Cool-off heat sink of steady-state tokamak divertor

A tokamak and divertor technology, applied in cooling/ventilation/heating transformation, thermonuclear fusion reactors, nuclear reactors, etc., can solve the problem of discounting the cooling effect, difficulty in meeting the needs of the device, and inability to ensure the contact area between the cooling pipe and the base material, etc. problem, to achieve good cooling effect and reduce the effect of heat transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

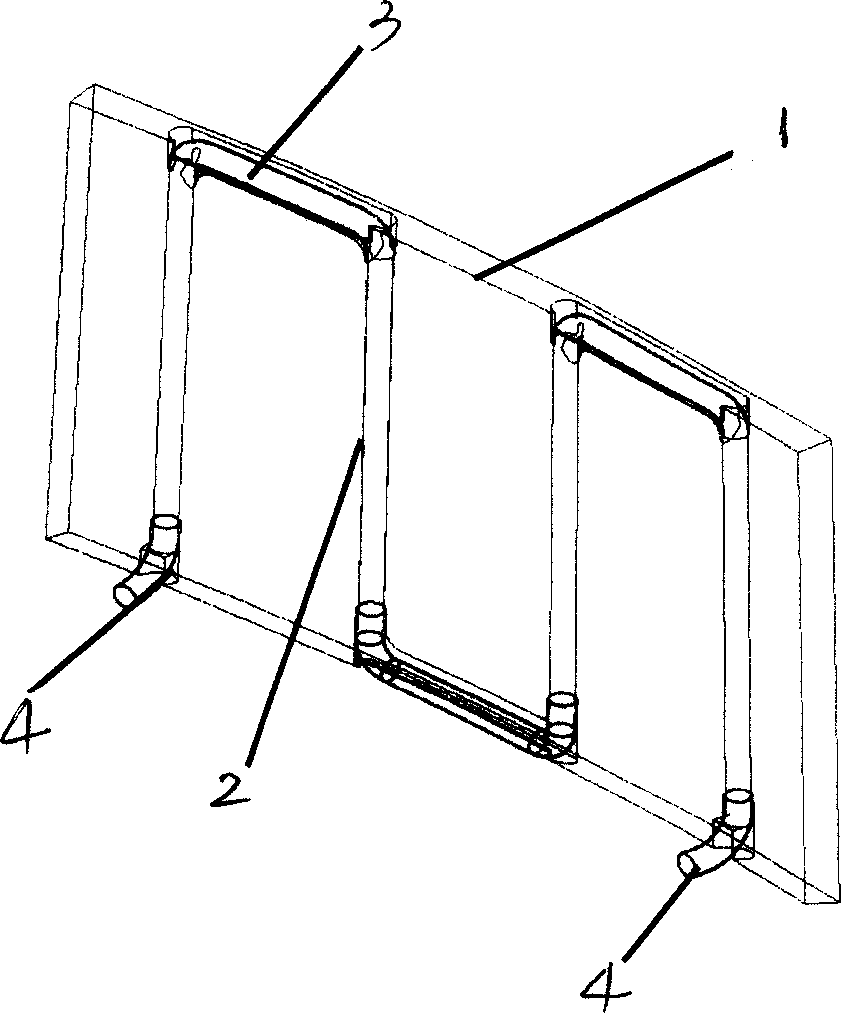

[0010] As shown in the figure, the present invention includes a copper alloy heat sink plate 1, a cooling channel 2, a connecting pipe 3 and a stainless steel outlet pipe 4, wherein the aperture of the cooling channel 2 and the density distributed on the heat sink plate can be adjusted as required.

[0011] The present invention is limited by the deep hole technology, and is only suitable for cooling channel holes with a depth of not more than 1.8 meters and a hole diameter of 3-36mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com