Hot rolling process of high-plasticity and low-anisotropy magnesium alloy and sheet thereof

An anisotropic, magnesium alloy technology, applied in the field of metal materials, can solve the problems of large anisotropy, poor room temperature plasticity, and low strain hardening index, and achieve high strain hardening rate, easy control, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Metal mold gravity casting is adopted, and Mg-Zn-Gd is melted and poured into a 150mm×200mm×200mm ingot through conventional magnesium alloy melting. The alloy composition weight percentage is Zn: 1.1%, Gd: 0.9%, and the magnesium content is more than Quantity, abbreviated as ZG11;

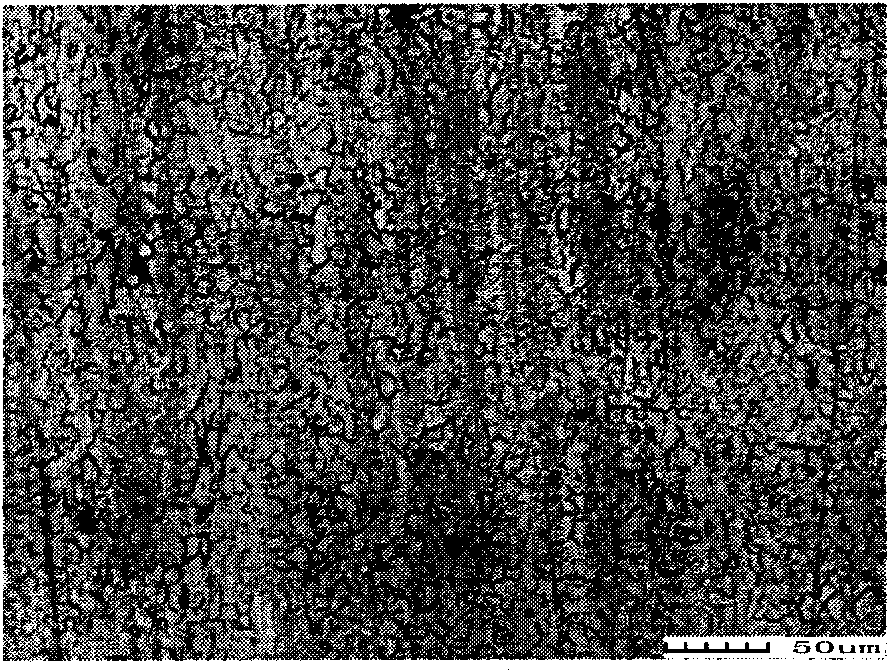

[0032] 2) After the ingot is homogenized at 450°C for 10 hours, the ingot is cut into billets of 150mm×100mm×20mm and face milled, and the billet after milling is kept at 450°C for rolling; the temperature of the rolls is room temperature 25 ℃, start rolling, the reduction in the first pass is 20%, and the reduction in each subsequent pass is 18%. After each rolling two passes, return to the furnace and heat it to temperature, then hold it for 5 to 10 minutes, take it out and continue rolling. Until the thickness of the plate is 3mm, the total reduction is 85%, due to the occurrence of complete dynamic recrystallization, the plate has a uniform and fine grain size, as shown in Figure 1(a...

Embodiment 2

[0036] 1) Metal mold gravity casting is adopted, Mg-Zn-Gd is melted and poured into a 150mm×200mm×200mm ingot through conventional magnesium alloy melting, the alloy composition weight percentage is Zn: 2.1%, Gd: 0.9%, and the magnesium content is more than balance Quantity, abbreviated as ZG21;

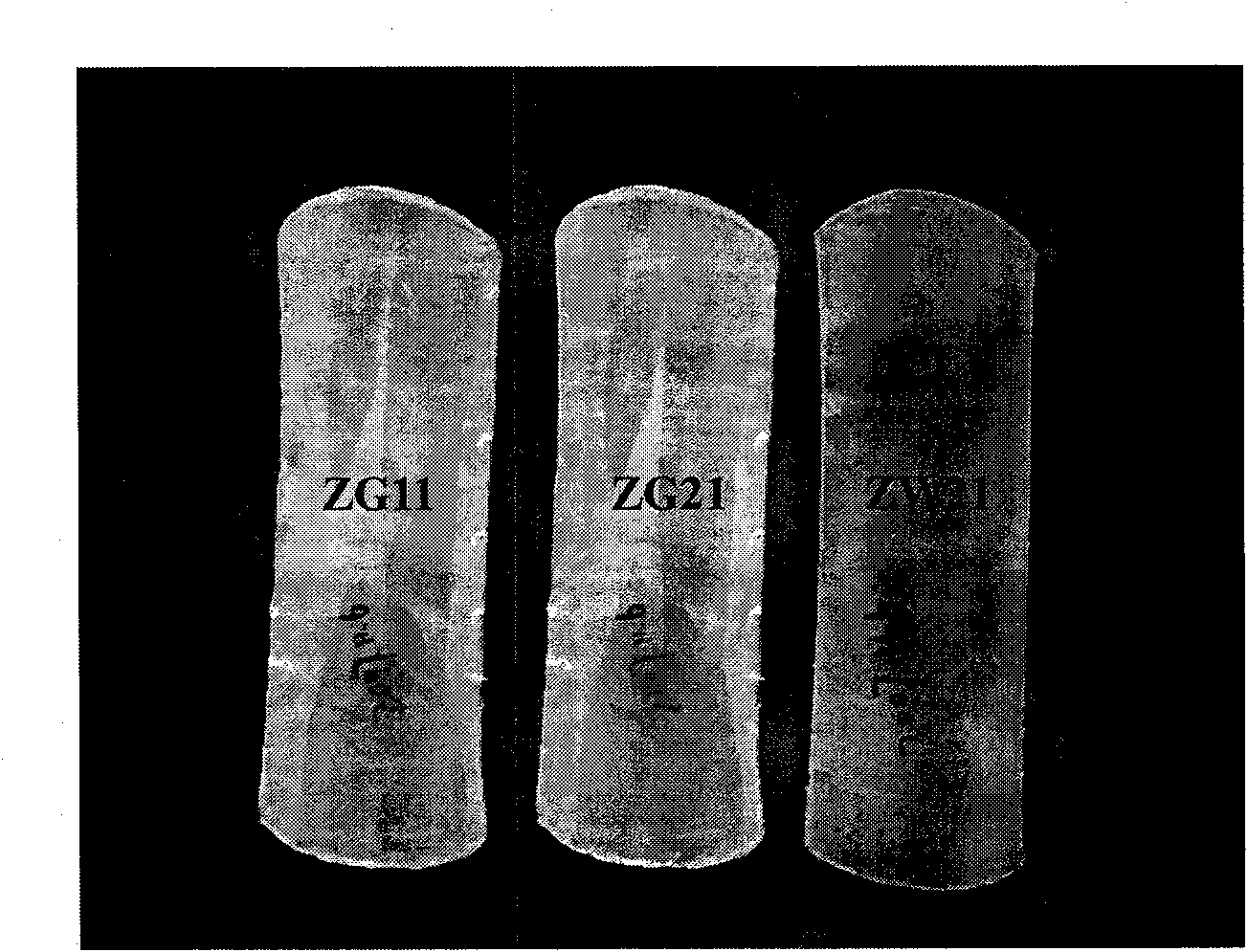

[0037]2) After the ingot is homogenized at 420°C for 10 hours, the ingot is cut into billets of 150mm×100mm×20mm and milled, and the milled billet is kept at 400°C for rolling; the roll is preheated to 100°C, start rolling, the reduction in the first pass is 20%, and the reduction in each subsequent pass is 15%. After each rolling two passes, return to the furnace to heat to temperature and keep it warm for 5 to 10 minutes to continue rolling , until the plate thickness is 3.2mm, the total reduction is 84%, and there is no crack on the surface of the plate, see figure 2 , has good rollability;

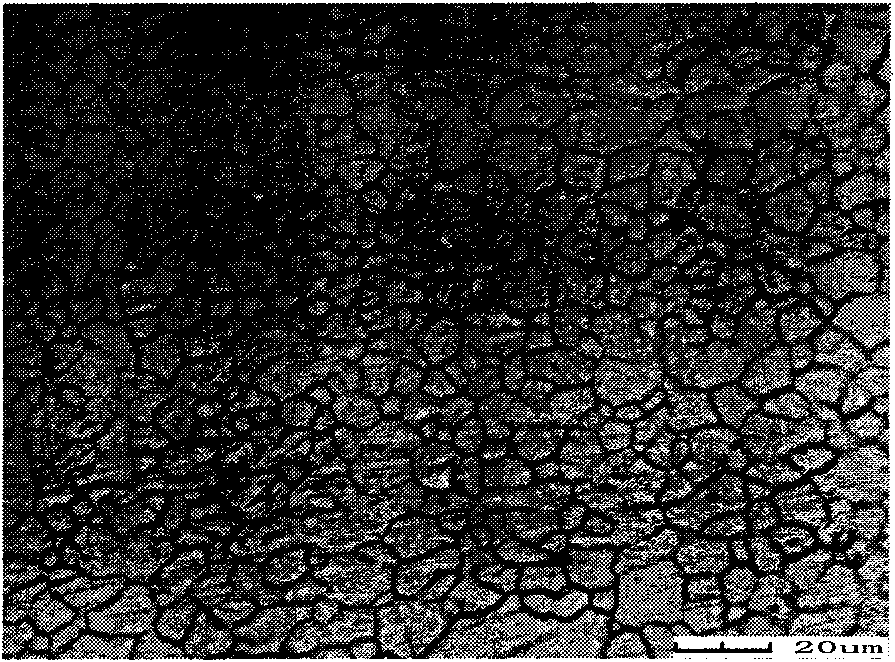

[0038] 3) The rolled plate is annealed at 320°C for 3 hours, the structure is shown in ...

Embodiment 3

[0041] 1) Metal mold gravity casting is adopted, and Mg-Zn-Y is melted and poured into a 150mm×200mm×200mm ingot through conventional magnesium alloy melting. The alloy composition weight percentage is Zn: 2.0%, Y: 1.1%, and the magnesium content is more than Quantity, abbreviated as ZW21;

[0042] 2) After the ingot is homogenized at 450°C for 10 hours, the ingot is cut into billets of 150mm×100mm×20mm and face-milled, and the billet after milling is kept at 450°C for rolling; the rolls are preheated to 25°C, start rolling, the reduction in the first pass is 18%, and the reduction in each subsequent pass is 18%, after each rolling two passes, return to the furnace to heat to temperature and keep it warm for 5 to 10 minutes to continue rolling , until the plate thickness is 3mm, the total reduction is 85%;

[0043] 3) The rolled plate is annealed at 350° C. for 1 hour, and then trimmed, covered with a plastic protective film and packaged.

[0044] 4) Refer to §3.6.2 of the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com