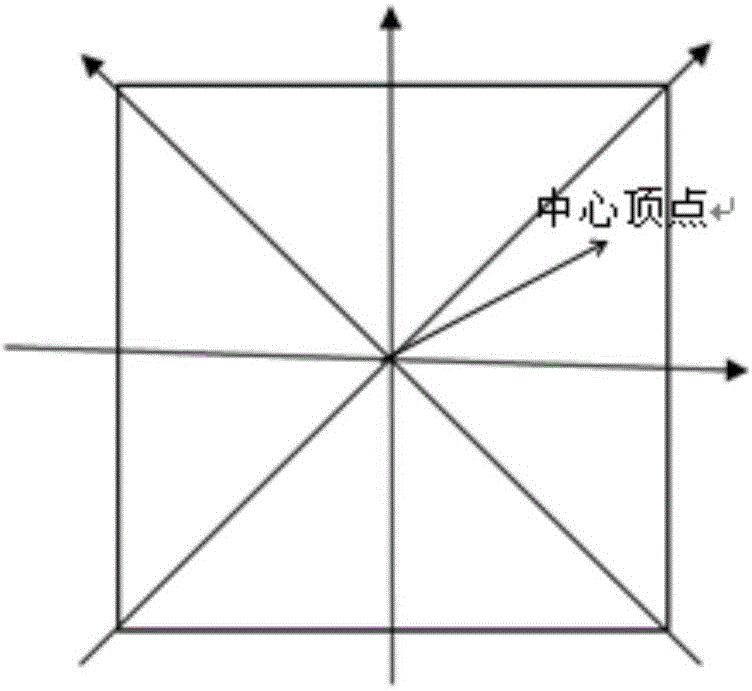

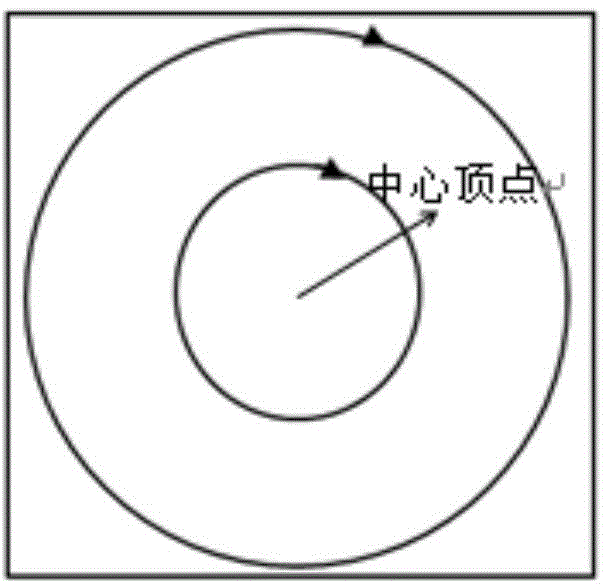

Swing arm contour surface shape detection method based on combination of radial scanning and circular scanning

A technology of radial scanning and detection method, applied in the direction of measuring devices, instruments, etc., can solve the problem of unsuitable optical singularity, and achieve the effect of improving measurement efficiency, improving measurement accuracy and wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 takes the detection of free-form surfaces as an example

[0034] Design a free-form surface whose surface shape is as Figure 5 Design the surface as shown, and process the above free-form surface.

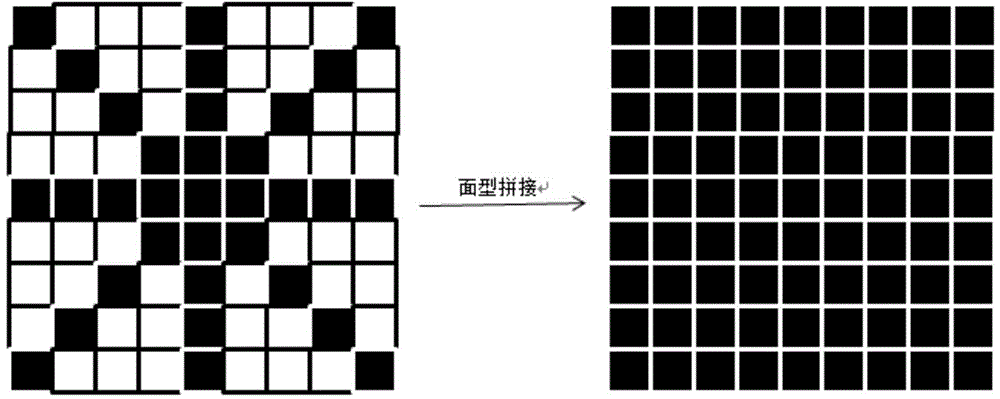

[0035] Utilize the swing arm profile surface shape detection method based on radial scanning combined with circular scanning of the present invention to detect the above-mentioned processed free-form surface shape information, the method steps are as follows:

[0036] The first step is to use the mathematical method based on Forbes polynomial fitting to scientifically describe the surface characteristics of the designed free-form surface, and obtain the surface gradient distribution of the free-form surface under non-analytic expression.

[0037] In the second step, according to the surface gradient distribution of the free-form surface under non-analytic expression, a mathematical model of the surface gradient and the free-form surface feature contour is esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com