Patents

Literature

141 results about "Surface gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In vector calculus, the surface gradient is a vector differential operator that is similar to the conventional gradient. The distinction is that the surface gradient takes effect along a surface. For a surface S in a scalar field u, the surface gradient is defined and notated as ∇Su=∇u-𝐧(𝐧·∇u) where 𝐧 is a unit normal to the surface. Examining the definition shows that the surface gradient is the (conventional) gradient with the component normal to the surface removed (subtracted), hence this gradient is tangent to the surface.

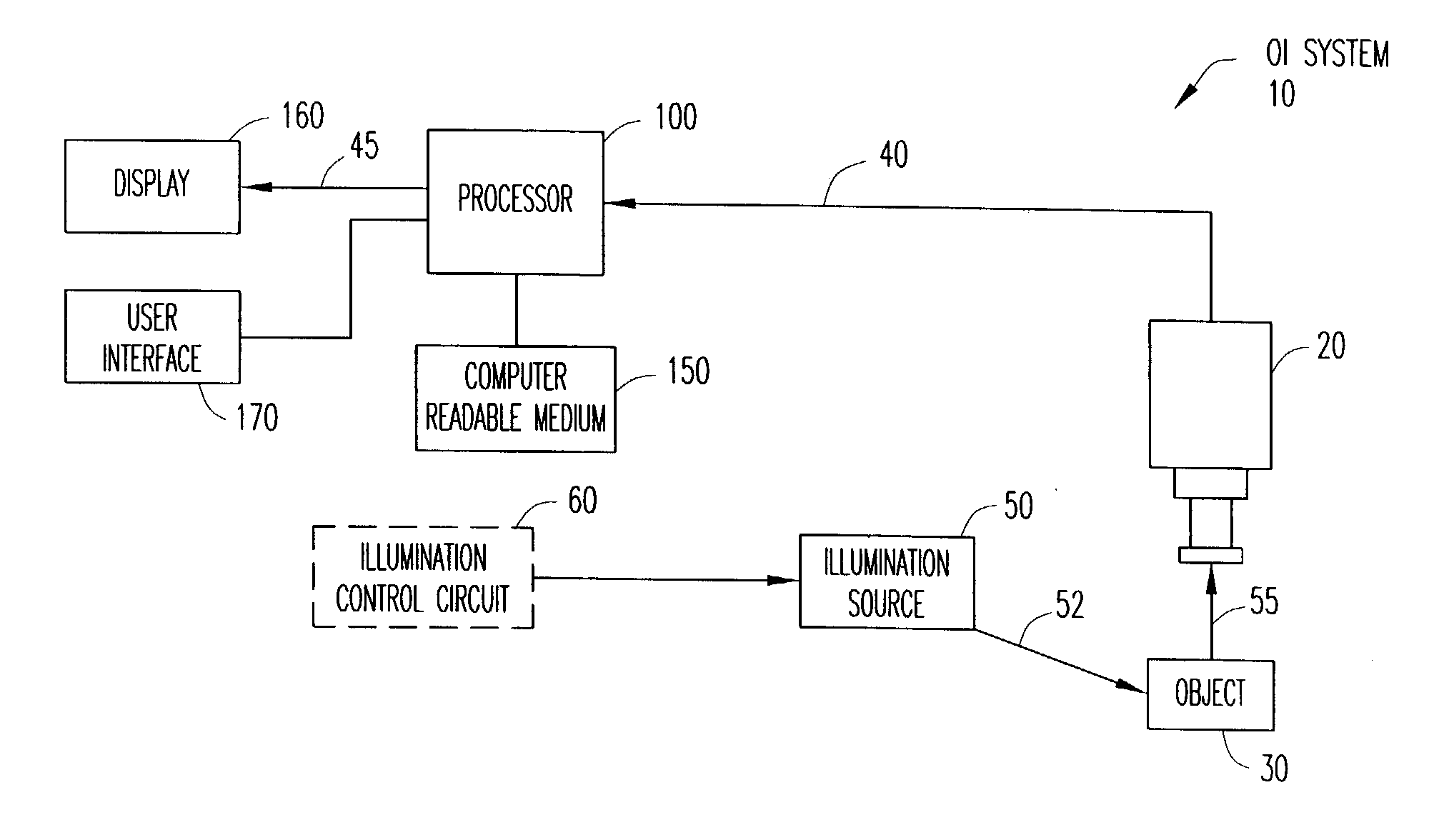

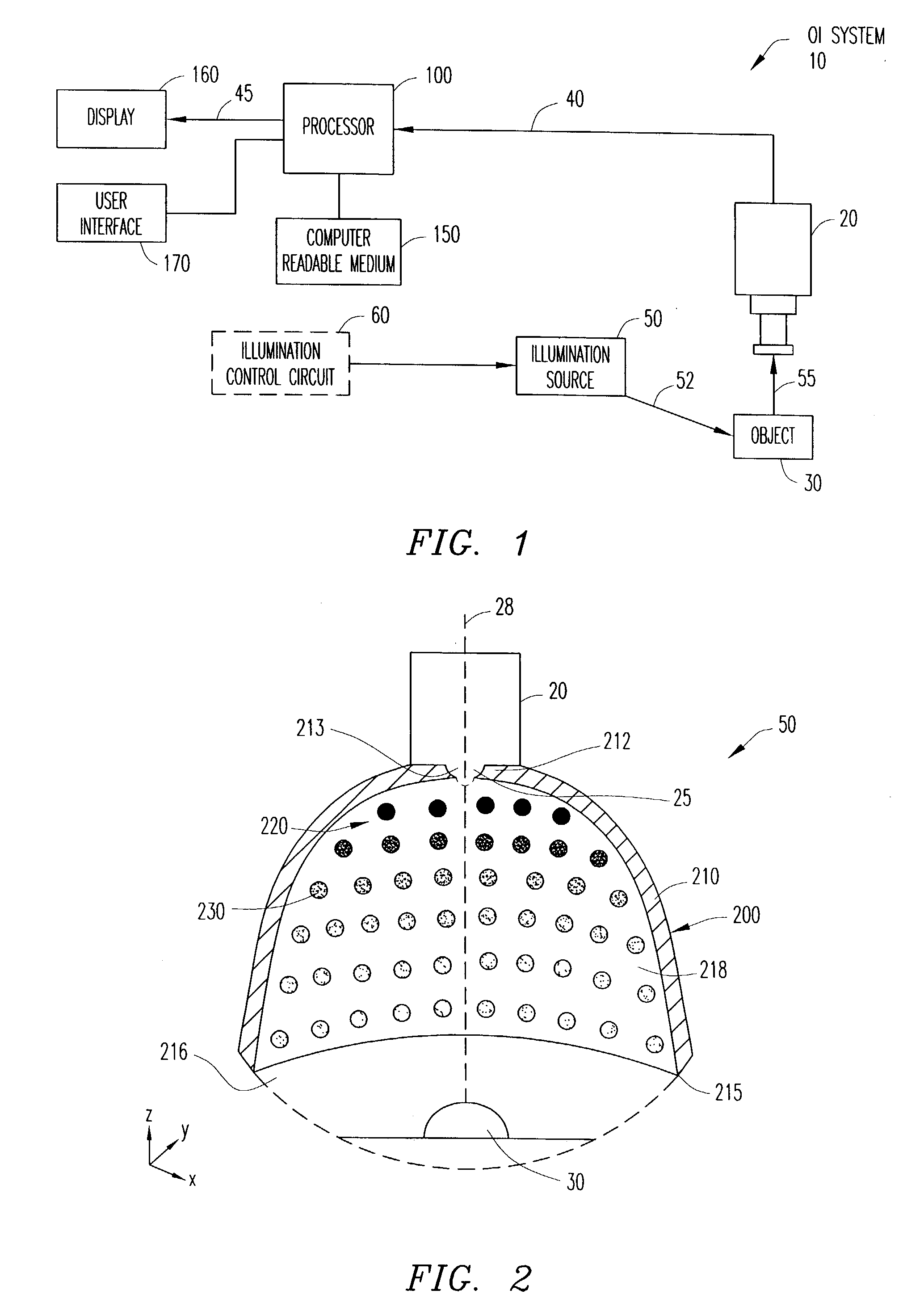

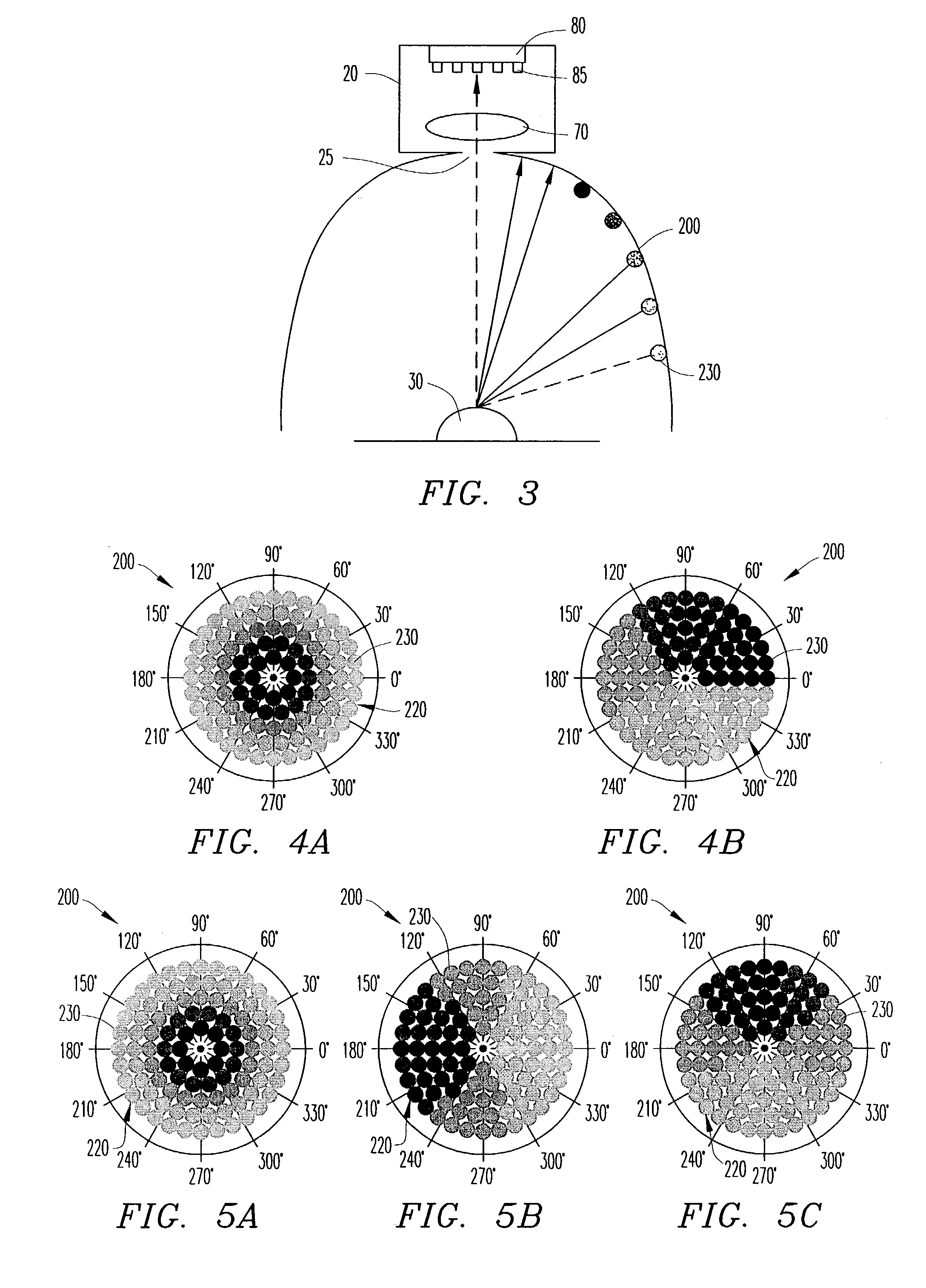

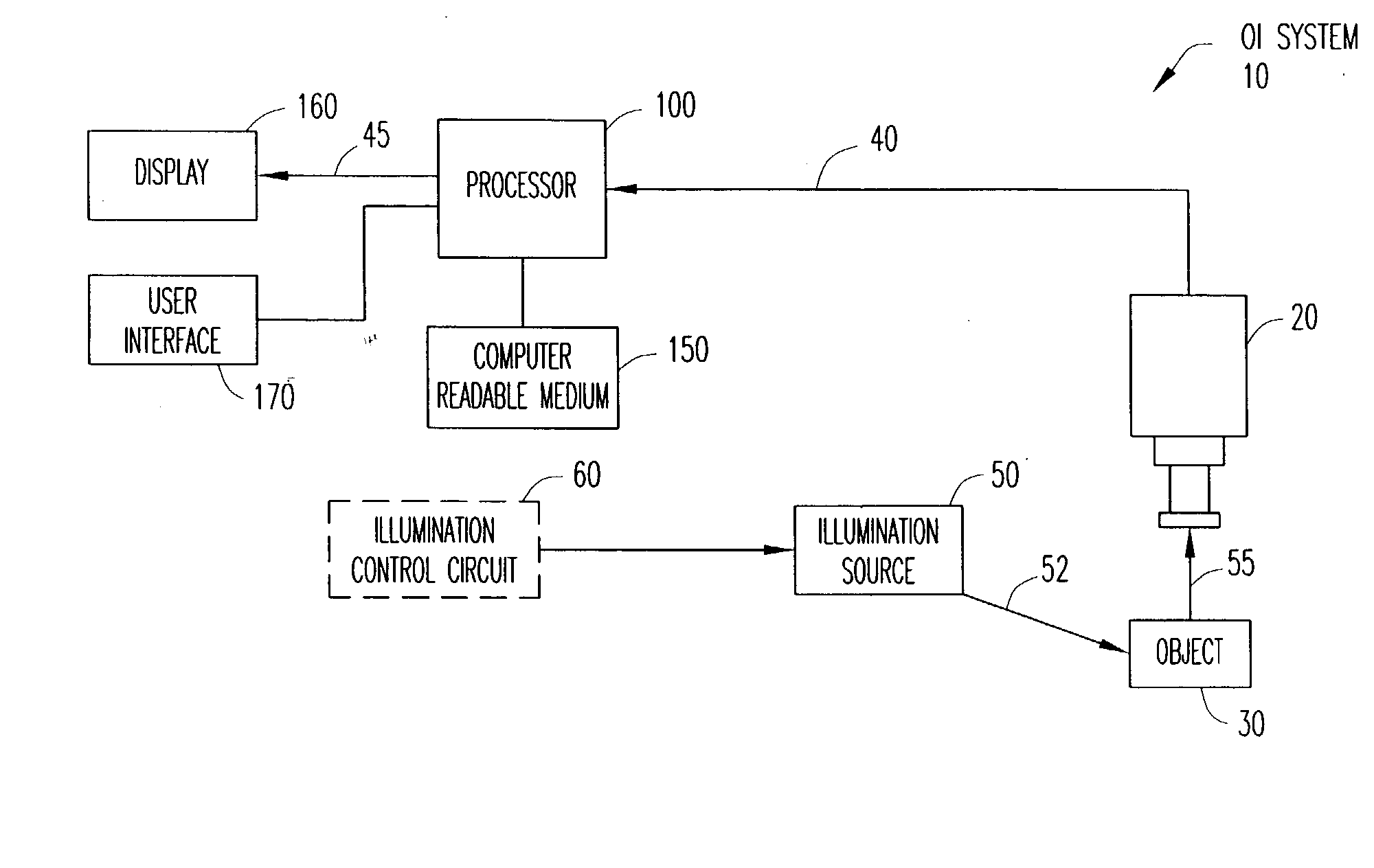

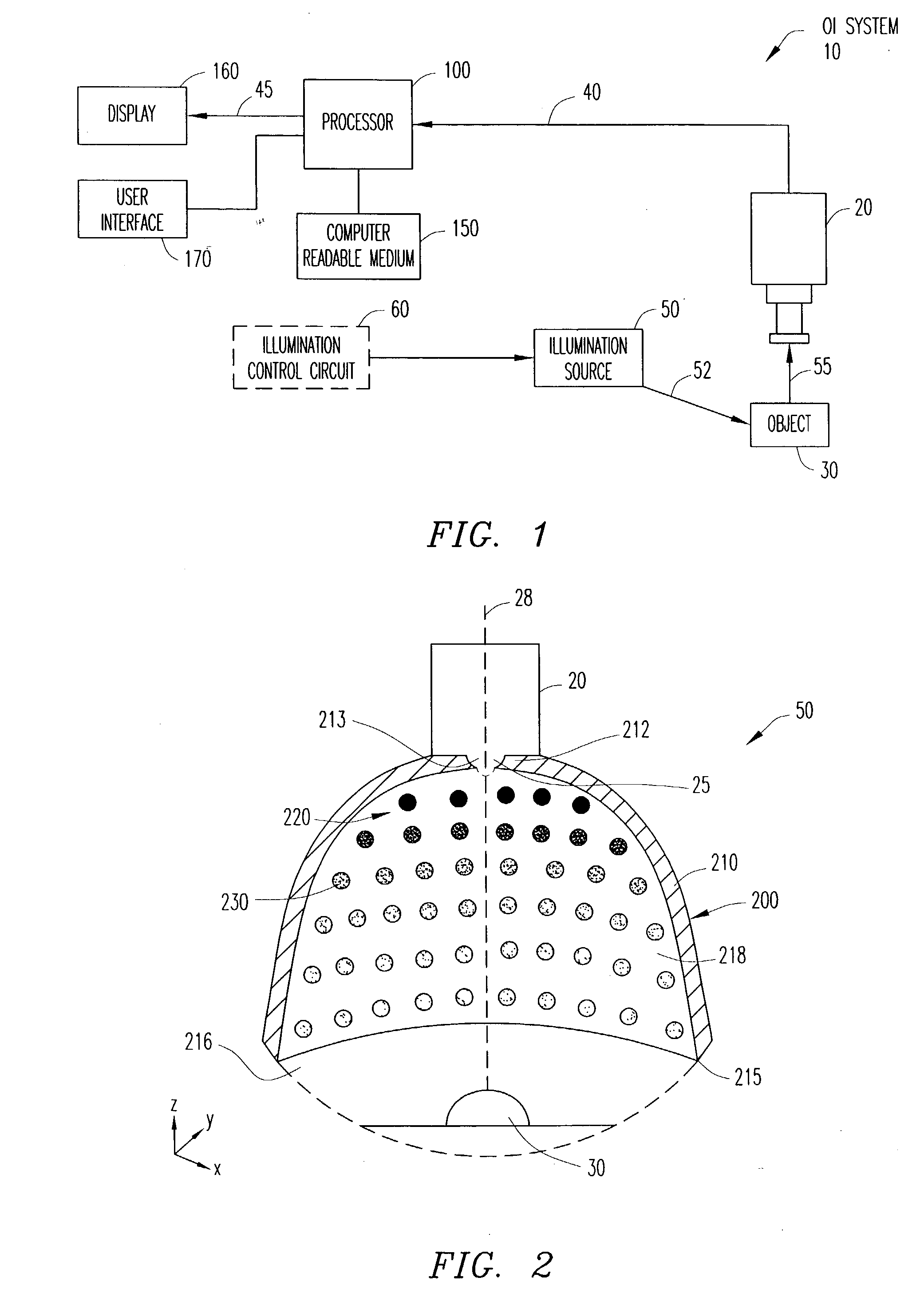

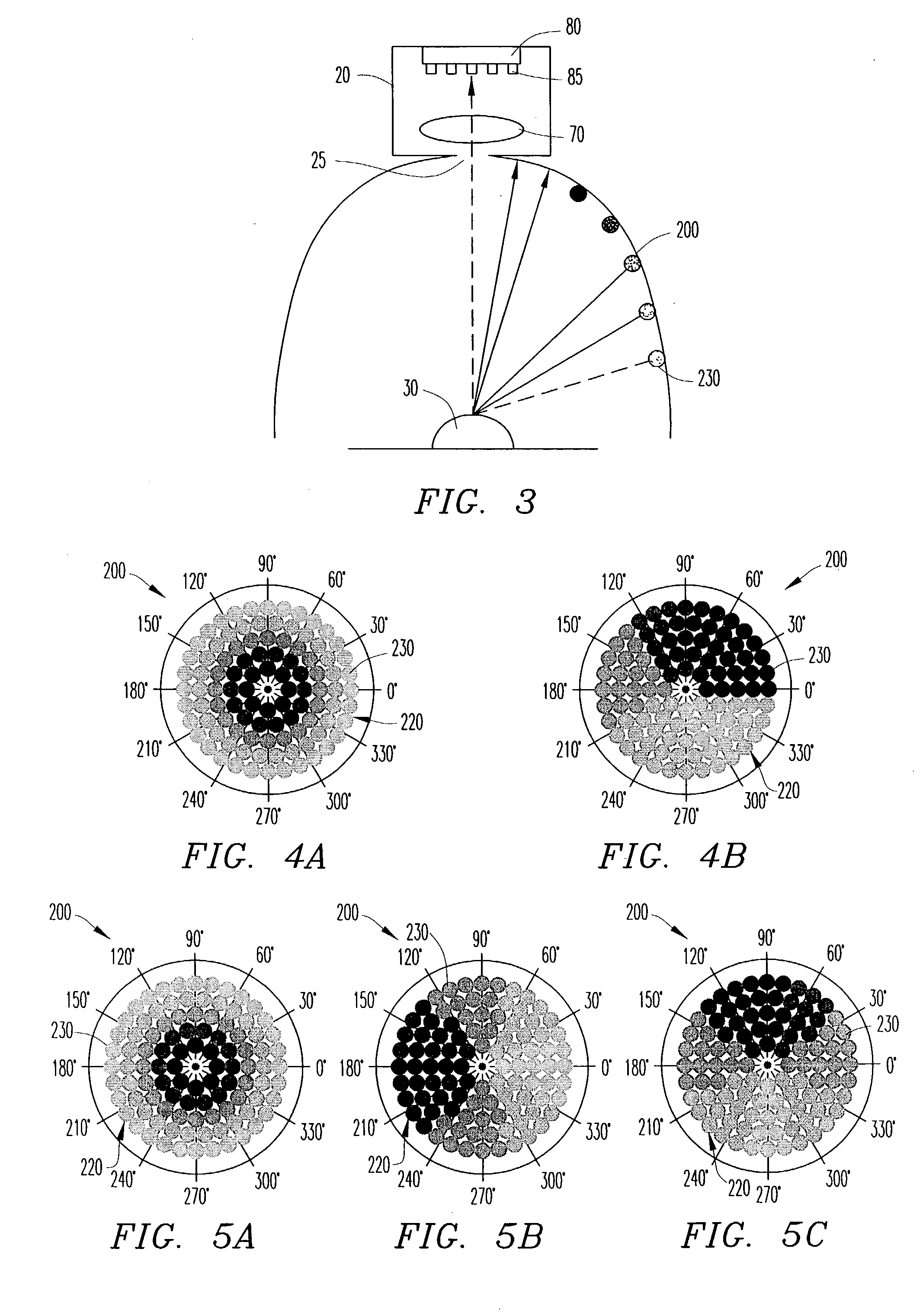

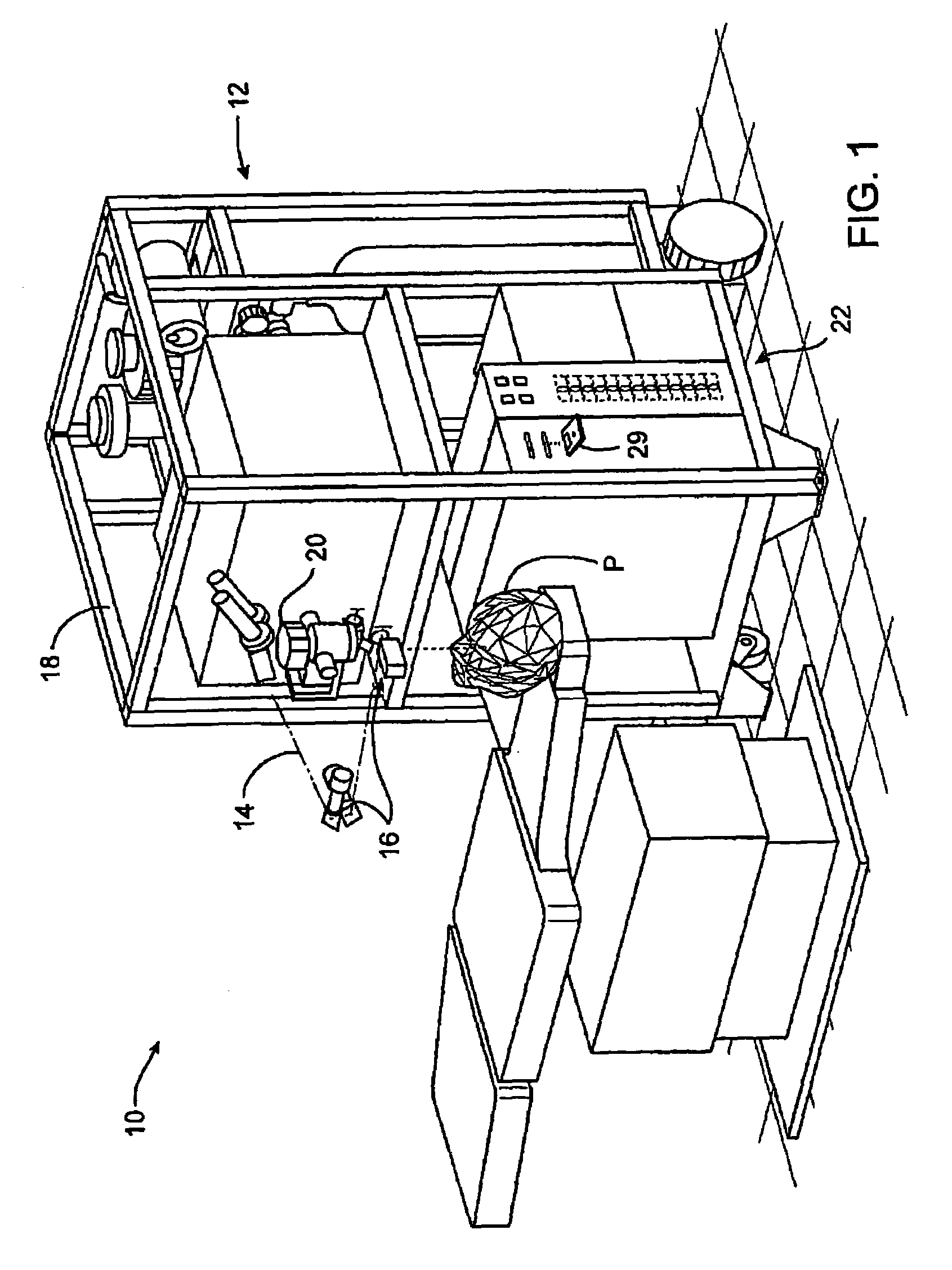

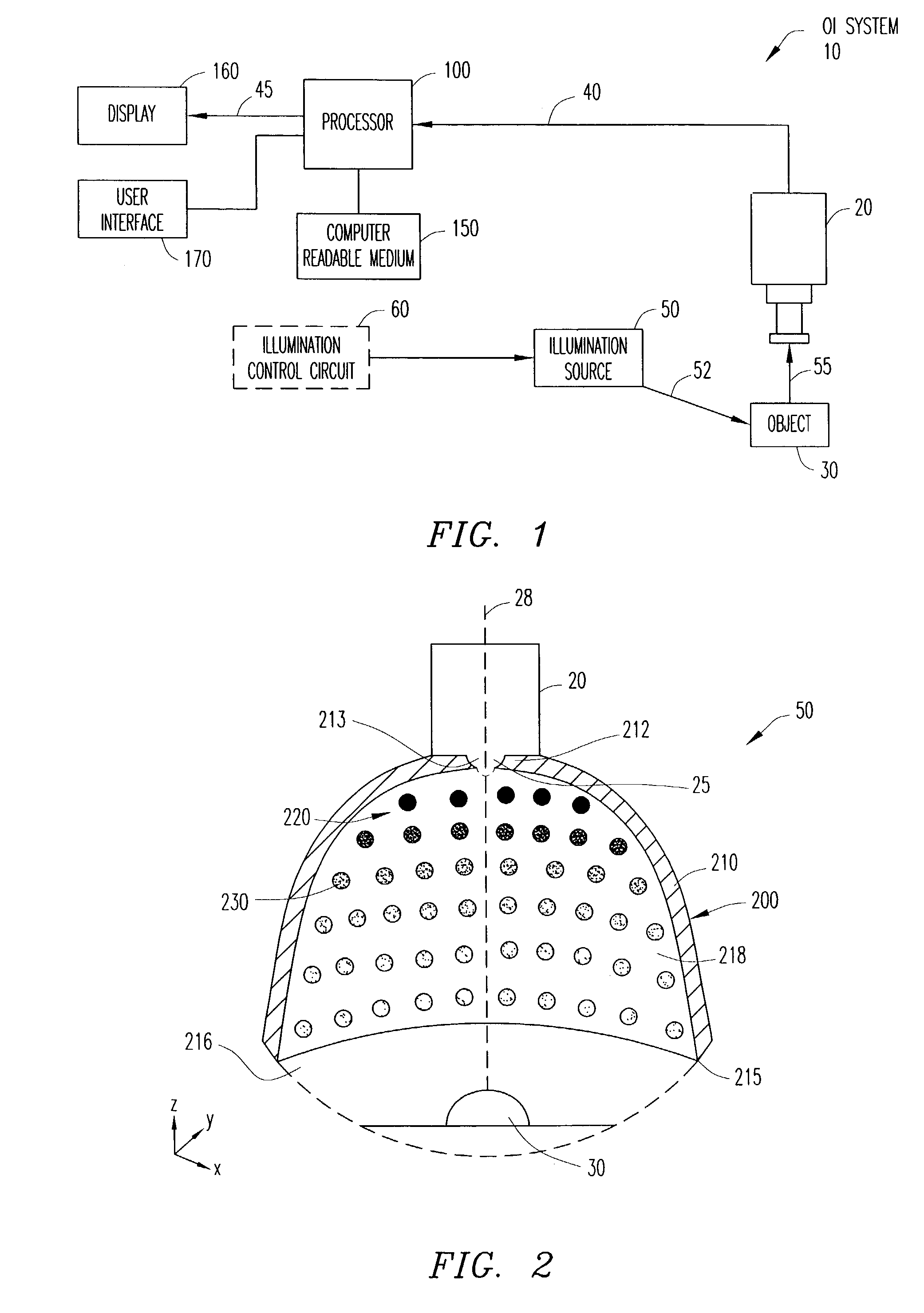

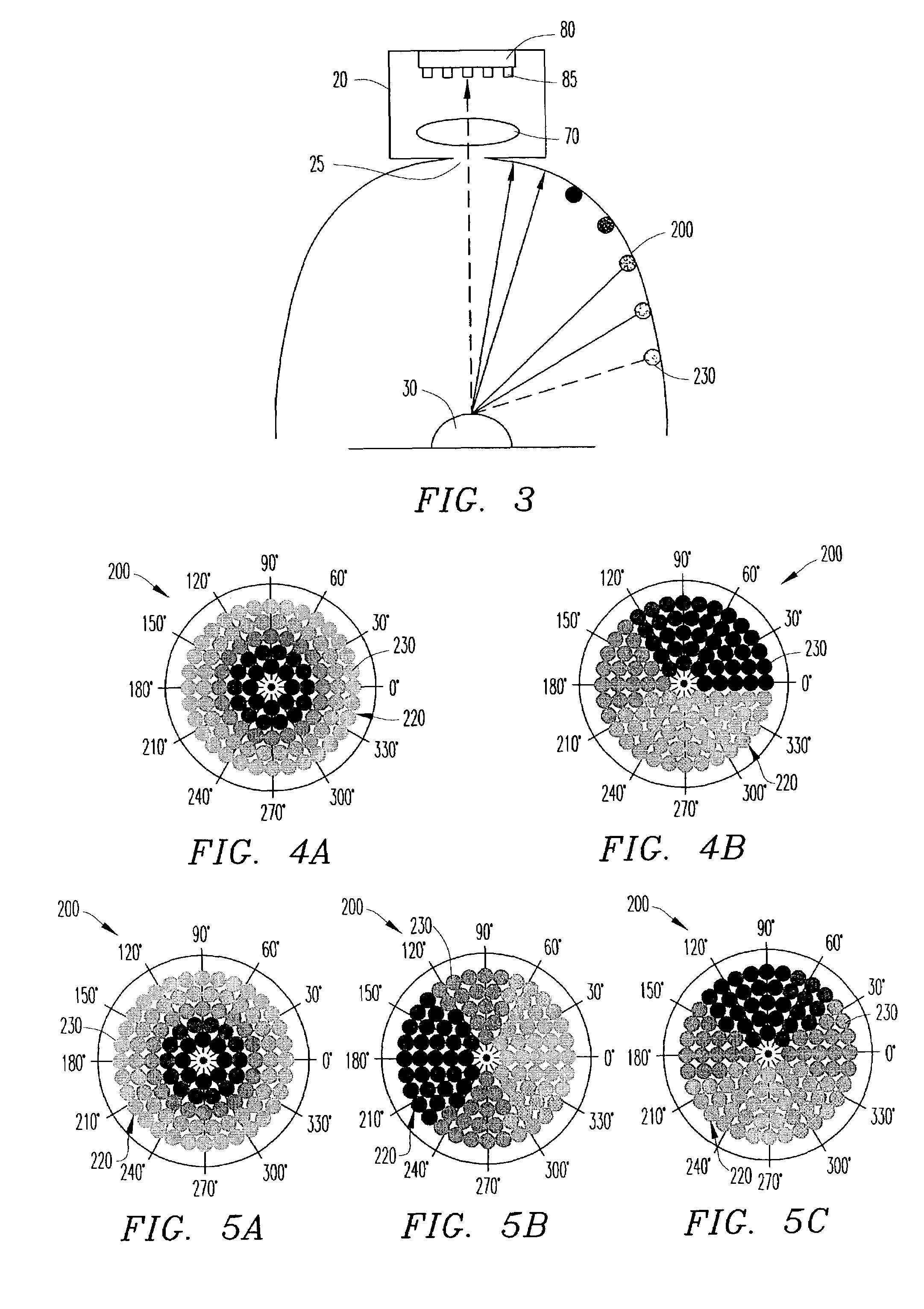

Optical inspection system, illumination apparatus and method for use in imaging specular objects based on illumination gradients

InactiveUS20040184653A1Image analysisCharacter and pattern recognitionLight equipmentSurface gradient

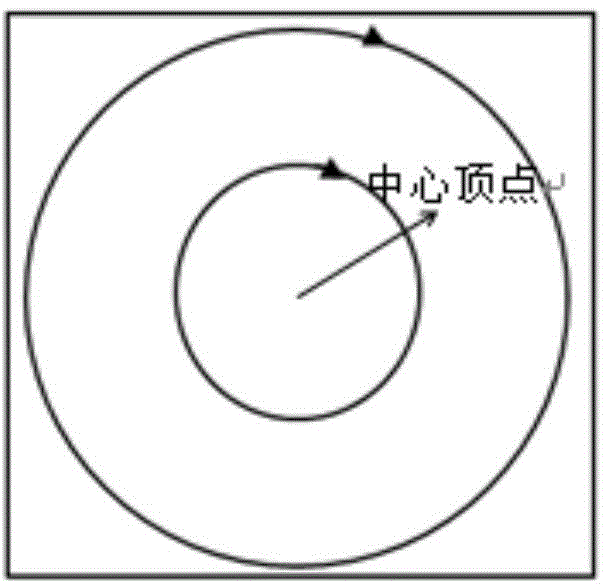

An optical inspection system uses an illumination gradient to gradually spatially vary the intensity and / or specular characteristics of the illumination reflected from the surface of a specular object to determine surface gradients of the object. The surface gradients can be used to reconstruct a three-dimensional image of the object. The illumination gradient can be produced by an illumination apparatus that includes circular arrays of light-emitting elements. The illumination gradient can also be produced using an optical element that gradually alters the illumination intensity of the reflected illumination in accordance with the incidence characteristics of the reflected illumination on the optical element. The illumination gradient enables the use of numerous illumination angles to reduce error in estimated surface gradients without increasing imaging or processing time.

Owner:AGILENT TECH INC

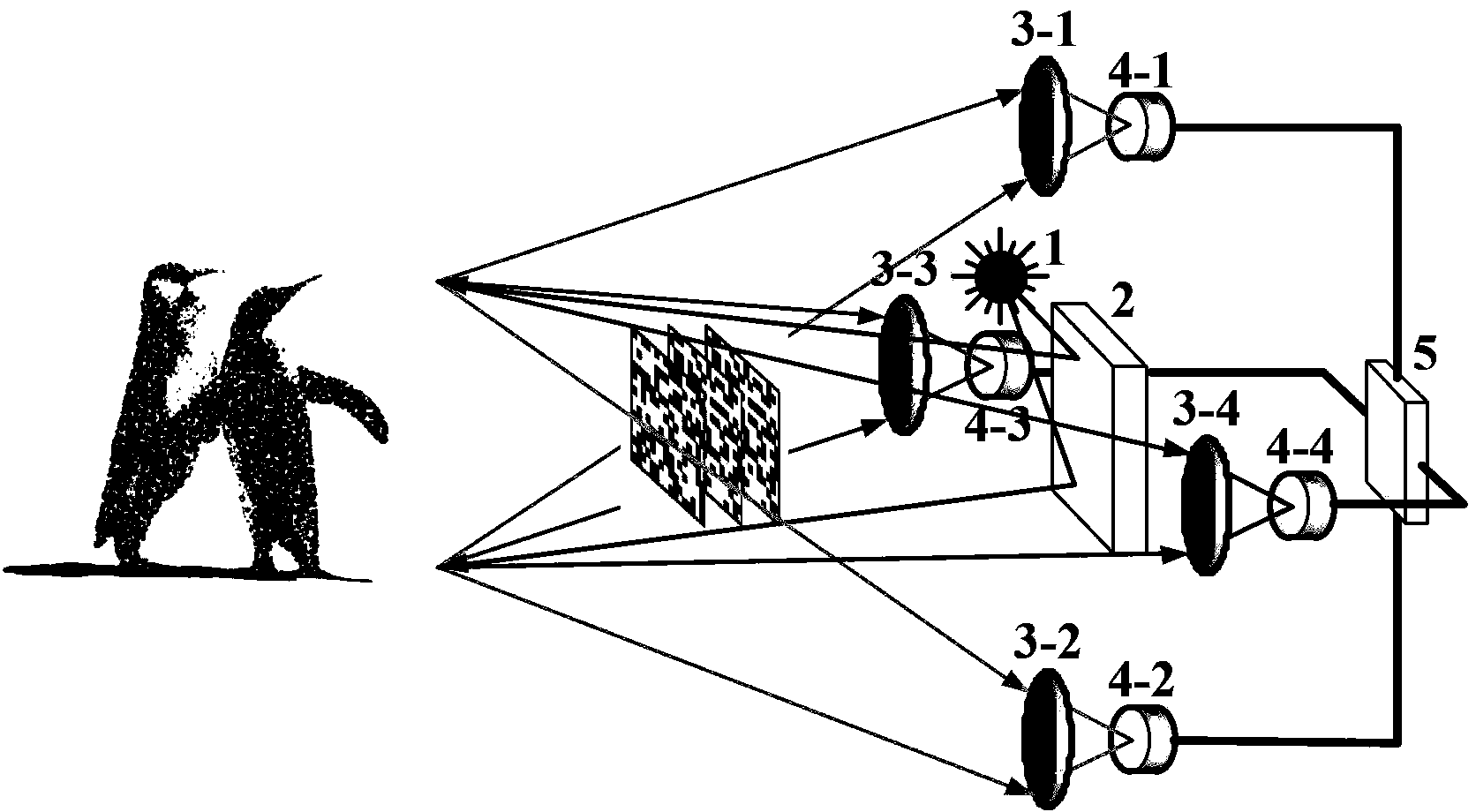

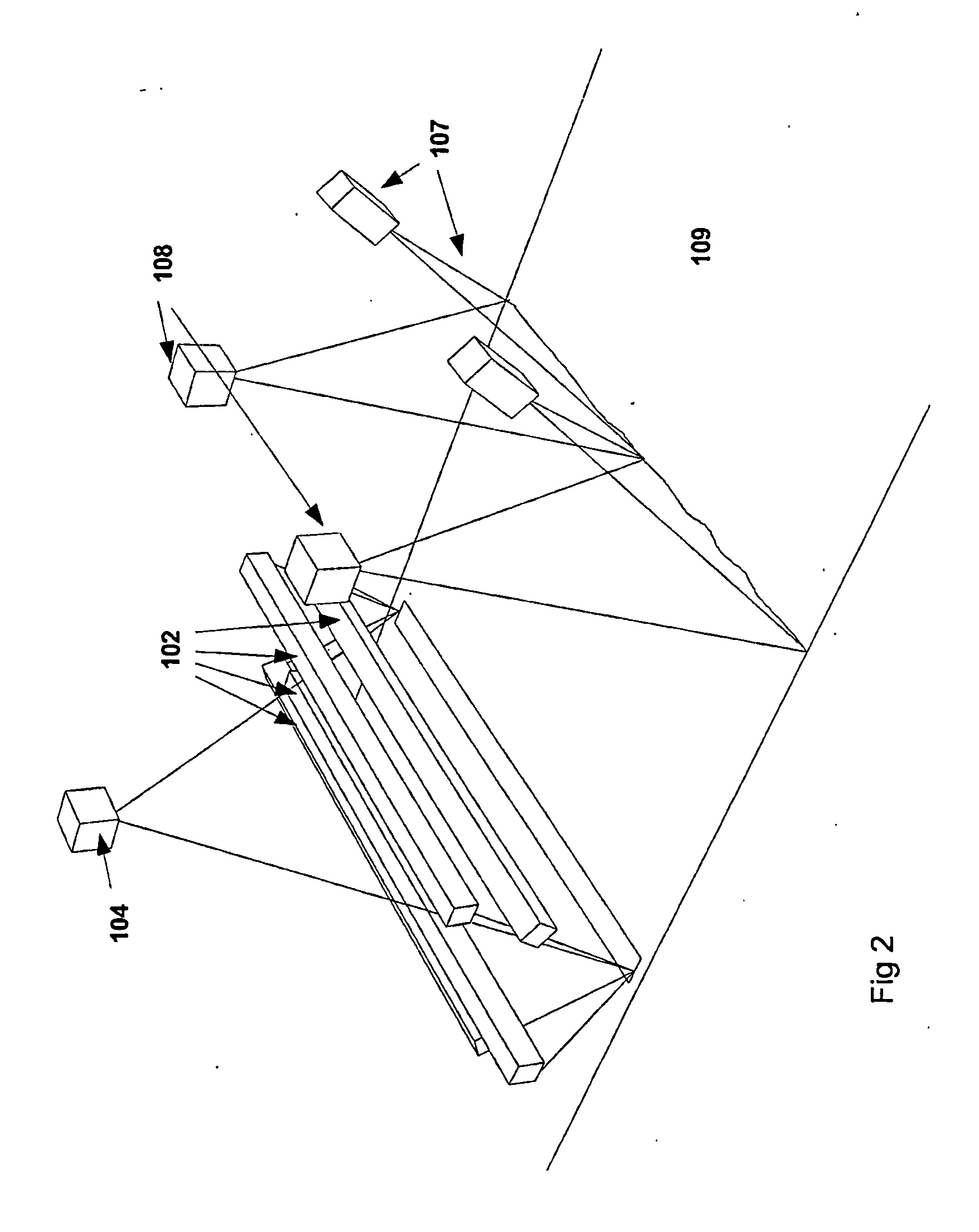

Compressing three-dimension calculation ghost imaging system and method

ActiveCN103363924AReduce redundancyReduce complexityUsing optical meansOptical elementsSpatial light modulatorSurface gradient

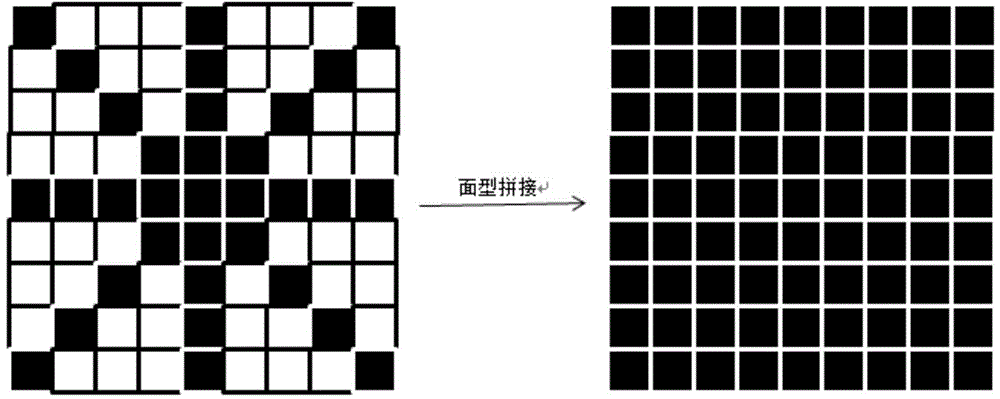

The invention relates to a compressing three-dimension calculation ghost imaging system. The system comprises a light source, a spatial light modulator, at least four sets of convergence light receiving lenses, at least four sets of point detectors corresponding to the convergence light receiving lenses and an algorithm module. Light emitted by the light source is projected on the spatial light modulator, the spatial light modulator modulates the light randomly, the modulated light is projected on an object, the object reflects the light in different directions, and one set of convergence light receiving lens and point detector are arranged in each of at least four reflecting directions. Total light intensity in all the directions are compressed and sampled by the point detectors, a compressing and sampling result is input into the algorithm module, the processes of the compression and sampling of the total light intensity and the input of the result are repeated for many times, the spatial light modulator modulates different patterns every time, the algorithm module inverts a two-dimension image corresponding to the direction of each point detector by the application of the compressed sensing algorithm according to a measurement matrix and the measurement results obtained by the repeated compression and sampling, the information of shadow parts of the images is compared to construct a three-dimension surface gradient, and finally a three-dimension object shape is reconstructed.

Owner:NAT SPACE SCI CENT CAS

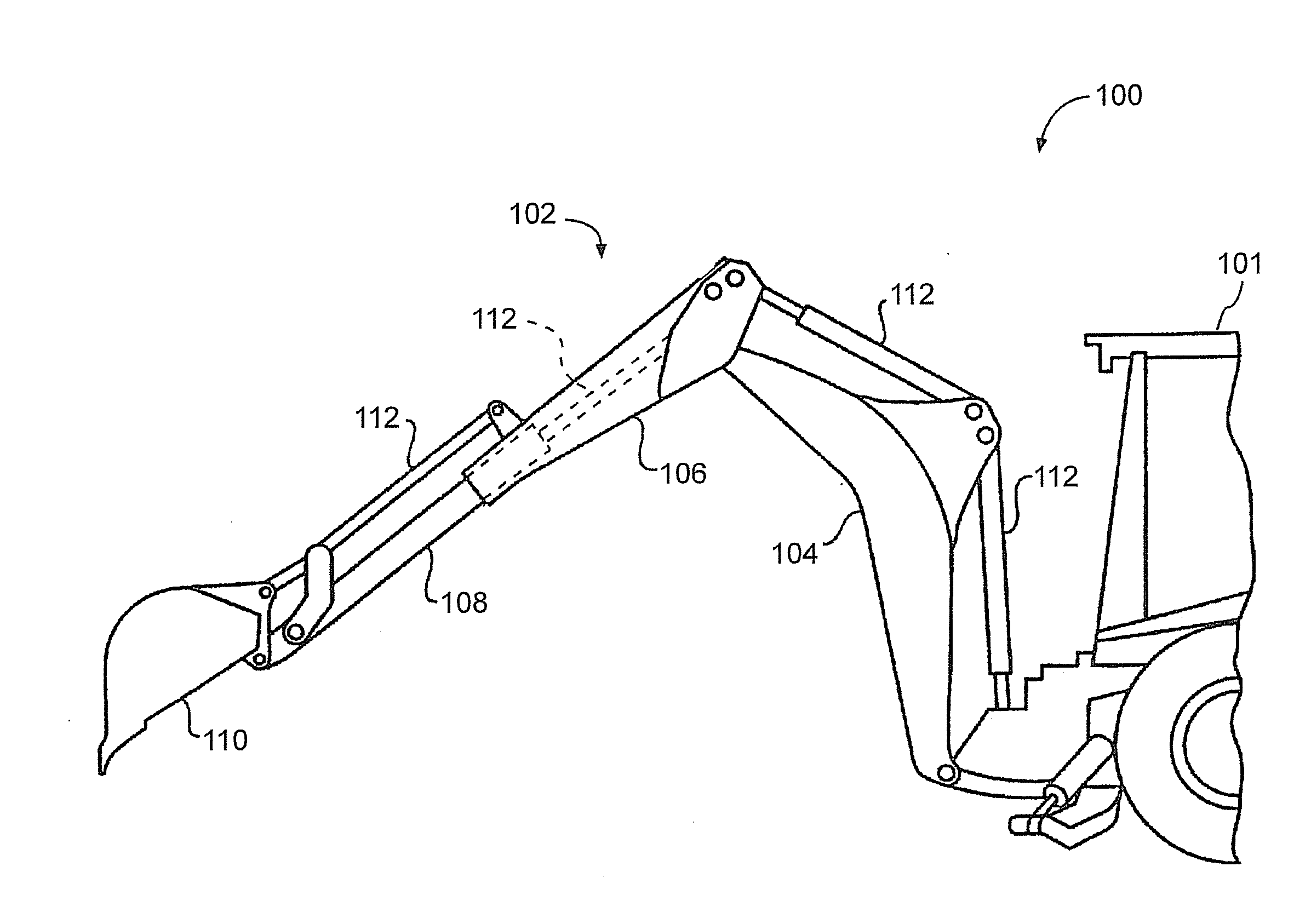

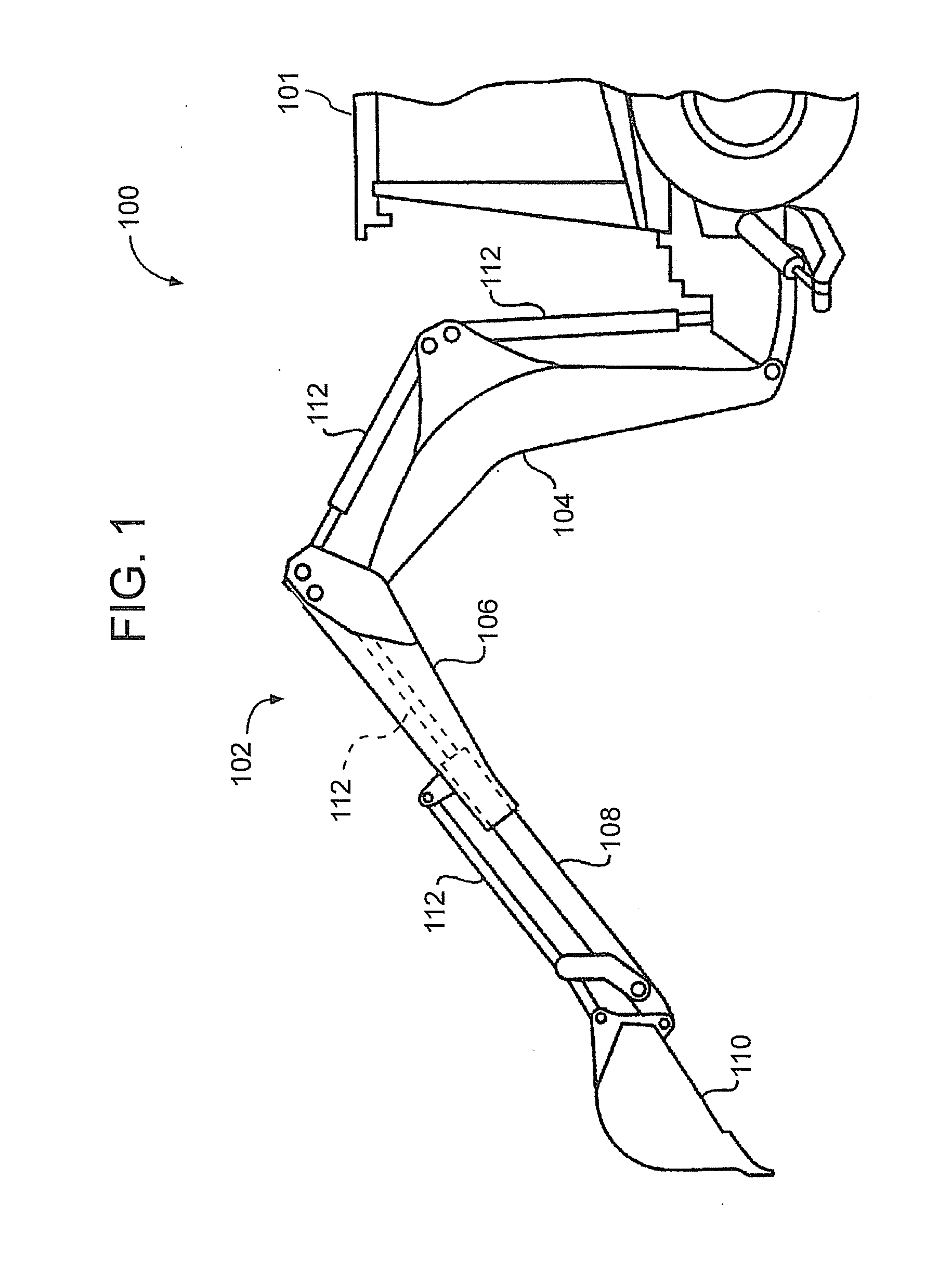

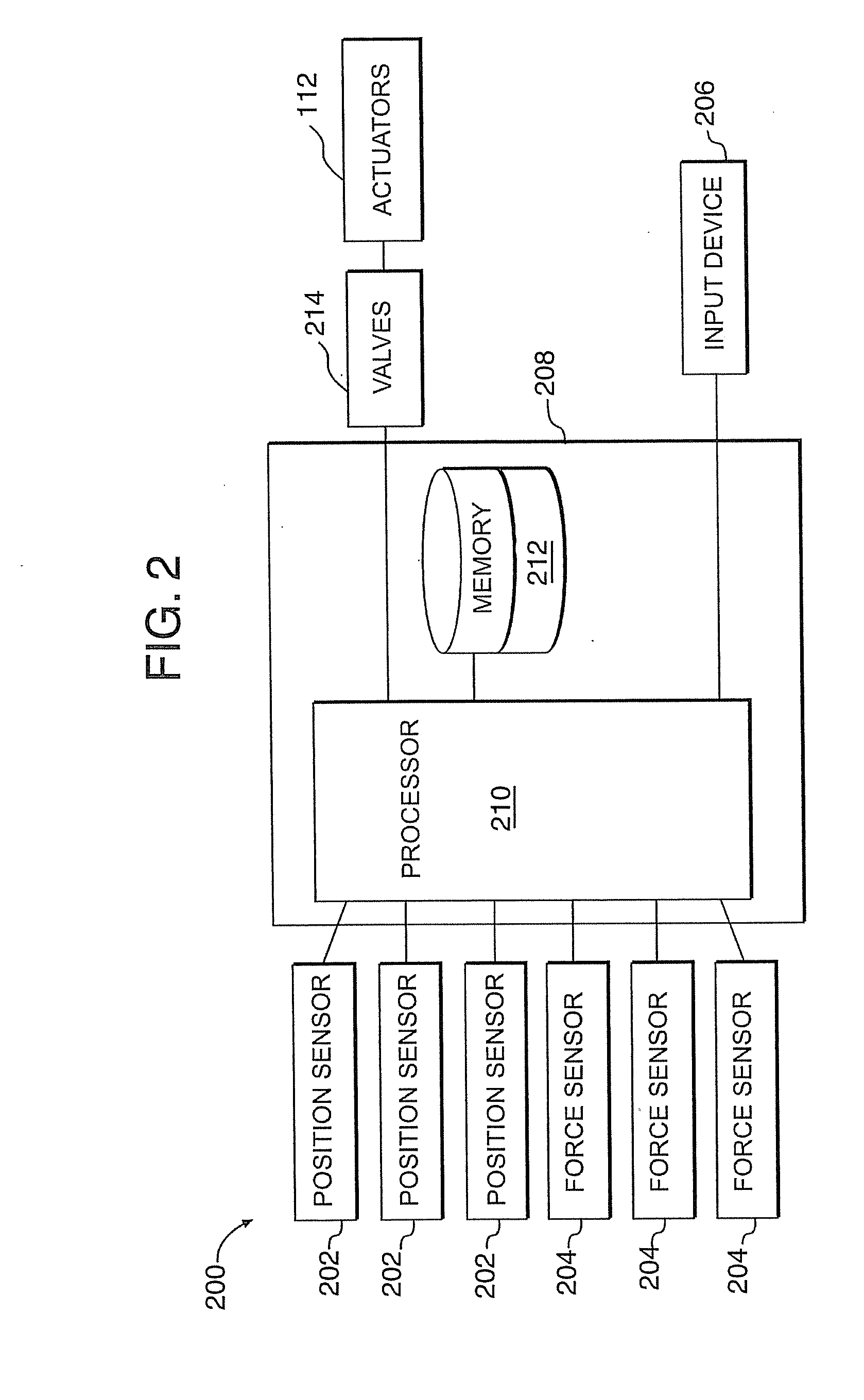

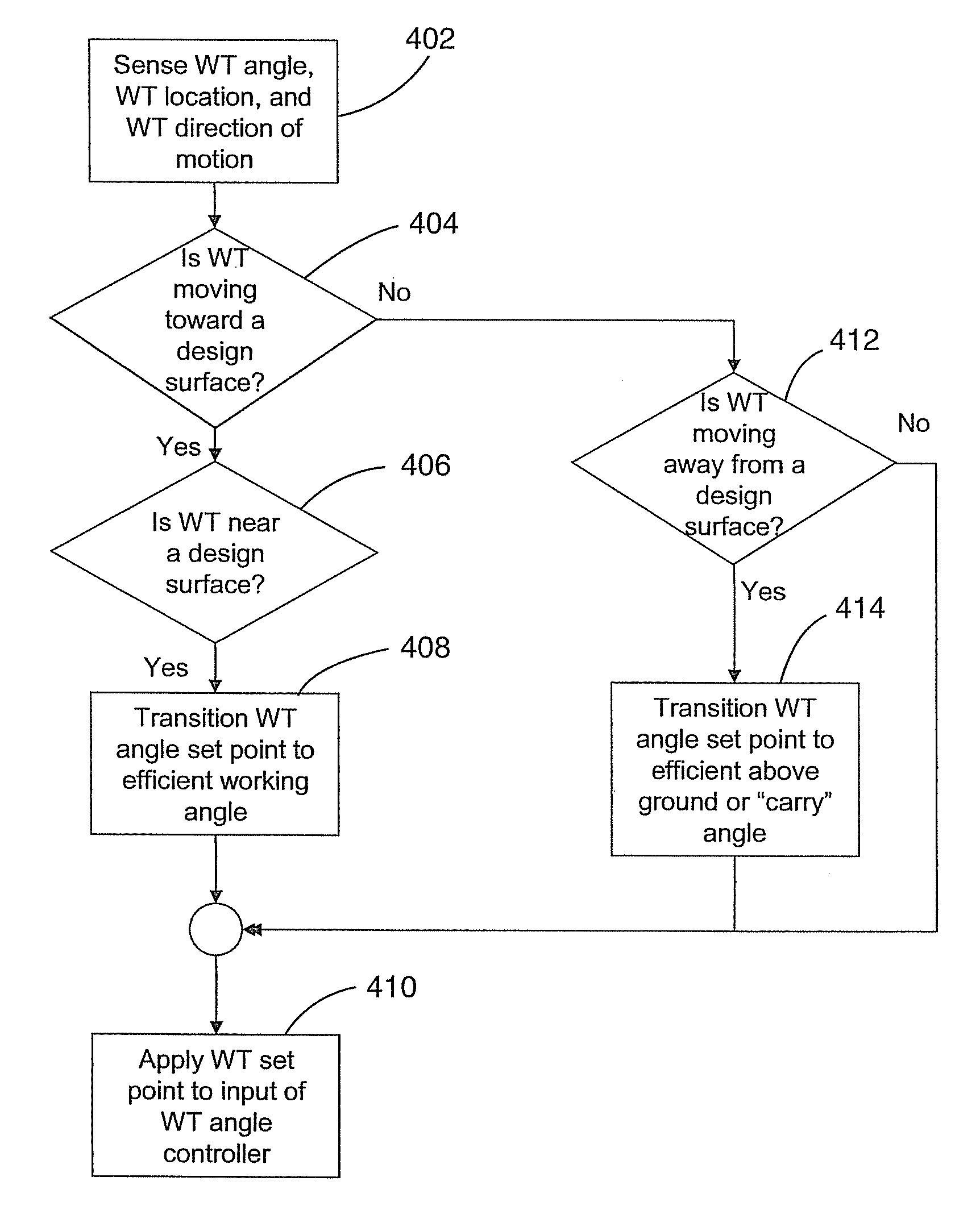

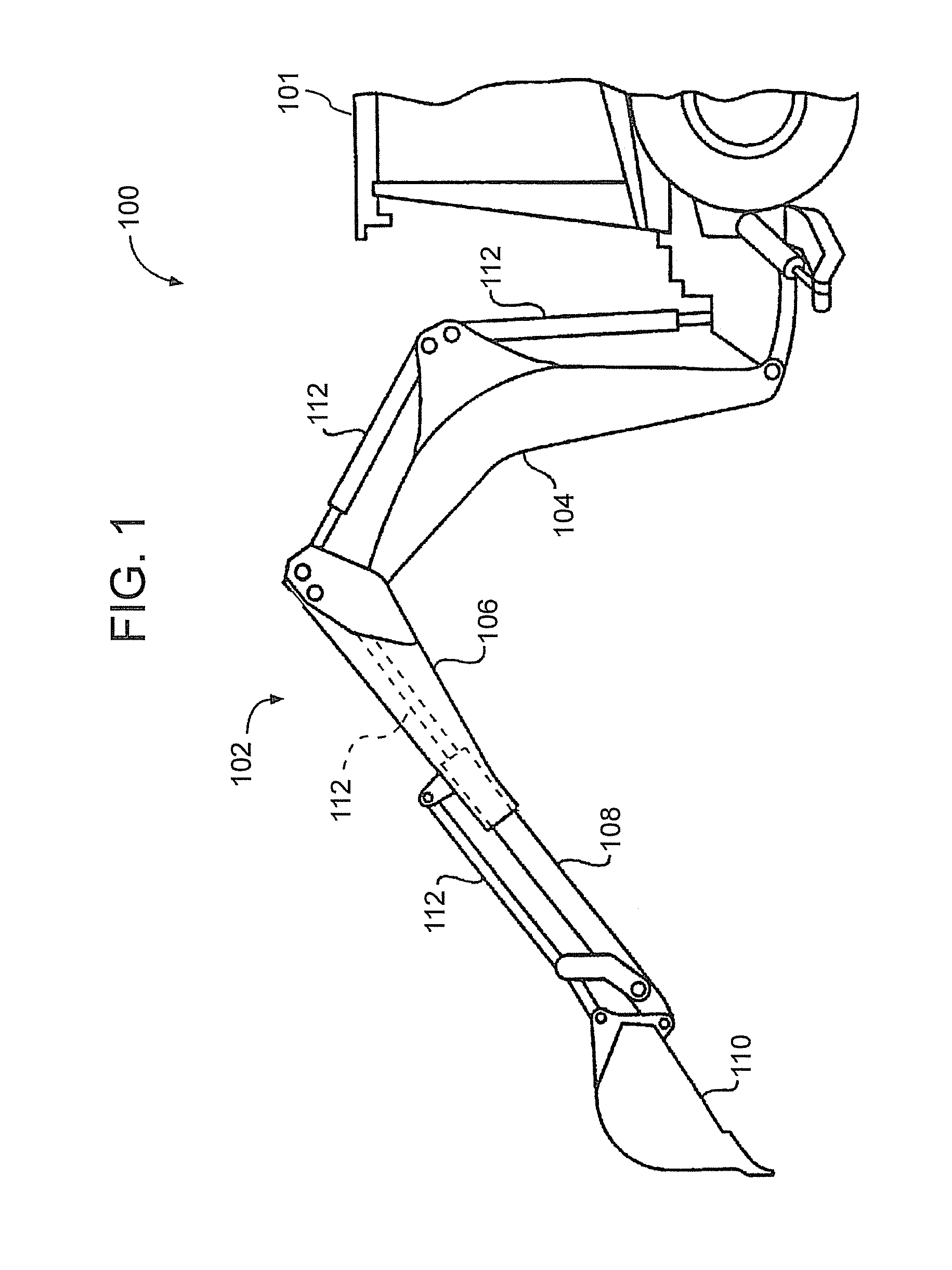

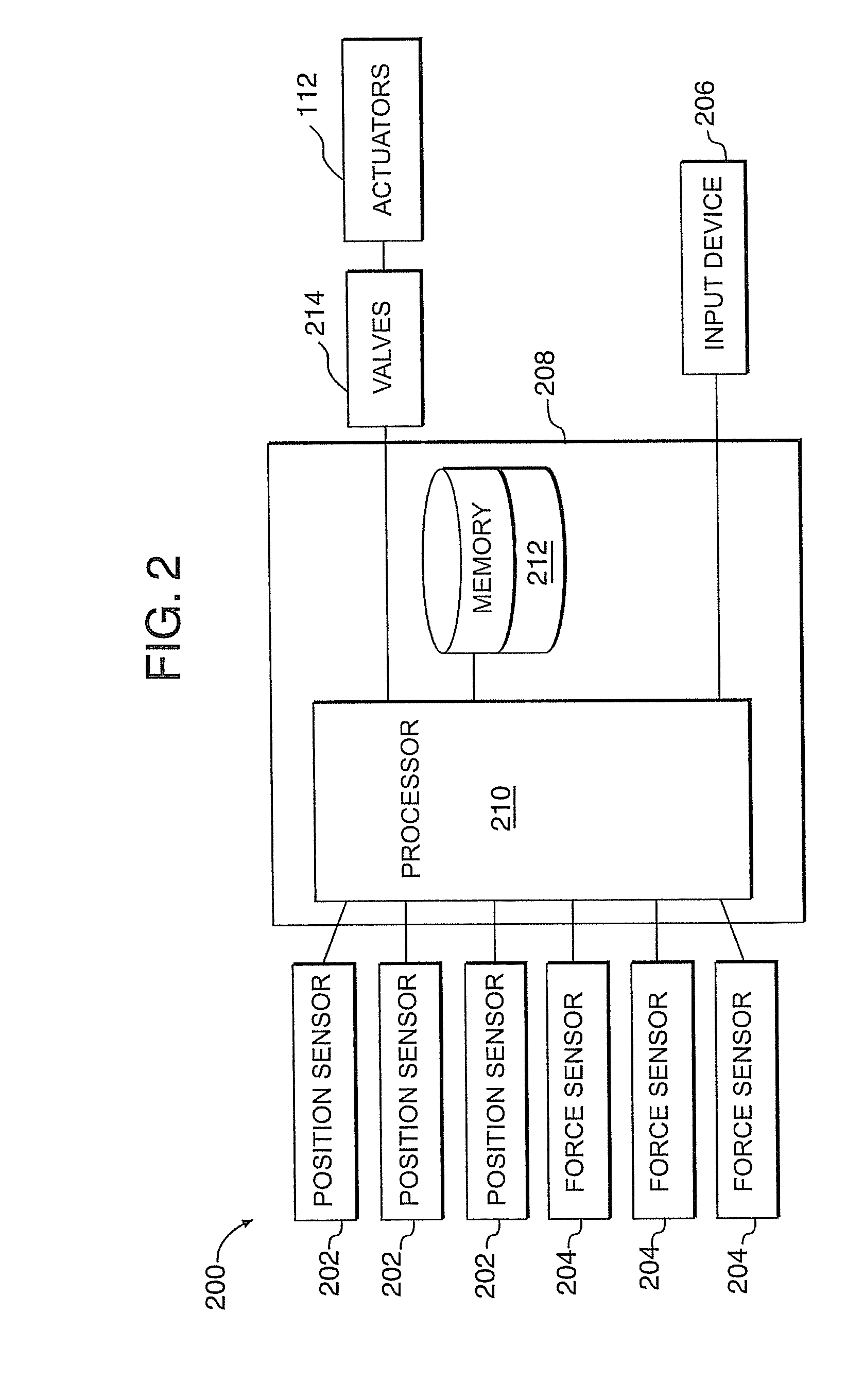

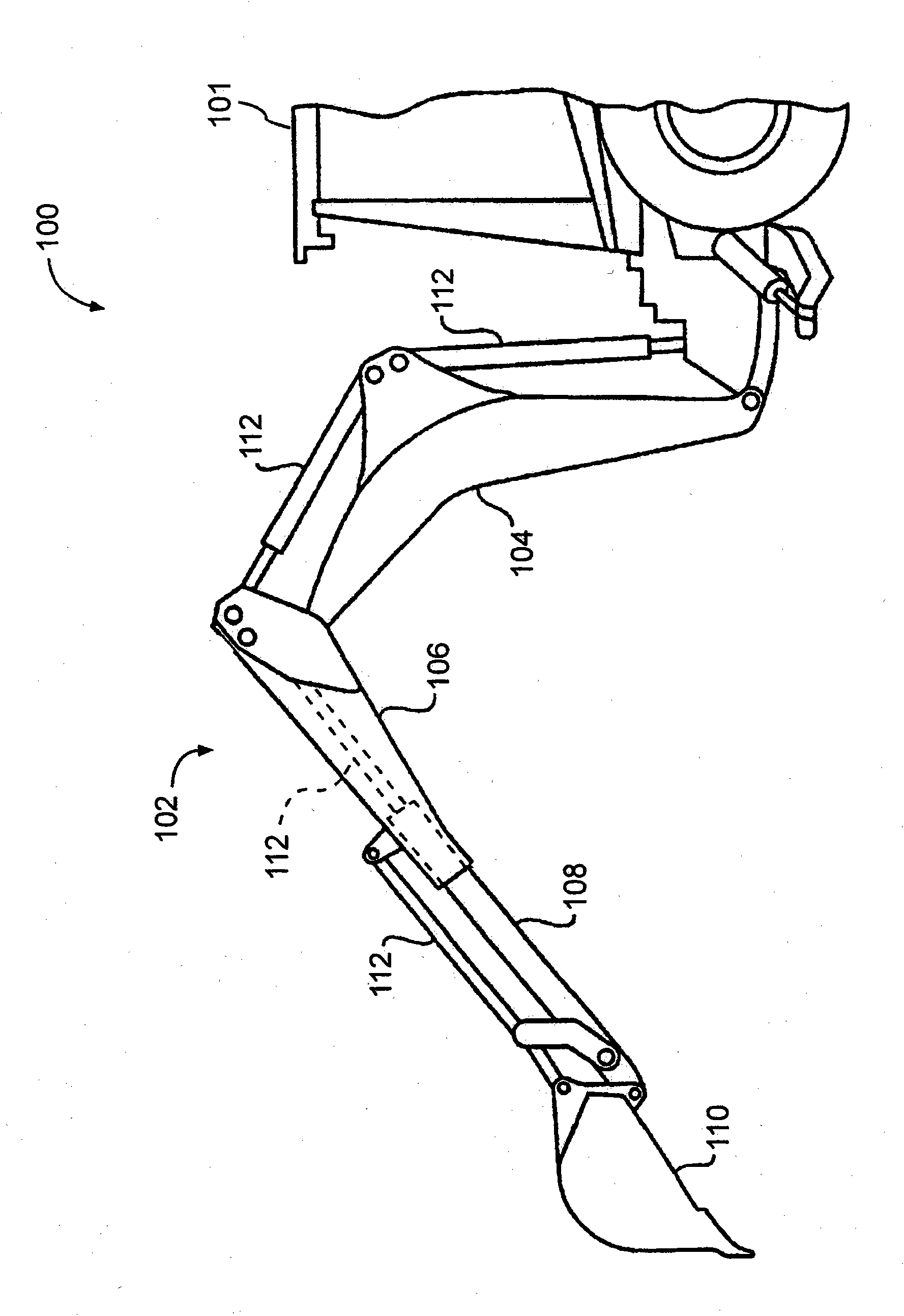

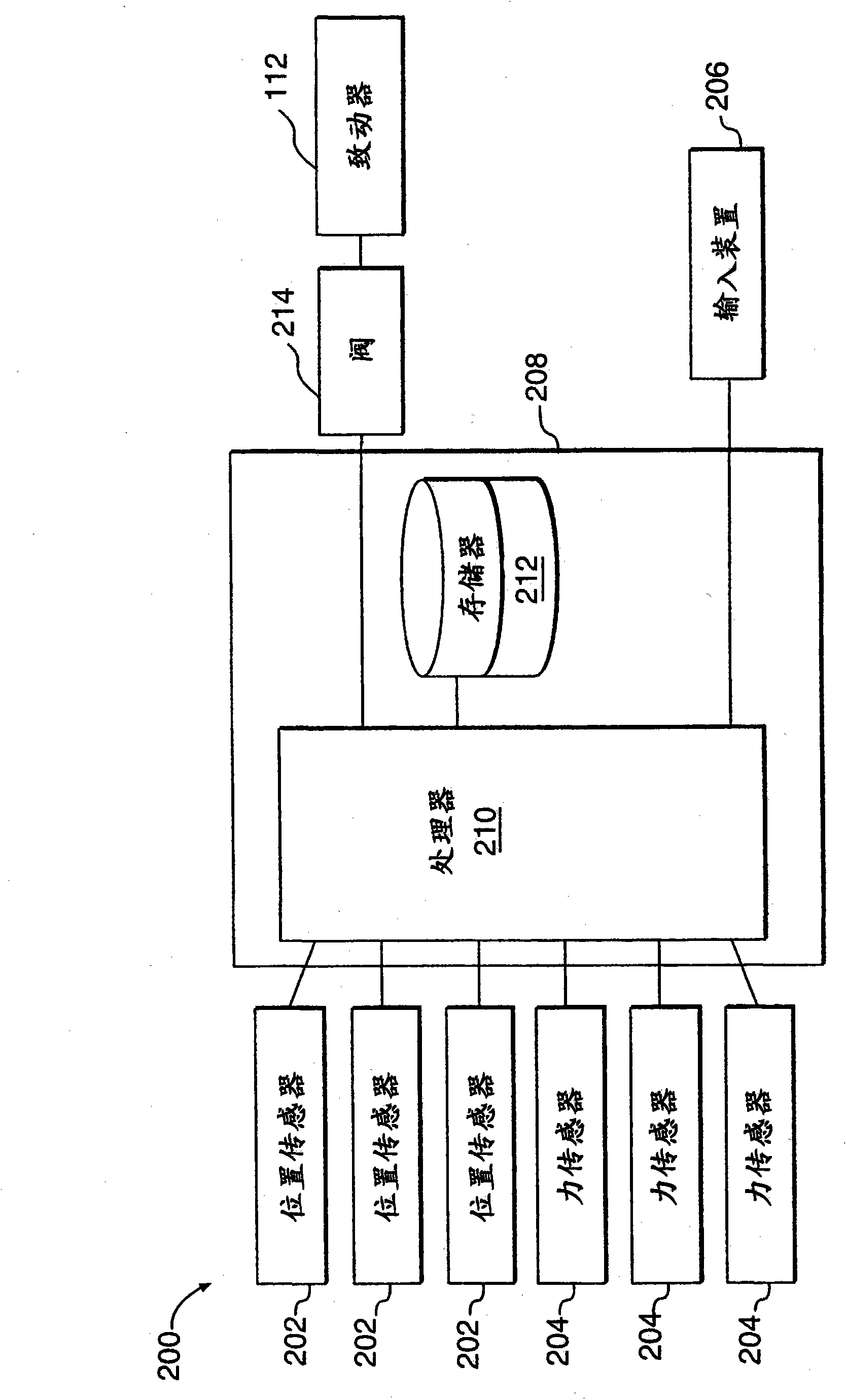

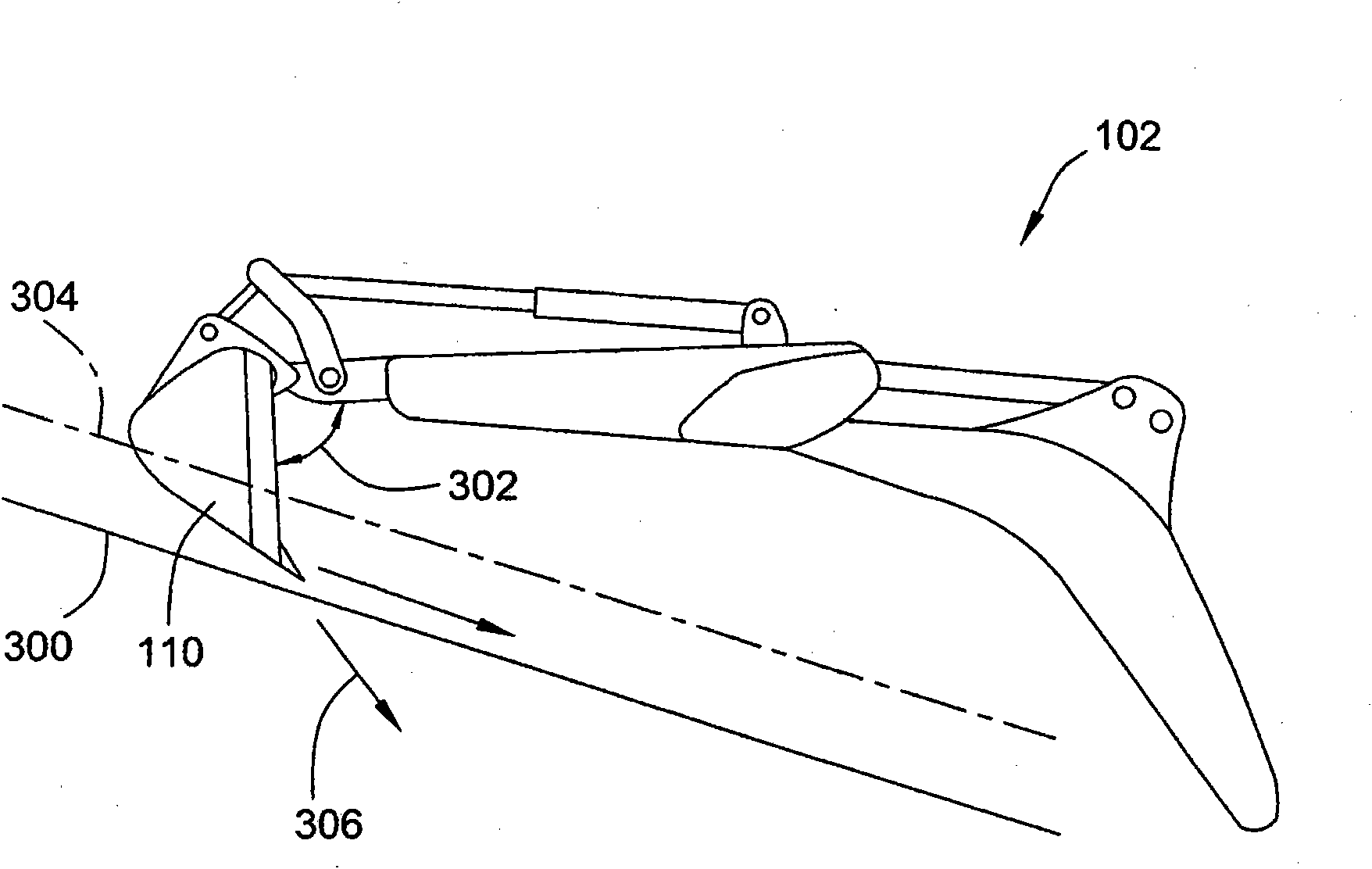

Constant work tool angle control

A method of controlling a work tool with respect to a design surface gradient identifies surface gradient and determines a desired angle for the work tool. Movement of the machine is monitored and the distance between the design surface gradient and the work tool is determined. The angle of the work tool is varied based on one or more of these parameters.

Owner:CATERPILLAR INC

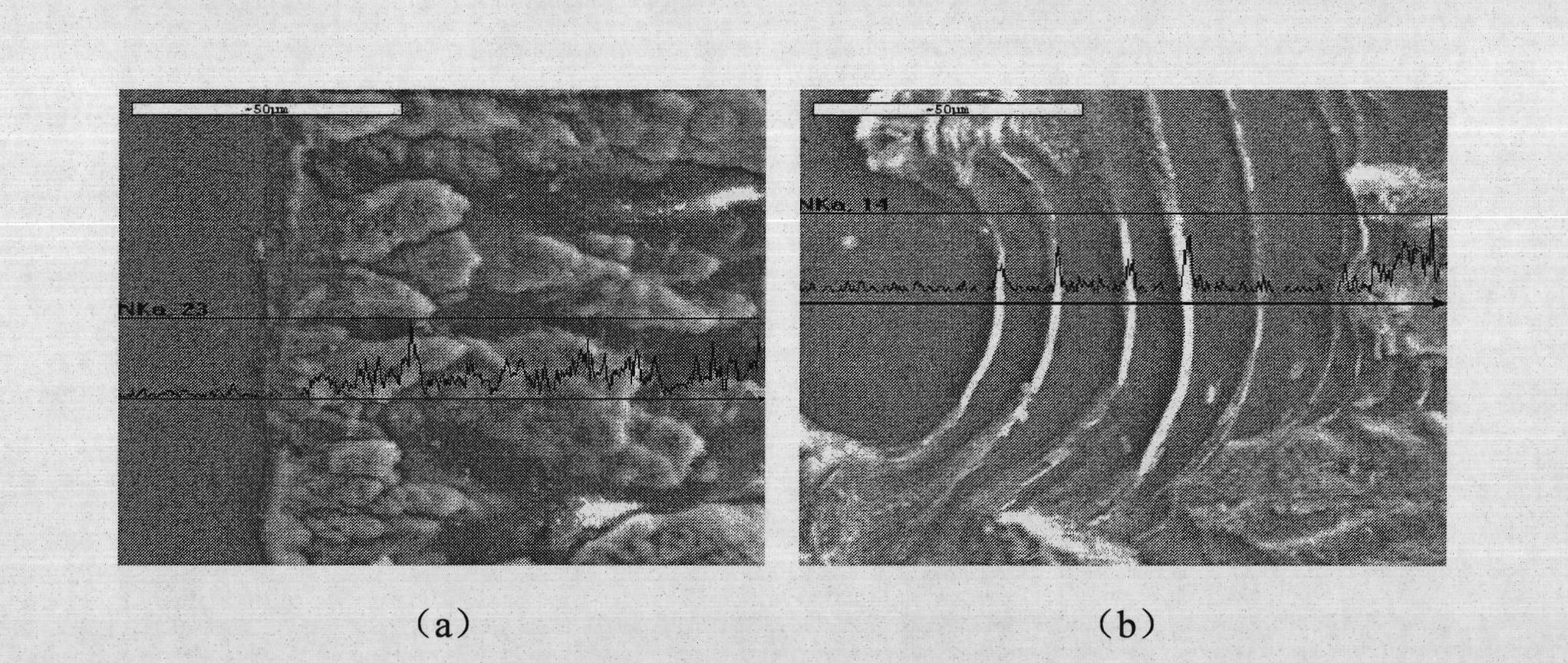

C/C and C/SiC composite material and metal connecting method

ActiveCN101143397AFirmly connectedSoldering apparatusWelding/soldering/cutting articlesParticulatesMetal fibers

The invention is a method of binding compound materials of the C / SiC and C / C, which belongs to the technology field of binding heterogeneous materials. The processing procedures are as following: 1. The surface of the e compound materials of the C / SiC and C / Cis pretreated, which comprise the surface of the connecting are grinding, cleaning, vacuum biscuit firing, preparation of double-layer metal film and microvacum heat treatment and so on. 2. The transition layer of the connecting area surface gradient of the compound materials of the C / SiC is coated and sintered. 3. The compound materials with the gradient transition layer as the felted phase is brazed with the metal in vacuum. The invention is characterized in that the gradient transition layer is directly used as the materials that bind the compound materials with the metal; the gradient transition layer is double-layered or multilayered (sub-layered) structure; from the inner basal body to the outer part of the compound materials, the melting points of active brazing alloy adopted by each sub-layer gradually lower, the coefficient of heat expansion that adjust volume percentage composition gradually lower and the coefficient of heat expansion of the sub-layers gradually rise. The brazing ceramic metal connecting piece of the invention has good strength, air tightness and wide application field, which is suitable for various non-metallic fibers, such as ceramics of SiC, Si3N4, Al2O3, AlN and so on and applicable for connecting the ceramic matrix compound materials with particulate reinforced with the metal.

Owner:GRIMAT ENG INST CO LTD

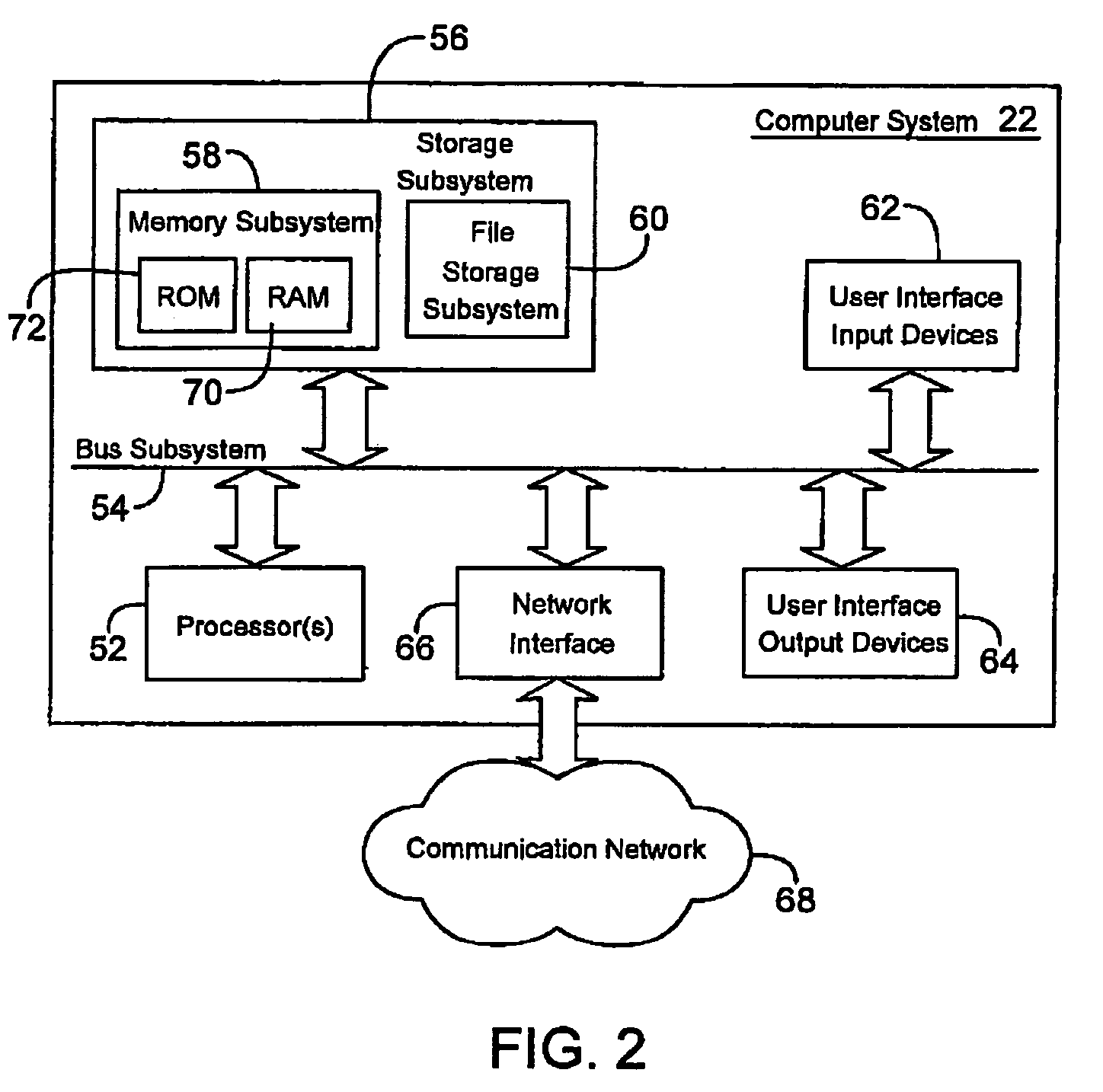

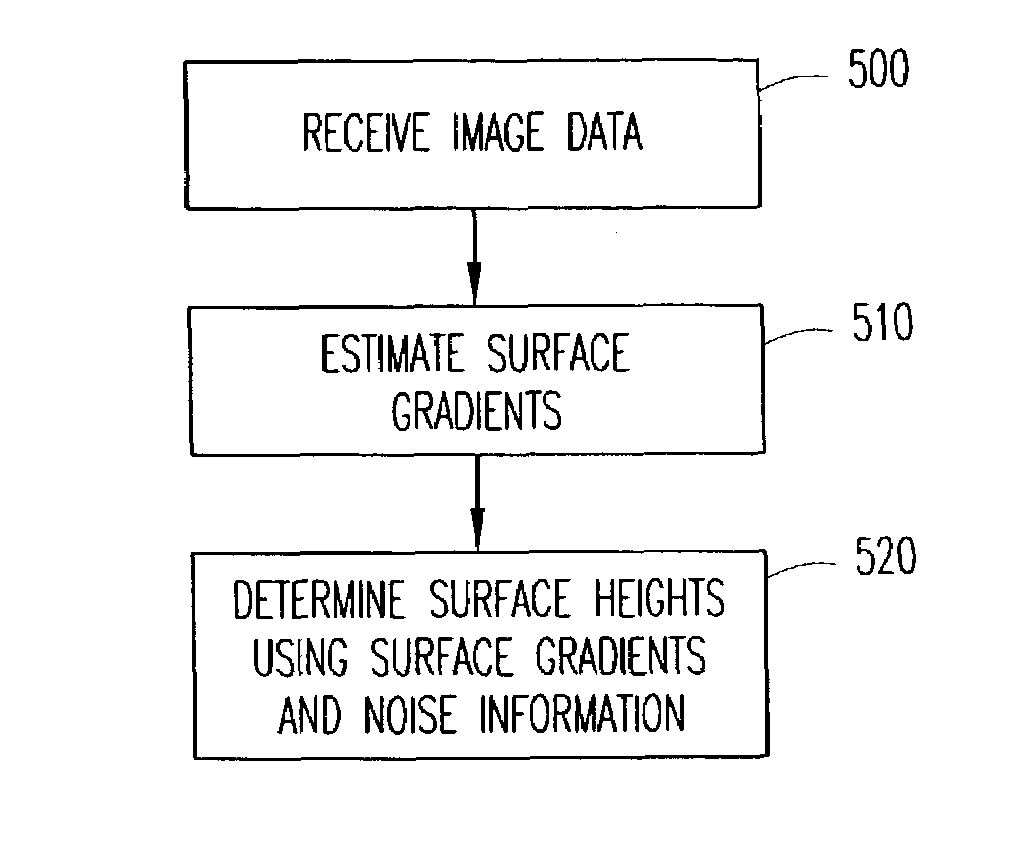

System and method for shape reconstruction from optical images

Reconstructing the shape of the surface of an object in greater than two dimensions is performed using a noise-tolerant reconstruction process and / or a multi-resolution reconstruction process. The noise-tolerant reconstruction process can be a Bayesian reconstruction process that adds noise information representing the noise distribution in optical image(s) of the object to surface gradient information estimated from the images to determine surface height information that defines the shape of the surface of the object in greater than two dimensions. In the multi-resolution reconstruction process, for each resolution of the image, the surface gradient information is estimated and the surface height information is calculated using the estimated surface gradient information. To obtain the final surface height map, the surface height information from each resolution is combined to reconstruct the shape of the surface of the object in greater than two dimensions. The multi-resolution reconstruction process can be used with the Bayesian reconstruction process or with another decomposition process, such as a wavelet decomposition process.

Owner:APTINA IMAGING CORP

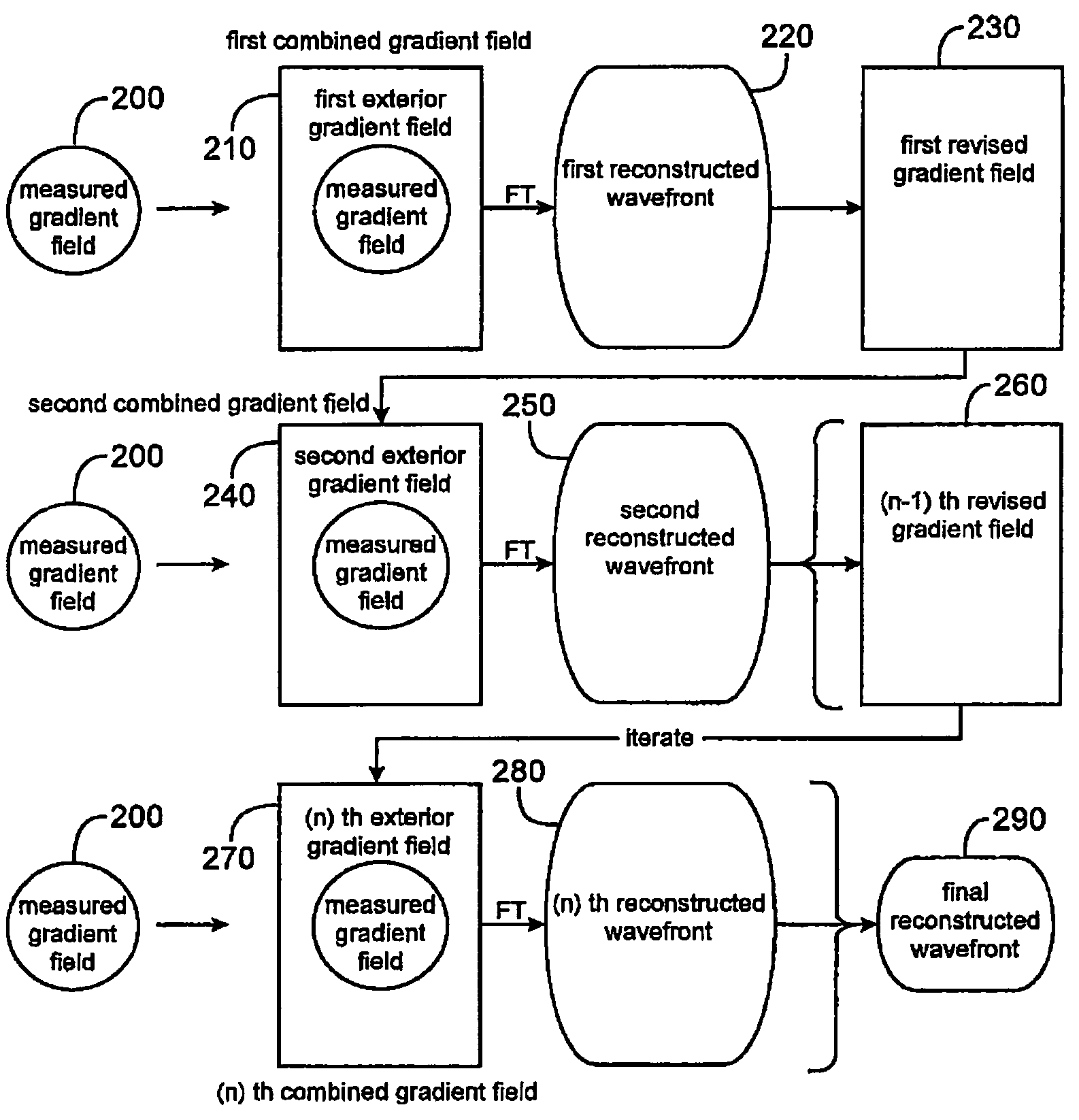

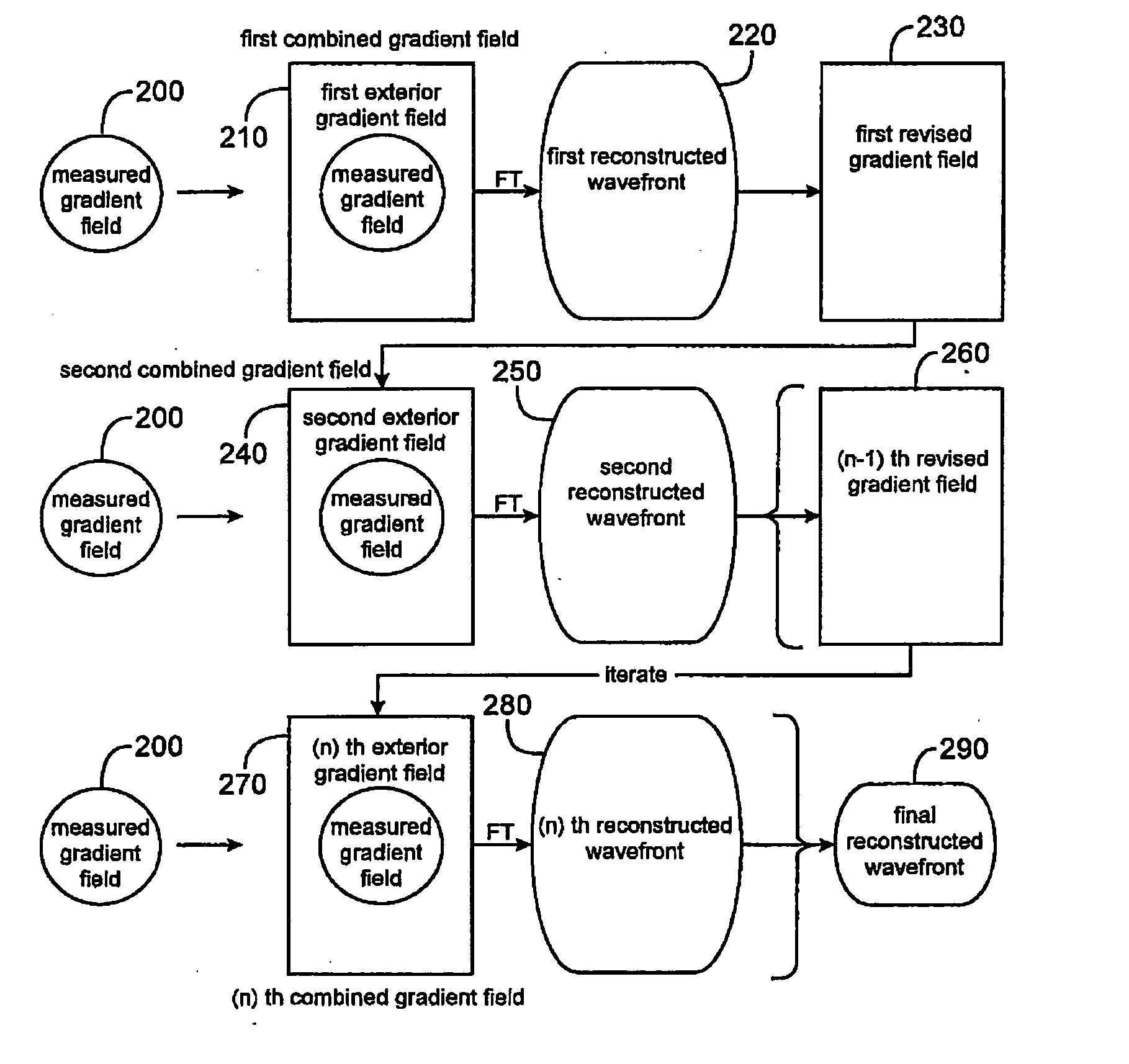

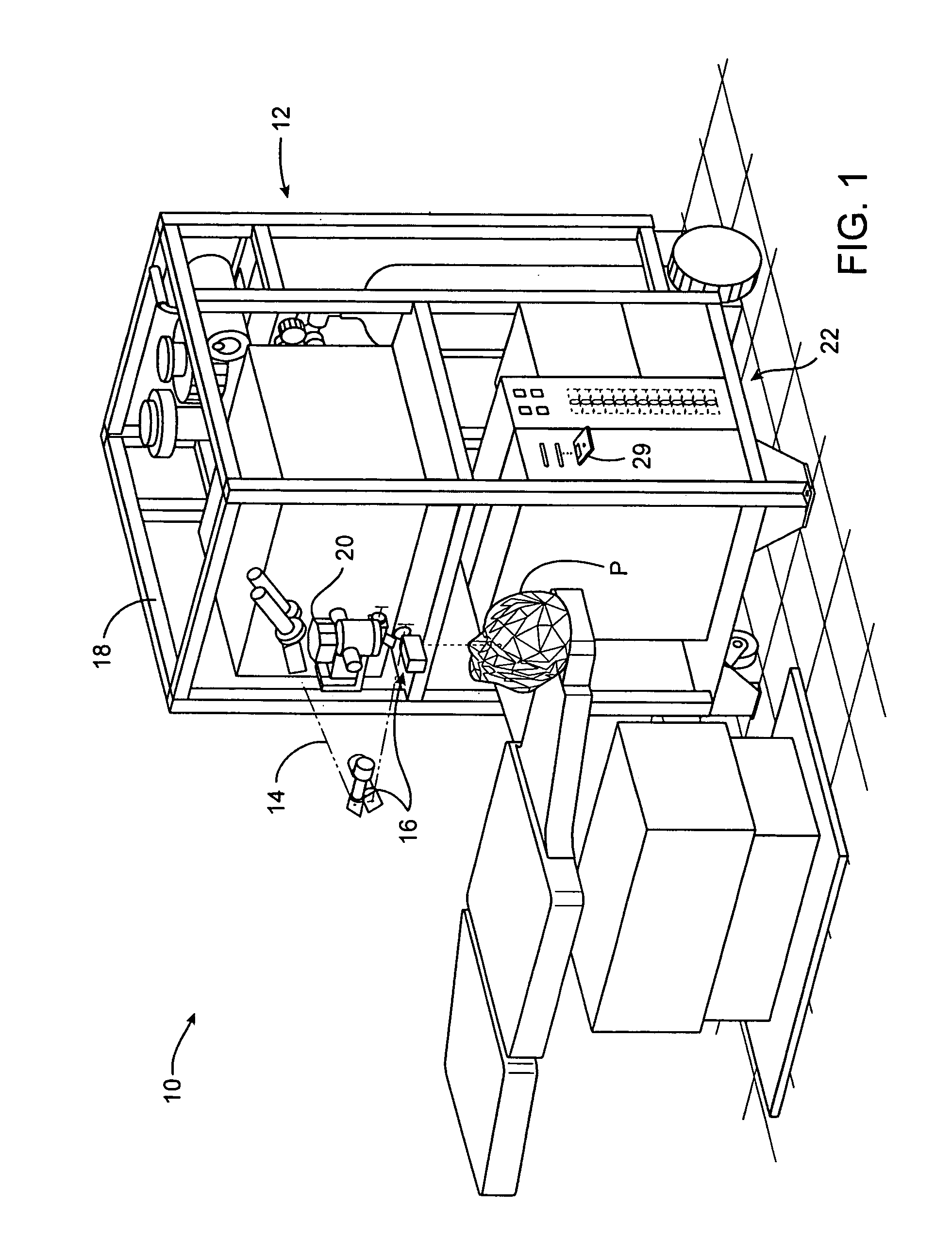

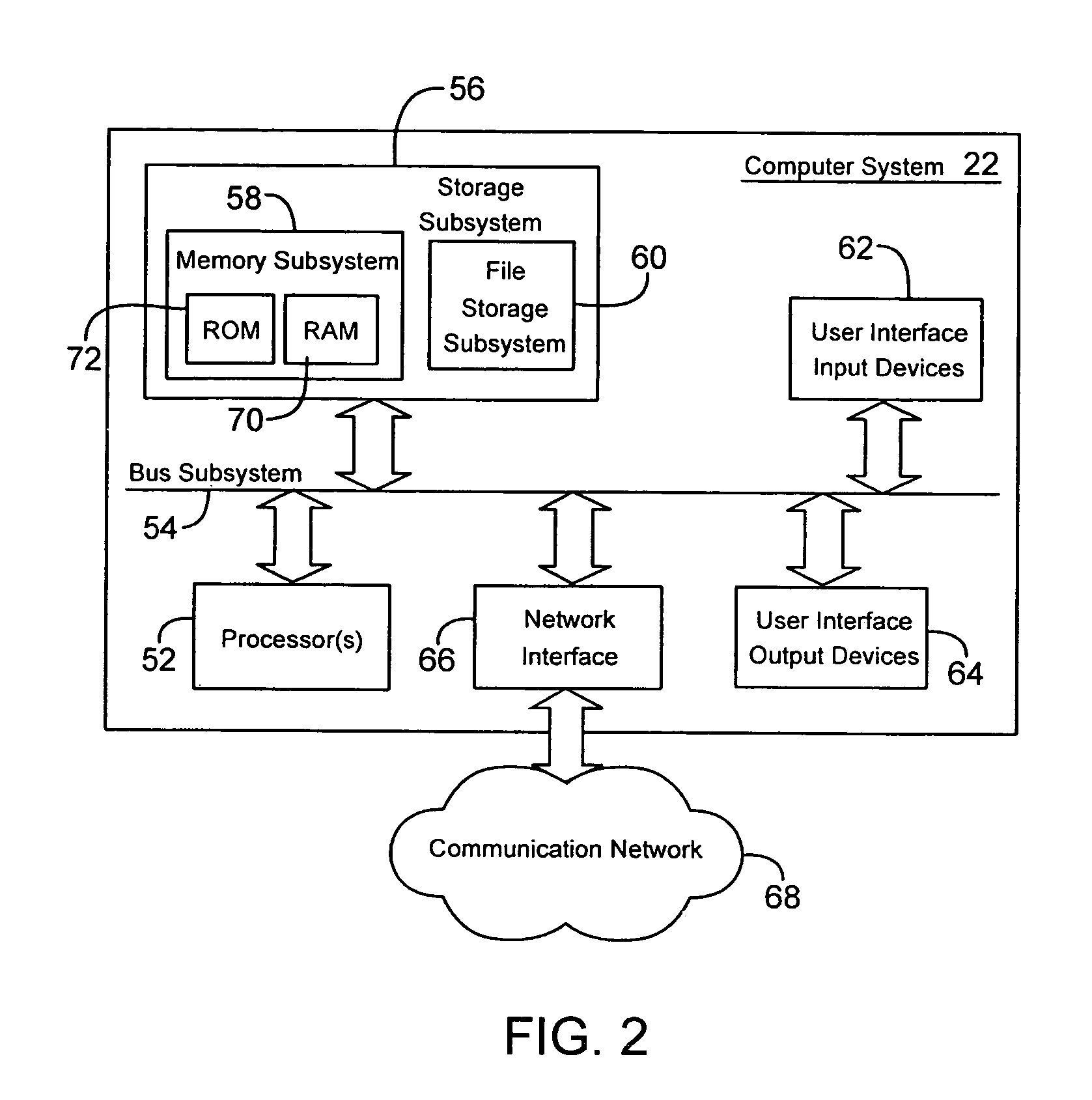

Iterative fourier reconstruction for laser surgery and other optical applications

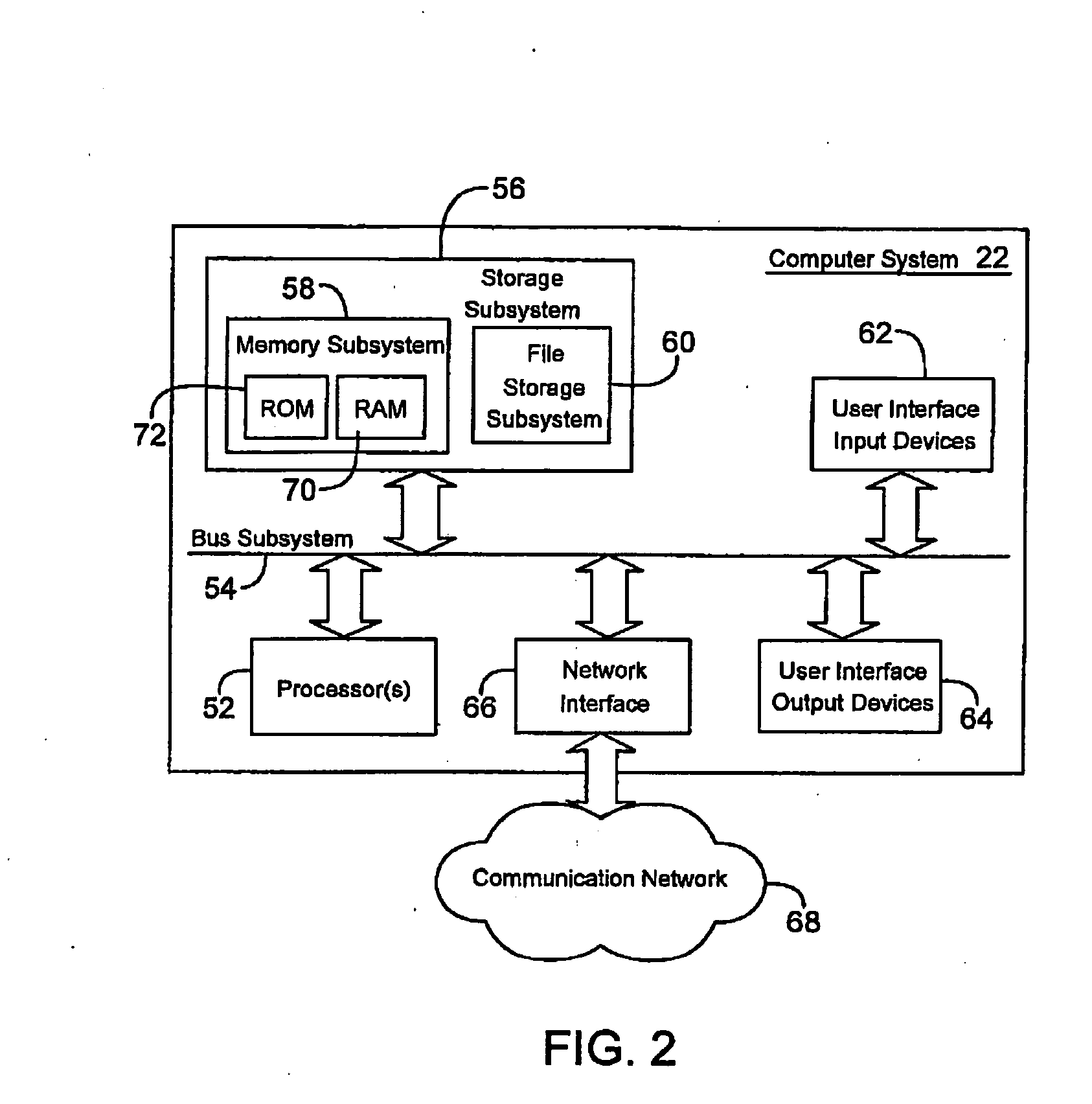

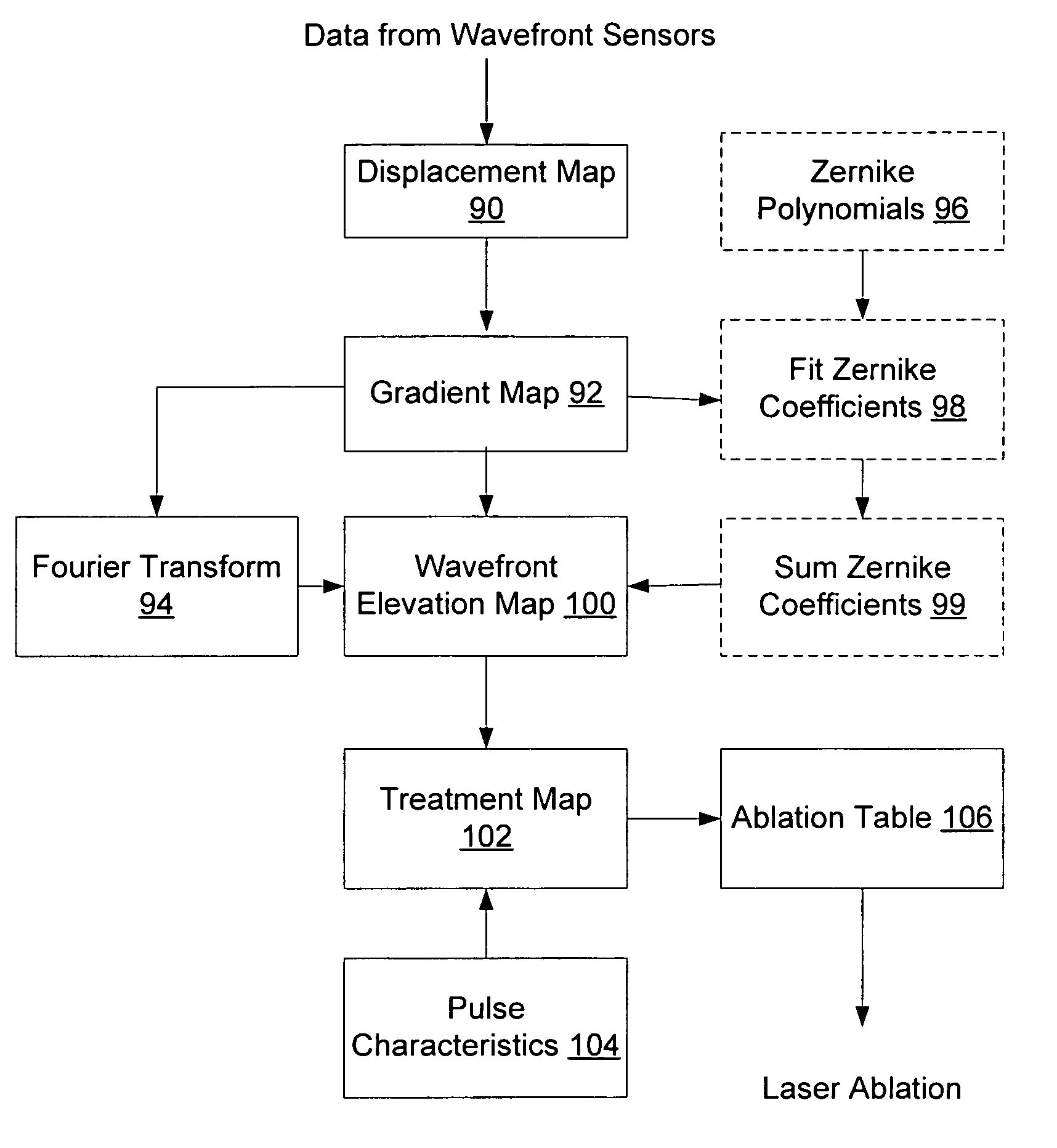

Methods, systems and software for determine an optical surface model for an optical tissue system using Fourier transformation algorithms. A method of reconstructing optical tissues of an eye comprises transmitting an image through the optical tissues of the eye. The surface gradients from the transmitted image are measured across the optical tissues of the eye. A Fourier transform algorithm is applied to the surface gradients to reconstruct an optical surface model that corresponds to the optical tissues of the eye.

Owner:AMO MFG USA INC

System and method for shape reconstruction from optical images

Owner:APTINA IMAGING CORP

Iterative fourier reconstruction for laser surgery and other optical applications

Methods, systems and software for determine an optical surface model for an optical tissue system using Fourier transformation algorithms. A method of reconstructing optical tissues of an eye comprises transmitting an image through the optical tissues of the eye. The surface gradients from the transmitted image are measured across the optical tissues of the eye. A Fourier transform algorithm is applied to the surface gradients to reconstruct an optical surface model that corresponds to the optical tissues of the eye.

Owner:AMO MFG USA INC

Process for preparing neodymium-iron-boron permanent magnetic material surface gradient function coating layer

InactiveCN1900361ARealize the purpose of industrial applicationPretreated surfacesLiquid/solution decomposition chemical coatingOxide ceramicsSurface gradient

A neodymium-iron-boron permanent magnetic materials surface gradient function coating preparation method overcomes current slug type neodymium iron boron surface processing method existent problem. Said method adopts new surface modification process means combined with tradition electroplating ( or chemical plating ) advantages and sol-gel technologic property, thereby avoiding single cladding material poor cladding material adhesion, less compactness, easy resulting slough, having pore and too thin single sol coating shortages. Said method forms tight sol coating on neodymium iron boron base material surface, to obtain oxide ceramics coating after sintering treatment, then cladding material on gel coating to form function gradient coating to take complete corrosion protection.

Owner:SOUTHWEST UNIVERSITY

Wavefront reconstruction using fourier transformation and direct integration

The present invention provides methods, systems and software for generating a wavefront elevation map using Fourier transformation algorithms. In one embodiment, the present invention provides a method of reconstructing optical tissues of an eye. The method comprises transmitting an image through the optical tissues of the eye. The surface gradients from the transmitted image are measured across the optical tissues of the eye. A Fourier transform algorithm is applied to the surface gradients to reconstruct a surface that corresponds to the optical tissues of the eye.

Owner:AMO MFG USA INC

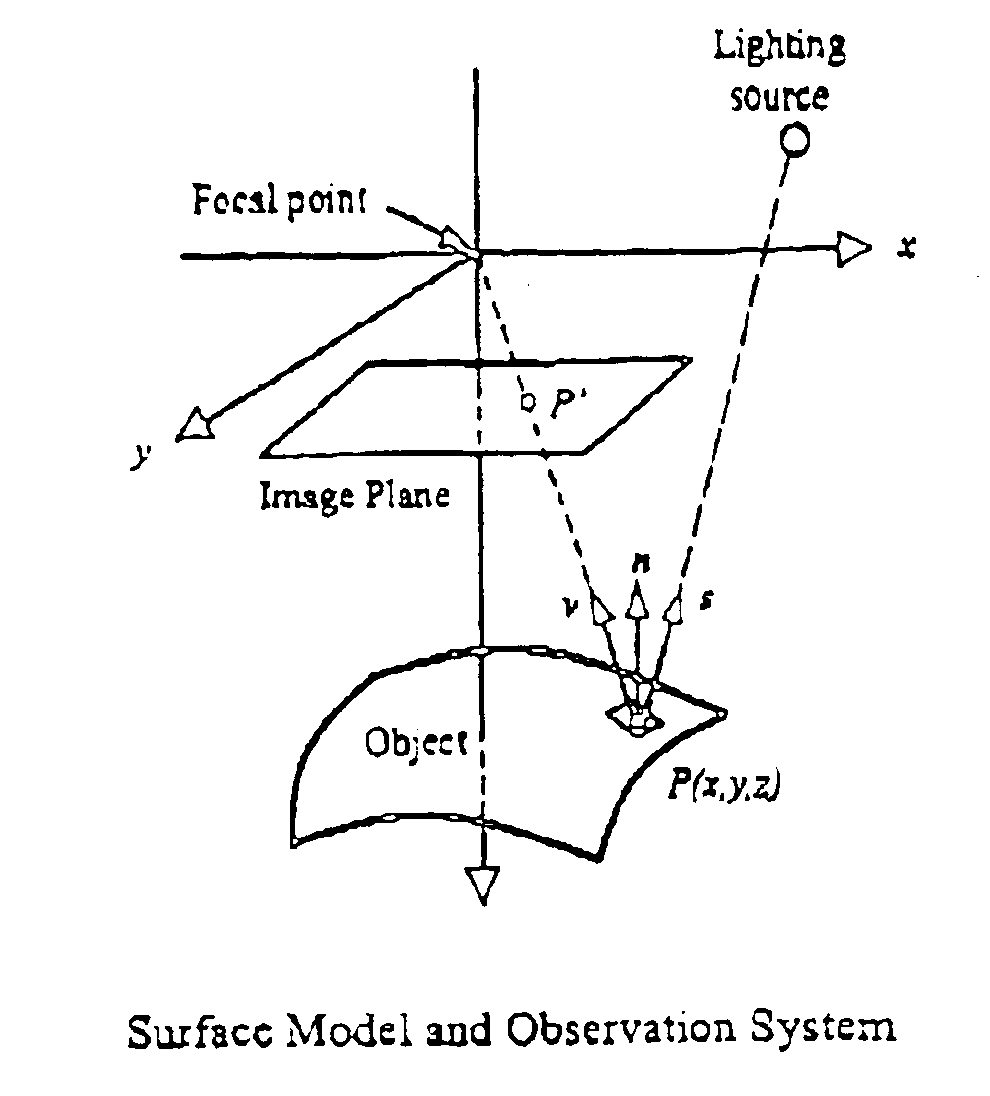

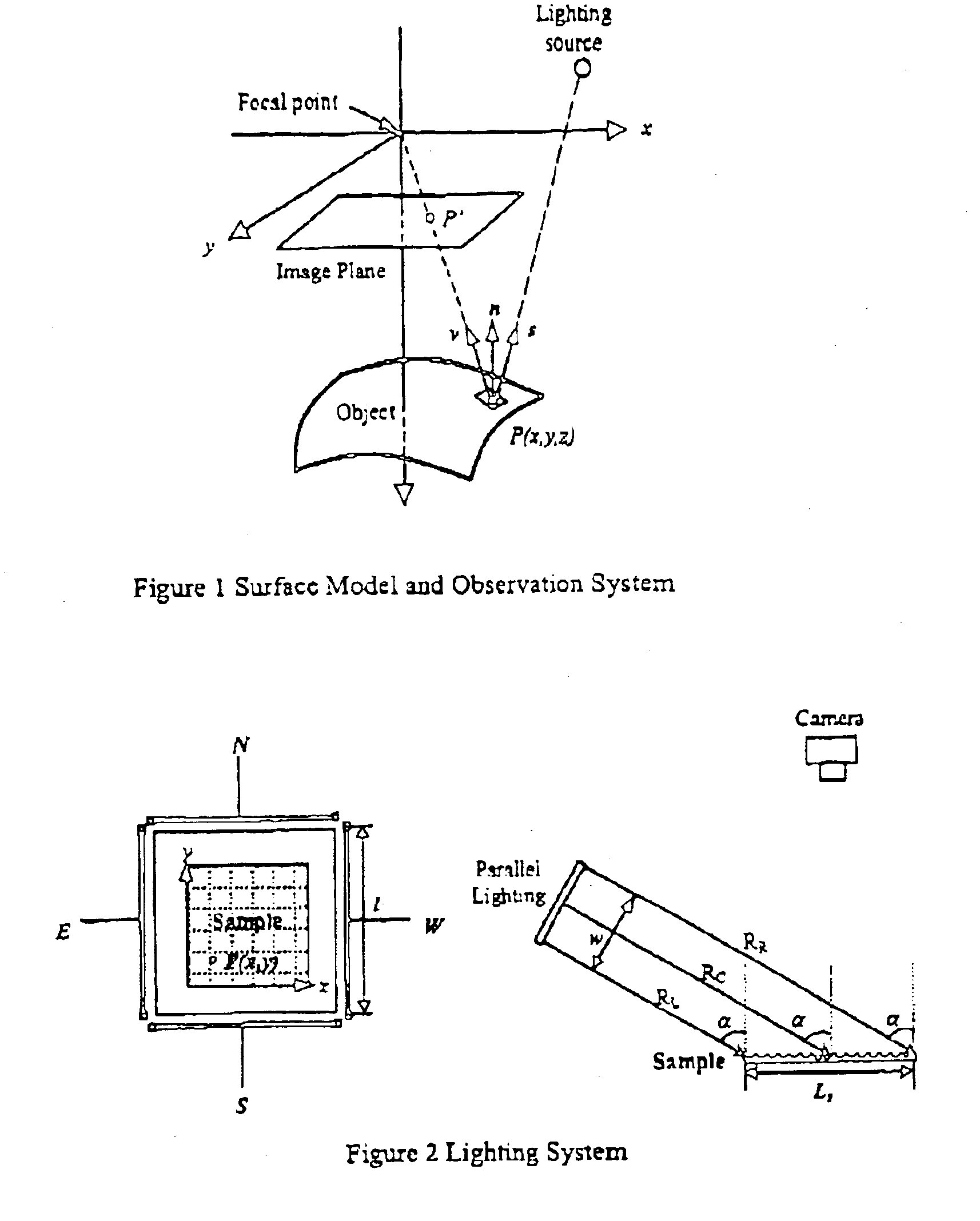

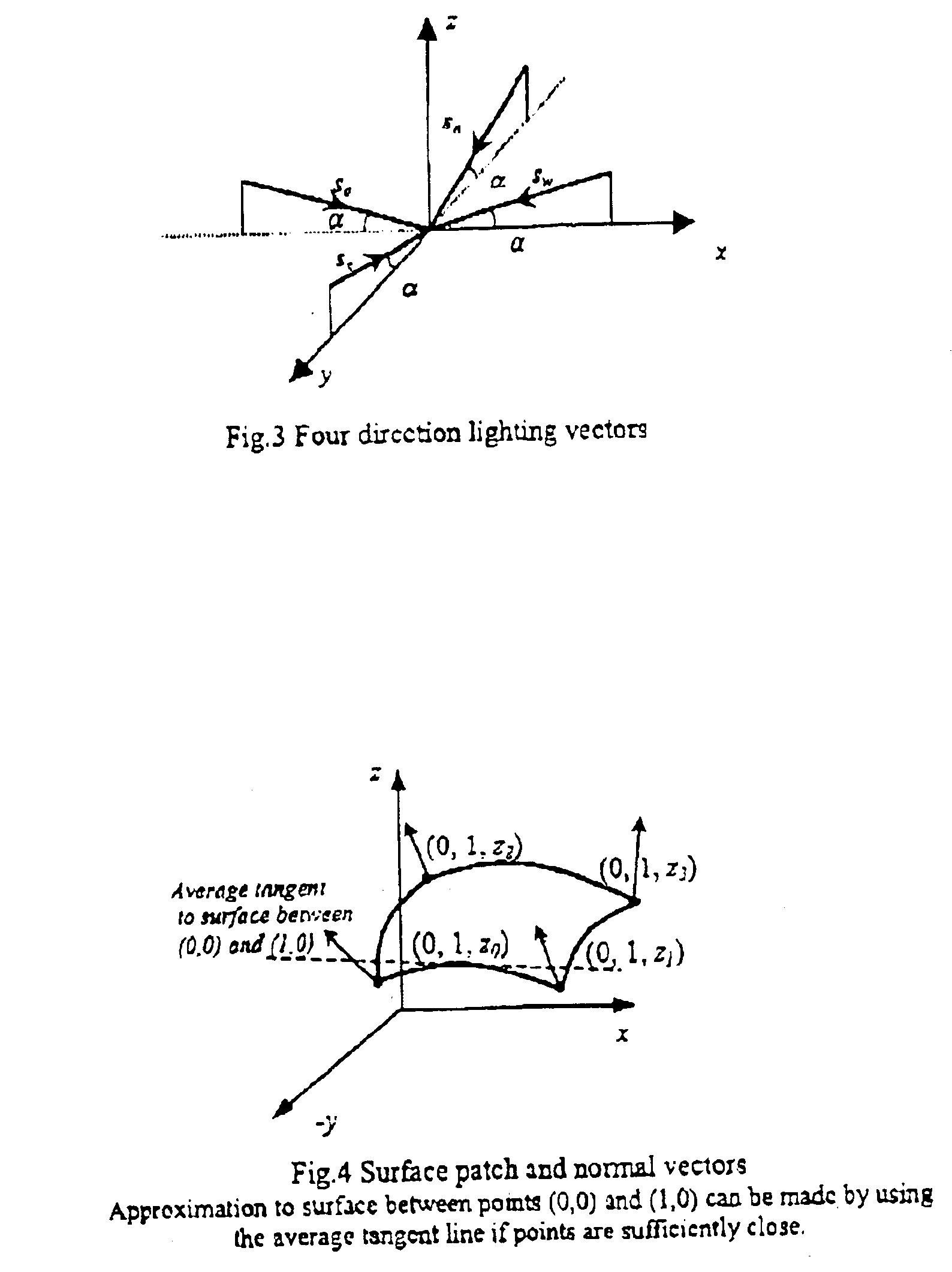

Three dimensional measurement, evaluation and grading system for fabric/textile structure/garment appearance

InactiveUS6842532B2Obtain 3-D surface information more quickly and easilyImage enhancementImage analysisSurface gradientLight beam

A method of three dimensional measurement, evaluation, and grading system for fabric / textile structure / garment appearance, based an values P and Q, is carried out using a fixed digital camera positioned above a piece of the fabric, shining at least two different parallel light beams from inclined directions onto the surface of the fabric and capturing different reflected images of the surface with the camera. The captured images are analysed to derive certain parameters relevant to the appearance. In particular, values of P+Q may be used in a grading evaluation, where P and Q are summations of the surface gradients for a plurality of evenly distributed points in an x direction and in a y direction of the surface, respectively.

Owner:THE HONG KONG POLYTECHNIC UNIV

Constant work tool angle control

ActiveUS7949449B2Analogue computers for trafficComputer controlSurface gradientMechanical engineering

A method of controlling a work tool with respect to a design surface gradient identifies surface gradient and determines a desired angle for the work tool. Movement of the machine is monitored and the distance between the design surface gradient and the work tool is determined. The angle of the work tool is varied based on one or more of these parameters.

Owner:CATERPILLAR INC

Gradient coating cutter and preparation method thereof

ActiveCN108165988AGood self-lubricating performanceReduce wearMetallic material coating processesSurface gradientHardness

The invention discloses a gradient coating cutter and a preparation method thereof. A basal body material of the gradient coating cutter is high-speed steel; a multilayer coating layer is arranged onthe surface of a basal body; and the coating layer is a gradient laminated coating layer of alternating hard alloy layers, added with MoS2, BN and LaF3, and Al2O3 base ceramic layers. The cutter coating layer is prepared by adopting a laser cladding method; and the preparation steps are (1) pretreatment, (2) cladding of the hard alloy layers, (3) cladding of the Al2O3 base ceramic layers, (4) alternate cladding of the hard alloy layers and the Al2O3 base ceramic layers, and (5) aftertreatment. Compared with the prior art, the gradient coating layer on the surface of a cutter has the characteristics of Al2O3 base ceramic and hard alloys, and achieves higher hardness and excellent toughness; and through adding of MoS2, BN and LaF3, the cutter achieves excellent self-lubrication effect in wider cutting temperature range. The coating cutter can be applied to dry cutting and cutting of difficultly machined materials.

Owner:SOUTHEAST UNIV

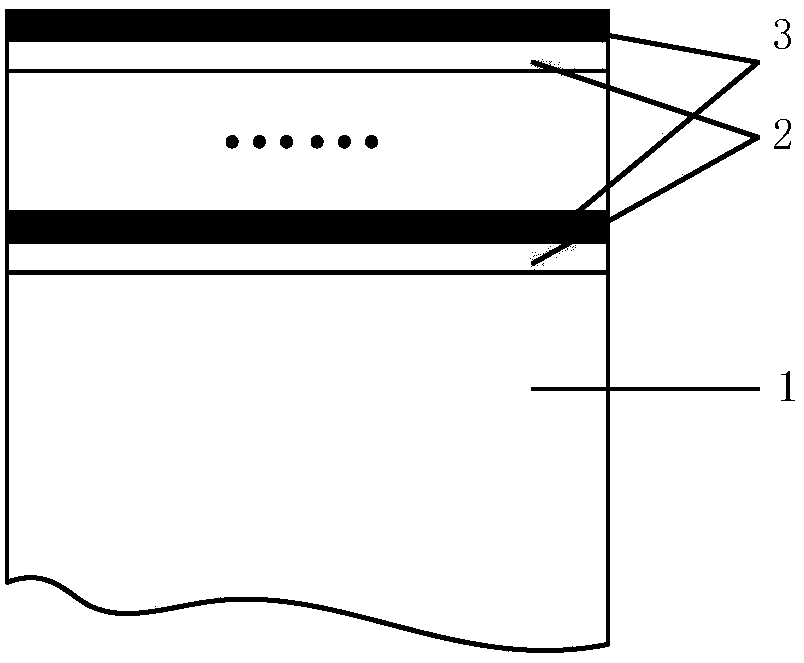

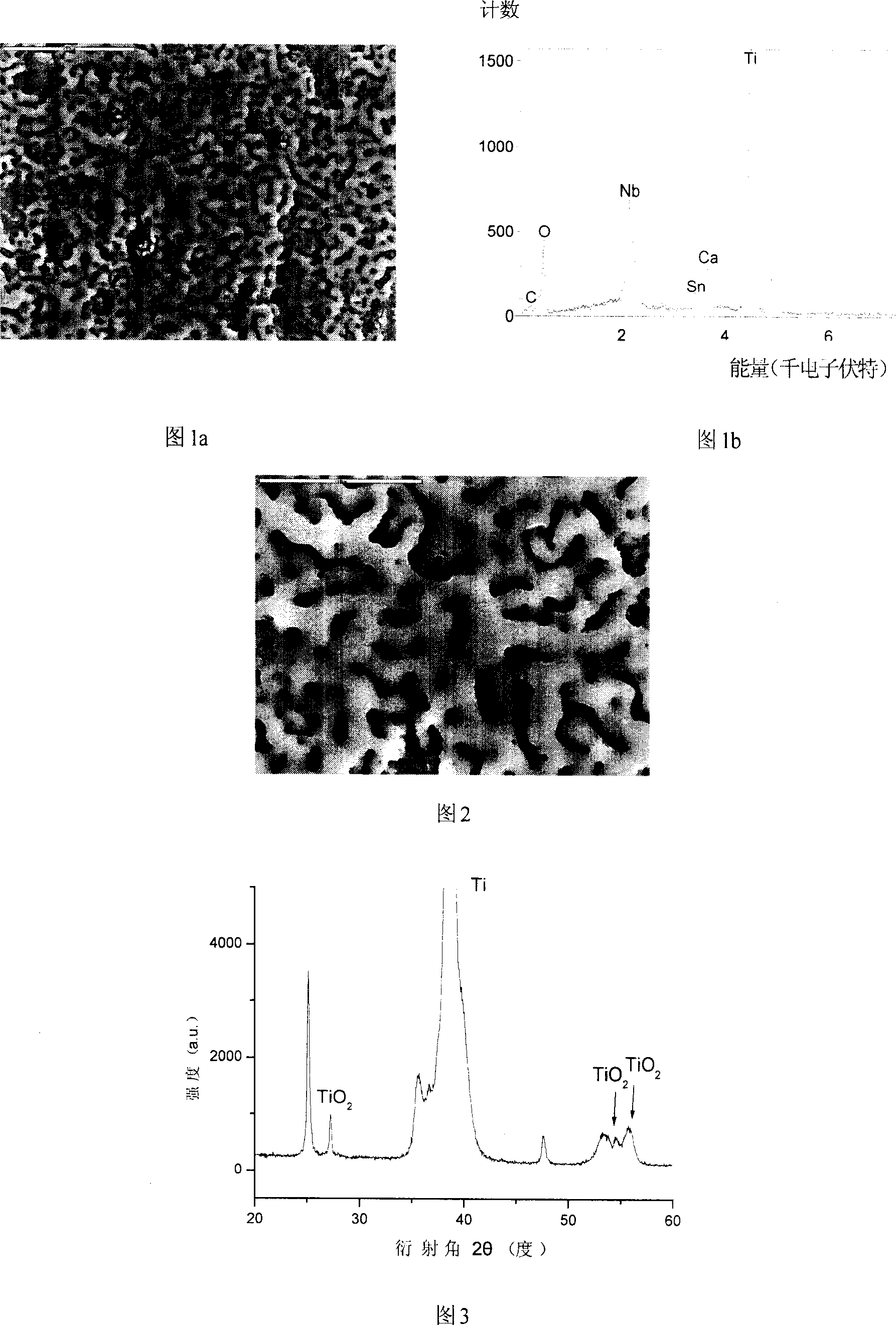

Bioactive coating on surface of Titanium or titanium alloy and its preparing method

InactiveCN1986003AGood biocompatibilityImprove biological activityCoatingsHigh cellBiocompatibility Testing

The present invention relates to bioactive coating on the surface of titanium or titanium alloy and its preparation process. The process includes the following steps: the first anode oxidation, alkali treatment and heat treatment of titanium or titanium alloy to form surface gradient coating in the thickness of 3 micron and comprising one inner thin and compact titania film and one outer porous titania film; introducing Ca element by means of the electrolyte solution into the coating to raise the biocompatibility; boiling in NaOH solution for 1-5 hr to form thin surface sodium titanate and calcium titanate layer; and final depositing a bone-like hydroxyapatite layer. The present invention raises the bioactivity of titanium or titanium alloy surface, and has high binding force of hydroxyapatite layer and high cell adhering capacity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

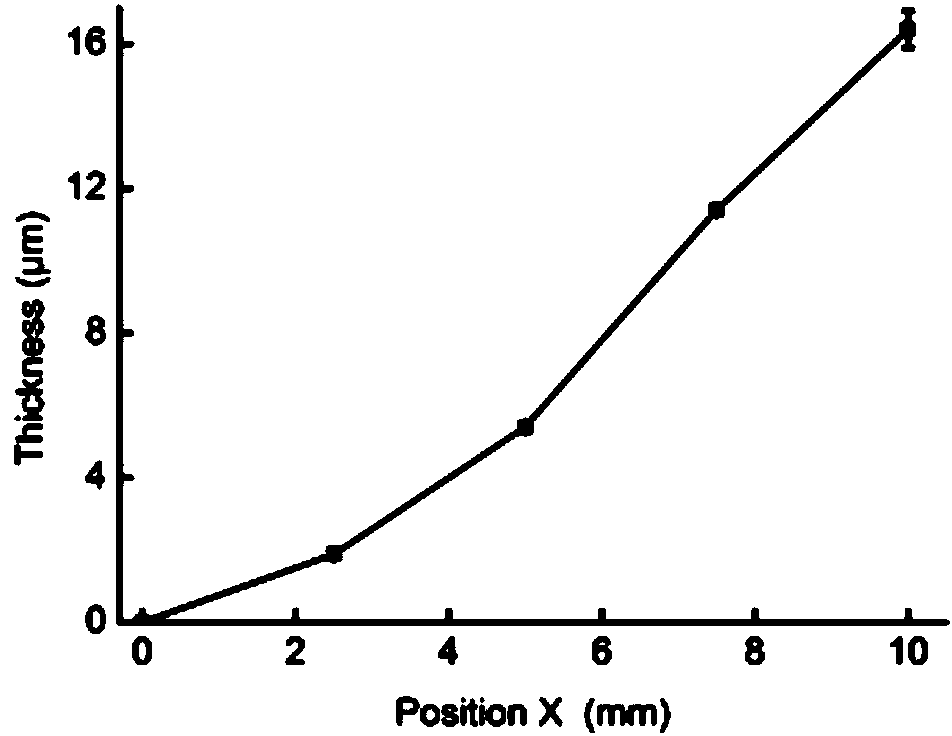

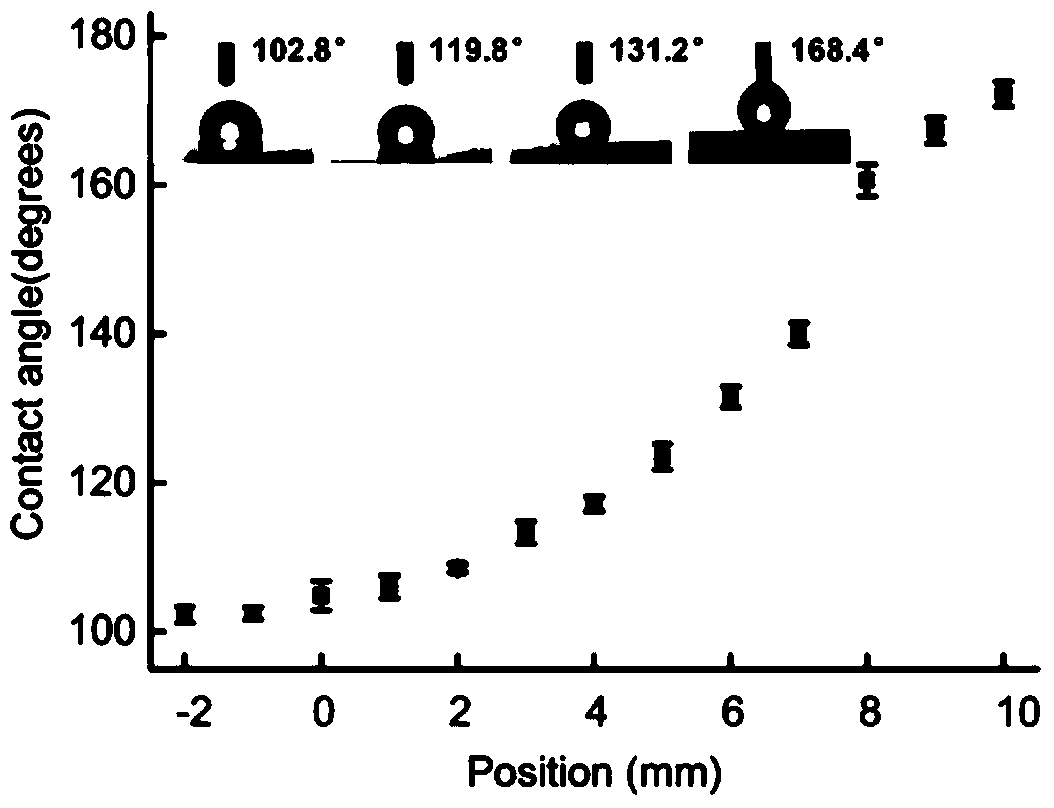

Gradient silica surface microfluid system construction method

ActiveCN105498867AEnhanced capillary driveFast self-conveyingLaboratory glasswaresSurface gradientUltraviolet lights

Embodiments of the present invention provide a gradient silica surface microfluidic system construction method based on ultra-hydrophilic-hydrophobic property. The method comprises: forming a flue dust layer having gradient on the carrier surface; forming a SiO2 nanometer film layer on the flue dust layer surface having the gradient; modifying the SiO2 nanometer film layer by using a hydrophobic material to form a hydrophobized SiO2 nanometer layer; and covering a photomask on the hydrophobized SiO2 nanometer layer, and carrying out ultraviolet light irradiation so as to form the ultra-hydrophilic-hydrophobic microfluid on the SiO2 nanometer structure film layer surface. According to the technical scheme of the present invention, the porous mesh flue dust structure having the surface gradient is used to obtain the porous mesh SiO2 structure having the surface gradient, the ultra-hydrophilic-hydrophobic property is used to prepare the microfluid channel, and the gradient and the microfluid channel are cleverly combined to enhance the capillary driving force of the microfluid so as to rapidly complete self-delivery of the fluid in the absence of external force.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum and aluminum alloy matrix aluminum nitride reinforced gradient composite surface layer

InactiveCN101880854AImprove wear resistanceSolid state diffusion coatingSurface gradientSurface layer

Owner:JILIN UNIV

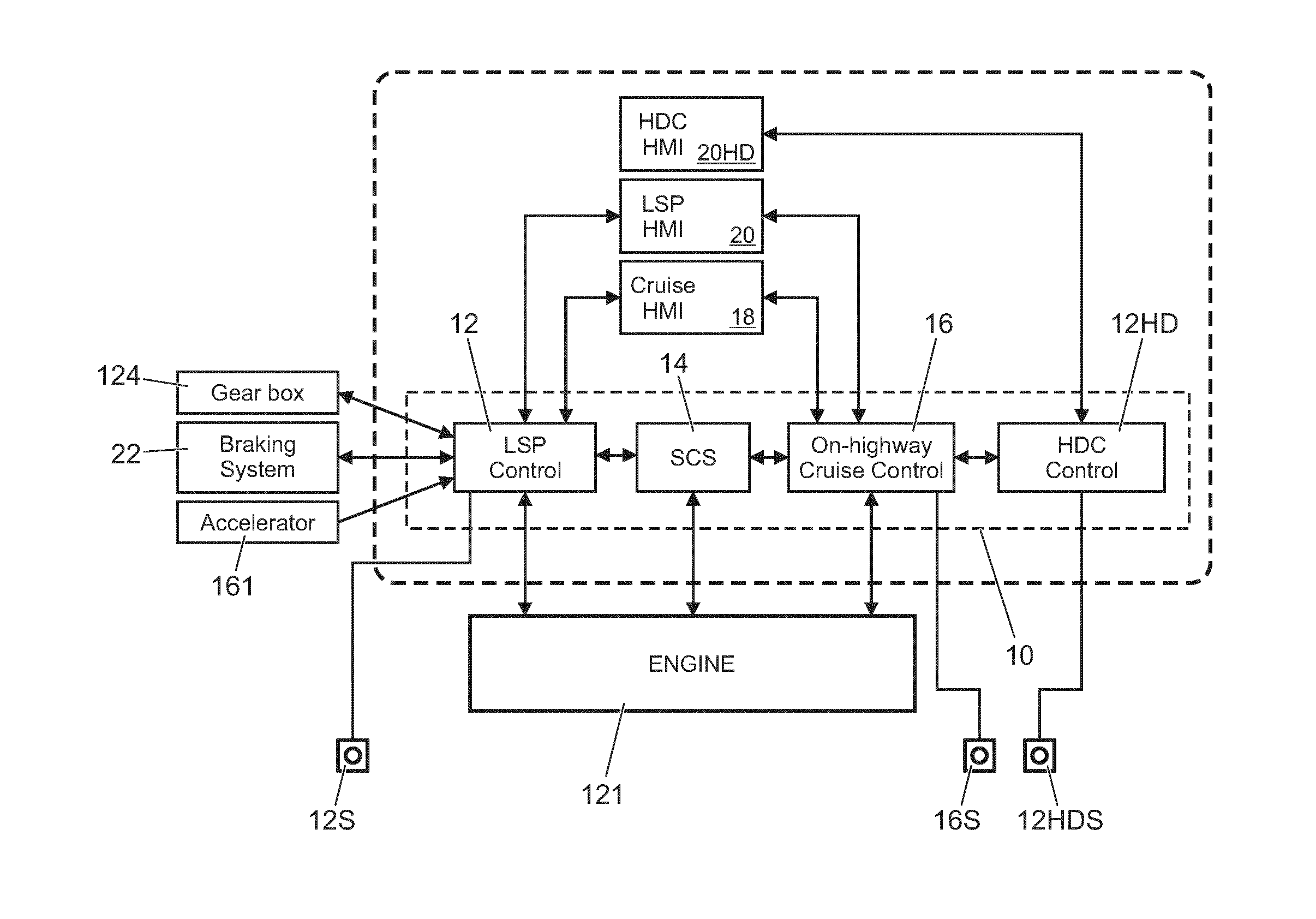

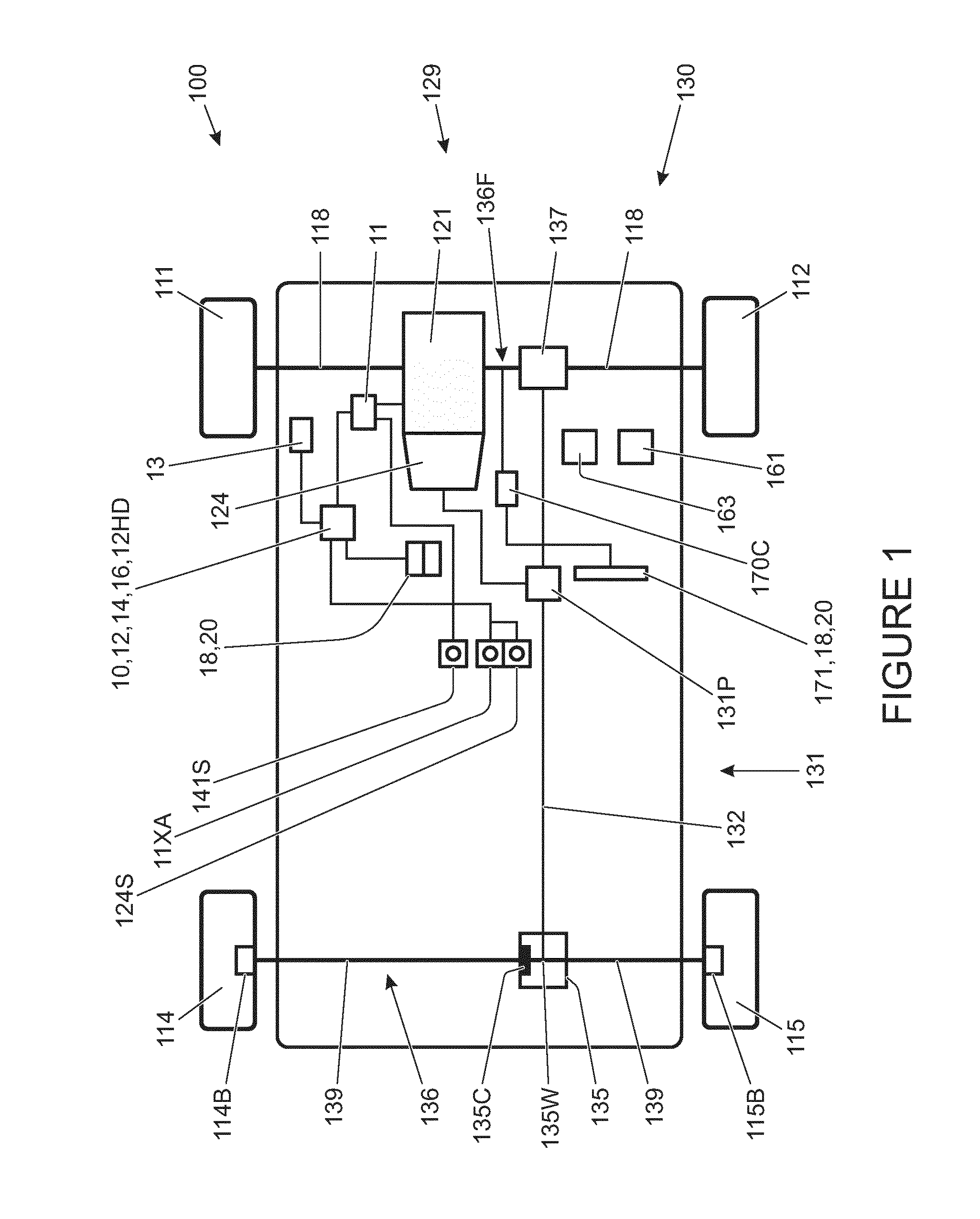

Vehicle speed control system and method

ActiveUS20160185350A1More riskReduce riskDigital data processing detailsExternal condition input parametersBrake torqueSurface gradient

Embodiments of the present invention provide a vehicle speed control system operable to cause a vehicle to operate in accordance with a target speed value by controlling an amount of brake torque applied by a braking system and an amount of drive torque applied by a powertrain to one or more wheels of the vehicle, the system being operable to detect a leading wheel step event in which a leading wheel encounters an abrupt increase in surface gradient, the system being operable in dependence on the detection of a leading wheel step event to cause brake torque to be applied against drive torque in anticipation of a trailing wheel step event corresponding to the leading wheel step event, the system being operable to cause the application of brake torque at least until a trailing wheel has travelled a sufficient distance to reach the location at which a leading wheel experienced the leading wheel step event.

Owner:JAGUAR LAND ROVER LTD

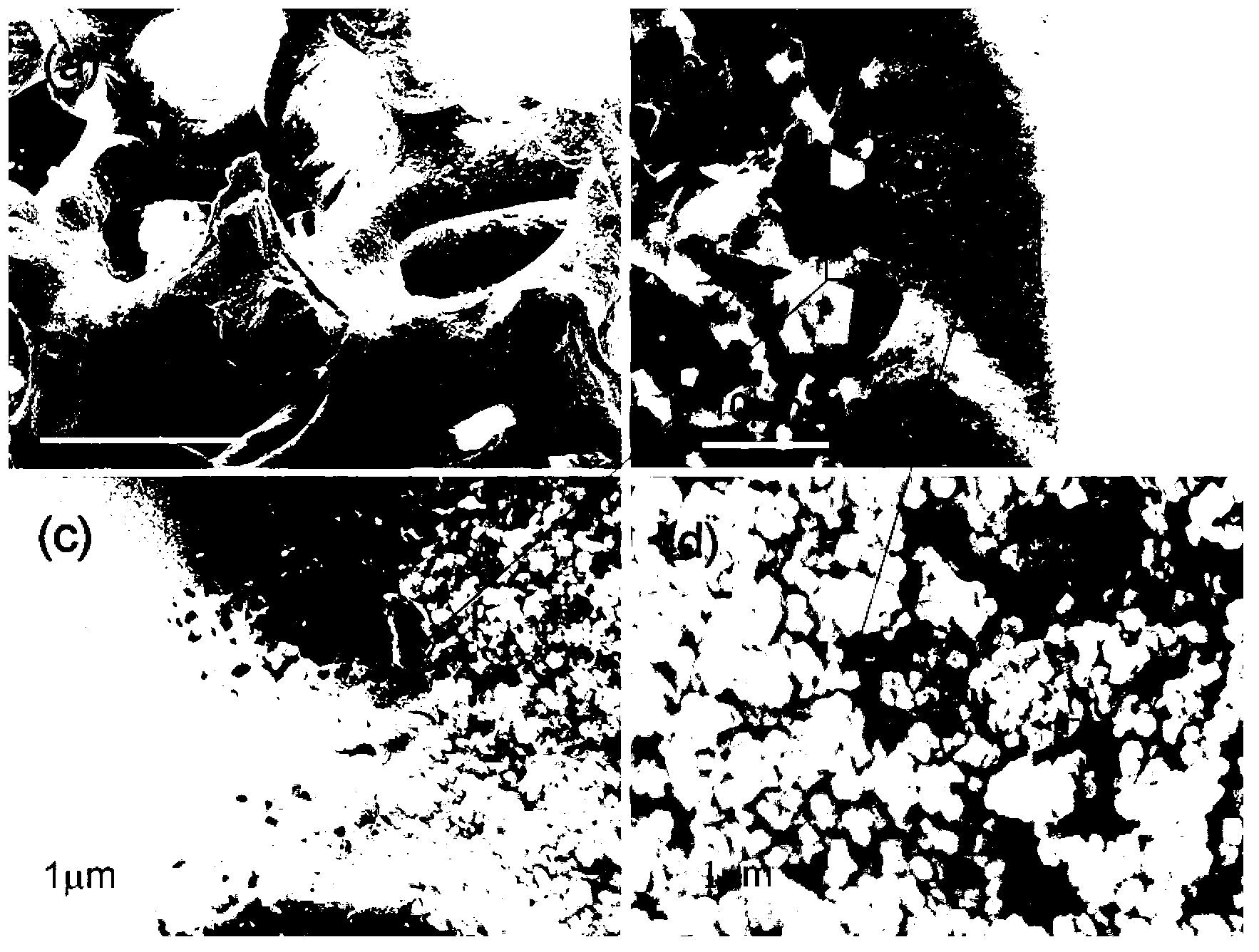

Porous silicon-carbide carrier surface gradient pore molecular sieve coating and preparation method thereof

ActiveCN103252253AImprove mass transfer effectExtend your lifeMolecular sieve catalystsMolecular sieveSurface gradient

The invention belongs to the field of catalysts and an application of the catalysts, and in particular relates to a porous silicon-carbide carrier surface gradient pore molecular sieve coating and a preparation method thereof. The porous silicon-carbide carrier surface gradient pore molecular sieve coating has the intercrystal porosity with continuous gradient change, the porosity among molecular sieve crystals in an inner molecular sieve coating is low, and the porosity among molecular sieve crystals in an outer molecular sieve coating is high. The coating is realized through two-step coating combined with steam treatment: a colloidal state molecular sieve precursor is coated on the surface of a foamed silicon-carbide carrier; a mixer of the colloidal state molecular sieve precursor, the molecular sieve crystals and a pore forming agent is coated; and finally, the molecular sieve precursor is converted into the molecular sieve crystals through steam treatment so as to realize the firm bonding between the coating and the carrier. The proportion of the colloidal state molecular sieve precursor to the molecular sieve crystals is controlled, the pore forming agent is added, and the intercrystal porosity of the coating can be regulated. The gradient coating and the carrier are firmly bonded, and the coating is high in mass transfer capacity and suitable for large-scale preparation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

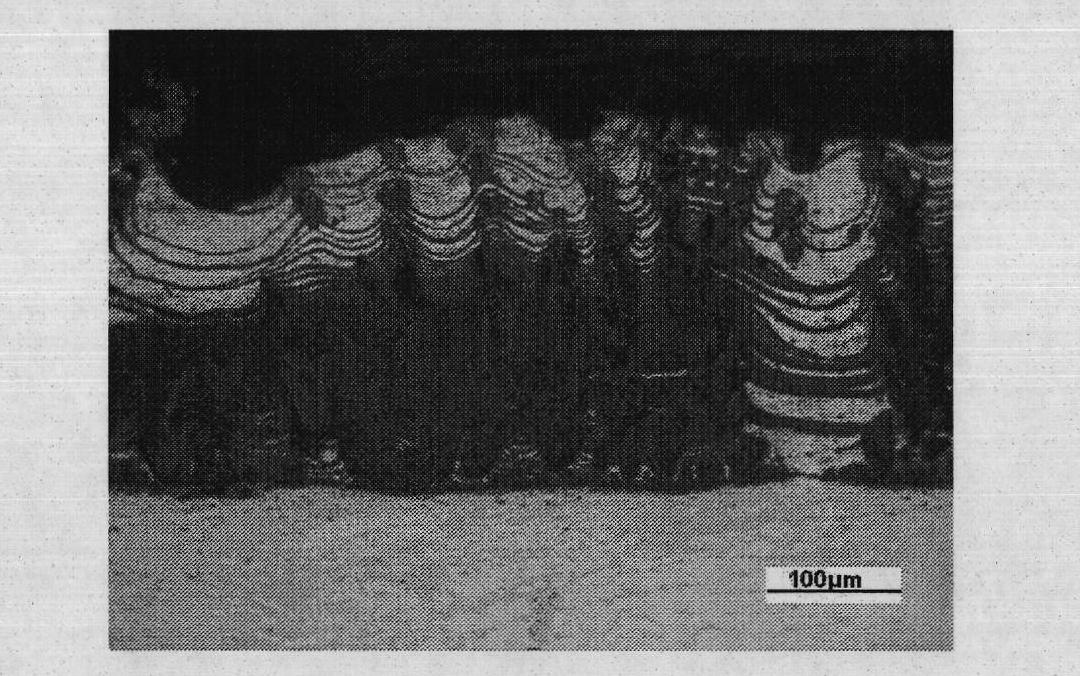

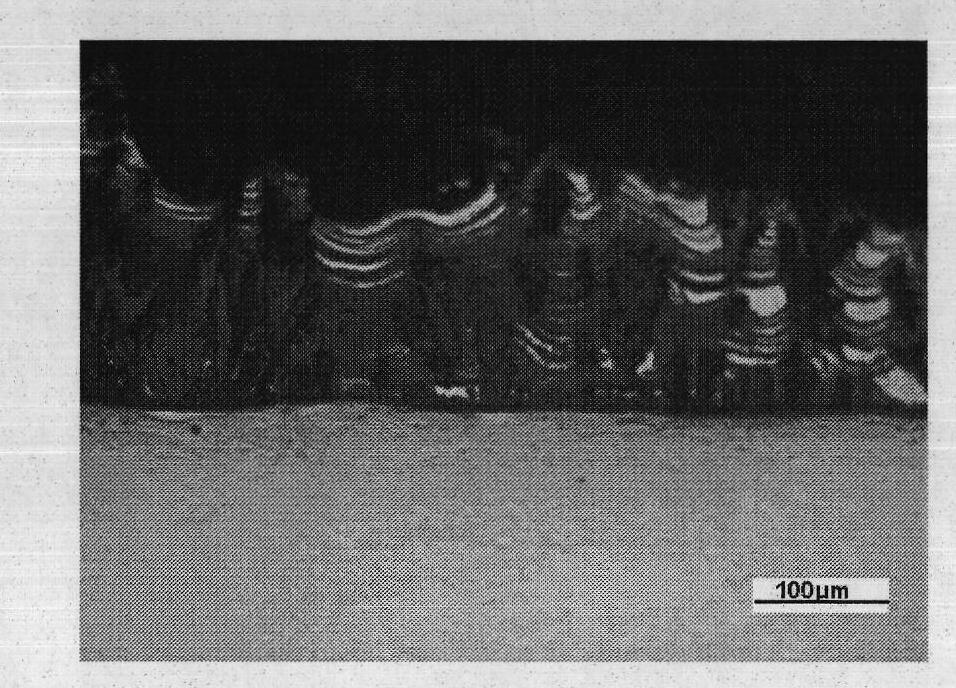

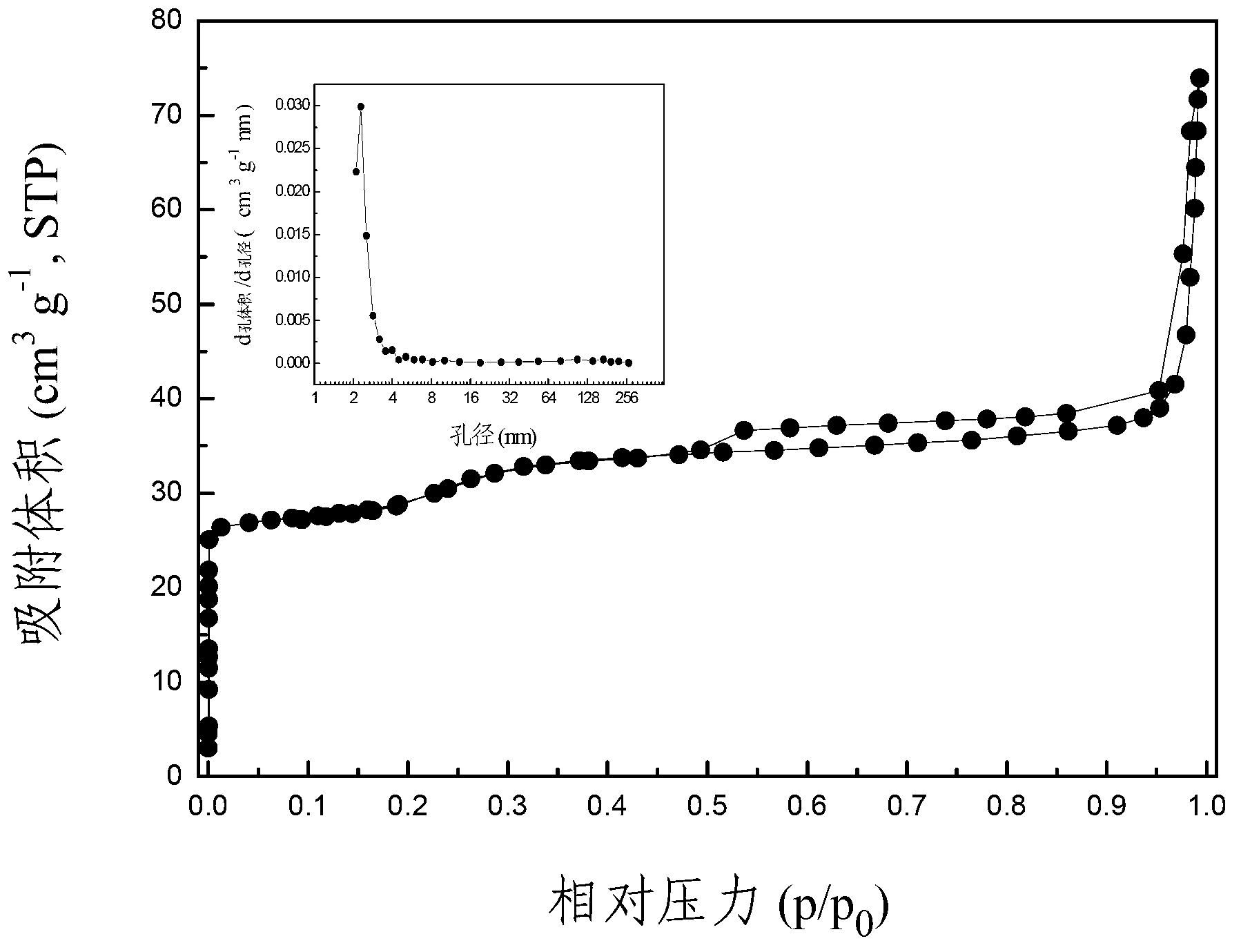

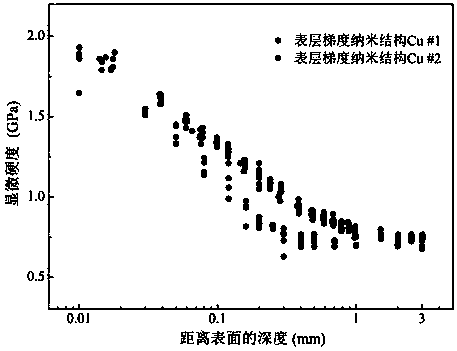

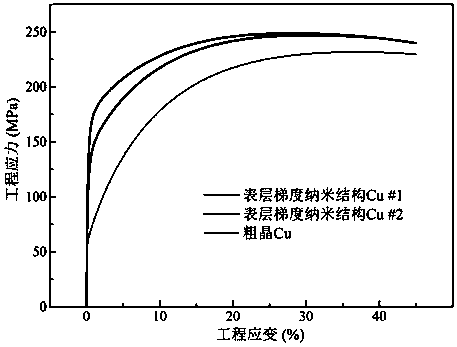

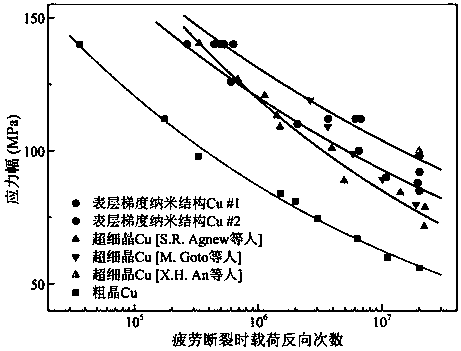

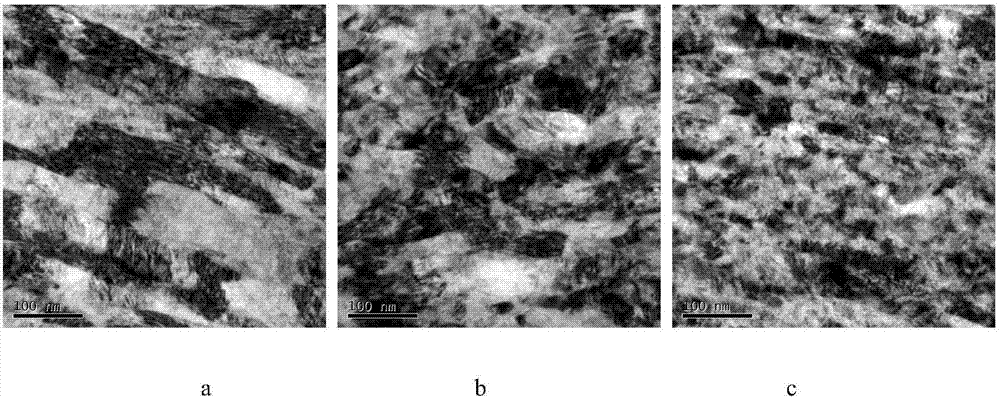

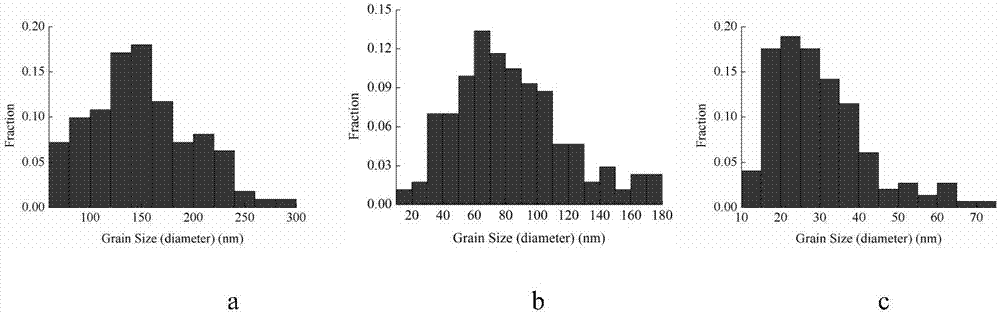

Gradient nanostructure with excellent comprehensive high cycle and low cycle fatigue performance

ActiveCN108913854AAchieve high cycleAchieve low cycle fatigue performancePerformance enhancementMetallic materials

The invention discloses a gradient nanostructure with excellent comprehensive high cycle and low cycle fatigue performance, and belongs to the technical field of metal material fatigue performance enhancement. Specifically, surface plastic processing is conducted, a gradient nanostructure is introduced to the surface of a metal material, and microstructures of the metal material are an surface layer nanocrystalline structure, a subsurface superfine / deformed twin structure and a core original coarse crystal structure, wherein the overall thickness of a gradient nanostructure layer is greater than 50 microns and is within 50-300 microns. Compared with uniform coarse grain structures of the same compositions, the stress control high cycle fatigue limit of a pure-Cu sample with the surface gradient nanostructure is improved by two times, and high cycle fatigue life is prolonged by 15 times; and the strain control low cycle fatigue life is doubled compared with common coarse grain samples.According to the surface layer gradient nanostructured metal material, both the high cycle and low cycle fatigue properties of the metal material are improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

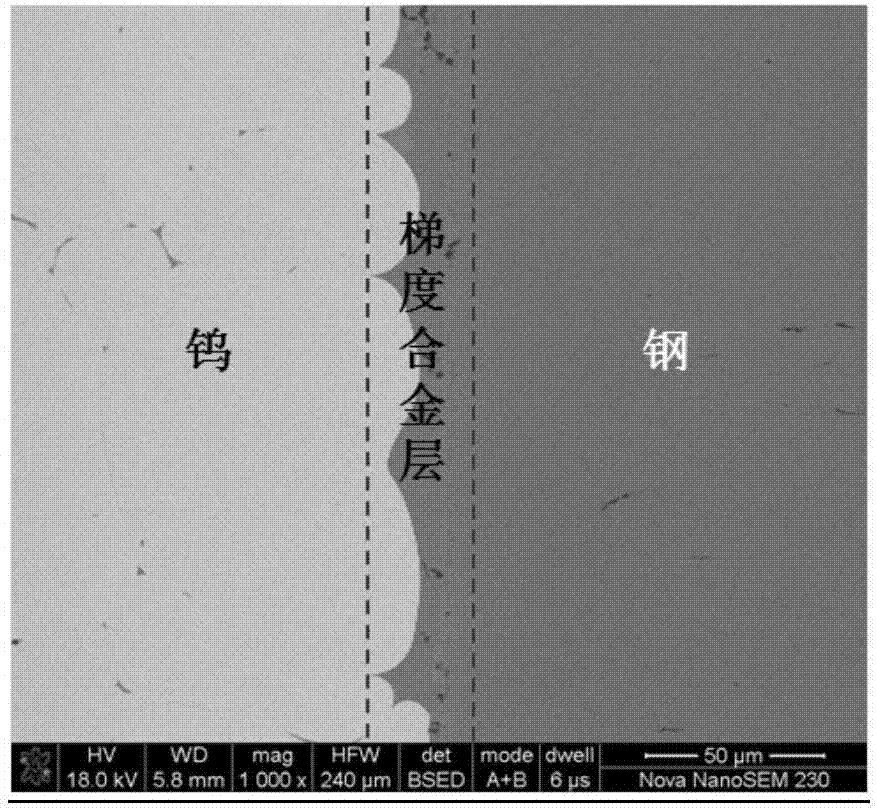

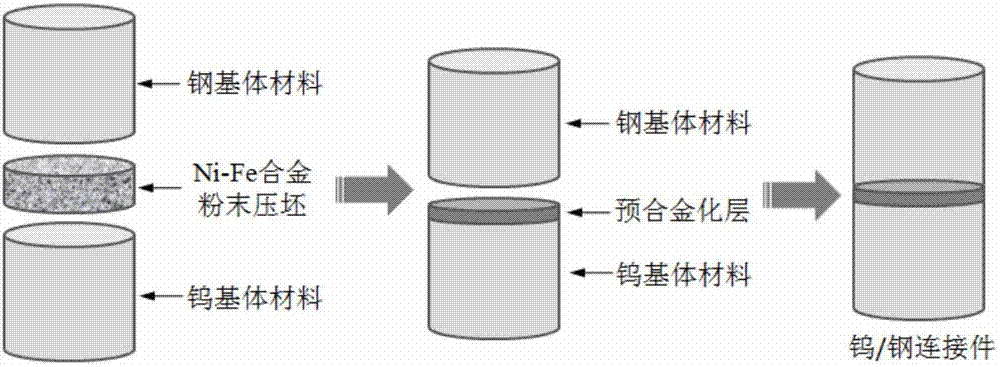

Tungsten/steel dispersion connecting method based on tungsten surface gradient alloying

InactiveCN107225249AImprove thermal fatigue performanceHigh strengthSoldering apparatusWelding/soldering/cutting articlesPowder mixtureDivertor

The invention relates to a tungsten / steel diffusion connection method based on tungsten surface gradient alloying, belonging to the technical field of composite material preparation. In the present invention, the nano-scale pre-alloyed mixed powder with a mass ratio of Ni and Fe of 7:3 is used as a raw material, and the surface of the tungsten substrate is subjected to gradient alloying treatment by high-temperature cladding and vacuum hot-pressing composite technology, and then the vacuum of tungsten and steel is carried out. Diffuse connection. The present invention forms a gradient alloy layer on the surface of the tungsten substrate through the configuration of nickel and iron components, vacuum hot pressing, high temperature cladding and vacuum diffusion and other process or parameter optimization, and obtains no defects at the interface and thermal fatigue performance Good, high interface stability of tungsten / steel composite structural parts. It can be used in the preparation of helium-cooled divertor components in magnetic confinement nuclear fusion experimental devices.

Owner:CENT SOUTH UNIV

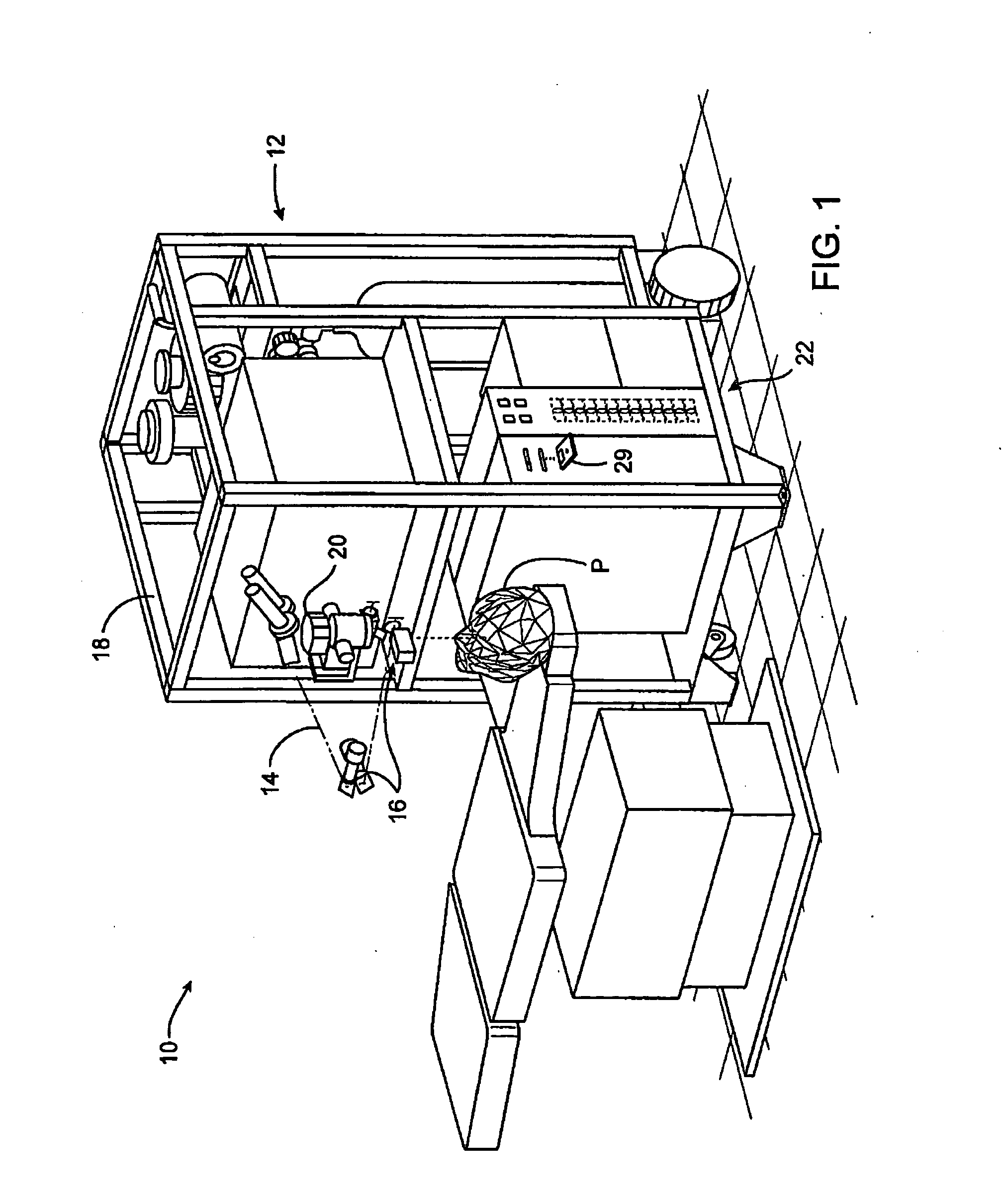

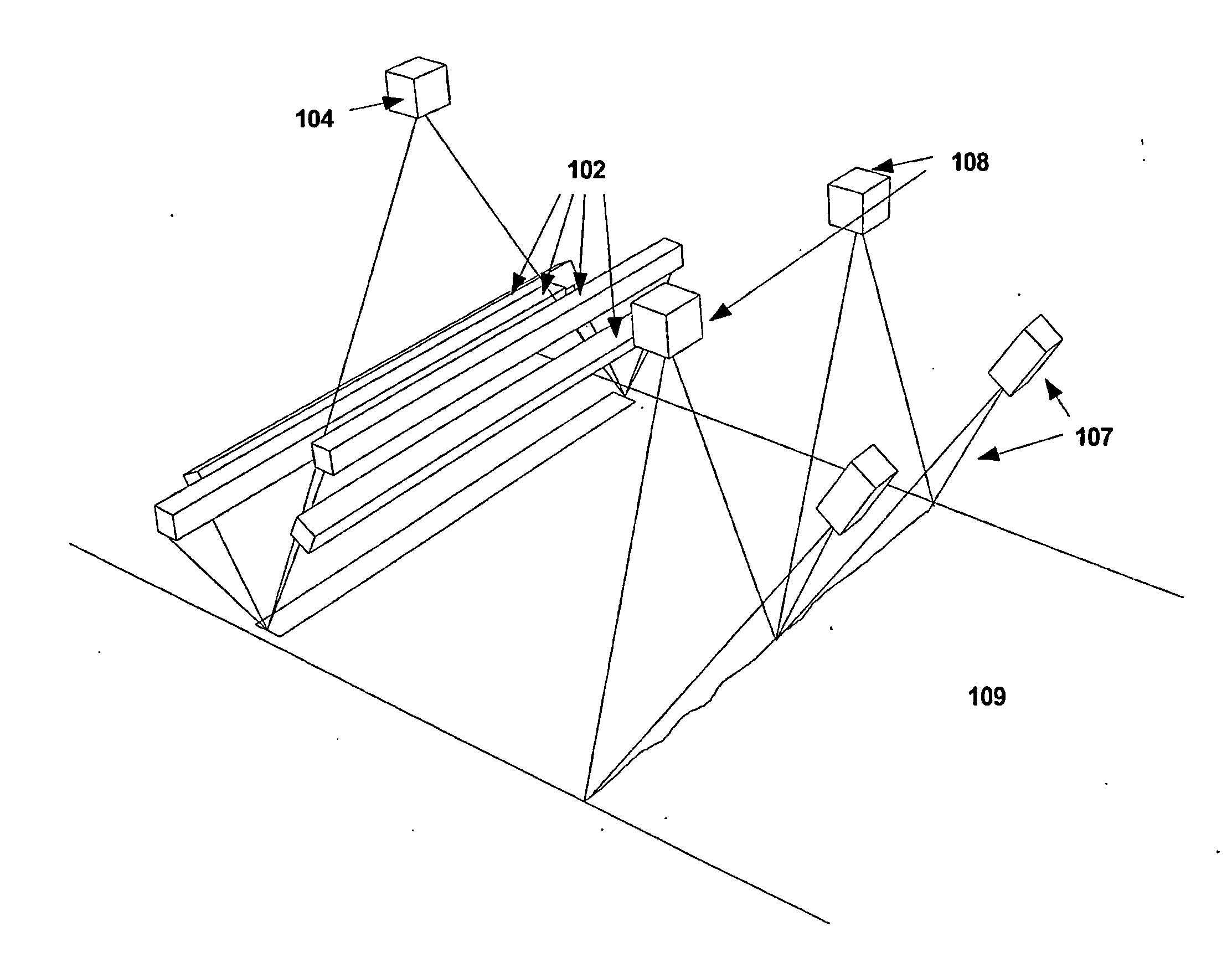

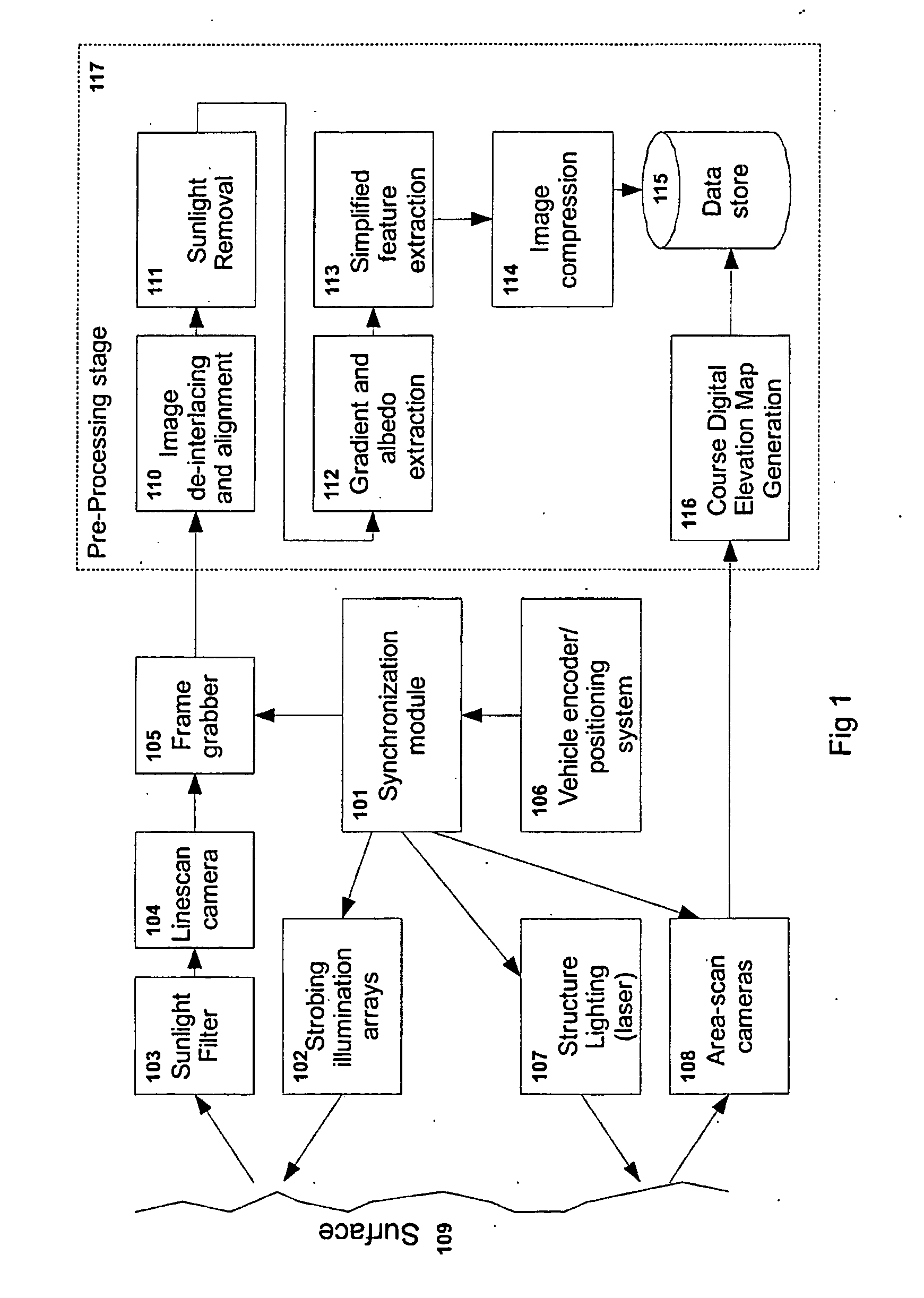

High speed photometric stereo pavement scanner

InactiveUS20130076871A1Overcome disadvantagesProvide usageUsing optical meansSteroscopic systemsSurface gradientAlbedo

The invention relates to a pavement scanning system having a movable platform, multiple light sources mounted on the platform for illuminating a pavement surface from multiple different angles, at least one image capture device mounted on the platform that captures sequential images of the illuminated pavement surface and a movement sensor that encodes movement of the platform and provides a synchronization signal for synchronizing the multiple light sources and the at least one image capture device for multiple image capture. The pavement scanning system also includes at least one processor that resamples the multiple captured sequential images to compensate for difference in collection time and calculates surface gradient and albedo for each point on the pavement surface or directly uses the multiple images to detect surface features.

Owner:RADAR PORTAL SYST

Copper surface gradient wetting self-assembly film and preparation method thereof

InactiveCN102527614ASimple processSave raw materialsCoatingsSpecial surfacesElectrochemistryFatty acid

The invention discloses a preparation method of a copper surface gradient wetting self-assembly film. The method comprises the steps of (1), depositing a layer of Cu(OH)2 precursor on the surface of copper through electrochemical deposition, (2), generating a layer of black CuO on the surface of sheet copper subjected to electrodeposition and high-temperature dehydration, and (3) adopting self-assembly method to gradually drip fatty acid ethanol solution with the concentration being 0.05mmol / L to 0.5mmol / L to the sheet copper obtained at step (2), and then flushing the sheet copper with absolute ethyl alcohol after 1 to 10min dripping, so as to obtain the copper surface gradient wetting self-assembly film after air drying at room temperature. Compared with the traditional method of plating noble metal of gold and silver on a substrate, the method has the advantages that simple electrochemical plating is only required to be performed on the substrate and then a required substrate for self-assembly can be obtained after dehydration treatment; and the electrochemical deposition has the advantages that the cost of raw material is low, the raw material can be reused, arrays of prepared CuO are uniform and stable, the technological process is simple, the preparation time is short, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of charcoal material surface gradient coating for resisting oxidation

The present invention is preparation process of gradient oxidation resisting coating on the surface of carbon material. The preparation process includes the steps of: cleaning and stoving the surface of the carbon material; compounding slurring with silica powder, water and adhesive in certain weight proportion, and coating the slurry onto the surface of the carbon material through soaking, spraying or brushing; compounding silica powder, molybdenum powder, water and adhesive into slurry A of Mo / Si ratio 0.3-0.4, slurry B of Mo / Si ratio 0.8-1.2 and slurry C of Mo / Si ratio 1.8-2.3, and coating slurry A, slurry B and slurry C successively onto the surface of the carbon material through soaking, spraying or brushing; and sintering to obtain the product. The present invention has simple technological process, high production efficiency, good repeatability and low production cost and is suitable for industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

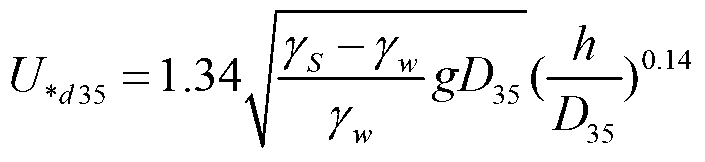

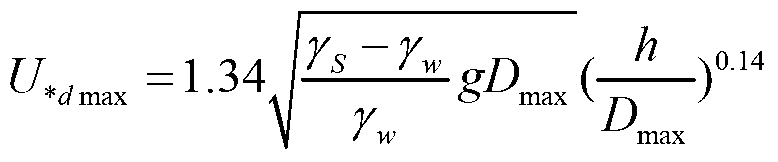

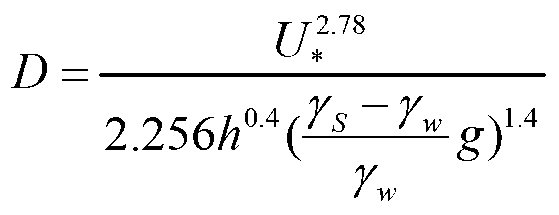

Method for determining pipeline critical burial depth in debris flow areas

The invention discloses a method for determining pipeline critical burial depth in debris flow areas. The method includes: for diluted debris flow, determining a forming initial flow velocity and a damaging initial flow velocity of an overlying soil armoring layer according to mutual effect between the diluted debris flow and pipeline overlying soil and critical hydraulic conditions of armoring layer forming and damaging, judging erosion modes of overlying soil according to scale and a flow velocity of the current debris flow, and calculating erosion depth of the pipeline overlying soil under the effect of the diluted debris flow; for viscose debris flow, judging erosion and deposition features of the debris flow according to relations between bed surface gradient and minimum slope required by debris flow movement, and calculating erosion depth, under erosion action, of the viscose debris flow if the bed surface gradient is larger than the minimum slope. The method has the advantages that erosion depth of the pipeline overlying soil under debris flows of different intensities is considered quantitatively, and technical guarantee is provided for scientific design and construction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

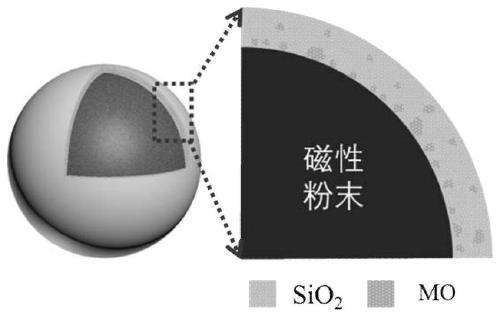

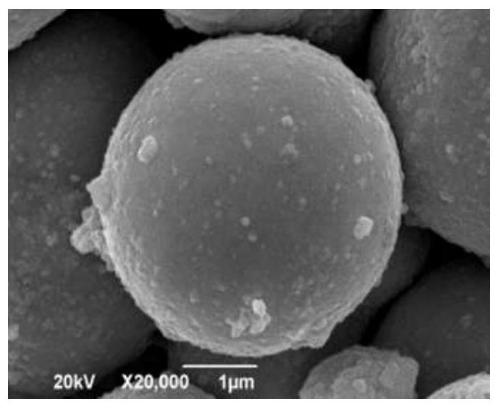

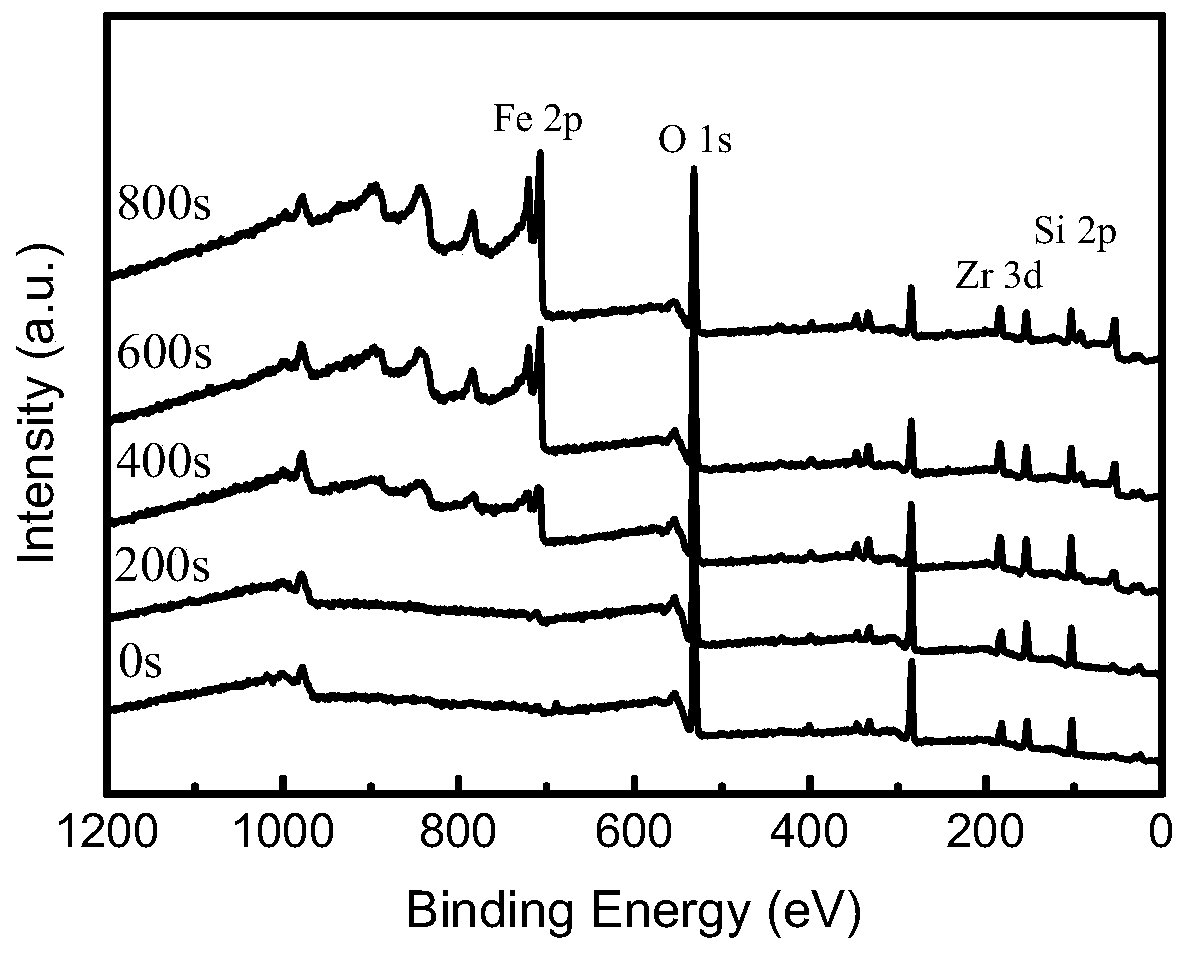

Magnetic powder surface gradient coating structure and coating method and soft magnetic composite

ActiveCN110405201ACoated evenlyCover tightlyTransportation and packagingMetal-working apparatusHigh resistivityThermal expansion

The invention relates to a magnetic powder surface gradient coating structure and coating method and a soft magnetic composite. The gradient coating structure is prepared from a coating layer which isformed on the surface of ferromagnetic powder by silicon dioxide and other coated components, and the contents of the silicon dioxide and other coated components in the coating layer are gradiently distributed. The coating method comprises the step of depositing the silicon dioxide and other coated components on the surface of the ferromagnetic powder in one step by adopting a chemical coprecipitation method, wherein the pH value of the system is adjusted in the deposition process. The soft magnetic composite is obtained by sectionally annealing the ferromagnetic powder with the coating layeron the surface after being pressed and formed. The coefficient of thermal expansion of the coating layer prepared by using the method can be controlled, the prepared soft magnetic composite has the advantages of low eddy current loss, high magnetic conductivity, high resistivity and high saturation magnetization, and the defects of low resistivity, mismatching of the coefficient of thermal expansion between coating layers and the like of the material in the prior art are overcome; in order to solve the problems of the reduction of the medium-high frequency magnetic conductivity, high eddy current loss, serious heating and the like of an existing magnetic powder core, a good method is provided.

Owner:CENT SOUTH UNIV

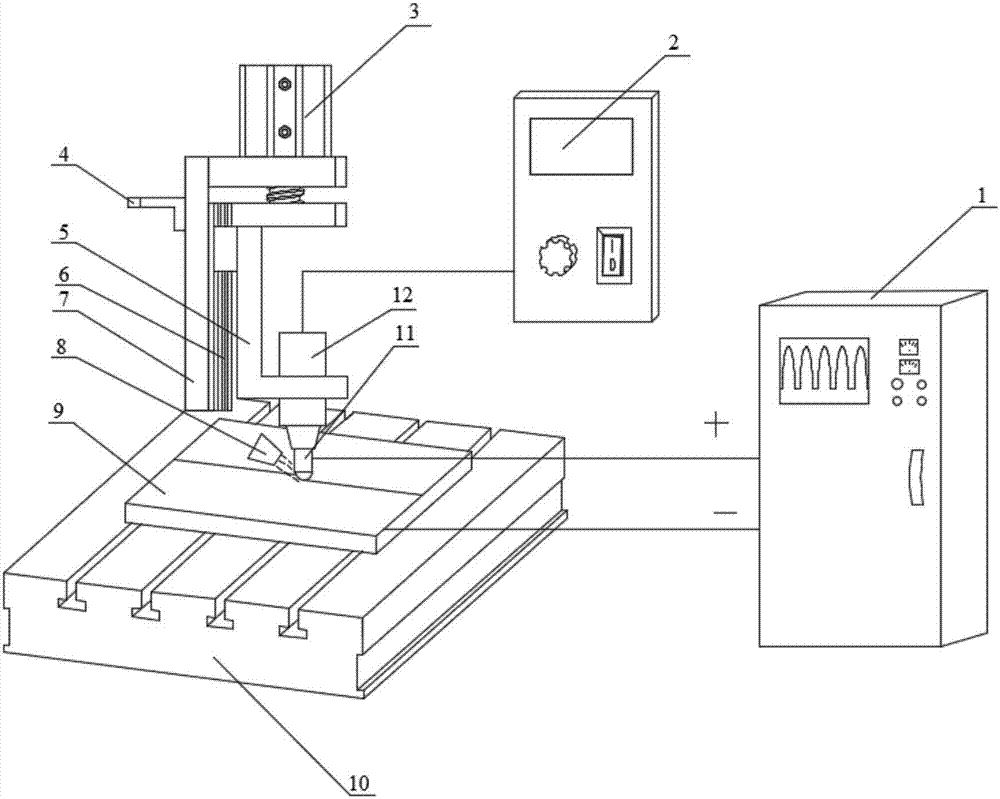

Method for preparing gradient nano-structure on surface of high-strength high-hardness metal material

ActiveCN107119183AIncreased local microplasticityEffective NanoizationNano structuringVolumetric Mass Density

The invention discloses a method for preparing a gradient nano-structure on the surface of a high-strength high-hardness metal material. The method comprises the following steps: a tool head (11) and a workpiece (9) are correspondingly connected with the positive pole and the negative pole of a high-instantaneous-energy-density pulsed power supply (1); and favorable contact between the tool head (1) and the workpiece (9) is kept, the high-instantaneous-energy-density pulsed power supply (1), an ultrasonic generator (2) and a nozzle (8) are started up, and the tool head (11) performs ultrasonic vibration along a Z axis under the action of the ultrasonic generator (2) to start to perform high-instantaneous-energy-density electric impulse and ultrasonic combined treatment on the surface of the workpiece. An instantaneous high temperature and ultrasonic micromechanical impact combined function formed by electric impulses can greatly improve the local micro plasticity at processing points of such high-strength high-hardness metal materials as nickle-based high-temperature alloy, die steel and the like, and severe plastic deformation occurs at the processing points, so that the surface of the workpiece can be effectively nano-crystallized, and the average size of surface grains can be 30 nanometers or below.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Constant work tool angle control

ActiveCN101903839ASoil-shifting machines/dredgersAltitude or depth controlSurface gradientEngineering

A method of controlling a work tool (110) with respect to a design surface gradient (300) identifies surface gradient and determines a desired angle for the work tool (110). Movement of the machine (100) is monitored and the distance between the design surface gradient (300) and the work tool (110) is determined. The angle of the work tool (110) is varied based on one or more of these parameters.

Owner:CATERPILLAR INC

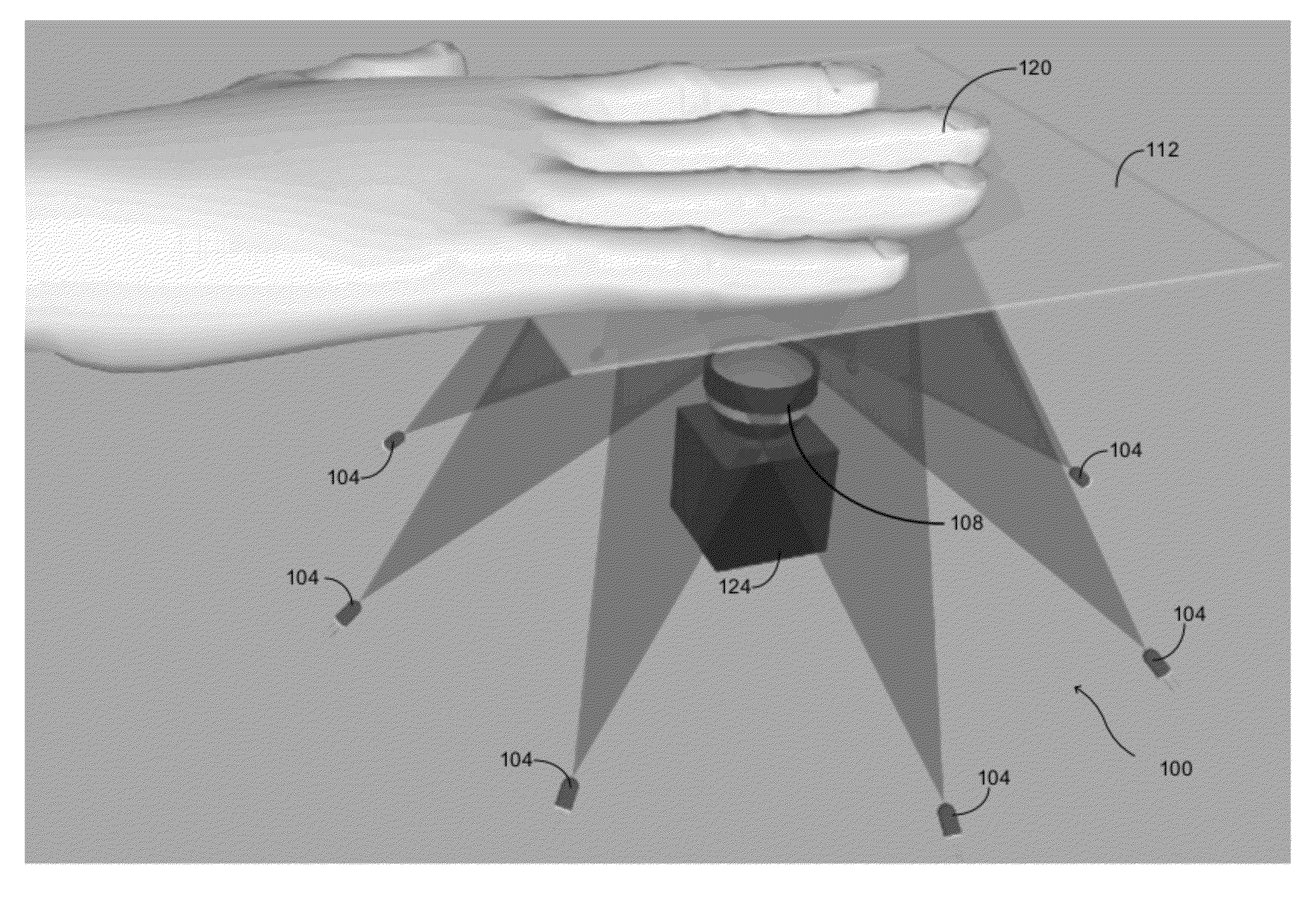

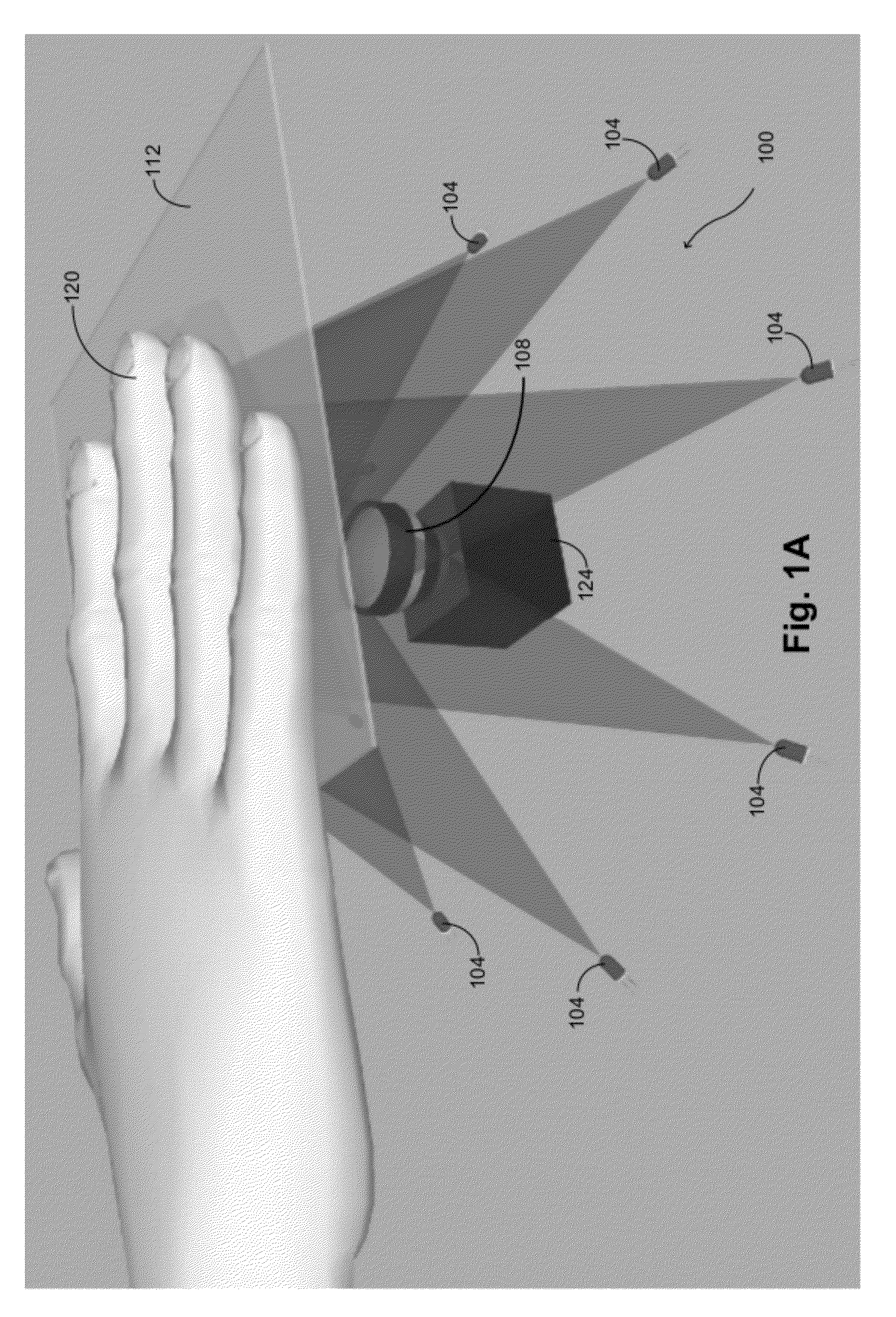

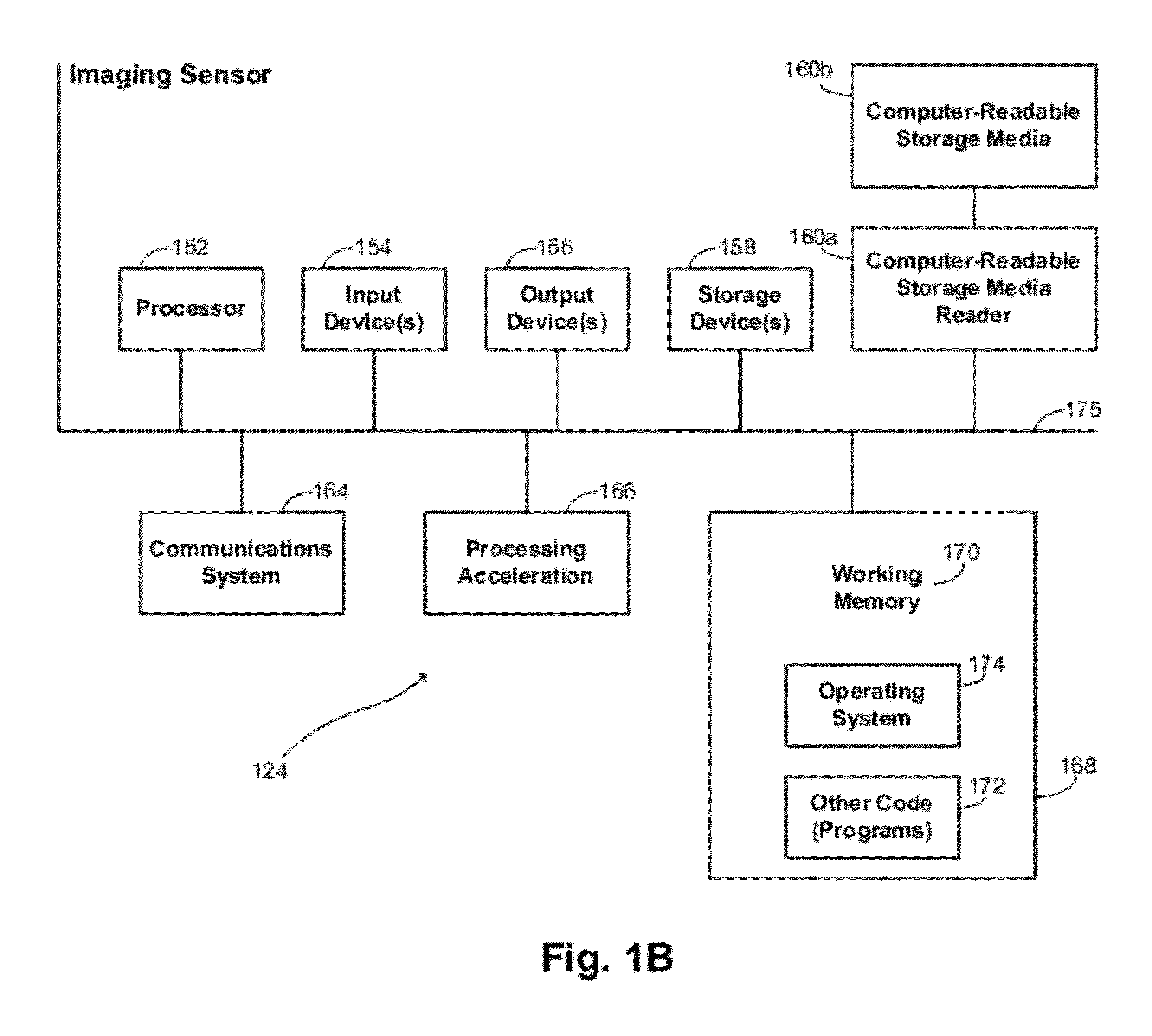

Optical topographic imaging

ActiveUS20120257046A1Reduce artifactsChange a contrast of the topographic imageImage enhancementImage analysisSurface gradientComputer vision

Methods and devices of studying a predefined portion of an object having a feature of interest are disclosed. The feature of interest defines a class of objects that includes the object. Light sources directly illuminate the object from different illumination directions. The light sources are maintained in a stable configuration relative to the object. For each illumination direction, an image is generated from light scattered from the object with a camera maintained in a stable configuration relative to the light sources. A methodology derived from machine learning for the class of objects is applied to filter the generated images are filtered for a characteristic consistent with the fetaure of interest. Surface gradients are determined from the filtered images and integrated to generate a topography of a surface of the object.

Owner:HID GLOBAL CORP

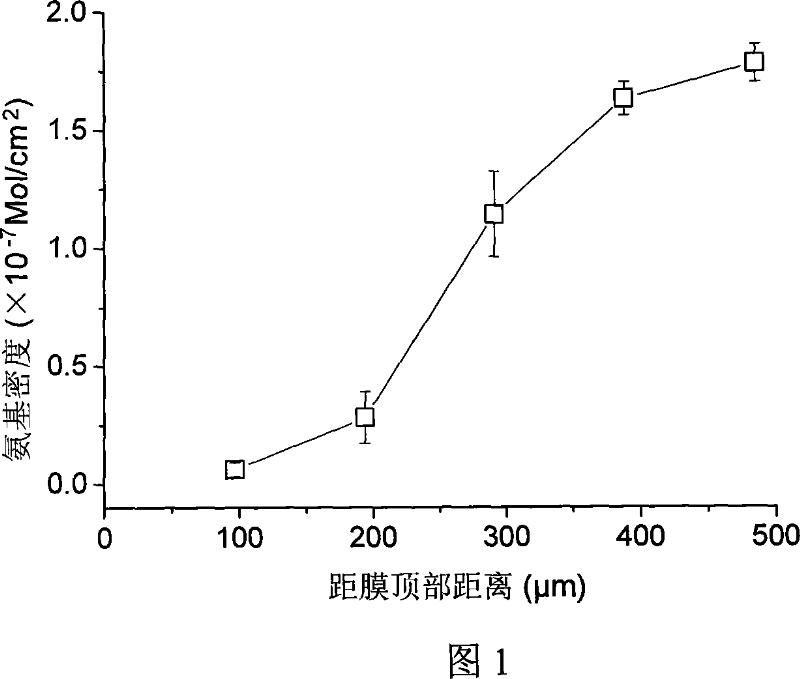

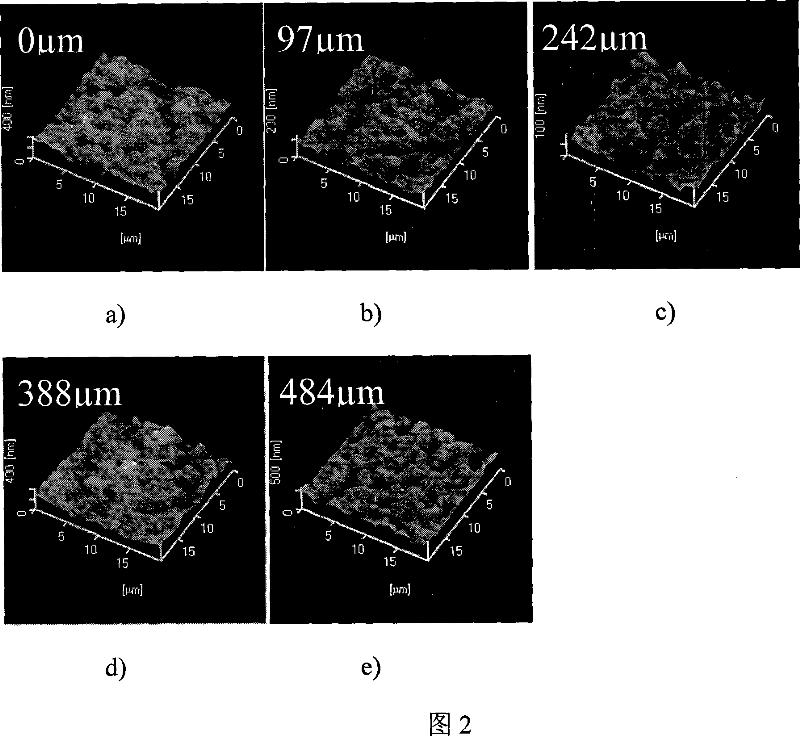

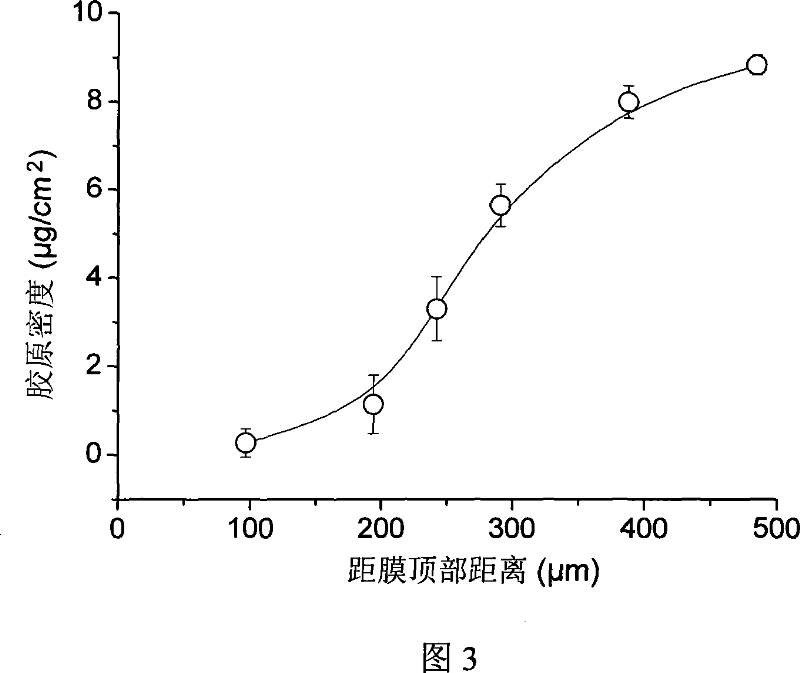

Method for preparing polymer material with gradient distributed surface biomacromolecule

InactiveCN101037512AWide variety of sourcesSimple and fast manufacturing methodCoatingsProsthesisSurface gradientPolymer thin films

The invention discloses a method of preparing polymer material with surface organism macromolecule of gradient distribution, which includes steps: putting polymer thin film with ester bond into container, continuously injecting amino-containing compound solution by injector, realizing gradient distribution of amino and eater bond reaction on polymer thin film surface, and obtaining polymer thin film of amino with gradient distribution surface; linking organism macromolecule and amino on polymer thin film surface by coupling agent, accordingly fixing the organism macromolecule on the polymer thin film surface and presenting the same gradient distribution. Advantages of the invention are: preparing method is simple, raw material is low-cost and facile, and the polymer material with gradient distribution surface is valuable for inducing gradient distribution of cell and leading growth of tissue.

Owner:ZHEJIANG UNIV

Swing arm contour surface shape detection method based on combination of radial scanning and circular scanning

ActiveCN104596464AHigh measurement accuracyImprove measurement efficiencyMeasurement devicesSurface gradientMathematical model

The invention discloses a swing arm contour surface shape detection method based on combination of radial scanning and circular scanning. The method includes: describing the surface features of a detected element by utilization of a method based on the Forbes polynomial fitting and obtaining the surficial gradient distribution of the detected element under a non-analytical expression; building a mathematical model of the surface gradient and the feature contour of the detected element and extracting a feature contour line of the detected element; planning a measuring path on the extracted feature contour line according to the radial direction and the circular direction; conducting the radial scanning and the circular scanning on the detected element according to the planned measurement path through a probe of a swing arm contourgraph and obtaining the one-dimensional feature contour data of the detected element; and conducting interpolation, fitting and reconstruction on the one-dimensional feature contour data of the detected element by utilization of a surface shape deviation fitting reconstruction algorithm and finally obtaining the two-dimensional holomorphism of the detected element. The swing arm contour surface shape detection method based on the combination of the radial scanning and the circular scanning has the advantages of being high in efficiency and precision and wide in application.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com