A power battery thermal management system based on the combination of two-stage heat pipe and vehicle body

A heat management system and power battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., to achieve the effects of compact system structure, improved heat exchange efficiency, and shortened heat exchange distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

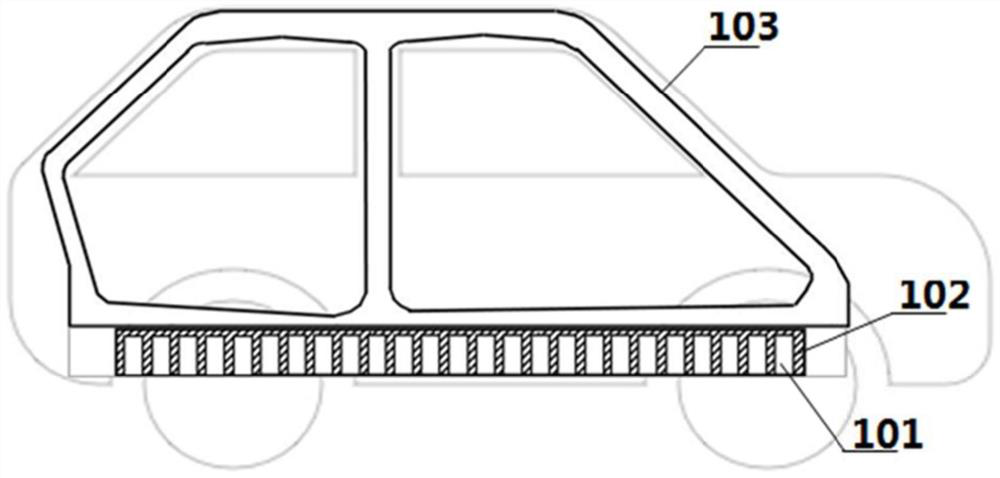

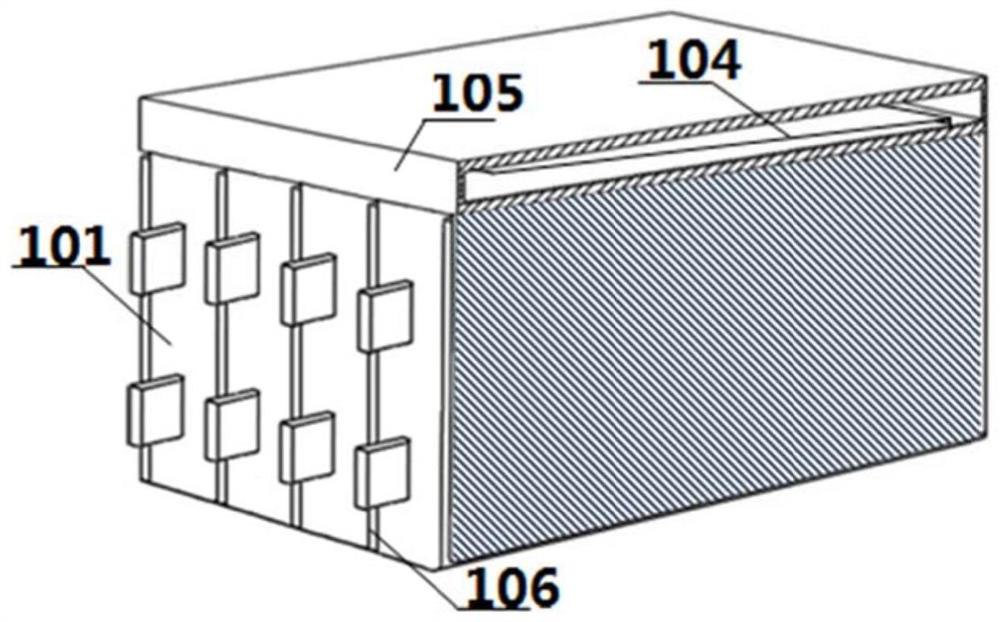

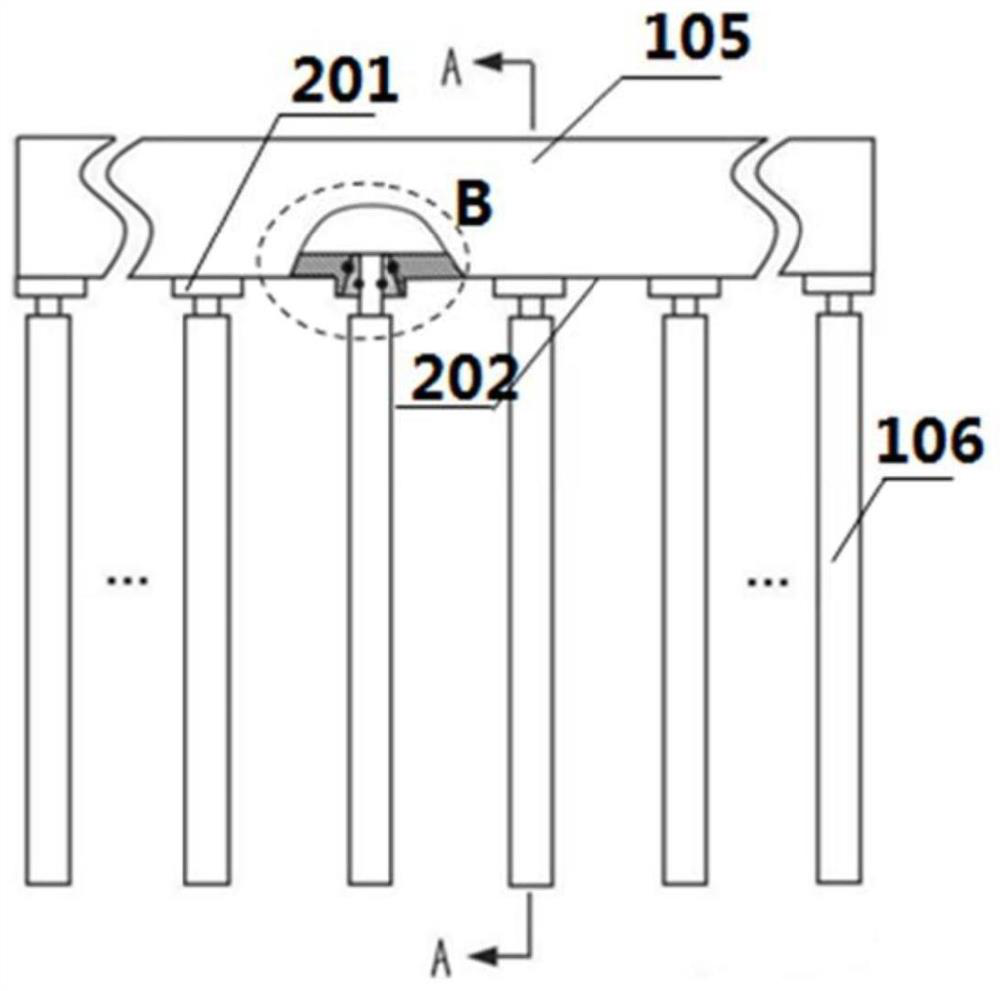

[0026] As shown in the figure, a power battery thermal management system based on the combination of two-stage heat pipes and a vehicle body includes several power battery cells 101, a three-dimensional ultra-thin heat pipe group 102 and a vehicle body heat pipe 103; the three-dimensional ultra-thin heat pipe group 102 is arranged on the vehicle body The bottom is composed of several ultra-thin evaporation plates 106 and a condenser 105; in order to enhance the detachability of the three-dimensional ultra-thin heat pipe group 102, the bottom surface 202 of the condenser 105 contains a tapered interface 201; the flexible joint of the ultra-thin evaporation plate 106 307 is connected with the tapered interface 201 through a sealing ring 305 and a self-clamping collar 306; the condenser 105 contains a gas-liquid splitter plate 104, and the gas-liquid splitter plate 104 separates the three-dimensional ultra-thin heat pipe group 102 into several parallel Complete circuit; the two su...

Embodiment 2

[0031] In this embodiment, the inner evaporation chamber of the ultra-thin evaporation plate 106 contains a micro-channel 501 structure with a stepped change in hydraulic diameter. The diameter of the micro-channel 501 gradually decreases in the direction away from the return channel 301 . Other implementations are the same as the first embodiment. .

Embodiment 3

[0033] In this embodiment, the inner evaporation chamber of the ultra-thin evaporation plate 106 contains a gradient porous structure 601 , and the average diameter of the pores gradually decreases in the direction away from the return channel 301 . Other implementations are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com