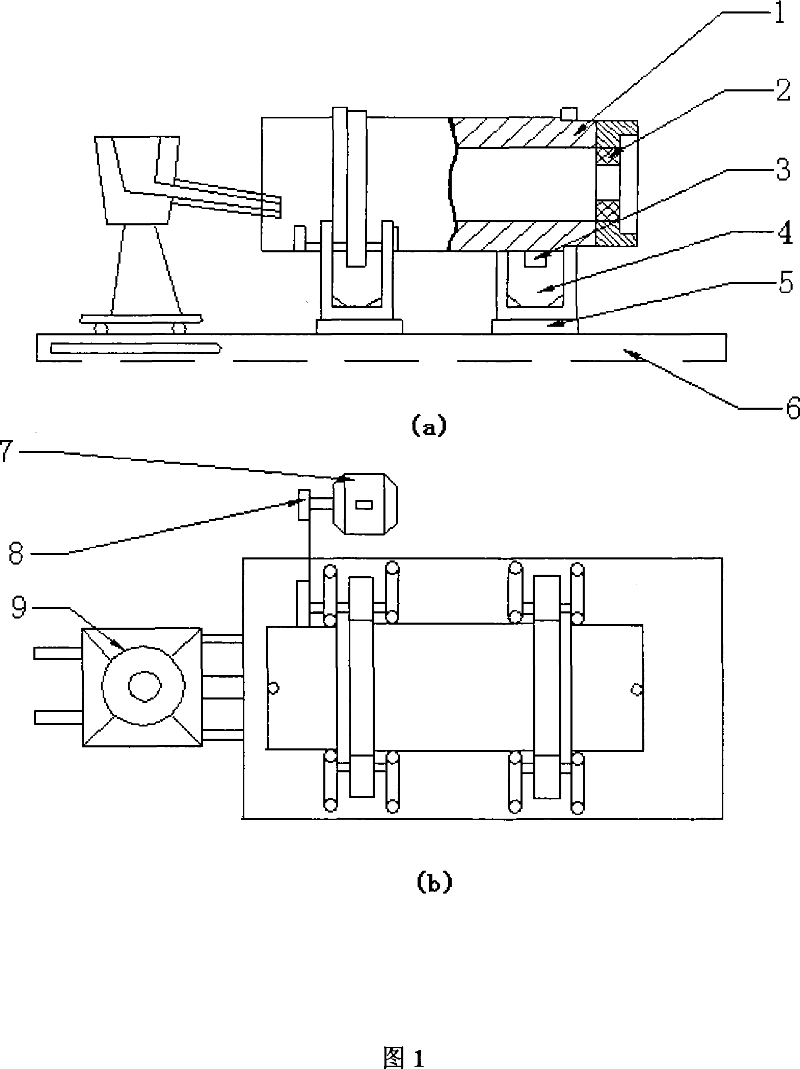

Low-aliquation high-speed steel roll and the preparing method

The invention discloses a low segregation centrifugal casting high speed steel roll and the method. The roll is constituted by high speed steel roll body and alloy ductile ion roll core. The roll is produced by electric furnace. The high speed steel roll body is cast on horizontal centrifuge. As the liquid steel is cast iron powder suspension concentrate with 4%-6% by weight of liquid steel is added. After the liquid steel is cast glass waste sludge is added and then it is cooled by spraying water to form the model. Meanwhile the rotate speed of casting model is changed continuously and finally the ductile ion roll core is cast at the top statically. There is no obvious element segregation in radial section of high speed steel roll manufactured in invention. The macro hardness of roll is high and can achieve 63-65HRC. The difference of roll face hardness is less than 2HRC. The hardness fall of roll along the radial direction is small. The tensile strength of roll body is more than 600MPa and the elongation of roll core is more than 3%. The service life is improved by 5-8 times than high chromium cast iron roll and is improved by 35%-48% than common high speed steel roll. It can decrease the producing cost of rolling steel and prolong roll changing period.

Owner:XI AN JIAOTONG UNIV

Phenolic resin foam material and preparing method thereof

The invention discloses a phenolic resin foam material and a preparing method thereof. The phenolic resin foam material is composed of an A component and a B component, wherein the A component is composed of 100 parts by weight of A-stage phenolic resin, 10-20 parts by weight of medium-viscosity chitosan, 10-30 parts by weight of lignin polyether polyols, 0-20 parts by weight of aluminium hydroxide, 5-10 parts by weight of surface active agents, 10-20 parts by weight of foaming agent dichlorofluoroethane (HCFC-141b) and 10-30 parts by weight of diluent methyl formate, and the B component contains 20-50 parts by weight of compound toughening acid catalysts. The preparing method includes: respectively mixing the A component and the B component uniformly, mutually mixing the A component and the B component, and pouring the mixture into a mold for foaming at temperature of 80 DEG C to obtain the phenolic resin foam material. The phenolic resin foam material has high compressive strength and flexibility while not being reduced in fireproof and flame retardant property, and is suitable for outer wall heat preservation construction of buildings with high fireproof level requirements.

Owner:上海柯瑞冶金炉料有限公司 +1

Vacuum electron beam brazed joint method of tungsten/low activation steel

InactiveCN102000895AImprove efficiencyWell combinedSoldering apparatusWelding/soldering/cutting articlesVacuum electronicsTungsten

The invention discloses a vacuum electron beam brazed joint method of tungsten / low activation steel, belonging to the field of metal materials. According to the method, with an amorphous state T-based belt as brazing filler metal, the tungsten and the low activation steel are subjected to the brazed joint by using the vacuum electron beam braze technology wherein the amorphous state T-based belt contains 30-50 percent by weight of Ti, 30-50 percent by weight of Zr, 10-15 percent by weight of Cu and 5-10 percent by weight of Ni. During soldering, the scanning and the heating are carried out on the electron beam surface from the surface of the tungsten under the conditions that the temperature is controlled to 800-1,200DEG C, the work vacuum degree in the chamber is 1.0-5.0*10<-3>Pa, the accelerating voltage is 100-150KV, the focusing current is 100-600mA, the electron beam current is 1-10mA and the scanning frequency is 0.1-1KHz. The coil is scanned at high frequency by controlling through a computer and the heating time is 1-5 minutes. By using the method, the tungsten and the low activation steel are connected in a short time with high efficiency; and the weld seam interface can be better combined and has no defects of pore, inclusion, cracks and the like. The invention can be widely applied to connecting components of a helium cooled partial filter in a magnetic-confinement nuclear fusion experimental device.

Owner:UNIV OF SCI & TECH BEIJING

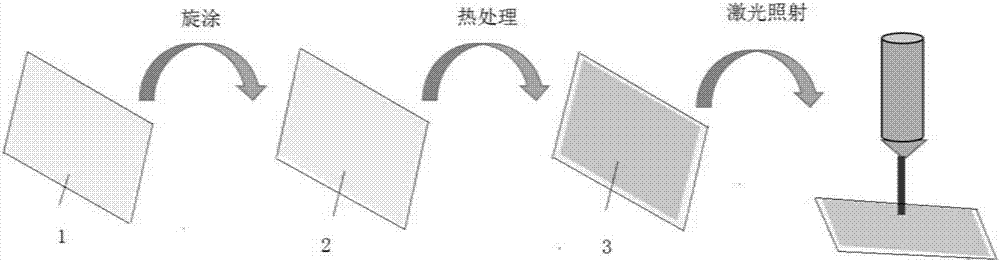

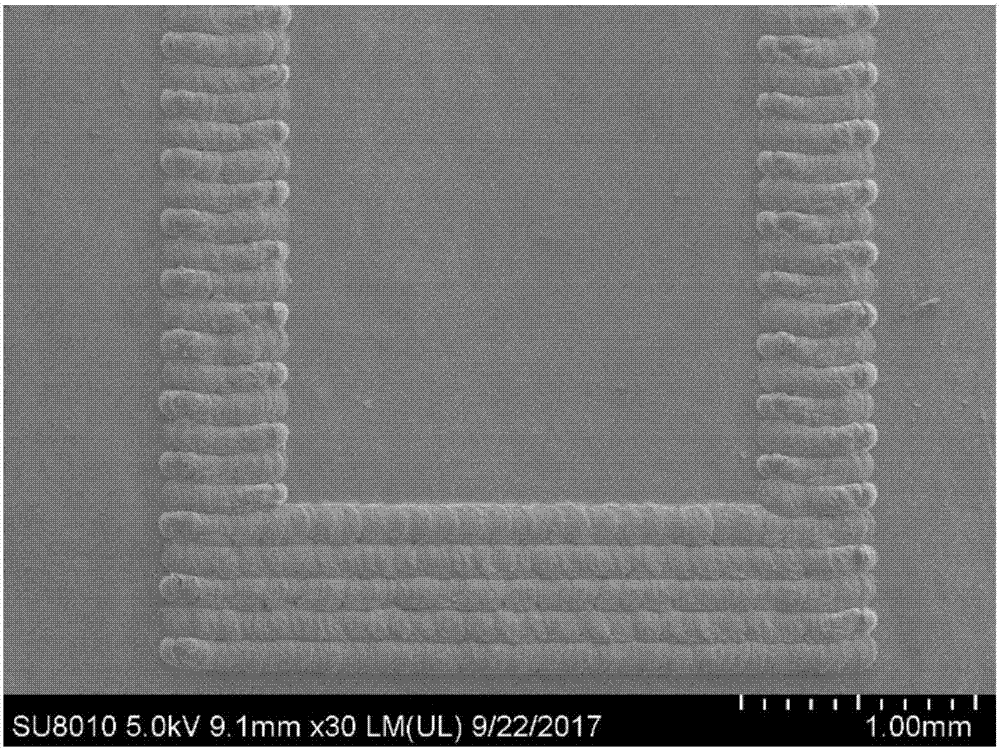

Preparation method of flexible sensor

ActiveCN108007480AWell combinedImprove stabilityRespiratory organ evaluationSensorsSurface modificationAutomatic processing

The invention relates to a preparation method of a flexible sensor, which comprises the following steps: modifying carbonated polymer on part of the surface of a flexible matrix to form a carbonated polymer layer; irradiating at least part of the carbonated polymer layer with laser to realize in-situ carbonization and form a sensing element; and electrically connecting at least two positions of the sensing element to form electrodes, and then, obtaining a flexible sensor. The method of the invention has the advantages of low cost, strong universality, flexible design, simple manufacture, automatic processing and good technological controllability. The flexible sensor prepared is multifunctional and highly sensitive.

Owner:深圳感碳科技有限公司

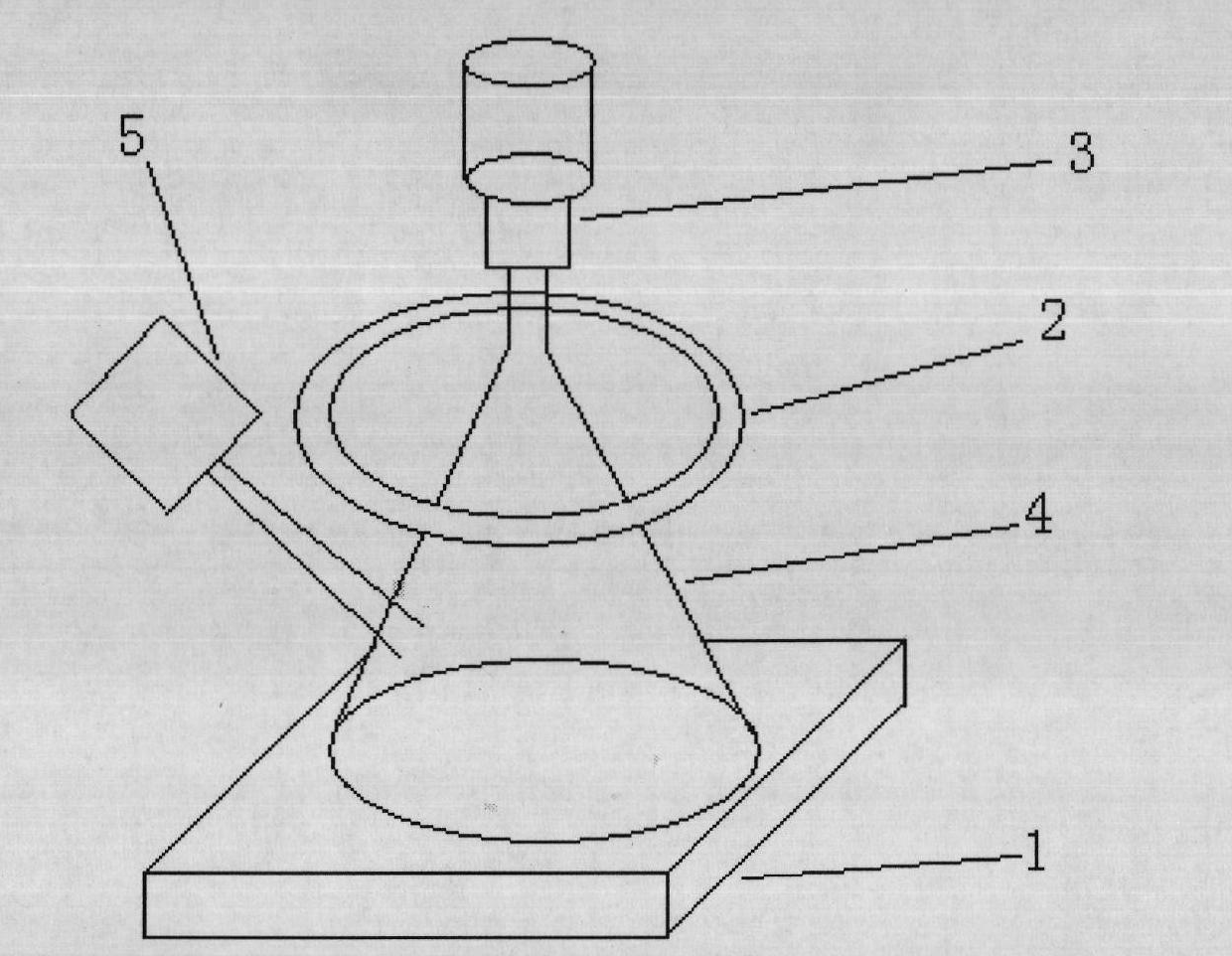

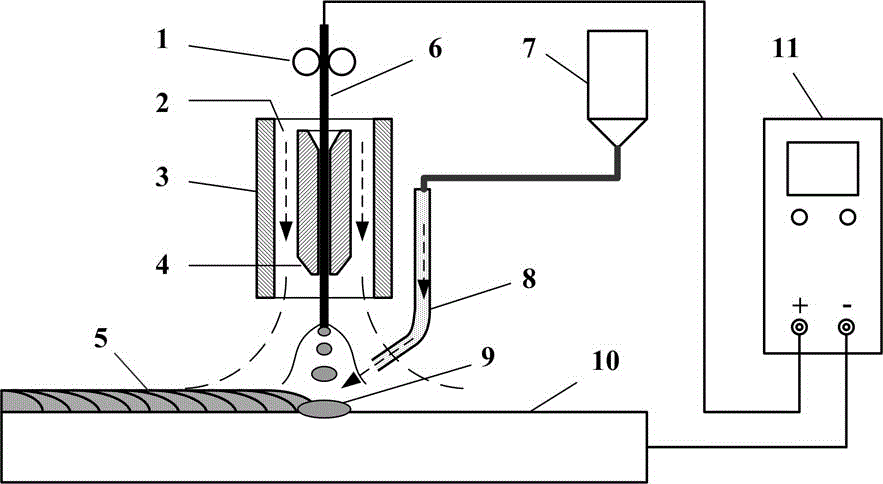

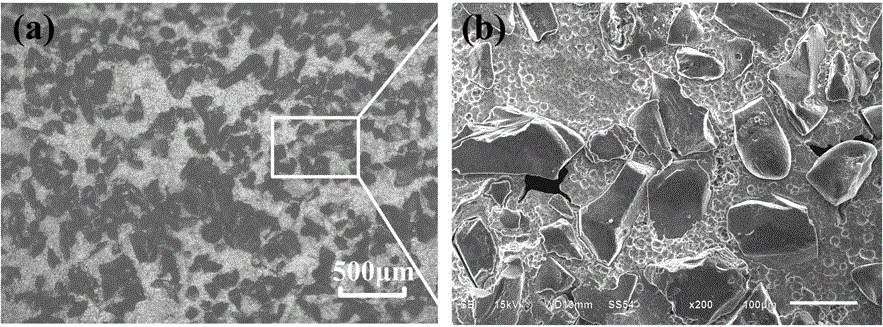

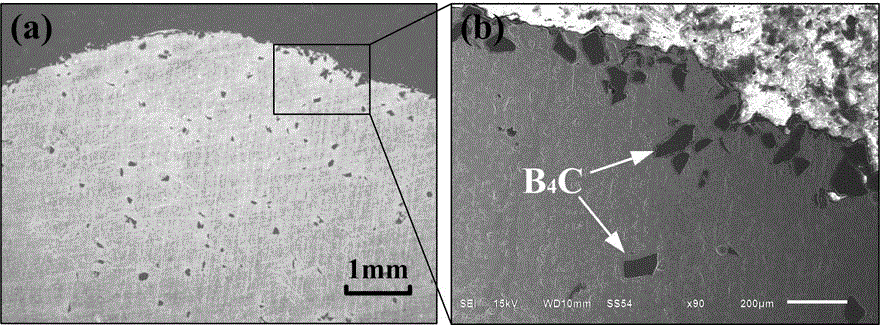

Aluminum alloy surface B4C particle reinforced Al base composite cladding layer and preparation method

ActiveCN106513929AWell combinedGood wear resistanceArc welding apparatusMetallic material coating processesAlloy substrateAlloy surface

The invention discloses an aluminum alloy surface B4C particle reinforced Al base composite cladding layer and a preparation method, overcomes the problem that a traditional technology is difficult to remove compact oxide films quickly grown on surfaces of aluminum and an alloy of the aluminum, solves the problems of difficult powder feeding due to light mass of B4C particles and weak wettability with aluminum alloy molten liquid, and effectively leads the B4C particles in the aluminum alloy surface layer to form an Al base composite cladding layer with excellent metallurgic bonding. In cooperation with the powder-wire composite cladding technical scheme, by using consumable electrode inert gas protective welding-MIG welding, aluminum alloy welding wires are transited to the aluminum alloy wire, the side injection of the B4C particles is assisted to fuse in the Al base cladding layer, that is, the B4C particle reinforced Al base composite cladding layer is prepared on the aluminum alloy surface. The B4C particle reinforced Al base composite cladding layer and an aluminum alloy substrate are excellently bonded, and the B4C particles in the cladding layer and an Al matrix are excellently bonded, and obvious defects such as air holes and cracks are avoided; and the aluminum alloy surface B4C particle reinforced Al base composite cladding layer is higher in wear resistance compared with 45 steel.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Method for preparing copper-coated aluminium composite material

InactiveCN102103906AReduce heat treatment processWell combinedSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAluminum compositesSoldering

The invention relates to a method for preparing a copper-coated aluminium composite material. The method comprises the following steps: spinning the head of a copper tube which is utilized as a raw material to form a cone, turning the head of the aluminium bar which is utilized as a raw material to form a cone, mechanically polishing the aluminium bar and then sleeving the aluminium bar with the copper tube to form an extrusion billet; coating a colloidal graphite lubricating film on the exterior of the extrusion billet and carrying out copper and aluminium soldering and sealing on the tail of the extrusion billet; ensuring the container temperature of a hot hydrostatic extruder to be 350-450 DEG C, the temperature of an extruding die to be 150-350 DEG C, the temperature of the copper tube forming the extrusion billet to be 350-450 DEG C and the temperature of the aluminium bar to be 150-250 DEG C; and feeding the extrusion billet into the container, filling extrusion media and then carrying out hydrostatic extrusion, thus obtaining the copper-coated aluminium composite material, wherein the internal diameter of the copper tube is the same as the external diameter of the aluminium bar; and the extrusion ratio is 4-100. The method has the following beneficial effects: the copper-coated aluminium composite material prepared by the method has high copper / aluminium interface bond strength and good bending and forming performance; the frequency of annealing needed in the preparation process is low and the annealing temperature is low; and the production procedure is simplified and the production cost is lowered.

Owner:厦门火炬特种金属材料有限公司

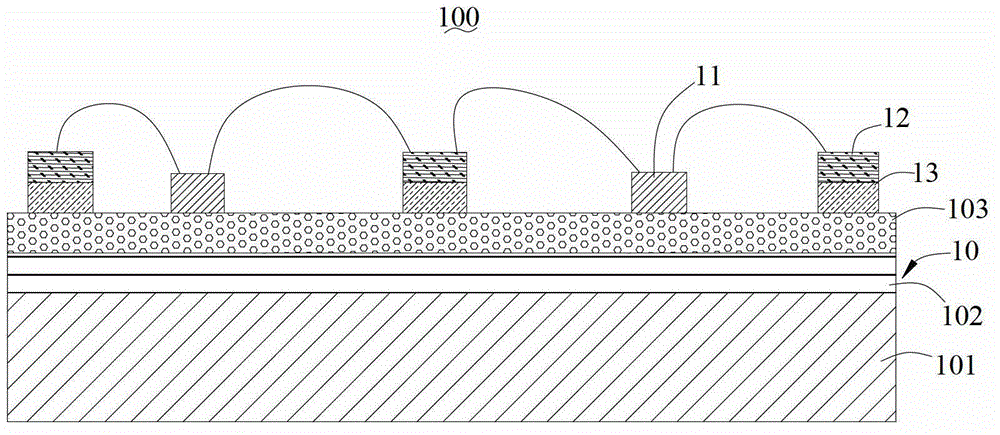

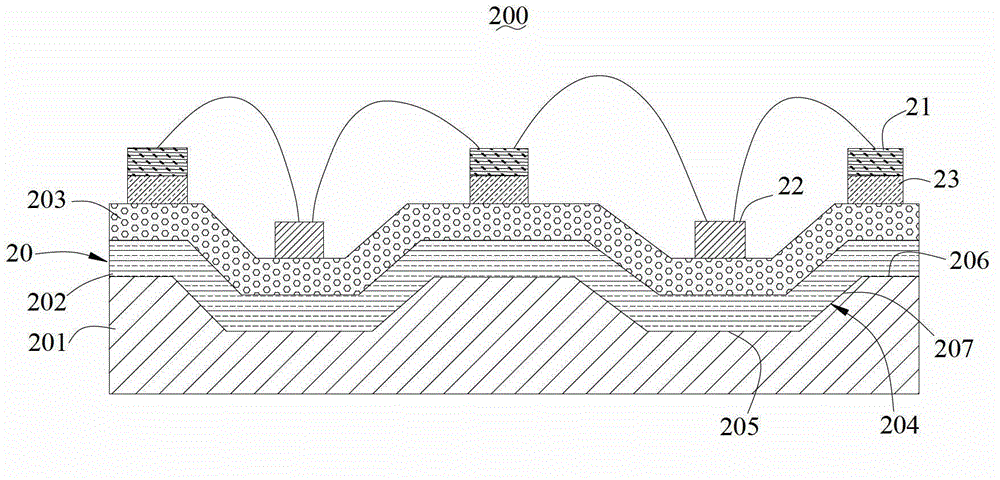

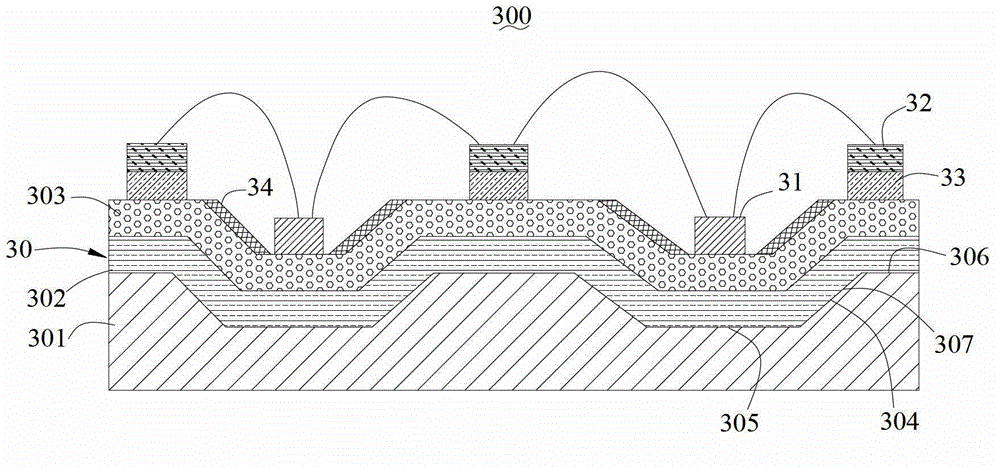

Light emitting diode (LED) light source with cooling device

ActiveCN102983124AImprove thermal mismatch problemWell combinedPoint-like light sourceLighting heating/cooling arrangementsLight sourceMetal

The invention discloses a light emitting diode (LED) light source which comprises a cooling device, an LED chip and an electrode layer. The cooling device is composed of a base plate, a first transitional layer and a diamond-like carbon layer, the first transitional layer is adhered between the base plate and the diamond-like carbon layer, adhesive force which is produced among the first transitional layer, the base plate and the diamond-like carbon layer is greater than that of the base plate and the diamond-like carbon layer when the base plate and the diamond-like carbon layer are mutually attached, a coefficient of thermal expansion of the first transitional layer is between that of the diamond-like carbon layer and the base plate, and the LED chip is arranged on the diamond-like carbon layer and electrically connected to the electrode layer. By the mode, the diamond-like carbon layer and a metal base plate of the LED light source are combined well, and service life of the LED light source can be prolonged.

Owner:SHENZHEN UNIV

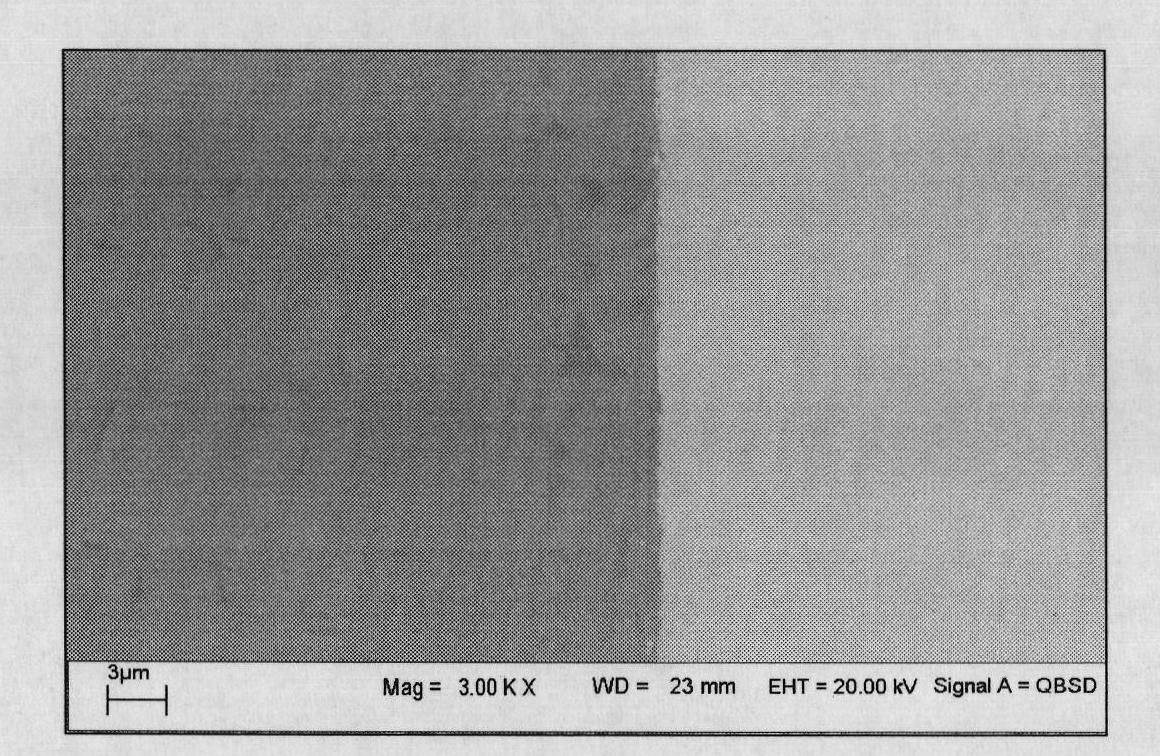

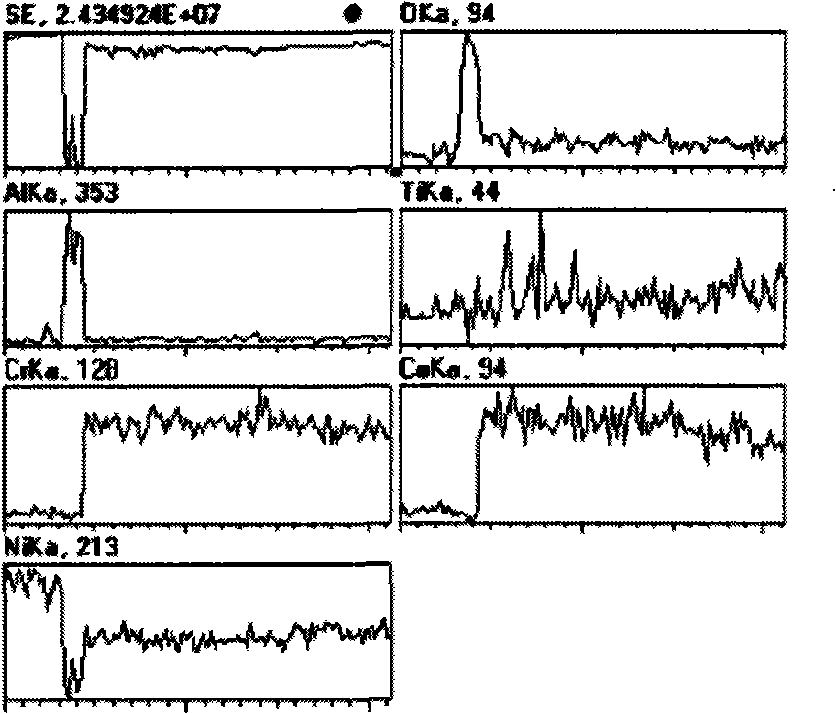

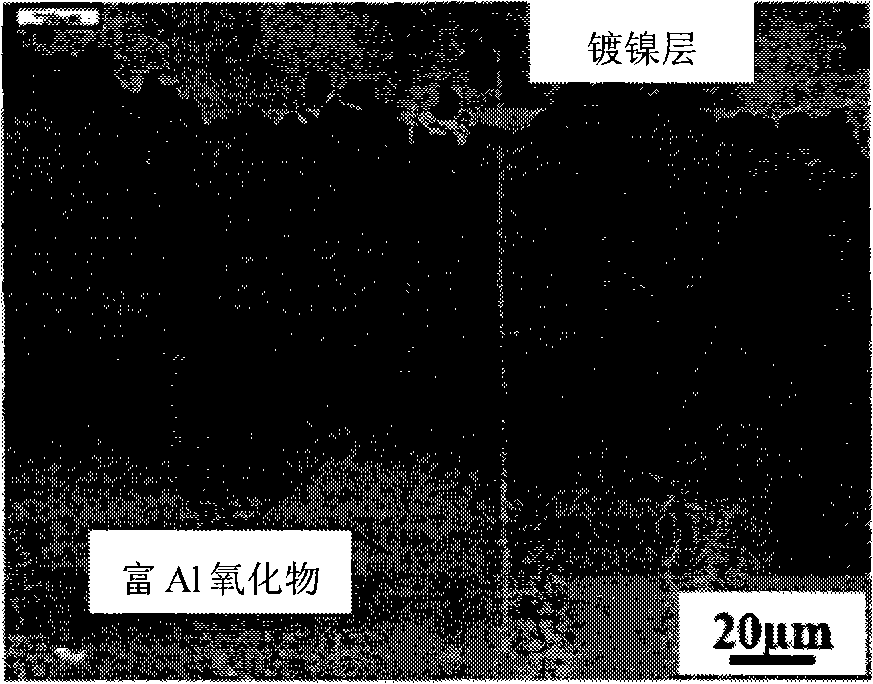

Cr-O-N active diffusion blocking layer and production method thereof

InactiveCN101314854ADense tissueWell combinedBlade accessoriesVacuum evaporation coatingBlock layerOxidation resistant

The invention relates to a coating technology, in particular to a Cr-O-N activated diffusion impervious layer. An arc ion plating technology is adopted, pure chrome is used as target material, the impervious layer which can effectively reduce the mutual diffusion of metal elements between a coating and a high-temperature alloy matrix under high-temperature oxidation conditions through controlling the flow quantity of O2 and N2 during the reaction process; a MCrAlY coating is deposited on the impervious layer to be used as an oxidation resistant coating. The referred Cr-O-N activated diffusion impervious layer has compact structure, combines well with the matrix, has simple and low preparation cost, and is a good diffusion impervious layer. The Cr-O-N activated diffusion impervious layer is applied to the matrixes that are nickel-base, cobalt-base or ferrum-base high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

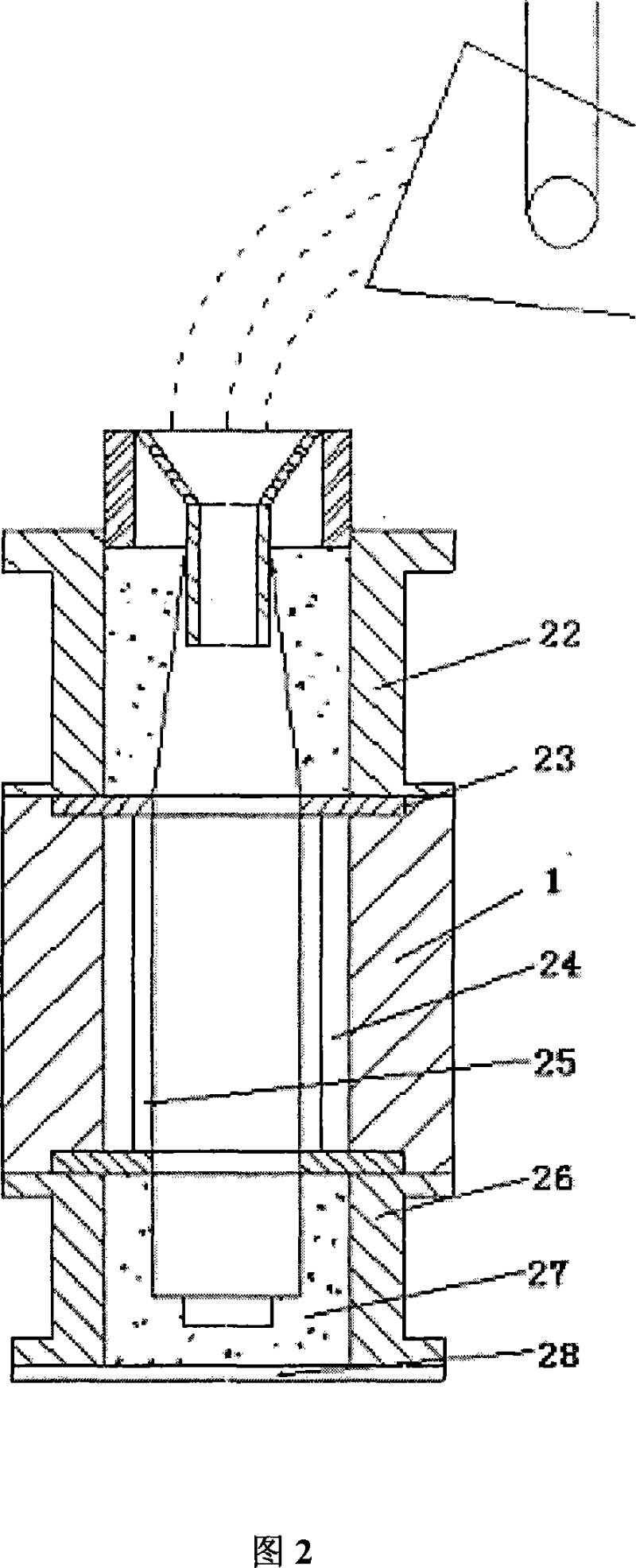

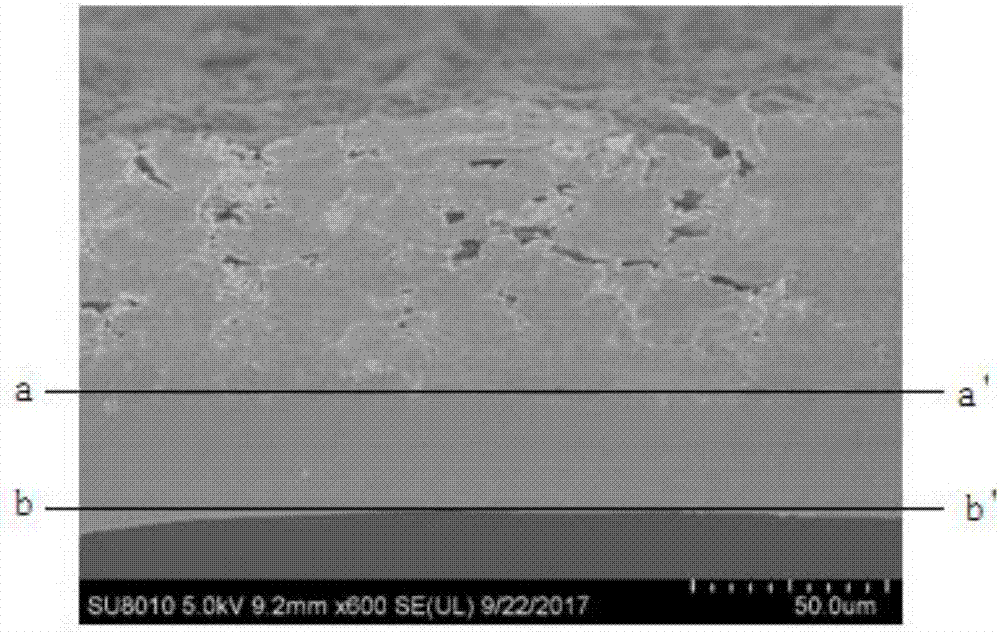

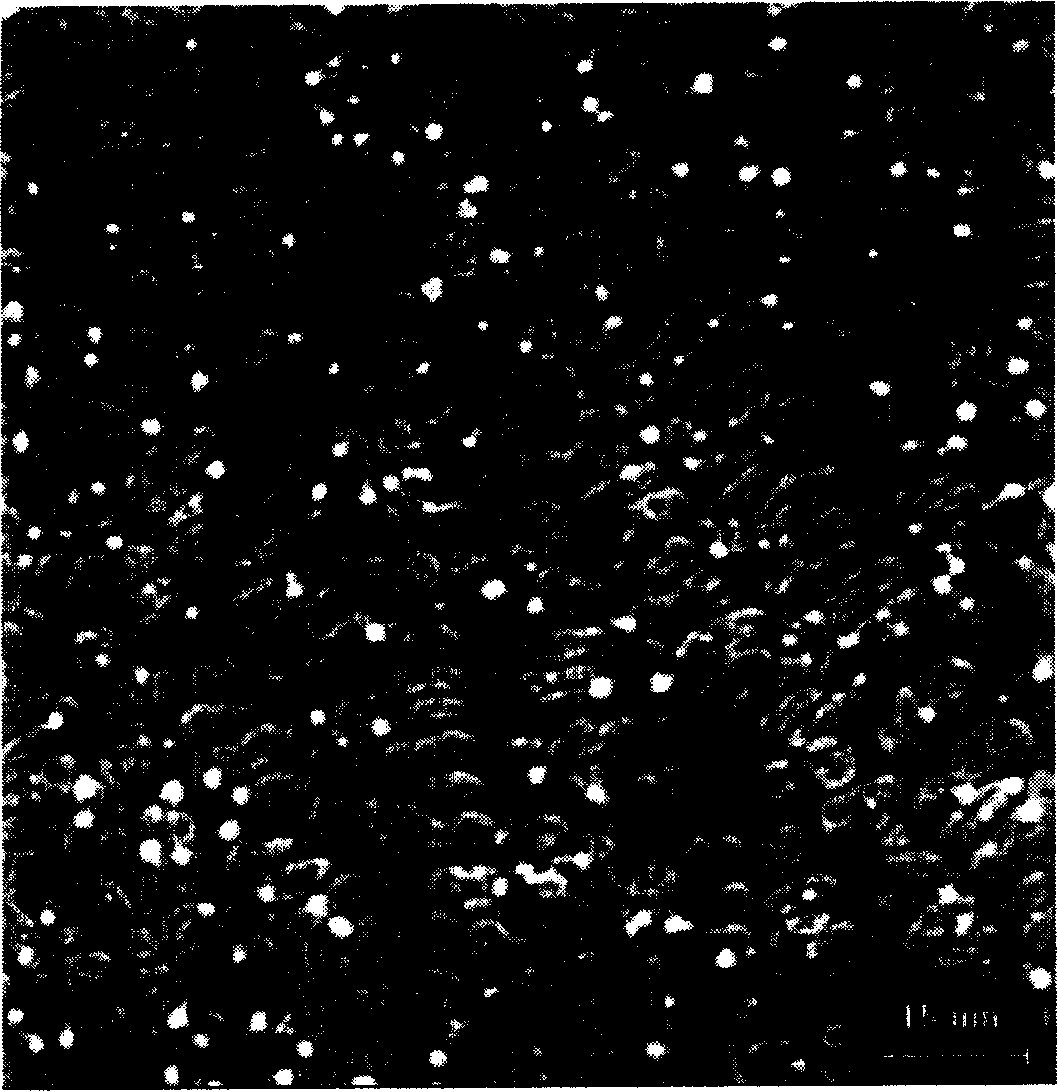

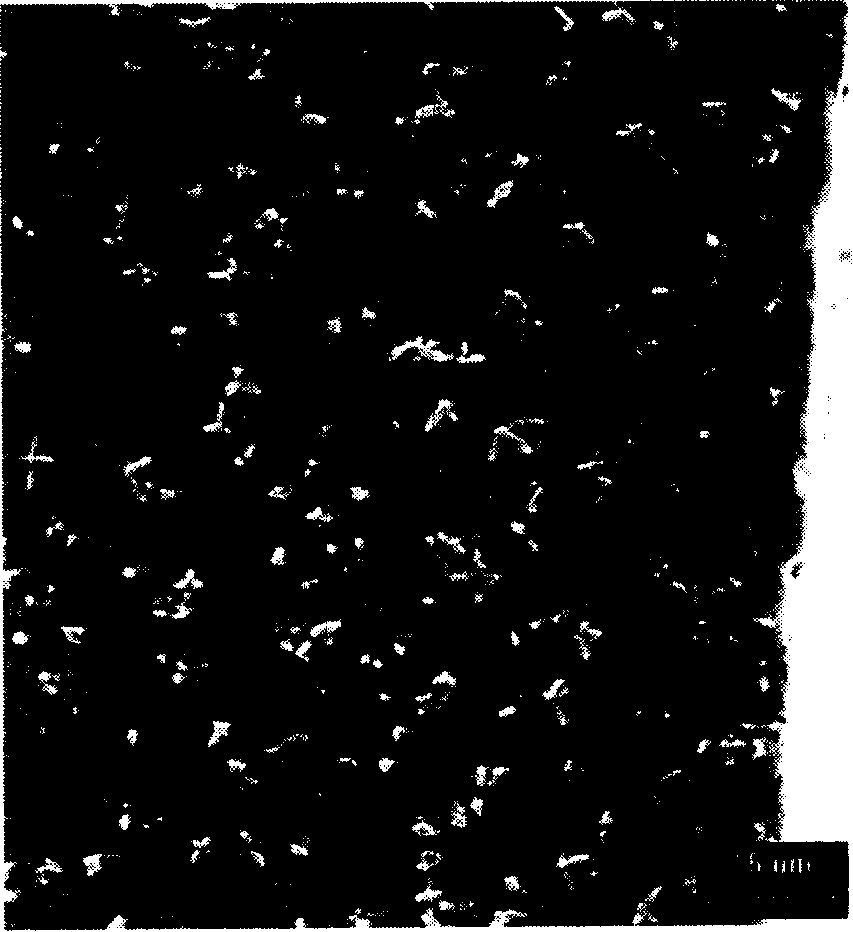

Ni3(Si,Ti)-WC composite coating material and preparation method thereof

InactiveCN101161864AWell combinedHigh hardnessMetallic material coating processesLaser beam welding apparatusTitaniumThermal spraying

The present invention relates to a laser cladding nickel silicon titanium - tungsten carbide composite coating material and a method for preparation the same; the propose of the invention is to prepare a composite coating consisting of intermetallic compound of Ni3 (Si, Ti), a Ni-based solid solution, TiC coated WC ceramic on a high-temperature ultratek substrate by laser cladding; the coating material mainly comprises Ni powder, Si powder, Ti powder and WC powder with the following weight percentages: 8 percent to 20 percent WC, 78 percent Ni, 13 percent Si and 9 percent Ti; the preparation method adopts the laser to clad and has the following technique parameters: the output power is between 1200 W and 1500 W; the scanning speed is 4-8 mm / s; the spot diameter is 4 mm; the protective gas is Ar gas in cladding; the cladding substrate material is high-temperature ultratek; the invention has the following procedures: according to the mixing ratio, the coating material is mixed uniformly and pre-coated or hot-sprayed on the surface of the high-temperature ultratek substrate with the thickness between 0.8 mm and 1.0 mm; the laser scans cladding with multilayer and multi-path; each path has related joint of 1.8 mm, thereby achieving the cladding layer with different thickness.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Carbon fiber cloth-aluminum alloy compound material and preparation method thereof

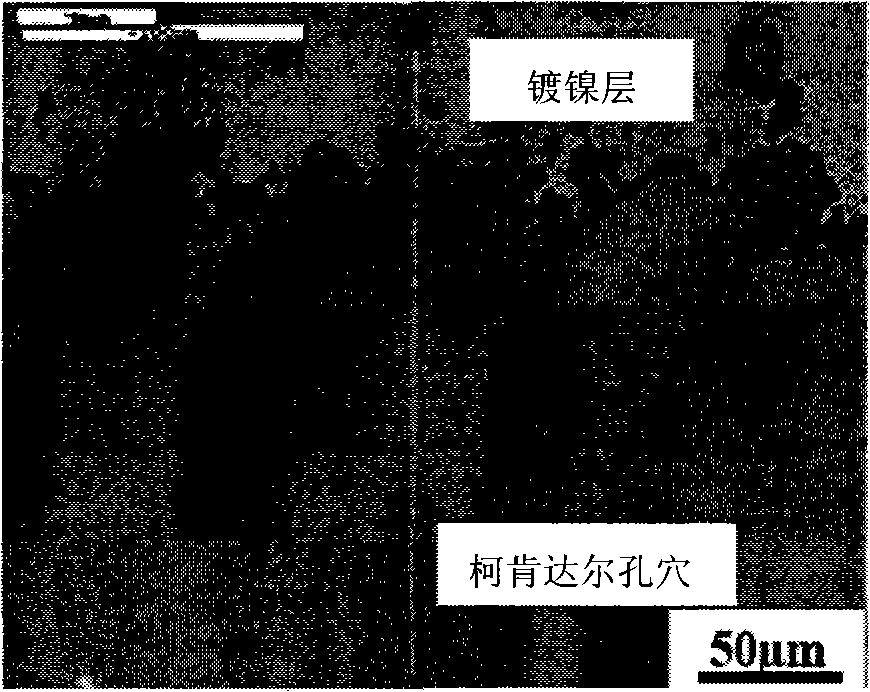

InactiveCN102642011AWell combinedNot easy to take offCarbon fibresFoundry mouldsChemical platingSpecific modulus

The invention discloses a carbon fiber cloth-aluminum alloy compound material and a preparation method thereof. The carbon fiber cloth-aluminum alloy compound material is obtained by cladding carbon fiber cloth with copper and then casting aluminum alloy. The preparation method comprises the following steps: 1) pre-treating the carbon fiber cloth; 2) cladding the carbon fiber cloth with copper: cladding the surface of the carbon fiber cloth with the copper according to a chemical plating or electroplating method; 3) preparing a casting mould,wherein the casting mould is prepared according to the demand on the arrangement of the carbon fiber cloth in the aluminum alloy; and 4) smelting the aluminum alloy and casting, thereby lastly obtaining the carbon fiber cloth-aluminum alloy compound material in required shape. The carbon fiber cloth-aluminum alloy compound material prepared according to the preparation method is excellently compounded; the components of the aluminum alloy are adjustable; the distribution of the carbon fiber cloth is controllable; and the compound material has higher specific modulus, low density and high specific strength, and is suitable for the building field and the protecting field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

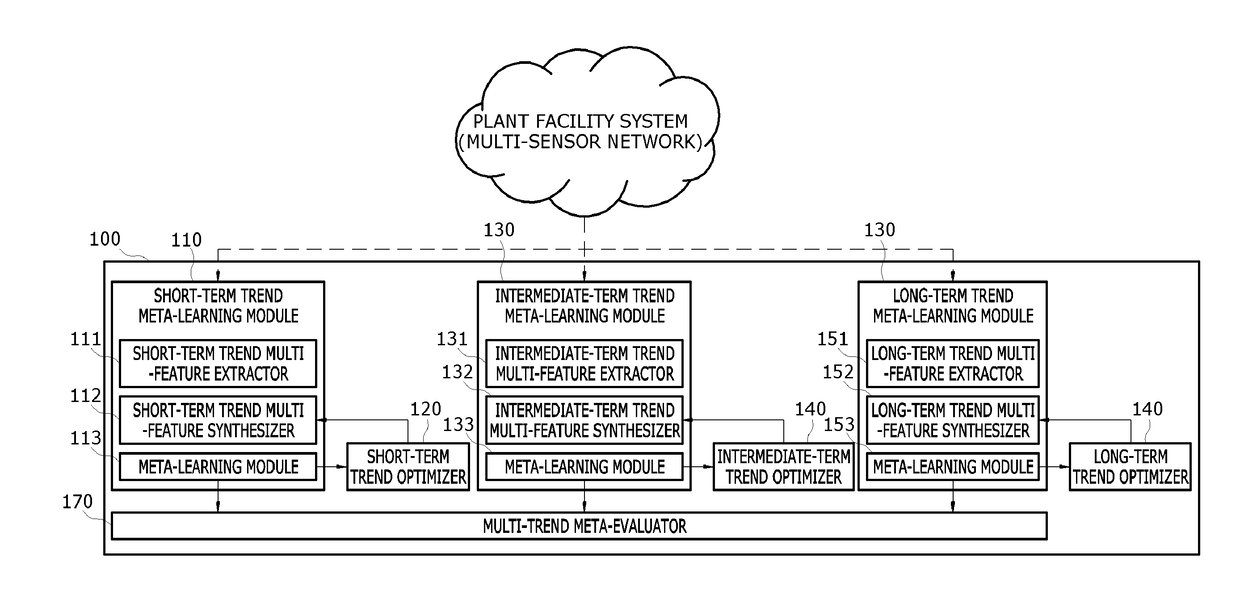

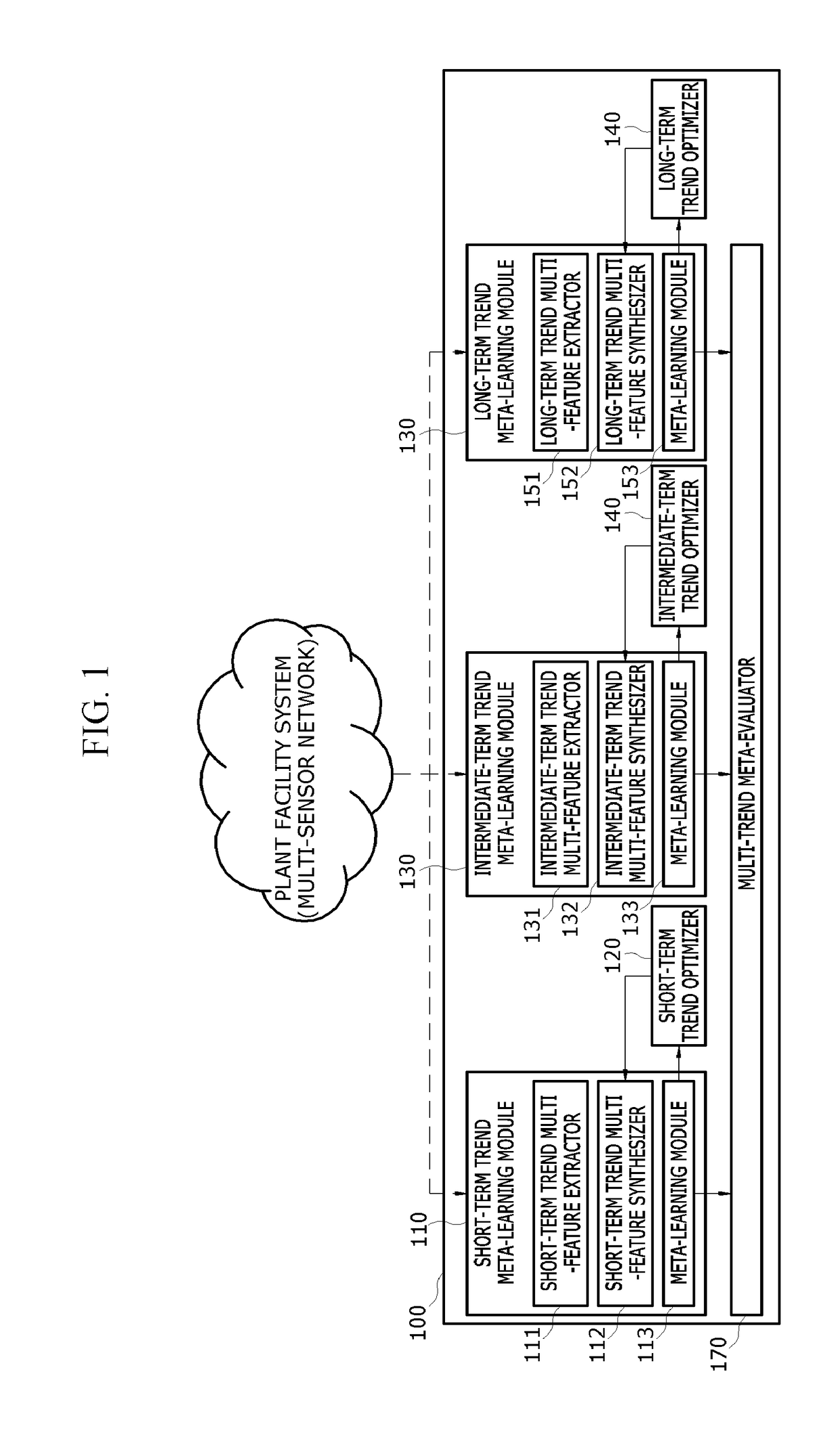

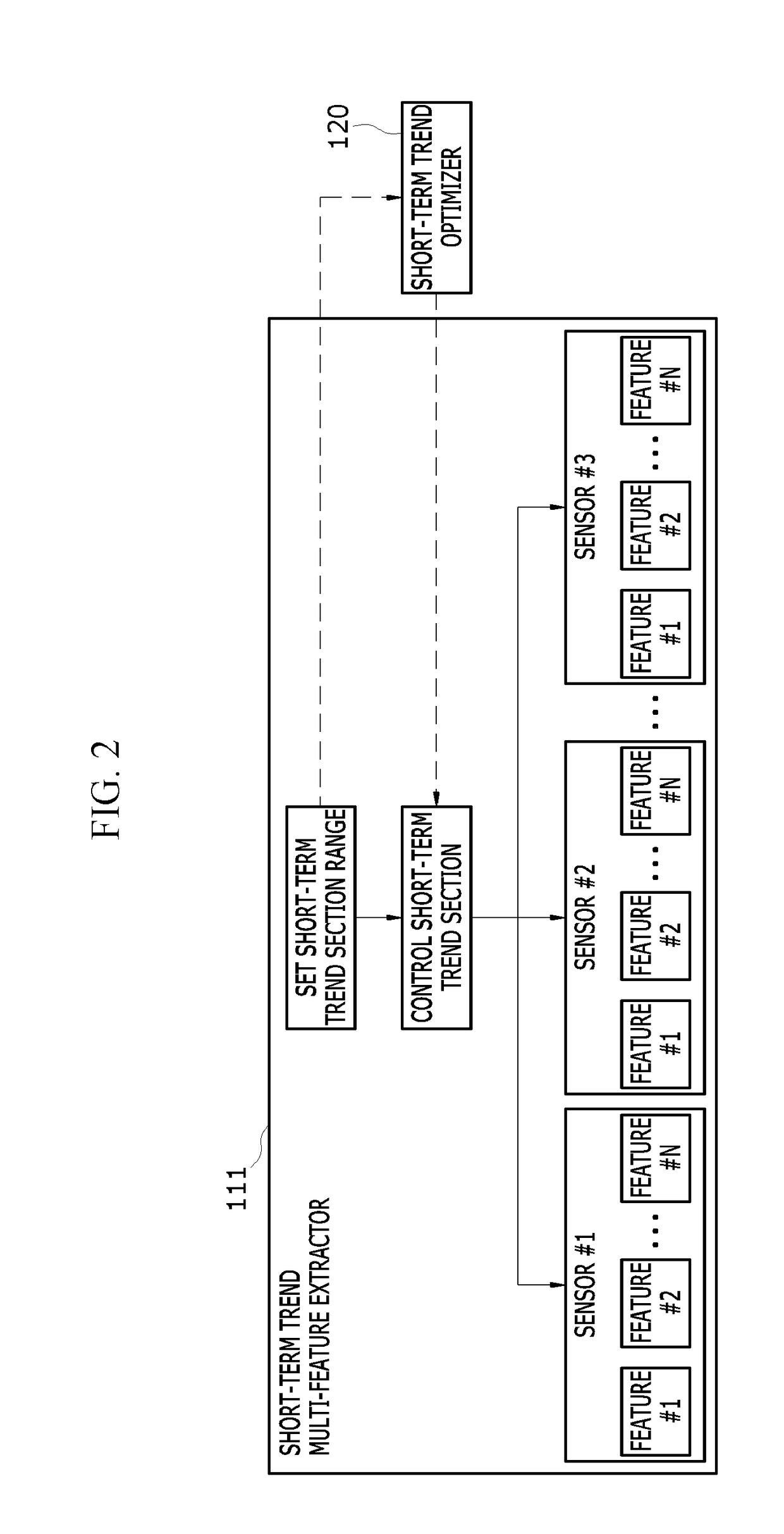

Apparatus and method for detecting anomaly in plant pipe using multiple meta-learning

ActiveUS20180293723A1Anomaly detectionWell combinedImage enhancementImage analysisSpecific timeOptimal combination

Provided are an apparatus and method for detecting an anomaly in a plant pipe using multiple meta-learning. When a multi-sensor data stream about a plant pipe is received, each of a plurality of meta-learning modules for processing different packet section ranges, extracts one or more preset types of features from sensor data of packet section ranges set according to trend from an arbitrary reception time point, generates 2D image features of the features according to multi-sensor-specific times, generates 3D volume features by accumulating the 2D image features in a depth direction according to multiple sensors, and learns the 3D volume features in parallel through multi-sensor-specific learning modules. Results of the learning of the meta-learning modules are aggregated, and it is determined whether there is an anomaly in a plant pipe according to a learning result selected based on an optimal combination of multiple features, multiple sensors, and multiple packet sections.

Owner:ELECTRONICS & TELECOMM RES INST +1

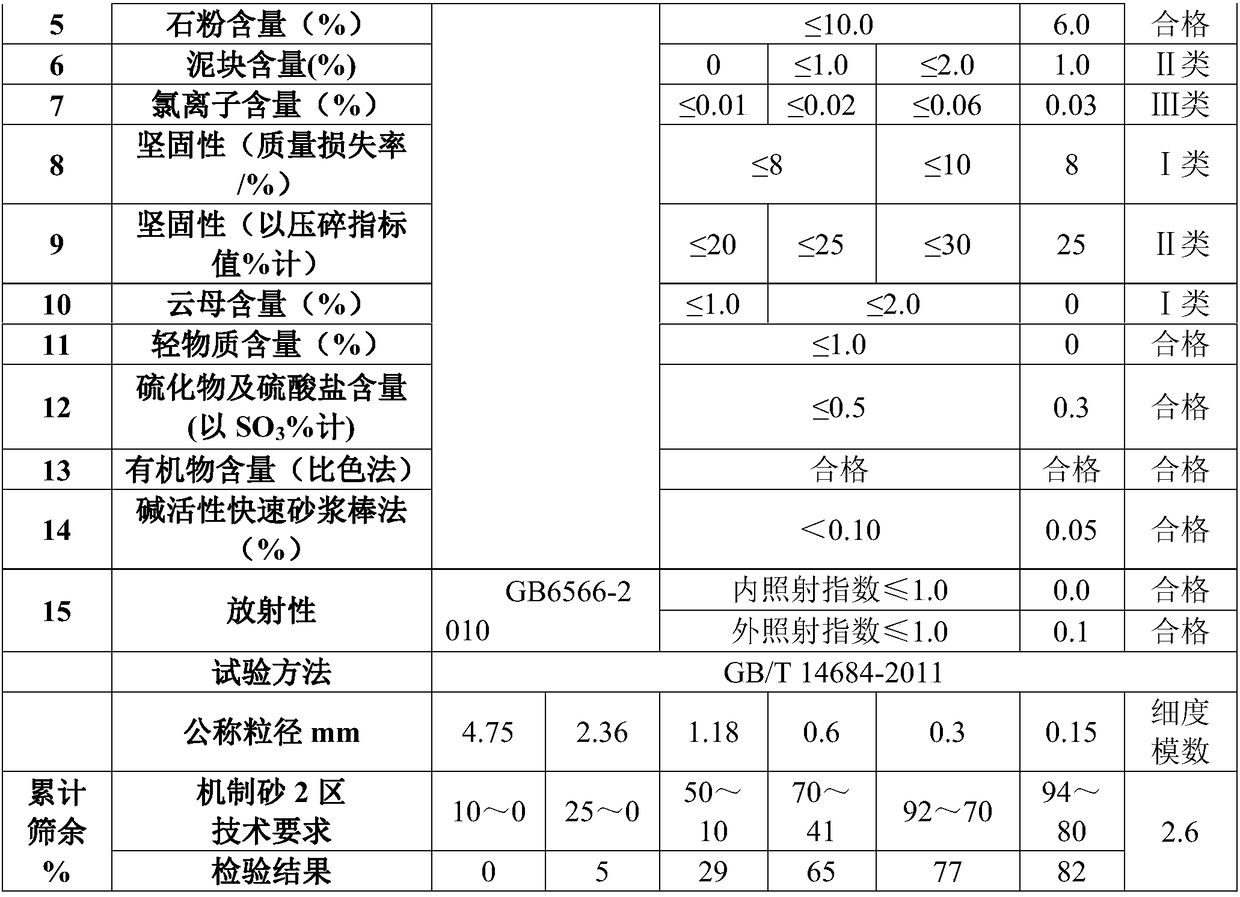

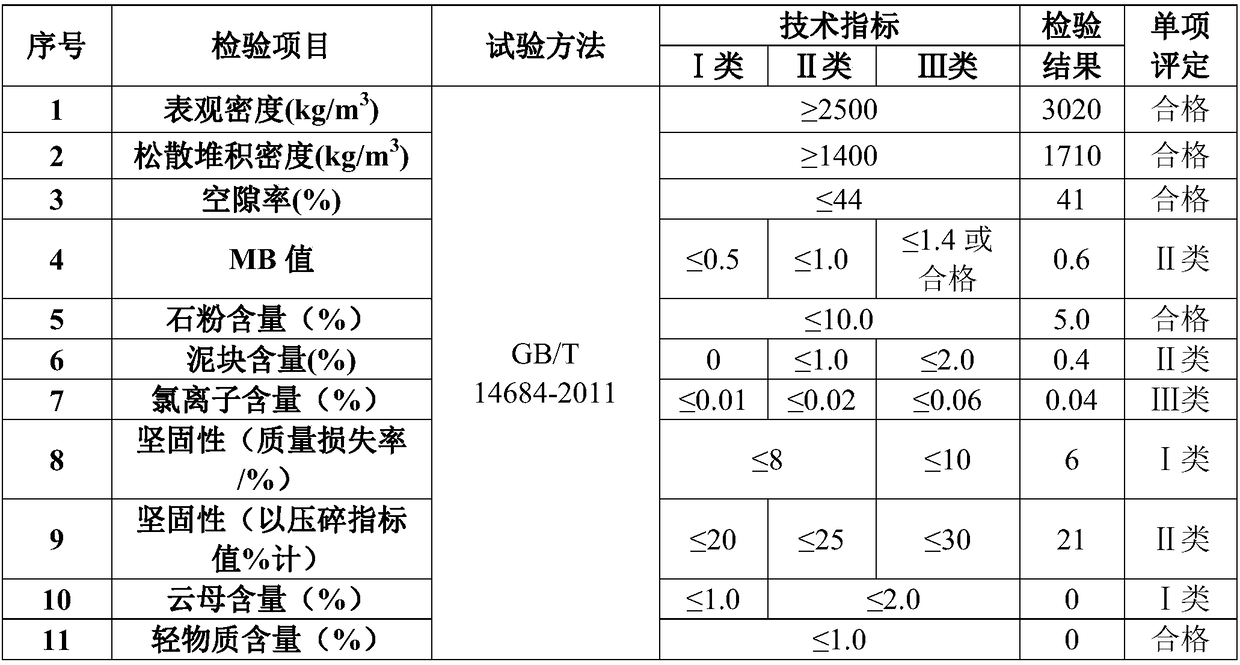

Nickel slag composite machine-made sand and production method thereof

InactiveCN109180039ASufficient sourceWell combinedSolid waste managementIndustrial wasteEnvironmental pressure

The invention discloses a nickel slag composite machine-made sand and a production method thereof. Electric furnace nickel-iron slag and refined mixed slag produced in the RKEF technology ferronickelsmelting process are screened and crushed, and then are mixed according to a certain ratio to obtain the composite machine-made sand. The nickel slag composite machine-made sand can meet the use requirements of mortar and concrete in the construction project, can improve the workability of a mortar and concrete mixture, and also can improve the strength of the mortar and the concrete. The invention also realizes the reuse of industrial waste slag, solves the problems of land occupation and soil and groundwater pollution of the waste slag, reduces the environmental pressure and obtains benefits.

Owner:SOUTH CHINA UNIV OF TECH +1

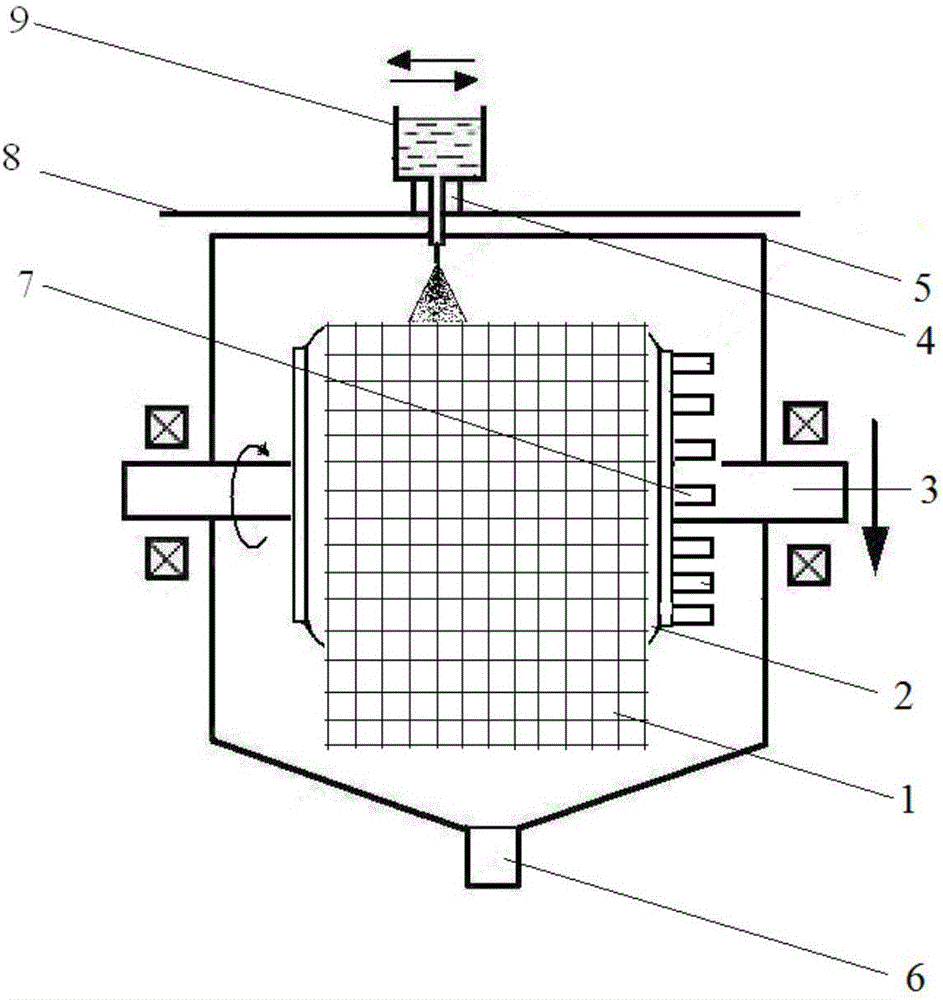

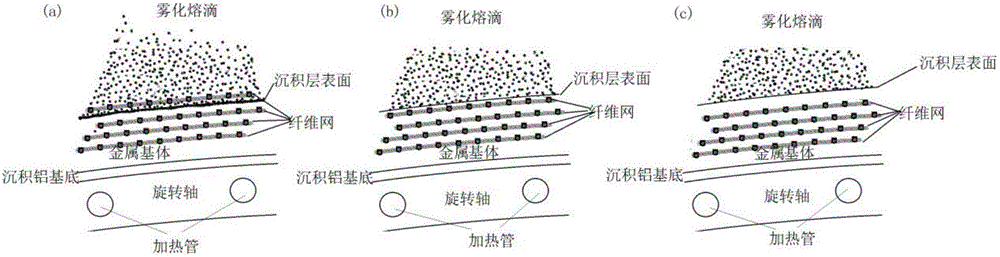

Preparation method and device for fiber reinforced metal matrix composite

The invention provides a preparation method for a fiber reinforced metal matrix composite. Good bonding between a matrix alloy and a fiber mesh and between the matrix alloy and a settled layer is realized by adopting the preparation method. The invention further provides a preparation device for realizing the preparation method and application of the preparation device. The preparation device can realize thickness control over a metal matrix layer between fiber layers and uniform distribution of fibers or enhancement of graded fibers. The preparation device can be used for preparing molten-state metal alloys of an aluminium alloy, a tin alloy, a lead alloy, a copper alloy, an iron alloy and a titanium alloy, and tubular bases made of an aluminium-base alloy, a copper-base alloy, an iron-base alloy, a tin-base alloy and a lead-base alloy. The preparation method and device can realize regulation of the thickness of the metal matrix layer between the fiber layers; the shorter the rotation interval time of a matrix rotating shaft is, the smaller the thickness of the metal matrix layer is, and otherwise, the larger the thickness of the metal matrix layer is; and progressive regulation of the rotation interval time can be realized by a controller, and enhancement of the graded fibers is conveniently realized.

Owner:HUAIHAI INST OF TECH

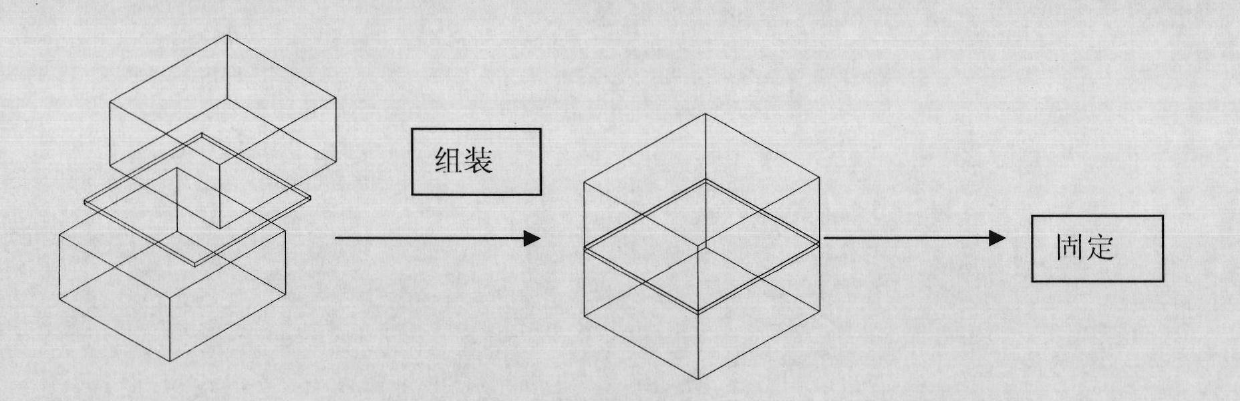

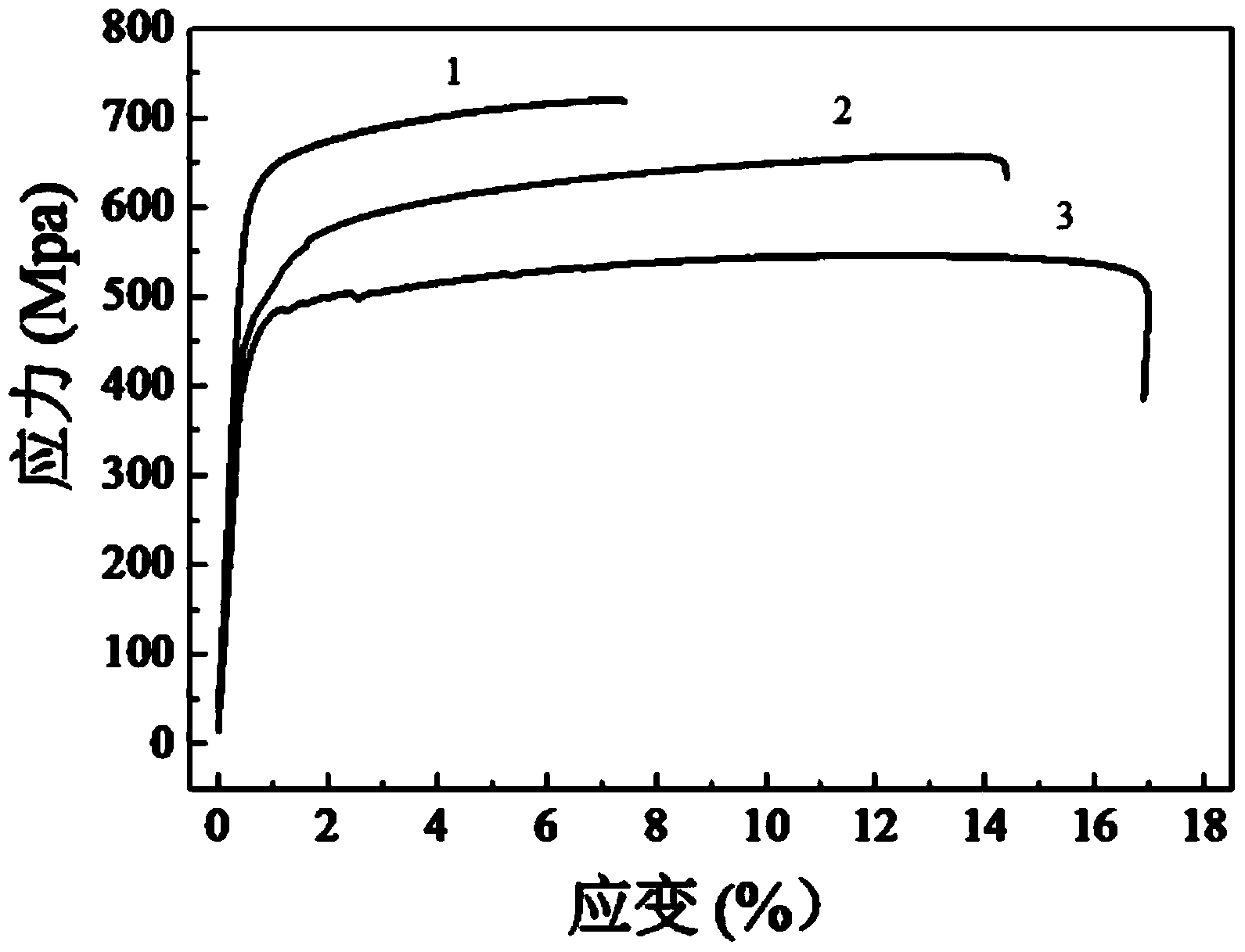

Method for preparing Ti-TiBw/Ti laminar composite material in diffusion welding mode

ActiveCN103521918AWell combinedHigh densityWelding/soldering/cutting articlesMetal working apparatusLamellar structurePlastic property

The invention relates to a method for preparing a Ti-TiBw / Ti composite material of a laminar structure, in particular to a method for preparing the Ti-TiBw / Ti laminar composite material in a diffusion welding mode. The method for preparing the Ti-TiBw / Ti laminar composite material in the diffusion welding mode solves the technical problem that the flatness and uniformity of an exiting laminar titanium matrix composite material layer are difficult to guarantee, and comprises the steps of weighing raw materials, preparing Ti-TiBw / Ti composite material, preparing Ti-TiBw / Ti composite material foils, and preparing the Ti-TiBw / Ti laminar composite material. The Ti-TiBw / Ti laminar composite material prepared through the method has good flatness and uniformity and is high in compactness, the compactness can reach 99.3%, the high plasticity and strengthening-toughening performance of the laminar material can be controlled by adjusting the thickness of a Ti board, the thickness of a Ti-TiBw / Ti composite material board, the layer thickness ratio between the Ti board and the Ti-TiBw / Ti composite material board, and the volume fraction of an enhanceosome, and breaking tenacity of the Ti-TiBw / Ti laminar composite material is largely improved.

Owner:HARBIN INST OF TECH

Method for preparing bone screw biological compound material

The invention provides a method for making a coaptation nail biological composite material, comprising the following steps of: firstly, soaking a carbon fiber with dimethyl sulfoxide liquid after pre-oxidizing the carbon fiber with nitric acid; then, orderly adding the carbon fiber and Ca(NO3)2.4H2O, K2HPO4 into acetic acid solution; after undergoing ultrasonic dispersion, adding glutaraldehyde solution to obtain solution A; extracting the solution A and adding chitosan; then placing in a ultrasound wave cleaning device to oscillate; and keeping stand to deaerate; slowly pouring the deaerated chitosan solution into a mould; placing the mould in NaOH solidification liquid to soak; placing the formed gel into a vacuum drying box to dry and solidify; and obtaining the desired product. The synthesized composite material has the advantages of higher flexural strength and compressive strength, even dispersion of the made composite material fiber, good combination of the fiber and a matrix interface, wherein the flexural strength of the composite material is between 35 and 90 MPa, the compressive strength is between 30 and 75 MPa, and bending modulus is up to between 250 and 320 MPa, and the flexural strength and flexibility of the material are higher than the flexural strength and flexibility of the single chitosan and hydroxyapatite, thereby having mechanical properties required by the coaptation nail.

Owner:SHAANXI UNIV OF SCI & TECH

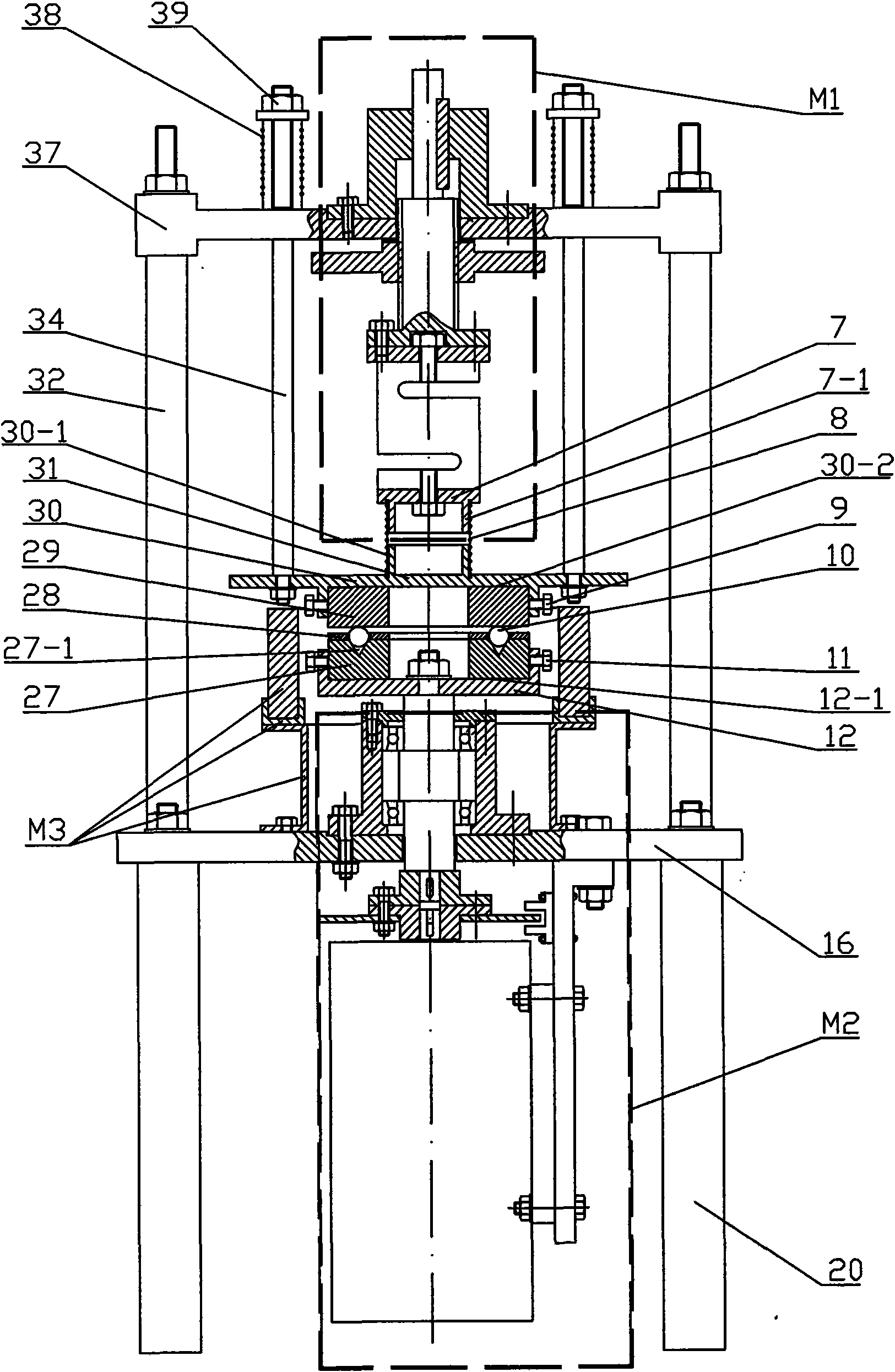

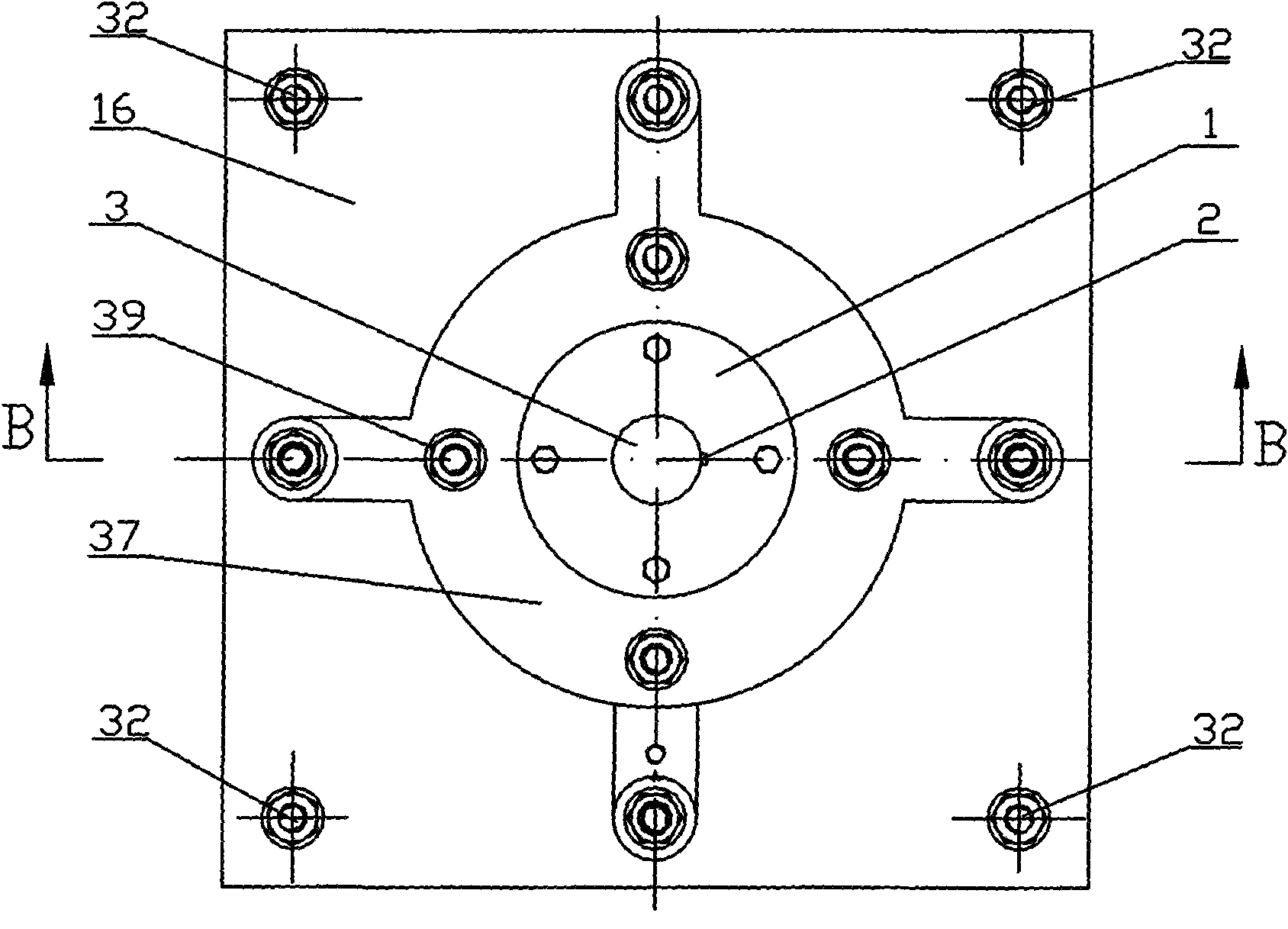

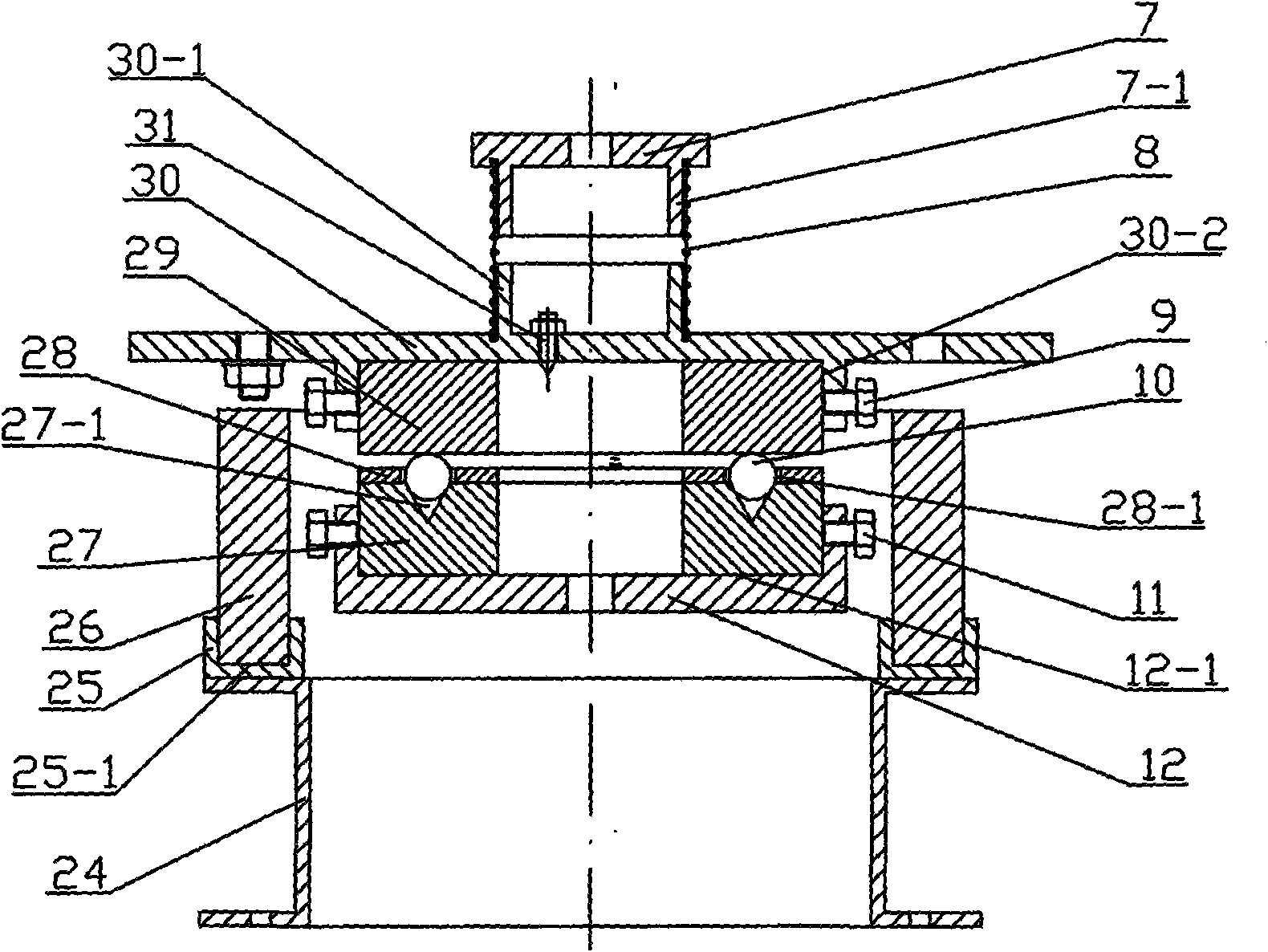

Device and method for preparing transfer lubricant film on surfaces of ceramic balls

The invention discloses a device and a method for preparing a transfer lubricant film on the surfaces of ceramic balls and relates to a device and a method for preparing a lubricant coating on the surfaces of ceramic balls. The invention aims at solving the problem that the self-lubricant coating of the ceramic balls prepared by the existing method has weak bonding force and is uneven. The device comprises a first spring; the upper end of the first spring is connected with a load assembly, while the lower end therof is connected with an upper grinding disc pedestal; an upper grinding disc is arranged in the upper grinding disc pedestal and a lower grinding disc is arranged in a lower grinding disc pedestal which is connected with a rotation speed control assembly; the lower grinding disc is fixed in the lower grinding disc pedestal by four second positioning bolts; a retainer is arranged on the lower grinding disc and a plurality of round holes thereon are opposite to a V-shaped groove. The method comprises the steps: ceramic balls roll freely in the V-shaped groove and slide and grind with the upper grinding disc and the lower grinding disc; and composite materials are ground on the surface of the ceramic balls. The invention causes the surfaces of the ceramic balls to have a self-lubricant coating. The ceramic balls roll and grind between the upper grinding disc and the lower grinding disc and form a lubricant film with even thickness on the surfaces of the ceramic balls.

Owner:HARBIN INST OF TECH

Preparation method of plating solution for electroplating tungsten-molybdenum-nickel alloy coating on surface of petroleum-pumping component

InactiveCN104233389AGood corrosion and friction resistanceWell combinedAmmonium sulfateMetallic Nickel

The invention discloses a preparation method of a plating solution for electroplating a tungsten-molybdenum-nickel alloy coating on a surface of a petroleum-pumping component. The preparation method comprises the steps of measuring half of water; heating the water to a temperature of 55-65 DEG C; adding 34-38 g / L of boric acid, 30-36 g / L of sodium sulfate and 20-24 g / L of ammonium sulfate; stirring to dissolve the above materials; adding 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate and 10-14 g / L of ascorbic acid; stirring for 3-5 minutes; adding 80-84 g / L of sodium tungstate, 6-10 g / L of sodium molybdate and 14-18 g / L of nickel sulfate; stirring for 10-20 minutes; and finally adding 1-3 ml / L of formaldehyde, 2-4 ml / L of dimethyl hexynol and the residual water; stirring uniformly; and regulating a pH value to 8.0-9.0 with ammonia water.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

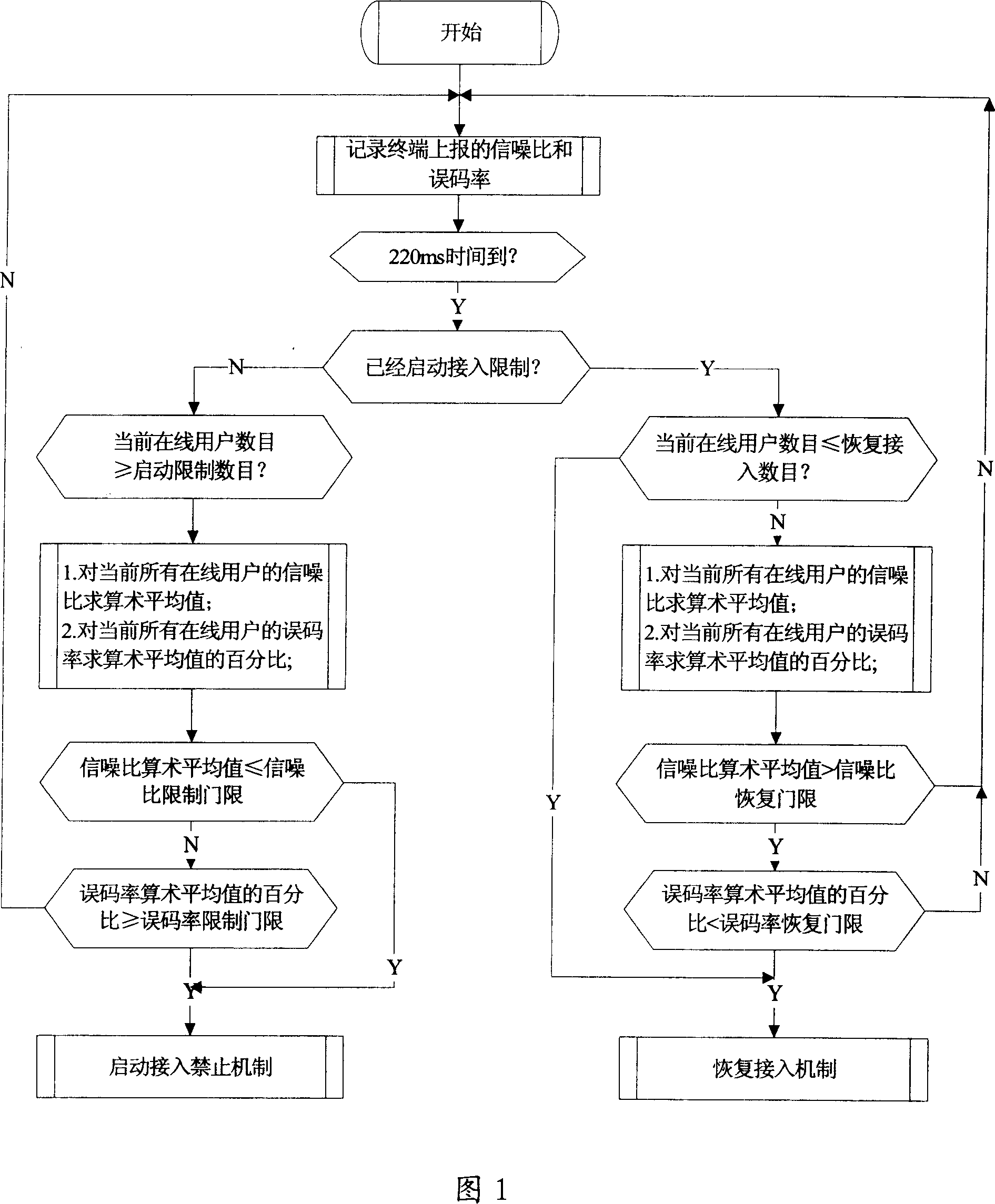

Qos processing method in SCDMA wireless communication system

InactiveCN101080085AWell combinedImprove system performanceAssess restrictionRadio/inductive link selection arrangementsSignal-to-noise ratio (imaging)Capacitance

This invention relates to a method for processing QoS in a SCDMA wireless communication system including the following steps: 1, a terminal maintains user information reported by frames by a spread link periodically after it enters into a session state, 2, a base station registers down S / N ratio and down error rate reported by the terminal and judges if it has started up the access limit currently, 3, if so, the base station judges if it needs to resume the access system and processes it accordingly based on a preset access resuming rule, 4, if the base station judges that the access limit is not started up currently, it judges if it needs starting up the limit system according to a preset rule of access limit and processes it accordingly, which can realize the maximum combination of session quality and capacitance of base stations.

Owner:BEIJING XINWEI TELECOM TECH

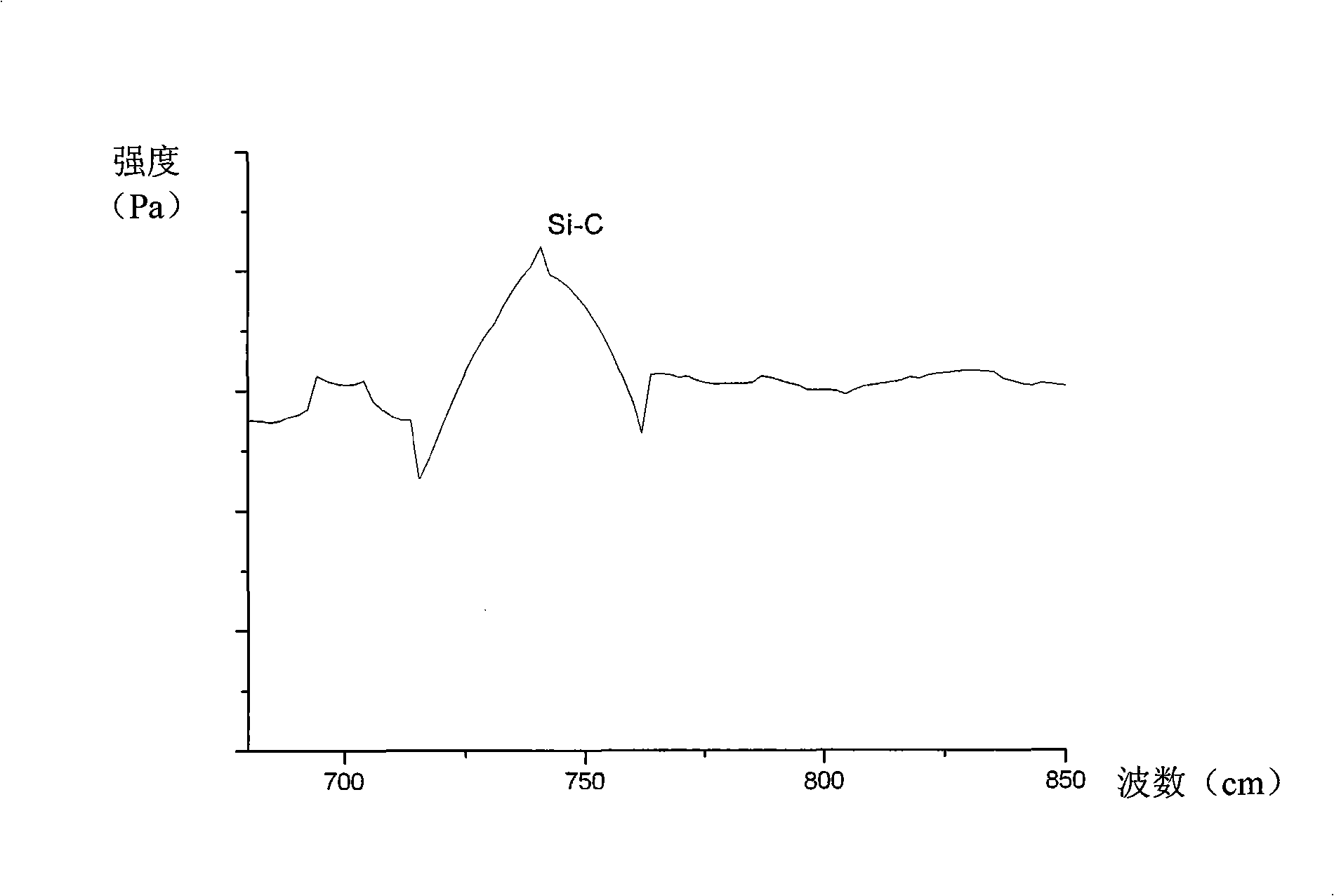

Method for depositing silicon carbide high radiation coating on cobalt based high-temperature alloy surface

InactiveCN101343731AImprove adhesionWell combinedVacuum evaporation coatingSputtering coatingMegasonic cleaningNegative bias

The invention discloses method to deposit silicon carbide high radiation coating on the surface of the cobalt based high temperature alloy surface, which in particular relates to a technology method to deposit silicon carbide high radiation coating on the surface of the cobalt based high temperature alloy surface. The method solves the problem that good binding between the silicon carbide coating and the cobalt based high temperature alloy is difficult to realize through the commonly used magnetism control sputtering method. The method of the invention comprises the procedures: firstly, the cobalt based high temperature alloy is cleaned with hydrofluoric acid, acetone solution ultrasonic wave, alcoholic solution ultrasonic wave and deionized water. secondly, the processed cobalt based high temperature alloy is fed into a magnetism control sputtering vacuum chamber, the sputtering vacuum chamber is vacuumize, the cobalt based high temperature alloy is heated and the temperature is retained; thirdly, Ar gas is filled into the chamber, and pulse negative bias voltage is exerted to perform reverse sputtering to the cobalt based high temperature alloy surface; fourthly, sputtering power glow is started, to perform pre-sputtering to the silicon carbide coating surface; fifthly, the formal sputtering is performed to the silicon carbide coating surface, to deposit silicon carbide high radiation coating; sixthly, the power source is shut off, and when the temperature in the chamber is reduced to the room temperature, the deposition is completed.

Owner:HARBIN INST OF TECH

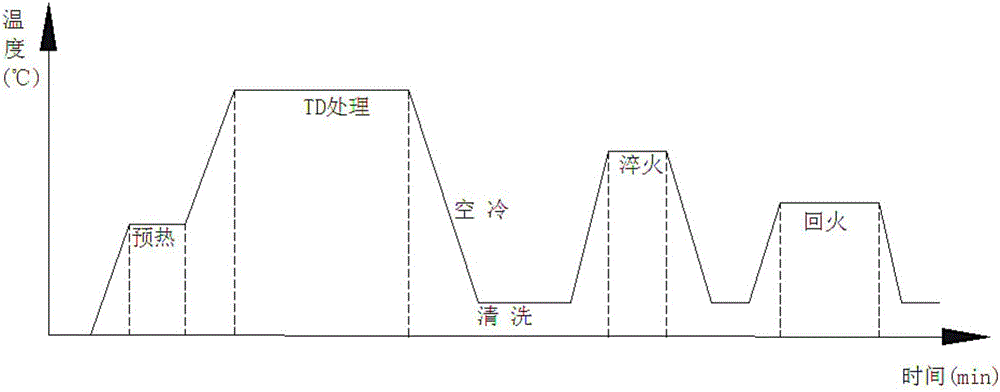

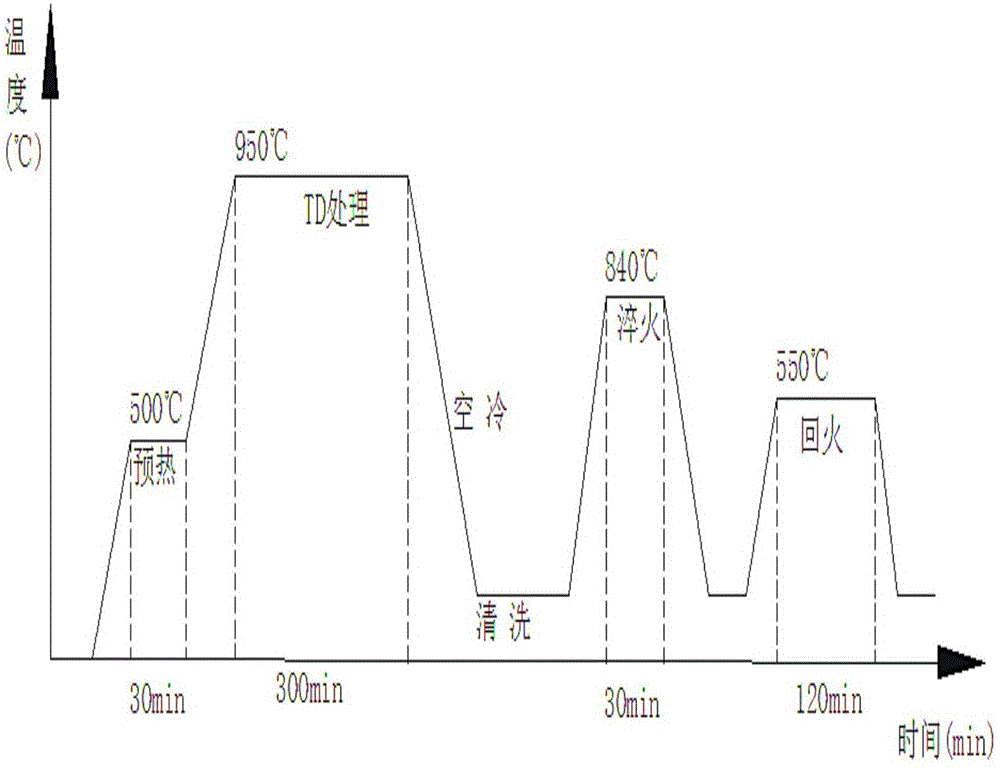

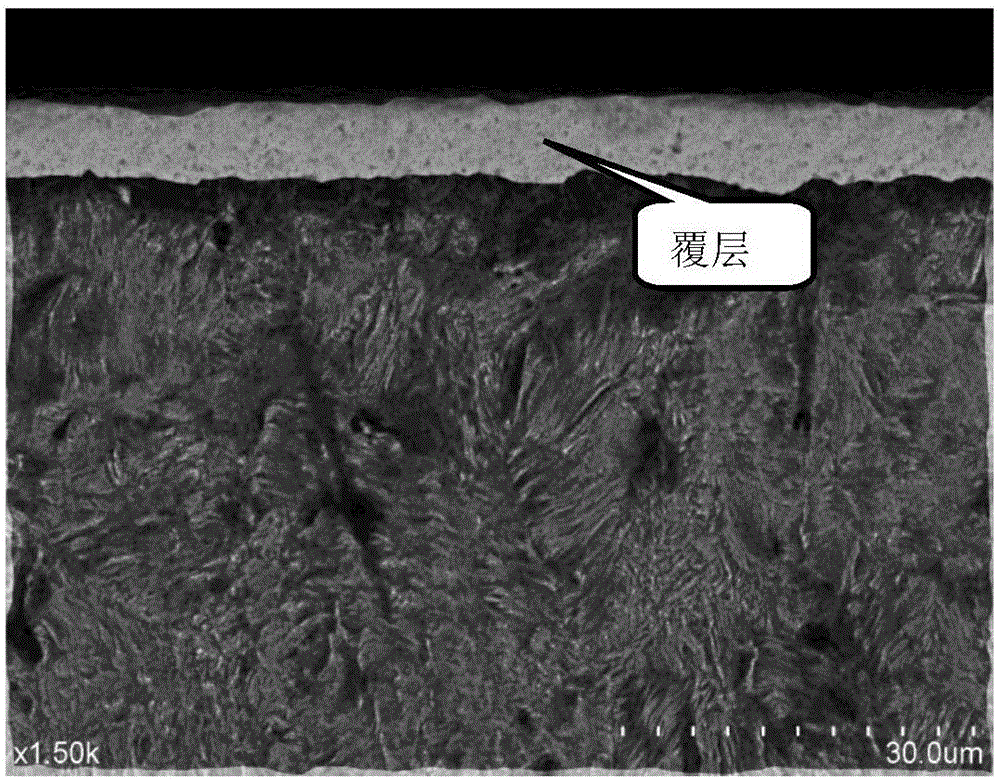

Surface wear resistance strengthening treatment method for agricultural soil touching part

InactiveCN106637070AWell combinedHigh hardnessSolid state diffusion coatingFurnace typesWear resistantThermal treatment

The invention discloses a surface wear resistance strengthening treatment method for an agricultural soil touching part. The surface wear resistance strengthening treatment method comprises the following steps: polishing, carrying out pretreatment, preheating, carrying out salt bath treatment, cleaning and carrying out thermal treatment. According to the surface wear resistance strengthening treatment method, a carbide wear-resistant coating is prepared on the surface of the agricultural soil touching part, and the coating has the advantages of good combination with matrix, high hardness, compactness and smoothness as well as low coefficient of friction with soil, so that wear resistance of the surface of the agricultural soil touching part can be improved, the service life of the agricultural soil touching part can be prolonged, and the agricultural cultivation cost can be reduced.

Owner:NORTHWEST A & F UNIV

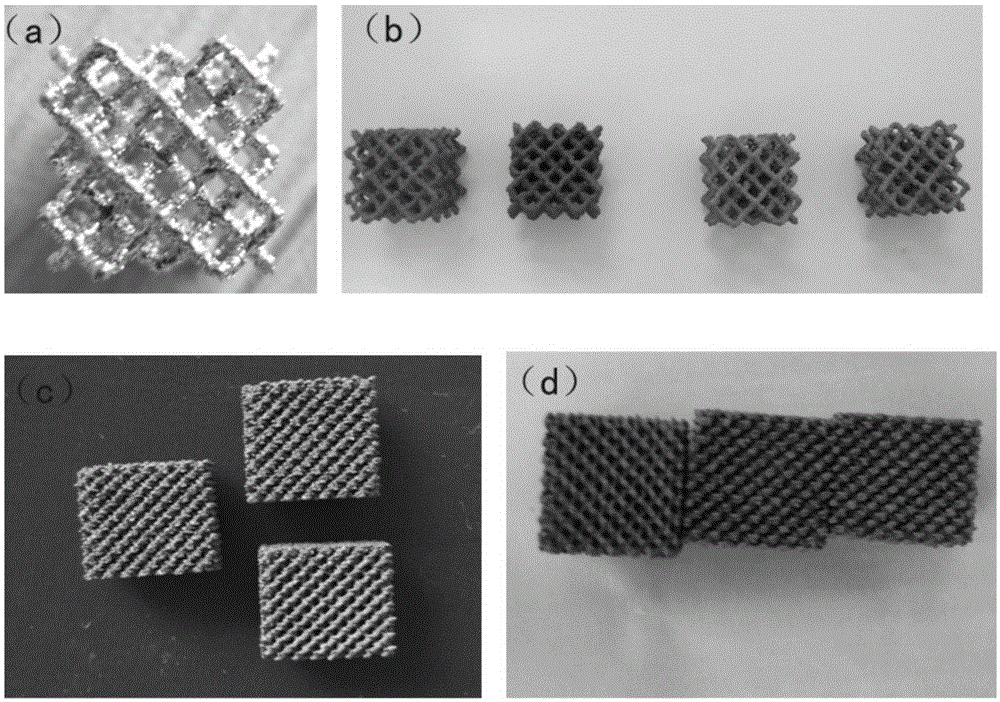

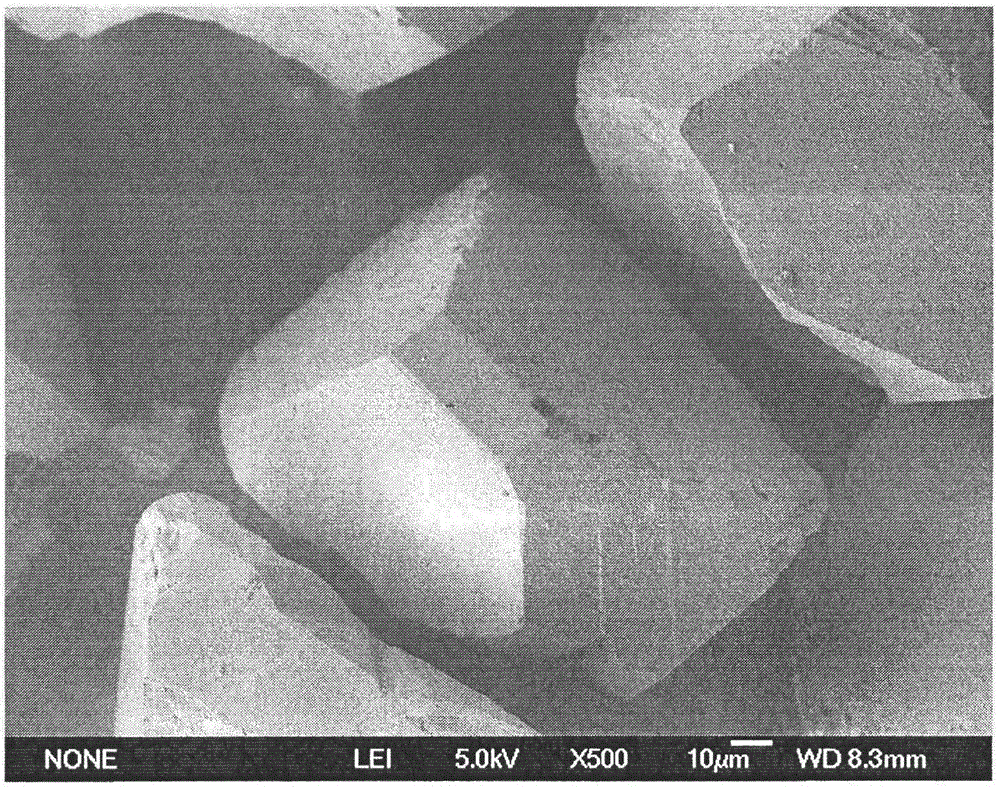

Preparation method of porous biological activity ceramic film on surface of porous pure titanium or titanium alloy with lattice structure and application thereof

ActiveCN106676605AUniform thicknessWell combinedSurface reaction electrolytic coatingProsthesisMicro arc oxidationAnodic oxidation

The invention discloses a preparation method of a porous biological activity ceramic film on a surface of a porous pure titanium or titanium alloy with a lattice structure and application thereof, and belongs to the technical field of metal surface treatment. The method comprises chemical polishing, preparation of a prefabricated oxide film under direct-current voltage, and preparation of the porous biological activity ceramic film under square wave pulse voltage. The chemical polishing is a chemical acid washing method. The oxide film prefabrication is a low-voltage direct-current anodic oxidation method; and a porous biologic activity functional ceramic layer adopts a micro arc oxidation preparation method. The ceramic layer obtained by the method is firm in combination with a basal body, has a micron-size cellular structure on the surface, can singly serve as a biologic functional coating layer, and can be subsequently treated to prepare a composite functional coating layer higher in corrosion resistance, wear resistance, biologic activity and bacteria resistance. An interbody fusion cage for the field of orthopedics or an implant for the field of dentistry manufactured based on the method shortens the synostosis time of the implant body.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for recycling CBN (Cubic Boron Nitride) abrasive from waste product obtained by producing ceramic bonding agent CBN grinding wheel

ActiveCN106675517AThe structure of the grinding wheel is uniformWell combinedOther chemical processesAir atmosphereQuenching

The invention discloses a process for recycling a CBN (Cubic Boron Nitride) abrasive in a ceramic bonding agent CBN grinding wheel waste product by a chemical etching method. The process comprises the following steps: heating a ceramic bonding agent CBN grinding wheel in an air atmosphere to be 500 to 550DEG C, and insulating for 1 to 2 hours; cooling the grinding wheel along with a furnace and then separating a ceramic CBN working layer from a metallic matrix; cleaning the ceramic bonding agent CBN working layer by ultrasonic waves, then putting into an electric furnace and heating to be 550DEG C; carrying out water quenching and then carrying out ball milling for a short time of 4 to 6 minutes, and breaking into powder; taking ceramic bonding agent CBN grinding wheel powder, impregnating into a NaOH solution at the temperature of 80 to 95DEG C, insulating for 3 to 5 hours and flushing to be neutral; subsequently impregnating the powder into an HF solution at the temperature of 80 to 95DEG C, insulating for 3 to 5 hours and flushing to be neutral; finally, enabling residual powder to pass through a corresponding screen mesh, thus obtaining CBN recycled abrasive of which the purity is higher and the grit size meets the service requirement. The problem that waste products generated by the ceramic bonding agent CBN grinding wheel in sintering and processing procedures are difficult to recycle is solved.

Owner:江苏华东砂轮有限公司

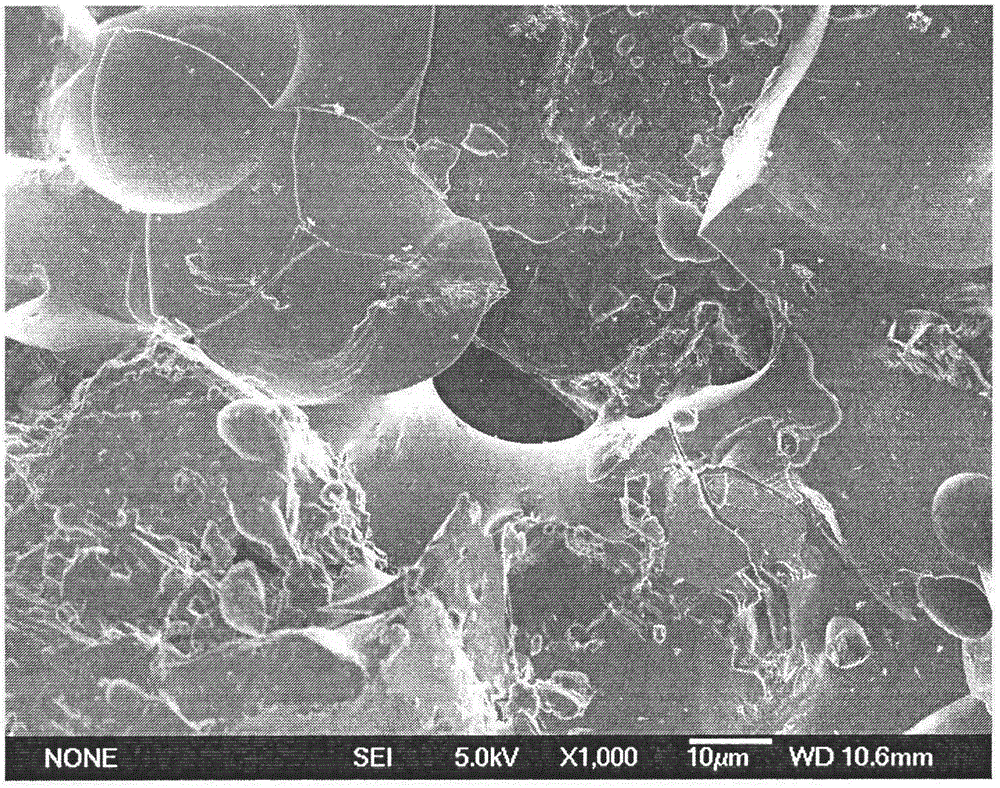

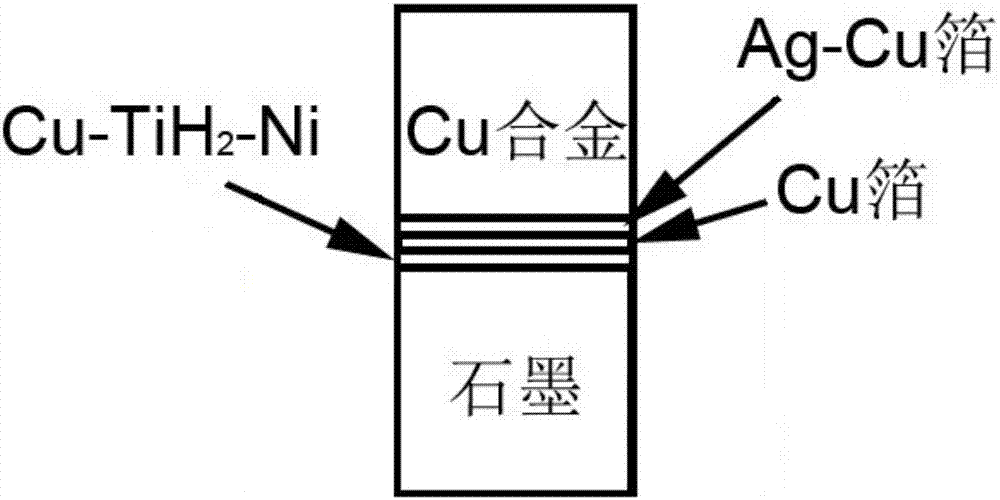

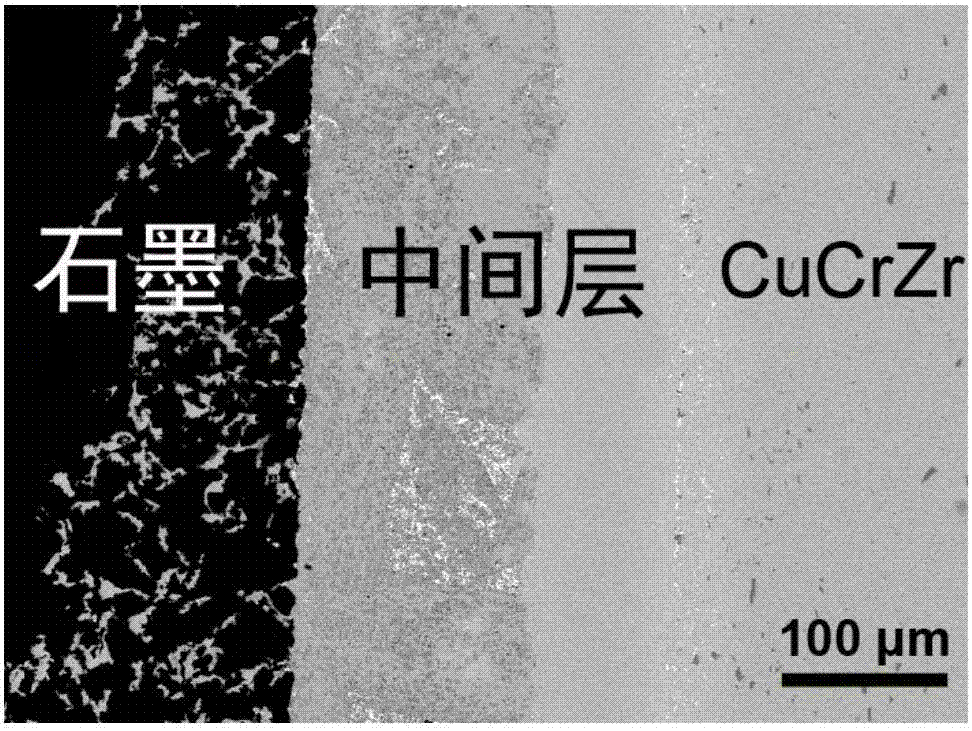

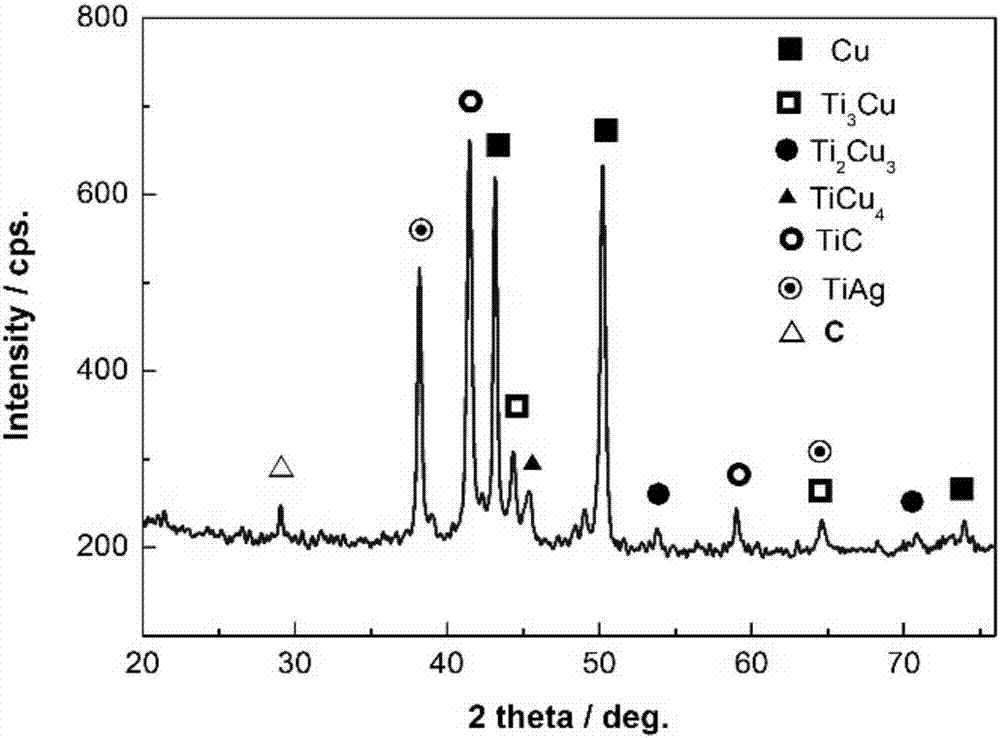

Graphite/Cu alloy connector and preparation method thereof

The invention discloses a graphite / Cu alloy connector and a preparation method thereof. A connection layer of the graphite / Cu alloy connector is of a sandwich type composite structure and comprises a Cu-TiH2-Ni layer connected with graphite, an Ag-Cu layer connected with Cu alloy, and a Cu layer located between the Cu-TiH2-Ni layer and the Ag-Cu layer. The preparation method of the graphite / Cu alloy connector comprises the following steps that (1) Cu powder, TiH2 powder and Ni powder are uniformly mixed and added with ethyl alcohol to be ground, so that Cu-TiH2-Ni mixed powder solder is obtained; (2) an appropriate amount of the Cu-TiH2-Ni mixed powder solder is taken and added with a little of absolute ethyl alcohol and glycerol drop by drop, so that thick cream solder is prepared; and (3) the cream solder is evenly smeared on the surface of the graphite, then, Cu foil and Ag-Cu foil are put on the cream solder in sequence, finally the Cu alloy is put, the mixture is overall put into a mold, and the connector is obtained after brazing. The graphite / Cu alloy connector prepared through the method is good in interface bonding and high in connection strength, and the problems that the wettability of copper on the surface of the graphite is poor, and residual thermal stress occurs due to the large thermal expansion coefficient difference between the graphite and the copper alloy are solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Alloy electrode suitable for Cu<2>SnSe<3>-based thermoelectric element and preparation technology of thermoelectric element

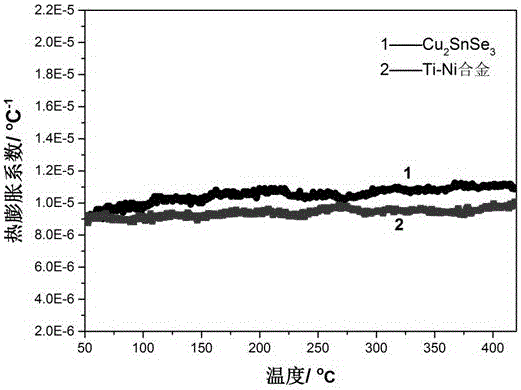

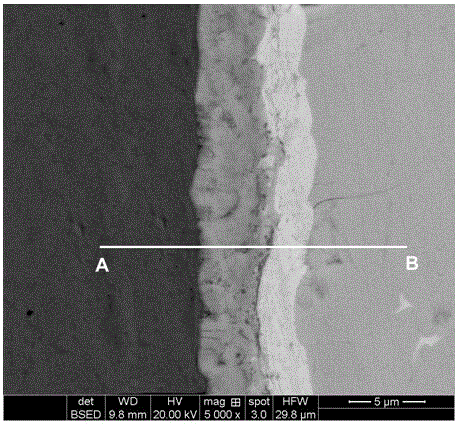

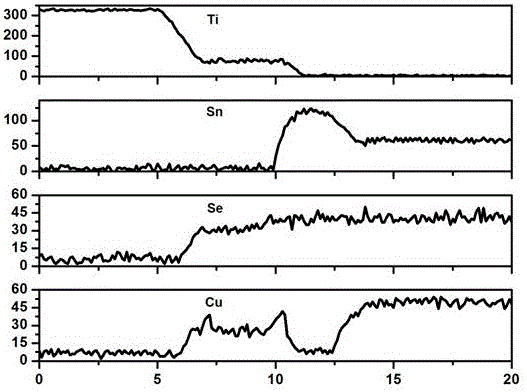

ActiveCN105679928AGood connectionWell combinedThermoelectric device manufacture/treatmentThermoelectric device detailsElectrode interfaceThermoelectric element

The invention relates to an alloy electrode matched with a p-type Cu<2>SnSe<3>-based thermoelectric material and a preparation technology of a Cu<2>SnSe<3>-based thermoelectric element. The alloy electrode is a Ti-Ni alloy, and has high electric conductivity and thermal conductivity. The Ti-Ni alloy provided by the invention has a coefficient of thermal expansion, which is very similar to that of the Cu<2>SnSe<3>-based thermoelectric material. According to preparation of the Cu<2>SnSe<3>-based thermoelectric element, the Cu<2>SnSe<3>-based thermoelectric element is formed by directly sintering the Cu<2>SnSe<3>-based thermoelectric material on the Ti-Ni alloy electrode by an (RHPS) technology; and an intermediate transition connection layer is not needed. The sintered electrode interface bonding is very stable; and the Cu<2>SnSe<3> / electrode interface is free of obvious resistance transition. The preparation technology is simple, is very suitable for preparation of the Cu<2>SnSe<3>-based thermoelectric element and can be applied to large-scale production and preparation.

Owner:UNIV OF JINAN

University science and technology park digital information management system

InactiveCN109493008AImprove conversion efficiencyWell combinedOffice automationNetwork information systemPatent application

The invention belongs to the technical field of network information systems, and discloses a university science and technology park digital information management system comprising an enterprise management module used for examining and approving enterprises which do not enter a science park; the scientific and technological achievement and conversion module is used for managing and counting scientific and technological achievements and conversion conditions thereof; the enterprise demand management module is used for managing demands submitted by science park enterprises; the project library management module is used for managing project application information and project establishment information of teachers or science park enterprises; the expert database and review module comprises anexpert database management sub-function module and an expert review sub-function module; and the intellectual property service module comprises a patent application agency service sub-function moduleand a proposal / teaching material publishing service sub-function module. The system gathers various resources, builds a communication bridge for scientific and technological achievements and enterprise demands, promotes the combination of industry, universities and studies, and achieves the efficient combination of science and technology and economic benefits.

Owner:四川西华科技园管理有限责任公司

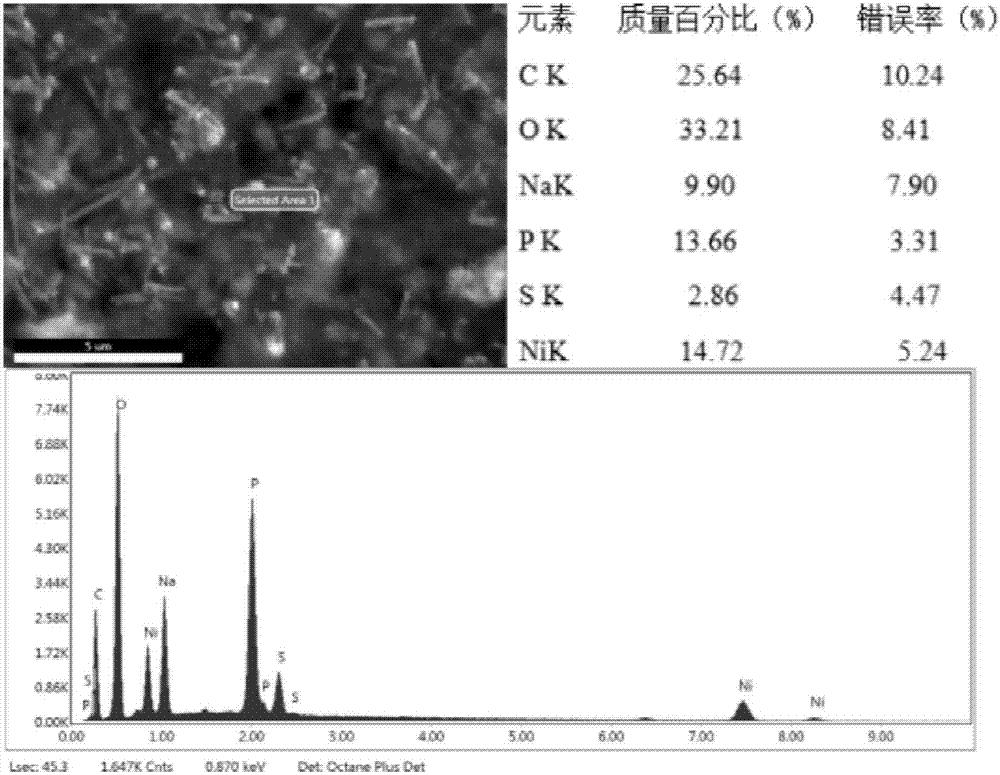

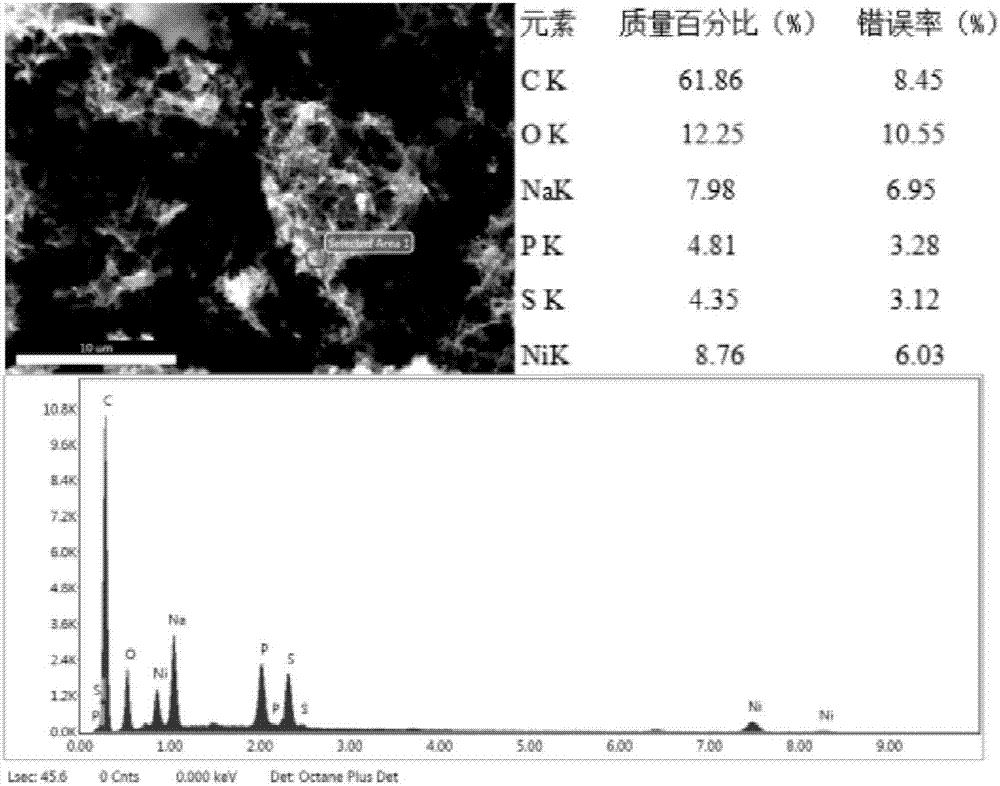

Plating solution and method for chemically plating Ni-P on surface of carbon nano tube

ActiveCN107475697AUniform coatingWell combinedLiquid/solution decomposition chemical coatingAluminum matrix compositesChemical plating

The invention discloses a plating solution and method for chemically plating Ni-P on the surface of a carbon nano tube. The chemical plating solution is characterized by comprising 18-34 g / L of nickel sulfate (NiSO4.6H2O), 10-20 g / L of citric acid (C6H8O7.H2O), 15-25 mL / L of lactic acid (C3H6O3), 8-16 g / L of anhydrous sodium acetate (CH3COONa), 20-30 g / L of sodium hypophosphite (NaH2PO2.H2O) and 80-120 mL / L of anhydrous alcohol (C2H5OH). The chemical plating method comprises the steps that the carbon nano tube is soaked into the anhydrous alcohol and subjected to alkaline washing and acid pickling, then, the carbon nano tube is put into the chemical plating solution, plating is conducted by controlling the PH value and the temperature, and the Ni-P is deposited onto the surface of a substrate of the carbon nano tube to form a plating layer. According to the plating solution and the method, operation and implementation are easy, and the economical efficiency is good. The carbon nano tube is expected to achieve appropriate-strength interfacial adhesion in an aluminum base composite material, and Al4C3 is effectively inhibited from being generated too much.

Owner:JIANGSU UNIV

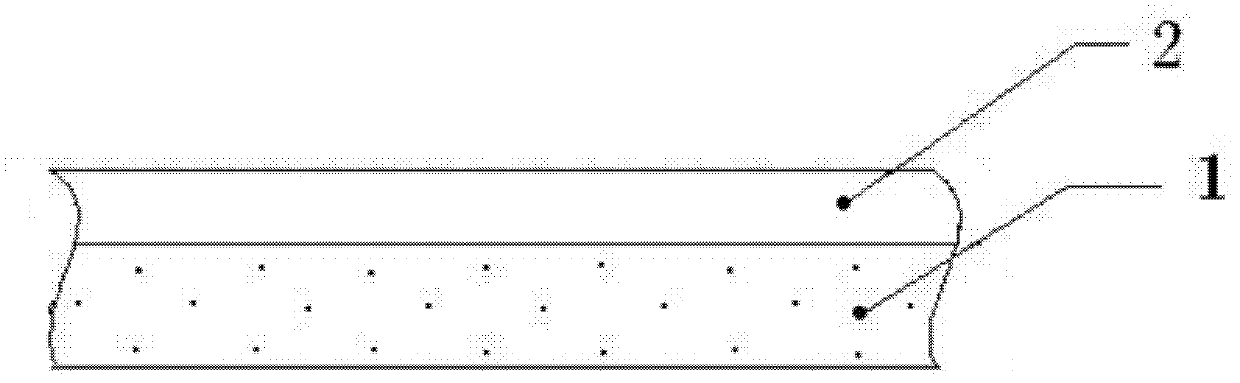

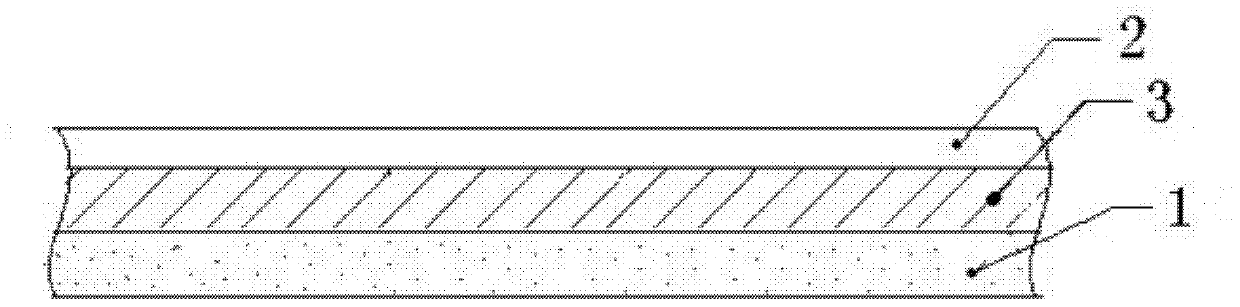

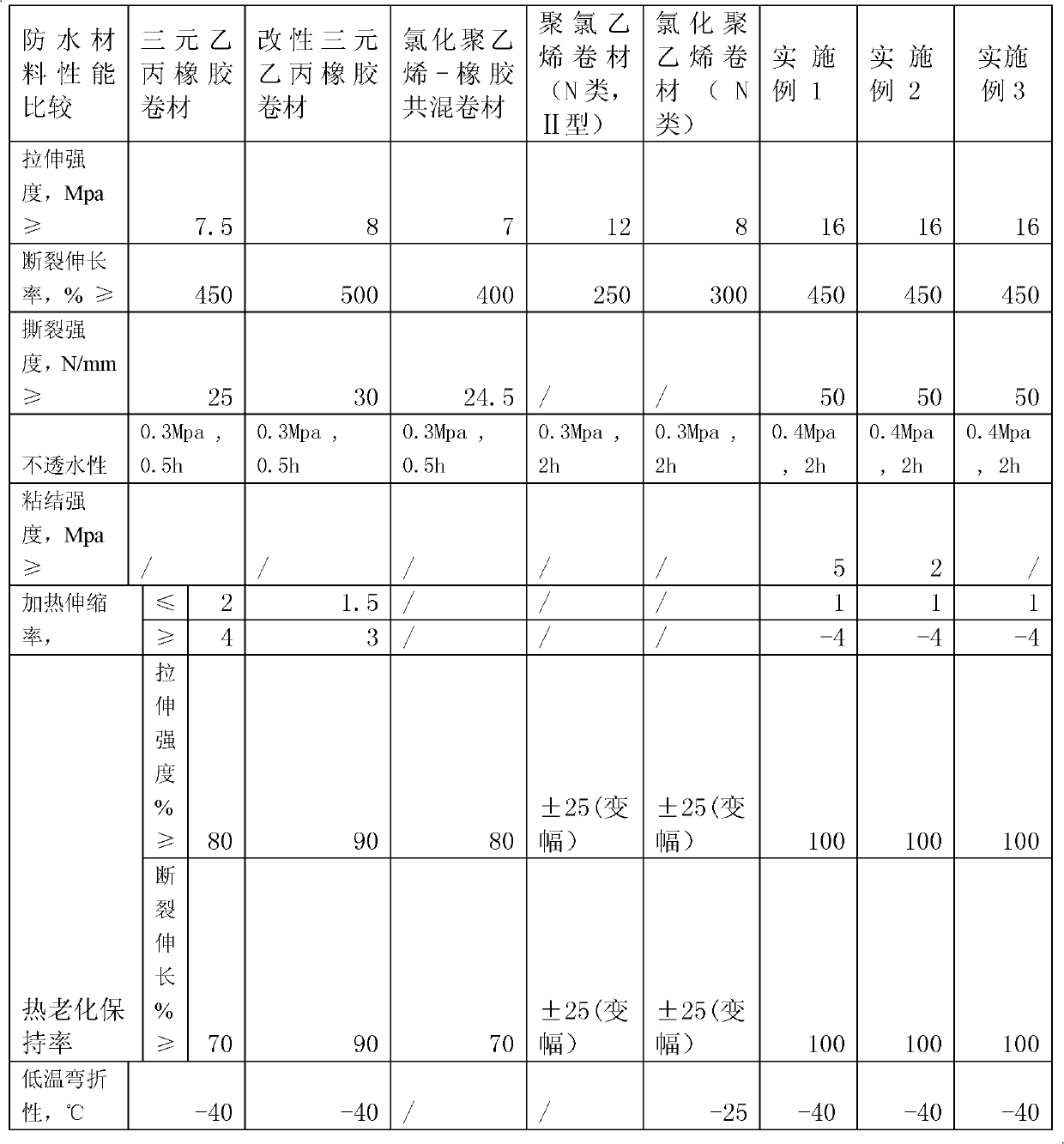

Polyurea waterproof coiled material

InactiveCN102312487AStrong adhesionWell combinedUnderground chambersRoof covering using flexible materialsWeather resistancePolyurea

The invention discloses a polyurea waterproof coiled material which is of a layered structure with a plurality of layer surfaces. At least one layer of the layered structure is a polyurea elastic layer. The polyurea waterproof coiled material provided by the invention has the excellent advantages of excellent bonding force, excellent combination with a concrete substrate, simple structure, stable construction property, convenience in operation, excellent waterproof property, excellent weather resistance and durability, high strength, difficulty in aging, longer service life, wide application prospects and the like.

Owner:KESHUN WATERPROOF TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com