Patents

Literature

438 results about "Binary alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An alloy is a mixture of a metal with one or more other elements. A binary alloy is made up of two elements. 1. A homogeneous 2 binary alloy is a solid solution: The primary element is a metal and is called the solvent 3. The secondary element is called the solute.

Metal alloy fine particles and method for producing thereof

A novel method for preparing fine particles comprising a transition metal and a noble metal which are monodispersed and have almost no particle diameter distribution, and are transferable to a CuAu-I type L10 ordered phase, with safety and at a low cost, wherein a salt or a complex of at least one transition metal selected from Fe and Co and a salt or a complex of at least one transition metal selected from Pt and Pd (exclusive of the combination of Co—Pd) is dissolved in an organic solvent miscible with water or an alcohol in the presence of an organic protecting agent, and the resultant solution is heated under reflux in the presence of an alcohol in an inert atmosphere, to thereby prepare a binary alloy comprising a transition metal and a noble metal, or a salt or a complex of at least one element selected from the group consisting of Cu, Bi, Sb, Sn, Pb and Ag is further dissolved in the above solvent and the resultant solution is heated under reflux in the presence of an alcohol in an inert atmosphere, to thereby prepare a ternary alloy comprising a transition metal, a noble metal and an additional element.

Owner:HITACHT MAXELL LTD

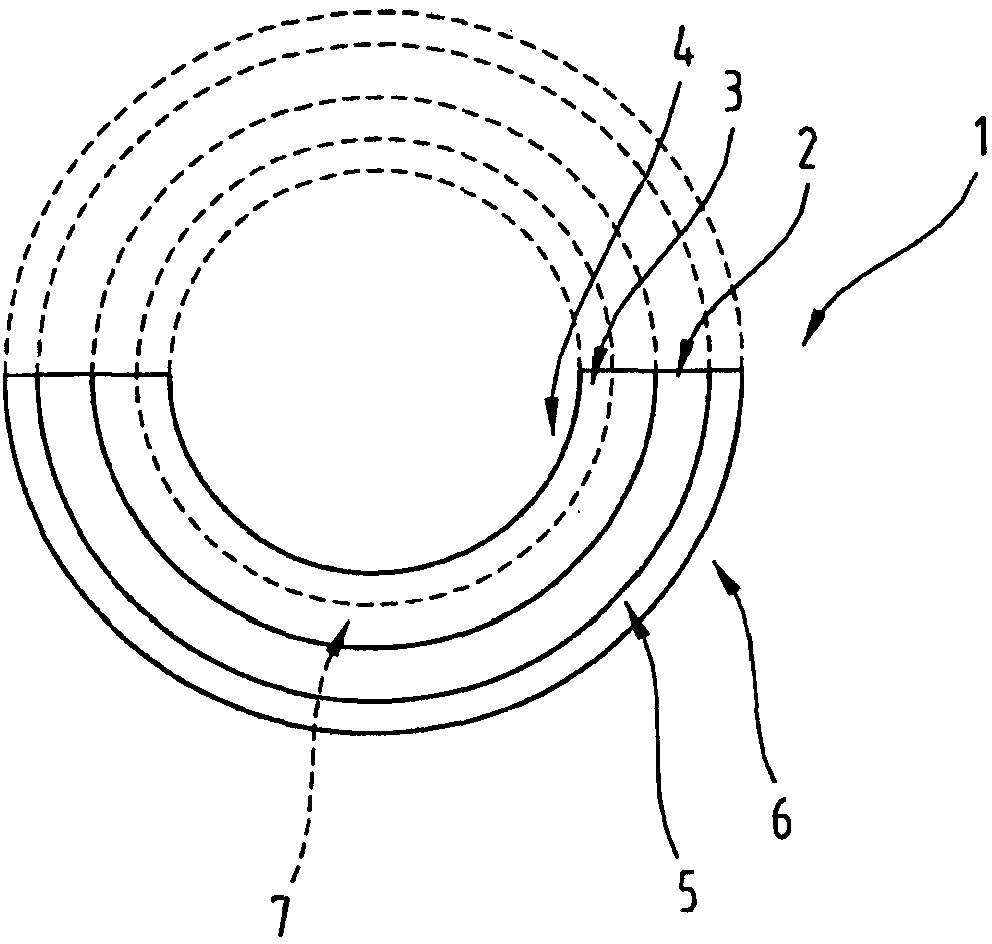

Multi-layer plain bearing having an anti-fretting layer

The invention relates to a multi-layer plain bearing (1) that has a front side (4) that can face the element to be supported and a rear side (6) opposite the front side, comprising a supporting layer (2), a sliding layer (3) arranged on the front side (4), and an anti-fretting layer (5) arranged on the rear side (6), wherein the anti-fretting layer (5) is made of a copper-based alloy having copper mixed-crystal grains. The copper-based alloy of the anti-fretting layer (5) is formed by a binary alloy having an alloying element from the group comprising aluminum, zinc, indium, silicon, germanium, and antimony or by an at least ternary alloy having one alloying element from the group comprising aluminum, zinc, indium, silicon, germanium, tin, and antimony and at least one further element from said group and / or the further group comprising nickel, cobalt, iron, manganese, bismuth, lead, silver, and phosphorus, possibly with unavoidable impurities originating from production, wherein the total fraction of said alloying elements is at least 1 wt % and at most 30 wt %.

Owner:MIBA SINTER AUSTRIA

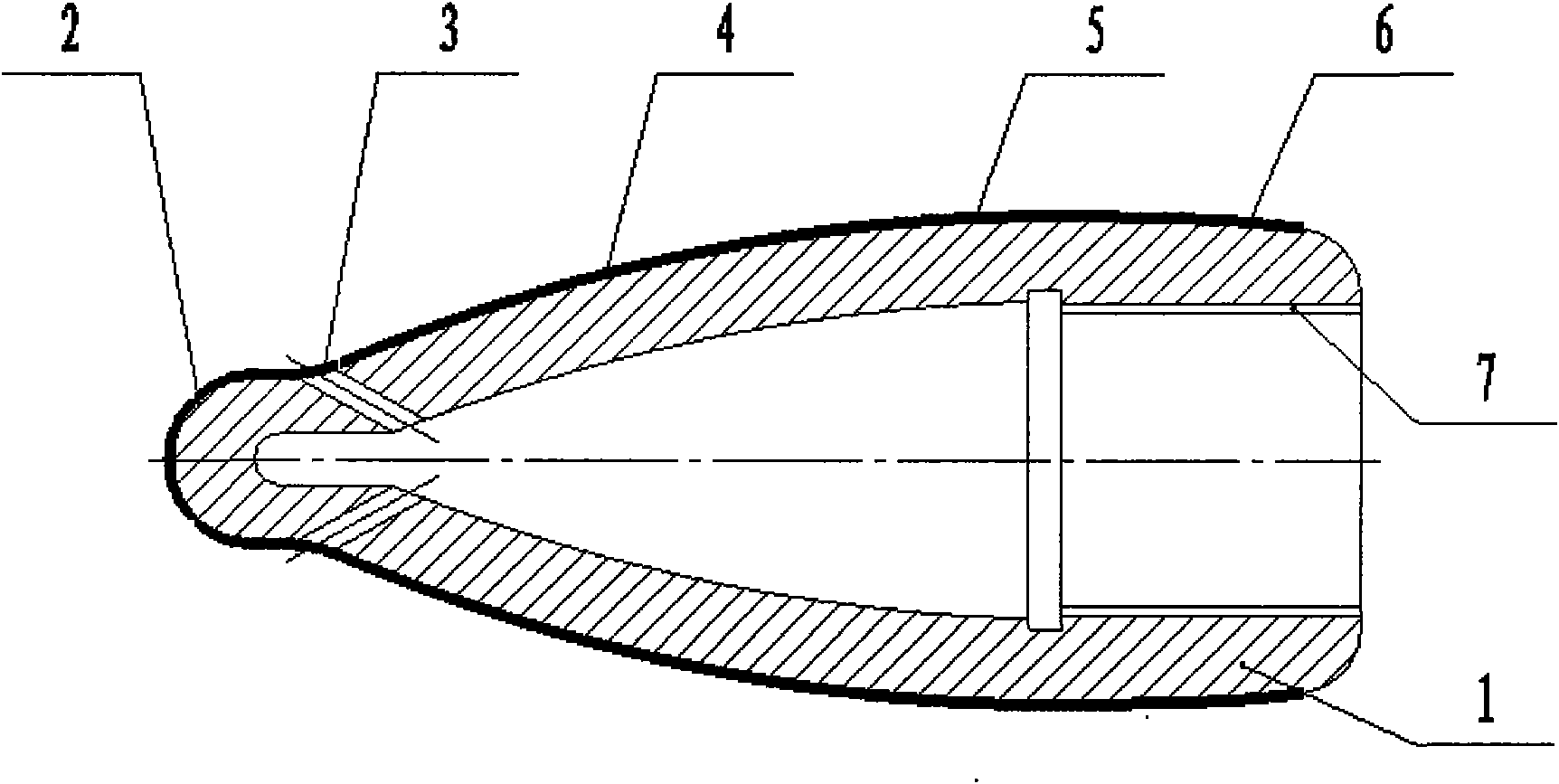

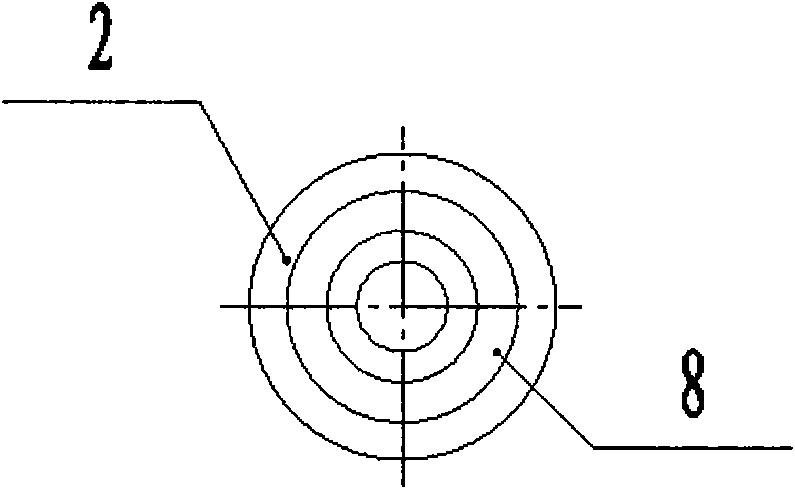

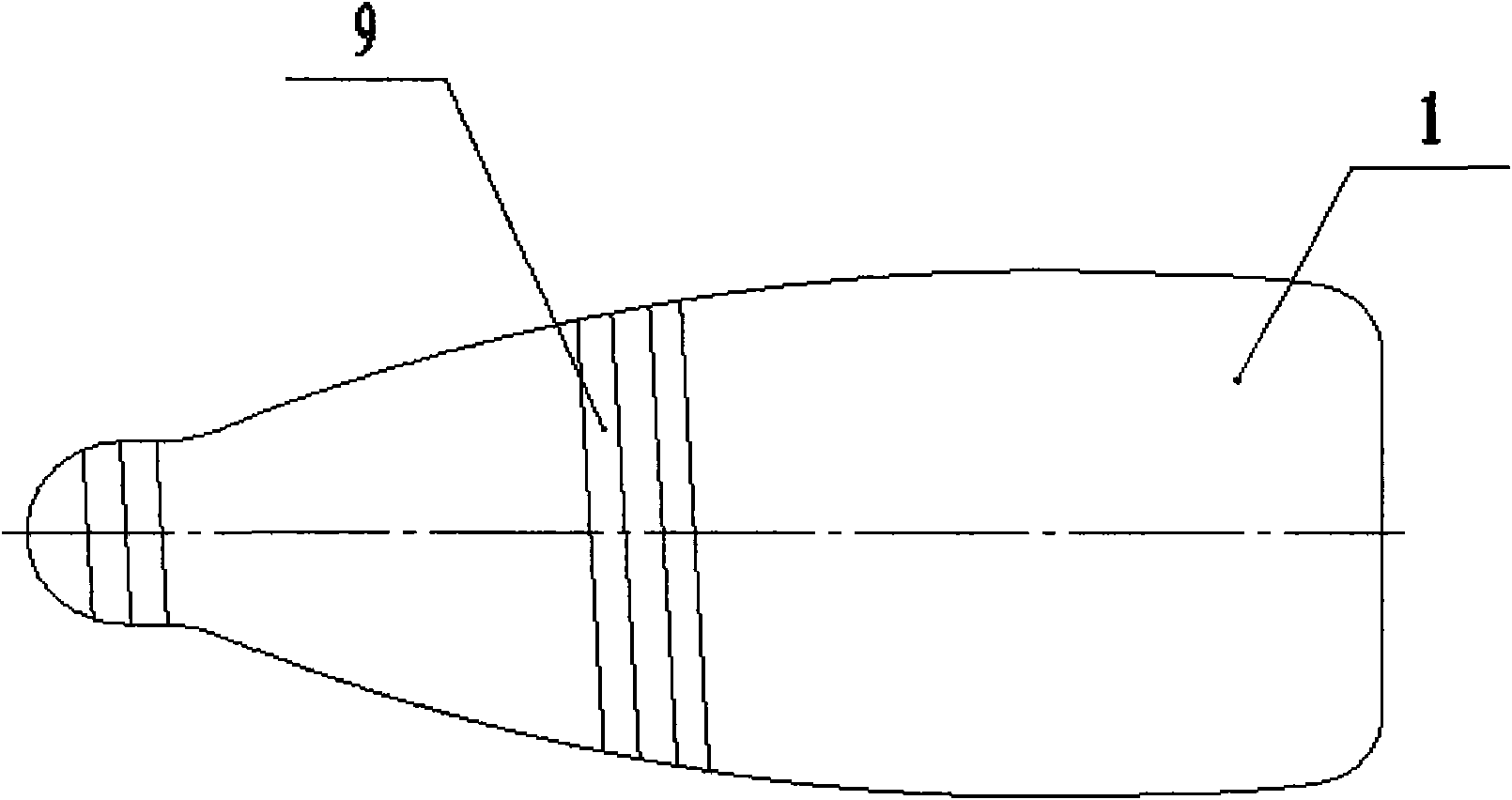

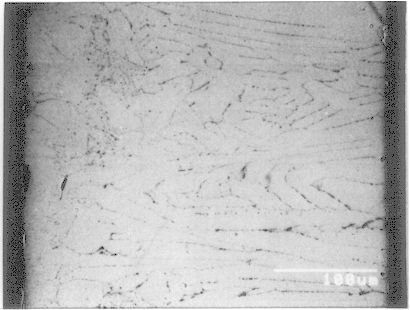

Binary alloy coating seamless steel tube top and manufacture method thereof

InactiveCN101596551AReduce stress concentrationEliminates crack-prone problemsMandrelsFurnace typesBinary alloyLaser coating

A binary alloy coating seamless steel tube top and a manufacture method belong to the field of laser processing. Aiming at solving the easy peel-off of molybdenum alloy of a molybdenum alloy top, prolonging service life and reducing cost, the invention melts and coats nickel-base or cobalt-base alloy coating at the nose or working part of the top, melts and coats iron-base alloy coating at the straightening part and the parallel part to obtain a binary alloy coating seamless steel tube top; the preparation of the top has the following steps of manufacturing the top by adopting a casting manner, performing mechanical processing on the cast top and reserving melt thickness of 1.0-3.0mm on the external surface of the top for laser melt process; using nickel-base or cobalt-base alloy to perform laser melt on the top end of the nose part; performing laser melt on the lateral of the nose part as well as the working part with nickel-base or cobalt-base alloy as melt powder, finishing laser melt on the straightening part and the parallel part with iron-base alloy incessantly; performing strain-removal treatment, namely performing mechanical processing of top nose spiracle and finishing laser coating polishing and grinding.

Owner:BEIJING UNIV OF TECH

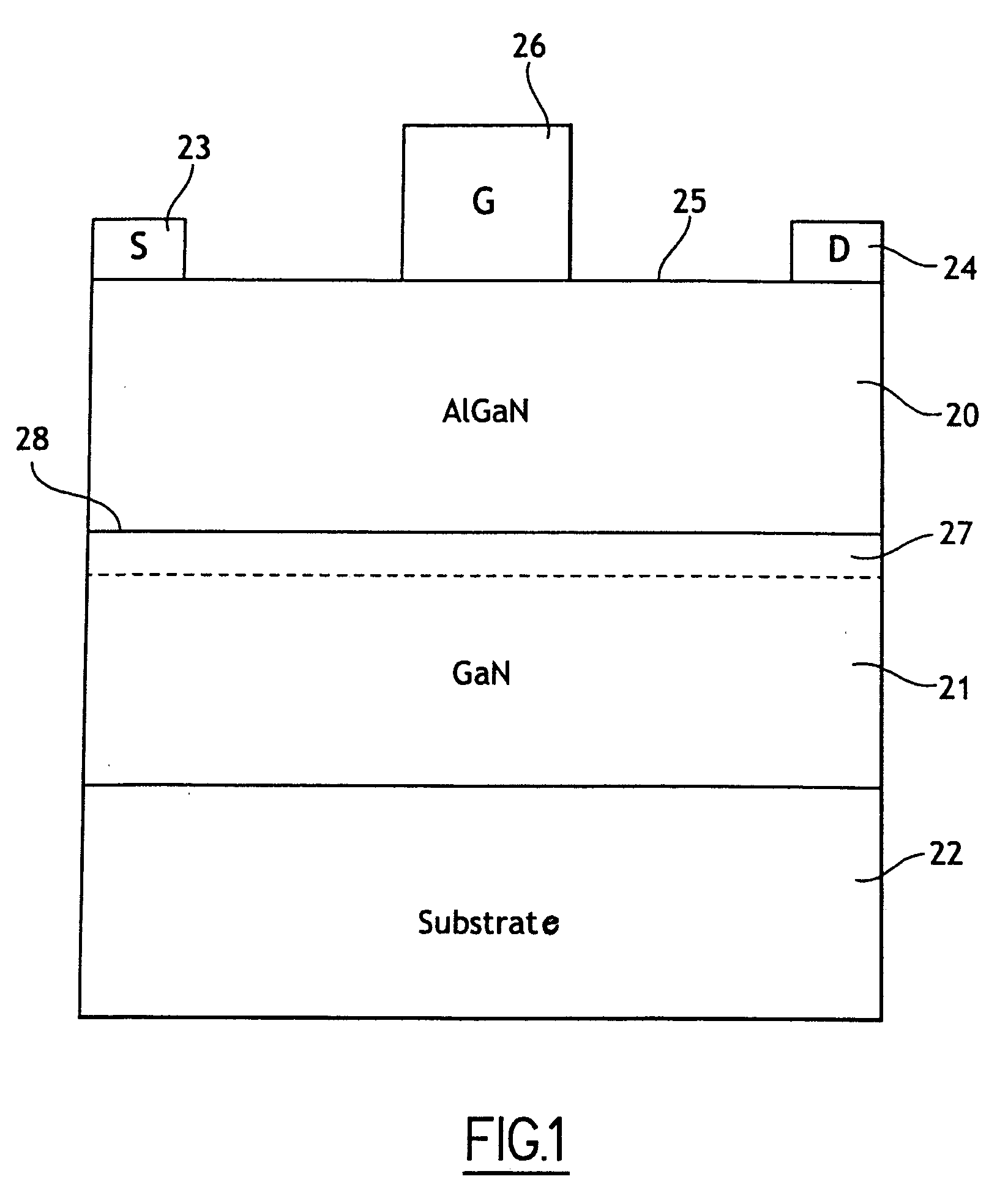

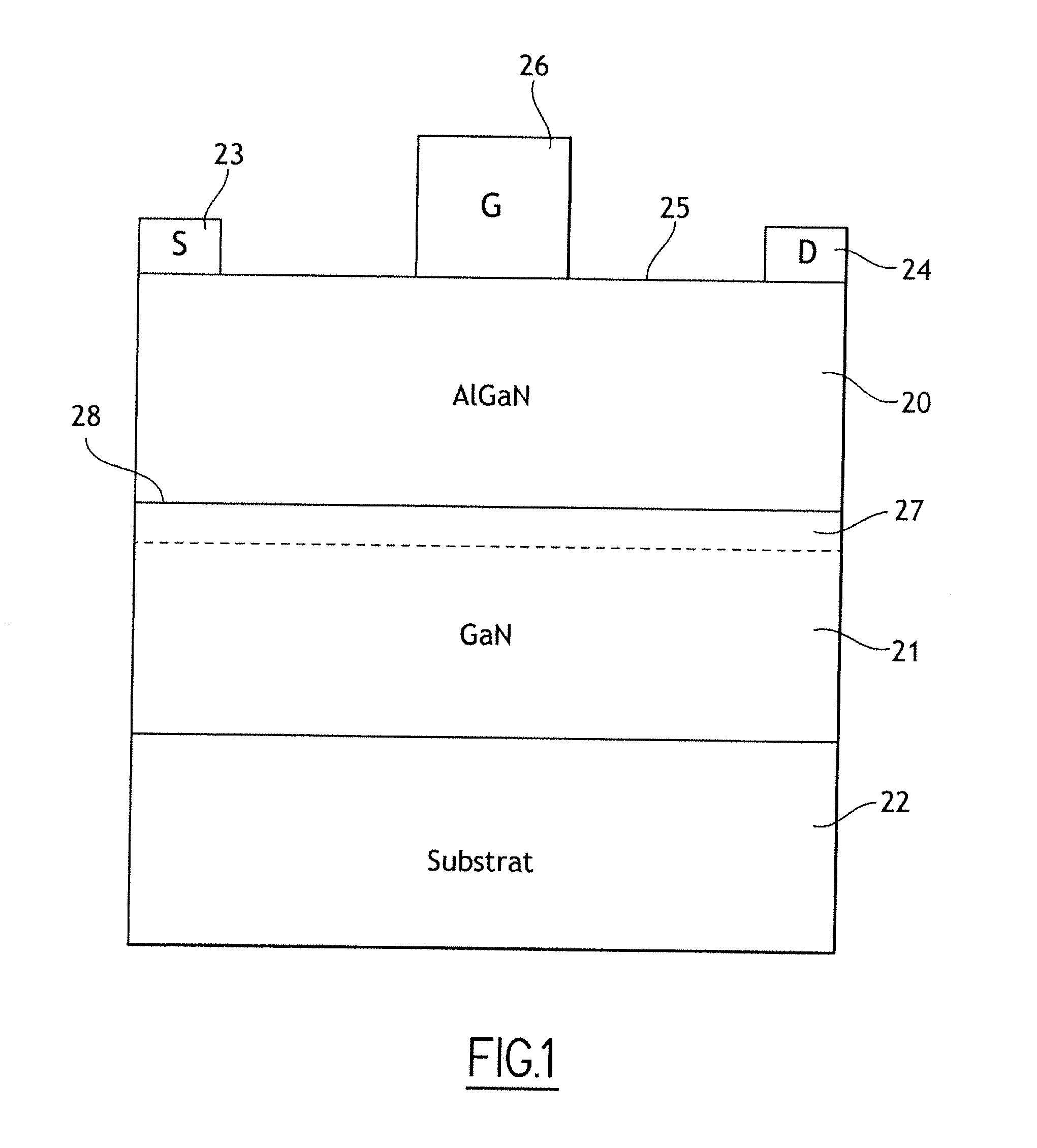

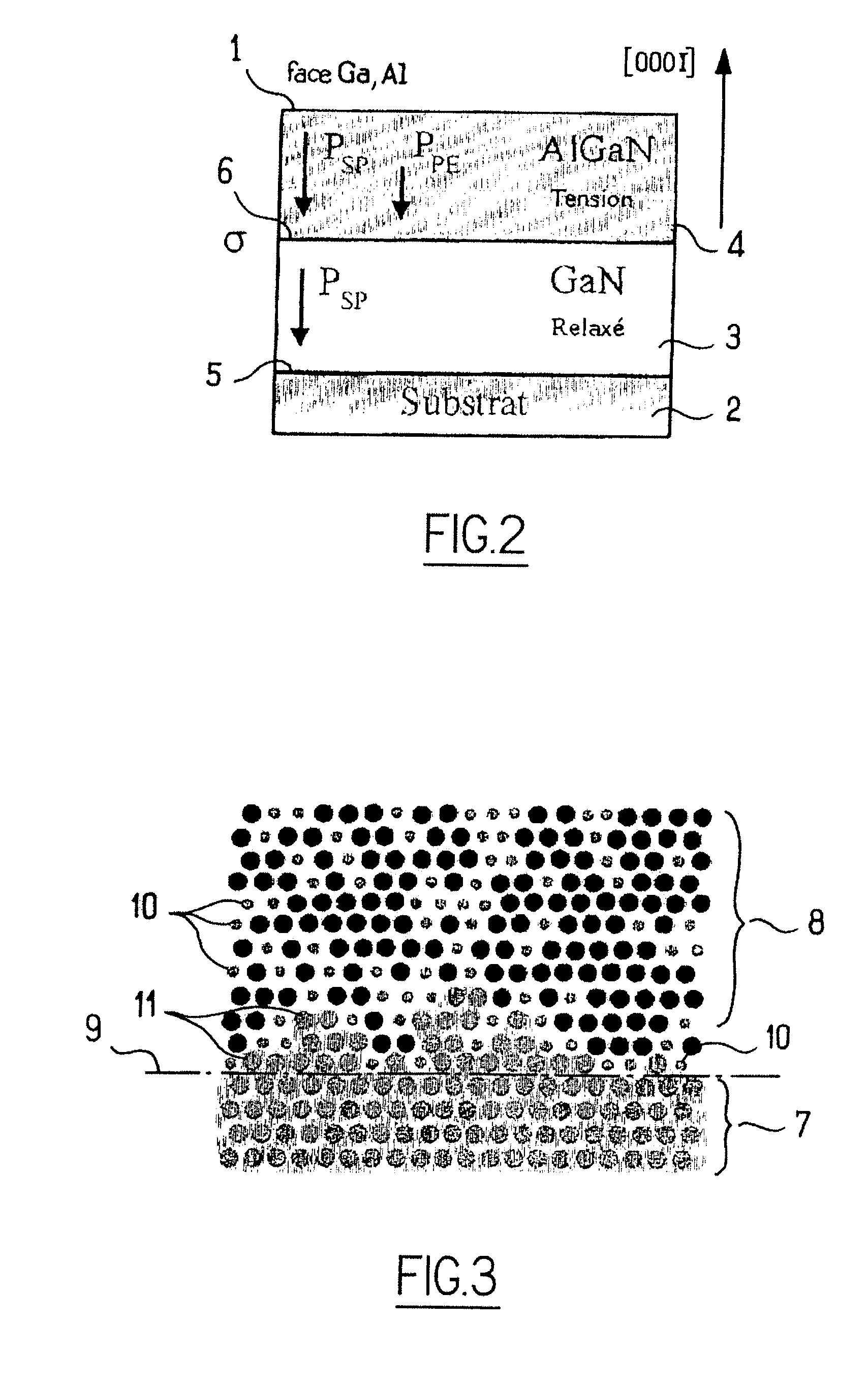

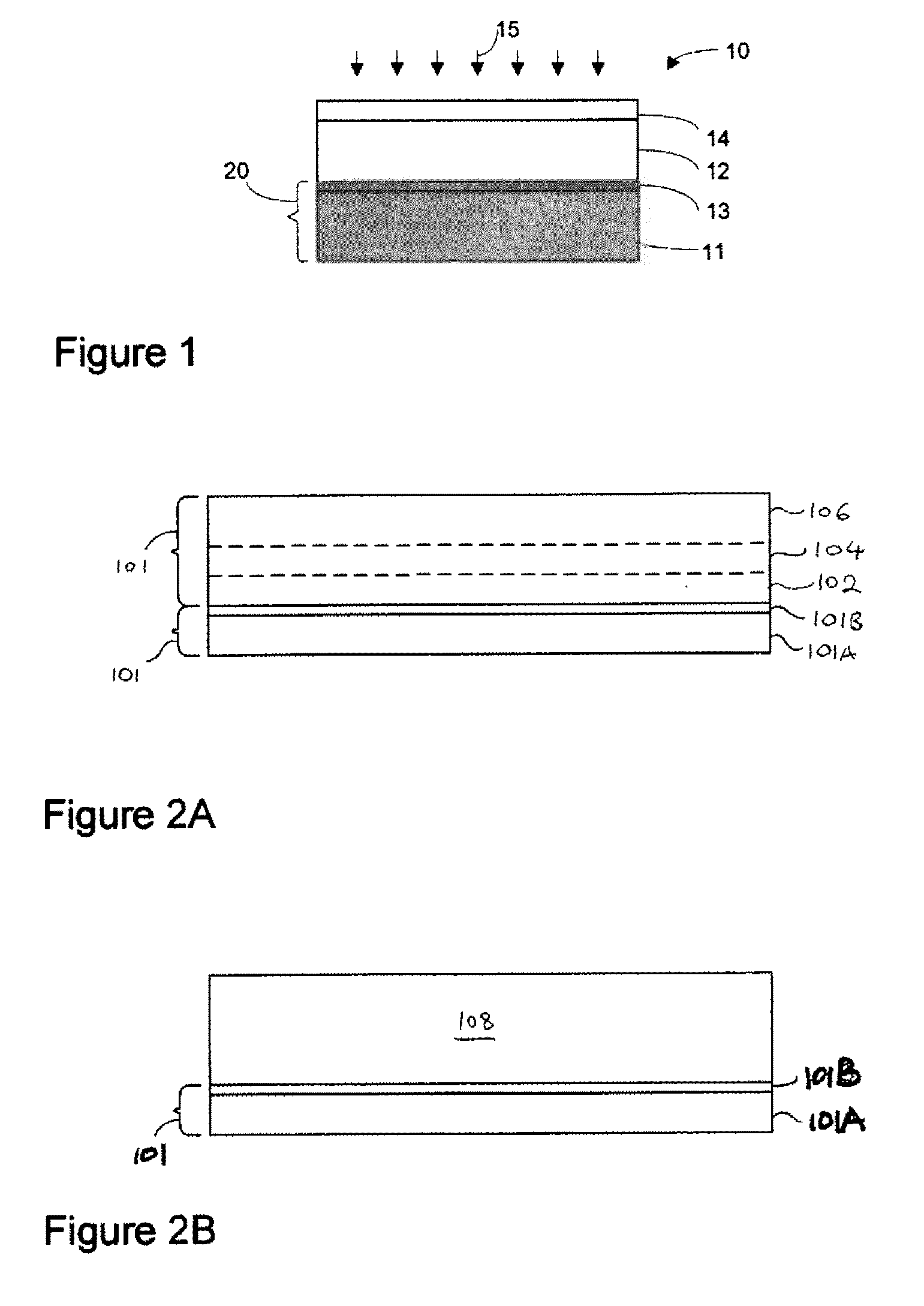

High electron mobility transistor piezoelectric structures

InactiveUS20060054926A1Simplify the viewing processSemiconductor devicesBinary alloySemiconductor materials

Piezoelectric semiconductor structures and methods for fabricating the same are described. In an embodiment, the piezoelectric semiconductor structure includes a support substrate, a channel layer arranged on one side of the support substrate, and a barrier layer formed on the channel layer. The barrier layer is made of alternating binary alloy layers of Type III-Type V semiconductor materials.

Owner:PICOGIGA INT

Ultrafine-grain medical magnesium alloy and preparation method thereof

The invention provides an ultrafine-grain medical magnesium alloy which is one of Mg-Zn, Mg-Ca, Mg-Mn or Mg-rare earth binary alloys, or one of ternary alloys or complex alloys formed by the same. The medical magnesium alloy contains at least one of the following metal components in percentage by mass: 0.5-10% of Zn, 0.5-10% of Ca, 0.5-10% of Mn or 0.1-10% of rare earth and the balance of magnesium; the purities of the components in the medical magnesium alloy are all above 99.9%. The invention also provides a preparation method of the superfine-grain medical magnesium alloy. By using the preparation method provided by the invention, mechanical property and corrosion resistance of the magnesium alloy can be greatly improved by combining quick solidification with vacuum hot compression. Compared with a traditional cast magnesium alloy, the ultrafine-grain medical magnesium alloy provided by the invention has the advantages that the room temperature is increased by above 40% compared with the tensile strength, the elongation rate is increased by above 5%, the corrosion speed is reduced to 0.15-0.25 mm / year, the grain size is thinned to be less than 10 microns; and the ultrafine-grain medical magnesium alloy has excellent biocompatibility.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

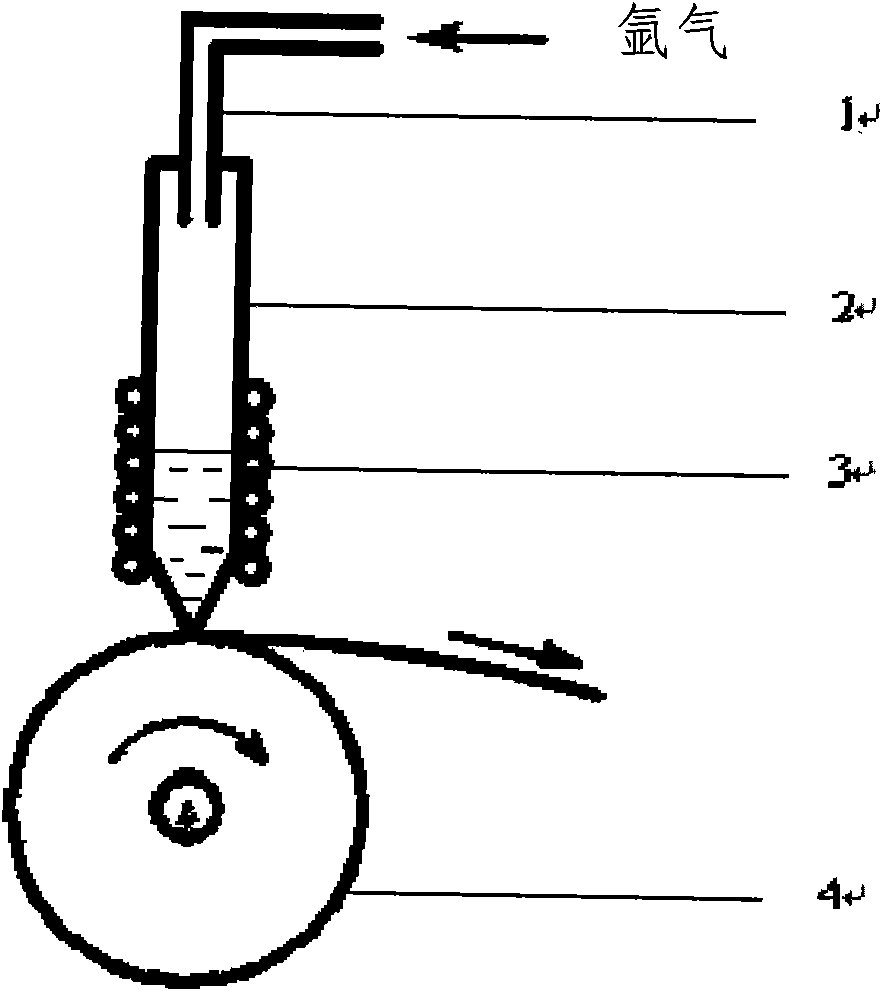

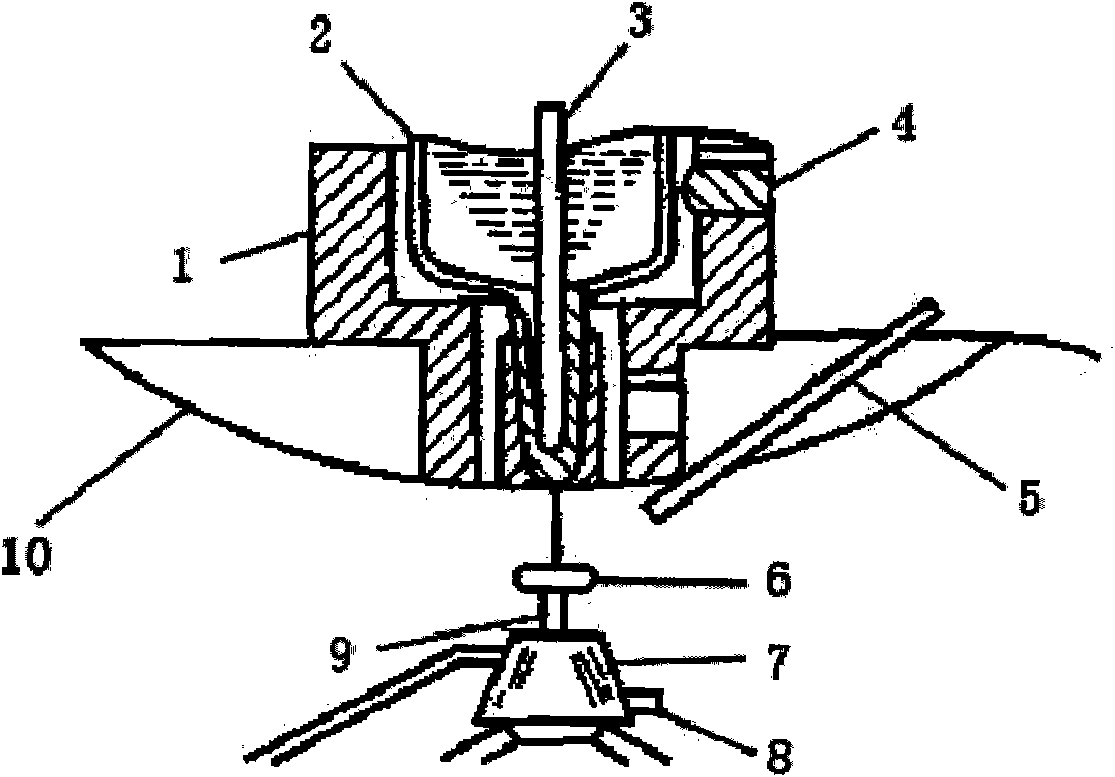

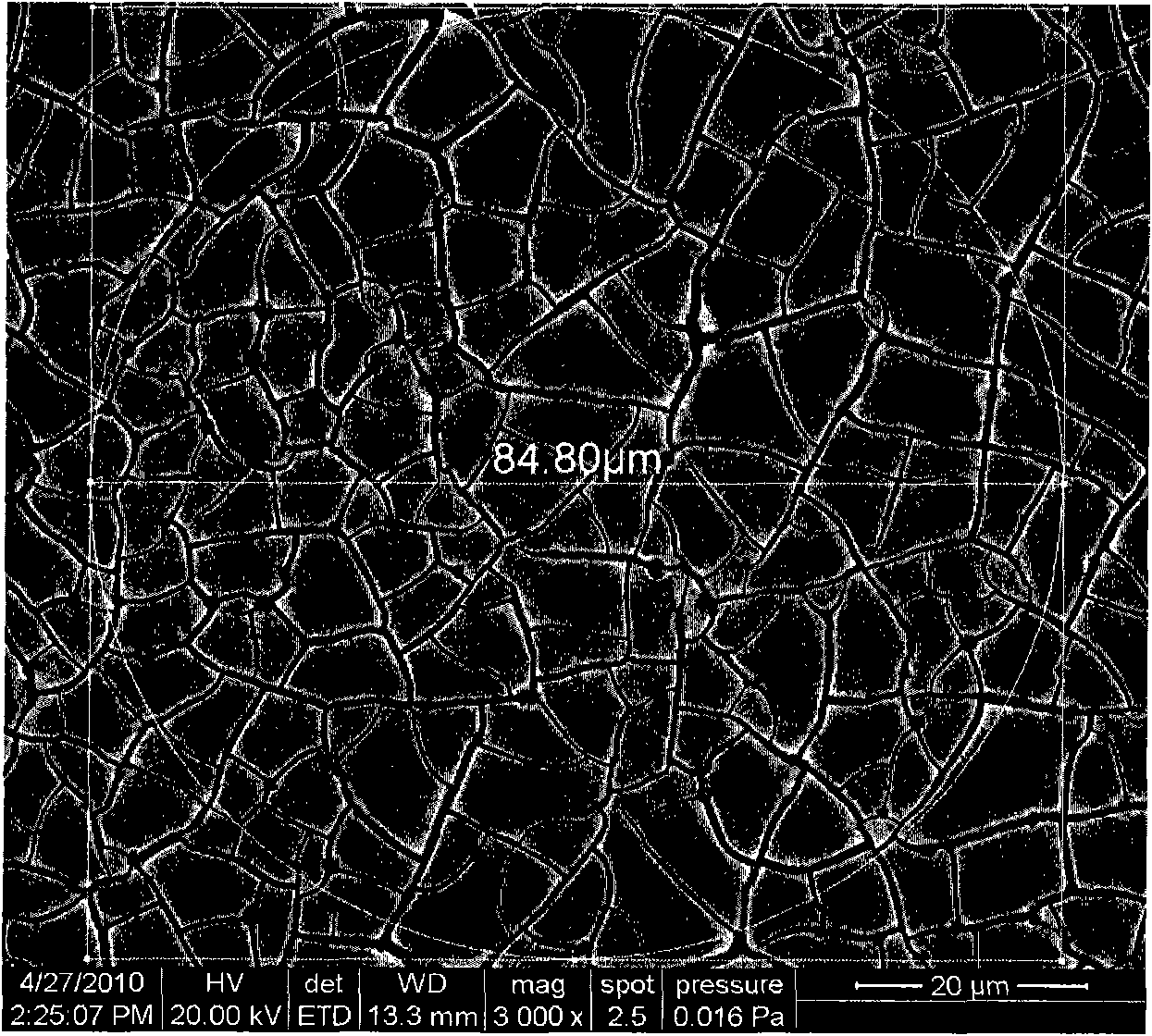

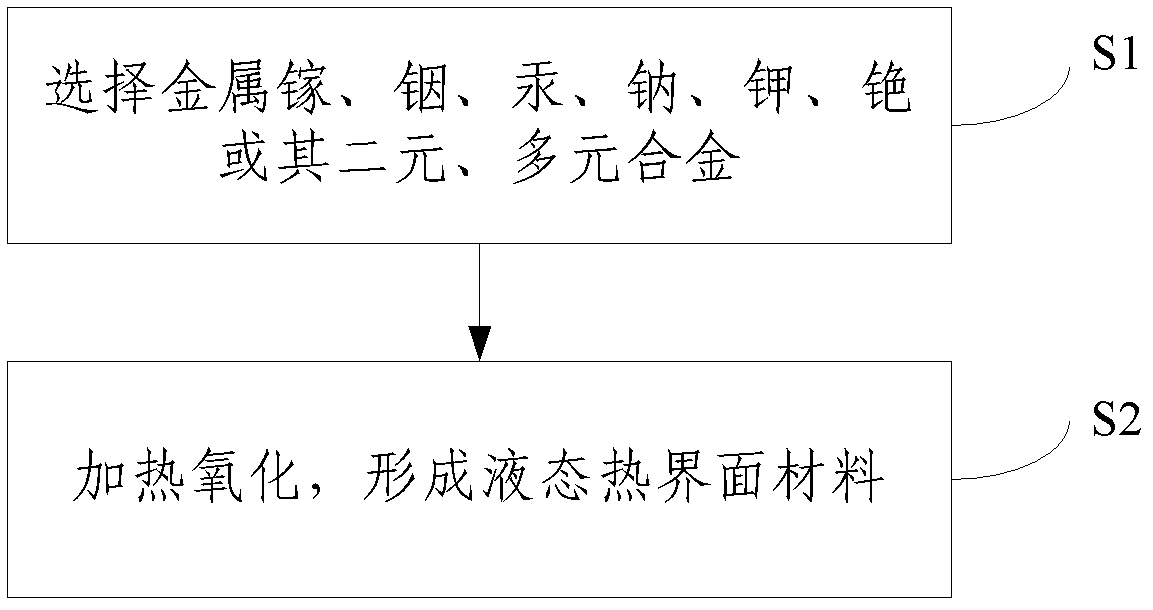

Thermal interface materials and manufacturing method thereof

The invention discloses thermal interface materials and a manufacturing method of the thermal interface materials. The interface materials are formed by means of heating and oxidization of metals such as gallium, indium, mercury, sodium, potassium, cesium or binary alloy and multicomponent alloy of the cesium. The manufacturing method comprises the following steps: selecting metals such as the gallium, the indium, the mercury, the sodium, the potassium, the cesium or the binary alloy and the multicomponent alloy of the cesium, and enabling the metals or the alloy to become liquid and enabling the liquid metals or the alloy to be placed in air or oxygen through heating. By means of placing the metals such as the gallium, the indium, the mercury, the sodium, the potassium, the cesium or the binary alloy and the multicomponent alloy of the cesium in the air and the oxygen to be oxidized to form the thermal interface materials, wettability between metal-based fluid and each interface can be greatly enhanced, thereby requirements of the thermal interface materials can be met. Due to the good thermal and wetting properties, the thermal interface materials can play significant roles in an aspect of electric chip thermal conductivity of the fields such as cryogenic engineering, boosters of computers, satellites and rockets and laser device.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

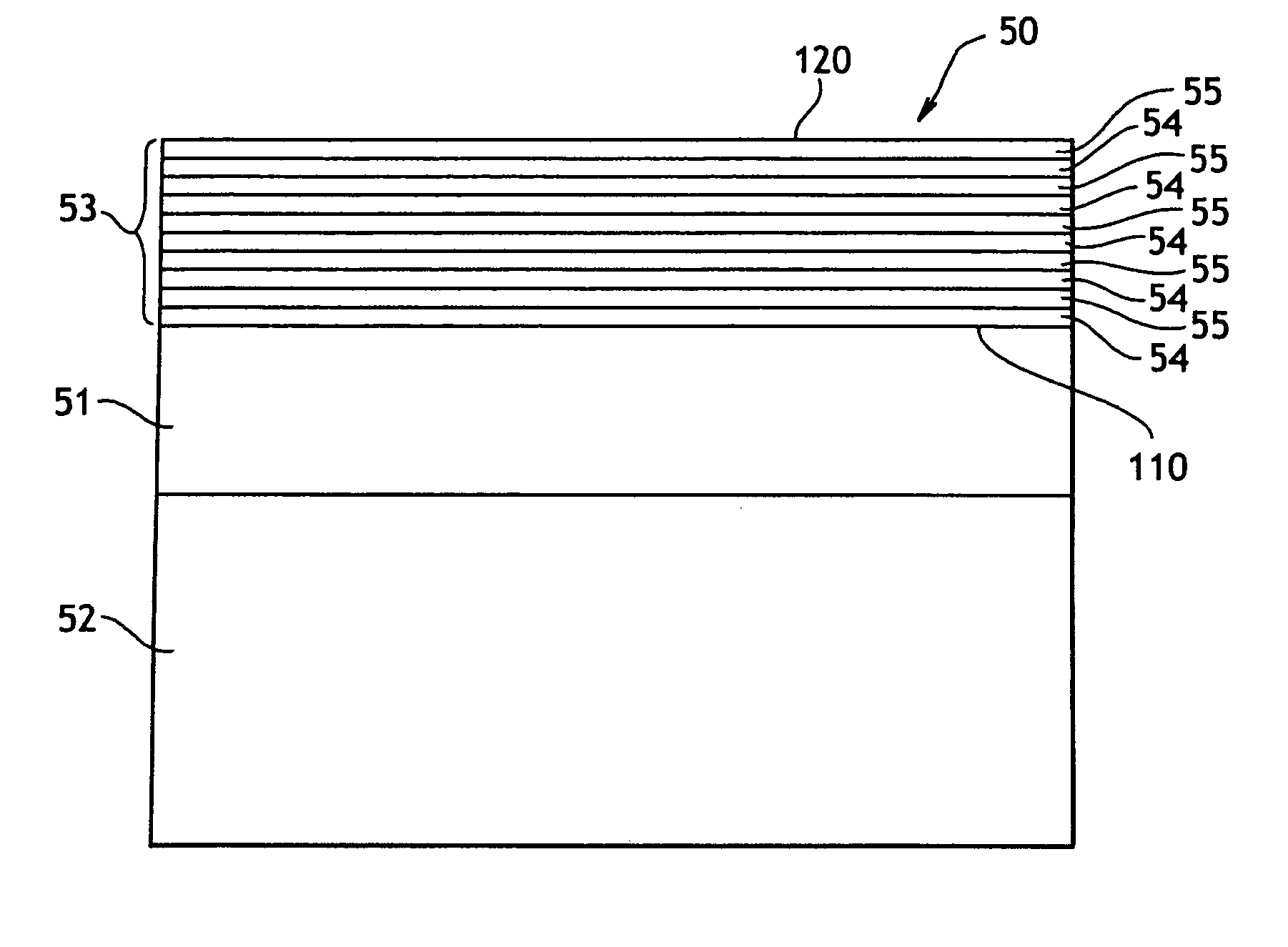

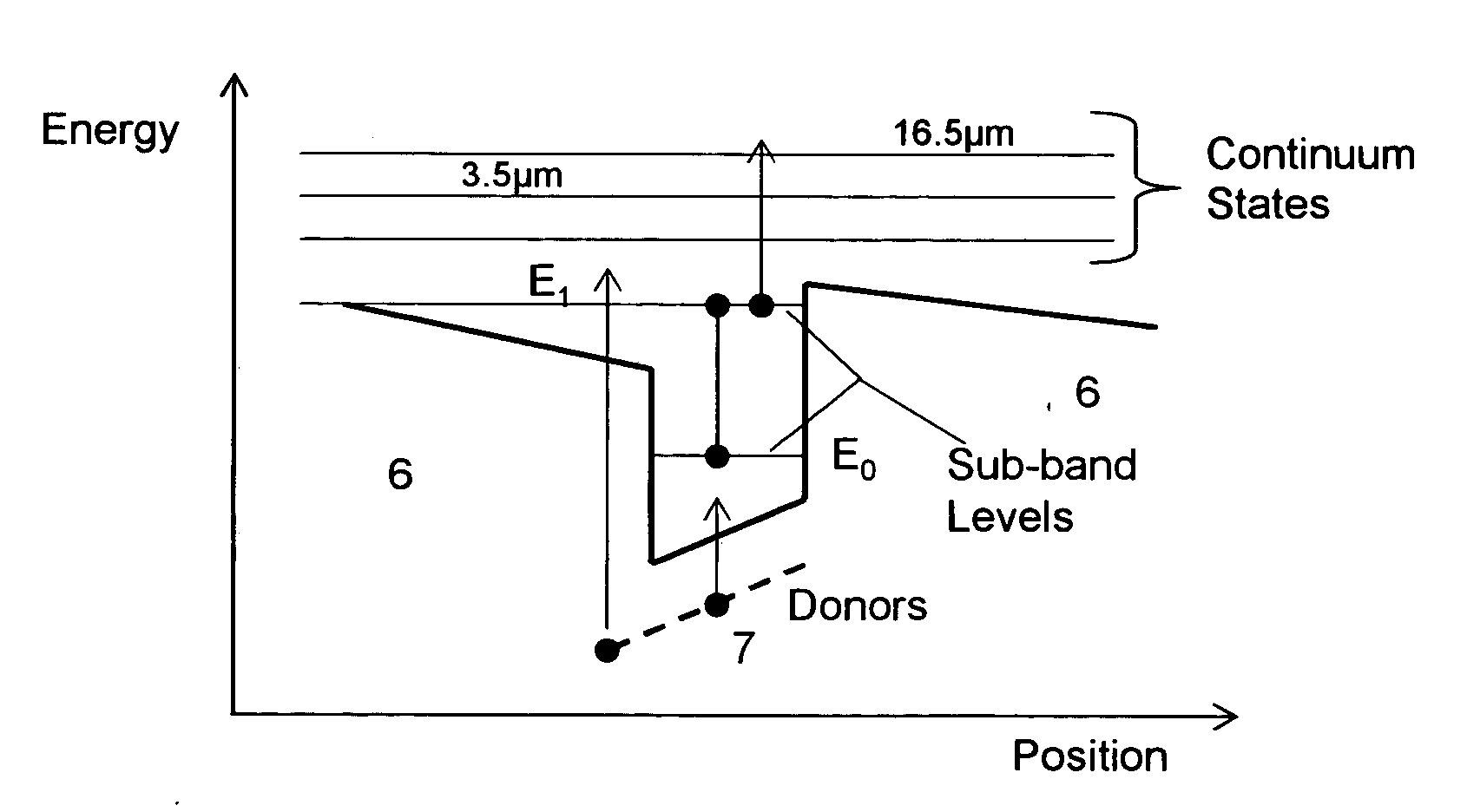

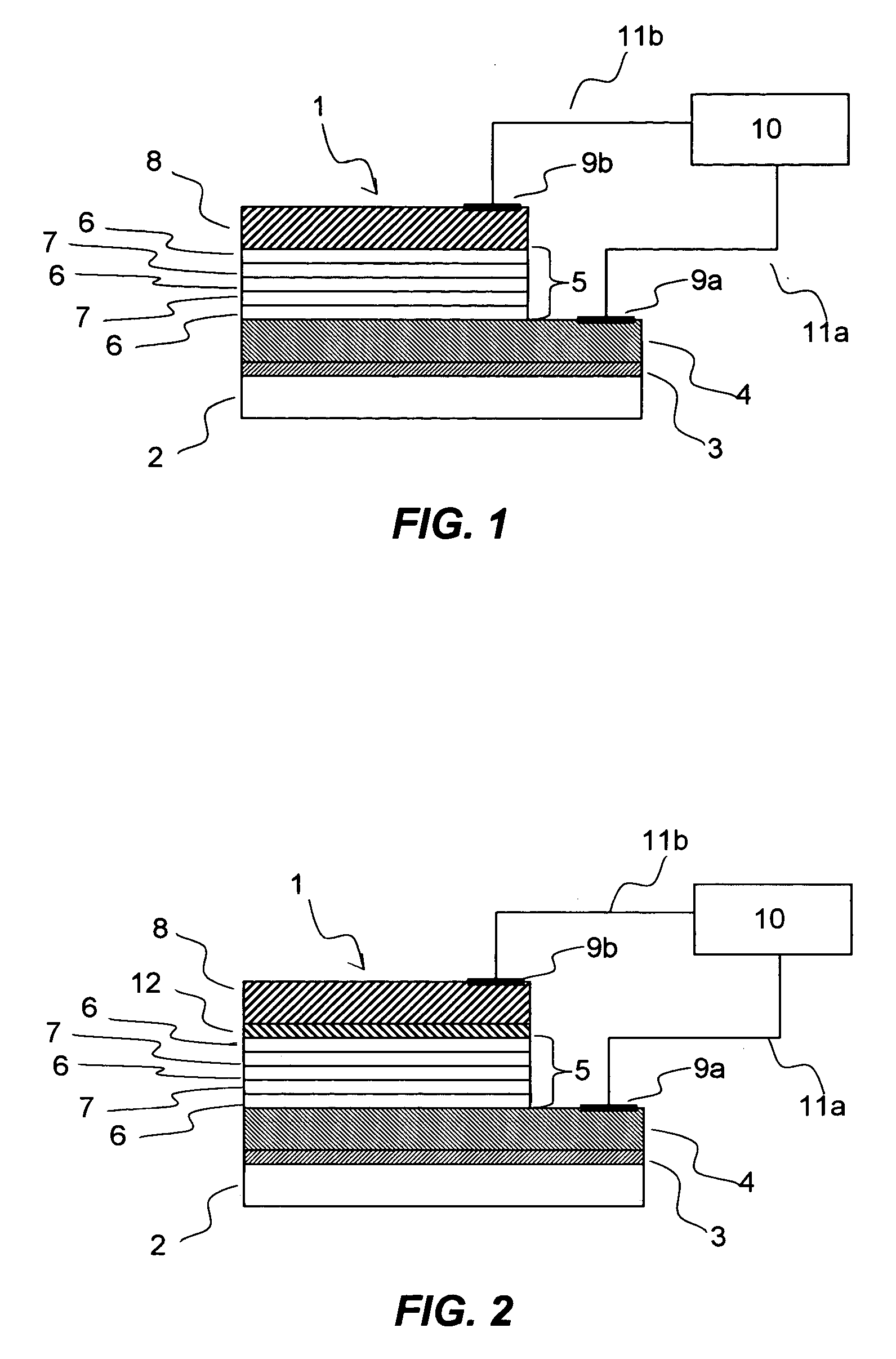

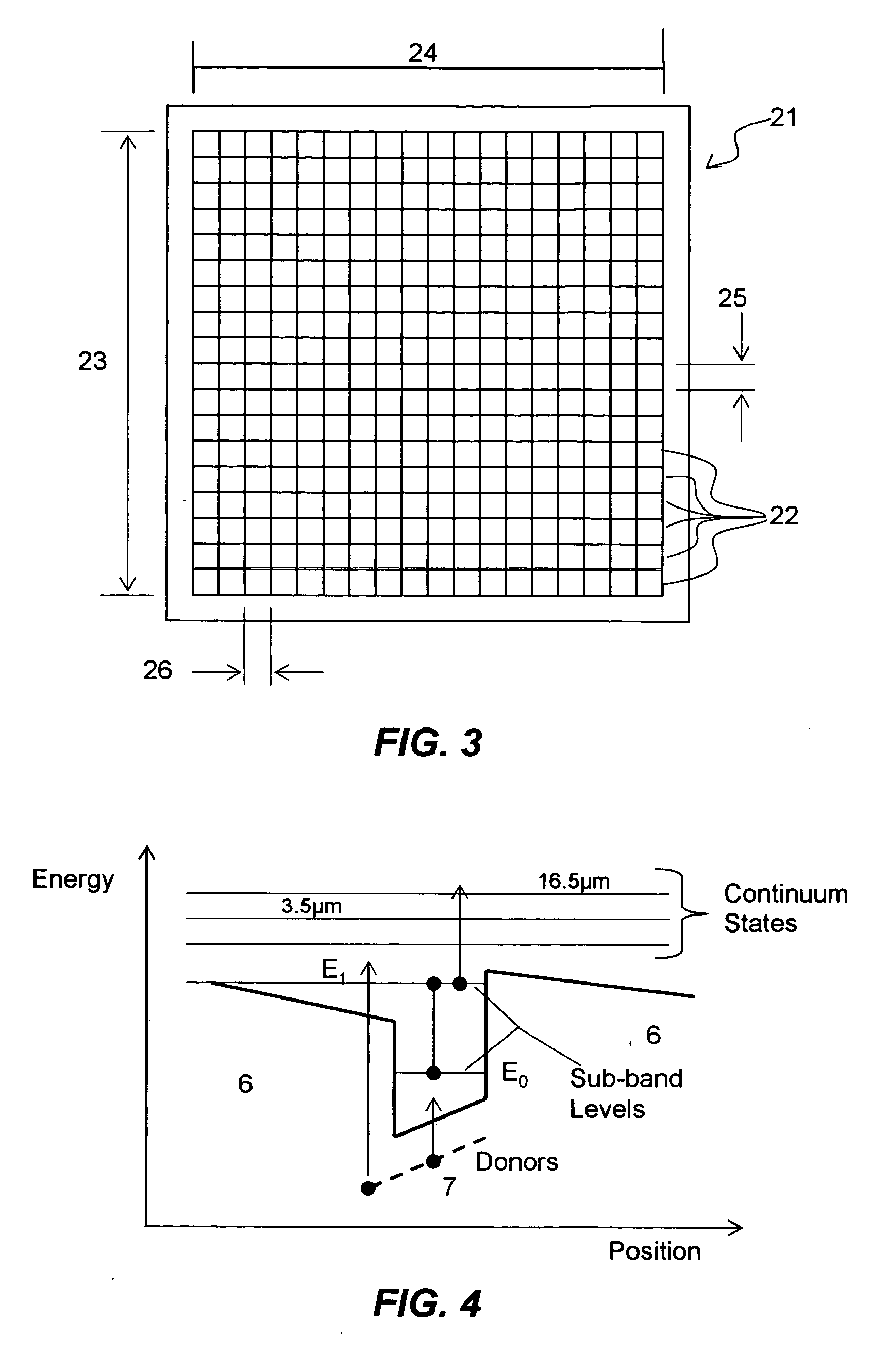

Ifrared detector composed of group III-V nitrides

InactiveUS20060108528A1High sensitivityLow costFinal product manufactureSolid-state devicesBinary alloyPhotovoltaic detectors

A quantum-well infrared photodetector (QWIP) is presented. The photodetector includes a substrate, a buffer layer, a first conductive layer, a multiple quantum well, an optional blocking layer, and a second conductive layer. Substrate is composed of a monocrystal which may be removed after fabrication. Remaining layers are composed of group III-V nitrides, including binary, ternary, and quaternary compositions. Alternate embodiments of the present invention include a doped binary alloy along first and second conductive layers, a binary alloy along buffer and blocking layers, and alternating alloys of binary, ternary and quaternary compositions within the multiple quantum well. The present invention responds to infrared light at normal and oblique incidences, from near infrared to very far infrared.

Owner:MISSILE DEFENSE AGENCY CTS

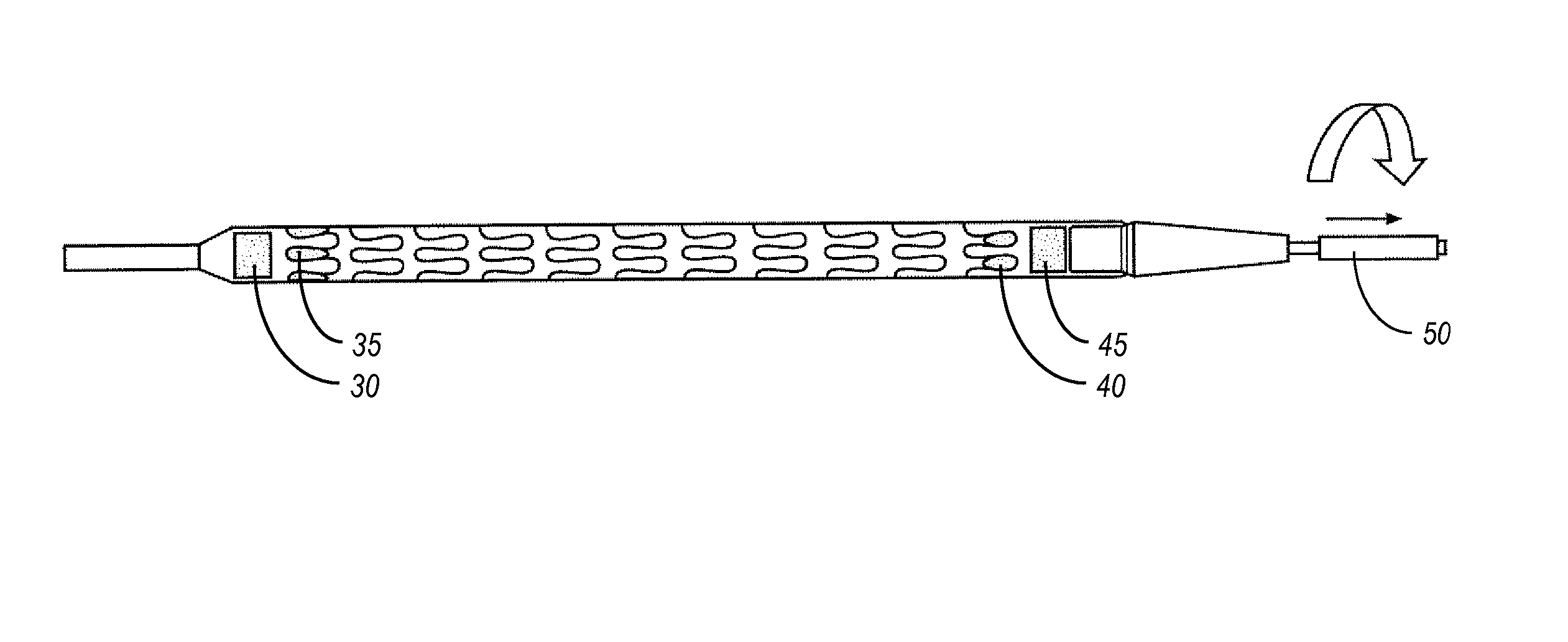

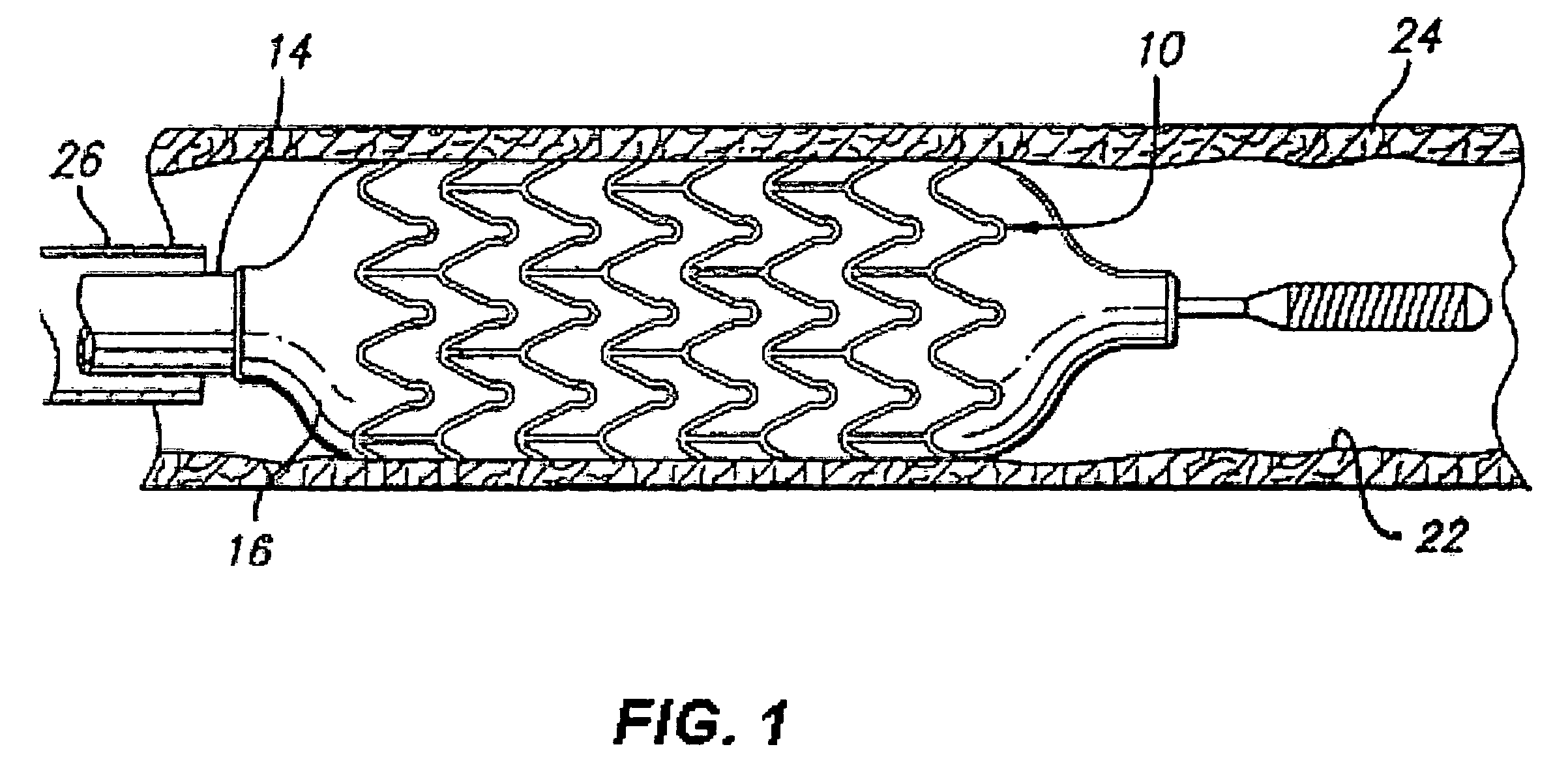

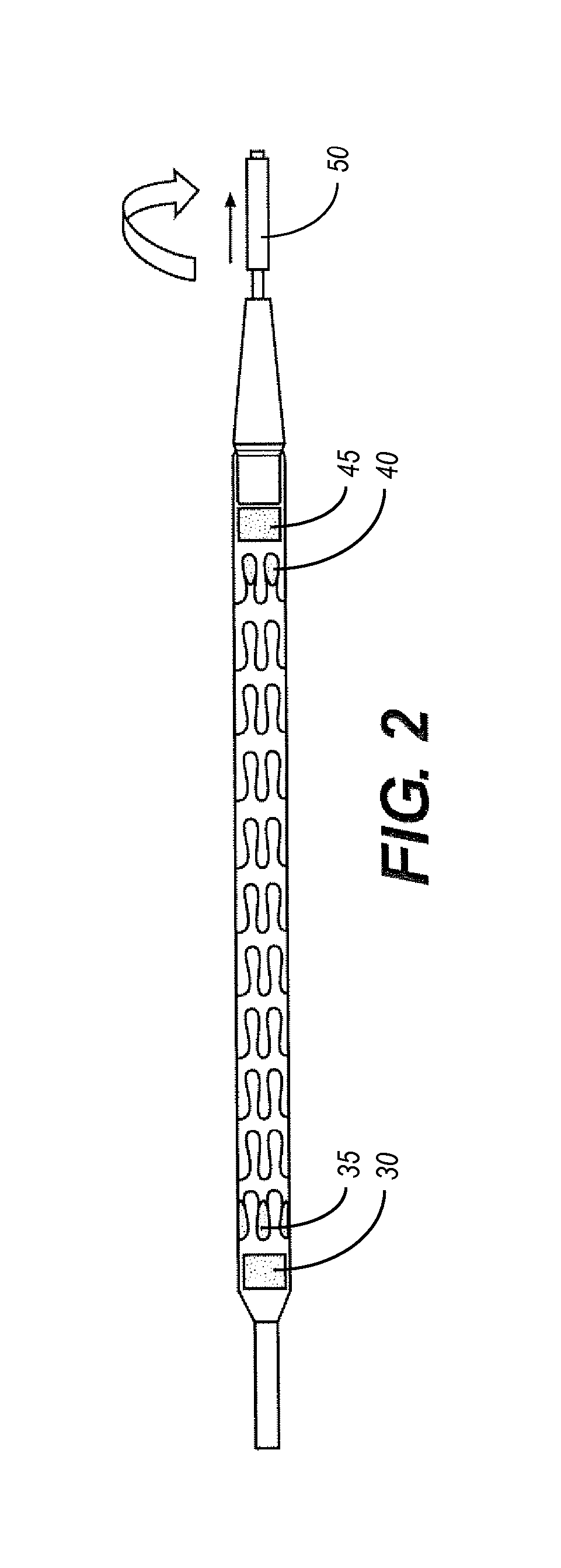

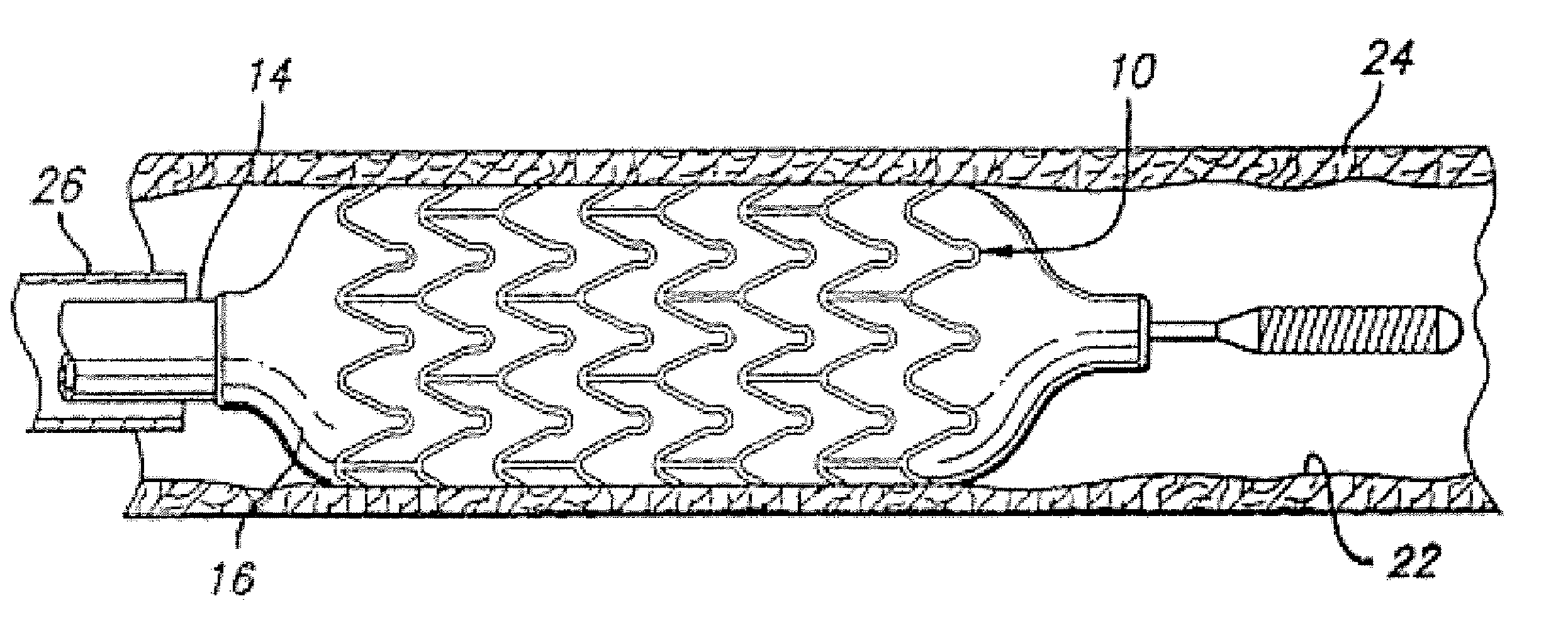

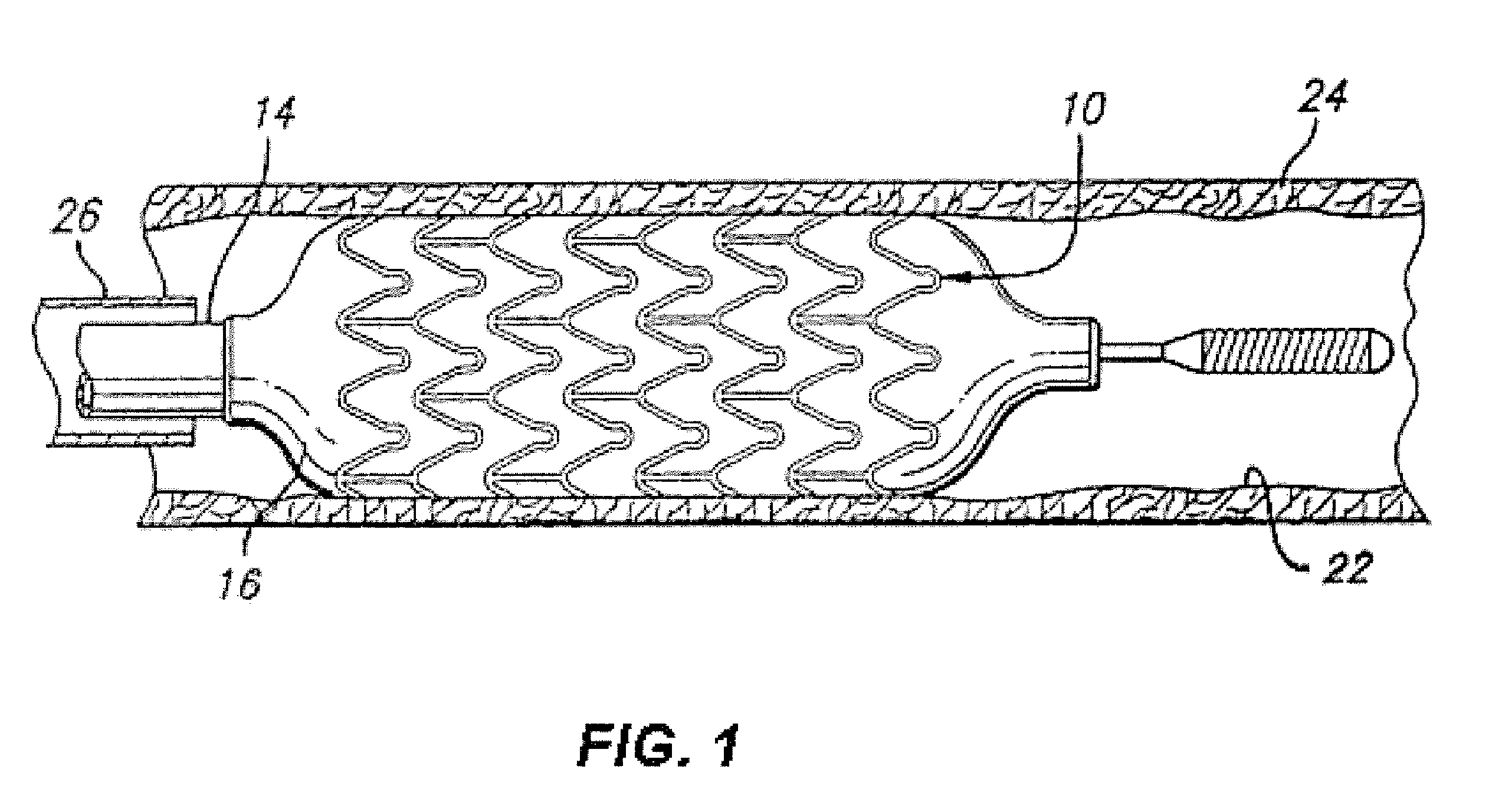

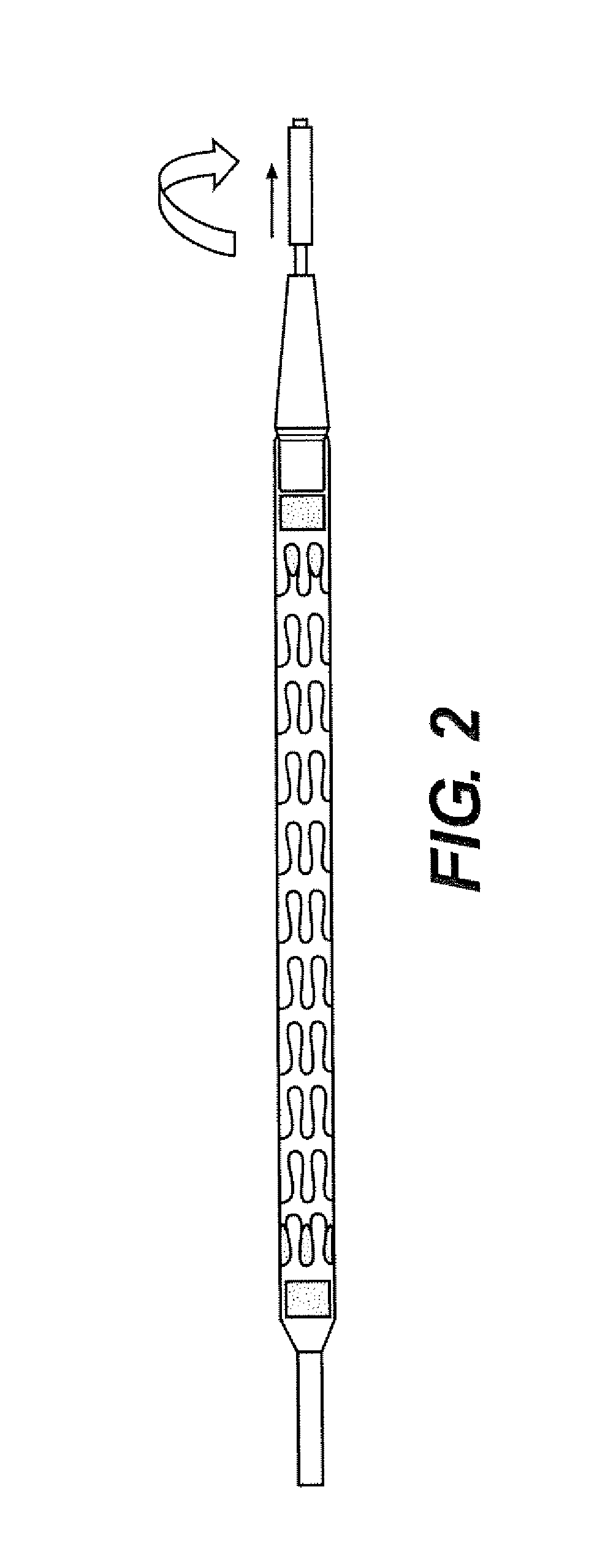

Radiopaque markers and medical devices comprising binary alloys of titanium

There is disclosed medical devices, such as stents, guidewires and embolic filters, comprising a binary alloy of titanium and one binary element selected from platinum, palladium, rhodium, and gold. There is also disclosed a radiopaque marker comprising the disclosed binary alloy, as well as medical devices having the radiopaque marker attached thereto. Methods of attaching the radiopaque marker to the medical devices, such as by welding, are also disclosure also disclosed.

Owner:ABBOTT LAB INC

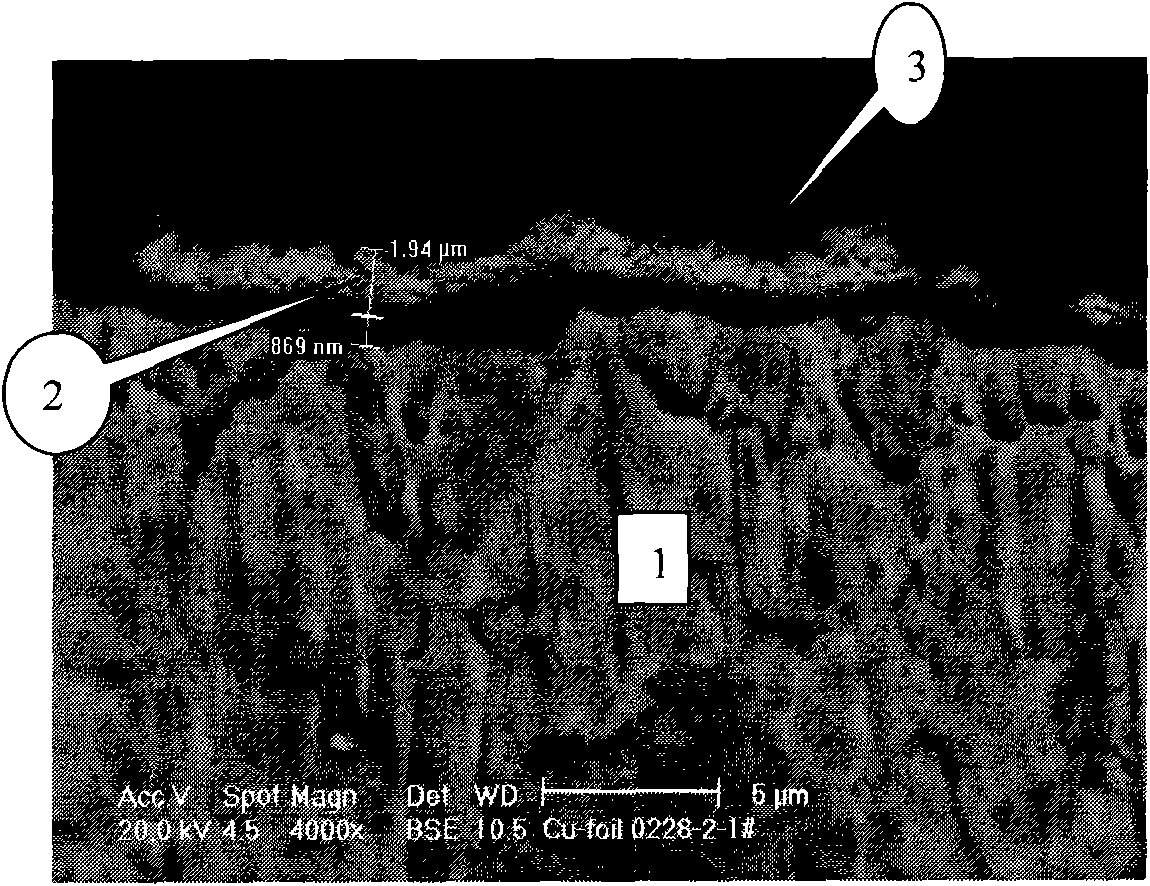

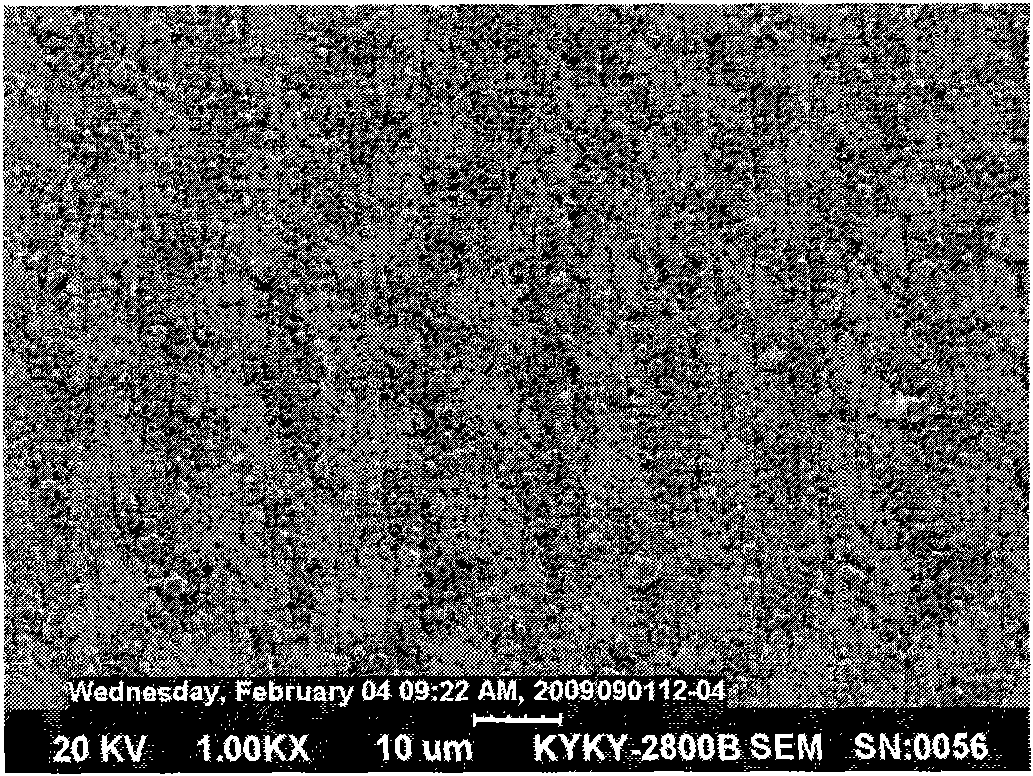

Peel-able ultra-thin copper foil using copper foil as carrier and preparation method thereof

The invention relates to a preparation technique for manufacturing an ultra-thin copper foil of printed circuit board, in particular to a peel-able ultra-thin copper foil using a copper foil as a carrier and a preparation method thereof. The carrier of the peel-able ultra-thin copper foil is 35-micron copper foil, and a peel-able layer consists of an organic layer and an alloy layer, wherein the organic layer is a nitrogenous compound, and the alloy layer consists of a tungsten-nickel binary alloy. A 1 to 5-micron ultra-thin copper foil prepared by the method can be peeled off from a support carrier after inactivation and heating processing, has moderate peeling strength, and avoids a phenomenon that the ultra-thin copper foil can be partially or wholly separated from the carrier in the process of preparing and using a composite foil; after peeling, the ultra-thin copper foil cannot be kept on a carrier foil, and the carrier foil also cannot be kept on the ultra-thin copper foil; and the ultra-thin copper foil has a bright and clean surface and is suitable for manufacturing a high-density printed circuit board.

Owner:JIANGXI UNIV OF SCI & TECH +1

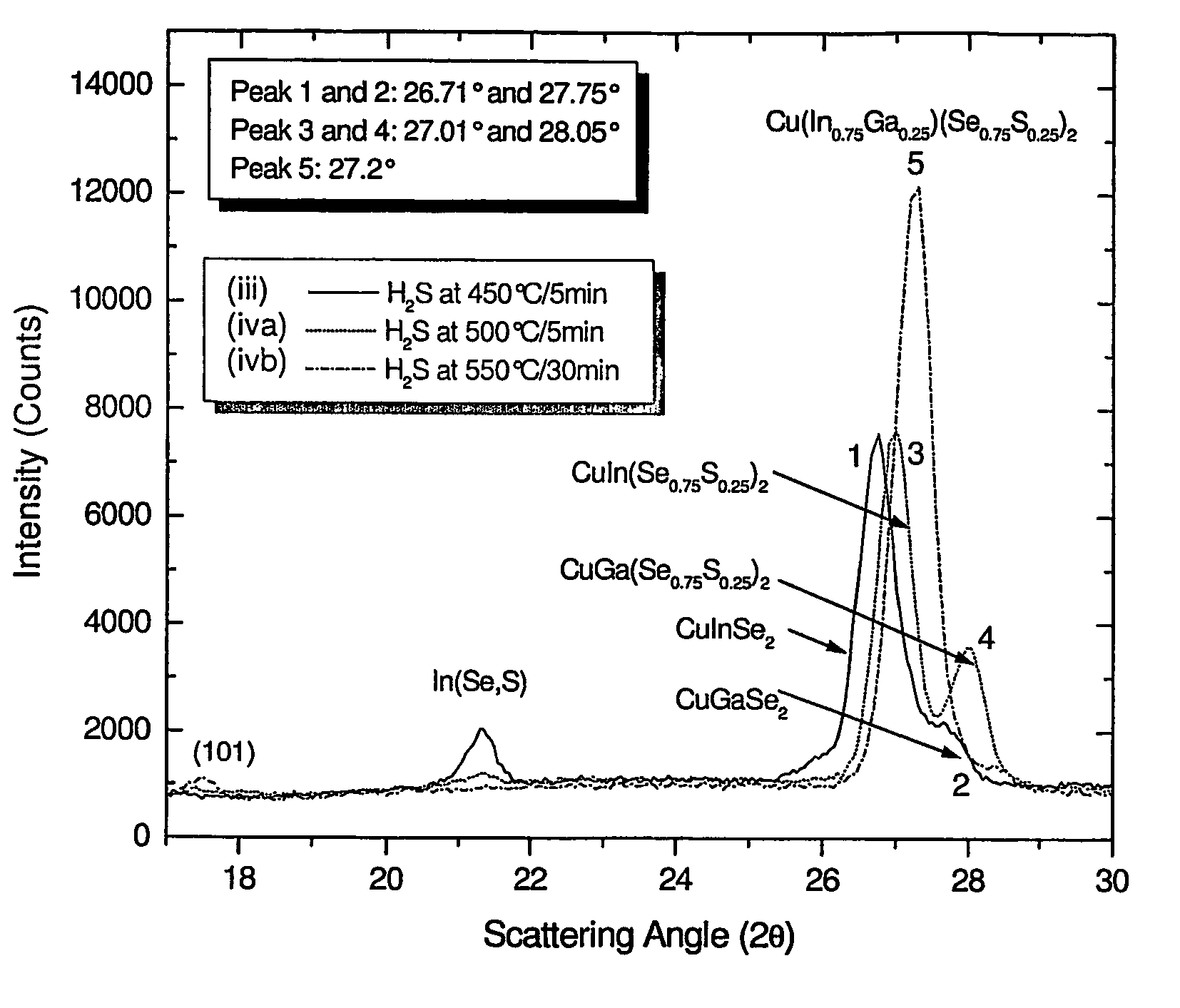

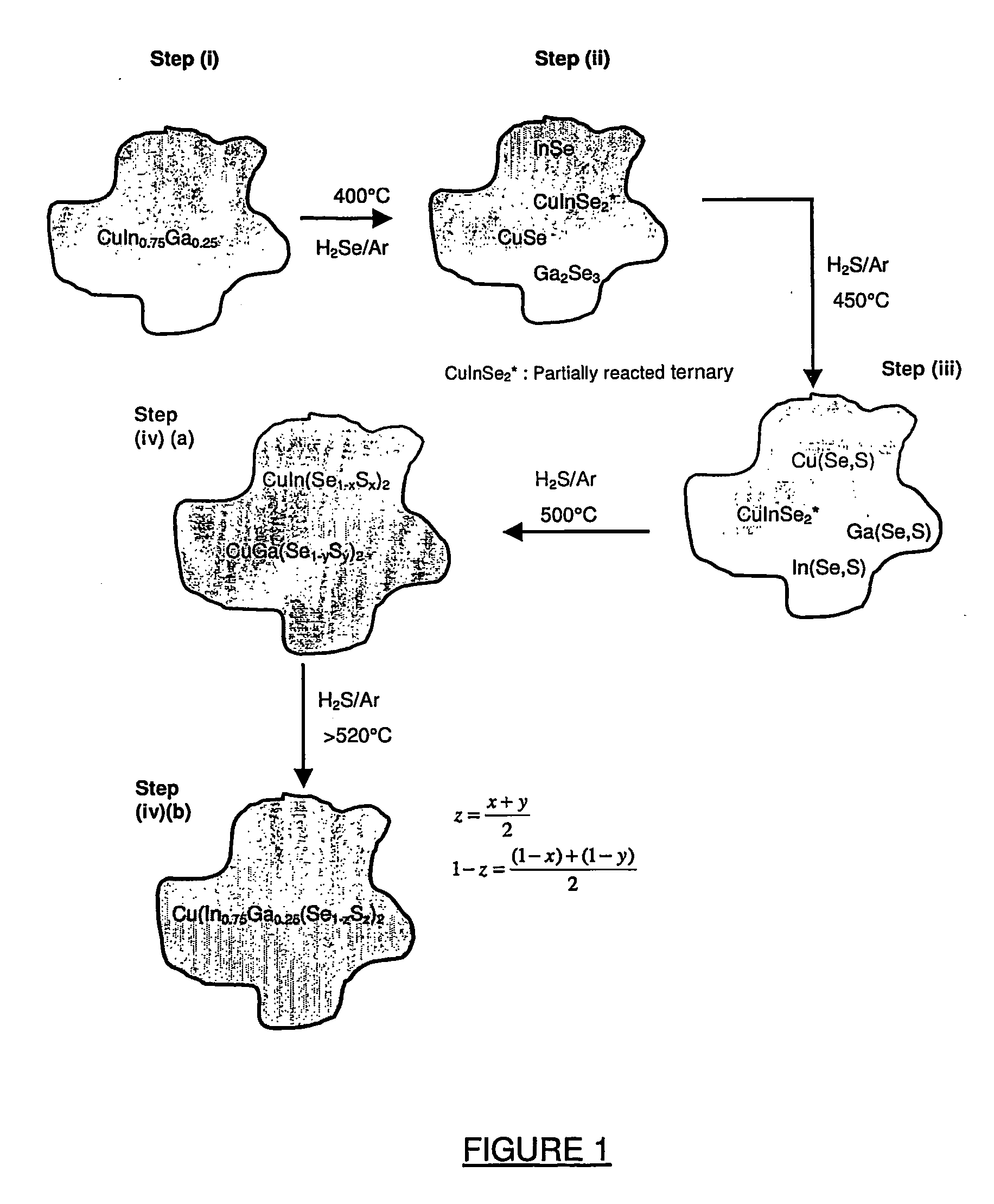

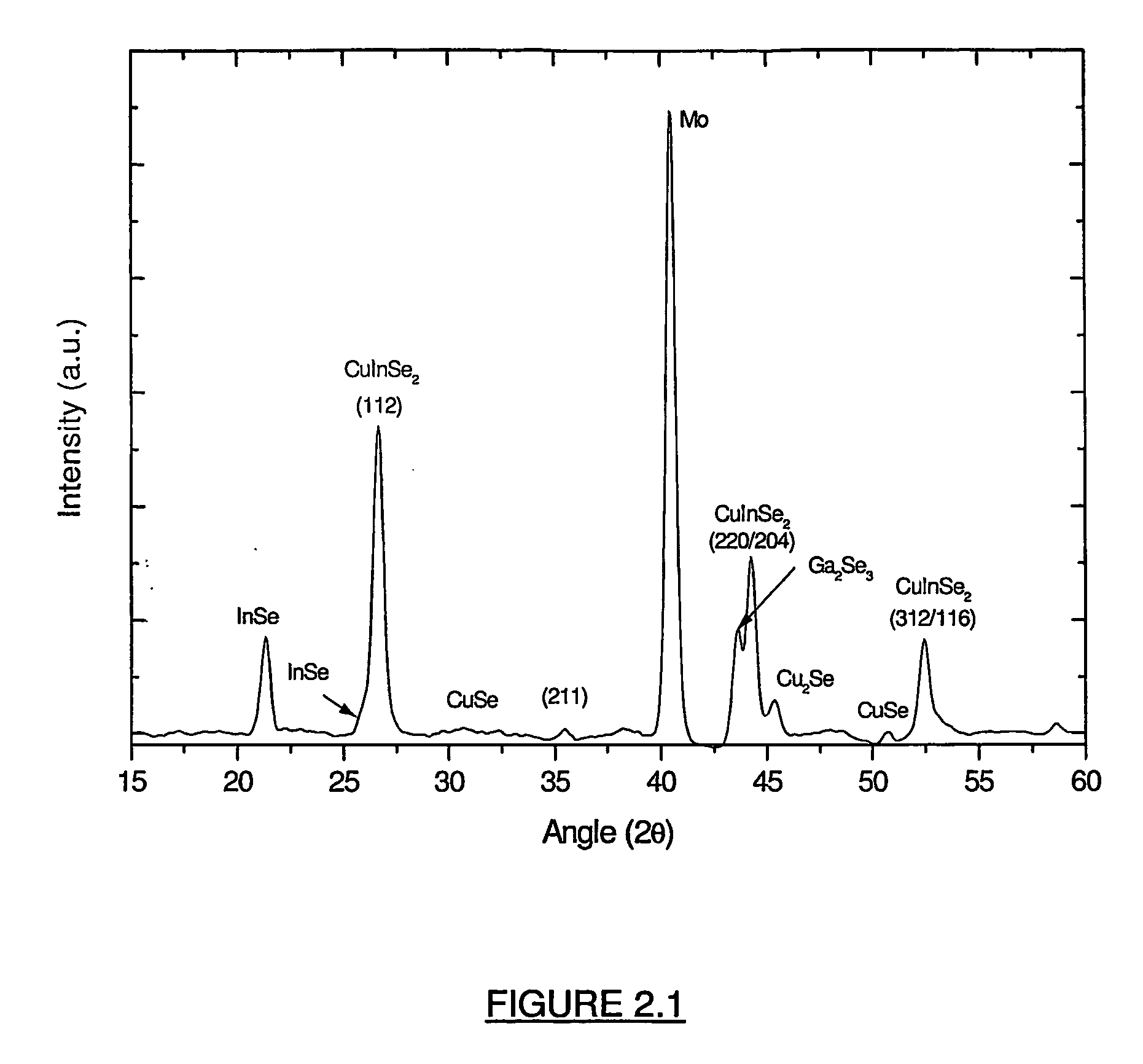

Method for the preparation of group ib-iiia-via quaternary or higher alloy semiconductor films

InactiveUS20070004078A1Final product manufactureSemiconductor/solid-state device manufacturingBinary alloyQuaternary

This invention relates to a method for producing group IB-IIA-VIA quaternary or higher alloy semiconductor films wherein the method comprises the steps of (i) providing a metal film comprising a mixture of group IB and group IIIA metals; (ii) heat treating the metal film in the presence of a source of a first group VIA element (said first group VIA element hereinafter being referred to as VIA1) under conditions to form a first film comprising a mixture of at least one binary alloy selected from the group consisting of a group IB-VIA1 alloy and a group IIIA-VIA1 alloy and at least one group IB-IIIA-VIA1 ternary alloy (iii) optionally heat treating the first film in the presence of a source of a second group VIA element (said second group VI element hereinafter being referred to as VIA2) under conditions to convert the first film into a second film comprising at least one alloy selected from the group consisting of a group IB-VIA1-VIA2 alloy and a group IIIA-VIA1-VIA2 alloy; and the at least one group IB-III-VIA1 ternary alloy of step (ii); (iv) heat treating either the first film or second film to form a group IB-IIIA-VIA quaternary or higher alloy semiconductor film.

Owner:JOHANNESBURG UNIV OF

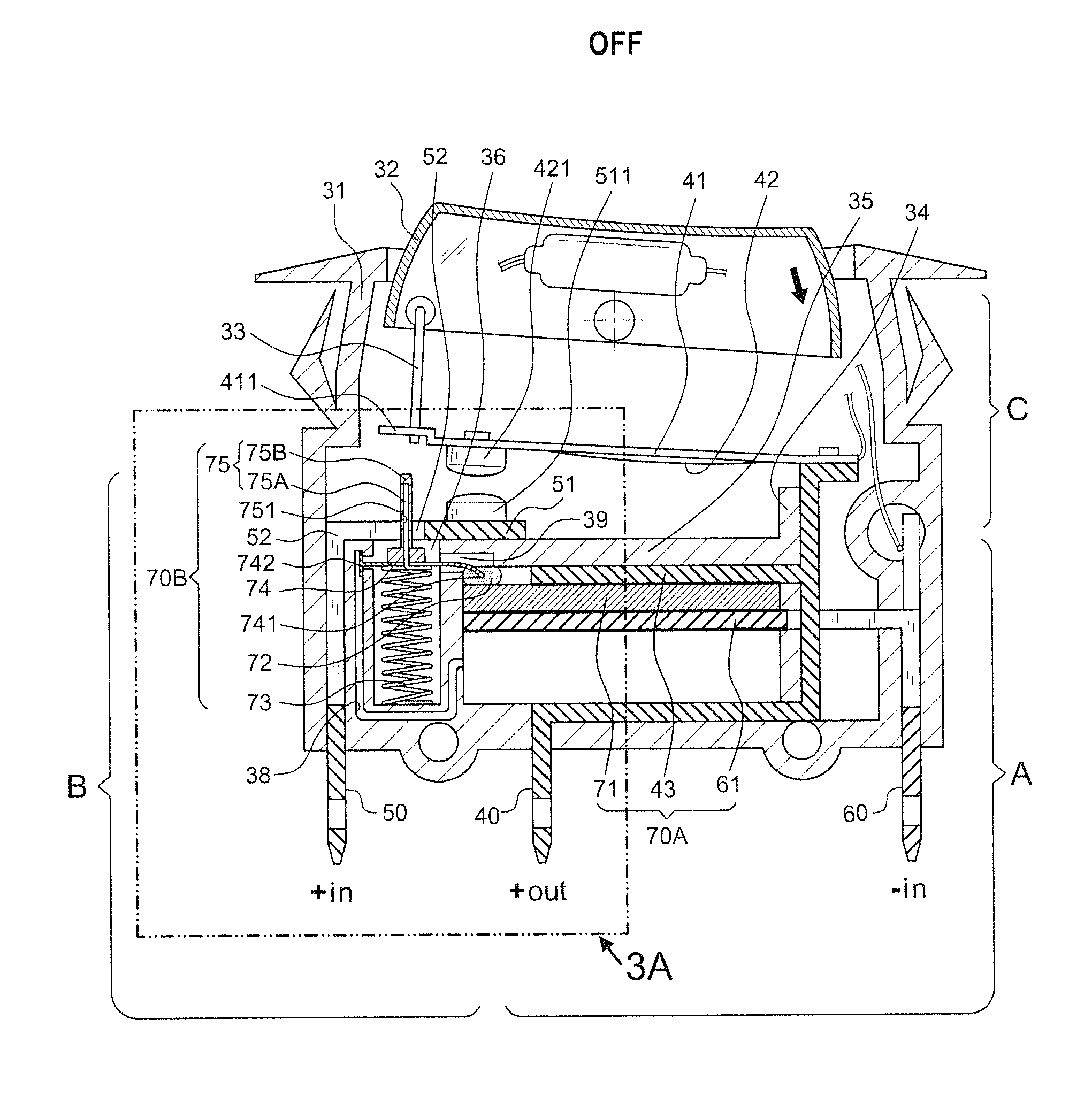

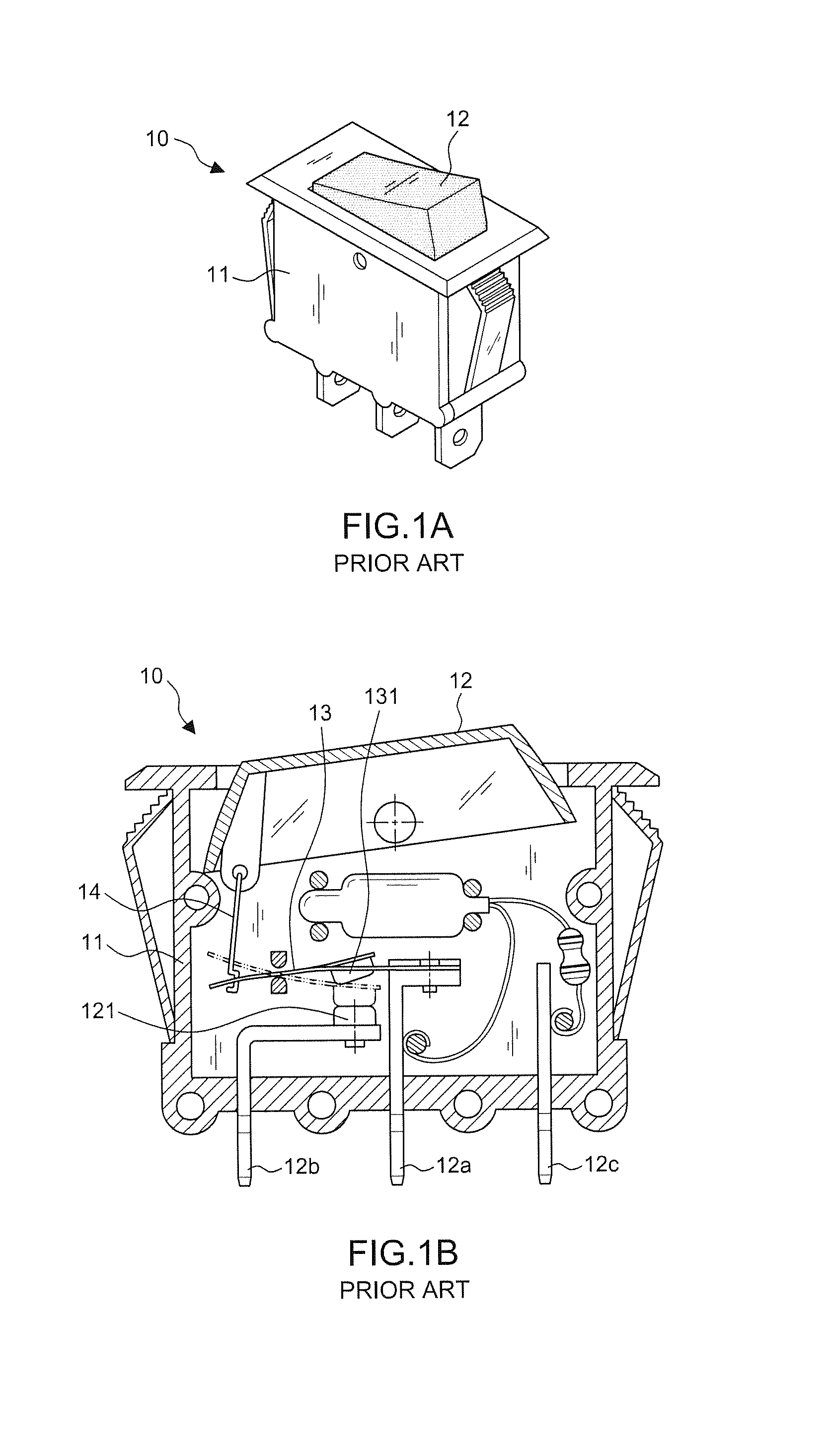

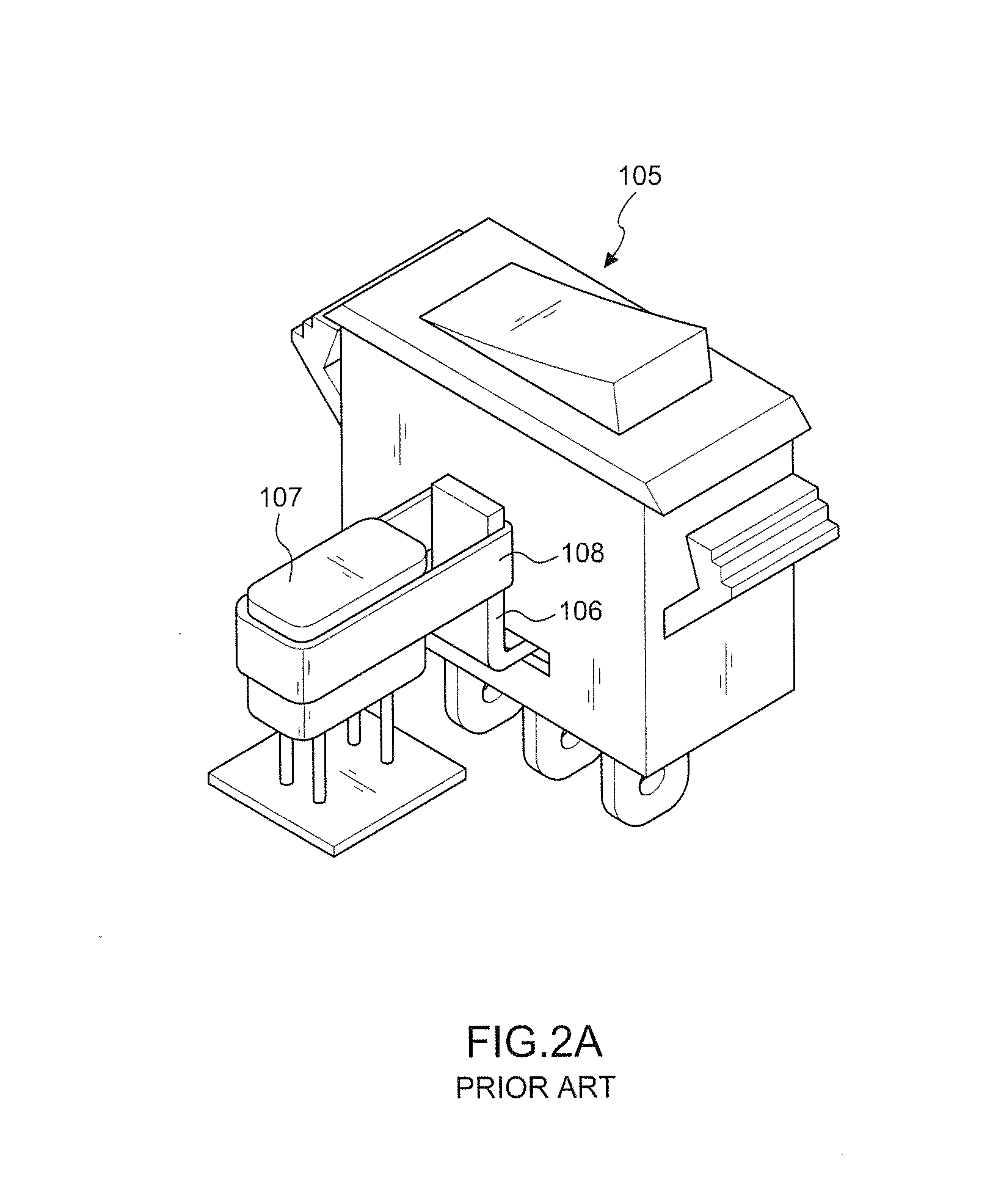

Switch module of built-in Anti-surge disconnection structure

InactiveUS20170047180A1Easy to assembleMore securityHeating/cooling contact switchesThermal switch detailsBinary alloyOvervoltage

A switch module of built-in anti-surge disconnection structure mainly comprises an overcurrent protection switch and has anti-surge and disconnection structures ingeniously built inside a fire-proof and heat-resisting housing. The present invention comprises a switch area formed by a binary alloy conductive spring leaf and two connecting points, an anti-surge area formed by at least one bare metal oxide varistor placed in the housing and a plurality of conductive plates, and a disconnection area formed by a spring element, a band, and a thermo-sensitive piece. When the connecting points in the switch area are contacting with each other—turning on the switch—and an overvoltage occurs, the temperature of the metal oxide varistor would suddenly rise up to a degree higher than a pre-determined number, melting the thermo-sensitive piece, loosening and displacing the band, thus ejecting the spring element and forcing the connecting points detaching from each other to turn off the switch, so as to ensure more of electricity safety.

Owner:WANG YI HSIANG +1

Radiopaque markers comprising binary alloys of titanium

There is disclosed a radiopaque marker comprising a binary alloy of titanium and one binary element selected from platinum, palladium, rhodium, and gold. There is also disclosed various medical devices, such as stents, guidewires and embolic filters, that have the radiopaque marker attached thereto. Methods of attaching the radiopaque marker to the medical devices, such as by welding, are also disclosed.

Owner:ABBOTT LAB INC

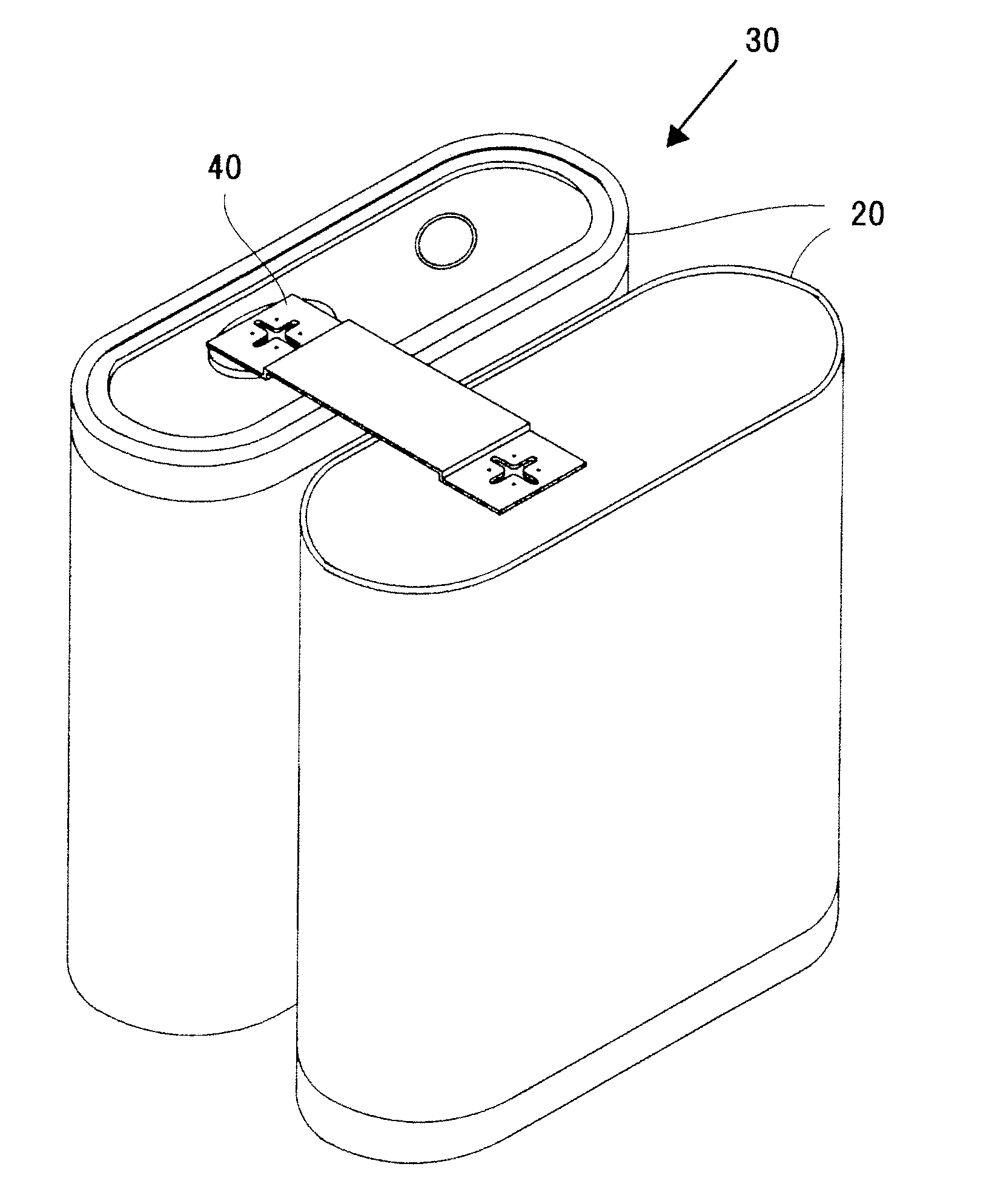

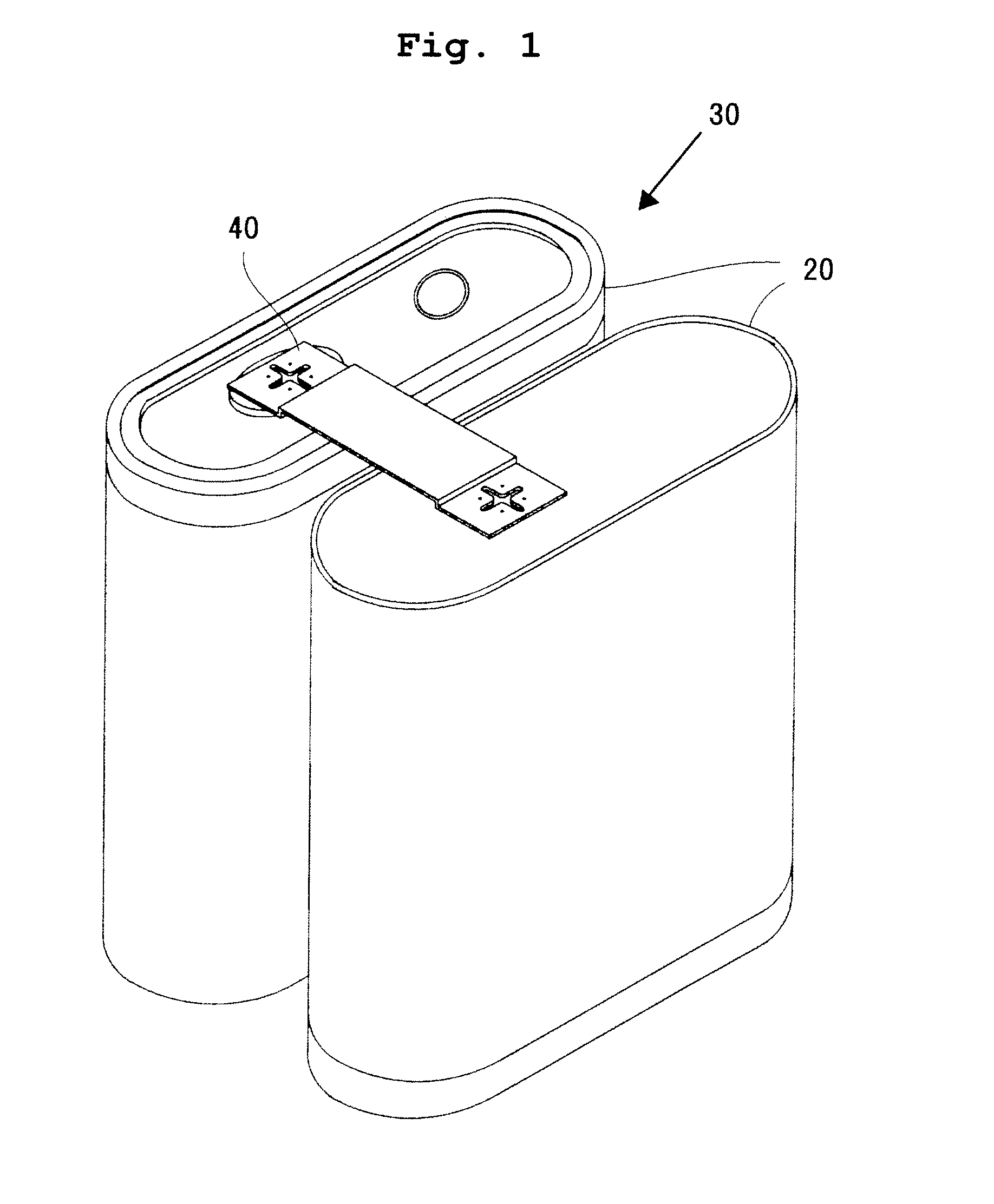

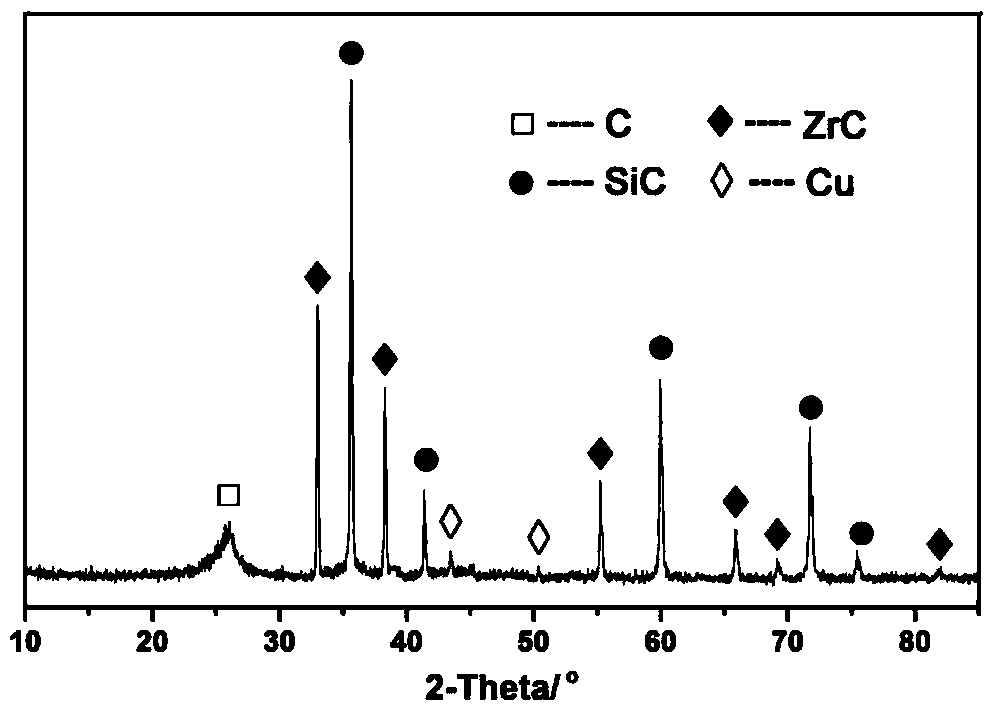

Assembled battery

InactiveUS20080063932A1Reduce weightLower resistancePrimary cell to battery groupingElectrically conductive connectionsBinary alloyCopper

The present invention provides an assembled battery which can improve output density. The assembled batter is configured by connecting four unit cells in series. The unit cells are disposed in parallel such that their polarities are alternate. Unit cells adjacent to each other are connected by a connection member 40. The connection member 40 is composed of a stacked metal plate obtained by stacking two metal plates 40a and 40b. Copper and nickel producing binary alloy by welding are used for the metal plates 40a and 40b, respectively. Since a volume resistance of copper is about ¼ of that of nickel, a ratio of volume resistances of metals used for the metal plates 40a and 40b, respectively, becomes ½ or less. Both end portions of the connection member 40 are joined to a positive electrode external terminal of one of the adjacent unit cells and a negative electrode external terminal of the other by resistance welding, respectively. Copper and nickel used for the metal plates 40a and 40b are alloyed by resistance welding.

Owner:HITACHI AUTOMOTIVE SYST LTD

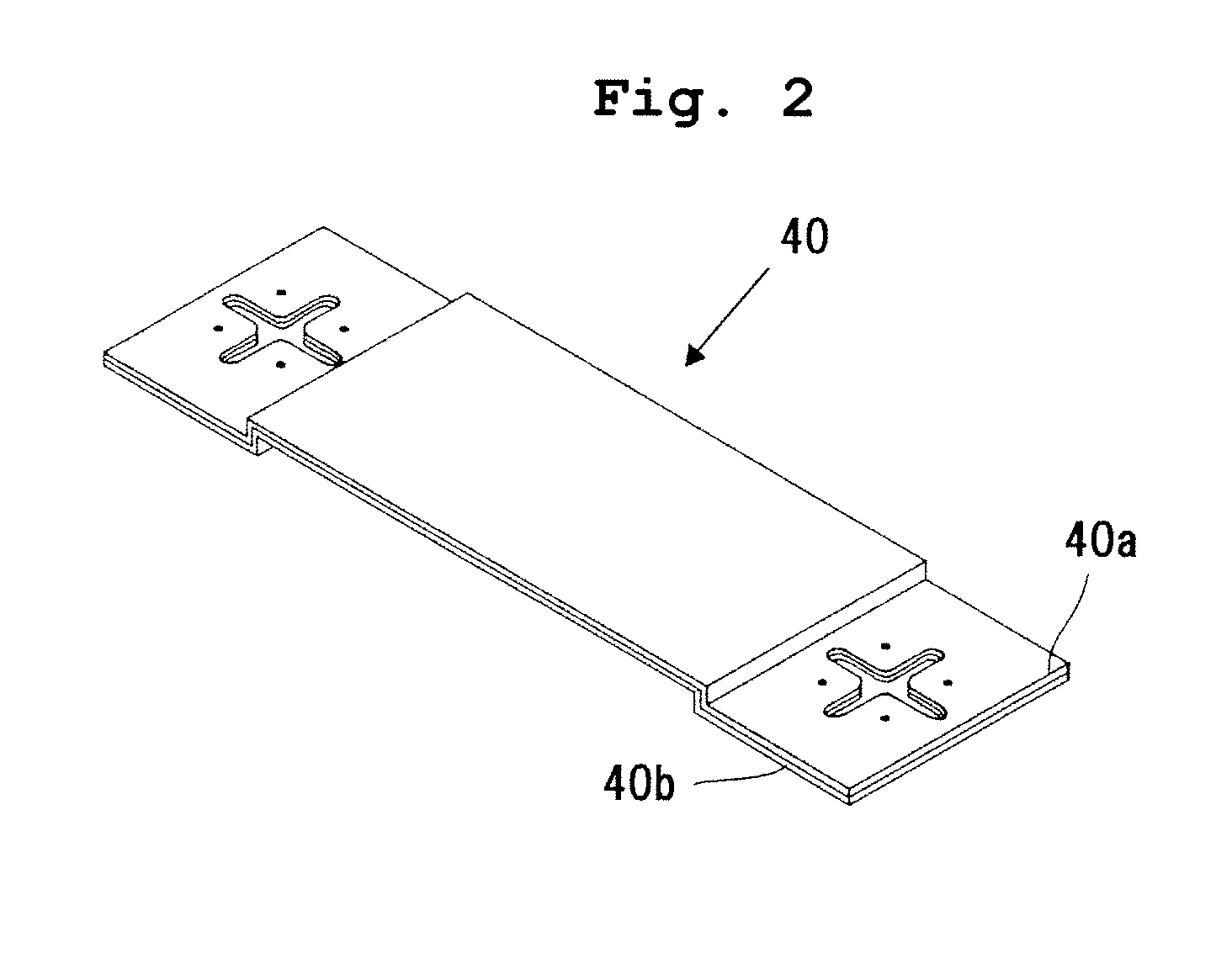

C/ZrC-SiC-Cu composite material and preparation method thereof

The invention discloses a C / ZrC-SiC-Cu composite material with spontaneous sweating function, and a preparation method thereof. The C / ZrC-SiC-Cu composite material takes carbon fiber as a reinforcement toughening phase, ZrC and SiC as matrixes and Cu as a diaphoretic, wherein the volume fraction of the carbon fiber is 10%-50%, the volume fraction of the ZrC is 5%-40%, the volume fraction of the SiC is 5%-20%, the volume fraction of the Cu diaphoretic is 5%-30%, the porosity rate is 3%-10%, the balance of impurities comprising less residual metal Zr and matrixes C and the like. The preparation method of the material comprises the steps of: by taking a carbon fiber prefabricated part as a fundamental, preparing C / C-SiC composite material, and then preparing the C / ZrC-SiC-Cu composite material by taking Zr-Cu binary alloy as a penetrating agent through metal infiltration reaction. The material is superhigh-temperature-resistant, good in fracture toughness, excellent in ablation resistance property, good in thermal shock resistance, and the preparation technique is simple, low in cost, corrosion-free for equipment, and free from environment pollution.

Owner:NAT UNIV OF DEFENSE TECH

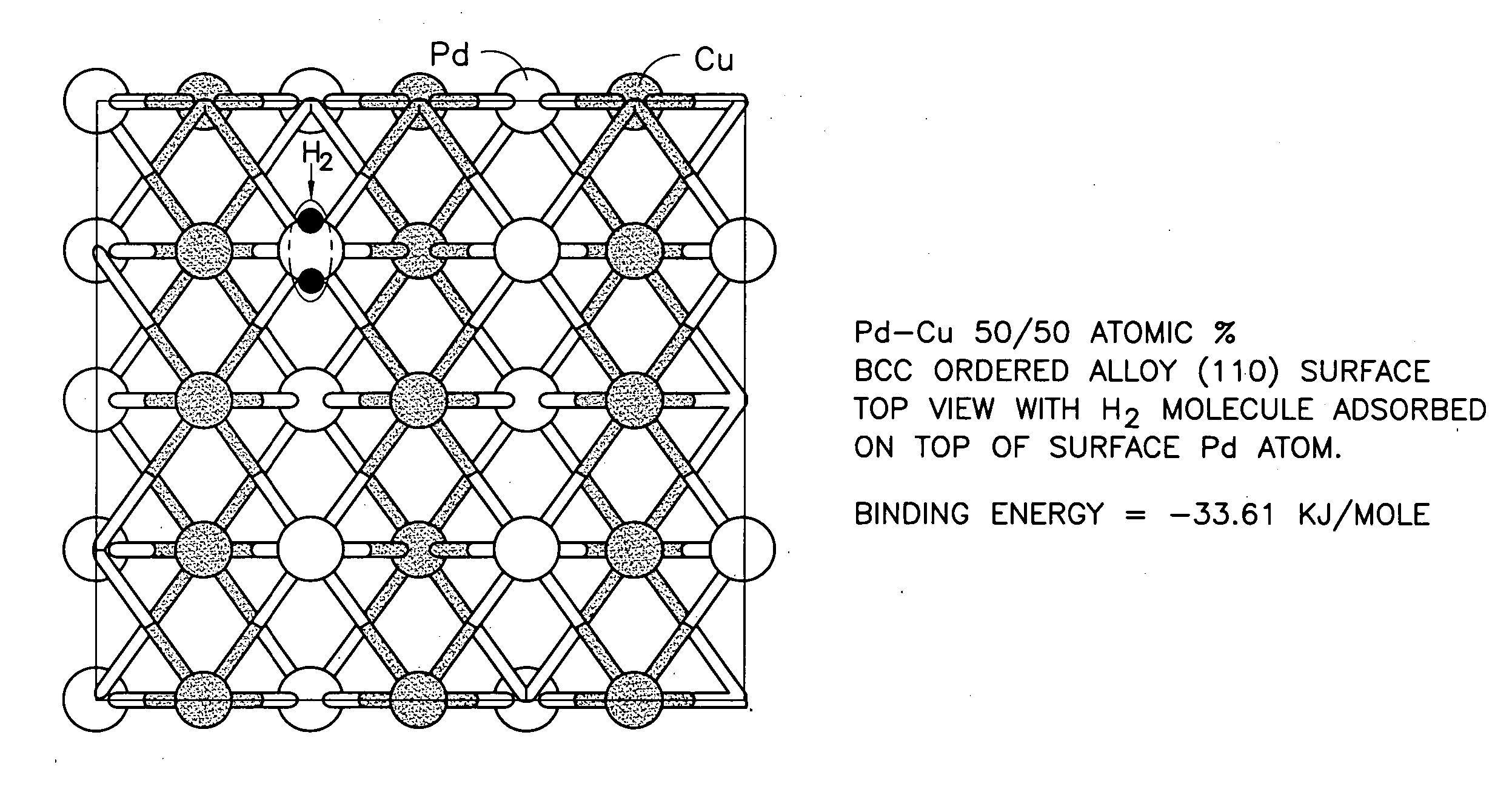

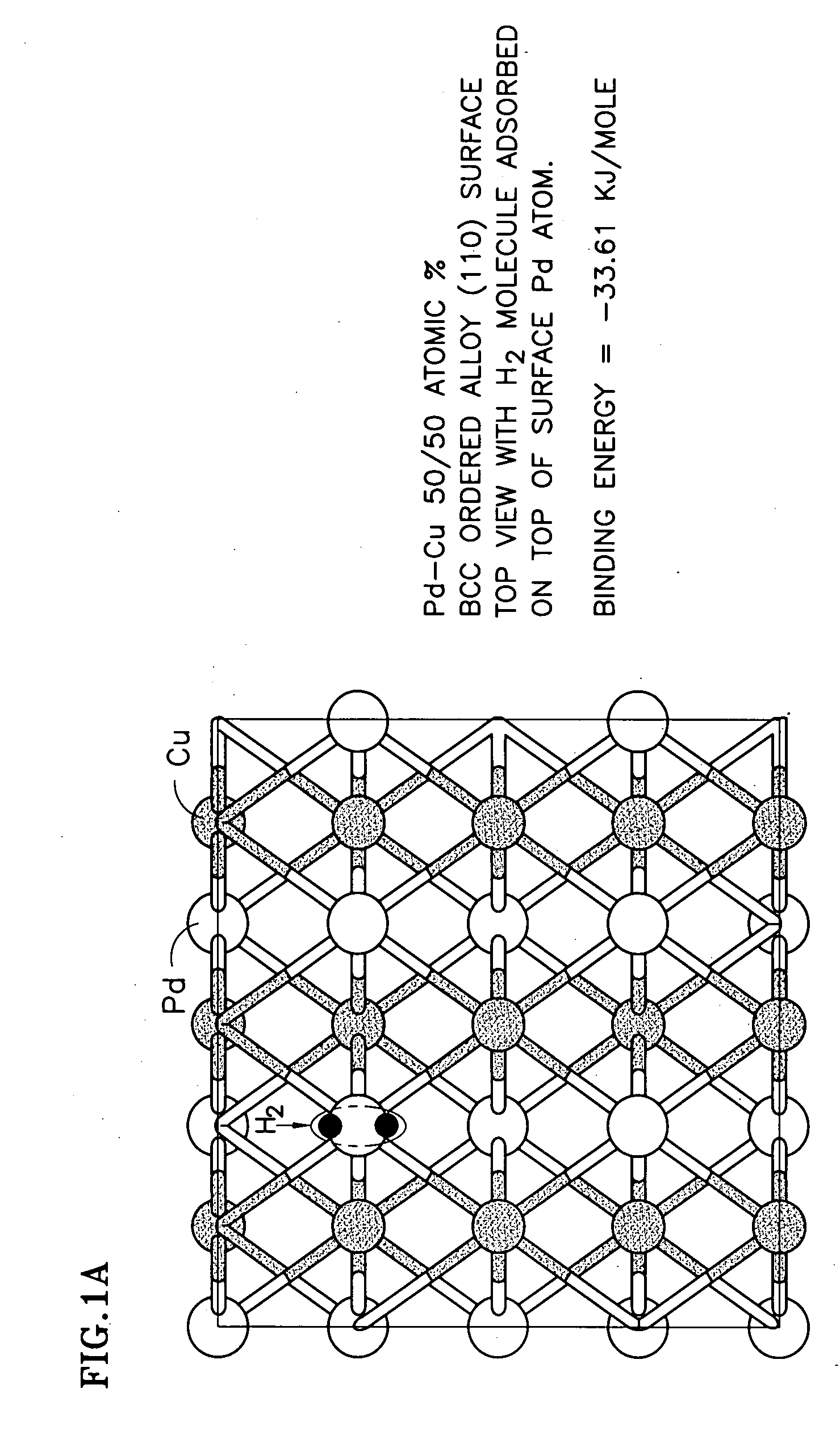

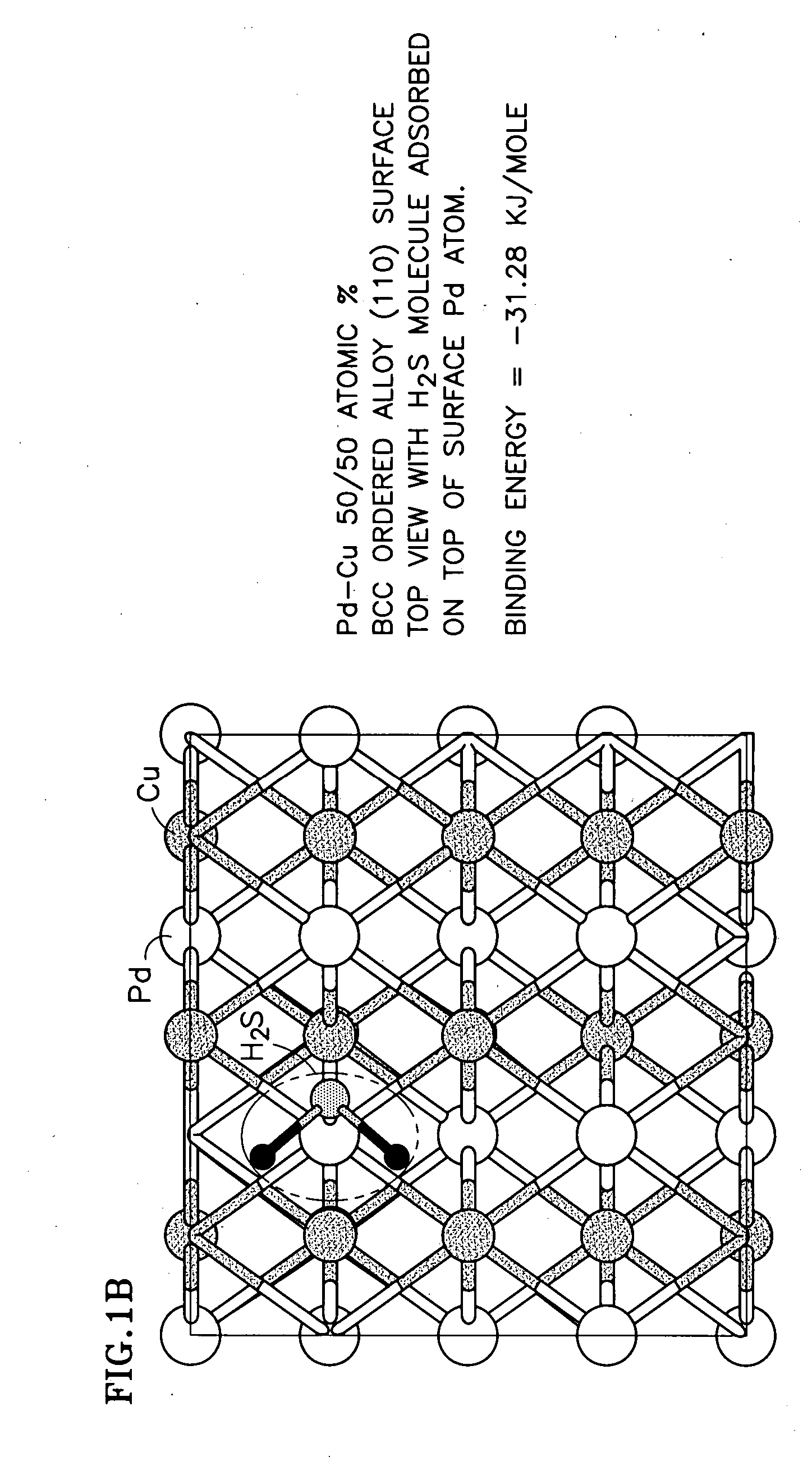

Duarable Pd-based alloy and hydrogen generation membrane thereof

InactiveUS20070240566A1High H permeanceCost-effective provisionSemi-permeable membranesMembranesBinary alloyHydrogen

A durable Pd-based alloy is used for a H2-selective membrane in a hydrogen generator, as in the fuel processor of a fuel cell plant. The Pd-based alloy includes Cu as a binary element, and further includes “X”, where “X” comprises at least one metal from group “M” that is BCC and acts to stabilize the β BCC phase for stability during operating temperatures. The metal from group “M” is selected from the group consisting of Fe, Cr, Nb, Ta, V, Mo, and W, with Nb and Ta being most preferred. “X” may further comprise at least one metal from a group “N” that is non-BCC, preferably FCC, that enhances other properties of the membrane, such as ductility. The metal from group “N” is selected from the group consisting of Ag, Au, Re, Ru, Rh, Y, Ce, Ni, Ir, Pt, Co, La and In. The at. % of Pd in the binary Pd—Cu alloy ranges from about 35 at. % to about 55 at. %, and the at. % of “X” in the higher order alloy, based on said binary alloy, is in the range of about 1 at. % to about 15 at. %. The metals are selected according to a novel process.

Owner:UNITED TECH CORP

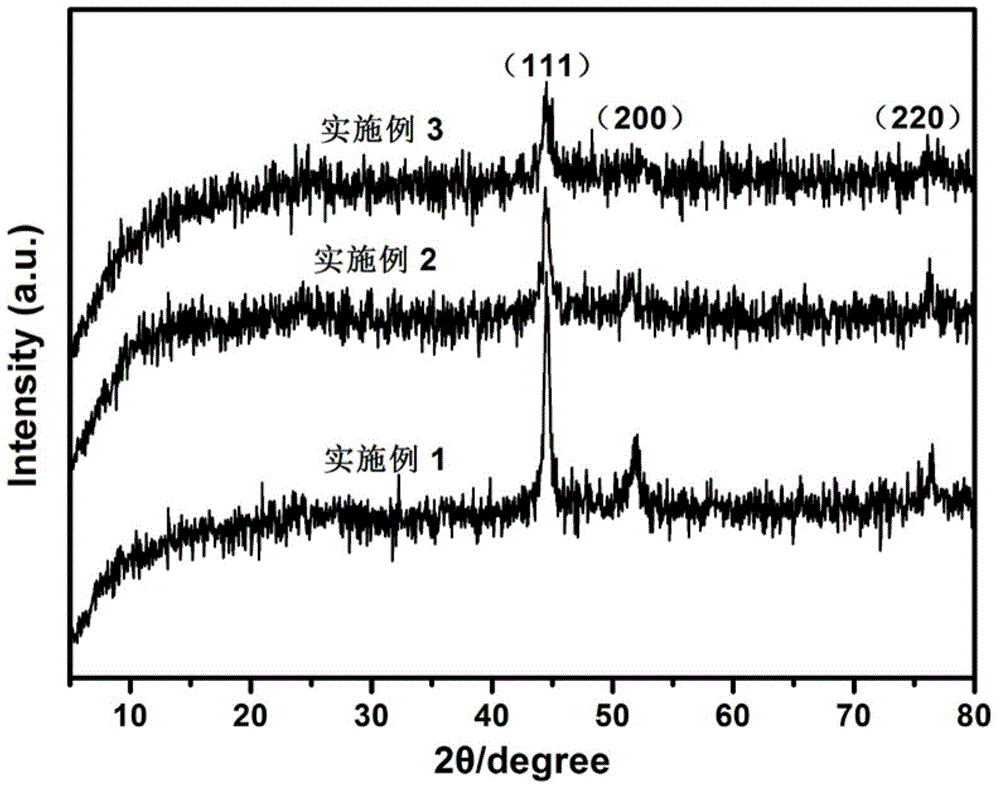

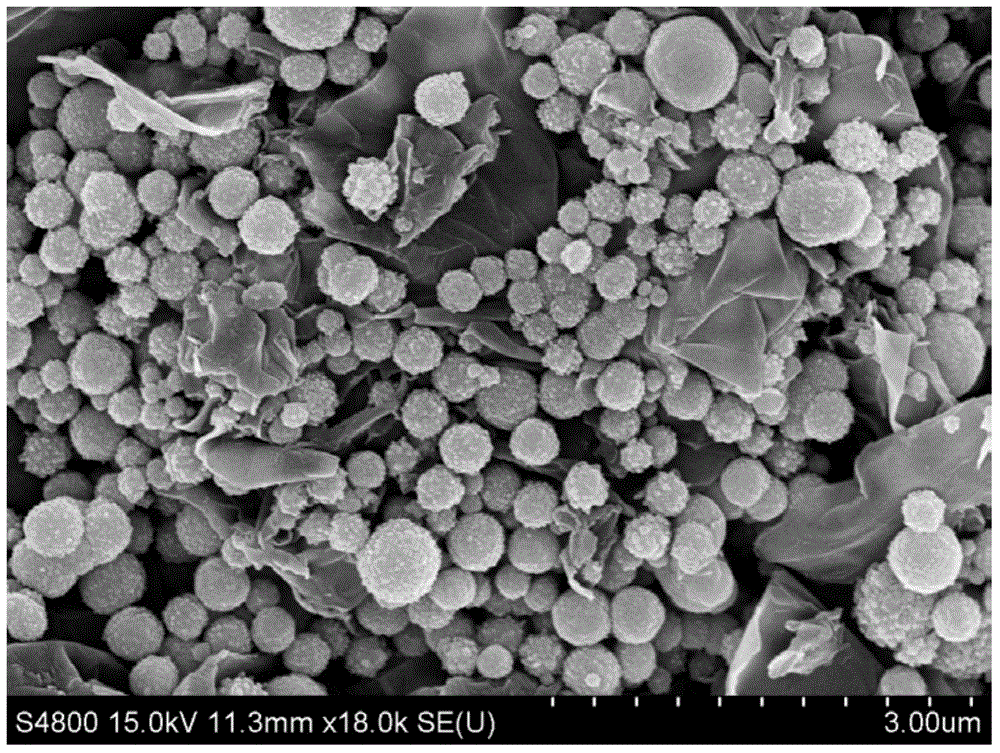

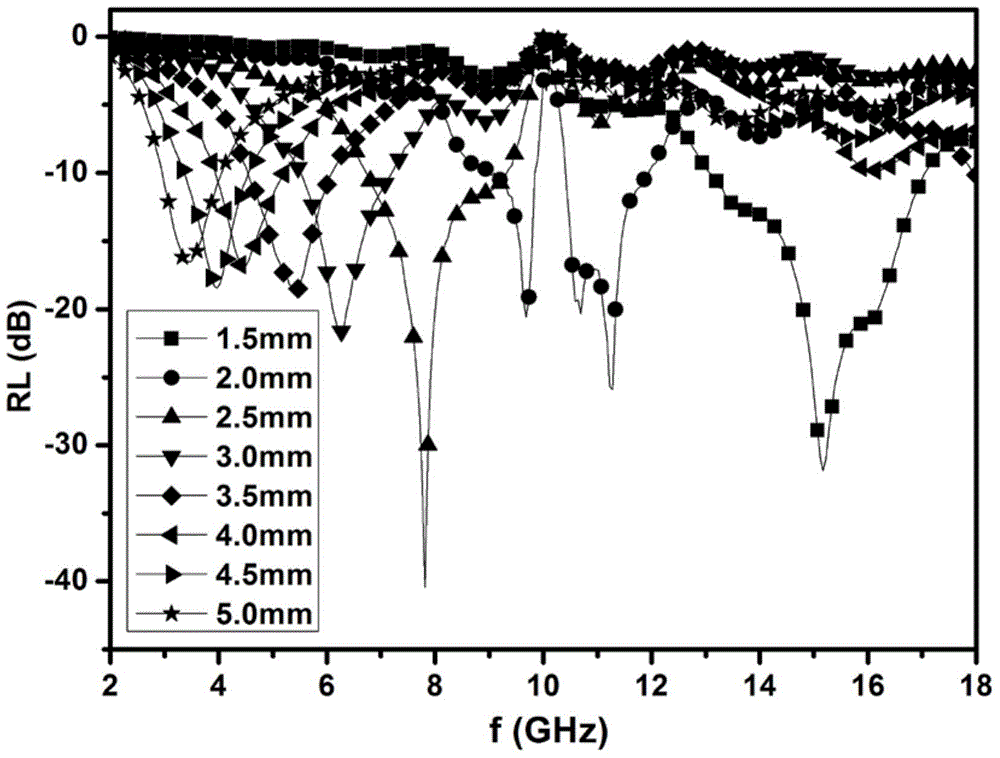

Preparation method for reduced graphene oxide/Ni-Co ternary composite wave-absorbing material

The invention discloses a preparation method for a reduced graphene oxide / Ni-Co ternary composite wave-absorbing material. According to the preparation method, graphite oxide, Co salt and Ni salt are adopted as precursors, hydrazine hydrate is adopted as a reducing agent, and the reduced graphene oxide / Ni-Co ternary composite wave-absorbing material can be prepared in one step of a hydrothermal reaction. Ni-Co binary alloy nanometer particles obtained during the preparation are directly loaded onto reduced graphene oxide (RGO) through in-situ growth, stable in structure, and high in dispersity; the preparation method is efficient, low in cost and short in consumed time; the prepared reduced graphene oxide / Ni-Co ternary composite wave-absorbing material is relatively good in performance; waves at different wavebands can be effectively absorbed by adjusting the addition proportions of graphite oxide, Co salt and Ni salt, the dosage of the reducing agent and the thickness of the reduced graphene oxide / Ni-Co ternary composite wave-absorbing material.

Owner:NANJING UNIV OF SCI & TECH

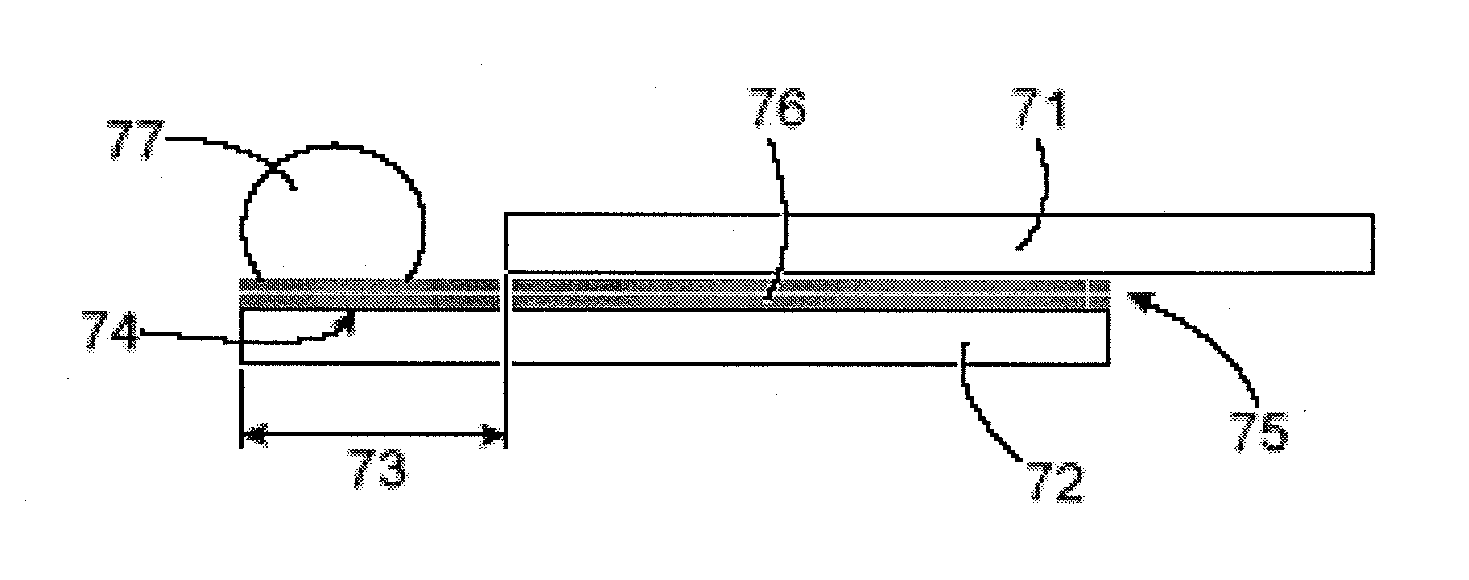

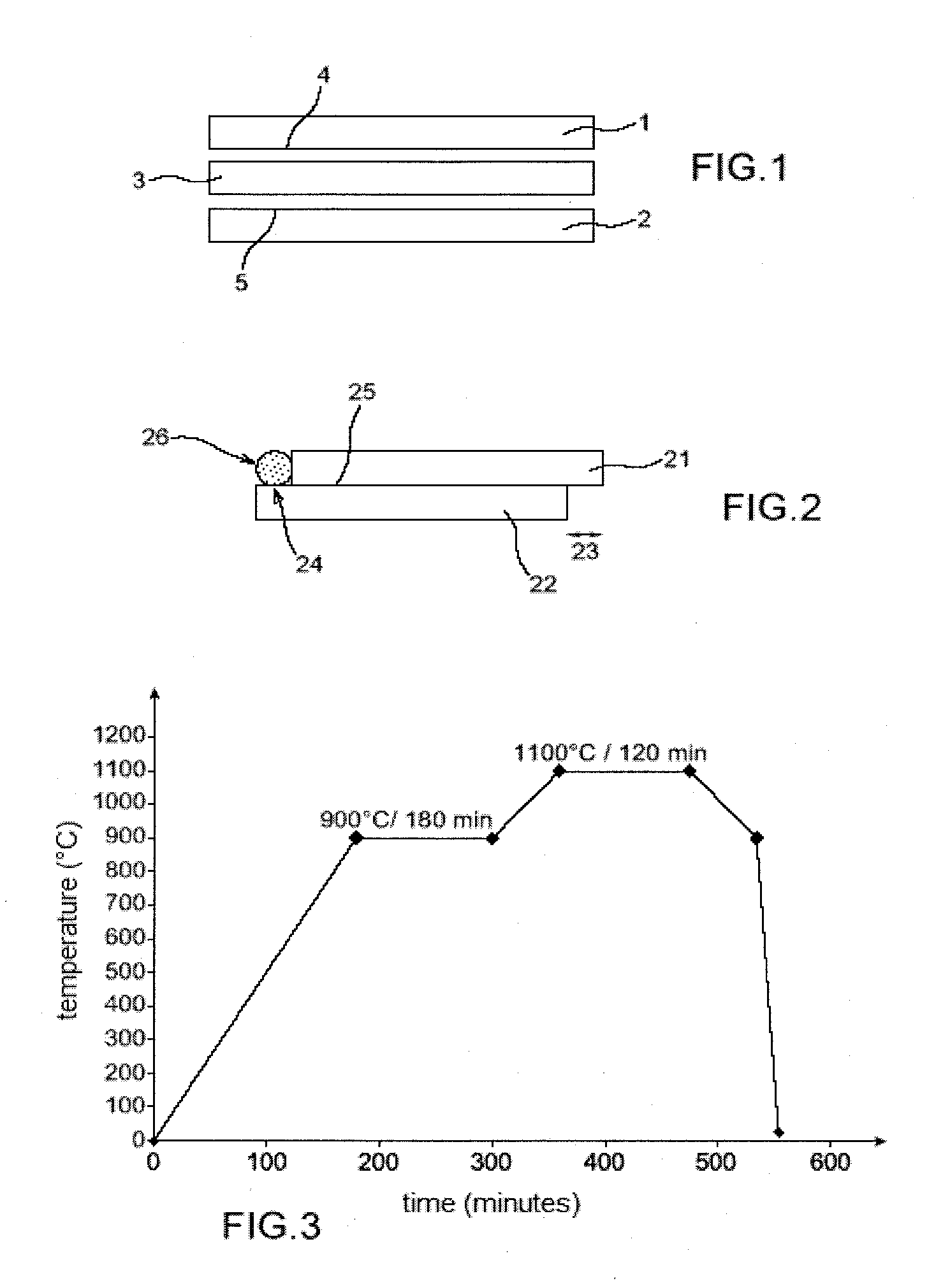

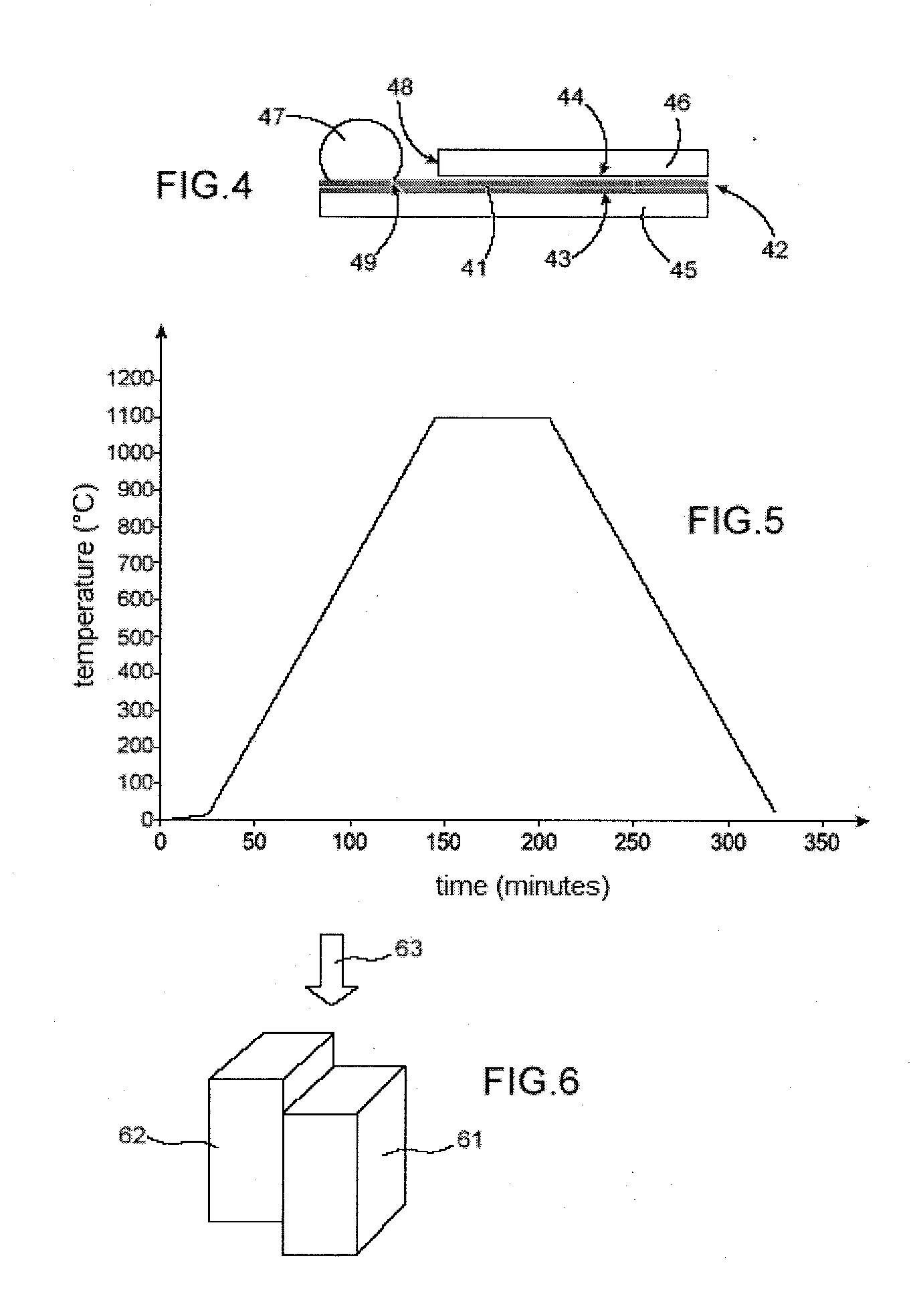

METHOD OF JOINING PARTS MADE OF SiC-BASED MATERIALS BY NON-REACTIVE BRAZING WITH ADDITION OF A REINFORCEMENT. BRAZING COMPOSITIONS AND JOINT AND ASSEMBLY THAT ARE OBTAINED BY SUCH A METHOD

InactiveUS20130064602A1Good wetting angleImprove adhesionMetal-working hand toolsTubular articlesBinary alloyOrganic fluid

A method for joining, assembling, at least two parts comprising silicon carbide-based materials is provided. The parts are contacted with a non-reactive brazing composition, the assembly having the parts and the brazing composition is heated to a brazing temperature sufficient to melt the brazing composition, and the parts and the brazing composition are cooled so that, after solidification of the brazing composition, a moderately refractory joint is formed. The brazing composition is a binary alloy consisting, in atomic percentages, of 60% to 66% silicon and 34% to 40% nickel. Prior to contacting the parts with the brazing composition, a reinforcement is added. A composition comprising the brazing composition and a reinforcement is provided. A brazing paste, suspension comprising a powder of the brazing composition, a reinforcement, and an organic liquid cement, binder, or an organic viscous gel is provided. A joint and assembly obtained by the foregoing method is provided.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

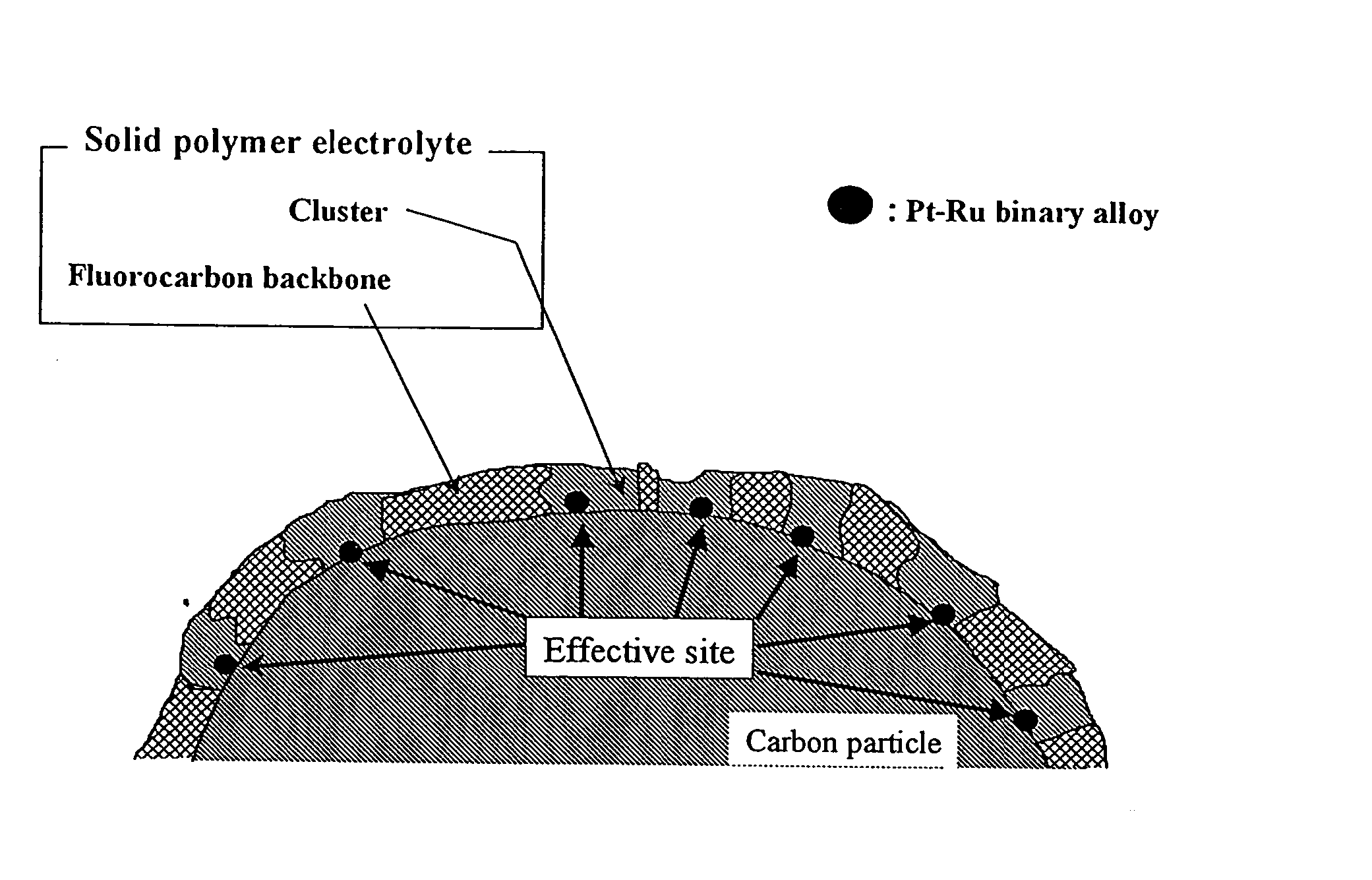

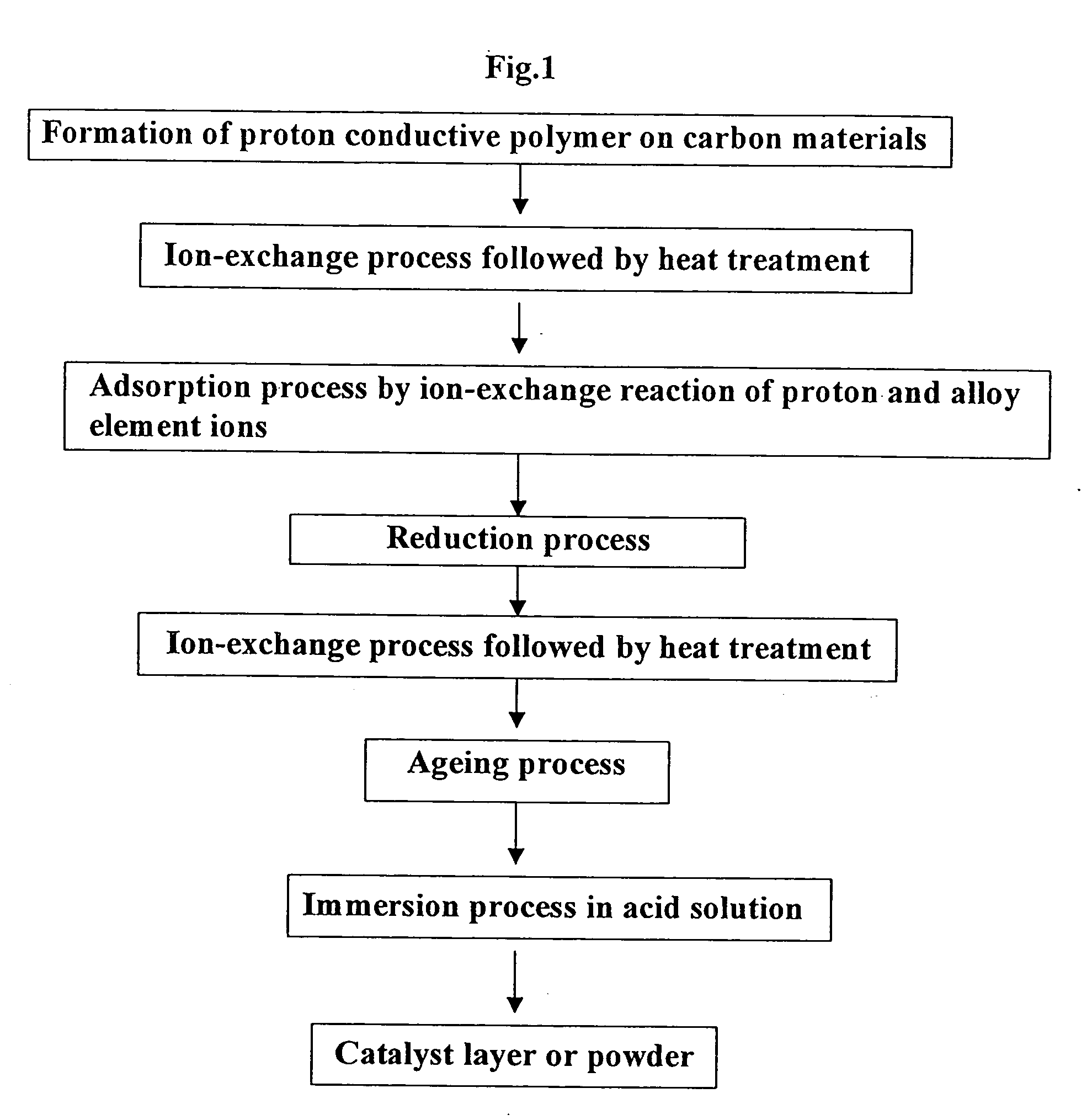

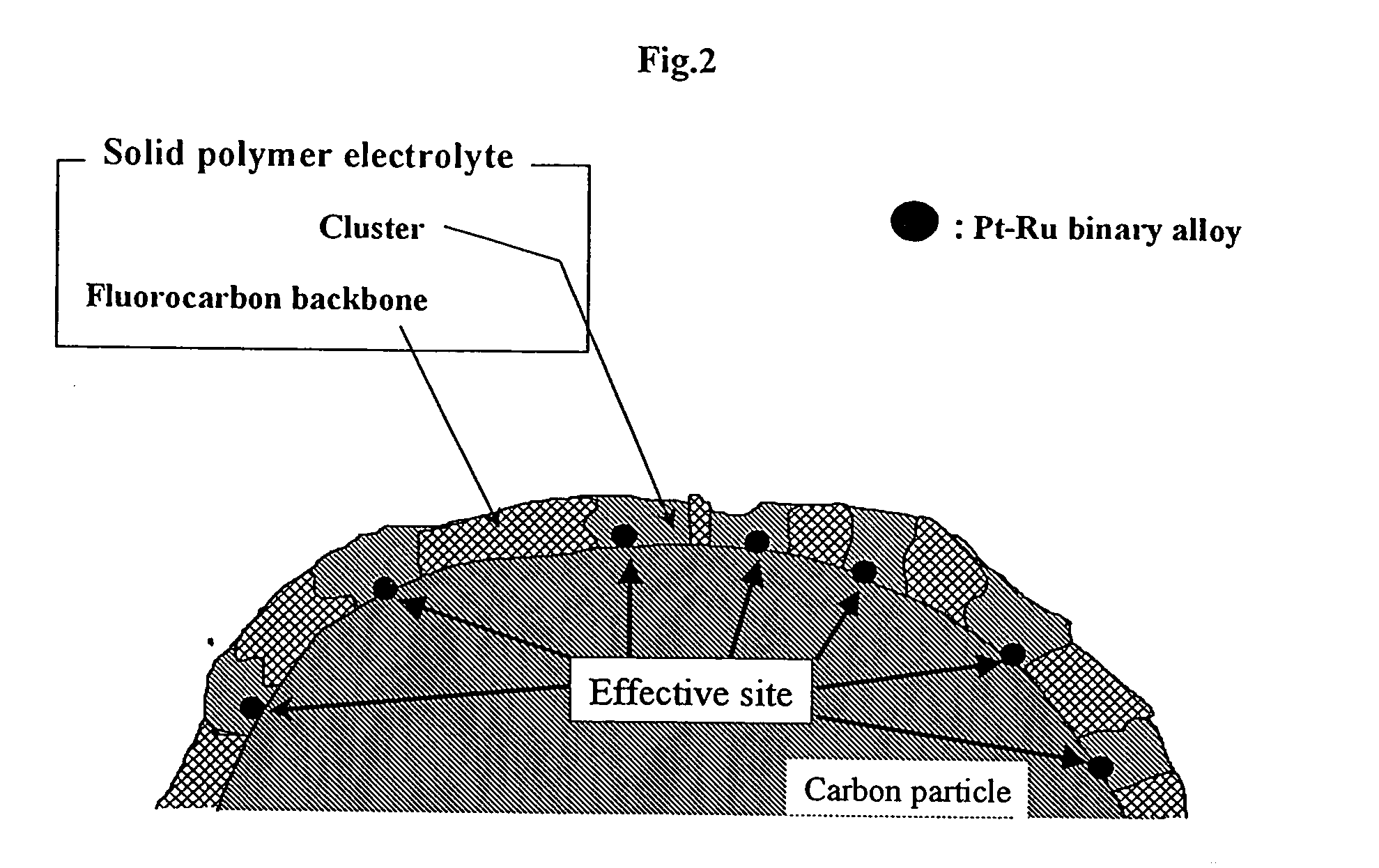

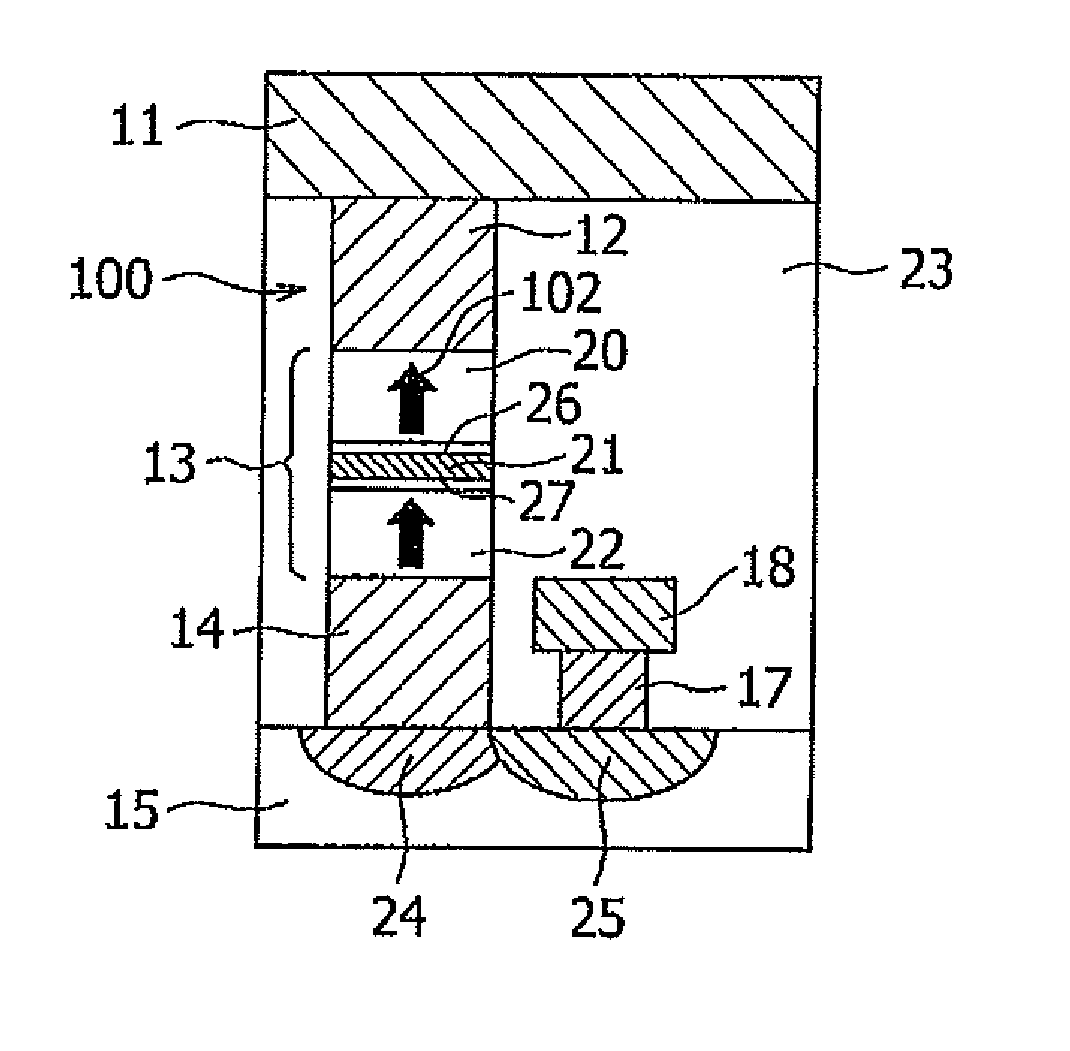

Manufacturing processes of catalyst layer for fuel cell

InactiveUS20050026772A1Shorten aging timeActive material electrodesSolid electrolyte fuel cellsBinary alloyPolymer electrolytes

The feature of the process for ultra-low alloy catalyst loading electrode according this invention is to reduce its alloy formation period of aging process subsequent to hydrogen reduction process of catalyst ions after ion exchange process of their ions and proton in the cluster of the polymer electrolyte on the surface of the carbon powder. The process is able to drastically shorten the aging time with temperature rise beyond 200° C. up to 400° C. under hydrogen atmosphere for the formation of Pt—Ru binary alloy for example catalyst by the additional processes of pre-treatment of K+, Na+, Li+, Rb+, Cs+, Mg2+, Ca2+, Ba2+, Fe2+, Sr2+, Ra2+, Cu2+, Ag+, Zn2+, Ni2+, and Co2+ ions substitution for proton before the hydrogen reduction process. More preference, the further post-treatment of K+, Na+, Li+, Rb+, Cs+, Mg2+, Ca2+, Ba2+, Fe2+, Sr2+, Ra2+, Cu2+, Ag+, Zn2+, Ni2+, and Co2+ ions substitution for proton before the ion exchange process. This new process is little harmful to the CO tolerance performance of PEFC.

Owner:GS YUASA INT LTD

Method for reducing contact resistance based on low-melting-point metal and oxide thereof

ActiveCN103066475AReduce contact resistanceImprove efficiencyLine/current collector detailsMetal/alloy conductorsIndiumRubidium

The invention relates to a method for reducing contact resistance based on low-melting-point metal and an oxide thereof. By coating the low-melting-point metal and the oxide thereof between electric terminals connected with machinery, the contact resistance between the mechanical electric terminals is reduced effectively. The invention further relates to a conductive paste composing of the low-melting-point metal and the oxide thereof. The oxide takes 0.05% to 50% of the total weight of the conductive paste. The low-melting-point metal is one type or a combination of any two types selected from sodium, potassium, lithium, rubidium, cesium, gallium, indium, mercury, lead bismuth alloy, gallium-base binary alloy, gallium-base complex alloy, indium-base alloy, bismuth-base alloy, mercury-base alloy and sodium-potassium alloy which are lower than 200 DEG C in melting point. With the compound of the low-melting-point metal and the oxide thereof as the conducting medium, the method for reducing contact resistance can effectively reduce the contact resistance between the electric terminals connected with the machinery, significantly reduce the contact resistance heat effect, improve transmission efficiency of electric energy and prolong the service life of the machinery. The method for reducing contact resistance based on the low-melting-point metal and the oxide thereof can be widely applied to the technical fields of electric power and energy.

Owner:郭瑞

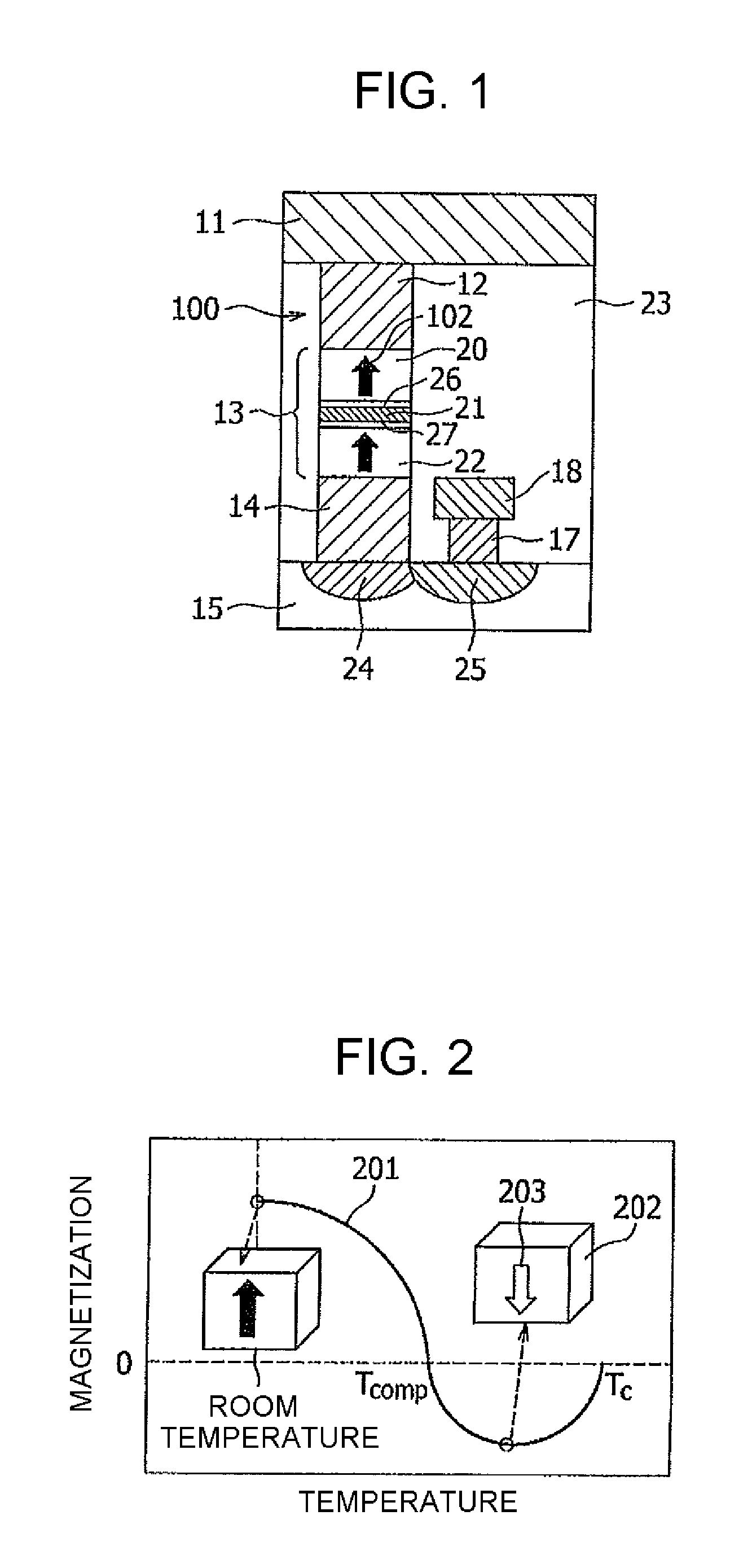

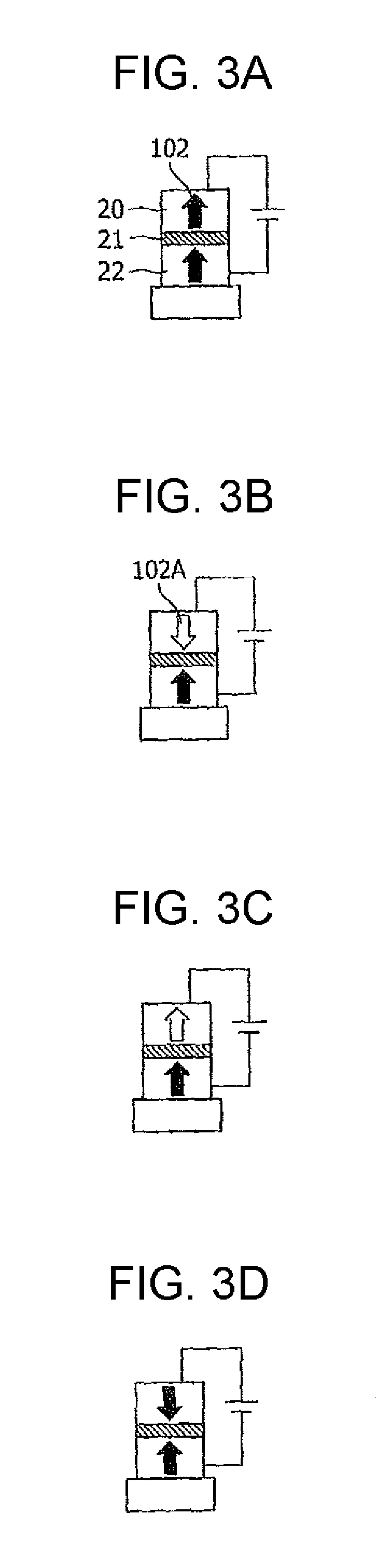

Magnetoresistance element and storage device using the same

ActiveUS20110310660A1Easy to operateIncrease the number ofNanomagnetismMagnetic-field-controlled resistorsMagnetic memoryNon magnetic

A magnetic memory element having a memory cell of size 4F2 is provided that realizes a crosspoint-type memory. In the magnetic memory element, a first magnetic layer, a third magnetic layer (spin polarization enhancement layer), an intermediate layer, a fourth magnetic layer (spin polarization enhancement layer), and a second magnetic layer are stacked in order. The intermediate layer is made of an insulating material or a nonmagnetic material. The second magnetic layer is composed of a ternary alloy of gadolinium, iron and cobalt, a binary alloy of gadolinium and cobalt, or a binary alloy of terbium and cobalt. Alternatively, the first magnetic layer is composed of a ternary alloy of terbium, iron and cobalt, or a binary alloy of terbium and cobalt.

Owner:III HLDG 3

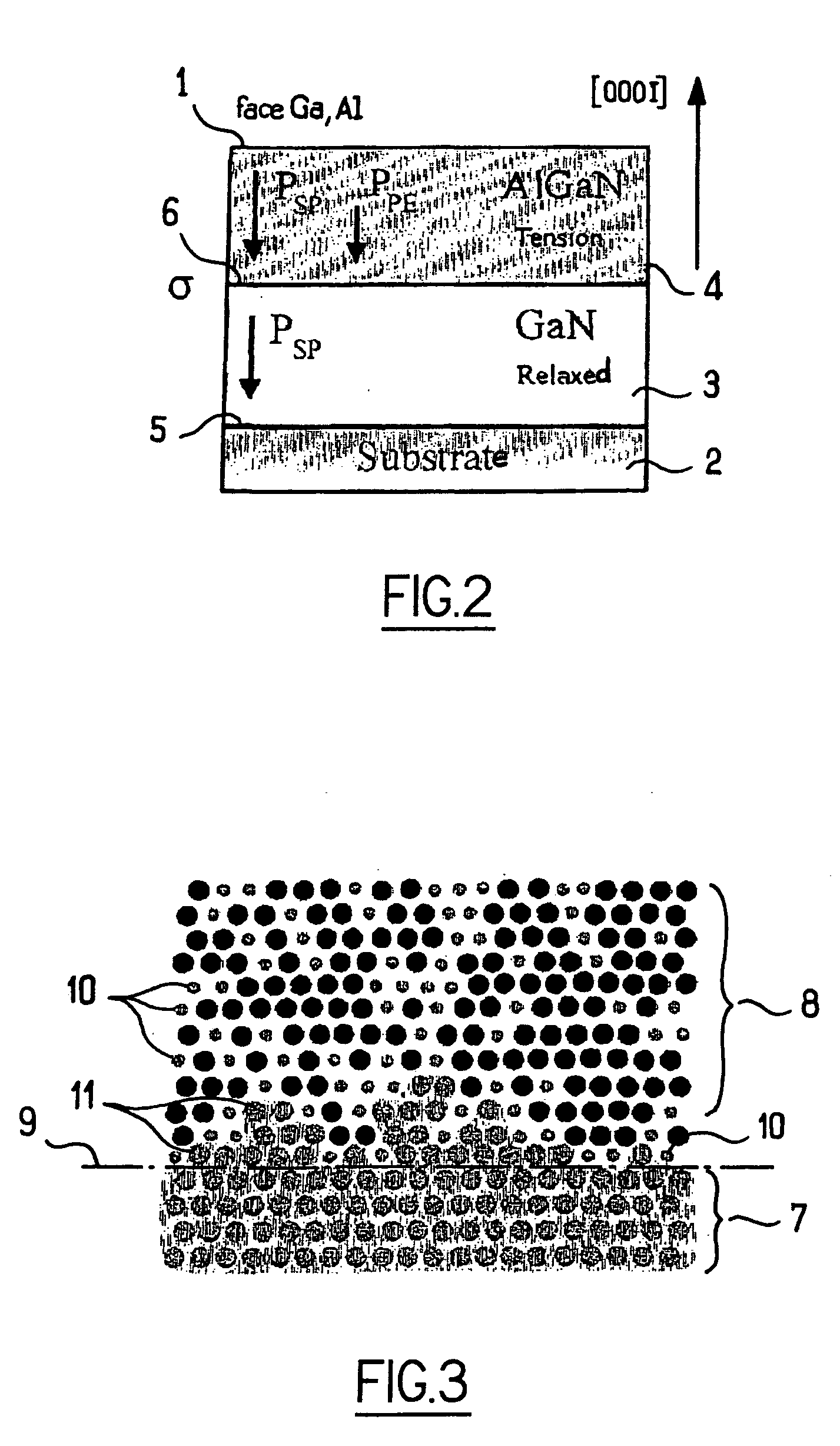

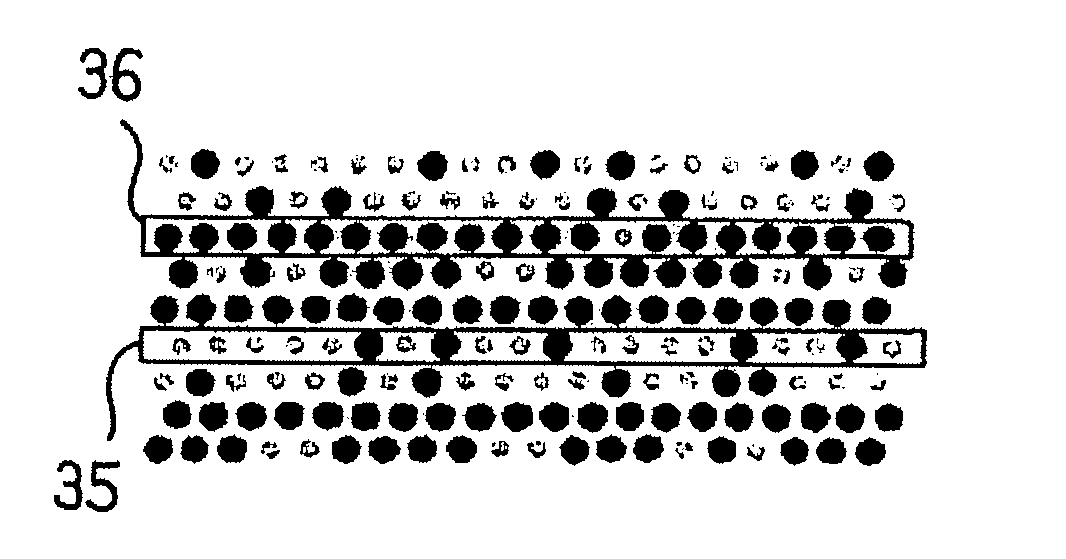

HEMT piezoelectric structures with zero alloy disorder

InactiveUS20070164299A1Excellent piezoelectric propertiesSemiconductor devicesBinary alloySemiconductor structure

Electronic circuits dedicated to high frequency and high power applications based on gallium nitride (GaN) suffer from reliability problems. The main reason is a non-homogenous distribution of the electronic density in these structures that originates from alloy disorders at the atomic and micrometric scale. This invention provides processes for manufacturing semiconducting structures based on nitrides of Group III elements (Bal, Ga, In) / N which are perfectly ordered along a preferred crystalline axis. To obtain this arrangement, the ternary alloy barrier layer is replaced by a barrier layer composed of alternations of binary alloy barrier layers. The lack of fluctuation in the composition of these structures improves electron transport properties and makes the distribution more uniform.

Owner:PICOGIGA INT

Method for manufacturing co-base sintered alloy sputtering target for formation of magnetic recording film which is less likely to generate partricles, and co-base sintered alloy sputtering target for formation of magnetic recording film

InactiveUS20100270146A1Inhibition formationCellsVacuum evaporation coatingBinary alloyChemical composition

A method for manufacturing a Co-base sintered alloy sputtering target for the formation of a magnetic recording film including providing a Cr—Co alloy powder consisting of 50 to 70 atomic % of Cr and remaining Co, a Pt powder, a non-magnetic oxide powder, and a Co powder, blending and mixing the powders together so as to give the chemical composition consisting of 2 to 15 mol % of a non-magnetic oxide, 3 to 20 mol % of Cr, and 5 to 30 mol % of Pt and a remainder containing Co, and sintering the mixture under pressure. Or alternatively providing a Pt—Cr binary alloy powder consisting of 10 to 90 atomic % of Pt and remaining Cr, a Pt powder, a non-magnetic oxide powder, and a Co powder, blending and mixing the powders so as to give the chemical composition above, and then sintering the mixture under pressure.

Owner:MITSUBISHI MATERIALS CORP

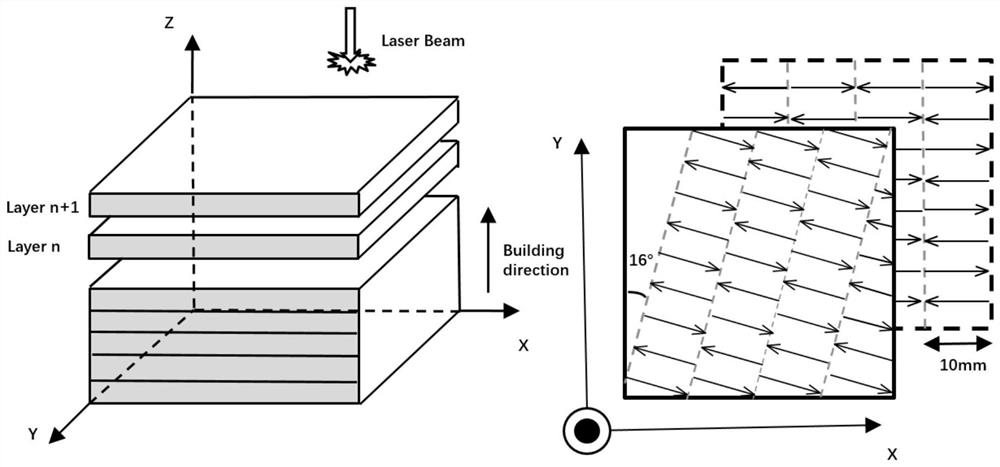

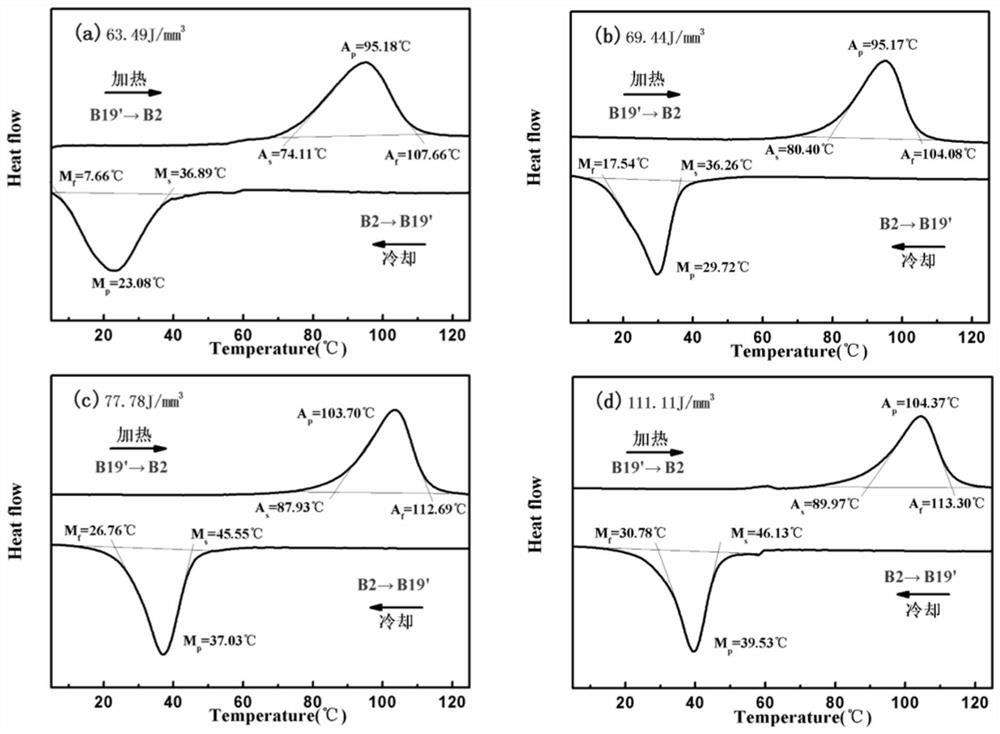

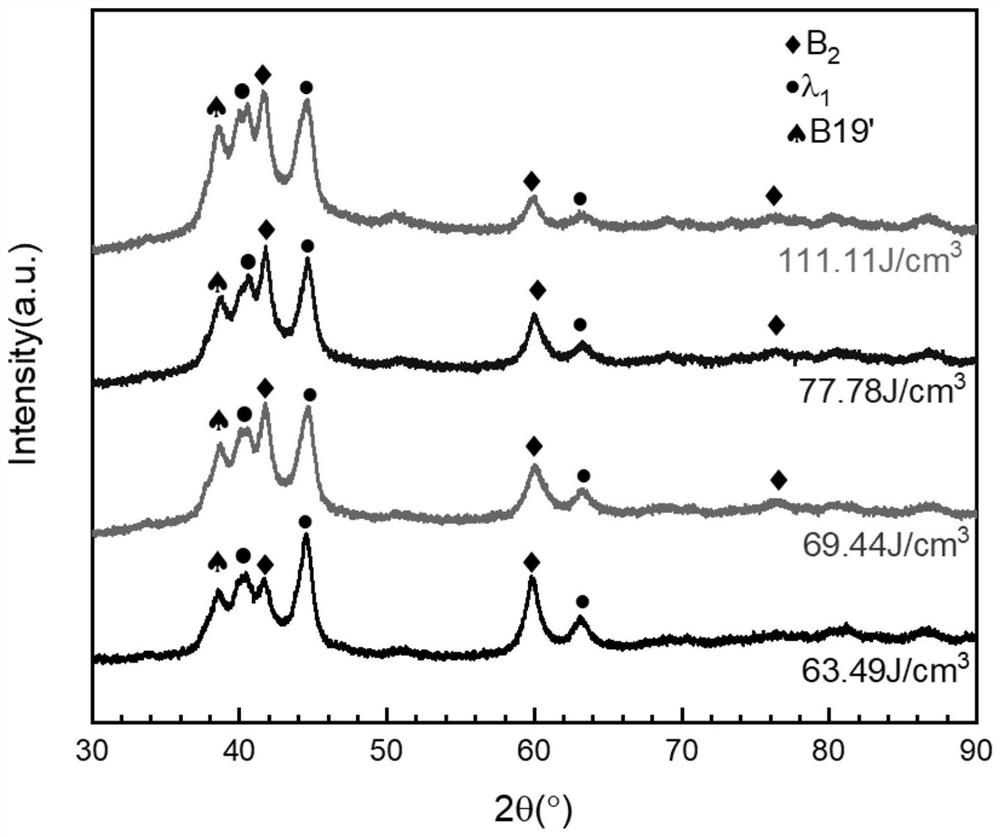

4D printing method of nickel-titanium-based ternary shape memory alloy

InactiveCN111842888AHas shape memory effectRaise the transition temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingBinary alloy

The invention belongs to the technical field of 4D printing additive manufacturing, and discloses a 4D printing method of a nickel-titanium-based ternary shape memory alloy. The 4D printing method ischaracterized in that a selective laser melting technology is adopted for printing gas atomized prefabricated NiTiZr ternary alloy powder, and a component obtained through printing has the shape memory function; and the laser energy density is changed by changing the technological parameters adopted in the selective laser melting technology, and therefore the changes of the structure and performance of the printed piece are regulated and controlled. According to the 4D printing method, the ternary component Zr is introduced into an existing nickel-titanium binary alloy, the martensite phase transformation temperature is obviously increased, the selective laser melting technology is adopted for forming, and complex parts uniform in structure and high in density can be obtained while the excellent shape memory performance and mechanical performance are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

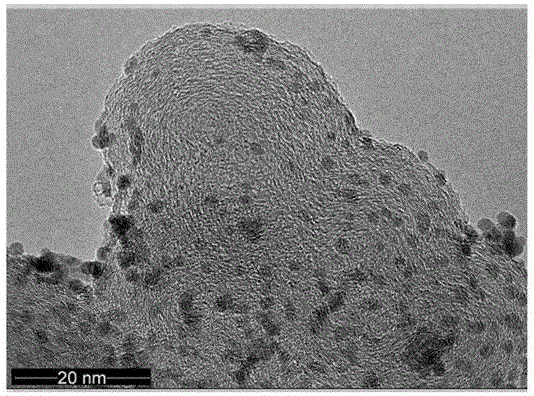

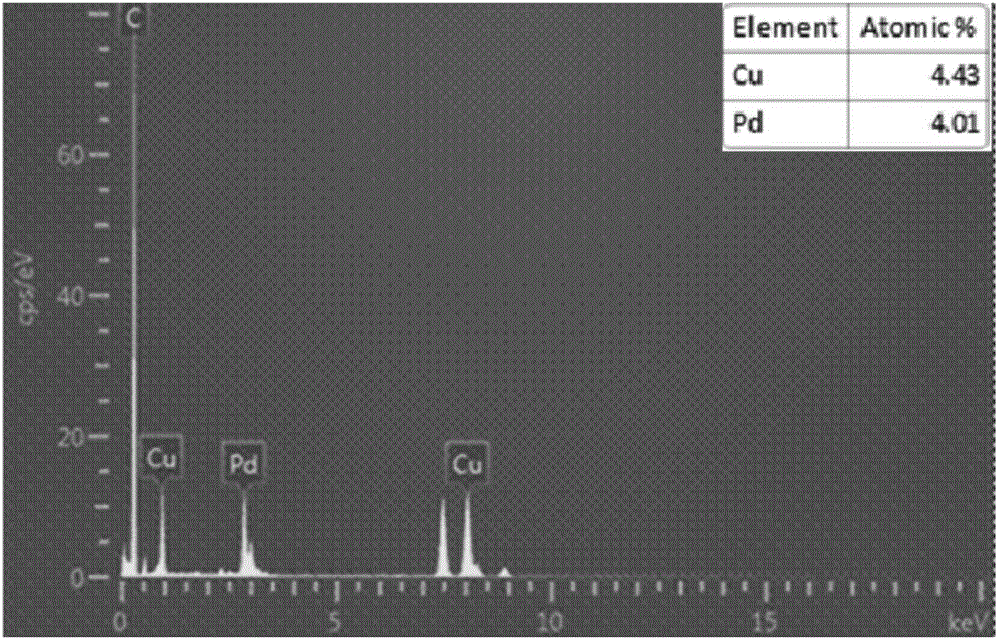

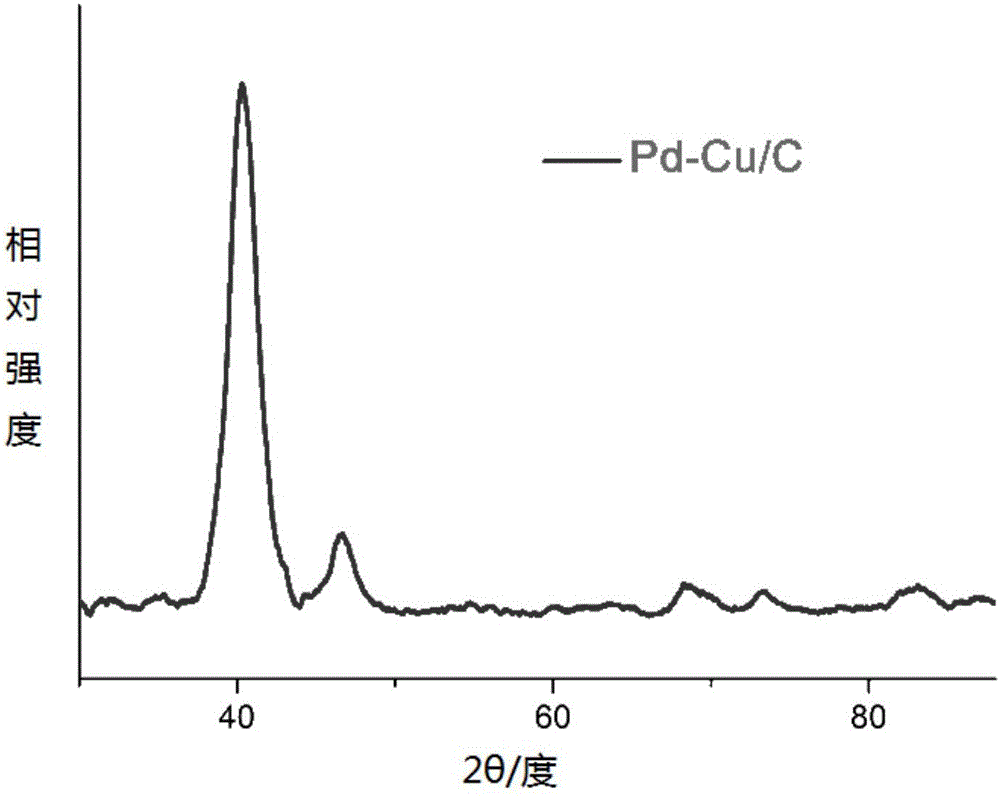

Palladium-copper binary alloy nanometer material, preparation method thereof and application thereof of serving as catalyst for electrocatalytic reduction

ActiveCN106180747AIncrease added valueSimple methodMaterial nanotechnologyTransportation and packagingIce waterResource utilization

The invention discloses a palladium-copper binary alloy nanometer material. The average particle size is in a range of 3-5 nanometers; and the particle size distribution is less than 10 nanometers. A preparation method of the palladium-copper binary alloy nanometer material comprises the following steps: chlorine palladium acid sodium solution and copper chloride solution are taken; activated carbons and high-purity water are added for fully and uniformly mixing; sodium borohydride solution is added for an ice-water bath reaction; and after the reaction is finished, the washing and the drying are performed to obtain the palladium-copper binary alloy nanometer material. The invention designs the palladium-copper binary alloy nanometer material; the palladium-copper binary alloy nanometer material can serve as a catalyst for electrocatalytic reduction; the catalyst can be used for efficiently converting CO2 to formic acid and natural gas (including methane, carbon monoxide, hydrogen and few such hydrocarbons as ethane and ethylene), so that the method is convenient, the cost is low, and the effect is obvious; and CO2 is converted to chemicals with high additional values, so that the important practical significance on environmental protection and resource utilization is obvious.

Owner:王荔

Alloy for use in preparation of R-T-B-based sintered magnet and process for preparing R-T-B-based sintered magnet

InactiveUS6444048B1Oxidation during the production of the sintered magnet can, therefore, be suppressedInorganic material magnetismAbnormal growthsBinary alloy

Processes for the preparation of a sintered alloy comprising R2Fe14B as a magnetic phase constituting a main phase include a binary alloy process wherein a main phase alloy having a lower R content than the above phase is mixed with a grain boundary phase alloy rich in R component and serving as a liquid phase in the sintering in order to prepare a mixture to be used as the starting material. The conventional main phase alloy has a structure comprising the R2Fe14B phase and, in addition, a large amount of an easily oxidizable lamella R-rich phase and a harmful dendrite alpha phase. On the other hand, the main phase alloy of the invention has a low dendrite a phase content and a low lamella R-rich phase and contains a lamella alpha Fe phase. This contributes to excellent oxidation resistance and improved properties of the magnet. The preparation of a sintered magnet by mixing the main phase alloy with the grain boundary phase alloy by the binary alloy method can reduce abnormal growth of crystal grains.

Owner:SHOWA DENKO KK

Silver alloy material

InactiveCN103710566AImprove mechanical propertiesSolve the problem of easy oxidative vulcanization and discolorationSilver copperDuctility

The invention provides a silver alloy material and a preparation technology. The silver alloy material is prepared from the following alloy components in parts by weight: 85-96 parts of silver, 1-3 parts of copper, 1.0-1.6 parts of zinc, 0.2-1.0 part of palladium, 0.2-0.8 parts of cadmium, 1.2-2.0 parts of zirconium, 1.1-2.0 parts of ruthenium and 0.5-1.3 parts of magnesium. By adopting the silver alloy material and the preparation technology thereof, the high temperature resistance, the ductility and the hardness of the silver alloy are improved, so that the silver alloy material is easier to mold; a mesh structure is added to the silver alloy material, so that the overall stability and the ductility of the silver alloy material are improved; the silver alloy is easier to process and mold. A ternary alloy wire with the mesh structure is thin, and coated inside silver-copper binary alloy, so that the fineness of the silver alloy material and the aesthetic degree of the processed ornament are not affected, and a silver alloy material is not easily oxidized after being cleaned by a plasma cleaning machine.

Owner:北海鑫利坤金属材料科技开发有限公司(微型企业)

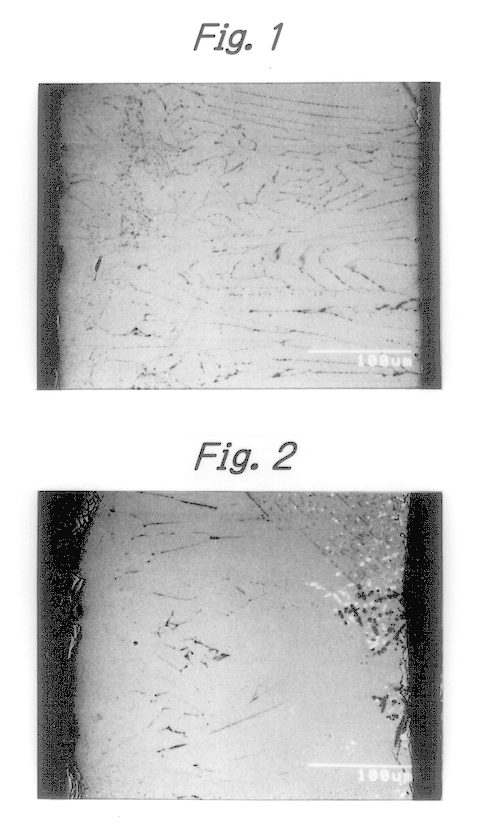

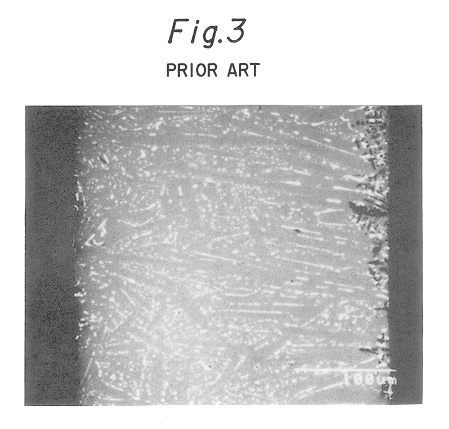

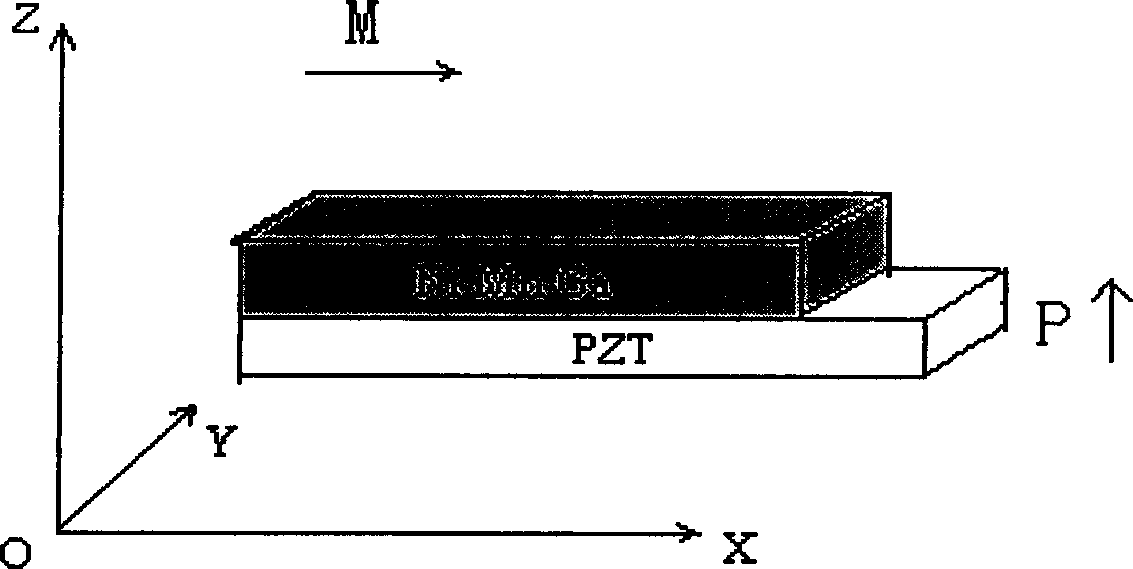

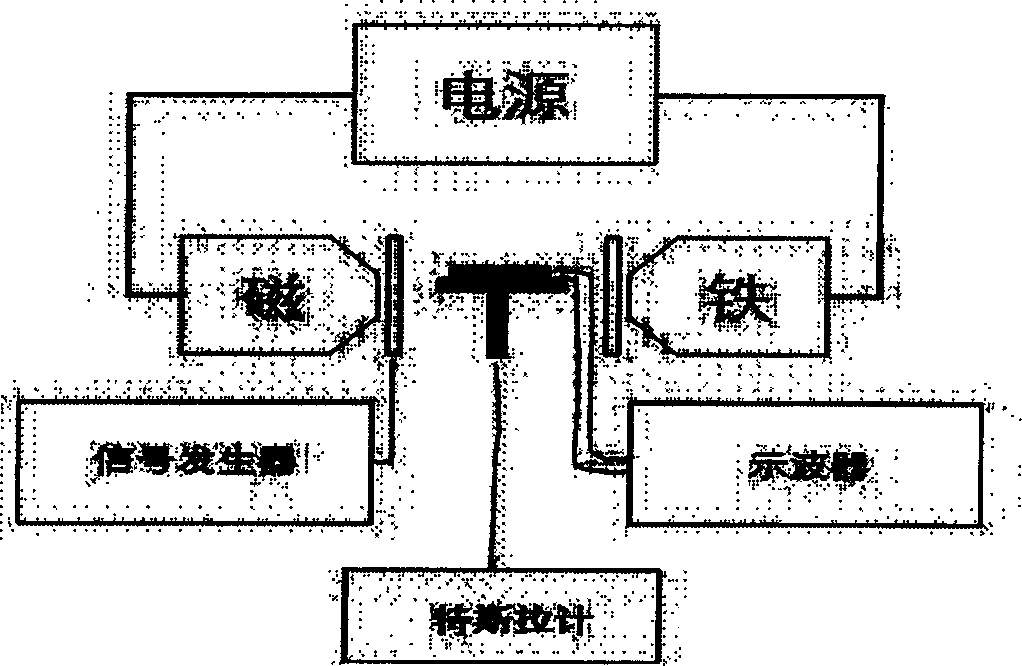

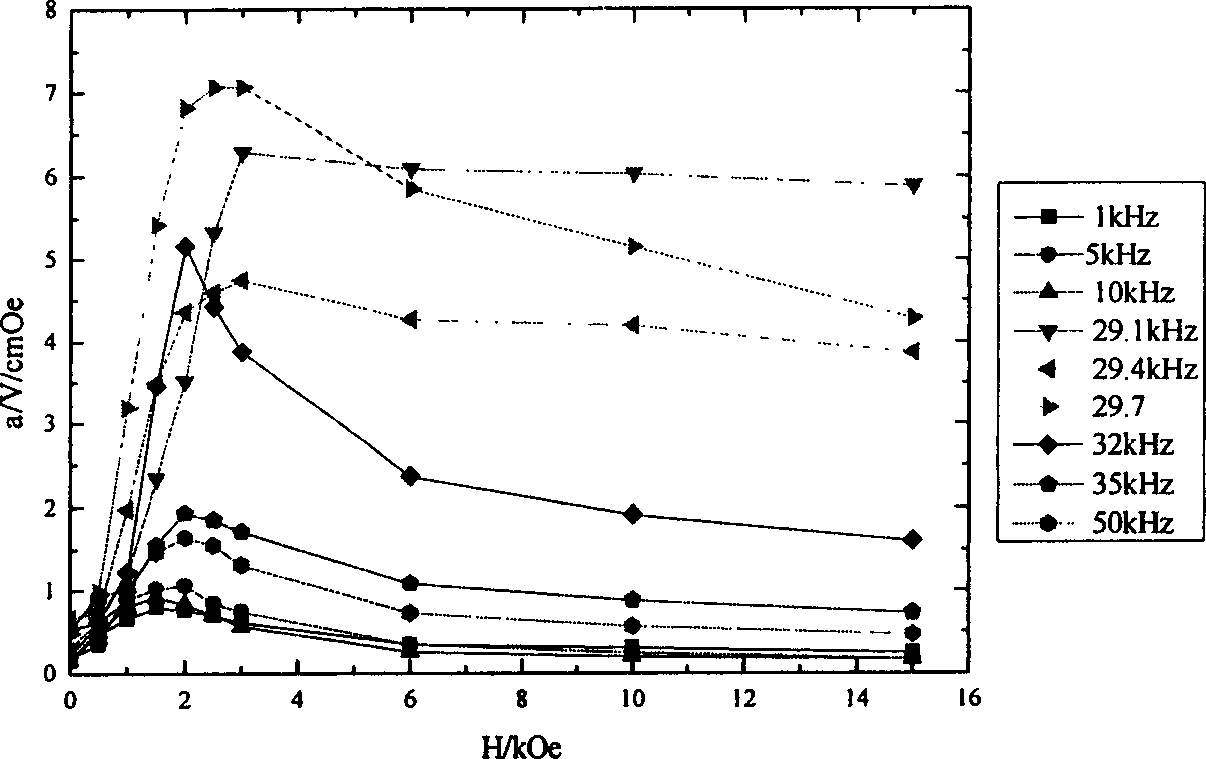

Composite material with tremendous electromagnetic coupling effect and its application

A new type of composite material with a huge magnetoelectric coupling effect. The Ni-based alloy and the piezoelectric material are made into a layered composite material. The Ni-based alloy can be a binary alloy of NiMn, NiFe, NiCo, and NiTi, or a ternary alloy of the above alloys , such as NiFeGa, NiTiHf, NiMnGa, NiFeO, NiCoO, NiTiPd, etc.; piezoelectric materials can be PZT, PMN-PT, LiNbO3, etc. with large piezoelectric coefficients. The invention adopts a novel composite material with magnetoelectric effect, and utilizes some temperature-related effects in Ni base alloy to obtain unexpected large magnetoelectric coupling effect. Thus, materials with temperature-dependent magnetoelectric coupling effects can be designed.

Owner:NANJING UNIV

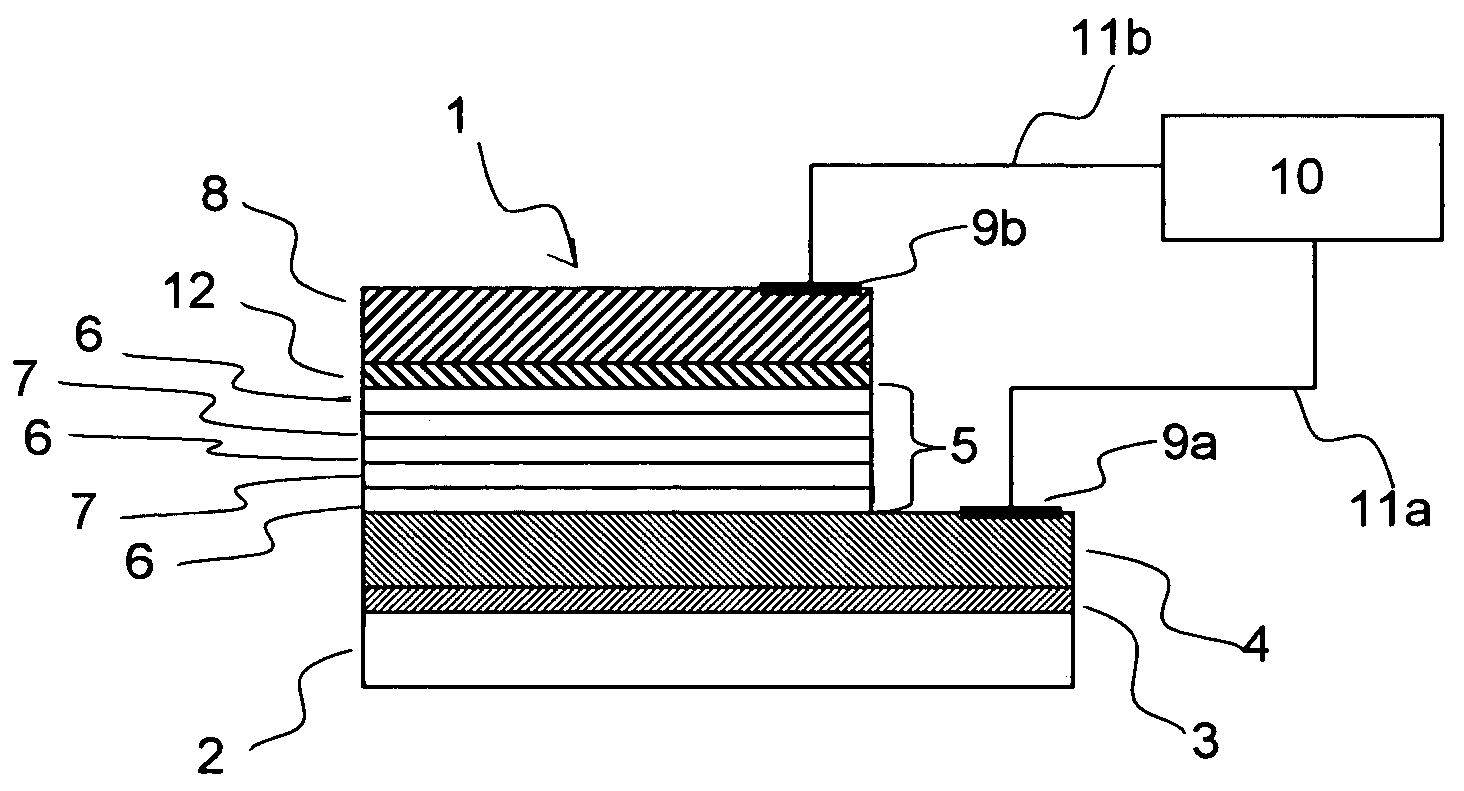

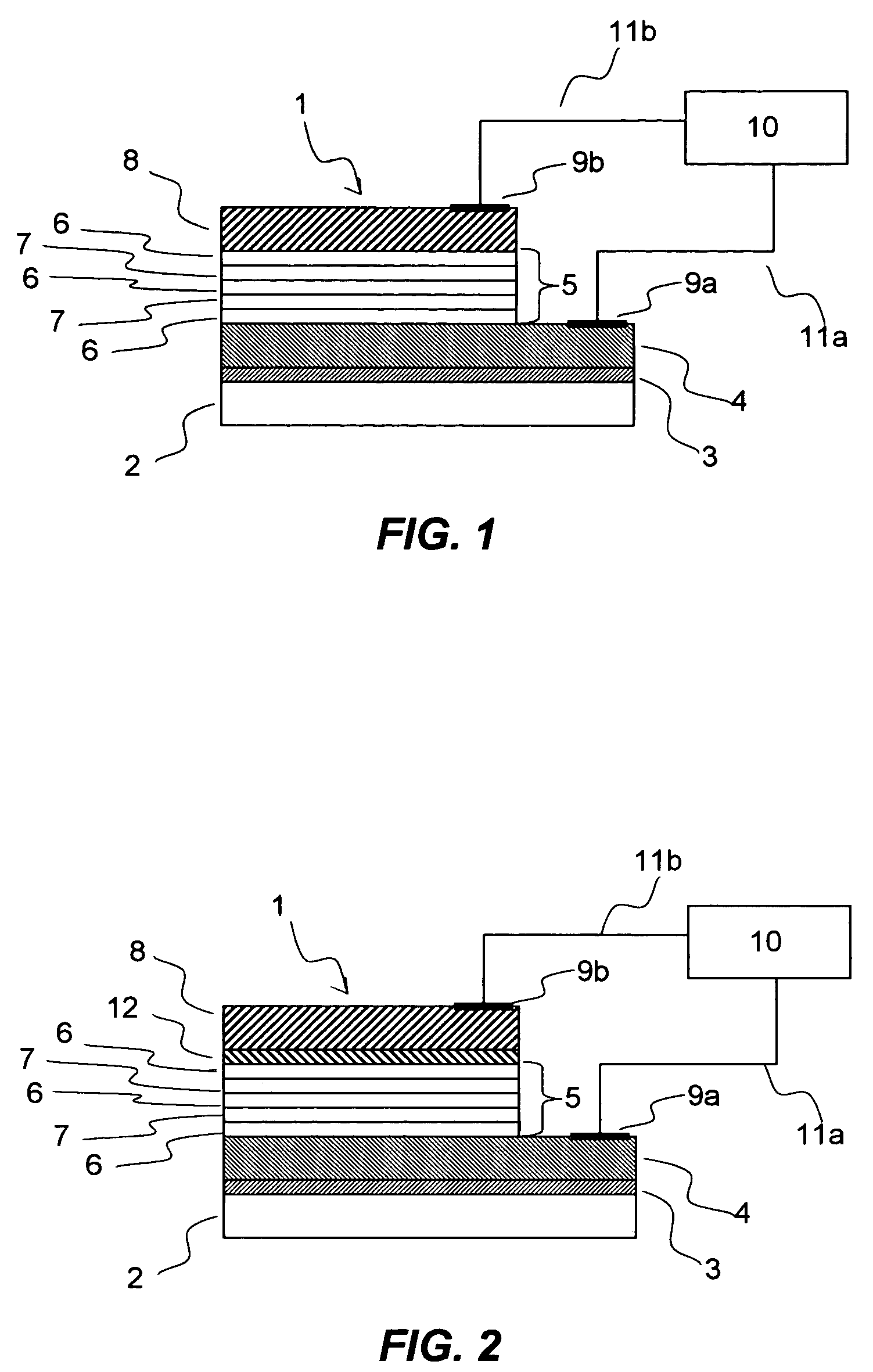

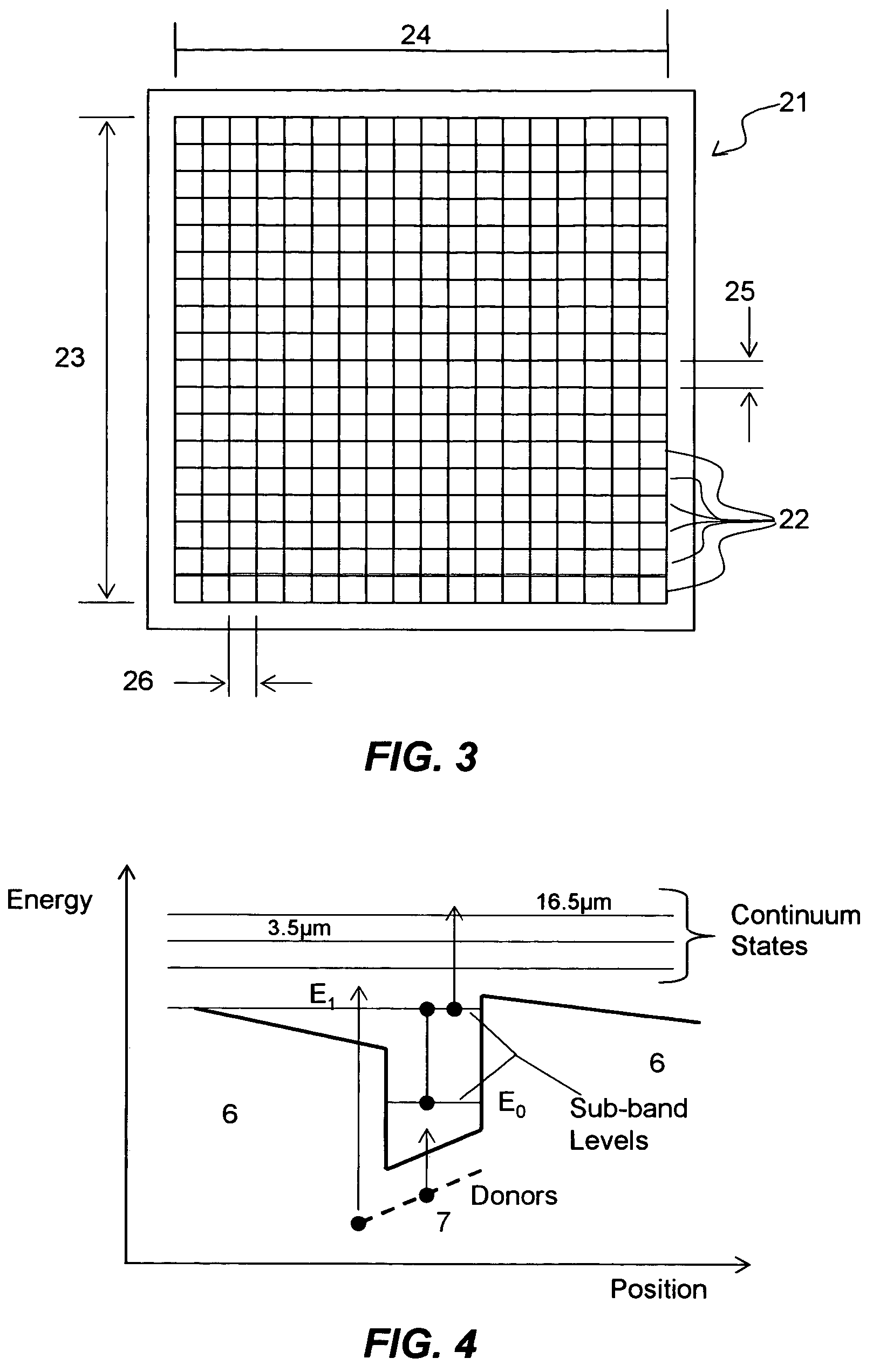

Infrared detector composed of group III-V nitrides

InactiveUS7180066B2High sensitivityLow costFinal product manufactureSolid-state devicesBinary alloyPhotovoltaic detectors

A quantum-well infrared photodetector (QWIP) is presented. The photodetector includes a substrate, a buffer layer, a first conductive layer, a multiple quantum well, an optional blocking layer, and a second conductive layer. Substrate is composed of a monocrystal which may be removed after fabrication. Remaining layers are composed of group III-V nitrides, including binary, ternary, and quaternary compositions. Alternate embodiments of the present invention include a doped binary alloy along first and second conductive layers, a binary alloy along buffer and blocking layers, and alternating alloys of binary, ternary and quaternary compositions within the multiple quantum well. The present invention responds to infrared light at normal and oblique incidences, from near infrared to very far infrared.

Owner:MISSILE DEFENSE AGENCY CTS

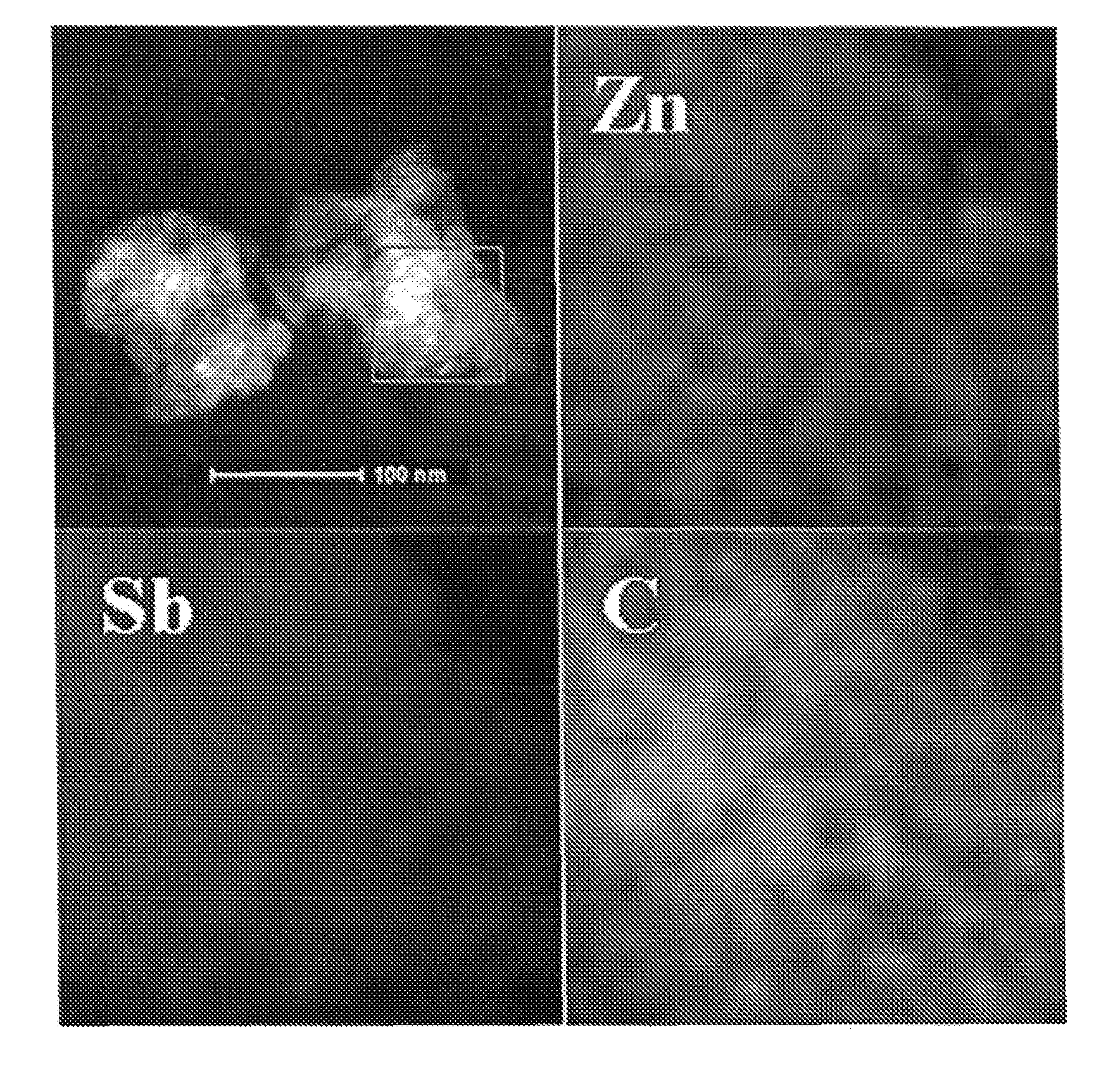

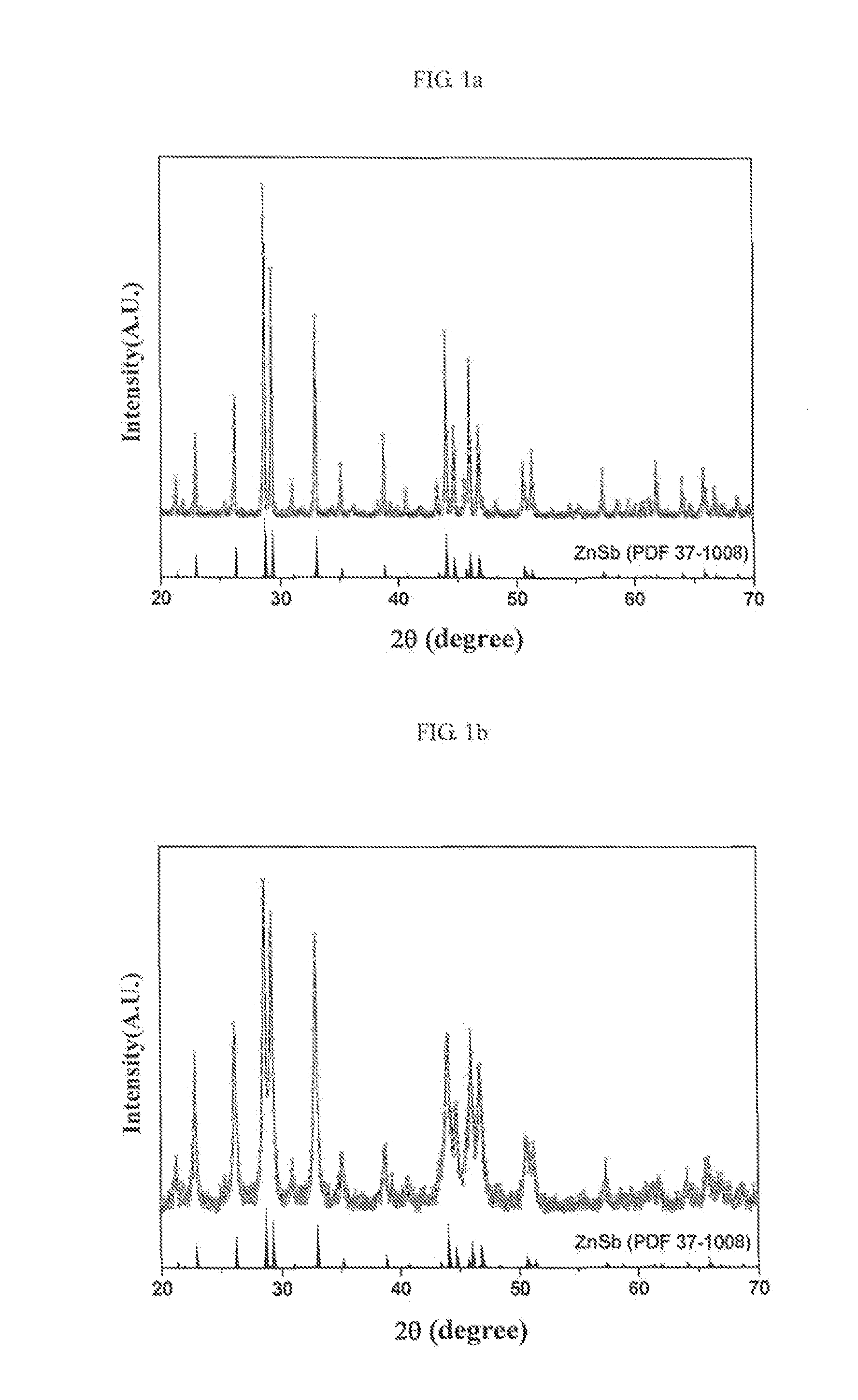

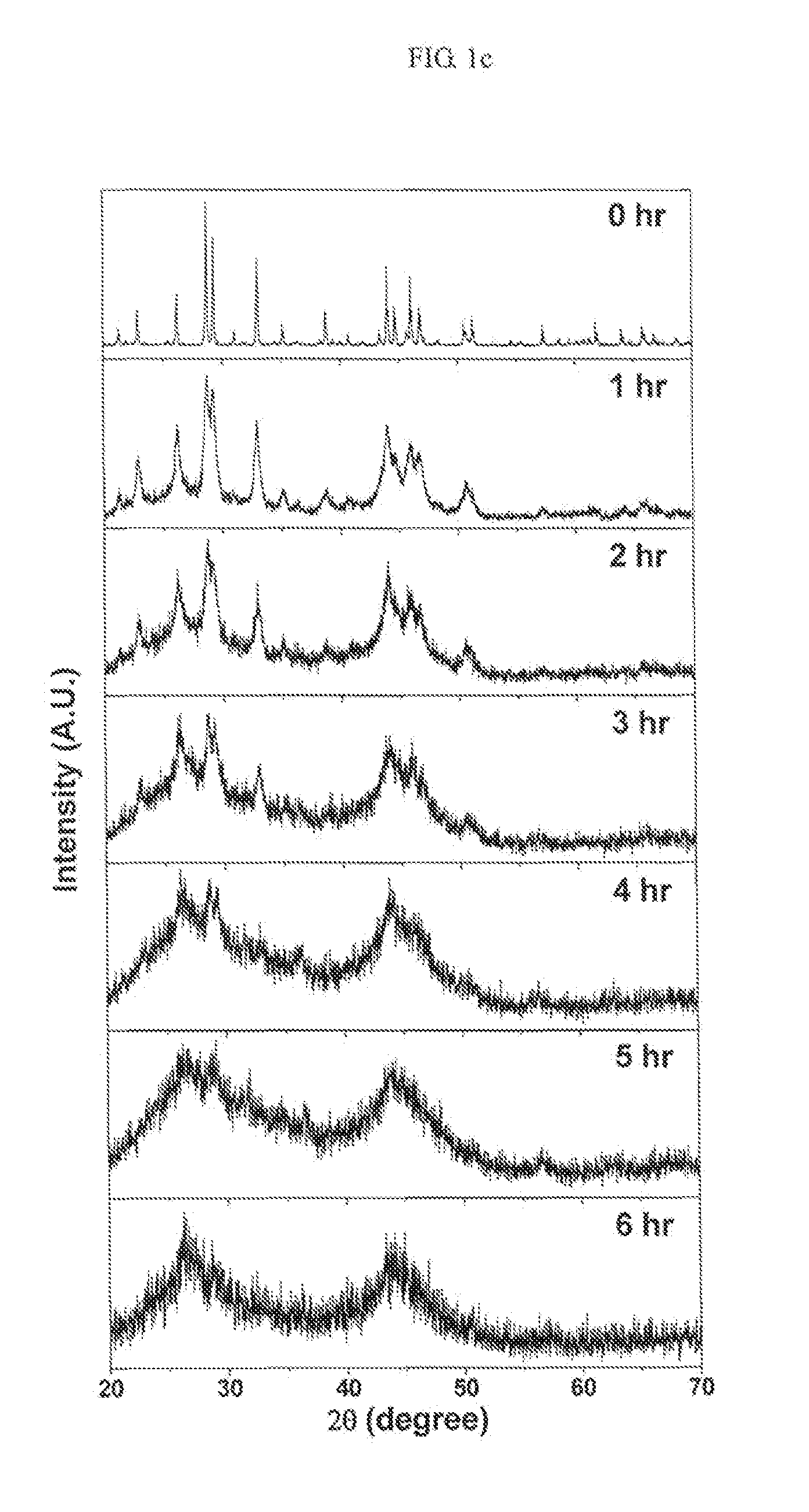

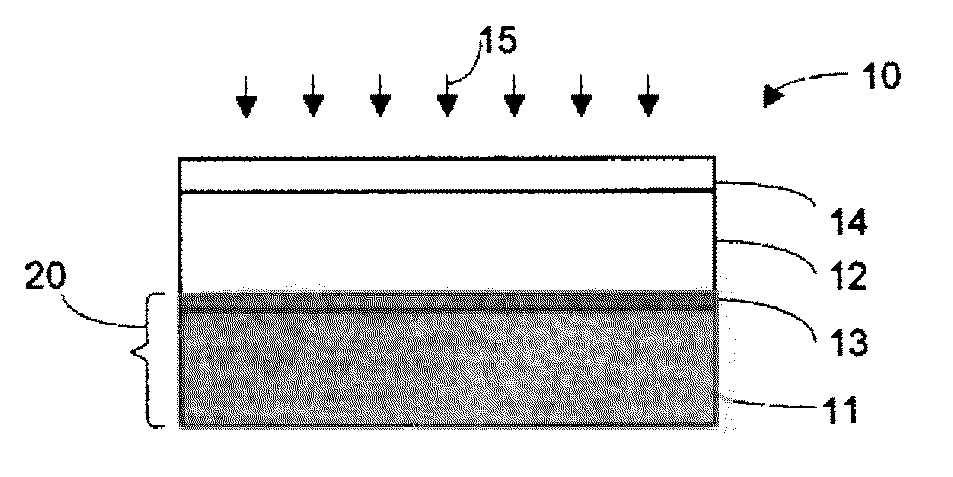

Preparation method of znsb-c composite and anode materials for secondary batteries containing the same composite

InactiveUS20100159328A1Improve initial efficiencyObtained efficiently and promptlyMaterial nanotechnologyElectrode manufacturing processesCarbon compositesBinary alloy

Provided are a method for preparing a zinc antimonide-carbon composite through a mechanical synthesis process of zinc (Zn), antimony (Sb) and carbon (C), and an anode material including the composite as an active material. The method for preparing a zinc antimonide-carbon composite allows simple and rapid preparation of the composite using mechanical properties of a binary alloy of zinc antimonide. In addition, when applying the anode material including the composite as an anode active material to a secondary battery, it is possible to provide excellent initial efficiency, to prevent the problem of a change in volume caused by formation of crude particles, and to realize excellent high-rate characteristics and charge / discharge characteristics.

Owner:SEOUL NAT UNIV R&DB FOUND

Electroplating methods and chemistries for deposition of copper-indium-gallium containing thin films

The present invention provides a method and precursor structure to form a solar cell absorber layer. The method includes electrodepositing a first layer including a film stack including at least a first film comprising copper, a second film comprising indium and a third film comprising gallium, wherein the first layer includes a first amount of copper, electrodepositing a second layer onto the first layer, the second layer including at least one of a second copper-indium-gallium-ternary alloy film, a copper-indium binary alloy film, a copper-gallium binary alloy film and a copper-selenium binary alloy film, wherein the second layer includes a second amount of copper, which is higher than the first amount of copper, and electrodepositing a third layer onto the second layer, the third layer including selenium; and reacting the precursor stack to form an absorber layer on the base.

Owner:SOLOPOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com