Vacuum electron beam brazed joint method of tungsten/low activation steel

A vacuum electron beam, low activation steel technology, applied in welding/welding/cutting items, welding equipment, manufacturing tools, etc., can solve problems such as large thermal stress, long welding time, and inability to accurately control energy input, and achieve high efficiency , combined with the perfect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

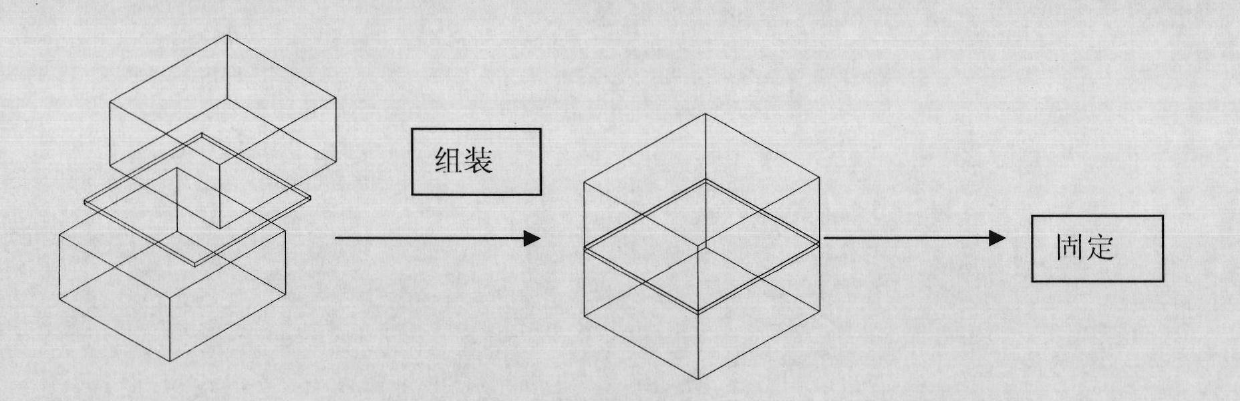

[0020] The tungsten used for brazing is a commercially available 5mm thick rolled tungsten plate, and the low activation steel is the CNSI low activation steel (9Cr2W) developed by our research group. The sample size is 10mm×8mm. Before brazing, use No. 150, No. 400, No. 600 and No. 800 sandpaper to grind the welded surface of the test piece step by step, and then use acetone to degrease the brazed surface, clean it ultrasonically with absolute ethanol, and dehydrate and dry it.

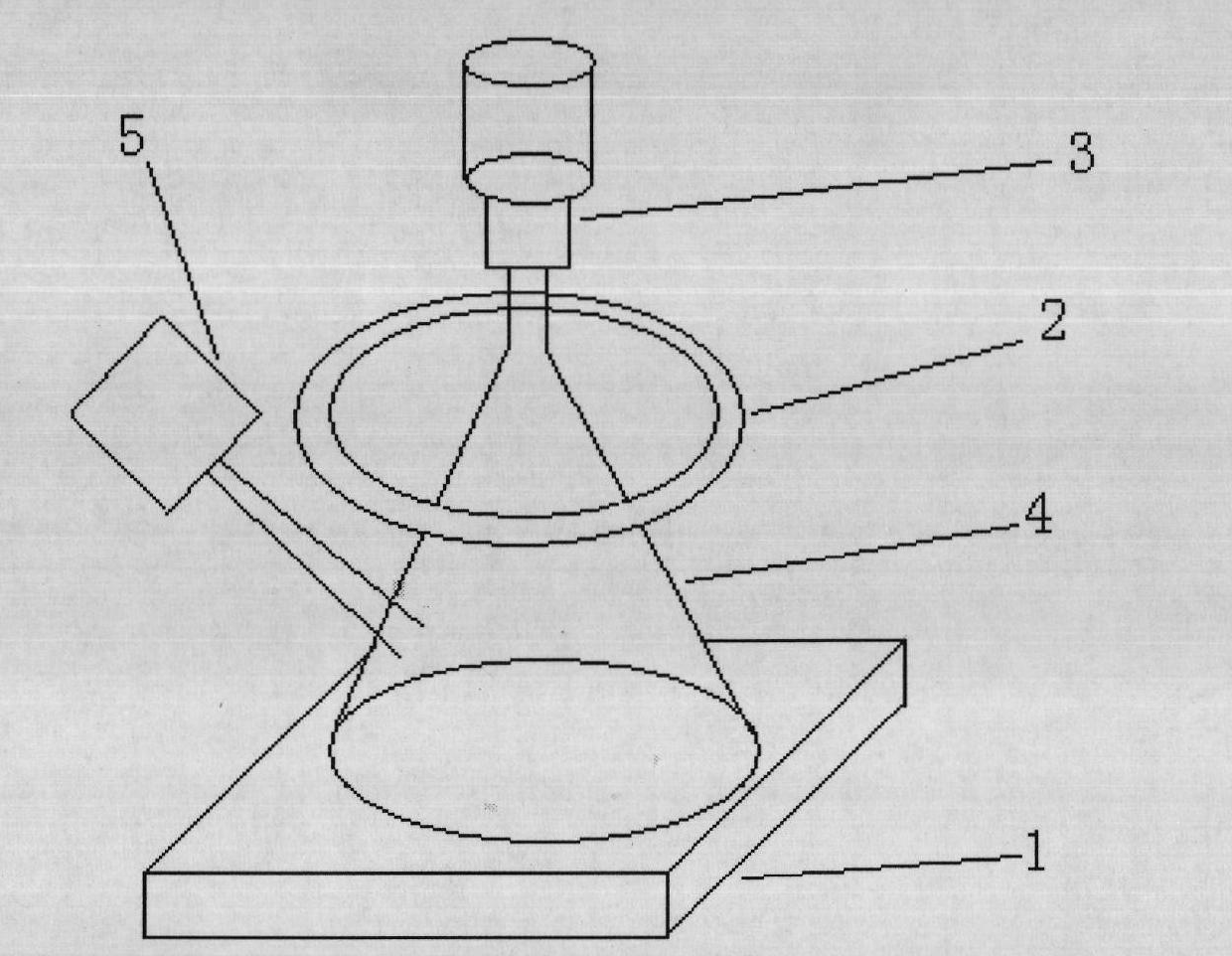

[0021] After placing the tungsten / brazing material / steel in the order from top to bottom, put them into a vacuum electron beam brazing furnace for welding. The process parameters are acceleration voltage 150kV, focusing current I f =402mA, electron beam current is I b =2mA, heating time t is 3min.

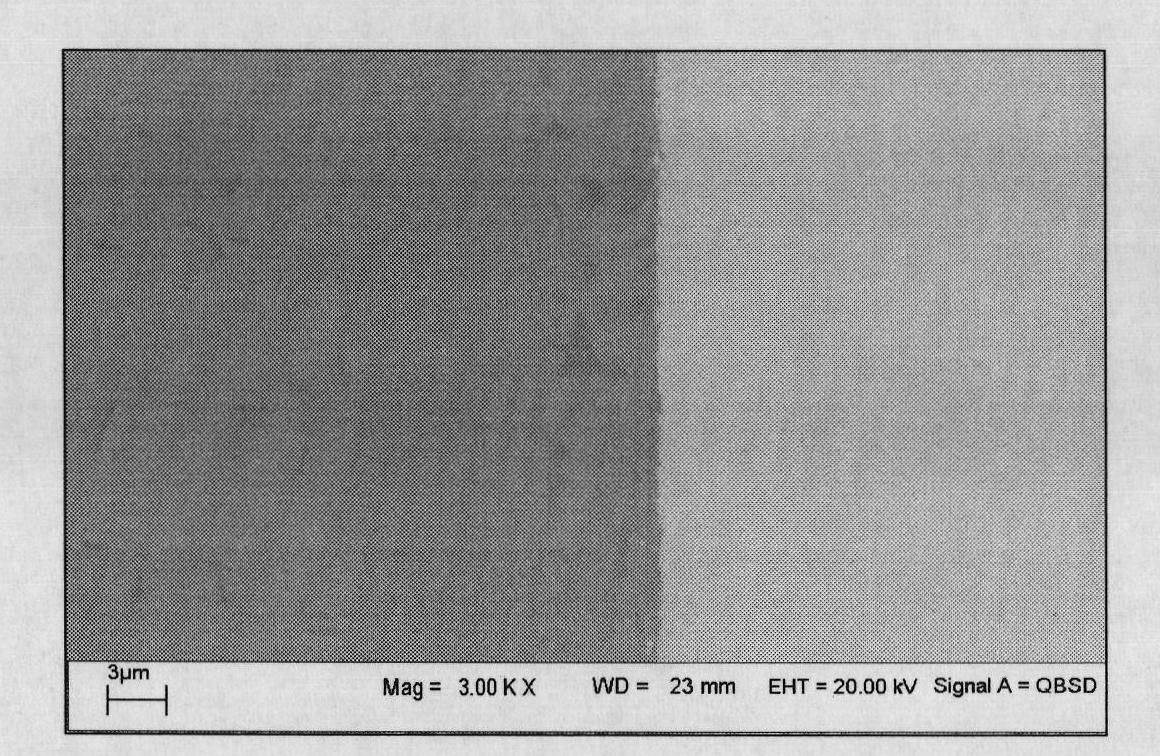

[0022] image 3 The SEM of the vacuum electron beam brazing sample is given, it can be seen that the interface is well bonded, and no large holes and cracks appear.

Embodiment 2

[0024] The tungsten used for brazing is a commercially available 5 mm thick rolled tungsten plate, and the low-activation steel is the CNSI low-activation steel (9Cr2W) developed by our research group. The sample size is 15mm×15mm. Before brazing, use No. 150, No. 400, No. 600 and No. 800 sandpaper to grind the welded surface of the test piece step by step, and then use acetone to degrease the brazed surface, clean it ultrasonically with absolute ethanol, and dehydrate and dry it.

[0025] After placing the tungsten / brazing material / steel in the order from top to bottom, put them into a vacuum electron beam brazing furnace for welding. The process parameters are acceleration voltage 150kV, focusing current I f =410mA, electron beam current is I b =2mA, heating time t is 3min.

[0026] Figure 4 The SEM of the vacuum electron beam brazing sample is given, it can be seen that the interface is well bonded, and no large holes and cracks appear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com