Patents

Literature

269 results about "Severe plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

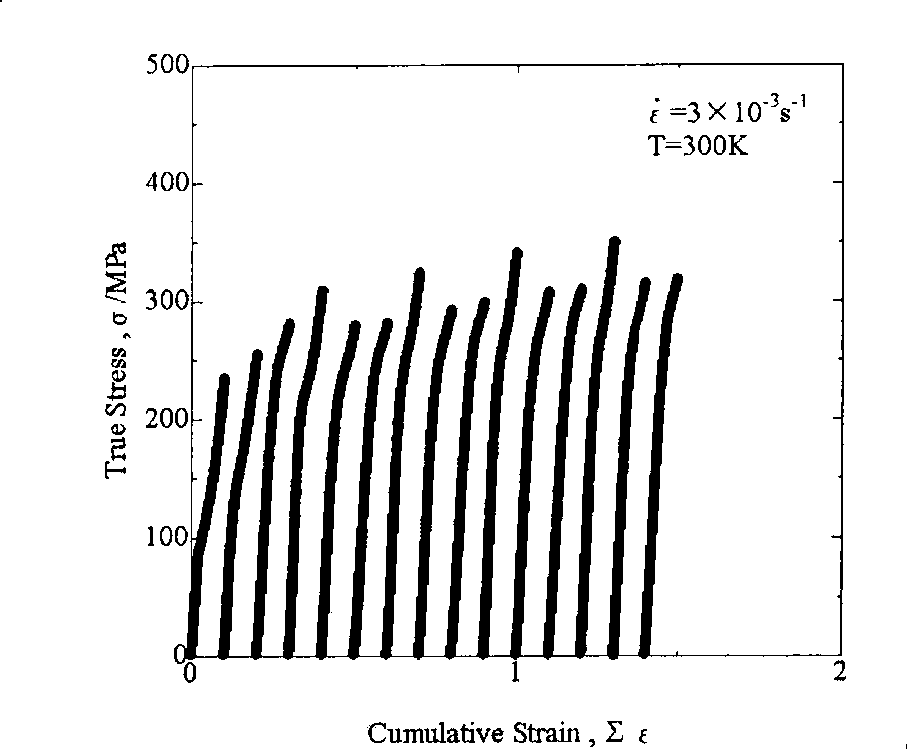

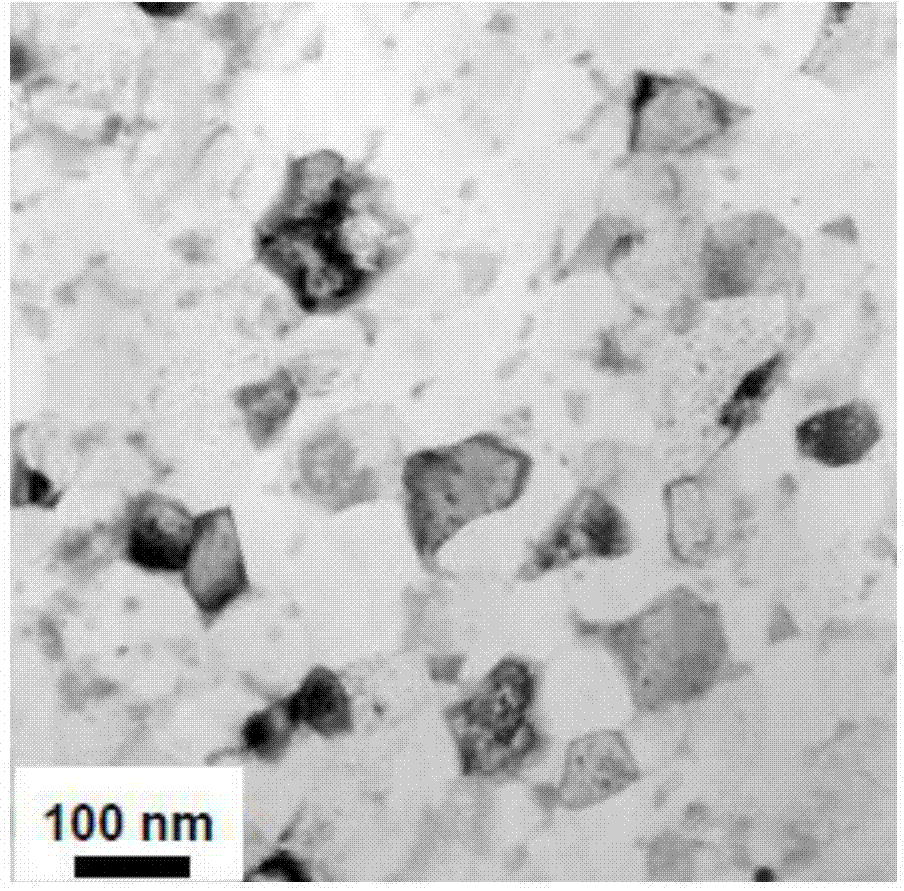

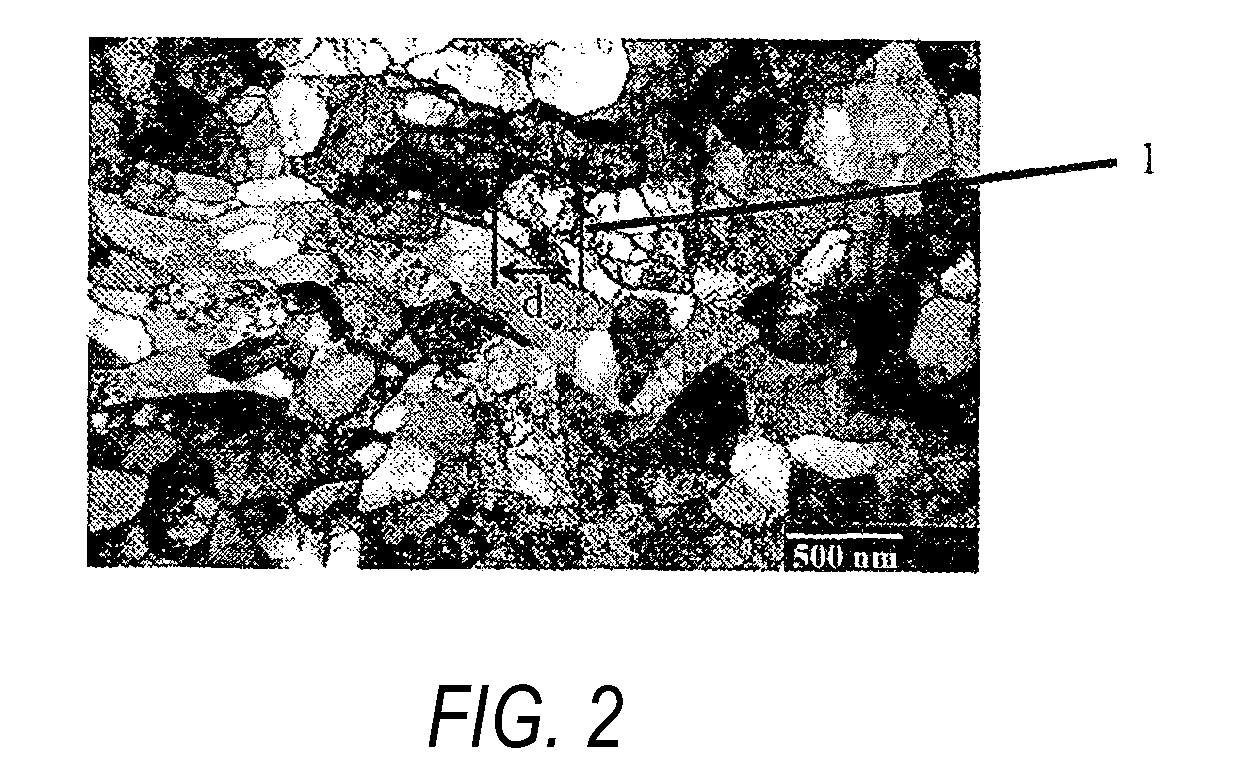

Severe plastic deformation (SPD) is a generic term describing a group of metalworking techniques involving very large strains typically involving a complex stress state or high shear, resulting in a high defect density and equiaxed "ultrafine" grain (UFG) size (d < 500 nm) or nanocrystalline (NC) structure (d < 100 nm).

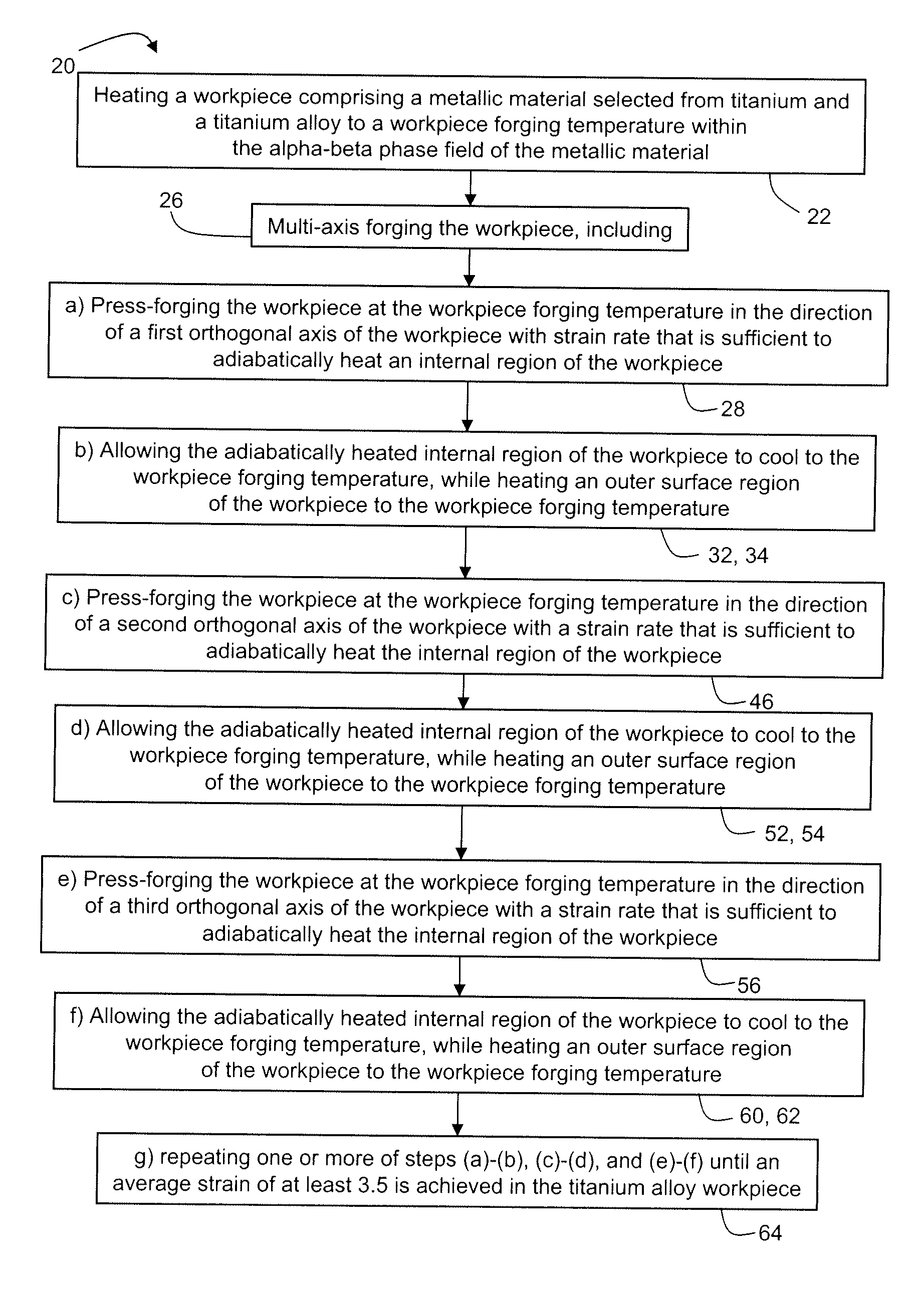

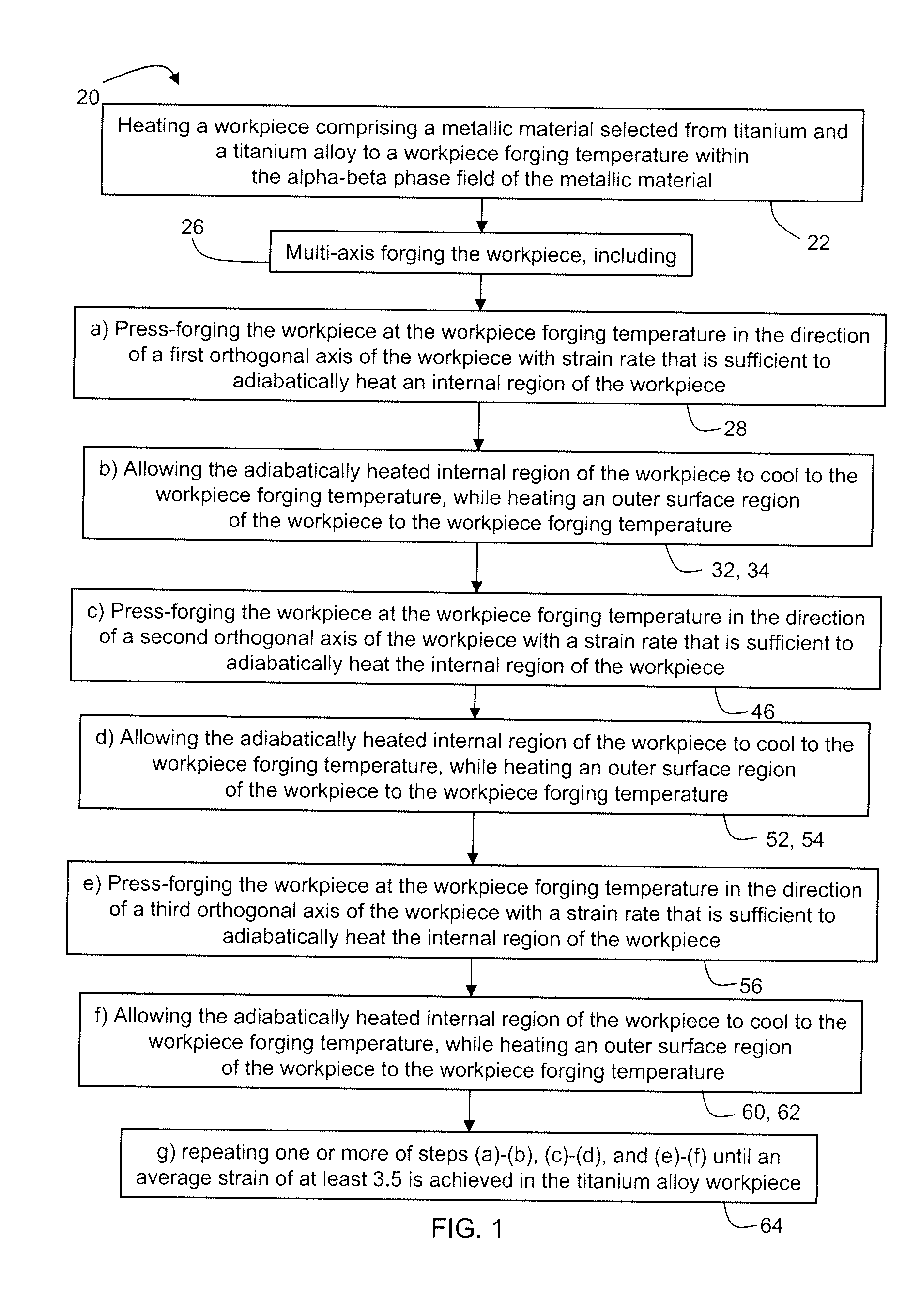

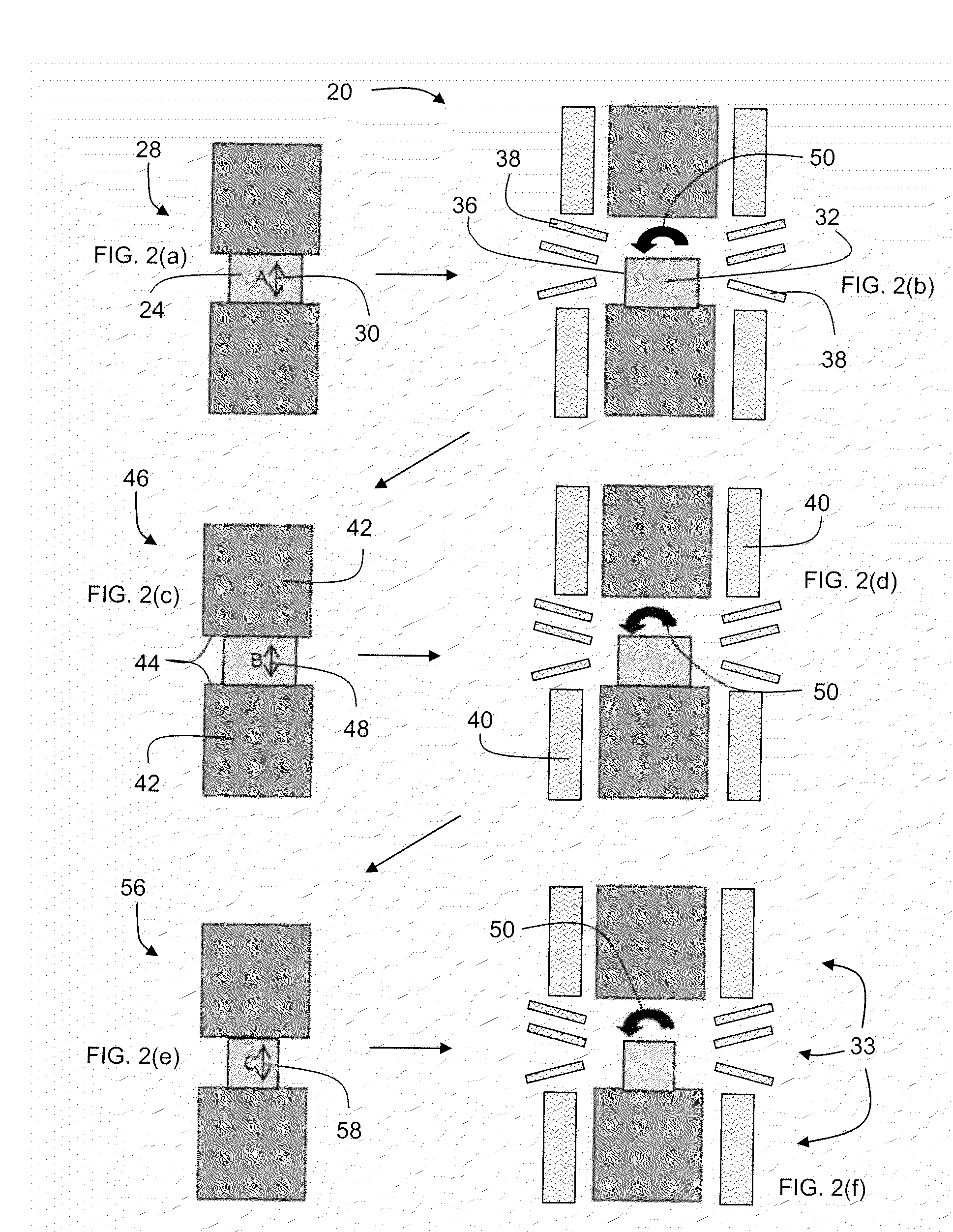

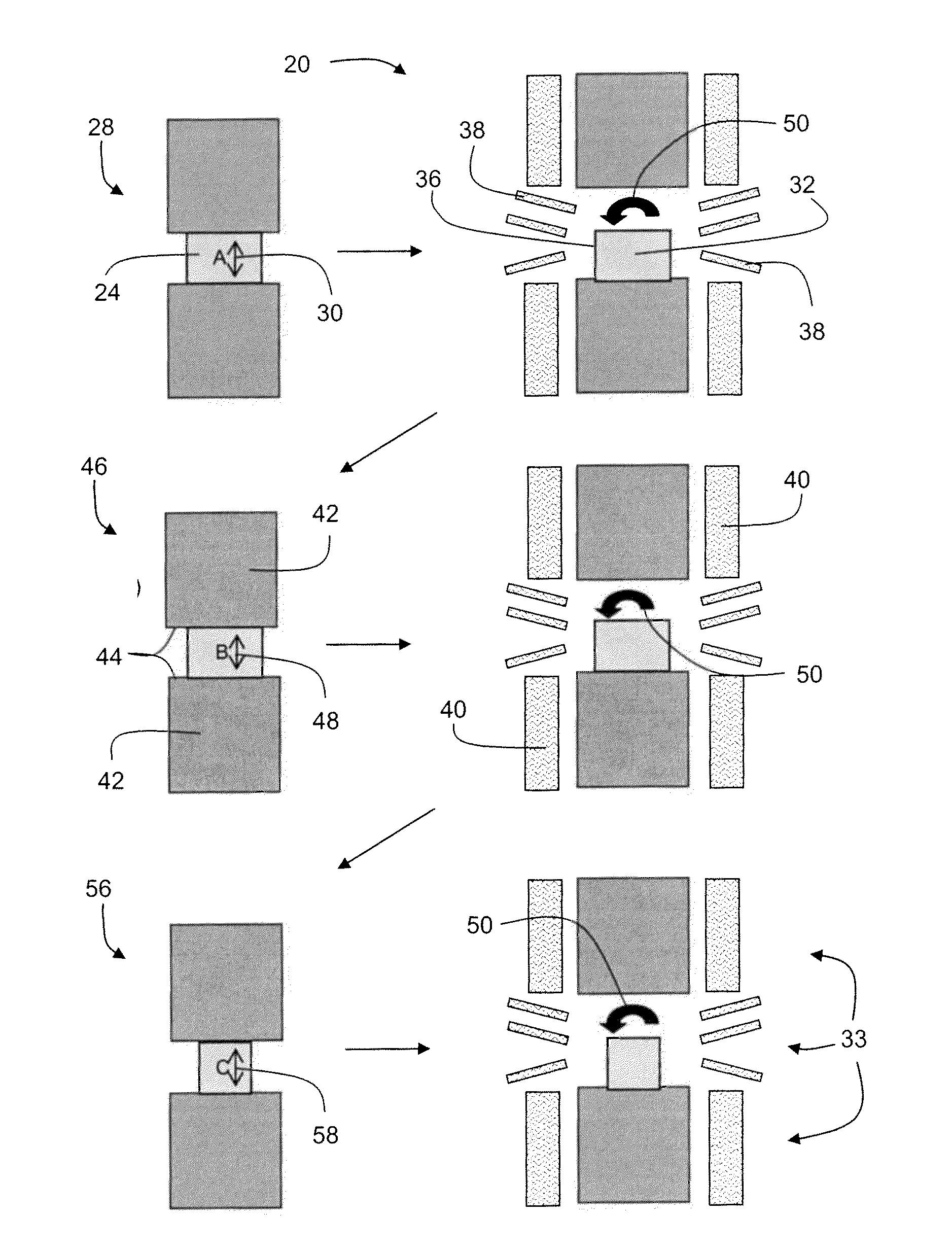

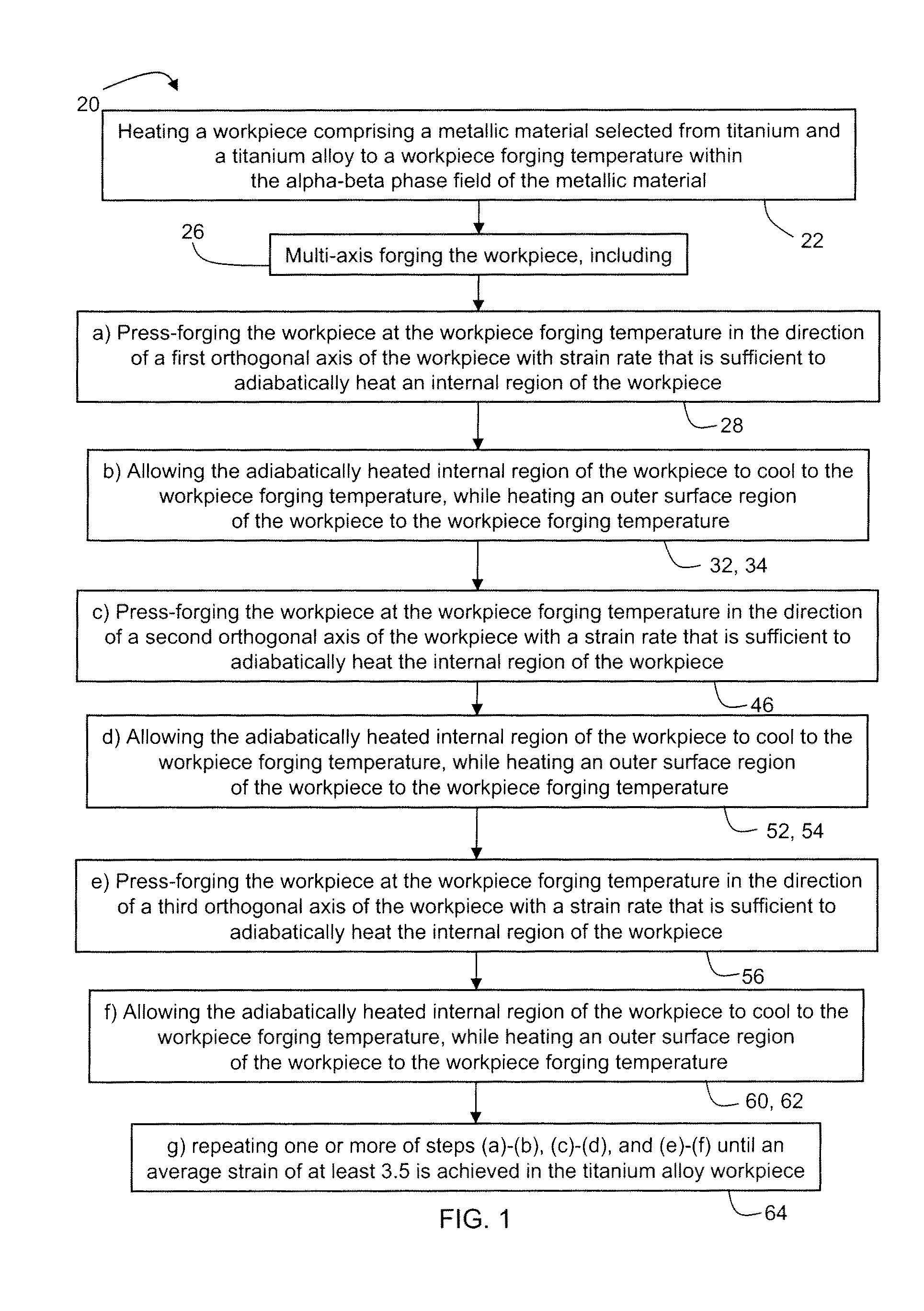

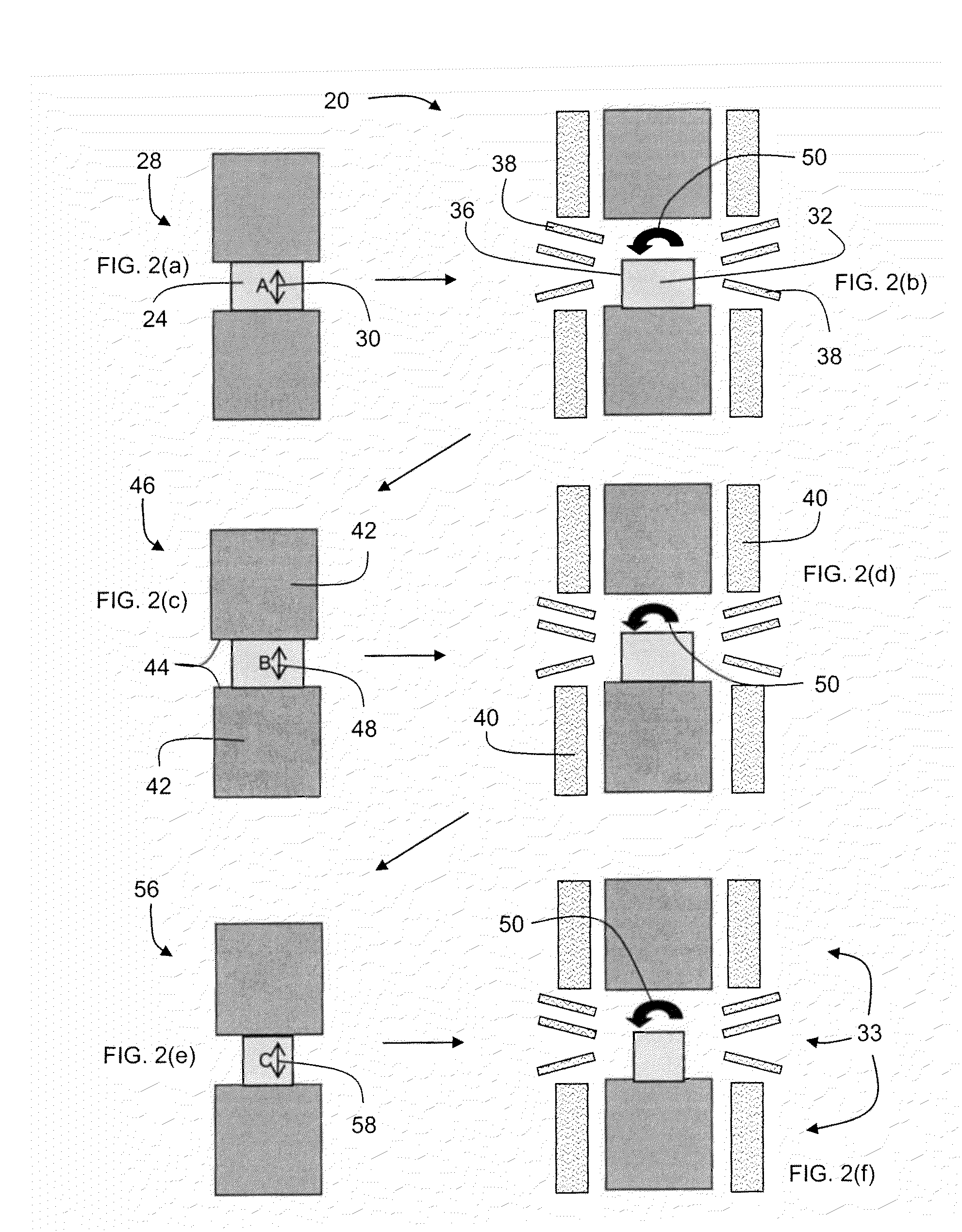

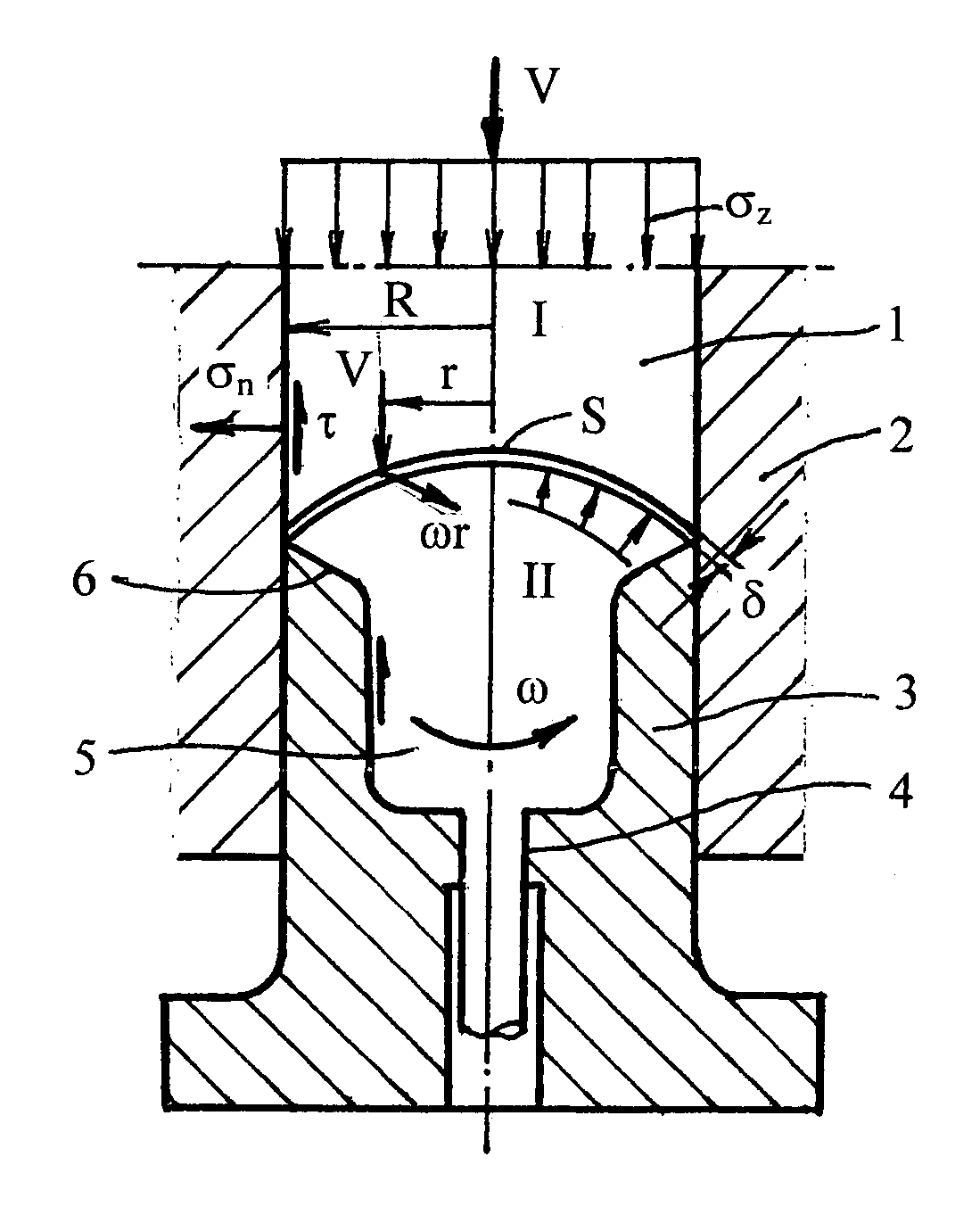

Processing Routes for Titanium and Titanium Alloys

Methods of refining the grain size of titanium and titanium alloys include thermally managed high strain rate multi-axis forging. A high strain rate adiabatically heats an internal region of the workpiece during forging, and a thermal management system is used to heat an external surface region to the workpiece forging temperature, while the internal region is allowed to cool to the workpiece forging temperature. A further method includes multiple upset and draw forging titanium or a titanium alloy using a strain rate less than is used in conventional open die forging of titanium and titanium alloys. Incremental workpiece rotation and draw forging causes severe plastic deformation and grain refinement in the titanium or titanium alloy forging.

Owner:ATI PROPERTIES LLC

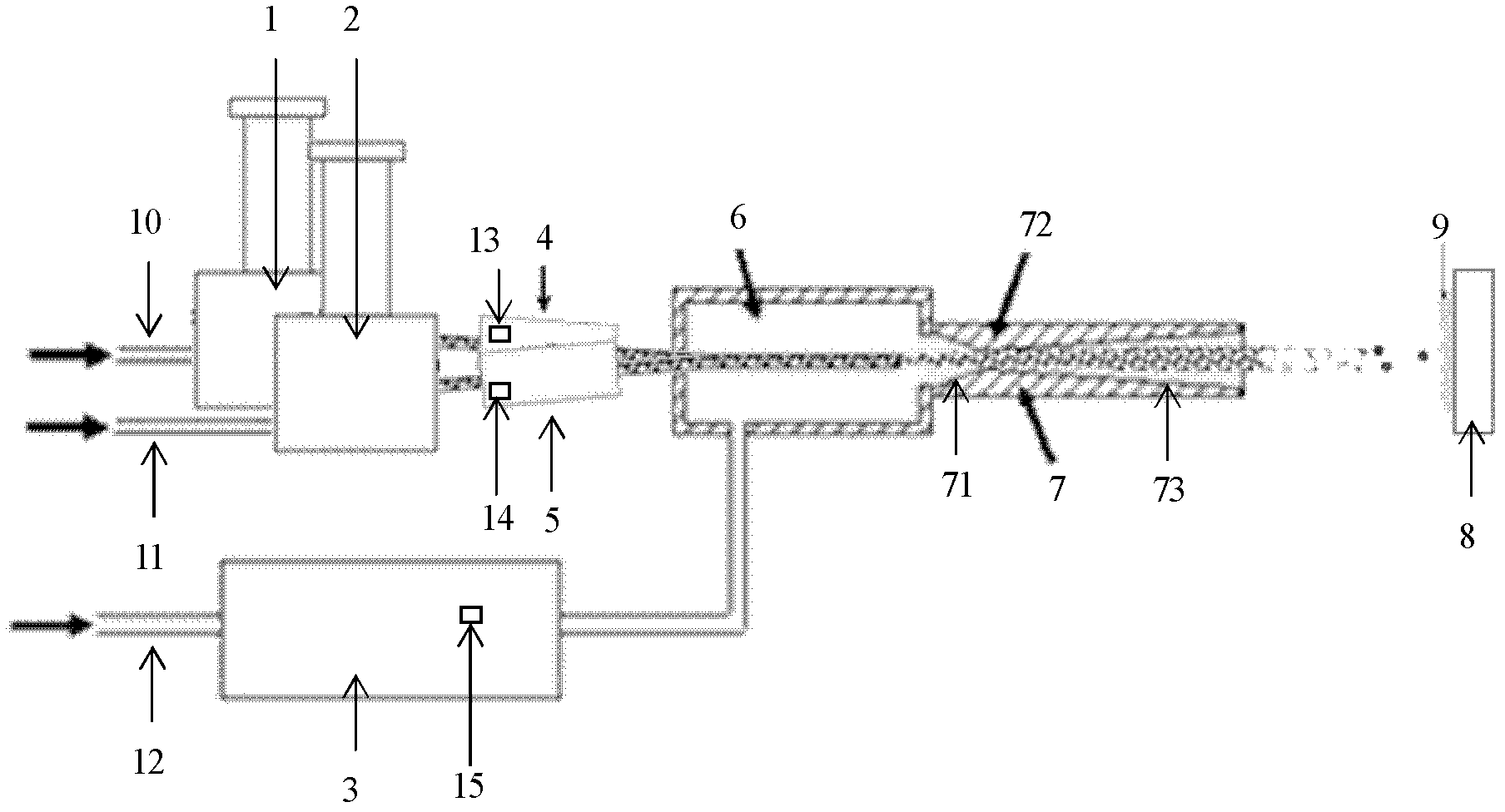

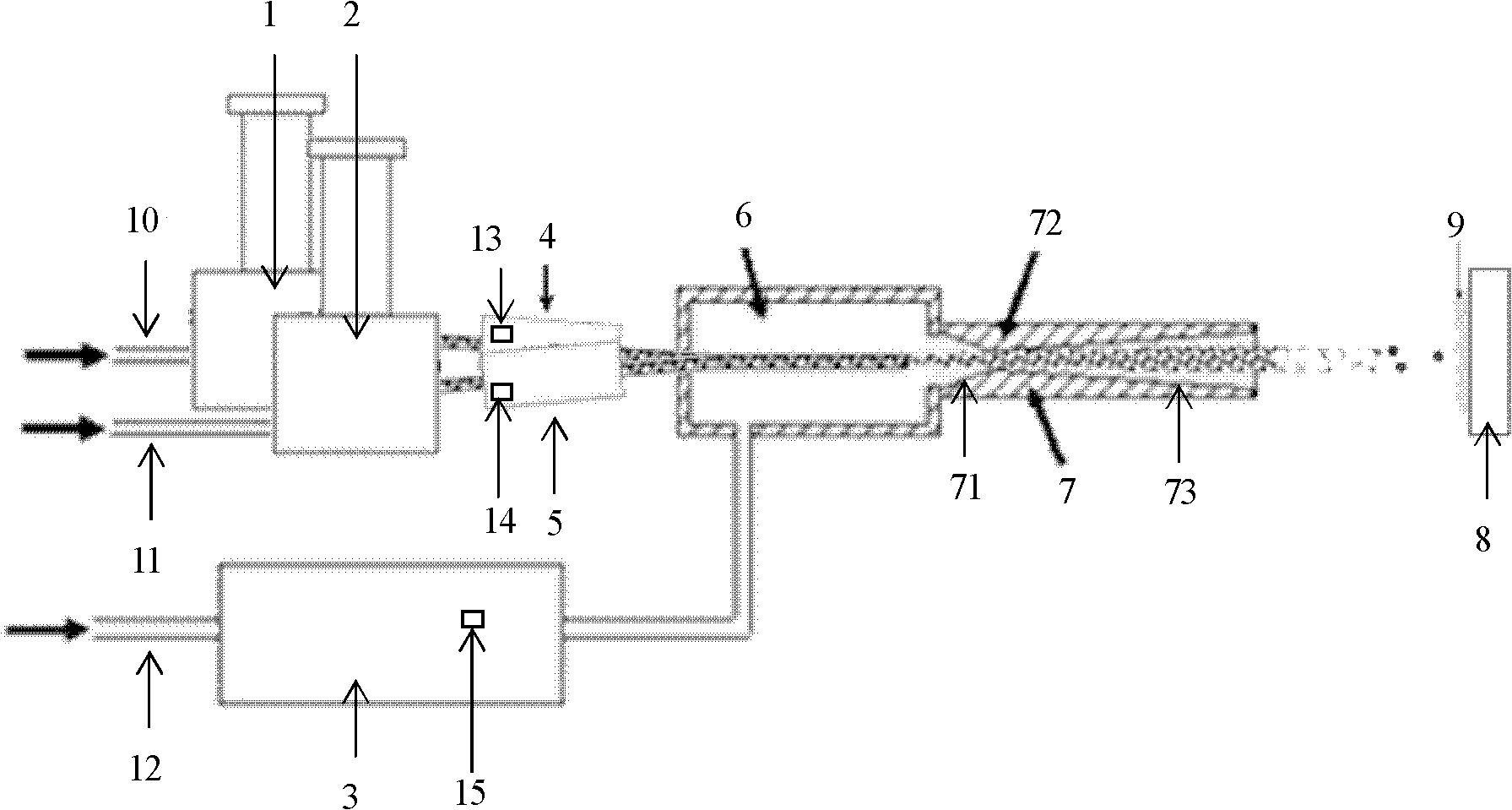

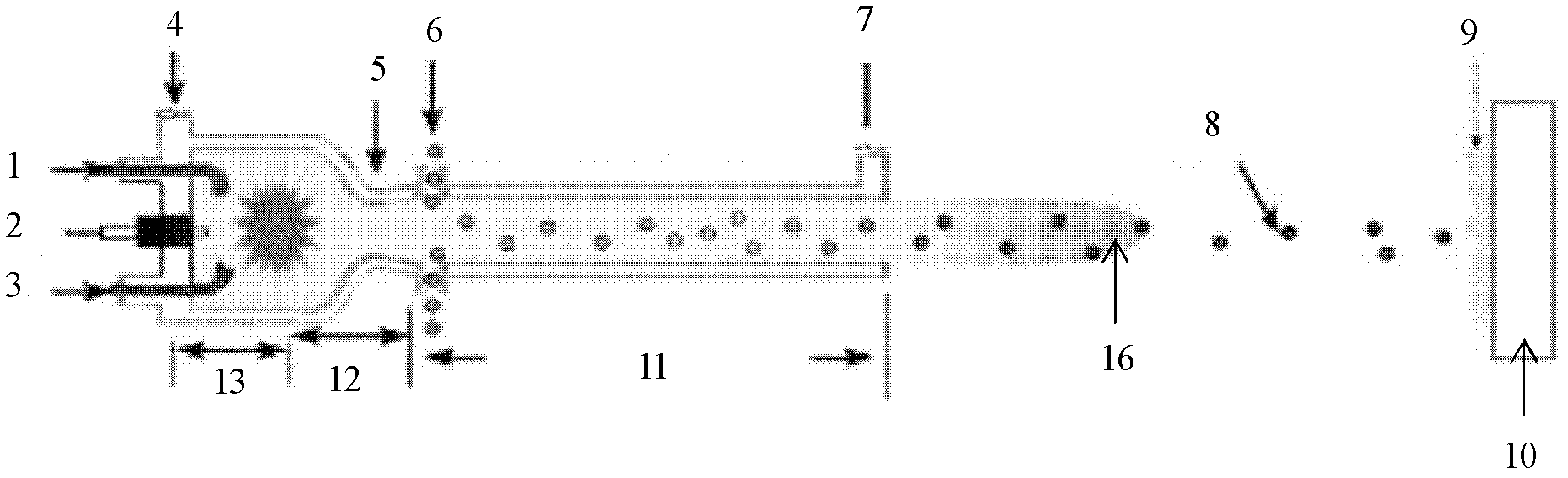

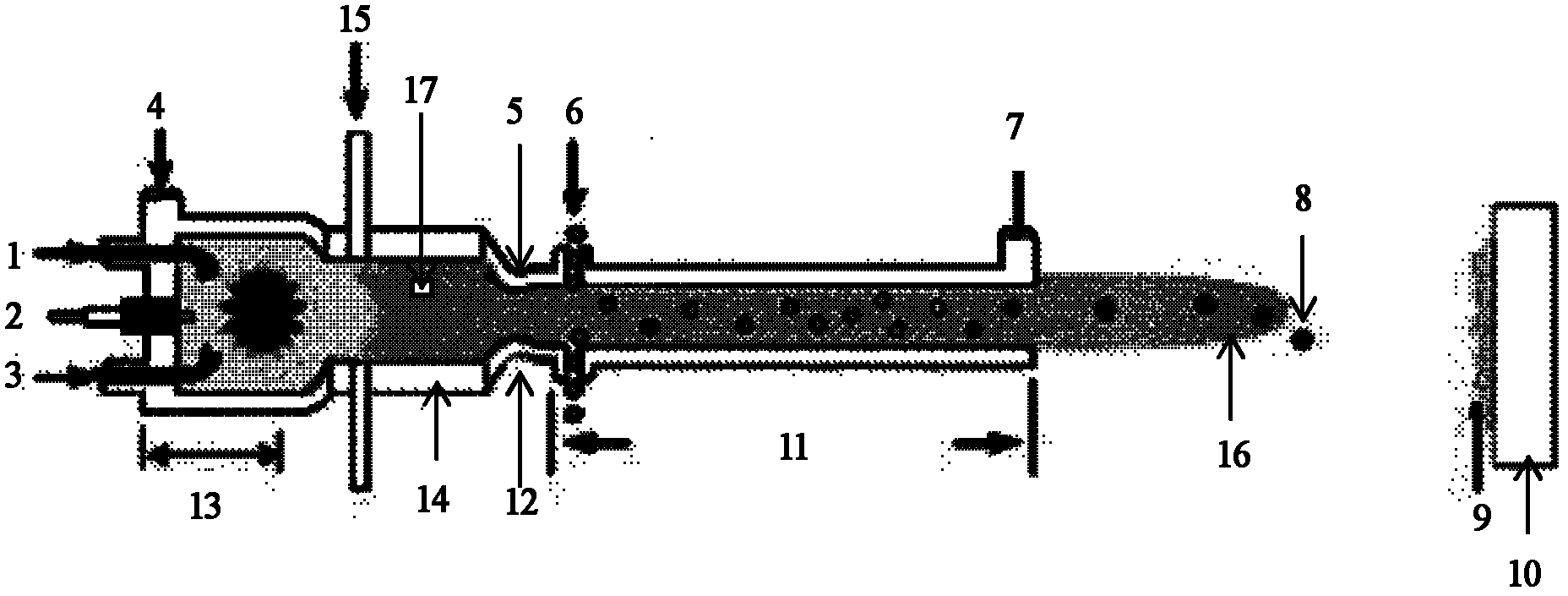

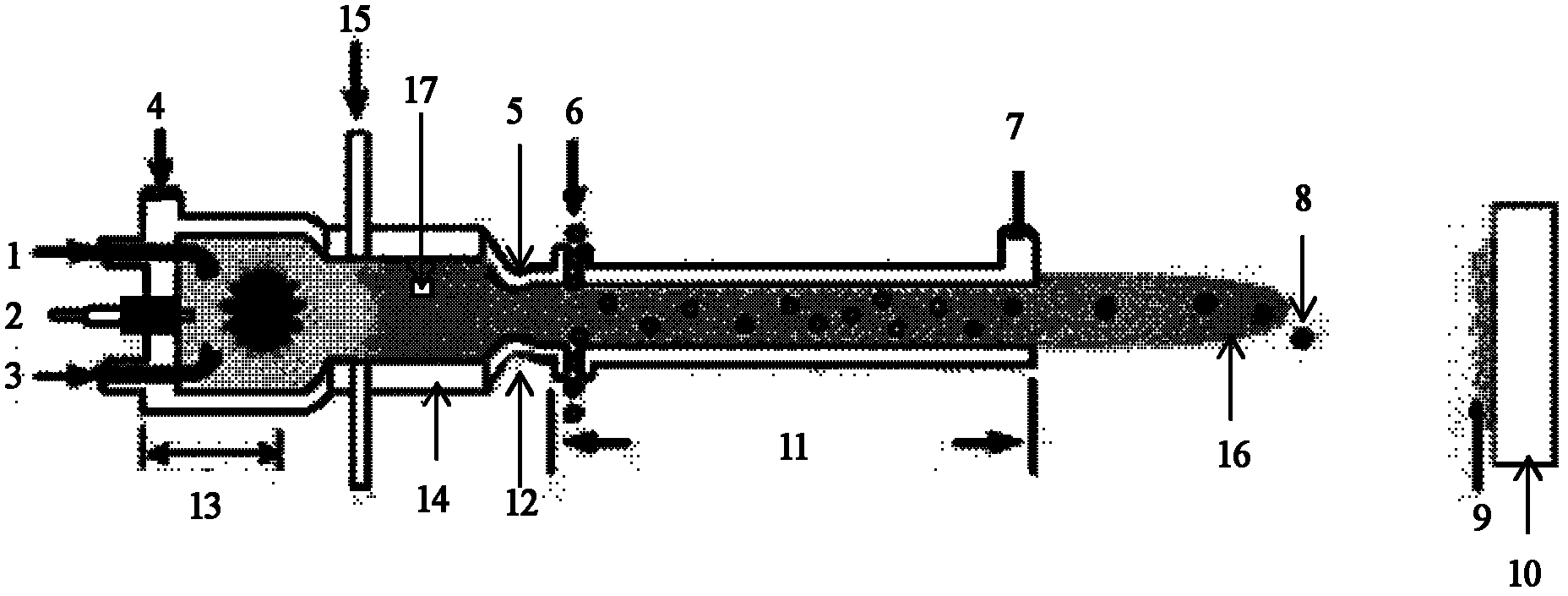

Cold spray device and method for preparing metal composite gradient quasicrystal coating

InactiveCN102527544AHigh speedLow spraying temperatureLiquid spraying apparatusSpecial surfacesForming gasGas heater

The invention relates to the field of surface coating preparation and particularly relates to a cold spray device and method for preparing a metal composite gradient quasicrystal coating. A quasicrystal powder feeder and a metal or alloy powder feeder of the device are respectively connected to a gas-solid mixing chamber through a pipeline to form a dual-channel powder feeding structure, a quasicrystal heater and a metal or alloy powder heater are respectively arranged on the pipelines, a gas heater is connected with the gas-solid mixing chamber through a pipeline and a supersonic flow nozzle is arranged at an outlet of the gas-solid mixing chamber. One path of the gas source compressed gas enters into the quasicrystal powder feeder, one path enters into the metal powder feeder, and one path enters into the heater, the gas and the powders enter into the supersonic flow nozzle via the gas-solid mixing chamber to form gas-solid dual-phase flow, solid particles in the gas-solid dual-phase flow are injected onto the surface of a workpiece and generate severe plastic deformation and finally deposit on the surface of the workpiece. The method provided by the invention can solve the problems of fragility and phase change and the like of coatings, and can be used for preparing two-component or multi-component alloy quasicrystal gradient coatings of various series.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

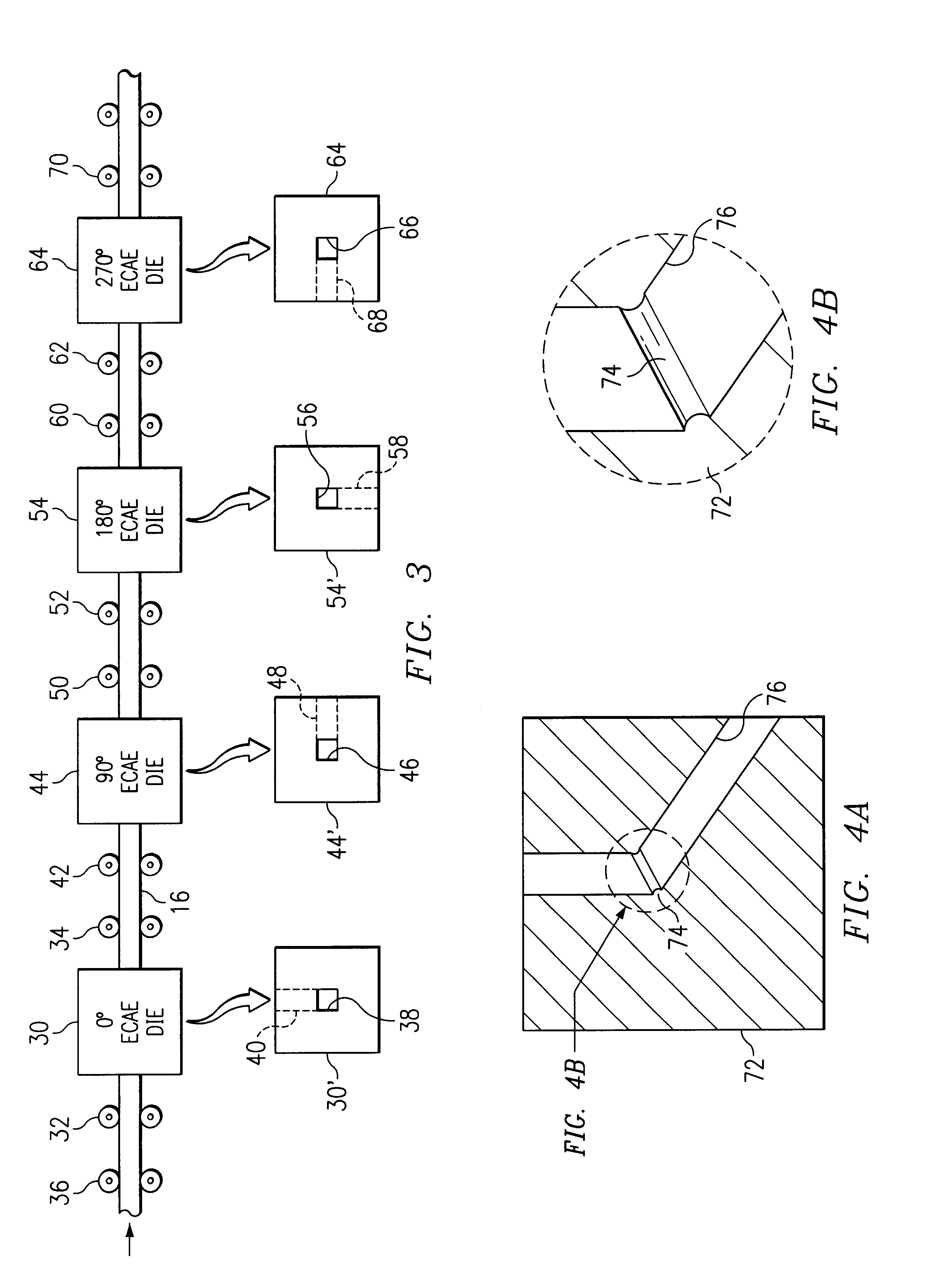

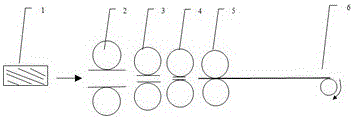

Continuous severe plastic deformation process for metallic materials

A method of processing a billet of metallic material in a continuous manner to produce severe plastic deformation. The billet is moved through a series of CSPD dies in one operation to efficiently produce a billet characterized by a controlled grain structure. The long billets of metal stock are moved along the processing path through the CSPD dies with plural sets of pinch rolls which grip the billet and push it into the entry channel of the dies. Other sets of pinch rolls pull the billet from the exit channel of the dies.

Owner:DATRON INTERCONTINENTAL MFG +3

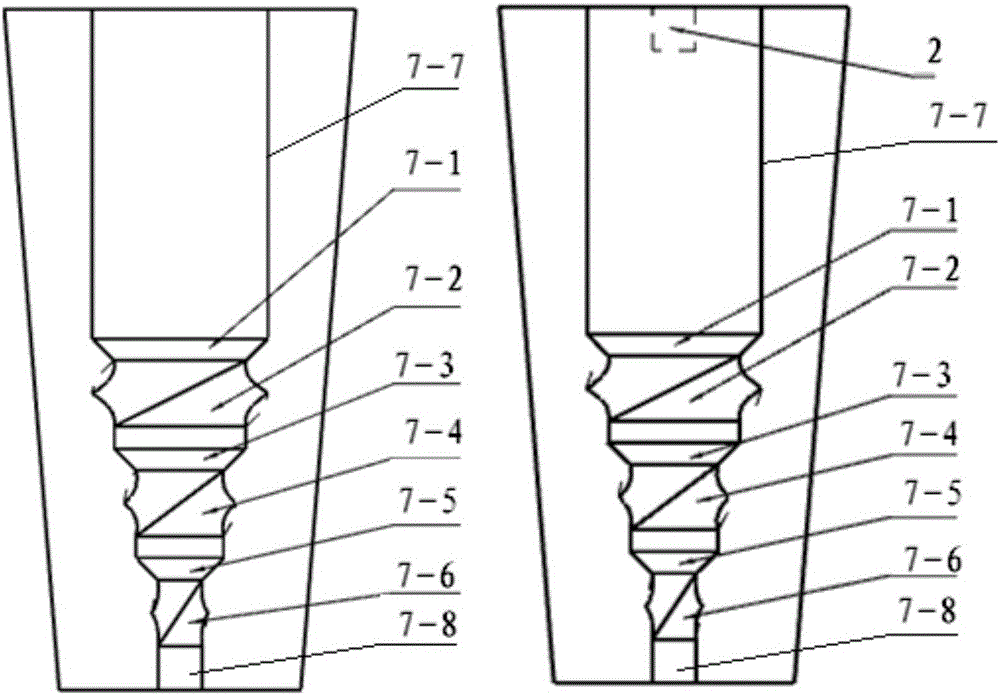

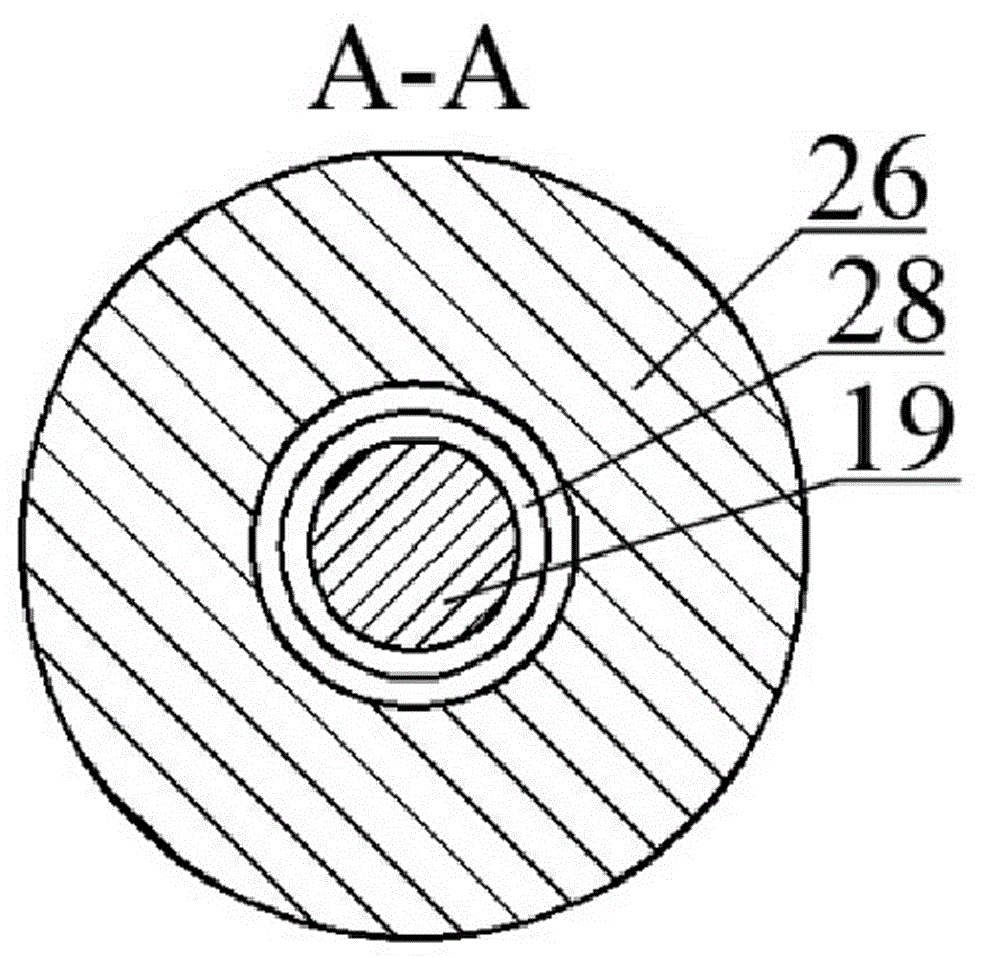

Pin tool for friction stir welding and ultrafine grain preparation method thereof

InactiveCN101537529AReduce use costIncrease the cost of useEngine sealsNon-electric welding apparatusTemperature controlEngineering

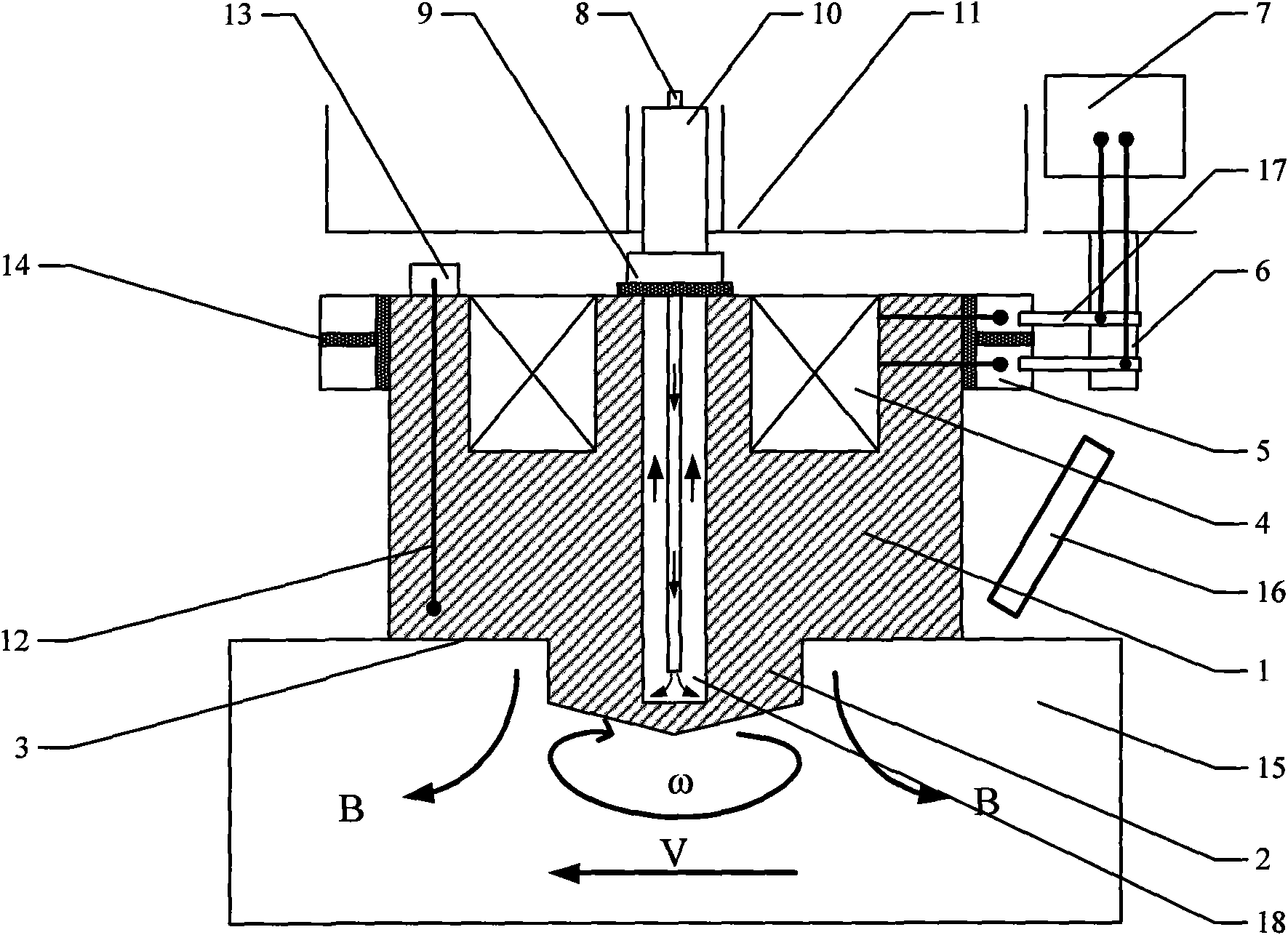

The invention discloses a pin tool used for friction stir welding, which integrates an electromagnetic vibration system, an electromagnetic action system, an internal forced cooling system, a gas-shielded forced cooling system, a temperature induction system and a sealing and insulation system, and is an integrated pin tool used for friction stir welding, which has the functions of electromagnetic vibration in-situ composite electromagnetic action, forced temperature control, gas shielding and temperature detection, and a device thereof is further disclosed, and can be applied in electromagnetic vibration in-situ composite electromagnetic action friction stir welding and the preparation of ultrafine grain materials with large thickness and large area by severe plastic deformation.

Owner:CHONGQING UNIV

Uniformly-dispersed particle reinforced metal-based composite material and preparation method thereof

InactiveCN102134664AGood for comprehensive performanceEvenly distributedMetal rolling arrangementsMetal matrix compositeMaterials processing

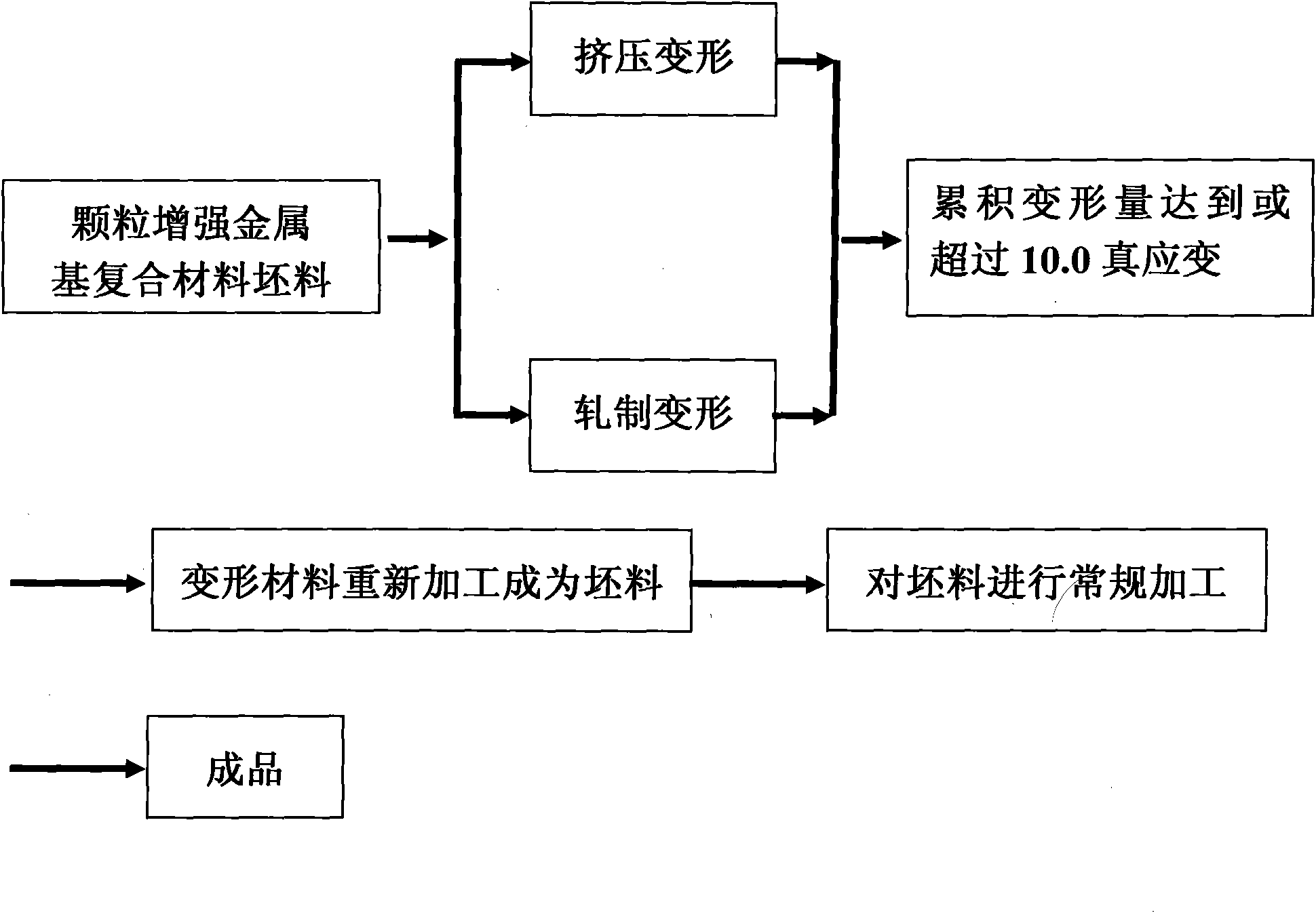

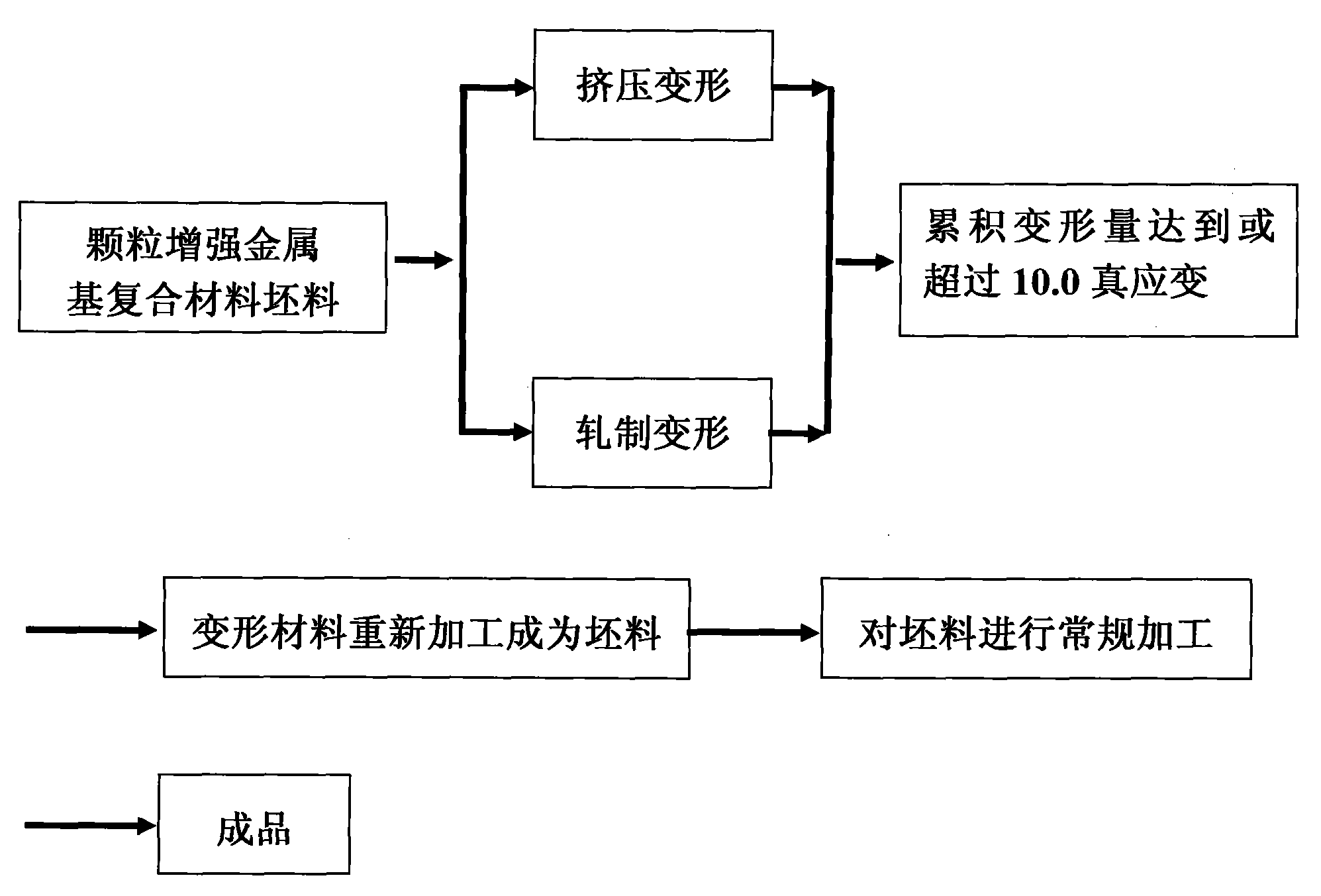

The invention discloses a particle reinforced metal-based composite material product (rods, wires, sheets or belts, or parts) which is obtained, based on the severe plastic deformation theory of material, by the step of performing severe plastic / accumulated deformation processing on a particle reinforced metal-based composite material so that second phase particles agglomerated in a metallic matrix are uniformly distributed (dispersed) in the matrix, and then carrying out subsequent processing, thereby enhancing the quality and the yield of the particle reinforced composite material and lowering the processing cost of the material, and thus a particle reinforced metal-based composite material having the characteristic of the uniformly distributed second phase particles and excellent performance is obtained.

Owner:KUNMING UNIV OF SCI & TECH

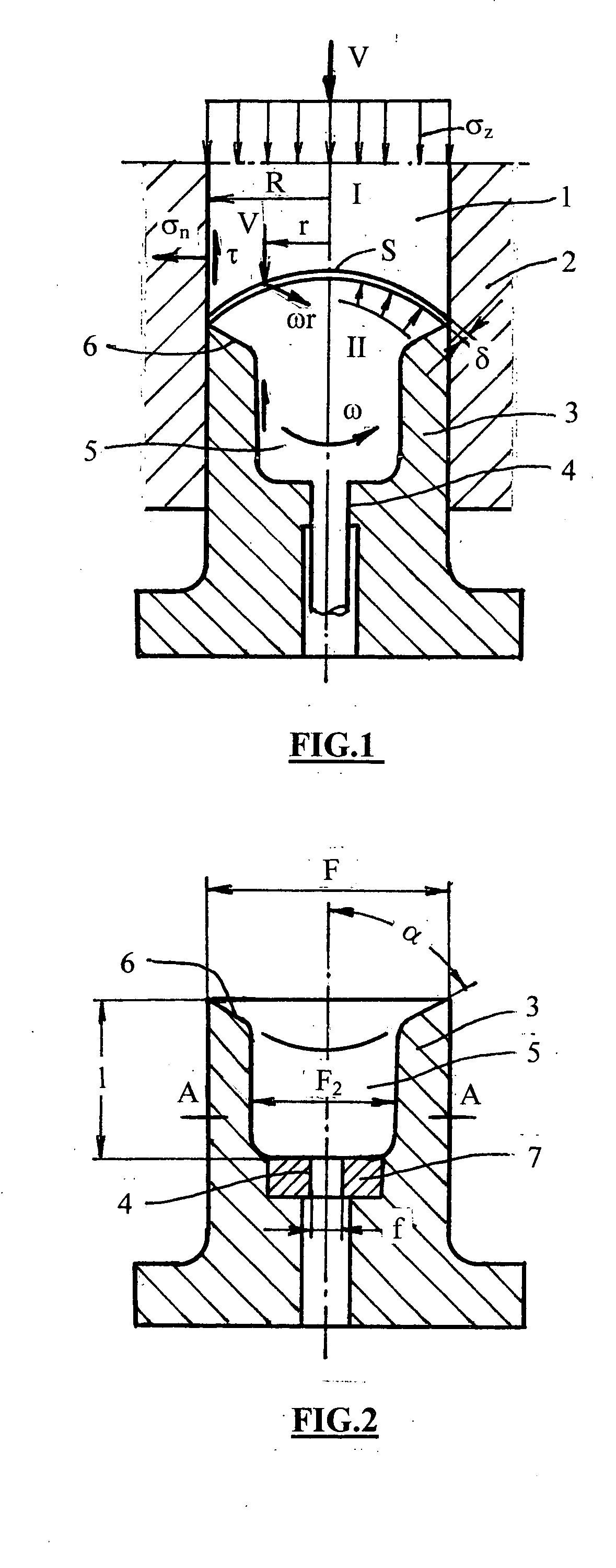

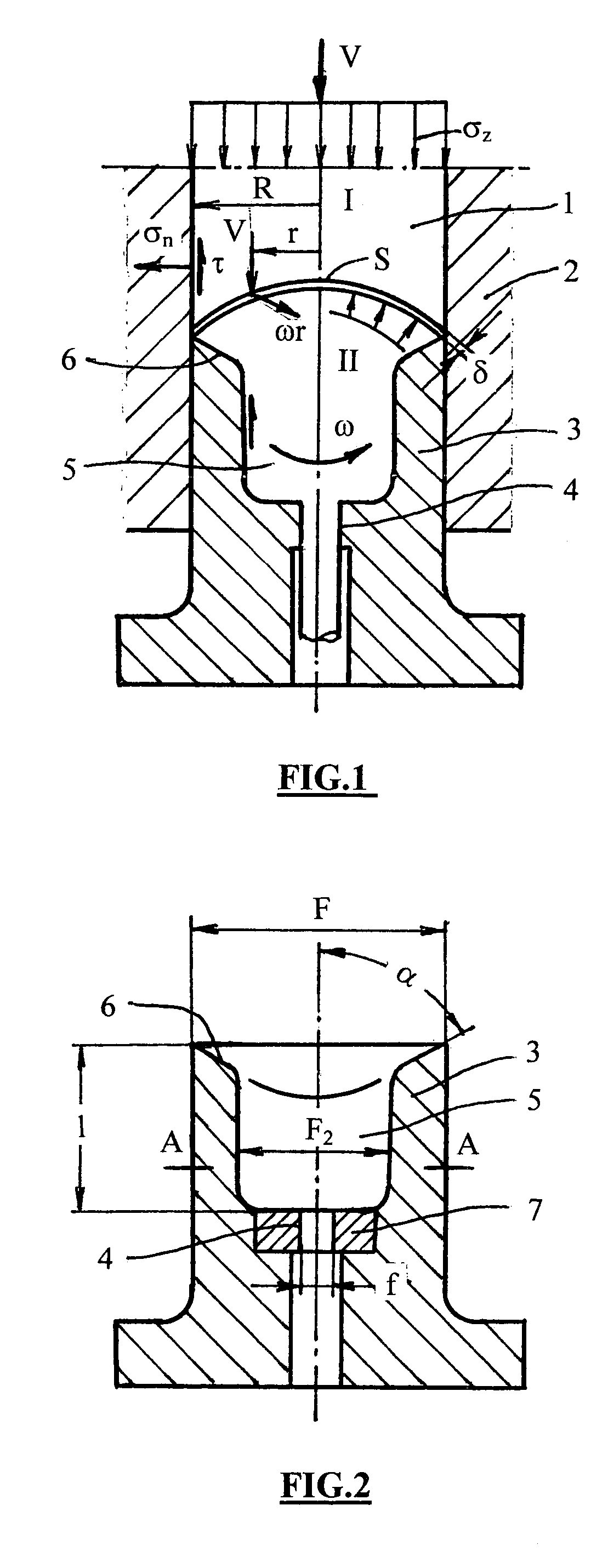

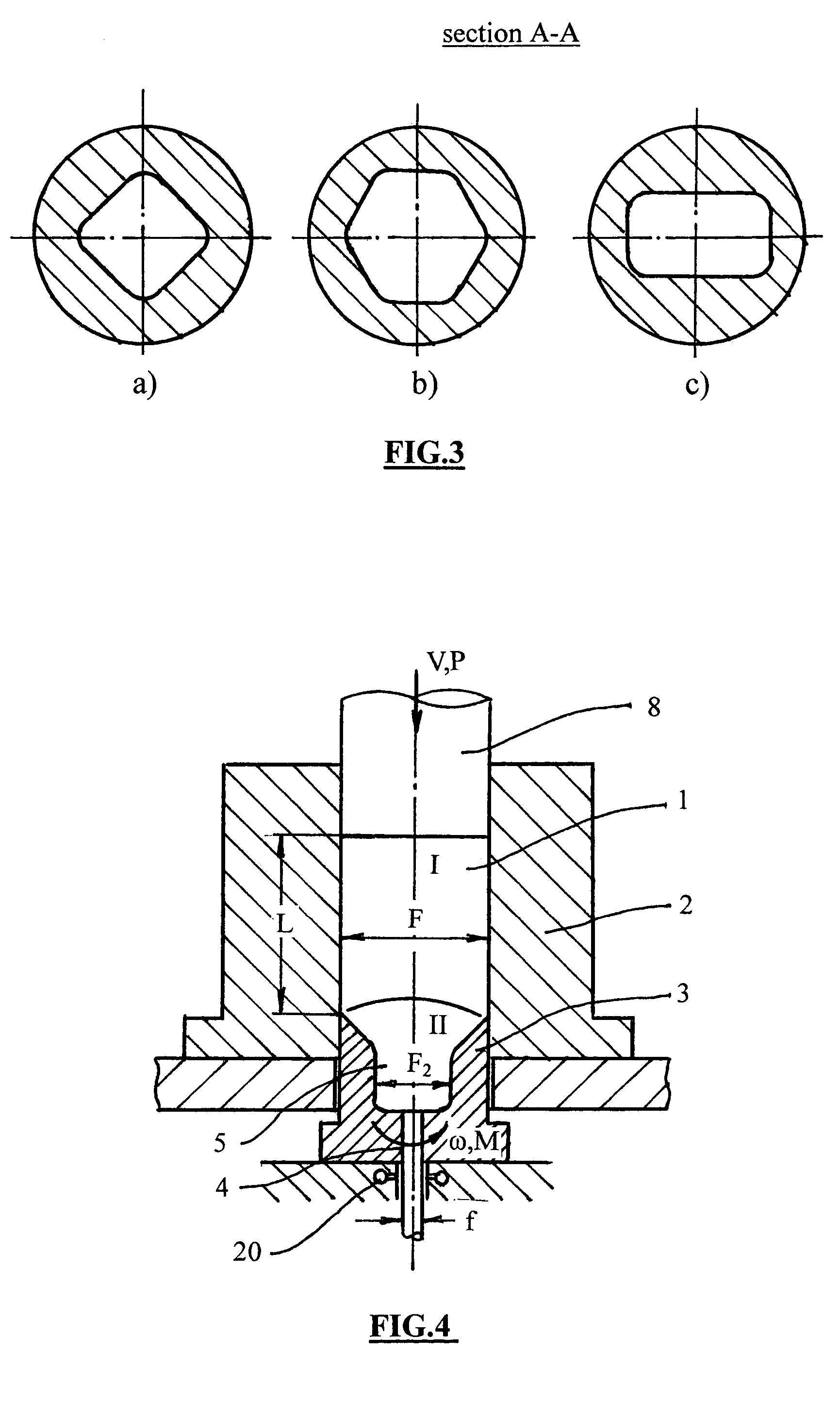

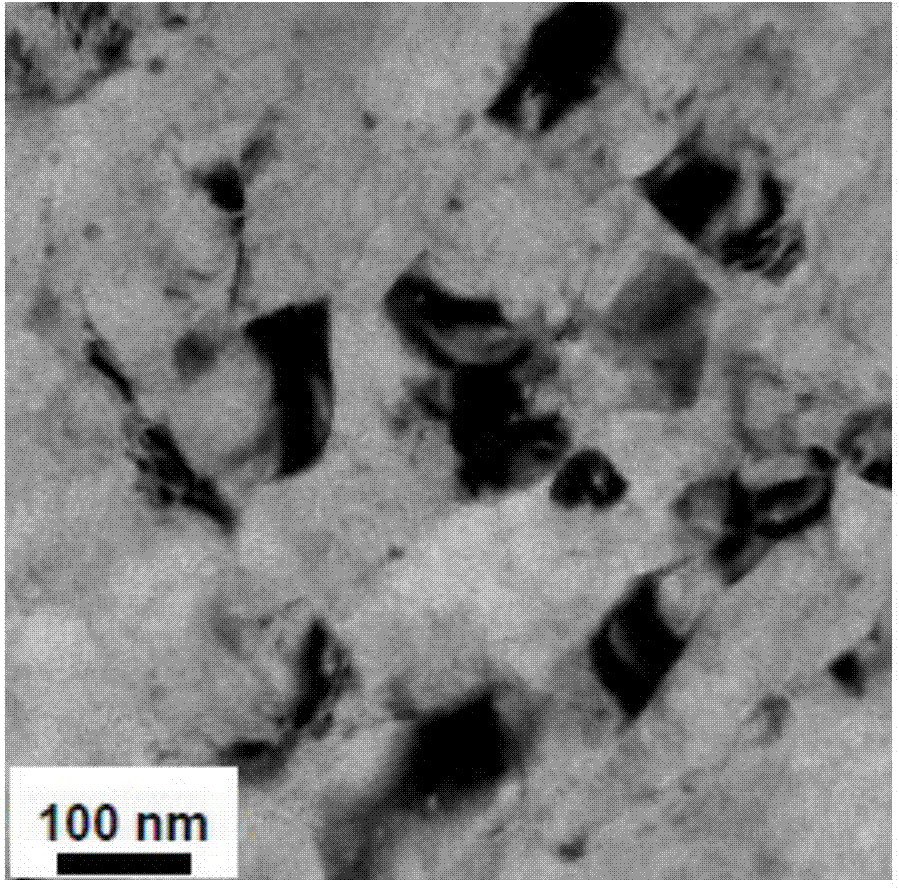

Twist-extrusion process

InactiveUS20050081594A1Extrusion containersMetal rolling arrangementsProduction rateHydrostatic pressure

A shear-extrusion method of severe plastic deformation for fabrication of metal shapes with ultra-fine structures is described. The improvements of the method include unidirectional shear of any required intensity during one step processing and under high hydrostatic pressures, fabrication of long products with different cross-sections, refinement of low ductile alloys, the increase of productivity and cost reduction. The method can be realized as forward extrusion, backward extrusion, semi continuous extrusion and extrusion of hollow shapes in portal dies with a welding chamber.

Owner:ENGINEERED PERFORMANCE MATERIALS

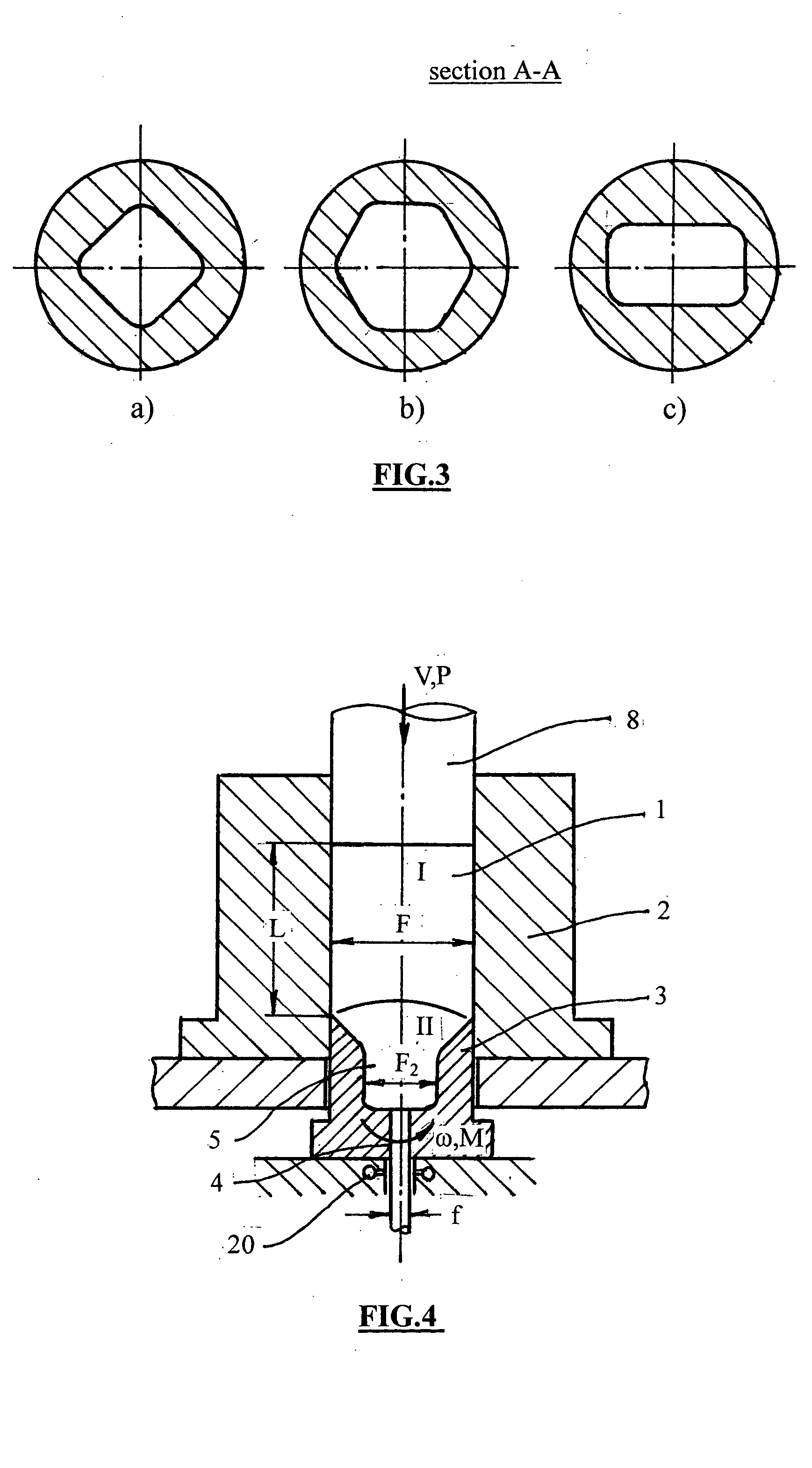

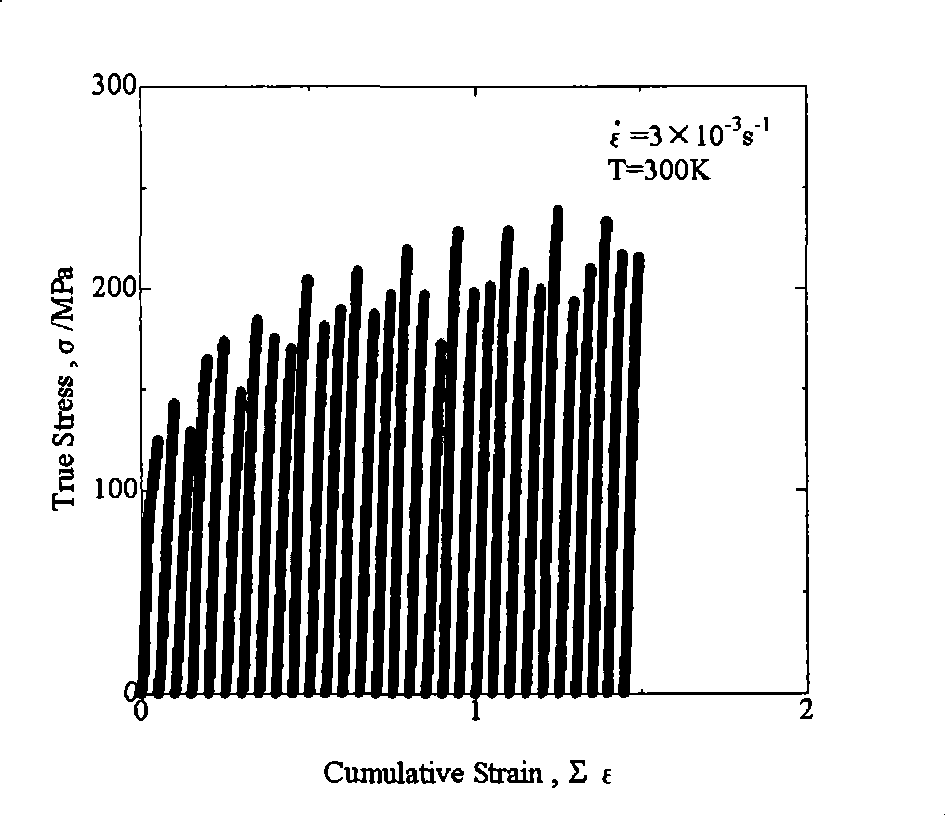

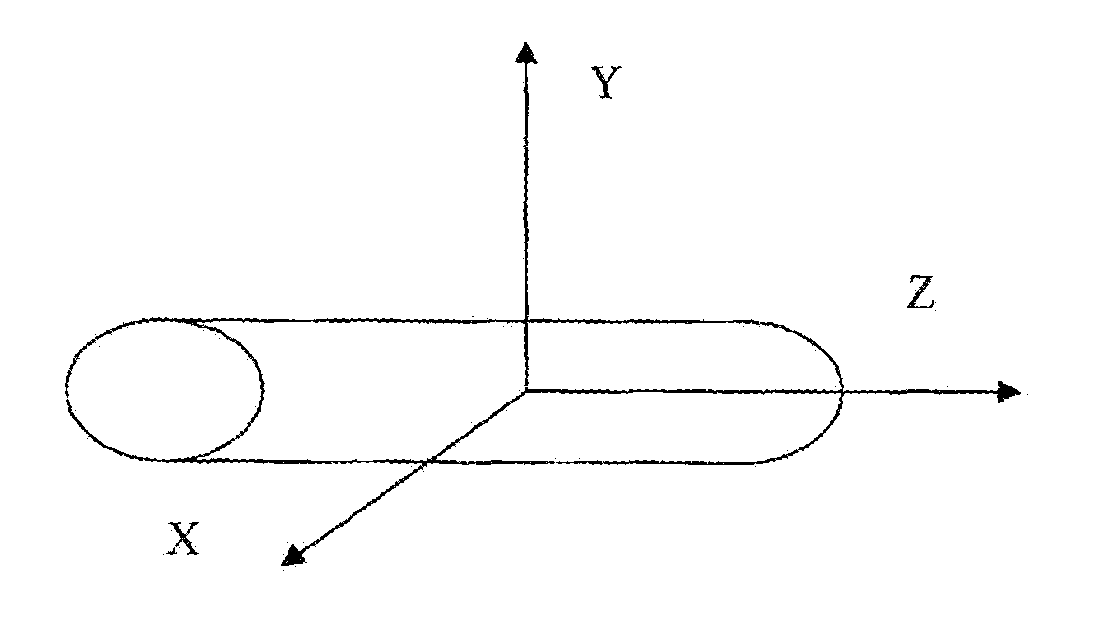

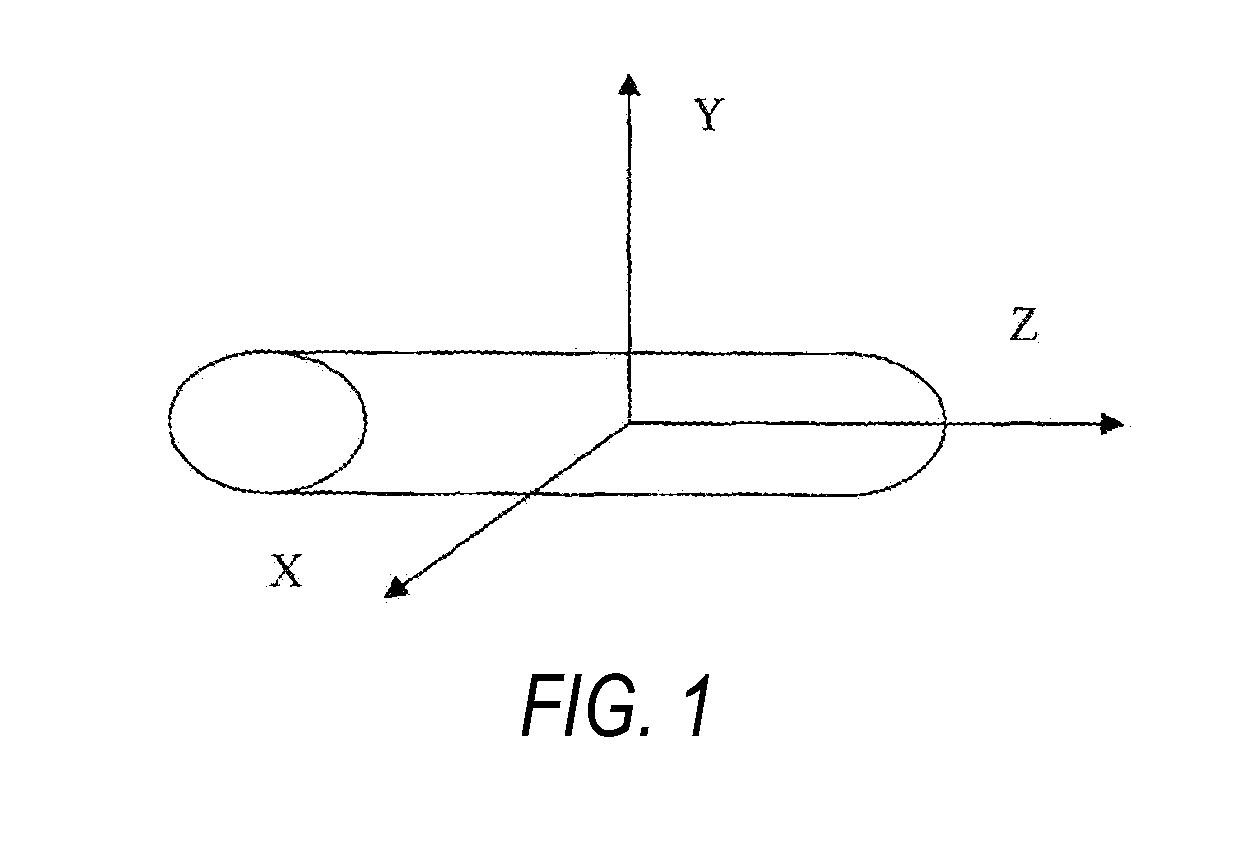

Method for preparing bulk nano/superfine crystal grain magnesium alloy by twinning deformation

A method for preparing block nano-magnesium alloy by utilizing twinning deformation comprises: magnesium alloy cast ingots or extruded bars are cut into rectangular blocks; compression twin crystal deformation with multiple channels and axes is respectively carried out along three direction of X axis, Y axis and Z axis of the rectangular block at the room temperature; the true strain capacity and the strain rate at every channel are controlled; when the true strain capacities along all the directions are accumulated to reach at least 1.5h, the twin crystal reinforced block nano-magnesium alloy having the average size being less than 0.5mum can be obtained. The method has simple processing technique and equipment requirements as well as convenient operation, and can overcome the problems of incontrollable recrystallization, poor effect of strain accumulation and difficult scale in severe plastic deformation of the prior art when in thinning magnesium alloy crystal grains; the method can be used for preparing large dense superfine grained magnesium alloy material and has good industrial application prospect.

Owner:CENT SOUTH UNIV

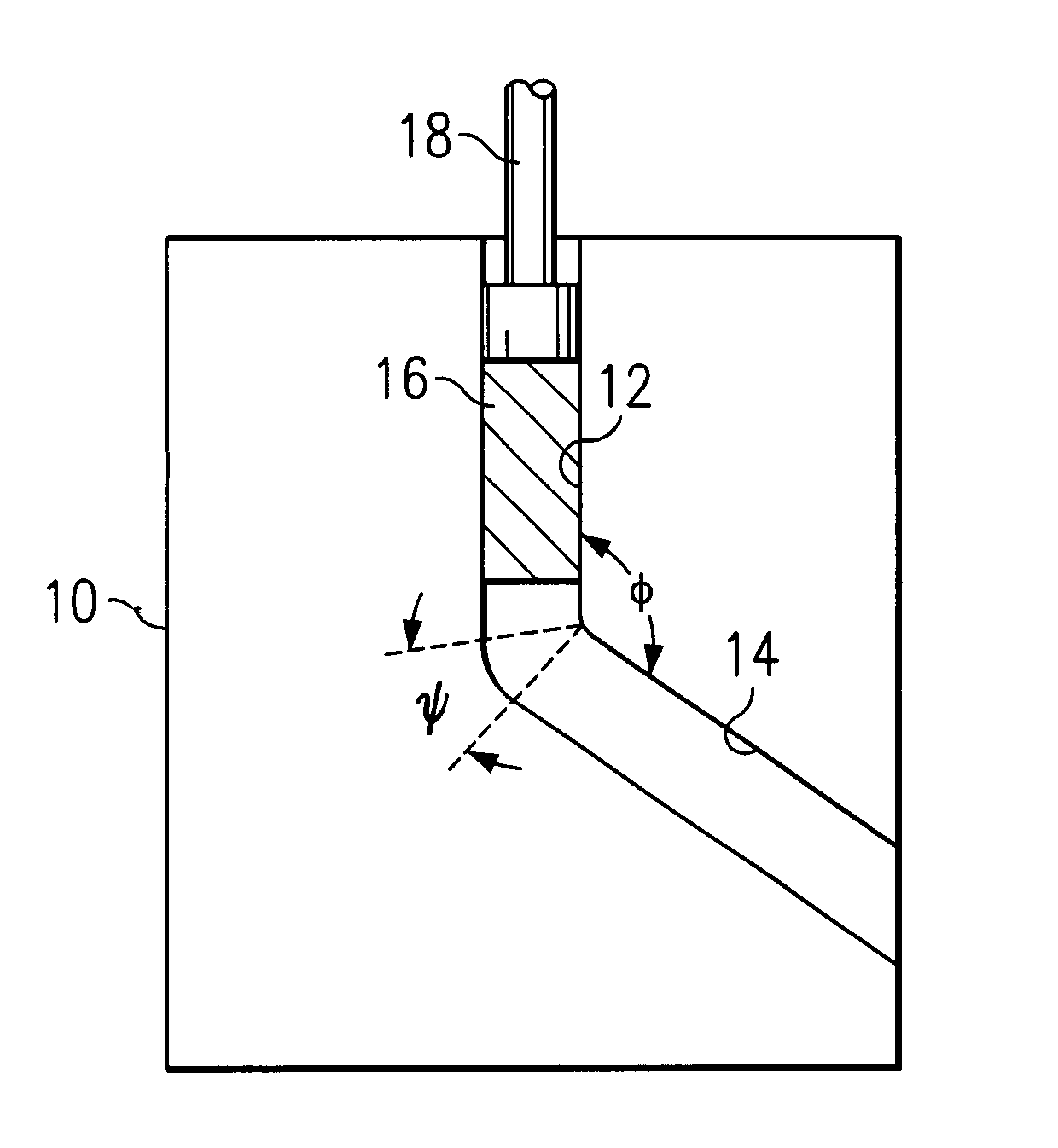

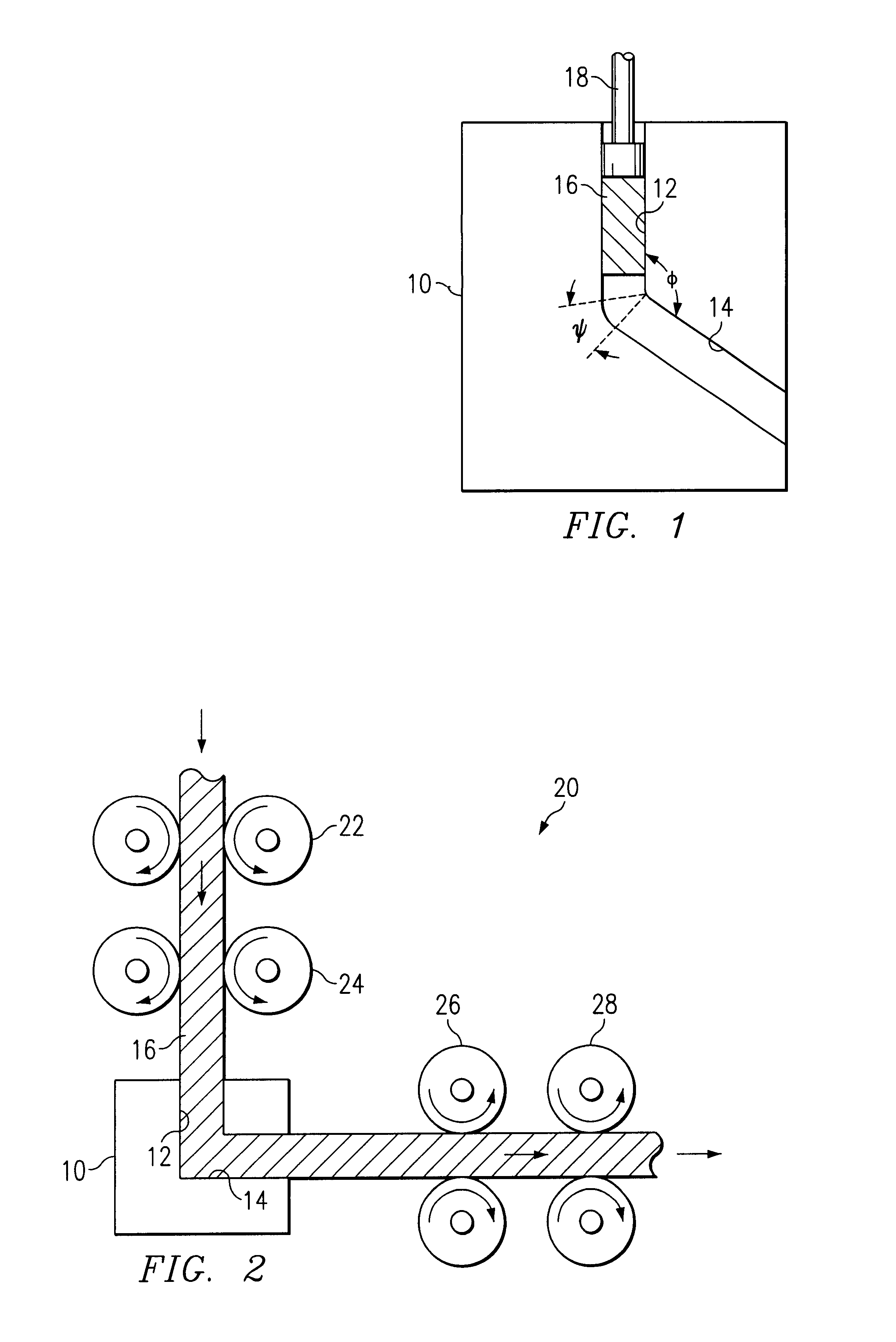

Nanostructured commercially pure titanium for biomedicine and a method for producing a rod therefrom

ActiveUS20110179848A1Improve failureImprove propertiesNanostructure manufactureMetal-working apparatusEqual channel angular extrusionCommercially pure titanium

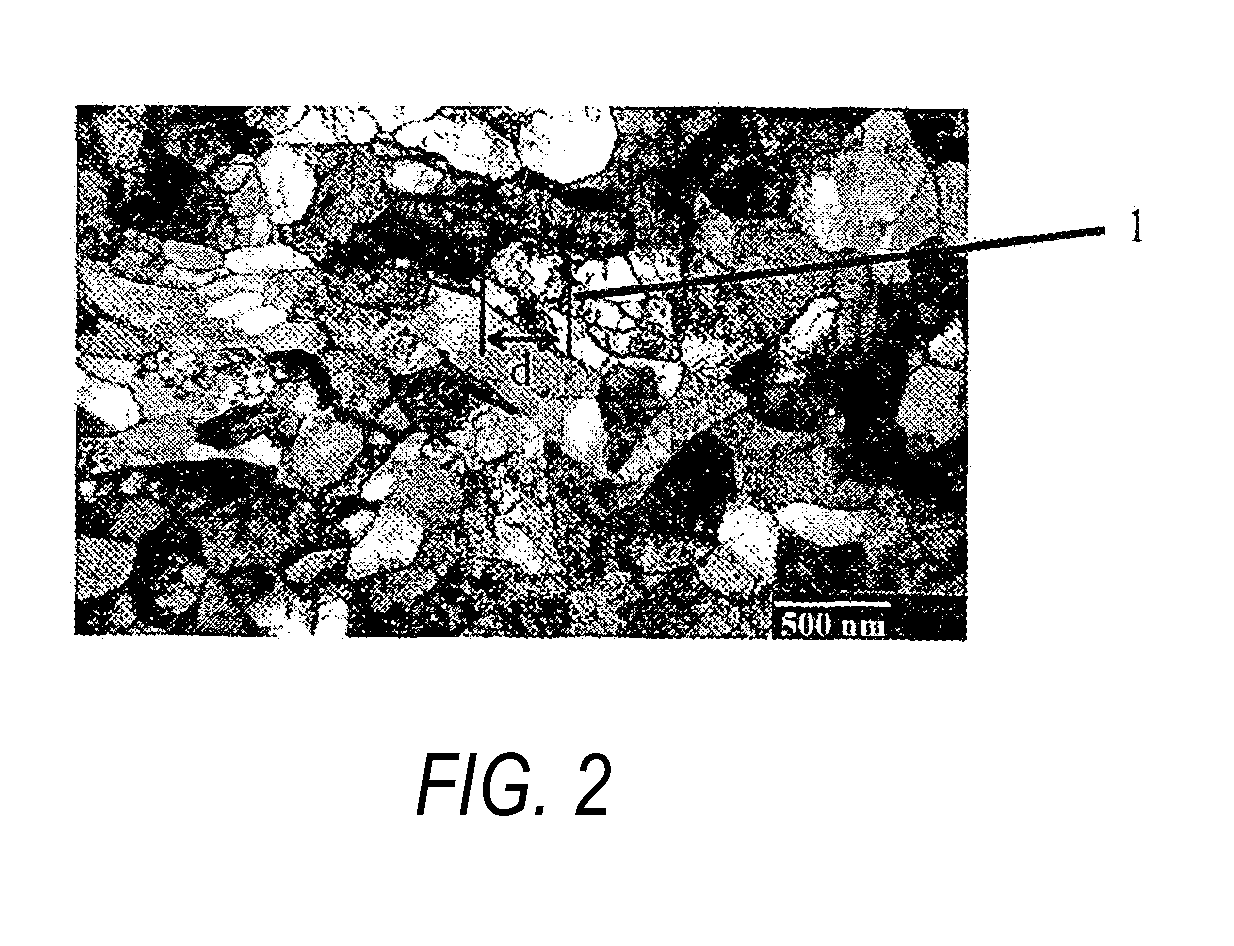

Commercially pure titanium having UFG structure and enhanced mechanical and biomedical characteristics has nanocrystalline alpha-phase grains with a hexagonal close-packed lattice, in which the share of grains with a size of 0.1 . . . 0.5 μm and a grain shape coefficient of no more than 2 in the mutually perpendicular planes makes no less than 90%, over 60% of the grains having high-angle boundaries disoriented in relation to the adjacent grains by the angles from 15 to 90°.The method for making a rod of the material provides for equal-channel angular pressing of a billet at T≦450° C. with the total accumulated true strain e≧4 to effect severe plastic deformation of the billet and subsequent thermomechanical treatment with a gradual decrease of the temperature in the range of 450 . . . 350° C. and the strain rate of 10−2 . . . 10−4 s−1 with the strain degree from 40 to 80% to effect additional plastic deformation.

Owner:FSBFEI HPE USATU 50 +1

Processing routes for titanium and titanium alloys

Methods of refining the grain size of titanium and titanium alloys include thermally managed high strain rate multi-axis forging. A high strain rate adiabatically heats an internal region of the workpiece during forging, and a thermal management system is used to heat an external surface region to the workpiece forging temperature, while the internal region is allowed to cool to the workpiece forging temperature. A further method includes multiple upset and draw forging titanium or a titanium alloy using a strain rate less than is used in conventional open die forging of titanium and titanium alloys. Incremental workpiece rotation and draw forging causes severe plastic deformation and grain refinement in the titanium or titanium alloy forging.

Owner:ATI PROPERTIES LLC

Shear-extrusion method

InactiveUS7096705B2Extrusion containersMetal rolling arrangementsProduction rateHydrostatic pressure

A shear-extrusion method of severe plastic deformation for fabrication of metal shapes with ultra-fine structures is described. The improvements of the method include unidirectional shear of any required intensity during one step processing and under high hydrostatic pressures, fabrication of long products with different cross-sections, refinement of low ductile alloys, the increase of productivity and cost reduction. The method can be realized as forward extrusion, backward extrusion, semi continuous extrusion and extrusion of hollow shapes in portal dies with a welding chamber.

Owner:ENGINEERED PERFORMANCE MATERIALS

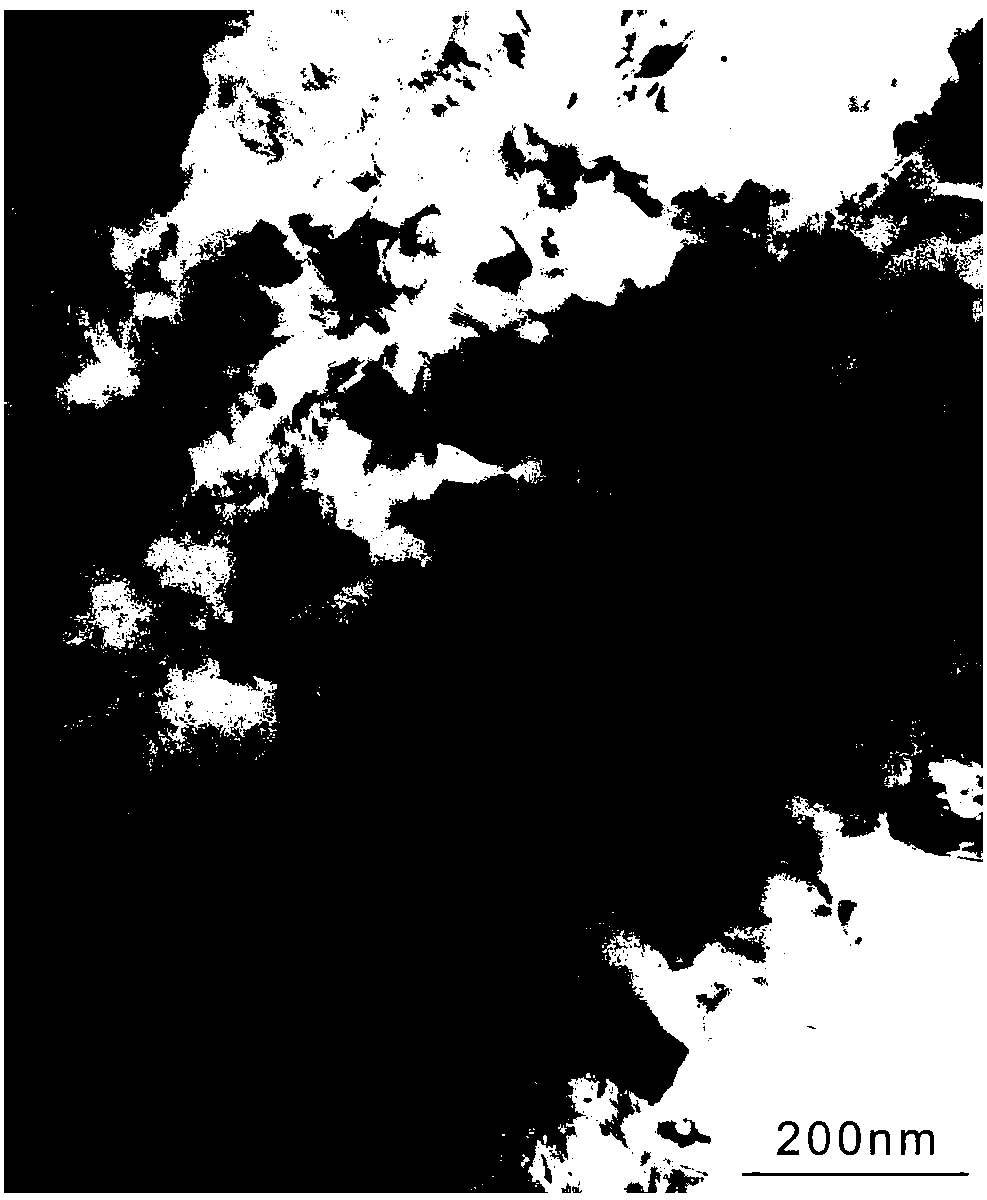

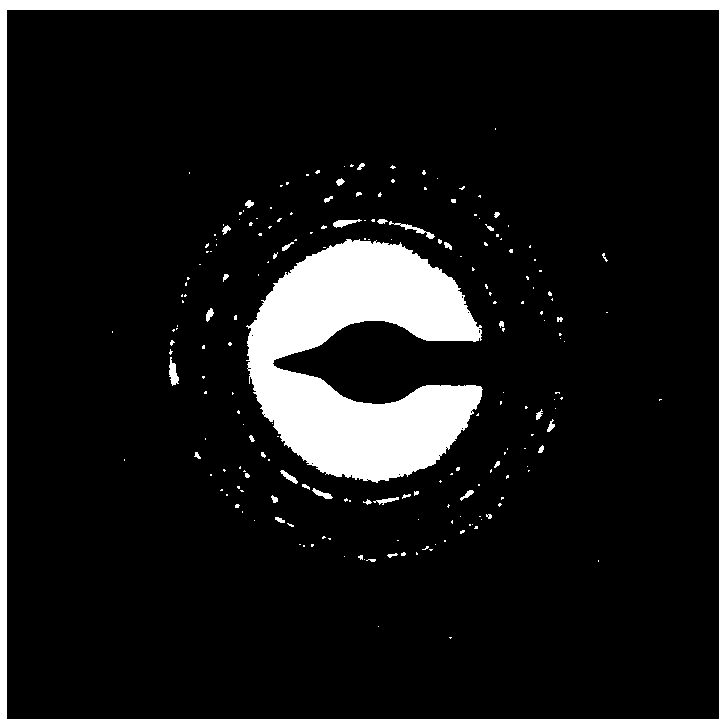

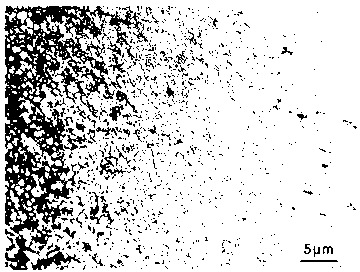

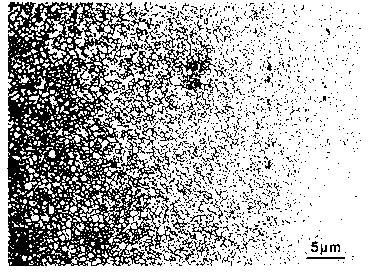

Method for preparing nanocrystalline metal material containing nano-sized precipitates within crystal

The invention provides a method for preparing a nanocrystalline metal material containing nano-sized precipitates within a crystal. The method comprises the following steps of firstly, performing high-temperature solution treatment on a coarse crystalline metal material, thereby obtaining single phase solid solution with supersaturated and dissolved alloy element, wherein the coarse crystalline metal material contains alloy element in a matrix, and the solid solubility is reduced as the temperature is reduced; then, performing severe plastic deformation and high-pressure reverse processing at or below the room temperature, thereby obtaining single phase solid solution nanocrystalline material composed of nanocrystalline grains with supersaturated and dissolved alloy element; and finally, ageing the obtained nanocrystalline material at a pressure of 3-25 GPa and at a temperature of 100-800 DEG C, and holding the temperature for 5-8 h, thereby obtaining a nanocrystalline metal material containing nano-sized precipitates within a crystal. The method provided by the invention is wide in suitable material component range, and can be used for effectively avoiding severe plastic deformation to produce microcrack in a material, and the prepared nano-sized precipitates in the nanocrystalline material are distributed uniformly.

Owner:YANSHAN UNIV

Thermal spraying device and method for manufacturing quasicrystalline coating

InactiveCN102560326AAvoid problems such as easy oxidationEven distribution of constituent phasesMolten spray coatingPorosityThermal spraying

The invention relates to the field of manufacturing of surface coatings, in particular to a thermal spraying device and a thermal spraying method for manufacturing a quasicrystalline coating. A fuel inlet, a spark plug and an oxygen inlet are arranged on one side of a mixing chamber of the thermal spraying device; the other side of the mixing chamber is communicated with a middle mixing chamber; a cooling gas inlet is formed on the middle mixing chamber; middle mixing chamber is communicated with a spray pipe through a supersonic nozzle; and an outlet of the supersonic nozzle and an inlet of the spray pipe are communicated with a quasicrystalline powder inlet. The middle mixing chamber for the cooling gas is added and the flame temperature is reduced, so that the powder and the gas form a gas-solid two-phase flow; solid particles in the gas-solid two-phase flow are sprayed onto the surface of a workpiece, and are plastically deformed seriously and deposited onto the surface of the workpiece; and subsequent particles with high kinetic energy repeat the process and form a quasicrystalline alloy coating. The problems that in the prior art, a crystalline phase is accompanied by a quasicrystalline phase, the porosity of the coating is high and micro-cracks exist are solved; and the thermal spraying device and the thermal spraying method can be used for manufacturing multiple series of quasicrystalline coatings.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

X70-degree large deformation resisting pipeline steel plate with excellent tenacity and preparation method for pipeline steel plate

The invention provides an X70-degree large deformation resisting pipeline steel plate with excellent tenacity and a preparation method for the pipeline steel plate, and belongs to the technical field of low-carbon micro-alloy steel. The pipeline steel plate comprises the following chemical constituents by weight percent: 0.03 to 0.08 percent of C, 0.10 to 0.45 percent of Si, 1.40 to 1.69 percent of Mn, 0 to 0.015 percent of P, 0 to 0.005 percent of S, 0.01 to 0.06 percent of Alt, 0.01 to 0.05 percent of Nb, 0.004 to 0.014 percent of Ti, 0 to 0.008 percent of N, and 0 to 0.0002 percent of H, and further comprises one to four types of the following chemical constituents by weight percent: 0 to 0.30 percent of Mo, 0 to 0.30 percent of Ni, 0 to 0.30 percent of Cr, 0 to 0.30 percent of Cu, andFe and unavoidable impurity elements in balancing amount. The preparation method comprises the following steps: revolving furnace smelting, outside furnace refining, continuous casting, heating, controllable rolling, accelerated cooling, and the like. The pipeline steel plate has the advantages of excellent tenacity and large deformation resistance, thereby being widely applied to land liquefaction subsidence and ground landslide deformation in a seismic area caused by a permafrost as well as to pipeline engineering such as deep sea pipeline laying where severe plastic deformation can be caused easily.

Owner:SHOUGANG CORPORATION

Surface strengthening method for metal component by vibration-assisted laser shock treatment

ActiveCN108660307AImprove mechanical propertiesImprove fatigue lifeVibration exciterMechanical property

The invention relates to the field of new techniques of laser processing and vibration aging, in particular to a surface strengthening method for a metal component by vibration-assisted laser shock treatment. According to the method, by combining laser shock strengthening technology with vibration aging treatment, a vibration exciter is used to excite vibration, a sensor picks up vibration, the vibration frequency is controlled to keep the amplitude value within a specified range, laser lap impact strengthening treatment is carried out with the aid of vibration aging treatment so that more serious plastic deformation can be generated on the surface of the metal component, and high-amplitude residual compressive stress is induced in an impact area; meanwhile under the condition that laser beam irradiates the metal surface, vibration further refines or even nanocrystallizes the surface grain, and under the action of the temperature field, vibration reduces the thermal stress field gradient, and thus the residual stress inside the material is uniformized; and the mechanical properties of the metal component are remarkably improved, and the metal surface is strengthened, so that the fatigue life of the metal component is prolonged effectively, and initiation and expansion of fatigue cracks are prevented.

Owner:JIANGSU UNIV

Nanostructured commercially pure titanium for biomedicine and a method for producing a rod therefrom

ActiveUS8919168B2Improve failureImprove propertiesNanostructure manufacturePig casting plantsEqual channel angular extrusionCommercially pure titanium

Commercially pure titanium having UFG structure and enhanced mechanical and biomedical characteristics has nanocrystalline alpha-phase grains with a hexagonal close-packed lattice, in which the share of grains with a size of 0.1 . . . 0.5 μm and a grain shape coefficient of no more than 2 in the mutually perpendicular planes makes no less than 90%, over 60% of the grains having high-angle boundaries disoriented in relation to the adjacent grains by the angles from 15 to 90°.The method for making a rod of the material provides for equal-channel angular pressing of a billet at T≦450° C. with the total accumulated true strain e≧4 to effect severe plastic deformation of the billet and subsequent thermomechanical treatment with a gradual decrease of the temperature in the range of 450 . . . 350° C. and the strain rate of 10−2 . . . 10−4 s−1 with the strain degree from 40 to 80% to effect additional plastic deformation.

Owner:FSBFEI HPE USATU 50 +1

Method for preparing graphene reinforced aluminum-based composite with multi-layer graphene nanoplatelets as raw materials

The invention discloses a method for preparing a graphene reinforced aluminum-based composite with multi-layer graphene nanoplatelets as raw materials, and relates to a method for the graphene reinforced aluminum-based composite. The method aims to solve the problems that the dispersion difficulty of single-layer or few-layer graphene is high in the preparation method of a graphene reinforced aluminum-based composite at present and the cost of the graphene reinforced aluminum-based composite is high. The preparation method comprises the steps that the multi-layer graphene nanoplatelets, aluminum metal and commercial pure aluminum blocks are weighed; secondly, the multi-layer graphene nanoplatelets are dispersed, and precast blocks are molded; thirdly, the aluminum metal is infiltrated; fourthly, severe plastic deformation treatment is conducted; and fifthly, composition homogenization treatment is conducted. The low-cost multi-layer graphene nanoplatelets are used as reinforcement raw materials, so that the cost is obviously lowered compared with composites with few-layer graphene as reinforcements directly; and the prepared graphene reinforced aluminum-based composite is excellent in comprehensive performance, and industrialization production and application can be achieved easily. The method is suitable for preparation of the graphene reinforced aluminum-based composite.

Owner:HARBIN INST OF TECH

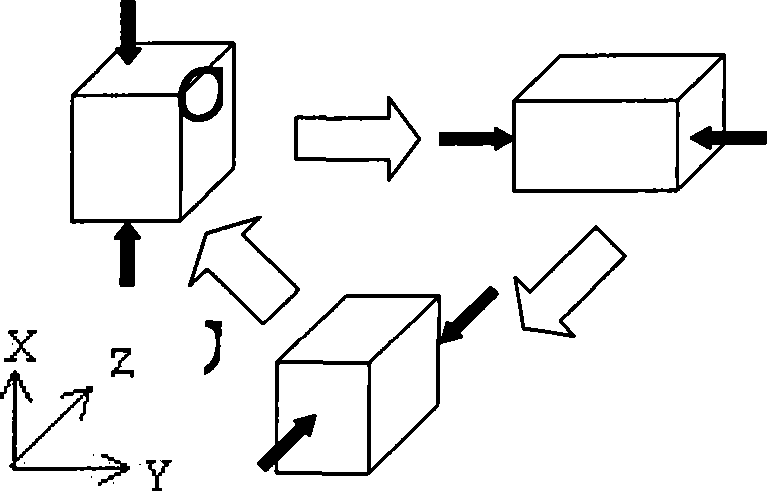

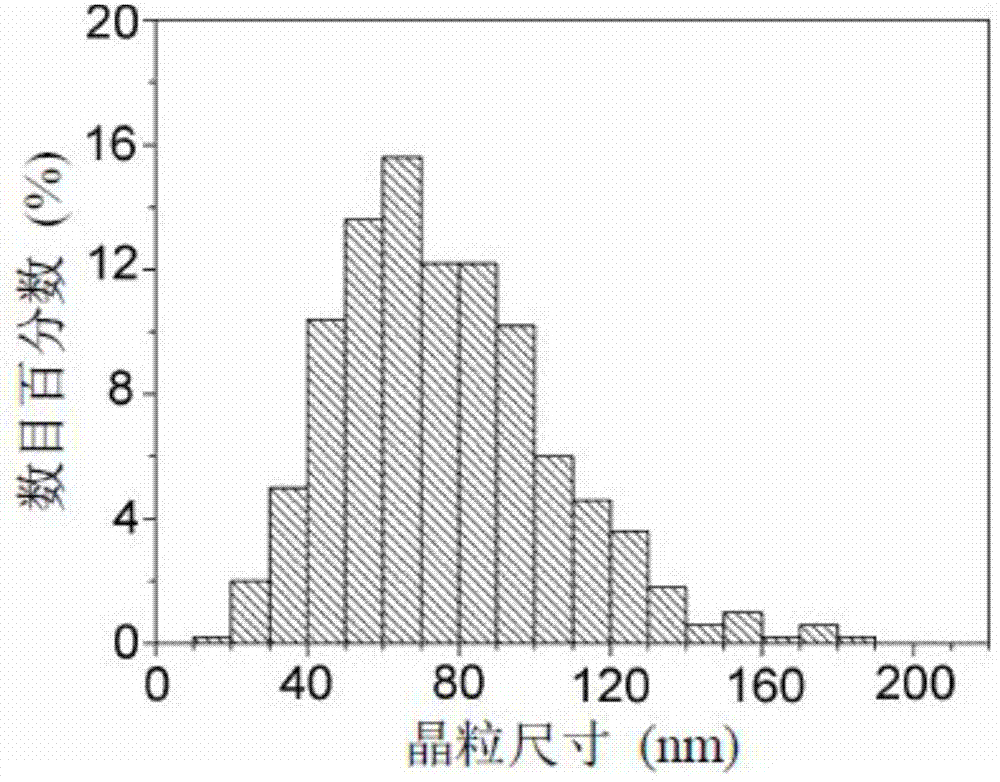

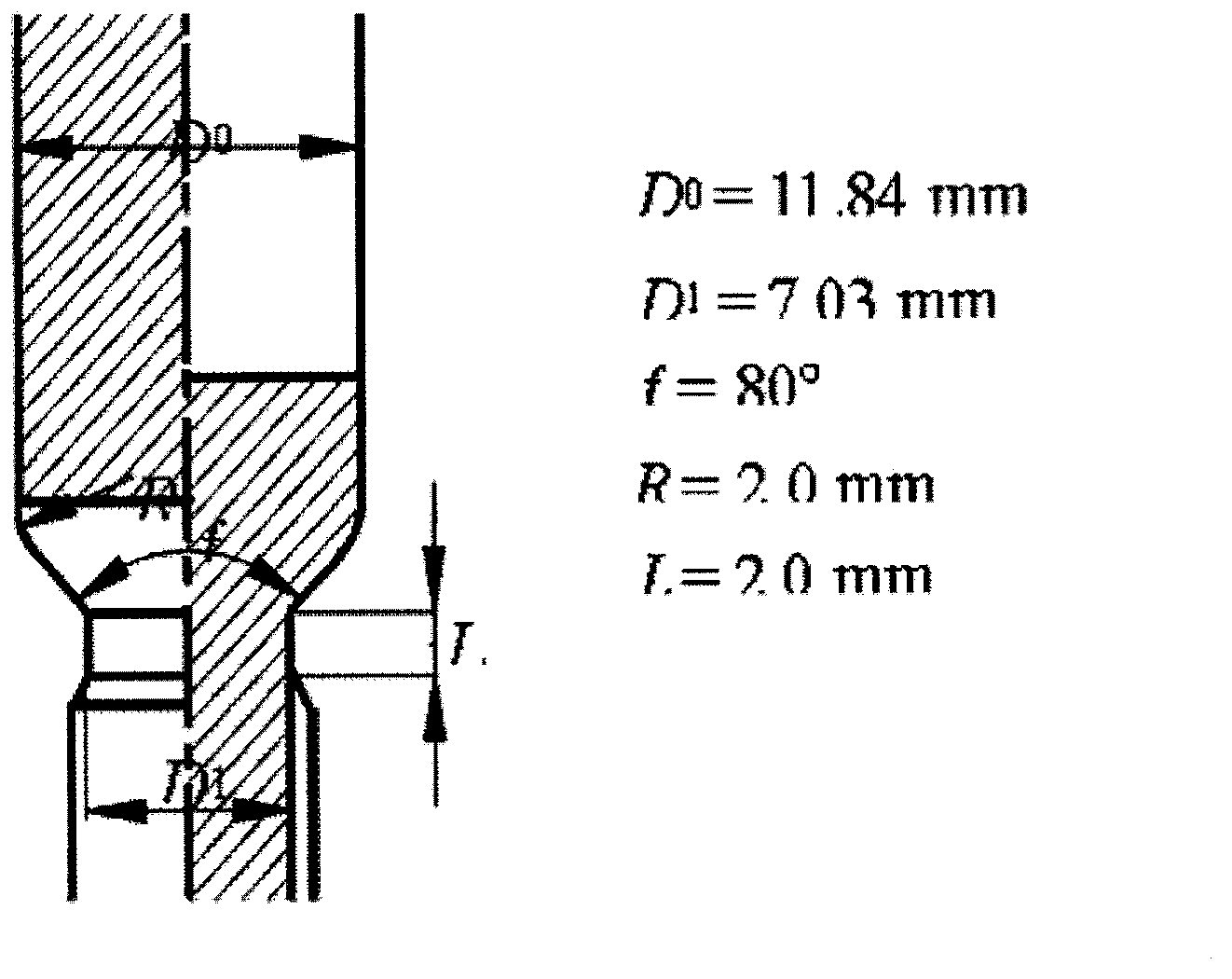

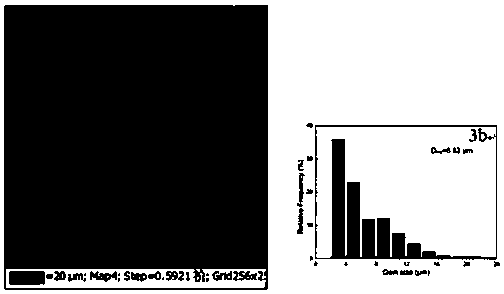

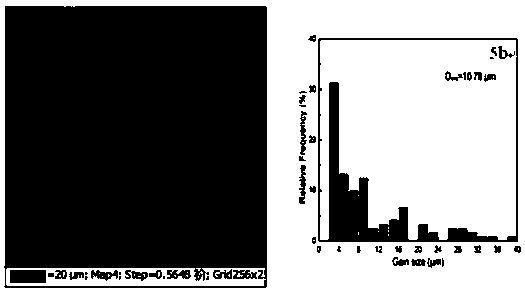

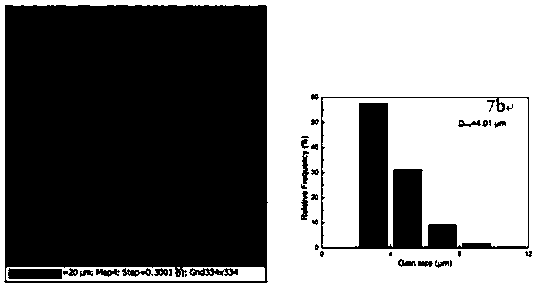

Preparation method of nanocrystalline magnesium alloy by continuous and severe plastic deformation

The invention discloses a preparation method of a nanocrystalline magnesium alloy by continuous and severe plastic deformation. The method comprises the following steps of: firstly, smelting a prepared magnesium alloy raw material and casting into a round cast ingot; then, thermally extruding at 340-460 DEG C to a bar with diameter of 9-12mm; cutting the extruded round bar and performing equal channel corner extrusion with 4-8 channels at 200-350 DEG C; and then, cutting the bar into wafer samples which are 0.8-1mm in thickness for twisting at room temperature and high pressure, wherein the pressure is 4-6Gpa and twisting for 2-10 rings. According to the method provided by the invention, conventional thermal extrusion is combined with equal channel corner extrusion and high pressure twisting belonging to a severe plastic deformation process, and the magnesium alloy with the average grain size below 100nm and uniform tissue can be easily prepared, so that the mechanical property of the magnesium alloy is greatly improved, and meanwhile, the method has the characteristics of large size of nanocrystalline magnesium alloy material, simple process, high processing efficiency, less impurities and defects and the like.

Owner:SOUTHEAST UNIV

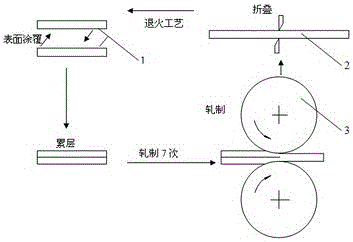

Preparation method of nano graphene copper foil

InactiveCN105845942AEffective refinement of grain structureHigh strengthElectrode carriers/collectorsNanotechnologyCopper foilGraphene

The invention relates to a preparation method of a composite and particularly relates to a preparation method of a nano graphene copper foil. The nano graphene copper foil can be applied to the field of lithium battery negative current collectors. The preparation method of the nano graphene copper foil comprises the following steps: uniformly coating graphene on the surface of a copper belt, folding a copper foil with surface coated by the graphene, accumulating rolling severe plastic deformation to obtain a graphene copper belt with a nano microstructure, cold rolling a nano graphene copper belt in which the graphene is uniformly distributed for four times, rolling the nano graphene copper belt in a manner of continuously reducing thickness to form the required specification of nano graphene copper foil.

Owner:SHANDONG JIANZHU UNIV

Preparation method of magnesium alloy wire based on severe plastic deformation

The invention discloses a preparation method of a magnesium alloy wire based on severe plastic deformation. The method comprises the following steps of: first, melting and pouring a magnesium alloy material to pole cast ingots with the diameter over 20mm; then, thermally extruding the cast ingots to fine pole bars with the diameter of 5-8mm at extrusion ratio of 16-36 at 300-360 DEG C; after sectioning the extruded poles and extruding the poles with 4-8 paths of equal channel corners at 200-300 DEG C; then, drawing the bars at room temperature; when the material accumulative percentage reduction of area is 70+ / -5%, annealing at 150-200 DEG C for 3-10 minutes; and repeating drawing and annealing till wires in required dimension are prepared. According to the invention, severe plastic deformation is performed on the magnesium alloy bars through an equal channel extruding process before drawing to greatly reduce the original grain size of magnesium alloy to be drawn, so that the drawing performance of the magnesium alloy and the comprehensive mechanical performance of final wires can be remarkably improved.

Owner:SOUTHEAST UNIV

Preparation method of high-purity titanium powder

The invention provides a preparation method of high-purity titanium powder. The method includes the steps: selecting high-purity molten salt electrolysis titanium as raw materials, obtaining ultra-fine grain titanium materials by a high-pressure torsion method, and enabling the titanium raw materials to absorb heat to generate hydrogen absorption reaction, tender and easily crush to a certain particle size by a hydrogenation-dehydrogenation and mechanical ball milling method under a special process control condition; performing dehydrogenation for the titanium raw materials; finally, further crushing the titanium raw materials to obtain ultra-fine high-purity titanium powder. The used raw materials are not sponge titanium obtained by a traditional magnesium heating method, the process is more environmentally friendly, the molten salt electrolysis titanium is high in purity and low in oxygen content, the ultra-fine grain titanium materials treated by severe plastic deformation of high-pressure torsion has high dislocation density and inner stress and a wide-angle non-equilibrium grain boundary, the hydrogenation temperature of the treated ultra-fine grain titanium materials is obviously reduced as compared with untreated titanium materials, raw material oxidation caused by over-high temperature can be effectively reduced, the particle sizes of the prepared titanium powder are small and uniform, and various production requirements are met.

Owner:CENT SOUTH UNIV

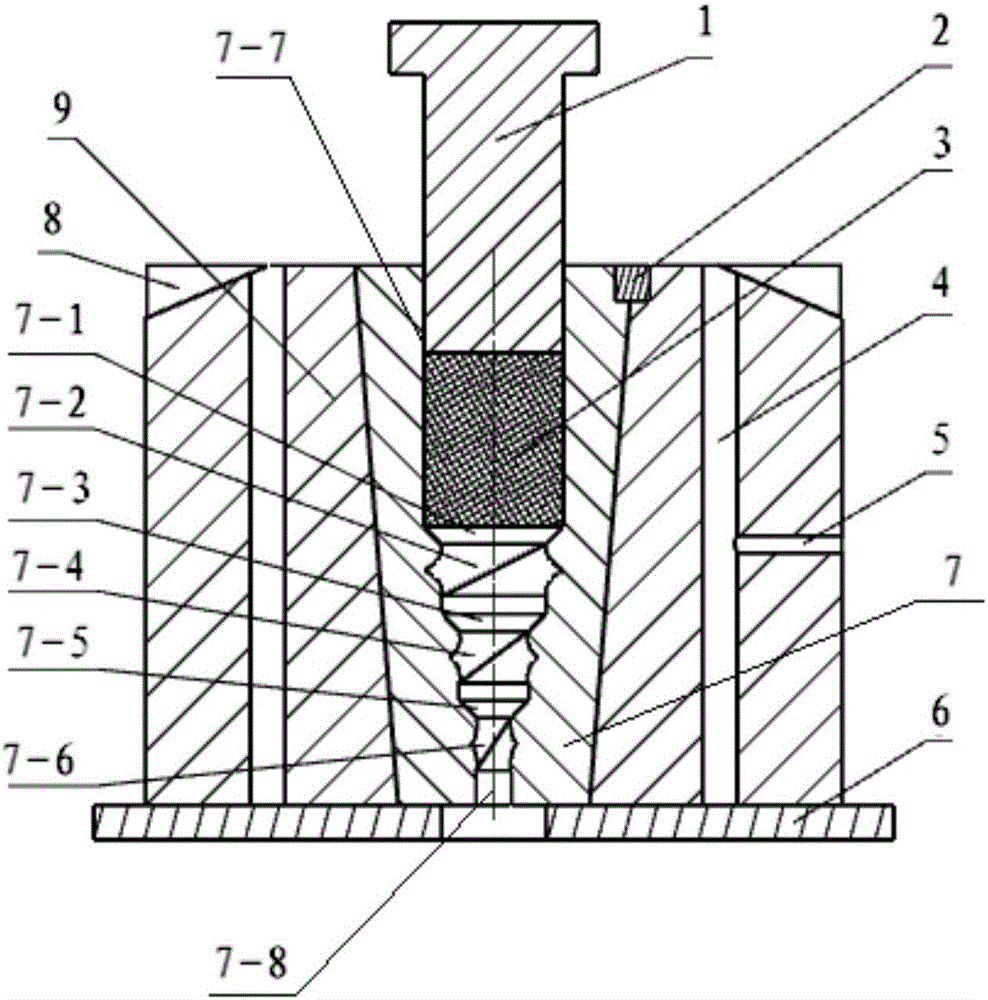

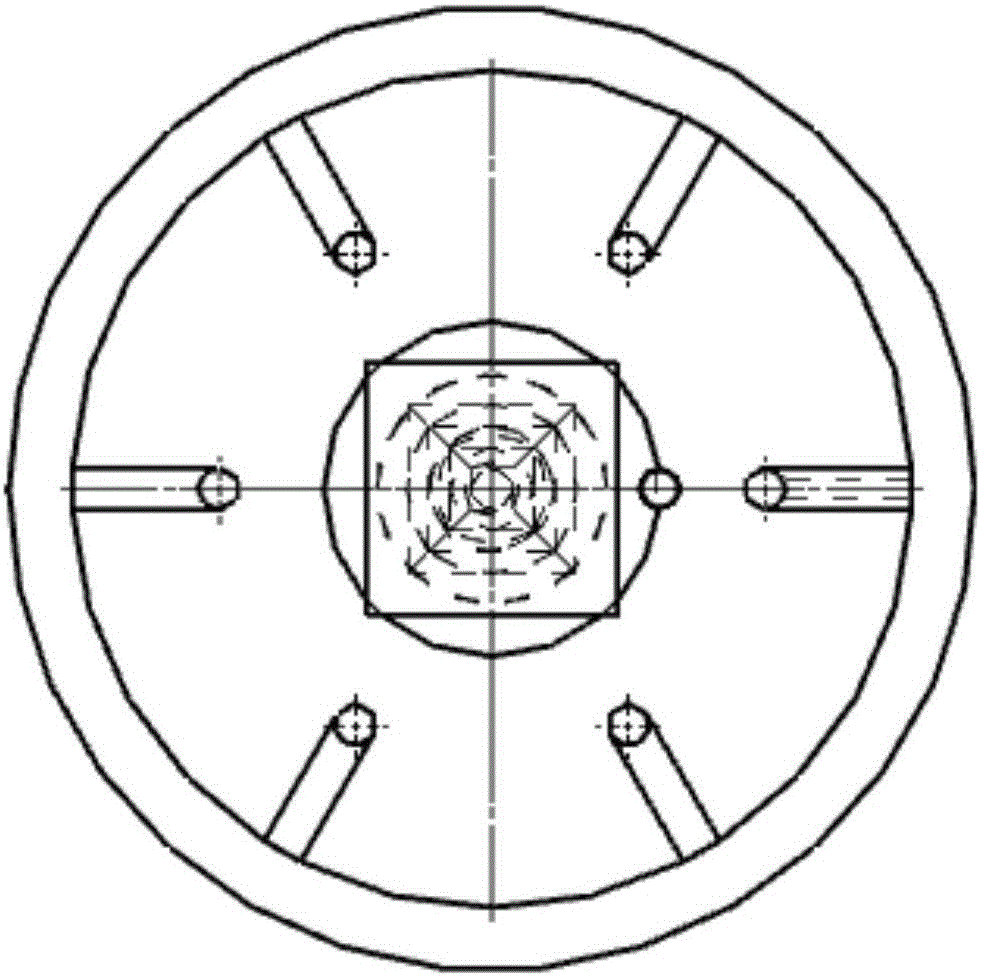

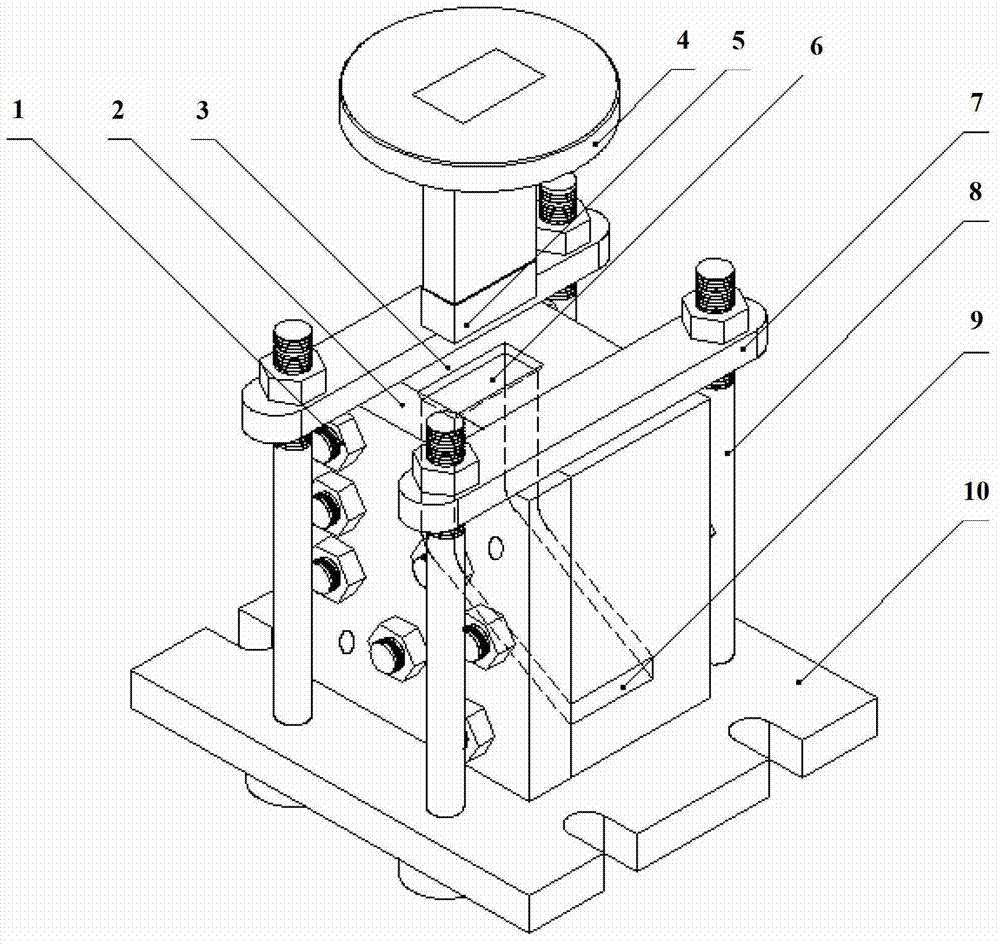

Device and method for continuous forward extrusion and twist extrusion composite molding

A device and method for continuous forward extrusion and twist extrusion composite molding belong to the technical field of machining. The device and method for continuous forward extrusion and twist extrusion composite molding are intended for solving the problems of many steps and high process requirements of an existing severe plastic deformation method, and have the following technical features: the device is constituted by three stages of extrusion passages; each stage of extrusion passages includes a forward extrusion passage and a twist extrusion passage; the forward extrusion passages allow reduction of the cross sectional area of a blank; after the blank passes through the three stages of extrusion passages, the cross sectional area of the blank is reduced gradually with gradual refining of grains, and therefore, a fine grain material is prepared. A preparation method provided by the present invention comprises the following steps: placing the device on a press machine and carrying out heating to a specified temperature; putting a blank into the device and then putting a punch thereinto; allowing the punch to go down to orderly complete forward extrusion and twist extrusion in each stage of extrusion passages, thus forming a final rectangular bar. The device and method for continuous forward extrusion and twist extrusion composite molding are used for composite molding of rectangular bars.

Owner:HARBIN UNIV OF SCI & TECH

Large plastometric set method for producing ultra-fine crystal material

InactiveCN101294238AOvercome deficienciesExtended service lifeProcess efficiency improvementEqual channel angular extrusionUltra fine

The invention provides a severe plastic deformation method for manufacturing ultra-fine grain material, which comprises an equal-channel angular extrusion step. The method is characterized in that the severe plastic deformation method has the following processing steps, namely the preparation of raw material, homogenizing annealing, compression extrusion deformation, equal-channel angular extrusion deformation, repeated upsetting-extrusion deformation, and annealing treatment. The shapes and sizes of the material before and after the extrusion deformation are the same so as to realize the multi-pass accumulated deformation; combining the other technologies, the disadvantages during the manufacture process of the ultra-fine grain material are effectively avoided because of absorbing the advantages of a equal-channel angular extrusion method, thereby realizing that the uniform ultra-fine grain microstructure material can be obtained after less-pass upsetting-extrusion deformation; therefore, the uniform and stable ultra-fine grain bulk material is obtained, in addition, the productivity effect is increased obviously, the service life of an extrusion die is prolonged, the manufacturing cost is lowered, and the severe plastic deformation method is favorable for realizing large-scale industrial production at the same time.

Owner:KUNMING UNIV OF SCI & TECH

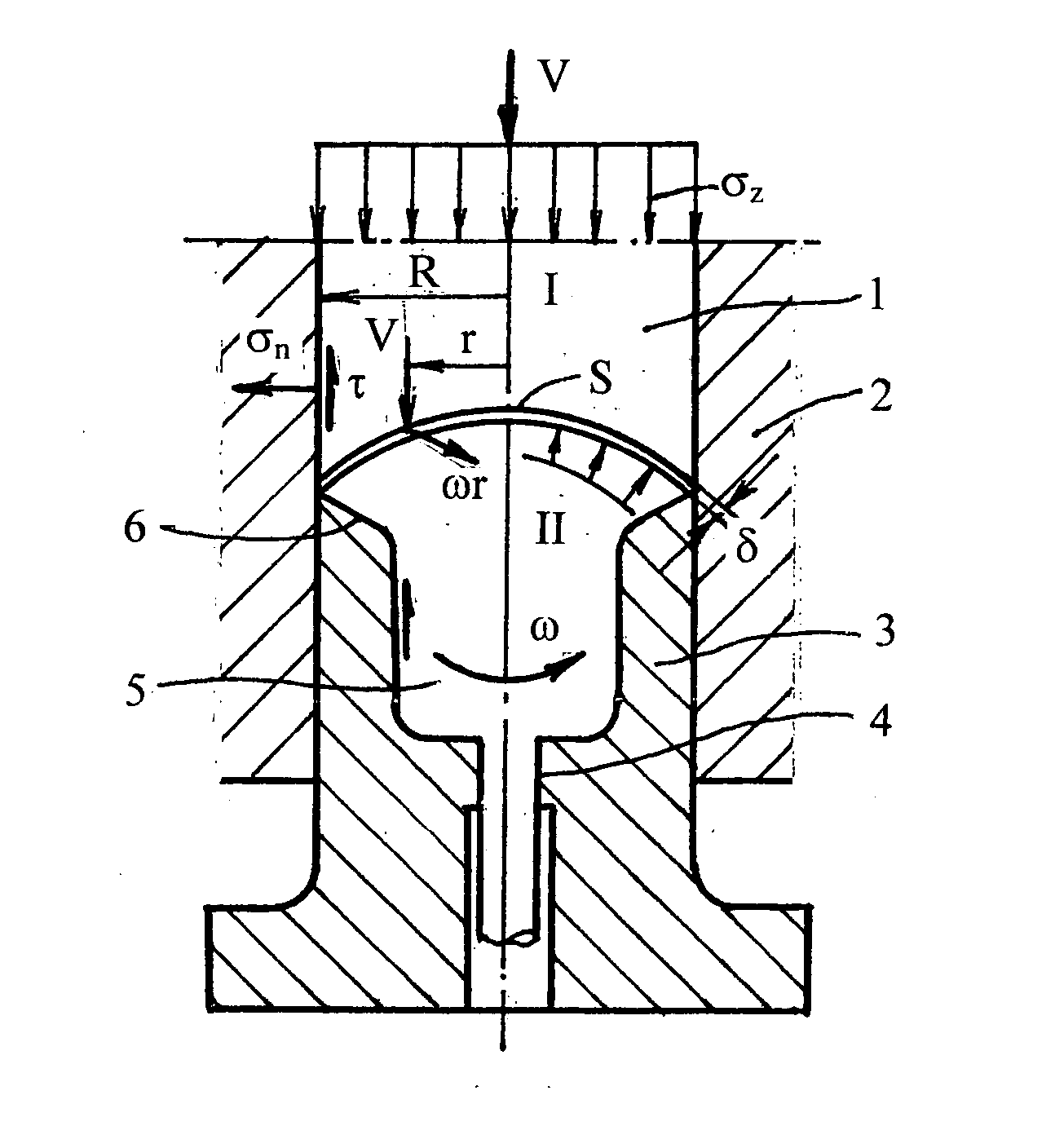

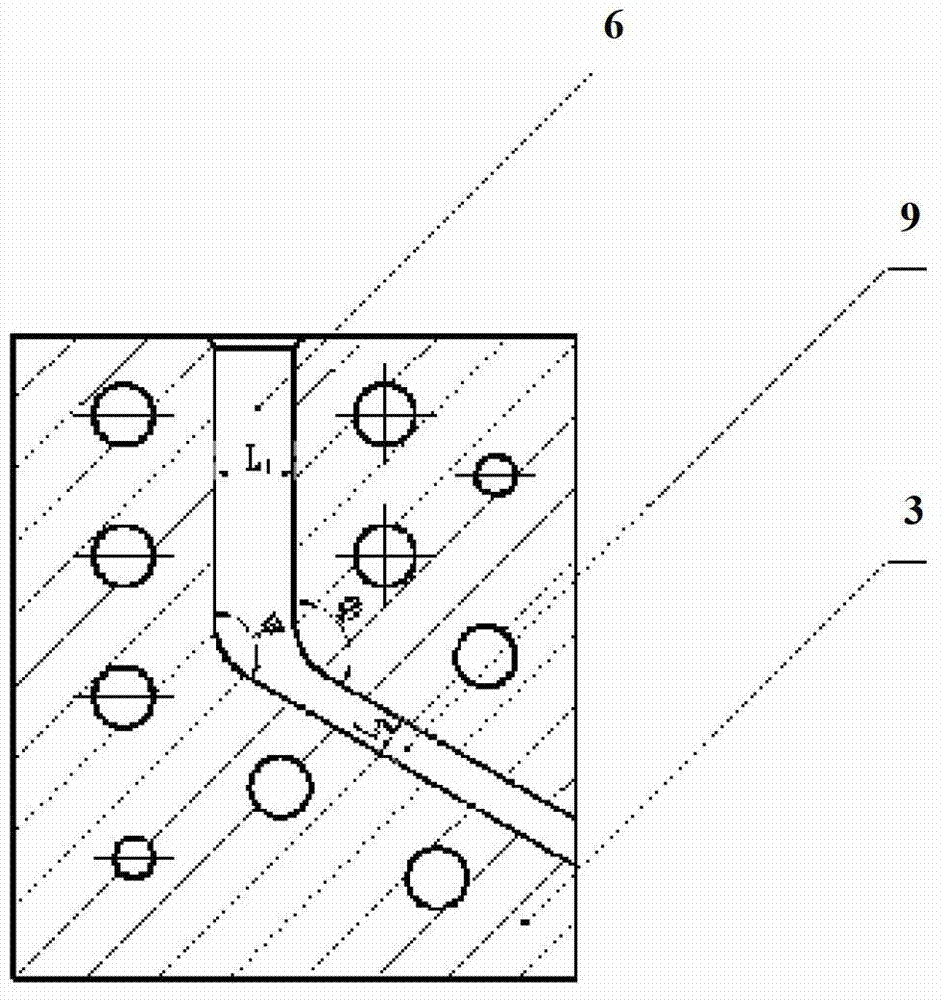

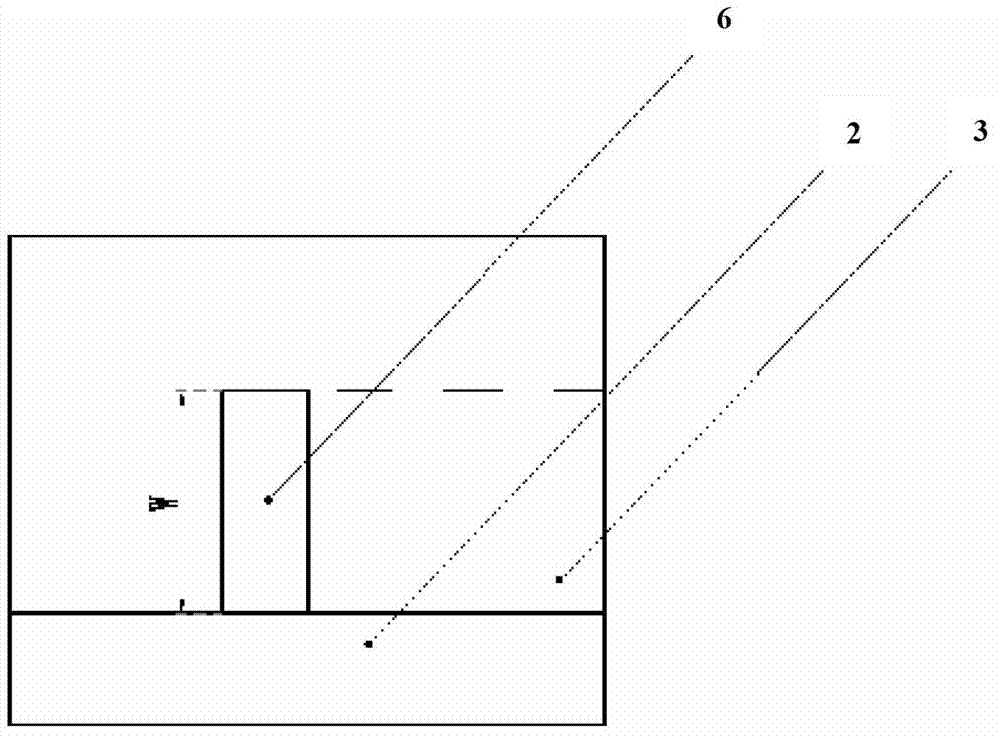

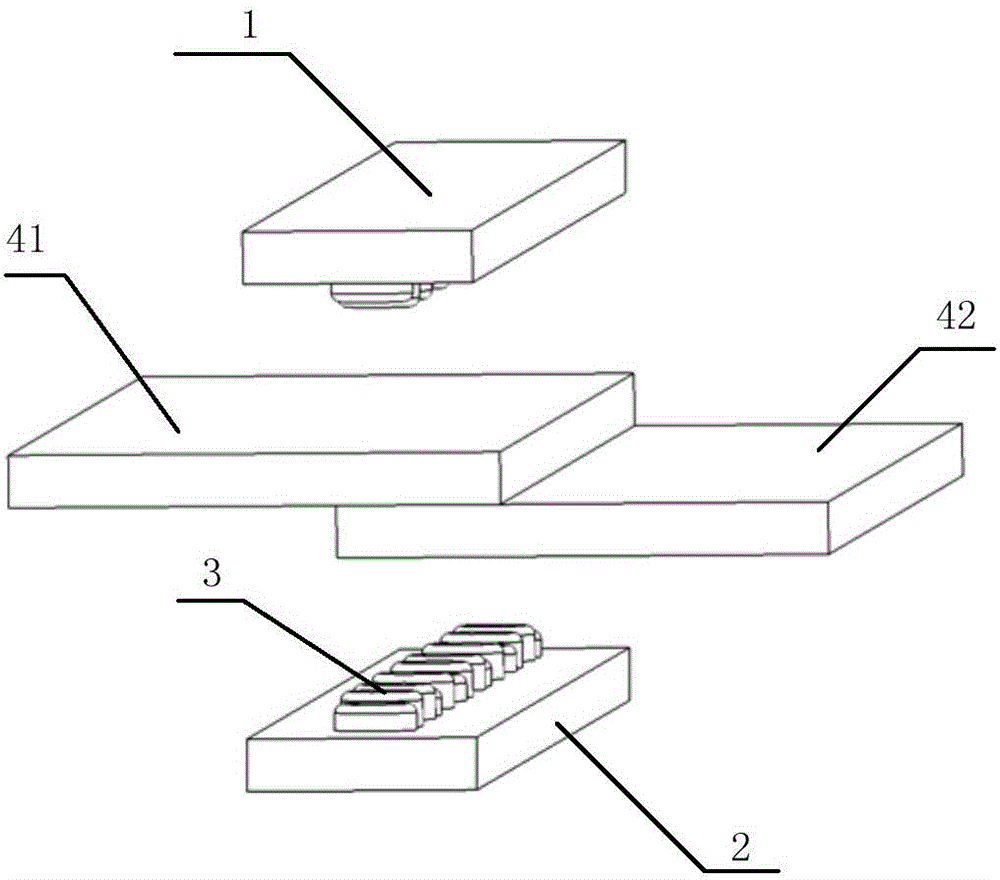

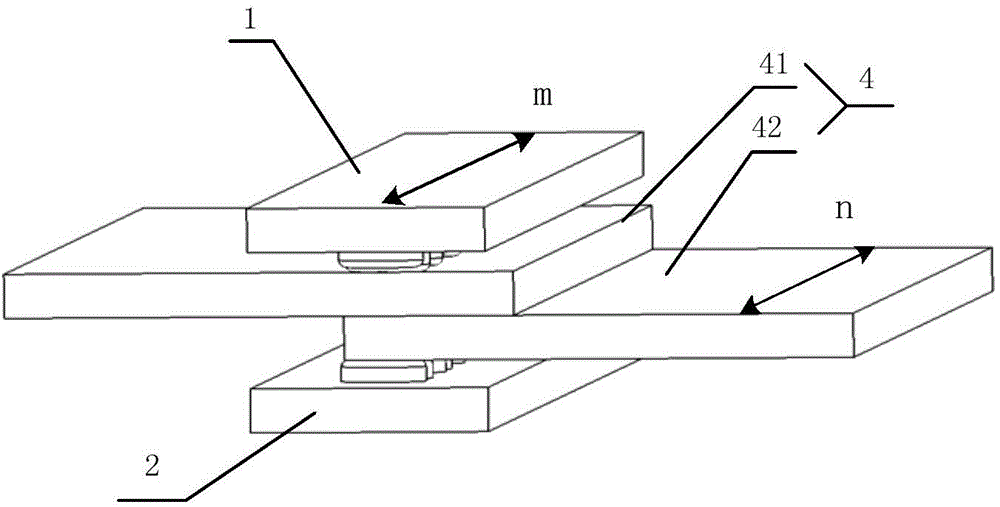

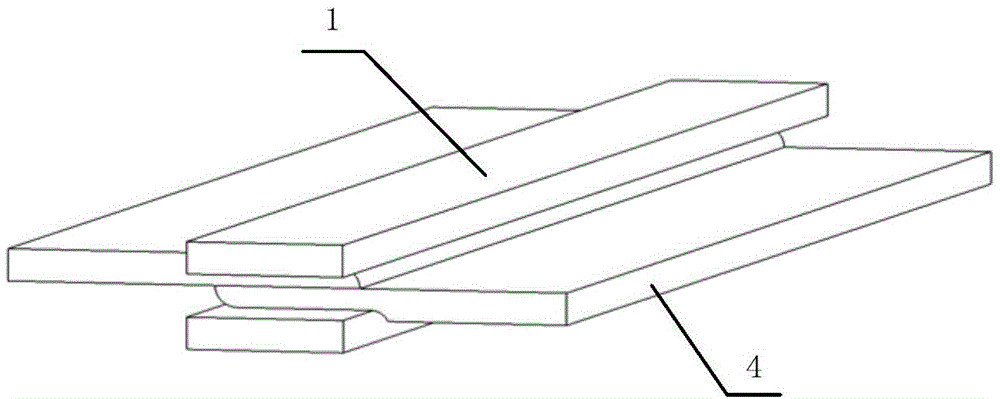

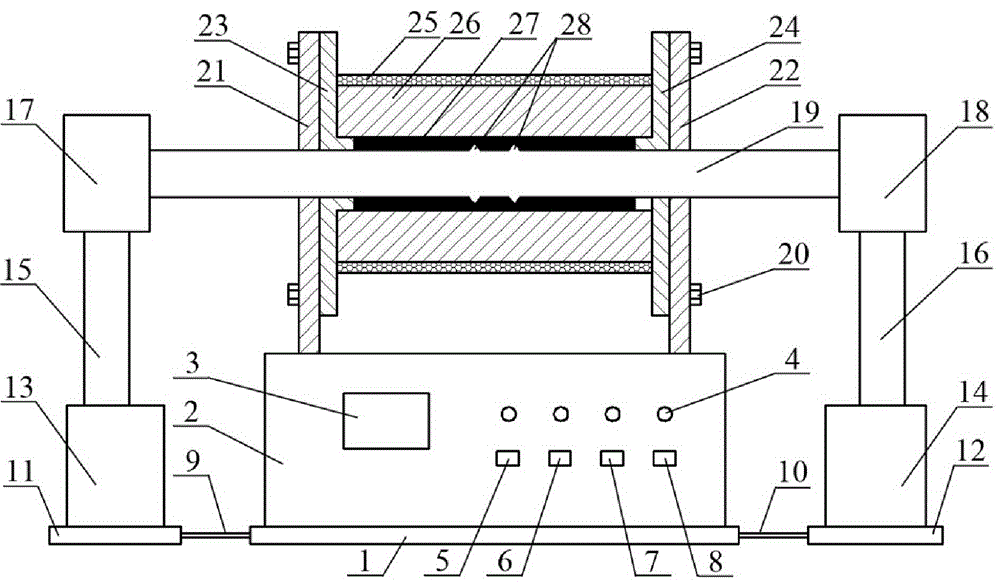

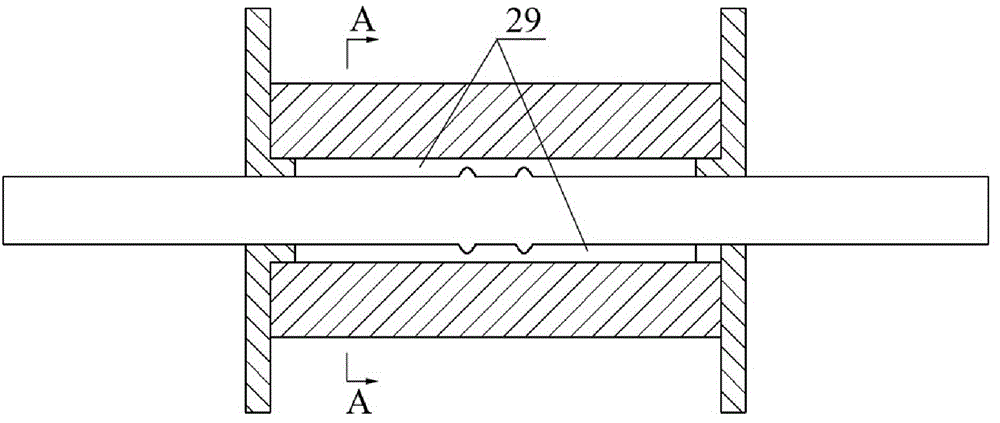

Severe plastic deformation method and severe plastic deformation device for pressing and rolling corner of non-equivalent passage

The invention discloses a severe plastic deformation method and a severe plastic deformation device for pressing and rolling the corner of a non-equal channel. According to the severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel, an equal-channel angular pressing (ECAP) technology and an ARB (Accumulative Roll Bonding) technology are integrated. The concrete process comprises the following steps that pressing force is applied after a test sample, a punching head and a mould are simultaneously preheated to pressing and rolling temperature, so that the test sample passes through the position of the channel corner of the device for pressing and rolling the corner of the non-equal channel completely; compressive deformation is generated when shear deformation is generated by the test sample so as to finish a first pass pressing and rolling process; the test sample is cut into L1 / L2 parts along a length direction, and the L1 / L2 parts are placed in an I channel; and the steps are repeated so as to finish multi-pass pressing and rolling deformation. The mould of the device is provided with the I channel and an II channel which are intersected and also have non-equal sections. The design is reasonable, the structure is simple, and the manufacturing cost is low. According to the method disclosed by the invention, the advantages of the ECAP technology and the ARB technology are integrated, and the mechanical property of a material is effectively enhanced. The process is short in procedure, high in efficiency and low in cost and is simple to operate. The severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel can be widely used for the field of processing metal materials, such as pure metal and alloy.

Owner:SOUTH CHINA UNIV OF TECH

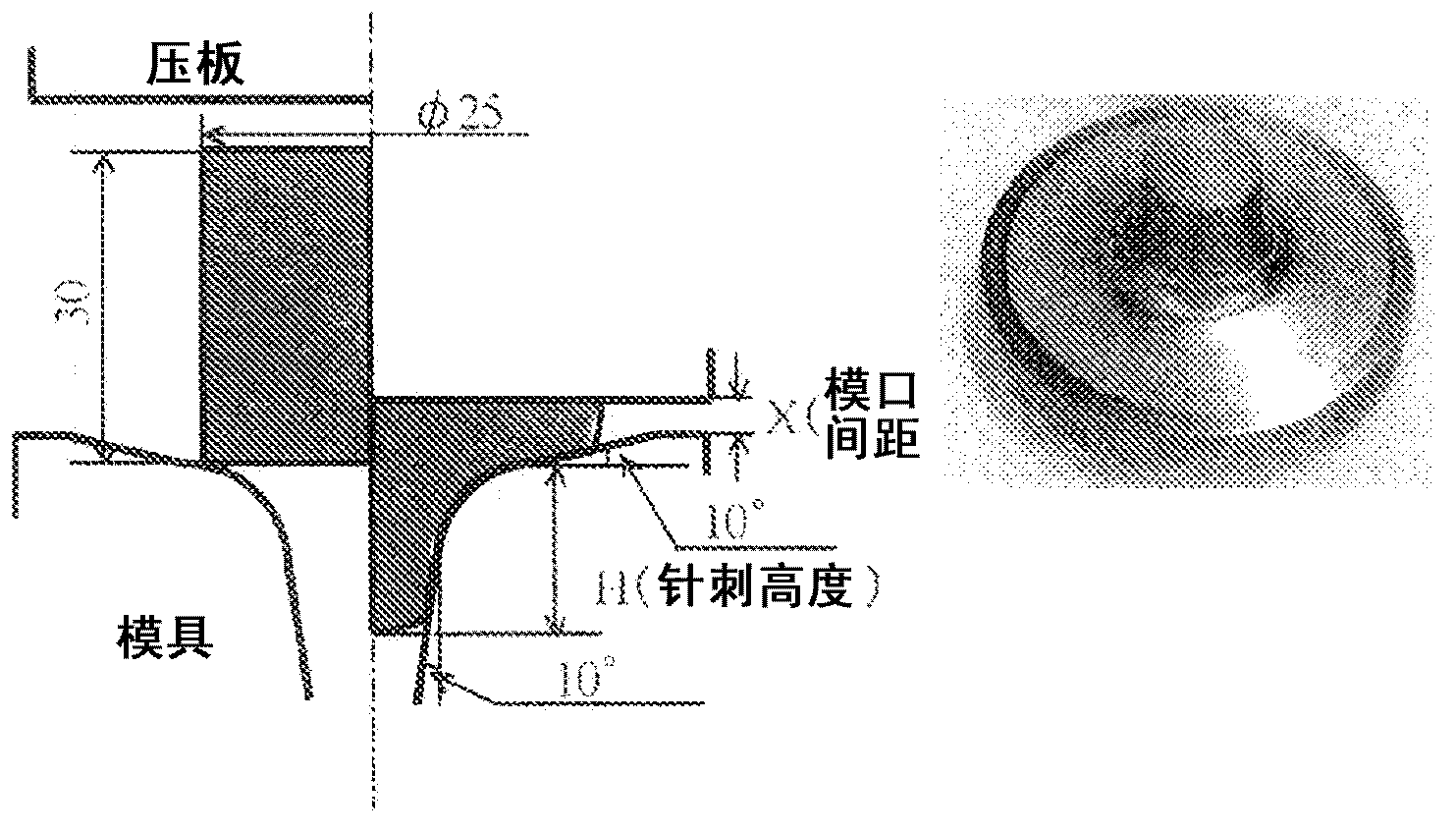

Method for improving mechanical surface strengthening effect

InactiveCN105886728AImprove the strengthening effectIncrease the value of residual compressive stressSurface layerMetallic materials

The invention relates to the technical field of metal strengthening, in particular to a method for improving the mechanical surface strengthening effect. According to the method, before mechanical surface strengthening treatment is conducted, a certain surface structure is machined on the surface of a treated metal material. The method for improving the mechanical surface strengthening effect includes the steps that the surface structure is machined before mechanical surface strengthening treatment is conducted, a larger and deeper residual compressive stress layer can be generated on the treated surface through mechanical surface strengthening treatment; residual compressive stress with preset directivity can be generated on the treated surface through mechanical surface strengthening treatment; the residual compressive stress value of the topmost surface is increased, so that the mechanical surface strengthening effect is further enhanced; and the treated surface layer is more likely to generate severe plastic deformation and grain refinement, and an ultra-fine grain or a nanocrystal surface layer material is prepared conveniently.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

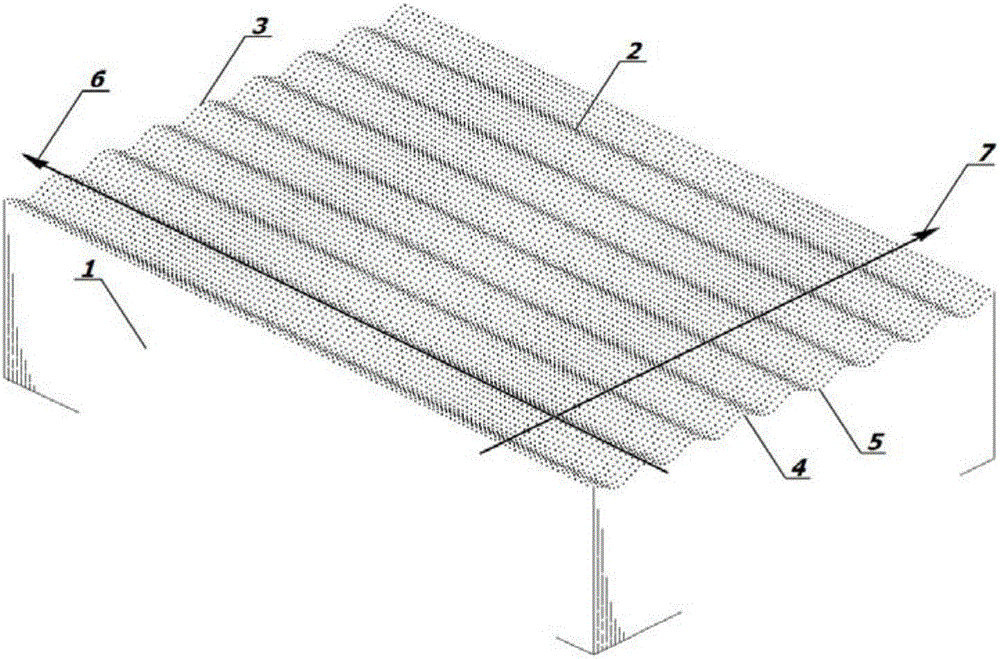

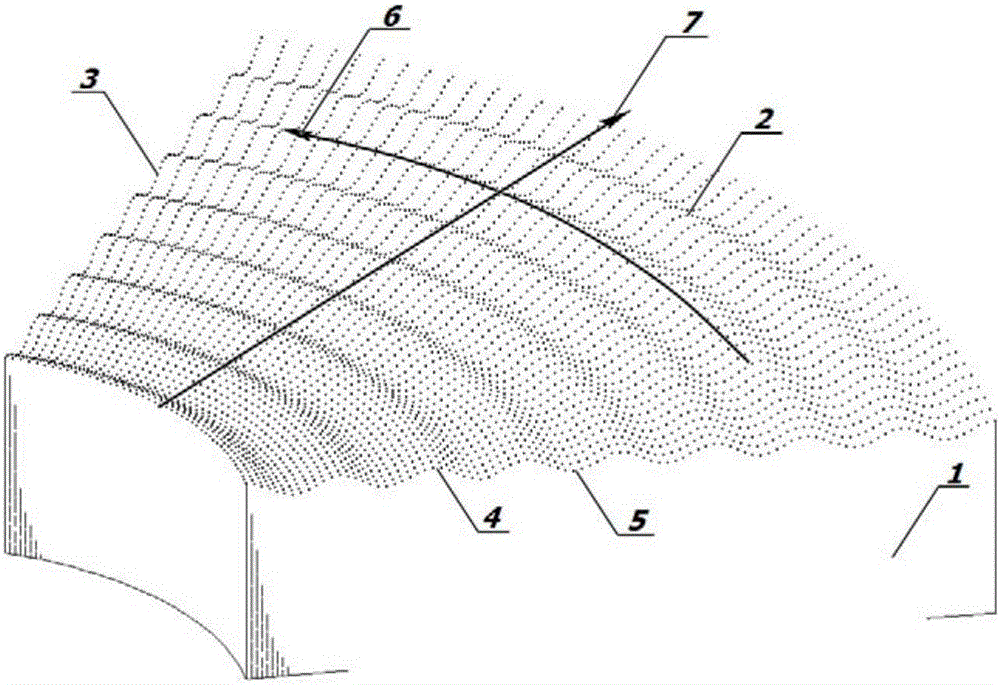

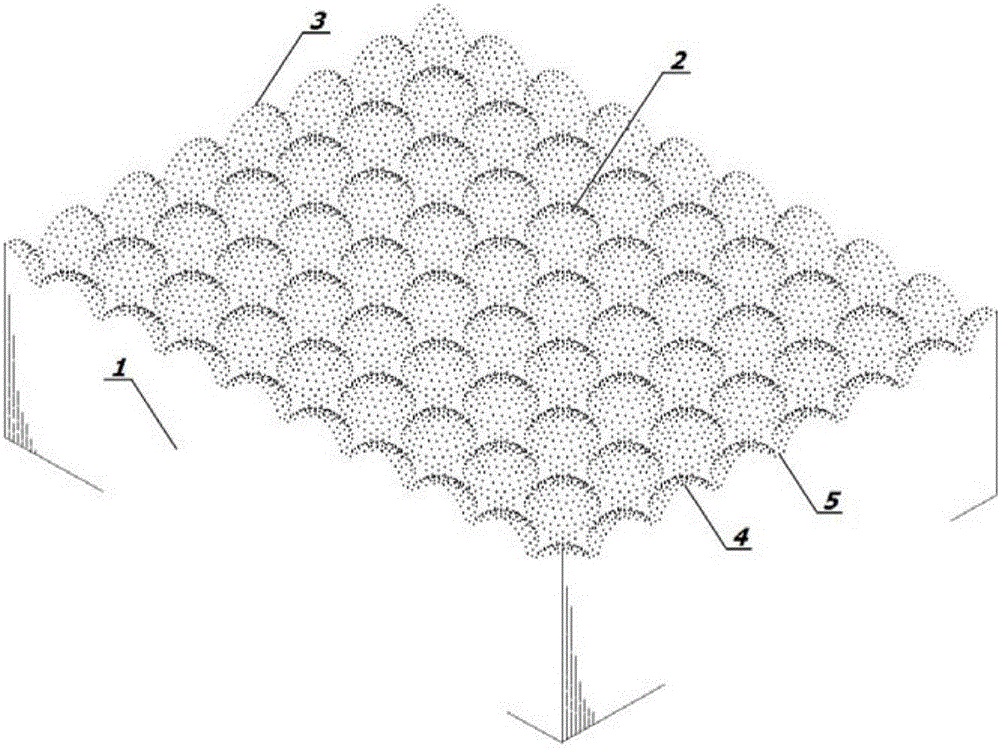

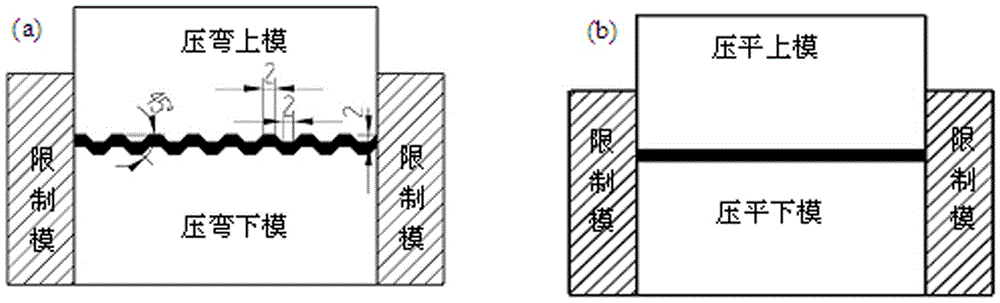

Preparation method for high-strength pure titanium panels

ActiveCN105483588AAvoid problems such as plastic recovery and strength decreaseSmall grain sizeAfter treatmentRoom temperature

The invention provides a preparation method for high-strength pure titanium panels. The preparation method comprises the technological steps that 1, a pure titanium panel is subjected to constrained groove pressing severe plastic deformation at the room temperature by adopting a pressure-controllable testing machine; 2, the pure titanium panel is subjected to electric pulse annealing treatment during every pass of constrained groove pressing deformation; and 3, the high-strength pure titanium panel is obtained after treatment at the last pass of constrained groove pressing severe plastic deformation. According to the preparation method, the advantages of severe plastic deformation and electric pulse treatment are integrated, so that the problems that hard-deformation hexagonal closed-packed metal pure titanium can be hardly subjected to room-temperature severe plastic deformation, and cracking occurs during a deformation process are solved; the large-sized high-strength pure titanium panel can be prepared; and compared with the original pure titanium panel, the increasing rate of yield strength of the large-sized high-strength pure titanium panel exceeds 160% at most, and the increasing rate of extension strength exceeds 80% at most.

Owner:NORTHEASTERN UNIV

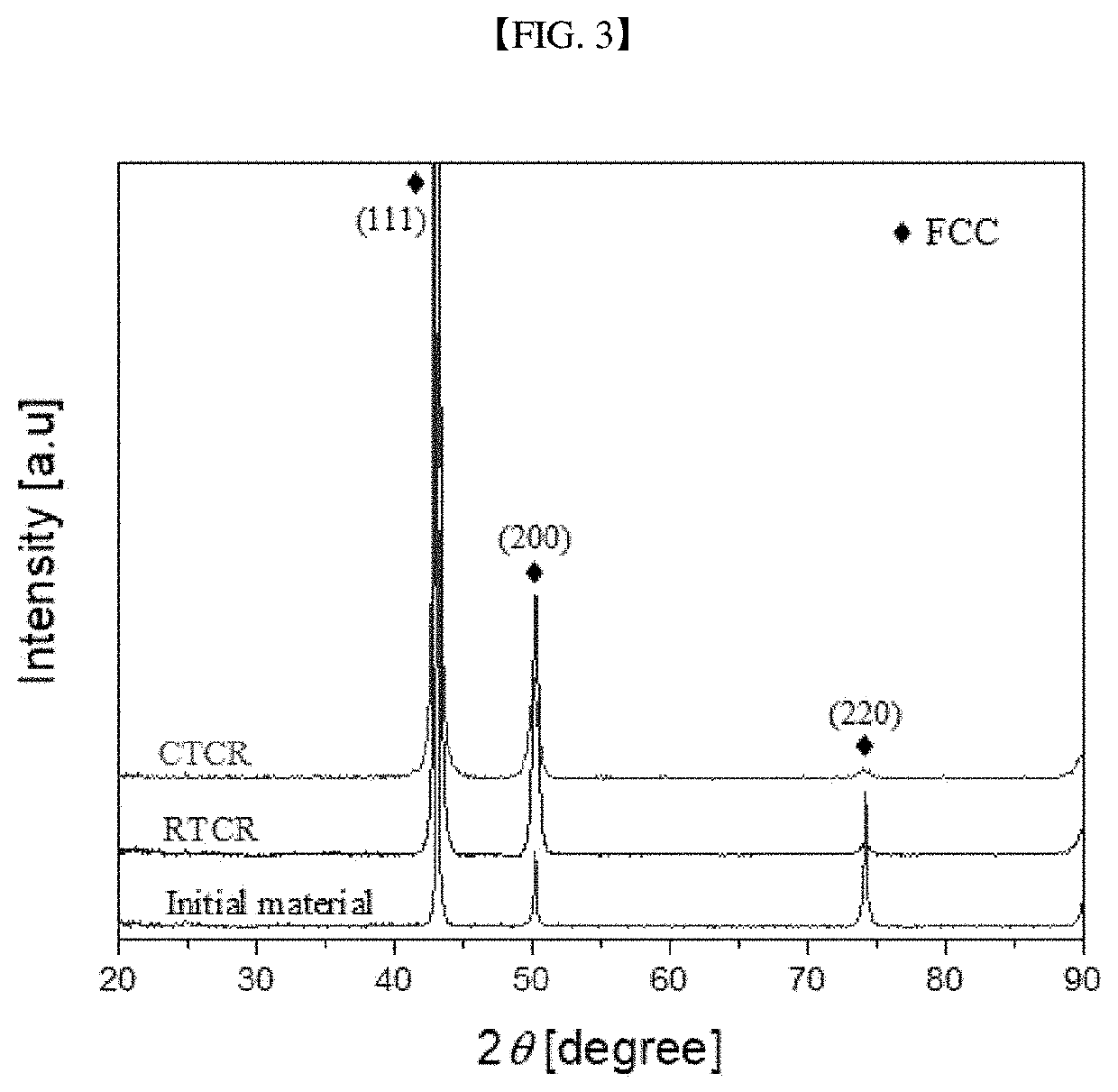

High-entropy alloy, and method for producing the same

ActiveUS20200392613A1Effective segmentationImprove refinementMetal rolling arrangementsHigh entropy alloysUltimate tensile strength

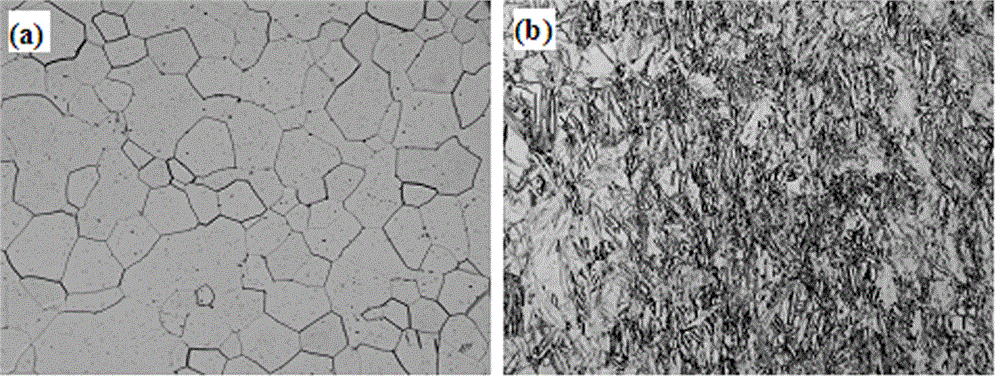

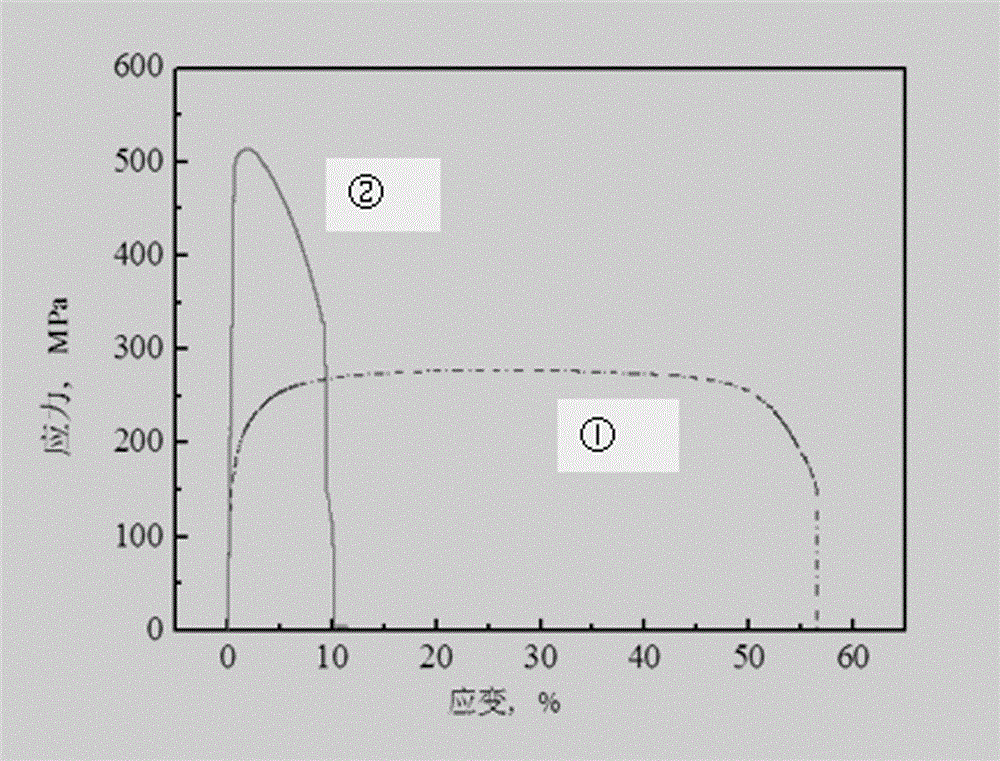

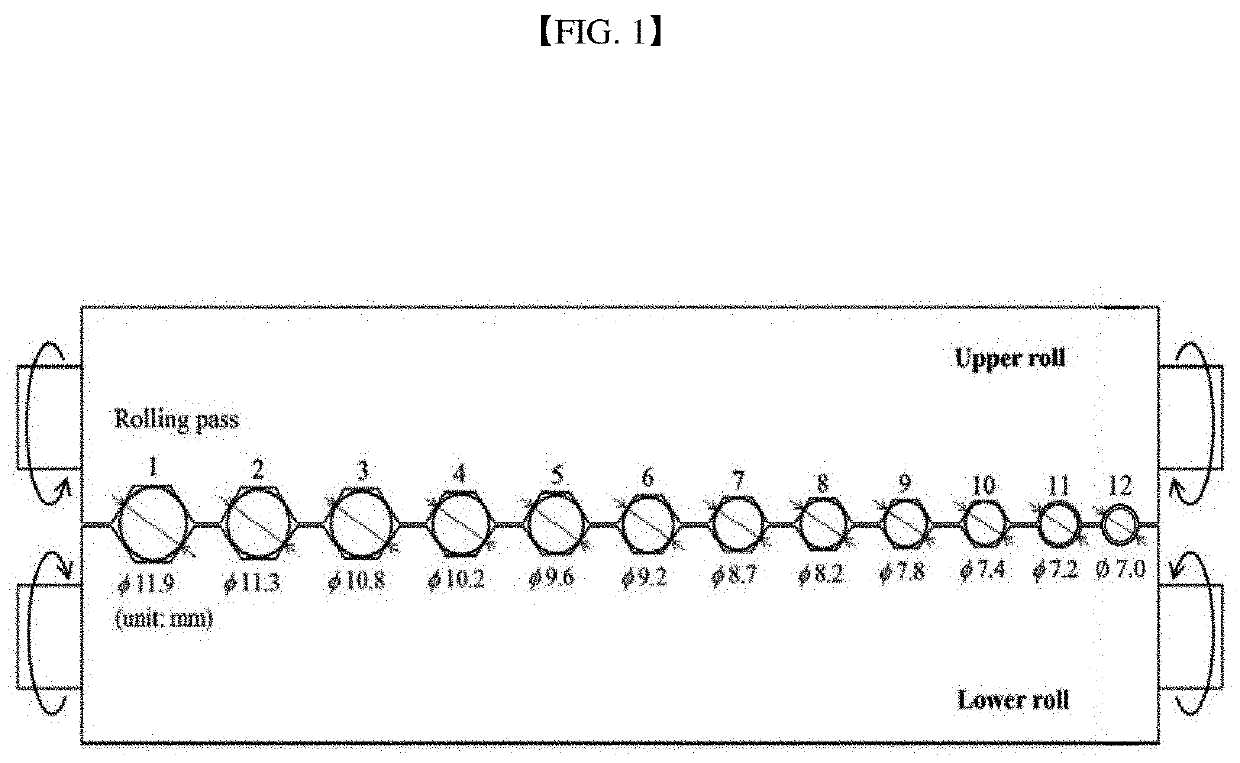

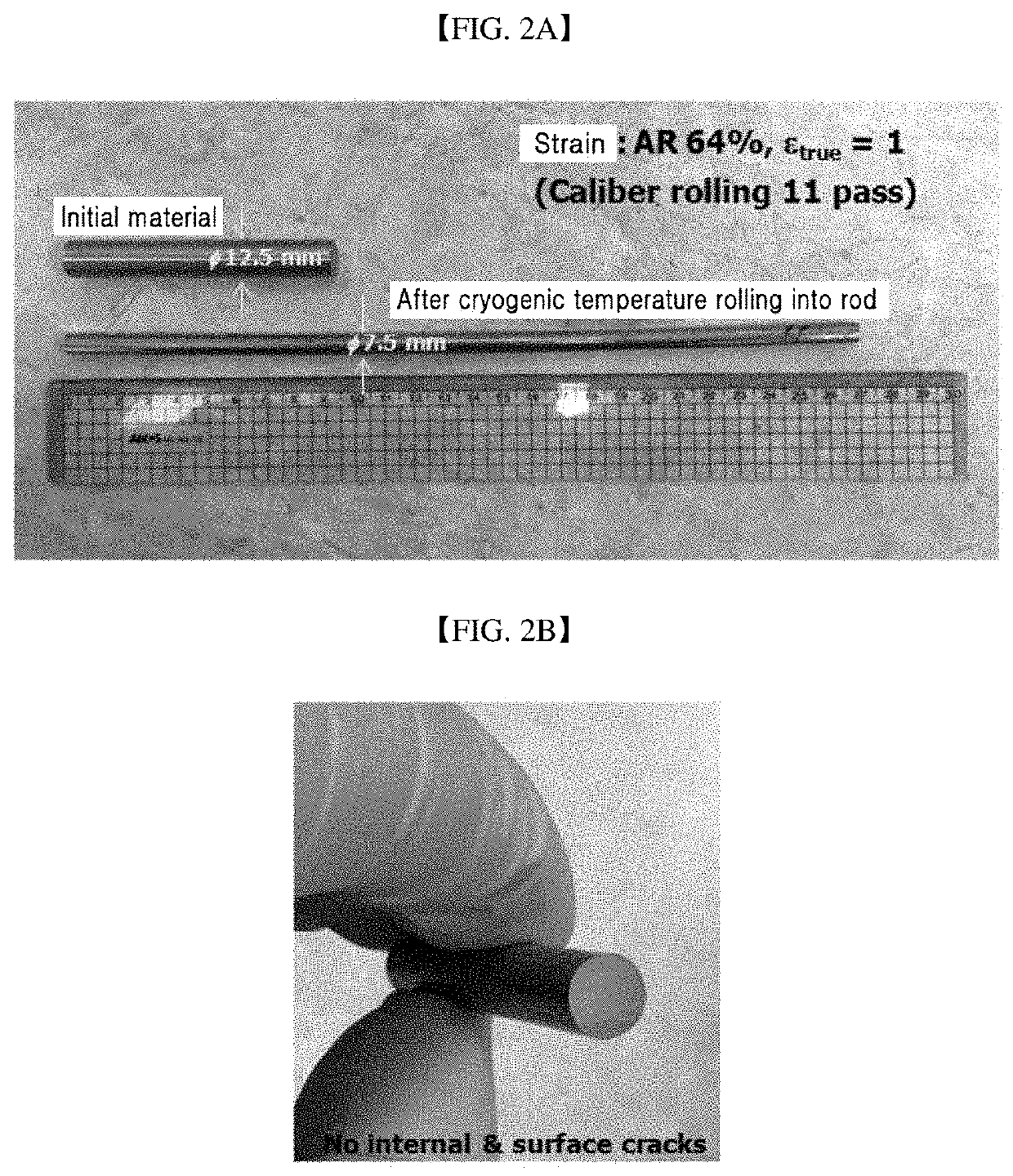

A high-entropy alloy having ultra-high strength and high hydrogen embrittlement resistance due to formation of a microstructure at a low strain may be produced without a severe plastic deformation.A method for producing the high-entropy alloy includes (a) annealing and homogenizing an initial alloy material at 1000 to 1200° C. for 1 to 24 hours; and (b) rolling the annealed and homogenized initial alloy material into a rod, at a cryogenic temperature of −100 to −200° C. while pressing the initial alloy material in multi-axial directions at a strain of 0.4 to 1.2, thereby to produce the high-entropy alloy having intersecting twins as a microstructure, and secondary fine twins formed in the intersecting twins, wherein the initial alloy material contains Co of 5 to 35%, Cr of 5 to 35%, Fe of 5 to 35%, Mn of 5 to 35%, and Ni of 5 to 35%, based on weight %.

Owner:KOREA INST OF MATERIALS SCI

Lubricant for plastic processing of metal material

ActiveCN103261384AAvoid pollutionSolve pollutionAdditivesBase-materialsSimple Organic CompoundsClay minerals

To provide a lubricant for plastic processing of metal materials which is also applicable in severe plastic deformation applications, does not have a black appearance that significantly stains a working environment, and does not tend to generate lubrication residue that cause molding defects. A lubricant for plastic processing of metal materials characterized by comprising in the range of 5-95%, in solid content ratio, an organic modified clay mineral supporting a cationic organic compound between the layers of the layered clay mineral.

Owner:NIHON PARKERIZING

Quick connection die and method for hot rolled strip intermediate billets

ActiveCN104815907ASimple structureImprove connection strengthShaping toolsMetal rolling arrangementsProcess equipmentLap joint

The invention provides a quick connection die and method for hot rolled strip intermediate billets. The die comprises an upper die and a lower die, wherein the upper die and the lower die are meshed with each other, a plurality of columnar teeth are arranged on the meshing face of the upper die, and a plurality of columnar teeth are arranged on the meshing face of the lower die. The method comprises the steps that first, the head and the tail of each intermediate billet which is processed through rough rolling are cut flat with a shears, so that each intermediate billet has a flat head end face and a flat tail end face; then, the adjacent ends of two adjacent intermediate billets in the front and rear direction are made to be flushed with each other to form a lap joint area; at last, pressure plastic deformation connection is carried out on the lap joint area of the intermediate billets through a press and the die on the press, and therefore, the lap joint area of the two intermediate billets in the front and rear direction is in connection through severe plastic deformation engagement. According to the quick connection die and method for hot rolled strip intermediate billets, process equipment is simple, the intermediate billets can be quickly connected, and the pressed intermediate billets are connected with high strenght.

Owner:UNIV OF SCI & TECH BEIJING

Method for eliminating original grain boundary of nickel-based powder metallurgy superalloy

The invention provides a method for eliminating the original grain boundary of a nickel-based powder metallurgy superalloy, belonging to the technical field of superalloys. According to the invention,the method adopts hot isostatic pressing and intense-plastic-deformation hot extrusion at a temperature below the complete dissolution temperature of a gamma' phase, makes full use of the pinning effect of the gamma' phase on the grain boundary in the hot isostatic pressing stage to control the grain size of the superalloy and prevent excessive grain growth, and then carries out optimized designon hot extrusion parameters to further refine grains and to crush and eliminate the original powder grain boundary. The method provided by the invention can eliminate the original grain boundary in the nickel-based powder metallurgy superalloy and prepare workpieces with particularly fine and uniform grain sizes.

Owner:CENT SOUTH UNIV

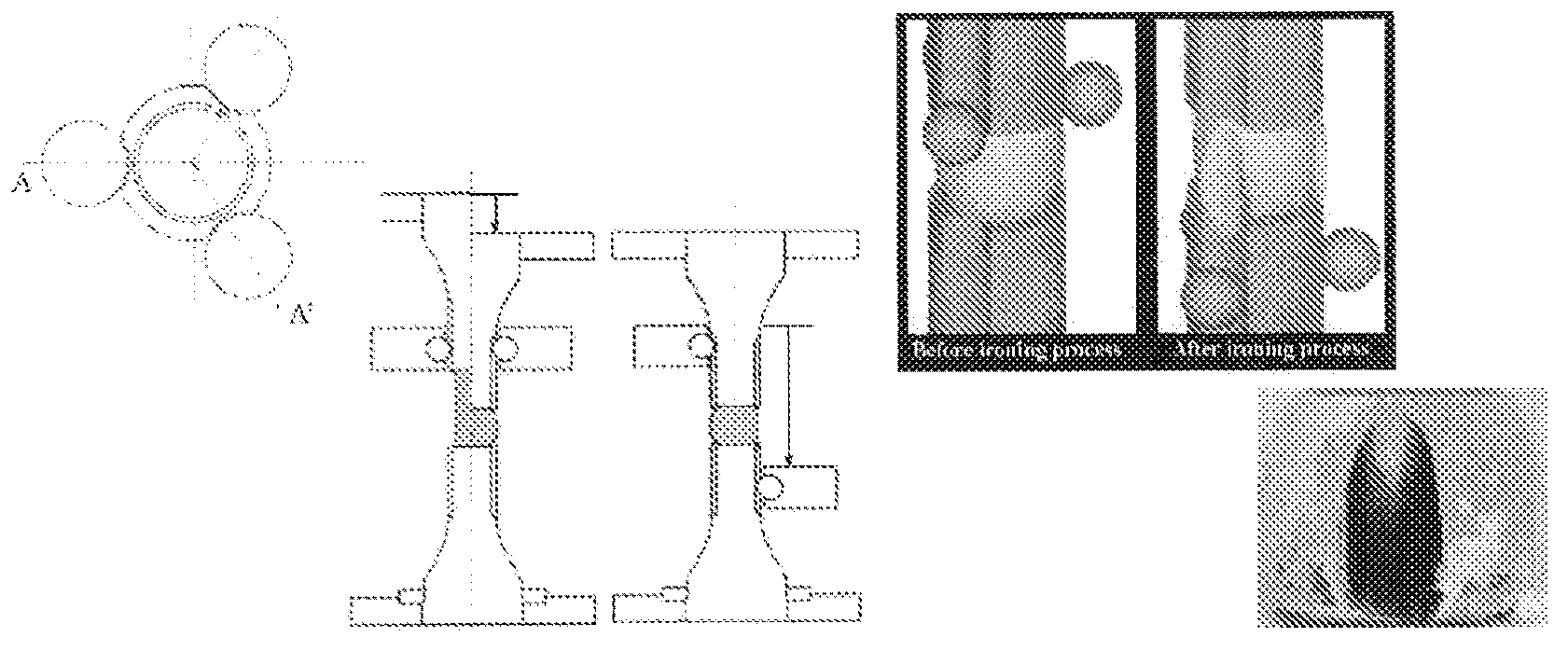

Machining method of enhanced magnesium-aluminum laminar composite tubular product

InactiveCN104801558AImprove plasticityLow densityExtrusion diesGrain structureUltimate tensile strength

The invention relates to improvements on composite tubular product enhancement and a machining method, in particular to a machining method of an enhanced magnesium-aluminum laminar composite tubular product. In the method, the advantages of light weight of a magnesium alloy and corrosion resistance and high plasticity of an aluminum alloy are effectively utilized, a grain structure is refined through pipe wall equal-diameter repeated extrusion, twice plastic deformation can be realized through one-time propelling, and severe plastic deformation is introduced circularly in a reciprocating way, so that the grain structure is effectively refined, and the intensity is enhanced; magnesium and aluminum layers are combined through a metallurgic reaction, so that the enhanced magnesium-aluminum laminar composite tubular product with excellent comprehensive performance is obtained, and the application range of the magnesium alloy is expanded.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com