Machining method of enhanced magnesium-aluminum laminar composite tubular product

A layered composite and enhanced technology, applied in the direction of metal extrusion dies, etc., can solve the problems of poor heat resistance, creep resistance, high temperature service performance, poor plastic processing ability, and restrictions on large-scale application, and achieve easy temperature control, The effect of improving strength and good prospects for large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

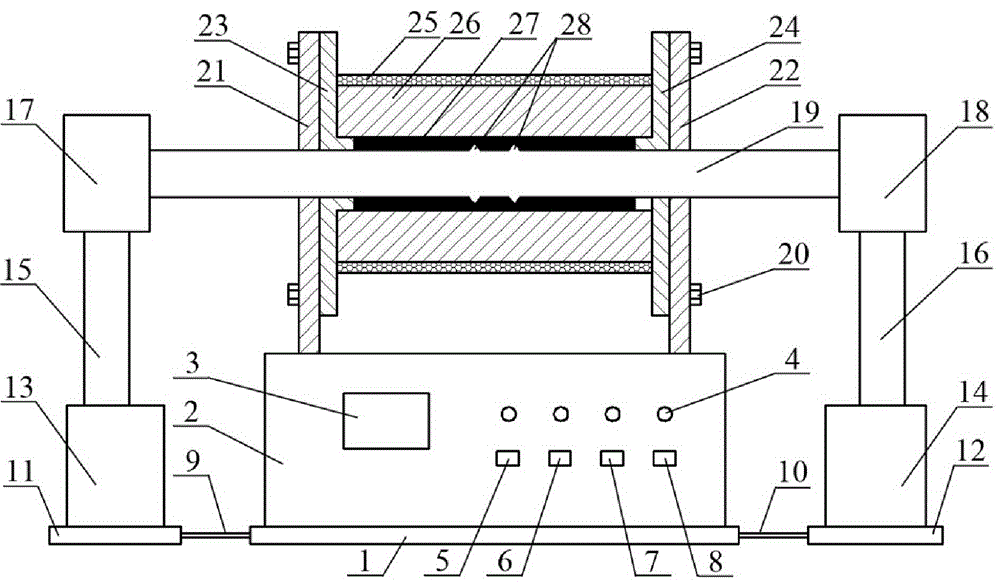

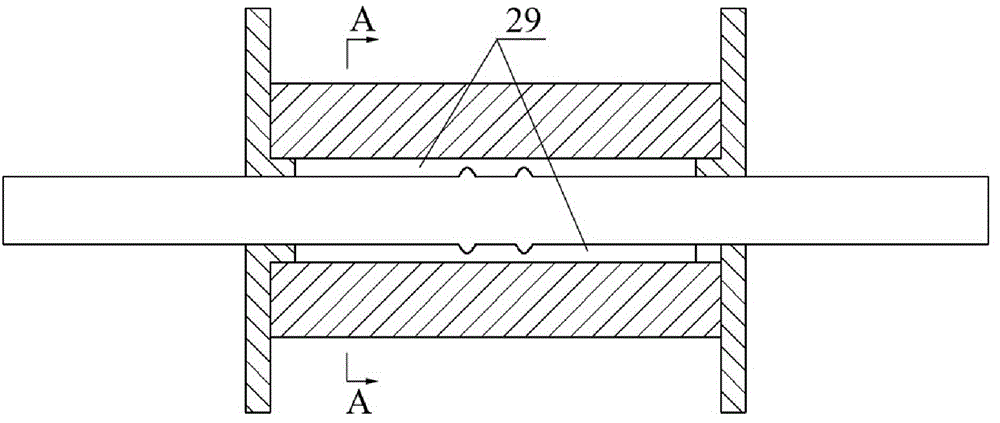

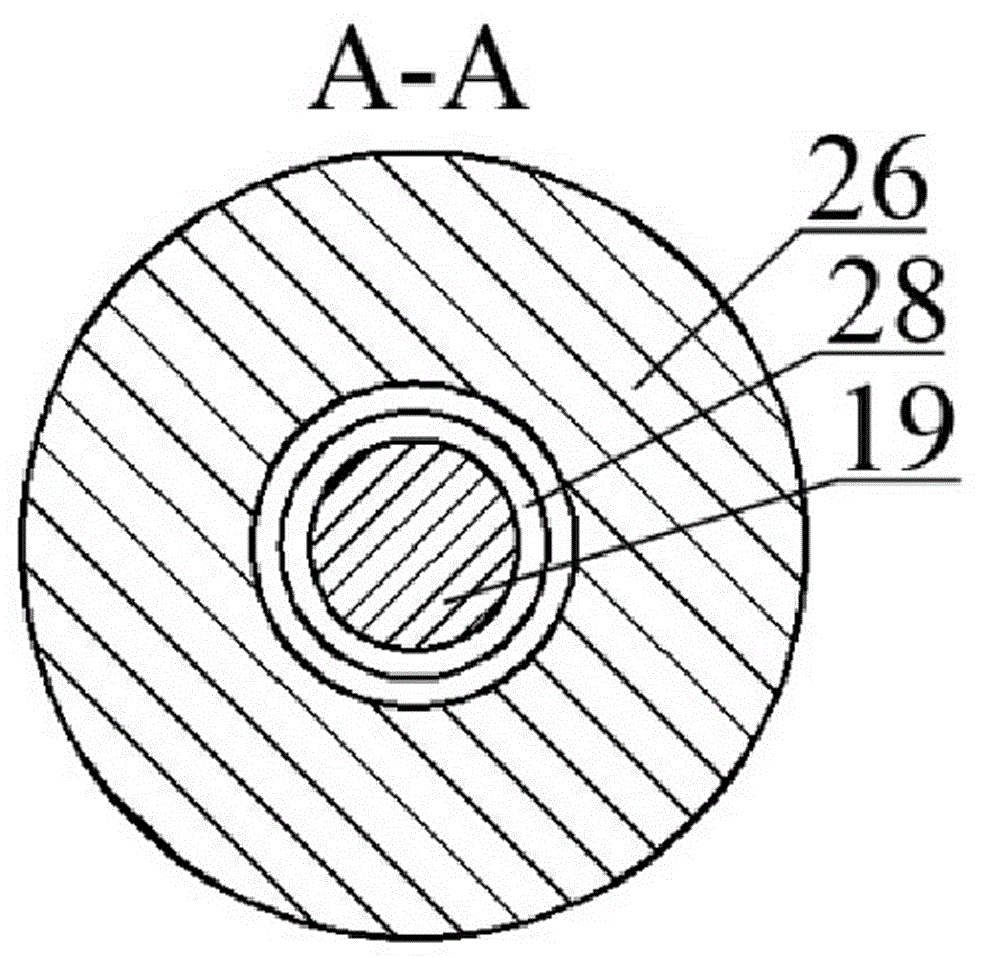

[0055] figure 1 As shown, it is the equidiametric reciprocating extrusion state diagram of the pipe wall of the reinforced magnesium-aluminum multilayer composite pipe. The installation is firm, and the position and connection relationship of each part must be correct and operated in sequence.

[0056] The quantity and value of the chemical reagents used in the equidiametric reciprocating extrusion of the magnesium-aluminum multilayer pipe wall are determined according to the preset ratio.

[0057] The equal-diameter reciprocating extrusion of the tube wall of the magnesium-aluminum multilayer pipe is carried out on a horizontal hydraulic reciprocating extrusion machine. Completed;

[0058] The horizontal hydraulic reciprocating extrusion machine includes a workbench 2, the extruder base 1 is located below the workbench 2, and a display screen 3, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com