Patents

Literature

112 results about "Divertor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

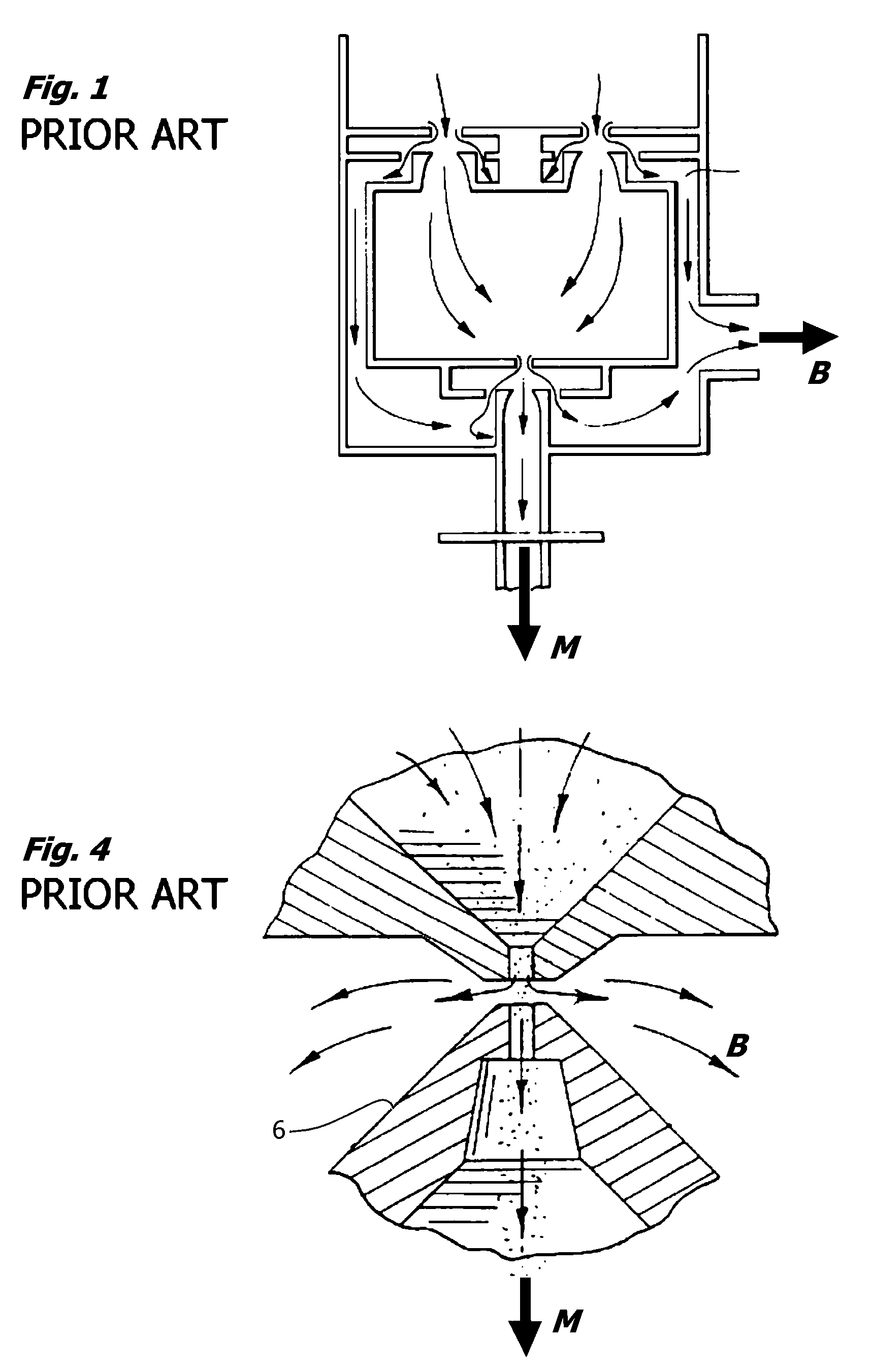

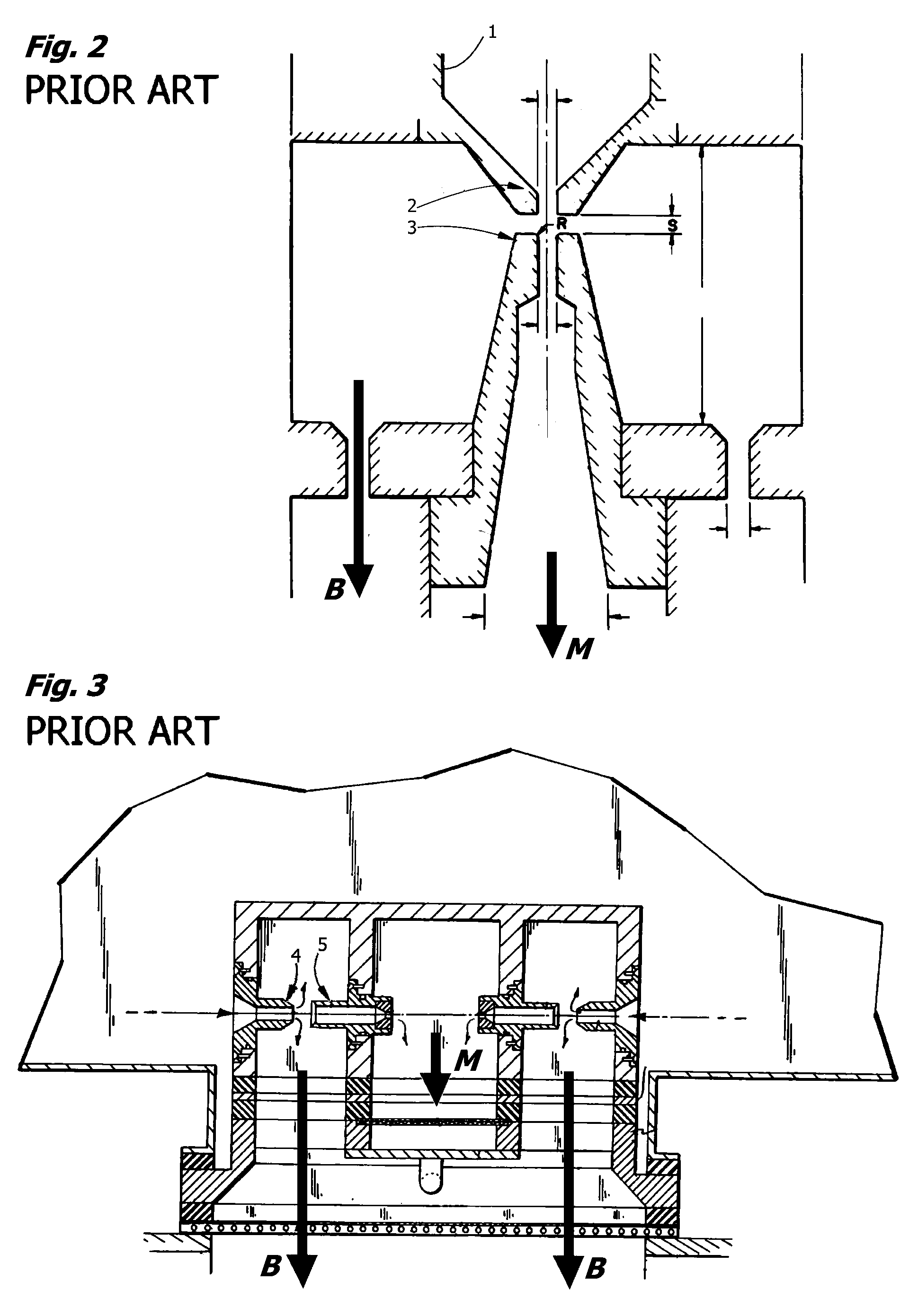

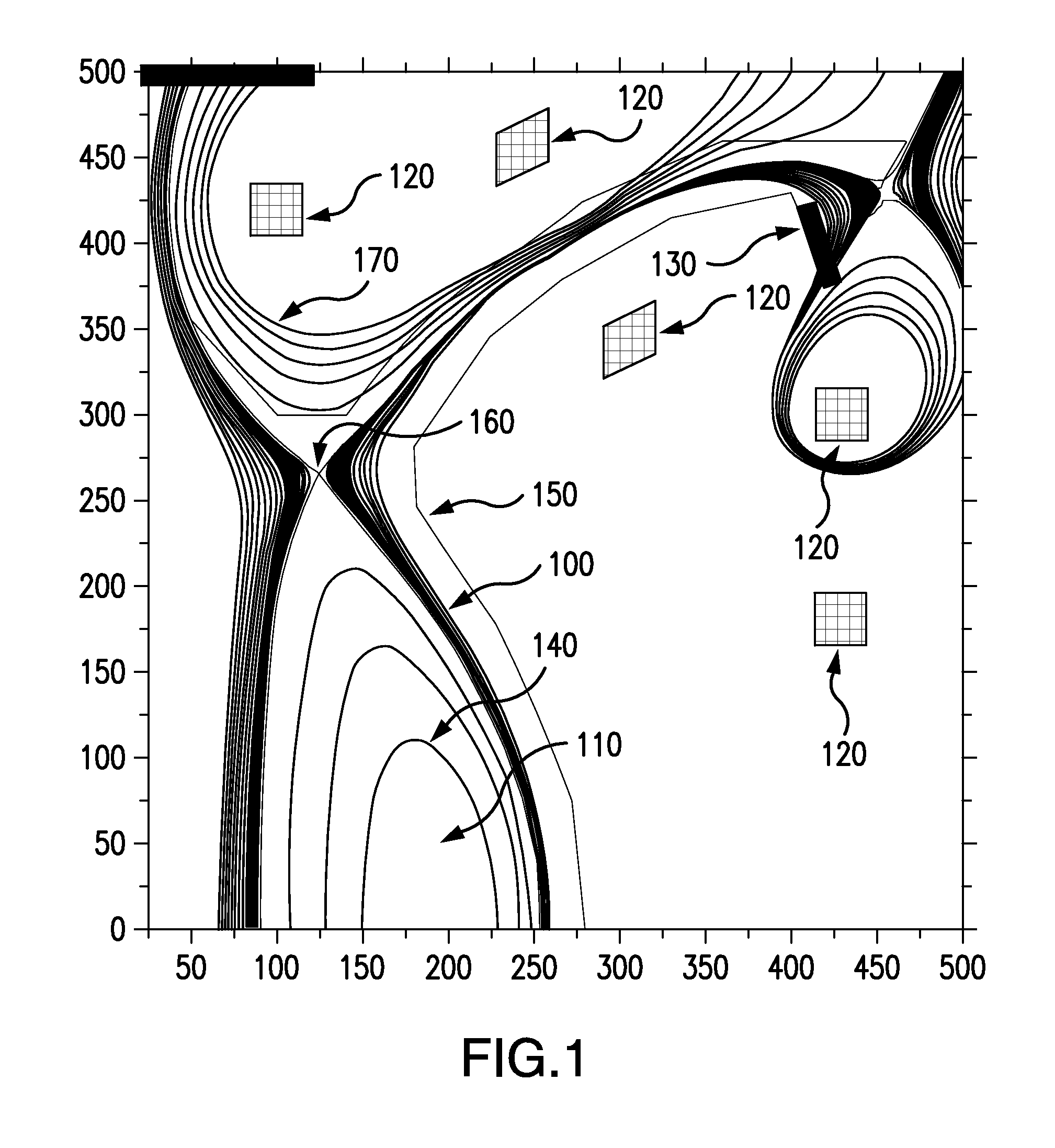

In nuclear fusion power research, a divertor is a device within a tokamak that allows the online removal of waste material from the plasma while the reactor is still operating. This allows control over the buildup of fusion products in the fuel, and removes impurities in the plasma that have entered into it from the vessel lining.

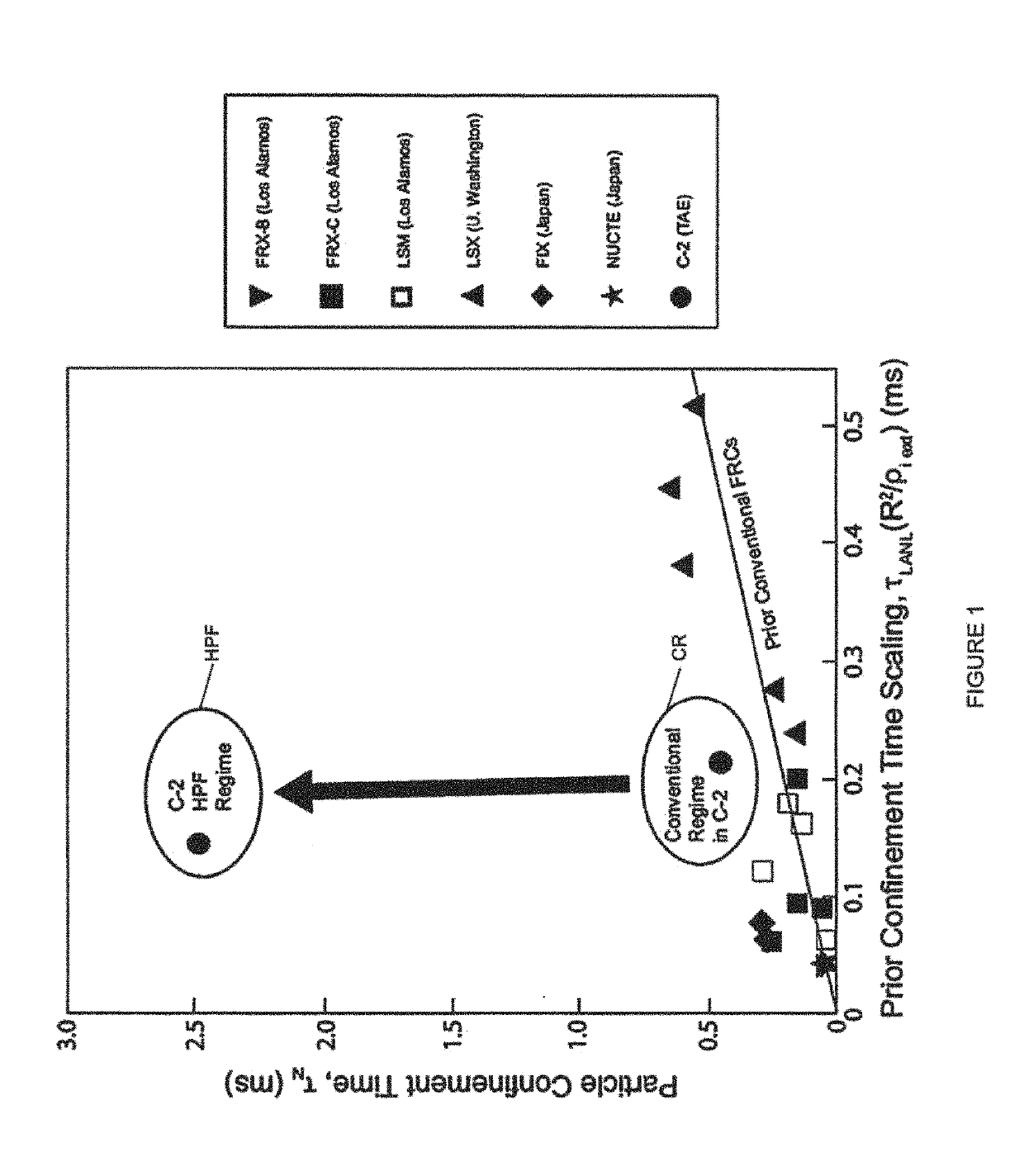

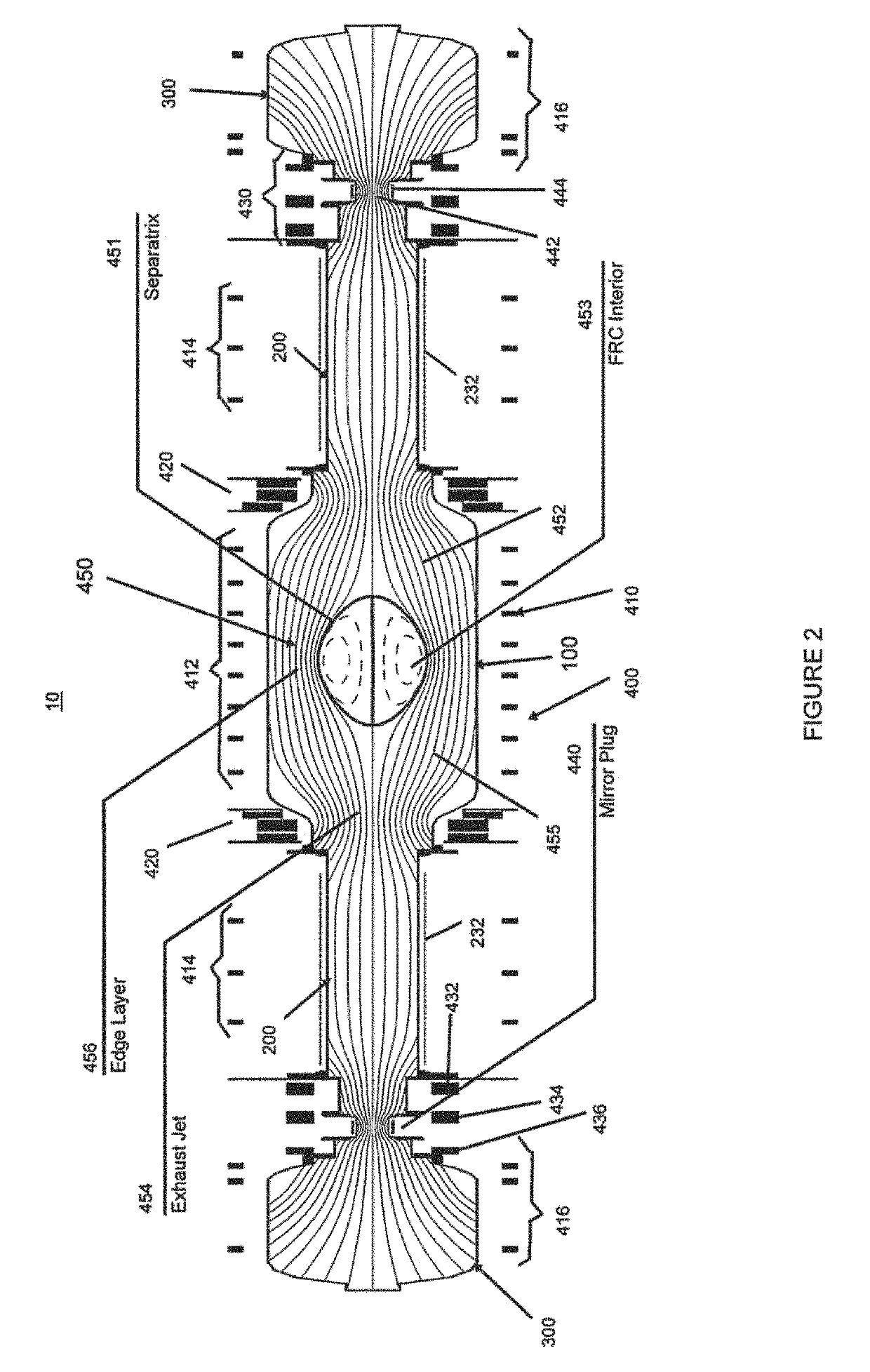

Systems and methods for forming and maintaining a high performance frc

ActiveUS20170359886A1Improve FRC confinementStability control without negative side-effectsNuclear energy generationAcceleratorsThermal energyDivertor

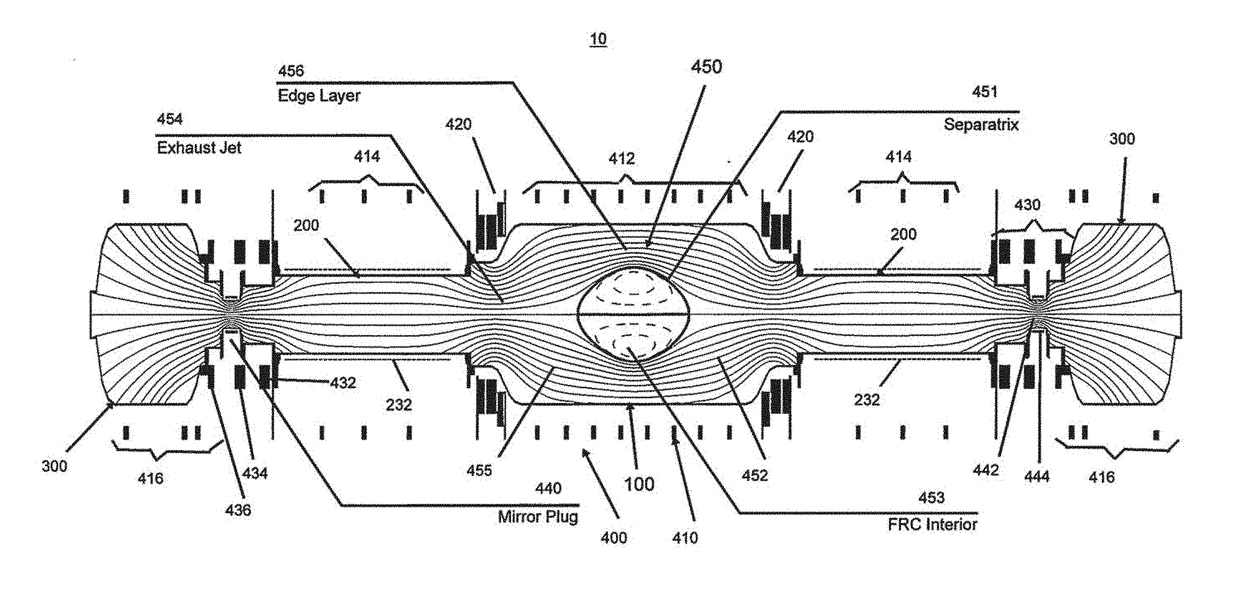

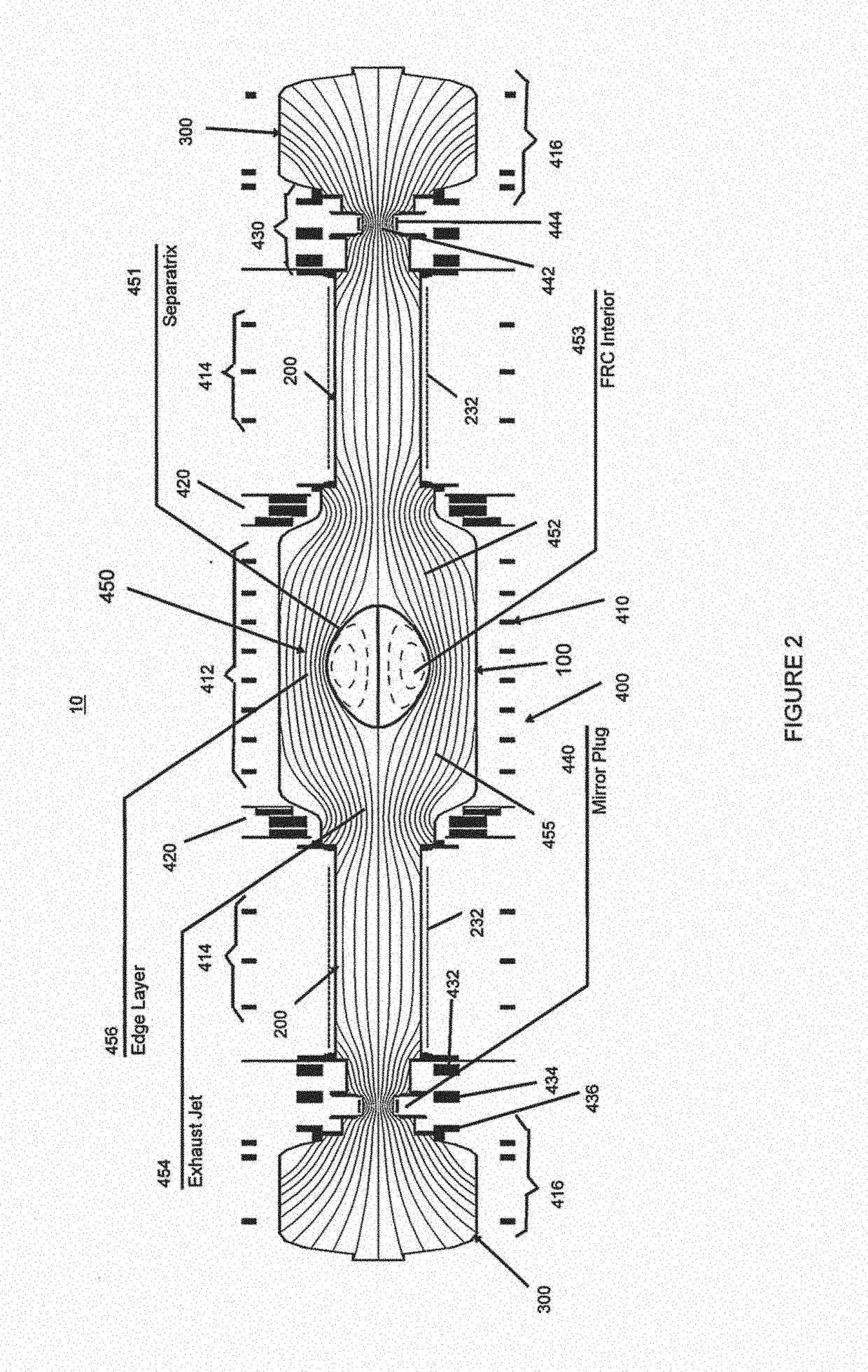

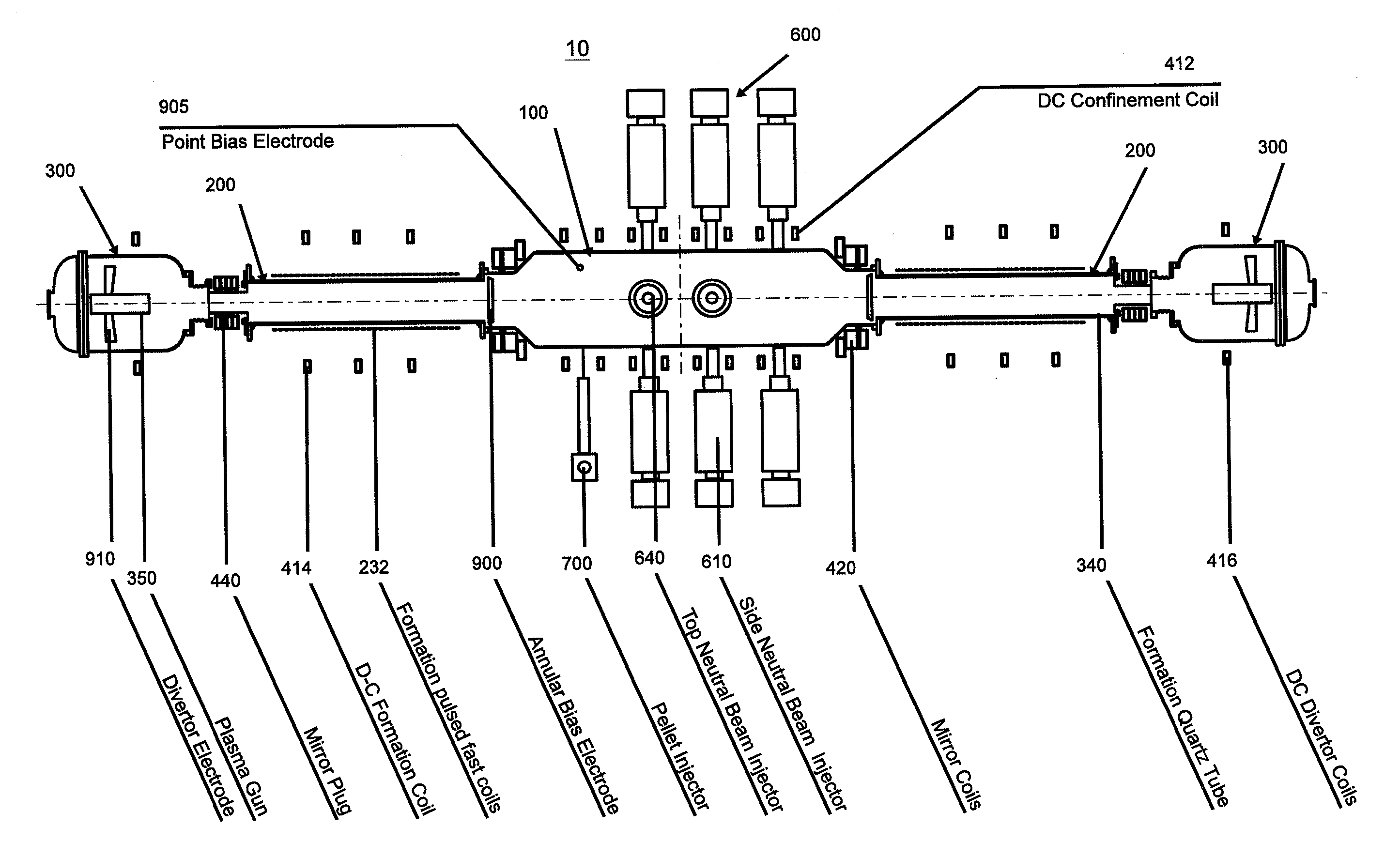

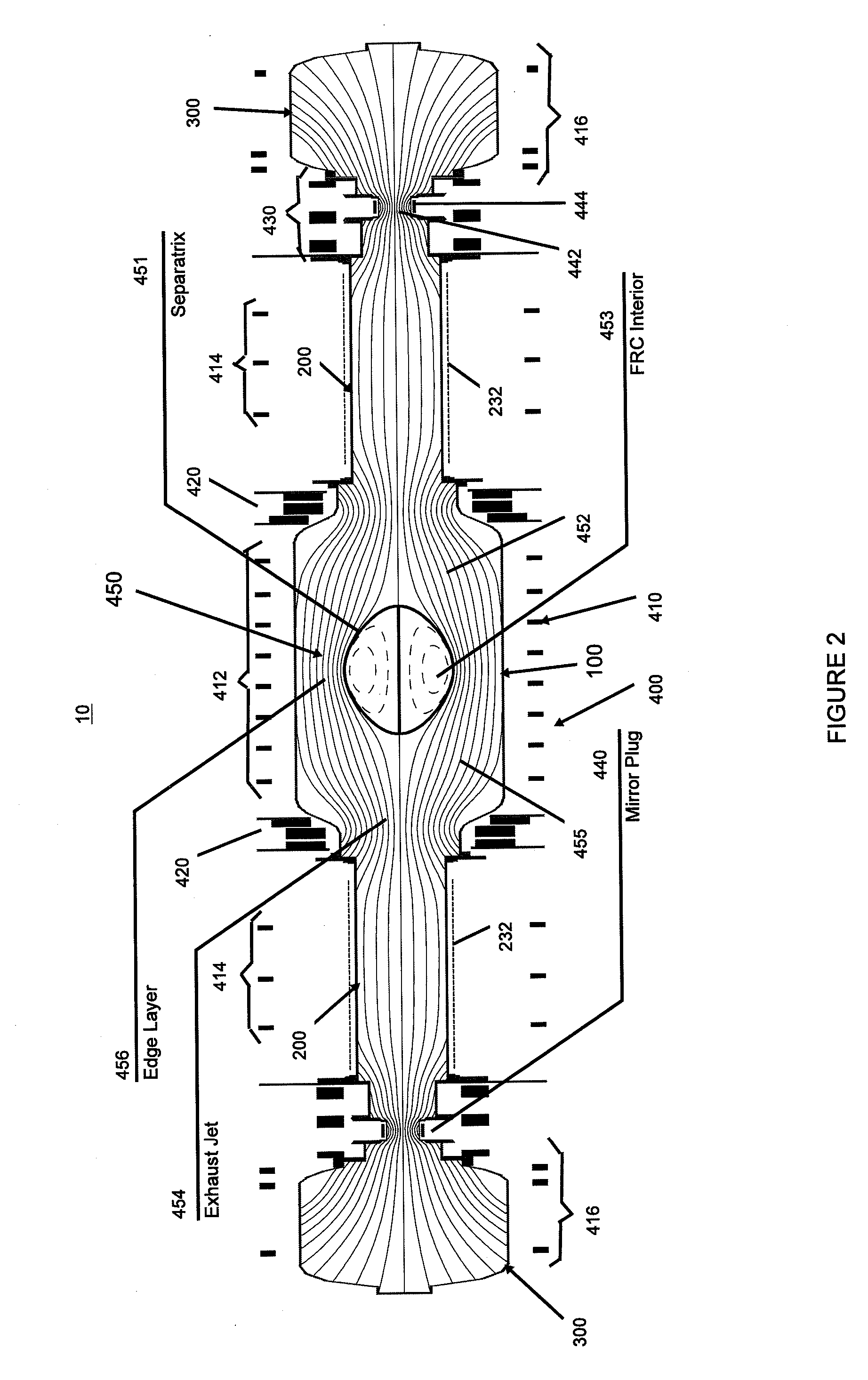

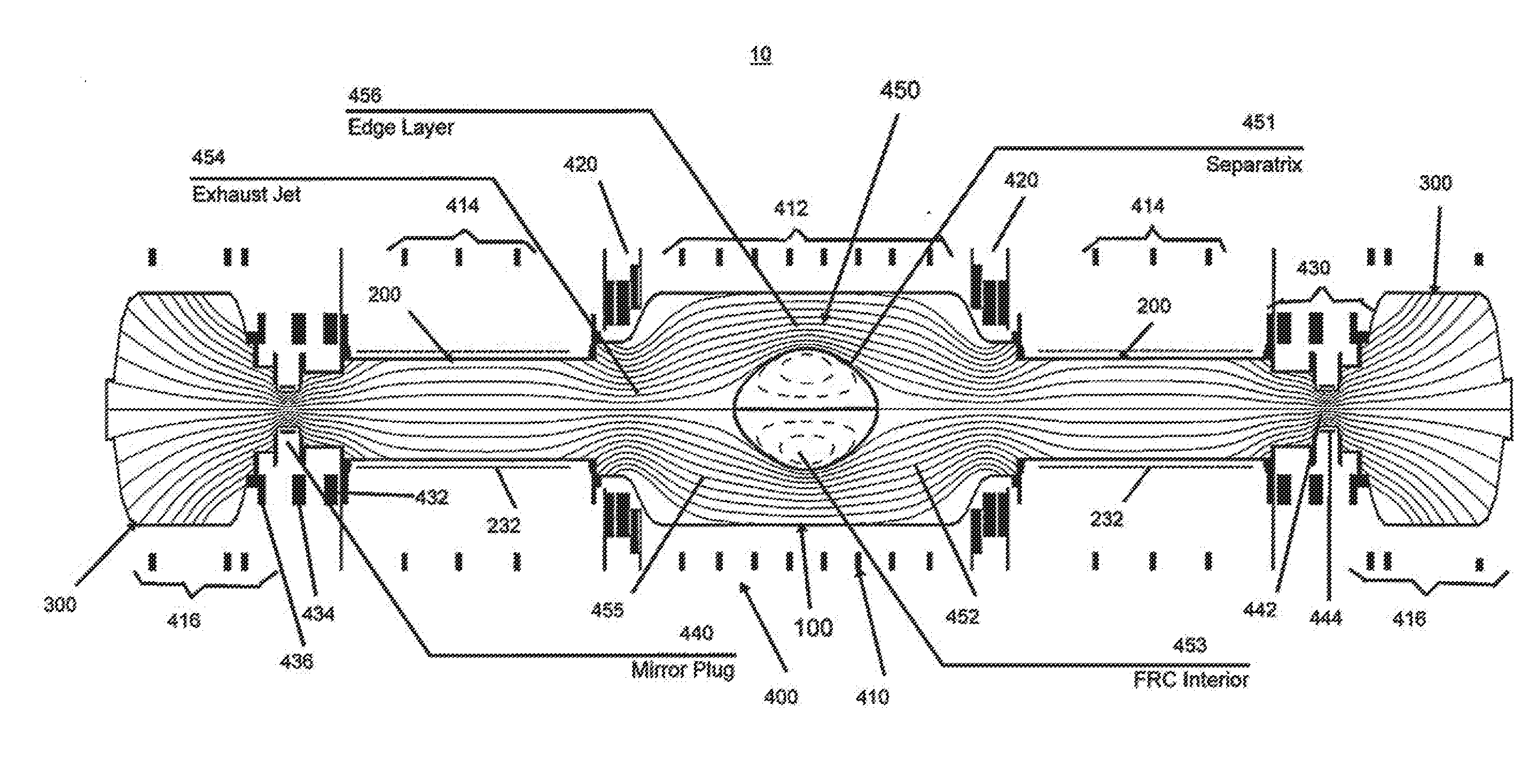

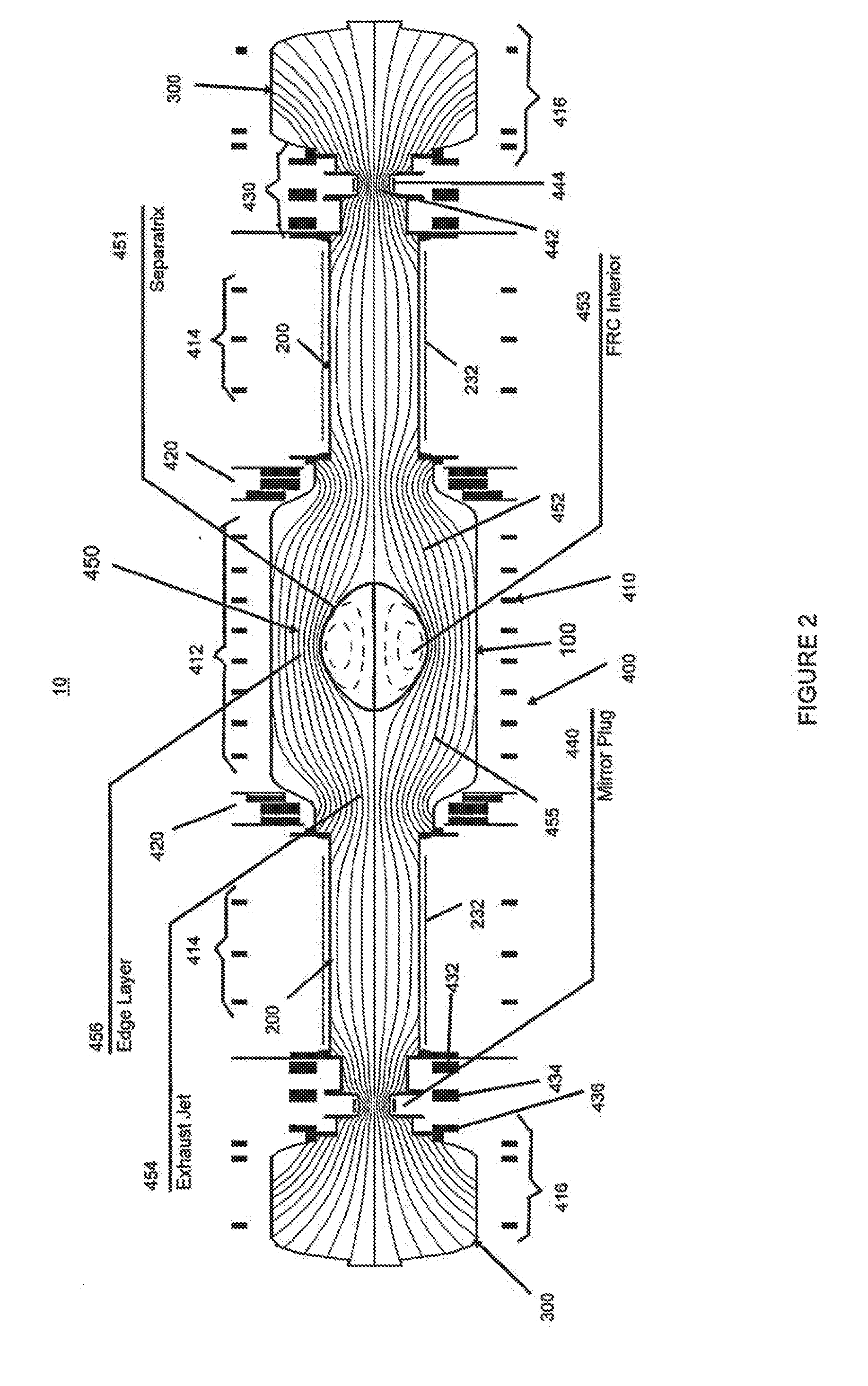

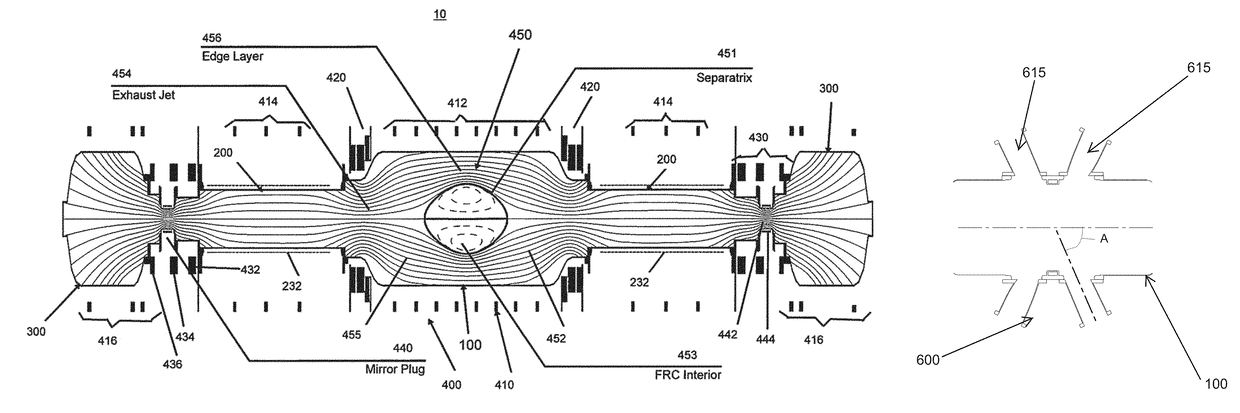

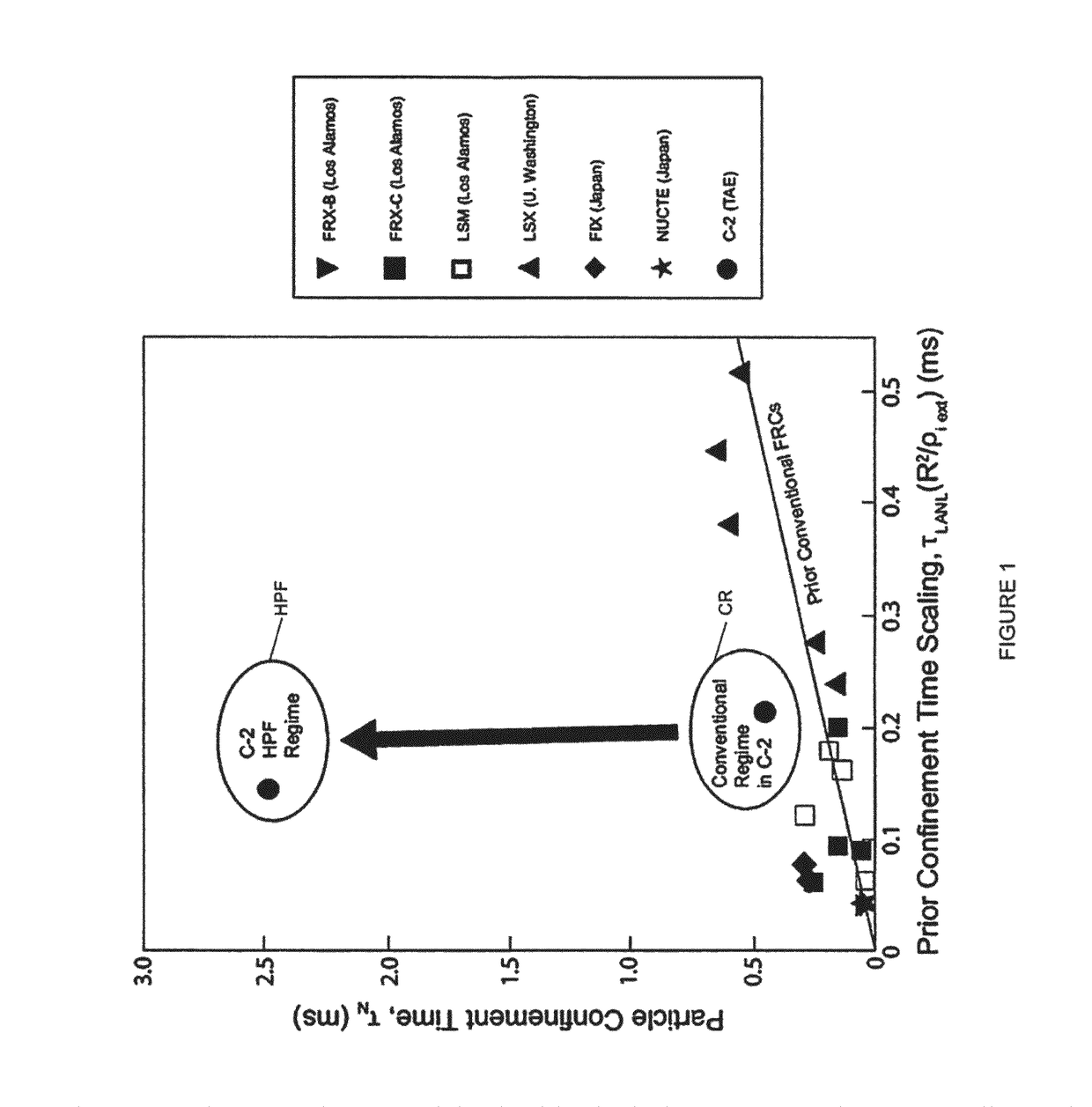

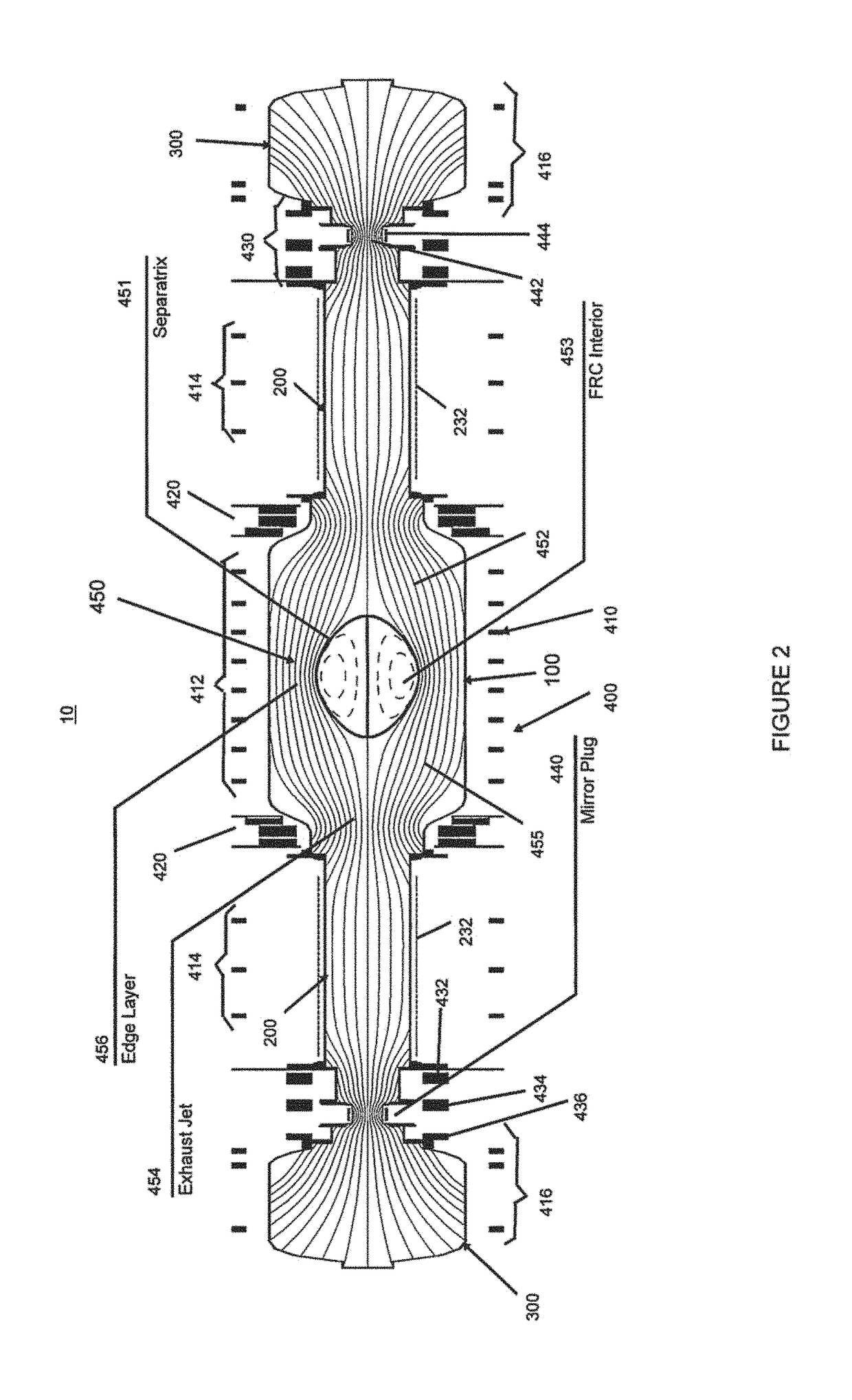

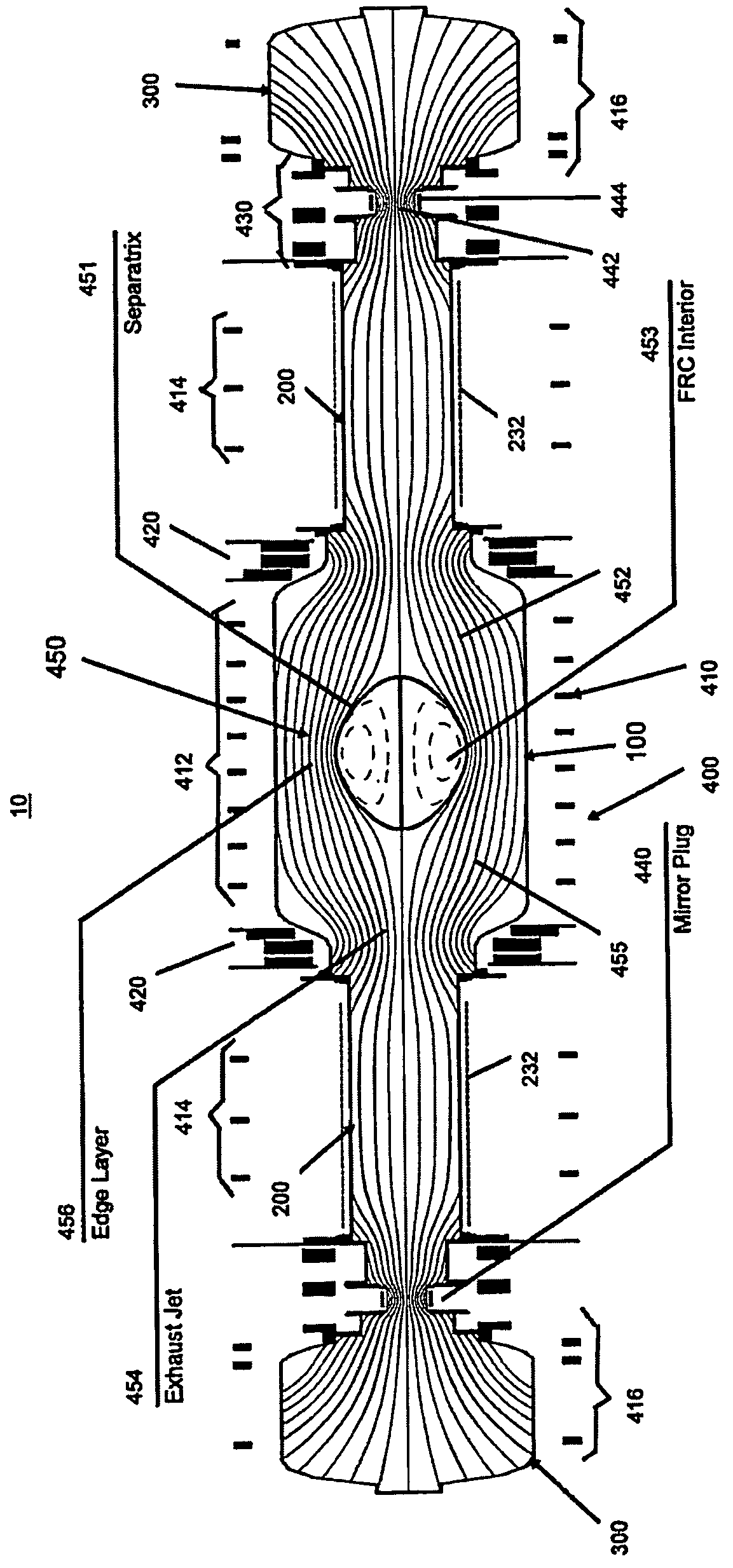

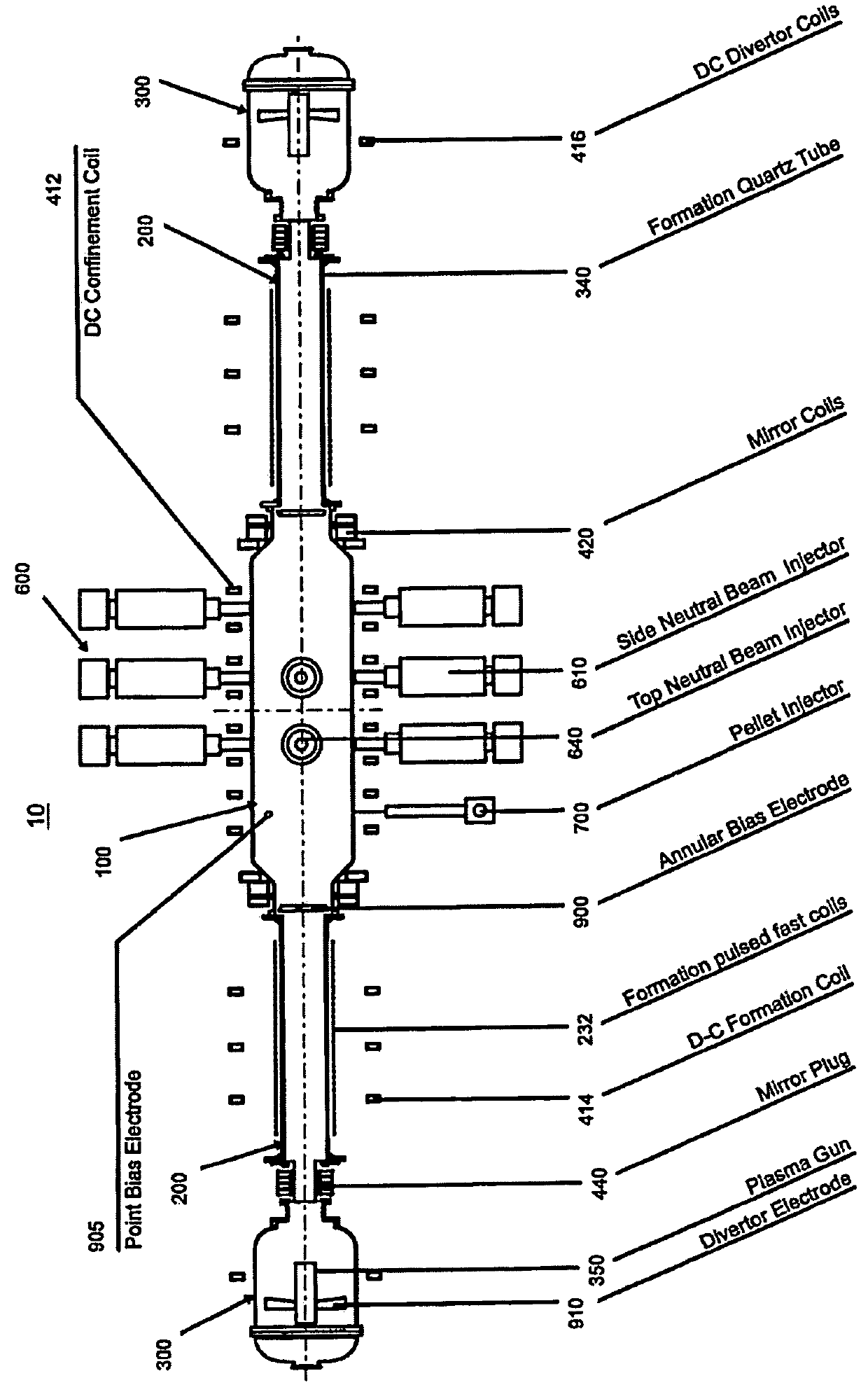

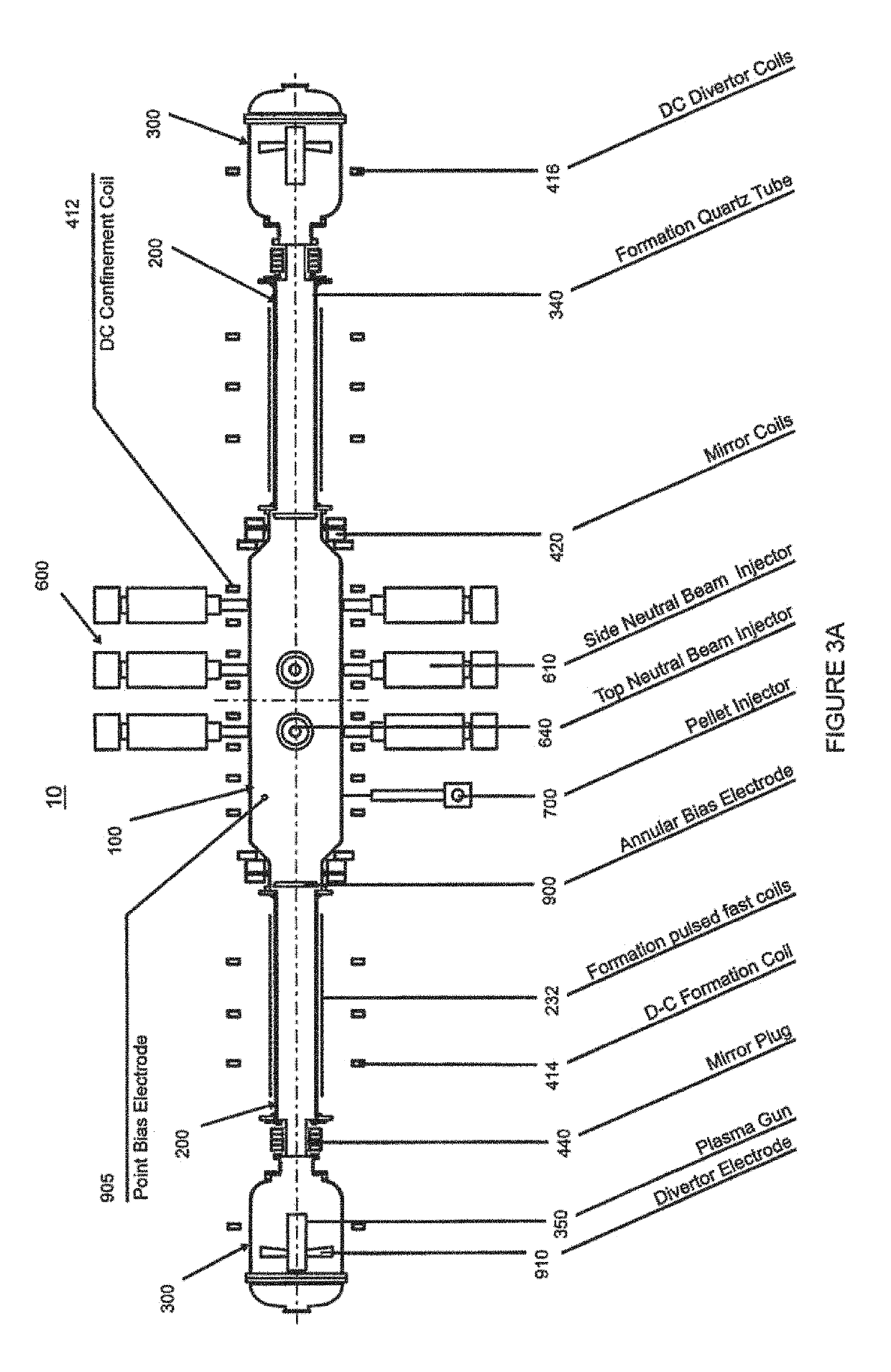

A high performance field reversed configuration (FRC) system includes a central confinement vessel, two diametrically opposed reversed-field-theta-pinch formation sections coupled to the vessel, and two divertor chambers coupled to the formation sections. A magnetic system includes quasi-dc coils axially positioned along the FRC system components, quasi-dc mirror coils between the confinement chamber and the formation sections, and mirror plugs between the formation sections and the divertors. The formation sections include modular pulsed power formation systems enabling static and dynamic formation and acceleration of the FRCs. The FRC system further includes neutral atom beam injectors, pellet or CT injectors, gettering systems, axial plasma guns and flux surface biasing electrodes. The beam injectors are preferably angled toward the midplane of the chamber. In operation, FRC plasma parameters including plasma thermal energy, total particle numbers, radius and trapped magnetic flux, are sustainable at or about a constant value without decay during neutral beam injection.

Owner:TAE TECH INC

Systems and methods for forming and maintaining a high performance frc

ActiveUS20150187443A1Improve FRC confinementStability control without negative side-effectsNuclear energy generationPlasma techniqueEngineeringDivertor

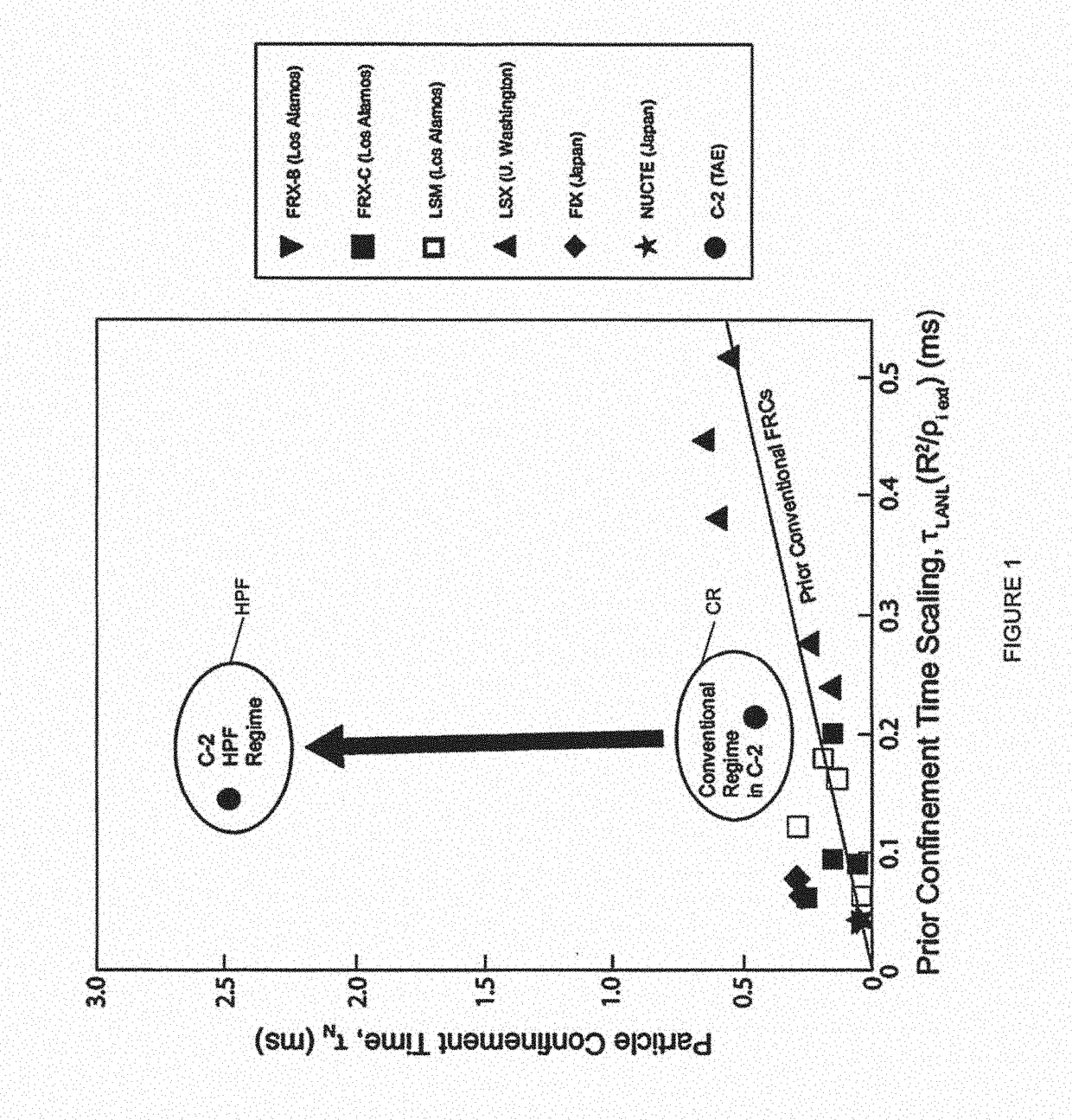

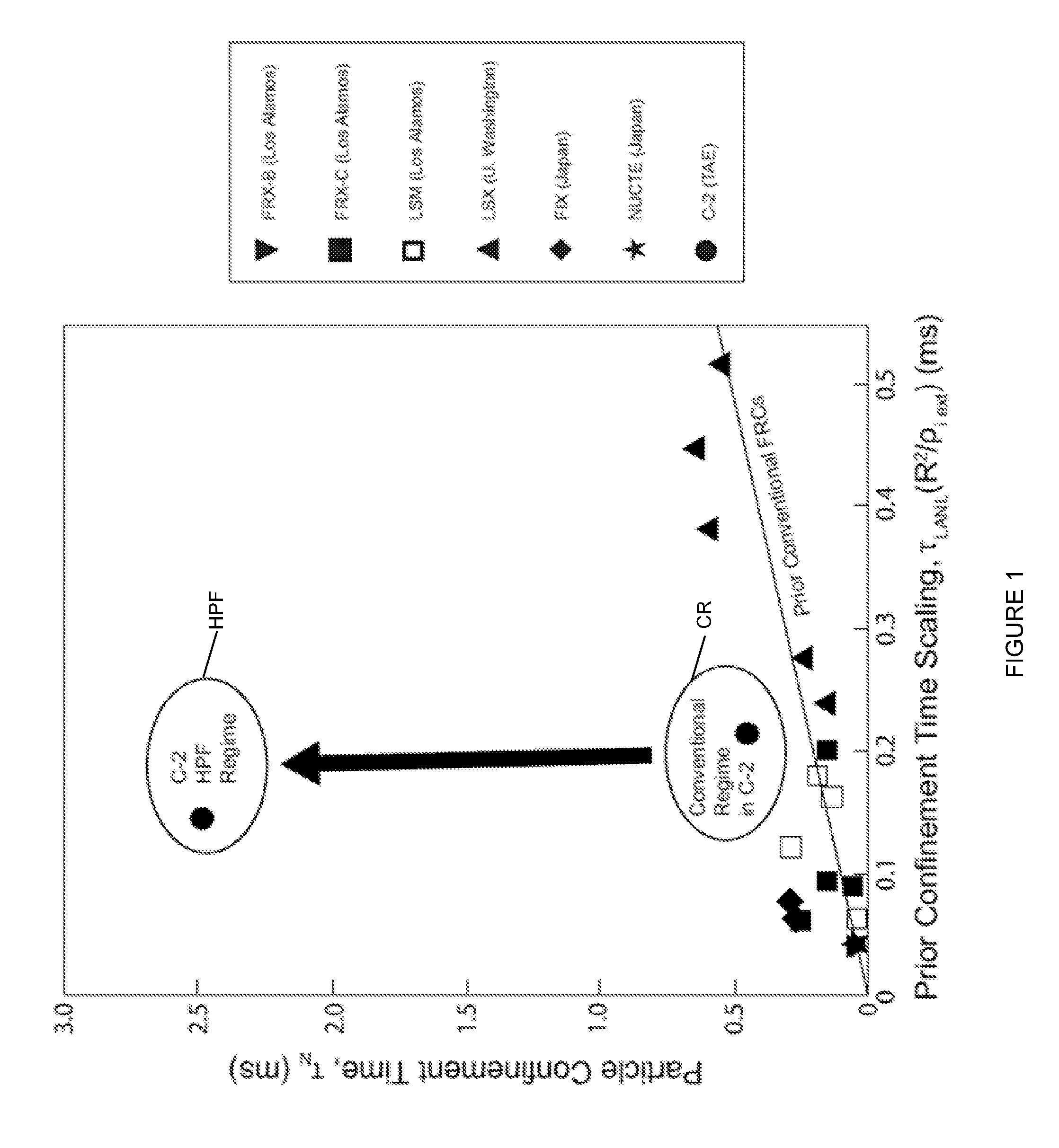

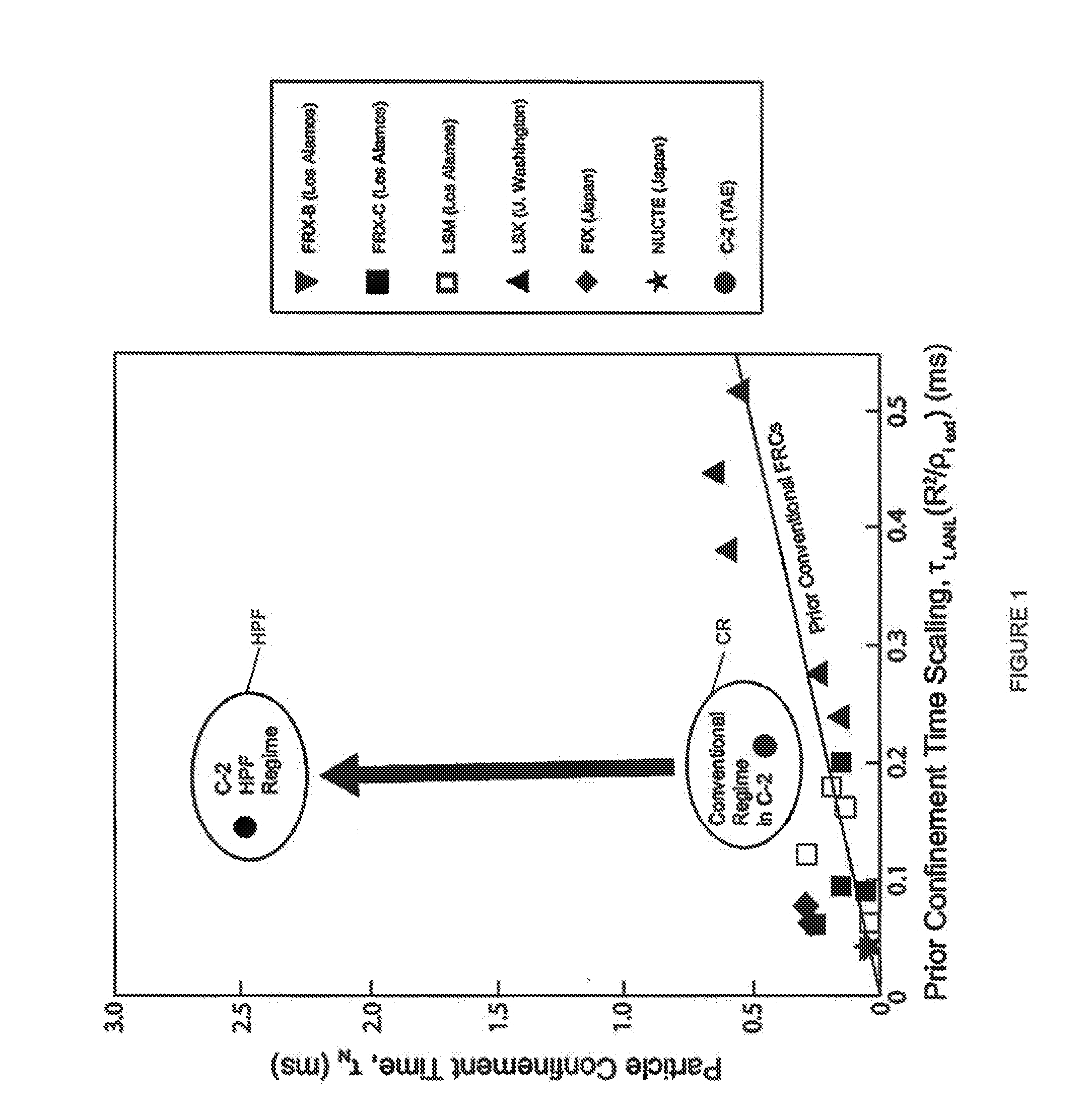

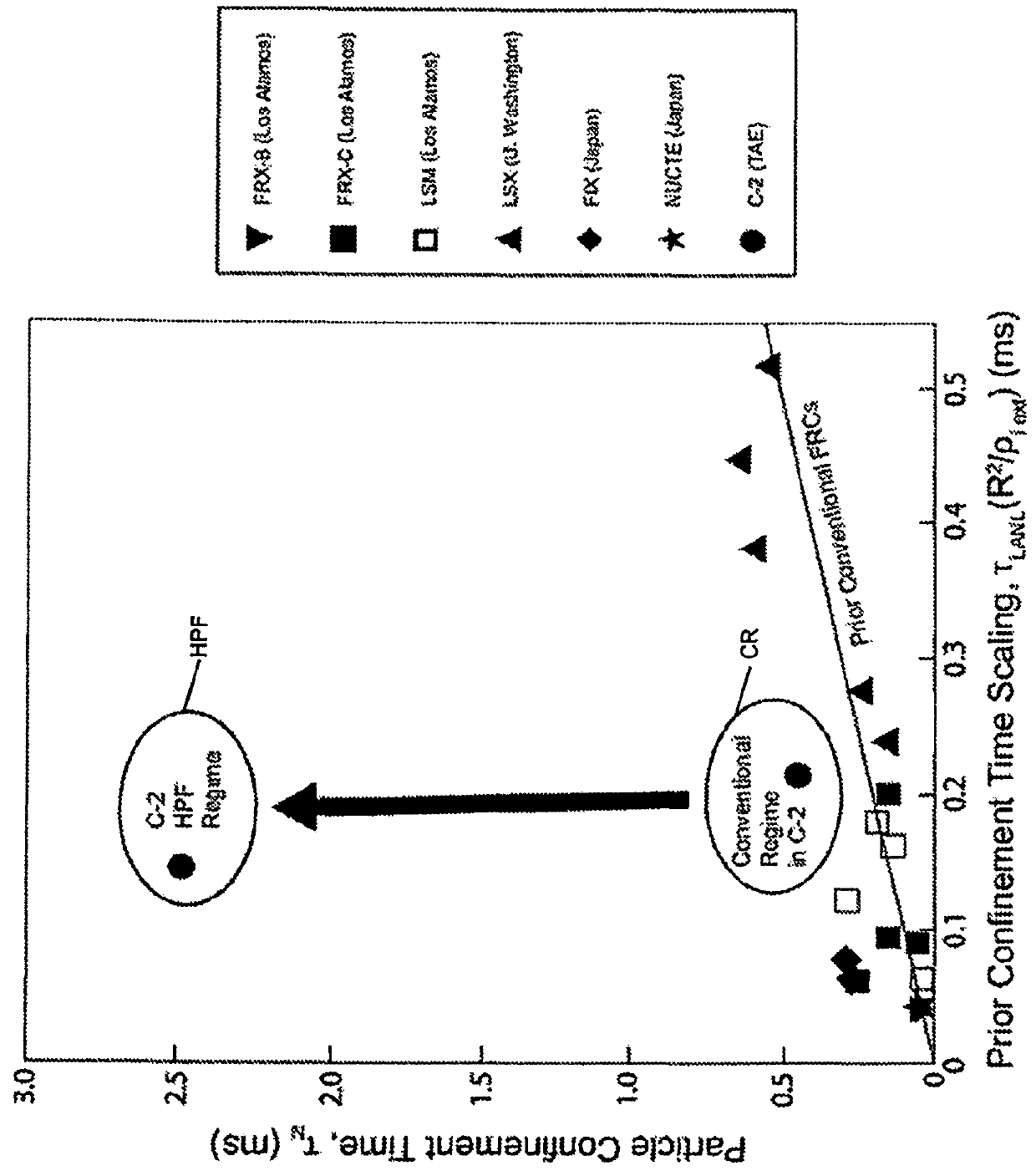

Systems and methods that facilitate the formation and maintenance of new High Performance Field Reversed Configurations (FRCs). An FRC system for the High Performance FRC (HPF) includes a central confinement vessel surrounded by two diametrically opposed reversed-field-theta-pinch formation sections and, beyond the formation sections, two divertor chambers to control neutral density and impurity contamination. A magnetic system includes a series of quasi-dc coils axially positioned along the FRC system components, quasi-dc mirror coils between the confinement chamber and the adjacent formation sections, and mirror plugs between the formation sections and the divertors. The formation sections include modular pulsed power formation systems that enable FRCs to be formed in-situ and then accelerated and injected (=static formation) or formed and accelerated simultaneously (=dynamic formation). The FRC system further includes neutral atom beam injectors, a pellet injector, gettering systems, axial plasma guns and flux surface biasing electrodes.

Owner:RGT UNIV OF CALIFORNIA

Systems and methods for forming and maintaining a high performance frc

ActiveUS20160276044A1Improve FRC confinementStability control without negative side-effectsNuclear energy generationPlasma techniqueThermal energyDivertor

A high performance field reversed configuration (FRC) system includes a central confinement vessel, two diametrically opposed reversed-field-theta-pinch formation sections coupled to the vessel, and two divertor chambers coupled to the formation sections. A magnetic system includes quasi-dc coils axially positioned along the FRC system components, quasi-dc mirror coils between the confinement chamber and the formation sections, and mirror plugs between the formation sections and the divertors. The formation sections include modular pulsed power formation systems enabling static and dynamic formation and acceleration of the FRCs. The FRC system further includes neutral atom beam injectors, pellet injectors, gettering systems, axial plasma guns and flux surface biasing electrodes. The beam injectors are preferably angled toward the midplane of the chamber. In operation, FRC plasma parameters including plasma thermal energy, total particle numbers, radius and trapped magnetic flux, are sustainable at or about a constant value without decay during neutral beam injection.

Owner:TAE TECH INC

Systems and methods for forming and maintaining a high performance FRC

ActiveUS10049774B2Improve FRC confinementStability control without negative side-effectsNuclear energy generationPlasma techniqueThermal energyDivertor

A high performance field reversed configuration (FRC) system includes a central confinement vessel, two diametrically opposed reversed-field-theta-pinch formation sections coupled to the vessel, and two divertor chambers coupled to the formation sections. A magnetic system includes quasi-dc coils axially positioned along the FRC system components, quasi-dc mirror coils between the confinement chamber and the formation sections, and mirror plugs between the formation sections and the divertors. The formation sections include modular pulsed power formation systems enabling static and dynamic formation and acceleration of the FRCs. The FRC system further includes neutral atom beam injectors, pellet injectors, gettering systems, axial plasma guns and flux surface biasing electrodes. The beam injectors are preferably angled toward the midplane of the chamber. In operation, FRC plasma parameters including plasma thermal energy, total particle numbers, radius and trapped magnetic flux, are sustainable at or about a constant value without decay during neutral beam injection.

Owner:TAE TECH INC

Systems and methods for forming and maintaining a high performance FRC

ActiveUS9997261B2Improve FRC confinementStability control without negative side-effectsNuclear energy generationPlasma techniqueEngineeringDivertor

Systems and methods that facilitate the formation and maintenance of new High Performance Field Reversed Configurations (FRCs). An FRC system for the High Performance FRC (HPF) includes a central confinement vessel surrounded by two diametrically opposed reversed-field-theta-pinch formation sections and, beyond the formation sections, two divertor chambers to control neutral density and impurity contamination. A magnetic system includes a series of quasi-dc coils axially positioned along the FRC system components, quasi-dc mirror coils between the confinement chamber and the adjacent formation sections, and mirror plugs between the formation sections and the divertors. The formation sections include modular pulsed power formation systems that enable FRCs to be formed in-situ and then accelerated and injected (=static formation) or formed and accelerated simultaneously (=dynamic formation). The FRC system further includes neutral atom beam injectors, a pellet injector, gettering systems, axial plasma guns and flux surface biasing electrodes.

Owner:RGT UNIV OF CALIFORNIA

Skimmer for Concentrating an Aerosol

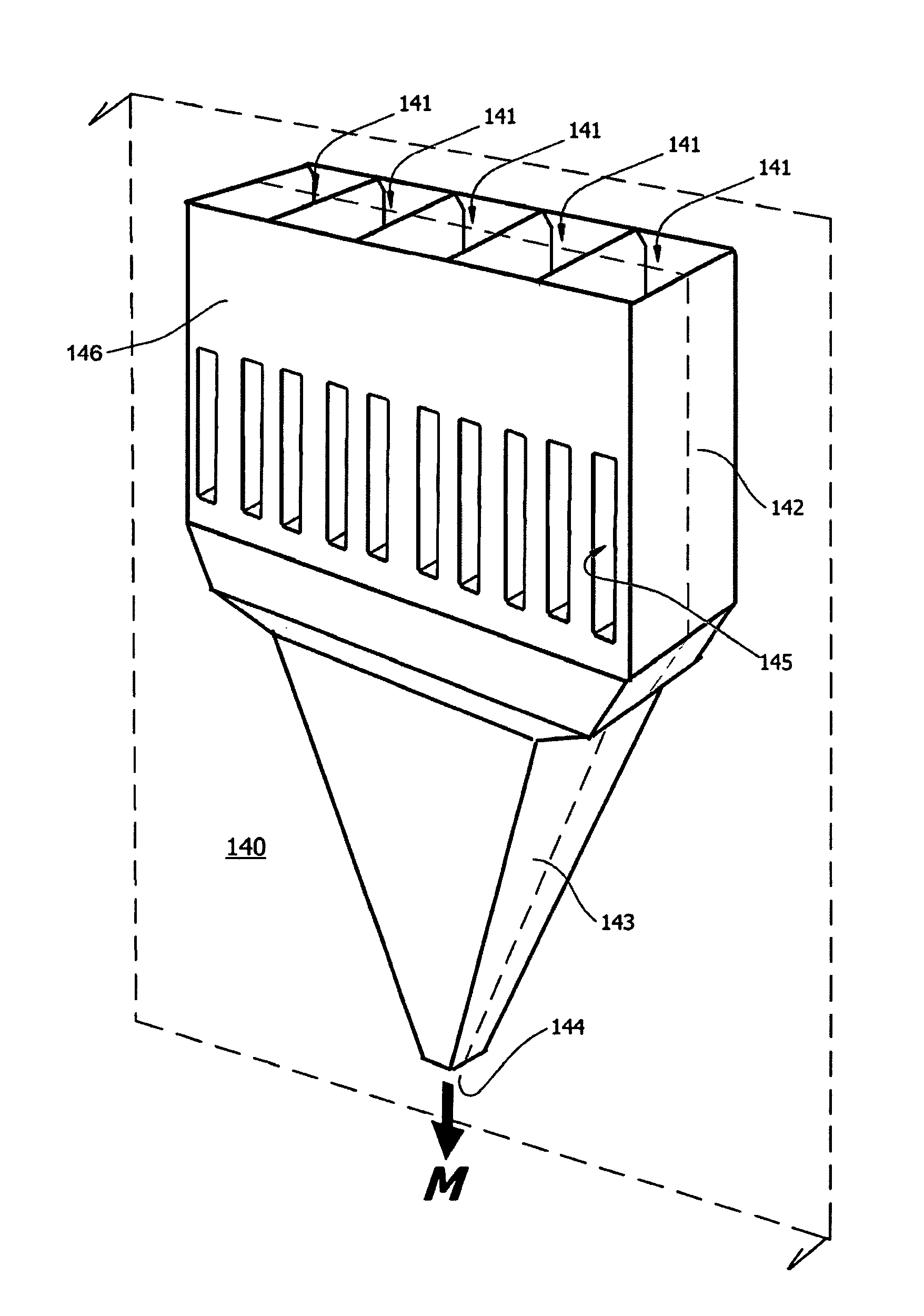

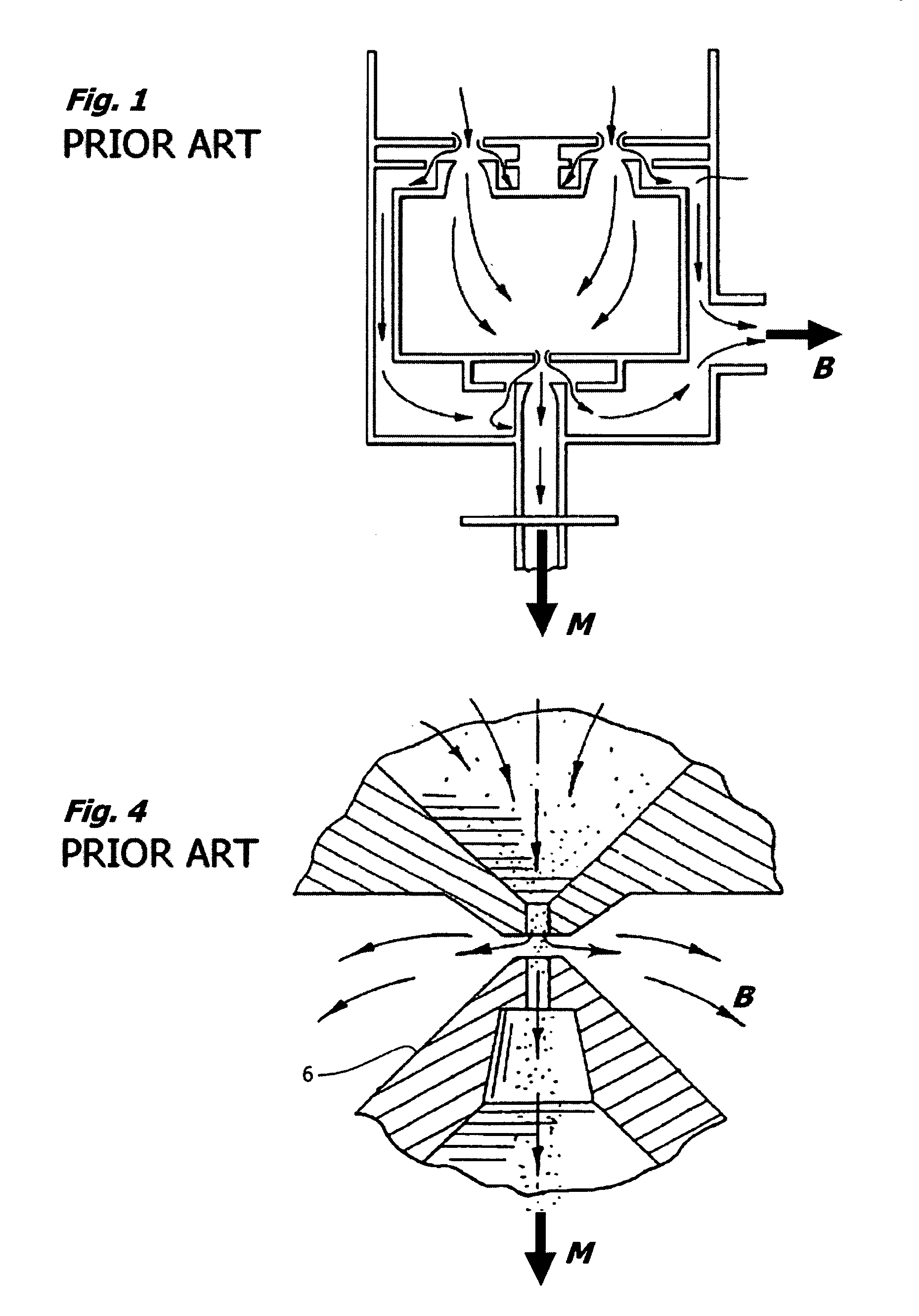

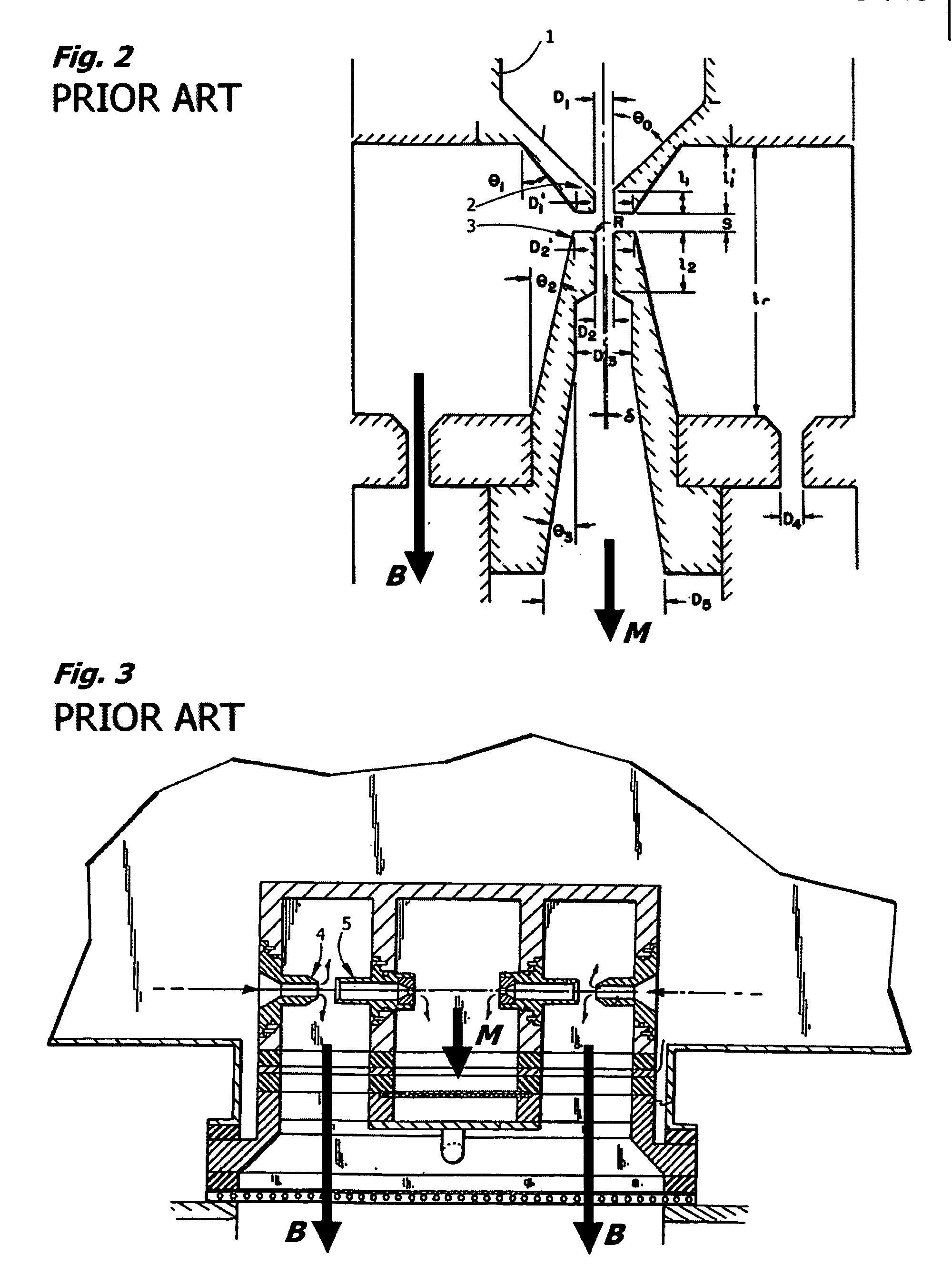

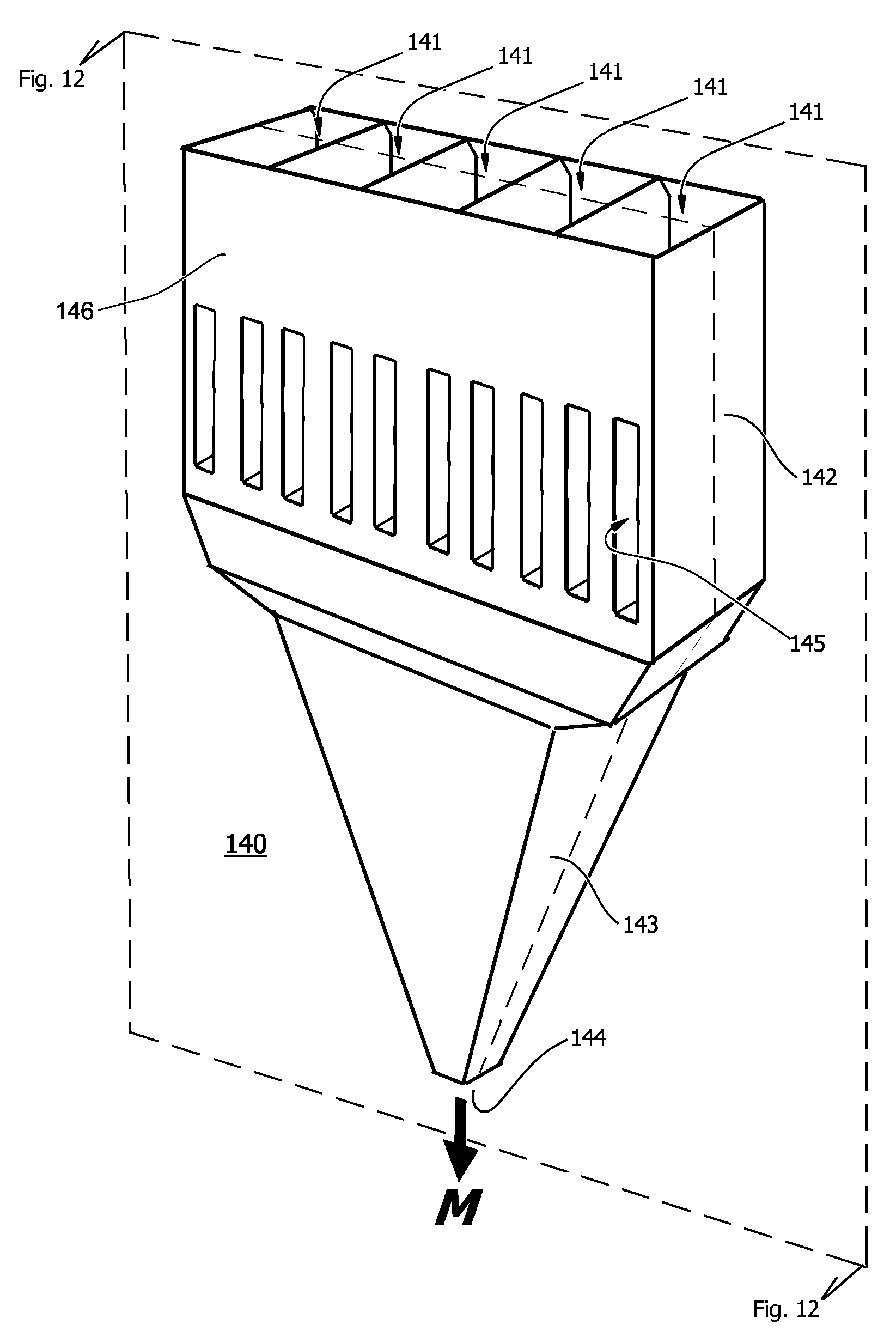

InactiveUS20090288475A1Improved particle recoveryMore compactWithdrawing sample devicesDispersed particle separationStreaming instabilityLong axis

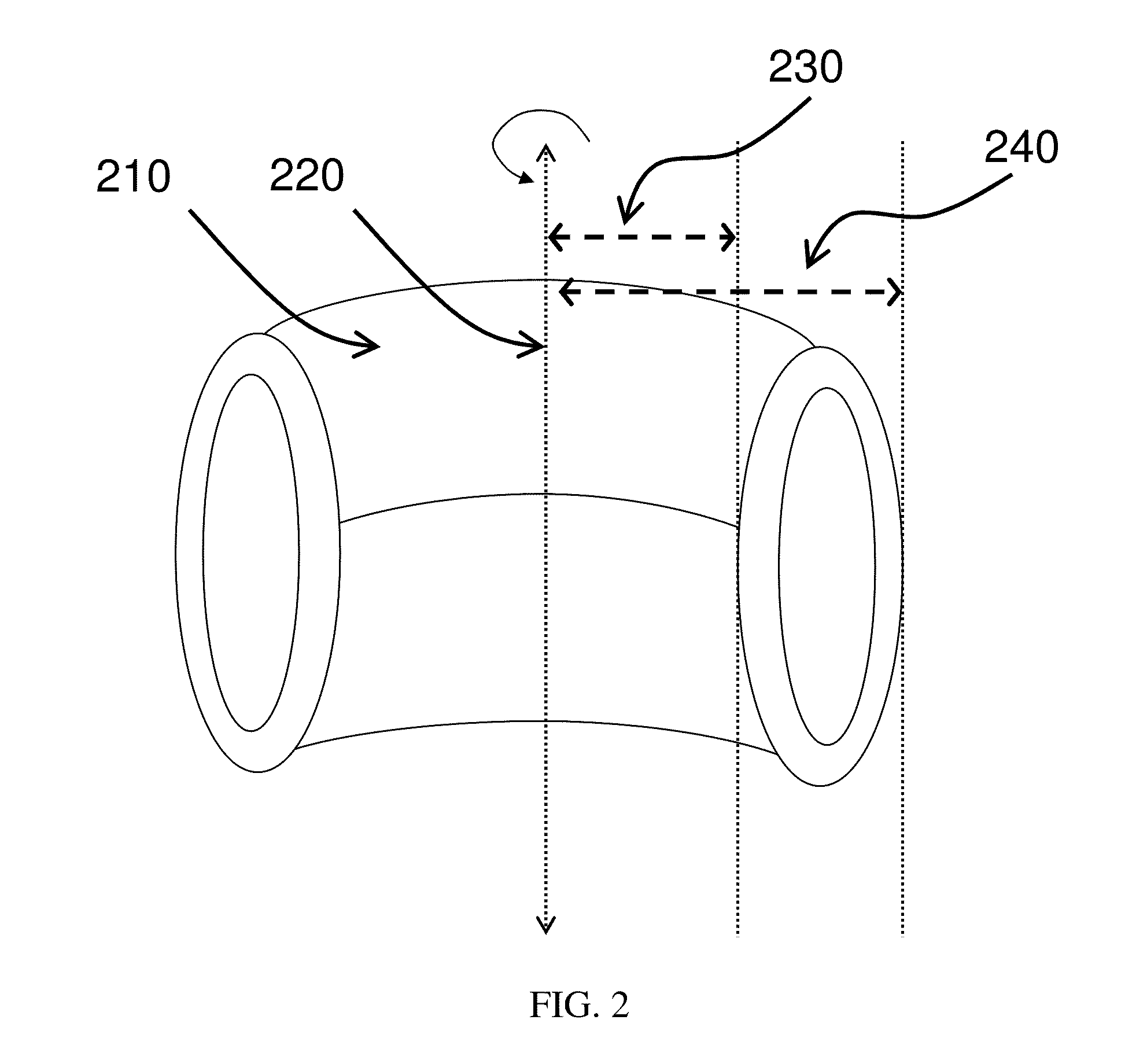

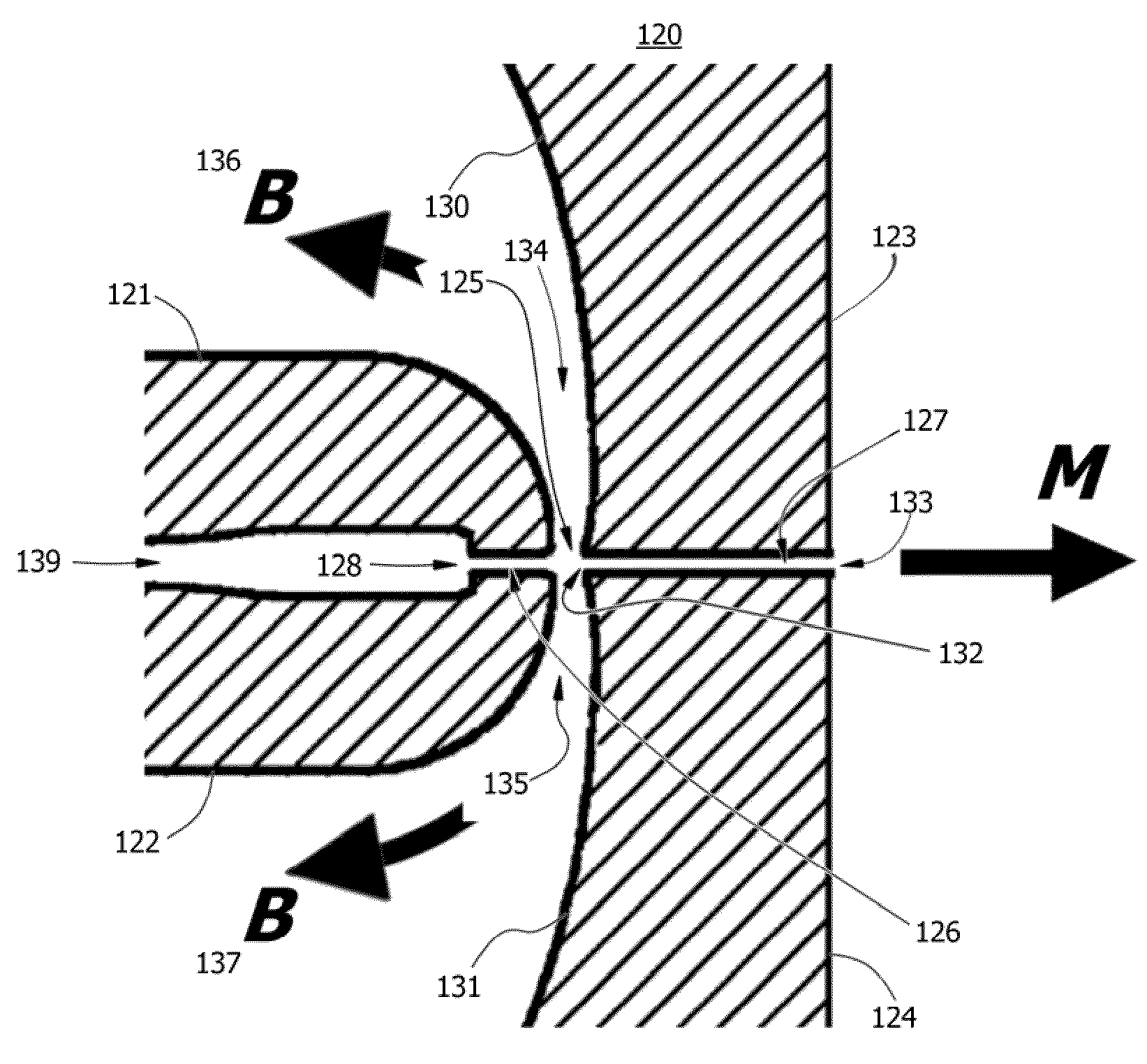

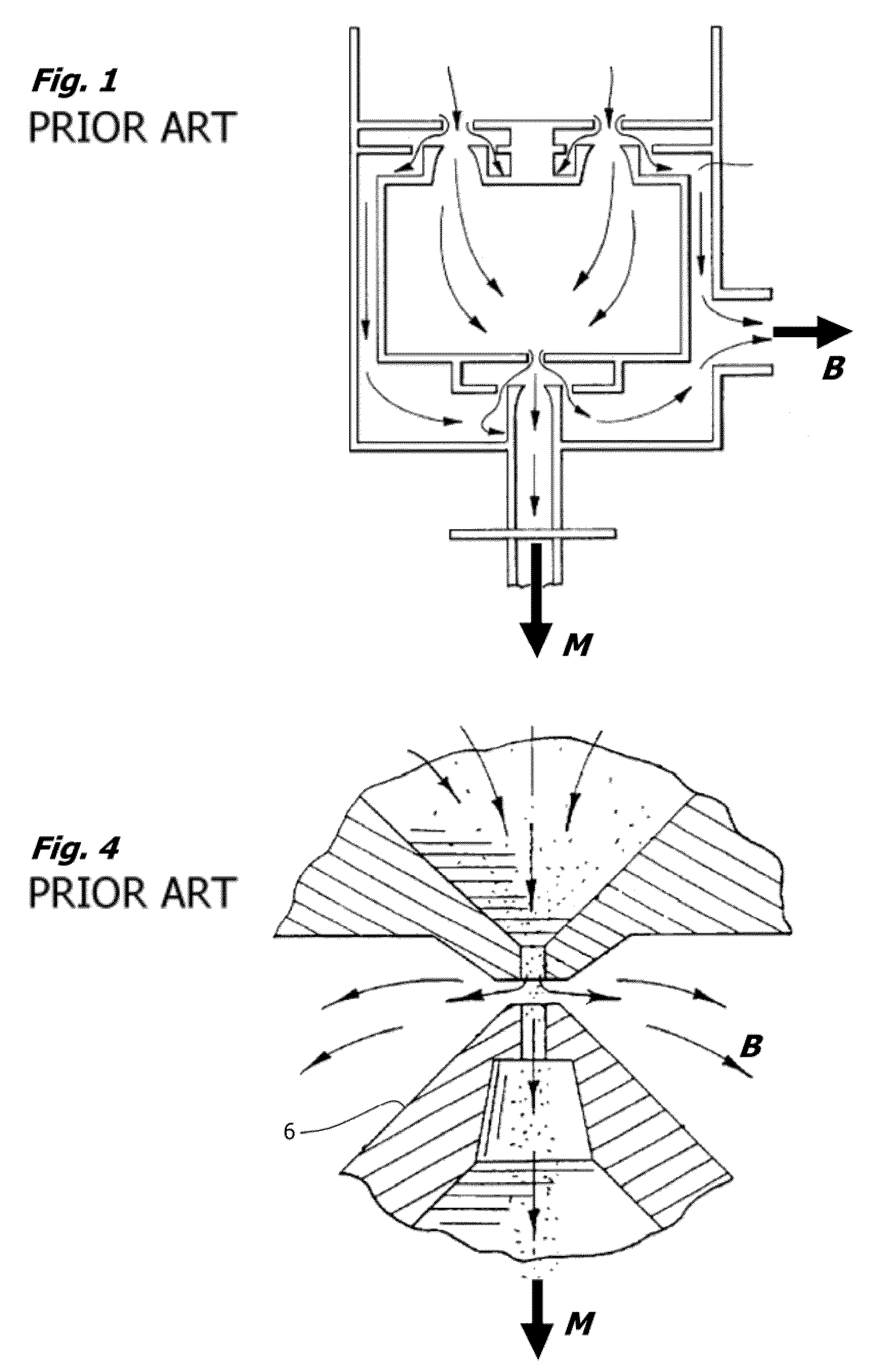

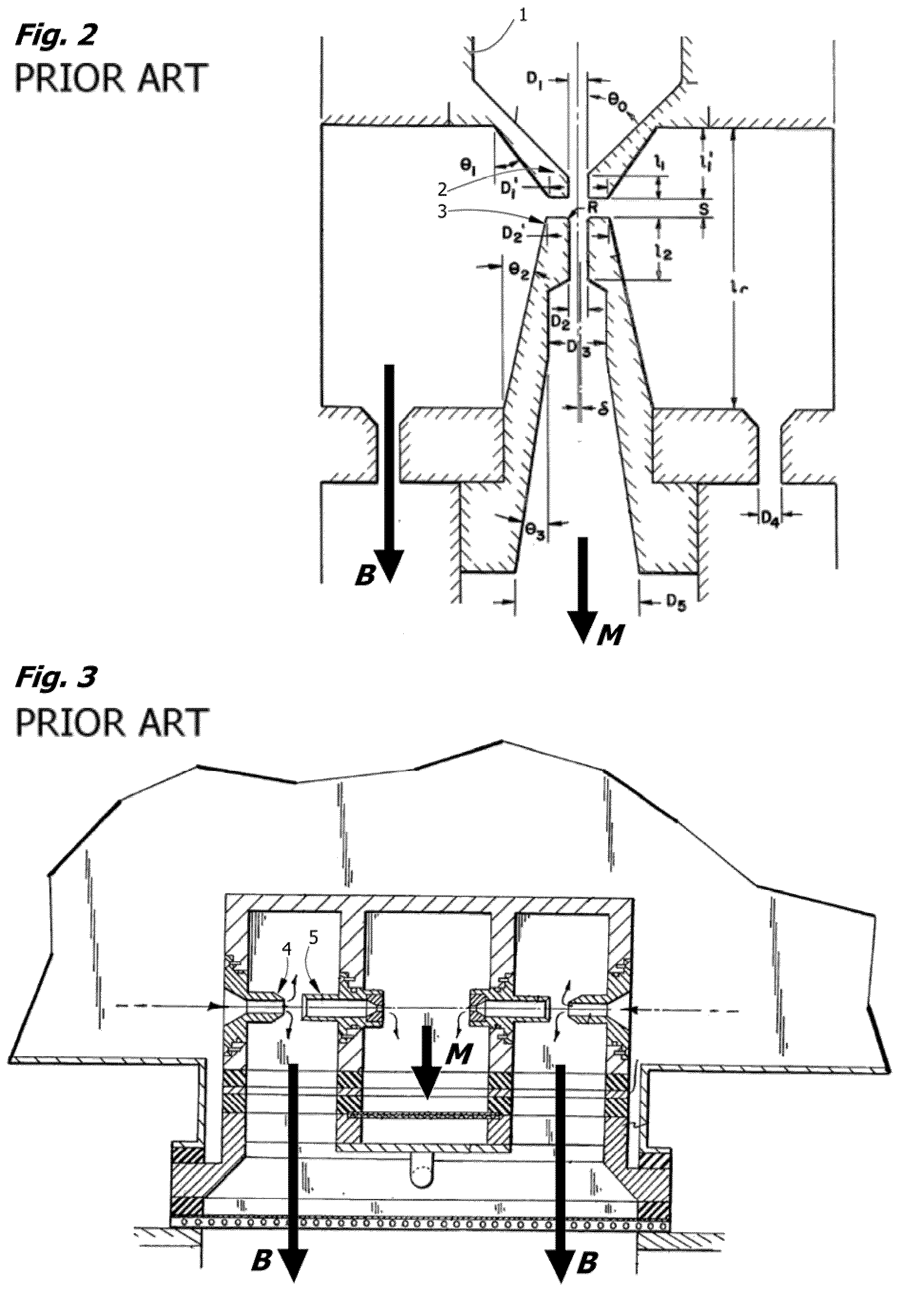

A skimmer device for concentrating an aerosol from a flowing gas stream, having an inlet with inlet aperture and inlet raceway, an outlet with virtual impact void and collector channel, and bulk flow divertors symmetrically disposed on either side of the long axis of flow, further characterized in that the downstream walls of the bulk flow divertors are concavedly curved and reverse the direction of bulk flow. In section, the four channels or passages of the “skimmer” thus form a “crossed tee” with concavedly contoured lateral arms curving back around. The lateral flow channels are for diverting the bulk flow into exhaust chimney spaces, and the chimney spaces are positioned proximate to the inlet element and anterior to the collection channel. In operation, the bulk flow streamlines are thereby folded more than 90 degrees away from the long axis of flow on the laterally disposed concave walls of the bulk flow channels. While counterintuitive, this was found using computational fluid dynamics (CFD) and experimentation to dramatically reduce wall separation and related instabilities and to improve particle recoveries. Large two-dimensional arrays of closely stacked inlet and skimmer elements are thus achieved by fitting the chimneys into spaces between parallel inlet elements. The interlinked problems of flow instability, manufacturability of arrays, and scale-up of chimney cross-sectional area to equalize pressure differentials in the bulk flow diverter exhaust ducts, particularly in two-dimensional arrays at high throughput, are uniquely solved with this geometry.

Owner:ENERTECHNIX

Multi-lithium-ball-projectile accurate automatic supply system special for plasma fracturing protecting

The invention discloses a multi-lithium-ball-projectile accurate automatic supply system for plasma fracturing protecting. According to the requirement for EAST Tokamak plasma fracturing relieving, only when a certain number of impurities need to be injected in a short time, relieving on plasma fracturing can be achieved, and accordingly damage on a Tokamak due to plasma fracturing is relieved. A novel impurity injection mode with projectile injection and high-pressure gas injection combined is provided, the multi-lithium-ball-projectile accurate automatic supply system is researched and developed, the success of the research signifies successful achieving of the novel impurity injection mode, and an effective tool is provided for carrying out plasma fracturing protecting research work on an EAST. The EAST is the first full-superconduction divertor device similar to an ITER in the world, a fracturing relieving experiment is carried out on the EAST, and experiment foundations, data references and accumulation can be provided for an ITER fusion device.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI +1

Skimmer for Concentrating an Aerosol and Uses Thereof

InactiveUS20110072772A1Improved particle recoveryMore compactSamplingDispersed particle filtrationInstabilityLong axis

Skimmer devices for concentrating an aerosol from a flowing gas stream, said skimmers having an inlet with inlet aperture and inlet raceway, an outlet with virtual impactor void and collector channel, and a bulk flow divertor positioned axisymmetrically on the long axis of flow, further characterized in that the downstream surface of the bulk flow divertor is curved for contactingly diverting the streamlines of the bulk flow by greater than 90 degrees away from the long axis of flow without wall separation or instability. Also described are combinations of slot-type and annular-type skimmers with upstream focusing elements such as aerodynamic lenses, and uses thereof.

Owner:ENERTECHNIX

Tungsten-transition layer/stainless steel hot isostatic pressing diffusion bonding method

ActiveCN109396631AReduce residual stressSpread evenlyNon-electric welding apparatusStress reliefDivertor

The invention discloses a tungsten-transition layer / stainless steel hot isostatic pressing diffusion bonding method. Through the tungsten-transition layer / stainless steel hot isostatic pressing diffusion bonding method, the problems that tungsten-steel connecting parts for first-wall plasma divertors of fusion reactors are likely to form large thermal stress at interfaces and microdefects in the prior art are solved. According to the tungsten-transition layer / stainless steel hot isostatic pressing diffusion bonding method provided by the invention, pure tungsten, a transition layer and stainless steel serve as raw materials, are subjected to enveloping treatment and then are subjected to hot isostatic pressing treatment, stress relief annealing and envelop removing, and hot isostatic pressing diffusion connecting pieces can be obtained. The tungsten-transition layer / stainless steel hot isostatic pressing diffusion bonding method is simple in operation, non-defective metallurgical bonding can be realized, and the joint performance is excellent and stable.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

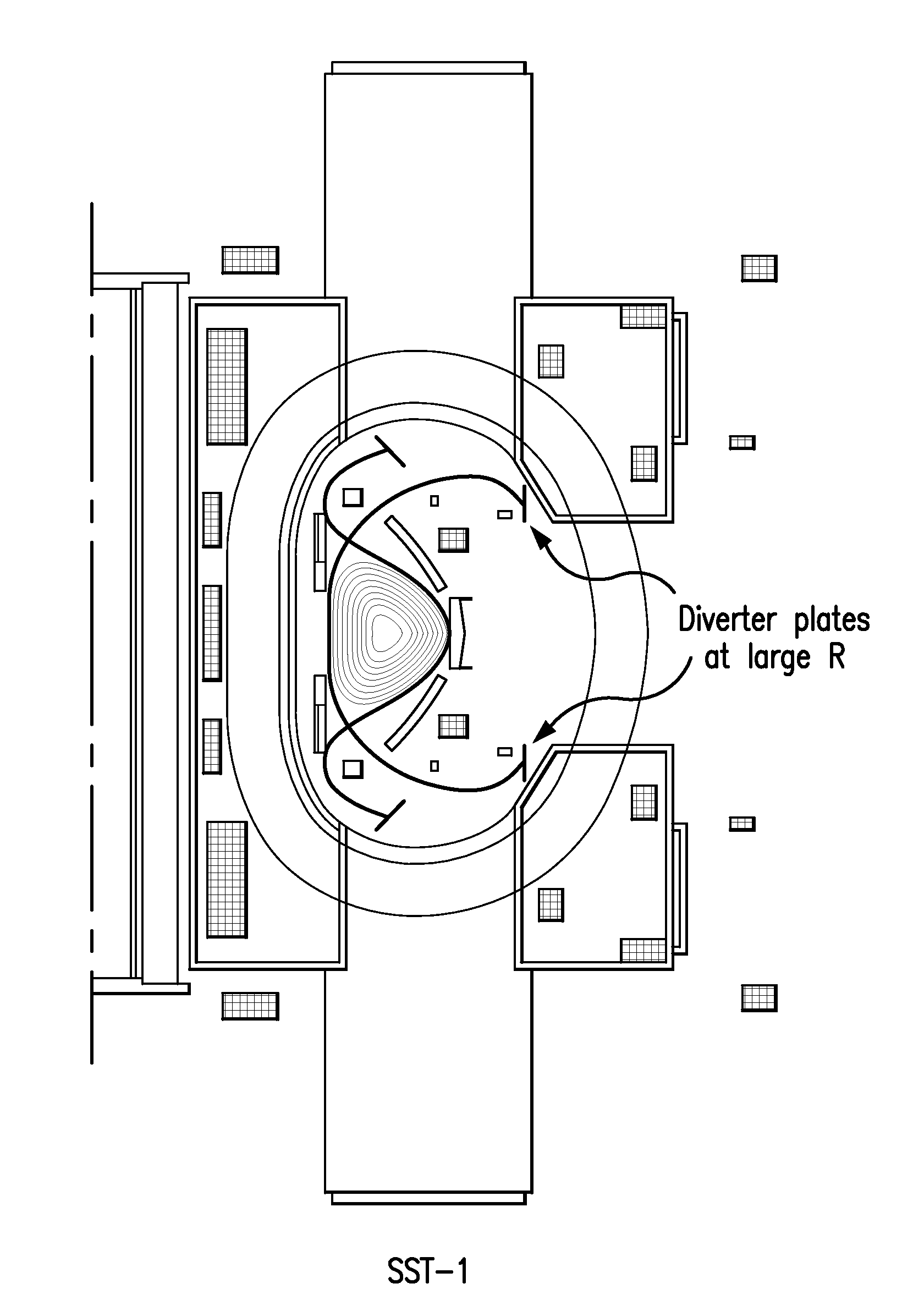

Magnetic confinement device with aluminum or aluminum-alloy magnets

Disclosed is a device comprising a chamber enclosed by walls about a central axis. The chamber has an inner radius and an outer radius relative to the central axis and is configured to magnetically contain a core plasma. The device is further comprised of a divertor plate configured for receiving exhaust heat. The divertor plate has a divertor radius relative to the central axis. The divertor radius is greater than or equal to the sum of a plasma minor radius and a major radius of the peak point closest to the corresponding divertor plate. The device can be used for containing a fusion plasma, as a compact fusion neutron source, or as a compact fusion energy source. Methods of exhausting heat from such a device when plasma is present therein are also described. This abstract is intended for use as a scanning tool only and is not intended to be limiting.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

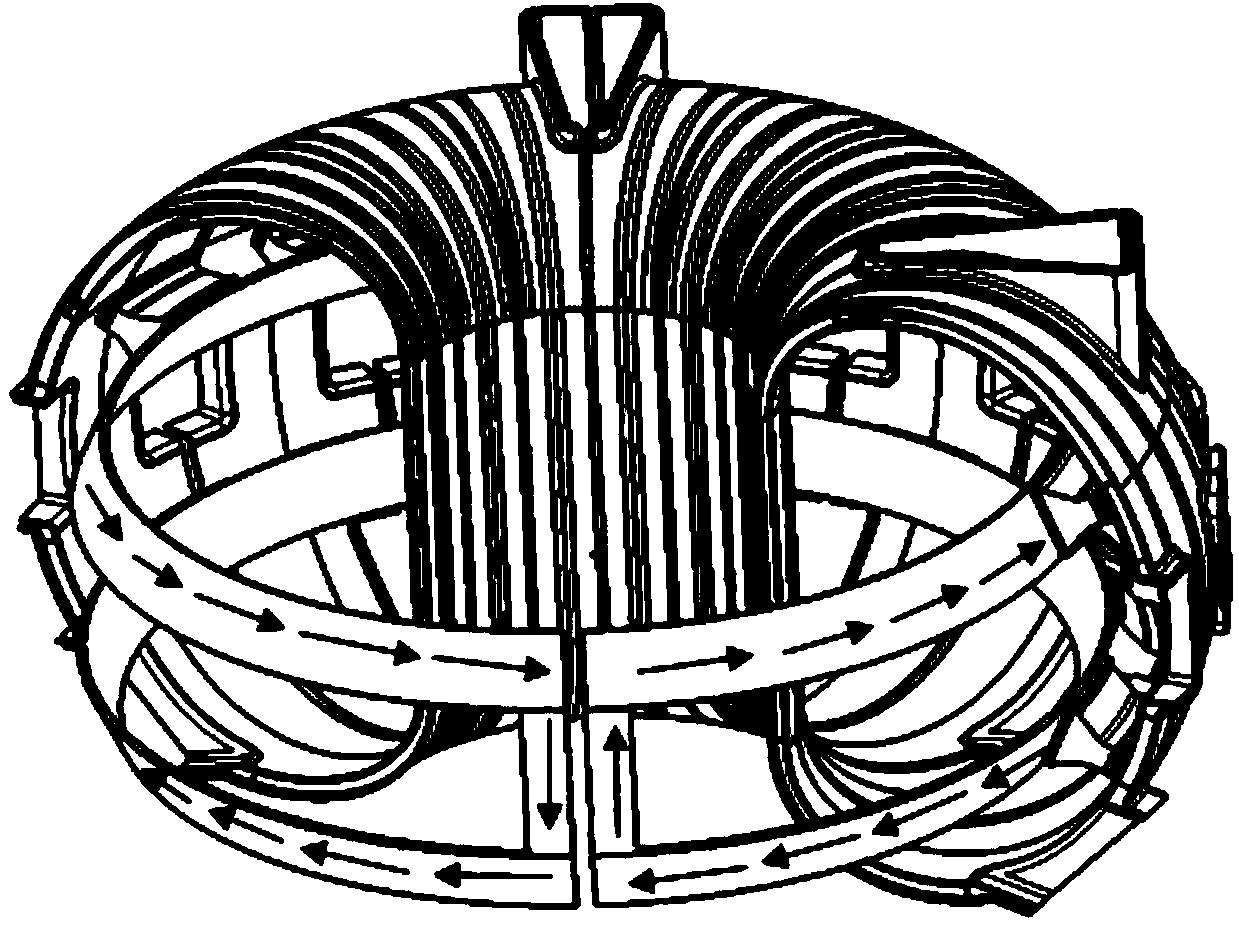

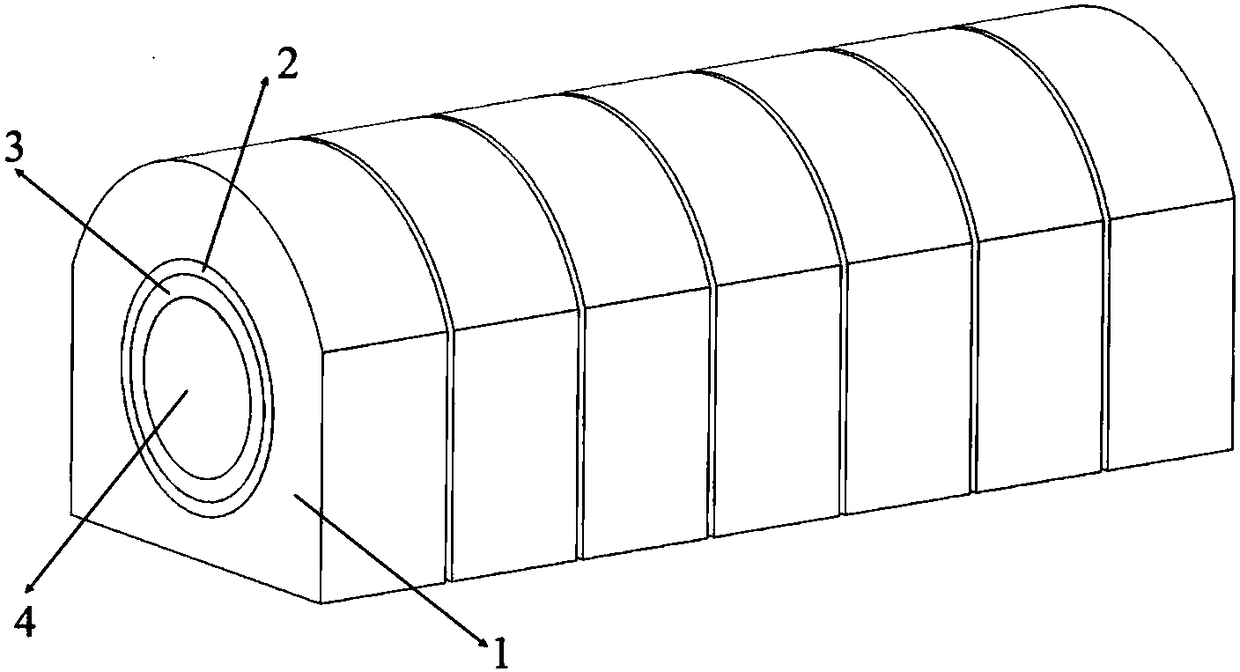

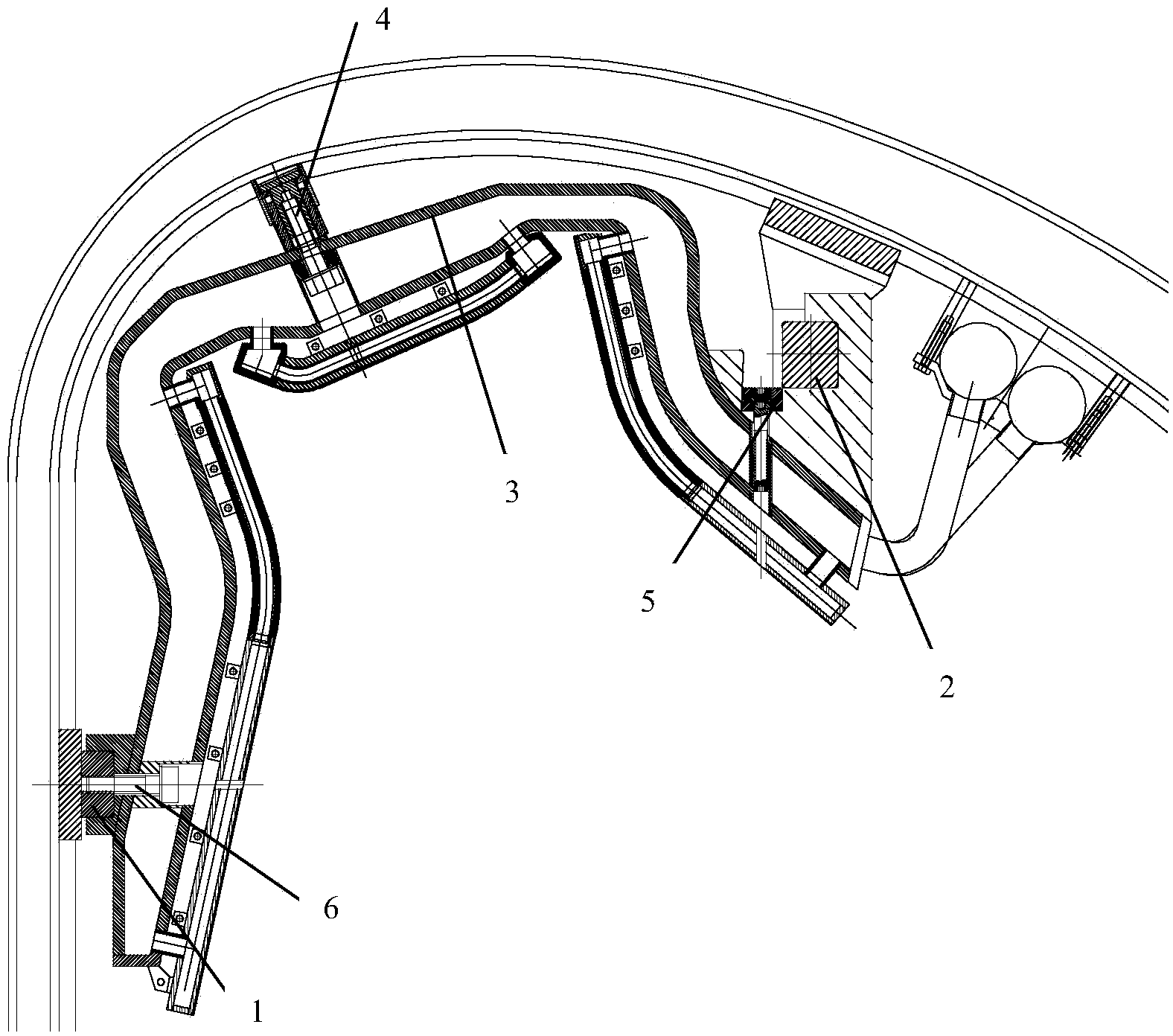

Dual-cold-loop divertor structure suitable for future Tokamak fusion reactor

ActiveCN107507651AReduce maintenance timesRapid coolingNuclear energy generationThermonuclear fusion reactorDivertorCooling pipe

The invention discloses a dual-cold-loop divertor structure suitable for a future Tokamak fusion reactor. The dual-cold-loop divertor structure comprises a box body support, wherein the inner side of the box body support is provided with an inner baffle plate, an inner striking plate, an inner backflow plate, a dome plate, an outer backflow plate, an outer striking plate and an outer baffle plate which are pipe penetrating structures and are matched with the inner side contour of the box body support in an erected manner by means of transition supports; a flow collecting cavity correspondingly communicated with one transition support is formed in the transition support; four cooling pipes are arranged in the box body support, and are respectively two water inlet pipes and two water outlet pipes; and a dual cold loop is formed by a parallel loop of the inner and outer striking plates and a parallel loop of the inner and outer baffle plates and a dome plate region. The dual-cold-loop divertor structure realizes rapid cooling of the divertor structure, improves the cooling efficiency, reduces the pressure drop along the course of a coolant in the flowing process, prolongs the service life of a first wall of the divertor, reduces the maintenance times of the divertor, and has the advantages of saving time, saving money, being stable, safe, efficient, reliable and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

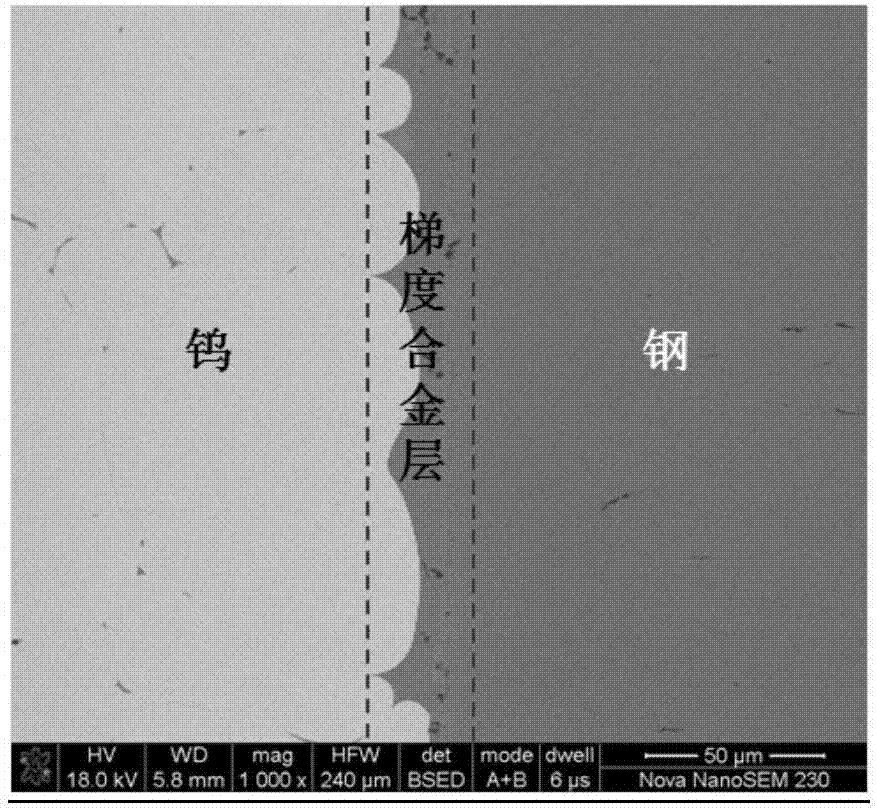

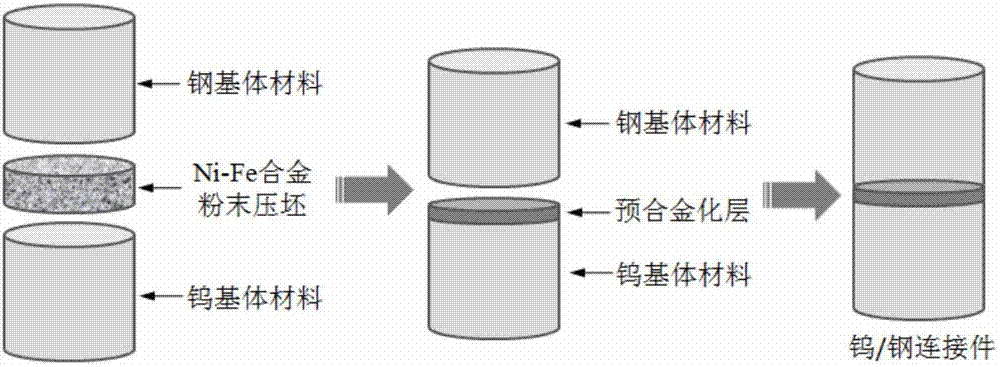

Tungsten/steel dispersion connecting method based on tungsten surface gradient alloying

InactiveCN107225249AImprove thermal fatigue performanceHigh strengthSoldering apparatusWelding/soldering/cutting articlesPowder mixtureDivertor

The invention relates to a tungsten / steel diffusion connection method based on tungsten surface gradient alloying, belonging to the technical field of composite material preparation. In the present invention, the nano-scale pre-alloyed mixed powder with a mass ratio of Ni and Fe of 7:3 is used as a raw material, and the surface of the tungsten substrate is subjected to gradient alloying treatment by high-temperature cladding and vacuum hot-pressing composite technology, and then the vacuum of tungsten and steel is carried out. Diffuse connection. The present invention forms a gradient alloy layer on the surface of the tungsten substrate through the configuration of nickel and iron components, vacuum hot pressing, high temperature cladding and vacuum diffusion and other process or parameter optimization, and obtains no defects at the interface and thermal fatigue performance Good, high interface stability of tungsten / steel composite structural parts. It can be used in the preparation of helium-cooled divertor components in magnetic confinement nuclear fusion experimental devices.

Owner:CENT SOUTH UNIV

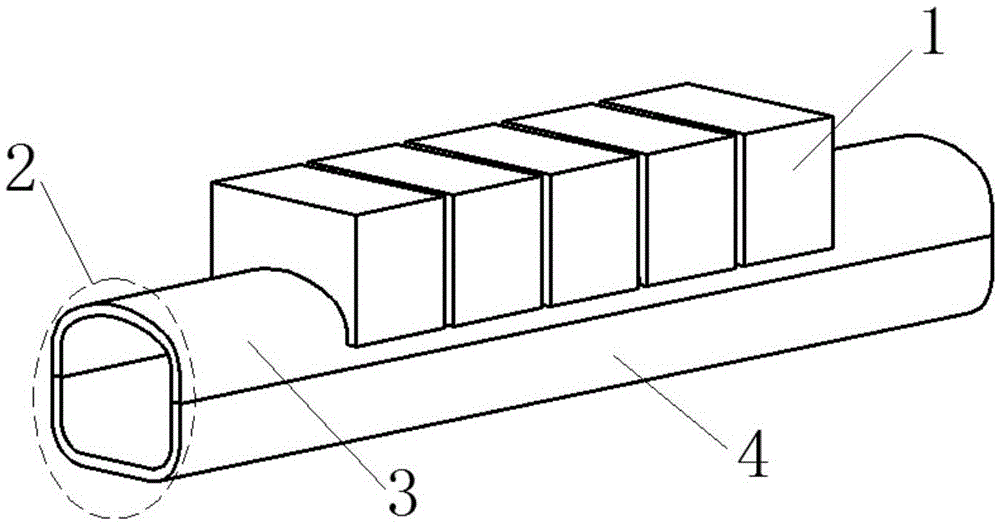

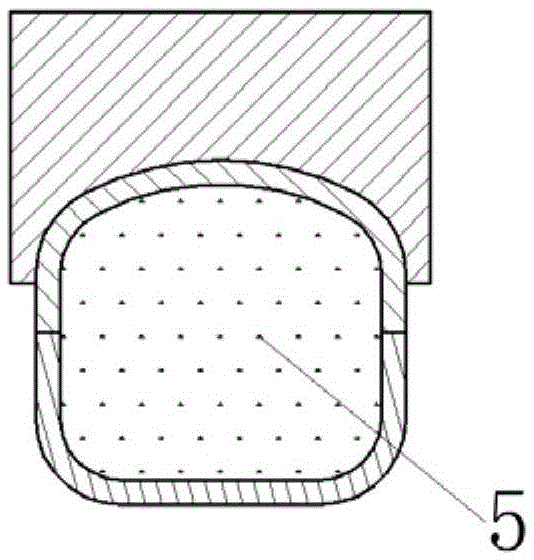

Fusion reactor tungsten divertor structure design based on high temperature fused salt cooling

InactiveCN105551530AImprove the economy of power generationEasy to handleNuclear energy generationThermonuclear fusion reactorNeutron irradiationAlloy

The present invention discloses a fusion reactor tungsten divertor structure design based on high temperature fused salt cooling. The fusion reactor tungsten divertor structure design comprises a tungsten surface pair plasma material and tungsten and lanthanum alloy heat sinks. The tungsten and lanthanum alloy heat sinks comprises a tungsten and lanthanum alloy heat sink 1 and a tungsten and lanthanum alloy heat sink 2. The tungsten and lanthanum alloy heat sink 1 is a half pipe with a C-shaped cross section, and the tungsten and lanthanum alloy heat sink 2 is a half pipe with a round angle and a semi-rectangle-shaped cross section. The tungsten surface pair plasma material is connected to the tungsten and lanthanum alloy heat sink 1, and the tungsten and lanthanum alloy heat sink 1 is connected to the tungsten and lanthanum alloy heat sink 2 to form a whole pipe. through the effective combination of tungsten and lanthanum alloy materials and a high-temperature fused salt cooling agent, the fusion reactor tungsten divertor structure design based on high temperature fused salt cooling is provided to adapt to a fusion reactor high-flux neutron irradiation environment, the heat bearing capacity can reach a 10-20MW / m2 steady-state thermal load, the structural material neutron activation is low, the , nuclear waste processing after component retirement is relatively easy, and the improvement of fusion reactor power generation economical efficiency is facilitated.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Free-standing diamond nano-film preparing device and method

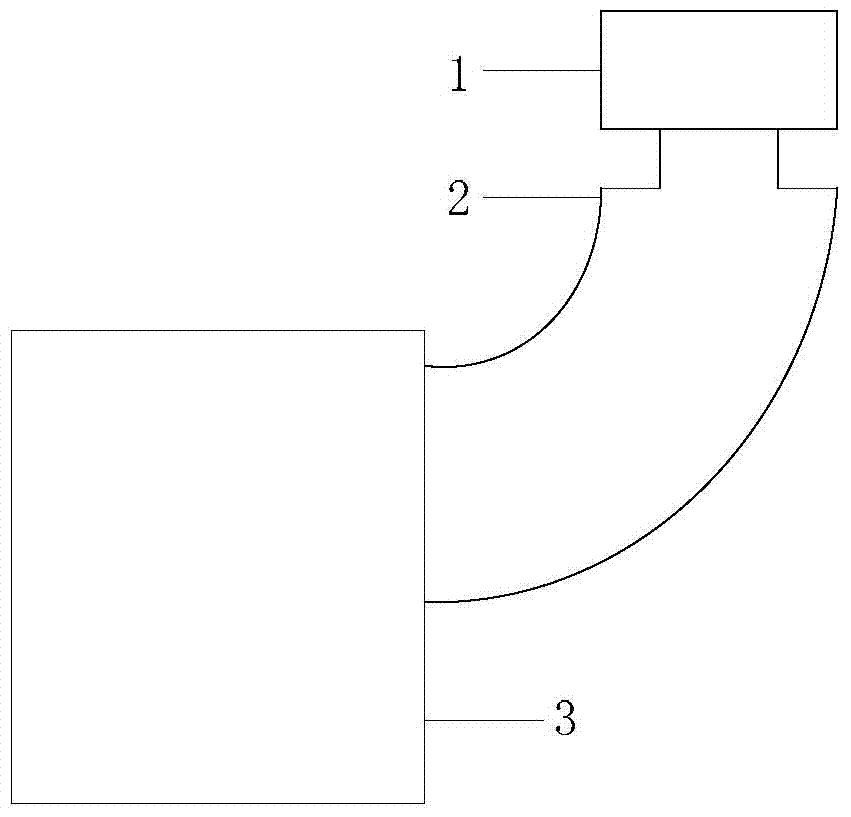

ActiveCN103589999ASustain discharge processIncrease ionization rateVacuum evaporation coatingSputtering coatingDivertorPulse discharge

The invention discloses a free-standing diamond nano-film preparing device and method. The free-standing diamond nano-film preparing device comprises an electrode system, a divertor elbow and a deposition cavity, wherein the electrode system is connected with the inlet of the divertor elbow; the deposition cavity is connected with the outlet of the divertor elbow; the electrode system, the divertor elbow and the deposition cavity constitute a vacuum cavity; the divertor elbow comprises an elbow and a divertor coil which is wound the outside of the elbow; a substrate table is arranged in the deposition cavity; direct current bias is applied between the cavity of the deposition cavity and the substrate table; the bending angle of the divertor elbow is 90 degrees. The liquid fed in the deposition cavity has high ionization rate and less large particles. The direct current bias between the cavity of the deposition cavity and the substrate table can be regulated to regulate the energy of ions deposited on a substrate, so that the performance control of the film is convenient and fast. The pulse discharge frequency of arc voltage can be accurately controlled to conveniently control the deposition thickness, thereby creating conditions for preparing ultrathin film layers.

Owner:PEKING UNIV

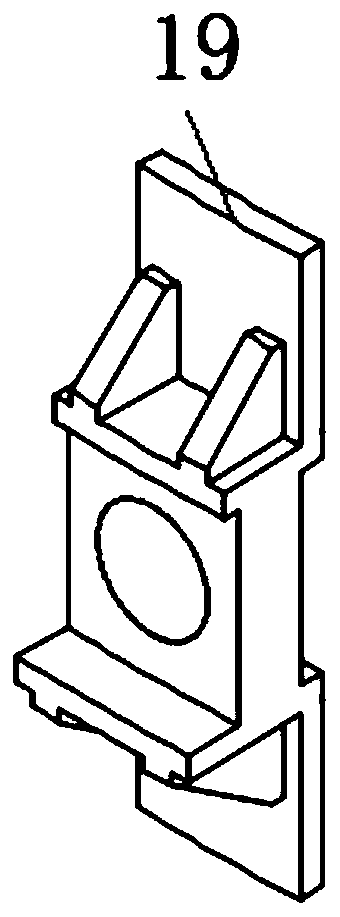

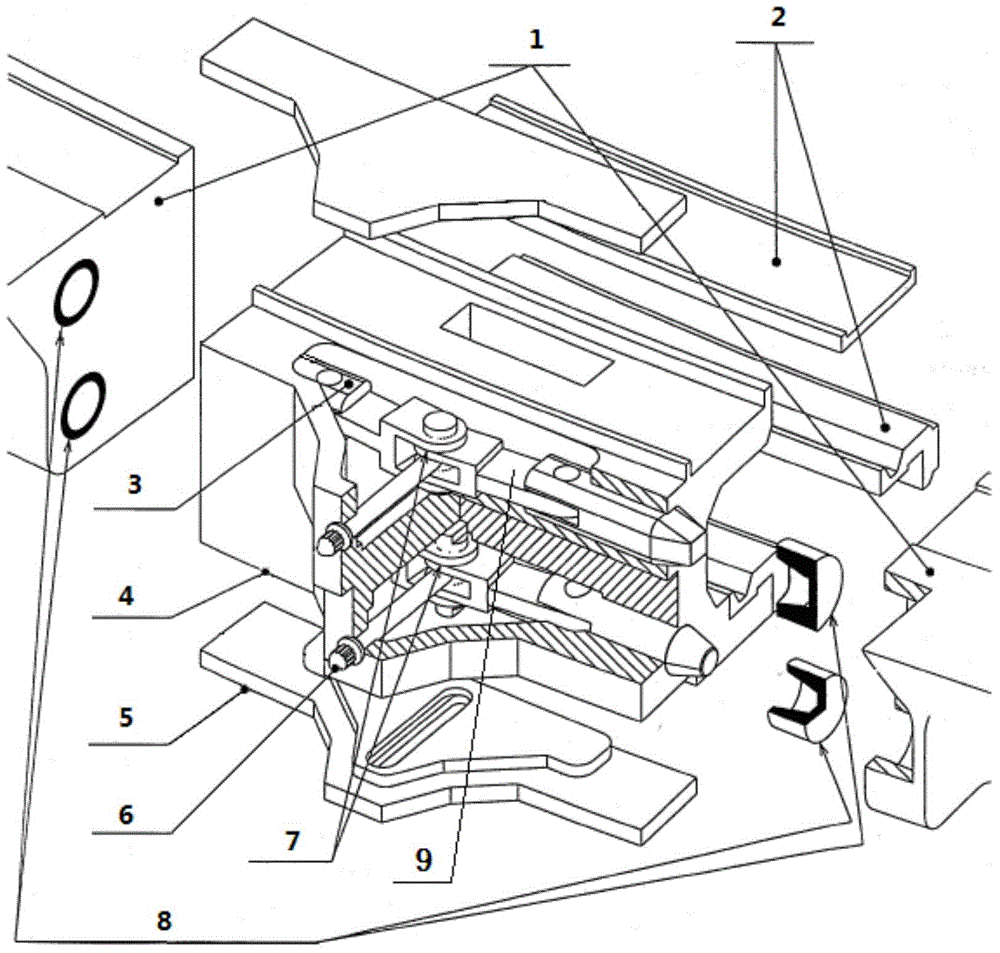

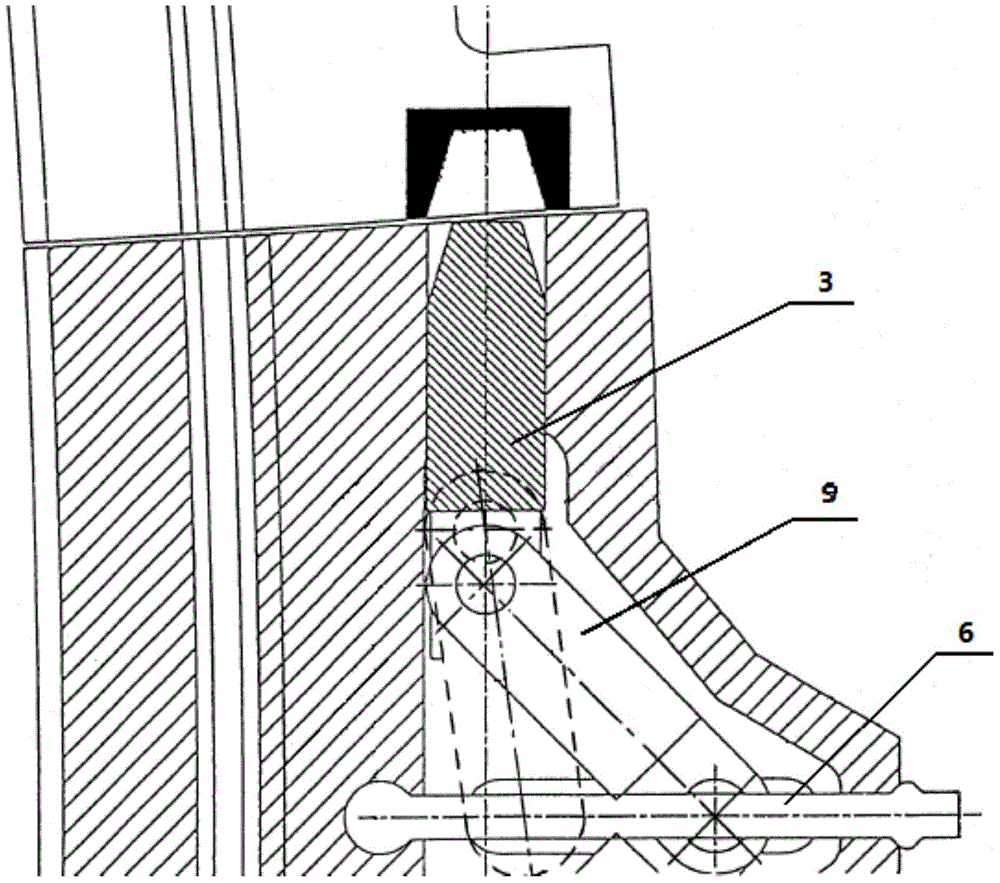

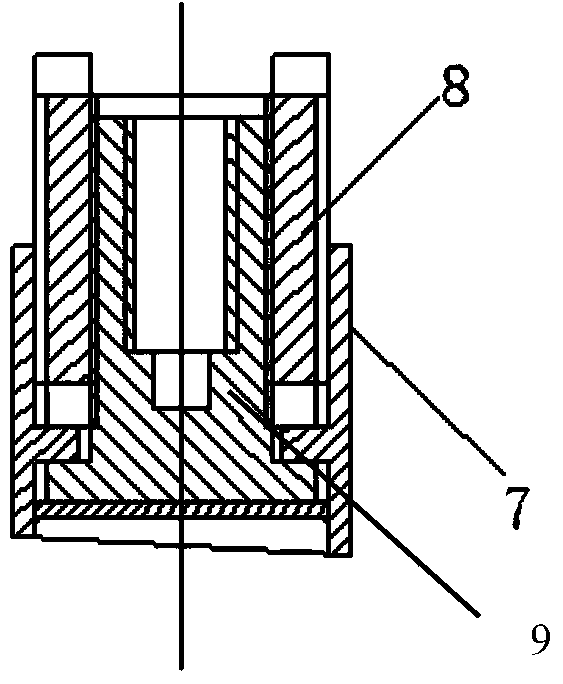

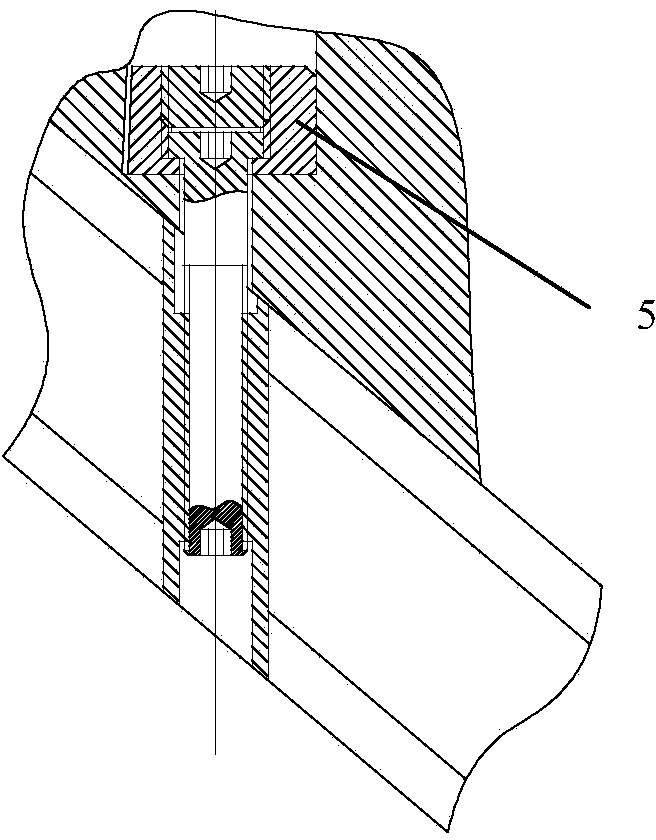

Box locking mechanism suitable for nuclear fusion reactor divertor teleoperation

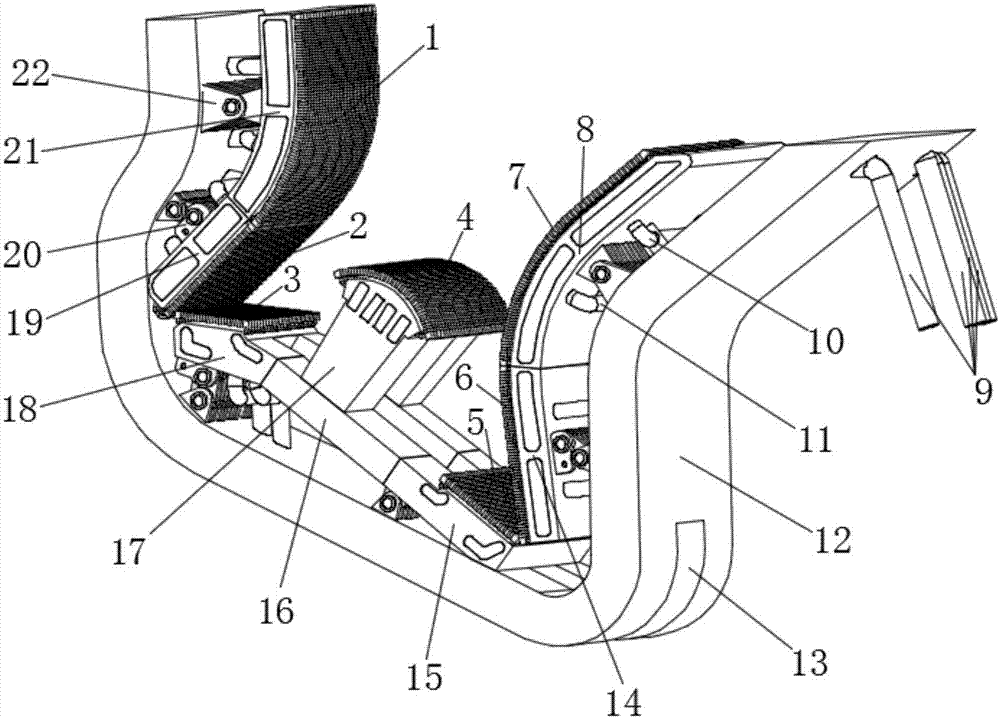

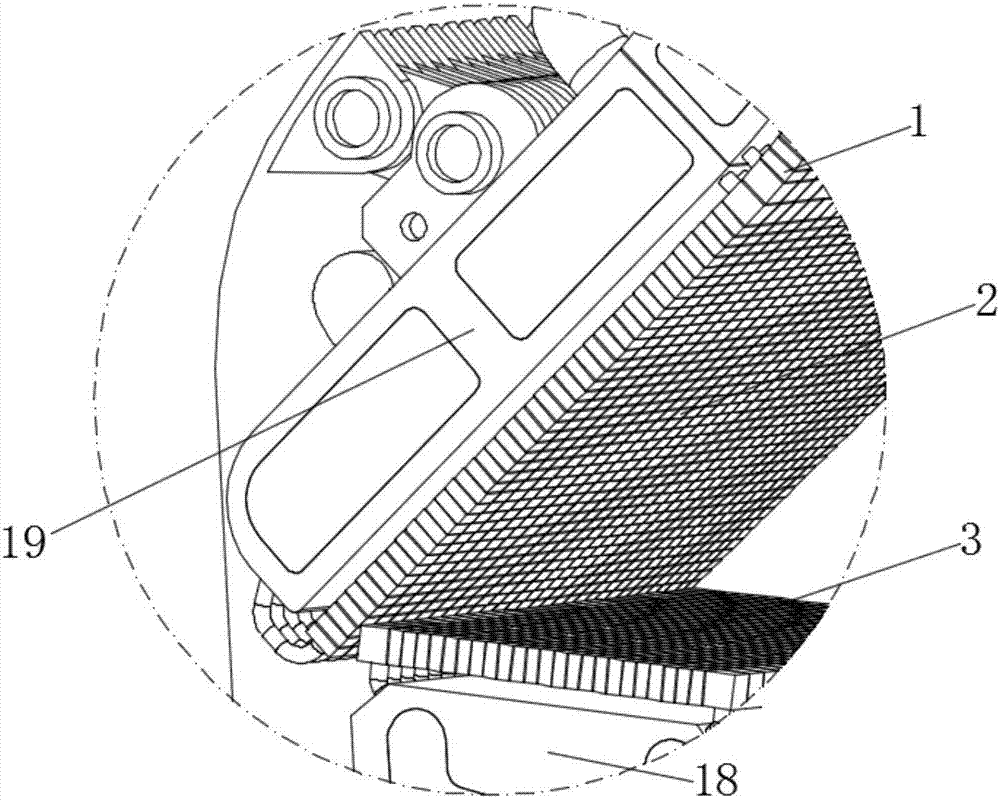

ActiveCN109780010ARapid positioningQuick disassemblyNuclear energy generationWork holdersNuclear fusionLocking mechanism

The invention discloses a box locking mechanism suitable for nuclear fusion reactor divertor teleoperation. The box locking mechanism comprises an inner side box locking mechanism and an outer side box locking mechanism; the inner side box locking mechanism comprises an inner shield plate mounted on an inner side annular rail, a hemispherical groove is formed in the middle of the inner shield plate, an inner side positioning block is mounted on the inner side of the inner shield plate and provided with a hemispherical head matched with the hemispherical groove, and the inner side positioning block is mounted on a supporting block; and the outer side box locking mechanism comprises an outer side positioning block, a compressible positioning block and a driven check block which can synchronously move are mounted at the two ends of the outer side positioning block, the outer side positioning block is mounted in a supporting block clamping groove corresponding to the outer side of a box, and a radial pre-tightening mechanism is mounted on the outer side of the supporting block. According to the box locking mechanism, high-precision automatic quick positioning, mounting and dismountingof a divertor module under a nucleus-involved environment are convenient, interior support and exterior support both adopt face contact, the strength of the box locking mechanism is improved, and theadvantages of money saving, time saving, high efficiency and high precision are achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

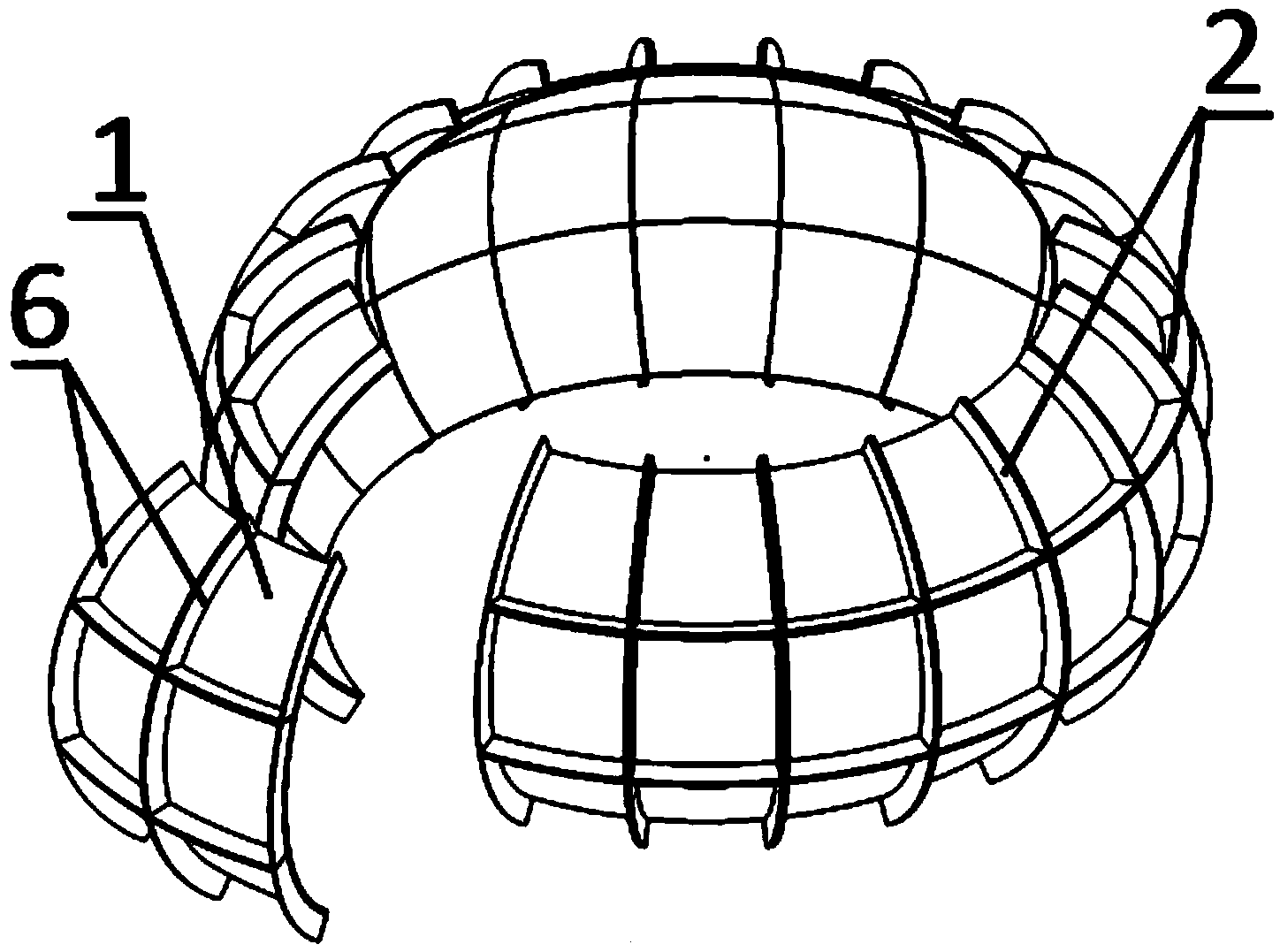

Passive feedback structure suitable for controlling plasmas of future fusion reactor rapidly

ActiveCN104051028AVertical Displacement ConstraintReduce breakage accidentsNuclear energy generationThermonuclear fusion reactorInstabilityCopper

The invention discloses a passive feedback structure suitable for controlling plasmas of a future fusion reactor rapidly. The passive feedback structure comprises a plurality of passive feedback structure independent blocks, the inner sides of the passive feedback structure independent blocks and the outer sides of the passive feedback structure independent blocks are provided with detachable cladding assemblies and permanent tritium breeding claddings respectively, and the passive feedback structure independent blocks are arranged evenly along the 360-degree angle in the large ring direction to form a structure with the overall appearance in the shape of a drum. The passive feedback structure independent blocks are composed of conductive copper sheets, stainless steel supporting base materials, cooling channels and side rib plates. The passive feedback structure can achieve rapid control over the plasmas and avoid instability of vertical displacement of the plasmas while meeting the requirements of the structure that a future fusion reactor increases a tritium breeding cladding, a divertor window and the like under the condition that space is limited, meanwhile, play the role of the supporting tritium breeding cladding structure, meet the requirements for long-term high-temperature resistance and irradiation, and guarantee stable operation of the plasmas of the future fusion reactor device.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Cool-off heat sink of steady-state tokamak divertor

InactiveCN101013610AShorten the heat transfer distanceNo leaksNuclear energy generationCooling/ventilation/heating modificationsActive coolingEngineering

The invention is a steady state Tokamak diverter cooling heat sink, including heat sink plate. Its characteristic is there are a number of cooling channels in the heat sink plate. In the lateral of the heat sink plate, the adjacent cooling channels are connected by pipes to form a series circuit. For the steady long - pulsed operated Tokamak device, the energy deposition on the diverter will be great. So the diverter must have a strong initiative cooling system. The invention can meet those requirements.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Method for preparing ultra-fine crystal grain pure molybdenum block material

A method for preparing ultra-fine crystal grain pure molybdenum block material belongs to the technical field of high-melting-point metal and metal-based heat sink material. The invention is characterized in that firstly the molybdenum powder with granularity which is smaller than 10mum and larger than 1mum is selected for executing the vacuum hot pressing pre-burning of green body. Then the pre-burned green body is placed in a pyrauxite mold and is placed into a press for exerting pressure of 1-10GPa on the sample. Then the 10-25 kW alternating current is exerted on two ends of the sample for sintering. The energized current is 1000A-3000A and lasts for 15 seconds to 3 minutes. After energizing and sintering, pressure is continuously maintained for 30 seconds to 3 minutes; then the sintered body is milled and polished. The relative density is 96-99.9% and the grain size is smaller than or equal to the initial powder size of used raw material. The pre-burning is executed under the following conditions: 20-50MPa of pressure, 10<-2>-10<-3>Pa of vacuum degree, 800-1000 DEG C of temperature and 30min-60min of time. The ultra-fine crystal grain pure molybdenum block material prepared by the invention has better mechanical performance and thermal-shock resistance and is suitable for electronic packaging materials, hot sink materials, electrical contact materials and fire-resistant plasma scouring components, such as divertor materials in nuclear fusion devices.

Owner:UNIV OF SCI & TECH BEIJING

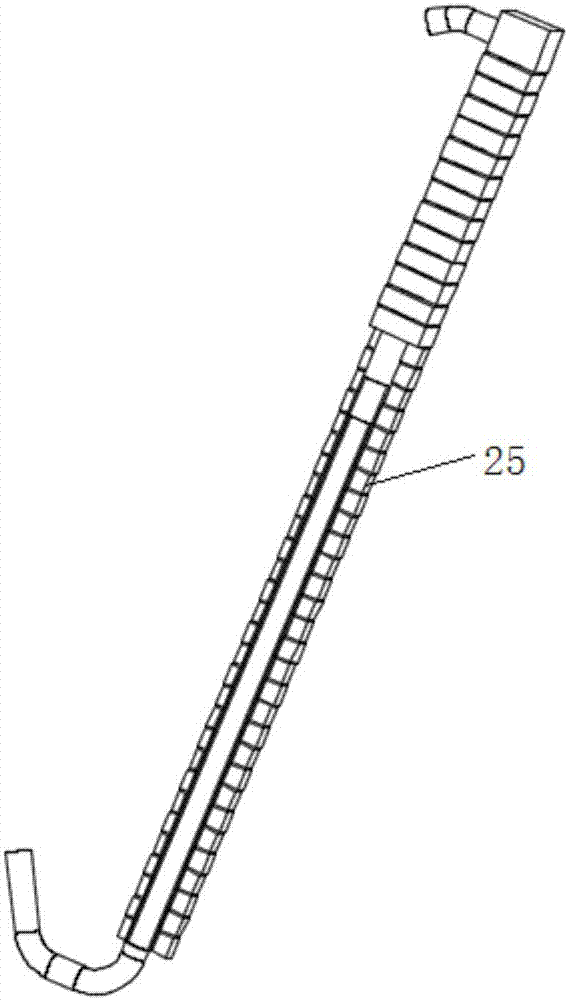

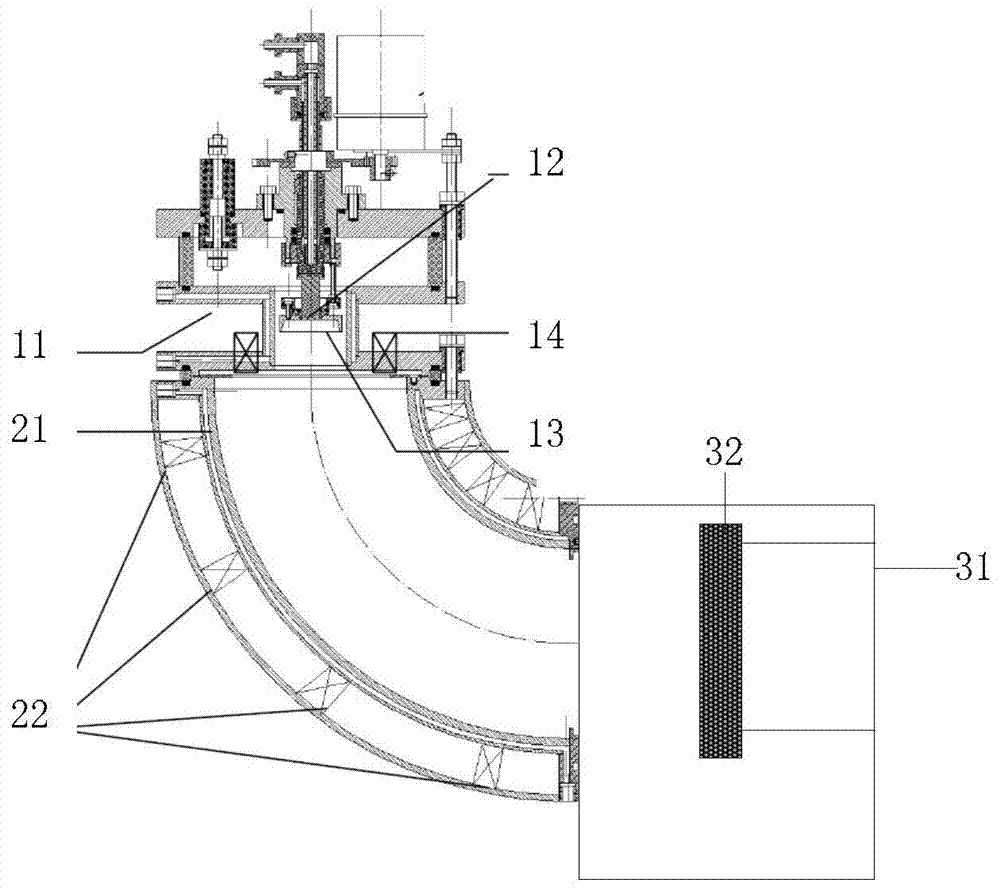

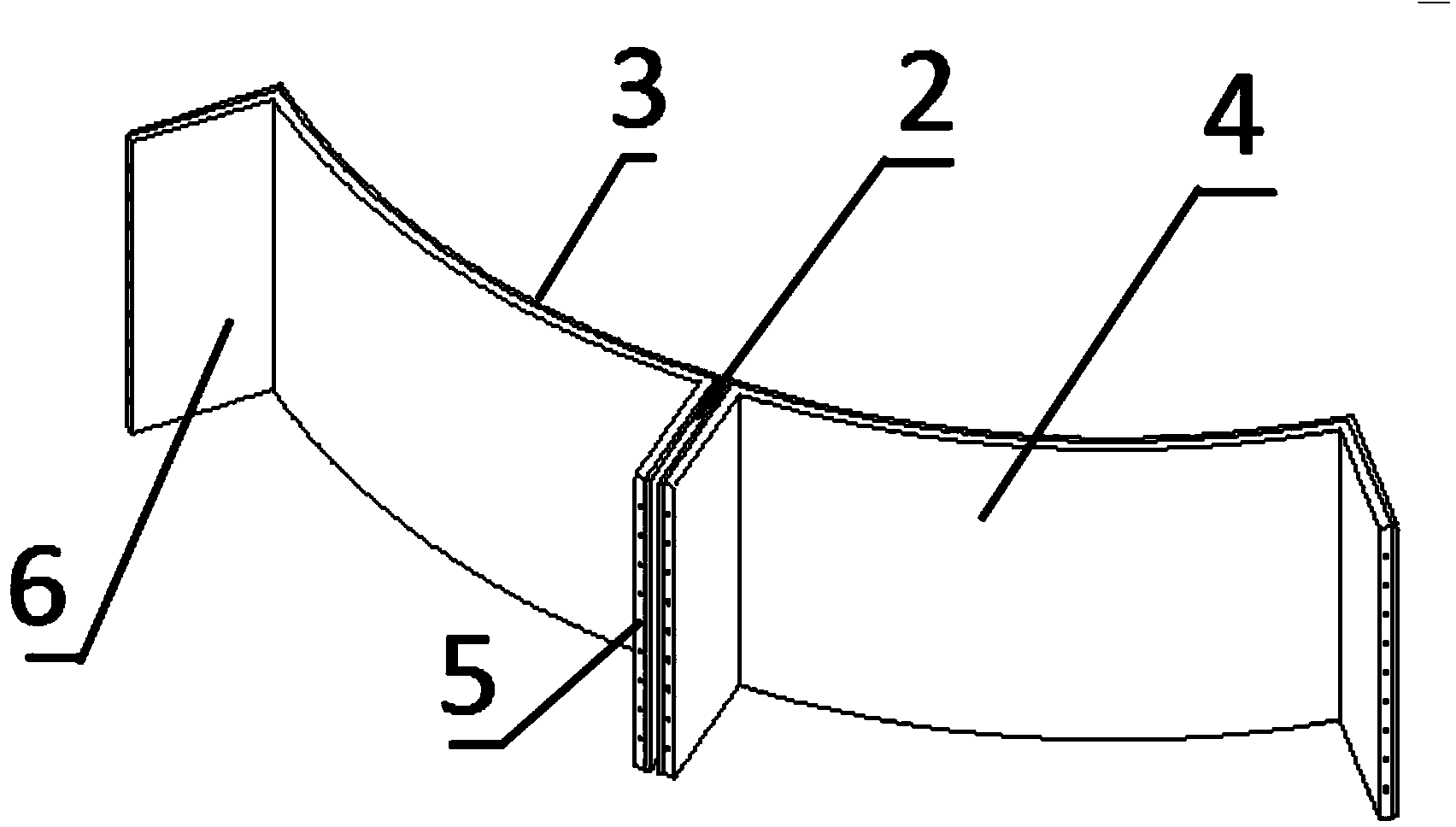

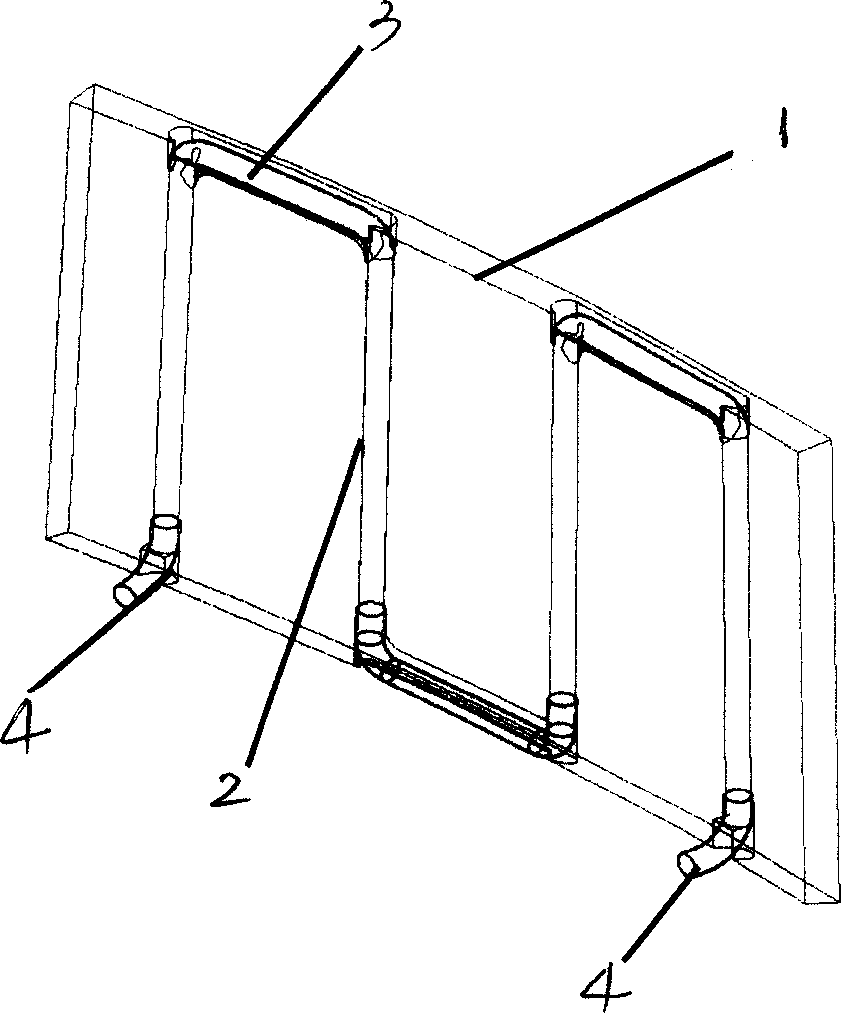

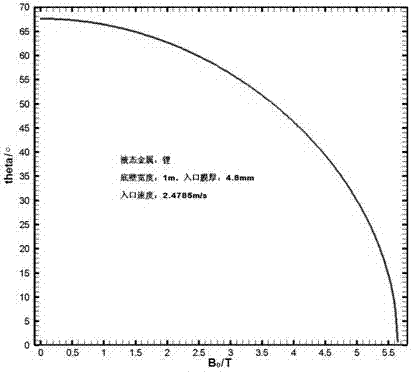

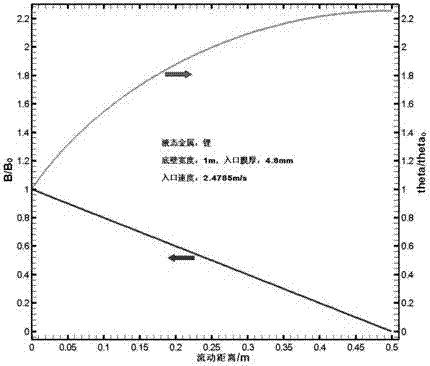

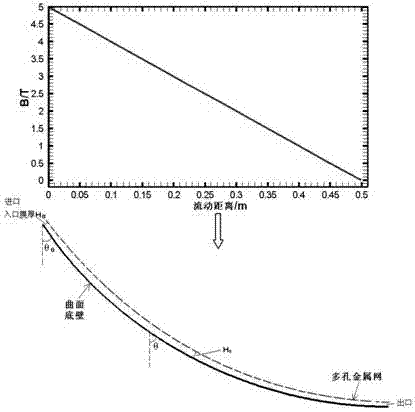

Method for establishing liquid curved membrane flow system of fusion reactor divertor flow stability

ActiveCN104751901APrevent splashAddressing Ferrofluid Instability IssuesNuclear energy generationMetal layered productsInstabilityLiquid metal

The invention relates to the technical field of liquid membrane flow control, and specifically relates to a method for establishing a liquid curved membrane flow system of fusion reactor divertor flow stability. The method comprises the following steps: step one, finding a relationship between a local magnetic field strength and an inclination angle under stable flow status of a liquid metal membrane, changing local inclination angles at different flow distances of the membrane flow to adapt variations of a gradient magnetic field, controlling a magnetofluid instability caused by a strong gradient magnetic field, i.e., utilizing the shape of a curved bottom wall to adapt the variations of the strong gradient magnetic field; step two, utilizing a method of fixing a metal screen above the curved bottom wall to ensure the liquid metal to flow along the curved bottom wall having a greater curvature variation; and step three, obtaining a stable membrane flow on the metal screen by regulating the sizes of metal meshes at different flow distances as well as regulating the distance between the metal screen and the curved bottom wall. By the method for establishing the liquid curved membrane flow system of the fusion reactor divertor flow stability, the instability of the magnetofluid of the liquid metal membrane flow under the strong gradient magnetic field environment having greater magnetic field strength variations is solved.

Owner:SOUTHWESTERN INST OF PHYSICS

Detachable track connecting mechanism applied to nuclear fusion device

ActiveCN103824602AStable supportReliable maintenanceNuclear energy generationThermonuclear fusion reactorNuclear fusionEngineering

The invention discloses a detachable track connecting mechanism applied to a nuclear fusion device. In the technical field of nuclear fusion reactor engineering, the detachable track connecting mechanism is applied to an annular bearing track for remote operation and maintenance of a divertor component inside a nuclear fusion device; and with utilization of the detachable track mechanism, the divertor component is separated from a track disconnection portion for realizing transport to the outside of a vacuum chamber. The detachable track connecting mechanism mainly comprises annular fixed tracks, a main detachable track body, a track cover plate, a bearing plate, bolts, a rotating shaft, insertion hole pins, and push rods and the like. During the internal component maintenance process, track dismounting and mounting can be realized quickly by using a mechanical arm front-end executer; and the component at the internal track disconnection portion of the nuclear fusion device, together with the detachable track, can be moved out of or placed into the vacuum chamber. According to the invention, the structure is simple; and the mechanism can be dismounted or mounted conveniently and rapidly and can work reliably in a vacuum and radiation environment. The quick maintenance and replacement requirements of the internal component of the vacuum chamber of the nuclear fusion device can be met; and the equipment operation efficiency can be improved.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Systems and methods for forming and maintaining a high performance FRC

ActiveUS10440806B2Improve FRC confinementStability control without negative side-effectsNuclear energy generationAcceleratorsThermal energyShunt Device

A high performance field reversed configuration (FRC) system includes a central confinement vessel, two diametrically opposed reversed-field-theta-pinch formation sections coupled to the vessel, and two divertor chambers coupled to the formation sections. A magnetic system includes quasi-dc coils axially positioned along the FRC system components, quasi-dc mirror coils between the confinement chamber and the formation sections, and mirror plugs between the formation sections and the divertors. The formation sections include modular pulsed power formation systems enabling static and dynamic formation and acceleration of the FRCs. The FRC system further includes neutral atom beam injectors, pellet or CT injectors, gettering systems, axial plasma guns and flux surface biasing electrodes. The beam injectors are preferably angled toward the midplane of the chamber. In operation, FRC plasma parameters including plasma thermal energy, total particle numbers, radius and trapped magnetic flux, are sustainable at or about a constant value without decay during neutral beam injection.

Owner:TAE TECH INC

Skimmer for concentrating an aerosol

InactiveUS7875095B2More compactImprove collection efficiencyWithdrawing sample devicesDispersed particle separationLong axisEngineering

A skimmer device for concentrating an aerosol from a flowing gas stream, having an inlet with inlet aperture and inlet raceway, an outlet with virtual impact void and collector channel, and bulk flow divertors symmetrically disposed on either side of the long axis of flow, further characterized in that the downstream walls of the bulk flow divertors are concavedly curved and reverse the direction of bulk flow. In section, the four channels or passages of the “skimmer” thus form a “crossed tee” with concavedly contoured lateral arms curving back around. The lateral flow channels are for diverting the bulk flow into exhaust chimney spaces, and the chimney spaces are positioned proximate to the inlet element and anterior to the collection channel. In operation, the bulk flow streamlines are thereby folded more than 90 degrees away from the long axis of flow on the laterally disposed concave walls of the bulk flow channels. While counterintuitive, this was found using computational fluid dynamics (CFD) and experimentation to dramatically reduce wall separation and related instabilities and to improve particle recoveries. Large two-dimensional arrays of closely stacked inlet and skimmer elements are thus achieved by fitting the chimneys into spaces between parallel inlet elements. The interlinked problems of flow instability, manufacturability of arrays, and scale-up of chimney cross-sectional area to equalize pressure differentials in the bulk flow diverter exhaust ducts, particularly in two-dimensional arrays at high throughput, are uniquely solved with this geometry.

Owner:ENERTECHNIX

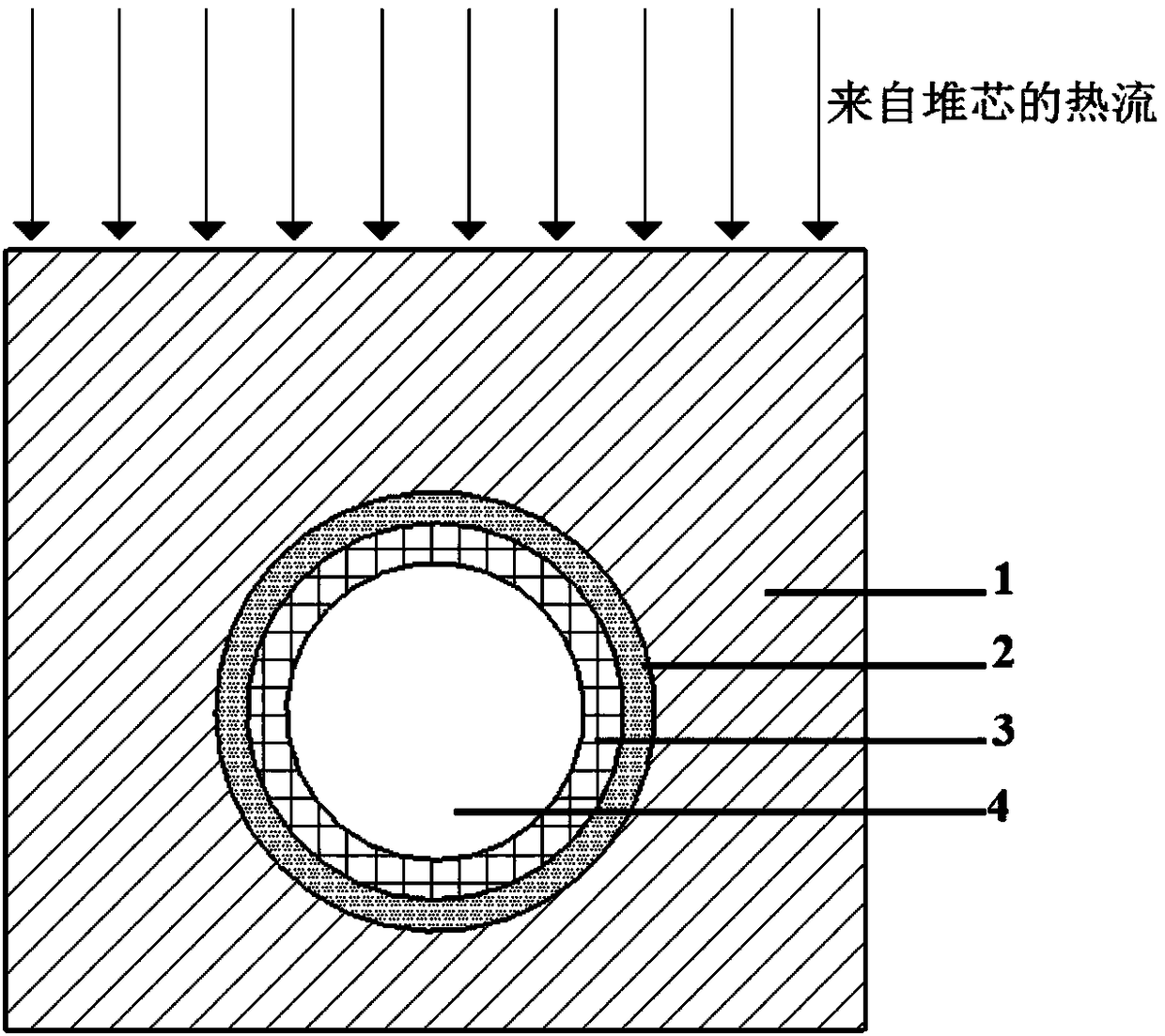

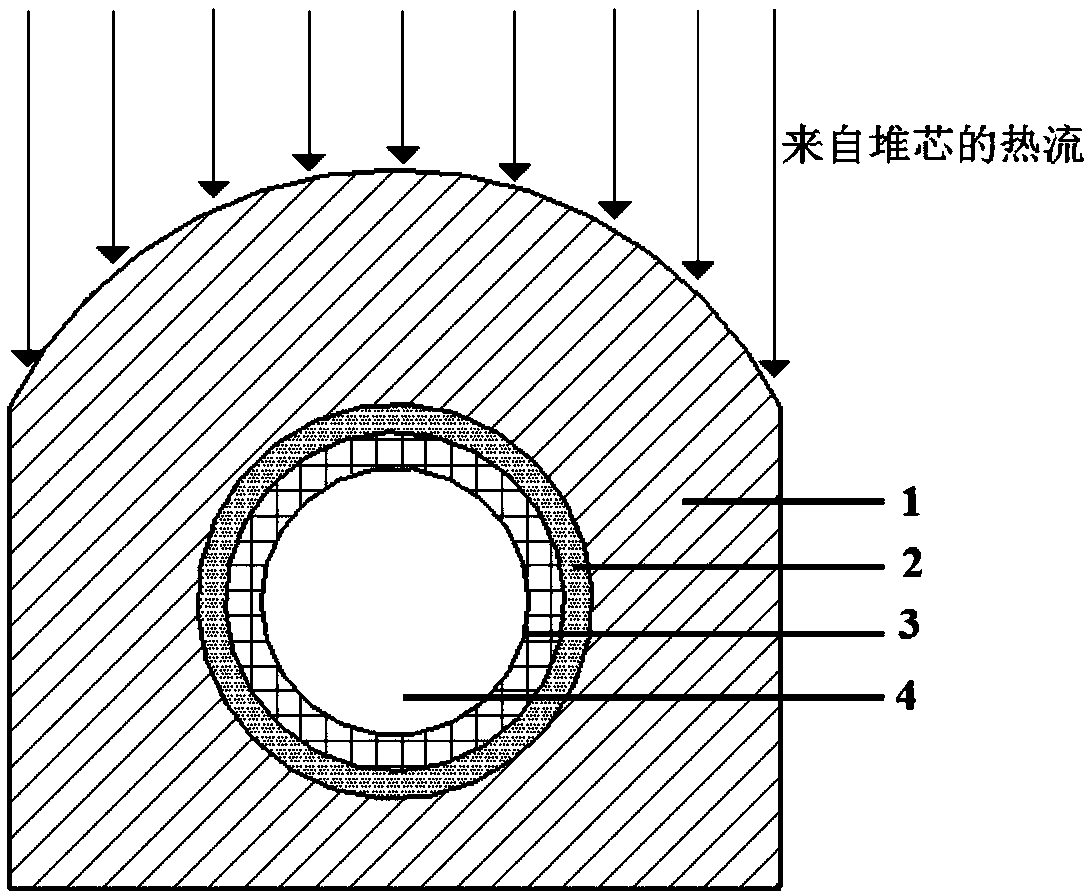

Fusion device divertor water cooling module and applied divertor cooling target board structure thereof

ActiveCN108615563AIncrease surface areaUniform heat flowNuclear energy generationThermonuclear fusion reactorNuclear fusionCoolant flow

The invention provides the structural design of a water cooling module used for cooling the divertor target board structure in a magnetic confinement nuclear fusion device. The fusion device divertorwater cooling module structure is composed of a plasma facing structure, a stress buffer layer structure welded in the plasma facing structure and a heat sink pipeline structure welded in the buffer layer structure. In the cooling structure, the coolant flows through the heat sink structure to bring away the high energy of the fusion reaction to the divertor part. The plasma facing structure is ahexahedron structure of which one surface protrudes to the fusion center direction with the heat sink pipeline and the stress buffer layer structure penetrating in the center position. The protrusionsurface structure directly bears the heat flow from the fusion center. The protrusion arc surface is coaxial with the annular stress buffer layer structure and the heat sink structure. The heat exchange capacity of the divertor can be directly enhanced from the aspect of structural design. The plasma energy flow can be more effectively dispersed by the design and the compatibility of the coolant pipeline and the plasma facing surface structure can be improved so as to enhance the heat exchange capacity.

Owner:XI AN JIAOTONG UNIV

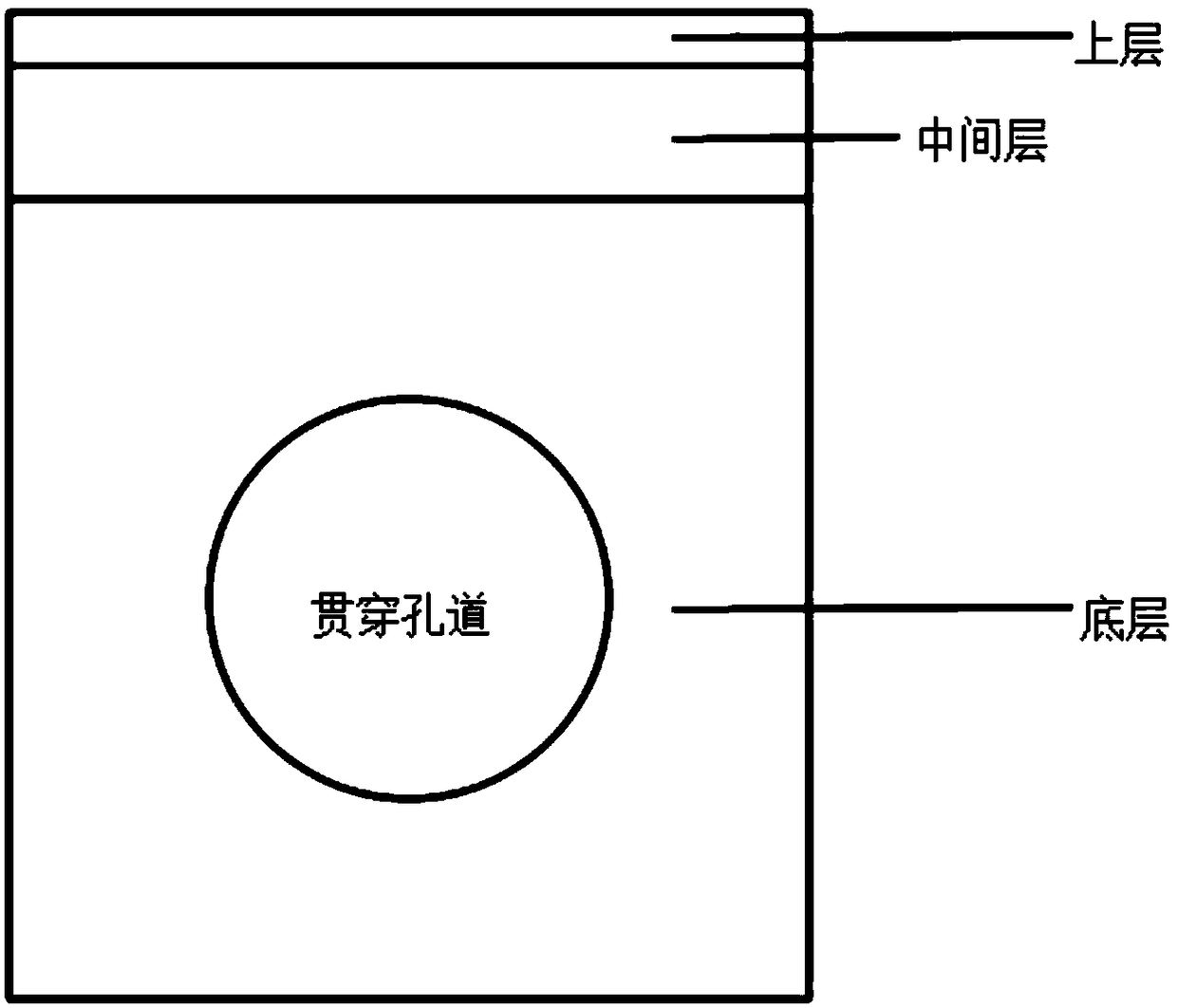

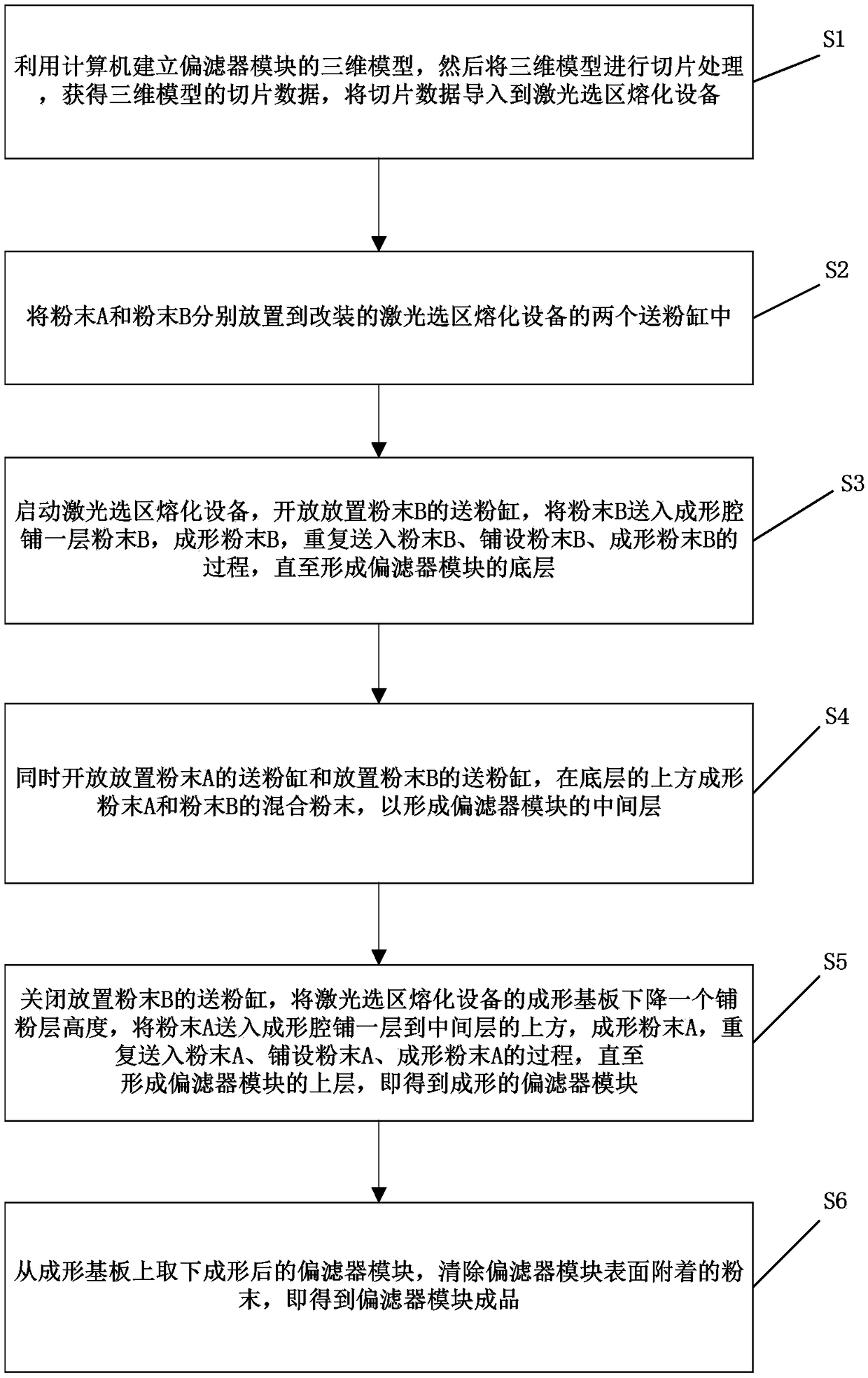

Sandwich structure divertor module and integral form manufacturing method thereof

InactiveCN109036590AIncrease stressGood effectAdditive manufacturing apparatusNuclear energy generationComputer moduleAlloy

The invention provides a sandwich structure divertor module including an upper layer, a middle layer and a bottom layer from top to bottom in sequence, the upper layer is made of metal A, and the metal A is made of a first wall material which is suitable for plasma, the bottom layer is made of metal B, and a round through hole channel is formed in the bottom layer, and the material selected by themetal B is a heat sink material with high heat conductivity, the middle layer is made of an alloy of the metal A and the metal B from the bottom layer to the upper layer, the mass percent of the metal B is continuously transited from 100% to 0, and the mass percent of the metal A is continuously transited to 100% from 0. The invention further provides a manufacturing method of the integral form of the sandwich structure divertor module. According to the manufacturing method provided by the invention, the integral forming of the upper layer, the middle layer and the bottom layer of the sandwich structure divertor module can be realized, the connection of different layers does not need to be carried out through processes such as welding and the like, so that the manufacturing process and the manufacturing cost are greatly shortened.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

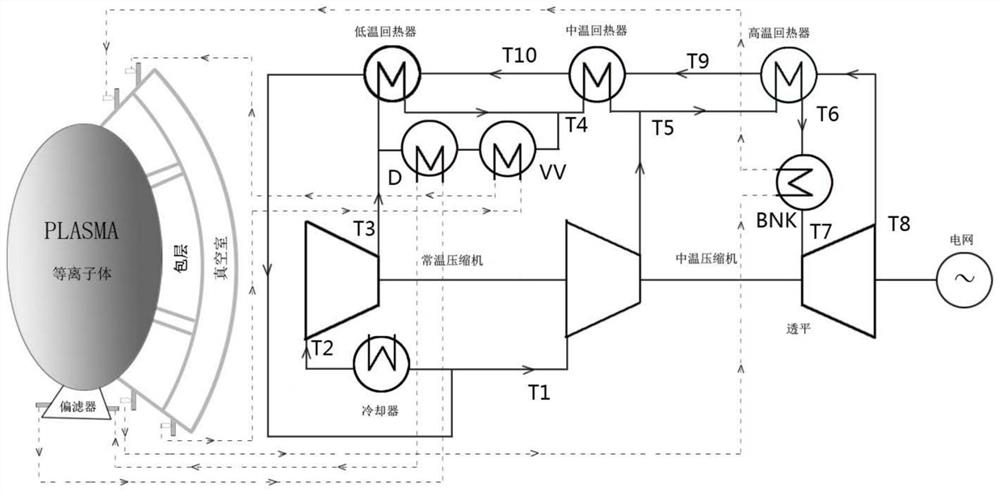

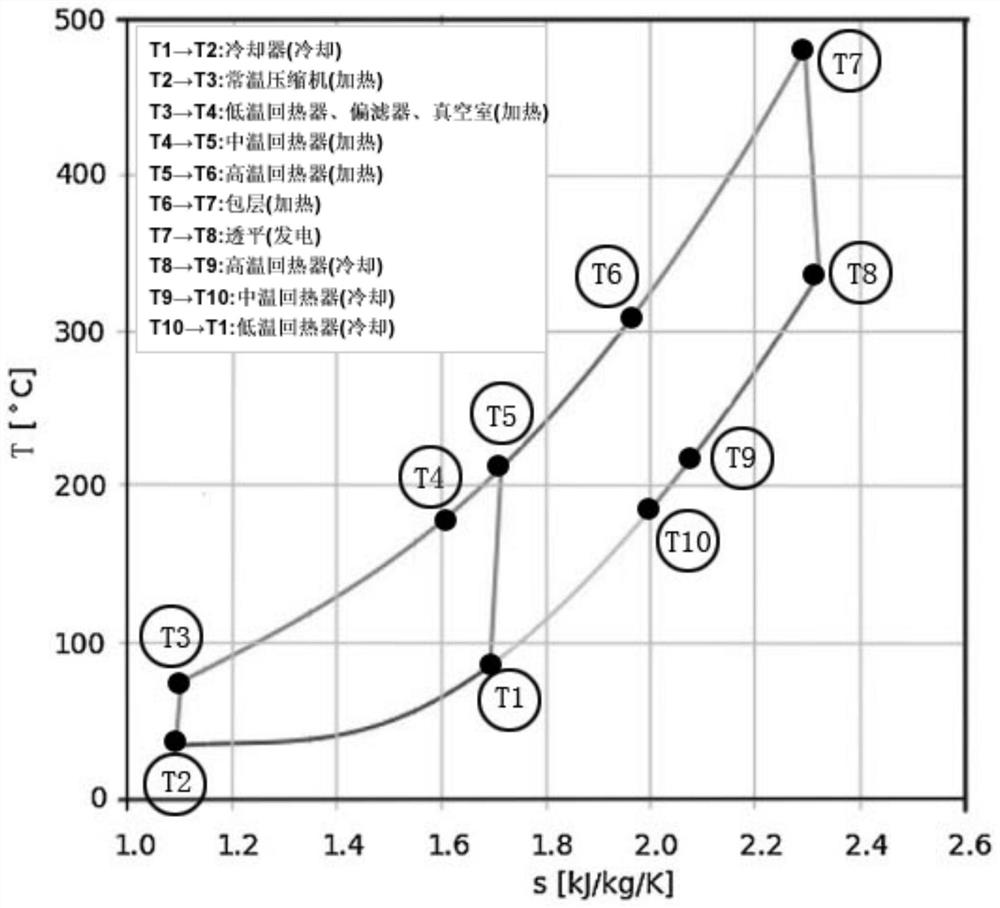

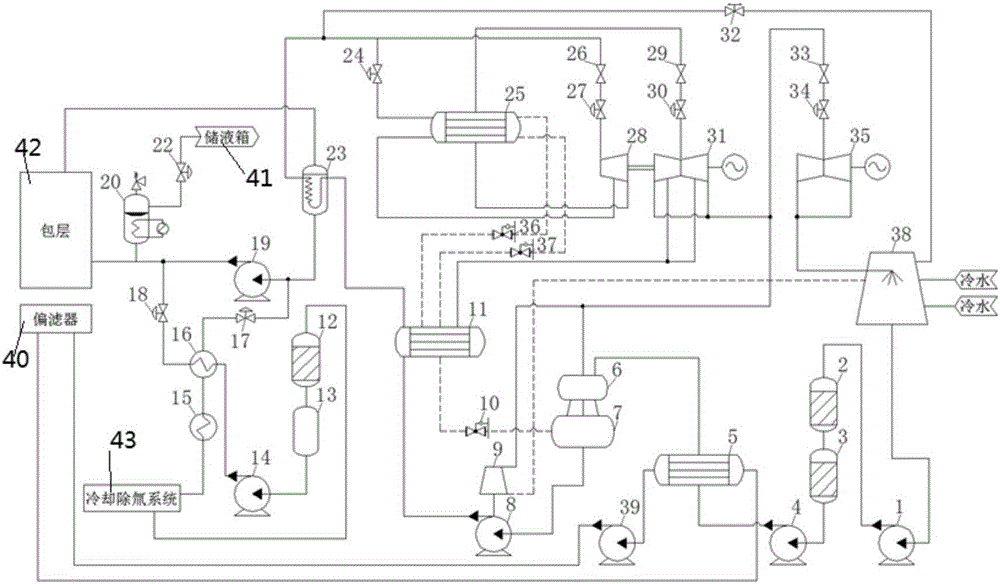

Supercritical carbon dioxide power circulating system and method for fusion reactor

ActiveCN111963267AHigh thermoelectric efficiencyEfficient use ofNuclear energy generationSteam useProcess engineeringDivertor

The invention discloses a supercritical carbon dioxide power circulating system and method for a fusion reactor. Aiming at different working medium conditions of different nuclear heat sources of a fusion reactor cladding layer, a divertor and a vacuum chamber, S-CO2 is heated by stage-by-stage heat regeneration on the high-pressure side and cooled by stage-by-stage heat regeneration on the low-pressure side through three stages, namely a low-temperature heat regenerator, a middle-temperature heat regenerator and a high-temperature heat regenerator; 20 percent of S-CO2 is selected to be cooledand then pressurized and heated so as to be used for heat regeneration of a low-temperature heater and cooling of the divertor and the vacuum chamber, so that the operation requirements of differentcooling media for different heat sources of three components in the reactor are met, a negative temperature effect during heat regeneration is avoided, the heat sources of all components in the reactor are effectively utilized, and the heat energy utilization efficiency is greatly improved; and compared with the current designs only using helium gas carrying cladding layer core heat and a Rankinecirculatory system with two-loop pressure water heat exchange to generate electricity, the thermoelectricity efficiency of the fusion reactor is improved to 41 percent from 30 percent, and the supercritical carbon dioxide power circulating system for the fusion reactor has the remarkable advantages of simple structure, low cost, high heat efficiency and the like.

Owner:ANHUI UNIVERSITY

Internal part cooling power generation system for future tokamak fusion reactor

ActiveCN105976873AAchieve coolingRealize the integrated design of power generationNuclear energy generationThermonuclear fusion reactorNuclear engineeringCooling power

The invention provides an internal part cooling power generation system for a future tokamak fusion reactor. The system comprises a divertor cooling circuit, a cladding cooling circuit and a main cooling circuit. The system is characterized in that the divertor cooling circuit comprises a first heat exchanger, a pump and a divertor; a coolant is inflated by the pump from one side of the first heat exchanger, flows into the divertor, and flows back to the first heat exchanger from the other side of the divertor; the cladding cooling circuit comprises a first main circuit, a first auxiliary circuit and a supplemental coolant circuit; and the main cooling circuit comprises a second main circuit and a second auxiliary circuit. According to the invention, on the premise that a tokamak device can continuously stably operate, cooling and power generation are integrated, and the system has the advantages of stability, safety, reliability and high efficiency.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

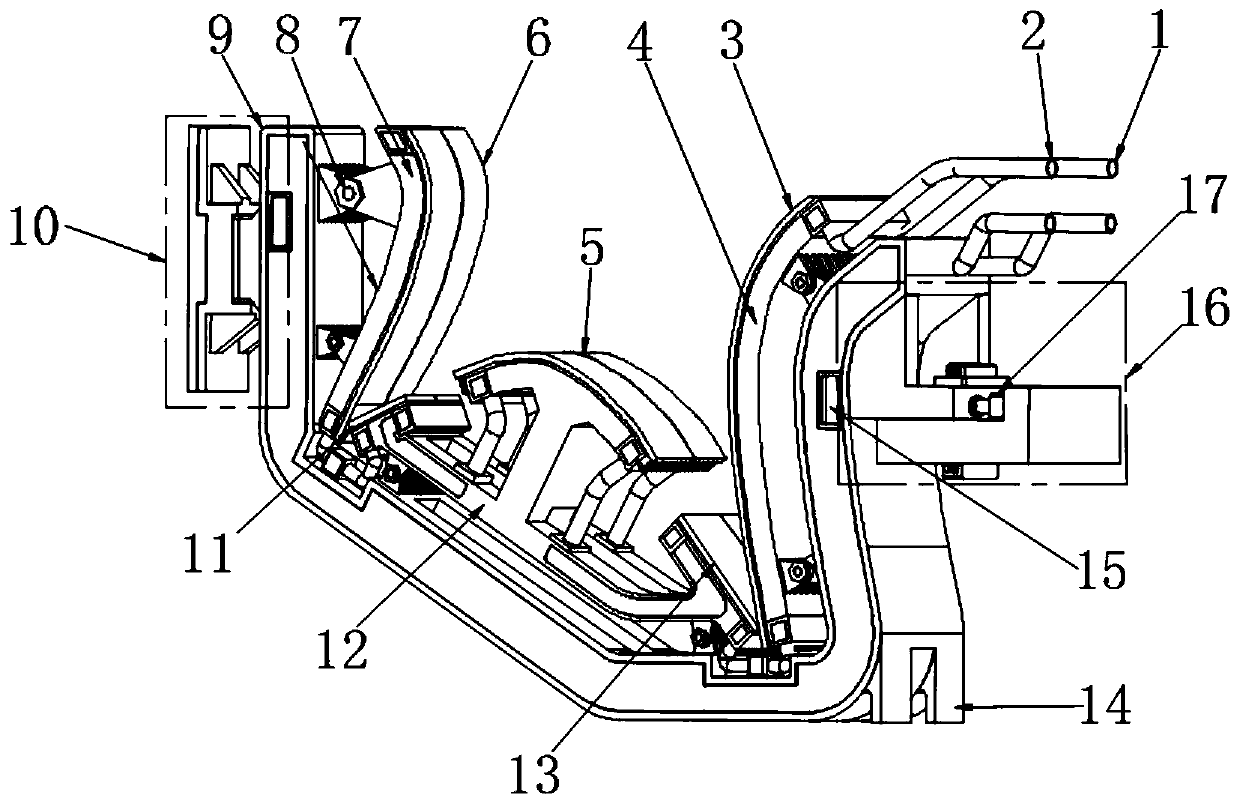

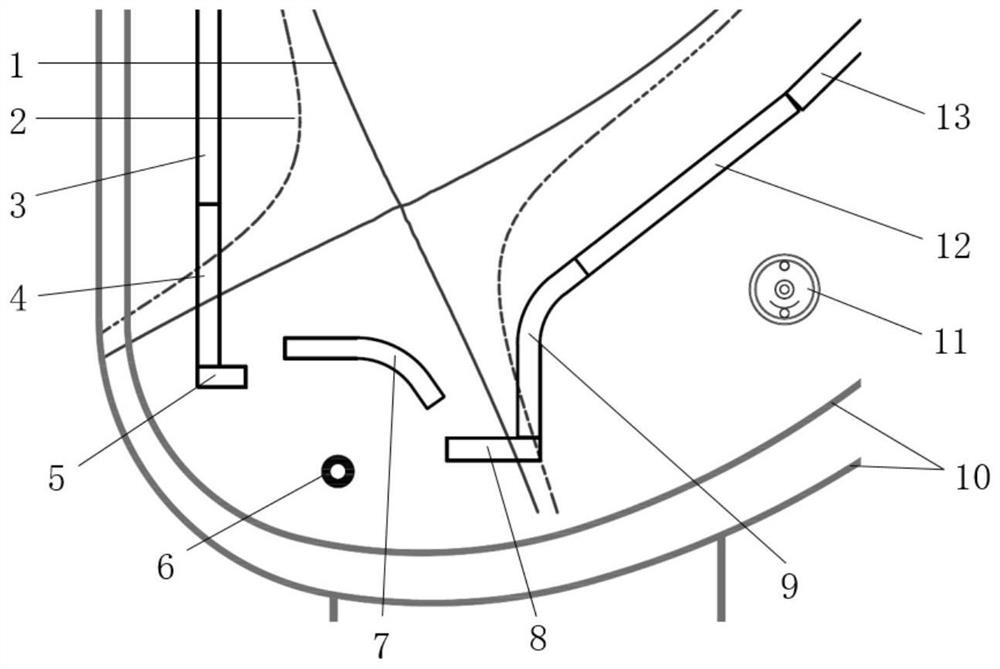

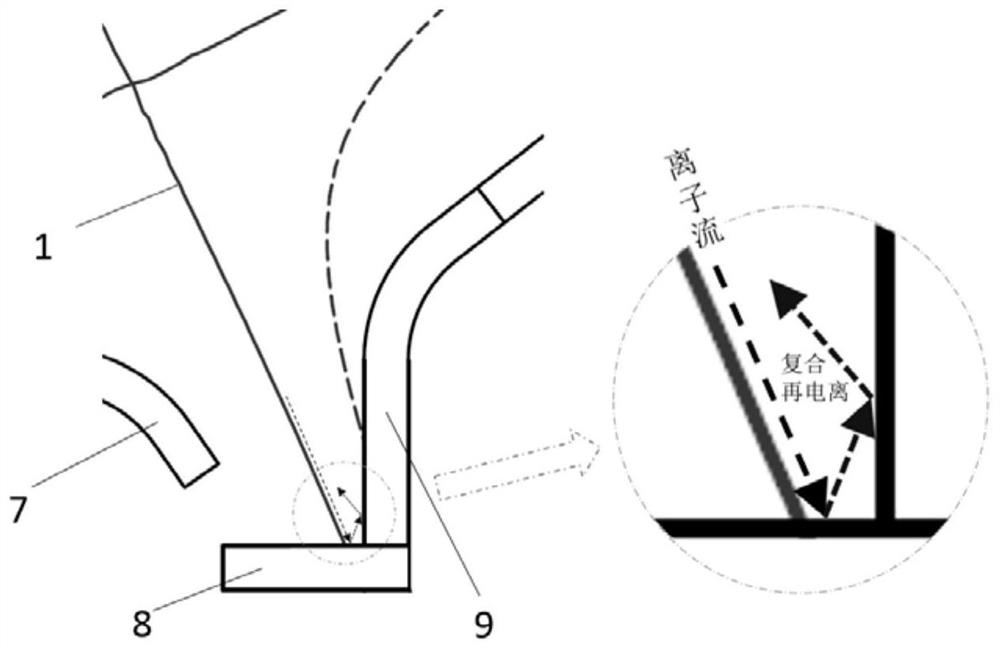

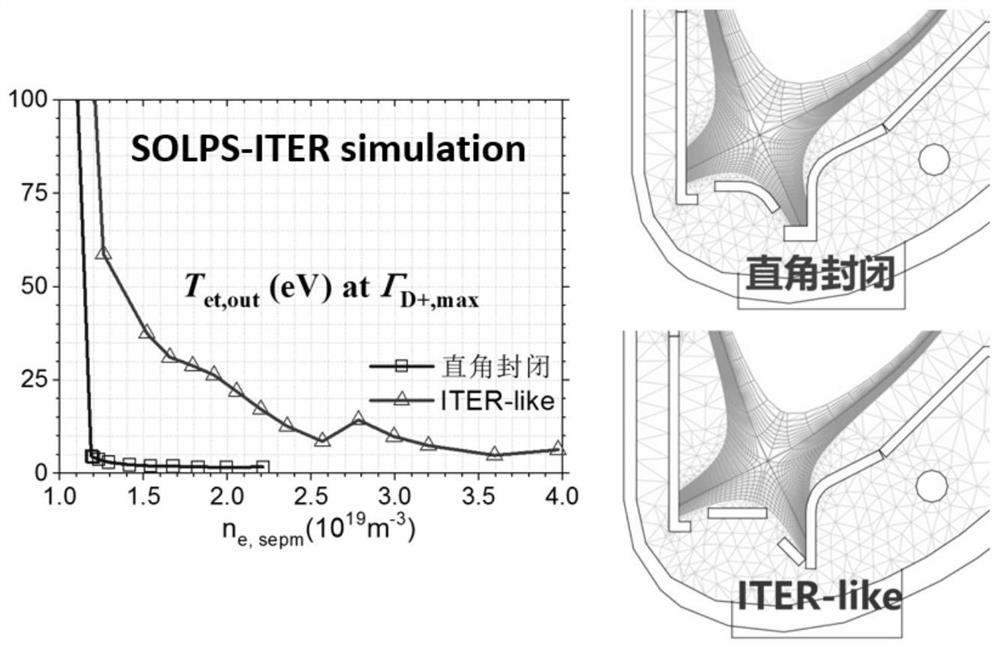

Right-angle closed all-tungsten divertor suitable for Tokamak nuclear fusion device

PendingCN113035378AReduce heat loadImprove closureNuclear energy generationThermonuclear fusion reactorDivertorMechanical engineering

The invention discloses a right-angle closed all-tungsten divertor suitable for a Tokamak nuclear fusion device. The right-angle closed all-tungsten divertor comprises a horizontal outer target plate, a vertical outer target plate, a vertical inner target plate, an inner target plate End Box, a Dome target plate, a high-field side baffle, a low-field side baffle, a passive target plate and a built-in water cooling coil. The horizontal outer target plate and the vertical outer target plate form a right-angle closed geometric structure, so that the sealing performance of the outer target plates of the divertor is improved, the density threshold value of natural miss can be greatly reduced, the use amount of impurity gas introduced to realize miss can also be remarkably reduced, miss can be realized while good core constraint is maintained, and the thermal load of the target plates is reduced. Through polar field integrated control, strike points can be scanned between the horizontal outer target plate and the vertical outer target plate in a second-order long discharge period, and thermal loads are effectively dispersed. The design structure is simple and compact, the manufacturing and mounting precision of the tungsten divertor is conveniently controlled, the manufacturing difficulty and cost are reduced, and meanwhile the thermal load level of the target plates of the tungsten divertor is easily controlled.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

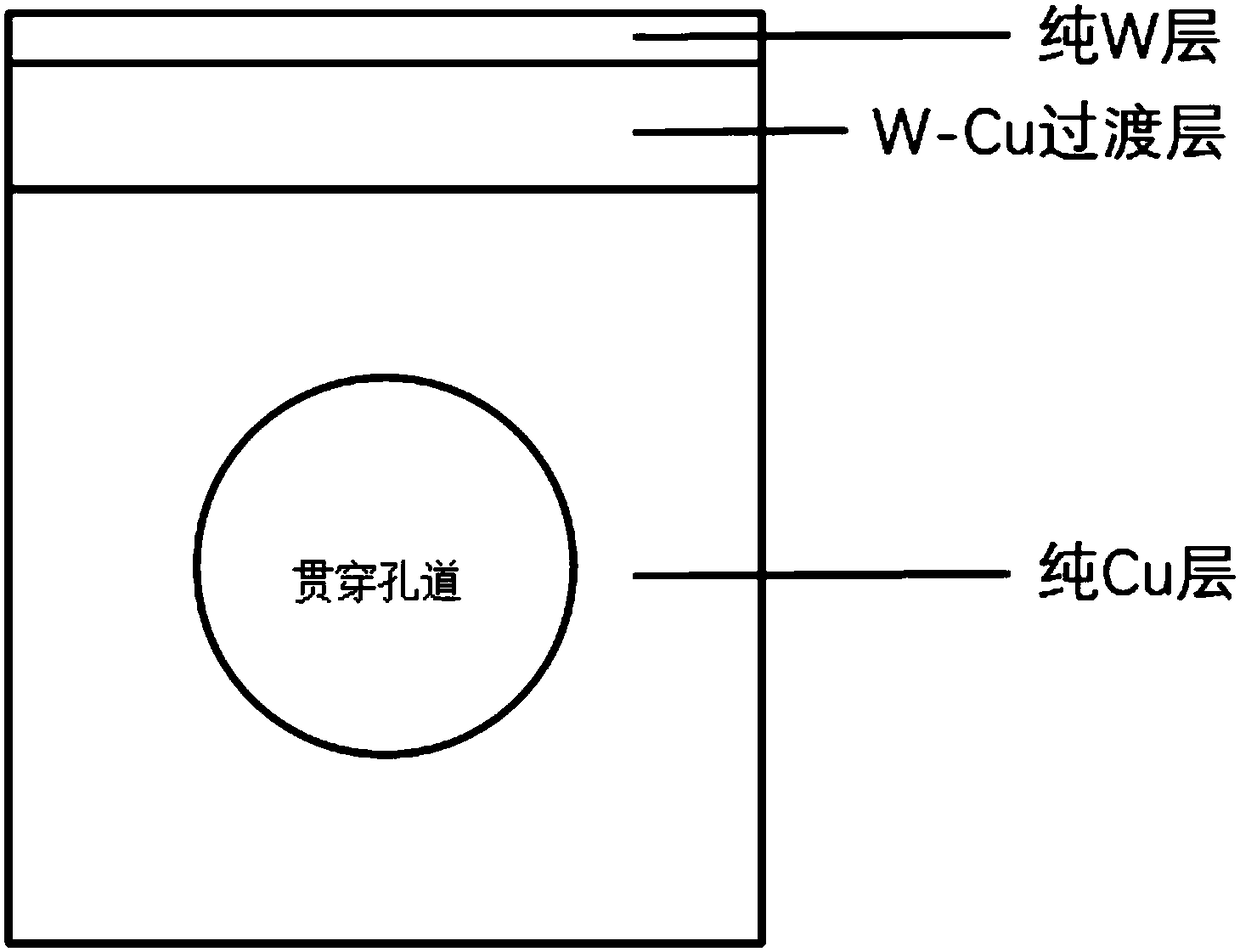

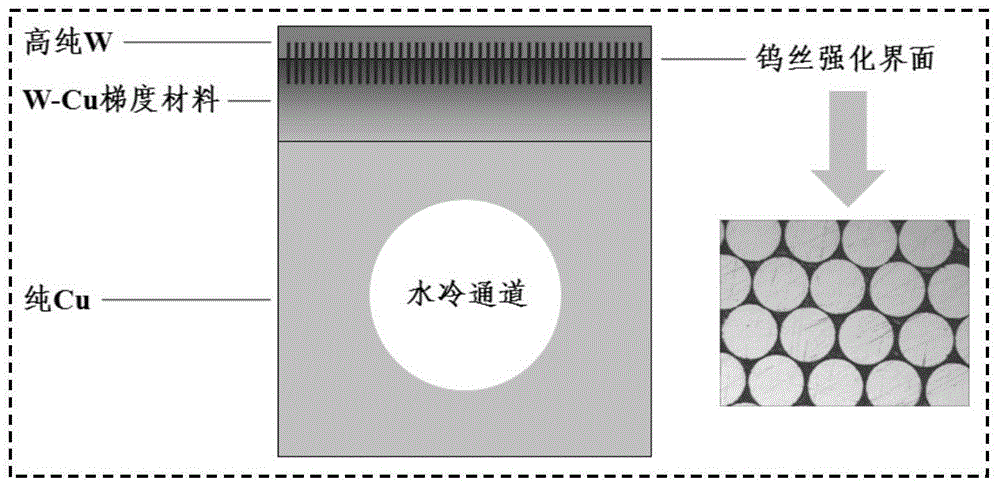

Divertor module and manufacturing method

ActiveCN105047231AImprove the bonding strength of the interfaceNuclear energy generationThermonuclear fusion reactorMetallurgyAlloy

The invention discloses a divertor module and a manufacturing method. The divertor module is formed by a three-layer structure of a pure Cu layer, a W / Cu gradient alloy layer and a pure W layer. An interface position of the pure W layer and the W / Cu gradient alloy layer is provided with a tungsten filament array. A through hole channel is arranged in the pure Cu layer. A metallurgical bonding is arranged between the pure Cu layer and the W / Cu gradient alloy layer. The divertor module possesses the characteristics that a gradient middle layer is used to mitigate a thermal stress and a tungsten filament array reinforcement structure is used to increase interface combination intensity.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

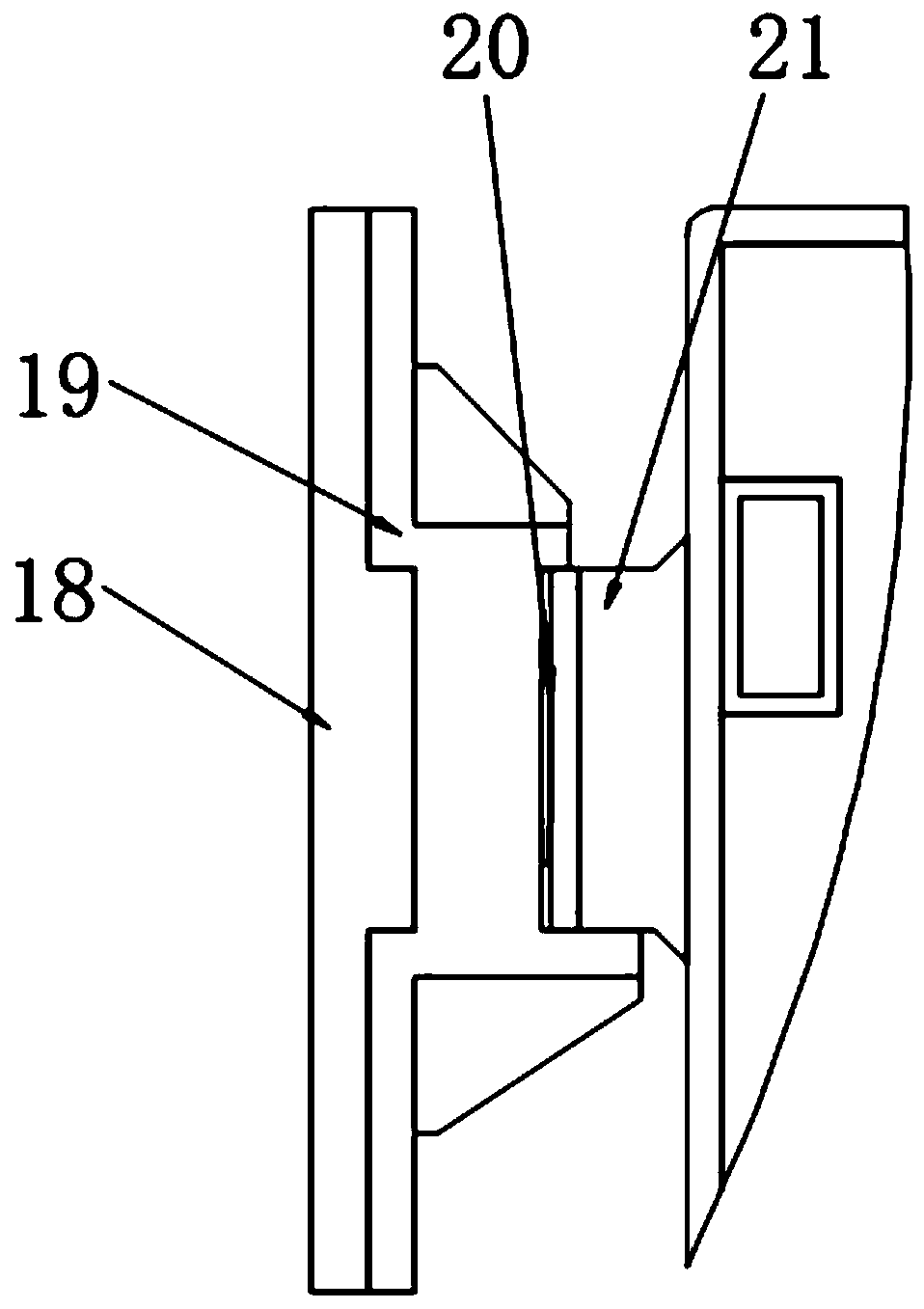

High-accuracy quick assembling and disassembling structure for tokamak divertor module

InactiveCN104021820AAvoid installation errorsSimplify the installation processNuclear energy generationThermonuclear fusion reactorDivertorMechanical engineering

The invention discloses a high-accuracy quick assembling and disassembling structure for a tokamak divertor module. The high-accuracy quick assembling and disassembling structure comprises two high-accuracy installed guide rails, the high-accuracy processed divertor module, a movable wedge block, an auxiliary support, two connecting bolts and two stopping blocks. The divertor module can be quickly installed in place through small-distance movement in two directions, and the divertor module and the guide rails are wedged by the wedge blocks to restrain the freedom degree in the axial direction and the freedom degree in the vertical direction. The stopping blocks are used for controlling the freedom degree in the annular direction, and the connecting bolts can further fasten the divertor module.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

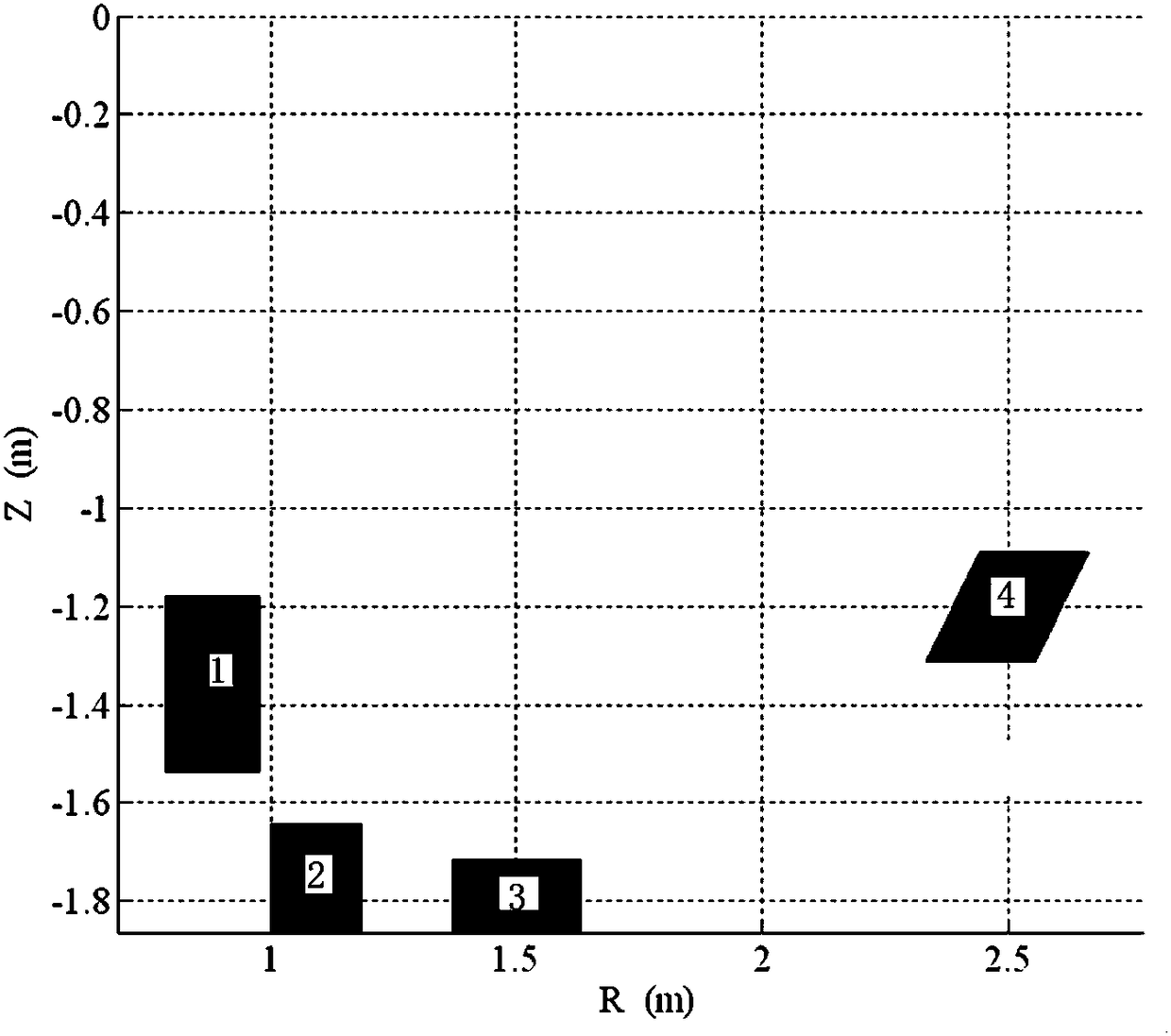

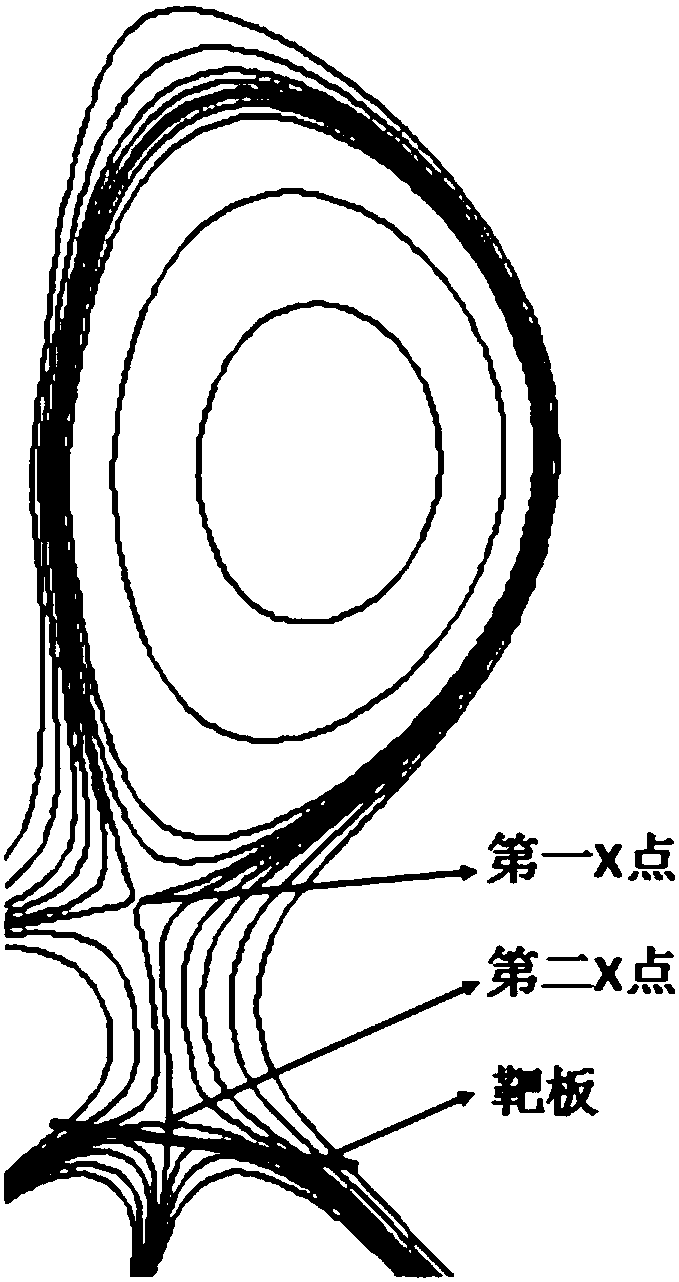

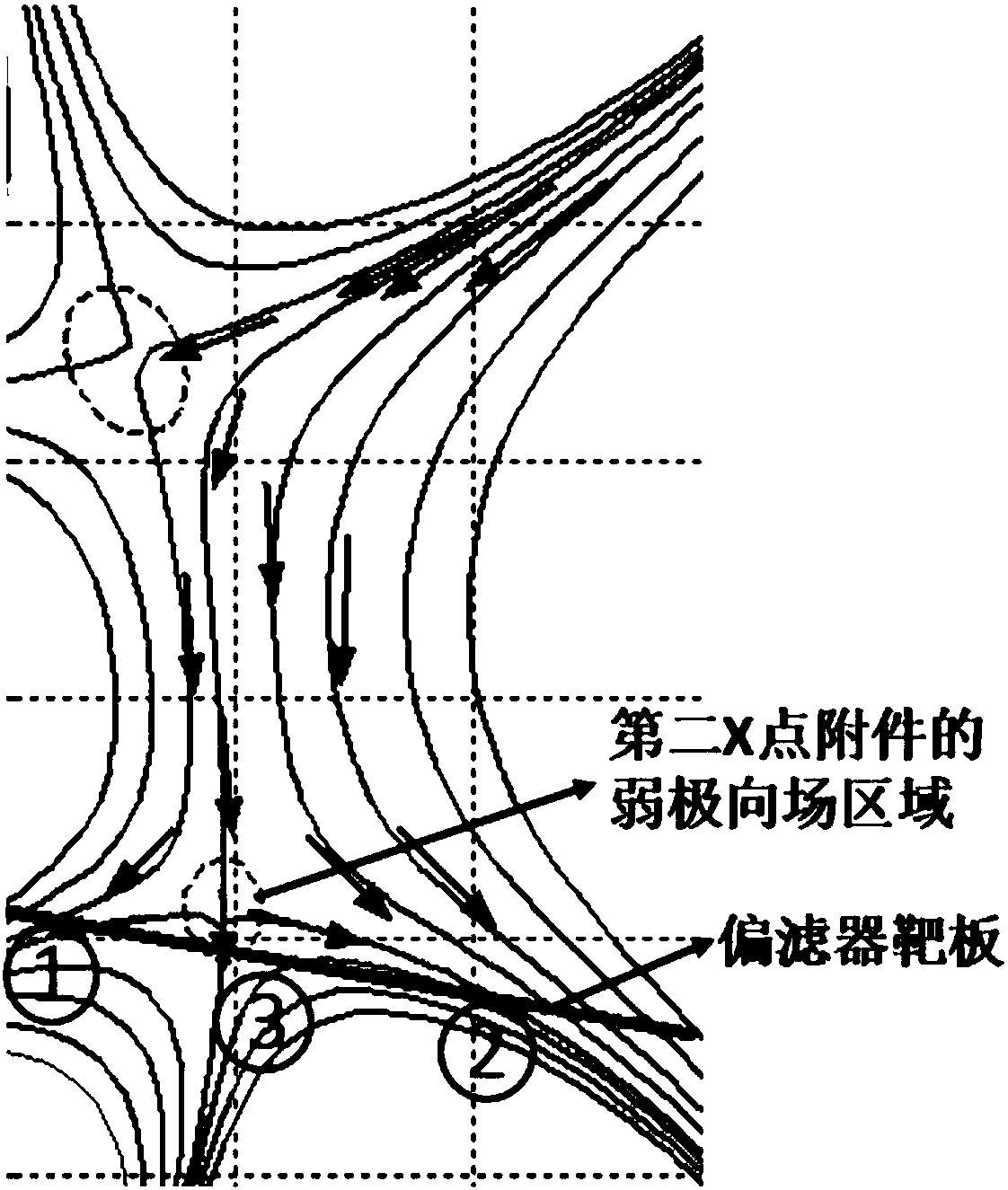

Tokamak tripod divertor magnetic field configuration construction method

ActiveCN108269620AIncrease distanceIncrease the heating areaNuclear energy generationThermonuclear fusion reactorCurrent strengthUltimate tensile strength

The invention belongs to the magnetic confinement fusion technical field and concretely relates to a Tokamak tripod divertor magnetic field configuration construction method. According to the method,distances between the geometric center position of a first poloidal field coil and a first X point, between the geometric center position of a second poloidal field coil and the first X point, betweenthe geometric center position of a third poloidal field coil and the first X point and between the geometric center position of a fourth poloidal field coil and the first X point are set to be 1-1.5a, 1.5-3a, 1.5-3a and 1.5-2.0a respectively, wherein a is the minor radius of a plasma. The method solves the technical problems that the target plate heating area of a common divertor of a conventional Tokamak magnetic confined plasma experiment apparatus is small and cooling of a target plate of the divertor faces huge technical challenges in a high heating condition. A constructed tripod divertor magnetic field configuration can alleviate heat load of a target plate and improve compatibility of running of a divertor and running of a core high heating plasma. The performance of dust removal and impurity shielding characteristics are better exhibited, and requirements of coil current strength and coil arrangement complexity are reduced for an advanced divertor configuration.

Owner:SOUTHWESTERN INST OF PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com